Page 1

Q7 Adjustable Speed Drive Installation

and Operation Manual

Document Number: 57246-001

Date: June, 2005

Page 2

Introduction

Congratulations on the purchase of the new Q7 Adjustable Speed Drive (ASD). The Q7 ASD is a solidstate AC drive. The Q7 ASD is ideally suited to drive the variable tor que load of an HVAC system.

Toshiba’s technology, quality, and reliabilit y enables the motor to develop high torque and provide

compensation for motor slip, which results in smooth, quick starts and highly efficie nt operation. The Q7

ASD uses digitally- controlled pulse width modulation. The programmable functions may be accessed via

the easy-to-use menu. These features, combined with Toshiba’s high-performance software, delivers

unparalleled motor control and reliability.

The Q7 ASD is a very powerful too l, yet surprisingl y s im ple to operate. The Q7 ASD has an easy-to-read

LCD screen that provides easy access to the many monitoring and programming features of the Q7 ASD.

The motor control software is menu-driven, which allows for easy acc ess to the motor control parameters

and quick changes when required.

To m aximize the abilities of your new Q7 ASD, a working familiarity with this manual will be requir ed.

This manual has been prepared for the Q7 ASD installer, operator, and maintenance personnel.

Whether you are using the Q7 ASD Powe r Unit or the Q7 Flow, both are truly

Reliability in motion.

Important Notice

The instructions contained in this manu al a r e not intended to cover all details or variations in equipment

types, nor may it provide for every possible contingency concerning the installation, operation, or

maintenance of this equipment. Should additional information be required contact your Toshiba

representative.

The contents of this ma nual shall not become a part of or modify any prior or existing agre ement,

commitment, or relationship. The sales contract contains the entire obligation of Toshiba International

Corporation. The warranty contained in th e cont ract between the partie s is the sole warranty of Toshiba

International Corpora tion and an y statement s containe d herein do not cre ate new warrant ies or modify the

existing warranty.

Any electrical or mechanical modifications to this equipment without prior written consent of Toshiba

International Corporation will void all warranties and may void the UL/CUL listing or other safety

certifications. Unauthorized modifications may also result in a safety hazard or equipment damage.

Misuse of this equipment could result in injury and equipment damage. In no event will Toshiba

Corporation be responsible or liable for direct, indirect, special, or consequential damage or injury that

may result from the misuse of this equipment.

Page 3

About This Manual

This manual was written by the Toshiba Technical Publications Grou p. Th is group is tasked with

providing technical documentation for the Q7 Adjustable Speed Drive. Every effort has been made to

provide accurate and concise informati on to you, our customer.

At Toshiba we’re continuously searching for better ways to meet the constantl y changing needs of our

customers. Email your comments, questions, or concerns about this publication to

Jay.Williams@TIC.TOSHIBA.COM.

Manual’s Purpose and Scope

This manual provides information on how to safely install, operate, maintain, and dispose of your

Q7Adjustable Speed Drive. The information provided in this manual is applicable to the Q7

Adjustable Speed Drive only.

This operation manual provides information on the various features and functions of this powerful c ostsaving device, including

• Installation,

• System operation,

• Configuration and menu options, and

• Mechani cal and electrical specifications.

Included is a section on general safety i ns tructions tha t describe the warning labels and symbols that a r e

used. Read the manual c omple tely be fore ins tal lin g, opera ting, perf orming mai ntena nce, or dispos ing of

this equipment.

This manual and the accompanying drawings should be considered a permanent part of the equipment

and should be readil y available for reference and review. Dimensions shown in the manual are in met ric

and/or the English equivalent.

Because of ou r commit ment to cont inu ous im prov ement, Toshiba Interna ti onal Cor pora tion re serve s the

right, without prior notice, to update information, make product changes, or to discontinue any product

or service identified in this publication.

Toshiba International Corporation (TIC) shall not be liable for direct, indirect, special, or

consequential damages resulting from the use of the information contained within this manual.

This manual is copy righted. No part of this manua l may be photocopied or reproduced in any form

without the pr ior written consent of Toshiba International Corporation.

© Copyright 2005 Toshiba International Corporation.

TOSHIBA is a registered trademark of the Toshiba Corpora tion. All other product or tra de re fere nces

appearing in thi s manual are registered trademarks of their respecti ve owners.

Reliability in m o ti on ™ is a registered trademark of the Toshiba Corporation.

All rights reserved.

Printed in the U.S .A.

Page 4

Contacting Toshiba’s Customer Support

Center

Toshiba’s Customer Support Center can be contacted to obtain help in resolving any Adjustable Speed

Drive system problem that you may experience or to provide application information.

The center is open from 8 a.m. to 5 p.m. (CST), Monday through Friday. The Support Center’s toll free

number is US (800) 231-1412/Fax (713) 466-8773 — Canada (800) 527-1204.

You may also contact Toshiba by writing to:

Toshiba Inte r national Corpor ation

13131 West Little York Road

Houston, Texas 77041-9990

Attn: ASD Product Manager.

For further information on Toshiba’s products and services, plea se visit our website at

www.tic.toshiba.com.

TOSHIBA INTERNATIONAL CORPORATION

Q7 Adjustable Speed Drive

Please complete the Warranty Card supplied with the ASD and return it to Toshiba by prepaid mail. This will

activate the 12 month warranty from the date of installation; but, shall not exceed 18 months from the shipping

date.

Complete the following information and retain for your records.

Model Number: ______________________________________________________________________

Serial Number:_____ ________________________________________________________ _________

Project Number (i f applicable):__________________________________________________________

Date of Installation:

Inspected By:______________________________________________________________________

Name of Application:_________________________________________________________________

__________________________________________________________________

Page 5

Table of Contents

Gener a l Sa fe t y Inf o r ma t i on ..... ... .. ............... .. ... .............. ... .. ............... .. ... .............. ... .. ............1

Safety A le r t Sy m b o l . .. ............... .. .. ............... .. ... .............. ... .. ............... .. ... .............. ... .. 1

Signa l Wo r ds ......... ... .. ...................... .. ... .............. ... .. ...................... .. ... ............... .. .. ... .. 1

Specia l S y mb o ls ........... ... .............. ... .. ............... .. .. ...................... ... .. ............... .. ... .............. 2

Electri cal Hazar d Symbol . ........ .. .. ...................... ... .. ............... .. ... ...................... .. .. ..... 2

Explosion Hazard Symbol .......................................................................................... 2

Equipment Warning Labels ................................................................................................ 2

Qualified Pers onnel .................................. .......... .......... ..................... .......... .......... .............3

Equipment Inspection ......................................................................................................... 3

Handling and Storage ......................................................................................................... 3

Disposa l ....... ....... .......... .......... .......... ....... .......... ......... .......... ....... .......... .......... .......... ......... 4

Install at i on P r ec au ti o n s ... .. .. ............... .. ... .............. ... .. ...................... ... .. ............... .. ... ......... 4

Location and Ambient Requirements ......................................................................... 4

Mounting Requirements .............................................................................................. 5

Conductor Requirements and Grounding ........................... ..................................... ...5

Power Connections .....................................................................................................5

Protection .................................................................................................................... 6

System I n tegrati o n Prec au t io n s .......... .. ... ...................... .. ... .............. ... .. ...................... .. ... .. 6

Personnel Protection ................................ .......... .......... .......... ..................... .......... ......7

System S et u p Req u i re m e n ts ............... .. ... .............. ... .. ...................... ... .. ............... .. ... ......... 7

Opera ti on a l an d Ma in t en ance Precautio n s ................. ... .. ............... .. ... .............. ... .. ............ 8

Service Life Information ............................................................................................. 9

CE Compliance Requirements ............................................................................................. 10

EMC Installation Guidelines ............................................................................................ 10

Gener al EMC G u id el i ne s for Co n si d er at i on ............ ....... ... .. ... ....... .. ... ...................... 10

CE Comp l ia n t I ns ta ll a t io n Gui d el in es .... ............... .. ... .............. ... .. ............... .. ... ....... 10

Motor C h a ra ct e ri s tics ....... ............... .. ... ..................... ... .. ............... .. ... ...................... .. ... ....... 12

Pulse Width Modulation Operation ............. ..................... .................. ........... .......... .........12

Overload Protection Adjustment ...................................................................................... 12

Power F ac to r Co rr ection . .............. ... .. ............... .. .. ...................... ... .. ............... .. ... ............ 12

Light Load Condi tions ............................. ........ ........... ........ .................................... .........12

Load-p ro d uc e d Neg ative Torque ... ....... ... .. ...................... ... .. ...................... .. ... ................. 12

Motor Braking ..................................................................................................................13

ASD Characteristics .............................................................................................................. 13

Over-current Protection .................................................................................................... 13

ASD Capacity ...................................................................................................................13

Instal la t io n a n d Con nectio ns ........... ....... .. ... .............. ... .. ............... .. ... .............. ... .. ............... 14

Install at i on N ot e s ... .. ...................... ... .. ............... .. .. ...................... ... .. ...................... ... .. ..... 14

Mounting the ASD ........................................................................................................... 16

Conne ct in g th e A SD ............... .. ... .............. ... .. ...................... .. ... .............. ... .. .................... 16

System G r o un d i ng . ... ..................... ... .. ............... .. ... ...................... .. .. ............... ... .. ..... 16

Power Connections ...................................................................................................17

Lead Length Specifications ....................................................................................... 18

Q7 ASD Installation and Operation Manual i

Page 6

Startup and Test ........................................................................................................ 18

I/O and Co n tr o l . .. ........ .. ... .............. ... .. ...................... .. ... .............. ... .. ...................... ... .. .....19

I/O Term in a l D escript io n s .......... .. ... .. ........ .. .. ............... .. ... ...................... .. ... ............ 20

Q7 ASD Control ............................................................................................................... 23

CNU1 and CNU2 Pinout ............................. ............................... .................... .......... .24

CNU3 Pinout ............................................................................................................. 24

CN7 Pino u t ....... ... .. ...................... .. ... .............. ... .. ...................... ... .. ............... .. ... ....... 24

