Page 1

Engineering

Super-MMS

Data Book

Super Modular Multi System

Page 2

1

Foreword

The engineering data book details all relevant data, charts

and drawings to enable you to get the best performance

from the Toshiba Super Modular Multi System for the

various applications.

The information is aimed to assist you by providing greater

detail of the system and the wider applications that the

Foreword

1

system will cover.

It is recommended the use of the data book is used in

accordance with the following as references.

Design manual : File No.A03-008

Installation manual : File No.A03-012

Service manual : File No.A03-009

1

Page 3

2

Contents

Foreword

2

1 Foreword

2 Contents

3 Introduction

4 System overview

..................................................................

...................................................................

..............................................................

.........................................................

5 Capacity compensation chart

6 Piping requirements

7 Refrigerant cycle diagram

8 Sensible capacity table

9 Part load performance

10 Wiring guideline

11 Wiring diagram

..........................................................

...................................................

..........................................

..............................................

...............................................

........................................................

.....................................

1

2

5

9

21

29

35

45

71

85

95

A. Connection schematic (field wiring)

B. Inner circuit

12 Controls

13 Fan characteristics

A. Static pressure

B. Air velocity profile (Air throw distance chart)

...................................................................

..................................................

14 Sound characteristics (NC curve)

15 Dimensional drawing

A. Indoor units

B. Outdoor units

16 Specifications

1. 50Hz models

2. 60Hz models

..........................................................

...............................................

.............................

111

133

143

163

189

Appendix

High Wall Type (2 series)

1-Way Air Discharge Cassette Type (2 series)

Slim Duct Type

2

Page 4

3

Introduction

3

Page 5

4

Page 6

3

Introduction

Foreword

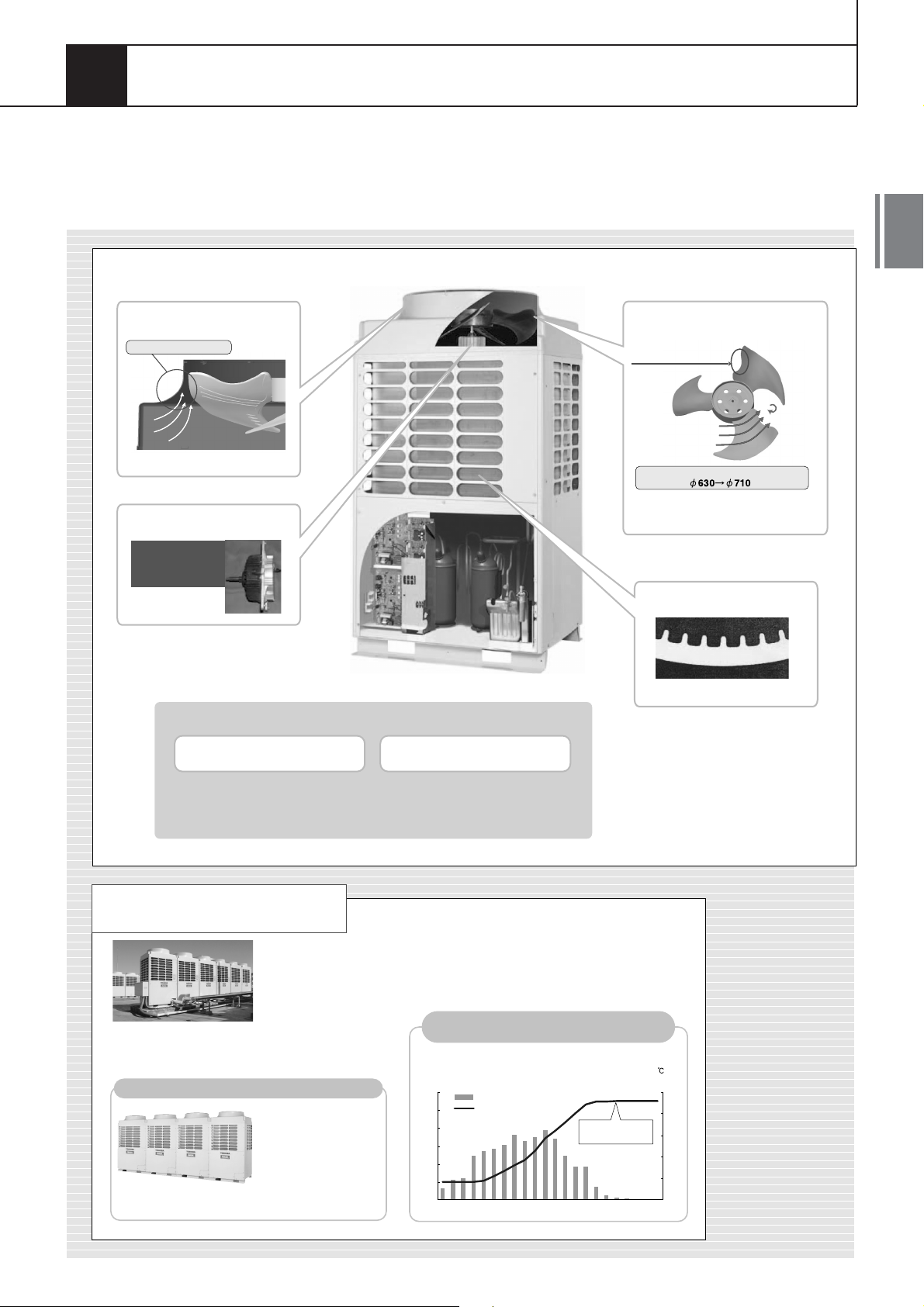

World,s Best Technology for Energy Saving System

Toshiba

comfort.

High performance new bell mouth

Enlarged suction R allows smoother flow.

has attained

(Smooth bell mouth)

Enlarged suction R

High efficiency DC fan motor

High output/

high efficiency

DC motor

+ Output 600W

+ Sine wave drive

the pinnacle of world technology in all aspects of efficiency, durability, and

New large diameter propeller fan

(Flash wing fan)

Reversed circular blade

Enlarged fan diameter

The reversed circular form reduces the

interference of the flow between the blades,

and the backward vortex.

High efficiency heat transfer pipe

R410A

3

AI dual inverter system

High speed calculation vector

control inverter

World,s first core technology: each module (singular outdoor unit) is installed with two (dual)

DC twin rotary compressors that work effectively with the highly efficient refrigerant R410A.

The system operates in the most optimum pattern for both energy saving and reliability.

-Installation Work:

Less Piping Material and Higher Efficiency

Smaller piping diameters than ever before.

This is due to the all inverter type dual compressors,

Automatic configuration of outdoor unit.

Improved reliability with identical casing

Each outdoor unit (1 module)

is of the same size and

design. Therefore the basic

installation work will be

identical.

The unit has been designed

for your convenience, so it is

possible to fit the unit

comfortably into a standard

size elevator.

* All our compressors are inverter type

High efficiency DC twin rotary

compressor

Cost Saving of Piping Material

Less piping work

Efficient Installation Work

Automatic low-noise mode, only possible where

dual inverter type compressors are used.

Froom the weather data of the Japanese Mechanical and

Electrical Engineers building in the year 2000.

Tokyo (8:00 21:00) remote control temperature setting at 27

Time generated(Hours/year)

300

250

200

150

100

50

Time generated

Outdoor unit noise

20 30 38352517

Outside temperature(

Outside noise(dB)

Automatic

low noise mode

Configuration of heat transfer pipe

60

55

50

45

40

35

o

)

C

Numbers used are expected numbers.

5

Page 7

3

High efficiency DC twin rotary compressor

DC twin rotary compressors are most congenial with R410A and are used within

the outdoor units. (Conversion to all inverter type)

DC

fan motor

COP

Super-MMS (410A)

10HP System 3.80

20HP System 3.55

Leading the world with high efficiency and high COP

in both 1:1 system and VRF system.

*1

DC twin rotary compressor installed on all the outdoor

units for combined use!(Conversion to all inverter type)

Active oil control

Oil control is the key to the reliability.

Top

Top

Outlet

disk

compressor

unit

Bottom

oil

Compression structure by the rotation of the rollers inside

the fixed cylinder allows the easy supply of oil to the

swaying surface. The compressing rollers move in the

same direction as the rotary shaft. This creates a force in

the direction of compression even at high compression.

Thus high efficiency and reliability are attained.

Weight

(Compared with the conventional unit)

Volume

(Compared with the conventional unit)

Congenial with high

pressure refrigerant R410A

Range of rotation

Compressor efficiency

Oil discharge

(ratio)

Large space

motor

roller

oil flow

67%

61%

Force on the vertical shaft

(roller) is small.

15-120rps

See diagram on

the right

1/40

(of the conventional unit)

High-speed

Calculation Vector

Control Inverter

Comparison of compressor efficiencies

This difference is

the energy saving

Twin rotary

Scroll

Total compressor efficiency (%)

20 40 60 80 100

Rotation(rps)

Therefore, all the compressor units can operate equally.

e.g. in case of a workload

of 2 compressor units;

Master/Follower

Part load COP

Compressor start

Super MMS

ON ON

OFF

ON

1 2

INV

INV

Comp

Comp

Comp

No Need

Higher COP

Equal start chance

INV

ON

3 4

OFF

INV

Comp

As both heat exchangers on the

2 outdoor units are usable,

higher energy-saving

(higher efficiency) can be achieved.

The sequence of the first

compressors start up, changes

whenever switching on.

4

3

1

today

tomorrow

the day

after

tomorrow

3

4

2

2

1

3

Super-MMS (8HP)

4.10

*1

high-level

-Design Work:

Flexible to meet the sophisticated condition of

buildings or various customer requirements

The longest piping in the industry enabling

a flexible floor design.

2)Height Difference - Upper Outdoor Unit

- Lower Outdoor Unit

3)Max Indoors Difference

50m

30m

Super MMS

Super MMS enable flexible branching.

You may change branching at installation sites.

"Header branch after Y joint"

according to original plan, but ....

High level, Energy saving VRF System

Super MMS will offer the best solution for the

customers requirements as well as consideration of

ecology, with the unique technologies and advantages.

2

1

4

1) Max Equivalent Length

(Max Actual Length 150m)

1) 2) 3) 4)

Max

Equivalent

Length

175m 150m 50m 40m 30m 65m 300m 48units

Y joint

Header branch

175m

8 storey building can be

4)Max from 1st Branch

covered by one piping system.

65m

Height Difference

Max

Actual

Upper

Length

Lower

Outdoor Unit

Outdoor Unit

Super MMS can quickly satisfy such

a requirement as addition of extra

indoor unit(s)...

Easy "Y joint branch after header

branch" solution in this example.

TOSHIBA

1 Piping

System,

30m

(8 floors)

Max

Indoors

Difference

Y joint

Max

from 1st

Branch

Header

branch

Total

Extension

Unique

technology

Y joint

Addition of extra

indoor unit

Max

Connectable

Indoor Units

Through avoiding concentration of the load at an individual unit,

prevention of failure and improvement of reliability are achieved.

6

Page 8

4

System overview

7

Page 9

8

Page 10

4

System overview

Foreword

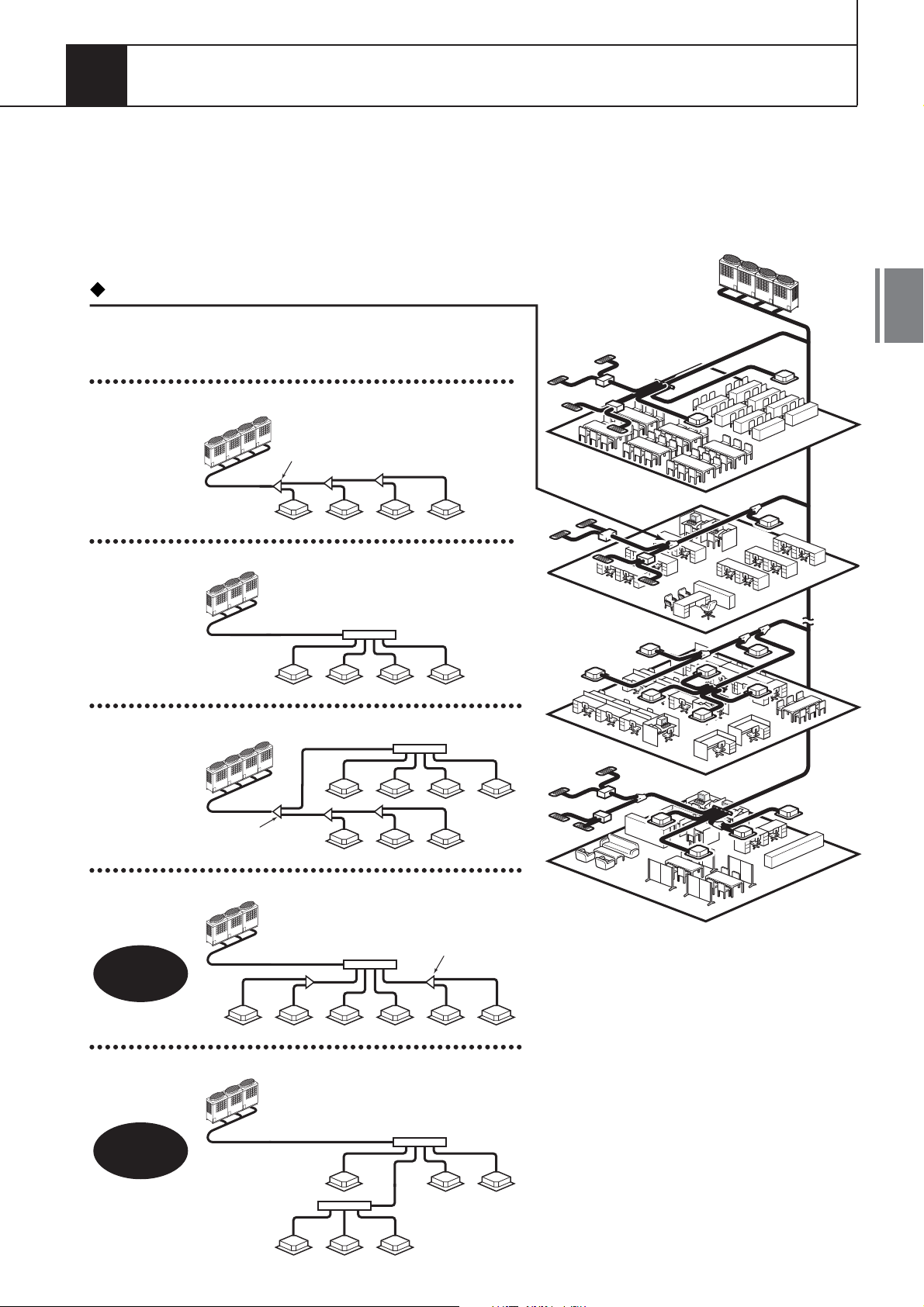

1. OUTLINE OF TOSHIBA SUPER MMS

(Super Modular Multi System)

Shortest route design by free branching

The Combination of line and header branching is highly flexible.

Following the shortest design route possible, thereby saving

on installation time and cost. Line/header branching after the

header branching is only available with TOSHIBA Super MMS.

