Page 1

INSTALLATION MANUAL

Heat Reco very Type

FILE NO. A04-002

R410A

Indoor Unit

<4-way Air Discharge Cassette Type>

MMU-AP0091H, AP0121H, AP0151H,

MMU-AP0181H, AP0241H, AP0271H,

MMU-AP0301H, AP0361H, AP0481H

MMU-AP0561H

<2-way Air Discharge Cassette Type>

MMU-AP0071WH, AP0091WH, AP0121WH,

MMU-AP0151WH, AP0181WH, AP0241WH,

MMU-AP0271WH, AP0301WH, AP0481WH*

* CHINA market only

<1-way Air Discharge Cassette Type>

MMU-AP0071YH, AP0091YH, AP0121YH,

MMU-AP0151SH, AP0181SH, AP0241SH

<Concealed Duct Standard Type>

MMD-AP0071BH, AP0091BH, AP0121BH,

MMD-AP0151BH, AP0181BH, AP0241BH,

MMD-AP0271BH, AP0301BH, AP0361BH,

MMD-AP0481BH, AP0561BH

<Concealed Duct High Static Pressure Type>

MMD-AP0181H, AP0241H, AP0271H,

MMD-AP0361H, AP0481H

Outdoor Unit

<Inverter Unit>

MMY-MAP0801FT8

MMY-MAP1001FT8

MMY-MAP1201FT8

FS unit

RBM-Y1121FE

RBM-Y1801FE

<Under Ceiling Type>

MMC-AP0151H, AP0181H, AP0241H,

MMC-AP0271H, AP0361H, AP0481H

<High Wall Type>

MMK-AP0071H, AP0091H, AP0121H,

MMK-AP0151H, AP0181H, AP0241H

<Floor Standing Cabinet Type>

MML-AP0071H, AP0091H, AP0121H,

MML-AP0151H, AP0181H, AP0241H

<Floor Standing Concealed Type>

MML-AP0071BH, AP0091BH, AP0121BH,

MML-AP0151BH, AP0181BH, AP0241BH

<Floor Standing Type>

MMF-AP0151H, AP0181H, AP0241H

MMF-AP0271H, AP0361H, AP0481H

MMF-AP0561H

PRINTED IN JAPAN, Aug, 2004 ToMo

Page 2

WARNINGS ON REFRIGERANT LEAKAGE

Check of Concentration Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its concentration will

not exceed a set limit.

The refrigerant R410A which is used in the air

conditioner is safe, without the toxicity or

combustibility of ammonia, and is not restricted by

laws to be imposed which protect the ozone layer.

However, since it contains more than air, it poses the

risk of suffocation if its concentration should rise

excessively. Suffocation from leakage of R410A is

almost non-existent. With the recent increase in the

number of high concentration buildings, however, the

installation of multi air conditioner systems is on the

increase because of the need for effective use of floor

space, individual control, energy conservation by

curtailing heat and carrying power etc.

Most importantly, the multi air conditioner system is

able to replenish a large amount of refrigerant

compared with conventional individual air conditioners.

If a single unit of the multi conditioner system is to be

installed in a small room, select a suitable model and

installation procedure so that if the refrigerant

accidentally leaks out, its concentration does not

reach the limit (and in the event of an emergency,

measures can be made before injury can occur).

In a room where the concentration may exceed the

limit, create an opening with adjacent rooms, or install

mechanical ventilation combined with a gas leak

detection device.

The concentration is as given below.

Total amount of refrigerant (kg)

Min. volume of the indoor unit installed room (m³)

≤ Concentration limit (kg/m³)

The concentration limit of R410A which is used in multi

air conditioners is 0.3kg/m³.

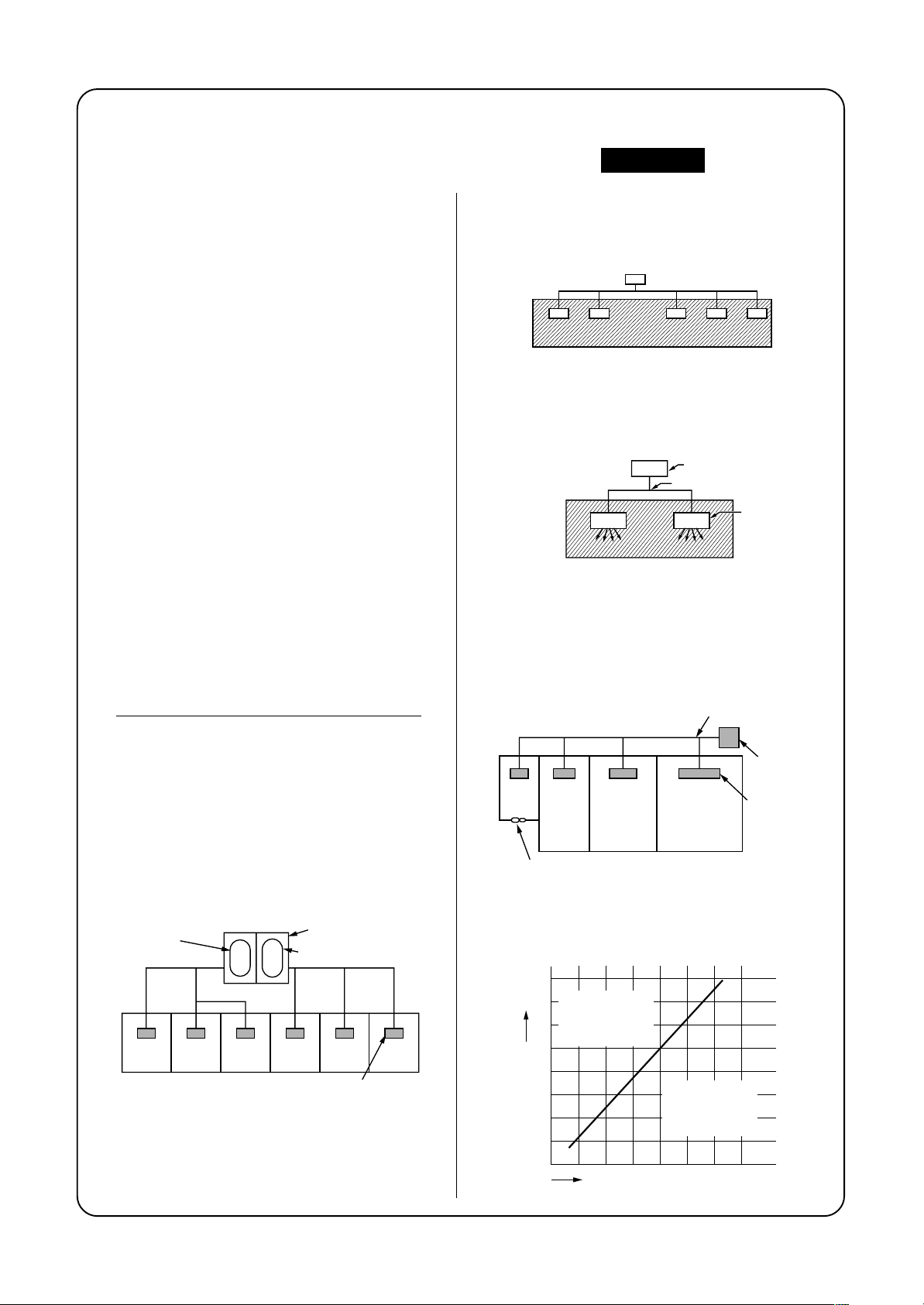

NOTE 1 :

If there are 2 or more refrigerating systems in a single

refrigerating device, the amounts of refrigerant should

be as charged in each independent device.

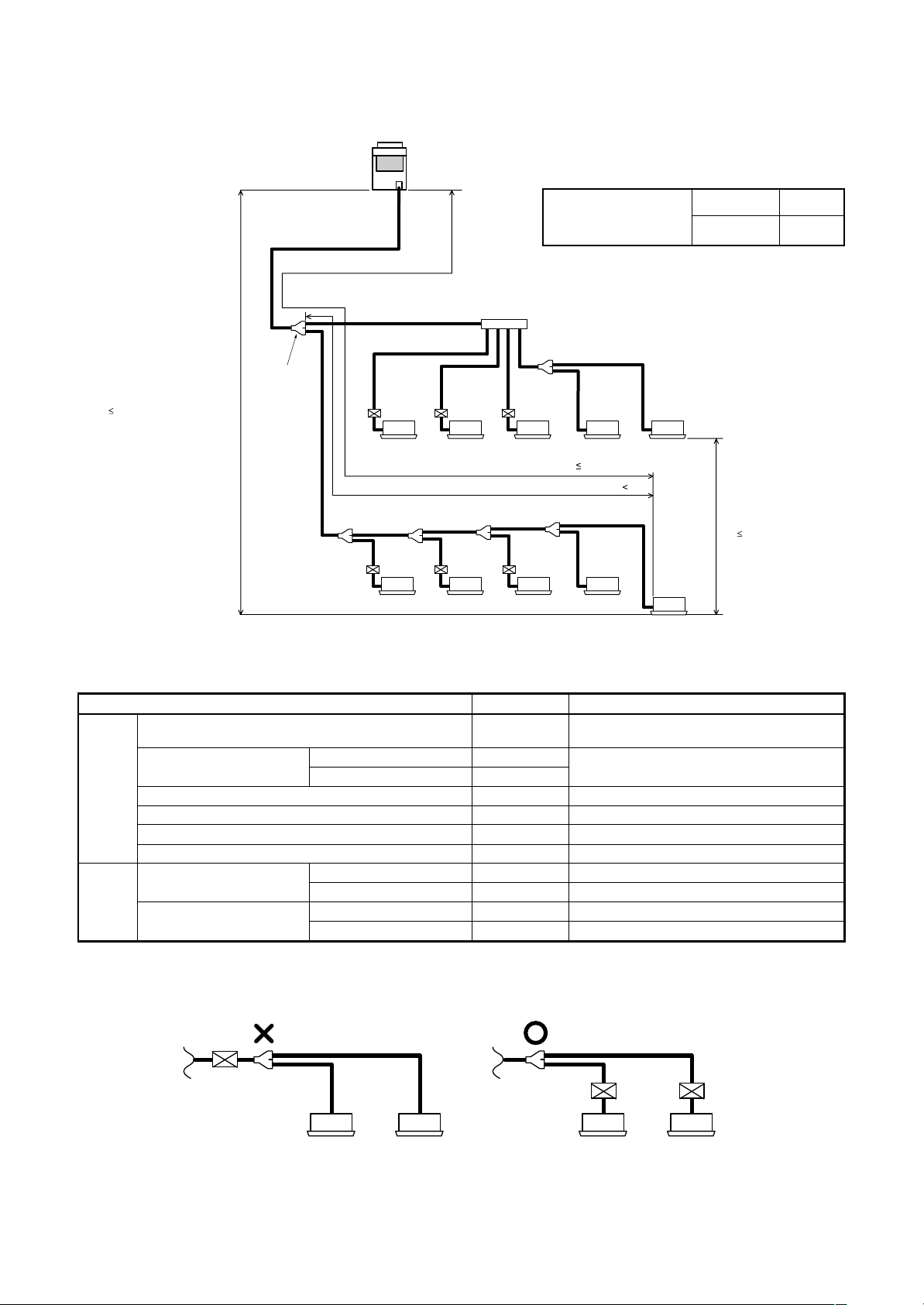

e.g., charged

amount (10kg)

Room A Room B Room C Room D Room E Room F

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in

rooms A, B and C is 10kg.

The possible amount of leaked refrigerant gas in

rooms D, E and F is 15kg.

Outdoor unit

e.g.,

charged amount (15kg)

Indoor unit

Important

NOTE : 2

The standards for minimum room volume are as

follows.

(1) No partition (shaded portion)

(2) When there is an effective opening with the

adjacent room for ventilation of leaking refrigerant

gas (opening without a door, or an opening 0.15%

or larger than the respective floor spaces at the

top or bottom of the door).

Outdoor unit

Refrigerant piping

Indoor unit

(3) If an indoor unit is installed in each partitioned

room and the refrigerant tubing is interconnected,

the smallest room of course becomes the object.

But when a mechanical ventilation is installed

interlocked with a gas leakage detector in the

smallest room where the density limit is exceeded,

the volume of the next smallest room becomes the

object.

Refrigerant piping

Outdoor unit

Very

small

room

Small

room

Mechanical ventilation device - Gas leak detector

Medium

room

Large room

NOTE 3 :

The minimum indoor floor area compared with the

amount of refrigerant is roughly as follows:

(When the ceiling is 2.7m high)

40

Range below the

35

m²

density limit

of 0.3 kg/m³

30

(countermeasures

not needed)

25

20

15

10

5

Min. indoor floor area

0

10 20 30

Total amount of refrigerant

Range above

the density limit

of 0.3 kg/m³

(countermeasures

needed)

Indoor unit

kg

Page 3

NOTE

A direct current motor is adopted for indoor fan motor in the Concealed Duct Standard Type air conditioner.

Caused from its characteristics, a current limit works on the direct current motor. When replacing the highperformance filter or when opening the service panel, be sure to stop the fan. If an above action is executed

during the fan operation, the protectiv e control works to stop the unit operation, and the check code “P12”

may be appear. However it is not a trouble. When the desired operation has finished, be sure to reset the

system to clear “P12” error code using the electric leak breaker of the indoor unit. Then push the operation

ON/OFF button of the remote controller to return to the usual operation.

CONTENTS

1. SELECTING A LOCATION FOR INSTALLATION ..................................... 4

2. SAFETY NOTES......................................................................................... 8

3. CHECK POINTS......................................................................................... 9

4. KEY POINTS OF AIR CONDITIONER INSTALLATION .......................... 10

5. REFRIGERANT PIPE INSTALLATION .................................................... 11

6. INDOOR UNIT INSTALLATION................................................................ 41

7. FLOW SELECTOR UNIT INSTALLATION ............................................... 77

8. OUTDOOR UNIT INSTALLATION............................................................ 81

9. ELECTRIC WIRING .................................................................................. 87

10. INDOOR UNIT TERMINAL BOARD PLACEMENT AND WIRING ......... 102

11. DRAIN PIPE INSTALLATION................................................................. 107

12. ADJUSTMENT OF AIR DIRECTION...................................................... 115

13. APPLIED CONTROL.............................................................................. 119

14. ADDRESS SETUP.................................................................................. 123

15. TEST OPERATION ................................................................................. 136

16. SUPPORT FUNCTION IN TEST OPERATION ....................................... 143

17. TROUBLESHOOTING............................................................................ 165

18. AIR SPEED CHARACTERISTICS.......................................................... 170

19. FAN CHARACTERISTICS...................................................................... 175

Page 4

CAUTION New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES

NOT DESTROY OZONE LAYER.

The characteristics of R410A refrigerant are ; easy to absorb water, oxidizing membrane or oil, and its

pressure is approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant,

refrigerating oil has also been changed. Therefore, during installation work, be sure that water, dust, former

refrigerant, or refrigerating oil does not enter the refrigerating cycle.

To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging

port of the main unit and installation tools are charged from those for the conventional refrigerant.

Accordingly the exclusive tools are required for the new refrigerant (R410A).

For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust

does not enter. Moreover, do not use the existing piping because there are problems with pressureresistance force and impurity in it.

1. SELECTING A LOCATION FOR INSTALLATION

WARNING

Install the air conditioner certainly at a location to sufficiently withstand the weight.

If the strength is insufficient, the unit may fall down resulting in human injury.

Perform a specified installation work to guard against a great wind such as typhoon or an

earth quake.

An incomplete installation can cause accidents by the units failing and dropping.

The following models must be installed at height 2.5m or more from the floor.

(Concealed type duct type and cassette type air conditioners)

If you insert your hands or others directly into the unit while the air conditioner operates, it is dangerous

because you may contact with revolving fan or active electricity.

Installation Location Selection for Outdoor unit

Obtain permission from the customer to install the unit in a location that satisfies the

following requirements :

• A location that permits level installation of the unit.

• A location that provides enough space to service the unit safety

• A location where water draining from the unit will not pose a problem

Avoid installing in the following places.

• Place exposed to air with high salt content (seaside area), or place exposed to large quantities of sulfide

gas (hot spring). (Should the unit be used in these places, special protective measures are needed.)

• Place exposed to oil, vapor, oil smoke or corrosive gas.

• Place where organic solvent is used nearby.

• Place close to a machine generating high frequency.

• Place where the discharged air blows directly into the window of the neighboring house. (For outdoor unit)

• Place where noise of the outdoor unit is easily transmitted.

(When installing the air conditioner on the boundary with the neighbor, pay due attention to the level of noise.)

• Place with poor ventilation.

(Especially in Concealed duct type indoor unit, before air ducting work, check whether value of air volume,

static pressure and duct resistance are correct.)

