Page 1

AIR TO WATER HEAT PUMP SYSTEM

HOT WATER CYLINDER

INDIRECT HEATING METHOD

CLOSED OUTLET (UNVENTED)

INSTALLATION AND SERVICE MANUAL

HWS-1501CSHM3-UK

HWS-2101CSHM3-UK

HWS-3001CSHM3-UK

36006030_Issue_D

1

Page 2

2

INSTALLATION AND SERVICING INSTRUCTIONS, FOR AIR TO WATER HEAT

Maximum water supply pressure to PRV 1.6MPa (16.0 bar)

Operating pressure of unit 0.35MPa (3.5 bar)

Expansion vessel charge pressure 0.35MPa (3.5 bar)

Expansion valve setting 0.6MPa (6.0 bar)

Nominal storage capacity of units (see Section 2 Table 2)

Max. primary working pressure 0.3MPa (3.0 bar)

Opening temperature of T&P Relief Valve 90deg C

Opening pressure of T&P Relief Valve 1.0 MPa (10 bar)

PUMP SYSTEM WATER CYLINDER. PLEASE LEAVE THIS MANUAL WITH THE

UNIT FOR FUTURE REFERENCE.

CONTENTS

SECTION CONTENT PAGE

1 INTRODUCTION . . . . . . . 2

2 GENERAL REQUIREMENTS . . . . . . 3

3 INSTALLATION - GENERAL . . . . . . 4

4 INSTALLATION – INDIRECT UNITS . . . . . 9

5 COMMISSIONING . . . . . . . 9

6 MAINTENANCE . . . . . . . 10

7 FAULT FINDING AND SERVICING . . . . . 11

8 USER INSTRUCTIONS . . . . . . 13

9 GUARANTEE . . . . . . . . 14

1.0 INTRODUCTION

IMPORTANT: THIS APPLIANCE IS NOT

INTENDED FOR THE USE BY PERSONS

(INCLUDING CHILDREN) WITH REDUCED

PHYSICAL, SENSORY OR MENTAL CAPABILITIES, OR LACK OF KNOWLEDGE AND EXPERIENCE, UNLESS THEY HAVE BEEN GIVEN

SUPERVISION OR INSTRUCTION CONCERNING THE USE OF THE APPLIANCE BY A PERSON RESPONSIBLE FOR THEIR SAFETY.

This unit, for use with the air to water heat pump

system, is a purpose designed unvented water cylinder. The unit has a stainless steel inner vessel which

ensures an excellent standard of corrosion resistance.

The outer casing is a combination of resilient thermoplastic mouldings and plastic coated corrosion

proofed steel sheet.

Table 1: Operational Summary

The unit is supplied complete with all the necessary

safety and control devices needed to allow connection to the cold water mains. All these components

are pre-adjusted.

This appliance complies with the requirements of the

CE marking directive and is KIWA approved to show

compliance with Building Regulations (Section G3)

and UK Water Regulations.

The following instructions are offered as a guide to

installation which must be carried out by a competent

plumbing and electrical installer in accordance with

Building Regulation G3, The Building Standards

(Scotland) Regulations Section 4 standard 4.9, or

The Building Regulations (Northern Ireland) Part P

Section P5.

NOTE: Prior to installation the unit should be stored

in an upright position in an area free from excessive

damp or humidity.

IMPORTANT: PLEASE READ ALL THESE INSTRUCTIONS BEFORE

COMMENCING INSTALLATION

Page 3

3

2.0 GENERAL REQUIREMENTS

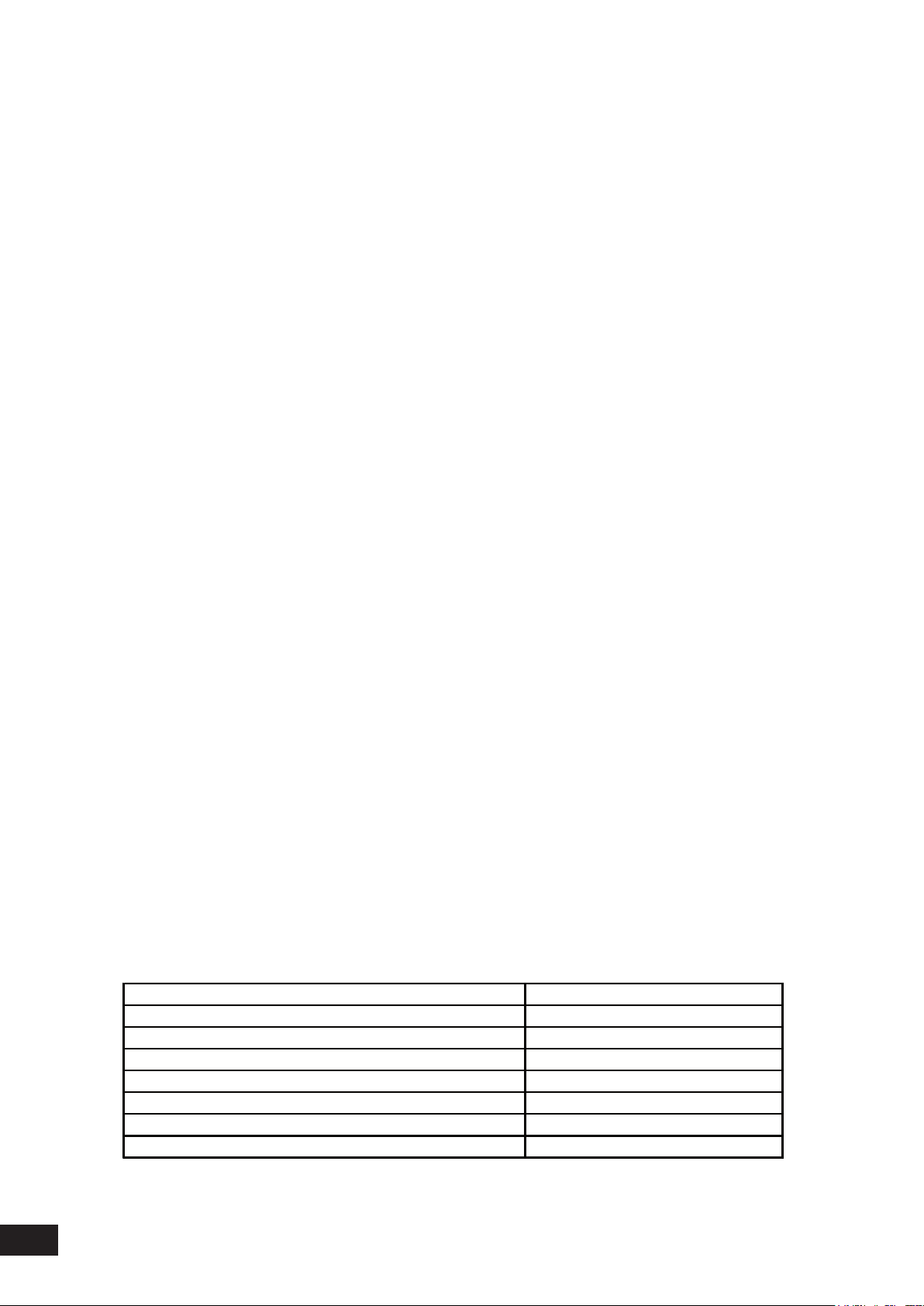

Type Nominal

capacity

(litres )

