SERVICE MANUAL

AIR-CONDITIONER

2-PIPE SUPER MULTI, HEAT PUMP

FILE NO. A90-9819

Outdoor Unit

Multi Controller

3-PIPE SUPER MULTI, HEAT PUMP WITH

SIMULTANEOUS HEATING AND COOLING

Outdoor Unit

Multi Controller

MAR-M102HTM8-PE

RBM-Y1032-PE (3-way)

RBM-Y1042-PE (4-way)

MAR-F102HTM8-PE

RBM-Y1032F-PE (3-way)

RBM-Y1042F-PE (4-way)

Printed in UK March 1998 s

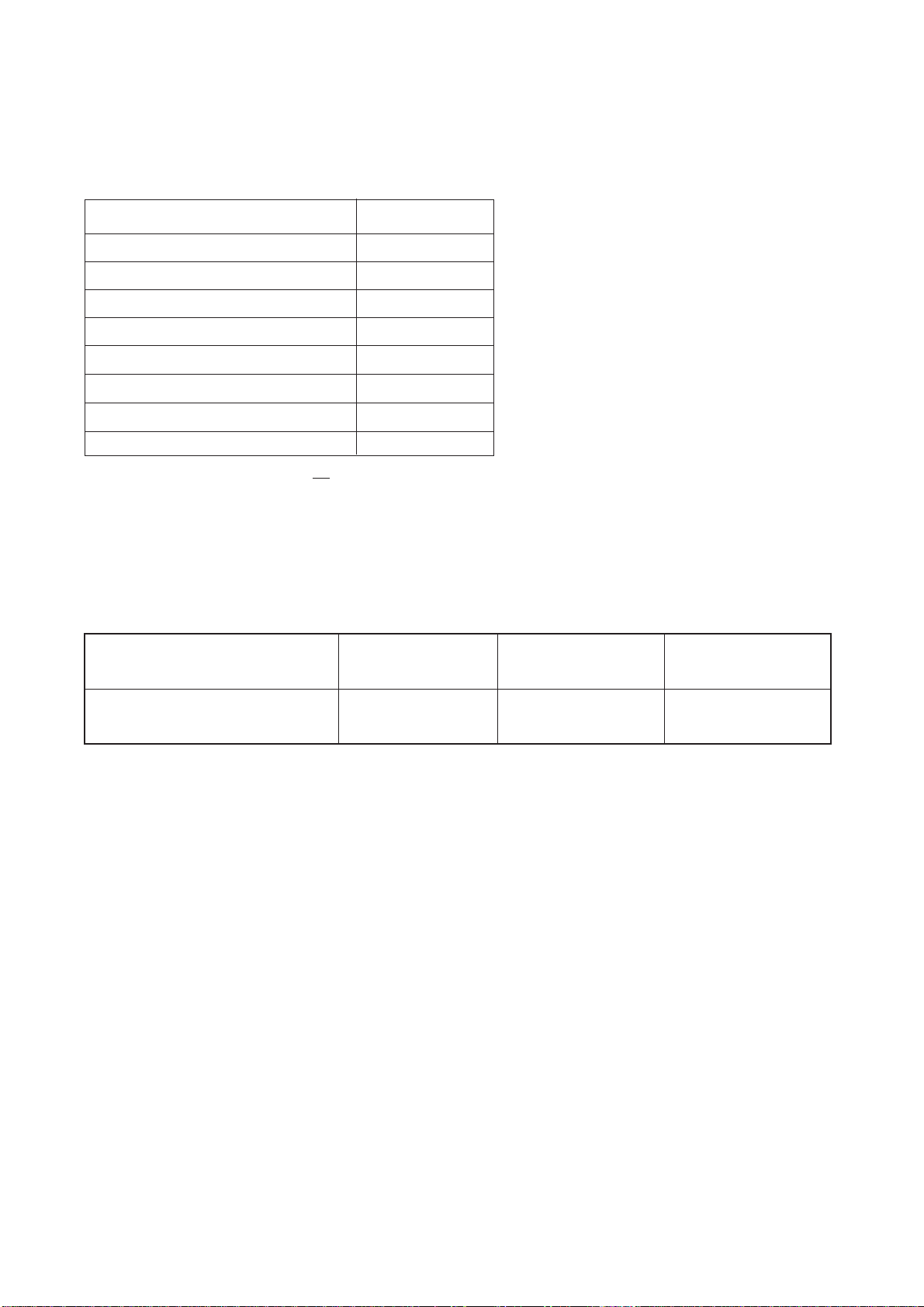

CONTENTS

1. SUPER MULTI SYSTEM BASIC COMPONENTS.....................................................................................

2. OUTLINE OF CONTROL SYSTEM............................................................................................................

3. SPECIFICATIONS......................................................................................................................................

4. CONSTRUCTION VIEWS..........................................................................................................................

5. WIRING DIAGRAMS..................................................................................................................................

6. REFRIGERANT CYCLE DIAGRAMS................................................................................................... .....

7. SELF DIAGNOSTIC DISPLAY INFORMATION........................................................................................

8. FAULT CODE DISPLAY INFORMATION..................................................................................................

9. CONTROL FEATURES.............................................................................................................................

10. VALVE & SENSOR FUNCTION AND OPERATION............................ ....................................................

11. PRESSURE TEST AND DEHYDRATION.................................................................................................

12. ADDITIONAL REFRIGERANT...................................................................................................................

13. EXPLODED VIEWS AND SERVICE PARTS LIST....................................................................................

10

13

19

21

36

43

45

49

50

51

SUMMARY

〈 The units referred to within this manual conform with the protection requirements of Directives 89/336/EEC

Electromagnetic Compatibility and 73/23/EEC Low voltage.

〈 Operating conditions of the unit are as follows:

3

4

6

Outdoor temperature -5 ~ 43°C Cooling

-10 ~ 21°C Heating

Room Temperature 18 ~ 32°C Cooling

15 ~ 29°C Heating

Room humidity < 80% Cooling

Note 1: Cooling capacity is rated at the following temperature conditions:

Indoor air inlet temperature 27°C DB, 19°C WB.

Outdoor air inlet temperature 35°C DB.

Note 2: Heating capacity is rated at the following temperature conditions:

Indoor air inlet temperature 20°C DB.

Outdoor air inlet temperature 7°C DB, 6°C WB.

Note 3: For details on the Outdoor unit installation, the Indoor units or Remote Controllers refer to

the relevant literature. i.e. Installation instructions supplied with the units or Service

manuals relevant to the indoor units.

Note 4: Operatives handling refrigerants must be suitably qualified in accordance with local and

national codes of practice and statutory requirements.

Note 5: Legislation may regulate the removal of waste refrigerant from the systems. We advise

awareness of any regulations and duty of care. Waste refrigerant must NEVER be discharged to

atmosphere.

Note 6: Electrical work should be in accordance with all relevant codes of practice and should be

carried out by suitably qualified personnel.

Note 7: Metric / Imperial pipe conversion.

Diameter (mm) 6.4 9.5 12.7 15.9 19.0 22.0 28.6

Nominal diameter (inch) 1/4 3/8 1/2 5/8 3/4 7/8 1 1/8

Note 8: Within this manual, O/D = Outdoor unit, M/C = Multi controller, I/D = Indoor unit, R/C = Remote

controller, D.O.L. = Direct on-line compressor.

2

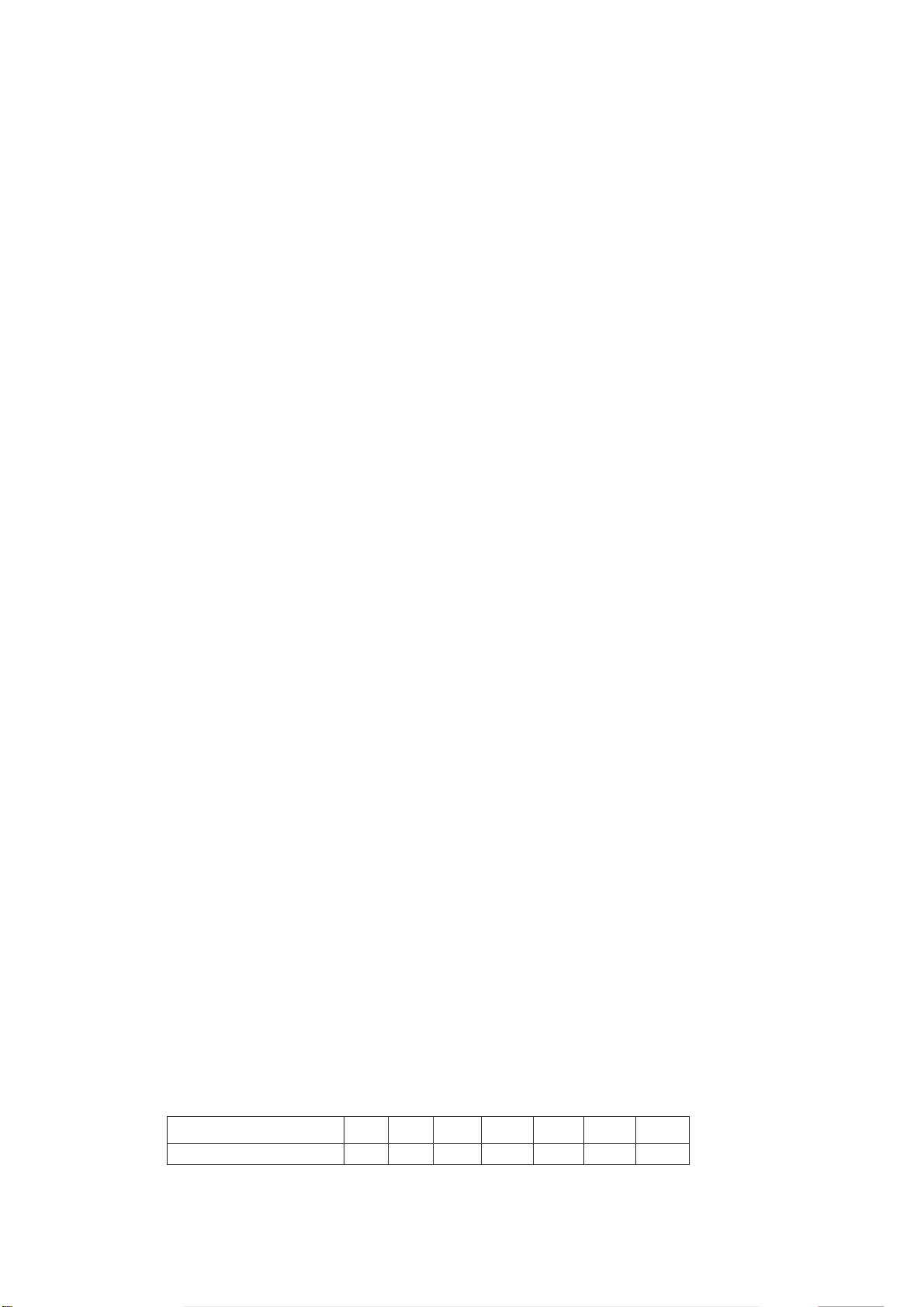

1. SUPER MULTI SYSTEM BASIC COMPONENTS

1.1 2-Pipe Heat Pump.

This system allows separate operation of each indoor unit in heating or cooling.

Heating operation has priority over cooling. In the event of an indoor unit requesting cooling operation when

another is in heating mode, the "PREHEAT DEFROST" will flash on the remote controller.

2-Pipe

Outdoor unit

T-Pieces

2 pipes

Multi controller

OFF

Indoor units

OFF

Remote controller

2 pipes

1.2 3-Pipe Heat Pump with simultaneous heating and cooling.

This system allows separate operation of each indoor unit in either heating or cooling simultaneously.

3 pipes

3-Pipe

Outdoor unit

T-Pieces

Multi controller

Indoor unit remote controller requesting cooling

Cooling operation

Indoor unit remote controller requesting heating

Heating operation

Indoor units

Remote controller

2 pipes

3

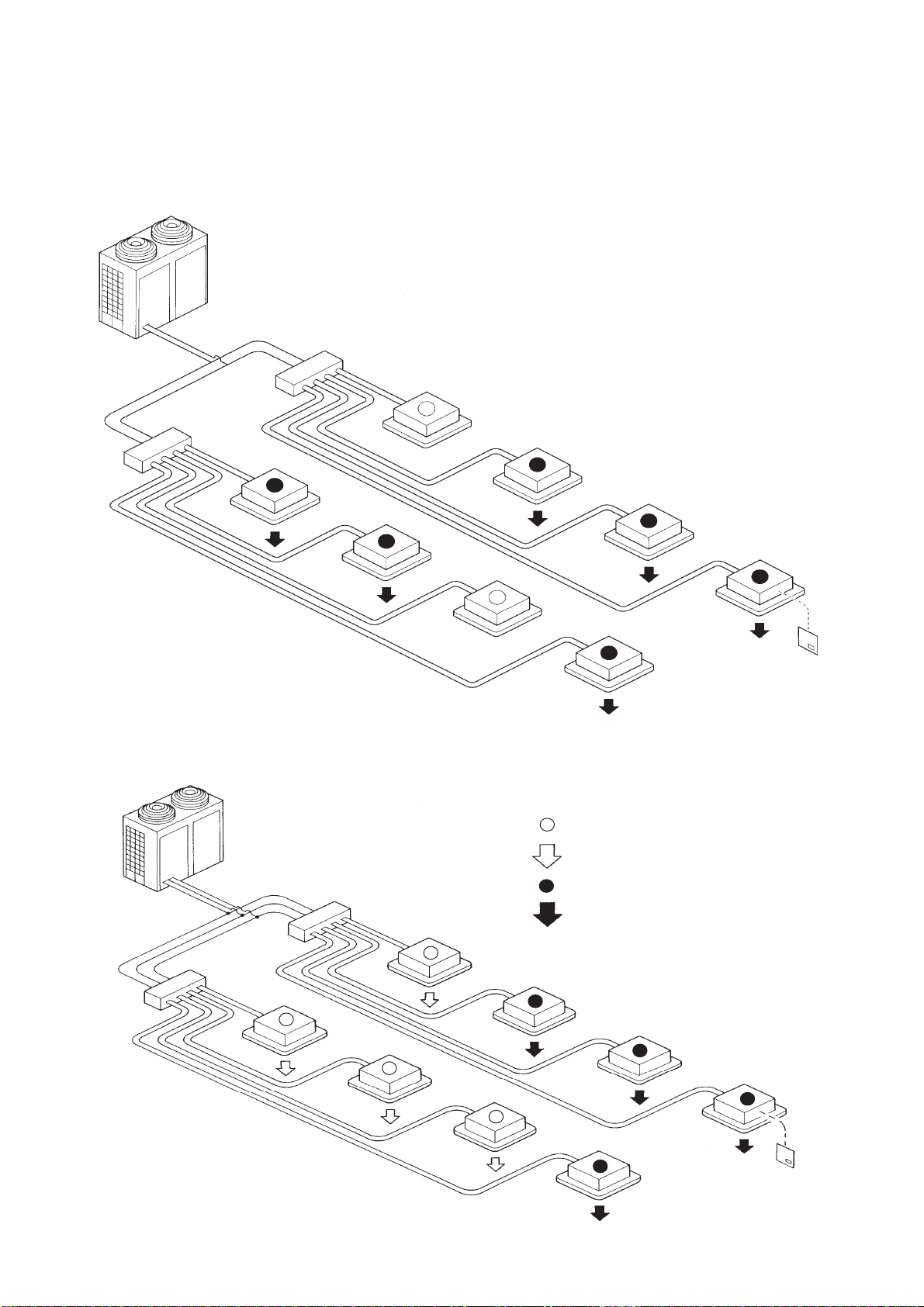

2. OUTLINE OF CONTROL SYSTEM

The refrigerant and electrical systems of the Super multi air conditioner are controllled by the Multi controller

and the Outdoor unit microprocessors.

