Page 1

A90-0132

Modular Multi System

Service Manual

Air Conditioner - Multi Split Type System

HFC R407C

Page 2

2

Page 3

Contents

Introduction ......................................................................................................................... 5

Summary.............................................................................................................................8

Outline of MMS (Modular Multi System)............................................................................ 10

Parts Specifications........................................................................................................... 12

Construction Views – Outdoor Units ................................................................................. 21

Construction Views – Indoor Units .................................................................................... 22

Wiring Diagrams................................................................................................................ 31

Refrigerant Piping Systematic Drawings ........................................................................... 44

Combined Refrigerant Piping Systematic Drawings.......................................................... 49

Refrigerant Cycle Schematic – Indoor Units ..................................................................... 53

1

2

3

4

5

6

7

8

9

10

Outline of Control ..............................................................................................................54

Self Diagnostic Display Information...................................................................................67

Control Circuit Configuration ............................................................................................. 71

Troubleshooting ................................................................................................................ 76

Back-up Operation ..........................................................................................................122

Forced Function of Oil Level Detection ........................................................................... 126

Refrigerant Pipe Installation ............................................................................................ 127

Trial Operation ................................................................................................................ 132

Replacing the Compressor.............................................................................................. 145

Exploded Views and Service Parts .................................................................................156

11

12

13

14

15

16

17

18

19

20

3

Page 4

4

Page 5

Introduction

Precautions

Please read these instructions carefully before starting the installation.

This equipment should only be installed by suitably trained operatives.

In all cases ensure safe working practice: Observe precautions for persons in the vicinity of the works.

Ensure that all local, national and international regulations are satisfied.

Check that the electrical specifications of the unit meet the requirements of the site.

Carefully unpack the equipment, check for damage or shortages. Please report any damage immediately.

These units comply with EU Directives:

73/23/EEC (Low Voltage Directive), 89/336/EEC (Electromagnetic Compatibility) and 97/23/EC (Pressure Equipment

Directive). Accordingly, they are designated for use in commercial and industrial environments*.

Avoid installation in the following locations:

Where there is danger of flammable gas leakages.

Where there are high concentrations of oil.

Where the atmosphere contains an excess of salt (as in coastal areas). The air conditioner is prone to failure when

used under this condition unless special maintenance is provided.

1

Where the airflow from the outdoor unit may cause annoyance.

Where the operating noise of the outdoor unit may cause annoyance.

Where the foundation is not strong enough to fully withstand the weight of the outdoor unit.

Where the water drainage may cause a nuisance or a hazard when frozen.

Where strong winds may blow against the air outlet of the outdoor unit.

Precautions for R407C outdoor units

R407C outdoor units use synthetic oils which are extremely hygroscopic. Therefore ensure that the refrigerant system

is NEVER exposed to air or any form of moisture.

Mineral oils are unsuitable for use in these units and may lead to premature system failure.

Use only equipment which is suitable for use with R407C. Never use equipment which has been used with R22.

R407C should only be charged from the service cylinder in the liquid phase. It is advisable to use a gauge manifold set

equipped with a liquid sight glass fitted in the centre (entry) port.

* 97/23/EC Pressure Equipment Directive information

Conformity assessment procedure: Module D1

Pressure equipment:

Compressor, category II, Module A1

Accumulator, category I

Liquid receiver, category II

High pressure switch, category II, Module A1

Notified body for inspection and quality assurance systems: BSI, Maylands Avenue, Hemel Hempstead, WP2 4SQ, UK.

5

Page 6

Introduction

Precautions

Precautions for R-407C outdoor units

1

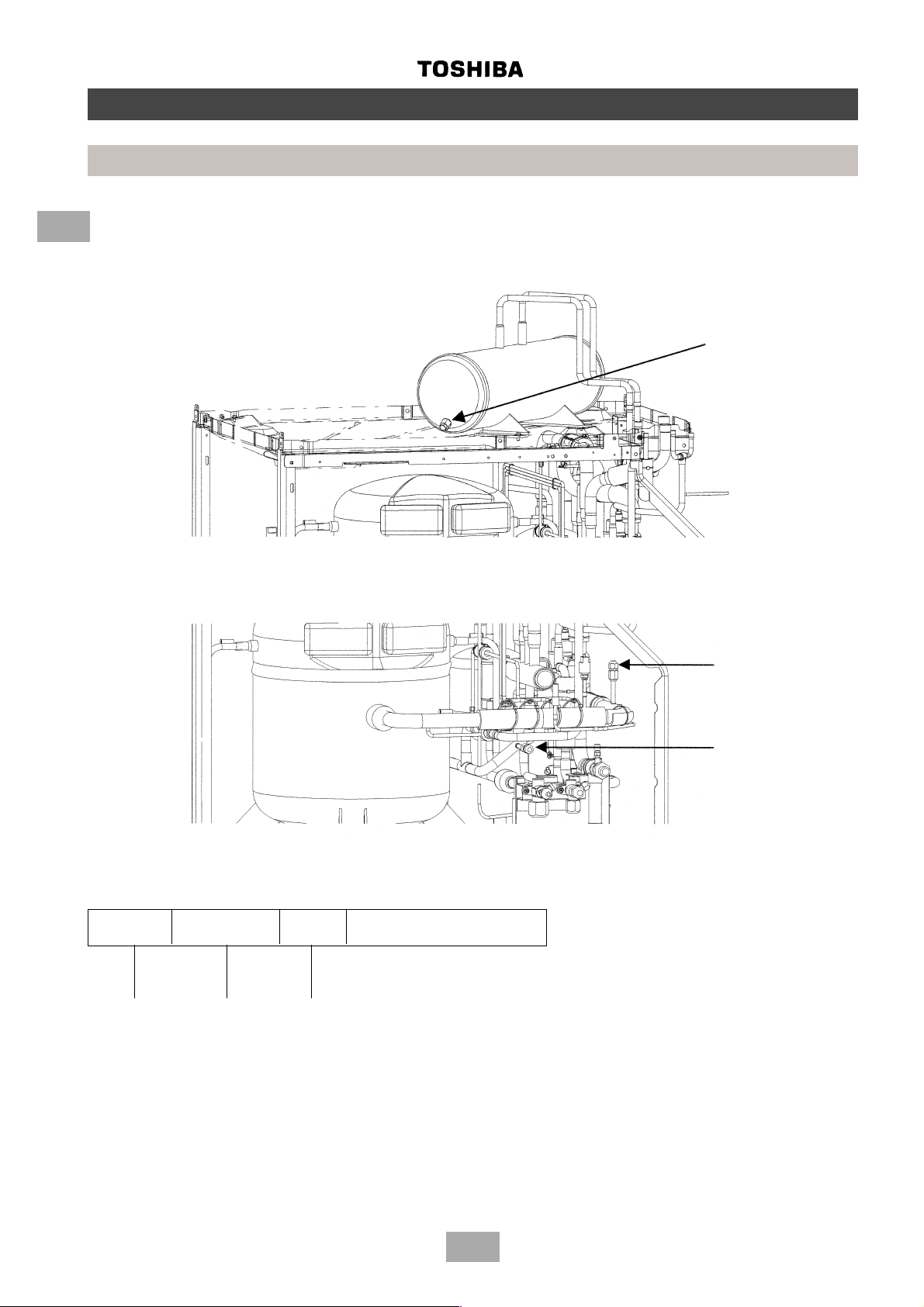

Liquid receiver fusible plug

In the event of the system being subjected to abnormal conditions it is protected by a fusible plug, positioned on the liquid

receiver, within the outdoor unit. It is rated to fail at 70°C.

Position of

fusible plug

System pressure measurement

To measure the system’s high and low pressures, connect a gauge manifold to the corresponding access port as indicated

below.

Low pressure

access port

High pressure

access port

Explanation of Toshiba serial number

A serial label is attached to all Toshiba air conditioning units. Located on the label is an 8-digit number, which represents the

month, year and batch number of the manufactured unit. A breakdown of the 8-digit number is defined below.

24480001

}

Year of

manufacture

2001 = 1

2002 = 2

2003 = 3

Month of

manufacture

41 = Jan.

42 = Feb.

43 = Mar.

44 = Apr.

45 = May

46 = Jun.

47 = Jul.

48 = Aug.

49 = Sep.

50 = Oct.

51 = Nov.

52 = Dec.

Site of

manufacture

8 = Plymouth

Model batch serial number

6

Page 7

Introduction

Components

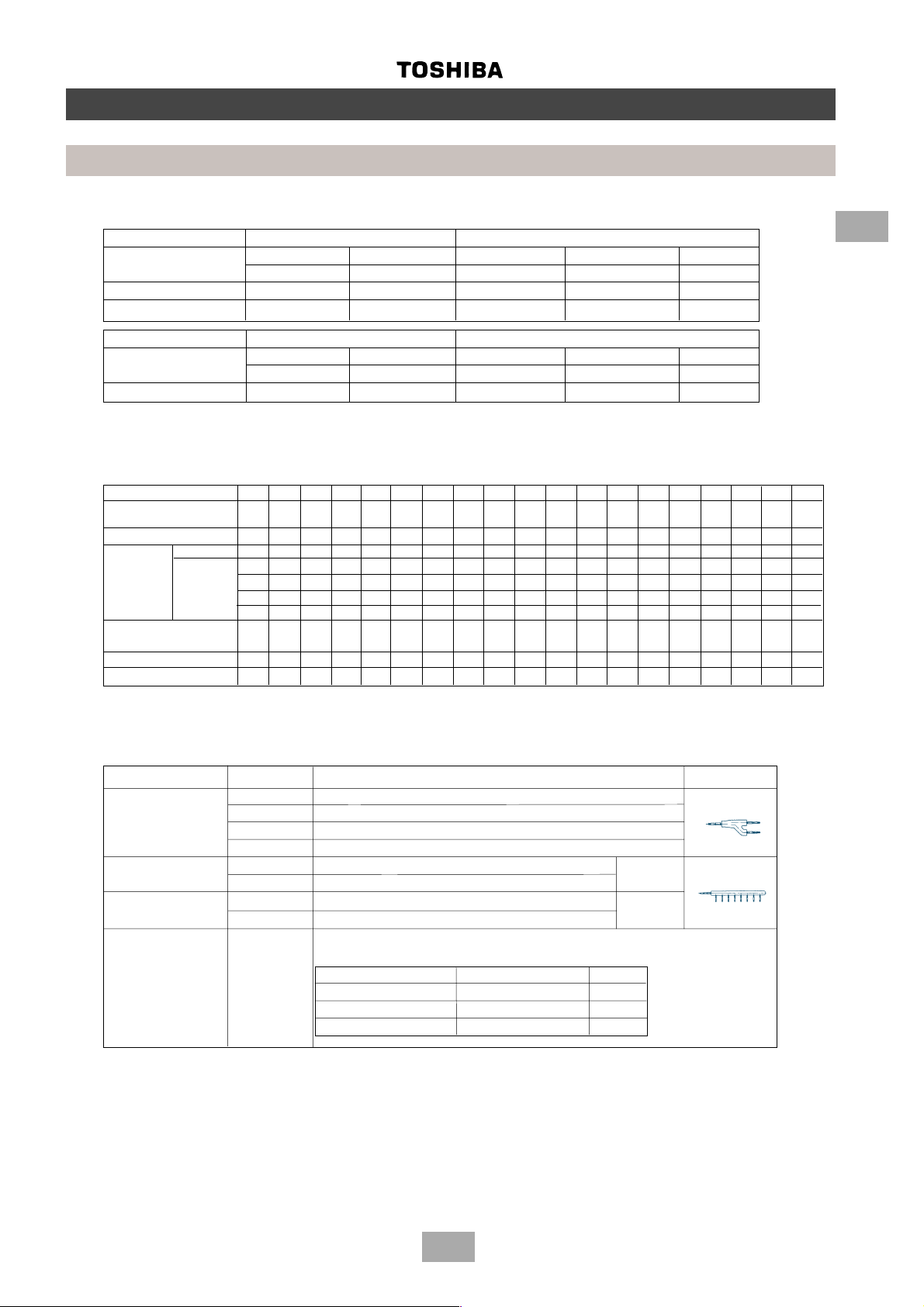

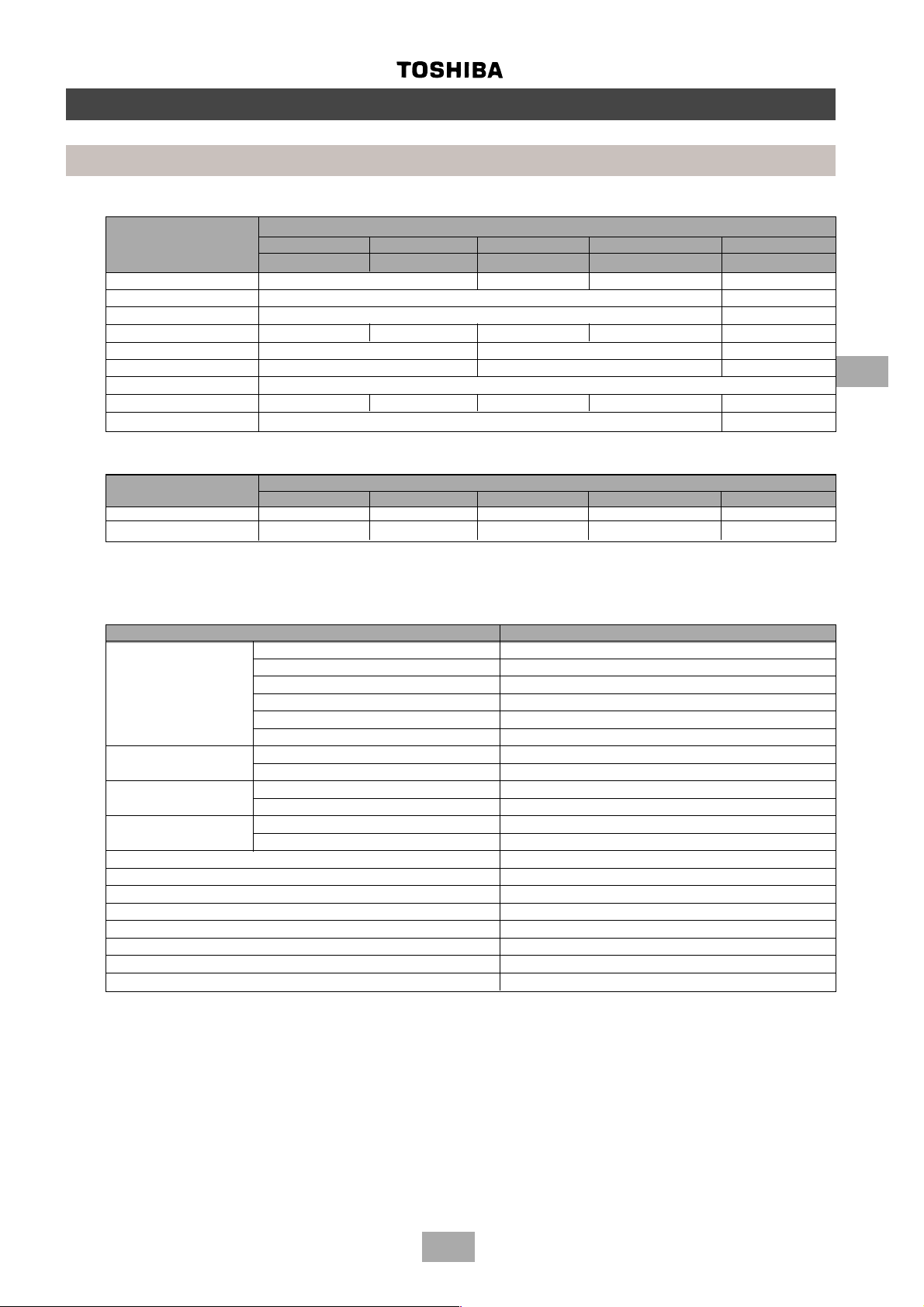

1. Outdoor unit

Corresponding HP Inverter unit Fixed-speed unit

8 HP 10 HP 6 HP 8 HP 10 HP

Model name MM-A0224HT MM-A0280HT MM-A0160HX MM-A0224HX MM-A0280HX

Cooling capacity (kW) 22.4 28.0 16.0 22.4 28.0

Heating capacity (kW) 25.0 31.5 18.0 25.0 31.5

Corresponding HP Inverter unit Fixed-speed unit

8 HP 10 HP 6 HP 8 HP 10 HP

Model name MM-A0224CT MM-A0280CT MM-A0160CX MM-A0224CX MM-A0280CX

Cooling capacity (kW) 22.4 28.0 16.0 22.4 28.0

2. Outdoor units (combination of outdoor units)

Corresponding HP 8HP 10HP 14HP 16HP 18HP 20HP 22HP 24HP 26HP 28HP 30HP 32HP 34HP 36HP 38HP 40HP 42HP 44HP 46HP

Combined model

MM-A-HT/MM-A-CT 0224 0280 0384 0440 0504 0560 0608 0672 0728 0784 0840 0896 0952 1008 1064 1120 1176 1232 1288

Cooling capacity (kW) 22.4 28.0 38.4 44.8 50.4 56.0 60.8 67.2 72.8 78.4 84.0 89.6 95.2 100.8 106.4 112.0 117.6 123.2 128.8

Combined Fixed-speed - - 6HP 8HP 8HP 10HP 8HP 8HP 8HP 10HP 10HP 8HP 8HP 10HP 10HP 10HP 8HP 10HP 10HP

outdoor units unit - -----6HP8HP8HP8HP10HP 8HP 8HP 8HP 10HP 10HP 8HP 8HP 10HP

No. of connectable

indoor units 13 16 16 18 18 20 22 2 4 26 28 30 32 34 36 38 40 40 40 40

Min. HP connected 4 57891011121314151617181920212223

Max. HP connected 10.8 13.5 18.9 21.6 24.3 27 29.7 32.4 35.1 37.8 40.5 43.2 45.9 48.6 51.3 54 56.7 59.4 62.1

Inverter unit 8HP 10HP 8HP 8HP 10HP 10HP 8HP 8HP 10HP 10HP 10HP 8HP 10HP 10HP 10HP 10HP 10HP 10HP 10HP

-----------8HP8HP8HP8HP10HP 8HP 8HP 8HP

----------------8HP8HP8HP

1

3. Branching joints/headers

Model name Usage Appearance

Y -shape branching joint RBM-Y018-SK Indoor unit capacity code (*1): Total < 6.4

RBM-Y037-SK Indoor unit capacity code (*1): 6.4 = Total < 13.2 (*2)

RBM-Y071-SK Indoor unit capacity code (*1): 13.2 = Tot al < 25.2 (*2)

RBM-Y129-SK Indoor unit capacity code (*1): 25.2 = Total (*2)

4-branching header (*3) RBM-H4037-SK Indoor unit capacity code (*1): Total < 6.4 Max. 4

RBM-H4071-SK Indoor unit capacity code (*1): 6.4 = Total < 13.2 branches

8-branching header (*3) RBM-H8037-SK Indoor unit capacity code (*1): Total < 6.4 Max. 8

RBM-H8071-SK Indoor unit capacity code (*1): 6.4 = Total < 13.2 branches

T-shape branching joint 1 set of 3 types of T-shape joint pipes as described below .

(For connection of The required quantity is arranged and they are combined at the site.

outdoor unit) RBM-T129-SK

Connecting pipe Corresponding dia. (mm) Quantity

Balancing pipe 9.52 1

Piping at liquid side 12.7 to 22.2 1

Piping at gas side 22.2 to 54.1 1

(*1) Code is determined according to the capacity code of the Indoor units connected.

(*2) If the total capacity code value of Indoor units exceeds that of Outdoor units, apply the capacity code of Outdoor units.

