Toshiba MM-A0160CX, MM-SB028, MM-A0224CX, MM-A0224HX, MM-U140 DATA BOOK

...

A90-0132

Modular Multi System

Service Manual

Air Conditioner - Multi Split Type System

HFC R407C

2

Contents

Introduction ......................................................................................................................... 5

Summary.............................................................................................................................8

Outline of MMS (Modular Multi System)............................................................................ 10

Parts Specifications........................................................................................................... 12

Construction Views – Outdoor Units ................................................................................. 21

Construction Views – Indoor Units .................................................................................... 22

Wiring Diagrams................................................................................................................ 31

Refrigerant Piping Systematic Drawings ........................................................................... 44

Combined Refrigerant Piping Systematic Drawings.......................................................... 49

Refrigerant Cycle Schematic – Indoor Units ..................................................................... 53

1

2

3

4

5

6

7

8

9

10

Outline of Control ..............................................................................................................54

Self Diagnostic Display Information...................................................................................67

Control Circuit Configuration ............................................................................................. 71

Troubleshooting ................................................................................................................ 76

Back-up Operation ..........................................................................................................122

Forced Function of Oil Level Detection ........................................................................... 126

Refrigerant Pipe Installation ............................................................................................ 127

Trial Operation ................................................................................................................ 132

Replacing the Compressor.............................................................................................. 145

Exploded Views and Service Parts .................................................................................156

11

12

13

14

15

16

17

18

19

20

3

4

Introduction

Precautions

Please read these instructions carefully before starting the installation.

This equipment should only be installed by suitably trained operatives.

In all cases ensure safe working practice: Observe precautions for persons in the vicinity of the works.

Ensure that all local, national and international regulations are satisfied.

Check that the electrical specifications of the unit meet the requirements of the site.

Carefully unpack the equipment, check for damage or shortages. Please report any damage immediately.

These units comply with EU Directives:

73/23/EEC (Low Voltage Directive), 89/336/EEC (Electromagnetic Compatibility) and 97/23/EC (Pressure Equipment

Directive). Accordingly, they are designated for use in commercial and industrial environments*.

Avoid installation in the following locations:

Where there is danger of flammable gas leakages.

Where there are high concentrations of oil.

Where the atmosphere contains an excess of salt (as in coastal areas). The air conditioner is prone to failure when

used under this condition unless special maintenance is provided.

1

Where the airflow from the outdoor unit may cause annoyance.

Where the operating noise of the outdoor unit may cause annoyance.

Where the foundation is not strong enough to fully withstand the weight of the outdoor unit.

Where the water drainage may cause a nuisance or a hazard when frozen.

Where strong winds may blow against the air outlet of the outdoor unit.

Precautions for R407C outdoor units

R407C outdoor units use synthetic oils which are extremely hygroscopic. Therefore ensure that the refrigerant system

is NEVER exposed to air or any form of moisture.

Mineral oils are unsuitable for use in these units and may lead to premature system failure.

Use only equipment which is suitable for use with R407C. Never use equipment which has been used with R22.

R407C should only be charged from the service cylinder in the liquid phase. It is advisable to use a gauge manifold set

equipped with a liquid sight glass fitted in the centre (entry) port.

* 97/23/EC Pressure Equipment Directive information

Conformity assessment procedure: Module D1

Pressure equipment:

Compressor, category II, Module A1

Accumulator, category I

Liquid receiver, category II

High pressure switch, category II, Module A1

Notified body for inspection and quality assurance systems: BSI, Maylands Avenue, Hemel Hempstead, WP2 4SQ, UK.

5

Introduction

Precautions

Precautions for R-407C outdoor units

1

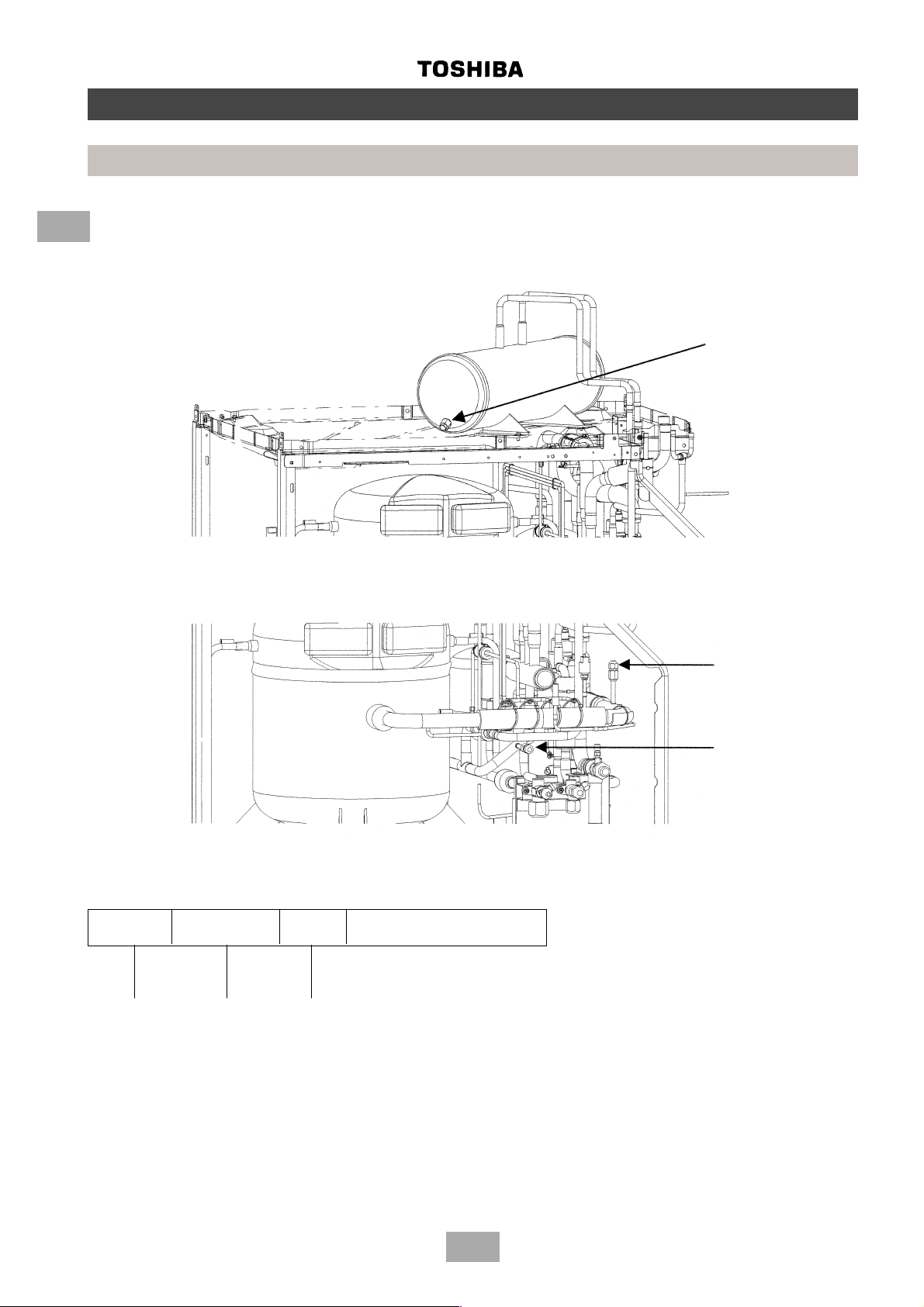

Liquid receiver fusible plug

In the event of the system being subjected to abnormal conditions it is protected by a fusible plug, positioned on the liquid

receiver, within the outdoor unit. It is rated to fail at 70°C.

Position of

fusible plug

System pressure measurement

To measure the system’s high and low pressures, connect a gauge manifold to the corresponding access port as indicated

below.

Low pressure

access port

High pressure

access port

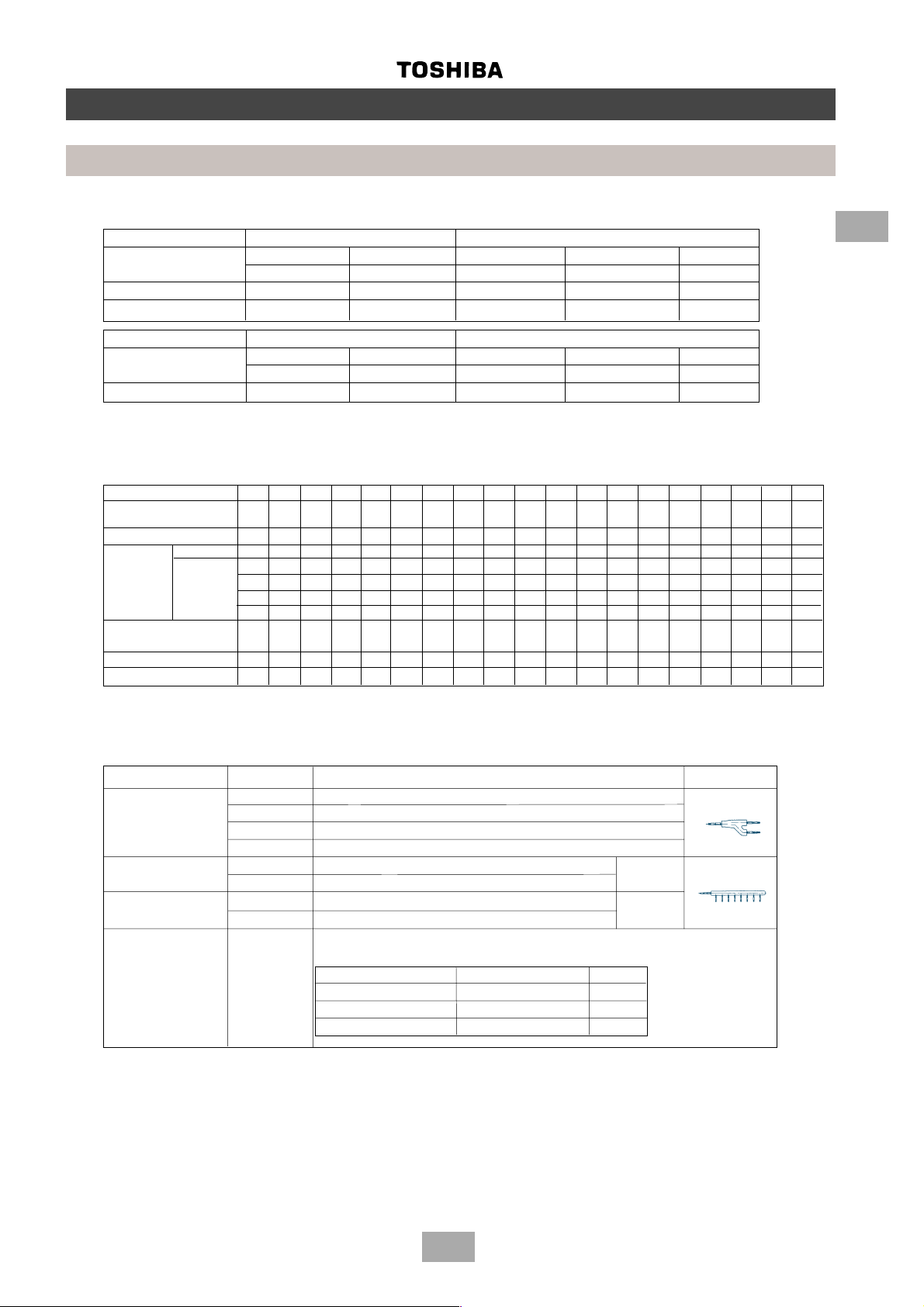

Explanation of Toshiba serial number

A serial label is attached to all Toshiba air conditioning units. Located on the label is an 8-digit number, which represents the

month, year and batch number of the manufactured unit. A breakdown of the 8-digit number is defined below.

24480001

}

Year of

manufacture

2001 = 1

2002 = 2

2003 = 3

Month of

manufacture

41 = Jan.

42 = Feb.

43 = Mar.

44 = Apr.

45 = May

46 = Jun.

47 = Jul.

48 = Aug.

49 = Sep.

50 = Oct.

51 = Nov.

52 = Dec.

Site of

manufacture

8 = Plymouth

Model batch serial number

6

Introduction

Components

1. Outdoor unit

Corresponding HP Inverter unit Fixed-speed unit

8 HP 10 HP 6 HP 8 HP 10 HP

Model name MM-A0224HT MM-A0280HT MM-A0160HX MM-A0224HX MM-A0280HX

Cooling capacity (kW) 22.4 28.0 16.0 22.4 28.0

Heating capacity (kW) 25.0 31.5 18.0 25.0 31.5

Corresponding HP Inverter unit Fixed-speed unit

8 HP 10 HP 6 HP 8 HP 10 HP

Model name MM-A0224CT MM-A0280CT MM-A0160CX MM-A0224CX MM-A0280CX

Cooling capacity (kW) 22.4 28.0 16.0 22.4 28.0

2. Outdoor units (combination of outdoor units)

Corresponding HP 8HP 10HP 14HP 16HP 18HP 20HP 22HP 24HP 26HP 28HP 30HP 32HP 34HP 36HP 38HP 40HP 42HP 44HP 46HP

Combined model

MM-A-HT/MM-A-CT 0224 0280 0384 0440 0504 0560 0608 0672 0728 0784 0840 0896 0952 1008 1064 1120 1176 1232 1288

Cooling capacity (kW) 22.4 28.0 38.4 44.8 50.4 56.0 60.8 67.2 72.8 78.4 84.0 89.6 95.2 100.8 106.4 112.0 117.6 123.2 128.8

Combined Fixed-speed - - 6HP 8HP 8HP 10HP 8HP 8HP 8HP 10HP 10HP 8HP 8HP 10HP 10HP 10HP 8HP 10HP 10HP

outdoor units unit - -----6HP8HP8HP8HP10HP 8HP 8HP 8HP 10HP 10HP 8HP 8HP 10HP

No. of connectable

indoor units 13 16 16 18 18 20 22 2 4 26 28 30 32 34 36 38 40 40 40 40

Min. HP connected 4 57891011121314151617181920212223

Max. HP connected 10.8 13.5 18.9 21.6 24.3 27 29.7 32.4 35.1 37.8 40.5 43.2 45.9 48.6 51.3 54 56.7 59.4 62.1

Inverter unit 8HP 10HP 8HP 8HP 10HP 10HP 8HP 8HP 10HP 10HP 10HP 8HP 10HP 10HP 10HP 10HP 10HP 10HP 10HP

-----------8HP8HP8HP8HP10HP 8HP 8HP 8HP

----------------8HP8HP8HP

1

3. Branching joints/headers

Model name Usage Appearance

Y -shape branching joint RBM-Y018-SK Indoor unit capacity code (*1): Total < 6.4

RBM-Y037-SK Indoor unit capacity code (*1): 6.4 = Total < 13.2 (*2)

RBM-Y071-SK Indoor unit capacity code (*1): 13.2 = Tot al < 25.2 (*2)

RBM-Y129-SK Indoor unit capacity code (*1): 25.2 = Total (*2)

4-branching header (*3) RBM-H4037-SK Indoor unit capacity code (*1): Total < 6.4 Max. 4

RBM-H4071-SK Indoor unit capacity code (*1): 6.4 = Total < 13.2 branches

8-branching header (*3) RBM-H8037-SK Indoor unit capacity code (*1): Total < 6.4 Max. 8

RBM-H8071-SK Indoor unit capacity code (*1): 6.4 = Total < 13.2 branches

T-shape branching joint 1 set of 3 types of T-shape joint pipes as described below .

(For connection of The required quantity is arranged and they are combined at the site.

outdoor unit) RBM-T129-SK

Connecting pipe Corresponding dia. (mm) Quantity

Balancing pipe 9.52 1

Piping at liquid side 12.7 to 22.2 1

Piping at gas side 22.2 to 54.1 1

(*1) Code is determined according to the capacity code of the Indoor units connected.

(*2) If the total capacity code value of Indoor units exceeds that of Outdoor units, apply the capacity code of Outdoor units.

(*3) When using a branch header, Indoor units with a maximum of 6.0 capacity code in total can be connected to each

branch.