All RAV Heat Pump series Indoor units are compatible with the Super multi system. i.e. 1 ~ 5 HP.

For system operation, initially the microprocessor in each Indoor unit calculates the difference between the

current room temperature (TA) and the requested temperature which has been set on the Remote controller.

A demand signal is determined and transmitted to the Multi controller microprocessor in the form of operation

commands. (i.e. ON / OFF, cooling or heating operation mode, operation demand frequency).

The Multi controller microprocessor receives operation commands from all Indoor units connected, calculates

the accumulative operation command and transmits this information to the Outdoor unit Interface

microprocessor.

The Interface microprocessor calculates the capacity required for heating or cooling and determines the

operation mode of the Outdoor unit and the actual frequency of the compressor.

2.1 Control system diagram.

Indoor unit 1 – A

Fan

Temp. sensor (TA)

Drain Pump

Indoor unit microprocessor

Remote

controller

1 - B

1 - C

1 - D

Multi controller 1

Capacity rank

setting switch

Temp. sensor

Pulse modulating

valve

Multi controller

microprocessor

Display LED

2-way valve

(3-Pipe ONLY)

Outdoor unit

Protection unit

Comp. sensor

Temp. sensor

Pulse modulating

valve

Interface microprocessor

D.O.L.

compressor

Display LED

2-way valve

Fan

2 - A

2 - B

2 - C

2 - D

Multi controller 2

Multi controller

microprocessor

4

4-way valve

Inverter

microprocessor

Protection

unit

Inverter

compressor

Inverter

Power

supply

2.2 Combination of Multi Controllers and Indoor Units.

Each Indoor unit is allocated a code number according to its capacity rank. Refer to the table below.

Capacity Rank of Indoor unit

No connection

10

13

16

20

26

36

46

Example: Indoor unit model RAV-362UH-PE, Capacity Rank = 36, Code No. = 8.

(Each Indoor unit Code No. is registered by the capacity rank setting switches on the Multi controller control

board).

Multiple Indoor units may be connected to each Outdoor unit, providing the total Indoor code does not exceed

the limits shown below.

Outdoor Unit

Code No.

0

2

3

4

5

6

8

10

Maximum No. of

Connected Units

Minimum Code No. Maximum Code No.

10HP 2-PIPE (MAR-M102HTM8-PE)

10HP 3-PIPE (MAR-F102HTM8-PE)

The option is available to use a 3-Way Multi controller (for 3 Indoor units), or a 4-Way Multi controller (for 4

Indoor units). If more than 4 Indoor units are required for an Outdoor unit, 2 multi controllers should be used

with T-Piece connections.

Note: It is possible to connect indoor units with a total capacity exceeding the capacity of the outdoor unit

by a maximum of 35%.

2728

5

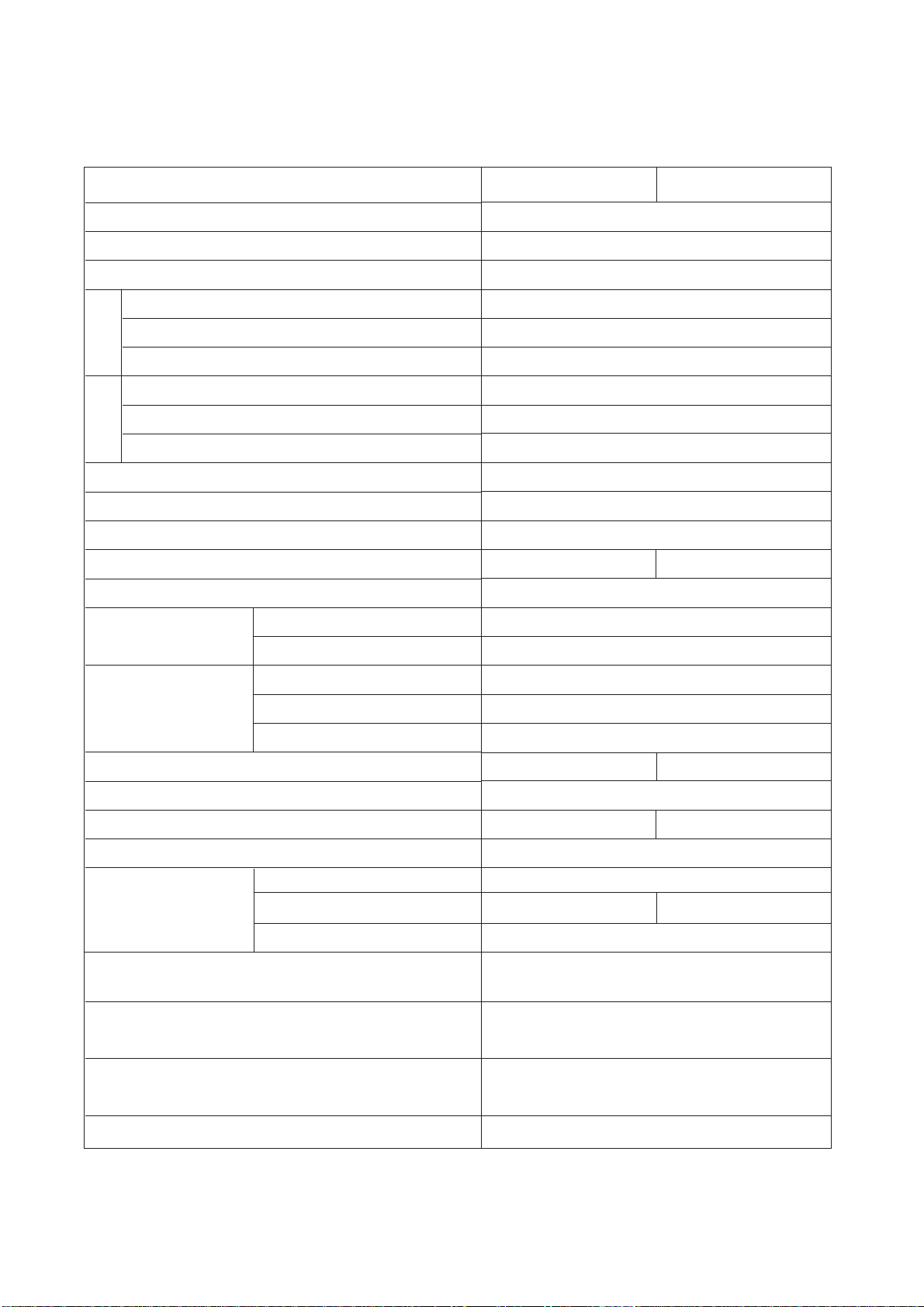

3.1 Specification of Outdoor unit.

3. SPECIFICATIONS

Model Name

Cooling capacity (kW)

Heating capacity (kW)

Power supply

Operating current (A)

Power consumption (W)

Cooling

Power factor (%)

Operating current (A)

Power consumption (W)

Heating

Power factor (%)

Starting current (A)

Starting method

Dimensions (H x W x D) (mm)

Net weight (kg)

Colour

Compressor

Type

Motor output (kW)

MAR-M102HTM8-PE

25.0 (28.0)

28.0 (31.5)

380 – 415V, 3-phase, 50Hz

15.7 (17.2)

10,600 (11,500)

17.7 (15.5)

11,800 (10,500)

1,530 x 1,290 x 834

356

To be confirmed

Hermetically sealed (Twin scroll)

MAR-F102HTM8-PE

97 (97)

96 (98)

60

Direct

370

7.5

Fan

Fan assembly

Refrigerant (charged weight) (kg)

Liquid (mm)

Discharge gas (mm)

Suction gas (mm)

Coupler style

Max. equivalent piping length (m)

Max. actual piping length (m)

Max. piping head (m)

Motor output (kW)

Air flow volume (m3/hr)

Liquid

Discharge gas

Suction gas

Propeller fan

0.15 x 2

10,000

R-22 (18.6)

ø15.9

- ø19.0

ø28.6

Flare connection

-

Brazing connection

120

100

50: When the outdoor unit is installed above.

20: When the outdoor unit is installed below.

R-22 (21.6)

Flare connection

Crank case heater (W)

The specification shown in ( ) denotes operation with the maximum capacity of indoor units connected

(i.e. 135% capacity of the outdoor unit).

Specifications are subject to change without notice.

6

74

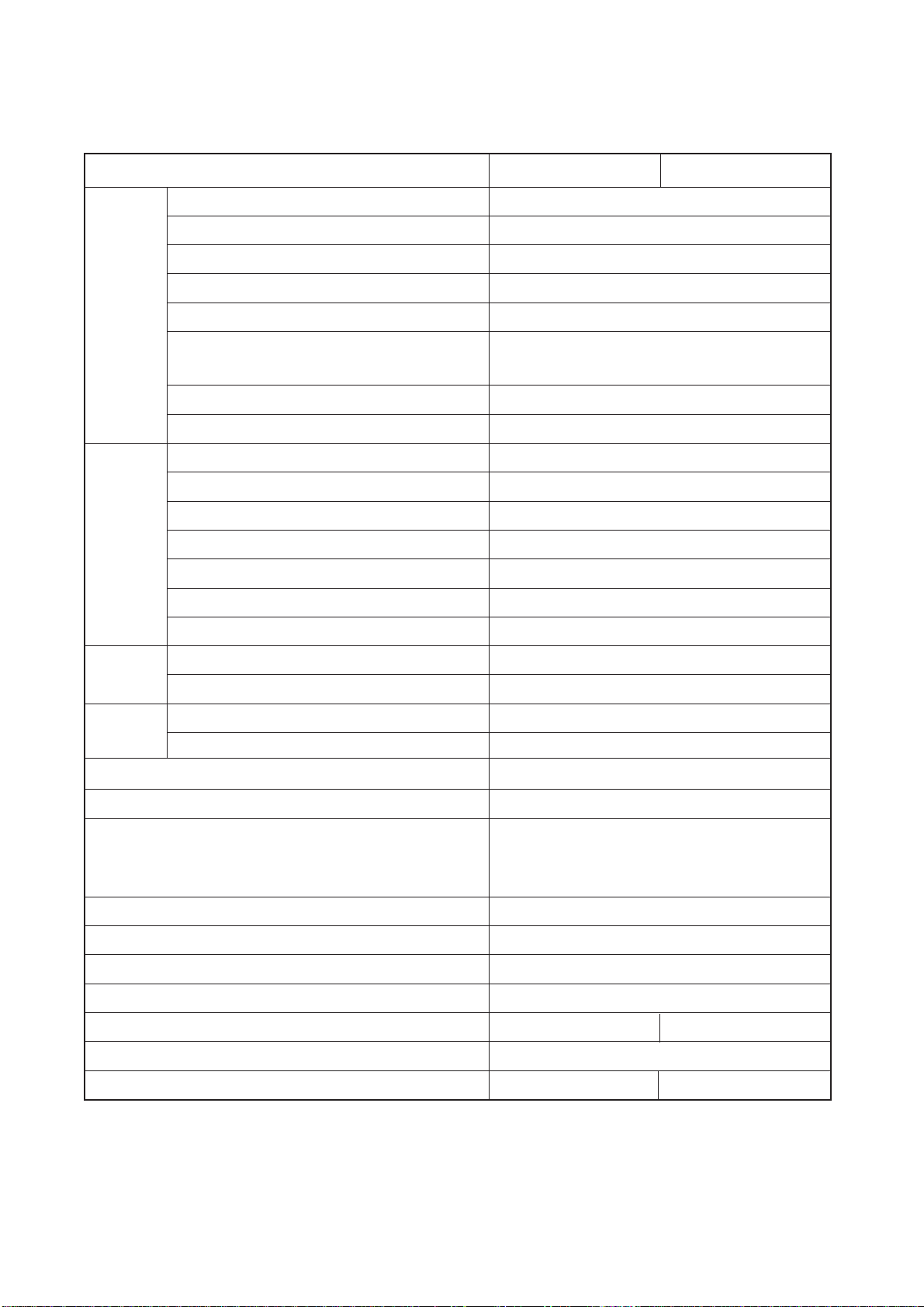

3.2 Specifications of Outdoor unit Refrigerant Cycle Parts

Compressor

motor

Fan

motor

Model Name

Model name

Motor type

Power supply

Output (kW)

Pole (P)

Coil resistance (Ω)

Compressor oil name

Amount of oil (cc)

Model name

Motor type

Power supply

Output (W)

Supply current (A)

Pole (P)

MAR-M102HTM8-PE MAR-F102HTM8-PE

HV1201CW-Y12

3-phase induction motor

380 – 415V, 3-phase, 50Hz

7.5

2/2 (Inverter side/Non-inverter side)

1.49/2.51

(Inverter side/Non-inverter side)

SUNISO 3GSD

7,000

STF-200-150C

1-phase, induction motor

220 – 240V, 1-phase, 50Hz

150

1.12 ~ 1.44

6

Inner over-load relay

High

pressure

switch

Low

pressure

switch

4-way valve

Compressor case heater

Pressure sensor

Discharge temperature sensor

Suction temperature sensor

Outdoor air temperature sensor

Pulse modulating valve (For bypass)

Pulse modulating valve

2-way valve

2-way valve

Model name

Operating pressure (kgf/cm2G)

Model name

Operating pressure (kgf/cm2G)

OFF: 115 ± 5°C

20PS-B (Inverter side), 20PS-G (Non-inverter side)

Operation 30, Reset 23

20PS-1

Operation 0.25, Reset 1.5

CHV-0712, Coil AC240V

AC 240V, 74W

Model name: NTP-Q250TF-2

Input voltage: DC 12V

Output voltage: DC 0.5 – 4.5V

At 25°C = 50kΩ, 50°C = 17.9kΩ, 100°C =3.35kΩ

At 0°C = 32.8kΩ, 25°C = 10kΩ, 50°C = 3.6kΩ

At 0°C = 32.8kΩ, 25°C = 10kΩ, 50°C = 3.6kΩ

NEV202DXF, Coil AC 240V

EV18RC2, Coil DC 12V

-

-

EV23RC8, Coil DC 12V

RP100-03, Coil AC 240V

Specifications are subject to change without notice.

