A+PUVCNNCVKQPA%1 8HO2CIG6WGU FC[,CPWCT[ 2/

INSTALLATION MANUAL

MANUEL D’INSTALLATION

EINBAUANLEITUNG

MANUALE DI INSTALLAZIONE

MANUAL DE INSTALACIÓN

ȅǻǾīǿǼȈ ǼīȀǹȉǹȈȉǹȈǾȈ

MANUAL DE INSTALAÇÃO

INSTALLATIEHANDLEIDING

ИНСТРУКЦИЯ ПО УСТАНОВКЕ

AIR CONDITIONER (SPLIT TYPE)

For general public use

CLIMATISEUR (TYPE SEPARE)

KLIMAGERÄT (GETEILTE AUSFÜHRUNG)

CONDIZIONATORE D’ARIA (TIPO SPLIT)

ACONDICIONADOR DE AIRE (TIPO SEPARADO)

ȀȁǿȂǹȉǿȈȉǿȀǾ Ȃȅȃǹǻǹ (ǻǿǹǿȇȅȊȂǼȃȅȊ ȉȊȆȅȊ)

AR CONDICIONADO (TIPO SPLIT)

AIRCONDITIONER (TWEEDELIG TYPE)

КОНДИЦИОНЕР (РАЗДЕЛИТЕЛЬНЫЙ ТИП)

Pour utilisation grand public

Für allgemeine Verwendung

Per l’uso in generale

Para el uso público general

īȚĮ ȖİȞȚțȒ įȘμȩıȚĮ ȤȡȒıȘ

Para utilização geral

Voor algemeen publiek gebruik

Для общего бытового использования

ENGLISHFRANÇAISDEUTSCHITALIANOESPAÑOLǼȁȁǾȃǿȀǹPORTUGUÊSРУССКИЙ ЯЗЫК NEDERLANDS

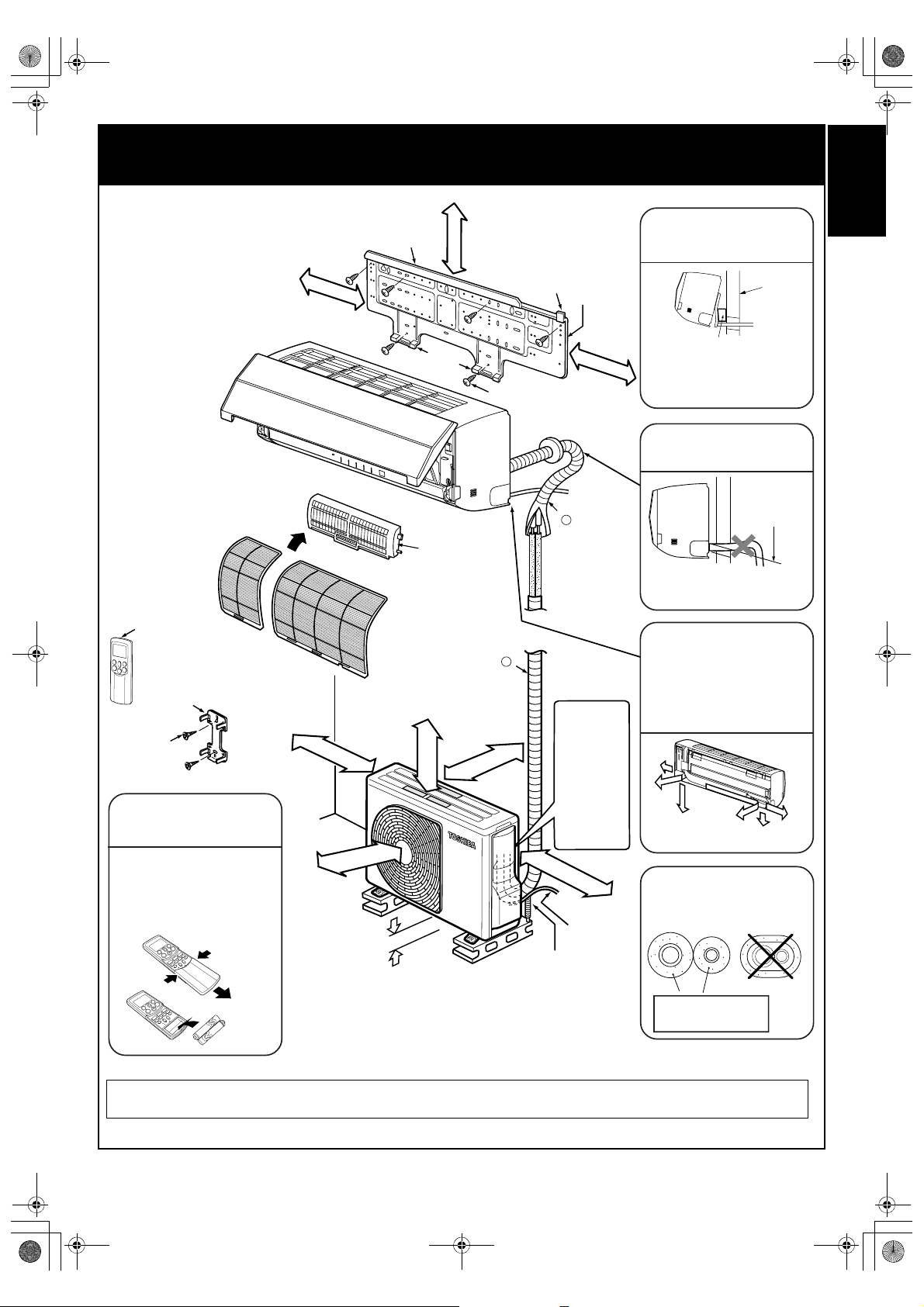

Indoor Unit Outdoor Unit

Unité intérieure Unité extérieure

Innenraumgerät Außengerät

Unità interna Unità esterna

Unidad interior Unidad exterior

ǼıȦIJİȡȚțȒ μȠȞȐįĮ ǼȟȦIJİȡȚțȒ μȠȞȐįĮ

Unidade interior Unidade exterior

Binnenapparaat Buitenapparaat

Внутренний блок Наружный блок

RAS-B10SKVP-E

RAS-B13SKVP-E

RAS-B16SKVP-E

RAS-M10SKCVP-E

RAS-M13SKCVP-E

RAS-M16SKCVP-E

nchasing this TOSHIBA Air Conditioner. Please read this owner’s manual carefully before using your Air Conr.

Please read this installation manual carefully before installing the air conditioner.

Veuillez lire attentivement ce manuel avant d’installer le climatiseur.

Lesen Sie diese Einbauanleitung sorgfältig durch, bevor Sie das Klimagerät installieren.

Prima di installare il condizionatore d’aria, si consiglia di leggere con attenzione il presente manuale di installazione.

Lea este manual de instalación atentamente antes de instalar el acondicionador de aire.

ȆĮȡĮțĮȜȠȪμİ įȚĮȕȐıIJİ ĮȣIJȑȢ IJȚȢ ȠįȘȖȓİȢ İȖțĮIJȐıIJĮıȘȢ ʌȡȠıİțIJȚțȐ ʌȡȚȞ İȖțĮIJĮıIJȒıİIJİ IJȘȞ

țȜȚμĮIJȚıIJȚțȒ μȠȞȐįĮ.

