Page 1

STACK FEED BYPASS

MY-1016

File No. 31100017

Page 2

General Precautions for Installation/Servicing/Maintenance for the MY-1016

The installation and service should be done by a qualified service technician.

1. When installing the MY-1016 to the Plain Paper Copier, be sure to follow the instructions described in

the “Unpacking/Set-Up Procedure for the MY-1016” booklet which comes with each unit of the

MY-1016.

2. The MY-1016 should be installed by an authorized/qualified person.

3. Before starting installation, servicing or maintenance work, be sure to turn off and unplug the copier

first.

4. When servcing or maintaining the MY-1016, be careful about the rotating or operation sections such

as gear, pulleys, sprockets, cams, belts, etc.

5. When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise

noted in this manual or other related materials. Be careful not to reassemble small parts such as

screws, washers, pins, E-rings, toothed washers to the wrong places.

6. Basically, the machine should not be operated with any parts removed or disassembled.

7. Delicate parts for preventing safety hazard problems (such as breakers, thermofuses, fuses, door

switches, sensors, etc. if any) should be handled/installed/adjusted correctly.

8. Use suitable measuring instruments and tools.

9. During servicing or maintenance work, be sure to check the serial No. plate and other cautionary

labels (if any) to see if they are clean and firmly fixed. If not, take appropriate actions.

10. The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity. Before using the wrist band, pull out

the power cord plug of the copier and make sure that there is no uninsulated charged objects in the

vicinity.

11. For the recovery and disposal of used MY-1016, consumable parts and packing materials, it is rec-

ommended that the relevant local regulations/rules should be followed.

12. After completing installation, servicing and maintenance of the MY-1016, return the MY-1016 to its

original state, and check operation.

Copyright 2000

TOSHIBA TEC CORPORATION

Page 3

CONTENTS

1. SPECIFICATIONS ...................................................................................................... 1-1

2. OUTLINE .................................................................................................................... 2-1

2.1 Names of Various Components ......................................................................................... 2-1

2.2 Layout of Electrical Parts .................................................................................................. 2-2

2.3 Harness Connection Diagram ............................................................................................ 2-3

3. OPERATIONAL DESCRIPTION ................................................................................ 3-1

3.1 General Operation ............................................................................................................. 3-1

3.2 Block Diagram .................................................................................................................. 3-1

3.3 Detection of Abnormal Status ........................................................................................... 3-2

3.3.1 Paper jam detection ............................................................................................... 3-2

3.4 Flow Charts ...................................................................................................................... 3-3

4. MECHANICAL DESCRIPTION .................................................................................. 4-1

4.1 Paper Feed System .......................................................................................................... 4-1

4.2 Drive System .................................................................................................................... 4-2

5. CIRCUIT DESCRIPTION ........................................................................................... 5-1

5.1 Meaning of Signals ...........................................................................................................5-1

5.2 Timing Chart ..................................................................................................................... 5-2

6. DISASSEMBLY AND REPLACEMENT ..................................................................... 6-1

October 2000 © TOSHIBA TEC 1 MY-1016 CONTENTS

Page 4

1. SPECIFICATIONS

Function : Pickup roller drop and paper feed roller method

Paper : Continuous feed64 to 80g/m2 (17 to 21 lbs)

: Single sheet feed 80 to 163g/m2 (21 to 43 lbs)

Transport speed : 260 mm/sec.

