SERVICE

Forçage des PMV dans le groupe.

Shunter TP1

Mettre le rotatif sw1 sur 0 et TP1 shunté ouverture de la PMV1 pendant 2 mn

Mettre le rotatif sw1 sur 1 et TP1 shunté ouverture de la PMV2 pendant 2 mn (page 42 du MARF102

Couper l'alimentation électrique pour que les vannes restent en ouverture.

Forçage des PMV sur les multi-controllers

Basculer le bouton rotatif de couleur (situé à droite) sur la position 0 et shunté TP1 pour forcer l'ouverture de la PMVA.

Basculer le bouton rotatif de couleur (situé à droite) sur la position 1 et shunté TP1 pour forcer l'ouverture de la PMVB.

Basculer le bouton rotatif de couleur (situé à droite) sur la position 2 et shunté TP1 pour forcer l'ouverture de la PMVC.

Basculer le bouton rotatif de couleur (situé à droite) sur la position 3 et shunté TP1 pour forcer l'ouverture de la PMVD.

Couper l'alimentation électrique pour que les vannes restent en ouverture.

DATA

TOSHIBA

SUPER

CCOOUHEAT

Outdoor Units

Multi-Controller

MULTI

AIR

CONDITIONER

FLEX SERIESI

FILE

NO.

300

-

950

RBM-Y

Forcaae des

Shunter TPI

Mettre le rotatif swl sur O et TPI shunté ouverture de la PMVI pendant 2 mn

Mettre le rotatif swl sur 1 et

Couper I'alimentation électrique pour que les vannes restent en ouverture.

Forcaae des

Basculer le bouton rotatif de couleur (situé à droite) sur la position O et shunté TPI pour forcer I'ouverture de la PMVA.

Basculer le bouton rotatif de couleur (situé à droite) sur la position 1 et shunté TPI pour forcer I'ouverture de la PMVB.

Basculer le bouton rotatif de couleur (situé à droite) sur la position 2 et shunté TPI pour forcer I'ouverture de la PMVC.

Basculer le bouton rotatif de couleur (situé à droite) sur la position 3 et shunté TPI pour forcer I'ouverture de la PMVD.

Couper

PMV

dans le aroupe.

TPI shunté ouverture de la PMV2 pendant 2 mn (page 42 du MARF102

PMV

sur les multi-controllers

I'alimentation électrique pour que les vannes restent en ouverture.

1031FE

PRINTED

IN

JAPAN,

July,

1993

@

TABLE

1

.

MULTI AIR CONDITIONER SYSTEMS AND

THEIR BASIC COMPONENTS

1.1

.

Indoor Remote Controllera

.

1.2 Outdoor Unlis 3 16.3 . Test Run Check

1.3 . Multi-wnlmllera

14

Indoor Units

2

.

CONTRO1 SYSTEM

3

.

REFRIGERANT CYCLE DIAGRAM

4

.

COMBINATION OF INDOOR UNITS AND

OUTDOOR UNITS

4.1 . Baslc Criterls for Combinatlons

4-2

Procedure for Checking ihe Comblnation 7 20.2 . How lo Read the Malfunction Check

4-3 . Exemplee of Connectlon Check

5

.

SPECIFICATIONS OF OUTDOOR UNIT

5.1 . Explanatlon of

Electrlc Characterlstlcs Calculation

6

.

EXTERNAL VIEW

6.1 Outdoor Unit 11

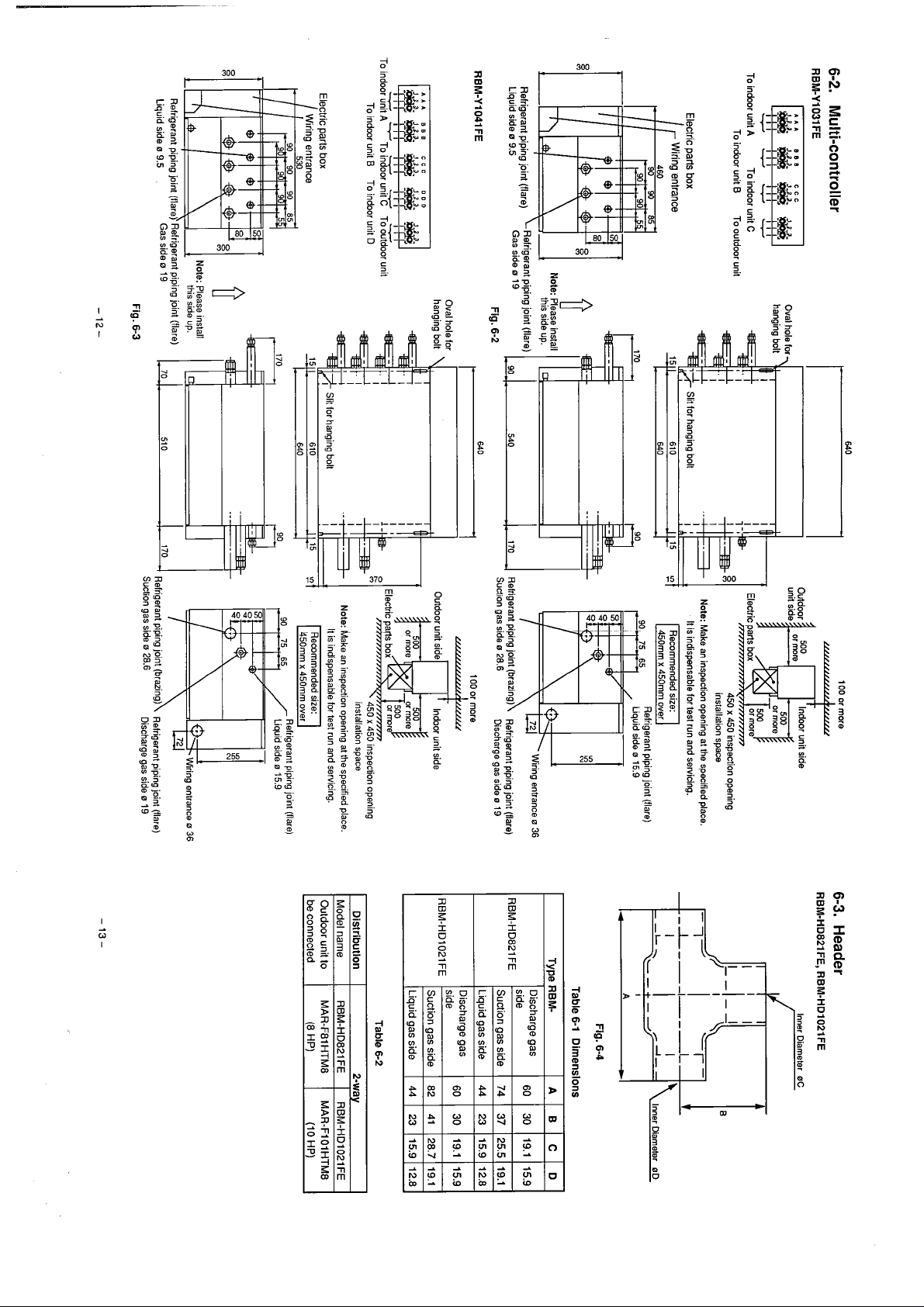

6.2 . Multlcontroller

.

6.3

Header

7

.

WIRING DIAGRAM

7.1. outdoor unlt (YAR.F~~H~~, MAR-F~O~HTM~) 14

7.2 . Mulll-wntmller (RBY.Y1031FE, Yl041FE)

.

8

ELECTRICAL SPECIFICATIONS

l

.

Speclflcatlons

8.2

.

Speclflcatlons oi Inverter Asssmbly Parts

8.3. Speciflcatlons of Multl-contraller Parts

.

9

Coollng/Heatlng Capaclty Characteristics

.

9.1

Range of Operalion 21

9.2 . Coollng Capaclty Calculation

9.3 . Heatlng Capaclty CaIculatIon

10

.

AIR TIGHTNESS TEST, AIR PURGING WITH

VACUUM PUMP AND CHARGING OF

ADDlTlONAL REFRIGERANT

10.1 . Air Tlghtness Test

10.2 . Alr Purging with a Vacuum Pump

10.3 . Addltlonal Refrlgerant Charglng and

Amount of Addltlon

11

.

PIPING LENGTH AND CHARGED

REFRIGERANT AMOUNT

11.1

.

Maln

Branch (One Mulii-Controller)

11.2 . Sub Branch (Two Multl-Controllers)

12

.

DESCRIPTION OF OPERATION

t

2.1 . Slmultaneous Coollngl

Heatlng Operatlon Control Outline

12.2 . Functlons

13

OPERATIONS OF EACH SENSOR

.

13.1. Multi-Controller 33

.

13.2 Outdoor Unlt

14

.

COOLINGIHEATING AUTOMATIC REMOTE

CONTROLLER

14-1

.

CoolinglHeatlng Automatic

ChangeOver Operatlon

15

.

IMPORTANT MATTERS T0 BE CHECKED

BEFORE TEST RUN AND SERVICING

15-1

.

Reglstered Indoor Unlt Code Numbers

15-2 . Connections o1 Refrigerant Piping and

Control Wires

Multi-Controller 37

15-3 . Conneclions of Control Wires between Units

..............................................................

.......................

................................................................ .

...........................................

...............................................

.............................................

.............................................................. .

..........................................................

........,..,

"-m.,.".-

...........................................

of

Refrlgerant Cycle Parto

...................................................

.............................

................................................

and

Operations of Solenoid Valves

.........................................................

.....................................................

..-...

-

..................................................

beiween Indoor Units and

......................................................

...........................

...,.......................

..

.............................

.............

..................

................................

................................

...-.".....

..................................

..................................

................

............

.......................

............................

............

....................

...............

.............

..................

..........................

..

...............

...........................

................................

........................

.......................

......................

.........................

.................

...........................................

...........

...................

....

...

.......

........

OF

2

3

3

3

3

5 19

6

6

8

9

10

11

12

13

14

16

18

18

19

20

21

22

23

A

25

25

26

27

28

28

29

30

30

31

33

34

35

35

36

36

37

CONTENTS

16

.

TEST RUN

.

16.1 Test Run Prooedure 38

16.2

.

Check

.

Guidelines

16.4

17

.

SERVICING PROCEDURES

18

.

CHECK CODE DISPLAY SYSTEM CHART

.

IDENTIFICATION PROCEDURES

20

.

JUDGMENT OF MALFUNCTIONS WITH THE

REMOTE CONTROLLER INDICATION

20.1 . Malfunction Check Dlsplay Operatlon

Monltor Display

20.3 . The Check Code and Ihe Judgmenl

20.4

.

Malfunctlon Judgmeni wlth the Self-Dlagnostlc

Function of the

20.5 . Malfunction Judgment wlth the Sell-Dlognoatlc

Functlon of the Multl-Controller

20.6. PMV Openlng

Pressure Sensor Data Code Display

Conversion Table

21

.OTHERS

21.1 . Microprocessor System Dlagram and the Tlme

Requlred lo Judge the Malfunctlon

21.2 . A Check of ihe Conlrol Clrcuit Power Voltage of

the

Multi-Controller Control Board

21.3

.

A

Check of rhe Control Clrcult Power Voltage of

theoutdoot Interface Board

21.4 220 - 240V Systein Dlagram

.

22 . REMOTE CONTROLLER DISCRIMINATION

FUNCTION, OUTDOOR UNIT

D

ISCRIMINATION FUNCTION

.

22.1 Search from the Remote Controller

.

22.2 Search from Outdoor Unit 76

23

.

CHECK FOR REFRIGERANT PIPING AND

INTER-UNIT WIRING CONNECTION

23.1

.

Check System Procedure8

24

.

REMOVAL METHOD

24.1 Outdoor Unlt (MAR.FSlHTM0, FlOlHTM8)

.

24.2. Multi-Controller (RBM.Y1031FE, Y1 WlFE)

25

.

EXPLODED VIEWS AND PARTS LIST

25.1 . Outdoor Units

(MAR-FS1 HTM8, MAR-FlOIHTM8)

25.2 . Electrical Parto Assembly

(MAR-FS1

25.3

.

Multi-Controller

(RBM.Y103IFE, RBM-Yl041FE)

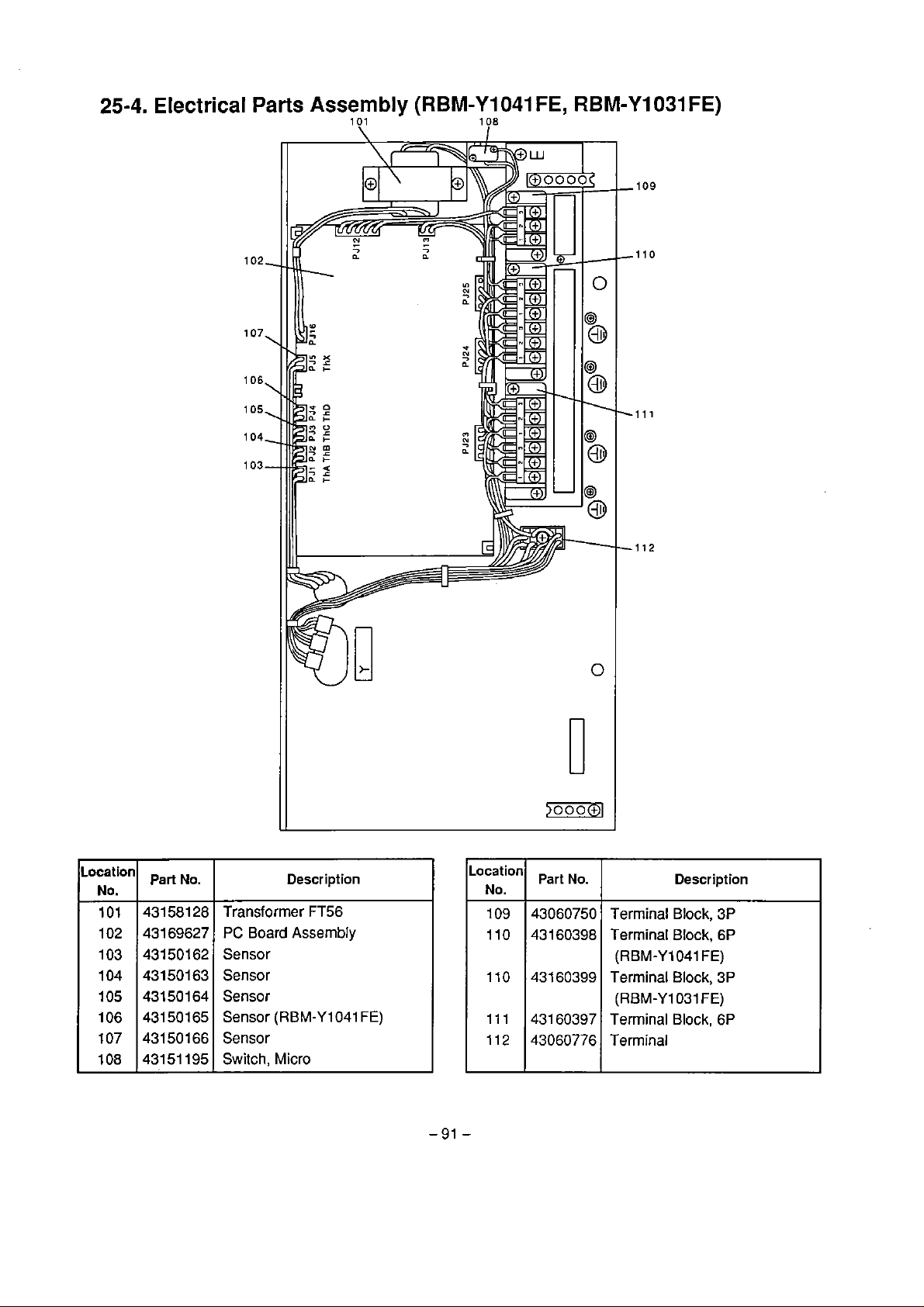

25.4 . Eleclrical Parts Assembly

(RBM.Y1031FE, RBM-Y1041FE)

.........................................................

...................................................

before

Test Run

..............................................

...........................................-.............

..................................................................

............................

...................

...........

.....................

.,.,.,

......,.....,..

"v-.

.........................

Outdoor Unlt

....................................

.....................

Degree,

Temperature Sensor and

.......................................................

............................................................

........................

...........................

..........................

.............................

.........................

........................

...............

J

..............

..............

...........

...........................

..........................

................................

................................

HTMB,

MAR-F101HTM8)

.........................................

...........................

........................................

30

38

39

41

43

....

45

46

49

49

50

51

57

.....

64

67

71

71

72

......

73

....

74

76

36

77

70

78

83

86

...8

6

.88

90

91

1.

MULTI AIR CONDITIONER

COMPONENTS

These multi

sirnultaneously.

air

conditioner systerns allow separale operation of each indoor unit

Multi-controller

SYSTEMS

AND THEIR BASIC

in

both heating and cooling

Cooling operaiion

0

Heating operation

+

Danger:

Fig.

1-1

Be

sure to provide a ventilator in a room, because;

This multi air conditioner system contains a large amount

a

case of a refrigerant leakage frorn

with a large volume of refrigerant gas.

Consequently, people or

anirnals in the room

indoor unit, a room equipped with the indoor unil

may

be

suffocated by lack of oxygen.

of

refrigerant

Indoor remote controller

(HCFC

22).

In

the worst

is

filled

1-1.

Indoor remote controllers come either with or without lhe automatic heatinglcooling mode lunction. Automatic

heating

1-2.

Two types of outdoor units are available in the iine-up:

both types are used in combination.

1-3.

Multi-controllers are refrigerant distributing devices to connecl multiple indoor units with the outdoor unit. The

series includes 3-way (for 3 indoor units)and 4-way multi-controllers. To make

indoor units) system, the 3-way and 4-way mu#icontrollers are used in combination wilh a header.

1-4.

There is a wide range ol indoor units totaling

Refer to

Indoor

and

Remote

cooling operations can be controlled by those that equipped with Ihe funclion.

Controllers

Outdoor Units

8

HP

and

10

HP.

For

16

Multi-controllers

Indoor

table

4-1.

Units

13

models

(3

types with 6 capacity ratings from

HP or larger applications,

a

5-,

6-,

7-

or 8-way (for

1.5

to 5 HP).

8

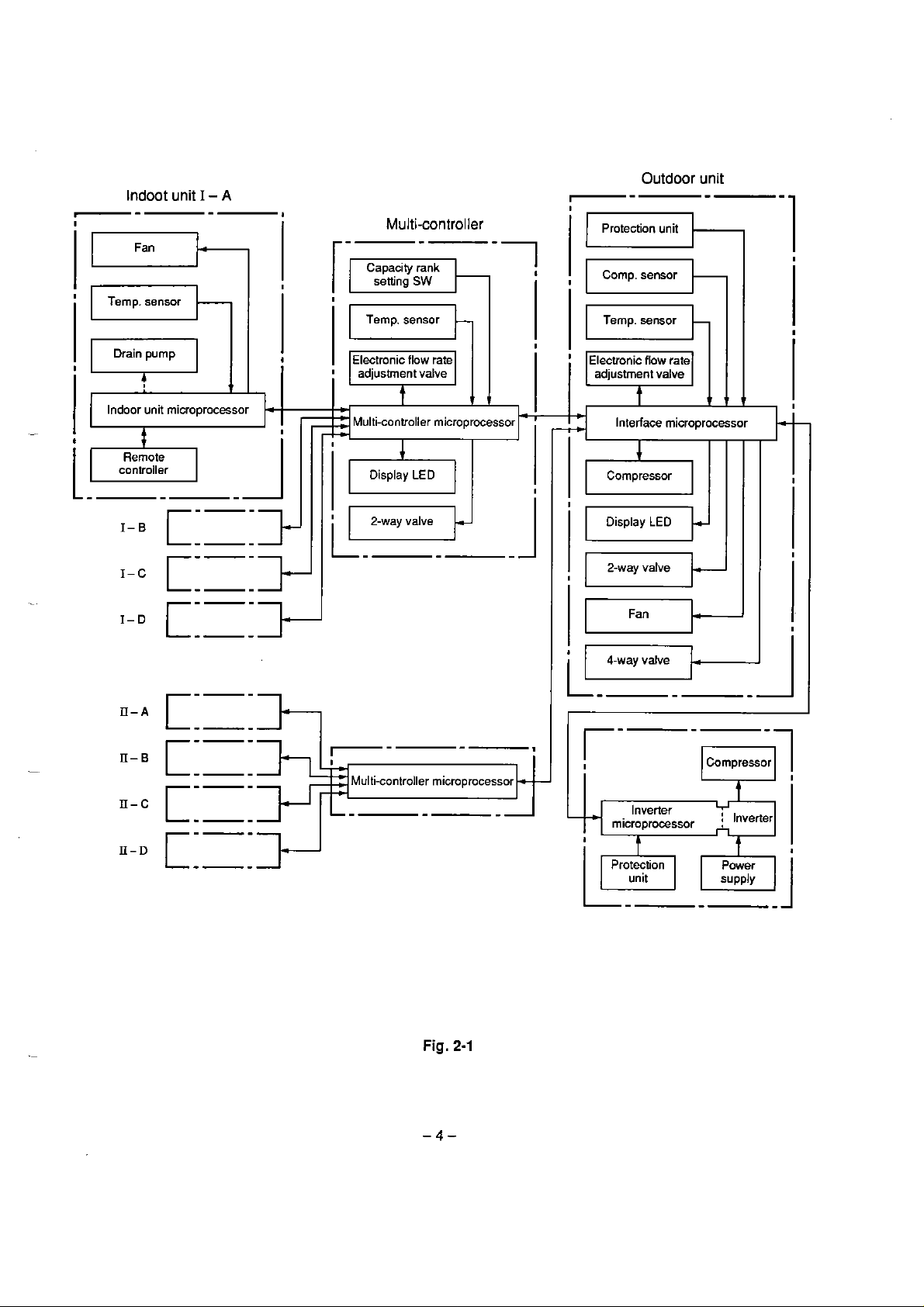

2.CONTROL

The refrigerant and electrical systems of the multi air conditioner system are controlled by the

multi-controllers and rnicroprocessor contained inside the outdoor unit. The indoor units of the CooltHeat

Flex Series of Multi Air Conditioner Systerns are the same units as in the RAV-series air wnditioner systems.