4

Page 5

Equipments

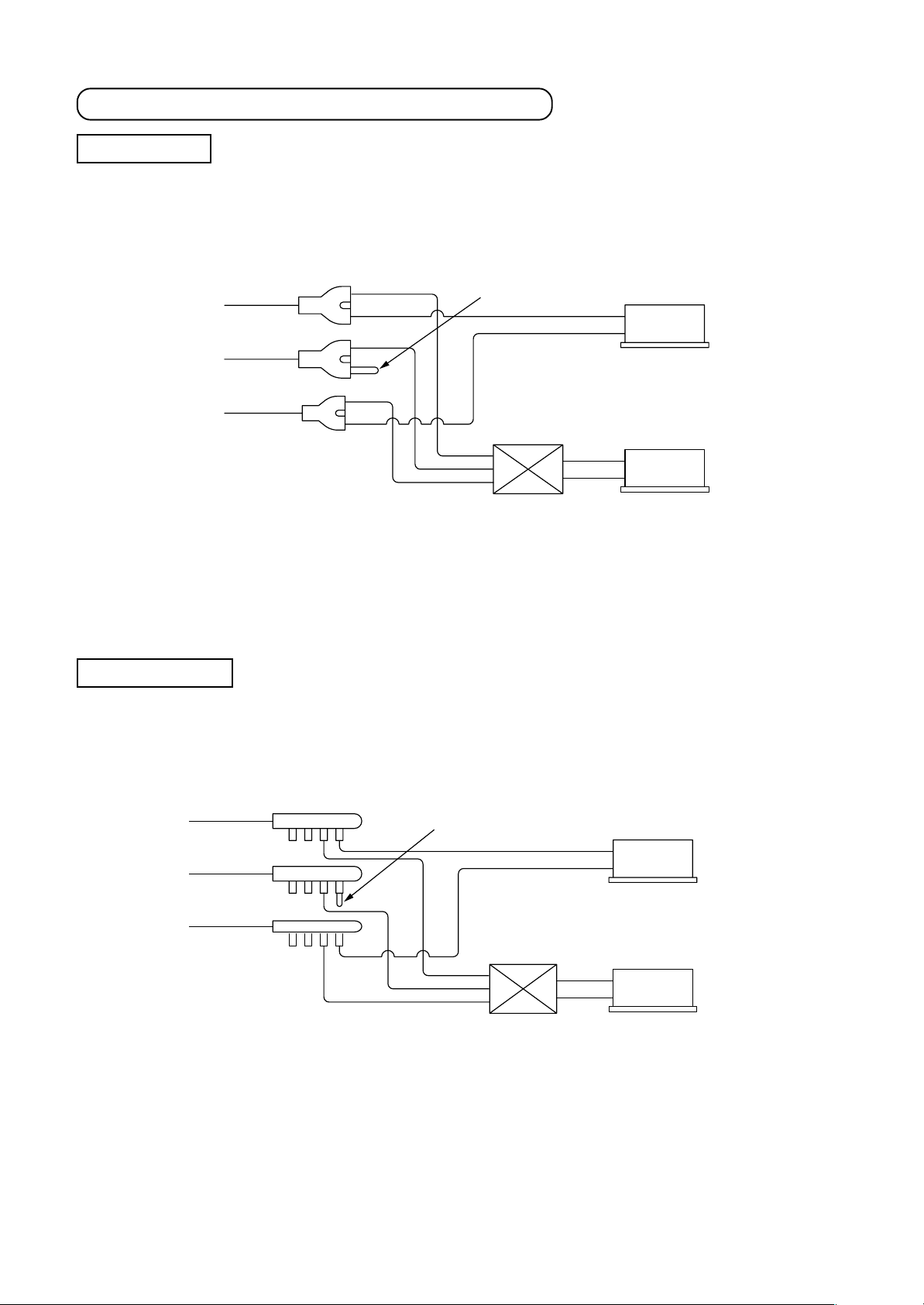

1. Outdoor units

Corresponding HP

Model name MMY- MAP0801FT8 MAP1001FT8 MAP1201FT8

Cooling capacity (kW) 22.4 28.0 33.5

Heating capacity (kW) 25.0 31.5 35.5

HP

(Capacity code)

8 HP ( 8) MAP0801HT8 1 MAP0801FT8 1

10 H P (10) MAP1001HT8 1 MAP1001FT8 1

12 H P (12) MAP1201HT8

Model name

MMY-

combined units

8 HP 10 HP 12 HP

No. of

1

Inverter 8HP

Inverter unit

MMY-

Used

Q’ty

Inverter 10HP

MMY-

Allocation atandard of model name

MMY– MAP T 8

F

Used

Q’ty

Appearance

Inverter 12HP

MMY-

MAP1201FT8

Used

Q’ty

1

Power supply specifications, 3Ø 380–415 V, 50Hz ....... 8

T : Capacity variable unit

F : Heat recovery

Development series No.

Capacity rank HP x 10

New refrigerant R410A

M : Single module unit, No mark : Combined Model name

Modular Multi

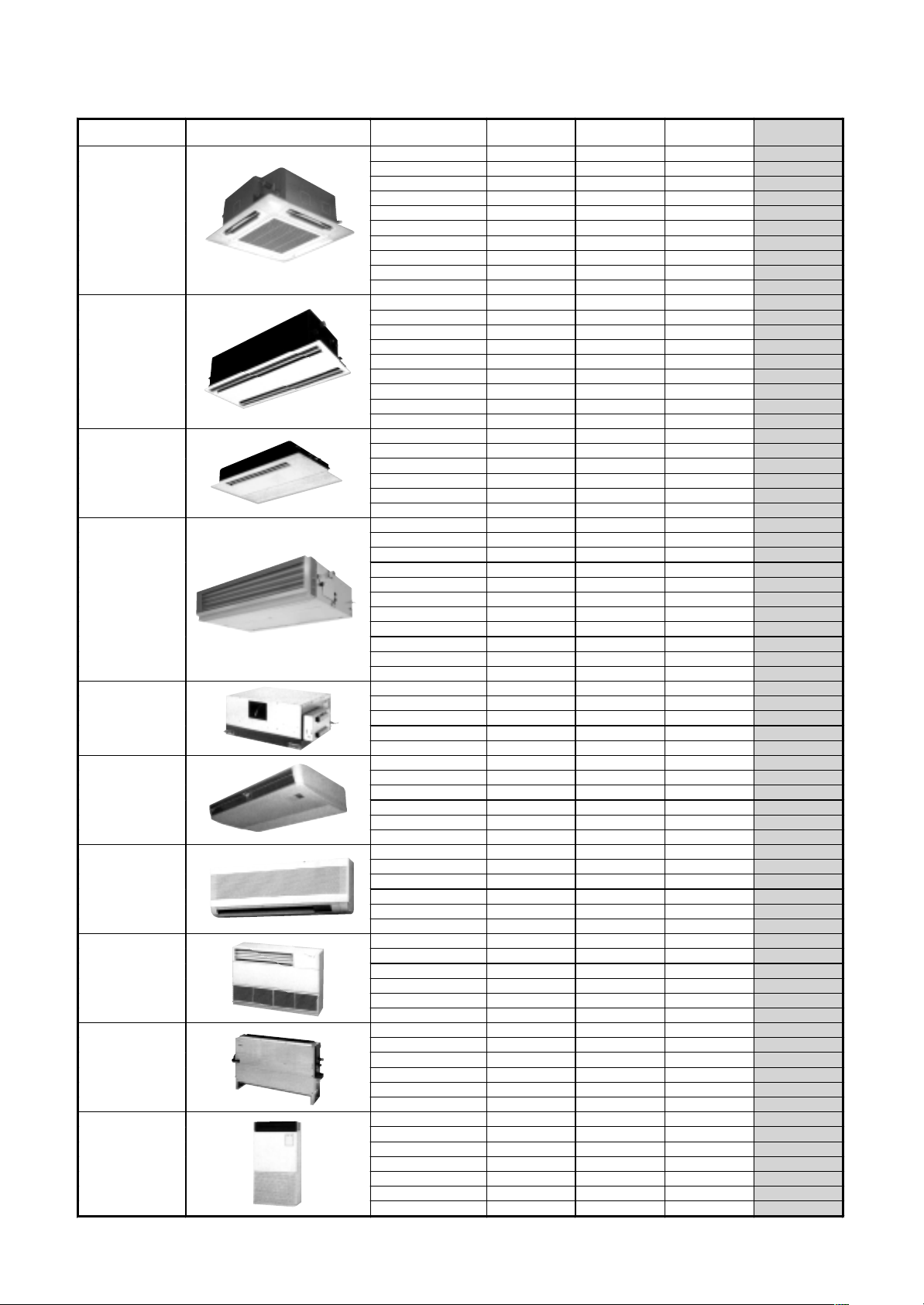

2. FS units (Flow selector units)

Model name Inverter unit Appearance

RBM-Y1121FE Capacity rank f or indoor unit : Type 007 to 030

RBM-Y1801FE Capacity rank f or indoor unit : Type 036 to 056

∗ Accessory part : Connection cable kit (RBC-CBK15FE), up to 15m.

5

Page 6

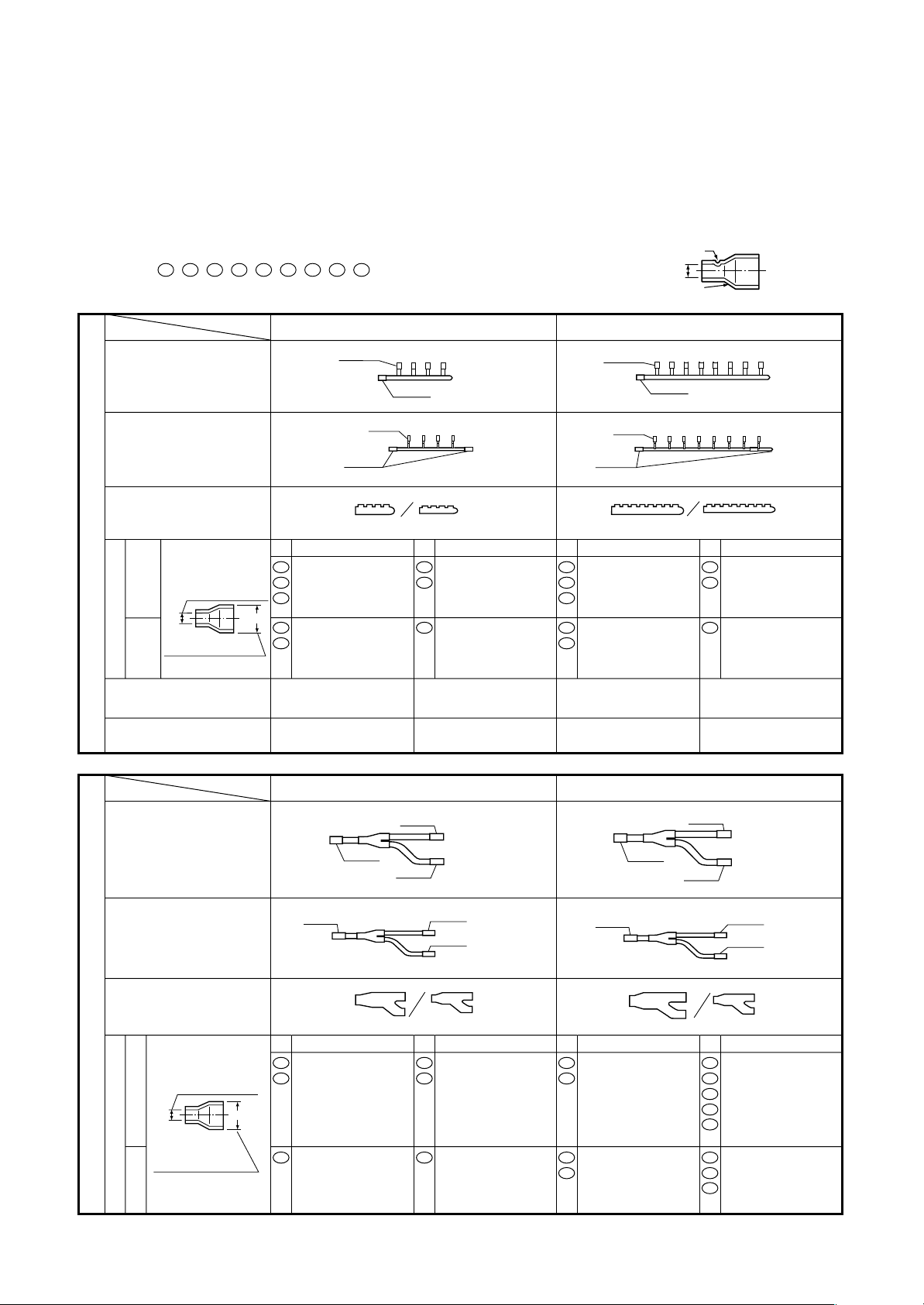

3. Indoor units

Type Appearance Model name Capacity rank Capaci t y code

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

030 type 3.2 9.0

036 type 4 11.2

048 type 5 14.0

056 type 6 16.0

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

030 type 3.2 9.0

1)

048 type 5 14.0 16.0

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

030 type 3.2 9.0

036 type 4 11.2

048 type 5 14.0

056 type 6 16.0

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

036 type 4 11.2

048 type 5 14.0

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

036 type 4 11.2

048 type 5 14.0

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8.0

036 type 4 11.2

048 type 5 14.0

056 type 6 16.0

4-way Air Discharge

Cassette Type

2-way Air Discharge

Cassette Type

1-way Air Discharge

Cassette Type

Concealed Duct

Standard Type

Concealed Duct

High Static

Pressure Type

Under Ceiling Type

High Wall Type

Floor Standing

Cabinet Type

Floor Standing

Concealed Type

Floor Standing Ty pe

MMU-AP0091H

MMU-AP0121H

MMU-AP0151H

MMU-AP0181H

MMU-AP0241H

MMU-AP0271H

MMU-AP0301H

MMU-AP0361H

MMU-AP0481H

MMU-AP0561H

MMU-AP0071WH

MMU-AP0091WH

MMU-AP0121WH

MMU-AP0151WH

MMU-AP0181WH

MMU-AP0241WH

MMU-AP0271WH

MMU-AP0301WH

MMU-AP0481WH*

MMU-AP0071YH

MMU-AP0091YH

MMU-AP0121YH

MMU-AP0151SH

MMU-AP0181SH

MMU-AP0241SH

MMD-AP0071BH

MMD-AP0091BH

MMD-AP0121BH

MMD-AP0151BH

MMD-AP0181BH

MMD-AP0241BH

MMD-AP0271BH

MMD-AP0301BH

MMD-AP0361BH

MMD-AP0481BH

MMD-AP0561BH

MMD-AP0181H

MMD-AP0241H

MMD-AP0271H

MMD-AP0361H

MMD-AP0481H

MMC-AP0151H

MMC-AP0181H

MMC-AP0241H

MMC-AP0271H

MMC-AP0361H

MMC-AP0481H

MMK-AP0071H

MMK-AP0091H

MMK-AP0121H

MMK-AP0151H

MMK-AP0181H

MMK-AP0241H

MML-AP0071H

MML-AP0091H

MML-AP0121H

MML-AP0151H

MML-AP0181H

MML-AP0241H

MML-AP0071BH

MML-AP0091BH

MML-AP0121BH

MML-AP0151BH

MML-AP0181BH

MML-AP0241BH

MMF-AP0151H

MMF-AP0181H

MMF-AP0241H

MMF-AP0271H

MMF-AP0361H

MMF-AP0481H

MMF-AP0561H

*1) China only

Cooling

capacity (kW)

Heating

capacity (kW)

