Toshiba HWS-804XWHT6, HWS-1404XWHT6, HWS-804XWHT9, HWS-1404XWHM3, HWS-1404XWHT9 Quick Reference Manual

...Page 1

Quick Reference

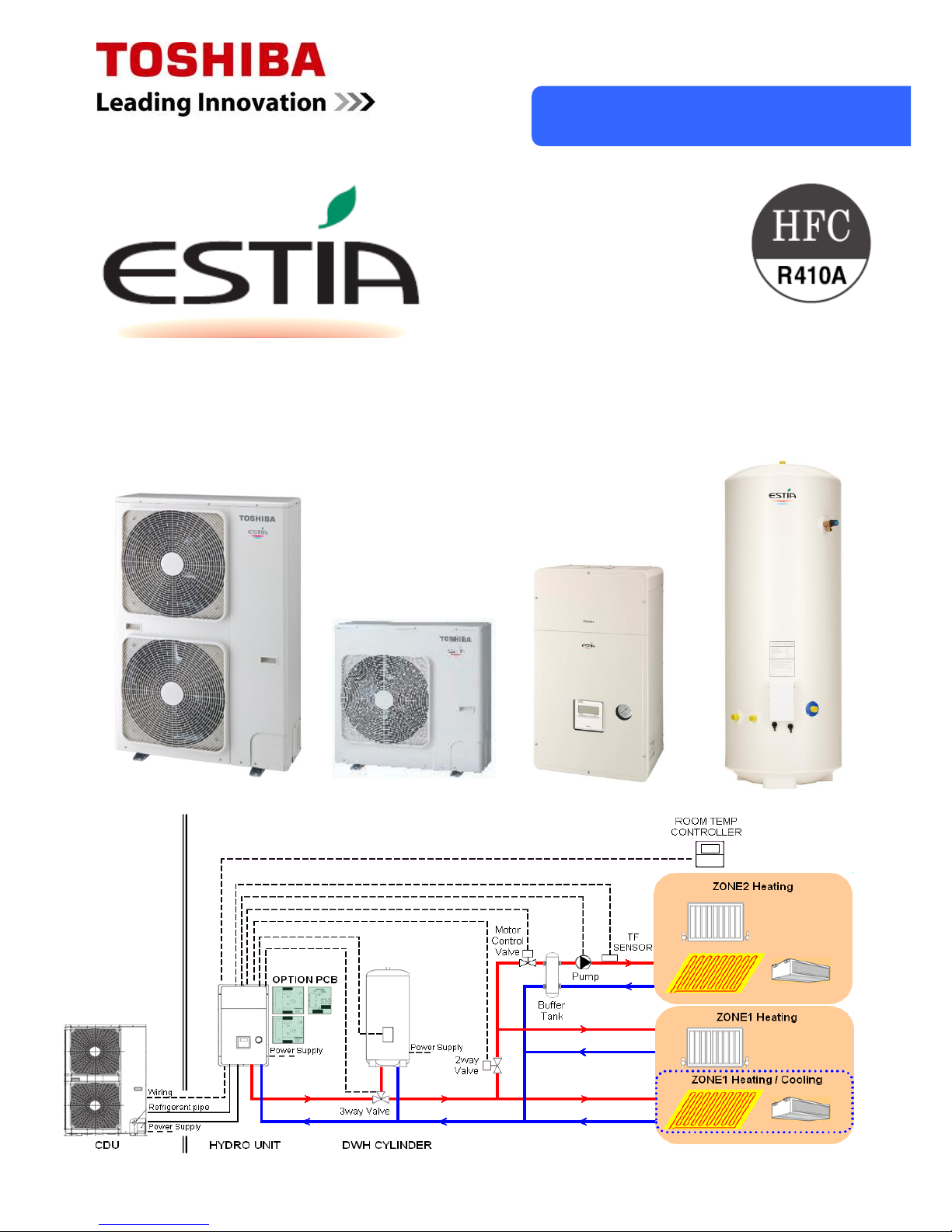

Air to Water Heat Pump

Series 4

Page 2

1

Hydro Unit

HWS-

804H-**

HWS-

1104H-**

HWS-

1404H-**

HWS-

1104H8-**

HWS-

1404H8-**

HWS-

1604H8-**

HWS-

1104H8R-**

HWS-

1404H8R-**

HWS-

1604H8R-E

Back Up

Heater

HWS-804XWHM3-** P

- - - - - - - - ~, 3Kw

HWS-804XWHT6-** P

- - - - - - - - 3N, 6kW

HWS-804XWHT9-** P

- - - - - - - - 3N, 9kW

HWS-1404XWHM3-**

- P P P P P P P P ~, 3Kw

HWS-1404XWHT6-**

- P P P P P P P P 3N, 6kW

HWS-1404XWHT9-**

- P P P P P P P P 3N, 9kW

Outdoor Unit

Hydro Unit

HWS-1501

CSHM3-E

HWS-2101

CSHM3-E

HWS-3001

CSHM3-E

HWS-1501

CSHM3-UK

HWS-2101

CSHM3-UK

HWS-3001

CSHM3-UK

HWS-804XWHM3-**

HWS-804XWHT6-**

HWS-804XWHT9-**

HWS-1404XWHM3-**

HWS-1404XWHT6-**

HWS-1404XWHT9-**

Hot Water Cylinder

P

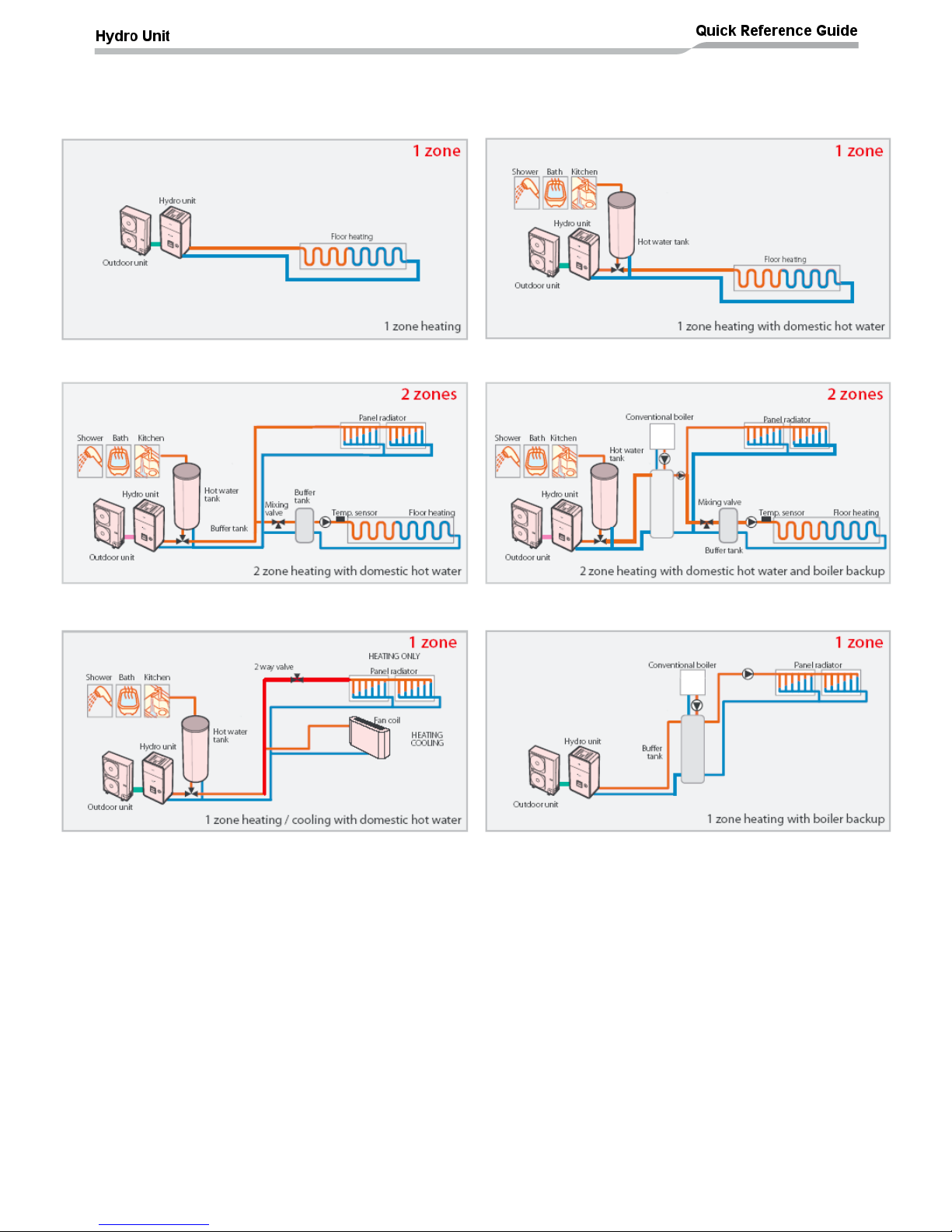

Estia System

Component Combinations

Outdoor unit

Hydro unit

Hot Water

Hot water

cylinder

Under floor heating

(Zone Control)

Radiator

Fan coil unit

(Heating or Cooling)

Heating or Cooling

Page 3

2

New Features for 4 Series ESTIA:

A-rated water circulating pump installed in hydro unit

Minimum target water temperature reduced to 7°C in cooling mode for improved compatibility with fan

coil units

Hydro unit pump ON / OFF cycling function – to momentarily operate water pump during long periods of

system OFF

Option to use an external cylinder thermostat, on locally supplied hot water cylinders, for domestic hot

water production

Improved control for second remote controller when used with under floor heating

Improved control for ESTIA / boiler connection

New expansion vessel for hydro unit

New compressor for single phase ESTIA outdoor units

Note:

Under floor heating components, fan coil units, radiators, valves and other installation materials must be

procured locally.

Notes on System Design

• The input water temperature to the hydro unit must be 50°C or less. This is especially important if the

hydro unit is used in conjunction with any other external heating source (auxiliary boiler, electric booster

heaters etc.)

Unit failure or water leaks may result if the return water temperature, to the hydro unit, exceeds 50°C

• The minimum flow rate for the circulating water in the heating/cooling circuit must meet the following

range:-

11, 14 and 16 kW: 17.5 L/minute or more

8 kW: 13 L/minute or more

If the flow rate becomes less than the flow rate specified above, the flow switch in the hydro unit is activated

to stop operation.

