Toshiba MAP0801T8, MAP1001T8, MMY-MAP0501T8, MAP0601T8, MAP0601HT8 Installation Manual

...

INSTALLATION MANUAL

MANUEL DINSTALLATION

INSTALLATIONS-HANDBUCH

MANUALE DI INSTALLAZIONE

MANUAL DE INSTALACIÓN

MANUAL DE INSTALAÇÃO

INSTALLATIEHANDLEIDING

ЕГЧЕЙСЙДЙП ЕГКБФБУФБУЗУ

Outdoor Unit

Unité extérieure / A ußengerät

Unità esterna / Unidad exterior

Unidade exterior / Buitenunit

ЕощфесйкЮ mпнЬдб /

Cooling Only Model

Modèle à froid seul / Geräte nur zur Kühlung

Modello solo raffreddamento/ Modelo de sólo frío

Modelo Só de Refrigeração / Model voor alleen koelen

МпнфЭлп мьнп шэозт /

MMY-MAP0501T8, MAP0601T8, MAP0801T8, MAP1001T8, MAP1201T8

Heat Pump Model

Modèle à thermopompe / Geräte mit Heizung

Modello con pompa per riscaldamento / Modelo con bomba de calor

Modelo de Bomba Térmica / Model met warmtepomp

МпнфЭлп ме БнфлЯб Иесмьфзфбт /

MMY-MAP0501HT8, MAP0601HT8, MAP0801HT8, MAP1001HT8, MAP1201HT8

Heat Pump Model

Modèle à thermopompe / Geräte mit Heizung

Modello con pompa per riscaldamento / Modelo con bomba de calor

Modelo de Bomba Térmica / Model met warmtepomp

МпнфЭлп ме БнфлЯб Иесмьфзфбт /

MMY-MAP0501HT7, MAP0601HT7, MAP0801HT7, MAP1001HT7, MAP1201HT7

50Hz

50Hz

60Hz

VOLUME-1

For commercial use

Pour usage commercial

Nur für gewerbliche Nutzung

Per uso commerciale

Para uso comercial

Para uso comercial

Voor commercieel gebruik

Гйб емрпсйкЮ чсЮуз

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new

refrigerant HFC (R410A) instead of the conventional

refrigerant R22 in order to prevent destruction of the

ozone layer.

UTILISATION DU NOUVEAU REFRIGERANT

Ce climatiseur est d’un type inédit qui utilise le nouveau

réfrigérant HFC (R410A) au lieu du réfrigérant

traditionnel R22, afin d’éviter la destruction de la couche

d’ozone.

EINFÜHRUNG EINES NEUEN KÜHLMITTELS

Dies ist ein neuartiges Klimagerät. Anstatt des

herkömmlichen Kühlmittels R22 verwendet es das neue

ozonschicht-schonende HFC Kühlmittel R410A.

ADOZIONE DI UN NUOVO REFRIGERANTE

Questo condizionatore d'aria è di un tipo nuovo che

adotta un nuovo refrigerate HFC (R410A) al posto del

refrigerante convenzionale R22, per prevenire la

distruzione dello strato di ozono dell'atmosfera terrestre.

ADOPCIÓN DE NUEVO REFRIGERANTE

Este aparato de aire acondicionado es un modelo

reciente que incorpora el nuevo refrigerante HFC

(R410A) en lugar del refrigerante convencional R22

para así evitar daños en la capa de ozono.

ADOPÇÃO DO NOVO REFRIGERANTE

Este ar condicionado é um modelo novo que adopta um

novo refrigerante HFC (R410A) em vez do refrigerante

convencional R22 para evitar a destruição da cama de

ozono.

ХЙПИЕФЗУЗ НЕПХ ШХКФЙКПХ

Фп рбсьн Клймбфйуфйкь еЯнбй нЭпт фэрпт рпх хйпиефеЯ нЭп

шхкфйкь HFC (R410A) уфз иЭуз фпх ухмвбфйкпэ

шхкфйкпэ R22 рспкеймЭнпх нб впзиЮуей уфзн рспуфбуЯб

фпх ьжпнфпт.

TOEPASSING VAN EEN NIEUW KOELMIDDEL

Deze airconditioner is een nieuwe type dat werkt met

een nieuw koelmiddel HFC (R410A) in plaats van met

het conventionele koelmiddel R22, als bijdrage om de

aantasting van de ozonlaag te reduceren.

Nous vous remercions pour avoir choisi un climatiseur TOSHIBA.

Veuillez lire attentivement ce Manuel du propriétaire avant d’utiliser votre

climatiseur.

• Assurez-vous que le constructeur (ou le revendeur) vous remette le

“Manuel du propriétaire” et le “Manuel d’installation”.

Demande au constructeur ou au revendeur

Veuillez expliquer clairement le contenu du Manuel du propriétaire et le

remettre au client.

Wir danken Ihnen, dass Sie sich für ein TOSHIBA Klimagerät entschieden

haben.

Bitte lesen Sie diese Betriebsanleitung, bevor Sie Ihr Klimagerät benutz en, sorgfältig.

• Lassen Sie sich die “Betriebsanleitung” und das “Installations-Handb uch”

unbedingt vom Installateur oder vom Lieferanten aushändigen.

Eine Bitte an den Installateur oder Lieferanten:

Bitte erklären Sie dem Käufer den Inhalt der Betriebsanleitung und händigen

sie ihm aus.

Grazie di aver acquistato un condizionatore d'aria TOSHIBA.

Prima di usare il condizionatore d'aria, leggere con attenzione questo

manuale del proprietario.

• Si raccomanda di tenere a portata di mano il “Manuale del proprietario”

e il “Manuale di installazione” ricevuti dal produttore (o dal r i venditore).

Richiesta al produttore o al rivenditore

Spiegare chiaramente il contenuto del Manuale del proprietario e

consegnarne una copia all'utente.

Muchas gracias por haber adquirido el aparato de aire acondicionado TOSHIBA.

Lea atentamente este manual del propietario antes de utilizar el aparato de aire

acondicionado.

• Asegúrese de que el fabricante (o distribuidor) le proporcione el “Manual del

propietario” y el “Manual de instalación”.

Solicitud al fabricante o distribuidor

Explique con claridad el contenido del Manual del propietario y entréguelo al

cliente.

Muito obrigada por adquirir o Ar Condicionado TOSHIBA.

Leia atentamente este manual do utilizador antes de utilizar o seu ar

condicionado.

• Não se esqueça de receber o “Manual do utilizador” e o “Manual de

inslatação” do fabricante (ou agente).

Pedido ao fabricante ou agente

Explique por favor o conteúdo do Manual do utilizador e entregue-o.

Hartelijk dank voor uw keuze voor een airconditioner van TOSHIBA.

Lees deze gebruiksaanwijzing zorgvuldig door voordat u de

airconditioner gaat gebruiken.

• Zorg ervoor dat u zowel de ‘gebruiksaanwijzing’ als de

‘installatiehandleiding’ van de installateur (of leverancier) krijgt.

Verzoek aan de installateur of de leverancier

Leg de inhoud van de gebruiksaanwijzing duidelijk uit en overhandig de

gebruiksaanwijzing nadien aan de klant.

Убт ехчбсйуфпэме рплэ рпх рспфймЮубфе гйб фзн бгпсЬ убт Энб

Клймбфйуфйкь TOSHIBA.

Рбсбкблпэме дйбвЬуфе рспуечфйкЬ фйт пдзгЯет чсЮузт рсйн брь фз чсЮуз

фпх Клймбфйуфйкпэ.

ВевбйщиеЯфе ьфй п кбфбукехбуфЮт (Ю п рщлзфЮт) убт рбсЭдщуе кбй фйт

ПдзгЯет ЧсЮузт кбй фп ЕгчейсЯдйп ЕгкбфЬуфбузт.

РбсЬклзуз гйб фпн кбфбукехбуфЮ Ю фпн рщлзфЮ

Рбсбкблю еозгЮуфе ме убцЮнейб фб ресйечьменб фщн Пдзгйюн ЧсЮузт кбй

рбсбдюуфе фп.

HFC

R410A R22

Thank you very much for purchasing TOSHIBA Air Conditioner.

• This manual describes the installation method at the outdoor unit side.

• Before installation, please read this Manual thoroughly to perform correct

installation.

• For pipe connection for the indoor and outdoor units, Y-shape branching joint or

branch header required sold separately. Select it according to the capacity.

• For pipe connection between the outdoor units, T-shape branching joint which is

sold separately is required.

CONTENTS

SOMMAIRE

INHALT

INDICE

CONTENIDO

ÍNDICE

РЕСЙЕЧПМЕНБ

INHOUD

ITALIANO

ESPAÑOLPORTUGUÊSЕЛЛЗНЙКБ FRANCAISDEUTSCHNEDERLANDS ENGLISH

VOLUME-1

ACCESSORY PARTS ......................................................................................................................................................................................................... 1

SAFETY CAUTION............................................................................................................................................................................................................. 1

1

INSTALLATION OF NEW REFRIGERANT AIR CONDITIONER ................................................................................................................................ 3

2

SELECTION OF INSTALLATION PLACE ................................................................................................................................................................... 4

3

OUTDOOR UNIT CARRYING IN ................................................................................................................................................................................. 7

4

INSTALLATION OF OUTDOOR UNIT ................................................................................................... ...................................................................... 8

5

REFRIGERANT PIPING ............................................................................................................................................................................................ 10

PIECES ACCESSOIRES.................................................................................................................................................................................................. 20

MESURES DE SECURITE ............................................................................................................................................................................................... 20

1

INSTALLATION DU CLIMATISEUR UTILISANT LE NOUVEAU REFRIGERANT.................................................................................................... 22

2

SELECTION DU LIEU D’INSTALLATION ................................................................................................................................................................. 23

3

TRANSPORT DE L’UNITE EXTERIEURE ................................................................................................................................................................. 26

4

INSTALLATION DE L’UNITE EXTERIEURE.............................................................................................................................................................. 27

5

TUYAUX DE REFRIGERANT .................................................................................................................................................................................... 29

ZUBEHÖR ........................................................................................................................................................................................................................ 39

SICHERHEITSHINWEISE ................................................................................................................................................................................................ 39

1

INST ALLA TION V ON KLIMAGERÄTEN MIT MODERNEN KÄLTEMITTELN ........................................................................................................... 41

2

AUSWAHL DES AUFSTELLUNGSORTES ............................................................................................................................................................... 42

3

TRANSPORT DER AU?ENEINHEIT ......................................................................................................................................................................... 45

4

INSTALLATION DER AUSSENEINHEIT ................................................................................................................................................................... 46

5

KÄLTEMITTELLEITUNGEN ...................................................................................................................................................................................... 48

ACCESSORI..................................................................................................................................................................................................................... 58

PRECAUZIONI DI SICUREZZA ....................................................................................................... ................................................................................ 5 8

1

INSTALLAZIONE DI UN NUOVO REFRIGERANTE PER IL CONDIZIONATORE D’ARIA ...................................................................................... 60

2

SCELTA DEL LUOGO D’INSTALLAZIONE ............................................................................................................................................................... 61

3

TRASPORTO DELL’UNITÀ ESTERNA ..................................................................................................................................................................... 64

4

INSTALLAZIONE DELL’UNITÀ ESTERNA ............................................................................................................................................................... 65

5

TUBAZIONI DEL REFRIGERANTE .......................................................................................................................................................................... 67

COMPONENTES ACCESORIOS ..................................................................................................................................................................................... 77

PRECAUCIONES DE SEGURIDAD ................................................................................................................................................................................. 77

1

INSTALACIÓN DEL AIRE ACONDICIONADO CON NUEVO REFRIGERANTE...................................................................................................... 79

2

SELECCIÓN DEL LUGAR DE INSTALACIÓN.............................................................................................................................. ............................ 80

3

TRANSPORTE DE LA UNIDAD EXTERIOR............................................................................................................................................................. 83

4

INSTALACIÓN DE LA UNIDAD EXTERIOR ............................................................................................................................................................. 84

5

TUBERÍA DE REGRIGERANTE ............................................................................................................................................................................... 86

PEÇAS ACESSÓRIAS ..................................................................................................................................................................................................... 96

PRECAUÇÃO DE SEGURANÇA ..................................................................................................................................................................................... 96

1

INSTALAÇÃO DE AR CONDICIONADO DE NOVO REFRIGERANTE .................................................................................................................... 98

2

SELECÇÃO DO LOCAL DE INSTALAÇÃO.............................................................................................................................................................. 99

3

TRANSPORTE DA UNIDADE INTERIOR ............................................................................................................................................................... 102

4

INSTALAÇÃO DA UNIDADE EXTERIOR................................................................................................................................................................ 103

5

TUBAGEM DE REFRIGERANTE ............................................................................................................................................................................ 105

ACCESSOIRES .............................................................................................................................................................................................................. 115

AANDACHTSPUNTEN V OOR UW VEILIGHEID ............................................................................................................................................................ 115

1

INSTALLEREN VAN EEN AIRCONDITIONER MET NIEUW KOELMIDDEL .......................................................................................................... 117

2

KEUZE VAN DE LOCATIE VOOR DE INSTALLATIE .............................................................................................................................................. 118

3

VERPLAATSING VAN DE BUITENUNIT ................................................................................................................................................................. 121

4

INSTALLATIE VAN DE BUITENUNIT ...................................................................................................................................................................... 122

5

KOELMIDDELLEIDINGEN ...................................................................................................................................................................................... 124

РБСЕЛКПМЕНБ БОЕУПХБС ............................................................................................................................................................................................ 134

РСПЦХЛБОЕЙУ ГЙБ ФЗН БУЦБЛЕЙБ ................................................................................................................................................................................ 134

ЕГКБФБУФБУЗ КЛЙМБФЙУФЙКПХ МЕ НЕП ШХКФЙКП .............................................................................................................................................. 136

ЕРЙЛПГЗ ИЕУЗУ ЕГКБФБУФБУЗУ ........................................................................................................................................................................... 137

! МЕФБЦПСБ ЕОЩФЕСЙКЗУ МПНБДБУ ..................................................................................................................................................................... 140

" ЕГКБФБУФБУЗ ЕОЩФЕСЙКЗУ МПНБДБУ ................................................................................................................................................................ 141

# УЩЛЗНЩУЗ ШХКФЙКПХ .............................................................................................................................................................................................. 143