For system operation, first the microprocessor in each indoor unit reads the difference between Ihe current

room temperature and desired temperature which has been set by the remote

corresponding

operation comrnands

On the basis of the operation commands sent lrom al1 the indoor microprocessors, the multi-controller

microprocessors adjust the cooling and heating operation commands and send them to the interface

microprocessor in the ouldoor unit. The inleriace microprocessor calculates the capacity required for cooling

and heating, determines Ihe operation mode in the outdoor unit and

compressor and

frequencies of

SYSTEM

controller, determines the

demand signai, and transmits this to the multicontroller rnicroprocessors in the form

(ONJOFF,

al1 the requested heating command dilference between al1 the requested cooling command

the compressor of al1 the indoor units.

coolinglheating operation mode, operation frequency of the compressor).

calculates frequencies of the

of

-

r-

Indoot unit

Fan

Temp. sensor

Outdoor

I

-

A

1

Multi-controller

Capacity rank

setting

SW

Temp. sensor

-

7-

Protection unit

Comp. sensor

Temp. sensor

unit

.

-

-

-

1

Electronic flow rate

adjustment valve adjustment valve

Indoor unit microprocessor

.>

I-.

cm-'>

-P-

Multi-controller microprocessor Interiace microprocessor

Display

LED

2-way valve Display

Electronic flow rate

Compressor

LED

2-way valve

Fan

v

4

"'"

:

L.

----

----

I-

Multi-controller microprocessor

r-

-

Inverter

microprocessor i Inverier

Compressor

V

-1

D

t-----

----

Fig.

2-1

Ptotection

L+

unit

3.

REFRIGERANT

CYCLE

DIAGRAM

Fig.

3-1

Exarnples

of

8

and

10

HP

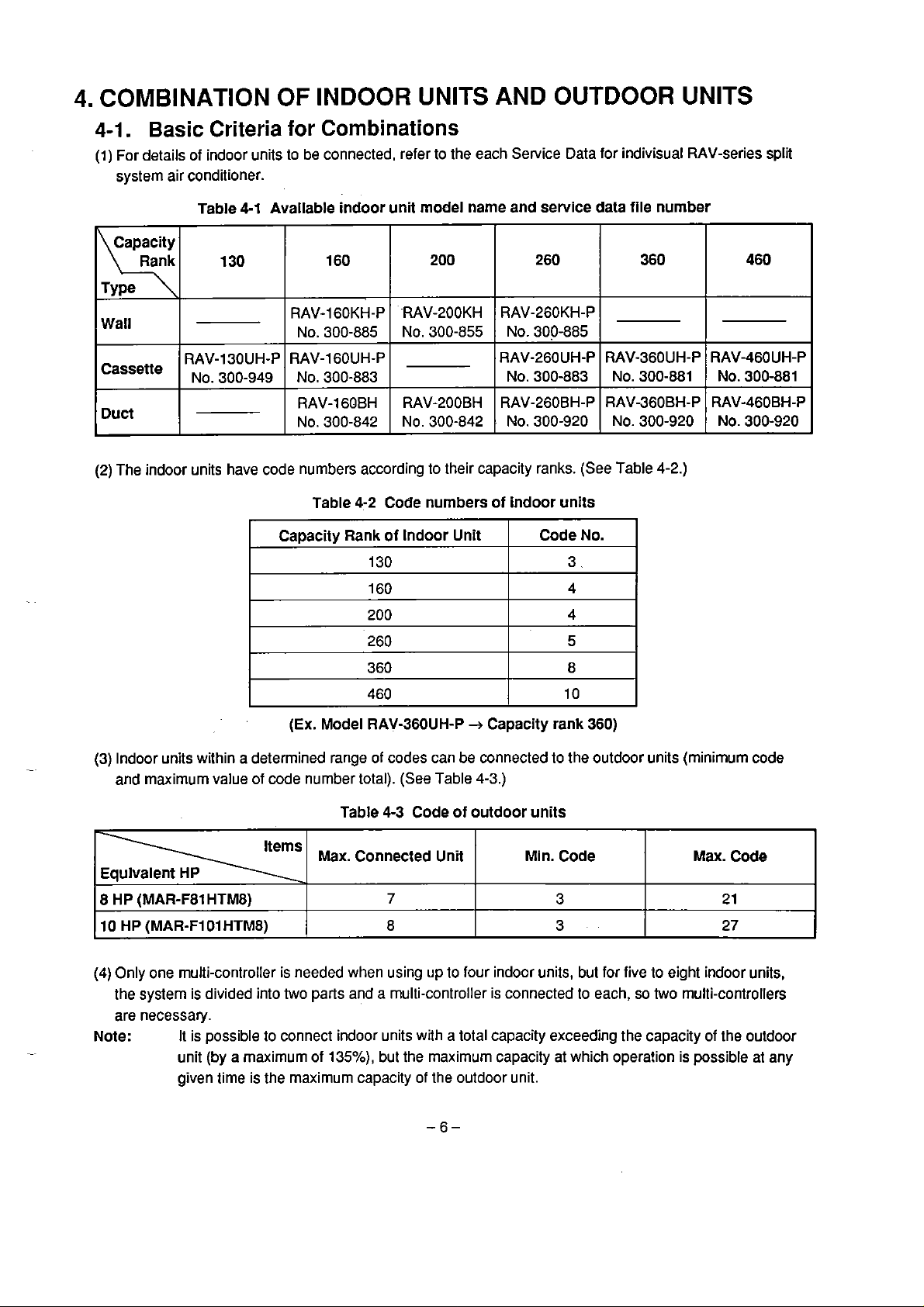

4.

COMBINATION OF INDOOR UNITS AND

OUTDOOR

UNITS

4-1.

(1) For details of indoor units to be connected, referto the each Service Data for indivisual RAV-series split

Wall

Cassette

Duct

(2)

Basic

systern air conditioner.

The indoor units have code numbers according to their capacity ranks.

Criteria for Combinations

Table

4-1

Available indoor unit mode1 name and service data file nurnber

130

RAV-130UH-P

No. 300-949

Capacity Rank of tndoor Unit

160

RAV-16OKH-P

NO. 300-885

RAV-1 6OUH-P

No.

300-883

RAV-160BH

NO.

300-842

Table

4-2

130

160

200

260

360

460

-RAV-200KH

NO. 300-855

RAV-200BH

NO. 300-842

Code numbers of indoor units

200

260

RAV-260KH-P

NO. 300-885

RAV-260UH-P

No. 300-883

RAV-260BH-P

NO.

300-920

Code No.

3.

4

4

5

8

10

360

RAV960UH-P

No. 300-881

RAV-36OBH-P

NO. 300-920

(See

Table

4-2.)

460

RAV46OUH-P

No.

300-881

RAV-460BH-P

NO. 300-920

(Ex.

Model RAVS6OUH-P + Capacity rank 360)

(3)

Indoor units within a determined range of codes can be connected to the outdoor units (minimum code

and maxirnum value of code number total). (See Table

4-3

Code of outdoor units

7

with

but the maximum capacity at which operation is possible at any

8

HP

(MAR-F81

l0

HP

(MAR-F1 O1 HTM8) 8

(4)

Only one multi-controller

the systern is divided into two

are necessary.

Note:

HTMB)

It is possible to connect indoor units

unit (by a maxirnurn

given time is the maximum capacity of the outdoor unit.

Table

Max.

Connected Unit Min. Code

is

needed when using up lo four indoor units, but for five to eight indoor units,

parts and a multi-controller is connected lo each, so two multi-controllers

of

13S0h),

4-3.)

Max.

3

3

a total capacity exceeding the capacity of the outdoor

2

27

Code

1

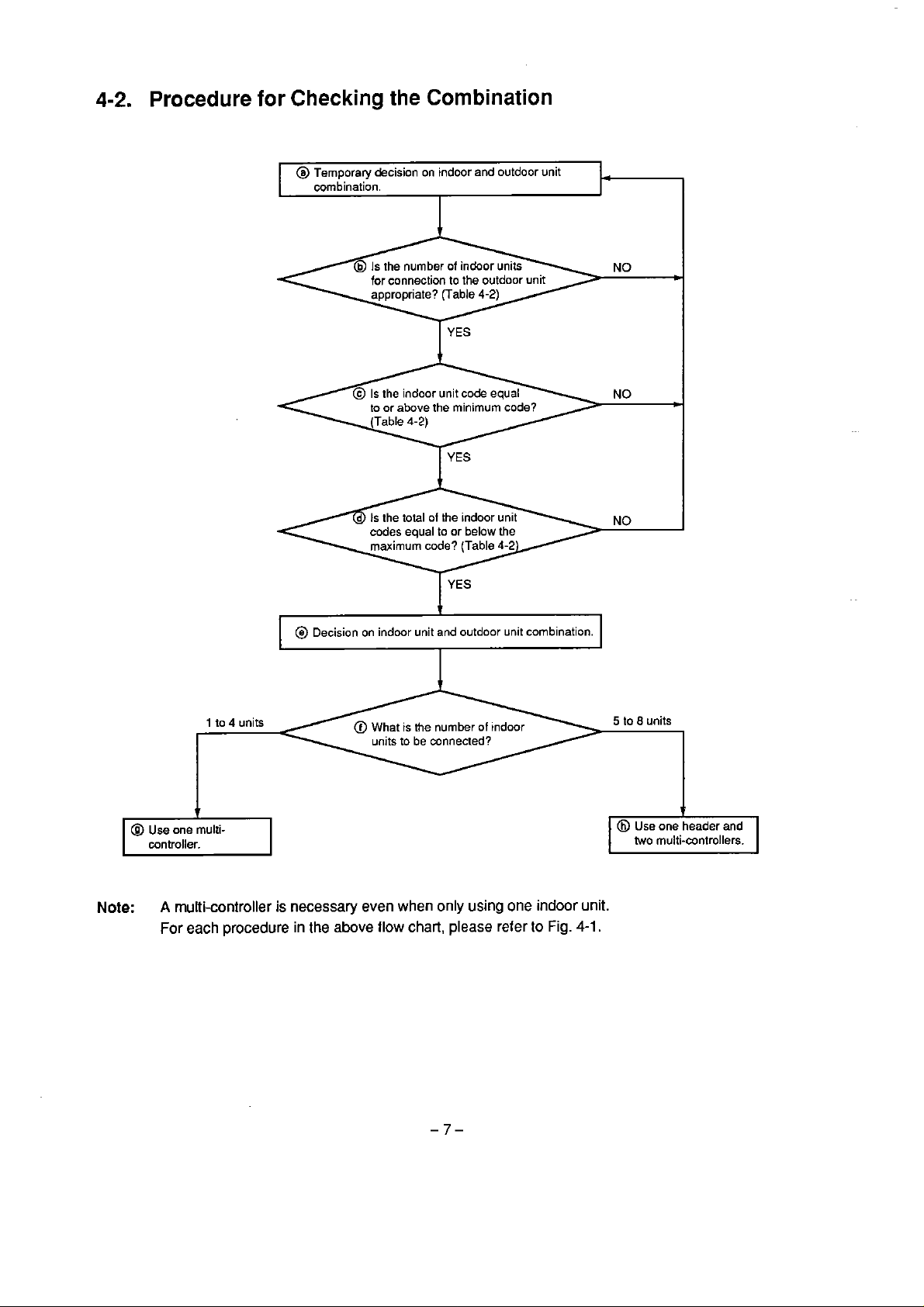

4-2.

Procedure

for

Checking

combination.

the

Combination

Note:

1

to

4

A

multi-controller

For

each

procedure

@

L

units

is

necessary

in

Decision on indmr unit and outdoor unit combination.

@

What

is

the

nurnber

of

indoor

the

even when

above

flow

only

chart,

using

please

one indoor

reter to

Fig.

unit.

4-1.

5

io

8

units

two

multi-wntrollers.

4-3.

Examples

of

Connection

Check

code

@Check

for

the

unii

qliantiy

Fig.

4-1

6-o)

.

Totai Indoor

<130>~9+3~3

0TYType33a3

Cr)

(130I~~pe-3ra

(200)

(200')

(200)

Totai Indoor

unitcode

Outdoor

unitcode

Outdoor

~ype

-

:

L,,,,,,J

unit

Max.

