Toshiba MAR-F102HTM8-PE, MAR-M102HTM8-PE SERVICE MANUAL

SERVICE MANUAL

AIR-CONDITIONER

2-PIPE SUPER MULTI, HEAT PUMP

FILE NO. A90-9819

Outdoor Unit

Multi Controller

3-PIPE SUPER MULTI, HEAT PUMP WITH

SIMULTANEOUS HEATING AND COOLING

Outdoor Unit

Multi Controller

MAR-M102HTM8-PE

RBM-Y1032-PE (3-way)

RBM-Y1042-PE (4-way)

MAR-F102HTM8-PE

RBM-Y1032F-PE (3-way)

RBM-Y1042F-PE (4-way)

Printed in UK March 1998 s

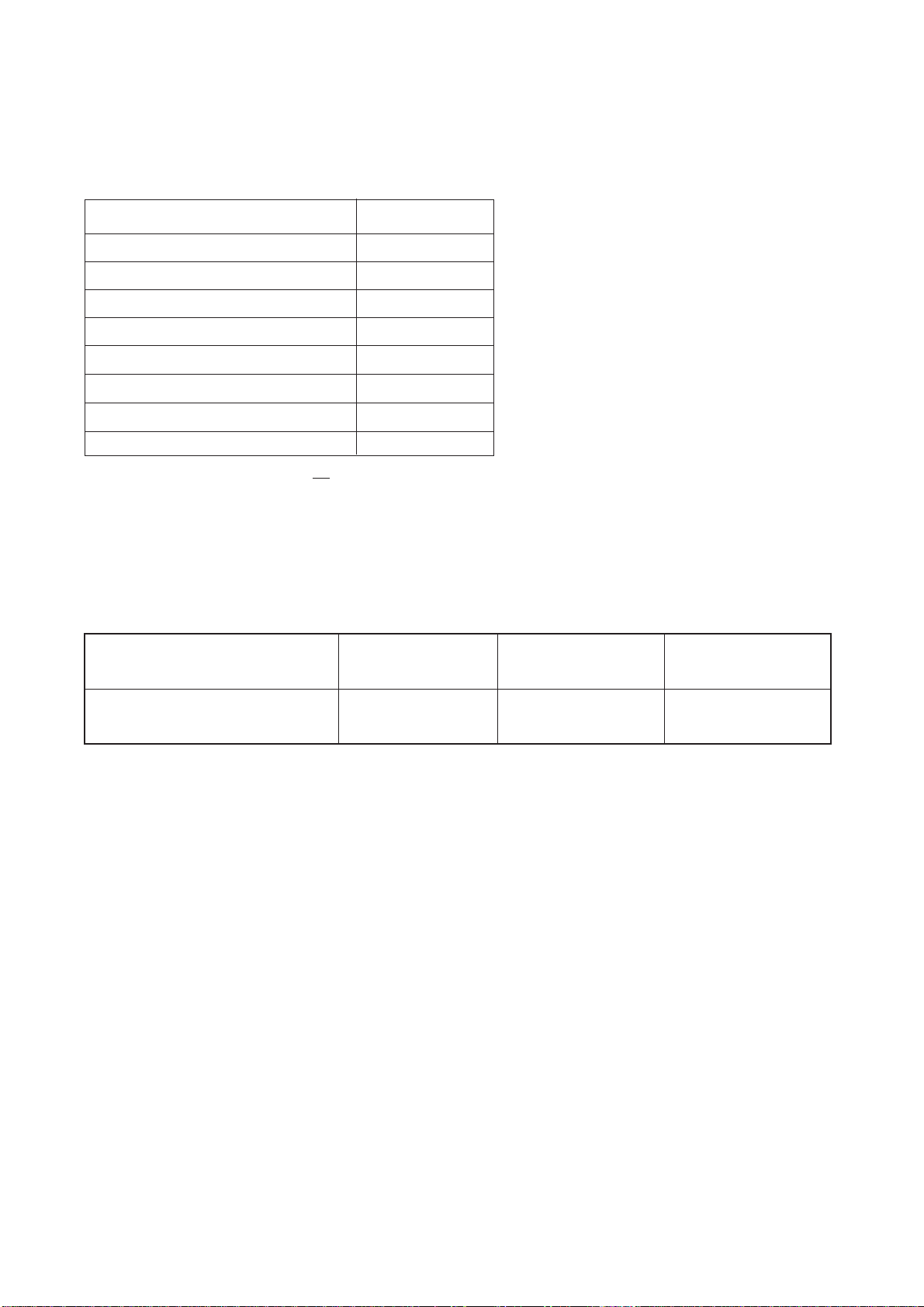

CONTENTS

1. SUPER MULTI SYSTEM BASIC COMPONENTS.....................................................................................

2. OUTLINE OF CONTROL SYSTEM............................................................................................................

3. SPECIFICATIONS......................................................................................................................................

4. CONSTRUCTION VIEWS..........................................................................................................................

5. WIRING DIAGRAMS..................................................................................................................................

6. REFRIGERANT CYCLE DIAGRAMS................................................................................................... .....

7. SELF DIAGNOSTIC DISPLAY INFORMATION........................................................................................

8. FAULT CODE DISPLAY INFORMATION..................................................................................................

9. CONTROL FEATURES.............................................................................................................................

10. VALVE & SENSOR FUNCTION AND OPERATION............................ ....................................................

11. PRESSURE TEST AND DEHYDRATION.................................................................................................

12. ADDITIONAL REFRIGERANT...................................................................................................................

13. EXPLODED VIEWS AND SERVICE PARTS LIST....................................................................................

10

13

19

21

36

43

45

49

50

51

SUMMARY

〈 The units referred to within this manual conform with the protection requirements of Directives 89/336/EEC

Electromagnetic Compatibility and 73/23/EEC Low voltage.

〈 Operating conditions of the unit are as follows:

3

4

6

Outdoor temperature -5 ~ 43°C Cooling

-10 ~ 21°C Heating

Room Temperature 18 ~ 32°C Cooling

15 ~ 29°C Heating

Room humidity < 80% Cooling

Note 1: Cooling capacity is rated at the following temperature conditions:

Indoor air inlet temperature 27°C DB, 19°C WB.

Outdoor air inlet temperature 35°C DB.

Note 2: Heating capacity is rated at the following temperature conditions:

Indoor air inlet temperature 20°C DB.

Outdoor air inlet temperature 7°C DB, 6°C WB.

Note 3: For details on the Outdoor unit installation, the Indoor units or Remote Controllers refer to

the relevant literature. i.e. Installation instructions supplied with the units or Service

manuals relevant to the indoor units.

Note 4: Operatives handling refrigerants must be suitably qualified in accordance with local and

national codes of practice and statutory requirements.

Note 5: Legislation may regulate the removal of waste refrigerant from the systems. We advise

awareness of any regulations and duty of care. Waste refrigerant must NEVER be discharged to

atmosphere.

Note 6: Electrical work should be in accordance with all relevant codes of practice and should be

carried out by suitably qualified personnel.

Note 7: Metric / Imperial pipe conversion.

Diameter (mm) 6.4 9.5 12.7 15.9 19.0 22.0 28.6

Nominal diameter (inch) 1/4 3/8 1/2 5/8 3/4 7/8 1 1/8

Note 8: Within this manual, O/D = Outdoor unit, M/C = Multi controller, I/D = Indoor unit, R/C = Remote

controller, D.O.L. = Direct on-line compressor.

