Page 1

VOLUME-1

INSTALLATION MANUAL

MANUEL DINSTALLATION

INSTALLATIONS-HANDBUCH

MANUALE DI INSTALLAZIONE

MANUAL DE INSTALACIÓN

Mini-SMMS MULTI SYSTEM

Mini-SMMS

Mini-SMMS

Mini-SMMS

Mini-SMMS

Outdoor Unit

Unité extérieure

Außengerät

Unità esterna

Unidad exterior

CLIMATISEUR

KLIMASYSTEM

CONDIZIONAT ORE D’ARIA

DE AIRE A CONDICIONADO

AIR CONDITIONER

Model/ Modèle / Modell / Modello / Modelo

MCY-MAP0401HT

MCY-MAP0401HT2D

MCY-MAP0501HT

MCY-MAP0501HT2D

MCY-MAP0601HT

MCY-MAP0601HT2D

Page 2

ADOPTION OF NEW REFRIGERANT

This air conditioner features a new HFC type

refrigerant (R-410A) which does not deplete the

ozone lay er.

Thank you very much for purchasing TOSHIBA Air Conditioner.

• This manual describes the installation method at the outdoor unit

side.

• Before installation, please read this Manual thoroughly to perf orm

correct installation.

• For pipe connection for the indoor and outdoor units , flow selector unit

Y-shape branching joint or branch header required sold separately.

Select it according to the capacity.

• For pipe connection between the outdoor units, T-shape branching

joint which is sold separately is required.

UTILISATION DU NOUVEAU REFRIGERANT

Ce climatiseur utilise le nouveau réfrigérant HFC

(R410A), qui ne détruit pas la couche d’ozone.

VERWENDUNG EINES NEUEN KÄLTEMITTELS

Dieses Klimagerät arbeitet mit dem neuen HFC

Kältemittel R410A. Dieses Kältemittel g reift die

Ozonschicht nicht an.

Nous vous remercions pour av oir choisi un climatiseur TOSHIBA.

• Ce manuel décrit la méthode d’installation du côté de l’unité

intérieure.

• Av ant de procéder à l’installation, veuillez lire attentivement ce

manuel pour que l’installation soit correcte.

• Pour effectuer le raccordement de la tuyauterie entre les unités

intérieure et extérieure vous devez vous procurer sur place un joint de

ramification en Y ou un joint collecteur, v endu séparément.

Choisissez-le en fonction de la puissance.

• Pour effectuer le raccordement de la tuyauterie entre les unités

extérieures vous de vez vous procurer sur place un joint de

ramification en T.

Wir danken Ihnen, dass Sie sich für ein TOSHIBA Klimagerät

entschieden haben.

• In diesem Handbuch wird die Installation der Außeneinheit

beschrieben.

• Bevor Sie mit der Installation beginnen, lesen Sie die dieses

Handbuch sorgfältig und installieren Sie das Produkt entsprechend.

• Für die Rohrleitungsverbindungen zwischen Innen- und Außeneinheit

sind Y-Abzweig oder Verteiler erforderlich, die bauseits beigestellt

werden müssen.

Wählen Sie diese Teile entsprechend der Leistung des Systems.

• Für die Rohrleitungsverbindungen zwischen den Außeneinheiten sind

T-Abzweige erforderlich, die bauseits beigestellt werden müssen.

IMPIEGO DI NUOVO REFRIGERANTE

Questo condizionatore d’aria utilizza il nuovo

refrigerante HFC (R 410A) che non svuota lo strato

d’ozono.

ADOPCIÓN DE NUEVO REFRIGERANTE

Este acondicionador de aire presenta el nuev o tipo

de refrigerante HFC (R-410A) que no daña la capa

de ozono.

Grazie di aver acquistato un condizionatore d’aria TOSHIBA.

• Questo manaule spiega come installare l’unità esterna.

• Prima d’iniziare l’installazione, leggere attentamente questo manuale,

per eseguire l’installazione correttamente.

• Per il collegamento dei tubi relativi alle unità interne ed esterne, sono

necessari l’unità di selezione del flusso, il giunto di derivazione a Y o il

collettore di derivazione, da acquistare a parte.

Selezionarli in base alla capacità.

• Per il collegamento dei tubi tra unità esterne, serve il giunto di

derivazione a T da acquistare a parte.

Muchas gracias por haber adquirido este aparato de aire

acondicionado TOSHIBA.

• Este manual describe el método de instalación de la unidad exterior.

• Lea con atención este manual antes de instalar la unidad para

hacerlo correctamente.

• Para la conexión de tubos entre las unidades interiores y exteriores,

es necesario utilizar un colector de derivación o una junta de

derivación en forma de Y para la unidad selectora de caudal

(vendidos por separado).

Seleccione este accesorio según la capacidad del sistema.

• Para la conexión de tubos entre las unidades exteriores, es necesario

utilizar una junta de derivación en forma de T (vendido por separado).

Page 3

VOLUME-1

CONTENTS

ACCESSORY PARTS ........................................................................................................................................................1

SAFETY CAUTION............................................................................................................................................................1

1

INSTALLATION OF NEW REFRIGERANT AIR CONDITIONER ...............................................................................3

2

SELECTION OF INSTALLATION PLACE..................................................................................................................4

3

REFRIGERANT PIPING.............................................................................................................................................8

4

ELECTRIC WIRING..................................................................................................................................................20

5

INSTALLATION OF OUTDOOR UNIT ......................................................................................................................26

6

ADDRESS SETUP ...................................................................................................................................................27

7

TEST OPERATION...................................................................................................................................................36

8

TROUBLESHOOTING..............................................................................................................................................38

SOMMAIRE

PIECES ACCESSOIRES .................................................................................................................................................40

MESURES DE SECURITE ..............................................................................................................................................40

1

INSTALLATION DU CLIMA TISEUR UTILISANT LE NOUVEAU REFRIGERANT ..................................................42

2

SELECTION DU LIEU D’INSTALLATION ................................................................................................................43

3

INSTALLATION DE L’UNITE EXTERIEURE ............................................................................................................47

4

INSTALLATION ELECTRIQUE ................................................................................................................................59

5

INSTALLATION DE L’UNITE EXTERIEURE ............................................................................................................65

6

REGLAGE D’ADRESSE ..........................................................................................................................................66

7

ESSAI DE FONCTIONNEMENT ..............................................................................................................................75

8

DEPANNAGE ...........................................................................................................................................................77

ENGLISHITALIANO FRANCAISDEUTSCHESPAÑOL

INHALT

ZUBEHÖR .......................................................................................................................................................................79

SICHERHEITSHINWEISE ...............................................................................................................................................79

1

INST ALLA TION VON KLIMAGERÄTEN MIT MODERNEN KÄLTEMITTELN .........................................................81

2

AUSWAHL DES AUFSTELLUNGSORTES .............................................................................................................82

3

KÄLTEMITTELLEITUNGEN.....................................................................................................................................86

4

ELEKTRISCHE VERDRAHTUNG ............................................................................................................................98

5

INSTALLATION DER AUSSENEINHEIT................................................................................................................104

6

ADRESS-EINSTELLUNG ......................................................................................................................................105

7

TESTLAUF .............................................................................................................................................................114

8

FEHLERSUCHE.....................................................................................................................................................116

INDICE

ACCESSORI..................................................................................................................................................................118

PRECAUZIONI DI SICUREZZA.....................................................................................................................................118

1

INSTALLAZIONE DI UN NUOVO REFRIGERANTE PER IL CONDIZIONA TORE D’ARIA ...................................120

2

SCELTA DEL POSTO D’INSTALLAZIONE ............................................................................................................121

3

TUBAZIONI DEL REFRIGERANTE.......................................................................................................................125

4

COLLEGAMENTI ELETTRICI................................................................................................................................137

5

INSTALLAZIONE DELL’UNITÀ ESTERNA............................................................................................................143

6

IMPOSTAZIONE DELL’INDIRIZZO ........................................................................................................................144

7

FUNZIONAMENTO DI PR OVA ...............................................................................................................................153

8

RISOLUZIONE DEI PROBLEMI ............................................................................................................................155

CONTENIDO

COMPONENTES ACCESORIOS ..................................................................................................................................157

PRECAUCIONES DE SEGURIDAD ..............................................................................................................................157

1

INSTALACIÓN DEL AIRE ACONDICIONADO CON NUEVO REFRIGERANTE...................................................159

2

SELECCIÓN DEL LUGAR DE INSTALACIÓN ......................................................................................................160

3

TUBERÍA DE REGRIGERANTE ............................................................................................................................164

4

Cableado elECtrico...............................................................................................................................................176

5

INSTALACIÓN DE LA UNIDAD EXTERIOR ..........................................................................................................182

6

CONFIGURAR LAS IDENTIFICACIONES.............................................................................................................183

7

PRUEBA DE FUNCIONAMIENTO .........................................................................................................................192

8

RESOLUCIÓN DE PROBLEMAS ..........................................................................................................................194

Page 4

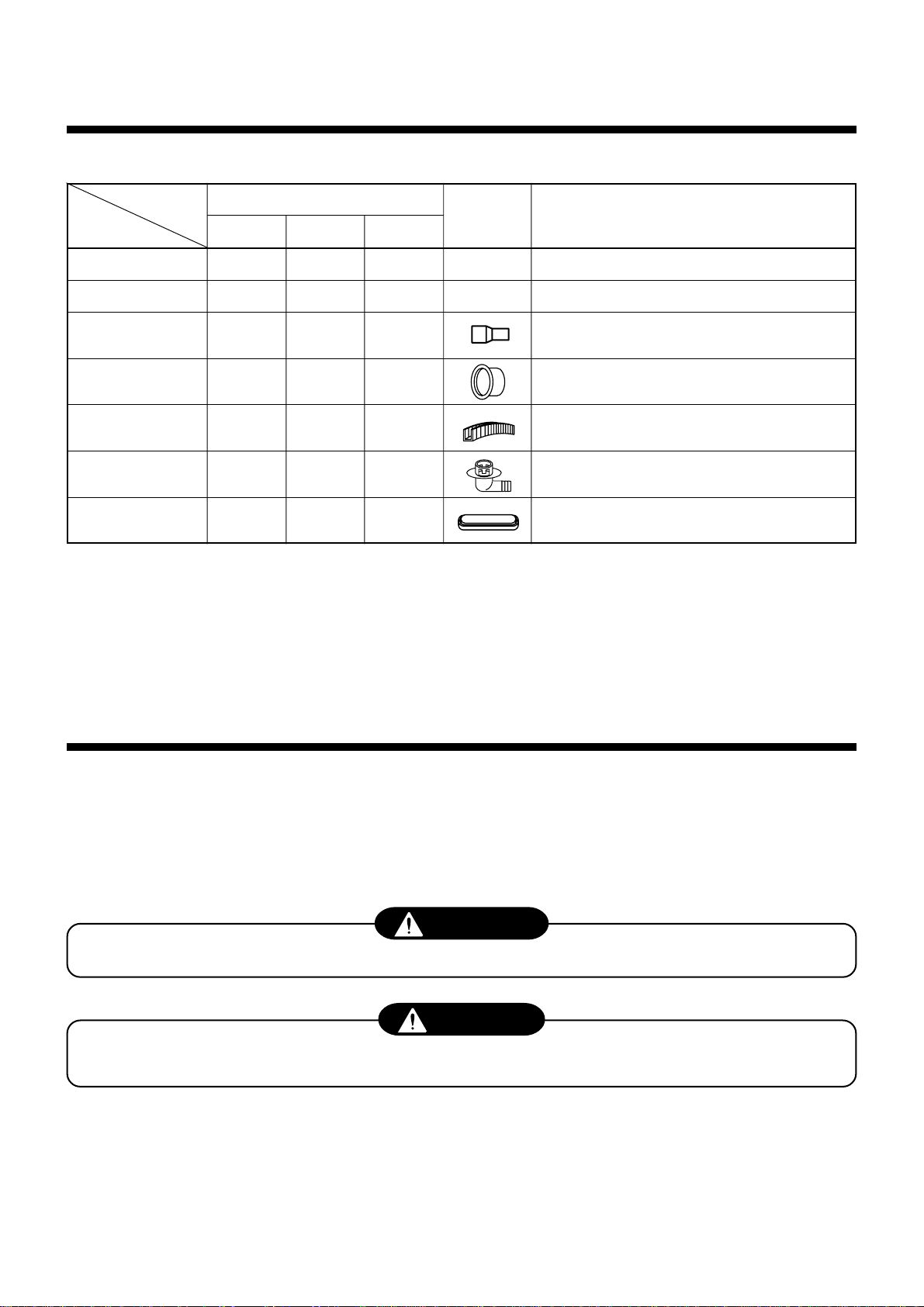

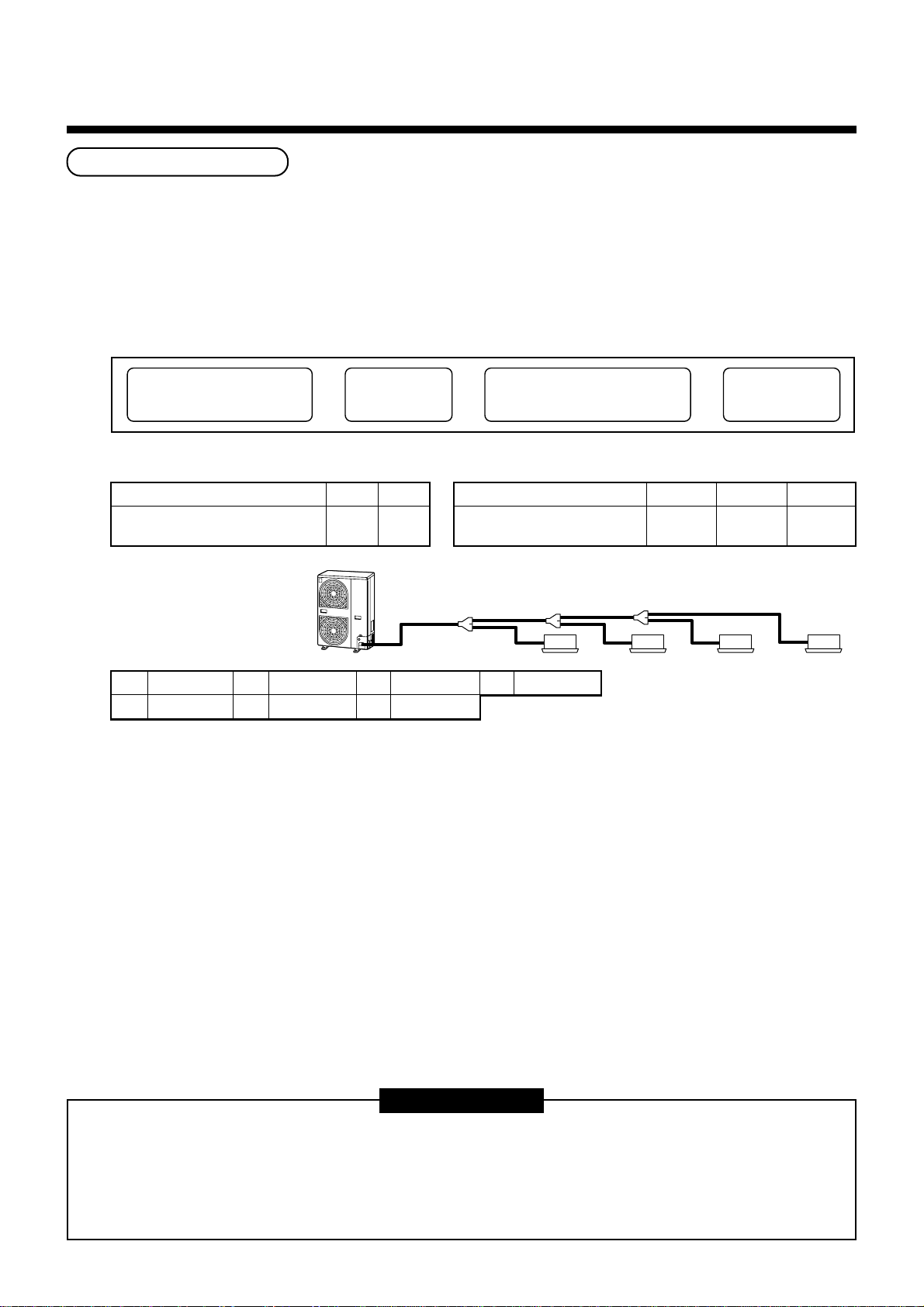

ACCESSORY PARTS

r Accessory parts

MCY-

Part name

Installation Manual

Owner’s Manual

Joint socket

Protective bush

Guard material for

passage part

Drain nipple

Waterproof rubber cap

0401 type 0501 type 0601 type

222

111

—— 1

111

111

111

111

Q’ty

Shape

—

—

Usage

(Be sure to handover to customers.)

