Page 1

PROGRAMMABLE CONTROLLERS

UG-TS02∗∗∗-E022

PROSEC T2-Series

USERS MANUAL

− Modbus Module −

TOSHIBA CORPORATION

Page 2

Important Information

Misuse of this equipment can result in property damage or human injury.

Because controlled system applications vary widely, you should satisfy yourself

as to the acceptability of this equipment for your intended purpose.

In no event will Toshiba Corporation be responsible or liable for either indirect

or consequential damage or injury that may result from the use of this equipment.

No patent liability is assumed by Toshiba Corporation with respect to use of

information, illustrations, circuits, equipment or examples of application in this

publication.

Toshiba Corporation reserves the right to make changes and improvements to this

publication and/or related products at any time without notice. No obligation shall be

incurred other than as noted in this publication.

This publication is copyrighted and contains proprietary material. No part of this book

may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means ⎯ electrical, mechanical, photocopying, recording, or otherwise ⎯ without

obtaining prior written permission from Toshiba Corporation.

© TOSHIBA Corporation 1998. All rights reserved

PROSEC and TOSLINE are registered trademarks of TOSHIBA Corporation.

Publication number: UG-TSxx∗∗∗-Exxx

1st edition August 1992

2nd edition March 1999

Page ii

Page 3

Safety Precautions

This application guide is prepared for users of Toshiba programmable controller PROSEC

T2-Series and EX100 Series (hereafter called T2).

Read this guide and your PLC's manual thoroughly to use the PLC system safely.

Hazard Classifications

In this guide, the following two hazard classifications are used to explain the safety

precautions.

!

WARNING

!

CAUTION

Even if a precaution is classified as CAUTION, it may cause serious results

depending on the situation. Observe all the safety precautions described on this

guide.

Safety Precautions

• Read the Safety Precautions described in your PLC's User's Manual before

using the PLC.

• Carefully design a fail-safe system in order to avoid an unsafe situation caused

by PLC failure. When the PLC detects an error in its self-diagnostics, the PLC

goes into the error mode. In the error mode, all the PLC outputs turn OFF and

the analog outputs go to 0 (zero).

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

!

CAUTION

Page iii

Page 4

About This Guide

This guide describes how to setup and use the Toshiba EX10-MML11 Modbus module. When

used in a Modbus network, the EX10-MML11 module allows any Modbus master to write

to/read from the registers in an EX100 or T2 PLC using standard Modbus RTU protocol.

Page iv

Page 5

Contents

Important Information................................................................................................................ii

Safety Precautions................................................................................................................... iii

About This Guide.....................................................................................................................iv

Contents ...................................................................................................................................v

1. Overview..............................................................................................................................1

2. System Configuration...........................................................................................................2

3. External Features and Switch Settings................................................................................4

4. Specifications.......................................................................................................................5

5. Modbus Module Operation....................................................................................................6

5.1. Modbus Commands......................................................................................................6

5.2. Modbus Data Types and T2 Register Mapping.............................................................7

5.3. Restricted Registers......................................................................................................8

6. Modbus Module Setup..........................................................................................................9

6.1. Modbus Module DIP Switch Settings ............................................................................9

6.2. Wiring Connection to the Modbus Module...................................................................14

7. CPU Setup for the Modbus Module...................................................................................15

8. Trouble Shooting ...............................................................................................................16

9. Additional References........................................................................................................17

Page v

Page 6

Page 7

1. Overview

The Modbus module (ML11) is used to connect T2E, T2N, or EX100 PLCs to a Modbus

Master. The addition of the EX10-MML11 (MODBUS Module) allows the T2E, T2N or EX100

PLC to communicate via standard MODBUS RTU protocol. This allows quick and easy

access to the PLC registers by a standard MODBUS Master.

Using the ML11 Modbus module any Modbus Master can read the status of registers in the

PLC and write to registers in the PLC. This allows the Modbus Master to know the status of

inputs to the PLC (both digital and analog) and to control the outputs of the PLC (also both

digital and analog).

The ML11 Modbus module cannot be a Modbus master, only a modbus slave. It has one

RS485 port for connection to the Modbus master. The preferred location of the EX10-MML11

is next to the CPU. However, the module may be located in any slot to the right of the CPU.