W eight of

unit full

(kg)

INDIREC T

HWS-1501CSHM3-UK

150

210

300

HWS-2101CSHM3-UK

HWS-3001CSHM3-UK

181

251

360

Model

Nomin a l

ca pa ci ty pe r d a y pe r ye a r

(litres ) (kW h/ 24h) (kW h/365d)

150 1.45 529.3

210 1.91 697.2

300 2.52 919.8

Standing He at Loss

2.1 COMPONENTS SUPPLIED

1. Unvented water cylinder incorporating

cylinder heater and thermal controls

2. Factory tted Temperature/Pressure Relief Valve

3. T&P Valve insulation and housing.

4. Cold Water Combination Valve.

5. Expansion Vessel and mounting bracket.

6. Tundish.

7. Compression nuts and olives

8. Immersion heater key spanner

2.2 SITING THE UNIT

The unit must be installed vertically. Although location is not critical, the following points should be

considered:

• The unit should be sited to ensure minimum dead

leg distances, particularly to the point of most frequent

use.

• Avoid siting where extreme cold temperatures

will be experienced. All exposed pipework should be

insulated.

• The discharge pipework from the safety valves

must have minimum fall of 1:200 from the unit and

terminate in a safe and visible position.

• Access to associated controls and cylinder heater

should be possible to allow for periodic servicing and

maintenance.

• Ensure that the base chosen for the unit is level

and capable of permanently supporting the weight

when full of water (see Table 2).

bar) that is controlled by the Cold Water Combination

Valve. The Cold Water Combination Valve can be

connected to a maximum mains pressure of 1.6MPa

(16 bar).

2.4 OUTLET/TERMINAL FITTINGS (TAPS, ETC.)

The unit can be used with most types of terminal ttings. It is advantageous in many mixer showers to

have balanced hot and cold water supplies. In these

instances a balanced pressure cold water connection

should be placed between the Cold Water Combination

Valve and the water cylinder. Outlets situated higher

than the unit will give outlet pressures lower than that

at the heater, a 10m height difference will result in a

0.1MPa (1 bar) pressure reduction at the outlet.

2.5 LIMITATIONS

The unvented water cylinder should not be used in

association with any of the following:

• Ascending spray type bidets or any other class 1

back syphonage risk requiring that a type A air gap

be employed.

• Situations where maintenance is likely to be

neglected or safety devices tampered with.

• Water supplies that have either inadequate pres-

sure or where the supply may be intermittent.

• Situations where it is not possible to safely pipe

away any discharge from the safety valves.

• In areas where the water consistently contains a

high proportion of solids, e.g. suspended matter that

could block the strainer, unless adequate ltration can

be ensured.

Table 2: Unit weights

2.3 WATER SUPPLY

Bear in mind that the mains water supply to the

property will be supplying both the hot and cold water requirements simultaneously. It is recommended

that the maximum water demand is assessed and the

water supply checked to ensure this demand can be

satisfactorily met.

NOTE: A high mains water pressure will not always

guarantee high ow rates.

Wherever possible the mains supply pipe should be

22mm. We suggest the minimum supply requirements

should be 0.15MPa (1.5 bar) pressure and 20 litres

per minute owrate. However, at these values outlet

owrates may be poor if several outlets are used si-

multaneously. The higher the available pressure and

owrate the better the system performance.

The unit has an operating pressure of 0.35MPa (3.5

Table 3: Standing heat losses

Based on an ambient air temperature of 20oC and a

stored water temperature of 65oC

Page 4

4

3.0 INSTALLATION – GENERAL

COLD

INLET

CONNECTION

COLD

SUPPLY

CHECK

VALVE

SECONDARY

RETURN

SECONDARY

CIRCULATION

PUMP

SWEPT

TEE

3.1 PIPE FITTINGS

All pipe ttings are made via 22mm compression

ttings directly to the unit. The ttings are threaded

3/4”BSP male parallel should threaded pipe connec-

tions be required.

3.2 COLD FEED

A 22mm cold water supply is recommended however,

if a 15mm (1/2”) supply exists which provides sufcient ow this may be used (although more ow

noise may be experienced).

A stopcock or servicing valve should be incorporated

into the cold water supply to enable the unit and its

associated controls to be isolated and serviced.

