Page 1

TOSHIBA

DIGITAL TRANSISTOR INVERTER

LOW ACOUSTICAL NOISE SERIES

o-nomavEn n

OPERATION MANUAL

October, 1995

Part #36933-000

dì) #

Page 2

NOTE

The instructions contained in this manual are not intended to cover all of the

details or variations in equipment, nor to provide for every possible contingency

to be met in connection with installation, operation, or maintenance. Should further

information be desired or should particular problems arise which are not covered

sufficiently for the purchaser's purposes, the matter should be referred to the local

Toshiba sales office.

The contents of this instruction manual shall not become a part of or modify any

prior or existing agreement, commitment, or relationship. The sales contract

contains the entire obligation of Toshiba International Corporation's Inverter

Division. The warranty contained in the contract between the parties is the sole

warranty of Toshiba International Corporation's Inverter Division and any

statements contained herein do not create new warranties or modify the existing

warranty.

Any electrical or mechnical modification to this equipment,

without prior written consent of Toshiba International

Corporation, will void all warranties and may void UL listing

and/or CSA certification.

TOSHIBA

AC ADJUSTABLE SPEED DRIVE

Please complete the Extended Warranty Card supplied with this inverter and return

it by prepaid mail to Toshiba. This activates the extended warranty. If additional

information or technical assistance is required call Toshiba's marketing department

toll free at (800) 231-1412 or write to: Toshiba International Corporation, 13131 W.

Little York Road, Houston, TX 77041-9990.

Please complete the following information for your records and to remain within this

equipment manual:

Model Number:

Serial Number:

Date of Installation:

Inspected By:

Reference Number:

Page 3

TOSHIBA

INTRODUCTION

Thank you for purchasing the Q-FLOWSAVER II. This adjustable frequency solid state AC drive features

low acoustical noise, pulse width modulation, digital control, and user programmability. The very latest

microprocessor and insulated gate bipolar transistor technology is used. This, combined with Toshiba's

high performance software, gives unparalleled motor control and reliability.

It is the intent of this operation manual to provide a guide for safe/y installing, operating, and maintaining

the drive. This operation manual contains a section of general safety instructions and is marked

throughout with warning symbols. Read this operation manua/thoroughly before installation and opera

tion of this electrical equipment.

All safety warnings must be followed to ensure personal safety.

Follow all precautions to attain proper equipment performance and longevity.

The manual is divided into major sections of interest. All of the initial inspection, storage, installation and

operating precautions can be found in Sections 1 and 2 with Section 3 and 4 containing all of the

standard specifications and information on grounding, wiring, and cable sizes.

Section 5 contains information about the printed circuit board layouts, connectors, wiring jumpers, and

connector functions.

Section 6 shows layout information about the keypad panel and readouts.

Sections 7, 8, 9, 10, and 11 are devoted to the functional parameter groups, functional parameter

access and operation, status monitoring, and input and output terminal functions.

Section 12 contains a major component list with recommended spare parts along with a problem sheet

showing the necessary information for after sales service.

Section 13 contains shipping weights, dimensional data, component layouts, and schematics.

We hope that you find this operation manual informative and easy to use. If additional information or

technical assistance is needed, please call toll free (800) 231-1412 or write to: Toshiba International

Corporation, 13131 W. Little York Road, Houston, TX 77041-9990.

Again thank you for the purchase of this product.

TOSHIBA INTERNATIONAL CORPORATION

Page 4

GENERAL SAFETY INSTRUCTIONS

Warnings in this manual appear in either of two ways:

1) Danger warnings - The danger warning symbol is an exclamation mark enclosed in a

triangle which precedes the 3/16" high letters spelling the word "DANGER". The

Danger warning symbol is used to indicate situations, locations, and conditions that

can cause serious injury or death:

!\ DANGER

2) Caution warnings - The caution warning symbol is an exclamation mark enclosed in a

triangle which precedes the 3/16" high letters spelling the word "CAUTION". The

Caution warning symbol is used to indicate situations and conditions that can cause

operator injury and/or equipment damage:

!\ CAUTION

TOSHIBA

Other warning symbols may appear along with the Danger and Caution symbol and are used to specify

special hazards. These warnings describe particular areas where special care and/or procedures are

required in order to prevent serious injury and possible death:

1) Electricai warnings - The electrical warning symbol is a lighting bolt mark enclosed in

a triangle. The Electrical warning symbol is used to indicate high voltage locations and

conditions that may cause serious injury or death if the proper precautions are not

observed:

A

2) Explosion warnings - The explosion warning symbol is an explosion mark enclosed in

a triangle. The Explosion warning symbol is used to indicate locations and conditions

where molten, exploding parts may cause serious injury or death if the proper

precautions are not observed:

III

Page 5

TOSHIBA

CONTENTS

SECTION PAGE

Disclaimer ....................................................................................................i

introduction..................................................................................................ii

Generai Safety instructions.........................................................................iii

Contents ...................................................................................................iv-vi

1.0 inspection/Storage/Disposai.....................................................................1-1

1.1 Inspection of the New Unit.............................................................1-1

1.2 Storage

1.3 Disposal.........................................................................................1-1

..........................................................................................

1-1

2.0 Safety in Instaiiation and Operation..........................................................2-1

2.1 Installation Precautions

.................................................................

2-1

2.2 Operating Precautions....................................................................2-2

2.3 Confirmation of Wiring....................................................................2-4

2.4 Start-up and Test............................................................................2-4

3.0 Standard Specifications............................................................................3-1

4.0 Wiring ........................................................................................................4-1

4.1 Simple Connection Diagrams........................................................4-1

4.2 Selection of Main Circuit Wiring Equipment and

Standard Cable Sizes.....................................................................4-3

4.3 Grounding.......................................................................................4-4

5.0 PWB Layout, Jumpers, and Terminai Connections

5.1 Control/Driver Board for 02-2035 through 02-2330

5.2 Control/Driver Board for 02-4055 through 02-4330

5.3 Control Board for 02-4400 through O2-420K

5.4 Driver Board for 02-4400 through Q2-420K

.................................

......................

......................

.................................

...................................

5-1

5-1

5-2

5-3

5-4

5.5 Jumper Details................................................................................5-5

5.6 Control/Driver Board Terminal Block Details

.................................

5-5

5.7 Jumper/Terminal Connections and Functions................................5-6

5.8 Terminal Connections and Functions.............................................5-7

IV

Page 6

CONTENTS (confd)

TOSHIBA

SECTION

PAGE

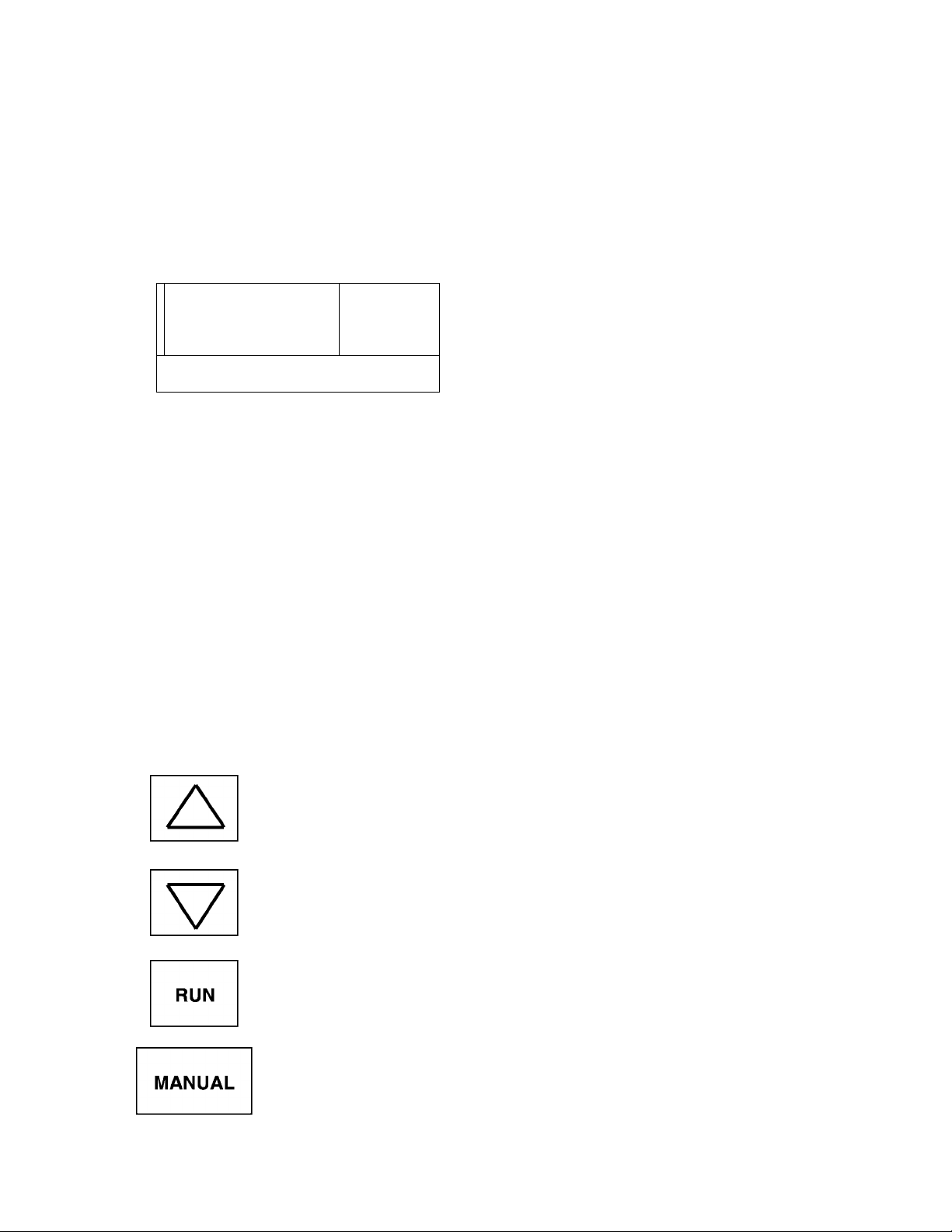

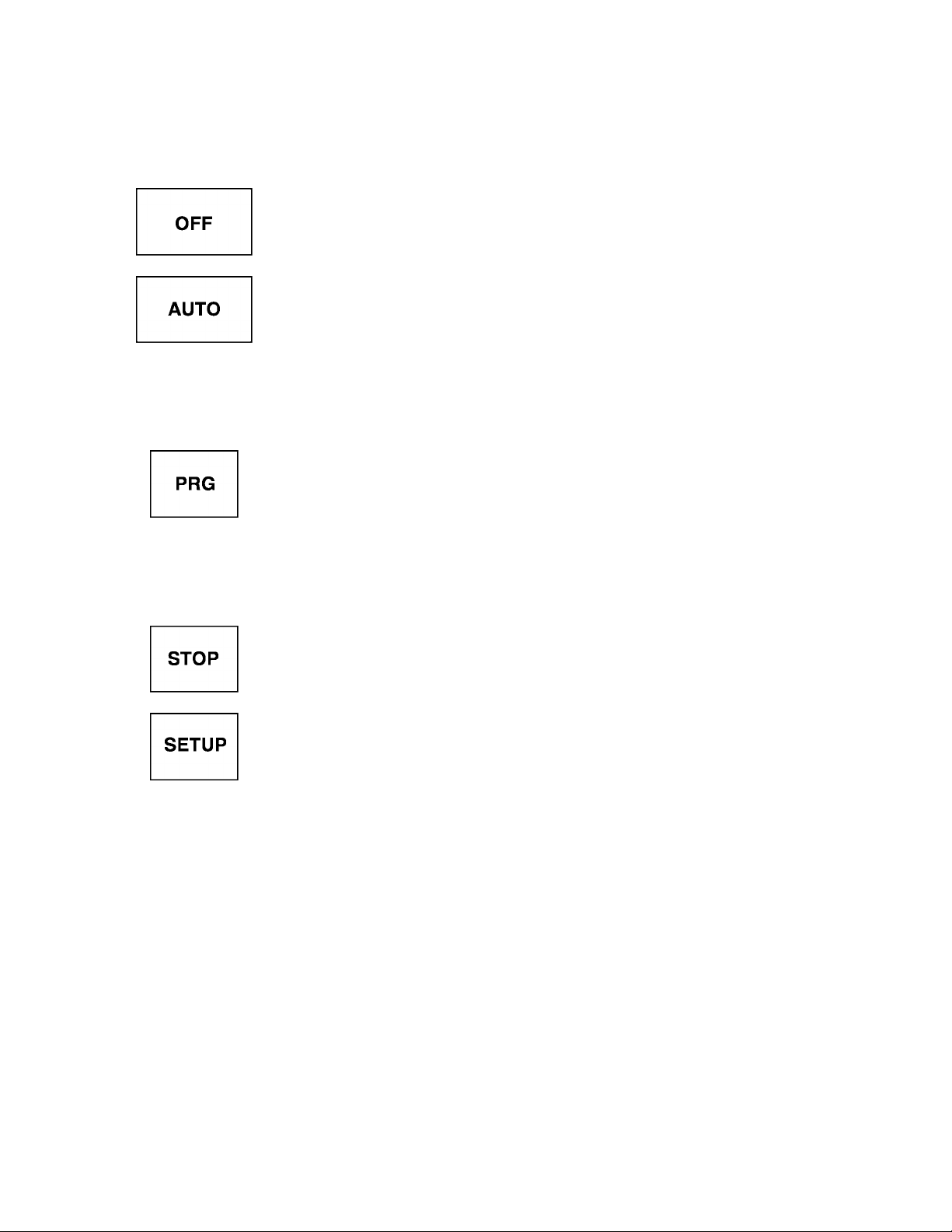

6.0 Operating Panel..........................................................................................6-1

6.1 Operating Panel Layout...................................................................6-1

6.2 Operating Panel Keys and Functions

6.3 LED Display and Display Monitoring

..............................................

...............................................

6-1

6-3

6.4 Display Alphanumerics....................................................................6-4

7.0 Parameter Groups.......................................................................................7-1

7.1 Definitions of Setup and Group Parameters....................................7-1

7.2 System Parameters Adjustment Range and Factory Settings

.......

7-2

8.0 System Status Monitoring........................................................................... 8-1

8.1 Normal Status Monitoring................................................................8-1

8.2 Automatic Status Monitoring............................................................8-2

8.3 Tripped Status Monitoring

...............................................................

8-3

8.4 Input Terminal Status Code.............................................................8-4

8.5 Output Terminal Status Code..........................................................8-5

9.0 Keypad Operating Functions

......................................................................

9-1

9.1 Setup Parameters............................................................................9-1

9.2 User Group Parameters

.................................................................

9-3

9.3 Communication Group Parameters.................................................9-5

9.4 Jump Frequency Group Parameters

...............................................

