Page 1

PAPER FEED UNIT

MY-1015

File No. 31100016

Page 2

General Precautions for Installation/Servicing/Maintenance for the MY-1015

The installation and service should be done by a qualified service technician.

1. When installing the MY-1015 to the Plain Paper Copier , be sure to f ollow the instructions described in

the “Unpacking/Set-Up Procedure for the MY-1015” booklet which comes with each unit of the

MY-1015.

2. The MY-1015 should be installed by an authorized/qualified person.

3. Before starting installation, servicing or maintenance work, be sure to turn off and unplug the copier

first.

4. When servcing or maintaining the MY-1015, be careful about the rotating or operation sections such

as gear, pulleys, sprockets, cams , belts, etc.

5. When parts are disassembled, reassembly is basically the reverse of disassemb ly unless otherwise

noted in this manual or other related materials. Be careful not to reassemble small parts such as

screws, washers, pins , E-rings, toothed washers to the wrong places.

6. Basically, the machine should not be operated with any parts removed or disassembled.

7. Delicate parts for preventing safety hazard problems (such as breakers, thermofuses, fuses, door

switches, sensors, etc. if any) should be handled/installed/adjusted correctly.

8. Use suitable measuring instruments and tools.

9. During servicing or maintenance work, be sure to check the serial No. plate and other cautionary

labels (if any) to see if they are clean and firmly fixed. If not, take appropriate actions.

10. The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity. Bef ore using the wrist band, pull out

the power cord plug of the copier and make sure that there is no uninsulated charged objects in the

vicinity.

11. For the recovery and disposal of used MY-1015, consumable parts and packing materials, it is recommended that the relevant local regulations/rules should be f o llow ed.

12. After completing installation, servicing and maintenance of the MY-1015, return the MY-1015 to its

original state, and check operation.

Copyright 2000

TOSHIB A TEC CORPORATION

Page 3

CONTENTS

1. SPECIFICATIONS ...................................................................................................... 1-1

2. OUTLINE .................................................................................................................... 2-1

2.1 Names of Various Components .........................................................................................2-1

2.2 Layout of Electrical Parts.................................................................................................. 2-2

2.3 Harness Connection Diagram............................................................................................ 2-3

3. OPERATIONAL DESCRIPTION................................................................................ 3-1

3.1 General Operation ............................................................................................................. 3-1

3.2 Block Diagram .................................................................................................................. 3-1

3.3 Detection of Abnormal Status ........................................................................................... 3 -2

3.3.1 Cover open/Close detection ................................................................................... 3-2

3.3.2 Paper empty detection........................................................................................... 3-2

3.3.3 Paper jam detection ............................................................................................... 3-2

3.3.4 T r ay-up motor f ailure .............................................................................................. 3-2

3.4 Flow Charts ...................................................................................................................... 3-3

4. MECHANICAL DESCRIPTION .................................................................................. 4-1

4.1 P aper Feed System .......................................................................................................... 4-1

4.2 Drive System.................................................................................................................... 4-2

5. CIRCUIT DESCRIPTION ........................................................................................... 5-1

5.1 Meaning of Signals ........................................................................................................... 5-1

5.2 Timing Chart ..................................................................................................................... 5-2

6. DISASSEMBLY AND REPLACEMENT ..................................................................... 6-1

October 2000 © TOSHIBA TEC 1 MY-1015 CONTENTS

Page 4

1. SPECIFICATIONS

Function : Automatic paper feed Single cassette front loading

Paper : Size A3 to A5-R/LD to ST-R

: Thickness Normal paper 64 to 80g/m2 (17 to 21 lbs)

Transport speed : 258.18 mm/sec.