Max. capacity : 11 mm (100 sheets)

Dimensions : 120 (W) x 485 (D) x 227 (H) mm

Weight : Approx. 2.5 kg

Power supply : 5VDC, 24VDC (Supplied from copier)

October 2000 © TOSHIBA TEC 1 - 1 MY-1016 SPECIFICATIONS

Page 5

2. OUTLINE

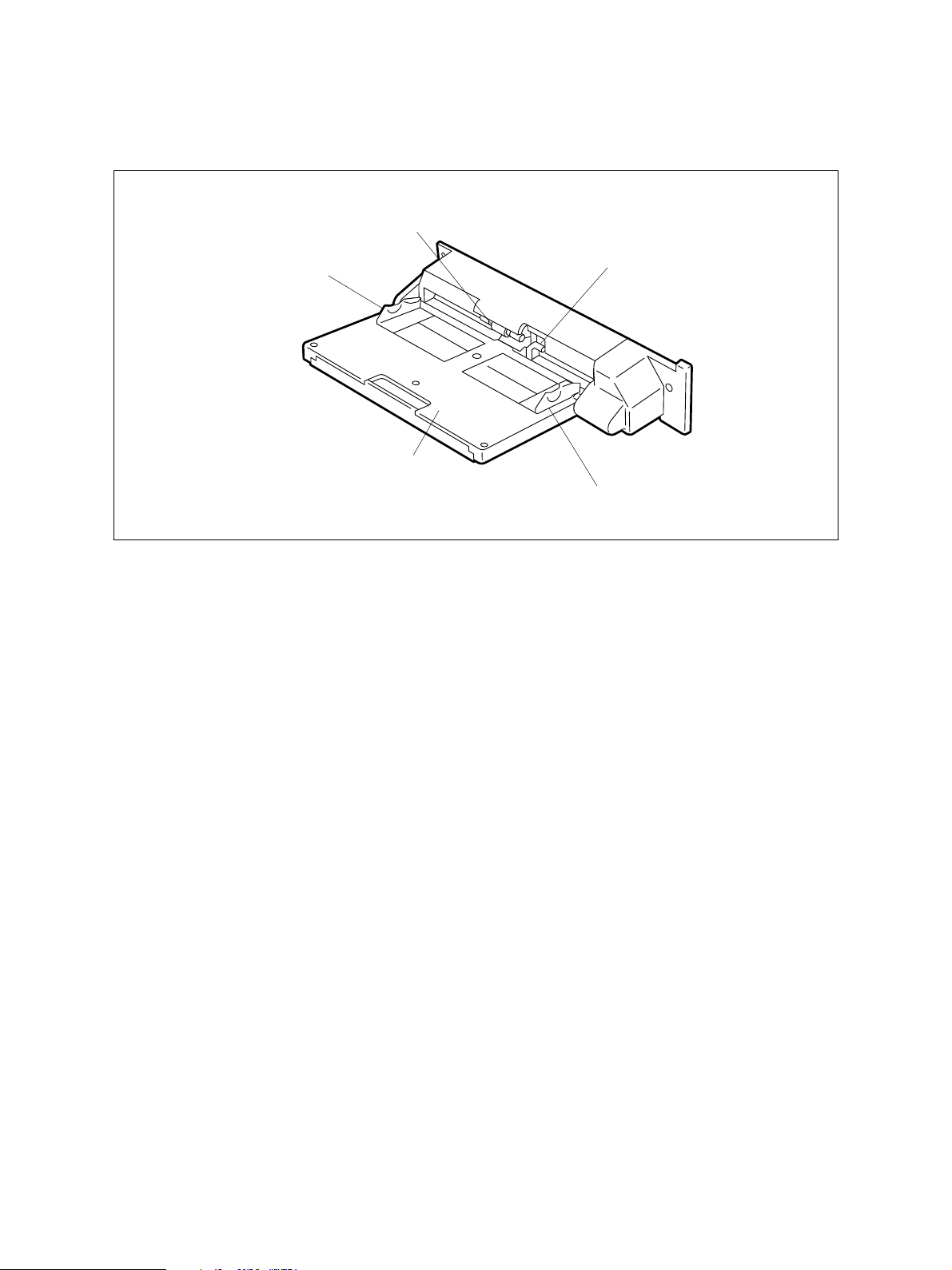

2.1 Names of Various Components

SFB pickup roller

SFB document guide F

SFB document tray

SFB feed sensor (Arm)

