FILE NO. 140-200422

DOCUMENT CREATED IN JAPAN, May, 2004

SERVICE MANUAL

COLOR TELEVISION/

DVD VIDEO PLAYER

MD14FP1C

CAUTION

THIS DIGITAL VIDEO PLAYER EMPLOYS A LASER SYSTEM.

TO ENSURE PROPER USE OF THIS PRODUCT, PLEASE READ THIS SERVICE MANUAL CARE-

FULLY AND RETAIN FOR FUTURE REFERENCE. SHOULD THE UNIT REQUIRE MAINTENANCE,

CONTACT AN AUTHORIZED SERVICE LOCATION-SEE SERVICE PROCEDURE.

USE OF CONTROLS, ADJUSTMENTS OR THE PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MA Y RESULT IN HAZARDOUS RADIATION EXPOSURE.

TO PREVENT DIRECT EXPOSURE TO LASER BEAM, DO NOT TRY T O OPEN THE ENCLOSURE.

VISIBLE LASER RADIA TION MAY BE PRESENT WHEN THE ENCLOSURE IS OPENED. DO NOT

ST ARE INTO BEAM.

Location of the required Marking

The rating sheet and the safety caution are on the rear of the unit.

CERTIFICATION: COMPLIES WITH FDA

RADIA TION PERFORMANCE STANDARDS,

21 CFR SUBCHAPTER J.

PREPARATION OF SERVICING

The laser diode used for a pickup head may be destroyed with external static electricity.

Moreover, even if it is operating normally after repair, when static electricity discharge is received at the

time of repair, a life of product may become short.

Please perform the following measure against static electricity, be careful of destruction of a laser diode

enough at the time of repair, and work.

• It works on the desk which performed measures against static electricity, such as conductive mat.

• Soldering iron with ground wire or ceramic type is used.

• A worker needs to use a ground conductive wrist strap for body.

A1-1

SERVICING NOTICES ON CHECKING

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an

electric shock while the electric current is

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

4. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

5. TAKE CARE TO DEAL WITH THE

CATHODE-RAY TUBE

In the condition that an explosion-proof cathoderay tube is set in this equipment, safety is

secured against implosion. However, when

removing it or serving from backward, it is

dangerous to give a shock. Take enough care to

deal with it.

6. AVOID AN X-RAY1. KEEP THE NOTICES

Safety is secured against an X-ray by considering about the cathode-ray tube and the high

voltage peripheral circuit, etc.

Therefore, when repairing the high voltage peripheral circuit, use the designated parts and

make sure not modify the circuit.

Repairing except indicates causes rising of high

voltage, and it emits an X-ray from the cathoderay tube.

PERFORM A SAFETY CHECK AFTER

7.

SERVICING

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

1.

Unplug the plug from the AC outlet.

2.

Remove the antenna terminal on TV and turn

on the TV.

3.

Insulation resistance between the cord plug

terminals and the eternal exposure metal

[Note 2] should be more than 1M ohm by

using the 500V insulation resistance meter

[Note 1].

4.

If the insulation resistance is less than 1M

ohm, the inspection repair should be

required.

[Note 1]

If you have not the 500V insulation

resistance meter, use a Tester.

[Note 2]

External exposure metal: Antenna terminal

HOW TO ORDER P ARTS

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

A1-2

IMPORTANT SAFEGUARDS

1.

READ INSTRUCTIONS

All the safety and operating instructions should be read before the unit is operated.

2.

RET AIN INSTRUCTIONS

The safety and operating instructions should be retained for future reference.

3.

HEED WARNINGS

All warnings on the unit and in the operating instructions should be adhered to.

4.

FOLLOW INSTRUCTIONS

All operating and use instructions should be followed.

5.

CLEANING

Unplug this unit from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a damp

cloth for cleaning.

6.

A TTACHMENTS

Do not use attachments not recommended by the unit’s manufacturer as they may cause hazards.

7.

WATER AND MOISTURE

Do not use this unit near water. For example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a wet

basement, or near a swimming pool.

8.

ACCESSORIES

Do not place this unit on an unstable cart, stand, tripod, bracket, or table. The

unit may fall, causing serious injury, and serious damage to the unit. Use only

with a cart, stand, tripod, bracket, or table recommended by the manufacturer.

8A.

An appliance and cart combination should be moved with care. Quick stops,

excessive force, and uneven surfaces may cause the appliance and cart

combination to overturn.

9.

VENTILATION

Slots and openings in the cabinet and in the back or bottom are provided for ventilation, to ensure reliable

operation of the unit, and to protect it from overheating. These openings must not be blocked or covered. The

openings should never be blocked by placing the unit on a bed, sofa, rug, or other similar surface. This unit

should never be placed near or over a radiator or heat source. This unit should not be placed in a built-in

installation such as a bookcase or rack unless proper ventilation is provided or the manufacturer’s instructions

have been adhered to.

10.

POWER SOURCES

This unit should be operated only from the type of power source indicated on the rating plate. If you are not sure

of the type of power supply to your home, consult your appliance dealer or local power company. For units

intended to operate from battery power, or other sources, refer to the operating instructions.

11.

GROUNDING OR POLARIZA TION

This unit is equipped with a polarized alternating-current line plug (a plug having one blade wider than the other).

This plug will fit into the power outlet only one way . This is a safety feature. If you are unable to insert the plug

fully into the outlet, try reversing the plug. If the plug should still fail to fit, contact your electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the polarized plug. If your unit is equipped with a 3-wire

grounding-type plug, a plug having a third (grounding) pin, this plug will only fit into a grounding-type power

outlet. This too, is a safety feature. If you are unable to insert the plug into the outlet, contact your electrician to

replace your obsolete outlet. Do not defeat the safety purpose of the grounding-type plug.

12.

POWER-CORD PROTECTION

Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed upon

or against them, paying particular attention to cords at plugs, convenience receptacles, and the point where they

exit from the appliance.

13.

LIGHTNING

To protect your unit from a lightning storm, or when it is left unattended and unused for long periods of time,

unplug it from the wall outlet and disconnect the antenna or cable system. This will prevent damage to the unit

due to lightning and power line surges.

14.

POWER LINES

An outside antenna system should not be located in the vicinity of overhead power lines or other electric light or

power circuits, or where it can fall into such power lines or circuits. When installing an outside antenna system,

extreme care should be taken to keep from touching such power lines or circuits, as contact with them might be

fatal.

15.

OVERLOADING

Do not overload wall outlets and extension cords, as this can result in a risk of fire or electric shock.

16.

OBJECT AND LIQUID ENTRY

Do not push objects through any openings in this unit, as they may touch dangerous voltage points or short out

parts that could result in fire or electric shock. Never spill or spray any type of liquid into the unit.

PORT ABLE CAR T WARNING

(symbol provided by RETAC)

S3125A

A1-3

IMPORTANT SAFEGUARDS (CONTINUED)

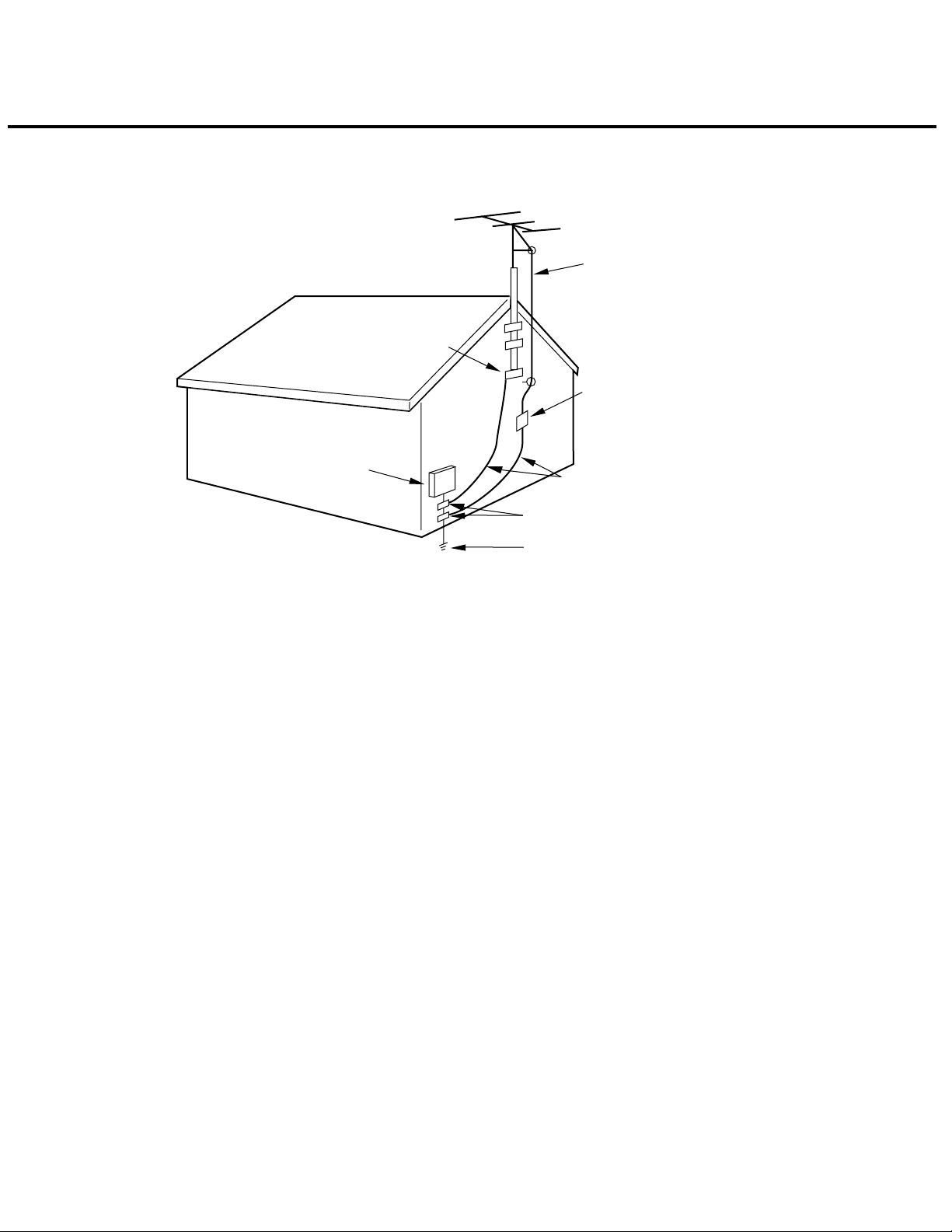

OUTDOOR ANTENNA GROUNDING

17.

If an outside antenna or cable system is connected to the unit, be sure the antenna or cable system is grounded

so as to provide some protection against voltage surges and built-up static charges. Section 810 of the National

Electrical Code, ANSI/NFPA 70, provides information with respect to proper grounding of the mast and supporting structure, grounding of the lead-in wire to an antenna discharge unit, size of grounding conductors, location of

antenna discharge unit, connection to grounding electrodes, and requirements for the grounding electrode.

SERVICING

18.

Do not attempt to service this unit yourself as opening or removing covers may expose you to dangerous voltage

or other hazards. Refer all servicing to qualified service personnel.

DAMAGE REQUIRING SERVICE

19.

Unplug this unit from the wall outlet and refer servicing to qualified service personnel under the following

conditions:

a.

When the power-supply cord or plug is damaged.

b.

If liquid has been spilled, or objects have fallen into the unit.

c.

If the unit has been exposed to rain or water.

d.

If the unit does not operate normally by following the operating instructions. Adjust only those controls that

are covered by the operating instructions, as an improper adjustment of other controls may result in

damage and will often require extensive work by a qualified technician to restore the unit to its normal

operation.

e.

If the unit has been dropped or the cabinet has been damaged.

f.

When the unit exhibits a distinct change in performance, this indicates a need for service.

REPLACEMENT P ARTS

20.

When replacement parts are required, be sure the service technician uses replacement parts specified by the

manufacturer or those that have the same characteristics as the original parts.

Unauthorized substitutions may result in fire, electric shock or other hazards.

SAFETY CHECK

21.

Upon completion of any service or repairs to this unit, ask the service technician to perform safety checks to

determine that the unit is in proper operating condition.

WALL OR CEILING MOUNTING

22.

The product should be mounted to a wall or ceiling only as recommended by the manufacturer.

HEAT

23.

The product should be situated away from heat sources such as radiators, heat registers, stoves, or other

products (including amplifiers) that produce heat.

DISC TRA Y

24.

Keep your fingers well clear of the disc tray as it is closing. It may cause serious personal injury.

CONNECTING

25.

When you connect the product to other equipment, turn off the power and unplug all of the equipment from the

wall outlet. Failure to do so may cause an electric shock and serious personal injury. Read the owner's manual of

the other equipment carefully and follow the instructions when making any connections.

SOUND VOLUME

26.

Reduce the volume to the minimum level before you turn on the product. Otherwise, sudden high volume sound

may cause hearing or speaker damage.

SOUND DISTORTION

27.

Do not allow the product output distorted sound for a longtime. It may cause speaker overheating and fire.

HEADPHONES

28.

When you use the headphones, keep the volume at a moderate level. If you use the headphones continuously

with high volume sound, it may cause hearing damage.

LASER BEAM

29.

Do not look into the opening of the disc tray or ventilation opening of the product to see the source of the laser

beam. It may cause sight damage.

DISC

30.

Do not use a cracked, deformed, or repaired disc. These discs are easily broken and may cause serious personal

injury and product malfunction.

NOTE TO CATV SYSTEM INSTALLER

31.

This reminder is provided to call the CATV system installer’s attention to Article 820-40 of the NEC that provides

guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the

grounding system of the building, as close to the point of cable entry as practical.