(*3) When using a branch header, Indoor units with a maximum of 6.0 capacity code in total can be connected to each

branch.

NOTE: If the length of the gas pipe exceeds 30m from the 1st branching to an Indoor unit, increase the gas pipe size by

1 size, i.e. MM-U140 = Gas Ø22.2, Liquid Ø9.5

7

Page 8

Summary

Operating conditions

• The units referred to within this manual conform with the protection requirements of Directives 89/336/EEC

Electromagnetic Compatibility and 73/23/EEC Low voltage.

• Operating conditions of the unit are as follows:

2

Note 1: Cooling capacity is rated at the following temperature conditions:

Indoor air inlet temperature 27°C DB, 19°C WB.

Outdoor air inlet temperature 35°C DB.

Note 2: Heating capacity is rated at the following temperature conditions:

Indoor air inlet temperature 20°C DB.

Outdoor air inlet temperature 7°C DB, 6°C WB.

Note 3: For details about the Outdoor unit, Indoor units or Remote Controller installation refer to the relevant literature, i.e.

Installation Instructions supplied with the units.

Note 4: Operatives handling refrigerants must be suitably qualified in accordance with local and national codes of practice

and statutory requirements.

Note 5: Legislation may regulate the removal of waste refrigerant from the systems. We advise awareness of any

regulations and duty of care. Waste refrigerant must NEVER be discharged to atmosphere.

Note 6: Electrical work should be in accordance with all relevant codes of practice and should be carried out by suitably

qualified personnel.

Outdoor temperature -5 ~ 43°C Cooling

-15 ~ 21°C Heating

Room temperature 18 ~ 32°C Cooling

15 ~ 29°C Heating

Room humidity <80% Cooling

Note 7: Metric/Imperial pipe conversion.

Diameter (mm) 6.4 9.5 12.7 15.9 19.0 2.0 28.6 34.9 41.3 54.1

Nominal diameter (inch) 1/4 3/8 1/2 5/8 3/4 7/8 1-1/8 1-3/8 1-5/8 2-1/8

Note 8: Within this manual:

ODU = Outdoor Unit IDU = Indoor Unit

R/C = Remote Controller D.O.L. = Direct On-Line compressor

INV = Inverter ODU FIX = Fixed-speed ODU

DB = Dry Bulb WB = Wet Bulb

Mg-Sw = Magnetic Contactor IOL = Inner Overload Relay

OCR = Over Current Relay IGBT = Inverter Gate Bi-Polar Transistor

Note 9: MPaG

1.0 MPaG = 10.2 kgf/cm

⇒ kgf/cm

2

G conversion multiplier

2

G

8

Page 9

1. Model name

OUTDOOR

MM-A0280HT

Summary

Operating conditions

2

INDOOR

A – Outdoor 0280 – 28 kW (10 HP) C - Cooling T – Inverter

Modular Multi

MM-TU056

B - Built-In Duct Type

C (CR) - Ceiling Type (IR Remote) 028 – 2.8 kW (1 HP)

Modular Multi

K (KR) - High Wall Type (IR Remote) 042 – 4.2 kW (1.5 HP)

N - Chassis Type 056 – 5.6 kW (2 HP)

S (SR) - Low Wall Type (IR Remote) 080 – 8.0 kW (3 HP)

SB - Built-In Slim Duct Type 112 – 12.2 kW (4 HP)

TU - 2-way Cassette Type 140 – 14.0 kW (5 HP)

U - 4-way Cassette Type

0224 – 22.4 kW (8 HP H - Heating X – Fixed-speed

0160 – 16.0 kW (6 HP)

2. Range of combined units

No. of combined units : 1 to 5 units

Capacity range : Equivalent to 38.4 kW type (14HP) to 128.8 kW (46HP)

3. Restriction for combination units

(1) The Inverter Unit should have the maximum capacity among all units in that combination.

(2) The 16.0 kW (6HP) fixed-speed unit is available only with the combination of 38.4 kW (14HP) and 60.8 kW

(22HP). (It cannot be used for any other combination.)

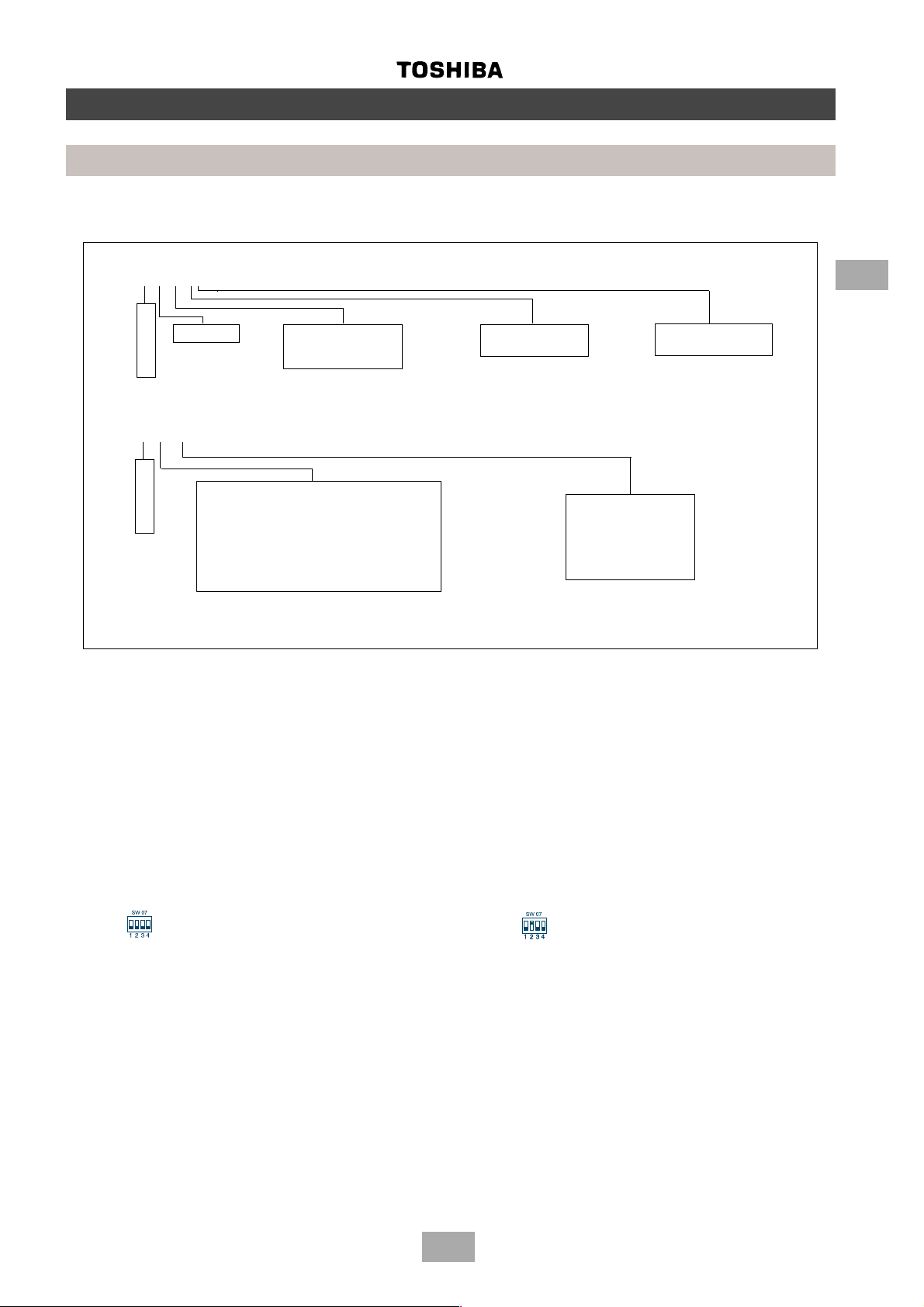

4. Mode priority

This Outdoor Unit is set to operate with the Heating mode taking precedence. This precedence can be switched

between Heat and Cool mode using the DIP switch 07 on the Outdoor Unit Interface PCB (MCC-1343-01) as follows:

ON

OFF

Heat priority (factory set) Cool priority

ON

OFF

9

Page 10

3

Outline of MMS (Modular Multi System)

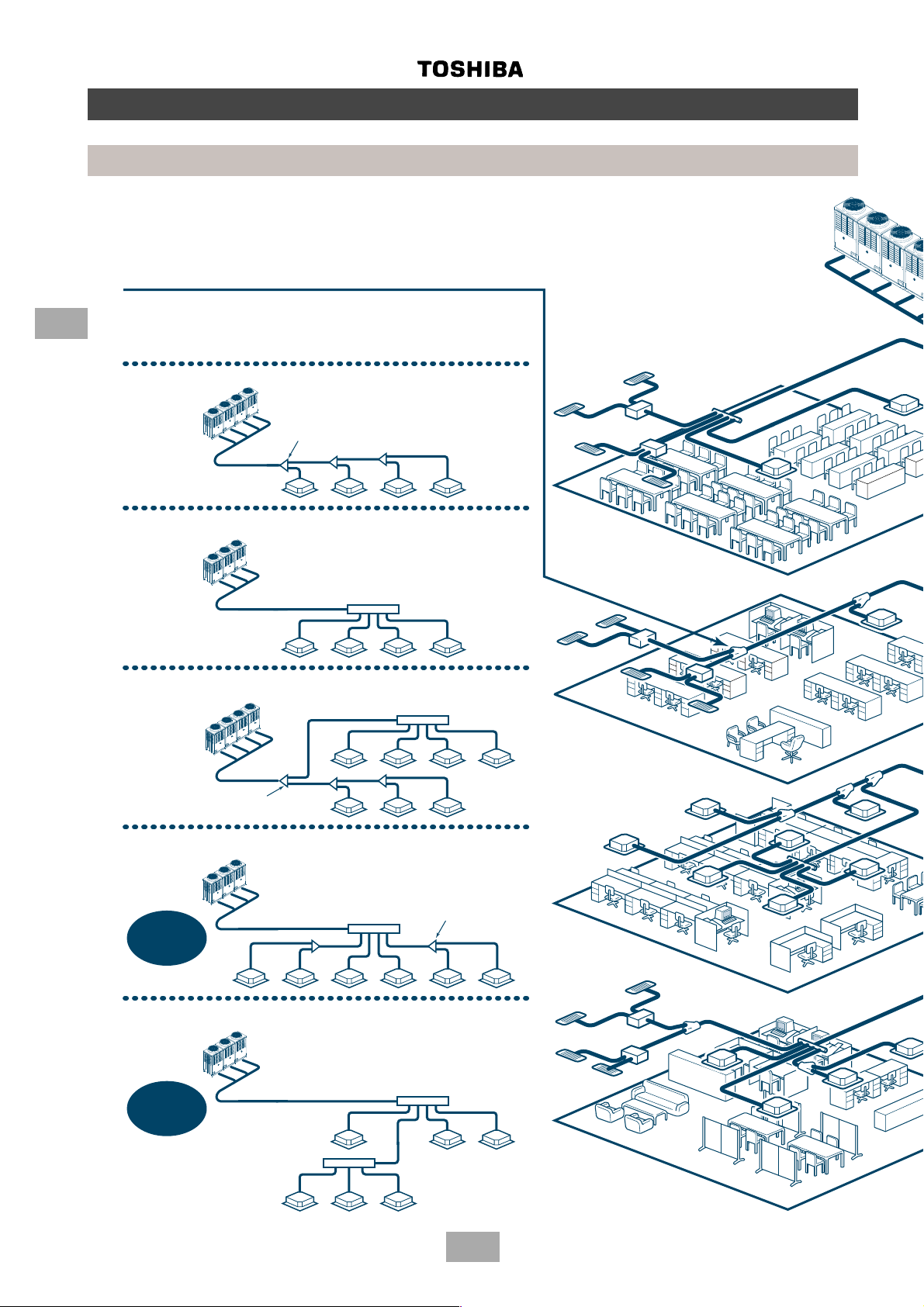

• Branching

Combination of line and header branching is highly flexible. This allows for the

shortest design route possible, thereby saving on installation time and cost.

Line/header branching after header branching is only available with Toshiba’s

Multi Modular System.

Line branching

Outdoor unit

Branching joint

Indoor unit

Header branching

Outdoor unit

Indoor unit

Line and header branching

Outdoor unit

Branching joint

Indoor unit

Line branching after header branching

Outdoor unit

MMS

ONLY

Branching

header

Header

Header

Branching joint

8F

7F

2F

Indoor unit

Outdoor unit

MMS

ONLY

Header

1F

Header

Indoor unit

10

Page 11

Outline of MMS (Modular Multi System)

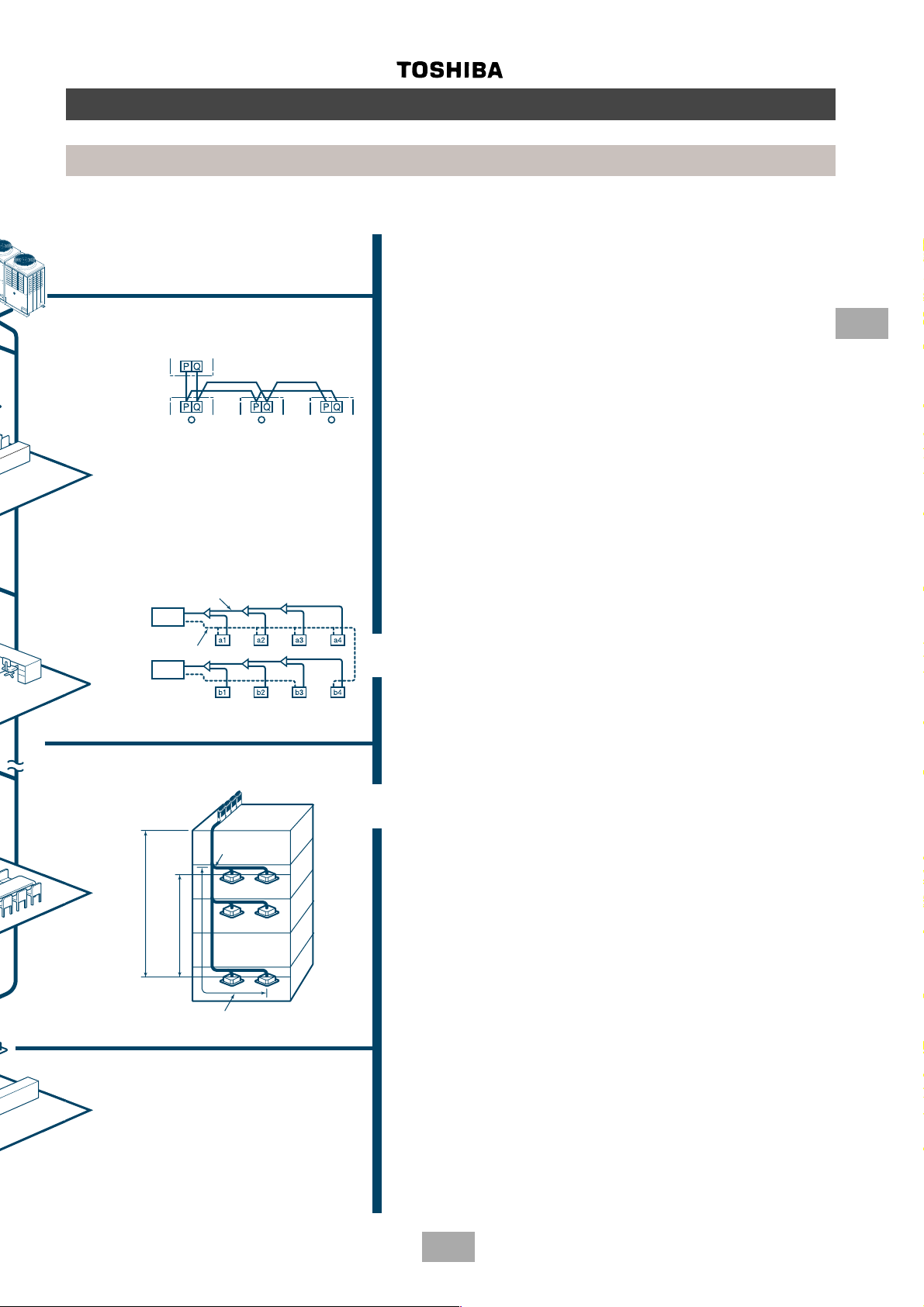

• Non-polarized control wiring between outdoor and

indoor units

Outdoor unit

Indoor unit

• Compact design

The design of the Toshiba MMS outdoor unit allows for

easy unit maneuvering into any standard lift. Its size also

allows it to be easily installed in limited spaces.

• Largest system capacity

Toshiba’s Multi Modular System can be combined up to

128.8 kW (46 HP).

3

• Wiring diagnosis system

[Example of wiring diagnosis]

Use the switches on the microcomputer PCB of the

outdoor unit.

• Detects wiring to the indoor unit b4 which should

not be in system A.

• b4 is missing in system B.

Piping

Outdoor

Circuit A

Circuit B

unit

Piping

Outdoor

unit

Allowable pipe length:

100 m real length

Outdoor unit

unit and outdoor unit: 50 m

Height difference between indoor

unit and outdoor unit: 30 m

Height difference between indoor

(Equivalent to 125 m)

1st branching

section

Indoor unit

• Advanced bus communication system

Wiring between indoor and outdoor unit is a simple 2wire system.

Communication address is also automatically configured.

A default test mode operation is available.

• Self diagnostic system

Comprehensive troubleshooting code enables quick

identification of problems arising.

• High lift design

Real pipe length of 100m (equivalent length 125m) and

vertical lift of 50m is made possible with Toshiba’s Multi

Modular System.

Vertical lift between indoor units of 30m is the highest in

the market.

This allows for greater flexibility in the location of the

system.

• Multiple indoor units

Indoor units with different capacities and configurations

can be combined up to 135% of the outdoor unit capacity.

A maximum of 40 indoor units can be combined with the

46 HP outdoor module.

• Intelligent control

Toshiba’s MMS intelligent controls and modulating

valves deliver the required capacity, according to the

load variation from 50% to 100%.

The intelligent controls and modulating valves limit or

increase the cooling/heating capacity dynamically so

humidity and temperature are kept in the comfort zone.

