Page 1

TO SH IB A

SERVICE M ANUAL

AIR-CONDITIONER

SPLIT W A LL TY PE

FILE N O . A 00-9701

RAS-13SK-E

RAS-13SKX

R A S -13S A -E

RAS-13SAX

P R IN T E D IN J A P A N , F e b .,1 9 9 7 T o M o

Page 2

CONTENTS

1. SPECIFICATIONS............................................................................................................ 4

2. CONSTRUCTION VIEWS................................................................................................ 6

2-1. Indoor Unit .................................................................................................................................. 6

2-2. Outdoor Unit ............................................................................................................................... 7

3. WIRING DIAGRAM.......................................................................................................... 8

4. SPECIFICATIONS OF ELECTRICAL PARTS ................................................................. 9

4-1. Indoor Unit .................................................................................................................................. 9

4-2. Outdoor Unit ............................................................................................................................... 9

5. REFRIGERANT CYCLE DIAGRAM .............................................................................. 10

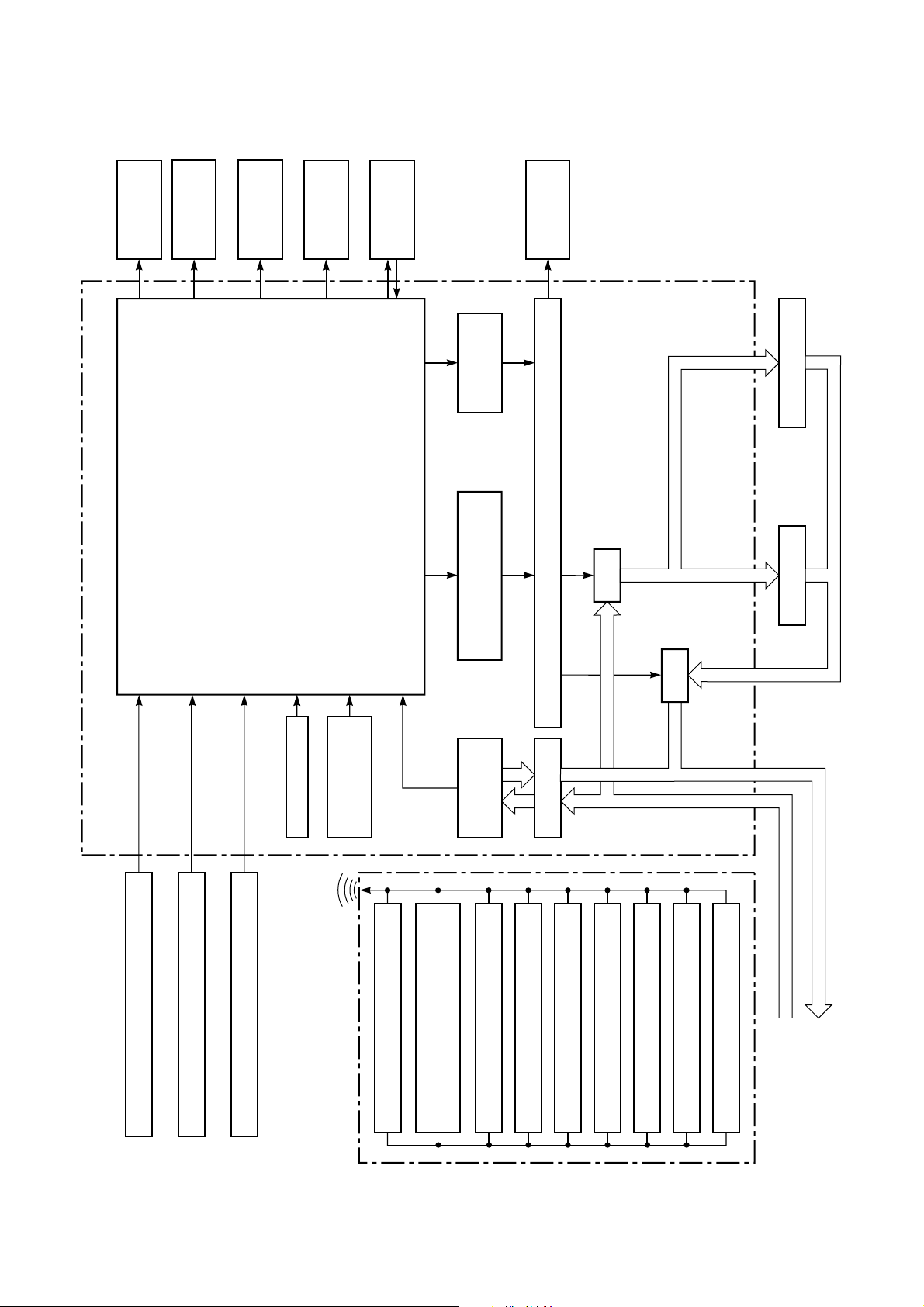

6. MICRO-COMPUTER BLOCK DIAGRAM .......................................................................11

7. OPERATION DESCRIPTIONS....................................................................................... 12

7-1. FAN ONLY Operation ......................................................................................................... ...... 12

7-2. COOL Operation ....................................................................................................................... 12

7-2-1. Louver Control ......................................................................................................................................13

7-3. DRY Operation.......................................................................................................................... 13

7-4. AUTO Operation ............................................................................................................. .......... 14

7-4-1. T emporary Auto .....................................................................................................................................14

7-5. ECONO. Mode................................................................................................................ ........... 15

7-5-1. Cooling................................................................................................................................................... 15

7-6. Low-Temperature Limit Control (Cooling Operation) .......................................................... 15

7-7. Auto Restart Function ............................................................................................................. 16

7-7-1. How to Set the Auto Restart.................................................................................................................16

7-7-2. How to Cancel the Auto Restart ..........................................................................................................17

7-7-3. In Case of Power Failure during the Timer Operation.......................................................................17

8. INSTALLATION PROCEDURE...................................................................................... 18

8-1. Safety Cautions ............................................................................................................ ............ 1 8

8-2. Installation Diagram of Indoor and Outdoor Units ............................................................... 20

8-3. Installation ................................................................................................................................ 21

8-3-1. Optional Parts........................................................................................................................................21

8-3-2. Installation Parts ...................................................................................................................................21

8-4. Indoor Unit ................................................................................................................ ................ 22

8-4-1. Cutting a Hole and Mounting Installation Plate .................................................................................22

8-4-2. Electrical Work ......................................................................................................................................23

8-4-3. Wiring Connection ................................................................................................................................24

8-4-4. Piping and Drain Hose Installation...................................................................................................... 26

8-4-5. Indoor Unit Installation .........................................................................................................................27

8-4-6. Drainage.................................................................................................................................................27

8-5. Outdoor Unit ............................................................................................................................. 28

8-5-1. Refrigerant Piping Connection ............................................................................................................29

8-5-2. Vacuum Pumping ..................................................................................................................................29

8-5-3. Wiring Connection ................................................................................................................................30

8-6. Others ........................................................................................................................................ 31

8-6-1. Gas Leak Test .................................................................................................................. ...................... 31

8-6-2. Test Operation .......................................................................................................................................31

8-6-3. Auto Restart Setting .............................................................................................................................31

– 2 –

Page 3

9. TROUBLESHOOTING CHART...................................................................................... 32

9-1. What to be Prechecked First .................................................................................................. 3 2

9-1-1. Power Supply Voltage........................................................................................................................... 32

9-1-2. Incorrect Cable Connection between Indoor and Outdoor Units.....................................................32

9-1-3. Misleading but Good Operations.........................................................................................................33

9-2. Primary Judgement of Trouble Sources ............................................................................... 3 4

9-2-1. Role of Indoor Unit Controller..............................................................................................................34

9-2-2. Display of Abnormalities and Judgement of the Abnormal Spots...................................................34

9-3. Troubleshooting Flowcharts ................................................................................................... 38

9-3-1. Power can not be Turned on ................................................................................................................ 38

9-3-2. Power can not be Turned on after Replacing Indoor PC Board .......................................................39

9-3-3. Outdoor Unit does not Operate ...........................................................................................................39

9-3-4. Only Compressor does not Operate ...................................................................................................4 0

9-3-5. Only Outdoor Fan does not Operate ...................................................................................................41

9-3-6. Only the Indoor Fan does not Operate................................................................................................42

9-4. How to Check the Remote Control (Including the Indoor PC Board) ................................ 43

9-4-1. How to Check the PC Board.................................................................................................................4 4

9-4-2. PC Board Layout ...................................................................................................................................4 6

9-4-3. How to Reduce the Operation Time of the Anti-Restar t Timer ......................................................... 4 7

10. PART REPLACEMENT ................................................................................................. 48

10-1. Indoor Unit ................................................................................................................................ 48

10-2. Microcomputer ......................................................................................................................... 50

10-3. Outdoor Unit ............................................................................................................................. 51

11. CAUTIONS ON REPLACEMENT OF PC BOARD ASSEMBLY.................................... 52

12. EXPLODED VIEWS AND PARTS LIST......................................................................... 53

12-1. Indoor Unit (1)........................................................................................................... ................ 53

Indoor Unit (2)........................................................................................................................... 54

12-2. Outdoor Unit ............................................................................................................................. 55

– 3 –

Page 4

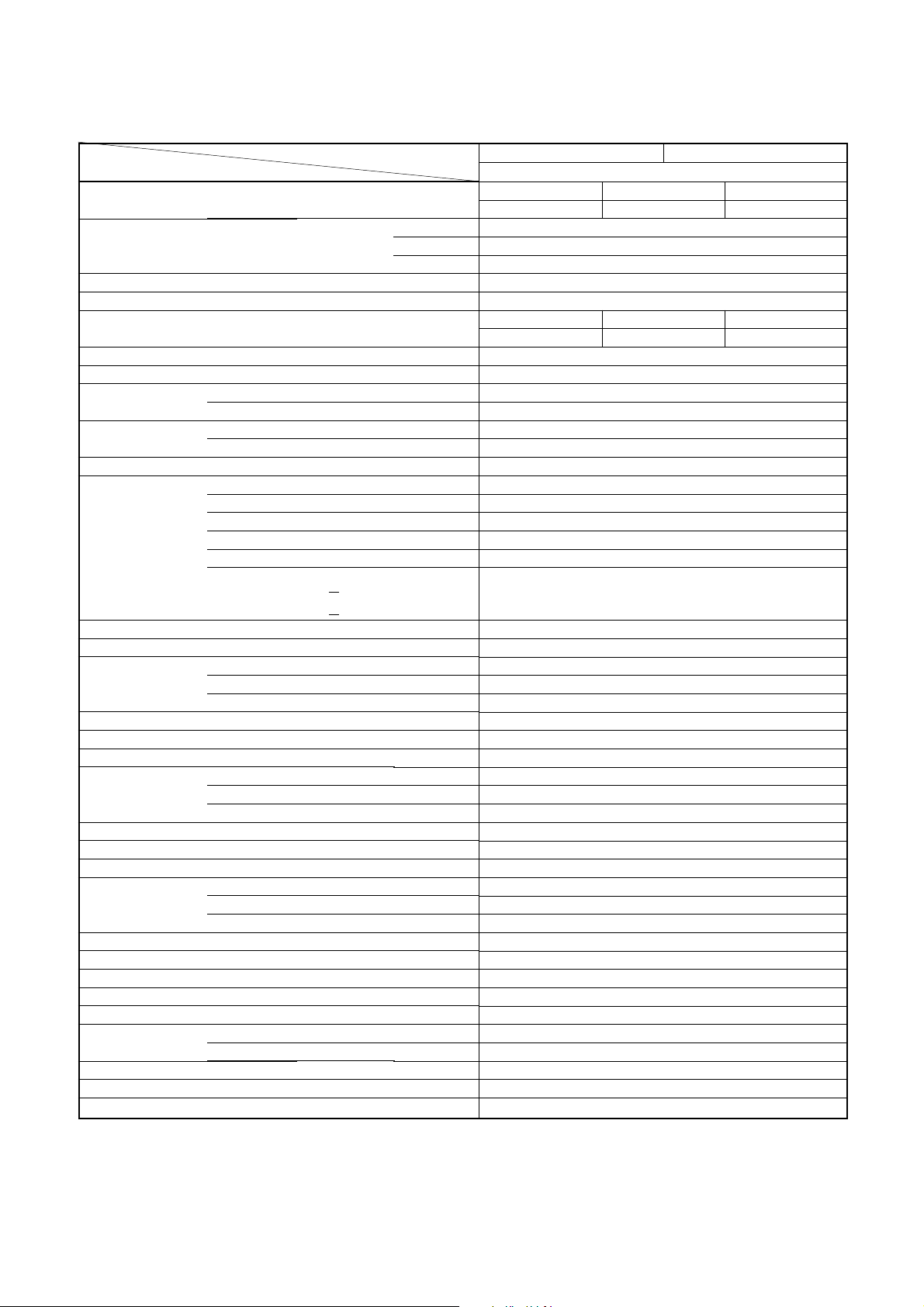

1. SPECIFICATIONS

Item

Capacity

Power source

Power consumption

Power factor

Running current

Starting current

Moisture removal

Noise

Refrigerant

Refrigerant control

Interconnection pipe

Condensate drain pipe

INDOOR UNIT

Dimensions

Net weight

Evaporator type

Indoor fan type

Air volume

Fan motor output

Air filter

OUTDOOR UNIT

Dimensions

Net weight

Condenser type

Outdoor fan type

Airflow volume

Fan motor output

Compressor

Safety device

Auto louver

Usable outdoor temperature range

Indoor (H/M/L)

Outdoor (220/230/240V)

Name of refrigerant

Rated volume

Gas side size

Connection type

Liquid side size

Connection type

Maximum length (of one way)

Maximum height difference

Indoor unit

Outdoor unit

Outer diameter

Height

Width

Depth

High fan

Medium fan

Low fan

Height

Width

Depth

(220/230/240V)

Model

Output

Model

*1

kW

Phase

V

Hz

kW

%

A

Indoor/Outdoor

A

lit/h

dB

dB

kg

mm

mm

m *2

↑

↓

m

mm

mm

mm

mm

kg

m3/h

m3/h

m3/h

W

mm

mm

mm

kg

m3/h

W

W

°C

RAS-13SK-E/13SA-E RAS-13SKX/13SAX

COOLING

220V 230V 240V

3.70 3.70 3.75

Single

220/230/240

50

1.25/1.27/1.29

98/97/95

220V 220V 220V

0.15/5.66 0.15/5.56 0.15/5.53

24

2.0

44/39/36

47/48/48

R22

0.83

Capillary tube

12.7

Flare connection

6.35

Flare connection

15

6

16

RAS-13SK-E/RAS-13SKX

265

790

174

8

Finned tube

Cross flow fan

650

560

510

19

Polypropylene net filter (Washable)

RAS-13SA-E/RAS-13SAX

538

780

300

37

Finned tube

Propeller

1710/1800/1890

27

PH160T2-4L2

1100

Fuse, Overload relay

Yes

21 ~ 43

Specifications are subject to change without notice.

