Toshiba MMY-MAP0804HT8-E, MMY-MAP1204HT8-E INSTALLATION MANUAL

í ½±³°®»--±®- ú í ·²ª»®¬»®- Í«°»® Ó±¼«´¿® Ó«´¬· ͧ-¬»³

ä Ú«´´ -»¬ ª»®-·±² â

Û²¹·²»»®·²¹

Ü¿¬¿ Þ±±µ

Ыпрункп

Notice: Toshiba is committed to

continuously improving its pr

oducts to ensure the highest

quality and reliability standard,

and to meet local regulati

ons and market requirements.

i

НУУНу· Ь¿¬¿ ¾±±µ

1 Foreword ........................

...........................

...........................

...................1-1

2 Safety caution ....................

.........................

.............................................2-1

3 Introduction .............

.................................................................................3-1

4 System overview ..........

...........................................................................4-1

4-1. OUTLINE OF TOSHIBA SMMS

(Super Modular Multi System).......................................................................4-1

4-2. SUMMARY OF SYSTEM EQUI

PMENTS..................................

.........................4-2

4-3. List of product and combined model name.........................................................4-3

4-4. Indoor unit...........................................................................................................4-5

4-5. Remote controller ...............................................................................................4-7

5 Basic system configuration ..................

...........................

.........................5-1

5-1. Basic systems (examples)..................................................................................5-1

5-2. Fresh Air Intake Indoor Unit Type.......................................................................5-5

6 Equipment selection procedure .............

..................................................6-1

6-1. Selection flow chart.............................................................................................6-1

6-2. Operational temperature range...........................................................................6-2

6-3. Combination conditions for indoor unit and outdoor unit....................................6-3

6-4. Cooling/heating capacity charac

teristics.............................................................6-4

6-5. Example of equipment selection.........................................................................6-9

6-6. Selection procedure for fresh air intake indoor unit..........................................6-14

7 Refrigerant piping design .....................

..................................................7-1

7-1. WARNINGS ON REFRIGERAN

T LEAKAGE............................

.........................7-1

7-2. Free branching system.......................................................................................7-2

7-3. Allowable length/height difference of refrigerant piping......................................7-3

7-4. Selection of refrigerant piping.............................................................................7-4

7-5. Charging requirement with additional refrigerant................................................7-5

8 Refrigerant cycle diagram

........................................................................8-1

8-1. Inverter Driven Unit (5, 6HP) ..............................................................................8-1

8-2. Explanation of Functional Parts..........................................................................8-4

8-3. Indoor Unit..........................................................................................................8-6

8-4. COMBINED REFRIGERATION CYCLE.............................................................8-7

9 Wiring Design .........

.................................................................................9-1

9-1. General...............................................................................................................9-1

9-2. Summary of wiring design ..................................................................................9-1

9-3. Electrical wiring design.......................................................................................9-1

9-4. Outdoor unit power supply..................................................................................9-1

9-5. Indoor unit power supply.....................................................................................9-3

10 Controls ..............................

..............................

.....................................10-1

10-1. Outline of application Control chart...................................................................10-1

10-2. Applications for indoor remote controller..........................................................10-2

10-3. Application control for central remote controller ...............................................10-3

10-4. Application controls by optional P.C. board of outdoor unit .............................10-6

10-5. Application control of optional devices connectable to indoor units................10-12

10-6. Application control for network........................................................................10-15

10-7. Dimensionel drawing ......................................................................................10-20

11 Technical Specifications

........................................................................11-1

11-1. Outdoor unit......................................................................................................11-1

11-1.1 Specifications ........................................................................................................11-

1

11-1.2 Dimensional drawing.........

..................................................................................11-16

11-1.3 Wiring diagram....................................................................................................11-23

11-1.4 Connectingdiagram ............................................................................................11-26

Contents

ii

Contents

11-1.5 Center of gravity..................................................................................................11-29

11-1.6 Branch header / branch joint...............................................................................11-30

11-1.7 Part Load performance..

......................................................................................11-33

11-1.8 Sound Pressure

level data (NC CURVE)............................................................11-70

11-2. Indoor unit...................................................................................................... 11-77

11-2-1. 4-way Air Discharge Cassette Type................................................................... 11-77

11-2-2. Compact 4-way Ca

ssette (600 x 600) Type....................................................... 11-95

11-2-3. 2-way Air Discharge Cassette Type.....

............................................................ 11-106

11-2-4. 1-way Air Discharge Cassette Type.....

............................................................ 11-121

11-2-5. Concealed Duct Type...........................

............................................................ 11-134

11-2-6. Concealed Duct High Static PressureType...................................................... 11-147

11-2-7. Slim Duct Type..............

................................................................................... 11-161

11-2-8. Ceiling Type ............................................

......................................................... 11-182

11-2-9. High-wall(1serires) Type

.................................................................................. 11-192

11-2-10.High-wall(2serires) Type

.................................................................................. 11-201

11-2-11.High-wall(3serires) Type

.................................................................................. 11-211

11-2-12.Floor Standing Concealed Type...........

............................................................ 11-221

11-2-13.FloorStanding Cabinet Type................

............................................................ 11-230

11-2-14.Floor Standing Type......................................................................................... 11-239

11-2-15.FreshAir Intake Indoor

Unit Type.................................................................... 11-249

Appendix Change plan of model name

-1

1

НУУНу· Ь¿¬¿ ¾±±µ

1

Foreword

The engineering data book details

all relevant data, charts

and drawings to enable you to

get the best performance

from the Toshiba Super Modu

lar Multi System i for the

various applications.

The information is aimed to as

sist you by providing greater

detail of the system and the

wider applications that the

system will cover.

-1

2

НУУНу· Ь¿¬¿ ¾±±µ

2

Safety caution

Þ»º±®» «»ô ®»¿¼ ½¿®»º«´´§ ¬¸®±«¹¸ ¬¸» Í¿º»¬§

½¿«¬·±² »½¬·±² ¬± »²«®» ½±®®»½¬ ±°»®¿¬·±²ò

̸» ·³°±®¬¿²¬ ½±²¬»²¬ ½±²½»®²»¼ ¬± ¬¸» ¿º»¬§ ¿®» ¼»½®·¾»¼ ·² ¬¸» Í¿º»¬§ Ý¿«¬·±²ò

Þ» -«®» ¬± µ»»° ¬¸»³ò Ú±® ײ¼·½¿¬·±²- ¿²¼ ¬¸»·® ³»¿²·²¹-ô -»» ¬¸» º±´´±©·²¹ ¼»-½®·°¬·±²ò

É¿®²·²¹ ײ¼·½¿¬·±²- ±² ¬¸» ß·® ݱ²¼·¬·±²»® ˲·¬

É¿®²·²¹ ·²¼·½¿¬·±²

Ü»-½®·°¬·±²

ЙЯОТЧТЩ

ЫФЫЭМОЧЭЯФ НШСЭХ ШЯЖЯОЬ

Disconnect all remote el

ectricpowersupplie

s before servicing.

ЙЯОТЧТЩ

Movingparts.

Do not operate unit withgrille removed.

Stop the unit before the servicing.

ЭЯЛМЧСТ

High temperature parts.

You might get burnedwhen removing this panel.

ЭЯЛМЧСТ

Do not touchthe aluminiumfins of the unit.

Doingso may result in injury.

ЭЯЛМЧСТ

ЮЛОНМ ШЯЖЯОЬ

Openthe servicevalvesbeforetheoperation,otherwisetheremightbe the

burst.

ЭЯЛМЧСТ

ܱ ²±¬ ½´·³¾ ±²¬± ¬¸» º¿² ¹«¿®¼ò

Doingso may result in injury.

ЙЯОТЧТЩ

ЫФЫЭМОЧЭЯФ НШСЭХ ШЯЖЯОЬ

Disconnect all remote

electric power supplies

ЙЯОТЧТЩ

Moving parts.

Do not operate unit with

grille removed.

ÝßË Ì×ÑÒ

High temperature parts.

You might get burned when

removing this panel.

ÝßË Ì×ÑÒ

Do not touch the aluminum

fins of the unit.

Doing so may result in injury.

ÝßË Ì×ÑÒ

ЮЛОНМ ШЯЖЯОЬ

Open the service valves

before the operation,

ÝßË Ì×ÑÒ

ܱ ²±¬ ½´·³¾ ±²¬± ¬¸» º¿²

¹«¿®¼ò

Doing so may result in

-2

2

2

Safety caution

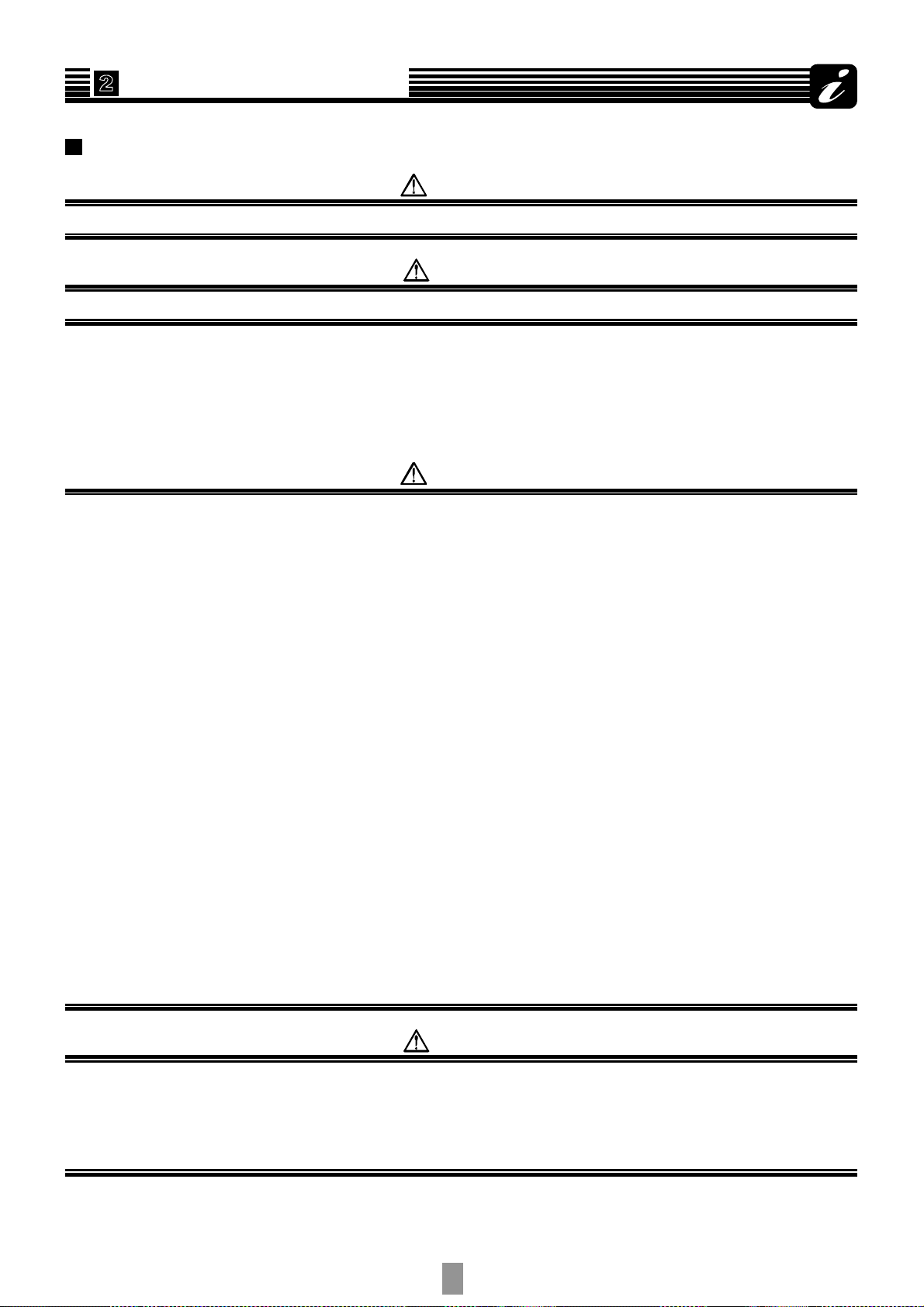

Û¨°´¿²¿¬·±² ±º ·²¼·½¿¬·±²-

ЙЯОТЧТЩ

Indicates possibilities that a death or serious in

jury of personnel is caus

ed by an incorrect handling.

ЭЯЛМЧСТ

Indicates contents that an injury (*

1

) or propertydamage(*

2

) only may be caused when aninco

rrect work has been executed.

*1: “Injury” meansa hurt, a burn, or an electric shock which does

not require hospitalization or a long-termgoing to the hospi

tal.

*2: “Property damage means an enlarged damage concerned to property, or breakage of materials.

ߺ¬»® ·²¬¿´´¿¬·±² ©±®µ ¸¿ º·²·¸»¼ô ½¸»½µ ¬¸»®» · ²± ¬®±«¾´» ¾§ ¿ ¬»¬ ±°»®¿¬·±²ô ¿²¼ »¨°´¿·² «·²¹ ³»¬¸±¼ ¿²¼

³¿·²¬»²¿²½» ³»¬¸±¼ ¬±

¬¸» ½«¬±³»® ¾¿»¼ ±² ¬¸» Ñ©²»® Ó¿²«¿´ò

д»¿-» ¿-µ ¬¸» ½«-¬±³»®- ¬± µ»»° ¬¸·- ײ-¬¿´´¿¬·

±² Ó¿²«¿´ ¬±¹»¬¸»® ©·¬¸ ¬¸» Ñ©²»® Ó¿²«¿´ò

ЙЯОТЧТЩ

ß-µ ¿ -¸±° ±® ¿ °®±º»--

·±²¿´ ¼»¿´»® ¬± ·²-¬¿´´ ¬¸» ¿·® ½±²¼·¬·±²»®ò

If youwill install by yourself, a fire, an electric shock, or water leak is caused.

Ì¿µ» ³»¿-«®»- -± ¬¸¿¬ ¬¸» ®»º®·¹

»®¿²¬ ¼±»- ²±¬ »¨½»»¼ ¬¸» ´·³·¬ ½±

²½»²¬®¿¬·±² »ª»² ·º ·¬ ´»¿µ- ©¸

»² ·²-¬¿´´·²¹ ¬¸» ¿·® ½±²¼·¬·±

²»®

·² ¿ -³¿´´ ®±±³ò

For the measures not to exceed the limit of concentration,contact the dealer. If the refrigerant leaks and it exceeds the limi

t of

concentration, an accident of oxygen shortage is caused.

ײ-¬¿´´ ¬¸» ¿·® ½±²¼·¬·±²»® ¿¬

¿ °´¿½» ©¸·½¸ ·- -¿¬·-º¿½¬±

®·´§ ¾»¿®¿¾´» ¬± ©»·¹¸¬ò

If strengthis insufficient,the unit may fall down resultingin human injury.

л®º±®³ ¿ -°»½·º·»¼ ·²-¬¿´´¿¬·±²

©±®µ ¿¹¿·²-¬ ¿ -¬®±²¹ ©·²¼

-«½¸ ¿- ¬§°¸±±² ±® »¿®¬¸¯«¿µ»ò

If theair conditioneris imperfectly installed, an accidentby falling or dropping may be caused.

׺ ®»º®·¹»®¿²¬ ¹¿- ´»¿µ- ¼«®·²¹ ·²-¬

¿´´¿¬·±² ©±®µô ª»²¬·´¿¬» ¬¸» ®±±³ò

If theleaked refrigerant gas approaches to fire, noxious gas may generate.

ߺ¬»® ·²-¬¿´´¿¬·±² ©±®µô ½±²º·®³ ¬¸

¿¬ ®»º®·¹»®¿²¬ ¹¿- ¼±»- ²±¬ ´»¿µò

If refrigerant gas leaks in the room, and approaches to fire such

as fan heater, stove or kitchenrange, generationof noxious

gas may be

caused.

Ò»ª»® ®»½±ª»® ®»º®·¹»®¿²¬ ·² ¬¸» ±«¬¼±±® «²·¬ò

Be sureto use a refrigerantrecovery device to recover refrigerant in reinstallation or repair work.

Recovery of refrigerant in the outdoor unit is unavailable;otherwise a serious accident such as crack or human injury is cause

d.

ß °»®-±² ¯«¿´·º·»¼ º±® ¬¸» »´»½¬®·½ ©±®µ -¸±«´¼ ¼»¿´ ©·¬¸ ¬¸»

»´»½¬®·½ ½±²-¬®«½¬·±² ½±

²º±®³·²¹ ¬± ¬¸» ®»¹«´¿¬·±²- ±º ¬¸» ´±½¿´

»´»½¬®·½ ½±³°¿²§ ¿²¼ ¬¸» ײ-¬

¿´´¿¬·±² Ó¿²«¿´ò Þ» -«®» ¬± «-» ¬¸» »¨½´«-·ª» ½·®½«·¬ò

If thereis capacityshortage of thepower supply circuit or incompleteinstallation, a fire or anelectric shock is caused.

Ú±® ½¿¾´·²¹ô «-» ¬¸» -°»½·º·»¼ ½¿

¾´»- ¿²¼ ½±²²»½¬ ¬¸»³ -»½«

®»´§ -± ¬¸¿¬ »¨¬»®²¿´ º±®½» ±º ½¿¾´» ¼±»- ²±¬ ¬®¿²-³·¬ ¬± ¬¸»

¬»®³·²¿´ ½±²²

»½¬·²¹ -»½¬·±²ò

If connectionor fixing is incomplete, a fire, etc. may be caused.

Þ» -«®» ¬± ½±²²»½¬ »¿®¬¸ ©·®»ò

Do notconnect earth wire to gas pipe, water pipe, lightning rod, nor earth wire of telephone.

If grounding is incomplete, an electric shock is caused.

ЭЯЛМЧСТ

ܱ ²±¬ ·²-¬¿´´ ¬¸» ¿·® ½±²¼·¬·±²»® ¿¬

¿ °´¿½» ©¸»®» ½±³¾«-¬·¾´» ¹¿- ³¿§ ´»¿µò

If gasleaks and is collectedat surrounding the unit, the production of fire may be caused.

Þ» -«®» ¬± ¿¬¬¿½¸ ¿² »¿®¬¸ ´»¿µ¿¹» ¾®»¿µ»®å

±¬¸»®©·-» ¿² »´»½¬®·½

-¸±½µ ³¿§ ¾» ½¿«-»¼ò

Ë-·²¹ ¿ ¬±®¯«» ©®»²½¸ô ¬·¹¸¬»² ¬¸»

º´¿®» ²«¬ ·² ¬¸»

-°»½·º·»¼ ³»¬¸±¼ò

If the flare nut is exceedingly tightened,

the flare nut is broken and a refrigerant

leakagemay be caused after a long time ha

s passed.

-3

2

2

Safety caution

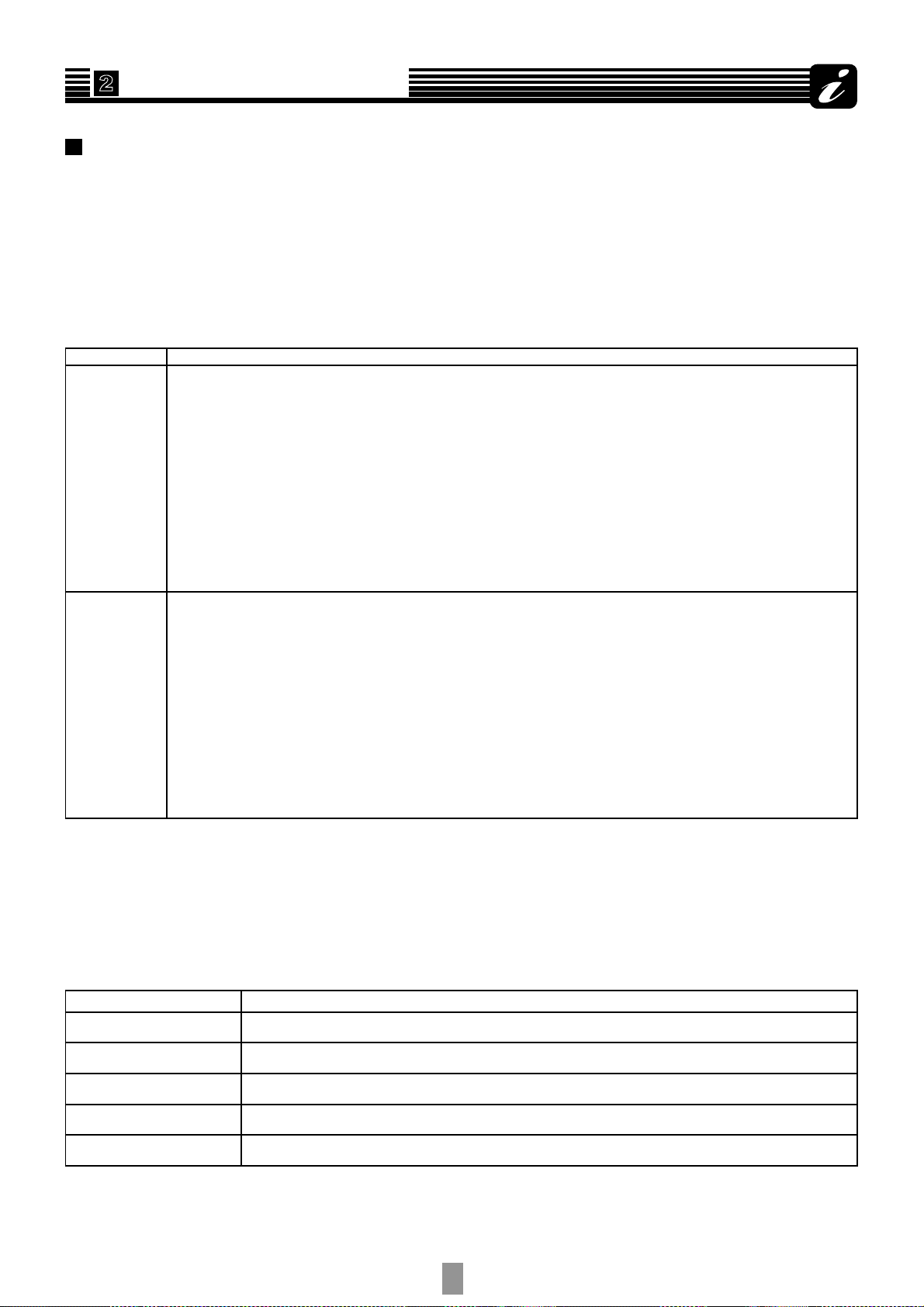

У¿½¸·²»½§ Ь·®»½¬·ª» шЬ·®»½¬·ª» оррксмосЫЭч

Please read carefully through these instructions that

containimportant informat

ion which comp

lies with the

"Machinery" Directive(Directive 2006/42/EC

), and ensure that you understand them.

