Page 1

NETWORK GATEWAY SERIES

ICC

INDUSTRIAL CONTROL COMMUNICATIONS, INC.

MBP-100

MODBUS PLUS

MULTIPROTOCOL NETWORK GATEWAY

August 2008

ICC #10498-3.100-001

Page 2

Introduction

Thank you for purchasing the ICC MBP-100 Modbus Plus Multiprotocol

Network Gateway. The MBP-100 allows information to be transferred

seamlessly among many different fieldbus networks with minimal configuration

requirements. The MBP-100 provides one Modbus Plus port, one RS485 port,

one RS232 port, and three common serial ports for direct connectivity to

Toshiba 7-series, 9-series, 11-series or VF-nC1 Adjustable Speed Drives

(ASDs). These various communication ports operate independently, and are

configurable along with the unit’s internal point database via a serial console

interface.

The gateway currently provides support for the following protocols:

Modbus RTU (RS485 master & slave)

Modbus RTU (RS232 master & slave)

Toshiba ASD (common serial master)

Toshiba ASD (RS485 master)

Mitsubishi 500-series & 700-series ASD (RS485 master)

Modbus Plus (host)

New network drivers are continuously being added, and can be downloaded for

free from our web site.

Before using the MBP-100 network gateway, please familiarize yourself with the

product and be sure to thoroughly read the instructions and precautions

contained in this manual. In addition, please make sure that this instruction

manual is delivered to the end user of the MBP-100, and keep this instruction

manual in a safe place for future reference or unit inspection.

This instruction manual describes the device specifications, wiring methods,

maintenance procedures, supported functions, usage methods and firmware

update procedure for the MBP-100 network gateway.

For the latest information, support, firmware releases or product configuration

files, please visit http://www.iccd esig ns.com

Before continuing, please take a moment to ensure that you have received all

materials shipped with your kit. These items are:

• MBP-100 gateway

• 2 meter DB9-RJ45 RS232 port cable (part number 10425)

• Documentation CD-ROM

MODBUS PLUS IS A REGISTERED TRADEMARK OF SCHNEIDER ELECTRIC

.

1

Page 3

MBP-100 Modbus Plus Multiprotocol Network Gateway

User's Manual

Part Number 10498-3.100-001

Printed in U.S.A.

©2008 Industrial Control Communications, Inc.

All rights reserved

Industrial Control Communications, Inc. reserves the right to make changes

and improvements to its products without providing notice.

Notice to Users

INDUSTRIAL CONTROL COMMUNICATIONS, INC.’S PRODUCTS ARE NOT

AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE-SUPPORT

DEVICES OR SYSTEMS. Life-support devices or systems are devices or

systems intended to sustain life, and whose failure to perform, when properly

used in accordance with instructions for use provided in the labeling and user's

manual, can be reasonably expected to result in significant injury.

No complex software or hardware system is perfect. Bugs may always be

present in a system of any size. In order to prevent danger to life or property, it

is the responsibility of the system designer to incorporate redundant protective

mechanisms appropriate to the risk involved.

2

Page 4

Usage Precautions

Operating Environment

• Please use the gateway only when the ambient temperature of the

environment into which the unit is installed is within the following

specified temperature limits:

Operation

Storage

• Avoid installation locations that may be subjected to large shocks or

vibrations.

• Avoid installation locations that may be subjected to rapid changes in

temperature or humidity.

: -10 ∼ +50°C (+14 ∼ +122°F)

: -40 ∼ +85°C (-40 ∼ +185°F)

Installation and Wiring

• Proper ground connections are vital for both safety and signal reliability

reasons. Ensure that all electrical equipment is properly grounded.

• Route all communication cables separate from high-voltage or noise-

emitting cabling (such as ASD input/output power wiring).

ASD Connections

• Do not touch charged parts of the drive such as the terminal block

while the drive’s CHARGE lamp is lit. A charge will still be present in

the drive’s internal electrolytic capacitors, and therefore touching these

areas may result in an electrical shock. Always turn all drive input

power supplies OFF, and wait at least 5 minutes after the CHARGE

lamp has gone out before connecting communication cables.

• To avoid misoperation, do not connect any gateway terminals to either

the ASD’s E/GND terminals, the motor, or to any other power ground.

• When making common serial connections between the gateway and

Toshiba ASDs, do not use cables that exceed 5 meters in length.

• For further drive-specific precaution, safety and installation information,

please refer to the appropriate documentation supplied with your drive.

• Internal ASD EEPROMs have a limited life span of write cycles.

Observe all precautions contained in this manual and your ASD

manual regarding which drive registers safely may and may not be

repetitively written to.

• When used without an Auxiliary power source (Toshiba ASD common

serial mode), the gateway derives its control power from the connected

drives. Therefore, removing power to all connected drives will also

cause the gateway to lose power.

3

Page 5

TABLE OF CONTENTS

1. The Network Gateway Series Concept.......................................6

2. Mechanical Diagrams...................................................................7

2.1 Enclosure..............................................................................................7

2.2 Mounting Clip........................................................................................8

2.3 External Interface..................................................................................9

3. Feature Summary........................................................................11

4. Installing the Gateway................................................................14

4.1 RS-485 Network in Use.......................................................................14

4.2 Toshiba ASD (Common Serial) Network in Use..................................15

4.2.1 Installation for G7 ASDs..................................................................15

4.2.2 Installation for S7, S9, S11, A7 and VF-nC1 ASDs.........................17

5. RS485 Port Electrical Interfaces ...............................................19

6. Environmental Specifications ...................................................20

7. Maintenance and Inspection .....................................................21

8. Storage and Warranty ................................................................22

8.1 Storage................................................................................................22

8.2 Warranty..............................................................................................22

9. LED Indicators ............................................................................23

9.1 Toshiba ASD Common Serial Port Indicators .....................................23

9.2 RS232 (MMI) Port Indicators...............................................................23

10. Configuration Switches .........................................................24

11. Auxiliary Power Supply..........................................................25

12. Unit Configuration Concepts.................................................26

12.1 Port and Protocol Configuration..........................................................26

12.2 Timeout Configuration.........................................................................26

12.3 Point Configuration..............................................................................27

12.4 General Configuration Procedure........................................................28

13. Console Access......................................................................30

13.1 RS232.................................................................................................30

13.1.1 Requirements.............................................................................30

13.1.2 Connection .................................................................................30

4

Page 6

13.1.3 Application Configuration........................................................... 30

13.2 Invocation........................................................................................... 33

13.3 Main Menu.......................................................................................... 34

13.3.1 View/Edit Points......................................................................... 35

13.3.2 View/Edit Ports .......................................................................... 44

13.3.3 Load Points................................................................................ 46

13.3.4 Xmodem Point File..................................................................... 46

13.3.5 MBP-100 Information................................................................. 48

14. Protocol-Specific Information ...............................................49

14.1 Modbus............................................................................................... 49

14.1.1 Coil & Discrete Input Mappings.................................................. 50

14.1.2 Modbus RTU Slave.................................................................... 51

14.1.3 Modbus RTU Master.................................................................. 51

14.2 Modbus Plus....................................................................................... 53

14.3 Toshiba Common Serial ASD Protocol............................................... 54

14.4 Toshiba RS485 ASD Protocol ............................................................54

14.5 Mitsubishi ASD Protocol.....................................................................57

14.6 Teco-Westinghouse ASDs.................................................................. 61

14.6.1 MA7200 .....................................................................................61

14.6.2 PA7300......................................................................................62

15. Modicon PLC Programming Examples.................................64

15.1 Ladder Logic and MSTR Instructions.................................................. 64

15.1.1 MSTR Parameters..................................................................... 65

15.1.2 MSTR Inputs and Outputs .........................................................66

15.2 MSTR Function Error Codes .............................................................. 66

15.3 MSTR Read Example......................................................................... 66

15.4 MSTR Write Example.........................................................................67

15.5 MSTR Global Read Example.............................................................. 68

15.6 MSTR Global Write Example.............................................................. 69

16. Firmware Updates...................................................................70

16.1 Requirements..................................................................................... 70

16.2 Connection ......................................................................................... 70

16.3 Using the RFU Utility .......................................................................... 71

16.3.1 Required Files............................................................................ 71

16.3.2 First-Time Configuration ............................................................71

16.3.3 Transmitting Firmware Files....................................................... 73

16.4 Wrap-Up............................................................................................. 74

5

Page 7

1. The Network Gateway Series Concept

The MBP-100 is a member of the ICC Network Gateway Series product family.

Members of this family are designed to provide a uniform interface,

configuration and application experience. This commonality reduces the user’s

learning curve, reducing commissioning time while simplifying support. The

MBP-100 provides simultaneous support for many different communication

protocols, allowing complex interchanges of data among otherwise

incompatible networks.

The heart of the Network Gateway Series concept is an element called the

“point database”. The point database is entirely user-configurable, and

provides the mapping information that allows requests from the various

supported networks to be interpreted and stored in a common format. This

allows data to be routed from any supported network to any other supported

network.