Line branching

Outdoor unit

Branching joint

Indoor unit

8F

4

Header branching

Outdoor unit

Branching

header

Indoor unit

Line + Header branching

Outdoor unit

Branching joint

Indoor

unit

Header

Line branching after header branching

Outdoor unit

Branching joint

Super MMS

MMS Only

Only

Header

7F

2F

1F

Indoor unit

Header branching after header branching

Outdoor unit

Header

Super MMS

Only

Header

Indoor unit

9

Page 11

4

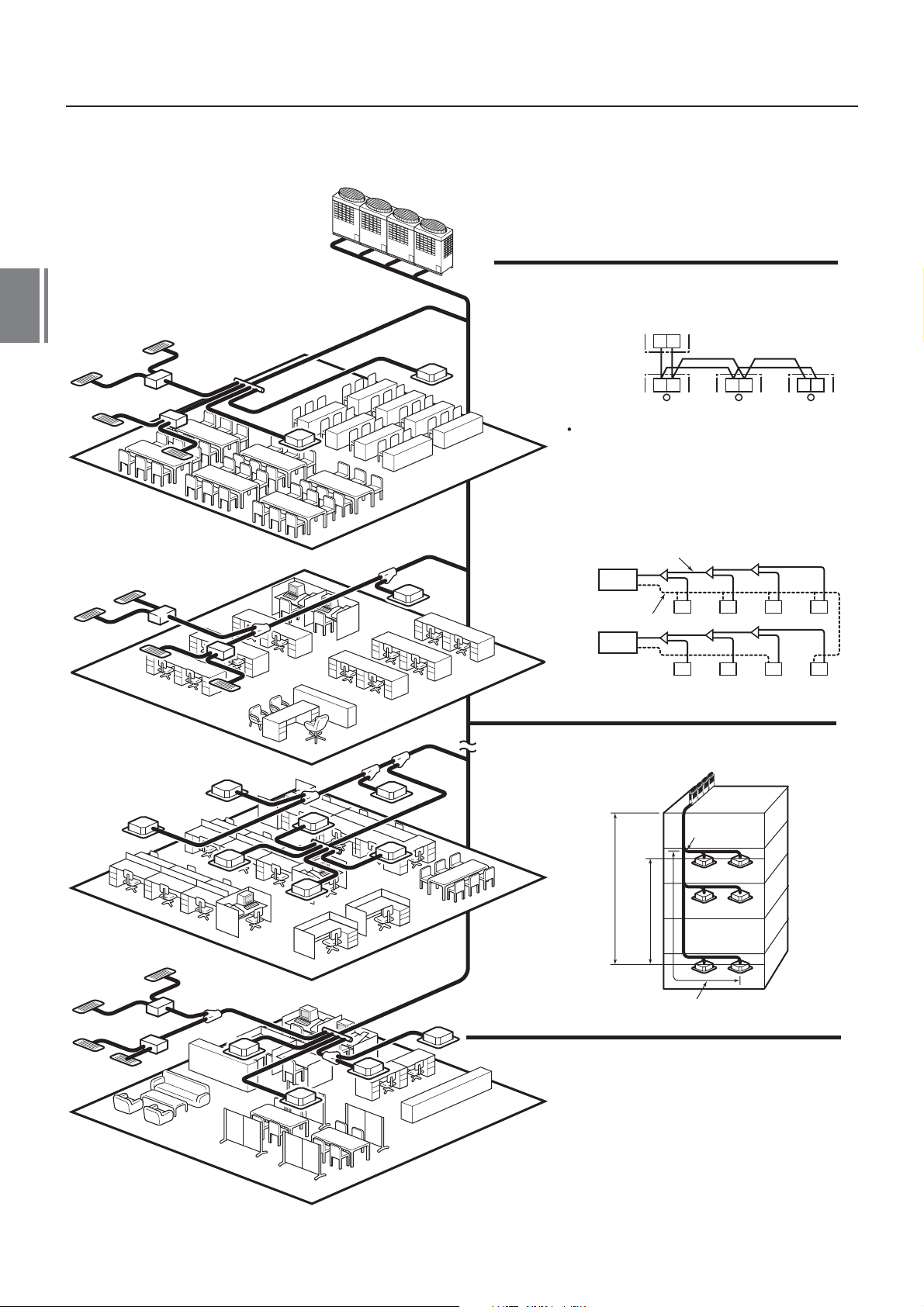

Non-polarized control wiring

between the outdoor and indoor units

8F

7F

Outdoor unit

Indoor unit

U1 U2

U1 U2 U1 U2 U1 U2

Wiring diagnosis system

Use the switches on the micro processor

P.C.B of the outdoor unit.

Detect wiring to the indoor unit b4 which

should not be in system A.

b4 is missing in the system B.

Piping

A

system

B

system

Outdoor

unit

a1 a2 a3 a4

Wiring Indoor unit

Outdoor

unit

b1 b2 b3 b4

Outdoor

unit

Allowable pipe length :

175m equivalent length

2F

1F

1st branching

section

Height difference between indoor

unit and outdoor unit : 50m

Height difference between indoor

unit and indoor unit : 30m

From 1st branching to the

furthest indoor unit : 65m

10

Page 12

Compact design

The design of the modular TOSHIBA Super MMS outdoor unit allows for easy manoeuvering of the unit.

The unit will fit into any standard size lift.

The compactness of the unit allows for it to be installed into a limited space.

Largest system capacity

TOSHIBA Super MMS can be combined up to 48 HP (135kW) as one refrigerant system.

Energy saving

No. 1 COP in VRF industry. Compared with a conventional chiller fan coil system a large energy

saving can be achieved.

Advanced bus communication system

Wiring between indoor and outdoor units is a simple 2 core wire system.

Communication of addresses is also automatically configured.

A default test mode operation is available.

Self diagnostics system

Comprehensive troubleshooting codes allows for a timely identification of possible problems arising.

High lift design

Equivalent pipe length of 175m and vertical lift of 50m is possible with TOSHIBA Super MMS.

The maximum vertical lift between indoor units is 30m, this being the highest in the industry.

This allows for greater flexibility within the building design of the system.

4

Multiplied indoor units

Indoor units with different capacities and configurations can be combined up to a maximum of

135% of the outdoor units capacity.

A maximum of 48 indoor units can be combined with the 30 _ 48 HP outdoor units.

Intelligent control

TOSHIBA Super MMS intelligent controls and modulating valves deliver the required capacity,

according to the load variation from 50% to 100%.

The intelligent controls and modulating valves limit or increase the cooling capacity dynamically so

humidity and temperature are kept within the comfort zone.

Conforms to building control law

IAQ (Indoor Air Quality) is also achieved by combining various accessories required by the Building

Control Law.

Wide control applications

Artificial Intelligence Network system.

Central control and monitoring system available.

Weekly schedule operation through weekly timer.

Integration with Building Management System (BMS) is available.

11

Page 13

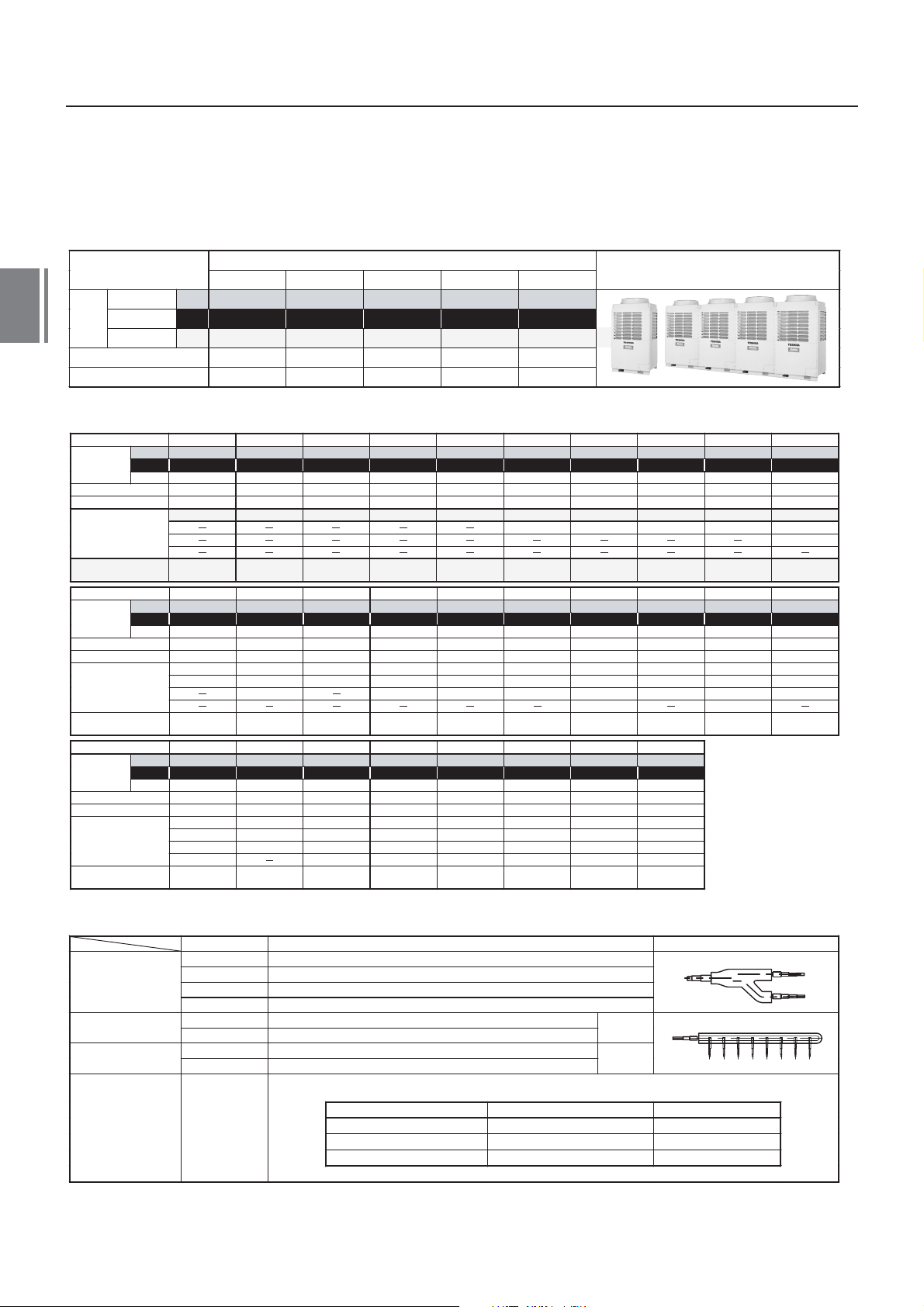

2. SUMMARY OF SYSTEM EQUIPMENTS

Equipment

1. Outdoor units

4

Corresponding HP

Heat pump

Model

Heat pump

name

Cooling only

Cooling capacity (kW)

Heating capacity (kW)

5 HP 6 HP 8 HP 10 HP 12 HP

MMY- MAP0501HT8 MAP0601HT8 MAP0801HT8 MAP1001H8 MAP1201HT8

MMY- MAP0501HT7 MAP0601HT7 MAP0801HT7 MAP1001HT7 MAP1201HT7

MAP0501T8 MAP0601T8 MAP0801T8 MAP1001T8 MAP1201T8

MMY-

14.0 16.0 22.4 28.0 33.5

16.0 18.0 25.0 31.5 37.5

Inverter unit

2. Outdoor units (Combination of outdoor units)

Corresponding HP

Combined

Model

Cooling capacity(kW)

Heating capacity(kW)

Combined

outdoor units

No. of connectable

indoor units

Corresponding HP

Combined

Model

Cooling capacity(kW)

Heating capacity(kW)

Combined

outdoor units

No. of connectable

indoor units

Corresponding HP

Combined

Model

Cooling capacity(kW)

Heating capacity(kW)

Combined

outdoor units

No. of connectable

indoor units

MMY- MAP0501HT8 MAP0601HT8 MAP0801HT8 MAP1001HT8 MAP1201HT8 AP1401HT8 AP1601HT8 AP1801HT8 AP2001HT8 AP2201HT8

MMY- MAP0501HT7 MAP0601HT7 MAP0801HT7 MAP1001HT7 MAP1201HT7 AP1401HT7 AP1601HT7 AP1801HT7 AP2001HT7 AP2201HT7

MMY- MAP0501T8 MAP0601T8 MAP0801T8 MAP1001T8 MAP1201T8 AP1401T8 AP1601T8 AP1801T8 AP2001T8 AP2201T8

MMY- AP2211HT8 AP2401HT8 AP2411HT8 AP2601HT8 AP2801HT8 AP3001HT8 AP3201HT8 AP3211HT8 AP3401HT8 AP3411HT8

MMY- AP2211HT7 AP2401HT7 AP2411HT7 AP2601HT7 AP2801HT7 AP3001HT7 AP3201HT7 AP3211HT7 AP3401HT7 AP3411HT7

MMY- AP2211T8 AP2401T8 AP2411T8 AP2601T8 AP2801T8 AP3001T8 AP3201T8 AP3211T8 AP3401T8 AP3411T8

MMY- AP3601HT8 AP3611HT8 AP3801HT8 AP4001HT8 AP4201HT8 AP4401HT8 AP4601HT8 AP4801HT8

MMY- AP3601HT7 AP3611HT7 AP3801HT7 AP4001HT7 AP4201HT7 AP4401HT7 AP4601HT7 AP4801HT7

MMY- AP3601T8 AP3611T8 AP3801T8 AP4001T8 AP4201T8 AP4401T8 AP4601T8 AP4801T8

5 HP 6 HP 8 HP 10 HP 12 HP 14 HP 16 HP 18 HP 20 HP 22 HP

14.0 16.0 22.4 28.0 33.5 38.4 45.0 50.4 56.0 61.5

16.0 18.0 25.0 31.5 37.5 43.0 50.0 56.5 63.0 69.0

5 HP 6 HP 8 HP 10 HP 12 HP 8 HP 8 HP 10 HP 10 HP 8 HP

8 101316202327303337

22 HP 24 HP 24 HP 26 HP 28 HP 30 HP 32 HP 32 HP 34 HP 34 HP

61.5 68.0 68.0 73.0 78.5 84.0 90.0 90.0 96.0 96.0

69.0 76.5 76.5 81.5 88.0 95.0 100.0 100.0 108.0 108.0

12 HP 8 HP 12 HP 10 HP 10 HP 10 HP 8 HP 12 HP 10 HP 12 HP

10 HP 8 HP 12 HP 8 HP 10 HP 10 HP 8 HP 10 HP 8 HP 12 HP

37 40 40 43 47 48 48 48 48 48

36 HP 36 HP 38 HP 40 HP 42 HP 44 HP 46 HP 48 HP

101.0 101.0 106.5 112.0 118.0 123.5 130.0 135.0

113.0 113.0 119.5 126.5 132.0 138.0 145.0 150.0

10 HP 12 HP 10 HP 10 HP 12 HP 12 HP 12 HP 12 HP

10 HP 12 HP 10 HP 10 HP 10 HP 12 HP 12 HP 12 HP

8 HP 12 HP 10 HP 10 HP 10 HP 10 HP 12 HP 12 HP

8 HP 8 HP 10 HP 10 HP 10 HP 10 HP 12 HP

48 48 48 48 48 48 48 48

8 HP 8 HP 8 HP 10 HP 8 HP 10 HP 8 HP 10 HP

6 HP 8 HP 8 HP 10 HP 8 HP

Appearance

6 HP

8 HP 8 HP

3. Branching joints and headers

12

*

*

*

*

*

*

Model name

RBM-BY53E

Y-shape branching

joint (*3)

4-branching header

(*4)

8-branching header

(*4) (*5)

T-shape branching

joint

(For connection of

outdoor units)

RBM-BY103E

RBM-BY203E

RBM-BY303E

RBM-HY1043E

RBM-HY2043E

RBM-HY1083E

RBM-HY2083E

RBM-BT13E

1 ‘‘Capacity code’’ can be obtained. (Capacity code is not actual capacity)

2 If total capacity code value of indoor unit exceeds that of outdoor unit, apply capacity code of outdoor unit.

3 When using Y-shape branching joint for 1st branching, select according to the capacity code of the outdoor unit.

4 Max. capacity code of 6.0 in total can be connected.

5 If capacity code of outdoor unit is 26 or more, it is not used for 1st branching.

6 Model names for outdoor and indoor units described in this guide are shortened because of the space constraint.

Indoor unit capacity code (*1) : Total below 6.4

Indoor unit capacity code (*1) : Total 6.4 or more and below 14.2 (*2)

Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2 (*2)

Indoor unit capacity code (*1) : Total 25.2 or more (*2)

Indoor unit capacity code (*1) : Total below 14.2

Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2

Indoor unit capacity code (*1) : Total below 14.2

Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2

1 set of 3 types of T-shape joint pipes as described below:

The required quantity is arranged and they are combined at the site.

