Toshiba HWS-803XWHM3-E, HWS-803XWHT6-E, HWS-803XWHD6-E, HWS-803XWHT9-E, HWS-1403XWHM3-E Engineering Data Book

...Page 1

Engineering Data Book

Air to Water Heat Pump

Hydro Unit

HWS-803XWHM3-E

HWS-803XWHT6-E

HWS-803XWHD6-E

HWS-803XWHT9-E

HWS-1403XWHM3-E

HWS-1403XWHT6-E

HWS-1403XWHD6-E

HWS-1403XWHT9-E

E10-371

Outdoor Unit

HWS-803H-E

HWS-1103H-E

HWS-1403H-E

HWS-1103H8-E

8 kw 11/14 kw

HWS-1403H8-E

HWS-1603H8-E

HWS-1103H8R-E

HWS-1403H8R-E

HWS-1603H8R-E

Hot Water Cylinder

HWS-1501CSHM3-E

HWS-2101CSHM3-E

HWS-3001CSHM3-E

HWS-1501CSHM3-UK

HWS-2101CSHM3-UK

HWS-3001CSHM3-UK

Page 2

Air to Water Heat Pump

Engineering Data Book

Contents

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1. System Combination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-2. Hydro Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-3. Outdoor Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-4. Hot Water Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-5. Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. SYSTEM SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4. HYDRO UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4-1. Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4-2. Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4-3. Piping Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4-4. Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4-5. Capacity Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4-6. Q-H characteristics of hydro unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-7. Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5. OUTDOOR UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5-1. Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5-2. Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5-3. Piping Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5-4. Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5-5. Sound Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5-6. Operation Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6. HOT WATER CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6-1. Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6-2. Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6-3. Piping Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6-4. Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7. HYDRO UNIT INSTALLATION MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8. OUTDOOR UNIT INSTALLATION MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

9. OWNER’S MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

1

Page 3

1. INTRODUCTION

2

Page 4

1.INTRODUCTION

to

te

Engineering Data book

Hot water cylinder

Hydro unit

Outdoor unit

Heat Pump System

Welcome Estía to your home!

Air-to-water Heat Pump System

World-leading energy efficiency –– COP of 4.77*

Comfortable heating and hot water supply

Versatile installation and operation

Introducing Toshiba’s super-efficient space heating and hot water supply system for homes and businesses. Estía

represents breakthrough thinking in intelligent heat pump and inverter technologies, by efficiently transferring

ambient thermal heat from outside air to heat water indoors. Based on Toshiba’s proven light commercial air

conditioning system, the Super Digital Inverter, this innovative unit features DC twin rotary compressor, DC

inverter and R410A refrigerant, providing the highest coefficient of performance (COP) in its class. This means

more power from less energy consumption, and the ideal ecological and economical solution for your home.

8 kW 11 / 14 kW

Outdoor unit

Hot water cylinder Hydro unit

* 11 kW model

3

Page 5

1.INTRODUCTION

Advantages

World-leading energy efficiency - COP of 4.77*

With its best in class COP performance, Estía air to water heat pump system delivers more heating

power with less energy consumption.

Estía uses high quality components and material which contribute to the overall savings in energy

consumption.

With the Toshiba advanced inverter, Estía air to water heat pump system only delivers the heating

capacity required; thus consuming only the necessary electricity.

The hot water temperature is also optimized thanks to Toshiba advanced control depending on

the outside air temperature. The milder outside, the air-to-water systems automatically produces

lower water temperature to anticipate decreased needs of space heating. The same control logic

allows to anticipate as well increasing heating needs when weather conditions become extreme;

this overall temperature management gives the best conditions of comfort.

All this s

reducing the CO

Easy

aving has a positive impact on the personal electricity bill and the whole community by

emissions in the atmosphere.

2

to install Environment conscious

Engineering Data book

*11kW model

Quick and easy to install. The hydro module

unit can be placed safely in the most suitable

place within the house.

There’s no need for chimney or underground

captors which require additional works on site.

The compact outdoor unit can be placed anywhere outside the

house or on a balcony, thanks to extensive piping options.

One system, multiple

solutions

Estía heat pump sys

combination with different types of emitters:

existing heating l

floor heating or fan coil units.

tems can be used in

ow temperature radiators,

he use of Toshiba Estía heat pump contribute

T

to the reduction of global CO

atmosphere and limit the use of fossil fuels or

other non-renewable energy primary sources.

Whenever required for maintenance purpose,

all the R410A refrigerant (non ozone depleting) can be

completely sucked back to the outdoor unit through the

powerful embedded Toshiba “pump down” operation.

emissions in the

2

The right temperature at the

right time

It can produce water at different temperatures

f

or several applications simultaneously.

Toshiba Estía air to water heat pump system operates smoothly

both with low outdoor air temperature down to -20 ˚C in winter

and up to 43 ˚C in the summer season. The system has a unique

anti-ice build-up protection embedded.

1

4

Page 6

1.INTRODUCTION

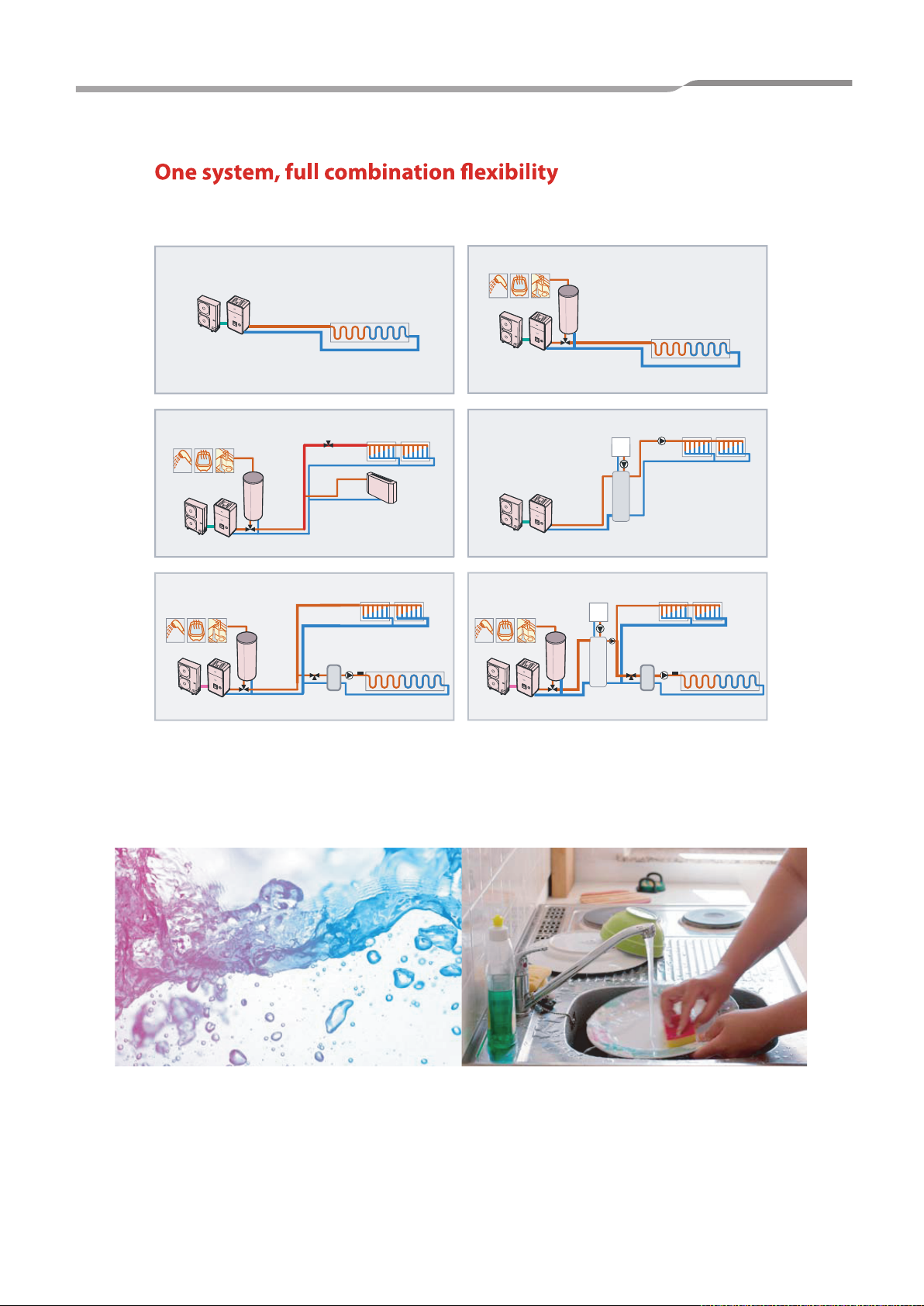

For new houses or refurbishment Estía heat pump offers a variety of combinations, some examples are shown below:

Engineering Data book

Outdoor unit

Shower Bath Kitchen

Hydro unit

Outdoor unit

Shower Bath Kitchen

Hydro unit

Outdoor unit

Hydro unit

Floor heating

2 way valve

Hot water

tank

1 zone heating / cooling with domestic hot water

Hot water

tank

Buffer tank

Mixing

valve

Buffer

tank

2 zone heating with domestic hot water

1 zone heating

HEATING ONLY

Panel radiator

Fan coil

Panel radiator

1 zone

1 zone

HEATING

COOLING

2 zones

Floor heatingTemp. sensor

Shower Bath Kitchen

Hydro unit

Outdoor unit

Outdoor unit

Shower Bath Kitchen

Hydro unit

Outdoor unit

1 zone

Hot water tank

1 zone heating with domestic hot water

Floor heating

1 zone

Hydro unit

Conventional boiler

Buffer

tank

1 zone heating with boiler backup

Panel radiator

2 zones

Conventional boiler

Hot water

tank

Mixing valve

2 zone heating with domestic hot water and boiler backup

Panel radiator

Floor heatingTemp. sensor

Buffer tank

I

n existing dwellings already equipped with traditional gas or

fuel boilers, Toshiba Estía air to water heat pump system can be

combined with the existing heating system to cover exclusively

and in an optimized way all the heating needs, all year round.

Then, the boiler is only used as a back-up source during some

extreme weather days of the winter.

T

he intelligent Toshiba control balances the energy source in the

most efficient way.