7

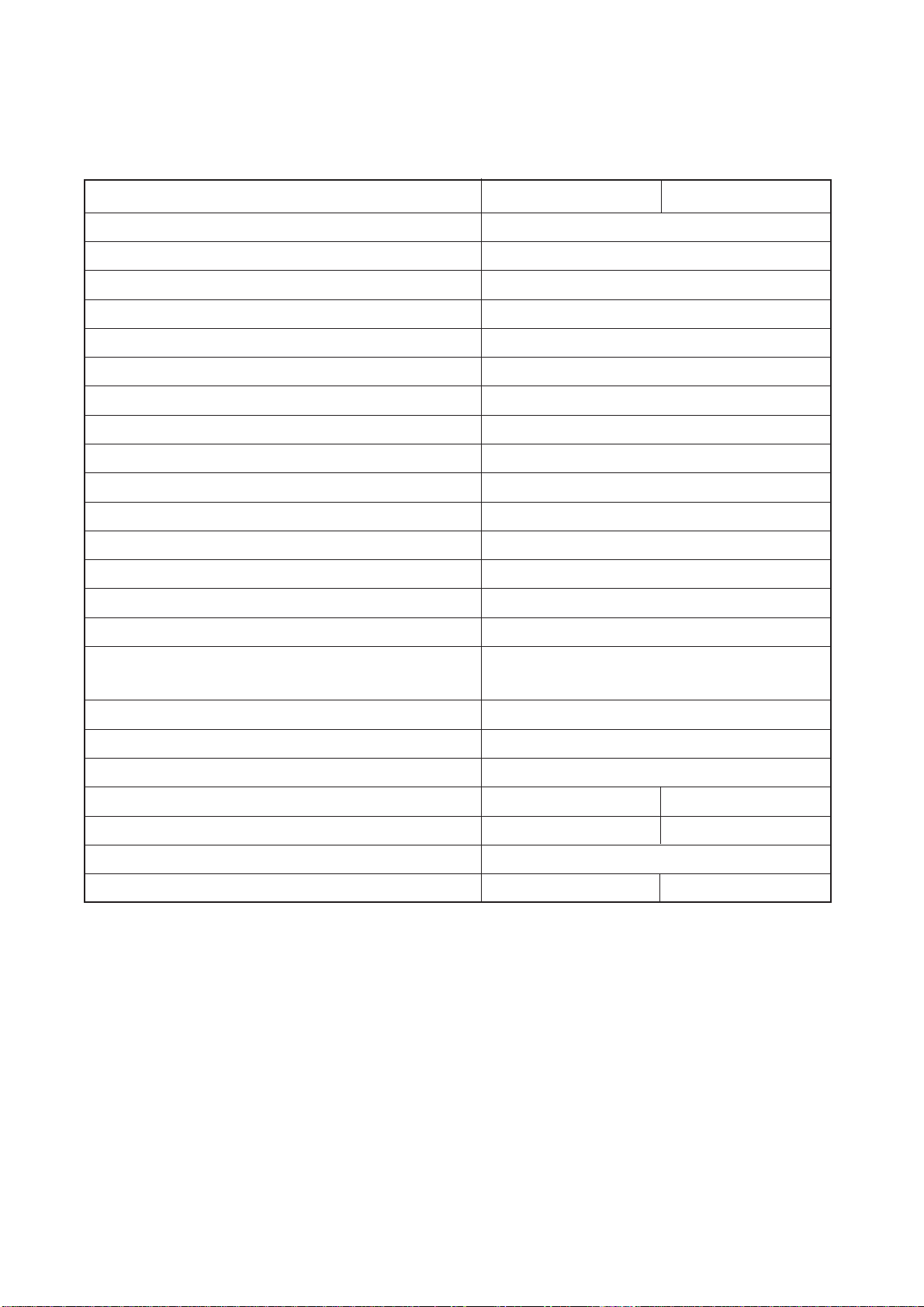

3.3 Specifications of Outdoor unit Inverter Assembly Parts.

Model Name MAR-M102HTM8-PE MAR-F102HTM8-PE

Power supply

Output voltage at operating frequency of 60Hz

IGBT

Relay

Fan motor running capacitor

Diode

AC noise filter

DC noise filter

Power supply rectifier capacitor

Fuse

Electronic starter

Reactor

Fan motor relay

Control relay

Magnetic contactor for compressor (Inverter side)

Magnetic contactor for compressor

(Non-inverter side)

380 – 415V, 3-phase, 50Hz

AC 266V

MG50Q6ES11

LY1F (AC 240V)

EAG45M605UF1, 6µF450V

SR130G-160

ZSG2208-02, 8A, 250V

LF215AV, 15A, 716V

LNT2G222KSMCTF, 2200µF/400V

20A

912X25E101YV20

CH-26-T, 6.2mH, 18A

G2R217PV

G4U-112P

13A

15A

Transformer (Inverter)

Transformer (Interface)

Power supply terminal plate

PC board (Inverter)

PC board assembly (Interface)

PC board (Gate)

Cooling fan

Specifications are subject to change without notice.

FT70

FT69

AC600V, 60A

MCC-1251 (INV-M-E) MCC-1251 (INV-F-E)

MCC-1211

MCC-1252

-

MCC-1223

3650EXV-5, 220-240V

8

3.4 Specification of 2-Pipe Multi Controller Parts.

Model Name

Pulse modulating valve

Temperature sensor

Float switch

Model name

Power supply transformer

Specification

Relay (PC board)

Heater

Thermal fuse for heater

Heater fuse

3.5 Specification of 3-Pipe Multi Controller Parts.

Model Name

Pulse modulating valve

Temperature sensor

RBM-Y1032-PE RBM-Y1042-PE

EV23RC7, Coil DC 12V

At 0ºC = 32.8kΩ, 25°C = 10kΩ, 50°C = 3.6kΩ

FS-085-0031

FT69

Primary side:AC240V, Secondary side:AC12V

G2R-117P, Coil DC 12V

10.4 W/m

65W50W

Cut out at 119°C

1A

RBM-Y1032F-PE RBM-Y1042F-PE

EV23RC7, Coil DC 12V

At 0ºC = 32.8kΩ, 25°C = 10kΩ, 50°C = 3.6kΩ

Float switch

Model name

Power supply transformer

Specification

Relay (PC board)

Heater

Thermal fuse for heater

Heater fuse

Discharge gas side 2-way valve

Suction gas side 2-way valve

2-way valve

2-way valve NEV603DXF-AC240V

Specifications are subject to change without notice.

Primary side:AC240V, Secondary side:AC12V

REV-1506DXFQ6, Coil AC240V

FS-085-0031

FT69

G2R-117P, Coil DC 12V

10.4 W/m

Cut out at 119°C

1A

RP100-03, Coil AC240V

NEV202DXF-AC240V

65W50W

9

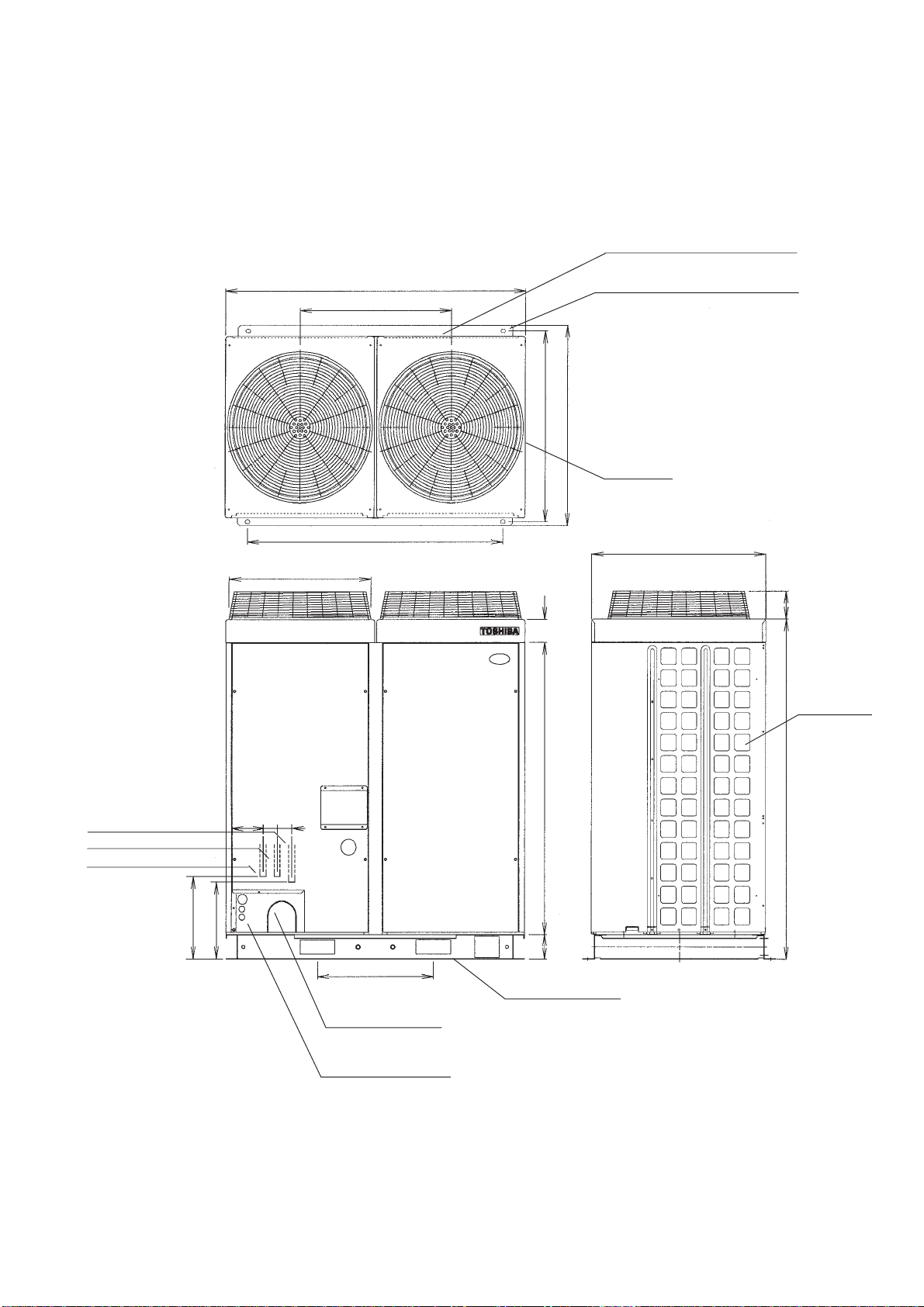

4. CONSTRUCTION VIEWS

4.1 2-Pipe Outdoor Unit (MAR-M102HTM8-PE).

Rear air inlet.

ø 610

1290

650

1100

4 slots (15 x 20) for fixing bolts.

790

834

Air outlet.

750

120

98

Side air inlet.

Refrigerant pipe

connection.

Liquid Ø 15.9

Gas Ø 28.6

365

335

140 65

1212

100

1410

500

2 x Fork lift slots.

Piping knockout.

(150 x 60)

Wiring knockouts.

1 x Ø25, 2 x Ø20

10

4.2 3-Pipe Outdoor Unit (MAR-F102HTM8-PE).

Rear air inlet.

ø 610

1290

650

1100

4 slots (15 x 20) for fixing bolts.

834

790

Air outlet.

750

120

98

Side air inlet.

Refrigerant pipe

connection.

Suction gas Ø 28.6

Discharge gas Ø 19.0

Liquid Ø 15.9

365

335

1212

65

65140

100

1410

500

2 x Fork lift slots.

Piping knockout.

(150 x 60)

Wiring knockouts.

1 x Ø25, 2 x Ø20

11

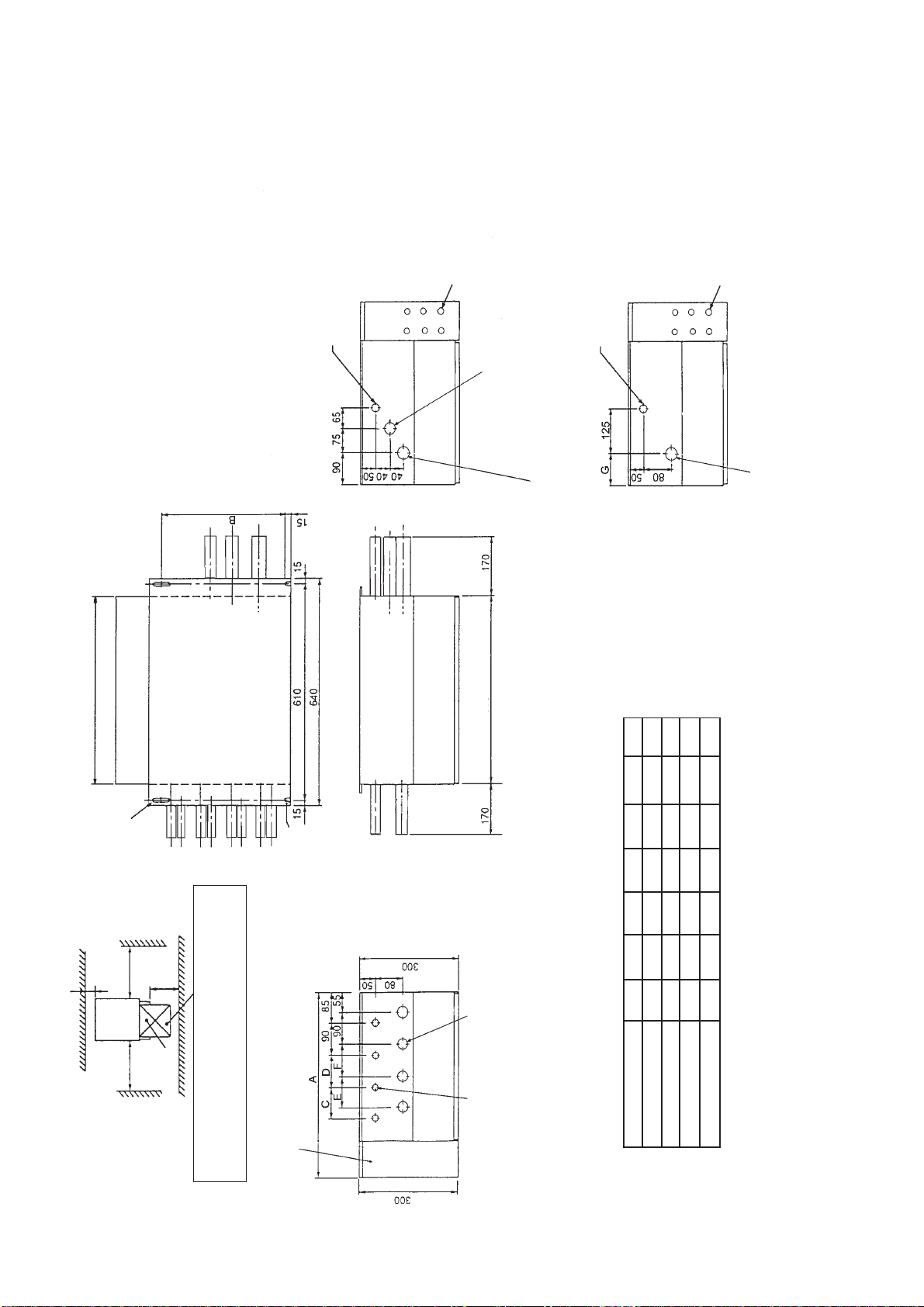

4.3 Multi Controllers.

Wiring knockouts

Refrigerant piping joint (brazing)

Liquid side φ 15.9

6 xφ 20

Refrigerant piping joint (brazing)

Discharge gas side φ 19

Wiring knockouts

Refrigerant piping joint (brazing)

Liquid side φ 15.9

6 xφ 20

540

2 Slots for

hanging bolts

(12 x 52)

3-PIPE: RBM-Y1032F-PE, RBM-Y1042F-PE

540

2-PIPE: RBM-Y1032-PE, RBM-Y1042-PE

Refrigerant piping joint (brazing)

Suction gas side φ28.6

---

---

---

---

---

---

Refrigerant piping joint (brazing)

Suction gas side φ28.6

Indoor unit piping

100 or more

Outdoor unit

side

500

or more

500

or more

piping side

500

or more

450 x 450 inspection opening

Electric parts box

Note: Make an inspection opening at the specified location.