Usage

Max.4

branches

Max.8

branches

Connection piping Corresponded dia. (mm) Qty

Balance pipe

Piping at liquid side

Piping at gas side

o/9.5 1

o/9.5 to o/22.2 1

o/15.9 to o/41.3 1

Appearance

Page 14

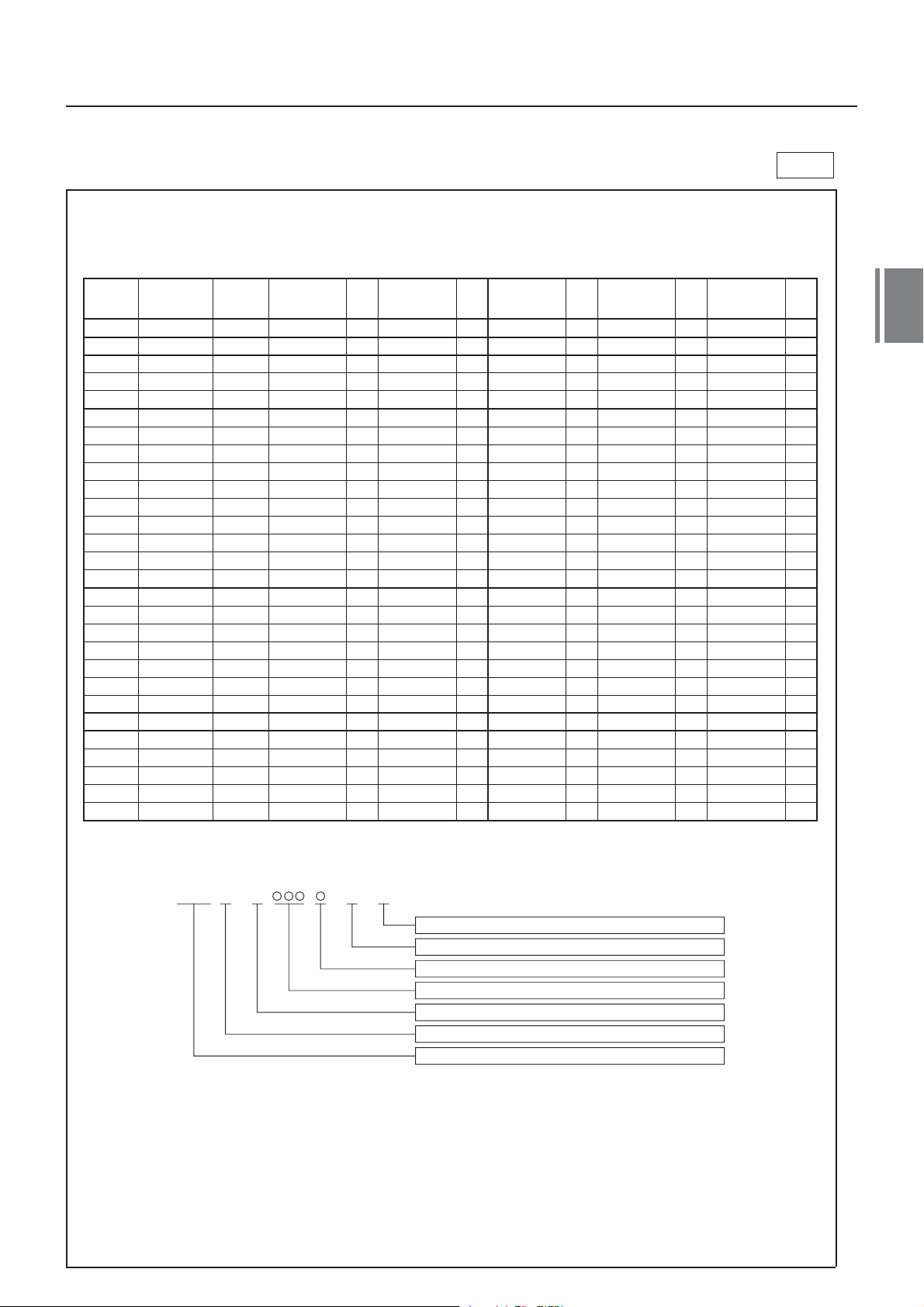

Cooling Only model

Super Modular Multi System Outdoor Unit :

List of Product and Combined Model Name

50Hz

HP

(Capacity

code)

5HP ( 5)

6HP ( 6)

8HP ( 8)

10HP (10)

12HP (12)

14HP (14)

16HP (16)

18HP (18)

20HP (20)

22HP (22)

22HP (22)

24HP (24)

24HP (24)

26HP (26)

28HP (28)

30HP (30)

32HP (32)

32HP (32)

34HP (34)

34HP (34)

36HP (36)

36HP (36)

38HP (38)

40HP (40)

42HP (42)

44HP (44)

46HP (46)

48HP (48)

Model name

MMY-

MAP0501T8

MAP0601T8

MAP0801T8

MAP1001T8

MAP1201T8

AP1401T8

AP1601T8

AP1801T8

AP2001T8

AP2201T8

AP2211T8

AP2401T8

AP2411T8

AP2601T8

AP2801T8

AP3001T8

AP3201T8

AP3211T8

AP3401T8

AP3411T8

AP3601T8

AP3611T8

AP3801T8

AP4001T8

AP4201T8

AP4401T8

AP4601T8

AP4801T8

No. of

combined

units

1

1

1

1

1

2

2

2

2

3

2

3

2

3

3

3

4

3

4

3

4

3

4

4

4

4

4

4

Inverter

5 HP

MMY-

MAP0501T8 1

Used

Qty

Inverter

6 HP

MMY-

MAP0601T8

MAP0601T8

MAP0601T8

Used

Qty

1

1

1

Inverter

8HP

MMY-

MAP0801T8

MAP0801T8

MAP0801T8

MAP0801T8

MAP0801T8

MAP0801T8

MAP0801T8

MAP0801T8

MAP0801T8

MAP0801T8

MAP0801T8

MAP0801T8

Used

Qty

1

1

2

1

2

3

2

1

4

3

2

1

Inverter

10HP

MMY-

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

MAP1001T8

Used

Qty

1

1

2

1

1

2

3

2

1

1

2

3

4

3

2

1

Inverter

12HP

MMY-

MAP1201T8

MAP1201T8

MAP1201T8

MAP1201T8

MAP1201T8

MAP1201T8

MAP1201T8

MAP1201T8

MAP1201T8

MAP1201T8

Used

Qty

1

1

2

1

2

3

1

2

3

4

4

1. Allocation standard of model name

MMY_MAP T 8

O

Power supply specifications, 3

T : Capacity variable unit

Development series No.

Capacity rank HP x 10

New refrigerant R410A

M : Single module unit, No mark : Combined Model name

Modular Multi

380_415 V, 50Hz ....... 8

/

2. Range of combined capacity

No. of combined units: 1 to 4 units

Capacity of combined units: 14 HP (140 type) to 48 HP (480 type)

3. Rated conditions (Rated mode : Condition)

Cooling: Indoor air temperature 27oC DB/19oC WB, Outdoor air temperature 35oC DB

13

Page 15

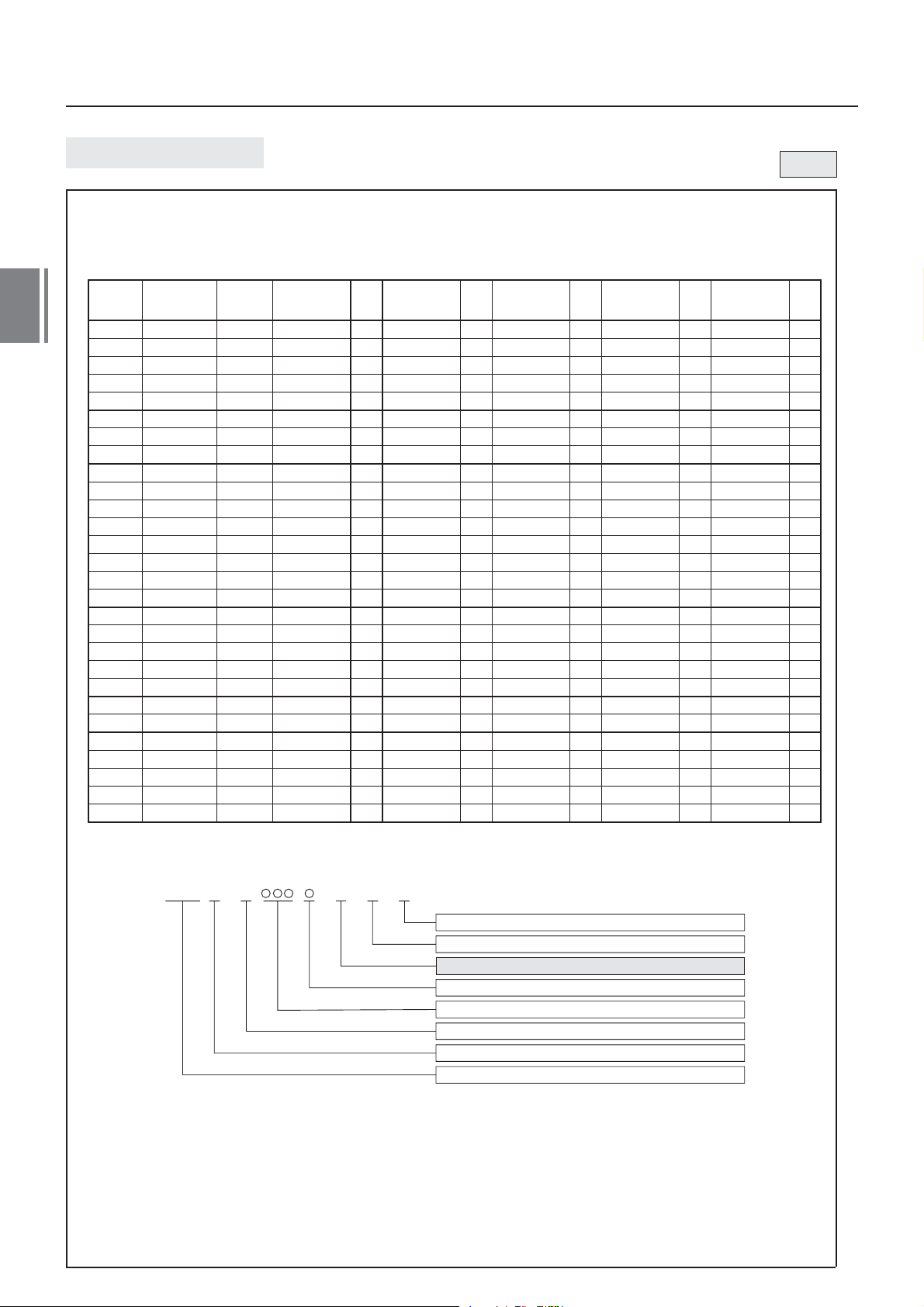

Heat Pump model

50Hz

4

HP

(Capacity

code)

5HP ( 5)

6HP ( 6)

8HP ( 8)

10HP (10)

12HP (12)

14HP (14)

16HP (16)

18HP (18)

20HP (20)

22HP (22)

22HP (22)

24HP (24)

24HP (24)

26HP (26)

28HP (28)

30HP (30)

32HP (32)

32HP (32)

34HP (34)

34HP (34)

36HP (36)

36HP (36)

38HP (38)

40HP (40)

42HP (42)

44HP (44)

46HP (46)

48HP (48)

Model name

MMY-

MAP0501HT8

MAP0601HT8

MAP0801HT8

MAP1001HT8

MAP1201HT8

AP1401HT8

AP1601HT8

AP1801HT8

AP2001HT8

AP2201HT8

AP2211HT8

AP2401HT8

AP2411HT8

AP2601HT8

AP2801HT8

AP3001HT8

AP3201HT8

AP3211HT8

AP3401HT8

AP3411HT8

AP3601HT8

AP3611HT8

AP3801HT8

AP4001HT8

AP4201HT8

AP4401HT8

AP4601HT8

AP4801HT8

No. of

combined

units

11

11

11

1 1

1 1

211

22

211

2 2

312

2 11

33

2 2

321

312

3 3

44

3 21

431

3 12

422

3 3

413

4 4

4 31

4

4 13

4 4

Inverter

5 HP

MMY-

MAP0501HT8

Used

Qty

Inverter

6 HP

MMY-

MAP0601HT8

MAP0601HT8

MAP0601HT8

Used

Qty

Inverter

8 HP

MMY-

MAP0801HT8

MAP0801HT8

MAP0801HT8

MAP0801HT8

MAP0801HT8

MAP0801HT8

MAP0801HT8

MAP0801HT8

MAP0801HT8

MAP0801HT8

MAP0801HT8

MAP0801HT8

Used

Qty

Inverter

10 HP

MMY-

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

MAP1001HT8

Used

Inverter

Qty

12 HP

MMY-

MAP1201HT8

MAP1201HT8

MAP1201HT8

MAP1201HT8

MAP1201HT8

MAP1201HT8

MAP1201HT8

MAP1201HT8

22

MAP1201HT8

MAP1201HT8

Used

Qty

14

1. Allocation standard of model name

MMY_MAP T 8H

Power supply specifications, 3O/ 380_415 V, 50Hz ....... 8

T : Capacity variable unit

H : Heat pump

Development series No.