153

153

1

155

2

156

3

159

4

160

5

162

1

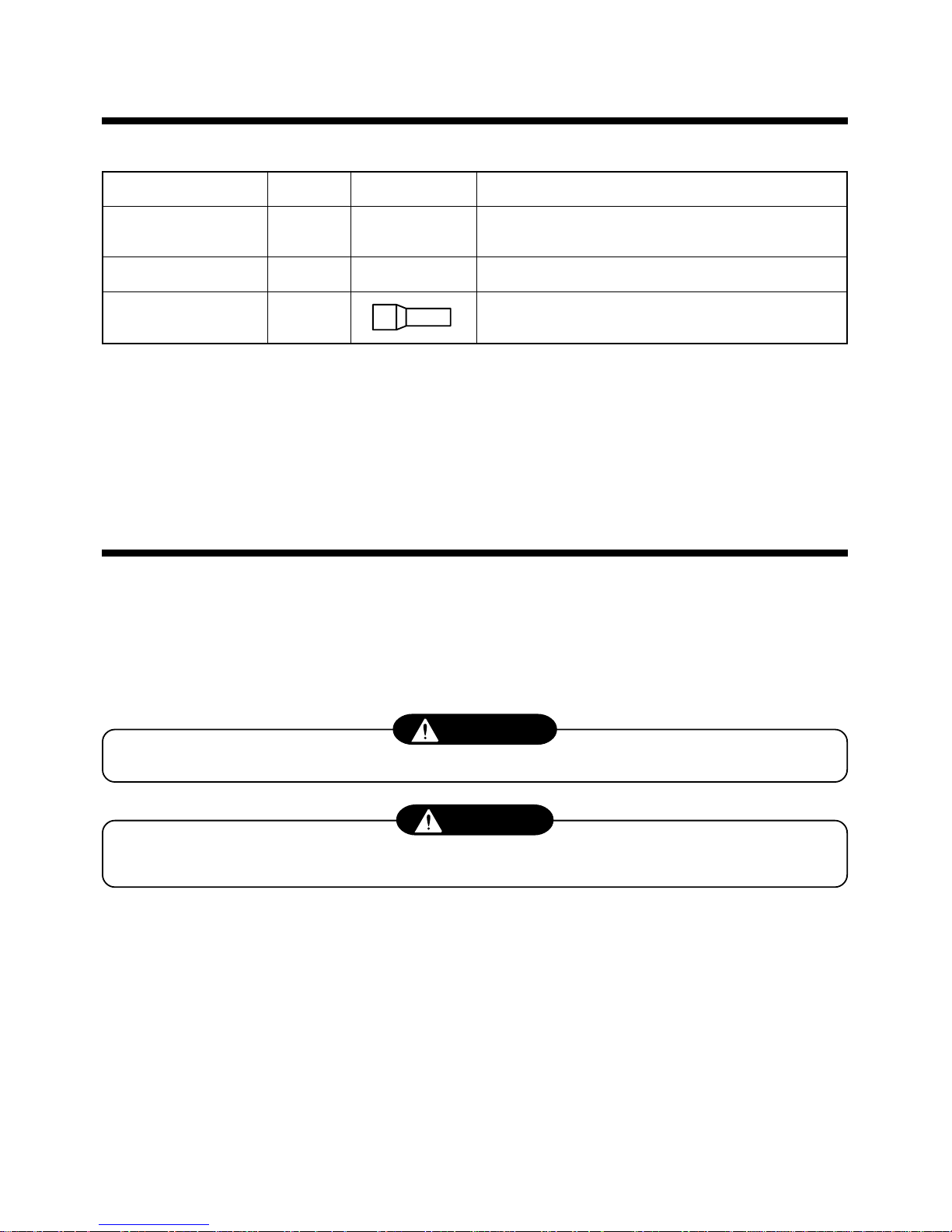

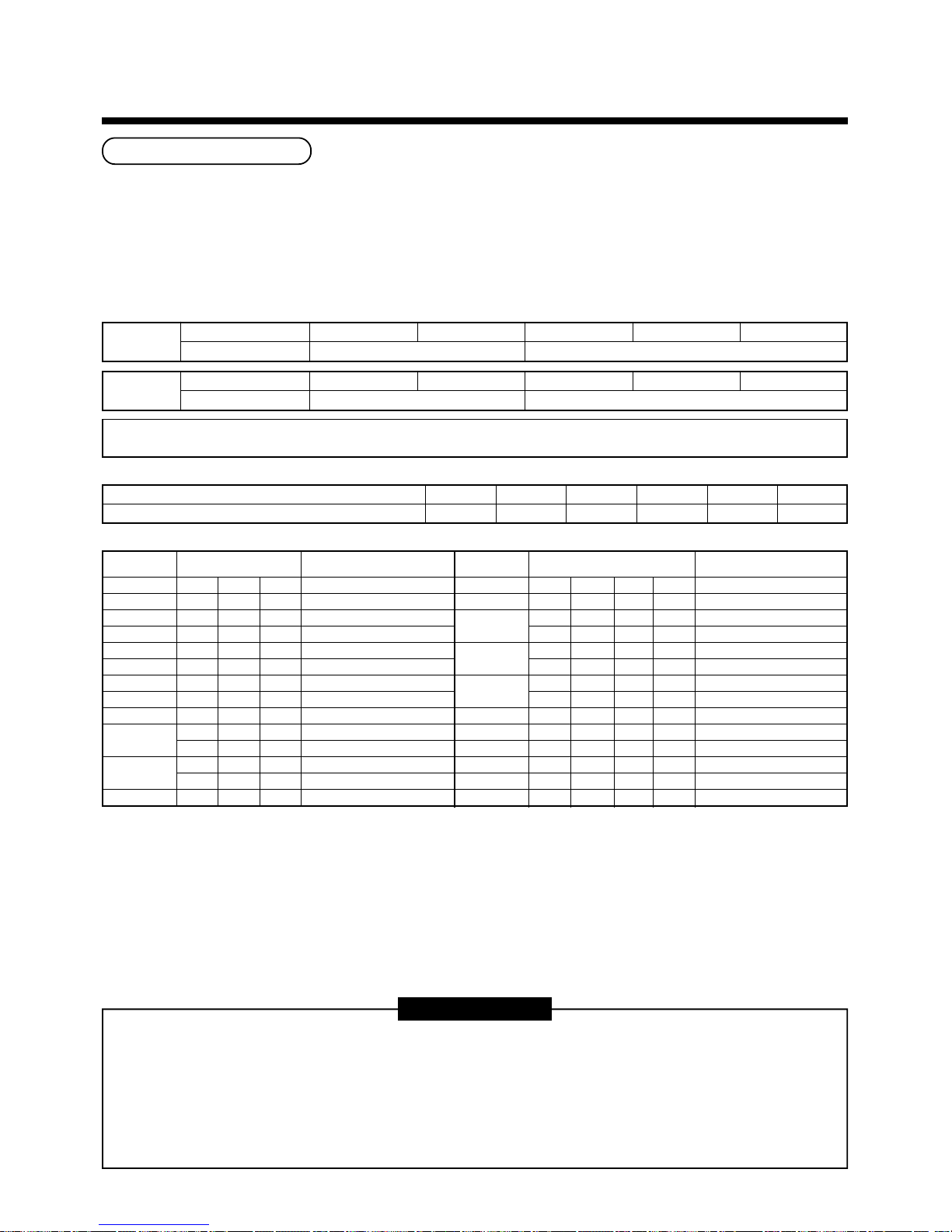

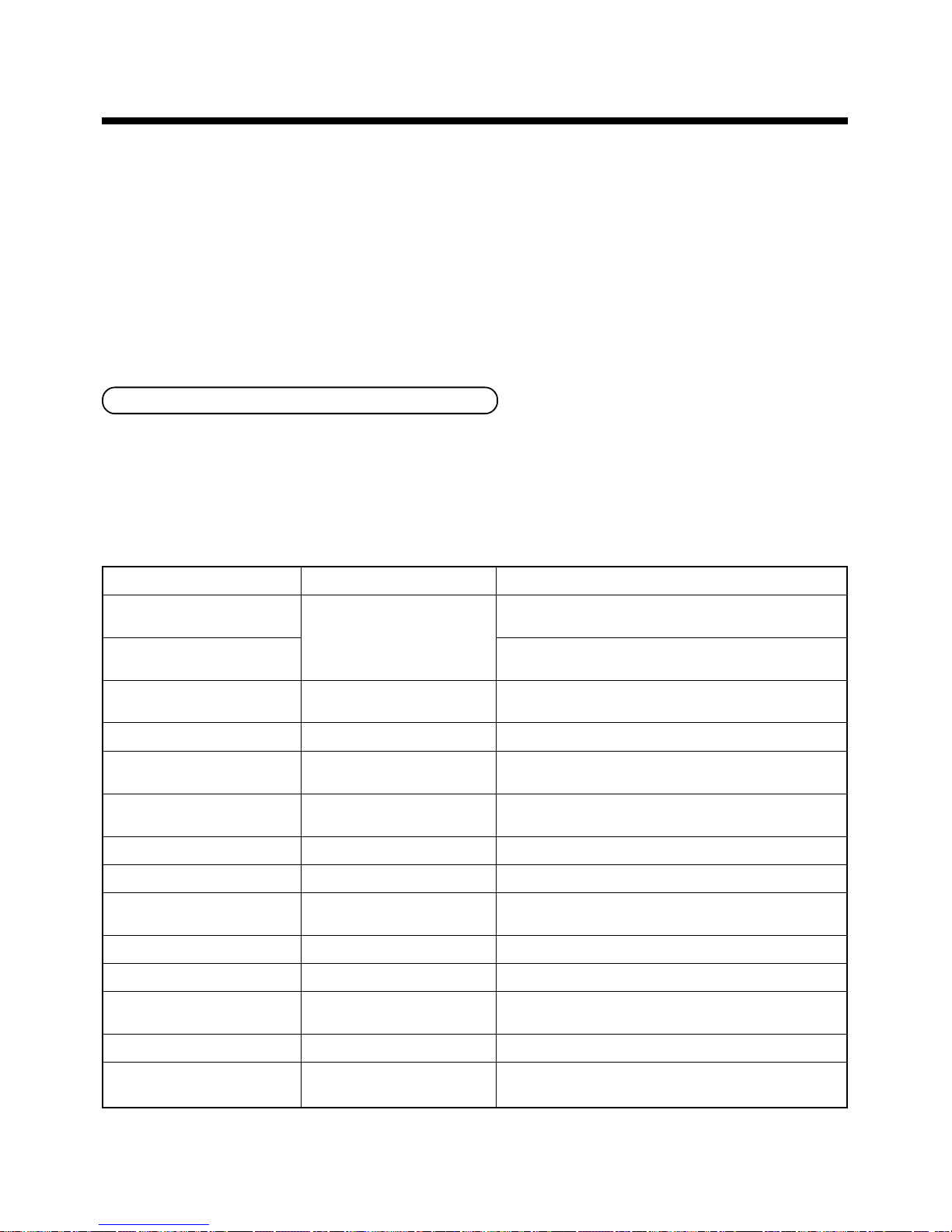

ACCESSORY PARTS

r Accessory parts

Part name

Installation Manual

Owner’s Manual

Attached pipes

Q’ty

2

1

Each 1

Shape

VOLUME-1

VOLUME-2

——

Usage

(Be sure to hand it to the customers.)

(Be sure to hand it to the customers.)

Connecting pipes for pipe at gas side

(Except MMY-MAP0501∗)

SAFETY CAUTION

• Please read this “Safety Cautions” thoroughly before installation to install the air conditioner

correctly.

• The important contents concerned to the safety are described in the “Safety Cautions”.

Be sure to keep them. For Indications and their meanings, see the following description.

n Explanation of indications

WARNING

Indicates possibilities that a death or serious injury of personnel is caused by an incorrect handling.

CAUTION

Indicates contents that an injury (∗1) or property damage (∗2) only may be caused when an incorrect work has

been executed.

∗1 : “Injury” means a hurt, a burn, or an electric shock which does not require hospitalization or a long-term going to

the hospital.

∗2 : “Property damage means an enlarged damage concerned to property, or breakage of materials.

• After installation work has finished, check there is no trouble by a test operation, and explain

using method and maintenance method to the customers based on the Owner’s Manual.

Please ask the customers to keep this Installation Manual together with the Owner’s Manual.

2

WARNING

Ask a shop or a professional dealer to install the air conditioner.

If you will install by yourself, a fire, an electric shock, or water leak is caused.

Using the tool or piping materials exclusive to R410A, install the air conditioner surely

according to this Installation Manual.

The pressure of the used HFC system R410A refrigerant is higher approx. 1.6 times of that of the former refrigerant.

If the exclusive piping materials are not used, or there is imperfection in installation, a crack or an injury is

caused and also a water leak, an electric shock, or a fire may be caused.

Take measures so that the refrigerant does not exceed the limit concentration even if it leaks

when installing the air conditioner in a small room.

For the measures not to exceed the limit of concentration, contact the dealer. If the refrigerant leaks and it

exceeds the limit of concentration, an accident of oxygen shortage is caused.

Install the air conditioner at a place which is satisfactorily bearable to weight.

If strength is insufficient, the unit may fall down resulting in human injury.

Perform a specified installation work against a strong wind such as typhoon or earthquake.

If the air conditioner is imperfectly installed, an accident by falling or dropping may be caused.

If refrigerant gas leaks during installation work, ventilate the room.

If the leaked refrigerant gas approaches to fire, noxious gas may generate.

After installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks in the room, and approaches to fire such as fan heater, stove or kitchen range,

generation of noxious gas may be caused.

Never recover refrigerant in the outdoor unit.

Be sure to use a refrigerant recovery device to recover refrigerant in reinstallation or repair work.

Recovery of refrigerant in the outdoor unit is unavailable; otherwise a serious accident such as crack or human

injury is caused.

A person qualified for the electric work should deal with the electric construction conforming

to the regulations of the local electric company and the Installation Manual. Be sure to use the

exclusive circuit.

If there is capacity shortage of the power supply circuit or incomplete installation, a fire or an electric shock is

caused.

For cabling, use the specified cables and connect them securely so that external force of

cable does not transmit to the terminal connecting section.

If connection or fixing is incomplete, a fire, etc may be caused.

Be sure to connect earth wire.

Do not connect earth wire to gas pipe, water pipe, lightning rod, nor earth wire of telephone.

If grounding is incomplete, an electric shock is caused.

CAUTION

Do not install the air conditioner at a place where combustible gas may leak.

If gas leaks and is collected at surrounding the unit, the production of fire may be caused.

Be sure to attach an earth leakage breaker; otherwise an electric shock may be caused.

Using a torque wrench, tighten the flare nut in the specified method.

If the flare nut is exceedingly tightened, the flare nut is broken and a refrigerant leakage may be caused after a

long time has passed.

ENGLISH

3

1

INSTALLATION OF NEW REFRIGERANT AIR CONDITIONER

This air conditioner adopts the new HFC refrigerant (R410A) which does not deplete the ozone layer.

• R410A refrigerant is apt to be affected by impurity such as water, oxidizing membrane, or oils because the

pressure of R410A refrigerant is higher than that of the former refrigerant by approx. 1.6 times. Accompanied with

adoption of the new refrigerant, refrigerating oil has been also changed. Therefore pay attention so that water,

dust, former refrigerant, or refrigerating oil does not enter into the refrigerating cycle of the new refrigerant air

conditioner during installation work.

• To prevent from mixing of refrigerant or refrigerating oil, the size of charge port of the main unit or connecting

section of installation tool differs from that of the air conditioner for the former refrigerant. Accordingly the

exclusive tools are required for the new refrigerant (R410A) as shown below.

• For connecting pipes, use the new and clean piping materials so that water or dust does not enter.

Required tools and cautions on handling

It is necessary to prepare the tools and parts as described below for the installation work.

The tools and parts which will be newly prepared in the following items should be restricted to the exclusive use.

Explanation of symbols

l

: Newly prepared (It is necessary to use it properly exclusive to R410A separated from those for R22 or R407C.)

¡ : Former tool is available.

Used tools

Gauge manifold

Charging hose

Charging cylinder

Gas leak detector

Vacuum pump

Vacuum pump with counter-

flow preventive adapter

Flare tool

Bender

Refrigerant recovery device

Torque wrench

Pipe cutter

Refrigerant cylinder

Welding machine/

Nitrogen gas cylinder

Refrigerant charging balance

Usage

Vacuuming or charging of

refrigerant and operation check

Charges refrigerant

Checks gas leak

Vacuum drying

Vacuum drying

Flare processing of pipes

Bending processing of pipes

Recovers refrigerant

Tightens flare nut

Cuts pipes

Charges refrigerant

Welding of pipes

Charges refrigerant

Proper use of tools/parts

l

Newly prepared, Exclusive to R410A

l

Newly prepared, Exclusive to R410A

Unusable (Use the Refrigerant charging balance.)

l

Newly prepared

Usable if a counter-flow preventive adapter is attached

¡

: R22 (Existing article)

¡

: Usable by adjusting size

¡

: R22 (Existing article)

l

Exclusive to R410A

l

Ø12.7mm, Exclusive for Ø15.9mm

¡

: R22 (Existing article)

l

Exclusive to R410A

ID : Refrigerant name entered

¡

: R22 (Existing article)

¡

: R22 (Existing article)

4

2

SELECTION OF INSTALLATION PLACE

WARNING

Install the air conditioner certainly at a place bearable to weight.

If strength is insufficient, the unit may fall down resulting in human injury.

CAUTION

Do not install the air conditioner at a place where combustible gas may leak.

If gas leaks and is collected at surrounding the unit, the production of fire may be caused.

Upon customer’s approval, install the air conditioner at a place where satisfies the following

conditions.

• Place where it can be installed horizontally.

• Place which can reserve a sufficient service space for safe maintenance or check.

• Place where there is no problem even if the drained water flows.

Apply electric insulation between metal section of the building and metal section of the air

conditioner in conformance with the Local Regulation.

Avoid the following places.

• Salty place (seaside area) or place with much gas sulfide (hot spring area)

(If selecting such a place, a special maintenance is required.)

• Place where oil (including machine oil), steam, oil smoke or corrosive gas generates.

• Place where a device generating high frequency (inverter, non-utility generator, medical apparatus, or

communication equipment) is set. (A bad influence may generate by malfunction of the air conditioner, control

error, or noise for such equipment.)

• Place where discharged air of the outdoor unit blows against windows of neighbor.

• Place where operation sound of the outdoor unit transmits.

(Especially at the boundary line with neighbor, install the air conditioner considering the noise.)

• Place unbearable to weight of the unit.

• Place with ill ventilation.

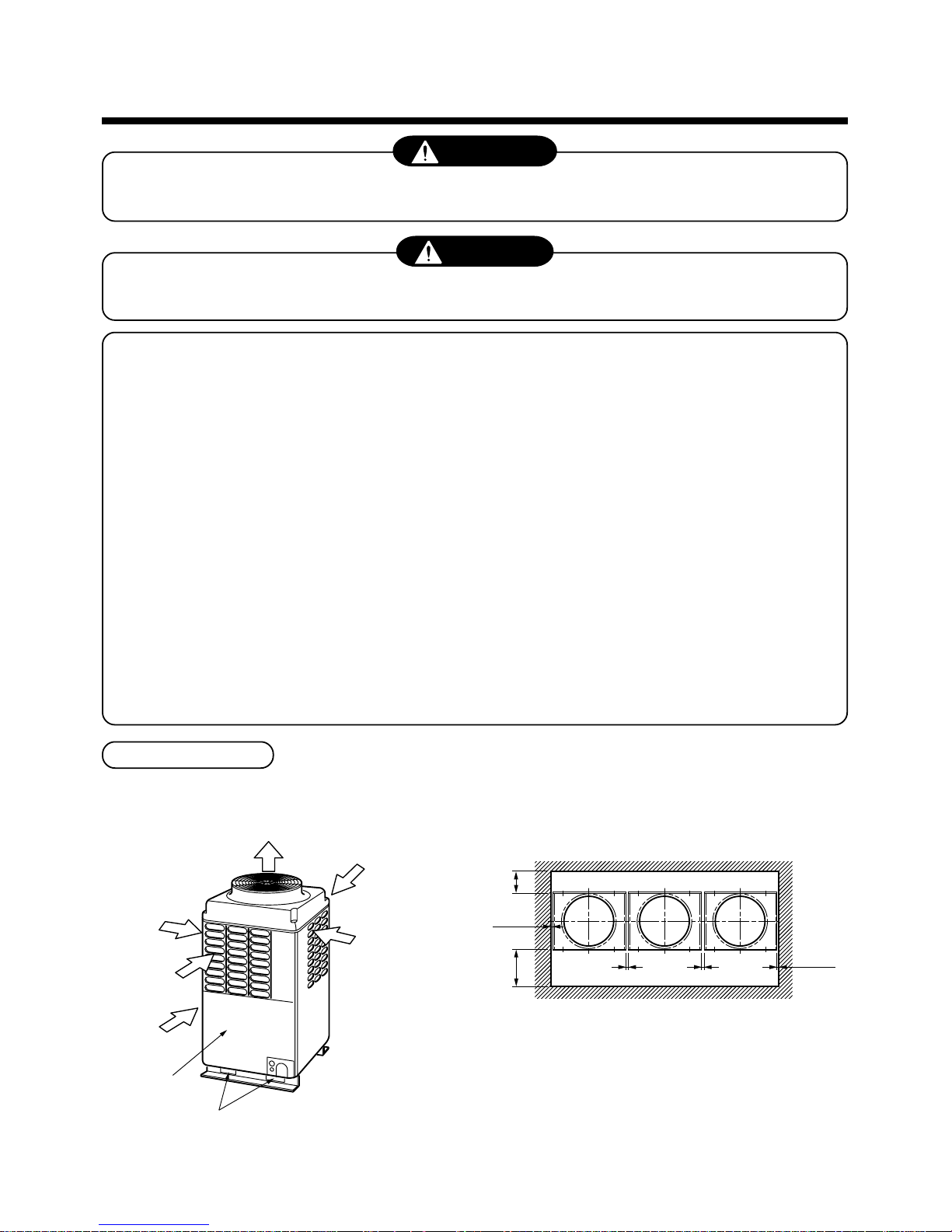

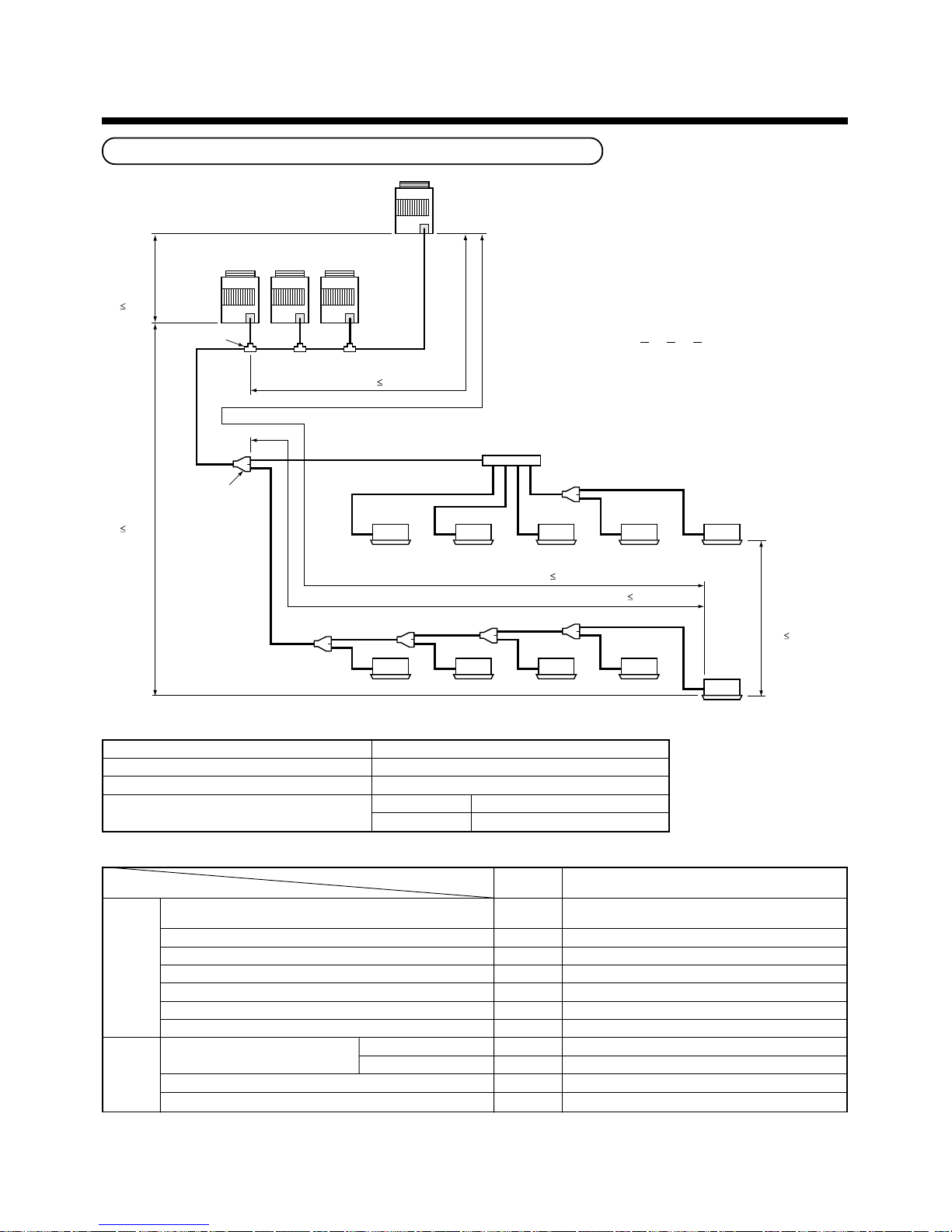

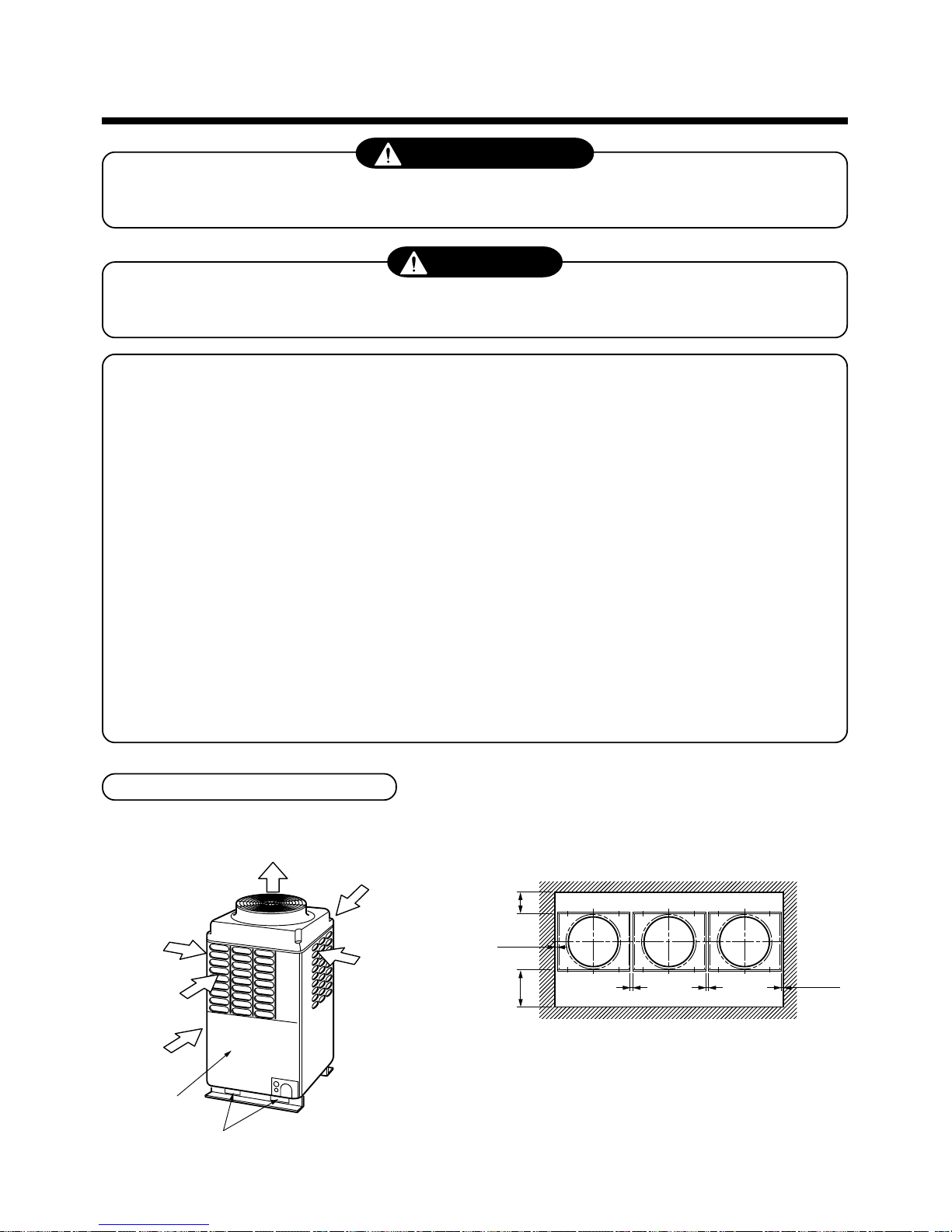

Installation space

Considering functions, reserve space necessary for installation work and servicing.