5

Page 7

2. SYSTEM OVERVIEW

6

Page 8

2.SYSTEM OVERVIEW

Engineering Data book

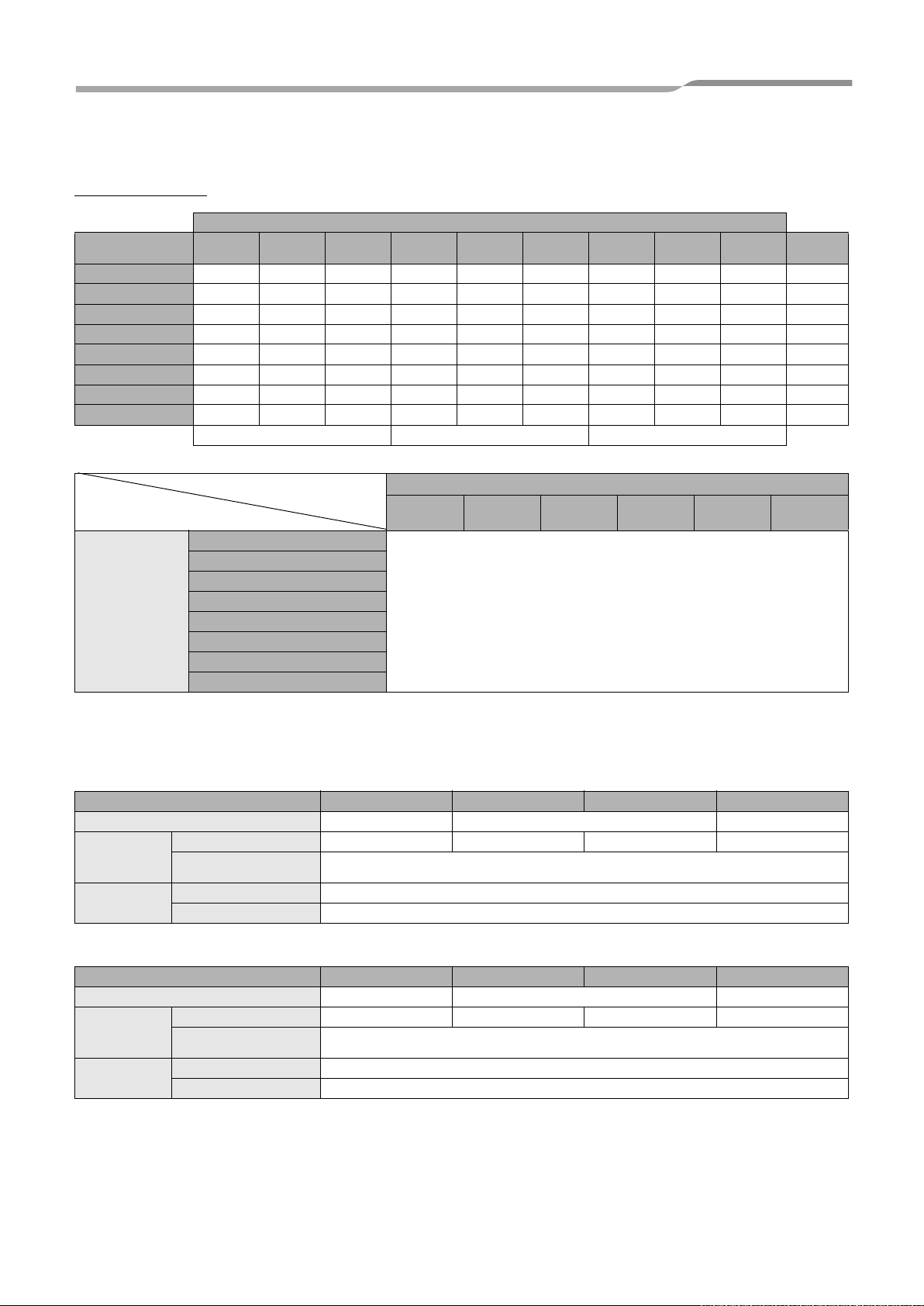

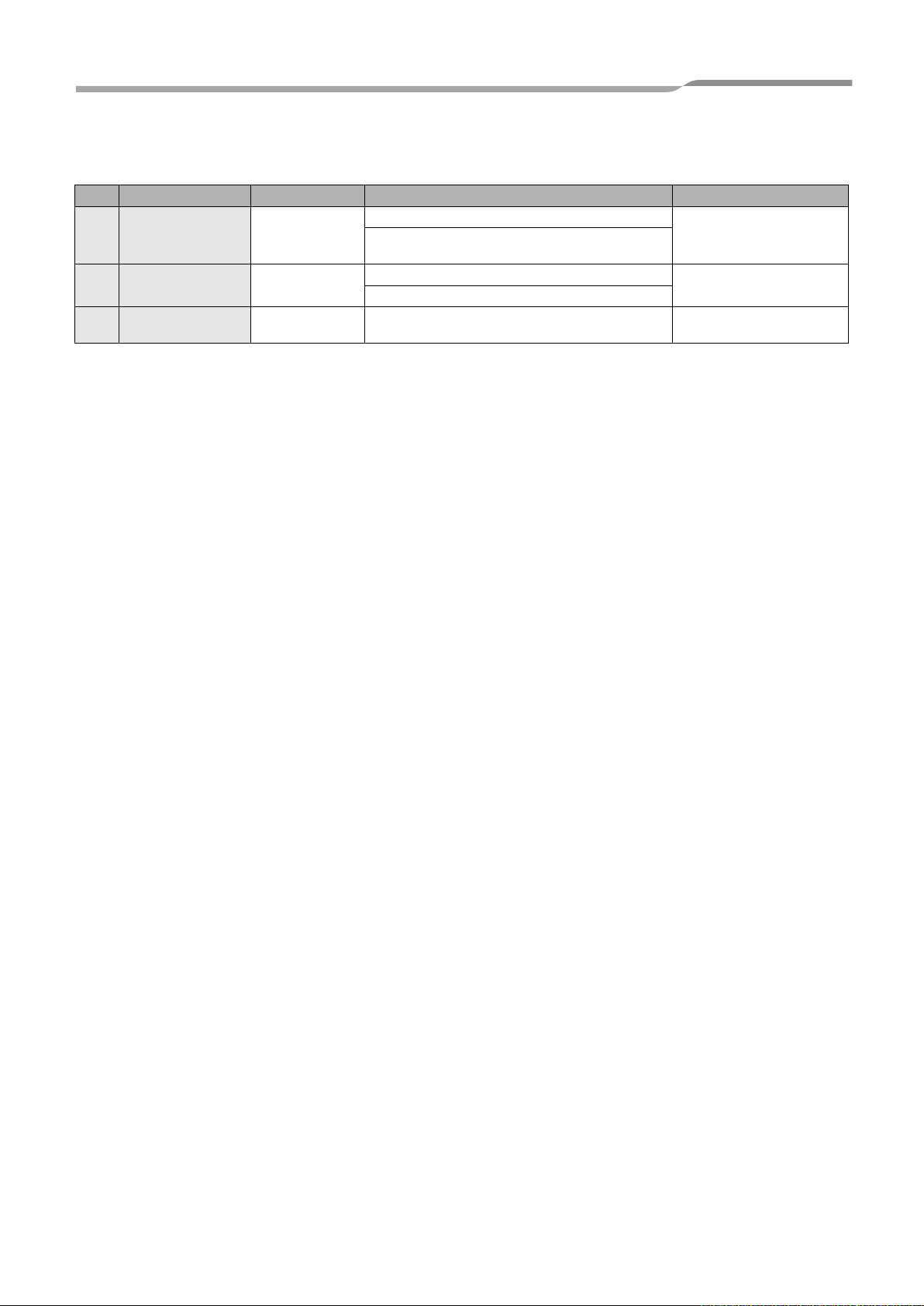

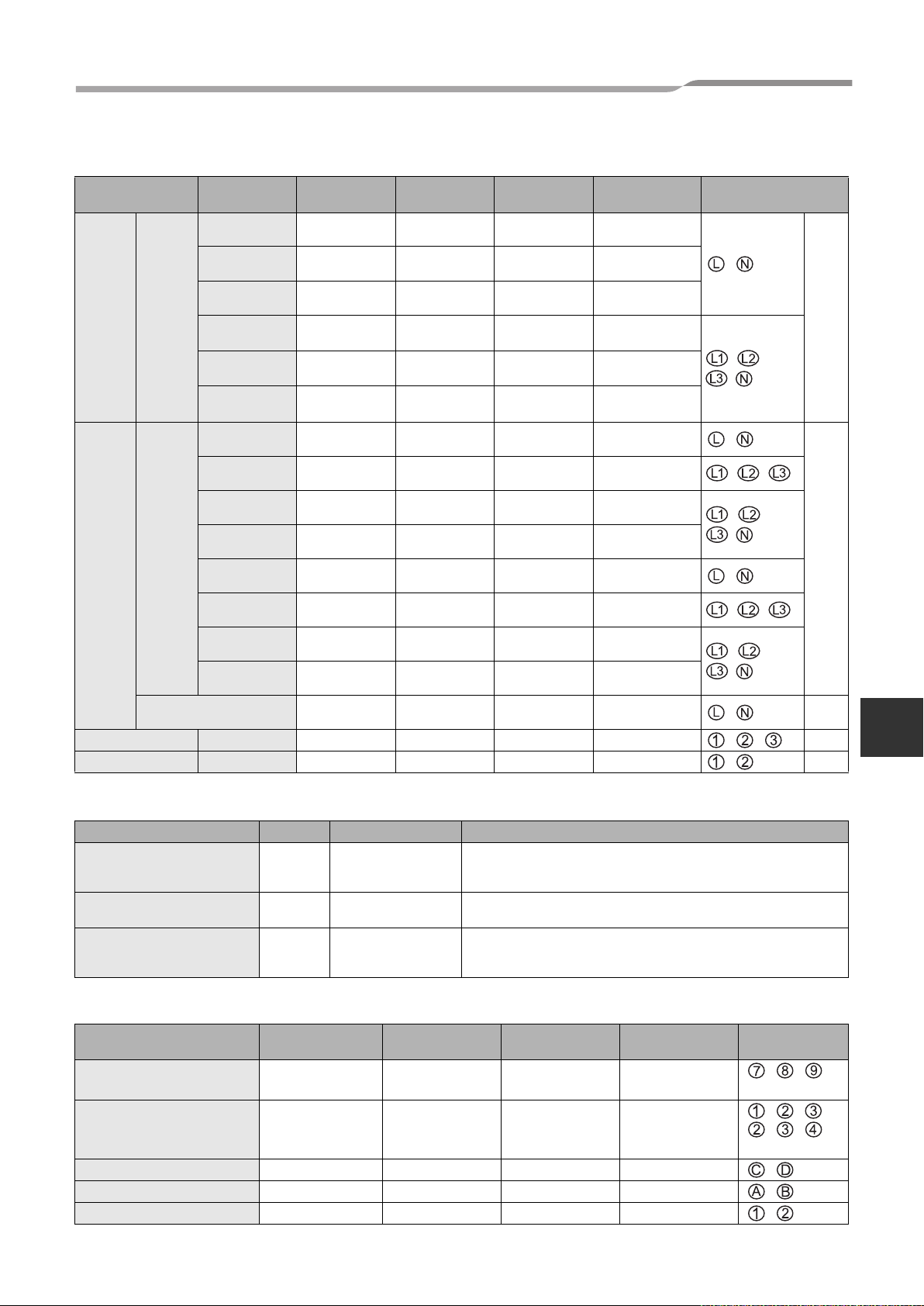

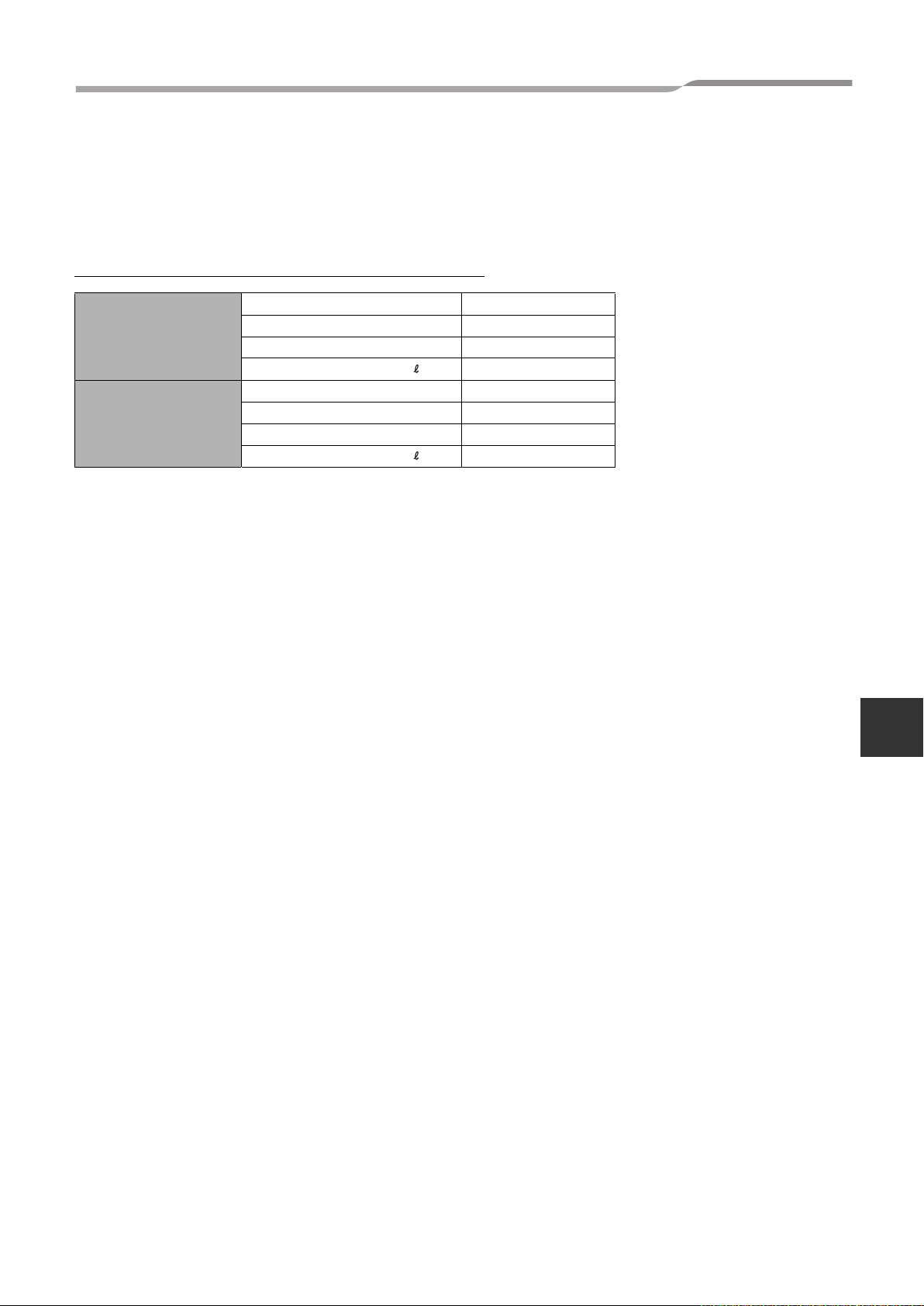

2-1. System Combination

Combination

Outdoor Unit

Hydro Unit

HWS-803XWHM3-E z ––––––––~, 3kW

HWS-803XWHT6-E z ––––––––3N ~, 6kW

HWS-803XWHD6-E z ––––––––3~, 6kW

HWS-803XWHT9-E z –– –––––3N~, 9kW

HWS-1403XWHM3-E – zzzzzzzz~, 3kW

HWS-1403XWHT6-E – zzzzzzzz3N~, 6kW

HWS-1403XWHD6-E – zz ––––––3~, 6kW

HWS-1403XWHT9-E – zzzzzzzz3N~, 9kW

Hydro unit

HWS-

803H-E

HWS-803XWHM3-E

HWS-803XWHT6-E

HWS-803XWHD6-E

HWS-803XWHT9-E

HWS-1403XWHM3-E

HWS-1403XWHT6-E

HWS-1403XWHD6-E

HWS-1403XWHT9-E

HWS-

1103H-E

Single phase model 3 phase model 3 phase with bottom plate heater

HWS-

1403H-E

HWS-

1103H8-E

HWS-

1403H8-E

HWS-

1603H8-E

HWS-

1103H8R-E

HWS-

1403H8R-E

HWS-

1603H8R-E

Hot water cylinder

HWS-1501

CSHM3-E

HWS-2101

CSHM3-E

HWS-3001

CSHM3-E

HWS-1501

CSHM3-UK

HWS-2101

CSHM3-UK

z

Backup

heater

HWS-3001

CSHM3-UK

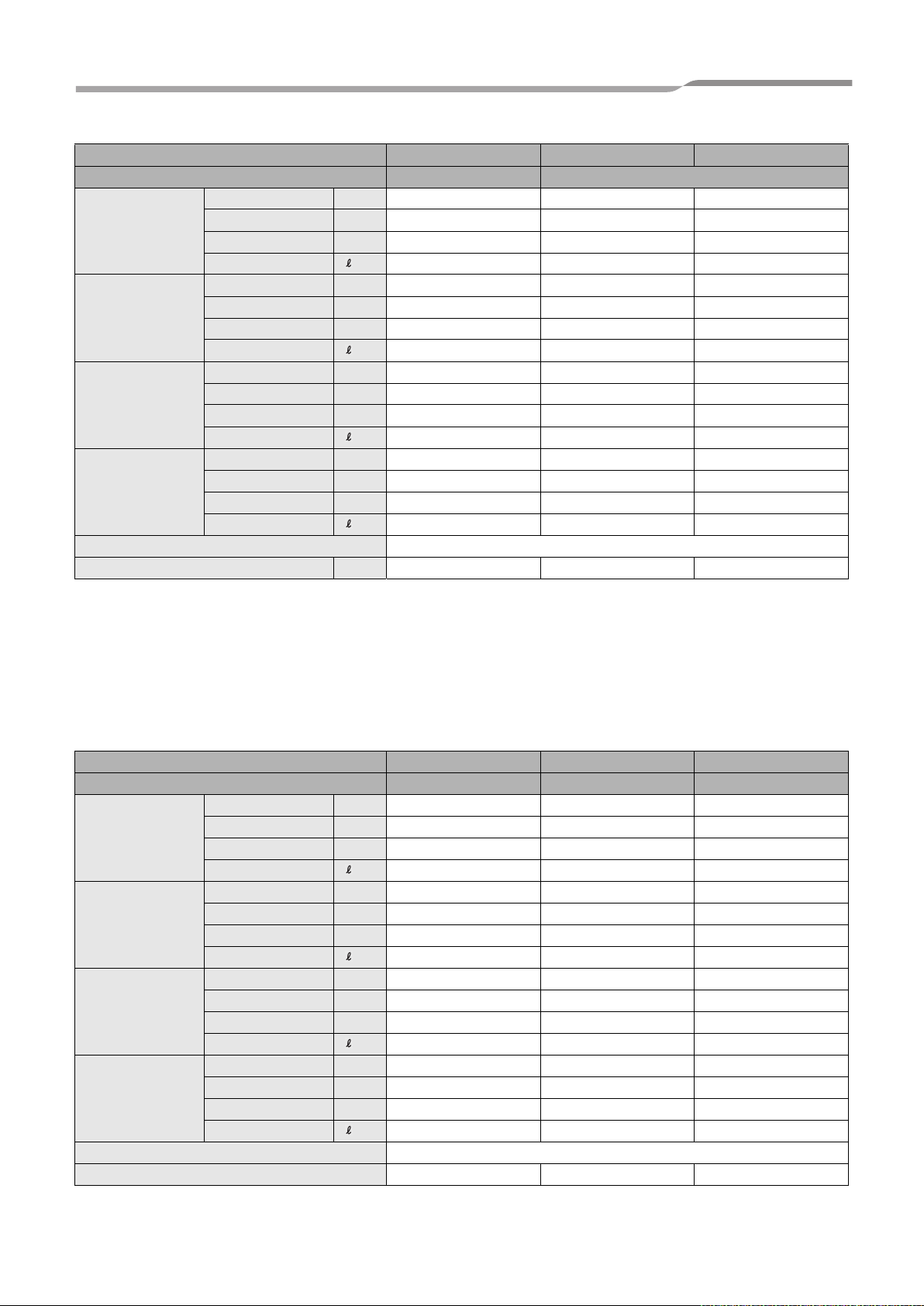

2-2. Hydro Unit

80 class

Hydro Unit HWS-803XWHM3-E HWS-803XWHT6-E

Back up heater capacity 3.0 6.0 9.0

for back up heater 220-230V ~ 50Hz 380-400V 3N~ 50Hz 220-230V 3~ 50Hz 380-400V 3N~ 50Hz

Power supply

Leaving water

temperature

for hot water cylinder heater

(option)

Heating (°C) 20-55

Cooling (°C) 10-25

220-230V ~ 50Hz

112,140,160 class

Hydro Unit HWS-1403XWHM3-E HWS-1403XWHT6-E

Back up heater capacity 3.0 6.0 9.0

for back up heater 220-230V ~ 50Hz 380-400V 3N~ 50Hz 220-230V 3~ 50Hz 380-400V 3N~ 50Hz

Power supply

Leaving water

temperature

for hot water cylinder heater

(option)

Heating (°C) 20-55

Cooling (°C) 10-25

220-230V ~ 50Hz

HWS-803XWHD6-E

HWS-1403XWHD6-E

HWS-803XWHT9-E

HWS-1403XWHT9-E

7

Page 9

2.SYSTEM OVERVIEW

Engineering Data book

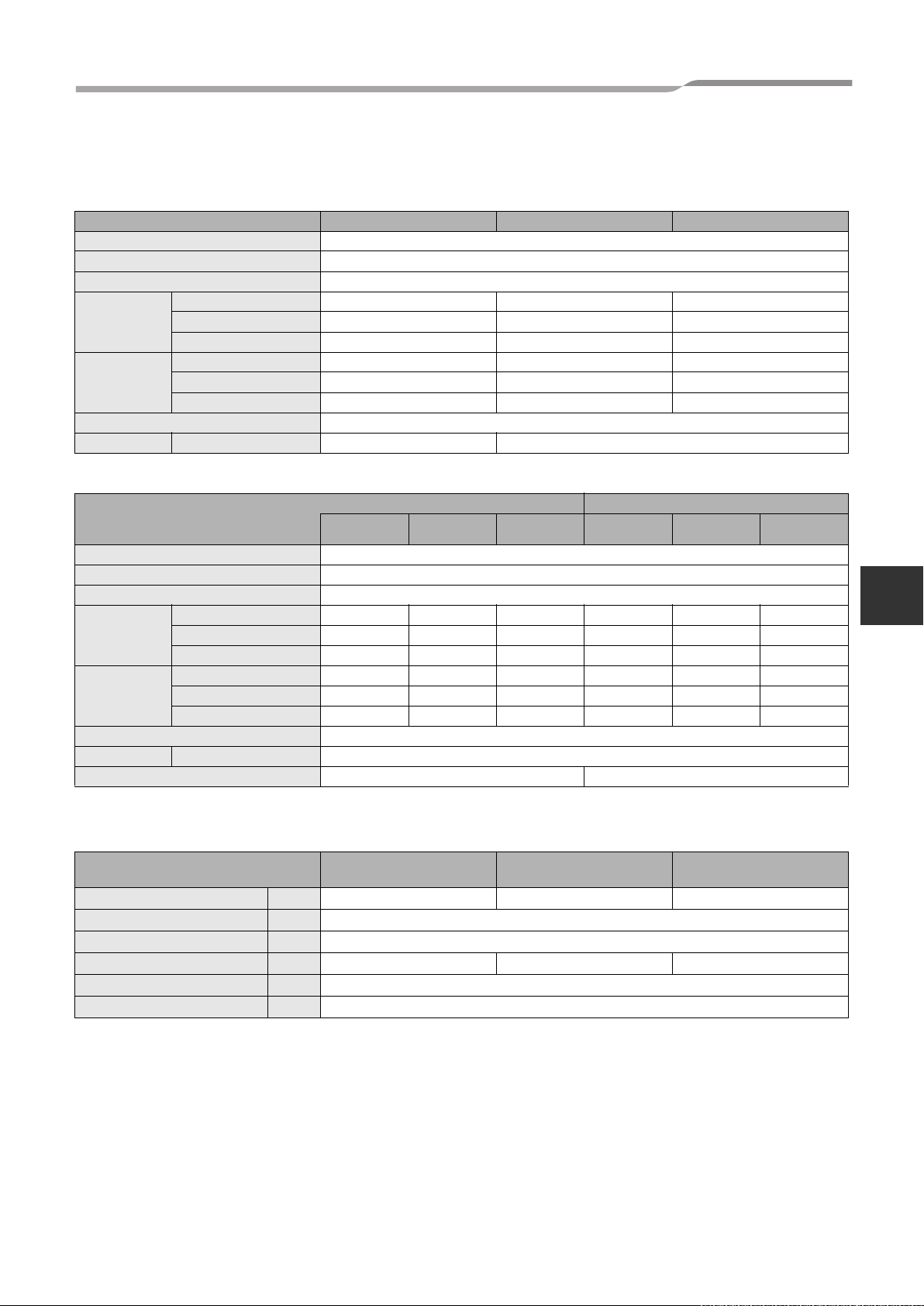

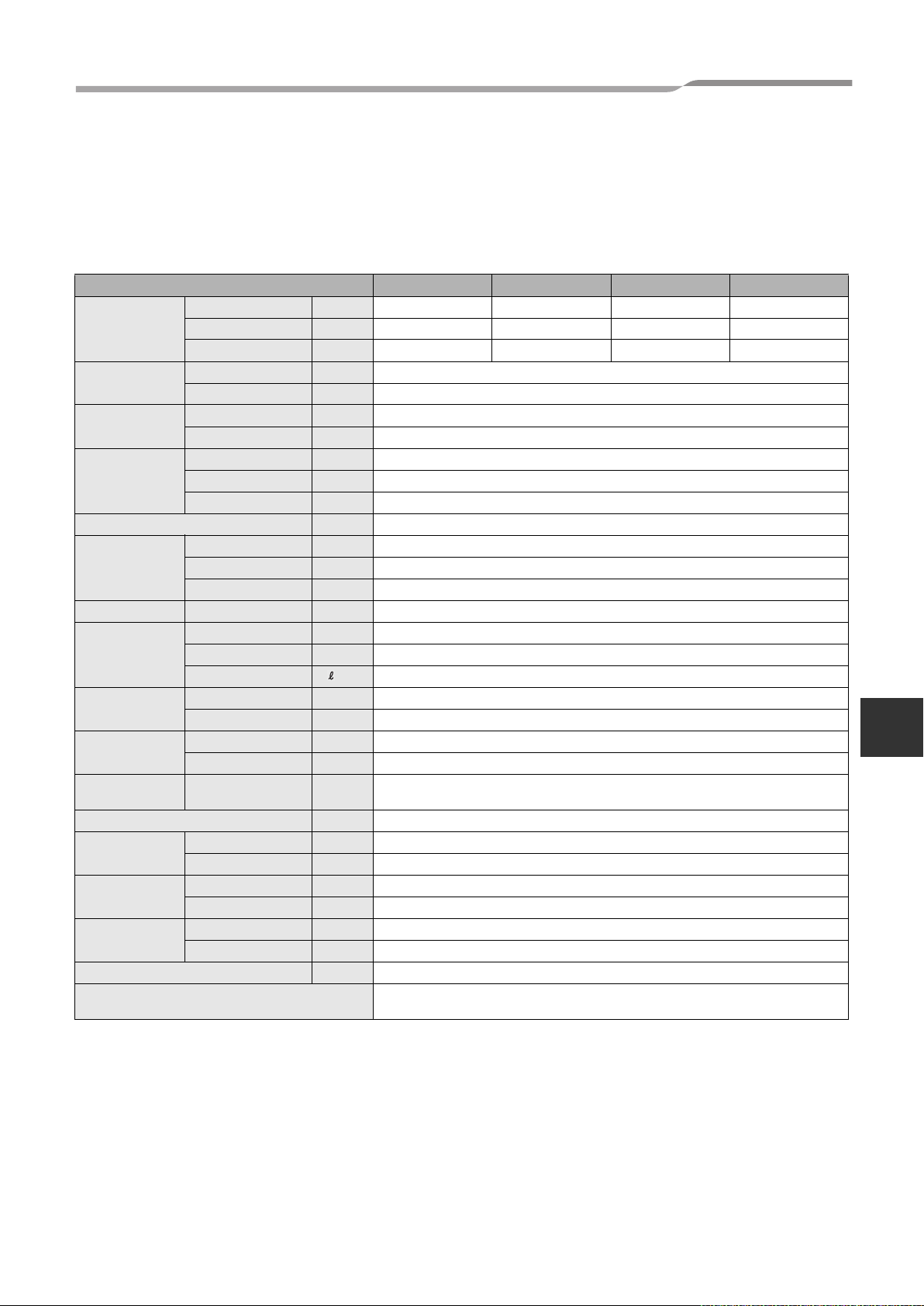

2-3. Outdoor Unit

Single Phase model

Outdoor unit HWS-803H-E HWS-1103H-E HWS-1403H-E

Power supply 220-230V ~ 50Hz

Type INVERTER

Function Heating & Cooling

Capacity (kW) 8.0 11.2 14.0

Heating

Cooling

Refrigerant R410A

Dimension HxWxD (mm) 890x900x320 1,340x900x320

3 Phase model

Power supply 380-400V 3N~ 50Hz

Type INVERTER

Function Heating & Cooling

Heating

Cooling

Refrigerant R410A

Dimension HxWxD (mm) 1,340x900x320

Bottom plate heater (W) – 75

Input (kW) 1.82 2.35 3.11

COP (W/W) 4.40 4.77 4.50

Capacity (kW) 6.0 10.0 11.0

Input (kW) 2.13 3.52 4.08

EER (W/W) 2.82 2.84 2.70

with bottom plate heater

Outdoor unit

Capacity (kW) 11.2 14.0 16.0 11.2 14.0 16.0

Input (kW) 2.39 3.21 3.72 2.39 3.21 3.72

COP 4.69 4.36 4.30 4.69 4.36 4.30

Capacity (kW) 10.0 11.0 13.0 10.0 11.0 13.0

Input (kW) 3.52 4.08 4.80 3.52 4.08 4.80

EER 2.84 2.70 2.71 2.84 2.70 2.71

HWS-

1103H8-E

HWS-

1403H8-E

HWS-

1603H8-E

HWS-

1103H8R-E

1403H8R-E

HWS-

HWS-

1603H8R-E

2

2-4. Hot Water Cylinder

Hot water cylinder (option)

HWS-1501CSHM3-E

HWS-1501CSHM3-UK

Water volume litres 150 210 300

Max water temperature (°C) 75

Electric heater (kW) 2.75 (230 V ~)

Height (mm) 1,090 1,474 2,040

Diameter (mm) 550

Material Stainless steel

8

HWS-2101CSHM3-E

HWS-2101CSHM3-UK

HWS-3001CSHM3-E

HWS-3001CSHM3-UK

Page 10

2.SYSTEM OVERVIEW

Engineering Data book

2-5. Options

No. Part name Model name Application Remarks

1 External output board TCB-PCIN3E

2 External input board TCB-PCMO3E

Second Remote

3

Controller

HWS-AMS11E

Boiler-linked output, Alarm output

Defrost signal output, compressor operation signal

output

Cooling/heating thermostat input

Forced-stop signal input

Wired Remote Controller for Room air temperature

control

Up to two boards (according

to applications)

Up to two boards (according

to applications)

9

Page 11

3. SYSTEM SPECIFICATION

10

Page 12

3.SYSTEM SPECIFICATION

Outdoor unit HWS-803H-E HWS-1103H-E HWS-1403H-E

Hydro unit HWS-803XWH**-E HWS-1403XWH**-E

Rated Heating

condition 1

LWT=35°C

dT=5deg

Rated Heating

condition 2

LWT=45°C

dT=5deg

Rated Cooling

condition 1

LWT=7°C

dT=5deg

Rated Cooling

condition 2

LWT=18°C

dT=5deg

Power supply 1~ 230V 50Hz

Maximum current A 19.2 22.8 22.8

Capacity kW 8.0 11.2 14.0

Power input kW 1.82 2.35 3.11

COP W/W 4.40 4.77 4.50

Rated water flow /min 22.9 32.11 40.13

Capacity kW 8.0 11.2 14.0

Power input kW 2.40 2.95 3.95

COP W/W 3.33 3.80 3.54

Rated water flow /min 22.9 32.11 40.13

Capacity kW 6.0 10.0 11.0

Power input kW 2.13 3.52 4.08

EER W/W 2.82 2.84 2.70

Rated water flow rate /min 17.2 28.67 31.53

Capacity kW 6.0 10 11.0

Power input kW 1.42 2.35 2.65

EER W/W 4.23 4.26 4.15

Rated water flow /min 17.2 28.67 31.53

Engineering Data book

* Rated condition capacity and power input are the data at rated compressor operating frequency.

