Engineering

Data Book

E14-361

Notice: Toshiba is committed to continuously improving its products to ensure the highest

quality and reliability standards, and to meet local regulations and market requirements. All

features and specifications are subject to change without prior notice.

Model name:

MCY-MHP0404HT-E

MCY-MHP0504HT-E

MCY-MHP0604HT-E

Outdoor units

Side blow VRF

1

Side blow VRF Data book

Safety caution............................................................................................................2

1 System overview.................. ......................................................................................5

1-1. Allocation standard of model name..................................................................5

1-2. Summary of system equipments......................................................................5

2 Equipment selection procedure ...............................................................................10

2-1. Selection flow chart ........................................................................................10

2-2. Combination conditions for indoor unit and outdoor unit................................11

2-3. Cooling / heating capacity characteristics ......................................................12

2-4. Operational temperature range ......................................................................15

3 Refrigerant piping design.........................................................................................16

3-1. Free branching system...................................................................................16

3-2. Allowable length / height difference of refrigerant piping................................17

3-3. Selection of refrigerant piping.........................................................................18

3-4. Allowable length / height difference of refrigerant piping with PMV Kit ..........19

3-5. Selection of refrigerant piping with PMV Kit ...................................................20

3-6. Charging requirement with additional refrigerant ...........................................21

4 Wiring design...........................................................................................................22

4-1. General...........................................................................................................22

4-2. Electrical wiring design...................................................................................22

4-3. Outdoor unit power supply..............................................................................22

4-4. Indoor unit power supply ................................................................................23

4-5. Design of control wiring..................................................................................26

5 Outdoor unit.............................................................................................................28

5-1. Specifications .................................................................................................28

5-2. Dimensional drawing......................................................................................29

5-3. Branch header / branch joint ..........................................................................30

5-4. Refrigerant cycle diagram ..............................................................................31

5-5. Wiring diagram ................................................................. ..............................32

5-6. Connecting diagram .......................................................................................33

5-7. Optional printed circuit board (PCB) of out

door unit

.......................................34

5-8. Part load performance....................................................................................39

5-9. Sound pressure level data..............................................................................42

5-10. PMV Kit ..........................................................................................................44

Contents

2

Side blow VRF Data book

Safety caution

• Before use, read carefully through the “Safety caution” section to ensure correct operation.

• The important contents concerned to the safety are described in the “Safety cautions”.

Be sure to keep them. For Indications and their meanings, see the following description.

Warning Indications on the Air Conditioner Unit

Warning indication Description

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote electric power supplies before servicing.

WARNING

Moving parts.

Do not operate unit with grille removed.

Stop the unit before the servicing.

CAUTION

High temperature parts.

You might get burned when removing this panel.

CAUTION

Do not touch the aluminium fins of the unit.

Doing so may result in injury.

CAUTION

BURST HAZARD

Open the service valves before the operation, otherwise there might be the

burst.

CAUTION

Do not climb onto the fan guard.

Doing so may result in injury.

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote

electric power supplies

WARNING

Moving parts.

Do not operate unit with

grille removed.

CAUTION

High temperature parts.

You might get burned when

removing this panel.

CAUTION

Do not touch the aluminum

fins of the unit.

Doing so may result in injury.

CAUTION

BURST HAZARD

Open the service valves

before the operation,

CAUTION

Do not climb onto the fan

guard.

Doing so may result in

3

Safety caution

Explanation of indications

WARNING

Indicates possibilities that a death or serious injury of personnel is caused by an incorrect handling.

CAUTION

Indicates contents that an injury (*1) or property damage (*2) only may be caused when an incorrect work has been executed.

*1: “In jury” means a hurt, a burn, or an electric shock which does not require hospitalization or a long-term going to the hospital.

*2: “Property damage means an enlarged damage concerned to property, or breakage of materials.

• After installation work has finished, check there is no trouble by a test operation, and explain using method and

maintenance method to the customers based on the Owner’s Manua l.

Please ask the customers to keep this Installation Manual together with the Owner’s Manual.

WARNING

Ask a shop or a professional dealer to instal l the air conditioner.

If you will install by yourself, a fire, an electric shock, or water leak is caused.

Take measures so that the refri gerant does not exceed the limit concentration even if it leaks whe n inst alling the air conditioner

in a small room.

For the measures not to exceed the limit of concentration, contact the dealer. If the refrigerant leaks and it exceeds the limit of

concentration, an accident of oxygen shortage is caused.

Install the air conditioner at a place which is satisfactorily bearable to weight.

If strength is insufficient, the unit may fall down resulting in human injury.

Perform a specified installation work against a strong wind such as typhoon or earthquake.

If the air conditioner is imperfectly installed, an accident by falling or dropping may be caused.

If refrigerant gas leaks during installation work, ventilate the room.

If the leaked refrigerant gas approaches to fire, noxious gas may generate.

After installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks in the room, and approaches t o f ire su ch as f an heate r, stove or kitchen range, generation of noxiou s g as ma y b e

caused.

Never recover refrigerant in the outdoor unit.

Be sure to use a refrigerant recovery device to recover refrigerant in reinstallation or repair work.

Recovery of refrigerant in the outdoor unit is unavailable; otherwise a serious accident such as crack or human injury is caused.

A person qualified for the electric work sh ou ld deal with the electric construction conforming to the regulations of the local

electric company and the Installation Manual. Be sure to use the exclusive circuit.

If there is capacity shortage of the power supply circuit or incomplete installation, a fire or an electric shock is caused.

For cabling, use the specified cables and connect them securely so that external force of cable does not transmit to the

terminal connecting section.

If connection or fixing is incomplete, a fire, etc. may be caused.

Be sure to connect earth wire.

Do not connect earth wire to gas pipe, water pipe, lightning rod, nor earth wire of telephone.

If grounding is incomplete, an electric shock is caused.

CAUTION

Do not install the air conditioner at a place where combustible gas may leak.

If gas leaks and is collected at surrounding the unit, the production of fire may be caused.

Be sure to attach an earth leakage breaker; otherwise an electric shock may be caused.

Using a torque wrench, tighten the flare nut in the specified method.

If the flare nut is exceedingly tightened, the flare nut is broken and a refrigerant leakage may be caused after a long time has passed.

4

Safety caution

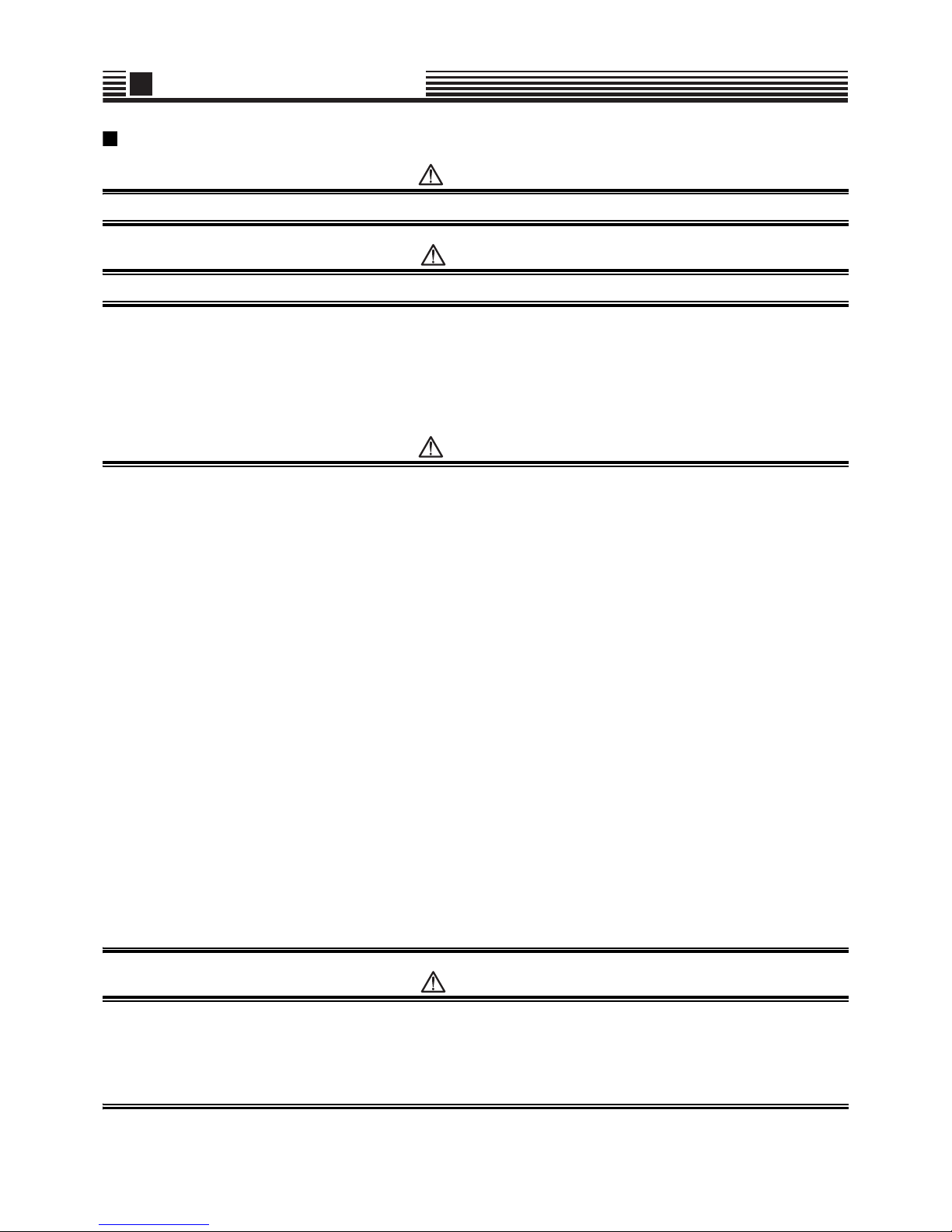

WARNINGS ON REFRIGERANT LEAKAGE

Check of Concentration Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its concentration will not

exceed a set limit.

The refrigerant R410A which is used in the air

conditioner is safe, without the toxicity or combustibility

of ammonia, and is not restricted by laws to be imposed

which protect the ozone layer. However, since it

contains more than air, it poses the risk of suffocation if

its concentration should rise excessively.

Suffocation from leakage of R410A is almost

nonexistent. With the recent increase in the number of

high concentration buildings, however , the installation of

multi air conditioner systems is on the increase because

of the need for effective use of floor space, individual

control, energy conservation by curtailing heat and

carrying power etc.

Most importantly , the multi a ir conditioner system is abl e

to replenish a large amount of refrigerant compared

with conventional individual air conditioners. If a single

unit of the multi conditioner system is to be

installed in a small room, select a suitable model and

installation procedure so that if the refrigerant

accidentally leaks out, its concentration does not reach

the limit (and in the event of an emergency, measures

can be made before injury can occur).

In a room where the concentration may exceed the limit,

create an opening with adjacent rooms, or install

mechanical ventilation combined with a gas leak

detection device.

The concentration is as given below.

≤ Concentration limit (kg/m

3

)

The concentration limit of R410A which is used in multi

air conditioners is 0.3 kg/m

3

.

NOTE 1:

If there are 2 or more refrigerating systems in a single

refrigerating device, the amounts of refrigerant should

be as charged in each independent device.

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in

rooms A, B and C is 10 kg.

The possible amount of leaked refrigerant gas in

rooms D, E and F is 15 kg.

NOTE 2:

The standards for minimum room volume are as fo llows.

(1) No partition (shaded portion)

(2) When there is an effective opening with the adjacent

room for ventilation of leaking refrigerant gas

(opening without a door, or an opening 0.15 % or

larger than the respective floor spaces at the top or

bottom of the door).

(3) If an indoor unit is installed in each partitioned room

and the refrigerant tubing is interconnected, the

smallest room of course becomes the object. But

when a mechanical ventilation is installed

interlocked with a gas leakage detector in the

smallest room where the density limit is exceeded,

the volume of the next smallest room becomes the

object.

NOTE 3:

The minimum indoor floor area compared with the

amount of refrigerant is roughly as follows: (When the

ceiling is 2.7 m high)

Total amount of refrigerant (kg)

Min. volume of the indoor unit installed room (m

3

)

Outdoor unit

e.g.,

charged amount (15 kg)

e.g., charged

amount (10 kg)

Indoor unit

Room A Room B Room C R oom D Room E Room F

Important

Outdoor unit

Refrigerant piping

Indoor unit

Refrigerant piping

Outdoor unit

Indoor unit

Mechanical ventilation device - Gas leak detector

Very

small

room

Small

room

Medium

room

Large room

0

5

10

10 20 30

15

20

25

30

35

40

kg

m²

Min. indoor floor area

Range below the

density limit of 0.3

kg/m

3

(countermeasures

not needed)

Range above the

density limit of 0.3

kg/m

3

(countermeasures

needed)

