Toshiba RAS-M16GDV-E, RAS-M10GDCV-E, RAS-M10GDV-E, RAS-M13GDCV-E, RAS-M16GDCV-E SERVICE MANUAL

...

Heat Pump Model Cooling Only Model

KIT commande filaire RBC-SHA1LE2

RAS-M10GDV-E RAS-M10GDCV-E

RAS-M13GDV-E RAS-M13GDCV-E

RAS-M16GDV-E RAS-M16GDCV-E

R410A

PRINTED IN JAPAN, Nov., 2005 ToMo

CONTENTS

1. PRECAUTIONS FOR SAFETY ................................................................. 3

2. SPECIFICATIONS..................................................................................... 5

3. CONSTRUCTION VIEWS ......................................................................... 8

4. WIRING DIAGRAM ................................................................................... 9

5. SPECIFICATIONS OF ELECTRICAL PARTS ........................................ 10

6. REFRIGERANT CYCLE DIAGRAM ....................................................... 11

7. CONTROL BLOCK DIAGRAM ............................................................... 12

8. OPERATION DESCRIPTION .................................................................. 13

9. INSTALLATION PROCEDURE ............................................................... 23

10. DRAIN-UP KIT (OPTION)....................................................................... 38

11. HO W TO DIA GNOSE THE TROUBLE ..................................................... 42

12. HOW TO REPLACE THE MAIN PARTS.................................................. 53

13. EXPLODED VIEWS AND PARTS LIST .................................................. 55

– 2 –

1. PRECAUTIONS FOR SAFETY

For general public use

Power supply cord of Outdoor unit shall be more than 2.5mm² (H07RN-F or 245 IEC66) polychloroprene

sheathed flexible cord.

• Read this “Precautions for Saf ety” carefully before servicing.

• The precautions described below include the important items regarding saf ety. Observe them without fail.

• After the servicing work, perf orm a trial operation to check for any problem.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

CAUTION New Refrigerant Air Conditioner Servicing

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT

DESTROY OZONE LAYER.

The characteristics of R410A refrigerant is easy to absorb water, oxidizing membrane or oil, and its pressure

is approx. 1.6 times of refrigerant R22. Accompanied with adoption of the new refrigerant, refrigerating oil

has been also changed. Therefore, during servicing work, be sure that water, dust, former refrigerant, or

refrigerating oil does not enter into the refrigerating cycle of new refrigerant air conditioner.

To prev ent from mixing of refrigerant and refrigerating oil, the sizes of connecting sections of charging port of

the main unit or installation tools are different from those f or the con ventional refrigerant.

Accordingly, the exclusive tools are required for the new refrigerant (R410A).

For connecting pipes, use ne w and clean piping materials with high pressure-tight force, which were made for

R410A only, so that water or dust does not enter. Moreover, do not use the existing piping because there are

problems about pressure-tight force and impurity it.

CAUTION To Disconnect the Appliance from the Main Power Supply.

This appliance must be connected to the main power supply b y means of a circuit breaker or a switch with a

contact separation of at least 3 mm.

If this is not possible, a power supply plug with g rounding must be used. This plug must be easily accessible

after installation. The plug must be disconnected from the power supply socket in order to disconnect the

appliance completely from the mains.

The installation fuse (25A D type ) must be used for the power supply line of this air

conditioner.

W ARNINGS

• Ask an authorized dealer or qualified installation professional to install/maintain the air

conditioner.

Inappropriate servicing may result in water leakage, electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Connect the connecting cable correctly.

If the connecting cable is connected by wrong way, electric parts may be damaged.

• When moving the air-conditioner for installing it in another place again, be very careful not to

get the specified refrigerant (R410A) with any other gaseous body into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes

abnormally high and it resultingly causes burst of the pipe and injuries on persons.

– 3 –

• Never modify this unit by removing any of the safety guards or by by-passing any of the

safety interlock switches.

• Exposure of unit to water or other moisture before servicing may cause a short circuit.

Do not store it in a wet basement or expose to rain or w ater.

• After unpacking the unit, examine it carefully for possible damage.

• Do not install in a place that can increase the vibration of the unit.

• To avoid personal injury, be careful when handling parts with sharp edges.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When installing the air conditioner in a small room, provide appropriate measures to ensure

that the concentration of refrigerant in the room does not exceed the critical level should

leakage occur.

It is not dangerous refrigerant; it has not toxicity or combustibility. However, a concentration above 0.3kg/m³

as criterion still causes suffocation. The volume of refrigerant charged to the Multi System air conditioner is

more than the volume charged to a conventional individual system.

• Install the air conditioner securely in a location where the weight of the unit can be sustained

adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the servicing work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, no xious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas

may generate.

• The electrical work must be performed by a qualified electrician in accordance with the Installation Manual. Make sure the air conditioner uses an exclusive circuit.

An insufficient circuit capacity or inappropriate installation may cause fire.

• When wiring, use the specified cables and connect the terminals securely to prevent external

forces applied to the cable from affecting the terminals.

• Be sure to provide grounding.

Do not connect ground wires to gas pipes, water pipes, lightning rods or ground wires for telephone cables.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

• Do not install the air conditioner in a location subject to a risk of exposure to combustible

gas.

Otherwise, the combustib le gas may leak and a fire may occur.

