MMD-AP___1HF2ULE15-3S2

MMD-AP0481HF2UL

MMD-AP0721HF2UL

MMD-AP0961HF2UL

Outside Air Unit Type

Contents

1. System summary

2. Specifications

3. Dimensions

4. Center of gravity

5. Piping diagram

6. System combination

7. Wiring diagram

8. Electrical characteristics

9. Fan characteristics

10. Sound data

1

1. System summary

• Connectable outdoor unit

Outdoor unit of SMMS-e series.

• Corresponding system

Corresponds to a system in which there are the outside air units and the indoor air

conditioners.

• Definition

The outside air unit means an air controller for taken-in outside air.

Intake of the outside air often influences on the system so that the normal control of the air conditioner

becomes difficult or gives a large load upon air controller and cooling performance.

Therefore it is frequently adopted to handle the outside air to a certain condition before the outside air

will enter in the main air conditioner.

This handling device is called an outside air unit.

NOTE:

The outside air unit is an air conditioner provided to handle the outside air load and is not to control

the room temperature. For correspondence to the load of the indoor air controller, set an air

conditioner separately.

Outside Air Unit Type

MMD-AP___1HF2ULE15-3S2

2

MMD-AP___1HF2ULE15-3S2

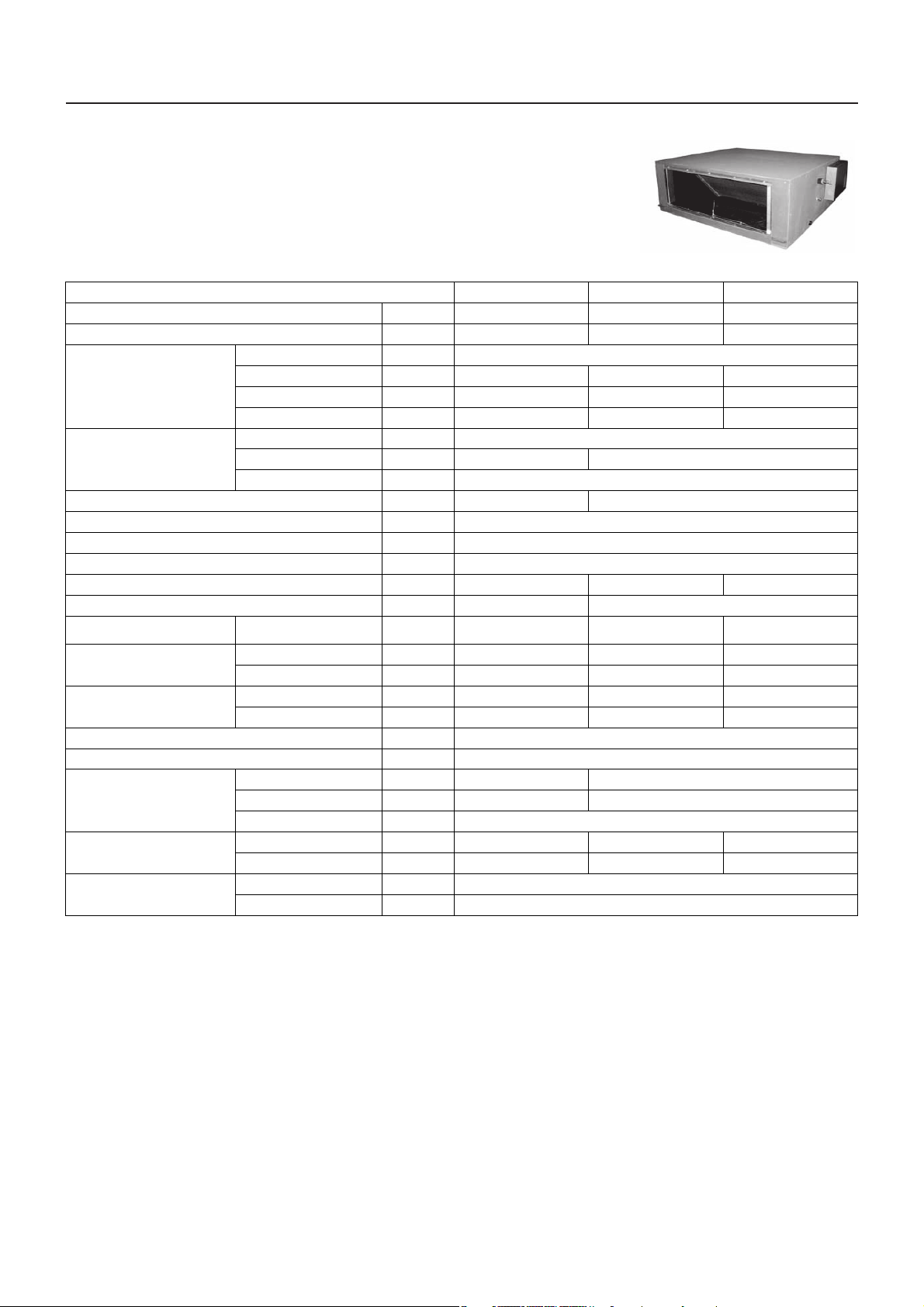

2. Specifications

Model name MMD- AP0481HF2UL AP0721HF2UL AP0961HF2UL

Cooling capacity (Note1)

Heating capacity (Note1)

Power supply 230 V (208/230 V) 1phase

Electrical

characteristics

Outer

dimension

Main unit weight lbs 212 349

Heat exchanger Finned tube

Soundproof / Heat-insulating material Non-flammable insulation

Fan Centrifugal fan

Standard air flow cfm 636 989 1237

Motor W AC 160 AC 160 x 2

External static pressure

(factory default)

External static

pressure

(factory default)

Air flow limit

Air filter Field supply

Controller Wired remote controller

Connecting

pipe

Sound pressure level

Operation

range for SMMS-e

Running current A 1.58/1.56 3.00/2.88 3.32/3.17

Power consumption kW 0.31/0.34 0.56/0.58 0.64/0.66

Starting current A 3.90/3.20 7.70/6.30 8.50/6.90

Height In 19.5"

Width In 35.4" 55"

Depth In 49.8"

208 V / 230 V In WG 0.55/0.86 0.74/1.00 0.41/0.85

208 V (H / M / L) In WG 0.75/0.55/0.16 0.84/0.74/0.24

230 V (H / M / L) In WG 1.06/0.86/0.50 1.08/1.00/0.65

Lower limit cfm 445 693 866

Upper limit cfm 700 1088 1360

Gas pipe In 5/8" 7/8"

Liquid pipe In 3/8" 1/2"

Drain pipe In VP25 (Polyvinyl chloride tube: External Dia.1-1/4 internal Dia.1)

208 V (H / M / L) dB(A) 44/43/36 47/46/40

230 V (H / M / L) dB(A) 46/45/42 48/47/46

Cooling (Note 2)

Heating (Note 3)

kBtu/h 48.0 72.0 96.0

kBtu/h 30.0 47.0 59.0

0.67/0.41

1.01/0.85

°F

°F

41 - 115

23 - 109

47/45

50/49

(H/L)

(H/L)

(H/L)

(H/L)

* The setting temperature is 60 - 80 °F

* Height difference between outside air units must be within 1.97" (0.5 m).

Note 1: Rated conditions Cooling: Outdoor air temperature 91 °F DB/82 °F WB setting temperature 64 °F

Heating: Outdoor air temperature 32 °FDB/26 °F WB setting temperature 77 °F

Note 2: * When supply air temperature is “setting temperature + 5.4 °F” or less, Outside air unit operates as FAN mode.

Note 3: * When supply air temperature is “setting temperature - 5.4 °F” or over, Outside air unit operates as FAN mode.