Leia atentamente este manual de instalação antes de instalar o ar condicionado.

Leest u vooral deze installatiehandleiding aandachtig door alvorens de airconditioner te installeren.

Перед установкой кондиционера прочитайте, пожалуйста, внимательно эту инструкцию по

установке.

RAS-10SAVP-E

RAS-13SAVP-E

RAS-16SAVP-E

RAS-M14GAV-E

RAS-M18GAV-E

RAS-M14GACV-E

RAS-M18GACV-E

00_Installation_TOC.fm Page i Tuesday, January 9, 2007 10:27 AM

CONTENTS/SOMMAIRE/INHALT/INDICE/ÍNDICE/

ÍNDICE/INHOUD/

ENGLISH

1 SAFETY PRECAUTIONS .............................................. 1

2 INSTALLATION DIAGRAM OF INDOOR AND

OUTDOOR UNITS .........................................................3

3 OPTIONAL PARTS, ACCESORIES AND TOOLS ........4

4 INSTALLATION OF INDOOR UNIT ...............................6

5 INSTALLATION OF OUTDOOR UNIT .........................12

6 TEST OPERATION ......................................................16

FRANÇAIS

1 MESURES DE SECURITE ............................................1

2 SCHEMAS D’INSTALLATION DES UNITES

INTERIEURE ET EXTERIEURE ....................................3

3 PIECES EN OPTION, ACCESSOIRES ET OUTILS .....4

4 INSTALLATION DE L’UNITE INTERIEURE ..................6

5 INSTALLATION DE L’UNITE EXTERIEURE ...............12

6 OPERATION D’ESSAI .................................................16

DEUTSCH

1 SICHERHEITSVORKEHRUNGEN ................................ 1

2 EINBAUZEICHNUNGEN FÜR INNENRAUM- UND

AUSSENGERÄT ............................................................3

3 SONDERTEILE, SONDERZUBEHÖR UND

WERKZEUGE ................................................................4

4 INSTALLATION DES INNENRAUMGERÄTS ...............6

5 INSTALLATION DES AUSSENGERÄTS ....................12

6 PROBELAUF ...............................................................16

ITALIANO

1 PRECAUZIONI PER LA SICUREZZA ...........................1

2 SCHEMA DI INSTALLAZIONE DELL’UNITÀ

INTERNA E DELL’UNITÀ ESTERNA ............................3

3 COMPONENTI OPZIONALI, ACCESSORI E

STRUMENTI ..................................................................4

4 INSTALLAZIONE DELL’UNITÀ INTERNA ..................... 6

5 INSTALLAZIONE DELL’UNIT À ESTERNA ................12

6 FUNZIONAMENTO DI PROVA ...................................16

ESPAÑOL

1 PRECAUCIONES SOBRE SEGURIDAD ......................1

2 DIAGRAMA DE INSTALACIÓN DE LAS UNIDADES

INTERIOR Y EXTERIOR ...............................................3

3 PARTES OPCIONALES, ACCESORIOS Y

HERRAMIENTAS ..........................................................4

4 INSTALACIÓN DE LA UNIDAD INTERIOR ...................6

5 INSTALACIÓN DE LA UNIDAD EXTERIOR ...............12

6 OPERACIÓN DE PRUEBA .......................................... 16

СОДЕРЖАНИЕ

ǼȁȁǾȃǿȀǹ

1 ȆȇȅĭȊȁǹȄǼǿȈ ǹȈĭǹȁǼǿǹȈ ....................................... 1

2 ǼǿȀȅȃǼȈ ǼīȀǹȉǹȈȉǹȈǾȈ ǼȈȍȉǼȇǿȀǾȈ Ȁǹǿ

ǼȄȍȉǼȇǿȀǾȈ ȂȅȃǹǻǹȈ ............................................. 3

3 ȆȇȅǹǿȇǼȉǿȀǹ ǹȃȉǹȁȁǹȀȉǿȀǹ, ǼȄǹȇȉǾȂǹȉǹ Ȁǹǿ

ǼȇīǹȁǼǿǹ ..................................................................... 4

4 ǼīȀǹȉǹȈȉǹȈǾ ǼȈȍȉǼȇǿȀǾȈ ȂȅȃǹǻǹȈ ................... 6

5 ǼīȀǹȉǹȈȉǹȈǾ ǼȄȍȉǼȇǿȀǾȈ ȂȅȃǹǻǹȈ ................. 12

6 ǻȅȀǿȂǹȈȉǿȀǾ ȁǼǿȉȅȊȇīǿǹ ...................................... 16

PORTUGUÊS

1 PRECAUÇÕES DE SEGURANÇA ................................ 1

2 DIAGRAMA DE INSTALAÇÃO DAS UNIDADES

INTERIOR E EXTERIOR ............................................... 3

3 PEÇAS OPCIONAIS, ACESSÓRIOS E

FERRAMENTAS ........................................................... 4

4 INSTALAÇÃO DA UNIDADE INTERIOR ...................... 6

5 INSTALAÇÃO DA UNIDADE EXTERIOR ...................12

6 TESTE ......................................................................... 16

NEDERLANDS

1 VEILIGHEIDSVOORSCHRIFTEN ................................. 1

2 INSTALLATIESCHEMA VOOR BINNEN- EN

BUITENAPPARAAT ...................................................... 3

3 OPTIONELE ONDERDELEN, ACCESSOIRES EN

GEREEDSCHAP ........................................................... 4

4 INSTALLEREN VAN HET BINNENAPPARAAT ............ 6

5 INSTALLEREN VAN HET BUITENAPPARAAT .......... 12

6 PROEFDRAAIEN ........................................................ 16

РУССКИЙ ЯЗЫК

1 МЕРЫ ПРЕДОСТОРОЖНОСТИ ................................. 1

2 ДИАГРАММА УСТАНОВКИ ВНУТРЕННЕГО И

НАРУЖНОГО БЛОКОВ ............................................... 3

3 ДОПОЛНИТЕЛЬНЫЕ ЧАСТИ,

ПРИНАДЛЕЖНОСТИ И ИНСТРУМЕНТЫ .................. 4

4 УСТАНОВКА ВНУТРЕННЕГО БЛОКА ....................... 6

5 УСТАНОВКА НАРУЖНОГО БЛОКА ......................... 12

6 ТЕСТОВАЯ ЭКСПЛУАТАЦИЯ .................................. 16

ȆǼȇǿǼȋȅȂǼȃǹ

/

i

01_Installation_EN.fm Page 1 Tuesday, January 9, 2007 10:36 AM

1 SAFETY PRECAUTIONS

For general public use

Power supply cord of outdoor unit shall be 1.5 mm2 (H07RN-F or 60245IEC66) polychloroprene sheathed flexible cord.

CAUTION

New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT DESTROY OZONE

LAYER.