Cassette capacity : Paper height 60.5 mm (Approx. 550 sheets)

Dimensions : 530 (W) x 536 (D) x 112 (H) mm

Weight : Approx. 7.7 kg

Pow er supply : 5VDC, 24VDC (Supplied from copier)

October 2000 © TOSHIBA TEC 1 - 1 MY-1015 SPECIFICATIONS

Page 5

2. OUTLINE

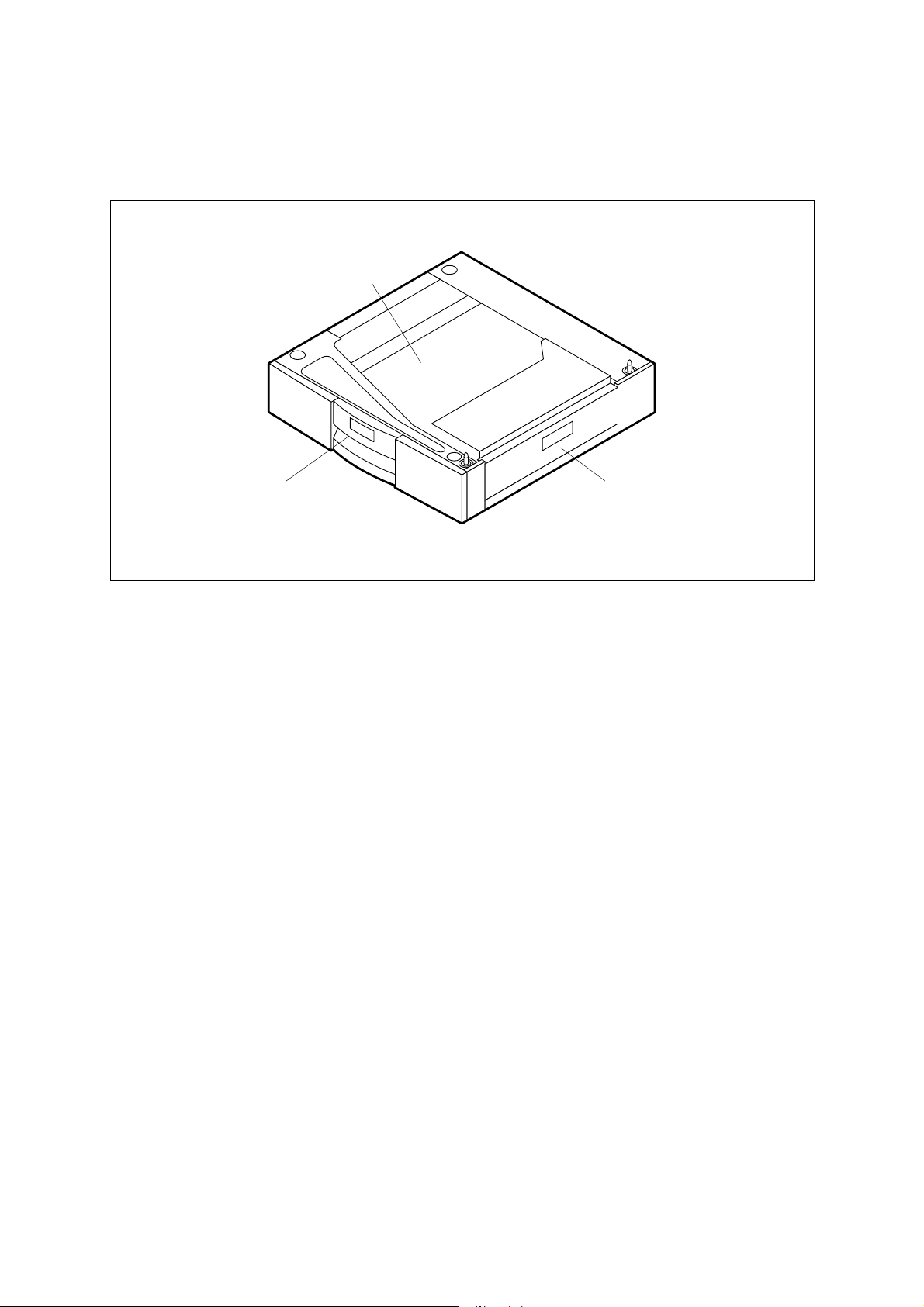

2.1 Names of Various Components

Cassette tray

Paper cassette

PFU open cover

PFU 02-01-01