NOTE: If the length of the gas pipe exceeds 30m from the 1st branching to an Indoor unit, increase the gas pipe size by

1 size, i.e. MM-U140 = Gas Ø22.2, Liquid Ø9.5

7

Summary

Operating conditions

• The units referred to within this manual conform with the protection requirements of Directives 89/336/EEC

Electromagnetic Compatibility and 73/23/EEC Low voltage.

• Operating conditions of the unit are as follows:

2

Note 1: Cooling capacity is rated at the following temperature conditions:

Indoor air inlet temperature 27°C DB, 19°C WB.

Outdoor air inlet temperature 35°C DB.

Note 2: Heating capacity is rated at the following temperature conditions:

Indoor air inlet temperature 20°C DB.

Outdoor air inlet temperature 7°C DB, 6°C WB.

Note 3: For details about the Outdoor unit, Indoor units or Remote Controller installation refer to the relevant literature, i.e.

Installation Instructions supplied with the units.

Note 4: Operatives handling refrigerants must be suitably qualified in accordance with local and national codes of practice

and statutory requirements.

Note 5: Legislation may regulate the removal of waste refrigerant from the systems. We advise awareness of any

regulations and duty of care. Waste refrigerant must NEVER be discharged to atmosphere.

Note 6: Electrical work should be in accordance with all relevant codes of practice and should be carried out by suitably

qualified personnel.

Outdoor temperature -5 ~ 43°C Cooling

-15 ~ 21°C Heating

Room temperature 18 ~ 32°C Cooling

15 ~ 29°C Heating

Room humidity <80% Cooling

Note 7: Metric/Imperial pipe conversion.

Diameter (mm) 6.4 9.5 12.7 15.9 19.0 2.0 28.6 34.9 41.3 54.1

Nominal diameter (inch) 1/4 3/8 1/2 5/8 3/4 7/8 1-1/8 1-3/8 1-5/8 2-1/8

Note 8: Within this manual:

ODU = Outdoor Unit IDU = Indoor Unit

R/C = Remote Controller D.O.L. = Direct On-Line compressor

INV = Inverter ODU FIX = Fixed-speed ODU

DB = Dry Bulb WB = Wet Bulb

Mg-Sw = Magnetic Contactor IOL = Inner Overload Relay

OCR = Over Current Relay IGBT = Inverter Gate Bi-Polar Transistor

Note 9: MPaG

1.0 MPaG = 10.2 kgf/cm

⇒ kgf/cm

2

G conversion multiplier

2

G

8

1. Model name

OUTDOOR

MM-A0280HT

Summary

Operating conditions

2

INDOOR

A – Outdoor 0280 – 28 kW (10 HP) C - Cooling T – Inverter

Modular Multi

MM-TU056

B - Built-In Duct Type

C (CR) - Ceiling Type (IR Remote) 028 – 2.8 kW (1 HP)

Modular Multi

K (KR) - High Wall Type (IR Remote) 042 – 4.2 kW (1.5 HP)

N - Chassis Type 056 – 5.6 kW (2 HP)

S (SR) - Low Wall Type (IR Remote) 080 – 8.0 kW (3 HP)

SB - Built-In Slim Duct Type 112 – 12.2 kW (4 HP)

TU - 2-way Cassette Type 140 – 14.0 kW (5 HP)

U - 4-way Cassette Type

0224 – 22.4 kW (8 HP H - Heating X – Fixed-speed

0160 – 16.0 kW (6 HP)

2. Range of combined units

No. of combined units : 1 to 5 units

Capacity range : Equivalent to 38.4 kW type (14HP) to 128.8 kW (46HP)

3. Restriction for combination units

(1) The Inverter Unit should have the maximum capacity among all units in that combination.

(2) The 16.0 kW (6HP) fixed-speed unit is available only with the combination of 38.4 kW (14HP) and 60.8 kW

(22HP). (It cannot be used for any other combination.)

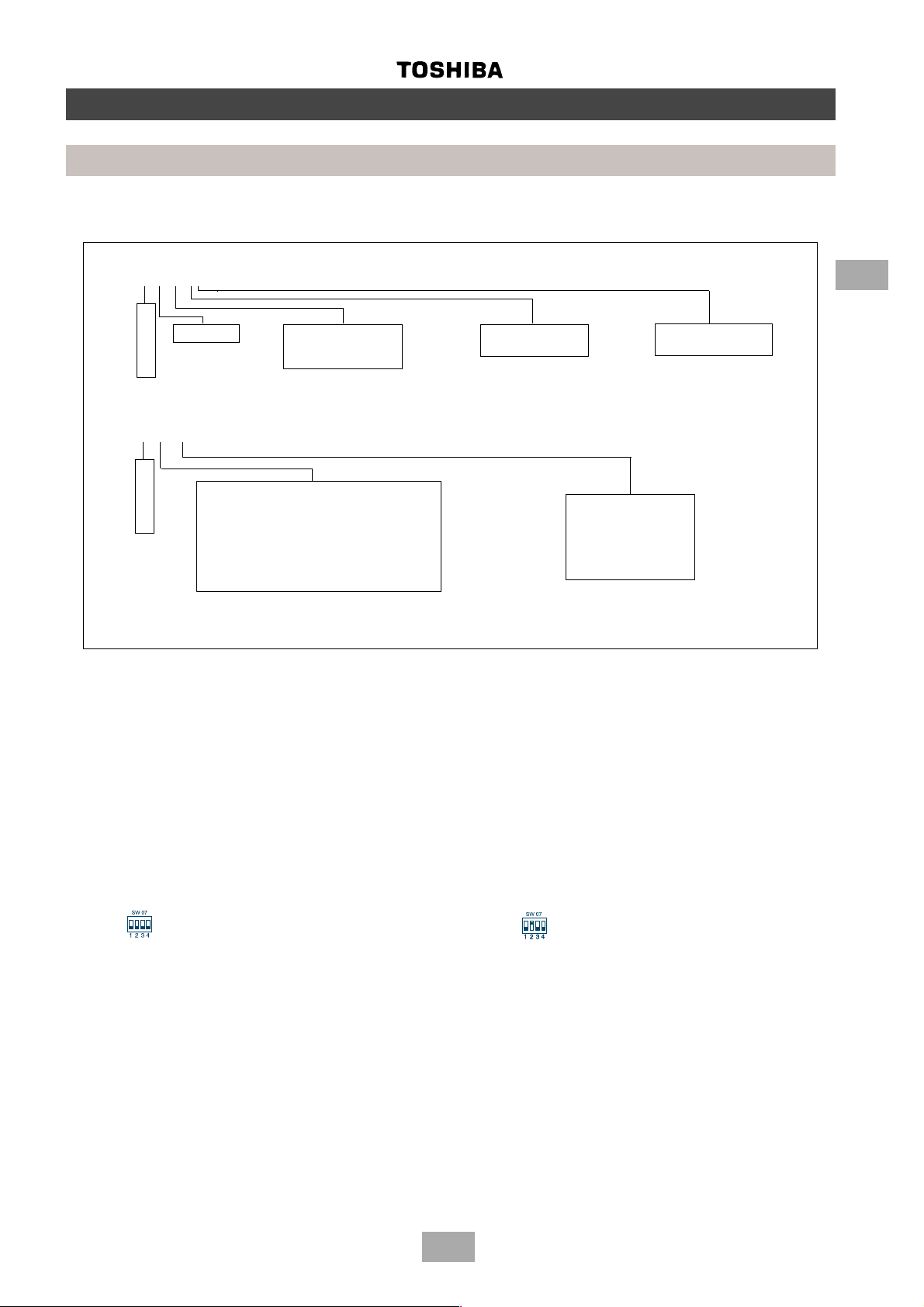

4. Mode priority

This Outdoor Unit is set to operate with the Heating mode taking precedence. This precedence can be switched

between Heat and Cool mode using the DIP switch 07 on the Outdoor Unit Interface PCB (MCC-1343-01) as follows:

ON

OFF

Heat priority (factory set) Cool priority

ON

OFF

9

3

Outline of MMS (Modular Multi System)

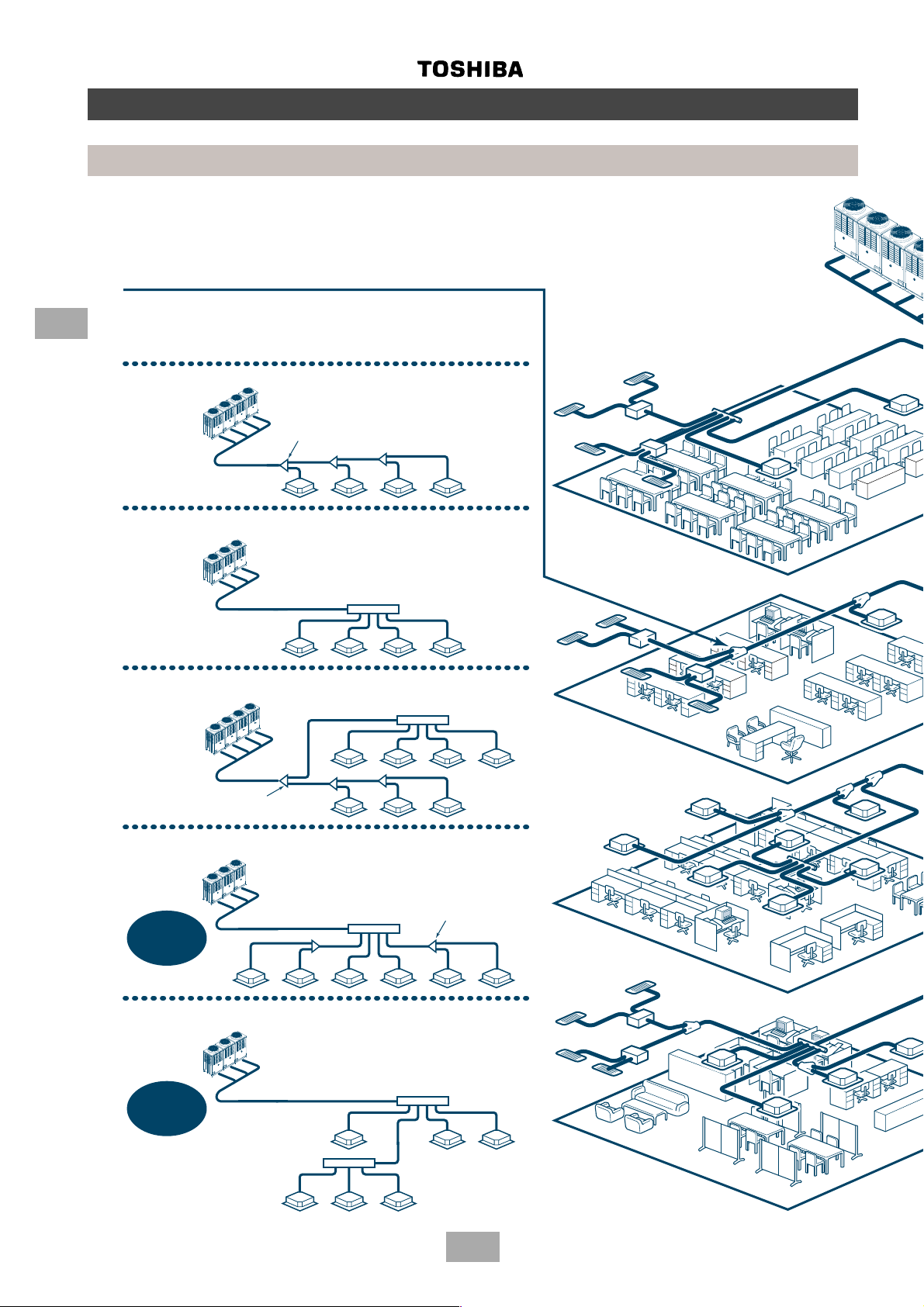

• Branching

Combination of line and header branching is highly flexible. This allows for the

shortest design route possible, thereby saving on installation time and cost.

Line/header branching after header branching is only available with Toshiba’s

Multi Modular System.

Line branching

Outdoor unit

Branching joint

Indoor unit

Header branching

Outdoor unit

Indoor unit

Line and header branching

Outdoor unit

Branching joint

Indoor unit

Line branching after header branching

Outdoor unit

MMS

ONLY

Branching

header

Header

Header

Branching joint

8F

7F

2F

Indoor unit

Outdoor unit

MMS

ONLY

Header

1F

Header

Indoor unit

10

Outline of MMS (Modular Multi System)

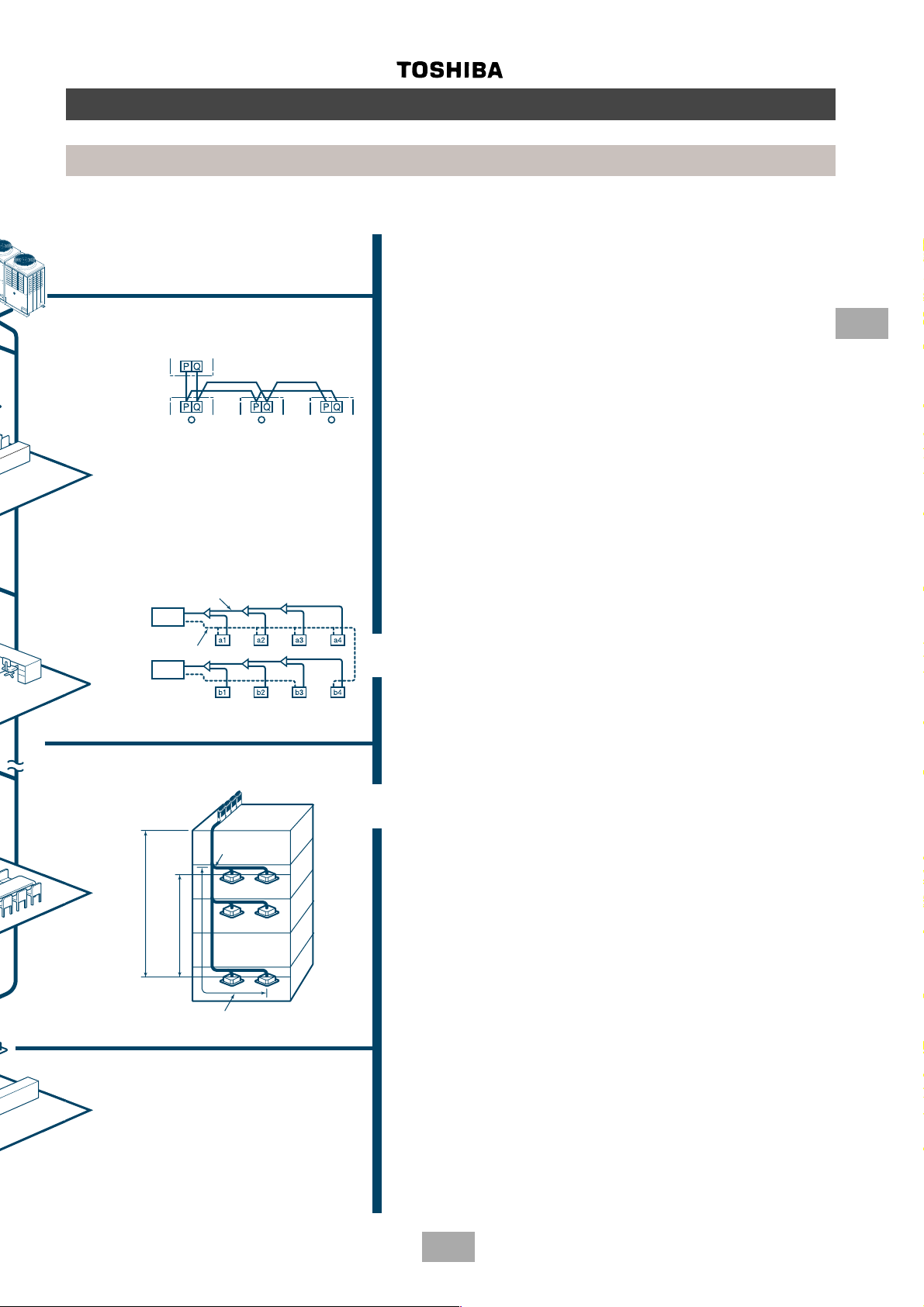

• Non-polarized control wiring between outdoor and

indoor units

Outdoor unit

Indoor unit

• Compact design

The design of the Toshiba MMS outdoor unit allows for

easy unit maneuvering into any standard lift. Its size also

allows it to be easily installed in limited spaces.

