Toshiba RAS-13SKV2-E, RAS-10SAV2-E, RAS-10SKV2-E, RAS-16SKV2-E, RAS-16SAV2-E INSTALLATION MANUAL

...Page 1

SERVICE MANUAL

Indoor Unit Outdoor Unit

<High Wall, Heat Pump Type> <Heat Pump Type>

FILE NO. SVM-10001

SPLIT TYPE

RAS-10SKV2-E RAS-10SAV2-E

RAS-13SKV2-E RAS-13SAV2-E

RAS-16SKV2-E RAS-16SAV2-E

R410A

January, 2010

Page 2

FILE NO. SVM-10001

CONTENTS

1. SAFETY PRECAUTIONS .......................................................................... 3

2. SPECIFICATIONS ..................................................................................... 5

3. REFRIGERANT R410A ............................................................................. 8

4. CONSTRUCTION VIEWS ........................................................................ 16

5. WIRING DIAGRAM .................................................................................. 18

6. SPECIFICATIONS OF ELECTRICAL PARTS ......................................... 20

7. REFRIGERANT CYCLE DIAGRAM ........................................................ 21

8. CONTROL BLOCK DIAGRAM ................................................................ 25

9. OPERATION DESCRIPTION................................................................... 28

10. INSTALLATION PROCEDURE ................................................................ 52

11. HOW TO DIAGNOSE THE TROUBLE...................................................... 66

12. HOW TO REPLACE THE MAIN PARTS................................................... 91

13. EXPLODED VIEWS AND PARTS LIST ................................................. 108

– 2 –

Page 3

FILE NO. SVM-10001

1. SAFETY PRECAUTIONS

For general public use

Power supply cord of outdoor unit shall be more than 1.5 mm2 (H07RN-F or 60245IEC66) polychloroprene

sheathed flexible cord.

• Read this “SAFETY PRECAUTIONS” carefully before servicing.

• The precautions described below include the important items regarding safety. Observe them without fail.

• After the servicing work, perform a trial operation to check for any problem.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

CAUTION

New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT

DESTROY OZONE LAYER.

R410A refrigerant is apt to be affected by impurities such as water, oxidizing membrane, and oils because

the working pressure of R410A refrigerant is approx. 1.6 times of refrigerant R22. Accompanied with the

adoption of the new refrigerant, the refrigeration machine oil has also been changed. Therefore, during

installation work, be sure that water , dust, former refrigerant, or refrigeration machine oil does not enter into

the new type refrigerant R410A air conditioner circuit.

To prevent mixing of refrigerant or refrigerating machine oil, the sizes of connecting sections of charging

port on main unit and installation tools are different from those used for the conventional refrigerant units.

Accordingly, special tools are required for the new refrigerant (R410A) units . For connecting pipes, use new

and clean piping materials with high pressure fittings made for R410A only, so that water and/or dust does

not enter. Moreover, do not use the existing piping because there are some problems with pressure fittings

and possible impurities in existing piping.

CAUTION

TO DISCONNECT THE APPLIANCE FROM THE MAIN POWER SUPPLY

This appliance must be connected to the main power supply by a circuit breaker or a switch with a contact

separation of at least 3 mm.

DANGER

• ASK AN AUTHORIZED DEALER OR QUALIFIED INSTALLATION PROFESSIONAL TO INSTALL/MAINTAIN THE AIR CONDITIONER.

INAPPROPRIATE SERVICING MAY RESULT IN WATER LEAKAGE, ELECTRIC SHOCK OR FIRE.

• TURN OFF MAIN POWER SUPPLY BEFORE ATTEMPTING ANY ELECTRICAL WORK. MAKE SURE

ALL POWER SWITCHES ARE OFF. FAILURE T O DO SO MAY CAUSE ELECTRIC SHOCK.

DANGER: HIGH VOLTAGE

The high voltage circuit is incorporated.

Be careful to do the check service, as the electric shock may be caused in case of touching parts

on the P.C. board by hand.

• CORRECTLY CONNECT THE CONNECTING CABLE. IF THE CONNECTING CABLE IS INCORRECTLY CONNECTED, ELECTRIC PARTS MAY BE DAMAGED.

• CHECK THAT THE EARTH WIRE IS NOT BROKEN OR DISCONNECTED BEFORE SERVICE AND

INSTALLA TION. FAILURE TO DO SO MAY CAUSE ELECTRIC SHOCK.

– 3 –

Page 4

FILE NO. SVM-10001

• DO NOT INSTALL NEAR CONCENTRATIONS OF COMBUSTIBLE GAS OR GAS VAPORS. FAILURE

TO FOLLOW THIS INSTRUCTION CAN RESULT IN FIRE OR EXPLOSION.

• TO PREVENT THE INDOOR UNIT FROM OVERHEATING AND CAUSING A FIRE HAZARD, PLACE

THE UNIT WELL AWAY (MORE THAN 2 M) FROM HEAT SOURCES SUCH AS RADIATORS, HEAT

REGISTORS, FURNACE, STOVES , ETC.

• WHEN MOVING THE AIR-CONDITIONER FOR INSTALLATION IN ANOTHER PLACE, BE VERY CAREFUL NOT TO ALLOW THE SPECIFIED REFRIGERANT (R410A) TO BECOME MIXED WITH ANY

OTHER GASEOUS BODY INTO THE REFRIGERATION CIRCUIT. IF AIR OR ANY OTHER GAS IS

MIXED IN THE REFRIGERANT, THE GAS PRESSURE IN THE REFRIGERATION CIRCUIT WILL

BECOME ABNORMALLY HIGH AND IT MAY RESULT IN THE PIPE BURSTING AND POSSIBLE PERSONNEL INJURIES.

• IN THE EVENT THAT THE REFRIGERANT GAS LEAKS OUT OF THE PIPE DURING THE SERVICE

WORK AND THE INSTALLATION WORK, IMMEDIATELY LET FRESH AIR INTO THE ROOM. IF THE

REFRIGERANT GAS IS HEATED, SUCH AS BY FIRE, GENERATION OF POISONOUS GAS MAY

RESULT.

WARNING

• Never modify this unit by removing any of the safety guards or bypass any of the safety interlock

switches.

• Do not install in a place which cannot bear the weight of the unit. Personal injury and property

damage can result if the unit falls.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas

may generate.

• The electrical work must be performed by a qualified electrician in accordance with the Installation

Manual. Make sure the air conditioner uses an exclusive circuit.

An insufficient circuit capacity or inappropriate installation may cause fire.

• When wiring, use the specified cables and connect the terminals securely to prevent external

forces applied to the cable from affecting the terminals.

• Be sure to provide grounding.

Do not connect ground wires to gas pipes, water pipes, lightning rods or ground wires for telephone cables.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

CAUTION

• Exposure of unit to water or other moisture before installation may result in an electrical short.

Do not store in a wet basement or expose to rain or water.

• Do not install in a place that can increase the vibration of the unit. Do not install in a place that can amplify

the noise level of the unit or where noise or discharged air might disturb neighbors.

• To avoid personal injury, be careful when handling parts with sharp edges.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

For Reference:

If a heating operation would be continuously perf ormed for a long time under the condition that the outdoor

temperature is 0°C or lower, drainage of defrosted water may be difficult due to freezing of the bottom plate,

resulting in a trouble of the cabinet or fan.

It is recommended to procure an antifreeze heater locally for a safe installation of the air conditioner.

For details, contact the dealer.

– 4 –

Page 5

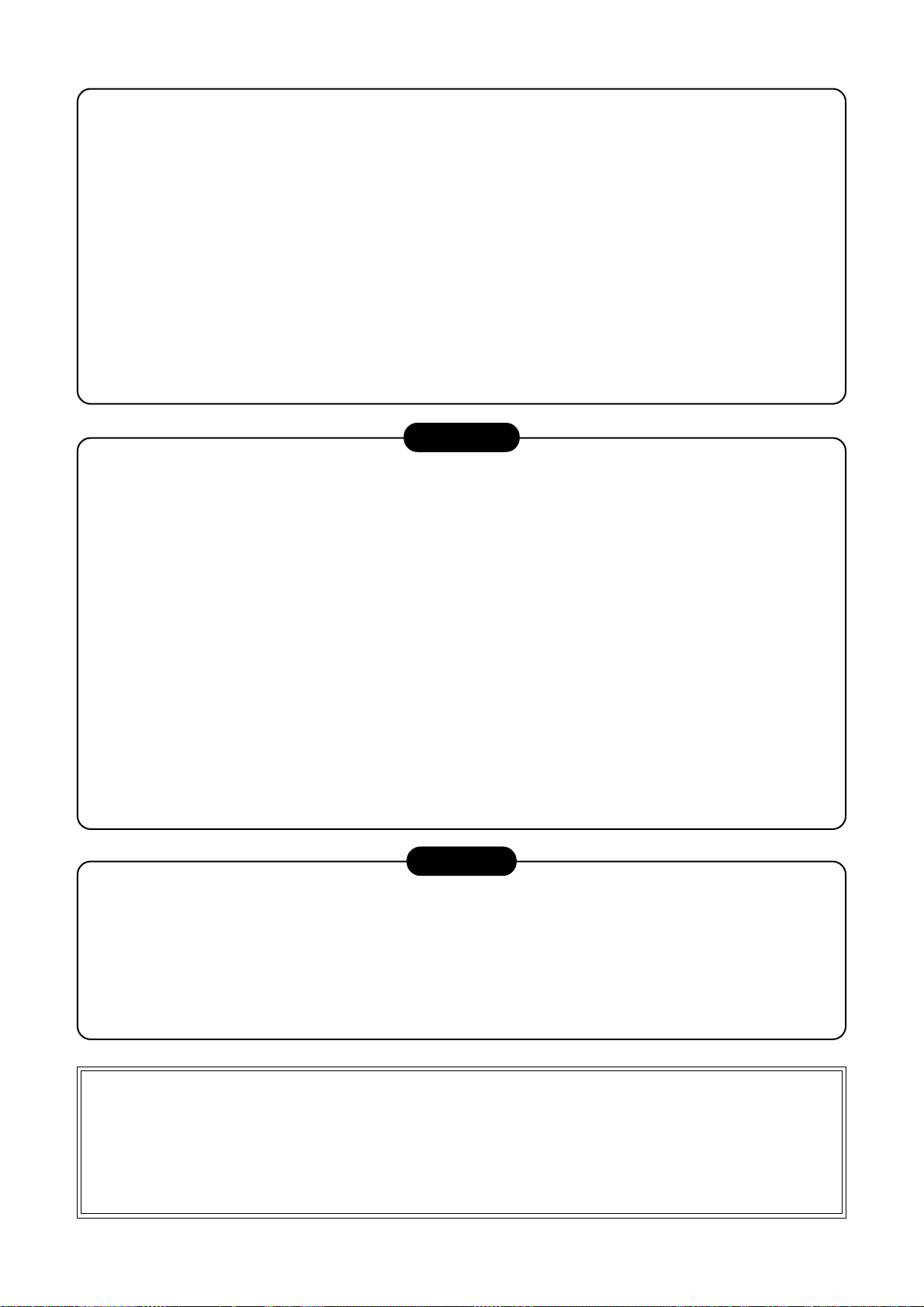

2-1. Specification

/

/

FILE NO. SVM-10001

2. SPECIFICATIONS

Unit model Indoor RAS-10SKV2-E RAS-13SKV2-E

Cooling capacity (kW) 2.5 3.5

Cooling capacity range (kW) 1.1-3.1 0.8-4.1

Heating capacity (kW) 3.2 4.2

Heating capacity range (kW) 0.9-4.8 0.9-5.6

Power supply

Electric Indoor Operation mode Cooling Heating Cooling Heating

characteristic Running current (A) 0.21-0.19 0.24-0.22 0.21-0.19 0.24-0.22

COP (Cooling / Heating)

Operating Indoor High (Cooling / Heating) (dB-A) 38/39 39/40

noise Medium (Cooling / Heating) (dB-A) 33/34 33/34

Indoor unit Unit model RAS-10SKV2-E RAS-13SKV2-E

Outdoor unit Unit model RAS-10SAV2-E RAS-13SAV2-E

Piping Type Flare connection Flare connection

connection Indoor unit Liquid side (mm)

Refrigerant Name of refrigerant R410A R410A

Wiring Power supply

connection Interconnection

Usable temperature range Indoor (Cooling / Heating)

Accessory Indoor unit Installation plate 1 1

* The specification may be subject to change without notice for purpose of improvement.

Outdoor RAS-10SAV2-E RAS-13SAV2-E

1Ph/50Hz/220-240V , 1Ph/60Hz/220-230V

Power consumption (W) 35 40 35 40

Outdoor Operation mode Cooling Heating Cooling Heating

Outdoor (Cooling / Heating) (dB-A) 46/47 48/50

Dimension Height (mm) 275 275

Net weight (kg) 9 9

Fan motor output (W) 20 20

Air flow rate (Cooling / Heating)

Dimension Height (mm) 550 550

Net weigh (kg) 33 33

Compressor Motor output (W) 750 750

Fan motor output (W)

Air flow rate (Cooling / Heating)

Outdoor unit Liquid side (mm) ∅ 6.35 ∅ 6.35

Maximum length (m) 20 20

Maximum charge-less length (m) 15 15

Maximum height difference (m) 10 10

Weight (kg) 0.80 0.80

Outdoor unit Drain nipple 1 1

Power factor (%)7 766 76 76

Running current (A) 2.81-2.58 3.43-3.14 4.57-4.20 4.93-4.52

Power consumption (W) 563 710 965 1040

Power factor (%)9194 96 96

Starting current (A) 3.67 5.17

Low (Cooling / Heating) (dB-A) 26/28 26/28

Width (mm) 790 790

Depth (mm) 205 205

3

min)

(m

Width (mm) 780 780

Depth (mm) 290 290

Type Single rotary type with DC-inverter variable speed control

Model DA89X1C-23FZ2

(m3 min)

Gas side (mm) ∅ 9.52 ∅ 9.52

Gas side (mm) ∅ 9.52 ∅ 9.52

Outdoor (Cooling / Heating)

Wireless remote controller 1 1

batteries 2 2

Remote controller holder 1 1

Pure Flow 2 2

Mounting screw

Pan head wood screw

Plasma air purifier - -

Installation manual 1 1

Owner's manual 1 1

Water proof rubber cap 2 2

∅ 6.35 ∅ 6.35

o

C)

(

(oC)

4.18/4.27 3.50/3.89

8.6/9.5 9.5/10.4

43

30/30 37.5/37.5

3 Wires: Includes earth (Outdoor)

4 Wires: Includes earth

21-32/0-28 21-32/0-28

-10-46/-15-24 -10-46/-15-24

6 ( ∅ 4 x 25L) 6 ( ∅ 4 x 25L)

2 ( ∅ 3.1 x 16L) 2 ( ∅ 3.1 x 16L)

– 5 –

Page 6

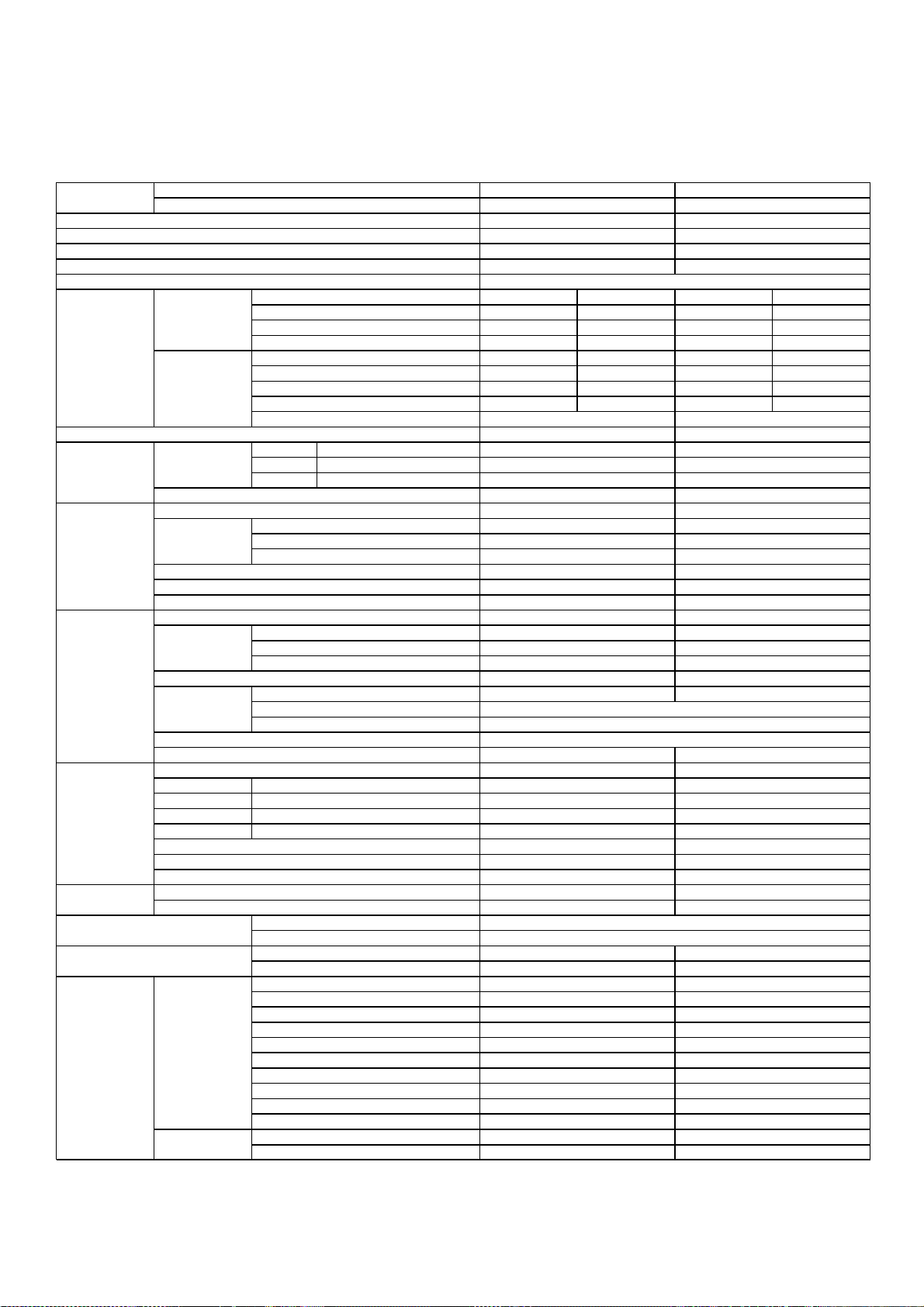

2-2. Specification

/

/

FILE NO. SVM-10001

Unit model Indoor RAS-16SKV2-E

Cooling capacity (kW) 4.5

Cooling capacity range (kW) 0.8-5.0

Heating capacity (kW) 5.5

Heating capacity range (kW) 0.9-6.9

Power supply

Electric Indoor Operation mode Cooling Heating

characteristic Running current (A) 0.21-0.19 0.24-0.22

COP (Cooling / Heating)

Operating Indoor High (Cooling / Heating) (dB-A) 45/45

noise Medium (Cooling / Heating) (dB-A) 40/40

Indoor unit Unit model RAS-16SKV2-E

Outdoor unit Unit model RAS-16SAV2-E

Piping Type Flare connection

connection Indoor unit Liquid side (mm)

Refrigerant Name of refrigerant R410A

Wiring Power supply

connection Interconnection

Usable temperature range Indoor (Cooling / Heating)

Accessory Indoor unit Installation plate 1

* The specification may be subject to change without notice for purpose of improvement.