I/O Circu i t Configu r a ti o ns ........ .. .. ........ .. ... .............. ... .. ............... .. .. ............... ... .. ..... 25

Typical Connection Diagram ................................................................................................ 26

Q7 ASD Keypad ..................................................................................................................... 27

Q7 Keypad Features ......................................................................................................... 27

Keypad O p eration ... ... ....... .. ... .............. ... .. ...................... ... .. ............... .. .. ...................... ... 28

Keypad Re m o t e M o un t in g ..... .. ........ .. .. ...................... ... .. ............... .. ... ...................... .. .. ... 2 9

Remot e K ey p ad Re q u ir e d H ar d w a re . ........ .. .. ............... .. ... .............. ... .. ............... .. ... 2 9

Keypad I ns ta ll at io n P r ec au ti o n s ....... .. ... .............. ... .. ...................... .. ... ............... .. .. ... 2 9

Keypad Re m o t e M o un t in g w/o th e A S D -M T G -K I T .... .. ... .............. ... .. ............... .. ... 3 0

Keypad Remote Mounting using the ASD-MTG-KIT ............................................. 30

System Operation .................................................................................................................. 32

Opera ti on ( L o ca l) ....... .. ....... ... .. ...................... ... .. ............... .. .. ... ....... ... .. ............... .. ... ....... 32

Default Setting Changes ................................................................................................... 32

Search (for default setting changes) .......................................................................... 33

System Configuration and Menu Options ........................................................................... 34

Root Menus ...................................................................................................................... 34

Outpu t Fr eq u e nc y Sc r ee n .. ............... .. ... .............. ... .. ... ....... .. ... .............. ... .. ............... 34

Setup Screen .............................................................................................................. 34

Progra m M en u .. ... .............. ... .. ...................... .. ... .............. ... .. ...................... ... .. .......... 34

Monit or M o de .. ... .. ...................... .. ... .............. ... .. ...................... ... .. ............... .. ... ....... 35

Menu Navigation ................................................................................................................... 36

Q7 Parameter Descriptions .................................................................................................. 43

Q7 Communications Numbers ........................................................................................... 134

Alarms, Trips, and Troubleshooting .................................................................................. 144

Alarms an d Trips ........ .. ... .............. ... .. ...................... .. ... .............. ... .. ...................... ... .. ... 144

Alarms ............................................................................................................................ 145

User No ti f ic at io n Co d es .. .. .. ............... .. ... .............. ... .. ............... .. ... .............. ... .. ............. 14 7

Trips/Fau lts ..... .. ..... ..... ..... .. ..... ..... ..... .. ..... ..... ..... .. ..... ..... ..... .. ..... ..... .. ..... ..... ..... .. ..... ..... ... 147

Viewi ng Tr i p I nfo r m a ti o n . ............... .. ... ...................... .. .. ...................... ... .. ............. 15 1

Cleari ng a Tr ip .... ...................... .. .. ............... .. ... ...................... .. ... .............. ... .. ........ 151

Enclosure Dimensions and Conduit Plate Information ................................................... 152

Enclosu r e D imensio n s /Weight ...... ...................... .. ... ...................... .. ... .............. ... .. ... ..... 15 3

Conduit Box Information ..... ........................... ........................... ................... .................158

Cable/Termin a l Sp ec if i ca t i o ns .... .............. ... .. ............... .. ... ...................... .. .. ............... ... .. ... 159

Current/Voltage Specifications ........................................................................................... 162

ii Q7 ASD Installation and O peration Manual

Page 7

General Safety Information

DO NOT attempt to install, operate, maintain or dispose of this equipment until you have read and

understood all of the product safety inf orma tion and directions that are contained in this manual.

Safety Alert Symbol

The Safety Alert Symbol indicates that a potential personal injury hazard exists. The symbol is

comprised of an equilateral triangle enclosing an exclamation mark.

Signal Words

Listed below are the signal words that are used throughout this manual followe d by their descriptio ns

and associated symbols. When the words DANGER, WARNING and CAUTION are used in th is

manual they will be followed by important safety information that must be carefully adhered to.

The word DANGER pre ce d ed by th e safety al er t symbol in di ca t es th a t an imminent l y h azardo us

situatio n exis ts that, if not avoided, will result in death or s erious injury to personnel.

DANGER

The word WARNING preceded by the safety alert sym bol indicates that a potentially hazardous

situatio n exis ts that, if not avoided, could result in deat h or ser ious injury to personnel.

WARNING

The word CAUTION preceded by the safety alert symbol indicate s that a potentially hazardous

situation exists which, if not avoided, may result in minor or moderate injury.

CAUTION

The word CAUTION without the safety ale r t symbol indicates a pote ntially hazardous si tuation exists

which, if not avoided, may result in equipment and property damage.

CAUTION

Q7 ASD Installation and Operation Manual 1

Page 8

Special Symbols

To identify special hazards, other symbols may appear in conjunction with the DANGER, WARNING

and CAUTION signal words. Thes e symbols indicate areas that require special and/or strict adherence

to the procedures to prevent serious injury to personnel or death.

Electrical Hazard Symbol

A symbol which indicates a hazard of injury from electrical

shock or burn. It is comprised of an equilateral triangle

enclosing a lightning bolt.

Explosion Hazard Symbol

A symbol which indicates a hazard of injury from exploding

parts. It is comprised of an equilateral triangle enclosing an

explosion image.

Equi pment Warning Labels

DO NOT attempt to insta ll, operate, perform main tenance, or dispose of this equipment until you have

read and understood all of the product labels and user directions that are contained in this ma nual.

Shown below are examples of safety labels tha t may be found attached to the equipment. DO NOT

remove or cover any of the labe ls. If the labels are damaged or if additional labels are required, contact

your Toshiba sales representative for additional labels.

Labels atta ched to the equipment are th ere to provide useful information or to indicate an im mi nently

hazardous s ituation that m ay result in serious injury, severe property a nd equipment damage, or death if

the inst r uctions are not followed.

Figure 1. Examples of labels that may be found on the equipment.

DANGER

DANGER

!

DO NOT REMOVE, DESTROY, OR COVER THIS LABEL.

READ THE INSTRUCTION MANUAL CAREFULLY BEFORE

ENTERING THIS COMPARTM ENT.

HAZARDOUS VOLTAGE Behind These Panels.

Contact With Energized Main Bus Will Cause

Severe Injury, Death, Fire, Explosion, Or

Property Damage.

Turn Off And Lockout Primary And

Control Circuit Power Before Opening

These Panels.

Qualified Operators Only.

CAUTION

!

Excessive Loading of Operat ing Shaft

Can Prevent Contactor From C l osing

Properly Result i ng In Major Dam age.

Do Not Use Contactor Shaft To Drive

Accessories Such As Mechanical Interlocks

Which Require More Than 5 Kgf-cm Of

Torque To Operate.

DO NOT OPEN THIS DOOR WHILE THE UNIT IS RUNNING.

THIS DOOR IS INTERLOCKED WITH ASD OPERATION.

!

DO NOT REMOVE, DESTROY, OR COVER THIS LABEL.

READ THE INSTRUCTION MANUAL CAREFULLY BEFORE

INSTALLING, OPERATING, OR SERVICING THIS EQUIPMENT.

HAZA RD OUS VOLTAGE

Can Cause Severe Injury, Death, Explosion,

Fire, Or Property Damage.

Only Qualified Personnel Should Be Permitted

To Operarate or Service This Equipment.

Disconnect And Lockout Primary And Control

Circuit Power Before Servicing.

Keep All Panels And Covers Securely In Place.

Never Defeat, Modify, Or Bypass Safety

Interlocks.

Foreign Voltage May Be Present At Interface

Terminals. Isolate Before Performing Service

Or Repairs.

Unauthorized Modifications To This Equipment

Will Void The Warranty.

!

DANGER

HAZARDOUS VOLTAGE MAY BE PRESENT .

Capacitors Are Charged. Wait

At Least 5 Minutes Before Entry.

Check For Charged Voltage

To Dissipate To A Safe Level

Before Opening The Equipment.

2 Q7 ASD Installation and Operation Manual

Page 9

Qualified Personnel

Installatio n, ope ratio n, and maint enanc e shal l be perfor med by Qualified Personnel Only. A Qualified

Person is one that has the skills and knowledge relating to the construction, insta llation, operation, and

maintenance of the el ec trical equipment and has received safety training on the hazards involved (Refer

to the latest edition of NFPA 70E for additional saf ety requirements).

Qualified Personnel shall:

• Have carefully rea d the enti re ope ration manual.

• Be familia r with the construction and func tion of the ASD, the equipment bei ng dr iven, and the

hazards involved.

• Able to recognize and properly addres s hazards associated with the application of motor-driven

equipment.

• Be traine d and au thorized to safely energize, de-energize, ground, lockout/tagout circuits and

equipment, and clear faults in accordance with established safety practice s.

• Be trained in the proper care and use of protecti ve eq uipment such as safety shoes, rubber gloves,

hard hats, safety glasses, face shields, flash clothing, etc., in ac cordance with established safety

practices.

• Be trained in rend ering first aid.

For further information on workplace safety visit www.osha.gov.

Equipment Inspection

• Upon receipt of the equipment inspect the packaging and equipment for shipping damage.

• Carefully unpack the equipment and check for parts that m ay have been damaged during shi pping,

missing par ts, o r conce aled da mage. I f any disc repanc ies a re dis covere d, it should be n oted wit h th e

carrier prior to accepting the shipment, if possible. File a claim with the carrier if necessary and

immediately notify your T oshiba sales repres entative.

• DO NOT install or energize equipment that has been damaged. Damaged equipment may fail

during operation resulting in equipment damage or personal injury.

• Check to see that the rated capacity and the model number specified on the nameplate conform to

the order specifi cations.

• Modification of this equipment is dangerous and must not be performed except by factory trained

representat ives. When modifications are required contact your Toshiba sales representative.

• Inspections may be required before and after moving installed equipment.

• Keep the equ ipm ent in an upright position.