3

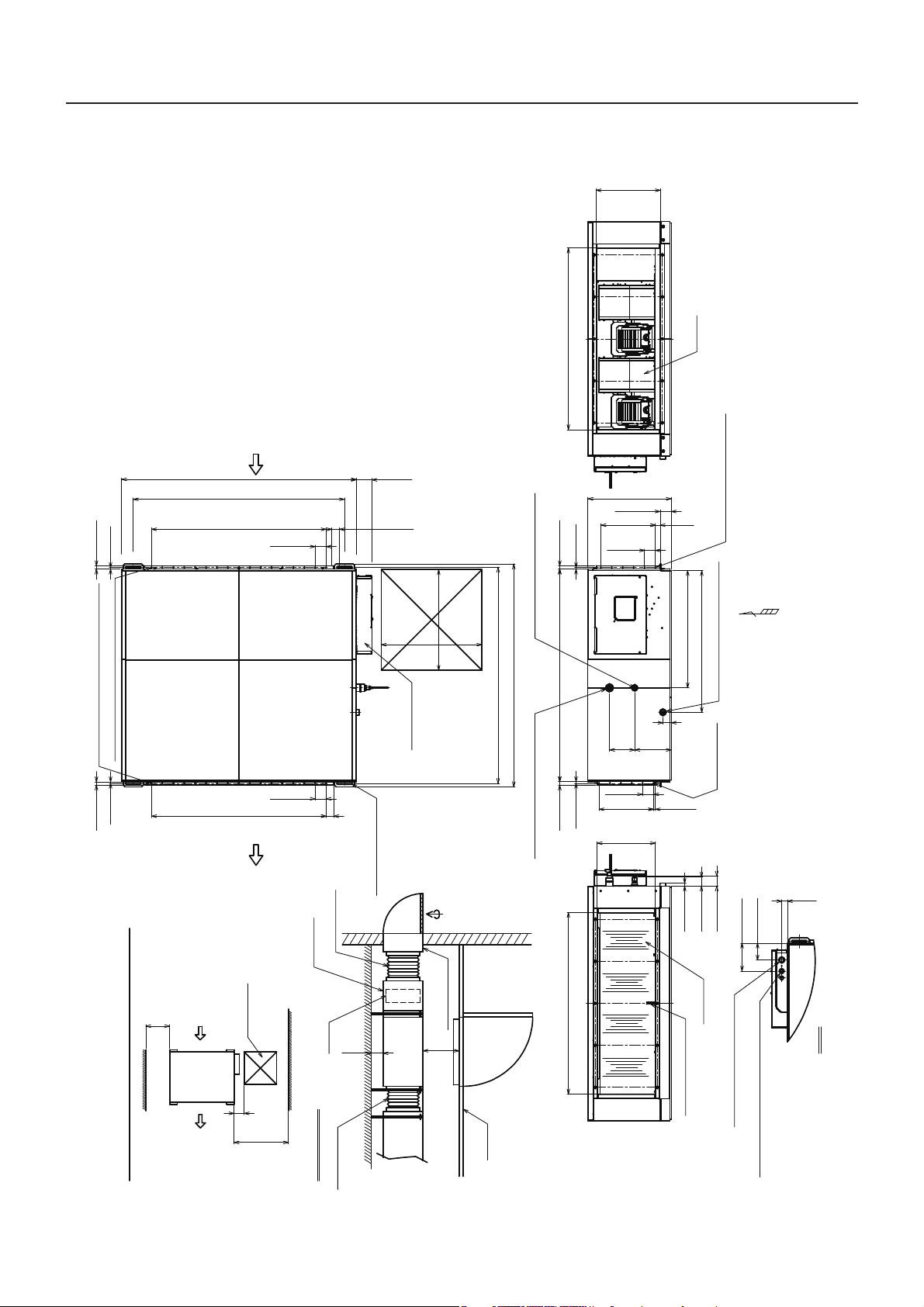

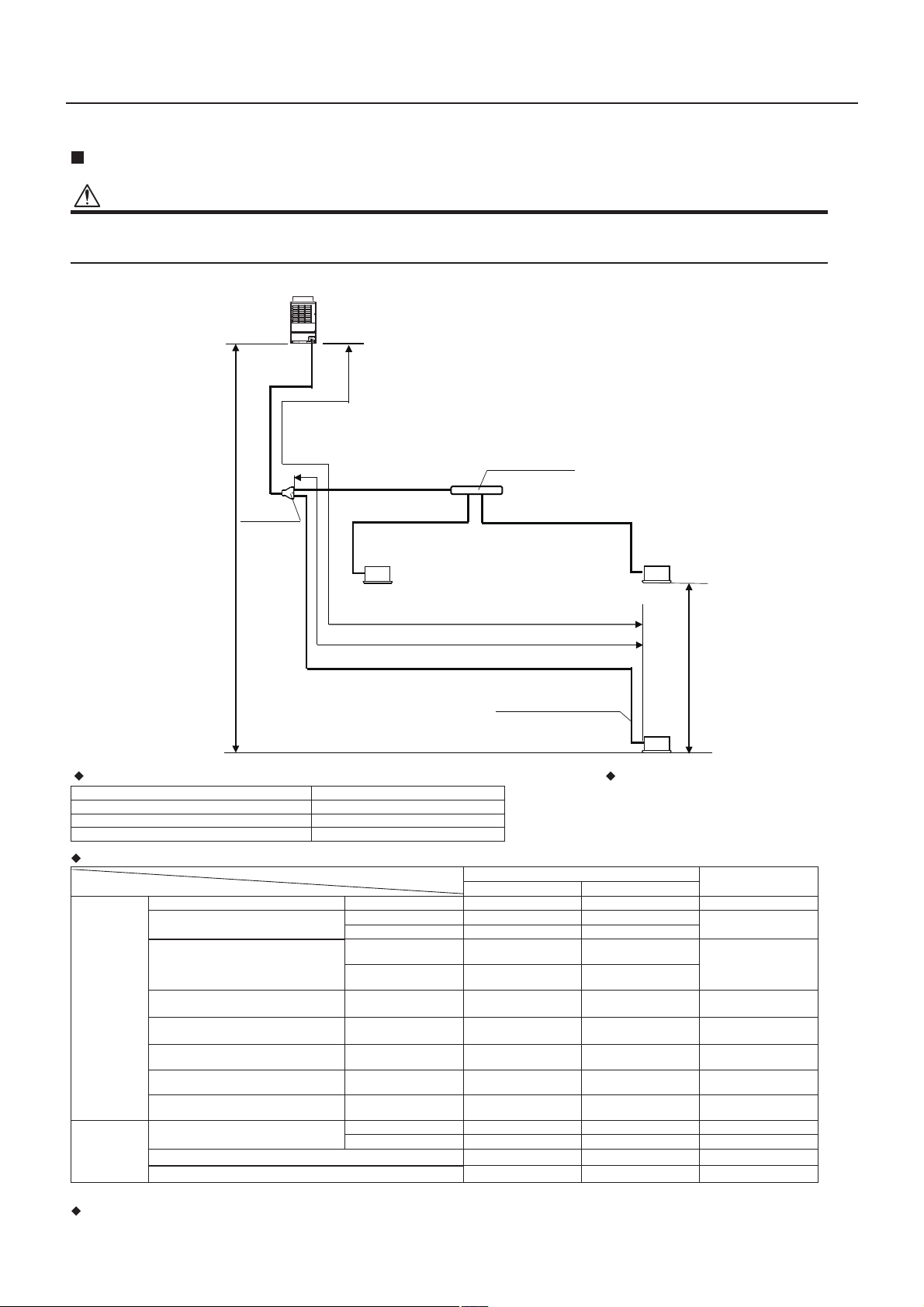

3. Dimensions

Installation Notes

Unit:in(mm)

1. Provide access area to the right of the unit as shown.

2. Condensate piping should slope downwards in the direction of

condensate flow, with a minimum gradient of 1in per 100 inches.

Condensate pipe should be insulated to avoid condensation.

3. Check condensate system for proper drainage before stating the unit.

4. Avoid installation of unit in Hazardous locations.

5. Filter and filter box are field provide and field installed items which

would prevent deposition of duct and dirt in the unit.

6. Install flexible duct for easy disassembly of the unit during major

service or breakdown.

7. Insulating the suction duct is recommended to avoid any

condensation on the exterior from untreated outside air.

8. Outside air louver with screen is recommended at the outside air

operating on the exterior wall.

Access Area

23.6"

(600)

23.6"

(600)

Space required for installation and servicing

Example

Access Area

23.6" (600)

Service

space

Over

7.9"

(200)

Service

space

7.9"

(200)

Over 39.4" (1000)

Outside Air

Unit

Outside Air

Unit

Flexible duct

Filter Box

Filter

Ceiling

Air intake duct

Access Area

Outside air

Over

3.9"

(100)

Over

2.0"

(50)

Air flow

23.0" (583)Outside

15.1" (383)

Outside

Suction

Discharge temp sensor

Discharge

28.7" (728)Outside

13.7" (347)

Outside

0.7" (18)

2.3" (59)

2.5" (65)

2.6" (65)

0.4" (9)

2.6" × 5 = 12.8"

(65 × 5 = 325)

Screw hole for

duct mounting

(6-ø0.2" (5))

1.9"

(49)

8.6"

(218)

5.9"

(150)

27.5" (699)

33.3" (845)

Drain pipe connection port (V25)

Taper screw for R1,1" (25.4) pipes

0.4" (10)

0.8" (20)

49.8" (1266)

0.7" (19)

0.4" (9)

Refrigerant pipe connection port

(Liquid side ø3/8" (9.5) Flared)

Refrigerant pipe connection port

(Gas side ø5/8" (15.9) Flared)

2.6" (65)

1.1"

(28)

2.6" × 5 = 12.8"

(65 × 5 = 325)

2.6" (66)

19.5" (496)

Electrical box

50.7" (1288) Mounting Location

52.3" (1328)

Hole for hanging bolt

(4-ø1/2" (12) × 1.6" (40))

2.6" (65)

2.5" (62)

2.6" × 10 = 25.6"

(65 × 10 = 650)

2.6" (65)

2.2" (55)

2.6" × 8 = 20.5"

(65 × 8 = 520)

32.2" (818) Mounting Location

3.4" (87) 35.4" (898)

0.4" (9)

0.7" (19)

0.4" (9)

0.7" (19)

Screw hole for duct mounting(9-ø0.2" (5))

Screw hole for duct mounting(11-ø0.2" (5))

7.6" (193)

11.8" (299)

1.2" (30)

1.3" (33)

Z

Z view

ø1.2" (30) Hole for control wire

and remote control wiring

ø7/8" (22.2) Hole for power supply cable

Screw hole for duct mounting

(6-ø0.2" (5))

MMD-AP0481HF2UL

MMD-AP___1HF2ULE15-3S2

4

0.7"(18)

2.3"(59)

Discharge temp sensor

Discharge

2.1"(52)

42.6"(1083) Outside

13.7"(347)

Outside

Z

2.6"(65)

2.6"×5=12.8"

(65×5=325)

0.4"(9)

2.6"(65)

1.1"

(28)

2.6"×5=12.8"

(65×5=325)

2.6"(66)

19.5"(496)

27.5"(699)

33.3"(845)

Drain pipe connection port(V25)

Taper screw for R1,1"(25.4) pipes

Screw hole for

duct mounting

(6-Ø0.2"(5))