R410A refrigerant is apt to be affected by impurities such as water, oxidizing membrane, and oils because the working pressure of

R410A refrigerant is approx. 1.6 times as that of refrigerant R22. Accompanied with the adoption of the new refrigerant, the

refrigeration machine oil has also been changed. Therefore, during installation work, be sure that water, dust, former refrigerant,

or refrigeration machine oil does not enter the new type refrigerant R410A air conditioner circuit.

To prevent mixing of refrigerant or refrigerating machine oil, the sizes of connecting sections of charging port on main unit and

installation tools are different from those of the conventional refrigerant units. Accordingly, special tools are required for the new

refrigerant (R410A) units as shown on page 5. For connecting pipes, use new and clean piping materials with high pressure

fittings made for R410A only, so that water and/or dust does not enter. Moreover, do not use the existing piping because there are

some problems with pressure fittings and possible impurities in existing piping.

CAUTION

TO DISCONNECT THE APPLIANCE FROM THE MAIN POWER SUPPLY

A switch or circuit breaker that can disconnect all poles must be included in the fixed wiring. Be sure to use an approved circuit

breaker or switch.

DANGER

• FOR USE BY QUALIFIED PERSONS ONLY.

• TURN OFF MAIN POWER SUPPLY BEFORE ATTEMPTING ANY ELECTRICAL WORK. MAKE SURE ALL POWER

SWITCHES ARE OFF. FAILURE TO DO SO MAY CAUSE ELECTRIC SHOCK.

• CORRECTLY CONNECT THE CONNECTING CABLE. IF THE CONNECTING CABLE IS INCORRECTLY CONNECTED,

ELECTRIC PARTS MAY BE DAMAGED.

• CHECK THAT THE EARTH WIRE IS NOT BROKEN OR DISCONNECTED BEFORE INSTALLATION. FAILURE TO DO SO

MAY CAUSE ELECTRIC SHOCK.

• DO NOT INSTALL THE UNIT IN A PLACE WHERE INFLAMMABLE GAS CAN LEAK. A FIRE CAN RESULT IF

INFLAMMABLE GAS ACCUMULATES AROUND THE UNIT.

• TO PREVENT THE INDOOR UNIT FROM OVERHEATING AND CAUSING A FIRE HAZARD, PLACE THE UNIT WELL

AWAY (MORE THAN 2 M) FROM HEAT SOURCES SUCH AS RADIATORS, HEAT REGISTORS, FURNACE, STOVES,

ETC.

• WHEN MOVING THE AIR-CONDITIONER FOR INSTALLATION TO ANOTHER PLACE, BE VERY CAREFUL NOT TO

ALLOW THE SPECIFIED REFRIGERANT (R410A) TO BECOME MIXED WITH ANY OTHER GASEOUS BODY INTO THE

REFRIGERATION CIRCUIT. IF AIR OR ANY OTHER GAS MIXES WITH THE REFRIGERANT, THE GAS PRESSURE IN

THE REFRIGERATION CIRCUIT WILL BECOME ABNORMALLY HIGH AND IT MAY RESULT IN THE PIPE BURSTING OR

PERSONNEL INJURIES.

• IN THE EVENT THAT THE REFRIGERANT GAS LEAKS OUT OF THE PIPE DURING THE INSTALLATION WORK,

IMMEDIATELY LET FRESH AIR INTO THE ROOM. IF THE REFRIGERANT GAS IS HEATED, POISONOUS GAS MAY

RESULT.

• WHEN INSTALLING THE AIR CONDITIONER UNIT, MAKE SURE THAT THE REFRIGERANT PIPE IS CONNECTED

SECURELY BEFORE THE COMPRESSOR IS OPERATED. IF THE COMPRESSOR IS OPERATED WITH THE

REFRIGERANT PIPE UNCONNECTED, WHICH MEANS THAT THE SERVICE VALVE WILL BE LEFT OPEN, AIR, ETC.

WILL BE SUCKED IN, CAUSING THE PRESSURE INSIDE THE REFRIGERATION CYCLE TO RISE TO AN

ABNORMALLY HIGH LEVEL, AND POSSIBLY RESULTING IN RUPTURE, INJURY, ETC.

• WHEN CARRYING OUT THE PUMP-DOWN WORK, SHUT DOWN THE COMPRESSOR BEFORE DISCONNECTING

THE REFRIGERANT PIPE. DISCONNECTING THE REFRIGERANT PIPE WITH THE SERVICE VALVE LEFT OPEN AND

WITH THE COMPRESSOR STILL OPERATING WILL CAUSE AIR, ETC. TO BE SUCKED IN, RAISING THE PRESSURE

INSIDE THE REFRIGERATION CYCLE TO AN ABNORMALLY HIGH LEVEL, AND POSSIBLY RESULTING IN

RUPTURING, INJURY, ETC.

ENGLISHFRANÇAISDEUTSCHITALIANOESPAÑOLǼȁȁǾȃǿȀǾPORTUGUÊS###SW######RU###

1 EN

01_Installation_EN.fm Page 2 Tuesday, December 26, 2006 4:36 PM

WARNING

• Never modify this unit by removing any of the safety guards.

• The installation of the air conditioner must be positioned in a location that can sufficiently support its weight. Failure to do so

may result in unit damage and human injury.

• Appliance shall be installed in accordance with national wiring regulations.

• If you detect any damage, do not install the unit. Contact your Toshiba dealer immediately.

CAUTION

• Exposure of unit to water or other moisture before installation may result in an electrical short. Do not store in a wet

basement or expose to rain or water.

• After unpacking the unit, examine it carefully for any damage.

• Do not install in a place that can increase the vibration of the unit. Do not install in a place that can amplify the noise level of

the unit or where noise or discharged air might disturb neighbors.

• To avoid personal injury, be careful when handling parts with sharp edges.

• Please read this installation manual carefully before installing the unit. It contains further important instructions necessary for

proper installation.

• Wear work gloves when carrying out the installation work or repairs. Contact with parts, etc. may cause injury if the work or

repairs are conducted without wearing gloves.