This is required for testing and servicing.

2 Notches for hanging bolt

(12 x 21)

Electrical parts box

Refrigerant piping joint (brazing)

Gas side φ 19

φ12.7

Refrigerant piping joint (brazing)

Liquid side

12

A BC DE F G

460 300 90 90 100

530 370 90 90 90 90 190

460 300 90 90

530 370 90 90 90 90

MODEL

RBM-Y1032-PE

RBM-Y1042-PE

RBM-Y1032F-PE

RBM-Y1042F-PE

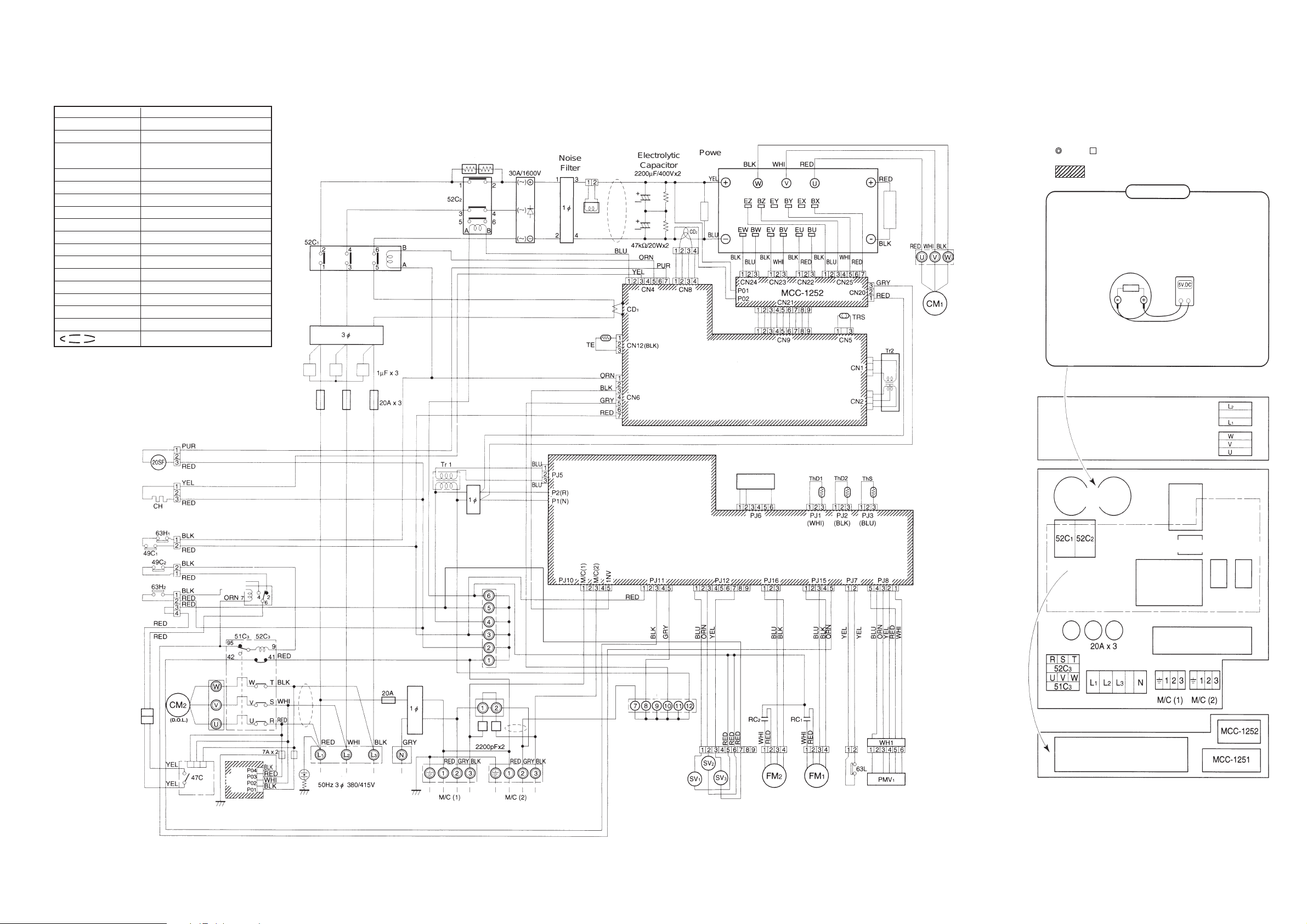

5.1 2-Pipe Outdoor Unit (MAR-M102HTM8-PE)

9

9

5. WIRING DIAGRAMS

Symbol Part Name

CM 1, 2 Compressor

FM 1, 2 Fan Motor

52C 1, 2, 3 Electromagnetic contactor

for compressor

49C 1, 2 Inner overload relay

51C 3 Overload relay

PMV1 Pulse modulating valve

63H 1, 2 High pressure switch

RC 1, 2 Running capacitor

SV 1, 2, 4 Two-way valve

20SF Four-way valve

63L Low pressure switch

CH Crank case heater

Tr 1, 2 Transformer

47C Reverse phase protector

Th D1, D2, S, E Temperature sensor

CD 1, 2 Current detector

Ferrite Core

Noise

filter

Capacitor

Fuse

Electric

Starter

3 ø

Rectifier

Noise

Filter

Reactor

Electrolytic

Capacitor

Power

Transistor

Clip

Diode

Inverter Control PC Board

MCC - 1251

Thermostat

Clip

Diode

(Inverter)

Notes :

1.The dashed lines indicate wiring on site.

2. and indicate terminal blocks, and

numbers within them are terminal numbers.

2345678

2345678

3. indicates a printed circuit board.

DANGER

THE ELECTROLYTIC CAPACITORS IN THIS PANEL ARE CHARGED

TO 600 VOLTS D. C.

BEFORE SERVICING, TURN OFF THE POWER SUPPLY

AND ALLOW AT LEAST 20 MINUTES FOR THE

CAPACITORS TO DISCHARGE TO A SAFE LEVEL OF 5

VOLTS D.C. OR LESS. TEST WITH A D.C. VOLT METER AS

SHOWN.

Resistor

NEVER SHORT THE CAPACITOR TERMINALS WITH ANY METAL

IMPLEMENT TO DISCHARGE. PERSONAL INJURY OR EQUIPMENT

DAMAGE MAY RESULT.

Parts layout

Fuse

Relay

Fuse

Noise

Filter

Noise

filter

Capacitor

Interface Control Board

MCC - 1211

Pressure

Sensor

Electrolytic

Capacitors

PC boards

Fuse

Power supply

PC board locations

MCC-1211

Inverter

Compressor

Power

Transistor

Rectifier

3 ø

Noise filter

Connectors

1~6

7~12

Surge

Absorber

Power Supply

Surge

Absorber

13

14

5.2 3-Pipe Outdoor Unit (MAR-F102HTM8-PE)

9

9

Symbol Part Name

CM 1, 2 Compressor

FM 1, 2 Fan Motor

52C 1, 2, 3 Electromagnetic

contactor for compressor

49C 1, 2 Inner overload relay

51C 3 Overload relay

PMV 1 Pulse modulating vavle

63H 1, 2 High pressure switch

RC 1, 2 Running capacitor

SV 1, 2, 4, 5, 13, 14, 15, 16 Two-way valve

20SF Four-way valve

63L Low pressure switch

CH Crank case heater

Tr 1, 2 Transformer

47C Reverse phase protector

LD 71, 72, 73, 74 Fault indicator lamp

Th D1, D2, S, E. O Temperature sensor

CD 1, 2 Current detector

Ferrite Core

Noise

filter

Fuse

Electric

starter

3 ø

Rectifier

Noise

filter

Reactor

Electrolytic

Capacitor

Power

Transistor

Clip

Diode

Inverter Control PC Board

MCC - 1251

Thermostat

Clip

Diode

(Inverter)

Notes :

1.The dashed lines indicate wiring on site.

2. and indicate terminal blocks, and

numbers within them are terminal numbers.

2345678

2345678

3. indicates a printed circuit board.

DANGER

THE ELECTROLYTIC CAPACITORS IN THIS PANEL ARE CHARGED

TO 600 VOLTS D. C.

BEFORE SERVICING, TURN OFF THE POWER SUPPLY

AND ALLOW AT LEAST 20 MINUTES FOR THE

CAPACITORS TO DISCHARGE TO A SAFE LEVEL OF 5

VOLTS D.C. OR LESS. TEST WITH A D.C. VOLT METER AS

SHOWN.

Resistor

NEVER SHORT THE CAPACITOR TERMINALS WITH ANY METAL

IMPLEMENT TO DISCHARGE. PERSONAL INJURY OR EQUIPMENT

DAMAGE MAY RESULT.