SFB document guide R

SFB 02-01-01

October 2000 © TOSHIBA TEC 2 - 1 MY-1016 OUTLINE

Page 6

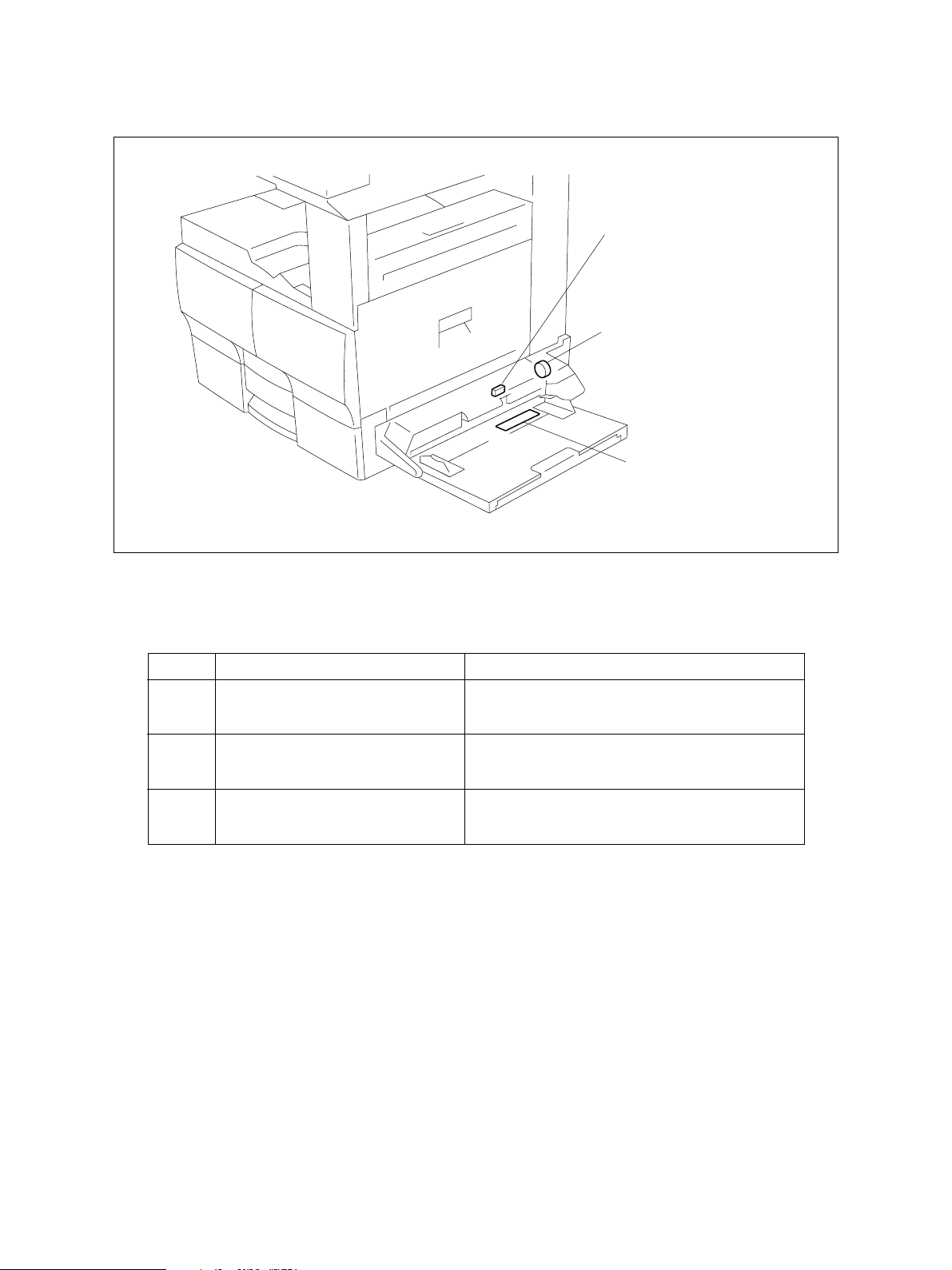

2.2 Layout of Electrical Parts

SEN1

CL1

PSS

SFB 02-02-01

Symbols and functions of various devices

Symbol

SEN1

SET-SEN

Name

SFB feed sensor

CL1

MPU-CLT

SFB clutch

PSS

PSS-PWA

SFB paper size sensor

Function

Detects the loading of paper.