– 4 –

Page 5

Note : *1

• Capacity is based on the following temperature conditions.

Condition

T emperature

(DB)

Indoor unit inlet air temperature

(WB)

(DB)

Outdoor unit inlet air temperature

(WB)

Notes : *2 CHARGELESS

• No additional refrigerant required.

• This air conditioner accepts a connection piping length of up to 15m and a head of up to 6m.

• There is no need to add the refrigerant as long as the total length of the connection piping is up to 15m.

JIS C9612-1994

Cooling

27°C

19°C

35°C

24°C

– 5 –

Page 6

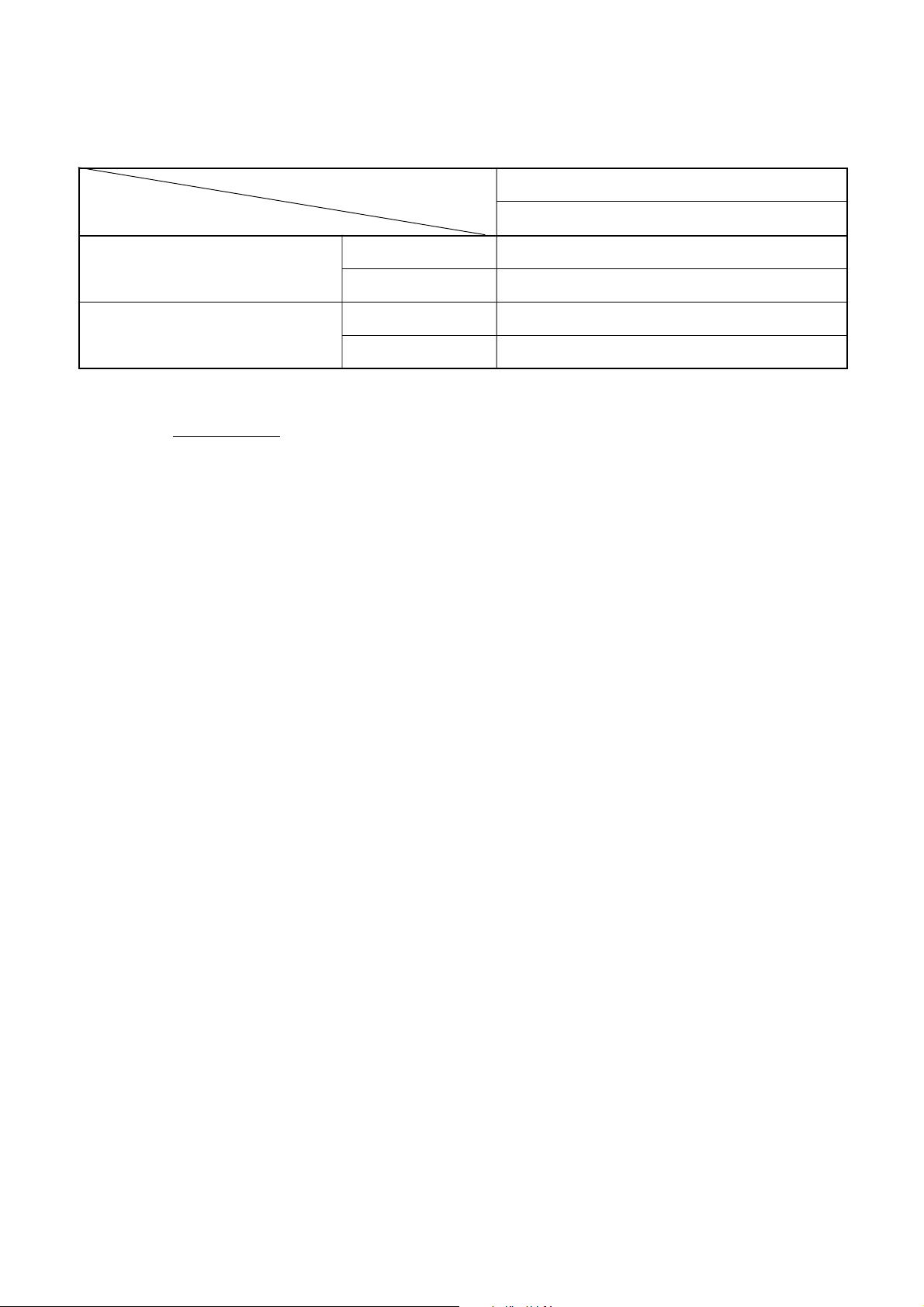

2-1. Indoor Unit

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,

RAS-13SK-E

RAS-13SKX

Air inlet

2. CONSTRUCTION VIEWS

Air filter

790

Heat exchanger

174

265

Air outlet

232 326 232

Drain hose (0.54m)

Hanger

Connecting pipe (0.39m)

(Flare ø12.7)

790

Hanger

321

1800

13SK-E : Without power cord

13SKX : With power cord

Connecting pipe (0.49m)

(Flare ø6.35)

Front panel

Back body

47

47

Knock out system

50

10

Knock out system

50

10

65965.5

450

Hanger

326

66 or more

Minimum

distance

2.5

46

Minimum

distance

17 20

265

to wall

120 or more 120 or more

3.5

40.5

Center line

to ceiling

Installation

plate outline

HangerHanger

790

– 6 –

12626931976

65.5

Hanger

For stud bolt

(ø8~ø10)

For stud bolt

(ø6)

Minimum

distance to wall

20 2037

40.5

60.5

Wireless

remote

control

Remote

control

holder

55

136

16

112.8

559.6

Page 7

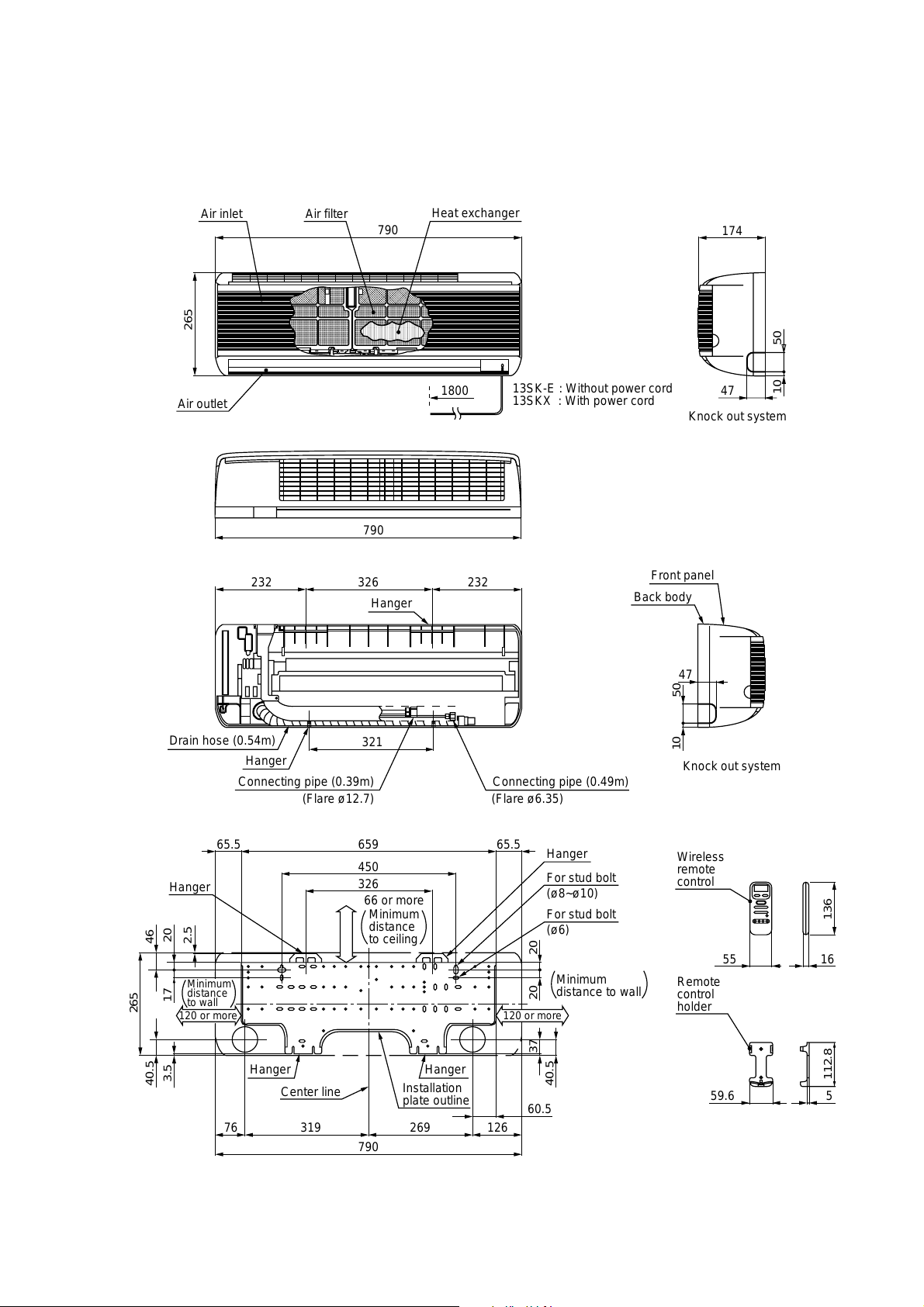

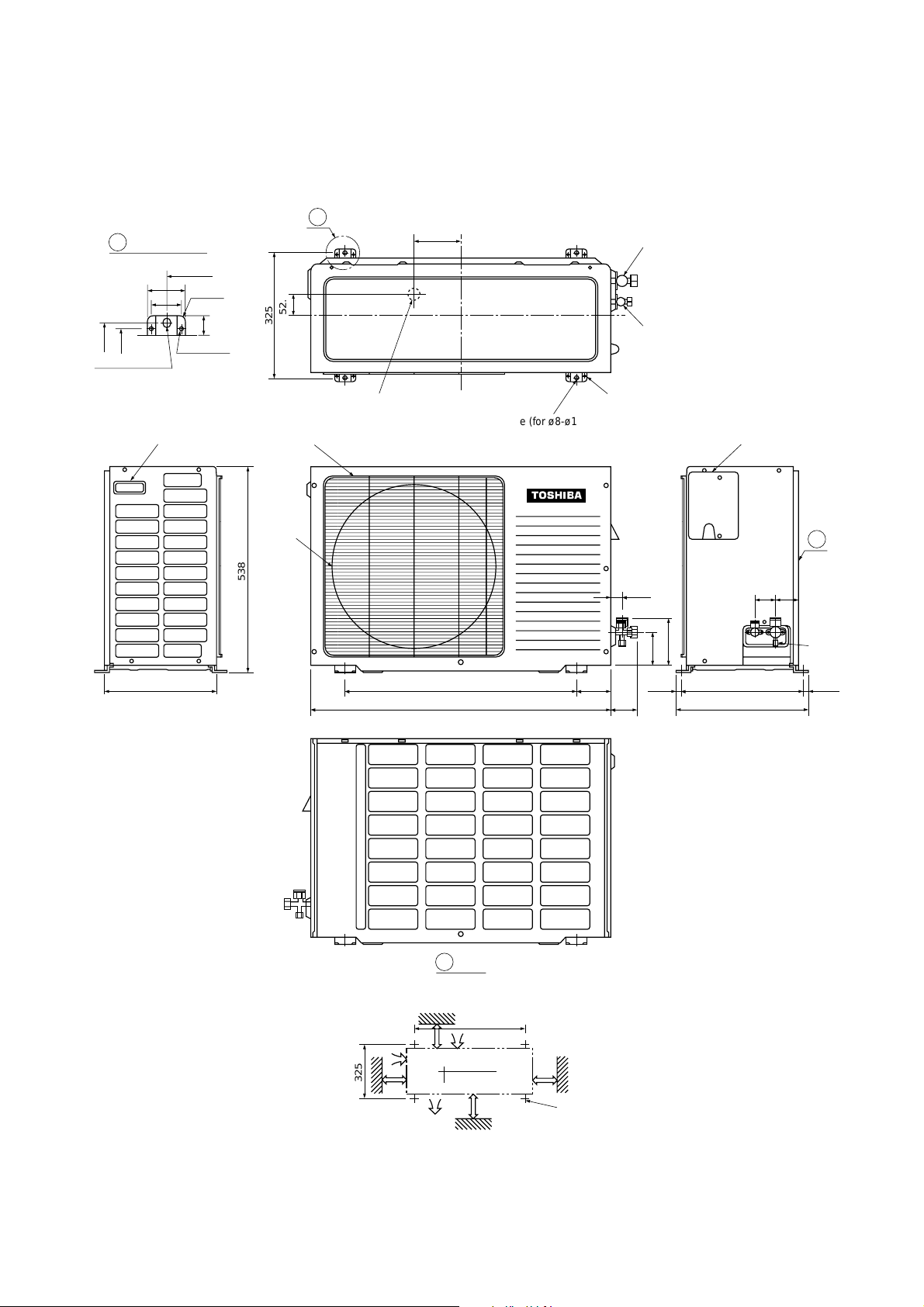

2-2. Outdoor Unit

RAS-13SA-E

RAS-13SAX

Detail Drawing

A

325

301

ø11x14 hole

Handle

300

50

36

600

R10

ø6 hole

A

120

52.5

538

325

Fan guard

ø420

ø25Drain outlet

6-ø11x14 hole (for ø8-ø10 anchor bolt)