2

1. SUPER MULTI SYSTEM BASIC COMPONENTS

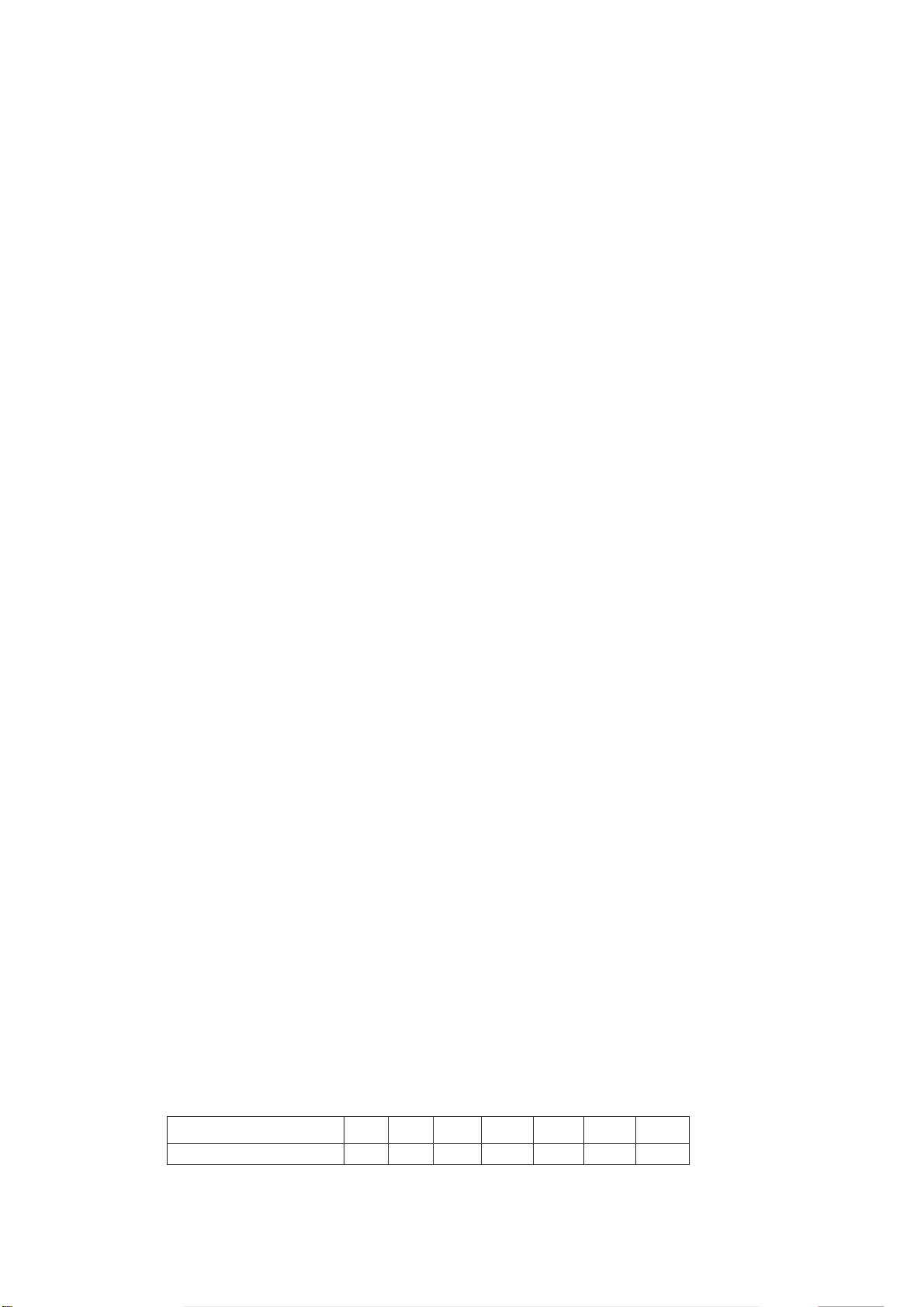

1.1 2-Pipe Heat Pump.

This system allows separate operation of each indoor unit in heating or cooling.

Heating operation has priority over cooling. In the event of an indoor unit requesting cooling operation when

another is in heating mode, the "PREHEAT DEFROST" will flash on the remote controller.

2-Pipe

Outdoor unit

T-Pieces

2 pipes

Multi controller

OFF

Indoor units

OFF

Remote controller

2 pipes

1.2 3-Pipe Heat Pump with simultaneous heating and cooling.

This system allows separate operation of each indoor unit in either heating or cooling simultaneously.

3 pipes

3-Pipe

Outdoor unit

T-Pieces

Multi controller

Indoor unit remote controller requesting cooling

Cooling operation

Indoor unit remote controller requesting heating

Heating operation

Indoor units

Remote controller

2 pipes

3

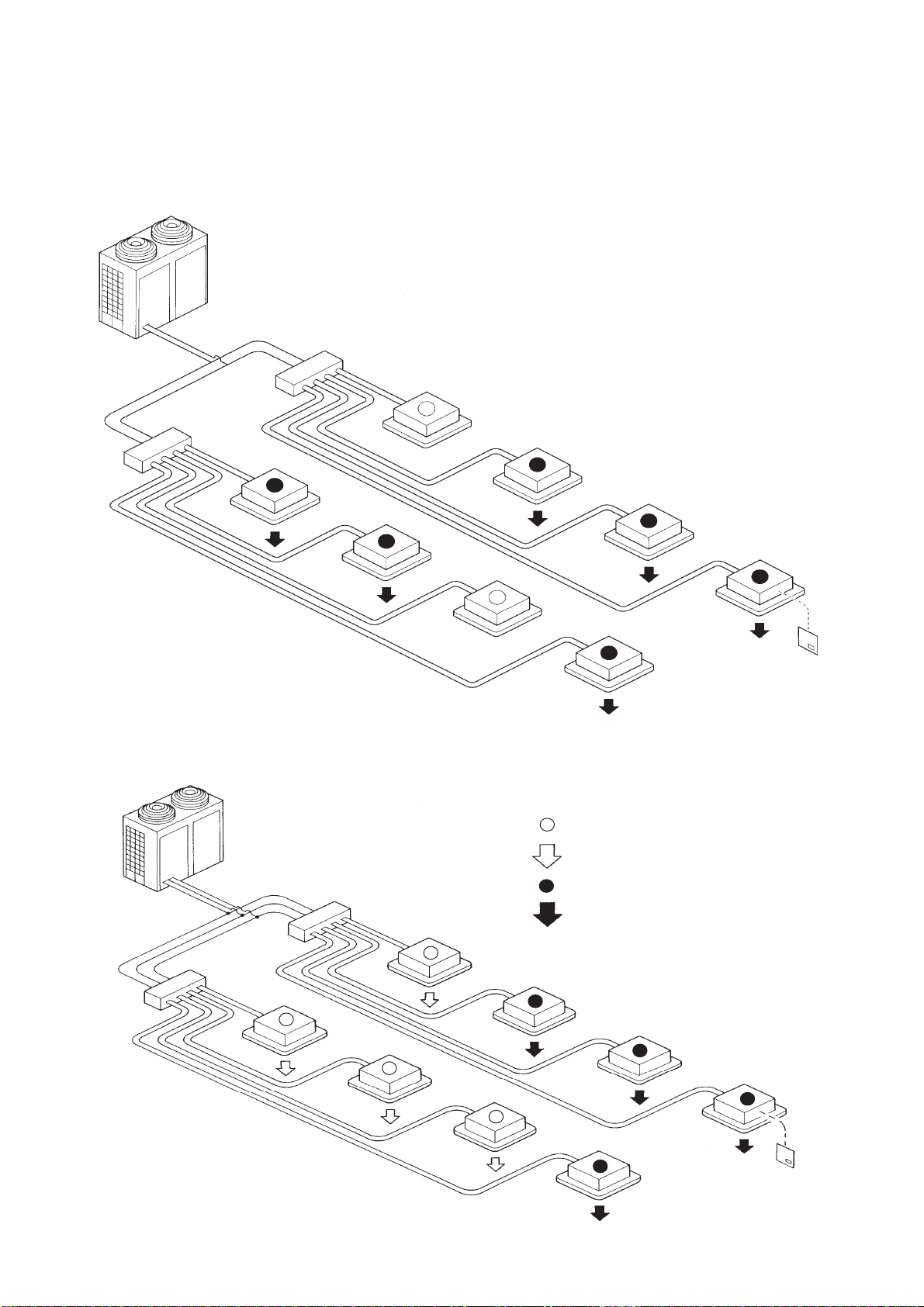

2. OUTLINE OF CONTROL SYSTEM

The refrigerant and electrical systems of the Super multi air conditioner are controllled by the Multi controller

and the Outdoor unit microprocessors.

All RAV Heat Pump series Indoor units are compatible with the Super multi system. i.e. 1 ~ 5 HP.

For system operation, initially the microprocessor in each Indoor unit calculates the difference between the

current room temperature (TA) and the requested temperature which has been set on the Remote controller.

A demand signal is determined and transmitted to the Multi controller microprocessor in the form of operation

commands. (i.e. ON / OFF, cooling or heating operation mode, operation demand frequency).

The Multi controller microprocessor receives operation commands from all Indoor units connected, calculates

the accumulative operation command and transmits this information to the Outdoor unit Interface

microprocessor.

The Interface microprocessor calculates the capacity required for heating or cooling and determines the

operation mode of the Outdoor unit and the actual frequency of the compressor.

2.1 Control system diagram.

Indoor unit 1 – A

Fan

Temp. sensor (TA)

Drain Pump

Indoor unit microprocessor

Remote

controller

1 - B

1 - C

1 - D

Multi controller 1

Capacity rank

setting switch

Temp. sensor

Pulse modulating

valve

Multi controller

microprocessor

Display LED

2-way valve

(3-Pipe ONLY)

Outdoor unit

Protection unit

Comp. sensor

Temp. sensor

Pulse modulating

valve

Interface microprocessor

D.O.L.