Additionally, the point database provides the added benefit of “data mirroring”,

whereby current copies of point values (populated by a “source port”

designation) are maintained locally within the gateway itself. This greatly

reduces the request-to-response latency times on the various networks, as

requests (read or write) can be entirely serviced locally, thereby eliminating the

time required to execute a secondary transaction on a different network.

When properly configured, the gateway will become essentially “transparent” on

the networks, and the various network devices can engage in seamless dialogs

with each other.

6

Page 8

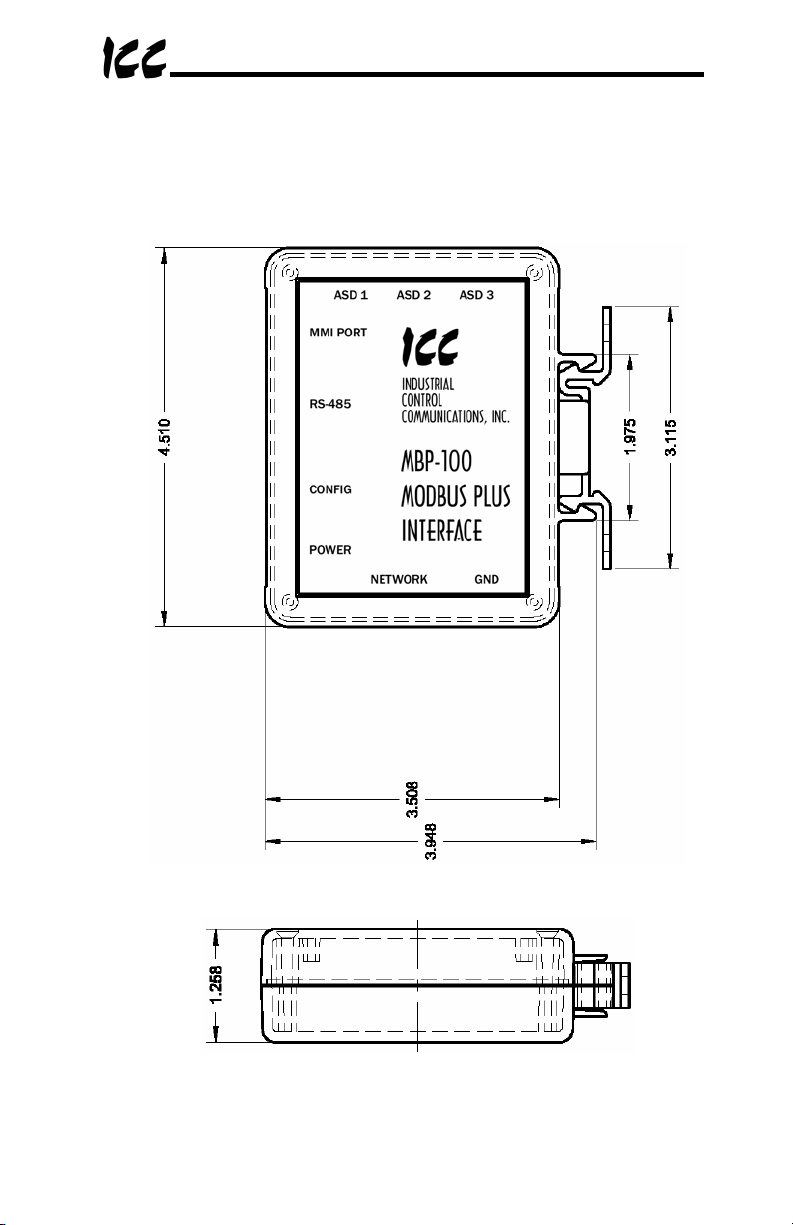

2. Mechanical Diagrams

2.1 Enclosure

Figure 1: Enclosure Dimensions (units are inches)

7

Page 9

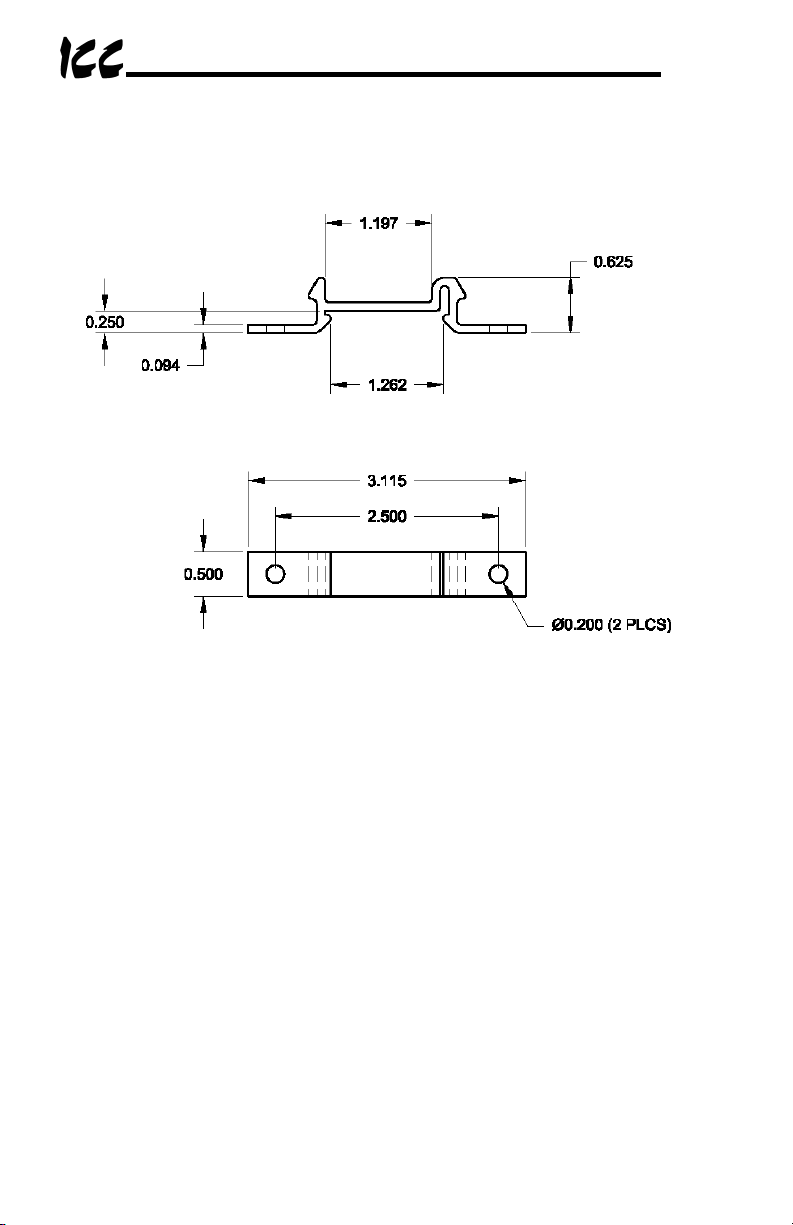

2.2 Mounting Clip

Figure 2: Mounting Clip Dimensions (units are inches)

8

Page 10

2.3 External Interface

Modbus Plus

Network

Figure 3: Bottom View

Reserved

MMI (RS232)

port

Modbus Plus

Status LED

RS485

port

Figure 4: Front View

Chassis

GND

Modbus Plus Node

Address Switches

AUX Power

9

Page 11

ASD #3

Data Write

LEDs

ASD #2

Figure 5: Top View

ASD #1

ASD Link

LEDs

10

Page 12

3. Feature Summary

Modbus Plus Port

Standard DB9 connector. Supports both standard (MSTR) read and write as

well as global data read and write instructions. Any internal data point has the

option of being mapped to the gateway’s “get” or “put” global data. “Get” global

data can be configured on a point-by-point basis to originate from any existing

device on the network, providing for powerful and efficient peer-to-peer

communication.

RS485 Port

One half-duplex 2-wire RS485 port (A / B / Signal Ground / Shield). This port

allows a selection of various master and slave protocols to be assigned to it.

RS232 Port

One RS232 port that can be used to configure the unit, update the internal

firmware, upload/download configuration files or act as a control protocol port.

Use the included DB9-to-RJ45 RS232 cable to interface with this port.

Toshiba ASD Ports

Three common serial (aka logic level) ports for connection of Toshiba 7-series,

9-series, 11-series or VF-nC1 ASDs. ASD connections use the same standard

RJ45 style 8-conductor UTP patch cables: any standard CAT5 Ethernet cable

(found in most electronics stores) 5 meters or less in length can be used. ASD

connections are automatically established and continuously monitored: no

drive configuration needs to be performed to connect the unit to the drives.

Just plug it in – it’s that simple.

Power Supply

When connected to Toshiba ASDs via the ASD1 / ASD2 / ASD3 ports, can be

either powered directly from the attached ASDs, or from the auxiliary power

(“POWER”) input jack. All other non-Toshiba applications require the use of the

“POWER” input to supply power to the unit. When more than one power source

is connected, the unit will draw its control power from the source with the

highest supply voltage.

Supported Protocols

Modbus Plus

Modbus RTU (RS485 master & slave)

Modbus RTU (RS232 master & slave)

Toshiba ASD (common serial master)

Toshiba ASD (RS485 master)

Mitsubishi 500-series & 700-series ASD (RS485 master) (also used by

MGI Technologies, Inc. ASDs)

11

Page 13

New network drivers are continuously being added, and can be downloaded for

free from our web site.