Ù»²»®·½ Ü»²±³·²¿¬·±²æ ß·® ݱ²¼·¬·±²»®

Ü»º·²·¬·±² ±º Ï«¿´·º·»¼ ײ-¬¿´´»® ±® Ï«¿´·º·»¼ Í»®ª·½» л®-±²

The air conditioner must be in

stalled, maintained, repaired and removed by

a qualified installer

or qualified service

person. When any of these jobs is to be done, ask a qualif

ied installer or qualified serv

ice person to do them for

you.A qualified installer or

qualified service person is an agent who has the qualifications and knowledge described

in the table below.

Ü»º·²·¬·±² ±º Ю±¬»½¬·ª» Ù»¿®

Whenthe air conditioner is tobe transported, installed,ma

intained, repaired orremoved,

wear protective gloves and

‘safety’ work clothing.

In addition to such normal protective gear, wear the

protective gear described below when undertaking the special

work detailed in the table below.

Failure to wear the pr

oper protective gear is

dangerous becausey

ou will be more susceptible

to injury, burns,

electric shocks and other injuries.

ß¹»²¬

Ï«¿´·º·½¿¬·±² - ¿²¼ µ²±©´»¼¹» ©¸ ·½¸ ¬¸» ¿¹»²¬ ³«-¬ ¸¿ª»

Qualified installer

• The qualified installer is a person who installs, maintains, relocates and removes the air conditioners made by Toshiba Carrie

r Corporation. He

or she has been trained to install, maintain, relocate and remove the air conditioners made by Toshiba Carrier Corporation or,

alternatively, he

or she has been instructed in such operations by an individual

or individuals who have been trained and is thus thoroughly acqu

ainted with the

knowledge related to these operations.

• The qualified installer who is allowed to do the electrical work

involved in installation, relocation and removal has the qual

ifications pertaining

to this electrical work as stipulated by the local laws and

regulations, and he or she is a

person who has been trained in matt

ers relating to

electrical work on the air conditioners made by Toshiba Carrier

Corporation or, alternatively, he or she has been instructed in

such matters by

an individual or individuals who have been trained and is thus

thoroughly acquainted with the knowledge related to this work.

• The qualified installer who is allowed to do the refrigerant handling and piping work involved in installation, relocation and

removal has the

qualifications pertaining to this refrigerant handling and piping

work as stipulated by the local laws and regulations, and he

or she is a person

who has been trained in matters relating to refrigerant handling and piping work on the air conditioners made by Toshiba Carrie

r Corporation

or, alternatively, he or she has been instructed in such matters

by an individual or individuals who have been trained and is t

hus thoroughly

acquainted with the knowledge related to this work.

• The qualified installer who is allowed to work at heights has been trained in matters relating to working at heights with the

air conditioners made

by Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such matters by an individual or individuals

who have been

trained and is thus thoroughly acquainted with the knowledge related to this work.

Qualified service

person

• The qualified service person is a person who installs, repairs,

maintains, relocates and removes the air conditioners made by

Toshiba Carrier

Corporation. He or she has been

trained to install, repair, ma

intain, relocate and remove the

air conditioners made by Toshiba

Carrier

Corporation or, alternatively, he or she has been instructed in

such operations by an individual or individuals who have been t

rained and is thus

thoroughly acquainted with the knowledge related to these operations.

• The qualified service person who

is allowed to do the electrical work involved

in installation, repair,

relocation and removal

has the qualifications

pertaining to this electrical work as st

ipulated by the local laws and regulations, and he or she is a person who has been trai

ned in matters

relating to electrical work on the air conditioners made by Tosh

iba Carrier Corporation or, alternatively, he or she has been i

nstructed in such

matters by an individual or individuals who have been trained and

is thus thoroughly acquainted with the knowledge related to t

his work.

• The qualified service person who is allowed to do the refrigerant

handling and piping work involved in installation, repair, r

elocation and removal

has the qualifications pertaining to this refrigerant handling and

piping work as stipulated by the local laws and regulations,

and he or she is a

person who has been trained in matters relating to refrigerant han

dling and piping work on the air conditioners made by Toshiba

Carrier

Corporation or, alternatively, he or she has been instructed in su

ch matters by an individual or individuals who have been trai

ned and is thus

thoroughly acquainted with the knowledge related to this work.

• The qualified service person who is allowed to work at heights

has been trained in matters relating to working at heights with

the air conditioners

made by Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such matters by an individual or indivi

duals who have

been trained and is thus thoroughly acquainted with the knowledge related to this work.

ɱ®µ «²¼»® ¬¿µ»²

Ю±¬»½¬·ª» ¹»¿® ©±®²

All types of work

Protective gl

oves ‘Safety’ working clothing

Electrical-related work

Gloves to provide

protection for electricians and from heat In

sulating shoes Clothing to provide protect

ion from electric shock

Work done at heights

(50 cm or more)

Helmets for use in industry

Transportation of heavy objects Shoes with additional protective toe cap

Repair of outdoor unit

Gloves to provi

de protection for electricians and from heat

-4

2

2

Safety caution

пт ЙЯОТЧТЩН СТ ОЫЪОЧЩЫОЯТМ ФЫЯХЯЩЫ

ݸ»½µ ±º ݱ²½»²¬®¿¬·±² Ô·³·¬

The room in which the air cond

itioner is to be installed

requires a design that in the event of refrigerant gas

leaking out, its concentratio

n will not exceeda set limit.

The refrigerant R410A which is used in the air

conditioner is safe, without th

e toxicity or combustibility

of ammonia,and is not restricted by laws tobe imposed

which protect the ozone layer. However, since it

contains more than air, it poses the risk of suffocation if

its concentration should rise excessively.

Suffocationfrom leakageof R410A is almost

nonexistent. With the recent increase in the number of

highconcentration buildings, however, the installationof

multi airconditionersystems is on the increase because

of the need for effective use of floor space, individual

control, energy conservati

on by curtailing heat and

carrying power etc.

Most importantly, the multi air conditioner system is able

to replenish a large amount of refrigerant compared

with conventional individual air conditioners. If a single

unit of the multi conditionersystem is to be

installed in a small room, se

lect a suitable model and

installation procedureso that if the refrigerant

accidentally leaks out, its concentration does not reach

the limit (and in the event of an emergency,measures

can be made before injury can occur).

In a room wherethe concentrationmay exceedthe limit,

create an opening with adjacent rooms, or install

mechanical ventilation combinedwith a gas leak

detection device.

The concentration is as given below.

Concentrationlimit (kg/m

3

)

The concentration limit of R410A which is used in multi

air conditioners is 0.3kg/m

3

.

ÒÑÌÛ ïæ

If there are 2 or more refrigerating systems in a single

refrigerating device, the amounts of refrigerant should

be as charged in each independent device.

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in

rooms A, B and C is 10kg.

The possible amount of leaked refrigerant gas in

rooms D, E and F is 15kg.

ÒÑÌÛ îæ

The standardsfor minimumroom volume are as follows.

(1) No partition (shaded portion)

(2) When there is aneffectiveopening with theadjacent

room for ventilation of leaking refrigerant gas

(opening without a door, or an opening 0.15% or

larger than the respective floor spaces at the top or

bottom of the door).

(3) If an indoor unit is installed in each partitioned room

and the refrigerant tubing

is interconnected, the

smallest room of course becomes the object. But

when a mechanical vent

ilation is installed

interlocked with a gas leakage detector in the

smallest room where the de

nsity limit is exceeded,

the volume of the next smallest room becomes the

object.

ÒÑÌÛ íæ

The minimum indoor floor area compared with the

amount of refrigerant is roughly as follows: (When the

ceiling is 2.7m high)

Total amount of refrigerant (kg)

Min. volume of the indoor

unit installed room (m

3

)

Outdoor unit

e.g.,

chargedamount(15kg)

e.g., charged

amount(10kg)

Indoor unit

Room A Room B Room C Room D Room E Room F

׳°±®¬¿²¬

Outdoor unit

Refrigerant piping

Indoor unit

Refrigerant piping

Outdoorunit

Indoor unit

Mechanical ventilationdev

ice - Gas leak detector

Very

small

room

Small

room

Medium

room

Large room

0510

10 20 30

152025303540kg

m²

Total amount of refrigerant

Min. indoor floor area

Rangebelowthe

densitylimitof

0.3 kg/m

3

(countermeasur

es not needed)

Range above

the density limit

of 0.3 kg/m

3

(countermeasur

es needed)

-1

3

НУУНу· Ь¿¬¿ ¾±±µ

3

Introduction

̸» ²»¨¬ó¹»²»®¿¬·±² 󯫿´·¬§ ¬®·±

Ü»¼·½¿¬·±² ¬± ·²²±ª¿¬·±² ¿²¼ ¿¼ª¿²½

»¼ ·²¬»´´·¹»²½» º±-

¬»®- ¬¸» ·³¿¹·²¿¬·ª»

½®»¿¬·ª·¬§ ©·¬¸ ©¸·½¸ ©» ¼»´·ª»® ¬±¬¿

´ ª¿´«» ·² ¿·® ½±²¼

·¬·±²·²¹ -§-¬»³-ò

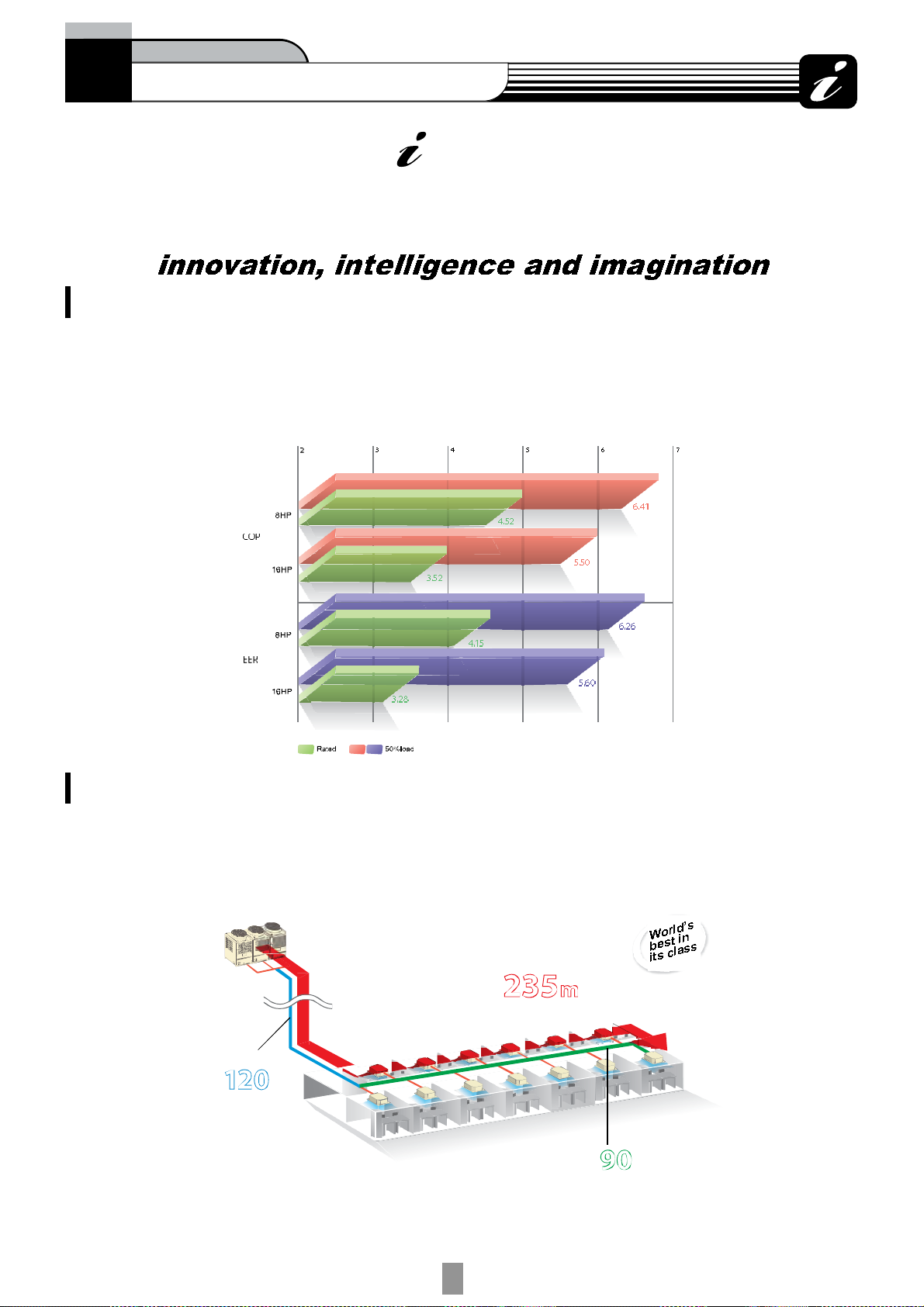

ײ¼«-¬®§ ´»¿¼·²¹ »²»®¹§ -¿ª·²¹-

Û²»®¹§ó»ºº·½·»²¬ °»®º±®³¿²½» º±® ¹®»¿¬»® »½±ó½±²-½·±«-²»--

Adoptingthe highly efficient new DC twin-rotary compre

ssors and advanced vector-controlledinverters realizes

a COP of 6.41 (under 50% partial load). Greater operati

ng performance is now possible when operating under

a constant load.

çð

³

ï-¬ ¾®¿²½¸·²¹ °·°·²¹ ´»²¹¬¸

ï

îð

³

Ó¿·² °·°·²¹ ´»²¹¬¸

ö

îíë

³

Ú¿®¬¸»-¬ »¯«·ª¿´»²¬ ´»²¹¬¸

ö

* As of December 2009 (according to independent Toshiba testing)

ײ¼«-¬®§ ´»¿¼·²¹ °·°» ´»²¹

¬¸ º±® ¹®»¿¬»® º´»¨·¾·´·¬§

Ô¿§±«¬ º´»¨·¾·´·¬§ ©·¬¸ º»© ¼»-·¹² ´·³·¬¿¬·±²-

System layouts can use a maximum equivalent distance of up to 235 metres. This makes it much easier to

design for floors with many small rooms, or for tenants who often rearrange their floor layouts.

-2

3

3

Introduction

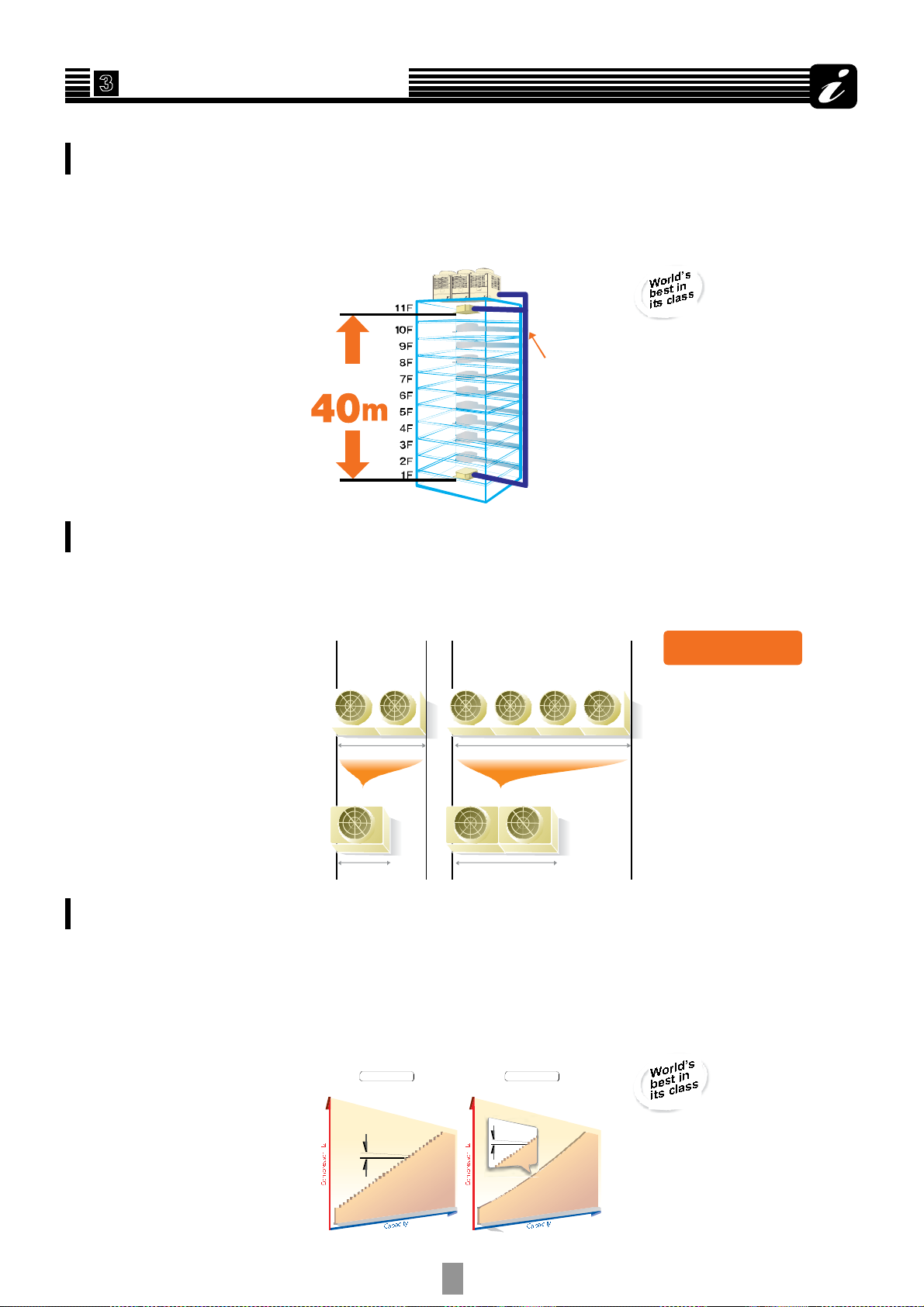

*Calculatedat3.5 metersper floor

Ø»·¹¸¬ ¾»¬©»»²

·²¼±±® «²·¬

-

Í·²¹´»

-§-¬»³

ö

ï

*As of December 2009 (according to independent Toshiba testing)

Ù®»¿¬»® -«°°±®¬ º±® ¸»·¹¸¬ ¼·ºº»

®»²½»- ¾»¬©»»²

·²¼±±® «²·¬-

Toshiba SMMS-i leads the industry with support for height

differences of up to 40 metres between indoor units

on a single system. For instance, in an 11-story building,

this is enough height to fully

cover the entire floor as

well as the elevator halls.

ïêØÐ

èØÐ

шпкШРч шноШРч

офррр

èØÐ

пфопр

офммр

ïêØÐ

ïêØÐ

èØÐ

мфрор

èØÐ

èØÐ èØÐ

ìð

û

®»¼«½¬·±²

ß ïêØÐ -§-¬»³ ·²- ¬¿´´¿¬·±² ²±©

±½½«°·»- ±²´ § îñí ¬¸» º±±¬°®·²¬

¿²¼ ©»·¹¸¬ ±º ¬ ©± «²·¬-

°®»ª·±«-´§ ®»¯« ·®»¼ò

ÍÓÓÍ

НУУНу·

ײ¼«-¬®§ ´»¿¼·²¹ ·²-¬

¿´´¿¬·±² º´»¨·¾·´·¬§

The outdoor units improve performance to achieve greate

r space efficiency that def

ies their compact module

size to deliver greater freedom in layout design. This

minimizes weight-related re

strictions and allows for

quicker installation.

ðòêئ

ðòïئ

ö

ÍÓÓÍ

НУУНу·

ײº·²·¬§ ª¿®·¿¾´» ½±²¬®±´

Ë´¬®¿ó°®»½·-» ðòï ئ ½±²¬®±´ ±ª»® ½±³°®»--±® ®±¬¿¬·±² -°»»¼

Infinityvariable controladjusts compre

ssorrotation speed in near-seamless

0.1 Hz steps. Responding precisely

to the capacity needs of the moment, this fine control minimizes energy loss when changing frequencies, and

also creates a comfortable environment su

bject to minimal temperature variations.