compressor

Display LED

2-way valve

Fan

2 - A

2 - B

2 - C

2 - D

Multi controller 2

Multi controller

microprocessor

4

4-way valve

Inverter

microprocessor

Protection

unit

Inverter

compressor

Inverter

Power

supply

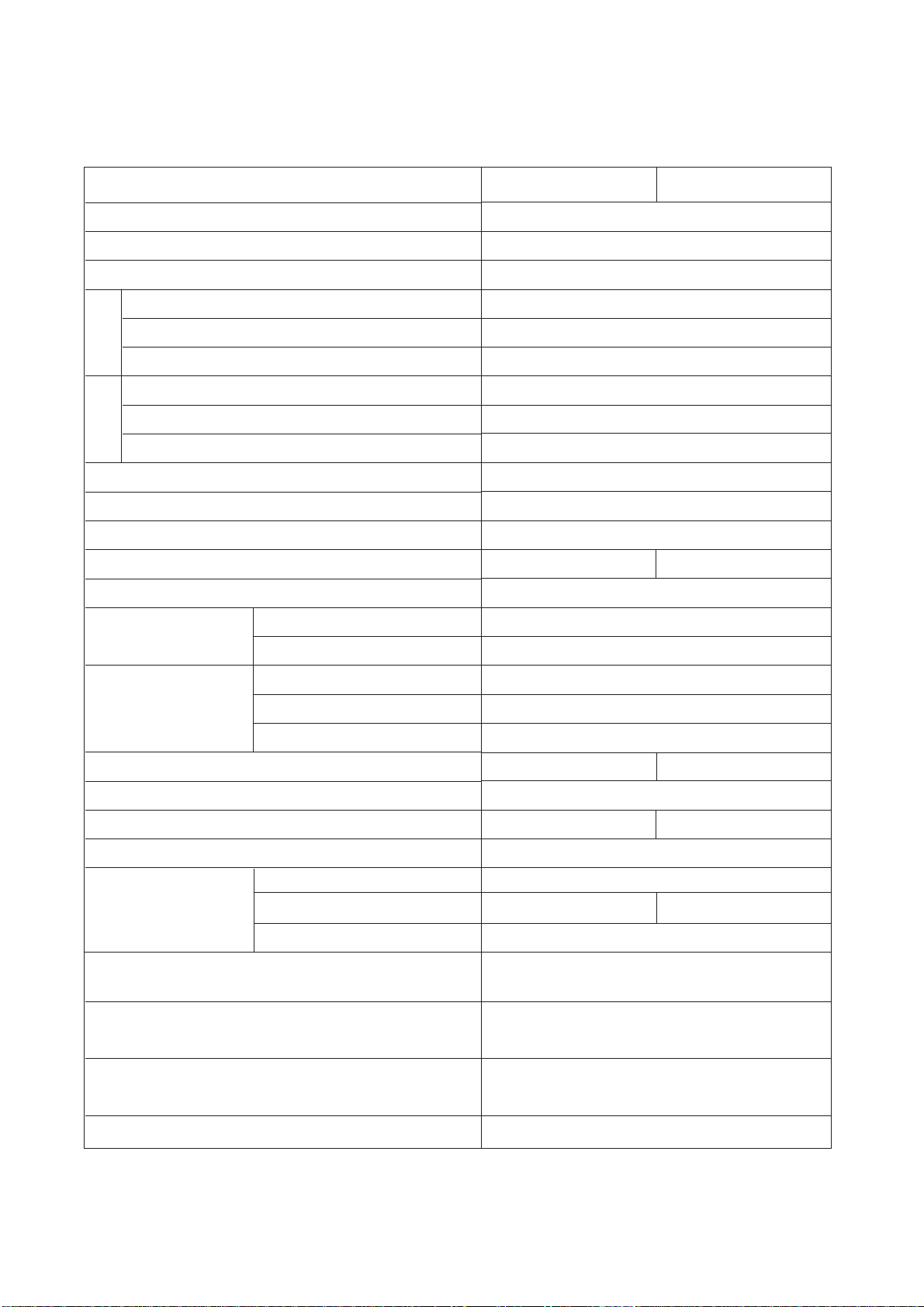

2.2 Combination of Multi Controllers and Indoor Units.

Each Indoor unit is allocated a code number according to its capacity rank. Refer to the table below.

Capacity Rank of Indoor unit

No connection

10

13

16

20

26

36

46

Example: Indoor unit model RAV-362UH-PE, Capacity Rank = 36, Code No. = 8.

(Each Indoor unit Code No. is registered by the capacity rank setting switches on the Multi controller control

board).

Multiple Indoor units may be connected to each Outdoor unit, providing the total Indoor code does not exceed

the limits shown below.

Outdoor Unit

Code No.

0

2

3

4

5

6

8

10

Maximum No. of

Connected Units

Minimum Code No. Maximum Code No.

10HP 2-PIPE (MAR-M102HTM8-PE)

10HP 3-PIPE (MAR-F102HTM8-PE)

The option is available to use a 3-Way Multi controller (for 3 Indoor units), or a 4-Way Multi controller (for 4

Indoor units). If more than 4 Indoor units are required for an Outdoor unit, 2 multi controllers should be used

with T-Piece connections.

Note: It is possible to connect indoor units with a total capacity exceeding the capacity of the outdoor unit

by a maximum of 35%.

2728

5

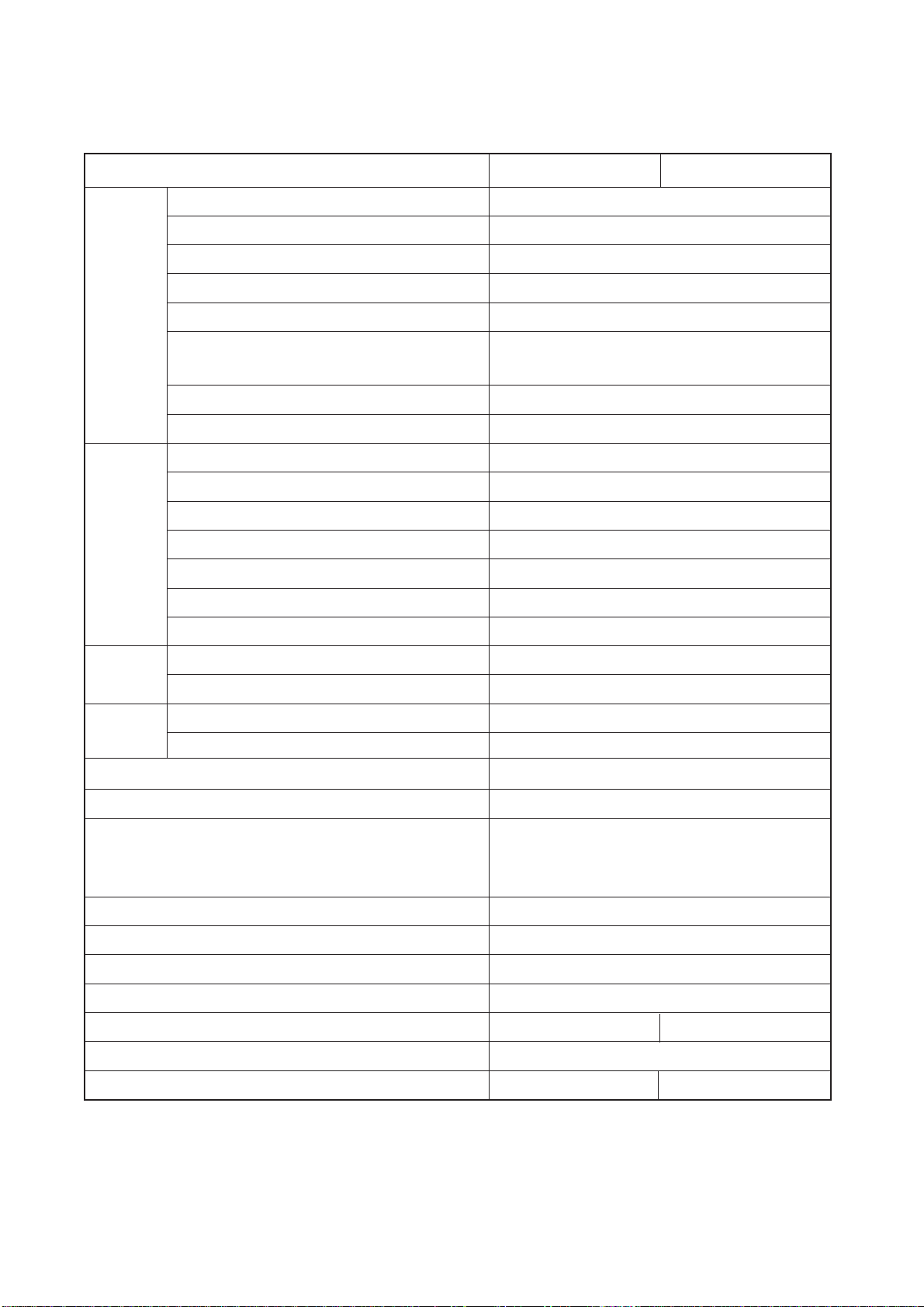

3.1 Specification of Outdoor unit.

3. SPECIFICATIONS

Model Name

Cooling capacity (kW)

Heating capacity (kW)

Power supply

Operating current (A)

Power consumption (W)

Cooling

Power factor (%)

Operating current (A)

Power consumption (W)

Heating

Power factor (%)

Starting current (A)

Starting method

Dimensions (H x W x D) (mm)

Net weight (kg)

Colour

Compressor

Type

Motor output (kW)

MAR-M102HTM8-PE

25.0 (28.0)

28.0 (31.5)

380 – 415V, 3-phase, 50Hz

15.7 (17.2)

10,600 (11,500)

17.7 (15.5)

11,800 (10,500)

1,530 x 1,290 x 834

356

To be confirmed

Hermetically sealed (Twin scroll)

MAR-F102HTM8-PE

97 (97)

96 (98)

60

Direct

370

7.5

Fan

Fan assembly

Refrigerant (charged weight) (kg)

Liquid (mm)

Discharge gas (mm)

Suction gas (mm)

Coupler style

Max. equivalent piping length (m)

Max. actual piping length (m)

Max. piping head (m)

Motor output (kW)

Air flow volume (m3/hr)

Liquid

Discharge gas

Suction gas

Propeller fan

0.15 x 2

10,000

R-22 (18.6)

ø15.9

- ø19.0

ø28.6

Flare connection

-

Brazing connection

120

100

50: When the outdoor unit is installed above.

20: When the outdoor unit is installed below.