* Power input does not include water pump power.

* Capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (°C)

LWT : Leaving water temperature (°C)

dT : Delta temperature (deg)

Leaving water temperature - return water temperature (Heating)

Return water temperature - leaving water temperature (Cooling)

Outdoor unit HWS-1103H8-E HWS-1403H8-E HWS-1603H8-E

Hydro unit HWS-1403XWH**-E HWS-1403XWH**-E HWS-1403XWH**-E

Rated Heating

condition 1

LWT=35°C

dT=5deg

Rated Heating

condition 2

LWT=45°C

dT=5deg

Rated Cooling

condition 1

LWT=7°C

dT=5deg

Rated Cooling

condition 2

LWT=18°C

dT=5deg

Power supply 3N ~ 380-400V 50Hz

Maximum current 14.6 14.6 14.6

Capacity kW 11.2 14.0 16.0

Power input kW 2.39 3.21 3.72

COP W/W 4.69 4.36 4.30

Rated water flow rate /min 32.11 40.13 45.70

Capacity kW 11.2 14.0 16.0

Power input kW 3.19 4.12 4.88

COP W/W 3.51 3.40 3.28

Rated water flow rate /min 32.11 40.13 45.70

Capacity kW 10.0 11.0 13.0

Power input kW 3.52 4.08 4.80

EER W/W 2.84 2.70 2.71

Rated water flow rate /min 28.67 31.53 37.20

Capacity kW 10.0 11.0 13.0

Power input kW 2.14 2.43 3.08

EER W/W 4.67 4.53 4.22

Rated water flow rate /min 28.67 31.53 37.20

11

Page 13

4.HYDRO UNIT

4. HYDRO UNIT

4-1. Specification

4-1-1. Hydro unit specifications

Hydro unit HWS-803XWHM3-E HWS-803XWHT6-E HWS-803XWHD6-E HWS-803XWHT9-E

back up heater kW3669

Back up heater

Hot water

cylinder heater*

Appearance

Outer dimension

Unit weight kg 50

Packing

dimension

Total weight Unit and packing kg 54

Heat exchanger

Water pump

Expansion

vessel

Pressure relief

valve

Sound pressure level dBA 29

Operation water

temp.

Water pipe

Refrigerant pipe

Drain port mm 16.0 inner diameter for drain hose

Note

Power supply 1 ~ 220-230V 50Hz 3N~ 380-400V 50Hz 3~ 220-230V 50Hz 3N~ 380-400V 50Hz

Maximum current A 13 13 (13A*2P) 23A 13 (13A*3P)

Power supply 1 ~ 220-230V 50Hz

Maximum current A 12.0

Color Silky shade (Muncel 1Y8.5-0.5)

Material PCM

Height mm 925

Width mm 525

Depth mm 355

Height mm 1070

Width mm 608

Depth mm 436

Type Brazed plate

Water volume litres 0.67

Minimum flow rate /min 13

Power input W 125 / 95 / 65

Delivery head m 6.5 / 6.1 / 4.5

Volume litres 12

Initial pressure MPa(bar) 0.1 (1)

Operating pressure MPa(bar) 0.3 (3)

Heating °C 20~55

Cooling °C 10~25

Outlet mm 34.92

Inlet mm 34.92

Gas mm 15.9

Liquid mm 9.5

* The electric heater, incorporated in the hot water cylinder, requires separete supply

to hydro unit.

Engineering Data book

4

12

Page 14

4.HYDRO UNIT

Engineering Data book

Hydro unit

back up heater kW3669

Back up heater

Hot water

cylinder heater*

Appearance

Outer dimension

Unit weight kg 54

Packing

dimension

Total weight Unit and packing kg 58

Heat exchanger

Water pump

Expansion

vessel

Pressure relief

valve

Sound pressure level dBA 29

Operation water

temp.

Water pipe

Refrigerant pipe

Drain port mm 16.0 inner diameter for drain hose

Note

Power supply 1 ~ 220-230V 50Hz 3N~ 380-400V 50Hz 3~ 220-230V 50Hz 3N~ 380-400V 50Hz

Maximum current A 13 13 (13A*2P) 13 (13A*2P) 13 (13A*3P)

Power supply 1 ~ 220-230V 50Hz

Maximum current A 12.0

Color Silky shade (Muncel 1Y8.5-0.5)

Material PCM

Height mm 925

Width mm 525

Depth mm 355

Height mm 1070

Width mm 608

Depth mm 436

Type Brazed plate

Water volume litres 1.18

Minimum flow rate /min 17.5

Power input W 190 / 180 / 135

Delivery head m 8.3 / 8.1 / 7.2

Volume litres 12

Initial pressure MPa(bar) 0.1 (1)

Operating pressure MPa(bar) 0.3 (3)

Heating °C 20~55

Cooling °C 10~25

Outlet mm 34.92

Inlet mm 34.92

Gas mm 15.9

Liquid mm 9.5

HWS-1403XWHM3-E HWS-1403XWHT6-E HWS-1403XWHD6-E HWS-1403XWHT9-E

* The electric heater, incorporated in the hot water cylinder, requires separete supply

to hydro unit.

13

Page 15

4.HYDRO UNIT

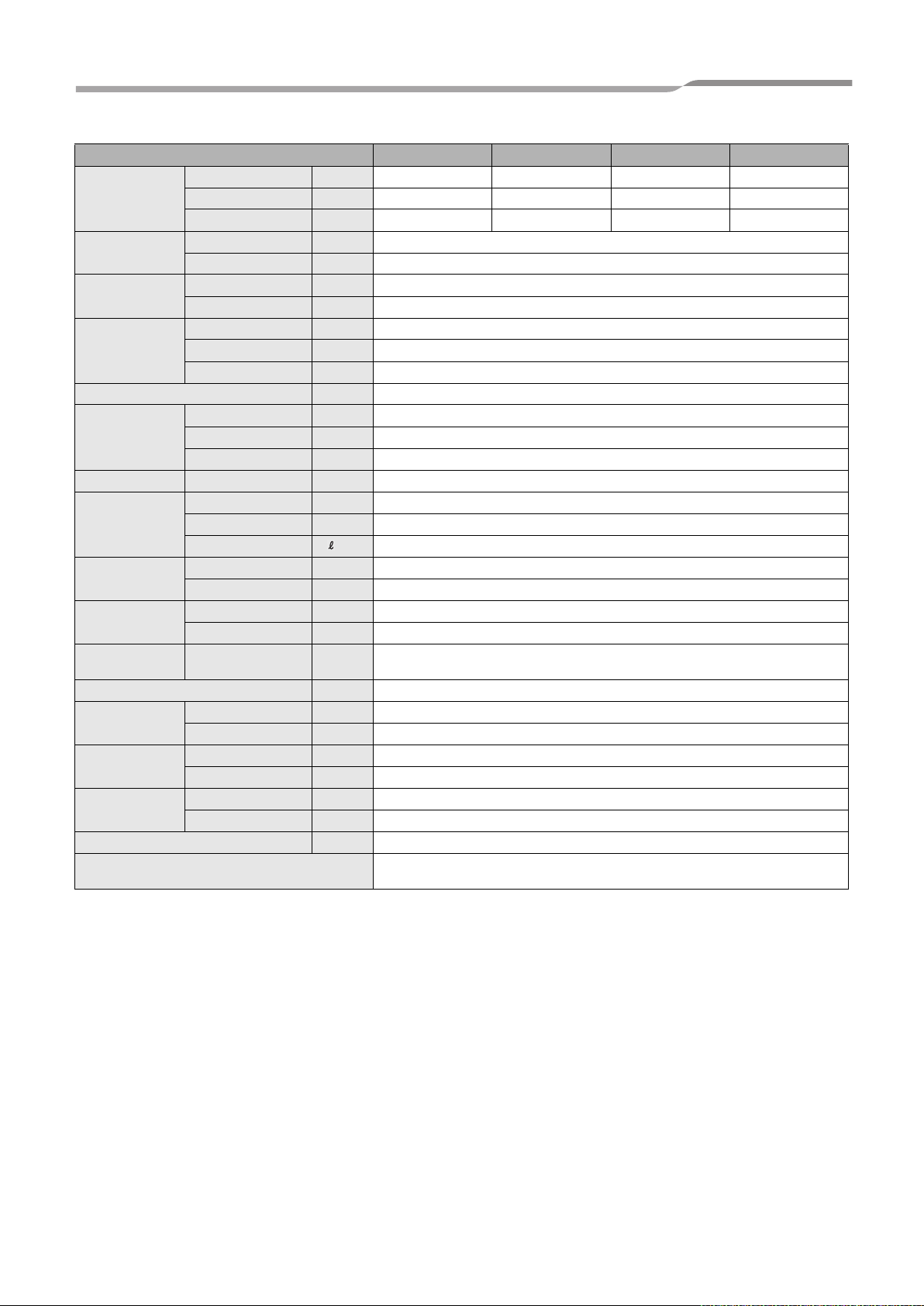

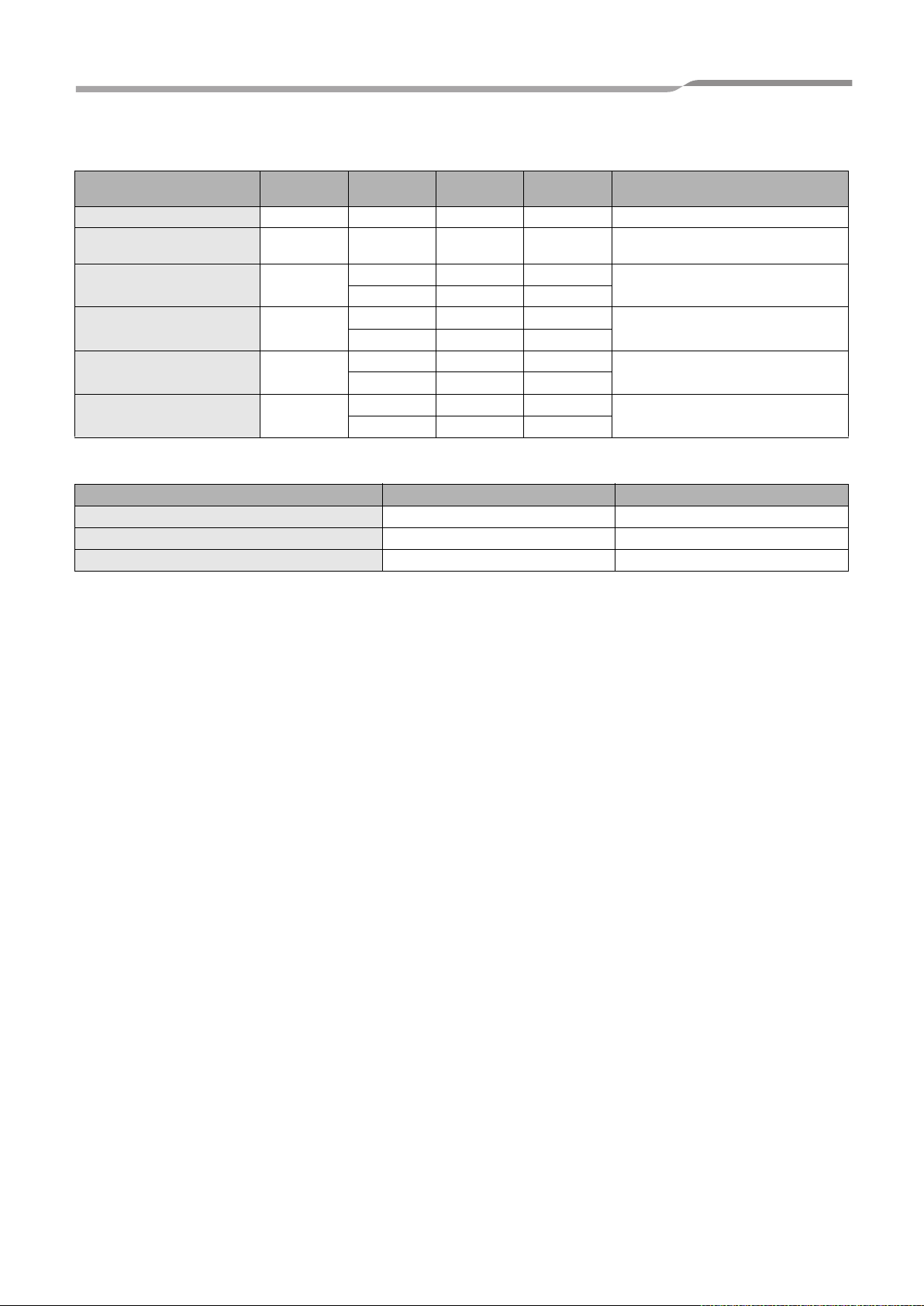

4-1-2. Power Wiring specifications

Engineering Data book

Description

Outdoor

unit

power

Hydro

inlet

heater

power

Outdoor-Hydro unit Connection 1.5 mm² or more , ,

Hydro -Cylinder Connection 1.5 mm² or more , TB03

Power

input

Power

input for

backup

heater

Power input for cylinder

heater

Model name

HWS-

1403H-E

1103H-E

803H-E

1603H8-E,

1603H8R-E

1403H8-E,

1403H8R-E

1103H8-E,

1103H8R-E

1403XWHM3-E

1403XWHD6-E

1403XWHT6-E

1403XWHT9-E

803XWHM3-E

803XWHD6-E

803XWHT6-E

803XWHT9-E

POWER

SUPPLY

220-230 V ~

50 Hz

220-230 V ~

50 Hz

220-230 V ~

50 Hz

380-400V 3N~

50Hz

380-400V 3N~

50Hz

380-400V 3N~

50Hz

220-230V ~

50Hz

220-230V 3~

50Hz

380-400V 3N~

50Hz

380-400V 3N~

50Hz

220-230V ~

50Hz

220-230V 3~

50Hz

380-400V 3N~

50Hz

380-400V 3N~

50Hz

220-230V ~

50Hz

Maximum

current

22.8A 25 A 2.5 mm² or more

22.8A 25 A 2.5 mm² or more

19.2A 20A 2.5 mm² or more

14.6A 16A 2.5 mm² or more

14.6A 16A 2.5 mm² or more

14.6A 16A 2.5 mm² or more

13A 16A 1.5 mm² or more ,

23A 25A 2.5 mm² or more , ,

13A(13A x 2P) 16A 1.5 mm² or more

13A(13A x 3P) 16A 1.5 mm² or more

13A 16A 1.5 mm² or more

23A 25A 2.5 mm² or more

13A(13A x 2P) 16A 1.5 mm² or more

13A(13A x 3P) 16A 1.5 mm² or more

12A 16A 1.5 mm² or more

Installation

fuse rating

Power wire Connection destination

,

, ,

,

, ,

,

,

, ,

, ,

,

,

TB02

TB03

4

4-1-3. External Device specifications

Power Maximum current Type

Motorized 3-way valve

(for hot water)

Motorized 2-way valve

(for cooling)

Motorized mixing valve

type 1 (for 2-zone)

AC 230 V 100 mA

AC 230 V 100 mA spring return type (normally open)

AC 230 V 100 mA

Spring return type

Note: 3-wire SPST and SPDT type can be used by changing the

DPSW 13-1.

60 sec 90º. SPDT type

Note: SPST and 20 to 240 sec type can be used by changing the

function code.