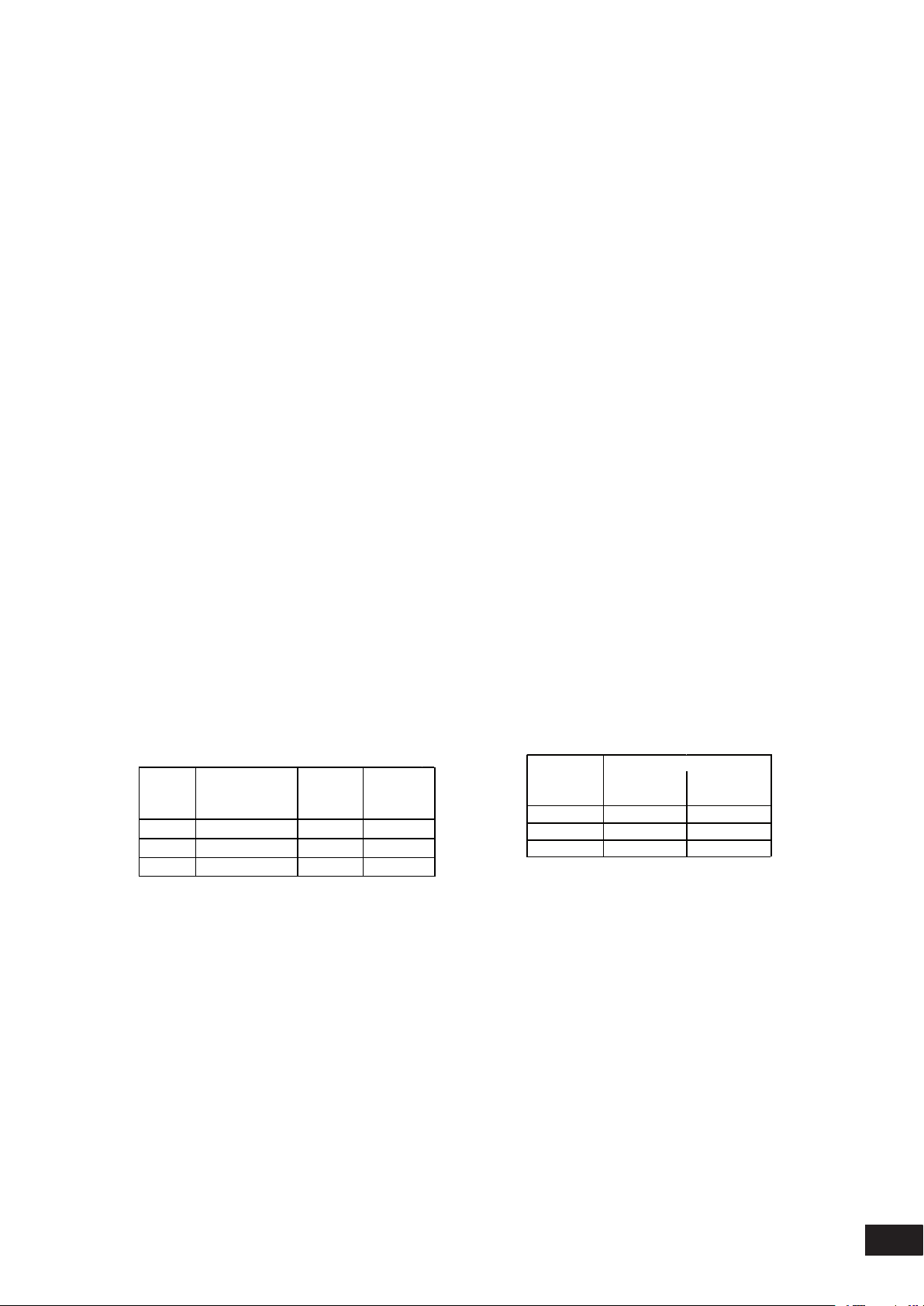

3.3 COLD WATER COMBINATION VALVE (FIG 1)

The Cold Water Combination Valve can be connected

anywhere on the cold water mains supply prior to the

Expansion Vessel (see Fig. 5). The Cold Water Combination Valve is installed as a complete one-piece

unit. The valve incorporates the Pressure Reducer,

Strainer, Expansion Valve and Check Valve. Ensure

that the valve is installed with the direction of ow

arrows pointing in the right direction. No other valves

should be placed between the Cold Water Combination

Valve and the unit. The Expansion Valve connection

must not be used for any other purpose.

3.5 EXPANSION VESSEL

The Expansion Vessel accommodates expansion that

results from heating the water inside the unit. The unit

is pre-charged at 0.35MPa (3.5 bar). The Expansion

Vessel must be connected between the Cold Water

Combination Valve and the water cylinder (see Fig.

5). The location of the Expansion Vessel should

allow access to recharge the pressure as and when

necessary, this can be done using a normal car foot

pump. It is recommended that the Expansion Vessel

is adequately supported. An Expansion Vessel wall

mounting bracket is supplied for this purpose

3.6 SECONDARY CIRCULATION

If secondary circulation is required it is recommended

that it be connected to the cylinder as shown in Fig. 2

via a swept tee joint into the cold feed to the unit.

The secondary return pipe should be in 15mm pipe

and incorporate a check valve to prevent backow. A

suitable WRAS approved bronze circulation pump

will be required. On large systems, due to the increase

in system water content, it may be necessary to t an

additional expansion vessel to the secondary circuit.

this should be done if the capacity of the secondary

circuit exceeds 10 litres.

Pipe capacity (copper)

15mm o/d = 0.13 l/m (10 litres = 77m)

22mm o/d = 0.38 l/m (10 litres = 26m)

28mm o/d = 0.55 l/m (10 litres = 18m)

EXPANSION VALVE

COLD MAINS

CONNECTION

(22mm)

PRESSURE

REDUCING

VALVE

HOUSING

PRESSURE

REDUCING

VALVE

CARTRIDGE (3.5 bar)

FIG. 1 Cold Water Combination Valve

3.4 DRAIN TAP

A suitable draining tap should be installed in the

cold water supply to the unit between the Cold Water

Combination Valve and the heater at as low a level as

possible. It is recommended that the outlet point of the

drain pipework be at least 1 metre below the level of

the cylinder (this can be achieved by attaching a hose

to the drain tap outlet spigot).

EXPANSION VALVE

OUTLET (15mm)

OUTLET

CONNECTION

(22mm)

FIG. 2 Secondary circulation connection

3.7 OUTLET

The hot water outlet is a 22mm compression tting

located at the top of the cylinder. Hot water distribution pipework should be 22mm pipe with short runs

of 15mm pipe to terminal ttings such as sinks and

basins. Pipe sizes may vary due to system design.