R-22 (21.6)

Flare connection

Crank case heater (W)

The specification shown in ( ) denotes operation with the maximum capacity of indoor units connected

(i.e. 135% capacity of the outdoor unit).

Specifications are subject to change without notice.

6

74

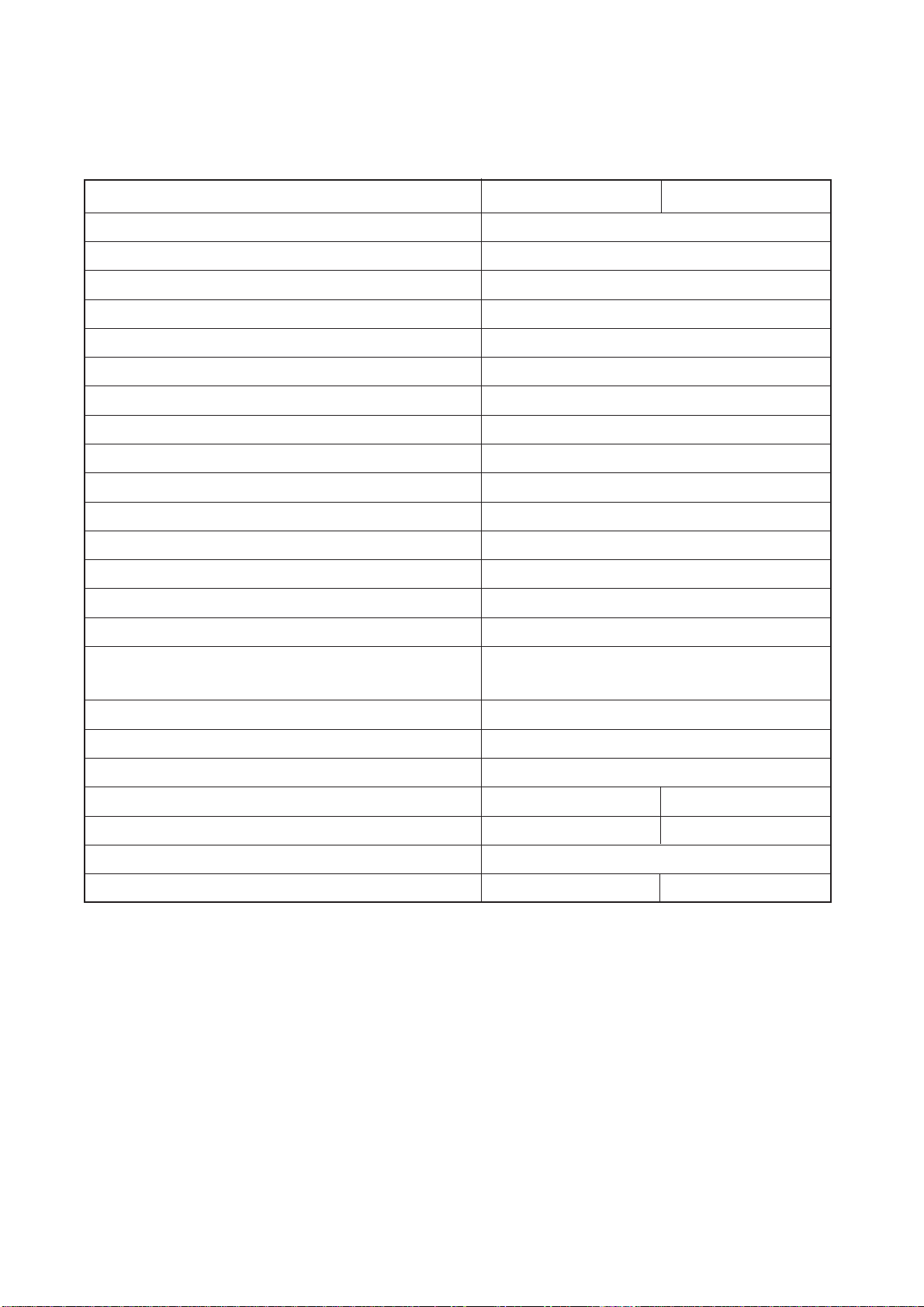

3.2 Specifications of Outdoor unit Refrigerant Cycle Parts

Compressor

motor

Fan

motor

Model Name

Model name

Motor type

Power supply

Output (kW)

Pole (P)

Coil resistance (Ω)

Compressor oil name

Amount of oil (cc)

Model name

Motor type

Power supply

Output (W)

Supply current (A)

Pole (P)

MAR-M102HTM8-PE MAR-F102HTM8-PE

HV1201CW-Y12

3-phase induction motor

380 – 415V, 3-phase, 50Hz

7.5

2/2 (Inverter side/Non-inverter side)

1.49/2.51

(Inverter side/Non-inverter side)

SUNISO 3GSD

7,000

STF-200-150C

1-phase, induction motor

220 – 240V, 1-phase, 50Hz

150

1.12 ~ 1.44

6

Inner over-load relay

High

pressure

switch

Low

pressure

switch

4-way valve

Compressor case heater

Pressure sensor

Discharge temperature sensor

Suction temperature sensor

Outdoor air temperature sensor

Pulse modulating valve (For bypass)

Pulse modulating valve

2-way valve

2-way valve

Model name

Operating pressure (kgf/cm2G)

Model name

Operating pressure (kgf/cm2G)

OFF: 115 ± 5°C

20PS-B (Inverter side), 20PS-G (Non-inverter side)

Operation 30, Reset 23

20PS-1

Operation 0.25, Reset 1.5

CHV-0712, Coil AC240V

AC 240V, 74W

Model name: NTP-Q250TF-2

Input voltage: DC 12V

Output voltage: DC 0.5 – 4.5V

At 25°C = 50kΩ, 50°C = 17.9kΩ, 100°C =3.35kΩ

At 0°C = 32.8kΩ, 25°C = 10kΩ, 50°C = 3.6kΩ

At 0°C = 32.8kΩ, 25°C = 10kΩ, 50°C = 3.6kΩ

NEV202DXF, Coil AC 240V

EV18RC2, Coil DC 12V

-

-

EV23RC8, Coil DC 12V

RP100-03, Coil AC 240V

Specifications are subject to change without notice.

7

3.3 Specifications of Outdoor unit Inverter Assembly Parts.

Model Name MAR-M102HTM8-PE MAR-F102HTM8-PE

Power supply

Output voltage at operating frequency of 60Hz

IGBT

Relay

Fan motor running capacitor

Diode

AC noise filter

DC noise filter

Power supply rectifier capacitor

Fuse

Electronic starter

Reactor

Fan motor relay

Control relay

Magnetic contactor for compressor (Inverter side)

Magnetic contactor for compressor

(Non-inverter side)

380 – 415V, 3-phase, 50Hz

AC 266V

MG50Q6ES11

LY1F (AC 240V)

EAG45M605UF1, 6µF450V

SR130G-160

ZSG2208-02, 8A, 250V

LF215AV, 15A, 716V

LNT2G222KSMCTF, 2200µF/400V

20A

912X25E101YV20

CH-26-T, 6.2mH, 18A

G2R217PV

G4U-112P

13A

15A

Transformer (Inverter)

Transformer (Interface)

Power supply terminal plate

PC board (Inverter)

PC board assembly (Interface)

PC board (Gate)

Cooling fan

Specifications are subject to change without notice.

FT70

FT69

AC600V, 60A

MCC-1251 (INV-M-E) MCC-1251 (INV-F-E)

MCC-1211

MCC-1252

-

MCC-1223

3650EXV-5, 220-240V

8

3.4 Specification of 2-Pipe Multi Controller Parts.

Model Name

Pulse modulating valve

Temperature sensor

Float switch

Model name

Power supply transformer

Specification

Relay (PC board)

Heater

Thermal fuse for heater

Heater fuse

3.5 Specification of 3-Pipe Multi Controller Parts.

Model Name

Pulse modulating valve

Temperature sensor

RBM-Y1032-PE RBM-Y1042-PE

EV23RC7, Coil DC 12V

At 0ºC = 32.8kΩ, 25°C = 10kΩ, 50°C = 3.6kΩ

FS-085-0031

FT69

Primary side:AC240V, Secondary side:AC12V

G2R-117P, Coil DC 12V

10.4 W/m

65W50W

Cut out at 119°C

1A

RBM-Y1032F-PE RBM-Y1042F-PE

EV23RC7, Coil DC 12V

At 0ºC = 32.8kΩ, 25°C = 10kΩ, 50°C = 3.6kΩ

Float switch

Model name

Power supply transformer

Specification

Relay (PC board)

Heater

Thermal fuse for heater

Heater fuse

Discharge gas side 2-way valve

Suction gas side 2-way valve

2-way valve

2-way valve NEV603DXF-AC240V

Specifications are subject to change without notice.