(Be sure to handover to customers.)

Connecting pipes for gas side (Ø15.9 to Ø19.1)

Protection for wiring

Protection for knockout

—

—

n The outdoor air conditioner requires the following additional components in order to complete

a MiNi-SMMS system. (Indoor unit, remote controller, Y-shape branch joint or branching

header.) These items must be selected in accordance to the system capacity.

SAFETY CAUTION

• Please read this “Safety Cautions” thoroughly before installation to install the air conditioner

correctly.

• The important contents concerned to the safety are described in the “Safety Cautions”.

Be sure to keep them. For Indications and their meanings, see the following description.

n Explanation of indications

WARNING

Indicates possibilities that a death or serious injury of personnel is caused by an incorrect handling.

CAUTION

Indicates contents that an injury (∗1) or property damage (∗2) only may be caused when an incorrect work has

been executed.

∗1 : “Injury” means a hurt, a burn, or an electric shock which does not require hospitalization or a long-term going to

the hospital.

∗2 : “Property damage” means an enlarged damage concerned to property, or breakage of materials.

• After the installation work has been completed, perform a trial operation to check for possible

problems.

Follow the owner’s manual and explain to the customer how to use and maintain the unit.

1

Page 5

WARNING

Ask an authorized dealer or qualified installation professional to install/maintain the air

conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

Using the tool or piping materials exclusive to R410A, install the air conditioner surely according

to this Installation Manual.

The pressure of the used HFC system R410A refrigerant is higher approx. 1.6 times of that of the former

refrigerant. If the exclusive piping materials are not used, or there is imperfection in installation, a crack or an

injury is caused and also a water leak, an electric shock, or a fire may be caused.

Take measures so that the refrigerant does not exceed the limit concentration even if it leaks

when installing the air conditioner in a small room.

For the measures not to exceed the limit of concentration, contact the dealer. If the refrigerant leaks and it

exceeds the limit of concentration, an accident of oxygen shortage is caused.

The location of the installation must be able to protect from abnormal environmental conditions,

such as earthquake and typhoons.

An incorrect installation will cause a risk of unit movement resulting in a possible accident.

Perform a specified installation work against a strong wind such as typhoon or earthquake.

If the air conditioner is imperfectly installed, an accident by falling or dropping may be caused.

If refrigerant gas leaks during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes into contact with fire, noxious gas may generate.

ENGLISH

After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks onto the room and flows near to a source of fire, noxious gas maybe generated.

Never recover refrigerant in the outdoor unit.

Be sure to use a refrigerant recovery device to recover refrigerant in reinstallation or repair work.

Recovery of refrigerant in the outdoor unit is unavailable; otherwise a serious accident such as crack or human

injury is caused.

Electrical work must be performed by a qualified electrician in accordance with the installation

manual. Ensure the air conditioner uses a designated power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

When connecting the installation wiring, be sure that all fixing terminals are securely fixed.

Ensure earth connection.

If earth wiring is poor, this will cause risk of electric shock.

If grounding is incomplete, an electric shock is caused.

CAUTION

Ensure that the unit is to placed where there is no risk of flammable gases.

If flammable gases accumulate around the outside of the unit combustion may occur.

Ensure the outdoor unit is fixed to the base, to prevent movement of the unit.

Ensure an electrical leakage breaker is fitted. This is to prevent the risk of electric shock.

Using a torque wrench, tighten the flare nuts to the specified torque setting.

Over tightening will risk damaging the flare nut, and may cause refrigerant to leak after a period of time.

2

Page 6

1

INSTALLATION OF NEW REFRIGERANT AIR CONDITIONER

This air conditioner adopts the new HFC refrigerant (R410A) which does not deplete the ozone layer.

• R410A refrigerant is apt to be affected by impurity such as water, oxidizing membrane, or oils because the

pressure of R410A refrigerant is higher than that of the former refrigerant by approx. 1.6 times. Accompanied with

adoption of the new refrigerant, refrigerating oil has been also changed. Therefore pay attention so that water,

dust, former refrigerant, or refrigerating oil does not enter into the refrigerating cycle of the new refrigerant air

conditioner during installation work.

• To prevent from mixing of refrigerant or refrigerating oil, the size of charge port of the main unit or connecting

section of installation tool differs from that of the air conditioner for the former refrigerant. Accordingly the

exclusive tools are required for the new refrigerant (R410A) as shown below.

• For connecting pipes, use the new and clean piping materials so that water or dust does not enter.

Required tools and cautions on handling

It is necessary to prepare the tools and parts as described below for the installation work.

The tools and parts which will be newly prepared in the following items should be restricted to the exclusive use.

Explanation of symbols

: Newly prepared (It is necessary to use it properly exclusive to R410A separated from those for R22 or R407C.)

l

¡ : Former tool is available.

Used tools

Gauge manifold

Charging hose

Charging cylinder

Gas leak detector

Vacuum pump

Vacuum pump with counter-

flow preventive adapter

Flare tool

Bender

Refrigerant recovery device

Torque wrench

Pipe cutter

Refrigerant cylinder

Welding machine/

Nitrogen gas cylinder

Usage

Vacuuming or charging of

refrigerant and operation check

Charges refrigerant

Checks gas leak

Vacuum drying

Vacuum drying

Flare processing of pipes

Bending processing of pipes

Recovers refrigerant

Tightens flare nut

Cuts pipes

Charges refrigerant

Welding of pipes

Proper use of tools/parts

Newly prepared, Exclusive to R410A

l

Newly prepared, Exclusive to R410A

l

Unusable (Use the Refrigerant charging balance.)

Newly prepared

l

Usable if a counter-flow preventive adapter is attached

: R22 (Existing article)

¡

: Usable by adjusting size

¡

: R22 (Existing article)

¡

Exclusive to R410A

l

Newly prepared, exclusive to Ø12.7mm and Ø15.9mm

l

: R22 (Existing article)

¡

Exclusive to R410A

l

ID : Refrigerant name entered

: R22 (Existing article)

¡

Refrigerant charging balance

Charges refrigerant

: R22 (Existing article)

¡

3

Page 7

2

SELECTION OF INSTALLATION PLACE

WARNING

The installation of the air conditioning unit must be positioned in a location that can sufficiently

support its weight and give protection against adverse environmental conditions.

Failure to do so may result in unit damage and possible human injury.

CAUTION

Ensure that the unit is to placed where there is no risk of flammable gases.

If flammable gases accumulate around the outside of the unit combustion may occur.

Ensure the outdoor unit is fixed to the base, to prevent movement of the unit.

Obtain permission from the customer to install the unit in a location that satisfies the following

requirements :

• A location that permits level installation of the unit.

• A location that provides enough space to service the unit safely

• A location where water draining from the unit will not pose a problem

Apply electric insulation between metal section of the building and metal section of the air

conditioner in conformance with the Local Regulation.

Avoid installing in the following places.

• Place exposed to air with high salt content (seaside area), or place exposed to large quantities of sulfide gas

(hot spring). (Should the unit be used in these places, special protective measures are needed.)

• Place exposed to oil, vapor, oil smoke or corrosive gas.

• Place where organic solvent is used nearby.

• Place close to a machine generating high frequency.

• Place where the discharged air blows directly into the window of the neighboring house. (For outdoor unit)

• Place where noise of the outdoor unit is easily transmitted.

(When installing the air conditioner on the boundary with the neighbor, pay due attention to the level of noise.)

• Place with poor ventilation.

(Especially in Concealed duct type indoor unit, before air ducting work, check whether value of air volume,

static pressure and duct resistance are correct.)

Equipments

Equivalent HP

Inverter unit

Appearance

Outdoor unit capacity type

Cooling capacity (kW)

Heating capacity (kW)

0401 type 0501 type 0601 type

4 HP 5 HP 6 HP

12.1 14.0 15.5

12.5 16.0 18.0

4

Page 8

2

SELECTION OF INSTALLATION PLACE

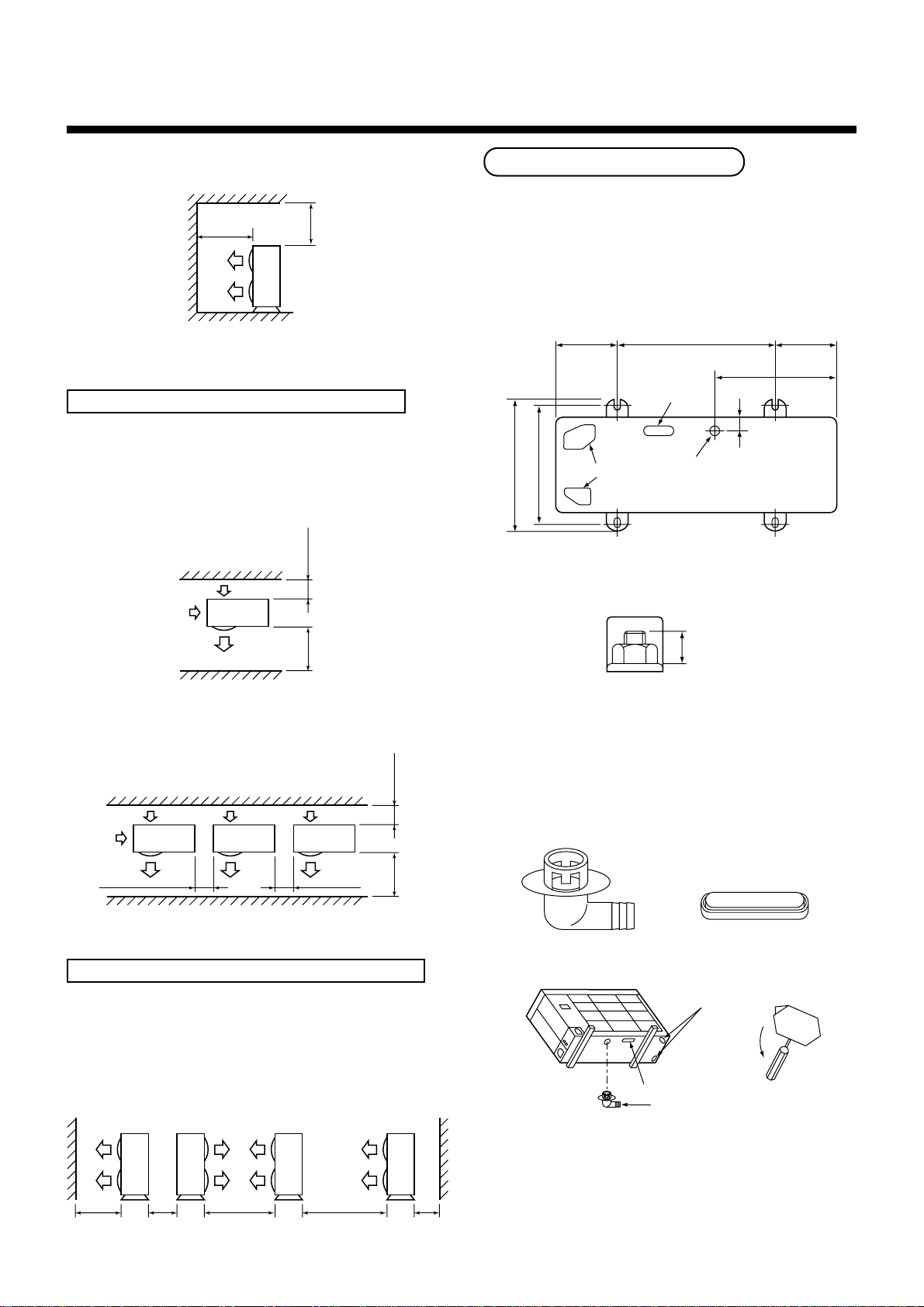

AInstallation space

Considering functions, reserve space necessary for

installation work and servicing.

Installation place

• A place which provides a specified space around the

outdoor unit.

• A place where the operation noise and discharged air

are not given to your neighbors.

• A place that is not exposed to a strong wind.

• A place that does not block a passage.

• When the outdoor unit is installed in an elevated

position, be sure to secure its feet.

• There must be sufficient space for carrying in the unit.

• A place where the drain water does not make any

problem.

CAUTION

1. Install the outdoor unit at a place where dis-

charge air is not blocked.

2. When an outdoor unit is installed in a place that

is always exposed to a strong wind like a coast or

on a high story of a building, secure a normal fan

operation by using a duct or a wind shield.

3. When installing the outdoor unit in a place that is

constantly exposed to a strong wind such as the

upper stairs or rooftop of a building, apply the

windproof measures referring to the following

examples.

1) Install the unit so that its discharge port faces

to the wall of the building.

Keep a distance 500 mm

or more between the unit

and the wall surface.

500

Necessary space for installation

Obstacle at rear side

[Upper side is free]

1. Single unit installation

2. Obstacles at both right and left sides.

200

or more

150

or more

3. Serial installation of two or more units

150

or more

The height of the obstacle should be lower

than the height of the outdoor unit.

300

or more

[Obstacle also at the upper side]

150

or more

500

or more

The height of the

obstacle should be

lower than the height

of the outdoor unit.

300

or more

300

or more

300

or more

150

or more

200 or more

2) Supposing the wind direction during the

operation season of the air conditioner, install

the unit so that the discharge port is set at

right angle to the wind direction.

Strong wind

Strong wind

4. Installation in the following places may result in

some troubles. Do not install the unit in such

places below.

• A place full of machine oil.

• A place full of sulfuric gas.

• A place where high-frequency radio waves are

likely to be generated as from audio equipment,

welders, and medical equipment.

Obstacle at front side

[Upper side is free]

1. Single unit installation

2. Serial installation of two or more units

5

500

1000

or more

or more

Page 9

[Obstacle also at the upper side]

s

1000

or more

1000

or more

Obstacles at both front and rear sides

Open the upper side and both right and left sides.

The height of obstacle at both front and rear side,

should be lower than the height of the outdoor unit.

[Standard installation]

1. Single unit installation

150

or more

Installation of outdoor unit

• Before installation, check strength and horizontally

of the base so that abnormal sound does not

generate.

• According to the following base diagram, fix the

base firmly with the anchor bolts.

(Anchor bolt, nut: M10 x 4 pairs)

600150 150

430

Drain hole

40

365

400

Knockout hole

Set the out margin of the anchor bolt to 15mm or less.

Drain nipple mounting hole

1000

or more

2. Serial installation of two or more units

200

or more

300

or more

300

or more

1000

or more

Serial installation at front and rear sides

Open the upper side and both right and left sides.

The height of obstacle at both front and rear sides

should be lower than the height of the outdoor unit.

[Standard installation]

15 or les

• In case of draining through the drain hose, attach

the following drain nipple and the waterproof rubber

cap, and use the drain hose (Inner diam.: 16mm)

sold on the market. And also seal the screws

securely with silicone material, etc. so that water

does not drop down. Some conditions may cause

dewing or dripping of water.

Drain nipple Waterproof rubber cap

Knockout hole

Open

Waterproof rubber cap

Drain nipple

1000

or more

or more

300

1500

or more

2000

or more

200

or more

• When there is a possibility of freezing of drain at the

cold district or a snowfall area, be careful for

drainage ability of drain. The drainage ability

increases when a knockout hole on the base plate

is opened. (Open the knockout hole to outside using

a screwdriver, etc.)