Capacity rank HP x 10

New refrigerant R410A

M : Single module unit, No mark : Combined Model name

Modular Multi

2. Range of combined capacity

No. of combined units: 1 to 4 units

Capacity of combined units: 14 HP (140 type) to 48 HP (480 type)

3. Rated conditions (Rated mode : Condition)

Cooling : Indoor air temperature 27oC DB/19oC WB, Outdoor air temperature 35oC DB

Heating : Indoor air temperature 20

o

C DB, Outdoor air temperature 7oC DB/6oC WB

Page 16

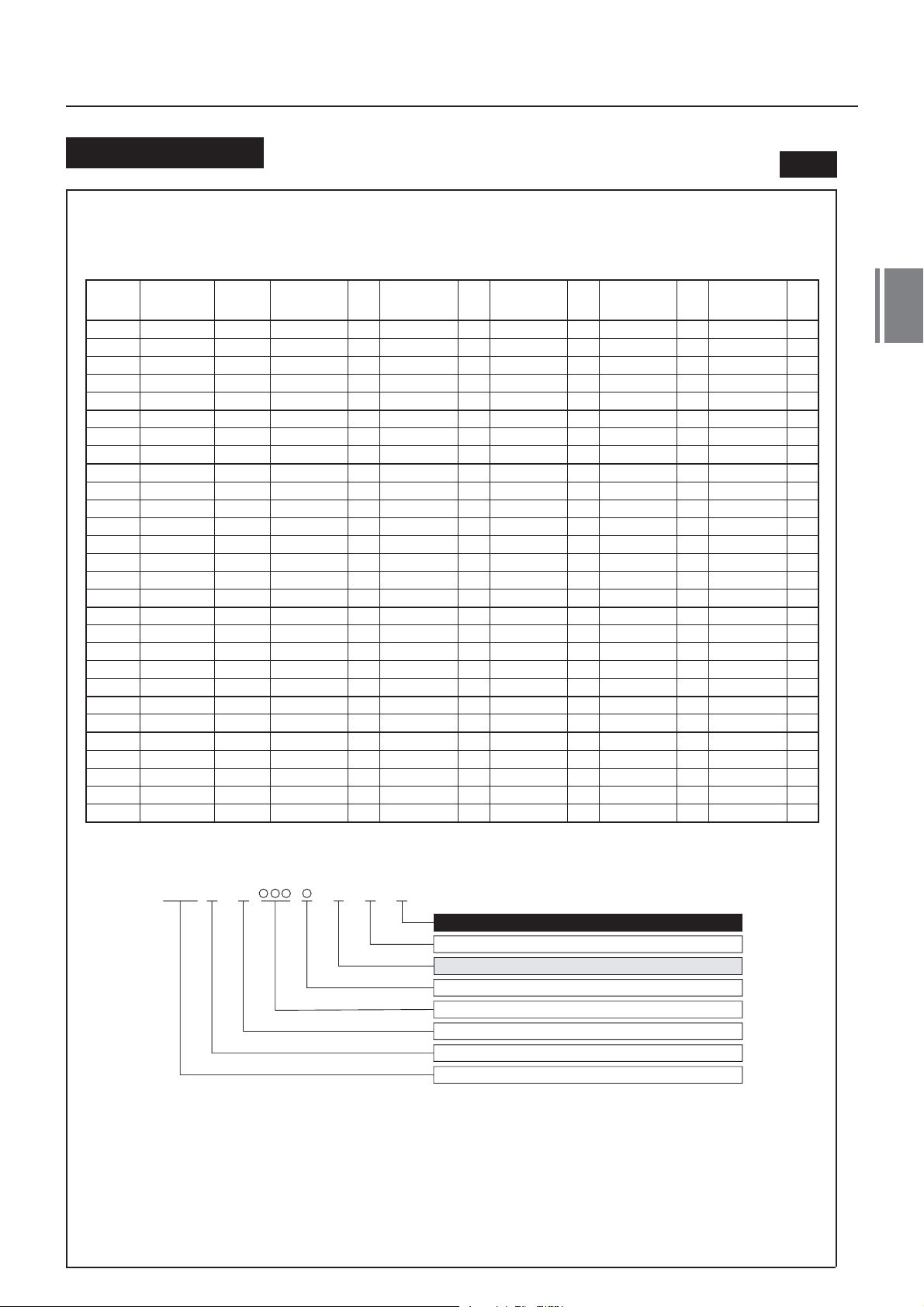

Heat Pump model

Super Modular Multi System Outdoor Unit :

List of Product and Combined Model Name

60Hz

HP

(Capacity

code)

5HP ( 5)

6HP ( 6)

8HP ( 8)

10HP (10)

12HP (12)

14HP (14)

16HP (16)

18HP (18)

20HP (20)

22HP (22)

22HP (22)

24HP (24)

24HP (24)

26HP (26)

28HP (28)

30HP (30)

32HP (32)

32HP (32)

34HP (34)

34HP (34)

36HP (36)

36HP (36)

38HP (38)

40HP (40)

42HP (42)

44HP (44)

46HP (46)

48HP (48)

Model name

MMY-

MAP0501HT7

MAP0601HT7

MAP0801HT7

MAP1001HT7

MAP1201HT7

AP1401HT7

AP1601HT7

AP1801HT7

AP2001HT7

AP2201HT7

AP2211HT7

AP2401HT7

AP2411HT7

AP2601HT7

AP2801HT7

AP3001HT7

AP3201HT7

AP3211HT7

AP3401HT7

AP3411HT7

AP3601HT7

AP3611HT7

AP3801HT7

AP4001HT7

AP4201HT7

AP4401HT7

AP4601HT7

AP4801HT7

No. of

combined

units

11

11

11

1 1

1 1

211

22

211

2 2

312

2 11

33

2 2

321

312

3 3

44

3 21

431

3 12

422

3 3

413

4 4

4 31

4 22

4 13

4 4

Inverter

5 HP

MMY-

MAP0501HT7

Used

Qty

Inverter

6 HP

MMY-

MAP0601HT7

MAP0601HT7

MAP0601HT7

Used

Qty

Inverter

8 HP

MMY-

MAP0801HT7

MAP0801HT7

MAP0801HT7

MAP0801HT7

MAP0801HT7

MAP0801HT7

MAP0801HT7

MAP0801HT7

MAP0801HT7

MAP0801HT7

MAP0801HT7

MAP0801HT7

Used

Qty

Inverter

10 HP

MMY-

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

MAP1001HT7

Used

Qty

Inverter

12 HP

MMY-

MAP1201HT7

MAP1201HT7

MAP1201HT7

MAP1201HT7

MAP1201HT7

MAP1201HT7

MAP1201HT7

MAP1201HT7

MAP1201HT7

MAP1201HT7

Used

Qty

4

1. Allocation standard of model name

MMY_MAP T 7H

Power supply specifications, 3O/ 380 V, 60Hz ....... 7

T : Capacity variable unit

H : Heat pump

Development series No.

Capacity rank HP x 10

New refrigerant R410A

M : Single module unit, No mark : Combined Model name

Modular Multi

2. Range of combined capacity

No. of combined units: 1 to 4 units

Capacity of combined units: 14 HP (140 type) to 48 HP (480 type)

3. Rated conditions (Rated mode : Condition)

Cooling : Indoor air temperature 27oC DB/19oC WB, Outdoor air temperature 35oC DB

Heating : Indoor air temperature 20

o

C DB, Outdoor air temperature 7oC DB/6oC WB

15

Page 17

4

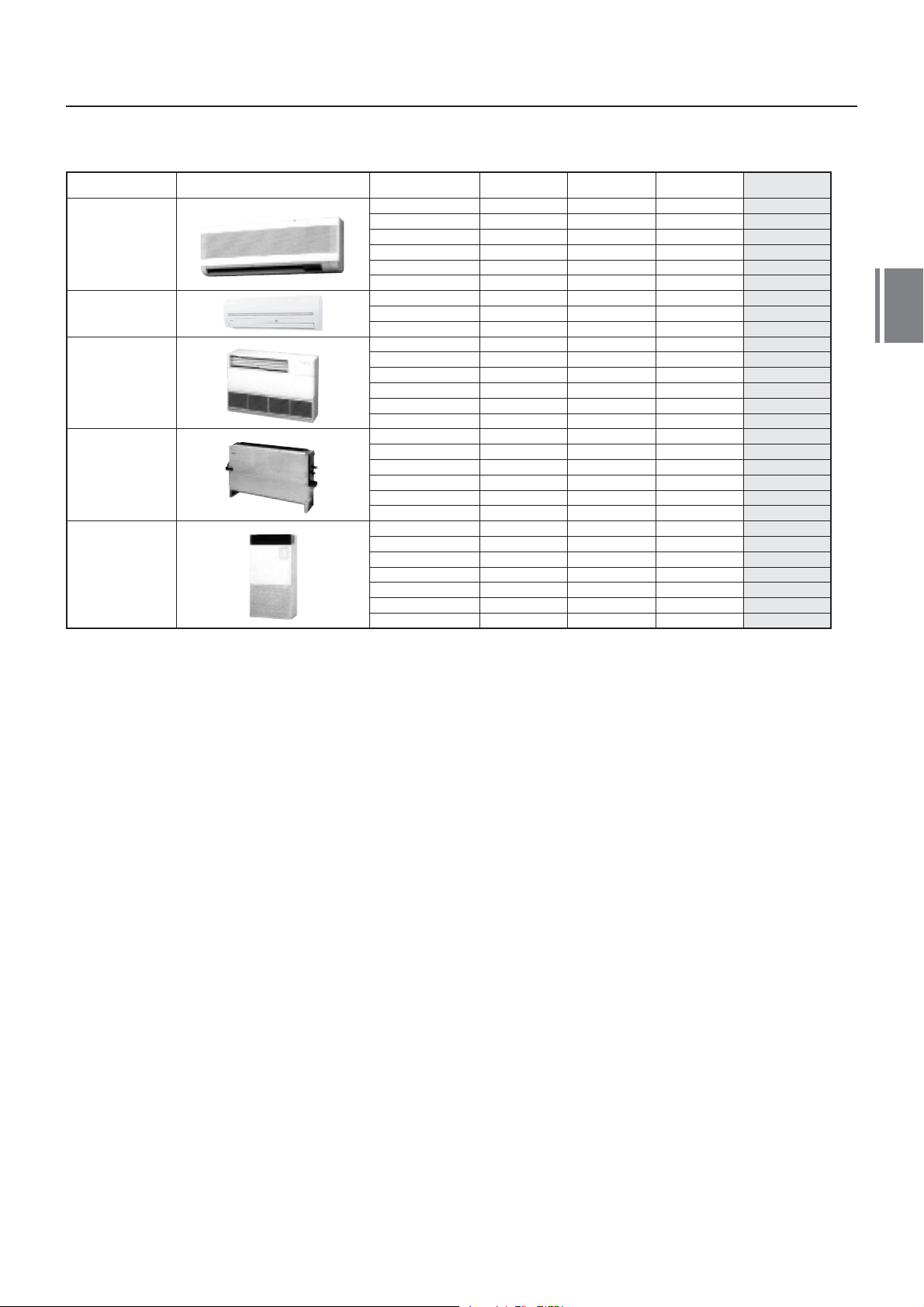

4. Indoor unit

*1) China market only *2) European market only *3) Korea market only

Type Appearance Model name Capacity rank Capacity code

009 type

012 type

015 type

018 type

024 type

027 type

030 type

036 type

048 type

056 type

007 type

009 type

012 type

015 type

018 type

024 type

027 type

030 type

1)

048 type

007 type

009 type

012 type

015 type

018 type

024 type

015 type

018 type

024 type

007 type

009 type

012 type

015 type

018 type

1)

007 type

*

1)

009 type

*

1)

012 type

*

1)

015 type

*

1)

018 type

*

3)

007 type

*

3)

009 type

*

3)

012 type

*

3)

015 type

*

3)

018 type

*

007 type

009 type

012 type

015 type

018 type

024 type

027 type

030 type

036 type

048 type

056 type

018 type

024 type

027 type

036 type

048 type

072 type

096 type

015 type

018 type

024 type

027 type

036 type

048 type

4-way Air Discharge

Cassette Type

2-way Air Discharge

Cassette Type

1-way Air Discharge

Cassette Type

Slim Duct Type

Concealed Duct

Standard Type

Concealed Duct

High Static

Pressure Type

Under Ceilling Type

MMU-AP0091H

MMU-AP0121H

MMU-AP0151H

MMU-AP0181H

MMU-AP0241H

MMU-AP0271H

MMU-AP0301H

MMU-AP0361H

MMU-AP0481H

MMU-AP0561H

MMU-AP0071WH

MMU-AP0091WH

MMU-AP0121WH

MMU-AP0151WH

MMU-AP0181WH

MMU-AP0241WH

MMU-AP0271WH

MMU-AP0301WH

MMU-AP0481WH*

MMU-AP0071YH

MMU-AP0091YH

MMU-AP0121YH

MMU-AP0151SH

MMU-AP0181SH

MMU-AP0241SH

MMU-AP0152SH

MMU-AP0182SH

MMU-AP0242SH

MMD-AP0071SPH

MMD-AP0091SPH

MMD-AP0121SPH

MMD-AP0151SPH

MMD-AP0181SPH

MMD-AP0071SPH(SH)-C

MMD-AP0091SPH(SH)-C

MMD-AP0121SPH(SH)-C

MMD-AP0151SPH(SH)-C

MMD-AP0181SPH(SH)-C

MMD-AP0071SPH-K

MMD-AP0091SPH-K

MMD-AP0121SPH-K

MMD-AP0151SPH-K

MMD-AP0181SPH-K

MMD-AP0071BH

MMD-AP0091BH

MMD-AP0121BH

MMD-AP0151BH

MMD-AP0181BH

MMD-AP0241BH

MMD-AP0271BH

MMD-AP0301BH

MMD-AP0361BH

MMD-AP0481BH

MMD-AP0561BH

MMD-AP0181H

MMD-AP0241H

MMD-AP0271H

MMD-AP0361H

MMD-AP0481H

MMD-AP0721H

MMD-AP0961H

MMC-AP0151H

MMC-AP0181H

MMC-AP0241H

MMC-AP0271H

MMC-AP0361H

MMC-AP0481H

1.00

1.25

1.70

2.00

2.50

3.00

3.20

4.00

5.00

6.00

0.8

1.00

1.25

1.70

2.00

2.50

3.00

3.20

5.00

0.80

1.00

1.25

1.70

2.00

2.50

1.70

2.00

2.50

0.80

1.00

1.25

1.70

2.00

0.80

1.00

1.25

1.70

2.00

0.80

1.00

1.25

1.70

2.00

0.80

1.00

1.25

1.70

2.00

2.50

3.00

3.20

4.00

5.00

6.00

2.00

2.50

3.00

4.00

5.00

8.00

10.00

1.70

2.00

2.50

3.00

4.00

5.00

Cooling

capacity (kW)

2.8

3.6

4.5

5.6

7.1

8.0

9.0

11.2

14.0

16.0

2.2

2.8

3.6

4.5

5.6

7.1

8.0

9.0

14.0

2.2

2.8

3.6

4.5

5.6

7.1

4.5

5.6

7.1

2.2

2.8

3.6

4.5

5.6

2.2

2.8

3.6

4.5

5.6

2.2

2.8

3.6

4.5

5.6

2.2

2.8

3.6

4.5

5.6

7.1

8.0

9.0

11.2

14.0

16.0

5.6

7.1

8.0

11.2

14.0

22.4

28.0

4.5

5.6

7.1

8.0

11.2

14.0

Heating

capacity (kW)