Transmits driving force to the rollers to pick up

and transport the paper.

Paper size detection.

MY-1016 OUTLINE 2 - 2 October 2000 © TOSHIBA TEC

Page 7

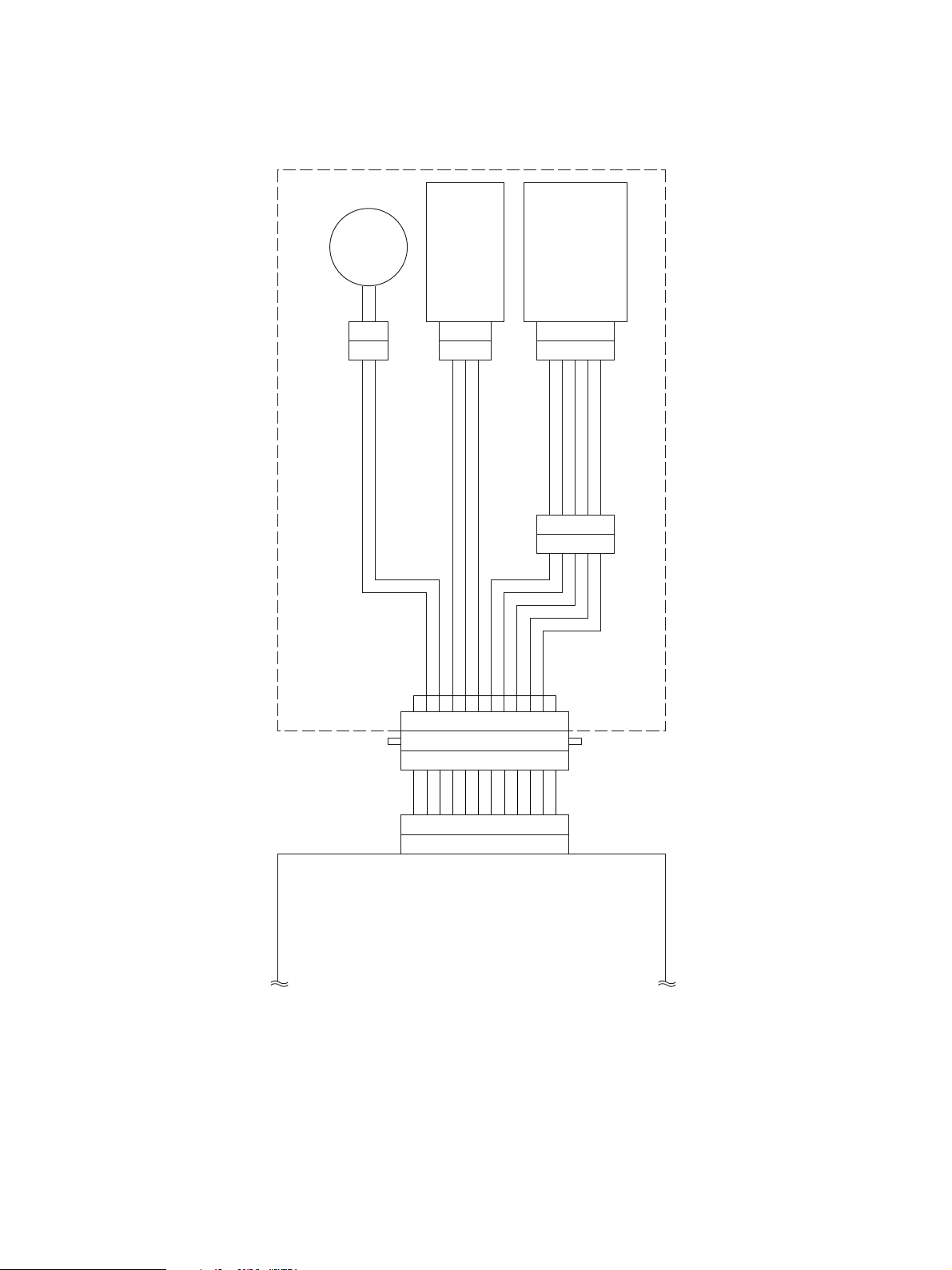

2.3 Harness Connection Diagram

SFB clutch

SFB feed sensor

SFB paper size sensor

SFB

CN303

2

1

CN304

321

CN302

123456789

987654321

121110

5

CN300

12345

54321

CN301

101112

4

321

123456789

2

4

6

SG 1

SG

CN31

MPFCON1

+5V

24VSW 3

MPESON 5

MPSS3ON 78MPSS1ON 9

10

10MPSS0ON

MPSS2ON

11

12

12MCONECT

SG 11

Relay PWA

SFB 02-03-01

October 2000 © TOSHIBA TEC 2 - 3 MY-1016 OUTLINE

Page 8

3. OPERATIONAL DESCRIPTION

3.1 General Operation

The SFB is a bypass feed unit mounted on the right side of the copier. This unit has no PWA and the

operation and detection signals are sent to the MAIN PWA through the RELAY PWA. The unit is con-

trolled by the MAIN PWA.

3.2 Block Diagram

SFB

Relay PWA

CN31

MPES

MPFCON

SSIZE0-3

SFB feed sensor

SFB clutch

SFB paper size sensor

SFB 03-02-01

The SFB consists of the one switch, one magnetic clutch, and paper size sensor. These signals connect

to the MAIN PWA through the relay cable and RELAY PWA. When the bypass feed is selected on the

copier side and paper is placed in the SFB, printing by the bypass feed is enabled.

October 2000 © TOSHIBA TEC 3 - 1 MY-1016 OPERATIONAL DESCRIPTION

Page 9

3.3 Detection of Abnormal Status

3.3.1 Paper jam detection

