SERVICE MANUAL

AIR-CONDITIONER

MULTI SPLIT WALL TYPE

FILE NO. A00-9709

PRINTED IN JAPAN, May,1997 ToMo

CONTENTS

1. SPECIFICATIONS............................................................................................................ 4

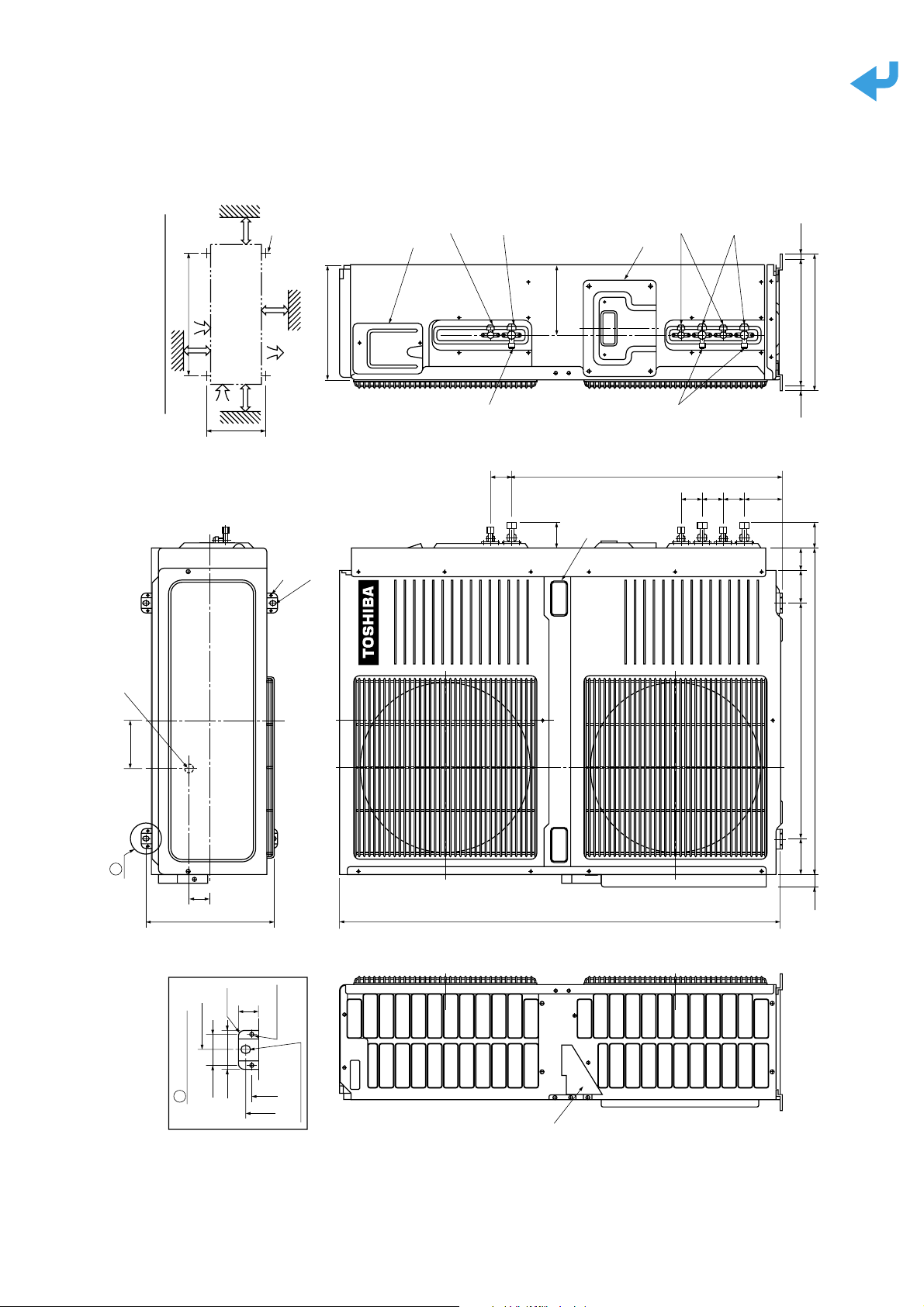

2. CONSTRUCTION VIEWS ................................................................................................ 7

2-1. Indoor Unit .................................................................................................................................. 7

2-2. Outdoor Unit ............................................................................................................................... 8

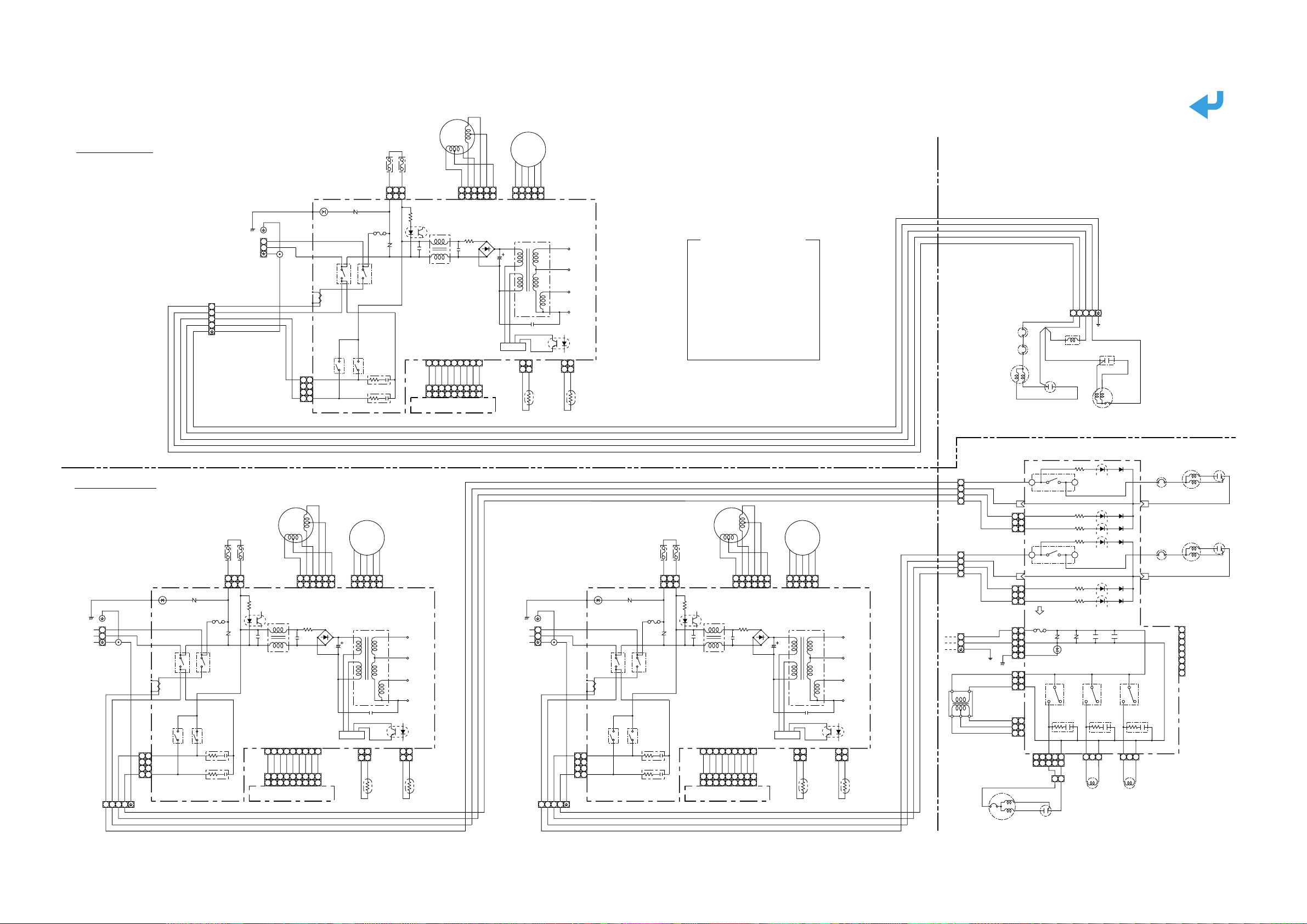

3. WIRING DIAGRAM .......................................................................................................... 9