From 1st branching to the

farthest indoor unit: 50 m

11

Page 12

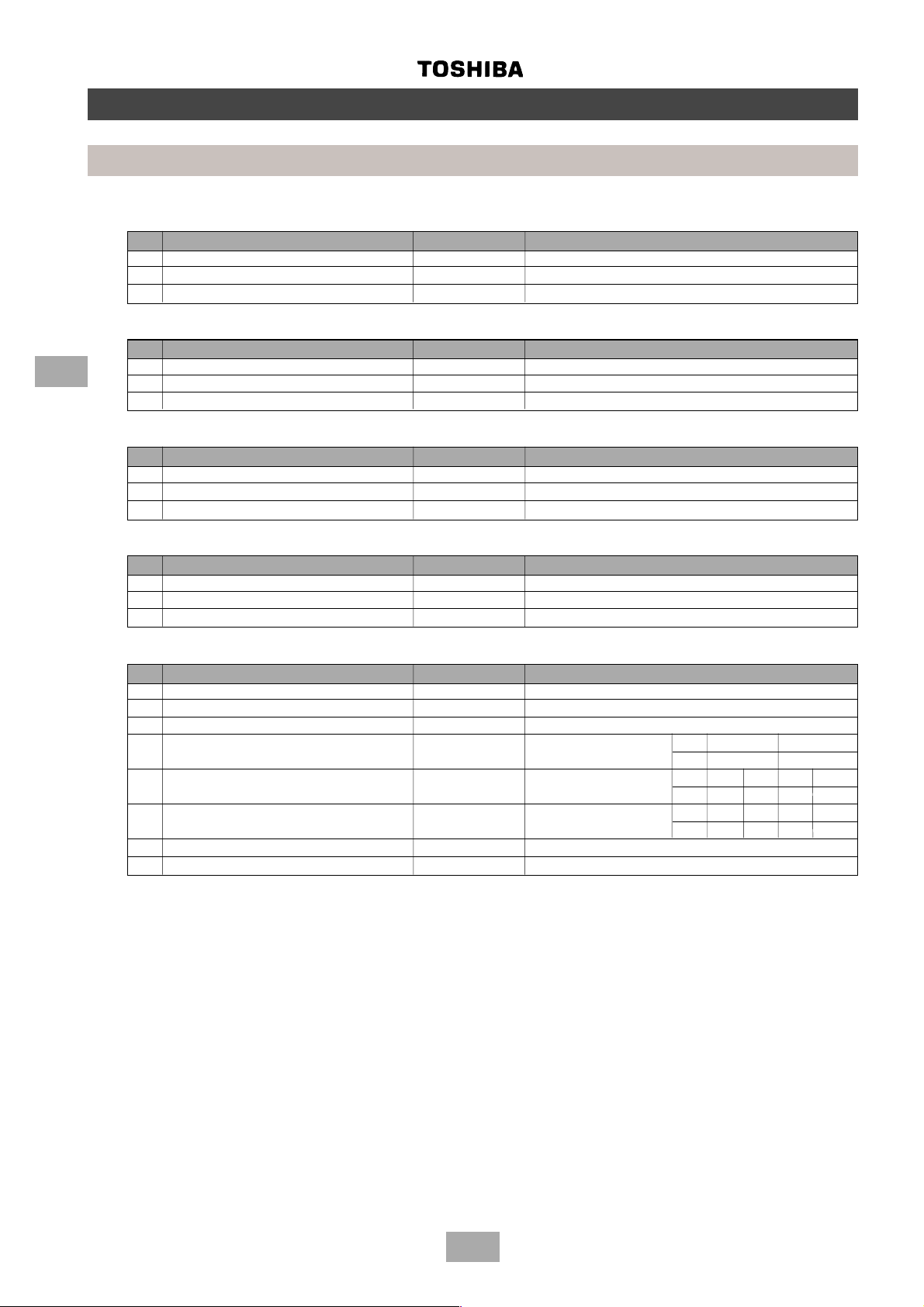

Parts specifications

Indoor units

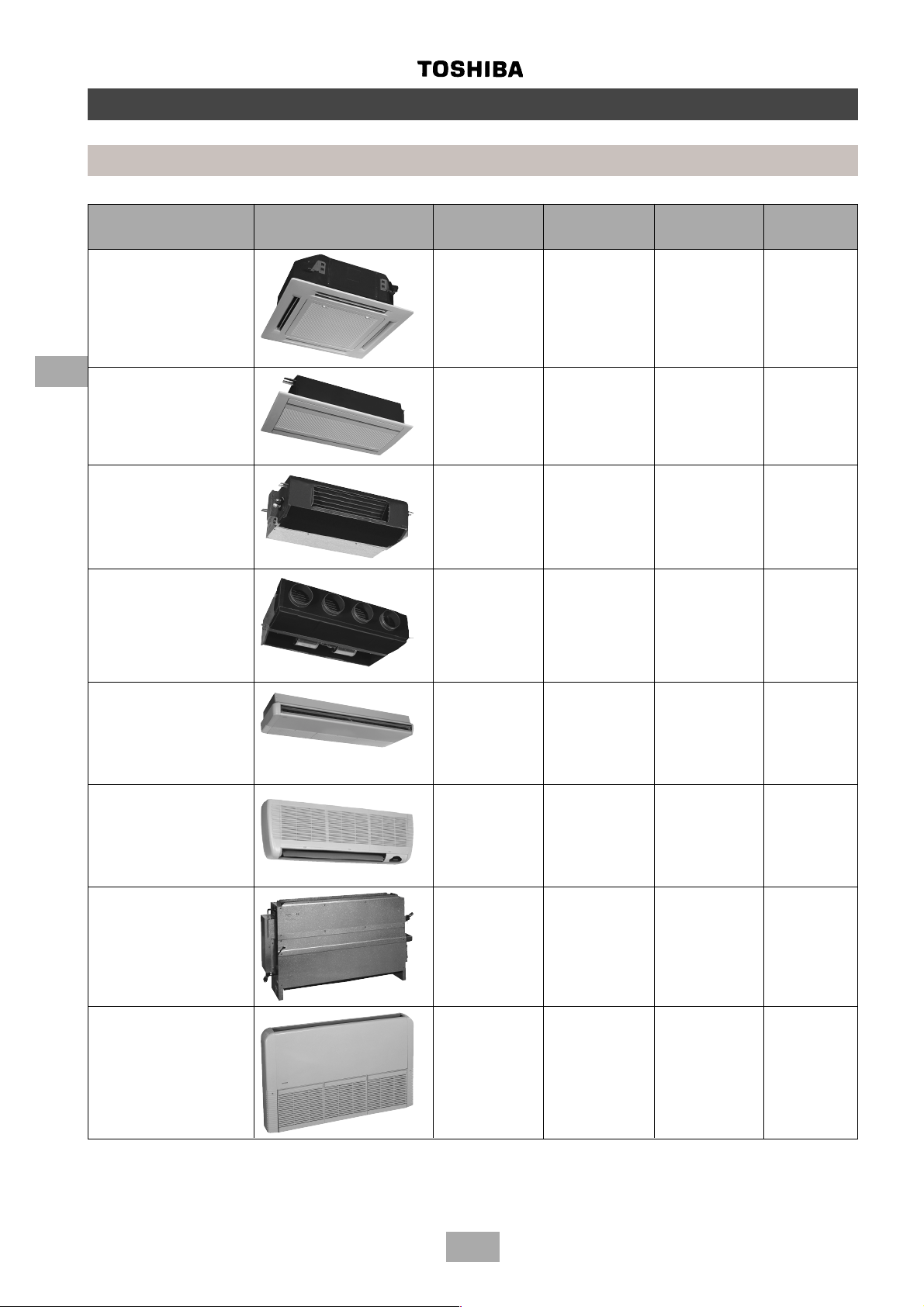

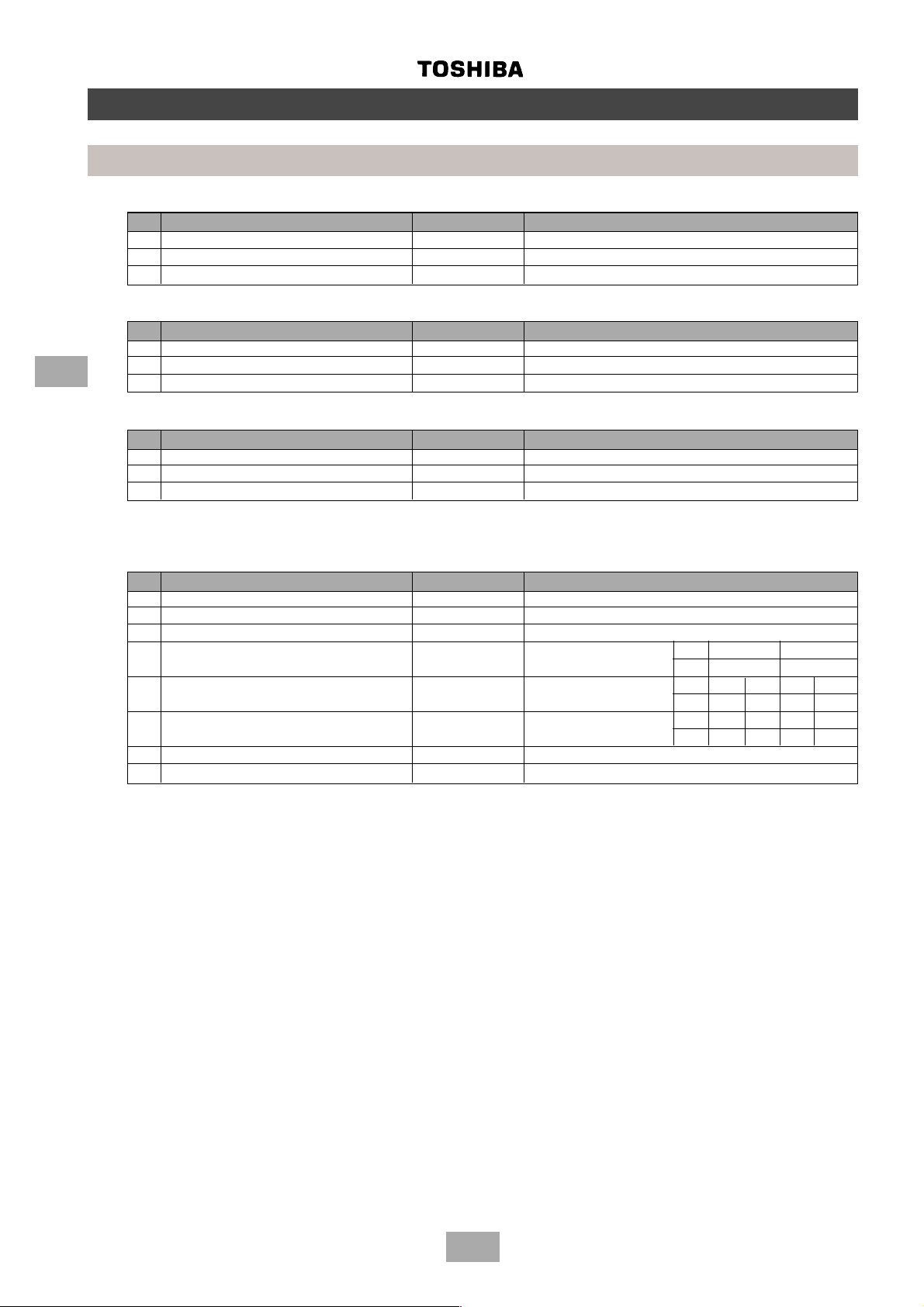

Type Appearance Model name Capacity code Cooling Heating

capacity (kW) capacity (kW)

4-Way Cassette MM-U056 2 5.6 6.4

Type ‘U’ MM-U080 3 8.0 9.6

MM-U112 4 11.2 12.8

MM-U140 5 14.0 15.8

4

2-Way Cassette MM-TU028 1 2.8 3.2

Type ‘TU’ MM-TU042 1.5 4.2 4.8

MM-TU056 2 5.6 6.4

Built-In Slim Duct MM-SB028 1 2.8 3.2

Type ‘SB’