9-7

9.5 Display Group Parameters..............................................................9-8

9.6 Speed Group Parameters................................................................9-9

9.7 Pattern Frequency Group Parameters

...........................................

9-10

9.8 Emergency Stop.............................................................................9-12

10.0 Input Terminal Operating Functions..........................................................10-1

10.1 Input Terminal Selection Function

.................................................

10-1

10.2 Starting/Stopping-Remote Control................................................ 10-2

10.3 Emergency Stop From a Remote Location...................................10-2

10.4 Remote Control Frequency Setting................................................10-2

10.5 Jog ................................................................................................. 10-3

10.6 Resetting After a Trip......................................................................10-3

10.7 Pattern Run.................................................................................... 10-4

10.8 PID Set Point Control

.....................................................................

10-5

Page 7

TOSHIBA

CONTENTS (cont'd)

SECTION PAGE

11.0 Output Terminal Operating Functions

11.1 Selectable Outputs

.......................................................................

11.2 Inverter to Relay/PC Connections

.........................................................

...............................................

11.3 Fault Detection Output Terminals................................................ 11-2

11.4 Calibration of Remote Meters...................................................... 11-3

12.0 Spare Parts List/After Saies Service

.......................................................

12.1 Requesting After Sales Service................................................... 12-1

12.2 Recommended Spare Parts......................................................... 12-2

12.3 Parts Service Life......................................................................... 12-5

13.0 Dimensions/Weights/Component Layouts/Schematics

13.1 Basic Dimensions.........................................................................13-1

13.2 Operating Panel Assembly........................................................... 13-3

13.3 Shipping Weights

..........................................................................

13.4 Component Layouts......................................................................13-5

13.5 Schematics...................................................................................13-14

..............................

11-1

11-1

11-2

12-1

13-1

13-4

VI

Page 8

1.0 Inspection/Storage

1.1 Inspection of the New Unit

Upon receipt of the Q-FLOWSAVER II, a careful inspection for shipping damage should

be made. After uncrating:

1) Check the unit for loose, broken, bent or otherwise damaged parts due to

shipping.

2) Check to see that the rated capacity and the model number specified on the

nameplate conform to the order specifications.

1.2 Storage

1) Store in a well ventilated location and preferably in the in the original carton if

the inverter will not be used immediately after purchase.

2) Avoid storage in locations with extreme temperatures, high humidity, dust, or

metal particles.

1.3 Disposal

Please contact your state environmental agency for details on disposal of electrical

components and packaging in your particular area.

TOSHIBA

1 - 1

Page 9

TOSHIBA

2.0 Safety in Installation and Operation

2.1 Installation Precautions /!\ CAUTION

2)

3)

4)

5)

6)

7)

8)

1)

Install in a secure and upright position in a well ventilated location where the

ambient temperature is between -10 deg C and 40 deg C (up to 50 deg C when

not enclosed in a cabinet). Do not allow direct sunlight to shine on the unit or

obstruct ventilating openings.

Allow a clearance space of 4 inches (10 cm) for the top and bottom and

2 inches (5 cm) on both sides. This space will insure adequate ventilation.

Avoid installation in areas where vibration, heat, humidity, dust, steel particles,

or sources of electrical noise are present.

Adequate working space should be provided for adjustment, inspection and

maintenance.

Adequate lighting should be available for troubleshooting and maintenance.

A noncombustible insulating floor or mat should be provided in the area

immediately surrounding the electrical system where maintenance is required.

Use separate metal conduits for routing the input power, output power,

and control circuits.

Always ground the unit to prevent electrical shock and to help reduce

electrical noise. A separate ground cable should be run inside of the

A

the conduit is not an acceptable ground.

conduit with the input, output, and control power cables. The metal of

9)

10)

11)

12)

13)

Connect three phase power of the correct voltage to input terminals LI, L2, L3

(R, S, T) and connect three phase power from output terminals T1, T2, T3

(U, V, W) to a motor of the correct voltage and type for the application. Size

the conductors in accordance with Article 310 of the National Electrical Code.

If conductors of a smaller than recommended size are used in parallel to share

current then the conductors should be kept together in as sets i.e. U1, VI, W1

in one conduit and U2, V2, W2 in another. National and local electrical codes

should be checked for possible cable derating factors if more than three power

conductors are run in the same conduit.

Install a molded case circuit breaker (MCCB) between the power source and the

inverter. Size the MCCB to clear the available fault current of the power source.

Installation of inverter systems should conform to the National Electrical Code,

regulations of the Occupational Safety and Health Administration, all national

codes, and all regional or industry codes and standards.

If a secondary Magnetic Contactor (MC) is used between the inverter output

and the load, it should be interlocked so the ST-CC terminals are disconnected

before the output contactor is opened. If the output contactor is used for bypass

operation, it must also be interlocked so that commercial power is never applied

to the inverter output terminals (U,V,W).

2 -1

Page 10

2.2 Operating Precautions /!\ CAUTION

TOSHIBA

2)

3)

4)

5)

6)

1)

Do not apply power and attempt to use the inverter until this entire operation

manual has been carefully reviewed.

The input voltage must be within +/-10% of the specified input voltage. Voltages

outside of this permissible tolerance range may cause internal protection

devices to turn on or can cause damage to the unit. Also, the input frequency

should be within +1-2 Hz of the specified input frequency.

Do not use this inverter with a motor whose rated input is greater than the rated

inverter output.

This inverter is designed to operate NEMA B motors. Consult the factory before

using the inverter for special applications such as an explosion proof motor or

one with a repetitive type piston load.

Kdanger/^

remove the source power and check that the charge and power LED's are out.

Do not touch any internal part with

power applied to the inverter. First

A hazard exists temporarily for electrical shock even if the source power

Is removed.

Do not apply commercial power to the output terminals T1 (U), T2 (V), or T3 (W)

even if the inverter source power is off. Disconnect the inverter from the motor

before applying a test or bypass voltage to the motor.

7)

8)

9)

10) Interface problems can occur when this inverter is used in conjunction with

Use caution when setting output frequency. Overspeeding of the motor can

cause serious damage to the motor and/or the driven load equipment.

Use caution when setting the acceleration and/or deceleration time.

Unnecessarily short acc/dec time can cause undue stress and tripping of the

drive.

some types of process controllers. Signal isolation may be required to

Do not operate this unit with the cabinet door open.

prevent controller and/or inverter damage.

Contact Toshiba or the process controller manufacturer for further

information about compatibility and signal isolation.

11) When operating the inverter in the PWM high carrier frequency mode (those

frequencies above 12 kHz), the electronic thermal protection /eve/function

parameter [:tHr] should be changed from the factory setting of 100% to 90%

(see Setup Parameters ITEM 9 page 7-2). This is to compensate for the 10%

derating factor required at 16 kHz operation. Follow the general procedures for

changing function parameters. Further derating may be required for cable runs

of greater than 100 feet. Contact Toshiba for more information.

12) Personnel who have access to the adjustments and operation of this equipment

should be familiar with these drive operating instructions and with the machinery

being driven.

2-2

Page 11

TOSHIBA

2.2 Operating Precautions (cont'd) /!\ CAUTION

2.3 Confirmation of Wiring /!\ CAUTION

13) Do not open and then re-close a secondary magnetic contactor (MC) between

the inverter and the load until the Inverter has been turned OFF (output frequency

has dropped to zero) and the motor has stopped rotating. Abrupt re-application

of the load while inverter is ON or motor is rotating can cause inverter

damage.

14) The operator of the drive equipment should be properly trained In the operation

of the equipment.

15) Follow all warnings and precautions; do not exceed equipment ratings.

Make the following final checks before applying power to the unit:

1)

2)

3)

4)

Confirm that source power is connected to terminals LI, L2, L3 (R, S, T).

Connection of incoming source power to any other terminals will damage

the inverter.

The 3-phase source power should be within the correct voltage and frequency

tolerances.

The motor leads must be connected to terminals T1, T2, T3 (U, V, W).

Make sure there are no short circuits or inadvertent grounds and tighten any

loose connector terminal screws.

2.4 Start-Up and Test /!\ CAUTION

Prior to releasing an electrical drive system for regular operation after installation,

the system should be given a start-up test by competent personnel. This assures

correct operation of the equipment for reasons of reliable and safe performance. It is

important to make arrangements for such a check and that time is allowed for It.

When power Is applied for the first time the inverter will come up in the factory settings

(See section 7.2). If these settings are incorrect for the application trial run then the

correct settings should be programmed from the control panel before activating the run

button. The inverter can be operated with no motor connected. Operation with no

motor connected or use with a small trial motor Is recommended for initial adjustment or

for learning to adjust and operate the inverter.

2.5 Maintenance A CAUTION

1)

2)

3)

Periodically check the operating inverter for cleanliness.

Keep the heatsink free of dust and debris.

Periodically check electrical connections for tightness

A

power is off and locked out).

2-3

(make sure

Page 12

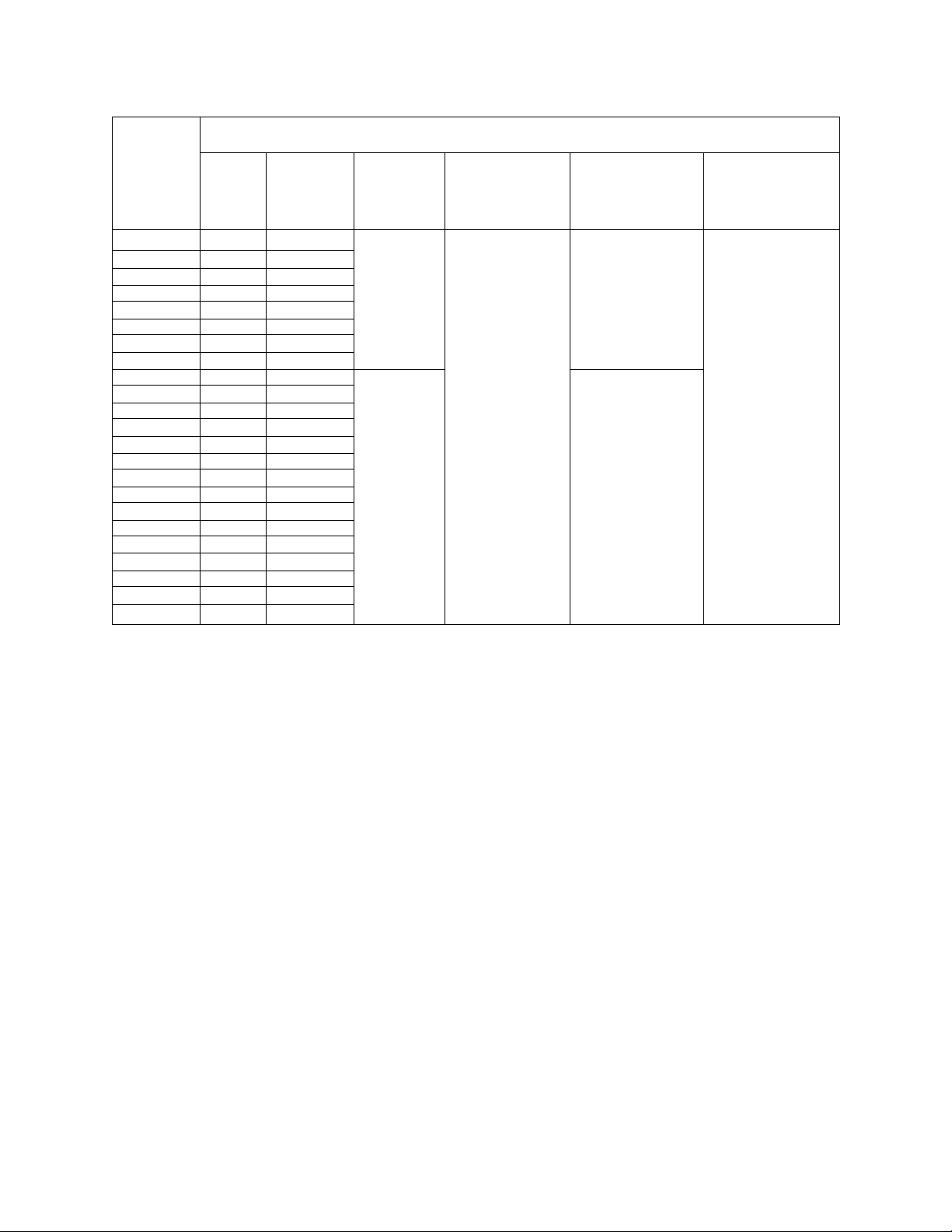

3.0 Standard Specifications

TOSHIBA

RATINGS

MODEL RATED

KVA

*02-2035 3.5 9.6

*02-2055 5.5

*02-2080 8

*02-2110

*02-2160 16

*02-2220

*02-2270

*02-2330 33

*02-4055 5.5 7.6

*02-4080 8

*02-4110

*02-4160 16

*02-4220

*02-4270

*02-4330 33 40

*02-4400 40 55

*02-4500 50 65

*02-4600 60

*02-4800 80

*02-41 OK

**02-412K

**02-415K

**Q2-420K

11

22

27

11

22

27

100

125

150

200 240

OUTPUT

CURRENT

AMPS

15.2 3-PHASE

14.5

28.5

36.5

104

124

162

194

OUTPUT

VOLTAGE

3-PHASE

200-230V

22 (MAX

28

42 VOLTAGE

56

68

84

11 3-PHASE 400-460V@60Hz

21 OUTPUT Hz +/-2HZ

84

OUTPUT

UNDER NO

LOAD)

380-460V 380V@50Hz or

(MAX

VOLTAGE

UNDER NO

LOAD)

OVERLOAD

CURRENT

120% FOR

60 SEC.

110% VOLT ±10%

CONTINUOUS

MAIN CIRCUIT

INPUT VOLTAGE

200V@50Hz or NO EXTERNAL

200-230V@60Hz CONTROL

VOLT+/-10%

3-PHASE

Hz ±2Hz REQUIRED

CONTROL

CIRCUIT

SINGLE PHASE

SOURCE

This unit is UL (Underwriters Laboratories Inc.'

Association) certified.