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

18.0

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

18.0

6.3

8.0

9.0

12.5

16.0

5.0

6.3

8.0

9.0

12.5

16.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

5.0

6.3

8.0

9.0

12.5

16.0

18.0

6

Page 7

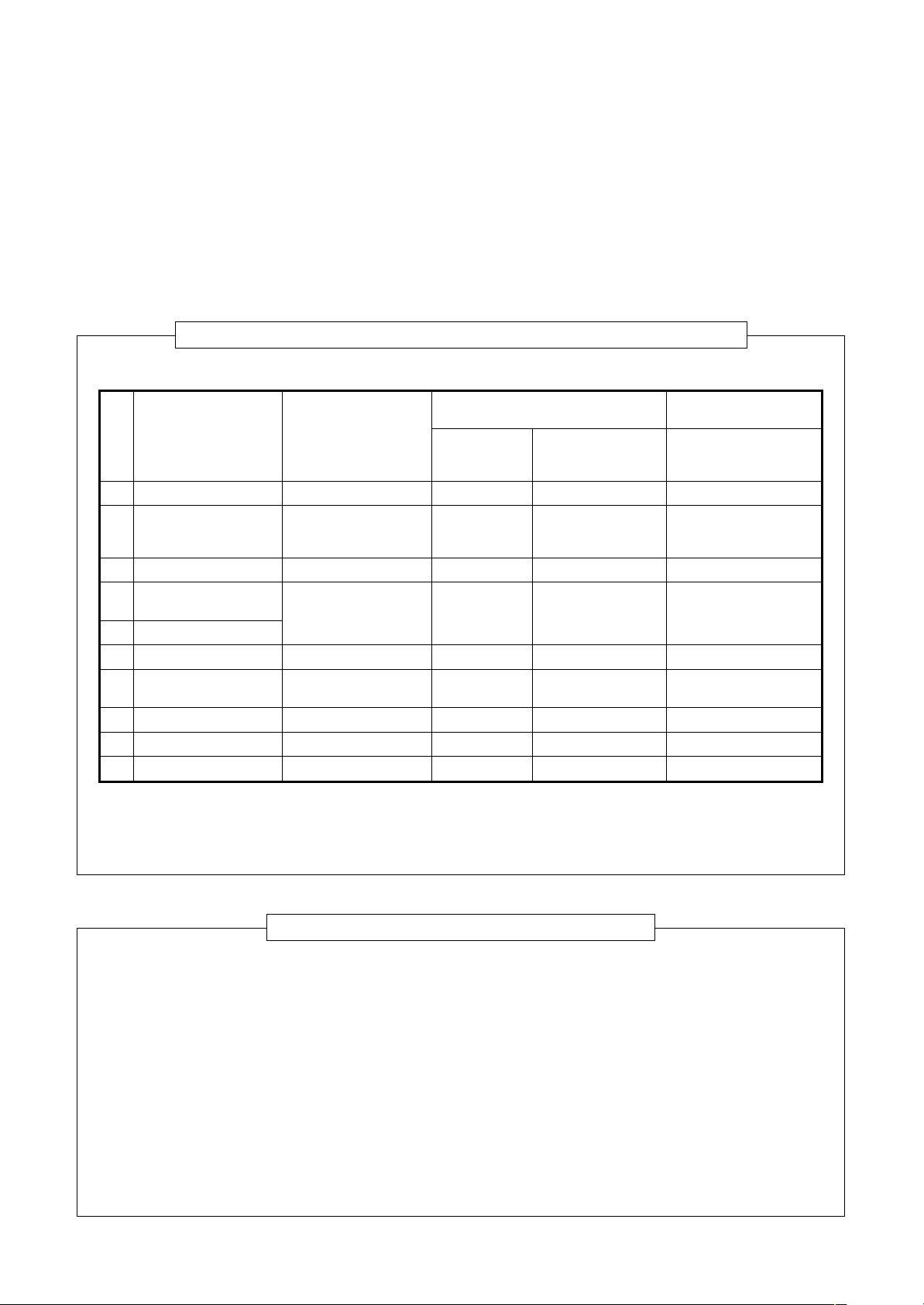

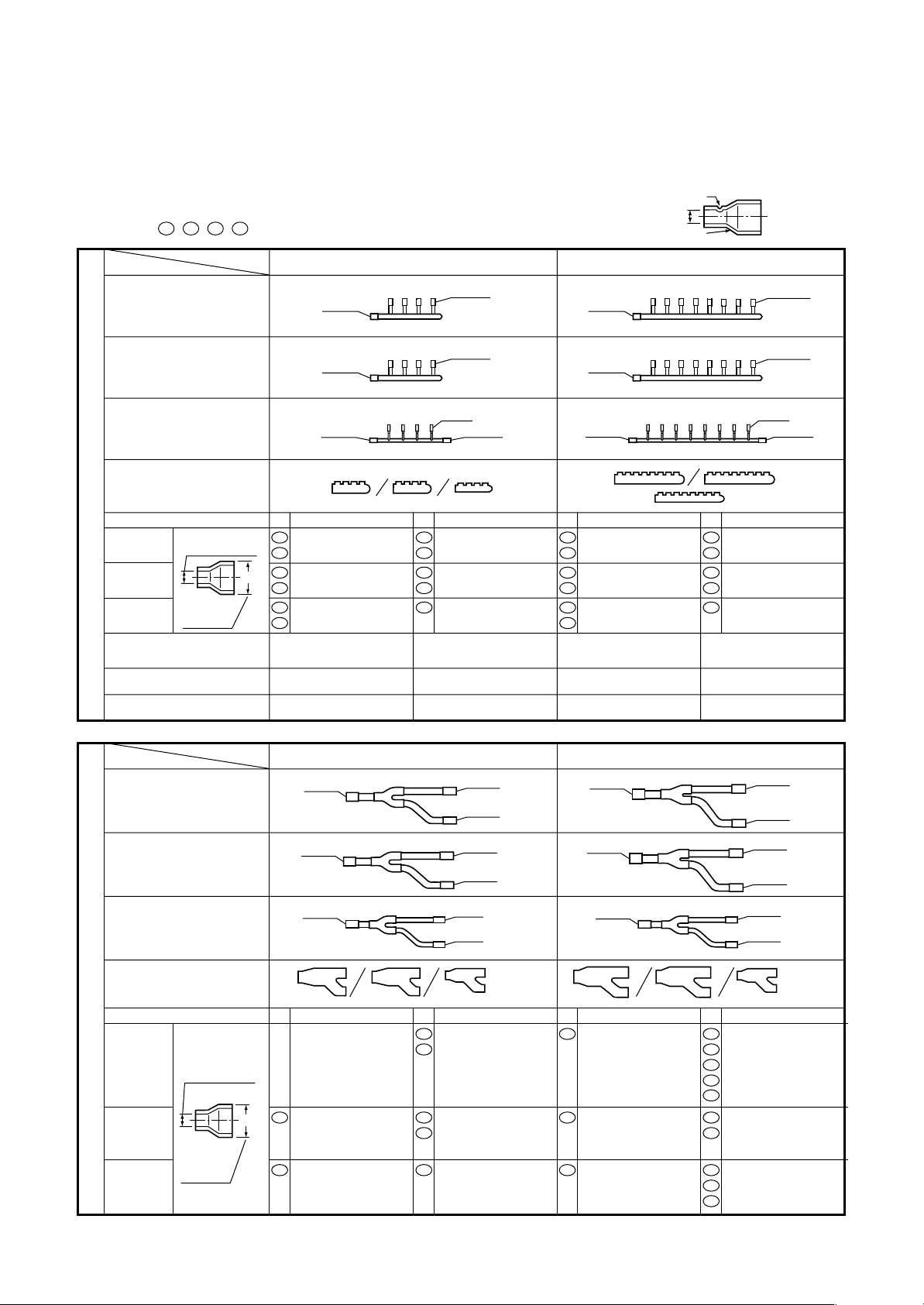

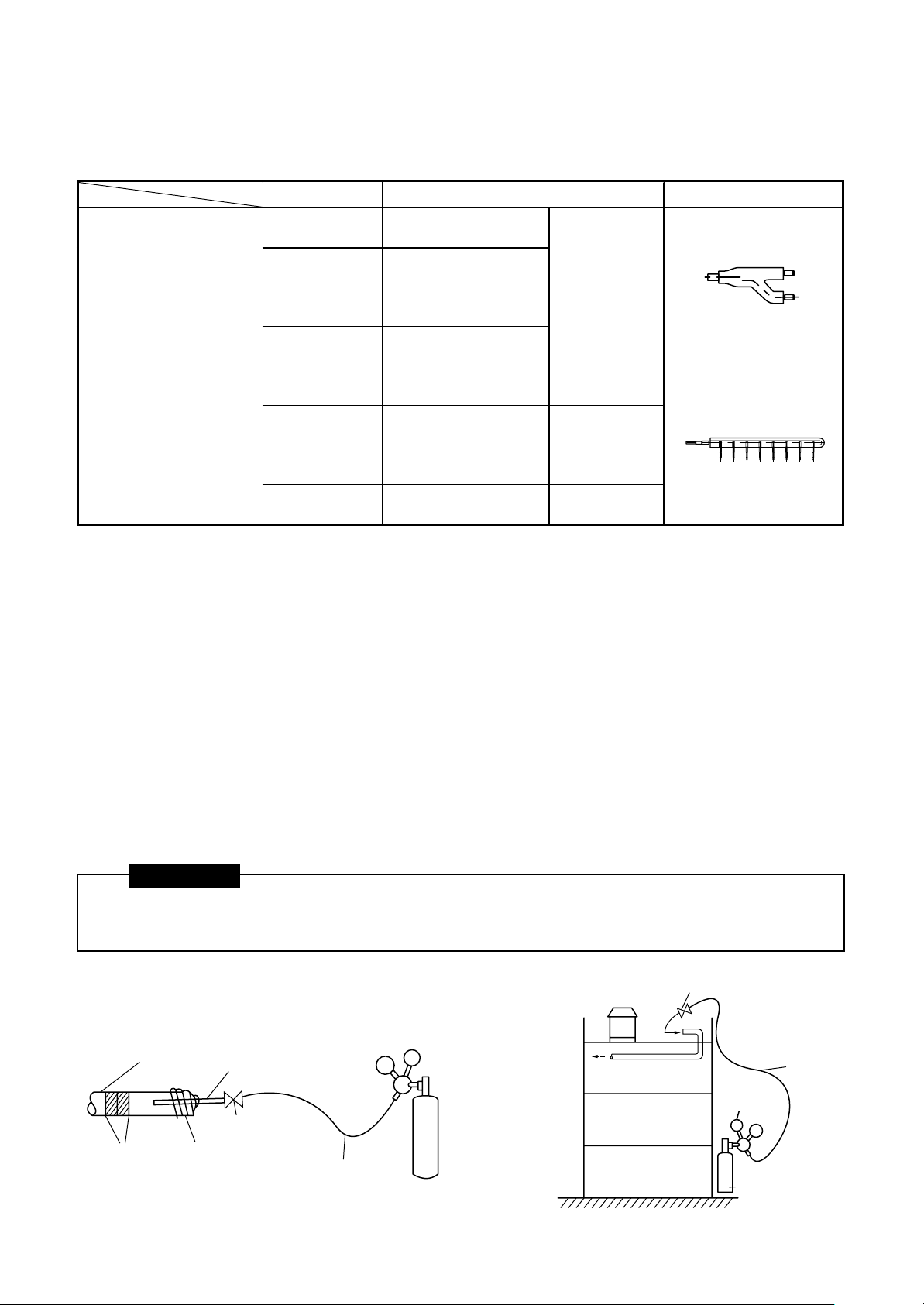

Tools

Required Tools

The used refrigerating oil is changed, and mixing of oil may cause a trouble such as generation of sludge,

clogging of capillary, etc. Accordingly, the tools to be used are classified into the following three types.

(1) Tools exclusive for R410A (Those which cannot be used for conventional refrigerant (R22))

(2) Tools exclusive for R410A, but can be also used for conventional refrigerant (R22)

(3) Tools commonly used for R410A and for conventional refrigerant (R22)

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

Conventional air

conditioner installation

Whether new equipment

can be used with

conventional refrigerant

¡

*(Note 1)

×

×

¡

¡

×

¡

×

No.

Used tool

Flare tool

Copper pipe gauge for

adjusting projection

margin

Torque wrench

Gauge manifold

Charge hose

Vacuum pump adapter

Electronic balance for

refrigerant charging

Refrigerant cylinder

Leakage detector

Charging cylinder

Usage

Pipe flaring

Flaring by conventional

flare tool

Connection of flare nut

Evacuating, refrigerant

charge, run check, etc.

Vacuum evacuating

Refrigerant charge

Refrigerant charge

Gas leakage check

Refrigerant charge

air conditioner installation

Existence of

new equipment

for R410A

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

(Note 2)

R410A

Whether conventional

equipment can be

used

*(Note 1)

*(Note 1)

×

×

×

Yes

×

×

×

(Note 1) When flaring is carried out for R410A using the conventional flare tools, adjustment of projection

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary.

(Note 2) Charging cylinder for R410A is being currently developed.

General tools (Conventional tools can be used.)

In addition to the above exclusive tools, the following equipments which serve also for R22 are necessary

as the general tools.

(1) Vacuum pump

Use vacuum pump by

attaching vacuum pump adapter.

(2) Torque wrench

(3) Pipe cutter

(4) Reamer

(5) Pipe bender

(6) Level vial

(7) Screwdriver (+, –)

(8) Spanner or Monkey wrench

(9) Hole core drill

(10) Hexagon wrench

(Opposite side 4mm)

(11) Tape measure

(12) Metal saw

Also prepare the following equipments for other installation method and run check.

(1) Clamp meter

(2) Thermometer

(3) Insulation resistance tester

(4) Electroscope

7

Page 8

2. SAFETY NOTES

• Ensure that all Local, National and International regulations are satisfied.

• Read this “SAFETY NOTES” carefully before Installation.

• The precautions described below include the important items regarding safety. Observe them without fail.

• After the installation work, perform a trial operation to check for any problem.

Follow the Owner’s Manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

WARNING

• Ask an authorized dealer or qualified installation professional to install/maintain the air

conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Connect the connecting wire correctly.

If the connecting wire is connected in a wrong way, electric parts may be damaged.

• When moving the air conditioner for the installation into another place, be very careful not to enter

any gaseous matter other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes abnormally

high and it as a result causes pipe burst and injuries on persons.

• Do not modify this unit by removing any of the safety guards or by by-passing any of the safety

interlock switches.

• Exposure of unit to water or other moisture before installation may cause a short-circuit of

electrical parts.

Do not store it in a wet basement or expose to rain or water.

• After unpacking the unit, examine it carefully if there are possible damage.

• Do not install in a place that might increase the vibration of the unit.

• To avoid personal injury (with sharp edges), be careful when handling parts.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the air conditioner is installed in a small room, provide appropriate measures to ensure that

the concentration of refrigerant leakage occur in the room does not exceed the critical level.

• Install the air conditioner securely in a location where the base can sustain the weight adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas might

generate.

• Electrical work must be performed by a qualified electrician in accordance with the Installation

Manual. Make sure the air conditioner uses an exclusive power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use the specified wires for wiring connect the terminals securely fix. To prevent external forces

applied to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible gas.

If a combustible gas leaks, and stays around the unit, a fire may occur.

8

Page 9

3. CHECK POINTS

Check before operation

• Turn on the main power switch 12 hours or more before starting the operation.

• Check whether earth wire is disconnected or out of place.

• Check that air filter is installed to the indoor unit.

Heating capacity

• For heating operation, a heat pump type which absorbs the outdoor heat and deliver the heat in the room is adopted.

If the outdoor temperature lowers, the heating capacity decreases.

• When the outdoor temperature is low, common use with other heating devices is recommended.

Defrost operation in heating operation

• If frost is found on the outdoor unit during heating operation, the defrost operation starts automatically (for approx. 2 to 10

minutes) so as to increase the heating effect.

• During defrost operation, the fans of both indoor and outdoor units stop.

Protection for 3 minutes

• The outdoor unit does not operate for approx. 3 minutes after air conditioner has been immediately restarted after stop, or

power switch has been turned on. This is to protect the system.

Main power failure

• If a power failure occurs during operation, all operations stop.

• When the power is turned on after power failure, the operation lamp of the remote controller flashes to notify.

• When restarting the operation, push ON/OFF button again.

Fan rotation of stopped unit

• While other indoor units operate, the fan on indoor units on “stand-by” rotates to protect the machine once per approx. 1

hour for several minutes.

Protective device (High pressure switch)

The high pressure switch operate the air conditioner automatically stops when excessive load is applied to the air

conditioner. If the protective device works, the operation lamp keeps lit but the operation stops.

When the protective device works, “CHECK” characters in the remote controller display section flash.

The protective device may work in the following cases.

Cooling

• When air inlet or outlet of the outdoor unit is closed.

• When strong wind blows continuously against air outlet of the outdoor unit.

Heating

• When much dust or dirt is excessively adhered to air filter of the indoor unit.

• When air outlet of the indoor unit is blocked.

NOTE

If the protective device works, turn off the main power switch, remove the cause, and then restart the operation.

Cooling/ heating operation of Multi system air conditioner

• When COOL or HEAT mode is fixed by the manager of the air conditioner, other operation than the set mode is

unavailable. If other operation than the set mode has been performed, [

operation part goes on and the operation stops.

Operating temperature of Super HRM

• When outdoor temperature goes out of specified range, “ or ” mark is indicated on the remote controller display and

required operation will stop. “

[Notice]

• This indication is not failure.

• When outdoor temperature goes back to specified range, “

• Operation stops because concurrent operation can not be kept in the condition of out of specification for Super HRM.

(Outdoor temp. (DB) < –5°C : Cooling, > 21°C : Heating)

• Do not use “Super HRM” for other than personal usage where the ambient temperature may go down below –5°C.

(For example, OA equipment/Electric device/Food/Animals and plants/Art object)

& ” : When heating operation. “ ” : When cooling operation.

or ” disappear and start normal operation.

Characteristics of heating operation

• Air does not blow out immediately after start of the operation. When the indoor heat exchanger has been heated after 3 to

5 minutes passed (differs according to temperature of indoor/outdoor temperature), hot air starts blowing.

• During operation, the outdoor unit may stop when outdoor temperature becomes high.

• When other indoor unit performs heating operation during fan operation, fan operation may be stopped temporarily to

prevent discharge of hot air.

9

PRE-HEAT] or [ Operation ready] on the

Page 10

4.

g

KEY POINTS OF AIR CONDITIONER INSTALLATION

In order to prevent problems before they arise, carefully read (1) the Installation Manual provided with the

equipment, and (2) the Owner’s Manual before installing the air conditioner.

4-1. Flow of Air Conditioner Installation Work

[Step] [Key Points]

(Prior to Installation)

Determination of extent of installation work

Drafting of diagrams

(Installation)

Sleeve/insert installation

Indoor unit and flow selector unit installation

Refrigerant pipe installation

(to outdoor outlet)

Drain pipe installation

Duct installation

Insulation work

Clearly determine the extent of the installation work.

Draft :

• Control wiring system diagram

• Refrigerant line system diagram

• Power wiring system diagram

Pay careful attention to the downward slope of the drain pipe.

Be sure to check the name of the model in order to avoid any

installation mistakes. If the model has an installation pattern, attach

the pattern to the ceiling to mark the position of the ceiling openings

and to keep dust away.

Make sure that the pipe system is dry, clean, and airtight.

When brazing pipes, blow out the system with nitrogen gas.

Do not forget the system indications.

Pipes should have downward slope (of at least 1/100).

Make sure the duct is lar

Be careful not to make any errors in the external static pressure

calculations.

Be especially careful to close off all gaps where connections are m ade

to the indoor unit, and at joints in the branching kit. Do not forget the

drain pipes.

e enough to carry the desired volume of air.

Use two-core shielded wires for the control wires, and use separate

(control wires and power wires)

Electrical work

Various s witc h setting s

Outdoor unit base installation

Outdoor unit installation

Outside circulation, refrigerant pipe instal lation

Gas-leak test

Vacuum suction

Addition of refrigerant

Ceiling panel installation

Test operation and adjustment

Owner’s Manual transfer

power supplies for the indoor and outdoor units. For connecting the

flow selector unit, be sure to use the attached cable or connection

cable kit sold separately.

Set the switches correctly, as indicated in the control wiring system

diagram.

Make sure that the base is level.

Provide for adequate air flow and service space around the outdoor

unit. Indicate the system names clearly.

From outside outlet to outdoor unit.

In the final test, the system must be pressurized at 3.73MPa

(38kg/cm²G) for 24 hours with no decrease in pressure.

Use a vacuum pump with reverse flaw prevention adaptor with a large

output volume and that can achieve a high level of vacuum.

Record the amount of refrigerant that was added to the system on

both the outdoor unit and on the pre-test operation checklist.

Make sure that the ceiling panel is attached to the ceiling material

tightly, with no gaps.

Operate the indoor units one by one, making sure that all wiring and

pipes are connected correctly, and fill out the checklist.

Explain how to operate the system clearly and concisely.

The procedure described above presents only the general sequence of steps; the sequence of steps may have

to be altered according to the circumstances of any specific installation job.

10

Page 11

5. REFRIGERANT PIPE INSTALLATION

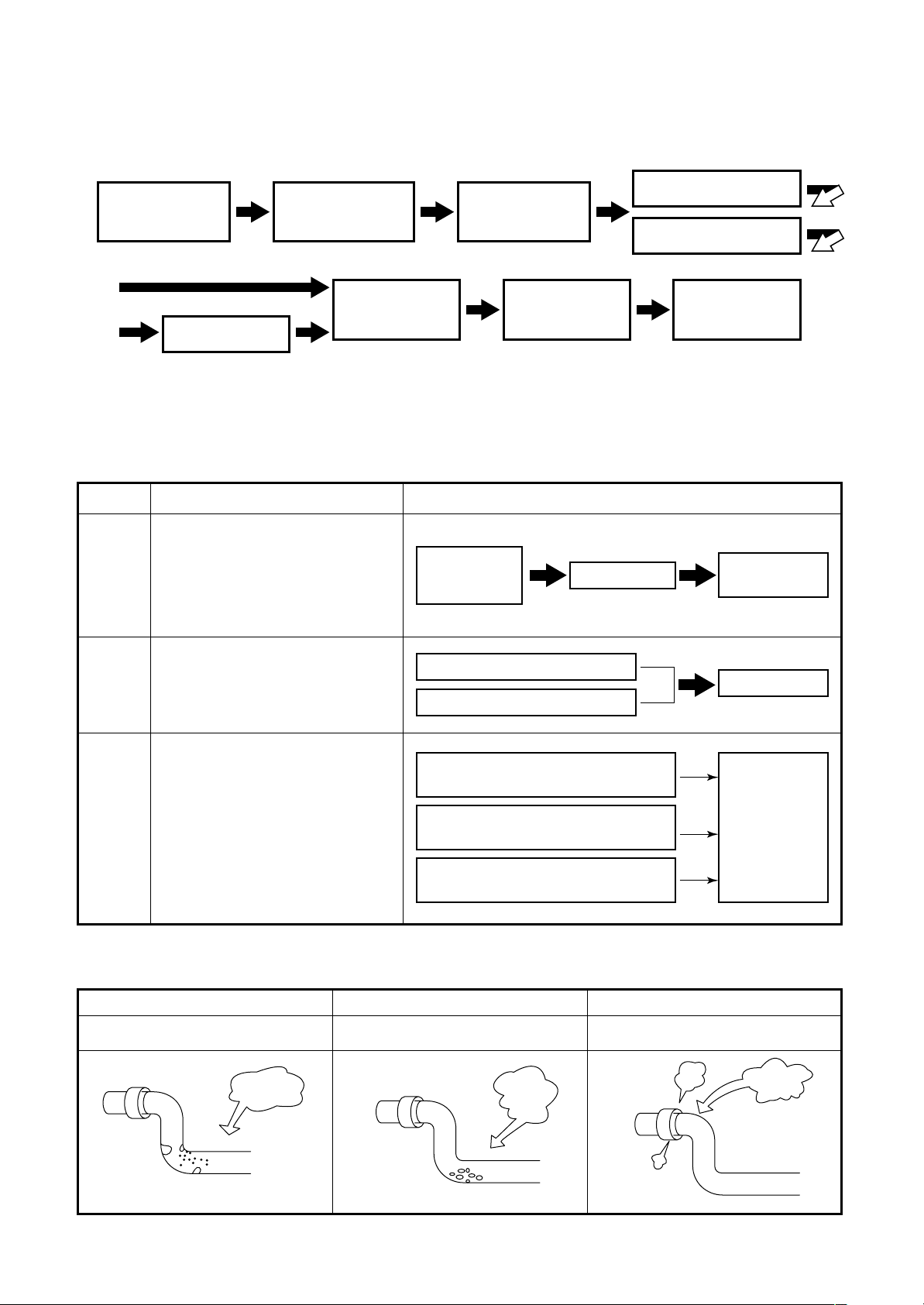

5-1. Work Procedure

Indoor unit

installation

Sizing

the pipes

Preliminary

installation

Nitrogen gas blow

Flaring

Flushing

Brazing

Leak test

5-2. Three Principles of Refrigerant Pipes

<Observe the three principles of refrigerant pipes>

Causes of Problems Preventing Problems

• Moisture (in the form of

Dry

Clean

rainwater or water used during

installation, for example)

getting inside of the pipes

• Moisture from condensation

forming or seeping into the pipes

• Oxidation inside pipes during

brazing

• Dirt, dust, or foreign matter

getting inside pipes

Careful

handling

of pipes

Nitrogen gas blow

Careful handling of pipes

Flushing

Vacuum

suction

Vacuum

suction

Flushing

Use of suitable materials

(copper pipes, solder, etc.)