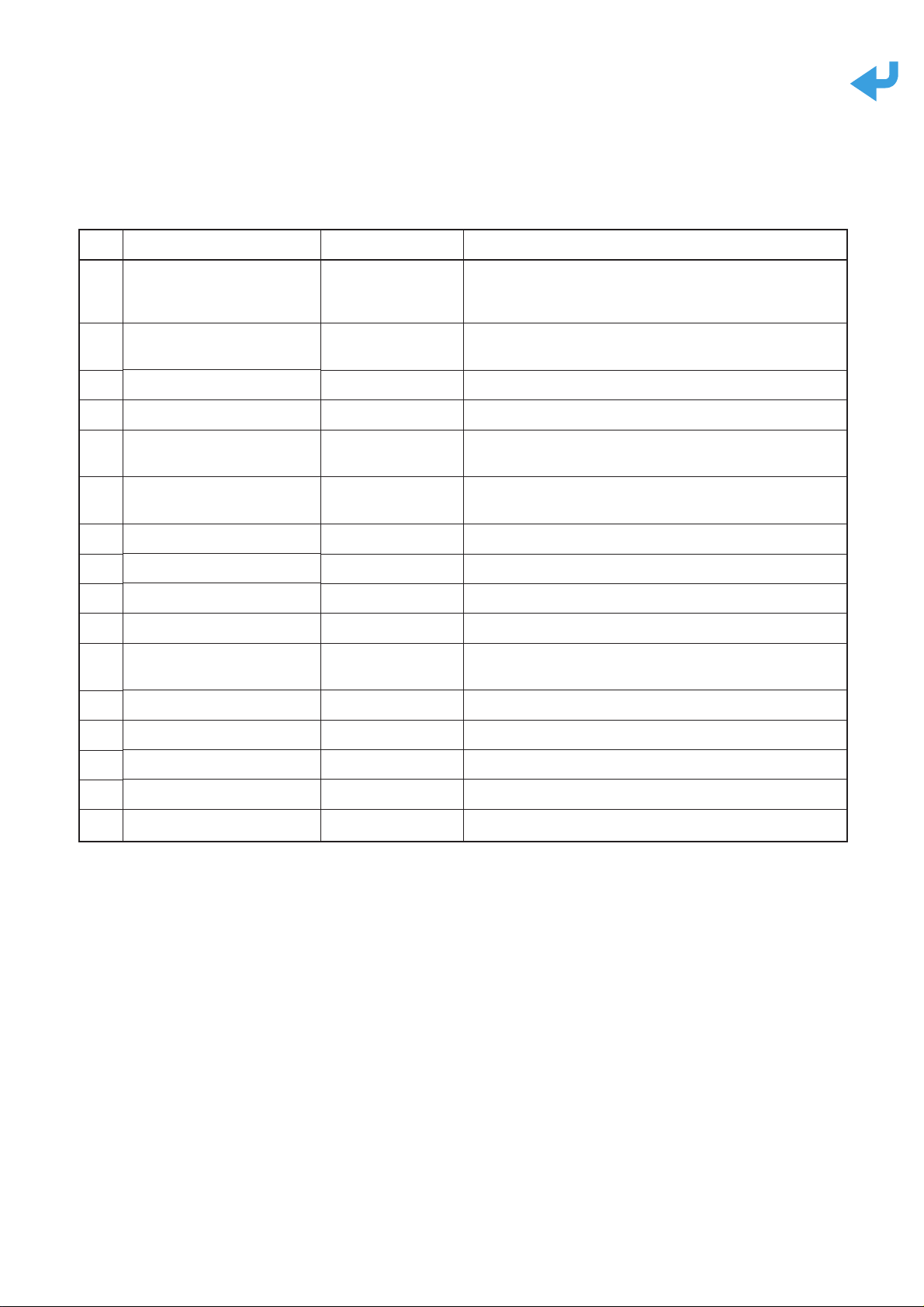

4. SPECIFICATIONS OF ELECTRICAL PARTS ............................................................... 11

4-1. Indoor Unit ................................................................................................................................ 11

4-2. Outdoor Unit ............................................................................................................................. 12

4-2-1. Upper Outdoor Unit...............................................................................................................................12

4-2-2. Lower Outdoor Unit...............................................................................................................................12

5. REFRIGERANT CYCLE DIAGRAM............................................................................... 13

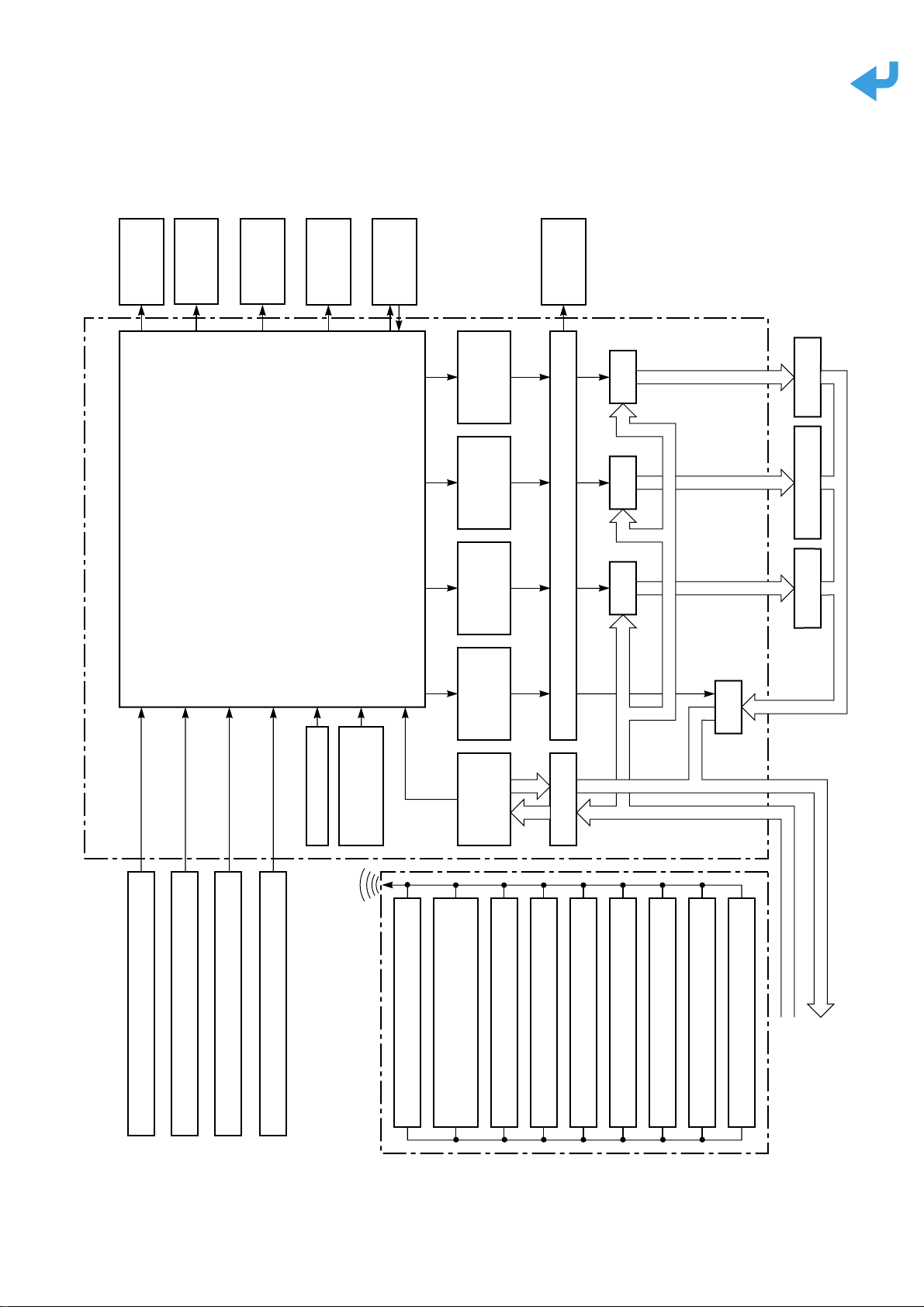

6. MICROCOMPUTER BLOCK DIAGRAM........................................................................ 15

6-1. Upper Unit ................................................................................................................................. 15

6-2. Lower Unit................................................................................................................. ................ 16

7. OPERATION DESCRIPTIONS....................................................................................... 1 7

7-1. FAN ONLY Operation ................................................................................................................ 17

7-2. COOL Operation............................................................................................................. .......... 17

7-2-1. Louver Control ......................................................................................................................................18

7-3. DRY Operation .............................................................................................................. ............ 18

7-4. HEAT Operation............................................................................................................. ........... 19

7-4-1. Louver Control ......................................................................................................................................19

7-4-2. Cool Airflow Control .............................................................................................................................19

7-5. AUTO Operation ....................................................................................................................... 20

7-5-1. Temporary Auto..................................................................................................................................... 20

7-6. ECONO. Mode ........................................................................................................................... 21

7-6-1. Cooling................................................................................................................................................... 21

7-6-2. Heating .................................................................................................................. ................................. 21

7-7. Current Limit Control............................................................................................................... 21

7-8. High-Temperature Limit Control (Heating Operation) .......................................................... 22

7-9. Low-Temperature Limit Control (Cooling Operation) .......................................................... 22

7-10. Cool Airflow Prevention Control (Heating Operation) ......................................................... 22

7-11. Defrost Operation......................................................................................................... ............ 23

7-11-1. Condition to Start the Defrost Operation............................................................................................23

7-11-2. Defrost Operation Time Control...........................................................................................................23

7-11-3. Ending Condition at Defrost Operation ..............................................................................................23

7-12. Auto Restart Function ..................................................................................................... ........ 24

7-12-1. How to Set the Auto Restart.................................................................................................................24

7-12-2. How to Cancel the Auto Restart ..........................................................................................................25

7-12-3. In Case of Power Failure During the Timer Operation .......................................................................25

7-13. Operation Control of Lower Outdoor Unit............................................................................. 26

7-13-1. In Case of Operation in a Single Room...............................................................................................26

7-13-2. In Case of Concurrent Operation in Two Rooms................................................................................26