Page 5

5

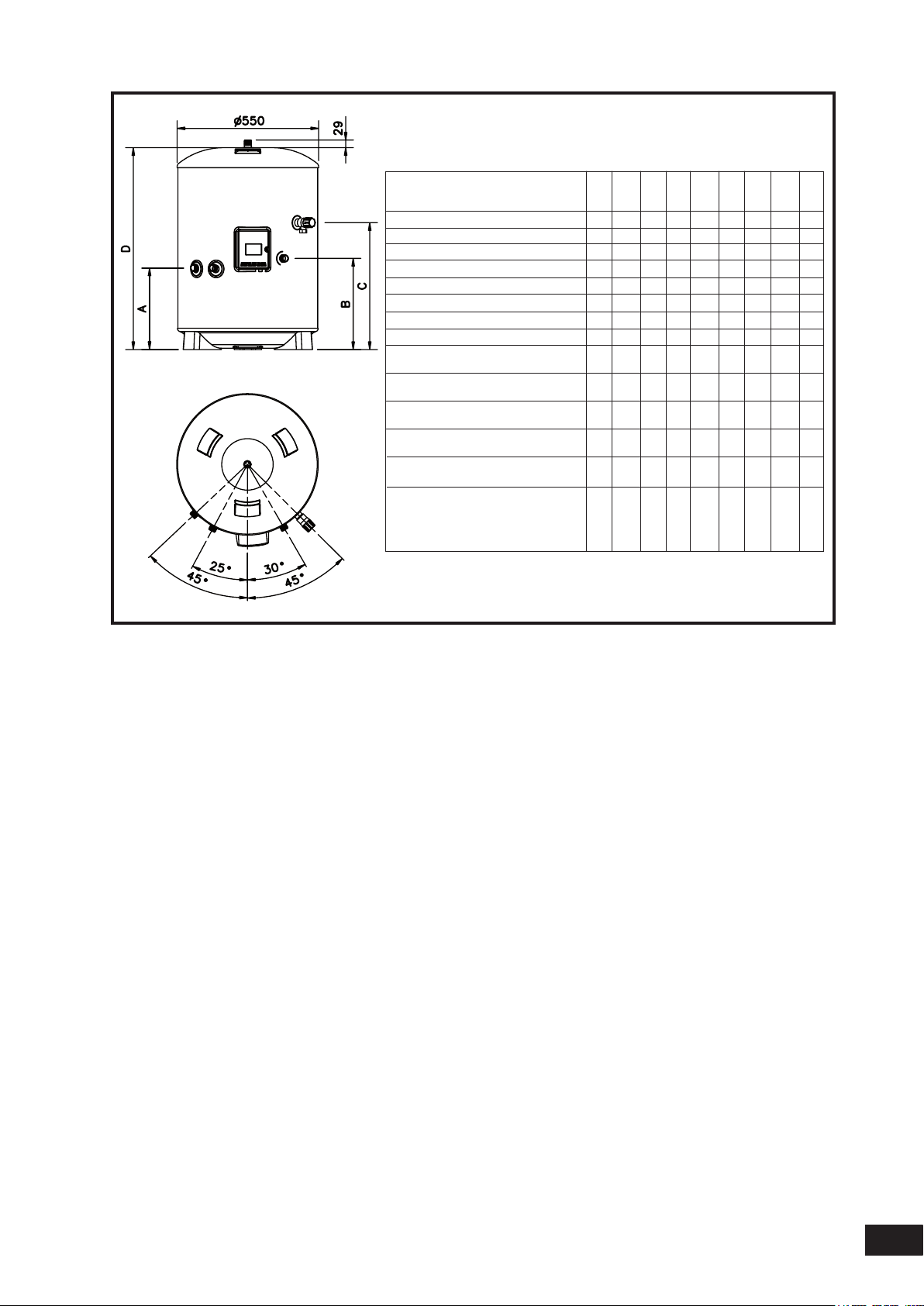

FIG. 3 General Dimensions and Performance

NOMINAL CAPACITY(litres)

A (mm)

B (mm)

C (mm)

D (mm)

SURFACEAREA (sq.m)

HOTWATER OUTPUT AT60ºC (litres)

MIXED HOTWATEROUTPUTAT40ºC(litres)

HEATLOSS (kWh/24h)

HEATING TIME 15ºC TO60ºC- USING ELECTRIC

IMMERSION HEATERONLY(mins)

CAPACITYHEATED USINGELECTRIC

IMMERSION HEATERONLY(litres)

HEATING TIME 10ºC TO40ºC- USING HEAT

PUMPONLY(mins)

HEATING TIME 10ºC TO60ºC- USING HEAT

PUMPAND ELECTRIC IMMERSION HEATER(mins)

RECOVERY TIME - FOLLOWING70%DRAW OFF

(min

s)

NOTE: Capacity heated using the electric

immersion heater only.

150 150 150 210 210 210 300 300 300

8kW 11.2kW 14kW 8kW 14kW 8kW 14kW

315 315 315 315 315 315 315 315 315

354 354 354 354 354 354 354 354 354

800 800 800 1184 1184 1184 1474 1474 1474

1090 1090 1090 1474 1474 1474 2040 2040 2040

0.55 0.55 0.55 0.68 0.68 0.68 0.79 0.79 0.79

102 102 102 163 163 163 254 254 254

243 243 243 329.5 329.5 329.5 476 476 476

1.45 1.45 1.45 1.91 1.91 1.91 2.52 2.52 2.52

123 123 123 188 188 188 262 262 262

102 102 102 163 163 163 254 254 254

24 23 22 35 33 31 49 45 41

65 63 61 92 85 78 160 154 147

53 5

3 51 71 68 65 103 99 95

HEAT PUMP RATING (kW)