Text-Based Console Configuration

Unit configuration is performed via a text-based console interface, available

locally over the RS232 port via a standard PC terminal program such as

Microsoft Windows HyperTerminal®.

Configuration File Upload/Download

A unit’s configuration can be uploaded from / downloaded to a PC, which

provides the capability for PC-based file backup and easy configuration copying

to multiple units. Pending availability, sample configuration files and related

documentation may also be downloaded from our web site, uploaded to a unit,

and custom-modified to suit a specific application.

Network Timeout Action

A per-port and per-point 2-level configurable network timeout action can be

programmed that allows each internal point to have its own unique “fail-safe”

condition in the event of a network interruption.

Indicators

2 green LEDs exist on each of the ASD ports and on the RS232 port connector.

Refer to section 9 for more detailed information about the LED indicators and

their meanings.

Field-Upgradeable

As new firmware becomes available, the unit can be upgraded in the field by

the end-user. Refer to section 16 for more information.

Versatile 3-Way DIN-Rail Mounting System

The unit’s enclosure is provided with a mounting clip attached to the rear of the

unit. This clip allows the unit to be mounted 3 different ways:

• For DIN rail mounting, snap the mounting clip onto a standard DIN rail,

and then snap the unit enclosure onto the clip’s retaining tabs. This

allows easy removal or repositioning of the unit on the DIN rail during

wiring.

• For panel mounting, the mounting clip can be bolted directly to a flat

panel via the two bolt holes at the top and bottom of the clip. Refer to

section 2.2 for mounting clip mechanical details. Once the mounting

clip is securely attached to the panel, the unit enclosure can be

snapped onto the clip’s retaining tabs.

• For fixed DIN rail mounting, a combination of the above two

techniques can be employed. First, snap the mounting clip onto a DIN

rail and position it in its desired location. Then, the mounting clip can

be bolted to the DIN rail support panel, securing it in place. Lastly, the

unit can be snapped onto the fixed mounting clip.

12

Page 14

In all cases, the unit can be easily unsnapped from the mounting clip to

temporarily provide easier access to the chassis ground terminal or network

connector.

13

Page 15

4. Installing the Gateway

The gateway’s installation procedure will vary slightly depending on the chosen

mounting method and the networks that will be used.

4.1 RS-485 Network in Use

Note that in order to power the unit when not connecting to Toshiba ASDs via

the common serial ports, the optional 120VAC/9VDC power supply (ICC part

number 10456) or a user-supplied power source meeting the requirements

outlined in section 11 must also be installed.

1. Mount the unit via the desired method (refer to page 12 for more

information).

2. Connect the Modbus Plus network to the “NETWORK” DB9 connector. Be

sure to follow all published guidelines pertaining to Modbus Plus network

connections, layout and routing.

3. Connect the RS485 network to the pluggable terminal block. Refer to

section 5 for detailed connection information. Ensure that the terminal

block is fully seated into the terminal block header, and route the network

cable such that it is located well away from any electrical noise sources,

such as ASD input power or motor wiring. Also take care to route the

cable away from any sharp edges or positions where it may be pinched.

4. Take a moment to verify that the gateway and all network cables have

sufficient clearance from electrical noise sources such as drives, motors, or

power-carrying electrical wiring.

5. Connect the power supply to the gateway’s “POWER” jack.

14

Page 16

4.2 Toshiba ASD (Common Serial) Network in Use

The gateway connects to each drive via the drive’s common serial (logic level)

communication port, typically located on either the main drive control board

(G7, S11), on the front of the drive enclosure under a small snap-on cover (A7,

S9), on the right-hand side of the drive enclosure under a small snap-on cover

(S7), or on the bottom side of the drive enclosure (VF-nC1). Although in

general no drive parameters need to be configured in order to use the gateway,

it is advantageous to check that the drive’s common serial communication data

rate is set to its maximum speed. Because the gateway will communicate to

each drive only at the drive’s configured data rate, this will provide the fastest

response time for drive-to-network data transfers. For information on checking

the drive’s common serial communication data rate, refer to the appropriate

manual supplied with your drive.

Note that the common serial communication parameters of each drive are

handled independently by the gateway, which means that different drive

families may be connected to different channels of the unit in any combination,

and that the drives connected to each channel may simultaneously

communicate to the unit at completely different baud rates, parity settings, etc.

Drives can be connected to the gateway on any ASD channel in any order or

combination. When more than one drive is connected to the unit, or if the

optional auxiliary power supply is used, the gateway will draw its control power

from the source with the highest power supply voltage.

Installation of the gateway should only be performed by a qualified technician

familiar with the maintenance and operation of the connected drives. To install

the gateway, complete the steps outlined in the following sections related to

your specific drive.

4.2.1 Installation for G7 ASDs

1. Mount the unit via the desired method (refer to page 12 for more

information).

2.

3. DANGER! Wait at least 5 minutes for the drive’s

CAUTION! Verify that all input power sources to the drives to

be connected have been turned OFF and are locked and tagged out.

electrolytic capacitors to discharge before proceeding to the next step. Do

not touch any internal parts with power applied to the drive, or for at

least 5 minutes after power to the drive has been removed. A hazard

exists temporarily for electrical shock even if the source power has

been removed. Verify that the CHARGE LED has gone out before

continuing the installation process.

15

Page 17

4. Remove the drive’s front cover / open the drive’s cabinet door (refer to the

appropriate drive manual for instructions how to do this).

5. The drive’s LCD panel (also called the “Electronic Operator Interface” or

“EOI”) can communicate with the drive via either the RS485/RS232

channel (CNU1/CNU1A) or the common serial channel (CNU2/CNU2A).

Because the gateway uses the common serial channel, the LCD panel

must be configured to use the RS485/RS232 channel. If the drive to be

connected is currently using CNU2 (on the drive control board) and

CNU2A (on the LCD panel), then this connection must first be switched

over to CNU1 (on the drive control board) and CNU1A (on the LCD panel).

Refer to Toshiba’s documentation for any precautions or notices regarding

this connection change. If the LCD panel is already connected via the

RS485/RS232 channel, then no change is required.

6. Configure the drive’s LCD panel to communicate via the RS485/RS232

channel by setting parameter ”Communication Setting

Parameters...Communication Settings...Select LCD Port

Connection” to “RS485/232 serial”.

7. Connect the drive’s common serial communication port (CNU2) to one of

the ASD channels of the gateway with the communication cable

(communication cable is not included with the gateway kit). When

choosing cables for this connection, standard 24 AWG category 5 (CAT5)

unshielded twisted-pair (UTP) 8-conductor cables found in Ethernet

networks in most office environments can be used. The maximum

allowable length for these cables is 5 meters. Although there are many

varieties and styles of CAT5 UTP cables available, ICC strongly

recommends using only high-quality cables from reputable manufacturers

to guarantee optimal noise immunity and cable longevity. Ensure that each

end of the cable is fully seated into the modular connectors, and route the

cable such that it is located well away from any drive input power or motor

wiring. Also take care to route the cable away from any sharp edges or

positions where it may be pinched.

8. Reinstall the drive’s front cover / close the drive’s cabinet door.

9. Repeat steps 2-8 to connect other drive(s) as needed.

10. Connect the Modbus Plus network to the “NETWORK” DB9 connector. Be

sure to follow all published guidelines pertaining to Modbus Plus network

connections, layout and routing.

11. If an auxiliary power supply is going to be used, connect it to the gateway’s

“POWER” jack.

12. Take a moment to verify that the gateway and all network cables have

sufficient clearance from drives, motors, or power-carrying electrical wiring.

13. Turn the power sources to all connected drives ON, and verify that the

drives function properly. If the drives do not appear to power up, or do not

function properly, immediately turn power OFF. Repeat steps 2 and 3 to

remove all power from the drives. Then, verify all connections. Contact

16

Page 18

ICC or your local Toshiba representative for assistance if the problem

persists.

4.2.2 Installation for S7, S9, S11, A7 and VF-nC1 ASDs

1. Mount the unit via the desired method (refer to page 12 for more

information).

2.

3. DANGER! Wait at least 5 minutes for the drive’s

4. Remove the drive’s common serial communication port cover if it has one

5. Connect the drive’s common serial communication port to one of the ASD

6. Repeat steps 2-5 to connect other drive(s) as needed.

7. Connect the Modbus Plus network to the “NETWORK” DB9 connector. Be

8. If an auxiliary power supply is going to be used, connect it to the gateway’s

CAUTION! Verify that all input power sources to the drives to

be connected have been turned OFF and are locked and tagged out.

electrolytic capacitors to discharge before proceeding to the next step. Do

not touch any internal parts with power applied to the drive, or for at

least 5 minutes after power to the drive has been removed. A hazard

exists temporarily for electrical shock even if the source power has

been removed. Verify that the CHARGE LED has gone out before

continuing the installation process.