Built-In Duct MM-B056 2 5.6 6.4

Type ‘B’ MM-B080 3 8.0 9.6

MM-B112 4 11.2 12.8

MM-B140 5 14.0 15.8

Ceiling MM-C/CR042 1.5 4.2 4.8

Type ‘C’ MM-C/CR056 2 5.6 6.4

MM-C/CR080 3 8.0 9.6

MM-C/CR112 4 11.2 12.8

MM-C/CR140 5 14.0 15.8

High Wall MM-K/KR042 1.5 4.2 4.8

Type ‘K’ MM-K/KR056 2 5.6 6.4

MM-K/KR080 3 8.0 9.6

Chassis MM-N028 1 2.8 3.2

Type ‘N’ MM-N042 1.5 4.2 4.8

MM-N056 2 5.6 6.4

MM-N080 3 8.0 9.6

Low Wall MM-S/SR056 2 5.6 6.4

Type ‘S’ MM-S/SR080 3 8.0 9.6

12

Page 13

Parts specifications

Outdoor units

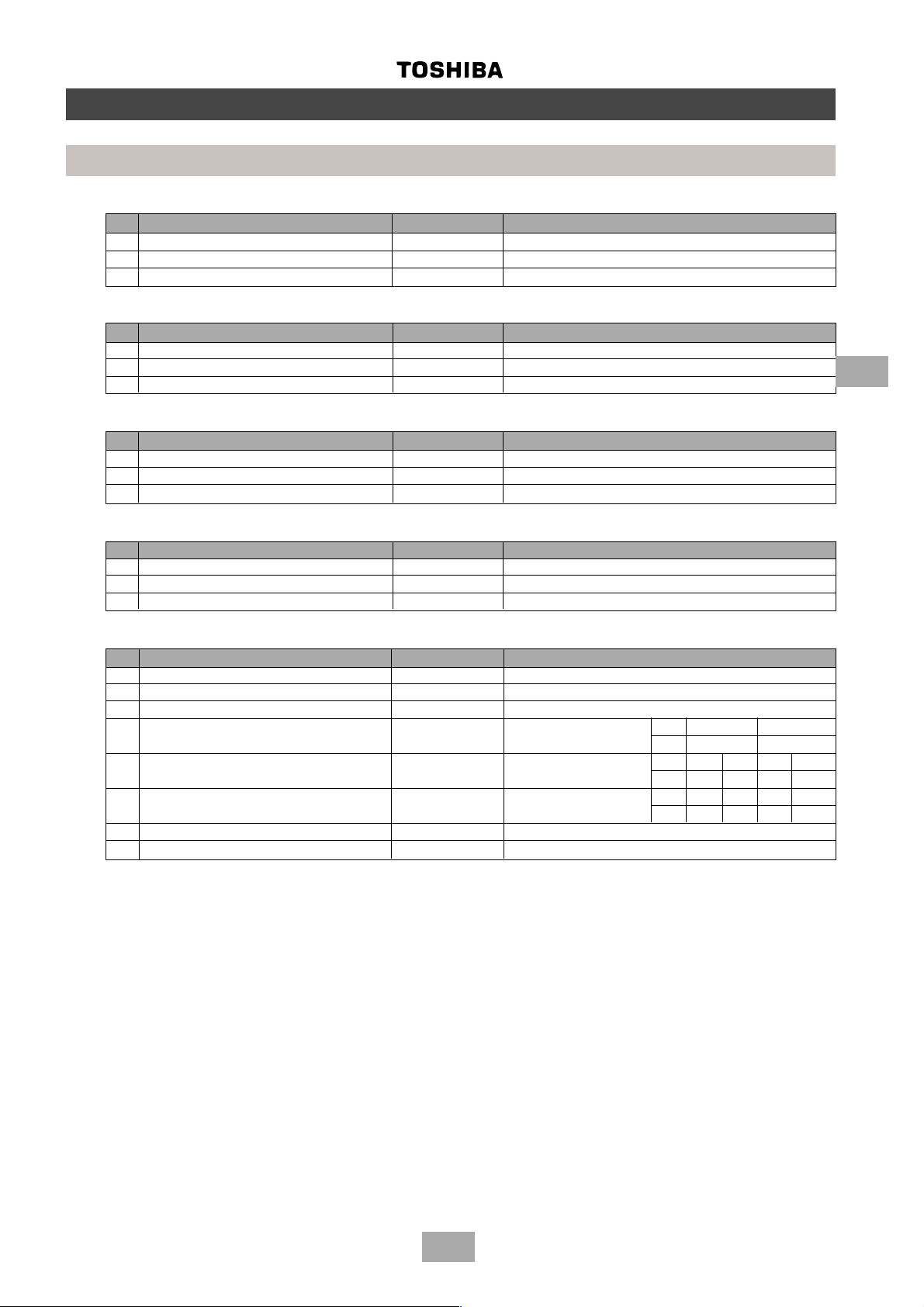

COMPRESSOR MODEL

MM-A0280HT MM-A0224HT MM-A0280HX MM-A0224HX MM-A0160HX

MM-A0280CT MM-A0224CT MM-A0280CX MM-A0224CX MM-A0160CX

Model name MG1450CW-21B YG1800CW-B1 YG1700CW-B1 YG890C-B1

Motor type 3-phase induction motor

Power supply 380-415 V, 3 ph, 50 Hz

Output (kW) 7.5 7.5 7.5 6.0 4.1

Pole (P) 2/2 (INV ./Fixed) 2/2 (Fixed/Fixed) 2

Coil resistance (Ω) 1.18/2.25 (INV./Fixed) 2.25/2.25 (Fixed/Fixed ) 2.250

Comp. oil name NISSEKI RB74AF VG 74

Amount of oil (ml) 7500 7500 7500 7500 2000

Inner overload relay Opens: 115±5°C Closes: 93±10°C

4-WA Y V ALVE MODEL

MM-A0280HT MM-A0224HT MM-A0280HX MM-A0224HX MM-A0160HX

Model name CHV-0712 CHV-0712 CHV-0712 CHV-0712 CHV-0401

Coil specification AC240V AC240V AC240V AC240V AC240V

4

MM-A0280HT, MM-A0224HT, MM-A0280HX, MM-A0224HX, MM-A0160HX

MM-A0280CT, MM-A0224CT, MM-A0280CX, MM-A0224CX, MM-A0160CX

PARTS NAME SPECIFICATION

Fan motor Model name STF-200-350A

Motor type 1-phase induction motor

Power supply AC 220 – 240 V. 1 phase, 50 Hz

Output (W) 400

Current (A) 4.81-5.89

Pole (P) 6

High pressure switch Model name INV = ACB-JB128 FIX = ACB-JA64

Operating pressure (mPa) Operation: 3.2 Reset: 2.55

High pressure sensor Model name 150NH4-H

Operating conditions (mPa) 0-3.33

Low pressure sensor Model name 150NH4-L

Operating conditions (mPa) 0-0.98

Compressor case heater (fixed-speed only) AC 240 V – 74 W

Accumulator case heater AC 240 V – 29 W

Discharge temperature sensor 18.1 kΩ at 50 °C – 3.35 kΩ at 100 °C

Suction temperature sensor 34.6 kΩ at 0 °C – 10.0 kΩ at 25 °C – 3.4 kΩ at 50 °C

Pulse modulating valve (heat pump unit only) L12A-03, DC 12 V

Pulse modulating valve (for cooling bypass) A12A-15, DC 12 V

2-way valve NEV-603DXF, coil 240 V

2-way valve NEV-202DXF, coil 240 V

13

Page 14

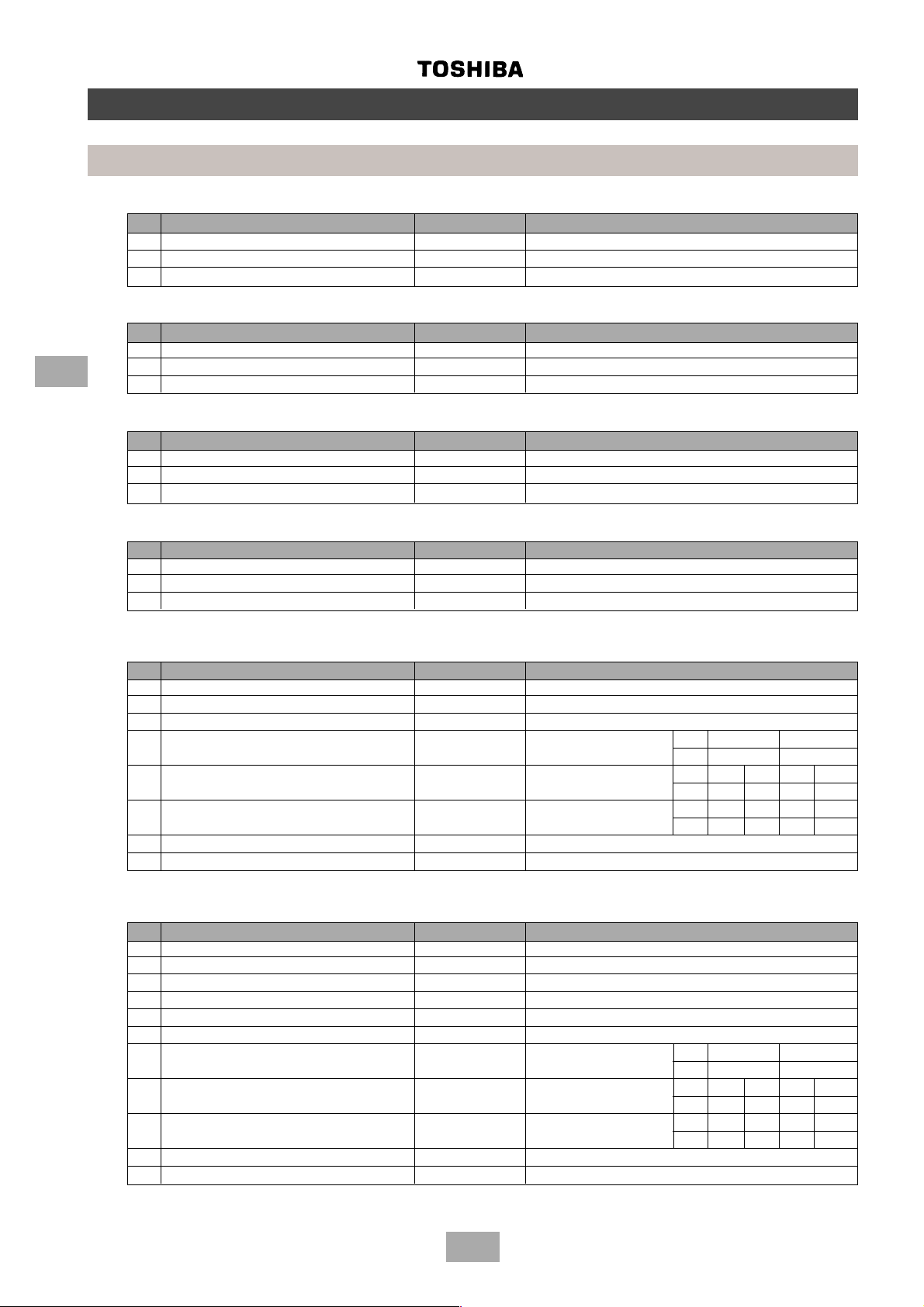

Built-In Duct: MM-B140

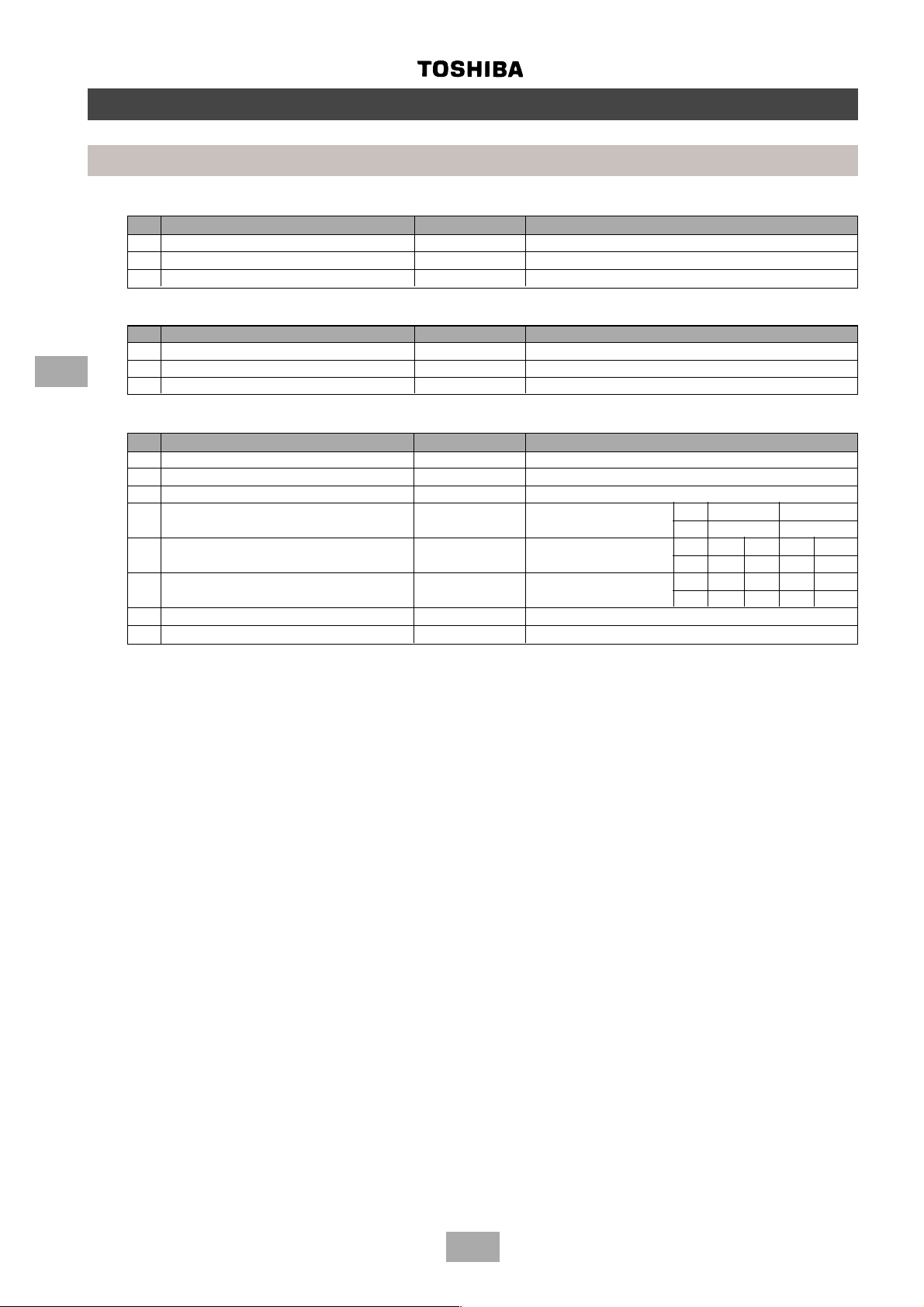

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor STF-200-140-4F Output (rated) 140 W, 4 pole, 200 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EAG40M106UF AC 400 V , 10 µF

3 Pulse motor valve EDM-B60YPTF-7B-A Capacity: 60

Built-In Duct: MM-B112

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor STF-200-120-4B Output (rated) 120 W, 4 pole, 200 V, 1 phase, 50 Hz

4

2 Running capacitor – Fan motor EAG40M505UF AC 400 V, 5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Built-In Duct: MM-B080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor STF-200-100-4B Output (rated) 100 W, 4 pole, 200 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EAG40M505UF AC 400 V, 5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Built-In Duct: MM-B056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor STF-230-60-4A Output (rated) 60 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2G405HQA114 AC 400 V, 4 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Parts specifications

Indoor units

Built-In Duct: MM-B140, MM-B112, MM-B080, M-B056

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C02 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

Built-In Duct: MM-SB028

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4J Output (rated) 34 W, 4 pole, 220 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 400 V , 1 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C02 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

14

Page 15

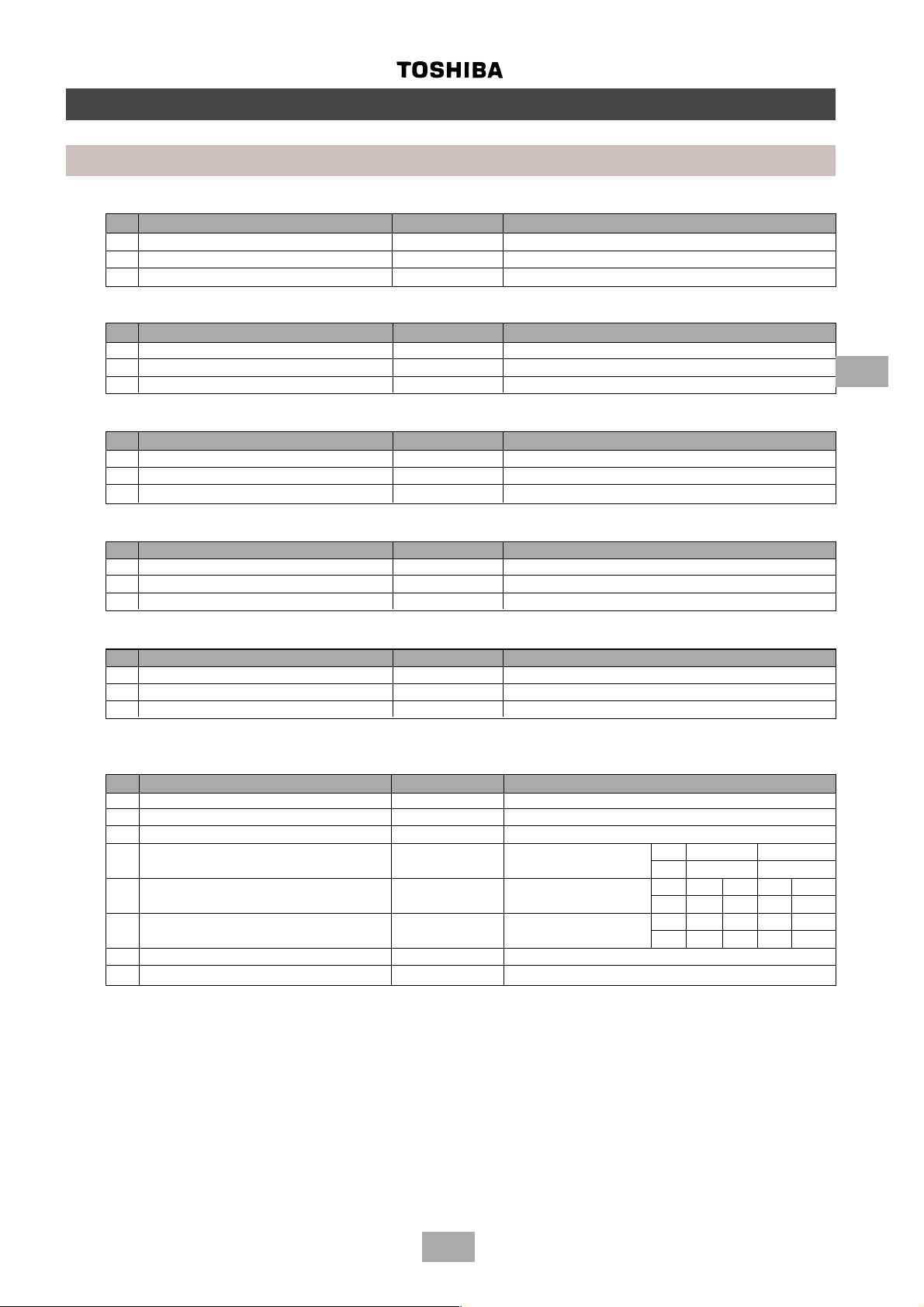

Parts Specifications

Indoor units

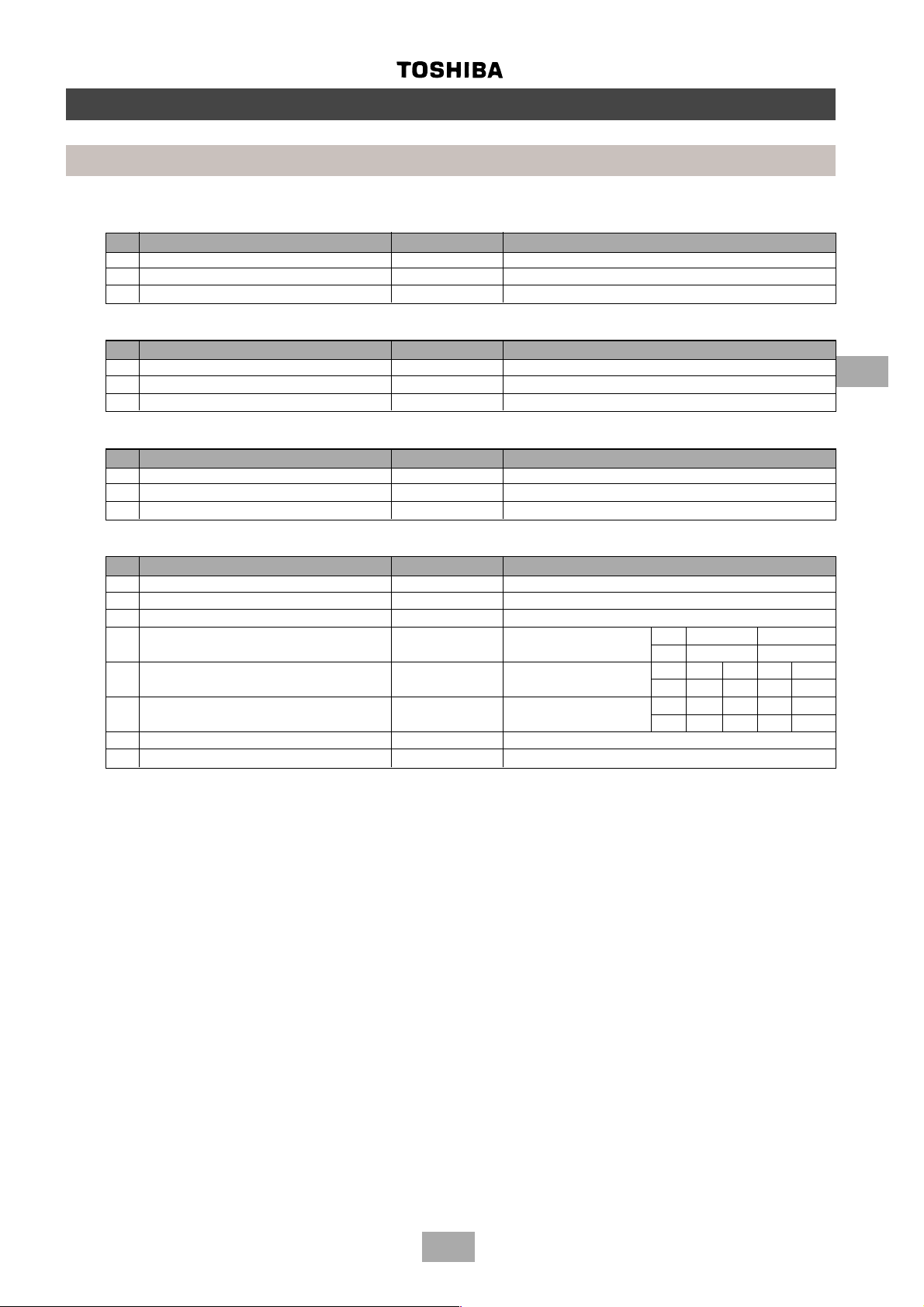

Ceiling: MM-C140, MM-CR140

No. PARTS NAME TIPO SPECIFICATIONS

1 Fan motor SMF-230-75-4B Output (rated) 75 W, 4 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2G405HQA114 AC 400 V , 4 µF

3 Pulse motor valve EDM-B60YPTF-7B-A Capacity: 60

Ceiling: MM-C112, MM-CR112

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-75-4U Output (rated) 75 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EVM45M305UF AC 450 V, 3 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Ceiling: MM-C080, MM-CR080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4D Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W255HQA113 AC 450 V, 2,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Ceiling: MM-C056, MM-CR056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4D Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W255HQA113 AC 450 V, 2,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

4

Ceiling: MM-C042, MM-CR042

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-34-4H Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 500 V, 1,5 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

Ceiling: MM-C140, MM-C112, MM-C080, MM-C056, MM-C042

MM-CR140, MM-CR112, MM-CR080, MM-CR056, MM-CR042

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C03 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

15

Page 16

High wall: MM-K080, MM-KR080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-27-4R Output (rated) 27 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W205HQA107 AC 400 V, 2 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

High wall: MM-K056, MM-KR056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-27-4P Output (rated) 27, 4 pole, 230 V , 1 phase, 50 Hz

4

2 Running capacitor – Fan motor EEP2H155HQA107 AC 400 V , 1,5 µF

3 Pulse motor valve EDM-B40YTR-7B-A Capacity: 40

High wall: MM-K042, MM-KR0042

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-27-4P Output (rated) 27 W , 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 400 V , 1 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

High wall: MM-K080, MM-KR080

MM-K056, MM-KR056

MM-K042, MM-KR042

Parts specifications

Indoor units

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT - 03 - 1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C03 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

16

Page 17

Parts specifications

Indoor units

Chassis: MM-N080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4O Output (rated) 34 W, 4 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H155HQA107 AC 500 V, 1,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Chassis: MM-N056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4D Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W205HQA107 AC 450 V, 2,0 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Chassis: MM-N042

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4H Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W205HQA107 AC 450 V, 2 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 25

Chassis: MM-N028

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4H Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H155HQA107 AC 500 V, 1,5 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

4

Chassis: MM-N080, NN-N056, MM-N042, MM-N028

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C02 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

17

Page 18

Parts specifications

Low wall: MM-S080, MM-SR080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4D Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W255HQA113 AC 450 V, 2,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Low wall: MM-S056, MM-SR056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor SMF-230-34-4D Output (rated) 34 W, 4 pole, 230 V, 1 phase, 50 Hz

4

2 Running capacitor – Fan motor EEP2W255HQA113 AC 450 V, 2,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

Low wall: MM-S080, MM-SR080, MM-S056, MM-SR056

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

10 Control PCB CM**C02 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

Indoor units

38 mA at 25 °C kΩ 10 3.45

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

26 mA at 25 °C kΩ 34.6 10 3.4

18

Page 19

Parts specifications

Indoor units

2-way cassette: MM-TU056

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor PAF-230-7-4 Output (rated) 7 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 500 V, 1 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

2-way cassette: MM-TU042

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor PAF-230-7-4 Output (rated) 7 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EVM45M504UF AC 500 V, 1 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

2-way cassette: MM-TU028

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor PAF-230-7-4 Output (rated) 7 W, 4 pole, 230 V, 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 500 V, 1 µF

3 Pulse motor valve EDM-B25YPTF-7B-A Capacity: 25

2-way cassette: MM-TU056, MM-TU042, MM-TU028

4

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT - 03 - 1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C01 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

19

Page 20

4-way cassette: MM-U140

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-36A Output (rated) 36 W, 6 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EVM45M305UF AC 450 V, 3 µF

3 Pulse motor valve EDM-B60YPTR-7B-A Capacity: 60

4-way cassette: MM-U112

No. PARTS NAME TYPE SPECIFICATIONS

4

1 Fan motor MMF-230-36A Output (rated) 36 W, 4 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W255HQA113 AC 450 V , 2,5 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

4-way cassette: MM-U080

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-28A Output (rated) 28 W, 6 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2W205HQA107 AC 450 V, 2 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