11.2kW 11.2kW

Page 6

6

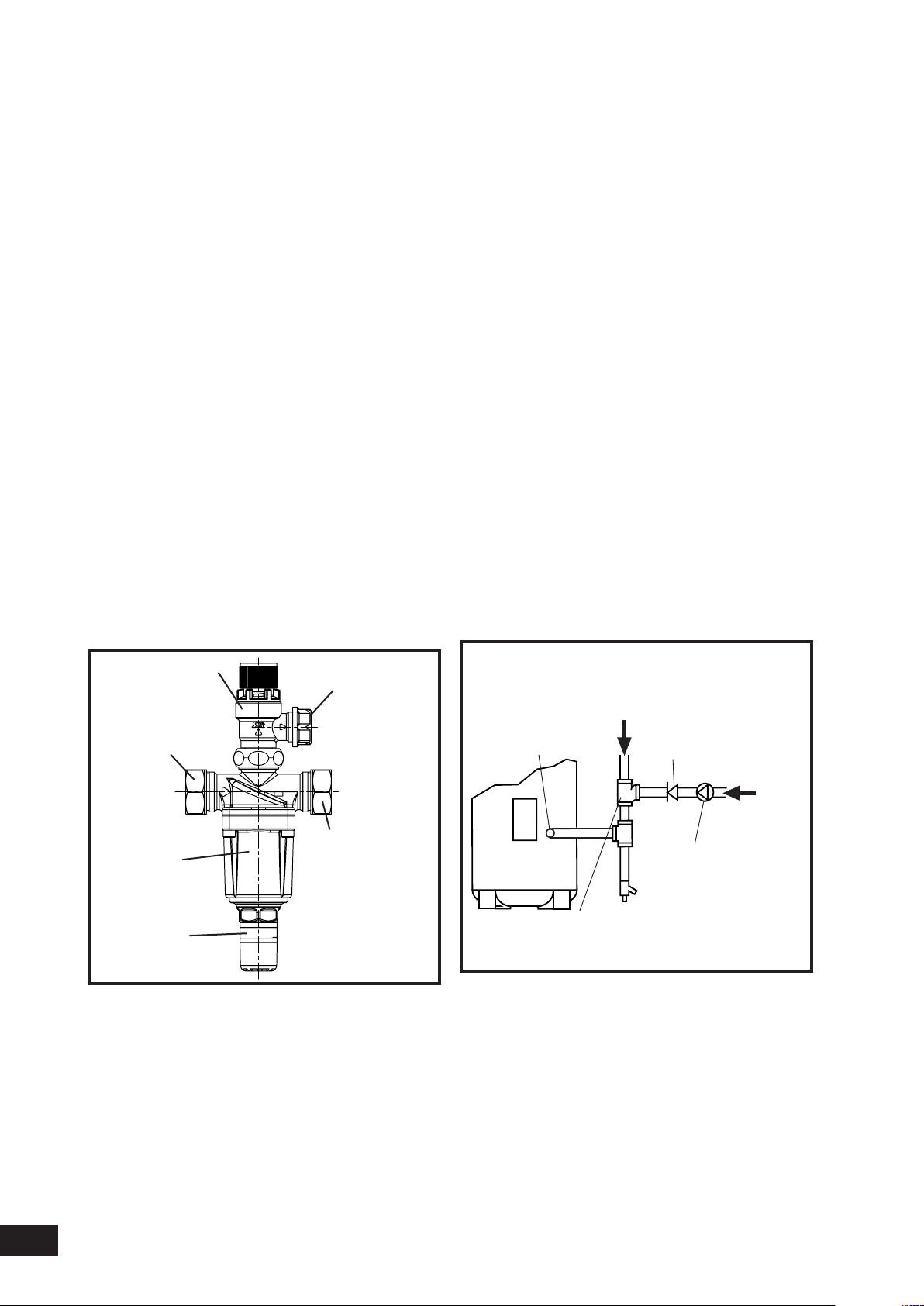

3.8 DISCHARGE PIPEWORK

It is a requirement of Building Regulation G3 that any

discharge from an unvented system is conveyed to

where it is visible, but will not cause danger to persons

in or about the building. The tundish and discharge

pipes should be tted in accordance with the requirements and guidance notes of Building Regulation G3.

The G3 Requirements and Guidance section 3.9 are

reproduced in the following sections.

Information Sheet No. 33 available from the British

Board of Agrement gives further advice on discharge

pipe installation. For discharge pipe arrangements not

covered by G3 Guidance or BBA Info Sheet No.33

advice should be sought from either your local Build-

ing Control Ofcer.

G3 REQUIREMENT

“...there shall be precautions...to ensure that the

hot water discharged from safety devices is safely

conveyed to where it is visible but will not cause

danger to persons in or about the building.”

G3 GUIDANCE SECTION 3.9

The discharge pipe (D1) from the vessel up to and

including the tundish is generally supplied by the

manufacturer of the hot water storage system. Where

otherwise, the installation should include the discharge

pipe(s) (D1) from the safety device(s). In either case

the tundish should be vertical, located in the same

space as the unvented hot water storage system and

be tted as close as possible and within 500mm of the

safety device e.g. the temperature relief valve.

The discharge pipe (D2) from the tundish should

terminate in a safe place where there is no risk to

persons in the vicinity of the discharge, preferably

be of metal and:

a. be at least one pipe size larger than the nominal

outlet size of the safety device unless its total equivalent hydraulic resistance exceeds that of a straight

pipe 9m long i.e. discharge pipes between 9m and

18m equivalent resistance length should be at least

two sizes larger than the nominal outlet size of the

safety device, between 18 and 27m at least 3 sizes

larger , and so on. Bends must be taken into account

in calculating the ow resistance. Refer to Diagram

1, Table 1 and the worked example.

An alternative approach for sizing discharge pipes

would be to follow BS 6700:1987 Specification

for design installation, testing and maintenance of

services supplying water for domestic use within

buildings and their curtilages, Appendix E, section

E2 and table 21.

b. have a vertical section of pipe at least 300mm

long, below the tundish before any elbows or bends

in the pipework.

c. be installed with a continuous fall.

d. have discharges visible at both the tundish and the

nal point of discharge but where this is not possible

or is practically difcult there should be clear vis-

ibility at one or other of these locations. Examples of

acceptable discharge arrangements are:

i. ideally below a xed grating and above the water

seal in a trapped gully.

ii. downward discharges at low level; i.e. up to

100mm above external surfaces such as car parks, hard

standings, grassed areas etc. are acceptable providing

that where children may play or otherwise come into

contact with discharges a wire cage or similar guard

is positioned to prevent contact, whilst maintaining

visibility.

iii. discharges at high level; e.g. into a metal hopper

and metal down pipe with the end of the discharge pipe

clearly visible (tundish visible or not) or onto a roof

capable of withstanding high temperature discharges

of water and 3m from any plastics guttering system

that would collect such discharges (tundish visible).

iv. where a single pipe serves a number of discharges,

such as in blocks of ats, the number served should

be limited to not more than 6 systems so that any

instalation discharging can be traced reasonably easily. The single common discharge pipe should be at

least one pipe size larger than the largest individual

discharge pipe (D2) to be connected. If unvented hot

water storage systems are installed where discharges

from safety devices may not be apparent i.e. in dwell-

ings occupied by blind, inrm or disabled people,

consideration should be given to the installation of an

electronically operated device to warn when discharge

takes place.

Note: The discharge will consist of scalding water and

steam. Asphalt, roong felt and non-metallic rainwater

goods may be damaged by such discharges.

Worked example of discharge pipe sizing

The example below is for a G1/2 temperature relief

valve with a discharge pipe (D2) having 4 No. elbows

and length of 7m from the tundish to the point of discharge.

From Table 4:

Maximum resistance allowed for a straight length of

22mm copper discharge pipe (D2) from a G1/2 temperature relief valve is 9.0m.

Subtract the resistance for 4 No. 22mm elbows at 0.8m

each = 3.2m

Therefore the permitted length equates to: 5.8m

5.8m is less than the actual length of 7m therefore calculate the next largest size.

Maximum resistance allowed for a straight length of

28mm pipe (D2) from a G1/2 temperature relief valves

equates to 18m.

Subtract the resistance of 4 No. 28mm elbows at 1.0m

each = 4.0m

Therefore the maximum permitted length equates to:

14m

As the actual length is 7m, a 28mm (D2) copper pipe

will be satisfactory.

Page 7

7

Fixed grating

Discharge below

fixed grating

(Building Regulation

G3 section 3.9d gives

alternative points

of discharge)

Trapped

gully

Discharge pipe (D2 ) from tundish,

with continuous fall. Se e Building

Regula tion G3 section 3.9d i-iv,

Table 4 and worked example

300mm

minimum

500mm maximum

Metal discharge pipe (D1) from

Temperature relief valve to tundish

Tundish

Safety device

(e.g. Temperature

relief valve)

Valve outl e t siz e M inim um size of

discha rge pipe

D1

Minim um size of

discha rge p ipe

D2 from tundish

Maxim um

re sistance

allow e d,

expressed a s a

le ng th of straight

pipe (I.e . no

elbow s or be nds)

Re sistance

create d by each

elbow or be nd

G1/2 15m m

22mm

28mm

35mm

up to 9m

up to 18m

up to 27m

0.8m

1.0m

1.4m

G3/4 22m m

28mm

35mm

42mm

up to 9m

up to 18m

up to 27m

1.0m

1.4m

1.7m

G1 28m m

35mm

42mm

54mm

up to 9m

up to 18m

up to 27m

1.4m

1.7m

2.3m

3.9 WARNINGS

• Under no circumstances should the factory tted

Temperature Relief Valve be removed other than by

an authorised installer. To do so will invalidate any

guarantee or claim.