The CPU module can be any of the following:

EX10-MPU11 EX100 CPU, now obsolete

EX10-MPU12A EX100 CPU, now obsolete

TPU215—S T2 CPU now obsolete

TPU224--S T2 CPU, now obsolete

TPU234E-S T2E CPU (replaces all obsolete CPUs)

TPU215N-S T2N CPU, basic

TPU235N-S T2N CPU, with Ethernet

TPU245N-S T2N CPU, with Ethernet and Tosline S20

The ML11 Modbus module is also used to connect a T2 or EX100 PLC into the Toshiba

ECBUS. The ECBUS allows the PLCs to share data with Toshiba’s EC300 series loop

controllers. The ECBUS is a LAN (local area network) which allows multiple EC300s and

T2/EX100 PLCs to share data. For more information on the ECBUS, please refer to ECBUS

Transmission Interface Manual, see Additional References.

Page 1

Page 8

y

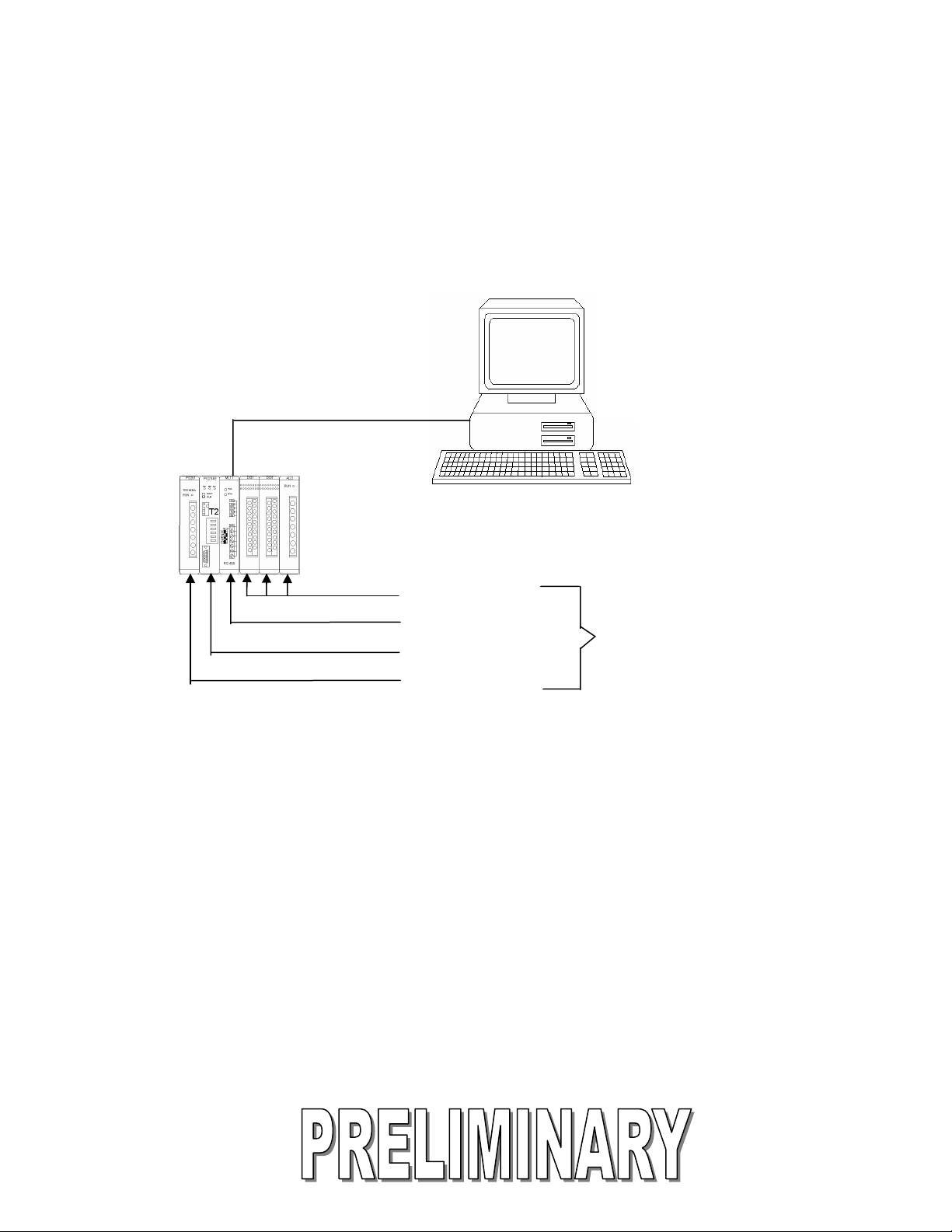

2. System Configuration

From 1 to 32 T2E or T2N PLCs can be connected to a Modbus master using the Modbus

module.

1 to 1 Configuration

Modbus Master

1. Higher Level PLC

2. Distributed Control System

3. Computer with SCADA or

RS485

T2E PLC

HMI Program

I/O Modules

Modbus Module

T2E CPU

Power Suppl

T2 Minimum

Configuration

Page 2

Page 9

1 to N Configuration

RS485

Modbus Master

1. Higher Level PLC

2. Distributed Control System

3. Computer with SCADA or

HMI Program

T2 Maximum Configuration

1 Main Unit

3 Exp. Units

Up to 32 Stations

For high-speed data transfer, one of

Toshiba’s Tosline Data Highway

modules is recommended.

Page 3

Page 10

3. External Features and Switch Settings

Page 4

Page 11

4. Specifications

ITEM SPECIFICATION

INTERFACE TERMINAL BLOCK

COMMUNICATION STYLE HALF-DUPLEX

SIGNAL CONFIGURATION TXA/RXA TXB/RXB

SYNCHRONIZATION START-STOP