Type

-c

Type

-

~~~e + 423

~ype

-,

,,,,,,

unit

Max.

8z3

code

3 r 3

4

r

3

423

code

7

,

'

@~heck

for

M,,co*

h

,

'I

i

C

lhe

-

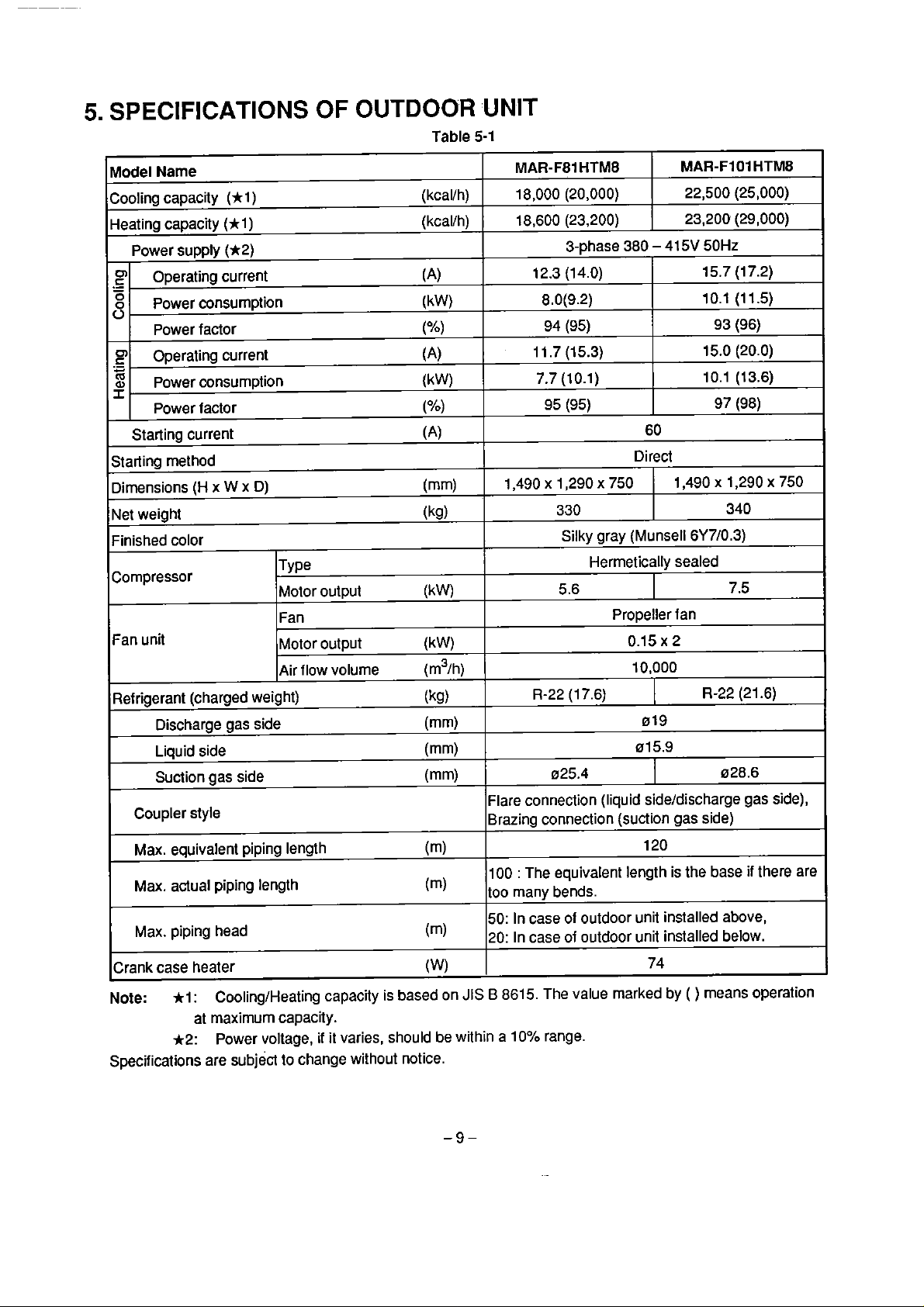

5.

SPECIFICATIONS

OF OUTDOOR

Table 5-1

UNIT

Model

Name

Cooling capacity (h 1) (kcallh)

Heating capacity (*l

Power supply

Operating current

.-

-

O

Power consumption (kW)

8

Power factor

Operating currenl

.-

C

m

CB

Power oonsumption (kW)

I.

Power facior ("/o)

Starìing current

Starting rnethod

Dimensions

Net

weight

Finished color

Compressor

Fan unii

(H

(*2)

x W x

)

D)

TYP~

Motor output

Fan

Motor output

Air flow volume (m3/h)

(kcallh)

(A)

(%l

(A)

(A)

(mm)

(kg)

(k

W)

(kW)

MAR-F81

18,000 (20,000)

18,600 (23,200)

12.3 (1

1 1.7 (15.3)

1,490 x 1,290

HTM8

3-phase 380 - 415V 50Hz

4.0)

8.0(9.2)

94

(95)

7.7 (10.1)

95

(95)

330

Silky gray (Munsell

5.6

MAR-FIO1

22,500 (25,000)

23,200 (29,000)

15.7 (17.2)

10.1 (11.5)

15.0 (20.0)

10.1 (13.6)

60

Direct

x

750

Herrnetically sealed

Propeller fan

0.15

1,490 x 1,290 x 750

6Y710.3)

x

2

10,000

93

97

HTMB

(96)

(98)

340

7.5

Refrigerant (charged weight)

Discharge gas side (mm)

Liquid side (mm)

Suction gas side (mm)

Coupler style

Max.

equivalenl piping length

Max. actual piping

Max. piping head

Crank case heater

Note:

Specificalions are subject to change without notice.

l:

al maxirnum capacity.

*2:

length

CoolingtHeating capacity

Power voltage,

ii

it varies, should be within a 10% range.

is

based on

(kg)

(m)

(m)

(m)

(W)

R-22

(17.6) R-22 (21.6)

019

015.9

025.4

Flare connection (liquid sideldischarge gas side),

Brazing connection

100

:

The equivalent length is the base

many bends.

too

50: In case of outdoor unit installed above,

20: In case of outdoor unit installed below.

JIS B 8615. The value marked by

1

(suction gas side)

120

74

028.6

(

)

means operation

if

there are

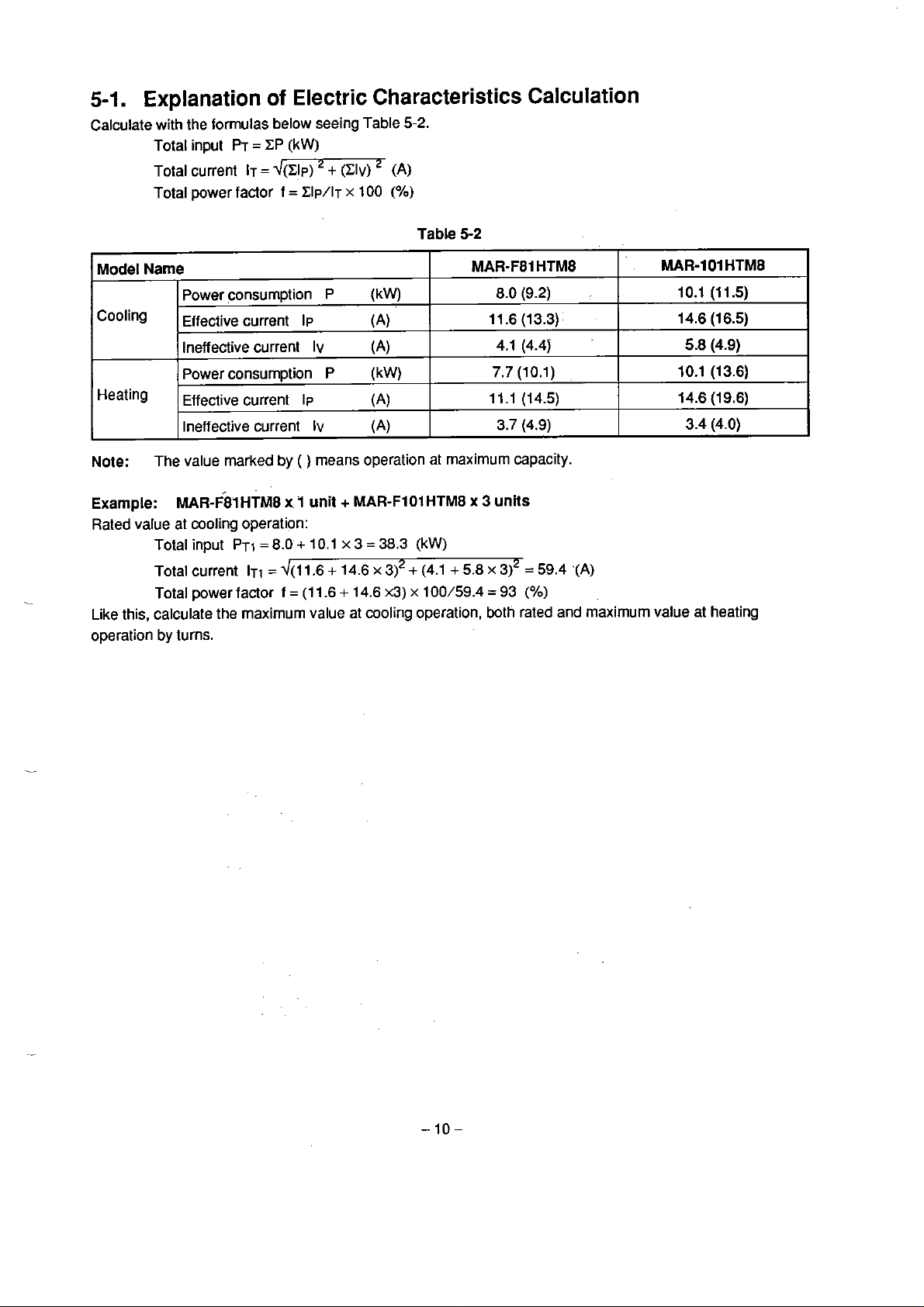

5-1.

Explanation

of

Electric Characteristics Calculation

Calculate with the formulas below seeing Table

Totat input

Total current

Total power factor

PT

=

CP

IT

=

~(CIP) + (CIv)

(kW)

f

=

Clp/l~

x

100

(A)

(Oh)

5-2.

Table

5-2

Model

Narne

Power consumption

CoOling

Effettive

Ineffective current

Power consurnption P

Heating

Effettive

Ineffective current

Note:

Exarnple:

Rated

The value marked

MAR-F01HTM8

value at moling operation:

Total input

Total current

Total power factor

Like this, calculate

by

operation

turns.

MAR-F81 HTM8

+

x

5.8

8.0 (9.2)

11.6 (13.3)

4.1

(4.4j

7.7

(10.1)

11.1

(14.5)

3.7

(4.9)

3

units

x

3)2

=

59.4

=

93

(%)

.(A)

P

(kW)

current

IIJ

IV

(A)

(A)

(kW)

current lp

Iv

by

(

)

means operation at rnaximum capacity.

x

1

unit

PT~

=

8.0 + 10.1 x 3 = 38.3

ITI

=

d(11.6 + 14.6

f

=

(1 1.6 + 14.6

the

maximurn value at cooling operation, both rated and maximurn value al heating

(A)

(A)

+

MAR-FlOlHTM8

(kW)

x

312

+

(4.1

x3)

x

100/59.4

MAR-101

10.1

14.6 (16.5)

5.8

10.1 (13.6)

14.6

3.4

HTMB

(l

1.5)

(4.9)

(19.6)

(4.0)

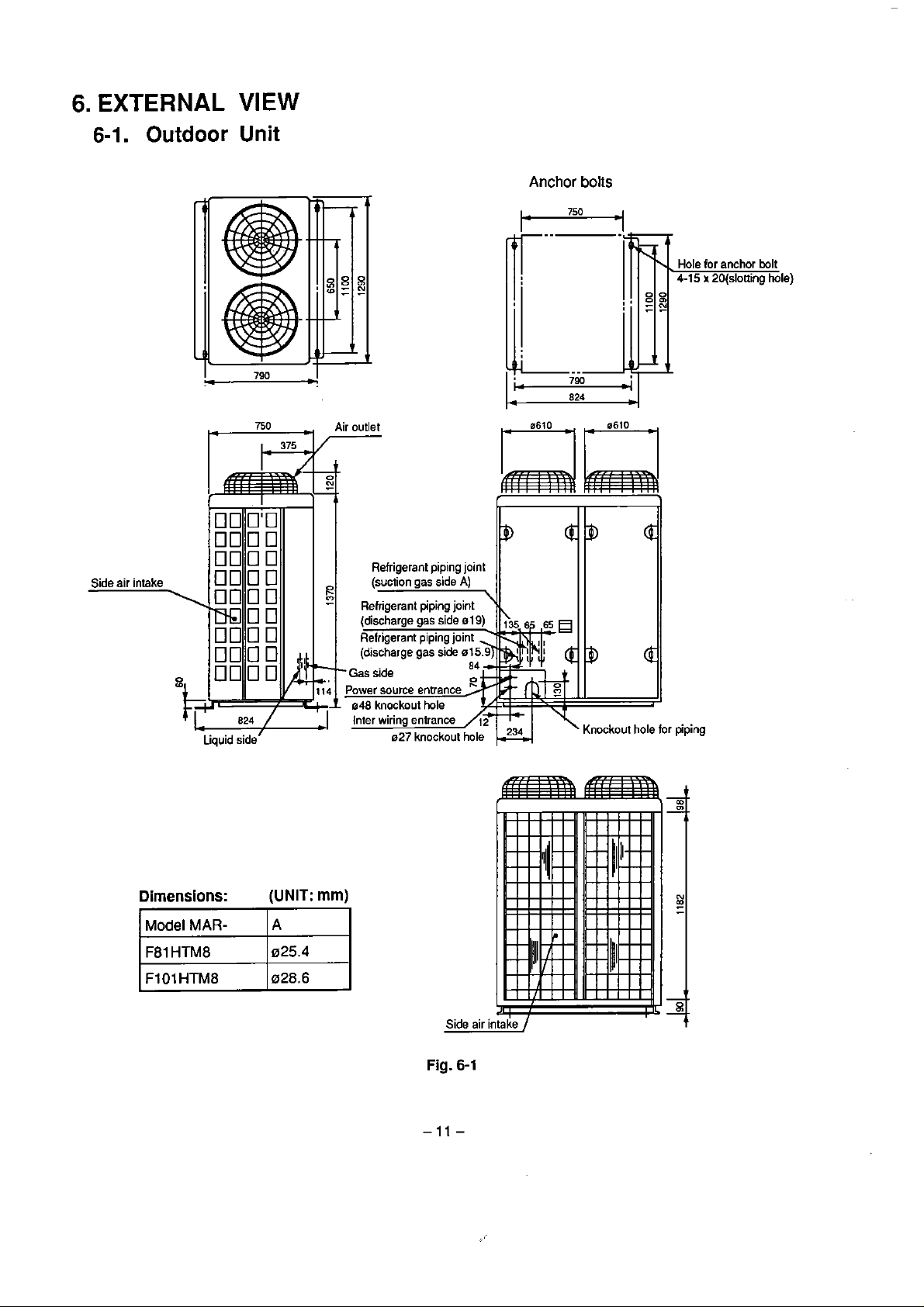

6.

EXTERNAL

VIEW

6-1.

Side

air intake

Outdoor

Unit

750

Air

outlet

Anchor

boiis

for

anchor bolt

x

20(slotting hole)

Dimensions:

Model

MAR-

(UNIT:

I

A

mm)

Fig.

6-1

'

piping

To indoor uni1

To indooX1

A

To indoor unii

To indoor uni1 B To outdwr uni1

Electric

parts

box

Refri ant piping joint (Ilare)

Liqui

A-TO

To indoor uni1 B To indoor unit

=or unx Toxdoor unit

C

Note: Please install

e019

D

Fig. 6-2

hole for

Oval

hanging bolt

4

100 or more

A

I

I

-F

Slit for hanging bolt It is indispensable for test run and servicing.

-1

\

1

I

,I

-

Outdoor uni1 side

M

Or

Electric paris box or more

1

Note: Make an inspection opening at the sp~ified p"..

450rnm x 450rnm over

Suction gas side

Outdoor uni1 sidel

or

Neciri!= 500

g

-

I

Note: Make an inspeciion opening ai the specified place.

Il is indispensable for test run and servicing.

0

28.6

more or more

Indoor unit side

or more

450 x 450 inspection opening

installation space

100 or more

I

T

Indoor unit side

500

or more

450 x 450 ins~ection

installation siace

iring entrance

igerant piping joint (Ilare)

Discharge gas side 0 19

I

opening

6-3.

RBM-HD821FE, RBM-HD1021FE

1-

0

36

O

O

Liquid side 0 9.5

Fig. 6-3

450mm x 450rnm over

Suction gas side

0

28.6

Discharge gas side 0 19

7.

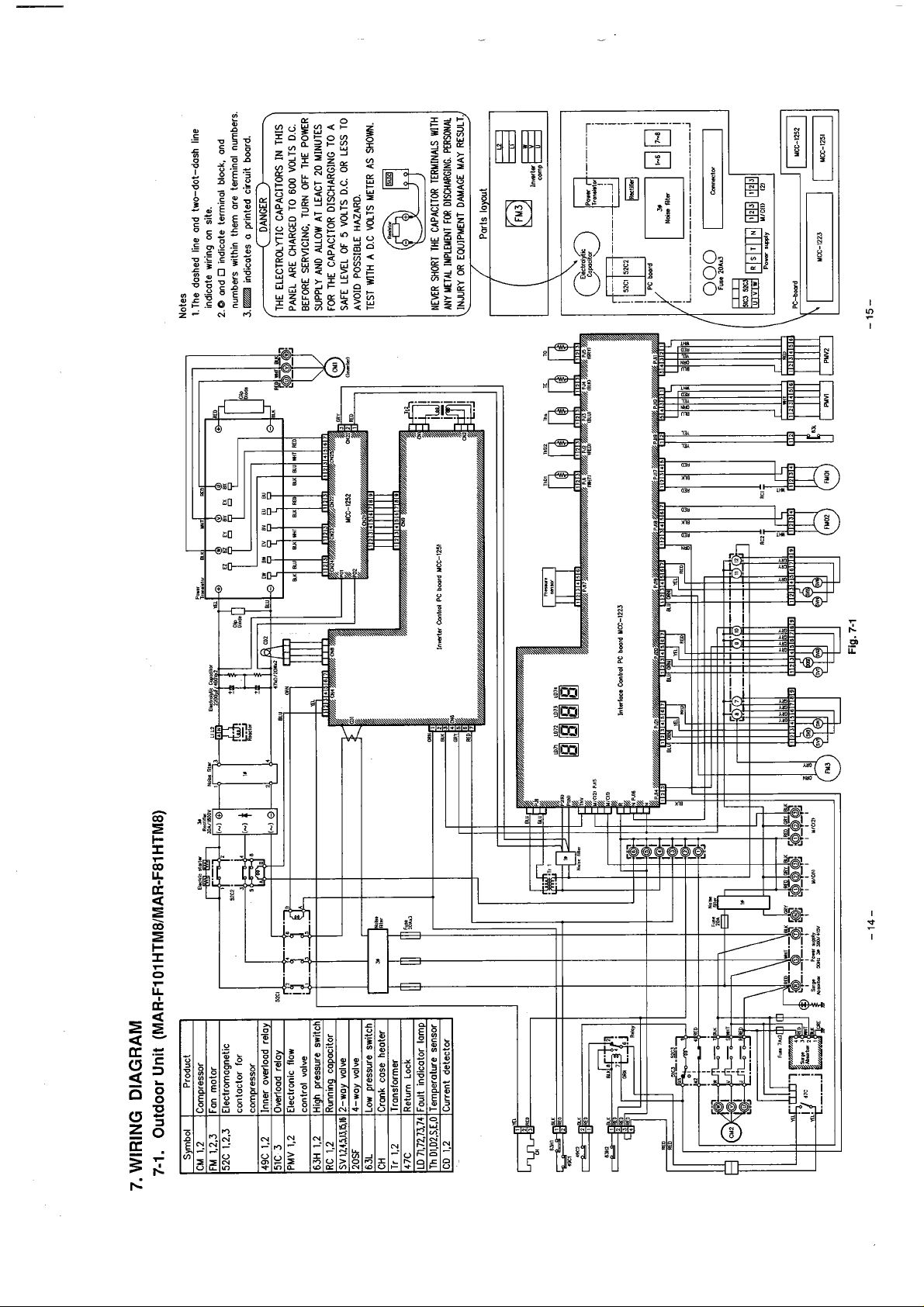

WIRING DIAGRAM

7-1.

Outdoor

Unit

(MAR-F1

01

HTMBlMARF81HTM8)

Inarlor

Cmtrol

PC bmrd

YCC-1251

Inlaloce Cmlrd

-14- -15-

PC

bmid

Fig.

YCC-1223

7-1

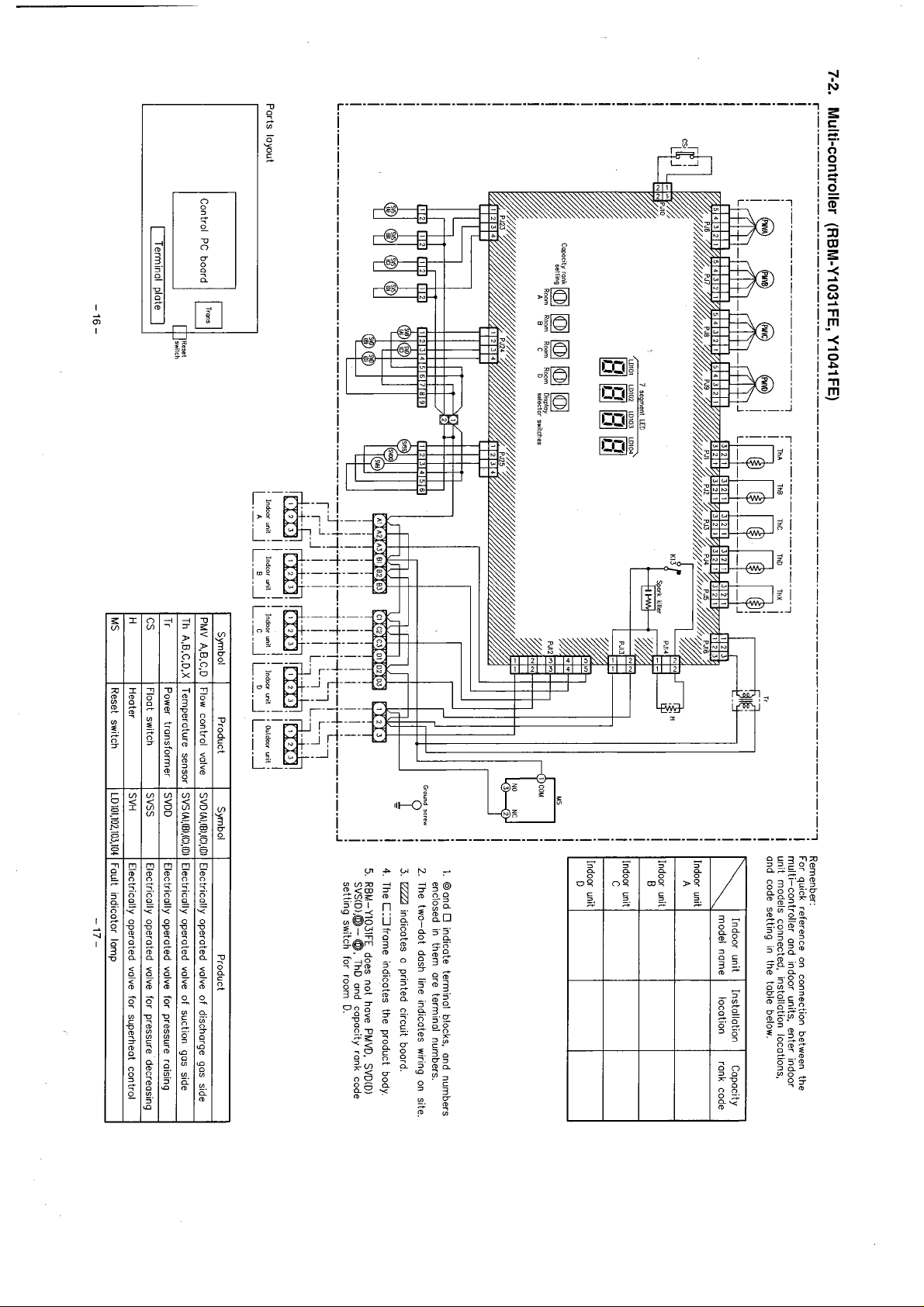

Multi-controller

r----------'------------------------------------------------------------------------

(RBM-Y1031 FE, Y1041 FE)

!

Rernenber:

7

For quick reference on connection between the

!

multi-controller ond indoor units. enter indoor

unit models connected. instollotion locations,

ond code setting in the toble below.

1. Oond

O

enclosed in them ore termino1 numbers.

2.

The two-dot dosh line indicotes wiring on site.

3.

EZZJ

indicates o printed circuit boord

4.

The C13frome indicotes the product body

5.

RBM-Y1031FE does not have PMVD. SVD(D)

SVS(D),@-

setting switch for room

Ports layout

Control

PC

boord

m

[

Termina1 plote

8

unii

8

I

i

L.B.A

a

Indoor

L.L.A

]

Indaor

,m

unit

i i

Indoor

L.2.J

8 8 8 8

unii

i

i

L-0-1

Syrnbol

PMV A,B.C.D

Th A.B.C,D,X

Tr

CS

H

MS

lndoar

unii

i i

Ouldcor

L--.l

Product

Flow control volve

Temperature sensor

Power tronsforrner

Float switch

Heater

Reset switch

unit

:

Symbol

SVDiA).IBI.IC).(DI

SVSiAl.(BI,(C).(DI

SVDD

SVSS

SVH

LD101.102.103.104

Electricolly operoted volve of discharge gas side

Electrically operoted volve of suction gas side

Electricolly operoted valve for pressure raising

Electricolly operoted valve for pressure decreasing

Electrically operated valve for superheot

Foult indicotor lomp

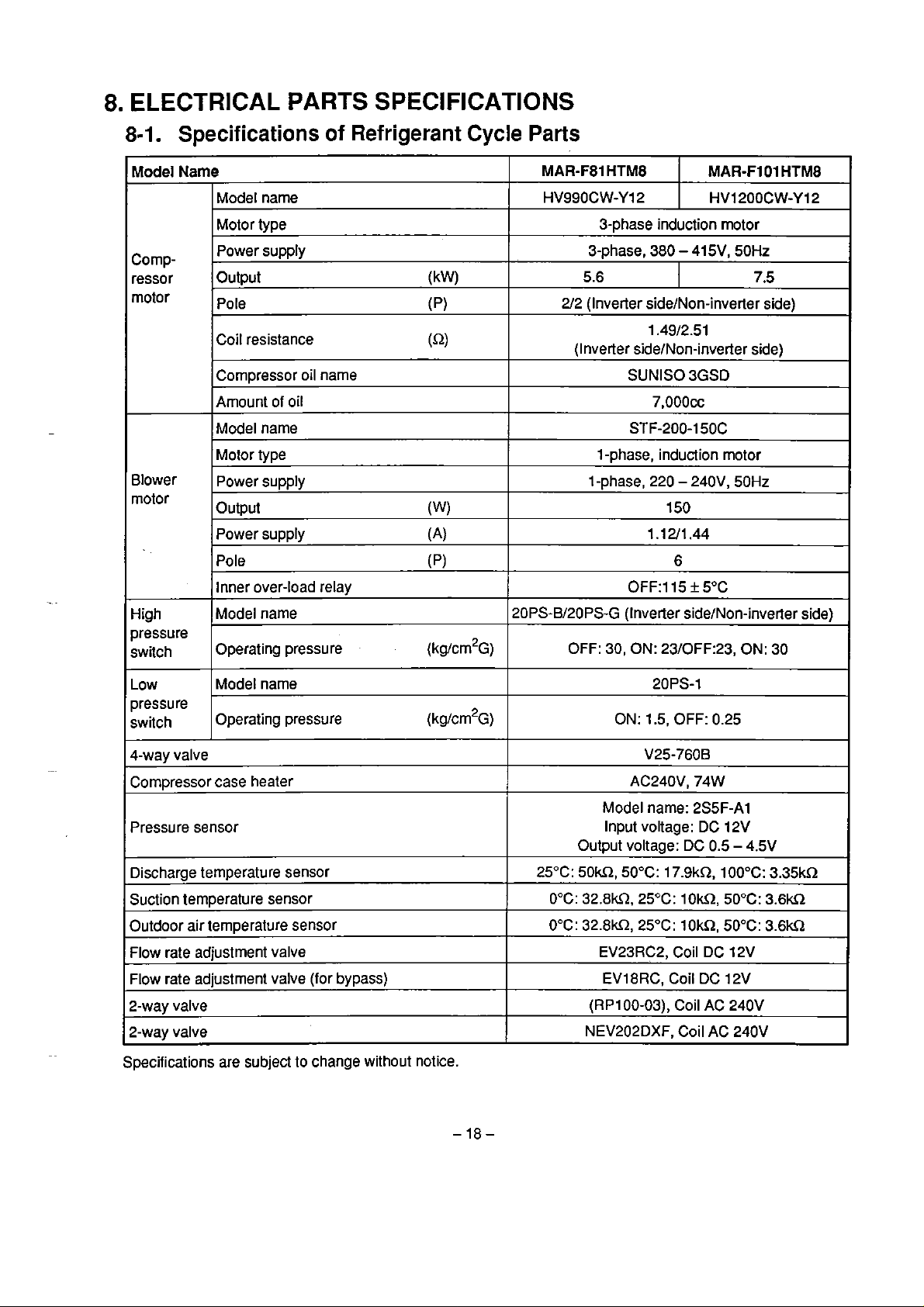

8.

ELECTRICAL

PARTS

SPECIFICATIONS

8-1.

Model

Cornpressor

motor

Blower

rnotor

Specifications

of

Refrigerant

Name

Model name

Motor type

Power supply

Output (kW)

Pole

Coil resistance

Cornpressor oil narne

Arnount of oil

Model narne

Motor type

Power supply

Output

Power supply (A)

Pole

Inner over-load relay

(p)

(Q)

(W)

(p)

Cycle

Parts

MAR-F81

HV990CW-YI 2

HTM8

3-phase induction motor

3-phase, 380 - 415V, 50Hz

5.6

212 (Inveder sidelNon-inverter side)

1.4912.51

(Inverter sidelbion-inverfer side)

SUNISO 3GSD

7,000~~

STF-200-150C

l

-phase, induction motor

1-phase, 220

1.12/1.44

OFF:115 f 5OC

MAR-FIO1

HV1200CW-Y12

-

240V, 50Hz

150

6

HTM8

7.5

High

pressure

switch

Low

pressure

switch

4-way valve

Compressor case heater

Pressure sensor

Discharge temperature sensor

Suction temperature sensor

Outdoor air temperature sensor

Flow rate adjustment valve

Flow rate

2-way valve

2-way valve

Specifications are subject to change without notice.

Model name

Operating pressure (kg/crn2~)

Model narne

Operating

adjustment valve (for bypass)

pressure (kg/cm2~)

20PS-Bl20PS-G (Inverter side/Non-inverter side)

OFF: 30, ON:

ON: 1.5, OFF: 0.25

Model narne: 2S5F-A1

Input voltage: DC 12V

Output voltage:

25°C:

50W,

0°C: 32.8kR, 25°C: 10k2,5O0C: 3,6m