Screw hole for duct mounting

(6-Ø0.2"(5))

1.9"

(49)

8.6"

(218)

5.9"

(150)

0.4"(10)

0.8"(20) 49.8"(1266) 0.7"(19)

0.4"(9)

Hole for hanging bolt

Refrigerant pipe connection port

(Liquid side Ø1/2"(12.7) Flared)

(4-Ø1/2"(12)×3.6"(92))

Suction

42.6"(1083) Outside

15.1"(383)

Outside

50.7"(1288) Mounting Location

52.3"(1328)

2.6"(65)

1.8"(45) 2.6"×16=40.9"(65×16=1040)

2.6"(65)

1.8"(45)

2.6"×16=40.9"(65×16=1040)

32.2"(818)

Mounting Location

55"(1398)

3.7"(93)

0.4"(9)

0.7"(19)

0.4"(9)

0.7"(19)

Screw hole for duct mounting(17-Ø0.2"(5))

Screw hole for duct mounting(17-Ø0.2"(5))

Refrigerant pipe connection port

(Gas side Ø7/8"(22.2) Brazed)

Access Area

23.6"

(600)

23.6"

(600)

Electrical box

Air flow

Space required for installation and servicing

Example

Access Area

23.6"(600)

Service

space

Over

7.9"

(200)

Service

space

7.9"

(200)

Over 39.4"(1000)

Outside

Air Unit

Outside

Air Unit

Flexible duct

Filter Box

Filter

Flexible duct

Ceiling

Air intake duct

Access Area

Outside air

Over

3.9"

(100)

Over

2.0"

(50)

4.0"(100)

6.6"(166)

1.3"

(33)

Ø1"(26) Hole for control wire

Ø7/8"(22.2) Hole for power supply cable

and remote control wiring

Z view

Installation Notice

1. Provide access area to the right of the unit as shown.

2. Condensate piping should slope downwards in the direction of

condensate flow,with a minimum gradient of 1in per 100 inches.

Condensate pipe should be insulated to avoid condensation.

3. Check condensate system for proper drainage before starting the unit.

4. Avoid installation of unit in Hazardous locations.

5. Filter and filter box are field provided and field installed items which

would prevent deposition of duct and dirt in the unit.

6. Install flexible duct for easy disassembly of the unit during major

service or breakdown.

7. Insulating the suction duct is recommended to avoid any

condensation on the exterior from untreated outside air.

8. Outside air louver with screen is recommended at the outside air

opening on the exterior wall.

Unit: in(mm)

MMD-AP___1HF2ULE15-3S2

5

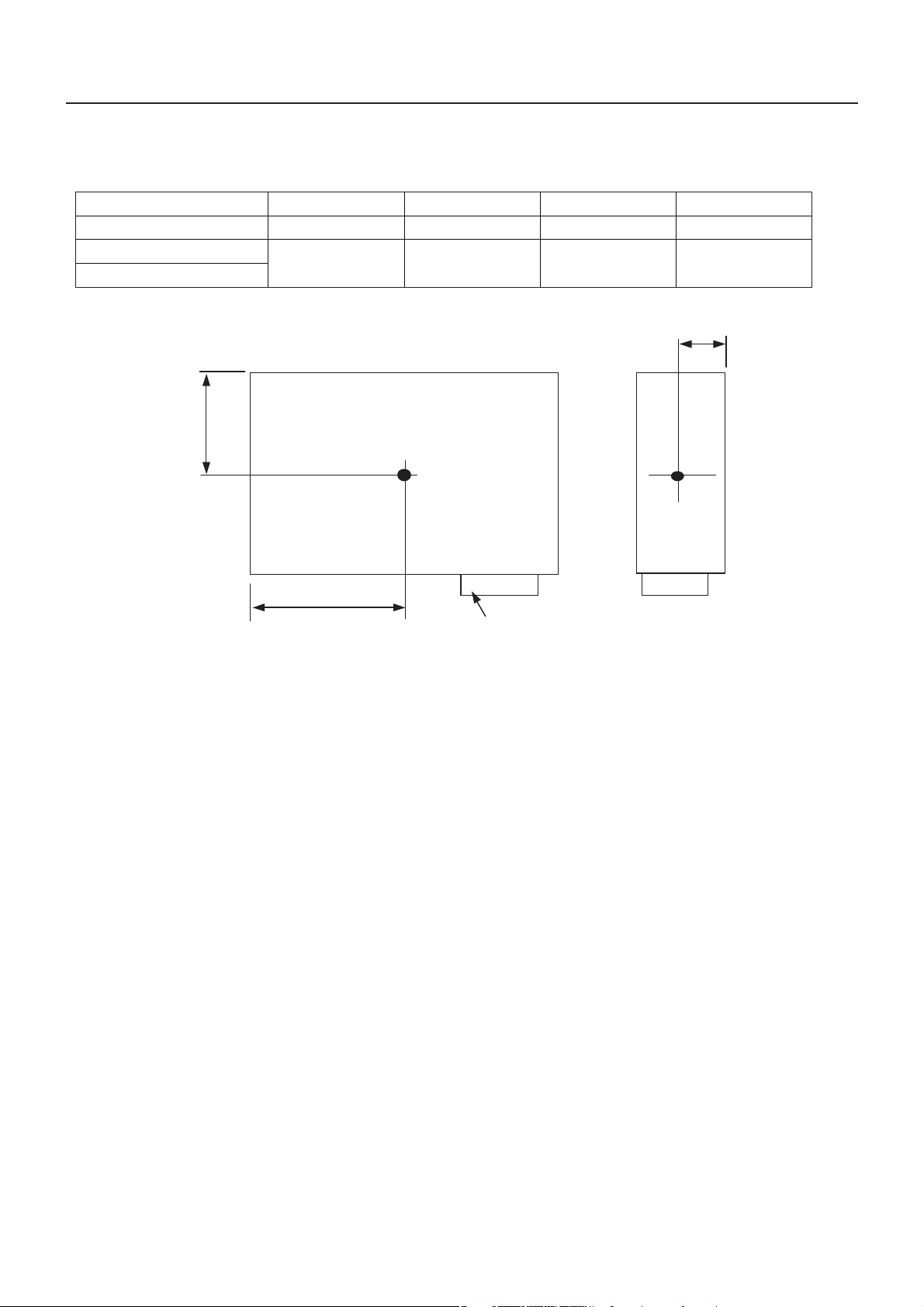

4. Center of gravity

Z

Y

X

Electrical box

Model name MMD-

AP0481HF2UL

AP0721HF2UL

AP0961HF2UL

X (In) Weight (lb)

26.4 18.9 8.7 212

26.4 30.3 8.7 349

Z (In)Y (In)

MMD-AP___1HF2ULE15-3S2

6

5. Piping diagram

M

Liquid side Gas side

Strainer

Pulse Motor

Val ve (PMV)

Sensor

(TC2)

Strainer

Capillary tube

Air heat exchanger

at indoor side

Sensor

(TCJ)

Fan

Sensor

(TA)

Fan motor

Sensor

(TC1)

Sensor

(TF)

MMD-AP___1HF2ULE15-3S2

Functional part name Functional outline

Pulse Motor Valve PMV (Connector CN082 (6P): Blue)

1) Controls super heat in cooling operation

2) Controls sub cool in heating operation

3) Recovers refrigerant oil in cooling operation

4) Recovers refrigerant oil in heating operation

Temp. sensor 1. TA (Connector CN104 (2P): White)