NETWORK TOPOLOGY PARTY LINE (MULTIDROP)

COMMUNICATION SPEED 300, 600, 1200, 2400, 4800, 9600, 19200 bps

TRANSMISSION DISTANCE 1 KM MAX

COMMUNICATION MODE RTU MODE

DATA LENGTH 8 BITS

STOP BITS 1 BIT

PARITY EVEN, ODD, NONE

STATION NUMBER 1 TO 31 (DO NOT SELECT 0 OR 32)

ERROR CHECK PARITY CRC

NUMBER OF CHANNELS 1 CHANNEL

Page 5

Page 12

5. Modbus Module Operation

5.1. Modbus Commands

When a MODBUS command is used, the Modbus module translates it to the

corresponding T2 register access protocol.

MODBUS FUNCTION CODE

01 Read Coil Status

02 Read Input Status

03 Read Holding Register

04 Read Input Register

05 Force Single Coil

06 Force Single Register

08 Loop Back Diagnostic test

15 Force Multiple Coils

16 Preset Multiple Registers

For more information on the Modbus protocol, please refer to the Modbus Protocol Reference

Guide, see Additional References.

For more information on the T2 register access protocol, please refer to the Computer Link

Function Operation Manual, see Additional References.

T2 COMMAND

DR Read Device/Register

DR Read Device/Register

DR Read Device/Register

DR Read Device/register

DW Write Device Register

DW Write Device/Register

**** Not Supported by EX10-MML11

DW Write Device/register

DW Write Device/register

Page 6

Page 13

5.2. Modbus Data Types and T2 Register Mapping

This table shows how the different Modbus data types are mapped into T2 registers. In other

words, a Modbus master would reference the following Modbus register ranges to access the

corresponding T2 PLC registers.

For example, Modbus Holding Register 4352 will map to T2 register D000, and Input Register

0000 will map to XW00.

