Page 1

General Precautions for Installation/Servicing/Maintenance for the MD-0101

The installation and service should be done by a qualified service technician.

1. When installing the MD-0101 to the Plain Paper Copier , be sure to follo w the instructions described in

the “Unpacking/Set-Up Procedure for the MD-0101” booklet which comes with each unit of the

MD-0101.

2. The MD-0101 should be installed by an authorized/qualified person.

3. Before starting installation, servicing or maintenance work, be sure to turn off and unplug the copier

first.

4. When servcing or maintaining the MD-0101, be careful about the rotating or operation sections such

as gear, pulleys, sprockets , cams, belts , etc.

5. When parts are disassembled, reassembly is basically the rev erse of disassembly unless otherwise

noted in this manual or other related materials. Be careful not to reassemble small parts such as

screws, washers, pins , E-rings, toothed washers to the wrong places .

6. Basically, the machine should not be operated with an y parts removed or disassembled.

7. Delicate parts for preventing safety hazard problems (such as breakers, thermofuses, fuses, door

switches, sensors, etc. if any) should be handled/installed/adjusted correctly.

8. Use suitable measuring instruments and tools.

9. During servicing or maintenance work, be sure to check the serial No. plate and other cautionary

labels (if any) to see if they are clean and firmly fixed. If not, take appropriate actions.

10. The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity. Before using the wrist band, pull out

the power cord plug of the copier and make sure that there is no uninsulated charged objects in the

vicinity.

11. For the recovery and disposal of used MD-0101, consumable par ts and packing materials, it is

recommended that the relevant local regulations/rules should be f ollow ed.

12. After completing installation, servicing and maintenance of the MD-0101, return the MD-0101 to its

original state, and check operation.

Copyright 2000

TOSHIB A TEC CORPORATION

Page 2

CONTENTS

1. SPECIFICATIONS....................................................................................................... 1-1

2. OUTLINE..................................................................................................................... 2-1

2.1 Names of Various Components........................................................................................ 2-1

2.2 Layout of Electrical Parts ................................................................................................. 2-2

2.3 Harness Connection Diagram .......................................................................................... 2-3

2.4 Board Assembly ............................................................................................................... 2-4

3. OPERATIONAL DESCRIPTION ................................................................................. 3-1

3.1 General Operation............................................................................................................ 3-1

3.2 Block Diagram.................................................................................................................. 3-1

3.3 Detection of Abnormal Status .......................................................................................... 3-2

3.3.1 Cover open/close detection................................................................................... 3-2

3.3.2 Paper jam detection .............................................................................................. 3-2

3.4 Flow Chart........................................................................................................................ 3-3

4. MECHANICAL DESCRIPTION................................................................................... 4- 1

4.1 Paper Feed System.......................................................................................................... 4-1

4.2 Drive System.................................................................................................................... 4-2

5. CIRCUIT DESCRIPTION ............................................................................................ 5-1

5.1 PWA Block Diagram......................................................................................................... 5-1

5.2 Meaning of Signals........................................................................................................... 5-2

5.3 Timing Chart .................................................................................................................... 5-3

6. DISASSEMBLY AND REPLACEMENT...................................................................... 6- 1

October 2000 © T OSHIBA TEC 1 MD-0101 CONTENTS

Page 3

1. SPECIFICATIONS

Function : Stackless unit for duplex printing

Paper : Size A3 to A5-R/LD to ST-R

: Thickness Normal paper 64 to 80g/m2 (17 to 21 lbs)

Transpor t speed : 92 mm/sec. (DP1600 series)

: 124 mm/sec. (DP2000/2500 series)

Dimensions : 101 (W) x 488 (D) x 345 (H) mm

Weight : Approx. 4.3 kg

Power supply : 5VDC, 24VDC (Supplied from copier)

