Page 1

AIR TO WATER HEAT PUMP SYSTEM

Installation manual

HOT WATER CYLINDER

INDIRECT HEATING METHOD

CLOSED OUTLET (UNVENTED)

150 litre HWS-1501CSHM3-E

210 litre HWS-2101CSHM3-E

300 litre HWS-3001CSHM3-E

AIR TO WATER HEAT PUMP SYSTEM

INSTALLATION AND SERVICE MANUAL 3

SYSTÈME DE POMPE À CHALEUR AIR-EAU

MANUEL D'INSTALLATION ET DE RÉPARATION 14

LUFT-WASSER-WARMERPUMPENSYSTEM

INSTALLATIONS - UND WARTUNGSANLEITUNG 26

SYSTÉM TEPELNÉHO ČERPADLA(VZDUCH - VODA)

SERVISNÍ A MONTÁŽNÍ MANUÁL 38

SUSTAV S TOPLINSKOM CRPKOM ZRAK-VODA

PRIRUČNIK ZA UGRADNJU I SERVISIRANJE 49

LEVEGŐ-VÍZ HŐSZIVATTYÚ RENDSZER

FELSZERELÉSI ÉS SZERVIZELÉSI KÉZIKÖN 60

ΣΥΣΤΗΜΑΑΝΤΛΙΑΣ ΘΕΡΜΑΝΣΗΣ ΑΕΡΑ- ΝΕΡΟΥ

ΕΓΧΕΙΡΙΔΙΟ ΕΓΚΑΤΑΣΤΑΣΗΣ ΚΑΙ ΣΥΝΤΗΡΗΣΗΣ 72

LUFT/VATTEN-VÄRMEPUMPSSYSTEM

INSTALLATIONS- OCH SERVICEMANUAL 84

LUFT-TIL-VANN VARMEPUMPESYSTEM

INSTALLASJONS- OG VEDLIKEHOLDSHÅNDBOK 95

EN

FR

DE

CZ

CR

HU

GR

SV

NO

SYSTÉM TEPELNÉHO ČERPADLA VZDUCH-VODA

NÁVOD NA INŠTALÁCIU A OBSLUHU 106

SISTEM TOPLOTNE ČRPALKE ZRAK–VODA

PRIROČNIK ZA MONTAŽO IN VZDRŽEVANJE 118

SK

SL

Page 2

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

AIR TO WATER HEAT PUMP SYSTEM

HOT WATER CYLINDER

INDIRECT HEATING METHOD

CLOSED OUTLET (UNVENTED)

INSTALLATION AND SERVICE MANUAL

IMPORTANT

PLEASE READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE

INSTALLING THE WATER CYLINDER. INCORRECT INSTALLATION MAY

INVALIDATE GUARANTEE. THE WATER CYLINDER MUST BE INSTALLED

BY A QUALIFIED INSTALLER IN ACCORDANCE WITH LOCAL PLUMBING,

BUILDING AND ELECTRICAL REGULATIONS. PLEASE LEAVE THIS MANUAL

WITH THE UNIT FOR FUTURE REFERENCE.

TECHNICAL SPECIFICATIONS

Rated pressure 1.0 MPa (10 bar)

Test pressure (hydraulic) 1.5 MPa (15 bar)

Minimum recommended supply pressure 0.1 MPa (1 bar)

Max. primary circuit working pressure 0.35 MPa (3.5 bar)

Electrical rating (cylinder heater) 2.75kW @ 230V~

Weight (full) 150 litre indirect 181 kg

210 litre indirect 251 kg

300 litre indirect 360 kg

COMPONENTS SUPPLIED

• Water cylinder incorporating electric cylinder heater and thermal controls.

• Safety Group incorporating a Pressure Relief Valve, Check (Non-return) Valve

and Isolating Valve.

• Compression nuts and olives.

• Cylinder heater key spanner.

EN

3

Page 3

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

1.0 IMPORTANT INSTALLATION POINTS

1.1 The unit, for use with the ESTIA air to water heat pump system, is a purpose

designed unvented water cylinder.

1.2 The water cylinder MUST be fitted with a Pressure Relief Valve that complies

with your local Plumbing and Building Regulations. FAILURE TO PROVIDE

ADEQUATE PRESSURE RELIEF WILL INVALIDATE ANY GUARANTEE

AND LEAD TO A DANGEROUS INSTALLATION.

1.3 Where the inlet pressure exceeds 0.6 MPa (6 bar) a Pressure Reducing Valve

(set at max. 0.5 MPa (5 bar)) should be fitted to the inlet supply to the water

cylinder

cylinder.

1.4 A Check (non-return) Valve should be fitted to the inlet supply to the water cylinder.

This MUST NOT be fitted between the Pressure Relief Valve and the water cylinder.

1.5 This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience or

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance.

. This MUST NOT be fitted between the Pressure Relief Valve and the water

EN

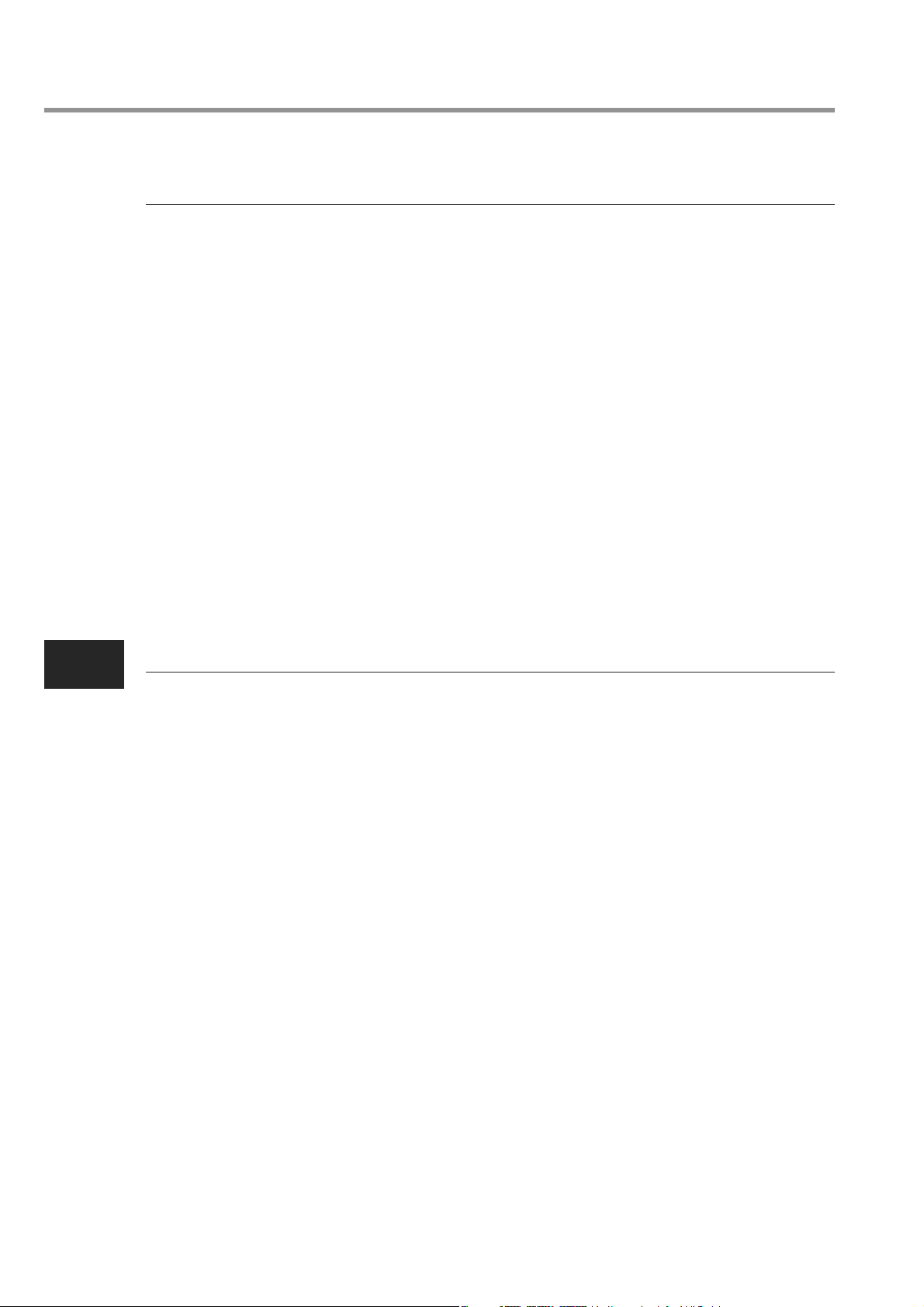

2.0 INSTALLATION – GENERAL REQUIREMENTS

2.1 National Wiring Regulations may contain restrictions concerning the installation

of these units in certain areas, eg. Bathrooms.