(refer to the appropriate drive manual for instructions how to do this). Do

not discard this cover, as it should be reinstalled to minimize contamination

of the port’s electrical contacts if the gateway is ever disconnected from the

drive.

channels of the gateway with the communication cable (communication

cable is not included with the gateway kit). When choosing cables for this

connection, standard 24 AWG category 5 (CAT5) unshielded twisted-pair

(UTP) 8-conductor cables found in Ethernet networks in most office

environments can be used. The maximum allowable length for these

cables is 5 meters. Although there are many varieties and styles of CAT5

UTP cables available, ICC strongly recommends using only high-quality

cables from reputable manufacturers to guarantee optimal noise immunity

and cable longevity. Ensure that each end of the cable is fully seated into

the modular connectors, and route the cable such that it is located well

away from any drive input power or motor wiring. Also take care to route

the cable away from any sharp edges or positions where it may be

pinched.

sure to follow all published guidelines pertaining to Modbus Plus network

connections, layout and routing.

“POWER” jack.

17

Page 19

9. Take a moment to verify that the gateway and all network cables have

sufficient clearance from drives, motors, or power-carrying electrical wiring.

10. Turn the power sources to all connected drives ON, and verify that the

drives function properly. If the drives do not appear to power up, or do not

function properly, immediately turn power OFF. Repeat steps 2 and 3 to

remove all power from the drives. Then, verify all connections. Contact

ICC or your local Toshiba representative for assistance if the problem

persists.

18

Page 20

A

5. RS485 Port Electrical Interfaces

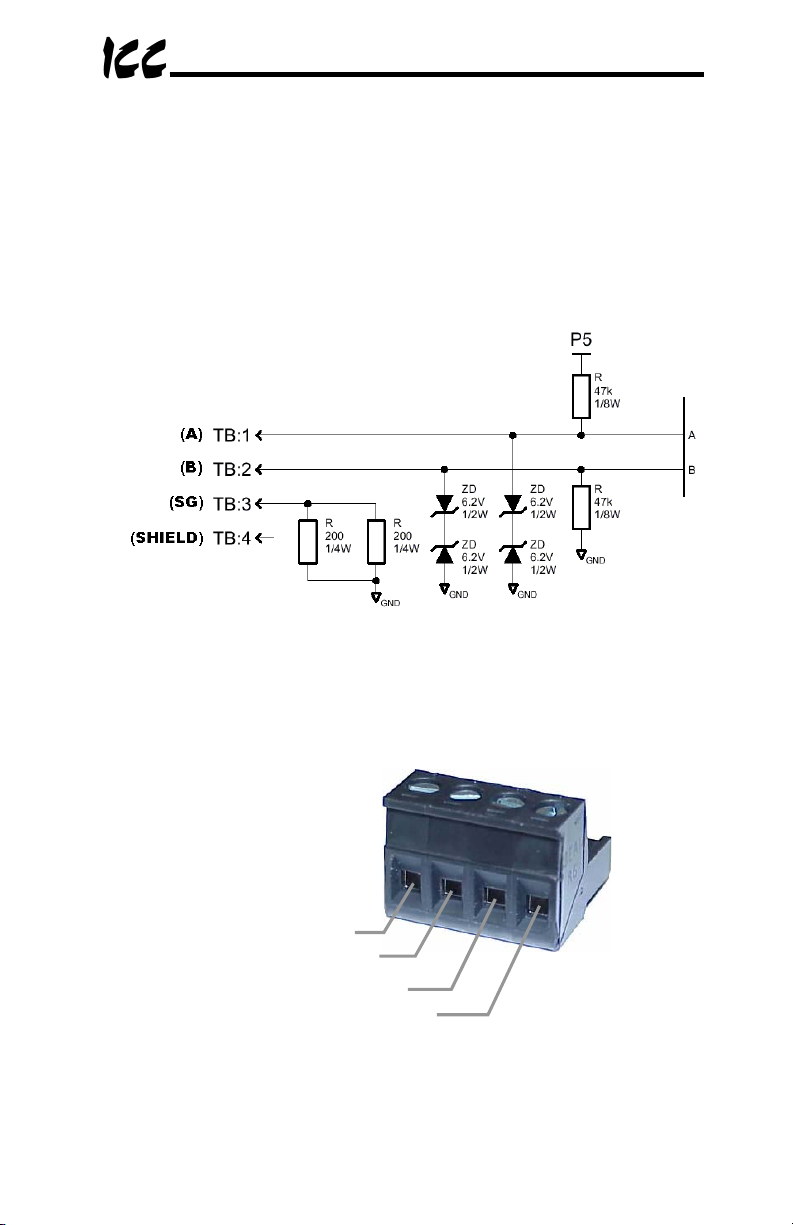

In order to ensure appropriate network conditions (signal voltage levels, etc.)

when using the gateway’s RS485 port, some knowledge of the network

interface circuitry is required. Refer to Figure 6 for a simplified network

schematic of the RS485 interface circuitry. Note that the “Shield” terminal has

no internal connection: its purpose is simply to provide a cable shield chaining

location between devices. The shield is then typically connected to ground at

one location only.

Figure 6: RS485 Interface Circuitry Schematic

Figure 7 details the specific network connections to the RS485 terminal block.

B

Signal Ground

Shield

Figure 7: RS485 Terminal Block Connections

19

Page 21

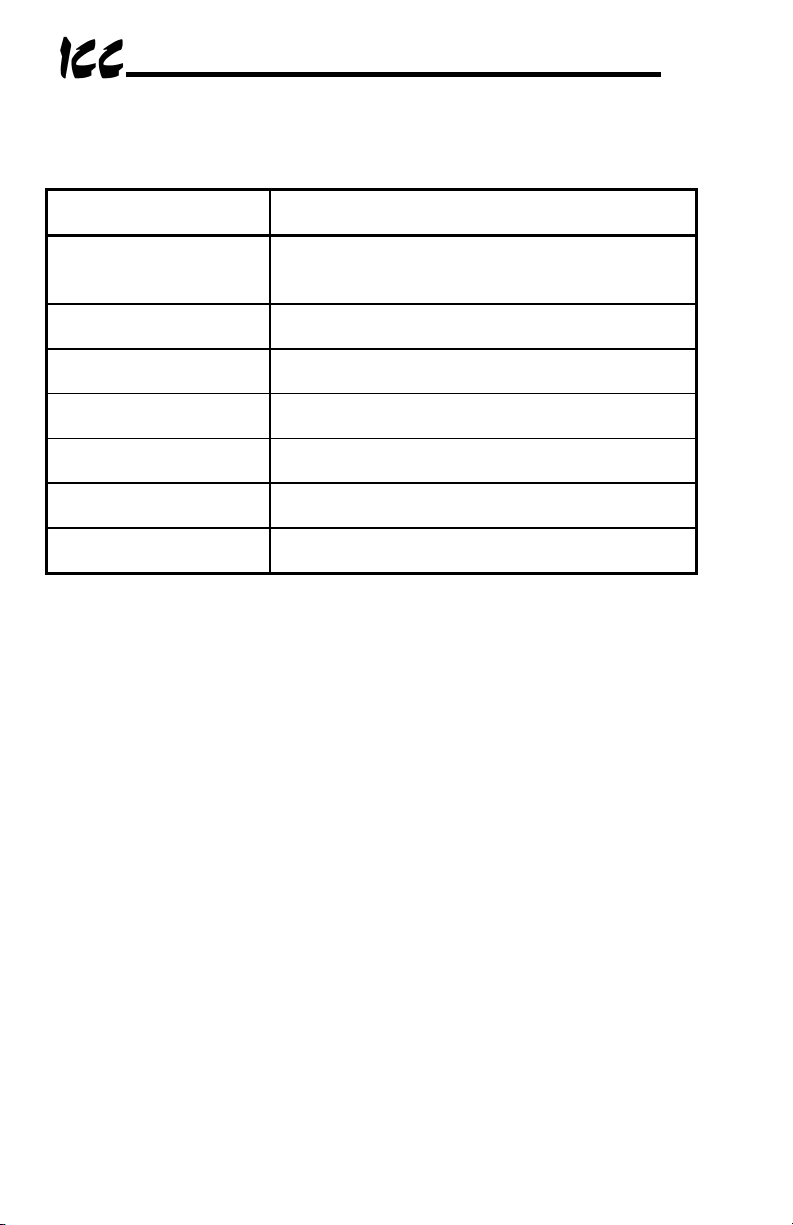

6. Environmental Specifications

Item Specification

Indoors, less than 1000m above sea level, do not

Operating Environment

expose to direct sunlight or corrosive / explosive

gasses

Operating Temperature

Storage Temperature

Relative Humidity

Vibration

Grounding Non-isolated, referenced to power source ground

Cooling Method Self-cooled

-10 ∼ +50°C (+14 ∼ +122°F)

-40 ∼ +85°C (-40 ∼ +185°F)

20% ∼ 90% (without condensation)

2

5.9m/s

{0.6G} or less (10 ∼ 55Hz)

20

Page 22

7. Maintenance and Inspection

Preventive maintenance and inspection is required to maintain the gateway in

its optimal condition, and to ensure a long operational lifetime. Depending on

usage and operating conditions, perform a periodic inspection once every three

to six months. Before starting inspections, disconnect all power sources.