Air-

tight

• Poor brazing

• Poor flaring

Perform basic work

of brazing carefully

Perform basic work

of flaring carefully

<Three principles of refrigerant pipes>

Dry

Make sure there is no moisture

inside of the pipes

Moisture

Make sure there is no dirt

Clean Airtight

Make sure the refrigerant

inside of the pipes

Dirt

Not good Not good Not good

Leak test

does not leak

Leak

11

Page 12

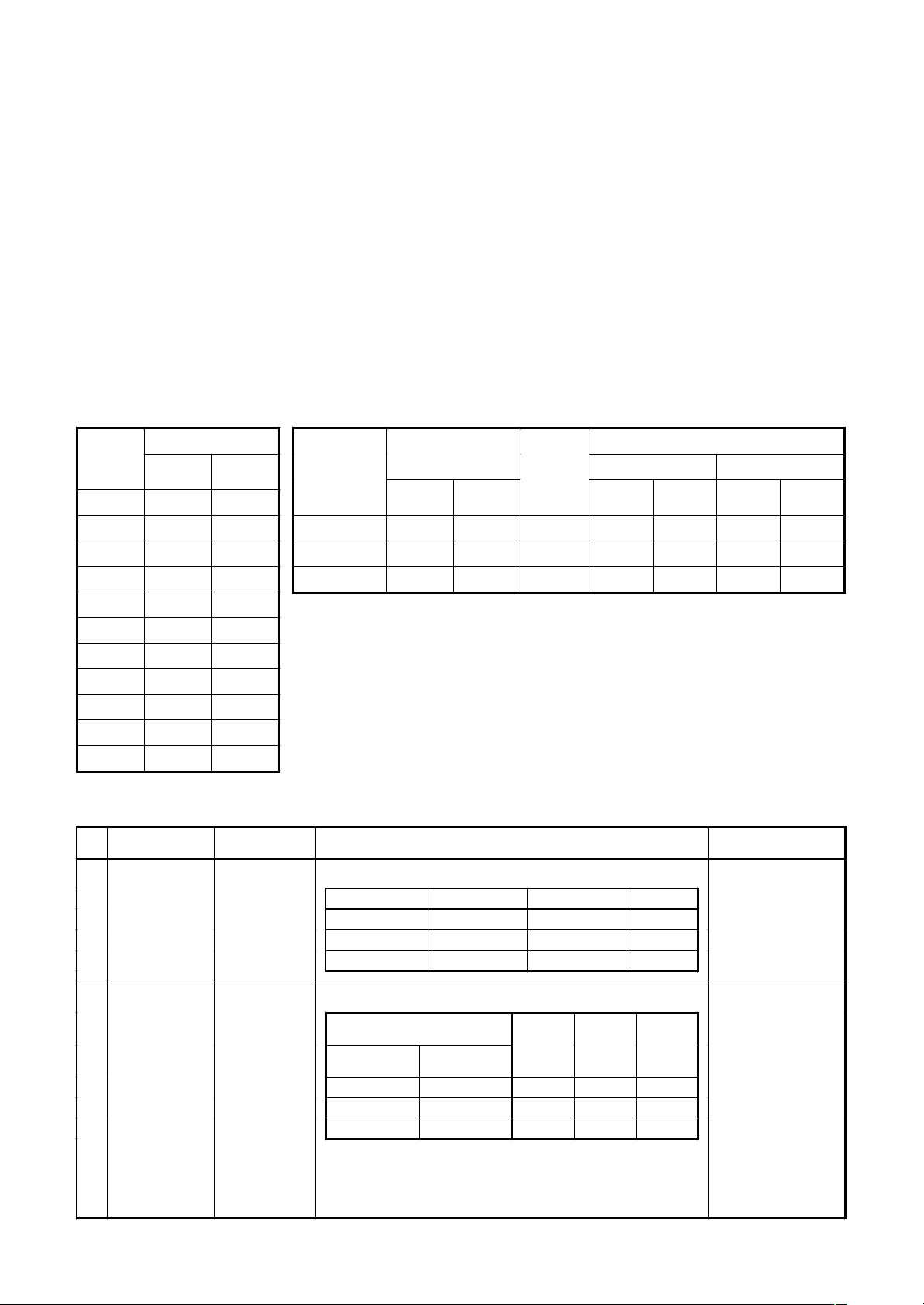

5-3. Selecting the Refrigerant Line Material

q

q

• Refrigerant pipes

• Material: Phosphoric deoxidized seam-less pipe

• Capacity code of outdoor unit / indoor unit

• For each indoor unit, the capacity code is determined for every capacity rank.

• For each outdoor unit, the capacity code is determined for every capacity rank. The Max. number of the

connectable indoor units and the total capacity code value of the indoor units are also determined.

Against the capacity code of the outdoor unit, the total capacity codes of the connectable indoor units differ

according to the height difference between indoor units.

• When the height difference between indoor units is 15m or less : Up to 135%* of capacity code of outdoor unit

(* For 12HP system, up to 120%.)

• When the height difference between indoor units is 15m or more : Up to 105% of capacity code of outdoor unit

Table 1 Table 2

Indoor unit

capacity rank

007 type 0.8 2.2

009 type 1 2.8

012 type 1.25 3.6

015 type 1.7 4.5

018 type 2 5.6

024 type 2.5 7.1

027 type 3 8

030 type 3.2 9

036 type 4 11.2

048 type 5 14

056 type 6 16

Capacity code

E

uivalent toHPEquivalent to

capacity

Outdoor unit

model name

MMY-MAP0801FT8 8 22.4 13 5.6 15.7 10.8 30.2

MMY-MAP1001FT8 10 28.0 16 7.0 19.6 13.5 37.8

MMY-MAP1201FT8 12 33.5 16 8.4 23.5 14.4 40.3

Capacity code

E

uivalent toHPEquivalent to

capacity

No. of

indoor units

Total capacity code of connectable indoor units

Min Max.

Equivalent

to HP

Equivalent

to capacity

Equivalent

to HP

Table 3

No. Piping parts Name Selection of pipe size Remarks

Outdoor unit

↓

1st branching joint

Outdoor unit

main pipe

1) Connecting pipe outdoor unit

Model name Suction gas side Discharge gas side Liquid side

MMY-MAP0801FT8 Ø22.2 Ø19.1 Ø12.7

MMY-MAP1001 FT8 Ø22.2 Ø19.1 Ø12.7

MMY-MAP1201 FT8 Ø28.6 Ø19.1 Ø12.7

Same to connecting

pipe size of outdoor unit

Equivalent

to capacity

Branching section

Branching pipe

2) Pipe size betw een branching sections

Pipe size differs based

on total capacity code

↓

Branching section

Total capacity codes of indoor units

at downstream side

Equivalent to

capacity

Below 18.0 Below 6.4 Ø15.9 Ø12.7 Ø9.5

18.0 to below 34.0 6.4 to below 12.2 Ø22.2 Ø19.1 Ø12.7

34.0 to below 45.5 12.2 to below 16.2 Ø28.6 Ø22.2 Ø15.9

∗

If exceeding the main pipe size, decide the size same to main pipe

Equivalent

to HP

Suction

gas side

Discharge

gas side

Liquid side

value of indoor units at

downstream side.

If the total value

exceeds the capacity

code of the outdoor unit,

apply capacity code of

the outdoor unit.

(See tables 1 and 2.)

size.

∗

When two pipes are used for the circuits exclusive to cooling, use

pipes at liquid and suction gas sides.

12

Page 13

No. Piping parts Name Selection of pipe size

g

g

End branching

section

↓

Flow selector unit

Branching section

or flow selector

unit

↓

Indoor unit

Branching section

Connecting pipe

of flow selector

unit

Connecting pipe

of indoor unit

Branchin

header

of Y-shape

branching joint

3) Pipe size between end branching section and flow selector unit

To tal capac ity codes of indoo r units

at downstream side

Equivale nt to capacity Equivalent to HP

Below 4.5 Below 1.7 Ø12.7 Ø9.5 Ø6.4

4.5 to below 18.0 1.7 to below 6.4 Ø15.9 Ø12.7 Ø9.5

Suction

gas side

Discharge

gas side

Liquid side

4) Connecting pipe size of indoor unit

Capacity rank Gas side Liqu id side

007 to 012 type

∗

When pipe len

Real length: Below 15m Ø9.5

Real length: Over 15m

015 to 018 type Ø12.7

024 to 056 type Ø15.9 Ø9.5

∗

Ø12.7

Ø6.4

th between the end branching section and cooling-only indoor unit exceeds 15m,

decide pipe size at gas side to the bigger one with Ø12.7.

5) Selection of branching joint/header

To tal capac ity codes of indoo r units Model name RBM-

Equivalent to

capacity

Y-shape branching joint

∗

1, 2

Branching header

∗

1, 2, 3

∗

1 For branching pipe of the 1st branching section, select one by the outdoor unit capacity code.

∗

2 When total capacity codes of indoor units exceed capacity code of outdoor unit, select one by

Below 18.0 Below 6.4 BY53FE BY53E

18.0 to below 40.0 6.4 to below 14.2 BY103FE BY103E

Below 40.0 Below 14.2 HY1043 FE HY1043E

Below 40.0 Below 14.2 HY1083 FE HY1083E

Equivalent to HP

For 3

pipes piping

For 2

pipes piping

capacity code of outdoor unit.

∗

3 1 line after header branching is connectable up to total maximum capacity codes 6.0

(Equivalent to HP).

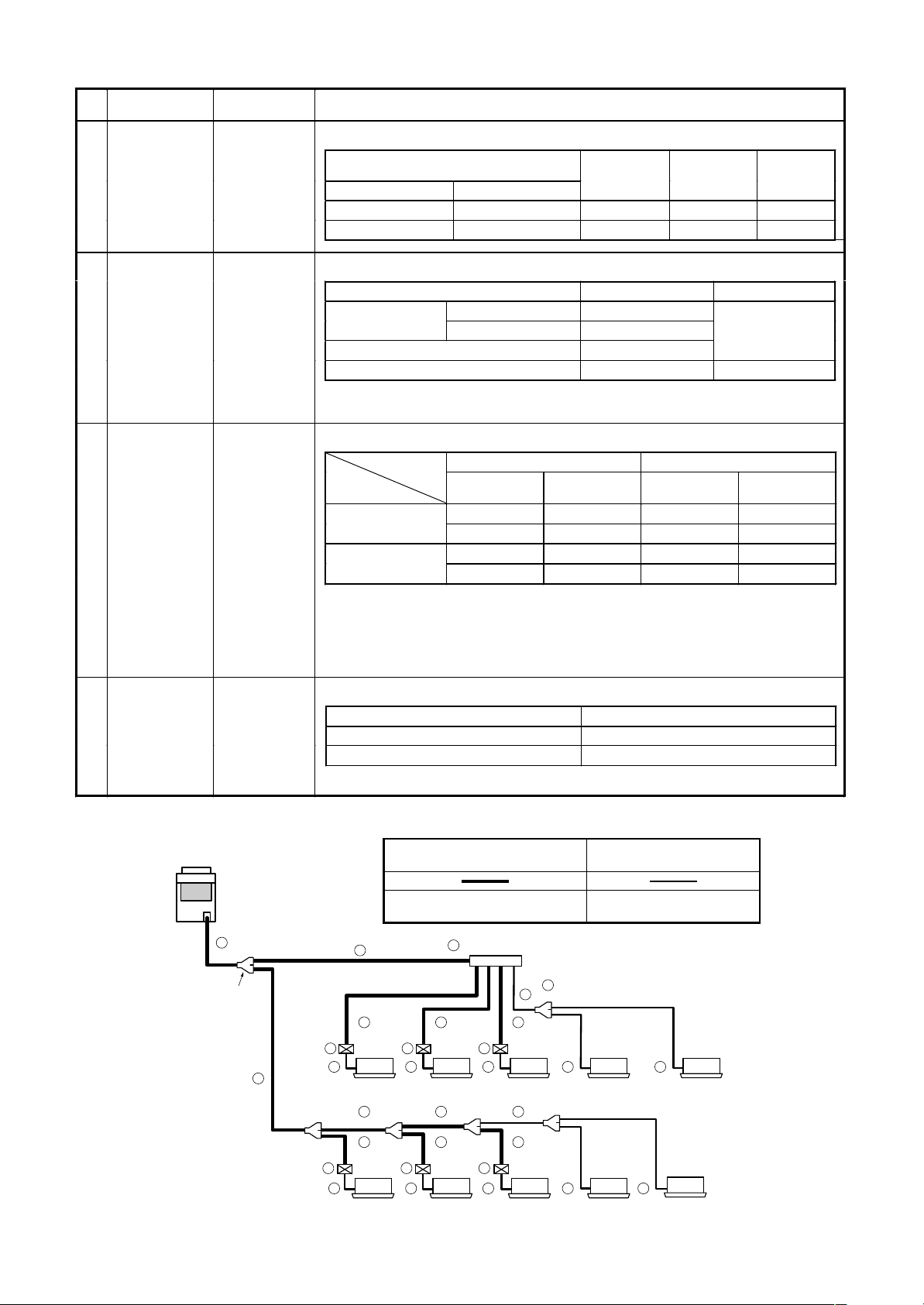

Branching Flow selector unit

Outdoor unit

1 Main piping

1st branching

section

6) Selection of flow selector unit

Model name Capacity rank of connectable indoor unit

RBM-Y1121FE 007 to 030 type

RBM-Y1801FE 036 to 056 type

∗

Confirm also Installation Manual of flow selector unit.

(Liquld,discharge gas,suction gas)

3 piping

Outdoor unit to FS unit

2

3

6 6 6

FS unit

2

4 4 4 4 4

Indoor unit

2 2 2

5 Header branching

3

5 Y-shape branching joint

2

3

FS unit to indoor unit

Branching section indoor unit

< Cooling only > < Cooling only >

2 piping

(Liquld, gas pipe)

3 3 3

6 6 6

FS unit

4 4 4 4 4

Indoor unit

< Cooling only > < Cooling only >

13

Page 14

5-4. Allowable Length/Height Difference of Refrigerant Piping

Height difference between outdoor

and indoor units

H1

50m

1st branching

section

Main

piping

Outdoor unit

L1

• System restrictions

∗ For 12HP system, up to 120%

Branching

Branching piping L2

Connecting piping of indoor unit

L3

FS unit

a

ghi j

Indoor unit

Equivalent length corresponded to farthest piping L 125m

Equivalent length corresponded to farthest piping after 1st branching Li 50m

L4 L5 L6

def

lmn

header

L7

bc

FS unit

Max. capacity of

combined indoor unit

k

< Cooling only >

o

< Cooling only >

< Cooling only >

p

< Cooling only >

H2 ≤ 15m

H2 > 15m

Height difference between

indoor units

35m

H2

135%

105%

• Allowable length and height difference of refrigerant piping

Allowable value Piping section

Total extension of pipe (Liquid pipe, real length) 250 m

Pipe

Length

Height

difference

1 The farthest indoor unit from the 1st Branch to be named as (p).

*

2 Attached connection cable can be used up to 5 m in pipe length between indoor and FS unit. When the pipe length

*

Farthest piping length L (*1)

Max. equivalent length of main piping 85 m L1

Equivalent length of farthest piping from 1st branching Li (*1) 50 m L3 + L4 + L5 + L6 + p

Max. real length of indoor unit connecting piping 30 m a + g, b + h, c + l, d + l, e + m, f + n, j, k, o, p

Max. real length between FS unit and indoor unit (

Height between indoor

and outdoor units H1

Height between indoor units H2

Real length 100 m

Equivalent length 125 m

2) 15 m g, h, i, l, m, n

Upper outdoor unit 50 m ——

Lower outdoor unit 30 m ——

Upper outdoor unit 35 m ——

Lower outdoor unit 15 m ——

*

between indoor and FS unit exceeds 5 m, be sure to use the connection cable kit (RBC-CBK15FE). (Sold separately)

FS unit

L1 + L2 + L3 + L4+ L5 + L6 + L7 + a + b + c +

d + e + f + g + h + i + j + k + l + m + n + o + p

L1 + L3 + L4 + L5 + L6 + p

FS unit

Indoor unit Indoor unit

[NOTE] :

Don’t connect two or more indoor units to one FS unit. Arrange one indoor unit and one FS unit set to 1 by 1.