6

Page 10

2

SELECTION OF INSTALLATION PLACE

Refrigerant piping connection

CAUTION

TAKE NOTICE THESE IMPORTANT

4 POINTS BELOW FOR PIPING WORK

1. Keep dust and moisture away from inside the

connecting pipes.

2. Tightly connect the connection between pipes

and the unit.

3. Evacuate the air in the connecting pipes using

VACUUM PUMP.

4. Check gas leak at connected points.

For reference

If a heating operation would be continuously performed

for a long time under the condition that the outdoor

temperature is 0°C or lower, draining of defrosted water

may be difficult due to freezing of the bottom plate,

resulting in a trouble of the cabinet or fan.

It is recommended to procure an anti-freeze heater

locally for a safety installation of the air conditioner.

For details, contact the dealer.

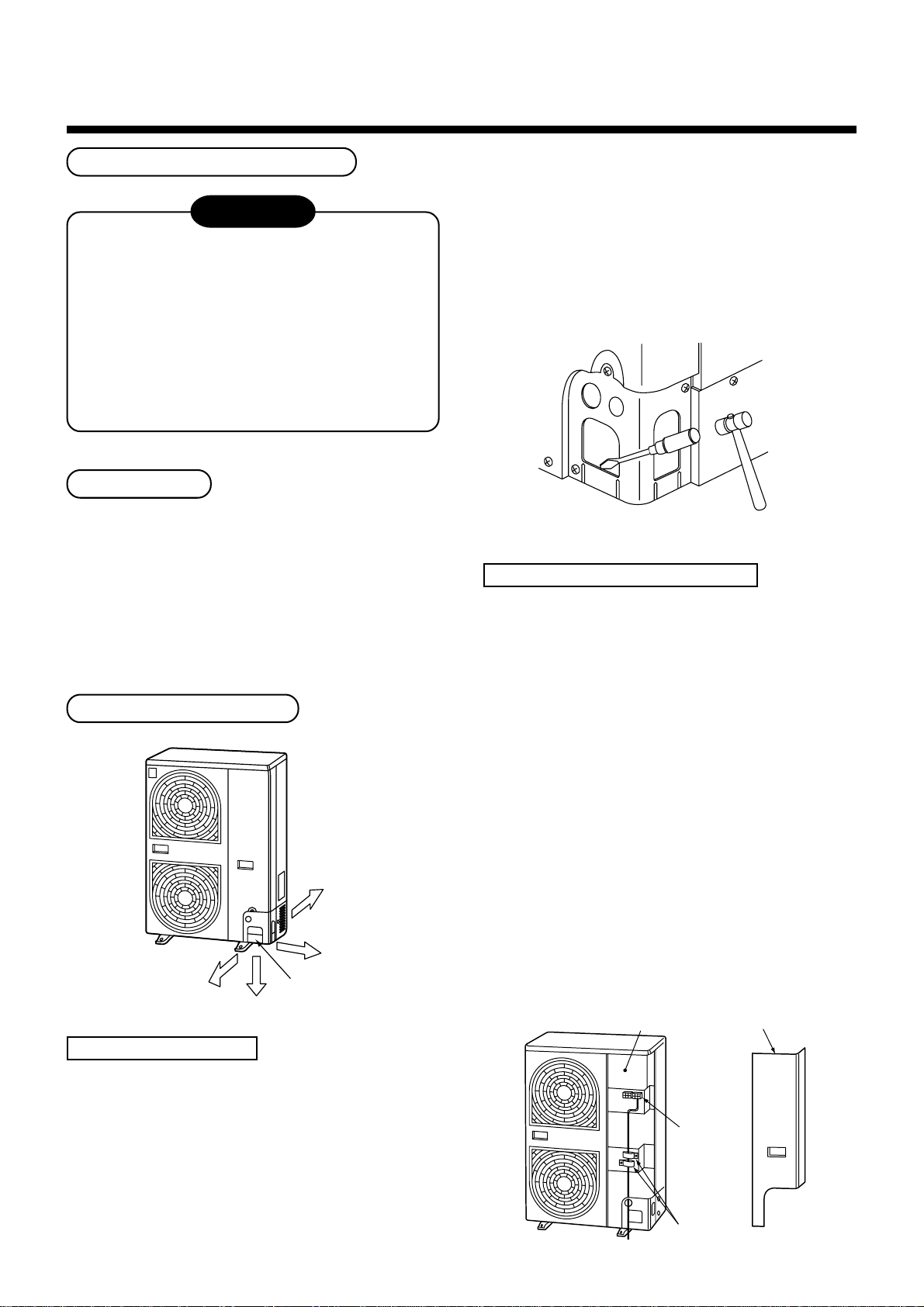

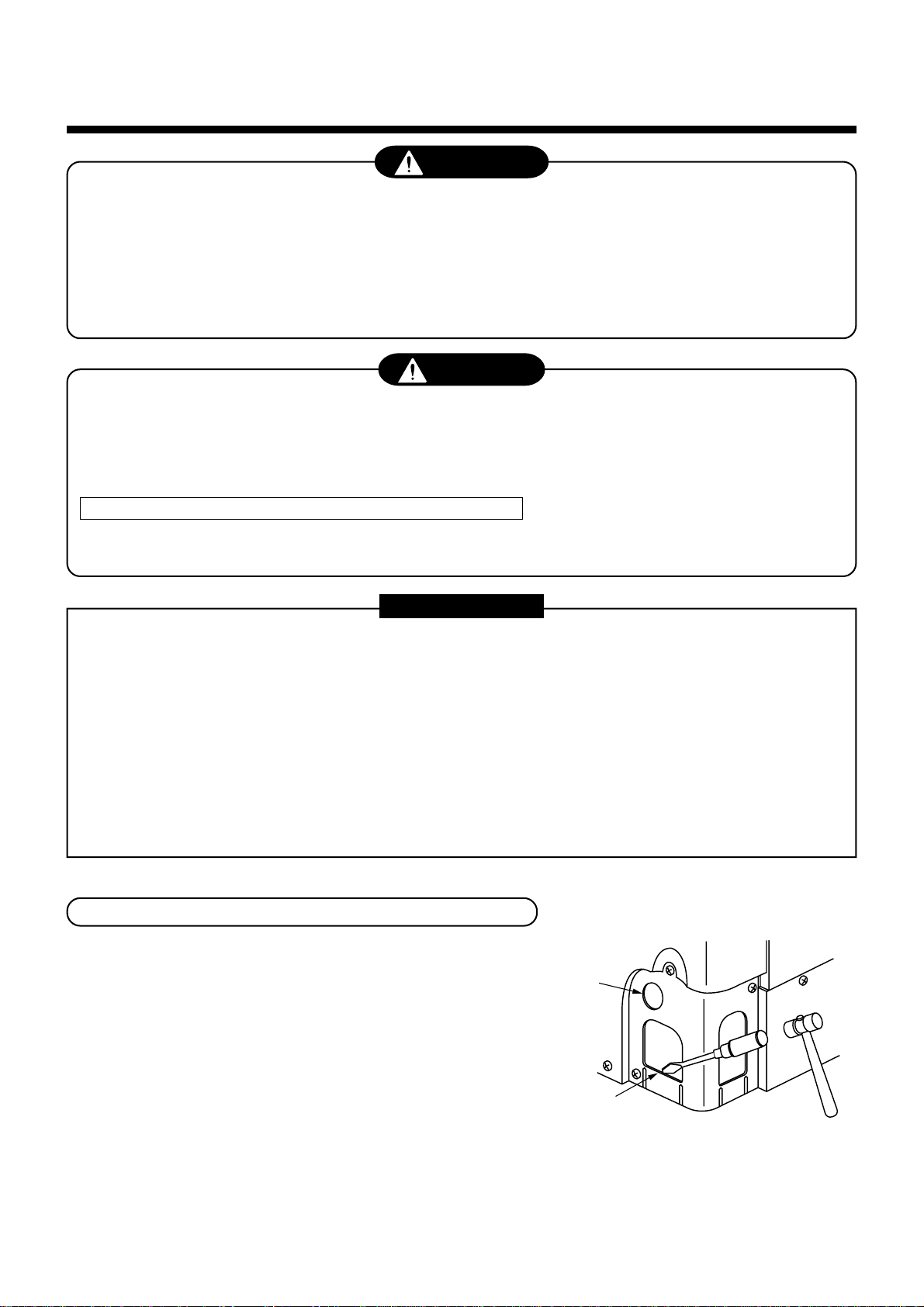

Knockout of pipe cover

Rear direction

Side direction

Front direction

Down direction

Pipe cover

• After marking the knockout hole, remove the burr

and mount the attached protective bush and guard

material for pass-through part in order to protect

pipes and wires.

After connecting the pipes, be sure to mount the pipe

cover. The pipe cover is easily mounted by cutting off

the slit at the lower part of the pipe cover.

How to remove the front panel

1. Remove screws of the front panel.

2. Pull the front panel downward.

Removing the front panel, the electric parts appear at

the front side.

• The metal pipes are attachable to the piping holes.

If the size of the used power pipe does not match

with the hole, adjust the hole size to match with pipe

size.

• Be sure to fix the power cable and indoor/outdoor

connecting cable with bundling band sold on the

market so that they do not make contact with the

compressor and discharge pipe.

(Temperature of the compressor and discharge pipe

becomes high.)

In order to avoid the force applied to on the connecting section, be sure to fix the cables to the cord

clamps provided on the pipe valve fixing plate and

the electric parts box.

Electric parts box

Front panel

Knockout procedure

• The indoor/outdoor connecting pipes can be connected to 4 directions.

Take off the knockout part of the pipe cover in which

pipes or wires pass through the base plate.

• As shown in the figure, do not remove the pipe cover

from the cabinet so that the knockout hole can be

easily punched. To knock out, it is easily taken off by

hands by punching a position at the lower side of 3

connected parts with screwdriver along the guide line.

Terminal

plate

Cord clamp

7

Page 11

3

REFRIGERANT PIPING

WARNING

If the refrigerant gas leaks during

installation work, ventilate the room

immediately.

If the leaked refrigerant gas comes into contact

with a source of fire, noxious gas maybe

generated.

After installation work is complete, check

refrigerant gas does not leak.

If the refrigerant leaks into the room and comes

into contact with a naked flame, noxious gas

maybe generated.

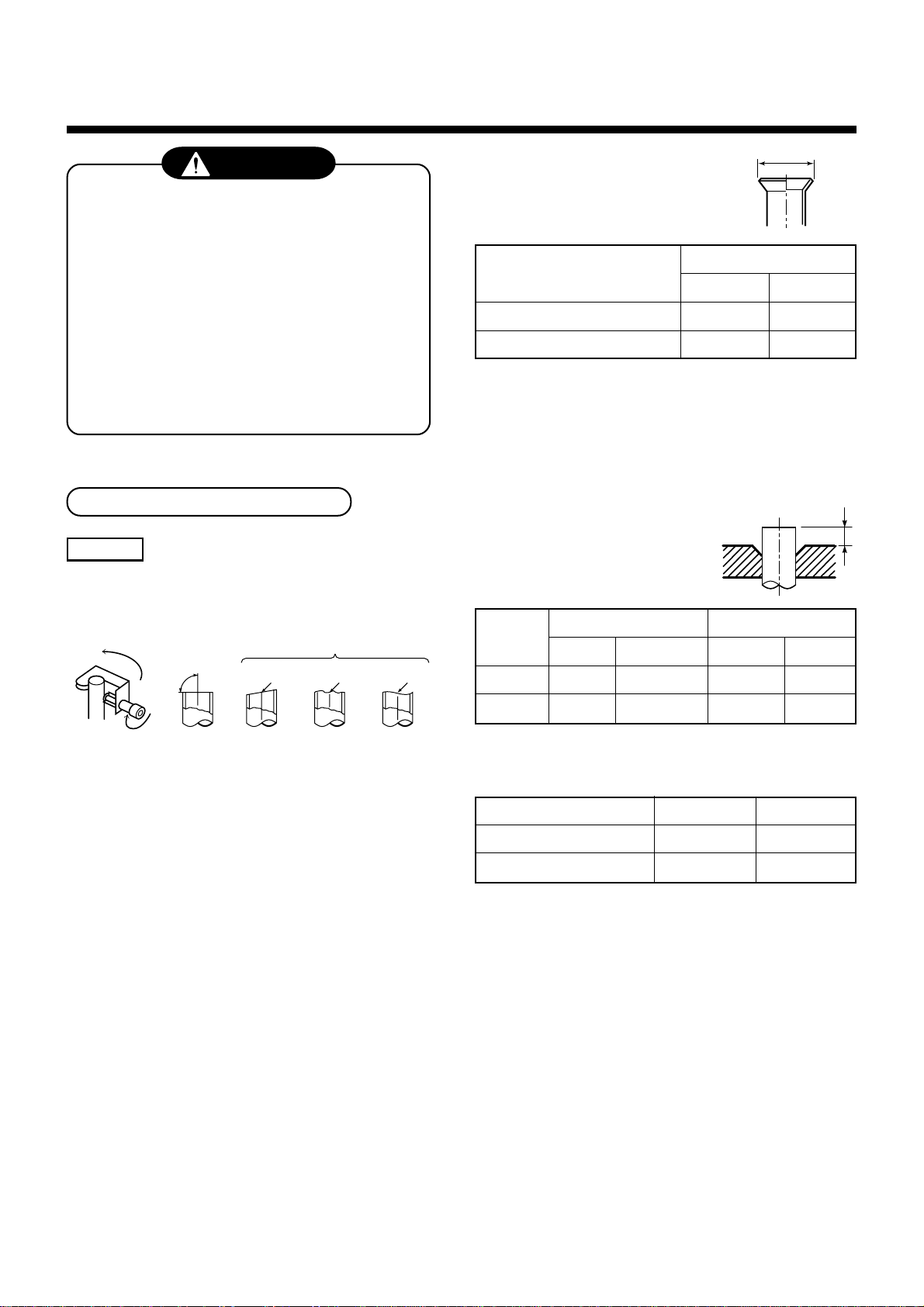

Pipe forming/End positioning

Flaring

1. Cut the pipe with a pipe cutter.

• Flaring size : A (Unit : mm)

Outer dia. of copper pipe

9.5

15.9

* In case of flaring for R410A with the conventional flare

tool, pull it out approx. 0.5 mm more than that of R22

to adjust to the specified flare size.

The copper pipe gauge is useful for adjusting

projection margin size.

R410A R22

13.2 13.0

19.7 19.4

A

+0

A

-

0.4

• Projection margin in flaring :

B (Unit : mm)

Rigid (Clutch type)

B

NO GOODOK

90˚

2. Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly

manufactured for R410A are recommended.

However, the conventional tools can be used by

adjusting projection margin of the copper pipe.