October 2000 © T OSHIBA TEC 1 - 1 MD-0101 SPECIFICATION

Page 4

2. OUTLINE

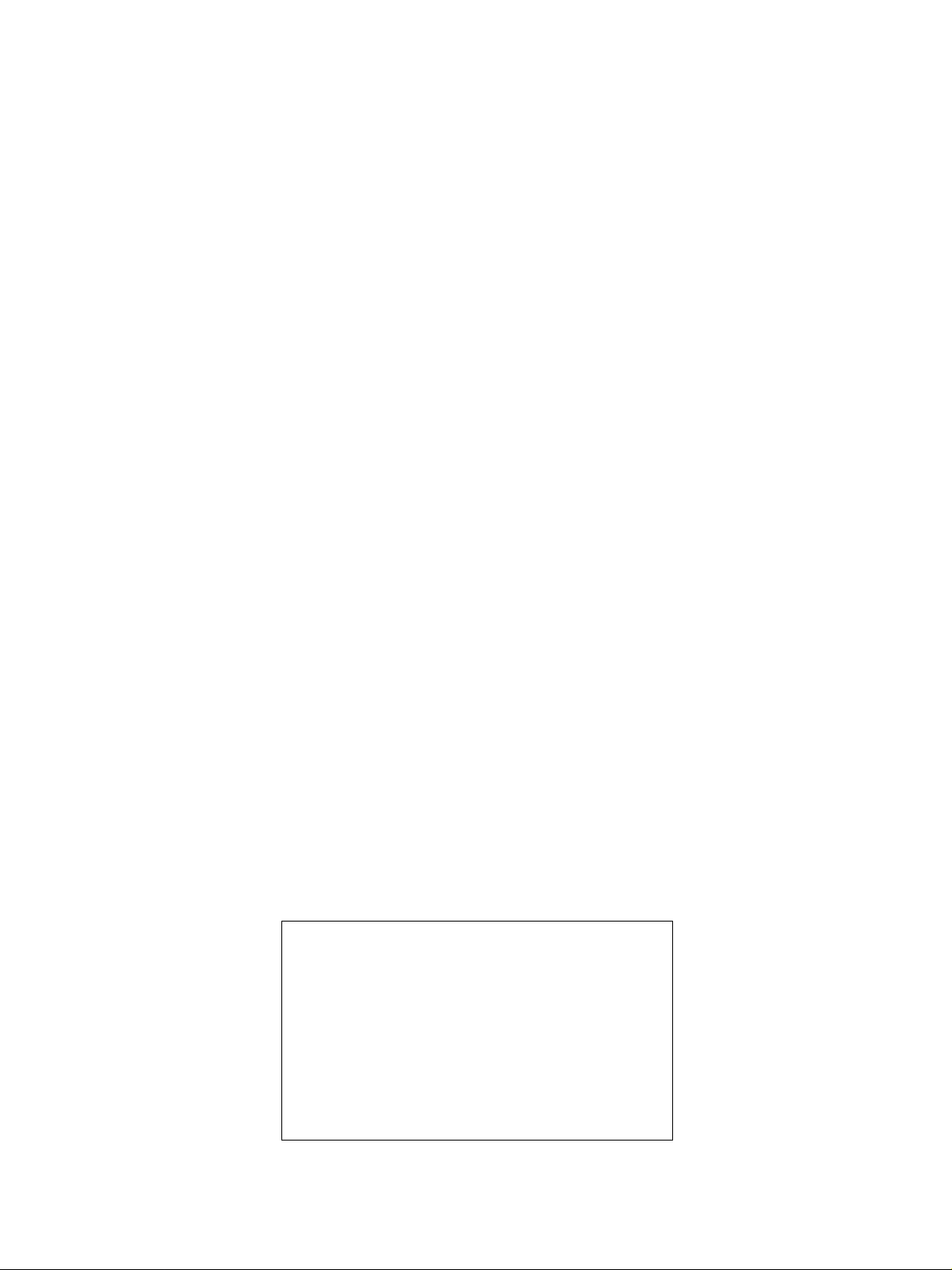

2.1 Names of Various Components

Release lever

ADU release hook F

ADU 02-01-01

ADU paper guide assembly

Connection cable

ADU release hook R

ADU 02-01-02

October 2000 © T OSHIBA TEC 2 - 1 MD-0101 OUTLINE

Page 5

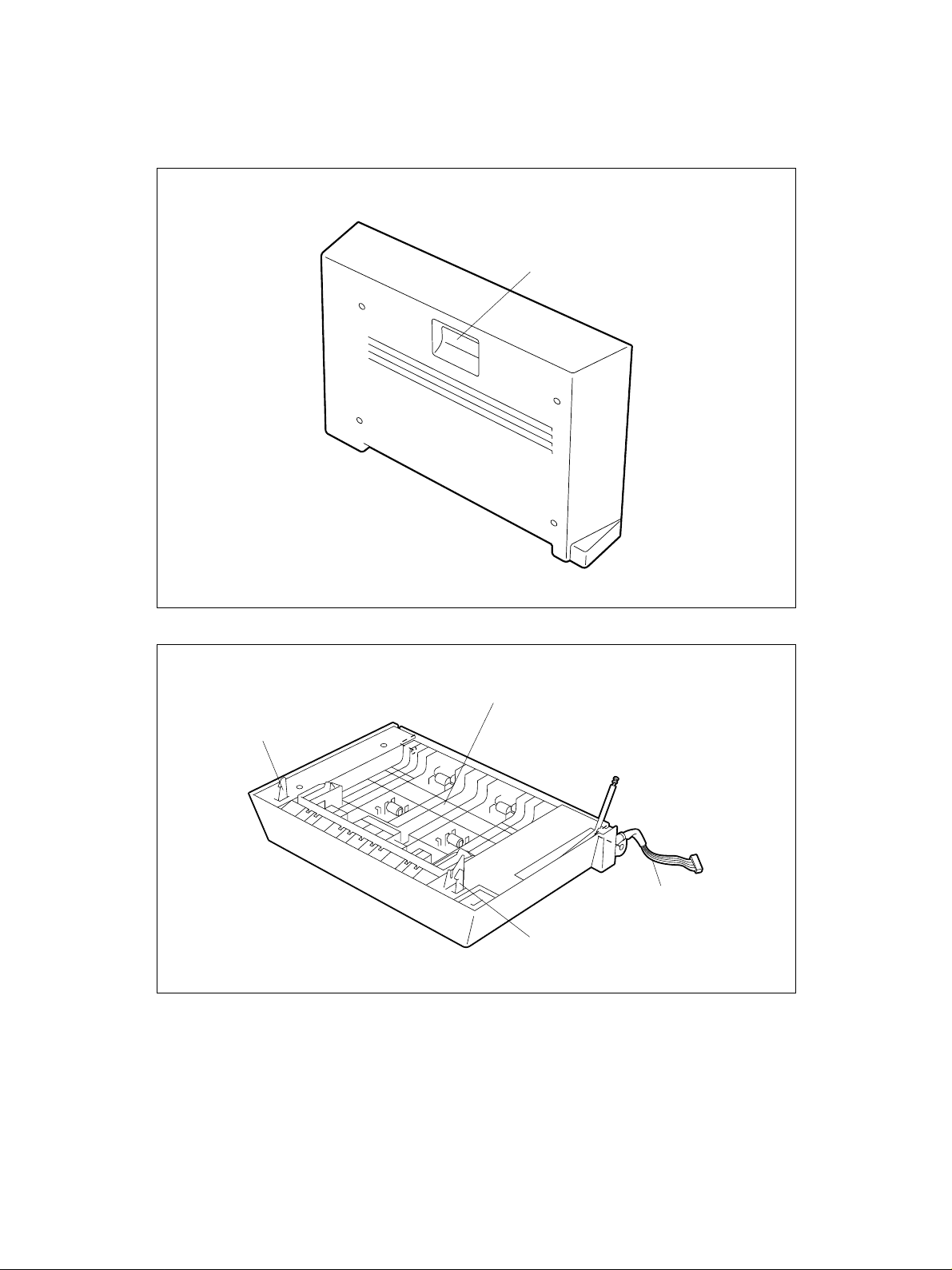

2.2 Layout of Electrical Parts

SW1

SEN2

SEN1

Symbols and functions of various devices

Symbol

SEN1

FED1-SEN

Name

ADU paper jam sensor (Lower)

SEN2

FED2-SEN

ADU paper jam sensor (Upper)

SW1

ADUCOV-SW

ADU cover open switch

M1

FED1-MOT

ADU motor (Lower)

M2

FED2-MOT

M2

ADU (PWA-F-ADU)

M1

ADU 02-02-01

Function

Detects the transport of paper (Lower).

Detects the transport of paper (Upper).

Detection of cover open/close status during jam

processing, etc.

Drives the roller to transport paper (Lower).

Drives the roller to transport paper (Upper).

ADU motor (Upper)

ADU

PWA-F-ADU

ADU PWA

MD-0101 OUTLINE 2 - 2 October 2000 © T OSHIBA TEC

PWA which relays the sensor signals and drives

the motor.

Page 6

2.3 Harness Connection Diagram

)

Lower

(

ADU paper jam sensor

321

CN312

123

DPF

VCC

GND

CN213

)

Upper

(

ADU paper jam sensor

321

CN328

123

DPF

VCC

GND

CN214

CN215

)

Lower

(

ADU motor

12345

12345

+24V

FDMA

FDMB

FDMC

ADU PWA

FDMD

12345

1

+24V

CN216

)