0°C: 32.8kLt25"C: IOkQ, 50°C:

EV23RC2, Coil DC 12V

EV18RC, Coil DC 12V

(RP100-03), Coil

NEV202DXF, Coil AC 240V

23/OFF:23,

20PS-1

V25-760B

AC240V, 74W

DC

50°C: 17.9kQ, 100°C:

ON:

0.5 - 4.5V

AC

240V

30

3.35kS1

3.6U

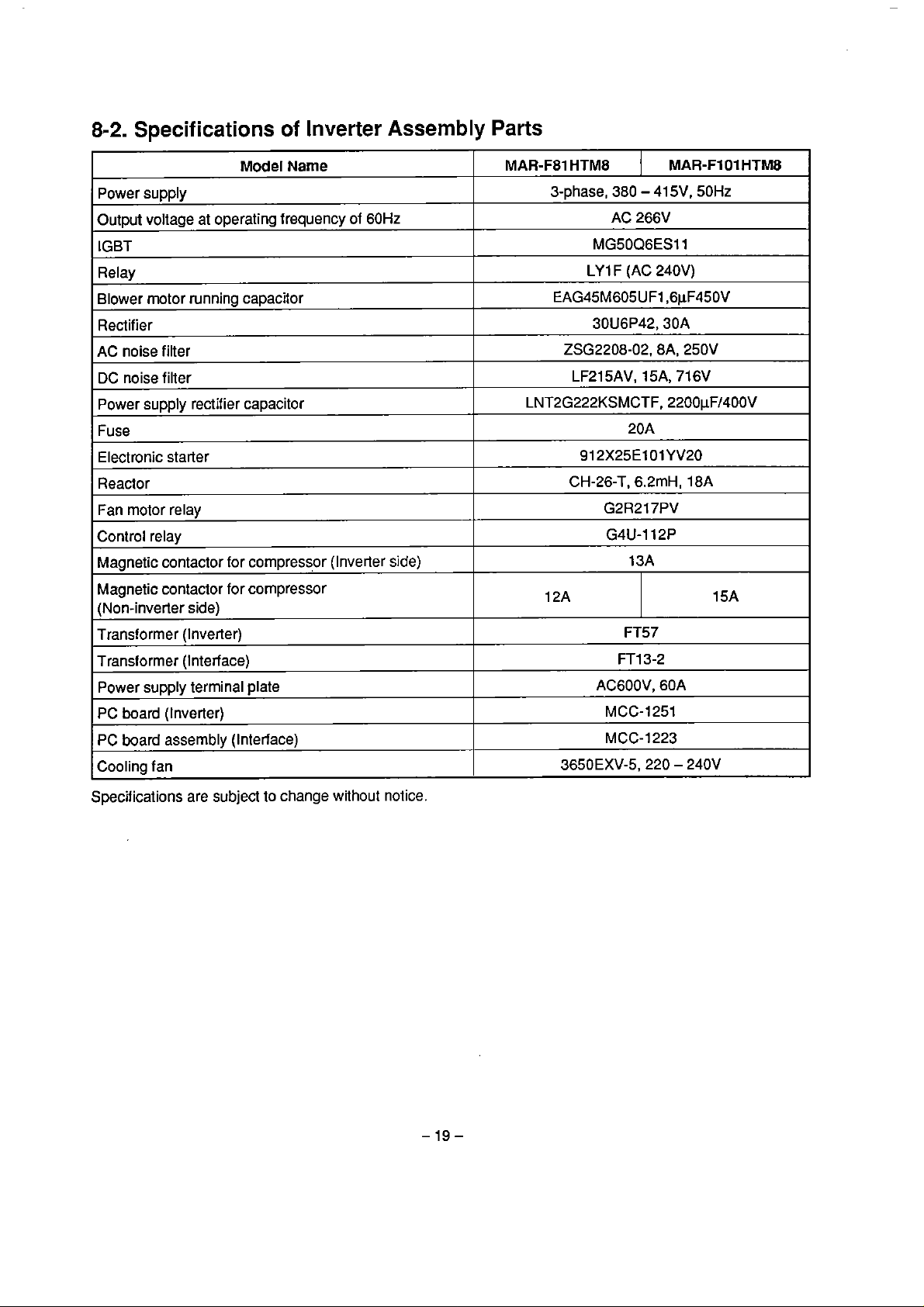

8-2.

Specifications

of

Inverter

Assembly

Parts

Model

Power supply

Output voiiage at operating frequency of

IGBT

Relay

Blower motor running capacitor

Rectifier

AC noise filter

DC noise filter

Power supply rectifier capacitor

Fuse

Electronic starter

Reactor

Fan

rnotor relay

Control relay

Magnetic contactor for

Magnetic contactor for compressor

(Non-inverler side)

Transformer (lnverter)

Transformer (Interface)

Power supply

PC

board (tnverter)

termina1 plate

Narne

compressor (Inverter

60Hz

side)

MAR-FS1

HTM8

3-phase,

EAG45M605UF1,6pF450V

ZSG2208-02,8A, 250V

LNT2G222KSMCTF, 2200pFl4OOV

12A

380

AC

MG50Q6ES11

LY

1 F (AC 240V)

30U6P42,30A

LF215AV, 15A, 71

912X25ElOlYV20

CH-26-T, 6.2mH, 18A

G2R217PV

G4U-112P

FT13-2

ACGOOV, 60A

MCC-1251

-

41 5V, 50Hz

266V

20A

13A

FT57

MAR-Fl 01

6V

HTM8

15A

PC

board assembly (Interface)

Cooling

Specifications are subject to change without notice.

fan

MCC-1223

3650EXV-5,220 - 240V

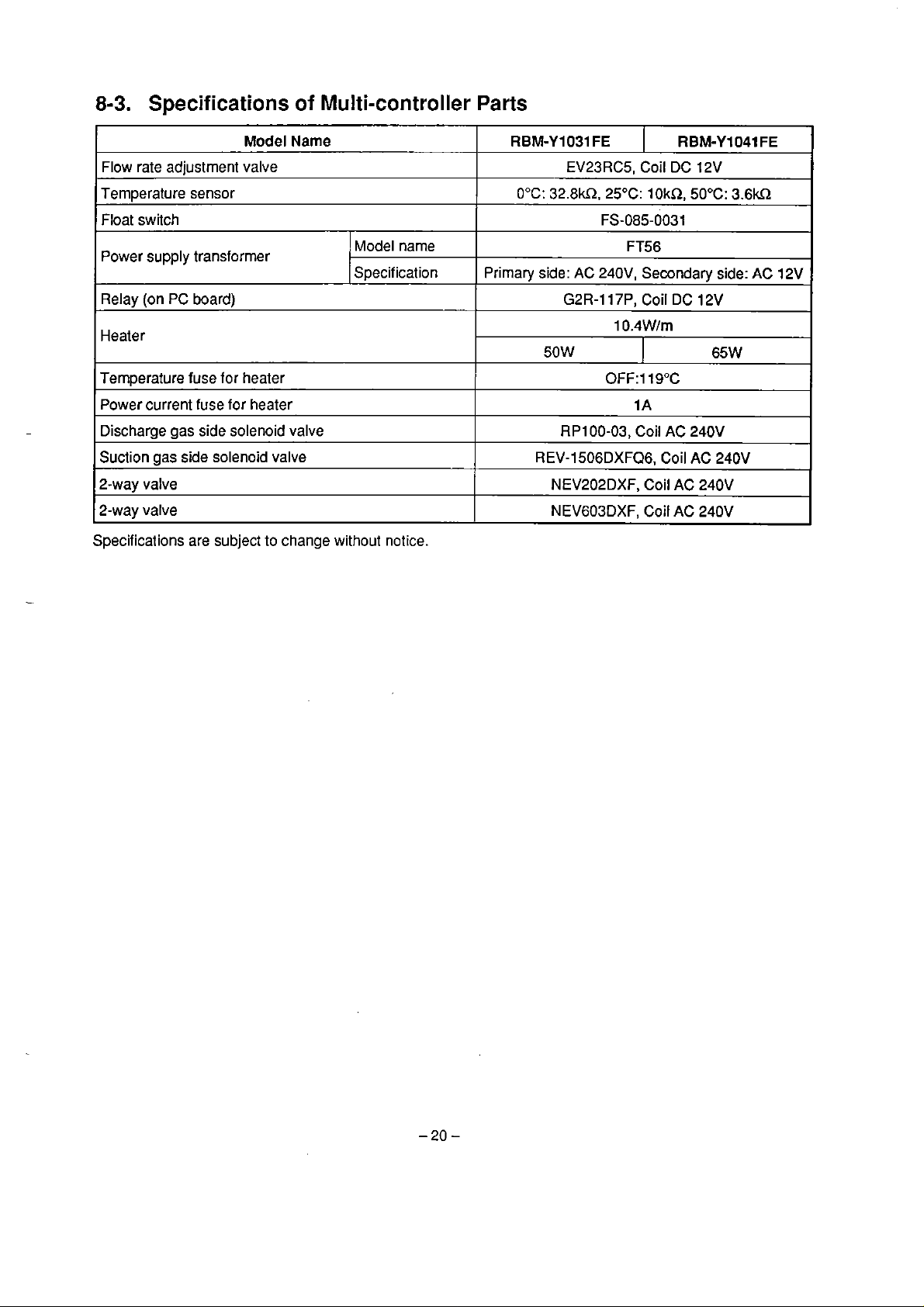

8-3.

Specìfications of Multi-controller

Parts

Model

Flow rate adjustment valve

Temperature sensor

Float switch

Power supply transformer

Relay (on

Heater

Temperature fuse for heater

Power current fuse for heater

Discharge gas side solenoid valve

Suction gas side

2-way valve

2-way valve

Specifications are subject to change without

PC

board)

solenoid valve

Name

Model narne

Specif ication

notice.

RBM-Y1031

0°C:

Prirnary side: AC 240V, Secondary side:

50W

REV-1506DXFQ6, Coil

FE

EV23RC5, Coil DC 12V

32.8m.

NEV202DXF, Coil

NEV603DXF, Coil AC 240V

25OC: 1 OkR, 50°C:

FS-085-0031

FT56

G2R-117P,

10.4W/m

0FF:11S0C

RP100-03, Coil

Coil

I

1 A

AC

RBM-Y1041

DC

12V

65W

240V

AC

240V

AC

240V

3.6kn

FE

AC

12V

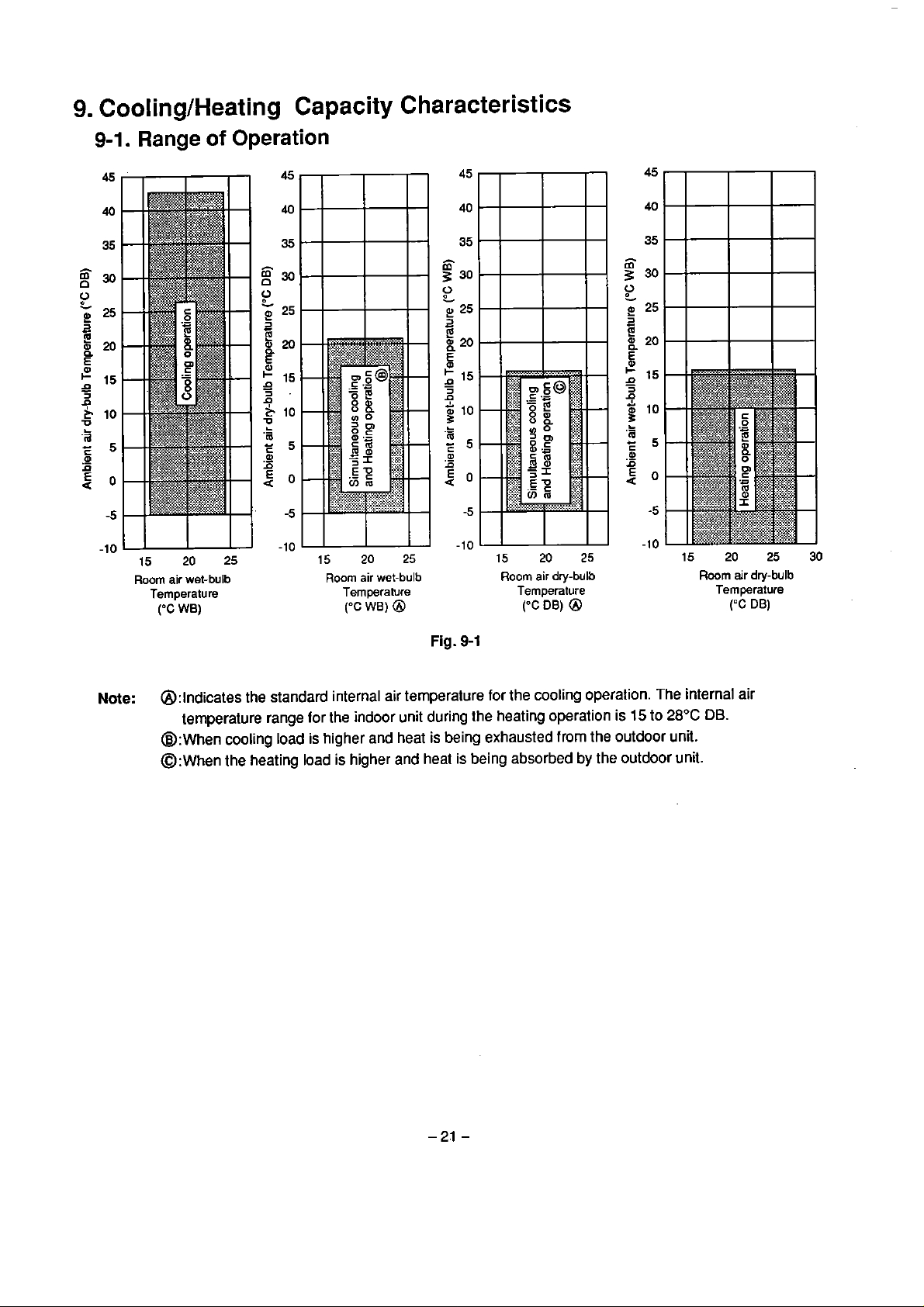

9.

CoolinglHeating Capacity Characteristics

9-1.

Range

15

Room

Temperature

('C

of

20 25

air wet-bulb

WB)

Operation

15

Room

20

25

air wet-bulb

Temperature Temperature

("C

WB)

@

15

Room

("C

20

air

dry-bulb

DB)

@

25

15

20

Room air dry-bulb

Temperature

('=C

DB)

25

30

Note:

Fig.

9-1

@:lndicates the standard internal air temperature

temperature range for

@:When cooling load

@:~hen

lhe

heating load

the indoor unit during the heating operation

is

higher and heat is being exhausted

is

higher and heat is being absorbed

for

the

cooling

from

operalion.

is

15

The

to

the outdoor una.

by

the outdoor unit.

internal air

28°C

DB.

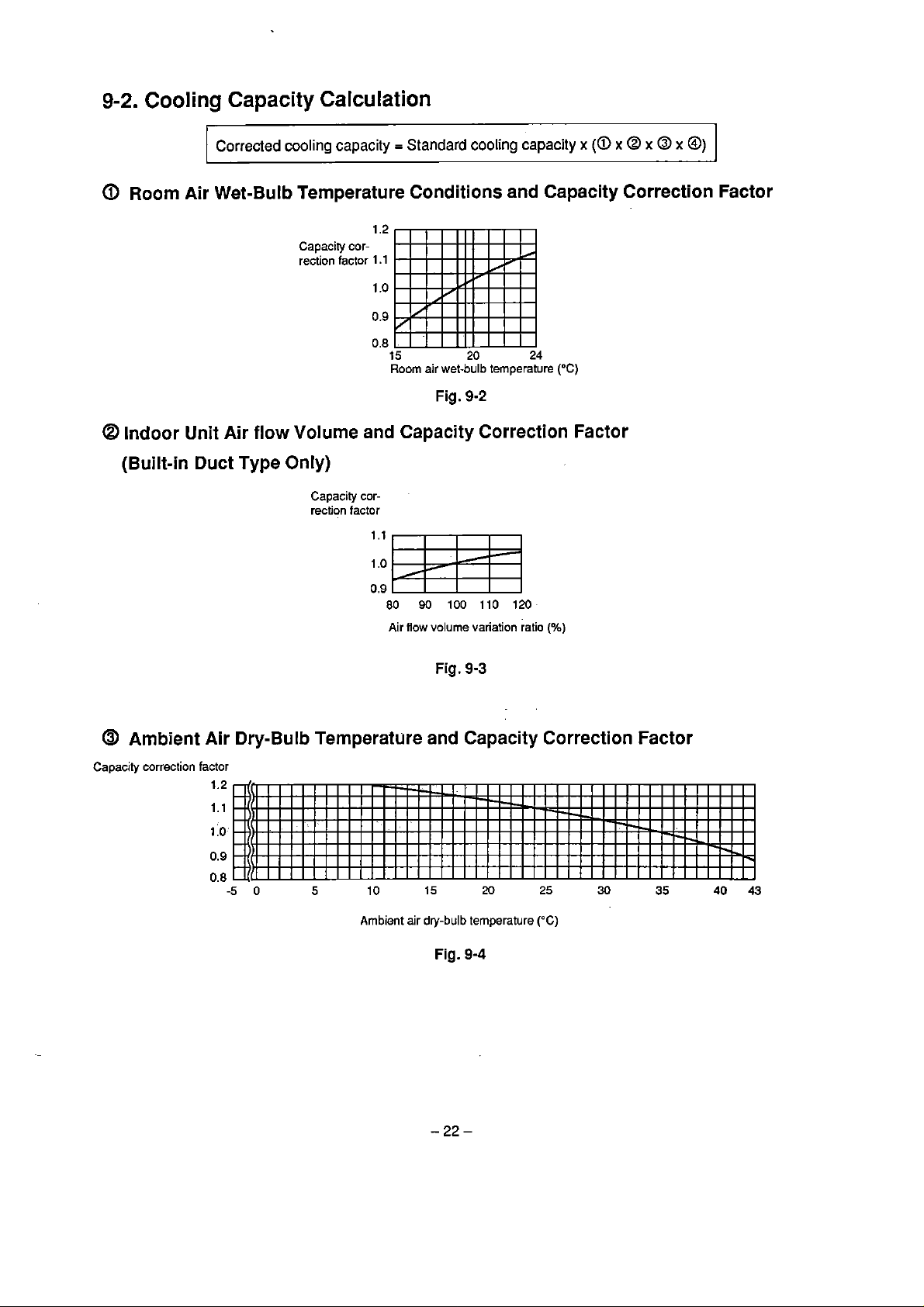

9-2.

Cooling Capacity Calculation

Corrected

a

Room Air Wet-Bulb Temperature Conditions and Capacity Correction Factor

@

Indoor Unit

(Built-in

Air

Duct

cooling capacity = Standard

1.2

flow

Capaciry

rection

Volume

cor-

factor

1

1

0.9

0.8

and Capacity Correction Factor

Type Only)

Capacity correction factor

cooling

.l

capacity

.o

15

Room air wet-bulb temperature

Fig.

20

9-2

24

("C)

x

(a

x

@ x @

x

@)

Air

flow

volume variation ratio

Fig.

9-3

@

Ambient Air Dry-Bulb Temperature and Capacity Correction Factor

Capacity correction factor

Ambient air

dry-bulb

Fig.

temperature

9-4

(%)

("C)

@

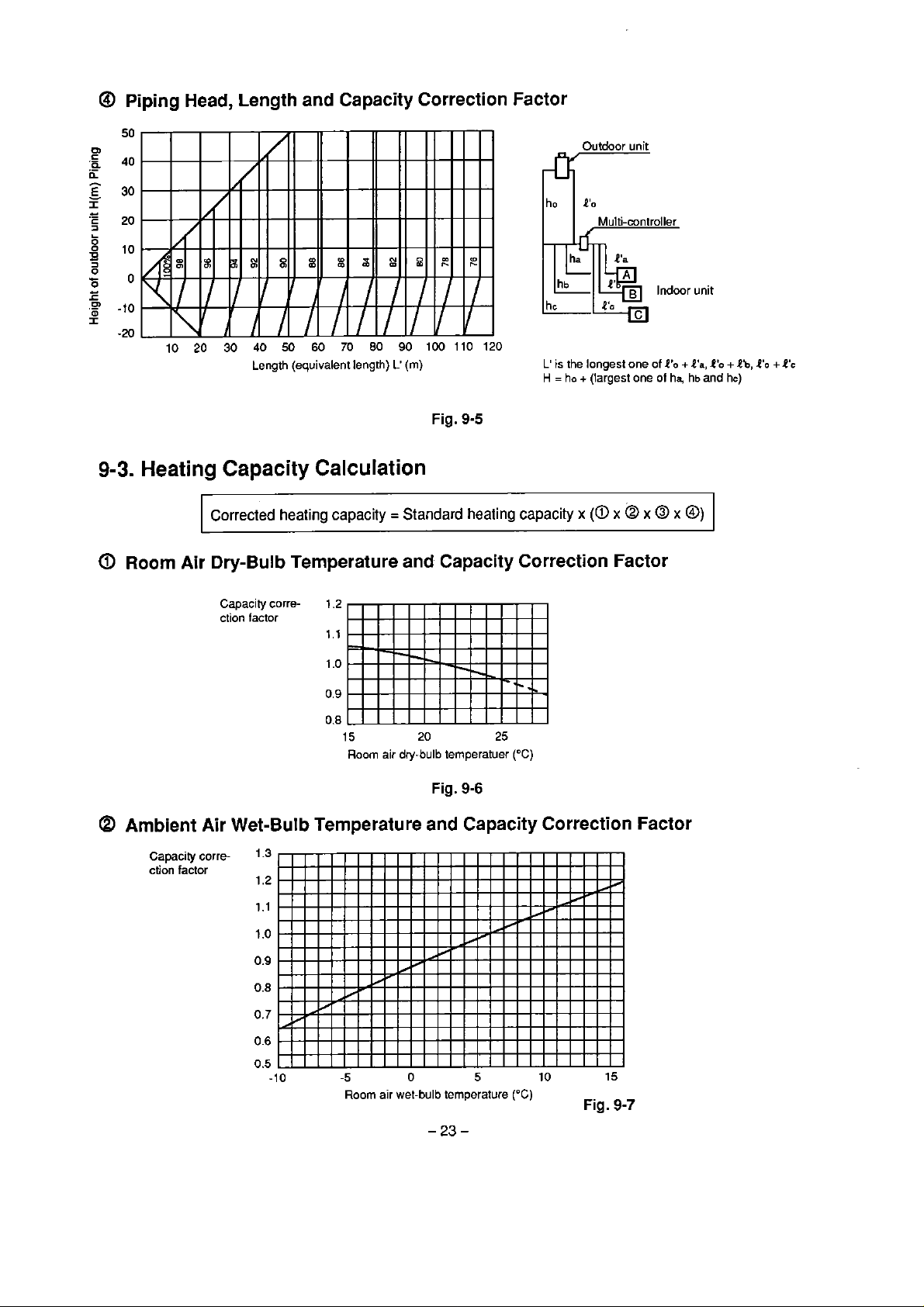

Piping

Head,

Length and Capacity Correction Factor

&'r

I

ho

Outdoor unit

I

P'o

unit

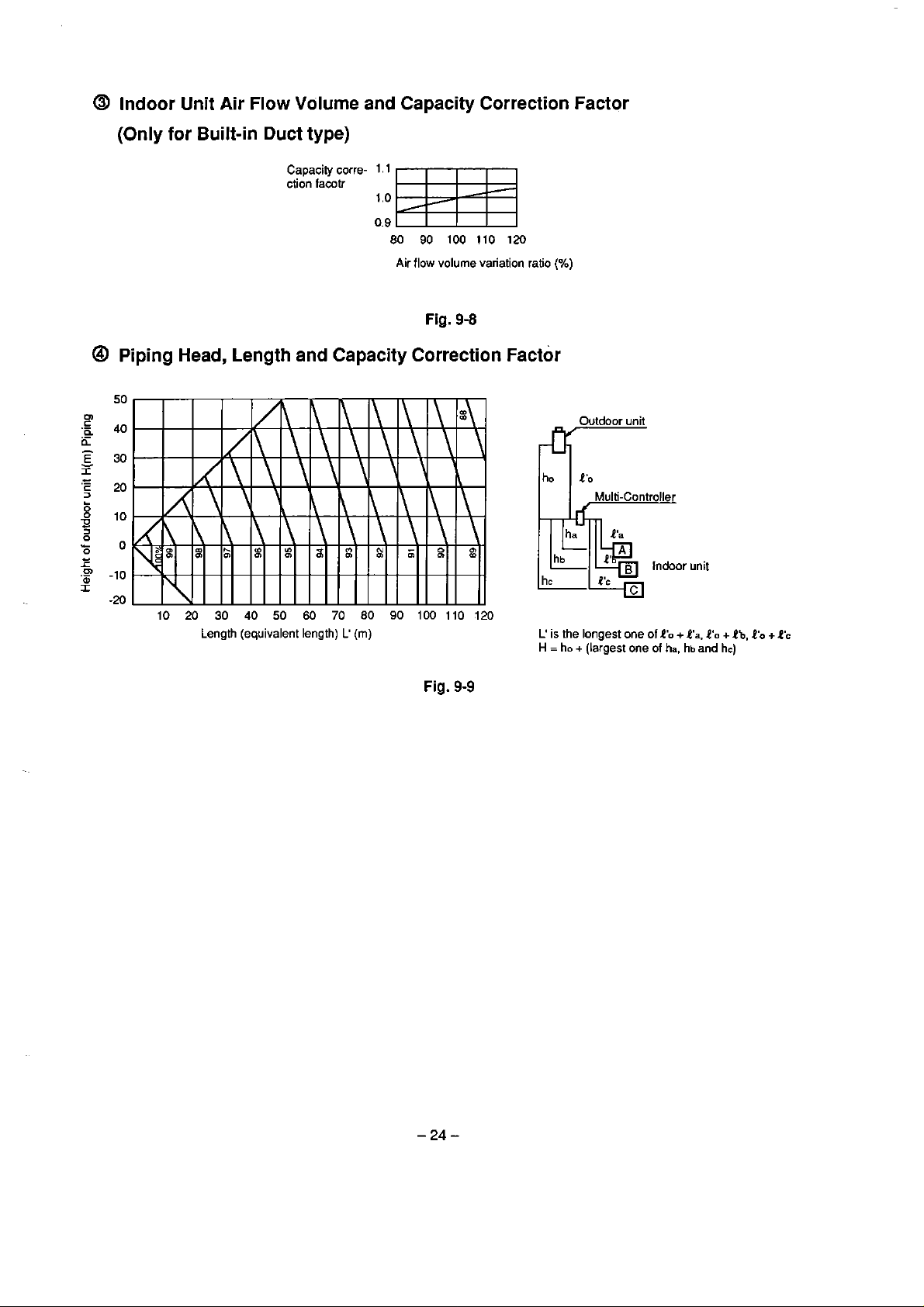

9-3.

Heating

@

Room Air

10 20 30

Capacity

Corrected

Dry-Bulb

Capacity correction

40

50

60

70

80

Length (equivalent length)

Calculation

heating

factor

capacity = Standard

Temperature and

1.2

1.1

0.8

15 20 25

Room air dry-bulb temperatuer

90

100 110 120

L'

(m)

Fig.

9-5

heating

Capacity

Fig.

9-6

L'

is

the longest one of

H

=

ho

+

(largest one of

capacity

x

(a

x Q x

Correction Factor

("C)

4'0

@

ha,

x

+l'a,

hb and

@)

O'O

+

hc)

Eb,

4'0

+

O'C

@

Ambient Air Wet-BuIb Temperature and Capacity Correction Factor

Capacity

ction factor

corre-

1.3

1.2

0.5

-1

O

-5

Room

O

air wet-bulb temperature

5

10 15

("C)

Fig.

9-7

@

Indoor Unit Air Flow Volume and Capacity Correction Factor

(Only for Built-in Duct type)

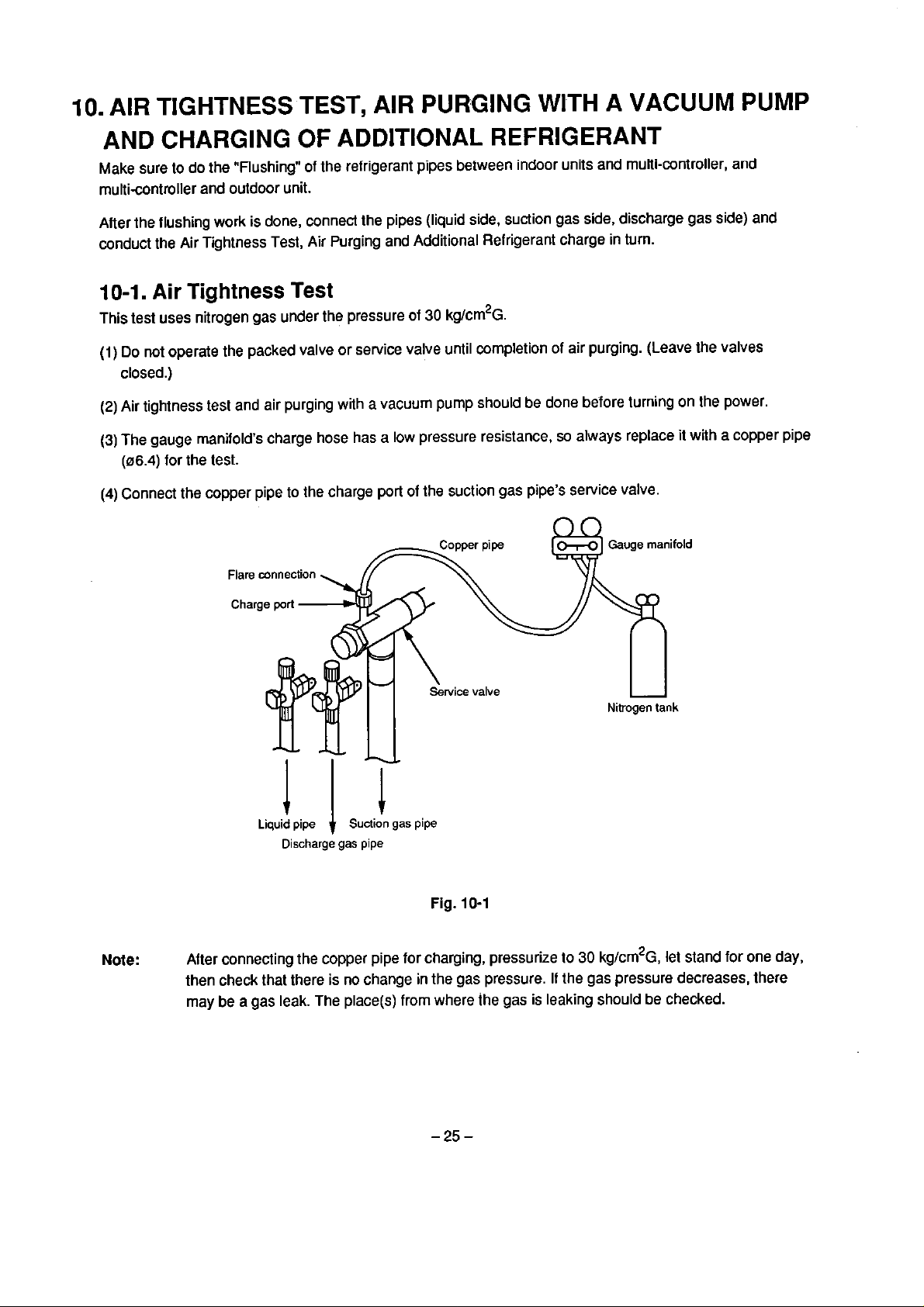

@

Piping

Capacity

ction

facotr

corre-

1.1

1

.o

0.9

80

90 100

Air flow volume variation ratio

110

l20

(%)

Fig. 9-8

Head, Length and Capacity Correction Factor

7

hc

Outdoor

unit

Multi-Controller

O'c

Indoor unit

Length (equivalent length)

L'

(m)

Fig.

9-9

C

is

the longest one of

H

=

ho

+

(largest one of

2'0

ha,

+

l'a,

hb

4'0

and

+

hc)

Ib,

I'o

+

O's

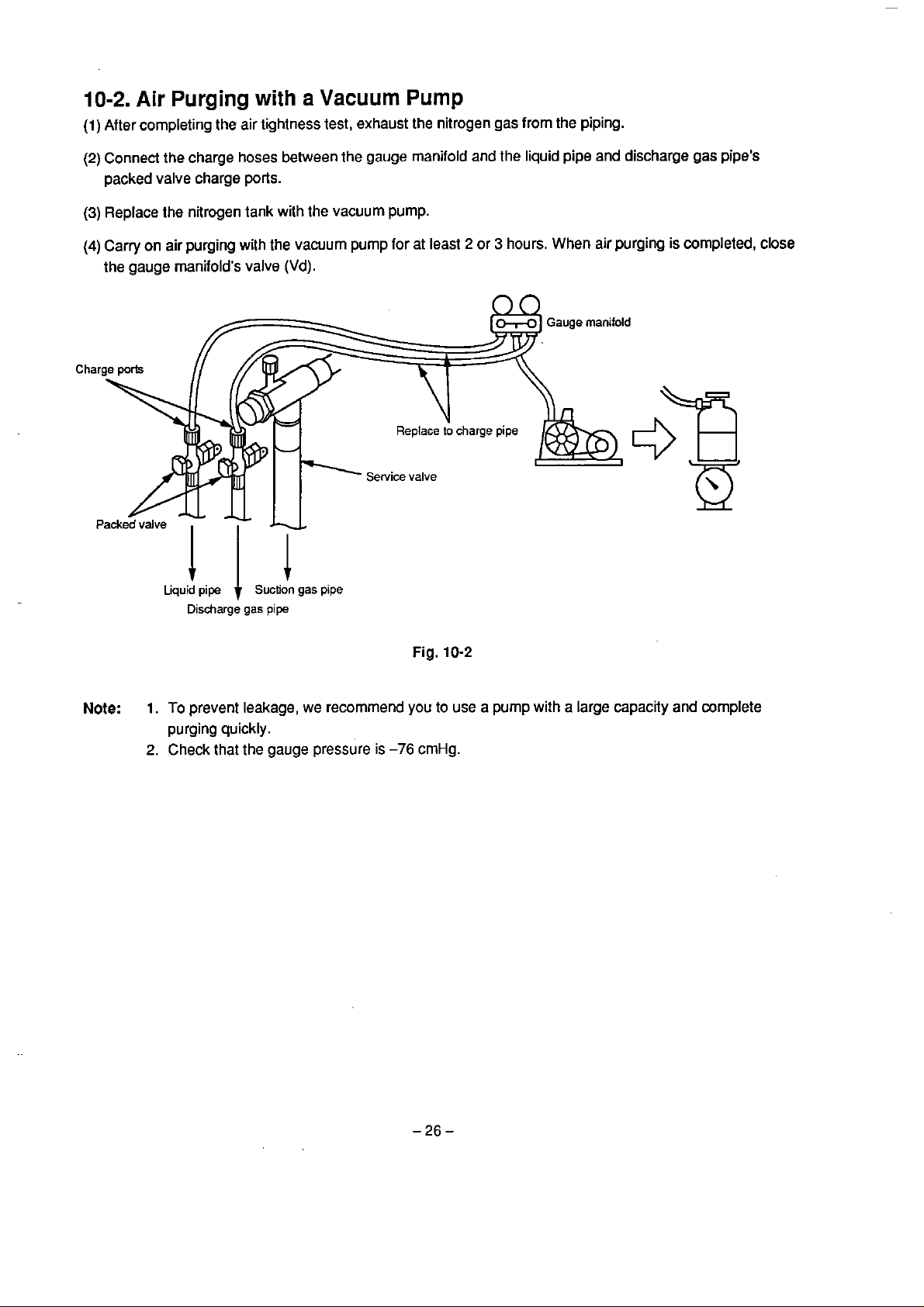

10.

AIR TIGHTNESS

TEST,

AIR

PURGING

WITH

A

VACUUM

PUMP

AND

Make sure Lo

multi-controller and outdoor unit.

Aiter the flushing

conduct the Air Tightness Test, Air Purging and Additional Refrigerant charge in turn.

10-1.

This test uses nitrogen gas under the pressure of

(1)

(2)

(3)

(4)

CHARGING

do

the "Flushing" of the refrigerant pipes between indoor units and multi-controller,

work

is done, connect the pipes (liquid side, suction gas side, discharge gas side)

Air

Tightness

Do

not

operate the packed valve or service valve until completion of air purging. (Leave the valves

closed.)

Air tightness test and air purging with a vacuum pump should be done before turning on the power

The

gauge rnanifold's charge hose has a

(06.4)

for the test.

Connect the copper pipe to the charge port

OF

Test

ADDITIONAL

30

kg/crn2~.

low

pressure resistance,

of

the suction gas pipe's service valve.

REFRIGERANT

so

always replace it

with

and

and

a

copper pipe

Note:

Liquid

pipe

Discharge

After connecting the copper pipe for charging, pressurize

then check that there

may be

a

gas leak. The piace(s) from where the gas is leaking should be checked.

Suction

gas

pipe

gas

pipe

Fig.

10-1

is

no change in the gas pressure.

to

30

kg/cm2~,

If

the gas pressure decreases, there

let stand for one day,

10-2.

(1)

(2)

(3)

(4)

Air

Purging

After completing the air lightness test, exhaust the nitrogen gas from the piping.

Connect the charge hoses behveen the gauge manifold and

packed valve charge

Replace the nitrogen tank with lhe vacuum pump.

Carry on air purging with the vacuum pump for at least 2 or 3 hours.

t

he gauge manifold's valve

with

ports.

a

Vacuum

(Vd)

.

Pump

the

liquid pipe and discharge gas pipe's

When

air purging is completed, close

Note:

Liquid

pipe t Suction

Discharge

1.

To prevent leakage, we recommend you to use a pump with a large capacity

purging

2.

Check that the gauge pressure

gas

quickly.

pipe

gas

pipe

is

-76

Fig.

10-2

cmHg.

and

complete

10-3.

(l)

(2)

(3)

(4)

Additional

Reptace the vacuum pump with the refrigerant tank, charge the stipulated arnount of refrigerant, and then

open both packed valve and service valve fully. If additional charge is needed, conduct the following.

Switch the charge hose lo the suction gas pipe's service valve charge port (dotted lines 4 solid tines, one

charge

Attach the charge hose lightly to the suction gas pipes service valve charge

loosen the refrigerant tank's valves (Va and

