NTDPJTV04

SERVICETRAINING

"CustomerSatisfactionThroughKnowledge"

SERVICINGTHEN5SS

COLORTELEVISION

CHASSIS/DIGITAL

CONVERGENCE

TOSHIBAAMERICACONSUMERPRODUCTS,INC.

NATIONALSERVICEDIVISION

TRAININGDEPARTMENT

1420-BTOSHIBADRIVE

LEBANON,TENNESSEE37087

PHONE:(615)449-2360

FAX:(615)444-7520

FOREWORD

The material presented in this manual is provided for the technical training of T ACP employees and

qualified service personnel only .

The specific circuit reference designations, pin numbers, etc., are taken from the TP48E50/60 Service

Manual, File Number 020-9508. The diagrams in this manual are simplified for training and should be used

as a reference guide only when servicing the N5SS CTV Chassis. Refer to the applicable service data for

detailed adjustment and servicing procedures.

NTDPJTV04

SERVICING T OSHIBA'S N5SS TELEVISION CHASSIS

©1996

TOSHIBA AMERICA CONSUMER PRODUCTS, INC.

National Service Division

National Training Department

1420 T oshiba Drive

Lebanon, TN 37087

(615) 449-2360

No part of this manual may be reproduced in whole or in part without prior written consent from

Toshiba America Consumer Products, Inc., Service Division.

CONTENTS

SECTION I

OVERALL UNIT CHARACTERISTICS,

BLOCK DIAGRAMS, LABS 1 & 2

1.MAIN FEATURES..................................1-2

2.MERITS OF BUS SYSTEM....................1-2

2-1.Improved Servciceability.................1-2

2-2.Reduction of Parts Count................1-2

2-3.Quality Control.................................1-2

3. COMPARISON/DIFFERENCES TG-1...1-2

4.SPECIFICATIONS..................................1-3

5.FRONT AND REAR CONTROL

VIEWS.....................................................1-4

5-1.Front View........................................1-4

5-2.Rear View.........................................1-5

5-3.Remote Control View.......................1-6

6.'95 PJ-TV CHASSIS LAYOUT...............1-7

7.CONSTRUCTION OF CHASSIS............1-8

8. VIDEO SIGNAL FLOW........................1-9

9.AUDIO SIGNAL FLOW.......................1-11

10.POWER SUPPLY..................................1-12

11.H and V DEFLECTION.........................1-13

12.I2C COMMUNICATIONS.....................1-14

13.DIGITAL CONVERGENCE.................1-15

14.LAB 1.....................................................1-16

15.LAB 2.....................................................1-20

SECTION II

TUNER, IF/MTS/S.PRO MODULE

1.CIRCUIT BLOCK....................................2-2

1-1.Outline..............................................2-2

1-2.Major Features..................................2-2

1-3.Audio Multiplex Demodulation

Circuit...............................................2-3

1-4.A.PRO Section (Audio Processor)...2-4

2.PIP TUNER..............................................2-6

2-1. Outline...............................................2-6

SECTION III

CHANNEL SELECTION CIRCUIT

1.OUTLINE OF CHANNEL

SELECTION CIRCUIT SYSTEM..........3-2

2.OPERATION OF CHANNEL

SELECTION CIRCUIT...........................3-2

3.MICROCOMPUTER...............................3-3

4.MICROCOMPUTER TERMINAL

FUNCTION..............................................3-4

5.EEPROM (QA02)....................................3-6

6.ON SCREEN FUNCTION.......................3-6

7.SYSTEM BLOCK DIAGRAM................3-7

8.LOCAL KEY DETECTION METHOD..3-8

9. ENTERING THE SERVICE MODE.......3-9

10.TEST SIGNAL SELECTION..................3-9

11.SERVICE ADJUSTMENT......................3-9

12.FAILURE DIAGNOSIS PROCEDURE3-10

13.TROUBLE SHOOTING CHARTS.......3-13

SECTION IV

AUDIO OUTPUT CIRCUIT

1.OUTLINE.................................................4-2

2.THEORY OF OPERATION....................4-2

2-1.Operation of TA8256H....................4-2

SECTION V

DSP CIRCUIT

1.ORIGINS OF DOLBY SURROUND......5-2

2.THE DOLBY MP MATRIX....................5-2

3.THE DOLBY SURROUND

DECODER...............................................5-3

4.DSP CIRCUIT..........................................5-3

5.DSP (Digital Surround Processor) IC......5-6

SECTION VI

A/V SWITCHING CIRCUIT

1.OUTLINE.................................................6-2

2.IN/OUT TERMINALS............................6-2

3.CIRCUIT OPERATION..........................6-2

3-1.Composite Video Signal...................6-2

3-2.S-Video Signal.................................6-2

SECTION VII

VIDEO PROCESSING CIRCUIT

1.OUTLINE.................................................7-2

2.SIGNAL FLOW.......................................7-2

3.CIRCUIT OPERATION..........................7-2

SECTION VIII

V/C/D/IC

1.OUTLINE.................................................8-2

2.LARGE SCALE EMPLOYMENT OF

BUS CONTROL OF PARAMETER FOR

PICTURE CONTROLS...........................8-2

3.EMPLOYMENT OF CONTAINING

EACH VIDEO BAND FILTER

INSIDE.....................................................8-2

4. EMPLOYMENT OF CONTAINING

EACH FILTER (FOR S/H) INSIDE ....... 8-2

5. LOW COST OF IC ..................................8-3

SECTION IX

PIP MODULE

1. BOARD LAYOUT...................................9-2

2. SIGNALS .................................................9-2

3. BLOCK DIAGRAM ................................9-3

SECTION X

SYNC SEPARATION, H-AFC,

H-OSCILLATOR CIRCUITS

1. SYNC SEPARATION CIRCUIT .......... 10-2

1-1. Theory of Operation .......................10-2

2. H AFC (Automatic Frequency Control)

CIRCUIT ................................................10-3

3. H OSCILLATOR CIRCUIT ..................10-4

3-1. Outline ............................................10-4

3-2. Theory of Operation .......................10-4

SECTION XI

VERTICAL OUTPUT CIRCUIT

1. OUTLINE...............................................11-2

1-1. Theory of Operation .......................11-2

2. V OUTPUT CIRCUIT ...........................11-3

2-1. Actual Circuit .................................11-3

2-2. Sawtooth Waveform Generation ....11-3

2-3. V Output .........................................11-4

2-4. V Linearity Characteristic

Correction .......................................11-6

3. PROTECTION CIRCUIT FOR

V DEFLECTION STOP ........................ 11-7

3-1. +35V Over Current

Protection Circuit ...........................11-8

SECTION XII

HORIZONTAL DEFLECTION CIRCUIT

1. OUTLINE...............................................12-2

2. HORIZONTAL DRIVE CIRCUIT........12-2

2-1. Theory of Operation .......................12-2

3. BASIC OPERATION OF HORIZONTAL

DRIVE....................................................12-3

3-1. Theory of Operation .......................12-3

3-2. Drive System ..................................12-4

3-3. Circuit Description .........................12-5

4. HORIZONTAL OUTPUT CIRCUIT ....12-6

4-1. Theory of Operation .......................12-7

4-2. White Peak Bending

Correction Circuit.........................12-11

4-3. H Blanking ...................................12-12

4-4. 200V Low Voltage Protection......12-13

5. HIGH VOLTAGE GENERATION

CIRCUIT ..............................................12-14

5-1. Theory of Operation .....................12-14

5-2. Operation Theory of the Harmonic

Non-Resonant System and Tuned

Waveforms ...................................12-16

6. HIGH VOLTAGE CIRCUIT ...............12-17

6-1. High Voltage Regulator................12-17

7. X-RAY PROTECTION CIRCUIT ...... 12-20

7-1. Outline ..........................................12-20

7-2. Operation ......................................12-20

8. OVER CURRENT PROTECTION

CIRCUIT ..............................................12-21

8-1. Outline ..........................................12-21

8-2. Operation ......................................12-21

SECTION XIII

DEFLECTION DISTORTION

CORRECTION CIRCUIT (DPC Circuit)

1. DEFLECTION DISTORTION

CORRECTION IC (TA8859P) ..............13-2

1-1. Outline ............................................13-2

1-2. Functions and Features ...................13-2

1-3. Block Diagram ...............................13-2

2. DIODE MODULATOR CIRCUIT ........13-3

3. ACTUAL CIRCUIT...............................13-4

3-1. Basic Operation and Current Path ..13-5

SECTION XIV

CLOSED CAPTION/EDS CIRCUIT

1. OUTLINE...............................................14-2

2. DATA TRANSMISSION FORMAT.....14-2

3. DISPLAY FORMAT ............................. 14-3

4. CIRCUIT OPERATION ........................14-4

SECTION XV

DIGITAL CONVERGENCE CIRCUIT

1. OUTLINE...............................................15-2

2. CIRCUIT DESCRIPTION .....................15-2

2-1. Configuration..................................15-2

2-2. Circuit Operation ............................15-2

3. PICTURE ADJUSTMENT ....................15-4

3-1. Change of Memory (E2PROM) ......15-4

3-2. Service Mode ..................................15-4

4. ADJUSTING PICTURE

DIMENSION (Green picture)................15-6

5. KEY FUNCTION OF REMOTE CONTROL

UNIT ......................................................15-7

6. CONVERGENCE OUTPUT

CIRCUIT ................................................15-8

6-1. Outline ............................................15-8

6-2. Circuit Description .........................15-8

7. CONVERGENCE TROUBLESHOOTING

CHART.................................................15-10

8. LAB 3 ...................................................15-11

SECTION XVI

OPTICAL SECTION

1. NECK COMPONENTS .........................16-2

1-1. Outline of Components Around

Neck of The Projection Tube .........16-2

1-2. Theory of Operation........................16-2

1-3. Projection Tube ..............................16-3

2. FUNCTION OF KEY

COMPONENTS .....................................16-4

2-1. Outline ............................................16-4

2-2. Theory of Operation .......................16-4

2-4. Optical Coupling Effect .................16-8

2-5. Lens ................................................16-9

2-6. Focus Adjustment .........................16-10

SECTION XVII

POWER CIRCUIT

1. OVERVIEW...........................................17-3

2. RECTIFYING CIRCUIT AND

STANDBY POWER SUPPLY ..............17-4

3. MAIN SUPPLY CIRCUIT .................... 17-4

4. OUTLINE OF CURRENT RESONANT

TYPE SUPPLY ......................................17-4

5. FUNDAMENTAL THEORY ................17-5

6. ACTUAL CIRCUIT...............................17-6

7. SCAN DERIVED VOLTAGES.............17-8

8. PROTECTOR MODULE (Z801) ..........17-9

9. SUB POWER SUPPLY .......................17-10

10. PROTECT CIRCUITS .........................17-11

11. LAB 4 ...................................................17-15

SECTION XVIII

DYNAMIC FOCUS CIRCUIT

1. OUTLINE...............................................18-2

2. H DYNAMIC FOCUS CIRCUIT ..........18-2

2-1. Theory of Operation .......................18-2

2-2. Circuit Operation ............................18-3

3. V DYNAMIC FOCUS CIRCUIT ..........18-4

3-1. Theory of Operation .......................18-4

3-2. Circuit Operation ............................18-5

SECTION I

OVERALL UNIT

CHARACTERISTICS

BLOCK DIAGRAMS

LABS 1 & 2

1-1

SECTION I

OVERALL UNIT

CHARACTERISTICS

1. MAIN FEATURES

The main feature of Toshiba's projection television model

TP48E60, is the use of the N5SS (TG-1C) chassis. This

chassis utilizes a bus control system, developed by PHILIPS

Corporation, called the I2C (or IIC) bus. IIC stands for InterIntegrated Circuit control. This bus co-ordinates the transfer

of data and control between ICs inside the Television. It is a

bi-directional serial bus consisting of two lines, namely SDA

(Serial DATA), and SCL (Serial CLOCK).

Digital data which is passed along the bus is received by

individual devices and can be either command or data.