– 2 –

8. INSTALLATION PROCEDURE ...................................................................................... 27

8-1. Safety Cautions ........................................................................................................................ 27

8-2. Installation Diagram of Indoor and Outdoor Units ............................................................... 2 9

8-3. Installation ................................................................................................................................ 30

8-3-1. Optional Parts........................................................................................................... .............................3 0

8-3-2. Kit Parts .................................................................................................................................................31

8-4. Indoor Unit ................................................................................................................................ 32

8-4-1. Cutting a Hole and Mounting Installation Plate .................................................................................32

8-4-2. Electrical W or k.......................................................................................................................................33

8-4-3. Wiring Connection ................................................................................................................................ 3 4

8-4-4. Piping and Drain Hose Installation......................................................................................................36

8-4-5. Indoor Unit Installation .........................................................................................................................37

8-4-6. Drainage.................................................................................................................................................37

8-5. Outdoor Unit ............................................................................................................................. 38

8-5-1. Refrigerant Piping Connection ............................................................................................................3 9

8-5-2. Vacuum Pumping ..................................................................................................................................39

8-5-3. Wiring Connection ................................................................................................................................ 4 1

8-6. Others ........................................................................................................................................ 43

8-6-1. Gas Leak Test ........................................................................................................................................43

8-6-2. Test Operation .......................................................................................................................................43

8-6-3. Auto Restart Setting .............................................................................................................................43

9. TROUBLESHOOTING CHART...................................................................................... 44

9-1. What to be Prechecked First ................................................................................................... 44

9-1-1. Power Supply Voltage ...........................................................................................................................44

9-1-2. Incorrect Cable Connection between Indoor and Outdoor Units.....................................................44

9-1-3. Misleading but Good Operations.........................................................................................................45

9-2. Primary Judgement of Trouble Sources ................................................................................ 46

9-2-1. Role of Indoor Unit Controller..............................................................................................................46

9-2-2. Display of Abnormalities and Judgement of the Abnormal Spots...................................................4 6

9-3. Troubleshooting Flowcharts ................................................................................................... 50

9-3-1. Power can not be Turned on .................................................................................................................5 0

9-3-2. Power can not be Turned on after Replacing Indoor PC Board ........................................................51

9-3-3. Outdoor Unit does not Operate ...........................................................................................................51

9-3-4. Only Compressor does not Operate ...................................................................................................52

9-3-5. Only Outdoor Fan does not Operate ...................................................................................................53

9-3-6. Only 4-Way Valve does not Operate ....................................................................................................54

9-3-7. Only the Indoor Fan does not Operate................................................................................................5 5

9-4. How to Check the Remote Control (Including the Indoor PC Board) .................................56

9-4-1. How to Check the PC Board.................................................................................................................57

9-4-2. PC Board Layout (Indoor Unit).............................................................................................................59

9-4-3. PC Board Layout (Outdoor Unit)..........................................................................................................60

9-4-4. How to Reduce the Operation Time of the Anti-Restart Timer..........................................................61

10. PART REPLACEMENT.................................................................................................. 62

10-1. Indoor Unit ............................................................................................................... ................. 62

10-2. Microcomputer ......................................................................................................................... 64

10-3. Outdoor Unit ............................................................................................................................. 65

11. CAUTIONS ON REPLACEMENT OF PC BOARD ASSEMBLY .................................... 69

12. EXPLODED VIEWS AND PARTS LIST ......................................................................... 70

12-1. Indoor Unit (1)........................................................................................................................... 7 0

Indoor Unit (2)........................................................................................................................... 71

Indoor Unit (3)........................................................................................................................... 72

12-2. Outdoor Unit ............................................................................................................................. 73

– 3 –

1. SPECIFICATIONS

Item

Capacity

Power source

Power consumption

Power factor

Running current

Starting current

Moisture removal

Noise

Refrigerant

Refrigerant control

Interconnection pipe

Condensate drain pipe

INDOOR UNIT

Dimensions

Net weight

Evaporator type

Indoor fan type

Air volume

Fan motor output

Air filter

OUTDOOR UNIT

Dimensions

Net weight

Condenser type

Outdoor fan type

Airflow volume

Fan motor output

Compressor

Safety device

Auto louver

Usable outdoor temperature range

Indoor (H/M/L)

Outdoor (220/230/240V)

Name of refrigerant

Rated volume

Gas side size

Connection type

Liquid side size

Connection type

Maximum length (of one way)

Maximum height difference

Indoor unit

Outdoor unit

Outer diameter

Height

Width

Depth

High fan

Medium fan

Low fan

Height

Width

Depth

(220/230/240V)

Model

Output

Model

kW

*1

Phase

V

Hz

kW

%

A

Indoor/Outdoor

A

lit/h

dB

dB

kg

mm

mm

m *2

↑

↓

m

mm

mm

mm

mm

kg

m3/h

m3/h

m3/h

W

mm

mm

mm

kg

m3/h

W

W

°C

RAS-10SKH-E, 10SKH-E, 13SKH-E / RAS-3M31SAH-E

Cooling Heating

220V 230V 240V 220V 230V 240V

8.45 8.50 8.50 9.60 9.65 9.70

Single

220/230/240

50

3.30/3.38/3.48 2.97/3.09/3.23

96/93/90 94/93/89

220V 230V 240V 220V 230V 240V

0.37/15.24 0.37/15.36 0.37/15.71 0.37/13.92 0.37/14.14 0.37/14.70

19+19+25

1.2+1.2+2.0

10SKH-E: 41/36/31 13SKH-E: 44/39/36

52/53/54

R-22

2.28 (0.7+0.7+0.88)

Capillary tube

10SKH-E: 9.52 13SKH-E: 12.7

Flare connection

6.35

Flare connection

15

6

16

RAS-10SKH-E RAS-13SKH-E

265

790

174

8

Finned tube

Cross flow fan

600 650

500 560

400 510

19

Polypropylene net filter (Washable)

RAS-3M31SAH-E

1125

830

300

106

Finned tube

Propeller

1830/1920/2010

28

PH120T1-4C x 2 + PH170T2-4L2

750W x 2 + 1100W x 1

Fuse, Overload relay

Yes

21 ~ 43 – 5 ~ 21

Specifications are subject to change without notice.

– 4 –

Item

Capacity *1

Power source

Power consumption

Power factor

Running current

Item

Capacity *1

Power source

Power consumption

Power factor

Running current

Item

Capacity *1

Power source

Power consumption

Power factor

Running current

Item

Capacity *1

Power source

Power consumption

Power factor

Running current

model

kW

Phase

V

Hz

kW

%

A

Indoor/Outdoor

model

kW

Phase

V

Hz

kW

%

A

Indoor/Outdoor

model

kW

Phase

V

Hz

kW

%

A

Indoor/Outdoor

model

kW

Phase

V

Hz

kW

%

A

Indoor/Outdoor

RAS-10SKH-E, 13SKH-E / RAS-3M31SAH-E

Cooling Heating

220V 230V 240V 220V 230V 240V

5.95 6.00 6.00 6.80 6.85 6.90

Single

220/230/240

50

2.28/2.33/2.39 2.08/2.16/2.25

97/94/91 95/93/90

220V 230V 240V 220V 230V 240V

0.26/10.47 0.26/10.51 0.26/10.73 0.26/9.73 0.26/9.81 0.26/10.12

RAS-10SKH-E, 10SKH-E / RAS-3M31SAH-E

Cooling Heating

220V 230V 240V 220V 230V 240V

5.0 5.0 5.0 5.6 5.6 5.6

Single

220/230/240

50

2.04/2.10/2.18 1.78/1.86/1.96

95/92/89 94/91/87

220V 230V 240V 220V 230V 240V

0.22/9.54 0.22/9.70 0.22/9.96 0.22/8.38 0.22/8.66 0.22/9.16

RAS-13SKH-E / RAS-3M31SAH-E

Cooling Heating

220V 230V 240V 220V 230V 240V

3.45 3.50 3.50 4.00 4.05 4.10

Single

220/230/240

50

1.26/1.28/1.30 1.19/1.23/1.27

98/96/92 95/95/93

220V 230V 240V 220V 230V 240V

0.15/5.70 0.15/5.66 0.15/5.75 0.15/5.54 0.15/5.48 0.15/5.54

RAS-10SKH-E / RAS-3M31SAH-E

Cooling Heating

220V 230V 240V 220V 230V 240V

2.50 2.50 2.50 2.80 2.80 2.80

Single

220/230/240

50

1.02/1.05/1.09 0.89/0.93/0.98

95/92/89 94/91/87

220V 230V 240V 220V 230V 240V

0.11/4.77 0.11/4.85 0.11/4.98 0.11/4.19 0.11/4.33 0.11/4.58

– 5 –

Note : *1

• Capacity is based on the following temperature conditions.

JIS C9612-1994Condition

Temperature

(DB)

Indoor unit inlet air temperature

(WB)

(DB)

Outdoor unit inlet air temperature

(WB)

Notes : *2

<RAS-13SKH-E / RAS-3M31SAH-E>

• No additional refrigerant required.

• This air conditioner accepts a connection piping length of up to 15m and a head of up to 6m.

• There is no need to add the refrigerant as long as the total length of the connection piping is up to 15m.