*As of December 2009 (according to independent Toshiba testing)

-3

3

3

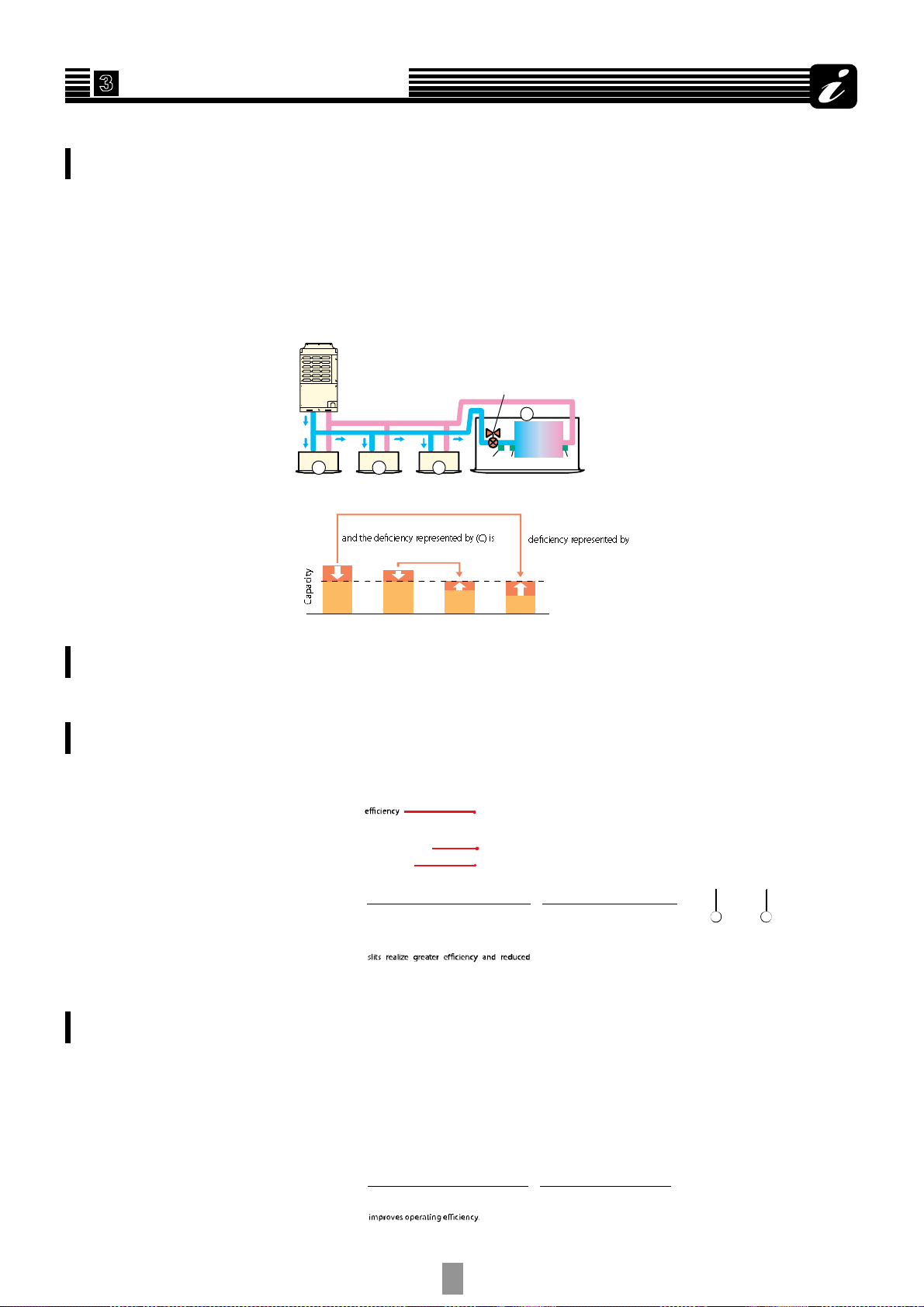

Introduction

Ì¿®¹»¬ ½¿°¿½·¬§

øß÷

øÞ÷

øÜ÷

øÝ÷

̸» -«®°´«- ®»°®»-»²¬»¼ ¾§

øß÷ ·- ¼·³·²·-¸»¼ ¿²¼ ¬¸»

øÜ÷ ·- ½±³°»²-¿¬»¼ º±®ò

̸» -«®°´«- ®»°®»-»²¬»¼ ¾§ø Þ÷ ·- ¼·³·²·-¸»¼

½±³°»²-¿¬»¼ º±®ò

ЬМЭЦМЭо

ÌÝï

Ы´-» ³±¬±® ª¿´ª»

Ø»¿¬

»¨½¸¿²¹» ®

ײ¼±±® «²·¬

λº®·¹»®¿²¬

-»²-±®

øײ÷

λº®·¹»®¿²¬

-»²-±®

øÑ«¬÷

ßÞÝ

Ñ«¬¼±±®«²·¬

Ñ°¬·³¿´ ®»º®·¹»®¿²¬ ½±²¬®±´

– When a multiplenumber of indoorunits are connected,an insufficientor excess amountof refrigerant maybe

supplied to indoor units depending on the difference in length of the connection pipe from the outdoor unit.

– This is caused by pressure loss and heat leaks as th

e refrigerant travels through the pipes, resulting in

incorrect amounts of refrigerantbeing supplied to the indoor units.

– Optimal refrigerant flow co

ntrol featuring intelligent cont

rol over the refrigerant se

nsors and opening rate of

individual pulse motor valves realizes stable indo

or temperatures throughout a building with height

differences of up to 40m between indoor units.

шпмШРфпк ШРч

î

ï

Ì©·²ó®±¬¿®§

Ò»© Üݬ©·²ó®±¬¿®§ ½±³°®»--±®

Ñ°¬·³·¦¿¬·±² ±º ¼·-½¸¿®¹» °±®¬ °±-·¬·±²·²¹

¿²¼ ¾´¿¼» ¬¸·½µ²»--®»¼«½»- ½±³°®»--·±² ´±--

¿²¼ º®·½¬·±² ®»-·-¬¿²½»ò× ²½®»¿-·²¹ ¬¸» -«®º¿½»

¿®»¿ ±º ¬¸» ®±¬±® ³¿¹²»¬- ¿²¼¬¸» ¿¼¼·¬·±² ±º

²±·-»ò

Û¿½¸ ³±¬±® »³°´±§- ¿ ½±³°¿½¬

¿²¼ °±©»®º«´³¿ ¹²»¬·½ ®±¬±® ø®¿®»

»¿®¬¸ ³¿¹²»¬÷ ¿²¼ º»¿¬«®»-

®»¼«½»¼ »¼¼§ó½«®®»²¬ ´±--ò

׳°®±ª»¼³±¬±®

Ò»©´§ ¼»-·¹²»¼

½±³°®»--·±² °¿¬¸

Ó±®» °®»½·-»

½±³°±²»²¬-

Ý

·®½«·¬ ¾±¿®¼

̸» ª»½¬±®ó½±²¬®±´´»¼ ·²ª»®¬»® ¯«·½µ´§

½±²ª»®¬- ½«®®»²¬ ·²¬± ¿ -³±±¬¸ -·²»

½«®ª» ¬± ¿ ½¸·»ª» -³±±¬¸»® ±°»®¿¬·±²

±º ¬¸» ½±³°®»±® ÜÝ ³±¬±®ò

Í

³±±¬¸ -·²» ½«®ª»

̸» º¿-¬ó½ ¿´½«´¿¬·²¹ ª»½¬ ±®ó½±²¬®±´´»¼

·²ª»®¬»® °®±¼«½»- ¿ -³±±¬¸ -·²» ½«®ª» ¬¸¿¬

ײ¬®±¼«½·²¹ ¸·¹¸ó°»®º±

®³¿²½» ±«¬¼±±® «²·¬-

©·¬¸ í ½±³°®»--±®- ¿²¼ í ·²ª»®¬»®-

öï

1

Ò»© ÜÝ ¬©·²ó®±¬¿®§ ½±³°®»--±®

Ô»¿¼·²¹ ¬¸» ©±®´¼ ©·¬¸ ̱¸·¾¿

±©² ²»© ÜÝ ¬©·²ó®±¬¿®§

½±³°®»--±®

Three new DC twin-rotary

compressorsthatfeature outstanding

capacity under partial load drive the

14 and 16HP outdoor unit models,

while two are used by the other

outdoor unit models. These new

compressors improve both energy

efficiency and comfort levels.

2

Ú¿-¬ó½¿´½«´¿¬·²¹ ª»½¬±

®ó½±²¬®±´´»¼ ·²ª»®¬»®

ß´´ó·²ª»®¬»® ½±²¬®±´ ®»¿´·¦»- º·²»®

½±²¬®±´ ±ª»® ±°»®¿¬·±² ¬± ³¿¬½¸

¬¸» ´±¿¼ ±² ¬¸» -§-¬»³

Toshiba SMMS-i leadsthe industryin

controlling all 3 compressors with a

dedicatedinverterboard thattaps the

compressor’s full pote

ntial to provide

smoother operation.

*1 14 and 16HP models

-1

4

НУУНу· Ь¿¬¿ ¾±±µ

4

System overview

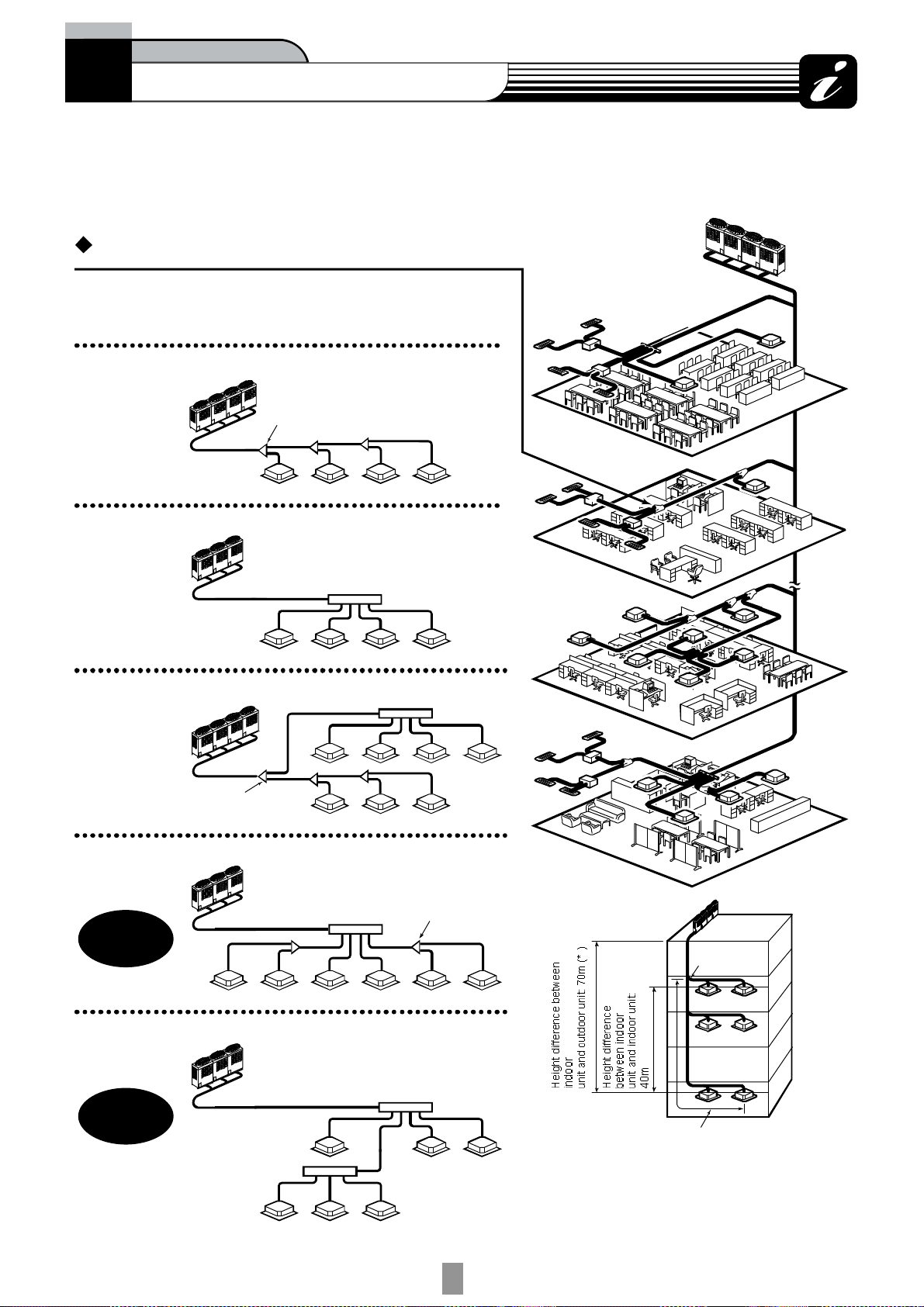

пт СЛМФЧТЫ СЪ МСНШЧЮЯ НУУН

øÍ«°»® Ó±¼«´¿® Ó«´¬· ͧ-¬»³÷

Ѳ´§

МСНШЧЮЯ

МСНШЧЮЯ

Ѳ´§

иЪйЪоЪ

ïÚ

̸» ݱ³¾·²¿¬·±² ±º ´·²» ¿²¼ ¸»¿¼»® ¾®¿²½¸·²¹ ·- ¸·¹¸´§ º´»¨·¾´»ò

Ú±´´±©·²¹ ¬¸» -¸±®¬»-¬ ¼»-·¹² ®±«¬» °±--·¾´»ô ¬¸»®»¾§ -¿ª·²¹

±² ·²-¬¿´´¿¬·±² ¬·³» ¿²¼ ½±-¬ò Ô·²»ñ¸»¿¼»® ¾®¿²½¸·²¹ ¿º¬»® ¬¸»

¸»¿¼»® ¾®¿²½¸·²¹ ·- ±²´§ ¿ª¿·´¿¾´» ©·¬¸ МСНШЧЮЯ Н«°»® УУНт

͸±®¬»-¬ ®±«¬» ¼»-·¹²

¾§ º®»» ¾®¿²½¸·²¹

Ô·²» ¾®¿²½¸·²¹

Ø»¿¼»® ¾®¿²½¸·²¹

Ô·²» õ Ø»¿¼»® ¾®¿²½¸·²¹

Ø»¿¼»® ¾®¿²½¸·²¹ ¿º¬»® ¸»¿¼»® ¾®¿²½¸·²¹

Ô·²» ¾®¿²½¸·²¹ ¿º¬»® ¸»¿¼»® ¾®¿²½¸·²¹

Outdoor unit

Branching joint

Indoor unit

Branching

header

Indoor unit

Outdoor unit

Outdoor unit

Branching joint

Indoor

unit

Branching joint

Header

Outdoor unit

Indoor unit

Header

Header

Header

Indoor unit

Outdoor unit

1st branching

section

Allowable pipe length:

235m equivalent length

Outdoor

unit

From 1st branching to the furthest

indoor unit: 90m (*

2

)1*1: If the height different between(H2)indoor

units exceeds 3m, set below 50m.

*2 : If the height different between(H1) indoor

and outdoor units exceeds 3m, set below

65m.

-2

4

4

System overview

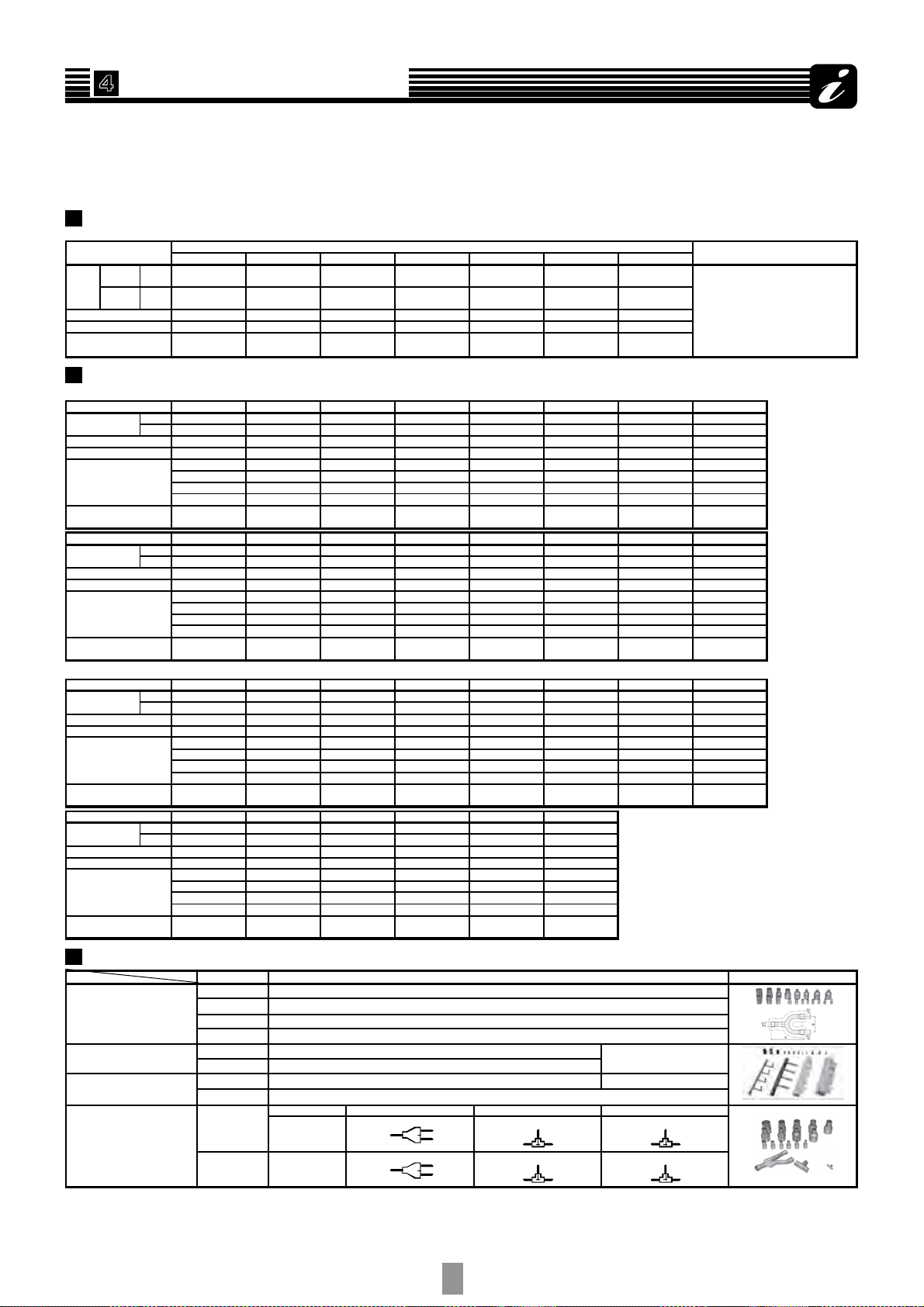

от НЛУУЯОЗ СЪ НЗНМЫУ ЫПЛЧРУЫТМН

Û¯«·°³»²¬

Ñ«¬¼±±® «²·¬-

ݱ³¾·²¿¬·±² ±º ±«¬¼±±® «²·¬-

Þ®¿²½¸·²¹ ¶±·²¬- ¿²¼ ¸»¿¼»®-

*1 “Capacity code” can be obtained by the lists on next page an

d after the next page.(Capacity code is not actual capacity.)

*2 If total capacity code value of indoor unit exceeds that of outdoor unit, apply capacity code of outdoor unit.

*3 When using Y-shape br

anching joint for 1st branching, select accord

ing to the capacity co

de of the outdoor unit.

*4 Max. capacity code of 6.

0 in total can be connected.

*5 If capacity code of outdoor unit is 26 or

more, it is not used for 1st branching.