Digital-to analog converters are also found within some of

the ICs, allowing them to be addressed and controlled by

strings of digital instructions, replacing those functions

which were previously implemented by external

potentiometers.

2. MERITS OF THE BUS SYSTEM

2-1. Improved Serviceability

Most of the adjustments previously made by resetting variable

resistors and/or capacitors can be made on the new chassis

by operating the remote control and seeing the results on the

television screen. This allows adjustments to be made without

removing covers on the unit thus increasing servicing speed

and efficiency.

2-2. Reduction of Parts Count

The use of digital-to-analog converters built into the ICs,

allowing them to be controlled by software, has eliminated

or reduced the requirement for many discrete parts such as

potentiometers and trimmers, etc.

2-3. Quality Control

The central control of adjustment data makes it easier to

understand, analyze, and review the data, thus improving

the quality of the product.

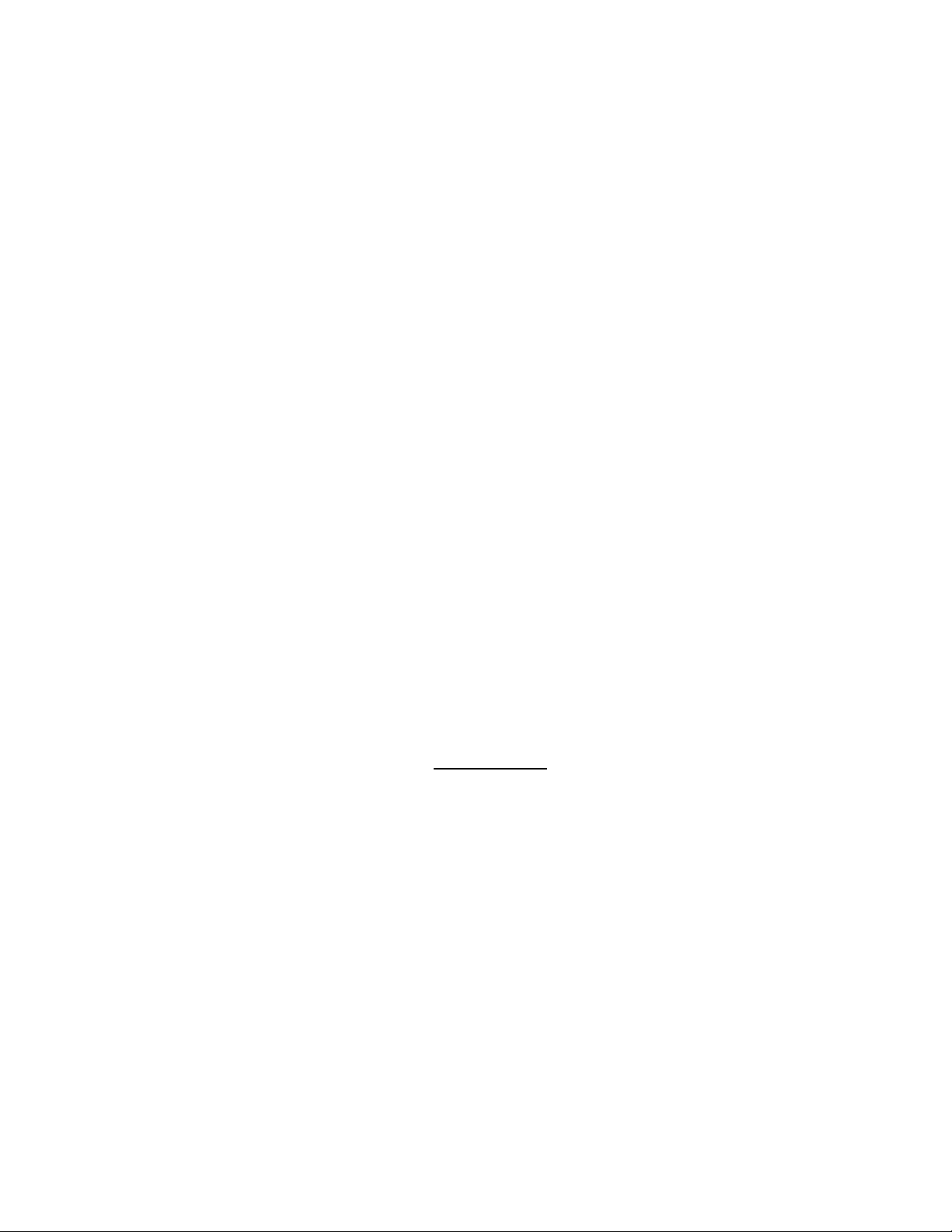

3. COMPARISON/DIFFERENCES OF TG-1 CHASSIS

Toshiba's concept for the TG-1 chassis was to create a sort

of universal chassis which, with minimal changes, could be

used as a standard throughout the entire Toshiba color

television lineup starting in 1995. TG-1 stands for "Toshiba

Global 1". The TG-1 chassis can be found in several

different models and varies in both complexity and features.

Ro ot TG-1 Typical Pic ture and

Chassis Chassis Sizes Features

N5E A1 13, 19 Less

N5ES A2 20, 32

N5S A2 - LEM 20, 32

N5S B 27, 32

N5SS C 27 thru 35 More

Typical Chassis Ex am ples

Model TG-1

CF13E22,23 A1

CF19E22 A1

CF20E30 A1

CF20E40 A1

CN27E55 A 2

CF30E50 A2

CF32E50 A2

CF32E55 A2

CX32E60 B

CX32E60 B

CN27E90 C

CX32E70 C

CN32E90 C

CN35E15 C

TP48E50,51 C

TP48E60,61 C

TP55E50,51 C

TP55E80.81 C

TP61E80 C

TP48E90 C

1-2

4. SPECIFICATIONS

CHASSIS CCCCCC

MODEL Nbr TP48E50 TP48E60 TP48E90 TP55E50 TP55E80 TP61E80

TP48E51 TP48E61 TP55E51 TP55E81 STEP-UP

SPECIFICATION

1 Picture Size# 48"-D/S 48"-D/S 48"-D/S 55"-D/S 55"-D/S 61"-D/S

2 Channel Capacity 181ch 181ch 181ch 181ch 181ch 181ch

*

3 C. Caption ●●●●●●

G

4 MTS with dbx ●●●●●●

E

N

5 Bass, Tre/Balance ●●●●●●

E

6 Sub-Audio-Program ●●●●●●

R

7 Remote Control *A-Uni (42k A-Uni (42k *Intelig+EZ A-Univ (42k A-Univ (43k A-Univ (43k

A

8 Picture-in-Picture * ●

L

9 LED Indicator (RED) ● (P) ● (P) ● (P) ● (P) ● (P) ● (P)

10 Local Key 8key 8key 8key 8key 8key 8key

11 Dolby Surround — — ●(Prolo) — ●●

12 Dig-Sound Processor — — ● (DSP4ch) — ● (DSP4ch) ● (DSP4ch)

*

13 Front Surround ●●—●——

S

14 Cyclone ABX ——————

O

15 Sub-Bass-System ●●●●●●

U

16 Audio Output 14Wx2 14Wx2

N

D

17 Speaker Size & Nbr 160Rx2 160Rx2 160Rx2 160Rx2 160Rx2 160Rx2

18 Comb Filter ●

*

19 Dynamic Focus # ●●●●●●

P

20 Scan Velocity Modu ●

I

21 Vert Contour Corre ——————

C

22 Black Level Expand ●●●●●●

T

23 Flesh Tone Correct ●●●●●●

U

R

24 Dynamic Noise Reduc ●●●●●●

E

25 Picture Preference ●●●●●●

26 Digital-Convergence ●●●●●●

27 Horiz Resolution 800 800 800 800 800 800

28 Parental-Ch Lock ●●●●●●

*

29 Channel Label (32ch) ●●●●●●

O

30 3-Language Display ●●●●●●

T

31 Clock/Off-Timer ● / ●●/●●/●●/●●/●●/●

H

32 Favorite Channel ●●●●●●

E

R

33 Extended-Data-Servi ●●●●●●

34 Star-Sight-Decoder ——————

35 S-Video In-Term ●

36 Audio, Video-In/Out 1+2/1 1+2/1 1+2/1 1+2/1 1+2/1 1+2/1

*

37 Front AV Jack ●●●●●●

T

E

38 Variable Audio Out ●●●●●●

R

39 2-RF Input *— ●●—●●

M

40 Ext Speaker Term ●●●●●

S

41 PIP Audio Out Jack — — ● ———

42 Center-Ch-Aud-Input ————●●

43 Speaker-Box — — ● (SS-SR94 — ● (SS-SR94 ● (SS-SR94

AC

*Cabinet NEW NEW NEW NEW NEW NEW

PARTS SUPPLY (ISO) ——————

(1TN)

(DIG)

(RGB)

(1+1)

●

●

●

●

(2TN)

(DIG)

(RGB)

(1+1)

●

(2TN)

14Wx2, 10Wx2

& 10Wx2

& REAR SPK & REAR SPK & REAR SPK

●

(DIG)

●

(RGB)

●

(1+1)

●

(1TN)

14Wx2 14Wx2 14Wx2

●

(DIG)

●

(RGB)

●

(1+1)

●

(2TN)

& 10Wx2 & 10Wx2

●

(DIG)● (3D-Y/C)

●

(RGB)

●

(1+1)

●

●

●

(2TN)

(RGB)

(1+1)

1-3

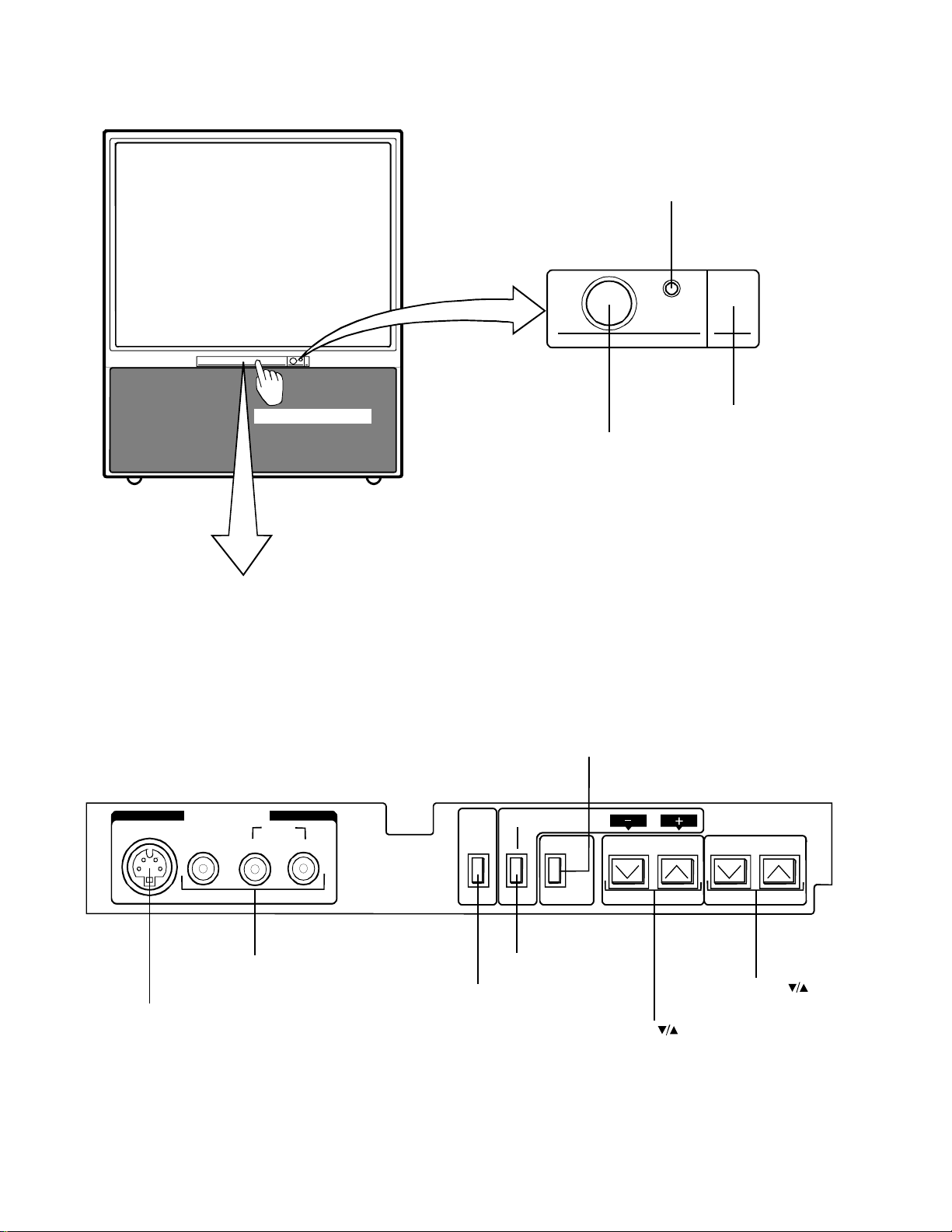

5. FRONT AND REAR CONTROL VIEWS

5-1. Front View

POWER indicator

POWER

S-VIDEO

Press to open the door.