1) Detects indoor suction temperature

2. TC1 (Connector CN100 (3P): Brown)

1) Controls PMV super heat in cooling operation

3. TC2 (Connector CN101 (2P): Blue)

1) Controls PMV sub cool in heating operation

4. TCJ (Connector CN102 (2P): Yellow)

1) Controls PMV super heat in cooling operation

5. TF (Connector CN103 (2P): Green)

1) Detects indoor discharge temperature

7

MMD-AP___1HF2ULE15-3S2

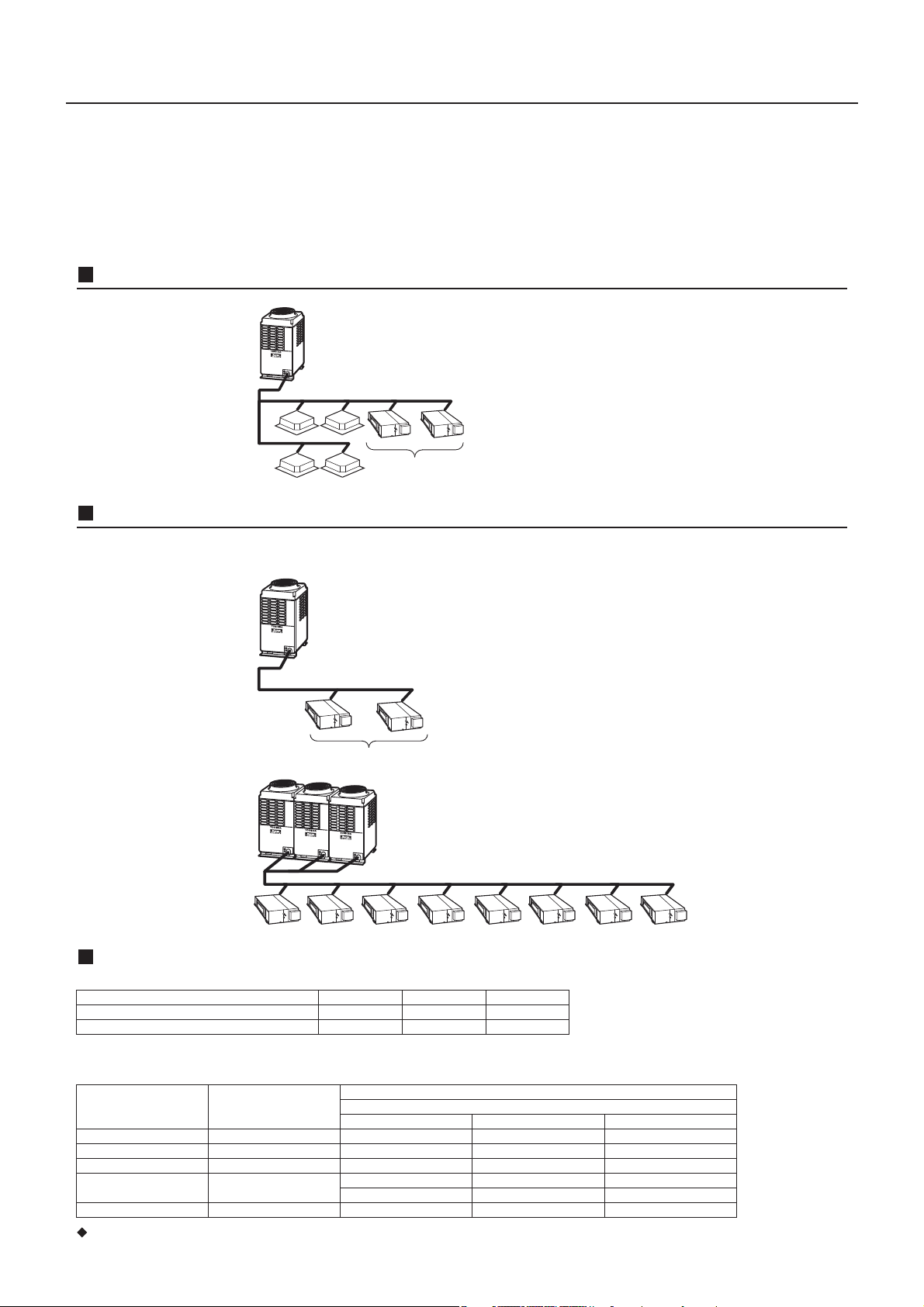

6. System combination 6-1. Case of MMY model

The Outside Air Unit is connectable to SMMS (Super Modular Multi system).

However this is not connectable to SHRM (Super Heat Recovery Multi system).

Keep the height difference between the Outside Air Units to 1.97" (0.5 m) or less.

Case of Outside Air connection with other indoor units

Connection which stretches over two floors is unavailable units

Correct

Height difference: 1.97" (0.5 m) or less

Case of All Outside Air connection to SMMS-e

• System that connected to Outside Air Unit only can be used with only single Outdoor unit on one line of the multi system.

The combination of indoor units is only available specified in following Table 2.

Correct

Height difference: 19.7" (0.5 m) or less

Incorrect

The combination of Indoor units

1. The capacity code of Indoor unit is decided for each capacity type.

emanledomtinuroodnI

pytyticapactinuroodnI

apactinuroodnI

ocytic

2. Combination of Indoor units is decided for Outdoor unit capacity type.

It allows only the combinations of Indoor units below.

Outdoor unit capacity type Outdoor unit capacity code

epyt270

7

441epyt441

861epyt861

Combination of Indoor unit capacity type

1

2702

69069epyt690

-021epyt021

-

-

-

Please refer to “Outside Air Unit’s Installation Manual” except the above contents.

690270840e

692784ed

Number of Indoor units

270

LU2FH1690PALU2FH1270PALU2FH1840PA-DMM

32

--

840+840

270+

70+690

-

-840+270

840+840+840

-840+690

02

840+840+27

8

MMD-AP___1HF2ULE15-3S2

Allowable length/height difference of refrigerant pipinJ&DVHRI$OO2XWVLGH$LU

CAUTION

Length and height of refrigerant piping keep the limitation blow.

If installed in out of the limitation, there is a possibility that heat-exchanger in Outdoor unit will burst and leak a refrigerant gas, for freezing heat-exchanger by shortage

of defrosting capacity.

Allowable length and height difference of refrigerant piping

(*1): Farthest Indoor unit from the first branching section is the Indoor unit (c).

Please refer to “Outdoor Unit’s Installation Manual” except the above contents.

System restrictions Cautions for installation

Y-shaped branching joint must be installed

horizontally.

Max. No. of combined Outdoor units 1 unit

Max. capacity of combined Outdoor units 14 ton

Max. No. of combined Indoor units 3 units

Max. capacity of combined Indoor units Refer to “ The combination of Indoor units”

Allowable value

Pipes

mtf

Pipe length Total extension of pipe (Liquid pipe) Actual length c + b + a + 2L + 1L003489

Farthest piping length

L (*1)

Equivalent length 051294

L1 + c

Actual length 031724

Main piping length

Equivalent length

Max. 394

0LQ

Max. 120

(Min. )

L1

Actual length

Max. 328

(Min. 164)

Max. 100

(Min. 50)

Farthest equivalent piping length from the first

branching section

Li

(*1)

Equivalent length c0389

Farthest equivalent piping length between

Outdoor units

LO

Equivalent length

Maximum equivalent piping length of Outdoor

unit connecting pipe

Equivalent length

Maximum actual length of pipes connected to

Indoor units

Actual length c ,b ,a0389

Maximum equivalent length between

branching sections

Equivalent length 2L0389

Height difference

Height between Outdoor and Indoor units

H1

Upper Outdoor units 04131

Lower Outdoor units 301

Height between Indoor units

H2

5.02

Height between Outdoor units

H3

Indoor unit

Outdoor unit

Unit (A)

Unit (b)

Branching header

Branching pipe

L2

Indoor unit connecting pipe

Indoor unit

Main

piping

L1

First branching

section

The longest piping length: L 492 ft (150 m)

The longest piping length from the first branch:

Li 98 ft (30 m)

Height difference between

Outdoor and Indoor units:

H1 131 ft (40 m)

Indoor unit connecting pipe

Height difference

between Indoor units:

H2 2 ft (0.5 m)

Unit (a)

b

H2

c

a

H1

Unit (c)

Indoor unit

Max. 100

(Min. 50)

Max. 120

(Min. 50)

Max. 394

(Min. 164)

Max. 328

(Min. 164)

9

MMD-AP___1HF2ULE15-3S2

6-2. Case of MCY model

Case of All Outside Air connection to Side Blow SMMS-e

The combination which can connect Outside Air Unit is only the 1:1 combination of MCY-MAP0487HS-UL and

MMD-AP0481HF2UL.

Other combination is not permitted.

Correct Incorrect

Allowable length/height difference of refrigerant piping (Case of All Outside Air)

CAUTION

Length and height of refrigerant piping keep the limitation blow.

If installed in out of the limitation, there is a possibility that heat-exchanger in Outdoor unit will burst and leak a refrigerant gas, for freezing heat-exchanger by shortage

of defrosting capacity.

Outdoor unit

Height difference between

an outside air unit and an

outdoor unit H3

Main

pipe

L4

Total extension of pipe (liquid pipe, real length) 328 100 L4

Real length

Equivalent length 410 125

Piping Length

Furthest piping length

(=Max.length of main pipe)

Max equivalent length of furthest piping from 1st branching Li ‒ ‒

Max real length of indoor unit connecting pipe ‒ ‒

Height

Difference

Height between indoor and outdoor units H3

Height between indoor units H2 ‒ ‒

Upper outdoor unit 164 50

Lower outdoor unit 9 3

(*1) The minimum piping length should set to the following figure by outside air temperature.

No restrictions (Operation permission)

Piping length 20 m or more

Piping length 50 m or more

No operation permitted

50

Outside air unit

Allowable value

(ft) (m)

Max 328 100

Min (*1) 164/66 50/20

Pipes

L4

41

32

23

Outside air unit temp. [°F] (*2)

14

(*2) Refer to [

-13 -4 5 14 23 32 41 50

■Use conditions] for Outside air unit temperature.

Outdoor unit temp. [°F]

◆Please refer to “Outdoor Unit’s Installation Manual” except the above contents.

10

6-3. Installation

Connecting flange

Refer to size in the figure attached to the main unit.

REQUIREMENT

If the air conditioner unit and the canvas joint are connected with the rivets, the fan and the refrigerating cycle cannot

be checked.

Be sure to use the flange as shown in the above and tighten it by the bolts.

(Fixing bolts 0.2" x 0.5"LQ (6 x 12 mm), locally procured)

<MMD-AP048 type>

<Air supply port connecting flange>

<MMD-AP072 type, AP096 type>

<Air supply port connecting flange>

<Air intake port connecting flange> <Air intake port connecting flange>

42.6" (1083)

25.6" (650) (2.6" × 10 (65 × 16))

2.6" (65)

1.8"

(45)

0.7" (19)

0.4" (9)

2.6" (65)

13.7" (347)

0.4" (9)

12.8" (325) (2.6" × 5 (65 × 5))

0.4" (9)

0.7" (19)

42.6" (1083)

40.9" (1040) (2.6" × 16 (65 × 16))

2.6" (65)

1.8"

(45)

0.7" (19)

0.4" (9)

2.6" (65)

13.7" (347)

0.4" (9)

12.8" (325) (2.6" × 5 (65 × 5))

0.4" (9)

0.7" (19)

23.0" (583)

20.5" (520) (2.6" × 8 (65 × 8))

2.6" (65)

2.2"

(55)

0.7" (19)

0.4" (9)

2.6" (65)

15.1" (383)

1.1" (28)

12.8" (325) (2.6" × 5 (65 × 5))

0.4" (9)

0.7" (19)

42.6" (1083)

40.9" (1040) (2.6" × 16 (65 × 16))

2.6" (65)

1.8"

(45)

0.7" (19)

0.4" (9)

2.6" (65)

15.1" (383)

1.1" (28)

12.8" (325) (2.6" × 5 (65 × 5))

0.4" (9)

0.7" (19)

Unit: in (mm)

MMD-AP___1HF2ULE15-3S2

11

MMD-AP___1HF2ULE15-3S2

<Example of construction>

1

Air intake duct

Connect the air intake duct (Locally procured) to the inlet flange.