* SMMS outdoor unit

ݱ®®»-° ±²¼·² ¹ ØÐ

ײª»®¬» ® «² ·¬

ß°°»¿® ¿²½ »

ëØÐö êØÐö èØÐ ïðØÐ ïîØÐ ïìØÐ ïêØÐ

Model

name

Heat

pump

УУЗу УЯР рлрпШМиуЫ УЯ РркрпШ МиуЫ УЯР рирмШМ иуЫ УЯРпррмШ МиуЫ УЯРпор мШМи уЫ УЯРп мрмШМ иуЫ УЯ РпкрмШ МиуЫ

Cooling

only

УУЗу УЯР рлрпМиуЫ УЯР ркрпМиуЫ УЯРрирм МиуЫ УЯРпррм МиуЫ УЯРпормМ иуЫ У ЯРпмрм МиуЫ У ЯРпкрмМи уЫ

Cooling capacity (kW) 14.0 16.0 22.4 28.0 33.5 40.0 45.0

Heating capacity (kW) 16.0 18.0 25.0 31.5 37.5 45.0 50.0

No. of connectable

indoor units

8 10 13 16 20 23 27

ͬ¿²¼¿®¼ ³±¼»´

ݱ®®»-° ±²¼·² ¹ ØÐ ïèØÐ

îðØÐ

îîØÐ

îìØÐ

îêØÐ

îèØÐ

íðØÐ

íîØÐ

ݱ³¾· ²»¼

Ó±¼» ´

УУЗу ЯРп ипмШМ иуЫ ЯРорп мШМиуЫ ЯРоопм ШМиуЫ ЯРо мпмШМиуЫ ЯР окпмШМиуЫ ЯР оипмШ МиуЫ ЯРнрпмШ МиуЫ ЯР нопмШМ иуЫ

ÓÓÇó ßÐï èïìÌ èóÛ ЯРорпм МиуЫ ßÐî îïìÌ èóÛ ЯРомпм МиуЫ ЯРок пмМиуЫ ЯРоипм МиуЫ ЯРн рпмМиуЫ ЯР нопмМи уЫ

Cooling

capacity (kW) 50.4 56.0 61.5 68.0 73.0 78.5 85.0 90.0

Heating

capacity (kW) 56.5 63.0 69.0 76.5 81.5 88.0 95.0 100.0

Combined outdoor units

10HP

10HP

12HP

12HP

16HP

16HP

16HP

16HP8H

P 1

0HP 1

0HP 1

2HP 1

0HP 1

2HP 1

4HP 1

6HP

– – – – – – – –

– – – – – – – –

No. of connectable

indoor units

3033374043474848ݱ®®»-° ±²¼·² ¹ ØÐ íìØÐ

íêØÐ

íèØÐ

ìðØÐ

ìîØÐ

ììØÐ

ìêØÐ

ìèØÐ

ݱ³¾· ²»¼

Ó±¼» ´

УУЗу ЯРн мпмШМ иуЫ ЯРнкп мШМиуЫ ЯРнипм ШМиуЫ ЯРм рпмШМиуЫ ЯР мопмШМиуЫ ЯР ммпмШ МиуЫ ЯРмкпмШ МиуЫ ЯР мипмШМ иуЫ

ÓÓÇó ßÐí ìïìÌ èóÛ ЯРнкпм ШМиу Ы ЯРнипмМиуЫ ЯРмрп мМиуЫ ЯР мопмМиуЫ ЯР ммпмМиуЫ ЯРм кпмМиуЫ ЯР мипмМиуЫ

Cooling

capacity (kW) 96.0 101.0 106.5 112.0 118.0 123.5 130.0 135.0

Heating

capacity (kW) 108.0 113.0 119.5 127.0 132.0 138.0 145.0 150.0

Combined outdoor units

12HP

12HP

16HP

16HP

16HP

16HP

16HP

16HP

12HP

12HP

12HP

12HP

14HP

16HP

16HP

16HP

10HP

12HP

10HP

12HP

12HP

12HP

14HP

16HP

– – – – – – – –

No. of connectable

indoor units

48484848484848

48

Ø·¹¸ »ºº·½·»²½§ ³±¼»´

ݱ®®»-° ±²¼·² ¹ ØÐ ïêØÐ

îìØÐ

îêØÐ

îèØÐ

íðØÐ

íîØÐ

íìØÐ

íêØÐ

ݱ³¾· ²»¼

Ó±¼» ´

УУЗу ЯРп комШМ иуЫ ЯРомо мШМиуЫ ЯРоком ШМиуЫ ЯРо иомШМиуЫ ЯР нромШМиуЫ ЯР ноомШ МиуЫ ЯРнмомШ МиуЫ ЯР нкомШМ иуЫ

ÓÓÇó ßÐï êîìÌ èóÛ ЯРомом МиуЫ ßÐî êîìÌ èóÛ ЯРоиом МиуЫ ЯРнр омМиуЫ ЯРноом МиуЫ ЯРн момМиуЫ ЯР нкомМи уЫ

Cooling

capacity (kW) 45.0 68.0 73.0 78.5 85.0 90.0 96.0 101.0

Heating

capacity (kW) 50.0 76.5 81.5 88.0 95.0 100.0 108.0 113.0

Combined outdoor units

8HP

8HP

10HP

10HP

10HP

8HP

10HP

10HP

8HP

8HP

8HP

10HP

10HP

8HP

8HP

10HP–8HP

8HP

8HP

10HP

8HP

8HP

8HP

– – – – – 8

H

P 8

H

P 8

HPNo. of connectable

indoor units

2740434748484848ݱ®®»-° ±²¼·² ¹ ØÐ íèØÐ

ìðØÐ

ìîØÐ

ììØÐ

ìêØÐ

ìèØÐ

ݱ³¾· ²»¼

Ó±¼» ´

УУЗу ЯРн иомШМ иуЫ ЯРмро мШМиуЫ ЯРмоом ШМиуЫ ЯРм момШМиуЫ ЯР мкомШМиуЫ ЯР миомШ МиуЫ

ÓÓÇó ßÐí èîìÌ èóÛ ЯРмром МиуЫ ßÐì îîìÌ èóÛ ЯРммом МиуЫ ßÐìê îìÌ èóÛ ЯРмиом МиуЫ

Cooling

capacity (kW) 106.5 112.0 118.0 123.5 130.0 135.0

Heating

capacity (kW) 119.5 127.0 132.0 138.0 145.0 150.0

Combined outdoor units

10HP

10HP

12HP

12HP

12HP

12HP

10HP

10HP

10HP

12HP

12HP

12HP

10HP

10HP

10HP

10HP

12HP

12HP8H

P 1

0HP 1

0HP 1

0HP 1

0HP 1

2HP

No. of connectable

indoor units

484848484848Ó±¼» ´ ²¿³»

Ë-¿¹» øÝ´¿--· º·½¿¬·±² ¿½½±®¼· ²¹ ¬± ·² ¼±±® « ²·¬ ½ ¿°¿½·¬§ ½ ±¼» øö

ï

÷÷

ß°°»¿® ¿²½»

Y-shape branching joint (*

3

)

RBM-BY55E Total below 6.4

RBM-BY105E Total 6.4 or more and below 14.2

(*2)

RBM-BY205E Total 14.2 or more and below 25.2

(*2)

RBM-BY305E Total 25.2 or more

(*2)

4-branching header (*

4

)

RBM-HY1043E Total below 14.2

Max.4 branches

RBM-HY2043E Total 14.2 or more and below 25.2

8-branching header (*

4

) (*5)

RBM-HY1083E Total below 14.2 Max.8 branches

RBM-HY2083E Total 14.2 or more and below 25.2

Branching joint for connection

of outdoor units

(1set of 1type of Y-shape joint

pipe and 2types ofT-joint pipes

as described right.)

RBM-BT14E

Usage

Piping at gas side (Y-shape) Piping at liquid side (T-shape) Balance pipe (T-shape)

Total below 26

RBM-BT24E Total 26 or more

ø28.6

ø25.4

ø31.8

ø19.1

ø19.1

ø19.1

ø9.5

ø9.5

ø9.5

ø38.1

ø28.6

ø38.1

ø22.2

ø22.2

ø22.2

ø9.5

ø9.5

ø9.5

-3

4

4

System overview

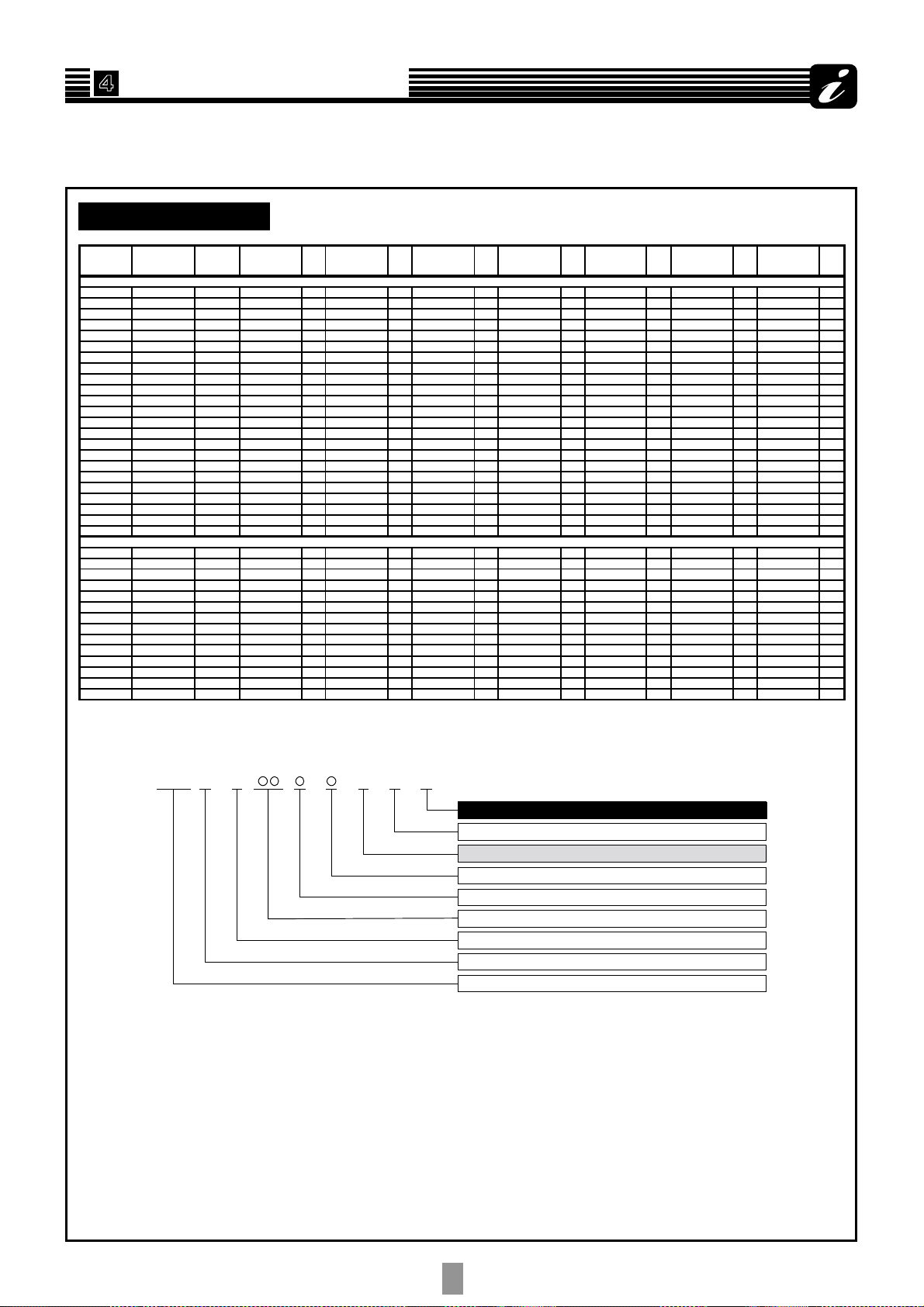

íò Ô·-¬ ±º °®±¼«½¬ ¿²¼ ½±³¾·²»¼ ³±¼»´ ²¿³»

* : SMMS outdoor unit

ïò ß´´±½¿¬·±² -¬¿²¼¿

®¼ ±º ³±¼»´ ²¿³»

îò ο²¹ ±º ½±³¾·²»¼ ½¿°¿½·¬§

No. of combined units: 1 to 4 units

Capacity of combined units: 16 HP(16type) to 48 HP(48type)

íò כּ¼ ½±²¼·¬·±²-

Cooling: Indoor air temperature 27ºC DB/19ºC WB, Outdoor air temperature 35ºC DB

Heating: Indoor air temperature 20ºC DB, Outdoor air temperature 7ºC DB/6ºC WB

Ø»¿¬ Ы³° ³±¼»´

ØÐ

øÝ¿°¿½·¬ §

½±¼»÷

Ó±¼ »´ ²¿³»

ÓÓÇó

Ò±ò ± º

½±³ ¾·²»¼

«²·¬-

ײª»®¬» ® ëØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬» ® êØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬»® èØ Ð

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬»® ïð ØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬»® ïî ØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬»® ïì ØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬»® ïê ØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ͬ¿²¼¿®¼ ³ ±¼» ´

5HP(5)*

MAP0 501HT 8-E 1 MAP0 501HT8-E 1

6HP(6)*

MAP0 601HT 8-E 1

MAP0 601HT 8-E 1

8HP(8)

MAP0 804HT 8-E 1

MAP0 804HT 8-E 1

10HP(10)

MAP1 004HT 8-E 1

MAP1 004HT 8-E 1

12HP(12)

MAP1 204HT 8-E 1

MAP1 204HT 8-E 1

14HP(14)

MAP1 404HT 8-E 1

MAP1 404HT 8-E 1

16HP(16)

MAP1 604HT 8-E 1

MAP1 604HT 8-E 1

18HP(18)

AP1814HT8-E 2

MAP0 804HT 8-E 1 MAP10 04HT 8-E 1

20HP(20)

AP2014HT8-E 2

MAP1 004HT 8-E 2

22HP(22)

AP2214HT8-E 2

MAP1 004HT 8-E 1 MAP12 04HT 8-E 1

24HP(24)

AP2414HT8-E 2

MAP1 204HT 8-E 2

26HP(26)

AP2614HT8-E 2

MAP1 004HT 8-E 1 MAP1 604HT 8-E 1

28HP(28)

AP2814HT8-E 2

MAP1 204HT 8-E 1 MAP1 604HT 8-E 1

30HP(30)

AP3014HT8-E 2

MAP1 404HT 8-E 1 MAP16 04HT 8-E 1

32HP(32)

AP3214HT8-E 2

MAP1 604HT 8-E 2

34HP(34)

AP3414HT8-E 3

MAP1 004HT 8-E 1 MAP12 04HT 8-E 2

36HP(36)

AP3614HT8-E 3

MAP1 204HT 8-E 3

38HP(38)

AP3814HT8-E 3

MAP1 004HT 8-E 1 MAP12 04HT 8-E 1 MAP16 04HT 8-E 1

40HP(40)

AP4014HT8-E 3

MAP1 204HT 8-E 2 MAP1 604HT 8-E 1

42HP(42)

AP4214HT8-E 3

MAP1 204HT 8-E 1 MAP14 04HT 8-E 1 MA P1604HT 8-E 1

44HP(44)

AP4414HT8-E 3

MAP1 204HT 8-E 1 MAP1 604HT 8-E 2

46HP(46)

AP4614HT8-E 3

MAP1 404HT 8-E 1 MAP16 04HT 8-E 2

48HP(48)

AP4814HT8-E 3

MAP1 604HT 8-E 3

Ø·¹¸ »ºº ·½·»²½§ ³ ±¼»´

16HP(16)

AP1624HT8-E 2

MAP0 804HT 8-E 2

24HP(24)

AP2424HT8-E 3

MAP0 804HT 8-E 3

26HP(26)

AP2624HT8-E 3

MAP0 804HT 8-E 2 MAP10 04HT 8-E 1

28HP(28)

AP2824HT8-E 3

MAP0 804HT 8-E 1 MAP10 04HT 8-E 2

30HP(30)

AP3024HT8-E 3

MAP1 004HT 8-E 3

32HP(32)

AP3224HT8-E 4

MAP0 804HT 8-E 4

34HP(34)

AP3424HT8-E 4

MAP0 804HT 8-E 3 MAP10 04HT 8-E 1

36HP(36)

AP3624HT8-E 4

MAP0 804HT 8-E 2 MAP10 04HT 8-E 2

38HP(38)

AP3824HT8-E 4

MAP0 804HT 8-E 1 MAP10 04HT 8-E 3

40HP(40)

AP4024HT8-E 4

MAP1 004HT 8-E 4

42HP(42)

AP4224HT8-E 4

MAP1 004HT 8-E 3 MAP12 04HT 8-E 1

44HP(44)

AP4424HT8-E 4

MAP1 004HT 8-E 2 MAP12 04HT 8-E 2

46HP(46)

AP4624HT8-E 4

MAP1 004HT 8-E 1 MAP12 04HT 8-E 3

48HP(48)

AP4824HT8-E 4

MAP1 204HT 8-E 4

MMY_M AP H T 8

_

E

Power supply specifications, 3Ø

380-400-415V, 50Hz ....... 8

T: Capacity variable unit

Øæ Ø»¿¬ °«³°

Development series No.

0 : Single model, 1: Standard model, 2 : High efficiency model

Capacity rank HP

Refrigerant R410A

M: Single module unit, No mark: Combined Model name

Modular Multi

-4

4

4

System overview

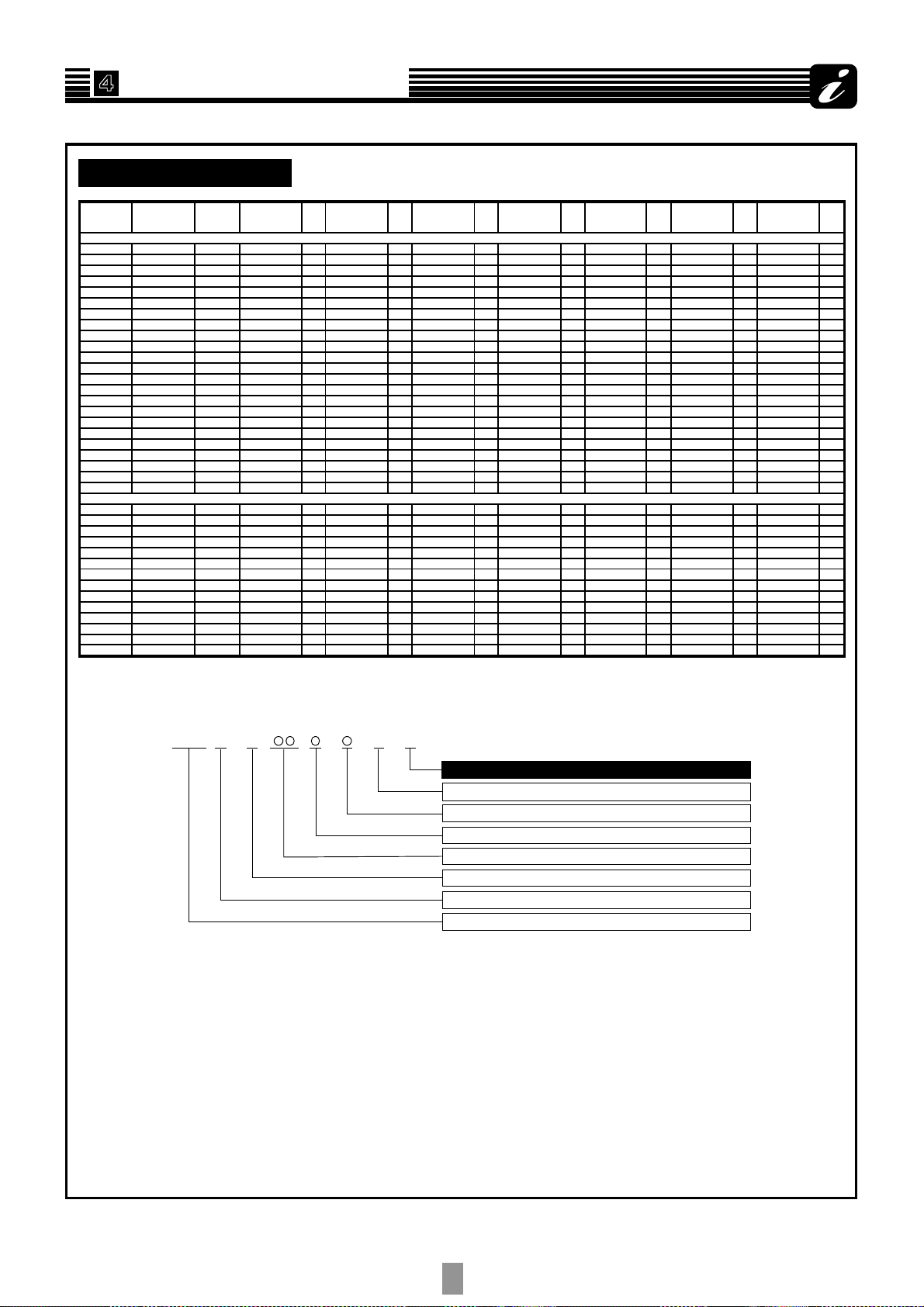

* : SMMS outdoor unit

ïò ß´´±½¿¬·±² -¬¿²¼¿

®¼ ±º ³±¼»´ ²¿³»

îò ο²¹ ±º ½±³¾·²»¼ ½¿°¿½·¬§

No. of combined units: 1 to 4 units

Capacity of combined units: 16 HP(16type) to 48 HP(48type)

íò כּ¼ ½±²¼·¬·±²-

Cooling: Indoor air temperature 27ºC DB/19ºC WB, Outdoor air temperature 35ºC DB

ݱ±´·²¹ Ѳ´§ ³±¼»´

ØÐøÝ¿°¿½ ·¬§

½±¼»÷

Ó±¼ »´ ²¿³»

ÓÓÇó

Ò±ò ± º

½±³ ¾·²»¼

«²·¬-

ײª»®¬» ® ëØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬» ® êØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬»® èØ Ð

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬»® ïð ØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬»® ïî ØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬»® ïì ØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ײª»®¬»® ïê ØÐ

ÓÓÇó

Ë-»¼

Ϭ§

ͬ¿²¼¿®¼ ³ ±¼» ´

5HP(5)* MAP0501T8-E 1 MAP0501T8-E 1

6HP(6)* MAP0601T8-E 1 MAP0601T8-E 1

8HP(8) MAP0804T8-E 1 MAP0804T8-E 1

10HP(10) MAP1004T8-E 1

MAP1004T8-E 1

12HP(12) MAP1204T8-E 1

MAP1204T8-E 1

14HP(14) MAP1404T8-E 1

MAP1404T8-E 1

16HP(16) MAP1604T8-E 1

MAP1604T8-E 1

18HP(18) AP1814T8-E 2 MAP0804T8-E 1 MAP1004T8-E 1

20HP(20) AP2014T8-E 2

MAP1004T8-E 2

22HP(22) AP2214T8-E 2

MAP1004T8-E 1 MAP1204T8-E 1

24HP(24) AP2414T8-E 2

MAP1204T8-E 2

26HP(26) AP2614T8-E 2

MAP1004T8-E 1 MAP1604T8-E 1

28HP(28) AP2814T8-E 2

MAP1204T8-E 1 MAP1604T8-E 1

30HP(30) AP3014T8-E 2

MAP1404T8-E 1 MAP1604T8-E 1

32HP(32) AP3214T8-E 2

MAP1604T8-E 2

34HP(34) AP3414T8-E 3

MAP1004T8-E 1 MAP1204T8-E 2

36HP(36) AP3614T8-E 3

MAP1204T8-E 3

38HP(38) AP3814T8-E 3

MAP1004T8-E 1 MAP1204T8-E 1 MAP1604T8-E 1

40HP(40) AP4014T8-E 3

MAP1204T8-E 2 MAP1604T8-E 1

42HP(42) AP4214T8-E 3

MAP1204T8-E 1 MAP1404T8-E 1 MAP1604T8-E 1

44HP(44) AP4414T8-E 3

MAP1204T8-E 1 MAP1604T8-E 2

46HP(46) AP4614T8-E 3

MAP1404T8-E 1 MAP1604T8-E 2

48HP(48) AP4814T8-E 3

MAP1604T8-E 3

Ø·¹¸ »ºº ·½·»²½§ ³ ±¼»´

16HP(16) AP1624T8-E 2 MAP0804T8-E 2

24HP(24) AP2424T8-E 3 MAP0804T8-E 3

26HP(26) AP2624T8-E 3 MAP0804T8-E 2 MAP1004T8-E 1

28HP(28) AP2824T8-E 3 MAP0804T8-E 1 MAP1004T8-E 2

30HP(30) AP3024T8-E 3

MAP1004T8-E 3

32HP(32) AP3224T8-E 4 MAP0804T8-E 4

34HP(34) AP3424T8-E 4 MAP0804T8-E 3 MAP1004T8-E 1

36HP(36) AP3624T8-E 4 MAP0804T8-E 2 MAP1004T8-E 2

38HP(38) AP3824T8-E 4 MAP0804T8-E 1 MAP1004T8-E 3

40HP(40) AP4024T8-E 4

MAP1004T8-E 4

42HP(42) AP4224T8-E 4

MAP1004T8-E 3 MAP1204T8-E 1

44HP(44) AP4424T8-E 4

MAP1004T8-E 2 MAP1204T8-E 2

46HP(46) AP4624T8-E 4

MAP1004T8-E 1 MAP1204T8-E 3

48HP(48) AP4824T8-E 4

MAP1204T8-E 4

MMY_E_M AP T 8

Power supply specifications, 3Ø

380-400-415V, 50Hz ....... 8

T: Capacity variable unit

Development series No.