The SFB has the SFB feed sensor to detect that the paper has been placed. When you press the Start

key on the copier after this sensor detects the presence of paper, the SFB clutch turns ON to start

feeding. If the paper has not reached the feed sensor on the copier side for a fixed time after feeding

begins, the program will judge it to be paper jamming and stop feeding. To reset the error state, once

remove the paper and turn the SFB feed sensor OFF.

MY-1016 OPERATIONAL DESCRIPTION 3 - 2 October 2000 © TOSHIBA TEC

Page 10

3.4 Flow Charts

Start button ON

Main motor ON

Polygon motor ON

Process unit fan motor high speed rotation

Development bias ON

Separation bias ON

Charge bias ON

Discharge lamp ON

Process system control Optical system control

Transfer system control

Retraction of carriage

Polygon motor

OK?

YES

Laser ON

Transfer bias ON

NO

Service call

"CA1"

Main motor

OK?

YES

SFB clutch ON

SFB feed sensor

NO

Service call

"C01"

NG

Black shading

Exposure lamp ON

Stop of carriage

check

Transfer guide bias ON

Laser OFF

OK

SFB clutch OFF

Paper jam

"E12"

Advance of carriage

White shading

Registration roller

Transfer bias OFF

Transfer guide bias OFF

clutch ON

Registration roller

Scanning of document

Stop of carriage

clutch OFF

Exposure lamp OFF

Retraction of carriage

Stop of carriage

NO

HSYNC

OK

YES

Remaining

copy count 0?

NO

Service call

"CA2"

NO

Remaining

copy count 0?