Outdoor RAS-16SAV2-E

1Ph/50Hz/220-240V , 1Ph/60Hz/220-230V

Power consumption (W) 30 35

Outdoor Operation mode Cooling Heating

Outdoor (Cooling / Heating) (dB-A)

Dimension Height (mm) 275

Net weight (kg) 9

Fan motor output (W) 30

Air flow rate (Cooling / Heating)

Dimension Height (mm) 550

Net weicht (kg) 39

Compressor Motor output (W) 750

Fan motor output (W)

Air flow rate (Cooling / Heating)

Outdoor unit Liquid side (mm)

Maximum length (m) 20

Maximum charge-less length (m) 15

Maximum height difference (m) 10

Weight (kg) 1.10

Outdoor unit Drain nipple 1

Power factor (%) 65 66

Running current (A) 6.26-5.74 6.81-6.24

Power consumption (W) 1365 1485

Power factor (%) 99 99

Starting current (A) 7.05

Low (Cooling / Heating) (dB-A) 30/31

Width (mm) 790

Depth (mm) 205

3

min)

(m

Width (mm) 780

Depth (mm) 290

Type Twin rotary type with DC-inverter variable speed control

Model DA111A1F-20F1

(m3 min)

Gas side (mm)

Gas side (mm)

o

C)

Outdoor (Cooling / Heating)

Wireless remote controller 1

batteries 2

Remote controller holder 1

Pure Flow 2

Mounting screw

Pan head wood screw

Plasma air purifier -

Installation manual 1

Owner's manual 1

Water proof rubber cap 2

(

(oC)

∅ 6.35

∅12.7

∅ 6.35

∅12.7

3 Wires: Includes earth (Outdoor)

21-32/0-28

-10-46/-15-24

6 (∅ 4 x 25L)

2 (∅ 3.1 x 16L)

3.23/3.62

49/50

11.4/12.3

43

36/32

4 Wires: Includes earth

– 6 –

Page 7

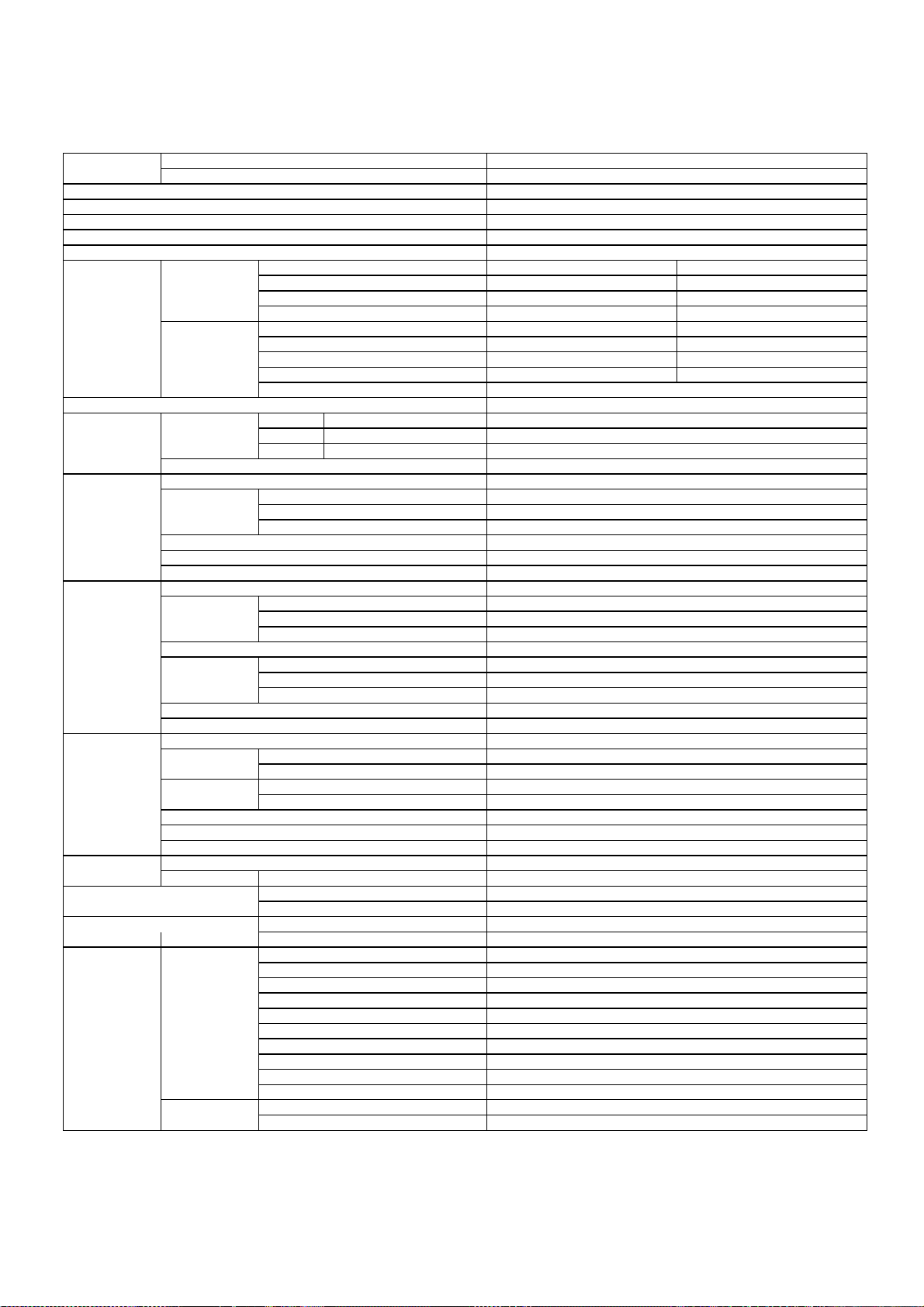

2-3. Operation Characteristic Curve

<Cooling> <Heating>

FILE NO. SVM-10001

10

9

8

RAS-16SKV2-E

7

6

RAS-13SKV2-E

5

4

Current (A)

3

2

1

RAS-10SKV2-E

Conditions

Indoor : DB 27

Outdoor : DB 35

Air Flow : High

Pip Length : 5m

Voltage : 230V

o

0

0 10 20 30 40 50 60 70 80 90 100 110 120

Compressor Speed (rps)

C/WB 19oC

o

C

9

8

7

RAS-16SKV2-E

RAS-10SKV2-E

6

RAS-13SKV2-E

5

4

Current (A)

3

2

1

Conditions

Indoor : DB 20

Outdoor : DB 7

Air Flow : High

Pip Length : 5m

Voltage : 230V

o

C

o

C/WB 6oC

0

0 102030405060708090100110120

Compressor Speed (rps)

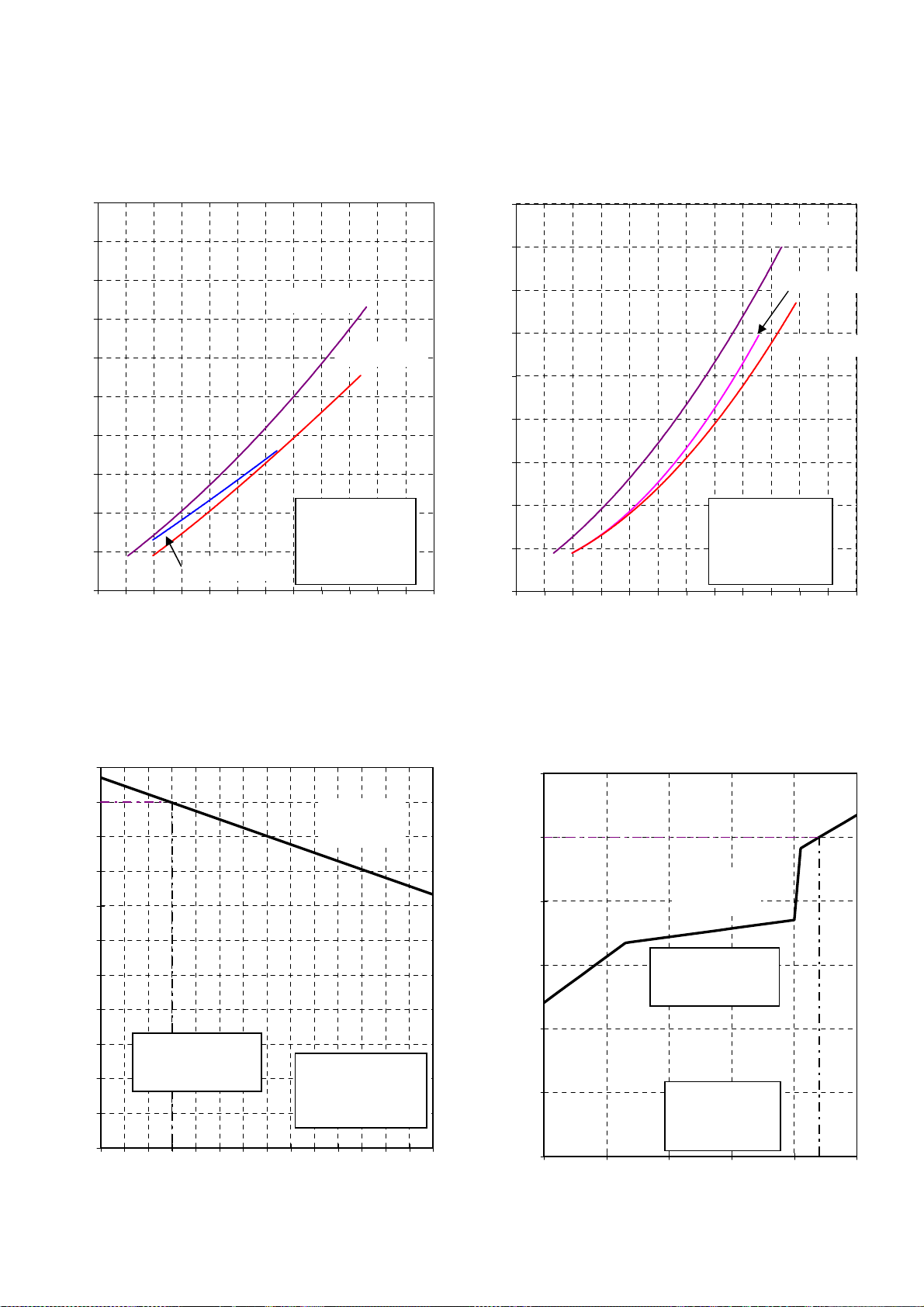

2-4. Capacity Variation Ratio According to Temperature

<Cooling>

105

100

95

90

85

80

75

Capacity ratio (%)

70

65

60

Capacity ratio:100%=

2.5kW(RAS-10SKV2-E)

3.5KW(RAS-13SKV2-E)

4.5kW(RAS-16SKV2-E)

55

50

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46

Outdoor temp. (℃)

RAS-10SKV2-E

RAS-13SKV2-E

RAS-16SKV2-E

Conditions

Indoor:DB27℃/WB19℃

Indoor air flow:High

Pipe length:5m

Voltage : 230V

<Heating>

120

100

RAS-10SKV2-E

80

60

40

Heating Capacity ratio (%)

20

0

-15 -10 -5 0 5 10

RAS-13SKV2-E

RAS-16SKV2-E

Capacity ratio:100%=

W(RAS-10SKV2-E)

3.2k

4.2KW(RAS-13SKV2-E)

5.5kW(RAS-16SKV2-E)

Condition

Indoor:DB20℃

Indoor air flow:High

Pipe length:5m

Voltage : 230V

Outdoor temp. (℃)

– 7 –

Page 8

3. REFRIGERANT R410A

FILE NO. SVM-10001

This air conditioner adopts the new refrigerant HFC

(R410A) which does not damage the ozone layer.

The working pressure of the new refrigerant R410A

is 1.6 times higher than conventional refrigerant

(R22). The refrigerating oil is also changed in

accordance with change of refrigerant, so be careful

that water , dust, and existing refrigerant or refrigerating oil are not entered in the refrigerant cycle of the

air conditioner using the new refrigerant during

installation work or servicing time.

The next section describes the precautions for air

conditioner using the new refrigerant. Conforming to

contents of the next section together with the

general cautions included in this manual, perform

the correct and safe work.

3-1. Safety During Installation/Servicing

As R410A’s pressure is about 1.6 times higher than

that of R22, improper installation/servicing may

cause a serious trouble. By using tools and materials exclusive for R410A, it is necessary to carry out

installation/servicing safely while taking the following

precautions into consideration.

1. Never use refrigerant other than R410A in an air

conditioner which is designed to operate with

R410A.

If other refrigerant than R410A is mixed, pressure

in the refrigeration cycle becomes abnormally

high, and it may cause personal injury, etc. by a

rupture.

2. Confirm the used refrigerant name, and use tools

and materials exclusive for the refrigerant R410A.

The refrigerant name R410A is indicated on the

visible place of the outdoor unit of the air conditioner using R410A as refrigerant. To prevent

mischarging, the diameter of the service port

differs from that of R22.

3. If a refrigeration gas leakage occurs during

installation/servicing, be sure to ventilate fully.

If the refrigerant gas comes into contact with fire,

a poisonous gas may occur.

4. When installing or removing an air conditioner, do

not allow air or moisture to remain in the refrigeration cycle. Otherwise, pressure in the refrigeration cycle may become abnormally high so

that a rupture or personal injury may be caused.

5. After completion of installation work, check to

make sure that there is no refrigeration gas

leakage.

If the refrigerant gas leaks into the room, coming

into contact with fire in the fan-driven heater,

space heater, etc., a poisonous gas may occur.

6. When an air conditioning system charged with a

large volume of refrigerant is installed in a small

room, it is necessary to exercise care so that,

even when refrigerant leaks, its concentration

does not exceed the marginal le vel.

If the refrigerant gas leakage occurs and its

concentration exceeds the marginal le vel, an

oxygen starvation accident may result.

7. Be sure to carry out installation or removal

according to the installation manual.

Improper installation may cause refrigeration

trouble, water leakage , electric shock, fire, etc.

8. Unauthorized modifications to the air conditioner

may be dangerous. If a breakdown occurs

please call a qualified air conditioner technician

or electrician.

Improper repair’s may result in water leakage,

electric shock and fire, etc.

3-2. Refrigerant Piping Installation

3-2-1. Piping Materials and Joints Used

For the refrigerant piping installation, copper pipes

and joints are mainly used. Copper pipes and joints

suitable for the refrigerant m ust be chosen and

installed. Furthermore, it is necessary to use clean

copper pipes and joints whose interior surfaces are

less affected by contaminants .

1. Copper Pipes

It is necessary to use seamless copper pipes

which are made of either copper or copper alloy

and it is desirable that the amount of residual oil

is less than 40 mg/10 m. Do not use copper

pipes having a collapsed, deformed or discolored

portion (especially on the interior surface).

Otherwise, the expansion valve or capillary tube

may become blocked with contaminants.

As an air conditioner using R410A incurs pressure higher than when using R22, it is necessary

to choose adequate materials.

Thicknesses of copper pipes used with R410A

are as shown in Table 3-2-1. Never use copper

pipes thinner than 0.8 mm even when it is

available on the market.