Data Type

Coils

Input

Status

Input

Register

Holding

Registers

Attribute Modbus No. Offset Reg/Device Address (T2)

Read/Write 0**** 0000 to 0511

0512 to 4095

4096 to 5112

7936 to 8447

Read only 1**** 0000 to 0511

0512 to 4095

Y

R

Z

Y000 to Y31F

Y320 to Y63F

R000 to R63F

Z000 to Z31F

X X000 to X31F

X320 to X63F

Read only 3**** 0000 to 0063 XW XW00 to XW63

Read/Write 4**** 0000 to 0063

0768 to 0831

1280 to 1311

3328 to 3455

3840 to 3967

4352 to 5887

YW

RW

ZW

T

C

D

YW00 to YW63

RW00 to RW63

ZW00 to ZW31

T000 to T127

C000 to C095

D000 to D1405

Page 7

Page 14

Modbus – T2 Address mapping Example:

Input module

(XW000)

Output Module

(YW001)

In this example, the T2 is being used

As a Modbus Remote Terminal Unit

slave. A Modbus master can access

The I/O or data registers in the T2.

See the following table for a Modbus to

T2 address mapping example.

T2E CPU Modbus Module

Modbus Address T2 Address T2 Data Type

30000 XW000 Input Register

40001 YW001 Output Register

44352 D0000 Data Register

Note: When dealing with I/O registers, make sure that the Modbus master is attempting to

access only the I/O points that physically exist in the T2 system. For example, Holding

Register 0 (40000) does not exist in the above example because there is no YW000 in the T2

system. In the above system, only have Holding Register 1 (40001) exists.

5.3. Restricted Registers

Registers D1406 to D1535 are reserved for “raw” data transmission with the EC300 loop

controllers on the ECBUS network. These registers are not available when the EX10-MML11

is used as a Modbus slave module. Do not use these registers.

Page 8

Page 15

6. Modbus Module Setup

The Toshiba Modbus module has been used reliably as a Modbus slave for several years.

First it was used on Toshiba’s EX100 Series PLCs and now on the T2 Series PLCs. Before it

can function as intended however, all the DIP switches must be properly set and all wiring

connections must be correct.

6.1. Modbus Module DIP Switch Settings

The following items are setup by DIP switches on the Modbus module:

• Station number

• Transmission rate (Baud rate)

• Parity

Station Number:

The station numbers identify the controllers and must be different from each other in

the network. If the EX10-MML11 address is less than 15, then set the third switch

(HAD) to the "off" position. If the EX10-MML11 address is higher than 16, set the

switch to the "on" position. Using the "STATION" dial switch (numbered in

hexadecimal) carefully set the station number. Do not set the dial switch to 0 with the

HAD switch off.

Page 9

Page 16

Transmission Rate (Baud Rate):

Select the combination of the three switches "BR2", "BR1", and "BRO" for the desired

communication speed. These are the 4th, 5th, and the 6th switches.

Baud Rate

BR2

19200

9600

ON

ON

4800

ON

2400

ON

1200

OFF

600

OFF

300

OFF

RESERVED

OFF

BR1

ON

ON

OFF

OFF

ON

ON

OFF

OFF

BR0

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Page 10

Page 17

Parity Check:

Select the parity check as odd, even or none. Use switches 7 and 8 to set the parity.

PARITY

NONE

ODD

EVEN

ASY and DLY switches:

The ASY and DLY switches are not used on the EX10-MML11, and should be set to

the “Off” position.

PEN (7)

EVN (8)

OFF

----

ON

OFF

ON

ON

Page 11

Page 18

Example Configuration Settings:

This section shows how to set the card up for network station address 2, 9600 baud,

and no parity.

1) “ASY and DLY”

Set these to the Off position.

2) "Station Address"

•Set the Station number on the rotary switch to 2.

• Set the HAD switch to OFF because our address is less than 16.

3) "Communication speed"

For 9600 baud, the following settings are required.

• BR2 is on

• BR1 is on

• BR0 is off

Page 12

Page 19

4) "Parity check"

For No Parity, the following settings are required.

• PEN is off.

• EVN is off.

OFF ON

ASY

DLY

HAD

BR2

BR1

BR0

PEN

EVN

Switch settings for 9600 baud, no parity, and address less than 16.

Page 13

Page 20

6.2. Wiring Connection to the Modbus Module

Sometimes it is necessary to convert from the standard RS485 to RS232 for connection to a

Personal Computer. The wiring between the Modbus module and the converter must be set

as follows:

RS485 Converter Modbus Module

TXA RXA

RXA TXA

TXB RXB

RXB TXB

SG SG

Note: Different RS485 converters have different connections. For example, when one

commonly available converter is used, TXA connects to RXB, TXB connects to RXA, etc.