When thermostatic devices are used for temperature control a bypass valve must be fitted to the heating

circuit, to ensure the minimum water flow rate is maintained in the event of all thermostatic devices closing

at the same time

• Only use the water pump, built into the hydro unit, to circulate the water in the heating circuit

• The hydro unit back up heaters will operate to assist the heat pump capacity output during low ambient

conditions

• The hydro unit has been designed for indoor installations. Do not install outside where there is a risk of

low ambient conditions. This may cause the water in the pipe work to freeze

• Make the water circuit closed. Never use it as an open circuit.

• To prevent damage to the system the volume of the circulating water must be 20 litres or more. If total

volume of water amount is less than 20 litres, then the unit may not function fully due to the operation of

protective controls.

Page 4

3

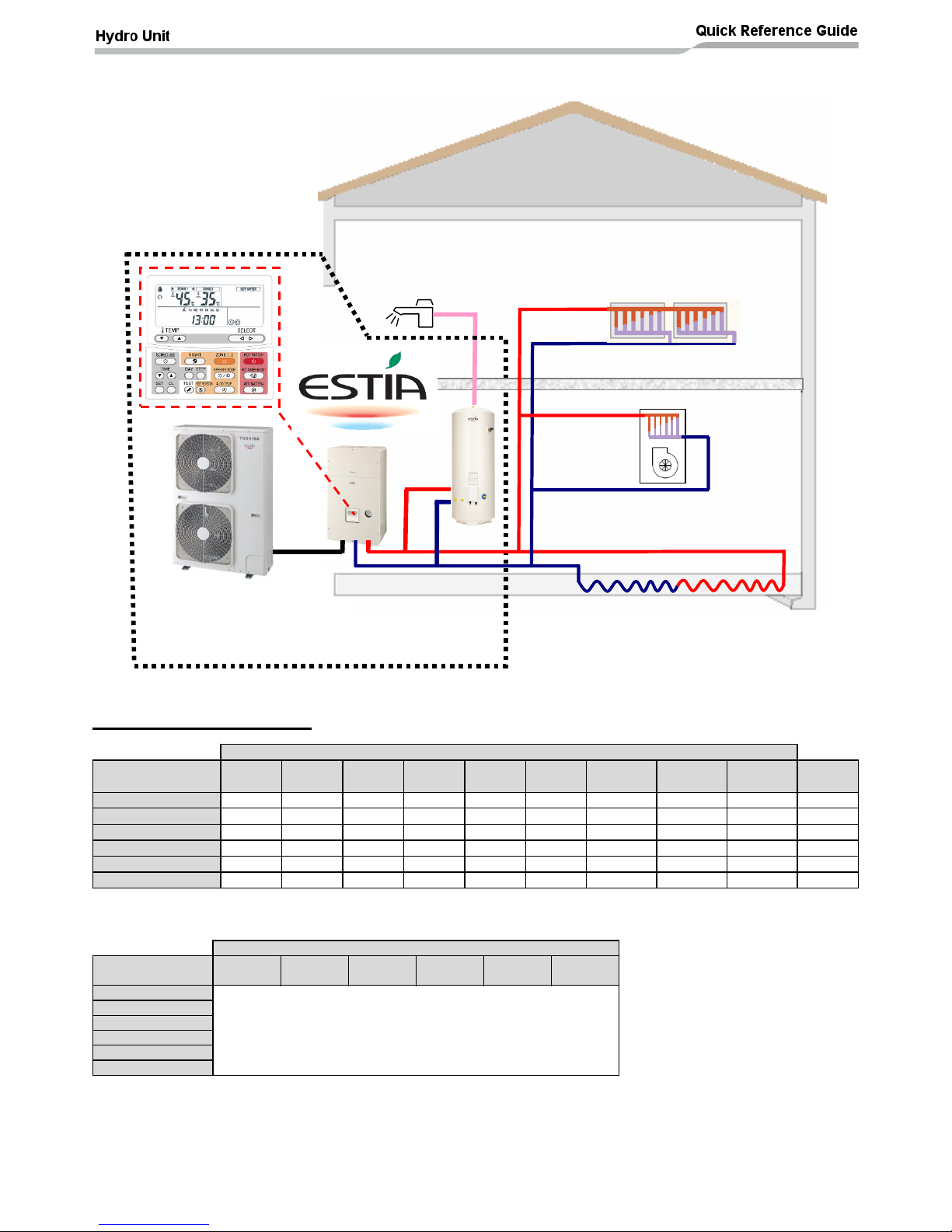

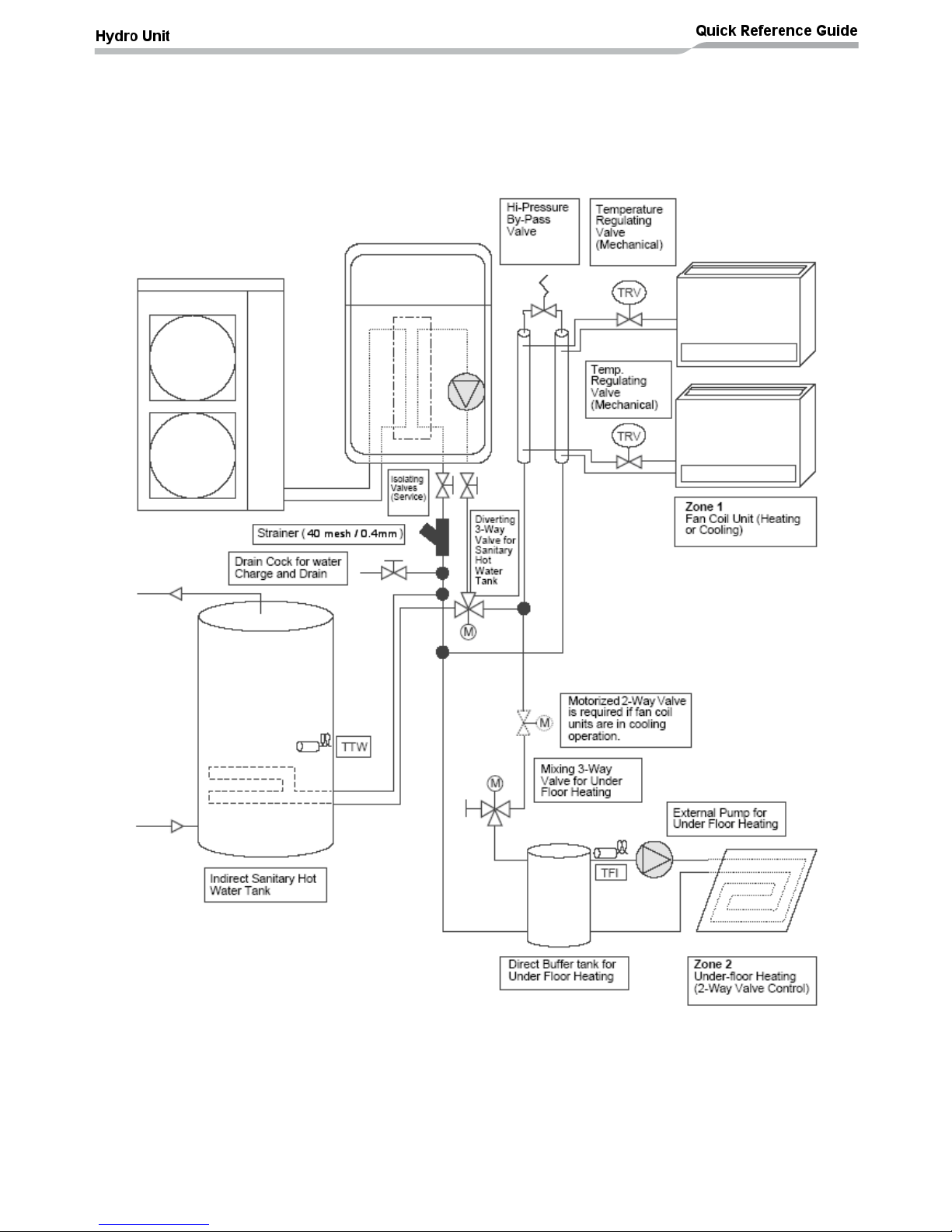

Installation Examples

Cooling and Heating with Domestic Hot Water

When both cooling and heating are used, install a 2-way valve (for cooling) to the pipe to the room

for heating only.

Page 5

4

Installation Examples (cont.)

2-Zone Temperature Control with Domestic Hot Water

The following shows an example of the 2-zone temperature control.

A buffer tank and a water pump are required for the 2-zone temperature control. This example is

Heating only, if the Fan Coils are to be used for Cooling then a 2-Way valve must be fitted.

Page 6

5

Installation example of water circuit:-

(1) (2)

(3) (4)

(5) (6)

The water circuit for a system without a buffer tank [ (1) , (2) , (3) , (5) ] requires 17.5l/min

(804XWH = 13.0l/min) or more. This water flowing requires 5 or more branches of Floor heating or

Radiators etc.

Less than 5 branches may cause a flow deficiency. In this case, please provide a buffer tank and

secondary pumps, as shown in (4).

Please check how to install the boiler.