600

780

90

23

Gas side (Flare ø12.7)

Liquid side (Flare ø6.35)

8-ø6 hole ( (for fixing outdoor unit)

Electric Parts cover

27

130

100

(8.5)

59

54

325 (pitch)

342

Z

61

Service

Port

(8.5)

Installation dimension

100 or more

325

100 or more

Air outlet

View

Z

600

– 7 –

Air inlet

600 or more

600 or more

4xø11x14 Long holes (for ø8-ø10 anchor bolt)

Page 8

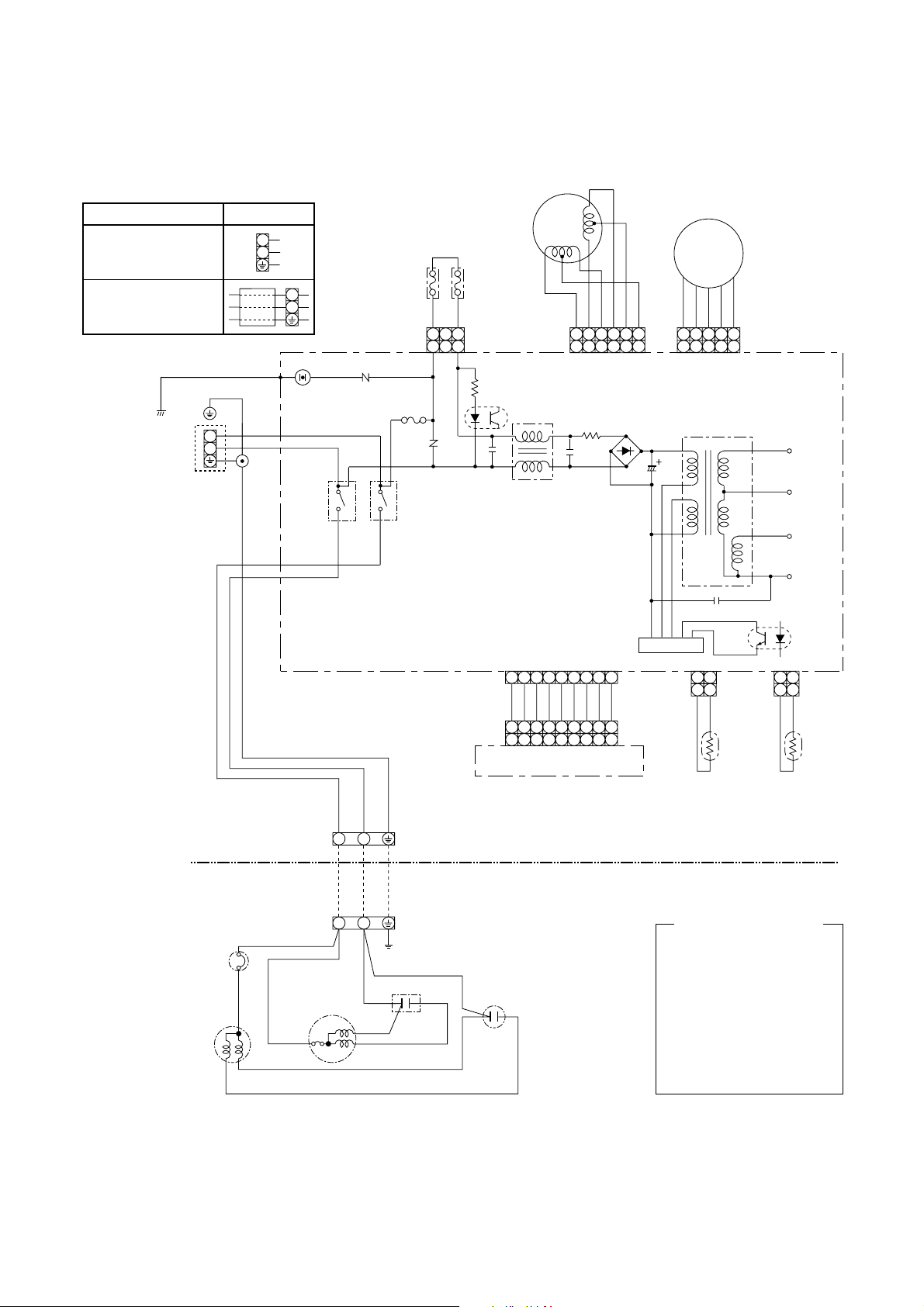

3. WIRING DIAGRAM

Model Section A

RAS-13SK-E/SA-E

220/230/240V ~

50Hz

RAS-13SKX/SAX

220/230/240V ~

50Hz

GRN&YEL

Section A

POWER

TERMINAL

BLOCK

OVER LOAD

RELAY

COMPRESSOR

LOUVER

L

N

MOTOR

DC

MOTOR

FAN MOTOR

THERMAL FUSE

L

N

P04

BRW

BLU

SG01

DSA

BLK

L

N

RY02

77˚C x 2

R109

VARISTOR

F01 FUSE

3

4

T3.15A

250V

3

RY01

4

GRY

1

1

R21

GRY

3

3

CN04

R116

C15

IC04

L01

CN07

BLU

6

6

R01

C01

PNK

4

5

4

5

YEL

3

3

ORN

RED

2

2

DB01

BRW

1

1

C02

BLK

BLU

YEL

WHI

5

5

RED

4

3

2

1

4

3

2

1

CN10

MAIN P.C. BOARD

MCC-713

T01

DC 35V

DC 12V

DC 7V

BLK

WHI

C06

DC 0V

IC02

IC

IC01

23

1

BLU

2

1

2

1

BLU

3

3

BLU

4

56789

BLU

BLU

BLU

4

56789

4

56789

PNK

BLK

CN13

WHI

CN25

2

1

CN03 CN01

2

1

BLK

BLK

1

1

BLK

2

2

BLK

INFRARED RAYS RECEIVE

INDOOR

TERMINAL

BLOCK

BLK

1

WHI

2

GRN&YEL

AND INDICATION PARTS

INDOOR

THERMO

SENSOR

(TA)

DSA : Surge absorber

HEAT

EXCHANGER

SENSOR

(TC)

OUTDOOR

OUTDOOR

TERMINAL

BLK

RED

WHI

BLOCK

BLK

FAN MOTOR

BLK

1

RED

2

GRN & YEL

CHASSIS

RED

CAPACITOR

RED

WHI

CAPACITOR

COLOR IDENTIFICATION

:

BROWN

BRW

:

RED

RED

:

WHITE

WHI

:

YELLOW

YEL

:

BLUE

BLU

:

BLACK

BLK

:

GRAY

GRY

:

PINK

PNK

:

ORANGE

ORN

:

GRN&YEL

GREEN &

YELLOW

– 8 –

Page 9

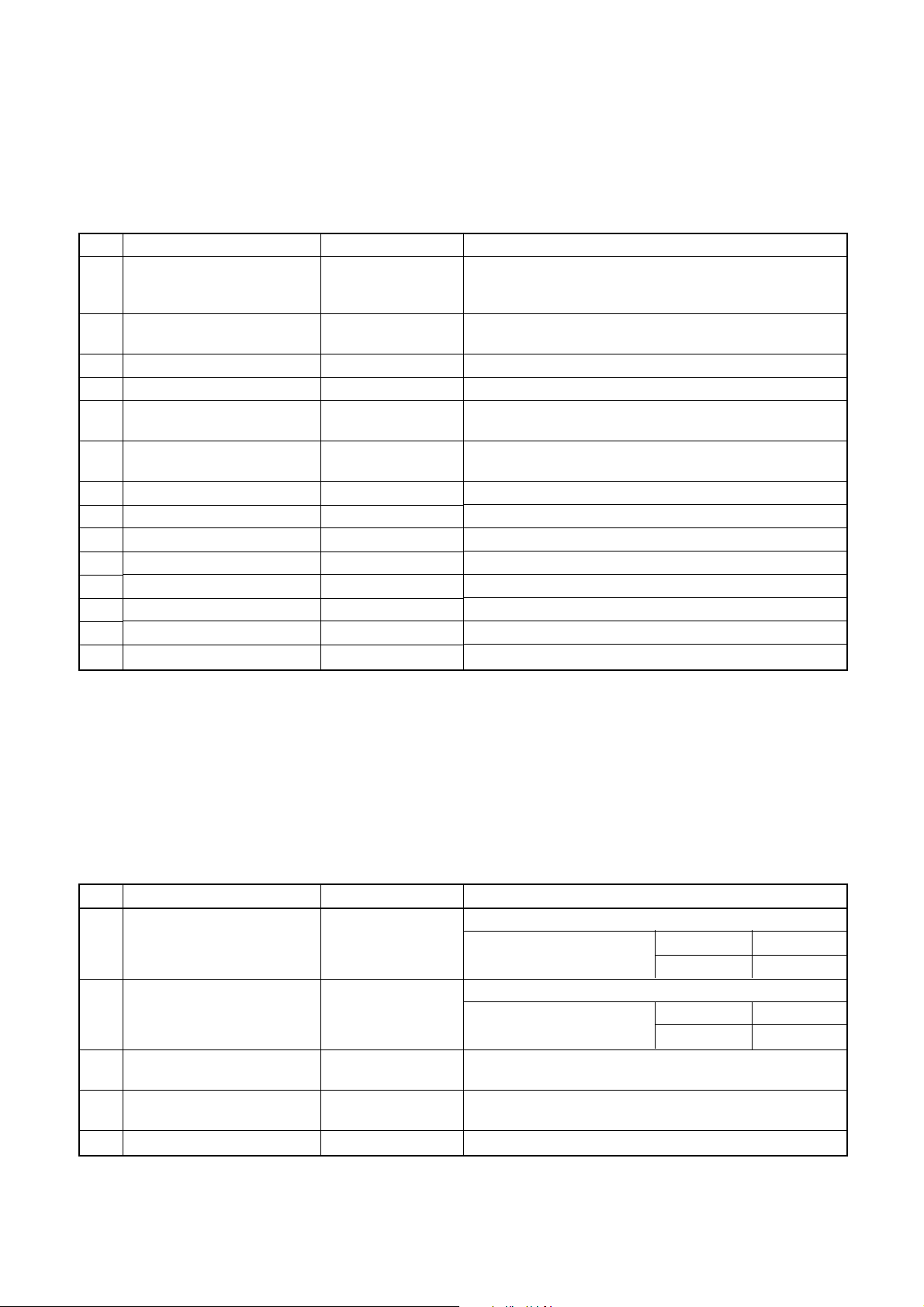

4-1. Indoor Unit

RAS-13SK-E

RAS-13SKX

4. SPECIFICATIONS OF ELECTRICAL PARTS

No.

1

Fan motor (for indoor)

Thermo sensor

2

(TA-sensor)

3

DC-DC transformer (T01)

4

Microcomputer

Power relay (RY01),

5

Common relay (RY02)

Heat exchanger sensor

6

(TC-sensor)

7

Line filter (L01)

8

Diode (DB01)

9

Capacitor (C02)

Fuse (F01)

10

11

Power supply IC (IC01)

Varistor (R21, R109)

12

13

Resistor (R01)

Louver motor

14

Parts name

Type

ICF-35-19-3

or

TICF-35-19-3

(microprocessor)

SWT-34

TMP87CK40F

DI1U

(microprocessor)

RF-103YOR6

RBV-406

CEAUF2W101M20

MT3

MA2830-FJ

15G561K

ERF-5TK5R6

MP35EA7

Specifications

DC35V, 19W

10kΩ at 25°C

DC390V, Secondar y DC35V, 12V, 7V

Coil : DC12V 75mA, Rated AC250V 20A

10kΩ at 25°C

10mH, AC 0.6A

4A, 600V

100µF, 450V

T3.15A, 250V

4A, 600V

560V

5.6 Ω, 5W

Output (Rated) 2W, 10poles, 1phase, DC12V

4-2. Outdoor Unit

RAS-13SA-E

RAS-13SAX

No.