2.2 The unit MUST be installed vertically.

2.3 The unit must be positioned on a level surface.

2.4 Enough space should be left around the unit for pipe connections and for access

to controls and any safety valves fitted. Refer to Diagram 1 and the Dimensions

Table to determine a suitable position for the water cylinder.

2.5 NOTE: Ensure the floor can support the full weight of the unit (see TECHNICAL

SPECIFICATIONS).

2.6 DO NOT install where the unit may freeze.

2.7 The mains water supply to the property will be supplying both the hot and cold

water requirements simultaneously. It is recommended that the maximum water

demand is assessed and the water supply checked to ensure this demand can

be satisfactorily met.

NOTE: a high mains water pressure will not always guarantee high flow rates.

We suggest the minimum supply requirements should be 0.1 MPa (1.0 bar)

pressure and 20 litres per minute flowrate. However, at these values outlet flow

rates may be poor if several outlets are used simultaneously. The higher the

available pressure and flow rate the better the system performance.

2.8 LIMITATIONS:

The water cylinder should not be used in association with any of the following:

• Situations where maintenance is likely to be neglected or safety devices

tampered with.

4

Page 4

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

• Water supplies that have either inadequate pressure or where the supply

may be intermittent.

• Situations where it is not possible to safely pipe away any discharge from the

safety valves.

• Areas where the water supply consistently contains a high proportion of

solids or suspended matter unless adequate filtration can be ensured on the

inlet water supply.

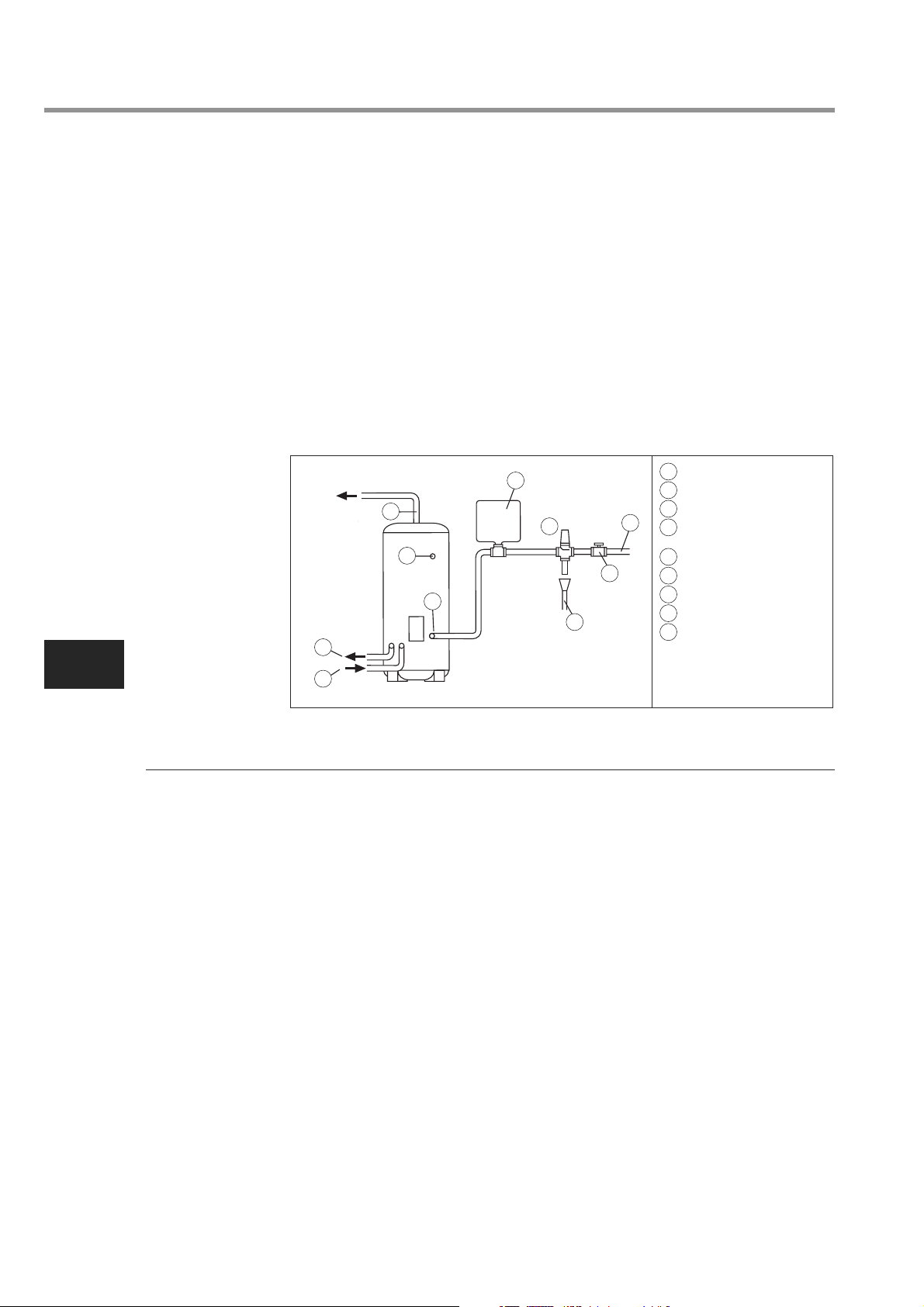

Diagram 1

NOMINAL CAPACITY (litres)

A (mm)

B (mm)

C (mm)

D (mm)

SURFACE AREA (sq.m)

HOT WATER OUTPUT AT 60ºC (litres)

MIXED HOT WATER OUTPUT AT 40ºC (litres)

HEAT LOSS (kWh/24h)

HEATING TIME 15ºC TO 60ºC - USING ELECTRIC

CYLINDER HEATER ONLY (mins)

CAPACITY HEATED USING ELECTRIC

CYLINDER HEATER ONLY (litres)

150 210 300

315 315 315

354 354 354

800 1184 1474

1090 1474 2040

0.65 0.79 0.79

102 163 254

243 329.5 476

1.45 1.91 2.52

123 188 262

102 163 254

EN

3.0 INSTALLATION – PLUMBING

3.1 Refer to section IMPORTANT INSTALLATION POINTS. Plumb in valves in the

sequence shown in Diagram 2. Ensure the valves are installed in the correct

orientation by reference to the direction of flow arrows marked on them.

The water cylinder MUST be fitted with a Pressure Relief Valve that complies

with your local Plumbing and Building Regulations. (Safety Group supplied).

FAILURE TO PROVIDE ADEQUATE PRESSURE RELIEF WILL INVALIDATE

ANY GUARANTEE AND LEAD TO A DANGEROUS INSTALLATION. Any

discharge pipe connected to the Pressure Relief device must be installed in a

continuously downward direction in a frost free environment.

3.2 The water connections on the unit accept direct connection of 22mm outside

diameter pipe; nuts and olives are supplied for this purpose. The thread on the

connections is G3/4 to enable the use of G3/4 female connections to be used if

required. DO NOT use zinc plated water pipes. When steel pipes are used the

pipe should be insulated from the stainless steel vessel by using di-electric

couplings.

3.3 The sanitary water INLET is marked BLUE,theOUTLET is marked RED.

Several hot outlets can be served, however, individual site demands should be

considered when choosing capacity and the number of outlets to be served.

3.4 It is recommended that an isolating valve is fitted on the cold water supply to

the water cylinder.

5

Page 5

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

3.5 A drain cock must be fitted below the water cylinder in the inlet pipework. It must

be sited between the water cylinder and the Check Valve.

3.6 A sanitary circuit expansion vessel may be fitted to the cold water supply as

shown in Diagram 2 to prevent wastage of expanded water. The following sizes

are recommended:

150 litre 12 litre vessel

210 litre 18 litre vessel

300 litre 24 litre vessel

3.7 A re-circulation circuit can be installed on the sanitary water circuit. A connection

is provided for the re-circulation circuit return pipe (threaded G3/4 female).

3.8 The primary heating circuit MUST be connected via the Hydro Unit. Refer to the

Installation Instructions supplied with the Hydro Unit for full details.