Upper

(

ADU motor

345

2

EXMA

EXMB

EXMC

EXMD

2

CN311

1

CVSW

CN217

ADU cover open switch

1

2

GND

ADU

1514131211

123456789

CN323

1514131211

123456789

2

FDM-B

FDM-D 1

FDM-C 3

CN203 CN211

987654312

10

987654312

10

4

6

VDD 7

FDM-A

ADUFL

CRT-DOWNA 5

1011121315

10

8

10ADUFU

GND

ADCNT 9

11

ADUCOVSW 11

12

12EXM-A

EXM-C 13

14

14EXM-B

PFC PWA

15EXM-D

CN324

CN204 CN212

432

123

432

123

2

GND

GND 1

1

4

1

4

4

+24V

+24V 3

ADU 02-03-01

October 2000 © T OSHIBA TEC 2 - 3 MD-0101 OUTLINE

Page 7

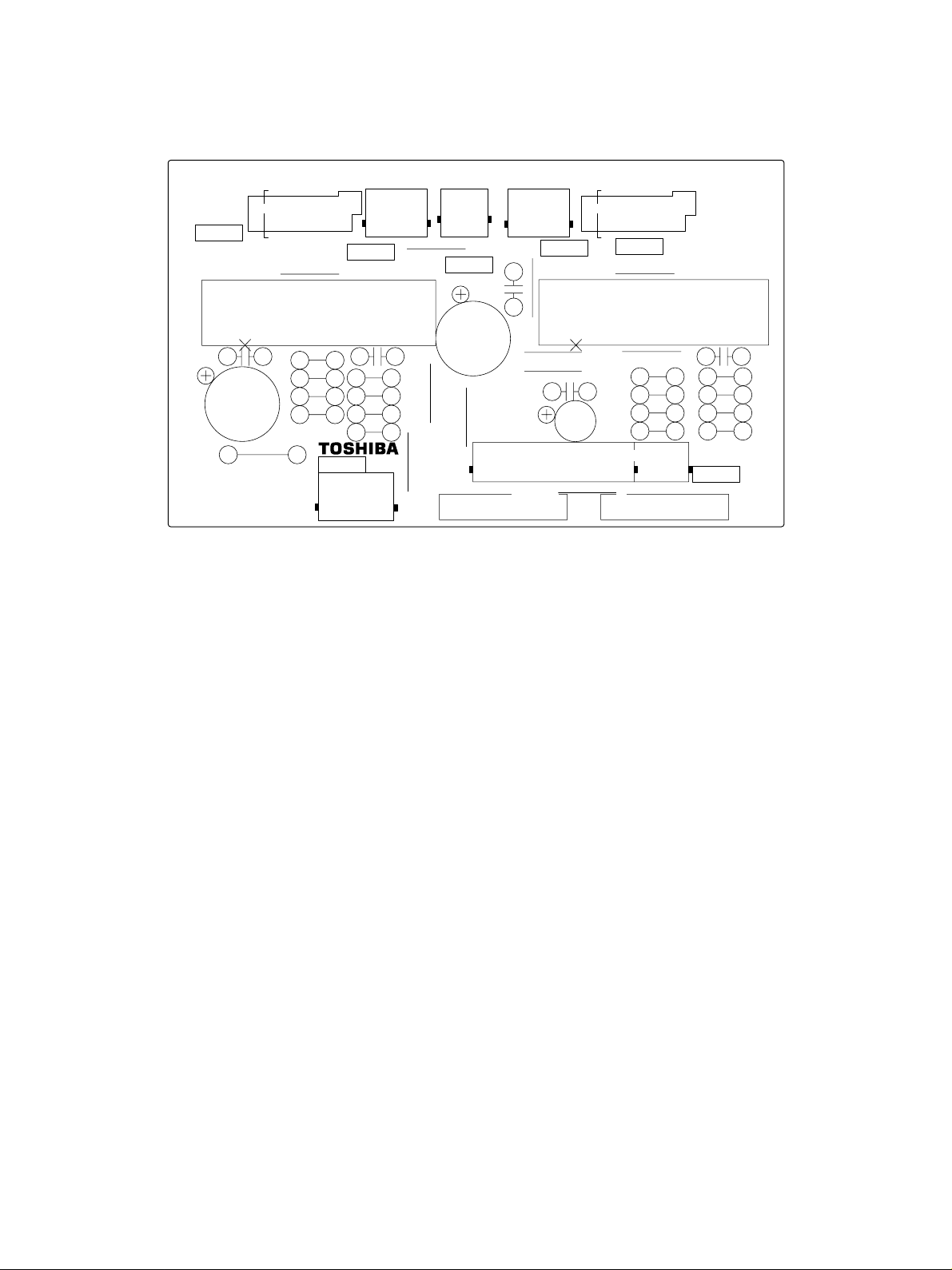

2.4 Board Assembly

6

PWB-F-ADU-520-3 41316208000

CN215

>

PF-WP

JP1

IC1

1

C4

C1

R1

1

3

CN213

<

STK672-210

R2

R4

R3

R5

R9

CN212

41

JP2

C7

R6

R7

R8

1

JP6

JP5

PD

2

CN217

12

C2

JP7

15

31

1

6

CN214

JP3

C5

112

JP10

JP8

C6

JP9

C3

JP11

RV

CN216

JP4

R10

R11

R12

R13

1

STK672-210

1

CN211

IC2

C8

R14

R15

R16

R17

ADU 02-04-01

MD-0101 OUTLINE 2 - 4 October 2000 © T OSHIBA TEC

Page 8

3. OPERATIONAL DESCRIPTION

3.1 General Operation

The ADU is a unit which turns over printed paper . Installation of the unit enab les duplex printing on paper .

No paper can be stacked in the ADU.