1

Compressor

2

Fan motor (for outdoor)

Running capacitor

3

(for fan motor)

Running capacitor

4

(for compressor)

5

Overload relay

Parts name

Type

PH160T2-4L2

UE6-31C5P

SK-50FMP

SK-40CMP35U1

J-MRA99253-9200

Specifications

Output (Rated) 1100W, 2pole, 1phase, 220/230/240V, 50Hz

Winding resistance (Ω)

(at 20°C)

Output (Rated) 27W, 6pole, 1phase, 220/230/240V, 50Hz

Winding resistance (Ω)

(at 20°C)

500V AC, 1.5µF

400V AC, 35µF

U/T 10.1A (80°C), OPEN 135±5°C, CLOSE 75±11°C

Red-Black White-Black

2.38 3.65

Red-Black White-Black

210 435

– 9 –

Page 10

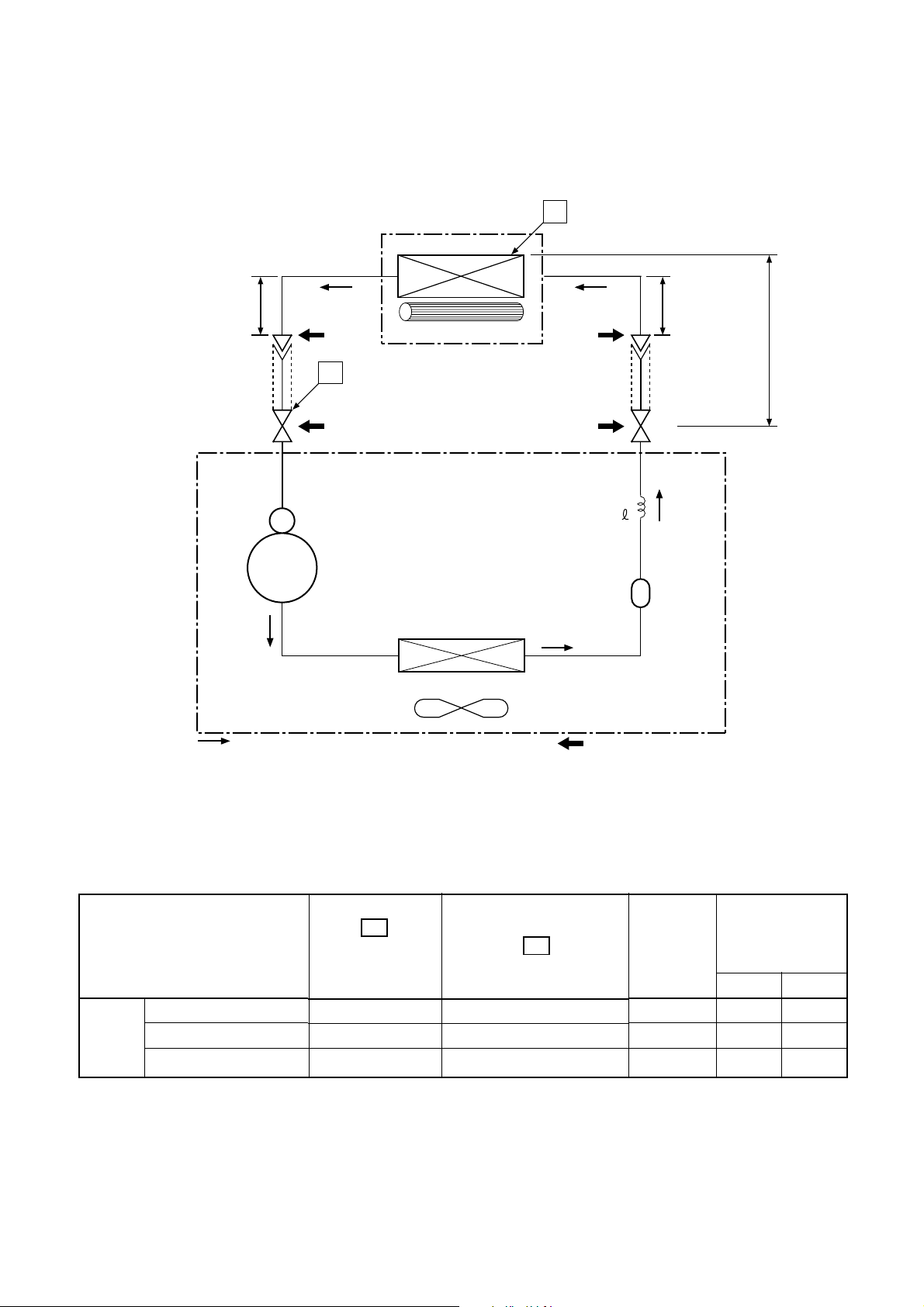

RAS-13SK-E / RAS-13SA-E

RAS-13SKX / RAS-13SAX

5. REFRIGERANT CYCLE DIAGRAM

Auxiliary pipe

0.39m

ø9.52 (ø3/8 in)

Connecting pipe

ø12.7 (O.D.)

(ø1/2 in)

Compressor

P

Accumulator

PH160T2-4L2

Indoor unit

Evaporator

Cross flow fan

Condenser

T1

Capillary tube

ø1.7 x 900

Dryer

Auxiliary pipe

0.49m

ø6.35 (ø1/4 in)

Connecting pipe

ø6.35 (O.D.)

(ø1/4 in)

Max. longth 15m

Allowable height 6m

Propeller fan

Refrigerant

R22 0.83kg

Cooling

Outdoor unit

Mark ( ) means check points of Gas Leak

Fig. 5-1

Table 5-1

50Hz

Standard

Cooling High temperature

Low temperature

Standard pressure

P

(kg/cm²G)

13SK-E

13SKX

5.0

6.0

3.0

Surface temp. of heat

exchanger interchanging

pipe T1 (°C)

13SK-E

13SKX

10.0

15.0

2.0

Fan speed

(indoor)

High

High

Low

Note :

• Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

Ambient temp.

conditions DB/WB

(°C)

Indoor Outdoor

27/19 35/24

32/23 43/26

21/15 21/15

– 10 –

Page 11

6. MICRO-COMPUTER BLOCK DIAGRAM

Operation

C. P. U

Timer

Display

Functions

Display

• Louver Control

ECONO.

Sign Display

• 3-minute Delay at Restart for Compressor

Indoor

FAN-ONLY

Sign Display

• Motor Revolution Control

• Processing

Fan Motor

(Temperature Processing)

• Timer

Motor

Louver

Louver

ON/OFF Signal

Relay Driver, Louver Driver

ON/OFF Signal

Compressor, Outdoor Fan

Relay

Outdoor Fan Motor

RY01

Compressor

RY02

Relay

Main Unit Control Panel

Thermo Sensor

Heat Exchanger Sensor

Initializing Circuit

Infrared

Infrared Rays Signal Receiver

Oscillator Circuit

Clock Frequency

Rays

Remote Control

Operation (START/STOP)

Circuit

Power Supply

Thermo Setting

Operation Mode Selection

AUTO, COOL, DRY, FAN ONLY

Noise Filter

ON TIMER Setting

Fan Speed Selection

– 11 –

OFF TIMER Setting

Louver AUTO Swing

Louver Direction Setting

ECONO.

220/230/240V~

50Hz

Page 12

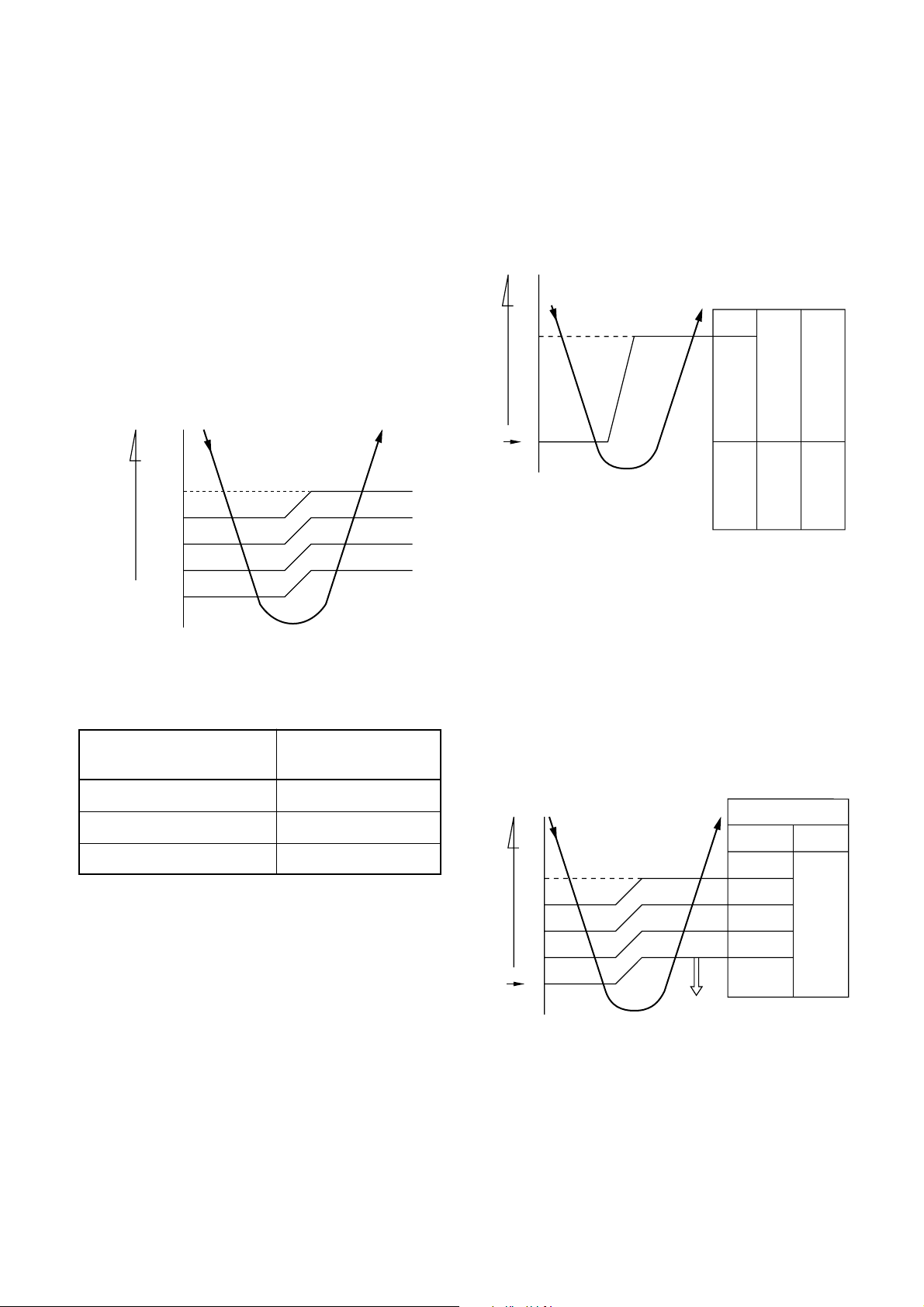

7. OPERATION DESCRIPTIONS

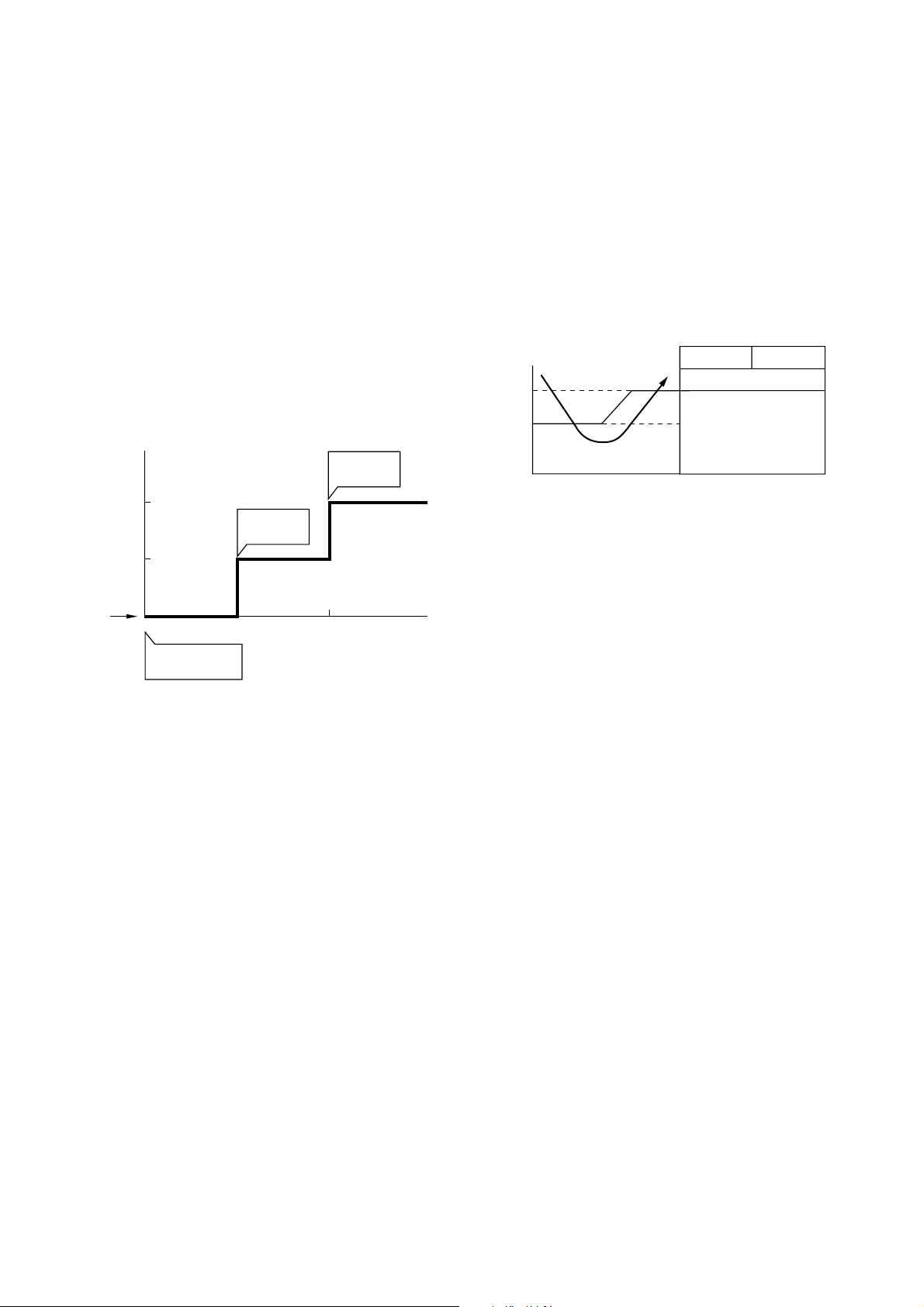

(Room temp. – Set temp.)

+1

0

Set

temp.

ON

OFF

OPERATION

display

ON ON

Compressor

Outdoor fan

(RY01)

Common relay

(RY02)

7-1. FAN ONLY Operation

(MODE of the remote control : FAN ONLY)

(1) During this mode, the relay RY01 is alwa ys turned

off so that only the indoor fan is operated. RY02 is

always turnd on.

1) When the FAN is set to AU TO, the indoor fan

motor operates as shown in Fig 7-1-1.

2) When the FAN is set to LOW, MED, or HIGH,

the indoor fan motor operates with a constant

in volume as listed in Table 7-1-1.