NOTES)

∗1 : If there is an obstacle at the upper side of the outdoor unit, reserve

a space by 2000mm or more to the top end of the outdoor unit.

∗2 : Arrange the height of obstacle around two outdoor units up to

below 800mm from the bottom end of the outdoor unit.

(Rear side)

(Front side)

(A case of 3 units are installed.)

500mm or more

500mm or more

10mm

or more

10mm

or more

20mm or more

20mm or more

Air outlet

Air inlet

Air inlet

Outdoor unit top view

Installation work/

servicing surface

Square hole for handling

Air inlet

Air inlet

5

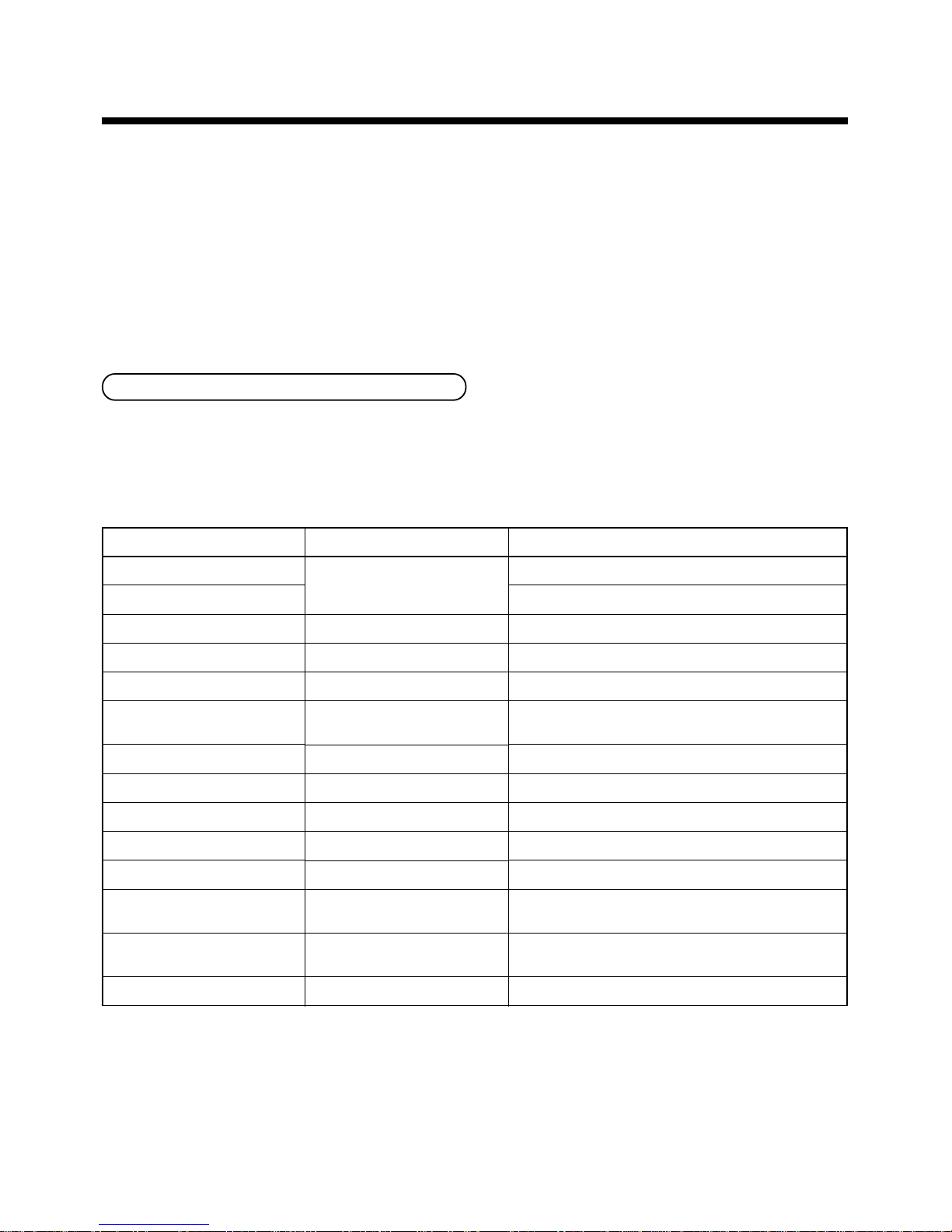

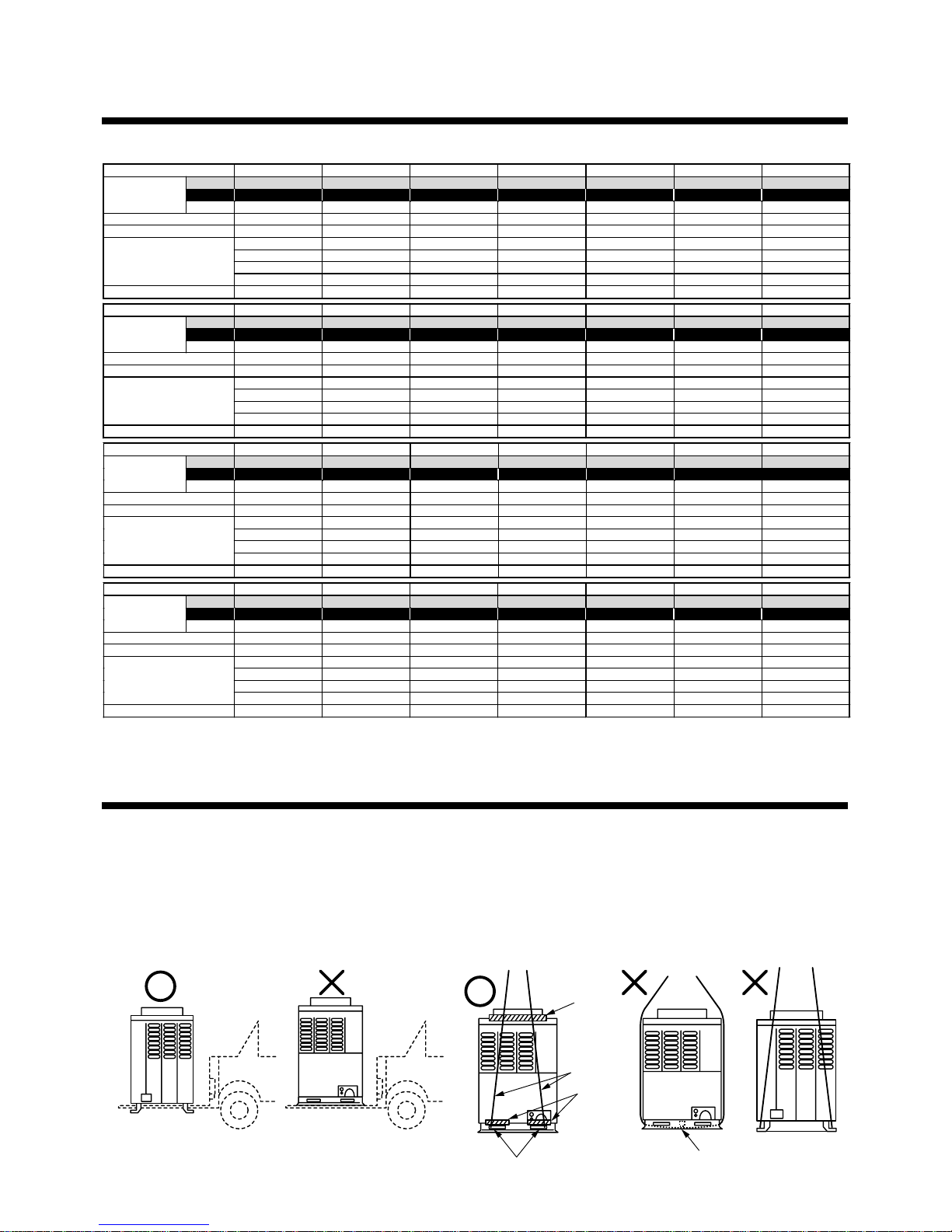

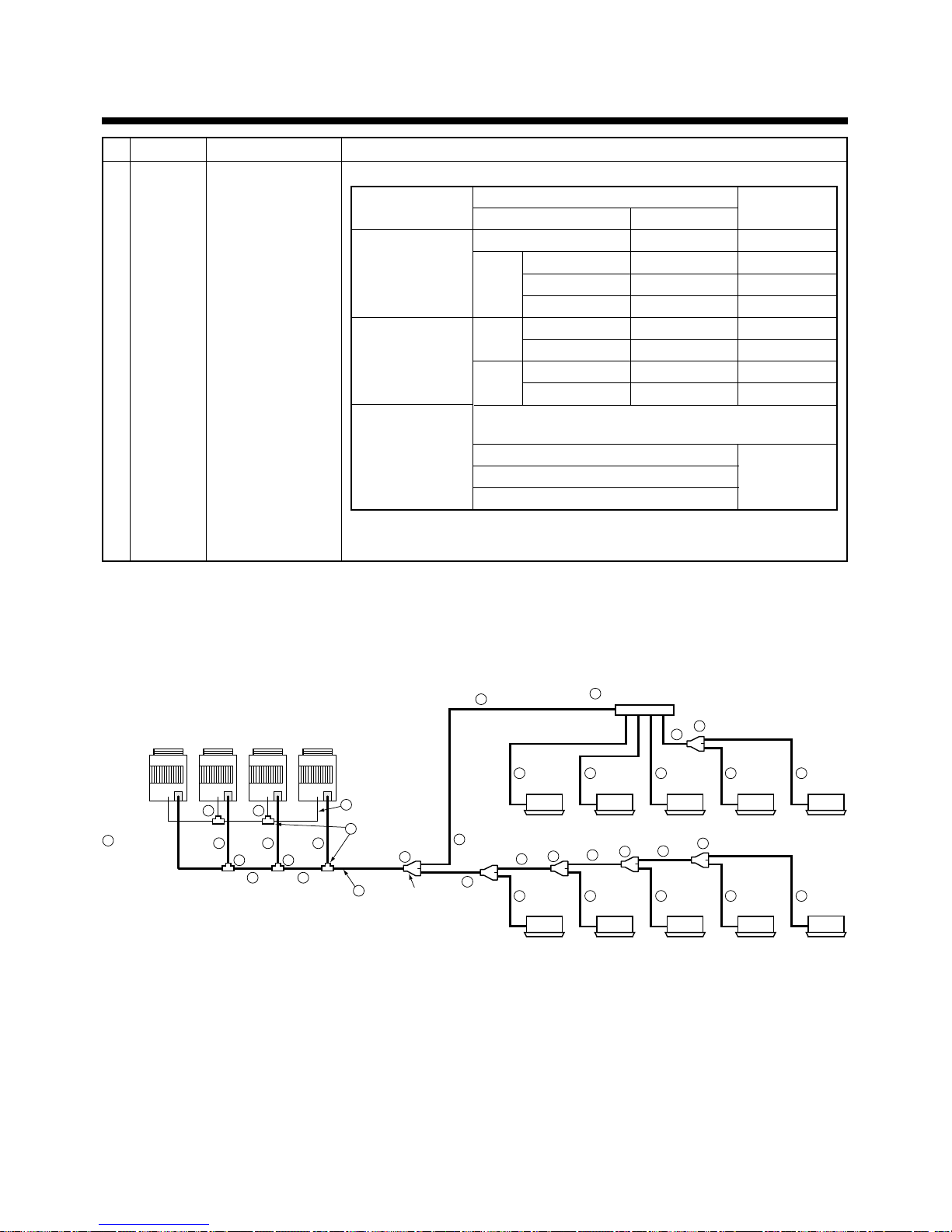

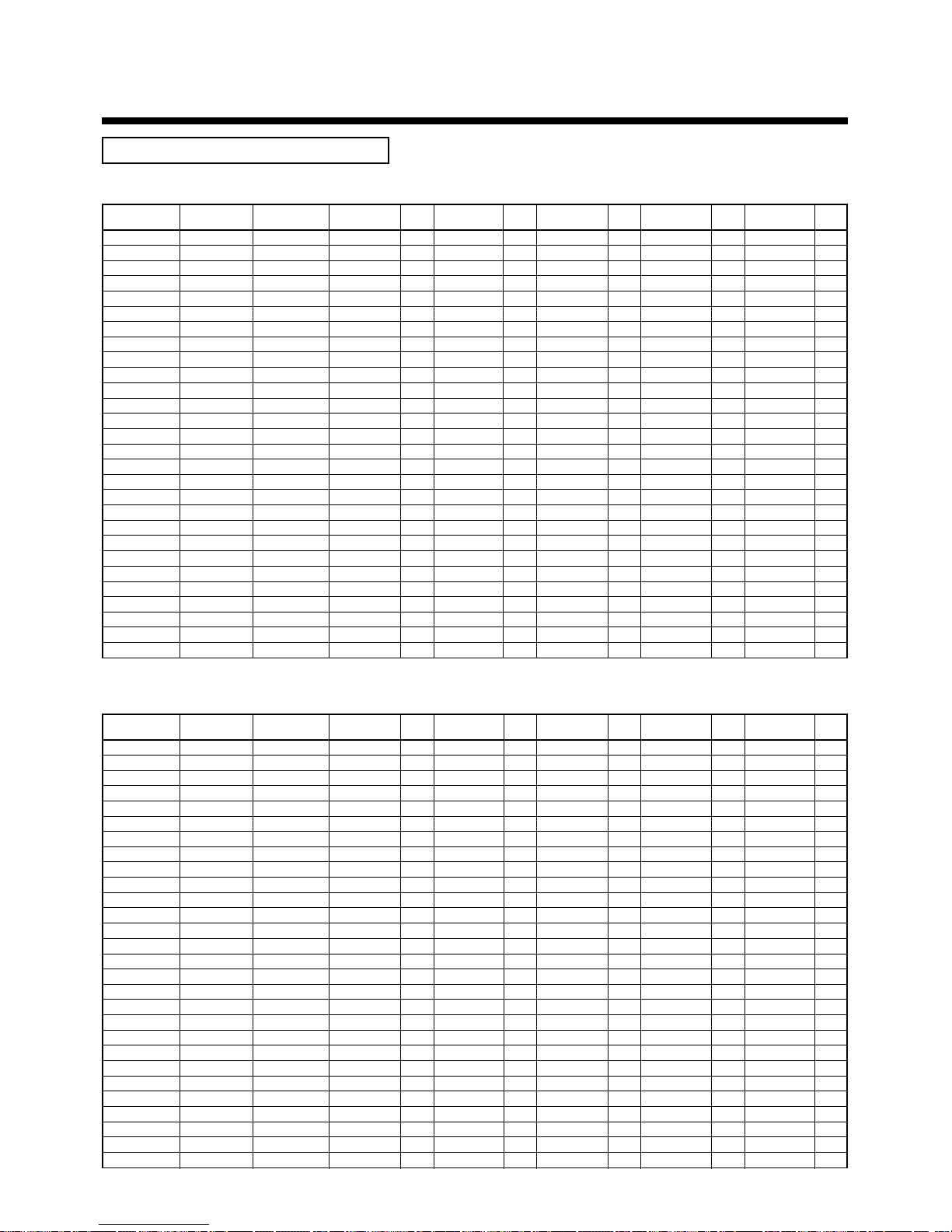

Combination of outdoor unit

Cooling Only Model

Heat-pump Model (50Hz)

HP

(Capacity code)

5HP ( 5)

6HP ( 6)

8HP ( 8)

10HP (10)

12HP (12)

14HP (14)

16HP (16)

18HP (18)

20HP (20)

22HP (22)

22HP (22)

24HP (24)

24HP (24)

26HP (26)

28HP (28)

30HP (30)

32HP (32)

32HP (32)

34HP (34)

34HP (34)

36HP (36)

36HP (36)

38HP (38)

40HP (40)

42HP (42)

44HP (44)

46HP (46)

48HP (46)

Model name

MMY-

MAP0501T8

MAP0601T8

MAP0801T8

MAP1001T8

MAP1201T8

AP1401T8

AP1601T8

AP1801T8

AP2001T8

AP2201T8

AP2211T8

AP2401T8

AP2411T8

AP2601T8

AP2801T8

AP3001T8

AP3201T8

AP3211T8

AP3401T8

AP3411T8

AP3601T8

AP3611T8

AP3801T8

AP4001T8

AP4201T8

AP4401T8

AP4601T8

AP4801T8

No. of

combined units

1

1

1

1

1

2

2

2

2

3

2

3

2

3

3

3

4

3

4

3

4

3

4

4

4

4

4

4

Inverter 5HP Used Inverter 6HP Used Inverter 8HP Used Inverter 10HP Used Inverter 12HP Used