October 2000 © TOSHIBA TEC 2 - 1 MY-1015 OUTLINE

Page 6

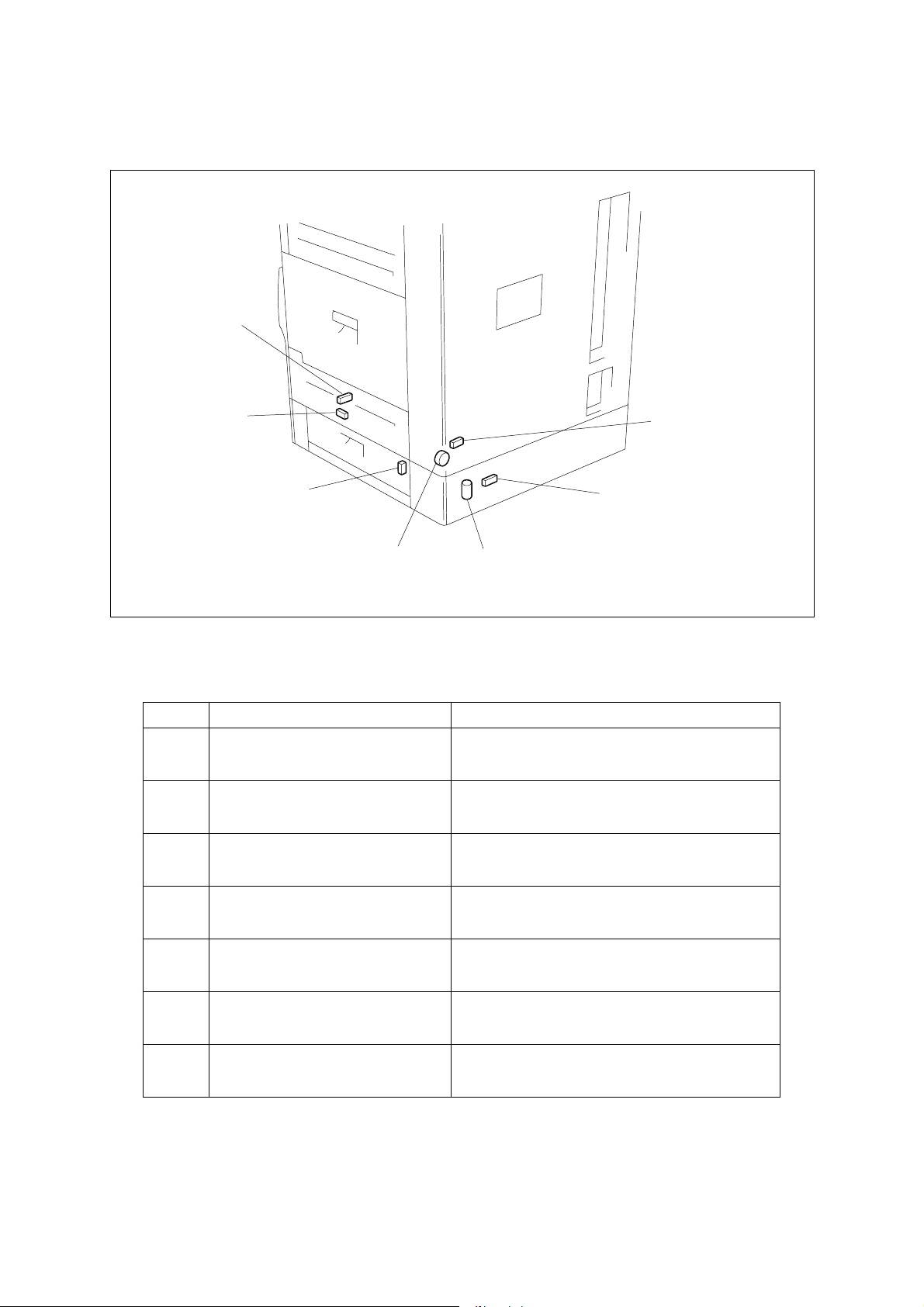

2.2 Layout of Electrical Parts

SEN2

SEN1

SW1

CL1

Symbols and functions of various devices

Symbol

SW1

2COV-SW

Name

PFU cover open switch

SW2

2CST-SW

PFU cassette switch

SEN1

2T-UP-SEN

SEN3

SW2

M1

PFU 02-02-01

Function

Detects the open/close state of the cover during

jam processing, etc.