– 8 –

Page 9

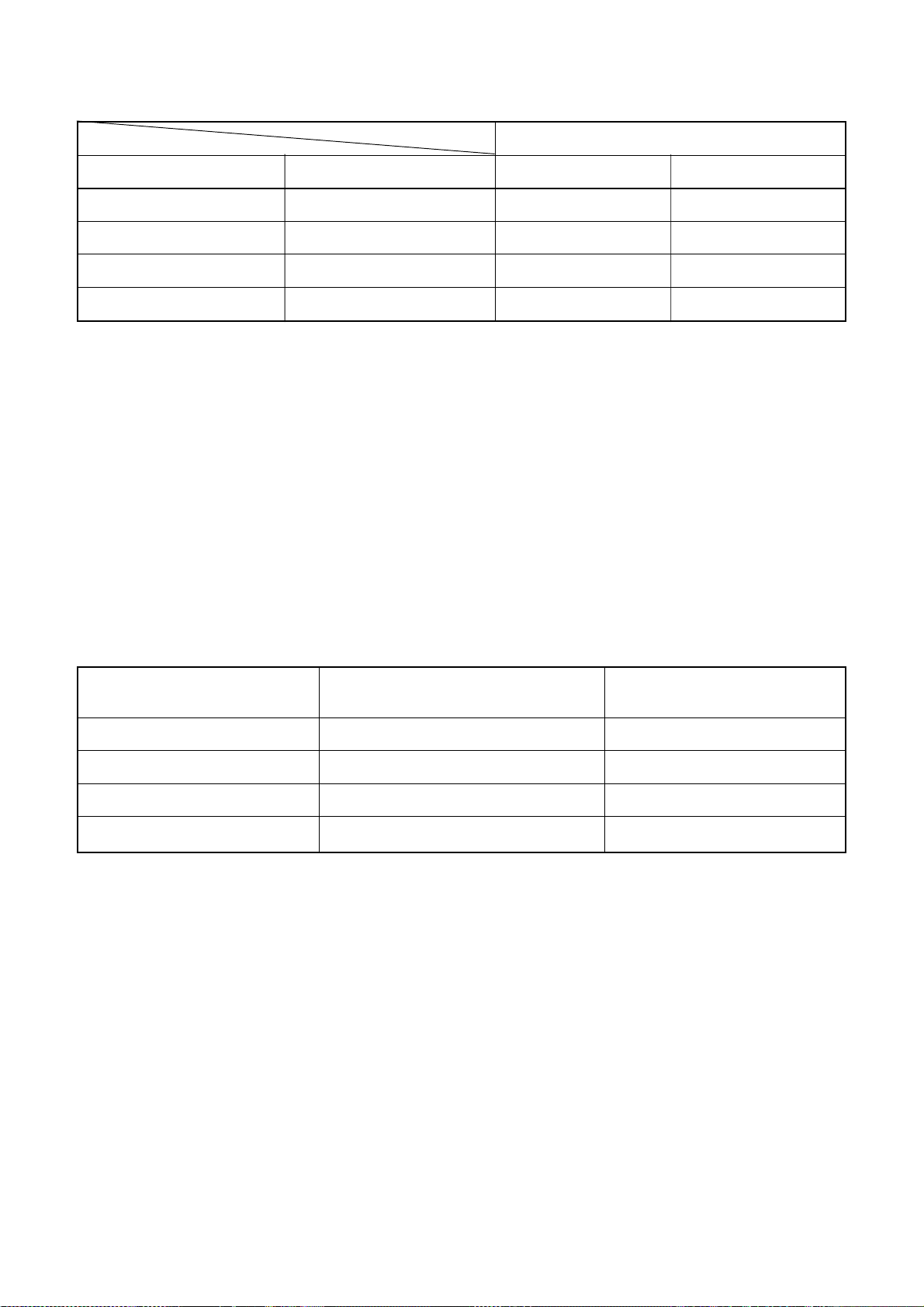

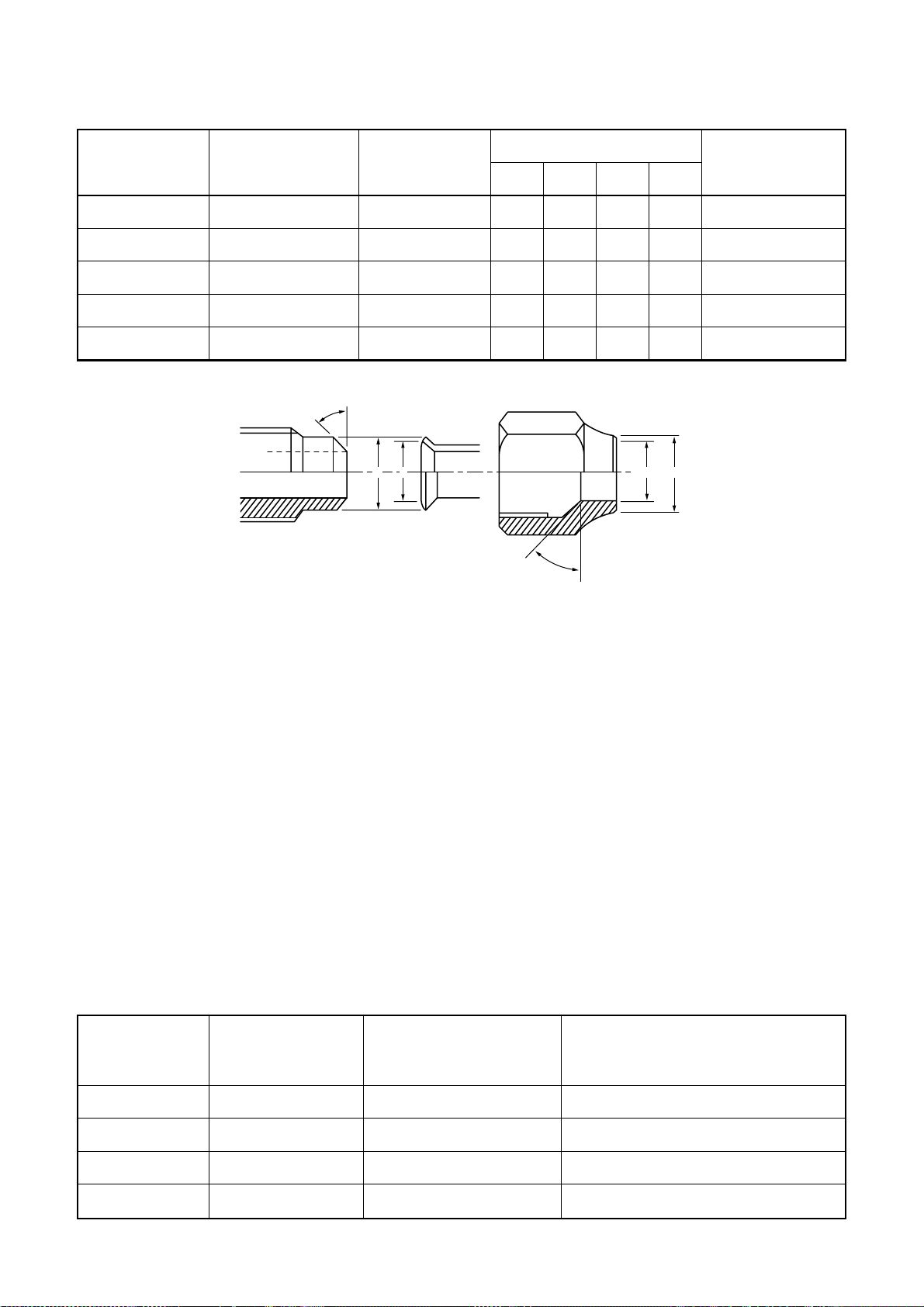

Table 3-2-1 Thicknesses of annealed copper pipes

Thickness (mm)

FILE NO. SVM-10001

Nominal diameter

1/4

3/8

1/2

5/8

Outer diameter (mm)

6.35

9.52

12.70

15.88

R410A R22

0.80 0.80

0.80 0.80

0.80 0.80

1.00 1.00

2. Joints

For copper pipes, flare joints or socket joints are used. Prior to use, be sure to remove all contaminants.

a) Flare Joints

Flare joints used to connect the copper pipes cannot be used for pipings whose outer diameter exceeds

20 mm. In such a case, socket joints can be used.

Sizes of flare pipe ends, flare joint ends and flare nuts are as shown in Tables 3-2-3 to 3-2-6 below.

b) Socket Joints

Socket joints are such that they are brazed for connections, and used mainly for thick pipings whose

diameter is larger than 20 mm.

Thicknesses of sock et joints are as shown in Table 3-2-2.

Table 3-2-2 Minimum thicknesses of socket joints

Nominal diameter

1/4

3/8

1/2

5/8

Reference outer diameter of

copper pipe jointed (mm)

6.35

9.52

12.70

15.88

Minimum joint thickness

(mm)

0.50

0.60

0.70

0.80

3-2-2. Processing of Piping Materials

When performing the refrigerant piping installation, care should be taken to ensure that water or dust does not

enter the pipe interior, that no other oil than lubricating oils used in the installed air-water heat pump is used,

and that refrigerant does not leak. When using lubricating oils in the piping processing, use such lubricating oils

whose water content has been removed. When stored, be sure to seal the container with an airtight cap or any

other cover.

1. Flare processing procedures and precautions

a) Cutting the Pipe

By means of a pipe cutter, slowly cut the pipe so that it is not deformed.

b) Removing Burrs and Chips

If the flared section has chips or burrs, refrigerant leakage ma y occur.

Carefully remove all burrs and clean the cut surface before installation.

c) Insertion of Flare Nut

– 9 –

Page 10

d) Flare Processing

Make certain that a clamp bar and copper

pipe have been cleaned.

By means of the clamp bar, perform the flare

processing correctly.

Use either a flare tool for R410A or conventional flare tool.

Flare processing dimensions differ according

to the type of flare tool. When using a conventional flare tool, be sure to secure “dimen-

sion A” by using a gauge for size adjustment.

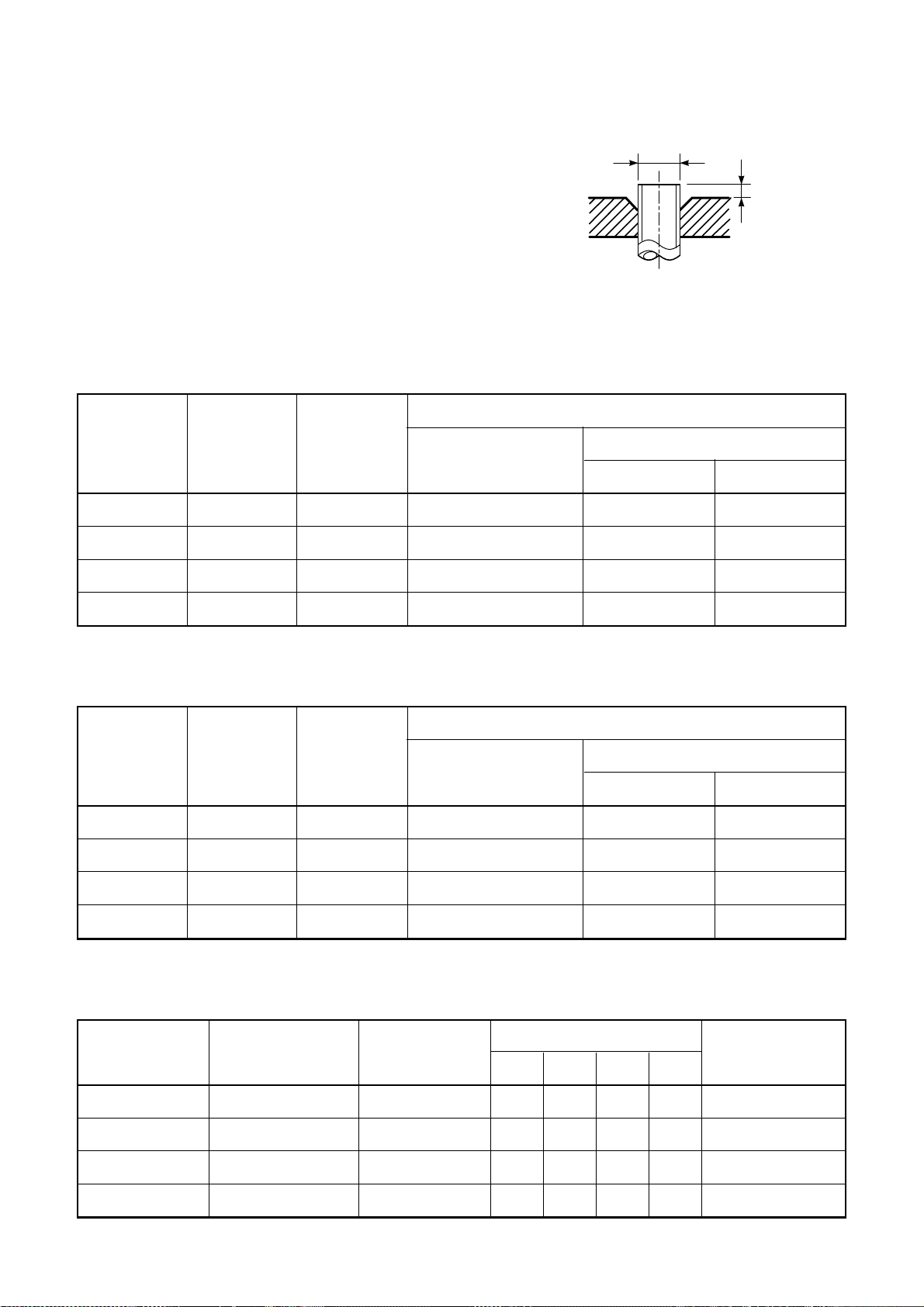

Table 3-2-3 Dimensions related to flare processing for R410A

Nominal

diameter

Outer

diameter

(mm)

Thickness

(mm)

Fig. 3-2-1 Flare pr ocessing dimensions

Flare tool for R410A

clutch type

FILE NO. SVM-10001

ØD

A

A (mm)

Conventional flare tool

Clutch type Wing nut type

1/4

3/8

1/2

5/8

Nominal

diameter

1/4

3/8

1/2

5/8

6.35

9.52

12.70

15.88

Table 3-2-4 Dimensions related to flare processing for R22

Outer

diameter

(mm)

6.35

9.52

12.70

15.88

0.8

0.8

0.8

1.0

Thickness

(mm)

0.8

0.8

0.8

1.0

0 to 0.5

0 to 0.5

0 to 0.5

0 to 0.5

Flare tool for R22

clutch type

0 to 0.5

0 to 0.5

0 to 0.5

0 to 0.5

1.0 to 1.5 1.5 to 2.0

1.0 to 1.5 1.5 to 2.0

1.0 to 1.5 2.0 to 2.5

1.0 to 1.5 2.0 to 2.5

A (mm)

Conventional flare tool

Clutch type Wing nut type

0.5 to 1.0 1.0 to 1.5

0.5 to 1.0 1.0 to 1.5

0.5 to 1.0 1.5 to 2.0

0.5 to 1.0 1.5 to 2.0

Nominal

diameter

1/4

3/8

1/2

5/8

Table 3-2-5 Flare and flare nut dimensions for R410A

Outer diameter

(mm)

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

Dimension (mm)

ABCD

9.1 9.2 6.5 13

13.2 13.5 9.7 20

16.6 16.0 12.9 23

19.7 19.0 16.0 25

– 10 –

Flare nut width

(mm)

17

22

26

29

Page 11

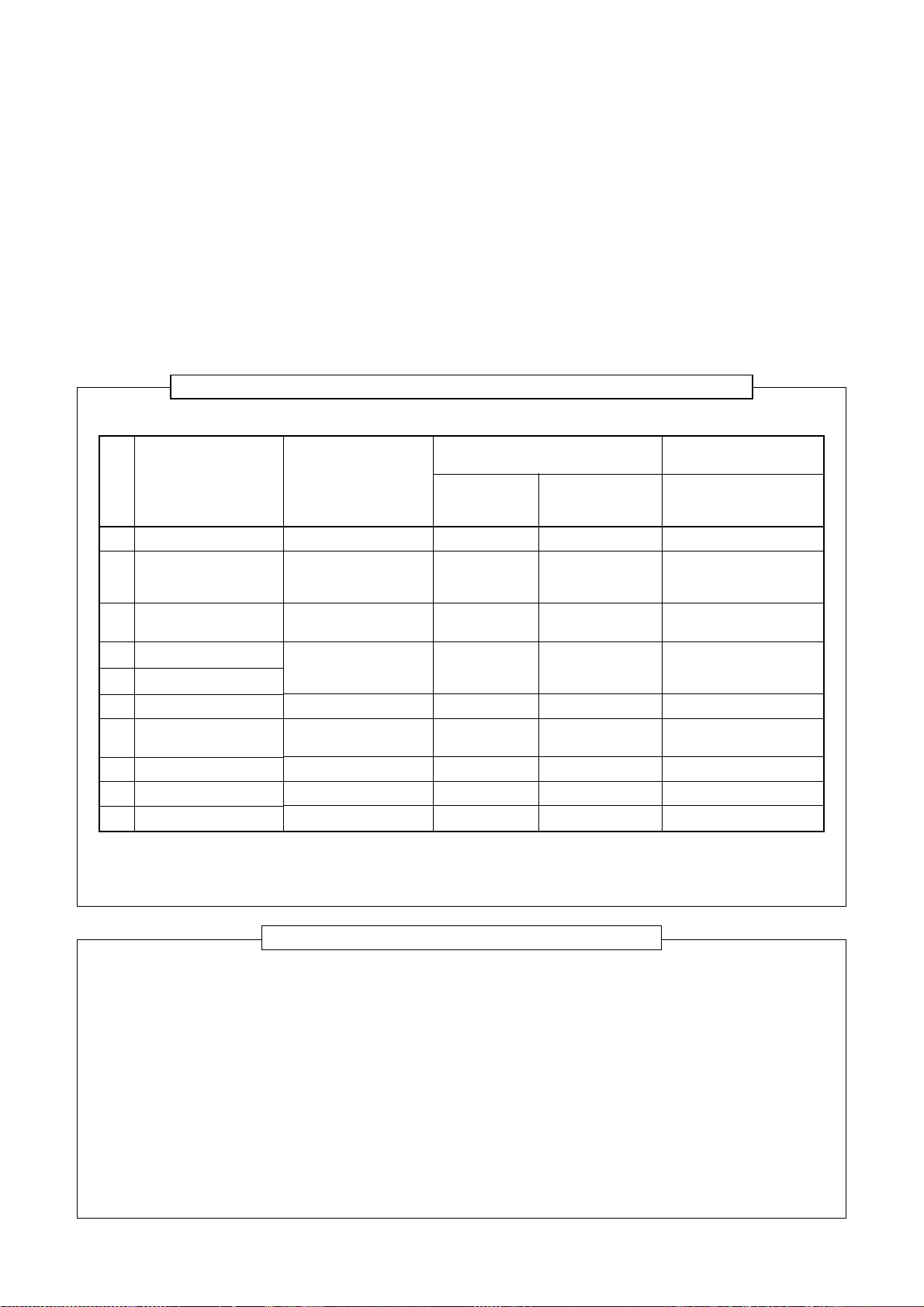

Table 3-2-6 Flare and flare nut dimensions for R22

FILE NO. SVM-10001

Nominal

diameter

1/4

3/8

1/2

5/8

3/4

Outer diameter

(mm)

6.35

9.52

12.70

15.88

19.05

45˚ to 46˚

Thickness

(mm)

0.8

0.8

0.8

1.0

1.0

B A

Dimension (mm)

ABCD

9.0 9.2 6.5 13

13.0 13.5 9.7 20

16.2 16.0 12.9 20

19.7 19.0 16.0 23

23.3 24.0 19.2 34

D

C

43˚ to 45˚

Flare nut width

(mm)

17

22

24

27

36

Fig. 3-2-2 Relations between flare nut and flare seal surface

2. Flare Connecting Procedures and Precautions

a) Make sure that the flare and union portions do not have any scar or dust, etc.

b) Correctly align the processed flare surface with the union axis.

c) Tighten the flare with designated torque by means of a torque wrench. The tightening torque for R410A is

the same as that for conventional R22. Incidentally, when the torque is weak, the gas leakage may occur.

When it is strong, the flare nut may crack and may be made non-removable. When choosing the tighten-

ing torque, comply with values designated by man ufacturers. Table 3-2-7 shows reference values.

NOTE :

When applying oil to the flare surface, be sure to use oil designated by the manufacturer.

If any other oil is used, the lubricating oils may deteriorate and cause the compressor to burn out.

Table 3-2-7 Tightening torque of flare for R410A [Reference values]

Nominal

diameter

Outer diameter

(mm)

Tightening torque

N•m (kgf•cm)

Tightening torque of torque

wrenches available on the market

N•m (kgf•cm)

1/4

3/8

1/2

5/8

6.35

9.52

12.70

15.88

14 to 18 (140 to 180)

33 to 42 (330 to 420)

50 to 62 (500 to 620)

63 to 77 (630 to 770)

– 11 –

16 (160), 18 (180)

42 (420)

55 (550)

65 (650)

Page 12

FILE NO. SVM-10001

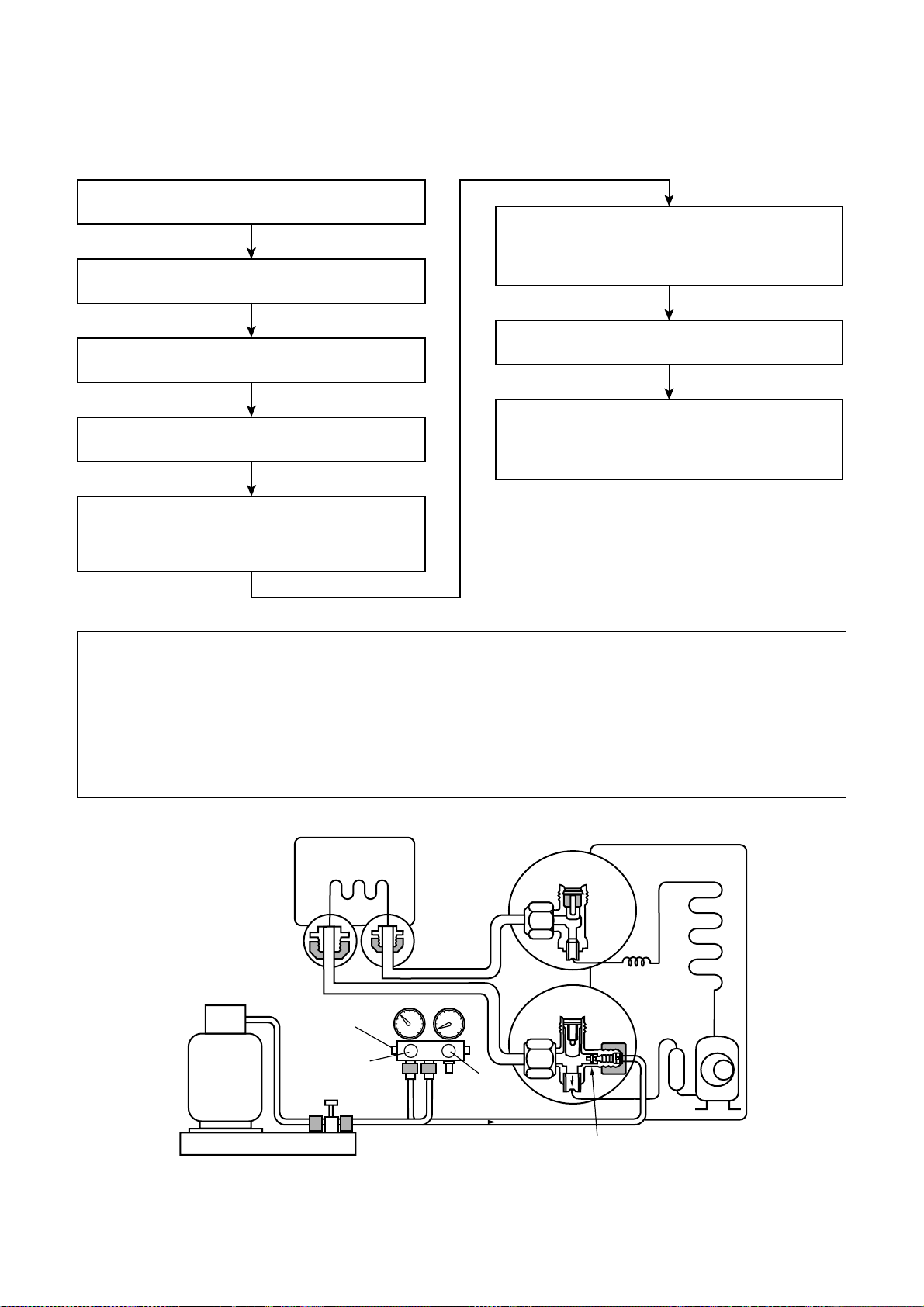

3-3. Tools

3-3-1. Required T ools

The service port diameter of packed valve of the outdoor unit in the air-water heat pump using R410A is

changed to prev ent mixing of other refrigerant. To reinforce the pressure-resisting strength, flare processing

dimensions and opposite side dimension of flare nut (For Ø12.7 copper pipe) of the refrigerant piping are

lengthened.