Inspection Points

• Check that the network cable(s) are properly terminated in the terminal

block(s), and ensure that pluggable terminal blocks are fully seated in their

headers. Reseat if necessary.

• Check that there are no defects in any attached wire terminal crimp points.

Visually check that the crimp points are not damaged or loose.

• Visually check all wiring and cables for damage. Replace as necessary.

• Clean off any accumulated dust and dirt.

• If use of the gateway is discontinued for extended periods of time, apply

power at least once every two years and confirm that the unit still functions

properly.

• Do not perform hi-pot tests on the gateway, as they may damage the unit.

Please pay close attention to all periodic inspection points and maintain a good

operating environment.

21

Page 23

8. Storage and Warranty

8.1 Storage

Observe the following points when the gateway is not used immediately after

purchase or when it is not used for an extended period of time.

• Avoid storing the unit in places that are hot or humid, or that contain large

quantities of dust or metallic dust. Store the unit in a well-ventilated

location.

• When not using the unit for an extended period of time, apply power at

least once every two years and confirm that it still functions properly.

8.2 Warranty

The gateway is covered under warranty by ICC, Inc. for a period of 12 months

from the date of installation, but not to exceed 18 months from the date of

shipment from the factory. For further warranty or service information, please

contact Industrial Control Communications, Inc. or your local distributor.

22

Page 24

9. LED Indicators

The gateway contains several different LED indicators, each of which conveys

important information about the status of the unit and connected networks.

These LEDs and their functions are summarized here.

9.1 Toshiba ASD Common Serial Port Indicators

Each Toshiba ASD common serial port RJ45 connector contains two integrated

green LEDs. Figure 8 indicates the functions of these LEDs.

The Data Write indicator is useful for confirming that a specific drive is having

data written to it, while the Drive Link indicator provides an easy method of

determining that the gateway and drive are successfully exchanging data,

independent of any other network activity.

Data Write

Flashes briefly when data is

written to the drive from the

point database

Figure 8: Toshiba Drive Connector Indicators

Drive Link

Solid green when a logical

connection exists with the

attached drive

9.2 RS232 (MMI) Port Indicators

The RS232 port RJ45 connector also contains two integrated green LEDs.

Figure 9 indicates the functions of these LEDs.

Reserved

Currently reserved for future

applications (always OFF)

Figure 9: RS232 Port Indicators

23

Modbus Plus Network

Status Indicator

Indicates Modbus Plus

network status/activity. Refer

to appropriate Modbus Plus

specifications for detailed

information.

Page 25

10. Configuration Switches

There are eight configuration DIP switches (marked “CONFIG”) located on the

front side of the gateway. Switches #1 - #6 set the Modbus Plus station

address of the gateway (refer to Table 1). Note that whenever the station

addressing switches (#1 - #6) are changed, power must

gateway to validate the change.

Table 1: Modbus Plus Station Addressing

SW1 SW2 SW3 SW4 SW5 SW6 Addr SW1 SW2 SW3 SW4 SW5 SW6 Addr

ON ON ON ON ON ON

OFF ON ON ON ON ON

ON OFF ON ON ON ON

OFF OFF ON ON ON ON

ON ON OFF ON ON ON

OFF ON OFF ON ON ON

ON OFF OFF ON ON ON

OFF OFF OFF ON ON ON

ON ON ON OFF ON ON

OFF ON ON OFF ON ON

ON OFF ON OFF ON ON

OFF OFF ON OFF ON ON

ON ON OFF OFF ON ON

OFF ON OFF OFF ON ON

ON OFF OFF OFF ON ON

OFF OFF OFF OFF ON ON

ON ON ON ON OFF ON

OFF ON ON ON OFF ON

ON OFF ON ON OFF ON

OFF OFF ON ON OFF ON

ON ON OFF ON OFF ON

OFF ON OFF ON OFF ON

ON OFF OFF ON OFF ON

OFF OFF OFF ON OFF ON

ON ON ON OFF OFF ON

OFF ON ON OFF OFF ON

ON OFF ON OFF OFF ON

OFF OFF ON OFF OFF ON

ON ON OFF OFF OFF ON

OFF ON OFF OFF OFF ON

ON OFF OFF OFF OFF ON

OFF OFF OFF OFF OFF ON

ON ON ON ON ON OFF

1

OFF ON ON ON ON OFF

2

ON OFF ON ON ON OFF

3

OFF OFF ON ON ON OFF

4

ON ON OFF ON ON OFF

5

OFF ON OFF ON ON OFF

6

ON OFF OFF ON ON OFF

7

OFF OFF OFF ON ON OFF

8

ON ON ON OFF ON OFF

9

OFF ON ON OFF ON OFF

10

ON OFF ON OFF ON OFF

11

OFF OFF ON OFF ON OFF

12

ON ON OFF OFF ON OFF

13

OFF ON OFF OFF ON OFF

14

ON OFF OFF OFF ON OFF

15

OFF OFF OFF OFF ON OFF

16

ON ON ON ON OFF OFF

17

OFF ON ON ON OFF OFF

18

ON OFF ON ON OFF OFF

19

OFF OFF ON ON OFF OFF

20

ON ON OFF ON OFF OFF

21

OFF ON OFF ON OFF OFF

22

ON OFF OFF ON OFF OFF

23

OFF OFF OFF ON OFF OFF

24

ON ON ON OFF OFF OFF

25

OFF ON ON OFF OFF OFF

26

ON OFF ON OFF OFF OFF

27

OFF OFF ON OFF OFF OFF

28

ON ON OFF OFF OFF OFF

29

OFF ON OFF OFF OFF OFF

30

ON OFF OFF OFF OFF OFF

31

OFF OFF OFF OFF OFF OFF

32

be cycled to the

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

24

Page 26

Switches #7 and #8 perform the following functions:

Switch #7.........RS232 port selection switch. When “OFF” at unit startup, the

RS232 port will act as the serial console, regardless of the

port’s configuration or protocol assignment (refer to section 13

for more information on the serial console). When “ON” at unit

startup, the RS232 port carries whatever protocol (if any) was

assigned to it at configuration time. Note that the state of this

switch is only detected when the gateway boots up.

Switch #8.........Firmware update switch. Place in “OFF” position for normal

operation, and in the “ON” position only when new firmware is

to be downloaded to the unit. Refer to section 16 for more

information.

11. Auxiliary Power Supply

The ICC part #10456 120VAC/9VDC power supply can be used to power the

unit via the “POWER” input. If providing your own auxiliary power supply,

ensure that it adheres to the following specifications:

Connection diagram................

Voltage rating.......................... 9 - 40VDC

Current rating.......................... 500mA (@9VDC)

The gateway’s “POWER” input uses the CUI, Inc. PJ-002A (2.1mm x 5.5mm) or

equivalent DC power jack, which mates with the PP-002A (2.1mm x 5.5mm) or

equivalent power plug.

+

25

Page 27

12. Unit Configuration Concepts

12.1 Port and Protocol Configuration

Each of the communication ports can be individually configured or

enabled/disabled. It is important to note that with one exception, the ports

function independently of one another, and can operate simultaneously. For

example, a Modbus RTU slave request on the RS485 port and a Modbus Plus

request can simultaneously

to this functionality is that the RS485 port and the ASD1 port are internally

shared, which means that they both cannot be active simultaneously. Also, the

RS485 port’s configuration has priority over that of the ASD1 port: if any

protocol is assigned to the RS485 port, then the ASD1 port will be automatically

disabled. Note, however, that the ASD2 and ASD3 ports will at all times

operate independently of all other network ports.

Although each communication port can be configured via the serial console

interface, their configuration selections vary slightly. The Toshiba ASD

common serial ports have a simple enable/disable selection. The RS232 and

RS485 ports can be disabled, or can have one of a selection of control

protocols assigned to them. The Modbus Plus port is always enabled.

Along with the protocol selection for the RS232/RS485 ports, each of these

ports also has a corresponding baudrate, parity, address and timeout time

assignment. Note that not all assignable protocols support the same range of

configuration options: therefore be sure to assign a valid entry in all cases (for

example, a Modbus RTU slave’s “address” assignment must be in the range 1247 to comply with the Modbus specification). Also note that certain protocols

may not make use of all available configuration options (e.g. certain protocols

operate only at one specified baudrate regardless of the “baudrate” selection

value). The protocol-specific sections of this manual will document these

cases.

access the same internal point. The sole exception

12.2 Timeout Configuration

The gateway’s points can be configured to perform a specific set of actions

when primary communications are lost on one or more of its various networks.

This allows each point to have its own unique “fail-safe” condition in the event

of a network interruption. There are three separate elements that define the

network timeout behavior:

• A port’s network timeout time

• A point’s “Timeout Enable” selection

• A point’s “Timeout Value” setting

The timeout time is adjustable in 1s increments from 0 to 500s.

26

Page 28

The default timeout time in all cases is 0, which disables network timeout

handling. When nonzero, timeout processing does not begin until after a valid

network packet has been received by the unit on that port.