Parts layout

FM3

Inverter

Compressor

Fuse

Surge

Absorber

Relay

Surge Absorber

Power supply

Fuse

Noise

filter

Noise

filter

Pressure

sensor

Interface Control PC Board

MCC - 1223

Electrolytic

Capacitors

PC boards

Fuse

Power supply

PC board locations

MCC-1223

Power

Transistor

Rectifier

3 ø

Noise filter

Connectors

1~6

7~12

15 16

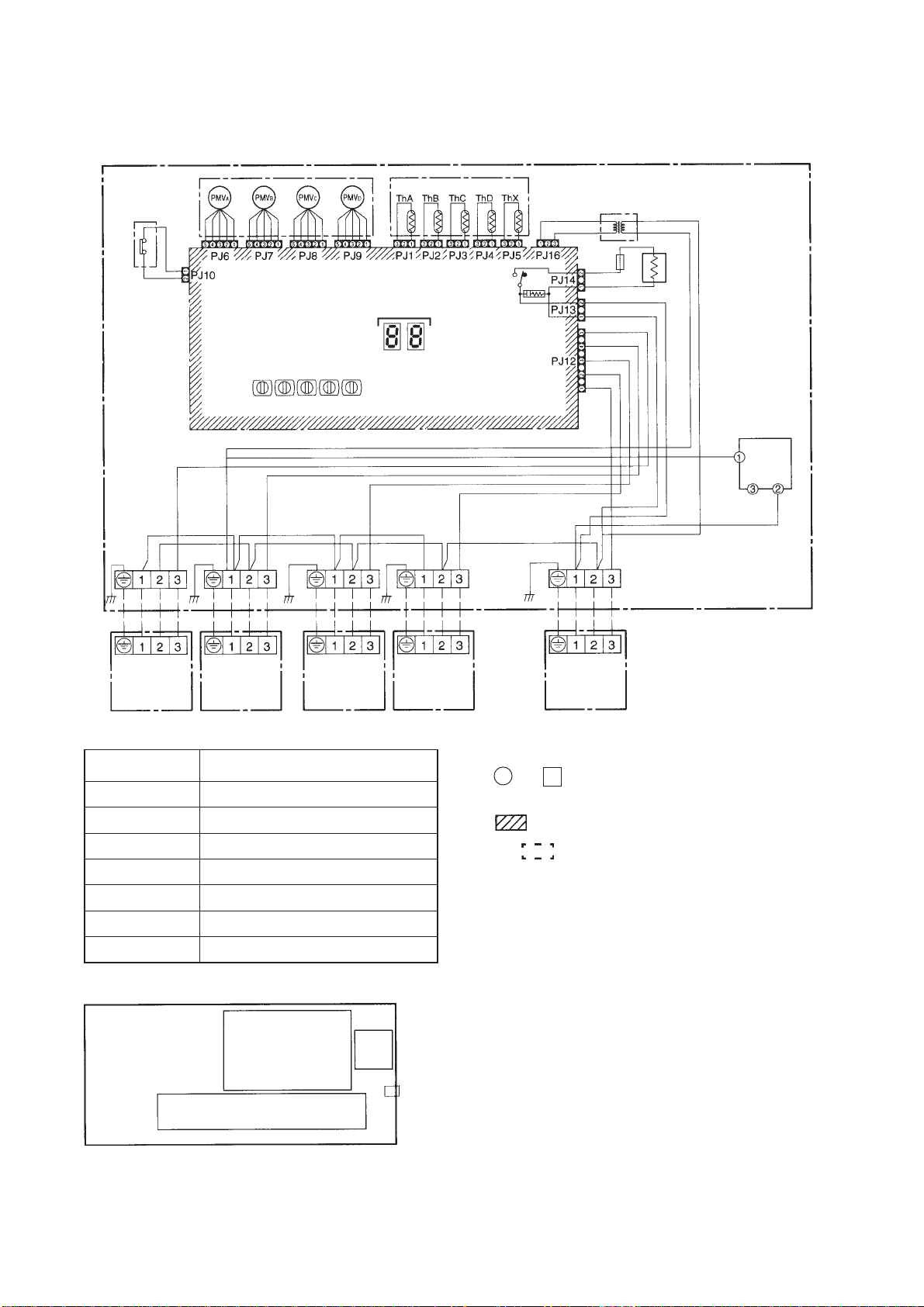

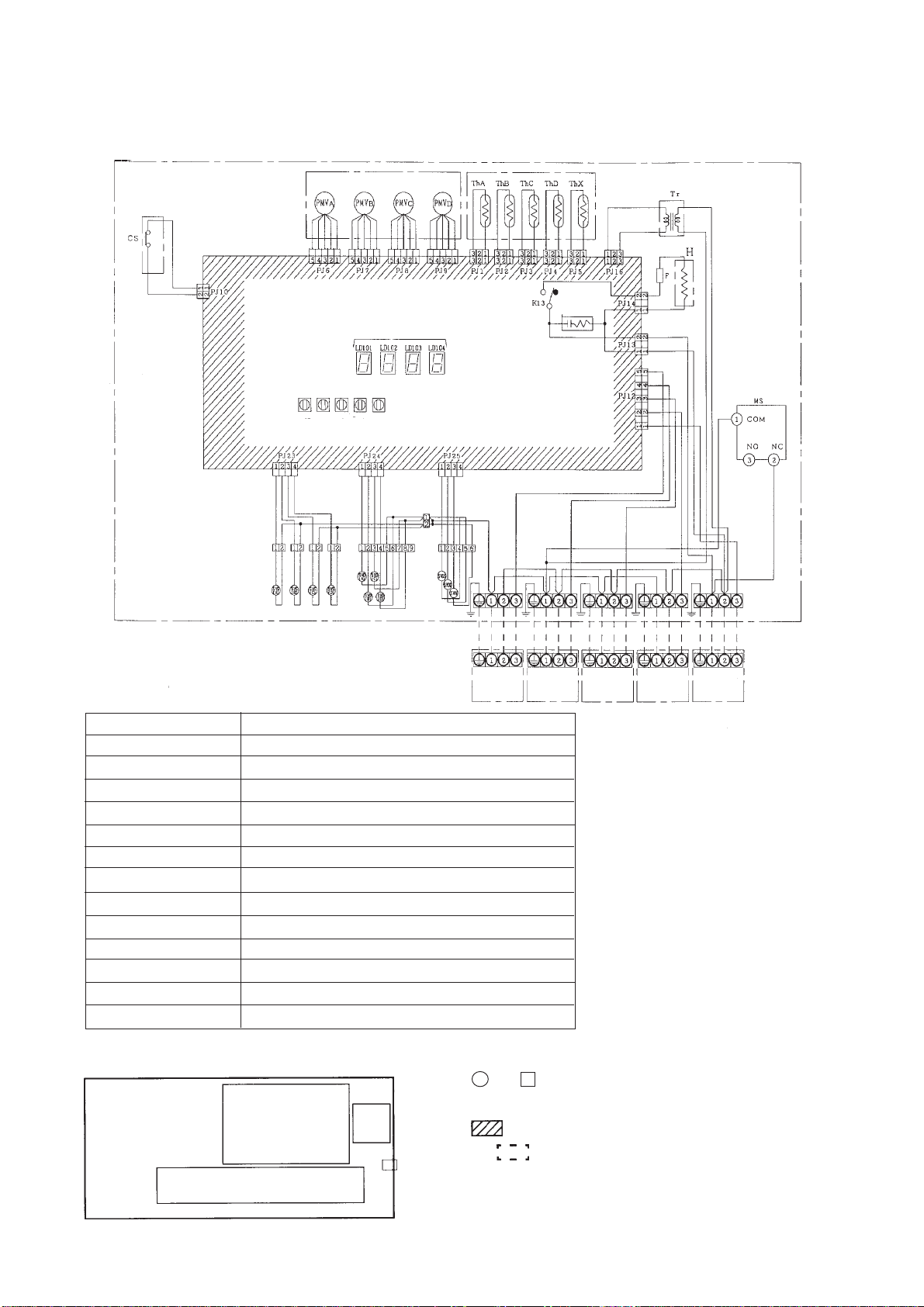

5.3 2-Pipe Multi Controller (RBM-Y1032-PE, RBM-Y1042-PE).

CS

K13

Spark

killer

Capacity

rank

setting

ABCD

7 Segment LED

LD1 LD2

Display selector

switch

Tr

F

H

MS

COM

NO NC

INDOOR

UNIT A

Symbol

PMVA, B, C, D

ThA, B, C, D, X

Tr

CS

H

MS

LD1, LD2

Parts layout

INDOOR

UNIT B

INDOOR

UNIT C

Part Name

Pulse modulating valve

Temperature sensor

Transformer

Float switch

Heater

Reset switch

Fault Indicator LED

Control PC Board

Terminal Plate

Trans

INDOOR

UNIT D

Reset

switch

OUTDOOR

UNIT

• The dashed lines indicate wiring on site.

• and indicate terminal blocks, and numbers

within them are terminal numbers.

• indicates a printed circuit board.

• The frame indicates the product body.

• RBM-Y1032-PE does not have PMVD, ThD or the

connection block for Indoor unit D .

The capacity rank code setting for unit D is to be set to "0".

17

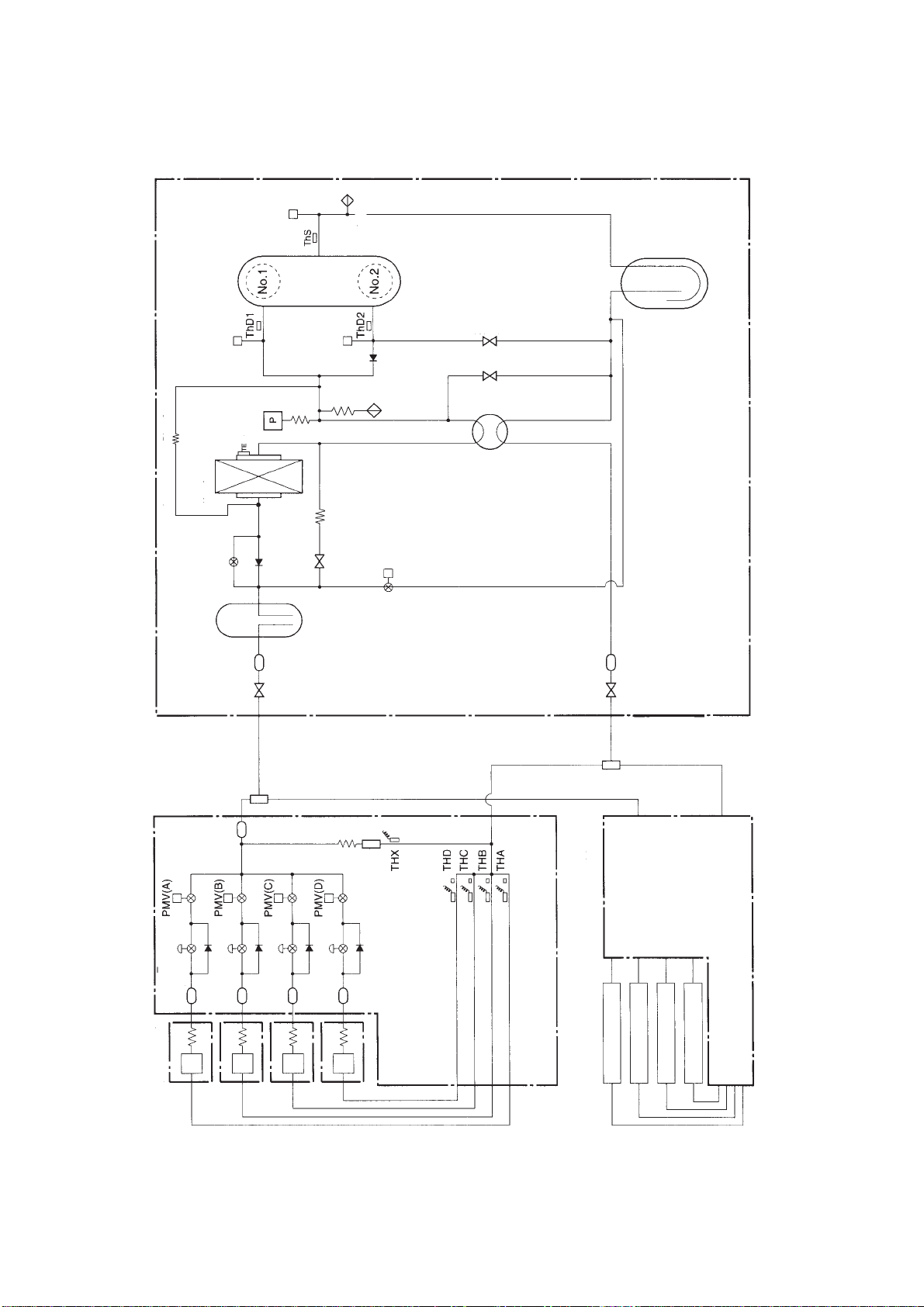

5.4 3-Pipe Multi Controller (RBM-Y1032F-PE, RBM-Y1042F-PE).

7 Segment LED

Capacity rank

setting

B

D C A

Display

selector switch

Spark

killer

Symbol

PMV A, B, C, D

Th A, B, C, D, X

Tr

CS

H

MS

F

SVD (A), (B), (C), (D)

SVS (A), (B), (C), (D)

SVDD

SVSS

SVH

LD 101, 102, 103, 104

Parts layout

Part Name

Pulse modulating valve

Temperature sensor

Power transformer

Float switch

Heater

Reset switch

Fuse (T1A)

Electrically operated valve for discharge gas side

Electrically operated valve for suction gas side

Electrically operated valve for increasing pressure

Electrically operated valve for decreasing pressure

Electrically operated valve for superheat control

Fault indicator LED

Control PC Board

Terminal Plate

Trans

Reset

switch

Indoor

unit A

• The dashed lines indicate wiring on site.

• and indicate terminal blocks, and numbers within them are

terminal numbers.

• indicates a printed circuit board.

• The frame indicates the product body.

Indoor

unit B

Indoor

unit C

Indoor

unit D

Outdoor

Unit

• RBM-Y1032F-PE does not have PMVD, SVD(D), SVS(D) ThD,or the

connection block for Indoor unit D.

The capacity rank code setting for unit D is to be set to "0".

18

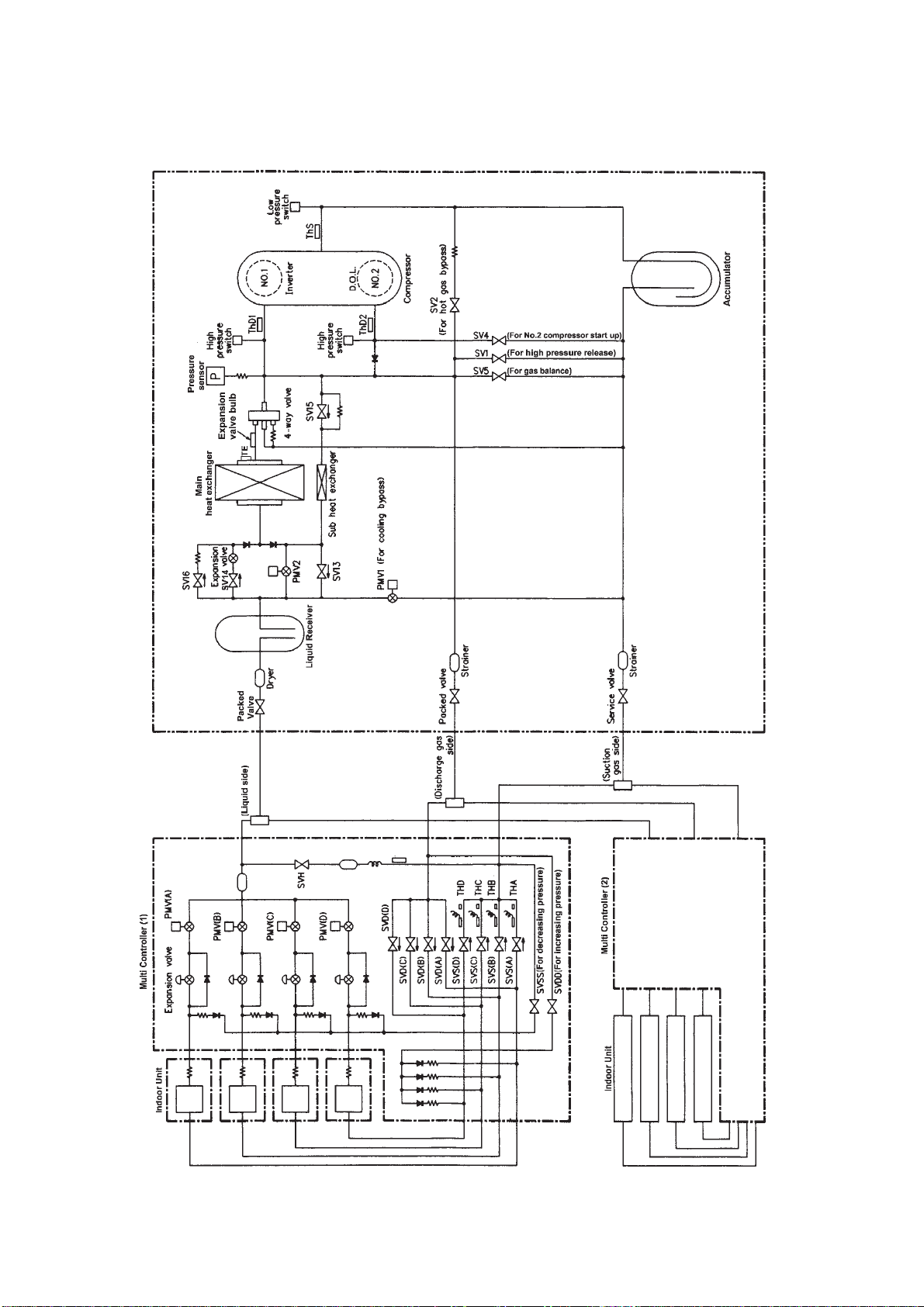

6.1 2-Pipe system.

6. REFRIGERANT CYCLE DIAGRAMS

Check

joint

Bypass capillary →1.5 x 600L

Outdoor unit

High pressure

switch

Pressure

sensor

Heat exchanger

Expansion

valve

Packed

valve

Inverter

Dryer

D.O.L.

High pressure

switch

Ø2.0 x 800L Capillary

SV1 (For high pressure release)

receiver

Liquid

Compressor

SV4 (For No. 2 compressor start up)

SV2 (For gas balance and hot gas bypass)

Check

joint

4-Way valve

PMV1 (For cooling bypass)

Service

valve

Accumulator

Strainer

Strainer

Expansion

valve

Multi controller (1)

Strainer

Indoor unit

(Liquid

side)

(Gas side)

Strainer

Multi controller (2)

Indoor unit

19

6.2 3-Pipe system.

THX

20

7. SELF DIAGNOSTIC DISPLAY INFORMATION

7.1 MAR-M102HTM8-PE, 2-Pipe Outdoor Unit.

Malfunction judgement is performed using the self-diagnostic function of the outdoor unit. The

combination of the display switch and the 8 LED's (LED 1 ~ LED 8) indicate the diagnostic details.