EN

Diagram 2

8

9

1

6

7

4

3

5

1

2

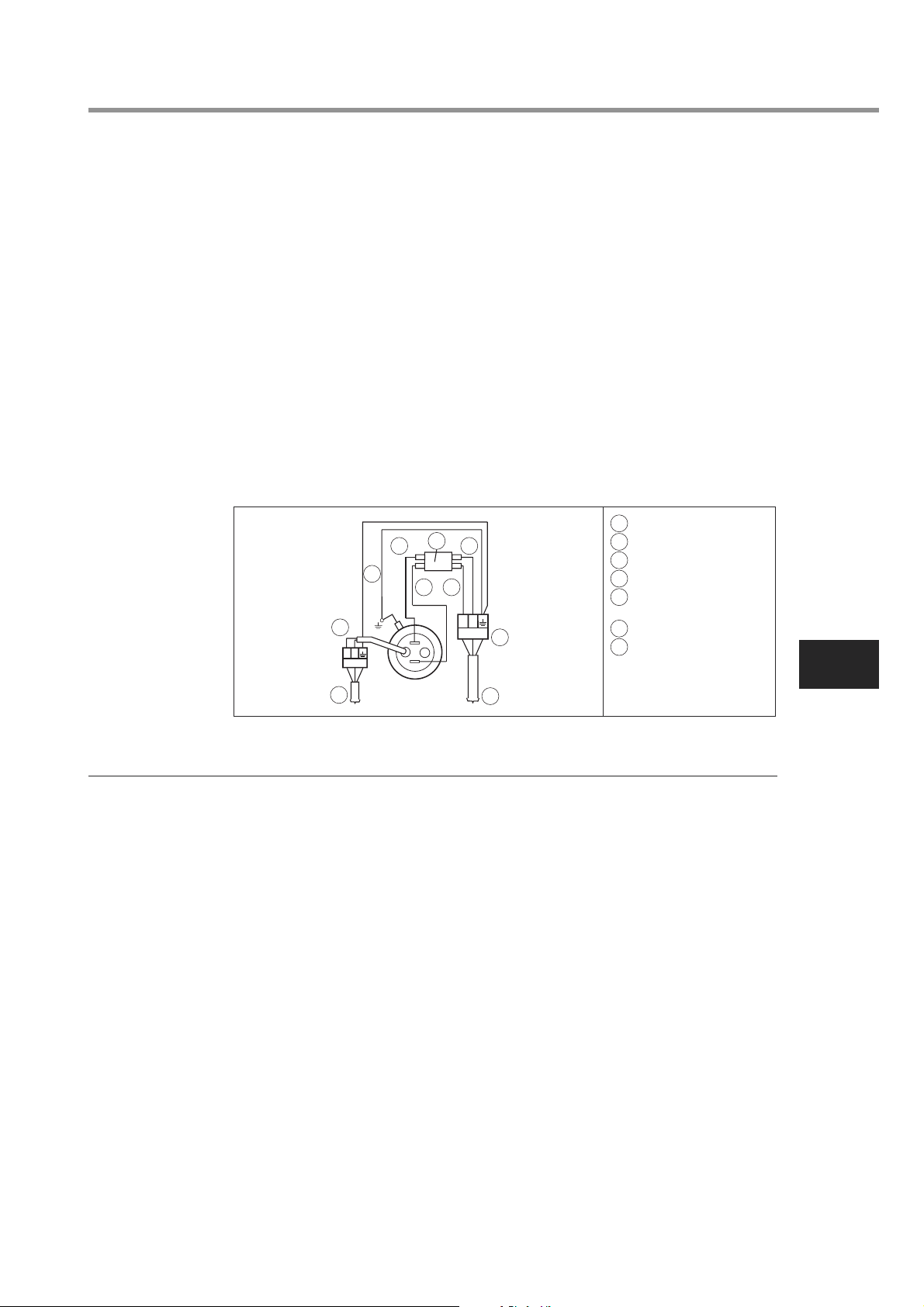

4.0 ELECTRICAL REQUIREMENTS

4.1 The unit is supplied with a factory fitted cylinder heater complete with thermal

sensor and over-temperature cut-out. The cylinder heater is rated 2.75kW at

230V~.

4.2 The cylinder heater is located behind the white terminal cover on the front of the

unit. The cover is secured by 2 screws on each side of the cover and a threaded

domed nut on the front of the cover. ISOLATE THE ELECTRICAL SUPPLY

BEFORE REMOVING THE COVER.

1 COLD WATER INLET

2 ISOLATING VALVE

3 SAFETY GROUP NF7 BAR

4 SANITARY WATER

EXPANSION VESSEL

5 DISCHARGE PIPE

6 PRIMARY CIRCUIT RETURN

7 PRIMARY CIRCUIT FLOW

8 HOT WATER OUTLET

9 SANITARY WATER

RE-CIRCULATION

CONNECTION

4.3 The cylinder heater MUST be earthed.

4.4 All electrical wiring should be carried out by a competent electrician and be in

accordance with the latest national Wiring Regulations. The circuit must be

protected by a suitable fuse and double pole isolating switch with a contact

separation of at least 3mm in both poles.

4.5 The cylinder heater should be wired in accordance with Diagram 3 and the Air to

Water Heat Pump Installation Manual. The supply cable must be via the Heat

Pump Controls Housing, direct connection to the mains electrical supply will

invalidate the guarantee and may result in a dangerous installation. The supply

cable must be routed through the right hand cable gland provided and the outer

sheath of the cable firmly secured by tightening the screw on the cable gland.

The recommended cable type is 2.5mm

2

3 core heat resistant sheathed.

4.6 The thermal sensor should be connected to the Heat Pump Controls Housing in

accordance with Diagram 3 and the Air to Water Heat Pump Installation Manual.

6

Page 6

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

1 TO HYDRO UNIT

2 SENSOR

3 GREEN/YELLOW

4BLUE

5 DOUBLE POLE THERMAL

CUT-OUT

6BROWN

7 230V~ MAINS SUPPLY

FROM HYDRO UNIT.

1.5mm

2

MIN. CABLE SIZE

The cable to the thermal sensor must be routed through the left hand cable gland

provided and the outer sheath of the cable firmly secured by tightening the screw on

2

the cable gland. The sensor cable should be 0.75mm

2 core + shield (ground) with

a maximum current rating of 100mA. The cable should not be longer than 5 metres.

4.7 Replace the terminal cover before operating.

4.8 DO NOT heat the unit until the water cylinder has been completely filled with

water.

4.9 Thermal control of the water cylinder is done by the Hydro Unit controls. Refer to

the Air to Water Heat Pump Installation Manual for instructions for setting the hot

water storage temperature.

4.10 The electrical supply from the Air to Water Heat Pump to the cylinder heater

incorporates an over-temperature thermal cut-out that will switch off the cylinder

heater in the event of a thermal control failure. DO NOT bypass the thermal

cut-out in any circumstances.

Diagram 3

5

4

4

3

2

B

A

TBO6 (TTW)

1

5.0 COMMISSIONING

WARNING: Water that is left standing in a stainless steel water cylinder for long

periods without draw off will become de-oxygenated and potentially corrode

the vessel material. If the installation is to be left unused following installation

and commissioning the water cylinder should be drained or regularly (once per

week) flushed through with fresh mains water.

When placing the unit into service the procedure for filling the unit and the

system checks detailed below should be repeated.

5.1 DO NOT switch on the Air to Water Heat Pump until the unit has been filled with

water and checked for leaks.

5.2 Check that all installation, electrical and discharge pipe requirements have been

met.

6

6

2

1

TBO3 (230V)

3

EN

7

5.3 Check that all water and electrical connections are correctly made and are tight.

5.4 Open a hot tap supplied by the unit, turn on the cold water supply to the unit.

5.5 Allow the unit to fill and leave the hot tap running for a short while to purge any

air and flush out the pipework. Close the hot tap.

5.6 Open successive hot taps to purge any air from the system.

5.7 With all hot taps closed, check the system for water leaks and rectify as necessary.

7

Page 7

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

5.8 Manually test the operation of the Pressure Relief Valve. Ensure water flows

freely from the valve and through the discharge pipe.

5.9 Fill the primary circuit following the “Water Pipe” section in the Hydro Unit

Installation Manual. Vent any trapped air by opening the air bleed point or

automatic air vent.

5.10 Switch on the electrical supply to the Air to Water Heat Pump and ensure the

programmer is set to HOT WATER mode. Check that any motorised valves or

primary pumps are working and allow the unit to heat. The hot water temperature

may be varied using the Hydro Unit remote controller, for details refer to the Air to

Water Heat Pump Owners Manual.

6.0 MAINTENANCE –

DESCALING CYLINDER HEATER

6.1 Little maintenance is required, however in hard water areas the unit will require

periodic descaling to ensure efficient operation. To descale the unit:

EN

6.2 Switch off and disconnect the electrical supply and shut down the heat pump.

Turn off the water supply to the unit.