4-way cassette: MM-U056

Parts specifications

Indoor units

No. PARTS NAME TYPE SPECIFICATIONS

1 Fan motor MMF-230-28A Output (rated) 28 W, 6 pole, 230 V , 1 phase, 50 Hz

2 Running capacitor – Fan motor EEP2H105HQA105 AC 450 V , 1 µF

3 Pulse motor valve EDM-B40YPTR-7B-A Capacity: 40

4-way cassette: MM-U140, MM-U112, MM-U080, MM-U056

No. PARTS NAME TYPE SPECIFICATIONS

4 Transformer TT-03-1 DC 16.3 V – 0.5 A / AC 11.6 V – 0.15 A

5 Pulse motor EDM-MD12TF-3 DC 12 V

6 Pressure sensor 150/100NH6-D Power voltage DC 12 V

7 Sensor for room temperature T A Maximum input: °C 25 50

38 mA at 25 °C kΩ 10 3.45

8 Sensor for heat exchanger Tc1 Maximum input: °C -12 0 25 50

34 mA at 25 °C kΩ 62.3 32.8 10 3.6

9 Sensor for heat exchanger Tc2 Maximum input: °C 0 25 50

26 mA at 25 °C kΩ 34.6 10 3.4

10 Control PCB CM**C02 AC 220 – 240 V

11 Power PCB P**RC01 AC 220 – 240 V

20

Page 21

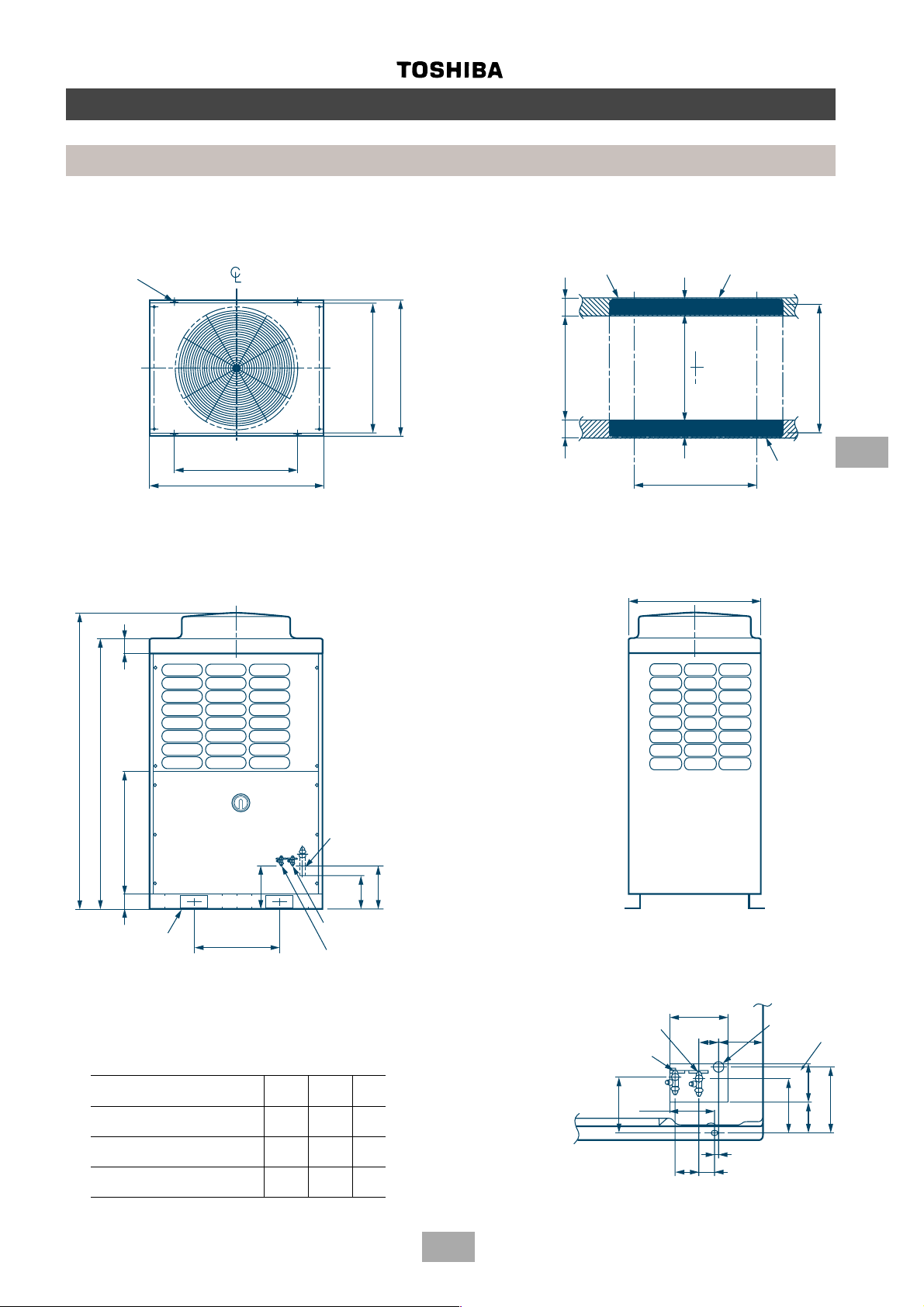

Construction views

Outdoor units

MM-A0280HT, MM-A0280HX, MM-A0224HT, MM-A0224HX, MM-A0160HX

MM-A0280CT, MM-A0280CX, MM-A0224CT, MM-A0224CX, MM-A0160CX

4 - 15 x 20 (slot)

Fixing bolt pitch

700

990

790

755

Fixing bolt pitch

(incluging fixed leg)

Grounding part of

bottom plate

610 100

100

Base

630 80

80

700

Fixing bolt pitch

Base bolt position

750

755

Fixing bolt pitch

5

Base

1700

1560

700 9088

245

2 - 60 x 150 slot

(for transport)

Note: All dimensions in mm

Model

MM-A0280HT, MM-A0280HX

MM-A0280CT, MM-A0280CX 28.6 12.7 9.52

MM-A0224HT, MM-A0224HX

MM-A0224CT, MM-A0224CX 22.2 12.7 9.52

MM-A0160HX

MM-A0160CX 22.2 9.52 9.52

500

(Slot pitch)

Balance pipe connecting

port flare connection (∅C)

∅∅

∅∅

∅A

∅B

∅∅

∅∅

mm mm mm

Refrigerant pipe connecting port

(Gas side) braze connection (∅A)

235

190

Refrigerant pipe connecting port

(Liquid side) flare connection (∅B)

∅∅

∅C

∅∅

Refrigerant pipe

connecting port

(liquid side)

Balance pipe

connecting port

145

Details of piping connections

(knock out)

130

65

173

35

60

20

115

Refrigerant pipe

connecting port

(gas side)

(knock out)

125

140

170

64

21

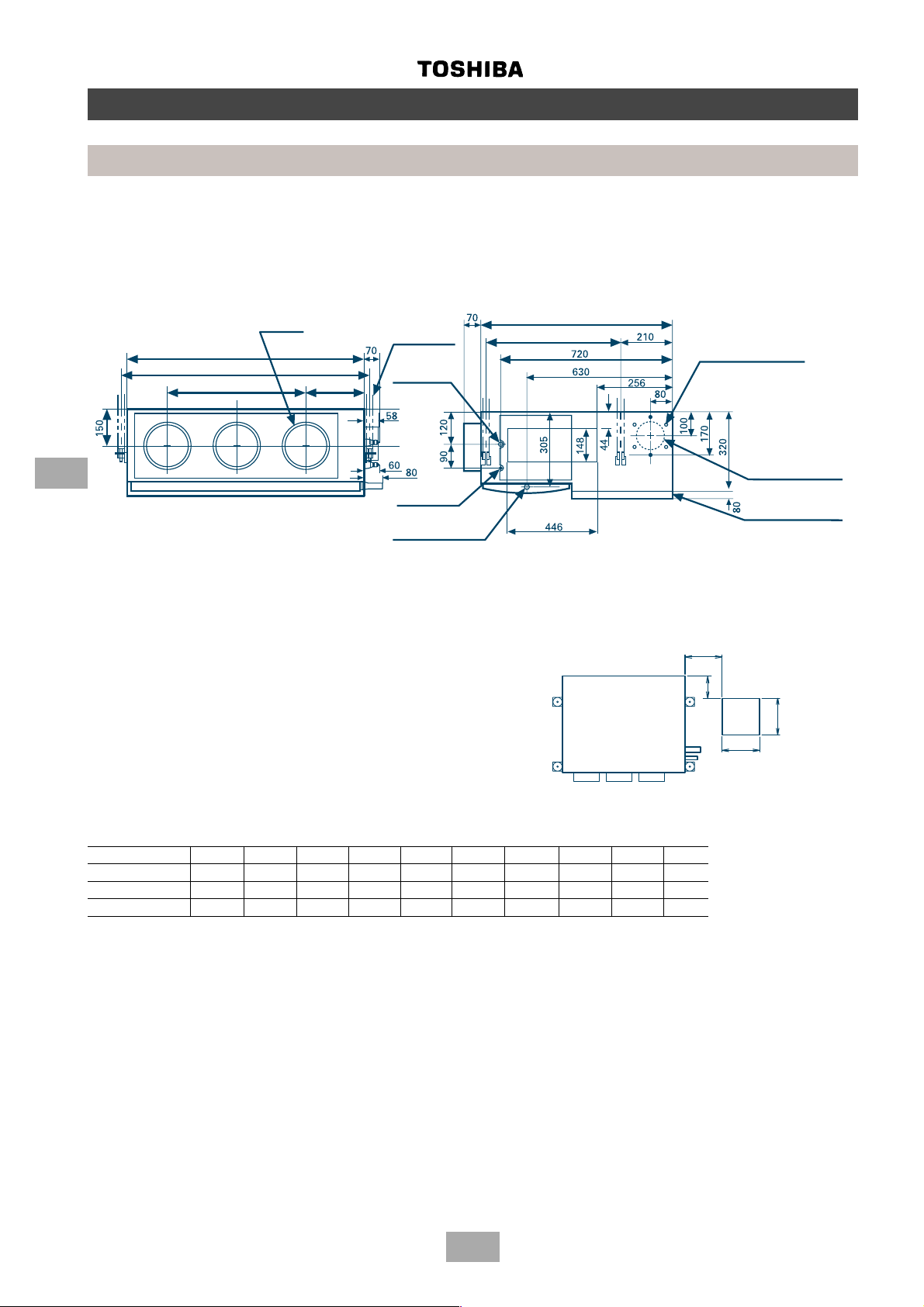

Page 22

200

450

450

300-400

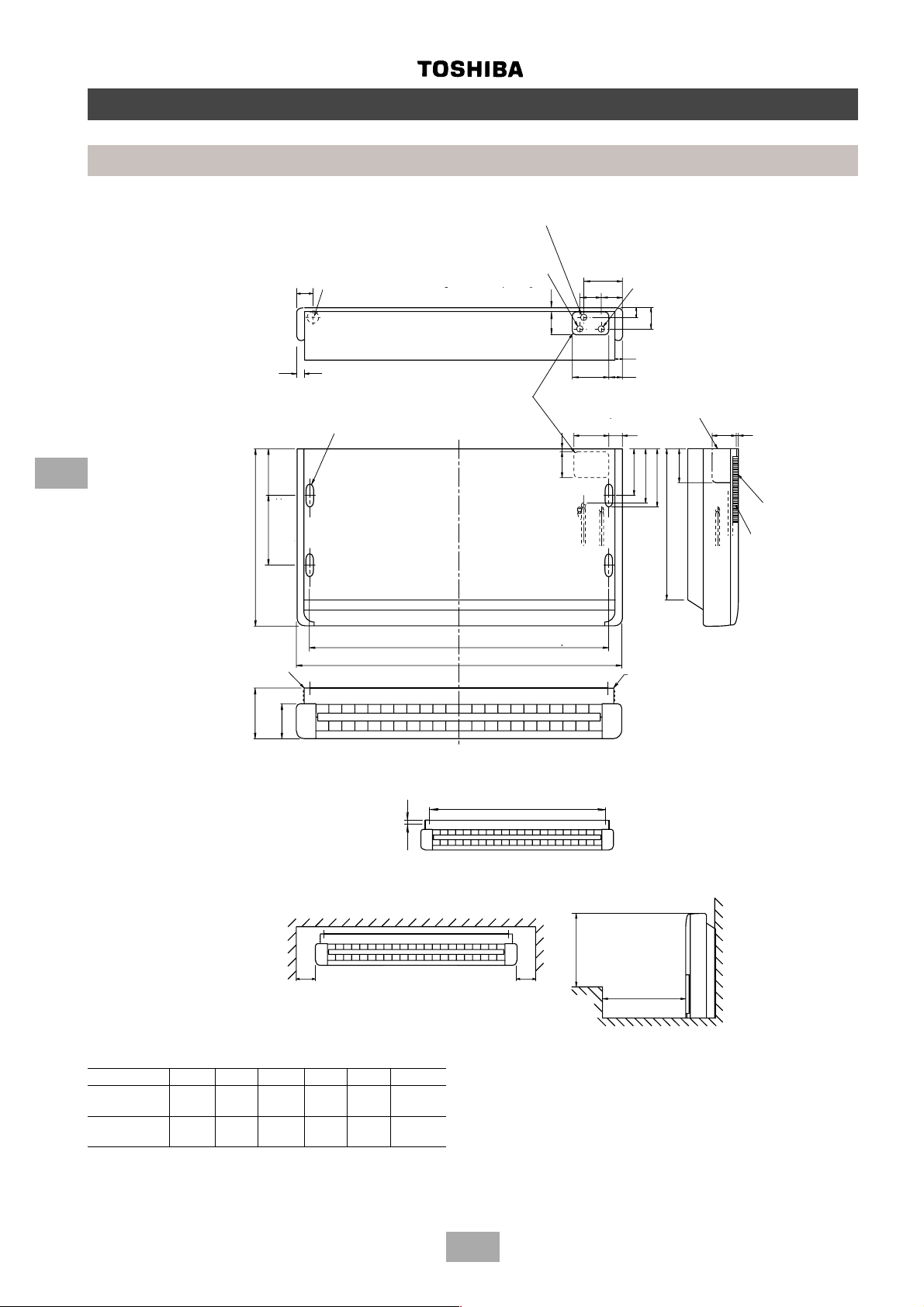

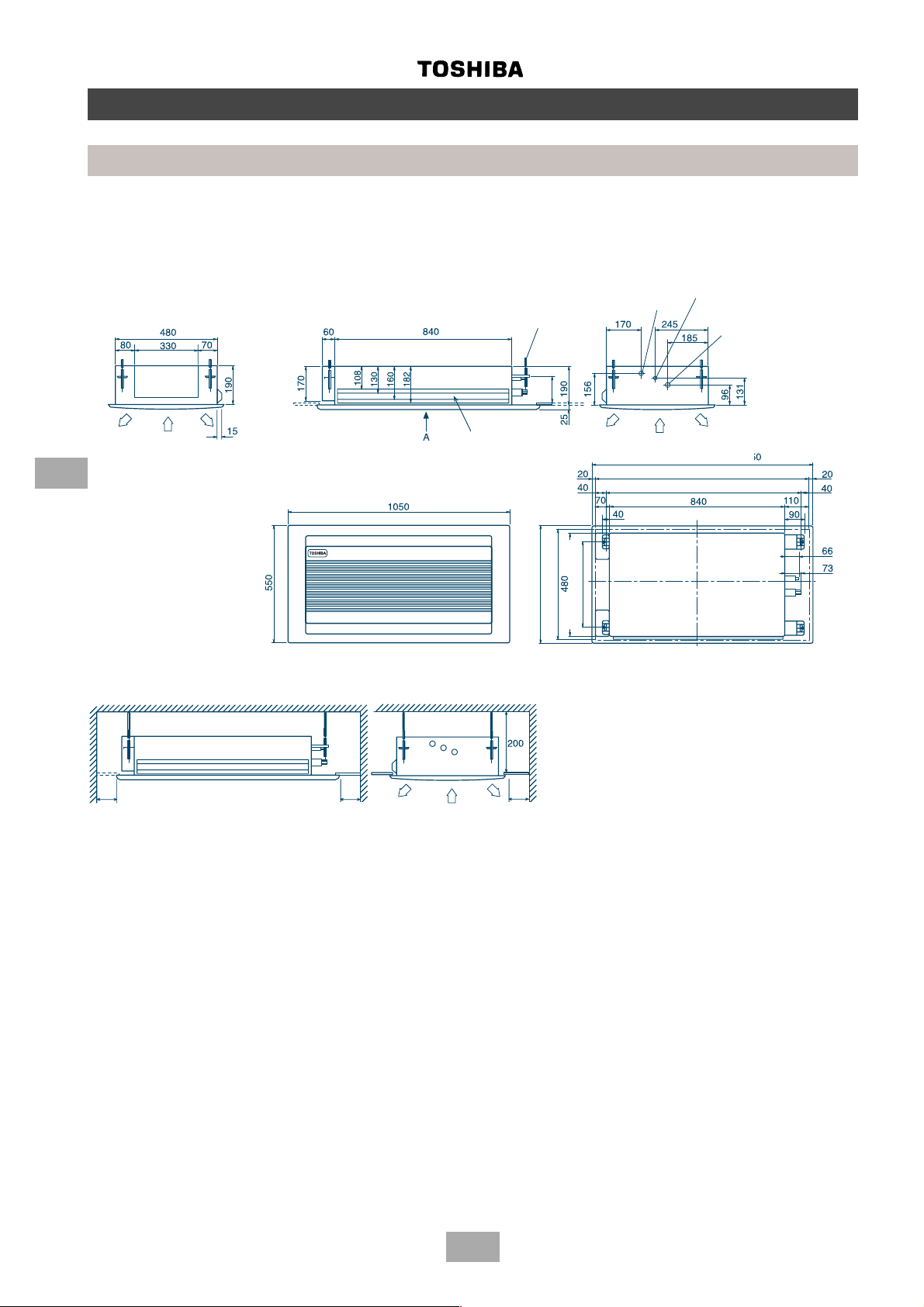

Built-In Duct

MM-B056, MM-B080, MM-B112, MM-B140

Construction views

Indoor units

6

A (Unit dimension)

B (Hanging bolt pitch)

J = M x K

N x ∅ 200

air outlet

Hanging bolt

4 - M10

provided at site

Refrigerant pipe

connection

(Gas ∅ F)

Refrigerant pipe

connection (liquid ∅ G)

Drain pipe connection

(Inner diameter: 32)

(Diameter 32 minimal for PVC pipes)

Hanging bolt pitch: 565

Unit dimension: 800

6 x ∅ 4 holes (∅160)

Fresh air inlet ∅ 125

cut-out (other side)

Filter kit

Ensure that there is sufficient space around the indoor

unit for installation and servicing

Indoor unit

Inspection hole

Model A B E

MM-B056 700 750 780 12.7 6.4 252 280 280 1 2

MM-B080 1000 1050 1080 15.9 9.5 252 580 290 2 3

MM-B112, B140 1350 1400 1430 19.0 9.5 252 930 310 3 4

(All dimensions in mm)