0 : Single model, 1: Standard model, 2 : High efficiency model

Capacity rank HP

Refrigerant R410A

M: Single module unit, No mark: Combined Model name

Modular Multi

-5

4

4

System overview

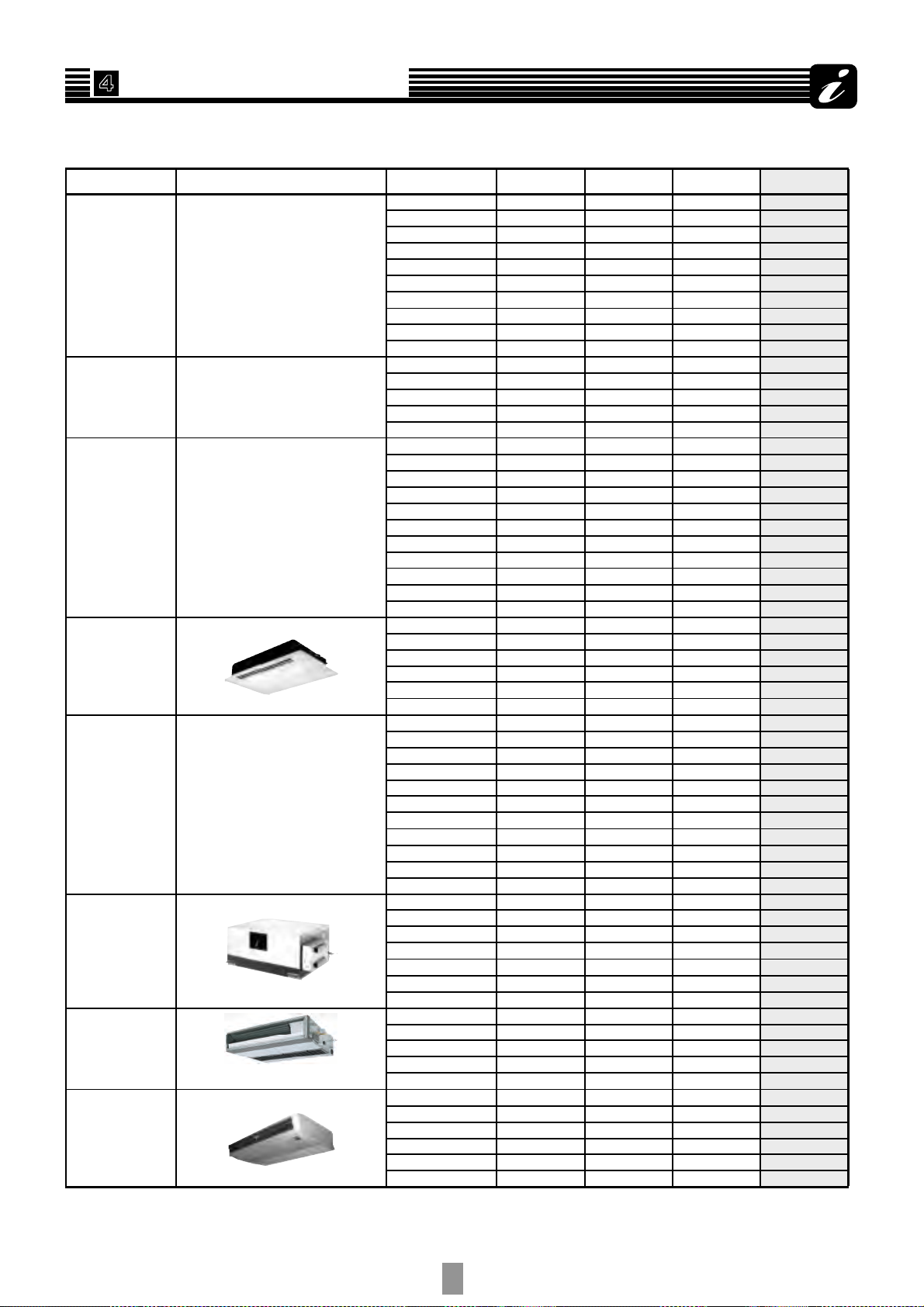

ìò ײ¼±±® «²·¬

̧°»

ß°°»¿® ¿²½ »

Ó±¼» ´ ²¿³» Ý¿ °¿½·¬§ ®¿ ²µ Ý¿°¿½·¬ § ½±¼»

ݱ±´·² ¹

½¿°¿½·¬ § øµÉ÷

Ø»¿¬· ²¹

½¿°¿½·¬ § øµÉ÷

4-way Air Discharge

Cassette Type

УУЛуЯ Рррзо Ш

009 type 1.00 2.8

3.2

УУЛуЯ Ррпоо Ш

012 type 1.25 3.6

4.0

УУЛуЯ Ррпло Ш

015 type 1.70 4.5

5.0

УУЛуЯ Ррпио Ш

018 type 2.00 5.6

6.3

УУЛуЯ Рромо Ш

024 type 2.50 7.1

8.0

УУЛуЯ Рройо Ш

027 type 3.00 8.0

9.0

УУЛуЯ Ррнро Ш

030 type 3.20 9.0

10.0

УУЛуЯ Ррнко Ш

036 type 4.00 11.2

12.5

УУЛуЯ Ррмио Ш

048 type 5.00 14.0

16.0

УУЛуЯ Ррлко Ш

056 type 6.00 16.0

18.0

Compact 4-way

Cassette (600

I

600)

Type

УУЛуЯ Рррйп УШ

007 type 0.80 2.2

2.5

УУЛуЯ Рррзп УШ

009 type 1.00 2.8

3.2

УУЛуЯ Ррпоп УШ

012 type 1.25 3.6

4.0

УУЛуЯ Ррплп УШ

015 type 1.70 4.5

5.0

УУЛуЯ Ррпип УШ

018 type 2.00 5.6

6.3

2-way Air Discharge

Cassette Type

УУЛуЯ Рррйо ЙШ

007 type 0.80 2.2

2.5

УУЛуЯ Рррзо ЙШ

009 type 1.00 2.8

3.2

УУЛуЯ Ррпоо ЙШ

012 type 1.25 3.6

4.0

УУЛуЯ Ррпло ЙШ

015 type 1.70 4.5

5.0

УУЛуЯ Ррпио ЙШ

018 type 2.00 5.6

6.3

УУЛуЯ Рромо ЙШ

024 type 2.50 7.1

8.0

УУЛуЯ Рройо ЙШ

027 type 3.00 8.0

9.0

УУЛуЯ Ррнро ЙШ

030 type 3.20 9.0

10.0

УУЛуЯ Ррнко ЙШ

036 type 4.00 11.2

12.5

УУЛуЯ Ррмио ЙШ

048 type 5.00 14.0

16.0

УУЛуЯ Ррлко ЙШ

056 type 6.00 16.0

18.0

1-way Air Discharge

Cassette Type

УУЛуЯ Рррйп ЗШ

007 type 0.80 2.2

2.5

УУЛуЯ Рррзп ЗШ

009 type 1.00 2.8

3.2

УУЛуЯ Ррпоп ЗШ

012 type 1.25 3.6

4.0

УУЛуЯ Ррпло НШ

015 type 1.70 4.5

5.0

УУЛуЯ Ррпио НШ

018 type 2.00 5.6

6.3

УУЛуЯ Рромо НШ

024 type 2.50 7.1

8.0

Concealed Duct

Standard Type

УУЬуЯ Рррйп ЮШ

007 type 0.80 2.2

2.5

УУЬуЯ Рррзп ЮШ

009 type 1.00 2.8

3.2

УУЬуЯ Ррпоп ЮШ

012 type 1.25 3.6

4.0

УУЬуЯ Ррплп ЮШ

015 type 1.70 4.5

5.0

УУЬуЯ Ррпип ЮШ

018 type 2.00 5.6

6.3

УУЬуЯ Рромп ЮШ

024 type 2.50 7.1

8.0

УУЬуЯ Рройп ЮШ

027 type 3.00 8.0

9.0

УУЬуЯ Ррнрп ЮШ

030 type 3.20 9.0

10.0

УУЬуЯ Ррнкп ЮШ

036 type 4.00 11.2

12.5

УУЬуЯ Ррмип ЮШ

048 type 5.00 14.0

16.0

УУЬуЯ Ррлкп ЮШ

056 type 6.00 16.0

18.0

Concealed Duct

High Static

Pressure Type

УУЬуЯ Ррпип Ш

018 type 2.00 5.6

6.3

УУЬуЯ Рромп Ш

024 type 2.50 7.1

8.0

УУЬуЯ Рройп Ш

027 type 3.00 8.0

9.0

УУЬуЯ Ррнкп Ш

036 type 4.00 11.2

10.0

УУЬуЯ Ррмип Ш

048 type 5.00 14.0

16.0

УУЬуЯ Ррйоп Ш

072 type 8.00 22.4

25.0

УУЬуЯ Ррзкп Ш

096 type 10.00 28.0

31.5

Slim Duct Type

УУЬуЯ Рррйп НРШ

007 type 0.80 2.2

2.5

УУЬуЯ Рррзп НРШ

009 type 1.00 2.8

3.2

УУЬуЯ Ррпоп НРШ

012 type 1.25 3.6

4.0

УУЬуЯ Ррплп НРШ

015 type 1.70 4.5

5.0

УУЬуЯ Ррпип НРШ

018 type 2.00 5.6

6.3

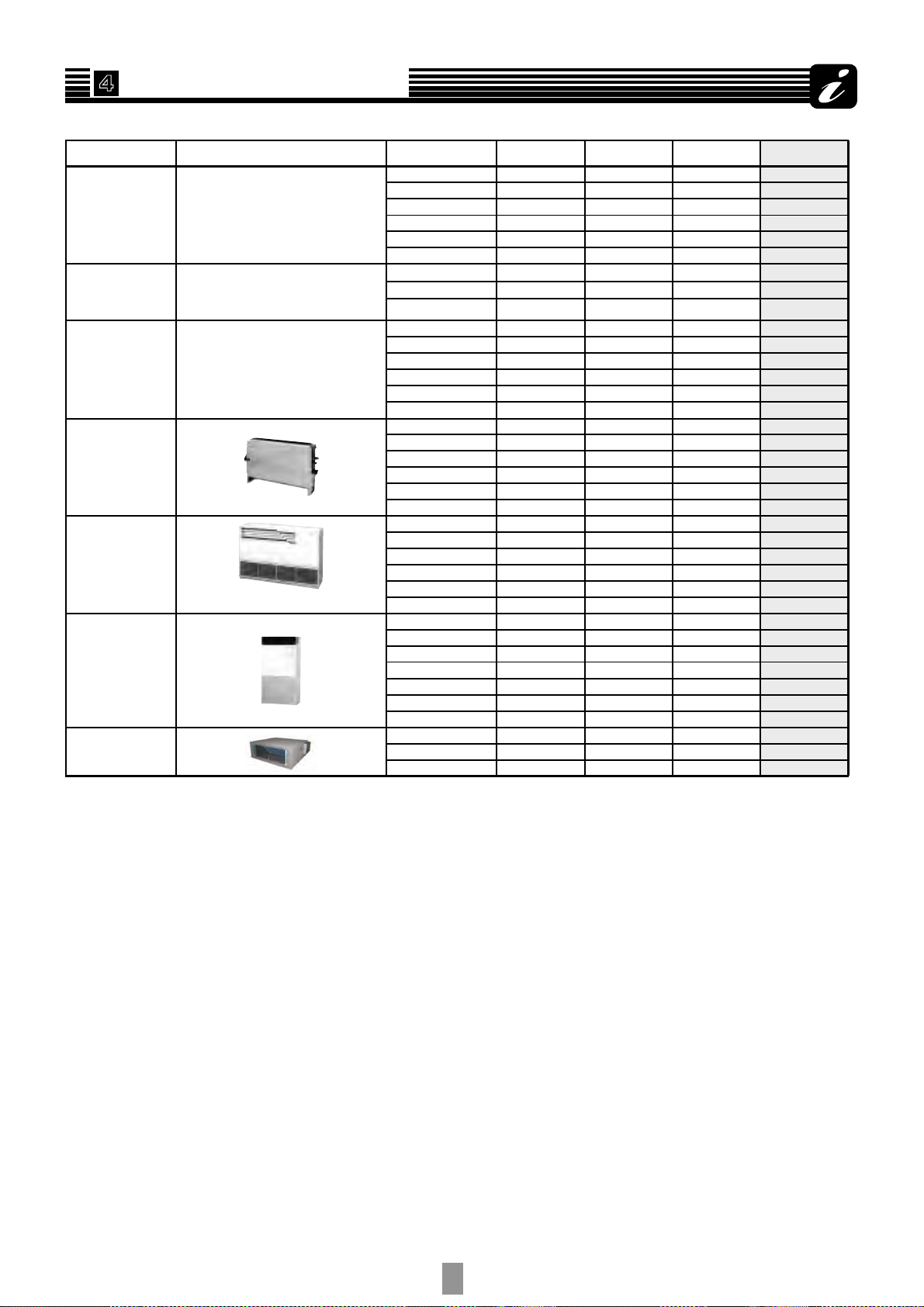

Under Ceiling Type

УУЭуЯ Ррплп Ш

015 type 1.70 4.5

5.0

УУЭуЯ Ррпип Ш

018 type 2.00 5.6

6.3

УУЭуЯ Рромп Ш

024 type 2.50 7.1

8.0

УУЭуЯ Рройп Ш

027 type 3.00 8.0

9.0

УУЭуЯ Ррнкп Ш

036 type 4.00 11.2

12.5

УУЭуЯ Ррмип Ш

048 type 5.00 14.0

16.0

-6

4

4

System overview

High-wall Type

1 series

УУХуЯ Рррйп Ш

007 type 0.80 2.2

2.5

УУХуЯ Рррзп Ш

009 type 1.00 2.8

3.2

УУХуЯ Ррпоп Ш

012 type 1.25 3.6

4.0

УУХуЯ Ррплп Ш

015 type 1.70 4.5

5.0

УУХуЯ Ррпип Ш

018 type 2.00 5.6

6.3

УУХуЯ Рромп Ш

024 type 2.50 7.1

8.0

High-wall Type

2 series

УУХуЯ Рррйо Ш

007 type 0.80 2.2

2.5

УУХуЯ Рррзо Ш

009 type

1.00

2.8

3.2

УУХуЯ Ррпоо Ш

012 type 1.25 3.6

4.0

High-wall Type

3 series

УУХуЯ Рррйн Ш

007 type 0.80 2.2

2.5

УУХуЯ Рррзн Ш

009 type 1.00 2.8

3.2

УУХуЯ Ррпон Ш

012 type 1.25 3.6

4.0

УУХуЯ Ррплн Ш

015 type 1.70 4.5

5.0

УУХуЯ Ррпин Ш

018 type 2.00 5.6

6.3

УУХуЯ Рромн Ш

024 type 2.50 7.1

8.0

Floor Standing

Concealed Type

УУФ уЯРррй пЮШ

007 type 0.80 2.2

2.5

УУФ уЯРррз пЮШ

009 type 1.00 2.8

3.2

УУФ уЯРрпо пЮШ

012 type 1.25 3.6

4.0

УУФ уЯРрпл пЮШ

015 type 1.70 4.5

5.0

УУФ уЯРрпи пЮШ

018 type 2.00 5.6

6.3

УУФ уЯРром пЮШ

024 type 2.50 7.1

8.0

Floor Standing

Cabinet Type

УУФу ЯРррй пШ

007 type 0.80 2.2

2.5

УУФу ЯРррз пШ

009 type 1.00 2.8

3.2

УУФу ЯРрпо пШ

012 type 1.25 3.6

4.0

УУФу ЯРрпл пШ

015 type 1.70 4.5

5.0

УУФу ЯРрпи пШ

018 type 2.00 5.6

6.3

УУФу ЯРром пШ

024 type 2.50 7.1

8.0

Floor Standing Type

УУЪу ЯРрпл пШ

015 type 1.70 4.5

5.0

УУЪу ЯРрпи пШ

018 type 2.00 5.6

6.3

УУЪу ЯРром пШ

024 type 2.50 7.1

8.0

УУЪу ЯРрой пШ

027 type 3.00 8.0

9.0

УУЪу ЯРрнк пШ

036 type 4.00 11.2

10.0

УУЪу ЯРрми пШ

048 type 5.00 14.0

16.0

УУЪу ЯРрлк пШ

056 type 6.00 16.0

18.0

Fresh Air Intake

Indoor Unit Type

УУЬуЯ Ррмип ШЪЫ

048 type 5.00 14.0

8.9

УУЬуЯ Ррйоп ШЪЫ

072 type 8.00 22.4

13.9

УУЬуЯ Ррзкп ШЪЫ

096 type 10.00 28.0

17.4

̧°» ß°°»¿® ¿²½» Ó±¼»´ ²¿³ » Ý¿°¿½· ¬§ ®¿² µ Ý¿°¿½·¬§ ½±¼ »