Total amount of refrigerant

5

Side blow VRF Data book

1 System overview

1-1. Allocation standard of model name

1-2. Summary of system equipments

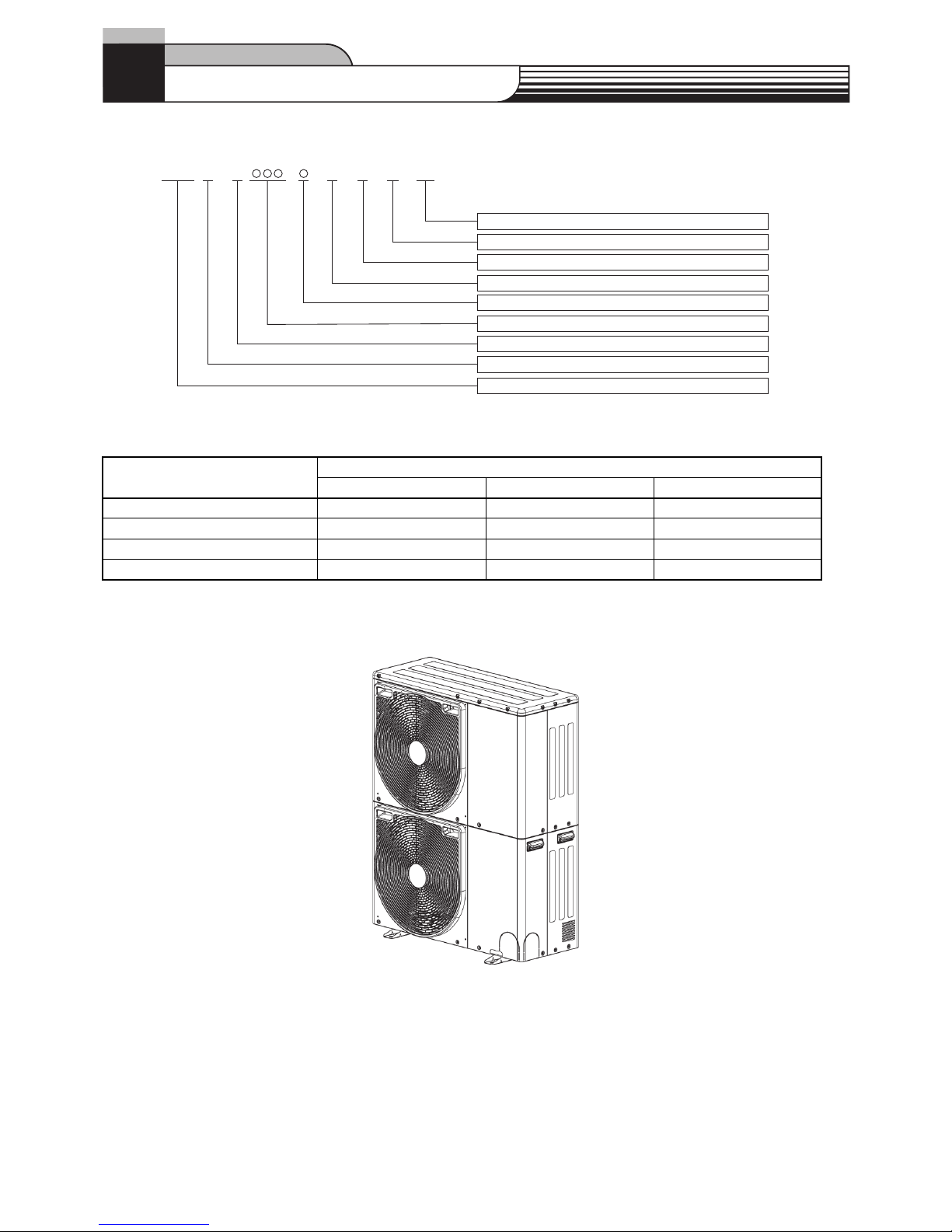

1-2-1. Outdoor units

*1 Rated conditions

Cooling : Indoor air temperature 27 °C DB / 19 °C WB. Outdoor air temperature 35 °C DB.

Heating : Indoor air temperature 20 °C DB. Outdoor air temperature 7 °C DB / 6 °C WB.

Corresponding HP

Inverter unit

4HP 5HP 6HP

Model name MCY-MHP0404HT-E MCY-MHP0504HT-E MCY-MHP0604HT-E

Cooling capacity (kW)*1 12.1 14.0 15.5

Heating capacity (kW)*1 12.5 16.0 18.0

No. of connectable indoor units 6 6 6

MCY

_

MH T J

HP

_

E

E : Europe, corresponding to European standard model

J : Anti-corrosion heavy protection

T : Capacity variable unit

H : Heat pump

Development series number

Capacity

Hangzhi products R410A

M : Single module unit

Multi Compact Type

6

1 System overview

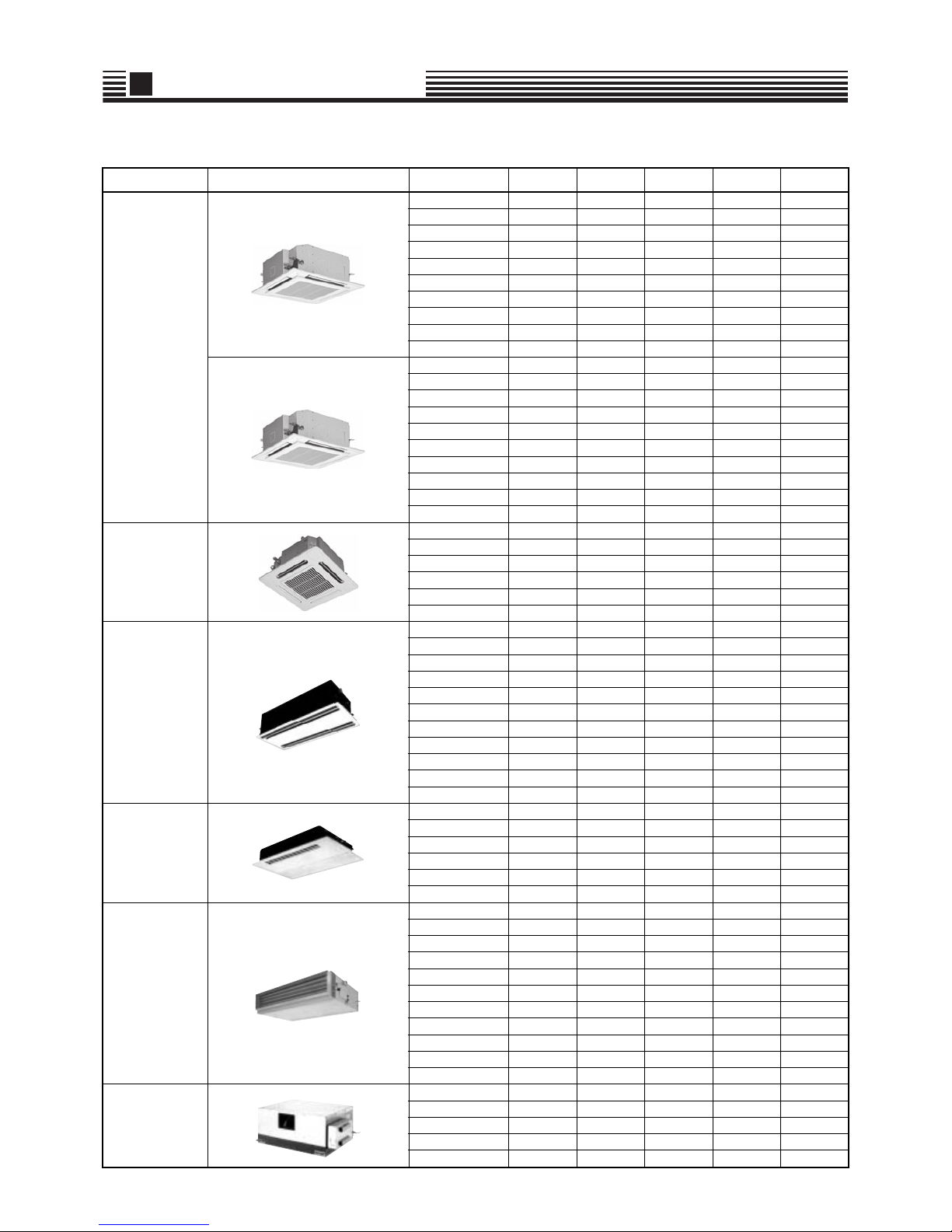

1-2-2. Indoor units

Type Appearance Model name Capacity rank Capacity code

Cooling

capacity (kW)

Heating

capacity (kW)

PMV Kit

4-way Air Discharge

Cassette Type

MMU-AP0092H 009 type 1.00 2.8 3.2 -

MMU-AP0122H 012 type 1.25 3.6 4.0 -

MMU-AP0152H 015 type 1.70 4.5 5.0 -

MMU-AP0182H 018 type 2.00 5.6 6.3 -

MMU-AP0242H 024 type 2.50 7.1 8.0 -

MMU-AP0272H 027 type 3.00 8.0 9.0 -

MMU-AP0302H 030 type 3.20 9.0 10.0 -

MMU-AP0362H 036 type 4.00 11.2 12.5 -

MMU-AP0482H 048 type 5.00 14.0 16.0 -

MMU-AP0562H 056 type 6.00 16.0 18.0 -

MMU-AP0094HP-E 009 type 1.00 2.8 3.2 -

MMU-AP0124HP-E 012 type 1.25 3.6 4.0 -

MMU-AP0154HP-E 015 type 1.70 4.5 5.0 -

MMU-AP0184HP-E 018 type 2.00 5.6 6.3 -

MMU-AP0244HP-E 024 type 2.50 7.1 8.0 -

MMU-AP0274HP-E 027 type 3.00 8.0 9.0 -

MMU-AP0304HP-E 030 type 3.20 9.0 10.0 -

MMU-AP0364HP-E 036 type 4.00 11.2 12.5 -

MMU-AP0484HP-E 048 type 5.00 14.0 16.0 -

MMU-AP0564HP-E 056 type 6.00 16.0 18.0 -

Compact 4-way

Cassette (600 × 600)