A1-4

IMPORTANT SAFEGUARDS (CONTINUED)

EXAMPLE OF ANTENNA GROUNDING AS PER THE NATIONAL ELECTRICAL CODE

ANTENNA LEAD

IN WIRE

GROUND

CLAMP

ANTENNA

DISCHARGE UNIT

(NEC SECTION 810-20)

ELECTRIC SERVICE

EQUIPMENT

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

GROUND CLAMPS

NEC-NATIONAL ELECTRICAL CODE

S2898A

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250, PART H)

A1-5

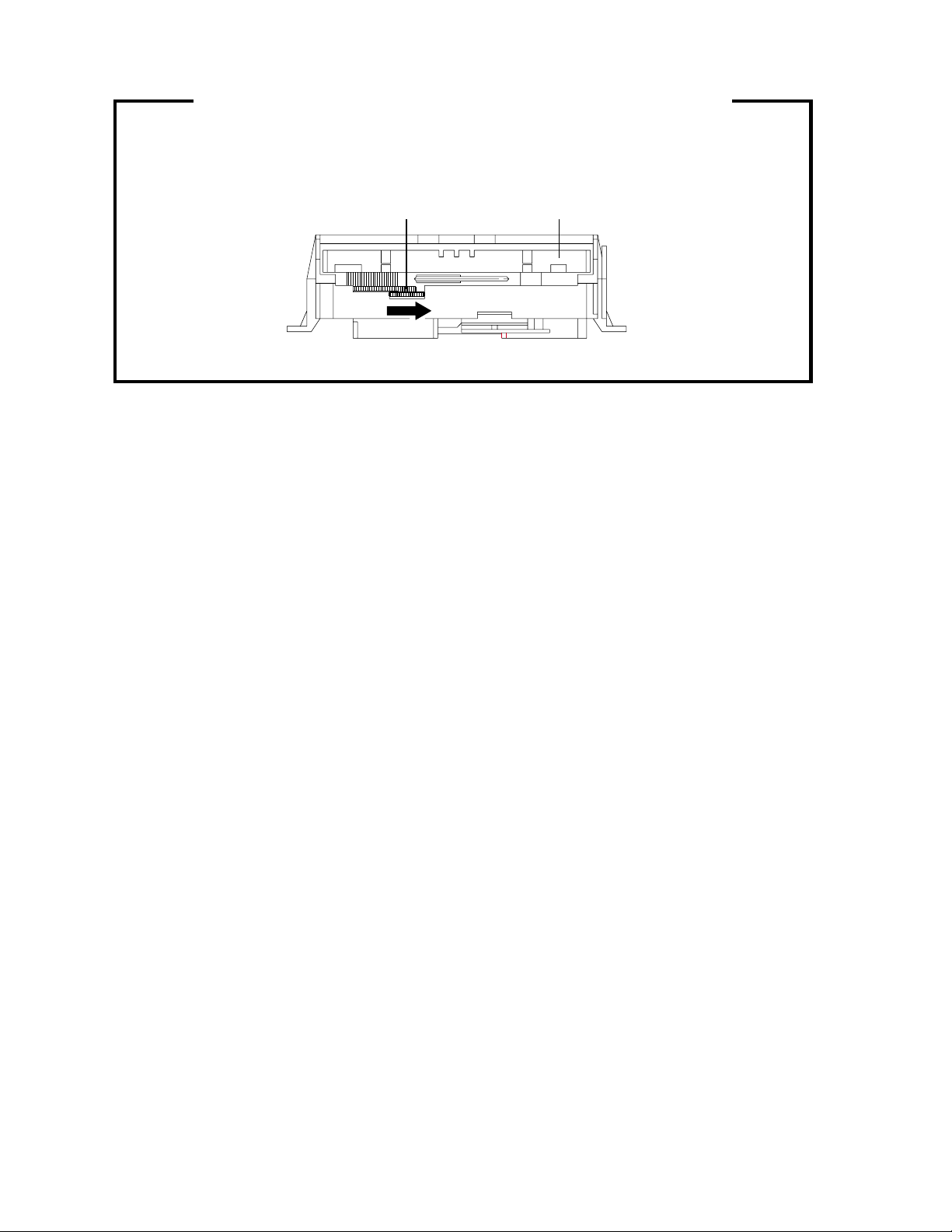

DISC REMOVAL METHOD AT NO POWER SUPPLY

1.

Remove the Back Cabinet and AV PCB/DVD Block. (Refer to item 1 of the DISASSEMBLY

INSTRUCTIONS.)

2.

Rotate the white gear of Deck CD section in the direction of the arrow by hand. (Refer to Fig. 1)

3.

Draw the Tray.

Deck CDGear (White)

Fig. 1

PARENTAL CONTROL - RATING LEVEL

4 DIGIT PASSWORD CANCELLATION

If the stored 4 digit password in the Rating Level menu needs to be cancelled, please follow the steps

below.

1.

Turn Unit ON.

2.

Press and hold the 'STOP' key on the front panel.

3.

Simultaneously press and hold the '7' key on the remote control unit.

4.

Hold both keys for more than 3 seconds.

The On Screen Display message 'PASSWORD CLEAR' will appear.

5.

The 4 digit password has now been cleared.

6.

NB: The above procedure will reset ALL of the player's settings to the default factory state.

TRAY LOCK

Tray cannot be opened by setting the Tray Lock, please follow the steps below.

Turn Unit ON.

1.

Set the DVD to the Stop Mode.

2.

Press and hold the '9' key on the remote control unit.

3.

Simultaneously press and hold the 'STOP' key on the front panel.

4.

Hold both keys for more than 3 seconds.

5.

Press the OPEN/CLOSE key on the front panel to check the Tray Lock setting.

6.

NB: No indications on the screen when the Tray Lock is setting.

To unlock the Tray Lock, please follow the steps below.

Turn Unit ON.

1.

Set the DVD to the Stop Mode.

2.

Set the VOLUME to minimum.

3.

Press and hold the 'VOL. DOWN' button on the front panel.

4.

Simultaneously press and hold the '4' key on the remote control unit.

5.

Hold both keys for more than 1 second.

6.

The On Screen Display message 'INITALIZE5 COMPLETE' will appear.

7.

The Tray Lock has now been cleared.

8.

NB: The above procedure will reset ALL of the player's settings to the default factory state.

A1-6

TABLE OF CONTENTS

CAUTION ....................................................................................................................................

SERVICING NOTICES ON CHECKING.....................................................................................

HOW TO ORDER PARTS ..........................................................................................................

IMPORTANT SAFEGUARDS.....................................................................................................

DISC REMOVAL METHOD AT NO POWER SUPPLY .............................................................

PARENTAL CONTROL-RATING LEVEL ..................................................................................

TRAY LOCK................................................................................................................................

TABLE OF CONTENTS..............................................................................................................

GENERAL SPECIFICATIONS ...................................................................................................

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS AND P. C. BOARDS............................................

2. REMOVAL OF DVD DECK PARTS ...................................................................................

3. REMOVAL OF ANODE CAP..............................................................................................

4. REMOVAL AND INSTALLATION OF FLAT PACKAGE IC ...............................................

SERVICE MODE LIST ................................................................................................................

CONFIRMATION OF HOURS USED .........................................................................................

WHEN REPLACING EEPROM (MEMORY) IC ..........................................................................

ELECTRICAL ADJUSTMENTS..................................................................................................

BLOCK DIAGRAMS

DVD..........................................................................................................................................

TV ............................................................................................................................................

POWER ..................................................................................................................................

PRINTED CIRCUIT BOARDS

DVD..........................................................................................................................................

AV/CRT ....................................................................................................................................

RELAY/SW ..............................................................................................................................

SCHEMATIC DIAGRAMS

MPEG/MICON .........................................................................................................................

MEMORY .................................................................................................................................

RF AMP/DSP ...........................................................................................................................

AUDIO/VIDEO .........................................................................................................................

REGULATOR...........................................................................................................................

MICON/TUNER .......................................................................................................................

VIF/SIF/CHROMA....................................................................................................................

SOUND AMP ...........................................................................................................................

IN/OUT .....................................................................................................................................

STEREO ..................................................................................................................................

DEFLECTION ..........................................................................................................................

CRT ..........................................................................................................................................

POWER ...................................................................................................................................

RELAY/SW/FG ........................................................................................................................

INTERCONNECTION DIAGRAM ...............................................................................................

WAVEFORMS .............................................................................................................................

MECHANICAL EXPLODED VIEWS...........................................................................................

DVD DECK EXPLODED VIEW...................................................................................................

MECHANICAL REPLACEMENT PARTS LIST .........................................................................

DVD DECK PLACEMENT PARTS LIST ....................................................................................

ELECTRICAL REPLACEMENT PARTS LIST...........................................................................

A1-1

A1-2

A1-2

A1-3~A1-5

A1-6

A1-6

A1-6

A2-1

A3-1~A3-6

B1-1, B1-2

B2-1~B2-4

B3-1

B4-1, B4-2

C-1

C-1

C-2

D-1~D-6

E-1, E-2

E-3, E-4

E-5, E-6

F-1, F-2

F-3~F-6

F-7, F-8

G-1, G-2

G-3, G-4

G-5, G-6

G-7, G-8

G-9, G-10

G-11, G-12

G-13, G-14

G-15, G-16

G-17, G-18

G-19, G-20

G-21, G-22

G-23, G-24

G-25, G-26

G-27, G-28

G-29, G-30

H-1~H-3

I1-1~I1-3

I2-1

J1-1

J2-1

J3-1~J3-5

A2-1

GENERAL SPECIFICATIONS

G-1 TV CRT CRT Size / Visual Size 14 inch / 357.0 mmV

System CRT Type Flat

Color System NTSC

Speaker 2 Speaker

Sound Output Max 2.5W + 2.5W

G-2 DVD System Color System NTSC

Disc DVD, CD-DA, CD-R/RW, Video CD

Disc Diameter 120 mm , 80 mm

Deck Disc Loading System Front Loading

Pick up 1-Lens 2-Beams System

Playback time(Max) DVD 1-Layer 135min (4.7GB)

Search speed Fwd 2-20 times / 4 step

Slow speed Fwd 1/7 - 1/2 times

G-3 Tuning Broadcasting System US System M

System Tuner and System 1Tuner

Receive CH Destination US(w/CATV)

Intermediate Picture(FP) 45.75MHz

Frequency Sound(FS) 41.25MHz

Preset CH No

Stereo/Dual TV Sound US-Stereo

Tuner Sound Muting Yes

G-4 Signal Video Signal Input Level 1 V p-p/75 ohm

RGB Signal Output Level -Audio Signal Input Level -8.0dBm/50k ohm

Deflection 90 degree

Magnetic Field BV/BH +0.45G / 0.18G

Position Front

Size 1.5 x 2.7 inch

Impedance 8 ohm

10%(Typical) 2.0W + 2.0W

Motor 2 Motors

DVD 2-Layer 245min (8.5GB)

CD 74min

Video CD 74min

Actual 2-45 times (DVD, VIDEO CD)

Rev 2-20 times / 4 step

Actual 2-45 times (DVD, VIDEO CD)

Actual --

Actual --

Tuning System F-Synth

Input Impedance VHF/UHF 75 Ohm

CH Coverage 2~69, 4A, A-5~A-1, A~I, J~W, W+1~W+84

FP-FS 4.50MHz

Output Level -S/N Ratio (Weighted) -Horizontal Resolution at DVD Mode --

Output Level

Digital Output Level 0.5 V p-p/75 ohm

S/N Ratio at DVD (Weighted) -Harmonic Distortion -Frequency Response : at DVD --

at Video CD --

at SVCD --

at CD --

4-40 times (CD)

4-40 times (CD)

Rev 1/7 - 1/2 times

--

--

A3-1

GENERAL SPECIFICATIONS

G-5 Power Power Source AC 120V, 60Hz

Power Consumption at AC 90W at 120V 60Hz

Protector Power Fuse Yes

G-6 Regulation Safety CSA

G-7 Temperature Operation +5oC ~ +40oC

G-8 Operating Humidity Less than 80% RH

G-9 On Screen Menu(TV) Yes

Display Menu Type Icon

TV Setup Yes

Channel Setup Yes

V-chip Setup

Language Yes

Sleep Timer Yes

CH / AV(LINE) / DVD Yes

Stereo/Audio Output Yes

Control Volume Yes

Level Bright / Contrast / Sharpness / Color Yes

Tint Yes

Bass/Treble/Balance

Caption / Text Yes

Auto Search/Position No

Game Yes

Mute Yes

DC --

Stand by (at AC) 5W at 120V 60Hz

Per Year -- kWh/Year

Radiation IC

X-Radiation HWC

Laser DHHS

Storage -20oC ~ +60oC

Picture Yes

Audio

Picture Preference Yes

TV/CATV Yes

Auto CH Memory Yes

Add/ Delete Yes

Bilingual No

SAP Yes

at DC --

No

No

No

A3-2

GENERAL SPECIFICATIONS

G-10 On Screen Menu (DVD) Yes

Display Menu Type Character

G-11 OSD Language (TV) English, French, Spanish

(DVD) English, French, Spanish

G-12 Clock and Sleep Timer Max Time 120 Min

Timer Step 10 Min

On/Off Timer Program(On Timer / Off Timer) No

Wake Up Timer No

Timer Back-up (at Power Off Mode) more than -- Min Sec

Language Yes

Menu Yes

Subtitle Yes

Audio Yes

Picture Yes

TV Screen Size Yes

OSD Display On/Off Yes

JPEG Interval Yes

Select Files No

Sound Yes

DRC (Dynamic Range Control) Yes

dts Decode No

Output(5.1ch/ 2ch) No

Surround On/Off No

Center On/Off No

Sub Woofer On/Off No

Parental Yes

Password Lock/ Un Lock Yes

Rating Level Yes

Other Yes

OSD Language(Set up Language) Yes

Output(RGB/Composite) No

Open Yes

Close Yes

No disc Yes

Reading Yes

Play Yes

Still/Pause Yes

Stop Yes

Prohibit Mark Yes

Step Yes

Skip(>>|) Yes

Skip(|<<) Yes

Random Yes (CD, VIDEO CD, JPEG )

Repeat Yes

Slow+ ## Yes

Slow- ## Yes

Search+ ## Yes

Search- ## Yes

Jump Yes

Resume Yes

Title No. Yes

Chapter No. Yes

Track No. Yes

Time Yes

Sub Title No. Yes

Angle No. Yes

Vocal On/Off Yes

Audio No. Yes

Audio Stereo L/R Yes (Video CD)

Zoom Yes

Marker No. No

Program Play Back Yes (CD, VIDEO CD, JPEG )