<RAS-10SKH-E / RAS-3M31SAH-E>

• This air conditioner accepts a connection piping length of up to 15m and a head of up to 5m.

• There is no need to add the refrigerant as long as the total length of the connection piping is up to 10m.

• There is need to add the refrigerant 20g/m as long as the each length of the connection piping is up to 11m to

15m.

Cooling

27°C

19°C

35°C

24°C

Heating

20°C

—

7°C

6°C

– 6 –

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

2-1. Indoor Unit

RAS-10SKH-E

RAS-13SKH-E

Air inlet

2. CONSTRUCTION VIEWS

Air filter

790

Heat exchanger

174

265

Air outlet

232 326 232

Drain hose (0.54m)

Hanger

Connecting pipe (0.39m)

13SKH-E: (Flare ø12.7)

10SKH-E: (Flare ø9.52)

790

Hanger

321

Connecting pipe (0.49m)

(Flare ø6.35)

Front panel

Back body

47

47

Knock out system

50

10

Knock out system

50

10

65965.5

450

Hanger

326

66 or more

Minimum

distance

2.5

46

Minimum

distance

17 20

265

to wall

120 or more 120 or more

3.5

40.5

Center line

to ceiling

Installation

plate outline

HangerHanger

790

– 7 –

12626931976

65.5

Hanger

For stud bolt

(ø8~ø10)

For stud bolt

(ø6)

Minimum

distance to wall

20 2037

40.5

60.5

Wireless

remote

control

Remote

control

holder

55

136

16

112.8

559.6

2-2. Outdoor Unit

RAS-3M31SAH-E

600 or more

4-φ11x14

for φ8-φ10

anchor bolt

Liquid side

Electrical

parts cover

(Flare φ6.35)

Gas side

(Flare φ12.7)

Liquid side

Electrical

parts cover

(Flare φ6.35)

Gas side

(Flare φ9.52)

Air inlet

600

Air inlet

Mounting dimension of anchor bolt

325

100 or more

φ25 Drain outlet

120

600 or more

300

Air outlet

100 or more

4-φ11x14 hole

(for φ8–φ10 anchor bolt)

8-φ6 hole

(for fixing outdoor unit)

186

Service port

54677.5

Handle

60

Service port

54545491

325 (pitch)(8.5) (8.5)

600 90 55

835 60 342

A

52.5

325

R12

600

Detail Drawing

36

50

A

23

φ 6 hole

311

325

φ11x14 hole

1125

Drain outlet

90

29

– 8 –

INDOOR UNIT

UPPER UNIT

(RAS-13SKH-E)

INDOOR UNIT

1

2

3

4

INDOOR

TERMINAL

BLOCK

BLK

WHI

RED

BLU

GRN&YEL

GRN&YEL

L

N

POWER

TERMINAL

BLOCK

BLK

P04

BRW

BLU

44

CN27

SG01

DSA

RY02

11

2

3

THERMAL FUSE

77˚C × 2

R109

VARISTOR

3

4

T02

C.T.

WHI

RY03

F01 FUSE

BLK

RY04

T3.15A

250V

3

RY01

4

CR01

CR02

LOUVER

MOTOR

GRY

GRY

3

1

CN04

1

3

R116

C15

R21

INFRARED RAYS RECEIVE

AND INDICATION PARTS

IC04

1

BLU

1

1

L01

23

BLU

2

2

CN07

4

BLU

BLU

4

3

4

3

PNK

YEL

BLU

4

6

5

5

R01

C01

56789

BLU

BLU

PNK

BLK

56789

56789

ORN

3

346

DB01

CN13

WHI

CN25

RED

2

2

BRW

1

1

C02

FAN MOTOR

DC

MOTOR

BLK

BLU

YEL

RED

WHI

4

3

5

2

1

4

3

5

2

1

CN10

MAIN P.C. BOARD

MCC-713

T01

C06

IC

IC01

2

1

CN03 CN01

2

1

BLK

BLK

THERMO

SENSOR

(TA)

DC 35V

DC 12V

DC 7V

DC 0V

IC02

2

1

2

1

BLK

BLK

HEAT

EXCHANGER

SENSOR

(TC)

COLOR IDENTIFICATION

:

BROWN

BRW

:

RED

RED

:

WHITE

WHI

:

YELLOW

YEL

:

BLUE

BLU

:

BLACK

BLK

:

GRAY

GRY

:

PINK

PNK

:

ORANGE

ORN

:

GRN&YEL

GREEN &

YELLOW

DSA : Surge absorbor

C.T : Current trans

OUTDOOR UNIT

(3M31SAH-E)

TERMINALS

OVERLOAD RELAY

THERMOSTAT FOR

COMPRESSOR

COMPRESSOR

BLK

BLK

BLK

PNK

WHI

BRW

SOLENOID

COIL

RED

CAPACITOR

1

BRW

RED

2

3

4

RED

FAN MOTOR

GRN & YEL

CHASSIS

CAPACITOR

WHI

BLK

LOWER UNIT

(RAS-10SKH-E)

BLK

GRN&YEL

L

N

POWER

TERMINAL

BLOCK

GRN & YEL

BLK

WHI

RED

BLU

INDOOR

1

2

3

TERMINAL

BLOCK

4

P04

44

CN27

SG01

DSA

BRW

BLU

RY02

11

2

3

THERMAL FUSE

VARISTOR

3

4

T02

C.T.

WHI

RY03

77˚C × 2

R109

F01 FUSE

BLK

RY04

T3.15A

250V

3

RY01

4

CR01

CR02

LOUVER

MOTOR

GRY

GRY

3

1

CN04

1

3

R116

IC04

C15

R21

INFRARED RAYS RECEIVE

AND INDICATION PARTS

1

BLU

1

1

L01

23

BLU

2

2

CN07

4

BLU

BLU

4

3

4

3

PNK

YEL

BLU

4

6

5

5

R01

C01

56789

BLU

BLU

PNK

BLK

56789

56789

ORN

3

346

DB01

CN13

WHI

RED

2

2

CN25

BRW

1

1

C02

DC

MOTOR

BLK

BLU

YEL

RED

WHI

4

3

5

2

1

4

3

5

2

1

CN10

MAIN P.C. BOARD

MCC-713

T01

C06

IC

IC01

2

1

CN03 CN01

2

1

BLK

BLK

THERMO

SENSOR

(TA)

FAN MOTOR

DC35V

DC12V

DC7V

DC0V

IC02

2

1

2

1

BLK

BLK

HEAT

EXCHANGER

SENSOR

(TC)

DSA : Surge absorbor

C.T : Current trans

GRN&YEL

L

N

POWER

TERMINAL

BLOCK

BLK

1

WHI

2

RED

3

BLU

4

BLK

P04

GRN & YEL

11

2

3

44

CN27

SG01

DSA

BRW

BLU

RY02

T02

C.T.

WHI

THERMAL FUSE

77˚C × 2

R109

VARISTOR

F01 FUSE

T3.15A

250V

3

3

RY01

4

4

BLK

RY03

RY04

CR01

CR02

LOUVER

MOTOR

GRY

GRY

3

1

CN04

1

3

R116

IC04

C15

R21

INFRARED RAYS RECEIVE

AND INDICATION PARTS

1

BLU

1

1

L01

23

BLU

2

2

CN07

4

BLU

BLU

4

3

4

3

PNK

YEL

BLU

4

6

5

5

R01

C01

56789

BLU

BLU

PNK

BLK

56789

56789

ORN

3

346

DB01

CN13

WHI

CN25

RED

2

2

BRW

1

1

C02

DC

MOTOR

BLK

BLU

YEL

RED

WHI

4

3

5

2

1

4

3

5

2

1

CN10

MAIN P.C. BOARD

MCC-713

T01

C06

IC

IC01

2

1

CN03 CN01

2

1

BLK

BLK

THERMO

SENSOR

(TA)

FAN MOTOR

DC35V

DC12V

DC7V

DC0V

IC02

2

1

2

1

BLK

BLK

HEAT

EXCHANGER

SENSOR

(TC)

1

2

3

4

TERMINALS

1

RED

2

WHI

3

BLK

4

TERMINALS

BLK

L

RED

N

YEL & GRN

BLK

RED

WHI

BLK

BLK

RED

WHI

TRANSFORMER

BLU

YEL

ORN

FAN MOTOR

4 3

RY01

CN09

1

1

3

3

CN04

4 3

RY02

CN10

1

1

CN05

3

3

MAIN P.C. BOARD (MCC-738)

F01

R01

Fuse

5

5

3

3

SG01

300V

1

1

CN01

1

1

CN02

3

3

CN

131

03

22

3

CN08 CN07 CN06

5

5

BLK RED

BLK

RED

WHI

R02

RY06

CR04 CR02 CR01

1

3

1

3

12

RED

CAPACITOR

C01 C02

RY04

13 13

BLK BLK

UNIT B

COIL FOR

4 WAY

VALVE

UNIT A

COIL FOR

4 WAY

VALVE

RY03

OVERLOAD

RELAY

BLK

OVERLOAD

RELAY

BLK

CAPACITOR

WHI

PNK

COMPRESSOR

CAPACITOR

WHI

PNK

COMPRESSOR

CN11

1

2

3

4

5

6

7

8

RED

RED

INDOOR UNIT

UPPER UNIT

(RAS-13SKH-E)

INDOOR UNIT

1

2

3

4

INDOOR

TERMINAL

BLOCK

BLK

WHI

RED

BLU

GRN&YEL

GRN&YEL

L

N

POWER

TERMINAL

BLOCK

BLK

P04

BRW

BLU

44

CN27

SG01

DSA

RY02

11

2

3

THERMAL FUSE

77˚C × 2

R109

VARISTOR

3

4

T02

C.T.