• The Cold Water Combination Valve must be tted

to the mains water supply to the unit.

• No control or safety valves should be tampered

with.

• The discharge pipe should not be blocked or used

for any other purpose.

• The tundish should not be located adjacent to any

electrical components.

Table 4 Sizing of copper discharge pipe (D2) for common temperature relief valve outlet

FIG. 4 Typical discharge pipe arrangement (extract from Building Regulation G3 Guidance section 3.9)

Page 8

8

FIG. 5 Typical installation - schematic

EXPANSION

VESSEL

COLD WATER

COMBINATION

VALVE

T&P RELIEF

VALVE

TO HOT

OUTLETS

MAINS

WATER

SUPPLY

ISOLATING

VALVE (NOT

SUPPLIED)

TUNDISH

DISCHARGE

PIPE

DRAIN COCK

(NOT SUPPLIED)

PRIMARY

RETURN

PRIMARY

FLOW

ELEMENT /

CONTROLS

HOUSING

INLET

SECONDARY

RETURN

TAPPING (IF

REQUIRED)

BALANCED

COLD WATER

CONNECTION

(IF REQUIRED)

1

GREEN/YELLOW

230V~ MAINS SUPPLY

FROM HYDRO UNIT.

2

1.5mm MIN. CABLE SIZE

GREEN/

YELLOW

BROWN

2

DOUBLE POLE THERMAL

CUT-OUT

A

B

BLUE

BLUE

BROWN

SENSOR

TO HYDRO UNIT

TBO6 (TTW)

TBO3 (230V)

FIG. 6 Electrical Connections (Schematic)

Page 9

9

4.0 INSTALLATION - INDIRECT

UNITS

4.1 PLUMBING CONNECTIONS

The water cylinder requires the following pipework

connections.

• Cold water supply to and from inlet controls.

• Outlet to hot water draw off points.

• Discharge pipework from valve outlets to

tundish

• Connection to the primary circuit. Refer to the

Hydro Unit Installation Instructions for details.

Primary connections are 22mm compression. How-

ever, 3/4”BSP parallel threaded ttings can be tted

to the primary coil connections if required.

4.2 ELECTRICAL SUPPLY (FIG. 6)

All units are tted with a 2.7kW (230V) cylinder

heater and a thermal cut-out to supplement the Air to

Water heat pump primary heating. The unit MUST

be earthed.

All wiring to the unit must be installed in accordance

with the latest IEE Wiring Regulations and the supply circuits must be protected by a suitable fuse and

double pole isolating switch with a contact separation

of at least 3mm in both poles.

ISOLATE FROM MAINS SUPPLY BEFORE

REMOVING ANY COVERS. DO NOT BYPASS

THE THERMAL CUT-OUT IN ANY CIRCUMSTANCES. Ensure the thermal sensor and thermal

cut-out sensing bulbs are pushed fully into the pockets

on the element plate assembly.

All wiring to the unit must be via the controls housing

on the Hydro Unit. Direct connection of the cylinder

heater to the mains electrical supply will invalidate

the guarantee and may result in a dangerous installation. Refer to the wiring details in the Hydro Unit

Installation Manual.

The supply cable to the cylinder heater must be routed

through the right hand cable gland provided and the

outer sheath of the cable rmly secured by tightening

the cable gland. Connection must be to the terminal

block marked ‘MAINS’. The recommended cable type

is 2.5mm2 3 core heat resistant sheathed.

The thermal sensor connection cable must be routed

through the left hand cable gland provided and the

outer sheath of the cable rmly secured by tightening

the cable gland. Connection must be to the terminal

block marked ‘SENSOR’. The sensor cable should be

0.75mm2 2 core and shield (ground) with a maximum

current rating of 100mA. The cable shielding wire

must be connected to the terminal marked on the

sensor terminal block.

Thermal control of the water cylinder is managed by

the Heat Pump controls on the Hydro Unit. Refer to

the Hydro Unit Installation Manual for details of how

to set up the thermal control. The electrical supply

from Hydro Unit to the cylinder heater incorporates

an over temperature thermal cut-out that will switch

off the heater in the event of a thermal control failure.

The thermal cut-out must not be bypassed in any

circumstances.

5.0 COMMISSIONING

Warning: Water that is left standing in a stainless

steel water cylinder for long periods without draw

off will become de-oxygenated and potentially corrode the vessel material. If the installation is to be

left unused following installation and commissioning the water cylinder should be drained or regu-

larly (once per week) ushed through with fresh

mains water.

5.1 FILLING THE UNIT WITH WATER

• Check Expansion Vessel pre-charge pressure. The

vessel is supplied pre-charged to 0.35MPa (3.5 bar) to

match the control pressure of the Pressure Reducing

Valve. The pre-charge pressure is checked using a car

tyre gauge by unscrewing the plastic cap opposite the

water connection.

• Check all connections for tightness including

the cylinder heater. An cylinder heater key spanner is

supplied for this purpose.

• Ensure the drain cock is CLOSED.

• Open a hot tap furthest from the water cylinder.

• Open the mains stop cock to ll the unit. When

water ows from the tap, allow to run for a few minutes to thoroughly ush through any residue, dirt or

swarf, then close the tap.

• Open successive hot taps to purge the system of

air.

5.2 SYSTEM CHECKS

• Check all water connections for leaks and rectify

as necessary.

• Remove the Pressure Reducing Valve headwork

to access the strainer mesh, clean and re-t.

• Manually open, for a few seconds, each relief

valve in turn, checking that water is discharged and

runs freely through the tundish and out at the discharge

point.

• Ensure that the valve(s) reseat satisfactorily.

5.3 PRIMARY CIRCUIT

Fill the primary circuit following the procedure detailed in the Hydro Unit Installation Manual. Vent any

trapped air by opening the air bleed point or automatic

air vent.

Ensure the water cylinder is full of water before

switching on the Air to Water heat pump System.

Switch on the electrical supply to the heat pump and

ensure the programmer is set to HOT WATER mode.

Check that any motorised valves or primary pumps

are working and allow the unit to heat.

Page 10

10

6.3 STRAINER

MAINS TERMINAL

BLOCK

SENSOR TERMINAL

BLOCK

THERMAL CUTOUT

TERMINAL BRACKET

NOTE:

THE COVER AND ELEMENT ASSEMBLY HAVE BEEN REMOVED

FROM THIS VIEW FOR CLARITY

RESET BUTTON LOCATED

ON THIS FACE

Turn off the cold water supply, air to water heat pump

system and cylinder heater. The lowest hot water tap

should then be opened to de-pressurise the system.