Wrap aluminum tape around connecting part between the air intake port flange and duct, or provide sealer

so that air does not leak.

For the outside air intake port, attach a hood so that outside air is sucked from lower side.

And attach wire netting, etc. to the air intake of the hood.

Set the air intake duct at descending inclination so that water

can be dr

ained even if rainwater enters in.

Wrap the outside of the intake duct with heat insulator because it intakes cold air while heating.

2

Air supply duct

Connect the air supply duct (Locally procured) to the Air supply flange.

Wrap aluminum tape around connecting part of the air supply port flange and duct or apply packing so that air

does not leak.

Wall

*1: Locally procured

Access Area

(23.6" × 23.6" in

(600 × 600 mm))

*1

Heat insulator *1 Flexible duct *1

Product main unit

Air supply duct *1

Air supply flange

*1

Air intake flange

*1

Filter Box *1

Flexible duct *1

Hood

(with wire netting)

*1

Air intake duct

*1

Descending

inclination

High-efficiency filter *1

Long life prefilter *1

Heat insulator *1

12

MMD-AP___1HF2ULE15-3S2

Selection of installation place

Avoid installing in the following places.

Select a location for the indoor unit where the cool or warm air will circulate evenly.

Avoid installation in the following kinds of locations.

Locations where inside the ceiling is used as route for outside air.

Saline area (coastal area)

Locations with acidic or alkaline atmospheres (such as areas with hot springs, factories where chemicals or

pharmaceuticals are made and places where the exhaust air from combustion appliances will be sucked into the

unit).

Doing so may cause the heat exchanger (its aluminum fins and copper pipes) and other parts to become

corroded.

Locations with atmospheres with mist of cutting oil or other types of machine oi

l.

Doing so

may cause the heat exchanger to become corroded, mists caused by the blockage of the heat

exchanger to be generated, the plastic parts to be damaged, the heat insulators to peel off, and other such

problems to result.

Places where iron or other metal dust is present. If iron or other metal dust adheres to or collects on the interior

of the air conditioner, it may spontaneously combust and start a fire.

Locations where vapors from food oils are formed (such as kitchens where food oils are used).

Blocked filters may cause the air conditioner’s performance to deteriorate, condensation to fo

rm, the plasti

c parts

to be damaged, and other such problems to result.

Locations near obstructions such as ventilation openings or lighting fixtures where the flow of the blown air will

be disrupted (a disruption of the air flow may cause the air conditioner’s performance to deteriorate or the unit to

shut down).

Locations where an in-house power generator is used for the power supply.

The power line frequency and voltage may fluctuate, and the air conditioner may not work properly as a result.

On truck cranes, ships or other moving conveyances.

The air conditioner must not be used for special applications (such as for storing food, plants, precision

instruments or art works).

(The

quality of the

items stored may be degraded.)

Locations where high frequencies are generated (by inverter equipment, in-house power generators, medical

equipment or communication equipment).

(Malfunctioning or control trouble in the air conditioner or noise may adversely affect the equipment’s operation.)

Locations where there is anything under the unit installed that would be compromised by wetness.

(If the drain has become blocked or when the humidity is over 80%, condensation from the indoor unit will drip,

possibly causing damage to anything underneath.)

Locations where organic solvents are being used.

T

he air conditioner

cannot be used for liquefied carbonic acid cooling or in chemical plants.

Location near doors or windows where the air conditioner may come into contact with high-temperature, high-

humidity outdoor air.

(Condensation may occur as a result.)

Locations where special sprays are used frequently.

13

Installation space

Keep the space necessary for installation and service.

REQUIREMENT

The Access Area should be îLQ (600 × 600 mm).

Unit: in (mm)

Installation under atmosphere of the high humidity

Although it has been confirmed that no trouble occurs on the unit, there is a fear of drip of the water if operation

under high humidity condition continues.

In some cases including the rainy season, especially inside of the ceiling may become high-humidity atmosphere

(dew-point temperature: 86 °F (30 °C) (humidity: 80%) or higher).

1

Installation to inside of the ceiling with tiles on the roof.

2

Installation to inside of the ceiling with slated roof.

3

Installation to inside of the ceiling with kitchen.

In the above cases, additionally attach the heat insulator (Glass wool, etc.) to all positions of the air

conditioner, which come to contact with the high-humidity atmosphere.

In this case, arrange the side plate (Service panel) so that it is easily removed.

Apply also heat insulating a sufficient thickness 0.39"LQ (10 mm) or more to the duct and connecting part of

the duct.

7.9" (200) or more

Electrical box

Access Area

Access Area

39.4" (1000) or more

23.6"

(600)

7.9" (200)

23.6" (600)

2.0" (50)

or more

3.9" (100) or more

Service panel

Duct

MMD-AP___1HF2ULE15-3S2

14

MMD-AP___1HF2ULE15-3S2

Use conditions

In “COOL” mode, if temperature of the outside air is under the setup temp. +5.4°F, FAN status is automatically made. When temperature of the outside air is under 66°F,

FAN status is also made regardless of the setup temperature.

In “HEAT” mode, if temperature of the outside air is over the setup temp. -5.4°F, FAN status is automatically made. When temperature of the outside air is over 59°F,

FAN status is also made regardless of the setup temperature.

REQUIREMENT

In “COOL” or “FAN” mode, if temperature of the outside air is under 41°F, the operation stop automatically in order to protect the equipment.

In this case, continue the operation by selecting “HEAT” mode.

In “HEAT” mode, if temperature of the outside air is under 23°F, the operation stops automatically in order to protect the equipment.

When operating the air conditioner with the outside air temp. under 23°F (minimum -4°F),

set temp. of the outside air to be taken in to 32 (*1)°F or upper using

a duct heater (locally procured).

For details, consult the dealer which you

purchased the air conditioner.

(*1) When 096type system with 1 indoor unit, be taken in to 41°F or upper using a duct heater.

In “HEAT” mode, if temperature is out of range in the Use condition, the fan of the Outside Air Unit intermittently operate. So take care not to overheat a duct heater,

when use a duct heater.

Please refer to “Outside Air Unit’s Owner’s Manual” except the above contents.

14 221401688605234-

51114

23

23-4

109

109

▼

▼

▼

▼

▼

▼

Outdoor Air Temperature °F

Setup temp.

Setup temp.

COOL mode

(Outside Air Unit

and Outdoor Unit)

CoolingFan

Automatic COOL

operation starts

Automatic HEAT

operation starts

HEAT mode

(Outside Air Unit)

Heating

Fan

Setup temp. +5.4°F

Setup temp. -5.4°F

Setup temp.

Automatic HEAT

operation starts

Heating

Fan

Setup temp. -5.4°F

Using duct heater

HEAT mode

(Outdoor Unit)

Outside Air Unit Outside air temp.

Duct heater

(locally procured)

14

23

32

41

50

-13 -4 5 14 23 32

14

23

32

41

50

-13 -4 5 14 23 32

Use condition

Outside air unit temp. [°F]

Outdoor unit temp. [°F]

Use condition

Outside air unit temp. [°F]

Outdoor unit temp. [°F]

aC )ii(metsys dradnats fo esaC )i( se of 096type system with 1 indoor unit

Case to use in SMMS-e “MMY-MAP___6HT_P-UL” and Side blow SMMS-e “MCY-MHP___7HS-UL”

6-4. Basic operation

15

MMD-AP___1HF2ULE15-3S2

REQUIREMENT

When the air conditioner is used for the first time, it will take some moments after

the power has been turned on before the remote control becomes available for

operations: This is normal and is not indicative of trouble.

• Concerning the automatic addresses (The automatic addresses are set up by

performing operations on the outdoor interface circuit board.)

While the automatic addresses are being set up, no remote control operations

can be performed. Setup takes up to

10 minutes (usually about 5 minutes).

• When the power is turned on after automatic address setup

It takes up to 10 minutes (usually about 3 minutes) for the Outdoor unit to start

operating after the power has been turned on.

Before the air conditioner was shipped from the factory, all units are set to

[STANDARD] (factory default). If necessary, change the Indoor unit settings.

The settings are changed by operating the wired remote control.

* The settings cannot be changed using only a wireless remote control, simple

remote control or group control remote control by itself so install a wired remote

control separately as well.

Basic procedure for changing settings

Change the settings while the air conditioner is not working.

(Stop the air

conditioner before making settings.

)

CAUTION

Case of RBC-AMT32UL

Set only the CODE No. shown in the following table: Do NOT set any other CODE No.

If a CODE No. not listed is set, it may not be possible to operate the air conditioner

or other trouble with the product may result.

1

Push and hold

+ +

buttons simultaneously for at

least 4 seconds. After a while, the display flashes as shown in

the figure. Confirm that the CODE No. is [01].

• If the CODE No. is not [01], push

button to clear the display content,

and repeat the procedure from the beginning. (No operation of the remote

control is accepted for a while after

button is pushed.)