The used refrigerating oil is changed, and mixing of oil may cause a trouble such as generation of sludge ,

clogging of capillary, etc. Accordingly, the tools to be used are classified into the following three types.

1. Tools exclusive for R410A (Those which cannot be used for conventional refrigerant (R22))

2. Tools exclusiv e for R410A, but can be also used for con ventional refrigerant (R22)

3. Tools commonly used for R410A and for conventional refrigerant (R22)

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

air-water heat pump installation

No.

1

2

3

4

5

6

7

8

9

10

(Note 1) When flaring is carried out for R410A using the conventional flare tools, adjustment of projection

(Note 2) Charging cylinder for R410A is being currently developed.

Used tool

Flare tool

Copper pipe gauge for

adjusting projection

margin

Torque wrench

(For Ø12.7)

Gauge manifold

Charge hose

Vacuum pump adapter

Electronic balance for

refrigerant charging

Refrigerant cylinder

Leakage detector

Charging cylinder

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary.

Pipe flaring

Flaring by

conventional flare tool

Connection of flare nut

Evacuating, refrigerant

charge, run check, etc.

Vacuum evacuating

Refrigerant charge

Refrigerant charge

Gas leakage check

Refrigerant charge

Usage

Existence of

new equipment

for R410A

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

(Note 2)

R410A

Whether conventional equipment

can be used

*(Note 1)

*(Note 1)

×

×

×

×

×

×

×

Conventional air-water

heat pump installation

Whether new equipment

can be used with

conventional refrigerant

¡

*(Note 1)

×

×

¡

¡

×

¡

×

General tools (Conventional tools can be used.)

In addition to the above exclusive tools, the following equipments which serve also for R22 are necessary

as the general tools.

1. Vacuum pump

Use vacuum pump by attaching

vacuum pump adapter.

2. Torque wrench (For Ø6.35, Ø9.52)

3. Pipe cutter

4. Reamer

5. Pipe bender

6. Level vial

7. Screwdriver (+, –)

8. Spanner or Monkey wrench

9. Hole core drill (Ø65)

10. Hexagon wrench

(Opposite side 4mm)

11 . Tape measure

12. Metal saw

Also prepare the following equipments for other installation method and run check.

1. Clamp meter

2. Thermometer

3. Insulation resistance tester

4. Electroscope

– 12 –

Page 13

FILE NO. SVM-10001

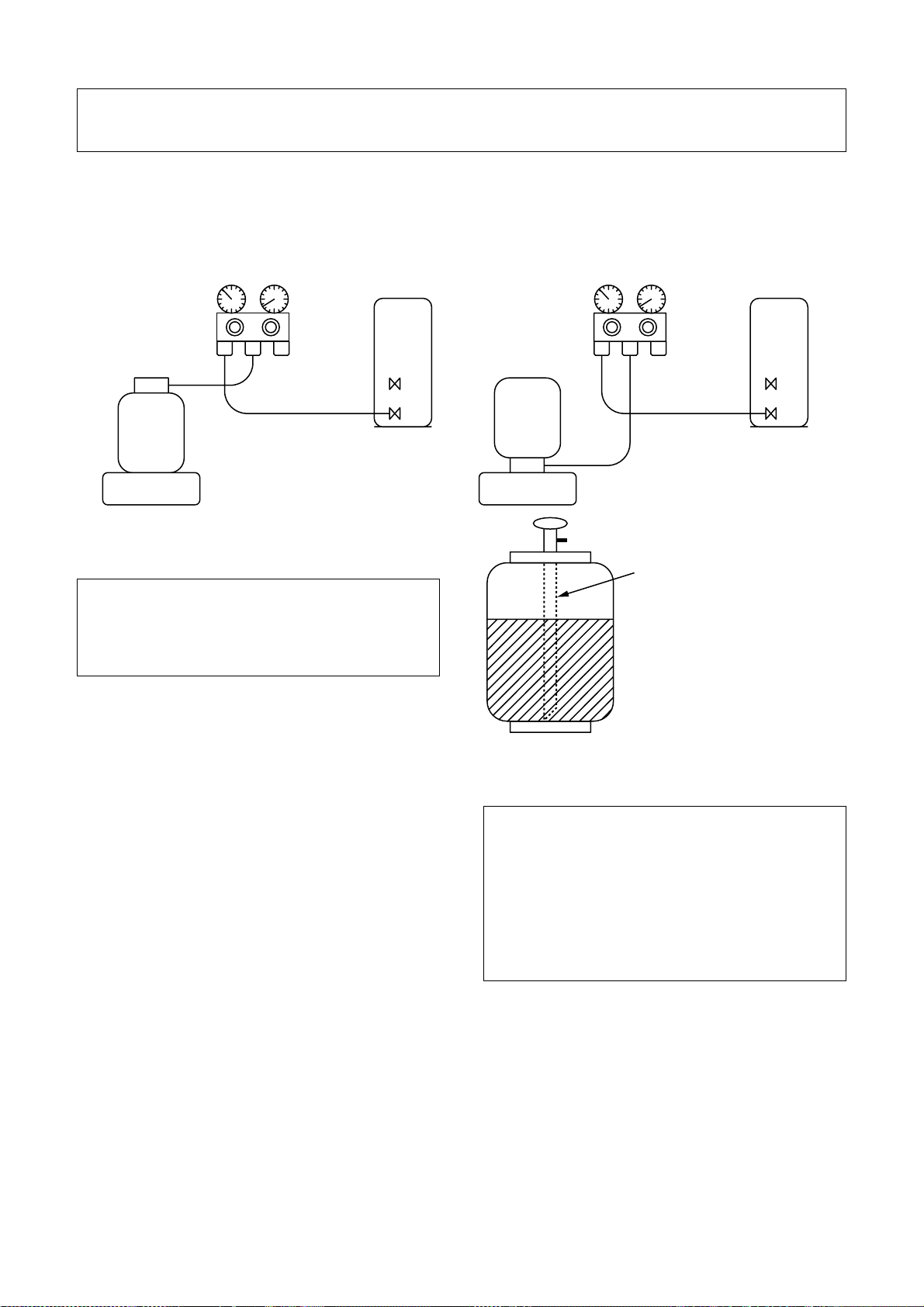

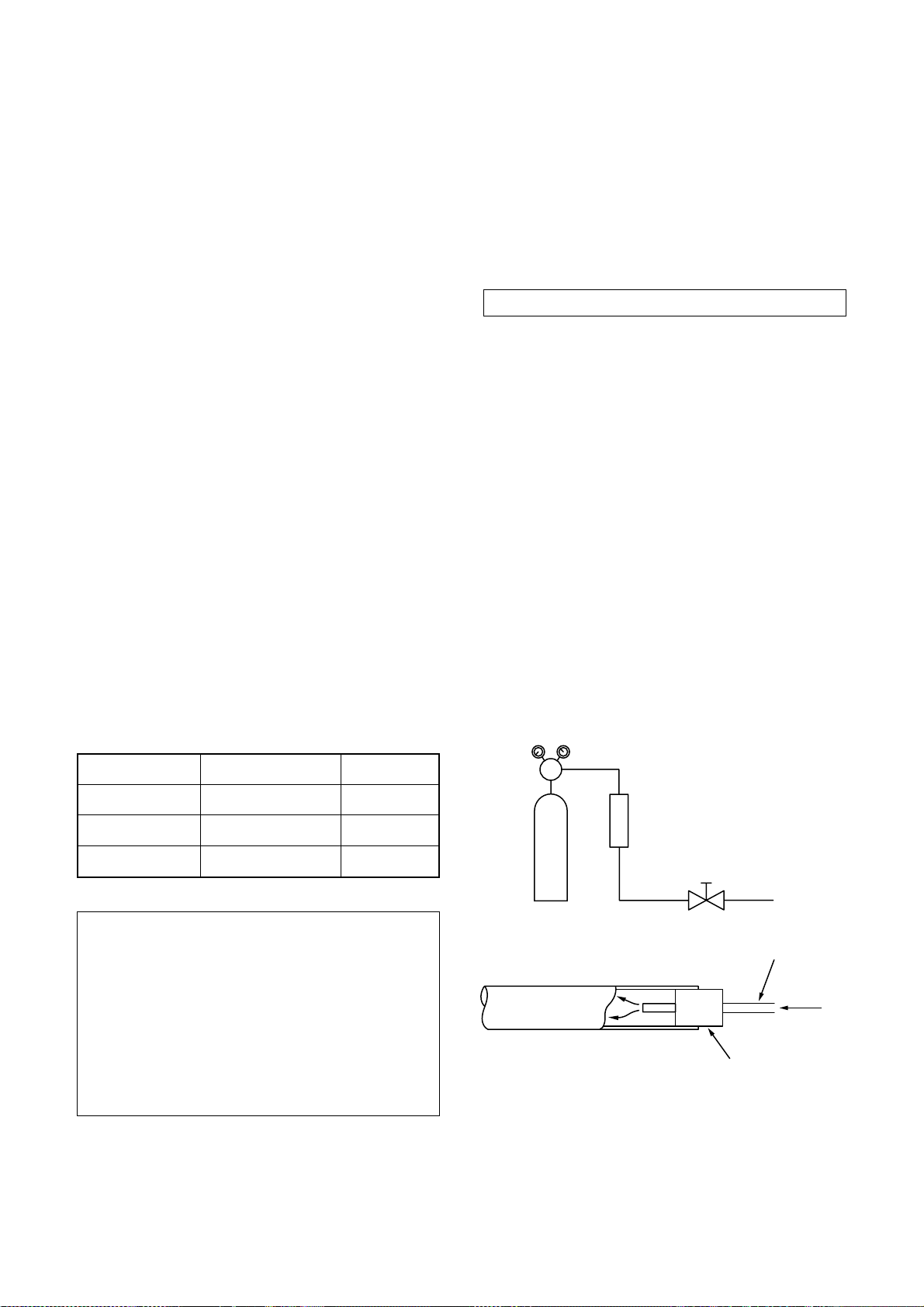

3-4. Recharging of Refrigerant

When it is necessary to recharge refrigerant, charge the specified amount of new refrigerant according to the

following steps .

Recover the refrigerant, and check no refrigerant

remains in the equipment.

Connect the charge hose to packed valve service

port at the outdoor unit’s gas side.

Connect the charge hose to the vacuum pump

adapter.

Open fully both packed valves at liquid and gas

sides.

When the compound gauge’s pointer has indicated

–0.1 Mpa (–76 cmHg), place the handle Low in the

fully closed position, and turn off the vacuum pump’s

power switch.

Keep the status as it is for 1 to 2 minutes, and ensure

that the compound gauge’s pointer does not return.

Set the refrigerant cylinder to the electronic balance,

connect the connecting hose to the cylinder and the

connecting port of the electronic balance, and charge

liquid refrigerant.

Place the handle of the gauge manifold Low in the

fully opened position, and turn on the vacuum pump’s

power switch. Then, evacuating the refrigerant in the

cycle.

(For refrigerant charging, see the figure below.)

1. Never charge refrigerant exceeding the specified amount.

2. If the specified amount of refrigerant cannot be charged, charge refrigerant bit by bit in COOL mode.

3. Do not carry out additional charging.

When additional charging is carried out if refrigerant leaks, the refrigerant composition changes in the

refrigeration cycle, that is characteristics of the air conditioner changes, refrigerant exceeding the

specified amount is charged, and working pressure in the refrigeration cycle becomes abnormally high

pressure, and may cause a rupture or personal injury.

(Indoor unit)

Opened

(Outdoor unit)

Refrigerant cylinder

(with siphon)

Check valve

Opened

Open/close

valve for charging

Electronic balance for refrigerant charging

Fig. 3-4-1 Configuration of refrigerant charging

Opened

Closed

Service port

– 13 –

Page 14

FILE NO. SVM-10001

1. Be sure to make setting so that liquid can be charged.

2. When using a cylinder equipped with a siphon, liquid can be charged without turning it upside down.

It is necessary for charging refrigerant under condition of liquid because R410A is mixed type of refrigerant.

Accordingly, when charging refrigerant from the refrigerant cylinder to the equipment, charge it turning the

cylinder upside down if cylinder is not equipped with siphon.

[ Cylinder with siphon ] [ Cylinder without siphon ]

Refrigerant

cylinder

Gauge manifold

OUTDOOR unit

Refrigerant

cylinder

Gauge manifold

OUTDOOR unit

Electronic

balance

R410A refrigerant is HFC mixed refrigerant.

Therefore, if it is charged with gas, the composition of the charged refrigerant changes and the

characteristics of the equipment varies.

3-5. Brazing of Pipes

3-5-1. Materials for Brazing

1. Silver brazing filler

Silver brazing filler is an alloy mainly composed

of silver and copper. It is used to join iron, copper

or copper alloy, and is relatively expensive though

it excels in solderability.

2. Phosphor bronze brazing filler

Phosphor bronze brazing filler is generally used

to join copper or copper alloy.

Electronic

balance

Siphon

Fig. 3-4-2

1. Phosphor bronze brazing filler tends to react

with sulfur and produce a fragile compound

water solution, which may cause a gas

leakage. Therefore, use any other type of

brazing filler at a hot spring resort, etc., and

coat the surface with a paint.

2. When performing brazing again at time of

servicing, use the same type of brazing filler.

3-5-2. Flux

3. Low temperature brazing filler

Low temperature brazing filler is generally called

solder, and is an alloy of tin and lead. Since it is

weak in adhesive strength, do not use it for

refrigerant pipes.

1. Reason why flux is necessary

• By removing the oxide film and any foreign

matter on the metal surface, it assists the flow

of brazing filler .

• In the brazing process, it prevents the metal

surface from being oxidized.

• By reducing the brazing filler’s surface tension,

the brazing filler adheres better to the treated

metal.

– 14 –

Page 15

2. Characteristics required for flux

• Activated temperature of flux coincides with the

brazing temperature.

• Due to a wide effective temperature range, flux

is hard to carbonize.

• It is easy to remove slag after brazing.

• The corrosive action to the treated metal and

brazing filler is minimum.

• It excels in coating performance and is harmless to the human body.

As the flux works in a complicated manner as

described above, it is necessary to select an

adequate type of flux according to the type and

shape of treated metal, type of brazing filler and

brazing method, etc.

3. Types of flux

• Noncorrosive flux

Generally, it is a compound of borax and boric

acid.

It is effective in case where the brazing temperature is higher than 800°C.

• Activated flux

Most of fluxes generally used for silver brazing

are this type.

It features an increased o xide film removing

capability due to the addition of compounds

such as potassium fluoride, potassium chloride

and sodium fluoride to the borax-boric acid

compound.

4. Piping materials for brazing and used

brazing filler/flux

FILE NO. SVM-10001

3-5-3. Brazing

As brazing work requires sophisticated techniques,

experiences based upon a theoretical knowledge, it

must be performed by a person qualified.

In order to prev ent the oxide film from occurring in

the pipe interior during brazing, it is effective to

proceed with brazing while letting dry Nitrogen gas

(N2) flow.

Never use gas other than Nitrogen gas.

1. Brazing method to prevent oxidation

1) Attach a reducing valve and a flow-meter to

the Nitrogen gas cylinder.

2) Use a copper pipe to direct the piping material, and attach a flow-meter to the cylinder.

3) Apply a seal onto the clearance between the

piping material and inserted copper pipe for

Nitrogen in order to prevent backflow of the

Nitrogen gas.

4) When the Nitrogen gas is flowing, be sure to

keep the piping end open.

5) Adjust the flow rate of Nitrogen gas so that it

is lower than 0.05 m3/Hr or 0.02 MPa

(0.2kgf/cm2) by means of the reducing valve.

6) After performing the steps above, keep the

Nitrogen gas flowing until the pipe cools down

to a certain extent (temperature at which

pipes are touchable with hands).

7) Remove the flux completely after brazing.

Piping material

Copper - Copper

Copper - Iron

Iron - Iron

Used brazing filler

Phosphor copper

Silver

Silver

Used flux

Do not use

Paste flux

Vapor flux

1. Do not enter flux into the refrigeration cycle.

2. When chlorine contained in the flux remains

within the pipe, the lubricating oil deteriorates.

Therefore, use a flux which does not contain

chlorine.

3. When adding water to the flux, use water

which does not contain chlorine (e.g. distilled

water or ion-exchange water).