This unit is UL (Underwriters Laboratories Inc.) listed and CUL (Canadian Underwriters

Laboratories Inc.) listed.

listed and CSA (Canadian Standards

3-1

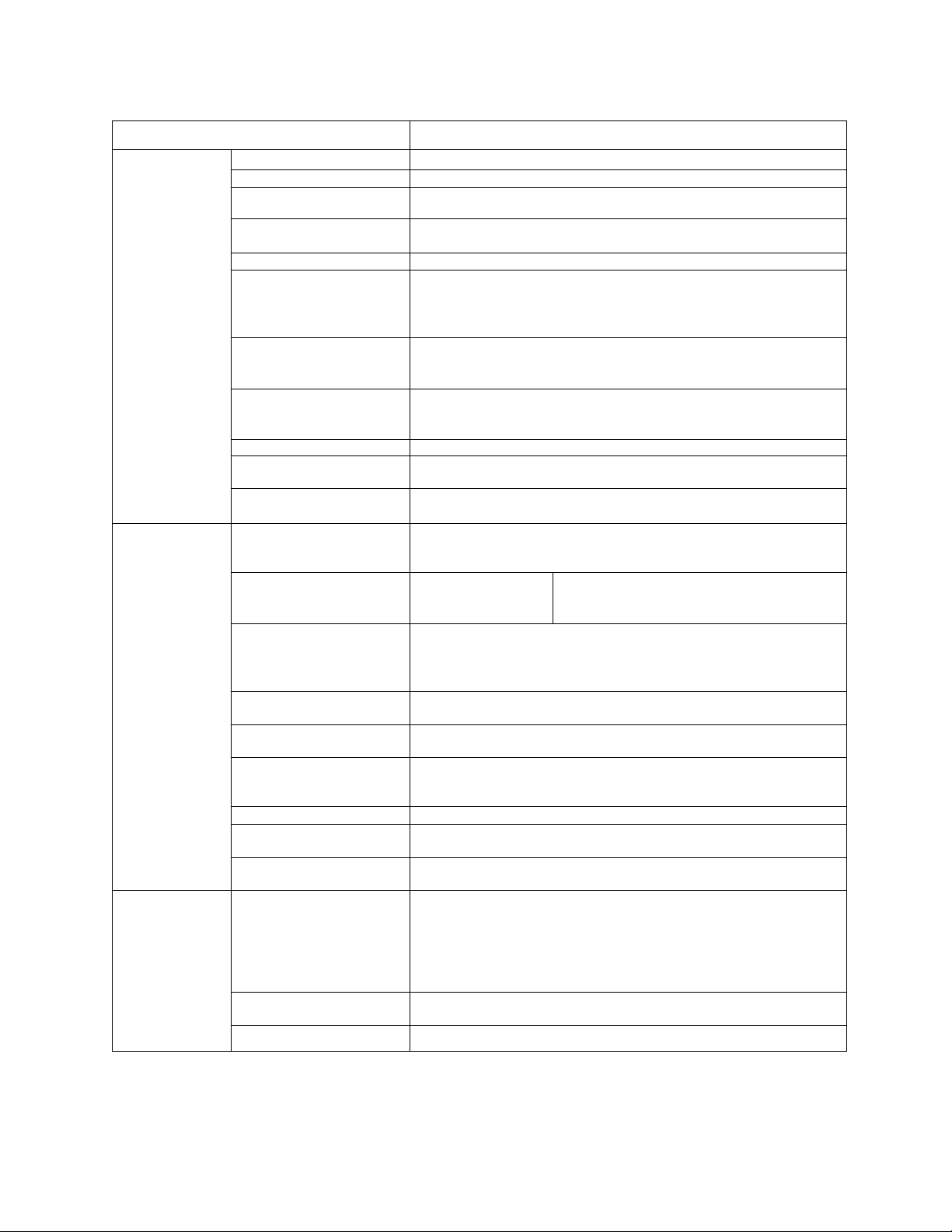

Page 13

TOSHIBA

3.0 Standard Specifications (cont'd)

ITEM STANDARD SPECIFICATIONS

Control Control Method Sinusoidal PWM control

Output voltage regulation Same as power line.

Output frequency 0.0 to 160.0 Hz (0.0 to 60 Hz setting when shipped); maximum

frequencv ranqe is 30 to 160 Hz *1

Operating

functions

Protection

Frequency setting

resolution

Frequency accuracy ±0.5% (at 25°C; ±10°C) aqainst the maximum frequency

Voltage/frequency

characteristics

Frequency setting signals

Output frequency

characteristics of IV

terminal input signal

Frequency jump

Upper/lower limit

frequencies

PWM carrier frequency

switching

Acceleration/deceleration

time

Electrical braking

Forward or reverse run Forward run when F-CC closed; reverse run when R-CC closed;

Jogging run

Multispeed run By opening and closing different combinations of CC, SSI, SS2,

Automatic fault latch reset When a protective function is activated, the system checks main

Soft stall Sustains a run in overload mode (set at ON when shipped)

Automatic restart

Programmable RUN

patterns

Protective functions Stall prevention, current limit, overcurrent, overvoltage, short-

Electronic thermal

characteristics

Reset Resets inverter when N.O. contact is closed.

0.1Hz: Operating panel input; 0.03 Hz: Analog input; 0.01Hz:

Input throuqh computer interface (aqainst a 60 Hz)

Second-order nonlinear mode for variable torque.

"Max voltage" frequency adjustment (25 to 160 Hz), torque

boost adjustment (0 to 30 %), start-up frequency adjustment

(Oto 10 Hz)

3k ohms potentiometer (a 1 k to 10k ohms-rated potentiometer can

be connected). 0 to 10 Vdc (input impedance: 30k ohms), 0 to

5 Vdc (15k ohms), 4 to 20 mAdc (250 ohms)

Can be set to an arbitrary characteristic by setting 2 points.

3-point setting; setting jump frequency and band width

Upper limit frequency: 0.0 Hz to maximum frequency

Lower limit frequency: 0.0 Hz to upper limit frequency

Adjusted in the range of 5 kHz to 16 kHz (12 kHz setting when

shipped)

0.1 to 1200 seconds, switching of acceleration time 1 or 2,

selection of S-shaped 1 or 2, or selection of acceleration/

deceleration patterns

DC injection braking

reverse run when both F-CC and R-CC closed; coasting stop

when ST-CC open; emergency coast stop by a command from

operating panel

Jogging run engaged when N.O. contact is closed, (adjustment

range 0.0 to 20.0 Hz)

and SS3, the set speed or seven preset speeds can be selected.

circuit devices, and attempts the restart up to 5 times (activated

when shipped)

Smoothly recovers a normal run of a free-running motor utilizing

motor speed detection control.

Allows setting of 7 different patterns of automatic operation

circuit at load, load-end ground fault, undervoltage, momentary

power interrupt, electronic thermal overload, main circuit over

current at start-up, load-end overcurrent at start-up, cooling

fin overheat, and emergency stop. Provisions for external

fault signal.

Standard motor/constant torque V/f motor switching, and

electronic thermal stall prevention activating level adjustment

Start-up frequency adjustment (0 to 10 Hz),

braking voltage adjustment (0 to 20 %),

braking time adjustment (0 to 5 seconds)

Consult the factory for applications above 80 Hz.

3-2

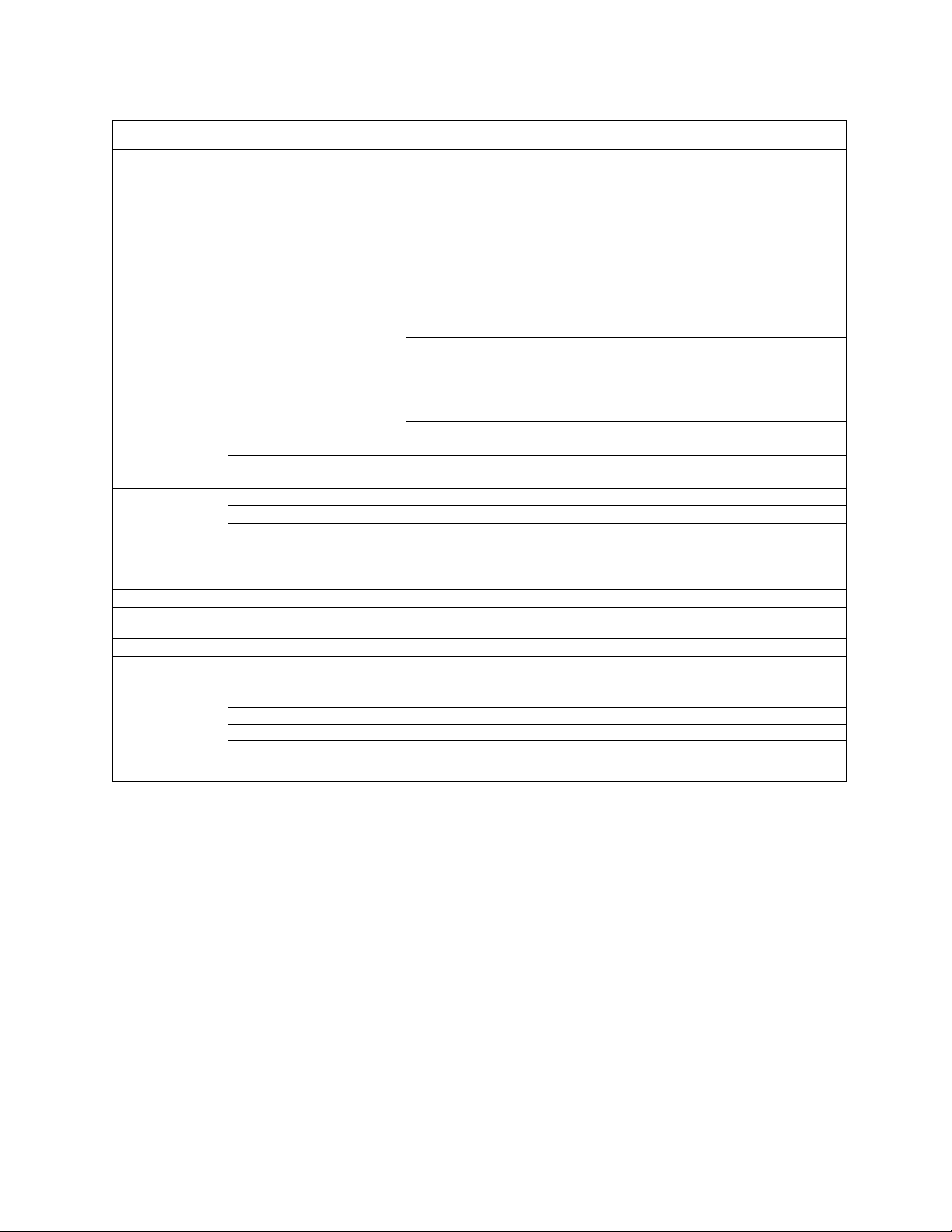

Page 14

3.0 Standard Specifications (cont'd)

ITEM STANDARD SPECIFICATIONS

Display (4) 7-segment red LED

digits with colon and

decimal points

(4) discrete green LED's

(1) discrete red LED

(located inside enclosure)

Output signals Fault detection signal One form C contact (250 AC / 30 Vdc)

Low speed/reach signals Open collector output (24 Vdc, 50 mA maximum)

Upper limit/lower limit

frequency signals

Frequency meter output

and ammeter output

Enclosure type NEMAType 1 (standard)

Cooling method

Color Sherwin Williams Precision Tan #F63H12

Service

conditions

Service environment Indoor, altitude 1000m (3,300 ft) maximum. Must not be exposed

Ambient temperature From -10 to 40°C (contact Toshiba about operation above 40°C)

Relative humidity

Vibration

Output

frequency/

OFF

Warning

indications

Fault

indications

Data and

status

Speed

scaling

Data

storage

DC charge

indicator

Open collector output (24 Vdc, 50 mA maximum)

Ammeter rated at 1 mAdc at full scale, or voltmeter rated at

7.5 Vdc, 1 mA

Convection-cooled 02-2035 and 02-4055

Fan-cooled 02-2055 thru 02-2330 and 02-4080 thru Q2-420K

to direct sunlight, or subjected to corrosive or explosive gas

or mists.

95 % maximum (no condensation allowed)

Acceleration at 0.5 G maximum (20 to 50 Hz), amplitude at

0.1 mm maximum (50 to 100 Hz)

Frequency range 0.0 to 160 Hz and OFF state

Stall preventive warning, overvoltage limit

warning, overload warning, power-end undervoltage

warning, DC main circuit undervoltage warning,

setting errors, EEPROM abnormality, and data

transfer abnormality warnings

Overcurrent, overvoltage, load-end ground fault,

overload, armature overcurrent at start-up, load-end

overcurrent at start-up, heat sink overheat.

Inverter status (forward/reverse run, frequency set

value, output current, etc.) and each set value

An arbitrary unit (revolution speed, linear velocity or

the like) as well as output frequency can be displayed

by use of an arbitrary multiplication factor

A number is assigned to each inverter (for 0 to 31

inverters).

Main DC bus circuit capacitors charge indicator

TOSHIBA

3-3

Page 15

TOSHIBA

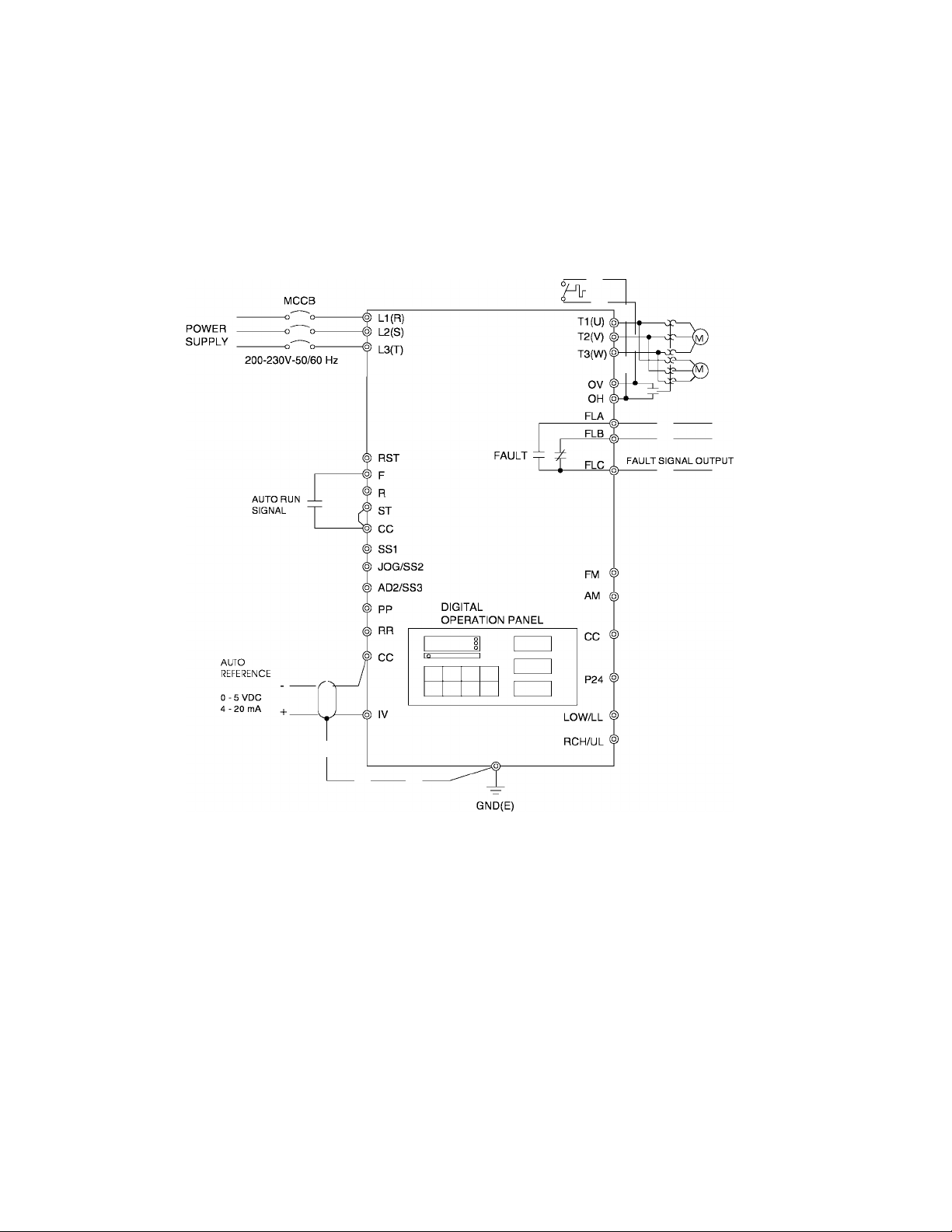

4.0 Wiring

4.1 Simple Connection Diagrams

Q-FLOWSAVER II

STANDARD CONNECTION

MODEL 2035 TO 2330

Notes:

1) For control/driver terminal block layout see Page 5-5.