Type

MMU-AP0054MH-E 005 type 0.60 1.7 1.9 Available

MMU-AP0074MH-E 007 type 0.80 2.2 2.5 Available

MMU-AP0094MH-E 009 type 1.00 2.8 3.2 Available

MMU-AP0124MH-E 012 type 1.25 3.6 4.0 Available

MMU-AP0154MH-E 015 type 1.70 4.5 5.0 Available

MMU-AP0184MH-E 018 type 2.00 5.6 6.3 Available

2-way Air Discharge

Cassette Type

MMU-AP0072WH 007 type 0.80 2.2 2.5 -

MMU-AP0092WH 009 type 1.00 2.8 3.2 -

MMU-AP0122WH 012 type 1.25 3.6 4.0 -

MMU-AP0152WH 015 type 1.70 4.5 5.0 -

MMU-AP0182WH 018 type 2.00 5.6 6.3 -

MMU-AP0242WH 024 type 2.50 7.1 8.0 -

MMU-AP0272WH 027 type 3.00 8.0 9.0 -

MMU-AP0302WH 030 type 3.20 9.0 10.0 -

MMU-AP0362WH 036 type 4.00 11.2 12.5 -

MMU-AP0482WH 048 type 5.00 14.0 16.0 -

MMU-AP0562WH 056 type 6.00 16.0 18.0 -

1-way Air Discharge

Cassette Type

MMU-AP0074YH-E 007 type 0.80 2.2 2.5 Available

MMU-AP0094YH-E 009 type 1.00 2.8 3.2 Available

MMU-AP0124YH-E 012 type 1.25 3.6 4.0 Available

MMU-AP0154SH-E 015 type 1.70 4.5 5.0 Available

MMU-AP0184SH-E 018 type 2.00 5.6 6.3 Available

MMU-AP0244SH-E 024 type 2.50 7.1 8.0 Available

Concealed Duct

Type

MMD-AP0076BHP-E 007 type 0.80 2.2 2.5 Available

MMD-AP0096BHP-E 009 type 1.00 2.8 3.2 Available

MMD-AP0126BHP-E 012 type 1.25 3.6 4.0 Available

MMD-AP0156BHP-E 015 type 1.70 4.5 5.0 Available

MMD-AP0186BHP-E 018 type 2.00 5.6 6.3 Available

MMD-AP0246BHP-E 024 type 2.50 7.1 8.0 Available

MMD-AP0276BHP-E 027 type 3.00 8.0 9.0 Available

MMD-AP0306BHP-E 030 type 3.20 9.0 10.0 Available

MMD-AP0366BHP-E 036 type 4.00 11.2 12.5 Available

MMD-AP0486BHP-E 048 type 5.00 14.0 16.0 Available

MMD-AP0566BHP-E 056 type 6.00 16.0 18.0 Available

Concealed Duct

High Static

Pressure Type

MMD-AP0184H-E 018 type 2.00 5.6 6.3 -

MMD-AP0244H-E 024 type 2.50 7.1 8.0 -

MMD-AP0274H-E 027 type 3.00 8.0 9.0 -

MMD-AP0364H-E 036 type 4.00 11.2 10.0 -

MMD-AP0484H-E 048 type 5.00 14.0 16.0 -

7

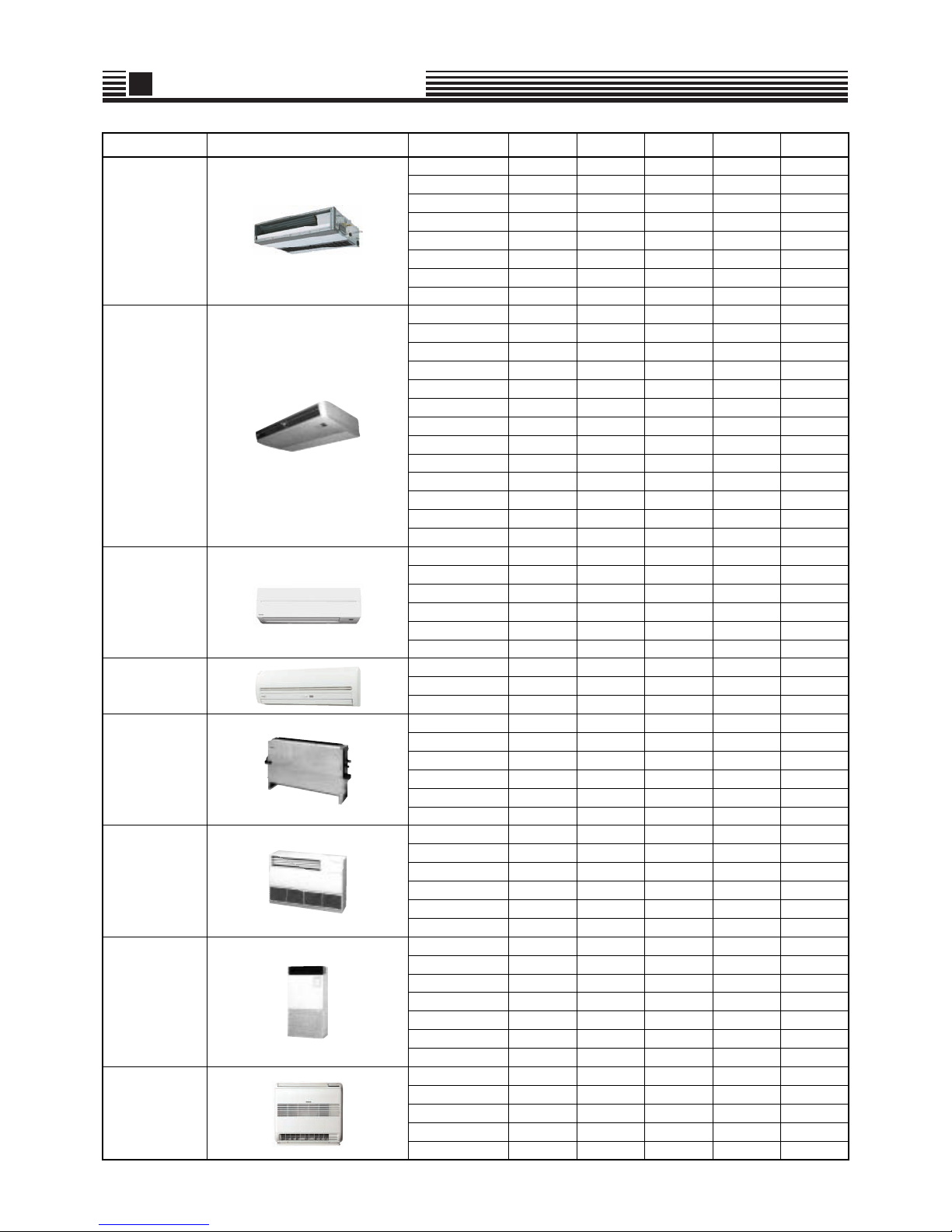

1 System overview

Slim Duct Type

MMD-AP0054SPH-E 005 type 0.60 1.7 1.9 Available

MMD-AP0074SPH-E 007 type 0.80 2.2 2.5 Available

MMD-AP0094SPH-E 009 type 1.00 2.8 3.2 Available

MMD-AP0124SPH-E 012 type 1.25 3.6 4.0 Available

MMD-AP0154SPH-E 015 type 1.70 4.5 5.0 Available

MMD-AP0184SPH-E 018 type 2.00 5.6 6.3 Available

MMD-AP0244SPH-E 024 type 2.50 7.1 8.0 Available

MMD-AP0274SPH-E 027 type 3.00 8.0 9.0 Available

Ceiling Type

MMC-AP0154H-E 015 type 1.70 4.5 5.0 -

MMC-AP0184H-E 018 type 2.00 5.6 6.3 -

MMC-AP0244H-E 024 type 2.50 7.1 8.0 -

MMC-AP0274H-E 027 type 3.00 8.0 9.0 -

MMC-AP0364H-E 036 type 4.00 11.2 12.5 -

MMC-AP0484H-E 048 type 5.00 14.0 16.0 -

MMC-AP0157HP-E 015 type 1.70 4.5 5.0 -

MMC-AP0187HP-E 018 type 2.00 5.6 6.3 -

MMC-AP0247HP-E 024 type 2.50 7.1 8.0 -

MMC-AP0277HP-E 027 type 3.00 8.0 9.0 -

MMC-AP0367HP-E 036 type 4.00 11.2 12.5 -

MMC-AP0487HP-E 048 type 5.00 14.0 16.0 -

MMC-AP0567HP-E 056 type 6.00 16.0 18.0 -

High-wall Type

3 series

MMK-AP0073H 007 type 0.80 2.2 2.5 Available

MMK-AP0093H 009 type 1.00 2.8 3.2 Available

MMK-AP0123H 012 type 1.25 3.6 4.0 Available

MMK-AP0153H 015 type 1.70 4.5 5.0 Available

MMK-AP0183H 018 type 2.00 5.6 6.3 Available

MMK-AP0243H 024 type 2.50 7.1 8.0 Available

High-wall Type

4 series

MMK-AP0074MH-E 007 type 0.80 2.2 2.5 Available

MMK-AP0094MH-E 009 type 1.00 2.8 3.2 Available

MMK-AP0124MH-E 012 type 1.25 3.6 4.0 Available

Floor Standing

Concealed Type

MML-AP0074BH-E 007 type 0.80 2.2 2.5 -

MML-AP0094BH-E 009 type 1.00 2.8 3.2 -

MML-AP0124BH-E 012 type 1.25 3.6 4.0 -

MML-AP0154BH-E 015 type 1.70 4.5 5.0 -

MML-AP0184BH-E 018 type 2.00 5.6 6.3 -

MML-AP0244BH-E 024 type 2.50 7.1 8.0 -

Floor Standing

Cabinet Type

MML-AP0074H-E 007 type 0.80 2.2 2.5 Available

MML-AP0094H-E 009 type 1.00 2.8 3.2 Available

MML-AP0124H-E 012 type 1.25 3.6 4.0 Available

MML-AP0154H-E 015 type 1.70 4.5 5.0 Available

MML-AP0184H-E 018 type 2.00 5.6 6.3 Available

MML-AP0244H-E 024 type 2.50 7.1 8.0 Available

Floor Standing Type

MMF-AP0154H-E 015 type 1.70 4.5 5.0 -

MMF-AP0184H-E 018 type 2.00 5.6 6.3 -

MMF-AP0244H-E 024 type 2.50 7.1 8.0 -

MMF-AP0274H-E 027 type 3.00 8.0 9.0 -

MMF-AP0364H-E 036 type 4.00 11.2 10.0 -

MMF-AP0484H-E 048 type 5.00 14.0 16.0 -

MMF-AP0564H-E 056 type 6.00 16.0 18.0 -

Console Type

MML-AP0074NH-E 007 type 0.80 2.2 2.5 Available

MML-AP0094NH-E 009 type 1.00 2.8 3.2 Available

MML-AP0124NH-E 012 type 1.25 3.6 4.0 Available

MML-AP0154NH-E 015 type 1.70 4.5 5.0 Available

MML-AP0184NH-E 018 type 2.00 5.6 6.3 Available

Type Appearance Model name Capacity rank Capacity code

Cooling

capacity (kW)

Heating

capacity (kW)

PMV Kit

8

1 System overview

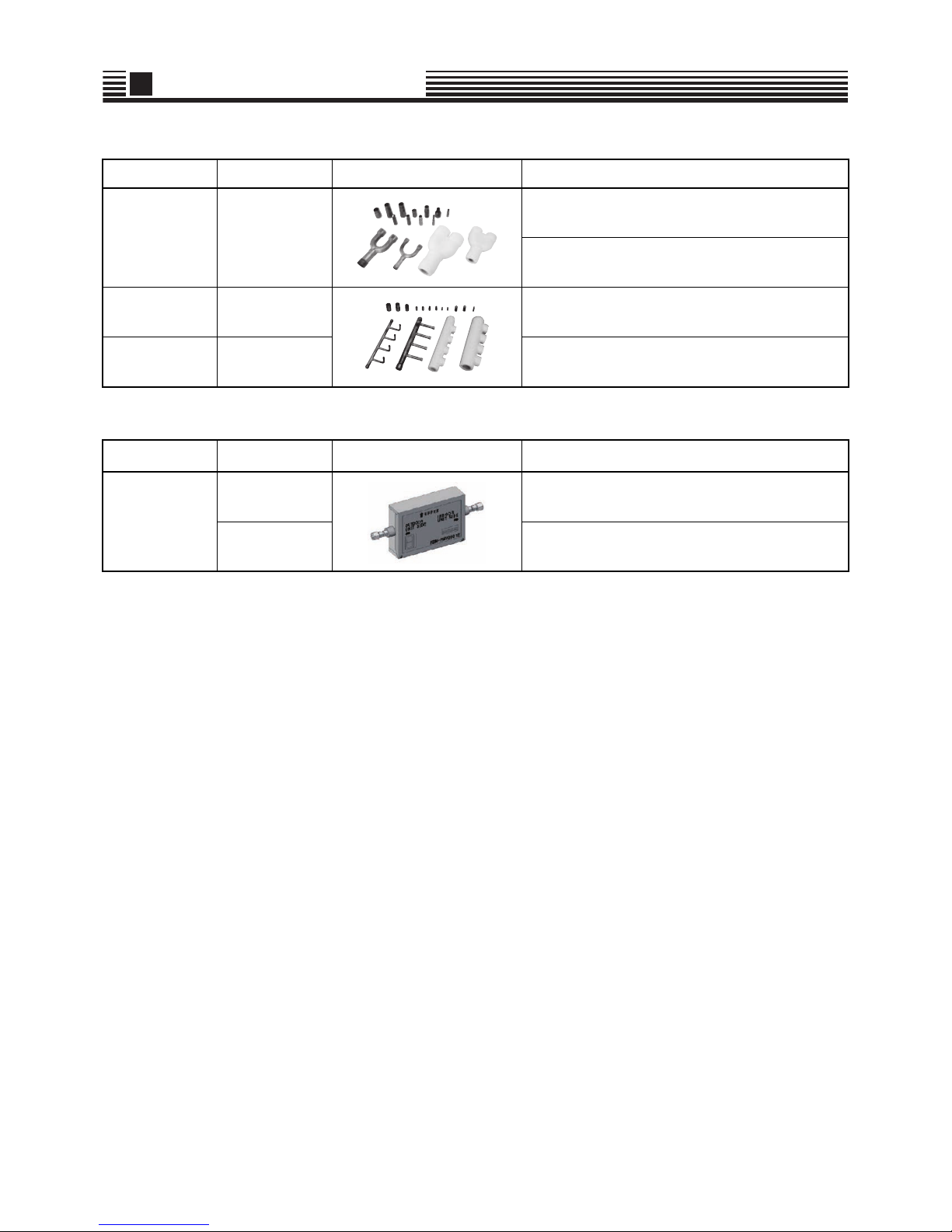

1-2-3. Branching joints and headers

1-2-4. PMV Kits

Name Model name Appearance Remarks

Y -shape branching

joint

RBM-BY55E

4-branching

header

RBM-HY1043E

8-branching

header

RBM-HY1083E

Name Model name Appearance Remarks

PMV Kits

RBM-PMV0362E

RBM-PMV0902E

9

1 System overview

1-2-5. Remote controllers

1-2-6. Optional PCB of outdoor unit

1-2-7. Controls

Name Model Name Remarks

Wired remote controller RBC-AMT32E

Simple wired remote controller RBC-AS41E2

Wireless remote controller kit

RBC-AX32U(W)-E

RBC-AX32U(WS)-E

For 4-way Air Discharge Cassette

RBC-AX32CE2

For Under Ceiling 4series, 1-way Air Discharge

Cassette SH

TCB-AX33CE

For Under Ceiling 7series, Under Ceiling and 1-way Air

Discharge Cassette SH 4series

TCB-AX32E2

For Compact 4-way Cassette, 1-way Air Discharge

Cassette YH, Concealed Duct Standard, Slim Duct,

Floor Standing Cabinet, Floor Standing

RBC-AX23UW(W)-E For 2-way Air Discharge Casette

ON-OFF controller TCB-CC163TLE2

Central remote controller

TCB-SC642TLE2

BMS-CM1280TLE

Schedule timer TCB-EXS21TLE

Remote controller with schedule timer

(7-day timer function)

RBC-AMS41E

Lite-Vision plus Remote Controller RBC-AMS51E-EN/ES

-EN : English, Italian, Polish, Greece, Russian, Turkish

-ES : English, Spanish, Portuguese, French, Dutch,

German

Name Model Name Remarks

Power peak-cut control board TCB-PCDM4E

External master ON/OFF control board TCB-PCMO4E

Output control board TCB-PCIN4E

Name Model Name Remarks

Touch Screen Controller

BMS-TP0641ACE

BMS-TP5121ACE

BMS-TP0641PWE

BMS-TP5121PWE

ACE:Without energy monitoring function

PWE:With energy monitoring function

0641:Maxmimum 64 indoor units connectable

5121:Maximum 512 indoor units connectable

Smart BMS manager BMS-SM1280HTLE

Smart BMS manager with data

analyzer

BMS-SM1280ETLE

WEB Based Controller

BMS-WB2561PWE

BMS-WB01GTE

TCS-NET Relay Interface BMS-IFLSV4E

Energy Monitoring Relay Interface BMS-IFWH5E

Digital I/O Relay Interface BMS-IFDD03E

LonWorks LN Interface TCB-IFLN642TLE

BACnet Server

BMS-LSV9E

BMS-STBN10E

Modbus Interface TCB-IFMB641TLE

Analog Interface TCB-IFCB640TLE

10

Side blow VRF Data book

2

Equipment selection procedure

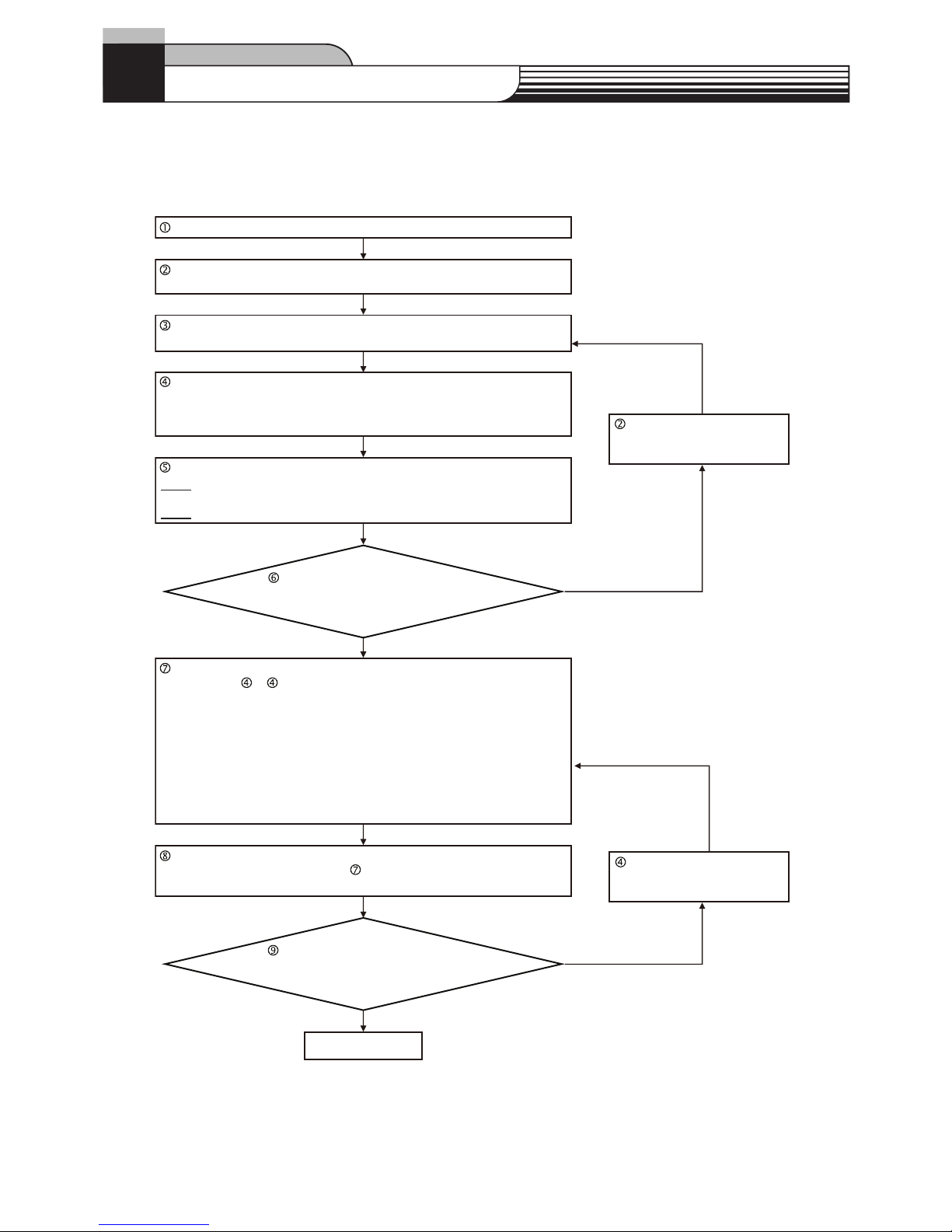

2-1. Selection flow chart

end

YES

NO

YES

NO

' Increase of indoor unit

capacity at object room against

air-conditioning load

Preliminary selection of indoor units in the standard capacity no less than

air-conditioning load at each room.