MMY- Q’ty MMY- Q’ty MMY- Q’ty MMY- Q’ty MMY- Q’ty

MAP0501T8 1

MAP0601T8 1

MAP0801T8 1

MAP1001T8 1

MAP1201T8 1

MAP0601T8 1 MAP0801T8 1

MAP0801T8 2

MAP0801T8 1 MAP1001T8 1

MAP1001T8 2

MAP0601T8 1 MAP0801T8 2

MAP1001T8 1 MAP1201T8 1

MAP0801T8 3

MAP1201T8 2

MAP0801T8 2 MAP1001T8 1

MAP0801T8 1 MAP1001T8 2

MAP1001T8 3

MAP0801T8 4

MAP1001T8 2 MAP1201T8 1

MAP0801T8 3 MAP1001T8 1

MAP1001T8 1 MAP1201T8 2

MAP0801T8 2 MAP1001T8 2

MAP1201T8 3

MAP0801T8 1 MAP1001T8 3

MAP1001T8 4

MAP1001T8 3 MAP1201T8 1

MAP1001T8 2 MAP1201T8 2

MAP1001T8 1 MAP1201T8 3

MAP1201T8 4

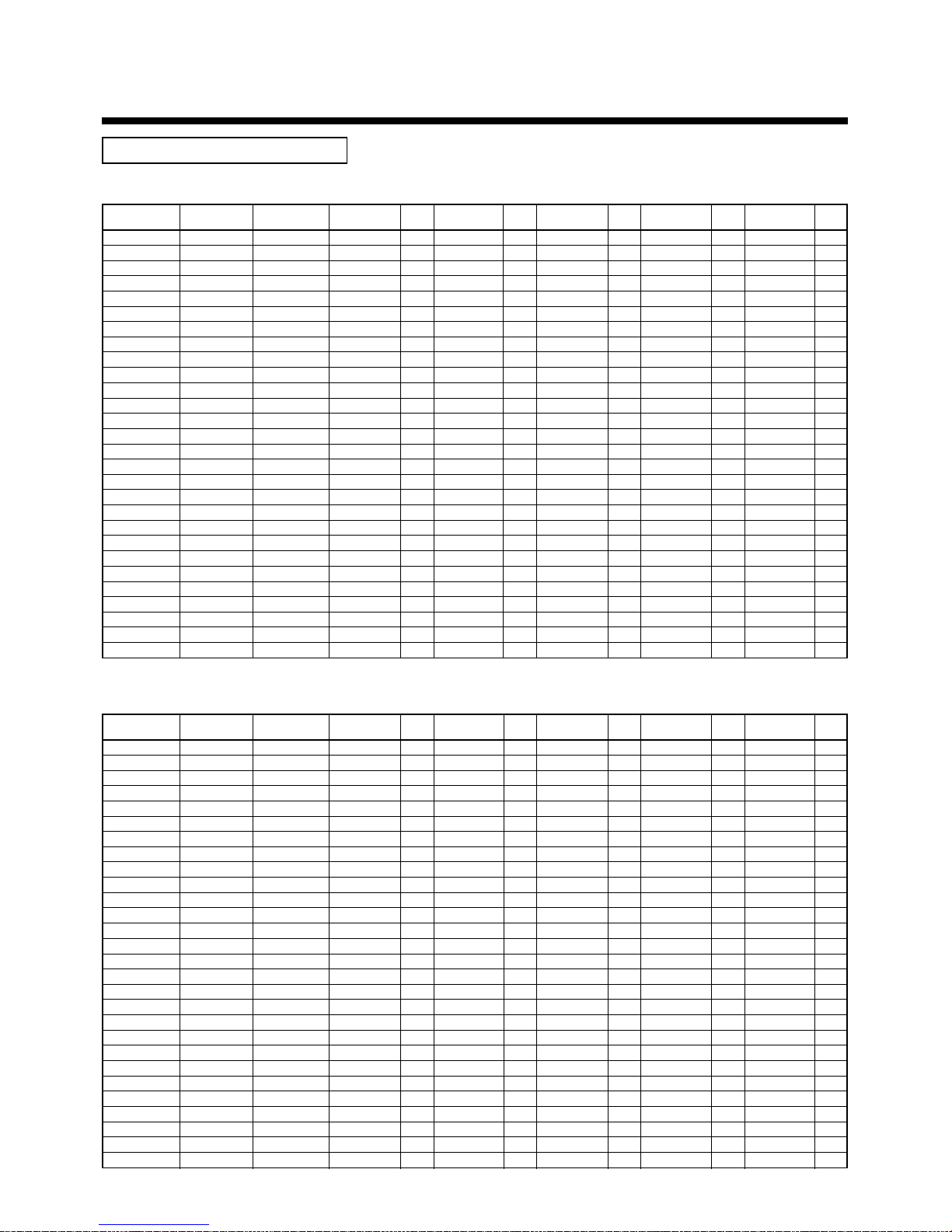

HP

(Capacity code)

5HP ( 5)

6HP ( 6)

8HP ( 8)

10HP (10)

12HP (12)

14HP (14)

16HP (16)

18HP (18)

20HP (20)

22HP (22)

22HP (22)

24HP (24)

24HP (24)

26HP (26)

28HP (28)

30HP (30)

32HP (32)

32HP (32)

34HP (34)

34HP (34)

36HP (36)

36HP (36)

38HP (38)

40HP (40)

42HP (42)

44HP (44)

46HP (46)

48HP (46)

Model name

MMY-

MAP0501HT8

MAP0601HT8

MAP0801HT8

MAP1001HT8

MAP1201HT8

AP1401HT8

AP1601HT8

AP1801HT8

AP2001HT8

AP2201HT8

AP2211HT8

AP2401HT8

AP2411HT8

AP2601HT8

AP2801HT8

AP3001HT8

AP3201HT8

AP3211HT8

AP3401HT8

AP3411HT8

AP3601HT8

AP3611HT8

AP3801HT8

AP4001HT8

AP4201HT8

AP4401HT8

AP4601HT8

AP4801HT8

No. of

combined units

1

1

1

1

1

2

2

2

2

3

2

3

2

3

3

3

4

3

4

3

4

3

4

4

4

4

4

4

Inverter 5HP Used Inverter 6HP Used Inverter 8HP Used Inverter 10HP Used Inverter 12HP Used

MMY- Q’ty MMY- Q’ty MMY- Q’ty MMY- Q’ty MMY- Q’ty

MAP0501HT8 1

MAP0601HT8 1

MAP0801HT8 1

MAP1001HT8 1

MAP1201HT8 1

MAP0601HT8 1 MAP0801HT8 1

MAP0801HT8 2

MAP0801HT8 1 MAP1001HT8 1

MAP1001HT8 2

MAP0601HT8 1 MAP0801HT8 2

MAP1001HT8 1 MAP1201HT8 1

MAP0801HT8 3

MAP1201HT8 2

MAP0801HT8 2 MAP1001HT8 1

MAP0801HT8 1 MAP1001HT8 2

MAP1001HT8 3

MAP0801HT8 4

MAP1001HT8 2 MAP1201HT8 1

MAP0801HT8 3 MAP1001HT8 1

MAP1001HT8 1 MAP1201HT8 2

MAP0801HT8 2 MAP1001HT8 2

MAP1201HT8 3

MAP0801HT8 1 MAP1001HT8 3

MAP1001HT8 4

MAP1001HT8 3 MAP1201HT8 1

MAP1001HT8 2 MAP1201HT8 2

MAP1001HT8 1 MAP1201HT8 3

MAP1201HT8 4

2

SELECTION OF INSTALLATION PLACE

6

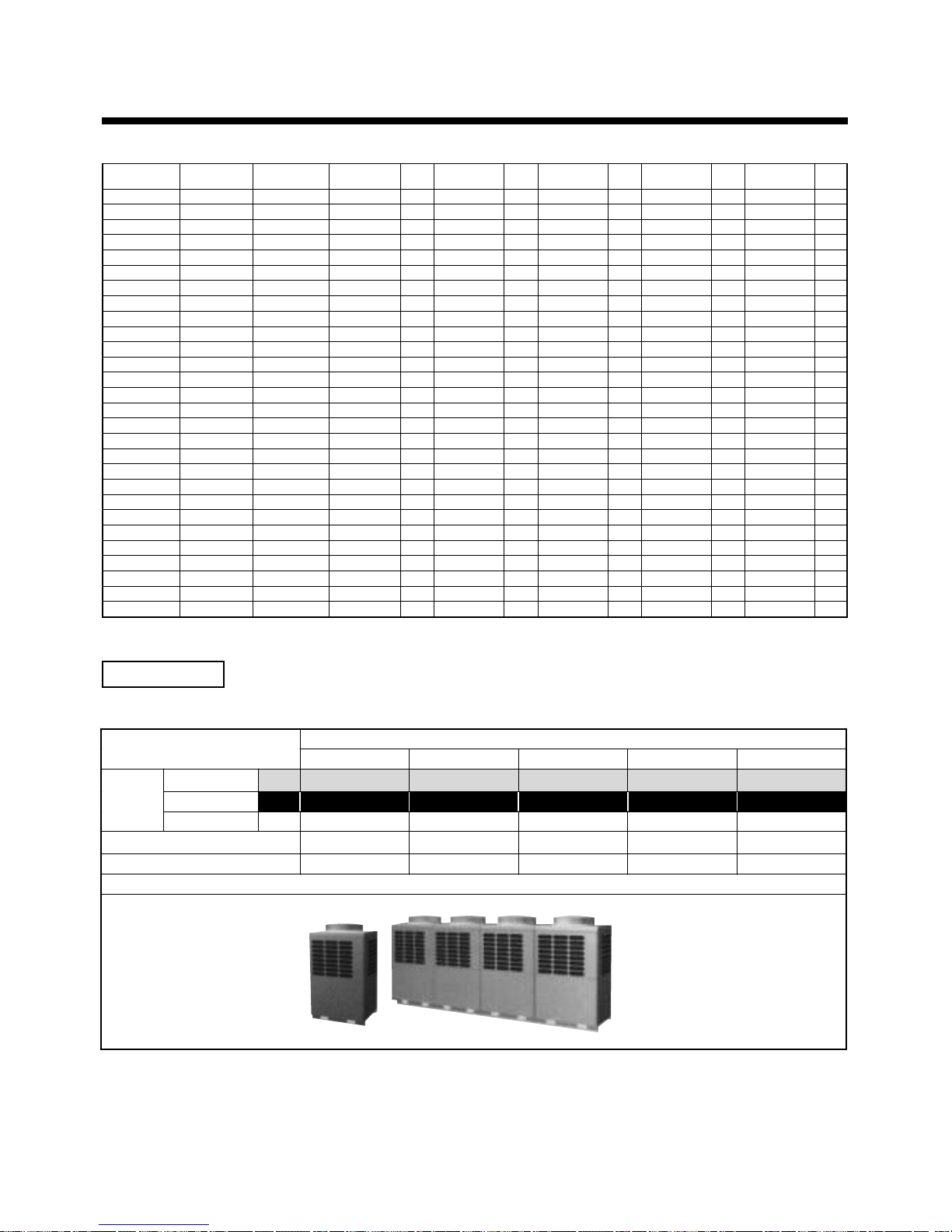

Heat-pump Model (60Hz)

HP

(Capacity code)

5HP ( 5)

6HP ( 6)

8HP ( 8)

10HP (10)

12HP (12)

14HP (14)

16HP (16)

18HP (18)

20HP (20)

22HP (22)

22HP (22)

24HP (24)

24HP (24)

26HP (26)

28HP (28)

30HP (30)

32HP (32)

32HP (32)

34HP (34)

34HP (34)

36HP (36)

36HP (36)

38HP (38)

40HP (40)

42HP (42)

44HP (44)

46HP (46)

48HP (46)

Model name

MMY-

MAP0501HT7

MAP0601HT7

MAP0801HT7

MAP1001HT7

MAP1201HT7

AP1401HT7

AP1601HT7

AP1801HT7

AP2001HT7

AP2201HT7

AP2211HT7

AP2401HT7

AP2411HT7

AP2601HT7

AP2801HT7

AP3001HT7

AP3201HT7

AP3211HT7

AP3401HT7

AP3411HT7

AP3601HT7

AP3611HT7

AP3801HT7

AP4001HT7

AP4201HT7

AP4401HT7

AP4601HT7

AP4801HT7

No. of

combined units

1

1

1

1

1

2

2

2

2

3

2

3

2

3

3

3

4

3

4

3

4

3

4

4

4

4

4

4

Inverter 5HP Used Inverter 6HP Used Inverter 8HP Used Inverter 10HP Used Inverter 12HP Used