– 4 –

2. SPECIFICATIONS

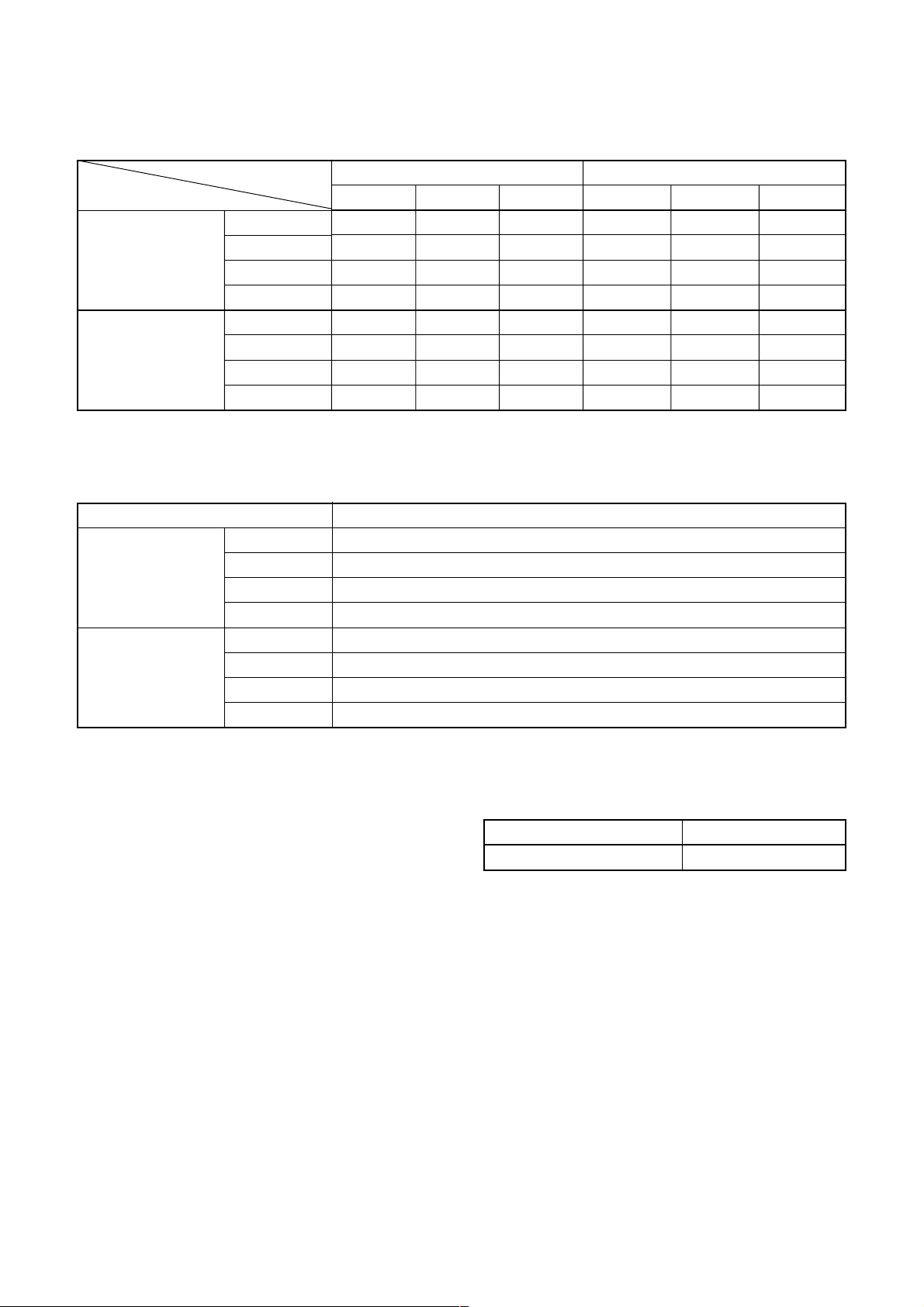

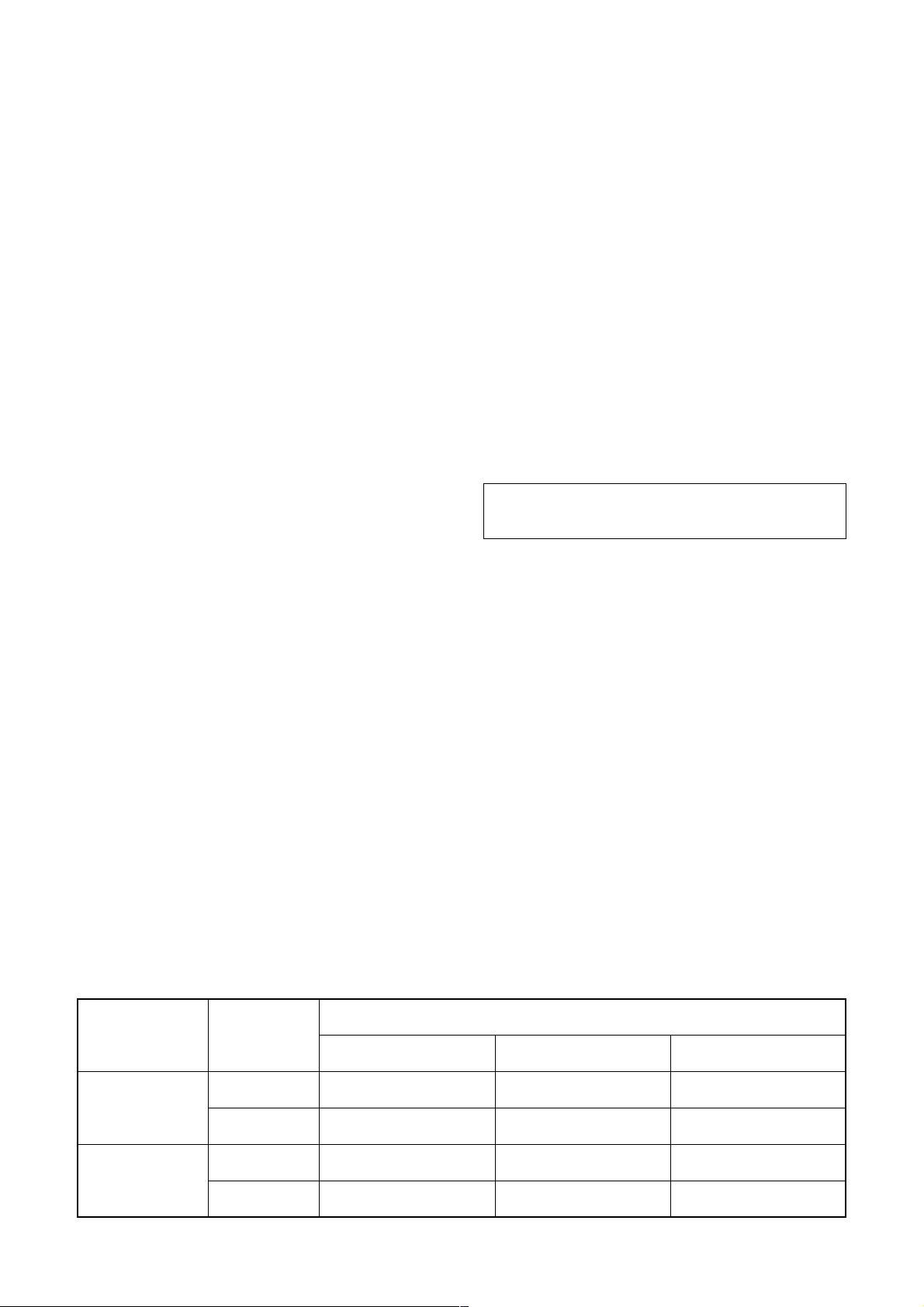

1. Combination List of Indoor/Outdoor Units (¡: Possible ×: Impossible)

Heat Pump Model RAS- Cooling Only Model RAS-

M10GDV-E M13GDV-E M16GDV-E M10GDCV-E M13GDCV-E M16GDCV-E

¡¡¡ ×××

¡¡¡ ×××

¡¡ ××××

¡¡¡ ×××

××ס¡¡

××ס¡¡

××ס¡ ×

××ס¡¡

Outdoor unit

Heat Pump Model

RAS-

Cooling Only Model

RAS-

Indoor unit

4M27GAV-E

3M26GAV-E

M14GAV-E

M18GAV-E

4M27GACV-E

3M23GACV-E

M14GACV-E

M18GACV-E

2. File No. List of Reference Service Manual (Outdoor Units of Multi Air Conditioner)

Outdoor unit

Heat Pump Model

RAS-

Cooling Only Model

RAS-

4M27GAV-E

3M26GAV-E

M14GAV-E

M18GAV-E

4M27GACV-E

3M23GACV-E

M14GACV-E

M18GACV-E

Reference Service Manual

File No. A05-011

File No. A05-011

File No. A05-009

File No. A05-009

File No. A05-011

File No. A05-014

File No. A05-009

File No. A05-009

3. For the details of the specifications of each

indoor/outdoor unit to be combined, refer to the

next page and after pages with the above service

manuals.

4. Optional Parts List

Product name

Drain-up kit

– 5 –

Model name

RB-F81E2

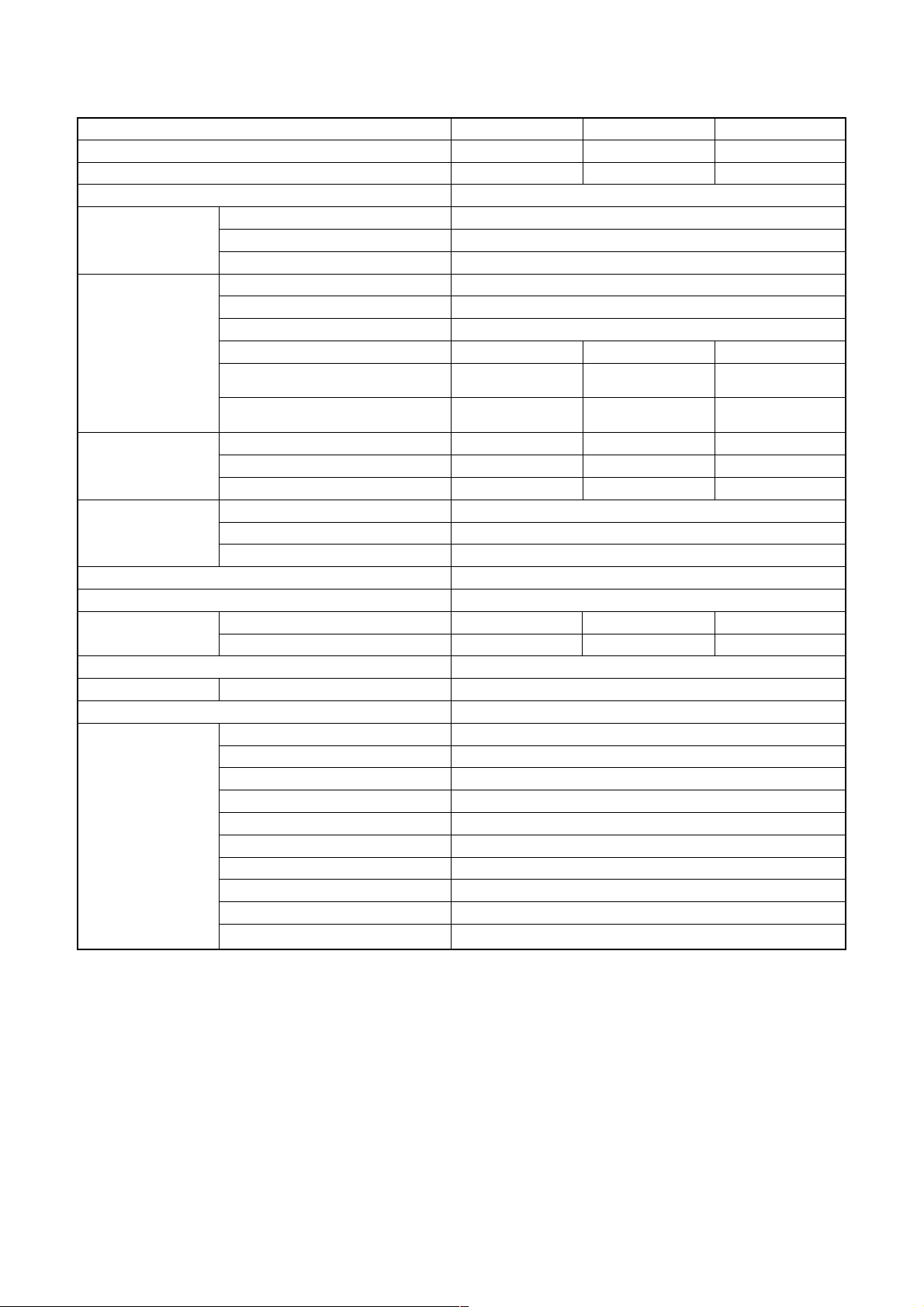

RAS-M10GDV-E, RAS-M13GDV-E, RAS-M16GDV-E (Heat Pump Model)