charge

Next, tighten

specified amount of refrigerant.

refrigerant

hose as shown in Fig.

hose

is

the

in

gas form from the low pressure side lo supply the specified amounl.

Refrigerant

10-3).

expelled by the refrigerant.

hose fully, then loosen the service valve and use the pressure in the tank to add the

Il not enough refrigerant can be added, operate the unit and

Charging

Vb).

The air in the lank's

Low

Charge hose

pressure

port

at first and slightly

gas

hose, gauge rnanifold and

Gauge

manifold

draw

in the

Lquid pipe

Discharge

t

gas

Suction

pipe

gas

pipe

--2.

Fig.

-2.

10-3

.

\

9)

Gas

Refrigerant

5kg

tank

Spring

scale

gas

(20kg)

11.

PIPING

LENGTH

AND

ADDITIONAL

REFRIGERANT

AMOUNT

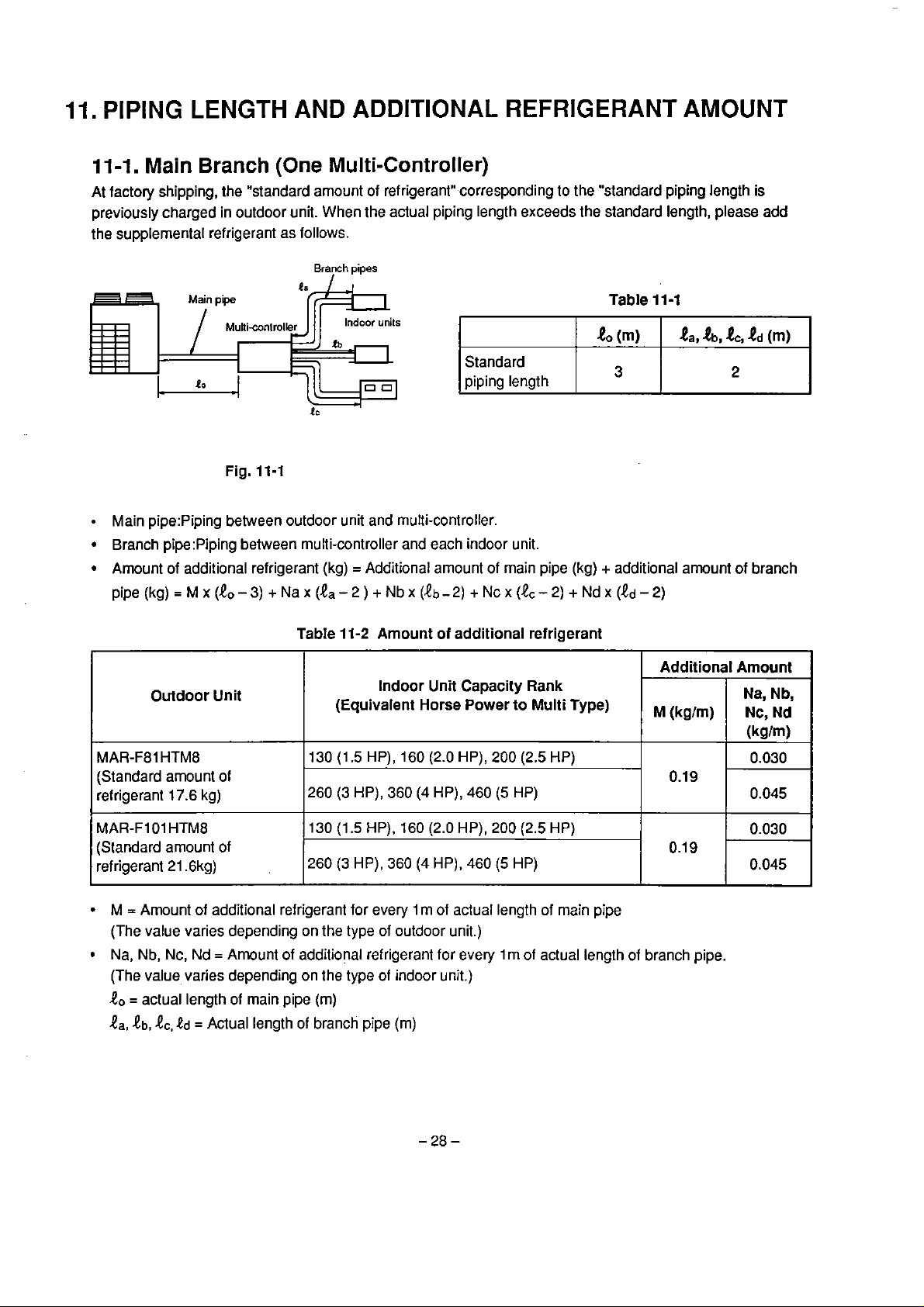

11-1.

At factory shipping, the "standard arnount of refrigerant" corresponding to the "standard piping length

previously charged in outdoor unit. When the actual piping length exceeds the standard length, please add

the supplemental refrigerant as follows.

Main

Main pipe:Piping between outdoor unit and multi-controller.

Branch pipe:Piping between multi-controller and each indoor unit.

Arnount of additional refrigerant (kg) = Additional amount of main pipe

pipe (kg)

Branch

Fig. 11-1

=~x(e,-3)

(One

+~ax

Multi-Controller)

Branch

(1,-2)

pipes

+Nbx

(lb-2) +Ncx(&-2) +Ndx (ed-2)

Table

11

-1

(kg)

+

additional amount of branch

is

Table

11-2 Amount of additional refrigerant

Outdoor Unit

MAR-F81

(Standard arnount of

refrigerant

MAR-Fl

(Standard arnount of

refrigerant 21.6kg)

M = Arnount of additional refrigerant for every

(The value varies depending

Na,

(The

t,,

HTMB

17.6

kg)

O1

HTM8

Nb,

Nc,

Nd

=

Amount of additional refrigerant for every l m of actual length of branch pipe.

value, varies depending on the type of indoor unit.)

= actual length of main pipe (m)

tb,

&,Od

=

Actual length

(Equivalent Horse Power

130

(1.5

HP), 160 (2.0 HP), 200 (2.5 HP)

260 (3HP), 360 (4HP),460(5 HP)

130

(1.5

HP),

260

(3

HP),

on

the type of outdoor unit.)

of

branch pipe (m)

Indoor

Unit

Capacity Rank

160 (2.0 HP), 200

360

(4

HP),

l

m

of actual length of rnain pipe

460

(5

to

(2.5

HP)

Multi Type)

HP)

Additional Arnount

Na,

,,,,

(kg,m,

0.19

0.1

9

Nc,

(kglm)

0.030

0.045

0.030

0.045

Nb,

Nd

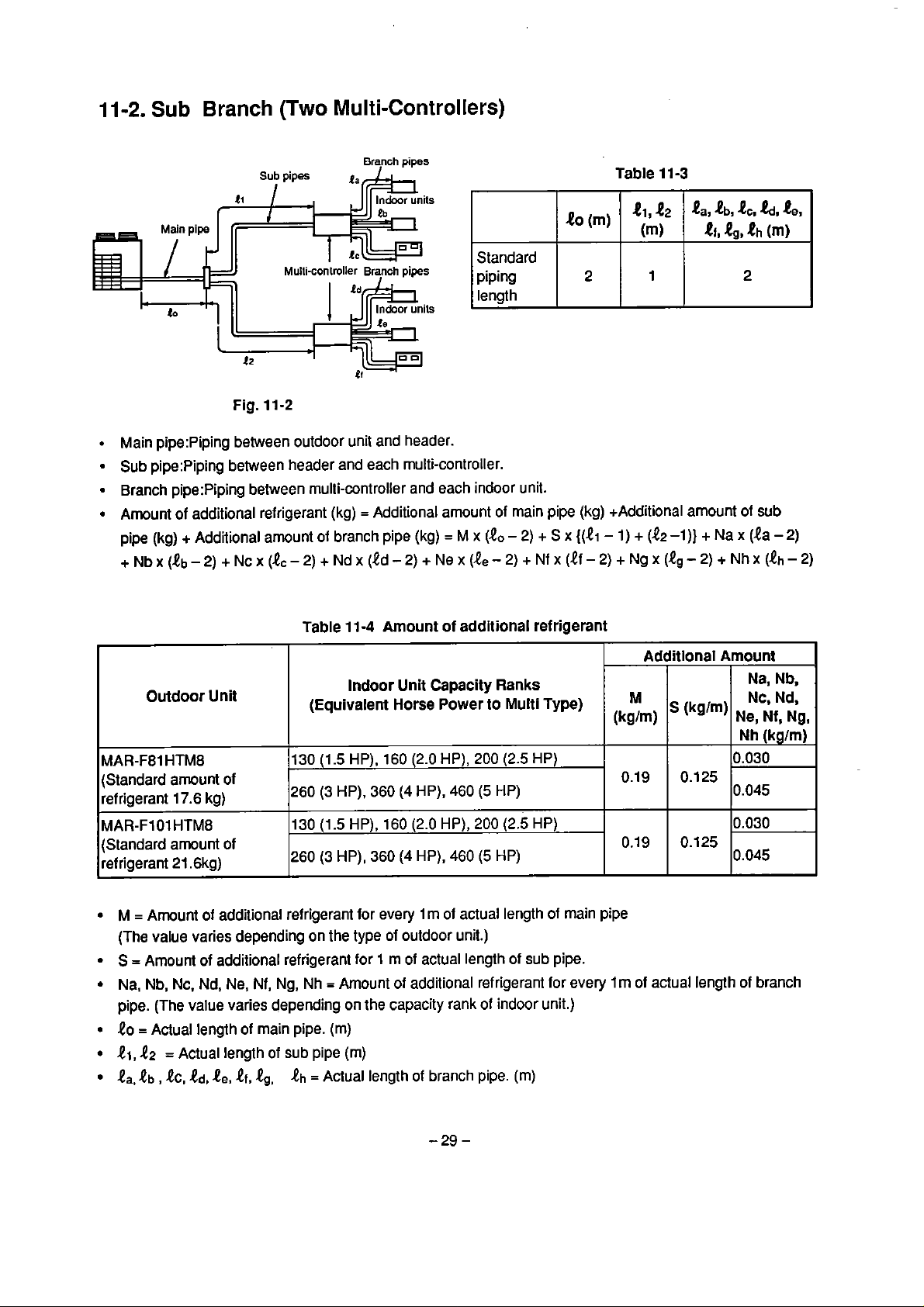

11-2.

Sub

Main pipe:Piping between outdoor unit and header.

Sub pipe:Piping between header and each rnulti-controller.

Branch pipe:Piping between multi-controller and each indoor unit.

Arnount of additional refrigerant (kg) = Additional amount of main pipe (kg) +Additional amount of

pipe

(kg)

+~bx(8b-2)+~~x(e,-2)+~d~(id-2)+~e~(8,-2)+~f~(tf-2)+~g~(Q~-2)+~h~(!h-2)

Branch

Pipe

(Two

Sub

pipes

Multi-Controllers)

Branch

pipes

t

~ulli-conirolkr

Fig.

l

1-2

+

Additional amount of branch pipe (kg)

Bych

pipes

=

M

Standard

piping

length

x

(10

-

2)

+

S

x

2

{(ti

Table

-

1)

11

-3

e,,

(m)

+

P,,

e2

&,&,eh

l

(e2

-l)} + Na x (ta - 2)

.tb,

4,

2

&,

te,

(m)

sub

Table

11-4

Amount of additional refrigerant

Outdoor

MAR-F81 HTM8

(Standard arnount of

refrigerant

MAR-FIO1

(Standard amount of

refrigerant

M

=

Arnount of additional refrigerant for every 1m ot actual length of main pipe

(The value varies depending on the type

S

=

Amount of additional refrigerant far 1 m o1 actual length of sub pipe.

Na, Nb, Nc.

pipe. (The

40

=

Aclual length of main pipe.

41,

t2

la,

tb

,

Unit

130 (1.5 HP), 160 (2.0 HP), 200

17.6

kg)

HTM8

21.6kg)

Nd,

Ne,

value varies depending on the capacity rank of indoor unit.)

=

Actual length of sub pipe (m)

h,

td,

te,

ef,

260 (3 HP),

130 (1.5 HP), 160

260

Nf,

Ng, Nh = Amount of additional refrigerant

.eg,

eh

Indoor Unit Capacity Ranks

(Equivalent Horse Power to Multi Type)

(2.5

360

(4

HP),

460

(5

HP)

(2.0

(3

HP),

360

(4

of

outdoor unit.)

HP), 200

HP), 460

(5

(2.5

HP)

(m)

=

Aclual length of branch pipe.

(m)

HP)

HP)

for

every

Additlonal Amount

M

(kglm)

0.19

0.19

Im

of actual length of branch

(kg'm)

0.125

0.125

Ne, Nf, Ng.

Nh

0.030

0.045

0.030

0.045

Na, Nb,

Nc, Nd,

(kglm)

12.

DESCRIPTION

OF

OPERATION

12-1.

Simultaneous CoolingtHeating Operation Control Outline

12-1-1. Switching between the Cooling and Heating Operations for

Each Indoor Unit

The solenoid valves inside the muiti-controller are switched with requested commands sent from the indoor

unii.

SVS

valve (at suction gas side) opens for a cooling command.

SVD

valve (al discharge gas side) opens for a heating command.

t

2-1-2.

Determining the Outdoor Unit Operation Mode (CoolingIHeating)

and Operation Frequency of the Compressor

The cooling or heating mode of the outdoor unit and Ihe operation frequency of the compressor are

determined

heating command frequencies of

by

difference between al1 ihe requested cooling command frequencies and al1 the requested

al1 the indoor units.

12-1-3. Controlling the Refrigerant Cycle in the Outdoor Unit during

SrmuItaneous Cooling-Dominant Operation

(I

)

FIOW

contro1

In order to divide the cooling exhaust heat appropriately to the indoor units in the heating operation and

outdoor heat exchanger, the opening of the

between

frequencies and by the operation frequency.

(2)

Pressure contro1

Constant high-pressure control is performed so that the capacity of the indoor units in the heating

operation is maintained.

1)

2)

al1 the requested cooling comrnand frequencies and al1 the requested heating command

Outdoor fan control

Switching between the outdoor main heat exchanger and the sub heat exchanger

PMV2

flow control valve is controlled by the difference

Since the high pressure

outside air temperature is low and the difference between the cooling and heating command frequencies

is

minimal, the main heat exchanger is switched to the sub heat exchanger which is srnaller than the

ordinary rnain exchanger.

12-1

-4.

Controlling the Refrigerant Cycle in the Outdoor Unit

may

drop even when the fan

is

shut down by the outdoor fan control

if

the

during Simultaneous Heating-Dominant Operation

(1)

Expansion valve control

Control for preventing superheat is

(2)

~vaporaiing, temperature control

The evaporating temperature control

units in the cooling operation is maintained.

periormed

is

by

the outdoor heating expansion valve.

performed by outdoor fan control so that the capacity of Ihe indoor

(3)

Swltching between outdoor expansion

When there is a minimal

by

the outdoor heat exchanger

the

flow. This results in capillary control being selected.

differente

is

between the cooling and heating frequencies and the heat absorption

low,

the

valve

control and capillary control

expansion valve is no longer capable of controlling adequately

12-2.

12-2-1.

(1)

PMV

SVS

SVD

Functions

Multi-controller

Valve functions

Symbol

(A,

B,

C,

(A,

B,

C,

(A,

8,

C,

svss

SVDD

SVH

and

Operations

Name of Valve

Flow rate contro1 valve

D)

Suction gas valve

D)

Discharge gas valve

D)

Pressure reducing solenoid

valve

Pressure increasing solenoid

valve

Superheat solenoid valve

of

Solenoici

This opens to the extent

and performance required of the indoor units in each

system.

Opens when cornrnands from the indoor units in each

system