MMY- Q’ty MMY- Q’ty MMY- Q’ty MMY- Q’ty MMY- Q’ty

MAP0501HT7 1

MAP0601HT7 1

MAP0801HT7 1

MAP1001HT7 1

MAP1201HT7 1

MAP0601HT7 1 MAP0801HT7 1

MAP0801HT7 2

MAP0801HT7 1 MAP1001HT7 1

MAP1001HT7 2

MAP0601HT7 1 MAP0801HT7 2

MAP1001HT7 1 MAP1201HT7 1

MAP0801HT7 3

MAP1201HT7 2

MAP0801HT7 2 MAP1001HT7 1

MAP0801HT7 1 MAP1001HT7 2

MAP1001HT7 3

MAP0801HT7 4

MAP1001HT7 2 MAP1201HT7 1

MAP0801HT7 3 MAP1001HT7 1

MAP1001HT7 1 MAP1201HT7 2

MAP0801HT7 2 MAP1001HT7 2

MAP1201HT7 3

MAP0801HT7 1 MAP1001HT7 3

MAP1001HT7 4

MAP1001HT7 3 MAP1201HT7 1

MAP1001HT7 2 MAP1201HT7 2

MAP1001HT7 1 MAP1201HT7 3

MAP1201HT7 4

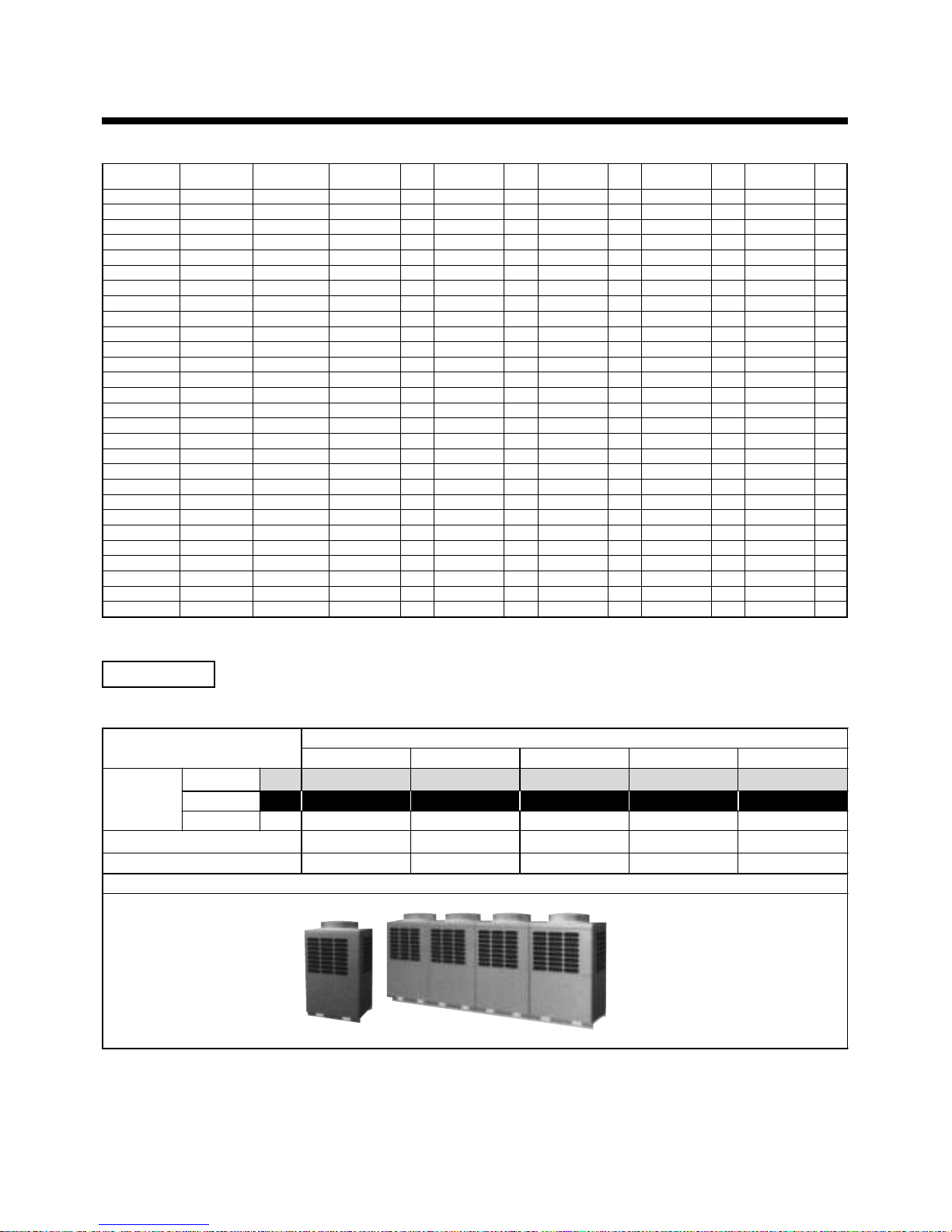

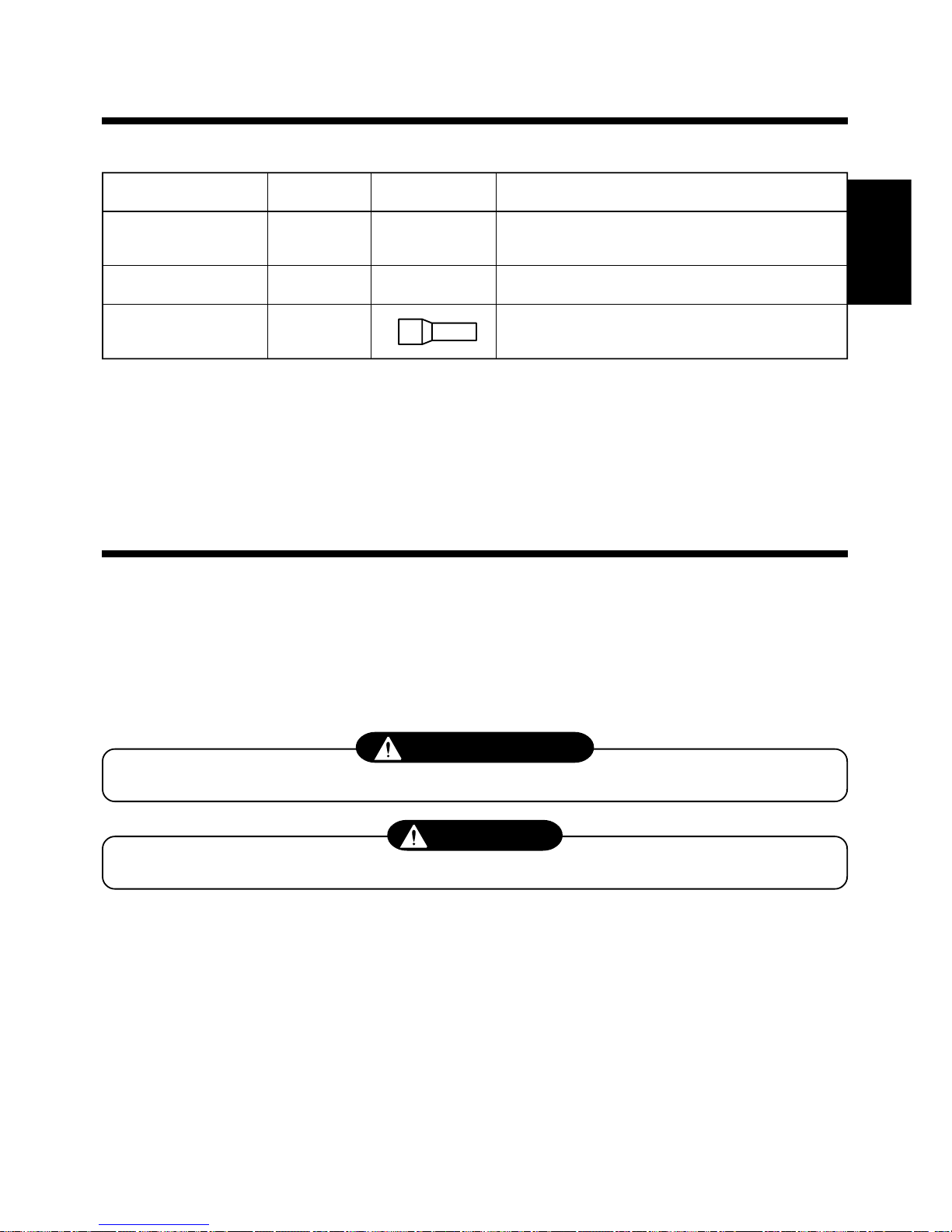

Inverter unit

Corresponding HP

5 HP 6 HP 8 HP 10 HP 12 HP

Heat pump

MMY- MAP0501HT8 MAP0601HT8 MAP0801HT8 MAP1001H8 MAP1201HT8

Heat pump

MMY- MAP0501HT7 MAP0601HT7 MAP0801HT7 MAP1001HT7 MAP1201HT7

Model name

Cooling only

MMY- MAP0501T8 MAP0601T8 MAP0801T8 MAP1001T8 MAP1201T8

Cooling capacity (kW) 14.0 16.0 22.4 28.0 33.5

Heating capacity (kW) 16.0 18.0 25.0 31.5 37.5

Appearance

Equipments

1. Outdoor units

7

3

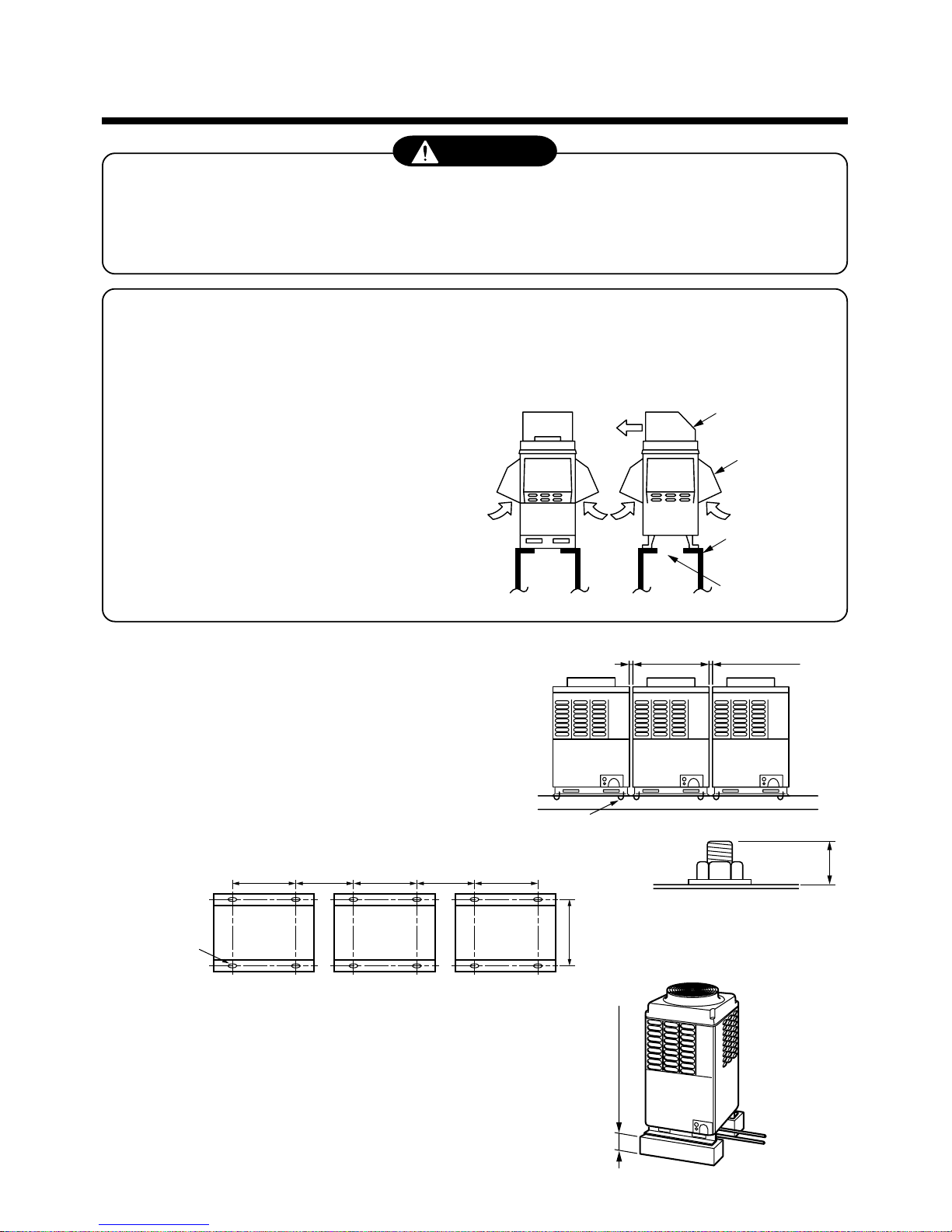

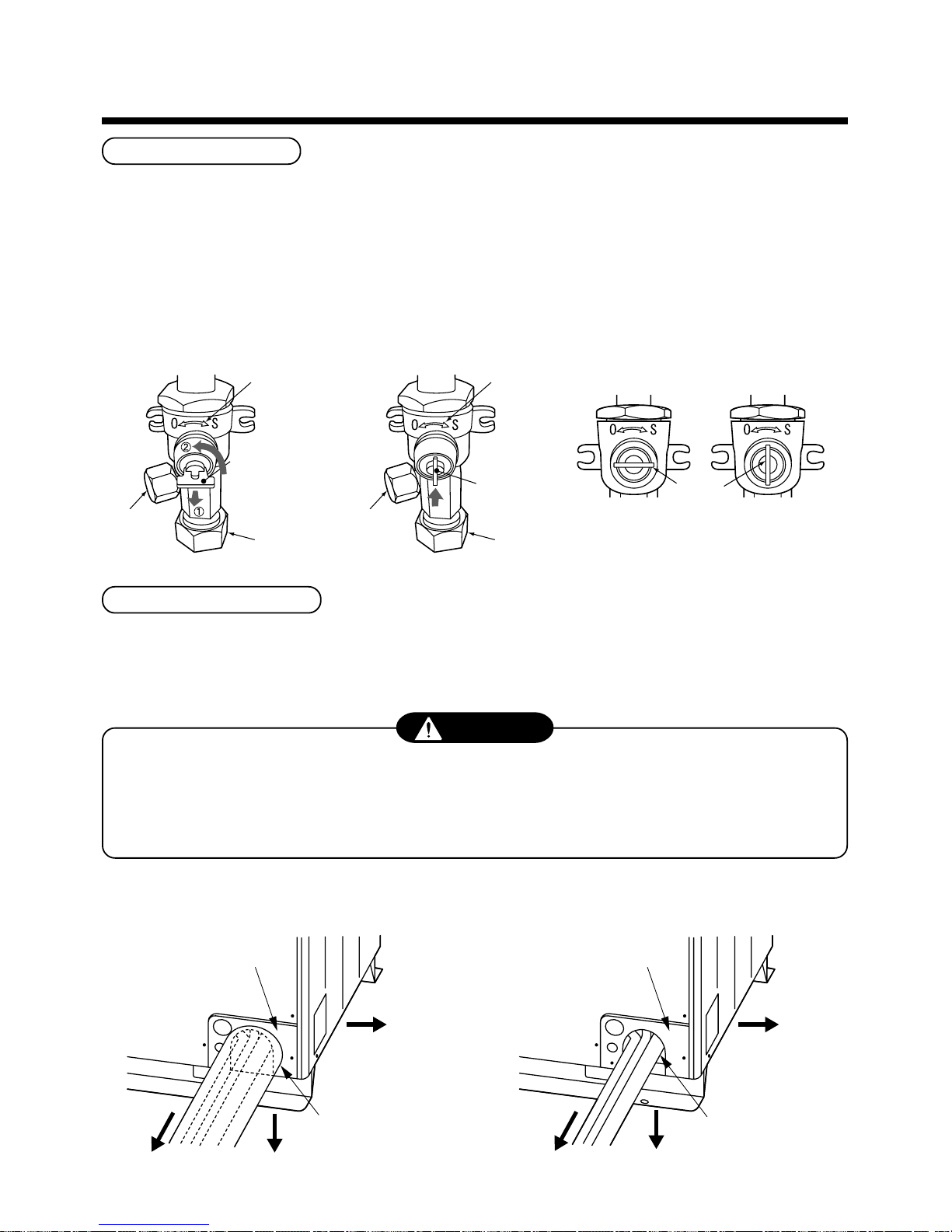

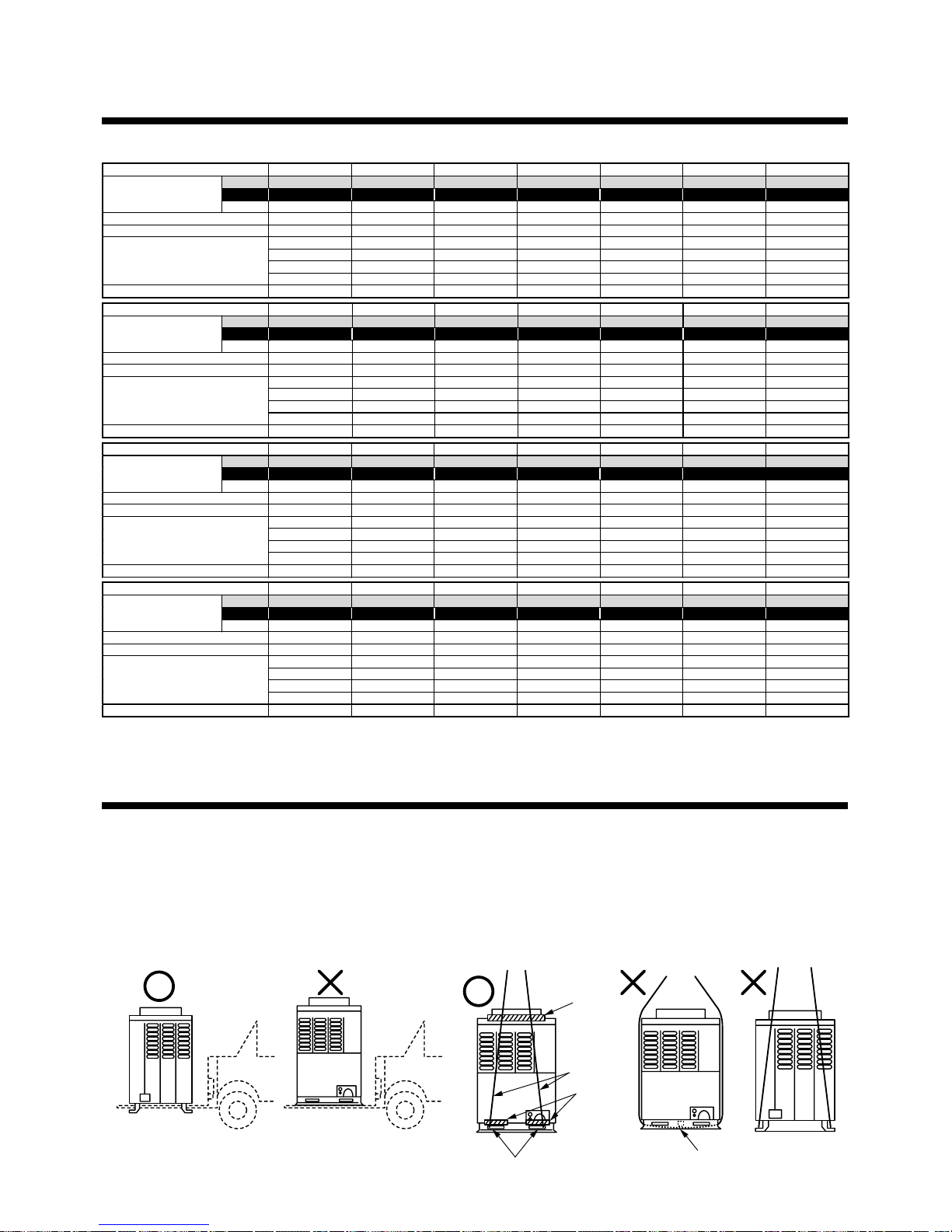

OUTDOOR UNIT CARRYING IN

Handle the outdoor unit in care with the following items.

1. When using a forklift, etc for loading/unloading in transportation, insert pawl of the forklift into the

square hole for handling as shown below.

2. When lifting up the unit, insert a rope sufficiently bearable to unit mass into the square hole for handling,

and cord the unit from four sides. (Apply a plaster to position where rope fits outdoor unit itself so that

flaw or deformation does not generate on the outer surface of the outdoor unit.)

(There provided the reinforcing plates on the side surfaces, so the rope cannot be passed.)

Corresponding HP 5 HP 6 HP 8 HP 10 HP 12 HP 14 HP 16 HP

MMY- MAP0501HT8 MAP0601HT8 MAP0801HT8 MAP1001HT8 MAP1201HT8 AP1401HT8 AP1601HT 8

MMY- MAP0501HT7 MAP0601HT7 MAP0801HT7 MAP1001HT7 MAP1201HT7 AP1401HT7 AP1601HT 7

Combined Model

MMY- MAP0501T8 MAP0601T8 MAP0801T8 MAP1001T8 MAP1201T8 AP1401T8 AP1601T8

Cooling capacity (kW) 14.0 16.0 22.4 28.0 33.5 38.4 45.0

Heating ca pa cit y (kW ) 16.0 18.0 25.0 31.5 37.5 43.0 50.0

5 HP 6 HP 8 HP 10 HP 12 HP 8 HP 8 H P

—————6 HP 8 HP

———————

Combined outdoor units

———————

No. of connectable indoor units 8 10 13 16 20 23 27

Corresponding HP 18 HP 20 HP 22 HP 22 HP 24 HP 24 HP 26 HP

MMY- AP1801HT 8 AP2001HT8 AP2201HT8 AP2211 HT8 AP2401HT8 AP2411HT8 AP2601 HT8

MMY- AP1801HT 7 AP2001HT7 AP2201HT7 AP2211 HT7 AP2401HT7 AP2411HT7 AP2601 HT7

Combined Model

MMY- AP1801T8 AP2001T8 AP2201T8 AP2211T8 AP2401T8 AP2411T8 AP2601T8

Cooling capacity (kW) 50.4 56.0 61.5 61.5 68.0 68.0 73.0

Heating ca pa cit y (kW ) 56.5 63.0 69.0 69.0 76.5 76.5 81.5

10 HP 10 HP 8 HP 12 HP 8 HP 12 HP 10 HP

8 HP 10 HP 8 HP 10 HP 8 HP 12 HP 8 HP

——6 HP — 8 HP — 8 HP

Combined outdoor units

———————

No. of connectable indoor units 30 33 37 37 40 40 43

Corresponding HP 28 HP 30 HP 32 HP 32 HP 34 HP 34 HP 36 HP

MMY- AP2801HT8 AP3001 HT8 AP3201HT8 AP3211HT8 AP3401HT 8 AP3411HT8 AP3601HT8

MMY- AP2801HT7 AP3001 HT7 AP3201HT7 AP3211HT7 AP3401HT 7 AP3411HT7 AP3601HT7

Combined Model

MMY-

AP2801T8 AP3001T8 AP3201T8 AP3211T8 AP3401T8 AP3411T8 AP3601T8

Cooling capacity (kW) 78.5 84. 0 90.0 90. 0 96.0 96. 0 101.0

Heat i n g c a pa c i t y (k W) 8 8.0 95.0 100.0 100.0 108.0 108.0 113.0

10 HP 10 HP 8 HP 12 HP 10 HP 12 HP 10 HP

10 HP 10 HP 8 HP 10 HP 8 HP 12 HP 10 HP

8 HP 10 HP 8 HP 10 HP 8 HP 10 HP 8 HP

Combined outdoor units

——8 HP — 8 HP — 8 HP

No. of connectable indoor units 47 48 48 48 48 48 48

Corresponding HP 36 HP 38 HP 40 HP 42 HP 44 HP 46 HP 48 HP

MMY- AP3611HT 8 AP3801HT8 AP4001HT8 AP4201 HT8 AP4401HT8 AP4601HT8 AP4801 HT8

MMY- AP3611HT 7 AP3801HT7 AP4001HT7 AP4201 HT7 AP4401HT7 AP4601HT7 AP4801 HT7

Combined Model

MMY-

AP3611T8 AP3801T8 AP4001T8 AP4201T8 AP4401T8 AP4601T8 AP4801T8

Cooling capacity (kW) 101.0 106.5 112.0 118.0 123.5 130.0 135.0

Heat i n g c a pa c i t y (k W) 113.0 119.5 126.5 132.0 138.0 145.0 150.0

12 HP 10 HP 10 HP 12 HP 12 HP 12 HP 12 HP

12 HP 10 HP 10 HP 10 HP 12 HP 12 HP 12 HP

12 HP 10 HP 10 HP 10 HP 10 HP 12 HP 12 HP

Combined outdoor units

— 8 HP 10 HP 10 HP 10 HP 10 HP 12 HP

No. of connectable indoor units 48 48 48 48 48 48 48

2. Outdoor units (Combination of outdoor units)

Plaster

Rope

Plaster

Square hole for handling

Reinforcing plate

Forklift Forklift

2

SELECTION OF INSTALLATION PLACE

8

4

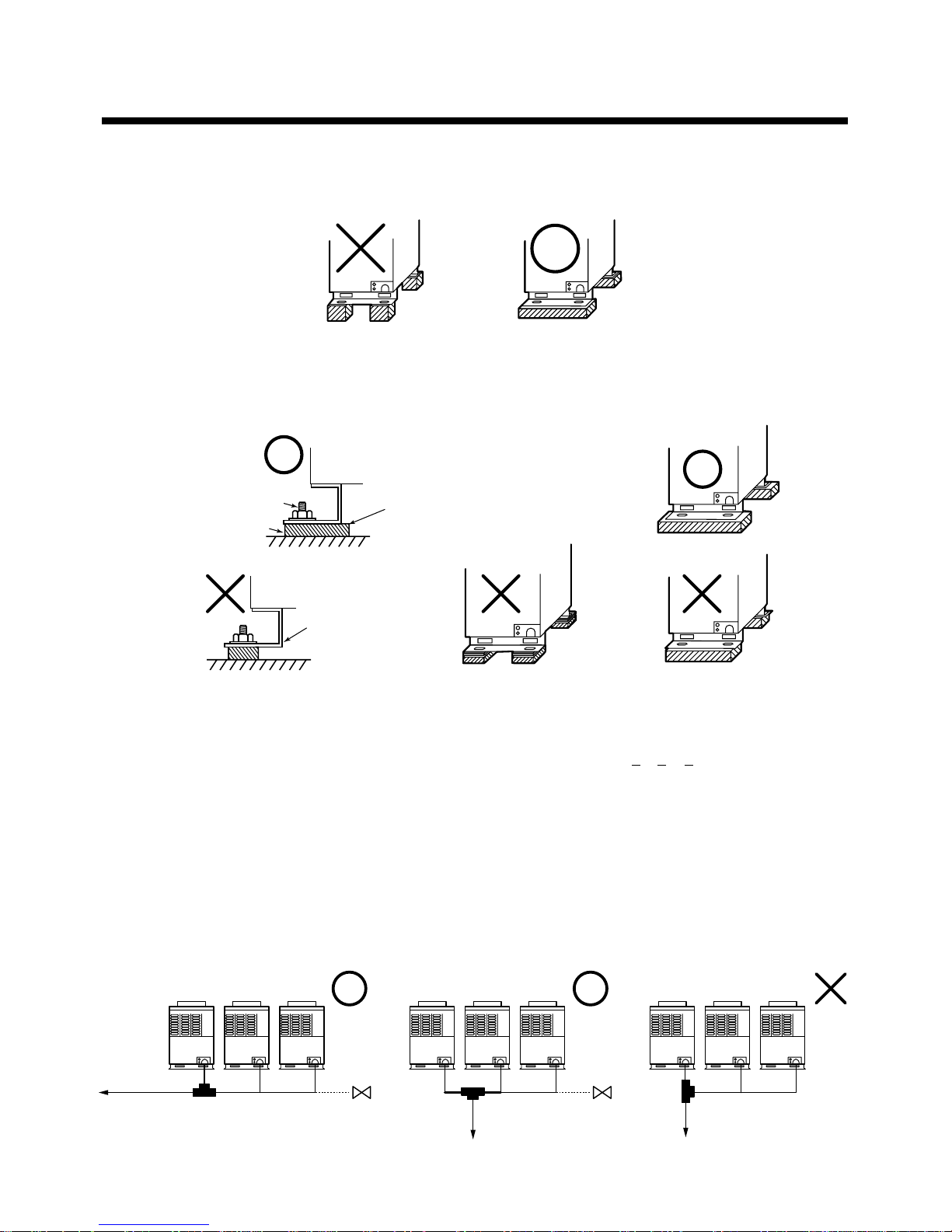

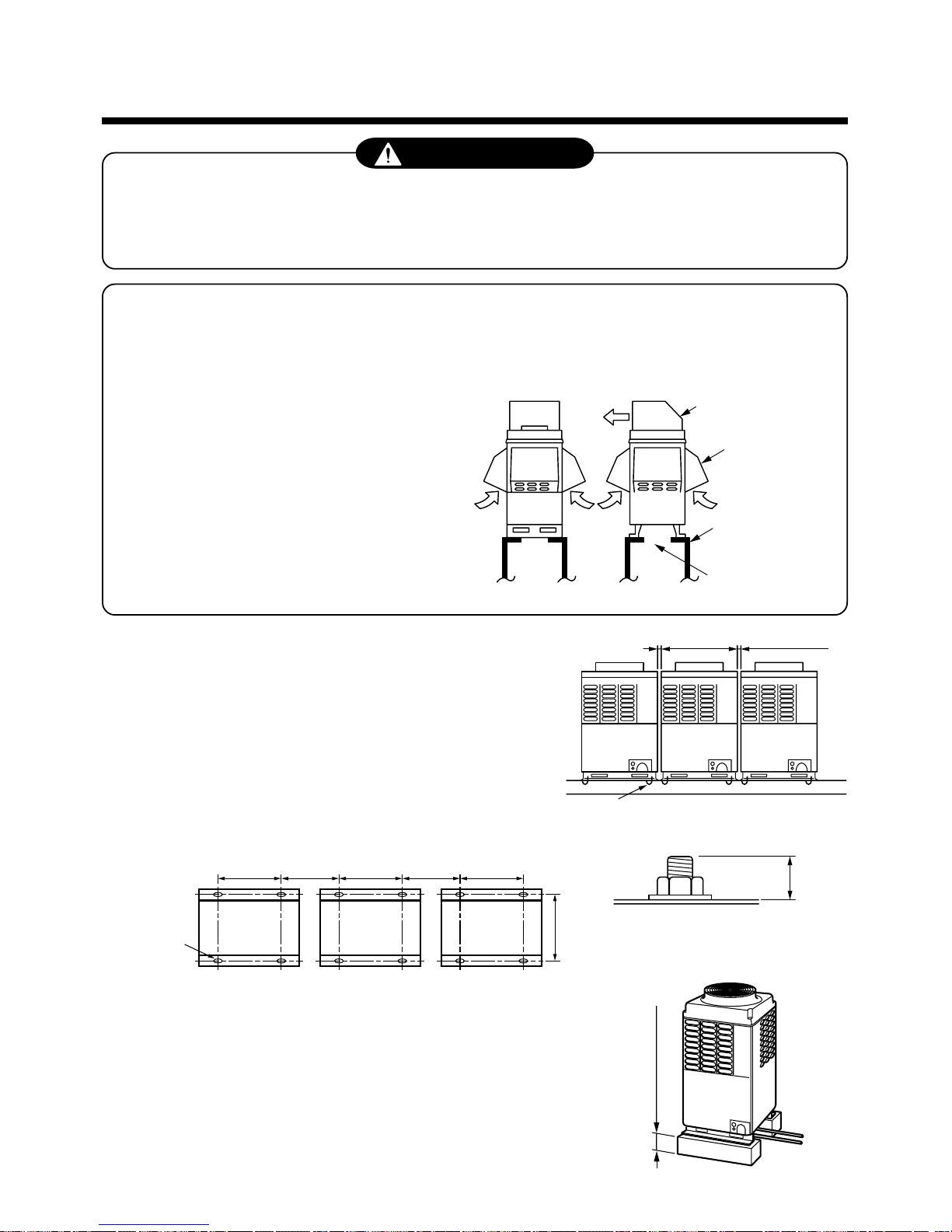

INSTALLATION OF OUTDOOR UNIT

WARNING

Perform a specified installation work against a strong wind such as typhoon or earthquake.