Indoor unit model name

Cooling capacity (kW)

Cooling capacity range (kW)

Heating capacity (kW)

Heating capacity range (kW)

Power supply (Ø-V-Hz)

Electric characteristics

2

*

Blower unit

Sound level *4

Dimension Width (mm)

Net weight (kg)

Connecting type

Connecting pipe

Refrigerant

Wiring connection Interconnection

Usable temperature range (Cooling/Heating) (°C)

Accessory

Operation current (A)

Power consumption (W)

Power factor (%)

Blower

Blower motor output (W)

Blower speed

Air flow (Cooling High *3) (m³/h)

Air flow (Heating High *3) (m³/h)

External static pressure (Pa)

(Upper limit)

External static pressure (Pa)

(Standard)

Cooling (high) (dB)

Cooling (Medium) (dB)

Cooling (Low) (dB)

Heating (high) (dB)

Heating (Medium) (dB)

Heating (Low) (dB)

Height (mm)

Depth (mm)

Liquid side (mm)

Gas side (mm)

Wireless remote controller

Remote controller holder

Mounting screws

Drain hose

Elbow thermal-insulation cover

Batteries (Manganese)

Black screws

Tapping screws

Owner’s manual

Installation manual

RAS-M10GDV-E RAS-M13GDV-E RAS-M16GDV-E

2.7 3.7 4.5

1

*

4.0 5.0 5.5

1

*

220 – 240 V – 1 Ph – 50 Hz / 220 V – 1 Ph – 60 Hz

Multi-blade blower

5 (Low, Low+, Med, Med+, High)

720 780 780

720 780 780

54.9 63.7 63.7

(5.6 mmAq) (6.5 mmAq) (6.5 mmAq)

35.3 41.2 41.2

(3.6 mmAq) (4.2 mmAq) (4.2 mmAq)

31 32 33

27 28 29

23 24 25

32 33 34

28 29 30

24 25 26

Ø6.35 Ø6.35 Ø6.35

Ø9.52 Ø9.52 Ø12.7

4 wires : includes earth

1

*

1

*

0.59

110

81

60

230

750

440

19

Full Operation

R410A

21 – 32 / 0 – 28

1

1

2 (Ø3.5 x 16 L)

1

1

2

2

16

1

1

1

*

1

*

1 : Refer to the service manual of the outdoor unit to be combined.

*

2 : Electrical characteristics at High fan speed under standard static pressure.

*

3 : Airflow volume at standard static pressure.

*

4 : Sound levels at standard static pressure are measured under the conditions specified by JIS B 8616.

*

Notes :

• For performance when each indoor unit combined with other unit, refer to the service manual of outdoor unit.

• The specification may be subject to change without notice for purpose of improvement.

– 6 –

RAS-M10GDCV-E, RAS-M13GDCV-E, RAS-M16GDCV-E (Cooling Only Model)

Indoor unit model name

Cooling capacity (kW)

Cooling capacity range (kW)

Power supply (Ø-V-Hz)

Electric characteristics

2

*

Blower unit Air flow (Cooling High *3) (m³/h)

Sound level *4 Cooling (Medium) (dB)

Dimension Width (mm)

Net weight (kg)

Connecting type

Connecting pipe

Refrigerant

Wiring connection Interconnection

Usable temperature range (°C)

Accessory

Operation current (A)

Power consumption (W)

Power factor (%)

Blower

Blower motor output (W)

Blower speed

External static pressure (Pa)

(Upper limit)

External static pressure (Pa)

(Standard)

Cooling (high) (dB)

Cooling (Low) (dB)

Height (mm)

Depth (mm)

Liquid side (mm)

Gas side (mm)

Wireless remote controller

Remote controller holder

Mounting screws

Drain hose

Elbow thermal-insulation cover

Batteries (Manganese)

Black screws

Tapping screws

Owner’s manual

Installation manual

RAS-M10GDCV-E RAS-M13GDCV-E RAS-M16GDCV-E

2.7 3.7 4.5

1

*

220 – 240 V – 1 Ph – 50 Hz / 220 V – 1 Ph – 60 Hz

Multi-blade blower

5 (Low, Low+, Med, Med+, High)

720 780 780

54.9 63.7 63.7

(5.6 mmAq) (6.5 mmAq) (6.5 mmAq)

35.3 41.2 41.2

(3.6 mmAq) (4.2 mmAq) (4.2 mmAq)

31 32 33

27 28 29

23 24 25

Ø6.35 Ø6.35 Ø6.35

Ø9.52 Ø9.52 Ø12.7

4 wires : includes earth

1

*

0.59

110

81

60

230

750

440

19

Full Operation

R410A

21 – 32

1

1

2 (Ø3.5 x 16 L)

1

1

2

2

16

1

1

1

*

1 : Refer to the service manual of the outdoor unit to be combined.

*

2 : Electrical characteristics at High fan speed under standard static pressure.

*

3 : Airflow volume at standard static pressure.

*

4 : Sound levels at standard static pressure are measured under the conditions specified by JIS B 8616.

*

Notes :

• For performance when each indoor unit combined with other unit, refer to the service manual of outdoor unit.

• The specification may be subject to change without notice for purpose of improvement.

– 7 –

230

156.5

228

(Inside flange)

Duct connecting flange

(Require at site)

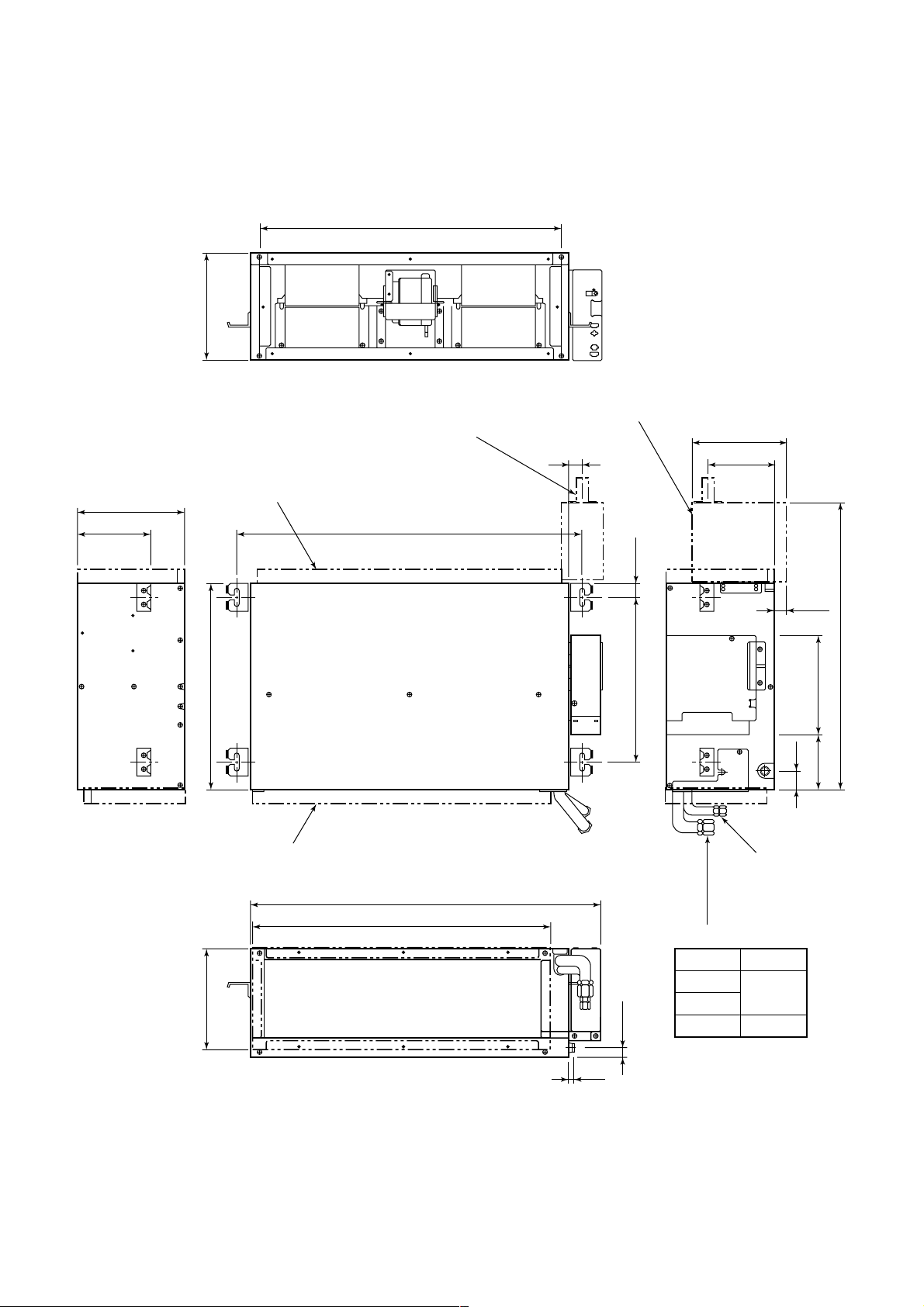

3. CONSTRUCTION VIEWS

650 (Inside flange)