(While air conditioners are operated under the group control, “ALL” is

displayed first. When is pushed, the Indoor unit number displayed

following “ALL” is the header unit.)

2

Each time

button is pushed, Indoor unit numbers in the

control group change cyclically. Select the Indoor unit to

change settings for.

The fan of the selected unit runs and the louvers start swinging. The Indoor

unit for change settings can be confirmed.

3

Specify CODE No. [ ] with “TEMP.” / buttons.

4

Select SET DATA [ ] with “TIME” / buttons.

5

Push

button. When the display changes from flashing to lit,

the setup is completed.

• To change settings of another Indoor unit, repeat from Procedure 2.

• To change other settings of the selected Indoor unit, repeat from

Procedure

3

.

Use

button to clear the settings. To make settings after

button was

pushed, repeat from Procedure

2.

6

When settings have been completed, push

button to

determine the settings.

When button is pushed, flashes and then the display content

disappears and the air conditioner enters the normal stop mode.

(While is flashing, no operation of the remote control is accepted.)

All Outside Air Unit connection setting

When only Outside Air Units connected to Outdoor unit, set the all Outside Air Unit

connection setting at Outside Air Units.

Firstly, follow to the basic operation procedure

(1

2

345)

• The CODE No. in Procedure

3 is [

C8].

• The [SET DATA] in Procedure

4

is [

0000].

Secondary, follow to the basic operation procedure

(3

4

5)

• The CODE No. in Procedure 3

is [

AE

].

• The [SET DATA] in Procedure

4

is [0016

].

Finally, follow to the basic operation procedure

(3456)

• The CODE No. in Procedure

3 is [

AF

].

• The [SET DATA] in Procedure

4

is [

0010

].

1

6

3

2

5

4

(* Display content varies with the Indoor unit model.)

CODE No. SET DATA

0000

8

C

6100E

A

010

0FA

Please refer to “Outside Air Unit’s Inst

allation Manual” except

the above contents.

Applicable controls (Case of All Outside Air with SMMS-e “MMY-MAP__HT_P-UL”)

16

MMD-AP___1HF2ULE15-3S2

Set

<

Yes

No

Return

Continue?

NoYes

DN setting

CODE No. SET DATA

C8 0000

AE 0016

AF 0010

Case of RBC-AMT54E-UL

Room A

12:00

75

Cool

Mode

1

2

1 [ MENU] button

Displays the menu screen.

2 [ CANCEL] button

Functions as indicated on the screen, such as returning to the previous

menu screen.

3 [ ∧ ] button

During normal operation: adjusts the temperature.

On the menu screen: selects a menu item.

4 [ ∨ ] button

During normal operation: adjusts the temperature.

On the menu screen: selects a menu item.

5 [ F1] button

Varies its function according to the setting screen.

6 [ F2] button

Varies its function according to the setting screen.

Fan Speed

3,4

5

6

Field setting menu

1.Test mode

2.Register service info.

3.Alarm history

4.Monitor function

5.Setting louver position

Return

DN setting

Code

(DN) Data

Set

10 0000

Return

<>

Code

(DN) Data

Fix

DN setting

10 0001

Return

<>

Fix

1 Push the [ MENU] button to

display the menu screen.

2 Push and hold the [ MENU]

button and the [

the same time to display the “Field

setting menu”.

Push and hold the buttons for more

than 4 seconds.

∨] button at

3 Push the [ ∧ ] / [ ∨ ]

button to select “7. DN setting” on

the “Field setting menu” screen, then

push the “ Set”

F2] button.

[

The fan and louver of the indoor unit

operate. When the group control is

used, the fan and louver of the

selected indoor unit operate.

Move the cursor to select “Code

(DN)” with the “

[ F1] button, then set “Code

(DN)” with the [

∨ ] button.

Move the cursor to select “Data” with

the “

button, then set “Data” with the [

4 Refer to the Installation Manual

supplied with the indoor unit or

service manual for details about the

Code (DN) and Data.

5 Push the [ MENU] button to set

the other Code (DN) and Data. After

“Continue?” is displayed on the

screen, push the “ Yes”

F1] button.

[

6 Push the “ No” [

F2] button to finish the setting

operation. “ Setting” appears on

the screen for a while, then the

screen returns to the “Field setting

menu” screen.

Pushing the “

selection screen when the group

control is used. Push the [

CANCEL] button on the unit

selection screen to finish the setting

operation. “ Setting” appears on

the screen for a while, then the

screen returns to the “Field setting

menu” screen.

>

>” [ F2]

∧ ] / [ ∨ ] button.

F2] button displays the unit

No

<”

∧ ] / [

No” [

All Outside Air Unit connection setting

When only Outside Air Units connected to Outdoor unit, set the all Outside Air

Unit connection setting at Outside Air Units.

Firstly, follow to the basic operation procedure

(1→2→3→5)

• For the CODE No. in Procedure 3 is [C8].

• For the [SET DATA] in Procedure

Secondary, follow to the basic operation procedure

3 is [0000].

(3→5)

• For the CODE No. in Procedure 3 is [AE].

• For the [SET DATA] in Procedure

Finally, follow to the basic operation procedure

3 is [0016].

(3→6)

• For the CODE No. in Procedure 3 is [AF].

• For the [SET DATA] in Procedure

3 is [0010].

17

When the air conditioner is used for the first time, it will take some moments after

the power has been turned on before the remote control becomes available for

operations: This is normal and is not indicative of trouble.

Concerning the automatic addresses (The automatic addresses are set up by

performing operations on the outdoor interface circuit board.)

While the automatic addresses are being set up, no remote control operations

can be performed. Setup takes up to 10 minutes (usually about 5 minutes).

When the power is turned on after automatic address setup

It takes up to 10 minutes (usually about 3 minutes) for the Outdoor unit to start

operating after the power has been turned on.

Before the air conditioner was shipped from the factory, all units are set to

[STANDARD] (factory default). If necessary, change the Indoor unit settings.

The settings are changed by operating the wired remote control.

* The settings cannot be changed using only a wireless remote control, simple

remote control or group control remote control by itself so install a wired remote

control separately as well.

Change the settings while the air conditioner is not working. (Stop the air

conditioner before making settings.)

Set only the CODE No. shown in the following table: Do NOT set any other CODE No.

If a CODE No. not listed is set, it may not be possible to operate the air conditioner

or other trouble with the product may result.

+ +

If the CODE No. is not [01], push

button to clear the display content,

and repeat the procedure from the beginning. (No operation of the remote

control is accepted for a while after button is pushed.)

(While air conditioners are operated under the group control, !ALL" is

displayed first. When is pushed, the Indoor unit number displayed

following !ALL" is the header unit.)

The fan of the selected unit runs and the louvers start swinging. The Indoor

unit for change settings can be confirmed.

To change settings of another Indoor unit, repeat from Procedure

.

To change other settings of the selected Indoor unit, repeat from

Procedure

.

Use button to clear the settings. To make settings after button was

pushed, repeat from Procedure .

When button is pushed, flashes and then the display content

disappears and the air conditioner enters the normal stop mode.

(While is flashing, no operation of the remote control is accepted.)

(* Display content varies with the Indoor unit model.)

Please refer to “Outside Air Unit’s Installation Manual” except the above contents.

Applicable controls (Case of All Outside Air with Side blow SMMS-e

“MCY-MAP__MHT_7HS-UL”)

REQUIREMENT

•

•

•

•

•

Basic procedure for changing settings

CAUTION

4

3

1

1

52

6

Push and hold buttons simultaneously for at

least 4 seconds. After a while, the display flashes as shown in

the figure. Confirm that the CODE No. is [01].

2

3

4

5

6

Each time button is pushed, Indoor unit numbers in the

control group change cyclically. Select the Indoor unit to

change settings for.

Specify CODE No. [ ] with “TEMP.” / buttons.

Select SET DATA [ ] with “TIME” / buttons.

Push button. When the display changes from flashing to lit,

the setup is completed.

2

2

3

When settings have been completed, push button to

determine the settings.

All Outside Air Unit connection setting

When Outside Air Unit connected to Outdoor unit, set the all Outside Air Unit

connection setting at Outside Air Unit.

Set the data as follows according to basic operation procedure.

(1→2→3→4→5→6)

• The CODE No. in Procedure 3 is [C8].

• The [SET DATA] in Procedure

4 is [0000].

Setting for Outside Air Unit’s fan ON

during defrost

If main piping length is less than 20 m and 50 m, Outside Air Unit must be

set for fan ON during defrost operation.

Without fan ON setting, there is a possibility that heat-exchanger in Outdoor

unit will burst and leak refrigerant gas, for freezing heat-exchanger by

shortage of defrosting capacity.

■Outside Air unit setting

Set the data as follows according to basic operation procedure.

(1→2→3→4→5→6)

• The CODE No. in Procedure 3 is [72].

• The [SET DATA] in Procedure

4 is [0000].

■Outdoor unit setting

Set the SW17-Bit2 "ON" on the Interface P.C. board of the outdoor unit.

CODE No. SET DATA

C8 0000

MMD-AP___1HF2ULE15-3S2

SW17

Interface P.C. board

18

MMD-AP___1HF2ULE15-3S2

Interface P.C. board

SW17

Set

<

Yes

No

Return

Continue?

NoYes

DN setting

CODE No. SET DATA

C8 0000

Case of RBC-AMT54E-UL

Room A

12:00

75

Cool

Mode

1

2

1 [ MENU] button

Displays the menu screen.