Remove the Pressure Reducing Valve Cartridge by

unscrewing from the housing. Pull the Reducing

Valve cartridge from the housing to access the strainer

mesh. Wash any particulate matter from the strainer

under clean water. Re-assemble ensuring the seal is

correctly tted, DO NOT use any other type of sealant. Ensure the Pressure Reducing Valve Cartridge is

fully tightened.

6.4 DESCALING CYLINDER HEATER

Before removing the cylinder heater the unit must be

drained. Ensure the water and electrical supply and

air to water heat pump are OFF before draining.

Attach a hose pipe to the drain cock having sufcient

length to take water to a suitable discharge point below

the level of the unit. Open a hot tap close to the unit

and open drain cock to drain unit.

FIG. 7 Thermal cut-out

6.0 MAINTENANCE

6.1 MAINTENANCE REQUIREMENTS

6.2 SAFETY VALVE OPERATION

Unvented hot water systems have a continuing maintenance requirement in order to ensure safe working

and optimum performance. It is essential that the

Relief Valve(s) are periodically inspected and manually opened to ensure no blockage has occurred in

the valves or discharge pipework. Similarly cleaning

of the strainer element and replacement of the air in

the Expansion Vessel will help to prevent possible

operational faults.

The maintenance checks described below should be

performed by a competent installer on a regular basis,

e.g. annually to coincide with the air to water heat

pump maintenance.

Manually operate the Temperature/Pressure Relief

Valve for a few seconds. Check water is discharged

and that it flows freely through the tundish and

discharge pipework. Check valve reseats correctly

when released. NOTE: Water discharged may be

very hot!

Repeat the above procedure for the Expansion Valve.

ISOLATE FROM MAINS BEFORE REMOVING

TERMINAL COVER.

Open the terminal cover. Disconnect the link wires

connecting the thermal cut-out to the cylinder heater.

Carefully remove the thermal sensor from its pocket

on the cylinder heater by pulling outwards. Carefully remove the thermal cut-out sensing bulb from

its pocket by pulling outwards. Remove the element

tail insulating shroud by pulling it outwards from the

element.

Unscrew the cylinder heater backnut. A key spanner

is provided with the unit for easy removal/tightening

of the backnut.

Remove the cylinder heater from the unit.

NOTE: Over time the cylinder heater gasket may

become stuck to the mating surface, to break the

seal insert a round bladed screwdriver into one of

the pockets and gently lever up and down. Carefully

remove any scale from the surface of the element. DO

NOT use a sharp implement as damage to the element

surface could be caused. Ensure sealing surfaces are

clean and seals are undamaged. If in doubt t a new

gasket.

Replace the cylinder heater ensuring the element tails

are in the horizontal plane (see Fig. 6). Secure in place

by re-tting cylinder heater backnut and tightening.

Replace the element tail insulating shroud by carefully

pushing it over the element tails until it sits ush with

the face of the element mounting plate. Replace the

thermal cut-out into the lower pocket of the cylinder

heater. Ensure it is fully inserted and that the capillary

tube is not kinked. Ensure the capillary tube is routed

such that it does not come into contact with the element tails. Replace the thermal sensor in the lower

pocket of the cylinder heater. Ensure it is fully inserted

behind the thermal cut-out, and the securing grommet

is pushed into the open end of the pocket.

Page 11

11

Ret the cylinder heater wiring links by inserting the

Expansion Valve

Cartridge

Expansion Valve

Complete (6 bar)

Valve Body

Check Valve

Housing

Pressure

Reducing

Valve Housing

Pressure Reducing

Valve Cartridge

(3.5 bar)

Strainer Mesh

Housing Securing

Screws (4 off)

Cold Water Combination Valve Complete

male terminations into the female terminals on the element tails in accordance to Figure 6. Check all wiring

terminations are tight and secure. Replace and secure

the terminal cover.

7.2 SPARE PARTS

A full range of spare parts are available for the range.

Refer to the Technical Data label on the unit to identify the model installed and ensure the correct part

is ordered.

6.5 EXPANSION VESSEL CHARGE PRESSURE

Remove the dust cap on top of the vessel. Check the

charge pressure using a tyre pressure gauge. The pressure (with system de-pressurised) should be 0.35MPa

(3.5bar). If it is lower than the required setting it

should be re-charged using a tyre pump (Schrader

valve type). DO NOT OVER CHARGE. Re-check the

pressure and when correct replace the dust cap.

6.6 RE-COMMISSIONING

Check all electrical and plumbing connections are secure. Close the drain cock. With a hot tap open, turn on

the cold water supply and allow unit to rell. DO NOT

switch on the air to water heat pump system until the

unit is full. When water ows from the hot tap allow

to ow for a short while to purge air and ush through

any disturbed particles. Close hot tap and then open

successive hot taps in system to purge any air.

When completely full and purged check system for

leaks. The air to water heat pump system can then be

switched on.

7.0 FAULT FINDING AND

SERVICING

Description

Cylinder heater 95606967

Cylinder heater gasket 95611012

Cylinder heater backnut 95607118

Cylinder heater key spanner 95607119

Tundish 95605062

Expansion valve cartridge - 6bar 95605063

Expansion valve complete - 6bar 95605064

Cold water combination valve complete 95605065

Cold water combination valve body 95605066

Check valve housing 95605067

Pressure reducing valve cartridge 3.5bar 95605068

Pressure reducing valve housing 95605069

Temperature/Pressure Relief Valve 95605070

Expansion vessel 12 litre (150 litre models) 95607127

Expansion vessel 18 litre (210 litre models) 95607128

Expansion vessel 25 litre (300 litre models) 95607129

T&P valve insulation set 95607130

Thermal sensor 95612037

Thermal cut-out (cylinder Heater) 95612038

Terminal cover 95614109

Terminal block (cylinder heater connection) 95607113

Terminal block (thermal sensor connection) 95607114

Element tail insulating shroud 95607115

Set of compression nuts and olives 95607116

Secondary re-circulation connection plug 95607117

7.1 IMPORTANT

• Servicing should only be carried by Service

Engineers or Agents or by competent installers in the

installation and maintenance of unvented water heating systems.

• Any spare parts used MUST be authorised

parts.

• Disconnect the electrical supply before removing

any electrical equipment covers.

• NEVER bypass any thermal controls or operate

system without the necessary safety valves.

• Water contained in the unit may be very hot, es-

pecially following a thermal control failure. Caution

must be taken when drawing water from the unit.