Page 7

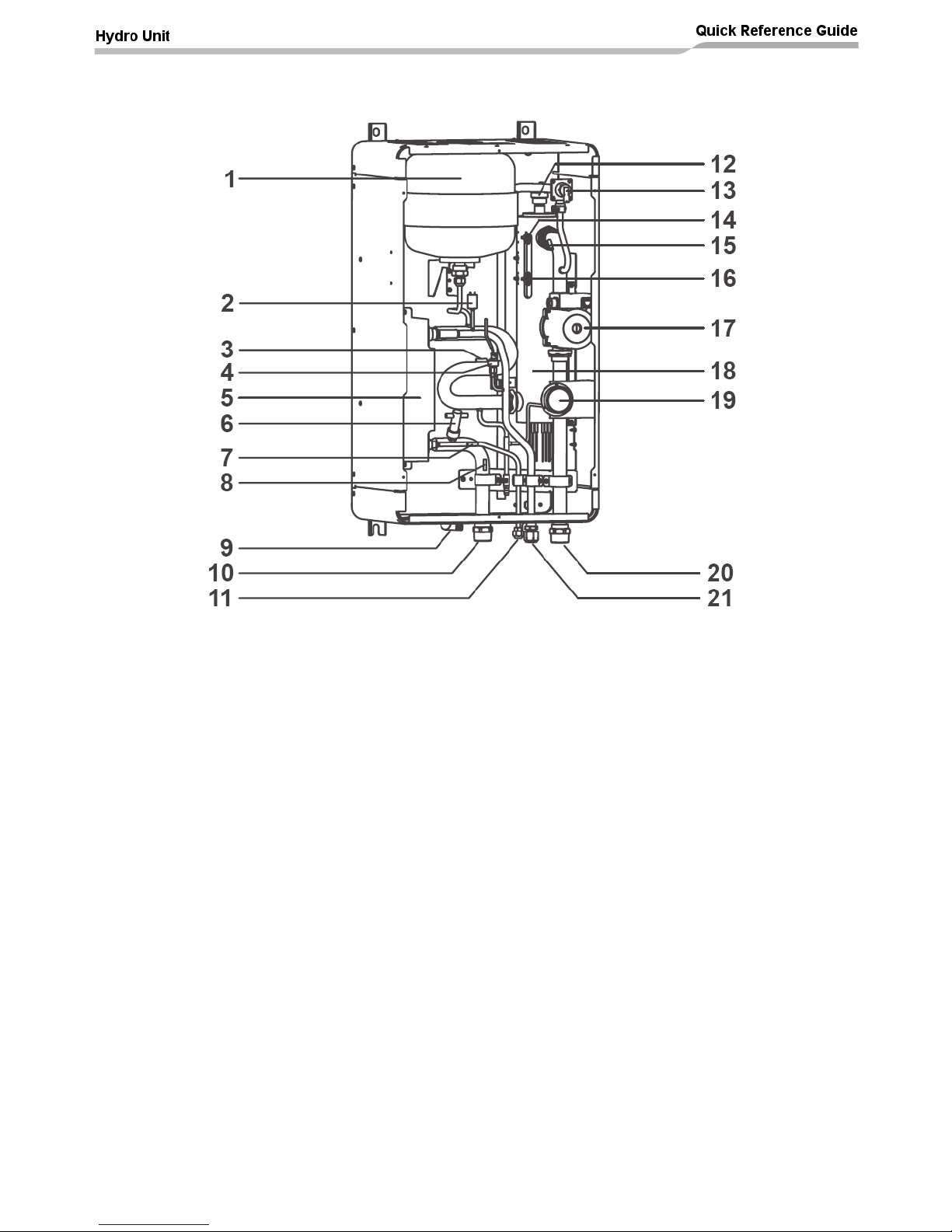

6

Hydro Unit – Exploded View

1. Expansion vessel

2. Hi Pressure switch (4.15 MPa)

3. Temperature sensor (for Heat pump outlet -TWO)

4. Pressure sensor

5. Heat exchanger

6. Flow switch (13.0 L/min 17.5 L/min)

7. Temperature sensor (for refrigerant -TC)

8. Temperature sensor (for water inlet -TWI)

9. Drain nipple

10. Water inlet connection

11. Refrigerant liquid connection

12. Air relief valve

13. Pressure relief valve (0.3 MPa (3 bar))

14. Thermal protector (auto)

15. Temperature sensor (for water outlet THO)

16. Thermal protector (Single operation)

17. A-rated water pump

18. Backup heater (3 kW, 3 kW x 2, 3 kW x 3)

19. Manometer

20. Water outlet connection

21. Refrigerant gas connection

Page 8

7

Refrigerant Pipe Lengths and Height

The length and height of the refrigeration pipe must be within the following values.

As long as the Hydro Unit is installed within these ranges, no additional refrigerant is required.

Minimum Pipe Length

HWS-804H-E : 5 m

HWS-1104H**-E : 5 m

HWS-1404H**-E : 5 m

HWS-1604H**-E: 5m

Maximum Pipe Length and Height

H: Max. ±30 m (above or below)