EN

2

01_Installation_EN.fm Page 3 Tuesday, December 26, 2006 4:36 PM

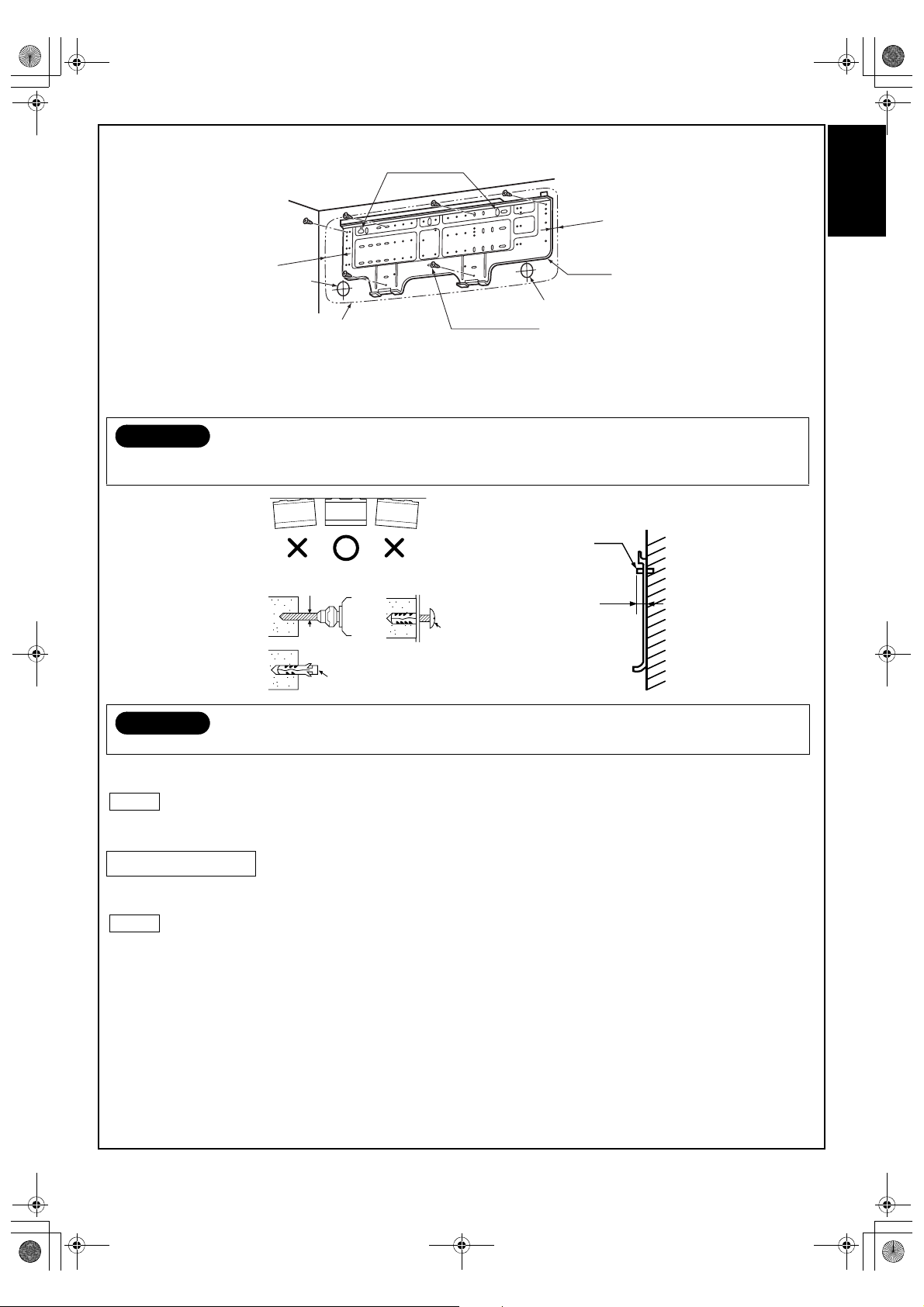

2 INSTALLATION DIAGRAM OF INDOOR AND OUTDOOR

UNITS

Hook

47 mm or more

For the rear left and left

piping

ENGLISHFRANÇAISDEUTSCHITALIANOESPAÑOLǼȁȁǾȃǿȀǾPORTUGUÊS###SW######RU###

b Wireless remote controller

d Remote controller holder

g Remote

controller holder

mounting screw

Before installing the wireless

remote controller

• With the remote controller

cover removed, correctly

load the supplied batteries

while observing their

polarity.

b Wireless remote controller

Cover

c Batteries

Air filters

100 mm or

more from

140 mm or

more

(C)

wall

200 mm or

more

When installing the

outdoor unit, leave

open in at least two

of directions (A),

(B), (C) and (D)

shown in the right

figure.

(B)

Hook

e Plasma pure filter

80 mm or more only

when unobstructed to

the front and both sides

In principle,

leave open

Ensure sufficient

space to allow

drainage

f Mounting screw

Y

50 mm or more

from wall

(D)

a Installation

Hook

plate

74 mm or

more

Shield pipe

Z

(for extension

drain hose)

As shown in the

figure, position

power cord and

connecting

cable

downward, and

lead out along

piping

connection port.

(A)

250 mm or

more from wall

power cord

Extension drain hose

(Option: RB–821SW)

Wall

Insert the cushion between

the indoor unit and wall, and

tilt the indoor unit for better

installation work.

Do not allow the drain hose

to become slack.

Cut the piping

hole slightly

sloped

Make sure the drain hose is

sloped downward.

The auxiliary piping can be

connected at the left, rear

left, rear right, right, bottom

right or bottom left as shown

below.

Right

Rear

right

Rear left

Bottom right

Bottom left

Insulate the refrigerant pipes

separately, not together.

6 mm thick heat resisting

polyethylene foam

Left

When using a multi-system outdoor unit, refer to the installation manual provided with the model

concerned.