• Largest system capacity

Toshiba’s Multi Modular System can be combined up to

128.8 kW (46 HP).

3

• Wiring diagnosis system

[Example of wiring diagnosis]

Use the switches on the microcomputer PCB of the

outdoor unit.

• Detects wiring to the indoor unit b4 which should

not be in system A.

• b4 is missing in system B.

Piping

Outdoor

Circuit A

Circuit B

unit

Piping

Outdoor

unit

Allowable pipe length:

100 m real length

Outdoor unit

unit and outdoor unit: 50 m

Height difference between indoor

unit and outdoor unit: 30 m

Height difference between indoor

(Equivalent to 125 m)

1st branching

section

Indoor unit

• Advanced bus communication system

Wiring between indoor and outdoor unit is a simple 2wire system.

Communication address is also automatically configured.

A default test mode operation is available.

• Self diagnostic system

Comprehensive troubleshooting code enables quick

identification of problems arising.

• High lift design

Real pipe length of 100m (equivalent length 125m) and

vertical lift of 50m is made possible with Toshiba’s Multi

Modular System.

Vertical lift between indoor units of 30m is the highest in

the market.

This allows for greater flexibility in the location of the

system.

• Multiple indoor units

Indoor units with different capacities and configurations

can be combined up to 135% of the outdoor unit capacity.

A maximum of 40 indoor units can be combined with the

46 HP outdoor module.

• Intelligent control

Toshiba’s MMS intelligent controls and modulating

valves deliver the required capacity, according to the

load variation from 50% to 100%.

The intelligent controls and modulating valves limit or

increase the cooling/heating capacity dynamically so

humidity and temperature are kept in the comfort zone.

From 1st branching to the

farthest indoor unit: 50 m

11

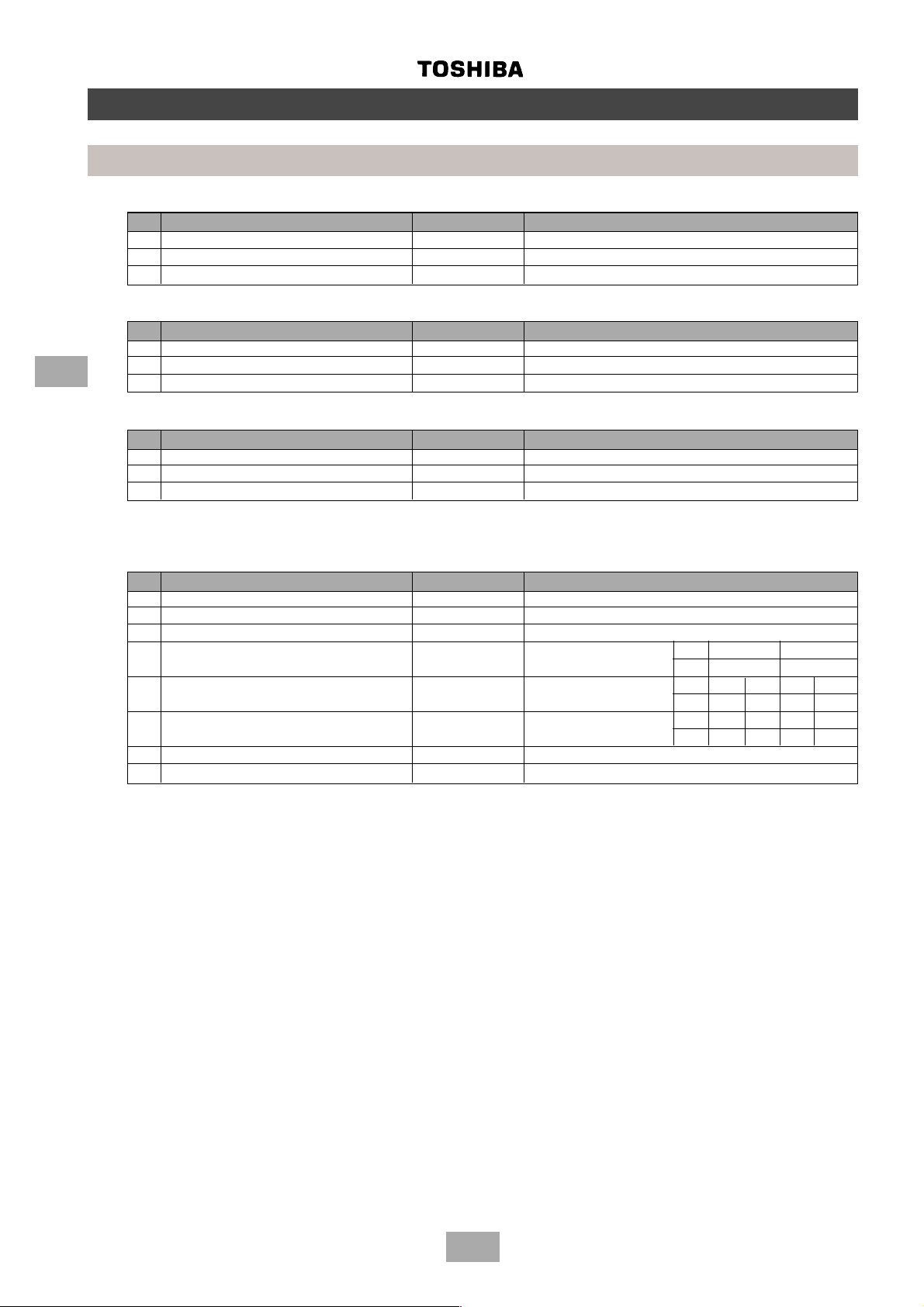

Parts specifications

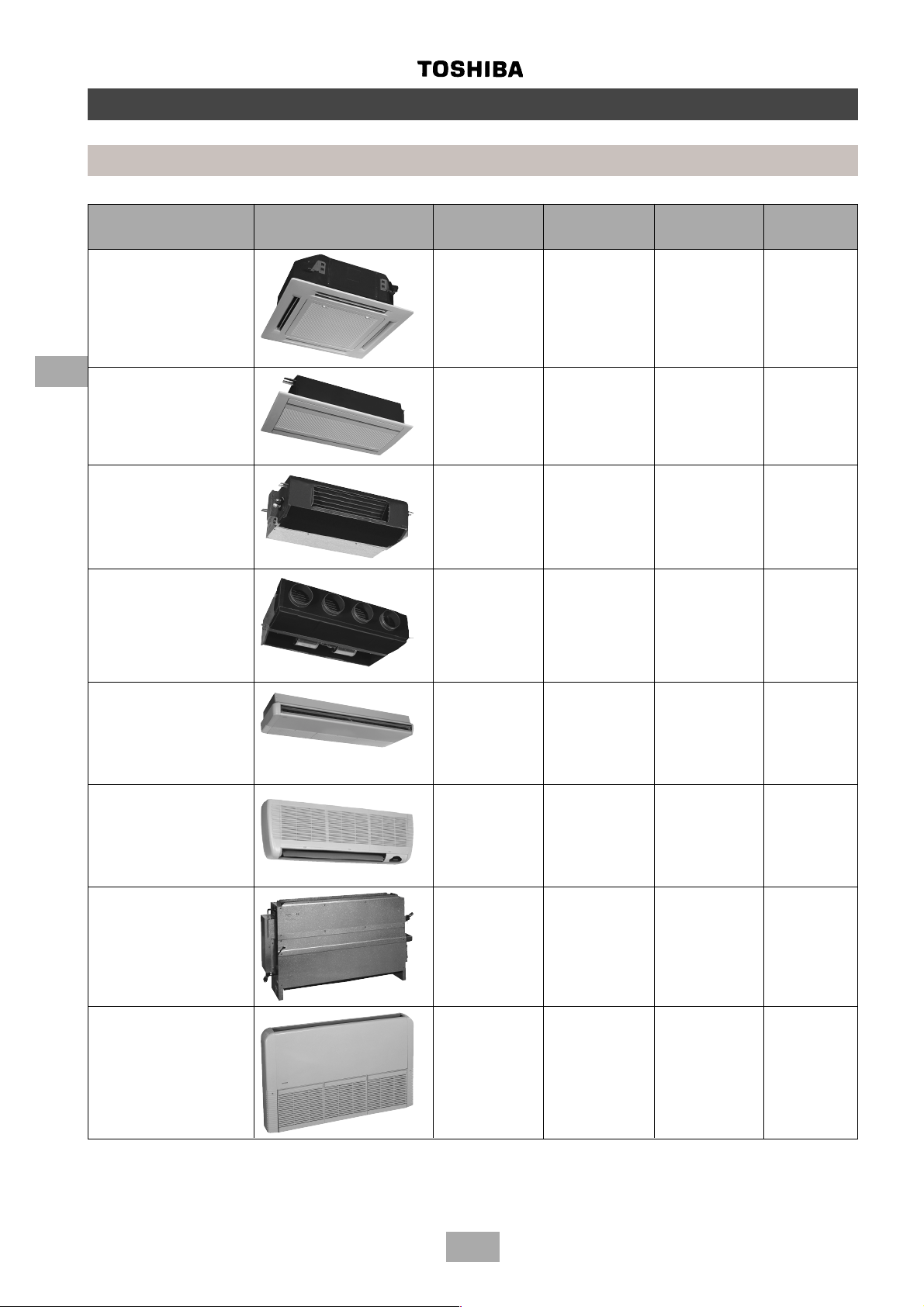

Indoor units

Type Appearance Model name Capacity code Cooling Heating

capacity (kW) capacity (kW)

4-Way Cassette MM-U056 2 5.6 6.4

Type ‘U’ MM-U080 3 8.0 9.6

MM-U112 4 11.2 12.8

MM-U140 5 14.0 15.8

4

2-Way Cassette MM-TU028 1 2.8 3.2

Type ‘TU’ MM-TU042 1.5 4.2 4.8

MM-TU056 2 5.6 6.4

Built-In Slim Duct MM-SB028 1 2.8 3.2

Type ‘SB’