2) For recommended wire sizes see Page 4-3.

3) For terminal connections and functions see Page 5-6 through 5-8.

4) Contact Toshiba when interfacing with a process controller.

4 -1

Page 16

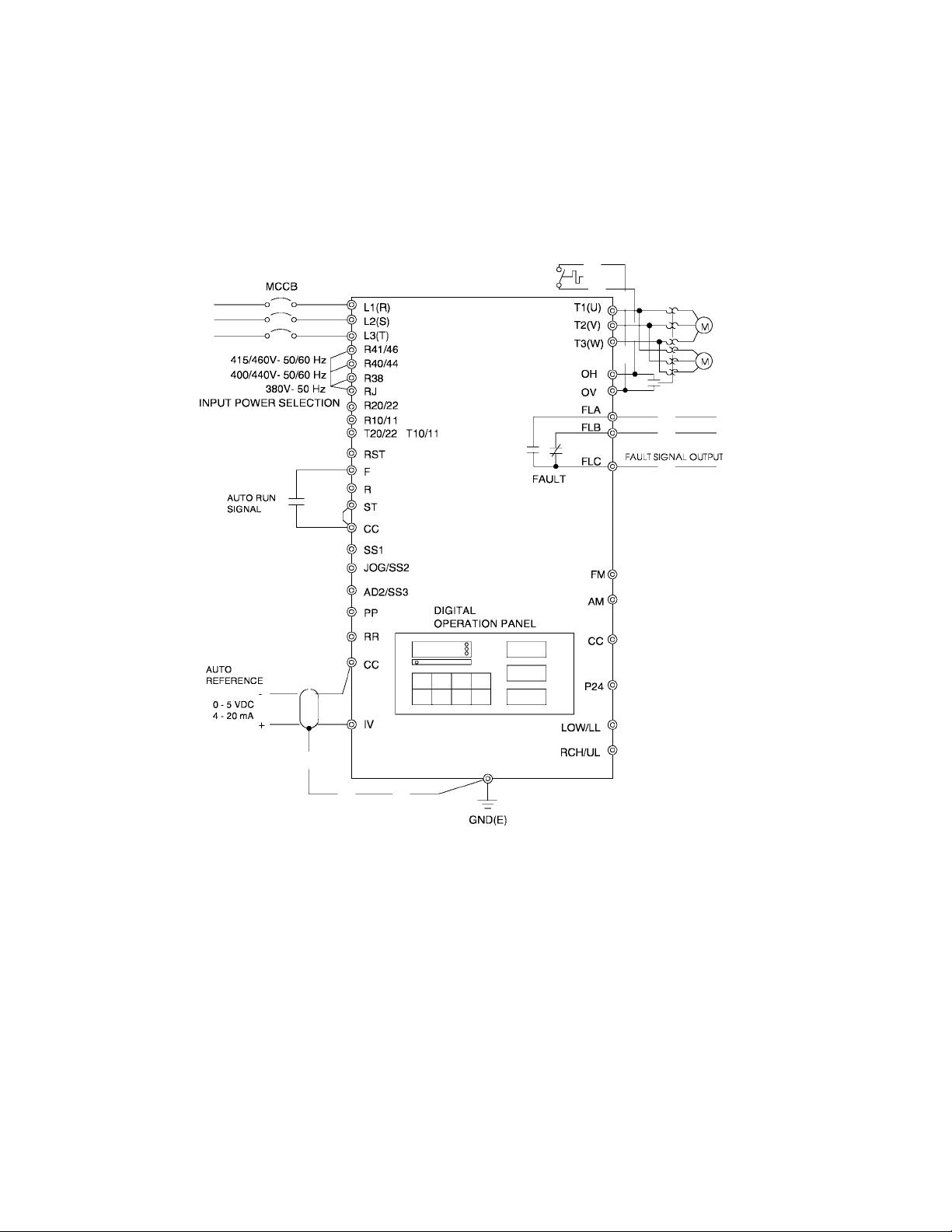

4.1 Simple Connection Diagrams (cont'd)

Q-FLOWSAVER II

STANDARD CONNECTION

MODEL 4055 TO 420K

POWER

SUPPLY

TOSHIBA

Notes:

1) For control/driver terminal block layout see Page 5-5.

2) For recommended wire sizes see Page 4-3.

3) For terminal connections and functions see Page 5-6 through 5-8.

4) Contact Toshiba when interfacing with a process controller.

4-2

Page 17

TOSHIBA

4.2 Selection of Main Circuit Wiring Equipment and Standard Cable Sizes

Inverter

Type form

•Molded case

circuit breaker

(MCCB)

Amp

rating

(A)

Q2-2035 20 13.8

Q2-2055 30 21.9

Q2-2080 50 31.6 #10

Q2-2110 70 40 #8

Q2-2160 90 60 #6

Q2-2220 100 78

Q2-2270 125 98 #3

Q2-2330 150 115

Q2-4055 15 10.9

Q2-4080 30 15.8

Q2-4110 30 20.1

Q2-4160 40

Q2-4220 50 38.8 #8

Ampacity

(FLA X 1.25) •'Typical cable size (AWG)

Main power

(A)

motor load

30.2

and

#14

#12

#4

#2

#14

#14

#12 #14

#10

230Vac and

460Vac control

power source

Frequency

command input,

frequency meter,

ammeter

3-core shield cable

(speed reference)

2-core shield cable

#20

Other

signal

circuits

#18

Q2-4270 70 48.8 #8

Q2-4330 90 57.5 #6

Q2-4400 100 74.8

Q2-4500 100

Q2-4600 125

Q2-4800 175 138 #1/0

Q2-410K

Q2-412K

Q2-415K

Q2-420K

200 178.3 #3/0

225 223 #4/0

300 268 ••• 2(#2/0)

350 330 ••• 2(#4/0)

93.4

110.7 #2

See next page for notes and precautions.

#4

#3

4-3

Page 18

4.2 Selection of Main Circuit Wiring Equipment and Standard Cable Sizes (cont'd)

* The customer supplied Molded Case Circuit Breaker (MCCB) or Magnetic Circuit

Protector (MCP) should be coordinated with the available short circuit current. The units

are rated for output short circuit faults of 5000A (1 - 50 HP), lO.OOOA (51 - 200 HP), and

18,000A (201 - 400 HP) according to the UL 508C "Power Conversion Equipment",

Table 58.2 or CSA Standard C22.2 No.14-M1987 "Industrial Control Equipment"

Table 24. The selection of breakers for this table is in accordance with 1990 NEC

Article 430. The selection of these breakers takes into consideration motor starting

at the low end of the output voltage specifications but does not consider the use of

high efficiency motors.

* For multiple motor applications, the magnetic only MCP should be replaced by a thermal

magnetic MCCB. The MCCB should be sized according to 1.25 X (largest motor Full

Load Amps) + (sum of all other motor Full Load Amps) to meet National Electric Code

(NEC) or Canadian Electrical Code (CEC) requirements. An individual overload relay

must be provided for each motor in multiple motor applications.

** Wire sizing is based upon NEC table 310-16 or CEC Table 2 using 75 deg C cable, an

ambient of 30deg C, cable runs for less than 200 FT., and copper wiring for not more

than three conductors in raceway or cable or earth (directly buried). The customer should

consult the NEC or CEC wire Tables for his own particular application and wire sizing.

TOSHIBA

** For cable runs greater than 200 FT. between the motor and inverter, consult the factory

before installing.

*** Use two parallel conductors instead of a single conductor (this will allow for the proper

wire bending radius within the cabinet). Use separate conduits for routing parallel

conductors. This prevents the need for conductor derating (see note 3 this page).

Use separate conduits for routing incoming power, power

CAUTION to motor, and control conductors. Use no more than three

K

Notes:

1. ) Auxiliary relays used to switch inverter signals should be capable of switching

low current signals (i.e. 5mA).

2. ) The inverter has internal overload protection, but the Local, National, or

Canadian Electrical Codes may require external motor overload protection.

3. ) When wiring with parallel conductors, the conductors should be kept together in

phase sets with U1, VI, W1 in one conduit and parallel conductors U2, V2, W2

in another conduit. The ground conductor should be in one of these conduits.

4) Twisted pair wiring should be used for external meters connected to AM and FM

terminals.

power conductors and a ground conductor per conduit.

4.3 Grounding

The inverter should be grounded in accordance with Article 250 of the National Electrical

Code or Section 10 of the Canadian Electrical Code, Part I and the grounding conductor

should be sized in accordance with NEC Table 250-95 or CEC, Part I Table 16.

!\ CAUTION Conduit is not a suitable ground for the inverter.