Obliquity Roughness Warp

Outer dia.

of copper

pipe

9.5

15.9

Imperial (Wing nut type)

Outer dia. of copper pipe

R410A tool used

R410A R22

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

9.5

15.9

Conventional tool used

R410A R22

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

R410A R22

1.5 to 2.0 1.0 to 1.5

2.0 to 2.5 1.5 to 2.0

8

Page 12

3

REFRIGERANT PIPING

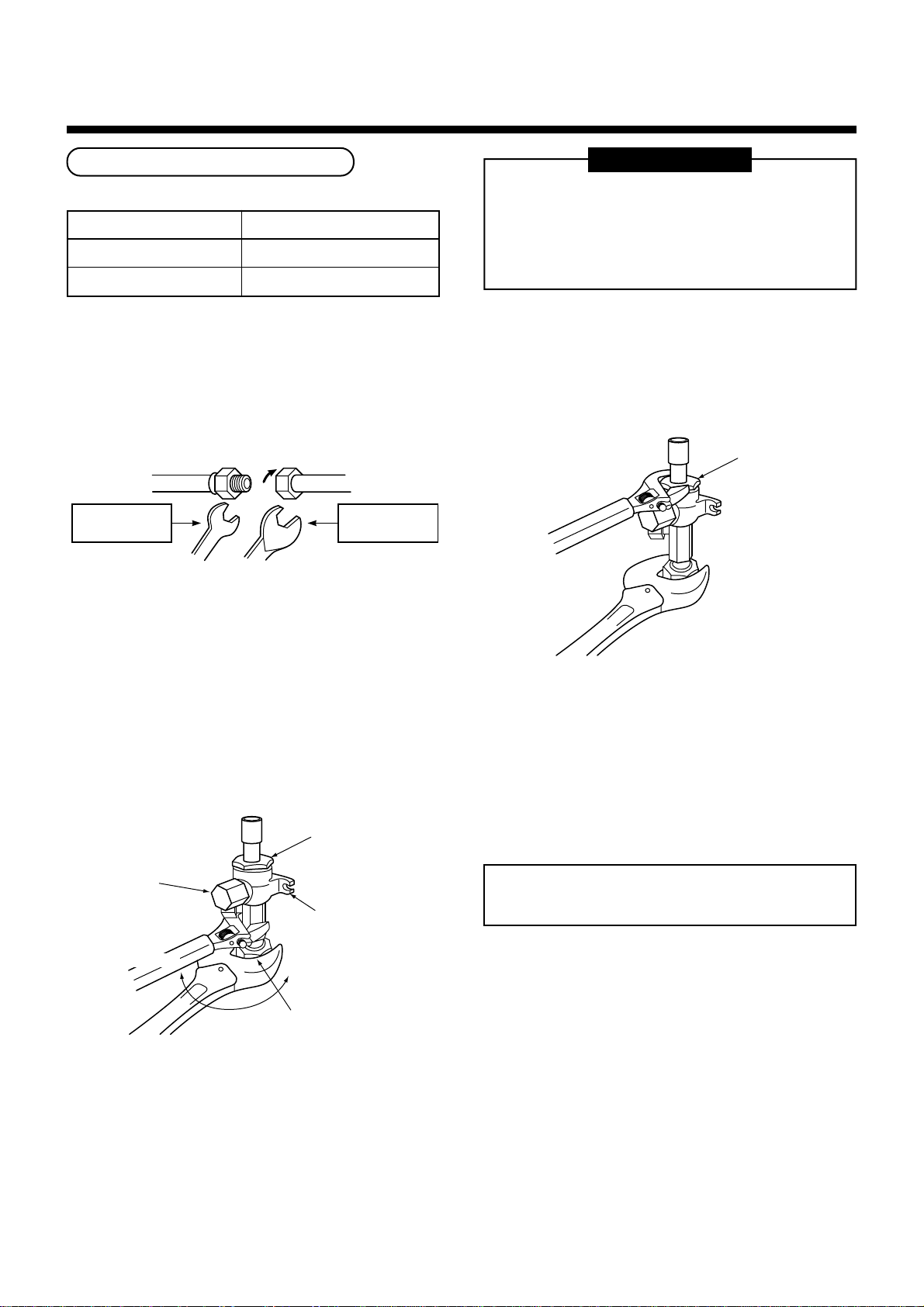

Tightening of connecting part

(Unit: N•m)

Outer dia. of copper pipe

9.5 mm (diam.)

15.9 mm (diam.)

• Align the centers of the connecting pipes and tighten

the flare nut strong as far as possible with your

fingers.

Then fix the nut with a spanner and tighten it with

torque wrench as shown in the figure.

Half union or packed valve Flare nut

Externally

threaded side

Fix with spanner.

Tightening torque

33 to 42 (3.3 to 4.2 kgf•m)

68 to 82 (6.8 to 8.2 kgf•m)

Internally

threaded side

Tighten with torque wrench.

REQUIREMENT

1. Do not put the spanner on the cap.

The valve may be broken.

2. If applying excessive torque, the nut may be

broken according to some installation

conditions.

• After the installation work, be sure to check gas leak

of connecting part of the pipes with nitrogen.

NO GOOD

Cover

• As shown in the figure, be sure to use a double

spanner to loosen or tighten the flare nut of the valve

at gas side. If using a single spanner, the nut cannot

be tightened with necessary tightening torque.

On the contrary, use a single spanner to loosen or

tighten the flare nut of the valve at liquid side.

Cover

Cap

Piping valve

Loosened

Tightened

Flare nut

Valve at gas side

• Pressure of R410A is higher than that of R22

(Approx. 1.6 times). Therefore, using a torque

wrench, tighten the flare pipe connecting sections

which connect the indoor/outdoor units at the

specified tightening torque. Incomplete connections

may cause not only a gas leak, but also a trouble of

the refrigeration cycle.

Do not apply refrigerating machine oil to the

flared surface.

9

Page 13

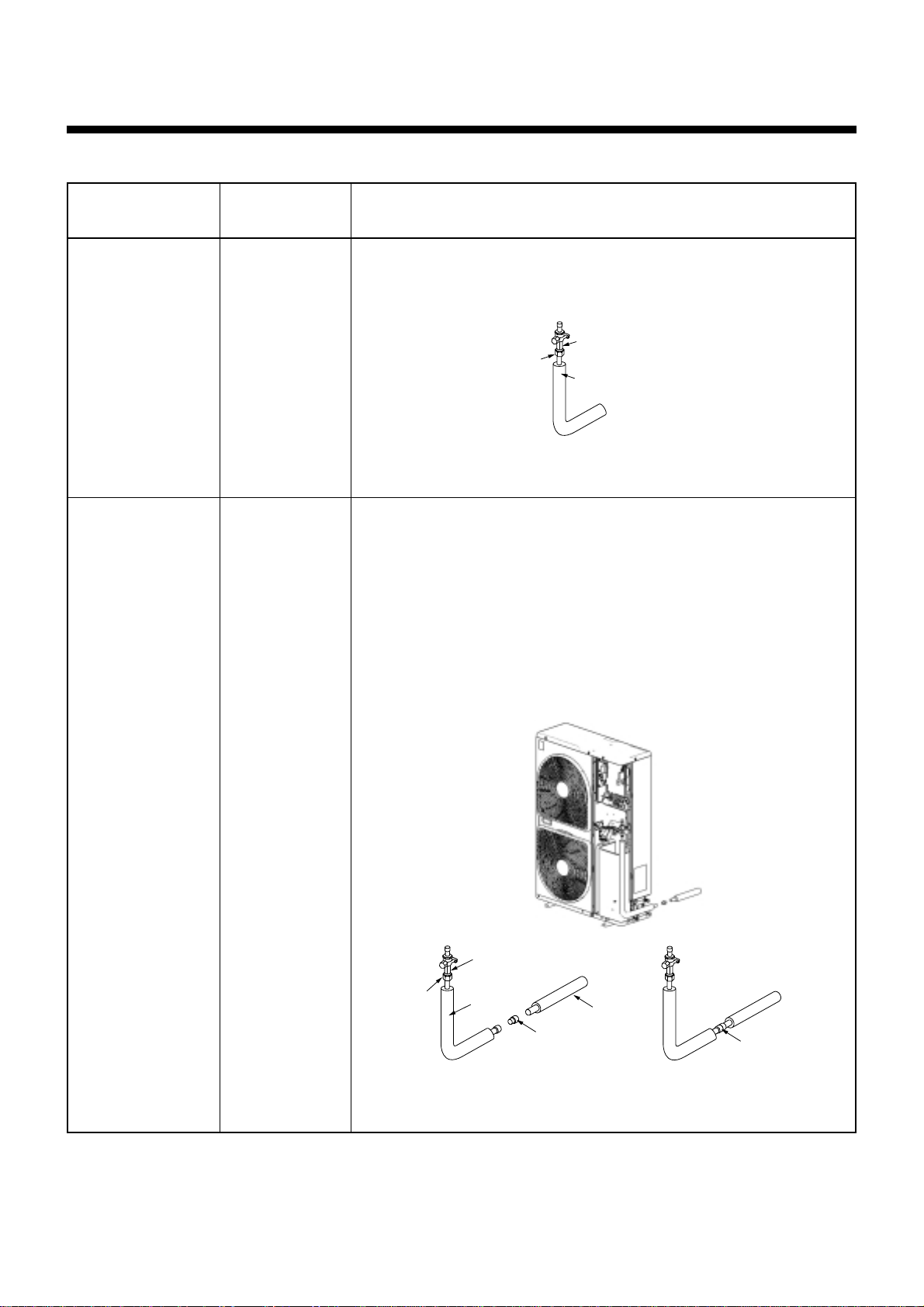

Pipe connecting method of valve at gas side

p.4

Ac

Outdoor unit

capacity type

0401 type

0501 type

0601 type

Gas pipe

diameter

Ø15.9

Ø19.1

Pipe connecting method of valve at gas side

Connect Ø15.9 pipe with flaring.

Ball valve of

Flare

connection

gas side Ø15.9

Gas pipe Ø15.9

(Local supply)

For braze connection of Ø19.1 gas pipe, refer to the following method.

1. Form the pipe so that the end part of the pipe will be out from the

outdoor unit along the taking-out direction of the pipe.

The Ø15.9 gas pipe to be supplied locally.

2. Using the joint socket (Accessory), connect with braze Ø15.9 gas

pipe and Ø19.1 gas pipe at outside of the outdoor unit.

3. After connecting the pipes, apply thermal insulation process to the

gas pipe until near the valve.

Flare

connection

Ball valve of

gas side Ø15.9

Gas pipe Ø15.9

(Local supply)

Joint socket

(Accessory)

10

Gas pipe Ø19.1

(Local supply)

Braze connection

(Aconnect with braze)

Page 14

3

REFRIGERANT PIPING

• Coupling size of brazed pipe

Connected section

External size Internal size

K

G

ØF

Connected section

+0.04

) 7 6 0.06 or less 0.50

–0.02

+0.04

) 8 7 0.08 or less 0.60

–0.02

+0.04

) 9 8 0.10 or less 0.70

–0.02

+0.04

) 9 8 0.13 or less 0.80

–0.02

+0.03

) 11 10 0.15 or less 0.80

–0.03

Min. depth

of insertion

Oval value

Min. thickness

of coupling

Standard outer dia. of

connected copper pipe

6.35 6.35 (±0.03) 6.45 (

9.52 9.52 (±0.03) 9.62 (

12.70 12.70 (±0.03) 12.81 (

15.88 15.88 (±0.03) 16.00 (

19.05 19.05 (±0.03) 19.19 (

ØC

External size Internal size

Standard outer dia. (Allowable difference)

CFKG

Selection of pipe materials and size

• Selection of pipe material

Material: Phosphorus deoxidation seam-less pipe

• Capacity code of indoor and outdoor units

• For the indoor unit, the capacity code is decided at each capacity rank.

• The capacity codes of the outdoor units are decided at each capacity rank.

The maximum No. of connectable indoor unit and the total value of capacity codes of the indoor units are also

decided.

(Unit: mm)

Minimum wall thickness for R410A application

Soft Harf Hard or Hard OD (Inch) OD (mm) Minimum wall thickness (mm)

OK OK 1/4” 6.35 0.80

OK OK 3/8” 9.52 0.80

OK OK 1/2” 12.70 0.80

OK OK 5/8” 15.88 1.00

NG * OK 3/4” 19.05 1.00

* If the pipe size is Ø19.0 or more, use a

suitable materia l .

Table 1 Table 2

Indoor unit

capacity type

007 type 0.8 2.2 0401 type 4 6 3.2 5.2

009 type 1 2.8 0501 type 5 8 4.0 6.5

012 type 1.25

015 type 1.7

018 type 2

024 type 2.5

027 type 3

030 type 3.2

036 type 4

048 type 5

Equivalent to HP Equivalent to capacity

Capacity code Capacity code

3.6

4.5

5.6

7.1

8

9

11.2

14

Outdoor unit

capacity type

0601 type 6 9 4.8 7.8

Equivalent to HP

No. of

connectable

indoor units

Total capacity code of

connectable indoor units

Min. (HP) Max. (HP)