When the timeout time is nonzero and a communication interruption is

detected, the timeout enable selections for each point are inspected. Those

points that are found to have their timeout enable selections set to “enabled”

will then have their configured timeout values automatically written to their

assigned “source port” objects. This mechanism provides for a flexible set of

device failsafe conditions to be established on a point-by-point basis.

12.3 Point Configuration

As mentioned in section 1, the Network Gateway Series concept revolves

around a central “point database”, containing the value and access

characteristics for each network. With respect to the Network Gateway Series,

a “point” is simply an object that defines some sort of network access, mapping

and configuration data, as well as a single “value” attribute that can be read

from or written to by various communication ports or protocols.

The only restriction placed on this “central clearinghouse” concept is that only

one port can autonomously update the point’s value, “mirroring” its designated

object for other protocols to access. What this means is that although any

protocol can read from or write to a point’s internal value, most of the time that

point’s value will simply be mirroring a remote data object that resides on one of

the gateway’s subnets. The selection of what a specific point is to mirror is

performed via its “source port” selection.

For example, a point may be configured to contain Toshiba ASD parameter

mapping and Modbus master ID and register mapping information. However,

because both of these protocols act as “master” protocols, only one of them

can be allowed to continuously update the point’s value. If both master

protocols could simultaneously update the point’s internal value, it would

erratically alternate back and forth between the values designated by the

Toshiba parameter and Modbus register objects. Any “slave” protocol (Modbus

RTU slave, Modbus Plus MSTR reads & writes, etc.) can read from or write to a

point at any time, but only the protocol designated by the point’s “source port”

assignment will autonomously update the point’s value independent of any

other protocol traffic.

The “source port” designation also determines where a new point value will be

written to when a “slave” protocol writes a new value to the point. For example,

if the Modbus Plus connection is used to write new data that changes the value

of a point, how do we know where this new value will exit the gateway to arrive

at its final destination? The answer is that any new point values written by

“slave” protocols will generate “write” transactions only on the “source port”.

27

Page 29

This concept may best be further explained by way of a representative

scenario. For example, let’s assume that the gateway’s RS485A port has been

designated to be a Modbus Master. Let’s further assume that the “Modbus

Master” portion of point #5 indicates an “Address” value of 8 and “Register”

value of 14, and that point #5’s “Source Port” selection is set to “RS485A”.

What this means is that independent of any other gateway traffic, point #5 will

continuously attempt to update its internal value by making requests to the

RS485A port. And, because the RS485A port has been designated as a

Modbus Master, then the “Modbus Master” portion of point #5’s configuration

will be referenced by the update task, and point #5’s value will therefore always

be mirroring the value of (holding or input, depending on the configuration)

register #14 of remote Modbus station address #8 connected to the Modbus

subnet attached to the gateway’s RS485A port. Perhaps register #14 of

Modbus station address #8 is a monitor item, indicating the pressure in

compressor tank. Whenever the tank’s pressure changes, therefore, the value

of point #5 will automatically update to reflect the new value read from the

remote device. Once the tank’s pressure reading has been brought into the

gateway, it can then be retrieved by any protocol (or ALL the protocols)

currently assigned to the gateway’s other communication ports.

As a modification to the previous example, let’s assume this time that register

#14 of Modbus remote station address #8 is the speed command of a conveyor

belt. In this case, point #5 of the gateway will be mirroring the current speed

command of the conveyor, in a similar fashion to how it previously mirrored the

compressor tank’s pressure. This time, however, the speed command

represents something that can also be written to. Therefore, any new data

value that is written to point #5 from any other port connection will automatically

cause a “write holding register” transaction to occur on the RS485A Modbus

master port, updating the value of register #14 on remote Modbus station #8,

causing the conveyor to accelerate (or decelerate) to the new speed.

Note that it is also perfectly acceptable to have a point’s “source port” assigned

to “NONE”. All this means that this point will not be autonomously updated (i.e.

that it will not automatically mirror anything.) In a sense, it will simply be

“scratchpad memory” that the various ports and protocols can use to exchange

information among themselves.

Although the various configuration possibilities may seem overwhelming at first,

it is clear that the gateway can perform powerful and flexible routing algorithms.

Through configuration experience, the “in” and “out” data flows will become

more clear.

12.4 General Configuration Procedure

Now that we have had a brief tutorial on port and point configuration, we can

proceed on to how these elements fit into the overall configuration procedure.

The general configuration procedure steps can be summarized as follows:

28

Page 30

1. Access the serial console configuration interface via Hyperterminal or

other text-based console program.

2. Assign (or enable/disable) the desired protocols and their

characteristics to the specific communication ports.

3. Perform the desired per-protocol mapping and definition assignments

for each point, including the name, timeout and “source port”

assignments.

4. Exit the serial console, which will prompt you to update the gateway’s

internal configuration file and then reboot the unit.

5. Download a copy of the unit’s configuration file to your PC for backup

purposes.

Of course, it is possible to simplify or even eliminate some of these steps by

starting your configuration from a pre-existing point database file (either

downloaded from the internet or previously-created by the user), and then

simply modifying those elements necessary to match your application.

29

Page 31

13. Console Access

13.1 RS232

The console is accessible via an RS232 interface for direct connection to a

computer’s serial (COM) port. This is performed by connecting the unit’s

RS232 (MMI) port to the computer’s serial port via the included serial cable.

13.1.1 Requirements

All that is needed is a computer with a serial (COM) port containing some sort

of communications software (such as HyperTerminal, included with Microsoft

Windows operating systems) and the included DB9-RJ45 RS232 port cable

(part number 10425). Any communications software and PC will work, provided

they support ASCII communications at 38.4kbaud.

13.1.2 Connection

The gateway ships from the factory with a dust cover installed in the RS232

(MMI) port. To minimize contamination of the port’s electrical contacts, keep

this dust cover in place whenever the RS232 port is not in use.

Connect the RJ45 end of the RS232 cable to the gateway’s RS232 port, and

connect the DB9 end to the computer’s serial port. Make sure that CONFIG

switch #7 is in the “OFF” (up) position to force the RS232 port to act as the

serial console. If the unit is currently using the RS232 port for control protocol

communication, then it must be rebooted (powered down and then back up

again) with CONFIG switch #7 in the OFF position to enable the serial console

on the RS232 port.

13.1.3 Application Configuration

As previously mentioned, any PC communication software and PC serial port

can be used. The software configuration example given here will be for

Windows HyperTerminal communicating via COM1.

Figure 10 shows the “Connect To” tab of the properties window for COM1.

Figure 11 shows the window that appears when “Configure” is selected in the

“Connect To” tab. Figure 12 shows the “Settings” tab of the properties window.

Most of these settings are their default values: usually the only change needed

is the “Bits per second” setting shown in Figure 11.

30

Page 32

Figure 10: HyperTerminal Properties…Connect To

Figure 11: HyperTerminal Properties…Connect To…Configure

31

Page 33

Figure 12: HyperTerminal Properties…Settings

32

Page 34

13.2 Invocation

The console provides standard access and editing methods for the various

configuration items (ports, points and their associated attributes). It is important

to note that whenever you modify the point database and are ready to restart

the gateway (“exit”), you must save the database to the internal file system prior

to restarting or your changes will be lost. The console will automatically ask

you if you would like to save the database to the file system every time you exit

even if you did not modify it. If the database was unchanged, then saving is not

required. Before modifying the configuration, it is a recommended practice to

download a configuration file to your PC for backup purposes, so that the

original configuration can be restored if any unintended changes are made.

To enter the console, simply type “menu” and press the Enter key. You will

then be notified that all communication tasks will be terminated for the duration

of the editing (refer to Figure 13). It is important to ensure that all connected

devices are in a safe state such that loss of communications will not pose a

danger to equipment or personnel. Exiting the console will reset the gateway

and restart network communications using the current configuration data.

At most console prompt locations, typing “x” will return you to the previous

menu, and typing “menu” will return you to the main menu. Also note that

console commands are not case-sensitive.

Figure 13: Console Invocation

33

Page 35

13.3 Main Menu

The main menu is shown in Figure 14. All gateway configuration is performed

by “drilling down” into progressively lower-level menus.

Figure 14: Console Main Menu

All navigation and data entry commands are input by simply entering the menu

selection number to the right of the “>” symbol along with any required data

fields at the console prompt. In Figure 14, for example, entering the menu

selection number “1” (without the quotation marks) will bring up the View/Edit

Points submenu. Throughout this manual, example console entry strings will

be provided enclosed in quotation marks to delineate them from the description

text: whenever actually entering the console strings, however, do not include

the quotation marks.

When additional data fields are required with a data entry command, they will

be indicated by square brackets (“[…]”) after the menu selection number. All

data entry commands and data fields must be separated by spaces. Because

data entry commands and data fields are delineated by spaces, spaces are

therefore not allowed within data fields (such as name strings). In these cases,

it is usually convenient to use an underscore “_” in place of a space. For

example, attempting to enter a point’s name as “My point” would result in an

error, but “My_point” would be perfectly acceptable.