Opens when cornrnands from the

system call for heating.

Opens when number of units in heating operation

reduced (heating 4 shutdown or cooling).

Opens when def rosting

Opens while

Opens when number

increased (shutdown or cooling + heating).

Opens while

discharge pipe from being blocked.

Opens when unit in cooling operation

Valves

Descriptlon of Function

corresponding to

call

lor cooling.

indoor units in each

starls.

oil

recovery is controlled in cooling.

o1 units in heating operation is

contro1 is performed to prevent liquid in

is

the

presenl.

capacity

is

(2)

Valve operatlons

Outdoor

Operation Mode

Shutdown

During operation

Indoor

Shutdown, fan

Shutdown, fan

Cooling

Cooling

Heating

Heating therrno-contro1 OFF

Operation

Iherrno-contro1

Mode

OFF

SVD

OFF

OFF

OFF

OFF

ON

ON

SVS

OFF

ON

ON

ON

OFF

OFF

PMV

(Normal)

Fully closed

Futly closed

Rated opening

Fully closed

Rated opening

Fully closed

12-2-2.

(1)

Valve

Outdoor

functlons

Unit

Symbol

20SF

Name

of

Valve

4-way switching varve

Sub heat exchanger solenoid

valve

Cooling solenoid valve

Outdoor flow control valve

I

solenoid valve

valve

Solenoid valve for capillary

Cooling bypass flow

valve

High-pressure release

solenoid valve

Hot gas bypass solenoid valve

Solenoid valve ior stariup

com~ensation

Gas balance

p--p

control

-

DescrIption

Selects whether outdoor main heat exchanger is to be

used as condenser or evaporator.

OFF: Condenser, ON: Evaporator

Selects whether outdoor main heat exchanger or sub

heat exchanger is to be used.

OFF:

Main exchanger,

Selects whether the sub heat exchanger is going to be

used

or

not,

1

Opens when sub heat exchanger

Opens for cooiing-oniy operations.

L

Controls flow to divide cooling exhaust heal between

indoor units in heating operation and outdoor heat

exchanger during sirnultaneous cooling-dorninant

operations.

Its opening

I

coolingtheating difference.

I

Its opening is adjusted by the adjustrnent signal

frorn the multi-controller.

Opens or closes to select the expansion valve or

capillary tube

coolirig/heating during sirnultaneous operation

(coolinqlheating) under the heating-dorninant operation.

Degree of opening is controlled by discharge and

suction temperature.

Opens and closes with the heat exchange temperature

(TE).

Opens and closes with the pressure and outside air

Opens

side starts up.

Opens when the

when the compressor (No.

is

increased

acmrding to the diflerence of

Inverler cornpressor is shut down.

of

Functlon

ON:

Sub exchanger

in

accordante

is

to be used.

with

2)

at the non-inverter

I

l

I

l

(2)

Valve

operations

Outdoor Operation Mode

Cooling operalion

Heating operation

Simultaneous

coolingdominant

operation

Simultaneous

heat ing-dominant

operation

13.

OPERATIONS

13-1.

Temperature sensor

Multi-Controller

SV13

ON

OFF

OFF

ON

OFF

ON

ON

OFF

ON

ON

ON

C,

SV15

OFF

OFF

OFF

D)

and pseudo saluration temperature (Thx)

20SF

Outdoor

exchanger

Sub

main

heat

heat exchanger

-

Outdoor main heat

exchanger

Sub

heat

exchanger

Expansion valve

Capillary

OF

EACH

According to a temperature difference belween the evaporator outlet

temperature

(1)

Performs the open compensation o1

only, and Cooling-dominant operation)

(2)

Performs the opening degree of

(cooling only, cooling-dominant operation)

SENSOR

(ThA,

B,

SV14

ON

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

PMV

the

outdoor flow rate contro1

SV16

OFF

OFF

ON

OFF

OFF

OFF

ON

OFF

ON

in each system. (Cooling

PMVP

-

-

Opening degree

control

Opening degree

control

valve.

-

13-2.

Outdoor

Unit

Pressure sensor

(High pressure)

Suction temperature sensor

(cooling

coolingdOminant 'peration1

heating-dOminant 'peration)

Discharge temperature

sensor (cooling, heating,

coolingdominant,

heating-dOminant Operation)

Outdoor unil heat exchanger

sensor (heating,

heating-dominant operation)

only, heating only,

Determines the frequency of the compressor Inveiter side

status of non-inverter side. (cooling only, heating only, coolingdorninant,

heating-dominant operation)

Controls the outdoor blower. (cooling only, cooling-dorninant operation)

Controls the hot gas bypass

1) Pd < 13kg/cm2~: Open (cooling)

2)

~d<l 7kg/cm2~: Open (cooling-dominant sub heat exchanger

operat ion mode)

Switches the outdoor unit

exchanger operation

Controls the open degrees of PMVl

Operation temperature:

Stops when the suction temperature

to detect the suction temperature abnormality.

Controls open degrees of PMV1 (cooling bypass).

Operation temperature: 11 0°C

Stops when the discharge temperature

discharge temperature abnorrnality.

Multiples the time during TE C -3°C and performs the defrost contro1 after

55

minutes.

Controls the outdoor unit blower.

Controls the high pressure

Opens when

(25

minutes when the Wwer is turned

TE

r

SV2.

main heat exchanger operation and sub heat

(cooling bypass)

20°C

>

40°C

continues for ten minutes due

>130°C due to detect the count

ON

release.

11°C.

and

ONIOFF

for the first time.)

3

Outdoor temperature

High pressure switch

Low pressure switch

Operation pressure:

0.25

kg/crn2~

sensOr

Controls the hot gas bypass

Opens when the outdoor temperature C 0°C

Opens when the outdoor temperature

Controls the outdoor blower.

Identifies whether the forced cooling operation

The forced

temperature

Stops when Pd>

compressor side due to

Stops al1 the operations

abnormality. (Cooling, cooling-dorninant operation)

Stops

al1 the operation after counting

to detect the gas leak abnormality. (Heating, heating-dominant operation)

Ignores the low pressure switch operation. (Defrost operation)

cooling operation

>

25%.

30

kgtcm2G in both of inverter side and non-inverter

SV2.

(10

HP).

e

13°C

(8

HP).

is

performed.

is

performed when the outdoor

detects the high pressure abnormality.

30

seconds after due to detect Ihe gas leak

10

rninutes by the timer counter due

14.

COOLINGIHEATING AUTOMATIC

REMOTE

CONTROLLER

14-1.

Cooling/Heating

Basic variation

rwm

temperature (example)

Automatic

of

Change-Over Operation

Load

Load

variation

variation

n

a

I

-

Cooling

operation

Fig.

0.5deg

14-1

15.

IMPORTANT MATTERS

T0

BE

CHECKED

BEFORE

TEST

RUN

AND

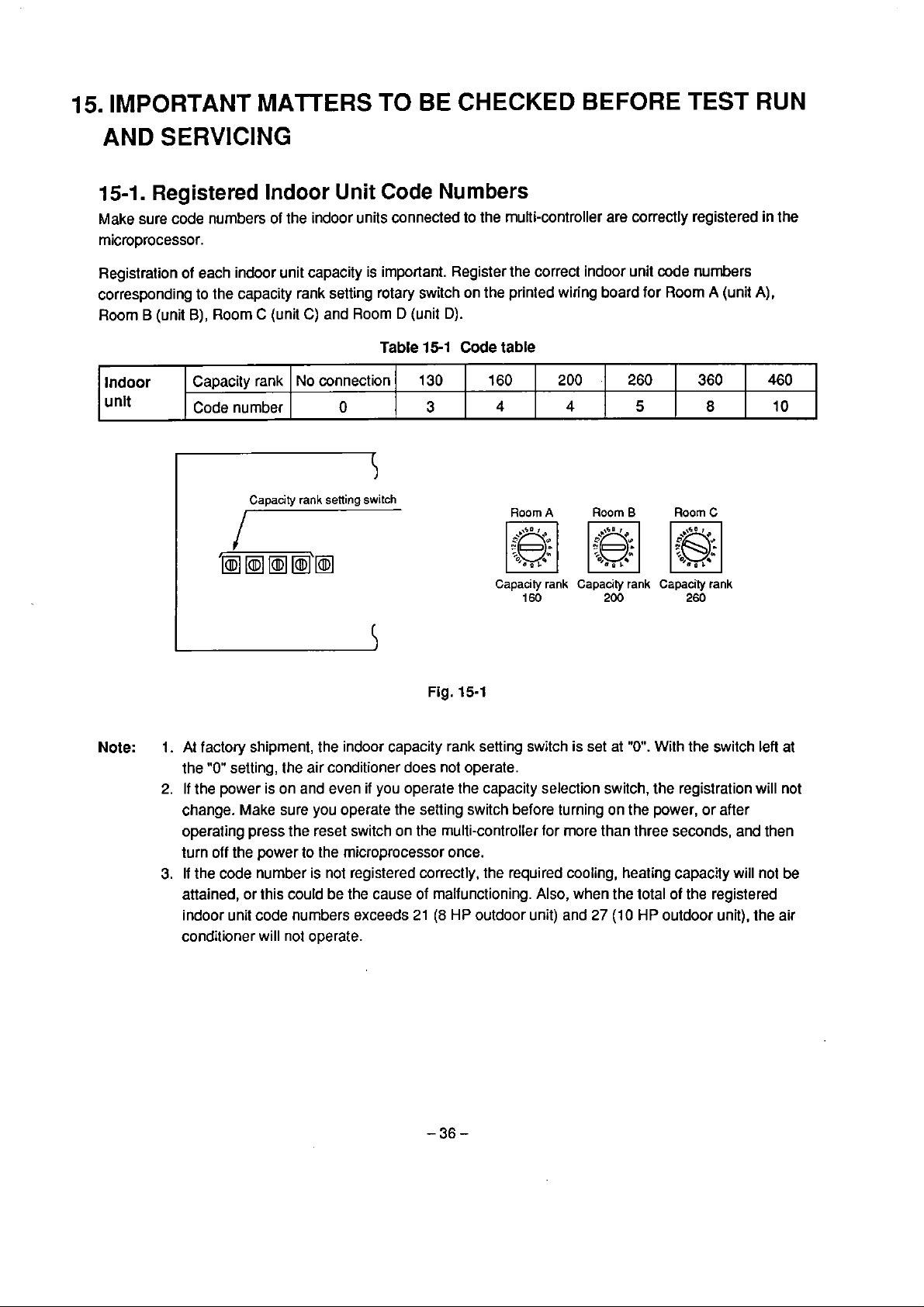

15-1.

Make

rnicroprocessor.

Registralion of each

corresponding to the capacity rank setting

Roorn B (unit

Indoor

unit

SERVICING

Registered

sure code nurnbers of the indoor units connected to the multi-controller are correctly registered in the

B),

Roorn C (unit

Capacity rank

Code number

Indoor

indoor unit capacity is important. Register the correct indoor unit code numbers

Capacity

Unit

Code

rotary switch on the printed wiring board far Roorn A (unit

C)

and Roorn D (unit

Table

No connection

O

rank

sening

switch

Numbers

D).

15-1

Code

130

3

table

160

4

Roorn

A

200

4

.

Room

260

5

B

360

Roorn

8

C

7

Capacity

160

rank

Capacity

200

rank

Capacity

260

rank

A),

460

10

Note:

Fig.

15-1

1.

At factory shipment, the indoor capacity rank setting switch is set at

the

"0"

setting, the air conditioner does not operate.

2.

If

the power is on and even if you operale the capacity selection switch, the registration will not

change. Make