L: Max. 30 m

Note

The maximum pipe length cannot be increased by increasing the

refrigerant charge

The minimum pipe length cannot be decreased by reducing the

refrigerant charge

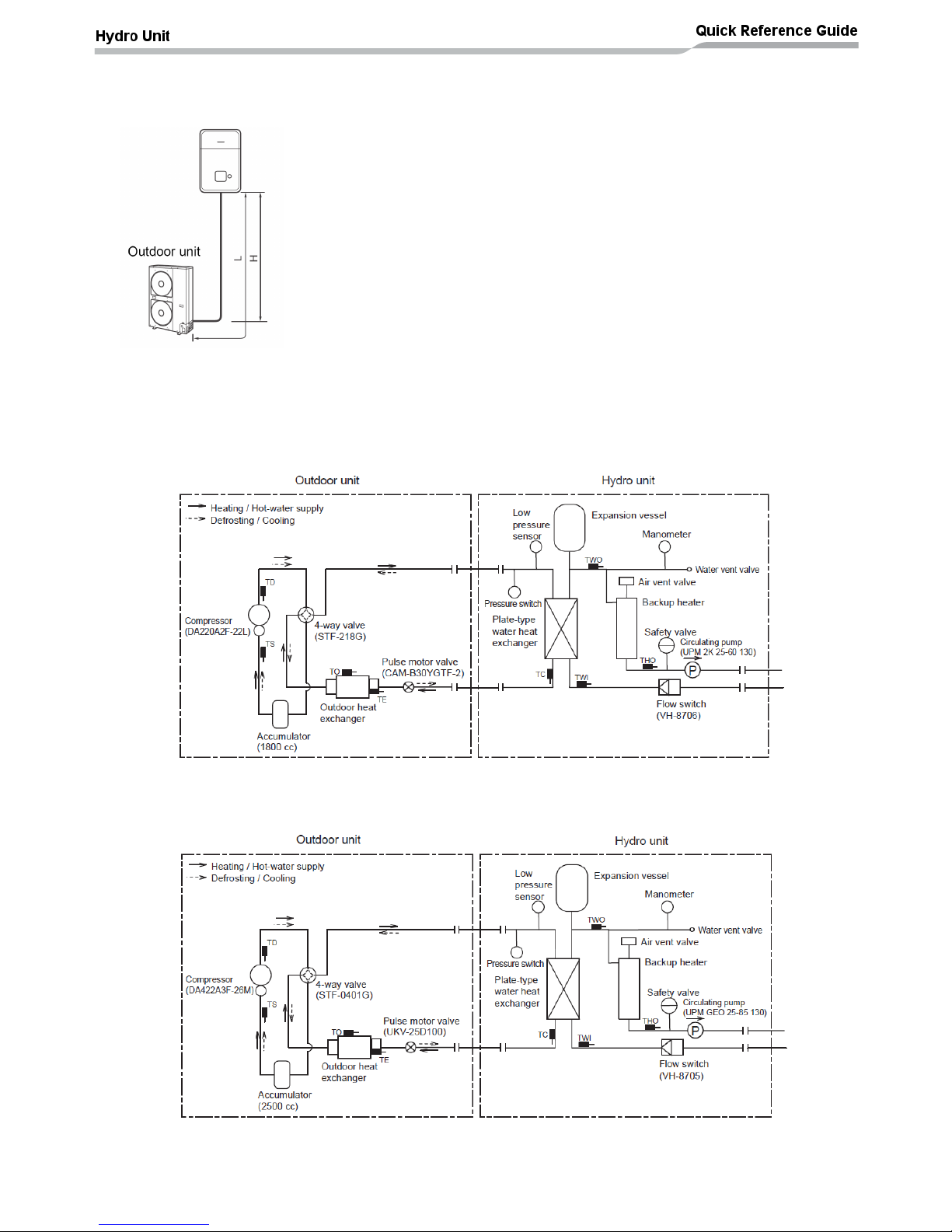

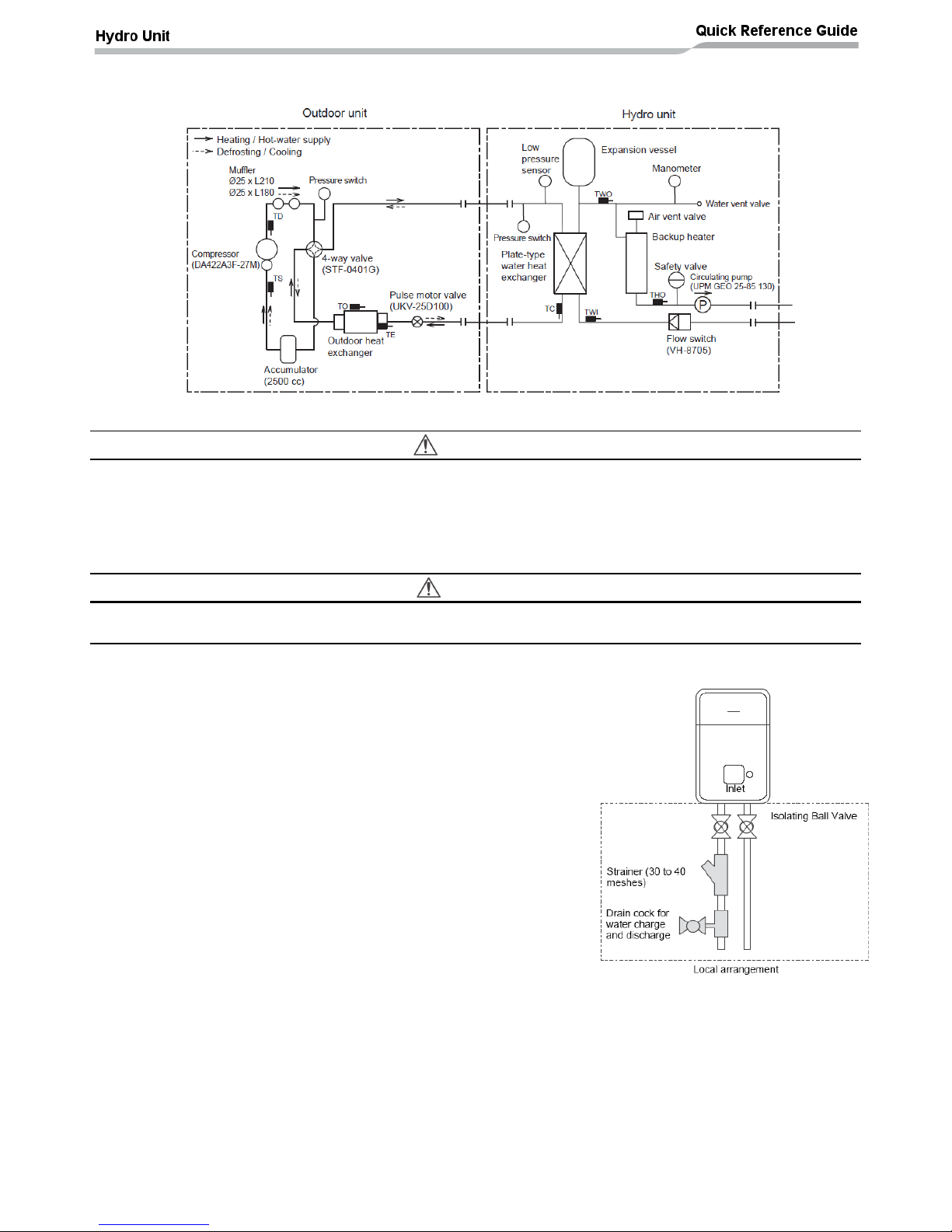

Refrigeration and Water Cycle Diagrams

Outdoor Unit: HWS-804H-E

Hydro Units: HWS-804XWH**-E

Outdoor Units: HWS-1104H**-E, HWS-1404H**-E

Hydro Units: HWS-1404XWH**-E

Page 9

8

Outdoor Units: HWS-1104H8(R)-E, HWS-1404H8(R)-E, HWS-1604H8(R)-E

