Toshiba MCY-MAP0401HT, MCY-MAP0601HT, MCY-MAP0501HT SERVICE MANUAL

FILE NO : A06-007

Quick reference

R410A

Refrigerant Piping

01

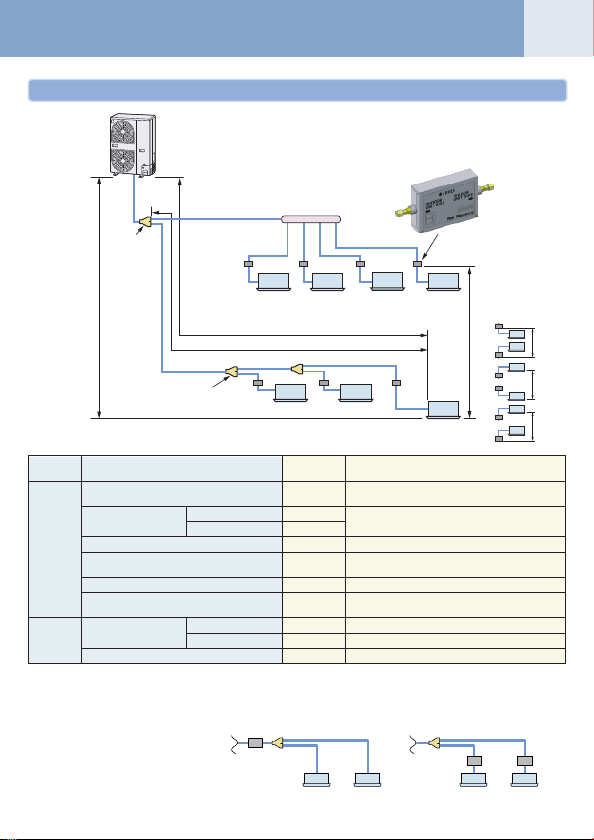

Allowable length/height difference of refrigerant piping

Outdoor unit

Main pipe

L1

Branch header

abcd

L4

ef

Height difference

between indoor and

outdoor units

H1

1st branching

section

Branching pipe

L3

Branching pipe L2

Equivalent length corresponded to farthest piping L

Equivalent length corresponded to farthest piping after 1st branching Li

Y-shape

branch joint

Indoor unit

Height difference

between indoor units

H2

g

*1

A

Total extension of pipe (Liquid pipe, real length)

Furthest piping length

L (*1)

Piping

Length

Max. equivalent length of main pipe

Equivalent length of furthest piping from

1st branching Li (*1)

Max. real length of indoor unit connecting pipe

Height between indoor

and outdoor units H1

Height

Difference

Height between indoor units H2

Real length

Equivalent length

Upper outdoor unit

Lower outdoor unit

*1 : Furthest indoor unit from 1st branch to be named “A”.

Allowable value

180 m

100 m

125 m

65 m

35 m

15 m

30 m

20 m

15 m

Piping section

L1 + L2 + L3 + L4 + a + b + c + d + e + f + g

L1 + L3 + L4 + g

L1

L3 + L4 + g

a, b, c, d, e, f. g

———

———

———

Allowable length/height difference of refrigerant piping for quiet places (with PMV Kit)

PMV Kit

Indoor unit Indoor unit

PMV Kit

NO GOOD OK

Outdoor unit

Main pipe

Height difference

between indoor

and outdoor units

H1

L1

1st branching

section

Branching pipe

L3

Branching pipe L2

Equivalent length corresponded to farthest piping L

Equivalent length corresponded to farthest piping after 1st branching Li

Y-shape

branch joint

Branch header

A

PMV Kit

*1

ab

cd

hi jk

Indoor unit

L4

e

f

lm

g

n

Height difference

between indoor unit

and PMV Kit

*

H2

* Between highest unit

and lower units.