3 EN

01_Installation_EN.fm Page 4 Tuesday, December 26, 2006 4:36 PM

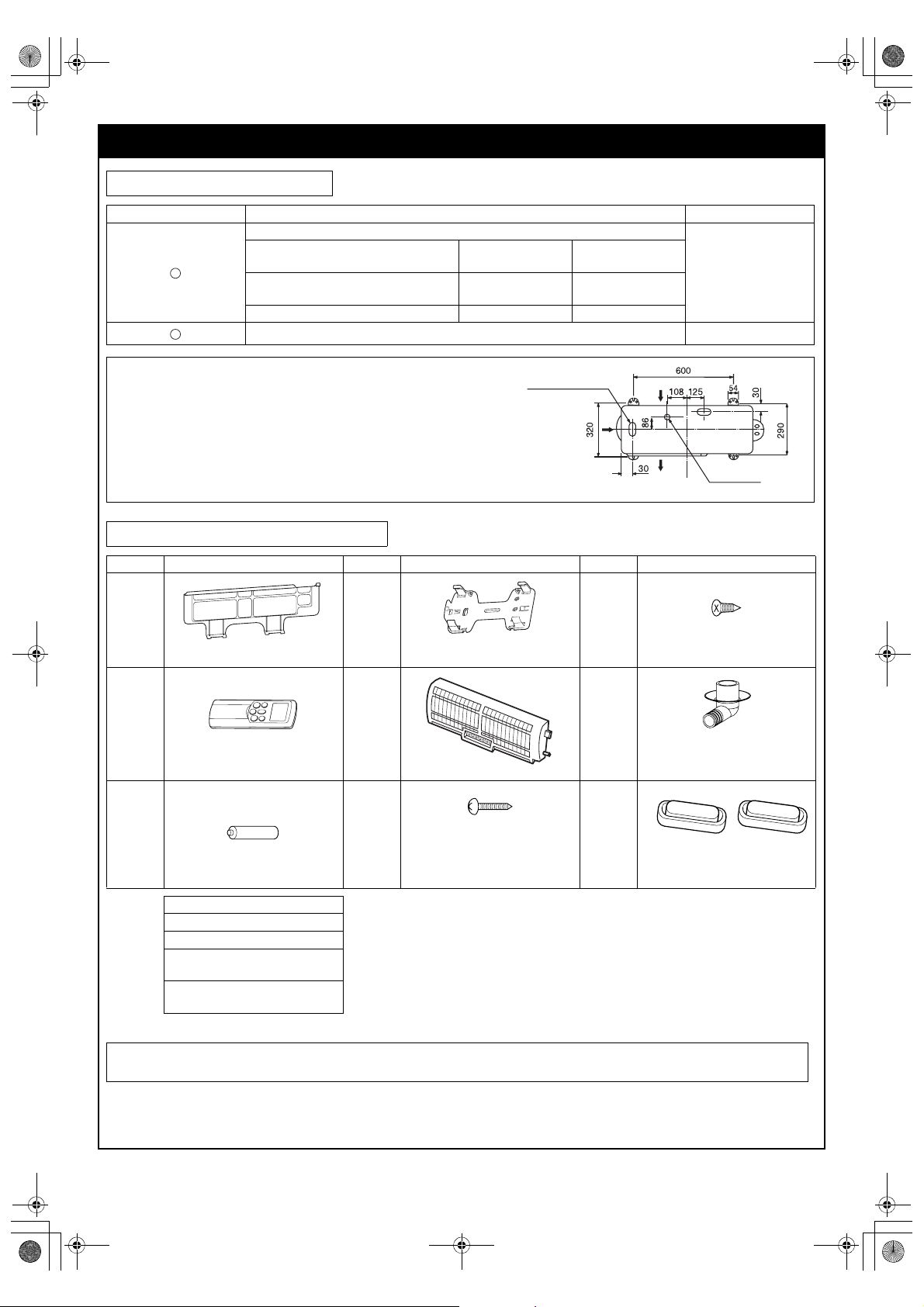

3 OPTIONAL PARTS, ACCESORIES AND TOOLS

Optional Installation Parts

Part Code Parts name Q’ty

Refrigerant piping

Indoor unit name

Y

Z

RAS-B10SKVP-E, B13SKVP-E

RAS-M10SKCVP-E, M13SKCVP-E

RAS-B16SKVP-E, M16SKCVP-E 6.35 mm 12.7 mm

Shield pipe (for extension drain hose) (polyethylene foam, 6 mm thick) 1

Liquid side

(Outer diameter)

6.35 mm 9.52 mm

Gas side

(Outer diameter)

1 ea.

Attachment bolt arrangement of outdoor unit

• Secure the outdoor unit with the attachment bolts and nuts if the unit is

likely to be exposed to a strong wind.

• Use I8 mm or I10 mm anchor bolts and nuts.

• If it is necessary to drain the defrost water, attach drain nipple to the

base plate of the outdoor unit before installing it.

Elongated drain

hole

(i)

Suction side

Diffuser

Drain hole

(h)

Accessory and Installation Parts

Part No. Part name (Q’ty) Part No. Part name (Q’ty) Part No. Part name (Q’ty)

a

Installation plate x 1

b

Wireless remote controller x 1

d

e

Remote controller holder x 1

Plasma pure filter x 1

g

h

Remote controller holder

mounting screw

I3.1 x 16L x 2

Drain nipple* x 1

(RAS-10SAVP-E, 13SAVP-E,

16SAVP-E)

c

Battery x 2

Others Name This model is not equipped with an

Owner’s manual

Installation manual

Important information

and warning*

B/W strips

(Energy efficiency labels)

f

extension drain hose.

Option:

For the extension drain hose, use the

optionally available RB-821SW or a

commercially available one.

Mounting screw

I4 x 25L x 6

i

Water-proof rubber cap* x 2

(RAS-10SAVP-E, 13SAVP-E,

Parts marked with asterisk (*) are packaged with the

outdoor unit.

When using a multi-system outdoor unit, refer to the installation manual provided with the model

concerned.

EN

4

16SAVP-E)

01_Installation_EN.fm Page 5 Tuesday, December 26, 2006 4:36 PM

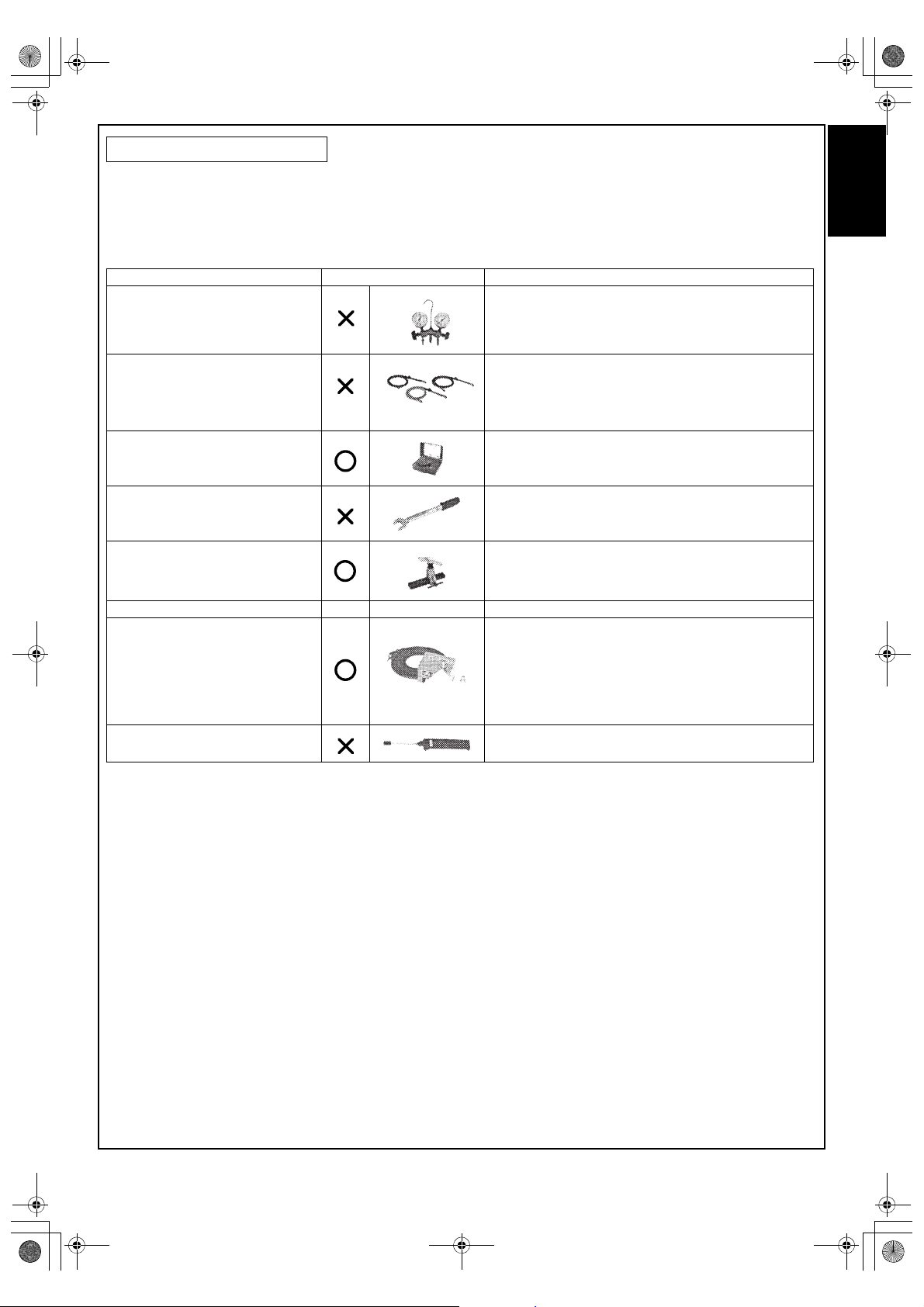

Installation/Service Tools

Changes in the product and components

On air conditioners using R410A, in order to prevent any other refrigerant from being accidentally charged, the service port diameter

size of the outdoor unit control valve (3 way valve) has been changed. (1/2 UNF 20 threads per inch)