4-4

Page 19

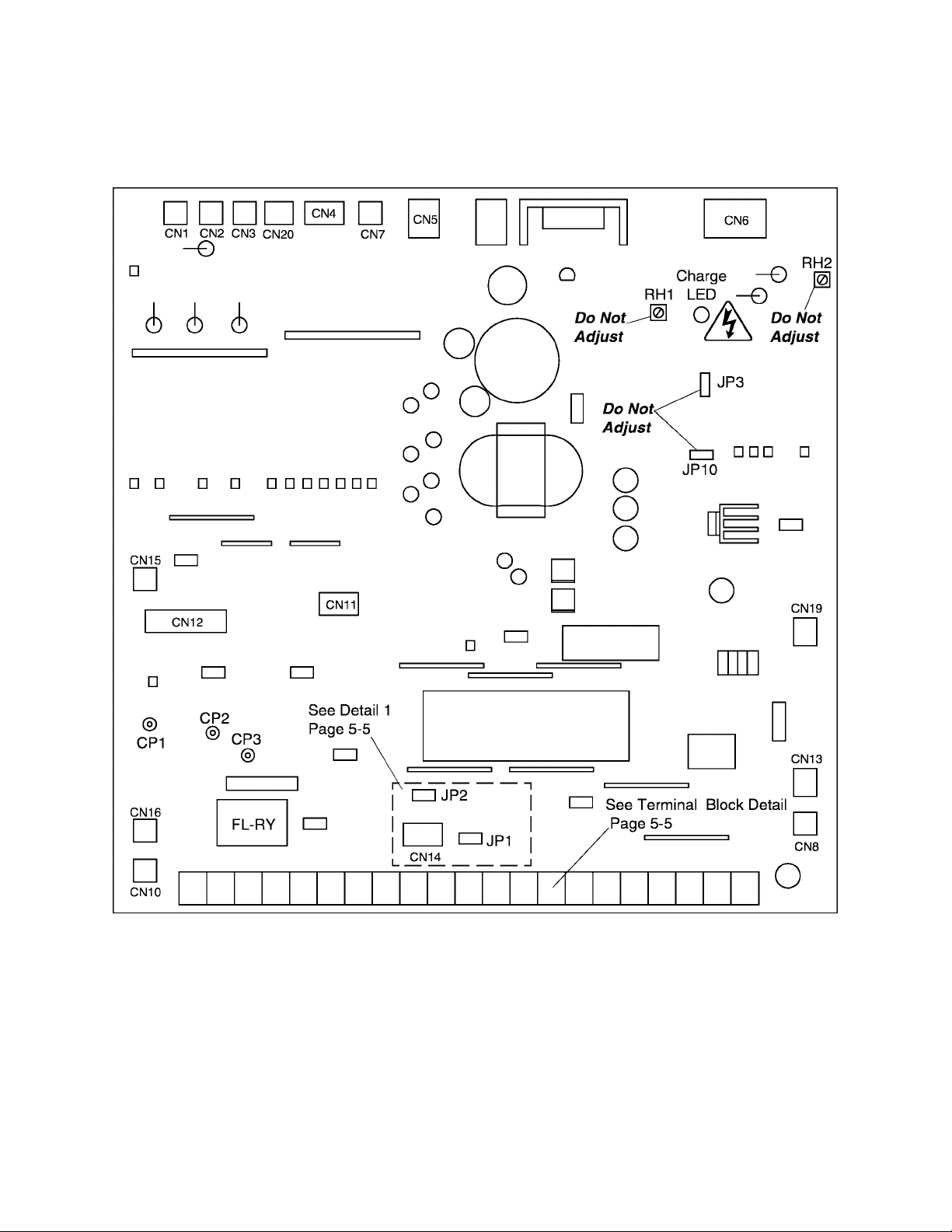

TOSHIBA

5.0 PWB Layout, Jumpers, and Terminal Connections

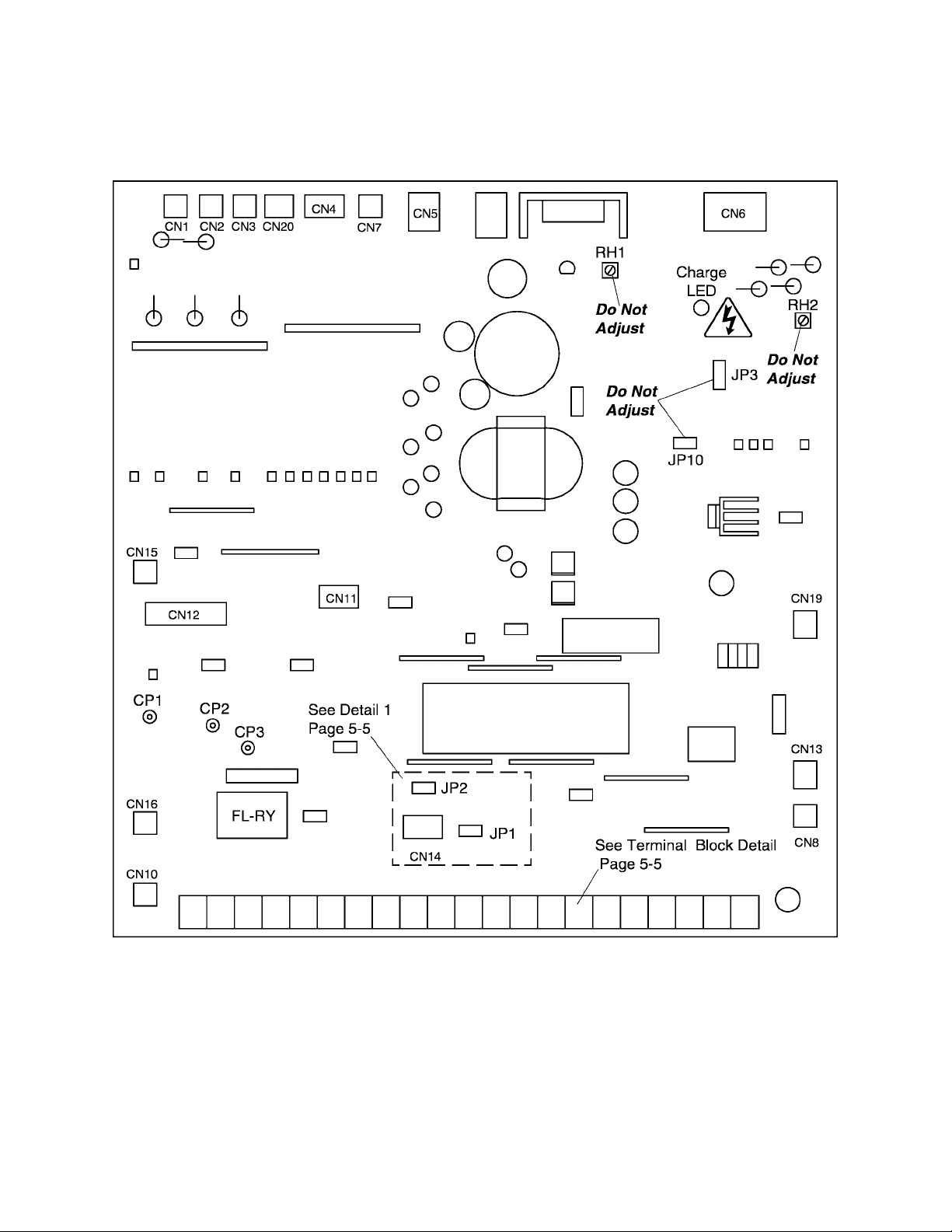

5.1 Control/Driver Board for Q2-2035 through Q2-2330

The following pictorial shows a layout of the major components located on the

control/dhver board VF3B-0100.

Note:

1) Potentiometer RH1 is used for control power supply stabilization. This adjustment is

factory set and any ADJUSTMENT BY THE USER SHOULD NOT BE ATTEMPTED.

2) Potentiometer RH2 is used for voltage detection level bias. This adjustment is factory

set and any ADJUSTMENT BY THE USER SHOULD NOT BE ATTEMPTED.

3) CPI, CP2,and CP3 are service testpoints.

4) Do not adjust JP3 and JP10.

5) Charge LED indicates charged capacitors. DO NOT TOUCH internal parts if lighted.

5-1

Page 20

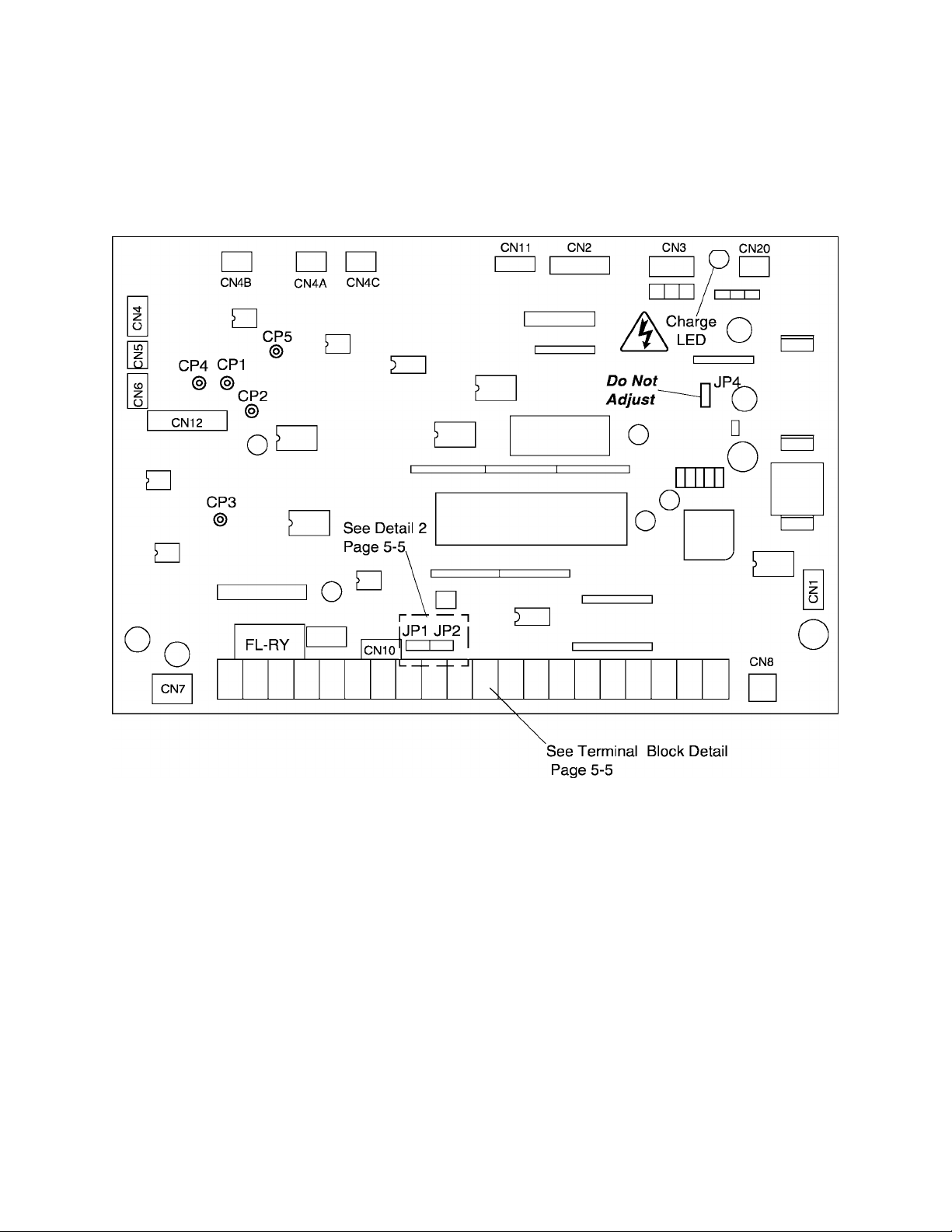

5.2 Control/Driver Board for Q2-4055 through Q2-4330

The following pictorial shows a layout of the major components located on the

control/dhver board VF3B-0101.

TOSHIBA

Note:

1) Potentiometer RH1 is used for control power supply stabilization. This adjustment is

factory set and any ADJUSTMENT BY THE USER SHOULD NOT BE ATTEMPTED.

2) Potentiometer RH2 is used for voltage detection level bias. This adjustment is factory

set and any ADJUSTMENT BY THE USER SHOULD NOT BE ATTEMPTED.

3) CP1, CP2, and CP3 are service testpoints.

4) Do not adjust JP3 and JP10.

5) Charge LED indicates charged capacitors. DO NOT TOUCH internal parts if lighted.

5-2

Page 21

TOSHIBA

5.3 Control Board for Q2-4400 through Q2-420K

The following pictorial shows a layout of the major components located on the

control board VF3C-1200.

Note:

1) CPI, CP2, CP3, CP4, and CPS are service testpoints.

2) Do not adjust JP4.

3) Charge LED indicates charged capacitors. DO NOT TOUCH internal parts if lighted.

5-3

Page 22

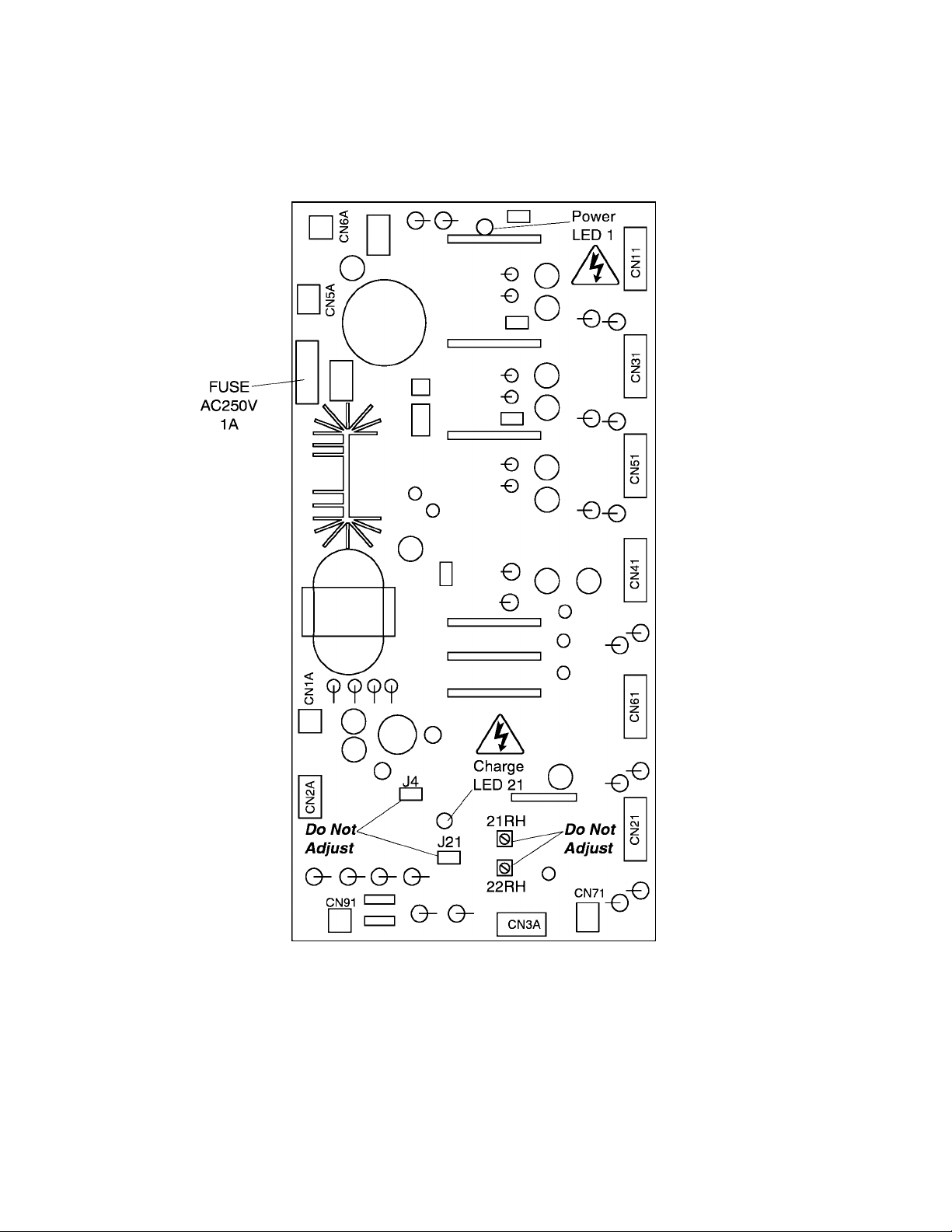

5.4 Driver Board for Q2-4400 through Q2-420K

The following pictorial shows a layout of the major components located on the

driver board 35589.

TOSHIBA

Note:

1) Potentiometer 21RH (OP) is the main circuit overvoltage detection trip set. This

adjustment is factory set and any ADJUSTMENT BY THE USER SHOULD NOT BE

ATTEMPTED.

2) Potentiometer 22RH (MUV) is the main circuit undervoltage detection trip set. This

adjustment is factory set and any ADJUSTMENT BY THE USER SHOULD NOT BE

ATTEMPTED.

3) Do not adjust J4 and J21.

5) Charge LED indicates charged capacitors. DO NOT TOUCH internal parts if lighted.

5-4

Page 23

TOSHIBA

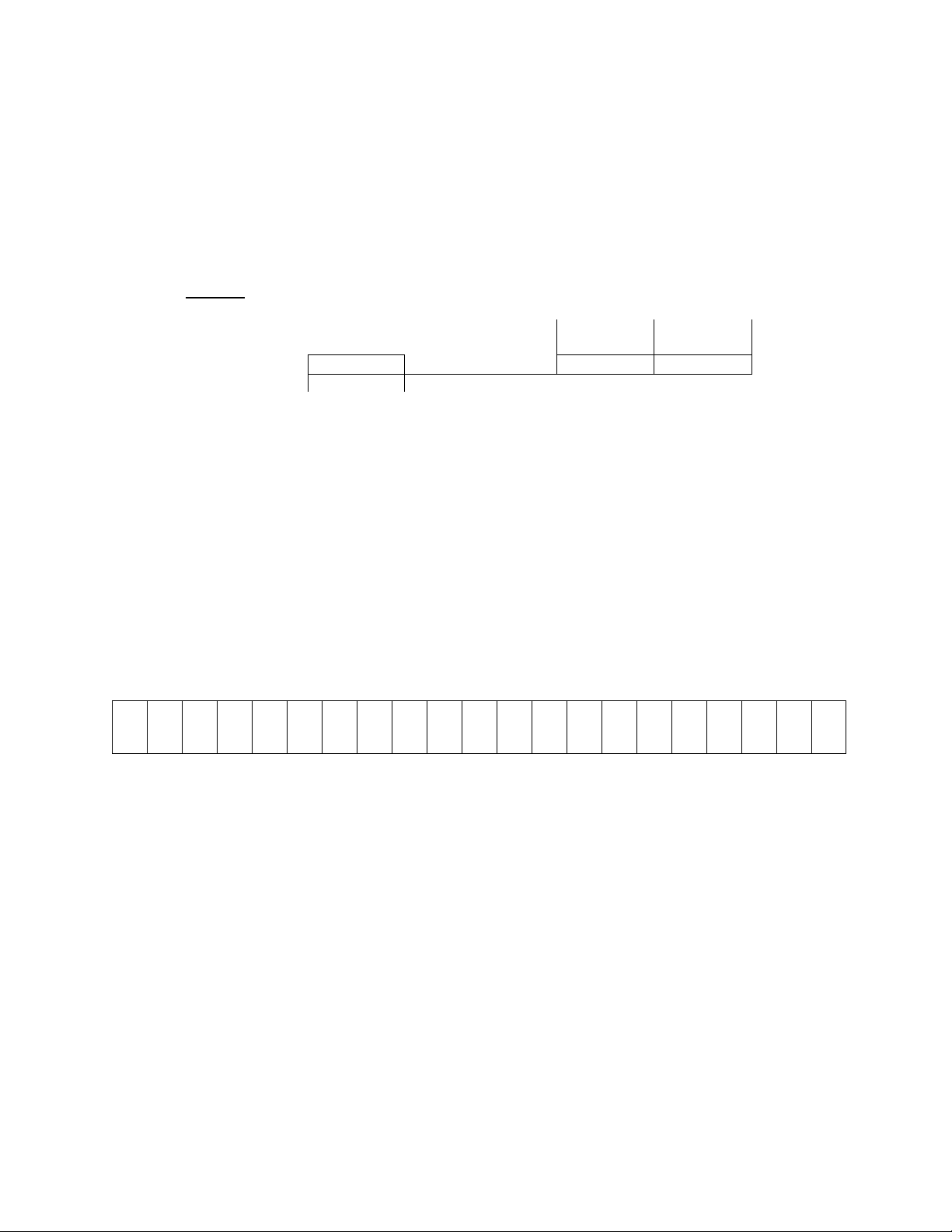

5.5 Jumper Details

10V 5V

IQ OlO

The jumper connections for each of the printed wiring boards on Pages 5-1 through

5-3 are shown in the enlarged details below. Only jumpers JP1 and JP2 should be

adjusted by the user. See Page 5-6 for jumper adjustments.