Please refer to the converter manufacturer’s instructions.

Page 14

Page 21

7. CPU Setup for the Modbus Module

Two lines of ladder logic are necessary to configure a T2 CPU for use with the Modbus

module.

1 Communications Priority: To insure uninterrupted communications between the CPU

and the Modbus module, the communications priority bit S0158 must be set ON.

2. Initialization: To initialize the Modbus module, write the initialization parameter into

data register D1470. Register D1470 must be set to H5555 (21845 Decimal) before the

Modbus module will start communicating.

When using the Modbus module, the above logic should be placed in Block 1, Rung 1 and

Rung 2 of the PLC program.

Page 15

Page 22

8. Trouble Shooting

The communication status LEDs can be used to verify correct operation of the Modbus

module. During normal operation, the LED indicators flash as follows:

• RXD LED: Flashes when the Modbus master sends a message to the EX10

-MML11. On a multi slave network, this can also flash when when the

master polls other slaves, or when other slaves respond to the master. In

general, it indicates activity on the network.

• TXD LED: Flashes when that specific EX10-MML11 responds to the master.

This LED is only relevant to the module on which it is being viewed,

regardless of how many slaves are on the network. It indicates that the

module has received a message that is uniquely addressed to it, and the

EX10-MML11 is responding. This LED is usually on longer than the RXD

LED because the responses have more data than the requests.

If the LED indicators are not flashing, check the following:

1) Wiring connections

2) Resistance at terminals

3) Baud rate setting

4) Station Number

5) HAD Switch

6) Parity selection

7) Modbus master is using standard Modbus RTU format

If the LED indicators are on solid:

The polarity has been reversed on the network wiring. For example, the “A” terminals

are wired to the “B” lines, the “+” terminals are wired to the “-“ lines, etc. Correct the

connections to the EX10-MML11.

Page 16

Page 23

9. Additional References

Toshiba Corporation, Instruction Manual - EC300 Series Controller – ECBUS Transmission

Interface Module – ML11. 6F8A0613 4th ed. Feb 1995. Tokyo, Japan.

Toshiba Corporation, Computer Link Function Operation Manual. UM-TS03-E008, 3rd ed.

Aug. 1977. Tokyo, Japan.

Gould Modicon, Modbus Protocol Reference Guide. PI-MBUS-300 Rev B. Jan 1985.

Andover, MA.

Page 17

Page 24

TOSHIBA

TOSHIBA INTERNATIONAL (EUROPE) LTD.

1 Roundwood Avenue

Stockley Park, Uxbridge

Middlesex UB11 1AR, UNITED KINGDOM

Tel: 081 848 4466 Fax: 081 848 4969

E_mail nigels@toshibai.co.uk

TOSHIBA INTERNATIONAL CORPORATION

Industrial Equipment Division

13131 West Little York Road

Houston, TX. 77041 U.S.A.

Tel: 713-466-0277 Fax: 713-466-8773

E_mail: plc@tic.toshiba.com

TOSHIBA do BRASIL, S.A.

Estrade dos Alvarengas 5500

Sao Bernardo do Campo

Sao Paulo 0985-5500, Brazil

Tel: 55-11-7689-7199

Fax: 55-11-7689-7189

antoneli@tbb.toshiba.com.br

TOSHIBA INTERNATIONAL

CORPORATION PTY. LTD.

Unit 1, 9 Orion Road Lane Cove

N.S.W. 2066, AUSTRALIA

Tel: 02-428-2077 Telex: AA25192

E_mail: preston@toshiba.co.au

TOSHIBA CORPORATION

Industrial Equipment Department

1-1, Shibaura 1-chome, Minato-ku

Tokyo 105, JAPAN

Tel: 03-3457-4900 Cable: Toshiba Tokyo

E_mail: osamu.seki@toshiba.co.jp

Toshiba Asia Pacific PTE. LTD

200 Cantonment Rd. #12-01

Southpoint, 089763 Singpore

Ph: 65-324-1048

Fax: 65-324-5286

Page 2

Loading...

Loading...