ݱ±´·² ¹

½¿°¿½·¬ § øµÉ÷

Ø»¿¬· ²¹

½¿°¿½·¬ § øµÉ÷

-7

4

4

System overview

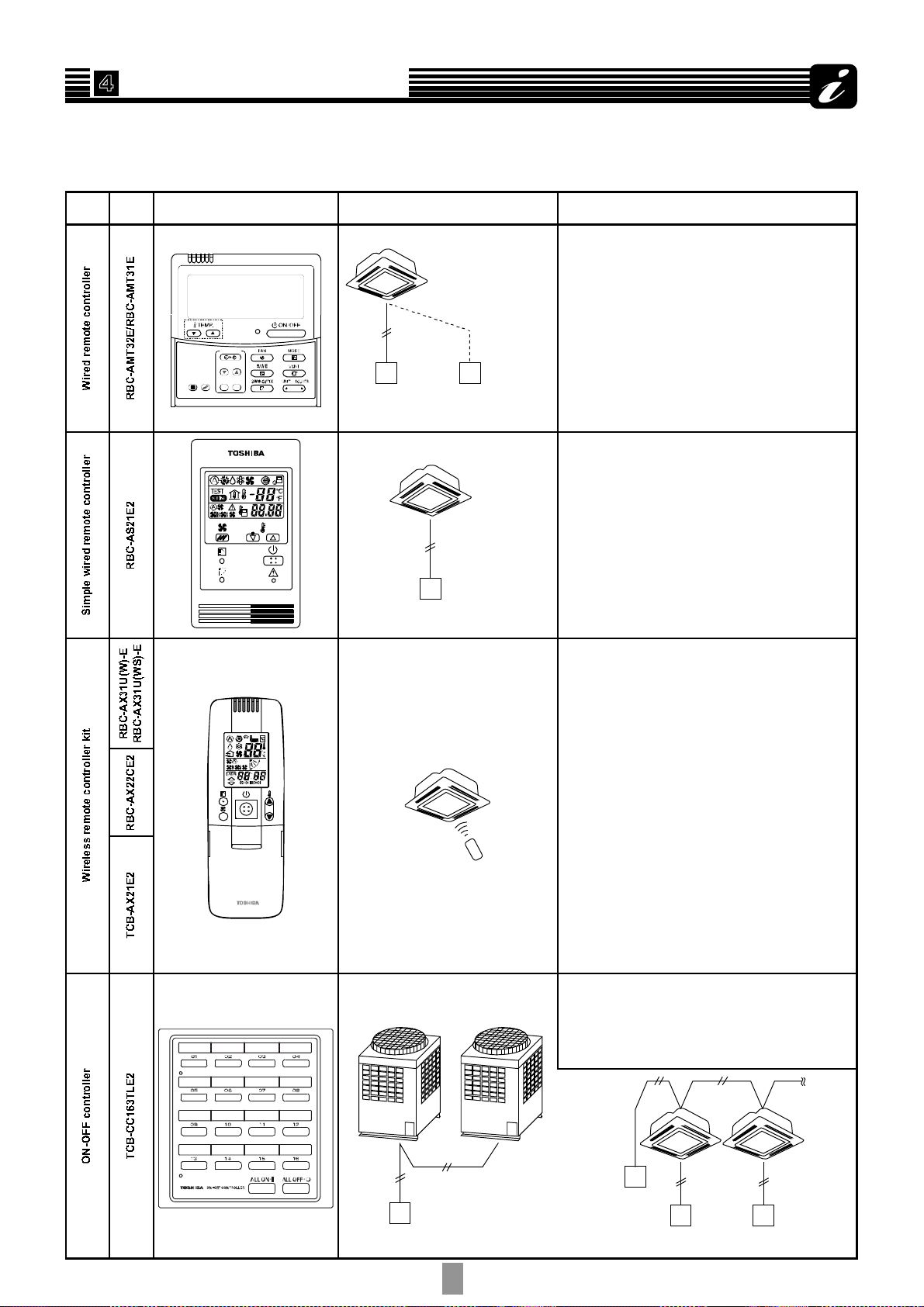

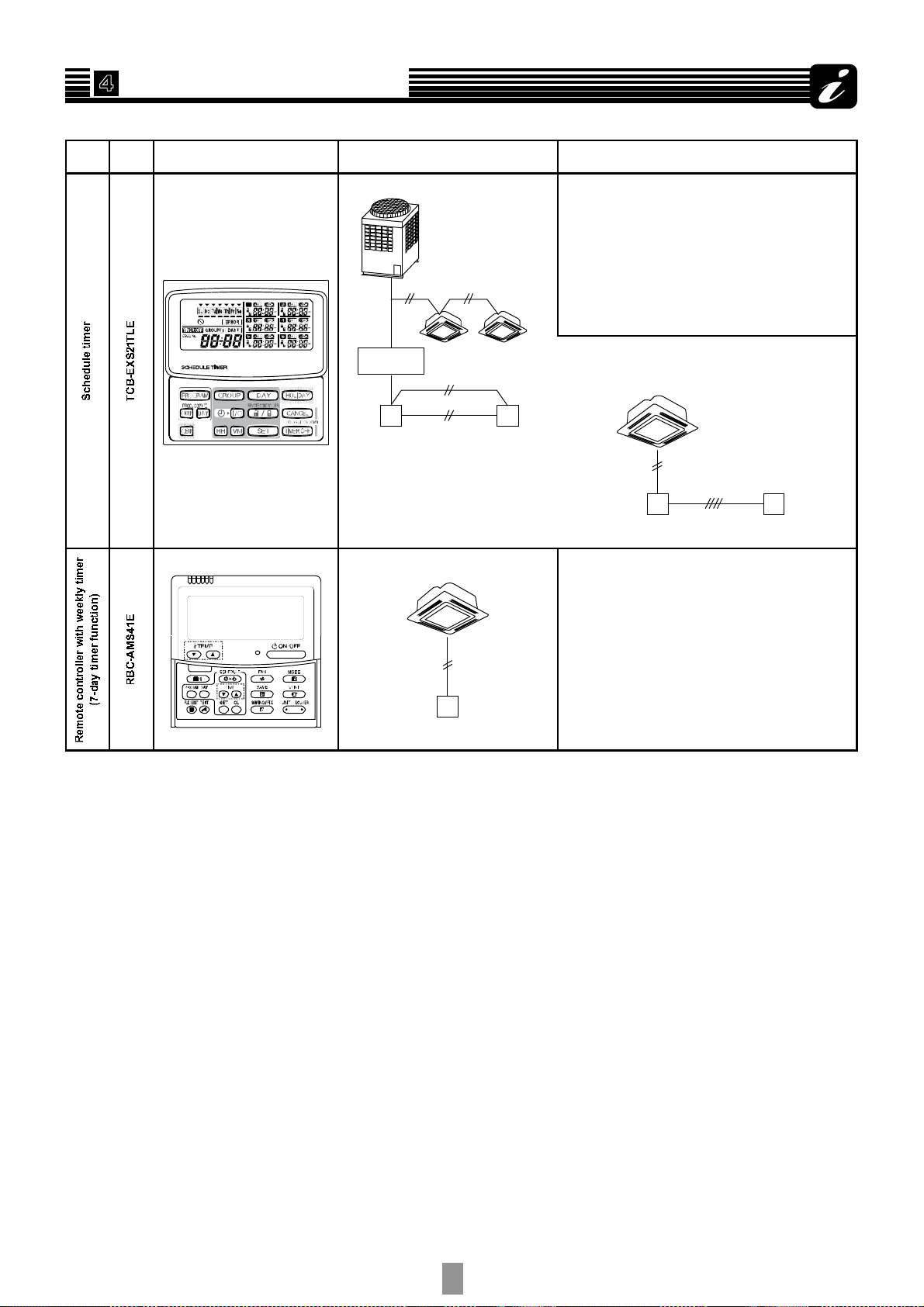

ëò λ³±¬» ½±²¬®±´´»®

Ò¿³»

Ó±¼»´

²¿³»

ß°°»¿® ¿²½» ß°°´·½¿¬·±² Ú«²½¬·±²

ݱ²²»½¬»¼ ¬± ·²¼±±® «²·¬

• Start/Stop

• Mode change

• Temperature setting

• Change of air flow

• Timer function

• Filter sign

• Self-diagnosis function

• Control by 2 remote controllers is available.

ݱ²²»½¬»¼ ¬± ·²¼±±® «²·¬

• Start/Stop

• Temperature setting

• Change of air flow

• Check code display

ݱ²²»½¬»¼ ¬± ·²¼±±® «²·¬

• Start/Stop

• Mode change

• Temperature setting

• Change of air flow

• Timer function

• Control by 2 remote controllers is available.

• Check code display

RBC-AX31U(W)-E

RBC-AX31U(WS)-E

(For 4-way Air Discharge Cassette)

RBC-AX22CE2

(For Under Ceiling, 1-way Air Discharge

Cassette SH)

TCB-AX21E2

(For Compact 4-way Cassette,2-way Air

DischargeCassette, 1-wayAir Discharge

Cassette YH, Concealed Duct Standard, Slim

Duct, Floor StandingCabinet, Floor Standing)

ݱ²²»½¬»¼ ¬± ±«¬¼±±® «²·¬ô

·²¼±±® «²·¬

• Individualcontrol up to 16 indoor units.

• Setting of simultaneousON/OFF 3 times for

each day of the week when combined with

schedule timer.

• Connected to 2 remote controllersis available.

SETTIME

TIMERSET

TEST

FIL

TER

RESET

CL

Wired remote

controller

Wired remote controller

(In case of control by 2

remote controllers)

Simple remote controller

Header

Outdoor unit

ON-OFF

controller

Follower

ON-OFF

controller

Indoor

remote controller

-8

4

4

System overview

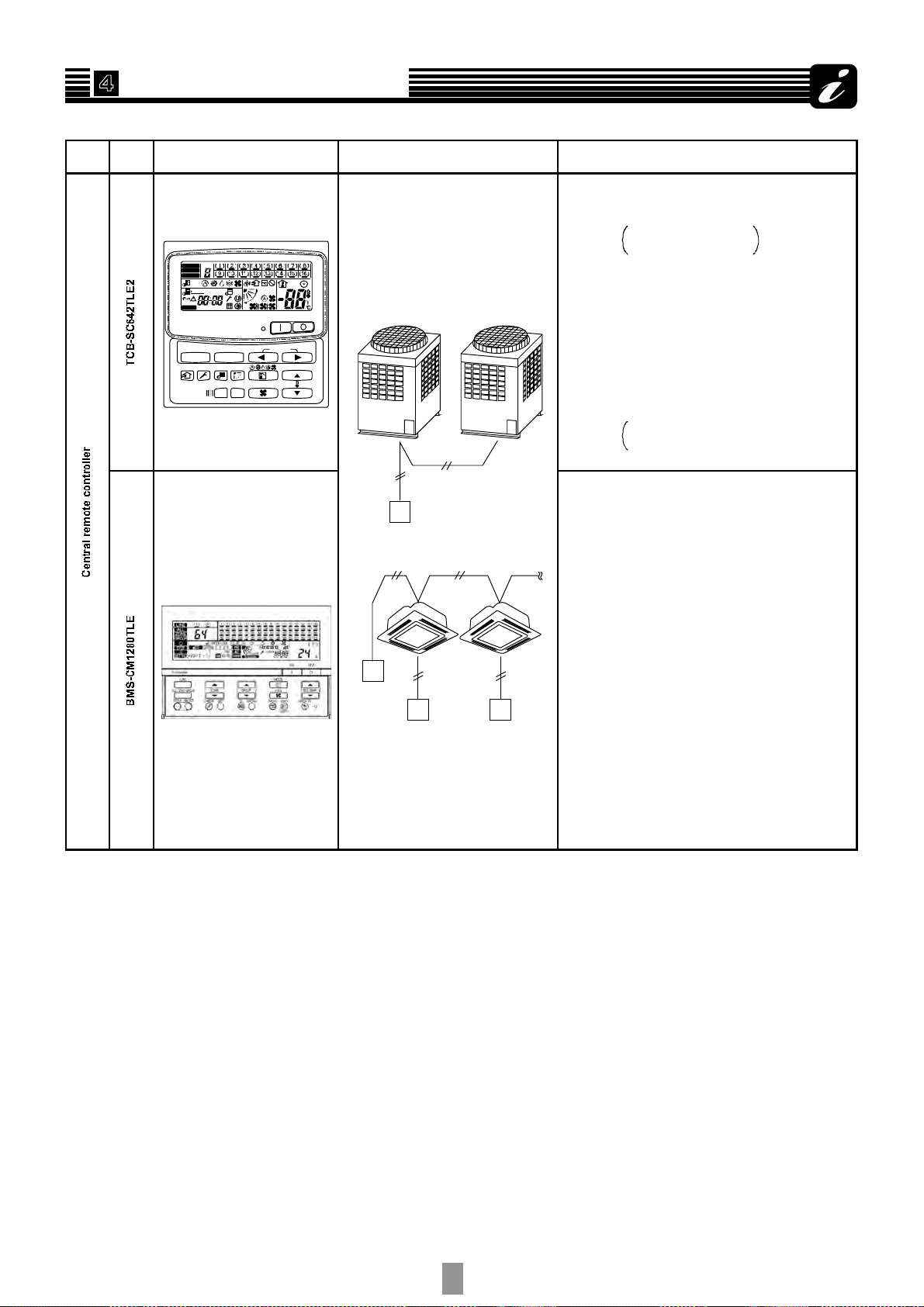

ݱ²²»½¬»¼ ¬± ±«¬¼±±® «²·¬ô

·²¼±±® «²·¬

• Individualcontrol up to 64 indoor units.

• Individualcontrol for max. 64 indoor units

divided into 4 zones.

Up to 16 indoor units

for eachzone

• Up to 16 outdoorheader units are connectable.

• 4 type centralcontrol settingto inhibitindividual

operation by remote controller can be selected.

• Setting for one of 1 to 4 zones is available.

• Can be used with other central control devices

(Up to 10 central control devicesandBMSI/Fin

one control circuit)

• Two selectablecontrol modes

Central controller mode

Remote controller mode

• Operatingwith SheduleTimer TCB-EX21TLE.

• Individualcontrol of up to (64 indoor units) x 2

TCC-LINK buses

• Individualcontrol of up to (64 indoor units

divided 1 to 64 zone) x 2 TCC-LINKbuses (Up

to 64indoor units for each zone)

• Up to 16 outdoorheader units are connectable

per 1 TCC-LINK bus

• 4 types of central control settingsof inhibit

individualoperation by remote controller can be

selected.

• Setting for (one of 1 to 64zones) x 2ch is

available.

• Setting for (one of 1 to 64groups) x 2ch is

available.

• Usable and BMSI/F other central control

devices

(Up to 10 central control devices in one TCC-

LINK bus).

• Two control mode selectively

(contral controller mode)

(Remote controllermode) bySW01 bit6.

• Operatingwith SheduleTimer TCB-EX21TLE.

• Return back setting

Ò¿³»

Ó±¼»´

²¿³»

ß°°»¿® ¿²½» ß°°´·½¿¬·±² Ú«²½¬·±²

SELECT ZONE

CL

SET

GROUP

CODE

No.

UNITNo.

No.

R.C.

TEST

ZONE

ALL

ZONE

GROUP

SETTING

1234

SETDATA

Header

Outdoor unit

Central

remote controller

Central

remote

controller

Indoor

remote controller

Follower

-9

4

4

System overview

ͽ¸»¼«´» ¬·³»® ³±¼»

ͽ¸»¼«´» ¬·³»® ³±¼»

• 6 programmings per day

• Enabling 8 groupsto be programmed

• A maximum of 64 indoor units can be controlled

• A maximum of 100 hours back-uppower supply

É»»µ´§ ¬·³»® ³±¼»

• 7 types of weekly schedule and 3

programmings per day

• Can set ON/OFF by one-minuteinterval

É»µ´§ ¬·³»® ³±¼»

ݱ²²»½¬»¼ ¬± ·²¼±±® «²·¬

• Clock display

• Scheduletimer:

Possible to program scheduletimer (7-day

timer) function

Possible to program 8functions for each day of

the week

* The following items can be set in program:

Operation time, Operation start/stop, Operation

mode, Temperaturesetting, Restrictionon

button operation.

Ò¿³»

Ó±¼»´

²¿³»

ß°°»¿® ¿²½» ß°°´·½¿¬·±² Ú«²½¬·±²

Indoor unit

Central

remote controller

Schedule

timer

TCC-LINK

Outdoor unit

Wired

remote controller

Schedule

timer

Connected to central remote controller or

wired remote controller

Simple remote controller

-1

5

НУУНу· Ь¿¬¿ ¾±±µ

5

Basic system configuration

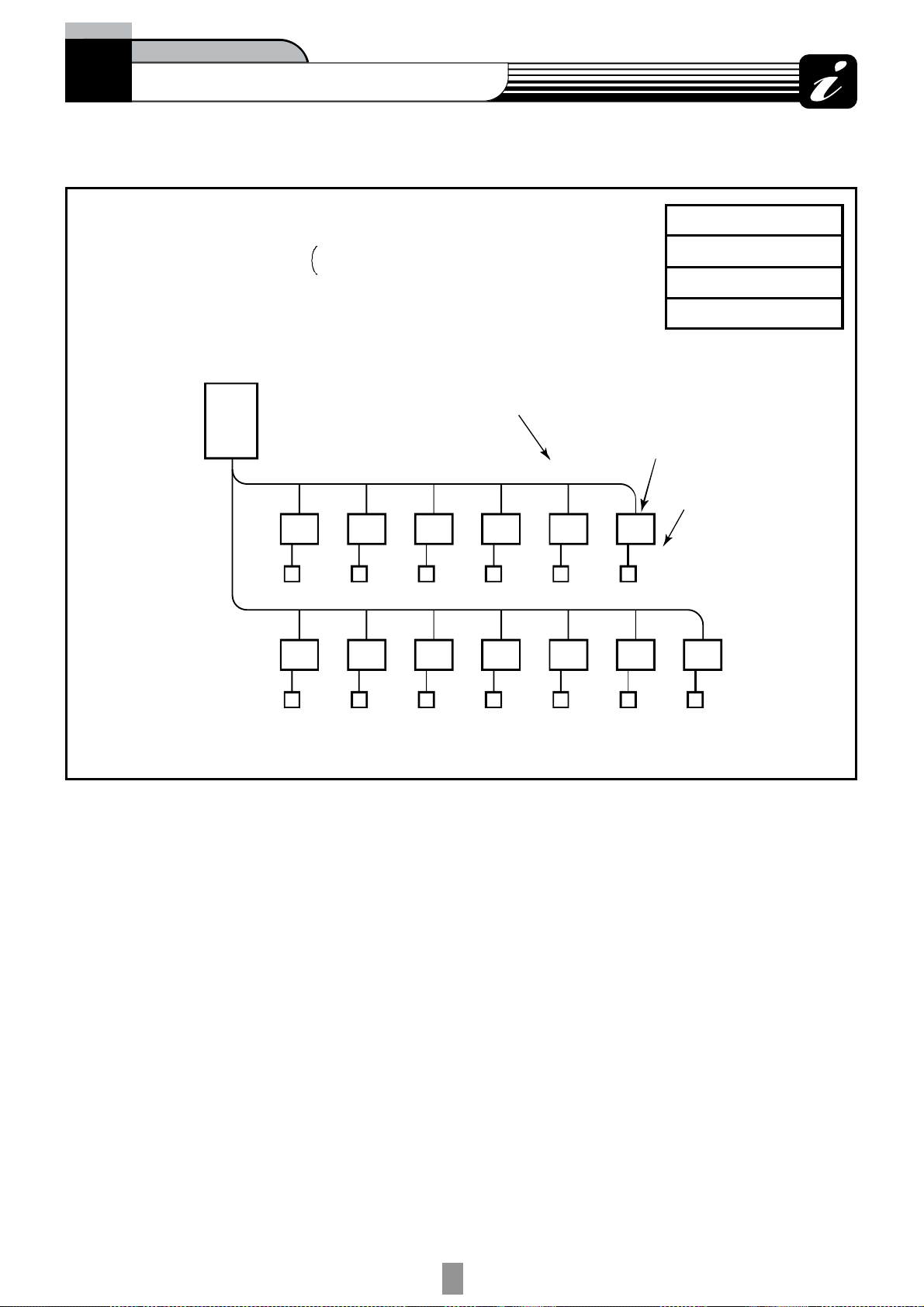

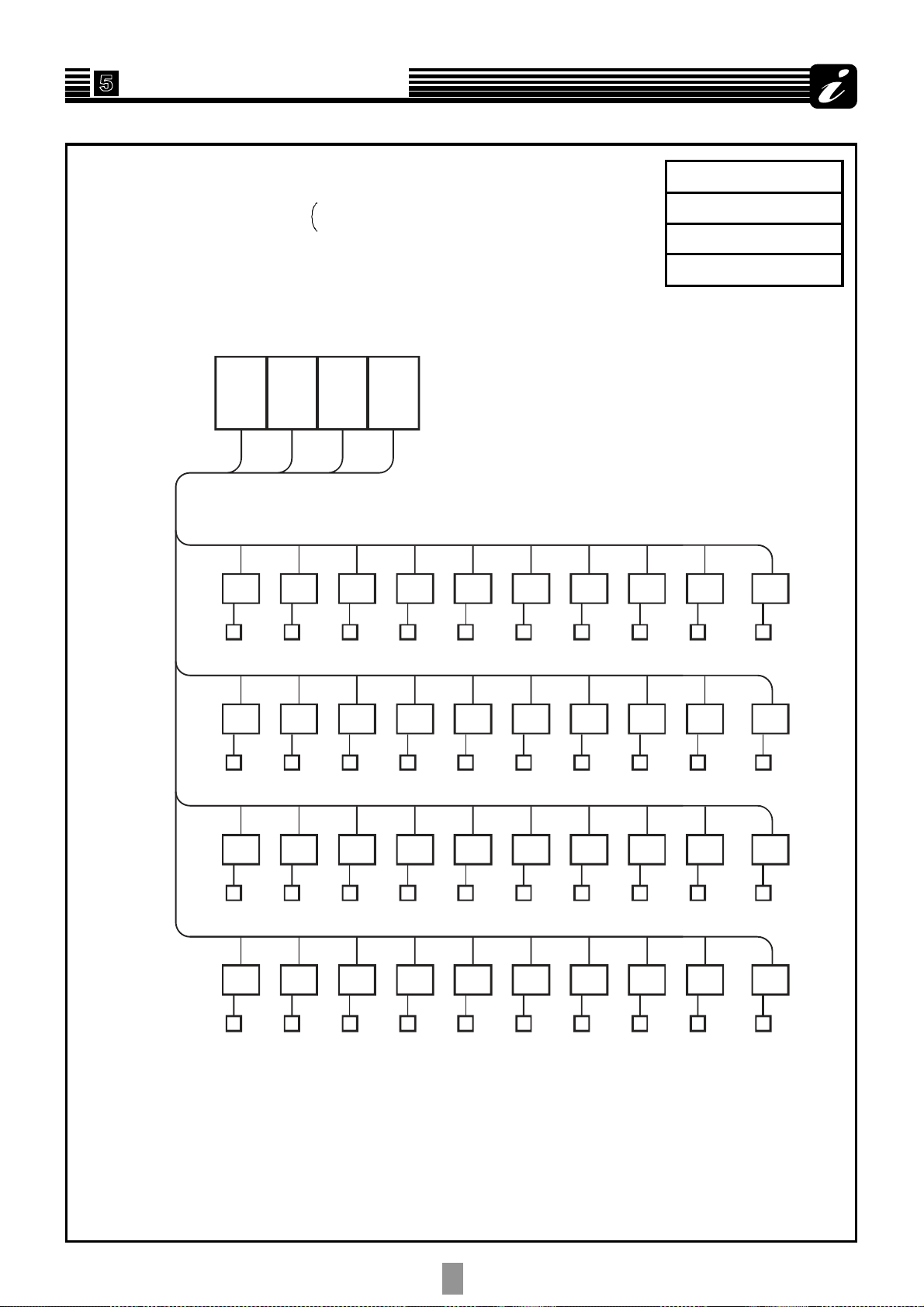

ïò Þ¿-·½ -§-¬»³- ø»¨¿³°´»-÷

007

(0.8)

007

(0.8)

007

(0.8)

007

(0.8)

007

(0.8)

007

(0.8)

007

(0.8)

4.8

10.4

4.0 3.2 2.4 1.6

5.6 4.8 4.0 3.2 2.4 1.6 0.8

007

(0.8)

007

(0.8)

007

(0.8)

007

(0.8)

007

(0.8)

007

(0.8)

èØÐ

è ØÐ -§-¬»³

• Max. indoor unit : 13 units

• Capacity code of indoor unit :

Min. : 4

Max. : 10.8

Capacitycode

Total 10.4

No. of total units

13

Capacity code

over the branch

(0.8 + 0.8 = 1.6)