4. Remove the flux after brazing.

M

Flow meter

Stop valve

Nitrogen gas

cylinder

From Nitrogen cylinder

Pipe

Nitrogen

gas

Rubber plug

Fig. 3-5-1 Prevention of oxidation during brazing

– 15 –

Page 16

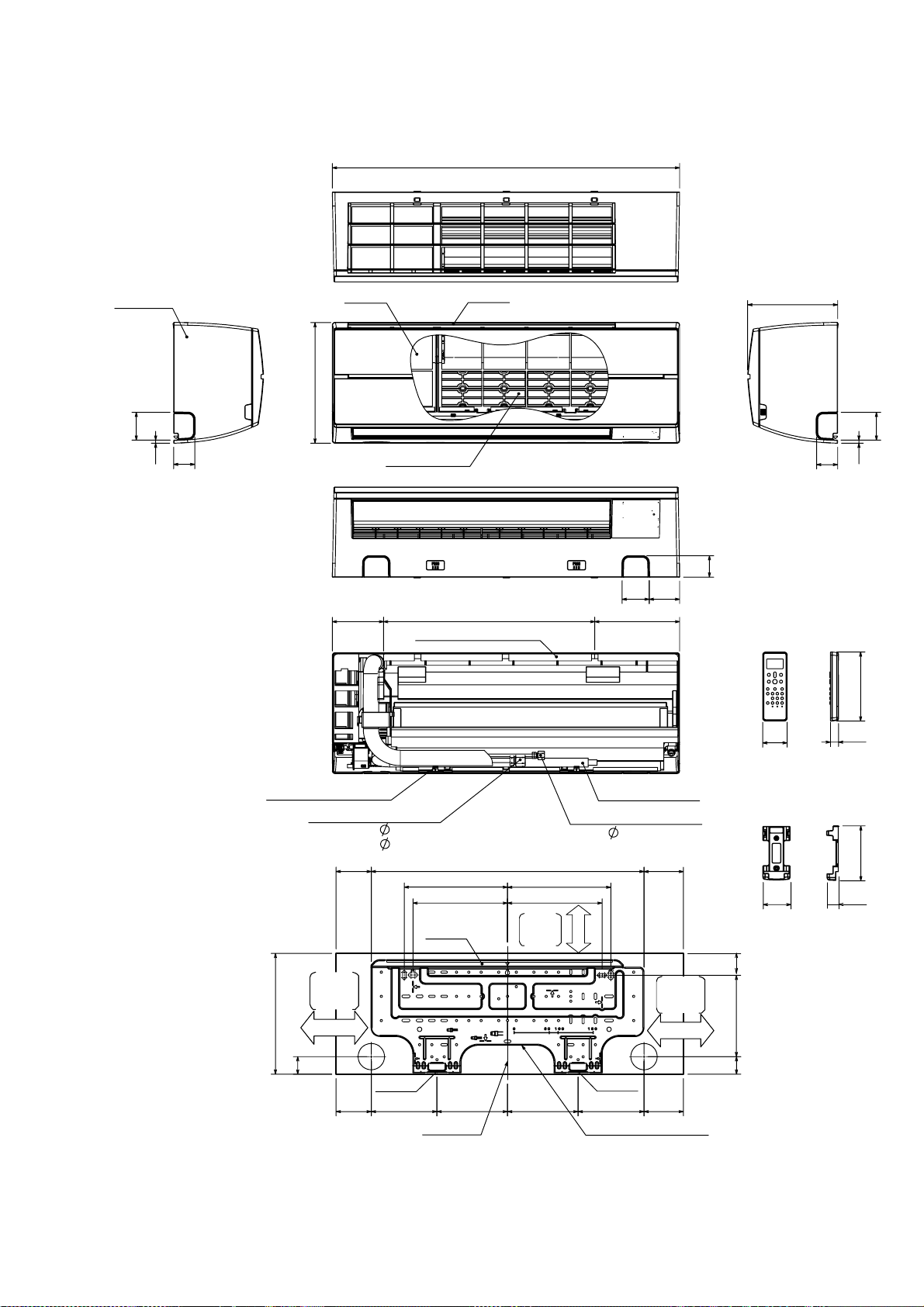

4-1. Indoor Unit

4. CONSTRUCTION VIEWS

790

FILE NO. SVM-10001

Front panel

63

7

48

Knock out system

275

Air filter

116

Heat exchanger

Installation plate hanger

Air inlet

62 69

193480

205

Knock out system

49

56

Wireless remote controller

48

63

7

157

19

Installation plate hanger

Connecting pipe (0.35m)

(For 10,13 series; Flare

(For 16 series; Flare

84.5

Minimum

distance

to wall

275

170 or more

40

84.5 150 84.5

9.52mm)

12.7mm)

Hanger

621

235

215

Minimum

Hanger

distance

to ceiling

160.5 160.5 150

Center line

Drain hose (0.50m)

Connecting pipe (0.40m)

(Flare 6.35mm)

235

215

65 or more

Hanger

Installation plate outline

84.5

Minimum

distance

to wall

170 or more

63

Remote controller holder

45

190

40

125

26

– 16 –

Page 17

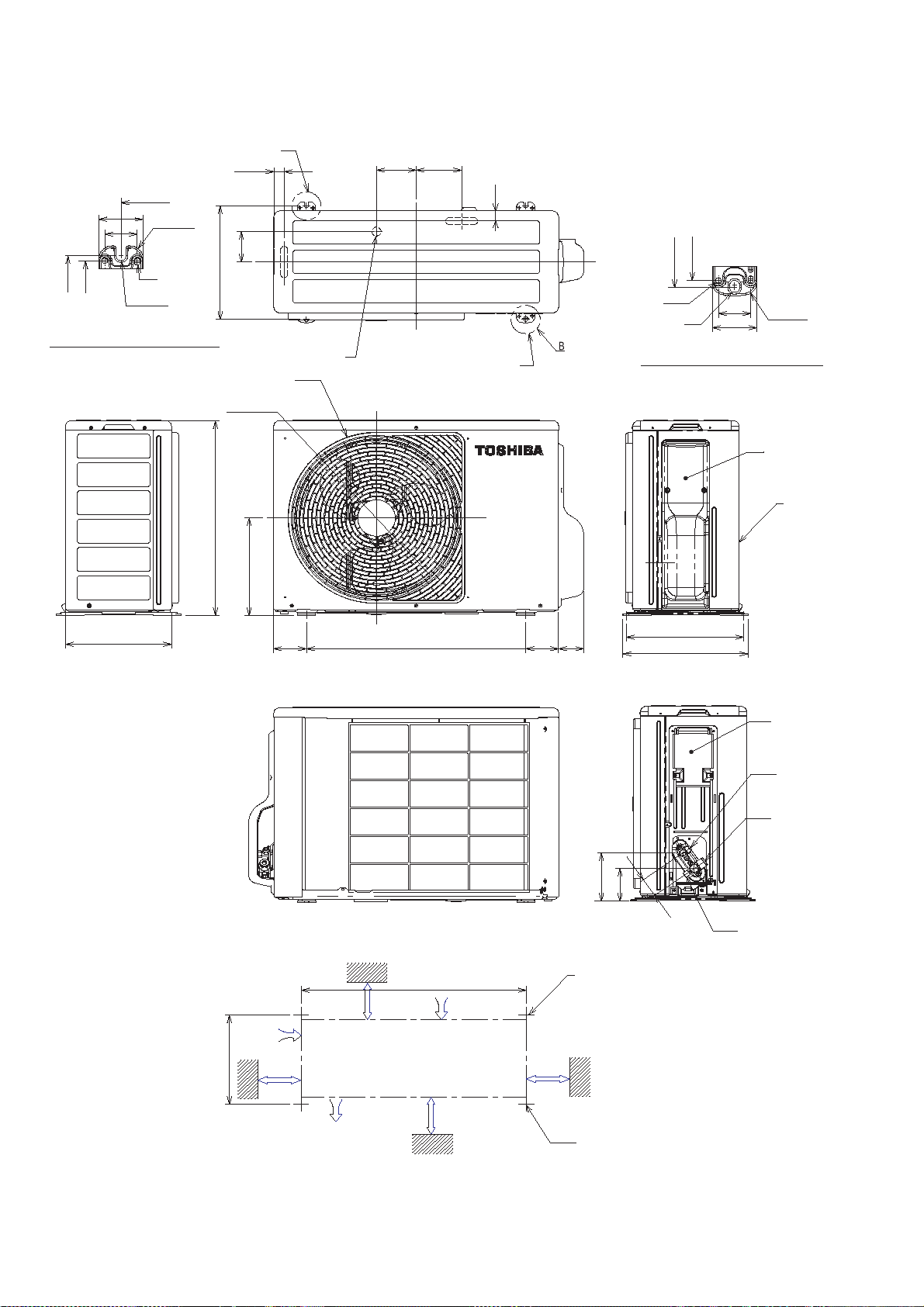

4-2. Outdoor Unit

28

FILE NO. SVM-10001

A

108 125

600

320

50

36

306

R5.5

R

Ø

15

6 hole

A detail Drawing (Back leg)

290

86

320

Ø

FAN-GUARD

436

Ø

550

275

25 Drain outlet

2

-

Ø

11 x 14

(For 8 -

Ø

Hole

10 anchor bolt)

Ø

30

306

320

Ø

6 hole

11x14 hole

Ø

36

50

R

15

B Detail Drawing (Front leg)

COVER-PV

Z

9060090

69

320

342

100 or more

320

100 or more

Air outlel

Z View

600

Air intlel

600 or more

5

92

4

Service port

137

2 - R5-5 x 17L Ushape

(For ∅ 8 - ∅10 anchor bolt)

600 or more

2 - ∅11 x 14 Long holes (For ∅8 - ∅10 anchor bolt)

Electrical part cover

Liquid side

(Flare 6.35)

Ø

Gas side

(10,13

: Flare ∅9.52)

(16

: Flare ∅12..7)

Installation dimension

– 17 –

Page 18

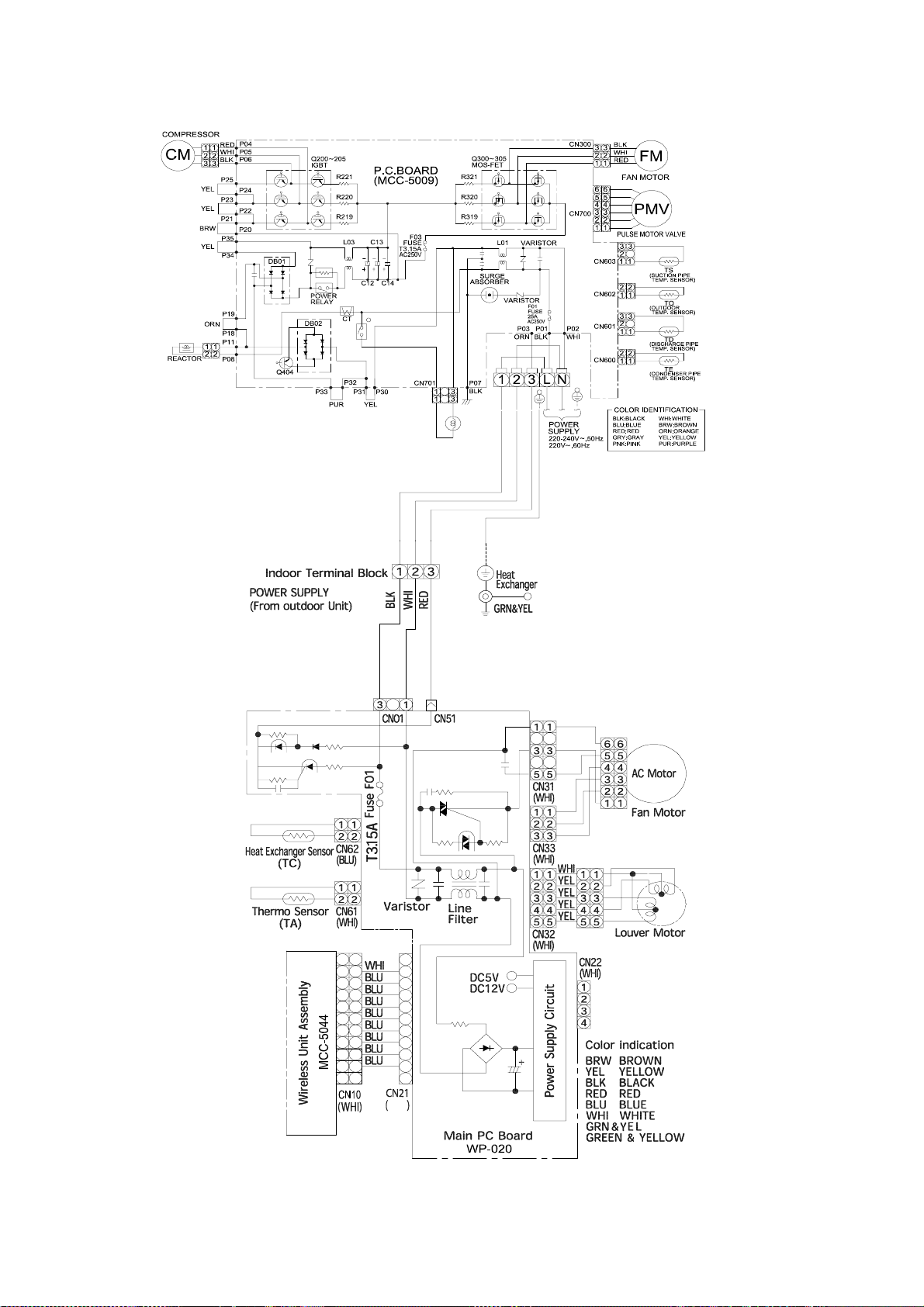

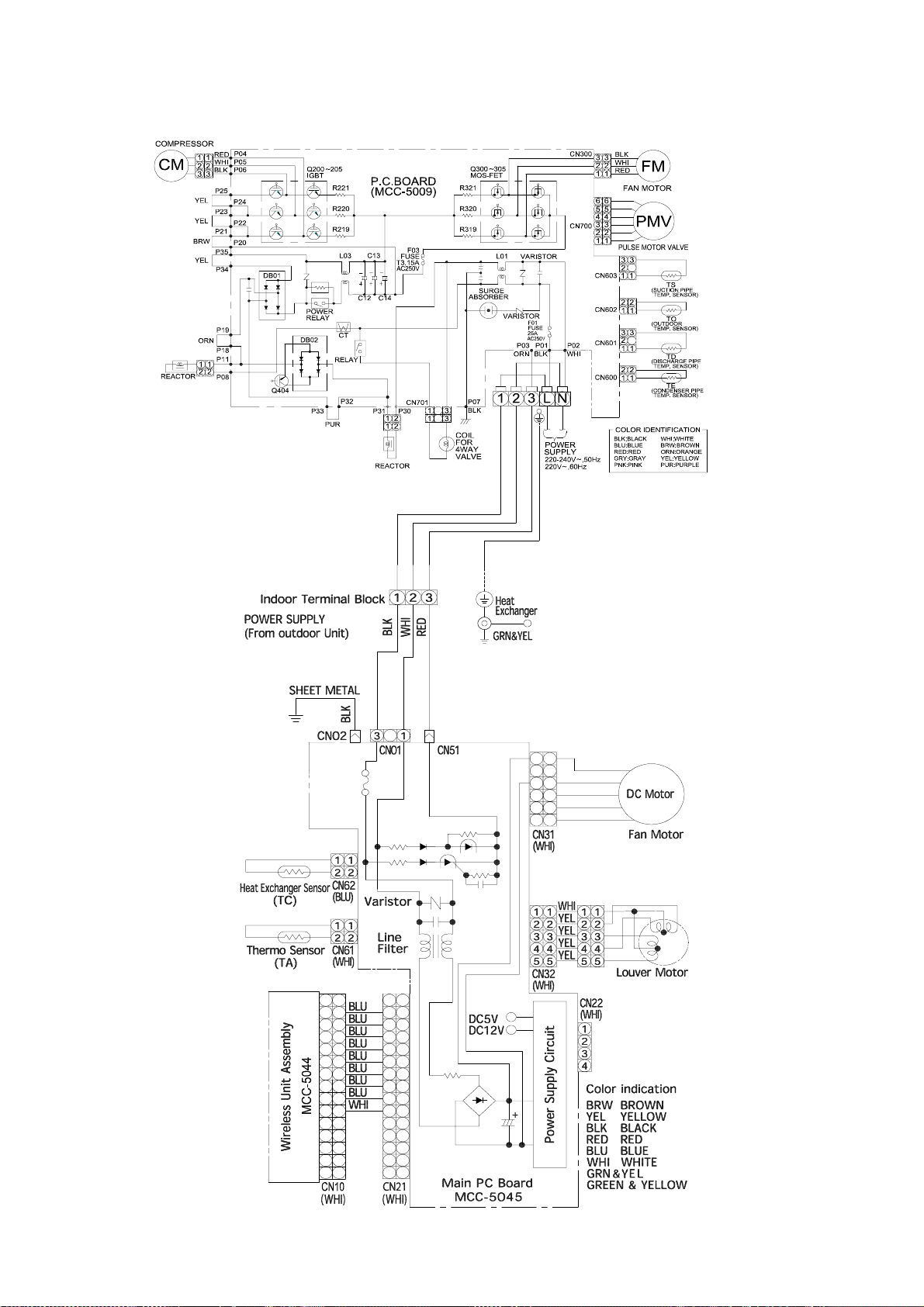

5. WIRING DIAGRAM

FILE NO. SVM-10001

5-1. RAS-10SKV2-E / RAS-10SAV2-E, RAS-13SKV2-E / RAS-13SAV2-E

1

RELAY

COIL

FOR

4WAY

VALVE

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

1

2

3

4

5

6

7

8

9

10

11

YEL

– 18 –

Page 19

5-2. RAS-16SKV2-E / RAS-16SAV2-E

FILE NO. SVM-10001

1

1

3

3

4

Fuse F01

T3.15A 250VAC

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

4

5

5

6

6

– 19 –

Page 20

FILE NO. SVM-10001

6. SPECIFICATIONS OF ELECTRICAL PARTS

6-1. Indoor Unit

No. Parts name Type Specifications

Fan motor

1

(for indoor)

2 Room temp. sensor (TA-sensor) ( - ) 10kΩ at 25°C

3 Heat exchanger temp. sensor (TC-sensor) ( - ) 10kΩ at 25°C

4 Louver motor MP24Z3T Output (Rated) 1W, 16 poles, DC12V

RAS-10,13SKV2-E AFN-220-20-4D AC 240V, 20W

RAS-16SKV2-E ICF-340-30-4 DC 340V, 30W

6-2. Outdoor Unit

No. Parts name Type Specifications

Reactor

1

2 Outdoor fan motor ICF-140-43-4R DC140V, 43W

3 Suction temp. sensor (TS sensor) (Inverter attached) 10kΩ (25°C)

4 Discharge temp. sensor (TD sensor) (Inverter attached) 62kΩ (20°C)

5 Outside air temp. sensor (TO sensor) (Inverter attached) 10kΩ (25°C)

6 Heat exchanger temp. sensor (TE sensor) (Inverter attached) 10kΩ (25°C)

Terminal block (5P)7

Compressor

8

COIL FOR P.M.V.