Behind the door

IN-VIDEO 3

VIDEO

L/MONO R

AUDIO

Fig. 1-1

DEMO

POWER button

ANT/VIDEO button*

ADV butto n

MENU-ADV

ANT/VIDEO

VOLUME

Remote se ns or loca tio n

CHANNEL

VIDEO/AUDIO INPUT

jacks

S-VIDEO INPUT jack

* These buttons have dual functions.

MENU buttom

DEMO button

Fig. 1-2

1-4

VOLUME buttons*

butto ns

−/+

CHANNEL

butttons

1-5

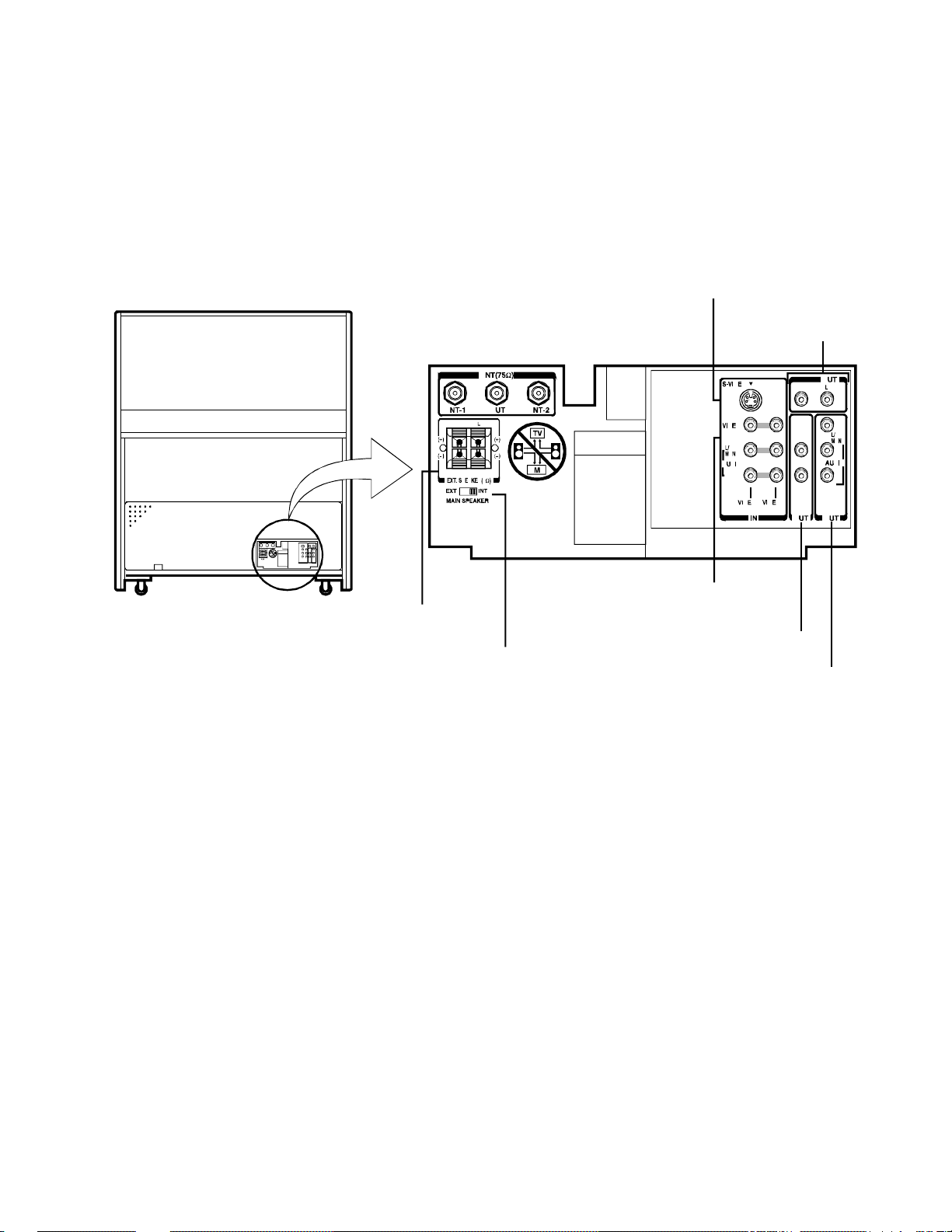

5-2. Rear View

OUTPUT jacks

TV rear

EXTERNAL

SPEAKER

terminals

A

A AO

R

A RP 8

MAIN

SPEAKER

switch

A P

S-VIDEO INPUT jack

D

O

D O

O O

D OA

R

O1 D O2

D

VIDEO 1 INPUT

jacks

VIDEO 2 INPUT

jacks

VARIABLE AUDIO

OUTPUT jacks

O

VAR

R

AUDIO

VIDEO

O O

L/MONO

AUDIO

O

D

R

R

PIP

OO

VIDEO/AUDIO

Fig. 1-3

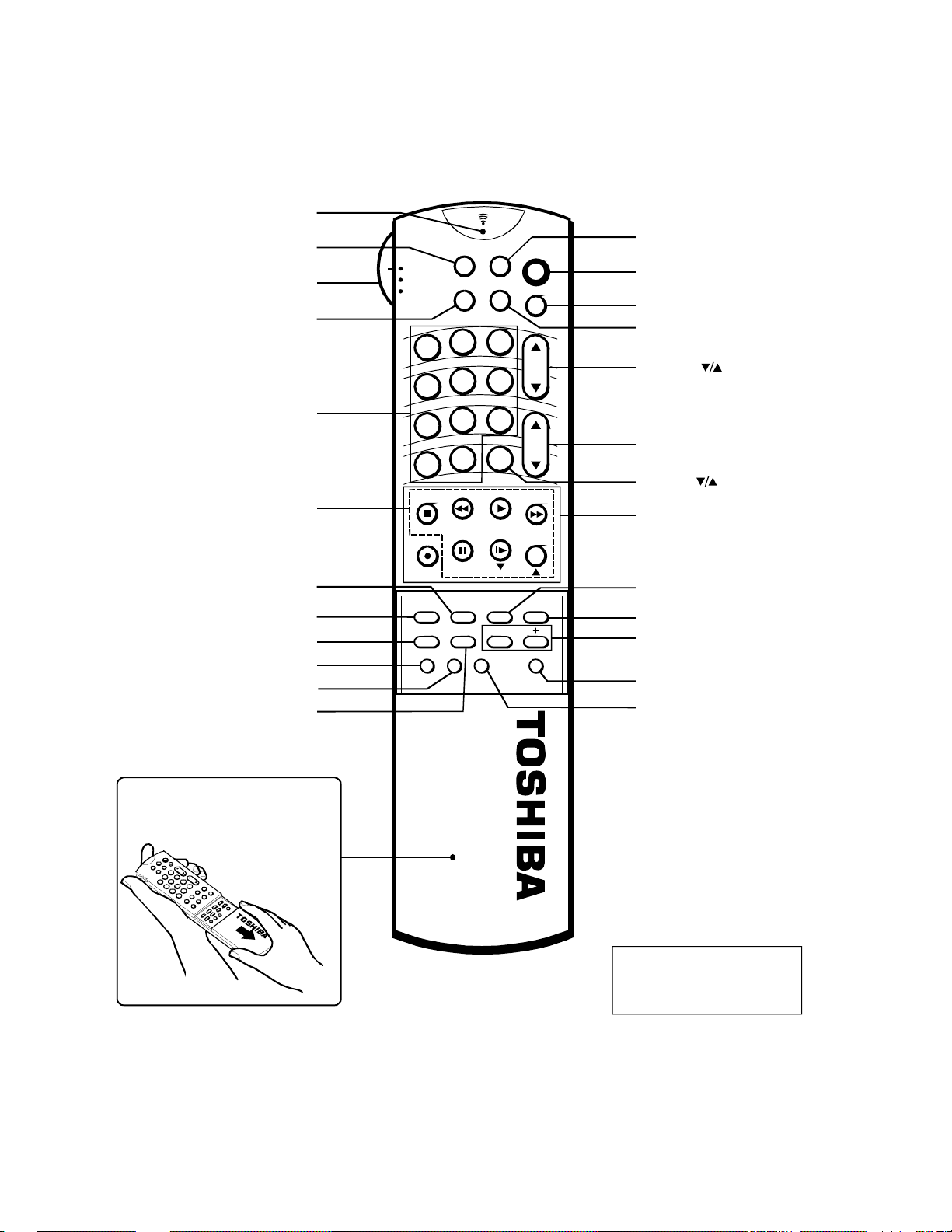

5-3. Remote Control View

y

y

y

Transmit indicator

TV/CABLE/VCR switch

Channel Number*

EDS*

TV/VIDEO*

PIP function*

AUDio*

PICture*

RESET*

C. CAPT*

ANT1/2*

EXIT*

S

D

E

V

T

E

L

B

A

C

R

C

V

1

4

7

100

STOP

LOCATE

REC

PIC.

RESETEXIT

C.CAPTANT1/ 2CYC/ SBS DSP/SUR

O

E

D

I

V

/

V

T

2

5

8

0

REW

SW APSOURCE

PAUSE/ STI LL

SLOW

STILL

AUD.SET UP

R

R

E

C

A

3

6

9

ENT

RTN

PLAY

FAV

O

W

L

L

M

U

T

E

CH

VOL

FF

PIP

TV/VC R

PIP

CH

OPTION

E

P

M

I

T

E

TIMER/Clock*

R

POWER

RECALL*

MUTE*

CHANNEL

RTN*

VOLUME

VCR function*

SET UP*

OPTION*

−/+

FAV −/+*

DSP/SUR*

SYC/SBS*

To operate buttons inside the cover,

slide the cover down and toward

ou.

*

These functions do not have

duplicate locations on the TV.

can be controlled only b

The

the Remote Control.