Fuse 20Ax3

R S T

52C3

U V W

51C3

Electrolytic

Capacitors

Interface control board

MCC-1211

L1 L2 L3 N

Power supply

Power

Transistor

1 2 3

M/C (1) M/C (2)

Electrical parts location

MCC-1211

J2

MCC-1252

Inverter control

board

MCC-1251

Connectors

1 2 3

LED 1~8

Display switch

Interface control board

7.1.1 Display switch information.

Switch position Malfunction information

0 System Communication

1 Status of Compressors

2 System Status

3 Fault Diagnostics (Outdoor Units)

4 M/C 1 Units A & B Indoor Capacity Codes

5 M/C 1 Units C & D Indoor Capacity Codes

6 M/C 2 Units A & B Indoor Capacity Codes

7 M/C 2 Units C & D Indoor Capacity Codes

8 Fault Diagnostics (Multi Controller)

9 Circuit Test

10 ~ 15 Not used

21

7.1.2 Display switch set to position "0".

LED 1

LED 2

LED 3

LED 4

LED 5

LED 6

LED 7

LED 8

7.1.3 Display switch set to position "1".

O: LED on

X: LED off

LED 5

LED 6

LED 7

LED 8

On: Receiving serial signal from multi controller 1

On: Sending serial signal to multi controller 1

On: Receiving serial signal from multi controller 2

On: Sending serial signal to multi controller 2

On: Receiving serial signal from inverter control board

On: Sending serial signal to inverter control board

LED 1

X

X

X

X

X

X

O

O

O

O

O

O

O

O

D.O.L. compressor

Frequency control

LED 2

X

X

O

O

O

O

X

X

X

X

O

O

O

O

LED 3

X

O

X

X

O

O

X

X

O

O

X

X

O

O

LED 4

X

O

X

O

X

O

X

O

X

O

X

O

X

O

LED's on: Frequency control due to protection circuit

Inverter frequency

0Hz

30Hz

36Hz

42Hz

46Hz

53Hz

61Hz

69Hz

76Hz

84Hz

92Hz

103Hz

111Hz

122Hz

LED's on : Run / LED's off : Stop

S0

S3

S4

S5

S6

S7

S8

S9

SA

SB

SC

SD

SE

SF

7.1.4 Display switch set to position "2".

LED 1

LED 2

LED 3

LED 4

LED 5

LED 6

LED 7

LED 8

Operating mode

Defrost operation

PMV status

Return signal

Inverter abnormality

D.O.L. Compressor

abnormality

LED on: Heating

LED off: Cooling

LED on: Defrost

LED on: Opening

LED off: Closing

LED on: Return signal not receiving from INV

22

7.1.5 Display switch set to position "3".

LED 1 ThD1 sensor abnormality LED on: Sensor open / short circuit

LED 2 ThD2 sensor abnormality

LED 3 ThS sensor abnormality

LED 4 High pressure abnormality LED on: High pressure abnormal

(detected by pressure sensor)

LED 5 Pressure sensor abnormality LED on: Pressure sensor abnormal

LED 6 Discharge temperature abnormality LED on: Discharge temperature abnormal

(detected by ThD1or ThD2 sensor)

LED 7 Suction temperature abnormality LED on: Suction temperature abnormal

(detected by ThS sensor)

LED 8 Low pressure, gas leakage abnormality LED on: Low pressure switch functioning

7.1.6 Display switch set to position "4", "5", "6" or "7"

Sw4

Sw5 Capacity rank of indoor unit connected to Capacity rank of indoor unit connected to

Sw6 Capacity rank of indoor unit connected to Capacity rank of indoor unit connected to

Sw7 Capacity rank of indoor unit connected to Capacity rank of indoor unit connected to

LED 1

Capacity rank of indoor unit connected to Capacity rank of indoor unit connected to

M/C (1) - Unit A M/C (1) - Unit B

M/C (1) - Unit C M/C (1) - Unit D

M/C (2) - Unit A M/C (2) - Unit B

M/C (2) - Unit C M/C (2) - Unit D

O: LED on X: LED off

X

X

X

X

X

X

O

O

LED 2

X

X

O

O

O

O

X

X

LED 3 LED 4 LED 5 LED 6 LED 7

O

O

X

X

O

O

X

O

Indoor unit model capacity rank Code No.

X

O

X

O

X

O

X

X

10

13

16

20

26

36

46

LED 8

2

3

4

5

6

8

10

(Indoor unit model example: Model RAV-362UH-PE, Capacity rank = 36)

7.1.7 Display switch set to position "8".

-

LED 1 Th(A) sensor abnormality LED on: sensor open / short circuit.

LED 2 Th(B) sensor abnormality

LED 3 Th(C) sensor abnormality

LED 4 Th(D) sensor abnormality

LED 5 Th(X) sensor abnormality

LED 6 Over-capacity

Light on when the total capacity of the indoor units exceeds 1.35 times the outdoor unit capacity.

LED 7 M/C (1) fault. LED on : Abnormal

LED 8 M/C (2) fault. LED on : Abnormal

7.1.8 Display switch on set to position "9".

LED 1 M/C (1) Unit A

LED 2 Unit B

LED 3 Unit C

LED 4 Unit D

LED 5 M/C (2) Unit A

LED 6 Unit B

LED 7 Unit C

LED 8 Unit D

When a LED is ON it indicates

that there is a wiring or piping

fault between the multi controller

and the relevant indooor unit.

(Refer to circuit connection test

procedure).

23

7.2 RBM-Y1032-PE / RBM-Y1042-PE, 2-Pipe Multi Controller.

The combination of the display switch and the two 7 segment LED's (LD1, LD2) indicate the diagnostic

details.

MCC - 1210

7 Segment LED

Capacity rank switches.

Unit A Unit C

Unit B Unit D

Multi controller control board

7.2.1 Display switch information.

Switch position Malfunction information

0 System Communication

1 Fault Codes

2 Level of Demand

3 Oil retrieval, Superheat control, Defrost

4 Operating Mode

5 Restart Timer

6 Circuit Test

7 PMV (A) Position

8 PMV (B) Position

9 PMV (C) Position

10 PMV (D) Position

11 ThA Sensor Data

12 ThB Sensor Data

13 ThC Sensor Data

14 ThD Sensor Data

15 ThX Sensor Data

LD 1

LD 2

∏

Display switch

24

Switch

Position

Indication

LD 1

7 Segment LED display.

LD 2

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Serial

signal

Fault

Codes

Demand

Oil

retrieval,

superheat

control

Defrost

Operation

mode

Restart

timer

Circuit test

PMV A

PMV B

PMV C

PMV D

ThA

ThB

ThC

ThD

ThX

---

Receiving

from

unit B

Sending

to

unit B

---

Sending

to

unit A

Receiving

from

unit A

Receiving

from

Outdoor

Unit

from

unit D

Sending

to

unit D

Receiving

--- ---

Sending

to

unit C

Receiving

from

unit C

Fault code display (Normal [00]) Refer to fault code section for details.

Instructed demand frequency of Cooling or Heating [00 - 1F] Refer to table below.

---

Oil

retrieval

unit B

Superheat

control

unit B

---

Superheat

control

unit A

Oil

retrieval

unit A

---

Oil

retrieval

unit D

Superheat

control

unit D

Superheat

control

unit C

Oil

retrieval

unit C

Displays [dF] during defrost operation

Multi controller

Heating [H], Cooling [C]

Stop [0]

Outdoor unit

Heating [H], Cooling [C]

Other [0], Defrost [J]

Normal display [00], Restart timer counting [01]

Displays unit being tested [A b C d]

Indicates faulty unit connection [A b C d]

Displays the degree of PMV opening (0 - 240) as a Hexadecimal Code:

[00] : Closed, [F0] : Fully Open

Displays sensor temperature

Refer to the sensor temperature conversion table (7.2.3).

Sending

to

Outdoor

Unit

------ ---

7.2.2 Display switch set to position "2"

Displays the instructed demand frequency of heating or cooling from the multi-controller to the outdoor unit.

Display conversion table

Display code

Frequency conversion

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

0 0 0 3.9 6.9 10.0 13.1 16.2 19.3 22.4 25.5 28.6 31.7 34.8 37.9 41.0

value (Hz)

Display code

Frequency conversion

value (Hz)

10 11 12 13 14 15 16 17 18 19 1A 1B 1C 1D 1E 1F

44.1 47.2 50.3 58.4 56.5 59.6 62.7 65.8 68.9 72.0 75.1 78.2 81.3 84.4 87.5 90.0

25

7.2.3 Display switch set to position "11", "12", "13" and "14".

Multi controller - ThA, B, C, D and X sensor conversion table.

Display

18 -10.0

1C -9.0

20 -8.0

24 -7.0

28 -6.0

2C -5.0

30 -4.0

34 -3.0

38 -2.0

3C -1.0

40 0.0

Display [00] signifies sensor open circuit.

7.2.4 Circuit connection test procedure.

The 2-Pipe system has a feature which enables it to check that the wiring and piping connections

Tempera-

ture (°C)

Display

44 1.0

48 2.0

4C 3.0

50 4.0

54 5.0

58 6.0

5C 7.0

60 8.0

64 9.0

68 10.0

6C 11.0

Tempera-

ture (°C)

Display

70 12.0

74 13.0

78 14.0

7C 15.0

80 16.0

84 17.0

88 18.0

8C 19.0

90 20.0

94 21.0

98 22.0

Tempera-

ture (°C)

Display

9C 23.0

A0 24.0

A4 25.0

A8 26.0

AC 27.0

B0 28.0

B4 29.0

B8 30.0

Tempera-

ture (°C)

are aligned with each other. This is carried out by allowing refrigerant to flow to one Indoor unit at

a time and monitor the Indoor units coil sensor for a corresponding drop in temperature. Each

indoor unit is tested in turn and where two Multi controllers are installed each Multi controller is

tested in turn.

This test would normally be used at the commisioning stage.

Procedure for initialising the circuit test.

1. Turn the power off.

2. Ensure capacity codes are set correctly, capacity switches set to "0" are not tested.

3. Put the Outdoor display switch to 9 and Multi controller(s) display switch to 6.

4. Turn the power back on.

5. Set all the Remote controllers to cool mode and 29ºC.

6. Press the on / off button to start the indoor units.

7. Go to the Outdoor unit and press switch J2 (above 8xLED's) for 3 seconds.

8. The system is now in self-testing mode (all 8 LED's will be flashing rapidly).

9. The system will stop at the end of the test.

In the event of cross wiring / piping the system will indicate which units are faulty. Refer to self

diagnostic information (7.1.8).

26

7.3 MAR-F102HTM8-PE, 3-Pipe Outdoor Unit.

Malfunction judgement is performed using the self-diagnostic function of the outdoor unit. The

combination of the display switches (SW1, SW2) and the LED's (LD 71 ~ LD 74) indicate the diagnostic

details.

Fuse 20Ax3

R S T

52C3

U V W

51C3

Electrolytic

Capacitors

Interface control board

MCC-1223

L1 L2 L3 N

Power supply

Power

Transistor

1 2 3

M/C (1) M/C (2)

Electrical parts location

MCC-1223

MCC-1252

Inverter control

board

MCC-1251

Connectors

1 2 3

7 Segment LED

LD71 LD72 LD73 LD74

SW1 SW2

SW4

SW3

Interface control board

Display switches

27

7.3.1 Display switch SW1 set to position "0"

Communication serial signals and the system operating status are displayed by changing display

switch SW2.

Display

Switch

SW2

Position

0

1

2

3

4

Indication

Sending / receiving status of

interface control board serial

signal

Operating

Operating instruction

from M/C (1)

Outdoor unit

operating condition

mode

Instruction

frequency

Operating

mode

7 Segment LED Display

Between

M/C (1)

Sending

only [S]

Receiving

only [J]

Heating [H], Simultaneous

cooling/heating [HC],

Cooling [C], Stop [ ]

Heating frequency [00-1F]

(Refer to conversion table)

Heating [H], Cooling [0C],

Simultaneous heating [Hc]

Defrost [J0], Simultaneous

cooling [hC]

M/C

operation

Off: [0]

1 unit: [1]

2 unit: [2]

Between

M/C (2)

Not sending

or receiving

[ ]

Sending and

receiving [0]

Frequency

release

No: [0]

Yes: [1]

LD74LD71 LD72 LD73

Between

Inverter

Cooling frequency [00-1F]

(Refer to conversion table)

Non-inverter

compressor

Abnormal [E]

Normal [0]

5

6

9

10

11

Operating

Operating instruction

from M/C (2)

Inverter operation status

Operating instruction to

inverter from interface

control board

Power supply frequency

mode

Instruction

frequency

Heating [H], Simultaneous

cooling/heating [HC],

Cooling [C], Stop [-]

Heating frequency [00-1F]

(Refer to conversion table)

Normal

[C]

Abnormal

[E]

Normal

[C]

Abnormal

[E]

50Hz [5]

60Hz [6]

Operating

frequency

[0-F],

(Refer to

table)

Instruction

frequency

,

[0-F]

(Refer to

table)

[0]

Cooling frequency [00-1F]

(Refer to conversion table)

28

Display code conversion table - Instruction frequency from Multi Controller.

Display

code

Frequency

conversion

value (Hz)

Display

code

Frequency

conversion

value (Hz)

Display code conversion table - Operating frequency of Inverter Compressor.

Display

code

Frequency

conversion

value (Hz)

00

0

10

44.1

0

0

01

0

11

47.2

3

30.5

02

0

12

50.3

4

38.1

03

3.9

13

53.4

5

42.0

04

6.9

14

56.5

6

45.8

05

10.0

15

59.6

7

53.4

06

13.0

16

62.7

8

61.0

07

16.2

17

65.8

68.7

9

08

19.3

18

68.9

22.4

72.0

A

76.3

09

19

0A

25.5

1A

75.1

B

83.9

0B

28.6

1B

78.2

91.6

0E

37.9

1E

87.5

0F

41.0

1F

90.0

F

121.6

0C

0D

31.7

34.8

1C

1D

81.3

84.4

C

D

103.0

E

110.6

7.3.2 Display switch SW1 set to position "1"

PMV opening information is displayed.

Display

switch

SW2

2

3

7.3.3 Display switch SW1 set to position "2"

Malfunction information is displayed, refer to fault code section for details.

Display

switch SW2

0

Indication

PMV1 opening

PMV2 opening

Indication

Check code

display for the

Outdoor unit,

M/C (1), M/C (2)

LD71

[P]

[P]

[E]

7 Segment LED Display

LD72 LD73

[1]

[2]

7 segment LED display

LD72LD71

Outdoor unit: [r]

M/C (1): [1]

M/C (2): [2]

LD74

Displays the degree of PMV

opening (0 - 240) as a

Hexadecimal Code:

[00] : Closed, [F0] : Fully Open

LD73

Refer to fault code section for

details.

LD74

29

7.3.4 Display switch SW1 set to position "3"

The indoor unit capacity rank setting is displayed.

Display

Switch

SW2

0

1

2

3

4

5

6

7

8

Indoor unit code No. conversion table.

Code No.

Outdoor unit HP

Capacity rank of

indoor unit

connected to

M/C (1)

Capacity rank of

indoor unit

connected to

M/C (2)

Indication

0

LD71

Unit A

Unit B

Unit C

Unit A

Unit B

Unit C

Unit D

2 3 4 5 6 8 10

7 Segment LED Display

LD72

[9]

[A]

[b]

[C]

Displays the code number of the indoor unit

registered to each M/C.