4-1-4. External Device Wiring specifications

Description Line spec Maximum current Maximum length Cable size

3-way valve control 2 line or 3 line 100 mA 12 m 0.75 mm² or more

Mixing valve control 3 line 100 mA 12 m 0.75 mm² or more

2-zone thermo sensor 2 line 100 mA 5 m 0.75 mm² or more , (TB06)

Cylinder thermo sensor 2+GND(shield wire) 100 mA 5 m 0.75 mm² or more , (TB06)

Second remote controller 2 line 50 mA 50 m 0.75 mm² or more , (TB07)

Connection

destination

, ,

(TB05)

, , or

, ,

(TB04)

14

Page 16

4.HYDRO UNIT

4-1-5. External Output specifications

Engineering Data book

Description Output

External pump No.1 AC230V 1 A – 12 m

External boost heater AC230V 1 A – 12 m

Boiler control

ALARM Output

Compressor Operation Output

Defrost Output

Non-voltage

contacts

Non-voltage

contacts

Non-voltage

contacts

Non-voltage

contacts

Maximum

current

0.5 A AC230 V 12 m

1 A DC24 V 12 m

0.5 A AC230 V 12 m

1 A DC24 V 12 m

0.5 A AC230 V 12 m

1 A DC24 V 12 m

0.5 A AC230 V 12 m

1 A DC24 V 12 m

Max voltage

Maximum

length

Output as required when outdoor air

temperature is -20°C or less

Output as required when outdoor air

temperature is -10°C or less

4-1-6. External Input specifications

Description Input Maximum length

Emergency stop control Non-voltage 12 m

Cooling thermostat input Non-voltage 12 m

Heating thermostat input Non-voltage 12 m

15

Page 17

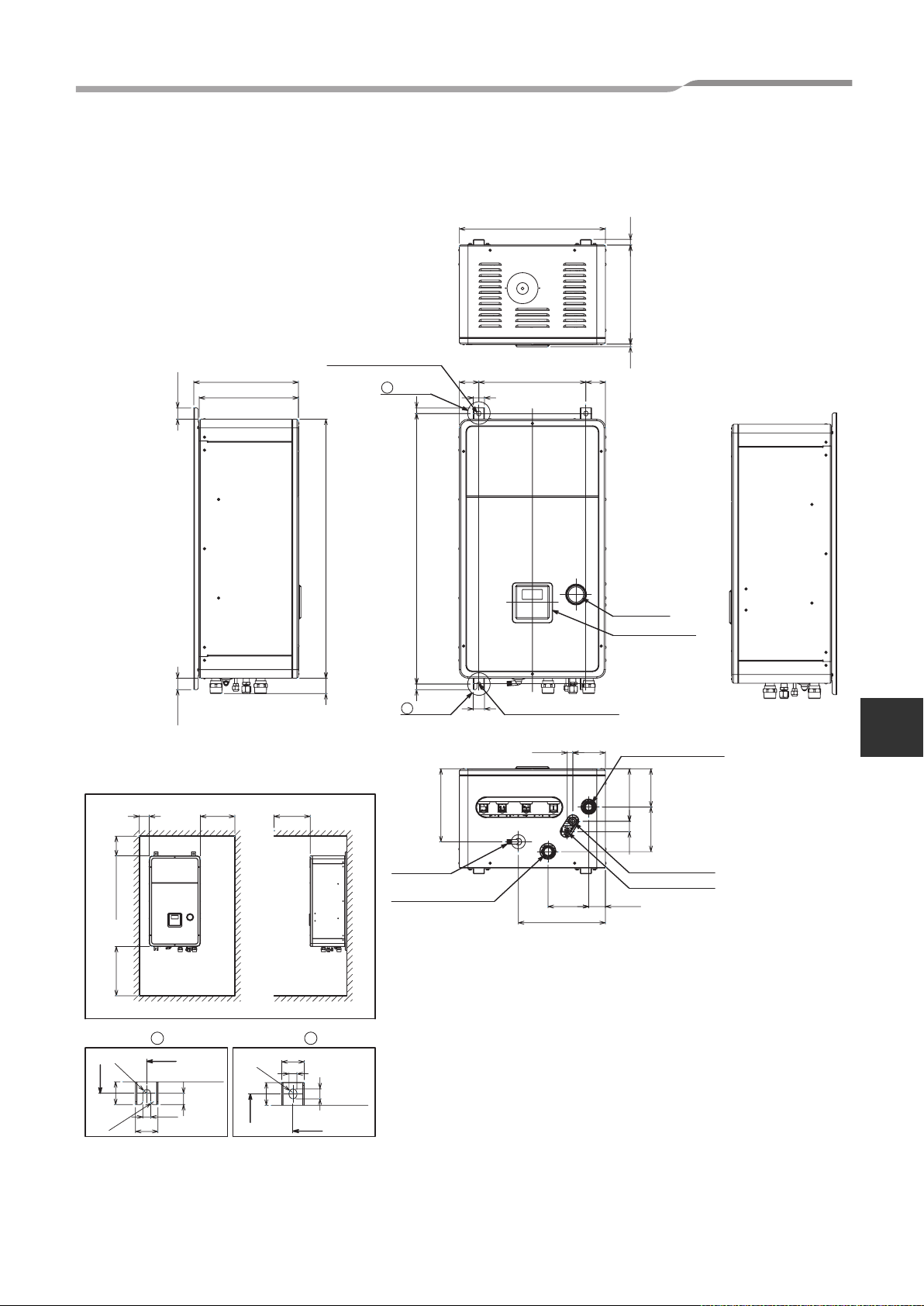

4.HYDRO UNIT

4-2. Dimension

▼Hydro unit

525

19.5

352

Engineering Data book

100 or more

200 or more

40.540.5

Service space

350 or more

371.5

355

500 or more

2-dia.12x17 long hole

(for dia.8-10 anchor bolt)

B leg part

2020

92554

960

A leg part

Drain nipple

Water inlet

connecting pipe 1 1/4"

72.5 72.5

40

Anchor bolt long hole pitch

40

259

380

Anchor bolt

long hole pitch

2-dia.12x17 U-shape hole

(for dia.8-10 anchor bolt)

309.5

Manometer

Remote controler

Hot water outlet

11619.5

connecting pipe 1 1/4"

59.5144.5

9

135.5

186.5

158

37.5

Gas line dia.15.88

Liquid line dia.9.52

4

500 or more

Detailed A leg part Detailed B leg part

960

R14

81

80

28

380

36

Outside line

of product

960

R14

81

2-R10

80

380

28

Outside line

of product

40

16

Page 18

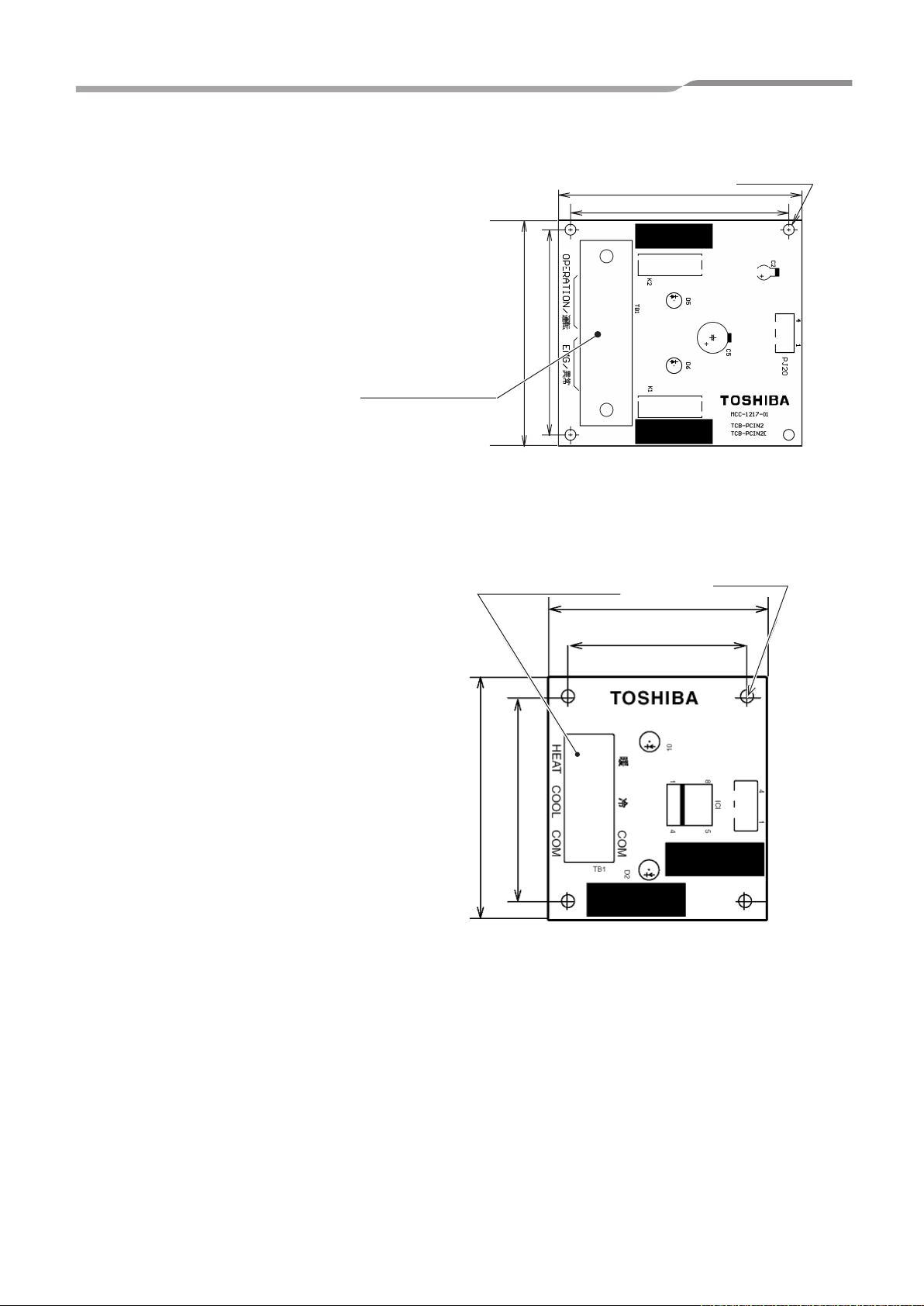

4.HYDRO UNIT

▼External output board (TCB-PCIN3E)

Engineering Data book

Size (mm) : H22 x L73 x W79

Weight (g) : 57

Terminal (Screw M3

▼External input board (TCB-PCMO3E)

Size (mm) : H18 x L55.5 x W60

Weight (g) : 20

63

73

)

Terminal (Screw M3)

79

69

55.5

4- 4Øhole

4-Ø4 hole

60

50

45.5

NCC-1214 TCB-PCMO2

TCB-PCMO2E

PJ17

17

Page 19

4.HYDRO UNIT

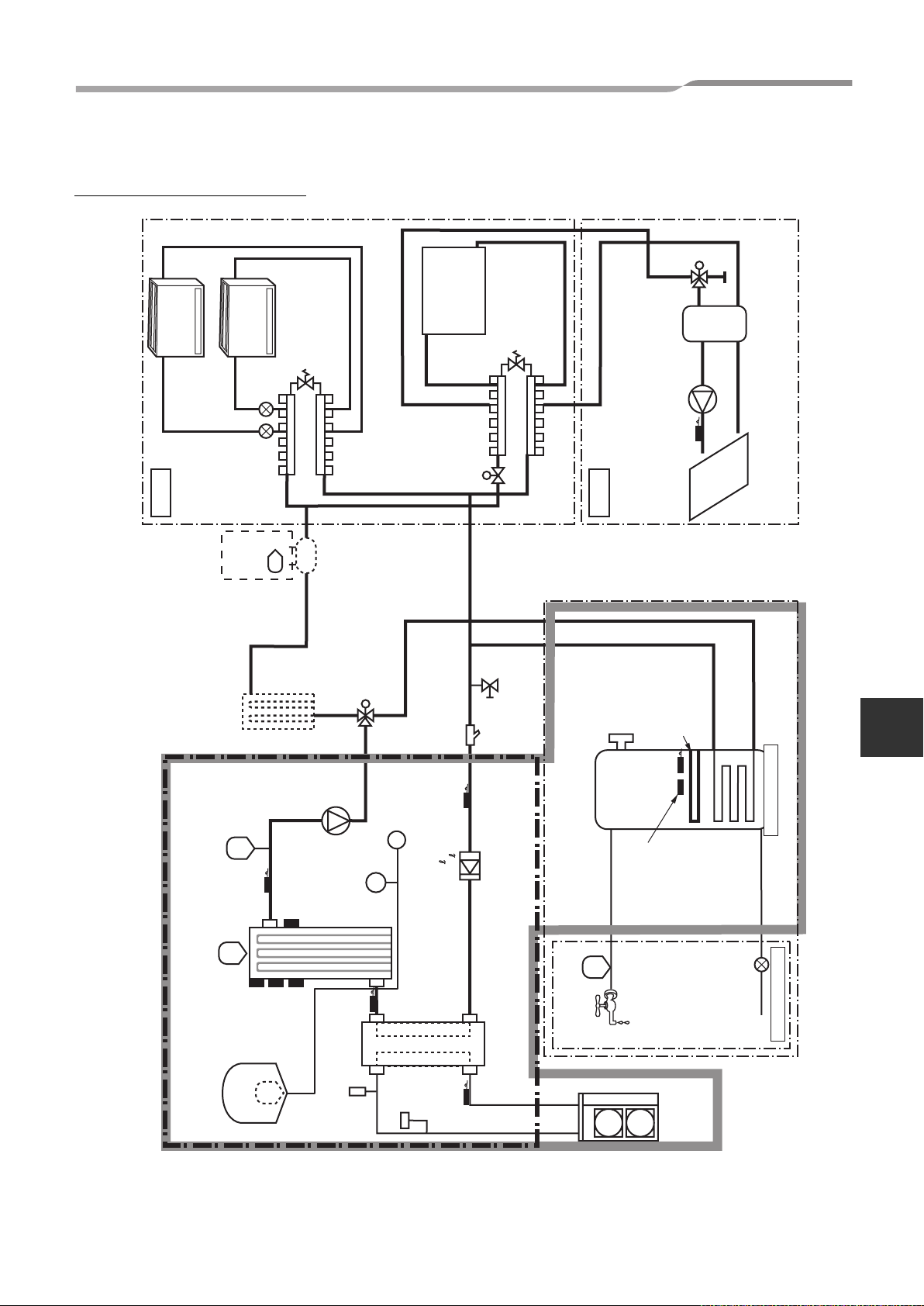

4-3. Piping Diagram

Water system diagram

Engineering Data book

M

Fan coil unit

zone1

Boiler

(locally

procured)

Booster heater

(locally procured)

By-pass valve

(locally procured)

AC230V

(locally procured)

Motorized 3-way valve

M

Radiator unit

2-way valve for

cooling mode

(locally procured)

AC230V

Strainer

40 mesh

(locally procured)

By-pass valve

(locally procured)

(locally procured)

Drain cock for water charge

Relief valve (UK)

zone2

10bar

90 °C

AC230V

(locally procured)

Moterized mixing valve

TFI

AC pump

(locally procured)

2.75kW

:

Ø1

Cylinder heater

TTW

Floor

heating

Buffer tank

(locally procured)

4

set : 3bar

Pressure relief valve

THO

Air vent valve

Expansion vessel

set : 1bar

AC pump

°C

(auto)

set : 75±3

Thermal protector

°C

set : 95±5

single operation

Thermal protector

Menometer

gage : ~6bar

TWO

Pressure sw

4.15MPa

Water vent valve

Flow sw

Backup heater

TWI

13 /min

17.5 /min

:

:

set

set

TC

Pressure sensor

Water heat exchanger

Water outlet

Pressure relief

°C

82+3-2

(manual reset)