• Contact your Toshiba sales representative to report discrepancies or for assistance if required.

Handling and Storage

• Use prope r lifting techniques when moving the ASD; including properl y s izing up the load, getting

assistance, an d usi ng a forklift if required.

• Sto re in a well-ventilated covered location and prefer ably in the original carton if the equipmen t

will not be used upon receipt.

• Store in a cool, clean, and dry location. Avoid storage locations with extreme temperatures, rapid

temperature ch anges, high humidity, moisture, dust, corrosive gase s, or metal particles .

Q7 ASD Installation and Operation Manual 3

Page 10

• The storage temperature range of the Q7 ASD is 14° to 104° F (-10 to 40° C).

• Do not store the unit in pl aces tha t are e xposed to outside we ather c onditi ons (i. e., wi nd, rain , snow,

etc.).

• Store in an upright position.

Disposal

Never dispose of electrical components via incineration. Contact your state environmental age ncy for

details on disposal of electrica l components and packaging in your area.

Installation Precautions

Location and Ambient Requirements

• The Toshiba ASD is intended for permanent installations only.

• Installation should conform to the 2005 National Electr ical Code — Article 110 (NEC)

(Requirements For Electrical Installations), all regulations of the Occupational Safety and

Health Administration, and any other applicable na tional, regional , or industry codes and

standards.

• Select a mounting location that is easily accessible, has adequate personnel working space, and

adequate il lum ination for adjustment, inspection, and maintenance of the equipment (refer to 2005

NEC Article 110-13).

• A noncombustible insulating floor or mat should be provide d in the area immediately s urrounding

the electrical system.

• Do Not mount the ASD in a location that would produce catast rophic results if it were to fall from

its mounting loca tion (equipment damage or injury).

• Do Not mount the ASD in a locati on that would allow it to be exposed to flammable chemicals or

gasses, water, solvents, or other fluids.

• Avoid installation in areas where vibration, heat, humidity, dust, fibers, metal particles, explosive/

corrosive mists or gases, or sources of electrical noise are present.

• The installation location shall not be expose d to direct sunlight.

• Allow proper cl earance spaces for installation. Do not obstruct the ventilation openings . Refer to

the section titled

requirements.

• The ambient operating temperature range of the Q7 ASD is 14° to 104° F (-10 to 40° C).

Installation and Connections on pg. 14 for further information on ventilation

• See th e sec ti on titl ed I nst alla tion an d Conne ctio ns on pg. 14 for a dditio nal informati on on i nsta lling

the drive.

4 Q7 ASD Installation and Operation Manual

Page 11

Mounting Requirements

• Only Qualified Personnel should install this equipment.

• Install the unit in a secure and upright position in a well-ventilated area.

• A noncombustible insulating floor or mat should be provide d in the area immediately s urrounding

the electrical system at t h e p lace where maintenance ope rations are to be perf o rmed.

• As a minimum, the installation of the equipment should conform to the NEC Article 110

Requirements F or Ele ctric al Ins tal latio ns , OSHA, as we ll as any o the r appli cable nati ona l, reg ional,

or industry codes and standards.

• Installation practi ces should conform to the late st revision of NFPA 70E Electrical Safety

Requirements for Employee Workplaces.

• It is the responsibility of the person installing the ASD or the electrical maintenance personnel to

ensure that the unit is installed in to an enclosure that will protect personnel aga ins t electric shock.

Conductor Requirements and Grounding

WARNING

• Use sepa rate me tal c ondui ts fo r rout ing the i nput power, output power, a nd cont rol cir cuits a nd e ach

shall have its own ground cable.

• A separate ground cable should be run inside the conduit with the inp ut power, output power, and

and control circuit s.

• DO NOT connect control terminal strip return marked CC to eart h ground.

• Always ground the unit to prevent electrical shock and to help r educe electrical noise.

• It is the responsibility of the person installing the ASD or the electrical maintenance personnel to

provide proper grounding and branch circuit protection in accordance with the 2005 NEC and any

applicable local codes.

The Metal Of Conduit Is Not An Acceptable Ground.

Power Connections

DANGER

Contact With Energized Wiring Will Cause Severe Injury Or Death.

• Turn off, lockout , and tagout all power source s be fore proceeding to connect the power wiring to

the equ ip ment.

• After ensuring that all power sources are turned off and isolated in ac cordance with established

lockout/ta gout procedures, connect three-phase power source wiring of the correct voltage to the

correct input terminals and connect the output terminals to a motor of the correct voltage and type

for the application (refer to NEC Article 300 – Wiring Methods and Article 310 – Conductors For

General Wiring). Size the branch circuit conductors in acc ordance with NEC Table 310.16.

• Adh er e to the recommended conductor si zes list ed in the section titled Cable/Terminal

Specifications on pg. 159. If multi ple conductors are used in parallel for the input or output power ,

each branch of the parallel set shall have its own conduit and not share its conduit with other

parallel set s (i .e., place U1, V1, and W1 in one conduit and U2, V2, and W2 in anoth er) (re fer to

NEC Article 300. 20 and Article 310.4). National and local electrical codes should be referenced if

Q7 ASD Installation and Operation Manual 5

Page 12

three or more power conductors are run in the same conduit (refer to 2005 NEC Article 310

adjustment factors).

Note: National and local codes should be referenced when running more than three

conductors in the same conduit.

• Ensure that the 3-phase input power is Not connect ed to the output of the ASD. This will damage

the ASD and may cause injury to personnel.

• Do not insta ll the ASD if it is damaged or if it is miss ing any component(s).

• Do Not connect resistors ac ross terminals PA – PC or PO – PC. This may cause a fire.

• Ensure the correct phase sequence and the desired direction of motor rotation in the Bypass mode

(if applicable).

• Turn the power on only after attaching and/or securing the front cover.

Protection

• Ensure that primary protect ion exis ts for the input wiring to the equipm ent. This protect ion must be

able to interru pt the available fault cu rrent from the power line. The equipme nt ma y or may not be

equipped with an in put disconnect (option).

• All cable entry openings must be sealed to reduce the risk of entry by vermin and to allow for

maximum cooling efficiency.

• Follow all warnings and precautions and do not exceed equipment ratings.

• If using multiple motors provide separate overload protection for each motor and use V/f control.

• External dynamic braking resistors must be thermally protected.

• It is the responsibility of the person installing the ASD or the electrical maintenance personnel to

setup the Emergency Off brak ing syste m of the ASD. The function of the Emergency Off braking

function is to remove output power from the drive in the event of an emergency. A supplemental

braking system may also be engaged in the event of an emergency. For further information on

braking systems, see

60.

Note: A supplemental emergency stopping system should be used with the ASD. Emergency

stopping shou ld not be a task of the ASD alone.

• Follow all warnings and precautions and do not exceed equipment ratings.

DC Injection Brak ing Current on pg. 57 and Dynamic Braking Enable on pg.

Syste m Integration Precautions

The following preca utions are provided as general guidelines for the setup of the ASD within the

system.

• The Toshiba ASD is a general-purpose product. It is a system component only and the system

design should take this into consideration. Please conta ct your Tos hiba sales representative for

application-specific information or for training support.

• The Toshiba ASD is part of a larger system and the safe operation of the ASD will depend on

observing certain precautions and perform ing proper system integ ration.

• A detailed system analysis and job safe ty ana lysis should be performed by th e systems designer

and/or syste ms inte grator be fore the i nstal lati on of t he ASD com ponent. Con tact your Toshiba sales

representat ive for opti ons availabilit y and for a pplication-specific system integration information if

required.

6 Q7 ASD Installation and Operation Manual

Page 13

Personnel Protection

• Instal lation, operation, and maintenance shall be performed by Qualified Personnel Only.

• A thorough understanding of the ASD will be required before the installation, operation, or

maintenance of the ASD.

WARNING

• Rotating machinery and live conductors can be hazardous and s hall not come into contact with

humans. Personnel should be protected from all rotating machinery and electrical hazards at all

times.

• Insulat ors , machine guards, and elect rical safeguards may fail or be defea ted by the purposeful or

inadvertent actions of workers. Insulators, machine guards, and electrical safeguards are to be

inspected (and tested where possible) at installation and periodically after installation for potential

hazardous conditions.

• Do not allow personnel near rotating machinery. Warning signs to this effect shall be posted at or

near the machinery.

• Do not all ow pe rsonne l near e lectr ical conduc tors. Human cont act wi th e lect rical conduct ors c an be

fatal. Warning signs to this effect s hall be posted at or near the haza r d.

• Personal protection equipment shall be provided and used to protect employees from any hazards

inherent to system operation.

• Follow all warnings and precautions and do not exceed equipment ratings.

System Setup Requirements

• When using the ASD as an integral part of a larger syste m, it is the responsibi lity of the ASD

installer or maintenanc e p er sonnel to en sure tha t th ere is a fai l-safe in place, i.e., an arr an gement

designed to switch the system to a safe condition if there is a fault or fail ure.

• System safety features should be empl oyed and designed into the integrated system in a manner

such that s ys te m op e r at io n , ev en in th e ev e nt of sy s te m fa i lu r e, wi ll no t cau s e h arm o r res ul t in

personnel injury or system damage (i.e., E-Off, Auto-Restart settings, System Inte rlocks, etc.).

• The programming s etup and system configuration of the ASD may allow it to start the motor

unexpectedly. A familiarity with the Auto-restart settings is a requi rem ent to use this product.

• Improperl y desig ned or impr operly inst al led syst em interl ocks may ren der the m otor unabl e to star t

or stop on command.

• The failure of external or ancillary components may cause intermittent system operation, i.e., the

system may sta rt the motor without warning.

• There may be thermal or physical properties, or ancillary devices integrated into the overall sy stem

that may allow for the ASD to start the motor without warning. Signs at the equipment installation

must be posted to this effect.

• If a secondary magnetic contactor (MC) is use d between the ASD and the load, it should be

interlocke d to halt the ASD before the secondary contact opens. If the output contactor is used for

bypass operati on, it must be interlocked such that commercial power is never appl ied to the ASD

output terminals (U, V, W).