28

27

Room temp.

26

25

24

Fig. 7-1-1 Auto setting of air volume

Table 7-1-1 Manual setting of FAN SPEED

Indication of

FAN SPEED

HIGH

MED

LOW(+)

LOW

LOW

HIGH Air volume

(m3/h)

7-2. COOL Operation

(MODE of the remote control : COOL)

(1) Compressor, outdoor fan and operation displa y are

controlled as shown in Fig. 7-2-1.

Fig. 7-2-1

(2) Relays R Y01 and R Y02 are turned on to energize

the outdoor unit, and a cool operation is carried

out.

1) When the FAN is set to AUTO, the indoor fan

motor operates as shown in Fig 7-2-2.

2) When the FAN is set to LOW, MED, or HIGH,

the indoor fan motor operates with a constant

in volume as listed in Table 7-1-1.

(2) Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing the START/STOP button.

LOW

MED

HIGH

510

560

650

– 12 –

FAN

Manual

According

to the set

position

+4

+3

+2

+1

(Room temp. – Set temp.)

Set

0

temp.

RY01

OFF

AUTO

HIGH

MED

LOW(+)

LOW

LOW

(continuous)

Fig. 7-2-2

(3) Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing the START/STOP button.

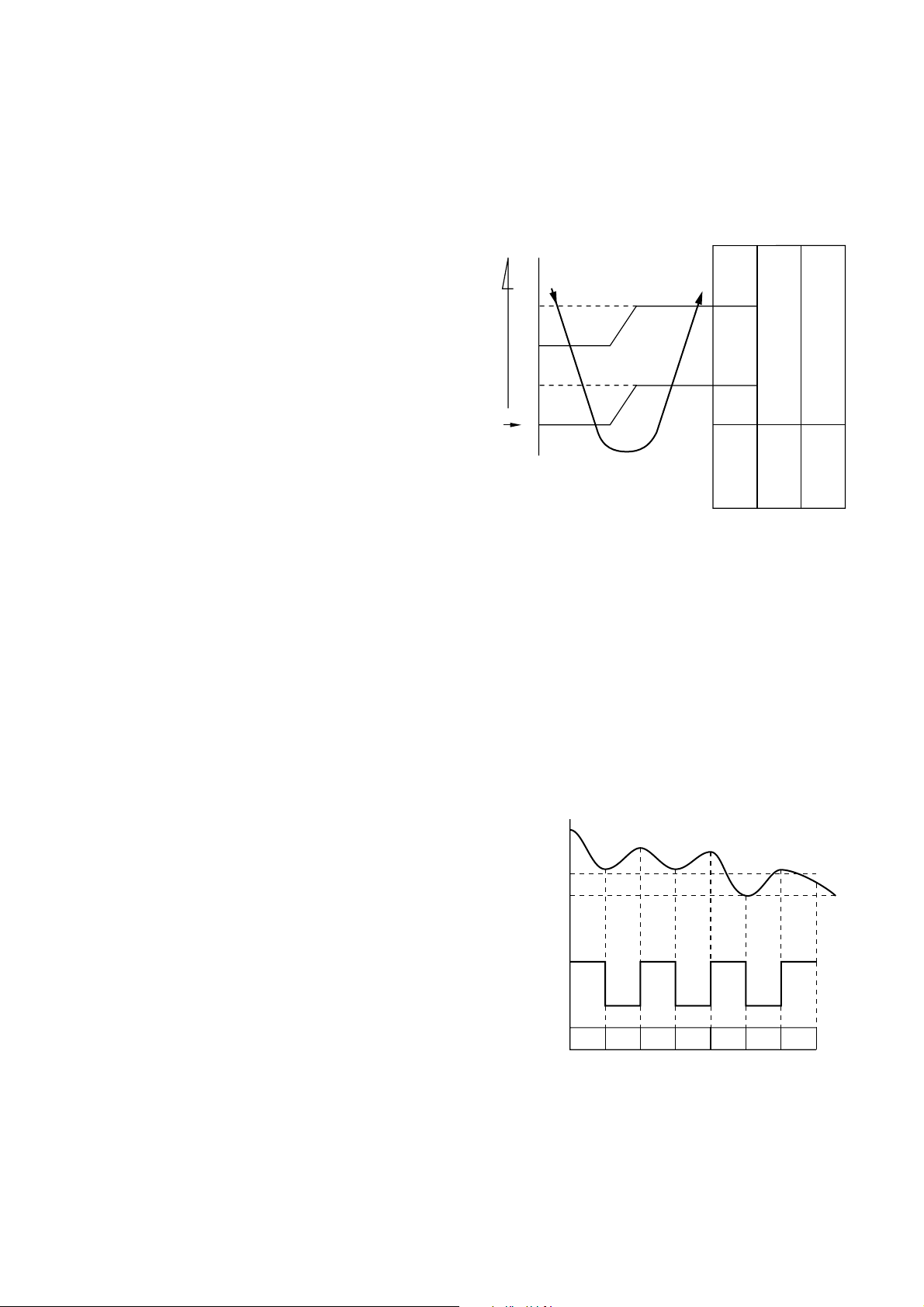

Page 13

7-2-1. Louver Control

(Room temp. – Set temp.)

Set

temp.

ON

+3

+2

+1

0

OFF

OPERATION

display

Compressor

Outdoor fan

(RY01)

Common relay

(RY02)

ON:6min.

OFF:4min.

ON:5min.

OFF:5min.

ON

(1) By pushing the SET button of the remote control

during the operation, the louver can be set to the

desired position.

And the louver position is stored in the microcomputer, the louvers will be set to the position automatically at the next operation.

(2) When the AUT O b utton is pushed, the louv er v er-

tically swings within range of 25deg.

7-3. DRY Operation

(MODE of the remote control : DRY)

(1) Compressor, outdoor fan and operation displa y are

controlled as shown in Fig. 7-3-1.

Fig. 7-3-1

– 13 –

• The microprocessor turns the compressor on

and off at regular intervals (4 to 6 minutes on

and/or off). During the compressor off, the indoor fan will operate in the super low position.

• The indoor fan will operate in the AUTO position.

(2) The pattern of operation depending on the rela-

tion between room temperature and set temperature is shown below:

Room temp.

Set temp.+1

Set temp.

Compressor

Outdoor fan

Indoor fan

ON ON ON ON

OFF OFF OFF

L.*S.L. S.L.L. L. S.L. L.

*

Super Low

Fig. 7-3-2

Page 14

7-4. AUTO Operation

(MODE of the remote control : AUTO)

(1) One of the 2 modes, Cooling or Dry is selected

according to room temperature at which operation is to start, as shown in Fig. 7-4-1. The Fan

mode will continue until room temperature reaches

a level at which another mode is selected.

7-4-1. Temporary Auto

When the TEMPORAR Y button is pushed, the set temperature is fixed at 24°C and controlled in accordance

with the chart shown in Fig. 7-4-1.

Cooling mode

+4

Cooling mode

+1

Dry mode

(Room temp. – Set temp.)

(The same cooling mode as the room temperature control is set at set temp.)

The Louver moved downward.

(The same cooling mode as the room temperature control is set at set temp. )

(The same dry operation as the room temperature control is set at set temp. )

Fig. 7-4-1

– 14 –

Page 15

7-5. ECONO. Mode

When the ECONO. button is pushed, during COOL ,

and AUTO operation, the OPERATION display is

turned off and the ECONO. display is lit and the indoor unit operates quietly and mildly with controlling

airflow.

7-5-1. Cooling

(1) In the ECONO. mode, the set temp. by the remote

control is changed automatically as shown in Fig.

7-5-1.

(2) Fan speed → LOW

(˚C)

Set temp.

is changed

+2

Set temp.

is changed

+1

7-6. Low-Temperature Limit Control

(Cooling Operation)

The microprocessor detects the indoor heat exchanger

temperature so as to prevent freezing up the indoor

heat exchanger.

Control is performed as shown in Fig. 7-6-1.

Heat exchanger

temperature

(˚C)

6

2

Fig. 7-6-1

Compressor

Less than 2˚C continues

Outdoor fan

ON

for 5 minutes

OFF

Set temp.

1H 2H TIME0H

ECONO. button

is pushed

Fig. 7-5-1

– 15 –

Page 16

7-7. Auto Restart Function

This unit is equipped with an Automatic restarting facility which allows the unit to restart and resume the

set operating conditions in the event of a power supply shutdown without the use of the hand control.

The operation will resume without warning three minutes after the power is restored.

The Auto Restart function is set not to work on shipment from the factory, and so it is necessary to set it

to function as required.

• When the system is stand-by (not running)

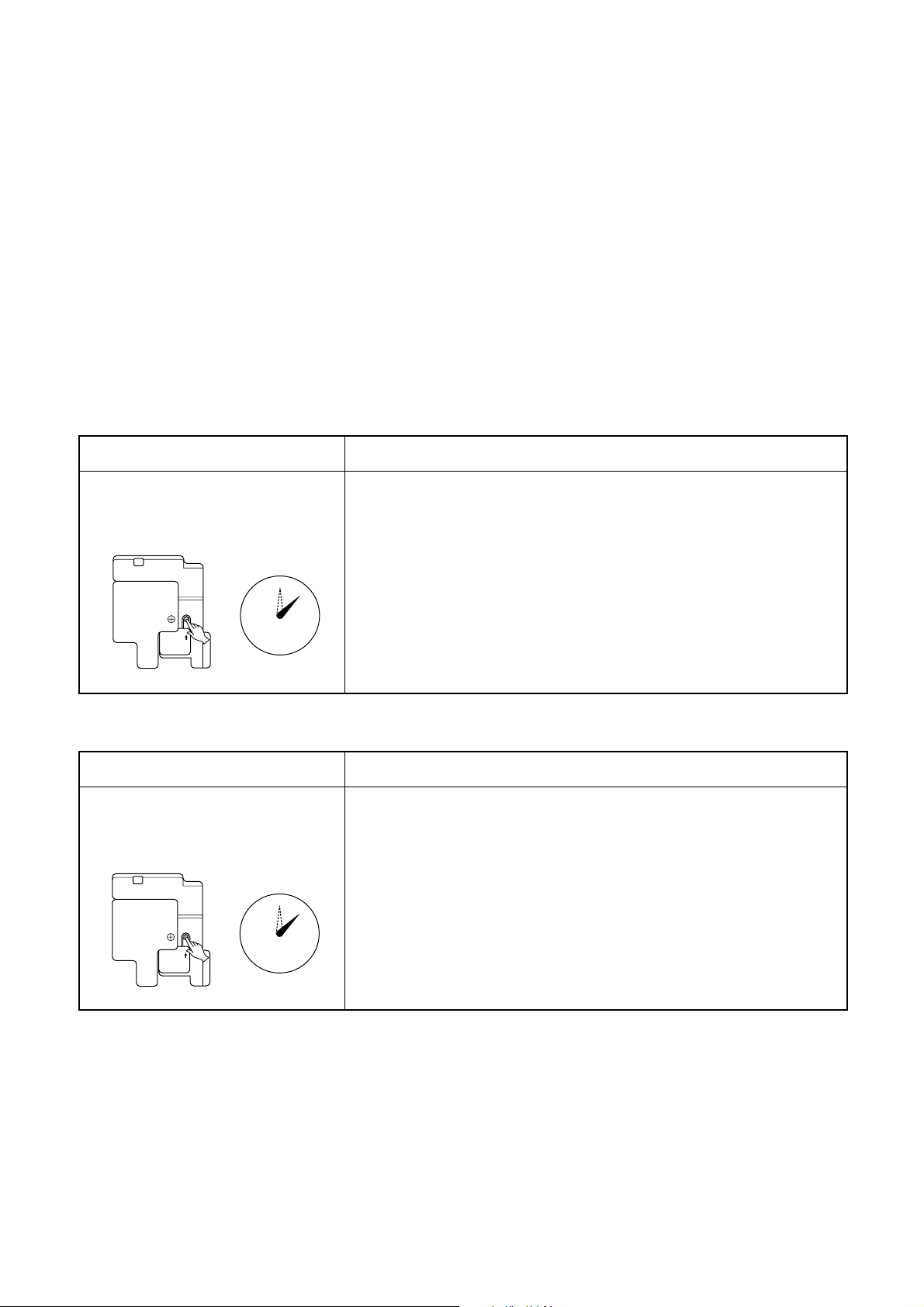

7-7-1. How to Set the Auto Restart

To set the Auto Restart function, proceed as follows:

Access the TEMPORARY button located in the lower

right hand corner beneath the hinged front panel of

the indoor unit (please refer to section on PARTS

NAME). The po wer supply to the unit must be on - the

function will not be set if the power is off.

To enable the Auto Restart function, press the TEMPORARY button continuously for three seconds.

The unit will acknowledge the setting and beep three

times. The system will now restart automatically.

The above A uto Restart settings can be carried out:

OPERATION

Press the TEMPORARY button

continuously more than three

seconds.

0

TEMPORARY

• When the system is operating

OPERATION

Press the TEMPORARY button

continuously more than three

seconds.

0

TEMPORARY

MOTION

Stand-by

↓

The system starts to operate. The green light will be lit.

↓ about three seconds after

3S

The unit beeps three times. The orange light will be lit.

↓

The system is operating. The orange light is lighting.

If the system is not required to run at this time, press the TEMPORARY

button once more or use the remote control to stop it.

MOTION

Operating The green light is lit.

↓

The system stops to operate. The green light is turned off.

↓ about three seconds after

3S

The unit beeps three times.

↓

The system stops.

If the system is not required to stop at this time, use the remote control

to restart it.

During subsequent operation, the orange light is lit.

• The Auto Restart function will not accept an instruction if timer operation with the remote control is

selected.

(Please refer to the section on setting the timer or

setting the louver.)

• During louver swing (A UT O) operation, after restart

by the Auto Restart function the louver swing stops.