Calculate corrected capacity A of each indoor unit by correcting of indoor

temperature for the standard capacity of each indoor unit.(Refer to Chart [1])

Preliminary selection of outdoor unit in the standard capacity no less than

total values of corrected capacity A in indoor units. And check both connectable indoor units number and the outdoor unit diversity(Connected ratio of

indoor units to outdoor units) for the specifications.

Calculate corrected capacity B of each indoor unit by following 2 steps.

Step1:Find the correction value of "Connecting pipe length and lift -" by both

the longest length and the largest height. (Refer to Chart [3])

Step2:Calculate by multiplying the value of step1 by corrected capacity A.

Calculate corrected capacity C of each indoor unit by multiplying the total

corrected capacity of outdoor unit at by proportional division of each indoor

unit standard capacity for total standard capacity of all indoor units.

Find correction values of below items for the standard capacity of outdoor

unit selected at or '.

Then determination of total corrected capacity of the selected outdoor unit by

all multiplying.

-Correction of indoor temperature condition(Refer to Chart [1])

-Correction of outdoor temperature condition(Refer to Chart [2])

-Correction of connecting pipe length and lift between indoor and outdoor

units by both the longest length and the largest height (Refer to Chart [3])

-Correction of outdoor unit diversity (Refer to Chart [4])

-Correction of frost condition on outdoor heat exchanger when in heating

(Refer to Chart [5])

Determination of indoor air-conditioning load at each room.

Corrected capacity C of indoor

unit >= air-conditioning load (for All

rooms)

Corrected capacity B of indoor

unit >= air-conditioning load (for All

rooms)

' Increase of outdoor unit

capacity. And check the outdoor

unit diversity

11

2

Equipment selection procedure

2-2. Combination conditions for indoor unit and outdoor unit

Indoor unit can connect 80 % to 130 % of Outdoor unit capacity.

2-2-1. For indoor unit, the capacity code is decided for each capacity rank.

NOTE:

Capacity rank : Correspondence to Btu/h. Capacity code : Correspondence to Horsepower.

*1 : Capacity code of 005 type is the same as 007 type.

2-2-2. For outdoor unit, maximum No. of connectable indoor units and total

capacity code of indoor units are decided.

Capacity rank type 005(*1) 007 008 009 010 012 014 015 017 018 020 024 027 030 036 048 056

Capacity

code

Equivalent to

HP

0.8 0.8 0.9 1.0 1.1 1.25 1.5 1.7 1.85 2.0 2.25 2.5 3.0 3.2 4.0 5.0 6.0

Outdoor unit Capacity code of outdoor unit No. of connectable indoor units Total capacity code of indoor units

MCY-MHP0404HT* 4 2 to 6 3.2 to 5.2

MCY-MHP0504HT* 5 2 to 6 4.0 to 6.5

MCY-MHP0604HT* 6 2 to 6 4.8 to 7.8

12

2

Equipment selection procedure

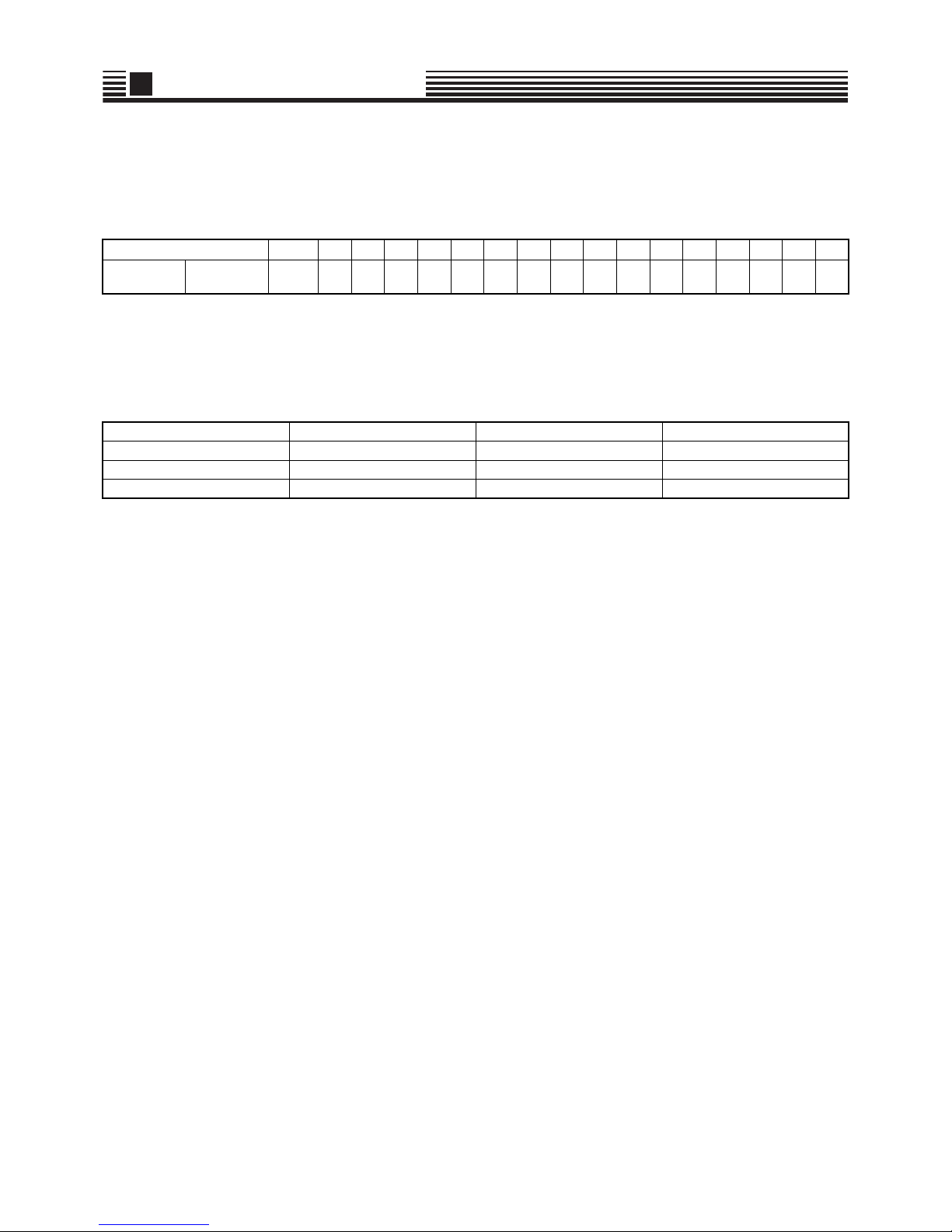

2-3. Cooling / heating capacity characteristics

2-3-1. Correction charts for cooling capacity calculation

[1] Capacity correction value vs. indoor air wet bulb temperature

[2] Capacity correction value vs. outdoor air dry bulb temperature

[3] Capacity correction value vs. connecting pipe length and lift difference between indoor and

outdoor units

[4]* Correction of outdoor unit diversity

* : Coefficient to use for correction of outdoor unit capacity when total capacity of the indoor units are not equal to the outdoor unit

capacity.

㪇㪅㪏㩷

㪇㪅㪐㩷

㪈㪅㪇㩷

㪈㪅㪈㩷

㪈㪅㪉㩷

㪈㪌 㪉㪇

Capacity correction value

Indoor air wet bulb temp. (°C)

0.8

0.9

1.0

1.1

1.2

-5 0 5 10 15 20 25 30 35 40

Capacity correction value

Outdoor air dry bulb temp. (°C)

Height of outdoor unit H [m]

Pipe length (Equivalent length) L [m]

Capacity correction value

Indoor units total capacity ratio (%)

Standard capacity ratio

13

2

Equipment selection procedure

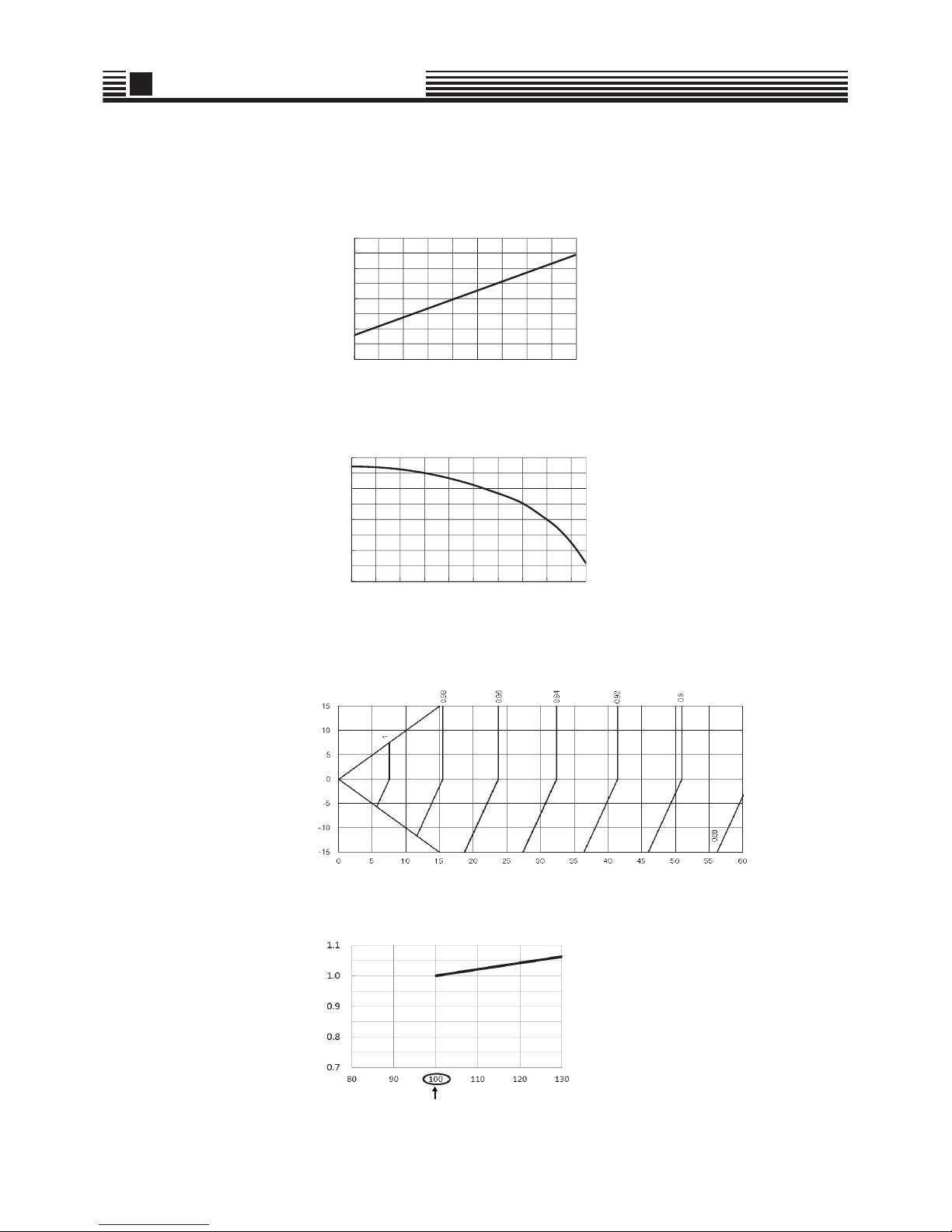

2-3-2. Correction charts for heating capacity calculation

[1] Capacity correction value vs. indoor air dry bulb temperature

[2] Capacity correction value vs. outdoor air wet bulb temperature

[3] Capacity correction value vs. connecting pipe length and lift difference between indoor and

outdoor units

[4]* Correction of outdoor unit diversity

* : Coefficient to use for correction of outdoor unit capacity when total capacity of the indoor units are not equal to the outdoor unit

capacity.