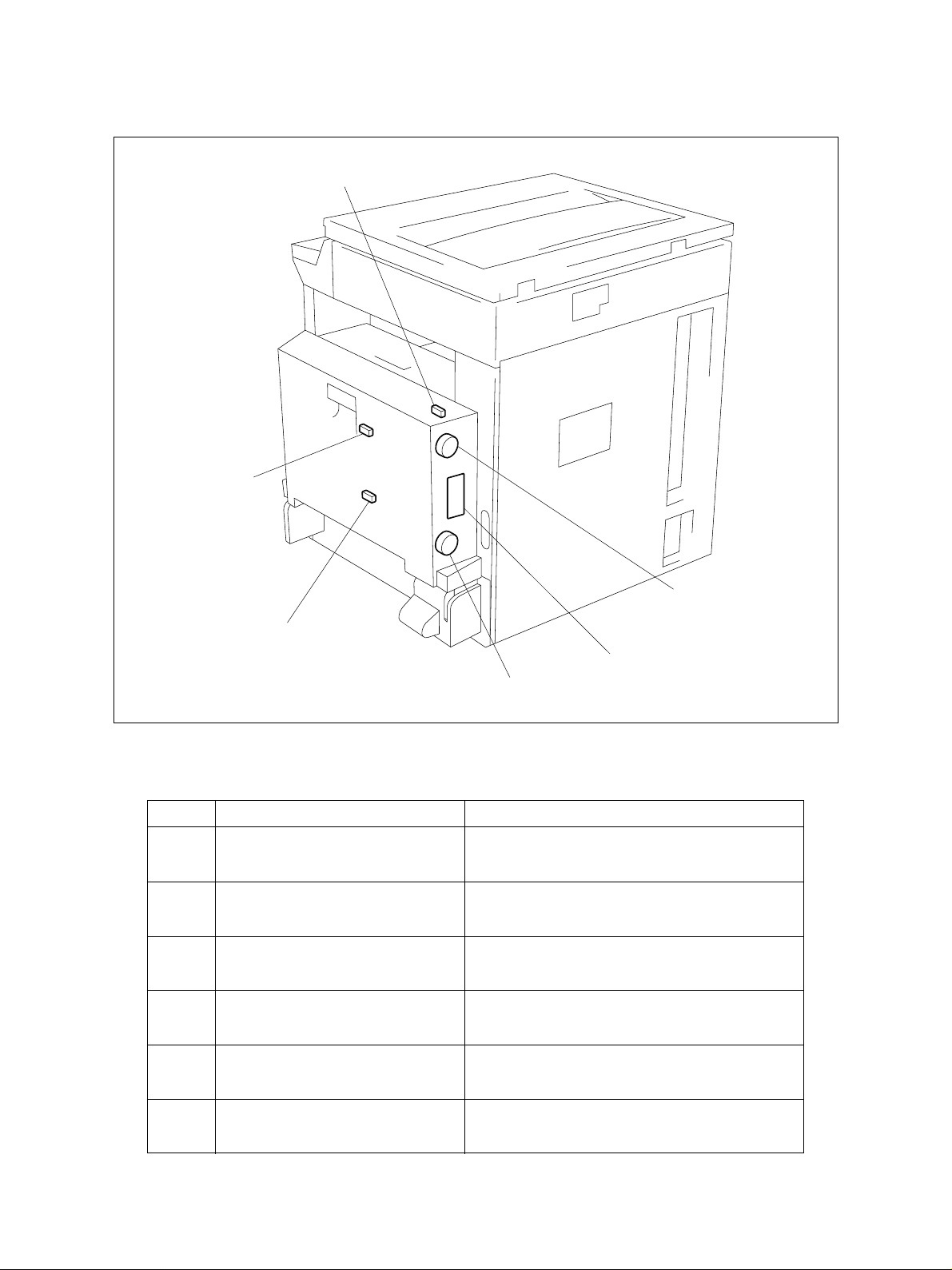

3.2 Block Diagram

ADU

PFC

PWA

CN203

+24V

CN204

CN211CN212

CN215

CN216CN213CN214CN217

FDMA-D

EXMA-D

ADU motor (Lower

M

ADU motor (Upper

M

)

)

ADU

PWA

ADUFL

ADUFU

ADUCOVSW

ADU paper jam sensor (Lower

ADU paper jam sensor (Upper

ADU cover open switch

)

)

ADU 03-02-01

The ADU has three sensors and two motors as shown above. One-side-printed paper passes through

the ADU unit to be turned over and returned to the copier. The motor drive circuits (IC1, IC2) only are

installed on the ADU PWA.

The motor signals (EXM-A - D , FDM-A - D) are amplified by IC1 and IC2 and drive the motors. The signal

of each sensor passes through the ADU PWA and is connected as it is to the PFC PWA.

October 2000 © T OSHIBA TEC 3 - 1 MD-0101 OPERATIONAL DESCRIPTION

Page 9

3.3 Detection of Abnormal Status

3.3.1 Cover open/close detection

When the ADU cover open sensor detects the open state of the cov e r, the detection signal is sent to the

copier to stop the transport of paper.

3.3.2 Paper jam detection

When the one-side-printed paper is loaded into the ADU, the ADU paper jam sensors (upper/lower) turn

ON (at “High” lev el) for a fixed time. If the ADU paper jam sensors (upper/lower) do not turn ON or their

ON time is too long, the program will judge it to be paper jamming and stop the operation. The paper

jamming can be cleared by opening the ADU and removing the paper.

MD-0101 OPERATIONAL DESCRIPTION 3 - 2 October 2000 © TOSHIBA TEC

Page 10

3.4 Flow Chart

Start button ON

Scanning of document

NO

All scanning?

YES

Cassette feed

Copy

Transport to ADU

Feed from ADU

Copy

Ejection

Final copy

NO

Change of document

Start button ON

YES

End

ADU 03-04-01

October 2000 © T OSHIBA TEC 3 - 3 MD-0101 OPERATIONAL DESCRIPTION

Page 11

4. MECHANICAL DESCRIPTION

4.1 Paper Feed System

Exit roller

Flow of paper

Copier

ADU paper jam sensor (Upper)

ADU

ADU paper jam sensor (Lower)

ADU 04-01-01

The ADU has one transport path as shown above and paper enters the ADU from the top and comes out

from the bottom. P aper is not stacked in the ADU b ut the ADU only transports the paper by using the two

motors.

Flow of Paper

The flow of paper is as follows:

The one-side-printed paper reversed at the exit unit.

The roller in the exit unit reversely turns to draw the paper into the ADU.

The paper having passed through the ADU is loaded again into the copier from the bottom of the

ADU.

ADU 04-04-02

October 2000 © T OSHIBA TEC 4 - 1 MD-0101 MECHANICAL DESCRIPTION

Page 12

Printing takes place on the back of the paper and the paper is ejected.

Copier side

Flow of paper

ADU motor (Upper)

ADU motor (Lower)

ADU 04-02-01

4.2 Drive System

In the ADU, paper is transported by two pulse motors . The ADU motor (upper) drives the upper roller and

the exit roller of the copier as a result of changing (moving) the gear on the copier side , thereb y drawing

in the one-side-printed paper from the copier.

The paper drawn into the ADU is fed into the copier again from the ADU (bottom) by the roller driven by

the ADU motor (lower). The central roller is driven by the ADU motor (lower) through the belt.