Detects the open/close state of the cassette.

Detects the lift-up of the tray.

PFU tray-up sensor

SEN2

SEN3

CL1

M1

2PE-SEN

PFU paper empty sensor

2PNE-SEN

PFU paper near empty sensor

2PU-CLT

PFU pickup clutch

2T-UP-MOT

Detects the presence or absence of paper placed

in the PFU cassette.

Detects a paper near empty state of the PFU

cassette. (option)

Transmits driving force to the rollers to pick up

and transport the paper.

Lifts up the tray of the PFU cassette.

PFU tray-up motor

MY-1015 OUTLINE 2 - 2 October 2000 © TOSHIBA TEC

Page 7

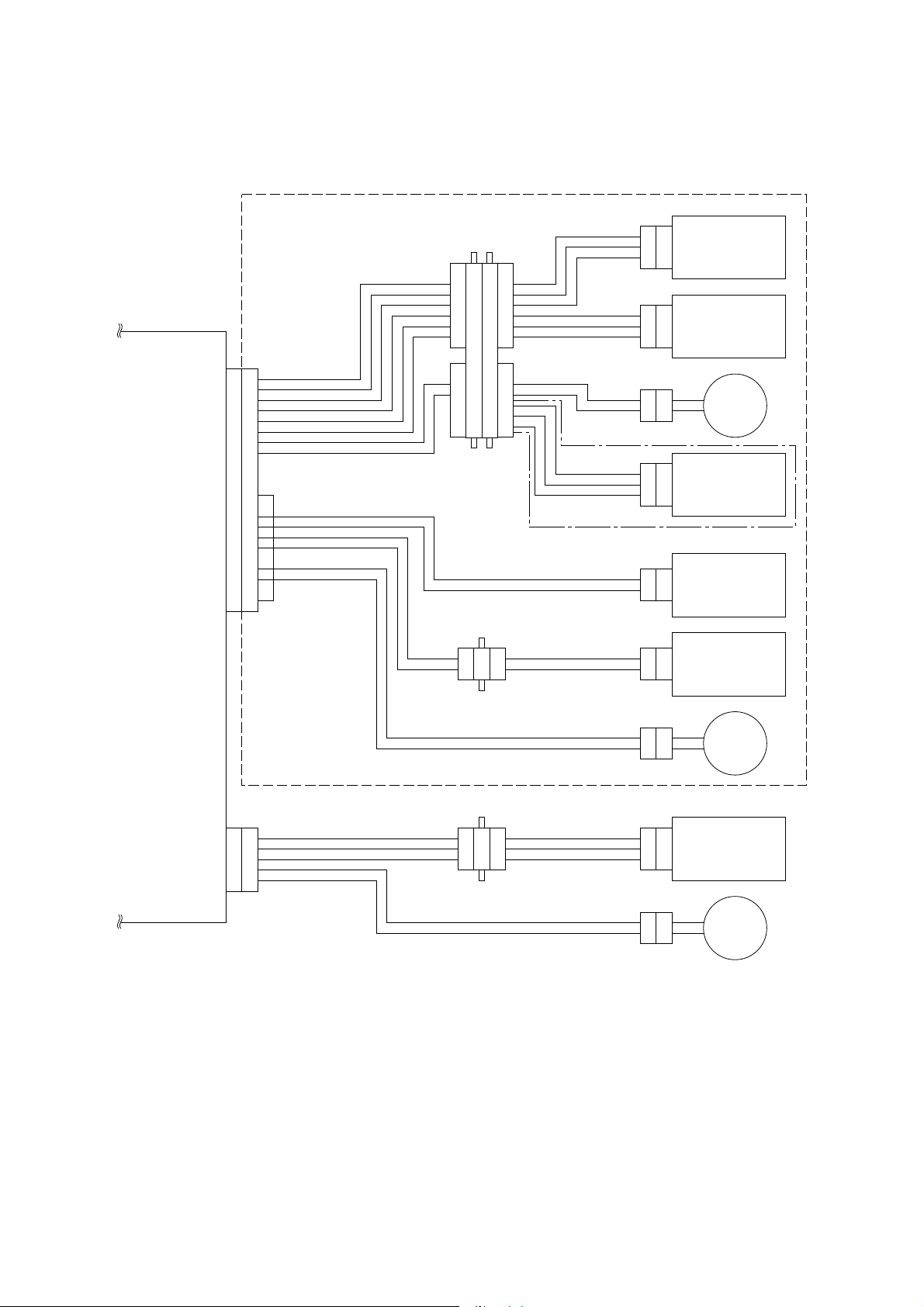

2.3 Harness Connection Diagram

PFU

CN208

PFUPEMP

PFUTUP A5

PFUPCLT A7

PFUTRM-A B8

GND A1

VDD A3

GND

VDD

+24V

VDD A9

GND A11

NC B2

GND B6

1

2

A2

3

4

A4

5

6

A6

7

8

A8

9

10

A10SIZPFU1

11

B1PFUCNT

12

B3SIZUPFU0

B4GND

B5PFUCOV

B7NC

B9PFUTRM-B

B10NC

B11GND

CN316A

CN316B

CN315

3

2

1

7

6

5

4

3

2

1

6

5

4

3

2

1

1

2

3

4

5

6

7

1

2

3

4

5

6

CN314

CN318

CN344

3

2

1

2

1

3

2

1

PFU

paper empty sensor

PFU

pickup sensor

PFU

pickup clutch

PFU

paper near empty

sensor

Not used

CN334

2

PFU cassette switch

1

PFC PWA

CN205

GND 1

PFUFD-SW

VDD 3

PFUFDCLT

+24V 5

CN317

211

2

CN165

1

2

2

3

4

4

1

3

2

2

3

1

CN345

CN319

CN154

CN163

2

PFU cover open switch

1

1

2

3

2

1

2

1

tray-up motor

2nd feed sensor

PFU

2nd feed

clutch

PFU 02-03-01

October 2000 © TOSHIBA TEC 2 - 3 MY-1015 OUTLINE

Page 8

3. OPERATIONAL DESCRIPTION

3.1 General Operation

The PFU is an additional paper feed unit (2nd cassette) and installed under the standard cassette (copier).

This unit has no PWA and its transport operation and detection are performed through the PFC PWA.

3.2 Block Diagram

PFU

PFC

PWA

CN208

PFUTRM-A,B

PFUPEMP

PFUTUP

PFUPCLT

SIZEPFU0

PFUCOV