Primary side:AC240V, Secondary side:AC12V

REV-1506DXFQ6, Coil AC240V

FS-085-0031

FT69

G2R-117P, Coil DC 12V

10.4 W/m

Cut out at 119°C

1A

RP100-03, Coil AC240V

NEV202DXF-AC240V

65W50W

9

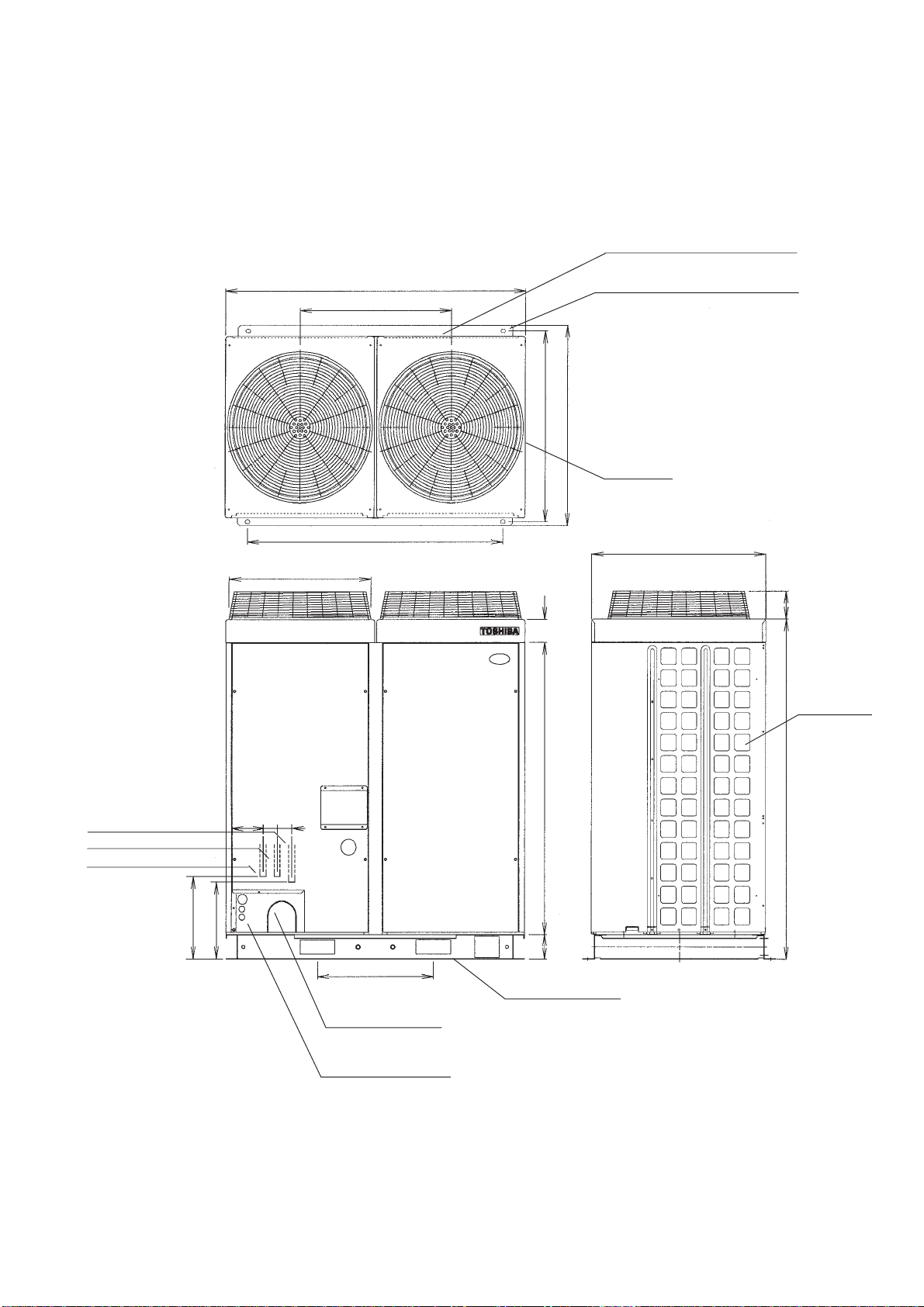

4. CONSTRUCTION VIEWS

4.1 2-Pipe Outdoor Unit (MAR-M102HTM8-PE).

Rear air inlet.

ø 610

1290

650

1100

4 slots (15 x 20) for fixing bolts.

790

834

Air outlet.

750

120

98

Side air inlet.

Refrigerant pipe

connection.

Liquid Ø 15.9

Gas Ø 28.6

365

335

140 65

1212

100

1410

500

2 x Fork lift slots.

Piping knockout.

(150 x 60)

Wiring knockouts.

1 x Ø25, 2 x Ø20

10

4.2 3-Pipe Outdoor Unit (MAR-F102HTM8-PE).

Rear air inlet.

ø 610

1290

650

1100

4 slots (15 x 20) for fixing bolts.

834

790

Air outlet.

750

120

98

Side air inlet.

Refrigerant pipe

connection.

Suction gas Ø 28.6

Discharge gas Ø 19.0

Liquid Ø 15.9

365

335

1212

65

65140

100

1410

500

2 x Fork lift slots.

Piping knockout.

(150 x 60)

Wiring knockouts.

1 x Ø25, 2 x Ø20

11

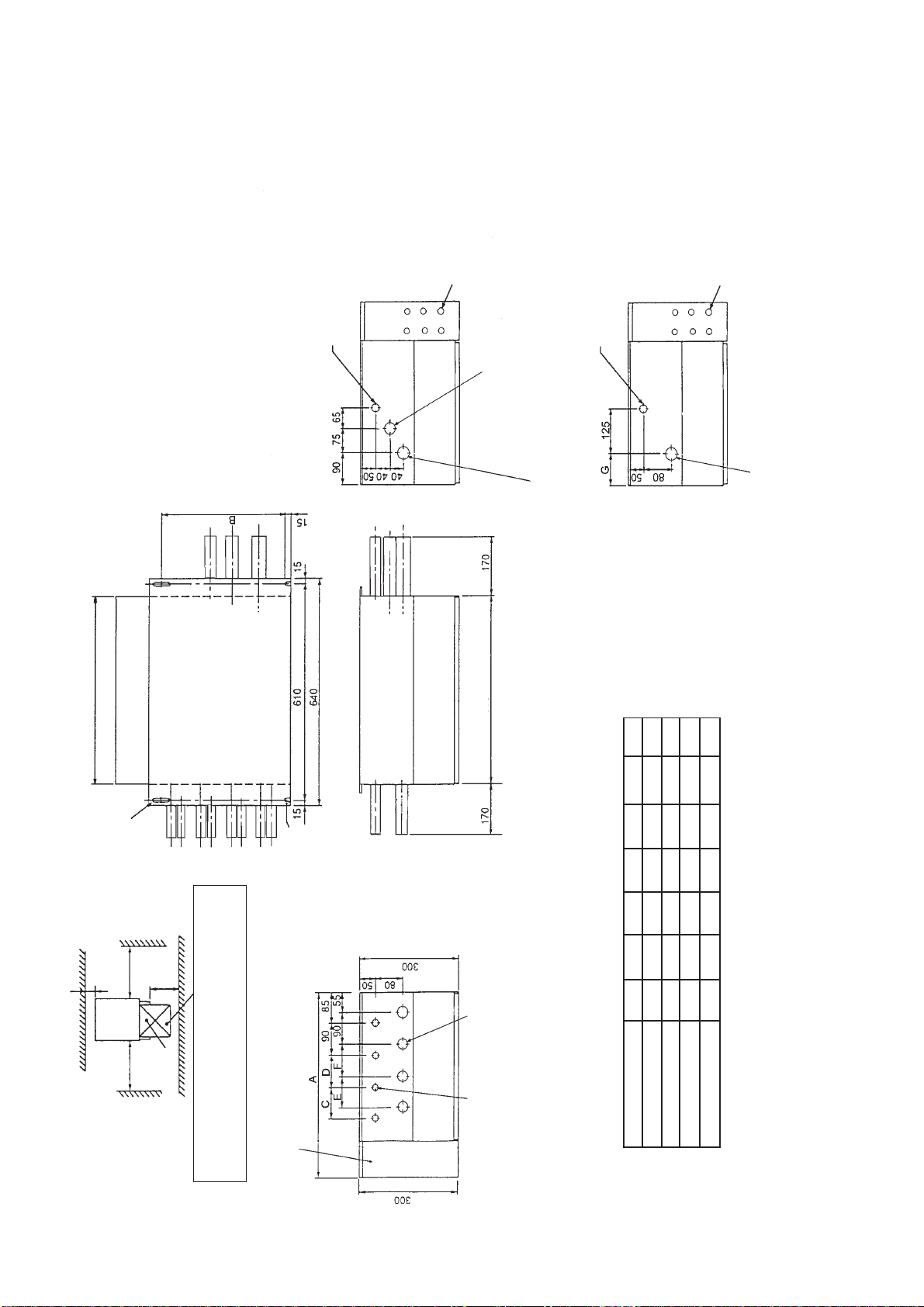

4.3 Multi Controllers.

Wiring knockouts

Refrigerant piping joint (brazing)

Liquid side φ 15.9

6 xφ 20

Refrigerant piping joint (brazing)

Discharge gas side φ 19

Wiring knockouts

Refrigerant piping joint (brazing)

Liquid side φ 15.9

6 xφ 20

540

2 Slots for

hanging bolts

(12 x 52)

3-PIPE: RBM-Y1032F-PE, RBM-Y1042F-PE

540

2-PIPE: RBM-Y1032-PE, RBM-Y1042-PE

Refrigerant piping joint (brazing)

Suction gas side φ28.6

---

---

---

---

---

---

Refrigerant piping joint (brazing)

Suction gas side φ28.6

Indoor unit piping

100 or more

Outdoor unit

side

500

or more

500

or more

piping side

500

or more

450 x 450 inspection opening

Electric parts box

Note: Make an inspection opening at the specified location.