11

Page 15

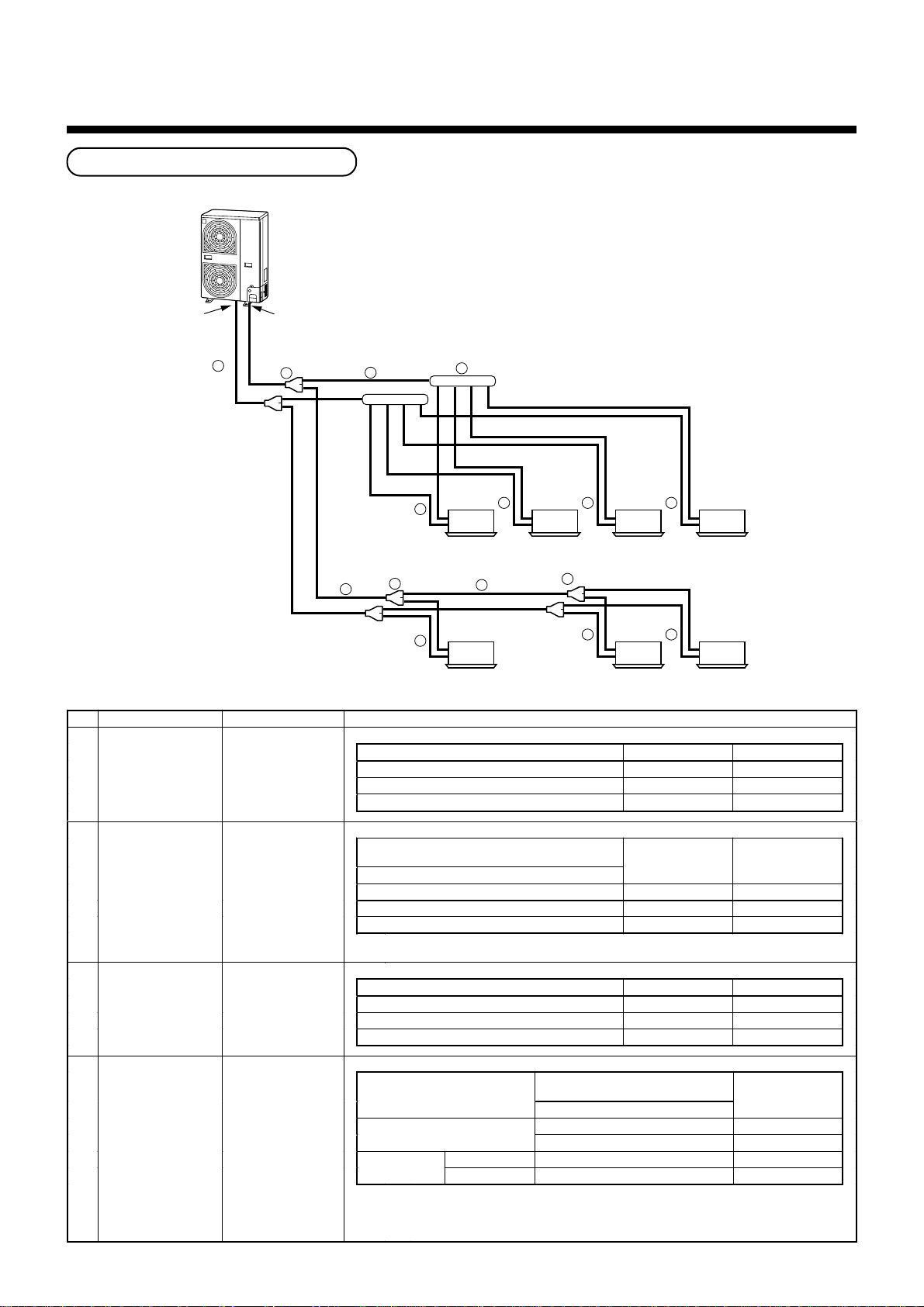

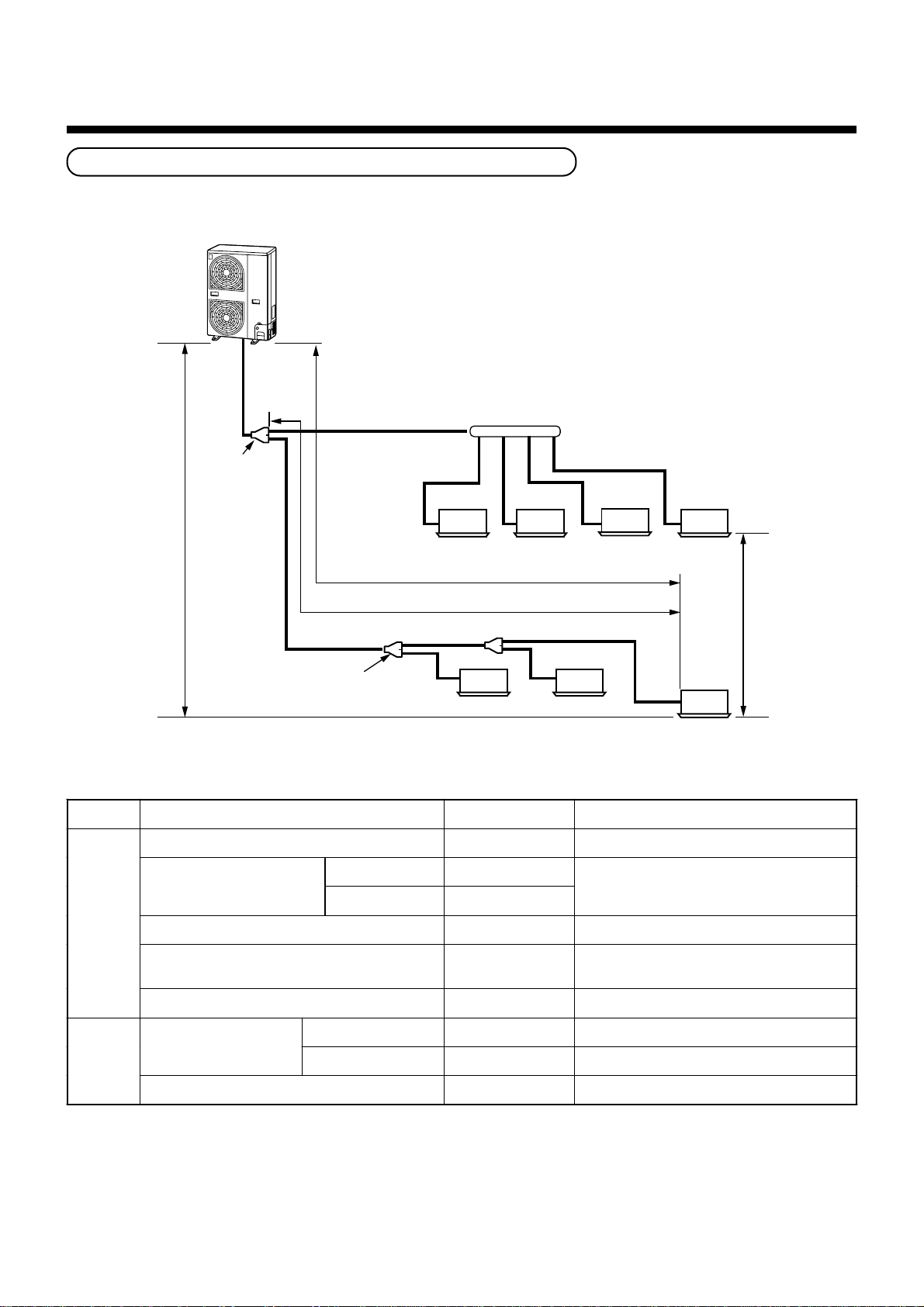

Selection of refrigerant piping

Outdoor unit

Gas pipe

Main pipe

1

No. Piping parts Name Selection of pipe size

Outdoor unit

↓

1st branching section

Main pipe

Liquid pipe

1st branching

section

4

Branching

pipe

Branching

pipe

2

3

Y-shape

branch joint

2

4

3

Size of main pipe

Outdoor unit capacity type Gas pipe Liquid pipe

Branch header

4

3 3 3

Indoor unit

2

0401 type 15.9 9.5

0501 type 15.9 9.5

0601 type 19.1 9.5

4

3 3

Branching sectio n

↓

Branching sectio n

Branching sectio n

↓

Indoor unit

Branching sectio n

Branching pipe

Indoor unit

connecting pipe

Y-shape branch joint

Branch header

Pipe size between branching sections

Total capacit y codes of indoor units

at down stream side

Equivalent to HP

Below 2.8 12.7 9.5

2.8 to below 6.4 15.9 9.5

6.4 to below 7.2 19.1 9.5

If the total capacity code value of indoor units exceeds that of the outdoor units,

Note)

apply the capacity code of outdoor units.

Connecting pipe size of indoor unit

Indoor unit capacity type Gas pipe Liquid pipe

007, 009, 012 type 9.5 6.4

015, 018 type 12.7 6.4

024, 030, 036, 048 type 15.9 9.5

Selection of branching section

Total capacit y codes of indoor

units at down stream side

Equivalent to HP

Y-shape branch joint

Branch header

*1 :

Note)

When using a Y-shape branching joint for the 1st branch, select according to

capacity code of the outdoor unit.

*2 :

For 1 line after branching header indoor units with a maximum capacity code of

6.0 in total can be connected.

For 4 branches Up to 7.8 RBM-HY1043E

For 8 branches Up to 7.8 RBM-HY1083E

6.4 or more and up to 7.8 RBM-BY103E

Gas pipe Liquid pipe

Below 6.4 RBM-BY53E

12

Model name

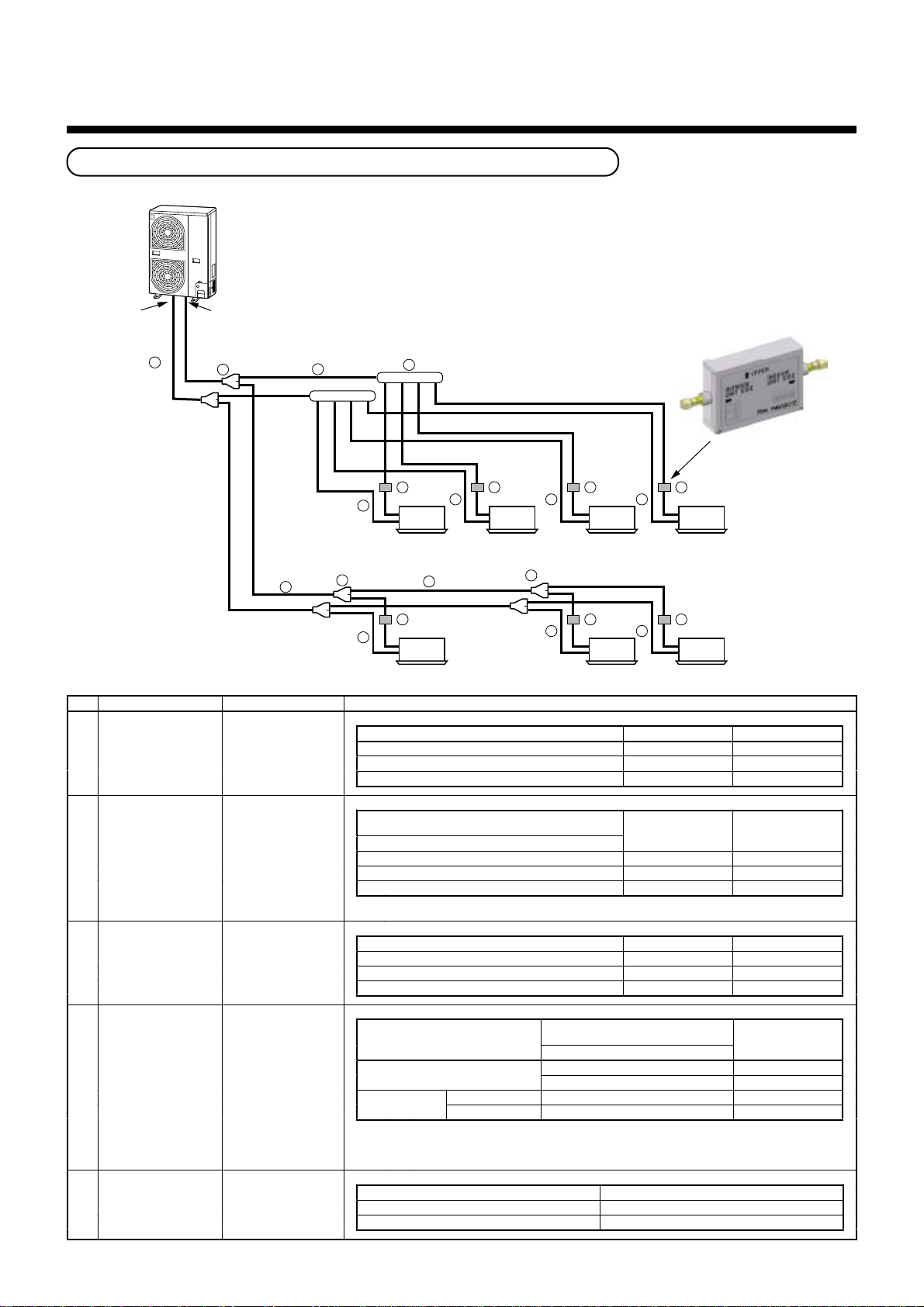

Page 16

3

REFRIGERANT PIPING

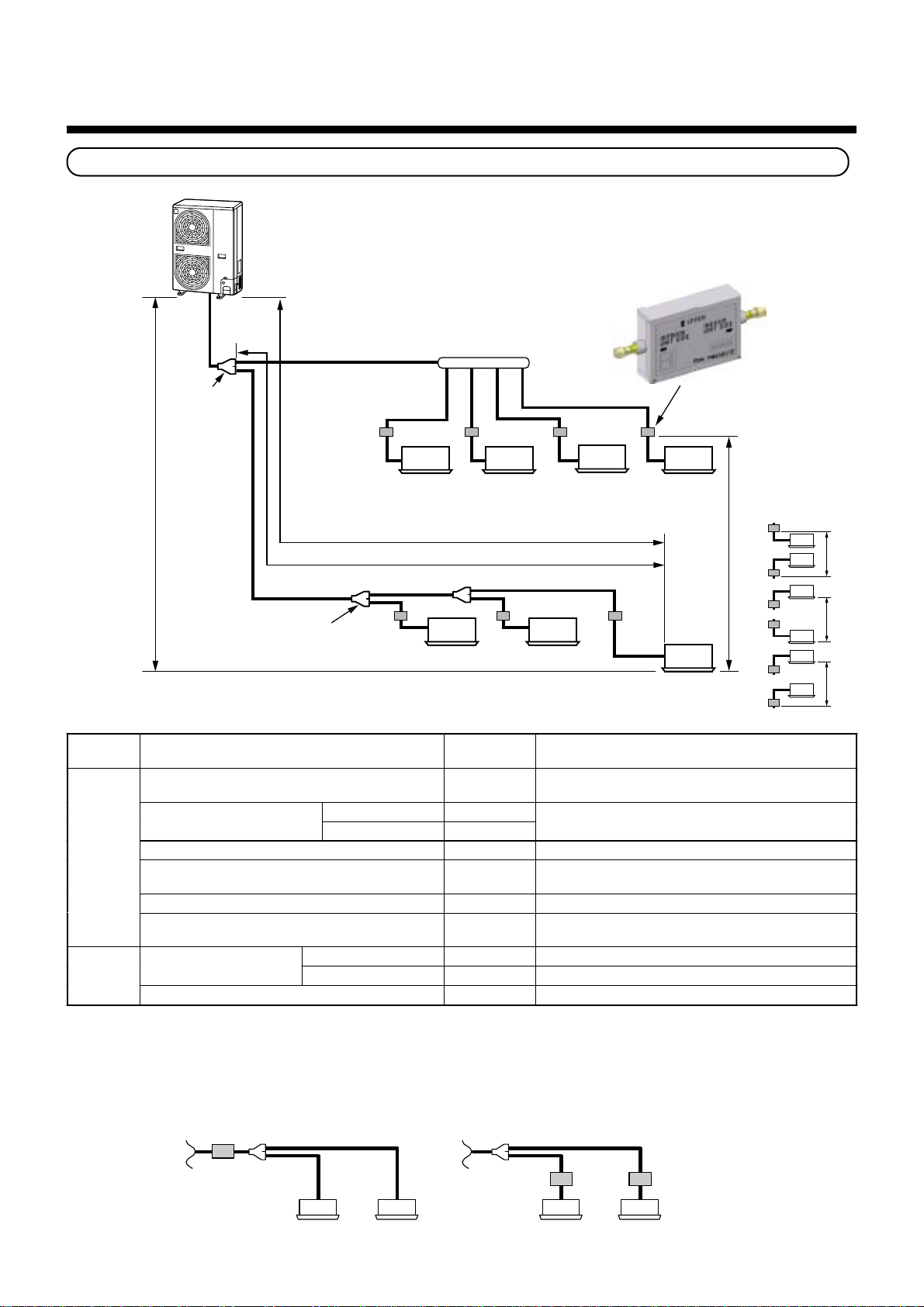

Selection of refrigerant piping for quiet place (with PMV Kit)

Outdoor unit

Gas pipe

Main pipe

1

No. Piping parts Name Selection of pipe size

Outdoor unit

↓

1st branching section

Branching sectio n

↓

Branching sectio n

Branching sectio n

↓

Indoor unit

Branching sectio n

PMV Kit PMV Kit

Liquid pipe

1st branching

section

4

Main pipe

Branching pipe

Indoor unit

connecting pipe

Y-shape branch joint

Branch header

Branching

pipe

2

Branching

pipe

2

Branch header

4

5

3

Y-shape

branch joint

4

3

Size of main pipe

Pipe size between branching sections

Note)

Connecting pipe size of indoor unit

Selection of branching section

Y-shape branch joint

Branch header

Note)

Selection of PMV Kit

2

5 5 5

Outdoor unit capacity type Gas pipe Liquid pipe

Total capacit y codes of indoor units

at down stream side

Equivalent to HP

If the total capacity code value of indoor units exceeds that of the outdoor units,

apply the capacity code of outdoor units.

Indoor unit capacity type Gas pipe Liquid pipe

007, 009, 012 type 9.5 6.4

024, 030, 036, 048 type 15.9 9.5

*1 :

When using a Y-shape branching joint for the 1st branch, select according to

capacity code of the outdoor unit.

*2 :

For 1 line after branching header indoor units with a maximum capacity code of

6.0 in total can be connected.

Indoor unit capacity type Model name

007, 009, 012 type RBM-PMV0361E

015, 018, 024 type RBM-PMV0901E

5 5 5

3 3 3

0401 type 15.9 9.5

0501 type 15.9 9.5

0601 type 19.1 9.5

Below 2.8 12.7 9.5

2.8 to below 6.4 15.9 9.5

6.4 to below 7.2 19.1 9.5

015, 018 type 12.7 6.4

For 4 branches Up to 7.8 RBM-HY1043E

For 8 branches Up to 7.8 RBM-HY1083E

4

3 3

Total capacity codes of indoor

units at down stream side

Equivalent to HP

Below 6.4 RBM-BY53E

6.4 or more and up to 7.8 RBM-BY103E

PMV Kit

Indoor unit

Indoor unit

Gas pipe Liquid pipe

Model name

13

Page 17

Allowable length/height difference of refrigerant piping

Outdoor unit

Main pipe

L1

Height difference

between indoor and

outdoor units

H1

Total extension of pipe (Liquid pipe, real length) 180 m L1 + L2 + L3 + L4 + a + b + c + d + e + f + g

1st branching

section

Branching pipe

L3

Branching pipe L2

Equivalent length corresponded to farthest piping L

Equivalent length corresponded to farthest piping after 1st branching Li

Y-shape

branch joint

ef

Branch header

abcd

Indoor unit

L4

g

Allowable value Piping section

Height difference

between indoor units

H2

∗1

A

Furthest piping length L (∗1)

Piping

Length

Max. equivalent length of main pipe 65 m L1

Equivalent length of furthest piping from

st

branching Li (∗1)

1

Max. real length of indoor unit connecting pipe 15 m a, b, c, d, e, f. g

Height between indoor

Height

and outdoor units H1

Difference

Height between indoor units H2 15 m ———

∗

1 : Furthest indoor unit from 1

Real length 100 m

L1 + L3 + L4 + g

Equivalent length 125 m

35 m L3 + L4 + g

Upper outdoor unit 30 m ———

Lower outdoor unit 20 m ———

st

branch to be named “A”.