WHI

RY03

F01 FUSE

BLK

RY04

T3.15A

250V

3

RY01

4

CR01

CR02

LOUVER

MOTOR

GRY

GRY

3

1

CN04

1

3

R116

C15

R21

INFRARED RAYS RECEIVE

AND INDICATION PARTS

IC04

1

BLU

1

1

L01

23

BLU

2

2

CN07

4

BLU

BLU

4

3

4

3

PNK

YEL

BLU

4

6

5

5

R01

C01

56789

BLU

BLU

PNK

BLK

56789

56789

ORN

3

346

DB01

CN13

WHI

CN25

RED

2

2

BRW

1

1

C02

FAN MOTOR

DC

MOTOR

BLK

BLU

YEL

RED

WHI

4

3

5

2

1

4

3

5

2

1

CN10

MAIN P.C. BOARD

MCC-713

T01

C06

IC

IC01

2

1

CN03 CN01

2

1

BLK

BLK

THERMO

SENSOR

(TA)

DC 35V

DC 12V

DC 7V

DC 0V

IC02

2

1

2

1

BLK

BLK

HEAT

EXCHANGER

SENSOR

(TC)

COLOR IDENTIFICATION

:

BROWN

BRW

:

RED

RED

:

WHITE

WHI

:

YELLOW

YEL

:

BLUE

BLU

:

BLACK

BLK

:

GRAY

GRY

:

PINK

PNK

:

ORANGE

ORN

:

GRN&YEL

GREEN &

YELLOW

DSA : Surge absorbor

C.T : Current trans

OUTDOOR UNIT

(3M31SAH-E)

TERMINALS

OVERLOAD RELAY

THERMOSTAT FOR

COMPRESSOR

COMPRESSOR

BLK

BLK

BLK

PNK

WHI

BRW

SOLENOID

COIL

RED

CAPACITOR

1

BRW

RED

2

3

4

RED

FAN MOTOR

GRN & YEL

CHASSIS

CAPACITOR

WHI

BLK

LOWER UNIT

(RAS-10SKH-E)

BLK

GRN&YEL

L

N

POWER

TERMINAL

BLOCK

GRN & YEL

BLK

WHI

RED

BLU

INDOOR

1

2

3

TERMINAL

BLOCK

4

P04

44

CN27

SG01

DSA

BRW

BLU

RY02

11

2

3

THERMAL FUSE

VARISTOR

3

4

T02

C.T.

WHI

RY03

77˚C × 2

R109

F01 FUSE

BLK

RY04

T3.15A

250V

3

RY01

4

CR01

CR02

LOUVER

MOTOR

GRY

GRY

3

1

CN04

1

3

R116

IC04

C15

R21

INFRARED RAYS RECEIVE

AND INDICATION PARTS

1

BLU

1

1

L01

23

BLU

2

2

CN07

4

BLU

BLU

4

3

4

3

PNK

YEL

BLU

4

6

5

5

R01

C01

56789

BLU

BLU

PNK

BLK

56789

56789

ORN

3

346

DB01

CN13

WHI

RED

2

2

CN25

BRW

1

1

C02

DC

MOTOR

BLK

BLU

YEL

RED

WHI

4

3

5

2

1

4

3

5

2

1

CN10

MAIN P.C. BOARD

MCC-713

T01

C06

IC

IC01

2

1

CN03 CN01

2

1

BLK

BLK

THERMO

SENSOR

(TA)

FAN MOTOR

DC35V

DC12V

DC7V

DC0V

IC02

2

1

2

1

BLK

BLK

HEAT

EXCHANGER

SENSOR

(TC)

DSA : Surge absorbor

C.T : Current trans

GRN&YEL

L

N

POWER

TERMINAL

BLOCK

BLK

1

WHI

2

RED

3

BLU

4

BLK

P04

GRN & YEL

11

2

3

44

CN27

SG01

DSA

BRW

BLU

RY02

T02

C.T.

WHI

THERMAL FUSE

77˚C × 2

R109

VARISTOR

F01 FUSE

T3.15A

250V

3

3

RY01

4

4

BLK

RY03

RY04

CR01

CR02

LOUVER

MOTOR

GRY

GRY

3

1

CN04

1

3

R116

IC04

C15

R21

INFRARED RAYS RECEIVE

AND INDICATION PARTS

1

BLU

1

1

L01

23

BLU

2

2

CN07

4

BLU

BLU

4

3

4

3

PNK

YEL

BLU

4

6

5

5

R01

C01

56789

BLU

BLU

PNK

BLK

56789

56789

ORN

3

346

DB01

CN13

WHI

CN25

RED

2

2

BRW

1

1

C02

DC

MOTOR

BLK

BLU

YEL

RED

WHI

4

3

5

2

1

4

3

5

2

1

CN10

MAIN P.C. BOARD

MCC-713

T01

C06

IC

IC01

2

1

CN03 CN01

2

1

BLK

BLK

THERMO

SENSOR

(TA)

FAN MOTOR

DC35V

DC12V

DC7V

DC0V

IC02

2

1

2

1

BLK

BLK

HEAT

EXCHANGER

SENSOR

(TC)

1

RED

2

3

4

TERMINALS

BLK

1

RED

2

WHI

3

BLK

4

TERMINALS

BLK

L

RED

N

YEL & GRN

BLK

WHI

BLK

RED

WHI

TRANSFORMER

BLU

YEL

ORN

FAN MOTOR

4 3

RY01

CN09

1

1

3

3

CN04

4 3

RY02

CN10

1

1

CN05

3

3

MAIN P.C. BOARD (MCC-738)

F01

R01

Fuse

5

5

3

3

SG01

300V

1

1

CN01

1

1

CN02

3

3

CN

131

03

22

3

CN08 CN07 CN06

5

5

BLK RED

BLK

RED

WHI

R02

RY06

CR04 CR02 CR01

1

3

1

3

12

RED

CAPACITOR

C01 C02

RY04

13 13

BLK BLK

UNIT B

COIL FOR

4 WAY

VALVE

UNIT A

COIL FOR

4 WAY

VALVE

RY03

OVERLOAD

RELAY

BLK

OVERLOAD

RELAY

BLK

CAPACITOR

WHI

PNK

COMPRESSOR

CAPACITOR

WHI

PNK

COMPRESSOR

CN11

1

2

3

4

5

6

7

8

RED

RED

4-1. Indoor Unit

RAS-10SKH-E

RAS-13SKH-E

4. SPECIFICATIONS OF ELECTRICAL PARTS

No.

1

Fan motor (for indoor)

Thermo sensor

2

(TA-sensor)

DC-DC transformer (T01)

3

4

Microcomputer

Power relay (RY01), Com-

5

mon relay (RY02)

Heat exchanger sensor

6

(TC-sensor)

Line filter (L01)

7

Diode (DB01)

8

Capacitor (C02)

9

10

Fuse (F01)

Relay (for outdoor fan motor,

11

solenoid coil) (RY03, RY04)

Parts name

Type

ICF-35-19-3

or

TICF-35-19-3

(microprocessor)

SWT-34

TMP87CK40F

DI1U

(microprocessor)

RF-103YOR6

RBV-406

CEAUF2W101M20

MT3

AJQ1341

Specifications

DC 35V, 19W

10kΩ at 25°C

DC390V, Secondary DC35V, 12V, 7V

Coil : DC12V 75mA, Rated AC250V 20A

10kΩ at 25°C

10mH, AC 0.6A

4A, 600V

100µF, 450V

T3.15A, 250V

Coil DC12V, 33mA, Rated 1A 250V AC

Power supply IC (IC01)

12

Var istor (R21, R109)

13

Resistor (R01)

14

Current trans (T02)

15

16

Louver motor

MA2830-FJ

15G561K

ERF-5TK5R6

CT422920S-01

MP35EA7

4A, 600V

560V

5.6 Ω, 5W

Output (Rated) 2W, 10 poles, 1 phase DC 12V

– 11 –

– 11 –

4-2. Outdoor Unit

RAS-3M31SAH-E

4-2-1. Upper Outdoor Unit

No.

Compressor

1

Fan motor (for outdoor)

2

Running capacitor

3

(for fan motor)

Running capacitor

4

(for compressor)

Solenoid coil

5

(for 4-way va lve)

Overload relay

6

Thermostat for Compressor

7

Parts name

4-2-2. Lower Outdoor Unit

Type

PH170T2-4L2

AF-230-28P

SK-50FMP

SK-40CMP35U1

LB60012

J-MRA99257-9200

CS-7

Specifications

Output (Rated) 1,100W, 2 pole, 1 phase, 220/230/240V, 50Hz

Winding resistance (Ω)

(at 20°C)

Output (Rated) 28W, 6 pole, 1 phase, 220/230/240V, 50Hz

Winding resistance (Ω)

(at 20°C)

500V AC, 1.5µF

400V AC, 35µF

AC : 200/240V

UT 8.0A (80°C), OPEN 145±5°C, CLOSE 75±11°C

130°C OFF, 70°C ON

Red-Black

2.22

Red-Black

198

White-Black

3.04

White-Black

160

No.