This is required for testing and servicing.

2 Notches for hanging bolt

(12 x 21)

Electrical parts box

Refrigerant piping joint (brazing)

Gas side φ 19

φ12.7

Refrigerant piping joint (brazing)

Liquid side

12

A BC DE F G

460 300 90 90 100

530 370 90 90 90 90 190

460 300 90 90

530 370 90 90 90 90

MODEL

RBM-Y1032-PE

RBM-Y1042-PE

RBM-Y1032F-PE

RBM-Y1042F-PE

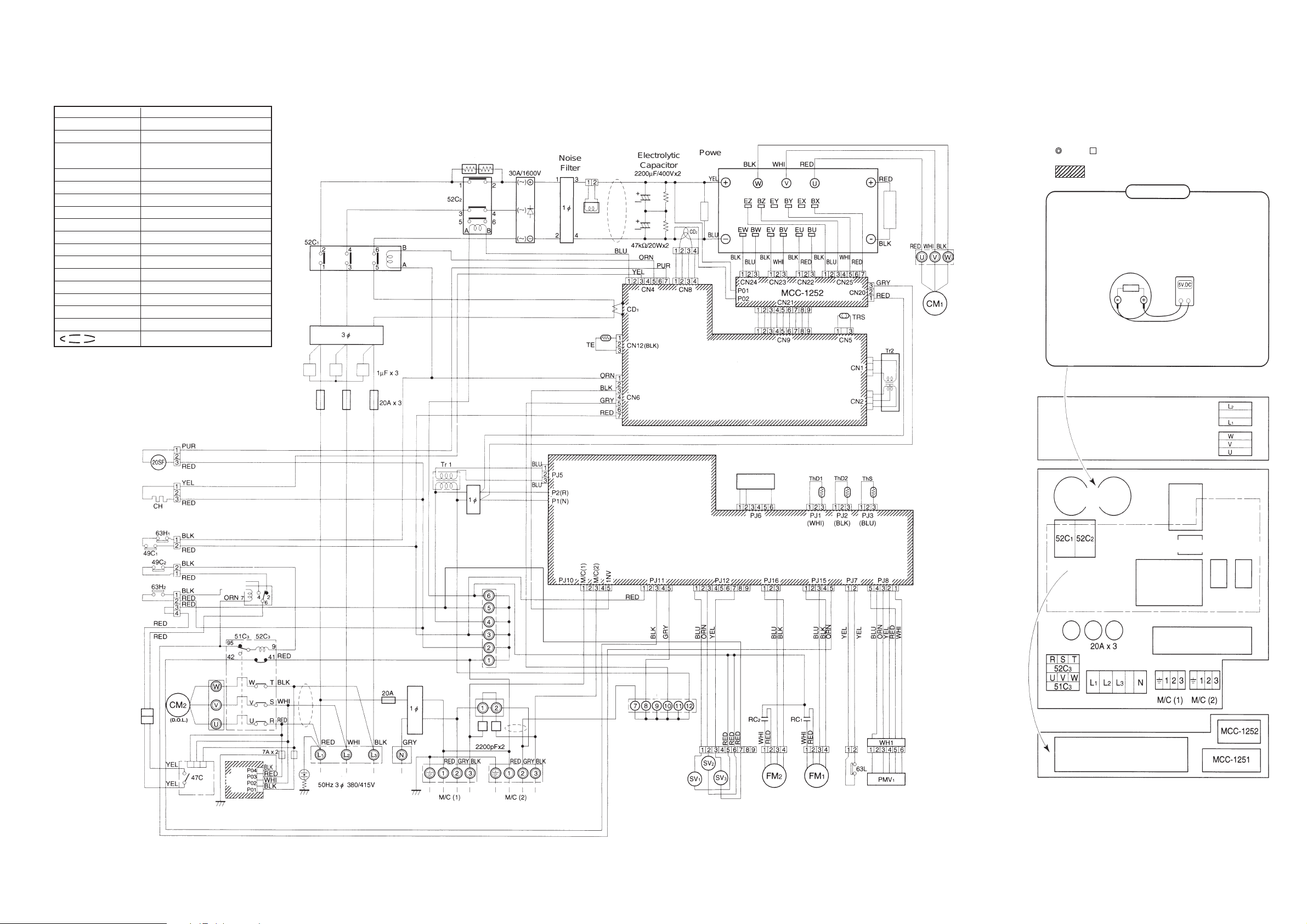

5.1 2-Pipe Outdoor Unit (MAR-M102HTM8-PE)

9

9

5. WIRING DIAGRAMS

Symbol Part Name

CM 1, 2 Compressor

FM 1, 2 Fan Motor

52C 1, 2, 3 Electromagnetic contactor

for compressor

49C 1, 2 Inner overload relay

51C 3 Overload relay

PMV1 Pulse modulating valve

63H 1, 2 High pressure switch

RC 1, 2 Running capacitor

SV 1, 2, 4 Two-way valve

20SF Four-way valve

63L Low pressure switch

CH Crank case heater

Tr 1, 2 Transformer

47C Reverse phase protector

Th D1, D2, S, E Temperature sensor

CD 1, 2 Current detector

Ferrite Core

Noise

filter

Capacitor

Fuse

Electric

Starter

3 ø

Rectifier

Noise

Filter

Reactor

Electrolytic

Capacitor

Power

Transistor

Clip

Diode

Inverter Control PC Board

MCC - 1251

Thermostat

Clip

Diode

(Inverter)

Notes :

1.The dashed lines indicate wiring on site.

2. and indicate terminal blocks, and

numbers within them are terminal numbers.

2345678

2345678

3. indicates a printed circuit board.

DANGER

THE ELECTROLYTIC CAPACITORS IN THIS PANEL ARE CHARGED

TO 600 VOLTS D. C.

BEFORE SERVICING, TURN OFF THE POWER SUPPLY

AND ALLOW AT LEAST 20 MINUTES FOR THE

CAPACITORS TO DISCHARGE TO A SAFE LEVEL OF 5

VOLTS D.C. OR LESS. TEST WITH A D.C. VOLT METER AS

SHOWN.

Resistor

NEVER SHORT THE CAPACITOR TERMINALS WITH ANY METAL

IMPLEMENT TO DISCHARGE. PERSONAL INJURY OR EQUIPMENT

DAMAGE MAY RESULT.

Parts layout

Fuse

Relay

Fuse

Noise

Filter

Noise

filter

Capacitor

Interface Control Board

MCC - 1211

Pressure

Sensor

Electrolytic

Capacitors

PC boards

Fuse

Power supply

PC board locations

MCC-1211

Inverter

Compressor

Power

Transistor

Rectifier

3 ø

Noise filter

Connectors

1~6

7~12

Surge

Absorber

Power Supply

Surge

Absorber

13

14

5.2 3-Pipe Outdoor Unit (MAR-F102HTM8-PE)

9

9

Symbol Part Name

CM 1, 2 Compressor

FM 1, 2 Fan Motor

52C 1, 2, 3 Electromagnetic

contactor for compressor

49C 1, 2 Inner overload relay

51C 3 Overload relay

PMV 1 Pulse modulating vavle

63H 1, 2 High pressure switch

RC 1, 2 Running capacitor

SV 1, 2, 4, 5, 13, 14, 15, 16 Two-way valve

20SF Four-way valve

63L Low pressure switch

CH Crank case heater

Tr 1, 2 Transformer

47C Reverse phase protector

LD 71, 72, 73, 74 Fault indicator lamp

Th D1, D2, S, E. O Temperature sensor

CD 1, 2 Current detector

Ferrite Core

Noise

filter

Fuse

Electric

starter

3 ø

Rectifier

Noise

filter

Reactor

Electrolytic

Capacitor

Power

Transistor

Clip

Diode

Inverter Control PC Board

MCC - 1251

Thermostat

Clip

Diode

(Inverter)

Notes :

1.The dashed lines indicate wiring on site.

2. and indicate terminal blocks, and

numbers within them are terminal numbers.

2345678

2345678

3. indicates a printed circuit board.

DANGER

THE ELECTROLYTIC CAPACITORS IN THIS PANEL ARE CHARGED

TO 600 VOLTS D. C.

BEFORE SERVICING, TURN OFF THE POWER SUPPLY

AND ALLOW AT LEAST 20 MINUTES FOR THE

CAPACITORS TO DISCHARGE TO A SAFE LEVEL OF 5

VOLTS D.C. OR LESS. TEST WITH A D.C. VOLT METER AS

SHOWN.

Resistor

NEVER SHORT THE CAPACITOR TERMINALS WITH ANY METAL

IMPLEMENT TO DISCHARGE. PERSONAL INJURY OR EQUIPMENT

DAMAGE MAY RESULT.