[d]Unit D

Refer to the table below for indoor unit model

capacity rank.

[A]

[b]

[C]

[d]

8 HP [8], 10 HP [A]

LD73

[H]

LD74

[P]

Capacity rank

(Indoor unit model example: Model RAV-362UH-PE, Capacity rank = 36)

7.3.5 Display switch SW1 set to position "4"

The sensor data is displayed.

Display

Switch

SW2

0

1

2

3

4

5

No Correction

Indication

Pressure sensor data

ThD1 sensor data

ThD2 sensor data

ThS sensor data

TE sensor data

TO sensor data

10 13 16 20 26 36 46

7 Segment

LED Display

LD71

[P]

[d]

[d]

[S]

[h]

[h]

LD72

[d]

[1]

[2]

[1]

[E]

[0]

LD73

Displays sensors reading.

Refer to the following

conversion tables.

LD74

30

7.3.6 Outdoor unit - Pressure sensor data.

Display

17 0.0

1E 1.0

25 2.0

2D 3.0

34 4.0

3B 5.0

43 6.0

4A 7.0

51 8.0

58 9.0

5C 9.5

60 10.0

63 10.5

These are sample displays. Intermediate displays to those above are possible.

Pressure

(kgf/cm2G)

Display

67 11.0

6B 11.5

6E 12.0

72 12.5

76 13.0

79 13.5

7D 14.0

81 14.5

84 15.0

88 15.5

8B 16.0

8F 16.5

93 17.0

Pressure

(kgf/cm2G)

Display

96 17.5

9A 18.0

9E 18.5

A1 19.0

A5 19.5

A9 20.0

AC 20.5

BD 21.0

B4 21.5

B7 22.0

BB 22.5

BE 23.0

C2 23.5

Pressure

(kgf/cm2G)

Display

C6 24.0

C9 24.5

CD 25.0

D1 25.5

D4 26.0

D8 26.5

DC 27.0

DF 27.5

E3 28.0

E7 28.5

EA 29.0

EE 29.5

F2 30.0

Pressure

(kgf/cm2G)

7.3.7 Outdoor unit - ThD1 and ThD2 sensor data.

Display

Tempera-

ture (°C)

05 -5.0

07 0.0

09 5.0

0C 10.0

0F 15.0

12 20.0

17 25.0

1C 30.0

22 35.0

These are sample displays. Intermediate displays to those above are possible.

Display [00] signifies sensor open circuit.

Display

28 40.0

30 45.0

38 50.0

41 55.0

4A 60.0

54 65.0

5E 70.0

68 75.0

72 80.0

Tempera-

ture (°C)

Display

7C 85.0

87 90.0

90 95.0

9A 100.0

A2 105.0

AB 110.0

B2 115.0

B9 120.0

C0 125.0

Tempera-

ture (°C)

Display

C6 130.0

CB 135.0

D0 140.0

Tempera-

ture (°C)

31

7.3.8 Outdoor unit - ThS, TE, TO sensor data.

Display

Tempera-

ture (°C)

2A -20.0

36 -15.0

42 -10.0

51 -5.0

60 0.0

63 1.0

66 2.0

69 3.0

6C 4.0

6F 5.0

73 6.0

76 7.0

79 8.0

These are sample displays. Intermediate displays to those above are possible.

Display [00] signifies sensor open circuit.

Display

7C 9.0

7F 10.0

82 11.0

85 12.0

88 13.0

8B 14.0

8E 15.0

91 16.0

94 17.0

97 18.0

9A 19.0

9C 20.0

9F 21.0

Tempera-

ture (°C)

Display

A2 22.0

A5 23.0

A7 24.0

AA 25.0

AC 26.0

AF 27.0

B1 28.0

B3 29.0

B6 30.0

B8 31.0

BA 32.0

BC 33.0

BE 34.0

Tempera-

ture (°C)

Display

C0 35.0

C2 36.0

C4 37.0

C6 38.0

C8 39.0

C9 40.0

D1 45.0

D8 50.0

DE 55.0

E3 60.0

E7 65.0

EA 70.0

Tempera-

ture (°C)

7.3.9 Circuit connection test procedure.

The 3-Pipe system has a feature which enables it to check that the wiring and piping connections are

aligned with each other. This is carried out by allowing refrigerant to flow to one indoor unit at a time and

monitor the Indoor units coil sensor for a corresponding drop in temperature. Each Indoor unit is tested in

turn and where two Multi controllers are installed each Multi controller is tested in turn.

This test would normally be used at the commisioning stage.

Procedure for inialising the circuit test:

1. Turn the power off.

2. Ensure capacity codes are set correctly, capacity switches set to "0" are not tested.

3. Set the Outdoor display switches SW1 and SW2 to 9 and Multi controller(s) display switch to 6.

4. Turn the power back on.

5. Set all the Remote controllers to cool mode and 29ºC.

6. Press the on / off button to start the Indoor units. The Outdoor LED's show "1020".

7. Press the Oudoor unit switch SW3 for 3 seconds.

8. The system is now in self-testing mode (LED's will be flashing).

9. The system will stop at the end of the test.

In the event of cross wiring / piping the system will indicate which units are faulty, as shown by the LED's.

Refer to the table below.

M/C 1

A

B

1

Units indicated

C

failed the test.

2

D

0

No faults

M/C 2

A

B

Units indicated

failed the test.

C

D

0

No faults

32

7.4 RBM-Y1032F-PE, RBM-Y1042F-PE, 3-Pipe Multi Controller

The combination of the display switch and the four 7 segment LED's (LD101 - LD104) indicate the

diagnostic details.

MCC - 1223

7 segment LED

Unit A Unit C

Unit B Unit D

Capacity rank switches

Multi controller control board

Display switch

LD101

Indication

LD102

Switch Position

Serial signal

0

1 Fault codes

--- ---

[E]

--- ---

---

Frequency

instructions to

2

the outdoor unit.

Oil retrieval,

Superheat

3

control

---

---

Refer to the 2-Pipe Multi controller display conversion table for display switch position "2".

---

Defrost

M/C operating

4

Operation mode

Restart timer

5

6

Circuit test

PMV A7

8

9

10

11

12

13

14

15

PMV B

PMV C

PMV D

ThA

ThB

ThC

ThD

ThX

and Simultaneous Cooling/Heating [HC], Defrost [J-].

*

mode:

Heating [H-]

Cooling: [C-]

---

---

[c]

[k]

[A]

[P]

[b]

[P]

[P]

[c]

[P]

[d]

[A]

[h]

[b]

[h]

[c]

[h]

[h]

[d]

[h]

[H]

*

7 Segment LED Display

LD103

Receiving

from

unit B

Sending

to

unit B

Sending

---

to

unit A

from

unit A

Receiving

from

outdoor

unit

Receiving

from

unit D

Sending

to

unit D

Receiving

Fault code display (Normal [00] ) Refer to fault code section for details.

Instructed demand frequency of Cooling or Heating [00 - 1F]

Oil

retrieval

unit B

Superheat

control

unit B

---

Superheat

control

unit A

Oil

retrieval

unit A

---

unit D

unit D

Superheat

Oil

control

retrieval

---

Displays [dF] during defrost operation

Outdoor unit operating mode:Heating [H-], Cooling [-C], Simultaneous Heating [Hc],

Simultaneous Cooling [hC], Stop [--], Defrost [J-]

---

Displays unit being tested [ A b C d ]

Normal display [0], Restart timer counting [1]

Indicates faulty unit connection [A b C d]

Displays the degree of PMV opening (0 - 240) as a Hexadecimal Code:

[00] : Closed, [F0] : Fully Open

Displays sensor temperature

Refer to the 2-Pipe Multi controller sensor temperature conversion table (7.2.3).

LD104

---

---

Sending

to

unit C

Superheat

control

unit C

Receiving

from

unit C

Oil

retrieval

unit C

Sending

to

outdoor

unit

---

33

7.5 Inverter control board, 2-Pipe and 3-Pipe Outdoor Units.

The combination of the dip switch SW1 and the four LED's (D1 ~ D4) indicate the inverter compressor

speed and diagnostic details.

MCC - 1251

SW1 position

1

ON

OFF

2

ON

ON

Inverter control board

Display information

Inverter compressor demand frequency

Inverter compressor actual frequency

D1D2D3

D4

SW1

2 1

ON

OFF

ON

OFF

OFF

Fault code indication

Fault indication sequence

7.5.1 Inverter compressor speed indication

LED Binary display

X X X X

X X O O

X O X X

X O X O

X O O X

X O O O

O X X X

O X X O

O X O X

O X O O

O O X X

O O X O

Inverter compressor freq.

OFF

3

4

5

6

7

8

9

A

B

C

D

0 Hz

30.5 Hz

38.1 Hz

42.0 Hz

45.8 Hz

53.4 Hz

61.0 Hz

68.7 Hz

76.3 Hz

83.9 Hz

91.6 Hz

103.0 Hz

Cooling operation maximum frequency.

O O O X

O O O O

E

F

110.6 Hz

121.6 Hz

Heating operation maximum frequency.

34

7.5.2 Inverter fault code indication.

LED Display

O O O ¤

¤ O O O

O O O O

O ¤ O O

O O ¤ O

Inverter high pressure or compressor winding temperature

Inverter compressor winding short circuit protection

TE sensor open / short circuit (2-Pipe only)

Inverter compressor overload protection

Inverter circuit / compressor failure

Fault indicated

7.5.3 Inverter fault indication sequence.

LED Display

X X X O

X X O X

X X O O

¤ O ¤ ¤

Fault indicated

First failure

Second failure

Third failure

System locked out

X LED off

O LED on

¤ LED flashing

7.6 Control board communication diagram.

Remote controller fault code

21

14

18

1d

1F

Multi controller

M/C (1)

Inverter

control board

INV

Remote

Controller

Indoor Unit

Multi controller

M/C (2)

Interface

control board

I/F

1 minute1 minuteA few seconds

1 minute

Remote controller fault code display time lapse for system malfunctions.

Serial signal abnormalities: Between the I/F and the INV More than 3 minutes.

Between the M/C and the I/F More than 2 minutes.

Between the indoor unit and the M/C More than 1 minute.

Between the remote controller and indoor unit A few seconds.

INV abnormality: More than 3 minutes.

I/F abnormality: More than 2 minutes.

M/C and Indoor unit abnormality: More than 1 minute

35

8. FAULT CODE DISPLAY INFORMATION

The remote controller, multi controller and outdoor unit have the facility to display fault codes which are

used to determine any malfunction of the system.

• The remote controller is provided with a "check" button and a malfunction check display.

• The multi controllers and outdoor units are provided with display switches and LED displays.

Initially malfunctions can be identified from the remote controller check display.

Details of the multi controller and outdoor unit malfunctions can be determined from their control boards.

(Multi controller malfunctions are also displayed on the outdoor unit interface control board).

8.1 Fault code identification.

When a malfunction has been identified, do not reset the system. Press the "CHECK" button on the remote

controller and observe the malfunction display.

The location and cause of the malfunction can be determined from the fault code.

Flashing "PREHEAT DEFROST"

• The total capacity rank settings of indoor units connected exceeds the allowable level,

or an indoor capacity rank is set at "0" (Multi controller).

• For the 2-Pipe system heating operation has priority over cooling. In the event of an

indoor unit requesting cooling operation when another is in heating mode, the

"PREHEAT DEFROST" will flash.

"MALFUNCTION CHECK"

Flashes when

phases are rotated.

Check button

• Pressing for 1 second will display the number of compressor actuations and fault codes.

• Pressing for 5 seconds will reset the indoor unit microprocessor.

• Pressing for 10 seconds will clear only the fault codes.

Reset button

• Pressing the reset button with a pin will clear the memory.

36

8.2 Details of the malfunction check display

The following display sequence occurs when the check button is pressed for 1 second.

(Note: Up to 16 indoor units can be connected to one remote controller using group control).

1. The number of compressor "ON" actuations for No.1 outdoor unit is displayed for 2 seconds,

followed by:

2. Fault codes. 2 fault codes for each of the 16 indoor units can be displayed at 2 second intervals.

Example:

Display for the number of compressor "ON" actuations:

MALFUNCTION CHECK

Display for fault codes:

The display is in Hexadecimal Code.

In this case [00 A4] represents 164 compressor "ON" actuations.

MALFUNCTION CHECK MALFUNCTION CHECK

•

•

•

Fault code

Indoor unit

number

MALFUNCTION CHECK

MALFUNCTION CHECK

The 1st fault detected

The 2nd fault detected

In this case indoor unit No.1 has [0C]

•

fault code and indoor unit No.15 has [0d] fault code

followed by [04] fault code.

•

In this case indoor unit No.1 has

[0C] fault code.

i.e. TA sensor abnormality.

MALFUNCTION CHECK

•

37

8.3 2-Pipe system fault code summary.

Fault codes can be identified from either the Remote controller, Multi controller or Outdoor unit as shown in

the diagram below.

Remote controller fault code Multi controller display switch position 1

No communication INV to I/F

No communication M/C to O/D

04

No communication I/D to M/C

Drain pump fault - I/D unit

0b

TA sensor fault

0C

TC sensor fault

0d

Reverse TC temperature change

08

No TC temperature change

09

No communication I/D to R/C

99

Refer to M/C

15

"Preheat Defrost" flashing

1C

Refer to O/D

Refer to O/D

14

1d

Refer to O/D

1F

Refer to O/D

18

Refer to O/D

Refer to O/D

Ü

Ü

Ü

Ü

ÜÜ

Ü

Ü

Ü

Ü Ü

No communication I/F to INV

04

No communication M/C to O/D

M/C control board fault

8A

No communication initially M/C to O/D

88

ThA sensor fault

80

ThB sensor fault

81

ThC sensor fault

82

ThD sensor fault

83

ThX sensor fault

84

M/C drain pump fault

0b

I/D capacity rank codes too high

89

I/D capacity code set to "0"

Refer to O/D

1C

Refer to O/D

14

Refer to O/D

1d

Refer to O/D

1F

18

Refer to O/D

21

Refer to O/D

Outdoor Unit

Ü

No communication I/F to INV

Refer to inverter control board diagnostics

Display switch set to position "8" (LED on)

Ü

LED 1

Ü

LED 2

Ü

LED 3

Ü

LED 4

Ü

LED 5

Ü

LED 6

LED 7

LED 8

Display switch set to position "3" (LED on)

LED 1

Ü

LED 2

LED 3

LED 4

LED 5

LED 6

LED 7

LED 8

Ü

Refer to the section on the inverter control

Ü

board diagnostics

Ü

ThA sensor fault

ThB sensor fault

ThC sensor fault

ThD sensor fault

ThX sensor fault

Over-capacity

M/C 1 fault

M/C 2 fault

ThD1 sensor fault

ThD2 sensor fault

ThS sensor fault

High pressure fault

Pressure sensor fault

Discharge temperature > 130ºC

Suction temperature > 40ºC

Low pressure < 0.25kgf/cm˝G

21

Phase rotation incorrect

"MALFUNCTION CHECK"

flashing on R/C.