34

Page 36

13.3.1 View/Edit Points

Main menu selection number 1 displays a screen which shows a summary of

the current point configuration (see Figure 15). This screen only displays the

point number and the point name: in order to access more detailed point

information, menu selection number 1 “Edit/View a Point” must be entered with

the additional argument of the targeted point’s number. The syntax used to

edit/view point #1 is shown at the bottom of Figure 15.

Only 10 points are shown at a time (of 100 total available in the unit). Menu

selection 2 “More Points” allows the next 10 points to be viewed.

Figure 15: View/Edit Points

Entering “1” with a point’s number (such as “1 1”, as shown at the bottom of

Figure 15) at the Edit Points submenu will display and allow editing of that

point’s mapping and definition information. Refer to Figure 16 for an example.

When editing a point, the top half of the screen (menu selections 1-4) contains

point attributes that are protocol-independent. The bottom half of the screen

(menu selections 5-9) contains the menu options for editing point attributes that

are protocol-specific.

35

Page 37

Figure 16: Edit a Point

• Edit Name: Menu selection number 1 allows you to change the point’s

name. For example, the bottom of Figure 16 shows an example of

changing point #1’s name to output_voltage. The point’s name is

purely for user recognition of a point, and has no bearing upon

communications functionality. To clear the point’s name field, just

enter the menu selection (“1”) with no additional argument.

• Edit Timeout Enable: Menu selection number 2 allows you to change

the point’s timeout enable selection. Refer to section 12.2 for more

information about timeout processing.

• Edit Timeout value: Menu selection number 3 allows you to change

the point’s timeout data value. Refer to section 12.2 for more

information about timeout processing.

• Edit Source Port: Menu selection 4 allows you to change the point’s

source port. Refer to section 12.3 for more information about source

ports.

• Edit Toshiba, Mitsubishi, Modbus Master/Slave/Plus: Menu

selections 5-9 allow you to edit/view protocol-specific point attributes.

Enter the menu selection corresponding to the protocol you wish to

edit/view.

36

Page 38

Toshiba Point Attributes

Figure 17: Edit Toshiba Attributes

• Edit Address: Menu selection 1 allows you to edit the network

address of the Toshiba ASD that this point refers to. This address

field is only used in conjunction with the Toshiba RS485 protocol:

Toshiba common-serial port connections are point-to-point, and

therefore do not require targeting a drive at a specific address.

• Edit Parameter: Menu selection 2 allows you to edit the Toshiba

ASD parameter that this point will access. Figure 17 shows an

example of how to change the current setting of FA00 to FA04 (which

would be a typical change if the Toshiba RS485 protocol were to be

used with this point). Note that Toshiba parameter values must be

entered in hexadecimal format.

37

Page 39

Mitsubishi Point Attributes

Figure 18: Edit Mitsubishi Attributes

• Edit Address: Menu selection 1 allows you to edit the network

address of the Mitsubishi ASD that this point refers to.

• Edit Parameter: Menu selection 2 allows you to edit the Mitsubishi

ASD parameter that this point will access. Figure 18 shows an

example of how to change the current setting of 1 to 1014.

38

Page 40

Modbus Master Point Attributes

Figure 19: Edit Modbus Master Attributes

• Edit Address: Menu selection 1 allows you to edit the network

address of the Modbus slave that this point refers to.

• Edit Register: Menu selection 2 allows you to edit the Modbus

holding register or input register that this point will access. The type of

register accessed (holding or input) will be determined on the basis of

the “Read FC” setting (see below). Figure 19 shows an example of

how to change the current setting of register 1 to register 50.

• Read FC: Menu selection 3 allows you to choose the Modbus “read”

function code that will be used to read from the designated register.

The default setting of function code 03 (read holding registers) will

access a holding

code 04 (read input registers), a Modbus input

register on the remote device. By selecting function

register will be

accessed instead.

• Write FC: Menu selection 4 allows you to choose the Modbus “write”

function code that will be used to write to the designated holding

register (this setting does not apply to input registers, as they are

read-only). The default setting is function code 16 (preset multiple

registers). Alternatively, this setting can be changed to function code

06 (preset single register) in order to connect to those Modbus slave

devices that do not support function code 16.

39

Page 41

Modbus Slave Point Attributes

Figure 20: Edit Modbus Slave Attributes

• Edit Register: Menu selection 1 allows you to assign a Modbus

register (accessible as either a holding register or input register) to this

point. Figure 20 shows an example of how to change the current

setting of 7 to 8. Note that this Modbus register index is used whether

accessing the point via Modbus RTU or Modbus Plus MSTR

commands.

40

Page 42

Modbus Plus Point Attributes

Figure 21: Edit Modbus Plus Attributes

• Edit Get Global Node: Menu selection 1 allows modification of the

selected node on the network from which this point will consume (get)

global data. This value is ignored if the “Get Global Offset” is

“DISABLED”.

• Edit Get Global Offset: Menu selection 2 allows modification of the

offset within the Get Global Node’s data block that this point will

consume (get) from. Figure 21 shows an example of changing this

point’s “get” offset from 0 to 10 in node #1’s data block. When set to

“DISABLED”, this point will not consume any global data.

• Edit Put Global Offset: Menu selection 3 allows modification of the

offset within the gateway’s global data block that will be populated with

this point’s “value” attribute. When set to “DISABLED”, this point will

not produce any global data.

41

Page 43

Implementing Global Data

As indicated above, three global data configuration items exist for each point in

the point database: a “get” node, a “get” offset, and a “put” offset. If a given

point is intended to be accessed only via standard MSTR write and read

commands (MSTR functions 1 and 2, respectively), then both the “get” and

“put” offsets should be set to “DISABLED”. Standard MSTR read and write

commands can then be used to access the point by targeting its “Modbus Slave

Register” assignment.

If global data is to be used, however, then one of the global data selections

must be enabled by programming it with an offset value (in the case of a “put”),

or with a node address and an offset value (in the case of a “get”). If the point

is to be written to by another device on the Modbus Plus network, then the

MBP-100 must be configured to “get” data from that selected device’s global

data block. If the point’s value is to be broadcast to the network, however, then

the MBP-100 will “put” the point’s value into its own global data block, where

other network nodes can “get” the data if desired. It is even possible to

configure a specific point to both “get” and “put” global data (in effect

performing global data “relaying”).

Because the gateway can be configured to retrieve global data from any offset

(offset values 0-31) from any node (address values 1-64), very powerful peerto-peer networking configurations can be created that entirely bypass the need

for a PLC “master” executing MSTR instructions. The only configuration

constraint with respect to global data is that “put” offsets must be unique. For

example, if point #9 has been assigned a “put” offset of 5 (meaning that this

point’s value will be placed in the 6

th

word from the start of the gateway’s global

data), and if point #13 is also assigned a “put” offset of 5, then only the value of

the point with the larger numerical index (in this case, point #13) would appear

at the duplicated offset. “Get” global data configuration has no such limitation:

it is perfectly acceptable for multiple points to consume data from the same

offset in a common node’s global data block. This type of configuration may be

particularly useful in synchronized systems, for example, where multiple points

(and their associated devices on other networks) follow a “leader” value being

broadcast by a single Modbus Plus node.

As a brief example of a global data implementation, Table 2 shows how 12

points in the point database might be configured for a specific application. Note

that some points are consuming global data, some points are producing global

data, and some points do not access global data at all (either they are not being

used for Modbus Plus access, or they are accessed only via “standard” MSTR

read or write commands).

42

Page 44

2

3

6

Table 2: Global Data Assignment Example (x=Don’t Care)

Point #

Get

Node

Get Offset Put Offset Note

1 3 2 DISABLED Get from node #3

2 x DISABLED DISABLED No global data access

3 8 5 DISABLED Get from node #8

4 8 5 DISABLED Get from node #8

5 3 3 DISABLED Get from node #3

6 x DISABLED 0 Put

7 x DISABLED 1 Put

8 x DISABLED 4 Put

9 x DISABLED DISABLED No global data access

10 x DISABLED 5 Put

11 x DISABLED 7 Put

12 x DISABLED 8 Put

With the indicated global data assignments, we can get a logical overview of

the three relevant global data areas from Figure 22, Figure 23 and Figure 24.

Offset 0

ignored ignored

Offset 1 Offset

Point #1

value

Offset

Point #5

value

………

………

Offset 31

ignored

Figure 22: "Get" Global Data From Node Address #3

Offset 0

ignored

………

………

Offset 5

Point #3 and

#4 value

Offset

ignored

Figure 23: "Get" Global Data From Node Address #8

………

………

Offset 31

ignored

Offset 0

Point #6

value

Offset 6

unused

Offset 1 Offset 2 Offset 3

Point #7

value

Offset 7 Offset 8

Point #11

value

unused unused

Offset 9

Point #12

value

unused

Offset 4

Point #8

value

………

………

Figure 24: "Put" Global Data From MBP-100

43

Offset 5

Point #10

value

Offset 31

unused

Page 45

13.3.2 View/Edit Ports

Main menu selection number 2 displays a screen which shows a summary of

the current port configuration (see Figure 25). This screen only displays the

current protocol selected for each port: in order to access more detailed port

information, select the menu number corresponding to the desired port. Menu

selections 1-3 correspond to the Toshiba common serial ASD ports, and these

contain no other port configuration other than enable/disable. The syntax used

to disable port ASD1 is shown at the bottom of Figure 25.