∅∅

∅F

∅∅

∅∅

∅GH J K M N

∅∅

Provide an inspection hole

in this position

22

Page 23

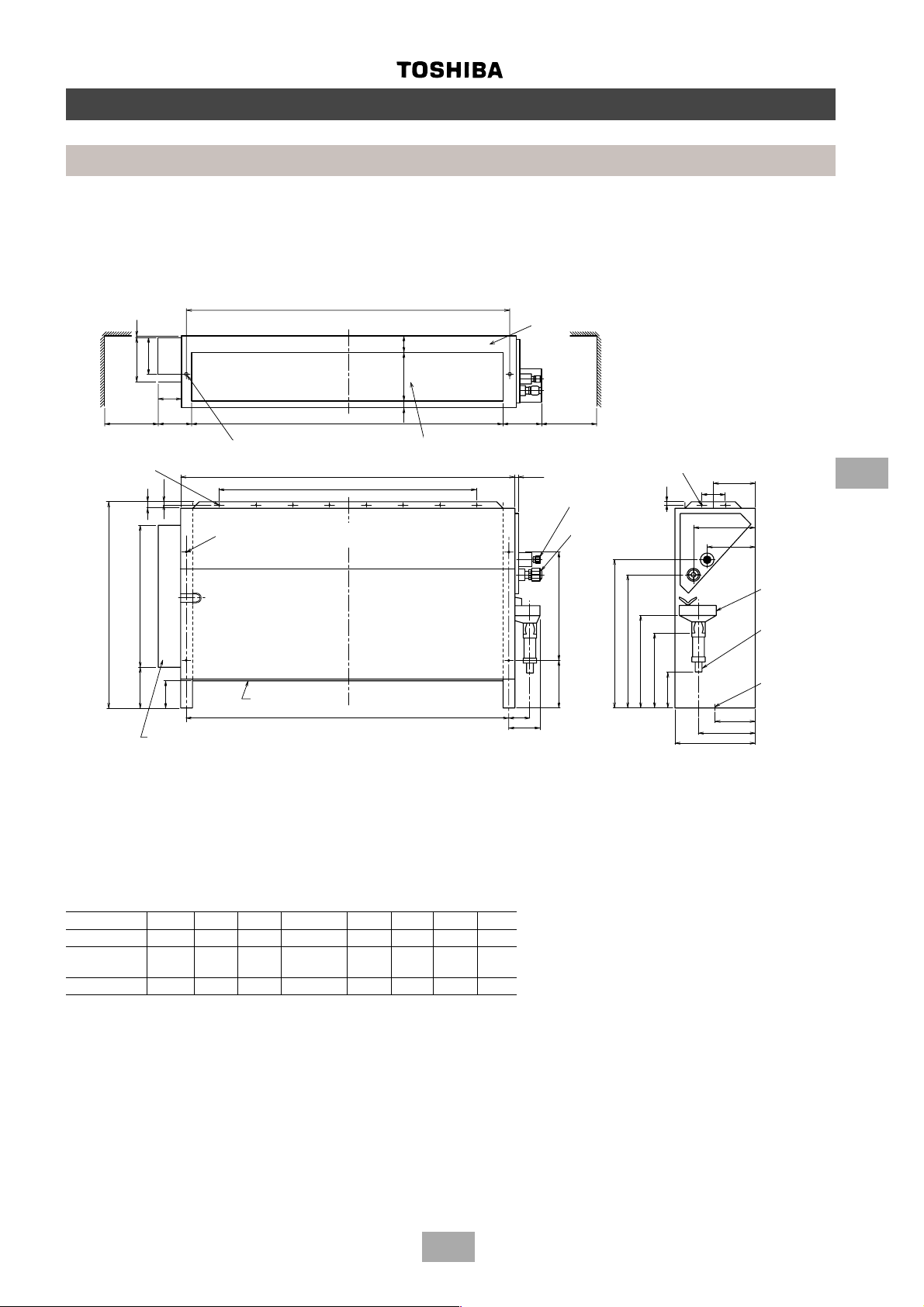

Built-In Slim Duct

MM-SB028

480

Refrigerant pipe

connection

(Liquid ∅ 6.4)

Construction views

Indoor units

220

265

276

331

35

Refrigerant pipe

connection

12

364

(Gas ∅ 12.7)

391

480

Drain pipe connection

(1” BSP threaded connection)

500

480

397

Hanging bolt pitch

Unit dimension

Washable filter

6

Air inlet

220

200

150

35

200

150

125

700

450

125

150150

342.5

150

800

750

700

Air outlet

57

Shelter board

333

Hanging bolt pitch

Unit dimensions

Filter

700

342.5

150

75

75

37.5

158

Electrical box

(PCB, transformer and MF capacitor)

45

Air flow

81

Filter

Air flow

Shelter board

Optional air flow (lower air inlet)

23

Page 24

Construction views

Indoor units

Low wall

MM-S056, MM-SR056

MM-S080, MM-SR080

6

HR-PE

640

sospensione

Hanging plate (Left)

Alternative knock-out

Foro incompleto

hole for drain piping

alternativo

62

per tubo drenaggio

30

Hanging bolt hole

4 - (12 x 25) slot

170

250

pitch

pitch

Hanging bolt

Hanging bolt

Raccordo tubo drenaggio

Tubo duro cloruro di vinile

Hard vinyl chloride pipe

diametro esterno mm. 20

outer dia. 20 mm

Collegamento tubo

Refrigerant pipe

refrigerante

connection (Liquid ∅ E)

Foro bullone di

sospensione Ð

Scanalatura 12x25 (4)

Drain piping joint

(Liquido ¿F)

Knock-out holes for

Fori incompleti

piping and wiring

per tubi e fili

Hanging bolt pitch

Passo bullone di sospensione

B

A

Collegamento tubo

Refrigerant pipe

145

refrigerante (Gas ¿G)

80

12

85

130

10

100

connection (Gas ∅ F)

80

34

78

30

50140

Right-side panel knock-

Foro incompleto pannello destro

out for piping and wiring

per tubi e fili

50

150

180

200

C

Piastra di sospensione

Hanging plate (Right)

(destra)

120

85

12

Air filter

Ingresso aria

Air inlet

Filtro aria

D

130

inferiore a 40

Hanging bolt

Less than 40

Bullone di sospensione

150

Minimum

Minimo

Space required for service and installation

Spazio necessario per installazione e manutenzione

Model A B C D ∅E ∅F

MM-S056

MM-SR056 1030 920 540 188 6.4 12.7

MM-S080

MM-SR080 580 581 582 583 584 585

All dimensions in mm

VISTA PIANO

PLAN VIEW

B

Passo bullone di sospensione interno

Hanging bolt pitch

400

150

Minimo

Minimum

Pi• di

Greater than

Pi• di

500

24

Page 25

Chassis

MM-N028, MM-N042, MM-N056, MM-N080

Space required for service and installation

20

140

160

65

150

Minimo

Foro Hx¯4.7

95

Fixing location to floor/base

10

20

Posizione di fissaggio

al pavimento/alla base

Foro ¯15 (4)

4 x ∅15 hole

Posizione di fissaggio alla parete

Fixing location to wall

Construction views

Indoor units

A

6014525

B

Uscita aria

Air outlet

C

D

t

Piastra superiore/Piastra condotto

Upper plate/duct plate

100 150

10

Minimo

Minimum

Flare joint

Raccordo a cartella

Liquid ∅ F

Liquido ¿F

Raccordo a cartella

Flare joint

Gas ¿G

Gas ∅ G

2 x ∅4.7 hole

Foro 2¯4.7

10

133

70

175

145

6

600

345

160

70

Centralina elettrica

Electrical box

Collegamento terra interno

Earth connection inside

Air filter

Filtro aria

Ingresso aria

Air intake

E

Model ABCD E∅F ∅GH

MM-N028 580 550 610 4 x 100 580 6.4 12.7 5

MM-N042

MM-N056 880 850 910 7 x 100 880 6.4 12.7 8

MM-N080 880 850 910 7 x 100 880 9.5 15.9 8

All dimensions in mm

Drain catch

315

436

397

274

224

140

65

95

104

230

155

110

Drain hose

connector

(OD ∅ 20)

Fixing location

to floor/base

25

Page 26

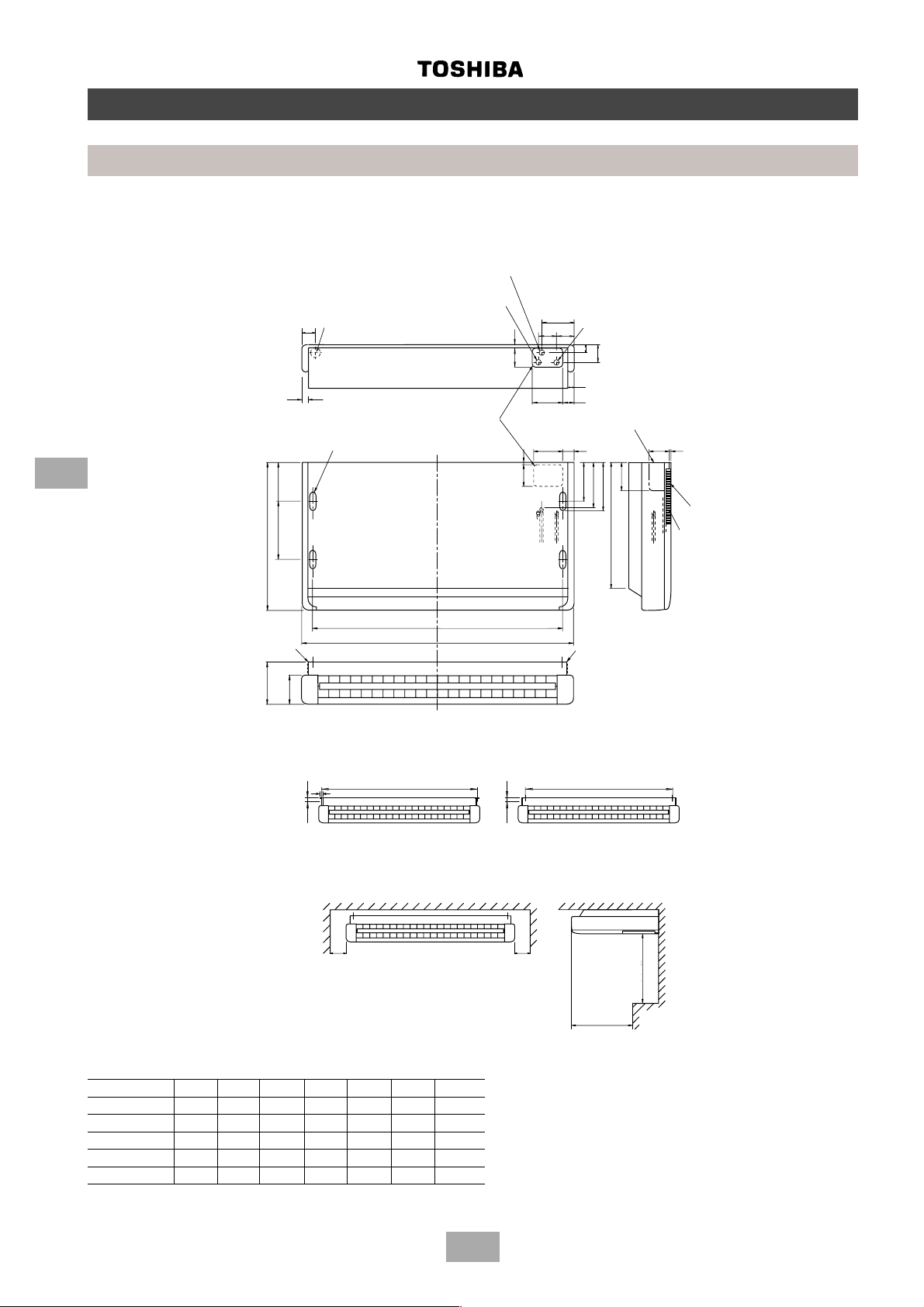

Construction views

Indoor units

Ceiling

MM-C042, MM-CR042, MM-C056, MM-CR056

MM-C080, MM-CR080, MM-C112, MM-CR112, MM-C140, MM-CR140

6

/CHR-PE

/CHR-PE

/CHR-PE

Alternative knock-out

/CHR-PE

hole for drain piping

640

Hanging plate

Hanging plate (Left)

(Left)

D

Foro incompleto

62

alternativo

per tubo drenaggio

30

Hanging bolt hole

4 - (12 x 25) slot

170

250

Hanging bolt

130

Foro bullone di

sospensione Ð

Scanalatura 12x25 (4)

pitch

Passo bullone

di sospensione

Raccordo tubo drenaggio

Drain piping joint

Tubo duro cloruro di

vinile diametro

Hard vinyl chloride pipe

esterno mm. 20

outer dia. 20 mm

Collegamento tubo

Refrigerant pipe

refrigerante

(Liquido

connection (Liquid ∅ F)

Knock-out holes for

piping and wiring

¿F)

Fori incompleti

per tubi e fili

Hanging bolt pitch

B

(

Passo bullone di sospensione

A

Collegamento tubo

Refrigerant pipe

145

refrigerante

connection (Gas ∅ G)

80

10

100

80

34

30

50140

Foro incompleto

pannello destro

per tubi e fili

130

50

150

)

Piastra di sospensione

Hanging plate (Right)

12

85

(Gas ¿G)

78

Right-side panel knockout for piping and wiring

85

12

120

180

200

Filtro aria

C

(destra)

Air filter

Ingresso aria

Air inlet

40

Hanging bolt

inferiore a 40

Less than 40

Passo bullone di sospensione interno

Bullone di sospensione

Inner hanging bolt pitch

150

Minimo

Minimum

Spazio necessario per installazione e manutenzione

Space required for service and installation

E

Model A BCDE∅F ∅G

MM-C042/CR042 1030 920 540 188 1020 6.4 12.7

MM-C056/CR056 1030 920 540 188 1020 6.4 12.7

MM-C080/CR080 1230 1120 540 188 1220 9.5 15.9

MM-C112/CR112 1430 1320 550 240 1420 9.5 19.0

MM-C140/CR140 1630 1520 550 240 1620 9.5 19.0

All dimensions in mm

B

inferiore a 40

less than 40

Hanging bolt

Passo bullone di sospensione interno

Bullone di sospensione

Outer hanging bolt pitch

150

Minimo

Minimum

Greater than

Pi• di

400

500

Pi• di

Greater than

26

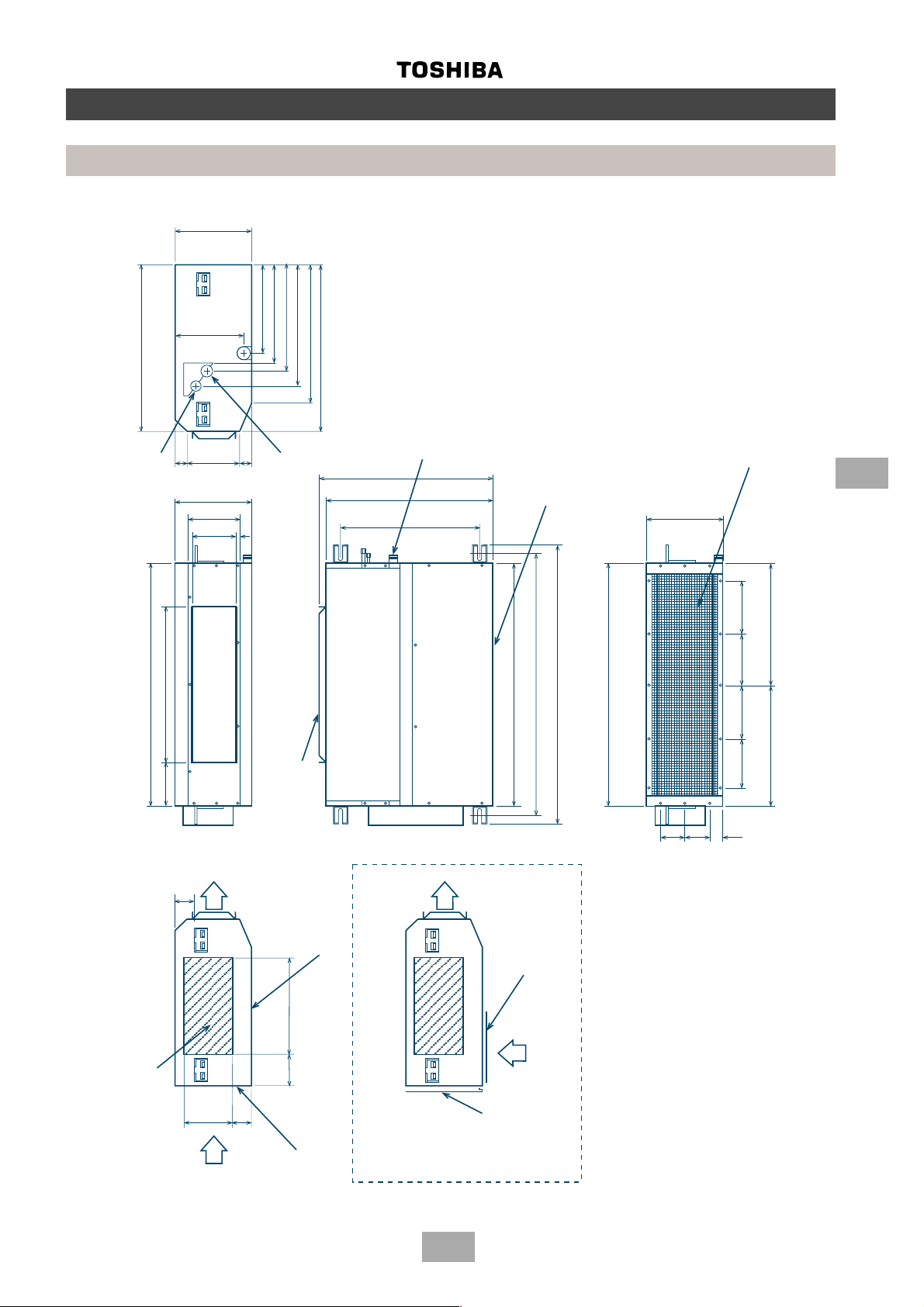

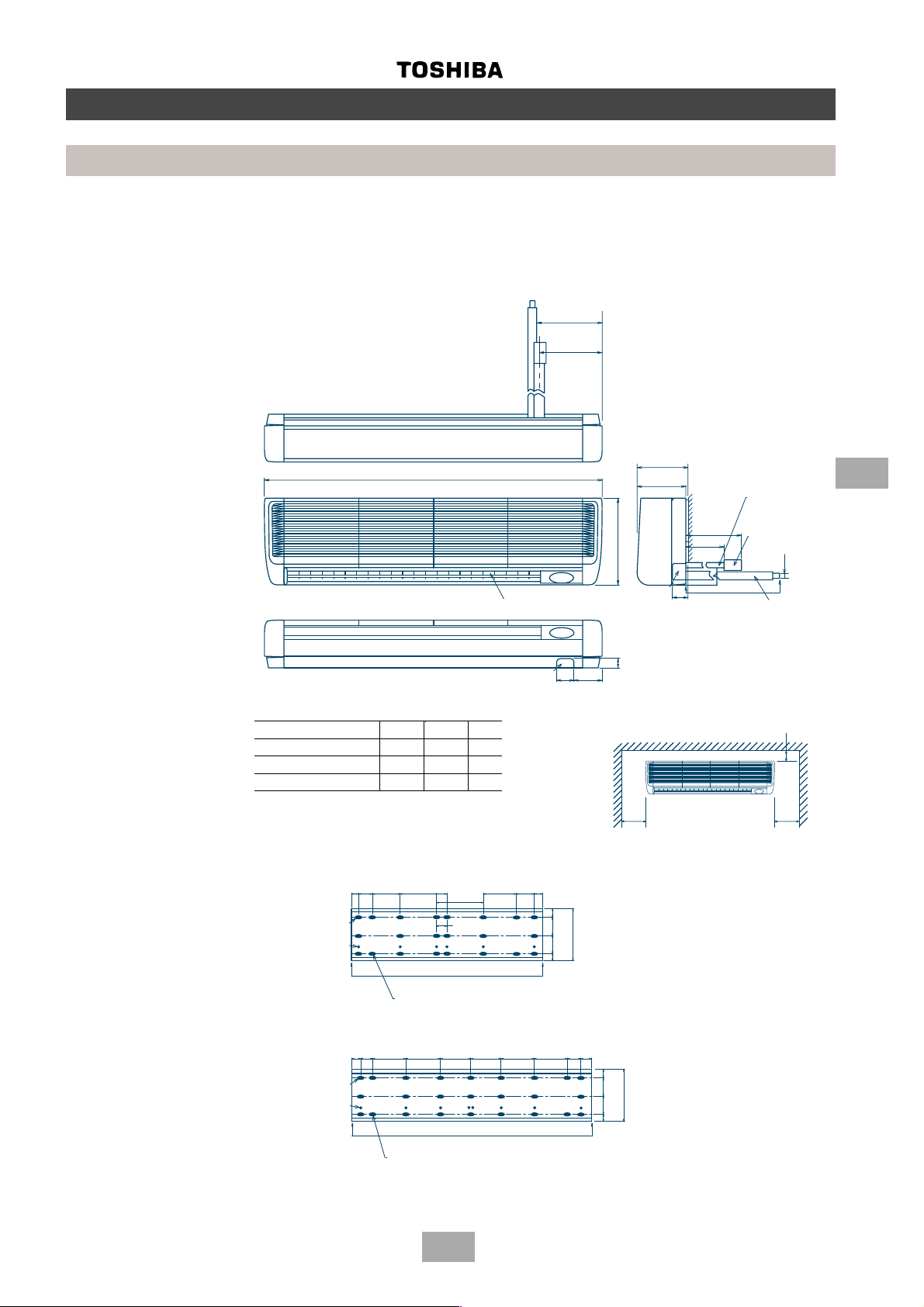

Page 27

p

Construction views

Indoor units

High wall

MM-K042, MM-K056, MM-K080, MM-KR042, MM-KR056, MM-KR080

158

143

MM-K042, MM-KR042

MM-K056, MM-KR056

MM-K080, MM-KR080

A

Piping hole

Piping hole

(Knockout hole)

(Knock-out hole)

Model A B C

MM-K042, MM-KR-042 1149 12.6 6.4

MM-K056, MM-KR056 1149 12.7 6.4

MM-K080, MM-KR080 1478 15.9 9.5

Slots

18-6x30

Slots

6-ø6 Holes

18 - 6 x 30

20 40 110 150

150

40

6 - ∅ 6 holes

600

Anchor bolt holes

Anchor bolt holes

4 - 10x20 slots

4 - 10 x 20 slots

Air outlet

Air outlet

4-way adjustable

4-way adjustable

40 20

110

43

50

26 50

226

216

595

372

(Both sides)

(Both sides)

Piping hole

Piping hole

(Knockout hole)

(Knock-out hole)

40

70 118

More than 300 More than 300

300 min.