• In order to increase the pressure resisting strength of the refrigerant piping, flare processing diameter and opposing flare nuts sizes

have been changed. (for copper pipes with nominal dimensions 1/2 and 5/8)

New tools for R410A

New tools for R410A Applicable to R22 model Changes

Gauge manifold As the working pressure is high, it is impossible to measure

Charge hose In order to increase pressure resisting strength, hose

Electronic balance for refrigerant

charging

Torque wrench

(nominal dia. 1/2, 5/8)

Flare tool (clutch type) By increasing the clamp bar’s receiving hole size, strength

the working pressure using conventional gauges. In order to

prevent any other refrigerant from being charged, the port

diameters have been changed.

materials and port sizes have been changed (to 1/2 UNF 20

threads per inch).

When purchasing a charge hose, be sure to confirm the

port size.

As working pressure is high and gasification speed is fast, it

is difficult to read the indicated value by means of charging

cylinder, as air bubbles occur.

The size of opposing flare nuts have been increased.

Incidentally, a common wrench is used for nominal

diameters 1/4 and 3/8.

of spring in the tool has been improved.

ENGLISHFRANÇAISDEUTSCHITALIANOESPAÑOLǼȁȁǾȃǿȀǾPORTUGUÊS###SW######RU###

Gauge for projection adjustment — Used when flare is made by using conventional flare tool.

Vacuum pump adapter Connected to conventional vacuum pump. It is necessary to

Gas leakage detector Exclusive for HFC refrigerant.

• Incidentally, the “refrigerant cylinder” comes with the refrigerant designation (R410A) and protector coating in the U.S’s ARI

specified rose color (ARI color code: PMS 507).

• Also, the “charge port and packing for refrigerant cylinder” requires 1/2 UNF 20 threads per inch corresponding to the charge hose’s

port size.

use an adapter to prevent vacuum pump oil from flowing

back into the charge hose. The charge hose connecting

part has two ports — one is for conventional refrigerant (7/

16 UNF 20 threads per inch) and the other is for R410A. If

the vacuum pump oil (mineral) mixes with R410A, a sludge

may occur and damage the equipment.

5 EN

01_Installation_EN.fm Page 6 Tuesday, December 26, 2006 4:36 PM

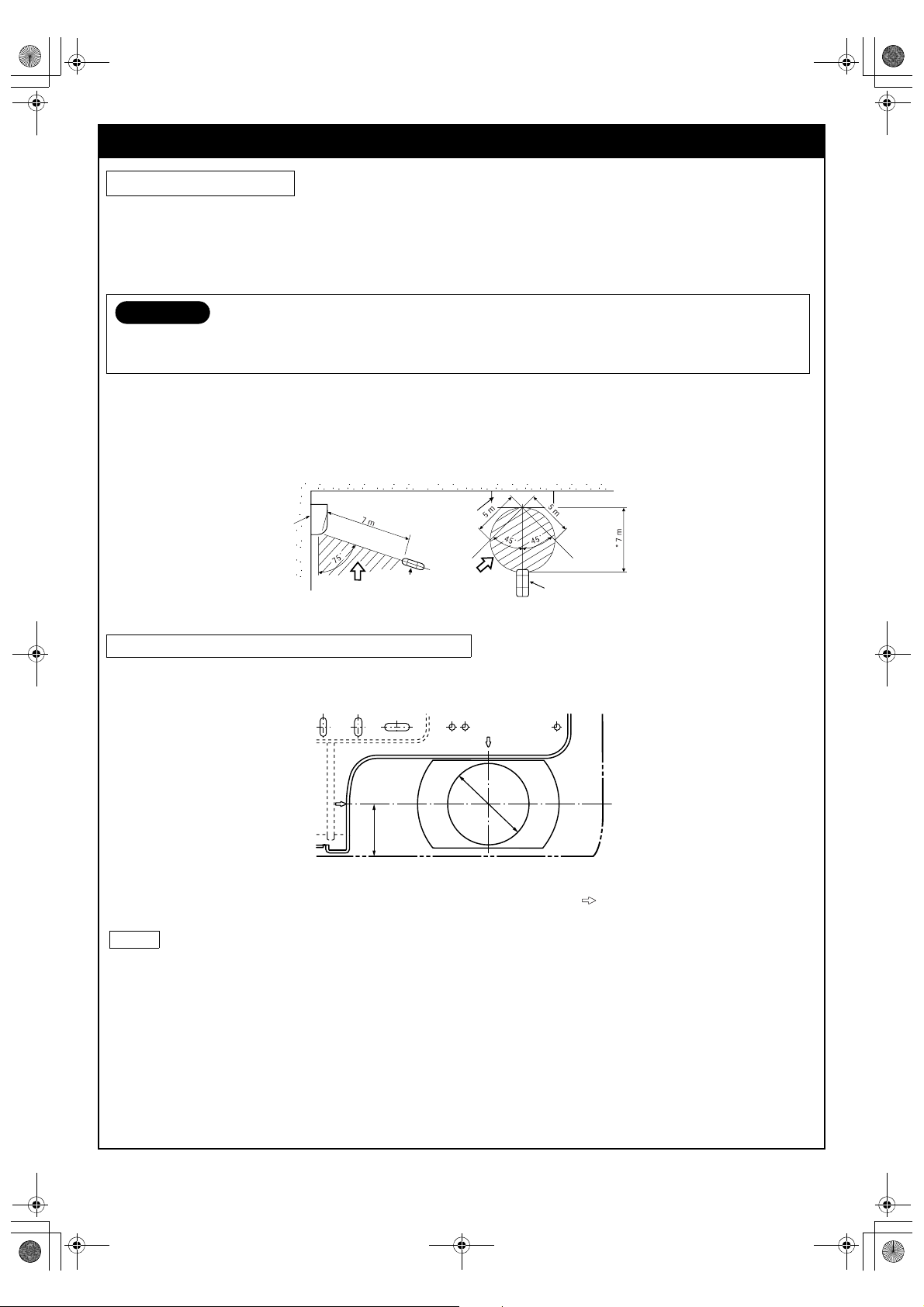

4 INSTALLATION OF INDOOR UNIT

Installation Location

• A place which provides enough space around the indoor unit as shown in the diagram. () see page 3.)

• A place where there are no obstacles near the air inlet and outlet.

• A place which allows easy installation of the piping to the outdoor unit.

• A place which allows the front panel to be opened.