0.8

0.9

1.0

1.1

1.2

15 20

Capacity correction value

Indoor air dry bulb temp. (°C)

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

-20 -15 -10 -5 0 5 10 15

Capacity correction value

Outdoor air wet bulb temp. (°C)

Height of outdoor unit H [m]

Pipe length (Equivalent length) L [m]

Capacity correction value

Indoor units total capacity ratio (%)

Standard capacity ratio

14

2

Equipment selection procedure

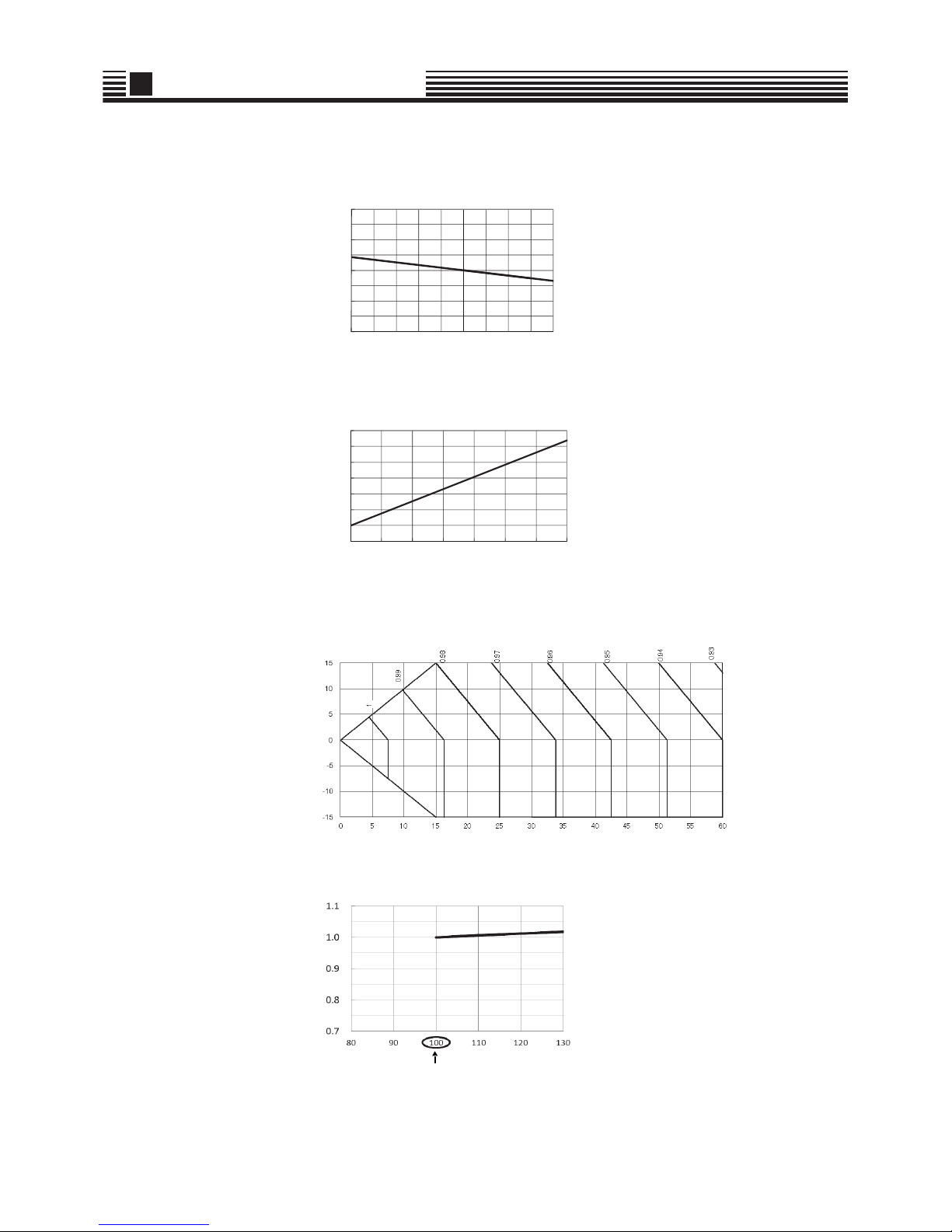

2-3-3. Capacity correction in case of frost on the outdoor heat exchanger in heating

Correct the heating capacity when frost was found on the outdoor heat exchanger.

Heating capacity = Capacity after correction of outdoor unit x Correction value of capacity resulted from frost

(Capacity after correction of outdoor unit: Heating capacity calculated in the above item 2.)

[5] capacity correction in case of frost on the outdoor heat exchanger

Capacity correction value

Outdoor air wet bulb temp. (°C)

15

2

Equipment selection procedure

2-4. Operational temperature range

The unit will operate down to an outdoor temperature of -20 °C, however considerable performance decrease will be expected below -15 °C.

Therefore please consider installation location/surroundings and system design when expected to operate between -15 °C and -20 °C.

Outdoor air dry bulb temp. (°C)

Indoor air wet bulb temp. (°C)

Cooling

Indoor air dry bulb temp. (°C)

Outdoor air wet bulb temp. (°C)

Heating

16

Side blow VRF Data book

3

Refrigerant piping design

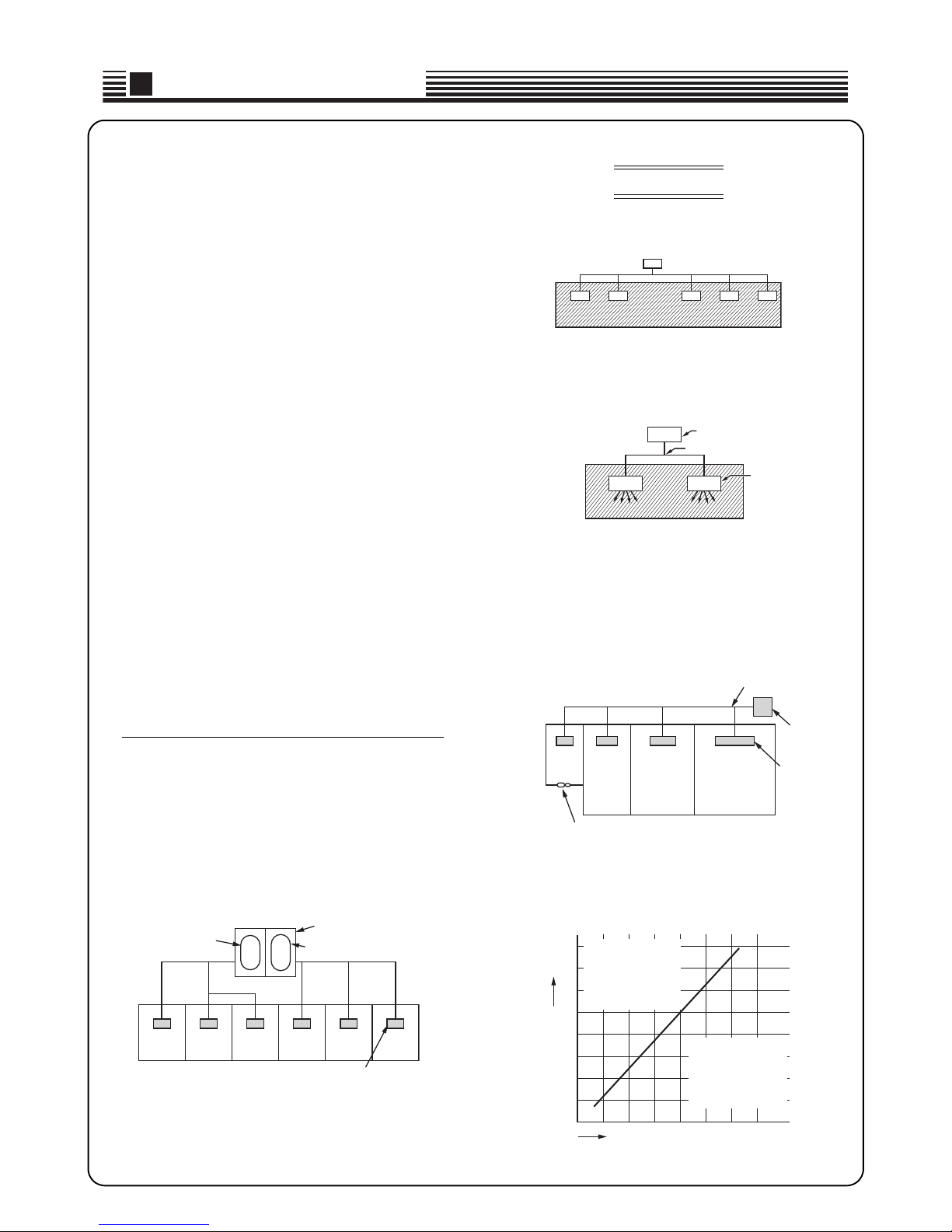

3-1. Free branching system

[1] Line br an ch ing syste m

[2] Header branching system

[3] Header branching system after line branching

[4] Line branching system after header branching

[5] Header branching system after header branching

The above five branching systems enable to dramatically increase the flexibility of refrigerant piping design.

Line branching

system

Header

branching

system

Header

branching

system

Line branching

system after

header

branching

Header

branching

system after

header

branching

Branching joint

Indoor unit

Remote

controller

Outdoor

Branching header

Remote

controller

Outdoor

* In case of "PMV Kit"

Branching header

Branching joint

Remote

controller

PMV Kit

*

Indoor unit

Outdoor

* In case of "PMV Kit"

Branching header

Branching joint

Remote

controller

*

Indoor unit

Branching header

Outdoor

17

3 Refrigerant piping design

3-2. Allowable length / height difference of refrigerant piping

*1 Furthest indoor unit from 1st branch to be named "A"

Allowable value Piping section

Pipe Length

Total extension of pipe (Liquid pipe, real length) 90 m L1 + L2 + L3 + a + b + c + d + e + f

Furthest piping length L (*1)

Real length 50 m

L1 + L3 + f

Equivalent length 60 m

Max. real length of main pipe 30 m L1

Max. real length of furthest piping from 1st branching Li (*1) 20 m L3 + f

Max. real length of indoor unit connecting pipe 10 m a, b, c, d, e, f

Height

Difference

Height between indoor and outdoor units H1

Upper outdoor unit 15 m ―

Lower outdoor unit 15 m ―

Height between indoor units H2 10 m ―

f

abcd

A

*1

L3

L1

L2

e

Outdoor unit

Height difference

between indoor and

outdoor units H1

Main

pipe

1st branching

section

Branching pipe

Branching

header

Indoor unit

Y-shaped

branching joint

Branching pipe

Equivalent length corresponded to farthest piping L

Equivalent length corresponded to farthest piping after 1st b ranching Li

Height

difference

between indoor

units H2

18

3 Refrigerant piping design

3-3. Selection of refrigerant piping

No. Piping parts Name Selection of pipe size Remarks

(1)

Outdoor unit

1st branching

section

Main pipe

Size of main pipe

Same as connecting pipe

size of the outdoor unit.

(2)

Branching section

Branching section

Branching pipe

Pipe size between branching sections

Pipe size differs based on the

total capacity code value of

indoor units at the

downstream side. If the total

value exceeds the capacity

code of the outdoor unit,

apply the capacity code of the

outdoor unit.

(3)

Branching section

Indoor unit

Indoor unit

connecting pipe

Connecting pipe size of indoor unit

(4) Branching section

Y-shaped

branching joint

Selection of branching section (Y-shaped branching joint)

(5) Branching section

Branching

header

Selection of branching section (Branching header)

(5)

(2)

(4)

(1)

(3)

(3)

(3)

(3)

(2)

(4)

(3)

(3)

Outdoor unit

Liquid pipe

Gas pipe

Main pipe

1st branching

section

Branching

pipe

Branching

header

Indoor

unit

Indoor

unit

Branching

pipe

Y-shaped

branching joint

→

Outdoor unit capacity type Gas pipe Liquid pipe

0404 type 15.88 9.52

0504 type 15.88 9.52

0604 type 19.05 9.52

→

Total capacity codes of indoor units at down

stream side

Gas pipe Liquid pipe

Equivalent to HP Equivalent to capacity

Below 2.4 Below 6.6 12.70 9.52

2.4 to below 6.4 6.6 to below 18.0 15.88 9.52

6.4 or more 18.0 or more 19.05 9.52

→

Capacity rank Gas pipe Liquid pipe

005 to 012 type 9.52 6.35

014 to 018 type 12.70 6.35

020 to 056 type 15.88 9.52

Model name

Y-shape branch joint RBM-BY55E

Model name

Branching header

For 4 branches RBM-HY1043E

For 8 branches RBM-HY1083E

19

3 Refrigerant piping design

3-4. Allowable length / height difference of refrigerant piping with PMV

Kit

*1 Furthest indoor unit from 1st branch to be named "A"

Allowable value Piping section

Pipe Length

Total extension of pipe (Liquid pipe, real length) 75 m

L1 + L2 + L3 + a + b + c + d + e + f + g + h + i

+ j + k + l

Furthest piping length L (*1)

Real length 40 m

L1 + L3 + f + l

Equivalent length 50 m

Max. real length of main pipe 25 m L1

Max. real length of furthest piping from 1st branching Li (*1) 15 m L3 + f + l

Max. real length of indoor unit connecting pipe 10 m a + g, b + h, c + i, d + j, e + k, f + l

Real length between PMV Kit and indoor unit

2 m or more

Below 10 m

g, h, i, j, k, l

Height

Difference

Height between indoor and outdoor units H1

Upper outdoor unit 15 m ―

Lower outdoor unit 15 m ―

Height between indoor unit and PMV Kit H2 10 m ―

NOTE

Do not connect two or more indoor units to one PMV Kit.

Arrange one indoor unit and one PMV Kit set to 1 by 1.

KODOOG ON

PMV Kit

PMV Kit

tinu roodnItinu roodnI

e

l

f

ab

ghij

cd

H2

H2

H2

A

*1

L3

L1

L2

k

Outdoor unit

Height

difference

between

indoor and

outdoor

units H1

Main

pipe

1st branching

section

Branching pipe

Branching

header

Indoor unit

Y-shaped

branching joint

Branching pipe

Equivalent length corresponded to farthest piping L

Equivalent length corresponded to farthest piping after 1st branching Li

Height difference

between indoor unit

and PMV Kit H2 *

* Between highest

unit and lower

units.

PMV Kit

Example)

20

3 Refrigerant piping design

3-5. Selection of refrigerant piping with PMV Kit

No. Piping parts Name Selection of pipe size Remarks

(1)

Outdoor unit

1st branching

section

Main pipe

Size of main pipe

Same as connecting pipe

size of the outdoor unit.

(2)

Branching section

Branching section

Branching pipe

Pipe size between branching sections

Pipe size differs based on the

total capacity code value of

indoor units at the

downstream side. If the total

value exceeds the capacity

code of the outdoor unit,

apply the capacity code of the

outdoor unit.

(3)

Branching section

Indoor unit

Indoor unit

connecting pipe

Connecting pipe size of indoor unit

(4) Branching section

Y-shaped

branching joint

Selection of branching section (Y-shaped branching joint)

(5) Branching section

Branching

header

Selection of branching section (Branching header)

(6) PMV Kit PMV Kit

Selection of PMV Kit

* PMV kit can be connected less than 027 type FCU.