Drain piping connecting port

(Nominal Ø20 Vinyl chloride pipe)

31

730 (Hanging bolt pitch)

Drain-up kit

RB-F81E2

(Accessory sold separately)

200

142

440

Duct connecting flange

(Require at site)

216.2

(Inside flange)

750

640 (Inside flange)

29.7

350

(Hanging bolt pitch)

Gas side D

Model

M10

M13

19.7

M16

24.5

612

40

118 211

Refrigerant pipe

connecting port

(Liquid side Ø6.35)

D

Ø9.52

Ø12.7

– 8 –

13

INFRARED RAYS

KIT commande filaire RBC-SHA1LE2

RECEIVING AND

INDICATING PARTS

1

BLK

9

9

WHI

8

8

GRY

7

7

GRN

6

6

BLU

5

5

YEL

4

4

ORN

3

3

MCC-5026

SWITCH P.C. BOARD

RED

2

2

BRW

1

1

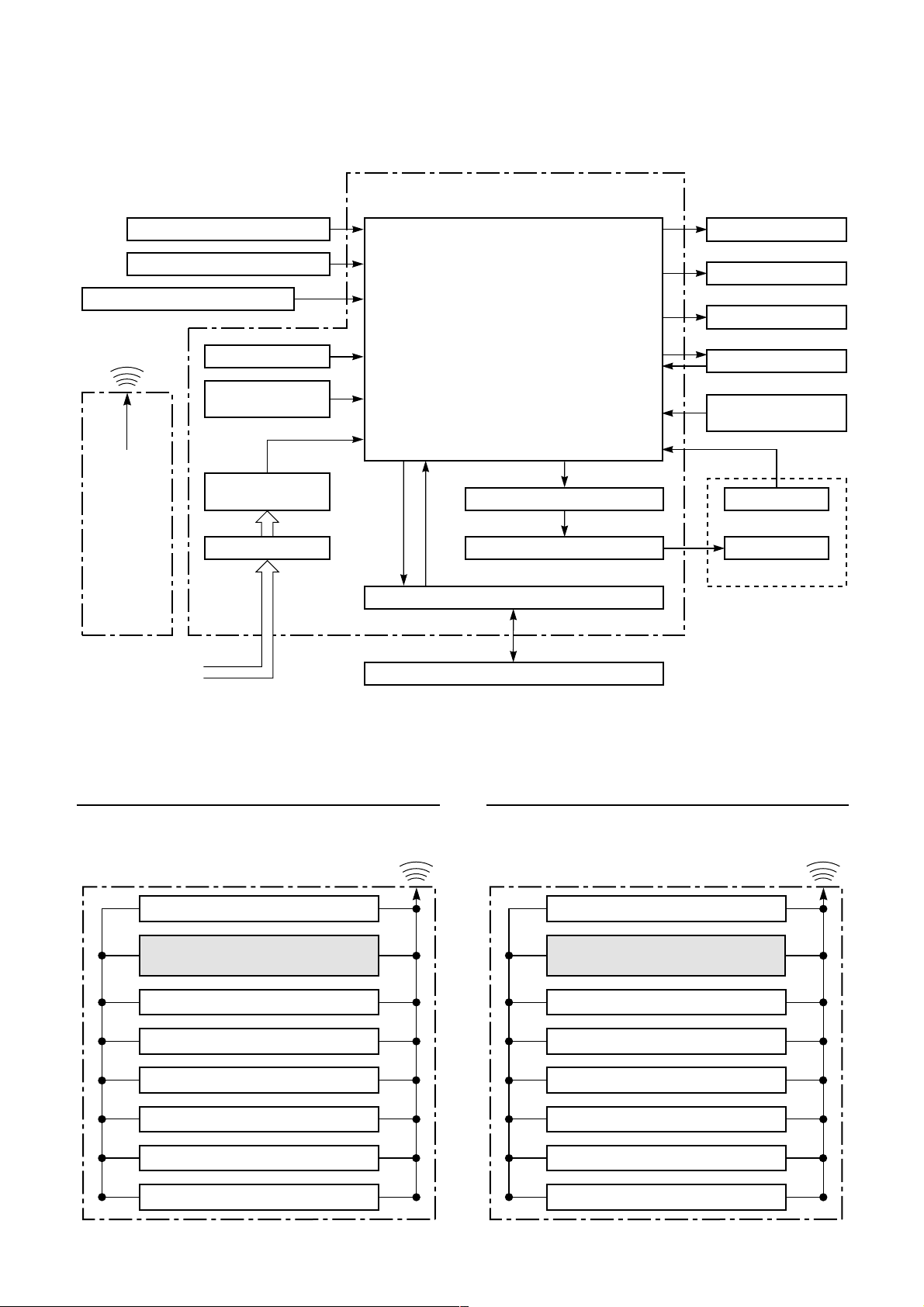

4. WIRING DIAGRAM

4

~

WHI

1

1

BLK

2

2

RED

3

3

BLU

4

4

BLU

5

5

1 2

3 4 5

1 2 3 4 5

CN11

9

9

8

8

7

7

6

6

5

5

CN05

4

4

3

3

2

2

1

1

1 2

1 2

CN17 CN04 CN03

TRANSFORMER

1

3

RED

WHI

1

3

RED

YEL

BLK

BLU

ORN

1 2

1 2 1 2 3

CN20

3

FUSE

T6, 3A, AC 250V

CN01

R01

CN19

BLK

WHI

220 –240V

CONNECTION

CABLE

2

INDOOR

TERMINAL

BLOCK

50Hz

220V ~60Hz

EARTH

EARTH

HEAT

EXCHANGER

SENSOR

(TC)

THERMO

SENSOR

(TA)

FLOAT

SWITCH

212

DRAIN-UP KIT

(OPTION)

Check items

OPERATION

1

indicator

Terminal

2

block

Fuse

3

6.3A

DC 5V

4

DC 12V

5

CN06

1

1

3

3

BLK

BLK

BLK

BLK

212

212

1

CN12

1

CN13

MAIN P.C. BOARD

R02

R03

RY01

SG01

CN30

CN15

WHI

5

BLK

3

RED

1

MCC-875

BLK

BLK

1

2

CN07

CN09

CN14

4321

P02P03

1

BLU

3

PUR

2

GRY

1

5

MF-CAPA

Table 4-1-1 Quick check for failure diagnosis

Diagnosis result

Check to see if the OPERATION indicator goes on and off when the main

switch or breaker is turned on. (Check the transformer and receiver unit.)

Check the power supply voltage between and . (Refer to the name

plate.) (Check the primary and secondary voltage of the transformer.)

Check for fluctuate voltage between

Check to see if the fuse blows out.

(Check the R01 of the Varistor.)

Check the voltage between and on CN11 connector.

(Check the transformer and the power supply circuit of the rated voltage.)

Check the voltage between and on CN14 connector.

(Check the transformer and the power supply circuit of the rated voltage.)

and .

GRY

GRY

DRAIN-PUMP

MOTOR

DRAIN-UP KIT

(OPTION)

BLK

3

3

WHI

2

2

RED

1

1

BLU

3

3

PUR

2

2

GRY

1

1

FAN MOTOR

Color

Identification

BRW : BROWN

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

GRN : GREEN

PUR : PURPLE

GRN : GREEN &

&YEL YELLOW

Refer to the service data for the detailed f ailure diagnosis.

– 9 –

5-1. Indoor Unit

5. SPECIFICATIONS OF ELECTRICAL PARTS

No.