Example)

H2

H2

H2

02

Total extension of pipe

(Liquid pipe, real length)

Furthest piping length

L (*1)

Piping

Max. equivalent length of main pipe

Length

Equivalent length of furthest piping from

1st branching Li (*1)

Max. real length of indoor unit connecting pipe

Real length

Equivalent length

Real length between PMV KIT and indoor unit

Height between indoor

Height

and outdoor units H1

Difference

Height between indoor unit and PMV kit H2

Upper outdoor unit

Lower outdoor unit

*1 : Furthest indoor unit from 1st branch to be named “A”.

Note)

Do not connect two or more indoor units

to one PMV Kit. Arrange one indoor unit

and one PMV Kit set to 1 by 1.

Allowable

value

150 m

65 m

80 m

50 m

15 m

15 m

2 m or more

below 10 m

30 m

20 m

15 m

Piping section

+ a + b + c + d + e + f + g + h + I + j + k+ l + m + n

L1 + L2 + L3 + L4

L1 + L3 + L4 + g + n

L1

L3 + L4 + g + n

a + h, b + i, c + j, d + k, e + l, f + m. g + n

h, i, j, k, l, m, n

———

———

———

Continued

03

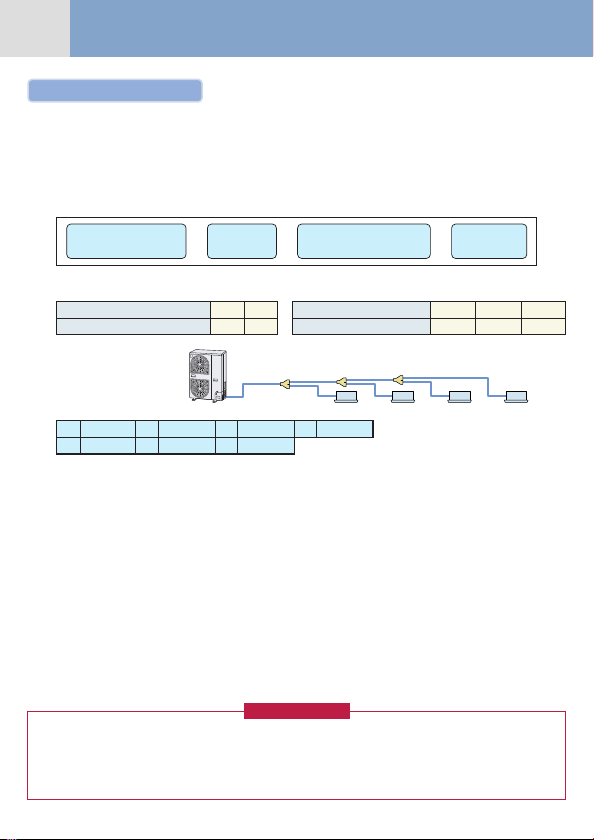

Addition of refrigerant

After vacuuming work, exchange the vacuum pump with the refrigerant bomb and then start the additional charging work

of refrigerant.

Calculating the amount of additional refrigerant required

When the system is charged with refrigerant at the factory, the amount of refrigerant needed for the pipes on site is not

included. Calculate the additional amount required, and add that amount to the system.

Additional refrigerant charge amount is calculated from size of liquid pipe at site and its real length.

Additional

refrigerant charge

amount at site

R (kg)

of liquid pipe

Real length

=× +

Additional refrigerant charge

amount per liquid pipe 1m

(Table 1)

Compensation

by outdoor HP

(Table 2)

Table 1

Pipe dia. at liquid side

Additional refrigerant amount/1m (kg)

Ø6.4 Ø9.5

0.025 0.055

Table 2

Outdoor unit capacity type

Compensation by outdoor HP (kg)

0401 type 0501 type 0601 type

–0.8 –0.4 0

Example : (0501 type)

L3

L2

L1

a

bcd

L1 Ø9.5 : 10m L2 Ø9.5 : 10m L3 Ø9.5 : 5m a Ø9.5 : 3m

b Ø6.4 : 3m c Ø6.4 : 4m d Ø6.4 : 5m

Additional charge amount R (kg)

= (Lx × 0.025kg/m) + (Ly × 0.055kg/m) + (–0.4kg)

= (12 × 0.025kg) + (28 × 0.055kg) + (–0.4kg)

= 1.44kg

Note)

If the additional refrigerant amount indicates a negative result from the calculation, use air conditioner without the

adding of any additional refrigerant.