9

Coil for 4-way valve

10

RAS-16SAV2-E CH-57 L = 10mH, 16A

RAS-10,13SAV2-E CH-69 L = 19mH, 10A

RAS-10,13SAV2-E DA89X1C-23FZ2

RAS-16SAV2-E DA111A1F-20F1

CAM-MD12TCTH-2

STF

20A, AC250V

3-phases 4-poles 750W

DC12V

AC220-240V

– 20 –

Page 21

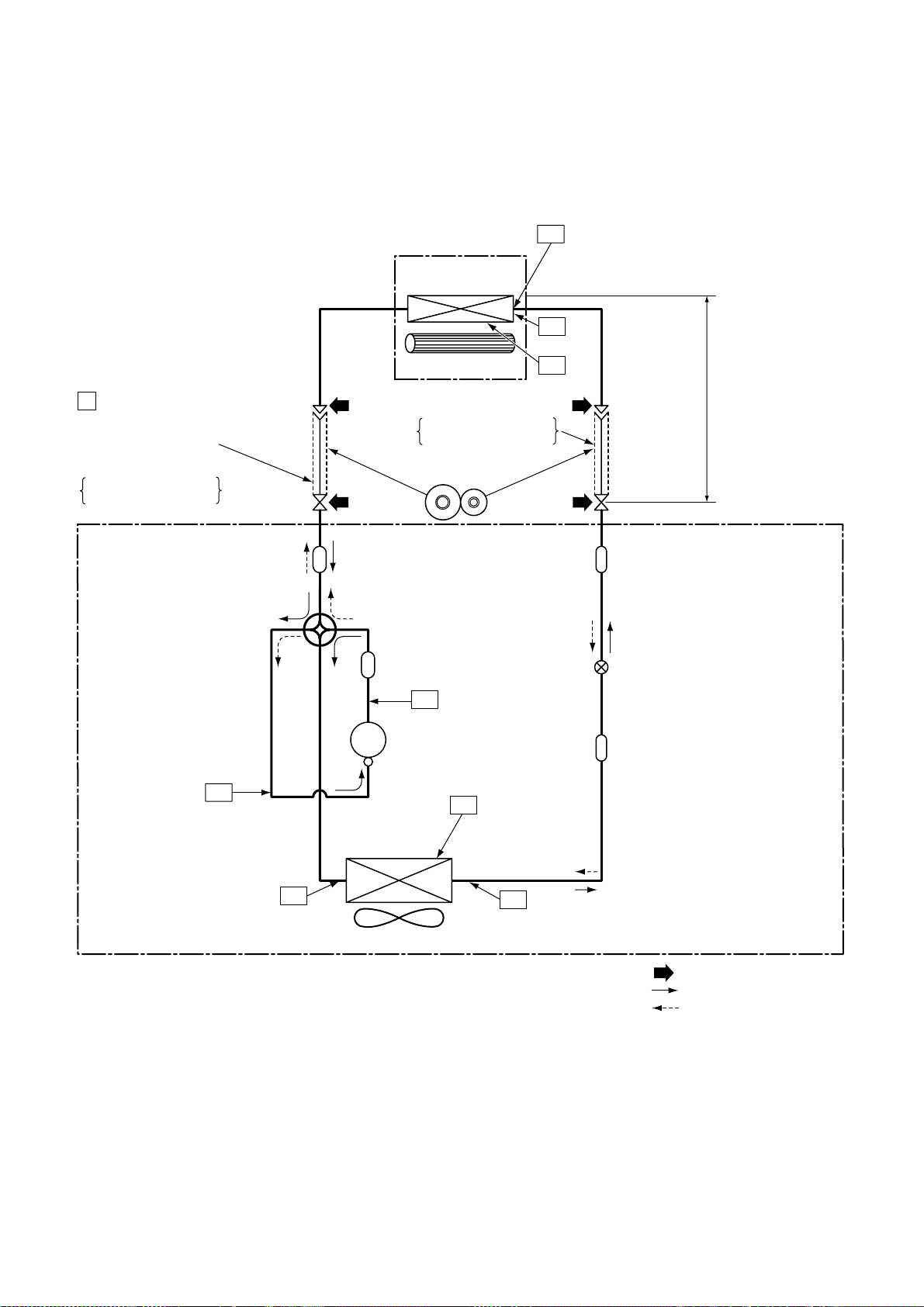

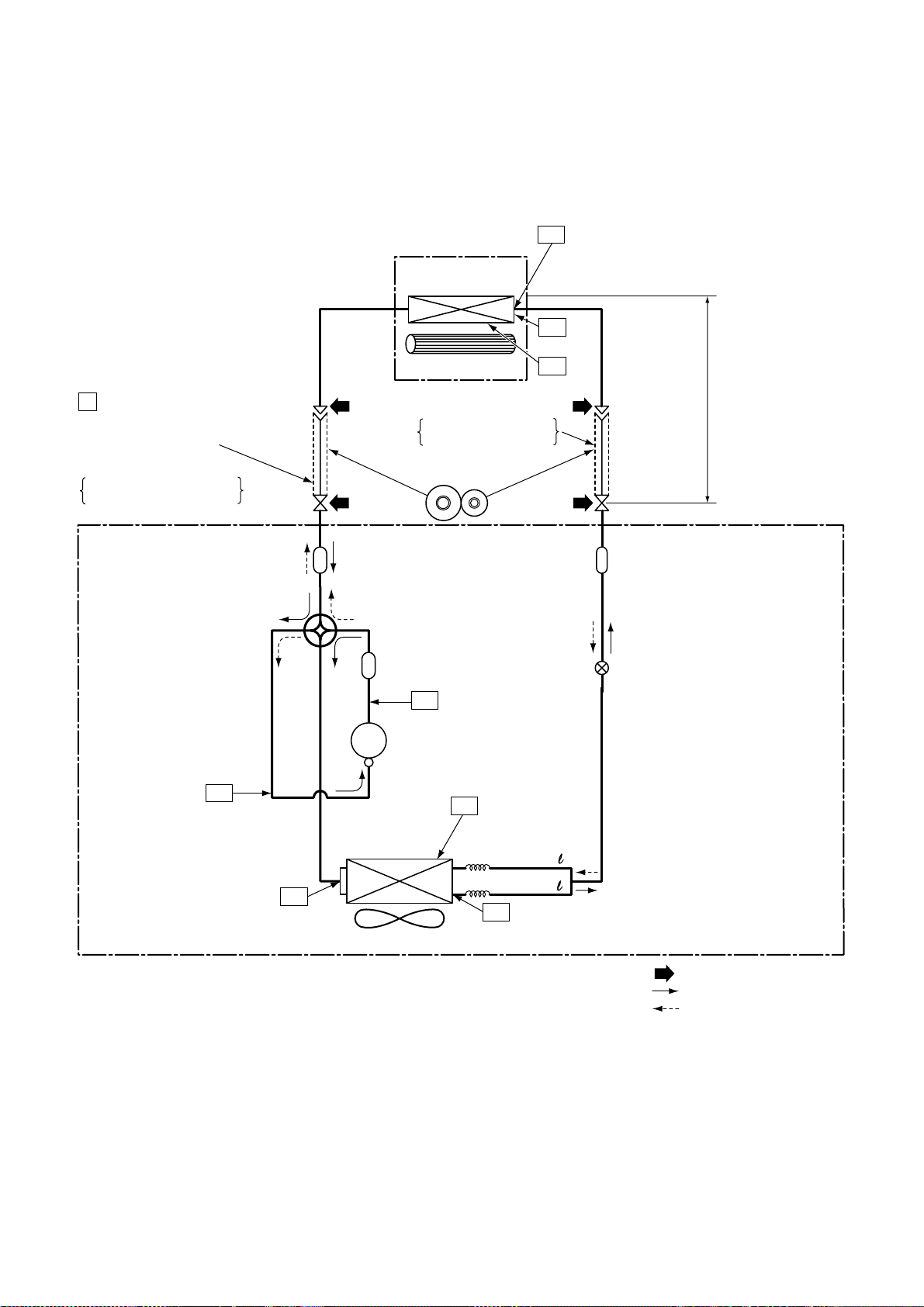

7. REFRIGERANT CYCLE DIAGRAM

7-1. Refrigerant Cycle Diagram

RAS-10SKV2-E / RAS-10SAV2-E

INDOOR UNIT

Indoor heat

exchanger

T1

Temp. measurement

TC

FILE NO. SVM-10001

P

Pressure measurement

Gauge attaching port

Vacuum pump connecting port

Deoxidized copper pipe

Outer dia. : 9.52mm

Thickness : 0.8mm

4-way valve

TS

Muffler

Muffler

Compressor

DA89X1C-23FZ2

Outdoor heat

exchanger

Cross flow fan

Deoxidized copper pipe

Outer dia. : 6.35mm

Thickness : 0.8mm

Sectional shape

of heat insulator

TD

TO

TA

Allowable height

difference : 10m

Strainer

Pulse Modulating

valve at liquid side

Strainer

Max. : 20m

Min. : 2m

Chargeless : 15m

Charge : 20g/m

(16 to 20m)

Allowable pipe length

Temp. measurement

T2

TE

Propeller fan

OUTDOOR UNIT

NOTE :

Refrigerant amount : 0.80kg

Gas leak check position

Refrigerant flow (Cooling)

Refrigerant flow (Heating)

NOTE :

• The maximum pipe length of this air conditioner is 20 m. When the pipe length exceeds 15m, the additional

charging of refrigerant, 20g per 1m for the part of pipe exceeded 15m is required. (Max. 100g)

– 21 –

Page 22

RAS-13SKV2-E / RAS-13SAV2-E

INDOOR UNIT

Indoor heat

exchanger

T1

Temp. measurement

TC

FILE NO. SVM-10001

P

Pressure measurement

Gauge attaching port

Vacuum pump connecting port

Deoxidized copper pipe

Outer dia. : 9.52mm

Thickness : 0.8mm

4-way valve

TS

Muffler

Muffler

Compressor

DA89X1C-23FZ2

Outdoor heat

exchanger

Cross flow fan

Deoxidized copper pipe

Outer dia. : 6.35mm

Thickness : 0.8mm

Sectional shape

of heat insulator

TD

TO

TA

Allowable height

difference : 10m

Strainer

Pulse Modulating

valve at liquid side

Max. : 20m

Min. : 2m

Chargeless : 15m

Charge : 20g/m

(16 to 20m)

Allowable pipe length

Temp. measurement

T2

TE

Propeller fan

OUTDOOR UNIT

NOTE :

Refrigerant amount : 0.80kg

Gas leak check position

Refrigerant flow (Cooling)

Refrigerant flow (Heating)

NOTE :

• The maximum pipe length of this air conditioner is 20 m. When the pipe length exceeds 15m, the additional

charging of refrigerant, 20g per 1m for the part of pipe exceeded 15m is required. (Max. 100g)

– 22 –

Page 23

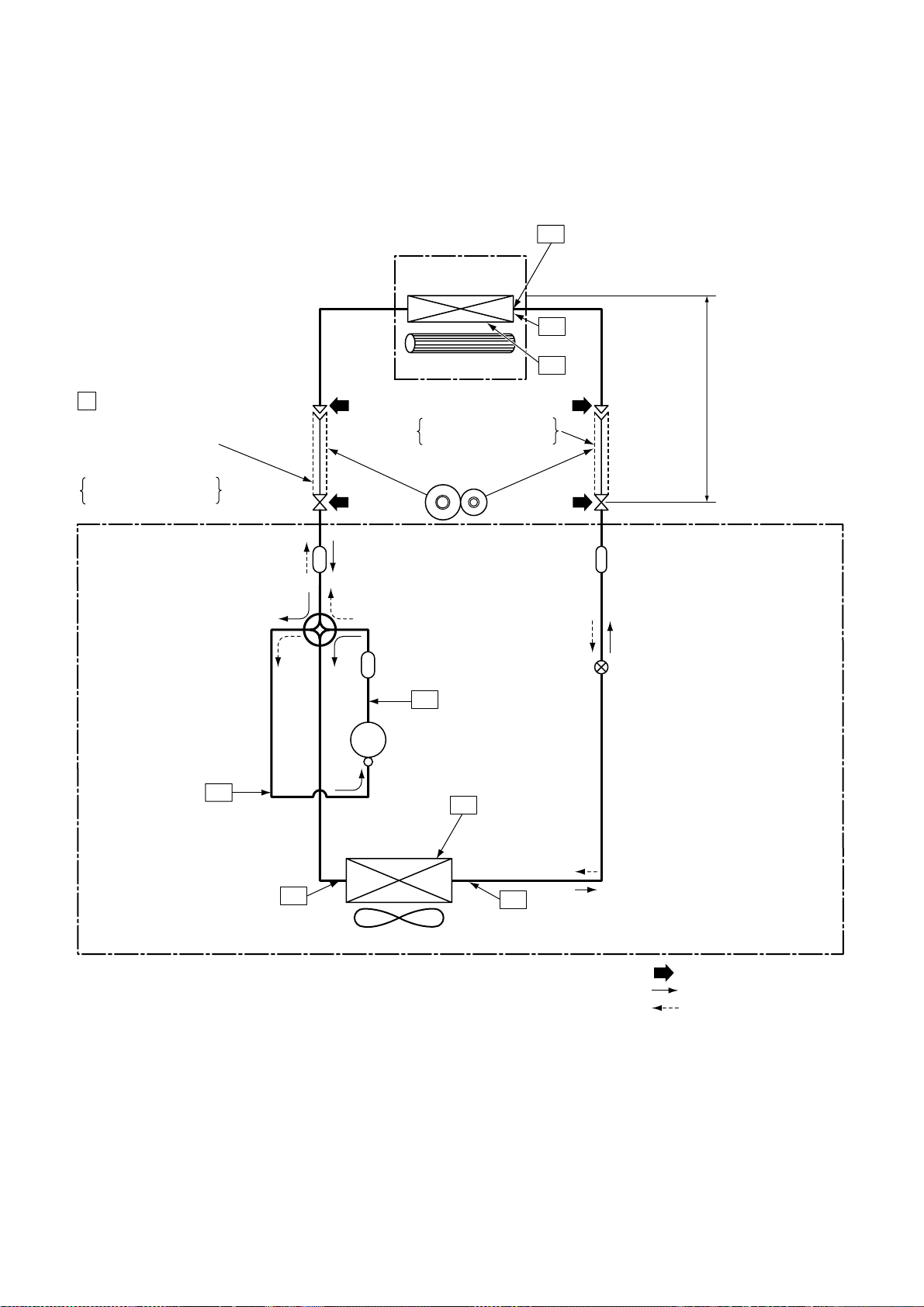

RAS-16SKV2-E / RAS-16SAV2-E

INDOOR UNIT

Indoor heat

exchanger

T1

Temp. measurement

TC

FILE NO. SVM-10001

P

Pressure measurement

Gauge attaching port

Vacuum pump connecting port

Deoxidized copper pipe

Outer dia. : 12.7mm(16)

Thickness : 0.8mm

4-way valve

TS

Muffler

Muffler

Compressor

DA111A1F-20F1

Outdoor heat

exchanger

Cross flow fan

Deoxidized copper pipe

Outer dia. : 6.35mm

Thickness : 0.8mm

Sectional shape

of heat insulator

TD

TO

Split capillary

Ø1.2 x 80

TA

Allowable height

difference : 10m

Strainer

Pulse Modulating

valve at liquid side

Max. : 20m

Min. : 2m

Chargeless : 15m

Charge : 20g/m

(16 to 20m)

Allowable pipe length

Temp. measurement

T2

Propeller fan

OUTDOOR UNIT

Ø1.2 x 80

TE

NOTE :

Refrigerant amount : 1.10kg

Gas leak check position

Refrigerant flow (Cooling)

Refrigerant flow (Heating)

NOTE :

• The maximum pipe length of this air conditioner is 15 m. When the pipe length exceeds 15m, the additional

charging of refrigerant, 20g per 1m for the part of pipe exceeded 15m is required. (Max. 100g)

– 23 –

Page 24

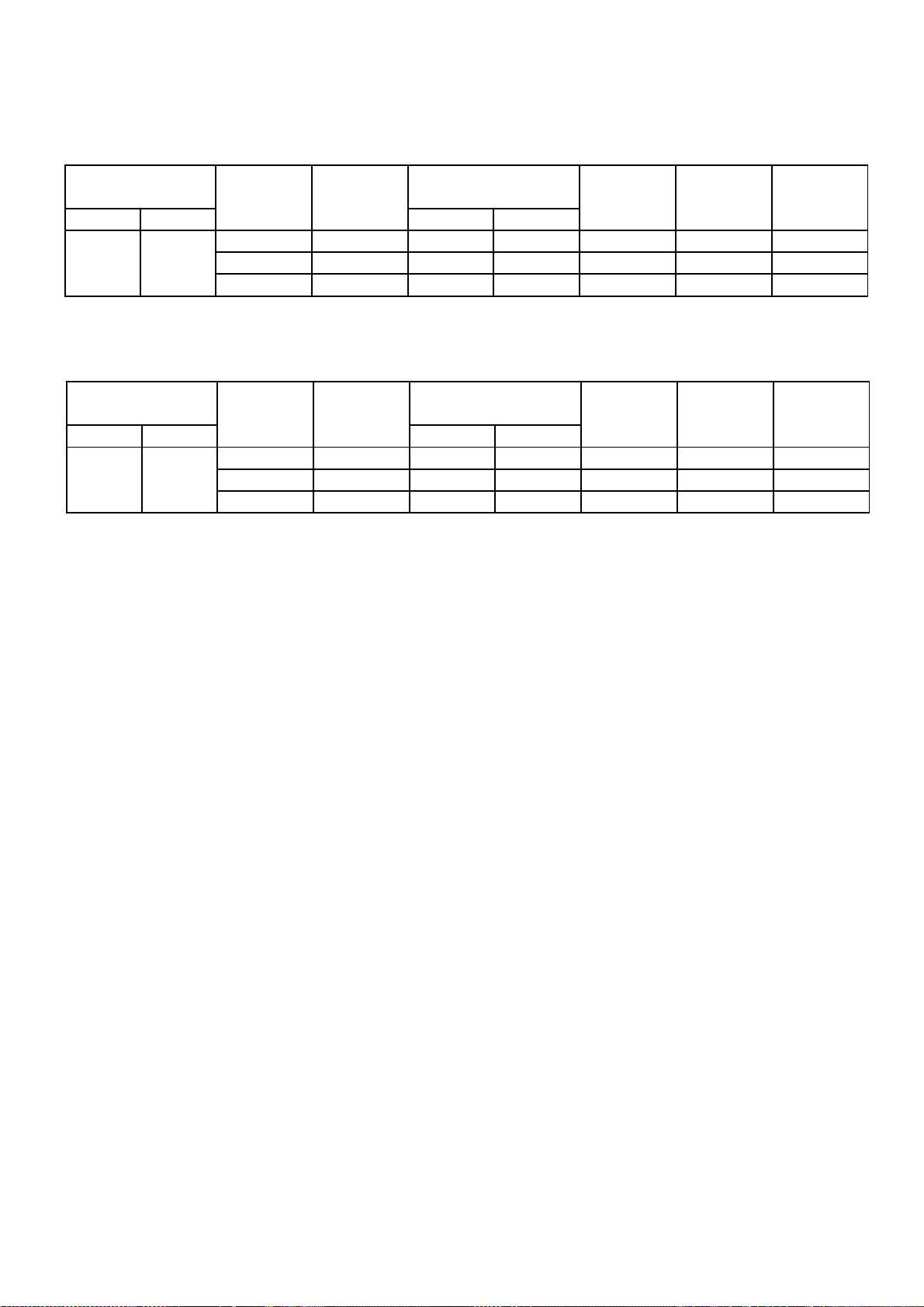

7-2. Operation Data

<Cooling>

FILE NO. SVM-10001

Tempeature Heat exchanger

condition(°C)

Indoor Outdoor P (MPa) T1 (°C) T2 (°C) (rps)

27/19 35/- 10SKV2-E 0.9 to 1.1 12 to 14 37 to 39 High High 49

Model name Standard Indoor Outdoor Compressor

RAS- pressure fan mode fan mode revolution

13SKV2 -E 0.8 to 1.0 11 to 13 46 to 48 High High 75

16SKV2 -E 0.8 to 1.0 11 to 13 40 to 42 High High 83

pipe temp.

<Heating>

Tempeature Heat exchanger

condition(°C)

Indoor Outdoor P (MPa) T1 (°C) T2 (°C) (rps)

20/- 7/6 10SKV2-E 2.5 to 2.7 39 to 41 0 to 3 High High 60

Model name Standard Indoor Outdoor Compressor

RAS- pressure fan mode fan mode revolution

13SKV2 -E 2.6 to 2.8 41 to 43 0 to 2 High High 80

16SKV2 -E 2.7 to 2.9 43 to 45 0 to 2 High High 83

pipe temp.