1

Fan motor (for indoor)

2

Thermo. sensor (TA-sensor)

3

Transformer

4

Microcomputer

5

Heat exchanger sensor

(TC-sensor)

6

Line filter (L02)

Running capacitor

7

(for indoor fan motor)

8

Fuse (F01)

9

Varistor (R01, R02, R03)

10

Drain pump control relay

Parts name

Type

MF-200-60-4R

( – )

TT-03-3

TMP87PM40ANG

( – )

HF-2430-253Y0R8

CMPS45B155UYF

CMPS45B305UYF

TSCR6.3A

15G471K

G2R-1-H

Specifications

Output (Rated ) 60W, 4 pole, 1 phase,

220 – 240, 50Hz/220, 60Hz

Winding resistance (Ω)

at 20°C

10kΩ at 25°C

AC 240V, Secondary DC 15V/DC 500mA

10kΩ at 25°C

25mH, AC 0.8A

1.5µF, AC 450V (M10, M13)

3.0µF, AC 450V (M16)

T6.3A, AC 250V

470V

10A, AC 250V

M coil A coil

73.8 100

– 10 –

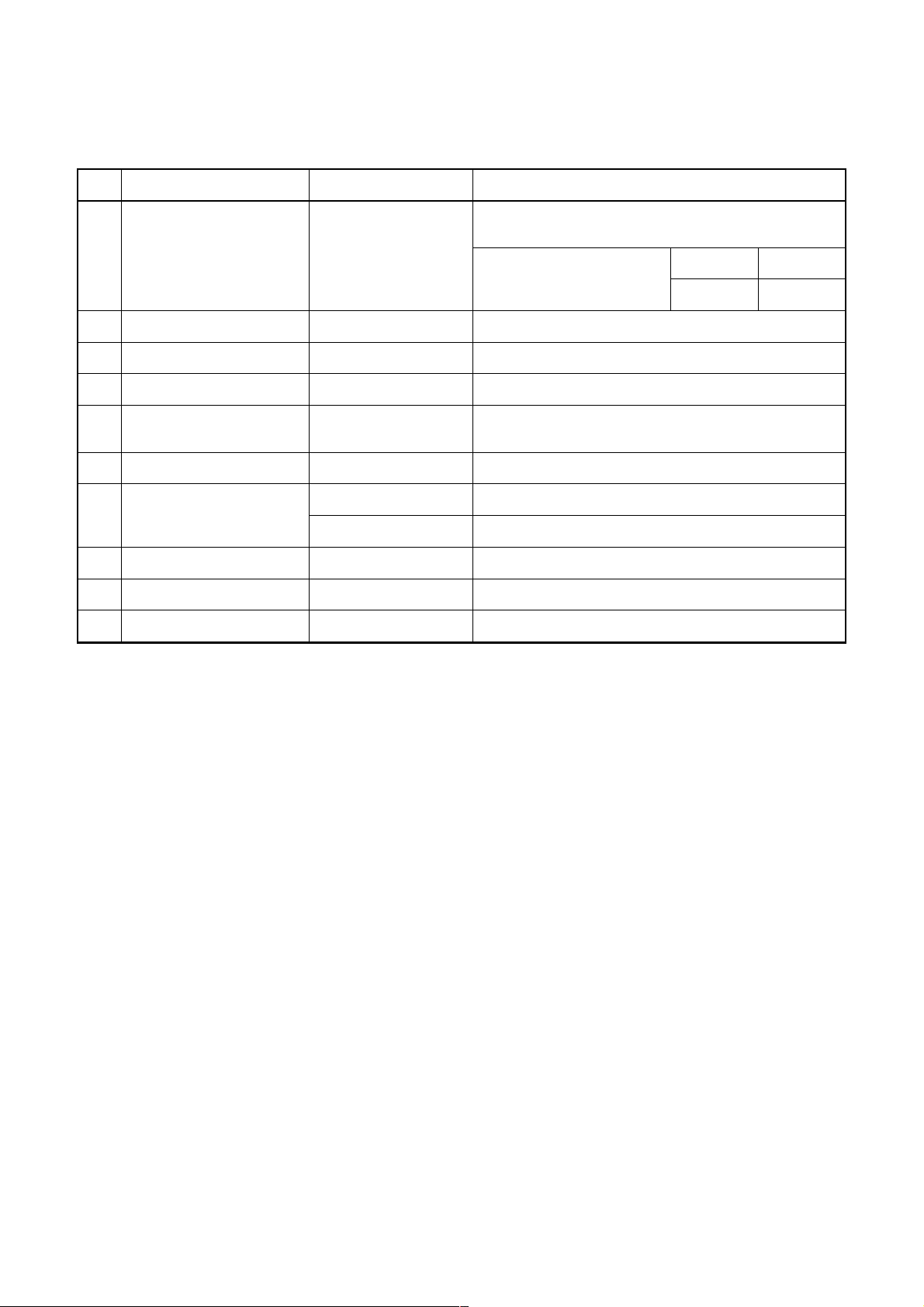

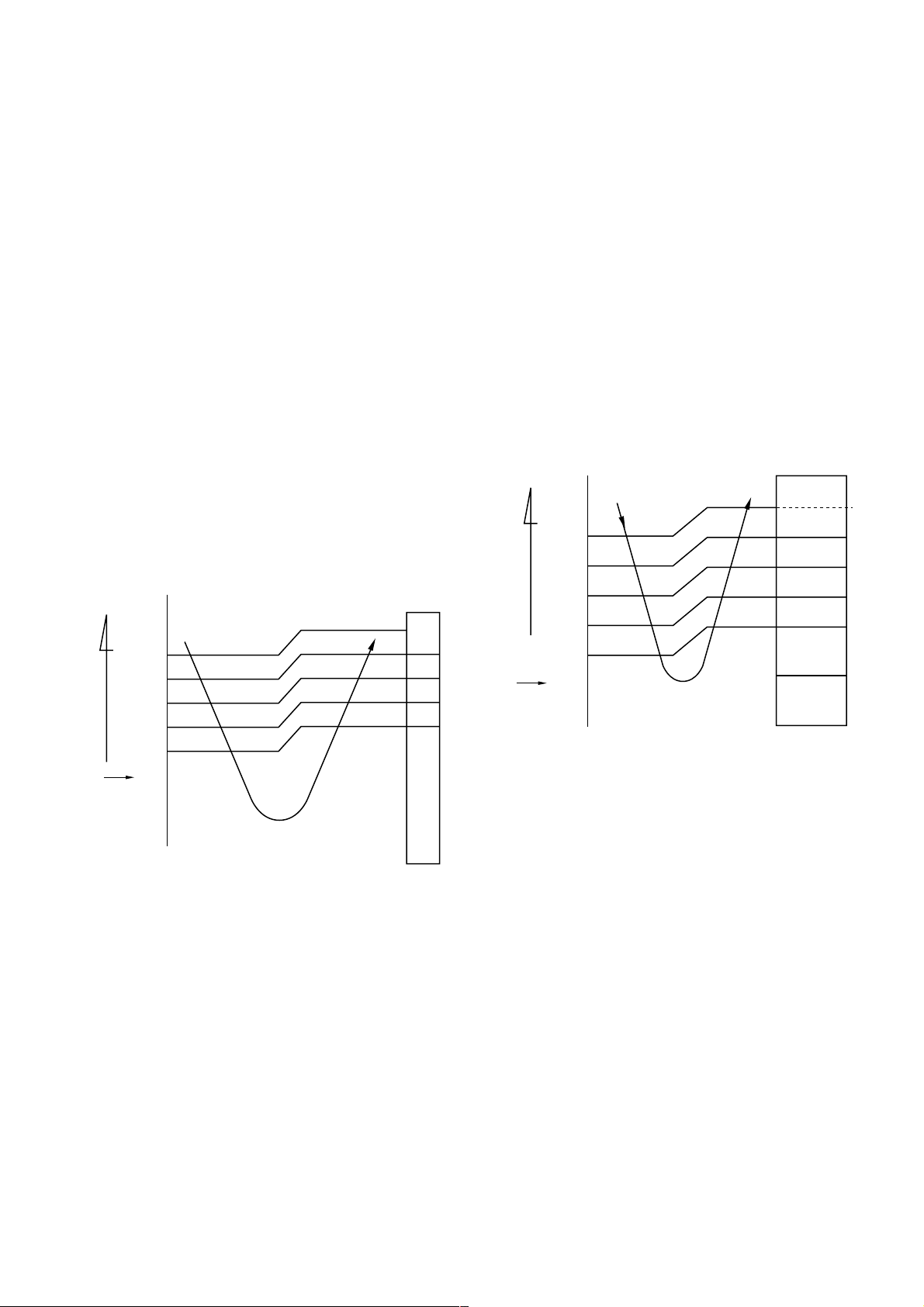

6. REFRIGERANT CYCLE DIAGRAM

RAS-M10GDV-E, RAS-M10GDCV-E

RAS-M13GDV-E, RAS-M13GDCV-E

Connecting pipe

Thickness : 0.8mm

Ø9.52

RAS-M16GDV-E, RAS-M16GDCV-E

INDOOR UNIT

Evaporator

TA

•

Multi-blade fan

Connecting pipe

Thickness : 0.8mm

Ø6.35

Sectional shape

of heat insulator

OUTDOOR UNIT

TC

∗2

∗2

Allowable pipe length

Allowable height difference

Connecting pipe

Thickness : 0.8mm

Ø12.7

INDOOR UNIT

Evaporator

TA

•

Multi-blade fan

Connecting pipe

Thickness : 0.8mm

Ø6.35

Sectional shape

of heat insulator

OUTDOOR UNIT

TC

∗2

∗2

Allowable pipe length

Allowable height difference

NOTE : Gas leak check position

Refrigerant flow (Cooling)

Refrigerant flow (Heating)

∗1

∗1: Heat pump model only

∗2: The allowable pipe length, charge amount of refrigerant, and allowable height difference differ according to

the outdoor unit to be combined. For details, refer to the service manual of the outdoor unit to be combined.