Hydro Units: HWS-1404XWH**-E

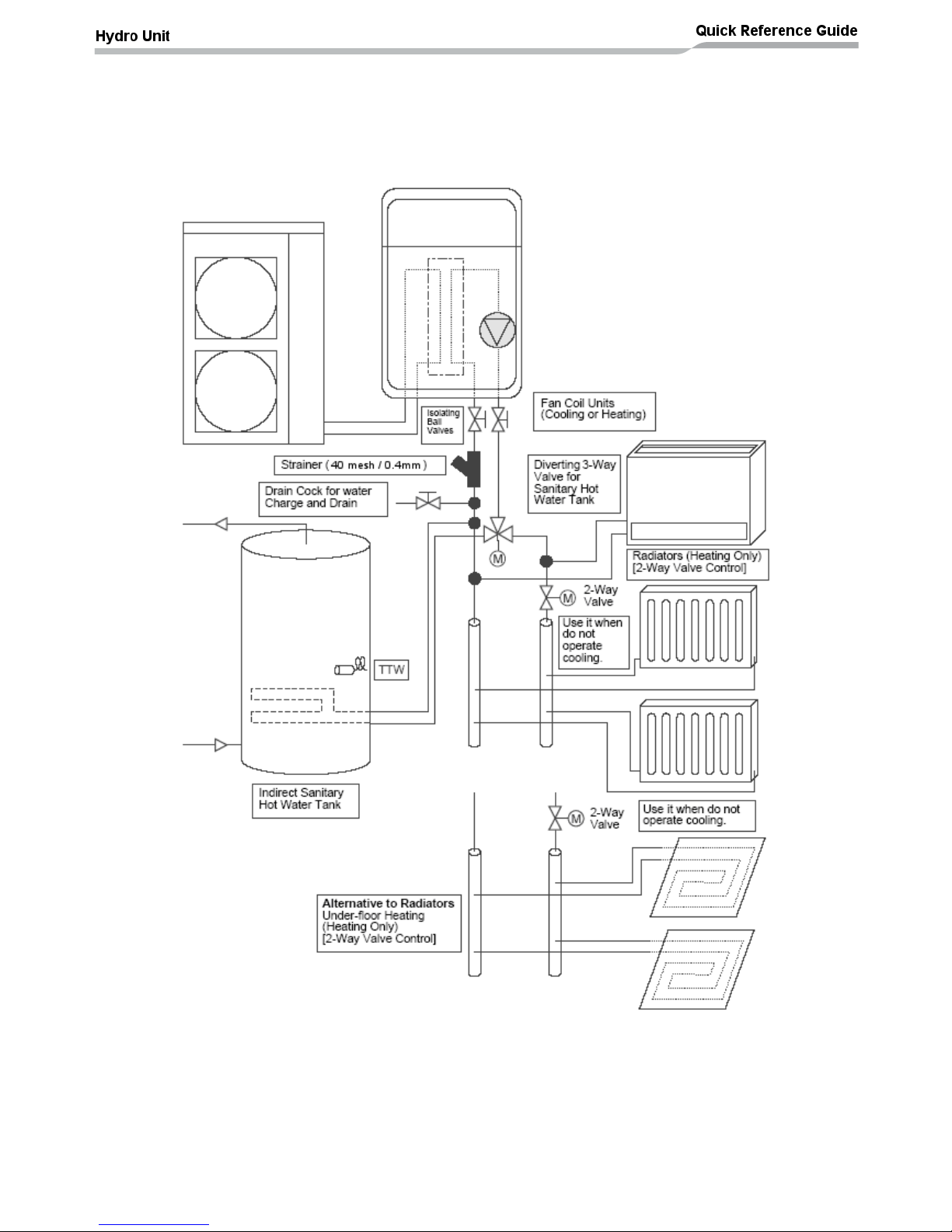

Water Piping

WARNING

• Ensure that the heating circuit, and all components of the heating circuit, are installed in accordance with

all National and local regulations

• The water pipes must not be installed where they are exposed to low ambient air temperatures. This is to

prevent the water freezing in the pipes

• Make sure that water pipes have sufficient pressure resistance

(The setting value of the pressure relief valve is 0.3 MPa).