Indoor unit

designation

Capacity

Code

Indoor unit

Remote

controller

Outdoor unit

-2

5

5

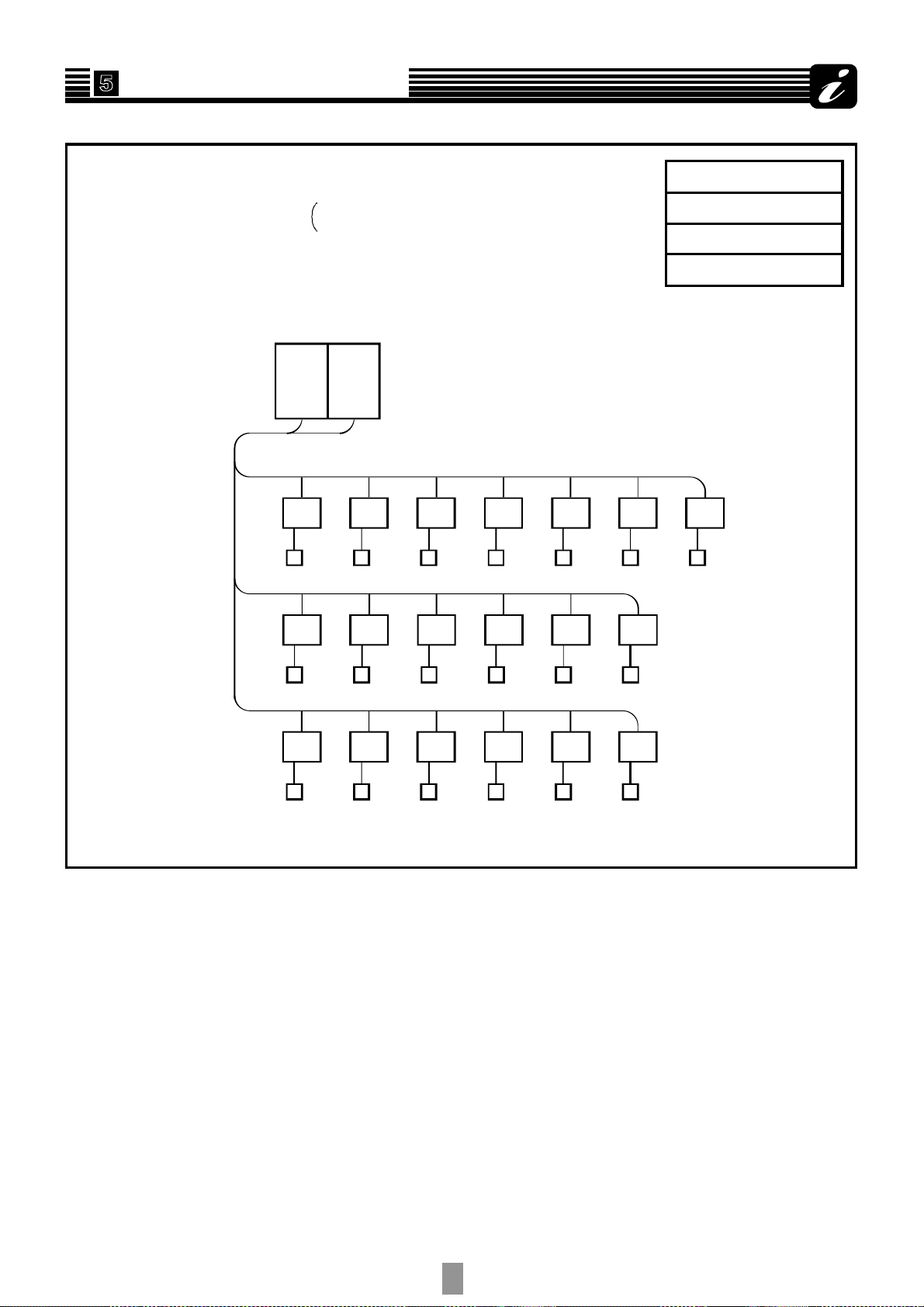

Basic system configuration

16.5

26.75

10.25 8.25

10

6.25 5.0 3.75 2.5

8.25 6.25 5.0 3.75 2.5

8.25 6.25 5.0 3.75 2.5

018

(2.0)

018

(2.0)

012

(1.25)

012

(1.25)

012

(1.25)

012

(1.25)

012

(1.25)

018

(2.0)

012

(1.25)

012

(1.25)

012

(1.25)

012

(1.25)

012

(1.25)

018

(2.0)

012

(1.25)

012

(1.25)

012

(1.25)

012

(1.25)

012

(1.25)

ïðØÐ

ïðØÐ

îð ØÐ -§-¬»³

• Max. indoor unit : 33 units

• Capacity code of indoor unit :

Min. : 10

Max. : 27

Capacitycode

Total 26.75

No. of total units

19

Indoor unit

Remote

controller

Outdoor unit

-3

5

5

Basic system configuration

26.5

39.75

53.75

14.0 13.0 12.0 11.0 9.75 8.5 6.5

009

(1)

009

(1)

009

(1)

012

(1.25)

012

(1.25)

018

(2.0)

024

(2.5)

036

(4)

13.25 12.25 11.25 10.25 9.0 7.75 6.5

009

(1)

009

(1)

009

(1)

012

(1.25)

012

(1.25)

012

(1.25)

024

(2.5)

036

(4)

13.25 12.25 11.25 10.25 9.0 7.75 6.5

13.25 12.25 11.25 10.25 9.0 7.75 6.5

009

(1)

009

(1)

009

(1)

012

(1.25)

012

(1.25)

012

(1.25)

024

(2.5)

036

(4)

009

(1)

009

(1)

009

(1)

012

(1.25)

012

(1.25)

012

(1.25)

024

(2.5)

036

(4)

ïêØÐ ïîØÐ ïîØÐ

16284

0

ìð ØÐ -§-¬»³ øͬ¿²¼¿®¼ ³±¼»´÷

• Max. indoor unit : 48 units

• Capacity code of indoor unit :

Min. : 20

Max. : 54

Capacitycode

Total 53.75

No. of total units

32

Indoor unit

Remote

controller

Outdoor unit

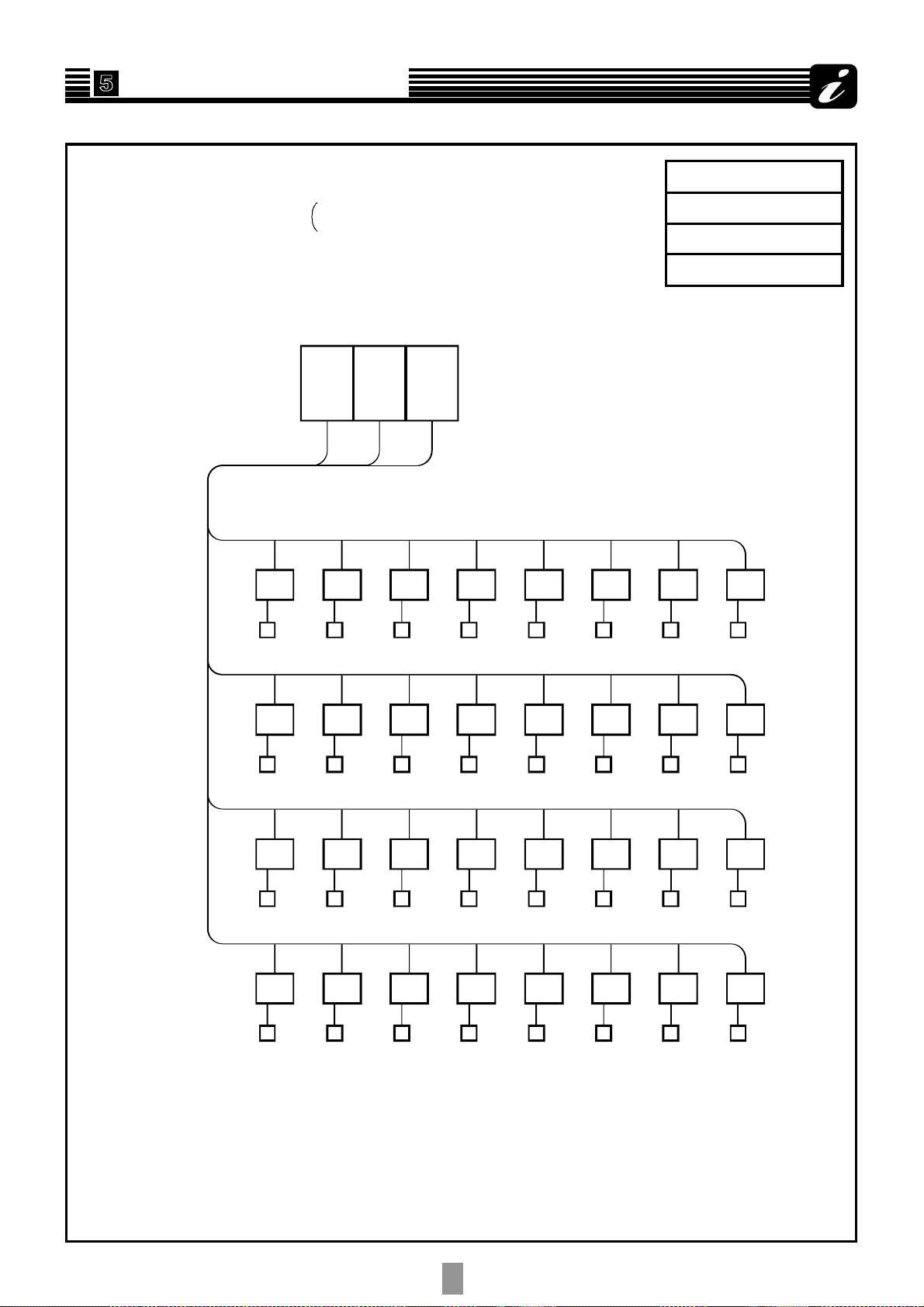

-4

5

5

Basic system configuration

29.05

45.35

61.9

16.55 15.75 14.5 13.25 12.25 11.25 9.25

007

(0.8)

012

(1.25)

012

(1.25)

009

(1.0)

009

(1.0)

018

(2)

7.25 5.25

018

(2)

018

(2)

012

(1.25)

036

(4)

16.3 15.5 14.25 13.25 12.25 11.25 9.25

007

(0.8)

012

(1.25)

009

(1.0)

009

(1.0)

009

(1.0)

018

(2.0)

7.25 5.25

018

(2.0)

012

(1.25)

018

(2.0)

036

(4)

14.3 13.5 12.25 11.25 10.25 9.25 7.25

14.75 13.5 12.25 11.25 10.25 9.25 7.25

007

(0.8)

012

(1.25)

009

(1.0)

009

(1.0)

009

(1.0)

018

(2.0)

5.25

018

(2.0)

018

(2.0)

012

(1.25)

012

(1.25)

009

(1.0)

009

(1.0)

009

(1.0)

018

(2.0)

5.25

018

(2.0)

018

(2.0)

3.25

012

(1.25)

018

(2.0)

3.25

012

(1.25)

018

(2.0)

ïîØÐ ïîØÐ ïîØÐ

ïîØÐ

12243

6

ìèØÐ -§-¬»³- øØ·¹¸

»ºº·½·»²½§ ³±¼»´÷

• Max. indoor unit : 48 units

• Capacity code of indoor unit :

Min.: 24

Max.: 64.8

Capacitycode

Total 61.9

No. of total units

40

Indoor unit

Remote

controller

Outdoor unit

-5

5

5

Basic system configuration

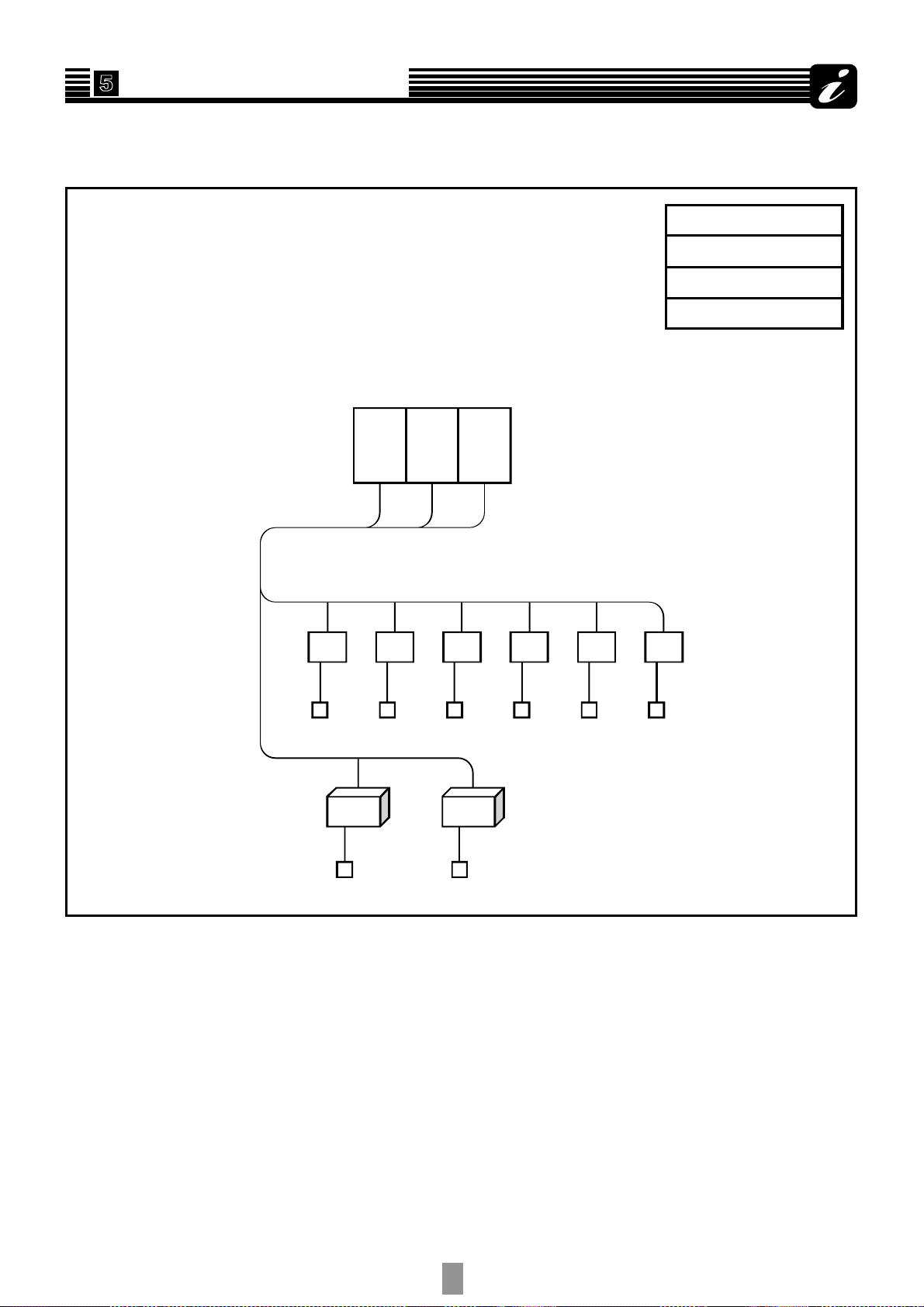

îò Ú®»-¸ ß·® ײ¬¿µ» ײ¼±±® ˲·¬ ̧°»

34

24 20 16 12 8

036

(4)

036

(4)

036

(4)

036

(4)

036

(4)

036

(4)10(5)

(5)

ïîØÐ ïîØÐ ïðØÐ

024

024

íì ØÐ -§-¬»³

Connecting limitation

• The total capacity of the fresh air intake un

its andthe indoor units is restricted to 80

to 100% against the capacity of the outdoorunits.

• Up to two fresh air intake units can be

connected on one line of the multi system.

• The allowable total capacity of fresh air intake units shall be 30% or less against

the total capacity of the indoor units

(including the fresh air intake units).

• The fresh air intake units only cannot connected.

Capacitycode

Total 34

No. of total units

8

Fresh Air Intake Indoor unit

Indoor unit

Remote

controller

Outdoor unit

Remote

controller

-1

6

НУУНу· Ь¿¬¿ ¾±±µ

6

Equipment selection procedure

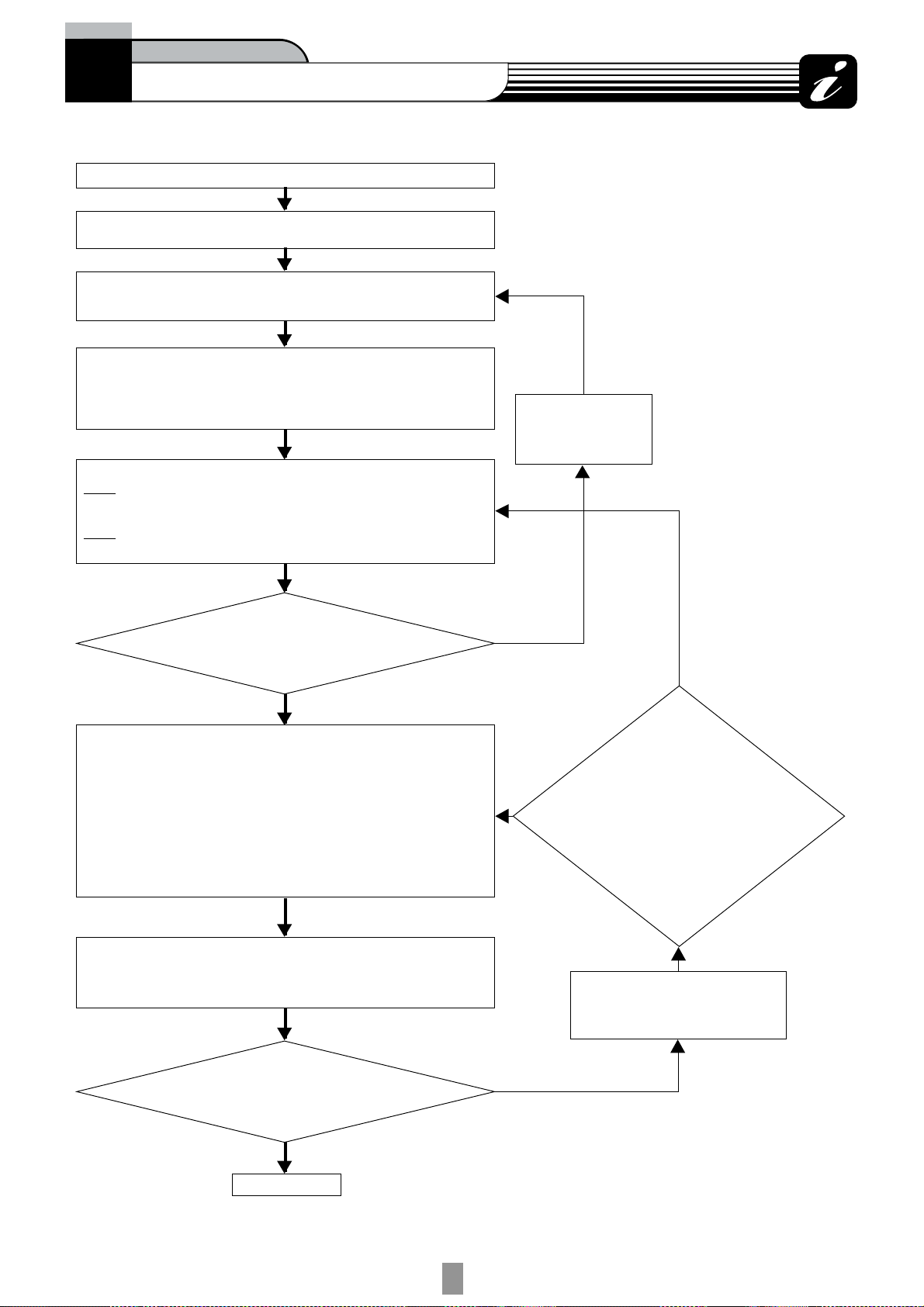

ïò Í»´»½¬·±² º´±© ½¸¿®¬

1

Determination of indoor air-conditioningload at eachroom.

2

Preliminary selection of indoor unitsin the standard capacity no less

than air-conditioning load at each room.

3

Calculate corrected capacityAof each indoor unitby correcting of

indoor temperature for the standard capacityof each indoorunit.(Refer

to Chart [1])

4

Preliminary selection of outdoor unit in the standard capacity no less

than total values of correctedcapacityA in indoor units. At the same time,

checkboth connectable indoor units numberand the outdoor unit

diversity(Connectedratio of indoor units to outdoor units) for the

specifications.

5

Calculate corrected capacityB of each indoor unit by following 2 steps.

Step1:Find the correction value of "Connecting pipe lengthand lift" by

both the longest length and the largest height with selectedpiping

condition at

4or4

'.(Refer to Chatrt [3])

Step2:Calculatecapacity B by multiplying the valueof step1 by corrected

capacityA.

6

Corrected capacity B of indoor

unit>= air-conditioningload (for All

rooms)

9

Corrected capacity C of indoor

unit>= air-conditioningload (for All

rooms)

7

Find correction values of below items for the standard capacity of

outdoorunit selected at

4or4

'.

Then determination of total corrected capacityof the selectedoutdoor unit

by all multiplying.

-Correction of indoortemperature condition(Referto Chart [1])

-Correction of outdoor temperature condition(Refer to Chart [2])

-Correction of connecting pipe length and lift between indoor andoutdoor

units by both the longest length and thelargest height (Refer to Chart [3])

-Correction of outdoor unit diversityin only over 100%(Referto Chart [4])

-Correction of frost conditionon outdoor heat exchanger when in heating

(Refer to Chart [5])

8

Calculate corrected capacityC of each indoor unit by multiplyingthe

total correctedcapacity of outdoor unit at

7

by proportional divisionof

each indoor unit standard capacity for total standard capacity of all indoor

units.

end5' Increase of outdoorunit capacity.

At the same time, check both

connectable indoor units number

and the outdoor unit diversity

5

' <Only cooling>

The correctioncharacteristic

of "connecting pipe length and

lift"(Graph [3]) between

increasedoutdoor unit at ?'

and preliminary selected

outdoorunit at ? is different.

(The both graphs are

different.)