Surround On/Off No

Screen Saver No

JPEG Folder Name Yes

File Name Yes

File No Yes

Time No

Track No Yes

A3-3

GENERAL SPECIFICATIONS

G-13 Remote Unit RC-GD

Control Glow in Dark Remocon Yes

Format NEC

Custom Code 71-8E h

Power Source Voltage(D.C) 3V

UM size x pcs UM-4 x 2 pcs

Total Keys 45 Key

Keys Power Yes

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

0 Yes

Play Yes

Stop Yes

Search+ Yes

Search- Yes

Skip+ Yes

Skip- Yes

Slow+ Yes

Slow- Yes

Pause Yes

Call Yes

TV/DVD Yes

Cancel Yes

Audio Select Yes

Angle Yes

Subtitle Yes

Top Menu Yes

Setup/ Menu Yes

DVD Menu Yes

Return Yes

Up/ Set+/ CH Up Yes

Down/ Set-/ CH Down Yes

Left/Select-/Vol Down Yes

Right/Select+/Vol Up Yes

Select/ Enter Yes

Play Mode Yes

Closed Caption Yes

Input Select Yes

Repeat A-B Yes

Zoom/ Quick View Yes

Mute Yes

Open/Close Yes

Sleep Yes

Jump Yes

Game Yes

A3-4

GENERAL SPECIFICATIONS

G-14 Features CATV Yes

G-15 Accessories Owner's Manual Language English/French

Auto Shut Off Yes

Auto CH Memory Yes

V-Chip USA V-chip No

Auto Search No

SAP Yes

Game Position Yes

FM Transmitter No

Energy Star No

Closed Caption Yes

Comb Filter No

Protect of FBT Leak Circuit Yes

Choke Coil No

Power On Memory No

Tray Lock Yes

Parental Lock (DVD Only) Yes

Video CD Playback Yes

SVCD Playback No

MP3 Playback No

WMA Playback

JPEG Playback Yes

Digital Out (Dolby Digital) Yes

Down Mix Out (Dolby Digital) Yes

Surround (Tru Surround) No

Screen Saver

Picture Preference Yes

Auto Setup Yes

Audio DAC 192kHz / 24bit

Remote Control Unit Yes

Battery Yes

Rod Antenna No

Loop Antenna No

U/V Mixer No

300 ohm to 75 ohm Antenna Adapter Yes

Antenna Change Plug No

Guarantee Card No

Registration Card

Warranty Card No

ESP Card No

Service Station List

DC Car Cord (Center+) No

Columbia Offer Sheet No

Sheet Information (Return) No

CANADA V-chip No

Overlay Graphics And Text No

Command List No

Entry Point Jump No

No

(MPEG) Yes

(PCM) Yes

(DTS) Yes

(DTS) No

No

w/Guarantee Card Yes

UM size x pcs UM-4 x 2 pcs

OEM Brand No

Poles No

Terminal --

Terminal --

No

No

A3-5

GENERAL SPECIFICATIONS

G-16 Interface Switch Front Power (Tact) Yes

Rear Main Power SW No

Indicator Power Yes (Red)

Terminals Front Video Input RCA x 1

Rear Video Input No

G-17 Set Size Approx. W x D x H (mm) 440x386x393

G-18 Weight Net (Approx.) 13.5kg (29.8lbs)

G-19 Carton Master Carton No

Gift Box Yes

Drop Test Natural Dropping At 1 Corner / 3 Edges / 6 Surfaces

Container Stuffing (40' container) 476 Sets

G-20 Material Cabinet Front PS 94V0 DECABROM

PCB Non-Halogen Demand No

G-21 Environment Pb Free Lead-free Solder No

Cd Free No

Channel Up Yes

Channel Down Yes

Volume Up Yes

Volume Down Yes

Play Yes

Open/Close Yes

Skip(>>|) Yes

Skip(|<<) Yes

Still/Pause No

Stop Yes

Main Power SW No

Stand-by No

On Timer No

Audio Input RCA x 2(Stereo)

Other Terminal HeadPhone

Audio Input No

Video Output No

Audio Output No

Digital Audio Output Coaxial (DVD Only)

Diversity No

DC Jack 12V(Center +) No

VHF/UHF Antenna Input F Type

Gross (Approx.) 15.5kg (34.2lbs)

Content --- Sets

Material --- / ---

Dimensions W x D x H(mm) ---

Description of Origin ---

Material Double/White

W/Color Photo Label No

Dimensions W x D x H(mm) 550x496x471

Design As Per Buyer 's

Description of Origin Yes

Height (cm) 62

Rear PS 94V0 DECABROM

Jack Panel -

Eyelet Demand Yes

Other No

A3-6

DISASSEMBLY INSTRUCTIONS

1.REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

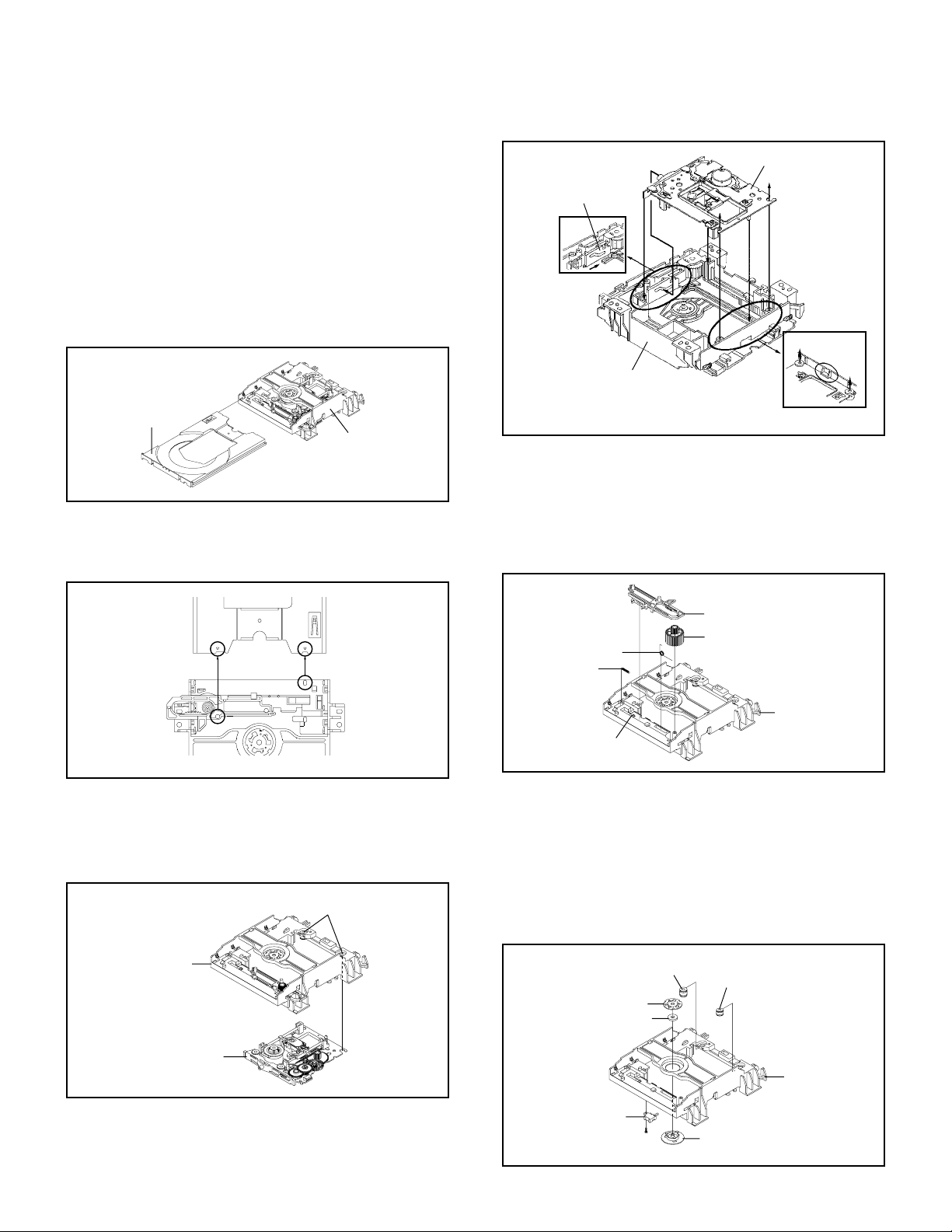

1-1: BACK CABINET (Refer to Fig. 1-1)

1.

Remove the 5 screws 1.

2.

Remove the screw 2 which are used for holding the Back

Cabinet.

3.

Remove the AC cord from the AC cord hook 3.

4.

Remove the Back Cabinet in the direction of arrow.

Front Cabinet

1

1

1

1

2

1

1-2: CRT PCB (Refer to Fig. 1-2)

CAUTION: BEFORE REMOVING THE ANODE CAP,

DISCHARGE ELECTRICITY BECAUSE IT

CONTAINS HIGH VOLTAGE.

BEFORE ATTEMPTING TO REMOVE OR

REPAIR ANY PCB, UNPLUG THE POWER

CORD FROM THE AC SOURCE.

1.

Remove the Anode Cap.

(Refer to REMOVAL OF ANODE CAP)

2.

Disconnect the following connector:

(CP801).

3.

Remove the CRT PCB in the direction of arrow.

Front Cabinet

3

Back Cabinet

CRT PCB

Fig. 1-1

1-3: AV PCB/DVD BLOCK (Refer to Fig. 1-3)

1.

Remove the 2 screws 1.

2.

Disconnect the following connectors:

(CP301, CP302, CP401 and CP3800).

3.

Remove the AV PCB/DVD Block in the direction of arrow.

1

Front Cabinet

AV PCB/DVD Block

1

1-4: DVD BLOCK (Refer to Fig. 1-4)

1.

Remove the 11 screws 1.

2.

Remove the Top Shield in the direction of arrow (A).

3.

Disconnect the following connectors:

(CP8001 and CP8002).

4.

Remove the 4 screws 2.

5.

Remove the DVD Block in the direction of arrow (B).

6.

Remove the screw 3.

7.

Remove the Jack Shield.

8.

Remove the AV PCB in the direction of arrow (C).

1

1

1

1

1

(A)

1

1

1

1

1

2

Top Shield

1

2

2

DVD Block

Fig. 1-3

Fig. 1-2

B1-1

AV PCB

Jack Shield

2

(B)

(C)