Built-In Duct MM-B056 2 5.6 6.4

Type ‘B’ MM-B080 3 8.0 9.6

MM-B112 4 11.2 12.8

MM-B140 5 14.0 15.8

Ceiling MM-C/CR042 1.5 4.2 4.8

Type ‘C’ MM-C/CR056 2 5.6 6.4

MM-C/CR080 3 8.0 9.6

MM-C/CR112 4 11.2 12.8

MM-C/CR140 5 14.0 15.8

High Wall MM-K/KR042 1.5 4.2 4.8

Type ‘K’ MM-K/KR056 2 5.6 6.4

MM-K/KR080 3 8.0 9.6

Chassis MM-N028 1 2.8 3.2

Type ‘N’ MM-N042 1.5 4.2 4.8

MM-N056 2 5.6 6.4

MM-N080 3 8.0 9.6

Low Wall MM-S/SR056 2 5.6 6.4

Type ‘S’ MM-S/SR080 3 8.0 9.6

12

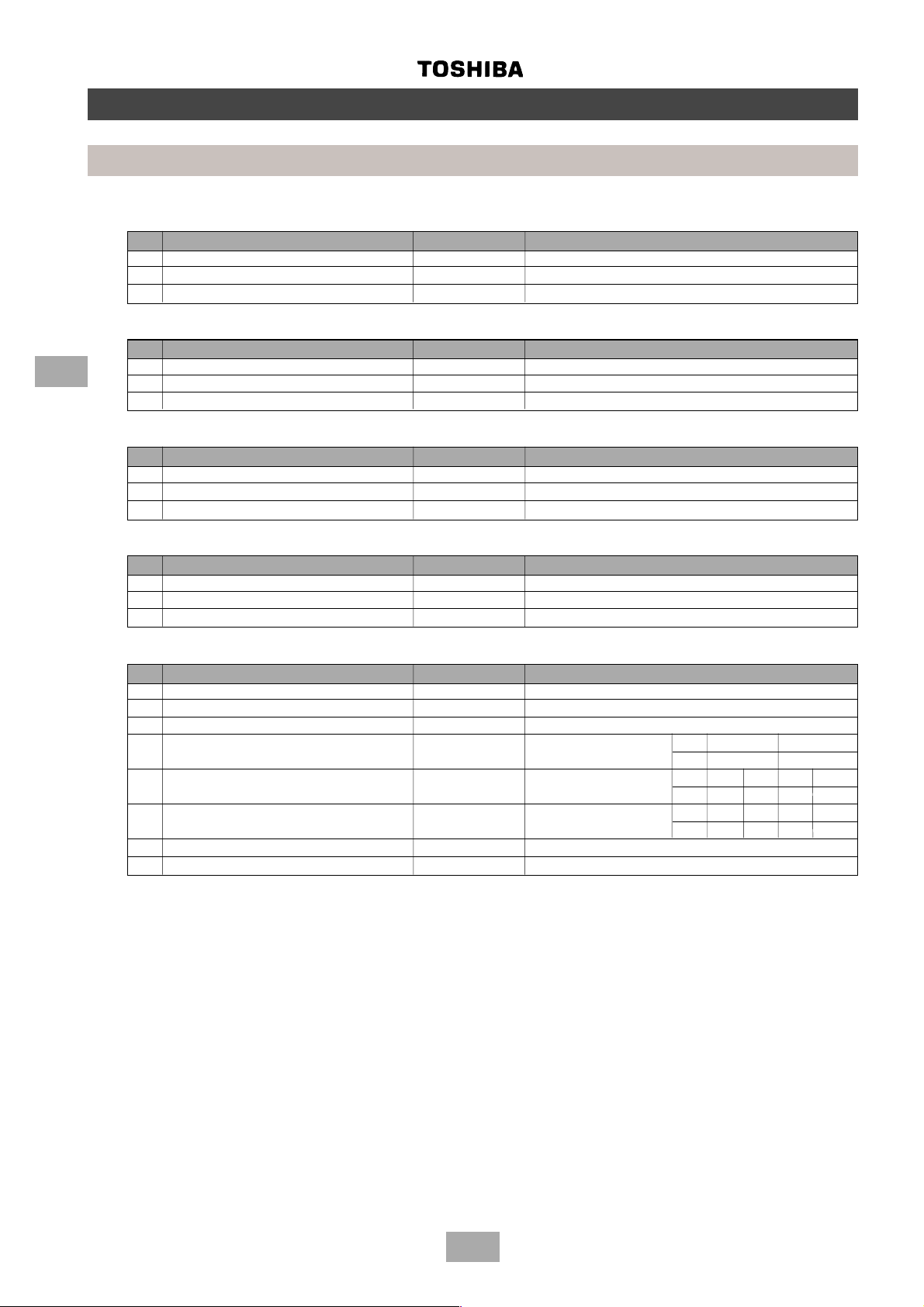

Parts specifications

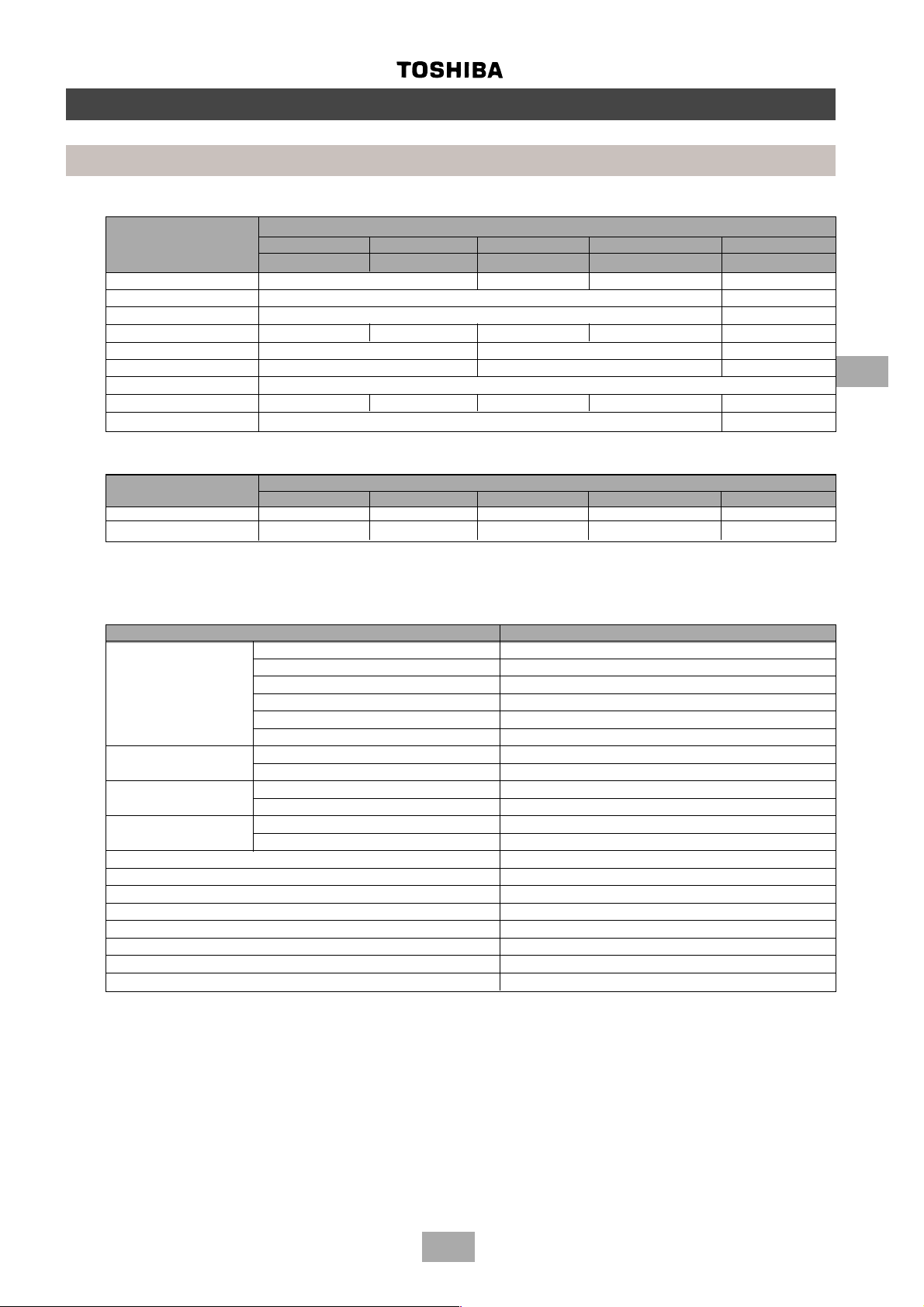

Outdoor units

COMPRESSOR MODEL

MM-A0280HT MM-A0224HT MM-A0280HX MM-A0224HX MM-A0160HX

MM-A0280CT MM-A0224CT MM-A0280CX MM-A0224CX MM-A0160CX

Model name MG1450CW-21B YG1800CW-B1 YG1700CW-B1 YG890C-B1

Motor type 3-phase induction motor

Power supply 380-415 V, 3 ph, 50 Hz

Output (kW) 7.5 7.5 7.5 6.0 4.1

Pole (P) 2/2 (INV ./Fixed) 2/2 (Fixed/Fixed) 2

Coil resistance (Ω) 1.18/2.25 (INV./Fixed) 2.25/2.25 (Fixed/Fixed ) 2.250

Comp. oil name NISSEKI RB74AF VG 74

Amount of oil (ml) 7500 7500 7500 7500 2000

Inner overload relay Opens: 115±5°C Closes: 93±10°C

4-WA Y V ALVE MODEL

MM-A0280HT MM-A0224HT MM-A0280HX MM-A0224HX MM-A0160HX

Model name CHV-0712 CHV-0712 CHV-0712 CHV-0712 CHV-0401

Coil specification AC240V AC240V AC240V AC240V AC240V

4

MM-A0280HT, MM-A0224HT, MM-A0280HX, MM-A0224HX, MM-A0160HX

MM-A0280CT, MM-A0224CT, MM-A0280CX, MM-A0224CX, MM-A0160CX

PARTS NAME SPECIFICATION

Fan motor Model name STF-200-350A

Motor type 1-phase induction motor

Power supply AC 220 – 240 V. 1 phase, 50 Hz

Output (W) 400

Current (A) 4.81-5.89

Pole (P) 6

High pressure switch Model name INV = ACB-JB128 FIX = ACB-JA64

Operating pressure (mPa) Operation: 3.2 Reset: 2.55

High pressure sensor Model name 150NH4-H

Operating conditions (mPa) 0-3.33

Low pressure sensor Model name 150NH4-L

Operating conditions (mPa) 0-0.98

Compressor case heater (fixed-speed only) AC 240 V – 74 W

Accumulator case heater AC 240 V – 29 W

Discharge temperature sensor 18.1 kΩ at 50 °C – 3.35 kΩ at 100 °C

Suction temperature sensor 34.6 kΩ at 0 °C – 10.0 kΩ at 25 °C – 3.4 kΩ at 50 °C

Pulse modulating valve (heat pump unit only) L12A-03, DC 12 V

Pulse modulating valve (for cooling bypass) A12A-15, DC 12 V

2-way valve NEV-603DXF, coil 240 V

2-way valve NEV-202DXF, coil 240 V

13

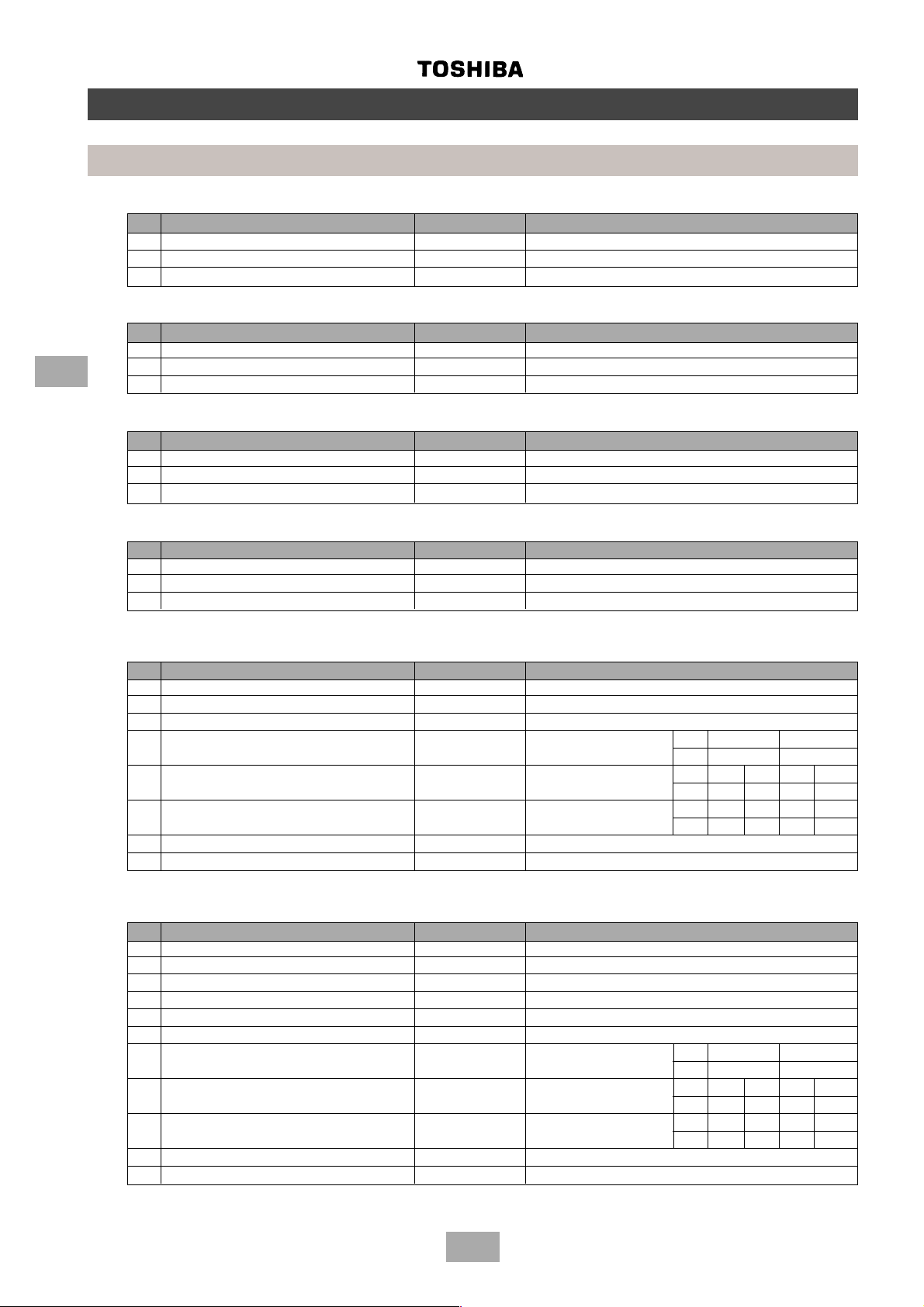

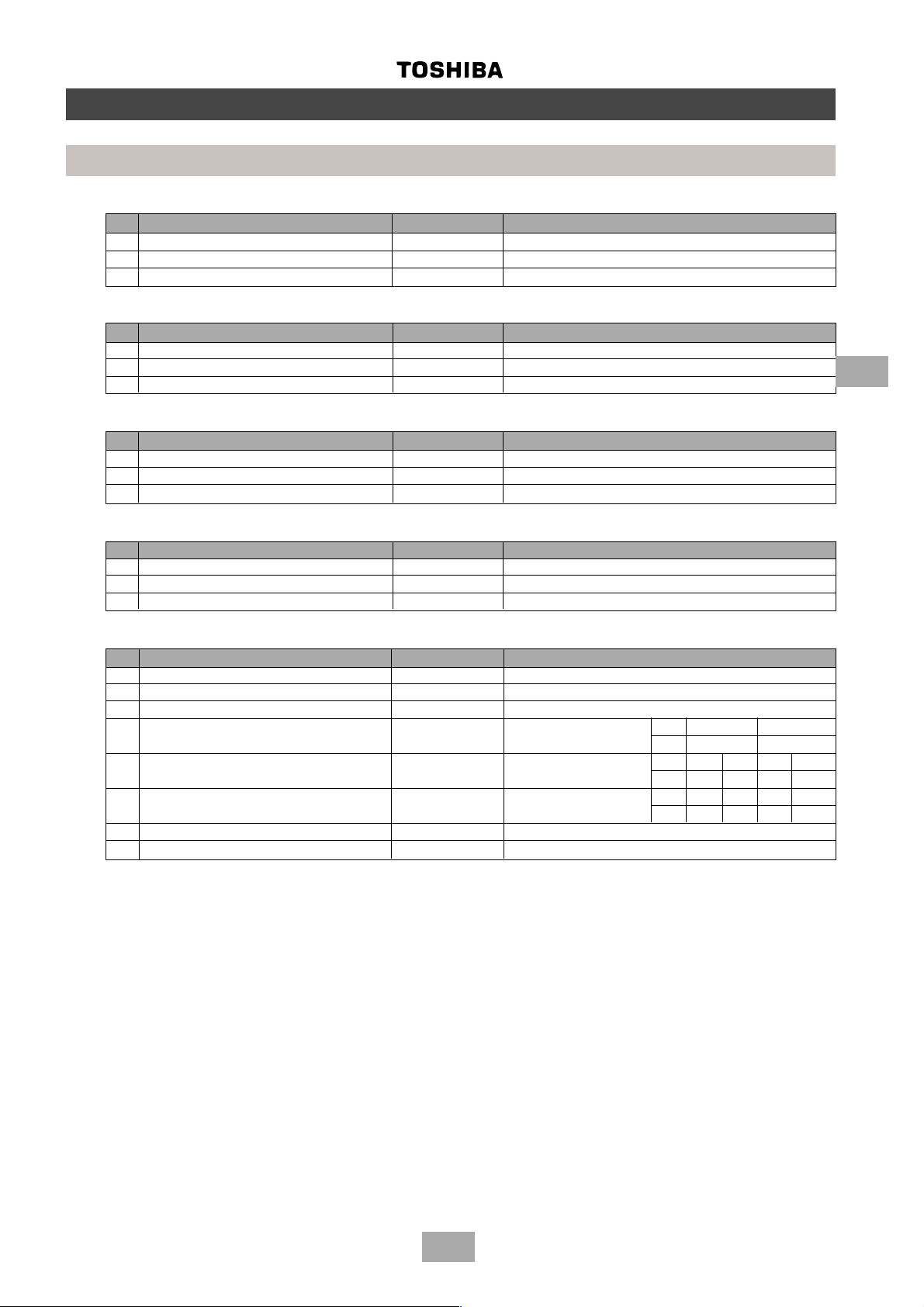

Built-In Duct: MM-B140

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor STF-200-140-4F Output (rated) 140 W, 4 pole, 200 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EAG40M106UF AC 400 V , 10 µF

3 Pulse motor valve EDM-B60YPTF-7B-A Capacity: 60

Built-In Duct: MM-B112

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor STF-200-120-4B Output (rated) 120 W, 4 pole, 200 V, 1 phase, 50 Hz

4

2 Running capacitor – Fan motor EAG40M505UF AC 400 V, 5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Built-In Duct: MM-B080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor STF-200-100-4B Output (rated) 100 W, 4 pole, 200 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EAG40M505UF AC 400 V, 5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Built-In Duct: MM-B056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor STF-230-60-4A Output (rated) 60 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2G405HQA114 AC 400 V, 4 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Parts specifications

Indoor units

Built-In Duct: MM-B140, MM-B112, MM-B080, M-B056

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C02 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

Built-In Duct: MM-SB028

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4J Output (rated) 34 W, 4 pole, 220 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 400 V , 1 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C02 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

14

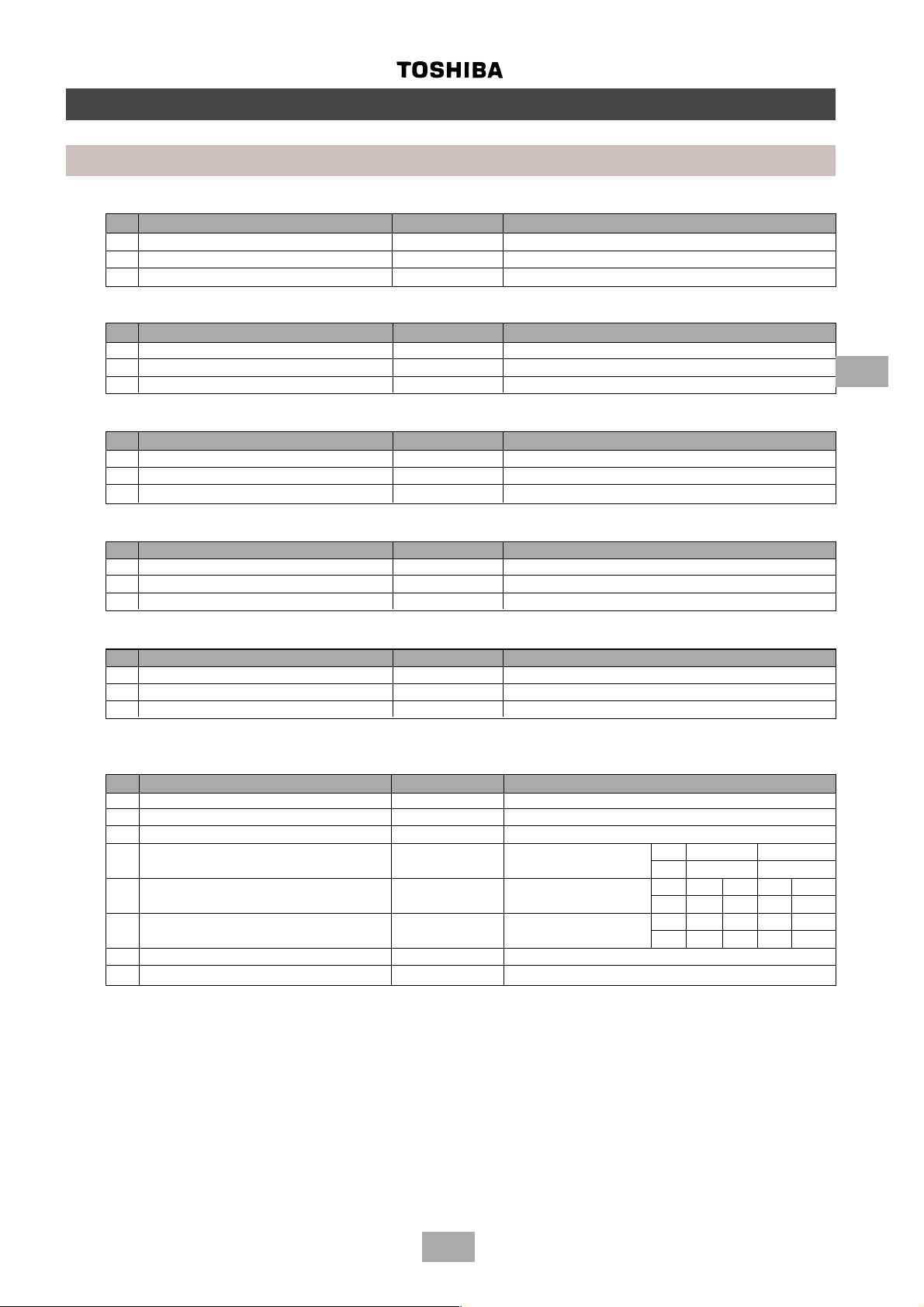

Parts Specifications

Indoor units

Ceiling: MM-C140, MM-CR140

No. PARTS NAME TIPO SPECIFICATIONS

1 Fan motor SMF-230-75-4B Output (rated) 75 W, 4 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2G405HQA114 AC 400 V , 4 µF