operaling press the reset switch on the multi-controfler for more than three seconds, and then

turn off the power to the microprocessor once.

3.

If

the

code nurnber is not registered correctly, the required cooling, heating capacity will nol be

attained, or this could be the cause of malfunctioning.

indoor unil code numbers exceeds

conditioner will not operate.

sure you operate the setting switch before turning on the power, or after

Also, when the iotal of the registered

21

(8

HP

outdoor

unit)

and

27

"O".

With the switch leit

(10

HP

outdoor unit), the air

at

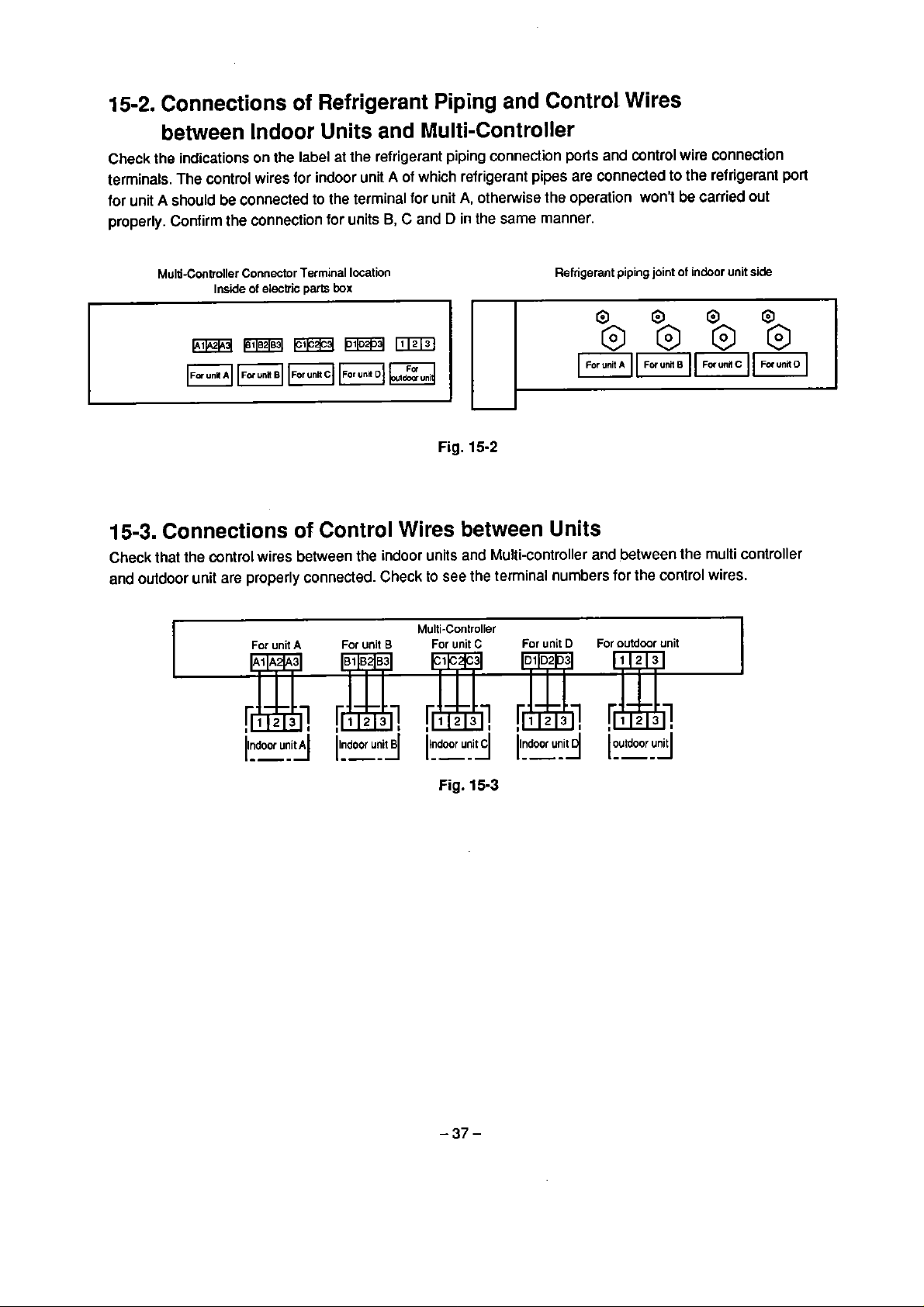

15-2.

Connections

of

Refrigerant Piping and Control Wires

between Indoor Units and Multi-Controller

Check

terrninals. The control wires for indoor unii A of which refrigerant pipes are connected to the refrigerant

for unit A should

properly. Confirm the connection for units

the indications on the label at the refrigerant piping connection

be

connected to the terrninal for unit

B,

C

A,

otherwise the operation won't

and D in the same manner.

ports

and control wire connection

be

carried

out

port

Multi-Controller Connector Termina1 location

15-3.

Check that the control wires between the indoor units and Multi-controller and between the multi controller

and outdoor unit are properly connected. Check

Connections of Control Wires between Units

I

Inside

of

electric

Far

unit

A

partc

box

For unit

to

Multi-Controller

B

Fig.

15-2

see the termina1 numbers for the control wires.

For

unit

C

Refrigerant piping joint

For

unit

D

of indoor

unit

I

side

z

Fig.

15-3

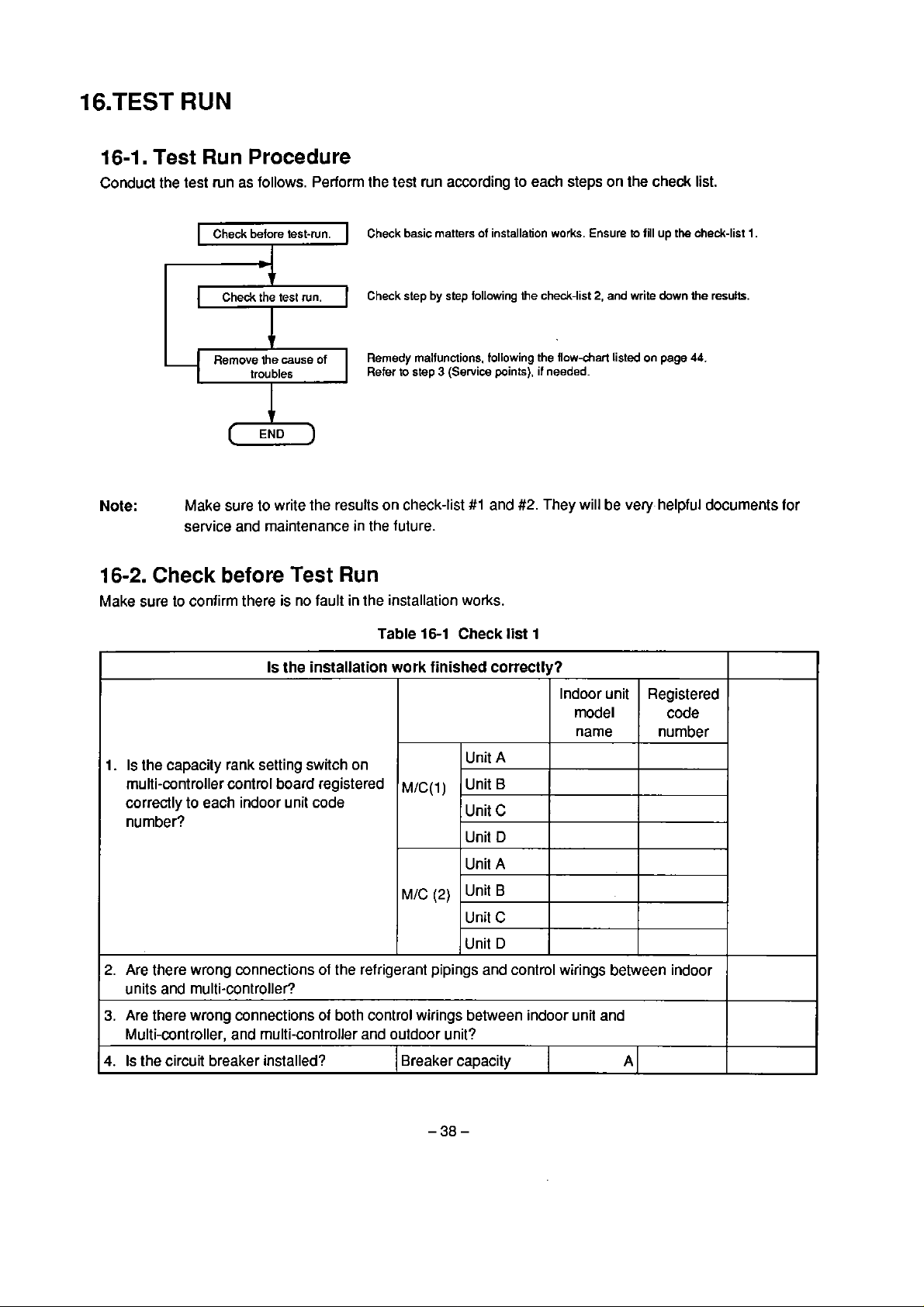

I6.TEST

RUN

16-1.

Conduct the test run as follows. Perform the test run according to

Test Run

Check before test-run.

Procedure

Check basic matters of installation works. Ensure

-

Che&

Remove

trou bles

the test run.

1

lhe

cause of

Check step by

Remedy malfunctions. following the

Refer

to

I

Make

Note:

16-2.

Make sure to confirrn there is no fault in the installation works.

Check

sure to write the results on check-list

service and maintenance in the future.

before

Test

Run

step

follawing

step

3

(Service points), if needed.

#l

and

#2.

each

lhe

che&-list

They will

steps on the

2.

and write

flow-chart

listeci on

be

che&

list.

lo

fill up the check-list

dawn

the

page

44.

very helpful docurnents for

1.

resultr.

Table

16-1

Check

Is

the

installation work finished correctly?

1.

Is

the

capacity rank setting switch on

multi-controller control

correctly

nurnber?

2.

Are there wrong connections of the refrigerant pipings and control wirings between indoor

units and multi-conlroller?

3.

Are there wrong connections

Multi-controller, and multi-controller and outdoor

4.

Is the circuit breaker installed?

to

each indoor unit code

board registered

of

both control wirings between indoor unii and

M/c(~)

M/C

(2)

unil?

Breaker capacity

Unit A

Unit B

C

Unit

Unit

D

Unit

A

Unit

B

Unit

C

Unit

D

list

1

Indoor unit

rnodel

name

Registered

nurnber

A

code

5.

Is the breaker capacity adequate?

6.

Is there any wrong wiring of power

cable?

7.

Is the wire size correct?

8.

Is there a wrong wiring between power source outlet and outdoor unit?

9.

Is the grounding wire attached?

10.

Is there adequate resistance?

(more than

11.

Is the voltage correct?

12.

Does the drainage flow smoothly?

13.

Is the heat insulation sufficient? (Especially connecting parts of indoor unit and

muli-cont roller)

14.

Is there a shorì-circuit of air flow frorn indoor unit?

15.

Is there a shori circuit of blowing air from outdoor unit?

16.

Is the refrigerant added adequately?

17.

Are the valves lully opened?

18.

Is the remote conlroller normal?

10Mn)

Power cable

Control wire

Insulation resistance

Voltage

mm2

rnm2

MQ

V

16-3.

After completion of the check before the test mn, conduct the test run check with the tollowing steps listed in

the check

(1)

(2)

(3)

(4)

(5)

(6)

Test

As for the actual procedure of check list 2 (See page

More than

heater. In the case

or heating operation won't work due to

The test run check, in principle, should be rnade for each and every indoor unit.

operating

piping and

To confirrn cooling and heating operation, operate the unit under the mode within the possible

temperature range to operate the units.

There are few cases when one of two operation modes is norrnal but the other is not. Make sure to write

down the

For this check, you need al least a tester and screw driver

lherrnometer, pressure gauge

Run

Check

Iist

2.

40.1,

and simultaneousty rernove the troubles.

12

hours in advance of the test run, turn on the switch lor supplying power to the crankcase

that the compressor was not warrned up sufticiently by crank case heater, the cooling

protettive

simultaneously, you can not carry on the check for the cross connection between refrigerant

contro1 wiring.

items you have checked.

and

other tools (spanners, pliers, nippers, and pins for reset switch.)

circuit activated.

(+,

-).

If

the multiple units are

We recornrnend you to prepare

a

Operatlon Procedure

1.

Turn on the power.

2.

(Check the Fan operation)

Set the operation mode to

and

start operation.

3.

(Check the Cooling operation)

Set ihe operaiion mode to

"Cooling" and stari operation.

(Once you stopped operation you

have lo wait for 3 minutes to

restart due to the

built in restart

delay circuit functioning.)

"Fan",

Table

16-2

Check list

2

Check Iterns

Is the

LED

on remote controller

blinking?

Are

Ihe conditions initialized for

operation?

Is the air flow discharging from

air-outlet?

1s

there abnormal noise from fan?

Does the compressor start normally?

Is there abnorrnal noise from the

cornpressor or pipes?

Is the cool air flow coming out?

Is the air flow circulaling

adequately?

Conflrmatlon

MIC

(1

)

MIC

(2)

amonamom

rr=crrrr

CCCCECCC

33333333

In this case, check

every indoor unit

operating

simultaneously.

Set the temperature to

the lowest.

4.

(Check for

the

heating operation)

Set the operation mode to

heating

and

start the operation.

(Once You stop~ed operation,

you have to wait for 3 minutes to

restart due to

the

built-in restart

delay circuit functioning.)

1)

(Note

Does Ihe thermostal work norrnally?

(Confirm that compressor stops at

high temperature setting, and

restarts at low temperature setting.)

Is the temperature diff erence correct

between suction air and exhaust air?

Is the voltage of power supply

correct?

(380

-

41

5V

f

10%)

Is the operating current correct?

Is the operating pressure correct?

Does the compressor

stati norrnally?

Is there abnormal sound?

(ComPressor~ PiPings)

Is the warm air flow coming out?

Is the air flow circulating adequately?

Does the thermostat work normally?

(Confirm that cornpressor stops at

low temperature setting, and restarts

at high temperature setting.)

p

/

Operatlon

Procedure

Check

Items

ConfirmatIon

M/C

(1)

UmOPUmOP

=====,C==

ECCEECCC

33333x33

MIC

(2)

In this case, check

every indoor unit

operating

simultaneously.

Se1 the temperature lo

the highest.

1.

When

the

Note:

16-4.

protect the units.

Guidelines

outdoor temperature rises above

16-4-1. Guideline for SuctionlDischarge Temperature

(1)

If