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

18.0

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

16.0

2.5

3.2

4.0

5.0

6.3

8.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

2.5

3.2

4.0

5.0

6.3

2.5

3.2

4.0

5.0

6.3

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

18.0

6.3

8.0

9.0

10.0

16.0

25.0

31.5

5.0

6.3

8.0

9.0

12.5

16.0

16-1

16

Page 18

4. Indoor unit

*1) China market only *2) European market only

Type Appearance Model name Capacity rank Capacity code

007 type

009 type

012 type

015 type

018 type

024 type

2)

007 type

2)

009 type

2)

012 type

007 type

009 type

012 type

015 type

018 type

024 type

007 type

009 type

012 type

015 type

018 type

024 type

015 type

018 type

024 type

027 type

036 type

048 type

056 type

High Wall Type

(1 series)

High Wall Type

(2 series)

Floor Standing

Cabinet Type

Floor Standind

Concealed Type

Floor Standind Type

MMK-AP0071H

MMK-AP0091H

MMK-AP0121H

MMK-AP0151H

MMK-AP0181H

MMK-AP0241H

MMK-AP0072H*

MMK-AP0092H*

MMK-AP0122H*

MML-AP0071H

MML-AP0091H

MML-AP0121H

MML-AP0151H

MML-AP0181H

MML-AP0241H

MML-AP0071H

MML-AP0091H

MML-AP0121H

MML-AP0151H

MML-AP0181H

MML-AP0241H

MMF-AP0151H

MMF-AP0181H

MMF-AP0241H

MMF-AP0271H

MMF-AP0361H

MMF-AP0481H

MMF-AP0561H

0.80

1.00

1.25

1.70

2.00

2.50

0.80

1.00

1.25

0.80

1.00

1.25

1.70

2.00

2.50

0.80

1.00

1.25

1.70

2.00

2.50

1.70

2.00

2.50

3.00

4.00

5.00

6.00

*3) Korea market only

Cooling

capacity (kW)

2.2

2.8

3.6

4.5

5.6

7.1

2.2

2.8

3.6

2.2

2.8

3.6

4.5

5.6

7.1

2.2

2.8

3.6

4.5

5.6

7.1

4.5

5.6

7.1

8.0

11.2

14.0

16.0

Heating

capacity (kW)

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

5.0

6.3

8.0

9.0

10.0

16.0

18.0

4

16-2

17

Page 19

4

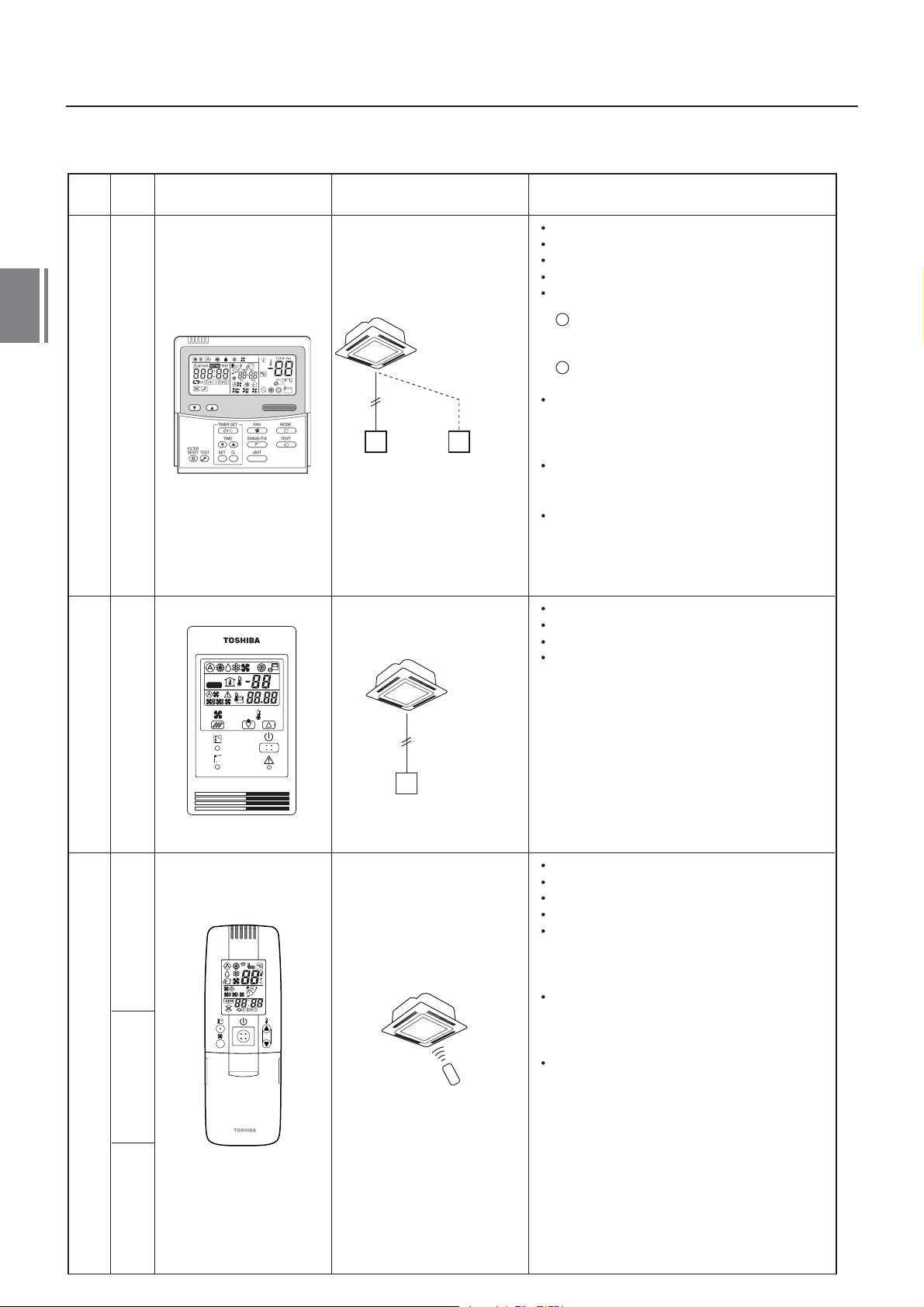

5. Remote controller

Model

Name

name

Wired remote controller

Appearance FunctionApplication

SET DATA

UNIT No.

SETTING

R.C. No.

TEST

UNIT

CL

SET

CODE No.

Connected to indoor unit

Wired remote

controller

Wired remote controller

(In case of control by

2 remote controllers)

Start / Stop

Mode Change

Temperature setting

Change of air flow

Timer function

1

On or off timer operation, setting in 30

minute increments.

Automatic Off function.

2

Combined with the weekly timer, weekly

schedule operation can be operated.

Filter sign

Displays automatically maintenance time of

indoor filter.

Filter sign flashes.

Self-diagnosis function

Pressing‘‘CHECK’’ button displays cause of

fault on the check code.

Control by 2 remote controllers is available.

Two remote controllers can be connected to

one indoor unit. The indoor unit can be

separately operated from a different location.

TEST

SETTING

ûC

ûF

RBC-AS21E/RBC-AS21E2 RBC-AMT21E/RBC-AMT31E

Simple wired remote controller

TCB-AX21U(W)-E

TCB-AX21U(W)-E2

RBC-AX22CE

RBC-AX22CE2

Wireless remote controller kit

Connected to indoor unit

Simple remote controller

Connected to indoor unit

Start / Stop

Temperature setting

Change of air flow

Check code display

Start / Stop

Mode change

Temperature setting

Change of air flow

Timer function

On or off timer operation, setting in 30 minute

increments.

Automatic Off function.

Control by 2 remote controllers is available.

Two wireless remote controllers can operate

one indoor unit. The indoor unit can be

separately operated from a different location.

Check code display

TCB-AX21U(W)-E

(for 4-way airdischarge cassette)

RBC-AX22CE

(for under ceiling)

TCB-AX21-E

(for other units except for the concealsed duct

high static pressure)

18

16-3

TCB-AX21E

TCB-AX21E2

Page 20

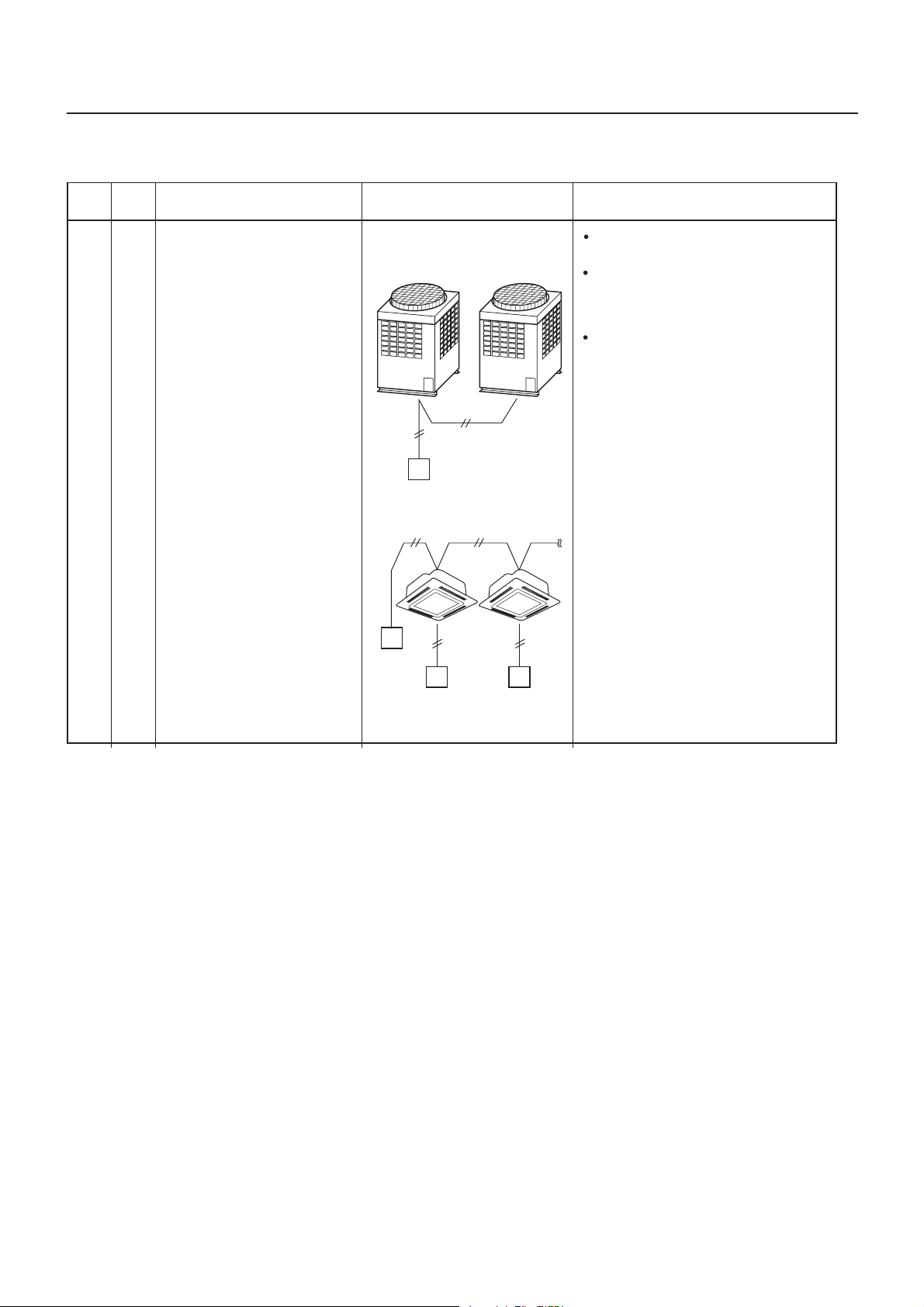

Name

Model

name

Appearance Application Performance

Weekly timer

RBC-EXW21E

RBC-EXW21E2

PROGRAM1

PROGRAM2

PROGRAM3

WEEKLY TIMER

SuMoTuWeThFr Sa

ERROR

Connected to central

remote controller or

wired remote controller

Wired

remote controller

Outdoor unit

Central

remote controller

Weekly

timer

Weekly

timer

Weekly schedule operation

1

Setting different start / stop time for

each day of the week

2

ON / OFF can be set 3 times a day.

ON

8:00 12:00 13:00 18:00 19:00 21:00

3

‘‘CHECK’’ ‘‘PROGRAM’’ ‘‘DAY’’

OFF OFFON ON OFF

button copying of setting easy.

4

Two different schedules for a

week can be specified.

(Summer schedule and winter

schedule, etc.)

5

‘‘CANCEL’’ ‘‘DAY’’ button enables

holiday setting.

6

If power supply fails, the setting

contents are stored in the memory

for 100 hours.

4

ZONE

ALL

ZONE

GROUP

1234

TEST

UNIT No.

SET DATA

SETTING

R.C.

No.

SELECT ZONE

TCB-SC642TLE

TCB-SC642TLE2

CL

SET

Central remote controller

GROUP

CODE

No.

Connected to outdoor unit,

indoor unit

Header

Central

remote controller

Central

remote

controller

Outdoor unit

Indoor remote

controller

Follower

Individual control up to 64 indoor units.

Individual control for max. 64 indoor

units divided into 4 zones.

Up to 16 indoor units

for each zone

Up to 16 outdoor header units are

connectable.

4 type central control setting to

inhibit individual operation by remote

controller can be selected.

Setting for one of 1 to 4 zones is

available.

Can be used with other central control

devices (Up to 10 central control

devices with in one control circuit)

Two selectable control modes

Central controller mode

Remote controller mode

Setting of simultaneous ON/OFF 3

times for each day of the week

combined with a weekly timer.

17

19

Page 21

Name

Model

name

Appearance Application Performance

TCB-CC163TLE

ON-OFF controller

TCB-CC163TLE2

Connected to outdoor unit,

indoor unit

Header

ON-OFF

controller

ON-OFF

controller

Outdoor unit

remote controller

Follower

Outdoor unit

Indoor

Individual control up to 16 indoor units.

Setting of simultaneous ON/OFF 3

times for each day of the week when

combined with a weekly timer.

Connected to 2 remote controllers is

possible.

18

20

Page 22

5

Capacity compensation chart

19

Page 23

Foreword

20

Page 24

5

, , , ,

*

1

1 2 3 4 5

Capacity compensation chart

Foreword

3. Cooling/heating capacity characteristics

1. Cooling capacity calculation method :

Required cooling capacity = Cooling capacity x Factor ( ) kW

1

Indoor air wet bulb temperature vs. capacity correction value

1.2

1.1

1.0

0.9

0.8

Capacity correction value

15

20 24

Indoor air wet bulb temp. ( )

2

Outdoor air dry bulb temperature vs.capacity correction value

1.2

1.1

1.0

0.9

5

3

Air flow variation ratio of indoor unit vs. capacity correction (For concealed duct type only)

1 : Coefficient to use for the correction of the outdoor unit capacity when the total capacity of

*

the indoor units are not equal to the outdoor unit capacity.