3 Pulse motor valve EDM-B60YPTF-7B-A Capacity: 60

Ceiling: MM-C112, MM-CR112

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-75-4U Output (rated) 75 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EVM45M305UF AC 450 V, 3 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Ceiling: MM-C080, MM-CR080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4D Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W255HQA113 AC 450 V, 2,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Ceiling: MM-C056, MM-CR056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4D Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W255HQA113 AC 450 V, 2,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

4

Ceiling: MM-C042, MM-CR042

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-34-4H Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 500 V, 1,5 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

Ceiling: MM-C140, MM-C112, MM-C080, MM-C056, MM-C042

MM-CR140, MM-CR112, MM-CR080, MM-CR056, MM-CR042

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C03 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

15

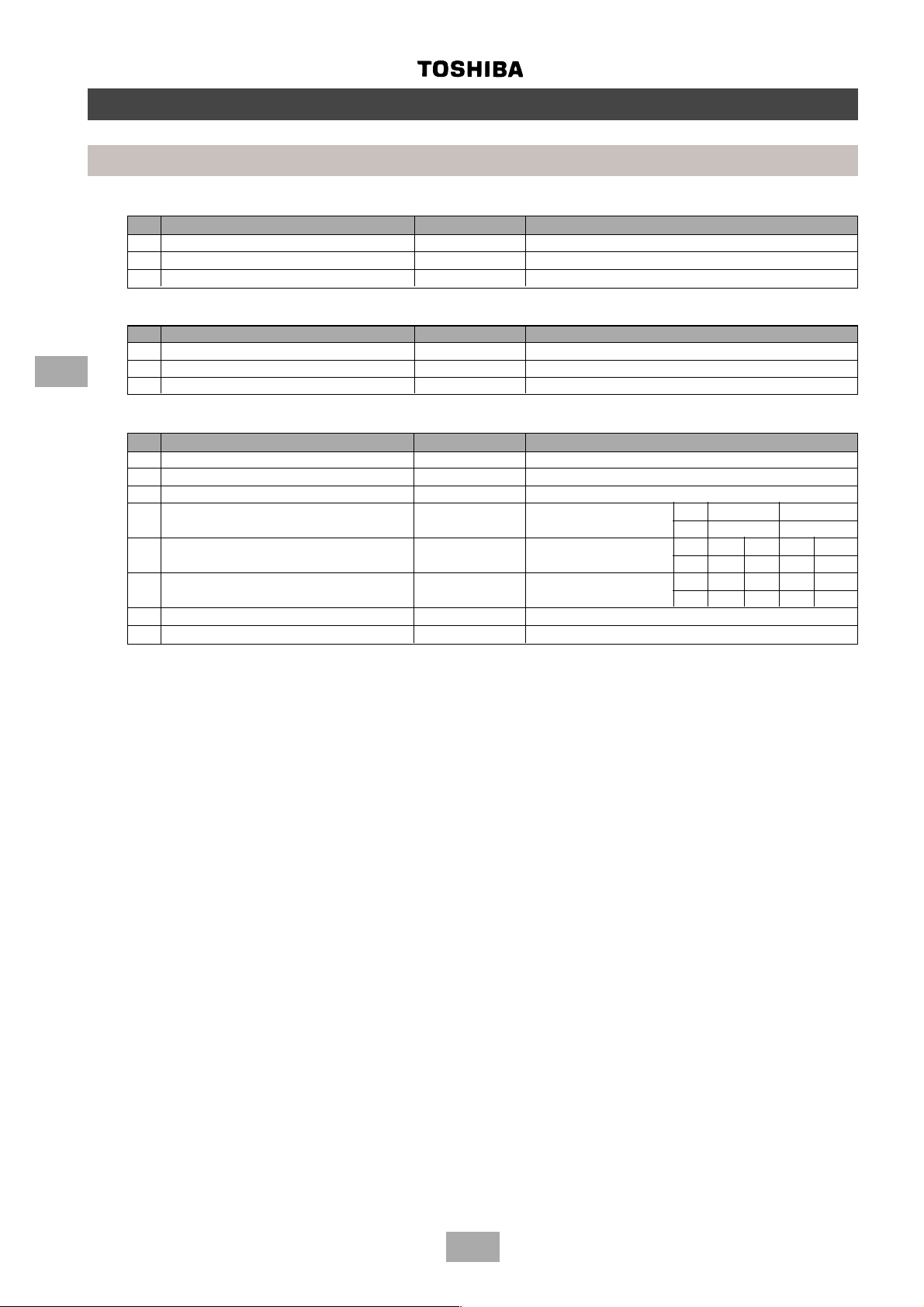

High wall: MM-K080, MM-KR080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-27-4R Output (rated) 27 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W205HQA107 AC 400 V, 2 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

High wall: MM-K056, MM-KR056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-27-4P Output (rated) 27, 4 pole, 230 V , 1 phase, 50 Hz

4

2 Running capacitor – Fan motor EEP2H155HQA107 AC 400 V , 1,5 µF

3 Pulse motor valve EDM-B40YTR-7B-A Capacity: 40

High wall: MM-K042, MM-KR0042

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-27-4P Output (rated) 27 W , 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 400 V , 1 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

High wall: MM-K080, MM-KR080

MM-K056, MM-KR056

MM-K042, MM-KR042

Parts specifications

Indoor units

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT - 03 - 1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C03 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

16

Parts specifications

Indoor units

Chassis: MM-N080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4O Output (rated) 34 W, 4 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H155HQA107 AC 500 V, 1,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Chassis: MM-N056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4D Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W205HQA107 AC 450 V, 2,0 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Chassis: MM-N042

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4H Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W205HQA107 AC 450 V, 2 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 25

Chassis: MM-N028

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4H Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H155HQA107 AC 500 V, 1,5 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

4

Chassis: MM-N080, NN-N056, MM-N042, MM-N028

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C02 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

17

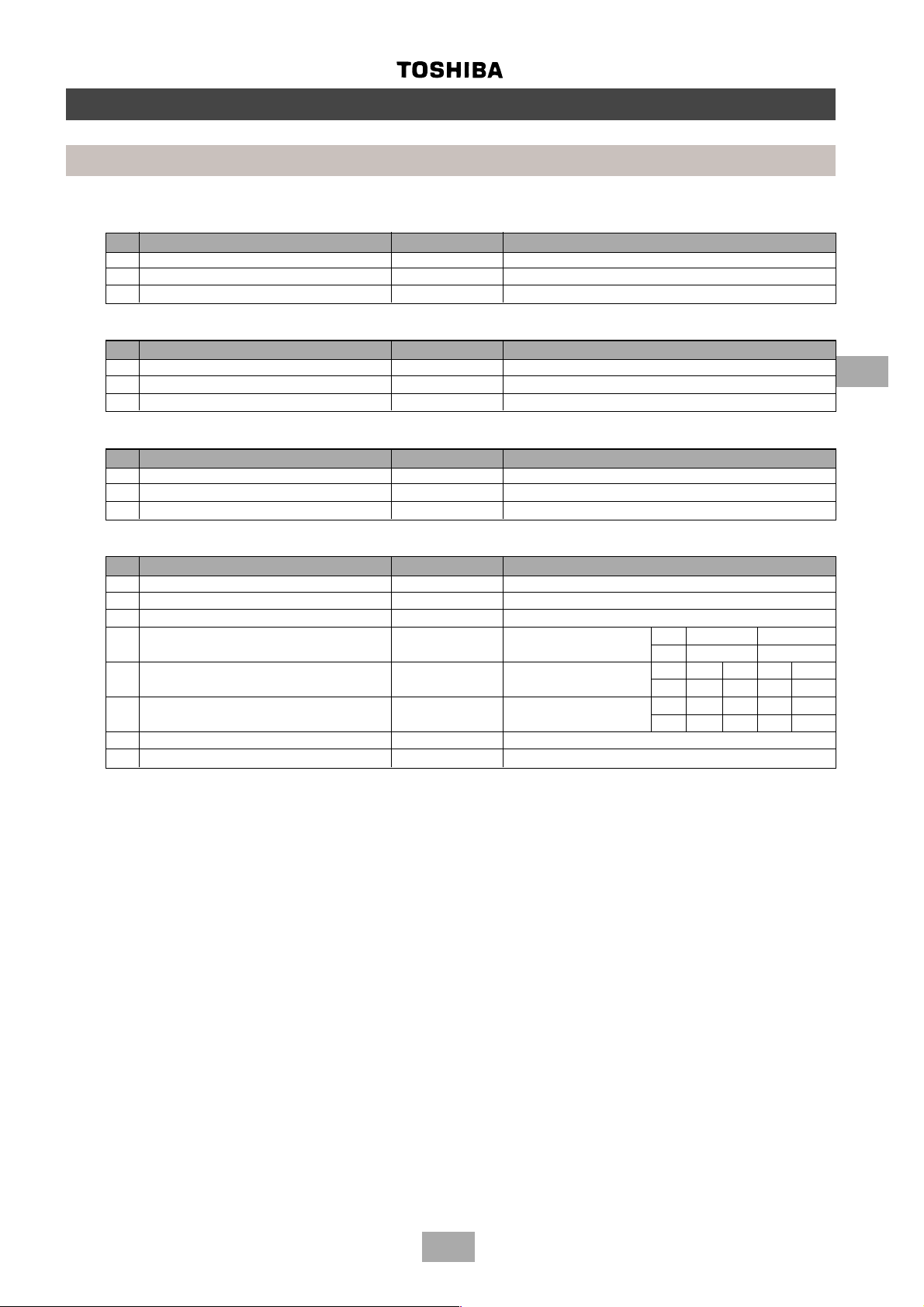

Parts specifications

Low wall: MM-S080, MM-SR080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4D Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W255HQA113 AC 450 V, 2,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Low wall: MM-S056, MM-SR056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4D Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

4

2 Running capacitor – Fan motor EEP2W255HQA113 AC 450 V, 2,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Low wall: MM-S080, MM-SR080, MM-S056, MM-SR056

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

10 Control PCB CM**C02 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

Indoor units

38 mA at 25 °C kΩ 10 3.45

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

26 mA at 25 °C kΩ 34.6 10 3.4

18

Parts specifications

Indoor units

2-way cassette: MM-TU056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor PAF-230-7-4 Output (rated) 7 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 500 V, 1 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

2-way cassette: MM-TU042

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor PAF-230-7-4 Output (rated) 7 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EVM45M504UF AC 500 V, 1 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

2-way cassette: MM-TU028

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor PAF-230-7-4 Output (rated) 7 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 500 V, 1 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

2-way cassette: MM-TU056, MM-TU042, MM-TU028

4

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT - 03 - 1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C01 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

19

4-way cassette: MM-U140

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-36A Output (rated) 36 W, 6 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EVM45M305UF AC 450 V, 3 µF

3 Pulse motor valve EDM-B60YPTR-7B-A Capacity: 60

4-way cassette: MM-U112

No. PARTS NAME TYPE SPECIFICATIONS

4

1 Fan motor MMF-230-36A Output (rated) 36 W, 4 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W255HQA113 AC 450 V , 2,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

4-way cassette: MM-U080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-28A Output (rated) 28 W, 6 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W205HQA107 AC 450 V, 2 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

4-way cassette: MM-U056

Parts specifications

Indoor units

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-28A Output (rated) 28 W, 6 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 450 V , 1 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

4-way cassette: MM-U140, MM-U112, MM-U080, MM-U056

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C02 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

20

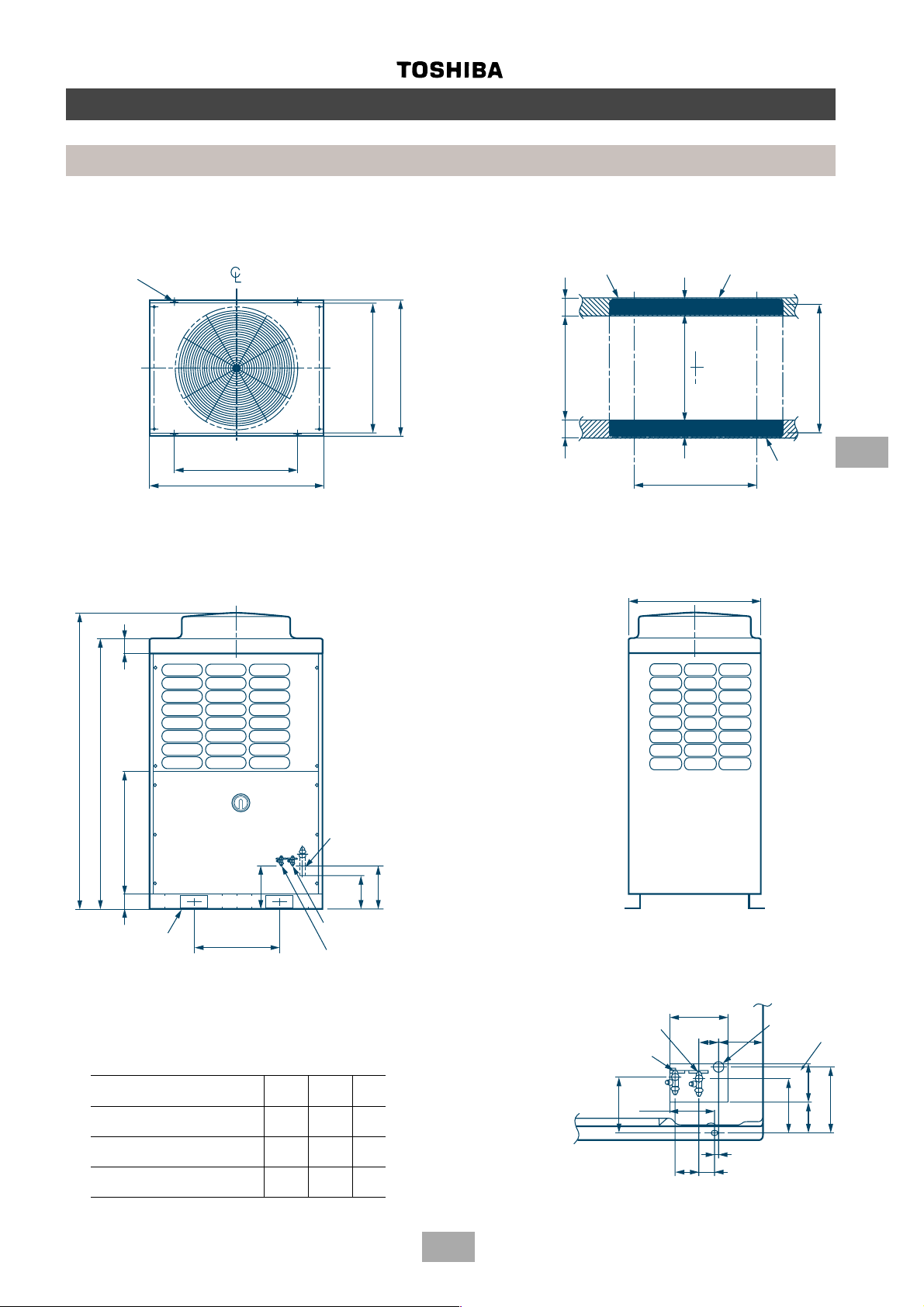

Construction views

Outdoor units

MM-A0280HT, MM-A0280HX, MM-A0224HT, MM-A0224HX, MM-A0160HX

MM-A0280CT, MM-A0280CX, MM-A0224CT, MM-A0224CX, MM-A0160CX

4 - 15 x 20 (slot)