Fig. 1-4

1-6

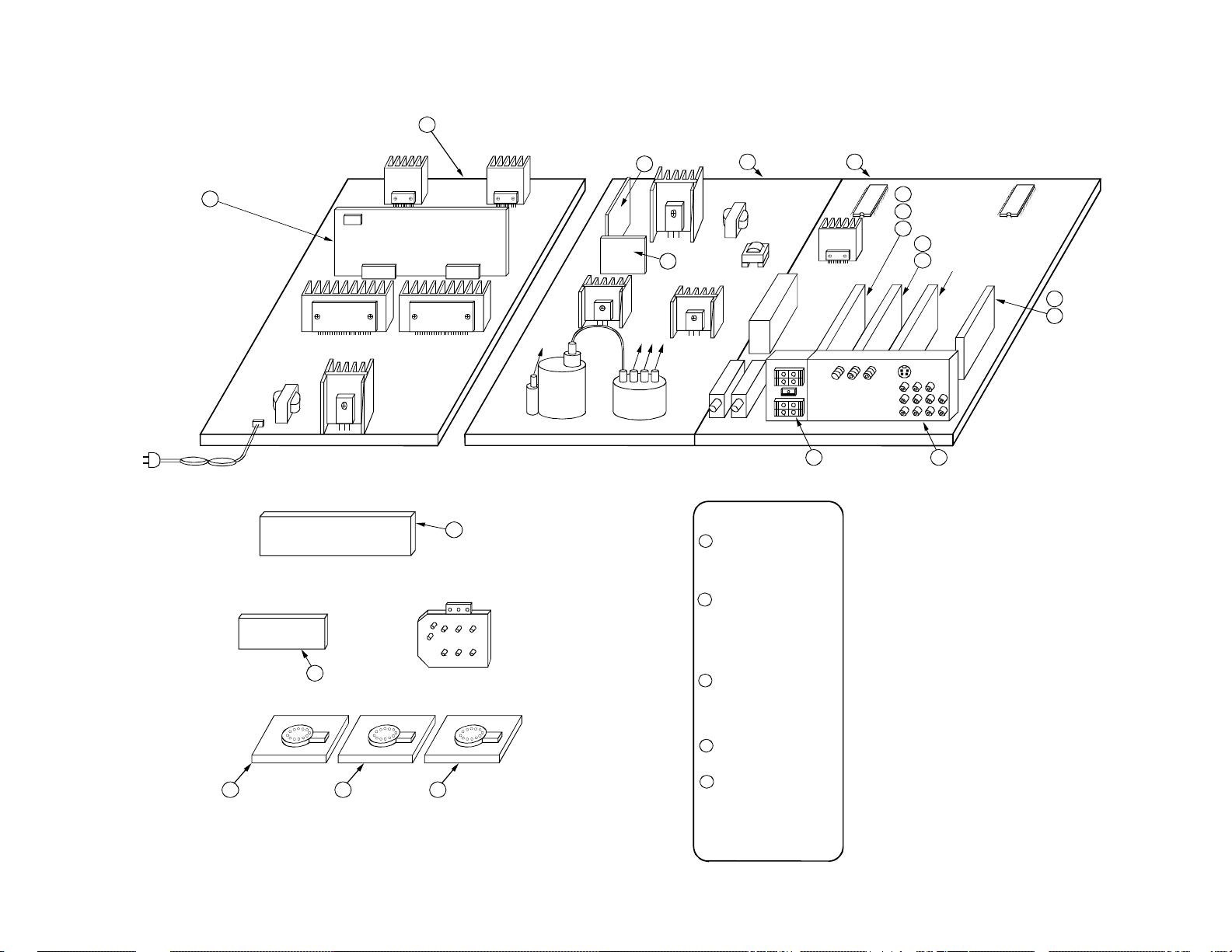

6. PJTV CHASSIS LAYOUT

3

1-7

Fig. 1-5

:DIGITAL CONVER

8

-1:CRT-D(R)

5

5

REAR

AMP 2CH

-5:SVH

-4:CRT-D(G)

5

-4:FRONT

5

FOCUS PACK

-4:CRT-D(B)

5

:CONV/POW2

CENTER

AMP 2CH

to FOCUS

PACK

F.B.T

-4:DYNAMIC FOCUS

4

to CRT

J-BOX

3:DPC

−

3

1. AUDIO

7A

7B

2. COMB FILTER

:DEF/POWER

1

FEATURE

FRONT SURROUND

TP48E50/51/60/61

TP55E50/51

* SPK. TREM. 1pcs

* REAR.CENTER AMP W/O

:DSP4CH

TP55E80/81

TP61E80

* SPK TERM. 2pcs

* REAR. AMP W/

* CENTER. AMP W/O

* CENTER INPUT W/

:DOLBY PRO

9

TP48E90

* SPK. TERM. 2pcs

* REAR. CENTER AMP W/

:DIGITAL COMB

6A

TP48E50/51/60/61/90

TP55E50/51

:3D Y/C TP61E80

6B

3. TUNER

* TP48E50/51

* TP55E50/51ONLY

1 TUNER

OTHER 2 TUNER

FRONT

AMP 2CH

-2:SPEAKER

4

2

:MAIN

-1:FRONT SURRO UND

7A

-1:DSP 4CH

7B

:DOLBY PRO

9

:DIGITAL COMB

6A

:3D Y/C

6B

PIP(HOKURIKU)