Charging of refrigerant

•Keeping valve of the outdoor unit closed, be sure to charge the liquid refrigerant into service port at liquid side.

• If the specified amount of refrigerant cannot be charged, open fully valves of outdoor unit at liquid and discharge/suction

gas sides, operate the air conditioner in COOL mode under condition that valve at suction gas side is a little returned to

close side, and then charge refrigerant into service port at suction gas side. In this time, choke the refrigerant slightly by

operating valve of the bomb to charge liquid refrigerant. The liquid refrigerant may be charged suddenly, therefore be

sure to charge refrigerant gradually.

•When refrigerant leaks and refrigerant shortage occurs in the system, recover the refrigerant in the system and recharge refrigerant newly up to the correct level.

Lx : Real total length of liquid pipe Ø6.4 (m)

Ly : Real total length of liquid pipe Ø9.5 (m)

REQUIREMENT

Entry of refrigerant charge amount

• Complete the refrigerant record column found on the wiring diagram, with detail of the additional refrigerant amount

and name of service engineer at the time of installation.

• The total amount of refrigerant refers to the shipment charge plus any additional refrigerant at the time of installation.

The refrigerant amount at shipment is indicated on the unit name plate.

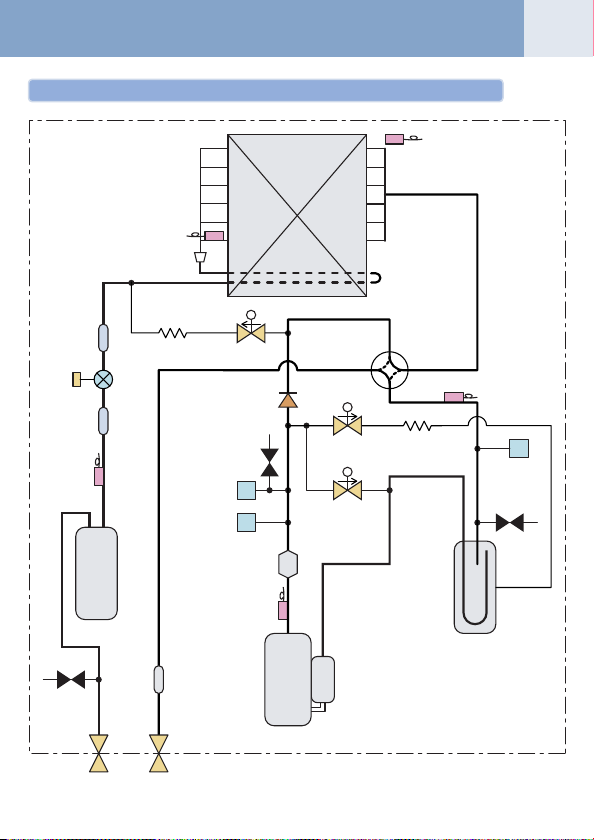

Refrigerant Cycle Diagram

Model : MCY-MAP0401/0501/0601HT, MCY-MAP0401/0501/0601HT2D

04

Outdoor unit

Strainer

PMV

Strainer

Sensor (TL)

Liquid tank

Check joint

Sensor (TE)

Capillary

tube 2

High-pressure

sensor

High-pressure

switch

Strainer

Solenoid valve

(SV5)

Check valve

Check joint

Sensor (TD)

Heat exchanger

Muffler

4-way valve

Solenoid valve

(SV2)

Solenoid valve

(SV4)

Capillary

tube 1

Sensor (TO)

Sensor (TS)