Fixing bolt pitch

700

990

790

755

Fixing bolt pitch

(incluging fixed leg)

Grounding part of

bottom plate

610 100

100

Base

630 80

80

700

Fixing bolt pitch

Base bolt position

750

755

Fixing bolt pitch

5

Base

1700

1560

700 9088

245

2 - 60 x 150 slot

(for transport)

Note: All dimensions in mm

Model

MM-A0280HT, MM-A0280HX

MM-A0280CT, MM-A0280CX 28.6 12.7 9.52

MM-A0224HT, MM-A0224HX

MM-A0224CT, MM-A0224CX 22.2 12.7 9.52

MM-A0160HX

MM-A0160CX 22.2 9.52 9.52

500

(Slot pitch)

Balance pipe connecting

port flare connection (∅C)

∅∅

∅∅

∅A

∅B

∅∅

∅∅

mm mm mm

Refrigerant pipe connecting port

(Gas side) braze connection (∅A)

235

190

Refrigerant pipe connecting port

(Liquid side) flare connection (∅B)

∅∅

∅C

∅∅

Refrigerant pipe

connecting port

(liquid side)

Balance pipe

connecting port

145

Details of piping connections

(knock out)

130

65

173

35

60

20

115

Refrigerant pipe

connecting port

(gas side)

(knock out)

125

140

170

64

21

200

450

450

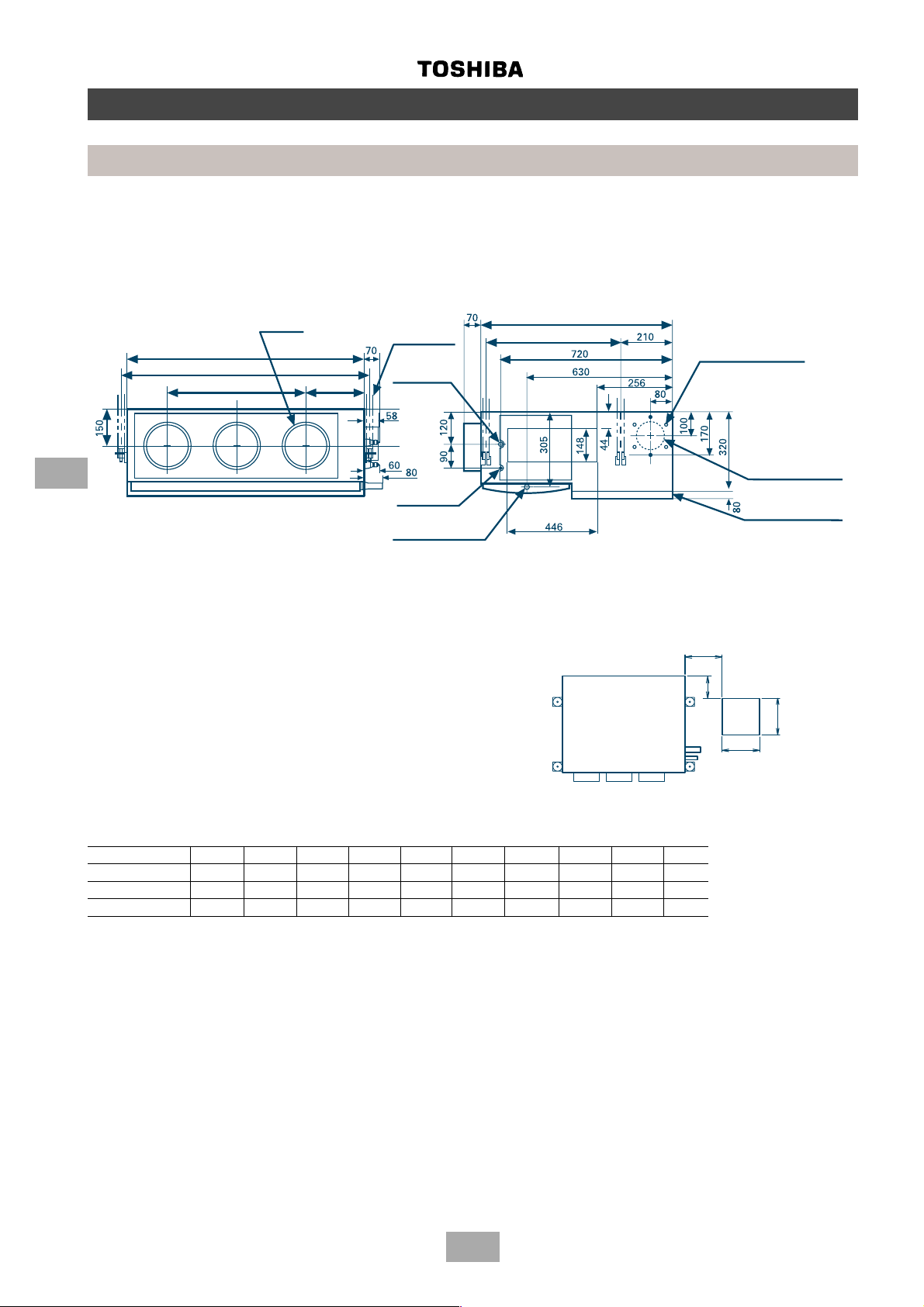

300-400

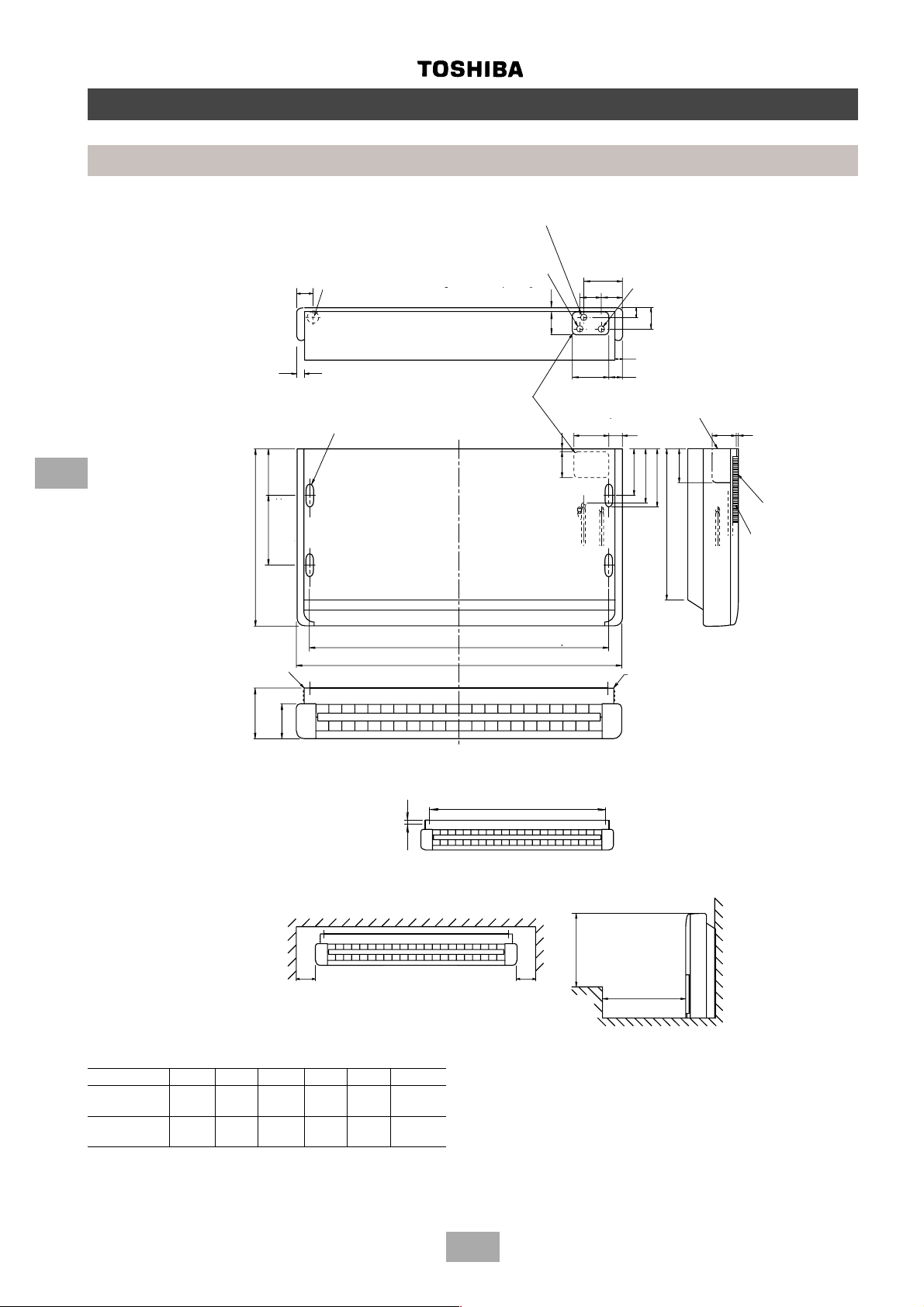

Built-In Duct

MM-B056, MM-B080, MM-B112, MM-B140

Construction views

Indoor units

6

A (Unit dimension)

B (Hanging bolt pitch)

J = M x K

N x ∅ 200

air outlet

Hanging bolt

4 - M10

provided at site

Refrigerant pipe

connection

(Gas ∅ F)

Refrigerant pipe

connection (liquid ∅ G)

Drain pipe connection

(Inner diameter: 32)

(Diameter 32 minimal for PVC pipes)

Hanging bolt pitch: 565

Unit dimension: 800

6 x ∅ 4 holes (∅160)

Fresh air inlet ∅ 125

cut-out (other side)

Filter kit

Ensure that there is sufficient space around the indoor

unit for installation and servicing

Indoor unit

Inspection hole

Model A B E

MM-B056 700 750 780 12.7 6.4 252 280 280 1 2

MM-B080 1000 1050 1080 15.9 9.5 252 580 290 2 3

MM-B112, B140 1350 1400 1430 19.0 9.5 252 930 310 3 4

(All dimensions in mm)

∅∅

∅F

∅∅

∅∅

∅GH J K M N

∅∅

Provide an inspection hole

in this position

22

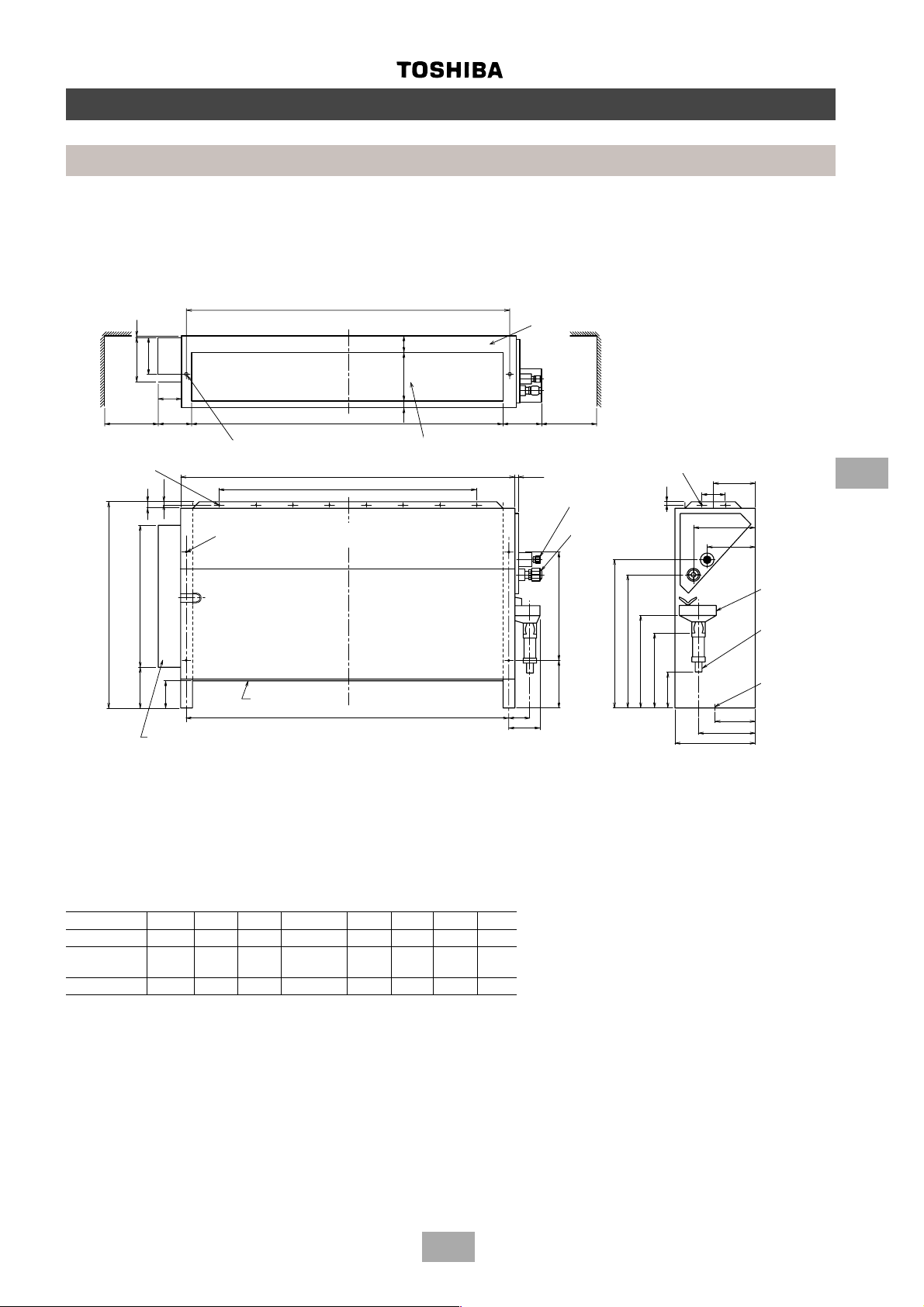

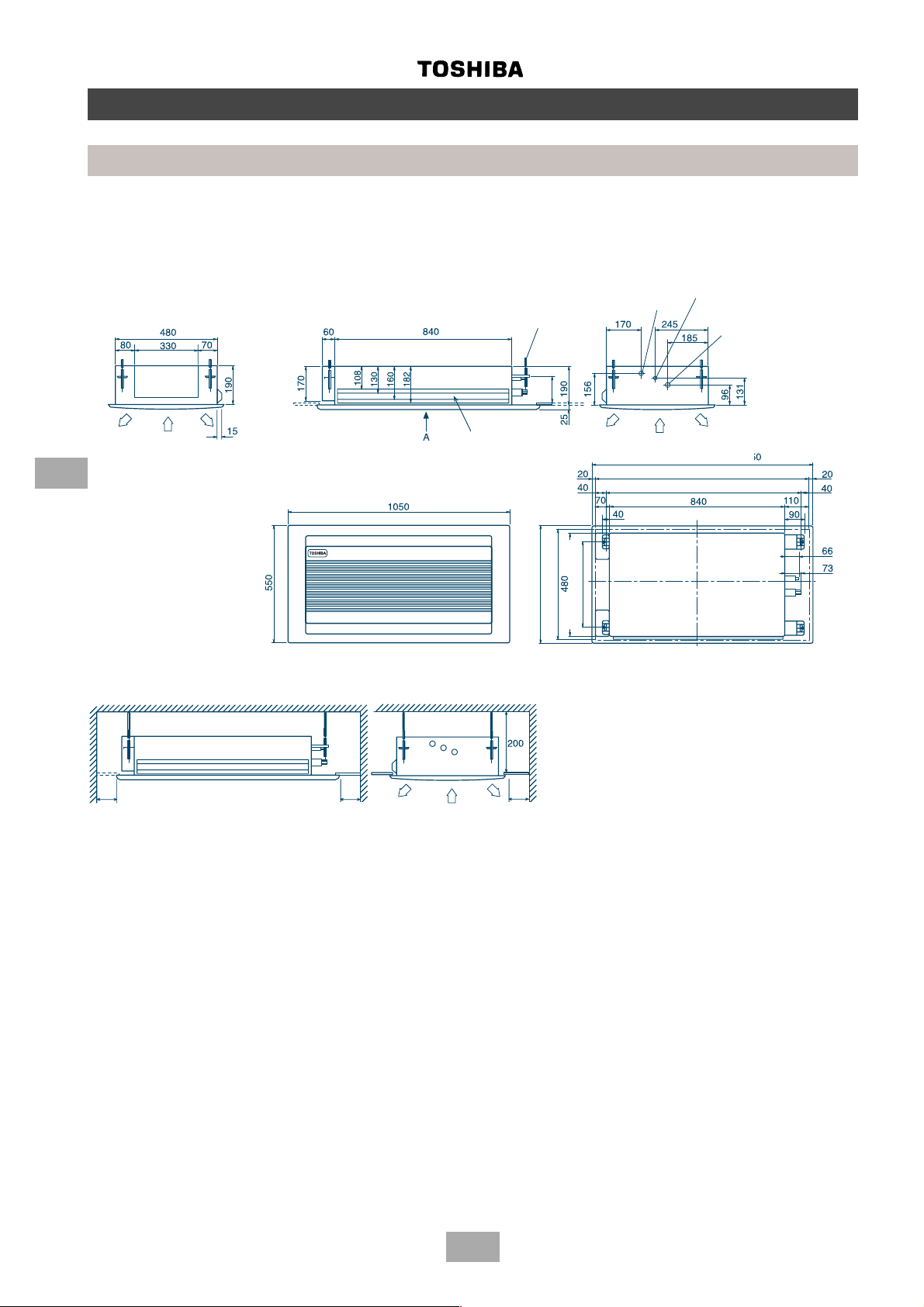

Built-In Slim Duct

MM-SB028

480

Refrigerant pipe

connection

(Liquid ∅ 6.4)