)5(

)2(

)4(

)1(

)3(

6()

)3(

()3

)2(

()4

)3(

()6

)6(

()6

)3(

6()

3()

)6(

Outdoor unit

Liquid pipe

Gas pipe

Main pipe

1st branching

section

Branching

pipe

Branching

header

Indoor

unit

Indoor

unit

Branching

pipe

Y-shaped

branching joint

PMV Kit

→

Outdoor unit capacity type Gas pipe Liquid pipe

0404 type 15.9 9.5

0504 type 15.9 9.5

0604 type 19.1 9.5

→

Total capacity codes of indoor units at down

stream side

Gas pipe Liquid pipe

Equivalent to HP Equivalent to capacity

Below 2.4 Below 6.6

12.7 9.5

2.4 to below 6.4 6.6 to below 18.0 15.9 9.5

6.4 or more 18.0 or more 19.1 9.5

→

Capacity rank Gas pipe Liquid pipe

005 to 012 type 9.5 6.4

014 to 018 type 12.7 6.4

024 to 056 type 15.9 9.5

Model name

Y-shape branch joint RBM-B Y55E

Model name

Branching header

For 4 branches RBM-HY1043E

For 8 branches RBM-HY1083E

Indoor unit capacity type Model name

005 to 014 type RBM-PMV0362E

015 to 027 type RBM-PMV0902E

21

3 Refrigerant piping design

3-6. Charging requirement with additional refrigerant

After finishing vacuuming, exchange the vacuum pump with a refrig erant canister and start additional charging of refrigerant.

Refrigerant amount charged in factory

Calculation of additional refrigerant charge amount

Refrigerant charge amount factory default does not include the refrigerant for pipes at the local site.

For refrigerant to be charged in pipes at the local site, calculate the amount and charge it additionally.

When the additional refrigerant amount indicates minus as the result of calculation, it is not necessary to subtract any refrigerant.

Calculating formula

Ta ble 1

Table2

*1: Capacity code of 005 type is the same as 007 type. (kg)

Ta ble 3

Outdoor unit type MHP0404 MHP0504 MHP0604

Charging amount (kg) 3.9 3.9 3.9

Liquid pipe diameter (mm) 6.4 9.5

Additional refrigerant amount /1 m liquid pipe (kg/m) 0.025 0.055

Capacity rank

005(*1) 007 009 012 015 018 024 027 030 036 048 056

Capacity code (Equivalent to HP)

0.8 0.8 1.0 1.25 1.7 2.0 2.5 3.0 3.2 4.0 5.0 6.0

Indoor unit

model name

4-way cassette

MMU-AP****H

- - 0.4 0.4 0.8 0.8 0.8 0.8 0.8 1.2 1.2 1.2

MMU-AP****MH*

0.40.40.40.40.60.6------

2-way cassette MMU-AP****WH*

- 0.4 0.4 0.4 0.5 0.7 0.7 0.7 0.7 1.1 1.1 1.1

1-way cassette MMU-AP****YH / SH*

-0.40.40.40.50.50.6-----

Duct

MMD-AP****BH*

- 0.3 0.3 0.3 0.5 0.5 0.8 0.8 0.8 1.1 1.1 1.1

MMD-AP****S(P)H*

0.30.30.30.30.50.50.80.8----

MMD-AP****H*

- ----0.81.01.0-1.01.3-

Under-ceiling

MMC-AP****HP*

- - - - 0.6 0.6 0.8 0.8 - 1.2 1.2 1.2

MMC-AP****H*

- - - - 0.5 0.5 0.7 0.7 - 1.1 1.1 -

High wall

MMK-AP****H*

-0.50.50.50.70.70.7-----

MMK-AP****MH*

-0.30.30.3--------

Floor standing

MMF-AP****H*

- - - - 0.7 0.7 1.0 1.0 - 1.3 1.3 1.3

MML-AP****H*

-0.50.50.50.50.80.8-----

MML-AP****BH*

-0.30.30.30.50.50.7-----

MML-AP****NH*

-0.50.50.50.50.5------

Outdoor unit capacity type MCY- MHP0404 MHP05 04 MHP0604

Compensation by outdoor HP (kg) -1.6 -1.6 -1.6

NOTE

Additional refrigerant

charge amount at

lacal site (kg)

Real length of

liquid pipe

Additional refrigerant

charge amount per 1 m

liquid pipe (Table 1)

Corrective amount of

refrigerant depending on

the indoor units (Table 2)

Compensation by

outdoor HP (Table 3)

=x + +

22

Side blow VRF Data book

4 Wiring design

4-1. General

• The appliance shall be installed in a accordance with national wiring regulations.

Capacity shortages of the power circuit or an incomplete installation may cause an electric shock or fire.

• Perform wiring of power supply complying with the rules and regulations of the local electric company.

• Never connect AC voltage power to the control wiring terminal block (U1,U2,U3,U4); otherwise the unit may break

down.

• Be sure that electric wiring does not come into contact with high-temperature parts of piping;

otherwise the coating of cables may melt and cause an accident.

• Locate wiring system for the control and refrigerant piping system in the same line.

• Do not turn on the power supply of the indoor units until vacuuming of the refrigerant pipe has finished.

• For the wiring of power to indoor units and that between indoor and outdoor units, follow the instructions in the

installation manual of each indoor unit.

4-2. Electrical wiring design

Determine the wire size for the indoor unit according to the number of connected indoor units downstream.

4-3. Outdoor unit power supply

Electrical characteristics

MCA : Maximum Circuit Amps

MOCP : Maximum Overcurrent Protection (Amps)

Model name

Normal Voltage

(V-Ph-Hz)

Voltage Range Compressor Fan Motor Power Supply

Min Max kW kW MCA MOCP

MCY-MHP0404HT-E 230 - 1 - 50 198 264 3.75 0.100 × 2 23.5 32.0

MCY-MHP0504HT-E 230 - 1 - 50 198 264 3.75 0.100 × 2 26.5 32.0

MCY-MHP0604HT-E 230 - 1 - 50 198 264 3.75 0.100 × 2 28.0 32.0

Pull box

Indoor unitIndoor unitIndoor unit

Indoor unitIndoor unitIndoor unit

Single phase

50 Hz 220-240V

Earth leakage breaker

power switch

Circuit breaker

(Earth leakage breaker)

Main switch

(Fuse)

Outdoor

power source

Indoor

power source

23

4 Wiring design

4-4. Indoor unit power supply

Electrical characteristics

Type Model

Nominal

Voltage

(V-Ph-Hz)

Voltage Range Fan Motor Power Supply

Min Max kW FLA MCA MOCP

4-Way Air

Discharge

Cassette Type

MMU-AP0092H

230-1-50 198 264 0.014 0.63 0.79 15

MMU-AP0122H

230-1-50 198 264 0.014 0.63 0.79 15

MMU-AP0152H

230-1-50 198 264 0.014 0.80 1.00 15

MMU-AP0182H

230-1-50 198 264 0.014 0.80 1.00 15

MMU-AP0242H

230-1-50 198 264 0.020 0.87 1.09 15

MMU-AP0272H

230-1-50 198 264 0.020 0.87 1.09 15

MMU-AP0302H

230-1-50 198 264 0.020 0.87 1.09 15

MMU-AP0362H

230-1-50 198 264 0.068 1.15 1.44 15

MMU-AP0482H

230-1-50 198 264 0.072 1.15 1.44 15

MMU-AP0562H

230-1-50 198 264 0.072 1.15 1.44 15

MMU-AP0094HP-E

230-1-50 198 264 0.014 0.63 0.79 15

MMU-AP0124HP-E

230-1-50 198 264 0.014 0.63 0.79 15

MMU-AP0154HP-E

230-1-50 198 264 0.014 0.80 1.00 15

MMU-AP0184HP-E

230-1-50 198 264 0.014 0.80 1.00 15

MMU-AP0244HP-E

230-1-50 198 264 0.020 0.87 1.09 15

MMU-AP0274HP-E

230-1-50 198 264 0.020 0.87 1.09 15

MMU-AP0304HP-E

230-1-50 198 264 0.020 0.87 1.09 15

MMU-AP0364HP-E

230-1-50 198 264 0.068 1.15 1.44 15

MMU-AP0484HP-E

230-1-50 198 264 0.072 1.15 1.44 15

MMU-AP0564HP-E

230-1-50 198 264 0.072 1.15 1.44 15

Compact 4-way

Cassette

(600 x 600) Type

MMU-AP0054MH-E

230-1-50 198 264 0.060 0.32 0.40 15

MMU-AP0074MH-E

230-1-50 198 264 0.060 0.32 0.40 15

MMU-AP0094MH-E

230-1-50 198 264 0.060 0.35 0.44 15

MMU-AP0124MH-E

230-1-50 198 264 0.060 0.36 0.45 15

MMU-AP0154MH-E

230-1-50 198 264 0.060 0.48 0.60 15

MMU-AP0184MH-E

230-1-50 198 264 0.060 0.48 0.60 15

2-Way Air

Discharge

Cassette Type

MMU-AP0072WH

230-1-50 198 264 0.020 0.32 0.40 15

MMU-AP0092WH

230-1-50 198 264 0.020 0.32 0.40 15

MMU-AP0122WH

230-1-50 198 264 0.020 0.32 0.40 15

MMU-AP0152WH

230-1-50 198 264 0.020 0.32 0.40 15

MMU-AP0182WH

230-1-50 198 264 0.030 0.70 0.88 15

MMU-AP0242WH

230-1-50 198 264 0.040 0.81 1.01 15

MMU-AP0272WH

230-1-50 198 264 0.040 0.81 1.01 15

MMU-AP0302WH

230-1-50 198 264 0.050 0.81 1.01 15

MMU-AP0362WH

230-1-50 198 264 0.070 0.87 1.09 15

MMU-AP0485WH

230-1-50 198 264 0.070 0.87 1.09 15

MMU-AP0562WH

230-1-50 198 264 0.070 0.87 1.09 15

1-Way Air

Discharge

Cassette Type

MMU-AP0074YH-E

230-1-50 198 264 0.022 0.28 0.35 15

MMU-AP0094YH-E

230-1-50 198 264 0.022 0.28 0.35 15

MMU-AP0124YH-E

230-1-50 198 264 0.022 0.28 0.35 15

MMU-AP0154SH-E

230-1-50 198 264 0.030 0.40 0.49 15

MMU-AP0184SH-E

230-1-50 198 264 0.030 0.42 0.53 15

MMU-AP0244SH-E

230-1-50 198 264 0.030 0.71 0.88 15

24

4 Wiring design

Concealed Duct Type

MMD-AP0076BHP-E

230-1-50 198 264 0.150 0.30 0.37 15

MMD-AP0096BHP-E

230-1-50 198 264 0.150 0.34 0.42 15

MMD-AP0126BHP-E

230-1-50 198 264 0.150 0.34 0.42 15

MMD-AP0156BHP-E

230-1-50 198 264 0.150 0.48 0.61 15

MMD-AP0186BHP-E

230-1-50 198 264 0.150 0.48 0.61 15

MMD-AP0246BHP-E

230-1-50 198 264 0.150 0.60 0.75 15

MMD-AP0276BHP-E

230-1-50 198 264 0.150 0.60 0.75 15

MMD-AP0306BHP-E

230-1-50 198 264 0.150 0.70 0.88 15

MMD-AP0366BHP-E

230-1-50 198 264 0.250 1.23 1.54 15

MMD-AP0486BHP-E

230-1-50 198 264 0.250 1.41 1.77 15

MMD-AP0566BHP-E

230-1-50 198 264 0.250 1.41 1.77 15

Concealed Duct

High Static

Pressure Type

MMD-AP0184H-E

230-1-50 198 264 0.160 0.93 1.16 15

MMD-AP0244H-E

230-1-50 198 264 0.160 1.55 1.94 15

MMD-AP0274H-E

230-1-50 198 264 0.160 1.55 1.94 15

MMD-AP0364H-E

230-1-50 198 264 0.260 1.87 2.34 15

MMD-AP0484H-E

230-1-50 198 264 0.260 2.12 2.65 15

Slim Duct Type

MMD-AP0054SPH-E

230-1-50 198 264 0.060 0.35 0.44 15

MMD-AP0074SPH-E

230-1-50 198 264 0.060 0.35 0.44 15

MMD-AP0094SPH-E

230-1-50 198 264 0.060 0.35 0.44 15

MMD-AP0124SPH-E

230-1-50 198 264 0.060 0.37 0.47 15

MMD-AP0154SPH-E

230-1-50 198 264 0.060 0.38 0.48 15

MMD-AP0184SPH-E

230-1-50 198 264 0.060 0.47 0.59 15

Ceiling Type

MMC-AP0154H-E

230-1-50 198 264 0.030 0.33 0.41 15

MMC-AP0184H-E

230-1-50 198 264 0.030 0.37 0.46 15

MMC-AP0244H-E

230-1-50 198 264 0.040 0.48 0.60 15

MMC-AP0274H-E

230-1-50 198 264 0.040 0.48 0.60 15

MMC-AP0364H-E

230-1-50 198 264 0.080 0.90 1.13 15

MMC-AP0484H-E

230-1-50 198 264 0.080 0.96 1.20 15

MMC-AP0157HP-E

230-1-50 198 264 0.139 1.14 1.43 15

MMC-AP0187HP-E

230-1-50 198 264 0.139 0.89 1.11 15

MMC-AP0247HP-E

230-1-50 198 264 0.139 0.89 1.11 15

MMC-AP0277HP-E

230-1-50 198 264 0.094 0.75 0.93 15

MMC-AP0367HP-E

230-1-50 198 264 0.094 0.75 0.93 15

MMC-AP0487HP-E

230-1-50 198 264 0.094 0.42 0.53 15

MMC-AP0567HP-E

230-1-50 198 264 0.094 0.41 0.52 15

High-wall Type

(3 series)

MMK-AP0073H

230-1-50 198 264 0.030 0.20 0.22 15

MMK-AP0093H

230-1-50 198 264 0.030 0.22 0.24 15

MMK-AP0123H

230-1-50 198 264 0.030 0.22 0.24 15

MMK-AP0153H

230-1-50 198 264 0.030 0.37 0.40 15

MMK-AP0183H

230-1-50 198 264 0.030 0.37 0.40 15

MMK-AP0243H

230-1-50 198 264 0.030 0.43 0.47 15

High-wall Type

(4 series)

MMK-AP0074MH-E

230-1-50 198 264 0.030 0.20 0.24 15

MMK-AP0094MH-E

230-1-50 198 264 0.030 0.21 0.26 15

MMK-AP0124MH-E

230-1-50 198 264 0.030 0.22 0.27 15

Type Model

Nominal

Voltage

(V-Ph-Hz)

V

o

ltage Range Fan Motor Power Supply

Min Max kW FLA MCA MOCP

25

4 Wiring design

• Wiring size

Must be independent from the outdoor unit power supply

NOTE:

The above connecting lengths stated in the table, indicate the length from the isolator to the outdoor unit. When the

power supply of the indoor units are connected in parallel, it is assumed that no more than a 2 % voltage drop will occur .

If the connecting length is to exceed the stated lengths, se lect a su it a ble wire in accordance with the local wiring

standards.