• Power factor improvement capacitors or surge absorbers must not be installed on the output of the

ASD.

Q7 ASD Installation and Operation Manual 7

Page 14

• Use of the built-in system protective fea tures is highly recommended (i.e., E-Off, Overload

Protection, etc.).

• The operating controls and system sta tus indicators should be cl ea rly readable and positioned

where the operator can se e the m wit hout obstruction.

• Additi onal warnings and notifi cations shall be posted at the equipment insta llation location as

deemed required by Qualified Personnel.

• Follow all warnings and precautions and do not exceed equipment ratings.

Operational and Maintenance Precautions

WARNING

• Turn off, lockout, and tagout the main power, the control power, and instrumentation conne ctions

before inspecti ng or servicing the drive, or ope ning the door of the enclosure.

• Turn off, lockout, and tagout the main power, the control power, and instrumentation conne ctions

before proceeding to disconnect or connect the power wiring to the equipment.

• The capac itors of t he ASD mai ntain a resi dual c harge for a pe riod of time after turn ing the ASD off .

The required time for each ASD typef orm is indicated with a cabinet label and a Charge LED.

Wait for at least the minimum time indicated on the enclosure- mounted label and ensure that the

Charge LED has gone out before opening the door of the ASD once the ASD power has been

turned of f.

• Turn the power on only after attaching (or closing) the front cover and Do Not remove the front

cover of the ASD when the power is on.

• Do Not attempt to disassemble, modify, or repair the ASD. Call your Toshiba sales representative

for repair information.

• Do not place any objects inside of the ASD.

• If the ASD should emit smoke or an unusual odor or sound, turn the power off immediately.

• The heat si nk and other components may become ext remel y hot to the t ouch. All ow the unit to cool

before coming in contact with these items.

• Remove power from the ASD during extended periods of non-use.

• The system should be inspected period ically for damaged or improperly functioning parts ,

cleanliness, and to ensure that the connectors are tightened securely.

• Ensure that the Run functions (F, R, Preset Speed, etc.) of the ASD are off before performing a

Reset. The post-rese t settings may allo w the ASD to star t unexpectedly.

• Retry or Reset settings may allow the motor to start unexpectedly. Warnings to this effect should

be clearly poste d near the ASD and motor.

• In the event of a power failure, the motor may restart after power is restored.

• Follow all warnings and precautions and do not exceed equipment ratings.

DO NOT install, operate, perform maintenance, or dispose of this equ ipm ent until you have read and

understood all of the product warnings and user direc tions. Failure to do so may result in equipment

damage, operator injury, or loss of life.

8 Q7 ASD Installation and Operation Manual

Page 15

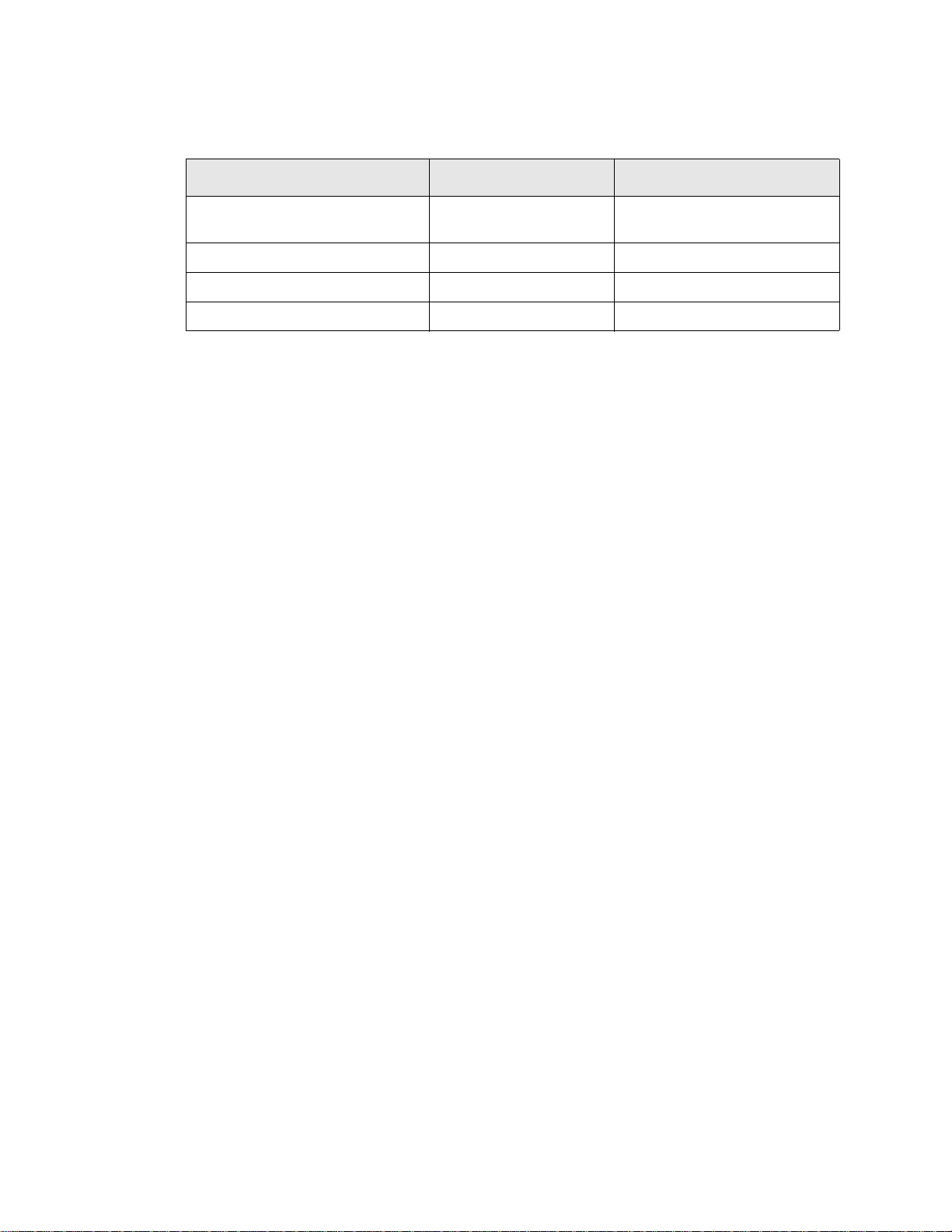

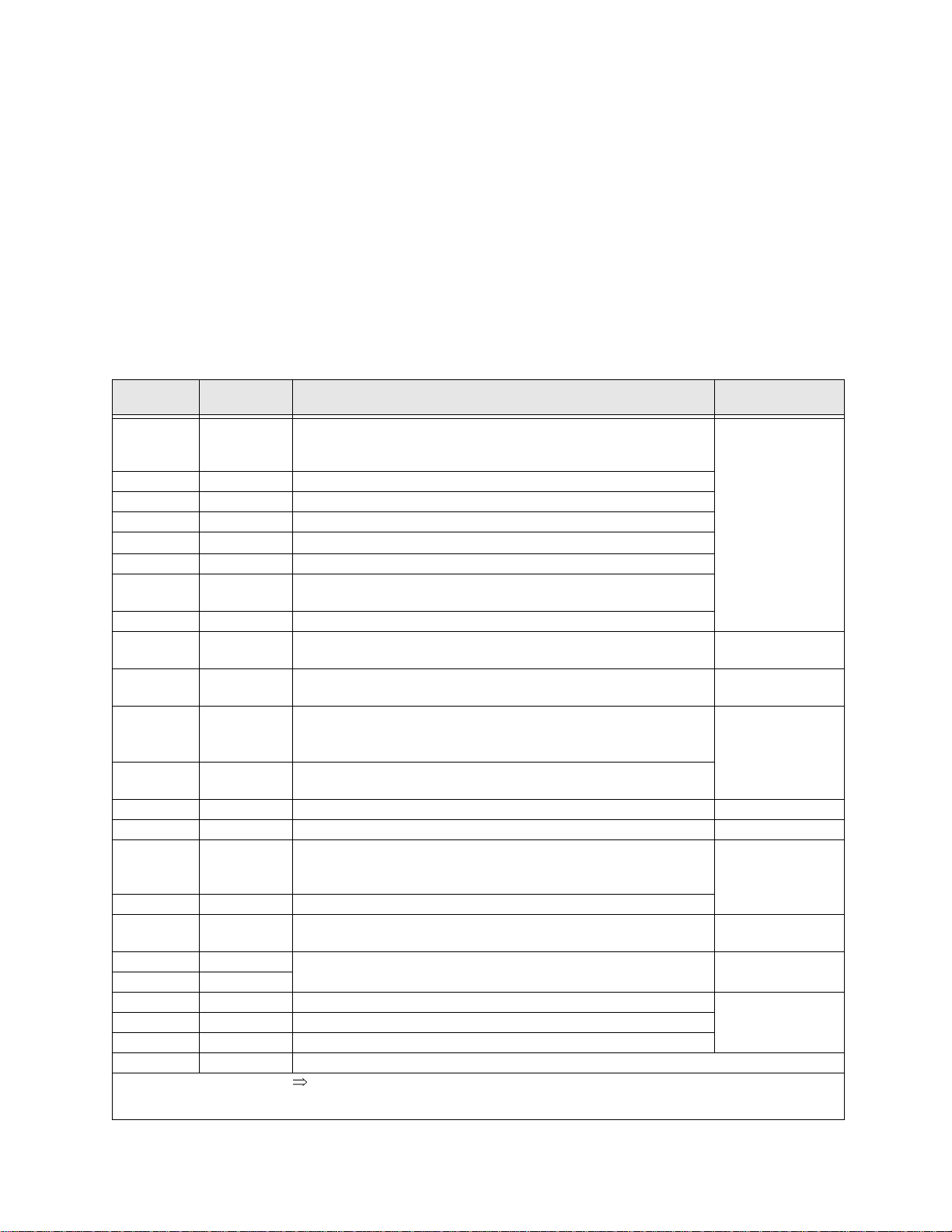

Service Life Information

Part Name Service Life Remarks

Large Capacity Electrolytic

Capacitor

Cooling Fan 26,00 0 H o urs

CN Connectors 100 Connec ts/Disconnects

On-board Relays 500,000 Actuations

5 Years

When not used for long periods,

charge semi-annually.