-1:A/V

4

-2:EDS.CC

7A

-2:EDS.CC

7B

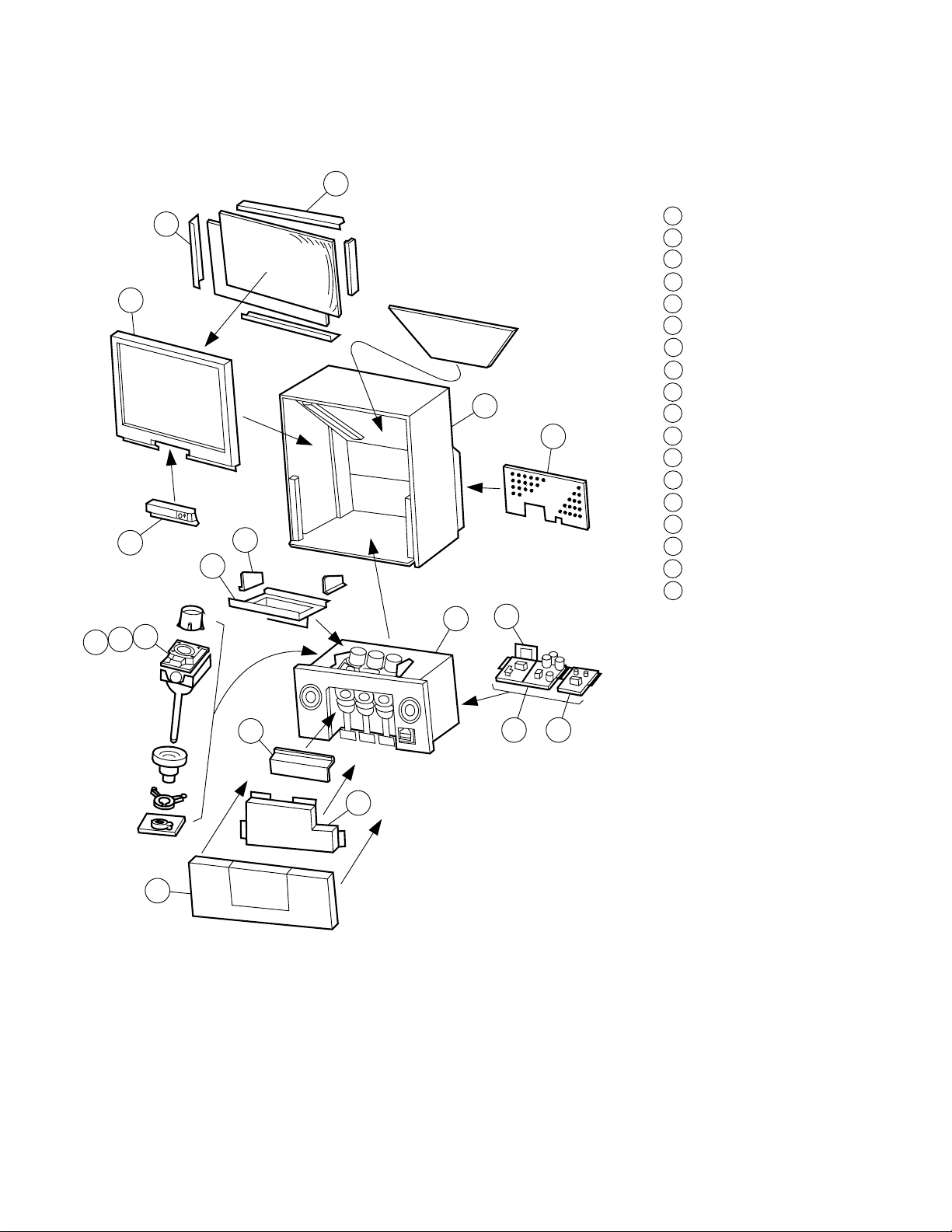

7. CONSTRUCTION OF CHASSIS

9

10

8

7

5

13

14

11

15

WOOD CABINET

1

LIGHT BOX

2

SPEAKER GRILLE

3

FRONT COVER

4

CRT MOUNTING

5

SHIELD FRONT

6

SHIELD SIDE

7

SCREEN BEZEL

8

SCREEN BRACKET L

1

12

2

18

9

SCREEN BRACKET S

10

CONTROL PANEL

11

BACK BOARD

12

COUPLING R

13

COUPLING G

14

COUPLING B

15

CHASSIS FRAME MAIN

16

CHASSIS FRAME POWER

17

AV TERMINAL BOARD

18

6

4

3

16 17

Fig. 1-6

1-8

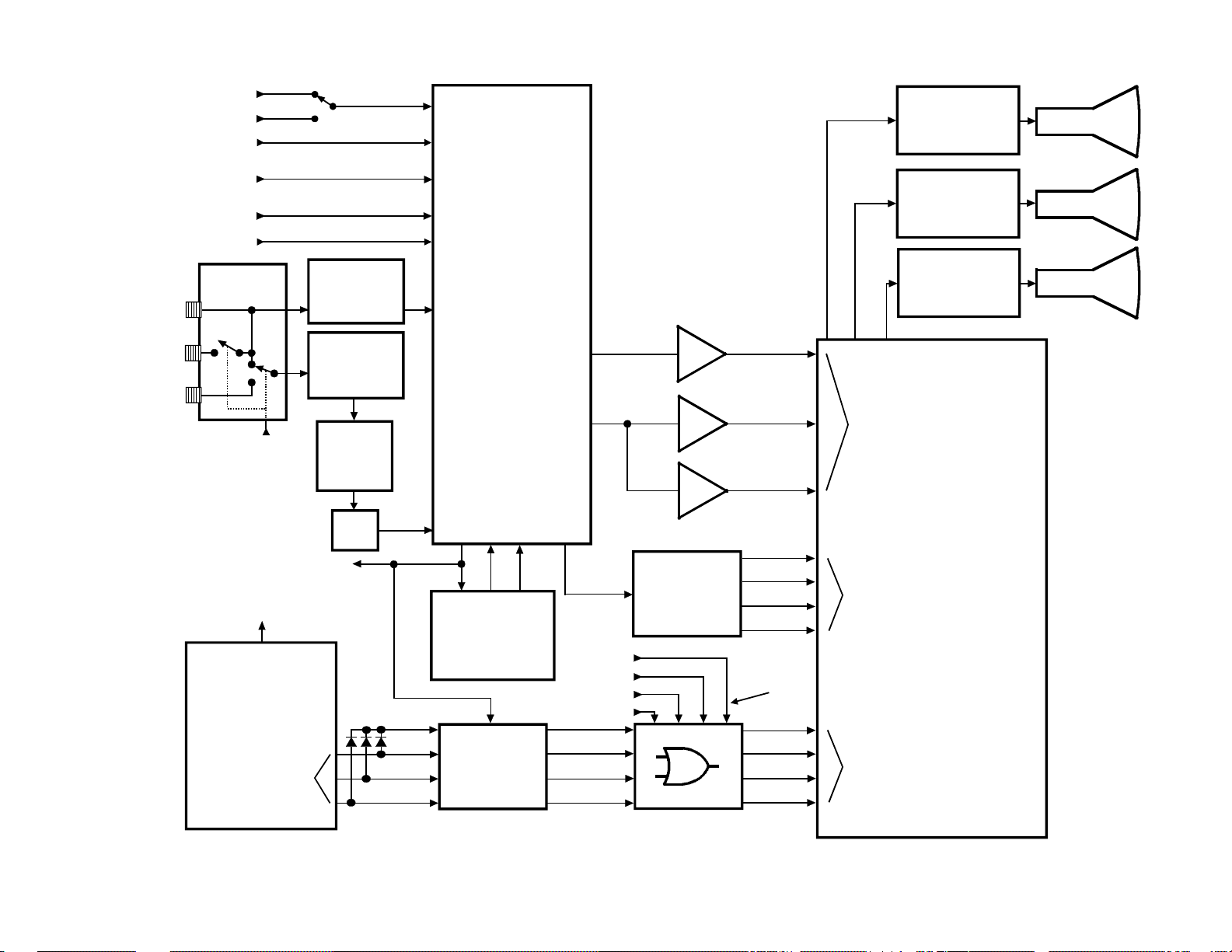

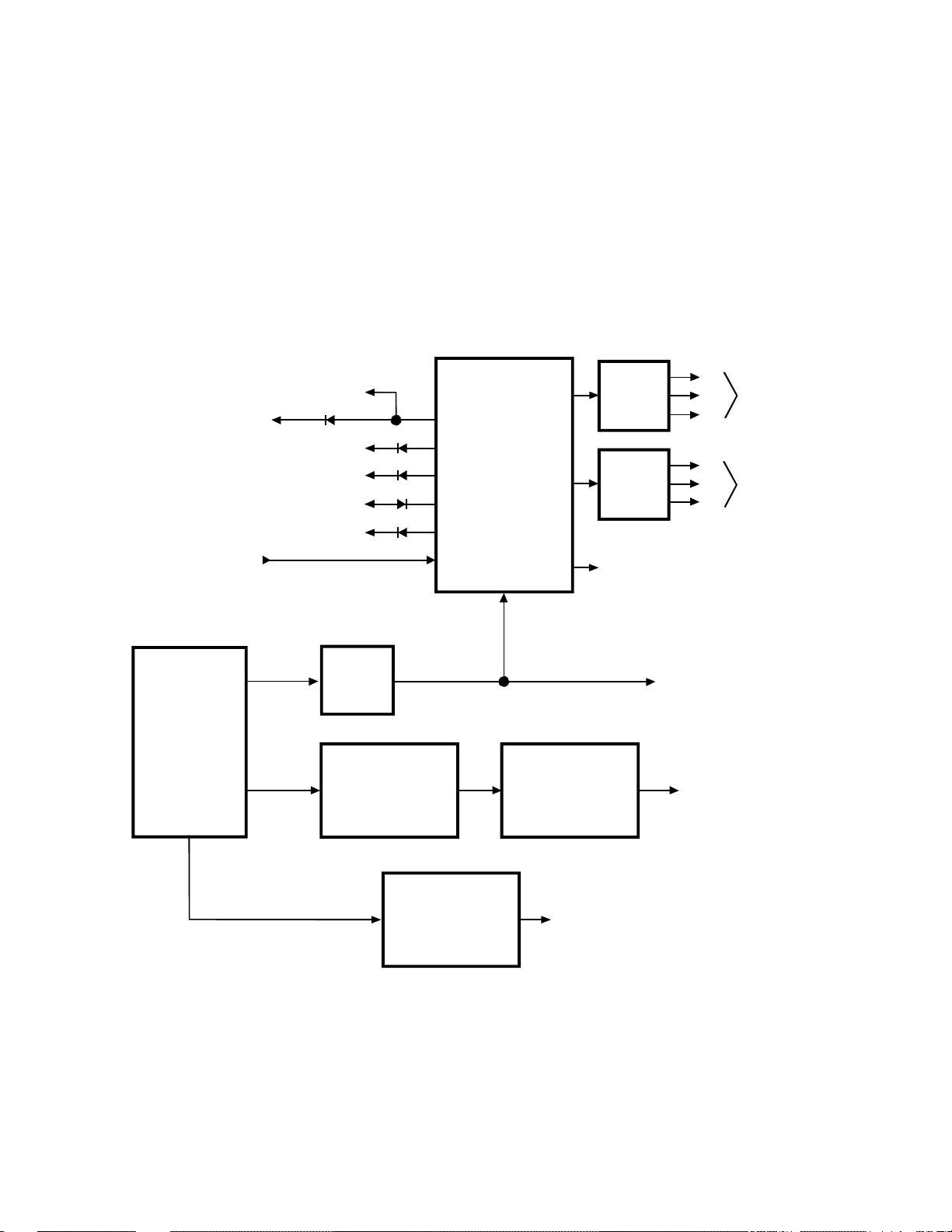

8. VIDEO SIGNAL FLOW BLOCK DIAGRAM

Basic Circuit Operation

The basic operation of the TG-1 chassis is illustrated in the

block diagrams, figures 1-7 through 1-12. Although these

diagrams focus on the TP48E60, the video and audio signal

flow diagrams can be applied to any TG-1 chassis with

minor modifications.

Video Signal Flow

Figure 1-7 illustrates the video signal flow through the TG1 chassis. The Antenna 1 (ANT 1) and Antenna 2 (ANT

2) inputs allow two separate RF signals to be connected to

the RF switcher. When the switch, which is controlled by

the microcomputer, QA01, is in the up position the ANT 1

signal is connected to the HY01 PIP Tuner/IF and the H001

Main Tuner. Moving the switch down connects the ANT

2 signal to the H001 Tuner. Due to the RF Switch the ANT

2 signal can’t be used as the PIP source, but when ANT 2

is selected the ANT 1 signal is available at RF OUT. The

PIP Tuner/IF produces a composite video (CV) signal and

sends it to the AV Switcher, QV01. An IF signal produced

by the Main Tuner is sent to H002, which produces a

composite video signal and sends it to the AV Switcher.

Three video inputs, video 1 through 3, are applied to the AV

Switcher. The video 1 input can be composite video, Y/C

video, or the test signal from QA01. Video 2 is composite

video only, and video 3 is either composite video or Y/C

video. A mechanical switch on the video 1 input defaults

to the test signal, so a video connector must not be plugged

into the video 1 input jack when the internal test signals are

used.

The selected video signal is output as composite video and

applied to the video output jack, the EDS/CC/RGB SW.,

and the Digital Comb Filter or the 3D - Y/C circuit. After

processing the video signal is sent back to the AV Switcher

as separate luminance (Y) and chrominance (C) signals.

The Y and C signals are then sent to Q501 the Video

Chroma Deflection Processing IC. A sync signal is tapped

off the Y signal and applied to Q501. Q501 processes the

video signal and sends separate R, G, and B signals to the

CRT drives and the CRTs.

If the PIP feature is selected, composite video from AV

Switcher is sent to the PIP circuit, ZY01. After processing,

the PIP signal is sent to Q501 as R, G, B, and YS where it

is mixed with the main video.

On screen display (OSD) R, G, and B signals produced by

the Microcomputer, QA01, are mixed with the Extended

Data Service (EDS) and Closed Caption (CC) data in

UM01. These new signals are applied to an OR gate,

QB91, and combined with the convergence signals from

the digital convergence circuit. The convergence signals

can be either the customer convergence cross hairs, or the

service cross hatch pattern. All of these signals are sent to

Q501 where they are mixed with the main video signal.

1-9

1-10

TEST

VIDEO 1

VIDEO 2

VIDEO 3

Figure 1-7 Video Signal Flow Block Diagram

ANT 1

RF

OUT

ANT 2

CV/Y

C

CV

CV/Y

C

RF

SWITC H

CONTROL

FROM

QA01

HY01 PIP

TUNER/IF

H001

MAIN

TUNER

IF

2

H002

IF/MTS

A. PRO

7

EQ

CV TO VIDEO

OUT JAC K

TEST SIGNAL

TO VIDEO 1

QA01

MICRO

COMPUTER

OSD

DATA

22

23

24

12

14

QV01

16

SWITCHING

18

15

CV

28

7

CV

38 30 32

CV

6

DIGITAL

COMB

FILTER

OR, 3D - Y/C

YS

R

G

B

18

19

20

21

9

UM01

EDS/CC

RGB SW.

AV

Y

2

CV

E031Z

9

RED CRT

RED CRT

DRIVE

E032Z

3

GREEN CRT

GRN CRT

DRIVE

E033Z

9

BLUE CRT

B

G

R

42 41

C

34

YY

36

Q503

Q202

SYNC

Q204

43

C

13

MAIN VIDEO

15

17

INPUT

VIDE O CHROMA

DRIVE

Q501

BLUE CRT

DEFLECTION

42

C

4

CV

ZY01

8

PIP

YS

R

G

B

10 13

YS

6

1

5

2

2

R

12

G

5

B

9

4

OR

QB91

1

4

R

5

G

B

6

FROM

DIGITAL

CONV.

1

3

11

6

8

YS

G

B

35

34

33

36

R

39

38

37

32

YS

PROCESSING

PIP VIDEO

INPUT

OSD, EDS, CC, &

CONVERGENCE

VIDEO INPUT

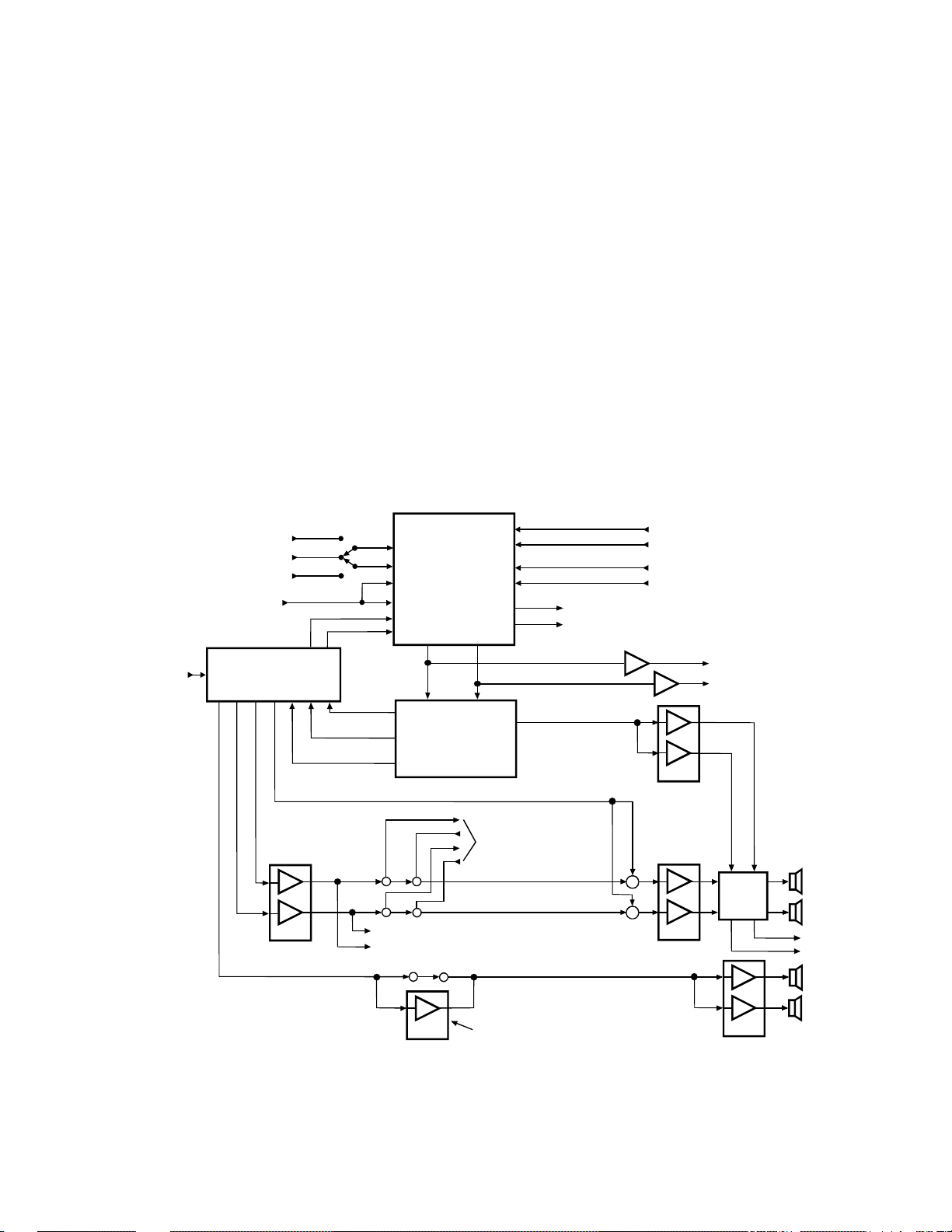

9. AUDIO SIGNAL FLOW BLOCK DIAGRAM

Audio Signal Flow

Audio signals are applied to the AV Switcher from the

three video jacks, H002, and the PIP Tuner, as shown in

Figure 1-8. Like the video signal, there must not be a

connector in the video 1 jack for the audio test signal to be

applied to the AV Switcher. In the TP48E90, PIP audio is

applied to the PIP output jack. The main audio signals are

applied to the audio output jacks and to the Front Surround

circuit, the DSP/Dolby circuit, or the Dolby Pro Logic

circuit. Afterprocessing, the left and right audio signals

are applied to the audio processor in H002 where the

volume, balance, treble, and bass are controlled. Next, the

audio signals are amplified by QS101 and applied to the

variable output jacks, and Q601. If the sub bass system

(SBS) is selected, a signal is mixed with the left and right

signals just before Q601 to increase the signals bass

response. In TP55E80/81 and TP61E80 models, the

jumper is removed so a center signal can be switched in to

replace the main left and right signals. The amplified left

and right audio signals are applied to the internal/external

speaker switch and routed to the desired speakers.