Floor Standing

Cabinet Type

MML-AP0074H-E

230-1-50 198 264 0.045 0.30 0.37 15

MML-AP0094H-E

230-1-50 198 264 0.045 0.30 0.37 15

MML-AP0124H-E

230-1-50 198 264 0.045 0.49 0.62 15

MML-AP0154H-E

230-1-50 198 264 0.045 0.49 0.62 15

MML-AP0184H-E

230-1-50 198 264 0.070 0.54 0.68 15

MML-AP0244H-E

230-1-50 198 264 0.070 0.54 0.68 15

Floor Standing

Concealed Type

MML-AP0074BH-E

230-1-50 198 264 0.019 0.29 0.36 15

MML-AP0094BH-E

230-1-50 198 264 0.019 0.29 0.36 15

MML-AP0124BH-E

230-1-50 198 264 0.019 0.29 0.36 15

MML-AP0154BH-E

230-1-50 198 264 0.070 0.52 0.65 15

MML-AP0184BH-E

230-1-50 198 264 0.070 0.52 0.65 15

MML-AP0244BH-E

230-1-50 198 264 0.070 0.53 0.66 15

Floor Standing Type

MMF-AP0154H-E

230-1-50 198 264 0.037 0.77 0.96 15

MMF-AP0184H-E

230-1-50 198 264 0.037 0.77 0.96 15

MMF-AP0244H-E

230-1-50 198 264 0.063 1.01 1.27 15

MMF-AP0274H-E

230-1-50 198 264 0.063 1.01 1.27 15

MMF-AP0364H-E

230-1-50 198 264 0.110 1.48 1.85 15

MMF-AP0484H-E

230-1-50 198 264 0.160 1.84 2.30 15

MMF-AP0564H-E

230-1-50 198 264 0.160 1.84 2.30 15

Console Type

MML-AP0074NH-E

230-1-50 198 264 0.041 0.21 0.26 15

MML-AP0094NH-E

230-1-50 198 264 0.041 0.21 0.26 15

MML-AP0124NH-E

230-1-50 198 264 0.041 0.25 0.31 15

MML-AP0154NH-E

230-1-50 198 264 0.041 0.32 0.40 15

MML-AP0184NH-E

230-1-50 198 264 0.041 0.46 0.58 15

Item

Model

Power supply wiring

Wire size

All models of indoor units

2.0 mm

2

(AWG#14) Max. 20 m 3.5 mm2 (AWG#12) Max. 50 m

Type Model

Nominal

Voltage

(V-Ph-Hz)

Voltage Range Fan Motor Power Supply

Min Max kW FLA MCA MOCP

26

4 Wiring design

4-5. Design of control wiring

4-5-1. Summary of control wiring

Control wiring and central control wiring use 2-core non-polarity wires.

Use 2-core shield wires to prevent noise trouble.

In this case, for the system grounding, close (connect) the end of shield wires, and isolate the end of terminal.

Use 2-core non-polarity wire for remote controller. (A, B terminals)

Use 2-core non-polarity wire for wiring of group control. (A, B terminals)

U1 U2U3 U4

U1 U2

U3 U4

U1 U2 A B 2UBAU1U2U1 A 2UBU1AB

BABABA

Central controller

Outdoor unit

Control wiring between indoor and outdoor unit

(Shield wire)

Control wiring between indoor units (Shield wire)

Indoor unit

Indoor unit

Indoor unit

Indoor unit

Remote controller

Remote controller

Remote controller

(Group control)

Open

27

4 Wiring design

4-5-2. Restriction of control wiring

Keep the rule of below tables about size and length of Control wiring.

Table-1 Control wiring between indoor and outdoor units (L1, L2, L3), Central control wiring (L4)

(*1): Total of control wiring length for all refrigerant circuits (L1 + L2 + L3 + L4)

Table-2 Control wiring between outdoor units (L5) (Other system)

Table-3 Remote controller wiring (L6, L7)

4-5-3. Group control through a remote controller

Group control of multiple indoor units (8 units) through a single remote controller

Wiring 2-core, non-polarity

Type Shield wire

Size/Length

*1

1.25 mm2: Up to 1000 m

2.0 mm

2

: Up to 2000 m

Wiring 2-core, non-polarity

Type Shield wire

Size/Length

1.25 mm

2

to 2.0 mm

2

Up to 100 m (L5)

Wire 2-core

Size

0.5 mm

2

to 2.0 mm

2

Length

Up to 500 m (L6 + L7)

Up to 400 m with of wireless remote controller in group control.

Up to 200 m total length of control wiring between indoor units (L6)

U3 U4

U1 U2

U1U3U2

U4

U1 U2

A B

U3 U4

U1 U2

U1 U2

A B

U1 U2

A B

U1

U2

A B

U1 U2

A B

U1

U2

A

B

U3 U4

U1 U2 U5 U6

U1 U2

A B

U1 U2

A B

U1 U2

A B

U3 U4

U1

U2

U5

U6

L1

L5

L6

L6

L7

L7

L4

3L2L

Header

unit

Follower

unit

Other system

Central

controller

Outdoor

unit

Indoor

unit

Table-1

Table-2

Table-1

Remote controller

Remote controllerRemote controller

U1 U2

A B

Table-3

This system

BABABABABABA

(A.B)

Remote controller

Indoor unit No.1

No.2

No.3

No.4

No.7

No.8

28

Side blow VRF Data book

5

Outdoor unit

5-1. Specifications

(*1) Rated conditions Cooling : Indoor 27 degC Dry Bulb / 19 degC Wet Bulb, Outdoor 35 degC Dry Bulb.

Heating : Indoor 20 degC Dry Bulb, Outdoor 7 degC Dry Bulb / 6 degC Wet Bulb.

The standard pipe means that equivalent piping length of 7.5 m and standard 0 m piping heigh t difference.

(*2) The source voltage must not fluctuate more than ±10%.

(*3) The amount dose not consider extra piping length and indoor unit type.

Refrigerant must be added on site in accordance with the actual piping length and indoor unit type.

(*4) Discharge temp. sensor / Suction temp. sensor / High-pressure sensor / Low-pressure sensor / Compressor case thermostat / PC board fuse

(*5) Select wire size base on the large value of MCA.

MCA : Minimum Circuit Amps

(*6) MOCP Maximum Overcurrent Protection (Amps)

Outdoor unit model name MCY-MHP0404HT-E MCY-MHP0504HT-E MCY-MHP0604HT-E

Outdoor unit type Inverter Inverter Inverter

Capacity code HP 4 5 6

Cooling Capacity

(*1)

kW 12.1 14.0 15.5

Heating Capacity

(*1)

kW 12.5 16.0 18.0

Electrical

characteristics

(Nominal) (*1)

Power supply (*2) 1phase 50Hz 220 / 230 / 240V 1phase 50Hz 220 / 230 / 240V 1phase 50Hz 220 / 230 / 240V

Cooling

Running current A 13.9 / 13.3 / 12.8 16.7 / 16.0 / 15.4 20.6 / 19.7 / 18.9

Power consumption kW 2.88 3.50 4.35

Power factor % 94 95 96

EER 4.20 4.00 3.56

Heating

Running current A 13.3 / 12.8 / 12.2 18.0 / 17.3 / 16.5 21.3 / 20.4 / 19.5

Power consumption kW 2.73 3.81 4.50

Power factor % 93 96 96

COP 4.58 4.20 4.00

Starting Current A Soft start Soft start Soft start

Dimension

Unit

Height mm 1,235 1,235 1,235

Width mm 990 990 990

Depth mm 390 390 390

Packing

Height mm 1,350 1,350 1,350

Width mm 1,102 1,102 1,102

Depth mm 552 552 552

Total Weight

Unit kg 116 116 116

Packed unit kg 124 124 124

Appearance (Color)

Silky shade

(Munsell 1Y8.5/0.5)

Silky shade

(Munsell 1Y8.5/0.5)

Silky shade

(Munsell 1Y8.5/0.5)

Compressor

Type Hermetic twin rotary compressor Hermetic twin rotary compressor Hermetic twin rotary compressor

Motor output kW 3.75 3.75 3.75

Fan unit

Fan Propeller fan (Quantity 2) Propeller fan (Quantity 2) Propeller fan (Quantity 2)

Motor output W 100 + 100 100 + 100 100 + 100

Air volume

m

3

/h

6,030 6,210 6,410

Heat exchanger Finned tube Finned tube Finned tube

Refrigerant R410A (Charged refrigerant amount (kg)) (*3) 3.9 3.9 3.9

Protective devices (*4)

Electrical

specifications

Unit

MCA (*5) A 23.5 26.5 28.0

MOCP (*6) A 32.0 32.0 32.0

Refrigerant

piping

Connecting port

diameter

Gas side (main pipe) mm 15.9 15.9 19.1

Liquid side (main pipe) mm 9.5 9.5 9.5

Connecting

method

Gas side Flare Flare Flare

Liquid side Flare Flare Flare

Max. No. of connected indoor units 6 6 6

Sound pressure level

Cooling dB(A) 50 51 52

Heating dB(A) 52 54 55

Operation temperature range

Cooling CDB -5 to 43 -5 to 43 -5 to 43

Heating CWB -20 to 15 -20 to 15 -20 to 15

29

5 Outdoor unit

5-2. Dimensional drawing

MCY-MHP0404HT-E, MCY-MHP0504HT-E, MCY-MHP0604HT-E

30

5 Outdoor unit

5-3. Branch header / branch joint

• Branch header

RBM-HY1043E, HY1083E

• Y-shape branch joint

RBM-BY55E

• Accessory socket

Model A B C øD øE n Accessory socket Qty

RBM-HY1043E

Gas side 380 90 8 3 .6 22.2 15.9 3

x 4, x 4, x 1, x 1, x 1

Liquid side 360 60 - 15.9 9.5 3

x 4, x 1, x 1

RBM-HY1083E

Gas side 700 90 8 3 .6 22.2 15.9 7

x 8, x 8, x 1, x 1, x 1

Liquid side 680 60 - 15.9 9.5 7

x 8, x 1, x 1

Model A B øC øD Accessory socket Qty

RBM-BY55E

Gas side 160 80 1 5 .9 15.9

x 1, x 2, x 2

Liquid side 130 70 9.5 9.5

x 2

Gas side

Liquid side

Gas side Liquid side

Outer dia.

Outer dia.

Outer dia.Outer dia.

369O1 dh{}+-

A B C D

58 9.5 12.7 15.9

71

15.9 19.1 22.2

80

22.2 25.4 28.6

87

25.4 28.6 31.8

95

28.6 31.8 38.1

A B

40d 15.9

40

h 19.1

48

{ 25.4

54

} 28.6

41

+ 12.7

44

- 9.5

A B

353 6.4

32

6 9.5

28

9 12.7

37.5

O 19.1

31

5 Outdoor unit

5-4. Refrigerant cycle diagram

Sensor (TO)

Heat exc han ger

Sensor (TE)

Compressor

thermo.

Solenoid

valve

(SV5)

Strainer

PMV

Strainer

Sensor (TL)

Liquid side

packed valve

Gas side

ball valve

Compressor

Strainer

Sensor (TD)

4-Way valve

Sensor (TS)

Solenoid

valve

Solenoid

valve

Capillary

tube

Check joint

Muffler

High pressure

sensor

Check joint

Low pressure

sensor

Accumulator

High pressure

SW

32

5 Outdoor unit

5-5. Wiring diagram

MCY-MHP0404HT-E, MCY-MHP0504HT-E, MCY-MHP0604HT-E

33

5 Outdoor unit

5-6. Connecting diagram

MCY-MHP0404HT-E, MCY-MHP0504HT-E, MCY-MHP0604HT-E

Central remote controller power supply

1N~ 50Hz 220-240V

䐢䐢

LN

U1

U2

U3 U4

䐟

U1

U2 U3U4

Earth

䐠 䐠 䐠 䐠

U1 U2

A

2U1UB

A

2U1UB

A

2U1UB

A

B

Indoor control

䐧 PC boad NLNLNL

LN

䐡 䐡 䐡

ABABA

B

Indoor unit

power supply

1N~ 50Hz

220-240V

䐦 䐦 䐦

Earth

htraEhtraEhtraE

Earth

CN02

CN01

䐣

䐤

䐣䐤

㻯㻺㻤㻞

(Open)

*1

*3

*2

W2

W1

䐣

䐤

LN

Outdoor power supply

1N~ 50Hz 220-240V

(Note)

1. When perform a central control, connect the wire of CN01 in CN02. (Factory

default : No connection)

2. Connection of shield wire must be connected. (Connected to all connecting

sections in each Indoor unit)

3. Group control

4. Select the power supply wiring and fuse of outdoor/indoor units according to e ach

models specification. Perform wiring of power supply complying with the rules

and regulations of the local electric company.

5. Fro the control wires connecting indoor units, outdoor units, and between indoor

and outdoor units, use 2-core and non-polarity shield wires.

6. As for details, see the wiring diagram of indoor/outdoor unit.

(1) Outdoor unit

(2) Indoor unit

(3) Remote controller

(4) Central remote controller (option)

(5) Main switch (Fuse)

(6) Circuit breaker (Earth leakage breaker)

(7) Pull box

(8) PMV Kit (option)

W1 Control wiring between indoor and outdoor units.

W2 Control wiring between indoor units.

34

5 Outdoor unit

5-7. Optional printed circuit board (PCB) of outdoor unit

Model

name

Appearance Function

TCB-PCDM4E

Size : 71 x 85 (mm)

Power peak-cut Control

Standard Specifications

(Wiring example)

Enhanced Specifications

(Wiring example)

Application

* Installation the optional PCB

in the interface board of the

outdoor unit.

PJ17

CN513

SW07

TB1

[ON]

[OFF]

TB2

COM

ON

COM

OFF

Bit 2 OFF

L1

SW1

SW2

SW2

SW1

ON

OFF

1234

Outdoor unit

interface PCB

Connection cable (attached in this optional PCB)

Locally procured

Power

supply

[OPERATION]

L1: Display lamp during power peak cut control

For SW1 and SW2, be sure to provide no-voltage

contacts for each terminal.

The input signals of SW1 and SW2 may be pulse

input (100 msec or more) or continuous make.

Do not turn on [SW1] and [SW2] simultaneously.