MD-0101 MECHANICAL DESCRIPTION 4 - 2 October 2000 © TOSHIBA TEC

Page 13

5. CIRCUIT DESCRIPTION

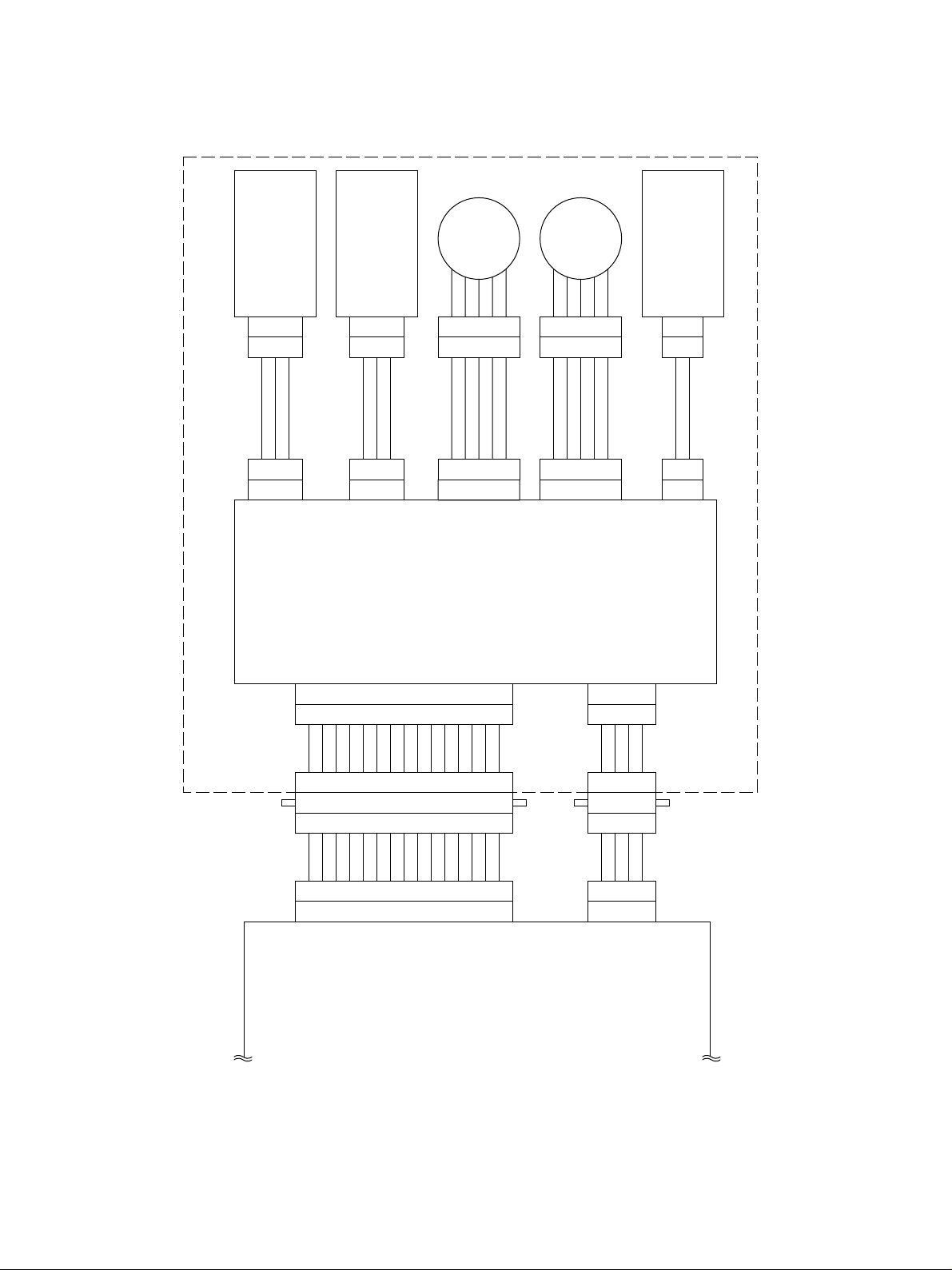

5.1 PWA Block Diagram

PFC

PWA

PFC

PWA

ADU PWA

1

2

3

4

5

ADUCOVSW

6

7

8

SG

CN211CN212

+5V

9

10

11

NC

14

15

14

15

+24V

1

+24V

2

3

PG

4

PG

EXM-D

EXM-B

EXM-C

EXM-A

ADUFU

ADCNT

ADUFL

FDM-A

FDM-C

FDM-B

FDM-D

+24V

1

SG

SG

+5V

SG

+5V

+24V

2

3

4

CN216

5

6

1

2

1

2

CN213 CN217CN214

3

1

2

3

1

2

3

4

CN215

5

6

ADU motor

(

)

Upper

ADU cover open switch

ADU paper jam sensor

(

)

Lower

ADU paper jam sensor

(

)

Upper

ADU motor

(

)

Lower

9

A

8

AB

IC2

7

B

Motor driver

6

BB

VREF

R6 R7,R8

9

A

8

AB

7

B

Motor driver

6

BB

VREF11SP

R14 R15,R16

12

IC1

12

+5V

SG

+5V

4

A1

5

A0

2

B1

3

B0

SP

11

4

A1

5

A0

2

B1

3

B0

EXMA

EXMB

EXMC

EXMD

FDMA

FDMB

FDMC

FDMD

ADU 05-01-01

The ADU PWA has the motor driving IC only and the other signals pass through the PWA.