– 16 –

Page 17

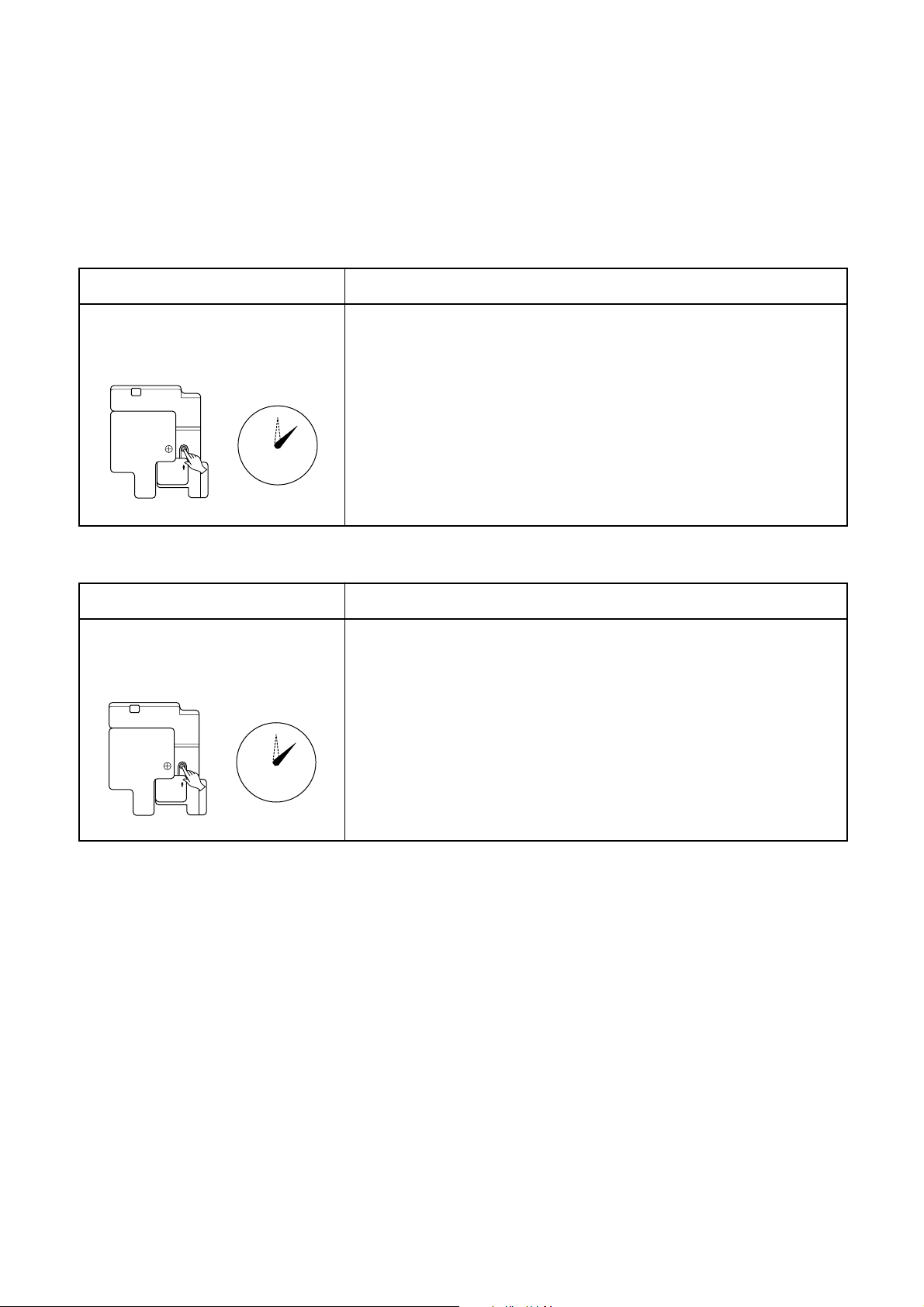

7-7-2. How to Cancel the Auto Restart

To cancel the Auto Restart function, proceed as follows:

Repeat the setting procedure: the unit will acknowledge the instruction and bleep three times.

• When the system is stand-by (not running)

The system will now be required to manually restart

with the remote control after the main supply is turned

off.

Cancellation is carried out:

OPERATION

Press the TEMPORARY button

continuously more than three

seconds.

0

TEMPORARY

• When the system is operating

OPERATION

Press the TEMPORARY button

continuously more than three

seconds.

0

TEMPORARY

MOTION

Stand-by

↓

The system starts to operate. The orange light will be lit.

↓ about three seconds after

3S

The unit beeps three times. The green light will be lit.

↓

The system is operating.

If the system is not required to run at this time, press the TEMPORARY

button once more or use the remote control to stop it.

MOTION

Operating The orange light is lit.

↓

The system stops to operate. The orange light is turned off.

↓ about three seconds after

3S

The unit beeps three times.

↓

The system stops.

If the system is not required to stop at this time, use the remote control

to restart it.

During subsequent operation, the green light is lighting.

7-7-3. In Case of Power Failure during the

Timer Operation

(1) If ON-TIMER operation is reserved with setting of

Auto Restart operation, it is cancelled with power

failure. (The OPERATION lamp on the main unit

goes on and off to inform of power failure.) In that

case, try to reserve ON-TIMER operation once

again.

(2) If OFF-TIMER operation is reserved without set-

ting of Auto Restart operation, the reservation is

cancelled with power failure. (The OPERATION

lamp on the main unit goes on and off to inform of

power failure.) In that case, try to reserve OFFTIMER operation. When Auto Restart operation

is set, OFF-TIMER reservation is also cancelled

with power failure.

– 17 –

Page 18

8. INSTALLATION PROCEDURE

8-1. Safety Cautions

For general public use

Power supply cord of parts of appliance for Outdoor use shall be more than polychloroprene sheathed flexible

cord (design H05 RN-F), or cord designation 245 IEC 57.

CAUTION

TO DISCONNECT THE APPLIANCE FROM THE MAINS SUPPLY.

This appliance must be connected to the mains by means of a circuit breaker or a switch with a contact

separation of at least 3 mm.

If this is not possible, a power supply plug with earth must be used. This plug must be easily accessible after

installation. The plug must be disconnected from the power supply soc ket in order to disconnect the appliance

completely from the mains.

DANGER

` FOR USE BY QUALIFIED PERSONS ONLY.

` TURN OFF MAIN POWER SUPPLY AND BREAKER BEFORE ATTEMPTING ANY ELECTRICAL W ORK.

MAKE SURE ALL POWER SWITCHES AND BREAKER TURN OFF. FAILURE TO DO S O MAY CAUSE

ELECTRICAL SHOCK.

` CONNECT THE CONNECTING CABLE CORRECTLY. IF THE CONNECTING CABLE IS CONNECTED BY

WRONG WAY, ELECTRIC PARTS MAY BE DAMAGED.

` CHECK THE EARTH WIRE IS NOT BROKEN OR DISCONNECTED BEFORE INSTALLATION.

` DO NOT INSTALL NEAR CONCENTRATIONS OF COMBUSTIBLE GAS OF GAS VAPORS.

FAILURE TO FOLLOW THIS INSTRUCTION CAN RESULT IN FIRE OR EXPLOSION.

` TO PREVENT OVERHEATING THE INDOOR UNIT AND CAUSING A FIRE HAZARD, PLACE THE UNIT

WELL AW AY (MORE THAN 2M.) FROM HEAT SOURCES SUCH AS RADIA T ORS, HEAT RESISTORS, FUR-

NACE, STOVES, ETC..

` WHEN MOVING THE AIR-CONDITIONER FOR INSTALLING IT IN ANOTHER PLACE AGAIN, BE VERY

CAREFUL NOT TO GET THE SPECIFIED REFRIGERANT (R-22) WITH ANY OTHER GASEOUS BODY

INTO THE REFRIGERA TION CYCLE. IF AIR OR ANY OTHER GAS IS MIXED IN THE REFRIGERANT, THE

GAS PRESSURE IN THE REFRIGERATION CYCLE BECOMES ABNORMALL Y HIGH AND IT RESUL TINGLY

CAUSES B URST OF THE PIPE AND INJURIES ON PERSONS.

` IN THE EVENT THAT THE REFRIGERANT GAS LEAKS OUT OF THE PIPE DURING THE INSTALLATION

WORK, IMMEDIATELY LET FRESH AIR INTO THE ROOM. IF THE REFRIGERANT GAS IS HEATED BY

FIRE OR SOMETHING ELSE, IT CAUSES GENERATION OF POISONOUS GAS.

WARNING

• Never modify this unit by removing any of the safety guards or by by-passing any of the safety interlock

switches.

• Do not install in a place which cannot bear the weight of the unit.

Personal injury and property damage can result if the unit falls.

• Before doing the electrical work, attach an approved plug to the power supply cord.

And make sure the equipment to be earthed.

• Appliance shall be installed in accordance with national wiring requlations.

If you detect any damage, do not install the unit. Contact your Toshiba dealer immediately.

– 18 –

Page 19

CAUTION

• Exposure of unit or water or other moisture before installation will result in an electrical short.

Do not store in a wet basement or expose to rain or water.

• After unpacking the unit, examine it carefully for possible damage.

• Do not install in a place that can increase the vibration of the unit. Do not install in a place that can amplify

the noise level of the unit or where noise and discharged air might disturb user’s neighbors.

• To avoid personal injury, be careful when handling parts with sharp edges.

• Please read the installation manual carefully before installing the unit. It contains further important instruc-

tions for proper installation.

UK Plugs and Sockets etc (Safety) Regulations 1994

SI Number 1768

With regard to Schedule 3, Item 7 of the above UK Regulations, this appliance must be permanently connected to the fixed wiring of the main electrical supply by means other than the use of an approved 13 Amp

plug-top as outlined in the Regulations.

Electrical work must be carried by suitably qualified persons and in accordance with all relevant safety standards and codes of practice.

We recommend that the power supply f or this appliance is derived from a suitab ly protected dedicated circuit.

(for U.K. only)

– 19 –

Page 20

8-2. Installation Diagram of Indoor and Outdoor Units

For installation of the indoor unit, use the paper pattern on the back.

For the rear and left piping

Front cabinet

Front panel

(Attach to the back side.)

11

Filter

frame

9 Deodorizing

filter

(Attach to the back side.)

10 Purifying

filter

3 Clip anchorClip anchor

120 mm or more

Air filter

2 Wireless

remote

control

Hook

Hook

6 Pan head

wood screw

4 Remote control

holder

66 mm or more

Hook

8 Mounting screw

1 Installation

plate

120 mm

or more

5 Shield pipe

Wall

Insert the remote control holder

cushion between the indoor

unit and wall, and lift indoor

unit to make work easier.

Do not allow the drain hose to

get slack.

Cut the piping hole

sloped slightly

Make sure to run the drain

hose sloped downward.

The auxiliary piping can be

connected the left, rear left,

rear, right or bottom.

Right

100 mm or more

Before install the wireless

remote control

• With the remote control cover

open, load the batteries

supplied correctly, observing

their polarity.

Wireless remote control

2

7

Batteries

Cover

400 mm or more

Electric parts

cover

45 mm or more

600 mm or more

600 mm or more

Loop the connective cable

(about 100 mm in diameter

and 300~350 mm long).

– 20 –

Extension

drain hose

(Option:

RB-821SW)

Rear

Bottom

Rear left

Left

Insulation of refrigerant pipes

insulates the pipes separately,

not together.

6 mm thick heat resisting

polyethylene foam

Page 21

8-3. Installation

<Anchor bolt arrangement of outdoor unit>

8-3-1. Optional Parts

Part

code

A

B

C

Refrigerant piping

Liquid side : ø6.35 mm

Gas side : ø12.7 mm

Pipe insulating material

(polyethylene foam, 6 mm thick)

Putty, PVC tapes

Parts name

8-3-2. Installation Parts

Q’ty

Each

one

1

Each

one

600mm

Air inlet

325mm

Air outlet

Fig 8-3-1 Air outlet

• Secure the outdoor unit with the anchor bolts if the

unit is likely to be exposed to a strong wind.

• Use ø8 or ø10 anchor bolts.

Part

No.

1

Name of parts

Q’ty

Installation plate x 1

2

Wireless remote control x 1

3

Clip anchor x 6

4 8

Remote control holder x 1

Others

Name

Part

No.

5

6

7

Name of parts

Q’ty

Shield pipe x 1

Pan head wood screw

ø3.1 x 16l x 2

Batteries x 2

Mounting screw ø4 x 25l x 6

* This model is not equipped with an extension drain

hose.

Part

No.

9

10

11

Name of parts

Q’ty

Deodorizing filter x 1

Purifying filter x 1

Filter frame x 2

Installation manual

Owner’s manual

Option : For the extension drain hose, use an optionally

available RB-821SW or commercially available one.

– 21 –

Page 22

8-4. Indoor Unit

t Installation place

• A place which provides the spaces around the indoor unit as shown in the diagram in section 8-2.

• A place where there is no obstacle near the air inlet and outlet.

• A place which allows an easy installation of the piping to the outdoor unit.

• A place which allows the front panel to be opened.

8-4-1. Cutting a Hole and Mounting

Installation Plate

<Cutting a hole>

When installing the refrigerant pipes from the rear

CAUTION

• Direct sunlight to the indoor unit wireless receiver should be avoided.

• The microprocessor in the indoor unit should

not be too close to r-f noise sources. (For details, see the owner’s manual.)

<Remote control>

• A place where there are no obstacles such as a

curtain that may block the signal from the remote

control.

• Do not install the remote control in a place exposed

to direct sunlight or close to a heating source, such

as a stove.

• Keep the remote control at least 1 m apart from

the nearest TV set or stereo equipment. (This is

necessary to prevent image disturbances or noise

interference.)

• The location of the remote control should be determined as shown below.

The center of the piping slot

The center of the pipe

hole is the above arrow.

is the above arrow.

Pipe hole

80mm

65mm

40.5

mm

Fig. 8-4-2

(1) After determining the pipe hole position with the

mounting plate (80 mm →), drill the pipe hole (ø65

mm) at a slight downward slant to the outdoor side.