Sets equipped with Dolby or Dolby Pro Logic have a

surround audio signal that is sent to the audio processor in

H002 from the Dolby circuit. The surround signal is then

sent to the rear amplifier, Q641, amplified, and applied to

the rear speakers. In the TP48E90 the surround signal is

routed through an amplifier in Q690 before it is applied to

Q641. Also, the TP48E90 is equipped with Dolby Pro

Logic, and has a center channel. The center channel is

amplified by the Center Amplifier, Q621, and applied to

the front speakers through the internal/external speaker

switch.

VIDEO 1

IF

FROM H001

MAIN TUNE R

SURROUND

TP48E90

TP55E80/81

TP61E80

TEST SIGNAL

FROM QA01

MONO AUDIO

FROM HY01

PIP TUNER

L

R

H002

IF/MTS/A. PRO

2326242217 16 18

L

R

5

L

3

R

QS101

11

13

29

31

L

5

6

R

L

6

R

SURROUND OUT

SBS (SUB BASS SYSTEM)

7

1

5

10

R

TO VARIABLE AUDIO

L

QV01

AV

SWITCHING

37 35

3

DSP/DOLBY,

OR

1

Q690

R

2

TO &FROM CEN TER

INPUT SWITCH & JACK

TP55E80/81 & TP61E80

TP48E90

ONLY

L

FRONT SURROUND,

DOLBY PRO LOGIC

OUT JACK

3

8

9

15

17

1

2

11

CENTER OUT

ONLY

L

TO PIP OUT JACK

(TP48E90 ONLY)

R

QS04

L

R

L

R

QV14

2

4

Q621

CENTER AMP

TP48E90 ONLY

5

+

2

+

Q601

VIDEO 2

VIDEO 3

L

R

12

7

7

INT/EXT

L

SWITCH

11

R

2

4

REAR AMP

TO AUDIO

OUT JACK

RL

Q641

12

7

FRONT OR

CENTER

SPEAKERS

EXTERNAL

REAR

SPEAKERS

Figure 1-8 Audio Signal Flow Block Diagram

1-11

10. POWER SUPPLY AND PROTECTION BLOCK DIAGRAM

The E model PTVs actually have three separate power

supplies as shown in Figure 1-9. These supplies consist of

the Standby Supply, the Main Switch Mode Supply, and

the Sub Switch Mode Supply. The Standby Supply provides

the 5 VDC needed to run the microcomputer and the

customer interface controls, such as the key pad and the IR

receiver. When the set is turned on, the switch closes to

activate the two switch mode supplies and provide the

numerous DC voltages needed to operate the set.

STANDBY

REGULATOR

The Control/Protection circuit, Z801, has two functions.

The first is to regulate the Main Switch Mode Supply, and

the second is to monitor over current, over voltage, and

under voltage sensors throughout the set. If any one of

these sensors activates the protection circuit, Z801 turns

off the switch powering the two switch mode supplies thus

turning off the set. If this occurs, a red LED on the front

panel flashes at half second intervals, and the set must be

unplugged to reset Z801.

+5VDC

RESET

TO MICROCO MPUTER

120VAC

POWER

ON/OFF FROM

MICROCOMPUTER

SWITCH

POWER

OFF

X-RAY SENSING

Figure 1-9 Power Supply/Protection Block Diagram

SWITCH

SWITCH

FEEDBAC K

Z801

16

CONTROL/PRO TEC TION

13

MODE

(SUB)

MODE

(MAIN)

3

14

+30VDC

+15VDC

-15VDC

+12VDC

+38VDC

+125VDC

1

OVERCURRENT,

OVERVOLT A GE, &

UNDER VOLTAGE

SENSING

REG

REG

REG

+5VDC

+15VDC

-9VDC

1-12

11. HORIZONTAL AND VERTICAL DEFLECTION

Deflection circuitry in the E model PTV’s is rather straight

forward as show in Figure 1-10. The horizontal pulse from

Q501 drives the horizontal drive circuitry, which in turn

drives the Horizontal Yokes and the Flyback Transformer,

T461. Numerous low voltage DC supplies are produced by

the Flyback, as well as the high voltages for the anode,

focus, and screen drives. To prevent excessive high

voltages, a sample X-Ray protection voltage is monitored

by the over voltage protection circuits.

AC TO HEATERS

+23VDC TO X-RAY

PROTECT

+12VDC

+35VDC

-27VDC

+200VDC

+125VDC FROM

MAIN POWER

9

TRANSFORMER

7

6

5

3

2

Vertical drive (VD) is applied to the DPC circuit, U421, to

correct any distortions before it’s sent to the Vertical Drive

circuit, Q301. Then the vertical drive circuit supplies the

signals required by the yokes for deflection.

To enhance horizontal transitions between dark and light

areas of the picture, a Velocity Scan Modulation (VSM)

signal is produced by Q501. This signal is sent to the SVM

circuit, E036Z, which in turn drives the SVM coils on the

CRTs.