YES

Exit sensor

NG

check 1

YES

Polygon motor OFF

End of process

system control

OK

Exit sensor

check 2

OK

Paper jam

"E01"

NG

Paper jam

"E02"

End of optical

system control

A

October 2000 © TOSHIBA TEC 3 - 3 MY-1016 OPERATIONAL DESCRIPTION

Page 11

A

Charge bias OFF

Main motor OFF

Development bias OFF

Separation bias OFF

Discharge lamp OFF

Process unit fan motor low speed rotation

Standby

MY-1016 OPERATIONAL DESCRIPTION 3 - 4 October 2000 © TOSHIBA TEC

Page 12

4. MECHANICAL DESCRIPTION

4.1 Paper Feed System

Flow of paper

SFB feed sensor

SFB pickup roller

SFB 04-01-01

Paper Pickup Operation

When you place the paper, the arm of the SFB feed sensor is pushed in causing the sensor to turn

ON (paper present). When you press the Start button on the copier to turn the gear on the copier

side, the gear of the SFB also turns and the SFB clutch turns ON, causing the SFB pickup roller to

lower and pull in the paper.

October 2000 © TOSHIBA TEC 4 - 1 MY-1016 MECHANICAL DESCRIPTION

Page 13

4.2 Drive System

Flow of paper

SFB clutch

SFB 04-02-01

The SFB is driven from the copier through the gear. When the SFB clutch turns ON, the rotation on the

copier side is transmitted to the SFB feed roller. The SFB pickup roller is connected to the SFB feed roller

through the belt. When the SFB feed roller turns, the SFB pickup roller lowers and starts picking up.

When the paper is pulled in, the SFB clutch turns OFF and the SFB pickup roller returns to its original

position.

MY-1016 MECHANICAL DESCRIPTION 4 - 2 October 2000 © TOSHIBA TEC

Page 14

5. CIRCUIT DESCRIPTION

5.1 Meaning of Signals

Signal name Part name Functional description Status Note

MPESON SFB feed sensor Detects the loading of paper Photo sensor

MPFCON SFB clutch Transmits driving force to Low: ON Magnetic

the rollers to pick up and clutch

transport the paper

MPSS 0-3 ON SFB paper size Paper size detection Low: Detection PWA pattern

sensor

The SFB feed sensor is a photo sensor which detects that the paper has been placed in the bypass tray.

The signal is usually at “High” level (no paper present) and goes LOW when the paper is placed. This

signal is sent to the MAIN PWA through the relay cable and RELAY PWA.

SFB clutch is an operation signal for the clutch to transmit driving from the copier to the SFB. The signal

output from IC36 (MFPCON) on the MAIN PWA connects to the transistor (Q16) on the RELAY PWA.

When the signal is at “High” level, Q16 turns ON to drive the clutch, causing the pickup roller to lower and

pull in the paper.

The SFB paper size sensor detects the width of the paper placed in the tray of the SFB. The brush

attached to the paper width guide is touching the pattern on the PWA, and one of the MPSS0 - 3 signals

is detected according to the position to which the paper width guide is slid. MPSS0 goes LOW at the

narrowest position, and MPSS3 at the widest position. (When each width sensor is at “Low” level, that

width is detected.) Since the detection areas overlap as shown below, two signals may be detected at

the same time depending on the position of the paper width guide

A4 Series LT Series MPSS 0 MPSS 1 MPSS 2 MPSS 3

A4 LT H H H L

A4-R LT-R H H L H

A5-R ST-R H L H H

A6 - L L H H

B4 COMP H H L L

B5-R - H L L H

B6 - L L H H

October 2000 © TOSHIBA TEC 5 - 1 MY-1016 CIRCUIT DESCRIPTION

Page 15

5.2 Timing Chart

2.65s

1.84s

610ms

The values are data (reference values) applicable when the A4 size paper is used.

SFB clutch

MY-1016 CIRCUIT DESCRIPTION 5 - 2 October 2000 © TOSHIBA TEC

SFB feed sensor

Feed sensor

SFB 05-02-01

Page 16

6. DISASSEMBLY AND REPLACEMENT

[A] SFB assembly/SFB cover

1. Remove 2 screws and detach SFB cover.

SFB cover

2. Remove one screw and detach harness fixing

plate.