Bottom Plate

3

Fig. 1-4

DISASSEMBLY INSTRUCTIONS

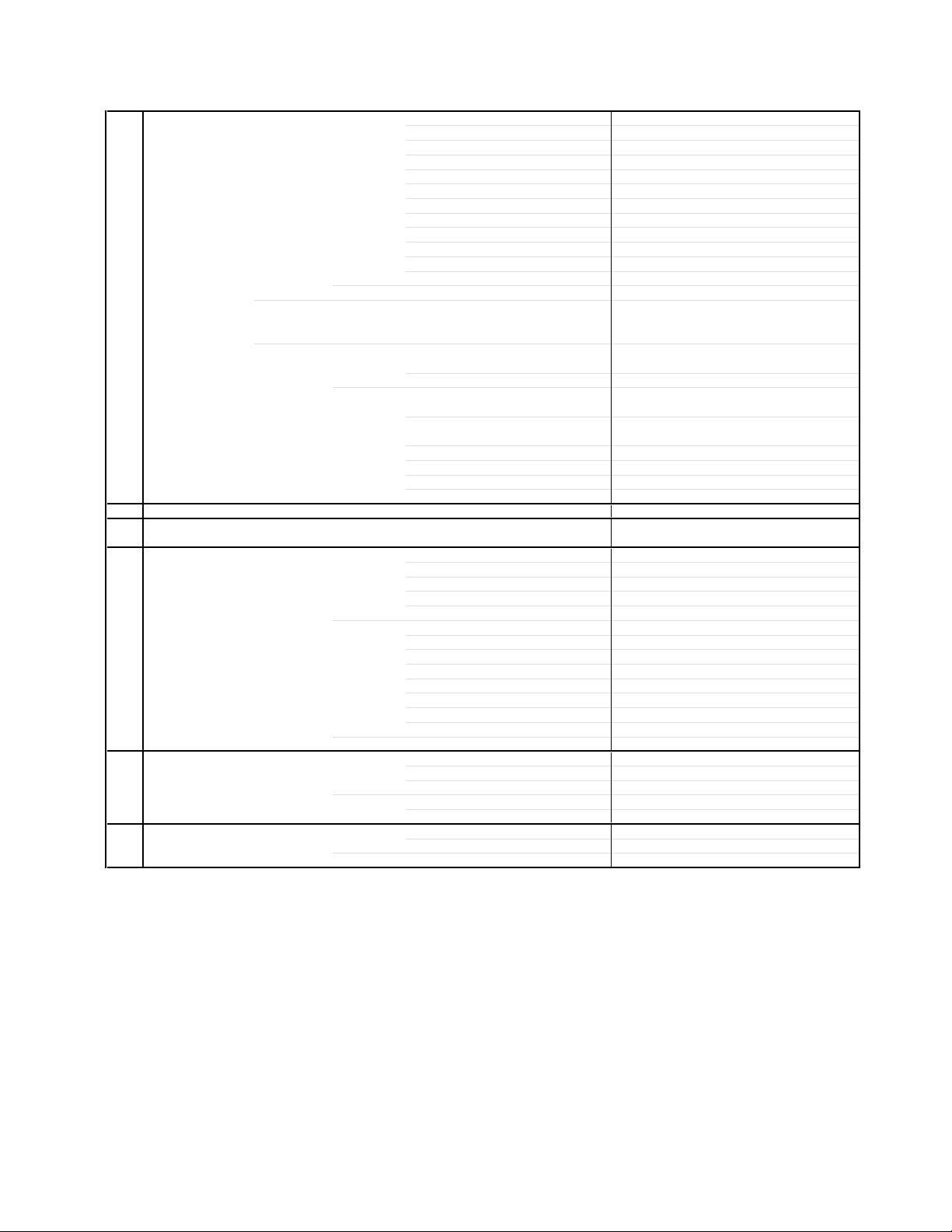

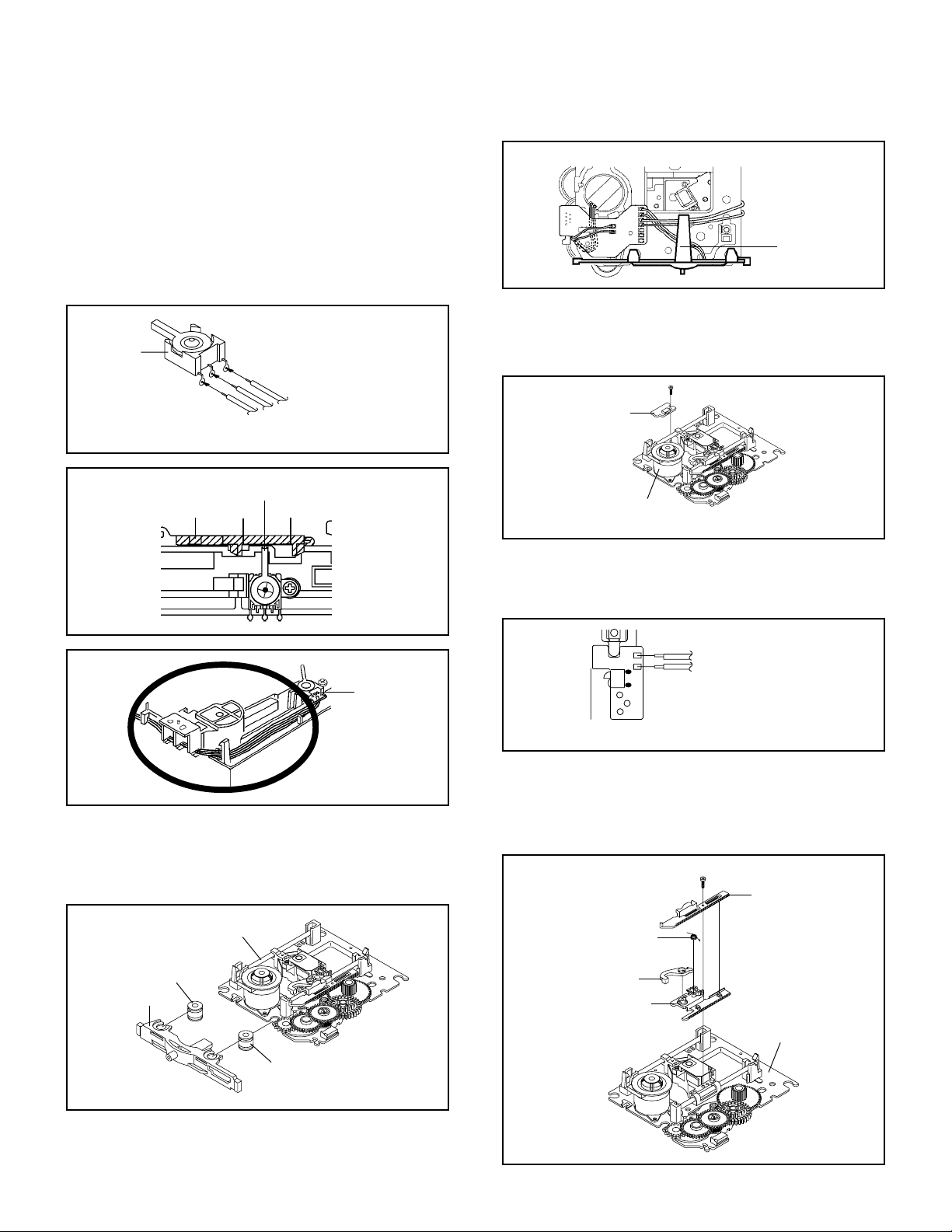

1-5: DVD PCB/DVD DECK (Refer to Fig. 1-5)

1.

Make the short circuit on the position as shown Fig. 1-5

using a soldering. If you remove the DVD Deck with no

soldering, the Laser may be damaged.

2.

Unlock the 2 supports 1.

3.

Remove the Front Tray Plate in the direction of arrow (A).

4.

Disconnect the following connectors:

(CP2601, CP2602 and CP2603).

5.

Remove the 4 screws 2.

6.

Remove the DVD Deck in the direction of arrow (B).

7.

Remove the 4 screws 3.

8.

Remove the DVD PCB in the direction of arrow (C).

DVD Deck

1

(A)

2

3

DVD PCB

Front Tray Plate

1

2

3

3

2

2

(B)

3

(C)

Make the short circuit

using a soldering.

Deck Angle

Pick Up PCB

Fig. 1-5

NOTE

When the installation of the DVD Deck, remove all the

soldering on the short circuit position after the connection of

Pick Up PCB and DVD PCB connector.

B1-2

DISASSEMBLY INSTRUCTIONS

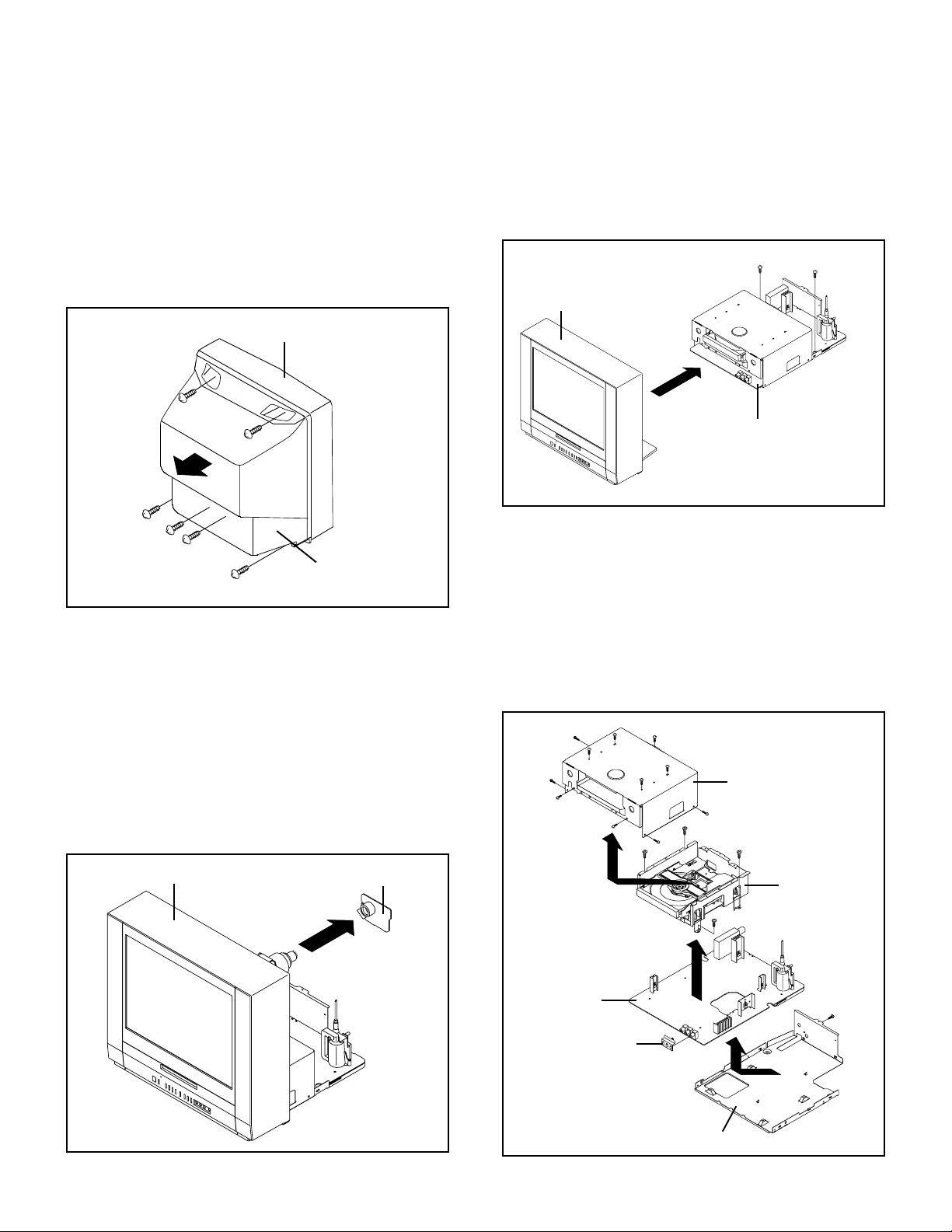

2. REMOVAL OF DVD DECK PARTS

NOTE

1. Do not disassemble the DVD DECK PARTS except listed

parts here. Minute adjustments are needed if the disassemble is done. If the repair is needed except listed parts,

replace the DVD MECHA ASS’Y.

2-1: TRAY (Refer to Fig. 2-1-A)

1.2.Set the Tray opened. (Refer to the DISC REMOVAL

METHOD AT NO POWER SUPPLY)

Unlock the support 1 and remove the Tray.

Tray

NOTE

1. In case of the Tray installation, install them as the circled

section of Fig. 2-1-B so that the each markers are met.

1

Main Frame Ass’y

Fig. 2-1-A

Tray

Main Chassis Ass’y

Rack Loading

Move it to the direction

of the arrow.

1

Main Frame Ass’y

2

3

5

6

4

6

Check Lock

4

Fig. 2-2-B

2-3: RACK LOADING/MAIN GEAR/ RACK LOADING

SPRING/ RACK L SPRING (Refer to Fig. 2-3)

1.

Remove the Rack L Spring.

2.

Press down the catcher 1 and slide the Rack Loading.

3.

Remove the Rack Loading, Rack Loading Spring and

Main Gear.

Rack Loading

Rack Loading Spring

Rack L Spring

Main Gear

5

Main Frame Ass’y

Fig. 2-1-B

2-2: MAIN CHASSIS ASS’Y (Refer to Fig. 2-2-A)

1.

Remove the Main Chassis Ass’y from the Insulator (R).

2.

Unlock the support 1.

3.

Remove the Main Chassis Ass’y.

Insulator (R)

(Green)

Main Frame Ass’y

Main Chassis Ass’y

1

Fig. 2-2-A

NOTE

1. In case of the Main Chassis Ass’y, install it from (1) to (6)

in order. (Refer to Fig. 2-2-B)

1

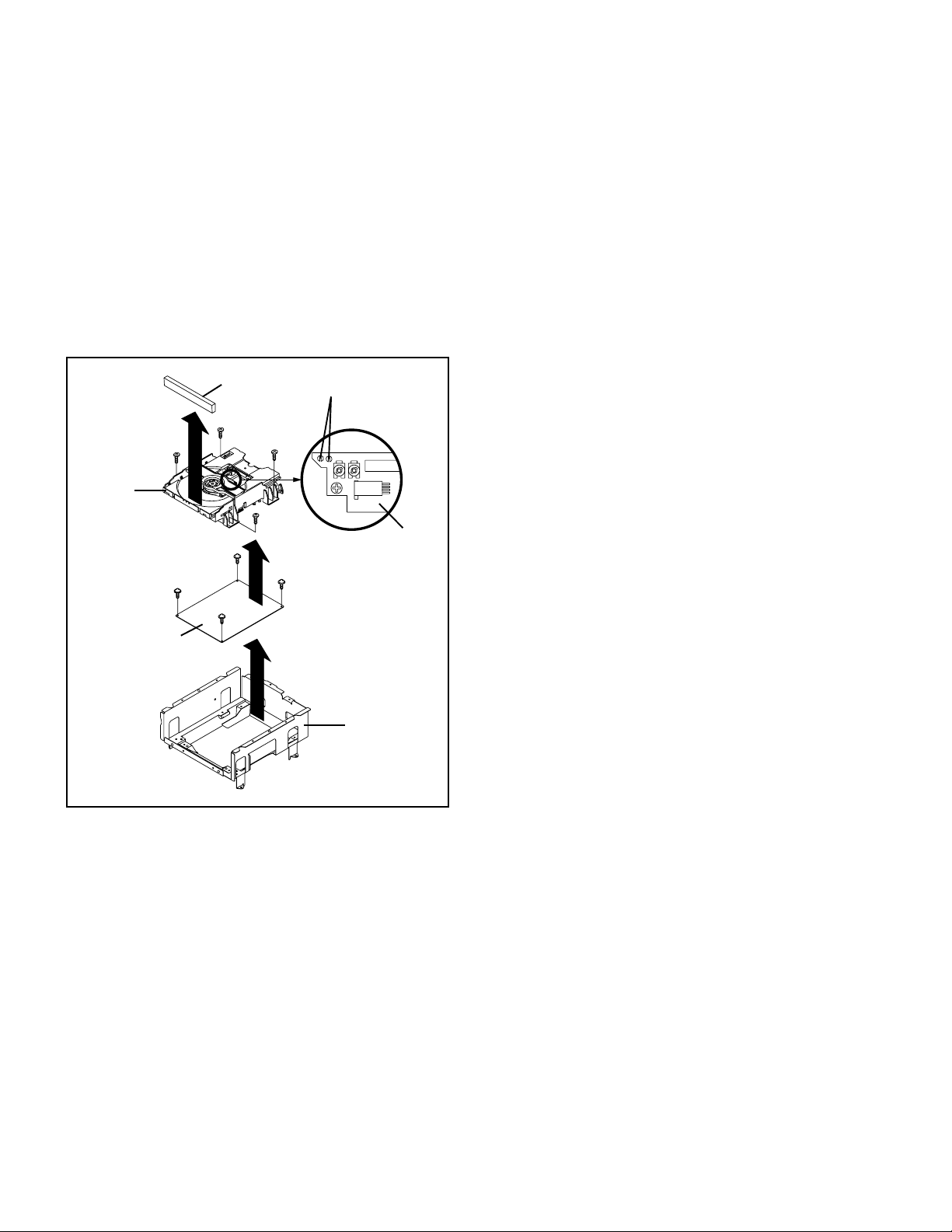

2-4: CLAMPER ASS’Y/INSULATOR(R)/LEVER SWITCH

(Refer to Fig. 2-4-A)

1.

Remove the screw 1.

2.

Remove the Lever Switch.

3.

Remove the 2 Insulator (R).

4.

Press the Clamper and rotate the Clamper Plate clockwise,

then unlock the 3 supports 2.

5.

Remove the Clamper Plate, Clamper Magnet and Clamper.