Space required for service

169

(All dimensions in mm)

(unit : mm)

495

40

Space required for service

900

Refrigerant pipe

Refrigerant pip

connection

connection

(Liquid ∅ C)

(Liquid øC)

Refrigerant pipe

Refrigerant pi

connection

connection

(Gas øB)

(Gas ∅ B)

ø20

(OD.)

Drain pipe

Drain pipe

30 min.

More than 30

300 min.

6

Slots

Slots

21-6x30

8-ø6 Holes

21 - 6 x 30

8 - ∅ 6 holes

2040 110 150 150 150 150 110 2040

Anchor bolt holes

Anchor bolt holes

4 - 10x20 slots

4 - 10 x 20 slots

Installation board mounting bolt hole location

940

Installation board mounting bolt hole location

27

43

169

50

26 50

Page 28

2-way cassette

MM-TU028, MM-TU042, MM-TU056

6

Construction views

Indoor units

Hanger bolt

(4 x M10)

Channel for routing TC sensors and

pressure sensor leads

Drain pipe joint

(outer ∅ 25.5)

Panel outer dimension 1050

Ceiling opening 1010

Hanging bolt pitch 930

Refrigerant piping joint

(Liquid ∅ 6.4)

Refrigerant piping joint

(Gas ∅ 12.7)

Minimum

600

View A

Minimum

600

Space required for service and installation

Ceiling opening 510

Panel outer dimension 550

Minimum

600

410

Hanging bolt pitch

(All dimensions in mm)

28

Page 29

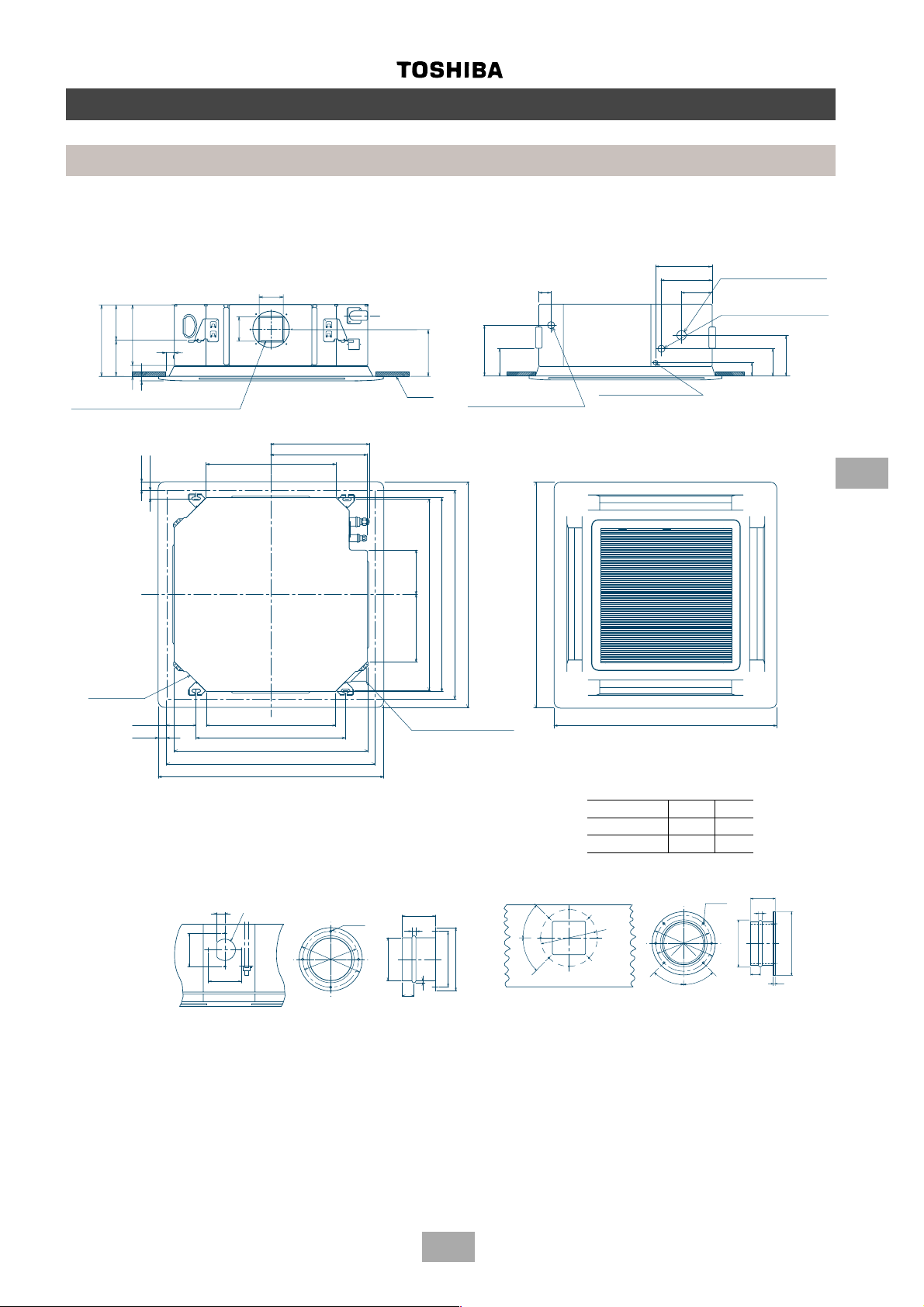

4-way cassette

MM-U056, MM-U080

Construction views

Indoor units

259

160

298

138

30

39

20

Knock-out for side ducts ∅ 150

(both sides)

40

30

Fresh air inlet

106

536

106

405

400

195

Ceiling

240

138

Drain pipe connection

(1” BSP threaded connection)

268 195

Ceiling opening 880

Hanging bolt pitch 800

Panel dimension 940

External cassette dimension 820

940

185

80

Refrigerant pipe

170

connection (Gas ∅ A)

100

Refrigerant pipe

connection (Liquid ∅ B)

200

140

73

Wiring connection

(Gland plate 3 x ∅ 20 holes)

6

130

30

Hanging bolt pitch 620

External cassette dimension 820

Ceiling opening 880

Panel dimension 940

Fresh air inlet duct size

32

130

130

∅100

536

∅144

∅130

4-∅6

Condensate pipe

(1” BSP threaded connection)

80

10

∅97

∅30

2

30

∅144

Side outlet duct size

45°

45°

940

Model (MM-) U056 U080

∅A 12.7 15.9

∅B 6.4 9.5

6-∅6

∅180

∅180

45°

45°

∅150

80

10

∅200

30

6

29

Page 30

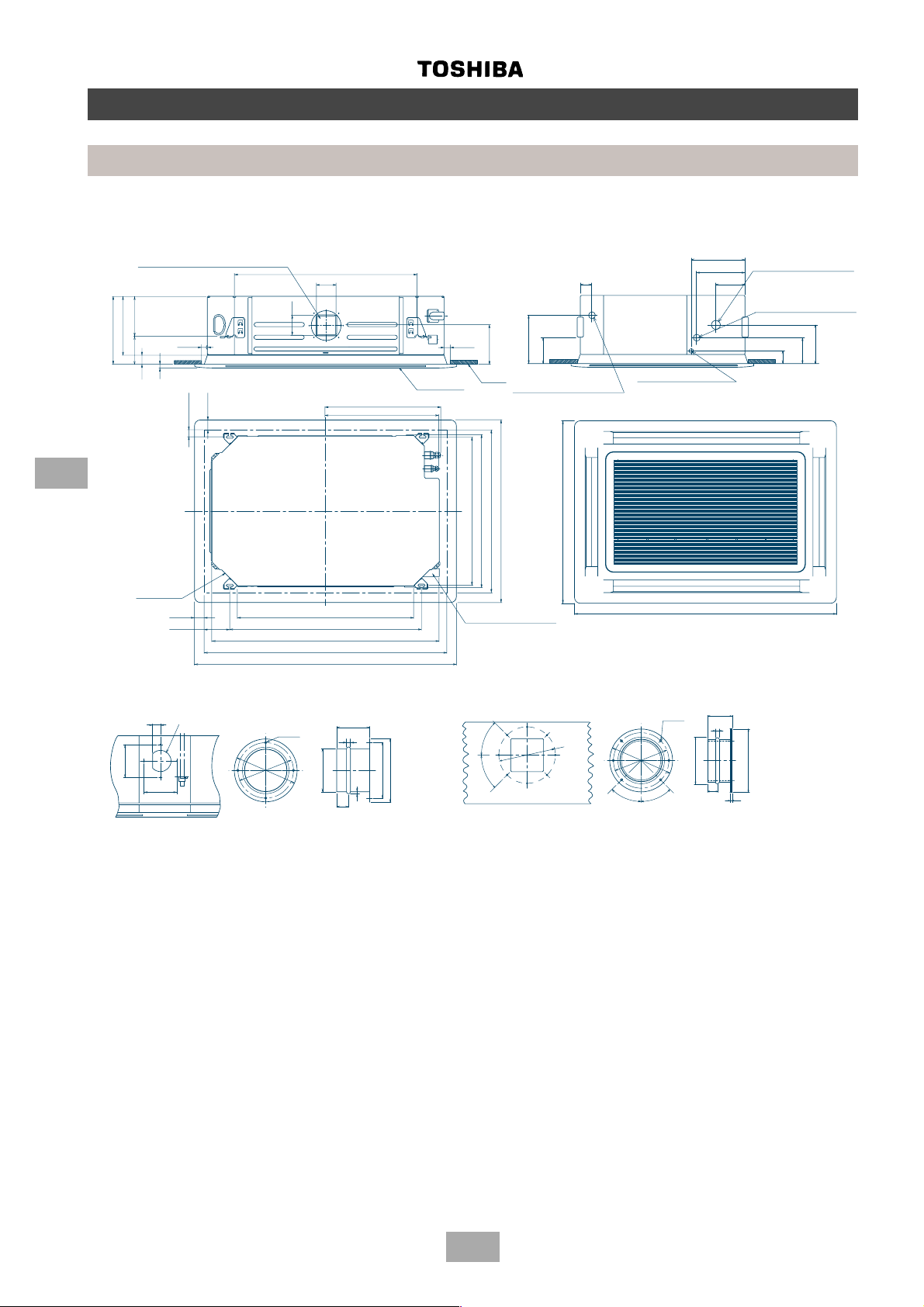

30

202

941

106

210

348

309

138

30

39

20

106

40

30

610

605

940

30

130

940

1350

80

240

138

185

170

100

73

140

200

80

10

30

6

32

130

130

80

10

30

2

4-way cassette

MM-U112, MM-U140

Construction views

Indoor units

6

Knock-out for side ducts ∅ 150

(both sides)

Fresh air

inlet

Hanging bolt pitch 1030

External cassette dimension 1230

Ceiling opening 1290

Panel dimension 1350

Ceiling

Ceiling panel

Drain pipe connection

(1” BSP threaded connection)

Hanging bolt pitch 800

External cassette dimension 820

Condensate pipe

(1” BSP threaded connection)

Ceiling opening 880

Panel dimension 940

Refrigerant pipe

connection

(Gas side ∅19.0)

Refrigerant pipe

connection

(Liquid side ∅9.5)

Wiring connection

(Gland plate 3 x ∅ 20 holes)

Fresh air inlet duct size

Side outlet duct size

6-∅6

45°

∅150

∅200

∅100

45°

45°

∅180

45°

4-∅6

∅144

∅130

∅97

∅30

∅144

30

Page 31

Inverter unit (10 HP, 8 HP)

1212121212

12

MM-A0280HT, MM-A0224HT

Symbol Part name

CM 1, 2 Compressor

FM Fan motor

52C 1, 2 Electromagnetic contactor for

compressor

49C 1, 2 Inner overload relay

51C Overload relay

PMV 1, 2, 3 Electronic flow control valve

63H 1, 2 High pressure switch

RC Running capacitor

SV 42, 2 2-way valve

3A, 3B, 3C

20SF 4-way valve

Tr Transformer

AH Accumulator heater

TD 1, 2 TE Temperature sensor

TK 1, 2, 3 TS

Ferrite core

FL 1, 2, 3 Fuse 20 A

31

Posistor

Filter board

MCC - 1366 - 01

REDREDRED

CN01

CN17

WHI

CN18

CN02

BLK

CN19

CN03

GRY

CN04

CN20

CN22

CN23

3 1

3 1

(WHI) (BLU)

3 1

3 1

WHI

RED

GRY

GRY

GRY

GRY

GRY

Q

Y

P

X

GRY

Q

P

Q

P

Y

X

Isolator

BLK

WHI

RED

L1 L2 L3

N

N T1 T2 T3 E

N L1 L2 L3 E

Power supply

3N, 380/415 V, 50 Hz

BLK

SV42

SV2

SV3A

SV3B

SV3C

AH

20SF

BLK

4 2 1

4 2 1

GRY

FL1

RED

FL2

WHI

BLK

GRY

GRY

PMV

1

RED

BLU

ORG

YEL

WHI

6 4 3 2 1

6 4 3 2 1

(WHI)

CN300

(BLU)

BLU

5 5

BLU

7 7

CN311

BLU

1 1

BLU

3 3

(BLK)

BLU

5 5

BLU

7 7

CN312

BLU

1 1

(BLU)

BLU

3 3

CN313

BLU

1 1

(BLK)

BLU

3 3

CN314

ORG

1 1

(RED)

ORG

3 3

CN316

BLU

3 3

(BLU)

BLU

1 1

CN317

BLK

3 3

3 3

(WHI)

RED

1 1

1 1

CN304

GRY

RC

WHI

RED

(WHI)

51C 52C1

PNK

WHI

U V W

FM

WHI

RED

BLK

CM2

(D.O.L.)

RED

RED

6 4 3 2 1

6 4 3 2 1

GRY

YEL

ORG

12

12

49C2

RED

R

S

52C2

RED

PMV

PMV

3

2

BLU

ORG

YEL

WHI

GRY

RED

BLU

ORG

YEL

WHI

6 5 4 3 2 1

21

6 5 4 3 2 1

21

(RED)

(WHI)

CN301

(RED)

ORG

(WHI)

CN302

CN602

D801

D802

Interface control PC board

Interface Control PC Board

(WHI)

CN308

5 3 1

5 3 1

5 3 1

5 3 1

BLK

PUR

BRN

1 2 3 4

(RED)

BLK

RED

BLK

63H2

RED

U

V

BLU

TK3

TD1

TS1TETD2

BLK

BLK

BLK

21

21

(BLU)

CN601

12

12

(WHI)

CN604

(BLK)

CN307

5 3 1

5 3 1

5 3 1

5 3 1

BRN

ORG

6 5 4 3 2 1

6 5 4 3 2 1

MCC

GRY

(WHI)

CN600

-

1343 - 03

5 3 1

5 3 1

5 3 1

5 3 1

BLK

21

(WHI)

(BLU)

CN505

CN504

1 2 3 4

ON

SW04

SW05

SW03 SW02 SW01

D716 D717 D715D714

5 3 1

5 3 1

5 3 1

5 3 1

BLK

BLK

BLK

3 1

212121

3 1

(RED)

CN503

1 2 3 4

ON

SW06

SW07

(BLU)

CN401

1 3

1 3

BLK

3 1

3 1

(WHI)

CN502

GRY

(WHI)

CN400

1 3

1 3

RED

BLK

BLK

BLK

3 1

3 1

(GRN)

CN507

1 2

ON

SW08

1 2

ON

SW09

CN402

WHI

CN403

(RED)

CN501

(BLU)

CN500

(WHI)

CN100

(BLK)

CN516

4

3

1

4

3

2

3

1

3

1

CN515

3

1

RED

WHI

RED

4

Pressure

3

BLK

sensor

1

WHI

PD

RED

Pressure

4

BLK

3

sensor

2

WHI

PS

BLU

3

BLU

1

BLK

3

TK1

BLK

1

(BLU)

BLK

3

TK2

BLK

1

BLU

BLU

1. The dashed line indicates wiring on the site.

2. and indicates terminal blocks and the numbers

within them are terminal numbers.

3. indicates a printed circuit board.