NOTES :

1. Measure surface temperature of heat exchanger pipe around center of heat exchanger path U bent.

(Thermistor themometer)

2. Connecting piping condition : 5 m

– 24 –

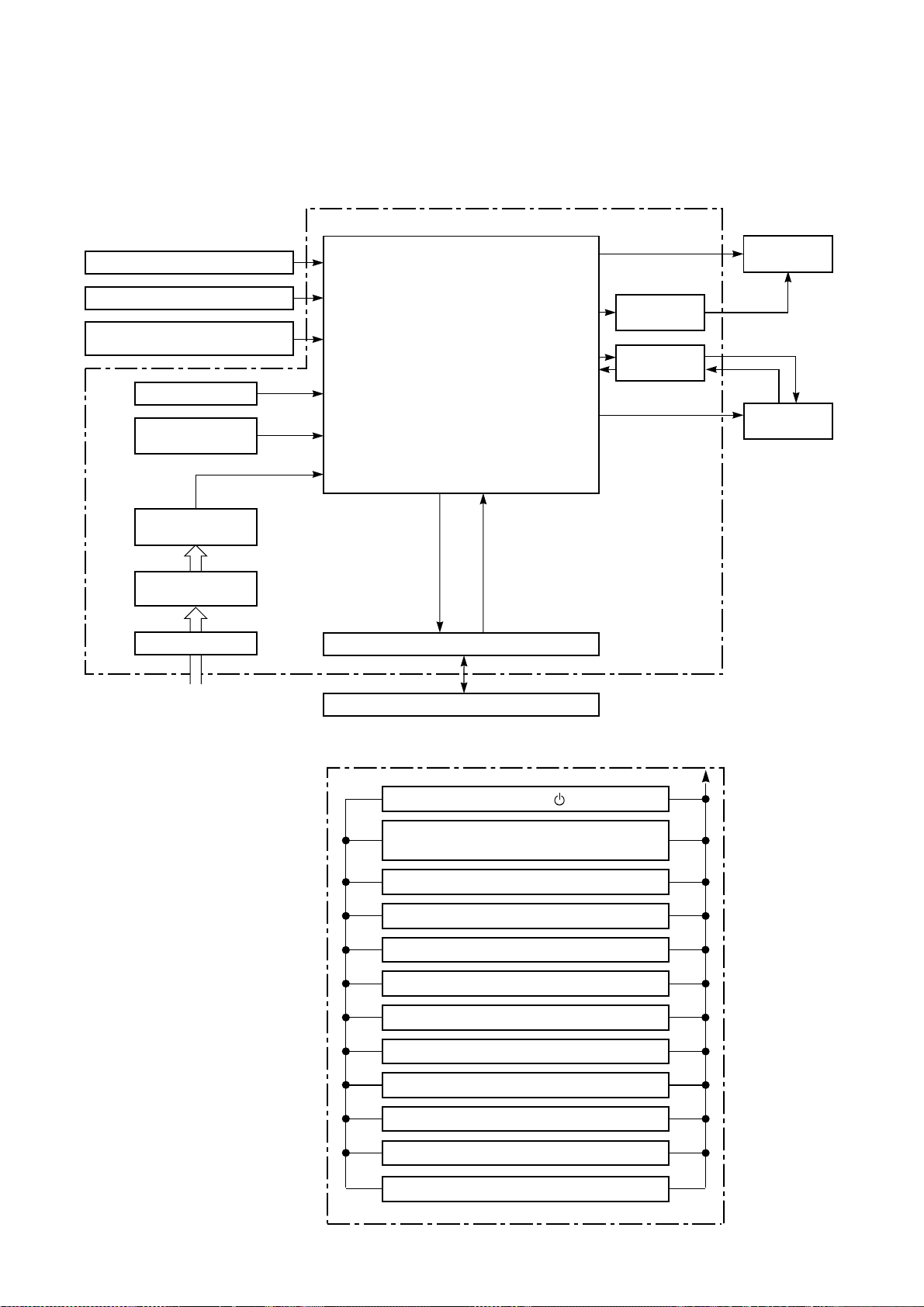

Page 25

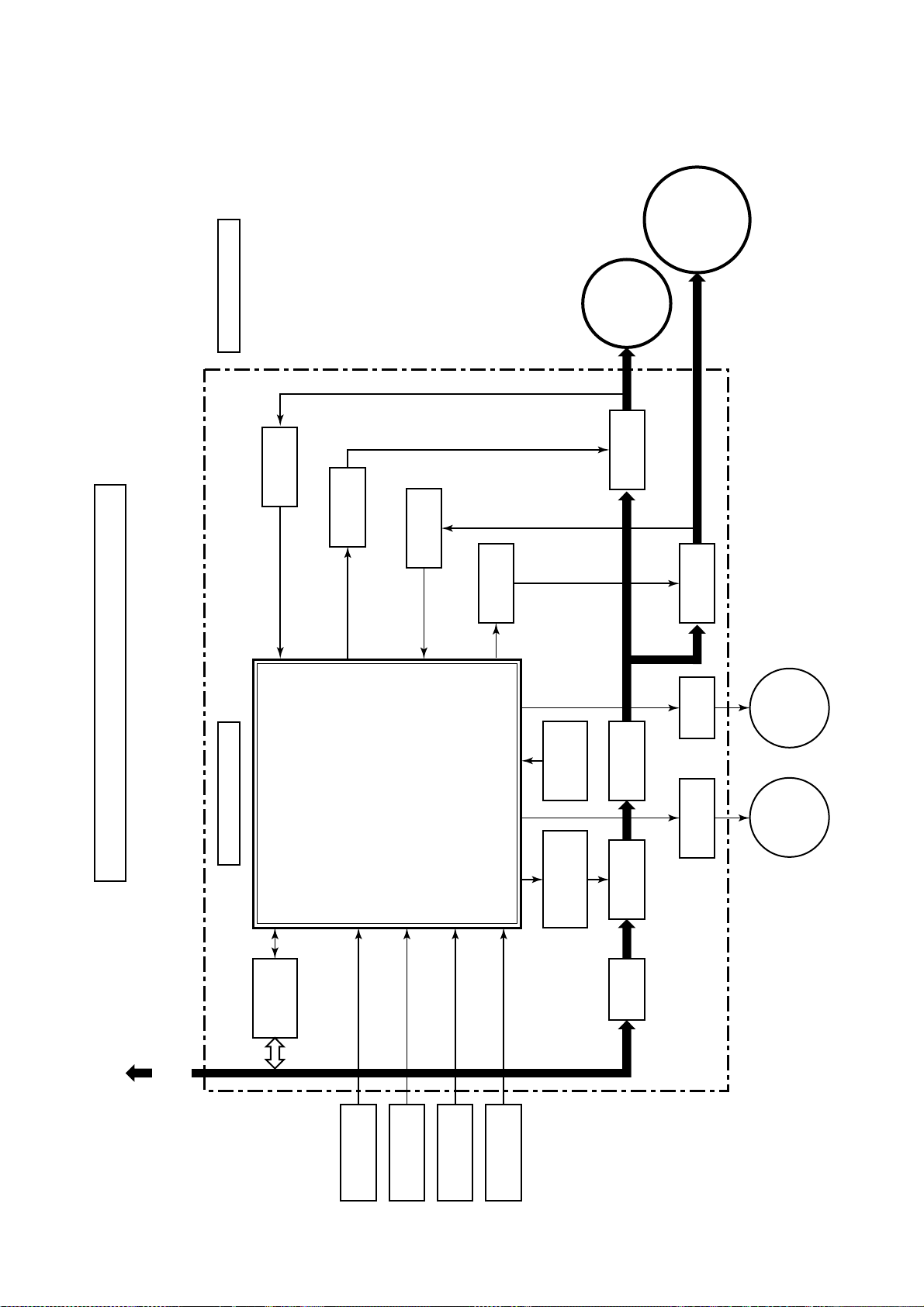

8-1. Indoor Unit

RAS-10SKV2-E, RAS-13SKV2-E

FILE NO. SVM-10001

8. CONTROL BLOCK DIAGRAM

Heat Exchanger Sensor (Tc)

Room Temperature Sensor (Ta)

Infrared Rays Signal Receiver

and Indication

Initializing Circuit

Clock Frequency

Oscillator Circuit

Power Supply

Circuit

Converter

(D.C circuit)

Noise Filter

M.C.U.

Functions

• Cold draft preventing Function

• 3-minute Delay at Restart for Compressor

• Fan Motor Starting Control

• Processing

(Temperature Processing)

• Timer

• Serial Signal Communication

• Clean Function

Serial Signal Transmitter/Receiver

Indoor Unit Control Unit

Louver

Motor

Louver Motor

Drive Control

Indoor Fan

Motor Control

Indoor

Fan Motor

From Outdoor Unit

~

220-240V

50Hz

REMOTE CONTROLLER

Serial Signal Communication

(Operation Command and Information)

Remote Controller

Operation [ ]

Operation Mode Selection

AUTO, COOL, DRY, HEAT

Thermo. Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver AUTO Swing

Louver Direction Setting

ECO

Hi-POWER

Infrared Rays, 36.7kHz

COMFORT SLEEP

QUIET

– 25 –

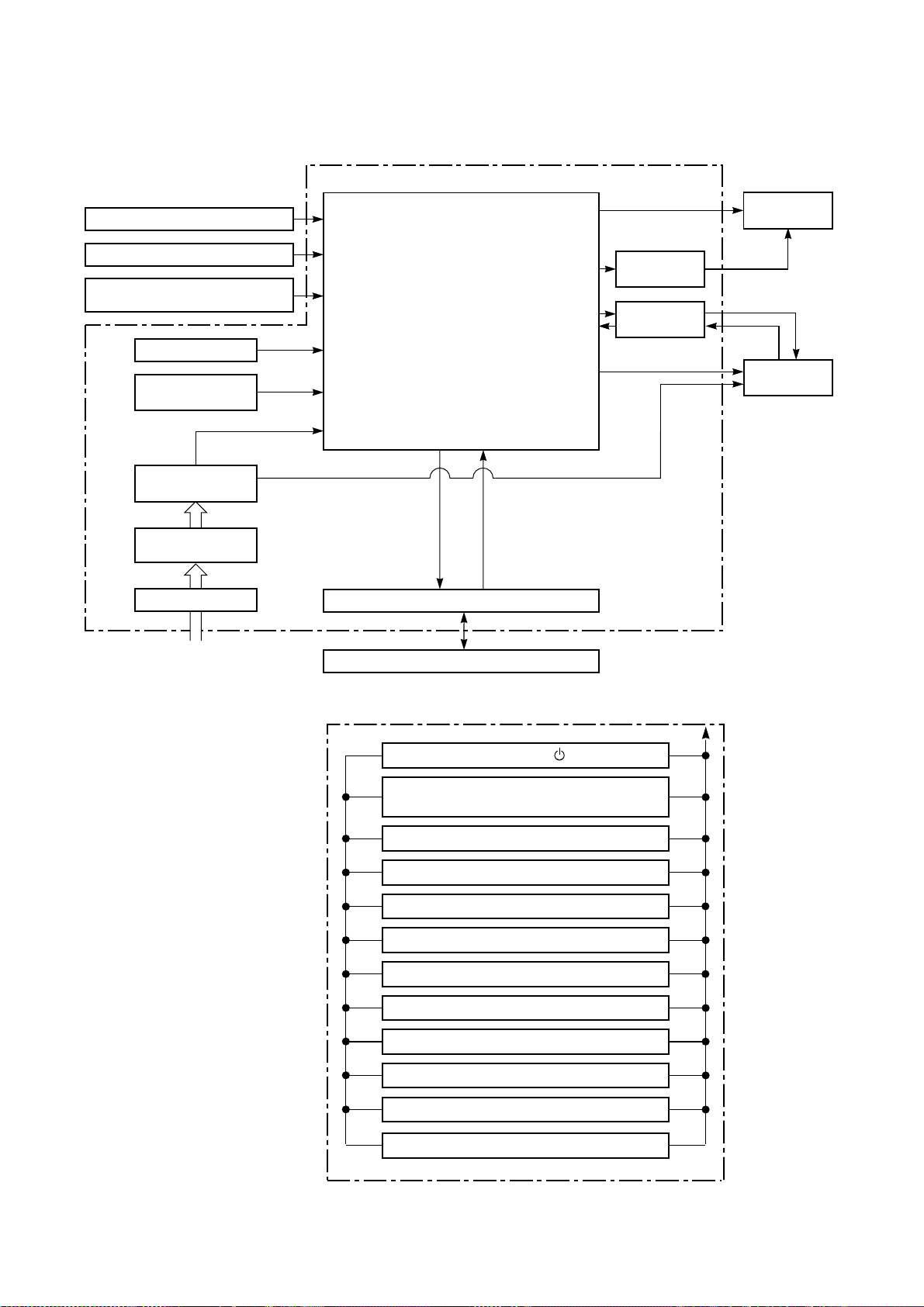

Page 26

RAS-16SKV2-E

FILE NO. SVM-10001

Heat Exchanger Sensor (TC)

Room Temperature Sensor (Ta)

Infrared Rays Signal Receiver

and Indication

Initializing Circuit

Clock Frequency

Oscillator Circuit

Power Supply

Circuit

Converter

(D.C circuit)

Noise Filter

M.C.U.

Functions

• Cold draft preventing Function

• 3-minute Delay at Restart for Compressor

• Fan Motor Starting Control

• Processing

(Temperature Processing)

• Timer

• Serial Signal Communication

• Clean Function

Serial Signal Transmitter/Receiver

Indoor Unit Control Unit

Louver

Motor

Louver Motor

Drive Control

Indoor Fan

Motor Control

Indoor

Fan Motor

From Outdoor Unit

~

220-240V

50Hz

REMOTE CONTROLLER

Serial Signal Communication

(Operation Command and Information)

Remote Controller

Operation [ ]

Operation Mode Selection

AUTO, COOL, DRY, HEAT

Thermo. Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver AUTO Swing

Louver Direction Setting

ECO

Hi-POWER

Infrared Rays, 36.7kHz

COMFORT SLEEP

QUIET

– 26 −

Page 27

8-2. Outdoor Unit (Inverter Assembly)

detect

Current

circuit

Gate drive

detect

Current

FILE NO. SVM-10001

Compressor

Outdoor

Fan motor

Inverter

(DC → AC)

P.M.V. : Pulse Motor Valve

M.C.U. : Micro Control Unit

MICRO-COMPUTER BLOCK DIAGRAM

M.C.U

MCC5009 (P.C.B) OUTDOOR UNIT

• PWM synthesis function

• Input current release control

circuit

Indoor unit

send/receive

circuit

Gate drive

• IGBT over-current detect control

• Outdoor fan control

• High power factor correction control

• Inverter output frequency control

• A/D converter function

• P.M.V. control

• Discharge temp. control

• 4-way valve control

• Signal communication to indoor unit

4MHz

Clock

frequency

circuit

High Power

factor Correction

Converter

(AC → DC)

sensor

Input current

Filter

Noise

Inverter

(DC → AC)

Relay

circuit

of P.M.V.

Driver circuit

valve

4-way

P.M.V.

220–240 V ~50Hz

For INDOOR UNIT

Discharge

temp. sensor

Outdoor air

temp. sensor

Suction temp.

– 27 –

sensor

Heat exchanger

temp.sensor

Page 28

9. OPERATION DESCRIPTION

FILE NO. SVM-10001

9-1. Outline of Air Conditioner Control

This air conditioner is a capacity-variable type air

conditioner, which uses AC or DC motor for the indoor

for motor and the outdoor fan motor. And the capacityproportional control compressor which can change the

motor speed in the range from 11 to 96 rps is

mounted. The DC motor drive circuit is mounted to the

indoor unit. The compressor and the inverter to control

fan motor are mounted to the outdoor unit.

The entire air conditioner is mainly controlled by the

indoor unit controller.

The indoor unit controller drives the indoor fan motor

based upon command sent from the remote controller,

and transfers the operation command to the outdoor

unit controller.

The outdoor unit controller receives operation command from the indoor unit side, and controls the

outdoor fan and the pulse Modulating valve. (P.M.V)

Besides, detecting revolution position of the compressor motor, the outdoor unit controller controls speed of

the compressor motor by controlling output voltage of

the inverter and switching timing of the supply power

(current transfer timing) so that motors drive according

to the operation command.

And then, the outdoor unit controller transfers reversely

the operating status information of the outdoor unit to

control the indoor unit controller.

As the compressor adopts four-pole brushless

DC motor, the frequency of the supply power

from inverter to compressor is two-times cycles

of the actual number of revolution.

1. Role of indoor unit controller

The indoor unit controller judges the operation

commands from the remote controller and assumes

the following functions.

• Judgment of suction air temperature of the indoor

heat exchanger by using the indoor temp. sensor.

(TA sensor)

• Judgment of the indoor heat exchanger temperature by using heat exchanger sensor (TC sensor)

(Prevent-freezing control, etc.)

• Louver motor control

• Indoor fan motor operation control

• LED (Light Emitting Diode) display control

• Transferring of operation command signal (Serial

signal) to the outdoor unit

• Reception of information of operation status

(Serial signal including outside temp. data) to the

outdoor unit and judgment/display of error

• Air purifier operation control

2. Role of outdoor unit controller

Receiving the operation command signal (Serial

signal) from the indoor unit controller, the outdoor

unit performs its role.

• Compressor operation control

• Operation control of outdoor fan motor

• P.M.V. control

• 4-way valve control

Operations follow ed to judgment

of serial signal from indoor side.

• Detection of inverter input current and current

release operation

• Over-current detection and prevention operation

to IGBT module (Compressor stop function)

• Compressor and outdoor fan stop function when

serial signal is off (when the serial signal does not

reach the board assembly of outdoor control by

trouble of the signal system)

• Transferring of operation information (Serial

signal) from outdoor unit controller to indoor unit

controller

• Detection of outdoor temperature and operation

revolution control

• Defrost control in heating operation (Temp.

measurement by outdoor heat exchanger and

control for 4-way valve and outdoor fan)

3. Contents of operation command signal

(Serial signal) from indoor unit controller to

outdoor unit controller

The following three types of signals are sent from

the indoor unit controller.

• Operation mode set on the remote controller

• Compressor revolution command signal defined

by indoor temperature and set temperature

(Correction along with variation of room temperature and correction of indoor heat exchanger

temperature are added.)

• Temperature of indoor heat exchanger

• For these signals ([Operation mode] and [Com-

pressor revolution] indoor heat exchanger temperature), the outdoor unit controller monitors the

input current to the inverter, and performs the

followed operation within the range that current

does not exceed the allowable value.

4. Contents of operation command signal

(Serial signal) from outdoor unit controller

to indoor unit controller

The following signals are sent from the outdoor unit

controller.

• The current operation mode

• The current compressor revolution

• Outdoor temperature

• Existence of protective circuit operation

For transferring of these signals, the indoor unit

controller monitors the contents of signals, and

judges existence of trouble occurrence.

Contents of judgment are described below.

• Whether distinction of the current operation

status meets to the operation command signal

• Whether protective circuit operates

When no signal is received from the outdoor

unit controller, it is assumed as a trouble.