Insulator (R)

Clamper Plate

Clamper Magnet

Lever Switch

(Green)

2

1

2

2

Insulator (R)

(Green)

Clamper

B2-1

Main Frame Ass’y

Fig. 2-3

Main Frame

Fig. 2-4-A

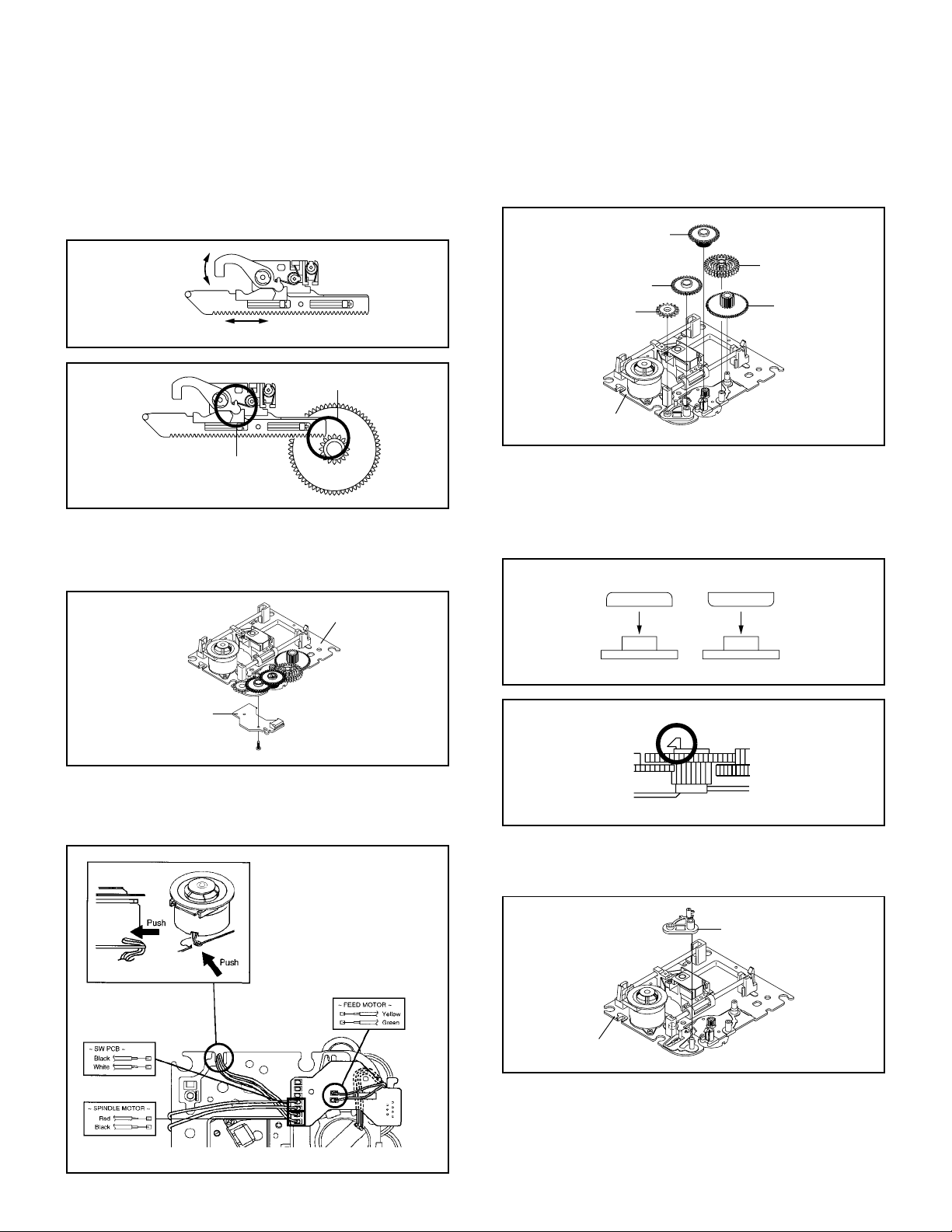

DISASSEMBLY INSTRUCTIONS

NOTE

1.

When installing the Clamper Magnet, install it with the

green face up.

2.

When installing the wire of the Lever Switch, install it

correctly as Fig. 2-4-B.

3.

When installing the Lever Switch, install it correctly as

Fig. 2-4-C.

4.

In case of the Lever Switch installation, hook the wire on

the Main Frame as shown Fig. 2-4-D.

Lever Switch

Red

White

Blue

From DVD PCB

Fig. 2-4-B

The Lever should be position

between A and B.

Rack Loading

A

B

Fig. 2-4-C

Lever Switch

Main Chassis Ass'y

Traverse Holder

2-6: SWITCH PCB ASS'Y (Refer to Fig. 2-6-A)

Remove the screw 1.

1.

Remove the Switch PCB Ass'y.

2.

1

Switch PCB Ass'y

Main Chassis Ass'y

• Screw Torque: 4 ± 0.5kgf•cm

NOTE

When installing the wire of the Switch PCB, install it

1.

correctly as Fig. 2-6-B.

Switch PCB Ass'y

Black

From Relay PCB

White

Fig. 2-5-B

Fig. 2-6-A

Fig. 2-4-D

2-5: TRAVERSE HOLDER/INSULATOR (F)

(Refer to Fig. 2-5-A)

1.2.Remove the Traverse Holder.

Remove the 2 Insulator (F).

Main Chassis Ass’y

Insulator (F)

(Black)

Traverse Holder

Insulator (F)

(Black)

Fig. 2-5-A

NOTE

1. After the installing of the Traverse Holder, check if the

wire is like Fig. 2-5-B.

Main Chassis Ass'y

2-7: RACK FEED ASS'Y (Refer to Fig. 2-7-A)

Remove the screw 1.

1.

Remove the Rack Feed 1 Spring, Rack Feed 1/2 and

2.

Rack Feed Lever.

1

Rack Feed 1 Spring

Rack Feed Lever

Rack Feed 1

• Screw Torque: 3.5 ± 0.5kgf•cm

B2-2

Fig. 2-6-B

Rack Feed 2

Main Chassis Ass'y

Fig. 2-7-A

DISASSEMBLY INSTRUCTIONS

NOTE

1.2.After the assembly of the Rack Feed, check if the Rack

Feed 1/2 is moving smoothly. (Refer to Fig. 2-7-B)

In case of the Rack Feed Ass’y installation, install correctly as Fig. 2-7-C.

Moving smoothly

Moving smoothly

Check the position of

the Rack Feed Lever.

Should not be engaged.

Fig. 2-7-B

Fig. 2-7-C

2-8: RELAY PCB ASS’Y (Refer to Fig. 2-8-A)

1.2.Remove the screw 1.

Remove the Relay PCB Ass’y.

2-9: GEAR (Refer to Fig. 2-9-A)

1.2.Unlock the support 1.

Remove the Middle Gear 1/2/3, Idler Gear and Feed Gear.

Middle Gear 2

Middle Gear 1

Middle Gear 3

Idler Gear

Main Chassis Ass’y

Feed Gear

Fig. 2-9-A

NOTE

1.2.In case of the Idler Gear installation, install correctly as

Fig. 2-9-B.

When installing the Middle Gear 2, check if the Middle

Gear 2 is locked correctly as Fig. 2-9-C.

[OK]

Idler Gear

[NG]

Idler Gear

Main Chassis Ass’y

Relay PCB Ass’y

• Screw Torque: 4 ± 0.5kgf•cm 1

Fig. 2-8-A

NOTE

1. When installing the wire of the Relay PCB, install it

correctly as Fig. 2-8-B.

Idler Arm

Check Lock

Middle Gear 2

Idler Arm

2-10: IDLER ARM (Refer to Fig. 2-10)

Remove the Idler Arm.1.

Idler Arm

Main Chassis Ass'y

Fig. 2-9-B

Fig. 2-9-C

Fig. 2-10

Fig. 2-8-B

B2-3

DISASSEMBLY INSTRUCTIONS

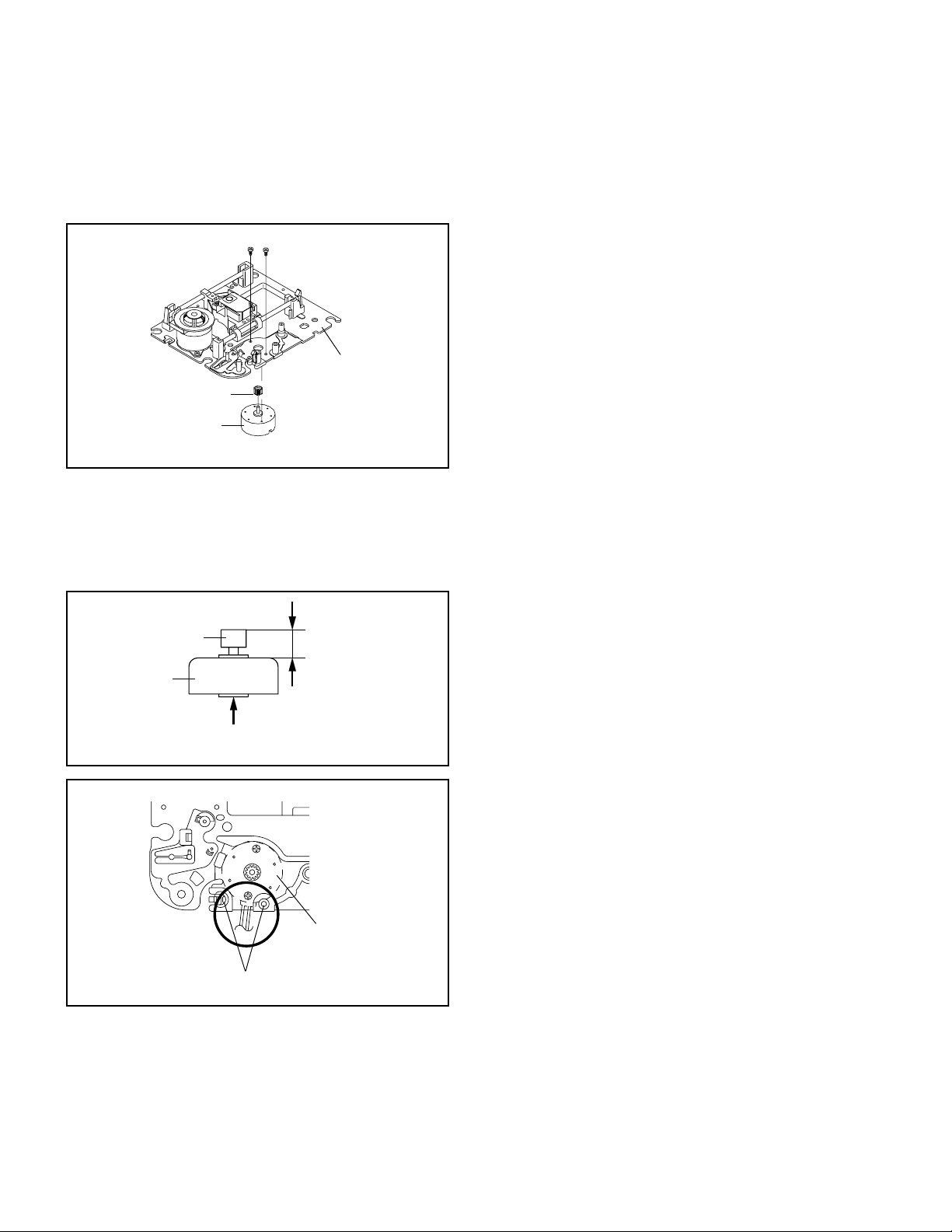

2-11: FEED MOTOR (Refer to Fig. 2-11-A)

Remove the 2 screws 1.

1.

Remove the Feed Motor.

2.

Remove the Motor Gear.

3.

1

1

Main Chassis Ass'y

Motor Gear

Feed Motor

• Screw Torque: 1 ± 0.5kgf•cm

NOTE

1.2.In case of the Motor Gear installation, check if the value

of the Fig. 2-11-B is correct.

When installing the Feed Motor, check if the cable is

positioned as Fig. 2-11-C.

Fig. 2-11-A

Motor Gear

Feed Motor

Safety surface for pressing

of the insert.

Main Chassis Ass'y

Pass the cable

between 2 pins.