NOTE :

• When drilling the wall that contains a metal lath,

wire lath or metal plate, be sure to use a pipe hole

brim ring sold separately.

<Mounting the installation plate>

For installation of the indoor unit, use the paper pattern on the back.

Anchor bolt hole

7m

75˚

(Side view) Indoor unit

Reception

range

Remote

control

Fig. 8-4-1

(Top view)

Indoor unit

*:Axial distance

5m

Reception

range

45˚

45˚

Remote

control

5m

*7m

– 22 –

65.5mm

Pipe

hole

Indoor unit

Thread

Weight

Fig. 8-4-3

8

Mounting

screw

Pipe hole

65.5mm

1

Installation

plate

Page 23

<When the installation plate is directly mounted

on the wall>

(1) Securely fit the installation plate onto the wall by

screwing it in the upper and lower parts to hook

up the indoor unit.

(2) Install the installation plate horizontally in the wall.

(3) To mount the installation plate on a concrete wall

with anchor bolts, utilize the anchor bolt holes as

shown in the above figure.

CAUTION

When installing the installation plate with mounting screw , do not use the anchor bolt hole. Otherwise the unit may fall down and result in personal

injury and property damage.

8-4-2. Electrical Work

(1) The supply voltage must be the same as the rated

voltage of the air conditioner .

(2) Prepare the power source for exclusive use with

the air conditioner.

Maximum

Model

RAS13SK-E/

13SA-E

RAS13SKX/

13SAX

Power source

50Hz

*220/230/240V~

Single-phase

running

current

* No adjustment is necessary .

7.5 A

Plug

socket

& fuse

rating

16 A

Wiring

1.3mm

or

more

2

Installation plate

Anchor bolt

Projection

15mm

or less

5mm dia, hole

Clip anchor

3

(Keep horizontal direction)

Mounting screw ø4 x 25

8

Fig. 8-4-4

CAUTION

Failure to firmly install the unit may result in

personal injury and property damage if the

unit falls.

CAUTION

• Use power specified in above table.

• This appliance can be connected to the mains

in either of the following two ways.

(1) Connection to fixed wiring:

A switch or circuit breaker which disconnects

all poles and has a contact separation of at

least 3 mm must be incorporated in the fixed

wiring. An approv ed circuit breaker or switches

must be used.

(2) Connection with power supply plug:

Attach power supply plug with power cord and

plug it into wall outlet. An approved power

supply cord and plug must be used.

NOTE :

• Perform wiring works so as to allow a generous

wiring capacity.

• In case of block, brick, concrete or similar type

walls, make 5 mm dia, holes in the wall.

• Insert3clip anchors for appropriate8 mounting screws.

NOTE :

• Install the installation plate using 4 to 6 pieces of

mounting screw securing four corners with screws.

– 23 –

Page 24

8-4-3. Wiring Connection

WARNING

Taking out the power cord

To plug the cable in the plug receptacle, take the following precaution.

THIS APPLIANCE MUST BE EARTHED.

IMPORTANT

THE WIRES IN THIS MAINS LEAD ARE COLORED

IN ACCORDANCE WITH THE FOLLOWING CODE:

L

: Brown

N

: Blue

: Green and Yellow

-LIVE

-NEUTRAL

-EARTH

L

N

Fig. 8-4-5

As the colors of the flexible cord of this appliance may

not correspond with the colored markings, to identify

terminals in your plug, as follows:

Connect BROWN colored core to plug terminal marked

letter "L".

Connect BLUE colored core to plug terminal marked

letter "N".

Connect GREEN AND YELLOW colored core to plug

terminal marked Earth Symbol " ".

The installation of the cables has to be done in such a

way that the basic insulated wires for the infrared sensor can not be touched.

<How to remove the front cabinet>

Slitted portion

• Cut off the slitted portion in the side face of the

rear panel to take out the power cord. After

this, remove burrs, sharp edges, etc., to smooth

the cut face.

<How to connect the power cord>

For the air conditioner that has no power cord,

connect a power cord to it as mentioned below.

• After removing the front cabinet, remove the terminal cover and the cord clamp.

• Connect and secure the power supply cord and

secure the cord clamp and the terminal cover.

• Cut the rear panel following the cutting mark and

put the power supply cord through the notch.

• Be sure to smooth out the notch with a file, etc.

Terminal block

Power supply

cord

L

N

Cord clamp

Terminal cover

Screw

4

4

2

1

3

Vertical air flow louver.

1

2

Fig. 8-4-6

How to open the screw cap

• Place your finger on the lower part and push

up to open the screw cap.

(1) Open the screw caps and remove the two screws

securing the front cabinet.

(2) Close the screw caps as behind.

(3) Open the vertical airflow louver horizontally by

hand.

(4) Slightly open the lower part of the front cabinet

then pull the upper part of the front cabinet toward

you to remove it from the rear plate.

– 24 –

Earth line

Fig. 8-4-7

<Stripping length of power cord>

30mm

10mm

L

N

10mm

40mm

NOTE :

• Use standard wire only.

• Wire type: More than H05-RN-F

Fig. 8-4-8

Screw

Screw

Earth line

Page 25

<How to connect the connecting cable>

Wiring of the connecting cable can be carried out

without removing of the front panel.

(1) Remove the front panel.

<Stripping length of connecting cable>

50mm

10mm

Earth line

Fully open the front panel. Disengage the support

arm located in the upper center while pushing its

handle leftwards, and then remove the front panel

toward you.

(2) Remove the terminal cover and cord clamp.

(3) Insert the connecting cable (according to local

codes) into pipe hole on the wall.

(4) Take out the connecting cable through the cable

slot on the rear panel so that it is exploded by about

15 cm long in the front side.

(5) Insert the connecting cable fully into the terminal

block and secure it by screw tightly.

(6) Tightening torque:1.2 N•m (0.12 kgf•m)

(7) Secure the connecting cable with the cord clamp.

(8) Fix the terminal cover and front panel on the in-

door unit.

CAUTION

• Be sure to refer the wiring system diagram labeled inside the front panel.

• Check local electrical codes and also any specific wiring instructions or limitation.

2

1

10mm

40mm

For a three conductor cable

NOTE :

• Use stranded wire only.

• Wire type:More than H05 RN-F

Fig. 8-4-10

<How to install the front cabinet on the indoor unit>

Install the front cabinet through the opposite order of

"How to remove the front cabinet".

When the panel is removed and mounted again, take

the following actions:

After fastening the two screws, one each at the left

and right of the air outlet, be sure to push the upper

center1right end2, left end3and the lower

center4of the air outlet, and confirm that no gap is

left between the front cabinet and the rear plate.

• If cooling (dry) operation is made without pushing the air outlet, dew can be deposited on the

front cabinet surface. In addition a gap between

the front cabinet and the rear plate will become

wider , spoiling the appearance.

Connecting

cable

about 15cm

Screw

Terminal

cover

Terminal block

Cord

clamp

Screw

Screw

Connecting cable

Fig. 8-4-9

21

Earth

line

Push Push

3

1

Push

Push

2

4

Fig. 8-4-11

– 25 –

Page 26

8-4-4. Piping and Drain Hose Installation

)

Indoor unit

Connecting

cable

Installation

plate

Auxiliary

pipes

To connect pipe after installation of unit (figure)

<In case of rightward piping>

• After scribing slits of the front panel and the rear

panel by a knife or a marking-off pin, cut them by a

pair of nippers or the like.

Slit (front panel)

Slit (rear panel

Fig. 8-4-12

<In case of downward piping>

• After scribing the slit of the front panel and slit in

the lower part of the rear panel by a knife or a marking-off pin, cut them by a pair of nippers or the like.

(To the forefront of flare)

196mm

Side of liquid flow

96mm

Side of gas flow

Outward form of indoor unit

R 30mm (Use polisin or the like for bending pipe.)

43mm

80˚

Use the handle of screwdriver,etc.

Fig. 8-4-14

NOTE :

If the pipe is bent incorrectly, the indoor unit may unstably be set on the wall.

After passing the connecting pipe through the pipe

hole, connect the connecting pipe to auxiliary pipes

and wrap the facing tape around them.

Slit (front panel)

Slit (rear panel)

Fig. 8-4-13

<Left-hand connection with piping>

Bend the connecting pipe so that it is laid within 43

mm above the wall surface. If the connecting pipe is

laid exceeding 43 mm above the wall surface, the indoor unit may unstably be set on the wall. When bending the connecting pipe, make sure to use spring

bender so as not to crush the pipe.

Bend the connection pipe within a radius of 30 mm.

CAUTION

• Bind the auxiliary pipes (two) and connecting

cable with facing tape tightly. In case of leftward piping and rear-leftward piping, bind the

auxiliary pipes (two) only with facing tape.

• Carefully arrange pipes so that any pipe does

not stick out of the rear plate of the indoor unit.

• Carefully connect the auxiliary pipes and connecting pipes to each other and cut off the insulating tape wound on the connecting pipe to

avoid doub le-taping at the joint, moreover , seal

the joint with the vinyl tape, etc.

• Since dewing results in a machine trouble,

make sure to insulate both the connecting

pipes. (Use polyethylene foam as insulating

material.)

• When bending a pipe, carefully do it not to crush

it.

– 26 –

Page 27

8-4-5. Indoor Unit Installation

(1) Pass the pipe through the hole in the wall, and

hook the indoor unit on the installation plate at the

upper hooks.

(2) Swing the indoor unit to right and left to confirm

that it is firmly hooked up on the installation plate.

(3) While pressing the indoor unit onto the wall by the

lower part, hook it up on the installation plate by

the lower part. Pull the indoor unit toward you by

the lower part to confirm that it is firmly hooked up

on the installation plate.

(1)

(2)

Hook

• For detaching the indoor unit from the installation

plate pull the indoor unit toward you while pushing

its bottom up by the specified parts.

Hook here

Installation

1

plate

Fig. 8-4-15

Push

8-4-6. Drainage

(1) Run the drain hose sloping downwards.

NOTE :

• Hole should be made at a slight downward slant to

the outdoor side.

Do not rise the drain hose.

50 mm

or more

Do not put the

drain hose end

into water.

Fig. 8-4-17

(2) Put water in the drain pan and make sure that the

water is drained outdoors.

(3) When connecting extension drain hose, insulate

the connecting part of extension drain hose with

shield pipe.

5

5

Shield pipe

Do not form the drain hose

into the wared shape.

Do not put the drain

hose end in the

drainage ditch.

Push Push

Fig. 8-4-16

Drain hose

Inside the room

Extension drain hose

Fig. 8-4-18

CAUTION

Arrange the drain pipe for proper drainage from

the unit.

Improper drainage can result in damage to property.

This air conditioner has the structure designed to drain

water collected from dew, which forms on the back of

the indoor unit, to the drain pan.

Therefore, do not store the power cord and other parts

at a height above the drain guide.

Wall

Drain guide

– 27 –

Space for pipes

Fig. 8-4-19

Page 28

8-5. Outdoor Unit

t Installation place

• A place which provides the spaces around the outdoor unit as shown in the diagram in page 23.

• A place which can bear the weight of the outdoor

unit and does not allow an increase in noise level

and vibration.

• A place where the operation noise and discharged

air do not disturb your neighbors.

• A place which is not exposed to a strong wind.

• A place free of a leakage of combustible gases.

• A place which does not block a passage.

• When the outdoor unit is to be installed in an elevated position, be sure to secure its feet.

• An allowable length of the connecting pipe is up to

15 m.

• An allowable head level is up to 6 m.

• A place where the drain water does not raise any

problem.

CAUTION

Installation in the following places may result in

trouble. Do not install the unit in such places.

• A place full of machine oil.

• A saline place such as coast.

• A place full of sulfide gas.

• A place where high-frequency waves are likely

to be generated as from radio equipment, welders, and medical equipment.

CAUTION

(1) Install the outdoor unit without anything

blodking the air discharging.

(2) When the outdoor unit is installed in a place

exposed always to a strong wind like a coast

or on a high story of a building, secure the

normal fan operation using a duct or a wind

shield.

(3) Specially in windy area, install the unit to pre-

vent the admission of wind.

Strong

wind

Fig. 8-5-1

– 28 –

Page 29

8-5-1. Refrigerant Piping Connection

(

)

<Flaring>

(1) Cut the pipe with a pipe cutter.

8-5-2. Vacuum Pumping

AIR PURGE

Evacuate the air in the connecting pipes and in

the indoor unit using vacuum pump.

90˚

Obliquity Roughness Warp

Fig. 8-5-2

(2) Insert a flare nut into the pipe, and flare the pipe.

A (mm)

Imperial

1.3 mm

1.8 mm

Rigid

0.7 mm

1.0~1.1

mm

Die Pipe

A

Outer

diam.

6.35 mm

12.7 mm

Fig. 8-5-3

<Tightening connection>

Align the centers of the connecting pipes and tighten

the flare nut as far as possible with y our fingers. Then

tighten the nut with a spanner and torque wrench as

shown in the figure.

Do not use the refrigerant in the outdoor unit.

For details, see the manual of vacuum pump.

<Use of vacuum pump>

(1) Connect the charge hose (A) from the manifold

valve to the charge inlet of the gas side packed

valve.

(2) Connect the charge hose (B) to the port of vacuum

pump.

(3) Open fully the low pressure side handle of the

manifold valve.

(4) Operate the vacuum pump.

(5) Close the low pressure side handle of manifold

valve after vacuumizing and stop the vacuum

pump.

Continue vacuumizing more than 15 minutes and

check the pressure gauge indicates –76 cmHg

(–101MPa).

CAUTION

• Do not apply excess torque. Otherwise, the

nut may crack depending on the installation

conditions.

(Unit : N·m)

Outer diam.

6.35 mm

12.7 mm

Half union or packed valve

Externally

threaded

side

Use a wrench

to secure.

Tightening torque

15.7 (1.6 kgf·m)

49.0 (5.0 kgf·m)

Fig. 8-5-4

Use a torque wrench

to tighten.