2

' Increase of indoor

unitcapacity at object

room against air-

conditioning load

NGNGNOOKOK

YES

-2

6

6

Equipment selection procedure

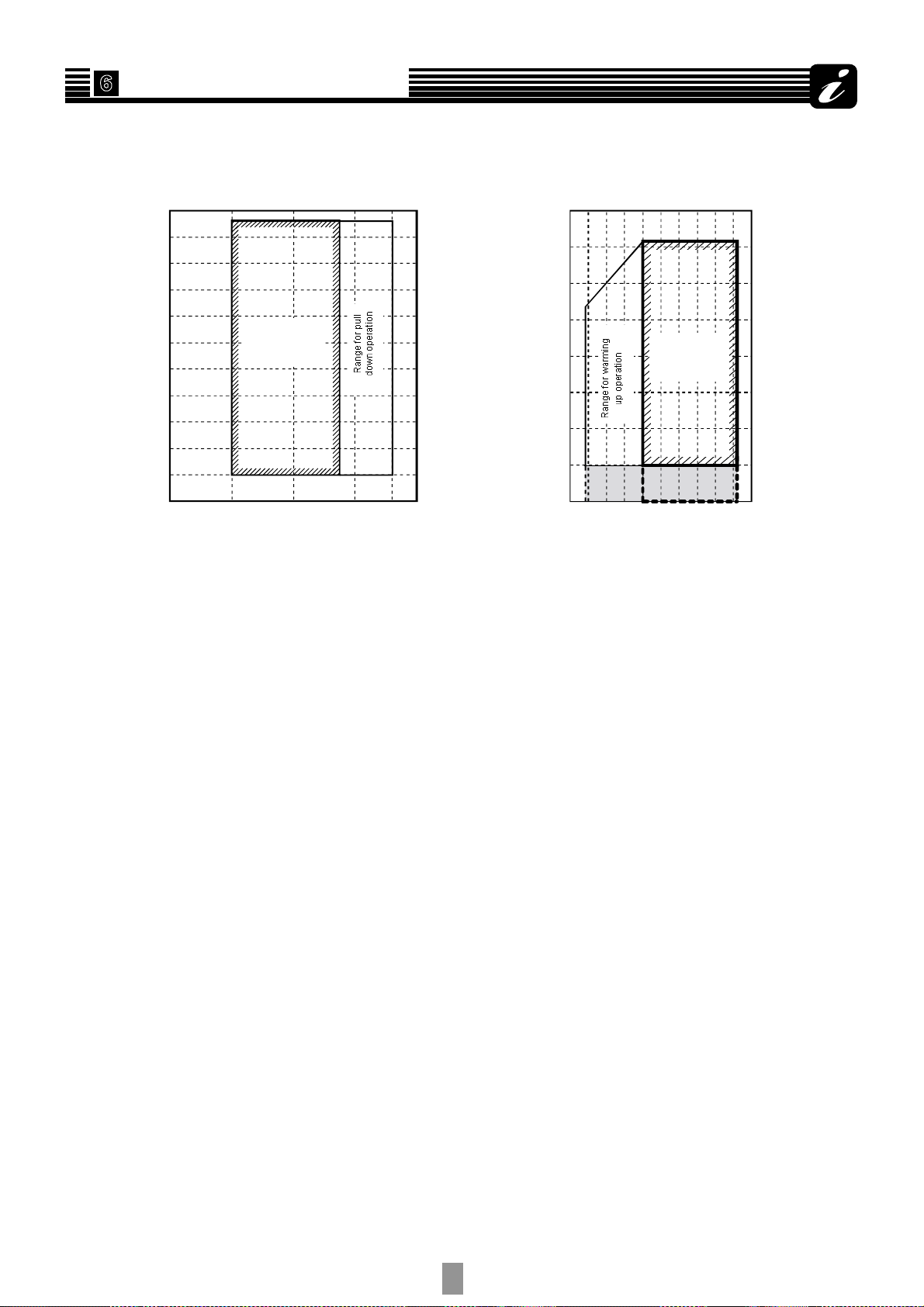

îò Ñ°»®¿¬·±²¿´ ¬»³°»®¿¬«®» ®¿²¹»

30

25 28

201510-10-5051015202530354045-20-15-10-5051015205 10 15 20 25 30

Ø»¿¬·²¹

ݱ±´·²¹

Outdoor air dry bulb temp. (°C)

Indoorairwet bulb temp.(°C)

Outdoorair wet bulbtemp. (°C)

Indoorair dry bulb temp.(°C)

Continuously

operable

range

Continuously

operable

range

The unit will operatedown to an outdoor

temperature of -20°C,however

considerable performance decrease will

be expected below -15°C.

Therefore please consider installation

location/surroundings and system design

when expected to operatebetween-15°C

and -20°C.

-3

6

6

Equipment selection procedure

íò ݱ³¾·²¿¬·±² ½±²¼·¬·±²- º±®

·²¼±±® «²·¬ ¿²¼ ±«¬¼±±® «²·¬

1. For indoor unit, the capacity code is decided for each capacity rank.

ТСМЫж

Capacity rank: Correspondence to Btu/h. Capacity code: Correspondenceto Horsepower.

2. For outdoor unit, maximum No. of connectable indoor units and total capacity code of indoor units are decided.

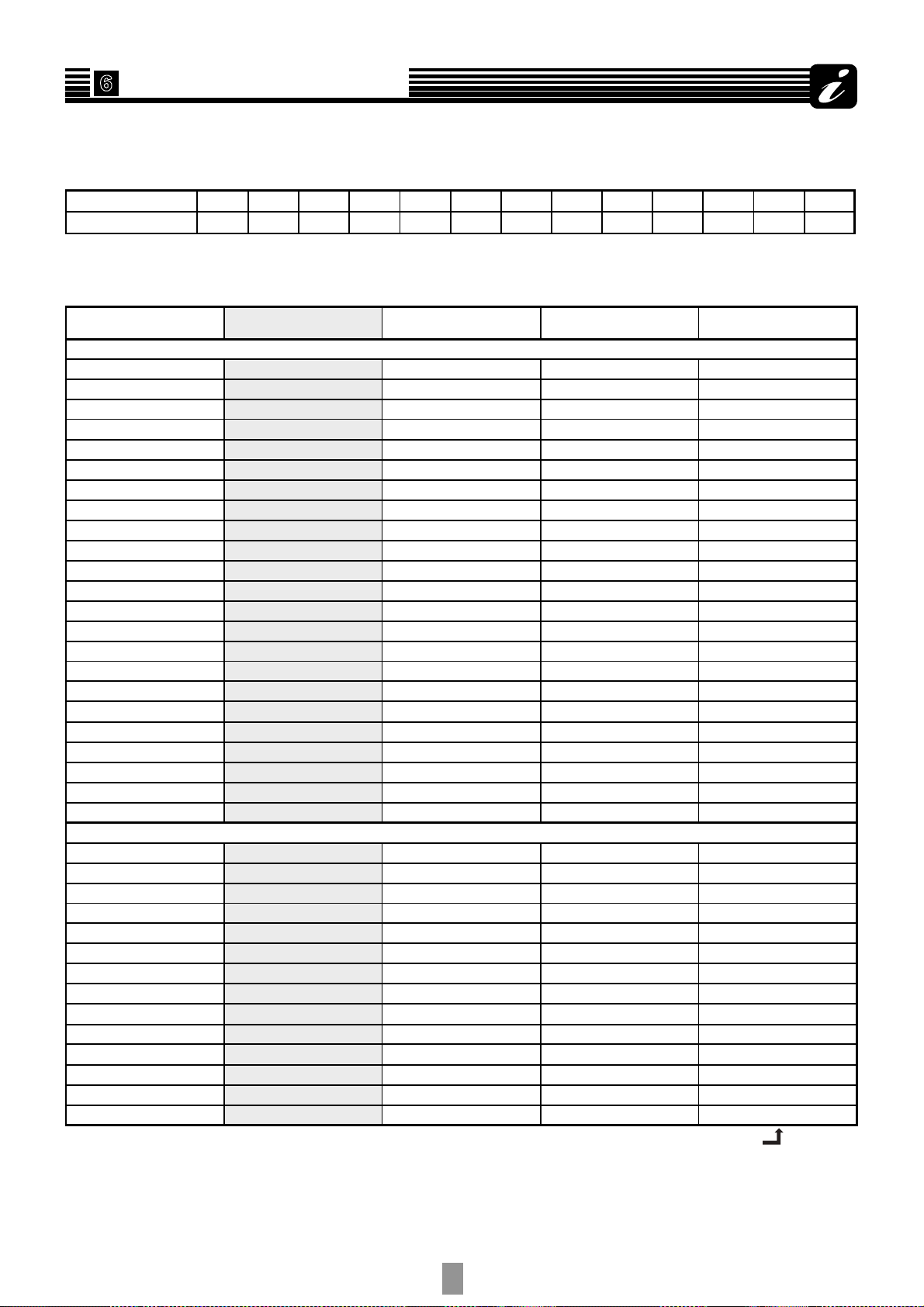

Ý¿°¿½·¬§ ®¿²µ ¬§°» ððé ððç ðïî ðïë ðïè ðîì ðîé ðíð ðíê ðìè ðëê ðéî ðçê

Ý¿°¿½·¬§ ½±¼»

0.8 1 1.25 1.7 2 2.5 3 3.2 4 5 6 8 10

Ñ«¬¼±±® «²·¬ øØ»¿¬ °«³°÷

Ñ«¬¼±±® «²·¬ øݱ± ´·²¹ ±²´§÷ Ý¿°¿½·¬§ ½±¼ » ±º ±«¬¼±±® «²·¬ Ó¿¨ò Ò±ò ±º ·²¼±±® «²·¬-

̱¬¿´ ½¿°¿½·¬§ ½±¼» ±º

·²¼±±® «²·¬-

ͬ¿²¼¿®¼ ³±¼ »´

MMY-MAP0501HT8-E*

MMY-MAP0501T8-E*

582.5 to 6.75

MMY-MAP0601HT8-E*

MMY-MAP0601T8-E*

6103 to 8.1

MMY-MAP0804HT8-E

MMY-MAP0804T8-E

8134 to 10.8

MMY-MAP1004HT8-E

MMY-MAP1004T8-E

10165 to 13.5

MMY-MAP1204HT8-E

MMY-MAP1204T8-E

12206 to 16.2

MMY-MAP1404HT8-E

MMY-MAP1404T8-E

14237 to 18.9

MMY-MAP1604HT8-E

MMY-MAP1604T8-E

16278 to 21.6

MMY-AP1814HT8-E

MMY-AP1814T8-E

18309 to 24.3

MMY-AP2014HT8-E

MMY-AP2014T8-E

203310 to 27

MMY-AP2214HT8-E

MMY-AP2214T8-E

223711 to 29.7

MMY-AP2414HT8-E

MMY-AP2414T8-E

244012 to 32.4

MMY-AP2614HT8-E

MMY-AP2614T8-E

264313 to 35.1

MMY-AP2814HT8-E

MMY-AP2814T8-E

284714 to 37.8

MMY-AP3014HT8-E

MMY-AP3014T8-E

304815 to 40.5

MMY-AP3214HT8-E

MMY-AP3214T8-E

324816 to 43.2

MMY-AP3414HT8-E

MMY-AP3414T8-E

344817 to 45.9

MMY-AP3614HT8-E

MMY-AP3614T8-E

364818 to 48.6

MMY-AP3814HT8-E

MMY-AP3814T8-E

384819 to 51.3

MMY-AP4014HT8-E

MMY-AP4014T8-E

404820 to 54

MMY-AP4214HT8-E

MMY-AP4214T8-E

424821 to 56.7

MMY-AP4414HT8-E

MMY-AP4414T8-E

444822 to 59.4

MMY-AP4614HT8-E

MMY-AP4614T8-E

464823 to 62.1

MMY-AP4814HT8-E

MMY-AP4814T8-E

484824 to 64.8

Ø·¹¸ » ºº·½·»²½§ ³±¼»´

MMY-AP1624HT8-E

MMY-AP1624T8-E

16278 to 21.6

MMY-AP2424HT8-E

MMY-AP2424T8-E

244012 to 32.4

MMY-AP2624HT8-E

MMY-AP2624T8-E

264313 to 35.1

MMY-AP2824HT8-E

MMY-AP2824T8-E

284714 to 37.8

MMY-AP3024HT8-E

MMY-AP3024T8-E

304815 to 40.5

MMY-AP3224HT8-E

MMY-AP3224T8-E

324816 to 43.2

MMY-AP3424HT8-E

MMY-AP3424T8-E

344817 to 45.9

MMY-AP3624HT8-E

MMY-AP3624T8-E

364818 to 48.6

MMY-AP3824HT8-E

MMY-AP3824T8-E

384819 to 51.3

MMY-AP4024HT8-E

MMY-AP4024T8-E

404820 to 54

MMY-AP4224HT8-E

MMY-AP4224T8-E

424821 to 56.7

MMY-AP4424HT8-E

MMY-AP4424T8-E

444822 to 59.4

MMY-AP4624HT8-E

MMY-AP4624T8-E

464823 to 62.1

MMY-AP4824HT8-E

MMY-AP4824T8-E

484824 to 64.8

* : SMMS

50 to 135% of outdoor unit capacity

-4

6

6

Equipment selection procedure

ìò ݱ±´·²¹ñ¸»¿¬·²¹ ½¿

°¿½·¬§ ½¸¿®¿½¬»®·-¬·½-

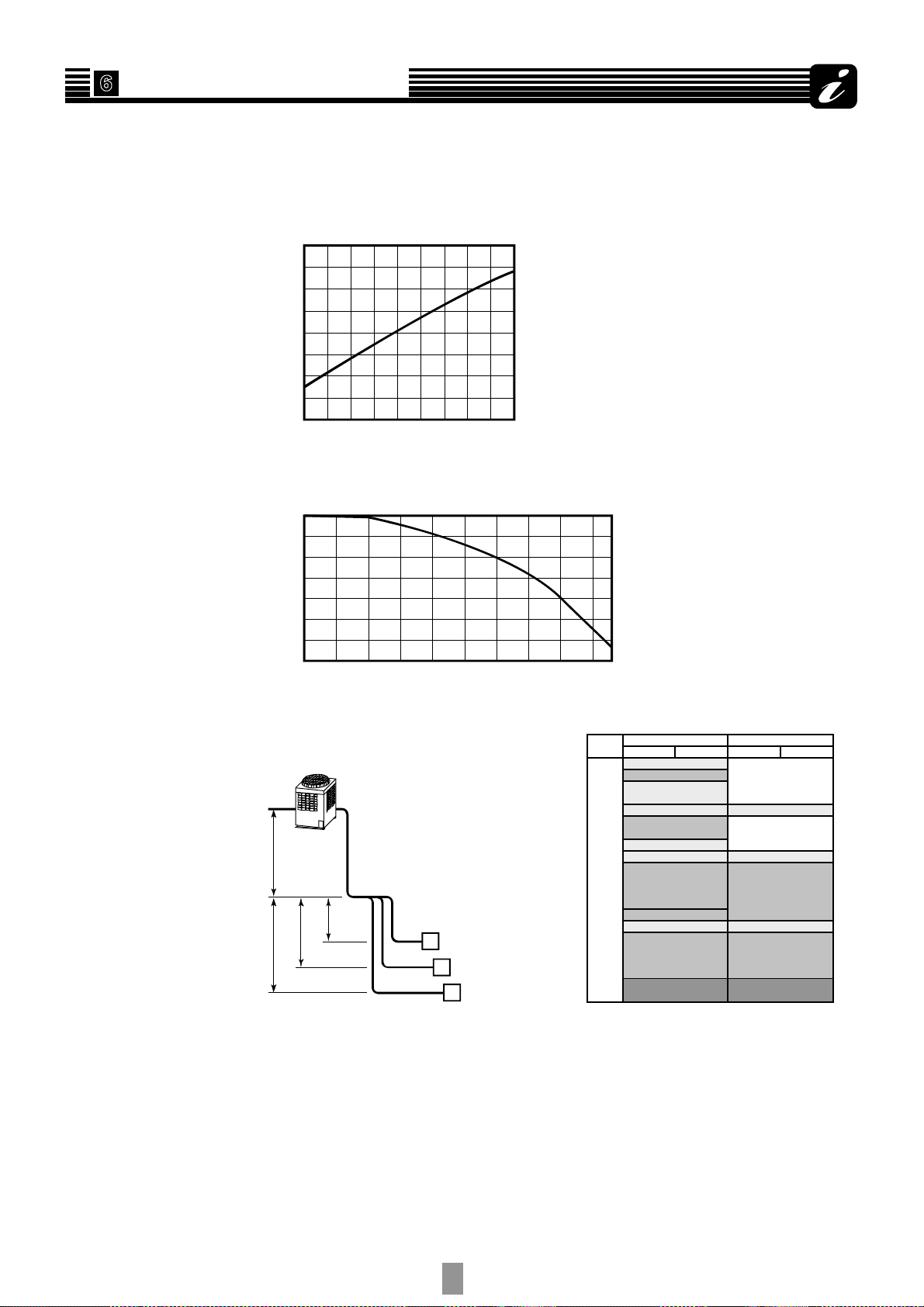

ïò ݱ®®»½¬·±² ½¸¿®¬- º±® ½±±´·²¹ ½¿°¿½·¬§ ½¿´½«´¿¬·±²

[1] Indoor air wet bulb temperatur

e vs. capacity correction value

t

[2] Outdoor air dry bulb temperature vs.capacity correction value

[3] Connectingpipe length and lift difference between indoor

and outdoorunits vs.capacity correction value

15

1.2

1.1

1.0

0.9

0.8

20 24

Capacity correction value

Indoor air wet bulb temp. (°C)

-10-

5 10

0 15 20 25 30 35 40 43

1.2

1.1

1.0

0.9

Capacity correction value

Outdoor air dry bulb temp. (°C)

Outdoor unit

Indoor unit

L' is the longest one of

(l'o + l'a, l'o + l'b, l'o + l'c)

H = ho +

(Largest one of ha, hb, and hc)

Ahahbhcho l'o

l'a

l'b

l'cBC

HP

Standard model High efficiency model

Pipe length Graph Pipe length Graph

8

210A110

210B112

210A114

210A116

210A1220A218

220B220

220B222

220A224

220A2235A326

220B2235B328

220B2235B330

220B2235B332

220B2235B334

235B3235B336

235A3235A338

235B3235B340

235B3235B342

235B3235B344

235B3235B346

185C1185C148

185C1185

C1

-5

6

6

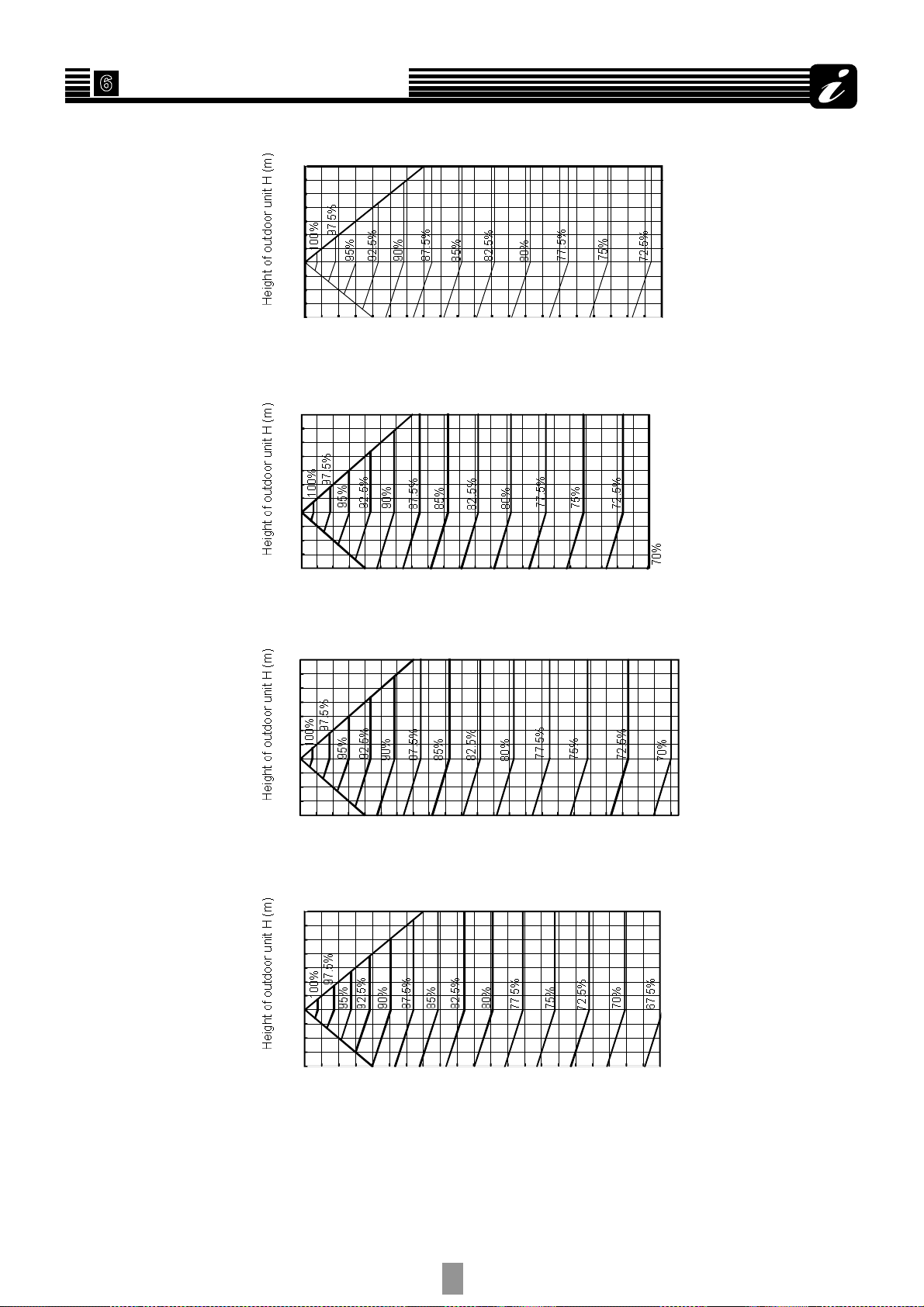

Equipment selection procedure

-40

-30

-20

-10010203040506070

20 30 40 50 60 70 80 90

100110120130140 150160170 180190200210

10

0

Pipe length(Equivalent length) L’(m)

Outdoor unit (A1)

-40

-30

-20

-10010203040506070

20 30 40 50 60 70 80 90

100 110 120

130 140 150160 170 180190 200 210 220

10

0

Pipelength (Equivalent length) L’(m)

Outdoor unit (A2)

20 30 40 50 60 70 80 90

100 110 120

130 140 150160 170 180190 200 210 220 230

10

0

-40

-30

-20

-10010203040506070

Pipe length(Equivalent length) L’(m)

Outdoor unit (A3)

-40

-30

-20

-10010203040506070

20 30 40 50 60 70 80 90

100110120130140 150160170 180190200210

10

0

Pipelength (Equivalent length) L’(m)

Outdoor unit (B1)

Loading...

Loading...