Compressor

1

Fan motor (for outdoor)

2

Running capacitor

3

(for fan motor)

Running capacitor

4

(for compressor)

Solenoid coil

5

(for 4-way va lve)

Overload relay

6

Transformer

7

Outdoor PC board

8

Parts name

Type

PH120T1-4C

AF-230-28P

SK-45FMP

SK-40CMP25U1

LB60012

J-MRA99269-9200

FT-70

MCC-738

Specifications

Output (Rated) 750W, 2 pole, 1 phase, 220/230/240V, 50Hz

Winding resistance (Ω)

(at 20°C)

Output (Rated) 28W, 6 pole, 1 phase, 220/230/240V, 50Hz

Winding resistance (Ω)

(at 20°C)

450V AC, 2µF

400V AC, 25µF

AC : 200/240V

U/T 6.8A (90°C), OPEN 135±5°C, CLOSE 69±11°C

AC : 220/240V

Red-Black

4.53

Red-Black

198

White-Black

8.73

White-Black

160

– 12 –

5. REFRIGERANT CYCLE DIAGRAM

RAS-13SKH-E

RAS-3M31SAH-E (Upper Unit)

Cooling

Indoor Unit

Heat exchanger

T1

(Note)

Maximum pipe length is 15m

Maximum pipe head is 6m

0.49m

(Connecting pipe)

ø12.7

O.D.:12.7mm O.D.:6.35mm

Cooling

Heating

Heating

P

Packed valve

(ø12.7)

Gas container connection (Reinstall etc.)

Heating

4-way valve

Cooling

Cooling

Heating

Compressor

Accumulator

PH170T2-4L2

Heat exchanger

Propeller fan

Cross flow fan

Outdoor Unit

Packed valve

(ø6.35)

Capillary tube

ø0.6x1500

Capillary tube

ø1.7x400

Mark ( ) means check points of Gas Leak

Capillary tube

ø1.2x400

Refrigerant

R-22 0.88kg

0.39m

(Connecting pipe)

ø6.35

Fig. 5-1

Table 5-1

Surface temp. of heat

exchanger interchanging

pipe T1 (°C)

13SKH-E

43.0

52.0 ~ 59.0

35.0

10.0

14.0

2.0

Fan speed

(indoor)

High

Low

High

High

High

Low

Heating

Cooling

50Hz

Standard

High temperature*1

Low temperature

Standard

High temperature

Low temperature

Standard pressure

P

(kg/cm²G)

13SKH-E

15.0

19 ~ 23

12.5

5.0

6.0

4.0

Note :

• Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

1 • During heating overload, the high temperature limit control operation is included.

*

– 13 –

Ambient temp.

conditions DB/WB

(°C)

Indoor

20/–

27/–

20/–

27/19

32/23

21/15

Outdoor

7/6

21/15

–10/–10

35/24

43/26

21/15

RAS-10SKH-E, RAS-10SKH-E

RAS-3M31SAH-E (Lower Unit)

Indoor Unit

Indoor heat exchanger A

Indoor heat exchanger B

Packed valve Packed valve

(3/8) (1/4)

Heating

Cooling

PH120T1-4C

Accumulator

50Hz

Standard

High temperature*1

Low temperature

Standard

High temperature

Low temperature

4-way valve

PH120T1-4C

Outdoor heat exchanger

Outdoor Unit

Standard pressure

P

(kg/cm²G)

10SKH-E

15.0

19 ~ 23

12.5

6.0

6.5

4.0

Check

valve

CompressorCompressor

Fig. 5-2

Table 5-2

Surface temp. of heat

exchanger interchanging

pipe T1 (°C)

10SKH-E

40.0

52.0 ~ 59.0

35.0

12.0

15.0

2.0

Capillary

for heating

ø1.7x300

Capillary

for cooling & heating

ø1.7x700

Dryer

Fan speed

(indoor)

High

Low

High

High

High

Low

Cooling

Heating

Ambient temp.

conditions DB/WB

(°C)

Indoor

20/–

27/–

20/–

27/19

32/23

21/15

Outdoor

7/6

21/15

–10/–10

35/24

43/26

21/15

Note :

• Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

1 • During heating overload, the high temperature limit control operation is included.

*

– 14 –

6. MICROCOMPUTER BLOCK DIAGRAM

6-1. Upper Unit

RAS-13SKH-E / RAS-3M31SAH-E

Operation

C. P. U

Functions

Timer

Display

• Louver Control

Display

ECONO.

Sign Display

• 3-minute Delay at Restart for Compressor

PRE-DEF.

Sign Display

• Motor Revolution Control

Indoor

Fan Motor

• Processing

(Temperature Processing)

• Timer

Signal

Louver

ON/OFF

Signal

ON/OFF

4-Way Valve

Signal

ON/OFF

Outdoor Fan

Signal

ON/OFF

Compressor

Motor

Louver

Relay

Relay

RY01 RY03 RY04

Relay Driver, Louver Driver

Relay

4-Way ValveOutdoor Fan MotorCompressor

RY02

Relay

Main Unit Control Panel

Current Sensor

Thermo Sensor

Heat Exchanger Sensor

Initializing Circuit

(Compressor Current)

Infrared Rays Signal Receiver

Oscillator Circuit

Clock Frequency

Rays

Infrared

Remote Control

Power

Circuit

Supply

Thermo Setting

Fan Speed Selection

Operation Mode Selection

Operation (START/STOP)

AUTO, COOL, DRY, HEAT, FAN ONLY

– 15 –

Noise Filter

ON TIMER Setting

OFF TIMER Setting

ECONO.

Louver AUTO Swing

Louver Direction Setting

AC220/230/240V ~

50Hz

6-2. Lower Unit

RAS-10SKH-E / RAS-3M31SAH-E

50Hz

ON/OFF Signal

Compressor (A)

C. P. U

4-Way

Valve (A)

RY03

Relay

Relay

Driver

ON/OFF Signal

Compressor (B)

ON/OFF Signal

4-Way Valve (A)

4-Way

Valve (B)

RY04

Relay

Outdoor Fan

ON/OFF Signal

4-Way Valve (B)

Outdoor

Fan Motor

RY06

Relay

ON/OFF Signal

Circuit

Initializing

Oscillator Circuit

Clock Frequency

• Compressor (A), (B) Control

• 4-Way Valve (A), (B) Control

• Outdoor Fan Control

• Defrost Control

Circuit

Power Supply

AC 220/230/240V

Transformer

Relay

ON/OFF Signal

Compressor (A)

RY01

ON/OFF Signal

4-Way Valve (A)

Compressor (A)

Indoor

Unit (A)

Outdoor Fan

ON/OFF Signal

Compressor (B)

– 16 –

RY02

Relay

ON/OFF Signal

ON/OFF Signal

4-Way Valve (B)

Compressor (B)

Indoor

Unit (B)

Outdoor Fan

ON/OFF Signal

Note:

If unit (A) and (B) operation modes are different (as Cool, Heater Auto), operating priority is

given for “Heat” mode unit, and “Cool” mode unit will be stopped due to overload relay actuate.

7. OPERATION DESCRIPTIONS

7-1. FAN ONLY Operation

(MODE of the remote control : FAN ONLY)

(1) During this mode, the relay R Y01 is always turned

off so that only the indoor fan is operated. RY02

is always turnd on.