– 11 –

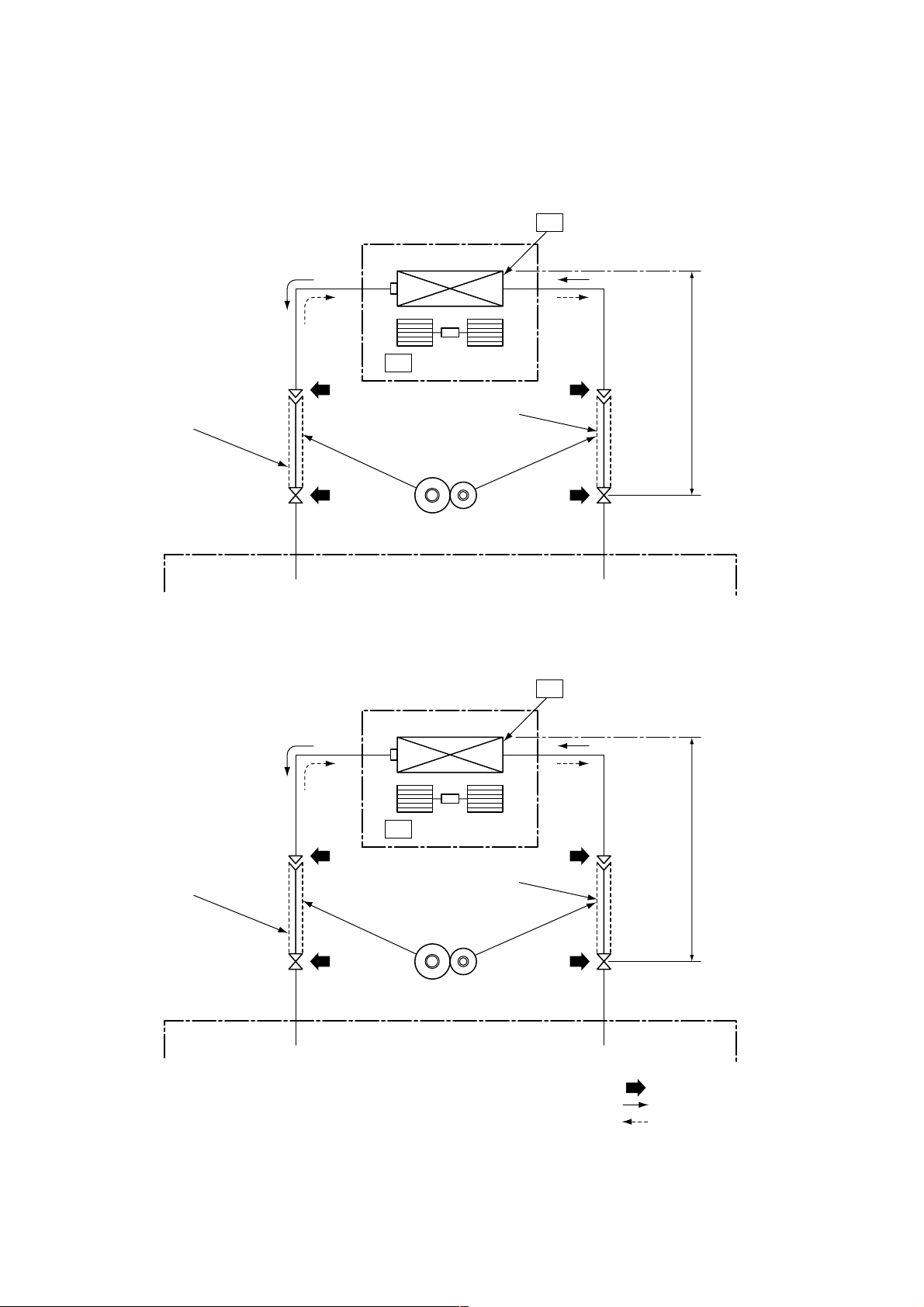

7-1. Indoor Unit

Heat Exchanger Sensor

7. CONTROL BLOCK DIAGRAM

Indoor Unit P.C. Board (MMC-875)

M.C.U

Functions

Operation Display

Temperature Sensor

Infrared Rays Signal Receiver

Infrared

Rays

Initializing Circuit

Clock Frequency

Oscillator Circuit

Power Supply

Remote

Controller

Noise Filter

From Outdoor Unit

Circuit

• Drain Pump Control

• 3-minutes Delay at Restart for Compressor

• Motor Revolution Control

• Processing

(Temperature Processing)

• Timer

• Serial Signal Communication

Drain Pump ON/OFF Signal

Drain Pump Relay

Serial Signal Transmitter/Receiver

Serial Signal Communication

Timer Display

Check Display

Indoor Fan Motor

Voltage setup &

TEMPORARY Switch

Float Switch

Drain Pump

Option

Remote controller

RAS-M10GDV-E, M13GDV-E, M16GDV-E

(Heat Pump Model)

Wireless Remote Controller

Operation (START/STOP)

Operation Mode Selection

AUTO, COOL, DRY, HEAT

Thermo. Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

ECO (SLEEP)

Infrared

Rays

RAS-M10GDCV-E, M13GDCV-E, M16GDCV-E

(Cooling Only Model)

Infrared

Rays

Wireless Remote Controller

Operation (START/STOP)

Operation Mode Selection

AUTO, COOL, DRY, FAM ONLY

Thermo. Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

ECO (SLEEP)

Hi-POWER

Hi-POWER

– 12 –

8. OPERATION DESCRIPTION

8-1. Outline of Air Conditioner Control

This air conditioner is a capacity-variable type air

conditioner, which uses AC motor for the indoor fan

motor and DC motor for the outdoor fan motor. And

the capacity-proportional control compressor which

can change the motor speed in the range around

from 20 to 100 rps is mounted. The AC motor drive

circuit is mounted to the indoor unit. The compressor and the inverter to control outdoor fan motor are

mounted to the outdoor unit. The entire air conditioner is mainly controlled by the indoor unit controller.

The indoor unit controller drives the indoor fan motor

based upon command sent from the remote controller, and transfers the operation command to the

outdoor unit controller.

The outdoor unit controller receives operation

command from the indoor unit side, and controls the

outdoor fan and the pulse modulating v alve. (PMV)

Besides, detecting revolution position of the compressor motor, the outdoor unit controller controls

speed of the compressor motor by controlling output

voltage of the inverter and switching timing of the

supply power (current transfer timing) so that motors

drive according to the operation command.

And then, the outdoor unit controller transfers

reversely the oper ating status information of the

outdoor unit to the indoor unit controller.

As the compressor adopts four-pole

brushless DC motor, the frequency of the

supply power from inverter to compressor

is two-times cycles of the actual number of

revolution.

1. Role of indoor unit controller

The indoor unit controller judges the operation

commands from the remote controller and performs the following functions .

• Judgment of suction air temperature of the

indoor heat exchanger by using the indoor temp.

sensor.

• Temperature setting of the indoor heat ex-

changer by using heat exchanger sensor

(Prevent-freezing control)

• Indoor fan motor operation control

• LED display control

• Transferring of operation command signal

(Serial signal) to the outdoor unit

• Reception of information of operation status

(Serial signal including outside temp. data) from

the outdoor unit and judgment/display of failure.

2. Role of outdoor unit controller

Receiving the operation command signal (Serial

signal) from the indoor unit controller, the outdoor

unit performs its role.

• Compressor operation

control

• Operation control of

outdoor fan motor

• PMV control

• Detection of inverter input current and current

release operation

• Over-current detection and prevention operation

to transistor module (Compressor stop function)

• Compressor and outdoor fan stop function

when serial signal is off (when the serial signal

does not reach the board assembly of outdoor

control by trouble of the signal system)

• Transferring of operation information (Serial

signal) from outdoor unit to indoor unit

• Detection of outdoor temperature and operation

revolution control

• Defrost control in heating operation ((Heat

pump model only.) Temp. measurement by

outdoor heat exchanger and control f or 4-way

valve and outdoor fan)

3. Contents of operation command signal (Serial

signal) from indoor unit controller to outdoor unit

controller

The following three types of signals are sent from

the indoor unit controller.

• Operation mode set on the remote controller

• Compressor revolution command signal defined

by indoor temperature and set temperature

(Correction along with variation of room temperature and correction of indoor heat exchanger temperature are added.)

• For these two types of signals ( [Operation

mode] and [Compressor revolution] ), the

outdoor unit controller monitors the input current

to the inverter, and performs the f ollowed

operation within the range that current does not

exceed the allow ab le value.