Accumulator

Low-pressure

sensor

Check joint

Liquid side

packed valve

Gas side

ball valve

Compressor (Inverter)

Continued

05

Explanation of Functional Parts

Functional part name

Solenoid valve SV2

SV4

SV5

Capillary tube 1

4-way valve

PMV (Pulse motor valve)

Temp. sensor TD

High-pressure sensor

Low-pressure sensor

Compressor case heater

Accumulator case heater

Functional outline

1) Low-pressure release function

2) High-pressure release function

3) Gas balance function during off time

4) Hot gas bypass into accumulator

1) High-pressure release function

2) Low-pressure release function

1) Preventive function for high-pressure rising in heating operation

ID : Ø1.5, Length : 200 mm

2

ID : Ø2.2, Length : 100 mm

1) Cooling/heating exchange

2) Reverse defrost

1) Super heat control function

2) Sub-cool adjustment function in cooling operation

1) Protection of compressor discharge temp. Used for release

TS

1) Controls super heat in heating operation

TE

1) Controls defrost in heating operation

2) Controls outdoor fan in heating operation

TL

1) Detects under cool in cooling operation

TO

1) Detects outside temperature

1) Detects high-pressure and controls compressor capacity

2) Detects high-pressure in cooling operation and controls the fan in low

ambient cooling operation

1) Detects low-pressure in cooling operation and controls compressor capacity

2) Detects low-pressure in heating operation and controls the super heat

1) Prevents liquid accumulation to compressor

1) Prevents liquid accumulation to accumulator

Connector

CN312 (White)

CN311 (Blue)

CN310 (White)

CN317 (Blue)

CN300 (White)

CN502 (White)

CN504 (White)

CN505 (Green)

CN521 (White)

CN507 (Yellow)

CN501 (Red)

CN500 (White)

CN316 (White)

CN321 (Red)

06

Wired

remote

controller

display

Communication error between indoor and remote controller

E01

(Detected at remote controller side)

E02 Remote controller sending error

Communication error between indoor and remote controller

E03

(Detected at indoor side)

Indoor/outdoor communication circuit error

E04

(Detected at indoor side)

E06 Decreased number of indoor units

Indoor/outdoor communication circuit error

—

(Detected at outdoor side) [E07]

E08 Duplicated indoor addresses

E09 Duplicated master remote controllers

E10 Communication error between indoor P. C. board assembly

E12 Automatic address start error

E15 No corresponding indoor unit during automatic address

E16 No. of connected indoor units / Capacity over

E18

Communication error between indoor header and follower units

E19 Outdoor unit quantity error

E20 Other line unit connected during automatic address

E23 Communication sending error

E25 Duplicated outdoor follower address setup

E31 IPDU communication error

F01 Indoor TCJ sensor error

F02 Indoor TC2 sensor error

F03 Indoor TC1 sensor error

F04 TD1 sensor error

F06 TE1 sensor error

F07 TL sensor error

F08 TO sensor error

F10 Indoor TA sensor error

F12 TS1 sensor error

F13 TH sensor error

F15 Outdoor temp sensor miscabling (TE1, TL)

F16 Outdoor pressure sensor miscabling (Pd, Ps)

F23 Ps sensor error

F24 Pd sensor error

F29 Indoor other error

F31 Outdoor EEPROM error

H01 Compressor breakdown

H02 Compressor error (lock)

Check code name

Wired

remote

controller

display

H03 Current detection circuit system error

H04 Compressor 1 case thermo operation

H06 Low-pressure protective operation

L03 Duplicated indoor center units

L04 Duplicated outdoor line address

Duplicated indoor units with priority

L05

(Displayed on indoor unit with priority)

Duplicated indoor units with priority

L06

(Displayed on the unit other than indoor unit with priority)

L07 Group line in individual indoor unit.