FIG. 8 Cold Water Combination Valve - Exploded view

Page 12

12

7.3 FAULT FINDING

F A U L T P O SSIB L E C AU S E R E M E D Y

N o ho t w a t e r fl o w 1. M ai n s s u p ply o ff 1. C he c k a n d turn on mains

water supply

2. Mains water filter (if

fitted) blocked .

3. C old W a t er C o m bin ation

valves fitted incorrectly.

3. C he c k a n d re fit a s re q u i red

1. Controller on Heat Pump

Hydro Unit set to space

heating only.

1.

C h e c k setting

2. Heat Pump not working

2.

Check operation of Heat

Pump. If a fault is suspected

consult the Heat Pump manual.

3. Check sensor operation.

Replace if necessary.

1. Water storage temperature

on Hydro Unit controller is set

too high.

2. Turn off water supply.

Remove filter and clean in

accordance with manufacturers

instructions.

water supply.

1. Cylinder heater

thermal cut-out has

operated

.

1. Check. Reset by

pushing button on cut-out.

2. Faulty water cylinder

temperature sensor.

2. Check sensor operation.

Replace if necessary.

3. Faulty water cylinder

temperature sensor

1. Check and adjust as required.

2. Faulty water cylinder

temperature sensor.

2. Check sensor operation.

Replace if necessary.

Water from hot taps is

cold

Water from hot taps is

only warm

Water from hot taps is

too hot

Water discharges from

Expansion Valve

1.INTERMITTENTLY

Expansion Vessel charge

has reduced below 0.35MPa

(3.5bar)

1. See Section 6.5 for recharging procedure

2. CONTINUALLY

a. Cold Water Combination

Valve Pressure Reducer

not working correctly

a. Check pressure from Cold

Water Combination Valve. If

greater than 0.35MPa (3.5bar)

replace Pressure Reducer

cartridge

b. Remove Expansion Valve

cartridge. Check condition of

seat. If necessary fit new

Expansion Valve cartridge.

b. Expansion Valve seat

damaged

Water discharges from

T&P Relief Valve

1.Thermal control failure

NOTE water will be very hot

1.Switch off power to cylinder

heater and shut down Hydro

Unit. DO NOT turn off water

supply. When discharge stops

check all thermal controls,

replace if faulty.

The Fault Finding chart below will enable operational

faults to be identied and their possible causes rectied.

Any work carried out on the unvented water heater and its

associated controls MUST be carried out by a competent

installer for unvented water heating systems. In case of

WARNING

DO NOT TAMPER WITH ANY OF THE

SAFETY VALVES OR CONTROLS SUPPLIED

WITH THE UNIT AS THIS WILL INVALIDATE ANY GUARANTEE

doubt contact installer.

TABLE 5 Fault Finding Chart

Page 13

13

8.0 USER INSTRUCTIONS

8.1 WARNINGS

IF WATER ISSUES FROM THE TEMPERATURE/PRESSURE RELIEF VALVE ON THE

UNIT SWITCH OFF ELECTRICAL SUPPLY TO

THE AIR TO WATER HEAT PUMP SYSTEM.

DO NOT TURN OFF ANY WATER SUPPLY.

CONTACT A COMPETENT INSTALLER FOR

UNVENTED WATER CYLINDERS TO CHECK

THE SYSTEM.

DO NOT TAMPER WITH ANY OF THE SAFETY

VALVES FITTED TO THE SYSTEM. IF A FAULT

IS SUSPECTED CONTACT A COMPETENT

INSTALLER.

8.2 TEMPERATURE CONTROL

The water storage temperature at the air to water heat

pump water heater is set at the control panel of the

Hydro Unit. This can be set to give temperatures in the

range of 40°C to 75°C, 60°C is recommended. Refer

to the Air to Water Owners Manual for details of how

to adjust the temperature if necessary.

The water cylinder is tted with an over temperature

thermal cut-out that will operate should the thermostatic control fail.

DO NOT bypass the thermal cut-out in any circumstances.

8.3 FLOW PERFORMANCE

When initially opening hot outlets a small surge in

ow may be noticed as pressures stabilize. This is

quite normal with unvented systems. In some areas

cloudiness may be noticed in the hot water. This is

due to aeration of the water, is quite normal and will

quickly clear.

8.4 OPERATIONAL FAULTS

Operational faults and their possible causes are detailed in Section 7.0. It is recommended that faults

should be checked by a competent installer.

The air volume within the expansion vessel will periodically require recharging to ensure expanded water

is accommodated within the unit. A discharge of water

INTERMITTENTLY from the Expansion Valve will

indicate the air volume has reduced to a point where

it can no longer accommodate the expansion.

Page 14

14

9.0 GUARANTEE

ENVIRONMENTAL INFORMATION

This product is guaranteed against faulty materials

and manufacture for a period of 25 years from date

of purchase (with the exception of the Expansion

Vessel which is guaranteed for a period of 5 years

and valves, ttings and electrical parts which are

guaranteed for a period of 2 years) provided that:

• The unit has been installed in accordance with the

Installation and Service instructions and all relevant

Codes of Practice and Regulations in force at the time

of installation, and that all necessary inlet controls and

safety valves have been tted correctly.

• Any valves and controls are of the recommended

type and specication.

• It has only been used for the storage of potable

water.

• The unit has not been modied or tampered with

in any way, and has been regularly maintained as

detailed in the Installation and Service instructions.

• The unit has not been subjected to high chloride

levels in the water supply or incorrect disinfection

methods.

These products are manufactured from many recyclable

materials. At the end of their useful life they should be

disposed of at a Local Authority Recycling Centre in order

to realise the full environmental benets.

Insulation is by means of an approved CFC/HCFC free

polyurethane foam with an ozone depletion factor of

zero.

• Following commissioning the unit is put into

service within a period of 7 days. If this is not the

case it must either be drained or regularly ushed as

required in the section ‘Commissioning - Warning’.

The unit is not guaranteed against damage by frost, and

the inner container with integral immersion heater is

not guaranteed against excessive scale build-up.

Periodic loss of charge pressure from the Expansion Vessel is normal (indicated by an intermittent

discharge of water from the Expansion Valve) and

is not covered under the product guarantee. Refer to

Section 6.5 for details on how to restore the Expansion

Vessel charge pressure.

This guarantee DOES NOT cover the Heat Pump

or Hydro Unit. Refer to the manuals supplied with

those units for details of the guarantee terms relating

to them.

This guarantee does not affect your statutory rights.

Page 15

15

NOTES

Page 16

16

CONTACT DETAILS

TCUK Ltd

Porsham Close,

Belliver Ind.Est.

Plymouth,

Devon, PL6 7DB

Our policy is one of continuous product development and, as such, we reserve the right to change specications

without notice.

Loading...

Loading...