R

T461

HV

HV

DIST

BLOCK

G

B

30.7KV

TO CRT

ANODES

FLYBACK

2

8

FOCUS

BLOCK

TO ABL

R

G

B

FOCUS &

SCREEN DRIVE

TO CRTs

CIRCUIT

Q501

VIDEO

CHROMA

DEFLECTION

PROCESSING

48

VSM

1

HORIZ

DRIVE

H-OUT

23

VD

31

4

HORIZ

DRIVE

U421

DPC

CIRCUIT

2

6

EO36Z

SVM

4

Q301

VERTICAL

DRIVE

1

TO SVM

COILS

CIRCUIT

Figure 1-10 Horizontal and Vertical Deflection Block Diagram

TO HORIZ

YOKES

TO VERT

2

YOKES

1-13

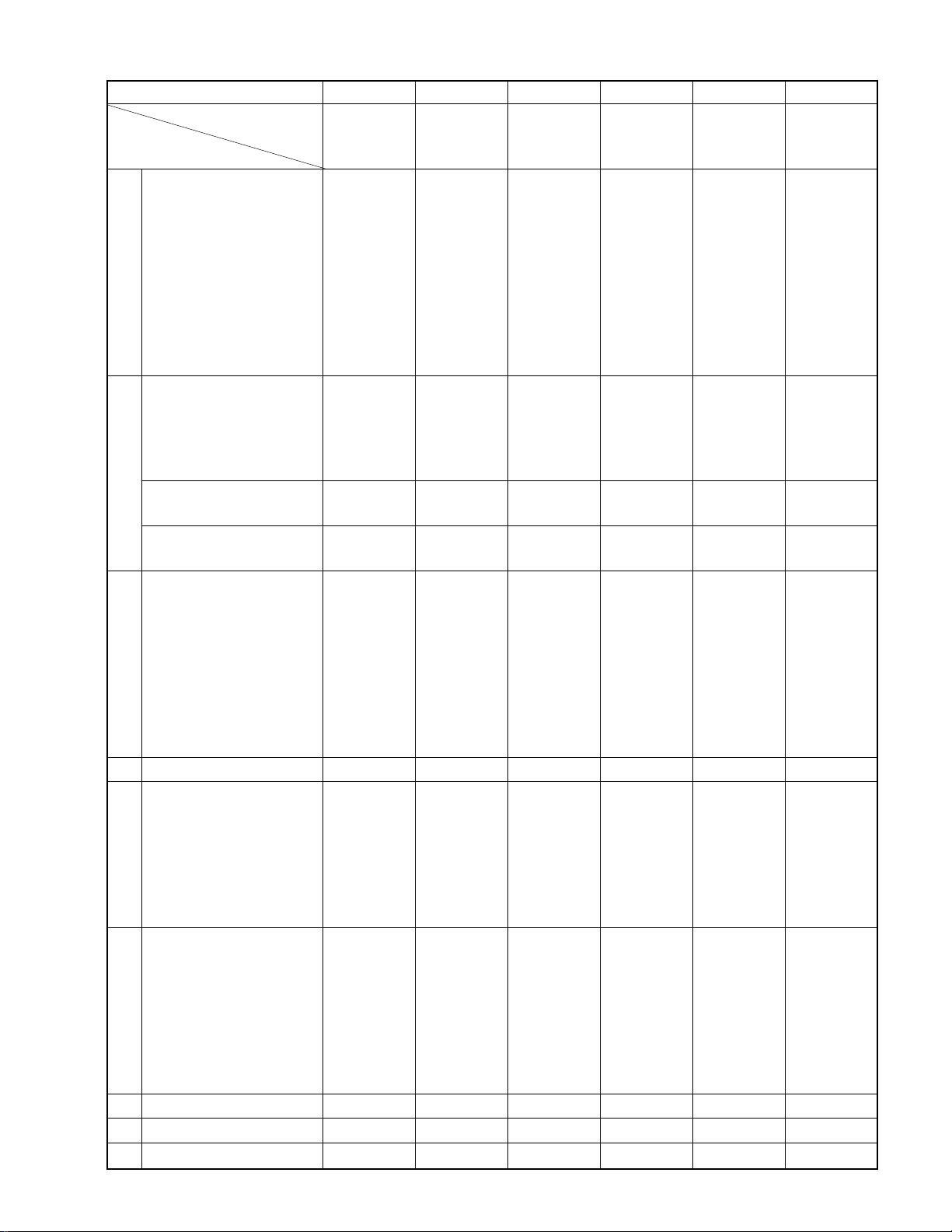

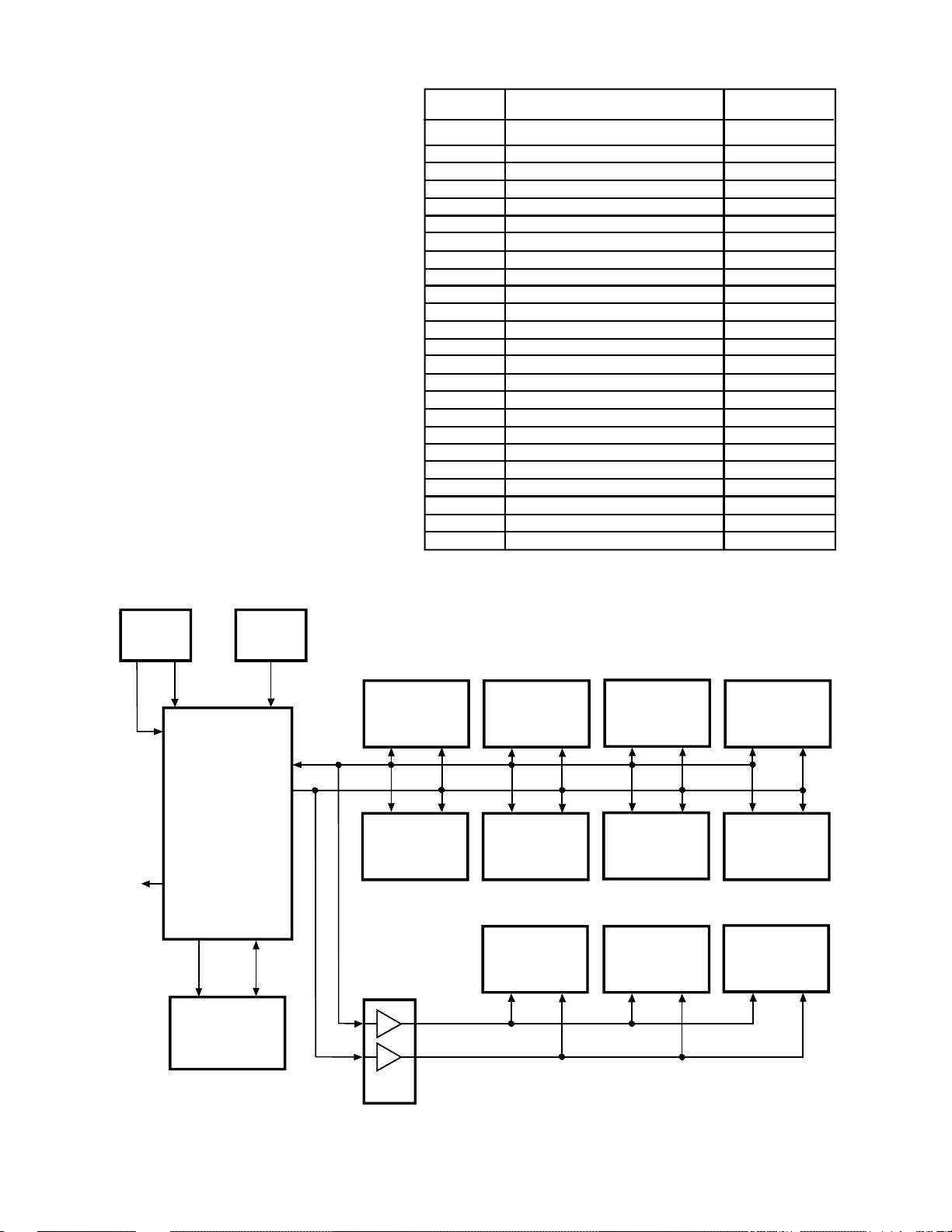

12. I2C Communications

REG

ADJUSTMENT

PRESET

The TG-1 chassis uses I2C data communications to

control all customer features and most of the service

adjustments that where previously done with discrete

devices, refer to Figure 1-11. All communications

are controlled by the Microcomputer, QA01 through

serial data lines (SDA) and serial clock lines (SCL).

Memory settings for customer controls and service

adjustments (except convergence data) are stored in

the E2PROM Memory, QA02, and communicated

to QA01 by the SCL0 and SDA0 lines. Data and

clock lines SDA1 and SCL1 communicate with

most of the circuits in the set. However, there are

three plug in circuits where the data and clock

signals are buffered by QB90 to provide isolation.

All customer functions and most services

adjustments are implemented through the Key Pad

and the Remote Sensor. The RMT OUT signal on

the microcomputer drives the IR Transmitter on the

front panel, but it’s only used in the manufacturing

process. Figure 1-12 shows the Service Registers

and their default values used for making adjustments

in the set.

RCUT RED CUTOFF 40

G C U T G R E E N C U T O F F 4 0

B C U T B L U E C U T O F F 4 0

R D R V R E D D R I V E 4 0

B D R V B L U E D R I V E 4 0

C N T X S U B - C O N T R A S T M A X 7 F

B R T C S U B - B R I G H T C E N T E R 8 0

COLC SUB-COLOR CENTER 50

TNTC SUB-TINT CENTER 40

SCOL SAP-COLOR 15

SCNT SUB-CONTRAST 15

HPOS HORIZ. POSITION 16

VPOS VERTICAL POSITION 00

HIT VERTICAL HEIGHT D1

GMPS GMPS 00

VLIN VERTICAL LINEARITY 12

VSC A-S CORRECTION 08

V P S V E R T I C A L S H I F T 1 5

VCP V-COMPENSATION 03

WID PICTURE WIDTH 25

TRAP TRAPEZIUM 10

HCP H-COMPENSATION 02

VFC V-F CORRECTION 0F

STRH HORIZ. START POSITION 82

Figure 1-12 Service Register Default Values

KEY A

TO IR

LED

TRANS

KEY

PAD

KEY B

18 35

17

REMOTE

SENSOR

QA01

MICRO-

COMPUTER

RMT OUT

3

12

SCL0 SDA0

11

65

QA02

EEPROM

MEMORY

38

SDA1

SCL1

37

IC501

V/C/D

PROCESSING

27 28 21

910

COMB FILTER

OR

3D-Y/C

3

2

QB90

SDA2

5

SCL2

6

H002

IF/MTS/A.PRO

20

25

QAV01

SWITCHING

F. SURR.,

DSP/DOLBY,

D. PRO LOGIC

14 15 14 13

24 44

AV

DPC CIRCUIT

CIRCUIT

H001

TUNER

U421

ZY01

PIP

21

HY01

TUNER/IF

34

43

Q701

CONV.

PROCESSOR

UM01

EDS/CC

RGB SW.

14 13

Figure 1-11 I2C Communication Block Diagram

1-14

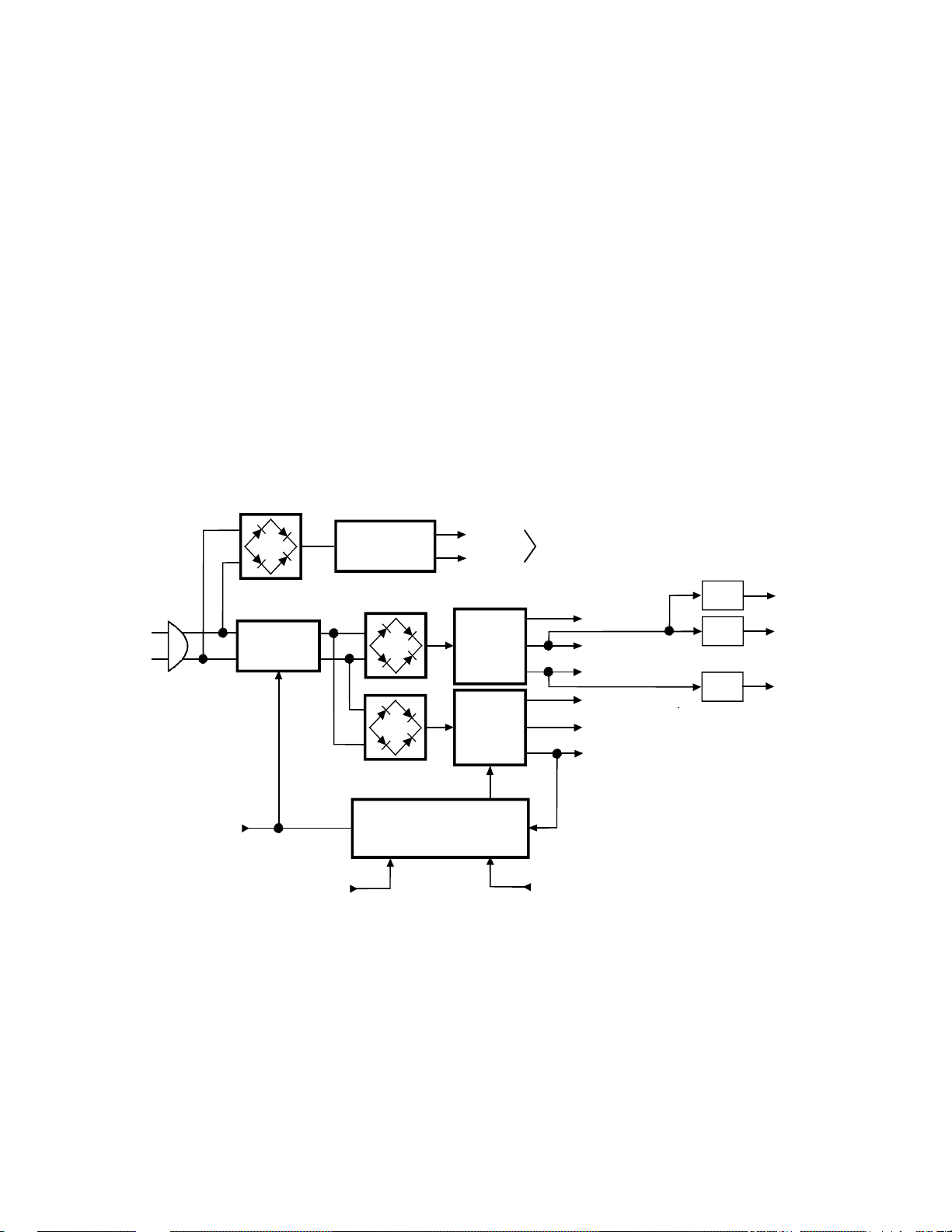

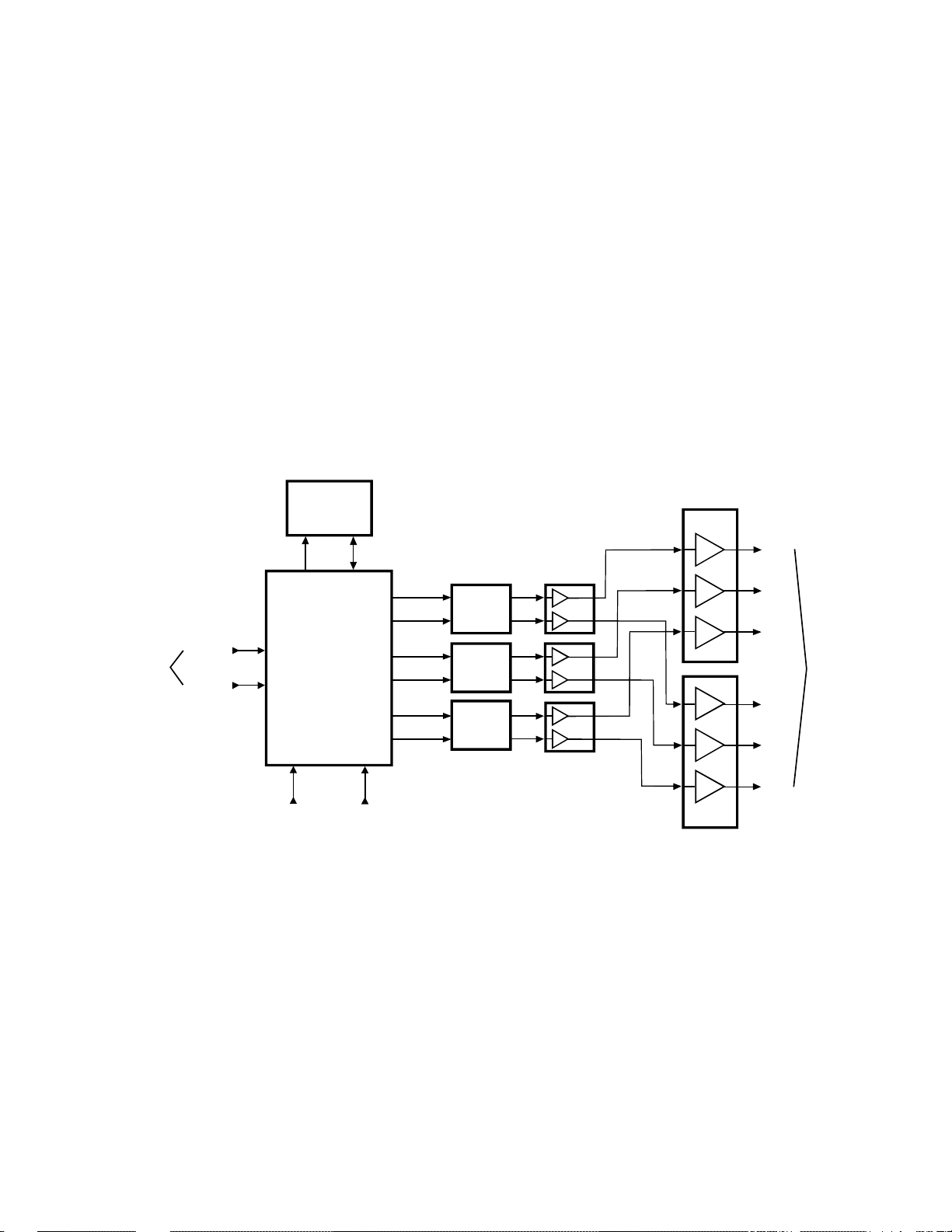

13. Digital Convergence

The TG-1 model PTV’s are equipped with a new digital

convergence circuit shown in Figure 1-13. This circuit

allows servicers to set the convergence with the remote

control. Q701, the Digital Convergence Processor aligns

the convergence from data received from the remote, and

saves the settings in the E2PROM, Q713. The digital

convergence signals are converted to analog by the D/A

Converters Q703, Q704, and Q705. Then they are amplified

Q713

EEPROM

FROM

QAO1

CLK

DATA

65

CLK

45

Q701

43

DIGITAL

CONVERGENCE

44

PROCESSOR

31 32

HD

FROM

IC501

46

VD

FROM

Q301

DATA

7

RH

86

6

RV

87

GH

89

GV

90

BH

96

BV

97

7

6

7

6

CONV.