L08 Indoor group / address unset

L09 Indoor capacity unset

L10 Outdoor capacity unset

L20 Duplicated central control addresses

L29 IPDU quantity error

L30 Interlock in indoor unit from outside

Extended IC (Integrated Circuit) error

—

(Detected at outdoor unit side) [L31]

P01 Indoor fan motor error

P03 Discharge temp TD1 error

P04 Actuation of high-pressure SW

P07 Heat sink overheat error

P10 Indoor overflow error

P12 Indoor fan motor error

The standard ducted unit air conditioner utilizes a direct current

(DC) indoor fan motor that features current limiting protection.

In the event power is not isolated prior to service, the protective

control circuit will activate and stop the unit operating.

The check code “P12”will be displayed on the remote controlleronce service work has been completed, this code can be cleared

by switching off then on the electrical isolation device of the indoor

unit and pressing the operation stop button on the remote

controller to reset the system.

P13 Outdoor liquid back detection error

Gas leak detection (TS1 condition)

P15

Gas leak detection (TD condition)

P17 Discharge temp TD2 error

P19 4-way valve operation error

P20 High-pressure protective operation

P22 Outdoor fan IPDU error

P26 G-Tr short-circuit protection error

P29 Compressor position detection circuit error

P31 Other indoor error (Group follower unit error)

Check code name

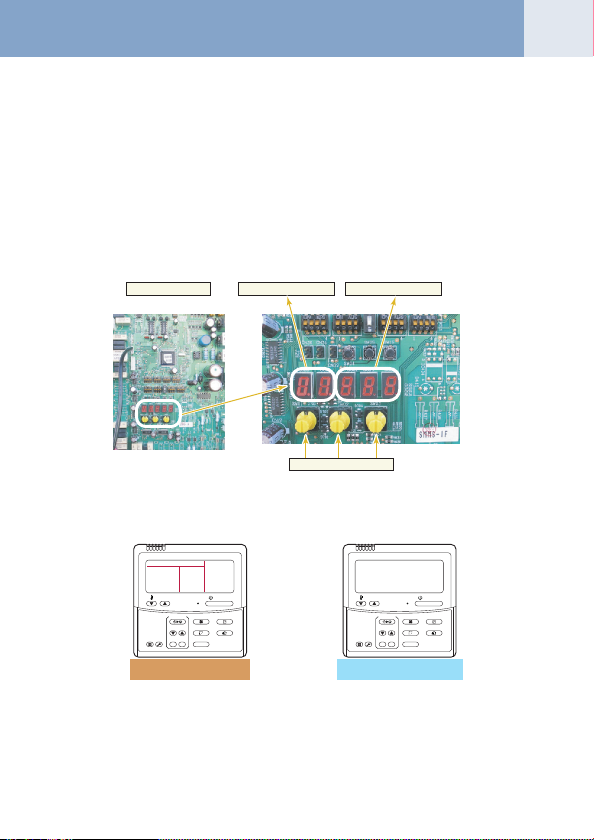

Switch (SW08) Set Up of The Outdoor Unit

07

When using the outdoor unit under the following conditions, it is necessary to set up DIP switch on the outdoor unit

interface P. C. board.

Cautions

When anyone of the following condition is applied, set up DIP switch.

1. When using PMV Kit in the Mini-SMMS system

2. When using the indoor unit under high humidity condition

[Reference]

Indoor side : 27°C dry bulb temperature

1 Setup method

•Turn on DIP switch [SW08] on the interface P. C. board of the outdoor unit.

24°C wet bulb temperature

Operation time 4 hours or more.

SW11

1ON2 3 4

SW06

1ON2 3 4

Outdoor unit interface P.C. board

SW12

SW13

1ON2 3 4

1ON2 3 4

SW07

ON ONON ON

1

2 3 4

Switch [SW08]

SW14

1ON2 3 4

SW09SW08

11 2 3 4

SW10

1 2 3 4

Check at Main Power-ON

After turning on the main power of the indoor units and outdoor unit in the refrigerant line to be executed with a test

operation, check the following items in outdoor and each indoor unit.