3. Detach one connector, remove one screw, and

detach the ground wire.

4. Remove 2 screws, release 2 hooks, and remove

SFB assembly.

Screw

Ground wire

Screw

SFB assembly

Fig. 6-1

Screw

Fig. 6-2

245-1

Connector

Harness

fixing plate

245-2

Screw

Hook

Fig. 6-3

246

[B] SFB hinge unit

1. Remove SFB cover. (See Fig. 6-1)

2. Release one clamp and detach the harness.

Harness

3. Remove 2 screws, slide SFB hinge unit in the

direction of the arrow, release one hook, and

remove SFB hinge unit.

Screw

Clamp

SFB hinge unit

247

Fig. 6-4

October 2000 © TOSHIBA TEC 6 - 1 MY-1016 DISASSEMBLY AND REPLACEMENT

Page 17

Notes: For installation, follow the procedure de-

scribed below.

1 Insert SFB hinge shaft into SFB docu-

ment tray assembly.

2 Turn SFB hinge unit by 180 degrees,

hook it to SFB, and fix it with 2 screws.

[C] SFB document tray assembly

1. Remove SFB cover. (See Fig. 6-1)

2. Detach one connector and release 2 clamps.

3. Remove SFB hinge unit. (See Fig. 6-4)

4. Release the stud and remove SFB document

tray assembly.

SFB document

tray assembly

[D] SFB document tray upper/SFB document tray lower/

SFB document tray support/SFB PWA plate/

SFB document guide flange

1. Remove SFB document tray assembly.

(See Fig. 6-6)

Hook

2. Remove 3 screws, release 7 hooks, and de-

tach SFB document tray upper.

Hook

Screw

SFB hinge unit

248

Fig. 6-5

Stud

Connector

249

Fig. 6-6

SFB document tray upper

Screw

Screw

SFB document

tray support

Hook

3. Remove SFB document tray support.

SFB document

tray lower

250-1

Fig. 6-7

4. Release 4 hooks and detach the SFB docu-

ment tray 2nd support.

250-2

Fig. 6-8

MY-1016 DISASSEMBLY AND REPLACEMENT 6 - 2 October 2000 © TOSHIBA TEC

Page 18

5. Remove one screw and remove SFB pinion

plate.

6. Remove one screw and remove SFB PWA plate.

7. Remove SFB document guide flange.

Notes: 1. Put 0.2 grams of silicon oil (TSF451) on

the side of the guide rail.

Never put silicon oil on the paper feed

side.

2. Put 0.05 grams of silicon oil (TSF451)

inside the SFB document guide rack.

Screw

SFB document

guide flange

SFB pinion plate

SFB PWA plate

Screw

250-3

Fig. 6-9

Note: Set SFB document guide flange so that the

convexity of SFB PWA plate is positioned

as shown right when SFB PWA plate is

mounted.

[E] SFB cover/SFB brake pad assembly

1. Remove SFB hinge unit. (See Fig. 6-1 to 6-4)

2. Remove SFB document tray assembly.

(See Fig. 6-6)

3. Remove 4 screws, release 2 tabs, and remove

SFB document

guide flange

Screw

Fig. 6-10

Fig. 6-11

Screw

250-5

SFB PWA plate

250-4

SFB brake pad assembly.

Note: For reassembly, mount the screws in the

order shown right.

SFB brake pad

assembly

251

Fig. 6-12

October 2000 © TOSHIBA TEC 6 - 3 MY-1016 DISASSEMBLY AND REPLACEMENT

Page 19

4. Release SFB pad spring and remove SFB

brake.

Note: Clean the SFB brake pad with a cloth moist-

ened with alcohol by pressing hard, and go-

ing back and forth on the brake pad more

than 20 times.

SFB brake

SFB brake pad

5. Remove 2 screws, release 2 tabs, and detach

SFB feed cover.