• Temperature of indoor heat exchanger by indoor

heat exchanger sensor

(Minimum rev olution control)

Operations fol-

lowed to judgment

of serial signal

from indoor side.

– 13 –

4. Contents of operation command signal (Serial

signal) from outdoor unit controller to indoor unit

controller

The following signals are sent from the outdoor

unit controller.

• The current operation mode

• The current compressor revolution

• Outdoor temperature

• Existence of protective circuit operation.

For transferring of these signals, the indoor unit

controller monitors the contents of signals, and

judges existence of trouble occurrence .

Contents of judgment are described below .

• Whether distinction of the current operation

status coincide with the operation command

signal

• Whether protective circuit operates

When no signal is received from the outdoor

unit controller, it is assumed as a trouble.

8-1-1. Capacity Control

The cooling capacity is varied by changing compressor motor speed. The inverter changes compressor

motor speed by changing AC 220 – 240V po w er to

DC once, and controls capacity by changing supply

power status to the compressor with transistor

module (includes 6 transistors). The outline of the

control is as follows : The re volution position and

revolution speed of the motor are detected by detecting winding electromotive force of the compressor

motor under operation, and the rev olution speed is

changed so that the motor drives based upon revolution speed of the operation command by changing

timing (current transfer timing) to e xchange inverter

output voltage and the power supply to the winding.

Detection of the revolution position for controlling is

performed 12 times per 1 rev olution of compressor.

The range of supply power frequency to the compressor differs according to the operation status.

8-1-2. Current Release Control

The outdoor main circuit control section (Inverter

assembly) detects the input current to the outdoor

unit. If the current value with compressor motor

speed instructed from indoor side exceeds the

specified value, the outdoor main circuit control

section controls compressor motor speed by reducing motor speed so that value becomes closest to

the command within the limited value.

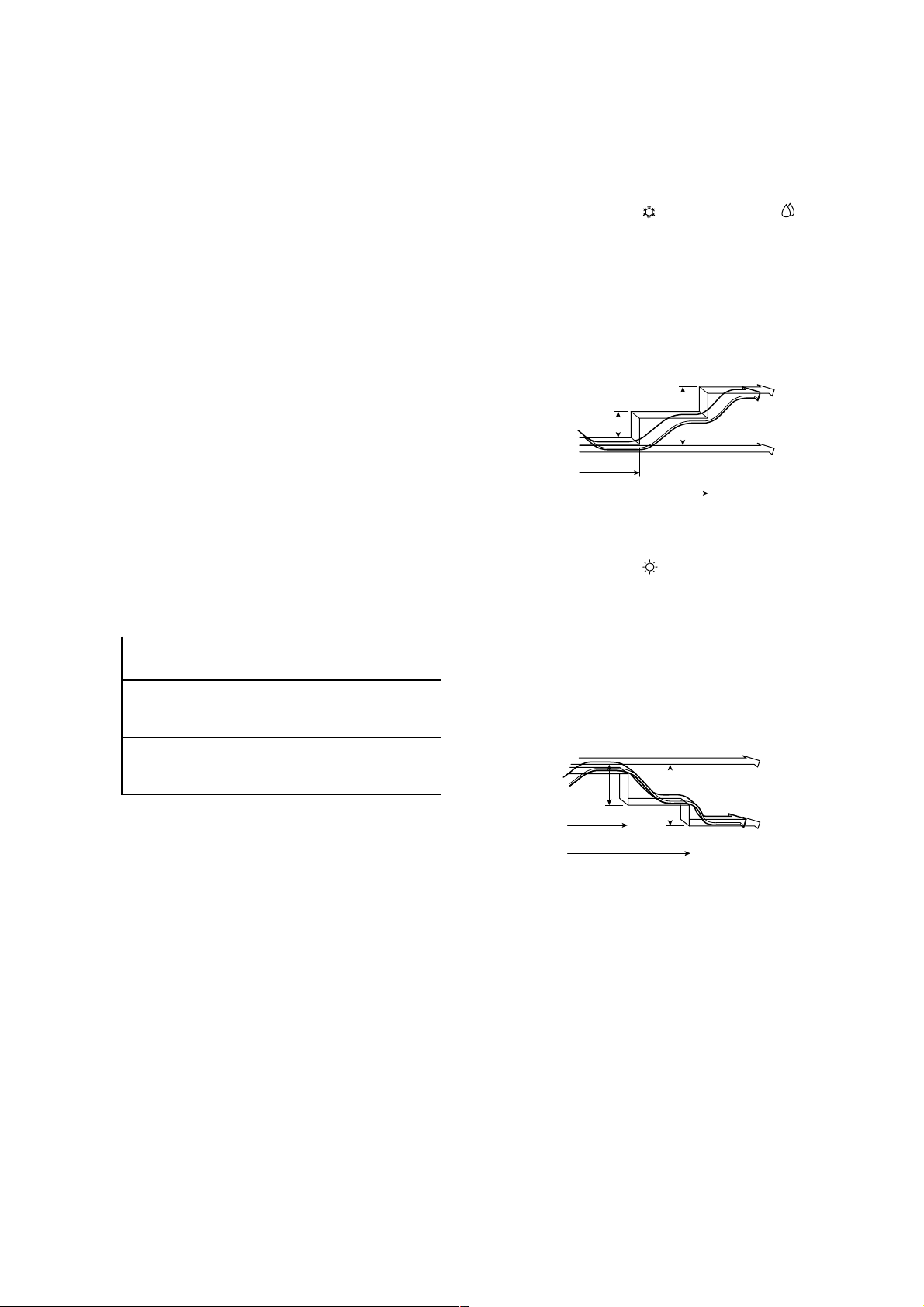

8-1-3. Indoor Fan Control (AC Fan Motor)

The indoor fan is operated by motor speed non-step

variable AC phase control drive system. For airflow

rate, motor speed is controlled manually in five steps

(LOW, LOW+, MED, MED+, HIGH), or automatically

adjusted in AUTO mode according to the room

temperature. It is not selected by relay, so the

switching noise will not be heard.

Table 8-1-1 shows the f an speed.

This indoor unit performs the phase output

constant control of the fan motor.

(Does not control the revolution speed.)

Since the fan speed varies according to the external

static pressure, the values described in the table can

be used to confirm the motor functions. However, the

maximum rev olution speed is limited to 1300rpm for

protection of the terminal voltage of the running

capacitor.

Operation mode

COOL

HEAT

Fan mode

H

L

H

L

Table 8-1-1 Reference fan speed

Fan speed (rpm)

M10 M13 M16

900 to 1150 950 to 1200 1000 to 1250

600 to 800 650 to 850 700 to 900

900 to 1150 950 to 1200 1000 to 1250

650 to 850 700 to 900 750 to 950

– 14 –

8-2. Description of Operation Circuit

• Turning [ON] the break er will flash the oper ation

lamp.

This is the display of pow er-ON (or notification of

power f ailure).

• When pushing [START/STOP] button on the

remote controller, receive sound is issued from the

main unit.

8-2-1. Fan Only Operation

(The Remote controller MODE Button

is Set to the FAN ONLY Operation)

• Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply b y

pushing [START/ST OP] b utton.

• When the FAN b utton is set to the AUTO position,

the indoor fan motor operates as shown in Fig.

8-2-1. When the FAN SPEED button is set

manually, the motor operates with a constant air

flow.

• ECO mode cannot be set.

˚C

Set

temp.

(Room temp.) – (Set temp.)

+3

+2.5

+2

+1.5

+1

+0.5

0

(Set temp.) 25˚C

M+

*1

*1

*1

L–

8-2-2. Cooling Operation

(The Remote controller MODE Button

is Set to the COOL Position)

• Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply b y

pushing [START/ST OP] b utton.

• A cooling operation signal is transmitted to outdoor

unit.

• The indoor fan motor operates as shown in Fig.8-22 when FAN button is set to AUTO.

• The motor operates with a constant air flow when

the FAN button is set manually.

• The outdoor unit controls the outdoor fan and the

compressor motor speed according to the operation command signal sent from the indoor unit.

˚C

+3

M+

*1

*1

*1

L–

In normal

operation

Set

temp.

+2.5

+2

+1.5

+1

(Room temp.) – (Set temp.)

+0.5

0

–0.5

NOTE :

1: Calculated from the difference in the motor speed

*

of M+ and L–.

Fig. 8-2-2 Setting of air flow [Air Flow AUTO]

NOTE :

1: Calculated from the difference in the motor speed

*

of M+ and L–.

Fig. 8-2-1 Auto setting of air flow

1. Cooling capacity control

• The cooling capacity and room temperature are

controlled by changing the compressor motor

speed according to both the difference between

the temperature detected by the room temperature sensor and the temperature set by TEMP

button and also any change in room temperature.

• When compressor has been activated or

reactivated, compressor motor speed goes up

with restricting the maximum speed gradually

from operation start.

• When room temperature is lower than set

temperature, indoor fan motor is operated at fan

speed L– as shown in Fig. 8-2-2 while the

outdoor unit stops.