CONV.

CONV.

by the pre amps (Q715, Q717, & Q719) and power amps

(Q751 & Q751) before being applied to the convergence

yokes. The Power Amps Q752 and Q751 dissipate allot of

heat because of their current draw, so the supplies to these

amps have a number of sensors for over current conditions.

Most of the convergence circuit is on a shielded board, but

the power amps are easily accessible for service.

Q752

18

11

9

18

11

9

Q703

D/A

Q704

D/A

Q705

D/A

15

20

Q715

Q717

Q719

1

7

1

7

7

1

3

1

5

20

3

1

5

20

5

1

3

14

6

15

14

6

Q751

RH

GH

BH

TO

CONV.

YOKES

RV

GV

BV

Figure 1-13 Convergence Block Diagram

1-15

LAB 1

BASIC OPERATION AND UNIT UNDERSTANDING

As a servicer, it is important now, more than ever, to fully understand the operation and functions of

a television set before proceeding with a repair. This is because many of the problems encountered by

a customer today can be caused by an incorrect menu selection or improper setup.

Therefore, the purpose of this lab is to familiarize you with menus and features of the television from

the customer’s point of view.

SECTION ONE

BASIC OPERATION

1. Verify that the unit is connected to an AC supply, and that a signal is connected to the ANT 1

input. While verifying signal connections, take time to examine all of the inputs on the rear and

front (behind door) of the unit.

2. Turn on the set with the remote control and tune to an active channel. Refer to page 9 of the

service manual provided and familiarize yourself with all of the keys on the remote paying,

particular attention to the following keys:

o EDS

o TIMER

o PIP Functions

Open the bottom door on the remote control by sliding it down. Try each key starting with the upper

row. Each of these buttons brings up another menu and/or sub-menus.

3. In the Picture Menu, What is Color Temperature?

____________________________________________________________________________

____________________________________________________________________________

4. In the Audio Menu, Where can the speakers be turned off by the user?

____________________________________________________________________________

____________________________________________________________________________

5. In the Setup Menu, What is Favorite Channel?, What is Channel Lock?

____________________________________________________________________________

____________________________________________________________________________

1-16

6. Refer to page 16 of the Service Manual and perform the User Convergence Adjustments. How

is this different from previous Toshiba PJTVs?

____________________________________________________________________________

____________________________________________________________________________

7. In the Option Menu , How many different languages are there? What are they used for? What is

Channel Label Used for?

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

NOTES:

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

SECTION TWO

DISASSEMBLY & SERVICE POSITION

Follow the procedure listed below to gain access to the tubes and circuit boards.

1. Remove the speaker grill by holding the sides and pulling straight out.

2. Take out the four screws holding the plastic shield in place. Then remove the shield.

3. Remove the control wires from the holder on the metal shield in front of the CRTs.

4. Remove the 4 screws holding the metal shield in place. The shield is notched, so slide it to the

right then down to remove it.

5. Remove the two screws holding the front control panel. Then release the tabs on either side and

let it hang down out of the way.

6. Remove the 4 screws holding the bottom of the screen. Then lift up on the top of the screen and

pull it away from the cabinet.

1-17

7. Remove the 5 screws holding the back panel. Then remove the back panel.

8. Reattach the control panel to the light box.

9. Remove the six screws on the front of the light box.

10. Remove the three screws on the back of the cabinet.

11. Remove the one screw holding the back of the light box to the cabinet.

12. From the front of the set, lift the light box up just a little, and pull it towards you.

13. Pull the light box all the way out of the cabinet and turn it on its side.

CAUTION: the light box weighs about 85 pounds, so get help if you need it.

SECTION THREE

IDENTIFICATION

1. Identify each of the board assemblies and note their locations. Use Figure 1-5 to help you

identify the various boards.

o Convergence/Output/Power Board

o Deflection/Power Board

o Main PCB

o Front Surround Board

o Digital Comb Filter Board

o PIP Board

o EDS/CC Board

2. Is there a convergence board in this unit?

If so, where?

____________________________________________________________________________

____________________________________________________________________________

3. How does this convergence setup differ from previous models?

____________________________________________________________________________

____________________________________________________________________________

4. Examine the Flyback and HV lead assemblies. What is different about this area from earlier

models?

____________________________________________________________________________

____________________________________________________________________________

1-18

5. Is it possible for one technician to perform a service call on this type of unit?

____________________________________________________________________________

____________________________________________________________________________

6. Put the lightbox in the cabinet, but don't screw it in. Then replace the screen and control panel.

Use a few screws to hold the screen and control panel in place.

SUMMARY

In this lab, the operation and function of the unit was determined, and the unit was set up for service

on the bench. Common user type problems in addition to overall serviceability was also discussed.

END OF LAB 1

1-19

LAB 2

TEST SIGNALS, SELF DIAGNOSTICS, & SERVICE REGISTERS

OBJECTIVES: After completing this lab you will be able to:

1. Enter and exit the set’s internal video and audio test signals.

2. Use the test signals for troubleshooting.

3. Use the set’s self diagnostic feature.

4. Make adjustments in the set with the service registers via the remote control.

SECTION ONE

VIDEO TEST SIGNALS

1. Verify that the unit is connected to an AC supply, and that a signal is connected to the ANT 1

input.

2. Enter the service mode by pressing mute on the remote. Press and hold mute a second time

while pressing menu on the control panel. An S appears in the upper right corner of the screen

indicating that the set is in the service mode. Press menu and the RCUT register appears in the

upper left corner of the screen.

3. Push the TV/VIDEO button on the remote once to enter the internal test pattern mode. The

screen should be red.

4. Slowly cycle through the test signals with the TV/VIDEO button until the white cross hairs on

a black background appear. (If the TV/VIDEO button is pushed in rapid succession, the set will

jump out of the test signal mode to one of the inputs - ANT 1, VIDEO 1, VIDEO 2, or VIDEO

3. The set is still in the service mode, so if this occurs, push the menu button then the TV/

VIDEO button to get back into the test signal mode.)

5. Plug a video cable into the VIDEO 1 input jack (make sure the other end of the cable is not

plugged into a video source)

6. What happened to the cross hairs?

____________________________________________________________________________

____________________________________________________________________________

7. If something did happen to the cross hairs, why did it happen?

____________________________________________________________________________

____________________________________________________________________________

1-20

8. Is there video on the screen?

____________________________________________________________________________

____________________________________________________________________________

9. If there is video on the screen, where does it come from?

____________________________________________________________________________

____________________________________________________________________________

10. Unplug the video cable.

SECTION TWO

AUDIO TEST SIGNALS

1. Push the 8 button on the remote to activate the audio test signal. (NOTE: The internal test

pattern mode must be activated for this feature to work.)

2. Push the mute button twice. Now you can control the volume of the signal.

3. Select AUD on the remote control.

4. Select BALANCE and adjust it from left to right with the + and - buttons.

5. Select SPEAKERS and turn them off then on. (NOTE: The speakers are turned off at Q601,

refer to Figure 1-8, while the volume, bass, treble, and balance are controlled in H002. This

means you can troubleshoot most of the audio system with the speakers off.)

6. Plug an audio cable into the left AUDIO 1 input jack (make sure the other end of the cable is

not plugged into an audio source)

7. What happened to audio?

____________________________________________________________________________

____________________________________________________________________________

8. If something did happen to the audio, why did it happen?

____________________________________________________________________________

____________________________________________________________________________

9. Push the 8 button to turn off the audio test signal.

10. Cycle the video test signals back to the ANT 1 signal with the TV/VIDEO button.

1-21

SECTION THREE

SELF DIAGNOSTICS

1. Push the 9 button to activate the self diagnostic feature.

2. What does POWER indicate?

____________________________________________________________________________

____________________________________________________________________________

3. What does BUS LINE indicate?

____________________________________________________________________________

____________________________________________________________________________

4. What does BUS CONT indicate?

____________________________________________________________________________

____________________________________________________________________________

5. What does BLOCK indicate?

____________________________________________________________________________

____________________________________________________________________________

6. Push the EXIT button to exit the self diagnostic feature.

7. Select the VIDEO 1 input with the TV/VIDEO button. (Make sure there is no signal applied to

VIDEO 1)

8. Push MENU on the control panel to display the registers.

9. Push 9 to activate the self diagnostic feature.

10. Is the display different from the previous display. ______

11. If it is, explain why.

____________________________________________________________________________

____________________________________________________________________________

12. Push the EXIT button to exit the self diagnostic feature.

13. Push MENU on the control panel to display the registers.

1-22

SECTION FOUR

SERVICE REGISTERS

NOTE: In each of the following exercises write down the register’s value before adjusting it. Then

restore the register to its original value before proceeding to the next exercise.

1. Enter the internal test pattern mode and select the test signal that has a white window in the

upper center of a black background as shown below.

2. Increase the RCUT register value and describe its effect on the picture.

RCUT______

____________________________________________________________________________

____________________________________________________________________________

3. Change the test signal to the white on black cross hatch pattern as shown below.

4. Select the HPOS register and vary its value between 00 and 1F. Describe its effect on the

picture. What happens if you increase the register to 20?

HPOS______

____________________________________________________________________________

____________________________________________________________________________

5. Select the VPOS register and vary its value between 00 and 07. Describe its effect on the

picture. What happens if you increase the register to 08?

VPOS______

____________________________________________________________________________

____________________________________________________________________________

1-23

6. Select the HIT register and vary its value 5 steps above and below the recorded value.

Describe its effect on the picture.

HIT______

___________________________________________________________________________

____________________________________________________________________________

7. Select the VLIN register and vary its value 8 steps above and below the recorded value.

Describe its effect on the picture.

VLIN______

___________________________________________________________________________

____________________________________________________________________________

8. Select the WID register and vary its value 8 steps above and below the recorded value.

Describe its effect on the picture.

WID______

___________________________________________________________________________

____________________________________________________________________________

9. Select the STRH register and vary its value 8 steps above and below the recorded value.

Describe its effect on the picture.

STRH______

___________________________________________________________________________

____________________________________________________________________________

SUMMARY

Now that you have completed Lab 2, you should be able to use the internal video and audio test

signals, the self diagnostic feature, and the service registers for making adjustments.

END OF LAB 2

1-24

SECTION II

TUNER, IF/MTS/S.PRO MODULE

2-1

Loading...

Loading...