6.3 Open a hot tap served by the unit to relieve any system pressure. Empty the unit

by opening the drain valve in the inlet pipework.

6.4 Open the terminal cover. Carefully remove the thermal sensor from its pocket on

the cylinder heater by pulling outwards.

6.5 Disconnect the link wires connecting the thermal cut-out to the cylinder heater.

Carefully remove the thermal cut-out sensing bulb from its pocket on the cylinder

heater by pulling outwards. Be careful not to kink the capillary tube.

6.6 Remove the element tail insulating shroud by pulling it outwards from the element.

6.7 Unscrew cylinder heater backnut. A key spanner is provided with the unit for

easy removal/tightening of the cylinder heater backnut. Remove the cylinder

heater from the unit. NOTE over time the cylinder heater gasket may become

stuck to the mating surface, to break the seal insert a round bladed screwdriver

into one of the pockets on the cylinder heater and gently lever up and down.

6.8 Carefully remove any scale from the surface of the element. DO NOT use a

sharp implement as damage to the element surface could be caused.

6.9 Ensure sealing surfaces are clean and seals are undamaged. If in doubt fit a

new gasket.

6.10 Replace cylinder heater ensuring the element tails are in the VERTICAL plane (see

Diagram 3). Secure in place by re-fitting cylinder heater backnut and tightening.

It may be helpful to support the cylinder heater using a round bladed screwdriver

inserted into one of the element pockets whilst the backnut is being tightened.

6.11 Replace the element tail insulating shroud by carefully pushing over the element

tails until it sits flush with the face of the element mounting plate.

6.12 Replace the thermal cut-out capillary in the LEFT HAND pocket of the cylinder

heater. Ensure it is fully inserted and that the capillary tube is not kinked.

Ensure the capillary tube is routed such that it does not come into contact with

the element tails.

8

Page 8

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

1 TERMINAL BRACKET

2 THERMAL CUT-OUT

3 SENSOR TERMINAL

BLOCK

4 MAINS TERMINAL

BLOCK

5 RESET BUTTON

LOCATED ON THIS FACE

NOTE:

THE COVER AND ELEMENT

ASSEMBLY HAVE BEEN

REMOVED FROM THIS VIEW

FOR CLARITY

6.13 Replace the thermal sensor into the LEFT HAND pocket of the cylinder heater

behind the thermal cut-out. Ensure it is fully inserted, and the securing grommet

is pushed into the open end of the pocket.

6.14 Refit the cylinder heater wiring links by inserting the male terminations into the

female terminals on the element tails in accordance with Diagram 3. Check all

wiring terminations are tight and secure. Replace and secure the terminal cover.

6.15 DO NOT SWITCH ON EITHER THE AIR TO WATER HEAT PUMP OR CYLINDER

HEATER UNTIL THE UNIT HAS BEEN RE-FILLED WITH WATER. Re-commission

the unit following the Installation and COMMISSIONING instructions.

Diagram 4

1

3

4

5

2

7.0 MAINTENANCE – SAFETY VALVES

7.1 The Pressure Relief Valve and any other safety valves fitted should be regularly

checked for correct operation.

7.2 Manually operate the valve(s) and ensure that water flows freely from the valve

and through the discharge pipe. NOTE: the water discharged may be very hot.

Ensure the valve re-seats correctly when released.

EN

8.0 USER INSTRUCTIONS

8.1 The water storage temperature at the Air to Water Heat Pump System Water

Cylinder is set at the control panel of the Hydro Unit. This can be set to give

temperatures in the range of 40ºC to 75ºC, 60ºC is recommended. Refer to the

Hydro Unit Installation Manual for details of how to adjust the storage

temperature should this be necessary.

8.2 To avoid any risk of freezing when the cylinder is not in use for long periods

during the winter months, it is recommended that the Air to Water Heat Pump

primary supply and the cylinder heater are switched off and the water cylinder is

drained. NOTE: this will not protect other parts of the system pipework. If this is

done the water cylinder must be fully re-commissioned prior to switching on the

Air to Water Heat Pump and cylinder heater or damage may be caused.

8.3 To ensure the water cylinder continues to operate at its optimum performance it

should periodically be maintained in accordance with the instructions given under

the sections headed MAINTENANCE.

9

Page 9

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

8.4 IMPORTANT NOTES TO THE USER

• Do not block or restrict the discharge from any safety valve fitted.

• Do not tamper with any safety valve fitted.

• Do not bypass the thermal cut-out in any circumstances.

• If a fault is suspected contact a qualified engineer to check the system.

9.0 SPARE PARTS

9.1 The following list of spare parts is available for the Air to Water Heat Pump water

cylinder. Refer to the technical data label on the unit to identify the model

installed and to ensure the correct parts are ordered.

9.2 DO NOT replace with parts not recommended by the manufacturer as this will

invalidate your guarantee and may render the installation dangerous.

EN

9.3 Description Part No.

1

Cylinder heater ................................................................................95:606:967

2

Cylinder heater gasket.....................................................................95:611:012

3

Cylinder heater backnut...................................................................95:607:118

Cylinder heater key spanner............................................................95:607:119

5

Thermal cut-out (cylinder heater) ....................................................95:612:038

6

Element tail insulating shroud..........................................................95:607:115

7

Terminal cover .................................................................................95:614:109

8

Terminal block (cylinder heater connection) ....................................95:607:113

9

Terminal block (thermal sensor connection)....................................95:607:114

Thermal sensor................................................................................95:612:037

Set of compression nuts and olives.................................................95:607:116

12

Secondary re-circulation connection plug .......................................95:607:117

Safety Group ...................................................................................95:605:073

Diagram 5

10

5

12

1

2

3

8

6

9

7

Page 10

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

10.0 FAULT FINDING

The table below lists some common faults, their possible causes and their remedy. Any

servicing of the water cylinder and Air to Water Heat Pump system must be carried out

by a trained competent installer.

FAULT

No hot

water flow

Waterfromhot

taps is cold

Waterfromhot

taps is only

warm

POSSIBLE CAUSE

1. Mains water supply off

2. Mains water filter

(if fitted) blocked

3. Inlet water control valves

incorrectly fitted

1. Controller on Heat Pump Hydro

Unit set to Space Heating only

2. Heat Pump not working

3. Faulty water cylinder temperature

sensor

1. Cylinder heater thermal cut-out

has operated

2. Faulty water cylinder temperature

sensor

REMEDY

1. Check and turn on mains water

supply

2. Turn off water supply. Remove

filter and clean in accordance with

manufacturers instructions

3. Check and refit as required

1. Check setting

2. Check operation of Heat Pump.

If a fault is suspected consult the

Heat Pump Manual

3. Check sensor operation.

Replace if necessary

1. Check. Reset by pushing button on

cut-out

2. Check sensor operation. Replace if

necessary

EN

Waterfromhot

taps is too hot

Water discharges

from Pressure

Relief Valve

continually

1. Water storage temperature on

Heat Pump Controller is set too

high

2. Faulty water cylinder temperature

sensor

1. Mains water pressure too high

2. Pressure Relief Valve seat is

damaged

1. Check and adjust as required

2. Check sensor operation.

Replace if necessary

1. Refer to section Important

Installation Points for correct

pressure. If necessary

fit a Pressure Reducing Valve

to inlet water supply

2. Remove and replace

11

Page 11

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

11.0 GUARANTEE

For warranty details please contact your ESTIA Heat Pump supplier.

This water cylinder is guaranteed provided that:

11.1 The unit has been installed in accordance with these instructions and all

necessary inlet controls and safety valves have been fitted correctly.

11.2 Any valves or controls are of the manufacturers recommended type.

11.3 The unit has not been tampered with and has been regularly maintained as

detailed in these instructions.

11.4 The unit has been used only for heating potable water (max. 250mg/l chloride).

11.5 The unit has not been subjected to high chloride levels in the water supply or

incorrect disinfection methods.

11.6 Following commissioning the unit is put into service within a period of 7 days.

If this is not the case it must either be drained or regularly flushed as required

in the section “Commissioning – Warning”.

EN

11.7 The unit is NOT guaranteed against damage by frost or due to build up of scale.

11.8 This guarantee does not affect the statutory rights of the consumer.

This guarantee DOES NOT cover the ESTIA Air to Water Heat Pump Outdoor

Unit or ESTIA Hydro Unit.

12.0 ENVIRONMENTAL INFORMATION

12.1 This product is manufactured from many recyclable materials. At the end of its

useful life it should be disposed of at a Local Authority Recycling Centre to

realise the full environmental benefits.