If the air conditioner is imperfectly installed, an accident by falling or dropping may be caused.

Install the air conditioner certainly at a place bearable to weight.

If strength is insufficient, the unit may fall down resulting in human injury.

Drain water is discharged from the outdoor unit. (Especially in heating time)

Install the outdoor unit at a place where has good drainage.

For installation, be careful to the strength and the level of the foundation so that an abnormal

sound (Vibration, noise) does not generate.

In the snowfall area, apply the following measures against

snowfall for the outdoor unit. (See the figure on the right.)

(Incomplete snowfall-proof measures causes a trouble.)

Place a higher stool under the unit, and mount the

snowfall-hoods to air inlet and air outlet so that

snows do not have influence.

(For the above works, please arrange at the field.)

1. To install the multiple outdoor units, arrange them with

20mm or more intervals.

Fix each outdoor unit with M12 anchor bolts at 4 positions.

Length by 20mm is appropriate for an anchor bolt.

• Anchor bolt pitch is as shown below:

2. When drawing out the refrigerant pipe from underside, set

height of the stool by 500mm or more.

20mm or more 20mm or more

M12 anchor bolt

4 positions/unit

20

700

310 or more

*

310 or more

700 700

755

Continuous hole

(15 x 20 long hole)

500mm or more

Snowfall-hood

for air outlet

Snowfall-hood

for air inlet

(4 faces)

Stool

Space for draining

9

3. Do not use four stools to set the four corners.

4. Mount the vibration-proof rubber (vibration-proof block etc.) so that it catch whole the clamping leg.

5. Be careful to connecting arrangement of the header unit and the follower units.

Set the outdoor units in the order from one with large capacity. (A (Header unit)

> B > C > D)

6. Be careful to connecting arrangement of header unit and follower unit.

1) Be sure to use a header unit for the leading outdoor unit to be connected to the main pipe. (Figure 1)

2) However, as shown in the figure below, T-shape branching joint which is sold separately can be connected to

connect to the main pie within piping indicated with a bold line in the following figure. (Figure 2)

3) Be careful to direction of T-shape branching joint. (As shown in Figure 3, T-shape branching joint cannot be

attached so that refrigerant of the main pipe flows directly to the header unit.)

Install the vibration-proof rubber so that

bent part of the fixing leg is grounded.

Bent part of the fixing

leg is not grounded.

Anchor bolt

Vibration-proof rubber

Figure 1 Figure 2 Figure 3

Extension

valve

To indoor unit To indoor unit

Header

Follower Follower

Header

Follower Follower

Header

Follower Follower

Main pipe

To indoor unit

Main pipe Main pipe

Extension

valve

4

INSTALLATION OF OUTDOOR UNIT

10

5

REFRIGERANT PIPING

WARNING

If the refrigerant gas leaks during installation work, ventilate the room.

If the leaked refrigerant gas comes to contact with a fire, the noxious gas may generate.

After installation work, check that the refrigerant gas does not leak.

If the refrigerant gas leaks in the room and comes to contact with a fire such as fan heater, stove, or kitchen

range, the noxious gas may generate.

REQUIREMENT

For brazing, be sure to use nitrogen gas to avoid oxidation of pipe inside.

1. In a welding work for the refrigerant pipes, be sure to use the nitrogen gas in order to prevent oxidation inside

of the pipes; otherwise clogging of the refrigerating cycle due to oxidized scale generates.

2. Use clean and new pipes for the refrigerant pipes

and perform piping work so that water or dust is

not mixed.

3. Be sure to use a double spanner to loosen or

tighten the flare nut. If a single spanner is used, a

required tightening cannot be obtained. Tighten

the flare not with the specified torque.

Connection of refrigerant pipe

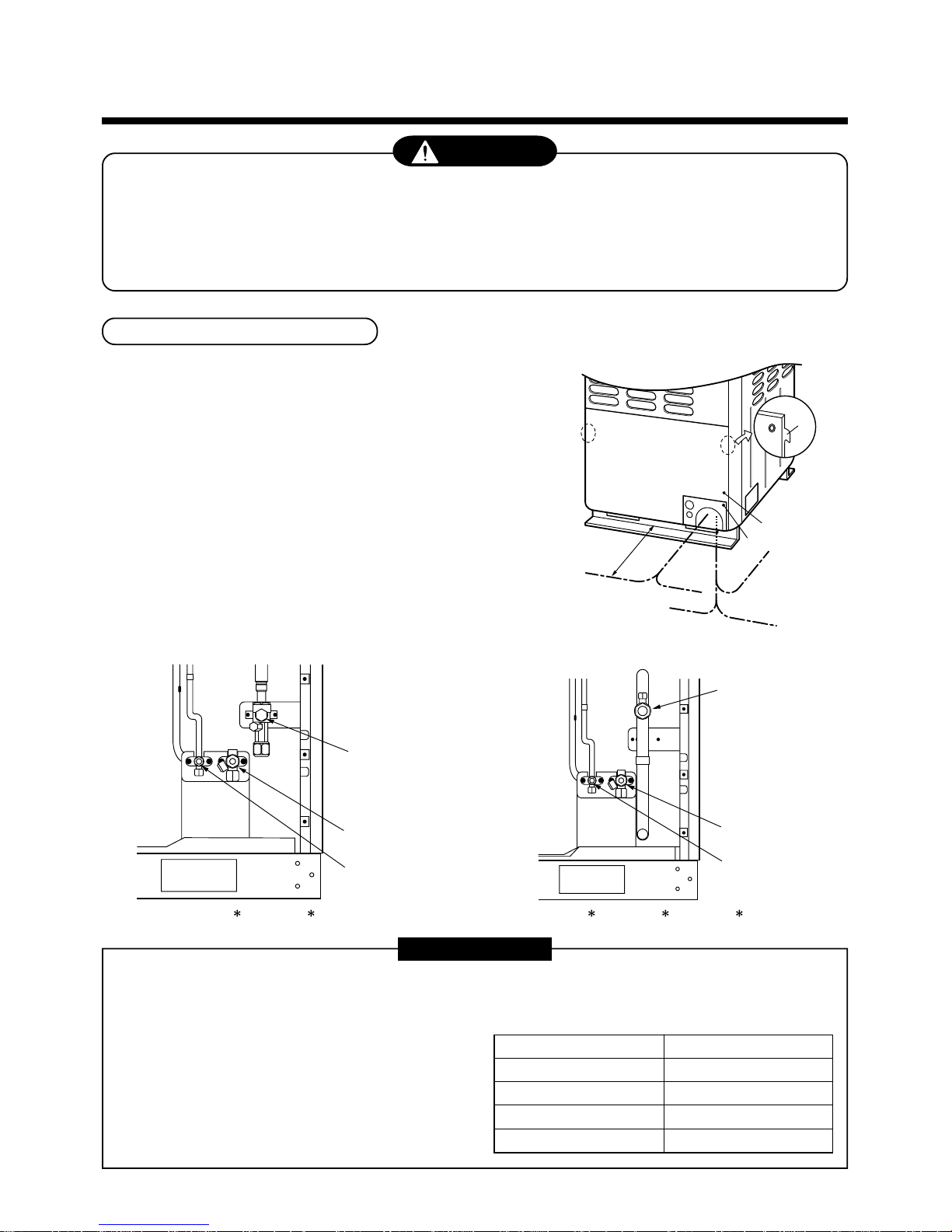

1. The refrigerant pipe connecting section is set in the outdoor unit.

Remove the front panel and the piping/wiring panel. (M5: 9 pcs.)

• As shown in the right figure, the hooking hooks are attached at

right and left sides each on the front panel. Lift up and remove

the front panel.

2. Pipes can be drawn out forward and downward from the outdoor

unit.

3. When drawing out the pipe forward, draw out the pipe to outside

via piping/wiring panel, and keep space of 500mm or more from

the main pipe connecting the outdoor unit with the indoor unit,

considering service work, etc. (For replacing the compressor,

500mm or more space is required.)

4. When drawing out the pipe downward, remove the knockout of

the base plate of the outdoor unit, apply the pipe to outside of the

outdoor unit, and perform piping at right/left or rear side. Leading

pipe of the balancing should be within 4m.

Outer dia. of copper pipe

6.4 mm

9.5 mm

12.7 mm

15.9 mm

Tightening torque (N•m)

14 to 18 (1.4 to 1.8 kgf-m)

33 to 42 (3.3 to 4.2 kgf-m)

50 to 62 (5.0 to 6.2 kgf-m)

68 to 82 (6.8 to 8.2 kgf-m)

500mm

or more

Hook

Front panel

Piping/wiring panel

Drawing out

forward

(Left piping)

(Left piping)

(Right piping)

(Rear piping)

(Right

piping)

Drawing out

downward

Packed valve of

gas side

Ball valve of

gas side

Packed valve

of liquid side

Packed valve of

balance pipe

Packed valve of

liquid side

Packed valve of

balance pipe

(MMY-MAP0801

, MAP1001 , MAP1201 )(MMY-MAP0501 , MAP0601 )

11

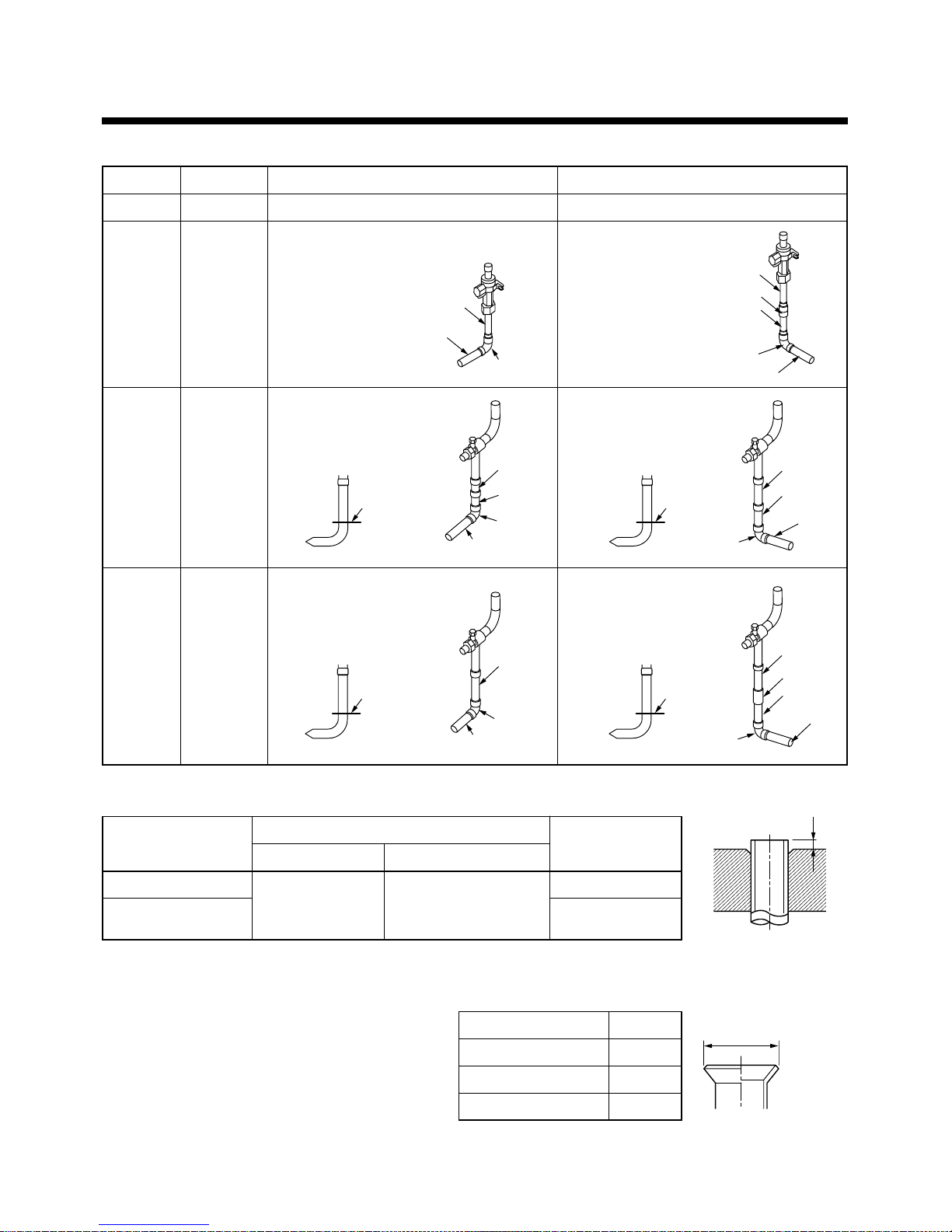

Pipe connecting method of valve at gas side (Example)

+0.0

–0.4

MMY-

MAP0501

∗∗

∗∗

∗

MAP0601

∗∗

∗∗

∗

MAP0801

∗∗

∗∗

∗

MAP1001

∗∗

∗∗

∗

MAP1201

∗∗

∗∗

∗

Pipe diameter

Ø15.9

Ø19.1

Ø22.2

Ø28.6

Draw-out forward

Connect Ø15.9 pipe with flaring.

Connect the attached pipe to the valve with

flaring, and then braze the elbow and pipe

procured locally.

Cut L-shape pipe at the straight

section, and then braze the elbow,

socket and pipe procured locally.

Cut L-shape pipe at the straight

section, and then braze the

elbow and pipe procured locally.

Draw-out downward

Connect Ø15.9 pipe with flaring.

Connect the attached pipe to the

valve with flaring, and

then braze the socket,

elbow and pipe

procured locally.

Cut L-shape pipe at the straight

section, and then braze the elbow,

socket and pipe procured

locally.

Cut L-shape pipe at the

straight section, and then

braze the elbow, socket

and pipe procured locally.

• Extruding margin of copper pipe with flare machining : B (Unit: mm)

Copper pipe outer dia.

9.5

12.7

15.9

Rigid (Clutch type)

R410A tool used Conventional tool used

0 to 0.5 1.0 to 1.5

Imperial (Wing nut)

1.5 to 2.0

2.0 to 2.5

• Extruding margin of copper pipe with flare tools :

A (Unit: mm)

Copper pipe outer dia.

9.5

12.7

15.9

A

13.2

16.6

19.7

B

A

5

REFRIGERANT PIPING

∗ When using the conventional flare tool, to

connect R410A pipes with flaring, make a

margin approx. 0.5mm longer than that of

R22 pipe so that the flare size matches

with the specified one. It is convenient to

use a copper pipe gauge for size

adjustment of the extruding margin.

Attached pipe

Pipe

Elbow

Attached pipe

Pipe

Pipe

Elbow

Socket

pipe

Elbow

L-shape

pipe

Attached

pipe

Pipe

Elbow

L-shape

pipe

Section to

be cut

Pipe

Pipe

Elbow

Socket

L-shape

pipe

Section to

be cut

Attached

pipe

Elbow

pipe

Pipe

L-shape

pipe

Section to

be cut

Section to

be cut

12

Table 1

Selection of pipe materials and size

• Selection of pipe material

Material: Phosphorus deoxidation seam-less pipe

• Capacity code of indoor and outdoor units

• For the indoor unit, the capacity code is decided at each capacity rank.

• The capacity codes of the outdoor units are decided at each capacity rank. The maximum No. of connectable

indoor unit and the total value of capacity codes of the indoor units are also decided.

Compared with the capacity code of the outdoor unit, the total value of capacity codes of the connectable indoor

units differs based on the height difference between the indoor units.

• When height difference between the indoor units is below 15m: Up to 135% of capacity code of the outdoor unit

• When height difference between the indoor units is over 15m: Up to 105% of capacity code of the outdoor unit

Table 2

* For combination of the outdoor units, refer to “Combination of outdoor units”.