Q7 ASD Installation and Operation Manual 9

Page 16

CE Compliance Requirements

In addition to the local and regional safety requirements, this section describes additional criteria that

must be met to qualify for European Conformity (CE) certification. All relevant apparatus placed on

the European market is required to comply to the European Community directive on electromagnet ic

compatibility (EMC). The following ins tructions provide a means of compliance for the Q7 ASD. A

Technical Construction File (TFC) indicates the rationale used to declare comp liance and is on file at

Toshiba International Corporation, Houston, Texas U.S.A.

EMC Installation Guidelines

All systems placed on the Eur o p ean market are requir ed to comply with the European Community

directive regarding electromagnet compatibility (EMC). Toshiba ensures that all systems deployed in

the European market ha ve be en s cre ened and are in 100% compliance with the following standards :

• Radiated Interference: EN 55011 Group 1 Class A

• Mains Interference: EN 55011 Group 1 Class A

• Radiate d S usceptibility: IEC 801-3 1984

• Conducted RFI Susceptibility: prEN55101-4 (prIEC801-6) Doc 90/30270

• Electrostatic Dischar ge: IEC801-2 1991

• Electrical Fast Transient: IEC 801-4 1988

• Surge : IEC1000-4-5 1995 2 KV line-to-line, 4 KV line-to-earth

• Voltage Interruption: IEC 1000-4-11

General EMC Guidelines for Consideration

• Input filters of the appropriate rating shall be used.

• Proper grounding is a requirement.

• Grounds shall be kept to the minimum length to accomplish the connection.

• Grounds shall have low RF impedance.

• A central ground shall employed in a comp lex system.

• Paint or corrosion can hamper good grounding; remove as required.

• Keep control and power cabling separated. Minimize exposed (unscreened) cable.

• Use 360° shielded connection s wher e pos sible.

CE Compliant Installation Guidelines

ASDs should be instal led in accordance with the following guideline s.

1. Filtering — An input f ilter sh al l be us ed with the ASD. A S chaf f ner F N258 seri es in put f ilt er of th e

appropriate rating shall be used and mounted next to the ASD.

2. Mechanical — The ASD and the associated equipment shall be mounted on a flat metallic

backpla ne. A mini mu m spac e of 5 cm (2 in ch es) s hal l ex ist b etw een th e ASD an d the fi lt er to a llo w

for ventilation. The filter output ca ble is to be connected from the bottom of the filter to the ASD

power input and is to be the minimum lengt h required for a connection. See

filter selection assistance.

Table 1 on page 11 for

Units received as an Open Chassis shall not be pla ced into operation until being placed into an

approved enclosure that will protect personnel against electrical shock.

10 Q7 ASD Installation and Operation Manual

Page 17

Opening and closing of enclosures or barriers should be possible only with the use of a key or a

tool.

3. Cabling — The power, filter, and motor cables shall be of the appropriate current rating. The

cables shall be connected in accordance with the guidelines of the manufacturer and the applic able

local and national agencies. A 4-core screened cable (such as RS 379-384) is to be used for the

power and earth connections to minimize RF emissions. Control cabling must be screened using

P/N RS 367-347 or a similar component.

4. Grounding — The mains (input) ground shall be conne cted at the grou nd ter minal provide d on the

filter. The filter and motor shall be grounded at the ground termina ls provided in the ASD.

5. Screening — The mains (input) screen is to be conne cted to the metallic b ac k-plane at the filter;

remove any finish coating as required. The screen over the filter output cables, the motor cable

screen, and the control wire screens must be connected to the ASD case using glands or conduit

connectors. The motor ca ble screen shall be connected to the motor case. When using a braking

resistor, the cabling between the resistor and ASD shall also be screened. This screen shall connect

to both the ASD enclo sure and the resistor enclosure.

See the Q7 Filter Selection below for the recommended input filters for a given typeform.

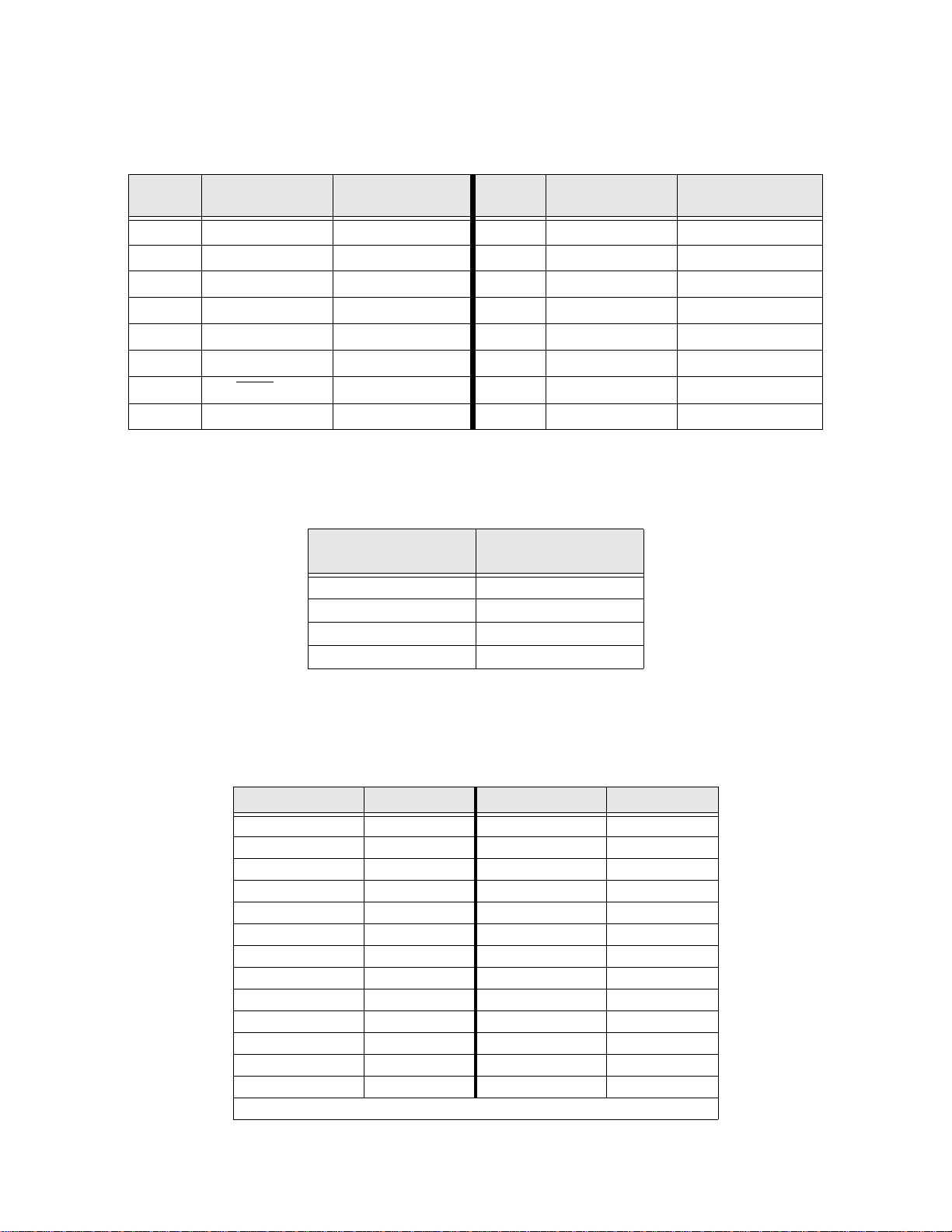

Table 1.

Q7 Filter Selection Table

230V

VT130Q7U2010B FN258-7 VT130Q7U4015B FN258-7 VT130Q7U6015B FN258-7

VT130Q7U2015B FN258-7 VT130Q7U4025B FN258-7 VT130Q7U6025B FN258-7

VT130Q7U2025B FN258-16 VT130Q7U4035B FN258-7 VT130Q7U6035B FN258-7

VT130Q7U2035B FN258-16 VT130Q7U4055B FN258-16 VT130Q7U6055B FN258-16

VT130Q7U2055B FN258-30 VT130Q7U4080B FN258-16 VT130Q7U6080B FN258-16

VT130Q7U2080B FN258-30 VT130Q7U4110B FN258-30 VT130Q7U6110B FN258-16

VT130Q7U2110B FN258-42 VT130Q7U4160B FN258-30 VT130Q7U6160B FN258-30

VT130Q7U2160B FN258-75 VT130Q7U4220B FN258-42 VT130Q7U6220B FN258-42

VT130Q7U2220B FN258-100 VT130Q7U4270B FN258-55 VT130Q7U6270B FN258-42

VT130Q7U2270B FN258-100 VT130Q7U4330B FN258-55 VT130Q7U6330B FN258-55

VT130Q7U2330B FN258-130 VT130Q7U4400B FN258-75 VT130Q7U6400B FN258-55

VT130Q7U2400B FN258-180 VT130Q7U4500B FN258-100 VT130Q7U6500B FN258-75

VT130Q7U2500B FS5236-180 VT130Q7U4600B FN258-100 VT130Q7U6600B FN258-100

VT130Q7U2600B FS5236-300 VT130Q7U4750B FS5236-130 VT130Q7U6750B FN258-100

VT130Q7U2750B FS5236-300 VT130Q7U410KB FS5236-180 VT130Q7U610KB FN258-130

VT130Q7U210KB FS5236-500 VT130Q7U412KB FS5236-300 VT130Q7U612KB FS5236-180

VT130Q7U212KB FS5236-500 VT130Q7U415KB FS5236-300 VT130Q7U615KB FS5236-180

VT130Q7U215KB FS5236-500 VT130Q7U420KB FS5236-300 VT130Q7U620KB FS5236-300

Filter

Number

460V

VT130Q7U425KB FS5236-500 VT130Q7U625KB FS5236-500

VT130Q7U430KB FS5236-500 VT130Q7U630KB FS5236-500

VT130Q7U435KB FS5236-500 VT130Q7U635KB FS5236-500

VT130Q7U440KB FS5236-500

Filter

Number

600V

Filter

Number

Q7 ASD Installation and Operation Manual 11

Page 18

Motor Characteristics

Listed below are some va riable speed AC motor control concepts with which the user of the

Q7 Adjustable Speed Drive should become familiar.