6.1 ± 0.1mm

Fig. 2-11-B

Feed Motor

Fig. 2-11-C

B2-4

DISASSEMBLY INSTRUCTIONS

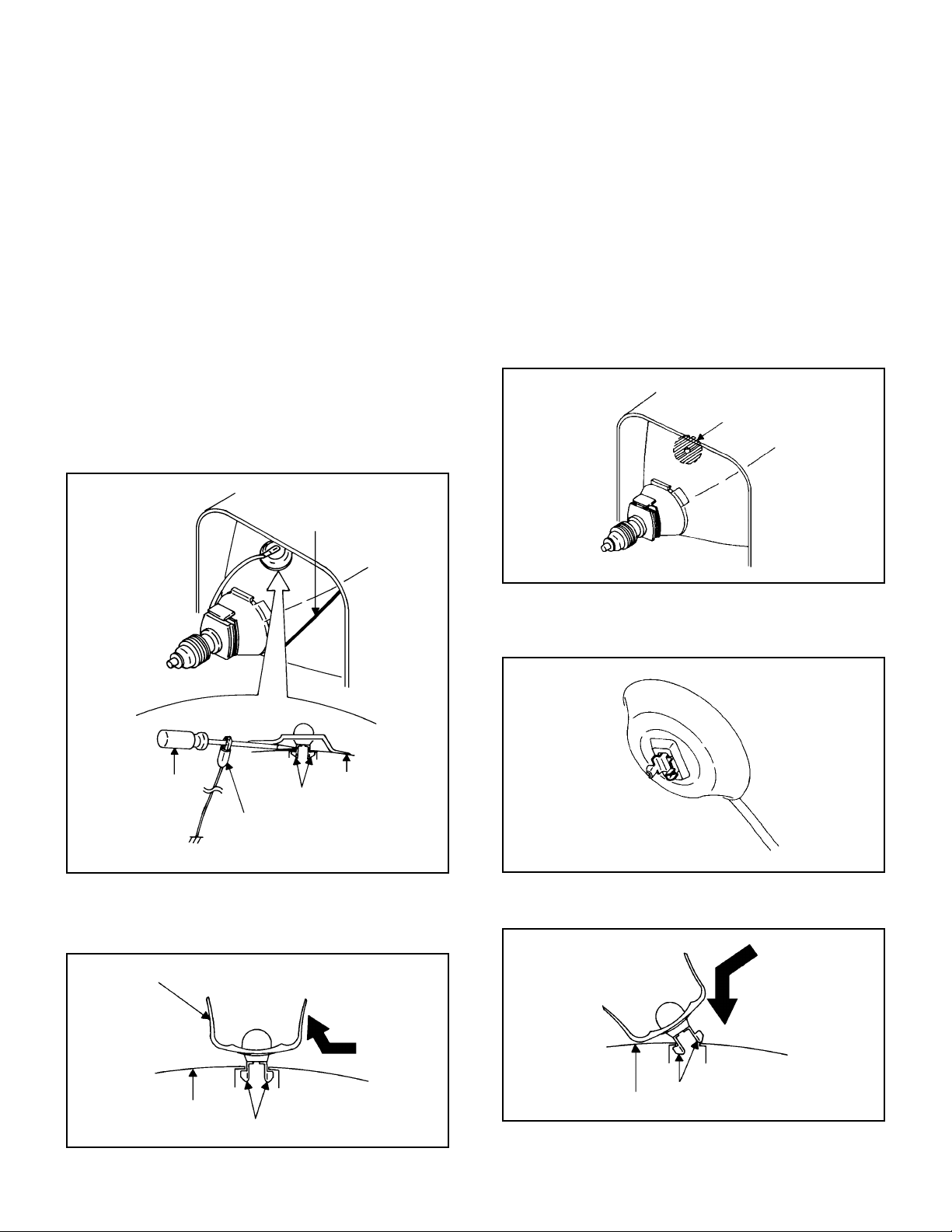

3. REMOVAL OF ANODE CAP

Read the following NOTED items before starting work.

After turning the power off there might still be a potential

*

voltage that is very dangerous. When removing the

Anode Cap, make sure to discharge the Anode Cap's

potential voltage.

*

Do not use pliers to loosen or tighten the Anode Cap

terminal, this may cause the spring to be damaged.

REMOVAL

1. Follow the steps as follows to discharge the Anode Cap.

(Refer to Fig. 3-1.)

Connect one end of an Alligator Clip to the metal part of a

flat-blade screwdriver and the other end to ground.

While holding the plastic part of the insulated Screwdriver,

touch the support of the Anode with the tip of the

Screwdriver.

A cracking noise will be heard as the voltage is discharged.

GND on the CRT

3. After one side is removed, pull in the opposite direction to

remove the other.

NOTE

Take care not to damage the Rubber Cap.

INSTALLATION

1. Clean the spot where the cap was located with a small

amount of alcohol. (Refer to Fig. 3-3.)

NOTE

Confirm that there is no dirt, dust, etc. at the spot where

the cap was located.

Location of Anode Cap

Fig. 3-3

Screwdriver

Alligator Clip

GND on the CRT

Flip up the sides of the Rubber Cap in the direction of the

2.

arrow and remove one side of the support.

(Refer to Fig. 3-2.)

Rubber Cap

Support

CRT

Fig. 3-1

2.3.Arrange the wire of the Anode Cap and make sure the

wire is not twisted.

Turn over the Rubber Cap. (Refer to Fig. 3-4.)

Fig. 3-4

4. Insert one end of the Anode Support into the anode button,

then the other as shown in Fig. 3-5.

CRT

Support

Fig. 3-2

Support

CRT

5.6.Confirm that the Support is securely connected.

Put on the Rubber Cap without moving any parts.

B3-1

Fig. 3-5

DISASSEMBLY INSTRUCTIONS

4. REMOVAL AND INSTALLATION OF FLAT

PACKAGE IC

REMOVAL

1. Put the Masking Tape (cotton tape) around the Flat

Package IC to protect other parts from any damage.

(Refer to Fig. 4-1.)

NOTE

Masking is carried out on all the parts located within

10 mm distance from IC leads.

Masking Tape

(Cotton Tape)

2. Heat the IC leads using a blower type IC desoldering

machine. (Refer to Fig. 4-2.)

NOTE

Do not add the rotating and the back and forth directions force on the IC, until IC can move back and forth

easily after desoldering the IC leads completely.

IC

Fig. 4-1

Blower type IC

desoldering machine

3. When IC starts moving back and forth easily after

desoldering completely, pickup the corner of the IC using

a tweezers and remove the IC by moving with the IC

desoldering machine. (Refer to Fig. 4-3.)

NOTE

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

leads or solder lands under the IC when removing it.

Blower type IC

desoldering machine

Tweezers

IC

4.5.Peel off the Masking Tape.

Absorb the solder left on the pattern using the Braided

Shield Wire. (Refer to Fig. 4-4.)

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Fig. 4-3

Braided Shield Wire

Soldering Iron

IC

Fig. 4-2

IC pattern

Fig. 4-4

B4-1

DISASSEMBLY INSTRUCTIONS

INSTALLATION

1. Take care of the polarity of new IC and then install the

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 4-5.)

Soldering Iron

Solder temporarily

Solder temporarily

Fig. 4-5

2. Supply the solder from the upper position of IC leads

sliding to the lower position of the IC leads.

(Refer to Fig. 4-6.)

4. When bridge-soldering between terminals and/or the

soldering amount are not enough, resolder using a Thintip Soldering Iron. (Refer to Fig. 4-8.)

IC

Thin-tip Soldering Iron

Fig. 4-8

5. Finally, confirm the soldering status on four sides of the

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

When the IC leads are bent during soldering and/or

repairing, do not repair the bending of leads. If the

bending of leads are repaired, the pattern may be

damaged. So, always be sure to replace the IC in this

case.

Solder

IC

Supply soldering

from upper position

to lower position

Soldering Iron

Fig. 4-6

3. Absorb the solder left on the lead using the Braided

Shield Wire. (Refer to Fig. 4-7.)

NOTE

Do not absorb the solder to excess.

Soldering Iron

IC

Braided Shield Wire

Fig. 4-7

B4-2

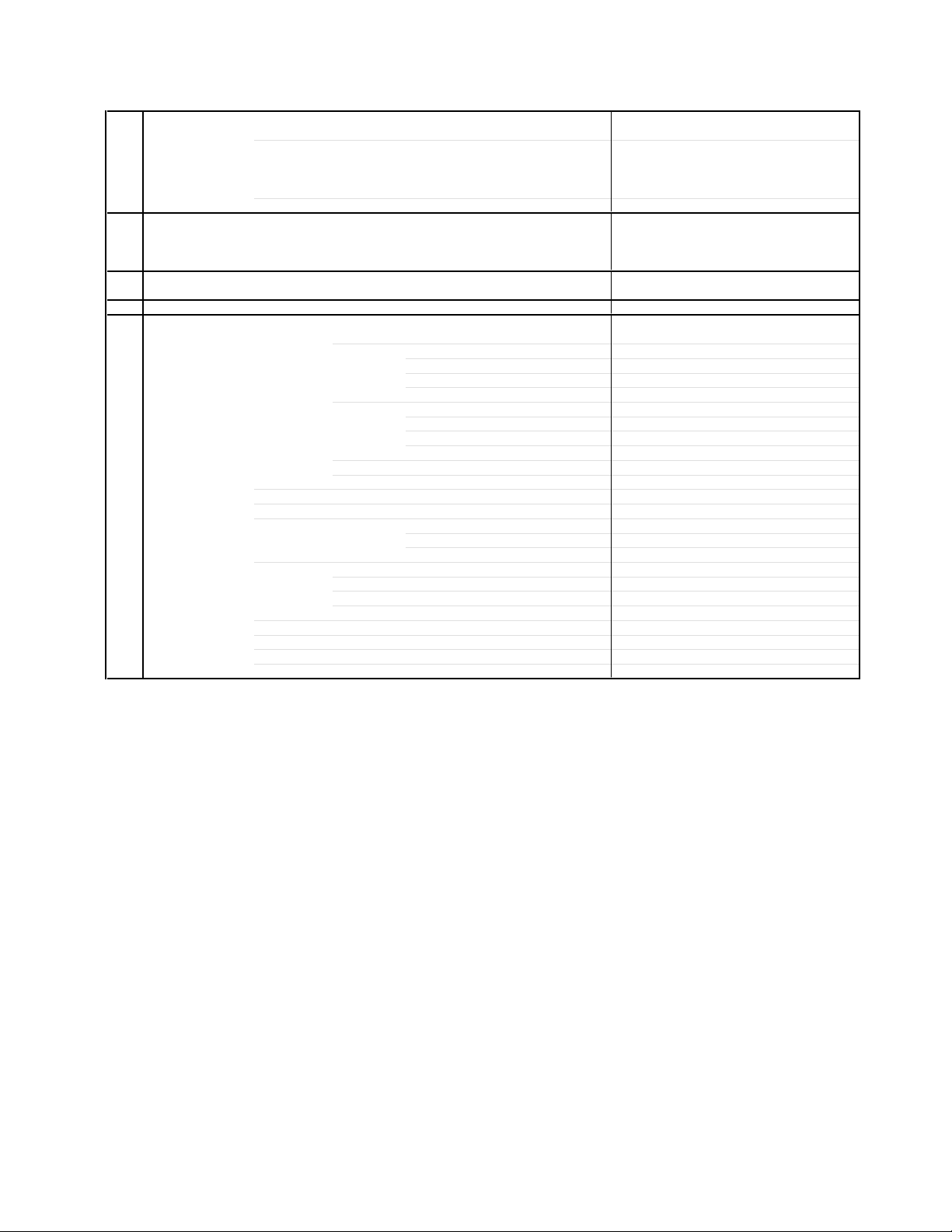

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter to the SERVICE MODE function, press and hold both buttons simultaneously on the main unit and on the remote control

for more than a standard time (second).

Set

Condition

TV mode

TV mode

DVD mode

(No disc)

TV mode

ALL mode

DVD mode

(No disc)

Set Key Operations

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

STOP 7 3 sec.

Remocon

Key

0 1 sec.

1 1 sec.

4 1 sec.

6 1 sec.

9 1 sec.

Standard

Time

Releasing of V-CHIP PASSWORD.

Initialization of the factory on TV.

NOTE:

Initialization of the factory on DVD.

NOTE: Do not use this for the normal servicing.

POWER ON total hours are displayed on the screen.

Refer to the "PREVENTIVE CHECKS AND SERVICE INTERVALS"

(CONFIRMATION OF HOURS USED).

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display

Adjustment).

Releasing of PARENTAL LOCK.

Refer to the “PARENTAL CONTROL - RATING LEVEL”.

NOTE:

Do not use this for the normal servicing.

If you set a factory initialization, the memories are reset such

as the channel setting, and the POWER ON total hours.

The function will only work without the setting of DVD disc at

DVD mode.

The function will only work without the setting of DVD disc at

DVD mode.

DVD mode

(Stop)

STOP 9 3 sec.

Tray cannot be opened.

Refer to the “TRAY LOCK”.

NOTE: No indications on the screen when the Tray Lock is setting.

CONFIRMATION OF HOURS USED

POWER ON total hours can be checked on the screen. Total hours are displayed in 16 system of notation.

NOTE: If you set a factory initialization, the total hours is reset to "0".

INIT 00 06

CRT ON 0010

C-1

ADDRESS DATA

FIG. 1

Initial setting content of MEMORY IC.

POWER ON total hours.

= (16 x 16 x 16 x thousands digit value)

+ (16 x 16 x hundreds digit value)

+ (16 x tens digit value)

+ (ones digit value)

1.

Turn on the POWER, and set to the TV mode.

2.

Set the VOLUME to minimum.

3.

Press both VOL. DOWN button on the set and Channel

button (6) on the remote control for more than 1 second.

4.

After the confirmation of using hours, turn off the power.

WHEN REPLACING EEPROM (MEMORY) IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to TABLE 1.

NOTE: No need setting for after INI 27.

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9

06 0F 44 20 D0 35 30 25 15 54

30 50 04 15 7D 23 50 20 77

10 50

0A 10 12 14 16 18 1A --- ---20 0D

Table 1

1.

Turn on the POWER, and set to the TV mode.

2.

Enter DATA SET mode by setting VOLUME to minimum.

3.

Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 1 second.

ADDRESS and DATA should appear as FIG 1.

ADDRESS DATA

INIT 00 06

CRT ON 0010

FIG. 1

4.

ADDRESS is now selected and should "blink". Using the VOL. UP/DOWN button on the remote, step through the ADDRESS

until required ADDRESS to be changed is reached.

5.

Press ENTER to select DATA. When DATA is selected, it will "blink".

6.

Again, step through the DATA using VOL. UP/DOWN button until required DATA value has been selected.

7.

Pressing ENTER will take you back to ADDRESS for further selection if necessary.

8.

Repeat steps 4 to 7 until all data has been checked.

9.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

+A

+B +C +D +E +FINI

00 C9 30 0F 4700

02

55 00 02 11 00 00

--- --- --- --- --- ---

After the data input, set to the initializing of shipping.

10.

Turn on the POWER, and set to the TV mode.

11.

Press both VOL. DOWN button on the set and Channel button (1) on the remote control for more than 1 second.

12.

After the finishing of the initializing of shipping, the unit will turn off automatically.

The unit will now have the correct DATA for the new MEMORY IC.