PFU tray-up motorM

PFU paper empty sensor

PFU pickup sensor

PFU pickup clutch

PFU cassette switch

PFU cover open switch

PFU 03-02-01

The PFU consists of the paper feed cassette, four sensors, one magnetic clutch, and one tray-up motor.

October 2000 © TOSHIBA TEC 3 - 1 MY-1015 OPERATIONAL DESCRIPTION

Page 9

3.3 Detection of Abnormal Status

3.3.1 Cover open/Close detection

When the PFU cover open switch detects the open state of the cover, the copier detects it to stop the

transport of paper.

3.3.2 Paper empty detection

When there is no paper in the cassette tray or the PFU paper empty sensor detects the absence of paper

during printing, the operation is stopped. The absence of paper is detected only when the cassette is

closed.

3.3.3 Paper jam detection

The PFU itself has no feed sensor but installation of the PFU allo ws the sensor (2nd cassette f eed sensor)

on the copier side to be effectiv e . When transporting the paper, if the 2nd cassette f eed sensor does not

detect the passing of paper or the paper is left detected for a fix ed time, the progr am will judge it to be paper

jamming and stop the operation. The error state is reset b y opening and then closing the cover.

3.3.4 Tr a y-up motor failure

If no paper is detected or the tray-up upper limit is not reached even if a specified amount of time has

elapsed after the cassette is mounted, a tray-up motor failure will be assumed. To reset the error state,

once draw out the cassette.

MY-1015 OPERATIONAL DESCRIPTION 3 - 2 October 2000 © TOSHIBA TEC

Page 10

3.4 Flow Charts

Start button ON

Main motor ON

Polygon motor ON

Process unit fan motor high speed rotation

Development bias ON

Separation bias ON

Charge bias ON

Discharge lamp ON

Process system control Optical system control

Transfer system control

Retraction of carriage

Polygon motor

OK?