• Coupling size of brazed pipe

K

ØC

G

ØF

Connected section

External size Internal size

Indoor unit

capacity rank

007 type

009 type

012 type

015 type

018 type

024 type

027 type

030 type

036 type

048 type

056 type

072 type

096 type

Capacity code

Equivalent Equivalent

to HP to capacity

0.8 2.2

1 2.8

1.25 3.6

1.7 4.5

2 5.6

2.5 7.1

38

3.2 9

4 11.2

514

616

8 22.4

10 28

Outdoor unit

model name

MMY-MAP0501

∗

MMY-MAP0601

∗

MMY-MAP0801

∗

MMY-MAP1001

∗

MMY-MAP1201

∗

MMY-AP1401

∗

MMY-AP1601

∗

MMY-AP1801

∗

MMY-AP2001

∗

MMY-AP2201

∗

MMY-AP2211

∗

MMY-AP2401

∗

MMY-AP2411

∗

MMY-AP2601

∗

Capacity code

Equivalent Equivalent

to HP to capacity

514

616

8 22.4

10 28

12 33.5

14 38.4

16 45

18 50.4

20 56

22 61.5

24 68

26 73

No. of

indoor

units

8

10

13

16

20

23

27

30

33

37

40

43

Outdoor unit

model name

MMY-AP2801

∗

MMY-AP3001

∗

MMY-AP3201

∗

MMY-AP3211

∗

MMY-AP3401

∗

MMY-AP3411

∗

MMY-AP3601

∗

MMY-AP3611

∗

MMY-AP3801

∗

MMY-AP4001

∗

MMY-AP4201

∗

MMY-AP4401

∗

MMY-AP4601

∗

MMY-AP4801

∗

Capacity code

Equivalent Equivalent

to HP to capacity

28 78.5

30 84

32 90

34 96

36 101

38 106.5

40 112

42 118

44 123.5

46 130

48 135

No. of

indoor

units

47

48

48

48

48

48

48

48

48

48

48

Standard outer dia. of

connected copper pipe

6.35

9.52

12.70

15.88

19.05

22.22

28.58

34.92

38.10

41.28

Connected section

External size Internal siz

Standard outer dia. (Allowable difference)

CF

6.35 (±0.03) 6.45 ( )

9.52 (±0.03) 9.62 ( )

12.70 (±0.03) 12.81 ( )

15.88 (±0.03) 16.00 ( )

19.05 (±0.03) 19.19 ( )

22.22 (±0.03) 22.36 ( )

28.58 (±0.04) 28.75 ( )

34.90 (±0.04) 35.11 ( )

38.10 (±0.05) 38.31 ( )

41.28 (±0.05) 41.50 ( )

Min. depth

of insertion

KG

76

87

98

98

11 10

11 10

13 12

14 13

15 14

15 14

Oval value

0.06 or less

0.08 or less

0.10 or less

0.13 or less

0.15 or less

0.16 or less

0.20 or less

0.25 or less

0.27 or less

0.28 or less

Min. thickness

of coupling

0.50

0.60

0.70

0.80

0.80

0.82

1.00

1.20

1.26

1.35

+0.04

–0.02

+0.04

–0.02

+0.04

–0.02

+0.04

–0.02

+0.03

–0.03

+0.03

–0.03

+0.06

–0.02

+0.04

–0.04

+0.08

–0.02

+0.08

–0.02

(Unit: mm)

13

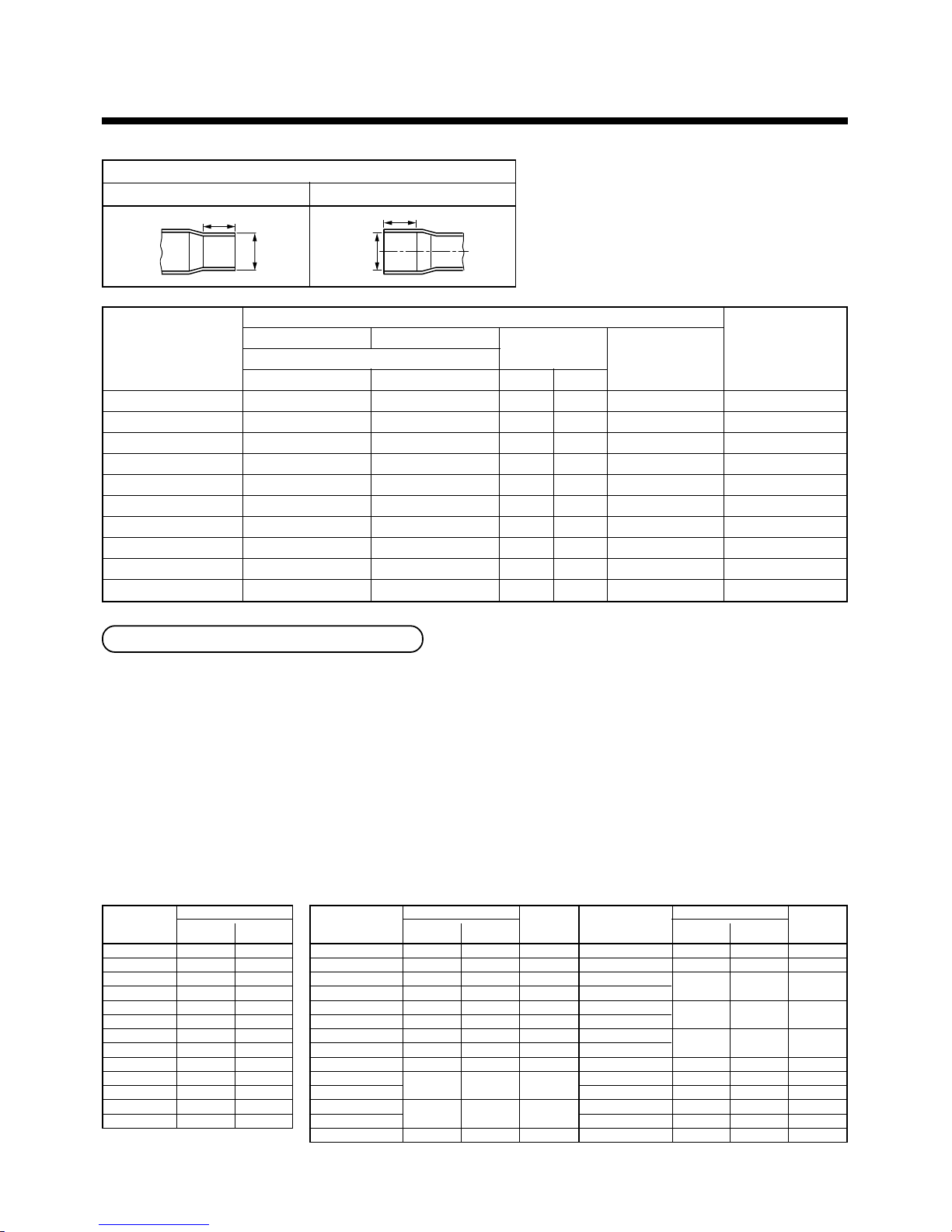

No.

Piping parts

Outdoor unit

↓

T-shape

branching joint

Between T-shape

branching joints

T-shape joint of

header unit

↓

1st branching

section

Branching section

↓

Branching section

Branching section

↓

Indoor unit

Name

Outdoor unit

connecting pipe

Main connecting

piping between of

outdoor units

Balance pipe

Main piping

Branching pipe

Indoor unit

connecting pipe

Selection of pipe size

1)Connecting pipe outdoor unit

Model

MMY-MAP0501H

MMY-MAP0601H

MMY-MAP0801H

MMY-MAP1001H

MMY-MAP1201H

Gas side

Ø15.9

Ø19.1

Ø22.2

Ø22.2

Ø28.6

Liquid side

Ø9.5

Ø9.5

Ø12.7

Ø12.7

Ø12.7

2)Pipe size for connecting piping between outdoor units

Total capacity codes of outdoor

units at downstream side

Equivalent Equivalent

to capacity to HP

Below 38.4 Below 14

38.4 to below 61.5 14 to below 22

61.5 to below 73.0 22 to below 26

73.0 to below 96.0 26 to below 36

Above 101.0 Above 36

Gas

side

Ø28.6

Ø28.6

Ø34.9

Ø34.9

Ø41.3

Liquid

side

Ø12.7

Ø15.9

Ø15.9

Ø19.1

Ø22.2

Balance

pipe

Ø9.5

3)Size of main piping

Total capacity codes of all outdoor units

Equivalent Equivalent

to capacity to HP

Below 16.0 Below 6

16.0 to below 22.4 6 to below 8

22.4 to below 33.5 8 to below 12

33.5 to below 38.4 12 to below 14

38.4 to below 61.5 14 to below 22

61.5 to below 73.0 22 to below 26

73.0 to below 101.0 26 to below 36

101.0 to below 118.0 36 to below 46

Above 118.0 Above 46

Gas side

Ø15.9

Ø19.1

Ø22.2

Ø28.6

Ø28.6

Ø34.9

Ø34.9

Ø41.3

Ø41.3∗

Liquid side

Ø9.5

Ø9.5

Ø12.7

Ø12.7

Ø15.9

Ø15.9

Ø19.1

Ø22.2

Ø22.2

∗Max. equivalent length of main pipe is below 70m.

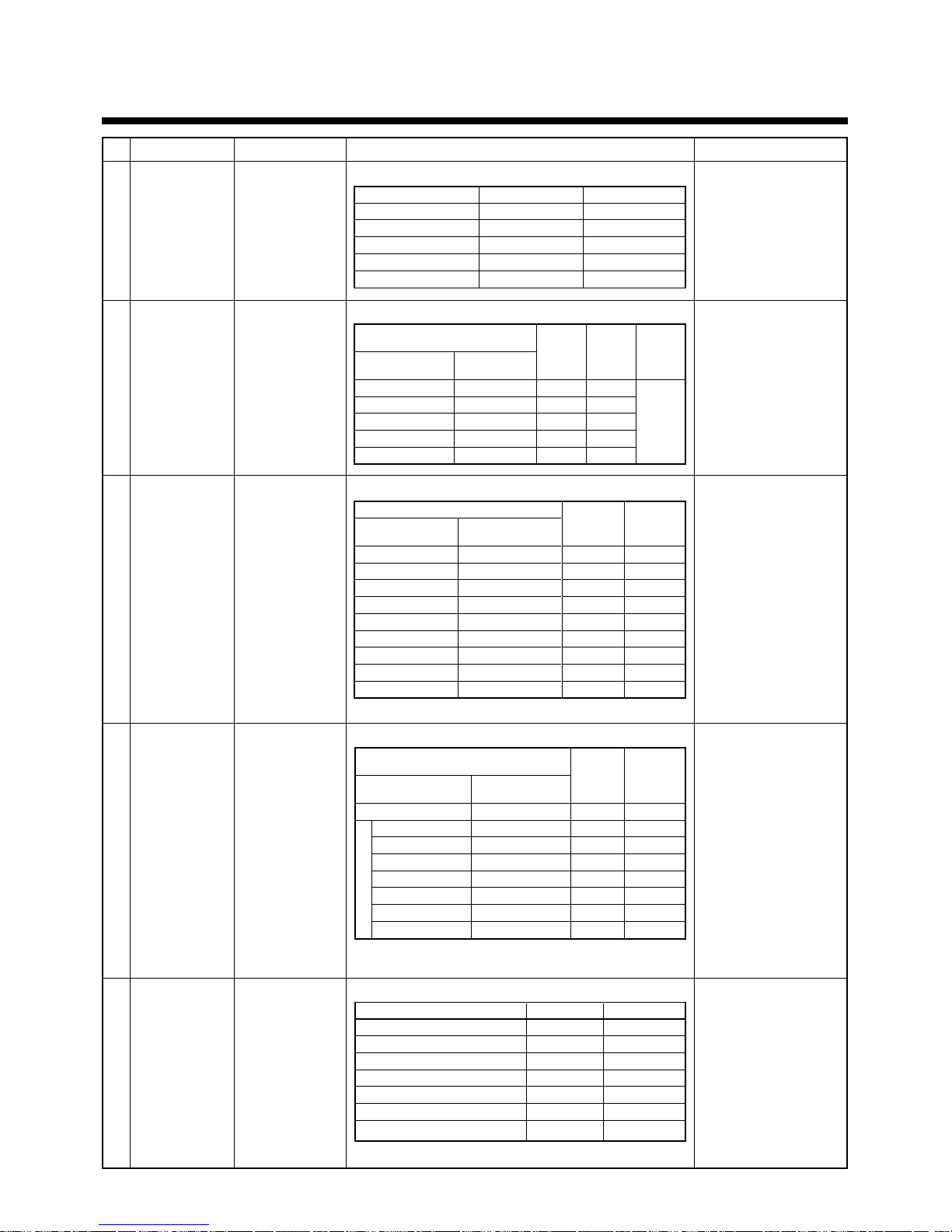

4)Pipe size between branching sections

Total capacity codes of indoor units

at downstream side

Equivalent Equivalent

to capacity to HP

Below 7.5 Below 2.8

7.5 to below 18.0 2.8 to below 6.4

18.0 to below 34.0 6.4 to below 12.2

34.0 to below 56.5 12.2 to below 20.2

∗

56.5 to below 70.5 20.2 to below 25.2

1

70.5 to below 98.5 25.2 to below 35.2

98.5 to below 118.5 35.2 to below 42.2

Above 118.5 Above 42.2

Gas side

Ø12.7

Ø15.9

Ø22.2

Ø28.6

Ø34.9

Ø34.9

Ø41.3

Ø41.3

Liquid side

Ø9.5

Ø9.5

Ø12.7

Ø15.9

Ø15.9

Ø19.1

Ø22.2

Ø22.2

5)Connecting pipe size of indoor unit

Capacity rank

007 to 012 type (15m or less)

007 to 012 type (15m or more)

015 to 018 type

024 to 048 type

056 type

072 type

096 type

Gas side

Ø9.5

Ø12.7

Ø12.7

Ø15.9

Ø15.9

Ø19.1

Ø22.2

Liquid side

Ø6.4

Ø6.4

Ø6.4

Ø9.5

Ø9.5

Ø12.7

Ø12.7

Remarks

Same to connecting pipe

size of outdoor unit

Pipe size differs based on

total capacity code value of

outdoor units at

downstream side.

(See Table 2.)

Pipe size differs based on

capacity code of outdoor

unit.

(See Table 2.)

Pipe size differs based on

total capacity code value of

indoor units at downstream

side.

If the total value exceeds

the capacity code of the

outdoor unit, apply capacity

code of the outdoor unit.

(See Table 1.2.)

∗1: If exceeding the main pipe size, decide the size same to

main pipe size.

5

REFRIGERANT PIPING

14

1

1 1 1

22

4

5 5 5

4

4

4

4

4

5 5

5 5 5 5 5

7

6

66

6 6

6

6

6

6

6

6

6

Outdoor

unit

Balance pipe

T-shape

branching joint

Outdoor unit

connecting

piping

Main connecting

piping between

outdoor units

Branching pipe

Branching header

1st branching

section

Indoor unit connecting pipe

Y-shape

branching

joint

Indoor unit

connecting pipe

Follower

unit 2

Follower

unit 3

Follower

unit 1

Header unit

Indoor unit

Indoor unit

3

Main piping

∗1: If exceeding the main pipe size, decide the size same to main pipe size.

∗2: Up to total 6.0 of Max. capacity codes is connectable to one line after branching of header.

No.

Piping parts

Branching

section

Name

Y-shape branching joint

Branching header

T-shape branching joint

Selection of pipe size

6)Selection of branching section

Y-shape branching joint

Branching header ∗2

T-shape branching joint

(For link of outdoor units)

Total capacity code of indoor units

Equivalent to capacity Equivalent to HP

Below 18.0 Below 6.4

18.0 to below 40.0 6.4 to below 14.2

*1 40.0 to below 70.5 14.2 to below 25.2

Above 70.5 Above 25.2

For 4

Below 40.0 Below 14.2

branches

40.0 to below 70.5 14.2 to below 25.2

For 8

Below 40.0 Below 14.2

branches

40.0 to below 70.5 14.2 to below 25.2

• Balance pipe (Corresponding dia. Ø9.5) × 1

• Pipe at liquid side (Ø9.5 to Ø22.1) × 1

• Pipe at gas side (Ø15.9 to Ø41.3) × 1

Model name

RBM-BY53E

RBM-BY103E

RBM-BY203E

RBM-BY303E

RBM-HY1043E

RBM-HY2043E

RBM-HY1083E

RBM-HY2083E

RBM-BT13E

The following 3 types of T-shape branching joint pipes are made to one set.

Arrange the required quantities and combine at the local site.

15

Allowable length of refrigerant pipe and height difference

Outdoor unit

T-shape branching

joint

La

LA

A

D

BC

LB

Lb Lc

Main

piping

L1

1st branching

section

Height

difference

between

outdoor

units

H3

5 m

Height

difference

between

outdoor

units

H1

50 m

Follower

unit 3

outdoor unit

connecting

pipe

Follower

unit 1

Follower

unit 2

Header

unit

Main connecting piping between outdoor units

Length corresponded to farthest piping

between outdoor units LO

25 m

Branching pipe L2

Connecting piping of indoor unit L7

bcdea

ghi jf

L4

L5

L6

L3

Branching

header

Indoor unit

Indoor unit

Equivalent length corresponded to farthest piping L

175 m

Equivalent length corresponded to farthest piping after 1st branching Li

65 m

Y-joint

Height difference

between indoor

units

H2

30 m

Ld

(a)

(d)

(b) (c)

• Cautions concerned with installation/

construction

1) The leading outdoor unit connected with the

indoor inter-unit pipe is made “A (Header unit)”.

2) Set the units in order of the outdoor capacity.

(A (Header unit)

> B > C > D)

3) For the combination of the outdoor units, refer to

“Combination of outdoor unit” list.

• Restriction to the system

• Allowable length/height difference of the refrigerant pipe

Pipe

length

Height

difference

Allowable

value

300m

175m

85m

65m

25m

10m

30m

50m

40m (*2)

30m

5m

Pipe section

LA + LB + La + Lb + Lc + Ld + L1 + L2 + L3 + L4

+ L5 + L6 + L7 + a + b + c + d + e + f + g + h + i + j

LA + LB + Ld + L1 + L3 + L4 + L5 + L6 + j

L1

L3 + L4 + L5 + L6 + j

LA + LB + Ld (LA + Lb, LA + LB + Lc)

Ld (La, Lb, Lc)

a, b, c, d, e, f, g, h, i, j

——

——

——

——

Total extended pipe length

(Liquid pipe/real length)

Farthest equivalent piping length L (∗1)

Max. equivalent length of main pipe (∗3)

Farthest equivalent piping length from 1st branch Li (∗1)

Farthest equivalent piping length between outdoor units LO (∗1)

Max. equivalent length of outdoor unit connecting pipe

Max. real length of outdoor unit connecting pipe

Height difference between

Outdoor at upper side

indoor unit and outdoor unit H1

Outdoor at lower side

Height difference between indoor units H2

Height difference between outdoor units H3

Max. No. of combined outdoor units

Max. capacity of combined outdoor units

Max. No. of connected indoor units

Max. capacity of connected indoor units

(Differs by height difference between indoor units)

4 units

48HP

48 units

H2 < 15m 135% of capacity of outdoor unit

15m < H2 < 30m 105% of capacity of outdoor unit

∗1 : Farthest outdoor unit: (d), farthest indoor unit: (j) from 1st branch

∗2 : If the height difference (H2) between indoor units exceeds 3m, set below 30m.

∗∗

∗∗

∗3 :If Max. capacity of the combined outdoor units exceeds 46HP, Max. equivalent length is up to 70m.

5

REFRIGERANT PIPING

16

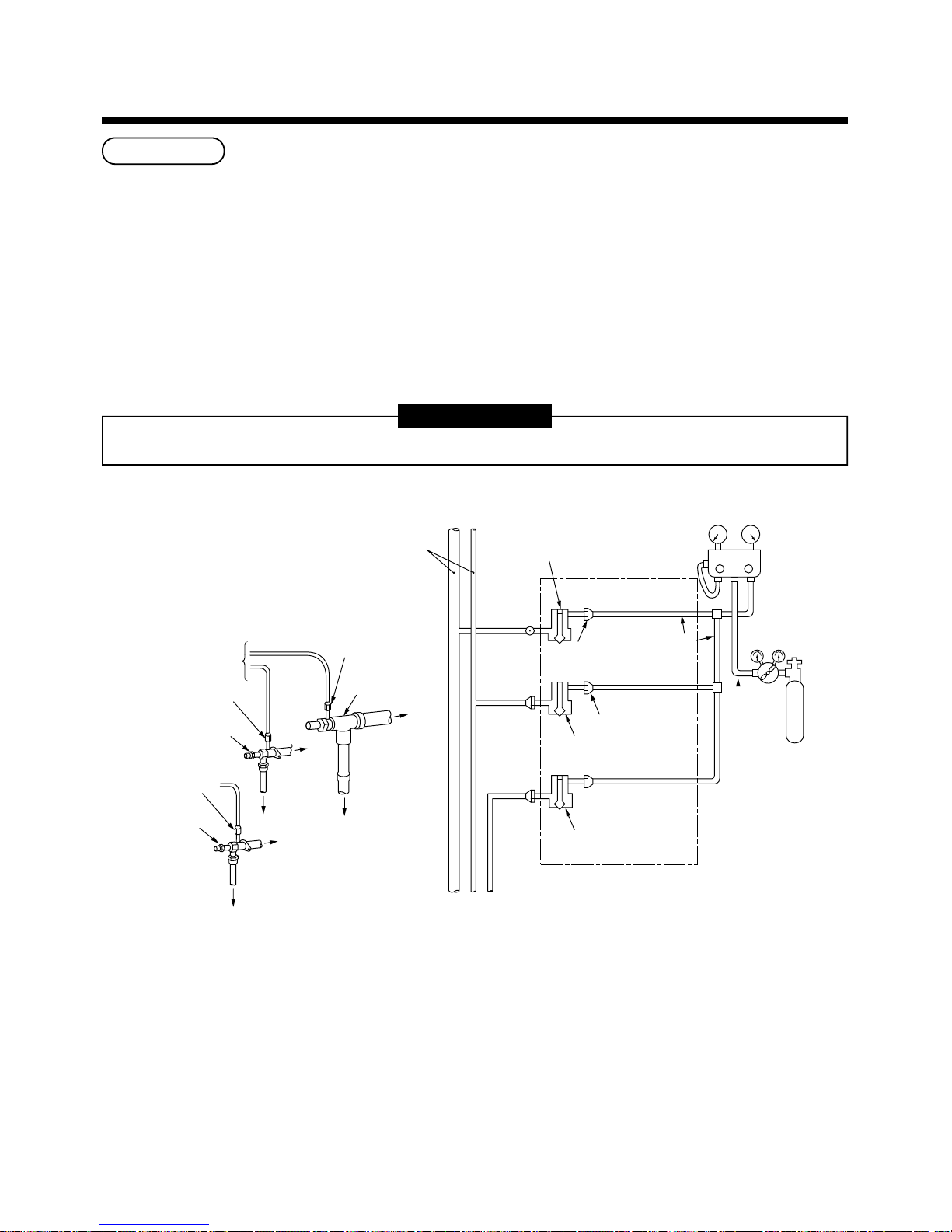

Airtight test

After the refrigerant piping has finished, execute an airtight test. For an airtight test, connect a nitrogen gas bomb as

shown in the figure below, and apply pressure.