Thermal cut-out

Outdoor unit

Hot water cylinder

Water inlet

Reducing valve

Local hot water system

18

Page 20

4.HYDRO UNIT

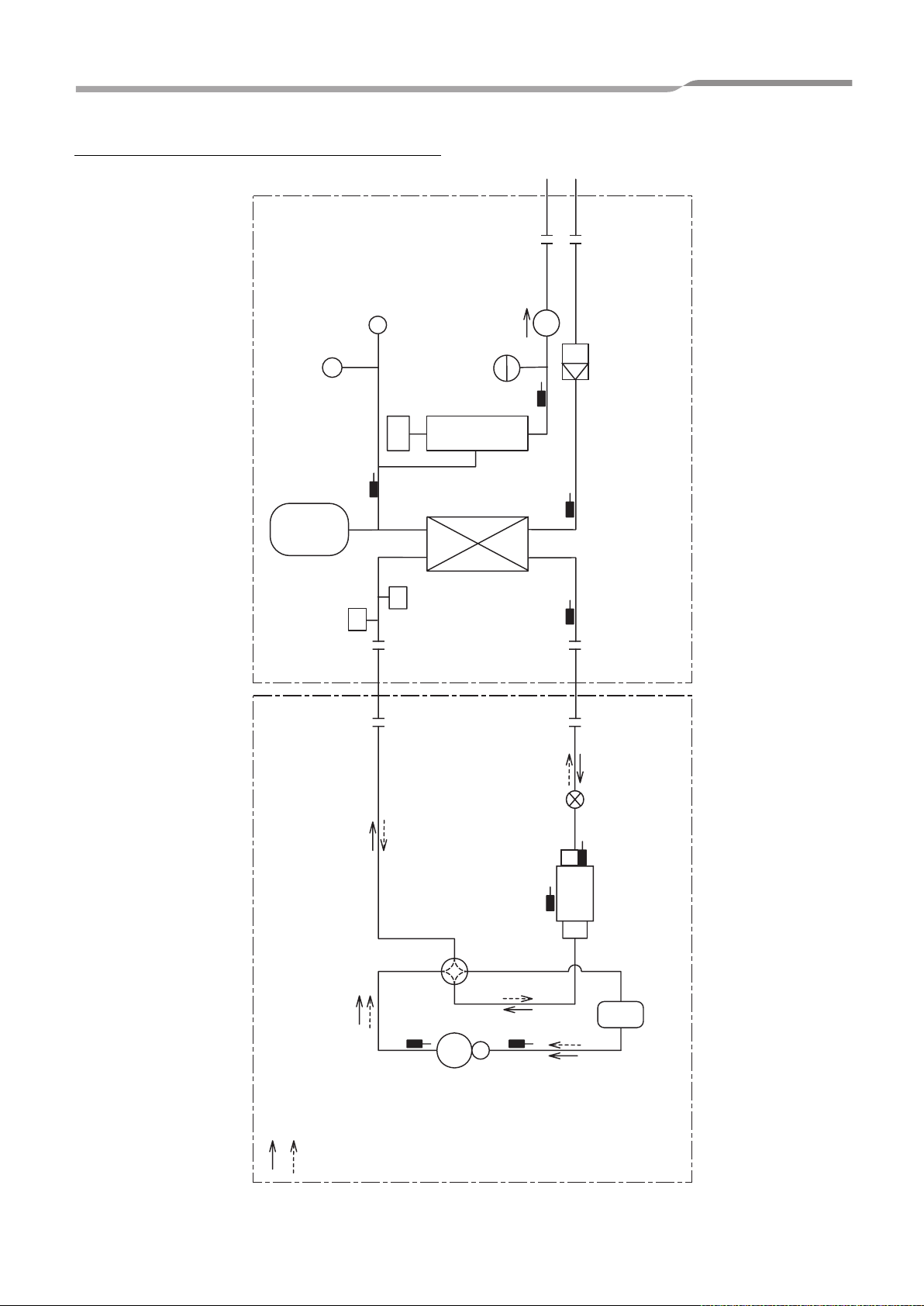

Refrigeration cycle system diagram

Water vent valve

Manometer

P

Circulating pump

Engineering Data book

Expansion vessel

TWO

Pressure Switch

Air vent valve

Backup heater

Low Pressure

sensor

THO

Safety valve

TWITC

heat exchanger

Pulse motor

valve

Flow switch

TE

Outdoor unit Hydro unit

Heating / Hot-water supply

Defrosting / Cooling

TD

4-way valve Plate-type water

Compressor

19

TS

TO

Outdoor heat

exchanger

Accumulator

Page 21

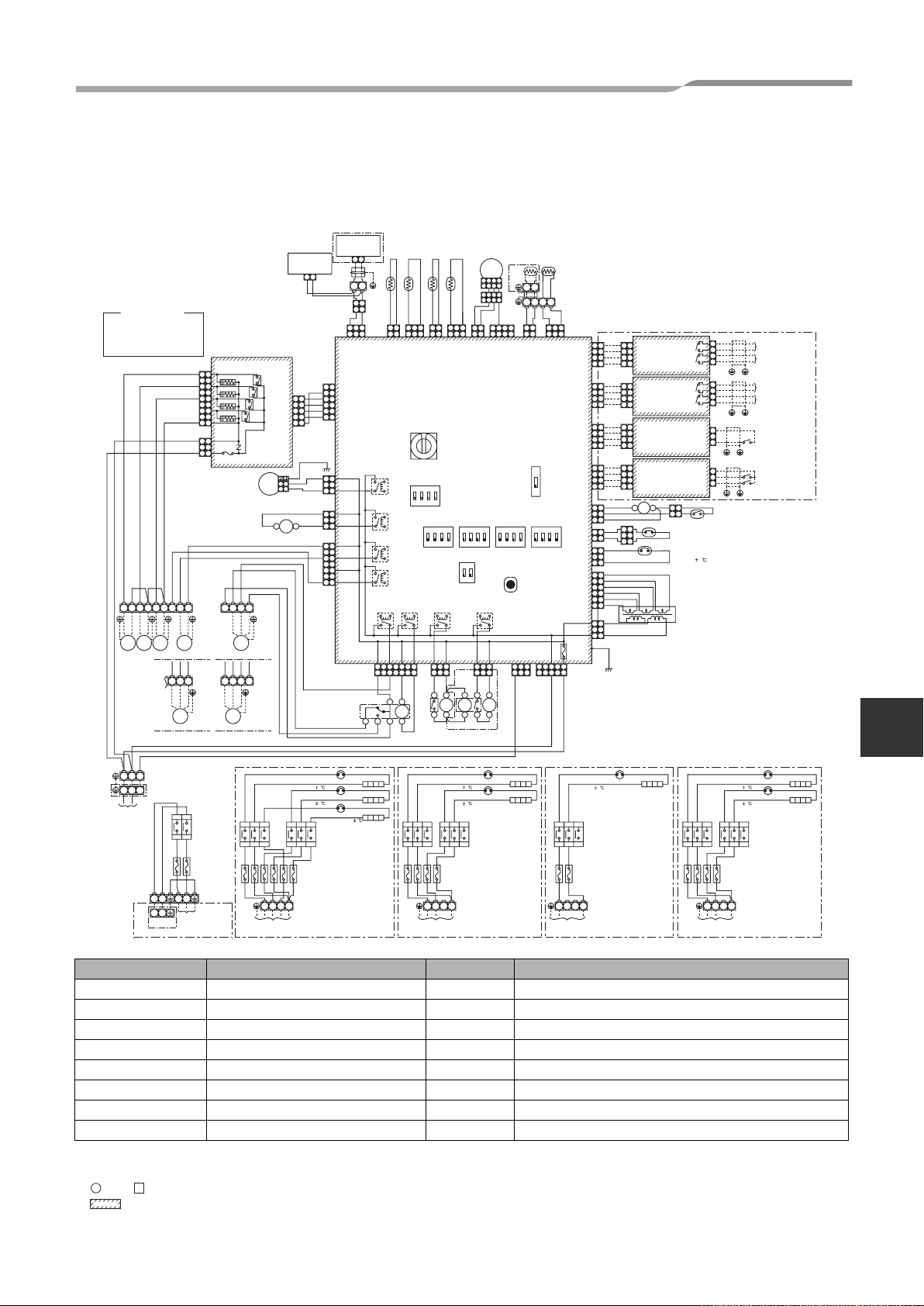

4.HYDRO UNIT

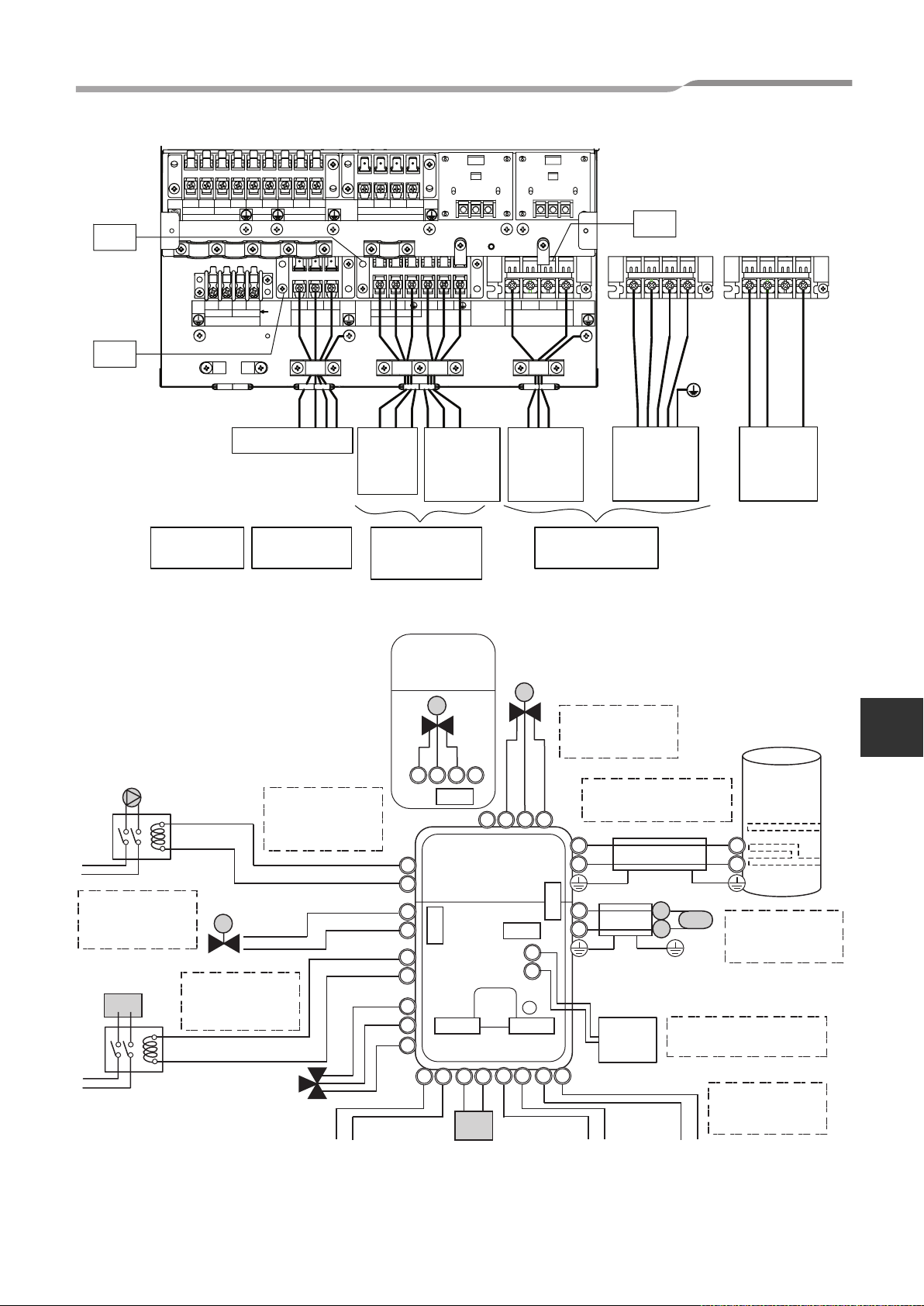

4-4. Wiring Diagram

4-4-1. Hydro unit

Remote

controller

(HWS-AMS11E)

AB

WHI

GRY

Color identification

BLU : BLUE

BLK : BLACK

GRN : GREEN

BRW : BROWN

ORN : ORANGE

GRY : GRAY

RED : RED

PNK : PINK

YEL : YELLOW

WHI : WHITE

WHI WHI

YEL

5251

WPM

*See DIP SW13_1

BLU

3

5

4

5

2WV

WHI

BRW

55

56

BH 3WV

(2-wire spring return)

(3-wire SPST type)

(3-wire SPDT type)

CN10

(WHI)

YEL

9

9

CR10

RY

787

6

55

4

3

2

11

3

3

11

CR11

CR12

CR13

CN01

(WHI)

2

F01 (5A)

10

RY

11

WHI

ORN

PNK

RED

4

3

44

41

2

4

MIXV

(3-wire SPDT type)

WHI

ORN

PNK

RED

43

4

4

41

42

MIXV

(3-wire SPST type)

RY

12

RY

13

Relay

p.c.board

(MCC-1431)

TB 04

Type 1

TB 04TB 05

Type 2

WPM

CN02

(WHI)

A2

RED

BLU

55

4

ORN

4334

3

GRN

2

BRW

2

2

1

11

BLK

BLU

BRW

LNNL

1

RED

WHI

RY

A1

1

05

YEL

7

WHI

5

RED

1

BLU

BRW

WHI

WHI

RED

RED

WHI

YEL

TB 05

5

8

59

5

7

Type 1

WHI

YEL

RED

59

57

8

5

3WV

Type 2

Type 3

controller

(HWS-AMS11E)

TB 07

6

515

4

CN501

(YEL)

3

2

313

CN603

(YEL)

313

CN601

(RED)

7

5

3

1

CN602

(WHI)

Remote

AB

A

7

GRY

1

1

CN41

(BLU)

PNK

*Option

7

B

2

1

2

1

WHI

3

2

3

CN604

(BLU)

2

ORN

BLK

BLK

2

1

2

1

CN203

(YEL)

RY601RY600RY603 RY602

5

3

7

5

3

7

WHI

RED

5

7

RY

06

468

RED

THOTWOTWITC

LPS

3

4

2

1

3

4

2

3

4

2

3

4

2

BLK

BLK

BLK

BLK

BLK

BLK

1

1

CN204

(BRW)

3

2

3

2

111

1

2

1

1

CN206

CN205

(WHI)

(RED)

P.C.board

(MCC-1511)

WHI

BLK

RED

3

2

2

2

22

3

1

CN207

CN212

(BLU)

(WHI)

1

SW01

SW02

ON

12 43

SW10 SW 11 SW12 SW13

ON

ON ON21ON

1234 1234 12341234

SW06

ON

SW07

RY607RY606RY605RY604

CN605

CN606

(YEL)

(BLU)

3

3

1

1

L

BLK

YE

RY

01

1

3

1

WHI

ORN

A2

6

RY

02

03

A1

7

4

WHI WHI

*

1

3

1

WHI

PNK

A1

648

RY04RY

A2

1

*Option

TTW

AB

6

C

D

A

6

6

B

6

BRW

BRW

RED

2

1

1

2

2

34

1

1

CN213

CN214

(WHI)

(WHI)

SW14

OFF

ON

CN305

CN100

(GRN)

(WHI)

5

3

3

1

33

WHI

GRY

TFI

TB 06

RED

3

3

1

2

CN208

(BLU)

3

414

1

2

CN209

(GRN)

3

414

1

2

CN210

(RED)

3

414

1

2

CN211

(BLK)

3

414

1

CN200

2

(RED)

33

CN201

11

(WHI)

22

11

CN202

(YEL)

1

2

CN102

3

(WHI)

4

5

6

CN101

(WHI)

11

33

F100

Fuse

T5A

P100

250V~

1

1

RED

1

HWS-803XWHT6-E : Installed

*

HWS-1403XWHT6-E : Installed

HWS-803XWHD6-E : Installed

HWS-1403XWHD6-E : Installed

HWS-803XWHT9-E : Installed

HWS-1403XWHT9-E : Installed

HWS-803XWHM3-E : Not installed

HWS-1403XWHM3-E : Not installed

Engineering Data book

*Option p.c.board

GRN

1

GRN

Relay

2

2

2

p.c.board

GRN

3

3

3

(MCC-1217)

GRN

414

PJ20

GRN

1

GRN

Relay

2

2

2

p.c.board

GRN

3

3

3

(MCC-1217)

GRN

414

PJ20

YEL

1

YEL

Photocoupler input

2

2

2

p.c.board

YEL

3

3

3

(MCC-1214)

YEL

414

PJ17

YEL

1

YEL

Photocoupler input

2

2

2

p.c.board

YEL

3

3

3

(MCC-1214)

YEL

414

PJ17

YEL

RY

8

7

1

01

GRN

2

RED

11

BLK

BLK

33

BLK

BLK

323

BRW

1

BRW

2

RED

3

RED

4

ORN

5

ORN

6

WHI

WHI

BLK

K1

K2

TB1

K1

K2

TB1

TB1

TB1

22

11

Pressure switch

4.15MPa

Thermal protector

(auto)

75 5

Transformer

4

3

2

1

4

3

2

1

3

2

1

3

2

1

Flow switch

Boiler control O/P

Alerm O/P

Compressor operation

O/P

Defrost O/P

Emergency stop I/P

Cooling thermostat I/P

Heating thermostat I/P

4

WHI

RED

GRY

TB 01

3

12

Power supply

220 - 230V~ 50Hz

or

380 - 400V~ 50Hz

TB 03

12111

Outdoor unit

3

BRW

BLU

12

33

12

Hot water cylinder

1L1

3L2

RY05

4T2

2T1

BLU

BRW

F1 F2

BLU

BRW

N

L

Power supply

220 - 230V~ 50Hz

F1, F2

Fuse

AC250V

T30A

YEL/GRN

*Option

5L3

1L1

3L2

RY02

4T2

6T3

2T1

GRY

BRW

BLU

F3F4F6F5F8

F7

BLU

BLK

BLU

BRW

L3

L1 L2

Power supply

380 - 400V 3N~ 50Hz

1L12L3

4T2

2T1

BLK

BLU

GRY

TB 02

N

Thermal protector

(Single operation)

95 5

Thermal protector

(Single operation)

95 5

Thermal protector

(Single operation)95 5

5L3

RY04

6T3

BLU

BLU

F3~8

Fuse

AC250V

T30A

HWS-803XWHT9-E

HWS-1403XWHT9-E

Backup heater 1

Backup heater 2

Backup heater 3

RY02

4T22T1 6T3

BLU

BRW

F5

F3 F6

F4

BLK

BLU

BRW

Power supply

380 - 400V 3N~ 50Hz

1L1 3L2

3L51L12L3

2T1 4T2

BLK

BLU

L3

1L2L

Thermal protector

(Single operation)

95 5

Thermal protector

(Single operation)

95 5

5L3

RY04

6T3

BLU

F3~6

Fuse

AC250V

T30A

TB 02

N

HWS-803XWHT6-E

HWS-1403XWHT6-E

Backup heater 1

Backup heater 2

Thermal protector

(Single operation)

5L31L1 3L2

6T32T1 4T2

BLU

BRW

F3

F4

F3,F4

Fuse

AC250V

T30A

BLU

BRW

LN

Power supply

220 - 230V~ 50Hz

95 5

RY02

TB 02

HWS-803XWHM3-E

HWS-1403XWHM3-E

Backup heater 1

4T22T1 6T3

BLU

BRW

F5

F3 F6

F4

BLU

BRW

Power supply

220 - 230V 3~ 50Hz

RY02

BLK

3L51L12L3

BLK

BLU

1L2L

Thermal protector

(Single operation)

95 5

Thermal protector

(Single operation)

95 5

1L1 3L2

2T1 4T2

F3~6

Fuse

AC250V

T30A

TB 02

L3

5L3

6T3

BLU

Backup heater 1

Backup heater 2

RY04

HWS-803XWHD6-E

HWS-1403XWHD6-E

Symbol Parts name Symbol Parts name

WPM Water pump motor TC Water heat exchanger temperature sensor

3WV 3-way valve (locally procured) TWI Water inlet temperature sensor

2WV 2-way valve (locally procured) TWO Water outlet temperature sensor

MIXV Mixing valve (locally procured) THO Heater outlet temperature sensor

BH Booster heater TTW Hot water cylinder temperature sensor

RY01~RY06 Relay01~Relay06 TFI Floor heating inlet temperature sensor

LPS Low pressure sensor TB Terminal block

Backup heater1, 2, 3 Heater AC230V, 3kW

1. The one-dot chain line indicates wiring at the local site, and the dashed line indicates accessories sold separately and service wires,

respectively.

2. , and indicates the terminal board and the numberals indicate the terminal numbers.

3. indicates P.C. board.

* Be sure to fix the electric parts cover surely with screws. (Otherwise water enters into the box resulting in malfunction.)

20

Page 22

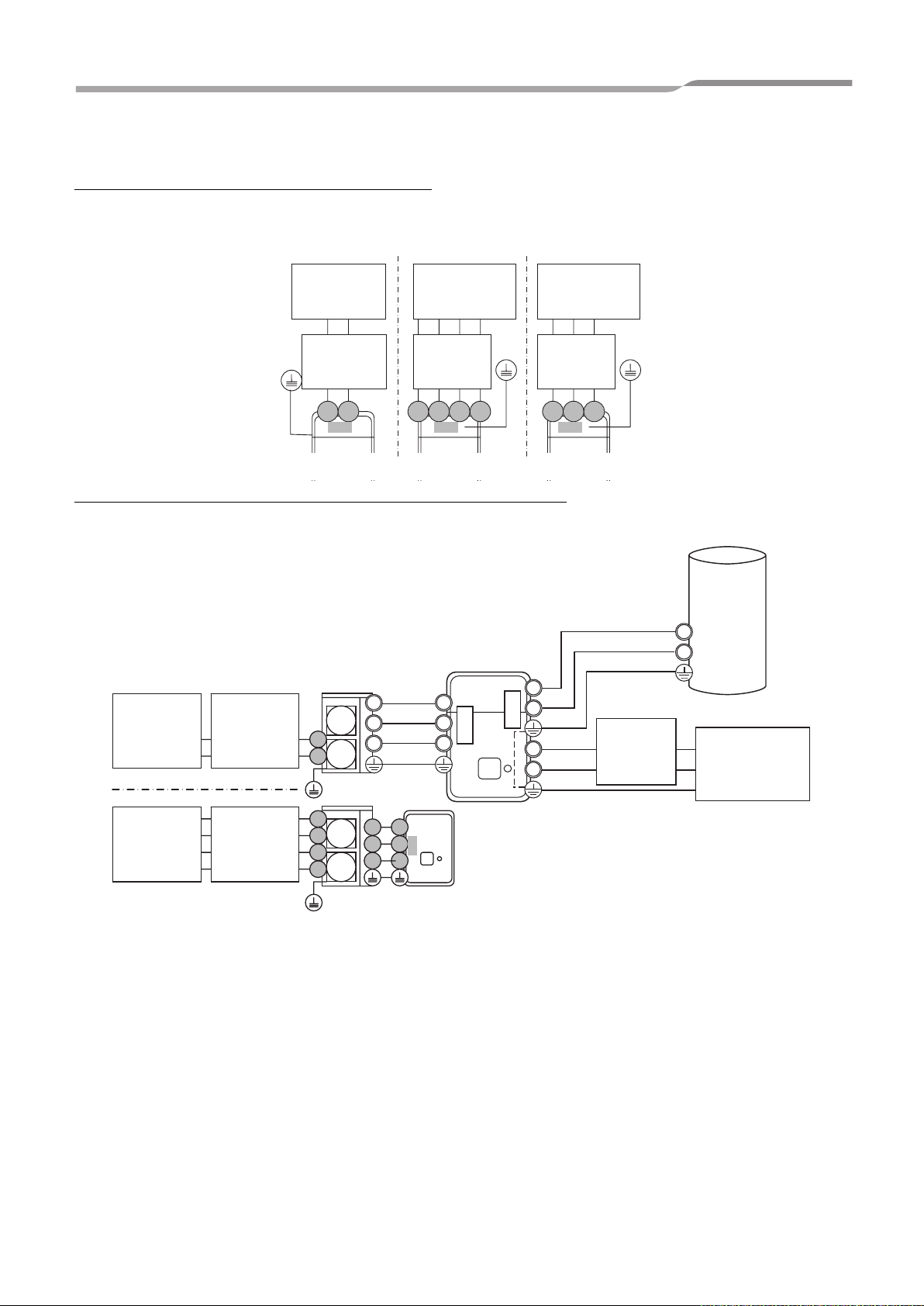

4.HYDRO UNIT

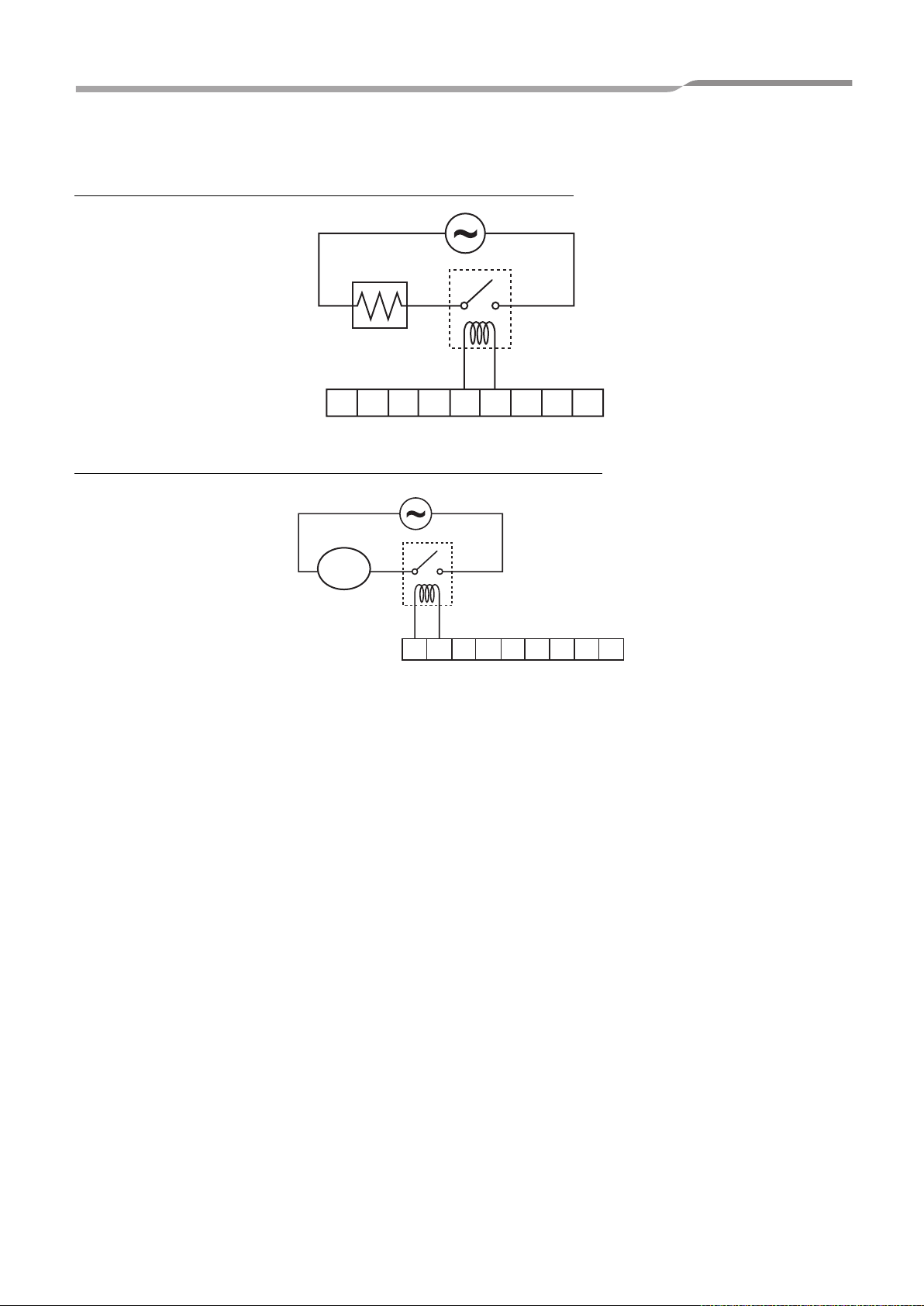

4-4-2. Power line

Electrical connection to hydro unit

Engineering Data book

Backup heater

220-230V ~ type

(3kW type)