Pulse Width Modula tio n Op e ration

The Q7 ASD uses a sinusoidal Pulse Width Modulation (PWM) contr o l system. The output current

waveform generated by the ASD approaches that of a perfect sine wave; however, the output waveform

is slightly dis torted. For this reason, the motor may produce more heat, noise, and vibration when

operated by an ASD, rather than directly from commercial power.

Overload Protection Adjustment

The Q7 ASD software monitors the output current of the system and determines when an overload

condition occ urs . The overload current level is a percentage of the rating of the motor. This function

protects the motor from overload.

The default setting for the overload detect ion circuit is set to the maximum ra ted current of the ASD at

the factor y. This sett ing will have to be adj usted to matc h the rating of the motor with which the ASD is

to be used. To change the overload reference level, see

(Electronic) Thermal Protection #1 on pg. 62.

Power Factor Correction

DO NOT connect a power factor correction capacitor or surge absorber to the output of the ASD.

If the ASD is used with a motor that is equipped with a capacitor for power factor correction, remove

the capacitor from the motor.

Connecting e ither of t hese device s to the out put of the ASD may c ause the ASD to mal func tion an d tri p,

or the output device may cause an over-current condition resu lting in damage to the device or the ASD.

Light Load Conditions

When a motor is operated under a continuous light load (i.e., at a load of less than 50% of its rated

capacity) or it drives a load which produce s a very small amou nt of inertia, it may become unstable and

produce abnormal vibration or trips because of an over-current condition. In such a case, the carrier

frequency may be lowered to compensate for this undesirable condition (see Program

Control Parameters

Note: For proper operation, the carrier frequency must be 2.2 kHz or above except whe n

operating in the Constant Torque or Variable Torque modes.

⇒

PWM Carrier Frequency).

Load-pro du ce d Nega tiv e Torque

When the ASD is used wi th a loa d that pro duc es negat ive torq ue (an ove rhauli ng loa d), the over -vol ta ge

or over-current protective functions of the ASD may cause nuisance tripping.

⇒

Special

To minimize the undesi rable effects of negative torque the dynami c braking system may be used. The

dynamic braking system converts the regenerated energy into heat that is dissipated using a braking

12 Q7 ASD Installation and Operation Manual

Page 19

resistor. The braking resistor must be s uitably matched to the load. Dynami c braking is also effective in

reducing the DC bus voltage during a momentary over-voltage condition.

If under extreme conditions the dynamic braking system or a component of this system were to fail, the

dynamic braking resistor may experience an extended over-current co ndition. The DBR circuit was

designed to di ssi pate excessive amou nts of heat and if t he extend ed over -curre nt condit ion were al lowed

to exceed the circuit parameters, this condition could result in a fire hazard.

To combat this condition, the 3-phase input may be connected using contactors that are configured to

open in the event of an extended DBR over-current condition or an interna l circuit failure. Usi ng a

thermal sen sor an d/or overloa d pro tect ion as th e 3- phase input c ont actor driv e sig nal, t he con tact ors wil l

open and remove the 3-phase input power in the event of an extende d DBR over-c urrent or syst em overvoltage condition.

Motor Braking

The motor ma y continue to rotate and coast to a stop after being shut off due to the inertia of the load . If

an immediate stop is required, a braking system shoul d be us ed. The two most common types of motor

braking system s use d with the Q7 ASD are DC Injection Braking and Dynamic Braking.

For further information on braking systems, see DC Injection Braking Current on pg. 57 and

Dynamic Braking Enable on pg. 60.

CAUTION

ASD Characteristics

Over- current Protection

Each Q7 ASD model was designed for a speci f ied operating power range. The ASD will incur a trip if

the design specifications are exceeded.

However, the ASD may be operated at 100% of the specified output-current range continuously or at

110% for a limited time as indicated in the section titled

Also, the Overcurren t Stall Level setting m ay be adjusted to help with nuis ance over-curre nt trips.

When using the ASD for an a pplication that controls a motor which is r ated signifi cantly less than the

maximum current rating of the ASD, the over-c urrent limit (Thermal Overload Protection) setting will

have to be changed to match the application. For further i n fo r mation on this paramete r, see

Thermal Prote ction #1 on pg. 62.

ASD Capacity

The Q7 ASD must not be used with a mot or that has a significantly larger capacity, even if the motor is

operated under a small load. An ASD being used in this way will be susceptible to a high-output peak

current which may result in nuisance trippin g.

Do not apply a level of input voltage to an ASD that is beyond that which the ASD is rated. The input

voltage may be stepped down if require d with the use of a step-down transformer or some other type of

voltage-reduction system.

Current/Voltage Specif ications on pg. 162.

(Electronic)

Q7 ASD Installation and Operation Manual 13

Page 20

Installation and Connections

The Q7 Adjustable Speed Drive may be set up initially by performing a few simple configura tion

settings. To operate properly, the ASD must be securely mounted and connected to a power source (3phase AC input at th e L1/R, L2/S, and L3/T terminals). The control terminals of the ASD may be used

by connecting th e termi nals of the Control T erminal Strip to the proper sensors or si gnal inpu t source s

(see the section titled

The output terminals of the ASD (T1/U, T2/V, and T3/W) must be connected to the motor th at is to be

controlled (see

As a minimum, the installation of the ASD shall conform to Article 110 of the 2005 NEC, the

Occupational Safety and Health Administration requirements, and to any other local and regional

industry code s a nd st andards.

Installation Notes

When a brake-equipped motor i s connected to th e ASD, it is po ssible that the brak e may not rele ase at

startup be cause of i nsuf f icie nt vo ltage . To avoid this, Do Not conn ect t h e b rake or t he b ra ke cont ac to r to

the output of the ASD.

If an output cont actor i s used for byp ass opera tion, it mus t be int erlock ed such tha t commer cial po wer is

never applied to the output terminals of the ASD (T1/U, T2/V, or T3/W).

If a secondary magnetic contact or (MC ) is used between the output o f the ASD and the motor, it should

be interlocked such that the ST – CC connection is disconnected before the output contac tor is opened.

I/O and Control on pg. 19).

Figure 18 on pg. 26).

Do Not open and then close a secondary magnetic c ontactor betwee n the ASD and the motor unless the

ASD is off and the motor is not rotating.

Note: Re-applicat ion of power via a secondary contact while the ASD is on or while the

motor is s t il l turni n g m a y ca u s e ASD dam a g e.

On some devices the ST-to-CC connection is further enhanced by the operation of the MS1 AUX relay

circuit. The MS1 AUX relay circuit is normally open and closes the ST-to-CC connection (via ST1)

only after norma l system pow er is available. The MS1 AUX relay circuit prohibits the ST-to-CC

connection in the event that the MS1 contactor fails to close during start up or if MS1 opens while th e

ASD is running. For the 230 volt ASD this feature is available on the 40 HP and above systems, on the

460 volt ASD this featu re is ava ilable on the 75 HP and above systems , and on the 600 volt ASD it is

available on the 60 HP and above systems.

Figure 2. Alternative ST activation using the MS1 AUX circuit configuration.

The ASD input voltage should remain within 10% of the spec ified input voltage ra nge. Input voltages

approaching the upper or lower limit setti ngs may require that the overvoltage and undervolta ge stall

protection level parameters be adjusted. Voltages outside of the permissible tolerance should be

avoided.

The frequency of the inp ut power should be ±2 Hz of the specified input frequency.

Do not use an ASD with a motor t hat has a power rating that is higher than the rate d output of the ASD.

14 Q7 ASD Installation and Operation Manual

Page 21

The ASD is designed to operate NEMA B motors. Consult with your sales repr es entative before using

Figure 3. Circuit breaker configuration.

the ASD for special applica tions such as with an explosion-proof motor or applications with a piston

load.

Do Not apply commercial power to the output terminals T1/U, T2/V, or T3/W.

Disconnect the ASD from the motor before megging or applying a bypass voltage to the motor.

Interface problems may occur when an ASD is used in conjunction with some types of process

controllers. Signal isolation ma y be req uired to prevent controll er and/or ASD malfunction (contact

your Toshiba sales representative or the process controller manufacturer for additional information

about compatibility and signal isolation).

Use caution when setting the output frequency . Over speeding a motor decreases its ability to deliver

torque and may result in da ma ge to the motor and/or the driven equipment.

All Q7 AS Ds are equipped with inte rnal DC bus fuses. However, not all Q7 ASDs are equipped with

internal primary power input fuses (HP dependent). When connecting two or more drives that have no

internal fuse to the same power line as shown in

Figure 3, it will be necessary to selec t a ci rcuit-

breaking configuration that will ensure that if a short circuit occurs in ASD 1, only MCCB2 trips, not

MCCB1. If it is not feasible to use this conf iguration, inse rt a fuse between MCCB2 and ASD 1 (repeat

for successive ASDs).

Q7 ASD Installation and Operation Manual 15

Page 22

Mounting the ASD

CAUTION

Install the unit securely in a well ventilated area that is out of direct sunlight using the mounting holes

on the rear of the ASD.

The ambient temperature rating for the Q7 ASD is from 14 to 104° F (-10 to 40° C). The process of

converting AC to DC, and then back to AC produces heat. During normal ASD operation, up to 5% of

the inp u t energy to the ASD may be dissipa ted as heat. If installing the AS D i n a cabinet, ensure that

there is adequate ventilation.

Do Not operate the ASD with the enclosure door open or removed.