IC1 and IC2 are driver IC’ s for the stepping motors and driv e the ADU motors (upper/lower) on the output

side according to the input signals. IC1 drives the ADU motor (lower), and IC2 the ADU motor (upper).

Vref is the input to determine the value of the current which flows through each motor . The input v oltage

there determines the load (current value) to the motor.

ADCNT is a signal which detects connection of the ADU and connected to GND. When its connector is

attached, the signal goes LOW so that the copier can confirm its connection.

October 2000 © T OSHIBA TEC 5 - 1 MD-0101 CIRCUIT DESCRIPTION

Page 14

5.2 Meaning of Signals

Signal name Part name Functional description Status Note

ADUFL ADU paper jam Detects the transport of High: Paper present Photo sensor

sensor (Lower) paper (Lower)

ADUFU ADU paper jam Detects the transport of High: Paper present Photo sensor

sensor (Upper) paper (Upper)

ADUCOVSW ADU cover Detection of cover High: Open Push switch

open switch open/close status during

jam processing, etc.

EXMA-D ADU motor Drives the roller to transport - PM type

(Upper) paper (Upper) pulse motor

FDMA-D ADU motor Drives the roller to transport - PM type

(Lower) paper (Lower) pulse motor

The ADU cover open s witch is a s witch which detects the open or close state of the cov er . A push switch

is used for the switch. The signal goes LOW when the cover is closed, and HIGH when it is open.

The ADU paper jam sensor (upper/lower) detects the presence or absence of paper in the transf er path.

Photo sensors are used for the sensors. When paper passes, the sensor arm in the transfer path is

pressed to turn on the sensor.

The ADU motor (lower) and ADU motor (upper) are 2-phase excitation PM type pulse motors (stepping

motors) and operate according to the drive signals from the driver IC’s (IC1, IC2).

MD-0101 CIRCUIT DESCRIPTION 5 - 2 October 2000 © T OSHIBA TEC

Page 15

5.3 Timing Char t

19.51s (15.49s)

17.14s (12.62s)

14.57s (10.72s)

14.59s (10.74s)

11.83s (8.79s)

5.67s (4.01s)

12.17s (8.95s)

10.96s (8.01s)

5.96s (4.30s)

5.84s (4.13s)

10.66s (7.79s)

8.07s (5.87s)

12.08s (8.97s)

11.52s (8.57s)

10.96s (8.01s)

8.43s (6.13s)

13.16s (9.69s)

9.74s (7.10s)

The values are data (reference values) applicable when the A4 size paper is used.

The value in brackets is for the DP2500 machine.

3.12s (2.18s)

3.11s (2.17s)

Feed sensor

October 2000 © T OSHIBA TEC 5 - 3 MD-0101 CIRCUIT DESCRIPTION

Exit sensor

3.13s (2.19s)

ADU motor

(Upper)

ADU paper

jam sensor

(Upper)

ADU motor

(Lower)

ADU paper

jam sensor

(Lower)

ADU 05-03-01

Page 16

6. DISASSEMBLY AND REPLACEMENT

[A] ADU hinge cover F/R

1. Remove 2 screws and detach ADU hinge co ver

F.

2. Remove 2 screws and detach ADU hinge co ver

R.

[B] ADU paper guide assembly

Screw

Screw

ADU hinge

cover R

Screw

ADU hinge cover F

223

Fig. 6-1

Screw

224

Fig. 6-2

1. Pull ADU release lev er to release one hook and

open ADU.

2. Release 2 hooks and remove ADU paper guide

assembly.

ADU release lever

ADU

225

Fig. 6-3

ADU paper guide assembly Hook

226

Fig. 6-4

October 2000 © TOSHIBA TEC 6 - 1 MD-0101 DISASSEMBLY AND REPLACEMENT

Page 17

[C] ADU

1. Detach ADU hinge cover F. (See Fig. 6-1)

2. Detach ADU hinge cover R. (See Fig. 6-2)

3. Remove one screw and detach harness fixing

plate.

4. Remove one screw , detach the g round wire and

the connector.

Screw

Harness fixing plate

227-1

Fig. 6-5

Screw

Connector

5. Remove stopper from ADU hinge F.

6. Open ADU, remove one screw, and remove

plate A.

Ground wire

Snap pin

Fig. 6-6

ADU hinge F

Fig. 6-7

Screw

227-2

228

Plate A

ADU

229

Fig. 6-8

MD-0101 DISASSEMBLY AND REPLACEMENT 6 - 2 October 2000 © TOSHIBA TEC

Page 18

7. Release one hook and detach the wire.

8. Release 2 hinges and remove ADU.

[D] ADU cover

1. Detach ADU hinge cover F. (See Fig. 6-1)

2. Detach ADU hinge cover R. (See Fig. 6-2)

3. Remove ADU. (See Fig. 6-5 to 6-9)

4. Remove 2 scre ws, release one hook and wire ,

and detach ADU hook cover R.

5. Release 2 hooks, detach one connector, and

remove ADU cover open sensor.