• The indoor unit shall be installed so that the top of the indoor unit is positioned at least 2 m high.

Also, avoid putting anything on the top of the indoor unit.

CAUTION

• Direct sunlight on the indoor unit wireless receiver should be avoided.

• The microprocessor in the indoor unit should not be too close to r-f sources.

(For details, see the owner’s manual.)

Remote controller

• Should be placed where there are no obstacles, such as curtains, that may block the signal.

• Do not install the remote controller in a place exposed to direct sunlight or close to a heating source, such as a stove.

• Keep the remote controller at least 1 m away from the nearest TV set or stereo equipment. (This is necessary to prevent image

disturbance or noise interference.)

• The location of the remote controller should be determined as shown below.

(Side view)

Indoor unit

Reception

range

(Top view)

Indoor unit

Remote

controller

*: Axial distance

Reception

range

Remote controller

Drilling and Mounting Installation Plate

Drilling

When installing the refrigerant pipes from the rear.

The center of the

pipe hole

Pipe

hole

65 mm

42 mm

1. Decide the installation plate mounting position on the wall.

2. Mark the corresponding pipe hole wall positions according to the positioning marks ( ) on the installation plate.

3. Drill the pipe holes (I65 mm) slightly slanted downward to the outside.

NOTE

• When drilling into a wall that contains a metal lath, wire lath or metal plate, be sure to use a pipe hole brim ring sold separately.

EN

6

01_Installation_EN.fm Page 7 Tuesday, December 26, 2006 4:36 PM

Mounting the installation plate

Anchor bolt holes

ENGLISHFRANÇAISDEUTSCHITALIANOESPAÑOLǼȁȁǾȃǿȀǾPORTUGUÊS###SW######RU###

25 mm

91 mm

Pipe hole

Indoor unit

f Mounting screw

a Installation plate

Pipe hole

When the installation plate is directly mounted on the wall

1. Securely fit the installation plate onto the wall by screws with the upper and lower catches.

2. To mount the installation plate on a concrete wall use anchor bolts. Drill the anchor bolt holes as illustrated in the above figure.

3. Place the level at the top end of the installation plate, and check that the plate is horizontal.

CAUTION

When installing the installation plate with mounting screws, do not use anchor bolt holes. Otherwise the unit may fall down and

result in personal injury and property damage.

Anchor bolt

5 mm dia. hole

Projection 15 mm or less

f Mounting screw

I4 x 25L

Clip anchor

(local parts)

CAUTION

Failure to securely install the unit may result in personal injury and/or property damage if the unit falls.

• In case of block, brick, concrete or similar type walls, drill 5 mm dia. holes in the wall.

• Insert clip anchors for the

f mounting screws.

NOTE

• Install the installation plate using between 4 to 6 mounting screws, making sure all four corners are secure.

Electrical Work

1. The supply voltage must be the same as the rated voltage of the air conditioner.

2. Prepare a power source for the exclusive use of the air conditioner.

NOTE

• Wire type: H07RN-F or 60245IEC66 (1.0 mm2)

7 EN

01_Installation_EN.fm Page 8 Tuesday, December 26, 2006 4:36 PM

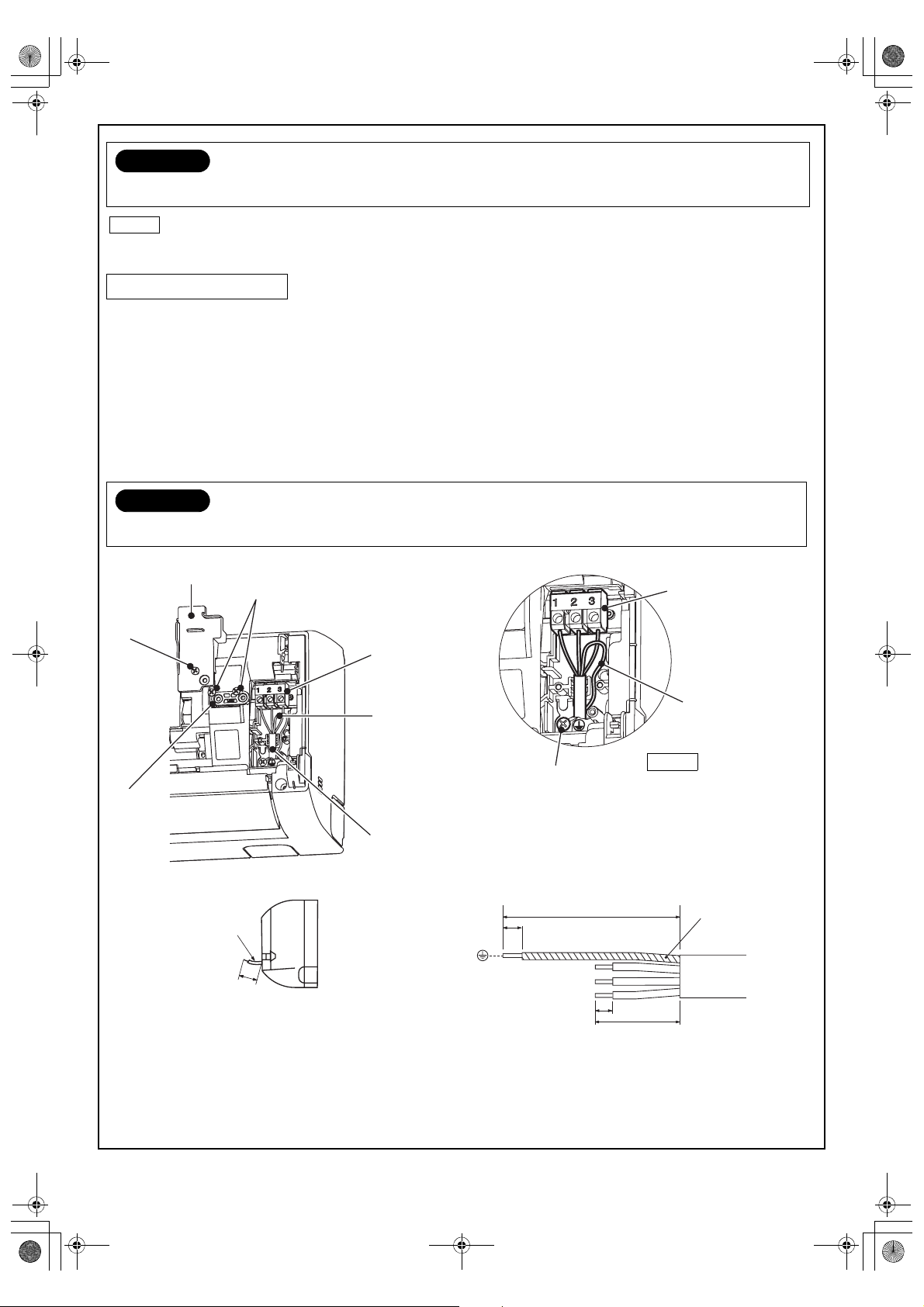

CAUTION

A switch or circuit breaker that can disconnect all poles must be included in the fixed wiring. Be sure to use an approved circuit

breaker or switch.