Construction views

Indoor units

220

265

276

331

35

Refrigerant pipe

connection

12

364

(Gas ∅ 12.7)

391

480

Drain pipe connection

(1” BSP threaded connection)

500

480

397

Hanging bolt pitch

Unit dimension

Washable filter

6

Air inlet

220

200

150

35

200

150

125

700

450

125

150150

342.5

150

800

750

700

Air outlet

57

Shelter board

333

Hanging bolt pitch

Unit dimensions

Filter

700

342.5

150

75

75

37.5

158

Electrical box

(PCB, transformer and MF capacitor)

45

Air flow

81

Filter

Air flow

Shelter board

Optional air flow (lower air inlet)

23

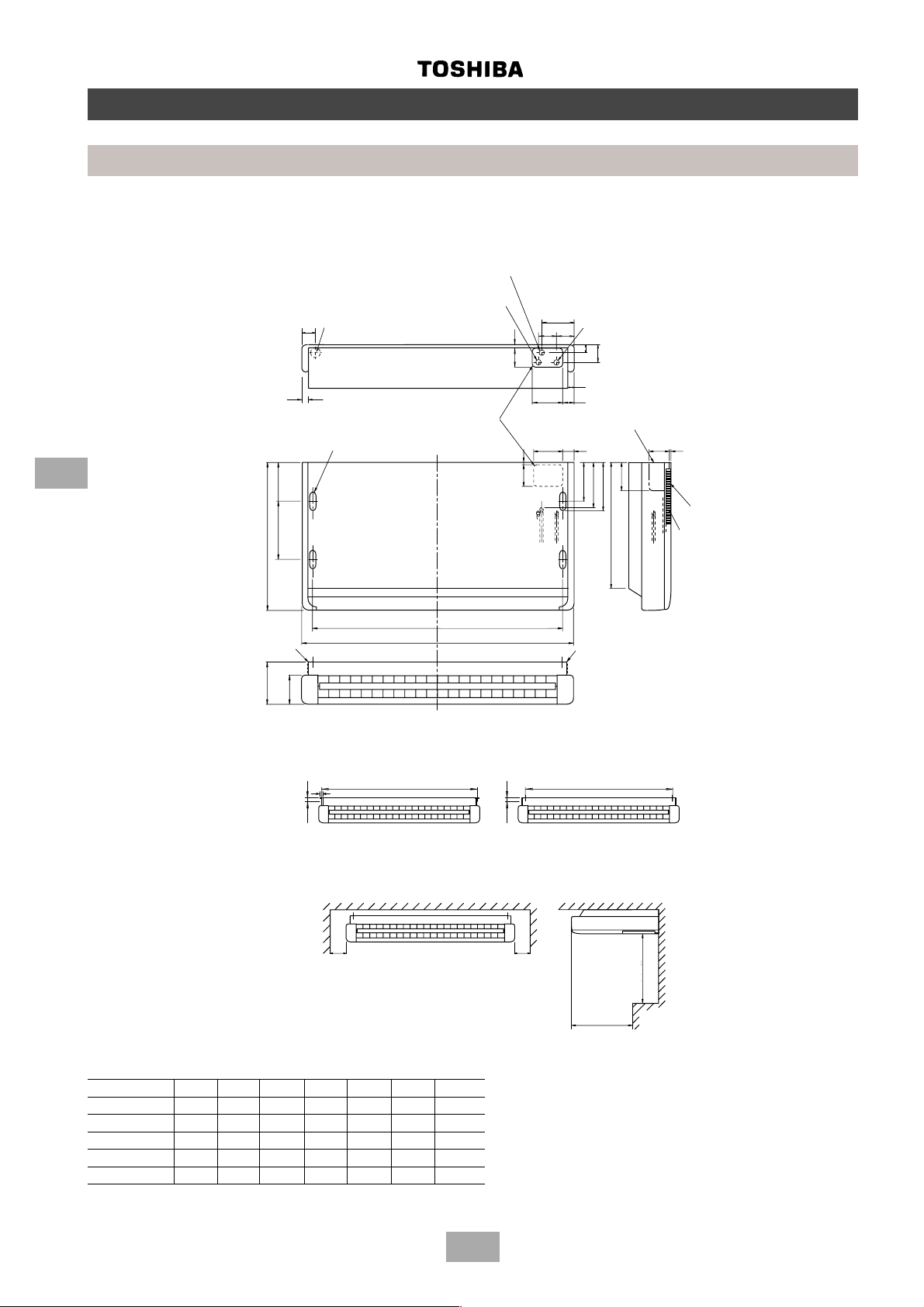

Construction views

Indoor units

Low wall

MM-S056, MM-SR056

MM-S080, MM-SR080

6

HR-PE

640

sospensione

Hanging plate (Left)

Alternative knock-out

Foro incompleto

hole for drain piping

alternativo

62

per tubo drenaggio

30

Hanging bolt hole

4 - (12 x 25) slot

170

250

pitch

pitch

Hanging bolt

Hanging bolt

Raccordo tubo drenaggio

Tubo duro cloruro di vinile

Hard vinyl chloride pipe

diametro esterno mm. 20

outer dia. 20 mm

Collegamento tubo

Refrigerant pipe

refrigerante

connection (Liquid ∅ E)

Foro bullone di

sospensione Ð

Scanalatura 12x25 (4)

Drain piping joint

(Liquido ¿F)

Knock-out holes for

Fori incompleti

piping and wiring

per tubi e fili

Hanging bolt pitch

Passo bullone di sospensione

B

A

Collegamento tubo

Refrigerant pipe

145

refrigerante (Gas ¿G)

80

12

85

130

10

100

connection (Gas ∅ F)

80

34

78

30

50140

Right-side panel knock-

Foro incompleto pannello destro

out for piping and wiring

per tubi e fili

50

150

180

200

C

Piastra di sospensione

Hanging plate (Right)

(destra)

120

85

12

Air filter

Ingresso aria

Air inlet

Filtro aria

D

130

inferiore a 40

Hanging bolt

Less than 40

Bullone di sospensione

150

Minimum

Minimo

Space required for service and installation

Spazio necessario per installazione e manutenzione

Model A B C D ∅E ∅F

MM-S056

MM-SR056 1030 920 540 188 6.4 12.7

MM-S080

MM-SR080 580 581 582 583 584 585

All dimensions in mm

VISTA PIANO

PLAN VIEW

B

Passo bullone di sospensione interno

Hanging bolt pitch

400

150

Minimo

Minimum

Pi• di

Greater than

Pi• di

500

24

Chassis

MM-N028, MM-N042, MM-N056, MM-N080

Space required for service and installation

20

140

160

65

150

Minimo

Foro Hx¯4.7

95

Fixing location to floor/base

10

20

Posizione di fissaggio

al pavimento/alla base

Foro ¯15 (4)

4 x ∅15 hole

Posizione di fissaggio alla parete

Fixing location to wall

Construction views

Indoor units

A

6014525

B

Uscita aria

Air outlet

C

D

t

Piastra superiore/Piastra condotto

Upper plate/duct plate

100 150

10

Minimo

Minimum

Flare joint

Raccordo a cartella

Liquid ∅ F

Liquido ¿F

Raccordo a cartella

Flare joint

Gas ¿G

Gas ∅ G

2 x ∅4.7 hole

Foro 2¯4.7

10

133

70

175

145

6

600

345

160

70

Centralina elettrica

Electrical box

Collegamento terra interno

Earth connection inside

Air filter

Filtro aria

Ingresso aria

Air intake

E

Model ABCD E∅F ∅GH

MM-N028 580 550 610 4 x 100 580 6.4 12.7 5

MM-N042

MM-N056 880 850 910 7 x 100 880 6.4 12.7 8

MM-N080 880 850 910 7 x 100 880 9.5 15.9 8

All dimensions in mm

Drain catch

315

436

397

274

224

140

65

95

104

230

155

110

Drain hose

connector

(OD ∅ 20)

Fixing location

to floor/base

25

Construction views

Indoor units

Ceiling

MM-C042, MM-CR042, MM-C056, MM-CR056

MM-C080, MM-CR080, MM-C112, MM-CR112, MM-C140, MM-CR140

6

/CHR-PE

/CHR-PE

/CHR-PE

Alternative knock-out

/CHR-PE

hole for drain piping

640

Hanging plate

Hanging plate (Left)

(Left)

D

Foro incompleto

62

alternativo

per tubo drenaggio

30

Hanging bolt hole

4 - (12 x 25) slot

170

250

Hanging bolt

130

Foro bullone di

sospensione Ð

Scanalatura 12x25 (4)

pitch

Passo bullone

di sospensione

Raccordo tubo drenaggio

Drain piping joint

Tubo duro cloruro di

vinile diametro

Hard vinyl chloride pipe

esterno mm. 20

outer dia. 20 mm

Collegamento tubo

Refrigerant pipe

refrigerante

(Liquido

connection (Liquid ∅ F)

Knock-out holes for

piping and wiring

¿F)

Fori incompleti

per tubi e fili

Hanging bolt pitch

B

(

Passo bullone di sospensione

A

Collegamento tubo

Refrigerant pipe

145

refrigerante

connection (Gas ∅ G)

80

10

100

80

34

30

50140

Foro incompleto

pannello destro

per tubi e fili

130

50

150

)

Piastra di sospensione

Hanging plate (Right)

12

85

(Gas ¿G)

78

Right-side panel knockout for piping and wiring

85

12

120

180

200

Filtro aria

C

(destra)