the difference between the dry-bulb temperatures al the suction port and discharge

conditioner is

lhe system is operating properly. (Operation at max.

(2)

11 the difference between the dry-bulb temperatures at Ihe suction

conditioner is

the system

10°C

or more when operation has continued for al least

18°C

or more when operation has continued

is operating norrnally. (Operation at max.

Is the temperature diflerence correct

between suction air and exhaust air?

Is the voltage

correct?

Is the operating currenl correct?

Is the operating pressure mrrect?

of

power supply

(380 - 41

21°C,

Hz)

Hz)

5V

f

1OoA)

it will

for

be

forced into reverse operation to

Diff

erence

30

port

and discharge

at

least

30

minutes in the

minutes in the

port

"COOL"

port

"HEAT"

of the air

mode,

of the

air

mode,

16-4-2. Guideline for

If

the current is within f

syslem is operaling normally. (Cooling: operation at max.

The

current varies as lollows depending on the operating conditions.

(t)

When the current is higher than the standard current

High indoor/outdoor temperatures

Poor heai dissipafion of outdoor

(2)

When the current

Low indoor/outdoor lemperatures

Gas leak (insufficient refrigeranl)

Operating

15%

of lhe value given in the catalog in both the heating and cooling modes, the

is

lower than the standard current

Current

unii

(during cooling)

Hz:

heating: operation at

max.

Hz)

16-4-3. Guideline

(1)

The operating pressure level is generatly as listed below.

for

Operating Pressure

Table

16-3

16

to

20

High pressure:

Low pressure:

Heating

Note:

(2) Changes in high and low pressures caused

Cooling: Operation at max.

The above figures indicate the pressure levels established

temperature

1)

Cooling:

Rise in indoor ternperature:Rise in high and low pressures

Drop in indoor temperature: Drop in high and low pressures

Rise

-

Drop

2) Heating:

Rise in indoor temperature: Rise in high and low pressures

Drop in indoor temperature:

Rise in outdoor air temperature: Rise in high and low pressures

Drop in outdoor air temperature: Drop in high and low pressures

High pressure:

Low pressure: 3 to

"C)

in

outdoor air temperature: Rise in high and low pressures

in outdoor air temperature: Drop in high and low pressures

3.5

15

kg/cm2~

to 5.5 kg/crn2~

to

21

kg/cm2G

4.5

kg/cm2G

Hz,

Heating: Operation at max.

by

changes

Drop

in high and low pressures

Indoor:

Outdoor: 25°C to

Indoor:

Outdoor:

15

rninutes after operation starts up. (dry-bulb

in

operating conditions

Hz

18°C

15°C

5°C

lo

to

to

32OC

35°C

25°C

10°C

16-4-4. Flashing

When the power is turned on, Ihe remote controller's operation lamp will flash (ON for

0.5

sec.). This is not indicative of a failure or rnalfunction.

16-4-5.

In the following cases, "PREHEAT/DEFROST" will flash (at 4 second intervals) on lhe

remote controller. This is not indicative of a failure or malfunction.

Case:

PREHEATtDEFROST

1.

When the cornbination of indoor units exceeds the capacity or when the code number entered

by the capacity rank setting switch

2.

When the indoor unit assigned

selector switch.

of

Remote Controller's Operation Lamp

Flashing

is

incorrect (so that capacity

by

the command has been excluded by the operaling mode

is

exceeded).

0.5

LCD

sec. and

display

OFF

of

the

for

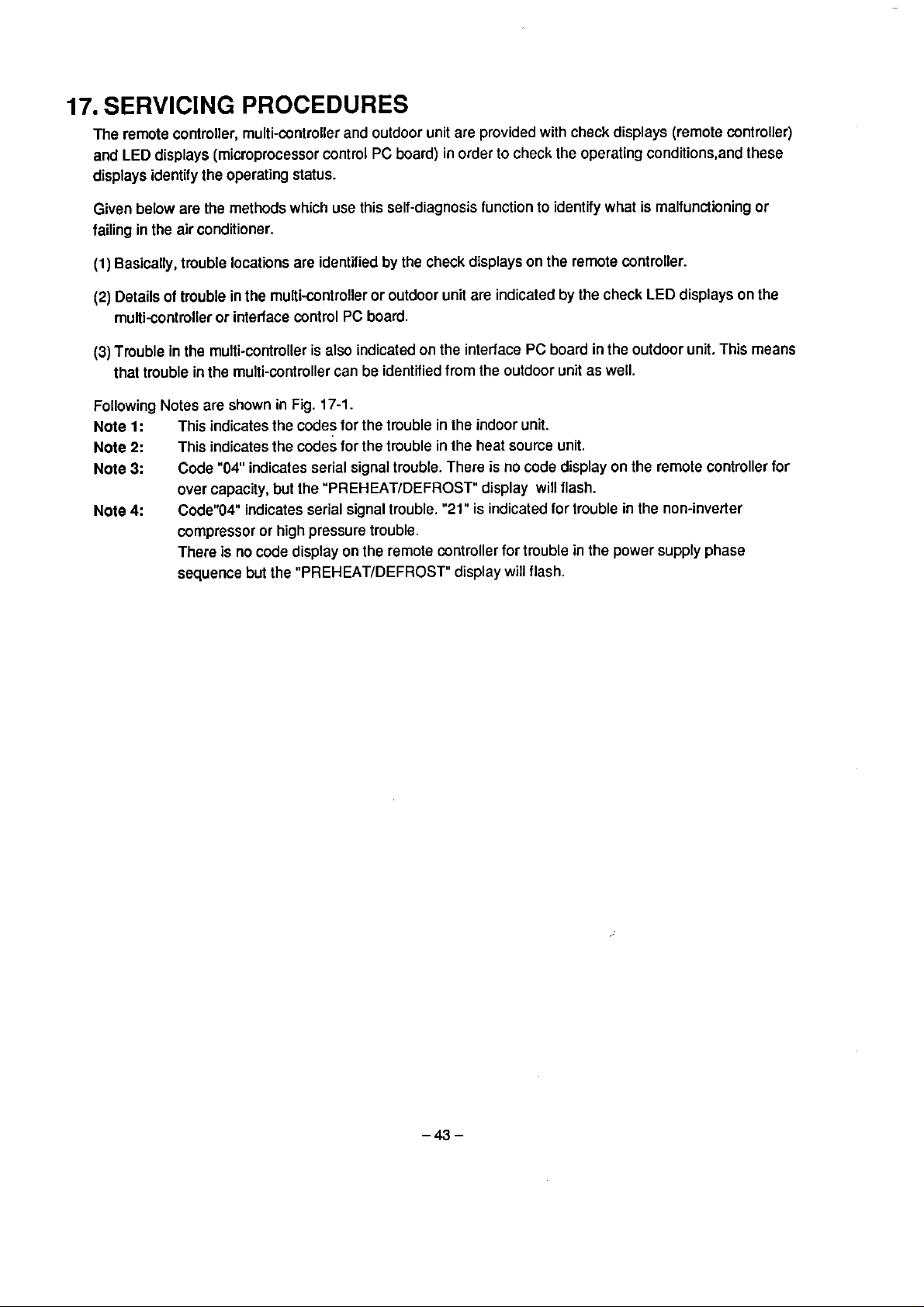

17.

SERVICING

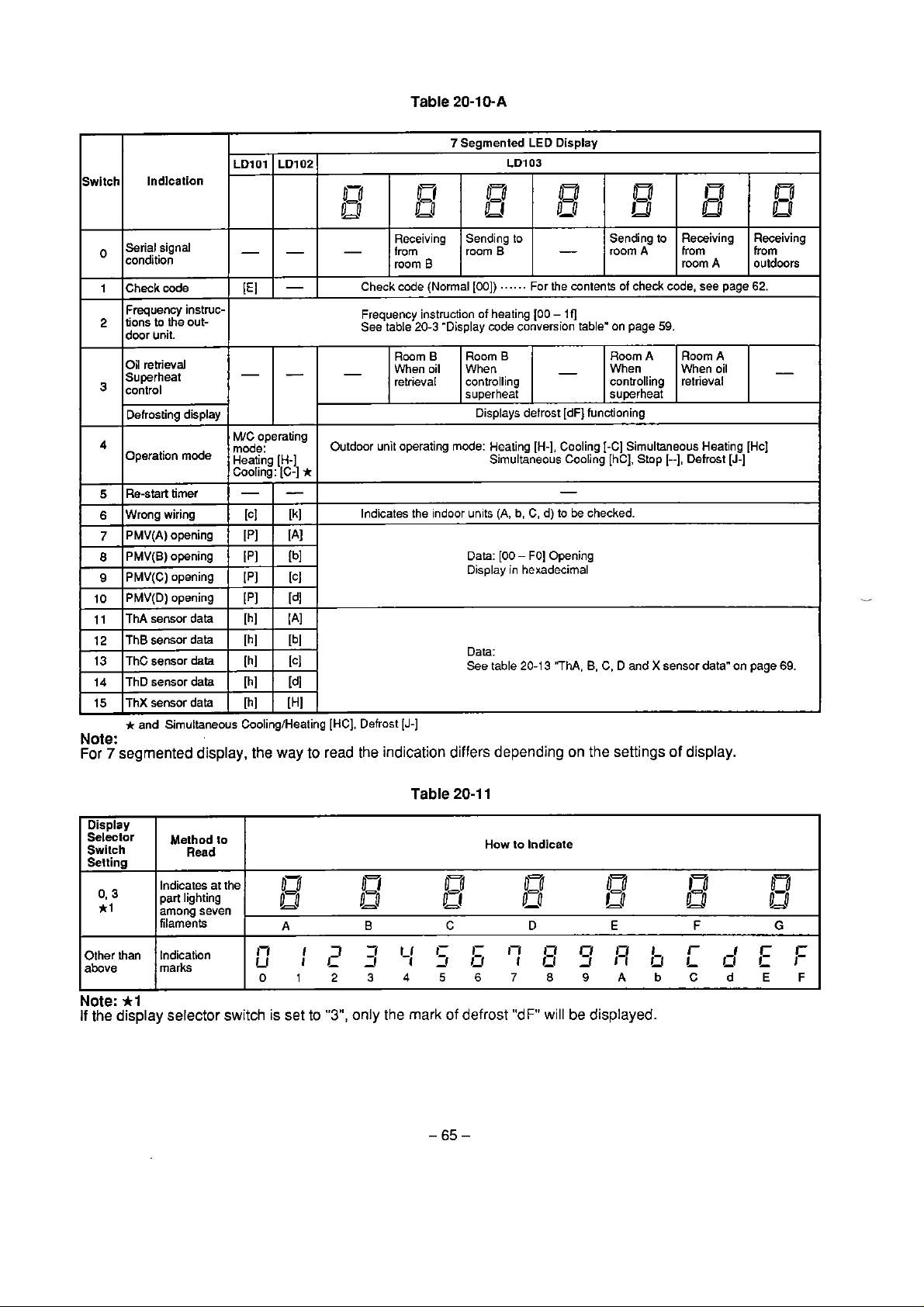

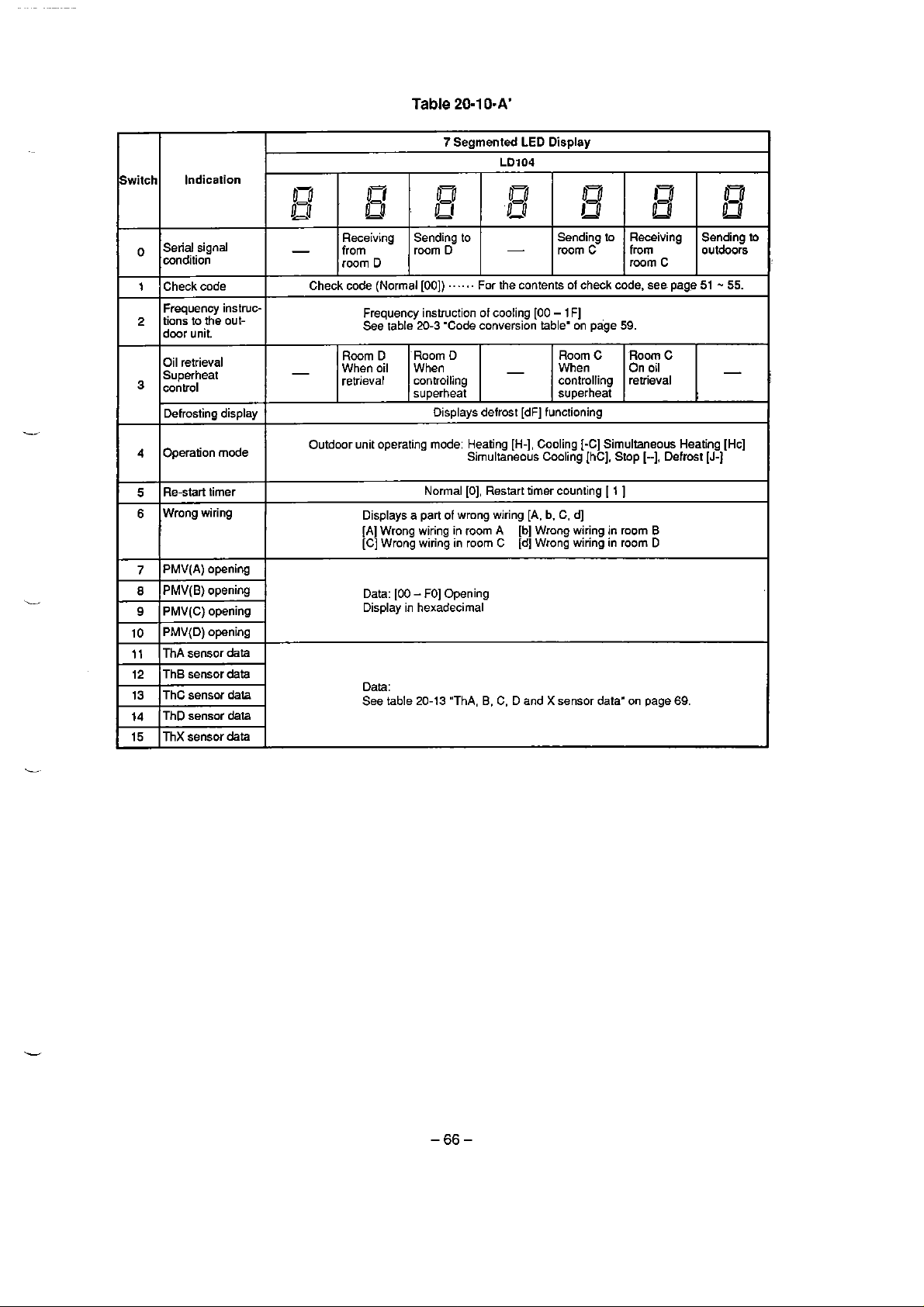

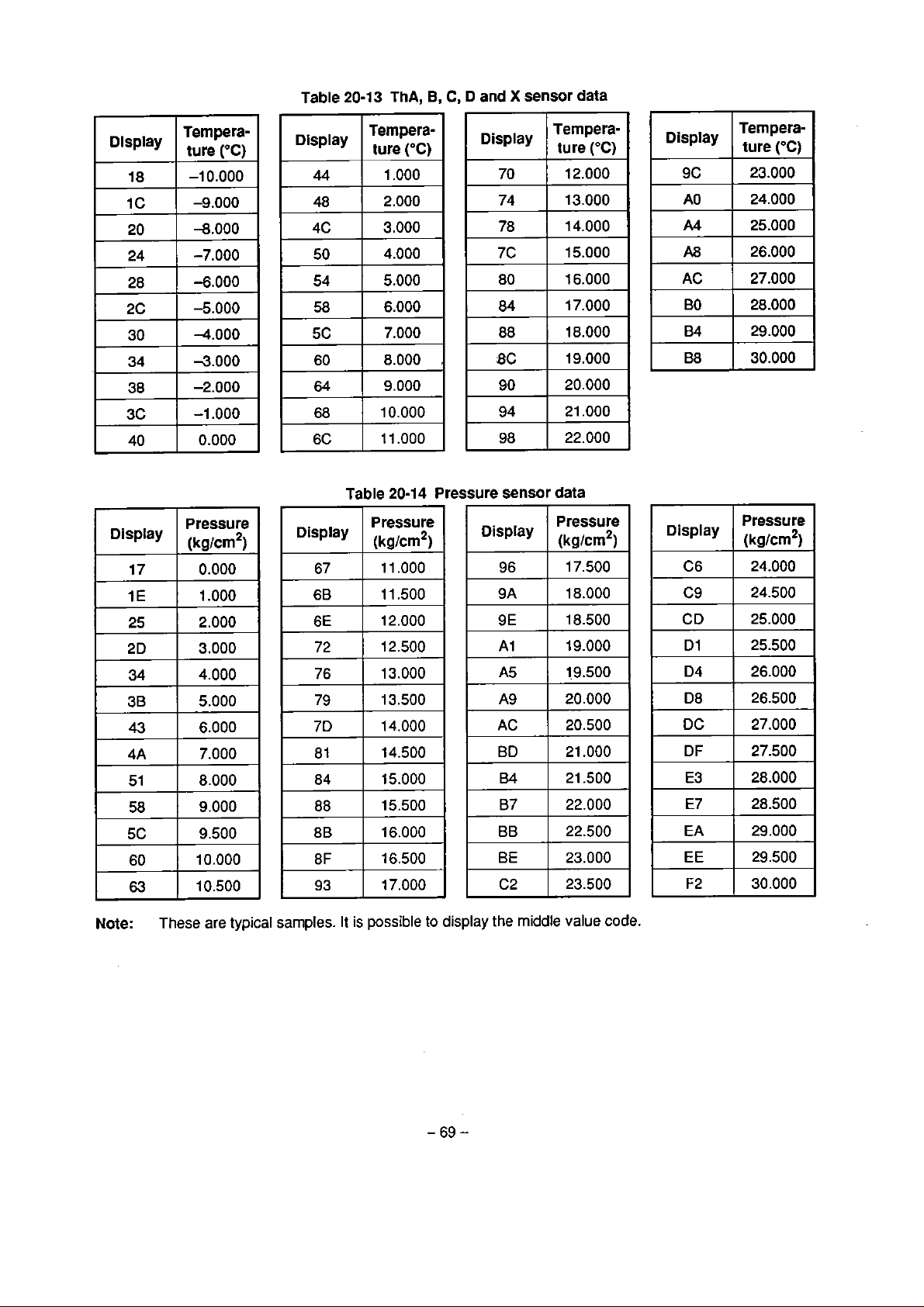

The remote coniroller, multi-controller and outdoor unit are provided with check displays (remote controller)

and

LED

displays ~microprocessor control

displays identify the operating

Given below are the methods which use this self-diagnosis function to identify what is malfunclioning or

failing in the air conditioner.

(l)

Basically, trouble locations are identified by the check displays on the remote controller.

(2)

Details o1 trouble in the muiti-controller or outdoor unit are indicaled by the check

muli-controller or interface control

(3)

Trouble in the multi-controller is

that trouble in the multi-controller can be identified frorn the outdoor unit as well.

PROCEDURES

PC

board) in order to check the operating conditions,and these

status.

PC

board.

also

indicated on the interface

LED

displays on the

PC

board in the outdoor unit. This means

Following Notes are shown in Fig.

Note

Note

Note

Note

1:

2:

3:

4:

This indicates the codes for the trouble in the indoor unit.

This indicates the codes for the trouble in the heat source unit.

Code "04" indicates serial signal trouble. There is no code display on the remote controller for

over capacity, but the

CodeW04" indicates serial signal trouble.

compressor or high pressure trouble.

is no code display on the remote controller for trouble in the power supply phase

There

sequence but the

"PREHEAT/DEFROST"

17-1.

"PREHEATtDEFROST"

"21"

is indicated for trouble in the non-inverter

display will flash.

display will flash.

Remote controller Che& code display

Multi-Controller

(MfC)

Outdoor unit

Interface Control

Inverter Control Board

Multi-Controller

(

M/c)

Board

(IIF)

(INV)

Remote

controller

Indoor

unil

"99.

(Note

1)

(Note

2)

(Note

3)

'15'

1

Remote controller

serial signal abnormality

-

t

Indoor unrt abnorrnality

*TA

sensor abnormality

*TC sensor abnormality 'Od"

=

Water level abnormality "Ob'

Serial

signal abnormality '04'

Outdoor unit abnormality

Power supply circuit abnormality '17" TE sensor abnomality

G-Tr abnorrnality "14"-

Compressor abnormality "ld' abnormality

Breakdown

High pressure SW operation

11

-

"OC'

V")

--)

"1F'

"21"-

MJC

abnormality

Th

(A)

sensor abnormality

Th

(8)

eensor abnormality

Th (C) sensor abnormality '82'

Th

(D)

sensor abnmality

Th

(X)

sensor abnorrnality

-

Water leve1 abnormality

e

Serial signal abnormality

*Outdoor unit capacity

is

not detected

Over capacity

MIC PC board abnormality

Outdoor unit abnormality

ThD1 sensor abnormality

ThD2 sensor abnorrnality

ThS sensor abnormality

T0

sensor abnormality

m

Pischarge temperature

Suction temperature

abnormality

Pressure sensor abnormality

Low pressure

abnormality

Non-inverter wrnpressor

abnormality

High pressure abnonnality

Serial signal abnormality

Power supply

sequence abnormality

gas

phase

leak

(Note

'80'

'81'

'83'

'84'

'Ob'

'04'

'88'

"89'

'8A'

4)

A

-

'AO'

'Al'

'A2'

"A4'

'AS

'A8'

-A

7

"AA'

'AE'

'AD'

'21'

'04'

'AF'

'1

C"

Fig.

17-1

-L

WC abnormality

Displays each

abnormality

Power supply circuit abnonnality

INV abnormality

code

of

IWC

"17

'AB"

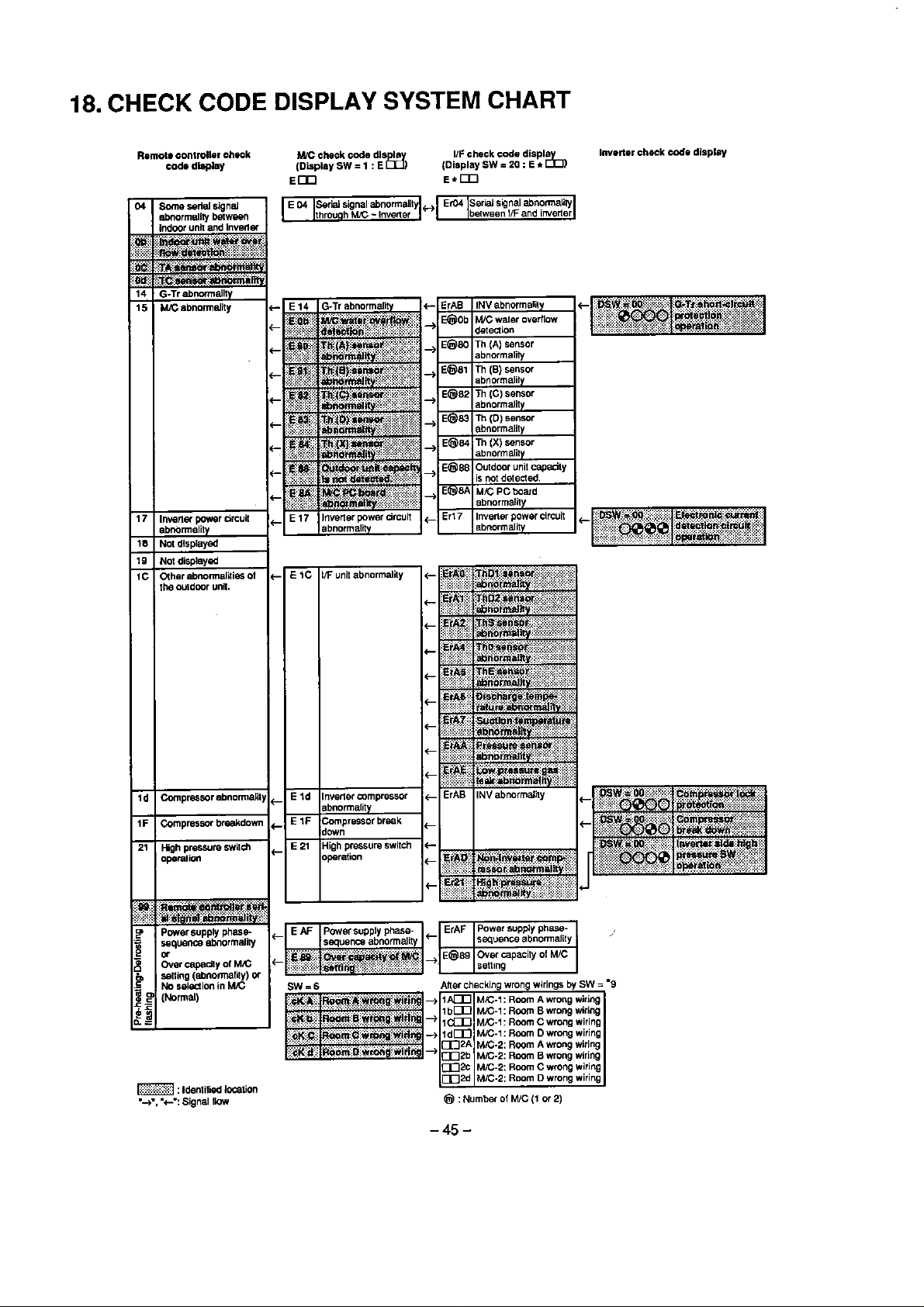

18.

CHECK

CODE

DISPLAY

SYSTEM

CHART

Remote

COdO

controllar

dlapley

chock

W

check code dls I

(Display

Em

SW = 1

I/F check code displa

(Display

SW

=

20 : E

r

:

E

l%

E*m

h)

Inverior check

code

dlsplay

19.

IDENTIFICATION

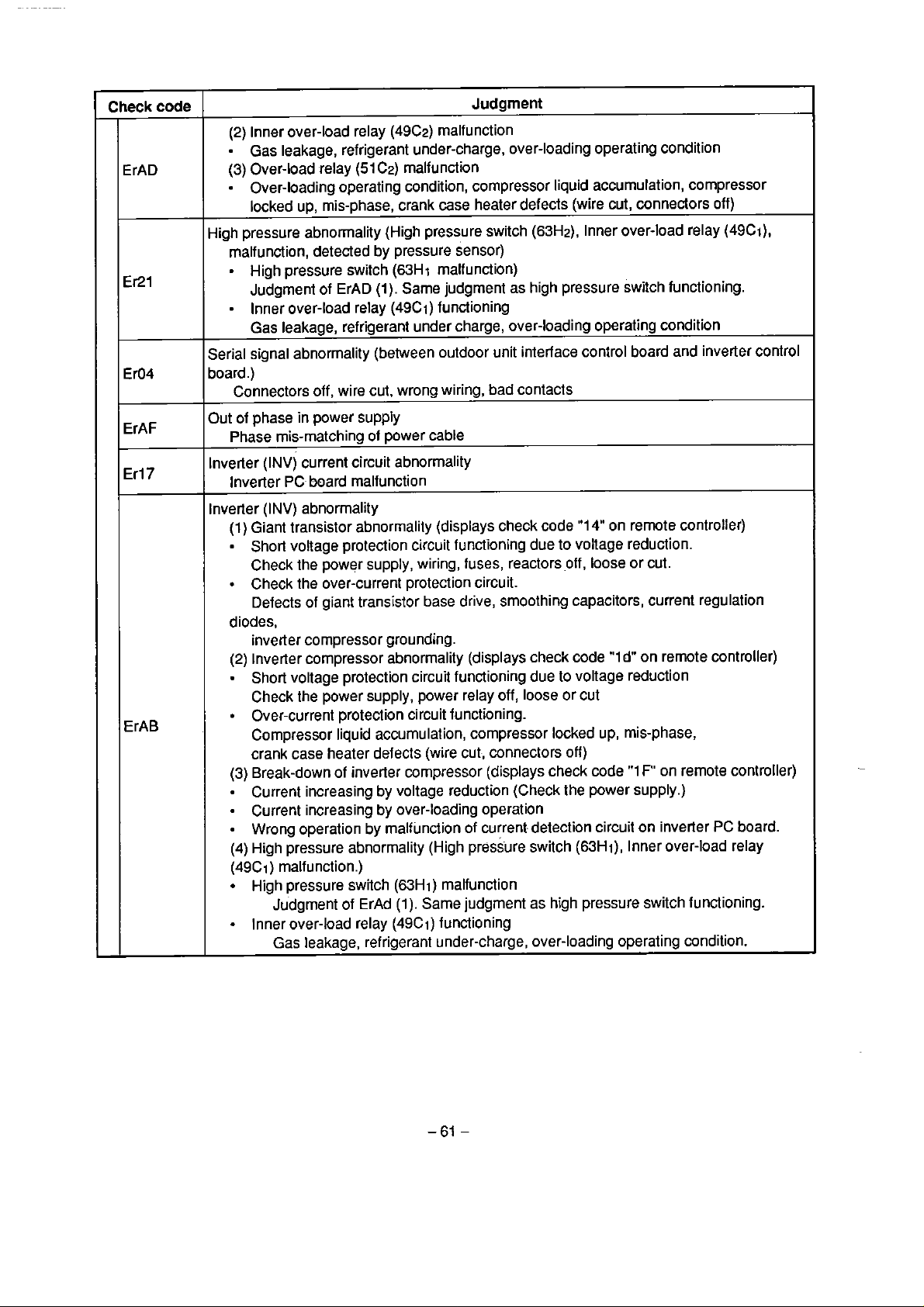

When there

the check code.

Whether the trouble location

check code.

is

a sign of trouble, do not reset but press the "check switch

PROCEDURES

is in

the

indoor unit, multi-controller or outdoor unit can be identiiied by lhe

on

the remote controller and check

When the failure has been identified to be in

the

LEDs

on

the

contro1

causes of multi-controller failure can also

PC