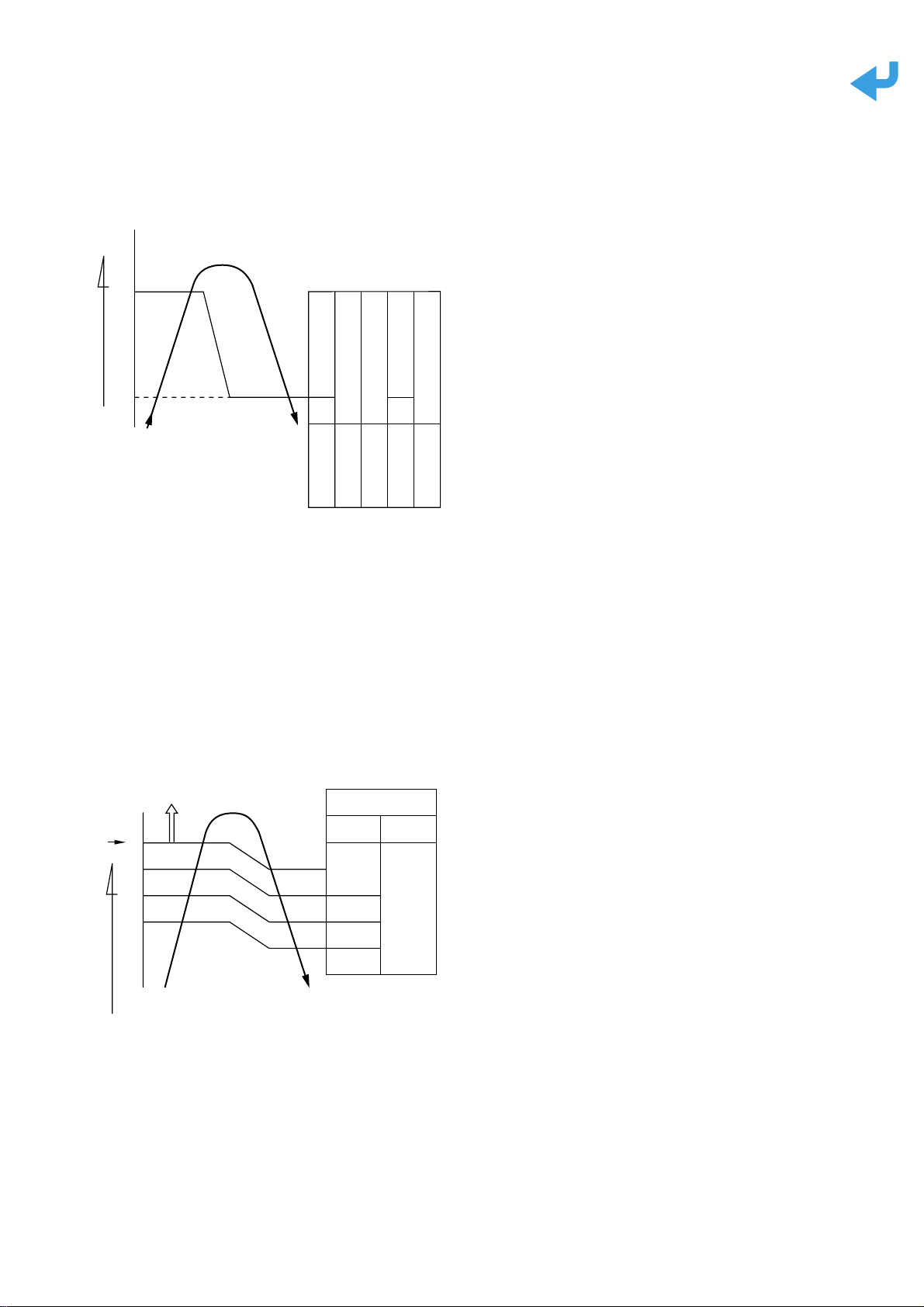

1) When the FAN is set to AUTO, the indoor fan

motor operates as shown in Fig 7-1-1.

2) When the FAN is set to LOW, MED, or HIGH,

the indoor fan motor operates with a constant

in volume as listed in Table 7-1-1.

28

27

Room temp.

26

25

24

Fig. 7-1-1 Auto setting of air volume

Table 7-1-1 Manual setting of F AN SPEED

Indication of

F AN SPEED

HIGH

MED

LOW(+)

LOW

LOW

HIGH Air volume (m3/h)

13SKH-E 10SKH-E

7-2. COOL Operation

(MODE of the remote control : COOL)

(1) Compressor, 4-way valve, outdoor fan and

operation display are controlled as shown in Fig.

7-2-1.

+1

(Room temp. – Set temp.)

Set

0

temp.

ON

ON ON

OFF

(RY01)

Compressor

Fig. 7-2-1

(2) Relays RY01 and RY02 are turned on to energize

the outdoor unit, and a cool operation is carried

out.

1) When the FAN is set to AUTO, the indoor fan

motor operates as shown in Fig 7-2-2.

2) When the FAN is set to LOW, MED, or HIGH,

the indoor fan motor operates with a constant

in volume as listed in Table 7-1-1.

ON

OFF

OFF

(RY02)

(RY04)

4-way valve

Common relay

Outdoor fan

(RY03)

OPERATION

display

LOW

MED

HIGH

510 400

560 500

650 600

(2) Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing the START/ST OP b utton.

AUTO

+4

+3

+2

+1

(Room temp. – Set temp.)

Set

0

temp.

RY01

OFF

HIGH

LOW(+)

(continuous)

Fig. 7-2-2

(3) Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing the START/ST OP b utton.

– 17 –

MED

LOW

LOW

FAN

Manual

According

to the set

position

7-2-1. Louver Control

(1) By pushing the SET button of the remote control

during the operation, the louver can be set to the

desired position.

And the louver position is stored in the microcomputer, the louvers will be set to the position

automatically at the next operation.

(2) When the AUTO button is pushed, the louver ver-

tically swings within range of 25deg.

7-3. DRY Operation

(MODE of the remote control : DRY)

(1) Compressor, 4-way valve, outdoor fan and

operation display are controlled as shown in Fig.

7-3-1.

ON:6min.

+3

ON:6min.

OFF:4min.

OFF:4min.

+2

+1

(Room temp. – Set temp.)

Set

0

temp.

ON

ON:5min.

OFF:5min.

OFF

(RY01)

Compressor

Common relay

OFF

OFF

(RY04)

(RY02)

4-way valve

ON

ON:5min.

OFF:5min.

(RY03)

Outdoor fan

OPERATION

Fig. 7-3-1

• The microprocessor tur ns the compressor on

and off at regular intervals (4 to 6 minutes on

and/or off). During the compressor off, the

indoor fan will operate in the super low position.

• The indoor fan will operate in the A UT O position.

(2) The pattern of operation depending on the relation

between room temperature and set temperature

is shown below:

display

– 18 –

Room temp.

Set temp.+1

Set temp.

Compressor

Outdoor fan

Indoor fan

ON ON ON ON

OFF OFF OFF

L.*S.L. S.L.L. L. S.L. L.

*

Super Low

Fig. 7-3-2

7-4. HEAT Operation

(MODE of the remote control : HEAT)

(1) Compressor, 4-way valve, outdoor fan and

operation display are controlled as shown in Fig.

7-4-1.

0

–1

(Room temp. – Set temp.)

Fig. 7-4-1

OFF

ON ON

ON

(RY01)

Compressor

OFF

ON

ON

(RY04)

(RY02)

Common relay

(RY03)

4-way valve

Outdoor fan

OPERATION

display

7-4-1. Louver Control

(1) By pushing the SET button of the remote control

during the operation, the louver can be set to the

desired position.

(2) When the AUTO button is pushed, the louver ver-

tically swings within range of 25deg.

And the louver position is stored in the microcom-

puter, and at the ne xt operation, the louvers will be

set to the stored position automatically at the next

operation.

7-4-2. Cool Airflow Control

(1) If the indoor heat-exchanger temperature detected

by the indoor heat-exchanger sensor is 20°C or

below , the indoor fan stops and if the temperature

rises to 25°C or above, the fan is restarted.

Details are in 7-10.

(2) Relays R Y01 and R Y02 are turned on to energize

the outdoor unit, and a heat operation is carried

out. The indoor fan motor operates as shown in

Fig. 7-4-2, when the FAN is set to AUTO.

The motor operates with a constant air volume as

listed in Table 7-1-1, when the F AN is set to LO W ,

MED , or HIGH.

RY01 OFF

Set

0

temp.

-1

-2

-3

-4

(Room temp. – Set temp.)

AUTO

LOW

LOW(+)

MED(-)

MED

FAN

Manual

According

to the set

position

Fig. 7-4-2

(3) Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing the START/ST OP b utton.

– 19 –

7-5. AUTO Operation

(MODE of the remote control : AUTO)

(1) One of the 3 modes, Cooling, F an only and Heat-

ing is selected according to room temperature at

which operation is to start, as shown in Fig. 7-5-1.

The Fan mode will continue until room temperature reaches a level at which another mode is

selected.

7-5-1. Temporary Auto

When the TEMPORARY button is pushed, the set

temperature is fixed at 24°C and controlled in accordance with the chart shown in Fig. 7-5-1.

Cooling mode

+4

Cooling mode

+1

Fan only mode

–1

Heating mode

(Room temp. – Set temp.)

(The same cooling mode as the room temperature control is set at set temp. –1˚C)

The Louver moved downward.

(The same cooling mode as the room temperature control is set at set temp. –1˚C)

(Only the indoor fan operates at Low speed)

(The same heating mode as the room temperature control is set at set temp. +1˚C)

Fig. 7-5-1

– 20 –

7-6. ECONO. Mode

7-7. Current Limit Control

When the ECONO. button is pushed, during COOL,

HEAT and AUTO operation, the OPERATION display

is turned off and the ECONO. display is lit and the

indoor unit operates quietly and mildly with controlling

airflow .

7-6-1. Cooling

(1) In the ECONO. mode , the set temp. by the remote

control is changed automatically as shown in Fig.

7-6-1.

(2) Fan speed → LOW

(˚C)

Set temp.

is changed

+2

Set temp.

is changed

+1

Set temp.

ECONO. button

is pushed

1H 2H TIME0H

The microprocessor detects the input current so as to

prevent it exceeds a specified value by means of

controlling the outdoor fan control as described in (1)

and (2).

(1) Current limit control (Cooling)

Control is performed as shown below by detecting

the compressor operation current with a current

sensor (C.T).

Input

current

13SKH: 13.5A

10SKH: 10.0A

13SKH: 12.5A

10SKH: 9.0A

I

4

I

3

Compressor Outdoor fan

More than I

More than I3 continues

4

continues

for 3 seconds

OFF

for 5 minutes

OFF

ON

Fig. 7-7-1

(2) Current limit control (Heating)

Control is performed as shown in Fig. 7-7-2.