12.2 The insulation material is CFC/HCFC free expanded polyurethane foam with an

ozone depletion factor of zero.

The pace of product development is such that we reserve the right to change product

specifications without notice. We do, however, strive to ensure that all information in this

leaflet is accurate at the time of publication.

12

Page 12

AIR TO WATER HEAT PUMP SYSTEM INSTALLATION AND SERVICE MANUAL

IMPORTANT INFORMATION AND WARNING

READ BEFORE INSTALLING THE UNIT. KEEP IN A SAFE PLACE. THE INFORMATION IN THE

FOLLOWING NOTES IS NEEDED FOR THE END OF LIFE DISPOSAL OR REUSE OF THE UNIT.

• We are very sensitive to the environment and welcome the 2002/96/EC WEEE

(Waste Electrical and Electronic Equipment) Directive.

• This product is compliant with EU Directive 2002/96/EC. It must be collected

separately after its use is completed and must not be disposed of as unsorted

municipal waste.

• The objectives of the EU Directive 2002/96/EC are to tackle the fast increasing

waste stream of electrical and electronic equipment, increase the recycling of

electric and electronic equipment (“EEE”), and to limit the total quantity of waste

EEE (“WEEE”) going to disposal.

• The crossed out wheeled bin symbol that is affixed to the product indicates that

this product may fall under the Directive.

• The user is responsible for returning the product to the appropriate collection

facility as specified by your municipality or the distributor. In case of installation of

a new product, it may be possible to have the distributor pick up old WEEE

directly.

• The producer, importer and distributor are responsible for collection and

treatment of WEEE, either directly or through a collective system. The distributor

for your country is shown below.

• In case of violation of the Directive, sanctions are set in each country.

• We are in general following the CECED interpretation which considers the

WEEE Directive applicable to Portable units, De-humidifiers, WRACs (Window

Room Air to Water Heat Pumps), Split systems up to 12kW, plug in refrigerators

and freezers.

• Nevertheless, there may be differences among various member state laws.

In cases where national laws exclude some products from the WEEE scope,

those laws must be followed. In countries where these products are not covered

by the WEEE scope the WEEE obligations do not have to be followed.

• The WEEE Directive does not apply to products sold outside the European

Community. In these cases the WEEE obligations do not have to be followed,

however compliance with any local regulations must be ensured.

• For additional information please contact the municipal facility, the

shop/dealer/distributor/installer that has sold the product, or the producer.

EN

13

Page 13

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

SYSTÈME DE POMPE À CHALEUR AIR-EAU

BALLON D’EAU DOMESTIQUE (NON

RACCORDÉ) FERMÉ EN SORTIE MÉTHODE DE CHAUFFAGE INDIRECTE

MANUEL D’INSTALLATION ET DE

FR

RÉPARATION

IMPORTANT

VEUILLEZ LIRE ET COMPRENDRE CES INSTRUCTIONS AVANT D’INSTALLER

LE BALLON D’EAU. UNE INSTALLATION INCORRECTE PEUT ANNULER LA

GARANTIE. LE BALLON D’EAU DOIT ÊTRE INSTALLÉ PAR UN INSTALLATEUR

QUALIFIÉ SELON LES RÈGLES DE PLOMBERIE, DE CONSTRUCTION ET

ÉLECTRIQUES LOCALES. VEUILLEZ RANGER CE MANUEL AVEC L’UNITÉ POUR

TOUTE CONSULTATION ULTÉRIEURE.

CARACTÉRISTIQUES TECHNIQUES

Pression nominale 1,0 MPa (10 bar)

Pression d’essai (hydraulique) 1,5 MPa (15 bar)

Pression d’alimentation minimale recommandée 0,1 MPa (1 bar)

Pression de travail du circuit principal 0,35 MPa (3,5 bar)

Puissance électrique (chauffe-ballon) 2,75 kW à 230 V~

Poids (plein) 150 litres indirect 181 kg

210 litres indirect 251 kg

300 litres indirect 360 kg

14

COMPOSANTS FOURNIS

• Ballon d’eau comprenant un chauffe-ballon électrique et des contrôles thermiques.

• Groupe de sécurité intégrant une soupape de surpression, une soupape de

vérification

(sans retour) et une soupape d’isolation.

• Écrous et olives de compression.

• Clé de chauffe-ballon.

Page 14

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

1.0 POINTS IMPORTANTS CONCERNANT

L’INSTALLATION

1.1 Cet appareil, à utiliser avec le système de pompe à chaleur air/eau ESTIA, est

un cylindre à eau non raccordé conçu à cet effet.

1.2 Le ballon d'eau DOIT être équipé d'une soupape de surpression conforme aux

règlements locaux de plomberie et de construction. LE DÉFAUT DE

FOURNITURE D’UN DISPOSITIF DE DÉCOMPRESSION ADAPTÉ

ANNULERA TOUTE GARANTIE ET RENDRA L’INSTALLATION

DANGEREUSE.

1.3 Si la pression d’admission dépasse 0,6 MPa (6 bar), un détendeur de pression

(réglé à 0,5 MPa (5 bar) au maximum) doit être monté sur la ligne d’admission

du ballon d’eau. Il NE DOIT PAS être monté entre la soupape de décharge et le

ballon d’eau.

1.4 Un clapet de non-retour doit être monté sur la ligne d’alimentation du ballon d’eau.

Il NE DOIT PAS être monté entre la soupape de décharge et le ballon d’eau.

1.5 Cet appareil n'est pas destiné à un usage par des personnes (y compris les

enfants) à capacités physiques, sensorielles ou mentales réduites, ou ayant un

manque d'expérience ou de connaissances, à moins qu'ils bénéficient d'une

supervision ou d'instructions relatives à l'utilisation de l'appareil par une

personne responsable de leur sécurité. Les enfants doivent être surveillés pour

garantir qu'ils ne jouent pas avec l'appareil.

2.0 INSTALLATION - CONDITIONS GÉNÉRALES

2.1 Les règles nationales de câblage peuvent contenir des restrictions au sujet de

l’installation de ces unités dans certaines zones, par exemple. Salles de bains.

2.2 L’unité DOIT être installée verticalement.

2.3 L’unité doit être placée sur une surface de niveau.

2.4 Se référer au schéma 1 et au Tableau des dimensions pour déterminer une

position appropriée du ballon d’eau.

2.5 NOTE : assurez-vous que le plancher peut supporter le poids total de l’unité

(voir les CARACTÉRISTIQUES TECHNIQUES).

2.6 NE PAS installer dans un endroit où l’unité peut geler.

2.7 L’adduction d’eau peut ensuite fournir l’eau chaude et l’eau froide simultanément

en fonction des besoins. Il est conseillé d’évaluer la demande d’eau maximale et

de vérifier l’adduction d’eau pour faire en sorte que cette demande soit satisfaite.

REMARQUE : une pression élevée de l’adduction d’eau n’est pas toujours la

garantie d’un débit important. Nous suggérons une exigence minimale en termes

de pression d’adduction d’eau de 0,1 MPa (1,0 bar) et un débit de 20 litres par

minute. Toutefois, à ces valeurs, le débit de sortie peut être faible si plusieurs

sorties sont utilisées simultanément. Plus la pression et le débit disponibles sont

élevés, meilleure sera la performance du système.

FR

2.8 LIMITES :

le ballon d’eau ne devrait pas être utilisé dans les situations suivantes :

• Lorsque la maintenance est susceptible d’être négligée ou les dispositifs de

sécurité endommagés.

15

Page 15

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

• Lorsque l’adduction d’eau n’offre pas une pression satisfaisante ou peut être

intermittente.

• Lorsqu’il n’et pas possible d’évacuer les eaux usées des soupapes de

sécurité.

• Dans les régions où l’adduction d’eau contient régulièrement une proportion

élevée de solides ou de particules en suspension, sauf si un filtrage adéquat

peut être assuré au niveau de l’arrivée d’eau.