Capacity correction value

-

50 51015202530354043

Outdoor air dry bulb temp. ( )

1.1

1.0

0.9

80 90 100 110 120

Capacity correction value

Air flow variation ratio (%)

21

Page 25

5

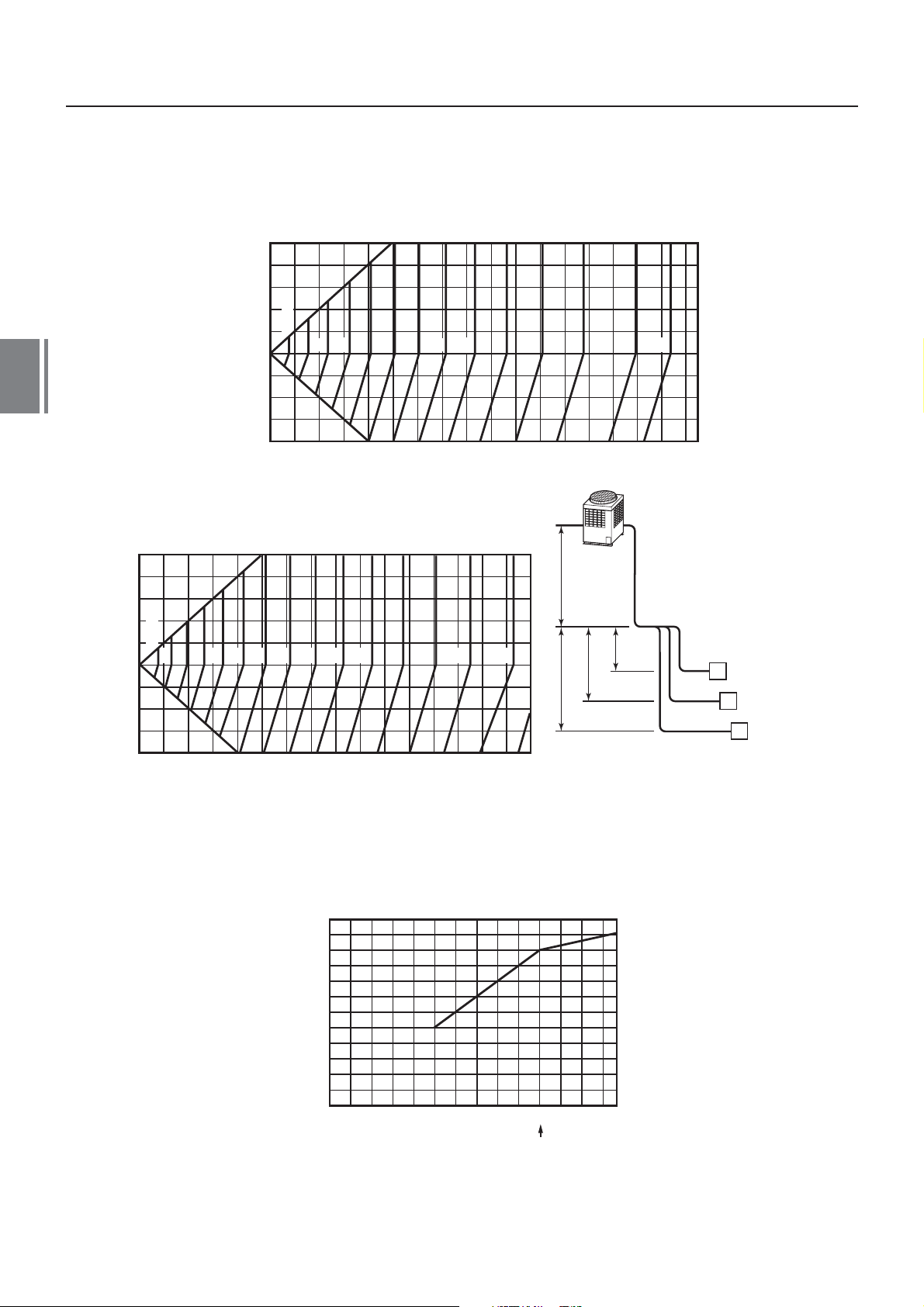

Connecting pipe length and lift difference between indoor and outdoor units vs. capacity correction value

Outdoor unit (5 to 44HP)

50

40

30

20

%100

10

0

-

10

-

20

-

30

-

40

Height of outdoor unit H (m)

9

98

20 30 40 50 60 70 80 90

100

94

92

908488

86

82

80

78

100 110 120 130 140 150 160 170

76

75

Pipe length (Equivalent length) L (m)

Outdoor unit

Outdoor unit (46 to 48HP)

50

40

30

20

10

100%

0

-

10

-

20

-

30

-

40

Height of outdoor unit H (m)

100 2030405060708090

98

96

94

92

90

88

86

84

Pipe length (Equivalent length) L (m)

Correction of outdoor unit diversity

120

100

80

76

78

80

82

100 110 120 130 140 150 160

74

72

ho l'o

hb

hc

L' is the longest one of

(l'o + l'a, l'o + l'b, l'o + l'c)

H = ho +

(Largest one of ha, hb, and hc)

ha

l'a

l'b

l'c

A

B

C

Indoor unit

60

40

Correction (%)

20

0

20 40 60 80 100 120 135

Standard capacity ratio

Indoor units total capacity ratio (%)

1 : Coefficient to use for the correction of the outdoor unit capacity when the total capacity of

*

the indoor units are not equal to the outdoor unit capacity.

22

Page 26

Foreword

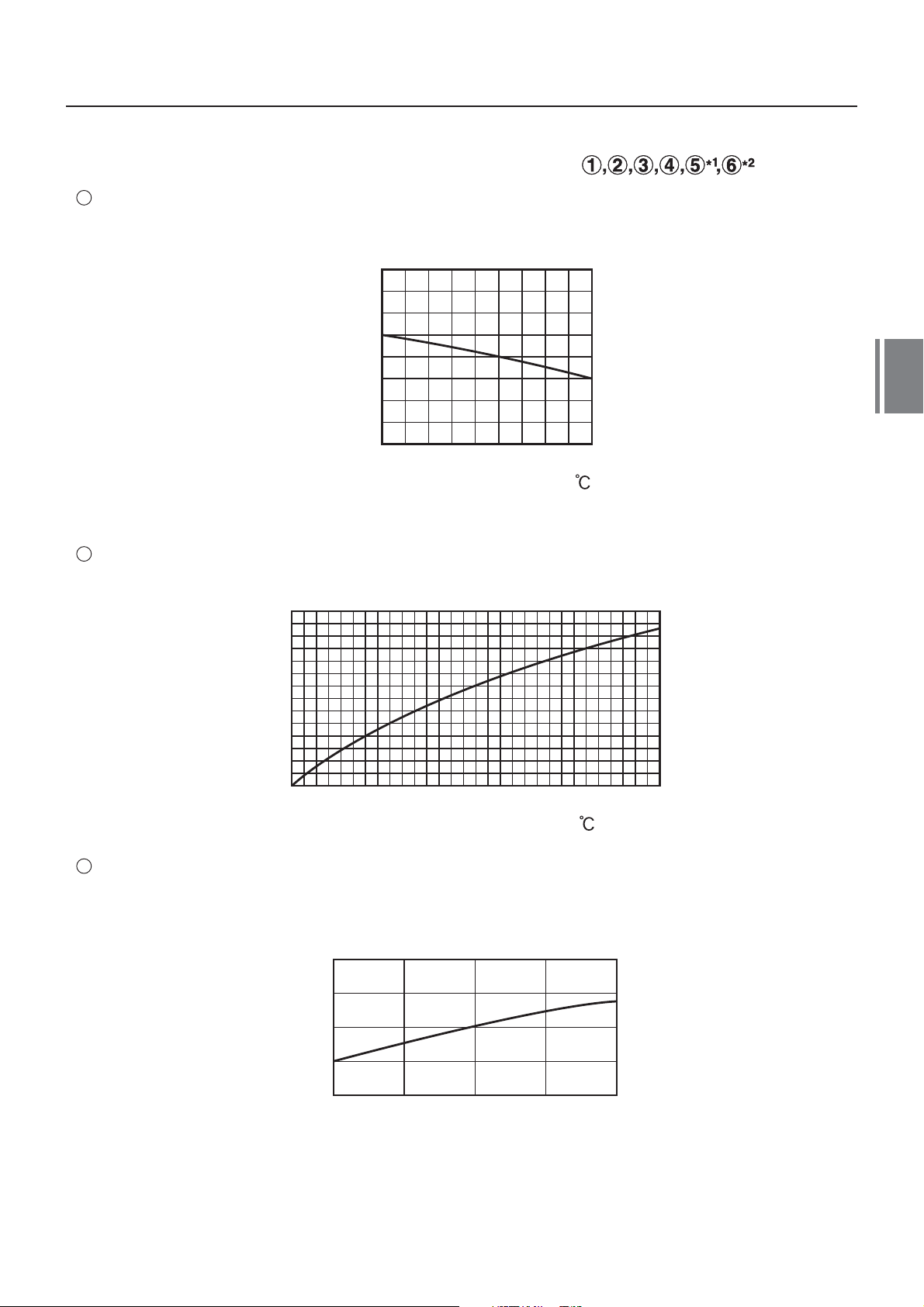

2. Heating capacity calculation method:

Required heating capacity = Heating capacity x Factor ( )kW

1

Indoor air dry bulb temperature vs. capacity correction value

1.2

1.1

1.0

0.9

0.8

15 20 24

Capacity correction value

Indoor air dry bulb temp. ( )

5

2

Outdoor air wet bulb temperature vs. capacity correction value

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

-

15

Capacity correction value

-

10

-

50 51015

Outdoor air wet bulb temp. ( )

3

Air flow variation ratio of indoor unit vs. capacity correction (For concealed duct type only)

1.1

1.0

0.9

80 90 100 110 120

Capacity correction value

1 : Coefficient to use for the correction of the outdoor unit capacity when the total capacity of

*

Air flow variation ratio (%)

the indoor units are not equal to the outdoor unit capacity.

2 : Refer to item 3

*

23

Page 27

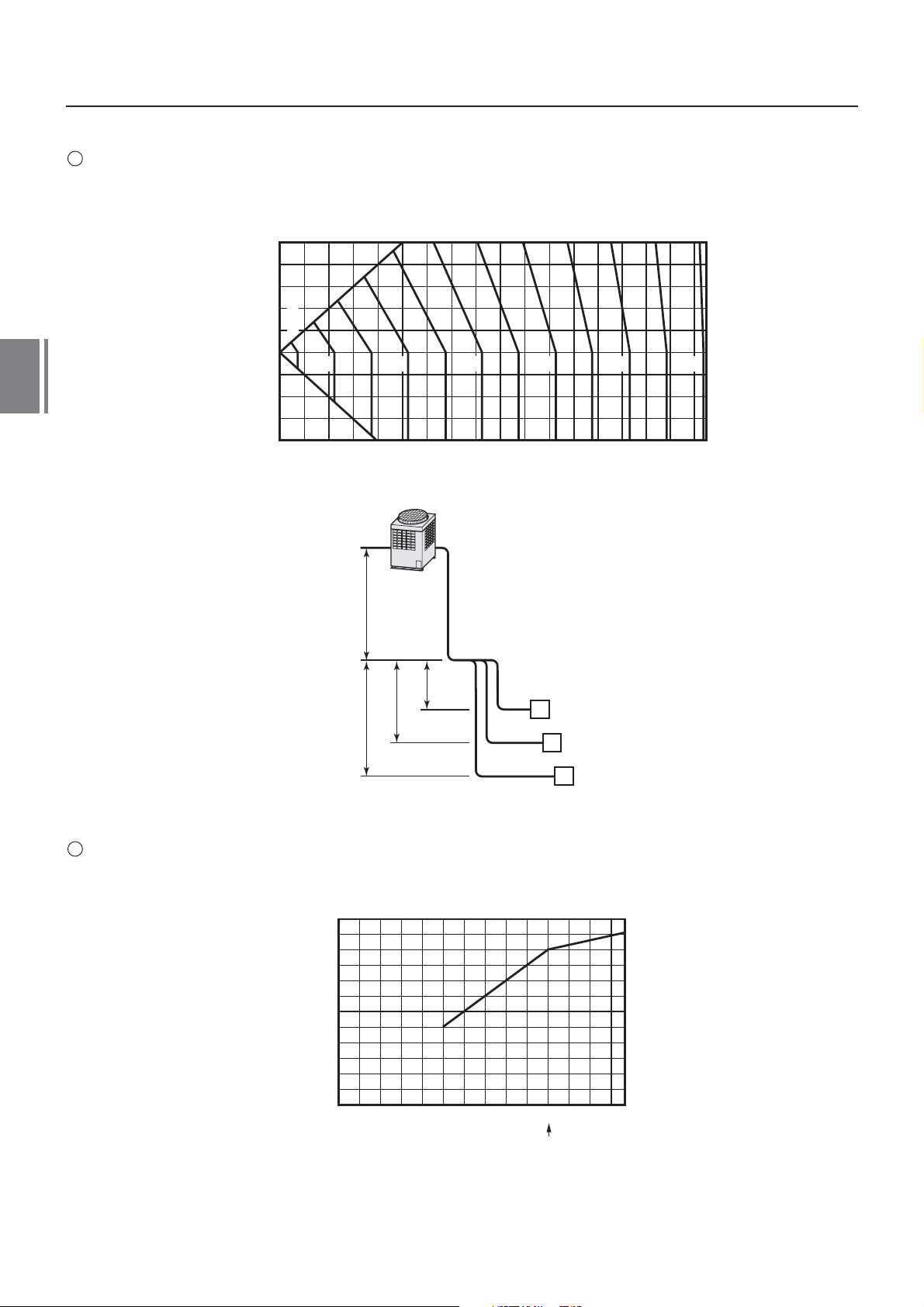

Outdoor unit

Indoor unit

L' is the longest one of

(l'o + l'a, l'o + l'b, l'o + l'c)

H = ho +

(Largest one of ha, hb, and hc)

A

ha

hb

hc

ho l'o

l'a

l'b

l'c

B

C

0

80

60

40

20

20 40 60 80 100 120 135

120

100

100 2030405060708090

100 110 120 130 140 150 160 170

-

40

-

20

-

10

0

10

20

30

40

50

-

30

100%

92

93

94

96

97

98

9

91

90

89

95

4

Connecting pipe length and lift difference between indoor and outdoor units vs. capacity correction value

5

Outdoor unit (5 to 48HP)

Height of outdoor unit H (m)

Pipe length (Equivalent length) L (m)

5

Correction of outdoor unit diversity

Correction (%)

Standard capacity ratio

Indoor units total capacity ratio (%)

1 : Coefficient to use for the correction of the outdoor unit capacity when the total capacity of

*

the indoor units are not equal to the outdoor unit capacity.