C-2

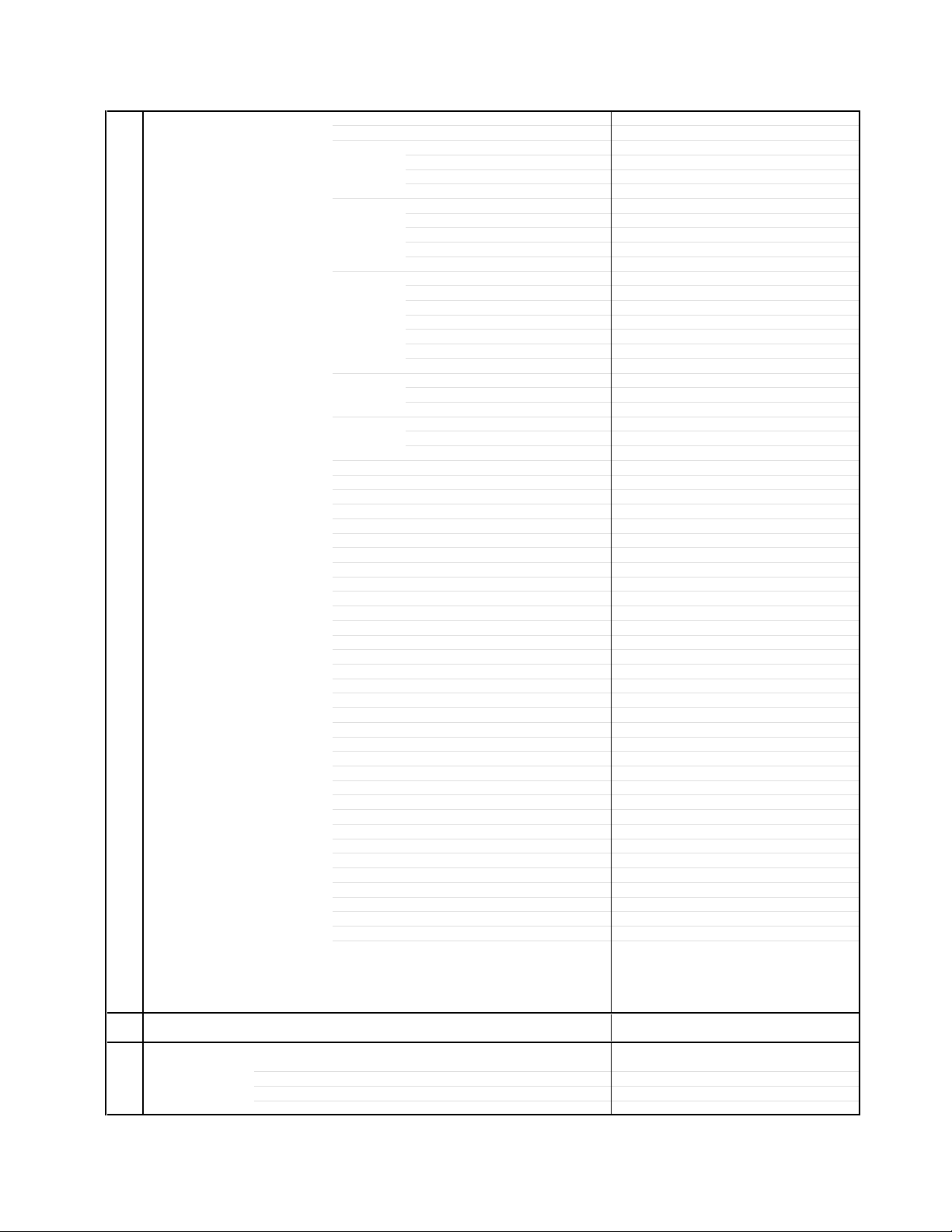

ELECTRICAL ADJUSTMENTS

1.

BEFORE MAKING ELECTRICAL

ADJUSTMENTS

Read and perform these adjustments when repairing the

circuits or replacing electrical parts or PCB assemblies.

CAUTION

•

Use an isolation transformer when performing any service

on this chassis.

•

Before removing the anode cap, discharge electricity

because it contains high voltage.

•

When removing a PCB or related component, after

unfastening or changing a wire, be sure to put the wire

back in its original position.

•

When you exchange IC and Transistor for a heat sink,

apply the silicon grease on the contact section of the heat

sink. Before applying new silicon grease, remove all the old

silicon grease. (Old grease may cause damages to the IC

and Transistor).

Prepare the following measurement tools for electrical

adjustments.

1. Oscilloscope

2. Digital Voltmeter

3. AC Voltmeter

4. Pattern Generator

5. Multi-Sound Signal Generator

On-Screen Display Adjustment

Set the VOLUME to minimum.

1.

Press the VOL. DOWN button on the set and the Channel

2.

button (9) on the remote control for more than 1 second

to appear the adjustment mode on the screen as shown

in Fig. 1-1.

Function

Step No.

01 OSD

14

NO.

FUNCTION

01

OSD H

02

OSD CONTRAST

03

CUT OFF

04

H POSITION

05

H BLK L

06

H BLK R

07

V SIZE

08

V POSITION

09

V LINEARITY

10

V S CORRECTION

11

V COMP

12

R CUT OFF

13

G CUT OFF

14

B CUT OFF

15

R DRIVE

16

G DRIVE

17

B DRIVE

18

BRIGHTNESS(CENT.)

19

BRIGHTNESS(MAX)

20

BRIGHTNESS(MIN)

21

CONTRAST(CENT.)

22

CONTRAST(MAX)

23

CONTRAST(MIN)

24

COLOR(CENT.)

25

COLOR(MAX)

26

COLOR(MIN)

27

TINT

28

SHARPNESS

29

SUB BIAS

30

BRI. AV(CENT.)

31

BRI. AV(MAX)

32

BRI. AV(MIN)

33

CONT. AV(CENT.)

34

CONT. AV(MAX)

35

CONT. AV(MIN)

36

COL. AV(CENT.)

37

COL. AV(MAX)

38

COL. AV(MIN)

FUNCTION

NO.

39

TINT AV

40

SHARPNESS AV

41

SUB BIAS

42

BRI. DVD(CENT.)

43

BRI. DVD(MAX)

44

BRI. DVD(MIN)

45

CONT. DVD(CENT.)

46

CONT. DVD(MAX)

47

CONT. DVD(MIN)

48

COL. DVD(CENT.)

49

COL. DVD(MAX)

50

COL. DVD(MIN)

51

TINT DVD

52

SHARPNESS DVD

53

SUB BIAS

54

BRI. GAME(CENT.)

55

BRI. GAME(MAX)

56

BRI. GAME(MIN)

57

CONT. GAME(CENT.)

58

CONT. GAME(MAX)

59

CONT. GAME(MIN)

60

SUB BIAS

61

TUNING V MUTE

62

POWER ON V MUTE

63

INPUT LEVEL

64

SEPARATION L

65

SEPARATION H

66

X-RAY TEST

67

H STOP

68

H FREQ

69

BAST/WEST DC

70

BAST/WEST AMP

71

BAST/WEST TILT

72

BAST/WEST COR, TOP

73

BAST/WEST COR, BOT

74

H SIZE COMP

75

H BLK L AV

76

H BLK R AV

2. BASIC ADJUSTMENTS

2-1: CONSTANT VOLTAGE

1.

Set condition is AV MODE without signal.

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Connect the digital voltmeter to TP401.

4.

Adjust the VR3800 until the digital voltmeter is 115 ± 1V.

2-2: FOCUS

1.

Receive the monoscope pattern.

2.

Turn the Focus Volume fully counterclockwise once.

3.

Adjust the Focus Volume until picture is distinct.

Fig. 1-2

Use the Channel UP/DOWN button or Channel button (1-

3.

0) on the remote control to select the options shown in

Fig. 1-2.

Press the MENU button on the remote control to end the

4.

adjustments.

Fig. 1-1

2-3: CUT OFF

1.

2.

3.

4.

5.

6.

D-1

Adjust the unit to the following settings.

R CUT OFF=7F, G CUT OFF=7F, B CUT OFF=7F,

R DRIVE=3F, G DRIVE=07, B DRIVE=3F

Place the set with Aging Test for more than 15 minutes.

Set condition is AV MODE without signal.

Using the remote control, set the brightness and contrast

to normal position.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (03) on the remote control to

select "CUT OFF".

Adjust the Screen Volume until a dim raster is obtained.

ELECTRICAL ADJUSTMENTS

2-4: WHITE BALANCE

NOTE: Adjust after performing CUT OFF adjustment.

1.

Place the set with Aging Test for more than 15 minutes.

2.

Receive the gray scale pattern from the Pattern

Generator.

3.

Using the remote control, set the brightness and contrast

to normal position.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (16) on the remote control to

select "G DRIVE".

5.

Press the CH. UP/DOWN button on the remote control to

select the "R CUT OFF", "G CUT OFF", "B CUT OFF", "R

DRIVE" or "B DRIVE".

6.

Adjust the VOL. UP/DOWN button on the remote control

to whiten the R CUT OFF, G CUT OFF, B CUT OFF, R

DRIVE, and B DRIVE at each step tone sections equally.

7.

Perform the above adjustments 5 and 6 until the white

color is looked like a white.

2-5: HORIZONTAL POSITION

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (04) on the remote control to

select "HPOSI".

4.

Press the VOL. UP/DOWN button on the remote control

until the SHIFT quantity of the OVER SCAN on right and

left becomes minimum.

2-6: VERTICAL POSITION

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (08) on the remote control to

select "VPOSI".

4.

Check if the step No. V POSI is "02".

5.

Adjust the VR401 until the horizontal line becomes fit

to notch of the shadow mask.

2-7: VERTICAL SIZE

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (07) on the remote control to

select "VSIZE".

4.

Press the VOL. UP/DOWN button on the remote control

until the Up/Down OVER SCAN Quantity becomes equal

to the Right/Left OVER SCAN Quantity.

5.

Receive a broadcast and check if the picture is normal.

2-8: VERTICAL LINEARITY

NOTE:

1.

2.

3.

4.

2-9: SEPARATION

Please do the method (1) or method (2) adjustment.

Method (1)

1.

2.

3.

4.

5.

6.

7.

Method (2)

1.

2.

3.

4.

5.

6.

7.

8.

9.

Adjust after performing adjustments in section 2-7.

After the adjustment of Vertical Linearity, reconfirm

the Vertical Position and Vertical Size adjustments.

Receive the monoscope pattern.

Using the remote control, set the brightness and contrast

to normal position.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (09) on the remote control to

select "VLIN".

Press the VOL. UP/DOWN button on the remote control

until the SHIFT quantity of the OVER SCAN on upside

and downside becomes minimum.

Set the multi-sound signal generator for each different Lch and R-ch frequency (Ex. L-ch=2KHz, R-ch=400Hz)

and receive the RF signal.

Connect the oscilloscope to the Audio Out Jack.

Press the AUDIO button on the remote control to set to

the stereo mode.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (64) on the remote control to

select “SEPAL”.

Press the VOL. UP/DOWN button on the remote control

to adjust it until the audio output wave becomes a fine

sine wave.

Press the CH UP button 1 time to set to "SEPAH" mode.

Press the VOL. UP/DOWN button on the remote control

to adjust it until the audio output wave becomes a fine

sine wave.

Set the multi-sound signal generator L-ch=1KHz, R-ch

=Non input and receive the RF signal.

Connect the oscilloscope to the Audio Out Jack (R-ch).

Press the AUDIO button on the remote control to set to

the stereo mode.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (64) on the remote control to

select “SEPAL”.

Press the VOL. UP/DOWN button on the remote control

to adjust it until the R-ch output becomes minimum.

Press the CH UP button 1 time to set to "SEPAH" mode.

Press the VOL. UP/DOWN button on the remote control

to adjust it until the R-ch output becomes minimum.

Set the multi-sound signal generator L-ch=Non input,

R-ch=1KHz and receive the RF signal.

Connect the oscilloscope to the Audio Out Jack (L-ch).

Then perform the above adjustments 3~7.

D-2

ELECTRICAL ADJUSTMENTS

2-10: OSD HORIZONTAL

Activate the adjustment mode display of Fig. 1-1.

1.

Press the VOL. UP/DOWN button on the remote control

2.

until the difference of A and B becomes minimum.

(Refer to Fig. 2-1)

01 OSD

14

A

2-11: LEVEL

1.

Receive the VHF HIGH (70dB).

2.

Connect the AC voltmeter to pin 6 of CP101.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (63) on the remote control to

select "LVL".

4.

Press the VOL. UP/DOWN button on the remote control

until the AC voltmeter is 75 ± 2mV.

2-12: BRIGHT CENTER

1.

Receive the monoscope pattern. (RF Input)

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (18) on the remote control to

select "BRTC".

4.

Press the VOL. UP/DOWN button on the remote control

until the white 0% is starting to be visible

5.

Receive the monoscope pattern. (Audio Video Input)

6.

Press the INPUT SELECT button on the remote control

to set to the AV mode.

7.

Using the remote control, set the brightness and contrast

to normal position.

8.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (30) on the remote control to

select "BRTCA".

9.

Press the VOL. UP/DOWN button on the remote control

until the white 0% is starting to be visible

10.

Press the TV/DVD button on the remote control to set to

the DVD mode.

11.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (42) on the remote control to

select "BRTCD".

12.

Press the VOL. UP/DOWN button on the remote control

to increase the step numbers by 5 step to the AV.

13.

Press the GAME button on the remote control to set to

the GAME mode.

14.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (54) on the remote control to

select "BRTCG".

15.

Press the VOL. UP/DOWN button on the remote control

to set the same step numbers as the AV.

B

Fig. 2-1

2-13: TINT CENTER

1.

Receive the color bar pattern. (RF Input)

2.

Using the remote control, set the brightness, contrast,

color and tint to normal position.

3.

Connect the oscilloscope to TP024.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (27) on the remote control to

select "TNTC".

5.

Press the VOL. UP/DOWN button on the remote control

until the section "A" becomes a straight line.

(Refer to Fig. 2-2)

6.

Receive the color bar pattern. (Audio Video Input)

7.

Press the INPUT SELECT button on the remote control

to set to the AV mode.

8.

Using the remote control, set the brightness, contrast,

color and tint to normal position.

9.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (39) on the remote control to

select "TNTCA".

10.

Press the VOL. UP/DOWN button on the remote control

until the section "A" becomes a straight line.

(Refer to Fig. 2-2)

11.

Press the TV/DVD button on the remote control to set to

the DVD mode.

12.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (51) on the remote control to

select "TNTCD".

13.

Press the VOL. UP/DOWN button on the remote control

to set the same step numbers as the AV.

D-3

"A"

Fig. 2-2

ELECTRICAL ADJUSTMENTS

2-14: COLOR CENTER

1.

Receive the color bar pattern. (RF Input)

2.