(After turning on the main power, be sure to check in order of indoor unit

If the power supply of the outdoor unit has been firstly turned on, [E19] appears on the 7-segment display on the interface

P. C. board until the power supply of the indoor unit is turned on. However it is not an error.

<Check on outdoor unit>

1. Check that all the rotary switches, SW01, SW02, and SW03 on the interface P. C. board of the outdoor unit are set up

to “1”.

2. If other error code is displayed on 7-segment [B], remove the cause of trouble referring to “ Troubleshooting”.

3. Check that [L08] is displayed on 7-segment display [B] on the interface P.C. board of the outdoor unit.

(L08: Indoor address unset up)

(If the address setup operation has already finished in service time, etc, the above check code is not displayed, and

only [U1] is displayed on 7-segment display [A].)

Interface P. C. board

7-segment display [A] 7-segment display [B]

®®

® outdoor unit.)

®®

08

SW01 SW02 SW03

<Check on indoor unit>

1. Display check on remote controller (In case of wired remote controller)

Check that a frame as shown in the following left figure is displayed on LC display section of the remote controller.

GOOD

TEMP.

ON / OFF

FAN

MODE

TIMER SET

SWING/FIXTIME

UNITSET CL

Normal status

VENT

FILTER

TEST

RESET

(Power and operation stop)

If a frame is not displayed as shown in the above right figure, the power of the remote controller is not normally turned on.

Therefore check the following items.

• Check power supply of indoor unit.

• Check wiring between indoor unit and remote controller.

• Check whether there is cutoff of cable around the indoor control P. C. board or not, and check connection failure of

connectors.

• Check failure of transformer for the indoor microcomputer.

• Check indoor control P. C. board failure.

NO

GOOD

(Power is not normally turned on.)

TEMP.

TIMER SET

FILTER

TEST

RESET

Abnormal status

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

Address Setup

09

After power-ON, set up the indoor address from the interface P. C. board of the outdoor unit.

(The address setup operation cannot be performed by power-ON only.)

Cautions

1. It requires approx. 5 minutes usually for 1 line to automatically set up address.

However in some cases, it may require maximum 10 minutes.

2. It is unnecessary to operate the air conditioner for address setup.

3. Manual address setup is also available besides automatic setup.

Automatic address: Setup from SW15 on the interface P.C. board of the outdoor unit

Manual address: Setup from the wired remote controller.

(For details, refer to section “Address setup procedure”)

Address Setup and Check Procedure

Procedure

1

2

3

4

5

6

Item

Indoor unit power-ON

Outdoor unit power-ON

7-segment display check

Address setup start

Display check after

setup

System information

check after setup

Turn on power of indoor unit in refrigerant line to which address is set up.

Turn on power of all the outdoor units in refrigerant line to which address is set up.

Check that [L08] is displayed on 7-segment display [B] on the interface P. C. board of the outdoor

unit in the system to which address is set up.

Confirm the corresponding items in “Address setup procedure”, and then set up address

according to the operation procedure.

(Be sure that the setup operation may differ in group control or central control.)

Note) Address cannot be set up if switches are not operated.

• After address setup, [U1] [ ] are displayed in 7-segment display section.

• If an error code is displayed in 7-segment display [B], remove the cause of trouble referring to

“Troubleshooting”.

Using 7-segment display function, check the system information of the scheduled system.

(This check is executed on the interface P.C. board of the outdoor unit.)

System capacity

No. of connected outdoor unit

No. of connected indoor units

After the above checks, return rotary switches SW01, SW02, SW03 to 1/1/1.

Operation and check contents

Rotary switch setup

SW01 SW02 SW03

123

133

143

[Connected No. of units] [

[Connected No. of units]

7-segment display

[A] [B]

[No. of HP] [HP]

P]

Interface P. C. board

7-segment

display [A]

Push-switch

SW04

SW01 SW02

Rotary switches

Push-switch

SW05

SW03

Push-switch

SW15

7-segment

display [B]

Loading...

Loading...