14

Page 18

3

REFRIGERANT PIPING

Allowable length/height difference of refrigerant piping for quiet places (with PMV Kit)

Outdoor unit

Main pipe

L1

Branching pipe L2

Branch header

1st branching

section

Height difference

between indoor

and outdoor units

H1

Branching pipe

L3

Total extension of pipe (Liquid pipe, real length) 150 m

Furthest piping length L (∗1)

Piping

Length

Max. equivalent length of main pipe 50 m L1

Equivalent length of furthest piping from

st

1

branching Li (∗1)

Max. real length of indoor unit connecting pipe 15 m a + h, b + i, c + j, d + k, e + l, f + m. g + n

Real length between PMV KIT and indoor unit

Height

Difference

1 : Furthest indoor unit from 1

∗

Height between indoor

and outdoor units H1

Height between indoor unit and PMV kit H2 15 m ———

ab

hi jk

Equivalent length corresponded to farthest piping L

Equivalent length corresponded to farthest piping after 1st branching Li

L4

Y-shape

branch joint

e

lm

cd

f

Indoor unit

g

n

Allowable

value

+ a + b + c + d + e + f + g + h + I + j + k+ l + m + n

Real length 65 m

Equivalent length 80 m

L1 + L3 + L4 + g + n

15 m L3 + L4 + g + n

2 m or more

Below 10 m

Upper outdoor unit 30 m ———

Lower outdoor unit 20 m ———

st

branch to be named “A”.

PMV Kit

∗1

A

Piping section

L1 + L2 + L3 + L4

h, i, j, k, l, m, n

Height difference

between indoor unit

and PMV Kit

∗

H2

* Between highest unit

and lower units.

Example)

H2

H2

H2

Note)

Do not connect two or more indoor units to one PMV Kit. Arrange one indoor unit and one PMV Kit set to 1 by 1.

NO GOOD OK

PMV Kit

Indoor unit Indoor unit

15

PMV Kit

Page 19

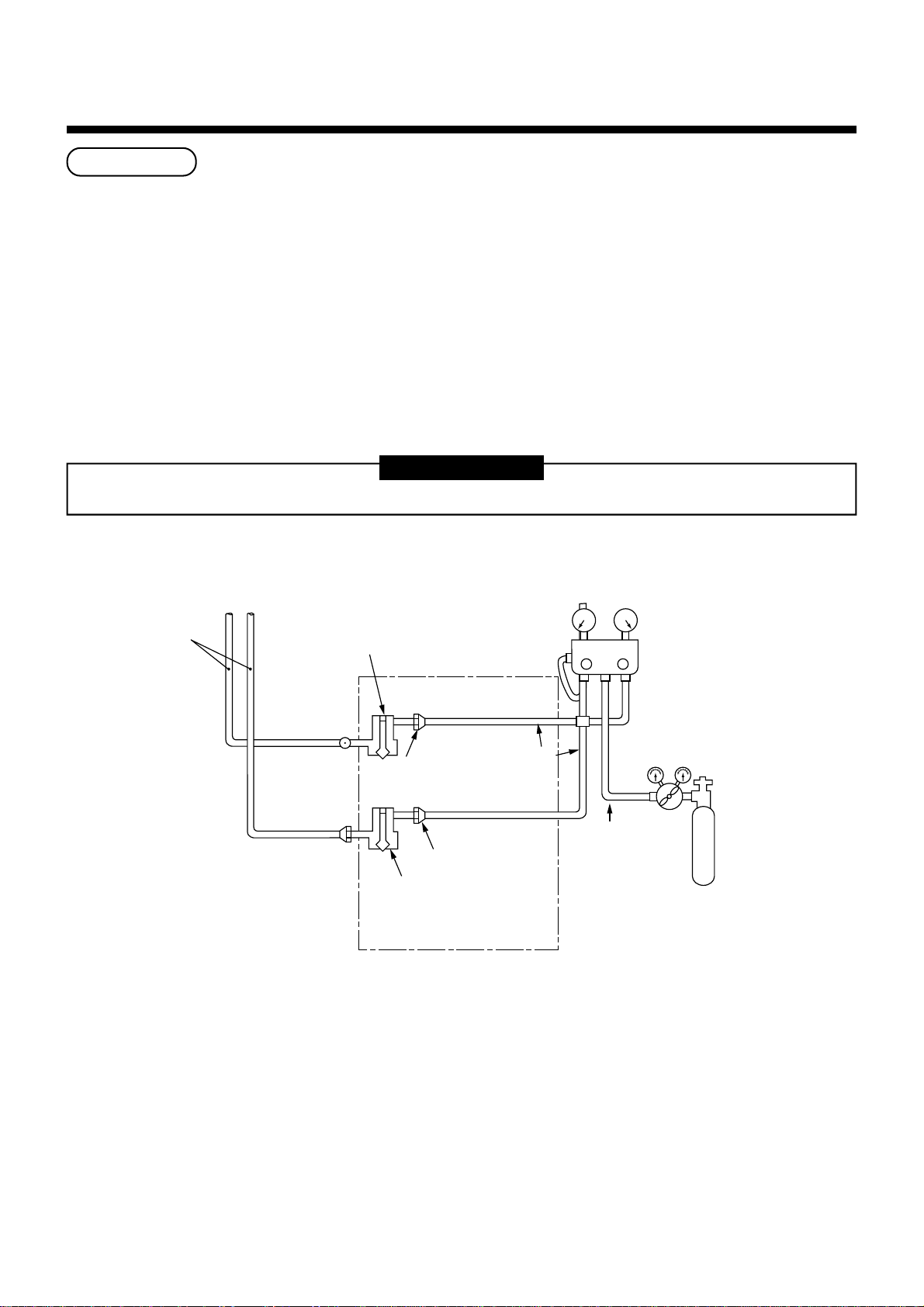

Airtight test

After the refrigerant piping has finished, execute an airtight test. For an airtight test, connect a nitrogen gas bomb as

shown in the figure below, and apply pressure.

• Be sure to apply pressure from the service ports of the packed valves (or ball valves) at liquid side, discharge gas

side, and suction gas side.

• An air tight test can be only performed to the service ports at liquid side, discharge gas side, and suction gas side

of the outdoor unit.

• Close fully valves at liquid side, discharge gas side, and suction gas side. As there is possibility that nitrogen gas

enters in the refrigerant cycle, re-tighten the valve rods before applying pressure.

(Re-tightening of the valve rods are unnecessary for valves at discharge gas side because they are ball valves.)

• For each refrigerant line, apply pressure gradually with steps at liquid side, discharge gas side, and suction gas

side.

Be sure to apply pressure to suction gas side, discharge gas side, and liquid side.

REQUIREMENT

Never use “Oxygen”, “Flammable gas” and “Noxious gas” in an airtight test.

Connected to indoor unit

Main pipe

Brazed

Fully closed

Packed valve fully closed

(Gas side)

STEP 1 : Apply pressure 0.3MPa (3.0kg/cm

STEP 2 : Apply pressure 1.5MPa (15kg/cm

STEP 3 : Apply pressure 3.73MPa (38kg/cm

Lowpressure

gauge

Outdoor unit

Service port

Ball valve fully closed

(Liquid side)

2

G) for 3 minutes or more.

2

G) for 3 minutes or more.

2

G) for approx. 24 hours. Available to detect slow leakage

Copper pipe

Service port

Ø6.4

⎞

⎠

Highpressure

gauge

VL VH

Ø6.4

Copper pipe

Gauge

manifold

Reducing

valve

Nitrogen gas

Available to detect a gross leakage

• Check pressure down.

No pressure down: Accepted Pressure down: Check the leaked position.

However, if there is difference of ambient temp. between when pressure has been applied and when

⎛ ⎞

24 hours passed, pressure changes by approx. 0.01MPa (0.1kg/cm²G) per 1°C. Correct the pressure.

⎝ ⎠

Leaked position check

When a pressure-down is detected in STEP 1, STEP 2, or STEP 3, check the leakage at the connecting points.

Check leakage with hearing sense, feeler, foaming agent, etc, and perform re-brazing or re-tightening of flare if

leakage is detected.

16

Page 20

3

REFRIGERANT PIPING

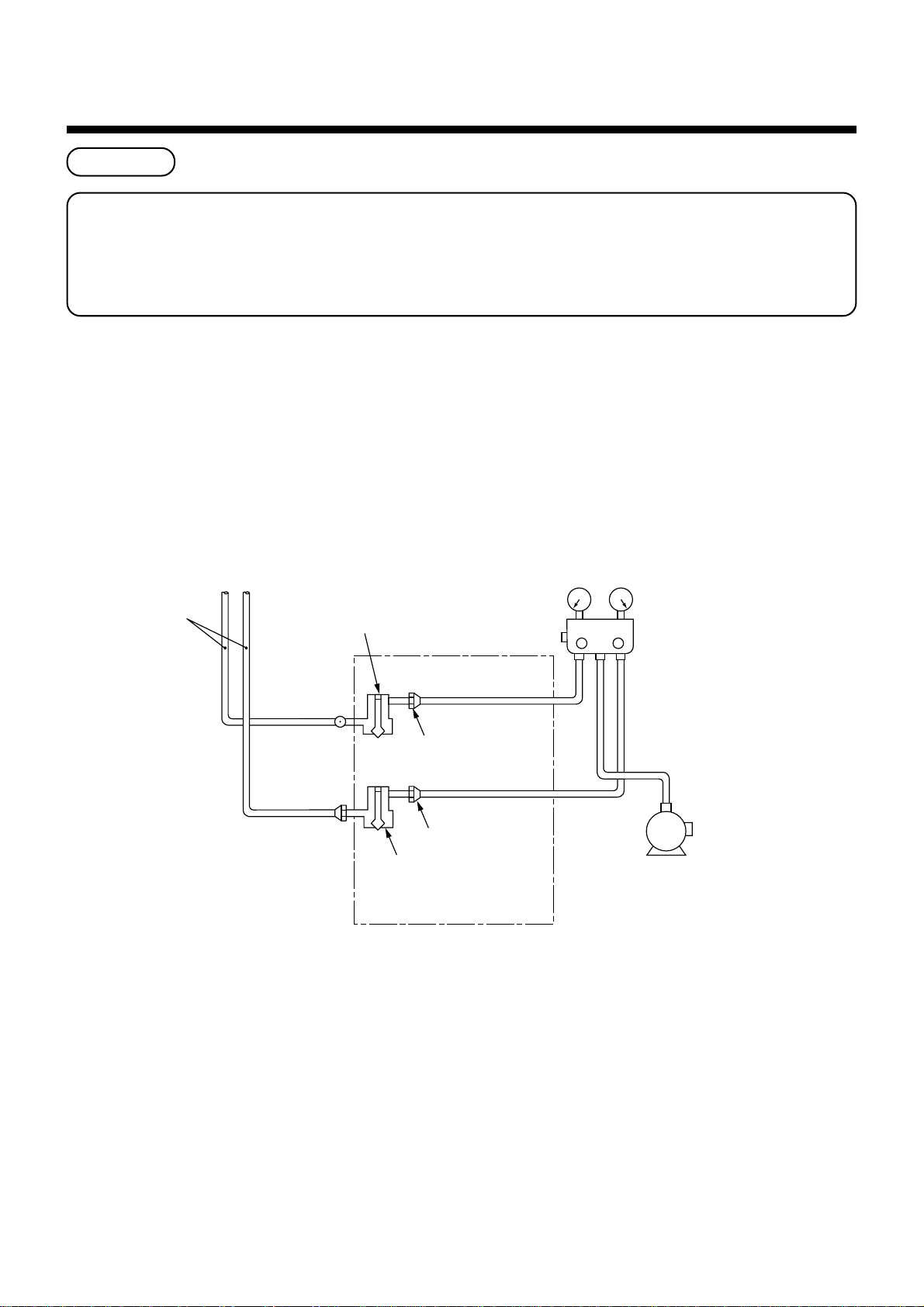

Air purge

For the air purge at installation time (Discharge of air in connecting pipes), use “Vacuum pump method” from

viewpoint of the protection of the earths environment.

• For protection of the earths environment, do not discharge the refrigerant gas in the air.

• Using a vacuum pump, eliminate the remaining air (nitrogen gas, etc.) in the unit. If gas remains, performance

and reliability of the unit may be reduced.

After the airtight test, discharge nitrogen gas. Then connect the gauge manifold to the service ports at suction gas

side, discharge gas side and liquid side, and connect the vacuum pump as shown in the following figure.

Be sure to perform vacuuming for suction gas side, discharge gas side and liquid side.

• Be sure to perform vacuuming from both suction gas side, discharge gas side and liquid side.

• Be sure to perform vacuuming from both liquid and gas sides.

• Use a vacuum pump with counter-flow preventive function so that oil in the pump does not back up in the pipe of

the air conditioner when the pump has been stopped. (If oil in the vacuum pump enters in to the air conditioner

with R410A refrigerant, an error may occur in the refrigeration cycle.)

Connected to indoor unit

Main pipe

Brazed

Fully closed

Packed valve fully closed

(Gas side)

Outdoor unit

Service port

Service port

Ball valve fully closed

(Liquid side)

Lowpressure

gauge

VL VH

Highpressure

gauge

Gauge manifold

P

Vacuum pump

• Use a vacuum pump that has a high vacuum (below -755mmHg) and a large exhaust gas amount (over 40L/

minute).

• Perform vacuuming for 2 or 3 hours though time differs due to pipe length. In this time, check all packed valves at

liquid, gas and balance sides are fully closed.

• If vacuuming valve amount is not decreased to below -755mmHg even after vacuuming for 2 hours or more,

continue vacuuming for 1 hour or more. If -755mmHg or less cannot be obtained by 3 hours or more vacuuming,

detect and repair the leak.

• When the vacuuming valve has reached -755mmHg or less after vacuuming for 2 hours or more, close valves VL

and VH on the gauge manifold fully. Stop the vacuum pump, leave it as it is for 1 hour and then check the vacuum

does not change. If it does change then there may be a leak within the system.

• After the above procedure for vacuuming has finished, exchange the vacuum pump with a refrigerant cylinder and

advance to the additional charging of refrigerant.

17

Page 21

Addition of refrigerant

After vacuuming work, exchange the vacuum pump with the refrigerant bomb and then start the additional charging

work of refrigerant.

Calculating the amount of additional refrigerant required

When the system is charged with refrigerant at the factory, the amount of refrigerant needed for the pipes on site is

not included. Calculate the additional amount required, and add that amount to the system.

Additional refrigerant charge amount is calculated from size of liquid pipe at site and its real length.

Additional

refrigerant charge

amount at site

R (kg)

Table 1

Pipe dia. at liquid side

Additional refrigerant amount/1m

(kg)

Real length

=× +

of liquid pipe

Ø6.4 Ø9.5

0.025 0.055

Additional refrigerant charge

amount per liquid pipe 1m

(Table 1)

Table 2

Outdoor unit capacity type

Compensation by outdoor HP

(kg)

Compensation

by outdoor HP

(Table 2)

0401 type 0501 type 0601 type

–0.8 –0.4 0

Example : (0501 type)

L1

L1 Ø9.5 : 10m L2 Ø9.5 : 10m L3 Ø9.5 : 5m a Ø9.5 : 3m

b Ø6.4 : 3m c Ø6.4 : 4m d Ø6.4 : 5m

Additional charge amount R (kg)

= (Lx × 0.025kg/m) + (Ly × 0.055kg/m) + (–0.4kg)

= (12 × 0.025kg) + (28 × 0.055kg) + (–0.4kg)

= 1.44kg

L2

a

L3

bcd

Lx : Real total length of liquid pipe Ø6.4 (m)

Ly : Real total length of liquid pipe Ø9.5 (m)

Note)

If the additional refrigerant amount indicates a negative result from the calculation, use air conditioner without

the adding of any additional refrigerant.