24

Page 28

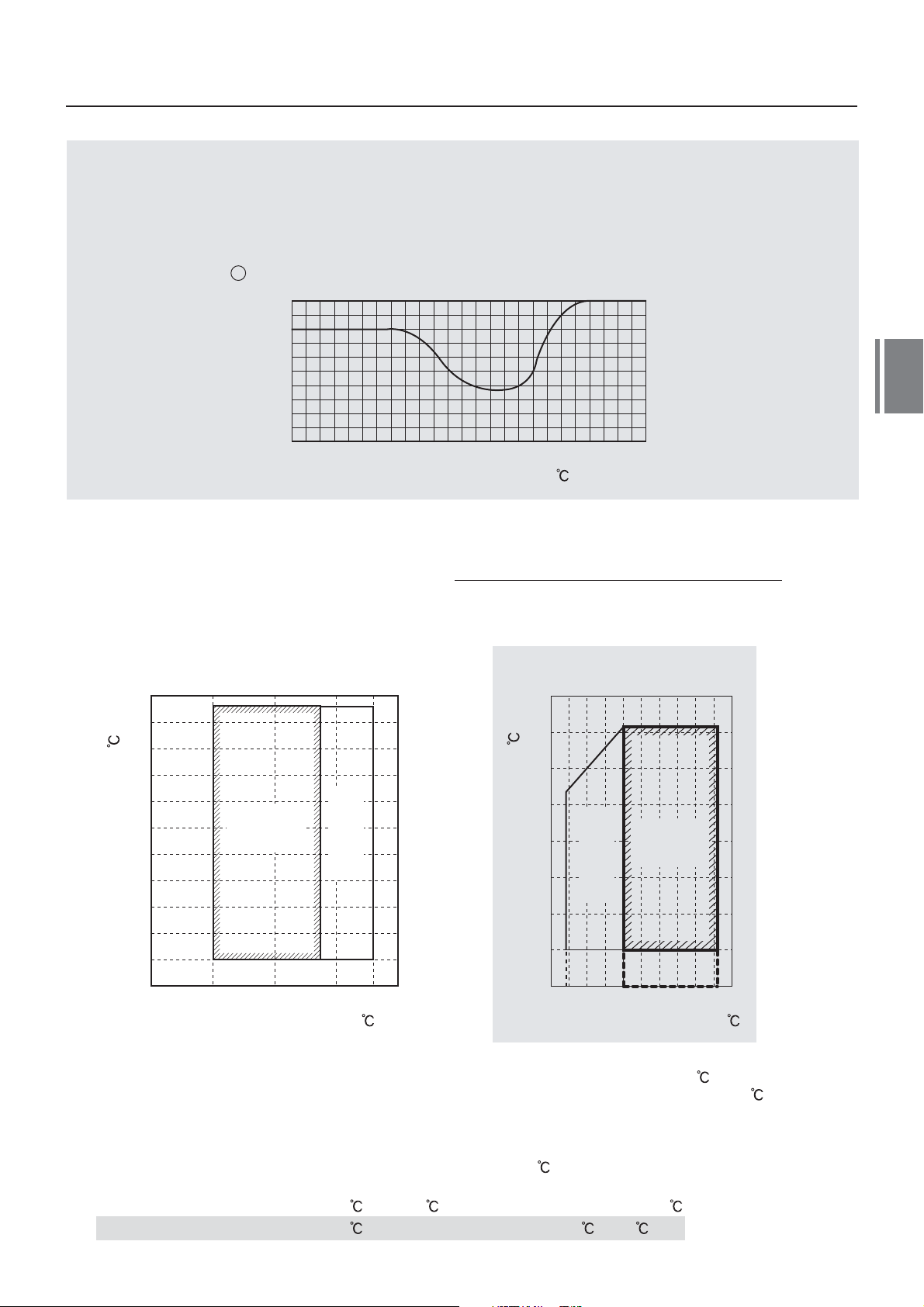

3. Capacity correction in case of frost on the outdoor heat exchanger when in heating

Correct the heating capacity when frost can be found on the outdoor heat exchanger.

Heating capacity = Capacity after correction of outdoor unit x Correction value of capacity resulted from frost

(Capacity after correction of outdoor unit : Heating capacity calculated in the above item 2.)

6

Capacity correction in case of frost on the outdoor heat exchanger

1.0

0.9

0.8

Capacity correction value

-

15

-

10

Outdoor air wet bulb temp. ( )

-

50 510

4. Capacity calculation for each indoor unit

Capacity for each indoor unit

= Capacity after correction of outdoor unit

x

5. Operating temperature range

In cooling time

45

40

35

30

25

20

15

10

5

0

Outdoor air dry bulb temp. ( )

-

5

-

10

Indoor air wet bulb temp. ( )

Continuously

operable

range

Usable range

(in pull down)

3025 28201510

Required standard capacity of indoor unit

Total value of standard indoor unit capacity

In heating time

20

15

10

5

0

-

5

-

10

Outdoor air wet bulb temp. ( )

-

15

-

20

5 1015202530

Indoor air dry bulb temp. ( )

Continuously

operable

range

Usable range

(in warming-up)

5

The unit can be operated even if outdoor tem-

*

perature gets down to

the warranty covers only up to

operation beyond that temperature is out of

specification.

When outdoor air temperature falls below

*

-

15 , it may cause shortening of the products

6. Rated conditions

lifetime.

Cooling : Indoor air temperature 27 DB/19.0 WB, Outdoor air temperature 35 DB

Heating : Indoor air temperature 20

DB, Outdoor air temperature 7 DB/6 WB

-

20 . However, note that

-

15 because

25

Page 29

26

Page 30

6

Piping requirements

27

Page 31

Foreword

28

Page 32

6

Piping requirements

Foreword

1. Allowable length/height difference of refrigerant piping

D

Follower

unit 3

Height

difference

between

outdoor

units

H3 5m

Header

unit

Outdoor unit

T-shape branching

joint

Main

piping

A

B

Follower

unit 1

La

LA LB

Main connecting piping between outdoor units

Length corresponded to farthest piping

between outdoor units LO

C

Follower

unit 2

Lb Lc

Connecting

piping of

outdoor unit

25 m

Header

Ld

NOTE :

In case of connecting method Ex. 2, a large amount of

refrigerant and refrigerant oil may return to the head unit.

Therefore, set the T-shape joint so that oil does not enter directly.

unit

Follower

unit 1

Follower

unit 2

Header

unit

Ex.2Ex.1

Follower

unit 1

Follower

unit 2

L1

Height

difference

between

outdoor

units

H1 50m

1st branching

section

L3

Y-joint

System restrictions

Max. No. of combined outdoor units

Max. capacity of combined outdoor units

Max. No. of connected indoor units

Max. capacity of combined

indoor units

H2 <15 135%

H2 >15 105%

Branching

Branching piping L2

Connecting piping of indoor unit L7

bc dea

Equivalent length corresponded to farthest piping L

Equivalent length corresponded to farthest piping after 1st branching Li

L5

ghi jf

4 units

48 HP

48 units

L4

Note 1)

Note 2)

Note 3)

Note 4)

Combination of outdoor units : Header unit (1 unit) + Follower units (0 to 3 units).

Header unit is the outdoor unit nearest to the connected indoor units.

Install the outdoor units in order of capacity.

(Header unit Follower unit 1 Follower unit 2 Follower unit 3)

Refer to outdoor unit combination table.

Piping to indoor units shall be perpendicular to piping to the header outdoor unit as <Ex.1>.

Do not connect piping to indoor units in the same direction of Header outdoor unit as <Ex.2>.

header

Indoor unit

175 m

L6

Indoor unit

65 m

Height difference

between indoor

units

H2

30m

6

Allowable length and height difference of refrigerant piping

Allowable value Piping section

Total extension of pipe (Liquid pipe, real length)

Farthest piping length L (*)

Piping

length

Height

difference

(D)

*

If the height difference (H2) between indoor units exceeds 3m, set below 30m.

**

***

Equivalent length of farthest piping from 1st branching Li (*)

Equivalent length of farthest piping between outdoor units LO (*)

Max. equivalent length of main piping (

Max. equivalent length of outdoor unit connecting piping

Max. real length of indoor unit connecting piping

Height between indoor

and outdoor units H1

Height between indoor units H2

Height between outdoor units H3

is outdoor unit

If the

maximum combined outdoor unit capacity

furthest

Real length

Equivalent length

)

***

Upper outdoor unit

Lower outdoor unit

from the 1st branch and ( j ) is the indoor unit furthest from the 1st branch.

300 m

150 m

175 m

65 m L3 + L4 + L5 + L6 + j

25 m LA + LB + Ld, (LA + Lb, LA + LB + Lc)

85 m L1

10 m Ld, (La, Lb, Lc)

30 m a, b, c, d, e, f, g, h, i, j

50 m

40 m (

30 m

5 m

is 46 HP or more, then the maximum equivalent

LA + LB + La + Lb + Lc + Ld + L1 + L2 + L3 + L4+

L5 + L6 + L7 + a + b + c + d + e + f + g + h + i + j

LA + LB + Ld + L1 + L3 + L4 + L5 + L6 + j

)

**

length is restricted to 70m.

_

_

_

_

29

Page 33

2. Selection of refrigerant piping

Branching piping

Header branching pipe

6

6

unit 3

Follower

unit 2

Follower

unit 1

1 1 1

Main connecting

piping between

outdoor units

Header unit

22

Outdoor

unit

Balance pipe

2

T-shape

6

branching joint

Main piping

3

1st branching

section

4

4

Indoor unit

connecting piping

Outdoor unit

1

connecting

piping

Follower

1 Pipe size of outdoor unit (Table 1)

Model name Gas side Liquid side

MAP0501T8 MAP0501HT8 MAP0501HT7

MAP0601T8 MAP0601HT8 MAP0601HT7

MAP0801T8 MAP0801HT8 MAP0801HT7

MAP1001T8 MAP1001HT8 MAP1001HT7

MAP1201T8 MAP1201HT8 MAP1201HT7

MMY-

O

/

O

/

O

/

O

/

O

/

15.9

19.1

22.2

22.2

28.6

O

9.5

/

O

9.5

/

O

12.7

/

O

12.7

/

O

12.7

/

2 Connecting pipe size between outdoor units (Table 2)

Total capacity code of outdoor

units at downstream side

14 to below 22

22 to below 26

26 to below 36

36 or more

Gas side

O

28.6

/

O

34.9

/

O

34.9

/

O

41.3

/

Liquid side Balance pipe

O

15.9

/

O

15.9

/

O

19.1

/

O

22.2

/

O

9.5

/

3 Size of main pipe (Table 3)

Total capacity code of all outdoor units *1

Below 6

6 to below 8

8 to below 12

12 to below 14

14 to below 22

22 to below 26

26 to below 36

36 to below 46

46 or more

Determine thickness of the main pipe according to capacity of the outdoor

units.

Gas side Liquid side

O

15.9

/

O

19.1

/

O

22.2

/

O

28.6

/

O

28.6

/

O

34.9

/

O

34.9

/

O

41.3

/

O

41.3 *5

/

O

9.5

/

O

9.5

/

O

12.7

/

O

12.7

/

O

15.9

/

O

15.9

/

O

19.1

/

O

22.2

/

O

22.2

/

4 Pipe size between branching sections (Table 4)

Total capacity code of indoor units at

downstream side *1

2.8 or less

2.8 to below 6.4

6.4 to below 12.2

12.2 to bel ow 20.2

20.2 to bel ow 25.2

25.2 to bel ow 35.2

35.2 or more

If the total capacity code value of indoor units exceeds that of the outdoor

units, apply the capacity code of outdoor units.

Gas side

O

12.7

/

O

15.9

/

O

22.2

/

O

28.6

/

O

34.9

/

O

34.9

/

O

41.3

/

Liquid side

O

9.5

/

O

9.5

/

O

12.7

/

O

15.9

/

O

15.9

/

O

19.1

/

O

22.2

/

Indoor unit connecting piping

5 5 5

6

Y-shape

branching

joint

4

4

4

5 5

Indoor unit

4

5 5 5 5 5

Indoor unit

5 Piping of indoor unit (Table 5)

007 type to

012 type

Capacity rank

Real length 15m or less

Real length exceeds 15m

015 type to 018 type

024 type to 056 type

072 type to 096 type

Gas side Liquid side

O

9.5

/

O

12.7

/

O

12.7

/

O

15.9

/

O

22.2

/

6 Selection of branching section (Table 6)

Total capacity code of indoor unit

Y-shape

branching joint

2

*

Branching

*

header

3

6

*

T-shape

branching joint

(For

connecting

outdoor unit)

For 4

branching

For 8

branching

1 set of 3 types of T-shape joint pipes as

described below:

The required quantity is arranged and

combined

at the site.

Balance pipe

(Corresponded difference

Piping at liquid side

(Corresponded difference O/ 9.5 to O/ 22.1) 1

Piping at gas side

(Corresponded difference O/ 15.9 to O/ 41.3) 1

Below 6.4 RBM-BY53E

6.4 to below 14.2 RBM-BY103E

14.2 to bel ow 25.2 RBM-BY203E

25.2 or more RBM-BY303E

Below 14.2 RBM-HY1043E

14.2 to below 25.2 RBM-HY2043E

Below 14.2 RBM-HY1083E

14.2 to below 25.2 RBM-HY2083E

O

9.52) 1

/

7 Minimum wall thickness for R410A application

(Table 7)

Half hard or hardSoft OD (Inch) OD (mm) Minimum wall thickness (mm)

OK OK 1/4'' 6.35 0.80

OK OK 3/8'' 9.52 0.80

OK OK 1/2'' 12.70 0.80

OK OK 5/8'' 15.88 1.00

NG*4 OK 3/4'' 19.05 1.00

NG*4 OK 7/8'' 22.20 1.00

NG*4 OK 1.1/8'' 28.58 1.00

NG*4 OK 1.3/8'' 34.92 1.10

NG*4 OK 1.5/8'' 41.28 1.25

*

1

O

6.4

/

O

6.4

/

O

6.4

/

O

9.5

/

O

12.7

/

Model name

RBM-BT13E

1 Code is determined according to the capacity rank.

*

2 When using a Y-shape branching joint for the 1st branch, select according to capacity code of the outdoor unit.

*

3 For 1 line after branching header indoor units with a maximum capacity code of 6.0 in total can be connected.

*

4 If the pipe size is O/ 19.0 or more, use a suitable material as detailed in the installation manual.

*

5 The maximum equivalent length of the main pipe should be 70m.

*

6 When the first branch is a header with the outdoor total capacity codes of 12 to 26, apply the model RBM-

*

HY2043E(4-branch) or RBM-HY2083E(8-branch) regardless of the total capacity codes of the down-stream

indoor units.

30

Page 34

Foreword

3. Charging requirement with additional refrigerant

After the system has been vacuumed, replace the vacuum pump with a refrigerant cylinder and charge the

system with additional refrigerant.

Calculating the amount of additional refrigerant required

Refrigerant in the system when shipped from the factory

R410A

5HP 6HP 8HP 10HP 12HP

Refrigerant amount

charged in factory

Heat pump model

Cooling only model

When the system is charged with refrigerant at the factory, the amount of refrigerant needed for the pipes at the

site is not included. Therefore, calculate the additional amount needed and add the required amount to the system.

(Calculation)

Additional refrigerant charge amount is calculated based on the size of liquid pipe at site and its real length.