FR

Schéma 1

CAPACITÉ NOMINALE (litres)

A (mm)

B (mm)

C (mm)

D (mm)

SUPERFICIE (m²)

PRODUCTION D'EAU CHAUDE À 60ºC (litres)

PRODUCTION D'EAU CHAUDE À 40ºC (litres)

PERTE DE CHALEUR (kWh/24h)

TEMPS DE CHAUFFAGE DE 15ºC À 60ºC –

AU MOYEN D'UN CHAUFFAGE À CYLINDRE

ÉLECTRIQUE UNIQUEMENT (minutes)

CAPACITÉ CHAUFFÉE AU MOYEN D'UN

CHAUFFAGE À CYLINDRE ÉLECTRIQUE

UNIQUEMENT (litres)

3.0 INSTALLATION - PLOMBERIE

150 210 300

315 315 315

354 354 354

800 1184 1474

1090 1474 2040

0.65 0.79 0.79

102 163 254

243 329.5 476

1.45 1.91 2.52

123 188 262

102 163 254

16

3.1 Se référer à la section POINTS IMPORTANTS CONCERNANT

L’INSTALLATION. Montez les vannes selon la séquence indiquée par le

schéma 2. Assurez-vous que les vannes sont installées et orientées

correctement conformément aux directions des flèches de débit marquées sur

les vannes. Le ballon d'eau DOIT être équipé d'une soupape de surpression

conforme aux règlements locaux de plomberie et de construction (fournie par le

Groupe de sécurité). LE DÉFAUT DE FOURNITURE D’UN DISPOSITIF DE

DÉCOMPRESSION ADAPTÉ ANNULERA TOUTE GARANTIE ET RENDRA

L’INSTALLATION DANGEREUSE. Toute tuyauterie de décharge branchée à la

soupape de décharge doit être installée dans un sens descendant sans

interruption, dans un environnement sans gel.

3.2 Les raccordements d’eau sur l’unité acceptent la connexion directe des

tuyauteries de diamètre extérieur de 22 mm ; des écrous et olives sont fournis à

cette fin. Le filetage des raccordements est G3/4 pour permettre l’utilisation des

raccordements G3/4 si nécessaire. NE PAS utiliser de canalisations d’eau

enrobées de zinc. En cas d’utilisation de canalisations en acier, celles-ci doivent

être isolées de la cuve en acier inoxydable à l’aide de raccords diélectriques.

3.3 L’ADMISSION sanitaire de l’eau est marquée en BLEU,laSORTIE est

marquée en ROUGE. Plusieurs sorties chaudes peuvent être alimentées,

cependant, il faut considérer les différentes demandes en eau chaude du site

pour déterminer la capacité et le nombre de sorties à alimenter.

Page 16

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

3.4 Recommandé qu’une vanne d’isolement soit montée sur l’alimentation d’eau

froide du ballon d’eau.

3.5 Un robinet de purge doit être monté au-dessous du ballon d’eau au niveau

de la canalisation d’admission. Il doit être placé entre le ballon d’eau et le clapet

anti-retour.

3.6 Un vase d’expansion du circuit sanitaire peut être monté sur l’alimentation en

eau froide selon les indications du schéma 2 pour éviter le gaspillage de l’eau

d’expansion. Les dimensions suivantes sont préconisées :

150 litres vase d’expansion de 12 litres

210 litres vase d’expansion de 18 litres

300 litres vase d’expansion de 24 litres

3.7 Un circuit de recyclage peut être installé sur le circuit d’eau sanitaire. Un

raccordement est fourni pour le tuyau de retour du circuit de recyclage (femelle

fileté G3/4).

3.8 E circuit de chauffage primaire DOIT être relié via Hydro Unit. Se référer aux

instructions d’installation fournies avec Hydro Unit pour des informations

détaillées complètes.

Schéma 2

4

8

3

9

2

1

5

6

7

1 ADMISSION D'EAU FROIDE

2 VANNE D’ISOLEMENT

3 GROUPE DE SÉCURITÉ NF

1

7 BARS

4 VASE D'EXPANSION DE

L'EAU SANITAIRE

5 TUYAU DE DÉCHARGE

6 FLUX DU CIRCUIT PRIMAIRE

7 RETOUR DU CIRCUIT

PRIMAIRE

8 SORTIE D'EAU CHAUDE

9 RACCORDEMENT DE

RECYCLAGE DE L'EAU

SANITAIRE

4.0 CARACTÉRISTIQUES ÉLECTRIQUES

4.1 L’unité est fournie avec un chauffe-ballon complet monté en usine avec un

détecteur thermique et le coupe-circuit de surchauffe. Le chauffe-ballon est

calibré sur 2,75 kW à 230 Vca.

4.2 Le chauffe-ballon est situé derrière le cache du terminal blanc sur l’avant de

l’unité. Le capot est fixé par 2 vis de chaque côté et par un écrou à dôme fileté

sur l’avant du capot. ISOLER L’ALIMENTATION ÉLECTRIQUE AVANT

D’ENLEVER LE CACHE.

FR

4.3 Le chauffe-ballon DOIT être relié à la terre.

4.4 L’intégralité du câblage électrique doit être réalisée par un électricien compétent

et conformément aux plus récentes réglementations de câblage nationales. Le

circuit doit être protégé par un fusible approprié et un commutateur d’isolement

bipolaire avec une séparation des contacts supérieure à 3mm entre les deux

pôles.

4.5 Le chauffe-ballon doit être câblé selon le schéma 3 et le manuel d’installation de

pompe à chaleur. Le câble d’alimentation doit passer par le boîtier de commandes

17

Page 17

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

de pompe à chaleur, la connexion directe au réseau électrique annulera la garantie

et pourrait rendre l’installation dangereuse. Le câble d’alimentation doit passer par

le presse-étoupe droit fourni et la gaine externe du câble fermement maintenue en

serrant la vis du presse-étoupe.

4.6 La sonde thermique doit être reliée au boîtier de commande de pompe à chaleur

selon le schéma 3 et le manuel d’installation de pompe à chaleur. Le câble de la

sonde thermique doit passer par le presse-étoupe de gauche fourni et la gaine

externe du câble fermement maintenue en serrant la vis sur le presse-étoupe.

4.7 Replacez le cache de la borne avant utilisation.

4.8 NE PAS mettre l’unité en chauffe tant que le ballon d’eau n’a pas été

complètement rempli d’eau.

4.9 Le contrôle thermique du ballon d’eau est assuré par les commandes de l’Hydro

Unit. Reportez-vous au Guide d’installation de la pompe à chaleur air-eau pour

obtenir des instructions concernant le réglage de la température d’eau de

stockage.

4.10 L’alimentation électrique de la pompe à chaleur au chauffe-ballon incorpore un

coupe-circuit thermique de surchauffe qui coupe le chauffe-ballon en cas de

défaillance du contrôle de température. NE PAS court-circuiter le coupe-circuit

thermique, en aucune circonstance.

FR

Schéma 3

4

2

1

B

A

TBO6 (TTW)

3

6

5.0 MISE EN SERVICE

ATTENTION : de l’eau laissée stagnante dans un ballon d’eau en acier

inoxydable pendant de longues périodes sans être purgée peut se désoxygéner

et potentiellement corroder le matériau du réservoir. Si l’installation doit rester

inutilisée après l’installation et la mise en route, le ballon d’eau doit être vidangé

ou régulièrement purgé (une fois par semaine) via l’alimentation en eau fraiche.

Lors de la mise en place de l’unité, la procédure relative à son remplissage et

aux contrôles du système détaillée ci-dessous doit être répétée.

5.1 NE PAS mettre sous tension la pompe à chaleur tant que l’unité n’a pas été

remplie d’eau et examinée pour déceler les fuites.

1 VERS LE SYSTÈME DE

5

4

6

2

1

TBO3 (230V)

3

7

POMPE À CHALEUR

2 SONDE

3 VERT/JAUNE

4 BLEU

5 COUPE-CIRCUIT

THERMIQUE BIPOLAIRE

6 MARRON

7 ALIMENTATION RÉSEAU

13 AMPÈRES 1,5 mm

DIAMÊTRE DE CÂBLE MINI

2

18

5.2 Contrôlez que toutes les conditions d’installation, électriques et de décharge ont

été respectées.

5.3 Contrôlez que tous les raccordements hydrauliques et électriques sont

correctement réalisés et sont serrés.

5.4 Ouvrez un robinet d’eau chaude fournie par l’unité, ouvrez l’eau froide fournie

à l’unité.

Page 18

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

5.5 Laissez l’unité se remplir et laissez le robinet d’eau chaude couler pendant un

moment pour purger l’air et nettoyer la tuyauterie. Refermez le robinet d’eau

chaude.

5.6 Ouvrez les robinets d’eau chaude successivement pour purger tout l’air du système.

5.7 Avec tous les robinets d’eau chaude fermés, examinez le système pour déceler

des fuites d’eau et les colmater si nécessaire.

5.8 Testez manuellement le fonctionnement de la soupape de décharge. Assurez-vous

que l’eau s’écoule librement de la vanne et à travers la tuyauterie de décharge.

5.9 Remplissez le circuit primaire conformément à la section “Canalisation d’eau”

du Guide d’installation de l’Hydro Unit. Évacuez l’air éventuellement piégé en

ouvrant la purge d’air ou la ventilation automatique.