Parts layout

FM3

Inverter

Compressor

Fuse

Surge

Absorber

Relay

Surge Absorber

Power supply

Fuse

Noise

filter

Noise

filter

Pressure

sensor

Interface Control PC Board

MCC - 1223

Electrolytic

Capacitors

PC boards

Fuse

Power supply

PC board locations

MCC-1223

Power

Transistor

Rectifier

3 ø

Noise filter

Connectors

1~6

7~12

15 16

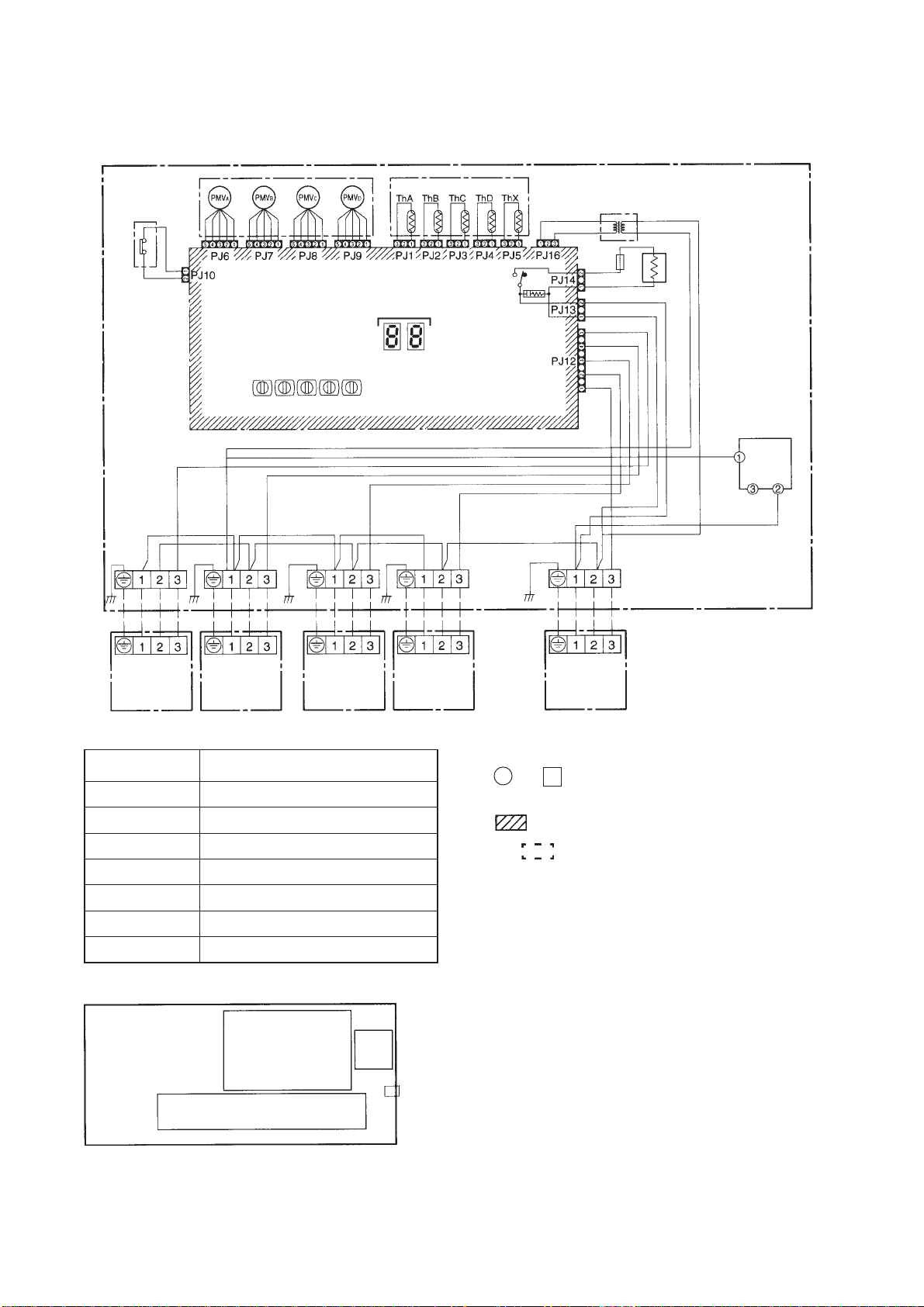

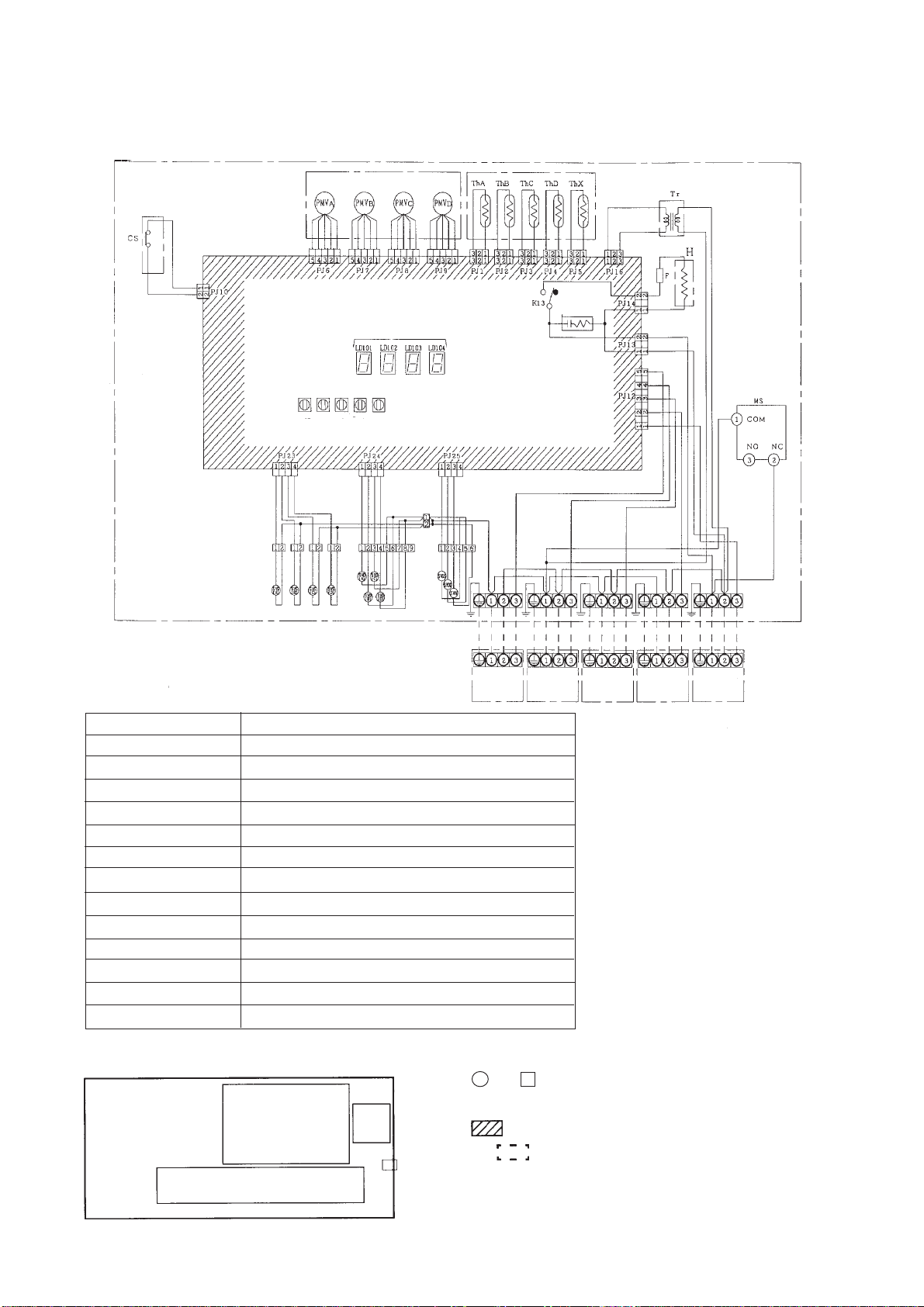

5.3 2-Pipe Multi Controller (RBM-Y1032-PE, RBM-Y1042-PE).

CS

K13

Spark

killer

Capacity

rank

setting

ABCD

7 Segment LED

LD1 LD2

Display selector

switch

Tr

F

H

MS

COM

NO NC

INDOOR

UNIT A

Symbol

PMVA, B, C, D

ThA, B, C, D, X

Tr

CS

H

MS

LD1, LD2

Parts layout

INDOOR

UNIT B

INDOOR

UNIT C

Part Name

Pulse modulating valve

Temperature sensor

Transformer

Float switch

Heater

Reset switch

Fault Indicator LED

Control PC Board

Terminal Plate

Trans

INDOOR

UNIT D

Reset

switch

OUTDOOR

UNIT

• The dashed lines indicate wiring on site.

• and indicate terminal blocks, and numbers

within them are terminal numbers.

• indicates a printed circuit board.

• The frame indicates the product body.

• RBM-Y1032-PE does not have PMVD, ThD or the

connection block for Indoor unit D .

The capacity rank code setting for unit D is to be set to "0".