– 28 –

Page 29

FILE NO. SVM-10001

9-2. Operation Description

1. Basic operation ........................................................................................................... 30

1. Operation control ................................................................................................... 30

2. Cooling/Heating operation ..................................................................................... 31

3. AUTO operation .....................................................................................................

4. DRY operation........................................................................................................ 31

2. Indoor fan motor control ............................................................................................. 32

3. Outdoor fan motor control........................................................................................... 34

4. Capacity control .......................................................................................................... 35

5. Current release control ............................................................................................... 35

6. Release protective control by temperature of indoor heat exchanger........................ 36

7. Defrost control (Only in heating operation) ................................................................ 37

8. Louver control ............................................................................................................. 38

1) Louver position....................................................................................................... 38

2) Air direction adjustment ......................................................................................... 38

31

3) Swing ..................................................................................................................... 38

9. ECO operation ............................................................................................................ 39

10. Temporary operation................................................................................................... 40

11.

Discharge temperature control ................................................................................... 40

12.

Pulse Modulating valve (P.M.V.) control ..................................................................... 41

13.

Self-Cleaning function ................................................................................................ 42

14.

Remote-A or B selection ............................................................................................ 43

15.

QUIET mode ............................................................................................................. 44

COMFORT SLEEP mode ......................................................................................... 44

16.

17.

One-Touch Comfort .................................................................................................. 44

18.

Hi-POWER Mode ...................................................................................................... 45

19. FIL

TER Indicator ...............................................................................................45

9-3. Auto Restart Function ..

9-3-1. How to Set the A uto Restart Function .............................. ........................................ 46

9-3-2. How to Cancel the Au to Restar t Function ................................................................. 47

9-3-3. Power Failure During Timer Operation .................................................................... 47

9-4. Remote Controller and Its Fuctions

9-4-1. Parts Name of Remote Contr oller .............................................................................. 48

9-4-2. Operation of remote control ...................................................................................... 48

9-4-3. Name and Functions of Indications on Remote Contr oller ........................................ 51

– 29 −

Page 30

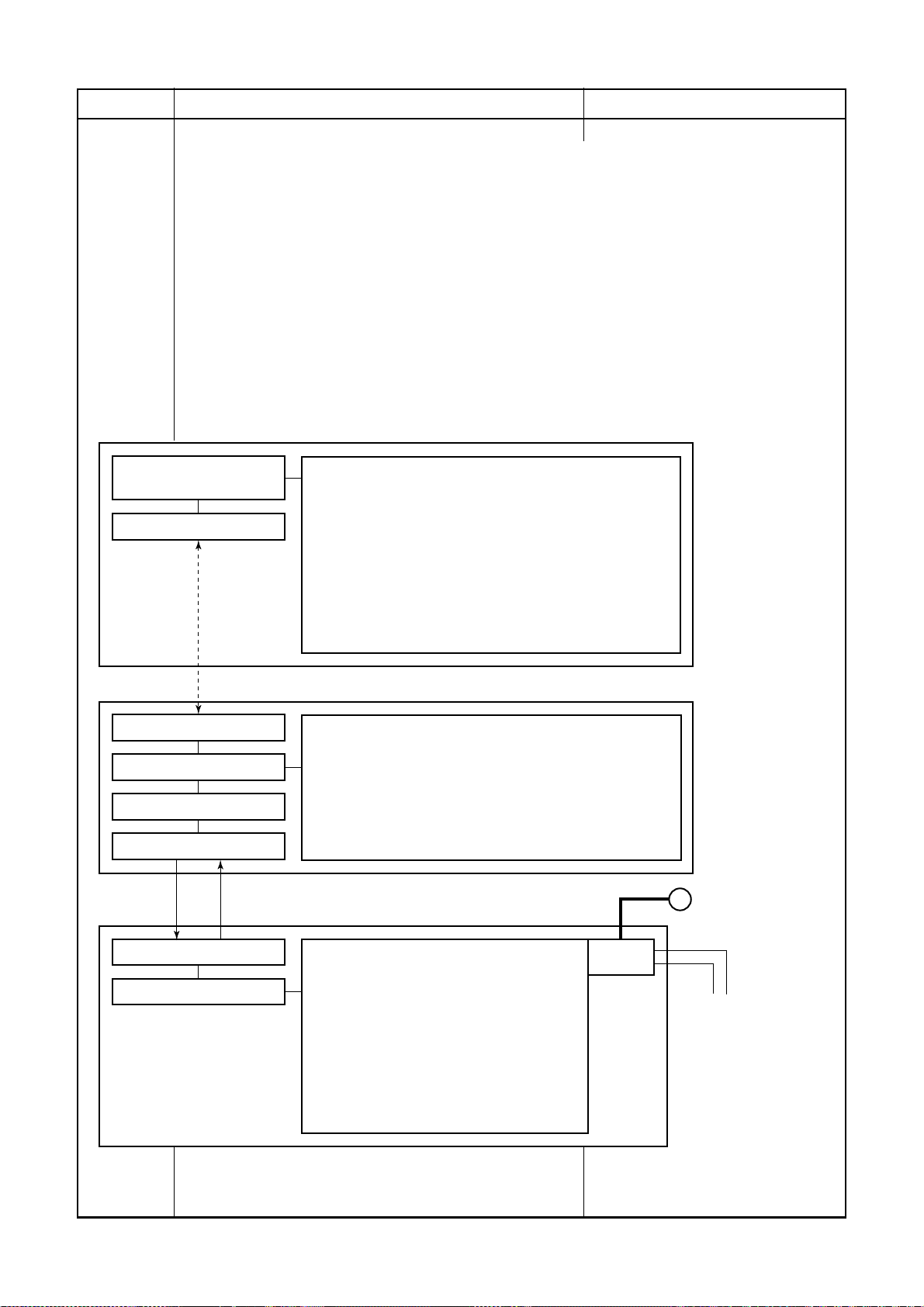

FILE NO. SVM-10001

Item

1. Basic

operation

Operation flow and applicable data, etc.

1. Operation control

Receiving the user’s operation condition setup, the operation statuses of indoor/outdoor units are

controlled.

1) The operation conditions are selected by the remote controller as shown in the below.

2) A signal is sent by ON button of the remote controller.

3) The signal is received by a sensor of the indoor unit and processed by the indoor controllers as

shown in the below.

4) The indoor controller controls the indoor fan motor and louver motor.

5) The indoor controller sends the operation command to the outdoor controller, and sends/receives

the control status with a serial signal.

6) The outdoor controller controls the operation as shown in the left, and also controls the compressor, outdoor fan motor, 4-way valve and pulse Modulating valve.

Selection of

operation conditions

ON/OFF

Remote controller

Control contents of remote controller

• ON/OFF (Air conditioner/Air purifier)

• Operation select (COOL/HEAT/AUTO/DRY)

• Temperature setup

• Air direction

• Swing

• Air volume select (AUTO/LOW/LOW+/MED/MED+/HIGH)

• ECO

• ON timer setup

• OFF timer setup

• Hi-POWER

• COMFORT SLEEP

• QUIET

• PRESET

• ONE-TOUCH

Description

Signal receiving

Indoor unit control

Operation command

Serial signal send/receive

Serial signal send/receive

Outdoor unit control

Indoor unit

Indoor unit control

• Command signal generating function of

indoor unit operation

• Calculation function (temperature calculation)

• Activation compensation function of indoor fan

• Cold draft preventive function

• Timer function

• Indoor heat exchanger release control

Outdoor unit

Outdoor unit control

• Frequency control of inverter output

• Waveform composite function

• Calculation function

(Temperature calculation)

• AD conversion function

• Quick heating function

• Delay function of compressor reactivation

• Current release function

• GTr over-current preventive function

• Defrost operation function

• Indoor fan motor

• Louver motor

~

Inverter

• Compressor

• Outdoor fan motor

• 4-way valve

• Pulse Modulating valve

(P.M.V.)

– 30 –

Page 31

FILE NO. SVM-10001

Ite m

1. Basic

operation

Operation flow and applicable data, etc.

2. Cooling/Heating operation

The operations are performed in the following parts by controls according to cooling/heating conditions.

1) Receiving the operation ON signal of the remote controller, the cooling or heating operation signal

starts being transferred form the indoor controller to the outdoor unit.

2) At the indoor unit side, the indoor fan is operated according to the contents of “2. Indoor fan

motor control” and the louver according to the contents of “9. Louver control”, respectively.

3) The outdoor unit controls the outdoor fan motor, compressor, pulse Modulating valve and

4-way valve according to the operation signal sent from the indoor unit.

Operation ON

Indoor unit control

Sending of operation command signal

Outdoor unit control

Setup of remote controller

Indoor fan motor control / Louver control / Operation Hz

Control (Requierment)

Compressor revolution control / Outdoor fan motor control /

Operation Hz control (Include limit control)

4-way valve control In cooling operation: ON

In heating operation: OFF

Pulse Modulating valve control

[ ]

Description

3. AUTO operation

Selection of operation mode

As shown in the following figure, the operation starts by

selecting automatically the status of room temperature

(Ta) when starting AUTO operation.

*1. When reselecting the operation mode, the fan

speed is controlled by the previous operation mode.

Ta

Cooling operation

Ts + 1

Monitoring (Fan)

Ts – 1

Heating operation

4. DRY operation

DRY operation is perfor med according to the difference

between room temperature and the setup temperature as

shown below.

In DRY operation, fan speed is controlled in order to

prevent lowering of the room temperature and to avoid air

flow from blowing directly to persons.

[˚C]

Ta

L– (W5)

1) Detects the room temperature (Ta) when

the operation started.

2) Selects an operation mode from Ta in

the left figure.

3) Fan operation continues until an

operation mode is selected.

4) When AUTO operation has started

within 2 hours after heating operation

stopped and if the room temperature is

20°C or more, the fan operation is

performed with ”Super Ultra LOW” mode

for 3 minutes.

Then, select an operation mode.

5) If the status of compressor-OFF

continues for 15 minutes the room

temperature after selecting an operation

mode (COOL/HEAT), reselect an

operation mode.

1) Detects the room temperature (Ta) when

the DRY operation started.

2) Starts operation under conditions in the

left figure according to the temperature

difference between the room temperature and the setup temperature (Tsc).

Setup temperature (Tsc)

= Set temperature on remote controller

(Ts) + (0.0 to 1.0)

3) When the room temperature is lower

1°C or less than the setup temperature,

turn off the compressor.

+

+

Tsc

1.0

0.5

(W5+W3) / 2

SUL (W3)

Fan speed

− 31 −

Page 32

FILE NO. SVM-10001

Item

2. Indoor fan

motor control

COOL ON

Fan speed setup

AUTO

Ta

[˚C]

+2.5

a

+2.0

b

+1.5

c

+1.0

Operation flow and applicable data, etc.

<In cooling operation>

(This operation controls the fan speed at indoor unit side.)

The indoor fan (cross flow fan) is operated by the phase-

control induction motor. The fan rotates in 5 stages in

MANUAL mode, and in 5 stages in AUTO mode, respectively. (Table 1)

MANUAL

(Fig. 1)

Indication

L

L+

M

M+

H

Fan speed

W6

(L + M) / 2

W9

(M + H) / 2

WC

(Fig. 2)

Air volume AUTO

M+(WB)

*3

*4

*5

*3 : Fan speed = (M + –L) x 3/4 + L

*4 : Fan speed = (M + –L) x 2/4 + L

*5 : Fan speed = (M + –L) x 1/4 + L

Description

* Symbols

UH : Ultra High

H : High

M+ : Medium+

M : Medium

L+ : Low+

L: Low

L- : Low–

UL : Ultra Low

SUL : Super Ultra Low

* The fan speed broadly varies due

to position of the louver, etc.

The described value indicates one

under condition of inclining

downward blowing.

1) When setting the fan speed to L,

L+, M, M+ or H on the remote

controller, the operation is

performed with the constant

speed shown in Fig. 1.

2) When setting the fan speed to

AUTO on the remote controller,

revolution of the fan motor is

controlled to the fan speed level

shown in Fig. 2 and Table 1

according to the setup temperature, room temperature, and heat

exchanger temperature.

+0.5

Tsc

d

e

L(W6)

(Linear approximation

from M+ and L)

(Table 1) Indoor fan air flow rate

Fan speed

level COOL HEAT DR

WF UH 1210 571 1300 620 1510 735

WE H 1210 571 1300 620 1510 735

WD UH M+ 1170 546 1250 590 1480 717

WC H 1120 515 1200 570 1430 686

WB M+ 1040 465 1080 490 1280 594

WA 1000 440 465

W9 M L+ 960 415 990 434 1150 514

W8 L 870 359 870 359 1000 421

W7 L+ L- L+ 850 347 860 353 980 409

W6 L L 760 291 770 297 920 372

W5 L- UL L- 760 291 770 297 900 360

W4 UL UL 700 253 720 266 840 323

W3 SUL SUL 650 222 670 234 770 280

W2 SUL 500 129 520 141 620 187

W1 500 129 500 129 520 126

Y

Fan speed Air flow rate Fan speed Air flow rate Fan speed Air flow rate

(rpm) (m3/h) (rpm) (m3/h) (rpm) (m3/h)

UH

H

M

M+

M

RAS-13SKV2-E RAS-16SKV2-ERAS-10SKV2-E

1050

1220 557

– 32 –

Page 33

d

O

ol

y.

c

e

C

[C]

b

5

c

5.5

)

)

U

.

)

c

U

g

y

g

ON

l

52

51

(

8

t

FILE NO. SVM-10001

Item

2. Indoor fan

motor control

HEAT

Fan speed setup

AUTO

TC ≥ 42˚C

NO

Operation flow and applicable data, etc.

<In heating operation>

MANUAL

Indication Fan speed

L

L+

M

M+

H

YES

Tc

(Fig. 3)

(L + M) / 2

(M + H) / 2

Min air flow rate contro

Limited to Min WD tap

W8

WA

WE

Description

1) When setting the fan speed to L,

L+, M, M+ or H on the remote

controller, the operation is performed with the constant speed

shown in Fig. 3 and Table 1.

2) When setting the fan speed to

AUTO on the remote controller,

revolution of the fan motor is

controlled to the fan speed level

shown in Fig. 5 according to the set

temperature and room temperature.

3) Min air flow rate is controlled by

temperature of the indoor heat

exchanger (Tc) as shown in Fig. 4.

4) Cold draft prevention, the fan

speed is controlled by temperature

of the indoor heat exchanger (Tc)

as shown in Fig. 6.

5) In order to prevent Cold draft when

compressor step during heating

operation. Then louver will move to

upper position and fan speed will

reduce or off.

*Fan speed=

TC

Fan spee

AUT

L+ (W9)

*1

*2

*3

M+ (WD)

H (WE

Basic fan contr

A

TS

–0.

d

–1.0

e

–1.5

f

–2.0

g

–2.5

–5.0

(Fig. 4)

*1: Fan speed = (M + -L+) x 1 4 + L+

*2: Fan speed = (M + -L+) x 2 4 + L+

*3: Fan speed = (M + -L+) x 3 4 + L+

(Calculated with linear approximation from M+ and L+)

(Fig. 5)

No limi

W8) + W

Cold draft preventive control

T

46 46

45 45 33

33 33 21

32 32 20

*A+4 *A+4 *A+4

*A-4 *A-4 *A-4

* No limitation while fan speed MANUAL mode is in stabilit

* A: When Tsc 24, A is 24, and when Tsc < 24, A is Ts

Tsc: Set valu

34

Fan speed MAN

Fan speed AUTO in stabilit

Fan speed AUTO in startin

H (WE

Line-approximate

H and S

SUL (W2

L with Tc

Stop

AL in startin

(Fig. 6)

[In starting and in stability]

FAN AUTO

F AN Man ual

In starting

• Until 12 minutes passed after operation star t

• When 12 to 25 minutes passed after operation

start and room temp. is 3°C or lo w er than set temp.

• Room temp. < Set temp. –4°C

• When 12 to 25 minutes passed after operation star t

and room temp. is higher than (set temp. –3°C)

• When 25 minutes or more passed after operation start

• Room temp. ≥ Set temp. –3.5°C

In stability

– 33 –

Page 34

FILE NO. SVM-10001

Item

3. Outdoor fan

motor control

1) Outdoor unit

operation command

(Outdoor fan control)

when the motor stopped.

Operation flow and applicable data, etc.

The blowing air volume at the outdoor unit side is controlled.

Receiving the operation command from the controller of

indoor unit, the controller of outdoor unit controls fan speed.

* For the fan motor, a DC motor with non-stage variable

speed system is used. However, it is limited to 8 stages for

reasons of controlling.

Air conditioner ON

(Remote controller)

Indoor unit controller

2) Fan speed ≥ 400

YES

OFF status of

fan motor continues.

NO

Fan motor ON

Description

1) The operation command sent

from the remote controller is

processed by the indoor unit

controller and transferred to the

controller of the outdoor unit.

2) When strong wind blows at

outdoor side, the operation of air

conditioner continues with the

fan motor stopped.

3) Whether the fan is locked or not

is detected, and the operation of

air conditioner stops and an

alarm is displayed if the fan is

locked.

4) According to each operation

mode, by the conditions of

outdoor temperature (To) and

compressor revolution, the speed

of the outdoor fan shown in the

table is selected.

3) Fan lock

YES

NO

4) Motor operates as shown in the table below.

In cooling operation

Compressor speed (rps)

To > 38°C

To > 28°C

To To > 15°C

To > 5.5°C

To > 0°C

To

°C f 0 f 0 f 0 f 1 f 1 f 2

< 0

During

ECO mode

When To is abnormal

Ta p

f 0 0 0 0

f 1

f 2

f 3

f 4

f 5

f 6

f 7

f 8

To > 38°C

To < 38°C

10SAV2-E

200 200 200

300 300 300

370 370 370

440 440 440

440 440 440

500 500 500

550 550 550

600 600 600

~ 13.8 ~ 31.7

MIN MAX MIN MAX MIN MAX

f 2 f 3 f C f D f E f F

f 2 f 3 f A f C f D f F

f 2 f 3 f 7 f A f 9 f C

f 1 f 3 f 2 f 5 f 4 f 7

f 1 f 1 f 1 f 2 f 2 f 4

f 2 f 3 f B f C f C f D

f 2 f 3 f 2 f 3 f B f C

f D f F f D f F f F

13SAV2-E 13SAV2-E

Air conditioner

OFF

32.3 ~ MAX

f D

Alarm

display

Compressor speed (rps)

During

ECO mode

When To is abnormal

Outdoor fan speed (rpm)

16SA

V2-E

Ta p

f 9

f A

f B

f C

f D

f E

f F

In Heating operation

~16.8 ~47.9

To > 15°C

To

To < 15°C

To < 5.5°C

To < − 5.0°C

To > 15°C

To < 15°C

To < 5.5°C

To < − 5.5°C

10SAV2-E

600 650 650

600 700 700

650 700 700

700 800 800

700 800 800

700 800 800

700 800 900

f 3 f 8 f 9

f 3 f 9 f A

f 8 f A f D

f B f C f D

f 3 f 3 f 6

f 3 f 3 f 8

f 5 f 9 f 9

f 7 f A f B

f A f B f D

48.5 ~ MAX

16SAV2-E

– 34 –

Page 35

FILE NO. SVM-10001

Item

4. Capacity

control

Remote controller Indoor unit

Operation flow and applicable data, etc.

The cooling or heating capacity depending on the load is

adjusted.