2 [ CANCEL] button

Functions as indicated on the screen, such as returning to the previous

menu screen.

3 [ ∧ ] button

During normal operation: adjusts the temperature.

On the menu screen: selects a menu item.

4 [ ∨ ] button

During normal operation: adjusts the temperature.

On the menu screen: selects a menu item.

5 [ F1] button

Varies its function according to the setting screen.

6 [ F2] button

Varies its function according to the setting screen.

Setting for Outside Air Unit’s fan ON

during defrost

If main piping length is less than 20 m and 50 m, Outside Air Unit must be set

for fan ON during defrost operation.

Without fan ON setting, there is a possibility that heat-exchanger in Outdoor

unit will burst and leak refrigerant gas, for freezing heat-exchanger by

shortage of defrosting capacity.

■Outside Air unit setting

Set the data as follows according to basic operation procedure.

(1→2→3→5→6)

• The CODE No. in Procedure 3 is [72].

• The [SET DATA] in Procedure

■Outdoor unit setting

Set the SW17-Bit2 "ON" on the Interface P.C. board of the outdoor unit.

3 is [0000].

Fan Speed

3,4

5

6

Field setting menu

1.Test mode

2.Register service info.

3.Alarm history

4.Monitor function

5.Setting louver position

Return

DN setting

Code

(DN) Data

Set

10 0000

Return

<>

Code

(DN) Data

Fix

DN setting

10 0001

Return

<>

Fix

1 Push the [ MENU] button to

display the menu screen.

2 Push and hold the [ MENU]

button and the [

the same time to display the “Field

setting menu”.

Push and hold the buttons for more

than 4 seconds.

∨] button at

3 Push the [ ∧ ] / [ ∨ ]

button to select “7. DN setting” on

the “Field setting menu” screen, then

push the “ Set”

F2] button.

[

The fan and louver of the indoor unit

operate. When the group control is

used, the fan and louver of the

selected indoor unit operate.

Move the cursor to select “Code

(DN)” with the “

[ F1] button, then set “Code

(DN)” with the [

∨ ] button.

Move the cursor to select “Data” with

the “

button, then set “Data” with the [

4 Refer to the Installation Manual

supplied with the indoor unit or

service manual for details about the

Code (DN) and Data.

5 Push the [ MENU] button to set

the other Code (DN) and Data. After

“Continue?” is displayed on the

screen, push the “ Yes”

F1] button.

[

6 Push the “ No” [

F2] button to finish the setting

operation. “ Setting” appears on

the screen for a while, then the

screen returns to the “Field setting

menu” screen.

Pushing the “

selection screen when the group

control is used. Push the [

CANCEL] button on the unit

selection screen to finish the setting

operation. “ Setting” appears on

the screen for a while, then the

screen returns to the “Field setting

menu” screen.

>

>” [ F2]

∧ ] / [ ∨ ] button.

F2] button displays the unit

No

<”

∧ ] / [

No” [

All Outside Air Unit connection setting

When Outside Air Unit connected to Outdoor unit, set the all Outside Air Unit

connection setting at Outside Air Unit.

Set the data as follows according to basic operation procedure.

(1→2→3→5→6)

• The CODE No. in Procedure 3 is [C8].

• The [SET DATA] in Procedure

3 is [0000].

19

7. Wiring diagram

MMD-AP0481HF2UL

MMD-AP___1HF2ULE15-3S2

PMV

FAN1

GRY

RED

WHI

3

BLK

2

ORN

1

BLU

4P

(WHI)

GRY

GRY

RED

RED

WHI

WHI

208/230-1-60

Power Supply

FM

G&Y

Screw

GRY

RED

WHI

L2

L1

4P

F3 F4

F1 F2

A

(WHI)

BLK

ORN

BLU

EXCT

PNL

TF

TC2 TC1

TCJ

TA

RED

LM

CN033

凚GRN)

凚BLU)

CN068

FAN

CN083凚WHI凛

CN080

凚GRN)

CN103

凚BRW)

CN100

凚BLK)

CN101

凚RED)

CN102

凚YEL)

CN104

凚RED)

CN030

ULL

H M

RY007

P301

BLK

spark killer

43F1

FS

FILTER

凚WHI)

CN070

凚BLK)

CN081

凚GRN)

凚RED)

CN073

MCC-1403

for Indoor Unit

Control P.C. Board

RY001

RY002

RY006

RY004

CN304凚GRY)

WHI

RY005

CN309

凚YEL凛

Power

Fuse

ACIN

RED

supply

T5.0A傍

傍傍傍傍傍250V到

WHI

CN082

circuit

CN067凚BLK)

凚BLU)

CN066凚WHI)

CN060凚WHI)

凚WHI)

CN032

CN061凚YEL)

凚WHI)

CN075

CN074凚WHI)

CN050凚WHI)

CN041凚BLU)

CN040

凚BLU)

CN044凚BRW)

FAN OPTION

DRIVE

T10

RC

OC

EMG

CN02

凚YEL)

BLK

BLK

BLU

BLU

CN01

凚WHI)

MCC-1520

Sub P.C.Board

Line Filter

WHI

RED

TR1

Remote

Controller

A B

Remote

Outdoor

RED

43F1

Board

Controller

Unit

WHI

Connector

46

WHI

F1

RED

RED

T10A,250V到

5

Indoor

43F1

RC

3

Unit

Ground

Fan Motor

Parts傍Name

Running Capacitor

RC

FM

Symbol

Transformer

TR1

Temp sensor

Blow temp. sensor

Intake air temp. sensor

TF

TA

Drain Control Relay

Fan Motor Control Relay

RY002

RY005~007

TC1,TC2,TCJ

Pulse Motor Valve

Fuse for Fan Motor

Fan Motor Control Relay

PMV

F1

43F1

凵刁凾刁刄

击凶凷刀分击凸击凵凳分击刁刀

刄凷凶凬刄凷凶

刋凷凾凬刋凷凾凾刁刉

刉出击凬刉出击分凷

凹刄刋凬凹刄凳刋

凴凾函凬凴凾凳凵函

凴凾切凬凴凾切凷

Fan motor inside

刂刀函凬刂击刀函

刁刄刀凬刁刄凳刀凹凷

凴刄刉凬凴刄刁刉刀

凹凙刋凬凹刄凷凷刀凙刋凷凾凾刁刉

20

ORN

BLU

wiring diagram

BLK

WHI

49F

RED

GRY

protection switch

Motor over heating

1.佘 indicates the terminal block.

number as figure and lead wire's color of fan motor.

Letter at inside indicates the terminal number.傍

exchange the lead wire of arrow ( ) position after check the terminal

4. A position is connected to terminal block when change to static pressure.

3. indicates the control P.C board.

2.A dotted line and broken line indicate the wiring at site.

MMD-AP___1HF2ULE15-3S2

number as figure and lead wire's color of fan motor.

exchange the lead wire of arrow ( ) position after check the terminal

4. A position is connected to terminal block when change to static pressure.

3. indicates the control P.C board.

2.A dotted line and broken line indicate the wiring at site.

Letter at inside indicates the terminal number.傍

49F

Motor over heating

protection switch

ORN

BLU

RED

GRY

WHI

BLK

Fan motor inside

wiring diagram

凵刁凾刁刄

刄凷凶凬刄凷凶

刋凷凾凬刋凷凾凾刁刉

刉出击凬刉出击分凷

击凶凷刀分击凸击凵凳分击刁刀

凹刄刋凬凹刄凳刋

刂刀函凬刂击刀函

凹凙刋凬凹刄凷凷刀凙刋凷凾凾刁刉

凴刄刉凬凴刄刁刉刀

凴凾函凬凴凾凳凵函

刁刄刀凬刁刄凳刀凹凷

凴凾切凬凴凾切凷

Fuse for Fan Motor

Fan Motor Control Relay

Pulse Motor Valve

Drain Control Relay

Fan Motor Control Relay

Temp sensor

Blow temp. sensor

Intake air temp. sensor

Transformer

Running Capacitor

Fan Motor

Parts傍Name

F1

43F1

Symbol

FM

RC

TR1

TA

TF

TC1,TC2,TCJ

RY005到007

RY002

PMV

MCC-1403

F3

(RED)

CN102

CN061(YEL)

Control P.C. Board

for Indoor Unit

Line Filter

Fuse

T5.0A 250V〜

F2

F1

FM2

8

WHI

WHI

RED

RY005

RY006

ULL

MH

RY007

6

43F2

43F1

RY001

RY002

L2

L1

43F2

BLK

ORN

BLU

FAN2

(BLU)

4P

GRY

RED

WHI

GRY

RED

WHI

WHI

RED

WHI

RED

F2

F1

RED

RED

BLK

BLK

BLU

BLU

Unit

Outdoor

RC

OC

EMG

(BLU)

CN068

(GRN)

CN033

LM

FS

(RED)

CN030

(YEL)

CN104

T10

CN075

(WHI)

CN074(WHI)

CN050(WHI)CN041(BLU)

CN040

(BLU)

CN044(BRW)

CN066(WHI)

CN067(BLK)

WHI

ACINRED

(YEL)

CN309

RY004

CN304(GRY)

P301

CN083(WHI)

FAN

BLK

WHI

WHI

RED

RED

RED

Power

supply

circuit

PMV

F4F3F2

F1

F4

FM1

43F1

FAN1

(WHI)

4P

WHI

RED

GRY

GRY

RED

WHI

ORN

(BLK)

CN101

(BRW)

CN100

PNL

EXCT

(RED)

CN073

FILTER

(WHI)

CN070

(BLK)