JP2

o in ni

Detail 1 (Reference pages 5-1 and 5-2)

1 1

1 1

IV 1 1

1 1

1

I V 10V 5V

lO OlO OlO OI

IP1

Detail 2 (Reference page 5-3)

JP2

Note:

Jumper settings as shown in these illustrations are for reference purposes only and do

not necessarily reflect factory settings nor correct settings for a particular application.

5.6 Control/Driver Board Terminal Block Details

The control/driver board terminal block is shown in detail below. Each of the twenty-one

terminals is functionally labeled. See Pages 5-7 and 5-8 for a list of terminal functions.

Control/Driver Board Terminal Block Detail (Reference pages 5-1,5-2, and 5-3)

© © © © © © © © © © © © © © © © © © © © ©

FLA FLB FLC P24 RCH LOW FM AM PP RR IV CC ST F R CC SSI JOG AD2 RST CC

(UL) (LL) (SS2) (SS3)

5-5

Page 24

5.7 Jumper/Terminal Connections and Functions

The following table shows how jumpers JP1 and JP2 are set for use with the analog

input terminal connections RR and IV. Jumper numbers and settings which are shown in

this table are applicable to all printed wiring boards (see page 5-5 for terminal block

and jumper details).

Terminal/Jumper Connections for Input Reference Signals

TOSHIBA

JP1

i V

0 olo

I V

N/A

I V

JP2

10V 5V

I 'vJ I 'v.3

N/A

O

N/A

N/A

10V 5V

I 0.") 'vJ I 00

Terminal Connections

No external connections; JP1 and

JP2 should be set as shown for

keypad operation (normal factory

settinoV

_______________________

0

PP

0-20mA

(4-20mA)

PP

0

PP0RR0IV

15Koh

RR IV

RR IV

0-5Vdc

+

CC

0

CC

0

CC

0-1 OVdc

Use when not inputting any external

reference signals into terminal RR or

IV. P.PrG parameter #2 "priority of

RR terminal input" is N/A.

Use when inputting a 4(0)-20mA

external reference signal to terminal IV.

P.PrG parameter #2 "priority of RR

terminal input" should be set to 0 "on".

See page 7-5.

Use when inputting 0-5Vdc external

reference signal to terminal IV.

P.Prg parameter #2 " priority of RR

terminal input" should be set to 0 "on"

See page 7-5.

Use when inputting 0-1 OVdc external

reference signal to terminal RR.

—

P.Prg parameter #2 " priority of RR

terminal input" should be set to 1 "on".

See page 7-5.

Use when inputting 0-1 OVdc external

reference signal to terminal RR.

P.Prg parameter #2 " priority of RR

terminal input" should be set to 1 "on".

See page 7-5.

Function

10V 5V

0 ('<\ ('i

PP

+

o

SW

c

+

•

.

-r0

s.„

0 o

RR IV CC

f

r-

A

---

y'“

0-20mA

(4-20mA)

Use when inputting a 4(0)-20mA

external reference signal to terminal IV

and a 0-1 OVdc reference signal to

terminal RR.

P.PrG parameter #2 "priority of RR

terminal input" should be set to 1 "on".

Terminal RR will override "have priority

over" terminal IV when switch (SW) is

closed.

See page 7-5.

3K ohm pot divides voitage between terminal PP and CC return. Any pot value between 1K to 10K ohms

can be used but makes adjustment more sensitive.

5-6

Page 25

TOSHIBA

5.8 Terminal Connections and Functions

Terminal

name

LI, L2, L3

(R, S, T)

T1, T2, T3

(U, V, W)

OH

ov

FLA, FLB, FLC

P24

RCH(UL)

Terminal functions Terminal

Input power terminals. Connect to either a 3-phase 50Hz, 200Vac

power supply or to a 3-phase 60Hz, 200 to 230Vac power supply

for models Q2-2035 to Q2-2330.

Input power terminals. Connect to either a 3-phase 50HZ, 380Vac

power supply or to a 3-phase 60HZ, 400 to 460Vac power supply

for models Q2-4055 to Q2-420K.

Output load terminals. Connect these terminals to a 3-phase

induction motor of the proper voltage.

Input terminal for external fault signal.

This is the return terminal for OH.

Output terminals of form C contact changes state when a protective

function has been activated (250Vac - 2A).

Output terminal for unregulated 24Vdc power supply

(100mA maximum output current).

Output terminal (open collector). Provides an output signal ground

(50 mAdc max) when the upper limit frequency is reached, when an

acc/dec is complete, or when the output frequency is within a specified

range. The choice is determined by settings of the Output Terminal

Selection function (:0.tb).

location

Bus bar

or

power

terminal

block

A

Terminal

block

LOW(LL)

FM

AM

PP

RR

IV

CC

(one of three)

Output terminal (open collector). Provides an output signal ground

(50 mAdc max) when a preset low speed or a preset lower limit is

reached. The choice is determined by settings of the Output Terminal

Selection function (:0.tb).

Output terminal for an external analog frequency meter.

Use either an ammeter rated at 1 mAdc at full scale or a voltmeter

rated at 7.5Vdc at full scale.

Output terminal for an external analog ammeter.

Use either an ammeter rated at 1 mAdc at full scale or a voltmeter

rated at 7.5Vdc at full scale.

Regulated 10Vdc power supply to be used with terminal RR for

remote terminal input.

Analog input terminal for a 0 - 5Vdc (JP2 @ 5V) or 0 -10Vdc

(JP2 @ 10V) external reference signal. Also used for wiring a Ik - 10k

ohm (3k ohm recommended) potentiometer to allow for remote speed

control operation.

Analog input terminal for a 0 - 5Vdc (JP1

(JP1 @ I) external reference signal.

This is the common return for PP,RR, and IV terminals.

Do not connect to GND(E).

V) or 4 (0) - 20mAdc

Control

PWB

terminal

block

5-7

Page 26

5.8 Terminal Connections and Functions (cont'd)

TOSHIBA

Terminal

name

ST

CC

(one of three)

SSI

JOG(SS2)

AD2(SS3)

Terminal functions Terminal

location

Input terminal for run interlock. When ST is shorted to CC, the inverter

is ready to run. With ST-CC open the unit will not run and if opened

while running a coasting stop begins.

Input terminal for forward run. When F is shorted to CC, a forward

run starts. With F-CC open, the unit decelerates to a complete stop.

Input terminal for reverse run. When R is shorted to CC, a reverse run

starts. With R-CC open, the unit decelerates to a complete stop.

If terminals F-CC and R-CC are shorted simultaneously, a reverse

run occurs.

This is the common return for ST terminal.

Do not connect to GND(E).

Input terminal for multi-speed run frequencies. Depends on setting of

function [1 .tb], JOG/SS2 and AD2/SS3 terminals. (See Page 10-1)

Input terminal for jogging run or multi-speed run frequencies. Depends

on setting of function [l.tb], SSI, AD2(SS3) terminals. (See Page 10-1)

Input terminal for multispeed run frequencies. Depends on setting of

function [l.tb], SSI, JOG/SS2 terminals. (See Page 10-1)

Control

PWB

terminal

block

RST

CC

(one of three)

GND(E)

(three provided)

R41/46

R40/44 *

R38

RJ *

R20/22

R10/11 *

With RST-CC shorted, the inverter's protective function resets.

This is the common return for ST, F, R, SSI, JOG(SS2), AD2(SS3),

and RST terminals. S

The inverter earth ground terminal.

o not connect to GND(E).

Do not connect to common return terminal (CC).

Jumper to RJ when using 415V-50Hz/460V-60Hz incoming power.

Do not jumper to R40/44 or R38.

Jumper to RJ when using 400V-50Hz/440V-60Hz incoming power.

Do not jumper to R41/46 or R38.

Jumper to RJ when using 380V-50Hz incoming power.

Do not jumper to R41/46 or R40/44.

Common for input power selection. Jumper to either R41/46, R40/44,

or R38. Do not jumper to more than one terminal at a time.

Output power terminal. Supplies 1-phase 200V-50Hz or 1-phase

220V-60HZ @ 40VA maximum.

Output power terminal. Supplies 1-phase 100V-50Hz or 1-phase

110V-60HZ @ 40VA maximum.

Frame

screw or

lug

Terminal

block

A

T10/11 T20/22

Supplied only on the Q2-4055 through Q2-420K units.

Output power return terminal for either 1-phase 200V-50Hz/220V-60Hz

@ 40VA or 1-phase 100V-50Hz/110V-60Hz @ 40VA.

5-8

Page 27

TOSHIBA

6.0 Operating Panel

6.1 Operating Panel Layout

The operating panel enables the user to enable or disable the keypad, input commands

from the keypad, and monitor the inverter operation on the LED displays. The panel

consists of the keypad and LED displays. The illustration below shows the operating

panel layout. See the following section for a description of each key and function.

See page 6-3 for a functional description of the LED display.

O M AN UAL CON TRO L

CLEAR

A

RESET

OH z

O %

OS LO

PRG

RUN

MANUAL

OFF

READ

V

WRITE

SETUP STOP

6.2 Operating Panel Keys and Functions

The following chart explains each of the key functions on the keypad

Keys and Functions

Key

Up scroll key used for increasing frequency or data values, scrolls parameter to

parameter, or upwards scaling of remote meters (FM, AM).

Down scroll key used for decreasing frequency or data values, scrolls parameter

to parameter, or downwards scaling of remote meters (FM, AM).

Used to start a normal forward/reverse run (only in manual mode), manual LED

will flash in run mode even at frequency = 0 Hz.

AUTO

Function

Key enables the manual control mode and allows commands to be entered from

either the keypad or a computer terminal. The Manual control LED is on when

operating in the manual control mode. When switching to auto mode, first press

"off" key; otherwise inverter must be at 0 Hz. If "auto" key is pressed while still

running in manual mode, an ":Err. 7" will flash.

6-1

Page 28

6.2 Operating Panel Keys and Functions (cont'd)

Keys and Functions

Key disables RUN or STOP commands until either the AUTO or MANUAL

key is pressed. Display reads "OFF". Motor coasts to a stop if key is pressed

while motor is running

Disables manual control and turns the manual control LED off; drive will accept

commands from terminal strip connector or computer input only.

This key is used to scroll through the system parameters (see page 7-2), read

READ

WRITE

data from within the group or setup parameters, write data changes into the

non-volatile memory. System status information is available while drive is

running.

Key used to scroll through the parameter groups and returns to frequency

setting if in any other mode.

TOSHIBA

CLEAR

RESET

When data changes have been made in error, this key will allow user to clear

data back to data = 0 (if allowed). Also resets trips, or returns to frequency

mode.

This key stops the drive in manual mode. The manual mode stop can be

programmed to coast or decelerate to a stop. Will cause the drive to trip and

coast in any other mode. Can be used as an emergency stop in any mode.

Allows access to setup parameters only and will automatically return to

frequency mode after all parameters have been stepped through.

6-2

Page 29

TOSHIBA

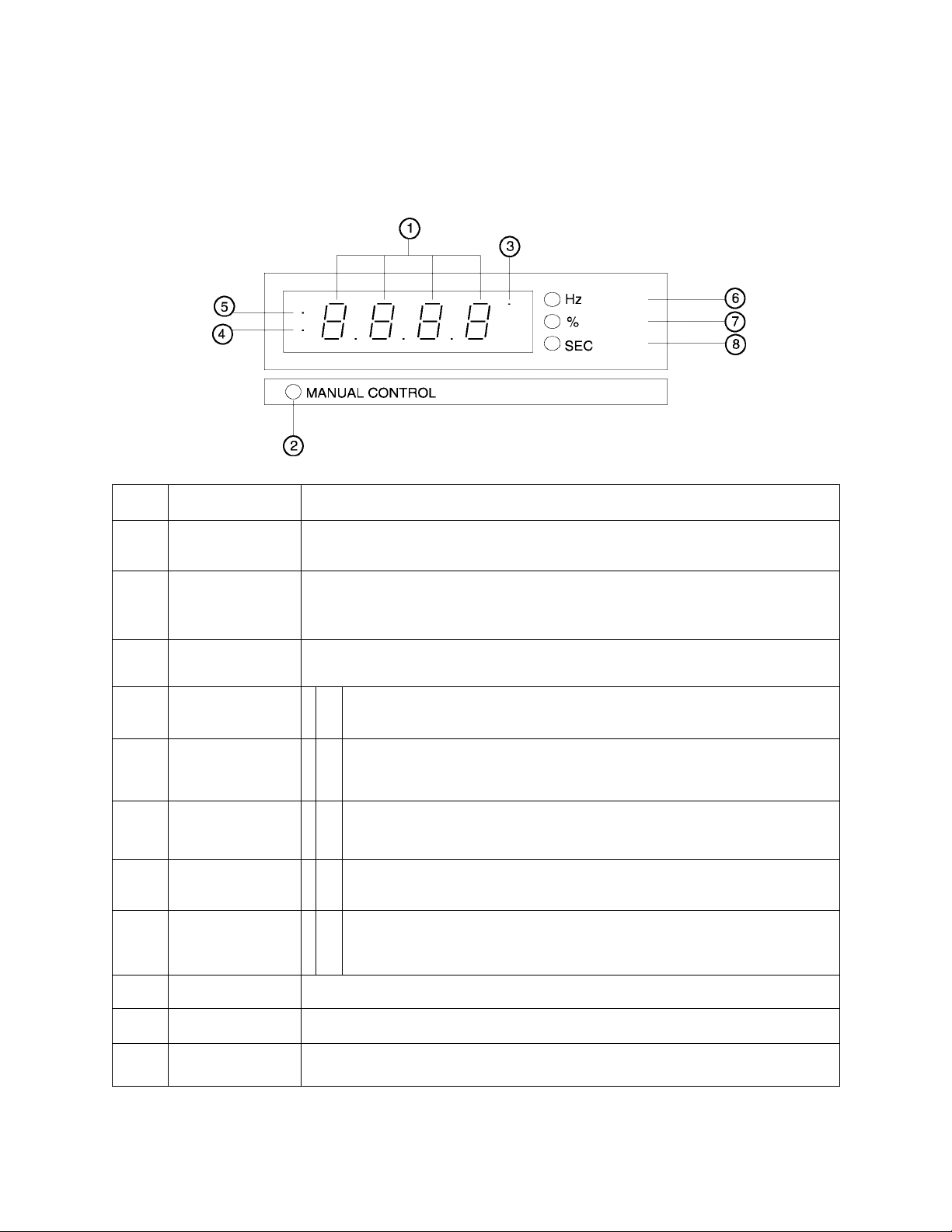

6.3 LED Display and Display Monitoring

The LED display provides the user with the operating frequency, function settings, and

status information necessary to easily monitor and set the operating parameters. The

individual LED's are identified and explained in the following chart.