Input power

220-230V 50Hz

Leakage

breaker 30mA

Backup heater

380-400V 3N~ type

(6,9kW type)

Input power

220-230V

3N~ 50Hz

Leakage

breaker 30mA

Backup heater

220-230V 3~ type

breaker 30mA

L N L1 L2 L3 N L1 L2 L3

Outdoor unit to hydro unit electrical connection

(6kW type)

Input power

220-230V

3~ 50Hz

Leakage

TB 20TB02TB02

Hot water cylinder

1

2

Input power

220-230V~ 50Hz

Input power

380-400V

3N~ 50Hz

Leakage breaker

30mA

Leakage breaker

30mA

L1

L2

L3

1

TB01

TB03

2

Leakage

L

N

breaker 30

mA

Input power for

cylinder heater

230 V ~ 50 Hz

1

2

L

N

3

1

2

N

3

Hydro unitOutdoor

unit

1

2

3

1

2

TB01

3

21

Page 23

4.HYDRO UNIT

Engineering Data book

55

53

51

52

WPM

TB 05

565758

54

BH

2WV

TB03

Don't apply

6B6A 6D

6C

TB 06

220-240V

TF1

or

breakdown

will occur.

TTW

TB01

to Outdoor unit

Sensor

connection

Outdoor unit

connection

4-4-3. Control line

3WV

1

11 12

TB 01

59

3

2

13

43

41

Hot

water

cylinder

44

42

MIXV

TB 04

31 32

HOT WATER CYLINDER

L

TB 03

Input power

220-230 V ~

50 Hz

Hot water cylinder

power supply

Mixing-Valve

type 2 for 2 zone

control

TB02

L3

N

L2L1

N

L

N

TB 02

Input power

220-230 V ~

50 Hz

Backup heater

power supply

Mixing-Valve type 1

for 2 zone control

Input power

380-400 V 3N

~ 50 Hz

L1 L2

L3

N

L1 L2

Input power

220-230 V

3 ~ 50 Hz

L3

Pump (local)

Max 12 m

230 V 100 mA

0.75 mm² or more

Booster heater

(local)

Max 12 m

230 V 1 A

0.75 mm² or more

2Way-Valve for

cooling stop

Max 12 m

230 V 1 A

0.75 mm² or more

3Way-Valve for hot

water cylinder

Alert output

(local)

4

2

3

1

TB04

1

2

3

4

TB05

5

6

7

8

CN208

OPTION OPTION

9

PJ20

2

1

Boiler operation

(local)

4

3

Max 12 m

230 V 100 mA

0.75 mm² or more

N

CW

4

2

3

1

Max 5 m shielded wire

0.75 mm² or more

CCW

A

B

Temp sensor in hot

water cylinder

A

B

4

TB06

TB07

1

2

CN209

C

D

Temp sensor for

2 zone control

Max 50 m shielded wire

0.75 mm² or more

Max 5 m shielded

wire 0.75 mm² or

more

PJ20

2

1

3

2nd Remote control

4

Max 12 m non

voltage 0.75 mm² or

more

Defrost output

(local)

Compressor

operation output

(local)

22

Page 24

4.HYDRO UNIT

4-4-4. External Device

Electrical connection for external booster heater

Booster Heater

Engineering Data book

1234567 8 9

Electrical connection for external additional pumps

Pump

01

1234567 8 9

Terminal Block 05

Terminal Block 05

23

Page 25

4.HYDRO UNIT

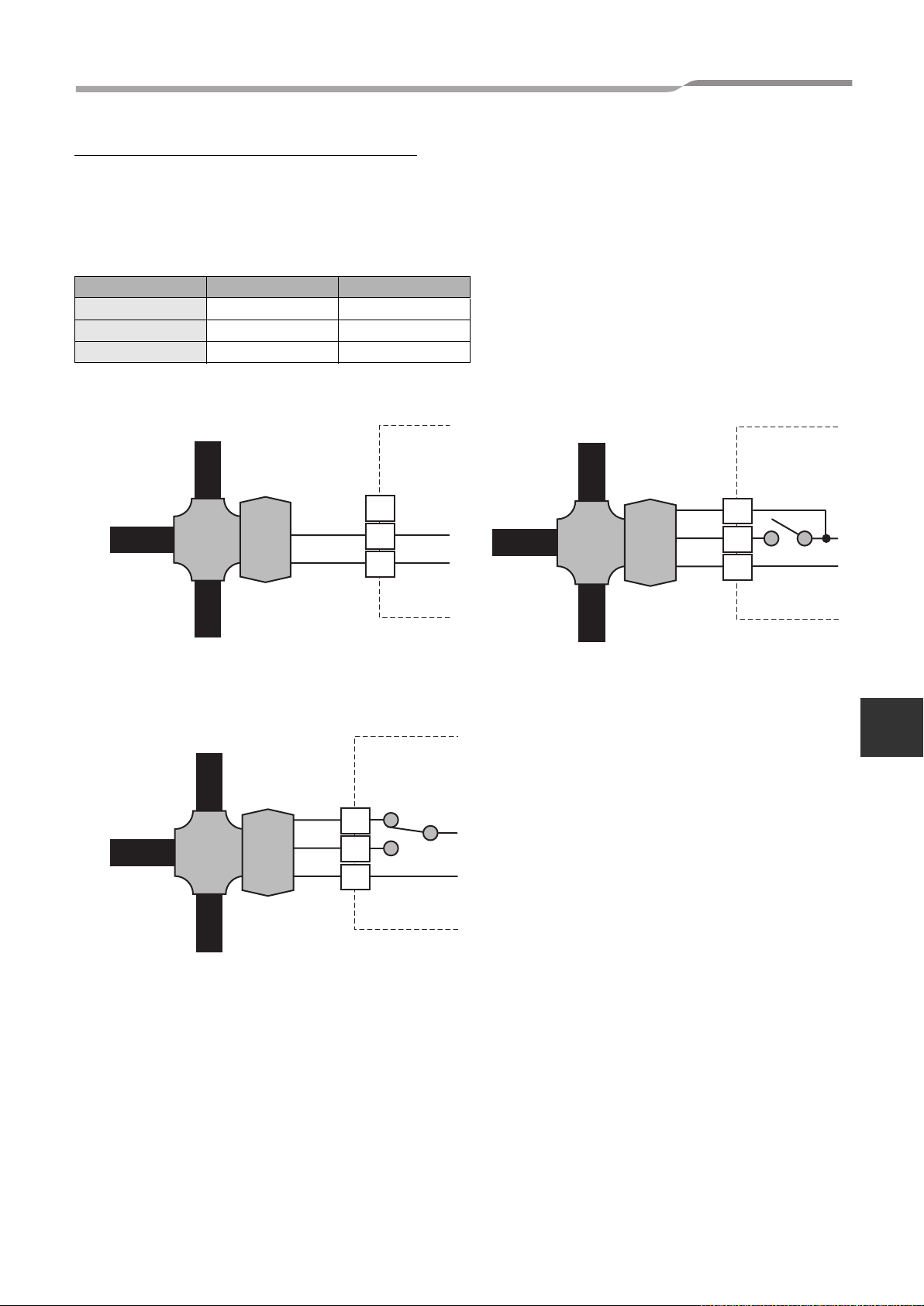

3-way valve (diverter) connection

Required Valve Specification:

Electrical Specification: 230 V; 50 Hz; <100 mA

Valve Diameters: Port A, Port B: Ø 1 1/4"

Return Mechanism: 3 types of 3-way valve (diverter) can be used.

Set the 3-way valve in use with the DIP switch SW13-1 on the Hydro Unit board.

SW13-1

Type 1 2-wire spring return OFF

Type 2 3-wire SPST OFF

Type 3 3-wire SPDT ON

Type 1: SPRING RETURN Type 2: SPST

port “A” to Hot water

cylinder

Hydro Unit

port “A” to Hot water

cylinder

Engineering Data book

Hydro Unit

port “AB” to

Hydro unit

Type 3: SPDT

port “AB” to

Hydro unit

port “A” open

port “B” to Room heating or

cooling

port “A” to Hot water

cylinder

port “A”

close

open

TB 05

7

8

9

Hydro Unit

TB 05

7

8

9

port “AB” to

Hydro unit

port “A”

close

open

port “B” to Room heating or

cooling

TB 05

7

8

9

4

port “B” to Room heating or

cooling

24

Page 26

4.HYDRO UNIT

Engineering Data book

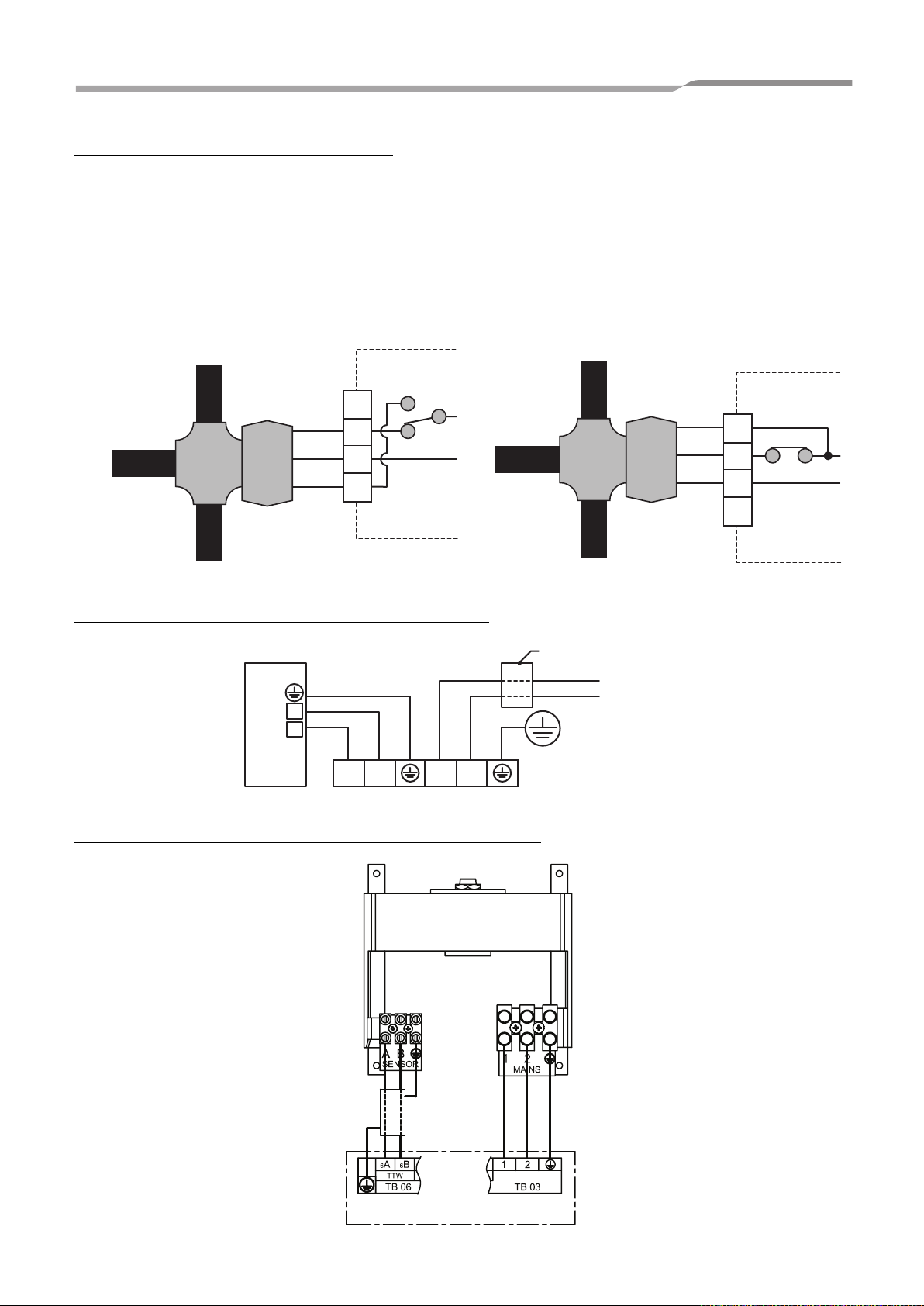

3-way mixing valve connection

Required Actuator Specification

Electrical Specification:230 V; 50 Hz; <100 mA

The 3-way mixing valve is used to achieve the temperature differential needed in a 2-zone heating system.

• Connect the 3-way mixing valve to terminals 2, 3 and 4 on Terminal Block 04 (for Type 1 mixing valve) or on

terminals 1, 2 and 3 on Terminal Block 04 (for Type 2 mixing valve).

• Connect the 3-way mixing valve in accordance with the diagrams below:-

Type 1: SPDT Type 2: SPST

port “A” to Zone 2 Heating

port “AB” to

Hydro unit

open

Hydro Unit

TB 04

1

2

3

port “A”

close

port “B” BLANK OFF

4

Hot water cylinder connection (optional)

2

1

12 LN

Hot water cylinder

port “A” to Zone 2 Heating

port “AB” to

Hydro unit

port “B” BLANK OFF

Earth leakage breaker

INPUT Power 230 V ~ 50 Hz

Terminal block 03

port “A”

close

open

Hydro Unit

TB 04

1

2

3

4

Hot water cylinder electrical box connections

Hydro unit

25

Page 27

4.HYDRO UNIT

4-5. Capacity Tables

▼Outdoor unit HWS-803H-E

Hydro unit HWS-803XWH**-E

Rated heating capacity and power input

Capacity kW 8.0

Rated condition 1

LWT=35°C

dT=5deg

Rated condition 2

LWT=45°C

dT=5deg

* Rated heating capacity and power input are the data at rated compressor operating frequency

* Power input does not include water pump power.

* Heating capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

dT : Delta temperature (deg)

Leaving water temperature - return water temperature

Power input kW 1.82

COP W/W 4.40

Rated water flow rate /min 22.9

Capacity kW 8.0

Power input kW 2.40

COP W/W 3.33

Rated water flow rate /min 22.9

Engineering Data book

4

26

Page 28

4.HYDRO UNIT

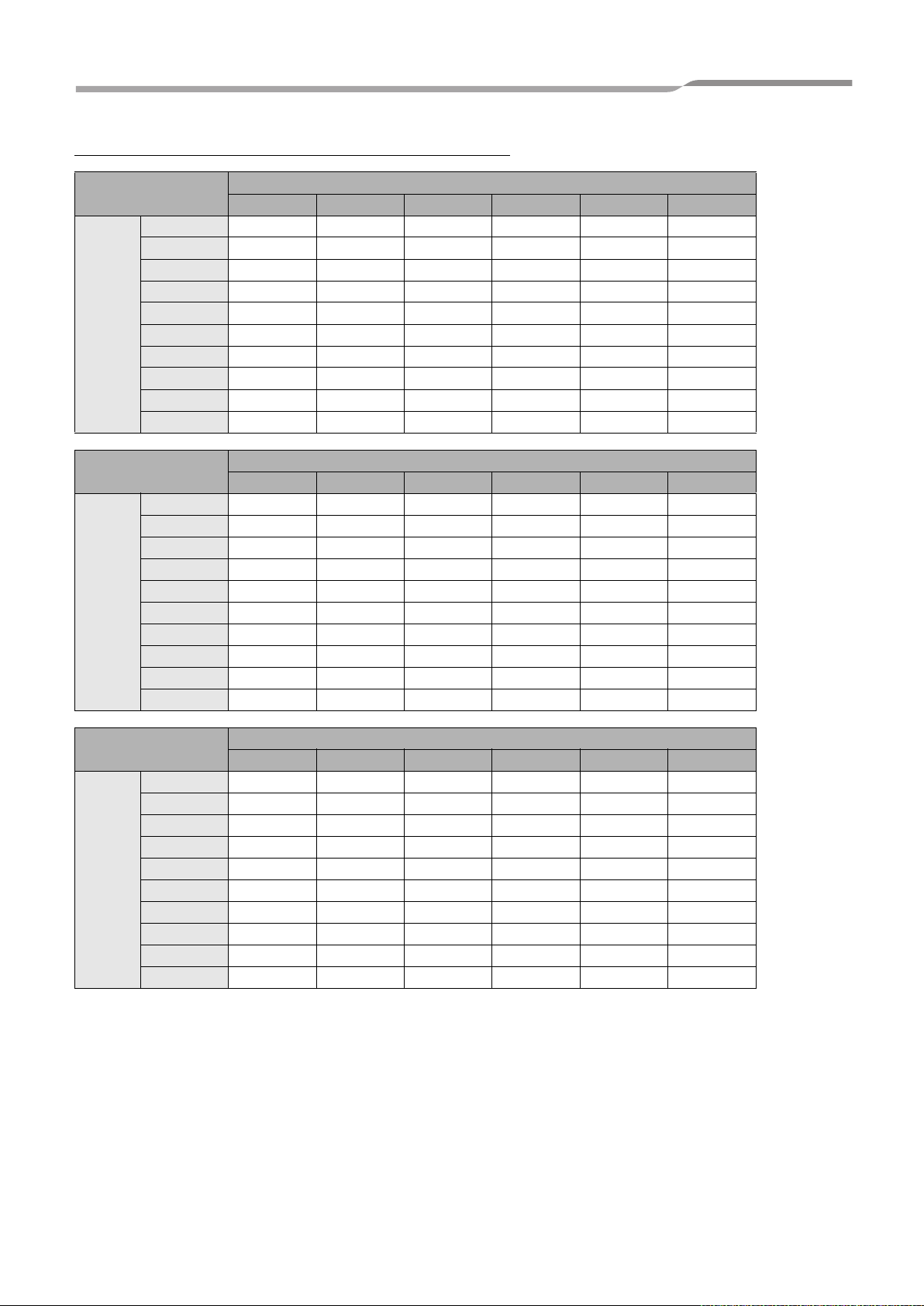

Average heating capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

LWT (°C)

30 35 40 45 50 55

-20 3.93 3.83 3.74 — — —

-154.664.544.444.27— —

-7 5.45 5.30 5.15 4.99 4.84 —

-2 6.24 6.11 5.97 5.84 5.69 5.55

2 6.86 6.75 6.64 6.52 6.47 6.38

7 9.02 8.78 8.58 8.34 8.11 7.87

10 9.56 9.29 9.10 8.84 8.42 8.29

12 10.11 9.81 9.62 9.35 8.92 8.87

15 10.94 10.60 10.41 10.13 9.68 9.52

20 12.42 11.99 11.82 11.50 11.03 10.78

LWT (°C)

30 35 40 45 50 55

-20 1.70 1.82 1.90 — — —

-151.781.902.002.13— —

-7 2.06 2.21 2.33 2.47 2.79 —

-2 2.10 2.26 2.39 2.56 2.86 3.14

2 2.11 2.28 2.43 2.60 2.88 3.17

7 1.87 2.07 2.25 2.46 2.65 2.85

10 1.84 2.03 2.21 2.42 2.61 2.86

12 1.83 2.02 2.20 2.41 2.60 2.87

15 1.83 2.02 2.20 2.41 2.60 2.88

20 1.82 2.01 2.18 2.44 2.58 2.91

COP

TO

(°C)

30 35 40 45 50 55

-20 2.32 2.11 1.97 — — —

-152.622.382.222.00— —

-7 2.64 2.40 2.21 2.02 1.73 —

-2 2.98 2.70 2.50 2.29 1.99 1.77

2 3.26 2.96 2.73 2.50 2.25 2.02

7 4.82 4.25 3.82 3.39 3.06 2.76

10 5.20 4.58 4.12 3.65 3.23 2.90

12 5.52 4.86 4.37 3.88 3.43 3.09

15 5.98 5.25 4.73 4.20 3.72 3.31

20 6.82 5.97 5.42 4.71 4.28 3.70

LWT (°C)

* Heating capacity and power input are include defrost cycle data.