Air filter

Ingresso aria

Air inlet

40

Hanging bolt

inferiore a 40

Less than 40

Passo bullone di sospensione interno

Bullone di sospensione

Inner hanging bolt pitch

150

Minimo

Minimum

Spazio necessario per installazione e manutenzione

Space required for service and installation

E

Model A BCDE∅F ∅G

MM-C042/CR042 1030 920 540 188 1020 6.4 12.7

MM-C056/CR056 1030 920 540 188 1020 6.4 12.7

MM-C080/CR080 1230 1120 540 188 1220 9.5 15.9

MM-C112/CR112 1430 1320 550 240 1420 9.5 19.0

MM-C140/CR140 1630 1520 550 240 1620 9.5 19.0

All dimensions in mm

B

inferiore a 40

less than 40

Hanging bolt

Passo bullone di sospensione interno

Bullone di sospensione

Outer hanging bolt pitch

150

Minimo

Minimum

Greater than

Pi• di

400

500

Pi• di

Greater than

26

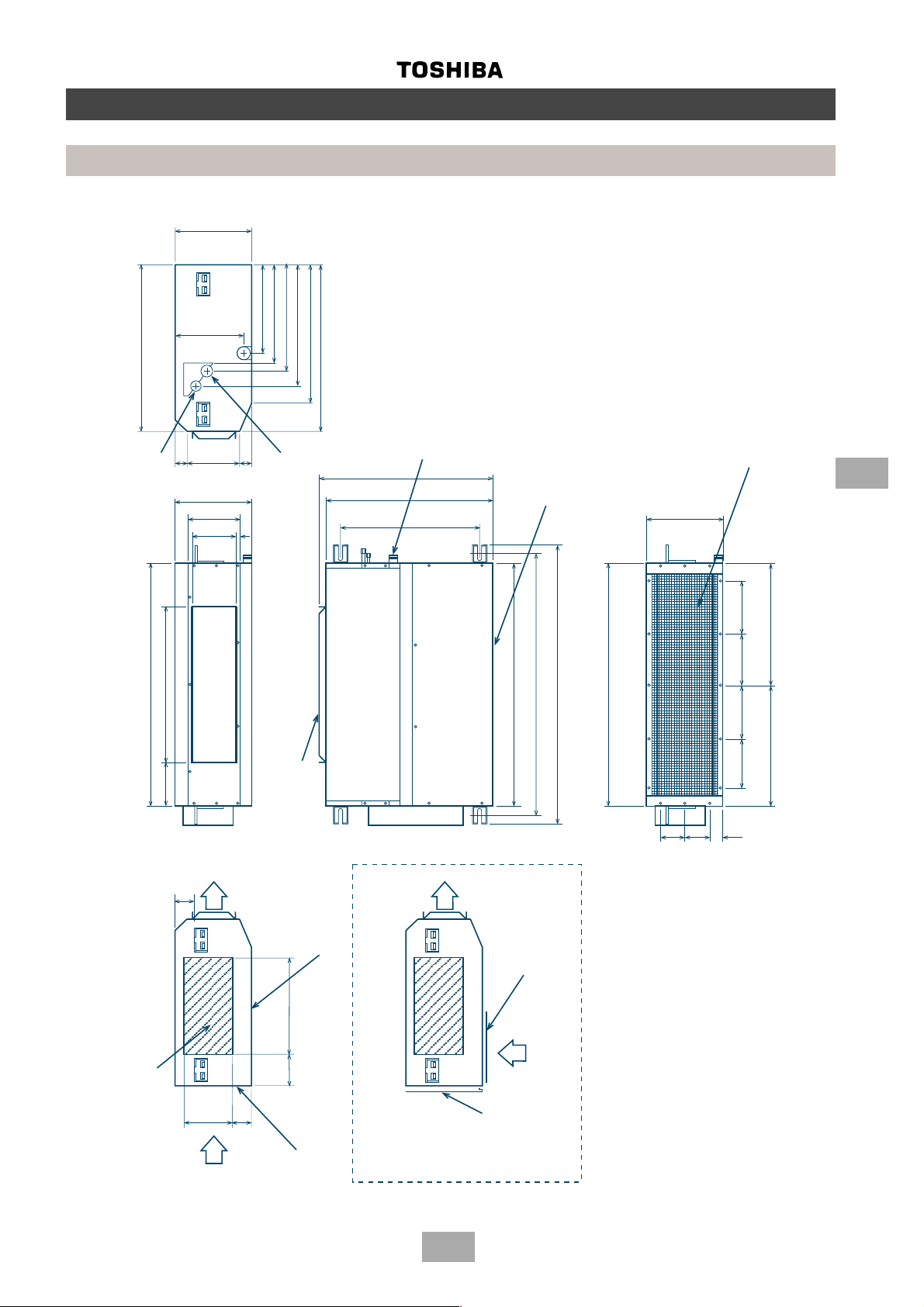

p

Construction views

Indoor units

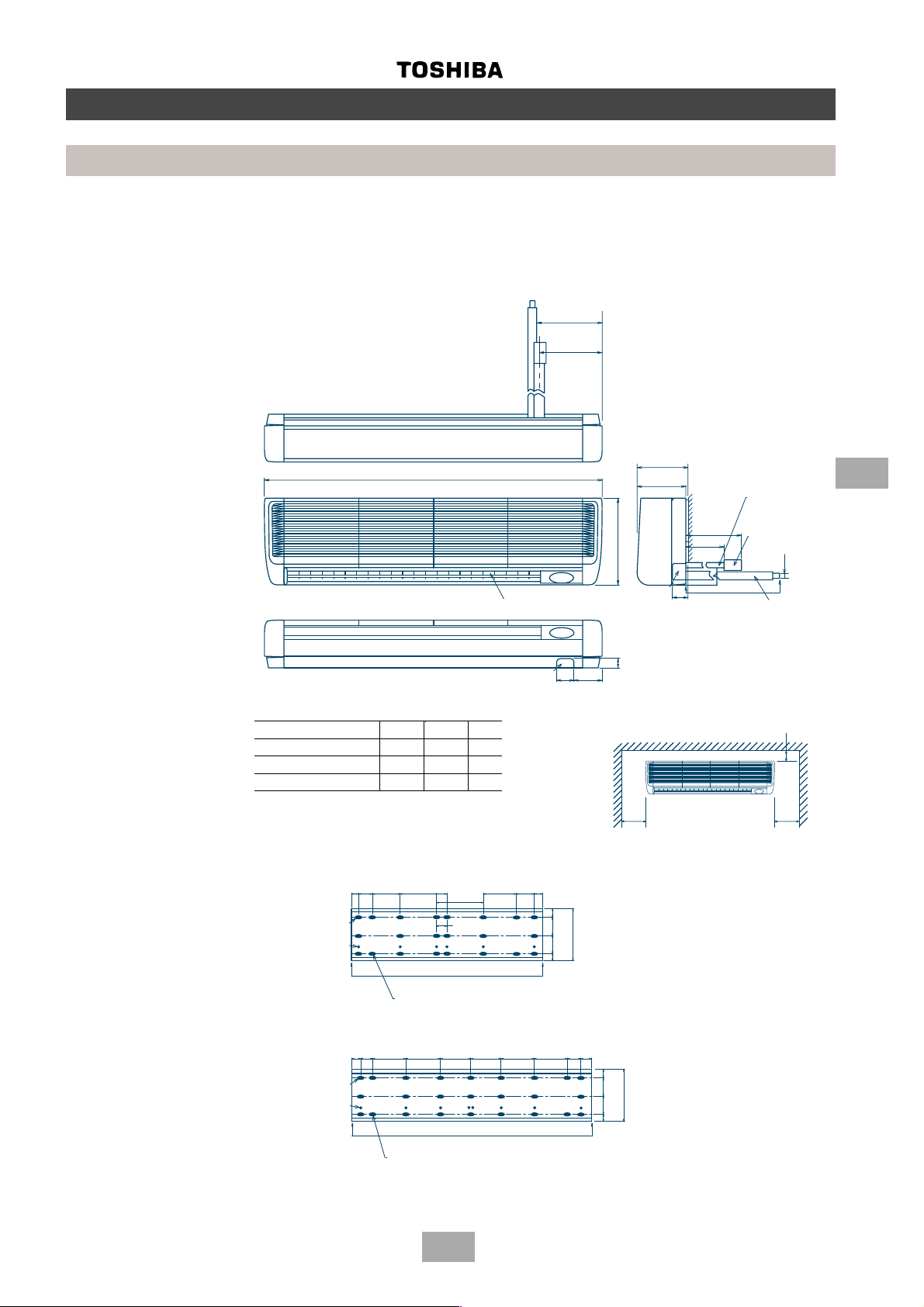

High wall

MM-K042, MM-K056, MM-K080, MM-KR042, MM-KR056, MM-KR080

158

143

MM-K042, MM-KR042

MM-K056, MM-KR056

MM-K080, MM-KR080

A

Piping hole

Piping hole

(Knockout hole)

(Knock-out hole)

Model A B C

MM-K042, MM-KR-042 1149 12.6 6.4

MM-K056, MM-KR056 1149 12.7 6.4

MM-K080, MM-KR080 1478 15.9 9.5

Slots

18-6x30

Slots

6-ø6 Holes

18 - 6 x 30

20 40 110 150

150

40

6 - ∅ 6 holes

600

Anchor bolt holes

Anchor bolt holes

4 - 10x20 slots

4 - 10 x 20 slots

Air outlet

Air outlet

4-way adjustable

4-way adjustable

40 20

110

43

50

26 50

226

216

595

372

(Both sides)

(Both sides)

Piping hole

Piping hole

(Knockout hole)

(Knock-out hole)

40

70 118

More than 300 More than 300

300 min.

Space required for service

169

(All dimensions in mm)

(unit : mm)

495

40

Space required for service

900

Refrigerant pipe

Refrigerant pip

connection

connection

(Liquid ∅ C)

(Liquid øC)

Refrigerant pipe

Refrigerant pi

connection

connection

(Gas øB)

(Gas ∅ B)

ø20

(OD.)

Drain pipe

Drain pipe

30 min.

More than 30

300 min.

6

Slots

Slots

21-6x30

8-ø6 Holes

21 - 6 x 30

8 - ∅ 6 holes

2040 110 150 150 150 150 110 2040

Anchor bolt holes

Anchor bolt holes

4 - 10x20 slots

4 - 10 x 20 slots

Installation board mounting bolt hole location

940

Installation board mounting bolt hole location

27

43

169

50

26 50

2-way cassette

MM-TU028, MM-TU042, MM-TU056

6

Construction views

Indoor units

Hanger bolt

(4 x M10)

Channel for routing TC sensors and

pressure sensor leads

Drain pipe joint

(outer ∅ 25.5)

Panel outer dimension 1050

Ceiling opening 1010

Hanging bolt pitch 930

Refrigerant piping joint

(Liquid ∅ 6.4)

Refrigerant piping joint

(Gas ∅ 12.7)

Minimum

600

View A

Minimum

600

Space required for service and installation

Ceiling opening 510

Panel outer dimension 550

Minimum

600

410

Hanging bolt pitch

(All dimensions in mm)

28

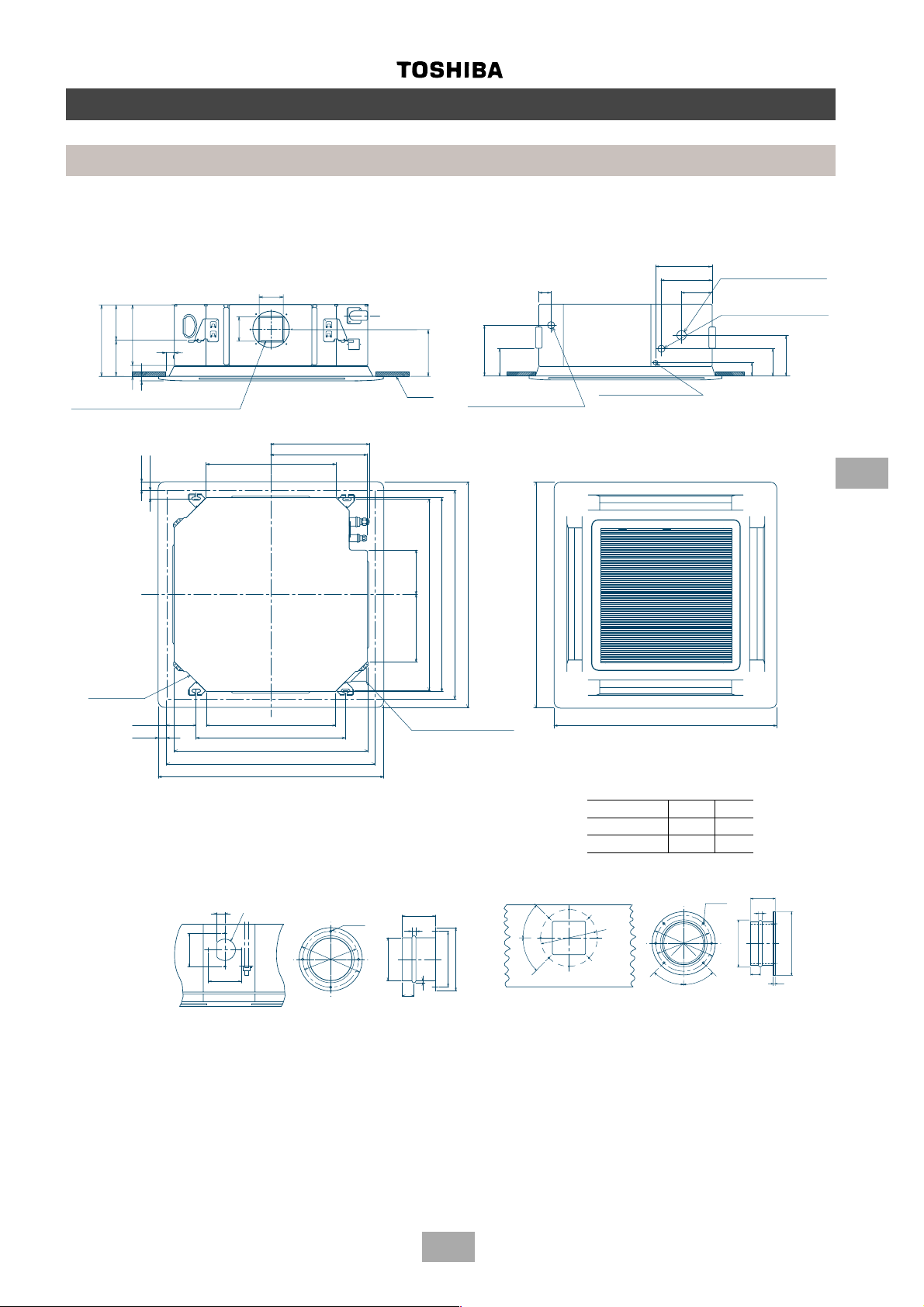

4-way cassette

MM-U056, MM-U080

Construction views

Indoor units

259

160

298

138

30

39

20

Knock-out for side ducts ∅ 150

(both sides)

40

30

Fresh air inlet

106

536

106

405

400

195

Ceiling

240

138

Drain pipe connection

(1” BSP threaded connection)

268 195

Ceiling opening 880

Hanging bolt pitch 800

Panel dimension 940

External cassette dimension 820

940

185

80

Refrigerant pipe

170

connection (Gas ∅ A)

100

Refrigerant pipe

connection (Liquid ∅ B)

200

140

73

Wiring connection

(Gland plate 3 x ∅ 20 holes)

6

130

30

Hanging bolt pitch 620

External cassette dimension 820

Ceiling opening 880

Panel dimension 940

Fresh air inlet duct size

32

130

130

∅100

536

∅144

∅130

4-∅6

Condensate pipe

(1” BSP threaded connection)

80

10

∅97

∅30

2

30

∅144

Side outlet duct size

45°

45°

940

Model (MM-) U056 U080

∅A 12.7 15.9

∅B 6.4 9.5

6-∅6

∅180

∅180

45°

45°

∅150

80

10

∅200

30

6

29

30

202

941

106

210

348

309

138

30

39

20

106

40

30

610

605

940

30

130

940

1350

80

240

138

185

170

100

73

140

200

80

10

30

6

32

130

130

80

10

30

2

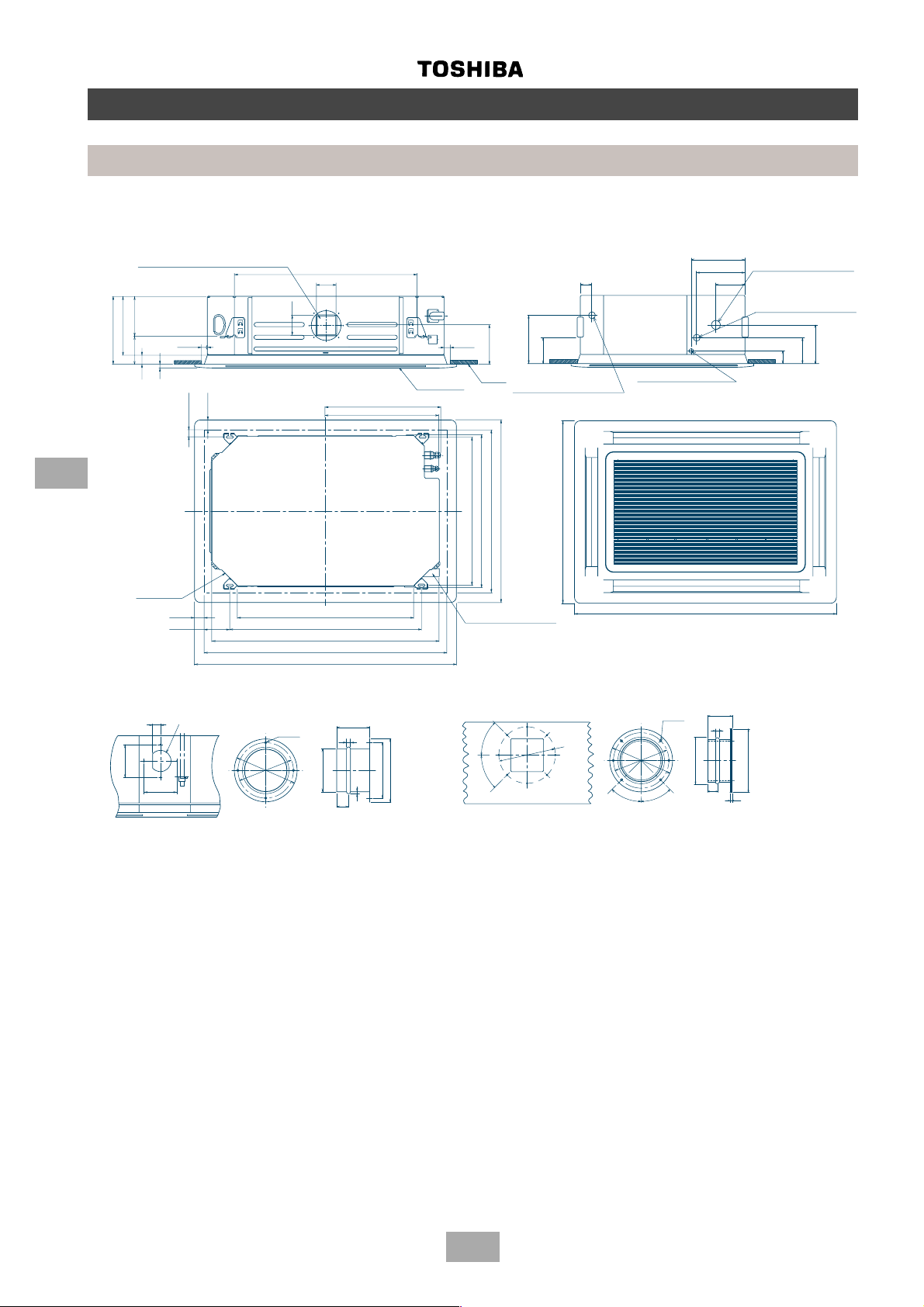

4-way cassette

MM-U112, MM-U140

Construction views

Indoor units

6

Knock-out for side ducts ∅ 150

(both sides)

Fresh air

inlet

Hanging bolt pitch 1030

External cassette dimension 1230

Ceiling opening 1290

Panel dimension 1350

Ceiling

Ceiling panel

Drain pipe connection

(1” BSP threaded connection)

Hanging bolt pitch 800

External cassette dimension 820

Condensate pipe

(1” BSP threaded connection)

Ceiling opening 880

Panel dimension 940

Refrigerant pipe

connection

(Gas side ∅19.0)

Refrigerant pipe

connection

(Liquid side ∅9.5)

Wiring connection

(Gland plate 3 x ∅ 20 holes)

Fresh air inlet duct size

Side outlet duct size

6-∅6

45°

∅150

∅200

∅100

45°

45°

∅180

45°

4-∅6

∅144

∅130

∅97

∅30

∅144

30

Loading...

Loading...