YES

Laser ON

Transfer bias ON

NO

Service call

"CA1"

Main motor

OK?

YES

PFU pickup clutch ON

2nd feed

NO

Service call

"C01"

NG

Black shading

Exposure lamp ON

Stop of carriage

sensor check

Transfer guide bias ON

Laser OFF

OK

Feed sensor

Paper jam

"E14"

NG

Advance of carriage

White shading

check

Transfer bias OFF

Transfer guide bias OFF

OK

PFU pickup clutch OFF

Paper jam

"E31"

Scanning of document

Stop of carriage

HSYNC

NO

2nd feed clutch ON

Exposure lamp OFF

OK

NO

Remaining

copy count 0?

Polygon motor OFF

End of process

YES

YES

Service call

"CA2"

2nd feed clutch OFF

NO

Remaining

copy count 0?

A

YES

Retraction of carriage

Stop of carriage

End of optical

system control

system control

October 2000 © TOSHIBA TEC 3 - 3 MY-1015 OPERATIONAL DESCRIPTION

Page 11

A

Exit sensor

NG

check 1

Paper jam

OK

Exit sensor

"E01"

NG

check 2

Paper jam

OK

"E02"

Charge bias OFF

Main motor OFF

Development bias OFF

Separation bias OFF

Discharge lamp OFF

Power supply unit fan motor low speed rotation

Standby

MY-1015 OPERATIONAL DESCRIPTION 3 - 4 October 2000 © TOSHIBA TEC

Page 12

4. MECHANICAL DESCRIPTION

4.1 Paper Feed System

PFU pickup clutch

PFU cassette tray

PFU feed roller

PFU pickup roller

PFU tray-up motor (cupling)

Flow of paper

PFU 04-01-01

The PFU pickup clutch is used to turn ON and OFF the driving force of the main motor . It turns ON when

picking up the paper and transmits the driving force to the f eed roller and pickup roller through the shaft and

belt. When the pickup clutch is turned ON to transport the paper, the feed roller and pickup roller turn and

the pickup roller begins to pick up the paper . When pic ked up , the paper is transported by the feed roller and

pulled into the transport path on the copier side.

The separate roller prevents the multi-feed of paper and contains a spring clutch. The roller separates

sheets of paper to prevent the feeding of multiple sheets of paper at a time.

October 2000 © TOSHIBA TEC 4 - 1 MY-1015 MECHANICAL DESCRIPTION

Page 13

4.2 Drive System

PFU pickup roller

PFU pickup clutch

Cupling

PFU tray-up motor

PFU 04-02-01

The PFU has no motor for transporting paper. Paper is transported by transmitting the driving force of the

main motor of the copier to the gear. The driving force from the copier side is transmitted to the PFU pickup

clutch through the gears (four pcs.). Installing the cassette causes the pickup roller to lower. The PFU

pickup clutch turns ON and OFF the gear driving force from the copier . When picking up the paper , it turns

ON to transmit the driving force to the feed roller and pickup roller through the shaft and belt. When the

pickup roller turns, the paper is picked up from the cassette and brought to the tr ansport path.

The tray-up operation is perf ormed by the PFU tra y-up motor . Consisting of the DC motor , w orm gear, gear,

coupling, etc., the PFU tray-up motor is housed within a case as a unit. When the cassette is installed, the

coupling of this motor unites with the coupling of the cassette to transmit the motor rotation to the arm

under the cassette and lift the cassette tray.

MY-1015 MECHANICAL DESCRIPTION 4 - 2 October 2000 © TOSHIBA TEC

Page 14

5. CIRCUIT DESCRIPTION

5.1 Meaning of Signals

Signal Name

PFUCOV

SIZPFU0

PFUTUP

PFUPEMP

PFUPCLT

PFUTRM-A, B

Part Name

PFU cover open

switch

PFU cassette

switch

PFU pickup

sensor

PFU paper

empty sensor

PFU pickup

clutch

PFU tray-up

motor

Functional Description

Detects the open/close

state of the cover during

jam processing, etc.