Additional refrigerant charge amount at site =

Real length of liquid pipe X

Additional refrigerant charge amount

per liquid pipe 1m (Table 1)

Example : Additional charge amount R (kg) = (L1 x 0.025kg/m) + (L2 x 0.055kg/m) + (L3 x 0.105kg/m) + (3.0kg)

Table 7-1

Pipe dia. at liquid side

Additional refrigerant amount/1m

o/6.4 o/9.5 o/12.7 o/15.9 o/19.0 o/22.2

0.025kg 0.055kg 0.105kg 0.160kg 0.250kg 0.350kg

8.5kg

8.0kg

8.5kg

8.0kg

+

Compensation by system HP (Table 2)

12.5kg

11.0kg

L1 : Real total length of liquid pipe

L2 : Real total length of liquid pipe

L3 : Real total length of liquid pipe

12.5kg

11.0kg

6.4 (m)

9.5 (m)

12.7 (m)

12.5kg

11.0kg

6

Table 7-2

Combined

horse power

(HP)

5

6

8

10

12

14

16

18

20

22

24

26

Outdoor combination

(HP)

5

6

8

10

12

86

88

10 8

10 10

12 10

886

12 12

888

10 8 8

Compensation

by System HP

(kg)

0.0

0.0

1.5

2.5

3.5

0.0

0.0

0.0

3.0

5.0

0.0

7.0

-

4.0

-

4.0

Combined

horse power

(HP)

28

30

32

34

36

38

40

42

44

46

48

Outdoor combination

(HP)

10 10 8

10 10 10

12 10 10

8888

12 12 10

10 8 8 8

12 12 12

10 10 8 8

10 10 10 8

10 10 10 10

12 10 10 10

12 12 10 10

12 12 12 10

12 12 12 12

Compensation

by System HP

(kg)

-

2.0

0.0

1.0

-

6.0

3.0

-

6.0

4.0

-

6.0

-

6.0

-

5.0

-

4.0

-

2.0

0.0

2.0

31

Page 35

32

Page 36

7

Refrigerant cycle diagram

33

Page 37

Foreword

34

Page 38

7

Refrigerant cycle diagram

Foreword

1. Inverter Unit (5, 6, 8, 10, 12HP)

Model: MMY-MAP0501HT, MAP0601HT, MAP0801HT, MAP1001HT, MAP1201HT

(8,10,12HP)

Propeller fan

(PMV1)

(PMV1)

Sensor

(TL)

(PMV2)

Liquid

tank

Strainer

Pulse motor

valve (PMV)

(5,6HP)

Strainer

Sensor

(TE1)

Solenoid valve (SV5)

Solenoid valve

(SV3D)

Solenoid valve

(SV41)

M

Fan motor

(Right side)

Air heat exchanger at outdoor side

(Left side)

Air heat exchanger at outdoor side

Check valve

High-pressure

sensor

Check joint

Capillary tube

Strainer

Capillary tube

Strainer

separator

Check

valve

Oil

4-Way valve

Solenoid valve

(SV2)

Capillary tube

Check

Solenoid valve

valve

(SV42)

Sensor

(TO)

Sensor (TS1)

Low-pressure

sensor

Check joint

7

Check

joint

Balance

pipe

servise

valve

Liquid

side

servise

valve

StrainerStrainer

Gas

side

servise

valve

Strainer

High-pressure

switch

Sensor

(TD1)

Solenoid

valve

(SV3E)

Capillary tube

Capillary

tube

Sensor

(TK3)

Strainer

Check

(Inverter)

valve

Compressor 1

Capillary tube

Sensor

(TK1)

Sensor

(TK4)

Check

valve

Solenoid

valve

(SV3C)

Strainer

Check

valve

Capillary tube

Sensor

(TK2)

Oil tank

Solenoid

valve

(SV3A)

High-pressure

switch

Sensor

(TD2)

(Inverter)

Compressor 2

Capillary tube

Solenoid

valve

(SV3B)

Check

valve

Accumulator

35

Page 39

7

2. Explanation of Functional Parts

Functional part name Functional outline

Solenoid valve

4-way valve

Pulse motor valve

Oil separator

Temp. sensor

Pressure sensor

Heater

Balance pipe

1.SV3A

2.SV3B

3.SV3C

4.SV3D

5.SV3E

6.SV2

7.SV4(n)

8.SV5

PMV1,2

1. TD1

TD2

2. TS1

3. TE1

4. TK1, TK2,

TK3, TK4

5. TL

6. TO

1.High pressure

sensor

2. Low pressure

sensor

Compressor case

heater

Accumulator case

heater

(Connector CN324: Red)

1) Collects oil in the oil tank during OFF time.

2) Supplies oil in the oil tank during ON time.

(Connector CN313: Blue)

1) Returns oil in the balance pipe to the compressor.

(Connector CN314: Black)

1) Pressurizes oil reserved in the oil tank during operation.

(Connector CN323: White)

1) Reserves oil in the oil separator during OFF time, and supplies oil during operation.

(Connector CN323: White)

1) Turns on during operation and balances oil between the compressors.

(Hot gas bypass) (Connector CN312: White)

1) Low pressure release function

2) High pressure release function

3) Gas ba

(Start compensation valve of compressor) (Connector CN311: Blue)

1) For gas balance start

2) High pressure release function

3) Low pressure release function

(Connector CN310: White) (for Heating model only)

1) Preventive function for high-pressure rising in heating operation

(Connector CN317: Blue)

1) Cooling/heating exchange

2) Reverse defrost

(Connector CN300, 301: White)

1) Super heat control function in heating operation

2) Liquid line shut-down function while follower unit stops

3) Under-cool adjustment function in cooling operation

1) Prevention for rapid decreasing of oil (Decreases oil flowing to the cycle)

2) Reserve function of surplus oil

(TD1: Connector, CN502: White, TD2: Connector, CN503: Pink)

1) Protection of compressor discharge temp. Used for release

(Connector CN504: White)

1) Controls super heat in heating operation

(Connector CN505: Green)

1) Controls defrost in heating operation

2) Controls outdoor fan in heating operation

TK1 Connector CN514: Black, TK2 Connector CN515: Green,

()

TK3 Connector CN516: Red, TK4 Connector CN523: Yellow

1) Judges oil level of the compressor

(Connector CN521: White)

1) Detects under cool in cooling operation

(Connector CN507: Yellow)

1) Detects outside temperature

(Connector CN501: Red)

1) Detects high pressure and controls compressor capacity

2) Detects high pressure in cooling operation, and controls the fan in low ambient

cooling operation

(Connector CN500: White)

1) Detects low pressure in cooling operation and controls compressor capacity

2) Detects low pressure in heating operation, and controls the super heat

(Compressor 1 Connector CN316: White, Compressor 2 Connector CN315: Blue)

1) Prevents liquid accumulation to compressor

(Connector CN321: Red)

1) Prevents liquid accumulation to accumulator

1) Oil balancing in each outdoor unit

lance during off status

36

Page 40

3. Indoor Unit

Foreword

Liquid side

Pulse Motor

Valve (PMV)

Gas side

Strainer

Sensor

(TC2)

Capillary tube

Strainer

Sensor

(TCJ)

Air heat exchanger

at indoor side

Fan

Sensor

(TA)

M

Fan motor

(NOTE) MMU-AP0071YH to AP0121YH type air conditioners do not have a TC2 sensor.

7

Sensor

(TC1)

Functional part name Functional outline

Pulse Motor Valve

Temp. sensor

PMV

1. TA

2. TC1

3. TC2

4. TCJ

(Connector CN082 (6P): Blue)

1)Controls super heat in cooling operation

2)Controls under cool in heating operation

3)Recovers refrigerant oil in cooling operation

4)Recovers refrigerant oil in heating operation

(Connector CN104 (2P): Yellow)

1)Detects indoor suction temperature

(Connector CN100 (3P): Brown)

1)Controls PMV super heat in cooling operation

(Connector CN101 (2P): Black)

1)Controls PMV under cool in heating operation

(Connector CN102 (2P): Red)

1)Controls PMV super heat in cooling operation

2)

MMU-AP0071 to AP0121YH only

Controls PMV under cool in heating operation

37

Page 41

COMBINED REFRIGERANT PIPES SYSTEMATIC DRAWING

1. Normal Operation (COOL Mode / DEFROST Mode)

7

PMV1 PMV2

TL

Liquid

tank

Header unit

(MMY-MAP1001H)

FM

TE1

SV5

TK3

TK4

SV2

OS

SV3C

TK2

Oil tank

Pd sensor

SV3D

SV41 SV42

HP HP

TD1

1

Compressor

TK1

SV3E

4-Way valve

Ps sensor

TD2

2

Compressor

TO

TS1

Accumulator

PMV1 PMV2

TL

Liquid

tank

Follower unit

(MMY-MAP1001H)

FM

TE1

SV5

TK3

TK4

SV2

OS

SV3C

TK2

Oil tank

Pd sensor

SV3D

SV41 SV42

HP HP

TD1

1

Compressor

TK1

SV3E

TO

4-Way valve

TS1

Ps sensor

Accumulator

TD2

2

Compressor

SV3A

SV3B

Balance pipe

Liquid pipe

Gas pipe

Gas pipe

Liquid pipe

PMV

TC2

Strainer

TCJ

Strainer Strainer

PMV

TC1

TC2

TCJ

Strainer Strainer

PMV

TC1

TC2

TCJ

Indoor unit

High-pressure gas or condensate liquid refrigerant

Evaporative gas refrigerant (Low-pressure gas)

NOTE

An outdoor unit which is connected with indoor/outdoor communication lines is

referred to as the ‘‘Header unit’’, and the other unit is called the ‘‘Follower unit’’.

SV3A

Strainer Strainer

PMV

TC1

TC2

TCJ

(Example: 20HP system)

SV3B

Strainer

TC1

38

Page 42

2. Normal Operation (HEAT Mode)

PMV1 PMV2

TL

Liquid

tank

Header unit

(MMY-MAP1001H)

FM

TE1

SV5

TK3

TK4

SV2

OS

SV3C

TK2

Oil tank

Pd sensor

SV3D

SV41 SV42

HP HP

TD1

1

Compressor

TK1

SV3E

4-Way valve

Ps sensor

TD2

2

Compressor

TO

TS1

Accumulator

PMV1 PMV2

TL

Liquid

tank

Follower unit

(MMY-MAP1001H)

FM

TE1

SV5

TK3

TK4

SV2

OS

SV3C

TK2

Oil tank

Pd sensor

SV3D

SV41 SV42

HP HP

TD1

1

Compressor

TK1

SV3E

TO

4-Way valve

TS1

Ps sensor

7

Accumulator

TD2

2

Compressor

SV3A

SV3B

Balance pipe

Liquid pipe

Gas pipe

Gas pipe

Liquid pipe

PMV

TC2

Strainer

TCJ

Strainer Strainer

PMV

TC1

TC2

TCJ

Strainer Strainer

PMV

TC1

TC2

TCJ

Indoor unit

High-pressure gas or condensate liquid refrigerant

Evaporative gas refrigerant (Low-pressure gas)

NOTE

An outdoor unit which is connected with indoor/outdoor communication lines is

referred to as the ‘‘Header unit’’, and the other unit is called the ‘‘Follower unit’’.

SV3A

Strainer Strainer

PMV

TC1

TC2

TCJ

(Example: 20HP system)

SV3B

Strainer

TC1

39

Page 43

3. Backup Operation

(Cooling Operation when Header Outdoor unit failure)

7

Failure

1

*

PMV1 PMV2

TL

Liquid

tank

Header unit

(MMY-MAP1001H)

FM

TE1

SV5

TK3

TK4

SV2

OS

SV3C

TK2

Oil tank

Pd sensor

SV3D

SV41 SV42

HP HP

TD1

1

Compressor

TK1

SV3E

4-Way valve

Ps sensor

TD2

2

Compressor

TO

TS1

Accumulator

Unit set temporarily

(MMY-MAP1001H)

to header unit during

emergent operation.

TE1

PMV1 PMV2

TL

Liquid

tank

Pd sensor

SV3D

SV41 SV42

Follower unit

FM

SV2

SV3C

TK2

Oil tank

4-Way valve

Ps sensor

TD2

2

Compressor

SV5

OS

HP HP

TD1

TK3

1

Compressor

TK1

SV3E

TK4

TO

TS1

Accumulator

SV3A

SV3B

TC1

Balance pipe

Liquid pipe

Gas pipe

PMV

TC2

TCJ

Gas pipe

Liquid pipe

Strainer Strainer

PMV

TC1

TC2

TCJ

1 When liquid leaks from PMV, packed valve

*

at liquid side = Close fully

2 Gas pipe service valve = Close fully

*

3 Balance pipe packed valve = Open fully

*

Strainer Strainer

*

PMV

3

TC2

Strainer

TCJ

2

*

Strainer Strainer

Indoor unit

High-pressure gas or condensate liquid refrigerant

Evaporative gas refrigerant (Low-pressure gas)

NOTE

An outdoor unit which is connected with indoor/outdoor communication lines is

referred to as the ‘‘Header unit’’, and the other unit is called the ‘‘Follower unit’’.

SV3A

SV3B

Strainer

PMV

TC1

TC2

TCJ

(Example: 20HP system)

TC1

40

Page 44

4. Emergent Operation

(Heating Operation when Header Outdoor unit failure)

Failure

1

*

PMV1 PMV2

TL

Liquid

tank

Header unit

(MMY-MAP1001H)

FM

TE1

SV5

TK3

TK4

SV2

OS

SV3C

TK2

Oil tank

Pd sensor

SV3D

SV41 SV42

HP HP

TD1

1

Compressor

TK1

SV3E

4-Way valve

Ps sensor

TD2

2

Compressor

TO

TS1

Accumulator

Unit set temporarily

(MMY-MAP1001H)

to header unit during

emergent operation.

TE1

PMV1 PMV2

TL

Liquid

tank

Pd sensor

SV3D

SV41 SV42

Follower unit

FM

SV2

SV3C

TK2

Oil tank

4-Way valve

Ps sensor

TD2

2

Compressor

SV5

OS

HP HP

TD1

TK3

1

Compressor

TK1

SV3E

TK4

TO

TS1

7

Accumulator

*

PMV

SV3A

SV3B

TC1

Balance pipe

Liquid pipe

Gas pipe

PMV

TC2

TCJ

Gas pipe

Liquid pipe

Strainer Strainer

PMV

TC1

TC2

TCJ

1 When liquid leaks from PMV, packed valve

*

at liquid side = Close fully

2 Gas pipe service valve = Close fully

*

3 Balance pipe packed valve = Open fully

*

Strainer Strainer

3

TC2

Strainer

TCJ

2

*

Strainer Strainer

SV3A

TC1

Indoor unit

High-pressure gas or condensate liquid refrigerant

Evaporative gas refrigerant (Low-pressure gas)

NOTE

An outdoor unit which is connected with indoor/outdoor communication lines is

referred to as the ‘‘Header unit’’, and the other unit is called the ‘‘Follower unit’’.

SV3B

Strainer

PMV

TC2

TCJ

TC1

(Example: 20HP system)

41

Page 45

5. Recovery of Refrigerant in Failed Outdoor Unit

(In Case of Failure of Follower Unit)

7

PMV1 PMV2

TL

Liquid

tank

Header unit

(MMY-MAP1001H)

FM

TE1

SV5

TK3

TK4

SV2

OS

SV3C

TK2

Oil tank

Pd sensor

SV3D