5.10 Mettez sous tension l’alimentation de la pompe à chaleur et assurez-vous que

le programmateur est réglé sur le mode EAU CHAUDE. Vérifiez que toutes les

vannes motorisées ou pompes primaires fonctionnent et permettent à l’unité

de chauffer. La température de l’eau chaude peut être modulée à l’aide de la

télécommande de l’Hydro Unit. Pour plus de détails, reportez-vous au Guide

du propriétaire de la pompe à chaleur air-eau.

6.0 MAINTENANCE - DÉTARTRAGE DU

CHAUFFE-BALLON

6.1 Peu d’entretien est nécessaire, toutefois dans des zones où l’eau est calcaire,

l’unité exige un détartrage périodique pour assurer un fonctionnement efficace.

Pour détartrer l’unité :

6.2 Éteignez et débranchez l’alimentation électrique et arrêtez la pompe à chaleur.

Coupez l’approvisionnement en eau à l’unité.

6.3 Ouvrez un robinet d’eau chaude fournie par l’unité pour relâcher toute pression du

système. Purgez l’unité en ouvrant la soupape de vidange au niveau de la

canalisation d’admission.

6.4 Ouvrez le cache des bornes. Déconnectez les fils reliant le coupe-circuit thermique

au chauffe-ballon. Enlevez soigneusement la sonde thermique de son

emplacement sur le chauffe-ballon en la tirant vers l’extérieur.

6.5 Enlevez soigneusement le coupe-circuit thermique détectant l’ampoule de

l’emplacement sur le chauffe-ballon en le tirant vers l’extérieur. Faites attention à ne

pas entortiller le tube capillaire.

6.6 Enlevez la monture isolante de l’élément en la tirant vers l’extérieur de l’élément.

6.7 Dévissez le contre-écrou du chauffe-ballon. Une clé est fournie avec l’unité pour

faciliter le déplacement/le serrage du contre-écrou du chauffe-ballon. Enlevez le

chauffe-ballon de l’unité. Sachez qu’avec le temps, le joint du chauffe-ballon peut

adhérer à la surface de contact. Pour casser le joint, insérez un tournevis à lames

rond dans l’un des emplacements sur le chauffe-ballon et soulevez-le doucement à

l’aide d’un levier par des mouvements oscillants.

FR

6.8 Enlevez soigneusement toute trace de calcaire de la surface de l’élément. NE PAS

utiliser d’outil pointu qui pourrait endommager la surface de l’élément.

19

Page 19

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

1 SUPPORT DE BORNES

2 COUPE-CIRCUIT

THERMIQUE

3 BORNIER

DE LA SONDE

4 BORNIER

D’ALIMENTATION

5 BOUTON DE RÉINITIALISATION

SITUÉ SUR CETTE SURFACE

NOTE:

LE COUVERCLE ET L'ÉLÉMENT

ONT ÉTÉ ENLEVÉS DE CETTE

VUE POUR PLUS DE CLARTÉ

6.9 Assurez-vous que les surfaces d’étanchéité sont propres et les joints intacts.

En cas de doute, montez un nouveau joint.

6.10 Remettez le chauffe-ballon en vous assurant que les tiges de l'élément se situent

dans le plan VERTICAL (vois schéma 3). Fixez en place en remettant le

contre-écrou du chauffe-ballon et en le serrant. Il peut être utile de soutenir le

chauffe-ballon à l’aide d’un tournevis à lames rond inséré dans l’un des

emplacements de l’élément pendant le serrage du contre-écrou.

6.11 Replacez la monture isolante de tige d’élément en poussant soigneusement sur

des tiges jusqu’à ce qu’elle repose à affleurement sur la surface du support de

montage de l’élément.

6.12 Remplacez le tube capillaire de coupure thermique dans la poche GAUCHE du

chauffe-ballon. Assurez-vous qu’il est parfaitement inséré et que le tube capillaire

n’est pas tordu. Vérifiez que le tube capillaire est orienté de telle manière qu’il

n’entre pas en contact avec les rejets de l’élément.

6.13 Replacez le capteur thermique dans la poche GAUCHE du chauffe-ballon, en aval

de la coupure thermique. Assurez-vous qu’il est parfaitement inséré et que le guide

de sécurité pénètre dans l’extrémité ouverte de la poche.

FR

6.14 Repositionnez les câbles du chauffe-ballon en insérant les terminaisons mâles

dans les terminaisons femelles sur les tiges de l’élément selon le schéma 3 Vérifiez

que toutes les terminaisons de câblage sont serrées et bloquées. Replacez et fixez

le cache des bornes.

6.15 NE PAS BRANCHER LA POMPE À CHALEUR OU LE CHAUFFE-BALLON

TANT QUE L’UNITÉ N’A PAS ÉTÉ REMPLIE D’EAU. Remettez l’unité en service

en suivant les instructions d’installation et de MISE EN SERVICE.

Schéma 4

1

3

4

5

2

20

Page 20

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

7.0 MAINTENANCE - SOUPAPES DE SÛRETÉ

7.1 La soupape de décharge et toutes les autres soupapes de sûreté montées

doivent être régulièrement examinées pour assurer un fonctionnement correct.

7.2 Actionnez manuellement les vannes et assurez-vous que l’eau s’écoule

librement de la vanne et à travers la tuyauterie de décharge. REMARQUE :

l’eau déchargée peut être très chaude. Assurez-vous que la vanne se

repositionne correctement une fois libérée.

8.0 INSTRUCTIONS D’UTILISATEUR

8.1 La température de stockage de l’eau dans le ballon d’eau du système de pompe

à chaleur air-eau est réglée sur le panneau de commande de l’Hydro Unit. On peut

la régler de manière à obtenir une température située entre 45ºC et 75ºC ; la

température recommandée est de 60ºC. Reportez-vous au Guide d’installation

de l’Hydro Unit pour plus de détails sur le réglage de la température de stockage

au besoin.

8.2 Pour éviter les risques de gel lorsque le chauffe-ballon reste inutilisé pendant de

longues périodes au cours des mois d’hiver, il est recommandé de déconnecter

l’alimentation primaire de la pompe à chaleur et le dispositif chauffant à

immersion, puis de vidanger le ballon d’eau . REMARQUE : cela ne protège pas

les autres éléments du réseau de canalisations. Si vous faites cela, le ballon

d’eau devra être entièrement remis en service avant la mise en marche de la

pompe à chaleur et du dispositif de chauffage à immersion ; dans le cas

contraire, le système pourrait être endommagé.

8.3 Afin de garantir le niveau de fonctionnement optimal du ballon d’eau, il doit

régulièrement être entretenu selon les instructions indiquées dans les différentes

sections MAINTENANCE.

8.4 NOTES IMPORTANTES À DESTINATION DE L’UTILISATEUR

• Ne bloquer ou limiter la décharge d’aucune soupape de sûreté montée.

• Ne manipuler aucune soupape de sûreté montée.

• Ne court-circuiter le coupe-circuit thermique en aucune circonstance.

• Si un défaut est suspecté, contacter un technicien qualifié pour

contrôler le système.

FR

21

Page 21

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

9.0 PIÈCES DE RECHANGE

9.1 La liste suivante de pièces de rechange est disponible pour le ballon d’eau à

pompe à chaleur. Référez-vous à l’étiquette des caractéristiques techniques

située sur l’unité pour identifier le modèle installé et pour vous assurer que les

pièces correctes sont commandées.

9.2 NE remplacez PAS par des pièces non recommandées par le fabricant car ceci

annulerait votre garantie et rendrait l’installation dangereuse.

9.3 Description N° de pièce

1

Chauffe-ballon .................................................................................95:606:967

2

Joint de chauffe-ballon.....................................................................95:611:012

3

Contre-écrou de chauffe-ballon.......................................................95:607:1 18

Clé de chauffe-ballon.......................................................................95:607:119

5

Coupe-circuit thermique (chauffe-ballon)........................................95:612:038

6

Monture isolante de tige d’élément .................................................95:607:1 15

7

Cache de bornes .............................................................................95:614:109

8

Bornier (raccordement du chauffe-ballon).......................................95:607:113

9

Bornier (raccordement de la sonde thermique)...............................95:607:114

Sonde thermique .............................................................................95:612:037

Ensemble d’écrous et d’olives de compression ..............................95:607:116

12

Prise secondaire de raccordement de recyclage............................95:607:1 17

Groupe de sécurité..........................................................................95:605:073

FR

Schéma 5

5

12

1

2

3

8

6

9

7

22

Page 22

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

10.0 DÉTERMINATION DES DÉFAUTS

Le tableau ci-dessous répertorie quelques défauts courants, leurs origines possibles et

leur remède. Toute opération de maintenance du système ballon d’eau et pompe à

chaleur doit être effectuée par un installateur parfaitement qualifié.