Charging of refrigerant

• Keeping valve of the outdoor unit closed, be sure to charge the liquid refrigerant into service port at liquid side.

• If the specified amount of refrigerant cannot be charged, open fully valves of outdoor unit at liquid and discharge/

suction gas sides, operate the air conditioner in COOL mode under condition that valve at suction gas side is a

little returned to close side, and then charge refrigerant into service port at suction gas side. In this time, choke the

refrigerant slightly by operating valve of the bomb to charge liquid refrigerant. The liquid refrigerant may be

charged suddenly, therefore be sure to charge refrigerant gradually.

• When refrigerant leaks and refrigerant shortage occurs in the system, recover the refrigerant in the system and

recharge refrigerant newly up to the correct level.

REQUIREMENT

Entry of refrigerant charge amount

• Complete the refrigerant record column found on the wiring diagram, with detail of the additional refrigerant

amount and name of service engineer at the time of installation.

• The total amount of refrigerant refers to the shipment charge plus any additional refrigerant at the time of

installation. The refrigerant amount at shipment is indicated on the unit name plate.

18

Page 22

3

REFRIGERANT PIPING

Full opening of the valve

• Open the valve of the outdoor unit fully.

• Using a 4mm-hexagonal wrench, open fully the

valve key on the liquid side.

• Using a spanner open fully the valve key on the

packed valve at suction gas side.

• Using a pair of pinchers, open fully the handle on the

ball valve at the discharge gas side.

Be careful that the handling of the ball valve differs

from that of the packed valve.

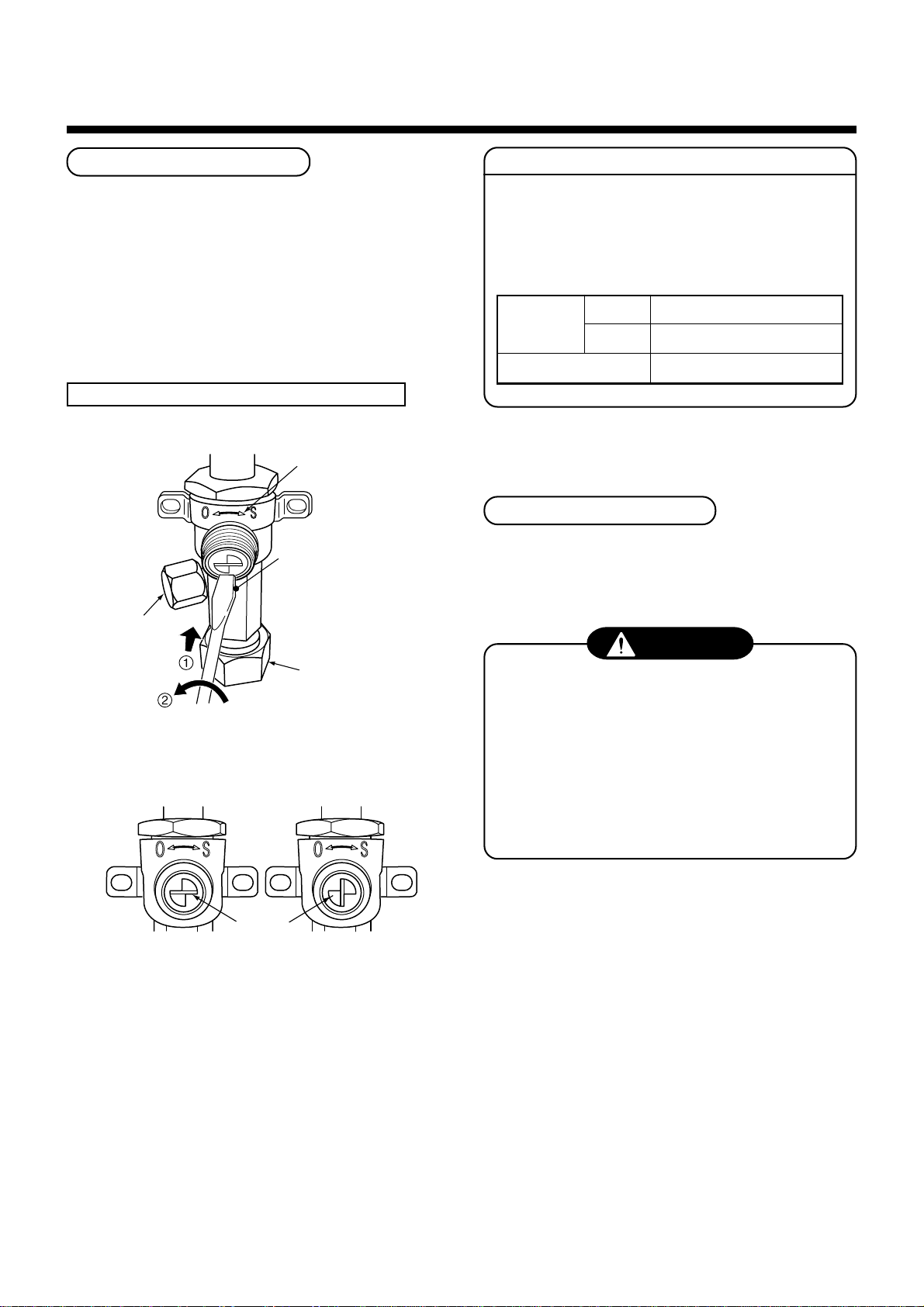

How to open the ball valve at gas side

Valve unit

Using a minus screwdriver,

turn it counterclockwise by

90˚ until it hits the stopper.

(Full open)

Charge port

Flare nut

Position of grooves for driver

Valve handling precautions

• Open the valve stem or the handle until it strikes

the stopper.

It is unnecessary to apply further force.

• Securely tighten the cap with a torque wrench.

• Cap tightening torque

Valve size

Ø9.5

Ø15.9

Charge port

33 to 42N•m (3.3 to 4.2kgf•m)

20 to 25N•m (2.0 to 2.5kgf•m)

14 to 18N•m (1.4 to 1.8kgf•m)

Heat insulation for pipe

• Apply the heat insulation to the pipework separately.

(liquid, suction and discharge).

• Use thermal heat insulation which can withstand

temperatures of 120°C or more.

CAUTION

• Upon completion of the pipework connections fit

the piping/wiring panel and the pipe cover.

Gaps between the pipes and the cover are to be

filled using a suitable putty or silicone.

• If the pipework is fitted in the downward or

sideways position, ensure that the base plate

and side plate are closed and sealed.

• If an opening is left unsealed there is a risk of a

fault due to the entering of water or dust.

Grooves

for driver

Closed completely Opened fully

*1. When opened fully, do not apply an excessive

torque after the screwdriver hit the stopper;

otherwise a trouble may be caused on the valve.

19

Page 23

4

ELECTRIC WIRING

WARNING

Electrical work must be performed by a qualified electrician in accordance with the installation manual.

Ensure the air conditioner uses a designated power supply.

An insufficient power supply capacity or inappropriate installation may cause a fire.

When connecting the installation wiring, be sure that all fixing terminal are securely fixed.

Ensure earthling practice is correctly performed.

Grounding is necessary, if earthling practice is incomplete an electric shock maybe caused.

CAUTION

The installation fuse must be used for the power supply line of this outdoor unit.

Incorrect/incomplete wiring might cause an electrical fire or smoke.

Prepare the exclusive power supply for the outdoor unit.

Ensure an electrical leakage breaker is fitted. This is to prevent the risk of electric shock.

To Disconnect the Appliance from Main Power Supply.

This appliance must be connected to a main power supply by means of a switch with a contact separation of at

least 3 mm.

REQUIREMENT

• Perform wiring of the power supply in conformance with the regulations of the local authorities.

• For wiring of the power supply in the indoor unit, refer to the Installation Manual of the relevant indoor unit.

• Never connect 220–240V to the terminal block (U1, U2, U3, U4). (Fault will be caused.)

• Arrange the electrical wiring so that they do not come into contact with high-temperature parts of the pipework;

this is to prevent the risk of insulation melting and causing a possible accident.

• After connecting wires to the terminal block, secure wiring with cable clamp.

• Install control wiring and refrigerant piping within the same line.

• Do not turn on power of the indoor unit until vacuuming of the refrigerant pipe has finished.

• For cabling of the power supply of the indoor units cabling between indoor and outdoor units, refer to the

Installation Manual of the indoor unit.

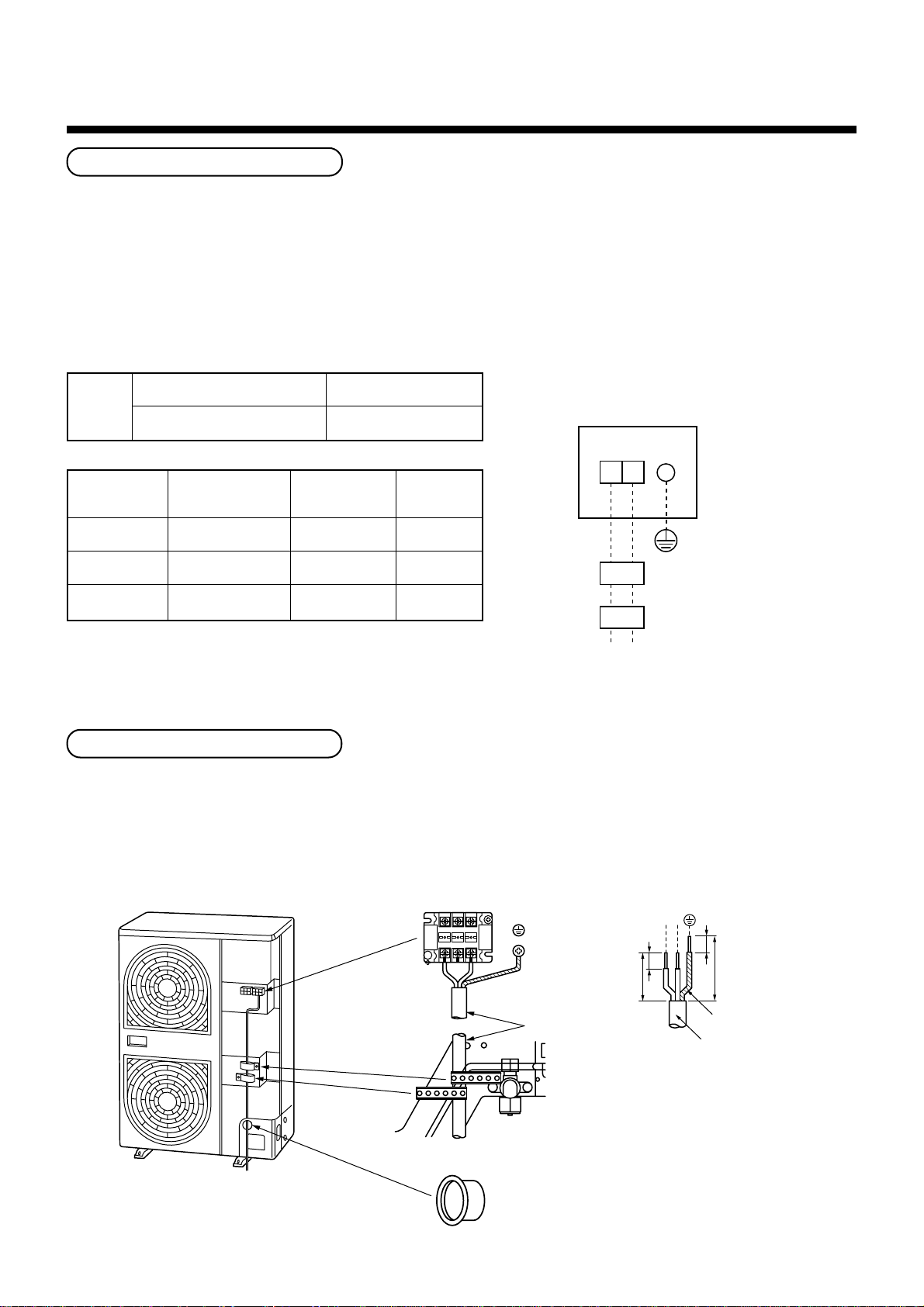

Connection of power supply wire with control wire

Insert power supply wire and control wire after

removing knockout of the piping/wiring panel at front

side of the outdoor unit.

The knockout piping and the wiring hole are also

provided to the front surface, the right side, and the

rear side.

Knockout for

power supply wiring

Knockout for

control wiring and

Note :

• Be sure to separate the power supply wires and each control wire.

• Arrange the power supply wires and each control wire so that they do not contact with the bottom surface of the

outdoor unit.

• A terminal block (U3, U4 terminal blocks) for connecting an optional part “Central remote controller etc.” is

provided on the inverter unit, so be careful to miswiring.

20

refrigerant piping

Page 24

4

ELECTRIC WIRING

Power supply specifications

Select the power supply cabling and fuse of each outdoor unit from the following specifications.

• Ensure an earth leakage breaker is installed, failure to install, may result in electric shock.

• The installation fuse must be used for the power supply line of this outdoor unit.

• Be sure to use the appropriate type of overcurrent breaker (fuse) switch.

• Observe local regulation regarding wire size selection and installation.

3-core cable in conformance with Design 60245 IEC 66.

Do not connect the units looping via the terminal blocks (L, N).

Power

supply

Outdoor unit

capacity type

0401 type

0501 type

0601 type

MCY-MAP###HT series

MCY-MAP###HT2D series

Wire size*

6 mm², Max. 28 m

6 mm², Max. 25 m

6 mm², Max. 22 m

Maxim running

1N~ 50Hz 220V-240V

1N~ 60Hz 220V

current

25A

28A

31A

Installation

fuse

32A

32A

40A

* Design 60245 IEC66

(Connection example)

LN

Outdoor unit power supply

Connection of power supply

n Power supply wire

• Connect the power supply cables and earthling wire to the power supply terminal block.

Tighten the screws on the terminal block and secure the cables with the cord clamp.

(Do not apply tension to the connecting section of the terminal block.)

Earth

Outdoor unit

Over current breaker (fuse) switch

Earth leakage breaker

(Terminal block) (Stripping length power cable)

NL

Power cable

(Cord clamp)

(Protective bush : Accessory)

21

LN

10

50

10

90

Earth line

Power cable

Page 25

For Indoor unit power supply (The outdoor unit has a separate power supply.)

Item

Model

Po wer supply wiring

Wire size

All models of indoor units 2.0 mm² Max. 20m 3.5 mm² Max. 50m

Note)

• Power supply cord specification : Cable 3-core 2.5 mm², inconformity with Design 60245 IEC57.

• The connecting length indicated in the table represents the length from the pull box to the outdoor unit when the

indoor units are connected in parallel for power, as shown in the illustration below. A voltage drop of no more than

2% is also assumed. If the connecting length will exceed the length indicated in the table, select the wire

thickness in accordance with indoor wiring standards.

• Determine the wire size for indoor unit according to the number of connected indoor units downstream.