NOTE

• Make sure the wire length is sufficient before performing wiring work.

Wiring Connection

How to connect the connecting cable

Wiring the connecting cable can be carried out without removing the front panel.

1. Remove the air inlet grille. Open the air inlet grille upward and pull it toward you.

2. Remove the terminal cover and cord clamp.

3. Insert the connecting cable (or as according to local regulations/codes) into the pipe hole on the wall.

4. Pull the connecting cable through the cable slot on the rear panel so that it protrudes about 15 cm out of the front.

5. Insert the connecting cable fully into the terminal block and secure it tightly with screws.

Make a loop with the earth wire under the terminal block and secure it with the earth screw.

6. Tightening torque: 1.2 N·m (0.12 kgf·m)

7. Secure the connecting cable with the cord clamp.

8. Attach the terminal cover, rear plate bushing and air inlet grille on the indoor unit.

CAUTION

• Be sure to refer to the wiring system diagram labeled inside the front panel.

• Check local electrical regulations for any specific wiring instructions or limitations.

Screw

Cord clamp

Ter mi n a l c o ve r

Connecting cable

about 15 cm

Screw

Ter m i n a l bl oc k

Earth wire

Connecting cable

Earth screw

10 mm

110 mm

10 mm

Terminal block

Earth wire

(loop)

NOTE

• Connecting cable

(Indoor unit/outdoor unit)

• Wire type:

H07RN-F or 60245IEC66

2

(1.0 mm

50 mm

)

Earth line

EN

8

01_Installation_EN.fm Page 9 Tuesday, December 26, 2006 4:36 PM

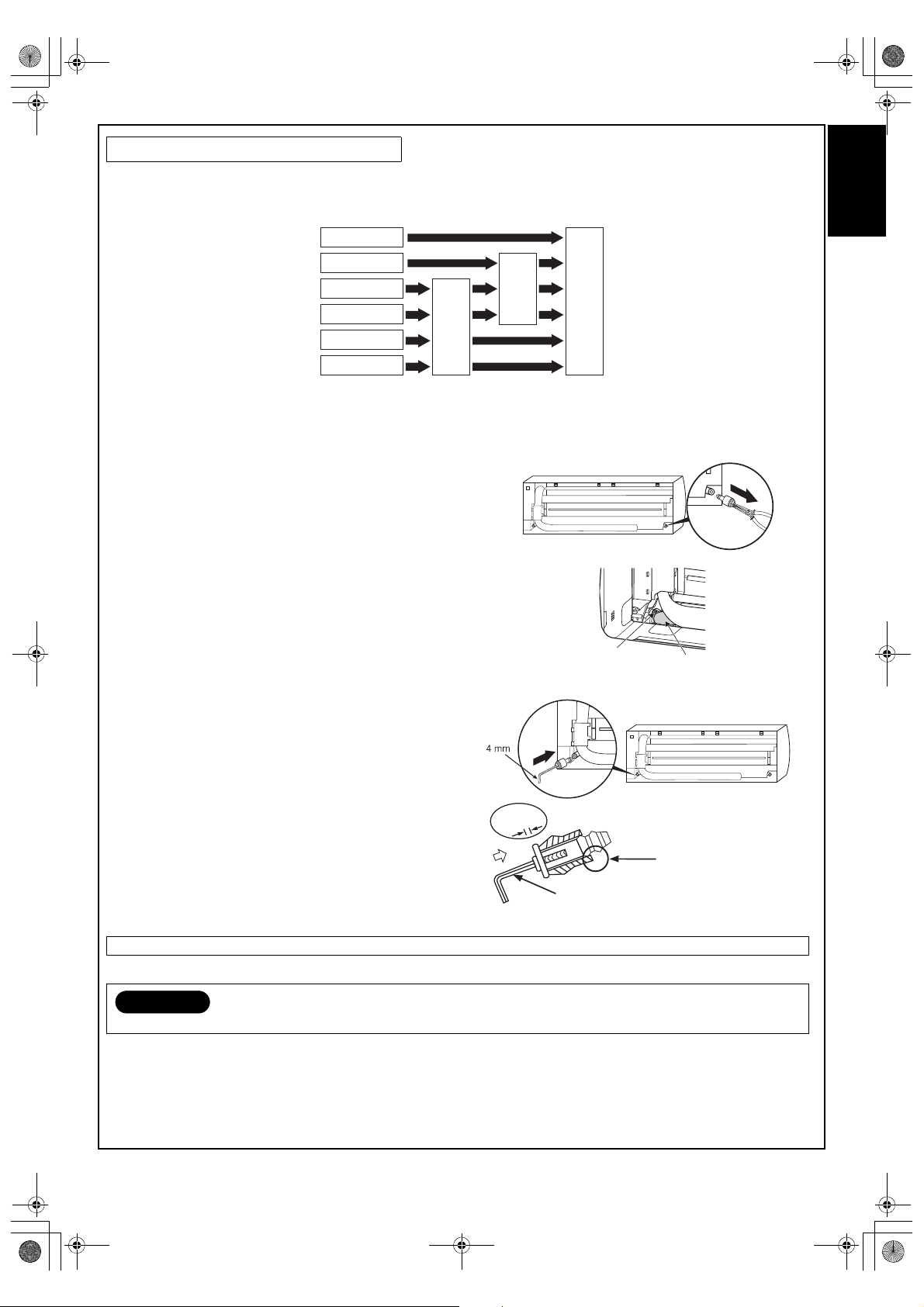

Piping and Drain Hose Installation

Piping and drain hose forming

• Since condensation results in machine trouble, make sure to insulate both the connecting pipes separately. (Use polyethylene foam

as insulating material.)

Rear right

Rear left

Bottom left

Left

Bottom right

Right

Die-cutting front

panel slit

1. Die-cutting front panel slit

Cut out the slit on the left or right side of the front panel for the left or right connection and the slit on the bottom left or right side of the

front panel for the bottom left or right connection with a pair of nippers.

2. Changing drain hose

For left connection, left-bottom connection and rear-left connection’s piping, it is necessary to relocate the drain hose and drain cap.

• How to remove the drain cap

Clamp drain cap with needle-nose pliers, and pull out.

Changing

drain hose

Piping preparation

ENGLISHFRANÇAISDEUTSCHITALIANOESPAÑOLǼȁȁǾȃǿȀǾPORTUGUÊS###SW######RU###

• How to remove the drain hose

The drain hose is secured in place by a screw.

Remove the screw securing the drain hose, then pull out the drain

hose.

Screw

Drain hose

• How to attach the drain cap

1. Insert hexagonal wrench (4 mm).

2. Firmly insert drain cap.

No gap

Insert a hexagon wrench

(4 mm)

Do not apply lubricating oil

(refrigerant machine oil) when

inserting the drain cap. If applied,

deterioration and leakage of the

drain plug may occur.

• How to attach the drain hose

Always use the original screw that secured the drain hose to the unit. Using a different screw may cause water to leak.

Insert the drain hose firmly until the connector contacts the insulation, then secure it in place using the original screw.

CAUTION

Securely insert the drain hose and drain cap; otherwise, water may leak.

9 EN

Loading...

Loading...