Display Monitoring

Item Name Function/status

o

©

©

©

©

Monitor display 7-segment, 4-column LED

Displays frequency, title, data, etc.

Panel control LED ON when the unit Is In the manual control mode

OFF when the unit Is In the auto (remote) control mode

FLASHING when the unit is in the manual control mode and the motor is running

Option mode LED ON when the computer interface option is enabled. (Contact Toshiba

for information.)

Both LED's are normally OFF when the monitor is displaying operating

Monitor display

o

frequency or scaled operating frequency from the display scaler.

o

'•

LED 5 is ON and LED 4 is OFF when unit is in a patterned run sequence.

o

Both LED's are ON when the unit is in the parameter setting mode using

the operating panel keypad and the motor is not running.

•

Both LED's are FLASHING when the unit is in the parameter setting mode

~0

using the operating panel keypad and the motor is running.

0

LED 4 is ON and LED 5 is OFF when the unit is in the parameter setting

o'

mode and the operating panel keypad is disabled.

•

(Computer Command Mode)

©

©

©

Hz display LED ON when the display is indicating frequency.

% display LED ON when the display is indicating a percentage.

Time display LED ON when displaying time in seconds.

6-3

Page 30

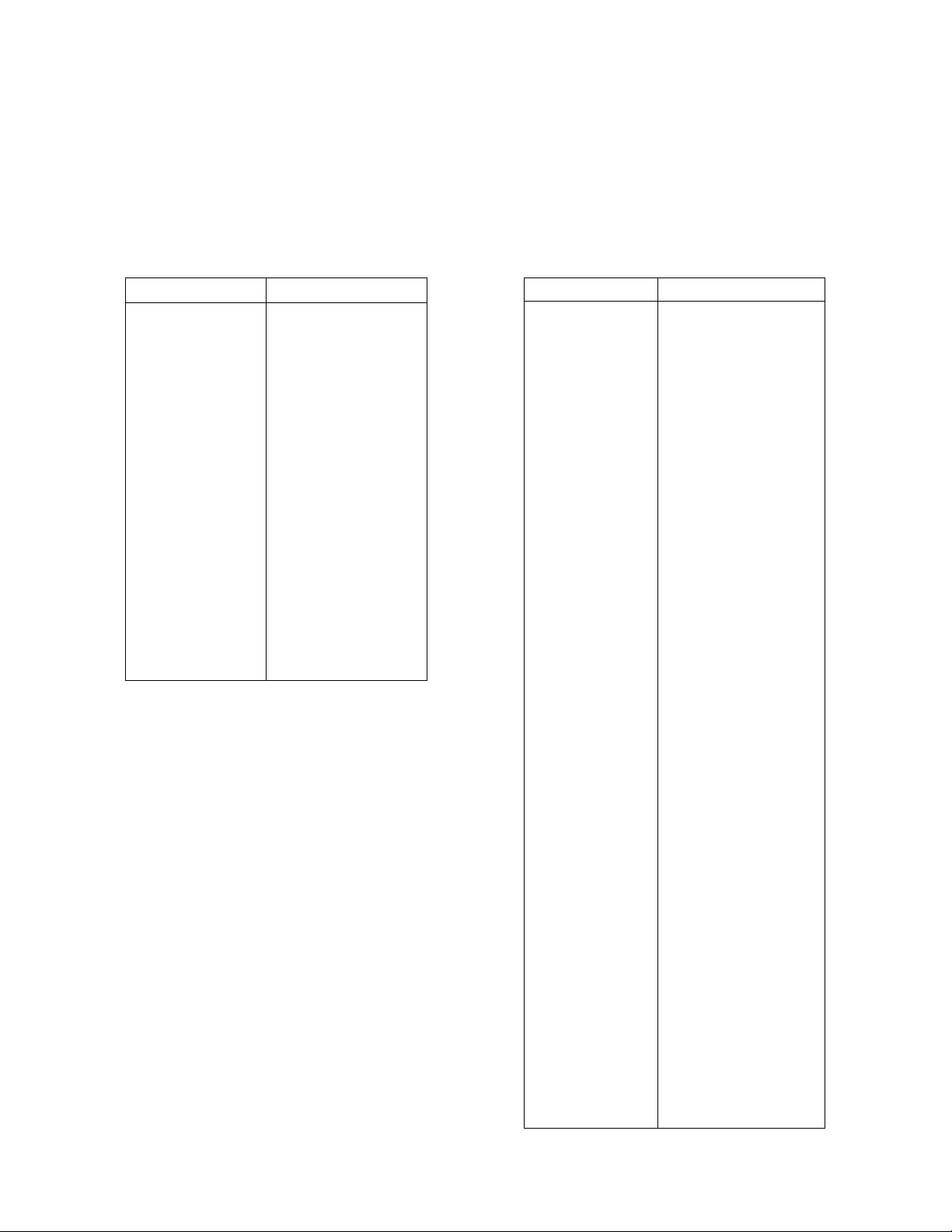

6.4 Display Alphanumerics

The 7 segment LED display is able to display all of the numerals but is unable to

properly form all of the characters of the alphabet. Therefore some characters of the

alphabet will appear as special symbols and others are not used at all. The tables

below show the numbers and characters that are used and how each appears on the

7 segment display.

TOSHIBA

Numerics LED display

0

1

2

3

4

5

6

7

8

9

/_/

l_

1 1

/_/

/_/

_l

n

/

/

~l

~l

1

l~

_f

l~

1

1

n

n

Characters LED display

A

b

C

d

E

F

G

H

1

1

J

L

M

n

1 1

1

u

r

l_

1

u

r

l_

r

1

r

u

1 1

1 1

1

1

1

u

1

l_

n

1 1

6-4

O

u

y

n

n

LI or U

P

r

S

t

V

-

n

1

r

1

1 1

u

LI

1 1

J

-

r

J

l_

Page 31

TOSHIBA

7.0 Parameter Groups

7.1 Definitions of Setup and Group Parameters

SETUP PARAMETERS

This parameter group is accessed by pressing the dedicated "SETUP" key on the

keypad. This parameter group should not be considered operationally any different

from other parameter groups. This group is assigned a dedicated key because of the

probable need to access It most often and because It contains the adjustable parameters

considered "fundamental" to drive operation and application. This includes parameters

such as acceleration and deceleration times, upper and lower frequency limits, bias and

gain, electronic thermal protection, and stall prevention activation.

USER GROUP PARAMETERS

This parameter group is accessible from the group parameter menu. The menu can be

scrolled by repeated pressing of the "PRG" key. This group contains features such as

assignment of a personal lockout code, options for the Volts per Hertz (V/F) ratios, reset

to factory settings, limiting maximum frequency, setup of automatic torque boost and

level, #2 acceleration and deceleration time and selection of patterns for #1 or #2.

COMMUNICATION GROUP PARAMETERS . l . r r u

This parameter group is accessible from the group parameter menu. The menu can be

scrolled by repeated pressing of the "PRG" key. This group contains features for setting

up the serial communication protocol, carrier frequency selection, input and output

terminal selection, and setting up the unit for power failure control and automatic

restarting.

JUMP FREQUENCY GROUP PARAMETERS . .

This parameter group is accessible from the group parameter menu. The menu can be

scrolled by repeated pressing of the "PRG" key. This group contains features for setting

three different operating patterns jump frequency and jump width. This group also

contains selections for PID control and adjustments.

DISPLAY GROUP PARAMETERS

This parameter group is accessible from the group parameter menu. The menu can be

scrolled by repeated pressing of the "PRG" key. This group contains features for setting

up low speed frequency detection and speed reach selection. It also contains settings

for DC braking.

■ I (

■ u .

L

LI .

I

LI

SPEED GROUP PARAMETERS

This parameter group is accessible from the group parameter menu. The menu can be

scrolled by repeated pressing of the "PRG" key. This group contains features for setting

multispeed run frequencies 1 - 6 and firespeed override frequency.

PATTERN FREQUENCY GROUP PARAMETERS

This parameter group is accessible from the group parameter menu. The menu can be

scrolled by repeated pressing of the "PRG" key. This group contains features for setting

pattern 1 - 7 forward or reverse and run time, number of cycles, jog frequency, jog stop

pattern selection, and setting of hysteresis.

In each of the above group parameters, some of the more important functions have been

mentioned. The following System Parameters Adjustment Range and Factory Setting

tables show all of the group parameters and each of the functions are shown in detail.

The ITEM NO. Is an Identifier used for reference only. It shows the correct numerical

order for each function. This is helpful when locating the function definition in Keypad

Operating Functions (See Section 9.0 page 9-1).

, I I

u

I I

7 -1

Page 32

7.2 System Parameters Adjustment Range and Factory Settings

TOSHIBA

PARAMETER

DISPLAY

• I ( / 1 /

.I'LL 1

• 1 r r 1

• LI L L I

•III

• /_i L

• / /

• /_ L

• /~/ (

• 1 1

• r n 1

, / “ 1 1

• /~/ “(

• 1 L

• /“ n 1

. I II-

• 1 II

»1-111

• r 1 1

• _/ L L

• r r 1 II

• _/ L L 1

• M n r

. L' . 1 r LI

• /“ M

. r I I

• n L L

. n . L LI

• / (

• L LI

• / r 1

• LI 1 L

• 1 1 ( n

. L _( 1

• n r r 1

. 1 1 L L L

• 1 r r 1

• LI L L L

• n L 1

.1 L . 1

• n / “1

.1 L . L

•/“LI “1

• _l L L L

• n 1

• 1 L

• L L r r

. 1

_

1, L -1

• r 1 r

• L LI LI L

ITEM

NO.

PARAMETER

DESCRIPTION

ADJUSTMENT

RANGE

FACTORY

SETTING

REFERENCE

SETUP PARAMETERS *

1 Acceleration time #1

2 Deceleration time #1

3 Upper frequency limit

4

5

Lower frequency limit

Terminal IV point #1 setting signal

6 Point #1 output frequency

7

Terminal IV point #2 setting signal 0-100% 100% 9-1

8 Point #2 output frequency

0.1 - 1200 sec 90.0 sec 9-1

0.1 - 1200 sec 120.0 sec 9-1

0.0 Hz - FH

0.0 Hz - UL

60.0 Hz 9-1

0.0 Hz 9-1

0-100% 20% 9-1

0.0 Hz - FH

0.0 Hz - FH

0.0 Hz 9-1

60.0 Hz 9-1

9 Electronic thermal protection level 10-100% 100% 9-1

10

11

Stall prevention activation level

10-120% 120% 9-1

Electronic thermal protection select 0: STD-motor, no soft stall

0

1: STD-motor, soft stall

2: VF-motor, no soft stall

3: VF-motot, soft stall

USER GROUP PARAMETERS **

1

2

Maximum frequency 30 - 160 Hz 60 Hz 9-3

Automatic torque boost 0: Off

0 9-3

1: On

3 Torque boost 0 - 30 % 3% 9-3

4

5

Base frequency of maximum voltage level 25 - 160 Hz 60 Hz 9-3

Standard setting mode selection

0: Factory settings

0 9-3

1: 50 Hz motor

2: 60 Hz motor

3: Reset to factory settings

6

7 Deceleration time # 2

8 Pattern of ACC/DEC #1

Acceleration time #2

0.1 - 1200 sec 10.0 sec 9-3

0.1 - 1200 sec 10.0 sec 9-3

0: Linear

0 9-3

1: S-curve

2: C-curve

9 Pattern of ACC/DEC #2

0: Linear

1 9-4

1: S-Curve

2: C-Curve

10 Selection to use ACC/DEC #1 or #2 0: Acc/Dec #1

0

1: Acc/Dec #2

11 V/F pattern

0: Constant torque

1 9-4

1: Variable torque

12

Timed stop/coast to stop selection

0: Deceleration stop

0

1: Coast to stop

13 Personal lock out code 0 - 255 0

PAGE

9-2

9-4

9-4

9-4

7-2

Page 33

TOSHIBA

7.2 System Parameters Adjustment Range and Factory Settings (cont'd)

PARAMETER

DISPLAY

• r n r

. L . 1 r LI

• n r 1

•III _l L

• _ L (1

. / LI 1

• n r r

• 1 / . L

• 1 r /

, L / . L L

• ( / /

• i . L LI

• ri 1 1

• IJ*L M 6 Output terminal selection

• n n L

• LI 1 L

• ( _ _

• ( . M LI .

• / n 1

, IJ.I II L

ITEM

NO.

1

Automatic restart after Instantaneous power

2

3

Power failure function selection

(This function valid on 230 volt units only)

4 Fault trip data retention selection

5 Input terminal selection 0: SS2, SS3

7

Option card multi-functional selections 0: Off

8

9 Baud rate (RS232/RS485) 0: 150/1200

PARAMETER

DESCRIPTION

COMMUNICATION GROUP PARAMETERS **

failure selection

Automatic reset selection 0: Off

Inverter number

ADJUSTMENT

RANGE

0: Off

1: On

1: On

0: Off

1: On

0: Cleared

1: Saved

1: JOG, SS3

2: SS2, AD2

3: JOG, AD2

0: LL, UL

1: LOW, UL

2: LL, RCH

3: LOW, RCH

1: 12 bit binary absolute

input

2: 12 bit binary relativity

input

3: 3 number BCD input

4: 3 number BCD input

5: Pulse frequency

reference incut

6: Multi-speed input

7: Selection 1 with write

signal

8: Selection 2 with write

signal

9: Selection 3 with write

signal

10:Selection 4 with write

signal

11 :Selection 5 with write

signal

12:Selection 6 with write

signal

0-31 0 9-6

1: 300/2400

2: 600/4800

3: 1200/9600

4: 2400/19200

FACTORY

SETTING

1

1

0 9-6

0 9-6

0 9-6

3 9-6

0 9-6

0 9-6

REFERENCE

PAGE

9-5

9-5

• r LI/

• L , LI 1 L

• r L n

. _/ L , 1 1

• r r

• L 1

10

Communication data bits

0: 7 bits

1: 8 bits

11 Communication parity check and stop bit 0: Even

1: Even

2: N/A

3: N/A

4: Odd

5: Odd

12 PWM carrier frequency

7-3

5 - 16 kHz

0 9-6

0 9-6

12 kHz

9-6

Page 34

7.2 System Parameters Adjustment Range and Factory Settings (cont'd)

PARAMETER

DISPLAY

• 1 n r

. LI • ' 1 l-l

• r II

, I LI 1

• I r II

• LI 1 LI '

• r 11

• ' LI L

• I r 1 “1

• LI 1 U L

• r 1 J

, r LI

• ( r 11

, LI 1 LI J

• L L M 1

.1 LI. r 1

• (1

• LI 1

• r 1

• LI >

• (1

• LI M

• r r r

• LI 1 J

• 1 (1

.(-/.( 1 LI

• J r n 1

. LI J 1 . L

ITEM

NO.