38

8.4 3-Pipe system fault code summary.

Fault codes can be identified from either the Remote controller, Multi controller or Outdoor unit as shown in

the diagram below.

Remote controller fault code Multi controller display switch position 1

No communication INV to I/F

04

No communication M/C to O/D

No communication I/D to M/C

0b

Drain pump fault - I/D unit

0C

TA sensor fault

0d

TC sensor fault

08

Reverse TC temperature change

09

No TC temperature change

99

No communication I/D to R/C

15

Refer to M/C

"Preheat Defrost" flashing

Refer to O/D

1C

Refer to O/D

14

Refer to O/D

1d

Refer to O/D

1F

Refer to O/D

Ü

Ü

Ü

Ü

ÜÜ

Ü

Ü

Ü

No communication I/F to INV

04

No communication M/C to O/D

M/C control board fault

8A

No communication initially M/C to O/D

88

ThA sensor fault

80

ThB sensor fault

81

ThC sensor fault

82

ThD sensor fault

83

ThX sensor fault

84

M/C drain pump fault

0b

I/D total capacity codes too high

89

I/D capacity code set to "0"

1C

Refer to O/D

14

Refer to O/D

Refer to O/D

1d

Refer to O/D

1F

Refer to O/D

21

Outdoor Unit

No communication I/F to INV

Ü

Refer to inverter control board diagnostics

Interface control board.

SW1 set to "2", SW2 set to "0".

[E] [1] [fault code] Refers to M/C 1

[E] [2] [fault code] Refers to M/C 2

Ü

80

ThA sensor fault

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Ü

Refer to the section on the inverter control

Ü

board diagnostics

Ü

ThB sensor fault

81

82

ThC sensor fault

83

ThD sensor fault

84

ThX sensor fault

0b

M/C drain pump fault

Over-capacity

89

[E] [r] [fault code] Refers to O/D

ThD1 sensor fault

AO

ThD2 sensor fault

A1

ThS sensor fault

A2

ThO sensor fault

A4

ThE sensor fault

A5

Discharge temperature > 130ºC

A6

Suction temperature > 40ºC

A7

Pressure sensor fault

AA

D.O.L. compressor fault

Ad

Low pressure < 0.25kgf/cm˝G

AE

Phase rotation incorrect

21

"MALFUNCTION CHECK"

flashing on R/C.

39

8.5 Fault codes displayed at the Remote controller.

Diagnostic Funtions

Fault

Code

Sympton

Status of Air

Conditioner

Notes

SERIAL SIGNAL FAULT

Inter-unit communication.

FLOAT SWITCH

OPERATION

Indoor unit or Multi

controller.

RETURN AIR

TEMPERATURE

SENSOR (TA)

INDOOR

HEAT EXCHANGER

SENSOR (TC)

Outdoor unit

stops.

Indoor unit fan

continues.

Operation stops

for Multi

controller fault.

Indoor unit fan

continues for

Indoor unit fault.

Operation

Continues.

Indoor unit fan

stops.

(PREHEAT

DEFROST is

displayed on

R/C)

1. Wiring fault between I/D and M/C, or M/C and O/D

Interface control board, or O/D Interface control

board and O/D Inverter control board.

2. This fault code is also displayed when the Inverter

heat sink TRS thermal switch operates.

1. For an I/D fault, when other I/D units are operating,

the O/D unit continues, the relevant M/C PMV

closes and the faulty I/D unit fan operation continues.

2. Float switch open circuit.

3. Drain pipe blocked.

4. Drain pump fault.

1. Sensor open / short circuit.

1. O/D unit stops when the faulty Indoor unit is the

only unit operating.

2. Sensor open / short circuit.

MULTI CONTROLLER

FAULT

OUTDOOR UNIT

FAULT

INVERTER FAULT

Operation

stops

Operation

stops

Operation

stops

1. Refer to Multi controller diagnostics and fault codes.

1. Refer to Outdoor unit diagnostics and fault codes.

1. Inverter compressor fault (short circuit).

2. Check the power supply, wiring, fuses, giant

transistor, base drive board, smoothing capacitor,

rectifier diode and compressor.

40

Fault

Code

Diagnostic Funtions

Sympton

Status of Air

Notes

Conditioner

INVERTER

COMPRESSOR FAULT

INVERTER

MALFUNCTION

OUTDOOR

HEAT EXCHANGER

SENSOR (TE)

2-Pipe Outdoor unit

ONLY.

HIGH PRESSURE

FAULT

Operation

stops

Operation

stops

Operation

stops

Operation

stops

1. Inverter compressor fault (overload).

2. Check the power supply, wiring and compressor.

1. Fault in the current detection circuit of the Inverter

control board.

2. Check the power circuit, wiring, control boards and

compressor.

1. Sensor open / short circuit.

1. High pressure switch or Inner over-load relay

malfunction.

2. Operation of the High pressure switch or Inner overload relay, or detected by the Pressure sensor.

REMOTE

CONTROLLER

COMMUNICATION

Indoor unit

stops

3. Possible causes - gas leak, refrigerant under charge

or over-load operating conditions.

4. Phase rotation detected at D.O.L compressor start

up.

1. Wiring fault between the Indoor unit and the Remote

controller.

41

8.6 Fault codes displayed at the Multi controller. Display switch set to position "1".

Fault code

80

81

82

83

84

88

89

8A

8.7 Fault codes displayed at the Outdoor unit. 2-Pipe ; Display switch set to position "3". 3-Pipe ; Display switch SW1 set to position "2", SW2 set to position "0".

Fault code

2-Pipe

ThA sensor fault

ThB sensor fault

ThC sensor fault

ThD sensor fault

ThX sensor fault

Communication between M/C and O/D

Total I/D capacity codes too high

Multi controller control board malfunction.

3-Pipe

Fault

Sensor open / short circuit.

No initial communication between M/C and O/D

Check the wiring and control boards.

Fault code is displayed when total I/D capacity

exceeds 1.35 times the O/D unit capacity.

Fault Note

Note

LED 1

LED 2

LED 3

LED 6

LED 7

LED 5

LED 8

ErA0

ErA1

ErA2

ErA4

ErA5

ErA6

ErA7

ErAA

ErAE

ThD1 sensor fault

ThD2 sensor fault

ThS sensor fault

ThO sensor fault

ThE sensor fault

Discharge temperature fault

Suction temperature fault

Pressure sensor fault

Low pressure fault

Sensor open / short circuit.

Detected by ThD1 and ThD2 >130ºC.

Possible cause - gas leak, refrigerant under

charge, over-load operating condition, or valve

blockage / malfunction.

Detected by ThS > 40ºC.

Possible cause - gas leak, refrigerant under

charge, over-load operating condition.

Open / short circuit, or pressure sensor capillary

tube block.

Possible cause - gas leak, refrigerant under

charge, over-load operating condition, or valve

blockage / malfunction.

LED 4

ErAd

D.O.L. compressor fault

Detected by low pressure switch. < 0.25kgf/cm˝G

High pressure switch or over-load relay

malfunction.

42

9. CONTROL FEATURES

NO. CONTROL

1

2

Defrost

(Heating mode)

Oil Retrieval

(Cooling mode)

DESCRIPTION

• During heating operation, defrost is

controlled by the Outdoor unit heat exchanger

temperature sensor (TE).

• When the cumulative operating time with TE

in zone [A] has amounted to 25 minutes,

defrost operation starts. Subsequent

defrosts occur after a cumulative time of 55

minutes. When heating operation resumes

after defrost, the timer is reset.

• The maximum defrost period after TE returns

to zone [B] is 1 minute.

• Heating operation resumes immediately after

TE returns to zone [C].

• During cooling operation, oil retrieval is

performed if one or more Indoor units are

OFF.

• If this condition is satisfied, when cooling

operation commences, oil retrieval takes

place for 1 minute.

If cooling operation continues, oil retrieval is

repeated for 1 minute every 60 minutes.

• During oil retrieval the following occurs:

a. All Multi controller PMV's are opened.

The degree of opening is dependant

on the capacity of the Indoor unit .

b. If the D.O.L. compressor is OFF the

inverter compressor speed increases

to SD.

• When cooling operation ends the timer is

reset.

Temp.

1 min.

Oil

retrieval

(ºC)

60 min.

DIAGRAM

A

Cooling mode

1 min.

Oil

retrieval

< 60 min.

Compressor

off

Timer

reset

Superheat control

3

(Cooling mode)

• Superheat is controlled by the Multi controller

for cooling operation.

The level of superheat is determined by the

difference between the evaporator outlet

temperature for each Indoor unit

(ThA, B, C, D) and the saturation temperature

(ThX).

• If the superheat of an Indoor unit enters zone

[Y], the relevant M/C PMV opens further to

compensate for this increase. The degree

of additional opening is dependant on the

capacity of the Indoor unit.

• When zone [Z] is reached the PMV

opening is held at the level set in zone [Y].

• When the level of superheat returns to zone

[X] the control is cancelled.

Superheat

(ºC)

13

Y

Z

9

X

43

NO.

CONTROL

DESCRIPTION

Simultaneous

4

Cooling / Heating

operation

3-Pipe ONLY

a. Changeover between cooling and heating operations for each indoor unit.

The solenoid valves inside the Multi controller are energised when operation

commands are sent from the Indoor units.

• SVS valve (suction side) opens for a cooling command.

• SVD valve (discharge side) opens for a heating command.

b. Determination of the Outdoor unit operation mode and frequency of the

compressor.

These are determined by the difference between the total requested cooling

command frequencies and the total requested heating command frequencies

of all Indoor units.

c. Outdoor unit refrigerant control during cooling dominant mode.

• Refrigerant flow is controlled by PMV2. The degree of opening is controlled

by the difference of all requested cooling and heating command frequencies

and the compressor operation frequency.

This flow control is required to divide cooling exhaust heat appropriately

between Indoor units in heating mode and the Outdoor unit heat exchanger.

• High pressure control is performed to ensure that the capacity of the

Indoor units in heating is maintained. This is controlled by the Outdoor unit

fan control and the changeover from the main heat exchanger to the sub

heat exchanger.

d. Outdoor unit refrigerant control during heating dominant mode.

• Superheat control is performed by the Outdoor unit expansion valve.

• Evaporating temperature control is performed by the Outdoor unit fan

control to ensure that the capacity of the Indoor units in cooling mode is

maintained.

• Changeover from expansion valve to capillary control is performed

when there is a minimal difference between the cooling and heating

demands and the heat absorbtion of the Outdoor unit heat exchanger is low.

44

10. VALVE & SENSOR FUNCTION AND OPERATION

10.1 Multi controller - Valve functions, 2-Pipe and 3-Pipe.

Symbol

PMV (A, B, C, D) Flow rate control valve

Multi controller - Valve functions, 3-Pipe ONLY.

SVS (A, B, C, D)

SVSS

SVDD

SVH Superheat solenoid valve

Name of Valve

Suction gas valve

Discharge gas valveSVD (A, B, C, D)

Pressure reducing

solenoid valve

Pressure increasing

solenoid valve

Description of Function

This opens to the extent corresponding to the

capacity and performance required of each Indoor

unit.

Opens when commands from the Indoor units

requires cooling operation.

Opens when commands from the Indoor units

require heating operation.

Opens when the number of units in heating operation is

reduced (heating to shutdown or cooling).

Opens when defrost operation starts.

Opens during oil retrieval control in cooling operation.

Opens when the number of units in heating operation is

increased (shutdown or cooling to heating).

Opens while control is performed to prevent liquid

in discharge pipe from being blocked.

Opens when unit in cooling operation is present.

10.2 Multi controller - Valve operation.

Outdoor

Operation Mode

Shutdown Shutdown, fan

During

operation

Indoor Operation Mode

Shutdown, fan

Cooling

Cooling thermo-control OFF

Heating

Heating thermo-control OFF

SVD

(3-Pipe ONLY)

OFF

OFF

OFF

OFF

ON

ON

SVS

(3-Pipe ONLY)

OFF

ON

ON

ON

OFF

OFF

PMV

Fully closed

Fully closed

Rated opening

Fully closed

Rated opening

Fully closed

45

10.3 Outdoor unit - Valve functions, 2-Pipe and 3-Pipe.

Symbol

20SF

SV1

SV2

SV4

Name of Valve

4-way reversing valve

Cooling operation

4-way reversing valve

Heating operation

High-pressure release

solenoid valve

Hot gas bypass solenoid

valve

Solenoid valve for D.O.L.

compressor startup

Description of Function

OFF: Normal operation.

ON: Low load condition when sub heat exchanger

is required. Used in combination with SV15

(3-Pipe ONLY).

ON: Normal operation.

OFF: Defrost operation.

Heating operation.

Energised when TE > 11ºC

Opens when Pd < 13kgf/cm˝G (cooling)

(For cooling dominant mode and sub heat exchanger

operation Pd < 17kgf/cm˝G - 3-Pipe ONLY).

Opens when Outdoor ThO < 0ºC (3-Pipe ONLY).

Opens for gas balance when compressor stops

(2-Pipe ONLY).

Opens when the D.O.L compressor starts for

unloading.

PMV1

Outdoor unit - Valve functions, 3-Pipe ONLY.

SV5

SV13 Cooling solenoid valve

SV14

SV16

SV15

PMV2

Cooling bypass flow

control valve

Gas balance

Solenoid valve for

expansion valve

Solenoid valve for

capillary

Sub heat exchanger

solenoid valve

Outdoor flow control

valve

Opens when ThD1 or ThD2 > 110ºC.

Opens when ThS > 20ºC

Opens when compressor stops.

Opens for cooling-only operations.

SV14 opens for heating operation.

SV16 opens for low load conditions during heating

dominant operation.

Opens for sub heat exchanger requirement.

Opens during cooling dominant operation.

Degree of opening depending on cooling / heating

demands.

46

10.4 Outdoor unit - Valve operation.

For the 2-Pipe system only cooling operation, heating operation and valve 20SF are applicable.

Outdoor Operation Mode

Cooling operation

Heating operation

Simultaneous

Outdoor main heat

exchanger

Sub heat exchanger

–

Outdoor main heat

exchanger

20SF SV15 SV13 SV14 SV16

OFF OFF ON OFF OFF

ON ON ON OFF OFF

ON OFF OFF ON OFF

OFF OFF OFF OFF OFF

cooling-dominant

operation

Simultaneous

Sub heat exchanger

Expansion valve

ON ON OFF OFF OFF

ON OFF OFF ON OFF

heating-dominant

operation

Capillary

ON OFF OFF OFF ON

10.5 Manual operation of valves.

Note: 1. Ensure that the system is OFF before valves are manually operated.

2. Valves will re-assume their required position unless electrically isolated.

PMV2

–

–

–

Opening degree

control

Opening degree