* Heating capacity and power input are shown at maximum compressor operating frequency

* Power input does not include water pump power.

* Heating capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

27

Page 29

4.HYDRO UNIT

Heating peak capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

COP

TO

(°C)

LWT (°C)

30 35 40 45 50 55

-20 4.11 4.01 3.92 — — —

-154.874.744.624.46— —

-7 6.25 6.08 5.92 5.74 5.41 —

-2 7.22 7.00 6.80 6.59 6.37 5.97

2 8.17 7.91 7.67 7.43 7.17 6.92

7 9.02 8.78 8.58 8.34 8.11 7.87

10 9.56 9.29 9.10 8.84 8.42 8.29

12 10.11 9.81 9.62 9.35 8.92 8.87

15 10.94 10.60 10.41 10.13 9.68 9.52

20 12.42 11.99 11.82 11.50 11.03 10.78

LWT (°C)

30 35 40 45 50 55

-20 1.72 1.85 2.04 — — —

-151.831.972.172.30— —

-7 1.85 2.01 2.21 2.43 2.59 —

-2 1.87 2.04 2.24 2.46 2.65 2.78

2 1.86 2.04 2.24 2.45 2.65 2.80

7 1.87 2.07 2.25 2.46 2.65 2.85

10 1.84 2.03 2.21 2.42 2.61 2.86

12 1.83 2.02 2.20 2.41 2.60 2.87

15 1.83 2.02 2.20 2.41 2.60 2.88

20 1.82 2.01 2.18 2.44 2.58 2.91

4

LWT (°C)

30 35 40 45 50 55

-20 2.38 2.17 1.92 — — —

-152.672.412.131.94— —

-7 3.37 3.02 2.68 2.37 2.09 —

-2 3.85 3.43 3.04 2.68 2.40 2.15

2 4.39 3.88 3.43 3.03 2.71 2.47

7 4.82 4.25 3.82 3.39 3.06 2.76

10 5.20 4.58 4.12 3.65 3.23 2.90

12 5.52 4.86 4.37 3.88 3.43 3.09

15 5.98 5.25 4.73 4.20 3.72 3.31

20 6.82 5.97 5.42 4.71 4.28 3.70

* Heating capacity and power input are shown peak value during operation.

* Heating capacity and power input are shown at maximum compressor operating requency

* Power input does not include water pump power.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

28

Page 30

4.HYDRO UNIT

▼Outdoor unit HWS-803H-E

Hydro unit HWS-803XWH**-E

Rated cooling capacity and power input

Capacity kW 6.0

Rated condition 1

LWT=7°C

dT=5deg

Rated condition 2

LWT=18°C

dT=5deg

* Rated cooling capacity and power input are the data at rated compressor operating frequency

* Power input does not include water pump power.

* Cooling capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C)

LWT : Leaving water temperature (°C)

dT : Delta temperature (deg)

Return water temperature - leaving water temperature

Power input kW 2.13

EER W/W 2.82

Rated water flow rate /min 17.2

Capacity kW 6.0

Power input kW 1.42

EER W/W 4.23

Rated water flow rate /min 17.2

Engineering Data book

29

Page 31

4.HYDRO UNIT

Cooling capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

COP

TO

(°C)

7 10 13 15 18

20 7.36 8.05 8.81 9.25 10.03

27 6.76 7.39 8.09 8.49 9.21

30 6.46 7.06 7.73 8.12 8.80

35 6.00 6.56 7.18 7.54 8.18

40 5.50 6.01 6.58 6.91 7.49

43 4.62 5.00 5.44 5.69 6.09

7 10 13 15 18

20 1.60 1.63 1.66 1.68 1.70

27 1.84 1.86 1.90 1.92 1.95

30 1.90 1.93 1.97 2.00 2.02

35 2.13 2.16 2.20 2.23 2.26

40 2.30 2.34 2.38 2.41 2.44

43 2.09 2.09 2.09 2.09 2.09

7 10 13 15 18

20 4.60 4.95 5.32 5.51 5.91

27 3.68 3.97 4.26 4.41 4.73

30 3.39 3.65 3.92 4.07 4.36

35 2.82 3.04 3.26 3.38 3.62

40 2.39 2.57 2.76 2.86 3.07

43 2.21 2.40 2.60 2.72 2.91

LWT (°C)

LWT (°C)

LWT (°C)

* Cooling capacity and power input are the data at rated compressor operating frequency of rated condition 1

* Power input does not include water pump power.

* Cooling capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C)

LWT : Leaving water temperature (°C)

4

30

Page 32

4.HYDRO UNIT

Heating capacity and input specifications

▼Outdoor unit HWS-1103H-E

Hydro unit HWS-1403XWH**-E

Rated heating capacity and power input

Capacity kW 11.2

Rated condition 1

LWT=35°C

dT=5deg

Rated condition 2

LWT=45°C

dT=5deg

* Rated heating capacity and power input are the data at rated compressor operating frequency

* Power input does not include water pump power.

* Heating capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

dT : Delta temperature (deg)

Leaving water temperature - return water temperature

Power input kW 2.35

COP W/W 4.77

Rated water flow rate /min 32.1

Capacity kW 11.2

Power input kW 2.95

COP W/W 3.80

Rated water flow rate /min 32.1

Engineering Data book

31

Page 33

4.HYDRO UNIT

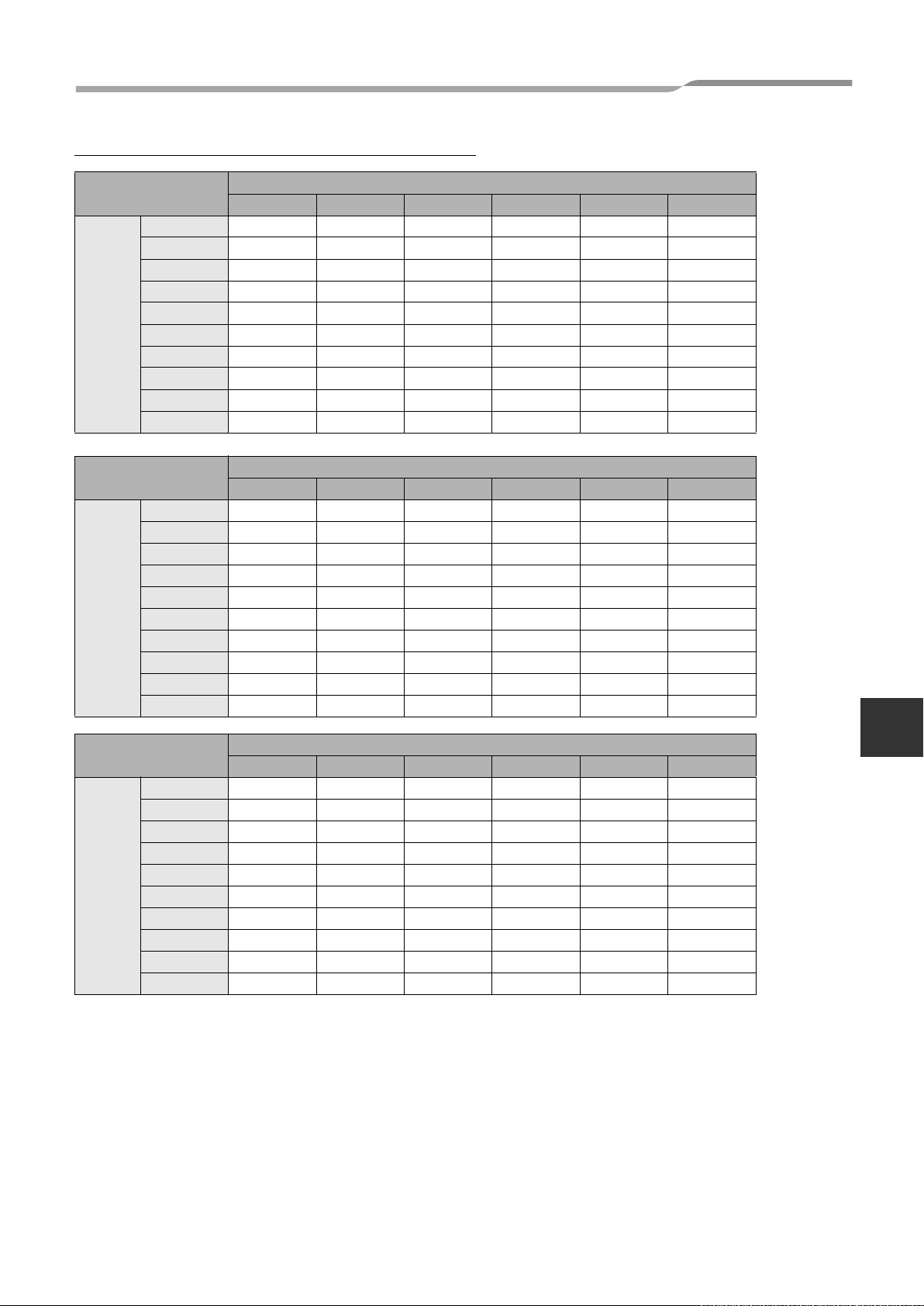

Average heating capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

LWT (°C)

30 35 40 45 50 55

-205.665.485.345.23— —

-157.096.866.696.55— —

-7 8.68 8.40 8.19 8.02 7.69 —

-2 10.23 9.90 9.65 9.46 9.07 7.97

2 10.90 10.55 10.28 10.08 9.66 8.49

7 15.47 14.97 14.59 14.30 13.71 11.48

10 16.40 15.87 15.47 15.16 14.53 12.17

12 17.35 16.62 16.20 15.88 15.22 12.75

15 18.84 17.70 17.25 16.91 16.21 13.57

20 21.71 20.01 19.50 19.11 18.33 15.35

LWT (°C)

30 35 40 45 50 55

-202.762.973.263.57— —

-152.873.093.403.71— —

-7 3.16 3.40 3.74 4.08 4.43 —

-2 3.11 3.35 3.68 4.02 4.37 4.32

2 3.07 3.30 3.63 3.96 4.30 4.26

7 3.00 3.23 3.55 3.88 4.21 4.17

10 2.98 3.21 3.53 3.86 4.18 4.14

12 2.97 3.20 3.52 3.84 4.17 4.13

15 2.96 3.19 3.51 3.83 4.16 4.12

20 2.94 3.17 3.48 3.81 4.13 4.09

COP

TO

(°C)

30 35 40 45 50 55

-202.051.851.641.46— —

-152.472.221.971.77— —

-7 2.75 2.47 2.19 1.96 1.74 —

-2 3.29 2.96 2.62 2.35 2.08 1.84

2 3.56 3.20 2.83 2.54 2.25 1.99

7 5.16 4.63 4.11 3.69 3.26 2.75

10 5.50 4.94 4.38 3.93 3.48 2.94

12 5.84 5.19 4.60 4.14 3.65 3.09

15 6.36 5.55 4.91 4.42 3.90 3.29

20 7.38 6.31 5.60 5.02 4.44 3.75

LWT (°C)

* Heating capacity and power input are include defrost cycle data.

* Heating capacity and power input are shown at maximum compressor operating frequency

* Power input does not include water pump power.

* Heating capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

4

32

Page 34

4.HYDRO UNIT

Heating peak capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

LWT (°C)

30 35 40 45 50 55

-206.646.486.376.18— —

-158.077.867.717.53— —

-7 10.40 10.10 9.89 9.69 9.23 —

-2 12.04 11.68 11.41 11.18 10.73 8.99

2 13.41 12.98 12.65 12.40 11.90 9.97

7 15.47 14.97 14.59 14.30 13.71 11.48

10 16.40 15.87 15.47 15.16 14.53 12.17

12 17.35 16.62 16.20 15.88 15.22 12.75

15 18.84 17.70 17.25 16.91 16.21 13.57

20 21.71 20.01 19.50 19.11 18.33 15.35

LWT (°C)

30 35 40 45 50 55

-202.632.783.083.36— —

-152.812.993.303.60— —

-7 2.91 3.11 3.43 3.75 4.07 —

-2 2.96 3.17 3.49 3.82 4.15 4.10

2 2.96 3.19 3.51 3.84 4.17 4.13

7 3.00 3.23 3.55 3.88 4.21 4.17

10 2.98 3.21 3.53 3.86 4.18 4.14

12 2.97 3.20 3.52 3.84 4.17 4.13

15 2.96 3.19 3.51 3.83 4.16 4.12

20 2.94 3.17 3.48 3.81 4.13 4.09

COP

TO

(°C)

30 35 40 45 50 55

-202.532.332.071.84— —

-152.872.632.332.09— —

-7 3.57 3.25 2.89 2.58 2.27 —

-2 4.07 3.68 3.27 2.93 2.59 2.19

2 4.53 4.07 3.61 3.23 2.86 2.41

7 5.16 4.63 4.11 3.69 3.26 2.75

10 5.50 4.94 4.38 3.93 3.48 2.94

12 5.84 5.19 4.60 4.14 3.65 3.09

15 6.36 5.55 4.91 4.42 3.90 3.29

20 7.38 6.31 5.60 5.02 4.44 3.75

LWT (°C)

* Heating capacity and power input are shown peak value during operation

* Heating capacity and power input are shown at maximum compressor operating requency

* Power input does not include water pump power.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

33

Page 35

4.HYDRO UNIT

Cooling capacity and input specifications

▼Outdoor unit HWS-1103H-E

Hydro unit HWS-1403XWH**-E

Rated cooling capacity and power input

Capacity kW 10.0

Rated condition 1

LWT=7°C

dT=5deg

Rated condition 2

LWT=18°C

dT=5deg

* Rated cooling capacity and power input are the data at rated compressor operating frequency

* Power input does not include water pump power.

* Cooling capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C)

LWT : Leaving water temperature (°C)

dT : Delta temperature (deg)

Return water temperature - leaving water temperature

Power input kW 3.52

EER W/W 2.84

Rated water flow rate /min 28.7

Capacity kW 10

Power input kW 2.35

EER W/W 4.26

Rated water flow rate /min 28.7

Engineering Data book

4

34

Page 36

4.HYDRO UNIT

Cooling capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

COP

TO

(°C)

LWT (°C)

7 10 13 15 18

20 12.78 13.64 14.99 16.03 16.98

27 11.60 12.38 13.61 14.55 15.42

30 11.03 11.77 12.94 13.83 14.66

35 10.00 10.67 11.73 12.54 13.29

40 8.96 9.56 10.51 11.24 11.91

43 6.89 7.35 8.08 8.64 9.16

LWT (°C)

7 10 13 15 18

20 2.64 2.70 2.74 2.77 2.78

27 3.04 3.11 3.16 3.18 3.20

30 3.23 3.30 3.35 3.38 3.40

35 3.52 3.59 3.65 3.68 3.70

40 3.82 3.84 3.86 3.88 3.91

43 3.28 3.28 3.28 3.29 3.29

LWT (°C)

7 10 13 15 18

20 4.83 5.05 5.47 5.80 6.11

27 3.81 3.98 4.31 4.57 4.81

30 3.41 3.57 3.86 4.09 4.31

35 2.84 2.97 3.21 3.41 3.59

40 2.34 2.49 2.72 2.90 3.04

43 2.10 2.24 2.46 2.62 2.78

* Cooling capacity and power input are the data at rated compressor operating frequency of rated condition 1

* Power input does not include water pump power.

* Cooling capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C)

LWT : Leaving water temperature (°C)

35

Page 37

4.HYDRO UNIT

Heating capacity and input specifications

▼Outdoor unit HWS-1403H-E

Hydro unit HWS-1403XWH**-E

Rated heating capacity and power input

Capacity kW 14.0

Rated condition 1

LWT=35°C

dT=5deg

Rated condition 2

LWT=45°C

dT=5deg

* Rated heating capacity and power input are the data at rated compressor operating frequency

* Power input does not include water pump power.