Additional

tightening torque

19.6 (2.0 kgf·m)

53.9 (5.5 kgf·m)

Flare nut

Internally

threaded

side

(6) Open the stems of packed valves A and B all the

way.

(7) Securely tighten the stem cap to each of the

packed valve stems.

Indoor unit

Pressure gage

Low pressure side handle

Charge hose (A)

Outdoor unit

Gas

(ø12.7)

C

A

Manifold valve

Service port

High pressure

side handle

Lo Hi

Charge

hose (B)

VP

D

B

Liquid

ø6.35

Fig. 8-5-5

Packed

valve

– 29 –

Page 30

CAUTION

• KEEP IMPORTANT 4 POINTS FOR INSTALLATION (PIPING WORK)

(1) Take away dust and moisture (Inside of the

connecting pipes.)

(2) Tight connection (between pipes and unit)

(3) Evacuate the air in the connecting pipes using

VACUUM PUMP.

(4) Check gas leak (connected points)

<Packed Valve Handling Precautions>

• Open the valve stem all the way out; so not try to

open it beyond the stopper .

• Securely tighten the valve stem cap with the wrench

or like.

• Valve stem cap tightening torque is as f ollows;

Gas pipes side (ø12.7) : 40.9 N•m (5.0 kgf•m)

Liquid pipe side (ø6.35) : 16.2 N•m (1.7 kgf•m)

<A5 mm hexagon wrench is required.>

8-5-3. Wiring Connection

(1) Remove the electric parts cover from the outdoor

unit. (1 screw)

(2) Connect the connecting cable to the terminals as

identified with their respective matched numbers

on the terminal block of indoor and outdoor units.

(Strip the sheath of connecting cable with following stripping length to and insert into the terminal

block.)

(3) When connecting the connecting cable to outdoor

unit terminal, make a loop as shown in the installation diagram of indoor and outdoor unit, to prevent water coming in the outdoor unit.

(4) Insulate the unused cords (conductors) with wa-

ter coming in the outdoor unit. Process them so

that they do not touch any electrical or metal parts.

<Stripping length of connecting cable>

10mm

60mm

Earth line

Terminal block

Terminal

screw

12

Valve body

Flare nut

Valve stem

Stopper

Valve stem cap

Fig. 8-5-6

5mm

2

1

10mm

50mm

Screw

Connecting

cable

Cord clamp

For a three conductor cable

Fig. 8-5-7

CAUTION

• Wrong wiring connections may cause some

electrical parts to burn out.

• Be sure to comply with local code on running

the wire from the indoor unit to outdoor unit.

(size of wire and wiring method etc.)

• Every wire must be connected firmly.

NOTE :

• Wipe type : More than H05 RN-F

Earth line

– 30 –

Page 31

8-6. Others

8-6-1. Gas Leak Test

Flare nut connections (indoor unit)

Electric parts

cover

Flare nut

connections

(Outdoor unit)

Valve stem cap

connection

8-6-3. Auto Restart Setting

This product is designed so that, after a power failure,

it can restart automatically in the same operating mode

as before the power failure.

C

Information

D

Valve stem cap

connection

A

B

Service cap

connection

The product was shipped with Auto Restart function in the off position. Turn it on as required.

<How to set the Auto Restart>

• Press and hold down the TEMPORARY button f or

about 3 seconds. After 3 seconds, the electronic

beeper makes three short beeps to tell you the Auto

Restart has been selected.

• To cancel the Auto Restart, follow the page 16,17.

Fig. 8-6-1

• Check the flare nut connections, valve stem cap

connections and service cap connections for gas

leak with a leak detector or soap water.

8-6-2. Test Operation

To switch the TEST RUN (COOL) mode, press TEMPORARY button for 10 sec. (The beeper will make a

short beep.)

TEMPORARY

button

TEMPORARY

Fig. 8-6-2

– 31 –

Page 32

9. TROUBLESHOOTING CHART

TROUBLESHOOTING PROCEDURES :

• Following details of “What to be pre-checked first”, make sure of the basic items.

• When there is no trouble corresponding to above, check in detail the faulty parts following “How to judge

faulty parts by symptoms” later.

9-1. What to be Prechecked First

9-1-1. Power Supply Voltage

The line voltage must be A C 220/230/240V. If the line

voltage is not within this range, this air conditioner may

not work normally.

9-1-2. Incorrect Cable Connection between

Indoor and Outdoor Units

The indoor unit is connected to the outdoor unit with 3

cables. Make certain that the indoor and outdoor units

have been connected properly , with terminals assigned

the same numbers wired to each other. If the connectors are not connected as specified, the outdoor unit

will not operate normally.

– 32 –

Page 33

9-1-3. Misleading but Good Operations

(Program Controlled Operation)

The microcomputer performs the operations listed in

Table 9-1-1 to control the air conditioner . If a claim is

made on the operation, check whether it corresponds

to the contents in the Table 9-1-1. If it does, it is an

indispensable operation for the control and maintenance of the air conditioner: it is not a failure of the

unit.

Table 9-1-1

No.

1

2

3

4

5

6

Operation of air-conditioner

When the power plug or the power cord

of the indoor unit is inserted, the OPERATION lamp on the setting indication part

flashes.

Fan speed remains unchanged in the dry

mode.

Room temperature is in the range under

which the compressor is turned off, but

the compressor will not stop.

The compressor will not switch on or off

even when the thermo control is operated in the dry operation.

Compressor does not work though room

temperature is in the range of turning the

compressor on.

During automatic operation, the operation mode changes.

Description

The OPERATION lamp flashes, indicating that power is turned

on. If this happens, push the START/STOP button once to cause

the lamp to stop flashing. A power outage also causes the lamp

to flash.

Fan speed is automatically controlled in the dry mode.

The compressor will not stop while the compressor on hold timer

(3-minutes timer) is actuated.

In the dry mode, the compressor goes on and off at regular intervals, independent of the thermo control.

Compressor does not work while the compressor restart delay

(3-min.) timer is active. The same is true after power is turned

on, as the time is still active.

After selection of the cooling and dry operation, the operation

mode is selected again when the compressor off mode continues for 15 min. according to the room temperature. And after

selection of the dry operation, the condition of the room temperature which is Room temp.≥Set temp.+1 and which is Room

temp.<Set temp.–4 continues for 15 min., the operation mode is

selected again.

7

When the power is turned on, the operation starts automatically .

When the auto restart controlling is selected, the operation is

performed automatically in the previous operation mode after the

power supply has been turned on.

– 33 –

Page 34

9-2. Primary Judgement of Trouble

Sources

9-2-1. Role of Indoor Unit Controller

The indoor unit controller receives the operation commands from the remote control and assumes the following functions.

• Measurement of the draft air temperature of the

indoor heat exchanger by using the thermo sensor

(TA).

• Louver motor control

• Control of the indoor fan motor operation

• Control of the LED display

• Control of the outdoor unit compressor, and the outdoor fan motor.

Table 9-2-1

9-2-2. Display of Abnormalities and

Judgement of the Abnormal Spots

The indoor unit of this machine observes the operation condition of the air conditioner and displays the

contents of the self-diagnosis as block displays on the

display panel of the indoor unit.

Block display

OPERATION display flashing (1 Hz)

A

OPERATION display flashing (5 Hz)

B

C

OPERATION display flashing (5 Hz)

OPERATION display flashing (5 Hz)

D

E

OPERATION display flashing (5 Hz)

F

OPERATION, TIMER and FAN-ONLY display

flashing (5 Hz)

(1) Judgement from defective operation or abnormal operation

Table 9-2-2

Symptom

No reaction on

remote control

operation

Turn off the power once, turn it on

again and try to operate the remote

control again.

Check

Power failure (when power is ON)

Thermo sensor (T A) short/break

Heat exchanger sensor (TC) short/break

Indoor fan lock, abnormality of indoor fan

Indoor PC board failure

• Gas shortage, other refrigerant cycle trouble

• Heat exchanger sensor open/break/short

• Overload relay trouble

Remote control is

not possible.

Remote control is

possible.

Block display

Primary judgement

The indoor part (including the

remote control) is defective.

OK.

The outdoor fan

does not rotate

The compressor operates.

The compressor does not operate.

– 34 –

The outdoor part is defective.

(outdoor fan motor)

The inside part is defective.

Page 35

(2) Self-diagnosis with remote control

(

)

With the indoor unit control, self-diagnosis of protective circuit action can be done by turning the

remote control operation into service mode, operating the remote control, observing the remote

control indicators and checking whether TIMER

lamp flashes (5 Hz).

2) Selecting ordinary mode

Push the all clear button (ACL) on the rear bottom of the wireless remote control with a tip of

pencil for more than 3 seconds. Make sure

the operation mode display, wind volume display, clock displa y and setting temperature display are turned on and “ : ” of the clock display

is flashing.

Note :

• To perform this self-diagnosis, the remote

control with the service code of 43069666 is

required.

<How to select remote control operation mode>

1) Selecting service mode

Push the switch button provided on rear bottom of the wireless remote control with a tip of

pencil for more than 3 seconds. Make sure

the setting temperature is displayed on

“ ”

the display and other display is turned off.

<Cautions when doing service>

1) After completion of servicing, always push the

all clear (ACL) button to return the operation

mode to the normal mode.

2) After completion of servicing by the check code,

turn off the power once and then turn on the

power to reset memorized contents of the microcomputer to the initial status.

All clear button

Switch for selecting

service mode

ACL CLOCK

Rear bottom of remote control

Fig. 9-2-1

– 35 –

ACL

CLOCK

Rear bottom cover

Page 36

<Self-diagnosis by check codes>

➞

”

“

”

“

➞

”

“

”

“

➞

”

“

”

“

➞

”

“

”

“

1) The self-diagnosis by the check codes is conducted under the block displays of item B-H in

Table 9-2-1.

2) Remote control key operation under the service mode is conducted by ON/OFF or TEMP.

The remote control display by each key operation is varied as shown below. Two digit number is displayed in a hexadecimal number.

3) The self-diagnosis by the check codes is conducted with procedures shown below .

a) Enter the service mode and make sure the

off timer display of the remote control shows

.

“ ”

b) Operate the “ON/OFF” key and make sure

the timer lamp on the display section is flashing (5 Hz).

Table 9-2-3

c) At the same time, also make sure the op-

eration lamp is also flashing. This shows

that the protection circuit on the indoor PC

board is working.

d) Operate the TEMP. ke y and mak e sure

the remote control display shows and

flashing of the operation lamp. If the operation lamp is flashing, it shows the protection

circuits for connecting cable is working or

thermal fuse is blown.

e) In the same way, operate the TEMP.

key so that the display is increased one

by one to continue checks by the self-diagnosis as shown in the next table. From

up to check operations of pro-

tection circuits for each block, and

“ ”

to check operations of the

typical protection circuits.

“ ”“ ”

“ ”

“ ”

Operating key

ON/OFF

TEMP. (Up)

TEMP. (Down)

“AUTO ” LOUVER

“SET” LOUVER

Indication after operation

“

1 is added to data before operation.

(Example)

1 is subtracted from data before operation.

(Example)

10 is subtracted from data before operation.

(Example)

Data before operation is directly transferred.

(Example)

”

– 36 –

Page 37

Table 9-2-4

Block level

Check

code

Block

Indoor PC

board

Check

code

Diagnosis function

Symptom

Thermo sensor

short/break.

Heat exchanger

sensor short/break.

Indoor fan lock,

abnormality of

indoor fan.

Air

Conditioner

status

Continued

operation

Continued

operation

All off

Condition

Indicated when

detected abnormal

Indicated when

detected abnormal

Indicated when

detected abnormal

Judgment and action

1. Check thermo sensor.

2. If it is OK, check PC board.

1. Check heat exchanger

sensor.

2. If it is OK, check PC board.

1. Disconnect the power plug

from AC outlet, and pull out

the connector (CN10) for the

motor, then connect the plug

of AC power cord again and

turn the power on.

2. Check the voltage between

pin 1 and 2 of the connector

(CN10).

3. If the output voltage is 35V,

PC board is OK, check

motor.

Abnormality of

other indoor unit PC

board.

Refrigerant

system

Contents detected by the check codes “ ” to “ ” are stored in memory of the microcomputer even if the power

supply is turned off. Therefore, contents of operations in the past are all displayed.

1) Gas shortage.

(gas leak)

2) Other refrigerant

cycle trouble.

3) Heat exchanger

sensor off/break/

short.

4) Overload relay

All off

All off

Indicated when

detected abnormal

Indicated when

detected abnormal

Replace PC board.

1. Check gas quantity.

(check gas leakage)

2. If it is OK, check heat exchanger sensor.

3. If heat exchenger sensor is

OK. check overload relay and

thermostat for compressor.

4. If overload relay is OK, check

refrigerant cycle.

5. If refrigerant cycle is OK,

check PC board.

– 37 –

Page 38

9-3. Troubleshooting Flowcharts

9-3-1. Power can not be Turned on (No Operation at All)

<Preliminary checks>

(1) Is the supply voltage normal?

(2) Is the connection to the AC output OK.?

Shut off the power supply

from AC outlet once and

turn it on after 5 seconds.

NO

Does the OPERATION

lamp flash?

YES

Operation

Check Items

Main cause

Countermeasure

Symptom

Does the fuse

Does the thermal

(Under PF. Terminal)

Is the indication voltage

NO

(DC12V or 5V) of main

PC board correct?

Is the voltage

across C02 measured

DC310V~340V?

YES

Does the power turn

on by pushing the

[START/STOP] button

of the remote control?

YES

(F01) blow?

NO

fuse blow?

NO

YES

Refer to the paragraph

NO

"Pre-check", or defective circuit

before power PC board block.

YES

YES

(No problem)

Parts (R21, R109, SG01,

C15, C01, DB01, C02,

IC01, T01) are defective.

Wrong wiring of

AC cord or connecting

cable is defective.

Does the transmission

indicator of remote