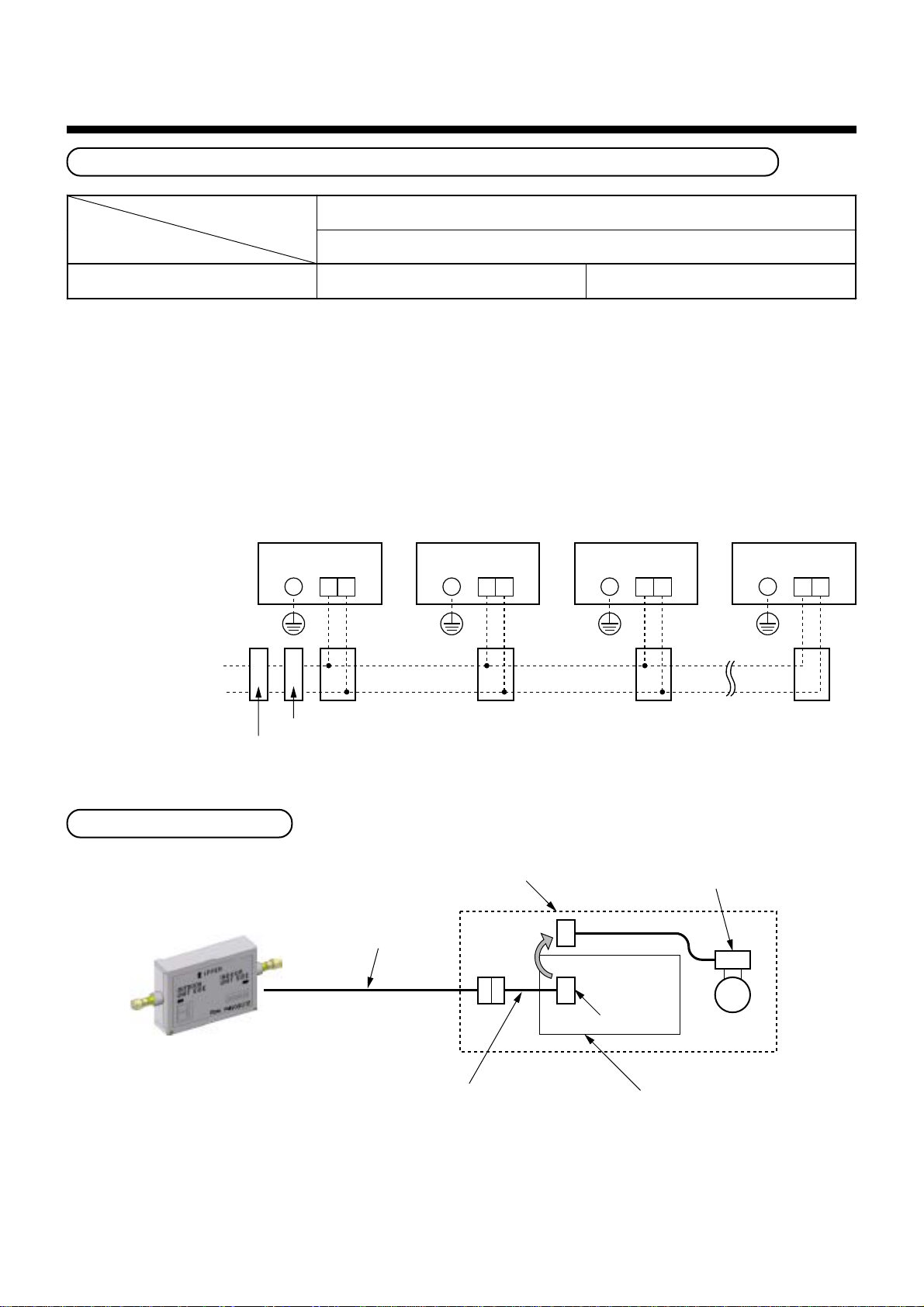

[Indoor unit]

Earth

Earth

NL

NL

Earth

NL

Earth

NL

Indoor unit power supply

1N~ 50Hz, 220 – 240V

1N~ 60Hz, 220V

Main switch

Connection of PMV Kit

PMV Kit

Connector conversion cable

(MMK-AP∗∗∗2H (High Wall) does not use a this conversion cable.)

Earth leakage breaker

Connection cable

Pull box

Indoor unit

Pulse motor valve (Indoor unit side)

PMV

CN82 connector

Indoor control P.C. board

For details of the PMV Kit, refer to the Installation Manual.

22

Page 26

4

ELECTRIC WIRING

Design of control wiring

1. All control wiring is 2-core and non-polarity wire.

2. Ensure use of shielded wiring in the following cases to prevent noise issues.

• Indoor-indoor / outdoor-indoor control wiring, Central control wiring.

Central control

device

U1U3U2

U4

Outdoor unit

Indoor unit

U3 U4

U1 U2

L1

U1 U2

A B

Table-3

Remote controller

U3 U4

U1 U2

U1 U2

A B

Mini-SMMS

L2 L3

U1 U2

A B

Table-1 Control wiring between indoor and

outdoor units (L1, L2, L3),

Central control wiring (L4)

L7

L4

U1 U2

U3 U4

A B

Header

unit

U5 U6

S-MMS

U1 U2

A B

U1 U2

A B

Table-1

L6

U1 U2

A B

(Super modular multi system)

U1 U2

Table-1

U1 U2

L7

Remote controllerRemote controller

Table-2 Control wiring between outdoor

units (L5) (S-MMS)

U1 U2

L5

A B

L6

Follower

unit

U3 U4

U5 U6

Table-2

U1 U2

A B

Wiring

Type

Size

Length

∗∗

∗1

∗∗

2-core, non-polarity

Shield wire

1.25 mm² : Up to 1000 m

2.0 mm² : Up to 2000 m

Wiring

Type

Size

Length

2-core, non-polarity

Shield wire

1.25 mm² to 2.0 mm²

Up to 100 m (L5)

Note ∗1 : Total of control wiring length for all refrigerant circuits ( L1 + L2 + L3 + L4 )

Table-3 Remote controller wiring (L6, L7)

Wire

Size

Length

2-core

0.5 mm² to 2.0 mm²

• Up to 500 m ( L6 + L7 )

• Up to 400m with of wireless remote controller in group control.

• Up to 200m total length of control wiring between indoor units ( L6 )

• Group Control through a Remote Controller

Group control of multiple indoor units (8 units) through a single remote controller

Indoor unit No.1

AB AB AB AB AB AB

No.8No.7No.4No.3No.2

Remote

controller

(A, B)

23

Page 27

Design of control wiring

• Connect each wire for controlling as shown below.

Central remote controller (Option)

U1U3U2

U4

(Open)

[Outdoor unit]

[Indoor unit]

PMV Kit

(Option)

(Open)

To other

refrigerant

system

U3 U4U2U1

Relay connector

(At shipment from factory : No connection)

Control wiring between indoor and outdoor units

Control wiring between indoor units

U2U1 U2U1 U2U1 U2U1

Indoor control

P.C. board

CN82

Relay

connector

U2U1

For control

wiring between

indoor and

outdoor

U3 U4

For wiring of

central control

system

Shield earth screw

Control wiring between indoor

and outdoor units

Connection of shield wire must be connected

(Connected to all connecting sections in each Indoor unit)

Cable clamp

• Wire specification, quantity, size of crossover wiring and remote controller wiring

Name Q’ty

Up to 500m Up to 1000m 1000 to 2000m

Control wiring

(indoor-indoor / indoor-outdoor / ou tdoor-

2 cores 1.25mm² 2.0mm² Shield wire

indoor control wiring, central control wiring)

Remote controller wi ring 2 cores 0.5 to 2. 0mm² — — —

Size

Specification

1. The crossover wiring and central control wiring use 2-core non-polarity transmission wires. Use 2-core shield

wires to prevent noise trouble. In this case, close (connect) the end of shield wires, and perform the functional

grounding for the end of the shield wires which are connected to both indoor and outdoor units.

For the shield wires which are connected between the central remote controller and the

outdoor unit, perform the functional grounding at only one end of central control wiring.

2. Use 2-core and non-polarity wire for remote controller. (A, B terminals)

Use 2-core and non-polarity wire for wiring of group control. (A, B terminals)

24

Page 28

4

ELECTRIC WIRING

n Example of system wiring design

Outdoor power supply

MCY-MAP###HT series : 1N~ 50Hz, 220 – 240V

MCY-MAP###HT2D series : 1N~ 60Hz, 220V

6

5

1

Earth

[Outdoor unit]

Central remote controller power supply

1N~ 50Hz, 220 – 240V

1N~ 60Hz, 220V

4

LN

U1U2

U3U4

U2U1 U3 U4LN

(Option)

Earth

Relay connector (As shipment from factory : No connection)

Communication wiring between indoor and outdoor units

Communication wiring between indoor units

Outdoor unit

1

Indoor unit

2

Remote controller

3

Central remote controller (Option)

4

Over current breaker (Fuse) switch

5

Earth leakage breaker

6

Main switch

7

Pull box

8

PMV Kit (Option)

9

Connection of shield wire must be connected

(Connected to all connecting sections in each Indoor unit)

[Indoor unit]

PMV Kit

(Option)

9

2

Indoor control

P.C. board

CN82

Earth

67

U2U1 A B

NL

3

BA

8

2

Earth

8

U2U1 A B

NL

3

2

U2U1 A B

Earth

NL

BA

3

BA

Remote controller

[Group control]

8

2

U2U1 A B

Earth

NL

CAUTION

1. Keep the refrigerant piping system and the indoor-indoor/indoor-outdoor control wiring systems together.

2. When running power supplies and control wires parallel to each other, run them through separate conduits or

maintain a suitable distance between them.

(Current capacity of power wires: 10A or less for 300mm, 50A or less for 500mm)

25

Page 29

5

When using the outdoor unit under the following conditions, it is necessary to set up DIP switch on the outdoor unit

interface P.C. board.

INSTALLATION OF OUTDOOR UNIT

CAUTION

When anyone of the following condition is applied, set up DIP switch.

1. When using PMV Kit in the Mini-SMMS system

2. When using the indoor unit under high humidity condition

[Reference]

Indoor side: 27°C dry bulb temperature

24°C wet bulb temperature

Operation time 4 hours or more.

Setup method

• Turn on DIP switch [SW08] on the interface P.C. board of the outdoor unit.

Outdoor unit interface P.C. board

SW11

1ON2 3 4

SW06

1ON2 3 4

SW12

1ON2 3 4

SW07

ON ONON ON

1

2 3 4

1ON2 3 4

Switch [SW08]

SW13

11 2 3 4

SW09SW08

SW14

1ON2 3 4

SW10

1 2 3 4

26

Page 30

6

ADDRESS SETUP

In this air conditioner, it is necessary to set up the indoor address before starting the operation. Set

up the address in the following procedure.

CAUTION

1. Set up the address after the wiring work has been completed.

2. Be sure to turn on the power in order of indoor unit → outdoor unit. If turning on the power in the reverse

order, a check code [E19] is displayed. When a check code is displayed, turn on the power again.

3. It requires a maximum of 10 minutes (Usually, approx. 5 minutes) to automatically set-up an address for 1

system.

4. To set up an address automatically, the set-up of the outdoor unit needs to be completed.

(Address setup cannot be performed by power-ON only.)

5. To set up an address, the air conditioner does not need to be in operation.

6. Manual address setup is also available besides automatic setup.

Automatic address : Setup from SW15 on the interface P.C. board of the outdoor unit

Manual address : Setup from the wired remote controller

* It is temporarily necessary to set-up the indoor unit as a 1:1 using a wired remote controller.

Automatic Address Setup

Without central control : To the address setup procedure 1

With central control : To the address setup procedure 2

(However, go to the procedure 1 when the central control is performed in a single refrigerant system.)

(Example)

Address setup procedure

Wire systematic diagram

In case of central control in a single refrigerant system

To procedure 1

Outdoor

Indoor Indoor

Remote

controller

Central remote

controller

Remote

controller

Outdoor

Indoor Indoor

Remote

controller

Central remote

controller

Address setup procedure 1

Turn on power of indoor/outdoor units.

(In order of indoor

After approx. 1 minute, check that U. 1. L08 (U. 1. flash)

is displayed in 7-segment display section on the interface

P.C. board of the outdoor unit.

Push SW15 and start setup the automatic address.

(Max. 10 minutes for 1 line (Usually, approx. 5 minutes))

When the count Auto 1 → Auto 2 → Auto 3 is displayed in

7-segment display section, and it changes from

U. 1. - - - (U. 1. flash) to

U. 1. - - - (U. 1. light) , the setup finished.

When perform a central control, connect a relay

connector between [U1U2] of the outdoor unit and

[U3U4] terminals.

→→

→ Outdoor)

→→

In case of central control over refrigerant system

To procedure 2

Outdoor

Indoor Indoor

Remote

controller

Remote

controller

Outdoor

Indoor Indoor

Remote

controller

Central remote

controller

Interface P.C. board

SW04

SW05 SW15

D600 D601 D602 D603 D604

SW01

SW02 SW03

1

1 1

5

Relay connector

U2U1

For control

wiring between

indoor and

outdoor

3

2 4

U3 U4

For wiring of

central control

system

27

Page 31

REQUIREMENT

(Example)

• When a group control is performed over multiple

refrigerant systems, be sure to turn on the power

supplies to all of the indoor units connected , so that

the address set-up can be completed correctly.

Wire

systematic

diagram

• If turning on the power for each refrigerant system

to set up the addresses, a header indoor unit must

be set for each system. Therefore, an alarm code

“L03” (Duplicated header indoor units) will be

displayed during in operation after the address

setup has been completed. In this case, change the

group address using the wired remote controller so

that only one header indoor unit is set-up.

Address setup procedure 2

Using SW13 and 14 on the interface P.C. board on the outdoor

unit in each system, set up the system address for each system.

(At shipment the address is set to 1 from the factory)

Note) Be careful not to duplicate with any other refrigerant systems

or other line (system) addresses.

Group control over

multiple refrigerant system

Outdoor

IndoorIndoor

Remote

controller

Interface P.C. board

ON

1

2 3 4

SW11

1ON2 3 4

SW06

1ON2 3 4

SW12

ON ONON ON

1

2 3 4

SW07

Outdoor

Indoor Indoor

1ON2 3 4

SW13

11 2 3 4

1ON2 3 4

SW09SW08

SW14

1 2 3 4

SW10

Line (System) address switch on outdoor interface P.C. board (

Line

address

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SW13 SW14

12341234

ЧЧЧЧЧ

Ч

ЧЧ

Ч

ЧЧЧ

Ч

ЧЧ

Ч

ЧЧЧЧ

Ч

ЧЧ

Ч

ЧЧЧ

Ч

×××

¡

××

¡

¡¡

¡

¡¡¡

¡

¡¡

¡

××

¡

×

¡

¡¡

××

×

¡

×

¡¡

×

¡¡

×

×

×

×

¡

¡

¡

¡

Line

address

15

16

17

18

19

20

21

22

23

24

25

26

27

28

12341234

: Switch ON, × : Switch OFF)

¡

SW13 SW14

××

×

¡

¡¡

¡

¡¡¡

¡

¡¡

¡

¡¡¡¡

¡

¡¡

¡

¡¡¡

¡¡¡

¡¡¡¡

××××

×××

×

¡

××

×

×

¡¡

×××

××

×

¡

: Is not used for setup of line address. (Do not change setup.)

Check that the relay connectors between [U1U2] and [U3U4] terminals are come out in all outdoor units to which

the central control is connected. (At shipment from factory: No connection of connector)

Turn on power of indoor/outdoor.

(In order of indoor

After approx. 1 minute, check that 7-segment display is

→→

→ outdoor)

→→

U.1.L08 (U.1. flash) on the interface P.C. board.

Push SW15 and start setup the automatic address.

(Max. 10 minutes for 1 line (Usually, approx. 5 minutes))

When the count Auto 1 → Auto 2 → Auto 3 is displayed in

7-segment display section, and it changes from

U. 1. - - - (U. 1. flash) to U. 1. - - - (U. 1. light) , the setup

finished.

Procedure to are repeated in other refrigerant systems.

2

Relay connector

For control

wiring between

indoor and

outdoor

U2U1

U3 U4

For wiring of

central control

system

××

××

×

¡

×

¡

×

×

¡

¡

×

¡

×

¡

28

Page 32

6

ADDRESS SETUP

When address setup has finished in all the systems, turn

off SW30-2 on the interface P.C. boards of the lines

connected to the identical central control except a line

with least line address number.