Detects the open/close

state of the cassette.

Detects the lift-up of the

cassette.

Detects the presence or

absence of paper placed

in the PFU cassette.

Operation signal for feed

clutch.

Lifts up the tray of the PFU

cassette.

Status

High: Open

Low: Cassette present

High: Paper feed

enabled

High: Paper absent

Low: ON

Low, High = Up

Note

Push switch

Push switch

Photo sensor

Photo sensor

Magnetic clutch

Brush motor

The PFU cover open switch detects the open or close state of the cover. A push switch is used for the

switch. The signal goes LOW when the cover is closed, and HIGH when it is open.

The PFU cassette switch is a s witch which detects the open or close state of the cassette. A push switch

is used for the switch. The signal goes LOW when the cassette is mounted, and HIGH when it is open.

The PFU pickup sensor is a switch which detects the lift-up of the cassette . A photo sensor is used for the

switch. Paper feed is enabled when the signal is at “High” level.

The PFU paper empty sensor detects the presence or absence of paper. A photo sensor is used for the

sensor. There is no paper when the signal is at “High” level.

PFU pickup clutch is an operation signal for the feed clutch and drives the magnetic clutch. Driving f orce

is transmitted to the pickup roller when the signal is at “Low” le vel.

The PFU tray-up motor lifts the tray of the cassette. The combination of the two signals permits setting of

lifting, braking, and OFF.

October 2000 © TOSHIBA TEC 5 - 1 MY-1015 CIRCUIT DESCRIPTION

Page 15

5.2 Timing Chart

2.67s

1.88s

810ms

750ms

350ms

20ms

PFU pickup

clutch

MY-1015 CIRCUIT DESCRIPTION 5 - 2 October 2000 © TOSHIBA TEC

Option cassette

340ms

feed clutch

Option cassette

feed sensor

Feed sensor

The values are data (reference v alues) applicab le when the A4 siz e paper is used.

PFU 05-02-01

Page 16

6. DISASSEMBLY AND REPLACEMENT

[A] PFU rear cover

1. Remove 3 screws, release 2 hooks, and detach

PFU rear cover.

PFU right cover

Screw

Hook

[B] PFU right cover F

2. Open PFU open cover, remove 2 screws, and

detach PFU right cover F.

[C] PFU right cover R

1. Remove 2 screws and detach PFU right cover

R.

PFU right cover F

Fig. 6-1

Fig. 6-2

Hook

Screw

Screw

193

PFU open

cover

194

PFU right cover R

Screw

195

Fig. 6-3

[D] PFU blind cover

Note: This cover cannot be used with PFP-1 in-

stalled.

1. Detach PFU right cover R. (See Fig. 6-3)

2. Release 2 hooks and detach PFU blind cov er.

PFU blind cover

196

Fig. 6-4

October 2000 © TOSHIBA TEC 6 - 1 MY-1015 DISASSEMBLY AND REPLACEMENT

Page 17

[E] PFU open cover

1. Detach PFU right cover F. (See Fig. 6-2)

2. Release 2 hooks and detach PFU switch co ver.

3. Release 2 hook, detach one connector , and remove PFU open cover switch.

PFU switch cover

PFU open cover switch

Connector

Hook

197

Fig. 6-5

Hook

4. Remove one scre w , release brac ket hook F, and

detach PFU open cover.

[F] PFU left cover R

1. Detach PFU rear cov er. (See Fig. 6-1)

2. Release 5 hooks and detach PFU left cover R.

Bracket hook F

Hook

PFU left

cover R

Fig. 6-6

Screw

Fig. 6-7

198

PFU open cover

199

Hook

200

Fig. 6-8

MY-1015 DISASSEMBLY AND REPLACEMENT 6 - 2 October 2000 © TOSHIBA TEC

Page 18

[G] PFU left cover

1. Detach PFU rear cover. (See Fig. 6-1)

2. Remove paper cassette of PFU and paper cassette of the copier.

Paper cassette

201

Fig. 6-9

3. Remove 17 scre ws and detach rear co ver.

4. Detach 3 harnesses from PFC PWA (CN206/

CN207/CN208).