* Heating capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

dT : Delta temperature (deg)

Leaving water temperature - return water temperature

Power input kW 3.11

COP W/W 4.50

Rated water flow rate /min 40.1

Capacity kW 14.0

Power input kW 3.95

COP W/W 3.54

Rated water flow rate /min 40.1

Engineering Data book

4

36

Page 38

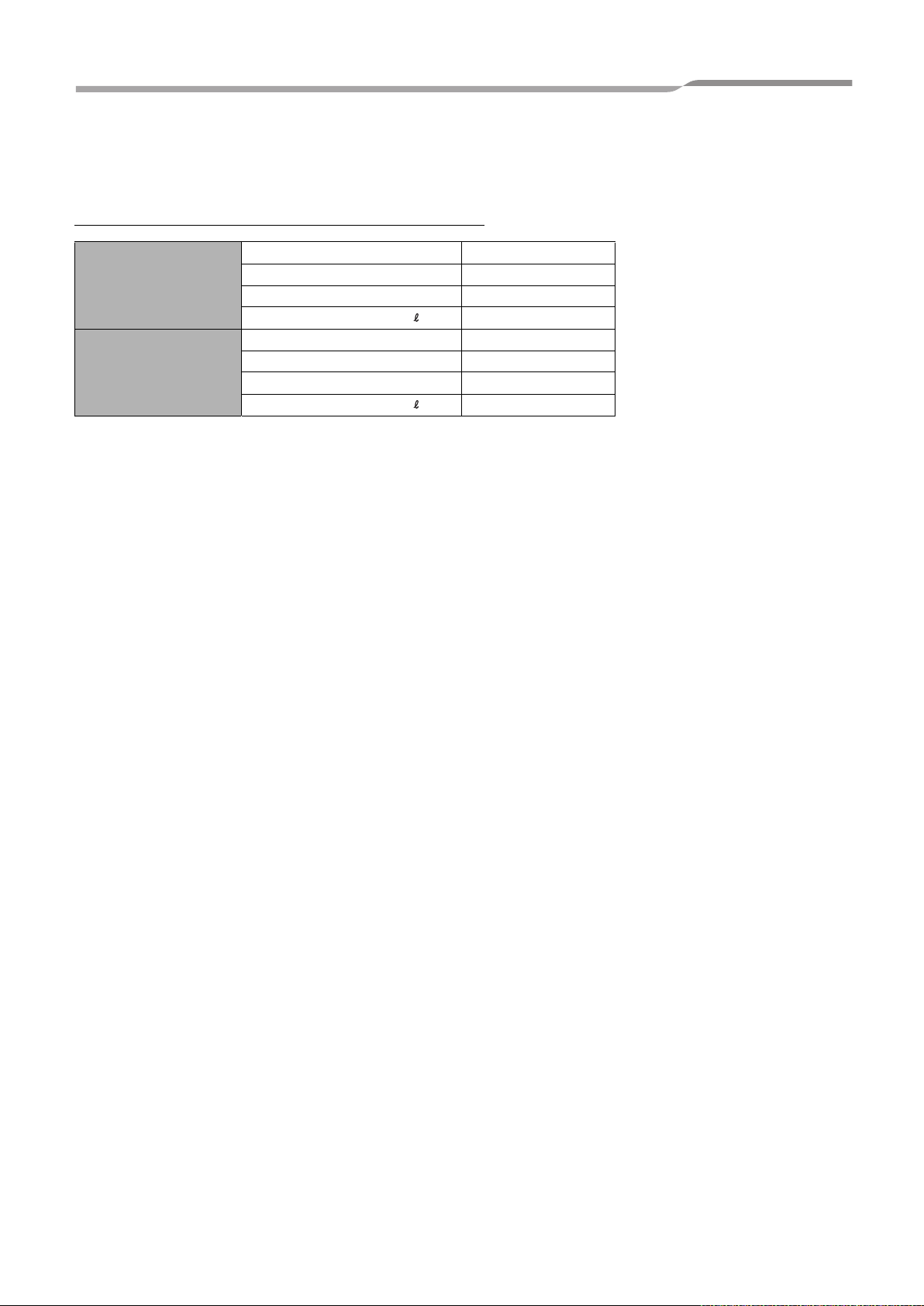

4.HYDRO UNIT

Average heating capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

LWT (°C)

30 35 40 45 50 55

-206.436.185.945.43— —

-158.267.947.646.98— —

-7 9.75 9.37 9.01 8.24 7.42 —

-2 11.37 10.93 10.52 9.61 8.66 8.15

2 12.03 11.56 11.12 10.17 9.16 8.62

7 17.77 17.08 16.43 15.02 13.53 12.13

10 18.66 17.93 17.25 15.77 14.21 12.74

12 19.92 18.96 18.24 16.67 15.02 13.47

15 21.53 20.09 19.33 17.67 15.91 14.27

20 23.89 21.87 21.04 19.23 17.32 15.53

LWT (°C)

30 35 40 45 50 55

-203.243.503.763.77— —

-153.413.693.963.98— —

-7 3.80 4.10 4.40 4.42 4.44 —

-2 3.74 4.04 4.34 4.36 4.38 4.41

2 3.69 3.98 4.27 4.29 4.31 4.34

7 3.65 3.94 4.23 4.25 4.27 4.30

10 3.65 3.94 4.23 4.25 4.27 4.30

12 3.66 3.95 4.24 4.26 4.28 4.31

15 3.69 3.98 4.28 4.30 4.32 4.35

20 3.48 3.75 4.03 4.05 4.07 4.10

COP

TO

(°C)

30 35 40 45 50 55

-201.981.771.581.44— —

-152.422.151.931.75— —

-7 2.57 2.29 2.05 1.86 1.67 —

-2 3.04 2.71 2.43 2.21 1.98 1.85

2 3.26 2.91 2.60 2.37 2.12 1.99

7 4.87 4.34 3.88 3.53 3.17 2.82

10 5.11 4.55 4.08 3.71 3.33 2.96

12 5.44 4.80 4.30 3.91 3.51 3.13

15 5.83 5.05 4.52 4.11 3.68 3.28

20 6.86 5.83 5.22 4.75 4.26 3.79

LWT (°C)

* Heating capacity and power input are include defrost cycle data.

* Heating capacity and power input are shown at maximum operating frequency

* Power input does not include water pump power.

* Heating capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

37

Page 39

4.HYDRO UNIT

Heating peak capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

LWT (°C)

30 35 40 45 50 55

-207.126.906.696.08— —

-159.369.058.767.95— —

-7 12.15 11.72 11.32 10.35 9.28 —

-2 14.09 13.57 13.08 11.96 10.78 9.23

2 15.35 14.75 14.19 12.97 11.70 10.01

7 17.77 17.08 16.43 15.02 13.53 12.13

10 18.66 17.93 17.25 15.77 14.21 12.74

12 19.92 18.96 18.24 16.67 15.02 13.47

15 21.53 20.09 19.33 17.67 15.91 14.27

20 23.89 21.87 21.04 19.23 17.32 15.53

LWT (°C)

30 35 40 45 50 55

-203.123.303.573.58— —

-153.313.523.803.82— —

-7 3.52 3.77 4.06 4.08 4.10 —

-2 3.60 3.87 4.16 4.19 4.21 4.24

2 3.59 3.88 4.16 4.18 4.21 4.25

7 3.65 3.94 4.23 4.25 4.27 4.30

10 3.65 3.94 4.23 4.25 4.27 4.30

12 3.66 3.95 4.24 4.26 4.28 4.31

15 3.69 3.98 4.28 4.30 4.32 4.35

20 3.48 3.75 4.03 4.05 4.07 4.10

COP

TO

(°C)

30 35 40 45 50 55

-202.282.091.871.70— —

-152.832.572.302.08— —

-7 3.45 3.11 2.79 2.54 2.26 —

-2 3.91 3.51 3.14 2.86 2.56 2.18

2 4.27 3.81 3.41 3.10 2.78 2.36

7 4.87 4.34 3.88 3.53 3.17 2.82

10 5.11 4.55 4.08 3.71 3.33 2.96

12 5.44 4.80 4.30 3.91 3.51 3.13

15 5.83 5.05 4.52 4.11 3.68 3.28

20 6.86 5.83 5.22 4.75 4.26 3.79

LWT (°C)

* Heating capacity and power input are shown peak value during operation

* Heating capacity and power input are shown at maximum compressor operating requency

* Power input does not include water pump power.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

4

38

Page 40

4.HYDRO UNIT

Cooling capacity and input specifications

▼Outdoor unit HWS-1403H-E

Hydro unit HWS-1403XWH**-E

Rated cooling capacity and power input

Capacity kW 11.0

Rated condition 1

LWT=7°C

dT=5deg

Rated condition 2

LWT=18°C

dT=5deg

* Rated cooling capacity and power input are the data at rated compressor operating frequency

* Power input does not include water pump power.

* Cooling capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C)

LWT : Leaving water temperature (°C)

dT : Delta temperature (deg)

Return water temperature - Leaving water temperature

Power input kW 4.08

EER W/W 2.70

Rated water flow rate /min 31.5

Capacity kW 11.0

Power input kW 2.65

EER W/W 4.15

Rated water flow rate /min 31.5

Engineering Data book

39

Page 41

4.HYDRO UNIT

Cooling capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

EER

TO

(°C)

7 10 13 15 18

20 13.95 15.48 16.82 17.53 18.34

27 12.60 13.98 15.19 15.83 16.56

30 12.01 13.33 14.49 15.10 15.80

35 11.00 12.21 13.27 13.83 14.47

40 8.83 9.80 10.65 11.10 11.62

43 6.81 7.56 8.21 8.56 8.95

7 10 13 15 18

20 3.14 3.21 3.26 3.27 3.30

27 3.57 3.64 3.70 3.72 3.76

30 3.77 3.85 3.91 3.92 3.97

35 4.08 4.17 4.23 4.25 4.29

40 3.84 3.85 3.85 3.87 3.88

43 3.25 3.23 3.23 3.22 3.22

7 10 13 15 18

20 4.44 4.83 5.16 5.36 5.55

27 3.53 3.84 4.10 4.26 4.41

30 3.19 3.46 3.71 3.85 3.98

35 2.70 2.93 3.14 3.26 3.37

40 2.30 2.55 2.76 2.87 3.00

43 2.10 2.34 2.54 2.65 2.78

LWT (°C)

LWT (°C)

LWT (°C)

* Cooling capacity and power input are the data at rated compressor operating frequency of rated condition 1

* Power input does not include water pump power.

* Cooling capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C)

LWT : Leaving water temperature (°C)

4

40

Page 42

4.HYDRO UNIT

Heating capacity and input specifications

▼Outdoor unit HWS-1103H8-E, HWS-1103H8R-E

Hydro unit HWS-1403XWH**-E

Rated heating capacity and power input

Capacity kW 11.2

Rated condition 1

LWT=35°C

dT=5deg

Rated condition 2

LWT=45°C

dT=5deg

* Rated heating capacity and power input are the data at rated compressor operating frequency

* Power input does not include water pump power.

* Heating capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

dT : Delta temperature (deg)

Leaving water temperature - return water temperature

Power input kW 2.39

COP W/W 4.69

Rated water flow rate /min 32.1

Capacity kW 11.2

Power input kW 3.19

COP W/W 3.51

Rated water flow rate /min 32.1

Engineering Data book

41

Page 43

4.HYDRO UNIT

Average heating capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

LWT (°C)

30 35 40 45 50 55

-205.655.455.315.18— —

-157.397.126.936.76— —

-7 8.76 8.43 8.19 7.99 7.86 —

-2 9.97 9.57 9.28 9.03 8.87 8.29

2 11.18 10.49 10.16 9.87 9.68 9.04

7 15.41 14.82 14.47 14.16 13.81 12.82

10 16.46 15.82 15.42 15.08 14.96 14.14

12 17.15 16.49 16.06 15.69 15.58 14.87

15 18.11 17.41 17.19 17.02 16.62 15.76

20 20.27 19.49 19.25 19.07 18.81 17.67

LWT (°C)

30 35 40 45 50 55

-202.592.782.943.08— —

-152.893.113.293.46— —

-7 3.23 3.47 3.69 3.89 4.15 —

-2 3.18 3.42 3.64 3.85 4.11 4.32

2 3.15 3.38 3.61 3.81 4.07 4.28

7 3.01 3.24 3.56 3.88 4.22 4.52

10 3.01 3.23 3.57 3.91 4.27 4.59

12 3.00 3.23 3.57 3.92 4.30 4.64

15 3.01 3.24 3.60 3.97 4.36 4.72

20 3.04 3.27 3.64 4.02 4.43 4.80

COP

TO

(°C)

30 35 40 45 50 55

-202.181.961.811.68— —

-152.562.292.101.95— —

-7 2.71 2.43 2.22 2.05 1.89 —

-2 3.13 2.80 2.55 2.35 2.16 1.92

2 3.55 3.10 2.82 2.59 2.38 2.11

7 5.12 4.57 4.06 3.65 3.27 2.84

10 5.47 4.89 4.32 3.86 3.51 3.08

12 5.71 5.11 4.49 4.00 3.62 3.21

15 6.01 5.37 4.77 4.29 3.81 3.34

20 6.67 5.96 5.29 4.75 4.25 3.68

LWT (°C)

* Heating capacity and power input are include defrost cycle data.

* Heating capacity and power input are shown at maximum compressor operating frequency

* Power input does not include water pump power.

* Heating capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

4

42

Page 44

5.OUTDOOR UNIT

Heating peak capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

LWT (°C)

30 35 40 45 50 55

-206.696.416.216.03— —

-157.977.647.407.19— —

-710.389.969.659.389.10—

-2 11.85 11.38 11.05 10.75 10.43 9.64

2 13.02 12.52 12.16 11.85 11.49 10.62

7 15.41 14.82 14.47 14.16 13.81 12.82

10 16.46 15.82 15.42 15.08 14.96 14.14

12 17.15 16.49 16.06 15.69 15.58 14.87

15 18.11 17.41 17.19 17.02 16.62 15.76

20 20.27 19.49 19.25 19.07 18.81 17.67

LWT (°C)

30 35 40 45 50 55

-202.312.482.682.88— —

-152.662.863.103.33— —

-7 2.85 3.07 3.33 3.57 3.86 —

-2 2.91 3.14 3.41 3.67 3.96 4.20

2 2.96 3.19 3.47 3.74 4.04 4.29

7 3.01 3.24 3.56 3.88 4.22 4.52

10 3.01 3.23 3.57 3.91 4.27 4.59

12 3.00 3.23 3.57 3.92 4.30 4.64

15 3.01 3.24 3.60 3.97 4.36 4.72

20 3.04 3.27 3.64 4.02 4.43 4.80

COP

TO

(°C)

30 35 40 45 50 55

-202.902.592.312.09— —

-152.992.672.382.16— —

-7 3.64 3.24 2.90 2.62 2.36 —

-2 4.07 3.63 3.24 2.93 2.64 2.29

2 4.41 3.92 3.51 3.17 2.85 2.48

7 5.12 4.57 4.06 3.65 3.27 2.84

10 5.47 4.89 4.32 3.86 3.51 3.08

12 5.71 5.11 4.49 4.00 3.62 3.21

15 6.01 5.37 4.77 4.29 3.81 3.34

20 6.67 5.96 5.29 4.75 4.25 3.68

LWT (°C)

* Heating capacity and power input are shown peak value during operation.

* Heating capacity and power input are shown at maximum compressor operating requency

* Power input does not include water pump power.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

43

Page 45

4.HYDRO UNIT

Cooling capacity and input specifications

▼Outdoor unit HWS-1103H8-E, HWS-1103H8R-E

Hydro unit HWS-1403XWH**-E

Rated cooling capacity and power input

Capacity kW 10.0

Rated condition 1

LWT=7°C

dT=5deg

Rated condition 2

LWT=18°C

dT=5deg

* Rated cooling capacity and power input are the data at rated compressor operating frequency

* Power input does not include water pump power.

* Cooling capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C)

LWT : Leaving water temperature (°C)

dT : Delta temperature (deg)

Return water temperature - leaving water temperature

Power input kW 3.52

EER W/W 2.84

Rated water flow rate /min 28.7

Capacity kW 10.0

Power input kW 2.14

EER W/W 4.67

Rated water flow rate /min 28.7

Engineering Data book

4

44

Page 46

4.HYDRO UNIT

Cooling capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

COP

TO

(°C)

LWT (°C)

7 10 13 15 18

20 10.09 11.06 12.03 12.67 13.63

27 10.40 11.40 12.40 13.06 14.05

30 10.02 10.98 11.95 12.58 13.54

35 9.37 10.27 11.17 11.77 12.66

40 8.66 9.50 10.33 10.88 11.57

43 8.24 9.03 9.82 10.35 10.91

LWT (°C)

7 10 13 15 18

20 2.04 2.07 2.10 2.12 2.14

27 2.67 2.71 2.75 2.77 2.80

30 2.80 2.84 2.88 2.91 2.94

35 3.00 3.05 3.10 3.12 3.15

40 3.32 3.37 3.42 3.45 3.47

43 3.51 3.56 3.62 3.64 3.66

LWT (°C)

7 10 13 15 18

20 4.94 5.34 5.72 5.98 6.37

27 3.89 4.20 4.50 4.71 5.02

30 3.58 3.86 4.14 4.33 4.61

35 3.12 3.37 3.61 3.77 4.02

40 2.61 2.82 3.02 3.16 3.34

43 2.35 2.53 2.72 2.84 2.98

* Cooling capacity and power input are the data at rated compressor operating frequency of rated condition 1

* Power input does not include water pump power.

* Cooling capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C)

LWT : Leaving water temperature (°C)

45

Page 47

4.HYDRO UNIT

Heating capacity and input specifications

▼Outdoor unit HWS-1403H8-E, HWS-1403H8R-E

Hydro unit HWS-1403XWH**-E

Rated heating capacity and power input

Capacity kW 14.0

Rated condition 1

LWT=35°C

dT=5deg

Rated condition 2

LWT=45°C

dT=5deg

* Rated heating capacity and power input are the data at rated compressor operating frequency

* Power input does not include water pump power.

* Heating capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

dT : Delta temperature (deg)

Leaving water temperature - return water temperature

Power input kW 3.21

COP W/W 4.36

Rated water flow rate /min 40.1

Capacity kW 14.0

Power input kW 4.12

COP W/W 3.40

Rated water flow rate /min 40.1

Engineering Data book

4

46

Page 48

4.HYDRO UNIT

Average heating capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

LWT (°C)

30 35 40 45 50 55

-205.905.695.545.40— —

-157.717.437.247.06— —

-7 9.14 8.80 8.55 8.34 8.20 —

-2 10.41 9.99 9.69 9.43 9.26 8.66

2 11.67 10.95 10.60 10.30 10.10 9.44

7 16.71 16.12 15.66 15.34 14.93 13.83

10 17.87 17.38 16.86 16.52 16.18 15.25

12 18.64 18.12 17.56 17.24 17.01 16.04

15 19.67 19.13 18.66 18.44 18.15 17.01

20 21.72 21.20 20.84 20.66 20.34 19.07

LWT (°C)

30 35 40 45 50 55

-202.863.013.183.33— —

-153.193.363.563.74— —

-7 3.56 3.76 3.99 4.20 4.49 —

-2 3.50 3.70 3.94 4.16 4.44 4.67

2 3.45 3.66 3.90 4.12 4.40 4.62

7 3.49 3.77 4.10 4.42 4.76 5.05

10 3.49 3.76 4.11 4.45 4.81 5.12

12 3.49 3.75 4.12 4.47 4.85 5.18

15 3.51 3.77 4.15 4.52 4.92 5.27

20 3.54 3.80 4.19 4.58 4.99 5.36

COP

TO

(°C)

30 35 40 45 50 55

-202.061.891.741.62— —

-152.422.212.031.89— —

-7 2.57 2.34 2.14 1.98 1.83 —

-2 2.97 2.70 2.46 2.27 2.09 1.86

2 3.38 2.99 2.72 2.50 2.30 2.04

7 4.79 4.28 3.82 3.47 3.14 2.74

10 5.12 4.62 4.10 3.71 3.36 2.98

12 5.34 4.83 4.27 3.85 3.51 3.10

15 5.60 5.08 4.50 4.08 3.69 3.23

20 6.13 5.57 4.97 4.51 4.07 3.56

LWT (°C)

* Heating capacity and power input are include defrost cycle data.

* Heating capacity and power input are shown at maximum compressor operating frequency

* Power input does not include water pump power.

* Heating capacity and power input are measured in accordance with EN14511.

TO : Outdoor temperature (DB°C) RH85%

LWT : Leaving water temperature (°C)

47

Page 49

4.HYDRO UNIT

Heating peak capacity and power input

Engineering Data book

Capacity (kW)

TO

(°C)

Power input (kW)

TO

(°C)

LWT (°C)

30 35 40 45 50 55

-207.286.986.756.56— —

-158.668.318.057.82— —

-7 11.29 10.83 10.50 10.20 9.90 —

-2 12.89 12.38 12.01 11.69 11.34 10.48

2 14.17 13.62 13.23 12.89 12.50 11.55

7 16.71 16.12 15.66 15.34 14.93 13.83

10 17.87 17.38 16.86 16.52 16.18 15.25

12 18.64 18.12 17.56 17.24 17.01 16.04

15 19.67 19.13 18.66 18.44 18.15 17.01

20 21.72 21.20 20.84 20.66 20.34 19.07

LWT (°C)

30 35 40 45 50 55

-202.682.883.123.35— —

-153.103.333.613.88— —

-7 3.32 3.57 3.87 4.16 4.49 —

-2 3.38 3.65 3.96 4.26 4.60 4.89

2 3.44 3.71 4.03 4.35 4.69 4.99

7 3.49 3.77 4.10 4.42 4.76 5.05

10 3.49 3.76 4.11 4.45 4.81 5.12

12 3.49 3.75 4.11 4.47 4.85 5.18

15 3.51 3.77 4.15 4.52 4.92 5.27

20 3.54 3.80 4.19 4.58 4.99 5.36

COP

TO

(°C)

30 35 40 45 50 55

-202.712.422.161.96— —

-152.802.492.232.02— —

-7 3.40 3.03 2.71 2.45 2.21 —

-2 3.81 3.39 3.03 2.74 2.47 2.14

2 4.12 3.67 3.28 2.96 2.66 2.32

7 4.79 4.28 3.82 3.47 3.14 2.74

10 5.12 4.62 4.10 3.71 3.36 2.98

12 5.34 4.83 4.27 3.86 3.51 3.10

15 5.60 5.08 4.50 4.08 3.69 3.23

20 6.13 5.57 4.97 4.51 4.07 3.56

LWT (°C)

* Heating capacity and power input are shown peak value during operation

* Heating capacity and power input are shown at maximum compressor operating requency

* Power input does not include water pump power.

TO : Outdoor temperature (DB°C) RH85%