Fig. 7-6-1

7-6-2. Heating

(1) In the ECONO. mode , the set temp. by the remote

control is changed automatically as shown in Fig.

7-6-2.

(2) Fan speed → LOW

ECONO. button

is pushed

1H 2H TIME0H

Set temp.

-1

Set temp.

is changed

-2

Set temp.

is changed

(˚C)

Input

current

13SKH: 13.5A

10SKH: 10.0A

13SKH: 12.5A

10SKH: 9.0A

13SKH: 10.0A

10SKH: 8.0A

13SKH: 9.0A

10SKH: 7.5A

Compressor Outdoor fan

More than I

I

4

I

3

I

2

I

1

More than I3 continues

4

continues

for 3 seconds

OFF

for 5 minutes

OFF

ON OFF

ON

Fig. 7-7-2

Fig. 7-6-2

– 21 –

7-8. High-Temperature Limit Control

(Heating Operation)

7-10. Cool Airflow Prevention Contr ol

(Heating Operation)

The microprocessor detects the indoor heat exchanger

temperature so as to prevent exceeding the condensate pressure.

Control is performed as shown in Fig. 7-8-1.

Heat exchanger

temperature

(˚C)

60

*

1

53

52

*

1 ····· Only outdoor fan is turned off.

Compressor,

Outdoor fan

OFF

ON

Fig. 7-8-1

7-9. Low-Temperature Limit Contr ol

(Cooling Operation)

The microprocessor detects the indoor heat exchanger

temperature so as to prevent freezing up the indoor

heat exchanger .

Control is performed as shown in Fig. 7-9-1 and 7-9-

2.

<RAS-13SKH-E>

Heat exchanger

temperature

(˚C)

6

2

Compressor

Less than 2˚C continues

Outdoor fan

ON

for 5 minutes

OFF

(1) During the heating operation, the indoor fan speed

is controlled automatically in accordance with the

indoor heat exchanger temperature to prevent

blowing the cool air.

Control is performed as shown in Fig. 7-10-1 and

7-10-2.

<RAS-13SKH-E>

Heat exchanger

temperature

(˚C)

35

32

30

20

Indoor fan speed

According to the

set position

U.L. (Ultra Low)

Room temp.

<

Set temp.

OFF

Room temp.

>

Set temp.

S.L (Super Low)

Fig. 7-10-1

< RAS-10SKH-E>

Heat exchanger

temperature

(˚C)

30

25

20

Indoor fan speed

According to the

set position

U.L. (Ultra Low)

Room temp.

<

Set temp.

OFF

Room temp.

>

Set temp.

S.L (Super Low)

Fig. 7-10-2

(2) As soon as the defrost operation starts, the in-

door fan stops.

< RAS-10SKH-E>

Heat exchanger

temperature

(˚C)

7

5

Fig. 7-9-1

Compressor

Less than 5˚C continues

Fig. 7-9-2

Outdoor fan

ON

for 5 minutes

OFF

– 22 –

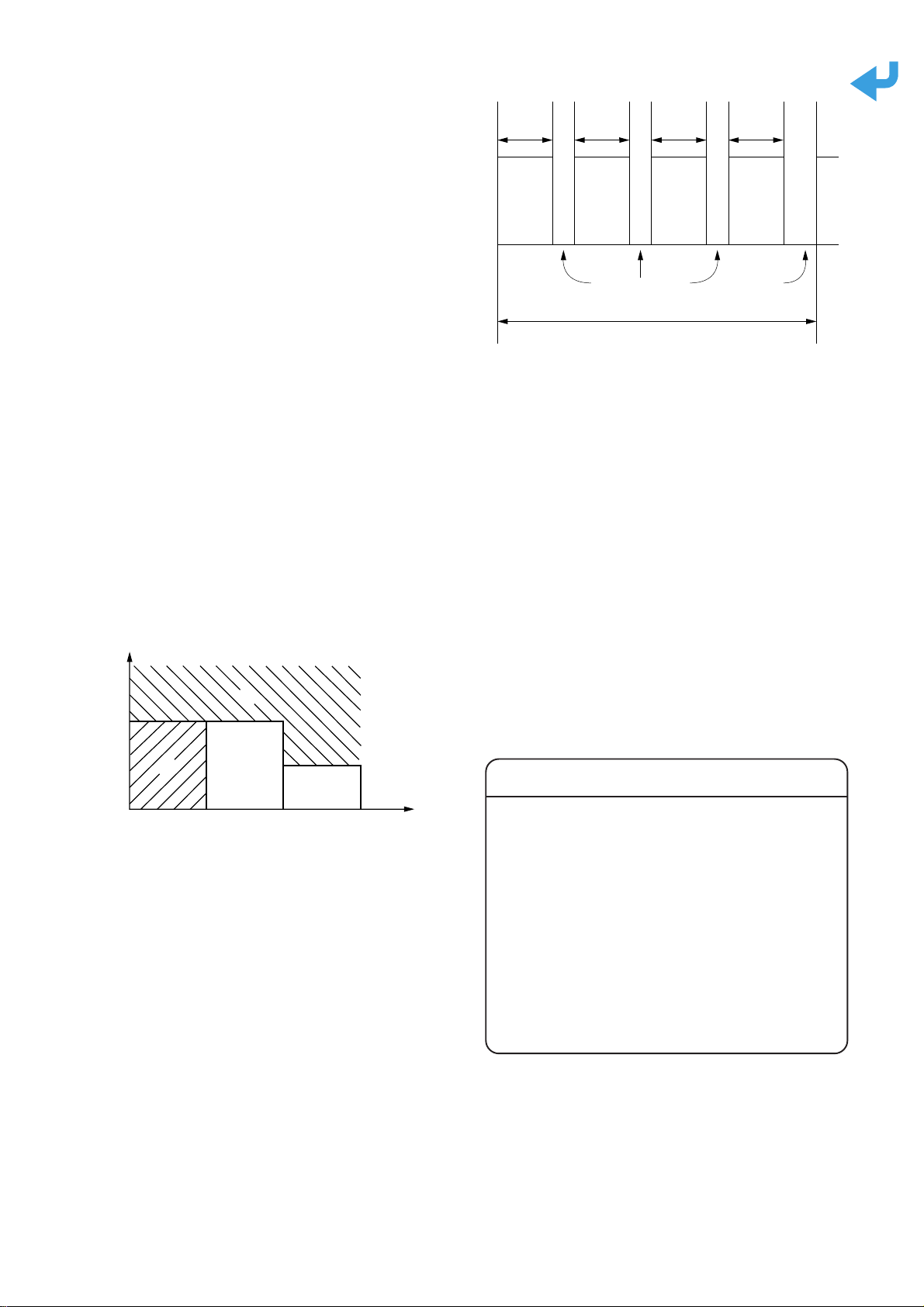

7-11. Defrost Operation

minutes40minutes40minutes40minutes

40

Max 6 minutes 10 minutes

1 cycle

Heating

Heating

Heating

Heating

Defrost

Defrost

Defrost

Defrost

(

)

During the heating operation, the outdoor heat

exchanger temperature goes down and sometimes it

is frozen.

In this case, the air conditioner stops the heating

operation and starts the defrost operation to melt ice.

7-11-1. Condition to Start the Defrost

Operation

The defrost operation starts whichever below

conditions are specified.

(1) When the cumulative compressor operation time

is longer than 40 or 90 minutes and difference

between the indoor heat exchanger temperature

and the room temperature is less than the

specified value. (This value is decided by the

microprocessor.) (Control e xample is shown in Fig.

7-11-1. In case of B or C, the defrost operation

starts.)

(2) When the current limit control or the high

temperature limit control is performed for total of

90 minutes.

(˚C)

D

19

Fig. 7-11-2

<In case of C>

(1) The heating operation is perf ormed for at least 90

minutes.

(2) The defrost operation time is 10 minutes.

7-11-3. Ending Condition at Defrost

Operation

(1) When the compressor current becomes 7.5A or

more during defrost operation, the defrost operation stops and the heat operation restarts. (The

current sensor detects the compressor current.)

(2) The defrost operation continues for at most 6

minutes or 10 minutes.

10

Indoor heat exchanger temp.

–Room temp.

A

40 90

B

Fig. 7-11-1 (Indoor fan speed : M)

7-11-2. Defrost Operation Time Control

<In case of B>

(1) The heating operation is perfo rmed for at least 40

minutes.

(2) The maximum defrost operation time is 6 minutes.

The defrost operation time for the 4th cycle is 10

minutes. (When the outdoor temperature is very

low, however, the defrost operation time is 10

minutes.)

C

min.

Cumulative

compressor

operation time

– 23 –

DEFROST LAMP :

• During defrost operation, the PRE-DEF . lamp is

on and the indoor and outdoor fans are off .

• The compressor star t protection timer is interlocked with the PRE-DEF. lamp. So the PREDEF. lamp is off (the f ans stop) for about 3 minutes after the START/STOP button is turned

on. When the compressor is turned on, the

PRE-DEF. lamp comes on. After the heat exchanger is preheated to about 30°C or higher,

the PRE-DEF. lamp goes off, and the indoor

fan starts.

Loading...

Loading...