Optional PCB

Display

relay

Shield

wire

Shield

wire

<SW07 (bit 2) OFF [2-stage switching]>

Input SW07 (bit 1)

Display relay (L1)

SW1 SW2 Bit 1 OFF Bit 1 ON

OFF ON

100 %

(normal operation)

100 %

(normal operation)

OFF

ON OFF 0 % (forced stop)

Approx. 60 %

(upper limit regulated)

ON

PJ17

TB1

[ON]

[OFF]

TB2

COM

ON

COM

OFF

CN513

SW07

Bit 2 ON

L1

SW1

ON

OFF

1234

SW2

Outdoor unit

interface PCB

Connection cable (attached in this optional PCB)

Locally procured

Power

supply

[OPERATION]

L1: Display lamp during power peak cut control

Optional PCB

Display

relay

For SW1 and SW2, be sure to

provide no-voltage contacts for

each terminal.

Shield

wire

Shield

wire

<SW07 (bit 2) ON [4-stage switching]>

Input SW07 (bit 1)

Display relay (L1)

SW1 SW2 Bit 1 OFF Bit 1 ON

OFF OFF

100 %

(normal operation)

100 %

(normal operation)

OFF

ON OFF

Approx. 80 %

(upper limit regulated)

Approx. 85 %

(upper limit regulated)

ON

OFF ON

Approx. 60 %

(upper limit regulated)

Approx. 75 %

(upper limit regulated)

ON

ON ON 0 % (forced stop)

Approx. 60 %

(upper limit regulated)

ON

35

5 Outdoor unit

TCB-PCMO4E

Size : 55.5 x 60 (mm)

[1] External master ON/OFF control

▼ Function

By connecting the cable (attached in this optional PCB) to the interface PC

board on an outdoor unit, all indoor units connecte d to the outdoor unit enable

to operate simultaneously.

SW1: Operation input switch

SW2: Stop input switch

Provide no-voltage pulse contacts for each terminal.

Hold the ON state for at least 100 msec.

Do not turn SW1 and SW2 ON simultaneously.

Application

* Installation the optional PCB

in the interface board of the

outdoor unit.

[2] Night time operation (sound reduction) control

▼ Function

As the cable (attached in this optional PCB) is connected to the “Interf ace

PCB” on an outdoor unit, both compressor speed and fan speed are restricted

while the signal of the night operation control is input. It makes the noise

reduction during the night time operation.

SW1: Night time signal switch

Each terminal should be connected to dry contact.

The input signal is recognized during its rising/falling phase.

(After reaching the top/bottom of the rising/falling edge, the signal must remain there for

at least 100 ms.)

Model

name

Appearance Function

71JP

CN512

TB1

SW1

SW2

COM

HEAT

COOL

Locally procured

Optional PCB

Shield

wire

Outdoor unit

interface PCB

Connection cable

(attached in this

optional PCB)

Terminal Input signal Operation

COOL (SW1)

ON

OFF

All indoor units operate together

HEAT (SW2)

ON

OFF

All indoor units stop together

71JP

TB1

SW1

COM

HEAT

COOL

Outdoor unit

interface PCB

Connection cable

(attached in this

optional PCB)

Locally procured

Optional PCB

Shield

wire

CN508

Terminal Input signal Operation

COOL (SW1)

ON

OFF

Night time control

ON

OFF

Normal operation

36

5 Outdoor unit

TCB-PCMO4E

Size : 55.5 x 60 (mm)

▼ Sound reduction and approximation capacity (reference)

* Position of noise measuring device: 1 m from the front face of the set and 1.5 m

above ground (anechoic sound)

[3] Operation mode selection control

▼ Function

The heating/cooling mode of the system can be selected by connecting to the

interface PCB of outdoor units.

SW1: Cooling mode specified input switch

SW2: Heating mode specified input switch

Each terminal should be connected to dry contact.

Indoor unit operation intervention function

The statuses of indoor units operating in a mode different from the selected

operation mode can be changed by changing the sta tus of a jumper wir e (J01)

provided on the interface P.C. board of outdoor unit.

Application

* Installation the optional PCB

in the interface board of the

outdoor unit.

Model

name

Appearance Function

Outdoor unit

(base unit)

During low-noise mode

dB(A)

Capacity

Cooling Heating Cooling Heating

Relative to

maximum

capacity

Model 0404* 47 50 approx. 85 % approx. 95 %

Model 0504* 47 50 approx. 80 % approx. 80 %

Model 0604* 50 50 approx. 80 % approx. 70 %

71JP

TB1

SW1

SW2

COM

HEAT

COOL

Outdoor unit

interface PCB

Connection cable

(attached in this

optional PCB)

Locally procured

Optional PCB

Shield

wire

CN510

Input Signal

Operation: Selected operation mode

Cooling (SW1) Heating (SW2)

ON OFF Cooling operation only

OFF ON Heating operation only

OFF OFF Normal operation

Jumper wire Descrip tion of intervention

J01 connected

(factory default)

All indoor units operating in a mode different from the selected

operation mode (prohibited-mode indoor units) become non-priority

units (thermostat OFF).

The display “ (operation ready)” appears on the remote controller

of prohibited-mode indoor units.

J01 cut The selected operation mode is imposed on all indoor units operating

in a different mode.

Mode selected at

P.C. board

Remote controller operation / display

Normal

All modes (COOL,

DRY , HEA T and FAN)

available

COOL

Only COOL, DRY

and FAN available

“ operation mode

control” (turned on

during remote

controller operation)

HEAT

Only HEAT and FAN

available

37

5 Outdoor unit

[PCB Installation Position]

TCB-PCIN4E

Size : 73 x 79 (mm)

Error / Operation Output

▼ Function

The operation error output PCB can indicate operation and error states by

connecting to the interface PCB of outdoor units.

▼ Operation

Operation output:The operation indicator is on while any indoor unit in the

system is operating.

Error output: The error indicator is on when an error is occurred on even

one of the indoor or outdoor units in the system.

Wiring example

* [OUTPUT3] is displayed when power is turned on.

Application

* Installation the optional PCB

in the interface board of the

outdoor unit.

Model

name

Appearance Function

OUTPUT1

PJ20

OUTPUT2

OUTPUT3

TB1

L1

L2

1

2

5

6

4

3

C1

PS

PS

K1

K2

1

ON

OFF

234

SW16

Outdoor unit

interface PCB

Optional PCB

Locally procured

Shield

wire

CN511

C1 Attached connection cable 1 (4wires)

CN511 Connector on interface side (green)

K1, K2 Relays

L1 Error indication Lamp

L2 Operation indication Lamp

OUTPUT1 Error output

OUTPUT2 Operation output

PJ20 Connector on optional PCB side

PS Power supply unit

TB1 Terminal block

There are holes on the metal of interface PCB, and the optional

PCBs are installed.

Two kinds of the optional PCBs are able to install on it.

TCB-PCIN4E

TCB-PCDM4E

TCB-PCMO4E

In case of

TCB-PCMO4E

TCB-PCDM4E

In case of

TCB-PCIN4E

TCB-PCMO4E

In case of

TCB-PCDM4E

TCB-PCIN4E

Installation position of optional PCB

Interface PCB

38

5 Outdoor unit

Dimensions of PCB

TCB-PCDM4E

TCB-PCMO4E

TCB-PCIN4E

Terminal

Screw M3 6

71

61

Terminal

Screw M4 8

4-4ø hole

85

75

OFF

OFF ON

MS

10

MS

OFF

COM COMON

ON

T82

T81

K100

PJ17

5

5

ICI

41

8

OPERATION

/

TOSHIBA

NCC-1212

Terminal

Screw M3 6

55.5

45.5

60

50

PJ17

TOSHIBA

NCC-1214

4-4ø hole

5

41

ICI

41

D2

HEAT

COM

COMCOOL

10

TB1

8

C4

C2

C3

K1

12

OUTPUT1 OUTPUT2 OUTPUT3

34 56

K2

1

PJ20

5

K3

TB1

MCC-1613-02

3D2D1D

63

73

69

79

4- 4 mm dia. mounting ho les

Te rminal block (M3)

39

5 Outdoor unit

5-8. Part load performance

MCY-MHP0404HT* (4HP, 12.1 kW system)

TC : Total Capacity PI : Power Input

Indoor air temperature conditions : 27.0 °C dry-bulb / 19.0 °C wet bulb

TC : Total Capacity PI : Power Input

Indoor air temperature conditions : 20.0 °C dry-bulb

All indoor unit operation

Cooling Compressor + Outdoor Fan Power consumption (kW)

Outdoor Unit

Dry-Bulb

(°C)

Outdoor Unit

100 % Cooling

Capacity (kW)

100 % 90 % 80 % 70 % 60 % 50 %

TC

(kW)

PI

(kW)TC(kW)PI(kW)TC(kW)PI(kW)TC(kW)PI(kW)TC(kW)PI(kW)TC(kW)PI(kW)

40 11.4 11.4

3.46 10.3 2.87 9.1 2.34 8.0 1.88 6.9 1.48 5.7 1.15

39 11.6 11.6

3.34 10.4 2.77 9.2 2.26 8.1 1.82 6.9 1.43 5.8 1.12

37 11.8 11.8

3.10 10.7 2.58 9.5 2.11 8.3 1.70 7.1 1.34 5.9 1.05

35 12.1 12.1

2.88 10.9 2.40 9.7 1.97 8.5 1.59 7.3 1.26 6.1 0.98

33 12.1 12.1

2.68 10.9 2.24 9.7 1.84 8.5 1.49 7.3 1.18 6.1 0.92

31 12.1 12.1

2.49 10.9 2.08 9.7 1.72 8.5 1.39 7.3 1.11 6.1 0.87

30 12.1 12.1

2.40 10.9 2.01 9.7 1.66 8.5 1.35 7.3 1.07 6.1 0.84

29 12.1 12.1

2.31 10.9 1.94 9.7 1.60 8.5 1.30 7.3 1.04 6.1 0.81

27 12.1 12.1

2.15 10.9 1.81 9.7 1.50 8.5 1.22 7.3 0.97 6.1 0.76

25 12.1 12.1

1.99 10.9 1.68 9.7 1.40 8.5 1.14 7.3 0.91 6.1 0.72

23 12.1 12.1

1.85 10.9 1.57 9.7 1.30 8.5 1.07 7.3 0.86 6.1 0.67

21 12.1 12.1

1.72 10.9 1.46 9.7 1.22 8.5 1.00 7.3 0.80 6.1 0.63

20 12.1 12.1

1.66 10.9 1.41 9.7 1.18 8.5 0.97 7.3 0.78 6.1 0.61

19 12.1 12.1

1.60 10.9 1.36 9.7 1.14 8.5 0.93 7.3 0.75 6.1 0.59

17 12.1 12.1

1.48 10.9 1.26 9.7 1.06 8.5 0.87 7.3 0.71 6.1 0.56

15 12.1 12.1

1.38 10.9 1.18 9.7 0.99 8.5 0.82 7.3 0.66 6.1 0.52

Heating Compressor + Outdoor Fan Power consumption (kW)

Outdoor Unit

Outdoor Unit

100 % Heating

Capacity (kW)

100 % 90 % 80 % 70 % 60 % 50 %

Dry-Bulb

(

°

C)

Wet-Bulb

(°C)

TC

(kW)PI(kW)TC(kW)PI(kW)TC(kW)PI(kW)TC(kW)PI(kW)TC(kW)PI(kW)TC(kW)PI(kW)

15.0 13.7 12.5 12.5

2.39 11.3 2.09 10.0 1.79 8.8 1.45 7.5 1.24 6.3 0.79

13.0 11.8 12.5 12.5

2.47 11.3 2.16 10.0 1.85 8.8 1.50 7.5 1.27 6.3 1.00

11.0 9.8 12.5 12.5

2.56 11.3 2.23 10.0 1.91 8.8 1.56 7.5 1.31 6.3 1.03

9.0 7.9 12.5 12.5

2.64 11.3 2.30 10.0 1.97 8.8 1.61 7.5 1.35 6.3 1.06

7.0 6.0 12.5 12.5

2.73 11.3 2.37 10.0 2.03 8.8 1.70 7.5 1.38 6.3 1.09

5.0 4.1 12.1 12.1

2.69 10.9 2.34 9.7 2.00 8.5 1.67 7.3 1.36 6.1 1.07

3.0 2.2 11.8 11.8

2.64 10.6 2.30 9.4 1.97 8.2 1.64 7.1 1.34 5.9 1.05

0.0 -0.7 11.2 11.2

2.58 10.1 2.24 9.0 1.92 7.8 1.60 6.7 1.31 5.6 1.03

-3.0 -3.7 10.6 10.6

2.52 9.6 2.19 8.5 1.87 7.4 1.56 6.4 1.28 5.3 1.00

-5.0 -5.6 10.3 10.3

2.47 9.2 2.15 8.2 1.84 7.2 1.54 6.2 1.26 5.1 0.98

-7.0 -7.6 9.9 9.9

2.43 8.9 2.12 7.9 1.81 6.9 1.51 5.0 1.24 4.9 0.97

-10.0 -10.5 9.3 9.3

2.37 8.4 2.06 7.5 1.76 6.5 1.47 5.6 1.21 4.7 0.94

-14.5 -15.0 8.5 8.5

2.27 7.6 1.98 6.8 1.69 5.9 1.41 5.1 1.16 4.2 0.90

40

5 Outdoor unit

MCY-MHP0504HT* (5HP, 14.0 kW system)

TC : Total Capacity PI : Power Input

Indoor air temperature conditions : 27.0 °C dry-bulb / 19.0 °C wet bulb

TC : Total Capacity PI : Power Input

Indoor air temperature conditions : 20.0 °C dry-bulb

All indoor unit operation

Cooling Compressor + Outdoor Fan Power consumption (kW)

Outdoor Unit

Dry-Bulb

(°C)

Outdoor Unit

100 % Cooling

Capacity (kW)

100 % 90 % 80 % 70 % 60 % 50 %

TC

(kW)

PI

(kW)TC(kW)PI(kW)TC(kW)PI(kW)TC(kW)PI(kW)TC(kW)PI(kW)TC(kW)PI(kW)

40 13.2 13.2

4.24 11.8 3.50 10.5 2.83 9.2 2.24 7.9 1.74 6.6 1.31

39 13.3 13.3

4.08 12.0 3.37 10.7 2.73 9.3 2.17 8.0 1.68 6.7 1.27

37 13.7 13.7

3.78 12.3 3.13 10.9 2.54 9.6 2.02 8.2 1.57 6.8 1.19

35 14.0 14.0

3.50 12.6 2.91 11.2 2.36 9.8 1.89 8.4 1.47 7.0 1.12

33 14.0 14.0