17

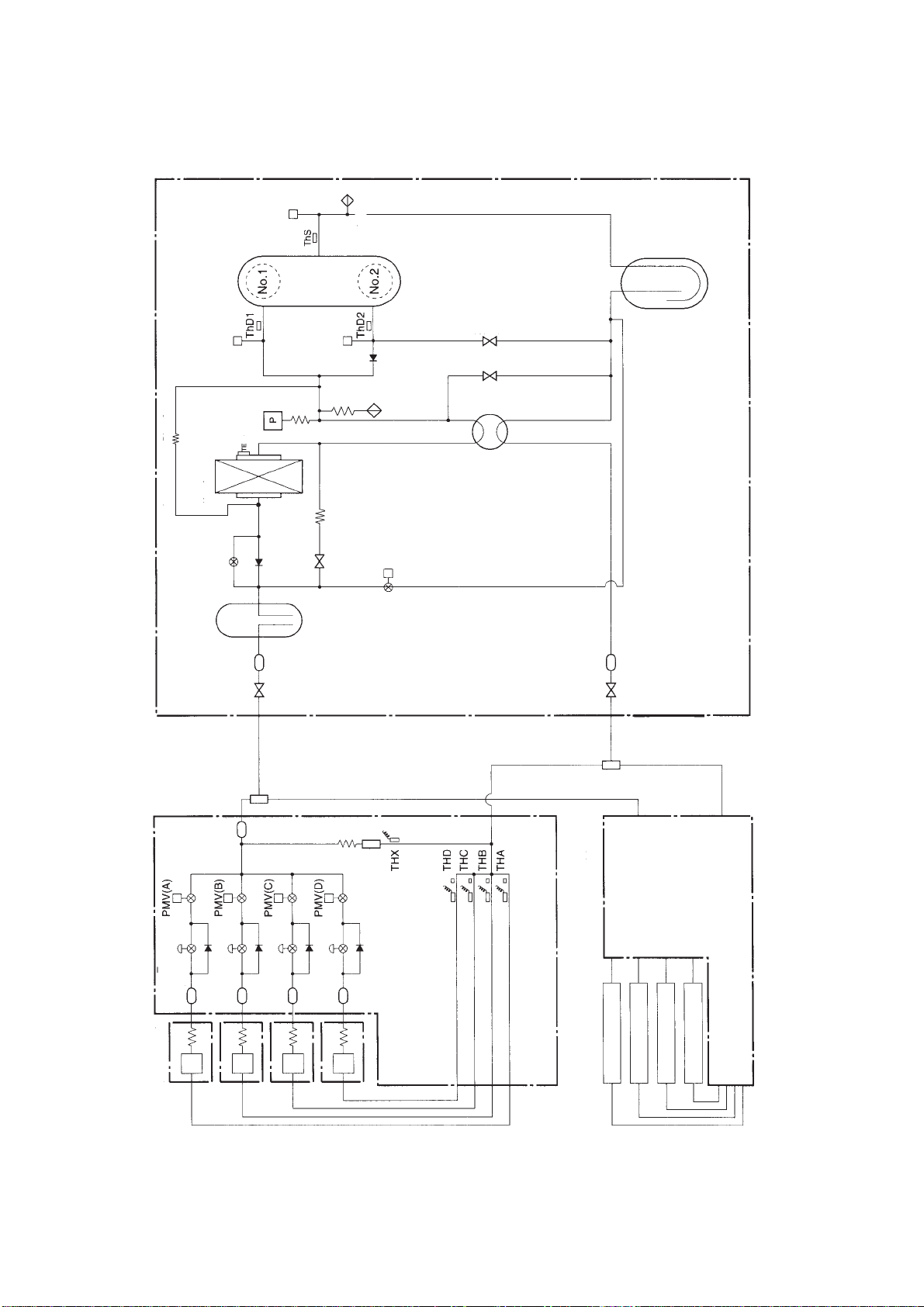

5.4 3-Pipe Multi Controller (RBM-Y1032F-PE, RBM-Y1042F-PE).

7 Segment LED

Capacity rank

setting

B

D C A

Display

selector switch

Spark

killer

Symbol

PMV A, B, C, D

Th A, B, C, D, X

Tr

CS

H

MS

F

SVD (A), (B), (C), (D)

SVS (A), (B), (C), (D)

SVDD

SVSS

SVH

LD 101, 102, 103, 104

Parts layout

Part Name

Pulse modulating valve

Temperature sensor

Power transformer

Float switch

Heater

Reset switch

Fuse (T1A)

Electrically operated valve for discharge gas side

Electrically operated valve for suction gas side

Electrically operated valve for increasing pressure

Electrically operated valve for decreasing pressure

Electrically operated valve for superheat control

Fault indicator LED

Control PC Board

Terminal Plate

Trans

Reset

switch

Indoor

unit A

• The dashed lines indicate wiring on site.

• and indicate terminal blocks, and numbers within them are

terminal numbers.

• indicates a printed circuit board.

• The frame indicates the product body.

Indoor

unit B

Indoor

unit C

Indoor

unit D

Outdoor

Unit

• RBM-Y1032F-PE does not have PMVD, SVD(D), SVS(D) ThD,or the

connection block for Indoor unit D.

The capacity rank code setting for unit D is to be set to "0".

18

6.1 2-Pipe system.

6. REFRIGERANT CYCLE DIAGRAMS

Check

joint

Bypass capillary →1.5 x 600L

Outdoor unit

High pressure

switch

Pressure

sensor

Heat exchanger

Expansion

valve

Packed

valve

Inverter

Dryer

D.O.L.

High pressure

switch

Ø2.0 x 800L Capillary

SV1 (For high pressure release)

receiver

Liquid

Compressor

SV4 (For No. 2 compressor start up)

SV2 (For gas balance and hot gas bypass)

Check

joint

4-Way valve

PMV1 (For cooling bypass)

Service

valve

Accumulator

Strainer

Strainer

Expansion

valve

Multi controller (1)

Strainer

Indoor unit

(Liquid

side)

(Gas side)

Strainer

Multi controller (2)

Indoor unit

19

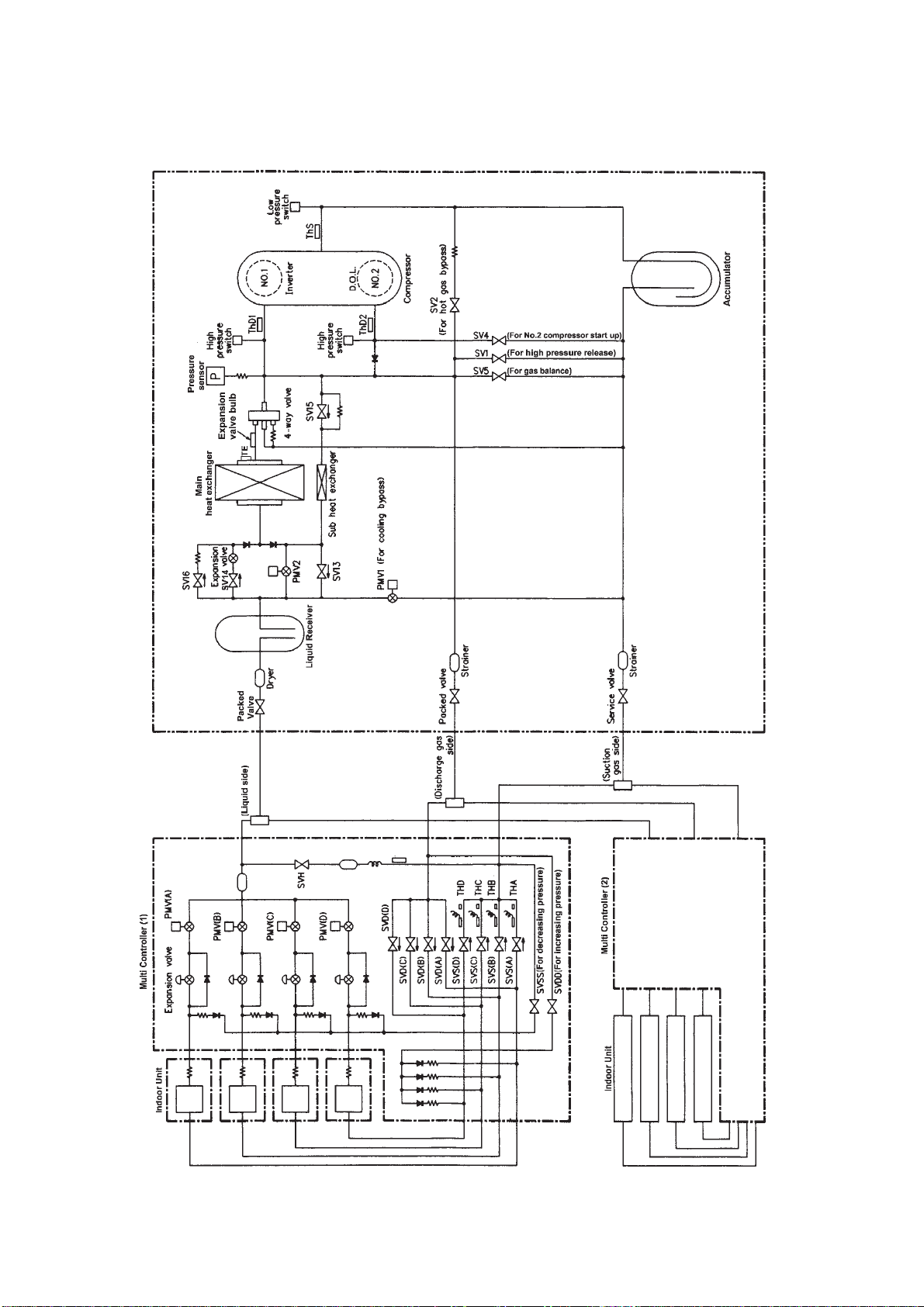

6.2 3-Pipe system.

THX

20

Loading...

Loading...