When ins t alling m ultiple ASDs , ensure th at there is a clearance space of at least 8 inches (20 cm ) from

the top and the bottom of adjacent units. Th ere should be at least 2 inches (5 cm) on either side of

adjacent un its. For the models below 50 HP the top and bot tom clea rance spe cific ations may be reduc ed

to 4 inch es (10 cm ) . Thi s sp ace ensur es th a t ad eq u ate vent ilation is p r ov i d ed (see the se ct io n ti tl e d

Enclosure Dimensions and Conduit Plate Information on pg. 152 for additional information on

mounting space requirements).

Note: Ensure that the ventilation openings are not obstructed.

ASDs produce high-frequency noise — steps must be taken during installa tion to avoid the negative

effects of noise. Listed below are some examples of measures that will help to combat noise problems.

• Separate the input and output power conductors of the main circuit. Do not install the input and

output wires in th e sam e duct or in parallel with each other, and do not bind them together .

• Do not insta ll the input or output powe r conductors of the main circuit and the wires of the control

circuit in the sa me duct or in parallel with each other, and do not bind them together.

• Use shielded wires or twis te d wires for the control circuits.

• Ensure that the grounding terminals (G/E) of the ASD are securely connected to ground.

• Connect a surge suppressor to every electromagnetic contactor and every relay installed near the

ASD.

• Install noise filters as required.

Connecting the ASD

DANGER

Refer to the section titled Installation Precautions on pg. 4 and th e section ti tled Lead Length

Specifications on pg. 18 before attempting to connect the ASD and the motor to electrical power.

System Grounding

Proper grounding helps to prevent electrical shock and to reduce electrical noise. The ASD is designed

to be grounded in accordance with Article 250 of the 2005 NEC or Section 10/Part One of the

Canadian Electrical Code (CEC).

The grounding condu ctor shall be sized in accordan ce with Arti cle 250-122 of the NEC or Part One-

Table

6 of the CEC.

16 Q7 ASD Installation and Operation Manual

Note: The metal of conduit is not an acceptable ground.

The input power, output power, and control lines of the system shall be run in separate metal conduits

and each shall have its own ground conductor.

Page 23

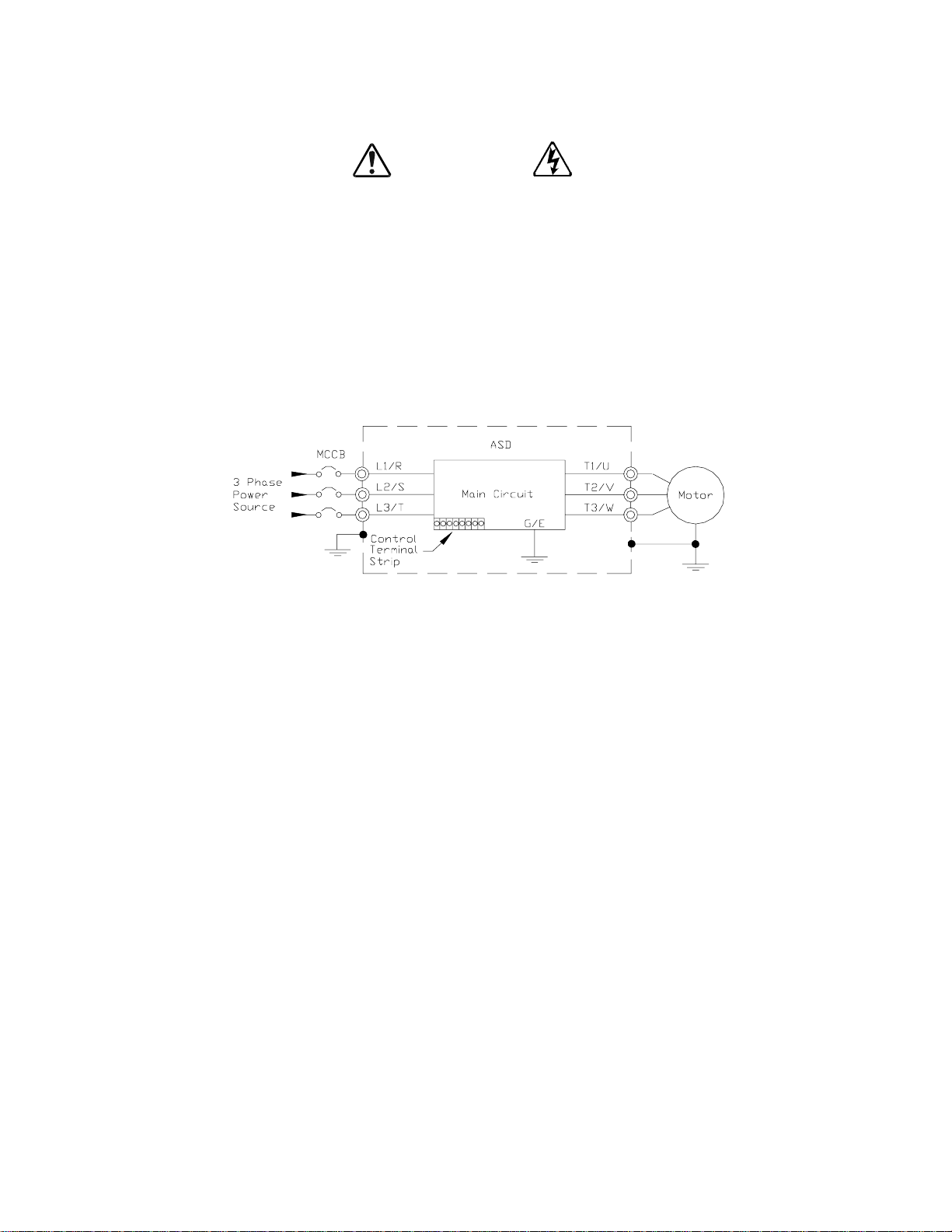

Power Connections

DANGER

L1/R, L2/S, and L3/T are the 3-phase input supply terminals for the ASD. The ASD may be operated

from a single-phase supply. When operating using a single-phase supply, use the L1 and L3 termin a ls.

T1/U, T2/V, and T3/W are the output terminals of the ASD that connect to the motor.

An inductor may be connecte d ac ross terminals PA and PO to provide additional filtering. When not

used, a jumper is connected across these terminals (see

Connect the inpu t and output power lines of the ASD as shown in Figure 4.

Note: In the event that the motor rotates in the wrong direction when pow ered up, reverse

any two of the three A SD output power leads connected to the motor.

Figure 4. ASD/Motor connection diagram.

Figure 18 on pg. 26).

Connect the 3-phase input power to the input terminals of the ASD at L1/R, L2/S, and L3/T. Conne ct

the output of the ASD to the motor from terminals T1/U, T2/V, and T3/W. The input and output

conductors and terminal lugs used shal l be in accordance with the specifications lis ted in the section

titled

Cable/Terminal Specifications on pg. 159.

Install a molded c ase ci rcuit bre aker (MCC B) or fuse bet ween the 3-ph ase power sourc e and th e ASD in

accordance with the fault current setting of the ASD and 2005 NEC Article 430.

CAUTION

For 600 volt ASDs, t he 15 HP or less ASDs (P/N VT1 30Q7U6015 – 616 0) re quire a class -J fuse ra ted a t

600 Volts/30 A.

On some Q7 devices 12-Pulse ope ration is available. A phase-shifting transformer must be suppli ed by

the user when configure d for 12-pulse operation.

External fuses may required on the ASDs that are configured for 12-pulse operation.

Use either the Ferra z Shawmut S em iconductor fuse (P/N A70QS200) an d fuse block P234C, or the

Toshiba ASD-FUSEKIT-12P. The Toshiba kit includes the required fuses and the mounting hardware

for the fuses.

Q7 ASD Installation and Operation Manual 17

Page 24

Lead Length Specifications

Adhere to the NEC and any local co des during the installation of ASD/Motor systems. Exces sive lead

lengths may adversel y ef fec t the p erforma nce of the m otor. Special cables are not r equi red. Lea d leng ths

from the ASD to the motor in excess of those listed in

output of the ASD. Table 2 lists the suggested maximum lead lengths for the listed motor voltages.

Table 2. Suggested max im um le ad lengths.

Table 2 may require filters to be added to the

Model

230 Volt All 1000 feet

460 Volt

600 Volt

Note: Contact Toshiba for application assistance when using lead lengths in excess of those

listed.

PWM Carrier

Frequency

< 5 kHz 600 feet

≥ 5 kHz 300 feet

< 5 kHz 200 feet

≥ 5 kHz 100 feet

NEMA MG-1-1998 Section IV Part 31

Compliant Motors

2

Exceeding the peak voltage rating or the allowable thermal rise time of the motor

insulation will reduce the life expectancy of the motor.

For proper operation, the carrier freq uenc y mus t be 2.2 kHz or above except when

operating in the Constant Torque or Variabl e Torque modes.

Startup and Test

Perform the following checks before turning on the unit:

• L1/R, L2/S, and L3/T are connected to the 3-phase input power.

• T1/U, T2/V, and T3/W are connected to the motor.

• The 3-phase input voltage is within the specified tole rance.

• There are no shorts and all grounds are secured.

18 Q7 ASD Installation and Operation Manual

Page 25

I/O and Control

The Q7 ASD can be controlled by several input types and combinations thereof, as well as operate

within a wide range of output frequency and voltage levels. This section describes the ASD control

methods and supported I/O functions.

Control Terminal Strip

The Control Terminal Strip PCB (P/N 48570) supports discrete and analog I/O functions.

The Control Terminal Strip is shown in Figure 6 on pg. 22. Table 3 and lists the names, the default

settings, and the descriptions of the input and output terminals.

Figure 18 on pg. 26 shows the basi c connection diagram for the Q7 syste m.

Table 3. Control Terminal Strip default assignment terminal names and functions.

Terminal

Name

ST Discret e Input

RES Discr ete Input Reset — Multifunct ional programmable discrete input.

F Discrete Input Forward — Multifunctional programmable discrete input .