14

Page 15

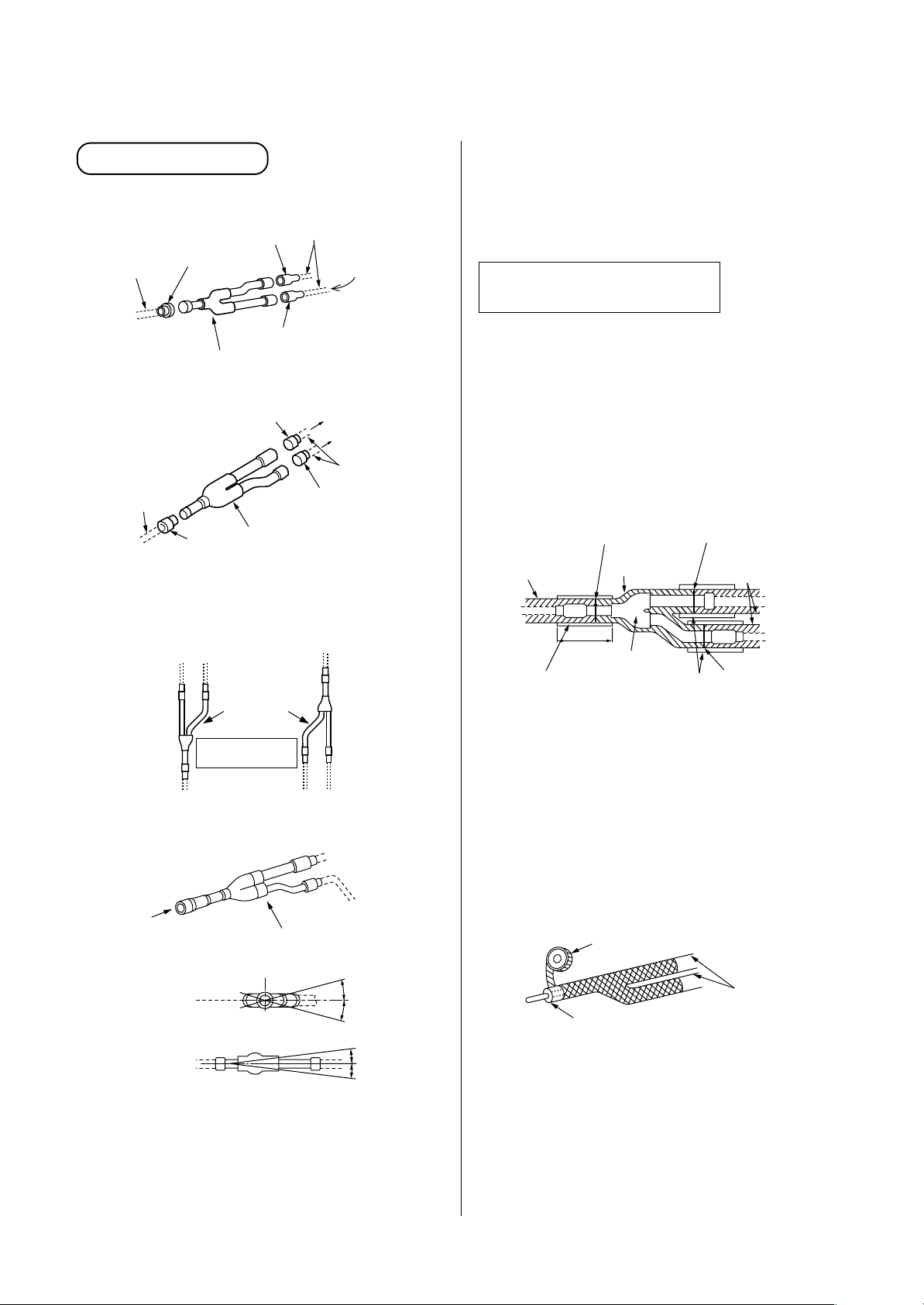

• Brazed couplings and special branches

• Use suitable parts for typical elbow couplings and socket couplings.

(Consider the size, material, thickness, etc.)

• Special branches

Use deoxidized parts sold separately.

Branching at indoor unit side

Branch header

Branching jo int

4 branching 8 branching

RBM-BY53E

RBM-BY103E

RBM-BY53FE

RBM-BY103FE

RBM-HY1043E

RBM-HY1043FE

RBM-HY1083E

RBM-HY1083FE

• Solder

Because only “copper-to-copper” connections are made in the multi type air conditioning system, use the hard

solder “phosphor copper solder.”

15

Page 16

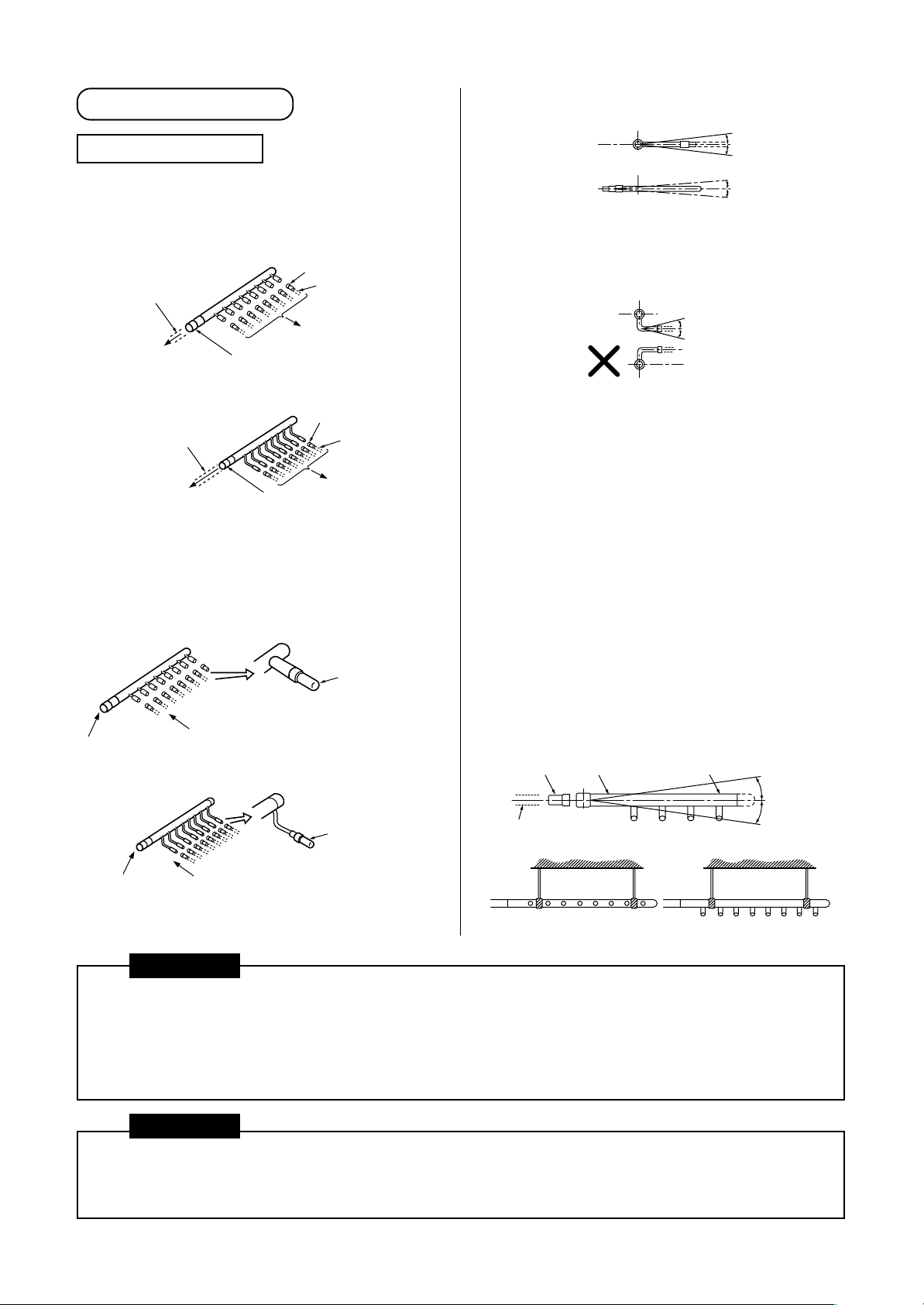

5-5. Careful Handling

Careful handling is the most important step in preventing moisture, dirt, and dust from getting inside of the pipes.

Moisture in pipes has caused major problems in numerous instances in the past. Therefore, it is important to be

as careful as possible in order to prevent problems before they occur.

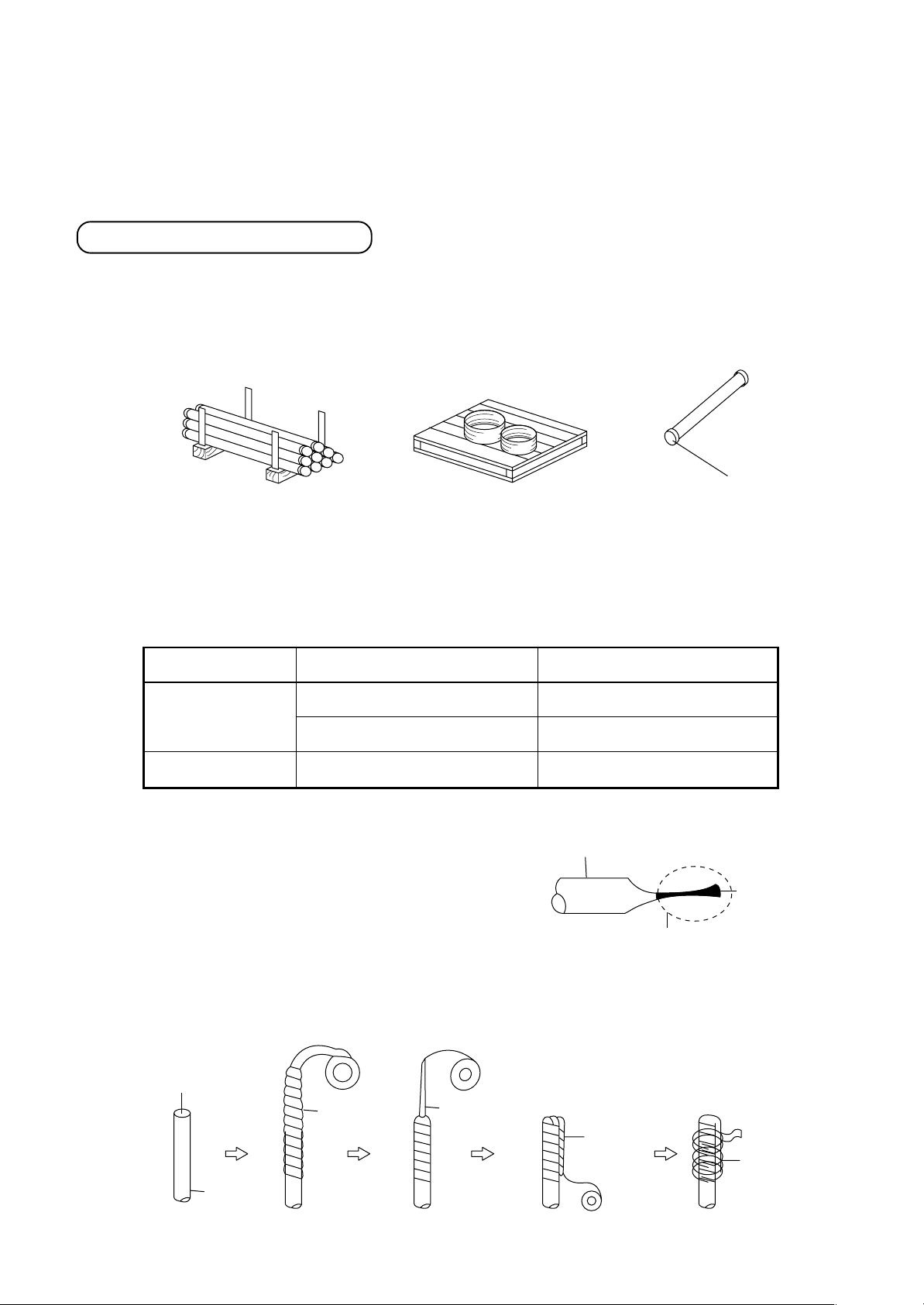

Pipe delivery and storage

When pipes are delivered, care should be taken to prevent it from becoming bent or deformed, and the ends of

the pipes should be capped in order to prevent dirt, mud, rain, etc., from getting inside. Build a wooden frame to

hold the pipes securely, and store the pipes in the specified location.

Delivery of copper pipes without caps to a work site is not acceptable.

Cap

Frame for careful handling

and to prevent rolling

Careful handling on a pallet

Pipe caps

The ends of all pipes must be sealed. The most reliable method is the “pinch method,” but the taping method

can be selected in some circumstances.

Location

Outdoors

Indoors

Time for installation

One month or more

Less than one month

Does not matter

Careful handling method

Pinch method

Pinch or taping method

Pinch or taping method

n Pinch method

Pinch the end of the copper pipe closed,

and braze any opening closed.

Copper pipe

Solder

Braze here

n Taping method

Cover the end of the copper pipe with vinyl tape.

[Taping method]

Opening

Copper

pipe

Vinyl tape

Flatten

Fold over

Tape again

16

Page 17

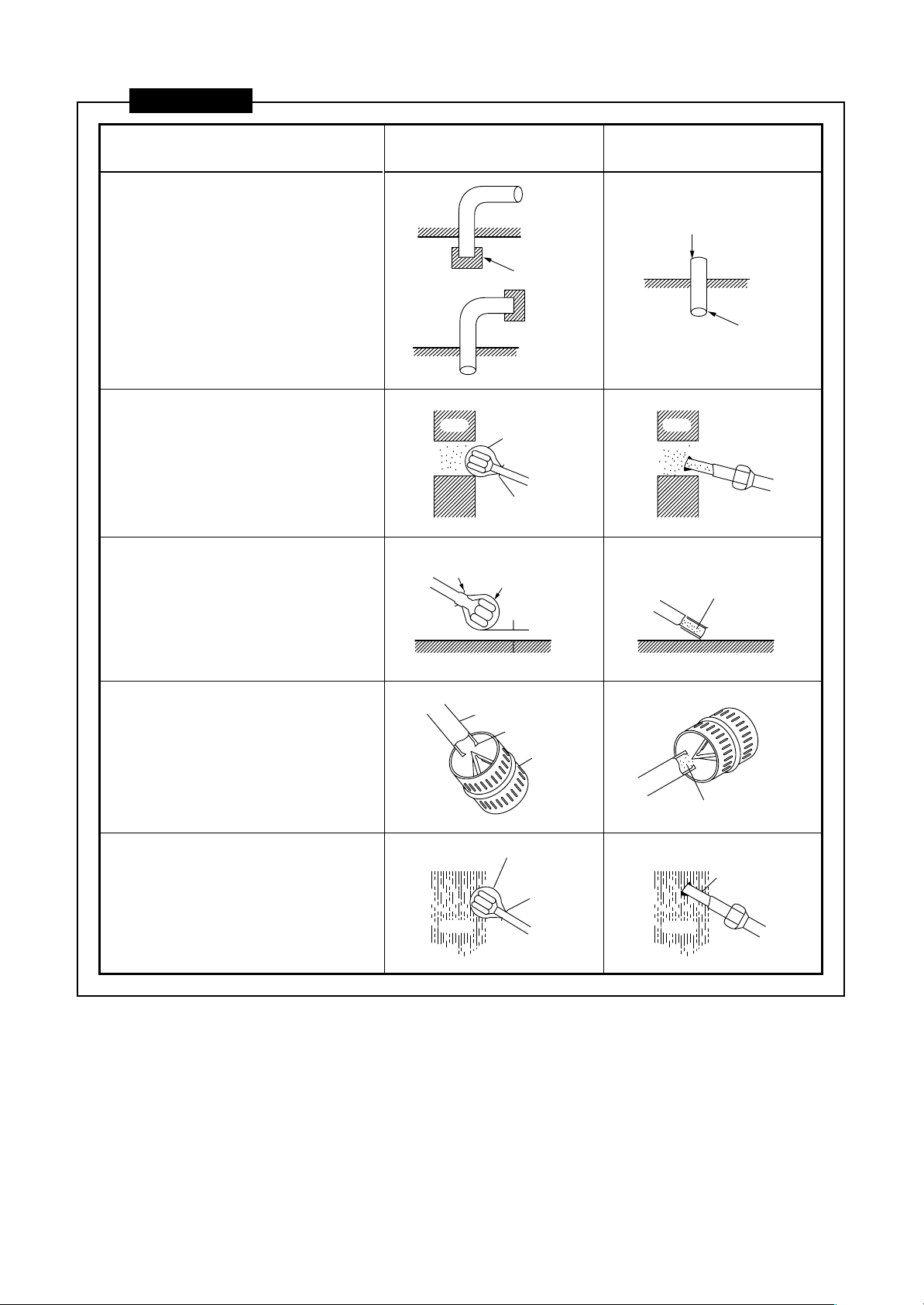

CAUTIONS

1) Do not allow dirt or moisture

inside of the pipes.

• Keep the open ends of all pipes

capped until all pipes have been

connected.

• Pipe openings should face

horizontally or downwards if at all

possible.

GOOD NOT GOOD

Dirt and moisture get inside

Cap

Pipe

2) When passing a pipe through an

opening in a wall, always keep

the end of the pipe capped.

3) Do not place pipes directly on

the ground. Do not scrape pipes

on the ground.

4) When deflashing (removing

burrs from) a pipe, point the

opening downwards so that no

scraps fall inside of the pipe.

5) When installing pipes on a rainy

day, always keep the ends of the

pipes capped.

Cap or

Wall

plastic bag

Rubber band

Rubber

Cap or

band

plastic bag

Do not allow

pipe to touch

ground

Ground Ground

Pipe

Burrs

Deflasher

Cap or

plastic bag

Rubber

band

Rain

Wall

Dirt gets inside of pipe

Scraps get inside of pipe

Rain

Particles of

the wall get

inside the pipe

Rain gets

inside of pipe

17

Page 18

5-6. Parts of Branching Header/Joint

Branching Header : RBM-HY1043E / HY1083E

Branching Joint : RBM-BY53E / BY103E

• Check the following parts in the package.

• For piping material and size of the refrigerant pipes, refer to the Installation Manual of the Air Conditioner.

NOTE : 1. All dimensions are in millimeters. In the following tables, ( ) indicates diameter of the indicated position, and

others indicate diameter of the connecting pipe.

2. Please connect pipe to the side with a projection of the socket.

( 51 , 52 , 54 , 58 , 59 , 61 , 62 , 70 , 89 : without projection)

Diameter of the

connecting pipe

projection

socket

NAME

MODEL

Branching header

gas side

Branching header

liquid side

Heat insulator

(gas side/liquid side)

side

diameter of the

connected pipe

Gas

Branching Header

Socket

Outlet sealed pipe at gas side

Header sealed pipe at liquid side

Outlet sealed pipe at liquid side

external diameter

of socket

side

Liquid

No.

Ø15.9 x (Ø22.2) 1pc

14

Ø19.1 x (Ø22.2) 1pc

18

Ø28.6 x (Ø22.2) 1pc

70

( )

06

Ø12.7 x (Ø15.9) 1pc

09

Ø15.9

Ø15.9

Ø9.5

Ø22.2

No.

Ø 9.5 x (Ø15.9) 4pcs

06

Ø12.7 x (Ø15.9) 4pcs

09

Ø 6.4 x (Ø 9.5) 4pcs01Ø 9.5 x (Ø15.9) 1pc

(Ø15.9) 1pc

(Ø15.9) 1pc

(Ø 9.5) 1pc

1pc

1pc

1pc each

Ø15.9

Ø9.5

Ø15.9

No.

Ø15.9 x (Ø22.2) 1pc

14

Ø19.1 x (Ø22.2) 1pc

18

Ø28.6 x (Ø22.2) 1pc

70

06

Ø12.7 x (Ø15.9) 1ps

09

RBM-HY1083ERBM-HY1043E

Ø22.2

No.

Ø 9.5 x (Ø15.9) 8pcs

06

Ø12.7 x (Ø15.9) 8pcs

09

Ø 6.4 x (Ø 9.5) 8pcs01Ø 9.5 x (Ø15.9) 1ps

1pc

1pc

1pc each

(Ø15.9) 3pcs

(Ø15.9) 1pc

(Ø 9.5) 3pcs

NAME

Branching joint

gas side

Branching joint

liquid side

Heat insulator

(gas side/liquid side)

Branching Joint

diameter of the

connected pipe

Gas side

Socket

external diameter

of socket

Liquid side

MODEL

( )

Ø12.7

No.

Ø12.7 x (Ø15.9) 1pc

09

Ø19.1 x (Ø15.9) 1pc

51

RBM-BY53E

Ø12.7

Ø15.9

Ø12.7

Ø9.5

Ø9.5

No.