• Be sure to apply pressure from the service ports of the packed valves (or ball valves) at liquid side, gas side, and

balance pipe side.

• An airtight test can be only performed to the service ports at liquid side, gas side, and balance side of the header

unit.

• Close fully valves at liquid side, gas side, and balance side. As there is possibility that nitrogen gas enters in the

refrigerant cycle, re-tighten the valve rods before applying pressure. (Re-tightening of the valve rods are

unnecessary for valves at gas side of MMY-MAP0501∗ and MAP0601∗ because they are ball valves.)

• For each refrigerant line, apply pressure gradually with steps at liquid side, gas side, and balance side.

Be sure to apply pressure to liquid side, gas side, and balance side.

REQUIREMENT

Never use “Oxygen”, “Flammable gas” and “Noxious gas” in an airtight test.

STEP 1 : Apply pressure 0.3MPa (3.0kg/cm2G) for 3 minutes or more.

Available to detect a gross leakage

STEP 2 : Apply pressure 1.5MPa (15kg/cm2G) for 3 minutes or more.

STEP 3 : Apply pressure 3.73MPa (38kg/cm2G) for approx. 24 hours. Available to detect slow leakage

• Check pressure down.

No pressure down: Accepted Pressure down: Check the leaked position.

However, if there is difference of ambient temp. between when pressure has been applied and when

24 hours passed, pressure changes by approx. 0.01MPa (0.1kg/cm²G) per 1°C. Correct the pressure.

Leaked position check

When a pressure-down is detected in STEP 1, STEP 2, or STEP 3, check the leakage at the connecting points.

Check leakage with hearing sense, feeler, foaming agent, etc, and perform re-brazing or re-tightening of flare if

leakage is detected.

VLV

H

Connected to indoor unit

Main pipe

Packed valve fully closed

(gas side)

Header outdoor unit

Lowpressure

gauge

Highpressure

gauge

Gauge

manifold

Brazed

Service

port

Service port

Ø6.4

Copper pipe

Ø6.4

Copper

pipe

Fully

closed

Fully

closed

Reducing

valve

Nitrogen

gas

Packed valve fully closed

(liquid side)

Packed valve fully closed

(balance)

Connected to other follower outdoor units

Detailed drawing of packed valve

To gauge manifold

Gas-side

service port

Gas-side

packed valve

To outdoor

unit

To outdoor unit

To

outdoor

unit

Liquid-side

packed valve

Liquid-side

service port

Balance

packed valve

Balance

service port

Piping at site

Piping

at site

Piping

at site

17

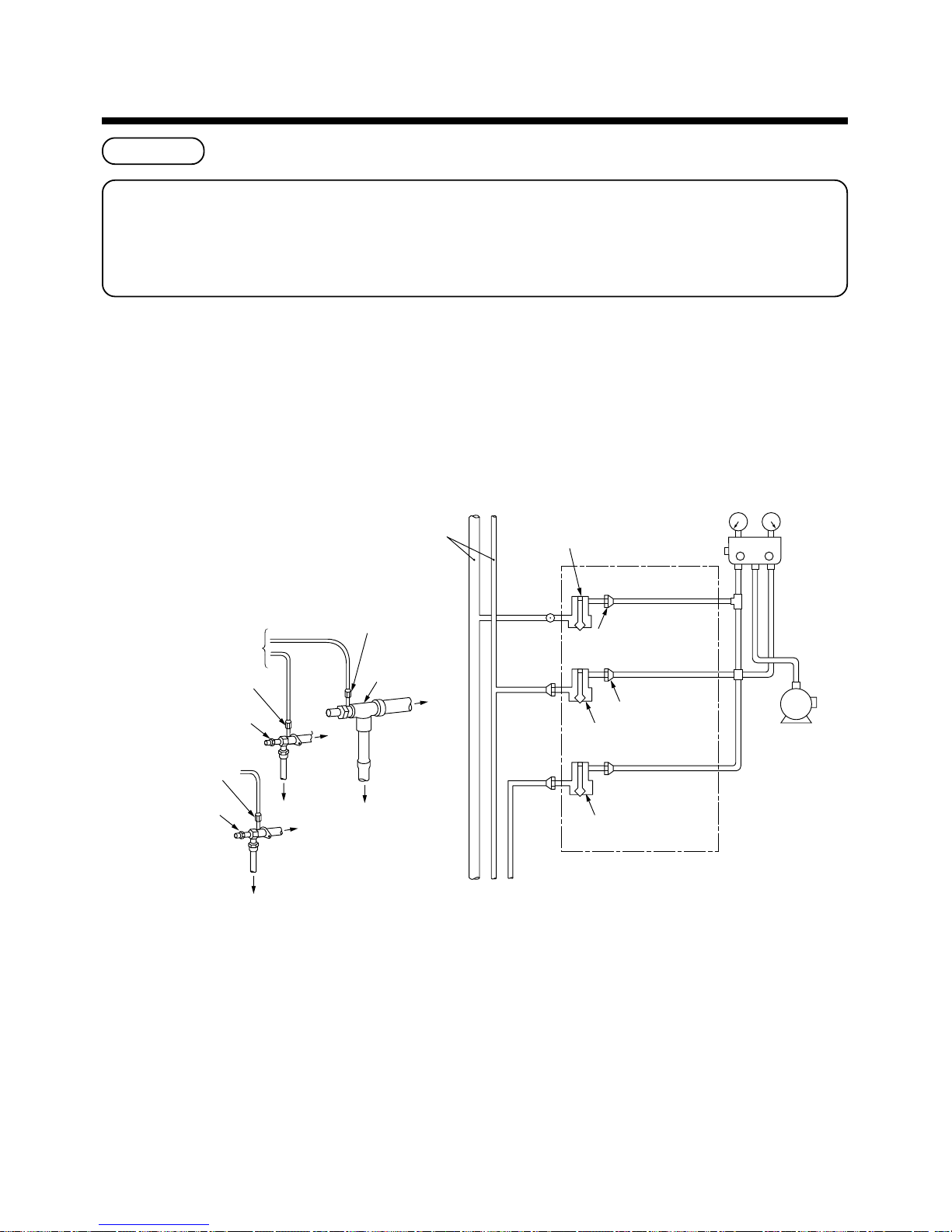

Air purge

For the air purge at installation time (Discharge of air in connecting pipes), use “Vacuum pump method” from

viewpoint of protection of earth environment.

• For protection of earth environment, do not discharge the flon gas in the air.

• Using a vacuum pump, eliminate the remained air (nitrogen gas, etc.) in the unit. If gas remains, an absence

of faculties may be caused.

After the airtight test, discharge nitrogen gas. Then connect the gauge manifold to the service ports at liquid, gas,

and balance sides, and connect the vacuum pump as shown in the following figure. Be sure to perform vacuuming

for liquid, gas and balance sides.

• Be sure to perform vacuuming from both liquid and gas sides.

• Be sure to use a vacuum pump with counter-flow preventive function so that oil in the pump does not back up in

the pipe of the air conditioner while the pump stops. (If oil in the vacuum pump enters in the air conditioner with

R410A refrigerant, a trouble is caused in the refrigerating cycle.)

• Use a vacuum pump having a high vacuuming degree (below -755mmHg) and a large exhaust gas amount (over

40L/minute).

• Perform vacuuming for 2 or 3 hours though time differs due to pipe length. In this time, check all packed valves at

liquid, gas, and balance sides are fully closed.

• If vacuuming valve amount is not decreased to below -755mmHg even after vacuuming for 2 hours or more,

continue vacuuming for 1 hour or more. If -755mmHg or less cannot be obtained by 3 hours or more vacuuming,

check the leaked position.

• When vacuuming valve reached to -755mmHg or less after vacuuming for 2 hours or more, close valves VL and

VH of the gauge manifold fully, stop the vacuum pump, leave it as it is for 1 hour, and then check the vacuuming

degree does not change. If it changed, there may be a leaked position. Check the leaked position.

• After the above procedure of vacuuming has finished, exchange the vacuum pump with a refrigerant cylinder and

advance to the additional charging of refrigerant.

P

VLV

H

Connected to indoor unit

Main pipe

Packed valve fully closed

(gas side)

Header outdoor unit

Lowpressure

gauge

Highpressure

gauge

Gauge

manifold

Brazed

Service

port

Service port

Fully

closed

Fully

closed

Packed valve fully closed

(liquid side)

Packed valve fully closed

(Balance)

Connected to other follower outdoor units

Detailed drawing of packed valve

To gauge manifold

Gas-side service port

Gas-side

packed valve

or ball valve

To outdoor

unit

To outdoor unit

To

outdoor

unit

Liquid-side

packed valve

Liquid-side

service port

Balance

packed valve

Balance

service port

Piping at site

Piping

at site

Piping

at site

Vacuum pump

5

REFRIGERANT PIPING

18

Addition of refrigerant

After vacuuming work, exchange the vacuum pump with the refrigerant bomb and then start the additional charging

work of refrigerant.

Calculation of additional refrigerant charge amount

Refrigerant charge amount at shipment from the factory does not include the refrigerant for pipe at the local site.

For refrigerant to be charged in pipe at the local site, calculate the amount and charge it additionally.

NOTE) If the additional refrigerant amount indicates minus as the result of calculation, use the air conditioner

without addition of refrigerant.

Additional refrigerant = Real length × Additional refrigerant charge + Corrective amount of refrigerant

charge amount at local site of liquid pipe amount per 1m liquid pipe (Table 1) combined horse power (Table 2)

Table 1

Charging of refrigerant

• Keeping valve of the outdoor unit closed, be sure to charge the liquid refrigerant into service port at liquid side.

• If the specified amount of refrigerant cannot be charged, open fully valves of outdoor unit at liquid and gas sides,

operate the air conditioner in COOL mode under condition that valve at gas side is a little returned to close side

(MAP0801∗, MA1001∗, MAP1201∗ only), and then charge refrigerant into service port at gas side. In this time,

choke the refrigerant slightly by operating valve of the bomb to charge liquid refrigerant. The liquid refrigerant may

be charged suddenly, therefore be sure to charge refrigerant gradually.

• When refrigerant leaks and refrigerant shortage occurs in the system, recover the refrigerant in the system and

recharge refrigerant newly up to the correct level.

REQUIREMENT

<Entry of refrigerant charge amount>

• Fill the additional refrigerant record column of the wiring diagram indication plate with the additional refrigerant

amount at installation work, total refrigerant amount and the name of the service man who charged refrigerant

at installation time.

• The total refrigerant amount means the total value of the refrigerant amount at shipment and the additional

refrigerant amount at installation time. The refrigerant amount at the shipment is one described on the “Unit

nameplate”.

Table 2

Liquid pipe dia. (mm)

Additional refrigerant amount/1m liquid pipe (kg/m)

6.4 9.5 12.7 15.9 19.1 22.2

0.025 0.055 0.105 0.160 0.250 0.350

Combined HP

(HP)

5

6

8

10

12

14

16

18

20

22

24

26

Combined outdoor units

(HP)

5

6

8

10

12

86

88

10 8

10 10

12 10

886

12 12

888

10 8 8

C (Corrective amount of refrigerant)

(kg)

0.0

0.0

1.5

2.5

3.5

0.0

0.0

0.0

3.0

5.0

0.0

7.0

–4.0

–4.0

Combined HP

(HP)

28

30

32

34

36

38

40

42

44

46

48

Combined outdoor units

(HP)

10 10 8

10 10 10

12 10 10

8888

12 12 10

10888

12 12 12

10 10 8 8

10 10 10 8

10 10 10 10

12 10 10 10

12 12 10 10

12 12 12 10

12 12 12 12

C (Corrective amount of refrigerant)

(kg)

–2.0

0.0

1.0

–6.0

3.0

–6.0

4.0

–6.0

–6.0

–5.0

–4.0

–2.0

0.0

2.0

Heat pump

model

MMY-MAP0501HT

∗∗

∗∗

∗ MMY-MAP0601HT

∗∗

∗∗

∗ MMY-MAP0801HT

∗∗

∗∗

∗ MMY-MAP1001HT

∗∗

∗∗

∗ MMY-MAP1201HT

∗∗

∗∗

∗

8.5 12.5

Outdoor unit Model

Charging amount (kg)

Cooling only

model

MMY-MAP0501T8 MMY-MAP0601T8 MMY-MAP0801T8 MMY-MAP1001T8 MMY-MAP1201T8

8.0 11.0

Outdoor unit Model

Charging amount (kg)

19

Full opening of valve

• Open valve of the outdoor unit fully.

• Using 4mm-hexagonal wrench, open fully the valve rods at liquid and balance sides.

• Using a spanner, etc, open fully the valve rod of packed valve (MMY-MAP0801∗, MAP1001∗, MAP1201∗) at gas

side.

• Using the pinchers, open fully the handle of the ball valve (MMY-MAP0501∗, MAP0601∗) at gas side.

Be careful that handling of ball valve differs from that of packed valve.

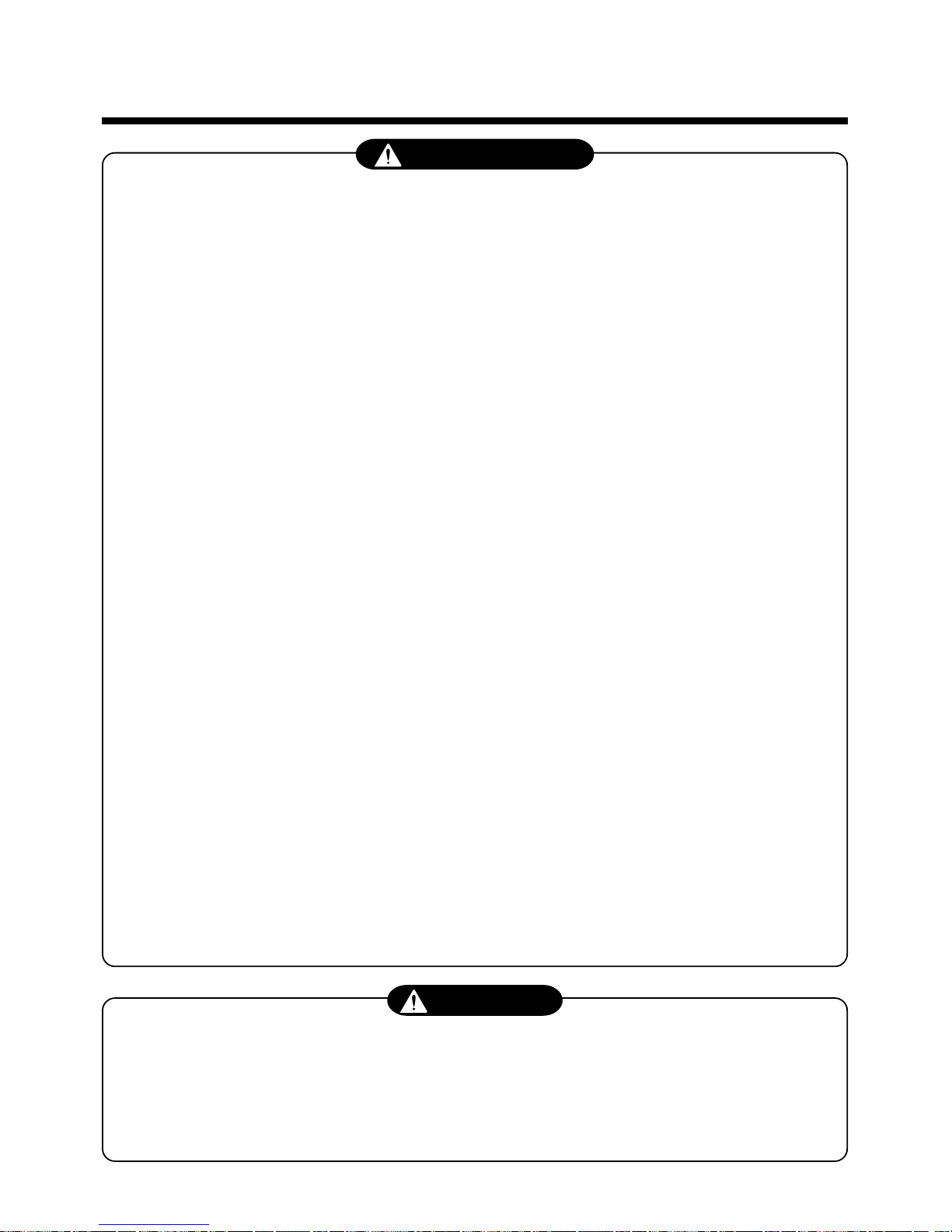

How to open the ball valve at gas side

Valve unit

Valve unit

Charge port

Charge port

Handle

Pull out the handle and

using cutting pliers, etc.

turn it counterclockwise

by 90˚. (Open fully)

Flare nut

Flare nut

Push in handle.

Closed completely

Handle

Handle position

Opened fully

Heat insulation for pipe

• Apply heat insulation of pipe separately at liquid, gas, and balance sides.

• Be sure to use thermal insulator with heat-resisting temp. 120°C or more.

5

REFRIGERANT PIPING

CAUTION

• After piping connection work has finished, cover the opening of the piping/wiring panel with the piping cover, or

fill silicon or putty in space of the pipes.

• In case of drawing-out the pipes downward or sideward direction, also close the openings of the base plate

and the side plate.

• Under the opened condition, a trouble may be caused due to entering of water or dust.

In case of using pipe cover In case of using no pipe cover

Piping/wiring panel

Drawing-out sideward

Drawing-out downward

Drawing-out

frontward

Fill silicon or putty in

periphery of the pipes.

Piping/wiring panel

Drawing-out sideward

Drawing-out downward

Drawing-out

frontward

Close the opening

with pipe cover.

20

PIECES ACCESSOIRES

r Pièces accessoires

Nom de la pièce

Manuel d’installation

Manuel du propriétaire

Tuyaux fournis

Quantité

2

1

1 de chaque

Forme

VOLUME-1

VOLUME-2

—

Usage

(S’assurer de le remettre aux clients.)

(S’assurer de le remettre aux clients.)

Tuyaux de raccordement côté gaz

(sauf MMY-MAP0501∗)

MESURES DE SECURITE

• Veuillez lire attentivement ces “Mesures de sécurité” avant l’installation pour installer correctement

le climatiseur.

• Les points importants relatifs à la sécurité sont décrits dans les “Mesures de sécurité”.

Assurez-vous de les conserver. Pour les indications et leur signification, voir la description ciaprès.

n Explication des indications

AVERTISSEMENT

Indique un risque de mort ou de blessures corporelles graves en cas de manipulation incorrecte.

ATTENTION

Indique un risque de blessure (∗1) ou de seul dommage matériel (∗2) en cas d’installation incorrecte.

∗1 :Le terme “blessure” représente un choc, une brûlure ou une électrocution ne requérant pas l’hospitalisation ou un

séjour de longue durée à l’hôpital.

∗2 :Le terme “dommage matériel” représente un dommage aggravé d’un bien ou la rupture du matériel.

• L’installation terminée, faites un essai de fonctionnement pour vous assurer de l’absence de

problèmes et expliquez les méthodes d’utilisation et d’entretien aux clients à partir du Manuel du

propriétaire.

Veuillez demander aux clients de conserver ce Manuel d’installation avec le Manuel du propriétaire.

FRANCAIS

21

AVERTISSEMENT

Demandez à un revendeur ou à un professionnel d’installer le climatiseur.

Si vous l’installez vous-même, vous risquez un incendie, une électrocution ou une fuite d’eau.

A l’aide des outils ou du matériel de tuyauterie exclusivement dédiés au R410A, installez le

climatiseur en toute sécurité conformément à ce Manuel d’installation.

La pression du réfrigérant HFC (R410A) est d’environ 1.6 fois plus élevée que celle du réfrigérant précédent.

En cas de non-utilisation du matériel de tuyauterie exclusif ou d’imperfection de l’installation, vous risquez une

rupture ou une blessure ainsi qu’une fuite d’eau, une électrocution ou un incendie.

Prenez des mesures afin que le réfrigérant ne dépasse pas la concentration limite même s’il fuit

lors de l’installation du climatiseur dans une petite pièce.