PARAMETER

DESCRIPTION

ADJUSTMENT

RANGE

FACTORY

SETTING

JUMP FREQUENCY GROUP PARAMETERS **

1 Jump frequency #1 0.0 Hz - FH 0.0 Hz 9-7

2 Jump width #1 0.0 Hz - FH 0.0 Hz 9-7

3 Jump frequency #2 0.0 Hz - FH 0.0 Hz 9-7

4 Jump width #2 0.0 Hz - FH 0.0 Hz 9-7

5 Jump frequency #3 0.0 Hz - FH 0.0 Hz 9-7

6 Jump width #3 0.0 Hz - FH 0.0 Hz 9-7

7 PID setpoint control select 0: Off

1: On

8 Proportional gain 0 - 9999 1000 9-7

9 Integral gain 0 - 9999 500 9-7

10 Differential gain 0 - 255 0 9-7

11 Lag time constant 0 - 255 255 9-7

DISPLAY GROUP PARAMETERS **

1 Universal unit multiplication factor 0.00 - 200.0

(0.00 = OFF)

0 9-7

0.00 9-8

TOSHIBA

REFERENCE

PAGE

• 1 r

• L r

• r 1 I

,1 L M

2 Low speed detection 0.0 Hz - FH 0.5 Hz 9-8

3 Speed reach selection 0: Complete ACC/DEC

1 9-8

1: Frequency reach

reference

• r M

.1 1 L M 4 Speed reach detection range 0.0 Hz - FH 2.5 Hz 9-8

• r r 1 1

• 1 / L M

• 1 1 r

• LI LI I

• 11/

, LI LI L

• III

, LI IJ L

• ll nil /

• r.lj LI L

• ll n (“ /“

• Ll 1 J, J

5 Speed reach reference 0.0 Hz - FH 60.0 Hz 9-8

6 DC injection voltage start frequency 0.0 Hz - 10.0 Hz 0.0 Hz 9-8

7 DC injection voltage 0 - 20 % 0 % 9-8

8 DC injection time 0.0 - 5.0 sec 0.0 sec 9-8

9 Output voltage regulation 0 - 100 % 100 % 9-8

10 Overvoltage stall protection select 0: On

0 9-8

1: Off

• r ri /“

.1.1 1 Ll

• r r 1 1 r

. L , L II IJ

1 AC line/inverter transfer signal 0: Off

SPEED GROUP PARAMETERS **

0 9-9

1: On

• r 1

.-If I

• r 1

. -1 I L

• L _ 1

. -1 ' 1

• r II

.-If 1

• r r

.-If -f

• r r

. -1 1 Ll

• r r r

. 1 -f Ll 1

2 Multispeed run frequency #1 LL - UL 0.0 Hz 9-9

3 Multispeed run frequency #2 LL - UL 0.0 Hz 9-9

4 Multispeed run frequency #3 LL - UL 0.0 Hz 9-9

5 Multispeed run frequency #4 LL - UL 0.0 Hz 9-9

6 Multispeed run frequency #5 LL - UL 0.0 Hz 9-9

7 Multispeed run frequency #6 LL - UL 0.0 Hz 9-9

8 Firespeed override frequency (Sr7) LL - UL 0.0 Hz 9-9

7-4

Page 35

TOSHIBA

7.2 System Parameters Adjustment Range and Factory Settings (cont'd)

PARAMETER ITEM PARAMETER ADJUSTMENT FACTORY REFERENCE

DISPLAY

• n n r

•1*1 I IJ

• r

• r r

• ' ' '

• ri r r /

• I • / 1 f

• ("1 / 1

. L , L

• l"l L

• / L . M

• l"l L 1 L

. / . 1 L

• ("1 / 1

. r 1 ,1

• (“1 1 11

. r L.LL

• n L J

•111 11

.1 L.JL

• n L J

• ( 1 L I ( L

. i L . -( L

• (“1 L 1 1

• J 1 • 1

• (“1 1 r 1

. r L.JL

• n L r

• J 1 • 1

• n 1 rl

• 1 1-0 LIL

• 0 L L

•111 11

0 1 1-0 1 L

• 0 L J

NO.

1 Forward/Reverse rotation select 0 Reverse 1 9-10

2 Priority of RR terminal input 0 IV terminal input "on" 0 9-10

3 Mode for pattern run *** 0 Off 0 9-10

4 Time unit for pattern run time seiect *** 0 Seconds 0 9-10

5 Quantity of pattern run cycles *** 0 - 255 0 9-10

6 Pattern #1 run time *** 0 - 8000 0 9-10

7 Pattern #1 drive characteristics *** 0 Fwd run #1 Acc/Dec 0 9-10

8 Pattern #2 run time *** 0 - 8000 0 9-10

9 Pattern #2 drive characteristics *** 0 Fwd run #1 Acc/Dec 0 9-10

10 Pattern #3 run time *** 0 - 8000 0 9-10

11

12 Pattern #4 run time ***

13 Pattern #4 drive characteristics *** 0 Fwd run #1 Acc/Dec 0 9-10

14 Pattern #5 run time ***

15 Pattern #5 drive characteristics *** 0 Fwd run #1 Acc/Dec 0 9-10

Pattern #3 drive characteristics *** 0 Fwd run #1 Acc/Dec 0 9-10

16

17

18

19 Pattern #7 drive characteristics *** 0 Fwd run #1 Acc/Dec 0 9-11

Pattern #6 drive characteristics *** 0 Fwd run #1 Acc/Dec 0 9-11

DESCRIPTION RANGE

PATTERN FREQUENCY GROUP PARAMETERS

1 Forward

1 RR terminal input "on"

1 Terminal

2 Computer

1 Minutes

1 Fwd run #2 Acc/Dec

2 Rev run #1 Acc/Dec

3 Rev run #2 Acc/Dec

1 Fwd run #2 Acc/Dec

2 Rev run #1 Acc/Dec

3 Rev run #2 Acc/Dec

1

Fwd run #2 Acc/Dec

2 Rev run #1 Acc/Dec

Rev run #2 Acc/Dec

3

1

Fwd run #2 Acc/Dec

2 Rev run #1 Acc/Dec

Rev run #2 Acc/Dec

3

1

Fwd run #2 Acc/Dec

2 Rev run #1 Acc/Dec

Rev run #2 Acc/Dec

3

Pattern #6 run time ***

1

Fwd run #2 Acc/Dec

2 Rev run #1 Acc/Dec

Rev run #2 Acc/Dec

3

Pattern #7 run time ***

1

Fwd run #2 Acc/Dec

2 Rev run #1 Acc/Dec

Rev run #2 Acc/Dec

3

SETTING

**

0 - 8000 0 9-10

0 - 8000 0 9-10

0 - 8000 0 9-11

0 - 8000 0 9-11

PAGE

7-5

Page 36

7.2 System Parameters Adjustment Range and Factory Settings (cont'd)

PARAMETER

DISPLAY

• n n r

. r . 1 r U

• 1 n r

• U U LI

• 1 r 1 n

• LI. _/L 1

• r r /

. ' ~ -1 L

• r

, I ,/ IJ 1 1

• r L' U r

. ' ' J J

ITEM

NO.

20 Jog frequency 0.0 - 20.0 Hz 5.0 Hz 9-11

21 Jog stop select 0: Deceleration stop

22 Start-up frequency 0.0 - 10.0 Hz 0.0 Hz 9-11

23 Run frequency 0.0 Hz - FH 0.0 Hz 9-11

24 Run frequency hysteresis 0.0 Hz - FH 0.0 Hz 9-12

PARAMETER

DESCRIPTION

PATTERN FREQUENCY GROUP PARAMETERS (cont'd) **

ADJUSTMENT

RANGE

1: Coast to stop

2: DC Injection stop

FACTORY

SETTING

0 9-11

Parameters are alternately exhibited from setup menu by alternately pressing SETUP

key. Value of parameter can be read by pressing READ/WRITE key. Value can be

changed by continued pressing of "up" or "down" key. When desired value is reached

press the READ/WRITE key to store new value.

TOSHIBA

REFERENCE

PAGE

Group parameters are exhibited from group parameter menu by pressing PRG key.

When the desired group parameter is reached, individual parameters within the group

can be exhibited by alternately pressing the "up" or "down" key. Value of exhibited

parameter can be read by pressing READ/WRITE key.

Value of exhibited parameter

can be changed by continued pressing of "up" or "down" key. When desired value is

reached press the READ/WRITE key to store new value.

When P.SEL (mode for pattern run) is set to 0; pattern run times (Pt.It through Pt.7t)

and pattern run selections (Pt.1 through Pt.7) will be skipped when scrolling through

the Pattern Frequency Group Parameters.

7-6

Page 37

TOSHIBA

8.0 System Status Monitoring

The inverter operates with varying levels of supply voltage and current. A variable output

frequency of voltage and current is generated to drive the motor load. These input and output

levels of operating voltage and current are continually monitored by the inverter. It also monitors

for over temperature, input and output terminal settings, and condition of the microprocessor

with associated memory elements. These operating settings and variables have a certain value

or "status" associated with them and are used for inverter operation. They can also be monitored

by the operator to show the setup and conditions existing at any time. Three types of status

monitoring are used and explained below.

8.1 Normal Status Monitoring

Normal status monitoring occurs during normal operation. The ST-CC terminal must be

closed to run. The following table shows applicable keys, display, and status conditions

for normal status monitoring. The display values are for factory settings where no trips

or errors occurred. The display will change only if a new value is programmed into the

associated group adjustment range or if trips or errors have occurred. Scrolling occurs

by repeatedly pressing the READ/WRITE key after output frequency is displayed. Trips

or errors that have occurred (up to a total of three), will be displayed in order immediately

after the keypad software version display.

Key Display Status Condition

OFF

AUTO

MAN

RUN

STOP

RD/WRT

RD/WRT

RD/WRT

RD/WRT

I I L L

U I I

I I I I

u. u

I I I I

u. u

[Output Frequency]

/ or /

i_ I I II

u u

•

u

I I

u

Inverter is in the off position when ":OFF" is flashing.

Inverter is ready to run from terminal or computer interface.

Inverter is ready to run from keypad and manual control LED

is on.

Displays inverter's output frequency.

Emergency stop executed from keypad while in an automatic

run or while in remote control mode when "E" is flashing.

Indicates a forward (F) or reverse (r) run. If not running,

the display refers to the direction the unit would run.

Displays the frequency which the inverter is set to output

when running (60 FIz is factory setting).

Displays the percentage of the inverter's rated output current

when running (displays "0" when not running).

Displays the percentage of the inverter's rated output voltage

when running (displays "3" when not running).

RD/WRT

RD/WRT

RD/WRT

RD/WRT

RD/WRT

RD/WRT

I u n

I - I u

II III

u - u I

/_ _i

LI .-I.-I

• Ul_ II

.U.i -i.u

’

u

I I .I 1.1- I I

[Output Frequency]

Displays input terminal status code. See page 8-4

Displays output terminal status code. See page 8-5

Displays inverter's software version.

Displays keypad's software version.

Displays 4th error (no error occurred).

Returns to the original display of output frequency.

8-1

Page 38

8.2 Automatic Status Monitoring

Automatic status monitoring displays abnormal status conditions that can occur during

normal inverter operation. These conditions will cause warnings and error messages

to be displayed but will not cause the inverter to trip. The table below shows these

abnormal conditions and the associated display that will appear. These displays usually

appear during the time that the abnormal condition is occurring and will go away when it

is corrected. The abnormal condition should be corrected as soon as possible.

TOSHIBA

Key Display

r L

_( L

U I I i_ i_

I U I I

I I I I L L

I I U I I

I_ [Output Frequency]

p [Output Frequency]

)_ [Output Frequency]

I-

L I I . I

L

I- I I . I

O P P n

__

/

____

I

Status Condition

ST-CC terminal connector is open (must be connected to run).

The main AC supply power is low.

The inverter's DC bus voltage is low.

Stall prevention is activated when flashing "C" appears in

front of output frequency.

Overvoltage limitation is activated when flashing "P" appears

in front of output frequency.

Overload detection is activated when flashing "L" appears in

front of output frequency.

This error occurs while trying to switch from manual to

automatic mode or automatic mode to manual while inverter

is outputting a frequency.

This is a frequency setting signal error. Points 1 and 2 of a

frequency setting signal are to close together. Correct the

setting of points 1 and 2 by providing an adequate distance

between them.

r I I

r r r. u

r I I

crr.i-i

This error can be seen when attempting to set any of the

parameters with incorrect data values.

This error can be seen when attempting to set any of the

parameters with incorrect data values.

8-2

Page 39

TOSHIBA

8.3 Tripped Status Monitoring

Tripped status monitoring displays abnormal status conditions that can occur during

normal inverter operation. The table below shows these abnormal conditions which will

cause the inverter to trip "off" (stop normal operations). They are usually caused by

excessive power dissipation in either the inverter or motor, or by other circuit

abnormalities. A tripped status monitoring display usually appears during the time that

the abnormal condition is occurring and then remains on the display after the inverter

trips off. The inverter will remain off and the tripped status will remain displayed until the

inverter is attended to (reset) by the operator. Most conditions, which cause the inverter

to trip, occur very rapidly and the operator usually will not be aware that the trip

conditions are in process until the inverter has stopped. Each of the trip statuses are

automatically recorded in the non-volatile EEPROM memory of the inverter. An ordered

semi-permanent record of each trip (up to four) is created and can be viewed during the

normal status monitoring "scroll". These recorded trips are viewed immediately after the

keypad's software version, in the order that they occurred, as the READ/WRITE key is

pressed. These trips remain in the memory until replaced by new trips.

Key Display

n r I

U

L

Ill _/

u i_ i_