05

54

1pc

1pc

1pc each

Ø 9.5 x (Ø12.7) 2pcs

Ø15.9 x (Ø12.7) 2pcs

Ø 6.4 x (Ø 9.5) 2pcs01Ø 9.5 x (Ø12.7) 1pc05

Ø15.9

No.

Ø19.1 x (Ø22.2) 1pc

18

Ø28.6 x (Ø22.2) 1pc

70

Ø 9.5 x (Ø15.9) 1pc

06

Ø12.7 x (Ø15.9) 1pc

09

RBM-BY103E

Ø19.1

Ø22.2

Ø19.1

Ø12.7

Ø12.7

No.

Ø 9.5 x (Ø19.1) 1pc

07

Ø12.7 x (Ø19.1) 1pc

10

Ø15.9 x (Ø19.1) 2pcs

13

Ø22.2 x (Ø19.1) 2pcs

52

Ø28.6 x (Ø19.1) 1pc

89

Ø 6.4 x (Ø12.7) 1pc

02

Ø 9.5 x (Ø12.7) 2pcs

05

Ø15.9 x (Ø12.7) 1pc

54

1pc

1pc

1pc each

18

Page 19

Branching Header : RBM-HY1043FE / HY1083FE

Branching Joint : RBM-BY53FE / BY103FE

• Check the following parts in the package.

• For piping material and size of the refrigerant pipes, refer to the Installation Manual of the Air Conditioner.

NOTE : 1. All dimensions are in millimeters. In the following tables, ( ) indicates diameter of the indicated position, and

others indicate diameter of the connecting pipe.

2. Please connect pipe to the side with a projection of the socket.

( 52 , 54 , 70 , 89 : without projection)

Diameter of the

connecting pipe

projection

socket

NAME

MODEL

Suction gas side

Discharge gas side

Liquid side

Heat insulator

(suction gas side/

discharge gas side/liquid side)

Socket

Suction

gas side

Discharge

gas side

Branching Header

Liquid

side

Outlet sealed pipe at suction gas side

Outlet sealed pipe at discharge gas side

Outlet sealed pipe at liquid side

Header sealed pipe at liquid side

diameter of the

connected pipe

external

diameter

of socket

No. No. No. No.

14

70

85

( )

18

06

09

Ø22.2

Ø22.2

Ø15.9

Ø15.9 x (Ø22.2) 1pc

Ø28.6 x (Ø22.2) 1pc

Ø12.7 x (Ø22.2) 1pc

Ø19.1 x (Ø22.2) 1pc

Ø 9.5 x (Ø15.9) 1pc

Ø12.7 x (Ø15.9) 1pc

Ø15.9

Ø15.9

Ø9.5

Ø15.9

06

Ø 9.5 x (Ø15.9) 3pcs

09

Ø12.7 x (Ø15.9) 4pcs

06

Ø 9.5 x (Ø15.9) 4pcs

09

Ø12.7 x (Ø15.9) 4pcs

01

Ø 6.4 x (Ø 9.5) 4pcs

(Ø15.9) 1pc

(Ø15.9) 3pcs

(Ø 9.5) 1pc

(Ø15.9) 1pc

RBM-HY1083FERBM-HY1043FE

Ø22.2

1pc 1pc

Ø22.2

1pc 1pc

Ø15.9

1pc 1pc

1pc each 1pc each

14

Ø15.9 x (Ø22.2) 1pc

70

Ø28.6 x (Ø22.2) 1pc

85

Ø12.7 x (Ø22.2) 1pc

18

Ø19.1 x (Ø22.2) 1pc

06

Ø 9.5 x (Ø15.9) 1pc

09

Ø12.7 x (Ø15.9) 1pc

06

09

06

09

01

Ø15.9

Ø15.9

Ø9.5

Ø15.9

Ø 9.5 x (Ø15.9) 7pcs

Ø12.7 x (Ø15.9) 8pcs

Ø 9.5 x (Ø15.9) 8pcs

Ø12.7 x (Ø15.9) 8pcs

Ø 6.4 x (Ø 9.5) 8pcs

(Ø15.9) 3pcs

(Ø15.9) 7pcs

(Ø 9.5) 3pcs

(Ø15.9) 1pc

NAME

MODEL

Suction gas side

Discharge gas side

Liquid side

Heat insulator

(suction gas side/

discharge gas side/liquid side)

Socket

Suction

gas side

Branching Joint

Discharge

gas side

Liquid

side

diameter of the

connected pipe

( )

external

diameter

of socket

RBM-BY103FERBM-BY53FE

Ø

Ø

15.9

Ø

15.9

Ø

12.7

No. No. No. No.

05

54

09

Ø12.7 x (Ø15.9) 1pc

05

Ø 9.5 x (Ø12.7) 1pc

05

54

01

12.7

Ø

12.7

Ø

12.7

Ø

12.7

Ø

9.5

Ø

9.5

Ø 9.5 x (Ø12.7) 2pcs

Ø15.9 x (Ø12.7) 2pcs

Ø 9.5 x (Ø12.7) 2pcs

Ø15.9 x (Ø12.7) 1pc

Sealed pipe

x (Ø19.1) 1pc

Ø 6.4 x (Ø 9.5) 2pcs

1pc 1pc

1pc 1pc

1pc 1pc

1pc each 1pc each

Ø

22.2

Ø

22.2

Ø

15.9

70

Ø28.6 x (Ø22.2) 1pc

18

Ø19.1 x (Ø22.2) 1pc

09

Ø12.7 x (Ø15.9) 1pc

07

10

13

52

89

10

52

02

05

54

Ø

19.1

Ø

19.1

Ø

19.1

Ø

19.1

Ø

12.7

Ø

12.7

Ø 9.5 x (Ø19.1) 1pc

Ø12.7 x (Ø19.1) 1pc

Ø15.9 x (Ø19.1) 2pcs

Ø22.2 x (Ø19.1) 2pcs

Ø28.6 x (Ø19.1) 1pc

Ø12.7 x (Ø19.1) 2pcs

Ø22.2 x (Ø19.1) 1pc

Sealed pipe

x (Ø19.1) 1pc

Ø 6.4 x (Ø12.7) 1pc

Ø 9.5 x (Ø12.7) 2pcs

Ø15.9 x (Ø12.7) 1pc

19

Page 20

5-7. Branching Kit Connection Method

[1] Branch joint

<Suction gas/Discharge gas side>

Socket

Pipe in use

on the site

Inlet

To outdoor unit

Socket

Gas side branch joint

Outlet (2)

Outlet (1)

<Liquid side>

Socket

Outlet (1)

Pipe in use

on the site

Inlet

To outdoor unit

Socket

• Installation direction of branch pipe

Install the branching pipes so that it branch either

vertically or horizontally.

Outlet (2)

Gas/Liquid side branch joint

Both directions

are possible.

Pipe in use on the site

To other branching

pipe or indoor unit

Socket

To other branching pipe or indoor

unit

Pipe in use

on the site

Socket

NOTE :

Install the branch pipes horizontally or vertically so

that they branch evenly.

Install the branching joint within ± 15 degrees.

Heat insulating for pipes

(Branching Joint)

• In order to prevent dripping at the place where the

insulation provided with the branching kit meets the

insulating material obtained on the site, butt the two

types of insulation up against each other, and then

wrap the seam between the two types of insulation

in at least 10mm of the insulating material (in use

on the site).

<Suction gas/Discharge gas/Liquid side>

Heat insulator

for piping

(in use on the site)

Heat insulator (in use on the site)

by 10mm or more thickness.

Butt together

150

Branching joint

Heat insulator

in package

Butt together

Heat insulator for piping

(in use on the site)

Butt together

In case of vertical

installation

<Suction gas/Discharge gas/Liquid side>

A

B

(Horizontal line)

(A view)

(Horizontal line)

(B view)

<In case of horizontal installation>

NOTE :

• Install the branch pipes horizontally or vertically so

that they are branched evenly.

• Install the branching joint within ±15 degrees.

Within

± 15

Within

± 15

degrees

degrees

• On the gas-side pipe, use insulation that can

withstand heat of 120°C or higher. For the branch

pipe, either use a commercially available coupling

cover (for T-shape) that is at least 10mm thick, or

else insulate the pipe as shown in the figure at

below.

• After applying insulation as outlined above, tape the

insulation in place.

Taping (in use on the site)

Heat insulator

Heat insulator

(in use on the site)

(in use on the site)

20

Page 21

[2] Branch header

<Suction gas/Discharge gas side>

Branching Header

Select and install the socket that matches the

diameter of a pipe to be connected to the indoor unit.

<Suction gas/Discharge gas side branch

header>

Pipe in use on the site

To outdoor unit

Socket

Socket

Pipe in use on the site

To indoor unit

<Liquid-side branch header>

Socket

Pipe in use on the site

To outdoor unit

Socket

Pipe in use

on the site

To indoor unit

• If the number of indoor units to be connected is

fewer than the maximum number of units that can

be connected to the branch header, attach a sealed

pipe to the unused connectors.

<Suction gas/Discharge gas side branch

header>

Outlet sealed pipe

(Provided with

branch header)

A

B

<Liquid-side branch header>

Outlet sealed pipe

(Provided with

branch header)

C

• Install the branch header so that it branches

horizontally. It cannot be used in a vertical position.

D

(Horizontal line)

(Horizontal line)

(A view)

(B view)

Within

± 15

Within

± 10

degrees

degrees

<Liquid-side>

(Horizontal line)

(C view)

When arranging the branching header at the liquid

side, attach a header sealed pipe on the sealing side

of the header as shown in the fiqure at below.

Be sure to install the branch pipe downward.

Horizontal viewed from D point should be within ± 10

degrees same as view B.

• Supporting branching header

After applying the insulation, set the hanging metals

as support. (in use on the site).

NOTE :

1. Install the branching header so that it branches

horizontally. It cannot be used in a vertical

position.

2. Do not use T-type pipe for the branching section.

Inlet socket

Pipe in use

on the site

Branching Header

(D view) Sealing side

Within

degrees

± 15

Header sealed pipe

Within

± 10

degrees

CAUTION

1. On the inlet side of a Y-type branch joint or branch header, allow for at least 300mm of straight pipe.

2. A Y-type branch joint can be installed so that it branches either vertically or horizontally; if branching

horizontally, it should be within an angle of ± 15°.

3. A branch header should be installed so that it branches horizontally.

4. Do not use T-type branch joints.

CAUTION

In the multi air conditioning system, because the refrigerant pipes congregate at the rooftop pipeshaft outlet

in the vertical pipeshaft, it is necessary to attach “labels” to each pipe in order to make clear to which system

a given pipe belongs so as to prevent pipes from being connected incorrectly.

21

Page 22

How to connect “Cooling Only” indoor unit

Branch joint

• When connecting a Cooling Only indoor unit, attach a sealed pipe to the unused connectors of the branching

pipe of discharge gas side.

Suction gas side

* Discharge gas side

Liquid side

∗ Refer to above. There is the method of connecting without using branching joint pipe of discharge gas side.

For details, refer to the Installation Manual of the Air Conditioner.

Connect sealed pipe.

Flow selector unit

Indoor unit

Cooling only

Indoor unit

Heating and Cooling

Branch header

• When connecting a Cooling Only indoor unit, attach a sealed pipe to the unused connectors of the branching

pipe of discharge gas side.

Suction gas side

Connect sealed pipe.

Discharge gas side

Liquid side

Flow selector unit

Indoor unit

Cooling only

Indoor unit

Heating and Cooling

[NOTE]

For cooling only indoor unit in Super-HRM system, item code (DN) setting from the wired remote controller is

necessary. (Refer to the section “13-1.”)

22

Page 23

5-8. External Dimensions of Branch Connectors

y

y

y

y

y

(Outline drawings are shown on the following pages.)

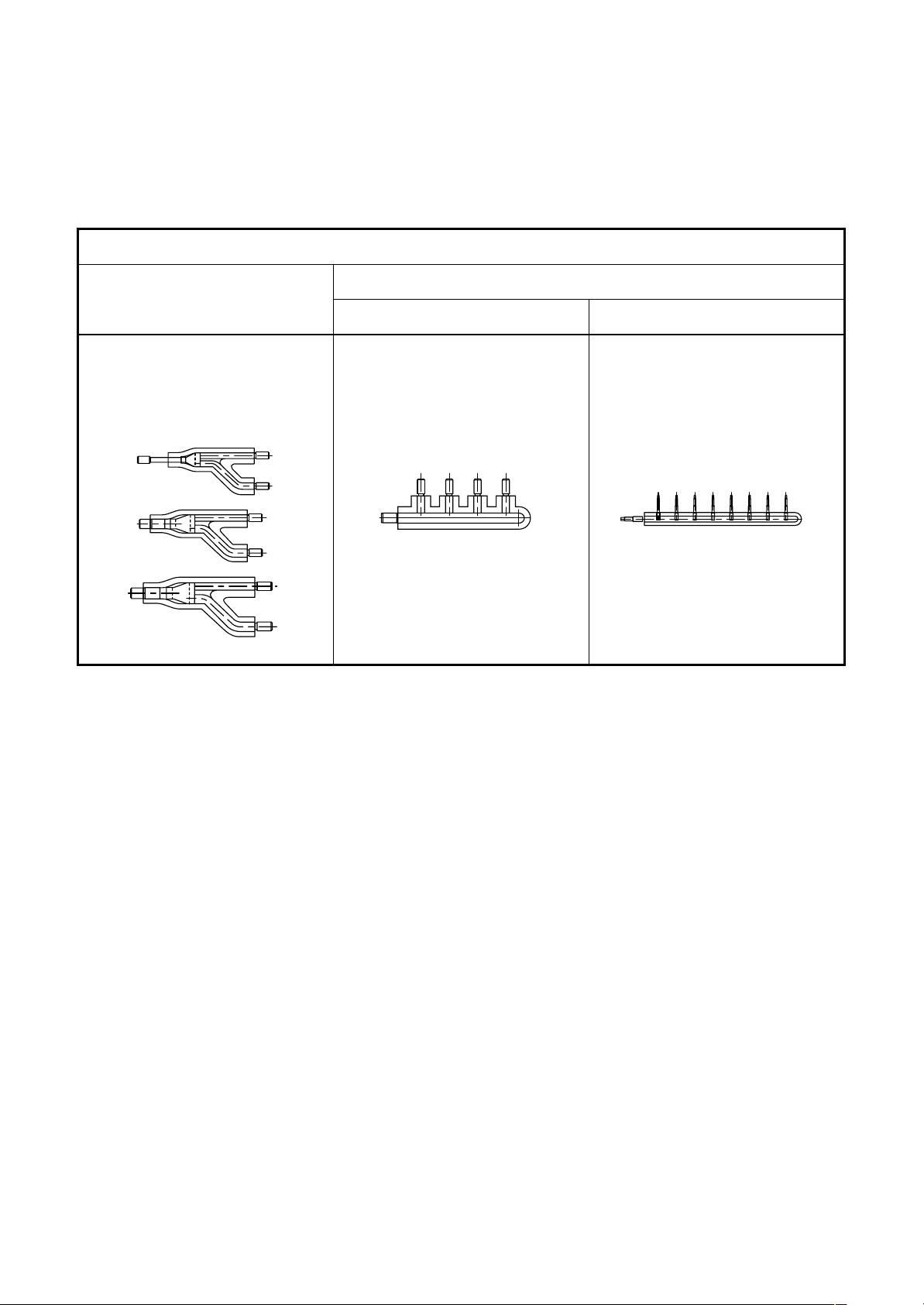

Branching joints and headers

Model name Usage Appearance

RBM-BY53FE

RBM-BY103FE

Y-shape branching joint (*2)

RBM-BY53E

RBM-BY103E

RBM-HY1043FE

4-branching header (*3)

RBM-HY1043E

RBM-HY1083FE

8-branching header (*3)

RBM-HY1083E

1 If total capacity code value of indoor unit exceeds that of outdoor unit, apply capacity code of outdoor unit.

*

2 When using Y-shape branching joint for 1st branching, select according to capacity code of outdoor unit.

*

3 Max. 6.0 capacity code in total can be connected.

*

4 This is used for branching to “cooling only” indoor unit.

*

5 Model names for outdoor and indoor units described in this guide are shortened because of the space constraint.

*

Indoor unit capacit

Total below 6.4

Indoor unit capacit

Total below 14.2

Indoor unit capacit

Total below 6.4

Indoor unit capacity code

Total below 14.2

Indoor unit capacit

Total below 14.2

Indoor unit capacity code

Total below 14.2

Indoor unit capacit

Total below 14.2

Indoor unit capacity code

Total below 14.2

code

code

code

code

code

For 3 piping

For 2 piping (*4)

For 3 piping

For 2 piping (

For 3 piping

For 2 piping (

4)

*

4)

*

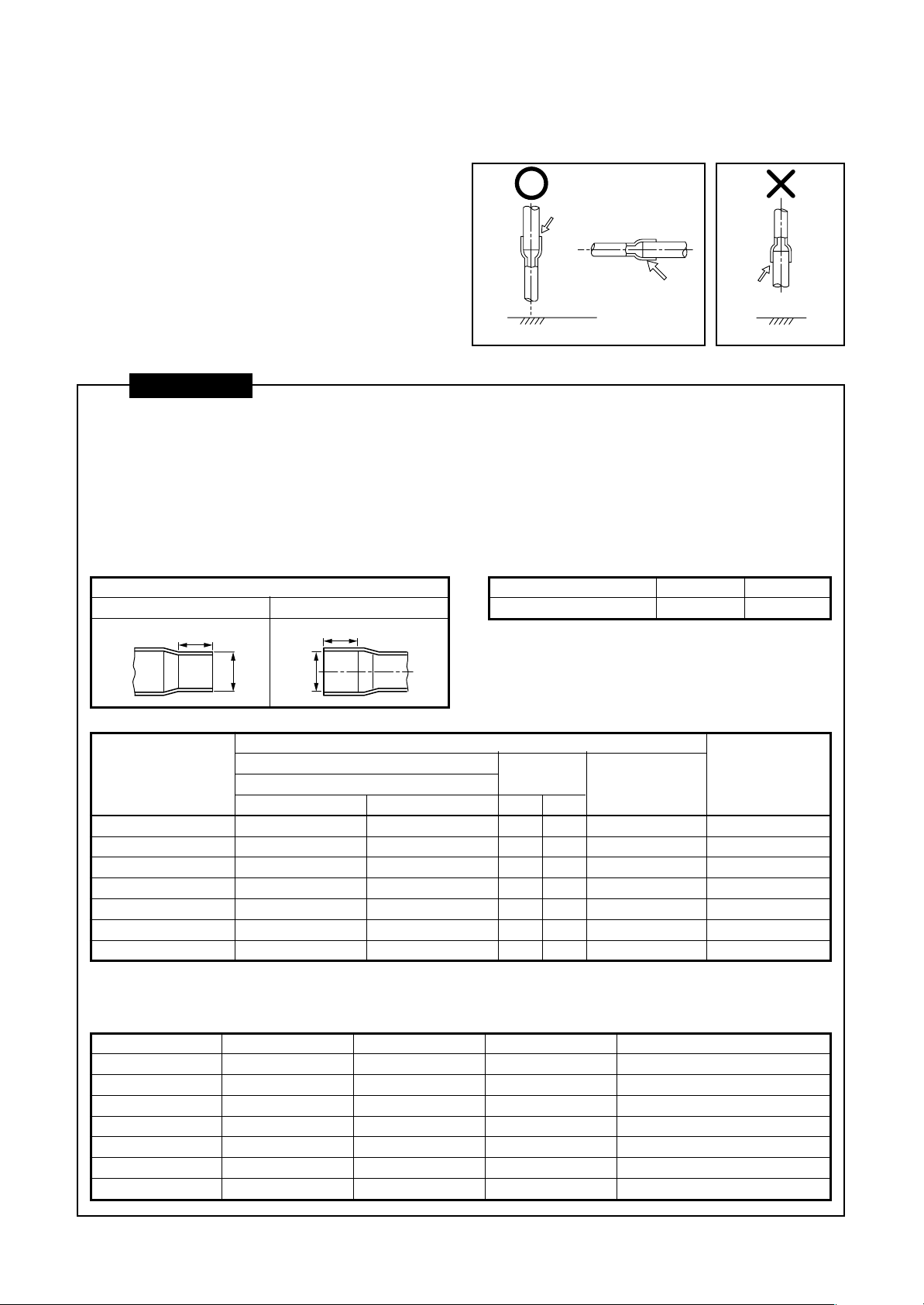

5-9. Nitrogen Gas Blow Method (During Brazing)

• If nitrogen gas is not passed through the pipes during brazing, a film of oxidized material will form on the inner

surfaces of the pipes. The presence of a such a film in the system will adversely affect the operation of the

valves and compressor in the refrigerant system, and will prevent the system from operating normally.