CN081

(BLU)

CN082

CN060(WHI)

OPTION

DRIVE

FAN

(WHI)

CN032

TCJ

TA

TC1

TC2

TR1

Sub P.C.Board

MCC-1520

(YEL)

CN02

CN01

(WHI)

spark killer

spark killer

TF

CN103

(GRN)

CN080

(GRN)

AB

Controller

Remote

Remote

Controller

Board

BLU

ORN

BLK

G&Y

G&Y

A

A

RC2

RC1

Power Supply

208/230-1-60

Indoor

Unit

Ground

Screw

GRY

RED

WHI

GRY

RED

WHI

4P

1

(WHI)

3

1

2

WHI

BLU

ORN

BLK

GRY

RED

BLU

4P

32

BLK

ORN

WHI

GRY

RED

(WHI)

43F2

43F1

072type

072type

F3F2

F1

BLK

ORN

BLU

F4

A

096type

F4F3F2

F1

BLU

ORN

BLK

A

096type

RED

RED

5

3 3

5

4

5

4

5

Connector

MMD-AP0721HF2UL, MMD-AP0961HF2UL

21

8. Electrical characteristics

Voltage Range(V) MOCP

Min. Max. kW A A

Power

consumption

FLA MCA

A

Model name

MMD-AP0481HF2UL

MMD-AP0721HF2UL

MMD-AP0961HF2UL

Nominal Voltage

(V-Ph-Hz)

208/230-1-60

MCA : Minimum Circuit Amps FLA : Full load Amps

MOCP : Maximum Overcurrent Protection(Amps) kW : Fan Motor Rated Output (kW)

187

187

187

253

253

253

0.16

0.16 x 2

0.16 x 2

1.84

3.43

3.80

2.30

4.29

4.76

15

15

15

MMD-AP___1HF2ULE15-3S2

22

9. Fan characteristics

230V䚷cfm - A 208V䚷cfm - A

230V䚷Fan characteristics 208V䚷Fan characteristics

㻜

㻜㻚㻞

㻜㻚㻠

㻜㻚㻢

㻜㻚㻤

㻝

㻝㻚㻞

㻝㻚㻠

㻝㻚㻢

㻠㻜㻜 㻡㻜㻜 㻢㻜㻜 㻣㻜㻜

External static pressure (in WG)

Air fl ow ra te (cfm)

㻝

㻝㻚㻝

㻝㻚㻞

㻝㻚㻟

㻝㻚㻠

㻝㻚㻡

㻝㻚㻢

㻝㻚㻣

㻝㻚㻤

㻝㻚㻥

㻞

㻠㻜㻜 㻡㻜㻜 㻢㻜㻜 㻣㻜㻜

Fan motor curre nt (A)

Air fl ow ra te (cfm)

㻜

㻜㻚㻞

㻜㻚㻠

㻜㻚㻢

㻜㻚㻤

㻝

㻝㻚㻞

㻝㻚㻠

㻝㻚㻢

㻠㻜㻜 㻡㻜㻜 㻢㻜㻜 㻣㻜㻜

Ex te rn al sta ti c pr essu re (i n W G)

Air fl ow ra te (cfm)

㻝

㻝㻚㻝

㻝㻚㻞

㻝㻚㻟

㻝㻚㻠

㻝㻚㻡

㻝㻚㻢

㻝㻚㻣

㻝㻚㻤

㻝㻚㻥

㻞

㻠㻜㻜㻡㻜㻜㻢㻜㻜㻣㻜㻜

Fan motor curre nt (A)

Air fl ow ra te (cfm)

Min

445(cfm)

Standard

636(cfm)

Min

445(cfm)

Standard

636(cfm)

Max

700(cfm)

Max

700(cfm)

Highstatic pressure tap

Midstatic pressure tap

Low static pressure tap

Highstatic pressure tap

Midstatic pressure tap

Low static pressure tap

Highstatic pressure tap

Midstatic pressure tap

Low static pressure tap

Highstatic pressure tap

Mid static pressure tap

Low static press ure tap

MMD-AP0481HF2UL

MMD-AP___1HF2ULE15-3S2

23

MMD-AP0721HF2UL

MMD-AP___1HF2ULE15-3S2

230V䚷cfm - A 208V䚷cfm - A

3.8

3.6

3.4

3.2

2.8

2.6

Fan motor curre nt (A)

2.4

2.2

Min

693(cfm)

4

Highs tatic press ure tap

3

2

Mid static pressure tap

Low static press ure tap

600 90 0 12 00

Air flow ra te (cfm )

Standard

989(cfm)

Max

1088(cfm)

Min

693(cfm)

4

3.8

3.6

3.4

3.2

3

2.8

2.6

Fan motor curre nt (A)

2.4

2.2

2

600 900 12 00

Highs tatic press ure tap

Midstatic pressure tap

Low static pressure t ap

Air fl ow ra te (cfm)

230V䚷Fan characteristics 208V䚷Fan characteristics

1.6

1.4

1.2

1

0.8

Mid static pressure tap

0.6

0.4

External static pressure (in.W G)

0.2

0

600 900 1200

Lowstatic pressure tap

Air fl ow ra te (cfm)

Highs tatic press ure tap

1.6

1.4

1.2

1

0.8

0.6

0.4

External static pressure (in.W G)

0.2

0

600 90 0 1200

Highs tatic press ure tap

Low static pressure tap

Air fl ow ra te (cfm)

Standard

989(cfm)

Mid static pressure tap

Max

1088(cfm)

24

MMD-AP___1HF2ULE15-3S2

230V䚷cfm - A 208V䚷cfm - A

230V䚷Fan characteristics 208V䚷Fan characteristics

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

800 11 00 14 00

External static pressure (in.WG)

Air fl ow ra te (cfm)

2

2.2

2.4

2.6

2.8

3

3.2

3.4

3.6

3.8

4

800 1100 1400

Fan motor current (A)

Air flow ra te (cfm )

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

800 1100 1400

External static pressure (in.WG)

Air fl ow ra te (cfm)

2

2.2

2.4

2.6

2.8

3

3.2

3.4

3.6

3.8

800 1100 1400

Fan motor current (A)

Air flow ra te (cfm )

Highs tatic pressur e tap

Low static pressure tap

Highs tatic press ure tap

Low s tatic press ure tap

Highs tatic press ure tap

Lowstatic pressure tap

Highs tatic press ure tap

Low static pressure tap

MMD-AP0961HF2UL

Min

866(cfm)

Standard

1237(cfm)

Min

866(cfm)

Standard

1237(cfm)

Max

1360(cfm)

Max

1360(cfm)

25

10. Sound data

Fan tap H M L Fan tap H M L

External static pressure

1.06 (in WG) 0.86 ( in WG) 0.50 (in WG)

External static pressure

0.75 (in WG) 0.55 ( in WG) 0.16 (in WG)

433644

MMD-AP0481HF2UL (230 V)

MMD-AP0481HF2UL (208 V)

Sound pressure

level (dB(A))

Sound pressure

level (dB(A))

464542

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Octave band center frequency (Hz)

Octave band sound pressure level (dB)

Audibility limits

of continuous

white l evel

NC 50

NC 40

NC 30

NC 20

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Octave band center frequency (Hz)

Octave band s ound pressure level (dB)

Audibility limits

of continuous

white level

NC 50

NC 40

NC 30

NC 20

1.06 (external static pressure (in WG))

0.16

0.86

0.50

0.75 (external static pressure (in WG) )

0.55

Air discharge

4.92 ft

6.56 ft

(2 m)

3.28 ft

(1 m)

Duct

Microphone

Duct

Air intake

(1.5 m)

MMD-AP___1HF2ULE15-3S2

26

Fan tap H M L Fan tap H M L

External static pressure

1.08 (in WG) 1.00 ( in WG) 0.65 (in WG)

External static pressure

0.84 (in WG) 0.74 ( in WG) 0.24 (in WG)

Fan tap H L Fan tap H L

External static pressure

1.01 (in WG) 0.85 ( in WG)

External static pressure

0.67 (in WG) 0.41 ( in WG)

474640

MMD-AP0721HF2UL (208 V)

MMD-AP0721HF2UL (230 V)

45

MMD-AP0961HF2UL (230 V)

MMD-AP0961HF2UL (208 V)

Sound pressure

level (dB(A))

Sound pressure

level (dB(A))

484746

Sound pressure

level (dB(A))

50

49

Sound pressure

level (dB(A))

47

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Octave band center frequency (Hz)

Octave band s ound pressure level (dB)

Audibility limits

of continuous

whitelevel

NC 50

NC 40

NC 30

NC 20

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Octave b and cen ter freq uency (H z)

Octave band s ound pressure level (dB)

Audibility limits

of continuous

white level

NC 50

NC 40

NC 30

NC 20

1.08 (external static pressure (in WG) )

1.00

0.65

0.84 (ex tern al static press ure ( in WG))

0.74

0.24

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Octave band center frequency (Hz)

Octave band sound pressure level (dB)

Audibility limits

of continuous

white l evel

NC 50

NC 40

NC 30

NC 20

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Octave b and cen ter freq uency (H z)

Octave band s ound pressure level (dB)

Audibility limits

of continuous

white level

NC 50

NC 40

NC 30

NC 20

1.01 (external static pressure (in WG))

0.41

0.85

0.67 (external static pressure (in WG) )

MMD-AP___1HF2ULE15-3S2

27

Outside Air Unit Type Engineering Data Book

Model name:

MMD-AP___1HF2UL

May, 2017 Third Edition

Loading...

Loading...