ADU

ADU hook cover R

Hook

ADU cover

open sensor

Wire

230

Fig. 6-9

Screw

Wire

231

Fig. 6-10

Connector

Hook

232

Fig. 6-11

6. Remove 4 scre ws and detach ADU cover.

Screw

Screw

ADU cover

233

Fig. 6-12

October 2000 © TOSHIBA TEC 6 - 3 MD-0101 DISASSEMBLY AND REPLACEMENT

Page 19

[E] ADU PWA

1. Detach ADU hinge cover F. (See Fig. 6-1)

2. Detach ADU hinge cover R. (See Fig. 6-2)

3. Remove ADU. (See Fig. 6-5 to 6-9)

4. Detach ADU cover. (See Fig. 6-10 to 6-12)

5. Remove 4 scre ws, release the harness from the

clamp, and detach PWA cover.

6. Detach all the connectors from ADU PWA, re-

lease 4 locking supports, and remove ADU

PWA.

Screw

Screw

Locking support

Clamp

Fig. 6-13

Clamp

PWA cover

234

ADU PWA

[F] ADU motor

1. Detach ADU hinge cover F. (See Fig. 6-1)

2. Detach ADU hinge cover R. (See Fig. 6-2)

3. Remove ADU. (See Fig. 6-5 to 6-9)

4. Detach ADU cover. (See Fig. 6-10 to 6-12)

5. Detach one connector from ADU PWA (CN216),

remove 2 screws, remove ADU motor by sliding in the direction of the arrow .

Note: Apply 0.1g of GREASE (X5-6020) to the

gear tooth surface.

ADU motor

Screw

Fig. 6-14

CN216

Connector

Fig. 6-15

235

ADU motor

236-1

MD-0101 DISASSEMBLY AND REPLACEMENT 6 - 4 October 2000 © TOSHIBA TEC

Page 20

[G] ADU feed roller shaft upper/clutch 08S018-06CL

1. Detach ADU hinge cover F. (See Fig. 6-1)

2. Detach ADU hinge cover R. (See Fig. 6-2)

3. Remove ADU paper guide assemb ly.

(See Fig. 6-3 and 6-4)

4. Remove ADU. (See Fig. 6-5 to 6-9)

5. Detach ADU cover. (See Fig. 6-10 to 6-12)

6. Detach PWB cover. (See Fig. 6-13)

7. Remove 2 scre ws and remove ADU release le-

ver.

8. Release Spring, remove one screw , and remov e

ADU release hook R.

Screw

Spring

ADU release lever

Fig. 6-16

Screw

Fig. 6-17

236-2

ADU release

hook R

237

9. Detach one connector from ADU PWA (CN216).

10. Remove 4 screws, release one clamp, and re-

move ADU motor brac k et upper.

ADU PWB

Screw

CN216

Harness

Screw

ADU motor bracket upper

Fig. 6-18

Clamp

238

October 2000 © TOSHIBA TEC 6 - 5 MD-0101 DISASSEMBLY AND REPLACEMENT

Page 21

11. Detach the E-ring, and remove clutch 08S018-

06CL and bushing.

E-ring

12. Detach stop ring, and remove bushing and ADU

feed roller shaft upper.

[H] ADU feed roller shaft middle

1. Detach ADU hinge cover F. (See Fig. 6-1)

2. Detach ADU hinge cover R. (See Fig. 6-2)

3. Remove ADU paper guide assemb ly.

(See Fig. 6-3 and 6-4)

4. Remove ADU. (See Fig. 6-5 to 6-9)

5. Detach ADU cover. (See Fig. 6-10 to 6-12)

6. Detach PW A co ver. (See Fig. 6-13)

7. Remove ADU PWA. (See Fig. 6-14)

8. Detach stop ring and remove pulle y and timing

Clutch 08S018-06CL

Pulley

Pin

Bushing

Fig. 6-19

Fig. 6-20

Pulley

Fig. 6-21

ADU feed roller

shaft upper

Bushing

Stop ring

Pin

Stop ring

Timing belt

Stop ring

239

240

Pulley

241

belt.

Note: Be sure to insert the pins when attaching.

MD-0101 DISASSEMBLY AND REPLACEMENT 6 - 6 October 2000 © TOSHIBA TEC

Page 22

9. Detach stop ring, remove 2 bushings, and re-

move ADU f eed roller shaft middle.

[I] ADU feed roller shaft lower/clutch 08S018-06CL

1. Detach ADU hinge cover F. (See Fig. 6-1)

2. Detach ADU hinge cover R. (See Fig. 6-2)

3. Remove ADU paper guide assemb ly.

(See Fig. 6-3 and 6-4)

4. Remove ADU. (See Fig. 6-5 to 6-9)

5. Detach ADU cover. (See Fig. 6-10 to 6-12)

Stop ring

CN215

ADU feed roller

shaft middle

Bushing

Bushing

242

Fig. 6-22

ADU PWA

ADU motor

bracket lower

6. Detach PWB cover. (See Fig. 6-13)

7. Remove timing belt. (See Fig. 6-21)

8. Detach one connector from ADU PWA (CN215).

9. Remove 4 screws, release one clamp, and re-

move ADU motor brac ket lower.

10. Detach the E-ring, remove clutch 08S018-06CL

and 2 bushings, and remove ADU feed roller

shaft lower .

Clamp

Harness

Clutch 08S018-06CL

Bushing

E-ring

Connector

Fig. 6-23

ADU feed roller

shaft lower

ADU feed roller

shaft lower

Fig. 6-24

Screw

243

Bushing

244

October 2000 © TOSHIBA TEC 6 - 7 MD-0101 DISASSEMBLY AND REPLACEMENT

Loading...

Loading...