• In order to prevent this from occurring, nitrogen gas is passed through the pipes while brazing is in progress.

This process of replacing the air in the pipes with nitrogen is called the “nitrogen gas blow.”

This is the basic method that is used for brazing work.

CAUTION

1. Nitrogen gas must be used. (Oxygen, carbon dioxide, and fluorocarbons cannot be used.)

2. Always be sure to use a pressure-reducing valve.

Piping

Valve

Hose

Reducing

valve

Nitrogen

gas bomb

Piping at site

Brazing

position

Copper pipe Ø6.4

Valve

Taping

Reducing valve

Pressure

tight hose

Outside

Nitrogen

gas bomb

23

Page 24

5-10. Brazing Work

1. Brazing work should be performed downwards or

(Recommended brazing)

sideways. Avoid brazing upwards (in order to

avoid incomplete brazing). (Recommendation)

2. Always used the specified piping materials for

liquid pipes and gas pipes, and make sure that

Brazing material

they are installed in the proper direction and at

the proper angle.

3. The “nitrogen gas blow” method should be used

when brazing.

(Direction downward) (Direction upward)

Lateral direction

Brazing

material

Brazing

material

CAUTIONS

1. Pay attention to fire prevention concerns. (Take preventative measures in the area where brazing work is

to be performed, such as keeping a fire extinguisher or water handy.)

2. Be careful not to burn yourself.

3. Make sure that any gaps between pipes and couplings are appropriate. (Do not miss brazing any joints.)

4. Make sure that pipes are adequately supported.

• The following table provides basic guidelines for the interval between supports for horizontal copper pipe.

Coupling size of brazed pipe

Connected section

External size Internal size

K

ØC

G

ØF

Interval between supports for copper pipe

Nominal dia.

Max. interval (m)

• Avoid securing copper pipes with metal brackets

directly.

20 or less 25 to 40

1.0 1.5

(Unit: mm)

Connected section

Standard outer dia. of

connected copper pipe

6.35

9.52

12.70

15.88

19.05

22.22

28.58

External size Internal size

Standard outer dia. (Allowable difference)

CF

6.35 (±0.03) 6.45 ( )

9.52 (±0.03) 9.62 ( )

12.70 (±0.03) 12.81 ( )

15.88 (±0.03) 16.00 ( )

19.05 (±0.03) 19.19 ( )

22.22 (±0.03) 22.36 ( )

28.58 (±0.04) 28.75 ( )

+0.04

–0.02

+0.04

–0.02

+0.04

–0.02

+0.04

–0.02

+0.03

–0.03

+0.03

–0.03

+0.06

–0.02

Min. depth

of insertion

KG

76

87

98

98

11 10

11 10

13 12

Oval value

0.06 or less

0.08 or less

0.10 or less

0.13 or less

0.15 or less

0.16 or less

0.20 or less

Min. thickness

of coupling

0.50

0.60

0.70

0.80

0.80

0.82

1.00

∗ Gas brazing of refrigerant pipes must be performed by personnel qualified to do so under local ordinances.

Minmum wall thickness for R410A application

Soft (Coil)

¡

¡

¡

¡

NG

NG

NG

Hard or Half hard

¡

¡

¡

¡

¡

¡

¡

OD (Inch)

1/4

3/8

1/2

5/8

3/4

7/8

1.1/8

OD (mm)

6.35

9.52

12.70

15.88

19.05

22.20

28.58

Minium wall thickness

0.80

0.80

0.80

1.00

1.00

1.00

1.00

24

Page 25

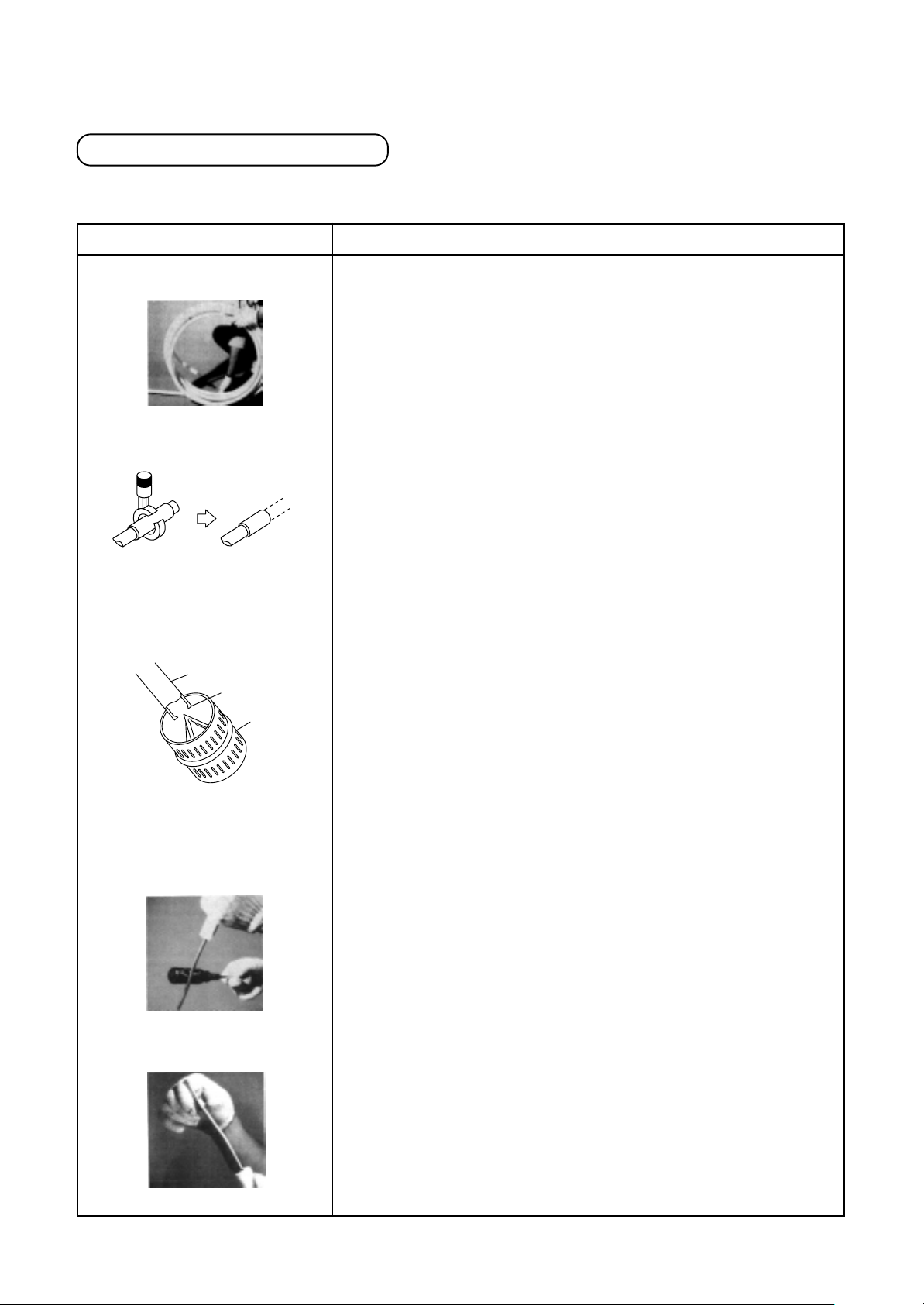

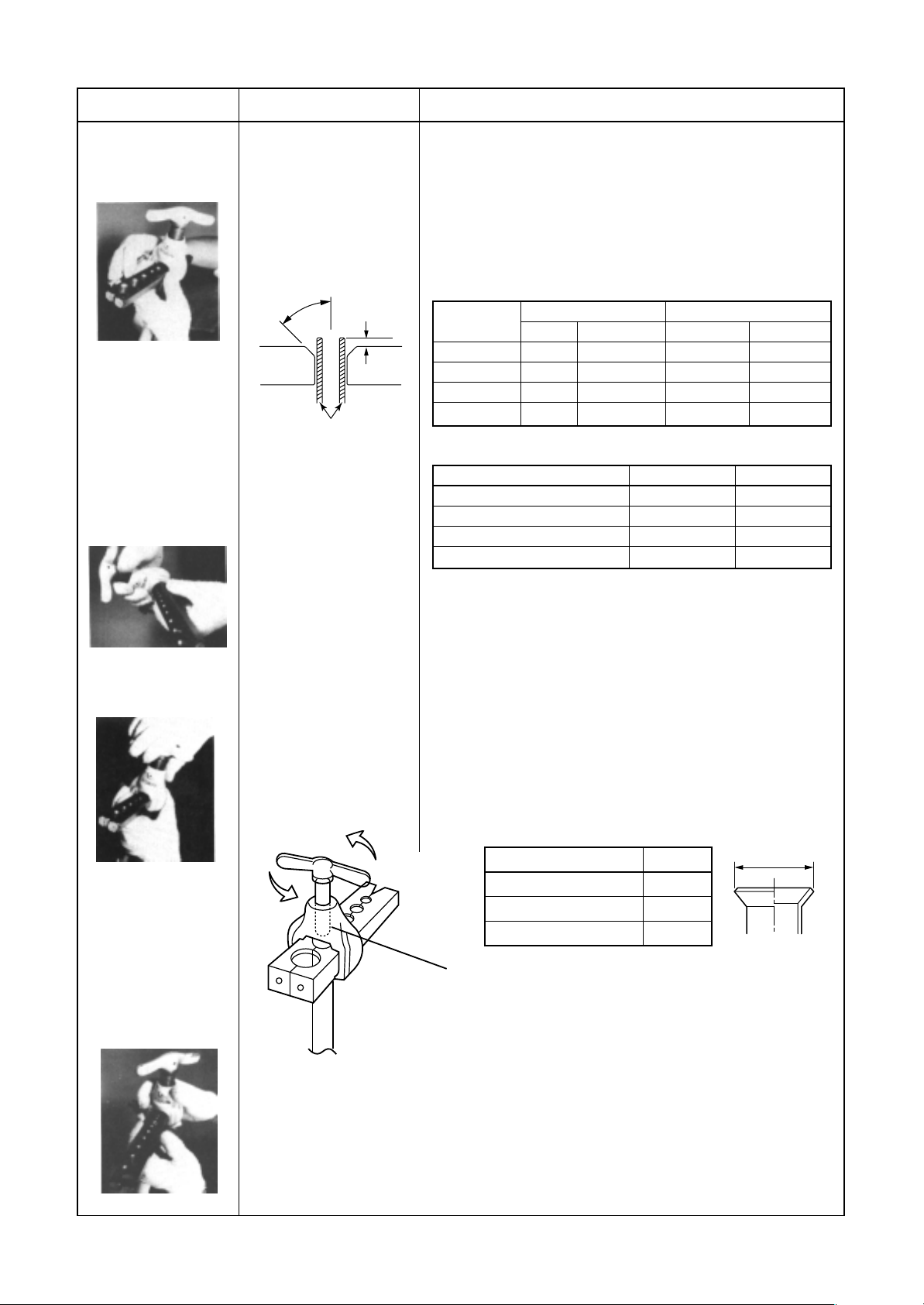

5-11. Flare Processing

Flare processing procedure

Parts and material : Copper pipe, flare nut. Flare nut shallbe of attached on the indoor unit or R410A exclusive.

Tools : Flare tool (“Rigid” type), reamer, pipe cutter

Work procedure

Straighten the coiled copper pipe.

Cut the pipe with the pipe cutter.

Use the reamer to remove burrs

from the cut surface of the pipe.

Pipe

Burr

Deburring

Key point

Uncoil the pipe.

1. Position the blade of the cutter

so that it will cut the pipe at a

perpendicular angle.

2. Rotate the pipe cutter to the

left to cut the pipe.

3. Move the pipe cutter slowly.

1 . Keep the opening of the pipe

facing downwards.

2. Be careful not to scratch the

inner surface of the pipe.

(Reason)

• It is difficult to cut the coiled pipe

correctly, which increases the

chance of failure.

• The cut surface will be at an

angle.

• The cutter will bite too tightly.

• The copper pipe will be

deformed.

• Scraps will get inside of the

pipe.

• A gas leak could result.

Clear out the inside of the pipe by

tapping on the end with a

screwdriver.

Insert the flare nut.

Make sure that all scraps of metal

are out of the tube by lightly

tapping on the tube while the

opening is pointing down.

Be certain to insert the flare nut

before beginning the flare

process.

25

• Metal scraps in the tube can

damage the compressor.

• If the scraps adhere to the

flared region, a gas leak may

result.

• The flare nut will not fit inside

the copper pipe after the flare

process.

Page 26

Work procedure

Key point

(Reason)

Attach the (“Rigid”)

flare tool to the

copper pipe.

Align the punch.

(Align the arrow with

the line adjacent to

the next hole.)

1. Make sure that the

inner surfaces of the

flare tool are clean.

2. Determine the

dimensions of the

copper pipe in

accordance with the

flare tool.

45˚

A

Flare tool

Copper pipe

Align the arrow on the

punch with the

prescribed position on

the flare tool.

• The copper pipe will slip out while the flaring process is in

progress.

• The flared dimensions vary.

Dimensions to end of copper tube when flared with one tool

surface

• Projection margin in flaring : A (Unit : mm)

Rigid (Clutch type)

Outer dia. of

copper pipe

6.4

9.5

12.7

15.9

R410A tool used

R410A R22

0 t o 0 .5 (Same as left)

0 t o 0 .5 (Same as left)

0 t o 0 .5 (Same as left)

0 t o 0 .5 (Same as left)

Conventional tool used

R410A R22

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

Imperial (Wing nut type)

Outer dia. of copper pipe

6.4

9.5

12.7

15.9

R410A R22

1.5 to 2.0 1.0 to 1.5

1.5 to 2.0 1.0 to 1.5

2.0 to 2.5 1.5 to 2.0

2.0 to 2.5 1.5 to 2.0

Flare the pipe.

Remove the flare tool

and check the flared

surface.

Slowly and carefully turn

the flare tool handle

while it clicks, until it

turns freely. Turn the

handle to the left and

raise it to the top.

If the handle is not raised to the

top, the flare tool will scratch the

extended portion of the pipe

(the cone-shaped portion).

• If the “A” dimension is small, the flared contact surface is

smaller and a gas leak becomes more likely.

• The pipe will not be flared fully.

• The extended portion of the pipe (the cone-shaped portion)

will be scratched.

• Extruding margin of copper pipe

with flare machining : A (Unit: mm)

Copper pipe outer dia.

9.5

12.7

15.9

A

13.2

16.6

19.7

+0.0

–0.4

A

Check list :

• Is the inner surface of the flared portion equal in width and shiny?

• Is the thickness of the flared portion equal?

• Is the flared portion of a suitable size?

26

Page 27

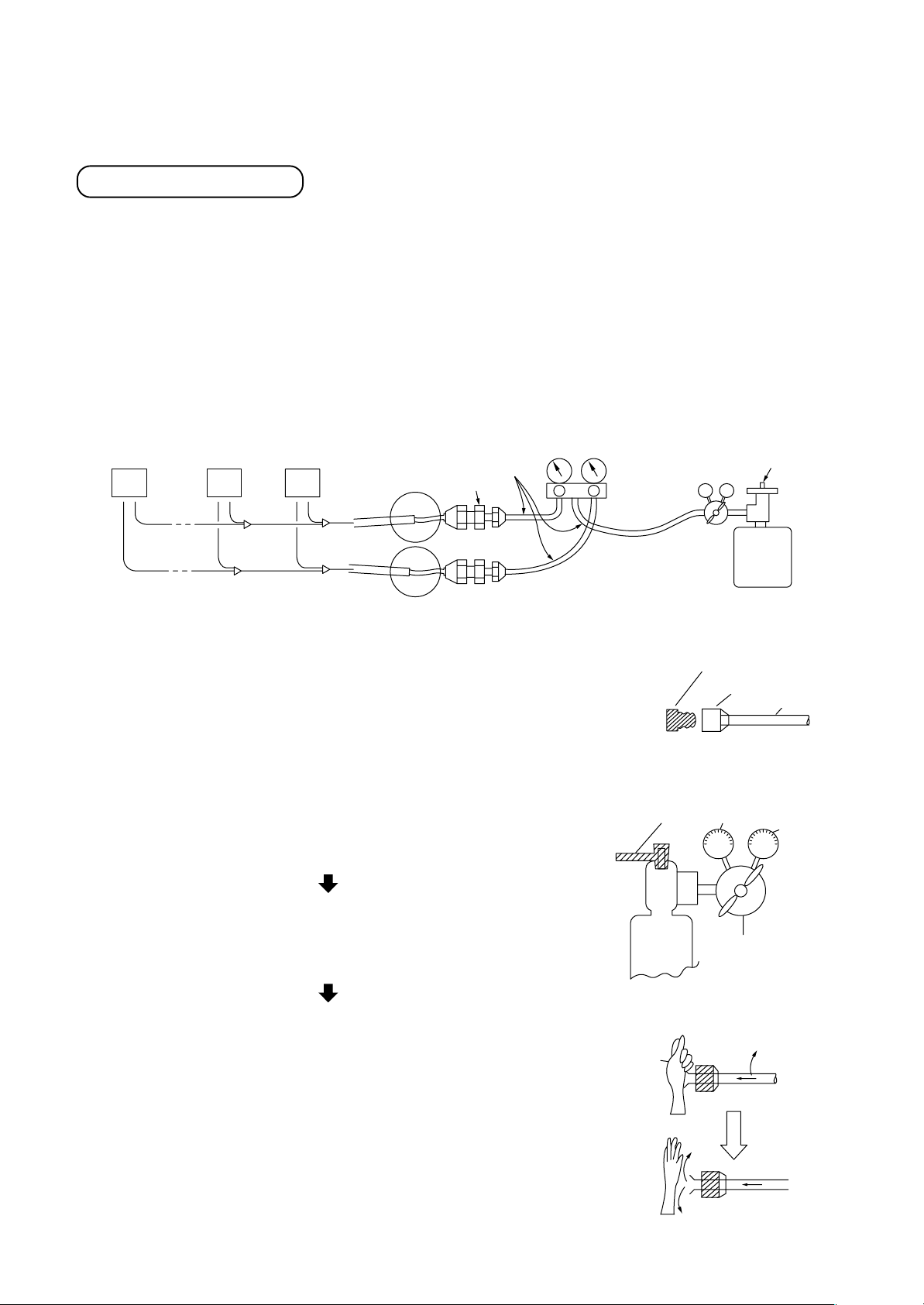

5-12. Flushing

The flushing process uses gas pressure to remove foreign matter from the inside of pipes.