R Discret e Input Reverse — Multifunctional programmable discrete input.

S1 Discrete Input

S2 Discrete Input Preset Speed 2 — Mul tifunctional programmable discre te input.

S3 Discrete Input

S4 Discrete Input Emergency Off — Multi functional programmabl e discrete input.

RR Analog Input

RX Analog Input

II Analog Input

VI Analog Input

P24 DC Output 24 VDC @ 50 mA output. Figure 12 on pg. 25.

PP DC Output PP — 10.0 VDC voltage source for the ext ernal potent iometer. Figure 13 on pg. 25.

OUT1 Discrete Output

OUT2 Discrete Output Reach Frequency — Multifunctional programmable discrete output.

FP Output

AM Output

FM Output

FLC Output F a ul t re la y (co m m o n) .

FLA Output F a ul t re la y (N. O .) .

CC — Control common (Do Not connect to Earth Gnd).

Discrete Input Terminals

Analog Input terminals reference CC.

Input/Output

Standby (jumper to CC to operate the unit) — Multifunctional

programmable discre te input (see

inform ation on this termin al).

Fire Speed — Multifunctional programmable discrete input.

Damper Fdbk — Mult ifunction al programmable discrete input (connect

to CC to operate the unit).

RR — Multifunction programmable analog input

(0.0 to 10 volt input — 0 to 80 Hz output). Reference CC.

RX — Multifunctional programmable analog input

(-10 to +10 VDC input — -80 to +80 Hz output). Refere n c e C C .

II — Multifuncti onal programmable analog input (4 [0] to 20 mADC

input — 0 to 80 Hz output) (see

the II terminal). Reference CC.

VI — Multifunctional programmable analog input

(0 to 10 VDC input — 0 to 80 Hz output). Reference CC.

Damper Command — Damper Command — Mu ltifunc tional

programmable output that is used to open/close the 120 VAC damper

motor power circuit when the motor is ASD-driven.

Frequency Pulse — an output pulse train that has a freq uency which is

based on the output frequen cy of the ASD.

Produces an output current that is proportional to the magnitude of the

function assigned to this terminal (see

⇒

On = connected to CC.

Terminal Function

(default setting if pr ogrammable)

Installation Notes on pg. 14 for further

Figure 6 on pg. 22 for the location of

Table 6 on page 48).

Circuit Config.

Figure 8 on pg. 25.

Figure 9 on pg. 25.

Figure 10 on pg. 25.

Figure 11 on pg. 25.

Figure 14 on pg. 25.

Figure 15 on pg. 25.

Figure 16 on pg. 25

Figure 17 on pg. 25.FLB Output Fault re la y (N. C .) .

Q7 ASD Installation and Operation Manual 19

Page 26

I/O Terminal Descriptions

Note: The programmable term inal assignments may be acc es sed and changed from their

default settings as mapped on

ST — The default setting for this terminal is ST. The function of this input as ST is a Sta ndby mode

controller (system is in Standby when on). As the default setting, this terminal must be connected to

CC for normal operation. If not connected to CC, Off is displayed on the LCD screen. This input

terminal may be programm ed to any 1 of the 68 functions that are listed in

RES — The default setting for this terminal is Reset. A momentary connection to CC resets the ASD

and any fault indications from the display. Reset is effect iv e when fau lt ed on l y.

F — The default setting for this terminal is Forward Run. Forward Run runs the motor in the

Forward direction when it is on. This input terminal may be programmed to any 1 of the 68 function s

that are li s t ed in

R — The default setting for th is terminal is Revers e Run. Rever s e Run runs the motor in the Reverse

direction when it is on. This input terminal may be programmed to any 1 of the 68 functions that are

listed in

S1 — The default setting for this terminal is Fire Spee d . The function of this input as Fire Speed is to

run the motor at the Preset Speed #1 setting when it is on (se e

may be activated by a fire alarm signal or fire sensing device. This discrete input terminal may be

programmed to any 1 of the 68 functions that are liste d in

Table 7 on page 130.

Table 7 on page 130.

pg. 36.

Table 7 on page 130.

Preset Speed #1 on pg. 90 ). This t erminal

Table 7 on page 130.

S2 — The default setting for this terminal is S2. The function of this input as S2 is to run the motor at

Preset Speed #2 (see

to any 1 of the 68 functions that are listed in Table 7 on page 130.

S3 — The default setting for this terminal is Damper Feedba ck. The function of this input as Damper

Feedback is to provide an indication that the damper is open. Connecting Damper Feedback to CC is

required for normal sy st em operation. This discre te input terminal may be programmed to any 1 of the

68 functions tha t are listed in

S4 — The default setting for this terminal is Emergency Off (normally closed). The function of this

input as Emergency O ff is to remove power from the output of the AS D and may apply a supplemental

braking system usi ng the method selected at the Emg Off Mode selection paramet er. This input

terminal may be programm ed to any 1 of the 68 functions that are listed in

RR — The default function assigned to this terminal is to carry out the Frequency Mode #1 setting.

The RR terminal accepts a 0 – 10 VDC input s ignal and controls the function assigned to this terminal.

This inpu t terminal may be programmed t o control the speed or torque of the motor. It may also be used

to regulate (li mi t) the speed or torque of the motor. The gain and bias of this t erm inal may be adjusted

for application-specific suitability.

RX — The RX termina l accepts a ±10 VDC input signal and c ontrols the function ass igned to this

terminal. This inp ut term inal m ay b e progr ammed t o con trol the sp ee d, tor que, or dire ct ion of the mo tor.

It may also be used to regulat e (limit) the speed or torque of the moto r. The gain and bias of this

terminal m ay be adjusted for application- specific suitability.

Preset Spee d #2 on pg. 90) when it is on. This input termina l may be programmed

Table 7 on page 130.

Table 7 on page 130.

II — The func tion of the II input is to receive a 4 – 20 mA input signal that controls a 0 – 80 Hz output.

This input te rminal may be progr ammed to cont rol the spee d or torque of the m otor an d may not be used

when using the VI in put. Also, the gain and bias of this terminal may be adjuste d.

20 Q7 ASD Installation and Operation Manual

Page 27

VI — The function of the VI input terminal is to rec eive a 0 – 10 VDC input signal that controls a

0 – 80 Hz output. This input te rm inal may be programmed to control the speed or torque of the motor

and may not be used when using the II input. Also, the gain and bias of this te rminal may be adjusted.

P24 — +24 VDC @ 50 mA power supply for customer use.

PP — The function of output PP is to provide a 10 VDC output that may be divided using a

potentiome ter. The tapped voltage is applied to the RR input to provide manual cont r ol of the RR

programmed functi on.

OUT1 — The default sett ing fo r thi s output te rmina l is Damper Command. This te rmina l may be used

to switch the externally-supplied On/Off power to the damper motor. The OUT1 contacts may be

programmed to provide an indication th at 1 of 60 possib le events has t aken place. This function may be

used to signal ext ernal equipment or to activate the brake. The OUT1 contact is rated at 2A/250 VAC.

OUT2 — The default setting f or this output terminal is ACC/DEC Complete. This output ter minal

may be program me d to provide an indication that 1 of 60 possi ble events ha s taken place. This function

may be u sed to signal ex ternal equipment or to activate the brake. The OUT2 contact is rated at 2A/25 0

VAC.

FP — The default function of this output terminal is to output a series of pulses at a rat e that is a

function of the output frequency of the ASD. As the output frequency of the ASD goes up so does the

FP output pulse rate. This term inal may be programmed to provide output pulses at a rate that is a

function of the output frequency or the magnit ude of any 1 of the 31 the functions listed in

Table 6 on

page 48.

AM — This output te rm inal produces an output curre nt that is proportional to the output frequency of

the ASD or of the magni tu d e of the fun ction assigned to this terminal. The available ass ignment s fo r

this outpu t terminal are listed in

Table 6 on page 48.

FM — This output terminal produces an output current that is proportional to the output frequency of

the ASD or of the magni tu d e of the fun ction assigned to this terminal. The available ass ignment s fo r

this outpu t terminal are listed in

Table 6 on page 48.

FLC — FLC is the middle leg of a single-pole double-throw (rel ay) switch. This FLC contact of the

relay is sw itche d be tween FLB and FLA. This contac t may b e programm ed to sw itch be tween FLB and

FLA as a function of any 1 of the 60 condition s li sted in

Table 8 on page 133.

FLB — One of two contacts that, under user-defined conditions, connect to FLC (see Figure 5).

FLA — One of two contacts that, under user -defined conditions , connect to FLC (see Figure 5).

Note: The FLA and FLC contacts are rated at 2A/250 VAC. The FLB contact is rated at

1A/250 VAC.

CC — Control common (Do Not connect to Earth Gnd).

Figure 5. FLA, FLB, and FLC switching contacts shown in the de-energized state.

Note: T h e rel ay is sho wn in th e Faulted or

de-energized condition. During

normal system oper ation the relay

connection is FLC-to-FLA.

Q7 ASD Installation and Operation Manual 21

Page 28

Figure 6. Control Terminal Strip PCB.

1

SW1 and SW2 may be switched to

change the full-scale reading of the

AM and FM output terminals. See

the AM Terminal Assignment and

the FM Terminal Assignment

descriptions for further information

on SW1 and SW2.

CN7A

{

0–1 mA 4–20 mA

SW1

{

0–1 mA 4–20 mA

SW2

TB

II Terminals

Shown below are the TB1 input and output te rmina ls of the Control Terminal Strip PCB.

For further information on these terminals see pg. 19.

RES

22 Q7 ASD Installation and Operation Manual

RRP24

F

ARS1S2S3S4C CA

OUT1 OUT2

Page 29

Q7 ASD Control

r.

l

The Control PCB (P/N 56000) serves as the primary control source for the Q7 ASD and receives input

from the

Keypad.

The Control PCB has been enhanced to support two new functions: Multiple Protocol Commun ications

and the ability to communicate in either half- or f u ll-duplex mode s.

Using the optional multiple-protocol communications interface: the ASD-NANOCOM, the Control