FL3

RED

11

GRY

33

BLK

33

ORG

11

RED

11

BLU

33

BLK

BLK

YEL

BLU

Parts layout

RC

MCC-1366-01

MCC-1343-03

RED

CN01

WHI

CN02

BLK

CN03

T02

(BLK)

CN04

(BLK)

CN501

(BLU)

CN06

CN10

T03

CN11

CN08

CN09

WHI

WHI

(WHI)

WHI

WHI

Reactor

MCC-1342-01

IPDU board

MCC - 1342 - 01

CN14

CN15

CN16

D406

PO4

PO5

BLU

BLU

(WHI)

WHI

WHI

Reactor

Electrolytic

Electolytic

Capacitor

capacitor

(WHI)

CN07

12345

12345

RED

PINK

BLU

WHI

BLK

FL1

FL2

FL3

52C2

L1 L2 L3

Power supply

Power Supply

WHI

RED

CM1

Posistor

Posistor

N

BLK

52C1

51C2

BLK

ORG

12

(BLK)

12

BLK

63H1

BLK

ORG

ORG

Outdoor units

Wiring diagrams

49C1

X YP Q

7

Page 32

Fixed-speed unit (10 HP, 8 HP)

3

3

3

3

MM-A0280HX, MM-A0224HX

Wiring diagrams

Outdoor units

7

TK3

TD1

TD2

TS

TE

PMV

PMV

PMV

(BLU)

5

5

BLU

BLU

3

3

(WHI)

D802

7

7

BLU

SV42

BLU

1

1

CN100

CN311

TK1

BLK

BLK

3

1

3

1

(BLK)

CN516

1 2

SW09

SW03 SW02 SW01

03

1343

-

ON

D716 D717 D715D714

1 2

ON

1 2 3 4

ON

1 2 3 4

ON

SW04

SW08

SW07

SW06

SW05

MCC

Interface Control PC Board

Interface control PC board

BLU

(BLK)

3 3

1 1

BLU

SV2

BLU

5 5

7 7

CN312

BLU

SV3A

1 1

BLU

(BLU)

3 3

BLU

SV3B

CN313

1 1

BLU

(BLK)

3 3

CN314

BLU

SV3C

ORG

(WHI)

(RED)

3 3

3 3

1 1

1 1

ORG

ORG

CN316

3 3

BLU

ORG

CN315

AH

PD

sensor

Pressure

BLK

RED

431

431

(RED)

CN501

BLK

3 1

3 1

BLK

(GRN)

CN507

321

BLK

3 1

3 1

BLK

CN502

BLK

3 1

BLK

(RED) (WHI)

CN503

BLK

21

21

BLK

(WHI)

CN504

BLK

21

21

BLK

(BLU)

CN505

21

21

(BLU)

CN601

21

WHI

YEL

ORG

3

BLU

RED

(RED)

CN302

GRY

6 5 4 3 2 1

6 5 4 3 2 1

WHI

YEL

ORG

2

BLU

(WHI)

CN301

RED

6 4 3 2 1

6 4 3 2 1

WHI

YEL

ORG

1

BLU

(WHI)

CN300

RED

6 4 3 2 1

6 4 3 2 1

PS

sensor

Pressure

BLK

RED

WHI

WHI

432

432

(BLU)

CN500

12

(WHI)

CN604

D801

3 3

1 1

BLU

BLU

SV41

CH

GRY

GRY

P Q

P QP Q

Surge absorber

(BLU)

BLU

20SF

1 1

01

-

1357

-

MCC

CN317

(BLU)

3 3

3 3

CN02

CN01

BLK

CN515

(WHI)

1 1

1 1

3

3

(WHI)

(BLU)

(RED)

(BLU)

(BLK)

(WHI)

BLK

(BLU)

3 1

3 1

(WHI)

TK2

BLK

1

1

CN403

CN402

CN400

CN401

CN305

CN306

CN307

CN308

CN304

CN03

3 1

3 1

1 3

1 3

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

RED

BLU

RED

WHI

RED

1 3

1 3

BLK

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

GRY

BLK

BLU

GRY

PUR

BLK

BRN

1 2 3 4

1 2 3 4

1234

1234

(RED)

YEL

ORG

BRN

RED

BLK

51C1 52C1

GRY

BLK

WHI

CM1

RED

(D.O.L.)

12

12

(RED)

49C1

WHI

GRY

GRY

63H1

GRY

ORG

BRN

12

12

BLK

W

V

U

51C2 52C2

L3

L2

L1

ORG

(BLK)

49C2

BLK

WHI

CM2

RED

N

(D.O.L.)

N T1 T2 T3 E

N L1 L2 L3 E

Power supply

3N, 380/415 V, 50 Hz

PUR

BLK

BRN

GRY

RC

GRY

WHI

RED

RED

1 2 3 4

1 2 3 4

(BLK)

YEL

RED

63H2

(WHI)

RED

FM

4 2 1

4 2 1

BLK

WHI

ORG

GRY

WHI

GRY

BLK

WHI

RED

Isolator

P Q

N

Symbol Part name

CM 1, 2 Compressor

FM Fan motor

52C 1, 2 Electromagnetic contactor for compressor

49C 1, 2 Inner overload relay

51C 1, 2 Overload relay

PMV 1, 2, 3 Electronic flow control valve

63H 1, 2 High pressure switch

RC Running capacitor

SV 41, 42, 2 2-way valve

3A, 3B, 3C

20SF 4-way valve

CH Crankcase heater

Tr Transformer

AH Accumulator heater

TD1, 2 TE Temperature sensor

Ferrite core

TK1, 2, 3 TS

MCC-1357-01

RC

MCC-1343-03

Parts layout 10, 8 HP (Fixed)

L1 L2 L3

52C1

51C1

U V W

R S T

Tr

2

52C

U V W

R S T

51C2

2

2

2

2

within them are terminal numbers.

1. The dashed line indicates wiring on the site.

2. and indicates terminal blocks and the numbers

3. indicates a printed circuit board.

32

Page 33

3

3

3

3

3

Fixed-speed unit (6 HP)

MM-A0160HX

MM-A0160CX

PD

sensor

Pressure

BLK

RED

WHI

431

431

(RED)

CN501

BLK

3 1

TK3

TD1

TS

TE

3 1

BLK

(GRN)

CN507

321

BLK

3 1

3 1

BLK

(WHI)

CN502

3 1

BLK

21

21

BLK

(WHI)

CN504

BLK

21

21

BLK

(BLU)

CN505

Pressure

RED

432

432

(BLU)

sensor

BLK

PS

WHI

CN500

Wiring diagrams

Outdoor units

(BLU)

BLK

3

CN515

3

(WHI)

(BLU)

(RED)

(BLU)

TK2

BLK

1

1

CN403

CN402

CN400

CN401

CN305

CN306

BLU

RED

1 3

1 3

1 3

1 3

BLK

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

BLU

GRY

PUR

BLK

BRN

1 2 3 4

1 2 3 4

1234

1234

(RED)

YEL

ORG

BRN

RED

BLK

51C1 52C1

GRY

BLK

63H1

)

BLK

WHI

CM1

D.O.L.

RED

(

12

12

(RED)

49C1

7

WHI

GRY

GRY

WHI

RED

TK1

BLK

BLK

BLU

BLU

3

1

3

1

3

1

3

1

(BLK)

(WHI)

CN516

CN100

1 2

SW09

SW03 SW02 SW01

ON

D716 D717 D715D714

1 2

ON

1 2 3 4

ON

1 2 3 4

ON

SW04

SW08

SW07

SW06

SW05

PMV

PMV

(BLU)

(RED)

(WHI)

CN601

CN302

CN300

12

(WHI)

CN604

D801

D802

03

1343

-

5 3 1

5 3 1

MCC

Interface control PC board

Interface Control PC Board

(BLU)

5

5

3 3

1 1

BLU

BLU

SV41

GRY

GRY

P Q

(BLK)

7

7

3 3

1 1

CN311

BLU

BLU

BLU

SV2

P QP Q

5 5

7 7

CN312

BLU

SV3A

1 1

BLU

(BLU)

3 3

BLU

SV3B

CN313

1 1

BLU

(BLK)

3 3

CN314

BLU

SV3C

ORG

(WHI)

(RED)

(BLU)

(WHI)

1 1

CN316

BLU

3 3

3 3

3 3

1 1

1 1

CN317

CN304

BLU

GRY

20SF

BLK

RED

GRY

BLK

WHI

RED

RC

(WHI)

WHI

RED

FM

4 2 1

4 2 1

3 3

3 3

1 1

1 1

CN315

ORG

ORG

ORG

AH

CH

CN03

01

CN02

1357

CN01

MCC

Surge absorber

3 1

3 1

(BLU)

(WHI)

GRY

3 1

3 1

BLK

WHI

RED

L3

L2

L1

N

Power supply

N T1 T2 T3 E

N L1 L2 L3 E

3N, 380/415 V, 50 Hz

21

21

21

WHI

YEL

ORG

3

BLU

RED

GRY

6 5 4 3 2 1

6 5 4 3 2 1

6 4 3 2 1

WHI

YEL

ORG

1

BLU

RED

6 4 3 2 1

6 4 3 2 1

Isolator

P Q

N

Symbol Part name

CM 1 Compressor

FM Fan motor

52C 1 Electromagnetic contactor for compressor

49C 1 Inner overload relay

51C 1 Overload relay

PMV 1, 3 Electronic flow control valve

63H 1 High pressure switch

RC Running capacitor

SV 41, 2 2-way valve

3A, 3B, 3C

20SF 4-way valve

CH Crankcase heater

Tr Transformer

AH Accumulator heater

TD1 TE Temperature sensor

Ferrite core

TK1, 2, 3 TS

MCC-1357-01

RC

MCC-1343-03

Parts layout 6 HP (Fixed)

L1 L2 L3

1

52C151C

U V W

R S T

Tr

2

52C

U V W

R S T

2

51C

2

2

2

2

2

within them are terminal numbers.

1. The dashed line indicates wiring on the site.

2. and indicates terminal blocks and the numbers

3. indicates a printed circuit board.

33

Page 34

Inverter unit (10 HP, 8 HP) Cooling only

3

3

3

3

MM-A0280CT, MM-A0224CT

01

1342

MCC

IPDU board

CN02

CN03

CN01

BLK

RED

WHI

CN14

CN15

CN16

T02

(BLK)

(BLK)

CN04

11

33

33

RED

GRY

BLK

FL3

CN501

11

ORG

D406

PO4

PO5

CN09

T03

CN08

CN11

CN10

(BLU)

CN06

33

11

RED

BLK

BLU

Wiring diagrams

Outdoor units

ORG

12

12

BLK

BLK

63H1

(BLK)

(WHI)

CN07

12345

12345

BLU

(WHI)

BLU

WHI

WHI

WHI

WHI

(WHI)

YEL

BLU

BLK

BLK

BLK

WHI

BLU

RED

PINK

WHI

WHI

Reactor

ORG

BLK

WHI

RED

Reactor

ORG

49C1

CM1

Posistor

Posistor

FL1

Parts layout

52C1

FL2

FL3

MCC-1342-01

RC

51C2

52C2

L1 L2 L3

N

Power Supply

Power supply

MCC-1366-01

X YP Q

Electolytic

Capacitor

Electrolytic

capacitor

MCC-1343-03

7

Posistor

V

U

RED

S

R

RED

RED

FL1

FL2

RED

WHI

01

-

CN18

CN17

1366

-

CN02

CN01

Filter board

MCC

REDREDRED

WHI

03

1343

MCC

3 3

3 3

CN317

BLK

(WHI)

TK2

BLU

BLU

BLK

BLK

3

1

(BLU)

CN515

3

1

WHI

RED

CN403

CN402

WHI

(WHI)

RED

1 3

1 3

CN400

GRY

BLK

1 3

1 3

(BLU)

CN401

5 3 1

5 3 1

5 3 1

5 3 1

2

5 3 1

5 3 1

5 3 1

5 3 1

GRY

ORG

(BLK)

CN307

5 3 1

5 3 1

BRN

5 3 1

5 3 1

PUR

RED

BLK

(WHI)

CN308

5 3 1

5 3 1

5 3 1

5 3 1

BRN

1 1

1 1

CN304

RED

BLK

1 2 3 4

BLK

63H2

(RED)

GRY

YEL

GRY

RC

GRY

Y

GRY

X

GRY

Q

GRY

P

WHI

RED

4 2 1

BLK

GRY

51C 52C1

(WHI)

WHI

PNK

GRY

4 2 1

BLK

W

V

U

FM

L3

WHI

L2

RED

L1

Y

X

Q

P

2

2

2

within them are terminal numbers.

1. The dashed line indicates wiring on the site.

2. and indicates terminal blocks and the numbers

3. indicates a printed circuit board.

ORG

(RED)

12

12

ORG

CM2

N T1 T2 T3 E

N L1 L2 L3 E

49C2

(D.O.L.)

Power supply

BLK

WHI

RED

N

3N, 380/415 V, 50 Hz

Isolator

TK1

Pressure

Pressure

sensor PS

sensor PD

BLK

RED

431

431

(RED)

CN501

BLK

(GRN)

BLK

3 1

3 1

TK3

TD1

TD2

TS1

TE

BLU

3

PMV

RED

52C2

2

PMV

1

PMV

GRY

BLK

GRY

BLK

3 1

3 1

GRY

CN23

CN19

CN20

RED

3 1

3 1

WHI

CN22

CN04

CN03

(WHI) (BLU)

BLK

GRY

CN507

BLK

3 1

BLK

3 1

(WHI)

CN502

BLK

BLK

3 1

3 1

(RED)

CN503

BLK

BLK

21

21

(WHI)

CN504

BLK

21

BLK

21

(BLU)

CN505

(WHI)

CN600

6 5 4 3 2 1

6 5 4 3 2 1

21

21

(BLU)

CN601

21

21

(WHI)

CN602

WHI

YEL

ORG

BLU

(RED)

RED

CN302

6 5 4 3 2 1

6 5 4 3 2 1

GRY

WHI

YEL

ORG

BLU

(WHI)

CN301

6 4 3 2 1

6 4 3 2 1

RED

WHI

YEL

ORG

BLU

(WHI)

CN300

6 4 3 2 1

6 4 3 2 1

RED

BLU

BLU

BLK

BLK

RED

WHI

432

432

(BLU)

CN500

12

12

BLK

WHI

3

1

3

1

3

1

3

1

(WHI)

(BLK)

CN100

CN516

1 2

1 2

SW08

ON

SW07

1 2 3 4

ON

SW06

1 2 3 4

ON

SW04

SW05

(WHI)

CN604

D801

D802

(BLU)

(BLK)

(BLU)

3 3

7 7

1 1

7 7

5 5

5 5

CN311

BLU

BLU

BLU

SV42

BLU

SV2

1 1

CN312

BLU

BLU

BLU

SV3B

SV3A

SW09

ON

SW03 SW02 SW01

D716 D717 D715D714

Interface Control PC Board

Interface control PC board

(BLK)

3 3

3 3

1 1

CN314

CN313

BLU

BLU

BLU

SV3C

(BLU)

(RED)

3 3

3 3

1 1

1 1

CN316

ORG

BLU

BLU

ORG

20SF

AH

Q

P

Symbol Part name

CM 1, 2 Compressor

FM Fan motor

52C 1, 2 Electromagnetic contactor for

compressor

49C 1, 2 Inner overload relay

51C Overload relay

PMV 3 Electronic flow control valve

63H 1, 2 High pressure switch

RC Running capacitor

SV 42, 2 2-way valve

3A, 3B, 3C

Tr Transformer

Ferrite core

AH Accumulator heater

TD 1, 2 TE Temperature sensor

TK 1, 2, 3 TS

FL 1, 2, 3 Fuse 20 A

34

Page 35

Fixed-speed unit (10 HP, 8 HP) Cooling only

12

12

12

12

12

12

12

MM-A0280CX, MM-A0224CX

Wiring diagrams

Outdoor units

TK3

TD1

TD2

TS

TE

PMV

PMV

PMV

(BLU)

5

5

BLU

BLU

3

3

(WHI)

D802

BLU

SV42

7

7

BLU

1

1

CN100

CN311

TK1

BLK

BLK

3

1

3

1

(BLK)

CN516

1 2

SW09

SW03 SW02 SW01

03

1343

-

ON

D716 D717 D715D714

1 2

ON

1 2 3 4

ON

1 2 3 4

ON

SW04

SW08

SW07

SW06

SW05

MCC

Interface Control PC Board

Interface control PC board

BLU

(BLK)

3 3

1 1

BLU

SV2

BLU

5 5

7 7

BLU

SV3A

CN312

BLU

(BLU)

1 1

3 3

BLU

SV3B

CN313

1 1

BLU

(BLK)

3 3

CN314

BLU

SV3C

ORG

(WHI)

(RED)

3 3

3 3

1 1

1 1

ORG

ORG

CN316

3 3

BLU

ORG

CN315

AH

PS

PD

sensor

sensor

Pressure

Pressure

BLK

BLK

RED

RED

WHI

432

432

(BLU)

12

BLU

CN500

(WHI)

1 1

WHI

CN604

D801

3 3

BLU

431

431

(RED)

CN501

BLK

3 1

3 1

BLK

(GRN)

CN507

321

BLK

3 1

3 1

BLK

CN502

BLK

3 1

BLK

(RED) (WHI)

CN503

BLK

21

21

BLK

(WHI)

CN504

BLK

21

21

BLK

(BLU)

CN505

21

21

(BLU)

CN601

21

WHI

YEL

ORG

3

BLU

RED

(RED)

CN302

GRY

6 5 4 3 2 1

6 5 4 3 2 1

WHI

YEL

ORG

2

BLU

(WHI)

CN301

RED

6 4 3 2 1

6 4 3 2 1

WHI

YEL

ORG

1

BLU

(WHI)

CN300

RED

6 4 3 2 1

6 4 3 2 1

SV41

CH

GRY

GRY

P Q

P QP Q

Surge absorber

(BLU)

BLU

20SF

1 1

01

-

1357

-

MCC

(BLU)

CN317

3 3

3 3

CN02

CN01

BLK

3

CN515

3

(WHI)

1 1

1 1

(WHI)

(BLU)

(RED)

(BLU)

(BLK)

(WHI)

BLK

(BLU)

3 1

3 1

(WHI)

TK2

BLK

1

1

CN403

CN402

CN400

CN401

CN305

CN306

CN307

CN308

CN304

CN03

3 1

3 1

BLU

RED

1 3

1 3

1 3

1 3

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

5 3 1

RED

BLU

GRY

PUR

BLK

BRN

1 2 3 4

1 2 3 4

1234

1234

(RED)

YEL

ORG

BRN

RED

BLK

51C1 52C1

GRY

BLK

WHI

CM1

RED

(D.O.L.)

12

12

(RED)

49C1

7

WHI

GRY

GRY

WHI

RED

BLK

63H1

GRY

ORG

BRN

12

12

BLK

W

V

U

51C2 52C2

L3

L2

L1

ORG

(BLK)

49C2

BLK

WHI

CM2

RED

N

(D.O.L.)

N T1 T2 T3 E

N L1 L2 L3 E

Power supply

30N, 380/415 V, 50 Hz

PUR

BLK

BRN

GRY

GRY

BLK

WHI

RED

RC

GRY

RED

1 2 3 4

1 2 3 4

(BLK)

YEL

WHI

RED

63H2

(WHI)

RED

FM

4 2 1

4 2 1

BLK

ORG

GRY

WHI

GRY

BLK

WHI

RED

Isolator

P Q

N

Symbol Part name

CM 1, 2 Compressor

FM Fan motor

52C 1, 2 Electromagnetic contactor for compressor

49C 1, 2 Inner overload relay

51C 1, 2 Overload relay

PMV 3 Electronic flow control valve

63H 1, 2 High pressure switch

RC Running capacitor

SV 41, 42, 2 2-way valve

3A, 3B, 3C

CH Crankcase heater

Tr Transformer

AH Accumulator heater

TD1, 2 TE Temperature sensor

TK1, 2, 3 TS

Ferrite core

MCC-1357-01

RC

MCC-1343-03

Parts layout 10, 8 HP (Fixed)

L1 L2 L3

52C1

51C1

U V W

R S T

Tr

2

52C

51C2

U V W

R S T

within them are terminal numbers.

1. The dashed line indicates wiring on the site.

2. and indicates terminal blocks and the numbers

3. indicates a printed circuit board.

35

Page 36

Built-In Duct

MM-B140, MM-B112, MM-B080, M-B056

Wiring diagrams

Indoor units

TA

TC2

TC1

RED

CN04

22

11

WHI

CN05

22

11

BLU

CN20

22

11

YEL

CN23

66

GRN

44

PS

WHI

BLK

22

11

7

WHI

RC

GRN/YEL

FM

GRY

RED

YEL

BLU

ORN

BLK

BRN

WHI

2

2

1

1

CN01 CN12

BLK

2

2

YEL

1

1

FC

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

RED

WHI

BLK

BLK

ORN

BLU

YEL

RED

CN26

5

3

1

5

3

1

CN07 CN25

1

3

5

7

9

5

3

1

22

BLU

22

33

33

BLU

44

55

RY02 RY03 RY04

CN28

CN27

WHI

11

BLU

11

22

BLU

22

RY01

33

BLU

33

44

BLU

44

55

BLU

55

66

66

BLK

MCC-1355-01

3

3

2

2