DÉFAUT

Aucun

écoulement

d’eau chaude

L’eau des

robinets d’eau

chaude est froide

L’eau des

robinets d’eau

chaude est tiède

CAUSE POSSIBLE

1. Coupure de l’alimentation en eau

2. Filtre d’alimentation d’eau (si

monté) obturé

3. Soupapes de commande

d’admission d’eau montées de

manière incorrecte

1. Le contrôleur sur la pompe à

chaleur l’Hydro Unit est réglé sur

chauffage des locaux uniquement

2. La pompe à chaleur ne fonctionne

pas

3. Sonde de température de

ballon d’eau défaillante

1. Le coupe-circuit thermique du

chauffe-ballon s’est enclenché

2. Sonde de température de

ballon d’eau défaillante

REMÈDE

1. Vérifiez et ouvrez

l’approvisionnement en eau

2. Coupez l’approvisionnement en

eau. Enlevez le filtre et nettoyez

selon des instructions indiquées

par les fabricants

3. Vérifiez et remontez si nécessaire

1. Vérifiez le réglage

2. Vérifiez le fonctionnement de la

pompe à chaleur. Si un défaut est

suspecté, consultez le manuel de

la pompe à chaleur

3. Vérifiez le fonctionnement de la

sonde. Replacez-la au besoin

1. Contrôlez. Réinitialisez en

appuyant sur le bouton du coupecircuit

2. Vérifiez le fonctionnement de la

sonde. Replacez-la au besoin

FR

L’eau des

robinets d’eau

chaude est trop

chaude

L’eau se

décharge de

façon continue

par la soupape

de décharge

1. La température de stockage de

l’eau est réglée sur une valeur trop

élevée sur le contrôleur de pompe

à chaleur

2. Sonde de température de

ballon d’eau défaillante

1. Pression d’eau de distribution trop

élevée

2. Le siège de la soupape de

décharge est endommagé

1. Vérifiez et ajustez au besoin

2. Vérifiez le fonctionnement de la

sonde. Replacez-la au besoin

1. Se référer à la section Points

importants concernant l’installation

pour définir la pression correcte.

Adaptez au besoin une vanne

réduisant la pression au niveau de

l’admission d’eau

2. Enlevez et remplacez

23

Page 23

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

11.0 GARANTIE

Pour les détails concernant la garantie, veuillez contacter votre fournisseur de

pompe à chaleur ESTIA.

1 1.1 L’unité a été installée selon ces instructions et toutes les commandes

d’admission et soupapes de sûreté nécessaires ont été montées correctement.

1 1.2 Toutes les vannes ou commandes sont du type préconisé par les fabricants.

1 1.3 L’unité n’a pas été démontée et a été régulièrement entretenue selon les

informations détaillées dans ces instructions.

1 1.4 L’unité a été utilisée uniquement pour le chauffage d’eau potable (max. 250 mg/l

de chlorure).

1 1.5 L’unité n’a pas fait l’objet de niveaux de chlorure élevés dans l’alimentation en

eau, ni de méthodes de désinfection incorrectes.

1 1.6 À la suite de la mise en service, l’unité doit être mise en service dans les 7 jours.

Si ce n’est pas le cas, elle doit être vidangée ou régulièrement purgée comme

cela est précisé dans la partie “Mise en service - attention”.

FR

1 1.7 L’unité n’est pas garantie contre des dommages provoqués par le gel ou par

l’accumulation de calcaire.

1 1.8 Cette garantie n’affecte pas les droits statutaires du consommateur.

Cette garantie NE couvre PAS l'appareil externe de la pompe à chaleur air/eau

ESTIA ou l’Hydro Unit ESTIA.

12.0 INFORMATIONS SUR L’ENVIRONNEMENT

12.1 Ce produit est fabriqué à partir de nombreux matériaux recyclables. À la fin de

sa vie d’utilisation, il devrait être éliminé dans un centre de recyclage local afin

de respecter les exigences environnementales.

12.2 Le matériel d’isolation est de la mousse de polyuréthane expansée sans

CFC/HCFC sans incidence sur l’appauvrissement de la couche d’ozone.

Le rythme du développement produit est tel que nous nous réservons le droit de modifier

certaines caractéristiques produit sans information préalable. Nous tâchons, cependant,

de nous assurer que toute l’information contenue dans ce livret est précise à l’heure de la

publication.

24

Page 24

SYSTÈME DE POMPE À CHALEUR AIR-EAU MANUEL D’INSTALLATION ET DE RÉPARATION

INFORMATIONS IMPORTANTES ET

AVERTISSEMENT

VEUILLEZ LIRE AVANT TOUTE INSTALLATION DE L'APPAREIL. GARDEZ EN LIEU SÛR. LES

INFORMATIONS PRÉSENTES DANS LES NOTES SUIVANTES SONT NÉCESSAIRES POUR

L'ÉLIMINATION EN FIN DE VIE D'UTILISATION DE L'APPAREIL ET POUR SA RÉUTILISATION.

• Nous sommes très sensibles à l'environnement et nous réjouissons de la

Directive 2002/96/EC DEEE (Directive relative aux déchets d'équipements

électriques et électroniques).

• Ce produit est conforme à la directive de l'UE 2002/96/EC. Vous devez collecter

ce produit séparément après la fin de son utilisation et ne devez pas le jeter

comme déchet ménager non trié.

• Les objectifs de la Directive de l'UE 2002/96/EC sont de s'attaquer au flux de

déchets à croissance rapide des équipements électriques et électroniques,

d'augmenter le recyclage des équipements électriques et électroniques (“EEE”)

et de limiter la quantité totale des déchets EEE (“DEEE”) qui part à la décharge.

• Le symbole de la poubelle rayée d'une croix qui figure sur le produit indique que

ce produit entre dans la catégorie de cette directive.

• L'utilisateur est responsable du renvoi du produit à l'installation de collecte

appropriée, tel que le stipule votre municipalité ou votre distributeur. En cas

d'installation d'un nouveau produit, il est possible d'organiser la collecte directe

de votre ancien DEE par votre distributeur.

• Le producteur, l'importateur et le distributeur sont responsables de la collecte et

du traitement des DEEE, que ce soit de façon directe ou par le biais d'un

système collectif. Le distributeur de votre pays est indiqué ci-dessous.

• En cas de violation de la Directive, des sanctions sont prévues dans chaque pays.

• Nous respectons en général l'interprétation du CECED qui considère que la

Directive DEEE est applicable aux unités portatives, aux déshumidificateurs, aux

Pompes à chaleur air/eau pour les pièces avec fenêtre, aux systèmes biblocs

jusqu'à 12 kW, aux réfrigérateurs et congélateurs électriques.

• T outefois, il peut exister des différences entre les diverses lois des États

membres. Dans les cas où les lois nationales excluent certains produits du

champ d'application de la DEEE, ces lois doivent être respectées. Dans les pays

où ces produits ne relèvent pas du champ d'application de la DEEE, les

obligations de la DEEE ne doivent pas être respectées.

• La Directive DEEE ne s'applique pas aux produits vendus en dehors de la

Communauté européenne. Dans ces cas-là, les obligations de la DEEE n'ont

pas besoin d'être respectées, mais le respect de tout règlement local doit être

assuré.

FR

• Pour de plus amples informations, veuillez contacter les équipements

municipaux, le magasin/négociant/distributeur/installateur qui vous a vendu le

produit ou bien le producteur.

France Carrier S.A. Route de Thil, BP 49 01122 Montiuel

Cedex, France.

25

Page 25

NOTES

130

Page 26

France

Carrier S.A. Route de Thil

BP 49 01122 Montiuel

Cedex France

Germany / Deutchsland

Carrier GmbH & Co. KG

Edisonstrasse 2 85716

Unterschleissheim

Czech Republic / Česko

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Greece / Ελλάδα

Carrier Hellas

Aircondilioning S.A.- 4g

Andersen street-11525

Athens Greece

Sweden / Sverige

Carrier AB - P.O.BOX 8946Arods Industrivag 32. S-402

73 Gothenburg Sweden

Norway / Norge

Carrier AB - P.O.BOX 8946Arods Industrivag 32. S-402

73 Gothenburg Sweden

Croatia / Hrvatska

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Austria / Österreich

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Hungary / Magyar

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Slovakia / Slovensko

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Slovenia / Slovenija

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

Loading...

Loading...