[F] SFB clutch pulley/SFB flange wheel

1. Remove SFB hinge unit. (See Fig. 6-1 to 6-4)

2. Remove SFB document tray assembly.

(See Fig. 6-6)

3. Detach SFB feed cover.

(See Fig. 6-12 and 6-14)

4. Detach stop ring and remove bushing.

SFB pad spring

252

Fig. 6-13

SFB feed cover

Screw

SFB feed assembly

Screw

253

Fig. 6-14

Clamp

Stop ring

Harness

5. Release 3 clamps and detach the harness.

6. Remove one screw and detach the ground wire.

Sop ring

MY-1016 DISASSEMBLY AND REPLACEMENT 6 - 4 October 2000 © TOSHIBA TEC

Bushing

Bushing

Screw

Ground wire

01/12

Screw

Ground wire

Clamp

Clamp

Fig. 6-15

Clamp

Fig. 6-15-1

Clamp

Harness

Harness

254-1

254

Page 20

7. Remove 2 screws, release 2 tabs, slide SFB

feed roller assembly in the direction of the ar-

row, and remove SFB clutch pulley assembly.

Notes: 1. SFB feed roller fixing plate type

Before attaching the SFB feed roller as-

sembly, loosen 2 screws securing the

SFB feed roller fixing plate. Attach the

SFB brake pad assembly (See Fig.6-12),

then fix the SFB feed roller fixing plate in

place.

2. SFB feed roller adjusting plate type

Attach the SFB feed roller adjusting plate

so that the edge of the tray holder is

placed at a center of the marking.

SFB feed roller

adjusting plate

SFB clutch motor

SFB feed roller

fixing plate

SFB clutch

pulley assembly

Fig. 6-16

SFB clutch

motor

Screw

SFB feed roller

assembly

Bushing

255

Screw

SFB feed roller

assembly

[G] SFB feed roller shaft assembly

1. Remove SFB hinge unit. (See Fig. 6-1 to 6-4)

2. Remove SFB document tray assembly.

(See Fig. 6-6)

3. Detach SFB feed cover.

(See Fig. 6-12 and 6-14)

4. Remove SFB feed roller assembly.

(See Fig. 6-15 to 6-16-1)

5. Detach one connector, loosen one screw, and

remove SFB clutch motor.

6. Remove one screw and remove guide plate R.

Marking

Connector

SFB clutch motor

Guide plate R

Fig. 6-16-1

Screw

Fig. 6-17

Bushing

SFB clutch

pulley assembly

255-1

256

Screw

257-1

Fig. 6-18

October 2000 © TOSHIBA TEC 6 - 5 MY-1016 DISASSEMBLY AND REPLACEMENT

01/12

Page 21

7. Remove one screw and remove roller bracket.

8. Detach E-ring and remove bushing.

(SFB feed roller fixing plate type)

9. Remove SFB feed roller shaft assembly.

Screw

Note: Be sure to attach the spring when attach-

ing the SFB feed roller shaft assembly.

[H] SFB feed roller

1. Remove SFB assembly. (See Fig. 6-1 to 6-3)

2. Remove the screw and detach the guide plate

F.

3. Detach stop ring, and remove clutch and SFB

feed roller.

SFB feed

roller shaft assembly

Guide plate F

Clutch

Bushing

Fig. 6-19

Fig. 6-20

SFB feed roller

E-ring

Spring

257-2

Screw

258

[I] SFB pickup roller

1. Remove the stop ring and take out the pickup

roller shaft.

2. Detach the pickup roller by releasing the timing

belt 142.

Stop ring

Stop ring

Fig. 6-21

Pickup roller

Fig. 6-22

259

Pickup roller shaft

260

MY-1016 DISASSEMBLY AND REPLACEMENT 6 - 6 October 2000 © TOSHIBA TEC

01/12

Page 22

1-1, KANDA NISHIKI-CHO, CHIYODA-KU, TOKYO, 101-8842 JAPAN

Loading...

Loading...