Using the remote control, set the brightness, contrast,

color and tint to normal position.

3.

Connect the oscilloscope to TP022.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (24) on the remote control to

select "COLC".

5.

Adjust the VOLTS RANGE VARIABLE knob of the

oscilloscope until the range between white 100% and 0%

is set to 4 scales on the screen of the oscilloscope.

6.

Press the VOL. UP/DOWN button on the remote control

until the red color level is adjusted to 110 ± 10% of the

white level. (Refer to Fig. 2-3)

7.

Receive the color bar pattern. (Audio Video Input)

8.

Press the INPUT SELECT button on the remote control

to set to the AV mode.

9.

Using the remote control, set the brightness, contrast,

color and tint to normal position.

10.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (36) on the remote control to

select "COLCA".

11.

Adjust the VOLTS RANGE VARIABLE knob of the

oscilloscope until the range between white 100% and 0%

is set to 4 scales on the screen of the oscilloscope.

12.

Press the VOL. UP/DOWN button on the remote control

until the red color level is adjusted to 110 ± 10% of the

white level. (Refer to Fig. 2-3)

13.

Press the TV/DVD button on the remote control to set to

the DVD mode.

14.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (48) on the remote control to

select "COLCD".

15.

Press the VOL. UP/DOWN button on the remote control

to decrease the step numbers by 8 steps to the AV.

White 0%

100%

White 100%

Red Level

Fig. 2-3

2-15: CONTRAST MAX

Activate the adjustment mode display of Fig. 1-1 and

1.

press the channel button (22) on the remote control to

select "CNTX".

Press the VOL. UP/DOWN button on the remote control

2.

until the contrast step No. becomes "54"

Receive a broadcast and check if the picture is normal.

3.

Press the INPUT SELECT button on the remote control

4.

to set to the AV mode.

Activate the adjustment mode display of Fig. 1-1 and

5.

press the channel button (34) on the remote control to

select "CNTXA".

Press the VOL. UP/DOWN button on the remote control

6.

until the contrast step No. becomes "53"

Receive a broadcast and check if the picture is normal.

7.

Press the TV/DVD button on the remote control to set to

8.

the DVD mode.

Activate the adjustment mode display of Fig. 1-1 and

9.

press the channel button (46) on the remote control to

select "CNTXD".

Press the VOL. UP/DOWN button on the remote control

10.

to set the same step numbers as the AV.

Press the GAME button on the remote control to set to

11.

the GAME mode.

Activate the adjustment mode display of Fig. 1-1 and

12.

press the channel button (58) on the remote control to

select "CNTXG".

Press the VOL. UP/DOWN button on the remote control

13.

to set the same step numbers as the AV.

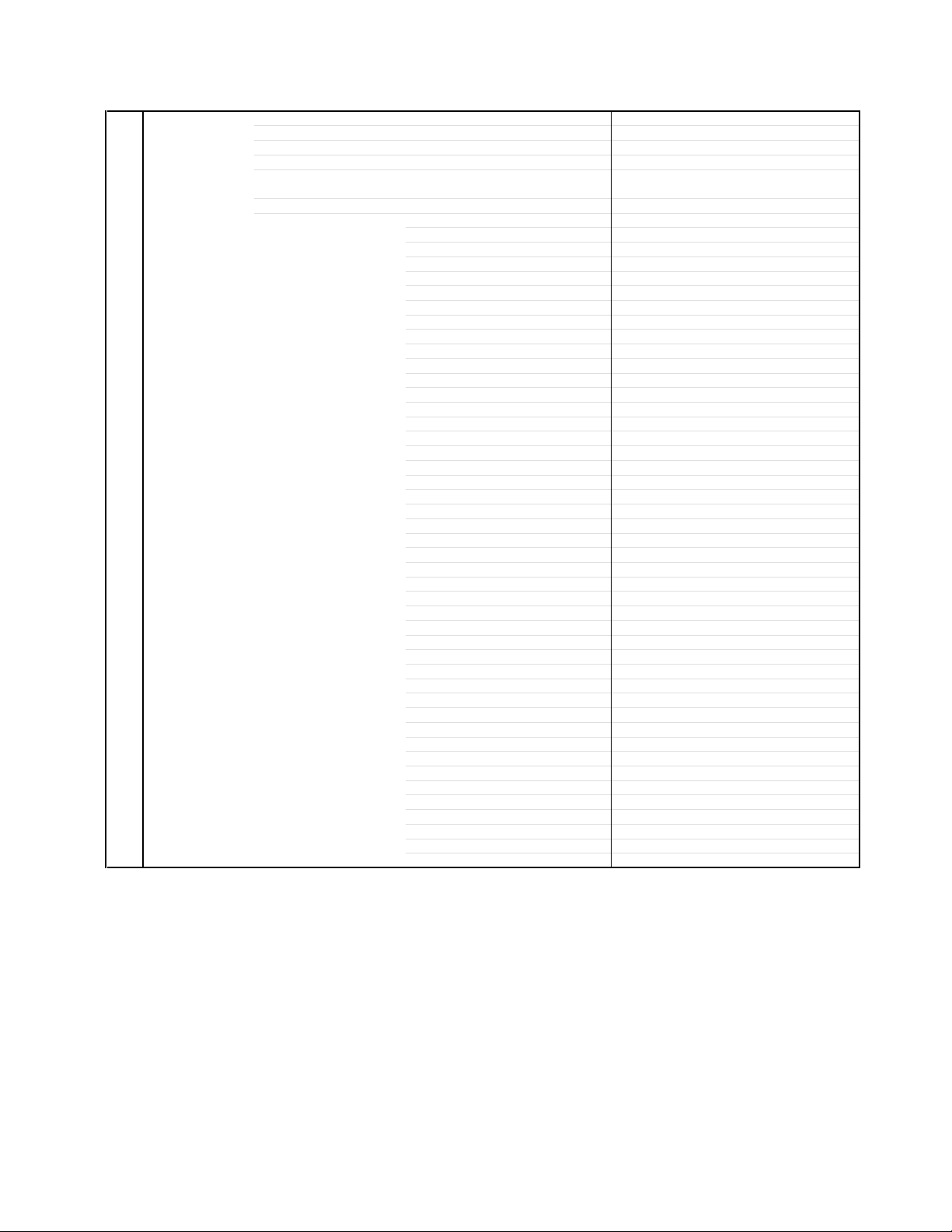

2-16: Confirmation of Fixed Value (Step No.)

Please check if the fixed values of the each adjustment

items are set correctly referring below.

NO.

FUNCTION

02

OSD CONTRAST

05

H BLK L

06

H BLK R

08

V POSITION

10

V S CORRECTION

11

V COMP

16

G DRIVE

19

BRIGHTNESS(MAX)

20

BRIGHTNESS(MIN)

21

CONTRAST(CENT.)

23

CONTRAST(MIN)

25

COLOR(MAX)

26

COLOR(MIN)

28

SHARPNESS

29

SUB BIAS

31

BRI. AV(MAX)

32

BRI. AV(MIN)

33

CONT. AV(CENT.)

35

CONT. AV(MIN)

37

COL. AV(MAX)

38

COL. AV(MIN)

40

SHARPNESS AV

41

SUB BIAS

43

BRI. DVD(MAX)

STEP NO.

03

04

02

02

0B

03

07

50

10

2A

10

70

10

18

00

50

10

2A

10

70

10

10

00

70

FUNCTION

NO.

BRI. DVD(MIN)

44

CONT. DVD(CENT.)

45

CONT. DVD(MIN)

47

COL. DVD(MAX)

49

COL. DVD(MIN)

50

SHARPNESS DVD

52

SUB BIAS

53

BRI. GAME(MAX)

55

BRI. GAME(MIN)

56

CONT. GAME(CENT.)

57

CONT. GAME(MIN)

59

SUB BIAS

60

TUNING V MUTE

61

POWER ON V MUTE

62

H FREQ

68

BAST/WEST DC

69

BAST/WEST AMP

70

BAST/WEST TILT

71

BAST/WEST COR, TOP

72

BAST/WEST COR, BOT

73

H SIZE COMP

74

H BLK L AV

75

H BLK R AV

76

STEP NO.

10

2A

10

70

10

10

00

3F

10

2A

10

00

00

40

3F

00

00

00

00

00

00

00

00

D-4

ELECTRICAL ADJUSTMENTS

3.

PURITY AND CONVERGENCE

ADJUSTMENTS

NOTE

Turn the unit on and let it warm up for at least 30

1.

minutes before performing the following adjustments.

Place the CRT surface facing east or west to reduce the

2.

terrestrial magnetism.

Turn ON the unit and demagnetize with a Degauss Coil.

3.

3-1: STATIC CONVERGENCE (ROUGH ADJUSTMENT)

1.

Tighten the screw for the magnet. Refer to the adjusted

CRT for the position. (Refer to Fig. 3-1)

If the deflection yoke and magnet are in one body,

untighten the screw for the body.

2.

Receive the green raster pattern from the color bar

generator.

3.

Slide the deflection yoke until it touches the funnel

side of the CRT.

4.

Adjust center of screen to green, with red and blue on the

sides, using the pair of purity magnets.

5.

Switch the color bar generator from the green raster

pattern to the crosshatch pattern.

6.

Combine red and blue of the 3 color crosshatch pattern

on the center of the screen by adjusting the pair of

4 pole magnets.

7.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

8.

Adjust the crosshatch pattern to change to white

by repeating steps 6 and 7.

3-2: PURITY

NOTE

Adjust after performing adjustments in section 3-1.

3-3: STATIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 3-2.

1.

Receive the crosshatch pattern from the color bar

generator.

2.

Combine red and blue of the 3 color crosshatch pattern

on the center of the screen by adjusting the pair of

4 pole magnets.

3.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

3-4: DYNAMIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 3-3.

1.2.Adjust the differences around the screen by moving

the deflection yoke upward/downward and right/left.

(Refer to Fig. 3-2-a)

Insert three wedges between the deflection yoke and

CRT funnel to fix the deflection yoke.

(Refer to Fig. 3-2-b)

R G B

R

G

B

UPWARD/DOWNWARD SLANT RIGHT/LEFT SLANT

R

G

B

Fig. 3-2-a

R G B

1.

Receive the green raster pattern from color bar

generator.

2.

Adjust the pair of purity magnets to center the

color on the screen.

Adjust the pair of purity magnets so the color at the

ends are equally wide.

3.

Move the deflection yoke backward (to neck side)

slowly, and stop it at the position when the whole

screen is green.

4.

Confirm red and blue colors.

5.

Adjust the slant of the deflection yoke while watching the

screen, then tighten the fixing screw.

DEFLECTION YOKE

DEFLECTION YOKE SCREW

MAGNET SCREW

6 POLE MAGNETS

4 POLE MAGNETS

PURITY MAGNETS

Fig. 3-1

D-5

WEDGE

WEDGE

WEDGE

WEDGE POSITION

Fig. 3-2-b

ELECTRICAL ADJUSTMENTS

4. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (WIRING CONNECTION)

CP801

CD805

CRT

CRT PCB

TP024

TP022

J801

CP802B

CP803B

AC IN

SPEAKER

CD301

CP101

CP8002

CP301

CP8001

CD802

J4201

TU001

CD3800

CP802A

CP3800

CD8501

VR3800

CP803A

CRT

TP401

CD803

J2202

FB401

CP401

J2203

CP302

J2204

CRT

VR401

CD302

SPEAKER

J2201

DVD DECK

D-6

AV PCB

CP8502

CD4002

CD2301

CD2001

CD2302

CP2601

CP2603

CP2602

DVD PCB

DVD BLOCK DIAGRAM

DVD LOADER

DM II

Pick up

Loading

Motor

Spindle/

Sled

Motor

A, B, C, D, E, F

RF

CD, DVD, LD

SPDL+/–

READ

CHANNEL

IC2601

ZR36708TQC

Dual OP-AMP

IC2602

BA10358F-E2

RFA_SDEN, DATA, SCLK

AAF_CE, FE, TE, PI

FNN, FNP

VBIASS0, S1

DEFECT, LINK, MIRR, LDON

SPDL_SENS

HOME, TIN SW, TOUT SW

FLASH

IC4007

SST39VF800A-

70-4C-EK

HA0~HA20,

HD0~HD15

MPEG/MICON/DSP

M12L64164A-7T

IC4001

ZR36762

64M SDRAM

IC4005

SDA0~SDA11

SDD0~SDD15

REG+1.8V

IC4003

PQ070XZ01ZP

VCR BLOCK

CD4002

TX

RX

P.CON+3.3V

P.CON+5V

P.CON+9V

SPDIF

CP8502

DVD RESET

TR+/–, FO+/–

SPDL+/–, SLED+/–

Motor Driver

IC2301

LA6560

SPINDLE, SLED_PWM

TRACK, FOCUS_DAC

ADC IN 5, 6, 7

S MUTE

2

I CDAT

EEPROM

IC4002

AT24C04N-10SI-2.7

ASDATA0

AMCLK

ABCLK

ALRCLK

STEREO DAC

IC8502

PCM1742KEG/2K

2

I CCLK

DAC B, C, D

DVD AUDIO L

DVD AUDIO R

VIDEO BUFFER

Q8502~Q8504

DVD VIDEO

Y

C

DVD AUDIO L

DVD AUDIO R

ZERO

E-1

E-2

TV BLOCK DIAGRAM

FROM DVD BLOCK

DVD C

DVD Y

DVD_RESET

RX

TX

DVD_A_OUT_L

DVD_A_OUT_R

ZERO

SPDIF

POWER

ON/OFF

OPEN/CLOSE

STOP

PLAY

SKIP FF

SKIP REW

AMP

3

IC4201

NJM4580M

(TE1)

5

Q4203

MUTE

Q4201

DRIVER

*E

CH UP

CH DOWN

VOL UP

VOL DOWN

IC103 PST3231NR

*A

2

1

*A

RESET

X101

16MHz

18

17

31

32

MICON

IC101

OEC6079A

33

22

23

24

26

27

36

TU001

SCL

10

SDA

11

Q105

6 11 12

38 437

BUFFER

*B *C

57

56

55

R.OUT

59

1

7

R

Q4209~Q4212

L

MUTE SW

19 18

24

SOUND

23

40

30

51

50