5. Remove one screw and detach the ground wire

from the copier.

Screw

Ground wire

Rear cover

Screw

Fig. 6-10

CN206

Screw

Screw

202

PFC PWA

CN207

Fig. 6-11

CN208

203

6. Remove 2 screws and remove fixing plate R.

Fixing plate R

Screw

204

Fig. 6-12

October 2000 © TOSHIBA TEC 6 - 3 MY-1015 DISASSEMBLY AND REPLACEMENT

Page 19

7. Remov e 4 screws and remove fixing plate F.

8. Remov e PFU from the copier.

Fig. 6-13

Screw

ScrewFixing plate F

205

Copier

PFU

9. If a PFP-1 (KD-1009) or the LCF (KD-1010) is a

attached to the copier, detach it.

10. Detach PFU rear cover (See Fig. 6-1)

11. Detach PFU left cover R. (See Fig. 6-8)

12. Remove 10 screws, release 10 tabs, and detach PFU left cover.

[H] Tray-up assembly

1. Detach PFU rear cov er. (See Fig. 6-1)

2. Remov e paper cassette of PFU. (See Fig. 6-9)

3. Remove 2 screws, detach the relay connector,

and remove tray-up assembly.

Screw

Screw

Fig. 6-14

Fig. 6-15

206

Screw

Screw

PFU left cover

207

Connector

Tray-up

assembly

Screw

Fig. 6-16

MY-1015 DISASSEMBLY AND REPLACEMENT 6 - 4 October 2000 © TOSHIBA TEC

208

Page 20

[I] PFU joint gear assembly

1. Detach PFU rear cover. (See Fig. 6-1)

2. Remove paper cassette of PFU. (See Fig. 6-9)

3. Remov e tray-up assembly. (See Fig. 6-16)

4. Release the clamp.

5. Remove 2 scre ws , release the tab , and remov e

PFU joint gear assembly.

[J] PF separate roller

1. Remove paper cassette of PFU and paper cassette of the copier. (See Fig. 6-9)

2. Remove one screw and remove PF pickup assembly.

3. Remove one screw and remove PF separate

holder assembly.

PFU joint gear

assembly

Screw

Fig. 6-17

PF pickup assembly

Fig. 6-18

Screw

Clamp

Screw

209

210

PF separator

holder assembly

211

Fig. 6-19

4. Pull up and take out separate roller lever.

5. Remove arbor F, draw out shaft, and remove

separate roller, separate spring, arbor R, and

Separator spring

Separator roller

Shaft

spring cover in this order.

Notes: 1. To detach/attach the separate roller from/

to the separate spring, rotate the separate roller in the direction of the arrow.

2. Since the separate spring is coated with

Spring cover

Arbor R

Spring

Arbor F

212

oil, the separate roller should not to be

touched by the separate spring.

October 2000 © TOSHIBA TEC 6 - 5 MY-1015 DISASSEMBLY AND REPLACEMENT

Fig. 6-20

Page 21

[K] Pickup feed roller

1. Remove paper cassette of PF and paper cassette of the copier. (See Fig. 6-9)

2. Remov e PF pic kup assembly. (See Fig. 6-18)

3. Remov e PF separate holder assemb ly.

(See Fig. 6-19)

4. Detach stop ring and remove pickup feed roller.

[L] Pickup roller

1. Remove paper cassette of PFU and paper cassette of the copier. (See Fig. 6-9)

2. Remov e PF pic kup assembly. (See Fig. 6-18)

3. Release the two hooks.

4. Release the timing belt and remove the pickup

roller shaft assembly.

Stop ring

Pickup feed

roller

Clutch

213

Fig. 6-21

Pickup roller shaft

assembly

5. Detach the E-ring and remove pickup roller gear

and clutch.

Hook

E-ring

Clutch

Pulley

Fig. 6-22

Fig. 6-23

Timing belt

214

Pickup roller

215

MY-1015 DISASSEMBLY AND REPLACEMENT 6 - 6 October 2000 © TOSHIBA TEC

Page 22

1-1, KANDA NISHIKI-CHO, CHIYODA-KU, TOKYO , 101-8842 JAPAN

Loading...

Loading...