Three major effects

(1) Removes oxidation that formed inside of the pipe during brazing as a result of an inadequate “nitrogen gas

blow” procedure.

(2) Removes foreign matter and moisture that has gotten inside of pipes due to improper handling.

(3) Checks the connections in the pipe system between the indoor unit and the outdoor unit.

[Example work procedure]

1. Install a pressure reducing valve on a nitrogen cylinder. (Fluorocarbon gases and carbon dioxide carry a risk

of promoting condensation, while oxygen causes explosion.)

2. Connect the pressure reducing valve to a gauge manifold and then to the gas-side pipe and the liquid-side

pipe on the outdoor unit.

Indoor unit

Ø6.4 copper pipe

N21

Diff. size union

3. On the indoor unit side, plug all gas-side pipes except those for the

indoor units that are to be flushed.

4. Open the source valve on the nitrogen cylinder and increase the

pressure on the secondary side of the pressure reducing valve until it

reaches 0.5MPa (5kg/cm2G), and then open the valve on the gauge

manifold connected to the gas-side pipe.

5. Flushing

Press down on the end of the indoor-side gas pipe with your palm.

VLV

H

Gauge

manifold

valve

Source

valve

Reducing

valve

Nitrogen gas bomb

Plug (Brass)

1st side

Source valve

Flare nut

Copper pipe

2nd side

0.5MPa

(5kg/cm²G)

When the pressure becomes so great that you can no longer hold it

against the end of the pipe, remove your hand from the pipe. (This is

the first flush.) Press down against the end with your hand again.

Flush the pipe a second time.

(When flushing, place a piece of gauze, etc., on the end of the pipe,

and then check the gauze for debris or moisture. Repeat the flushing

process until nothing more comes out of the pipe.)

6. Close the gauge manifold valve, and repeat the above process for

next indoor unit (No. 2 to No. N). Close the gauge manifold valve,

open the valve on the gauge manifold that is connected to the liquidside pipe to allow the nitrogen to flow, and flush that liquid-side pipe.

27

Nitrogen

Hand

gas

Reducing valve

Pressure

0.5MPa (5kg/cm²G)

Page 28

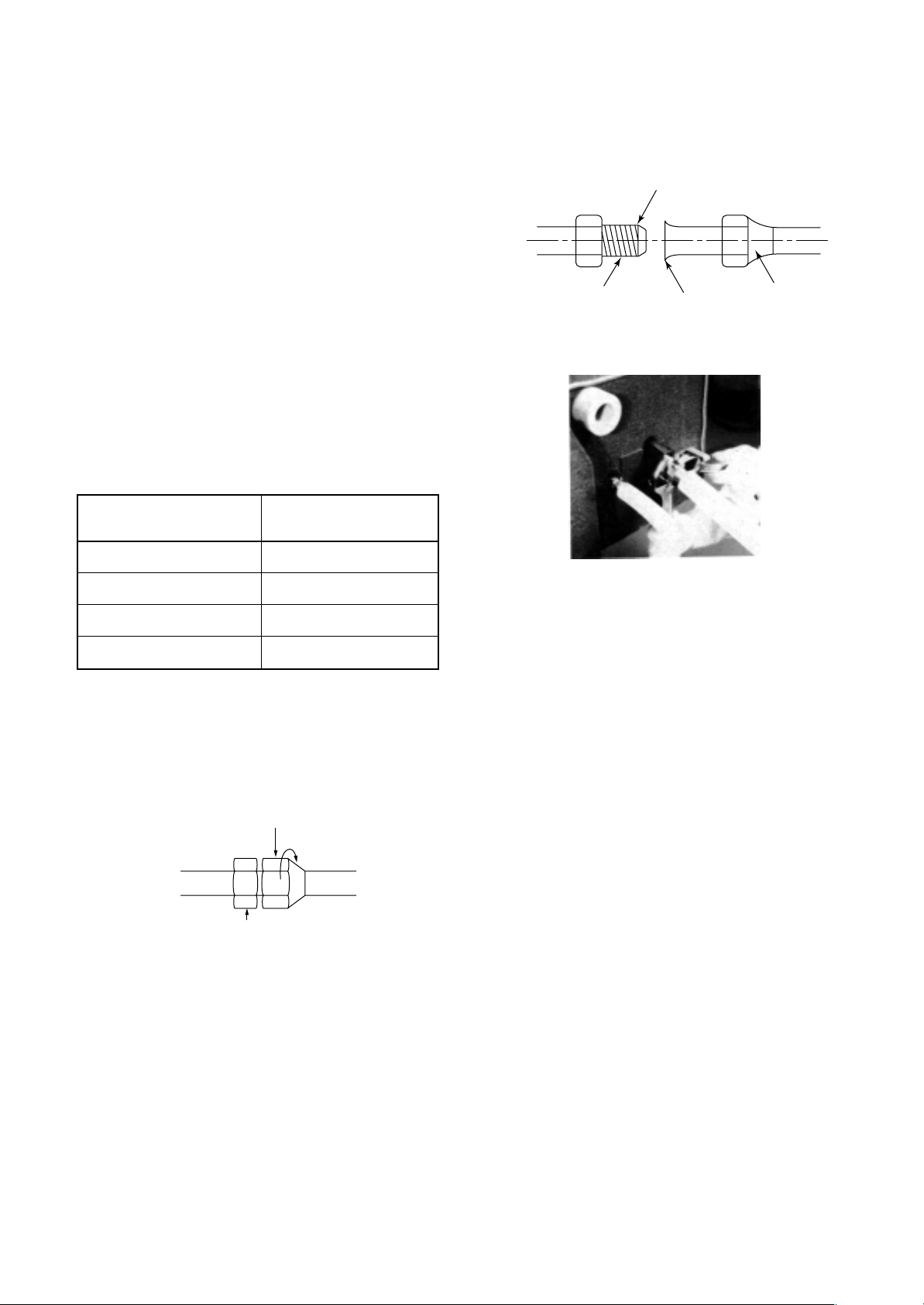

5-13. Pipe Connections to the Indoor Unit

1. Once you remove the flare nut from the pipe on

the indoor unit (always use a torque wrench), a

small amount of gas will escape, but this is simply

nitrogen gas with atmospheric pressure that was

sealed inside to prevent corrosion, and does not

indicate a problem.

2. Flare the pipe according to the procedure

described previously.

3. Centering

Center the pipes be seating the tapered portion of

the half union in the flared portion of the pipe.

4. Tightening the flare nut

First hand-tighten the flare nut as much as

possible, and then use a torque wrench to tighten

the nut completely.

<Indoor unit> <Pipe>

Center

Brazing union

(half union)

Tapered portion

Flared portion

Flare nut

Connecting pipe outer dia.

(mm)

Ø6.4

Ø9.5

Ø12.7∗

Ø15.9∗

Tightening torque

(N•m)

14 to 18 (1.4 to 1.8 kgf•m)

34 to 42 (3.4 to 4.2 kgf•m)

50 to 62 (5.0 to 6.2 kgf•m)

68 to 82 (6.8 to 8.2 kgf•m)

∗ : R410A torque wrench required.

<Two spanners>

Turn flare nut with a wrench

<Indoor unit> <Pipe>

Secure half union in place with a wrench

Tightening the flare nut with a torque wrench

* Avoid initially tightening the nut with a wrench.

* When tightening a 6.4mm-diameter pipe, tighten the nut lightly with a wrench, and then tighten the nut about

90° to 120° (1.5 to 2 corners of the nut) with a torque wrench.

28

Page 29

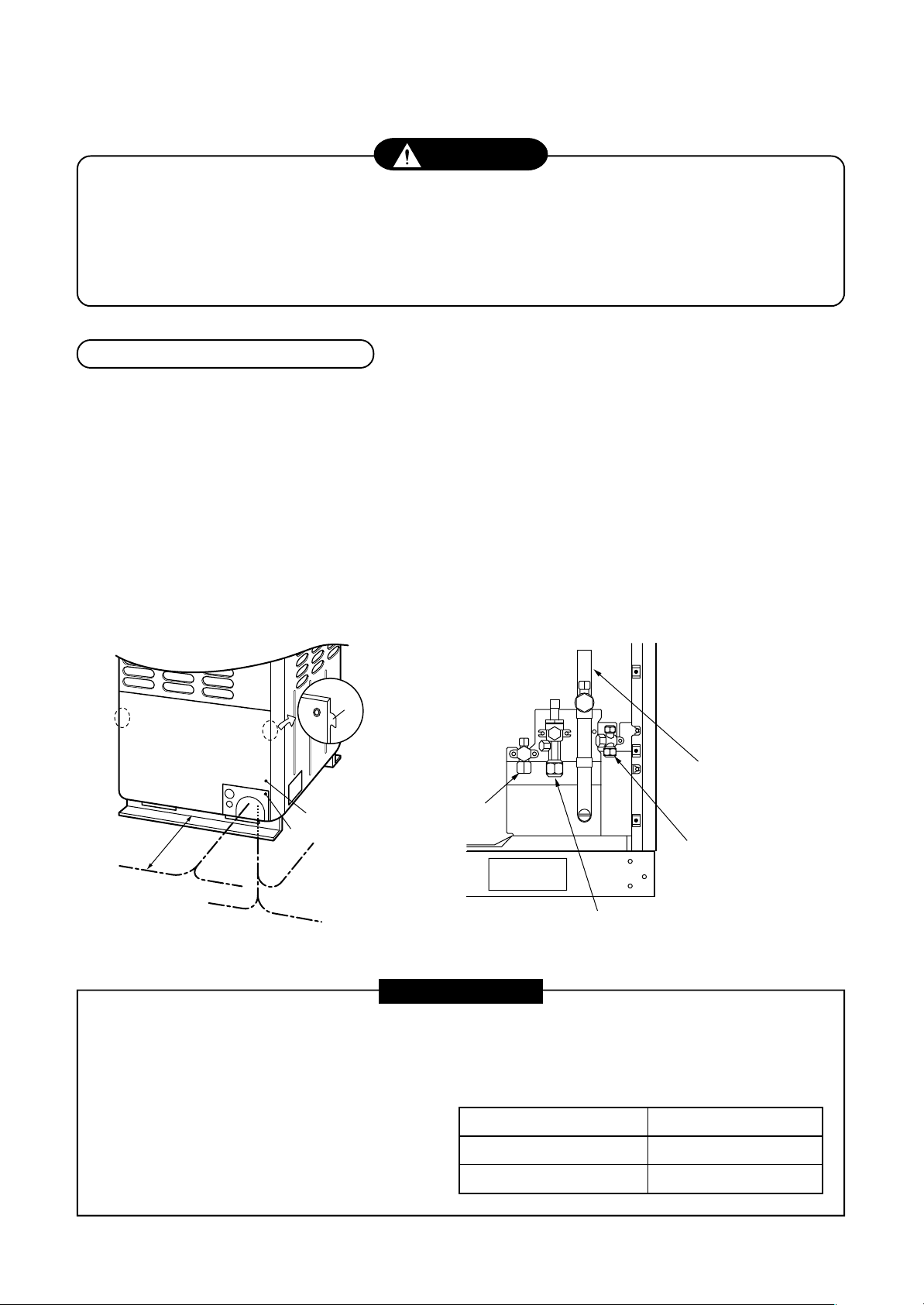

5-14. Pipe Connection to the Outdoor Unit

WARNING

If the refrigerant gas leaks during installation work, ventilate the room.

If the leaked refrigerant gas comes to contact with a fire, the noxious gas may generate.

After installation work, check that the refrigerant gas does not leak.

If the refrigerant gas leaks in the room and comes to contact with a fire such as fan heater, stove, or kitchen

range, the noxious gas may generate.

Connection of refrigerant pipe

1. The refrigerant pipe connecting section is set in the outdoor unit. Remove the front panel and the piping/wiring

panel. (M5: 9 pcs.)

• As shown in the right figure, the hooking hooks are attached at right and left sides each on the front panel.

Lift up and remove the front panel.

2. Pipes can be drawn out forward and downward from the outdoor unit.

3. When drawing out the pipe forward, draw out the pipe to outside via piping/wiring panel, and keep space of

500mm or more from the main pipe connecting the outdoor unit with the indoor unit, considering service work,

etc. (For replacing the compressor, 500mm or more space is required.)

4. When drawing out the pipe downward, remove the knockout of the base plate of the outdoor unit, apply the

pipe to outside of the outdoor unit, and perform piping at right/left or rear side. Leading pipe of the balancing

should be within 4m.

Hook

Packed valve at

suction gas side

(Left piping)

500mm

or more

Drawing out

forward

(Left piping)

(Right

piping)

Drawing out

downward

Front panel

Piping/wiring panel

(Rear piping)

(Right piping)

Packed valve

at liquid side

Packed valve at balance side

(It is not used in this model.)

Ball valve at discharge gas side

REQUIREMENT

For brazing, be sure to use nitrogen gas to avoid oxidation of pipe inside.

1. In a welding work for the refrigerant pipes, be sure to use the nitrogen gas in order to prevent oxidation

inside of the pipes; otherwise clogging of the refrigerating cycle due to oxidized scale generates.

2. Use clean and new pipes for the refrigerant pipes and perform piping work so that water or dust is not

mixed.

3. Be sure to use a double spanner to loosen

or tighten the flare nut. If a single spanner is

used, a required tightening cannot be obtained.

Tighten the flare not with the specified torque.

Outer dia. of copper pipe

12.7 mm

15.9 mm

Tightening torque (N•m)

50 to 62 (5.0 to 6.2 kgf-m)

68 to 82 (6.8 to 8.2 kgf-m)

29

Page 30

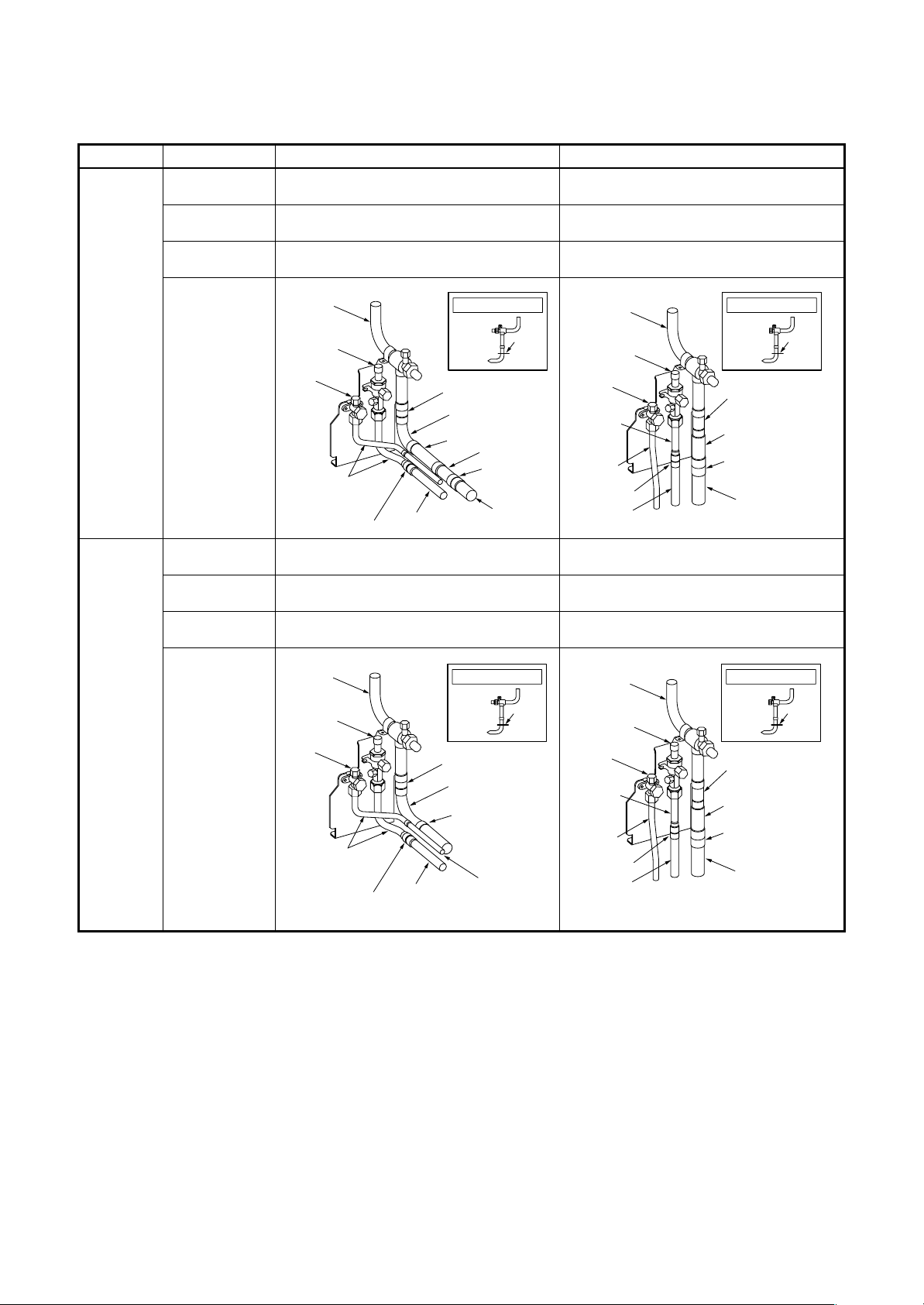

Pipe connecting method of valve (Example)

Using the attached pipes as shown in the following figure, braze elbows, sockets, and pipes which are procured locally.

MMY- Drawing out forward Drawing out downward

Liquid pipe Use the attached pipe for connection.

Discharge gas pipe

Suction gas pipe

Use the attached pipe (L-shape) and connect it

with socket.

Cut L-shape pipe and connect it with elbow,

attached pipe and socket.

Pipe connection at the local site

(Bend rightward slightly.)

Use the attached pipe (Straight pipe) and connect

it with socket.