– 15 –

2. Prevent-freezing control

If temperature of indoor heat exchanger detected

by the indoor heat exchanger sensor is 4 °C or

lower, compressor motor speed is gradually

lowered to pre vent freezing of the indoor heat

exchanger. If temperature is 6°C or higher, return

the operation to the above item 1.

3. Limit for maximum compressor motor

speed by indoor fan speed

When outdoor temperature sensor detected 32°C

or lower, and indoor heat exchanger sensor

detected 15°C or lower, the maximum compressor motor speed is limited by the indoor f an

speed.

8-2-3. DRY Operation

(The Remote controller MODE Button

is Set to the DRY Position)

• Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply b y

pushing [START/ST OP] b utton.

• Dry operation signal is transmitted to outdoor unit.

• The Cooling operation giving priority to dehumidify-

ing, which restrains the indoor fan speed and

compressor motor speed, is performed.

• The indoor fan motor operates as shown in Fig. 8-

2-3. (Fan speed is AUTO only.)

• The outdoor unit controls the outdoor fan relay and

the compressor motor speed according to the

operation command signal sent from the indoor

unit.

1. Dehumidifying-preferential Cooling capacity control

• The cooling capacity and room temperature are

controlled by changing the compressor motor

speed according to both the difference between

the temperature detected by the room temperature sensor and the temperature set by TEMP

button and also any change in room temperature.

• When the air conditioner operates in Dry mode,

the maximum compressor motor speed is

restricted.

While multiple indoor units operate, compressor

motor speed is calculated in the outdoor unit to

operate.

• When room temperature is lower than set

temperature, indoor fan motor is operated at fan

speed UL as shown in Fig. 8-2-3 while the

outdoor unit stops.

• Other controls than the above-mentioned

controls are common to those of Cooling

operation.

8-2-4. Heating Operation

(Heat pump model only)

Transferring of heating operation signal from indoor

unit to outdoor unit starts.

The indoor fan motor operates b y the room temper ature when selecting “AUTO” of “FAN” as shown in Fig.

8-2-4, and operates with a set air flow when selecting

“Low” to “High”.

However, to prev ent cold draft, revolution speed of

the fan is restricted by indoor heat exchanger temperature when air flow is AUTO (Fig. 8-2-5) and

starting of FAN Manual.

+2.5

+2.0

+1.5

+1.0

+0.5

(Room temp.) – (Set temp.)

Set

temp.

0

–0.5

NOTE :

1 : Middle motor speed betw een L– and UL

*

Fig. 8-2-3 Setting of air flo w

L–

*1

UL

[Basic control]

NOTE :

1, *2 : Approximate revolution speed of M+ and L to

*

– 16 –

Set

temp.

(Room temp.) –

–0.5

–1

–1.5

–2

(Set temp.)

–5.0

–5.5

[FAN AUTO]

0

linear according to temperature.

Fig. 8-2-4 Setting of air flo w

LOW

1

*

2

*

M+

HIGH

[Cold draft preventing control]

The upper limit of fan revolution speed is shown

below.

TC

(˚C)

44

43

31

30

A + 4

A – 8

FAN

AUTO

33

32

20

19

2

*

A

A – 8

Starting

of FAN

Manual

HIGH

Approximate

revolution speed

of HIGH and SUL

linear by Tc.

3

*

SUL

( NOTE : *1)

SUL

Stop

NOTES :

1 Stops for 2 minutes after thermostat-OFF.

*

224°C when the set temp. is 24°C or more

*

Set temp. when the set temp. is belo w 24°C

3 SUL : Super ultra low

*

Fig. 8-2-5 Cold draft preventing control

The outdoor unit controls the outdoor fan based upon

the operation signal sent from the indoor unit, and

also controls revolution speed of the compressor

motor.

The power coupler for 4-way valve is turned on, and

turned off in defrost operation.

1. Heating capacity control

Calculate the difference between temperature

detected by room temp. sensor every minute and

the set temp. set on “Temp. indicator” and variation amount of room temp.

Then, obtain the correction amount of the command signal, and correct the current frequency

command signal.

2. High-temp. release control

If temperature of the indoor heat exchanger

detected by the indoor heat exchanger sensor is

58°C or higher, compressor motor speed is

gradually lowered to prevent over-temp. rising of

compressed pressure.

If temperature becomes below 51°C, return to

above item 1.

3. Defrost control

1) Detection of frost

In heating operation, time duration while the

compressor operates is counted, and defrost

operation starts by any condition described

below.

a. The counted time is 28 minutes or more,

and status that temperature of the outdoor

heat exchanger detected by the outdoor

heat exchanger is –20°C or low er continued for 3 minutes or more.

b. The counted time is 28 minutes or more,

and status that temperature of the outdoor

heat exchanger detected by the outdoor

heat exchanger is –8°C or low er and

temperature lowered by 2.5 °C than the

minimum value of the outdoor heat e x changer during 10 to 15 minutes count time

continued for 3 minutes or more .

c. The counted time is 34 minutes or more,

and status that temperature of the outdoor

heat exchanger detected by the outdoor

heat exchanger is –5°C or low er and

temperature lowered by 3.0 °C than the

minimum value of the outdoor heat e x changer during 10 to 15 minutes count time

continued for 3 minutes or more .

d. The counted time is 4 hours or more, and

status that temperature of the outdoor heat

exchanger detected by the outdoor heat

exchanger is 0°C or lower and temper ature

lowered by 1.0 °C than the minimum value

of the outdoor heat exchanger during 10 to

15 minutes count time continued for 3

minutes or more.

e. If the following three conditions are satis-

fied, defrost operation (Timer defrost) starts

after heating operation for 48 minutes.

Setting on remote controller, HEAT

(mode), HIGH (Fan), 30°C (temp.).

Room temp. is 19°C to 24°C, and

outside air temp. is 5°C or lower.

Defrost operation has been already

performed once.

2) Defrost operation

Operation of the compressor is stopped once,

turn off power coupler for 4-way valve after 10

seconds, and then exchange the

4-way v alv e.

After 20 seconds, restart operation of the

compressor. Turn off the outdoor fan just when

the compressor stopped.

If temperature of the indoor heat exchanger is

lower than settimg temperature, stop the

indoor fan.

– 17 –

3) Defrost reset

Resetting operation from defrost to heating is

performed when any one of the following

conditions is satisfied.

a. Temperature of the outdoor heat exchanger

rose to +8°C or higher.

b. A status that temperature of the outdoor

heat exchanger is +5°C or higher continued

for 80 seconds.

c. Defrost operation continued for 10 minutes .

In resetting defrost operation, the compressor

stops for 50 seconds if defrost has started

under condition a. to d. in item 1, but the

compressor is reset to heating operation

keeping operated if defrost has started under

condition e. in item 1.

8-2-6. ECO Timer Operation

When you push the ECO button during cooling, Dry,

Heating, or A operation, the air conditioner will start

the following operation.

The fan speed will be automatically controlled.

• Cooling operation / Dry operation

In the operation suppression zone, where capacity

is kept to the minimum, overcooling is prevented by

raising the temperature setting by 1°C after 1 hour

and by 2°C after 2 hours of operation.

The room temperature is thus regulated between

the operation suppression zone and the set temperature.

Operation suppression zone

8-2-5. Auto Operation

1. Selection of operation mode

As shown in Fig. 8-2-6, the operation starts by

selecting automatically the status of the room

temperature (Ta) when starting AUTO oper ation.

Ts : Setting temper ature by remote controller

Ta

Cool operation

Ts + 1

Minitoring (Fan only)

Ts – 1

Heating operation (Heat pump model)

Fan only operation (Cooling only model)

*1 When reselecting the operation mode, the fa n

speed is controlled by the previous oper ation

mode.

Operation start

1˚C

1 hour

2 hours

2˚C

Room

temperature

Set

temperature

Fig. 8-2-7

• Heating operation

(Heat pump model only)

In the operation suppression zone, where capacity

is kept to the minimum, ov erheating is prevented by

lowering the temperature setting by 1°C after 1

hour and by 2°C after 2 hours of operation.

The room temperature is thus regulated between

the set temperature and the operation suppression

zone.

Set temperature

Room

2˚C

temperature

Operation

suppression zone

Operation start

1˚C

1 hour

2 hours

Fig. 8-2-8

Fig. 8-2-6

2. Mode selection is done again if the cpmpressor

turns off for 15 minutes continuesly, due to the

room temperature.

8-2-7. High POWER Operation

When you push the Hi-POWER button during Cooling, Heating, or A operation, the air conditioner will

start the following operation. (A operation : Auto

change over)

• Cooling operation

Performs the cooling operation at 1°C low er than

the setting temperature.

When the room temperature is above the setting

temperature. In addition, fan speed is high*.

* Noise level r aises in accordance with fan speed.

• Heating operation (Heat pump model only)

Performs the heating operation at 2°C higher than

the setting temperature.

– 18 –

Loading...

Loading...