Figure 25: View/Edit Ports

44

Page 46

RS485/232 Port Configuration

Figure 26: Edit Port Configuration

• Edit Protocol Selection: Menu selection 1 allows you to change

what serial protocol is running on the selected port. Note that not all

ports run the same protocols. Figure 26 shows an example of

changing the protocol selection on the RS485 port from Disabled to

Modbus Slave.

• Edit Baudrate: Menu selection 2 allows you to change the baudrate

for the selected port. Note that the baudrate for some protocols is

determined by the specification, and these will therefore ignore this

setting.

• Edit Parity: Menu selection 3 allows you to change the parity for the

selected port. Note that the parity for some protocols is determined by

the specification, and these will therefore ignore this setting.

• Edit address: Menu selection 4 allows you to edit the network

address that the selected port will respond to. This setting is

applicable for slave protocols only.

• Edit Timeout: Menu selection 5 allows you to edit the timeout time

for the selected port. Refer to section 12.2 for more information on

timeout processing.

45

Page 47

13.3.3 Load Points

Main menu selection number 3 allows the retrieval of a predefined configuration

into working memory (see Figure 27). Loading one of these configurations

overwrites the existing point configuration.

Currently, entering submenu selection 1 returns the gateway’s configuration to

its factory default state.

Figure 27: Loading a Point File

13.3.4 Xmodem Point File

Main menu selection number 4 gives access to the “xmodem” command, which

allows unit configuration files to be transferred between the gateway and a PC.

Whenever unit configuration is completed, it is strongly recommended that a

backup copy of the configuration file be downloaded from the unit to a PC. One

reason for this is in case it becomes necessary to restore a previous

configuration at a later time. Another reason is that it may be desirable to load

multiple units with the same configuration. Configuration files contain all point

and port settings. A downloaded configuration file can be uploaded to any

MBP-100, allowing the user to clone multiple units with the same configuration.

Two different variations of the Xmodem protocol are supported (CRC and

Checksum) for those serial communication packages that only support one or

the other. However, some programs can automatically adapt to the user’s

selection, making the specific Xmodem protocol selection arbitrary. The first

46

Page 48

argument of the xmodem command indicates the mode, and must be set to

either “/crc” for Xmodem CRC mode, or “/cs” for Xmodem checksum mode.

As mentioned above, configuration files can be both downloaded and uploaded.

The second argument in the xmodem command indicates the action to take,

and must be set to either “/d” to download the configuration file from the unit, or

“/u” to upload a configuration file to the unit.

Figure 28 shows an example of initiating an Xmodem download in CRC mode.

Once the message “The MBP-100 is ready to send its configuration file via

Xmodem…Download the file now” appears, the user has 30 seconds to start

the Xmodem download. This can be performed in HyperTerminal by clicking

the “receive” button (

) on the tool bar. Figure 29 shows the dialog box that

will appear after clicking the “receive” button. Specify the folder in which to

place the received file, select Xmodem as the receiving protocol, and click

“Receive”. One last dialog box will prompt the user to name the received file,

and then the transfer will begin. This will only take several seconds to

complete, and at the conclusion the console will indicate the status of the

transfer and return to the entry menu.

Figure 28: “Xmodem” Command Overview and Implementation

47

Page 49

Figure 29: HyperTerminal receive file dialog box

When uploading a file, the procedure is similar to downloading. Enter “/u”

instead of “/d” for the action parameter of the xmodem command. Once the

xmodem upload command is entered, the user will have 30 seconds to click the

“send” button ( ) on the tool bar in HyperTerminal and initiate the Xmodem

upload transaction. Upon successful completion of the Xmodem upload, the

integrity of the file will be checked and, if valid, will be copied to both the unit’s

working memory and flash file system. The previous configuration cannot be

recovered (unless a corresponding configuration file exists, of course).

13.3.5 MBP-100 Information

Main menu selection 5 provides some basic information about the gateway,

such as firmware version (see Figure 30).

Figure 30: MBP-100 Information

48

Page 50

14. Protocol-Specific Information

This section will discuss topics that are specific to each of the available network

selections.

14.1 Modbus

The gateway supports Modbus slave and master functionality via Modbus RTU.

The slave implementations share common access methods, which is to say

they support the same functions and reference the internal points via a

common “Modbus Slave” register assignment. Other notes of interest are:

• Points are addressed by their assigned holding register (4X reference) or

input register (3X reference) via Modbus slave protocols.

• Points can access both holding registers (4X references) and input

registers (3X references) via Modbus master protocols.

• Supported Modbus slave functions are indicated in Table 3.

Table 3: Supported Modbus Slave Functions

Function Code Function

1 Read coils

2 Read input status

3 Read multiple registers

4 Read input registers

5 Write coil

6 Write single register

8 Diagnostics (subfunction 0 only)

15 Force multiple coils

16 Write multiple registers

• Register number entry radix is decimal (e.g. 10 = 1010)

• Configuration tip: Improved network utilization may be obtained by

appropriately grouping points into blocks having contiguous register

assignments. In this way, the “read multiple registers”, “read input

registers” and “write multiple registers” functions can be used to perform

transfers of larger blocks of registers using fewer Modbus transactions

compared to a situation where the read/write registers were arranged in an

alternating or scattered fashion.

49

Page 51

−

=

• Because the transaction is handled locally within the gateway, write data

checking is not available. For example, if a write is performed to a register

with a data value that is out-of-range of the corresponding “source port”

object, no Modbus exception will be immediately returned. However, the

point will always reflect the “source port” status and object value. In other

words, if such an out-of-range write attempt is performed, the unsuccessful

“source port” network write can be observed by reading the current

(unchanged) value of the point during a subsequent Modbus transaction.

14.1.1 Coil & Discrete Input Mappings

The Modbus slave implementation provides read/write support for coils (0X

references) and read-only support for discrete inputs (1X references). These

will collectively be referred to from here on out as simply “discretes”. Accessing

discretes does not reference any new physical data: discretes are simply

indexes into various bits of Modbus registers. What this means is that when a

discrete is accessed, it is resolved by the gateway into a specific register, and a

specific bit within that register. The pattern of discrete-to-register/bit

relationships can be described as follows:

Discrete 1...16 map to register #1, bit0...bit15 (bit0=LSB, bit15=MSB)

Discrete 17...32 map to register #2, bit0...bit15, and so on.

Arithmetically, the discrete-to-register/bit relationship can be described as

follows: For any given discrete, the register in which that discrete resides can

be determined by:

+

15discrete

Where the bracket symbols “⎣ ⎦” indicate the “floor” function, which means that

any fractional result (or “remainder”) is to be discarded, with only the integer

value being retained.

Also, for any given discrete, the targeted bit in the register in which that discrete

resides can be determined by:

Where “discrete” ∈[1…65535], “bit” ∈[0…15], and “%” is the modulus operator,

which means that any fractional result (or “remainder”) is to be retained, with

the integer value being discarded (i.e. it is the opposite of the “floor” function).

From these equations, it can be seen that the largest register number that can

be accessed via this discrete-to-register mapping method is 4096 (which

contains discrete #65535).

register

⎢

=

⎢

16

⎣

discretebit …Equation 2

⎥

…Equation 1

⎥

⎦

16%)1(

50

Page 52

For clarity, let’s use Equation 1 and Equation 2 in a calculation example. Say,

for instance, that we are going to read coil #34. Using Equation 1, we can

determine that coil #34 resides in register #3, as ⎣3.0625⎦ = ⎣3 r1⎦ = 3. Then,

using Equation 2, we can determine that the bit within register #3 that coil #34

targets is (34-1)%16 = 1, as 33%16 = mod(2 r1) = 1. Therefore, reading coil

#34 will return the value of register #3, bit #1.

Note that this discrete-to-register/bit relationship holds true regardless of

whether or not register #3 is assigned to a point. If register #3 is not assigned

to a point, then a Modbus exception will be returned. Either way, coil #34 will

always

access register #3, bit #1.

14.1.2 Modbus RTU Slave

• Broadcast (for functions 5, 6, 15 and 16) is supported.

• Network characteristics selections

o Baud rate: 2400 / 4800 / 9600 / 19200 / 38400 bps

o Parity: odd / even / none (1 stop bit) / none (2 stop bits)

14.1.3 Modbus RTU Master

• Supported Modbus master functions are indicated in Table 4. These

functions are automatically invoked by the gateway in response to point

read or write requests. The specific read or write function code used

depends on the point’s assigned configuration.

Table 4: Supported Modbus Master Functions

Function Code Function

3 Read multiple registers

4 Read input registers

6 Write single register

16 Write multiple registers

• The slave response timeout (in seconds) is assigned via the designated

port’s “Timeout” selection. If “0” is chosen (an invalid timeout time), the

gateway will use a 2s timeout by default.

• Network characteristics selections

o Baud rate: 2400 / 4800 / 9600 / 19200 / 38400 bps

o Parity: odd / even / none (1 stop bit) / none (2 stop bits)

51

Page 53