CAUTION

• Do not use zinc plated water pipes. When steel pipes are used, insulate both ends of the pipes.

• The water to be used must meet the water quality standards specified in EN directive 98/83 EC.

Water Circuit

• Install a strainer with 30 to 40 meshes (procure locally) at the

water inlet of the Hydro Unit

• Install drain cocks (procure locally) for water charge and discharge

at the lower part of the Hydro Unit

• The ESTIA system can only be used on pressurised heating

circuits. If the system is used on gravity fed heating circuits then

system failure may occur

Page 10

9

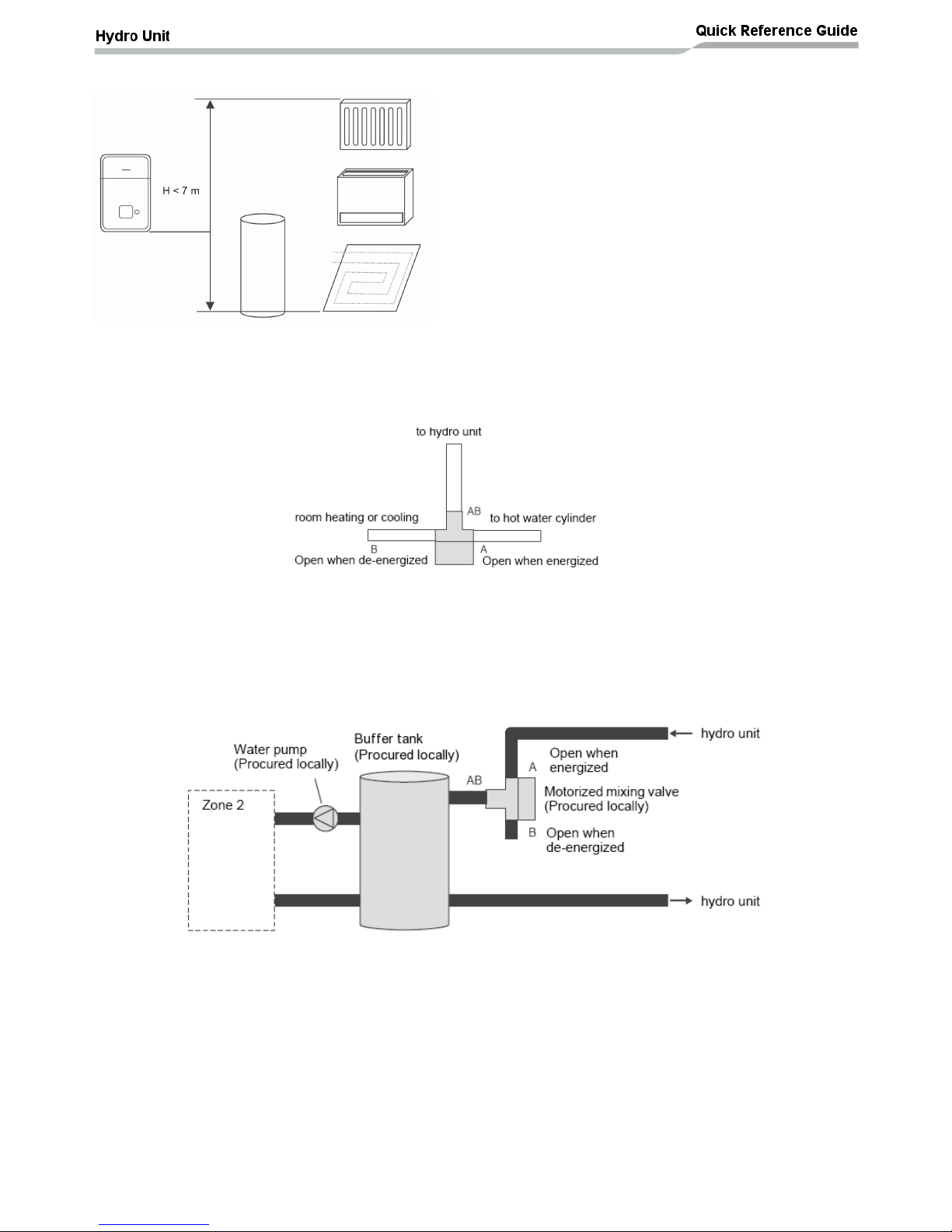

Water Piping Limitations

Design the water pipe length within the QH characteristics

of the pump (flow-rate and pump head).

The maximum height difference for the water pipes is 7

metres.

Piping to hot water tank (option)

Water supplied to the hot water cylinder is branched by a motorized 3-way valve (procured locally).

Connect the hot water cylinder to port A (open when energized) of the valve.

Piping to 2-zone operation (option)

To perform 2-zone temperature control circulate water using another pump (procured locally) through a

motorized mixing valve (procured locally) and a buffer tank (procured locally).

Page 11

10

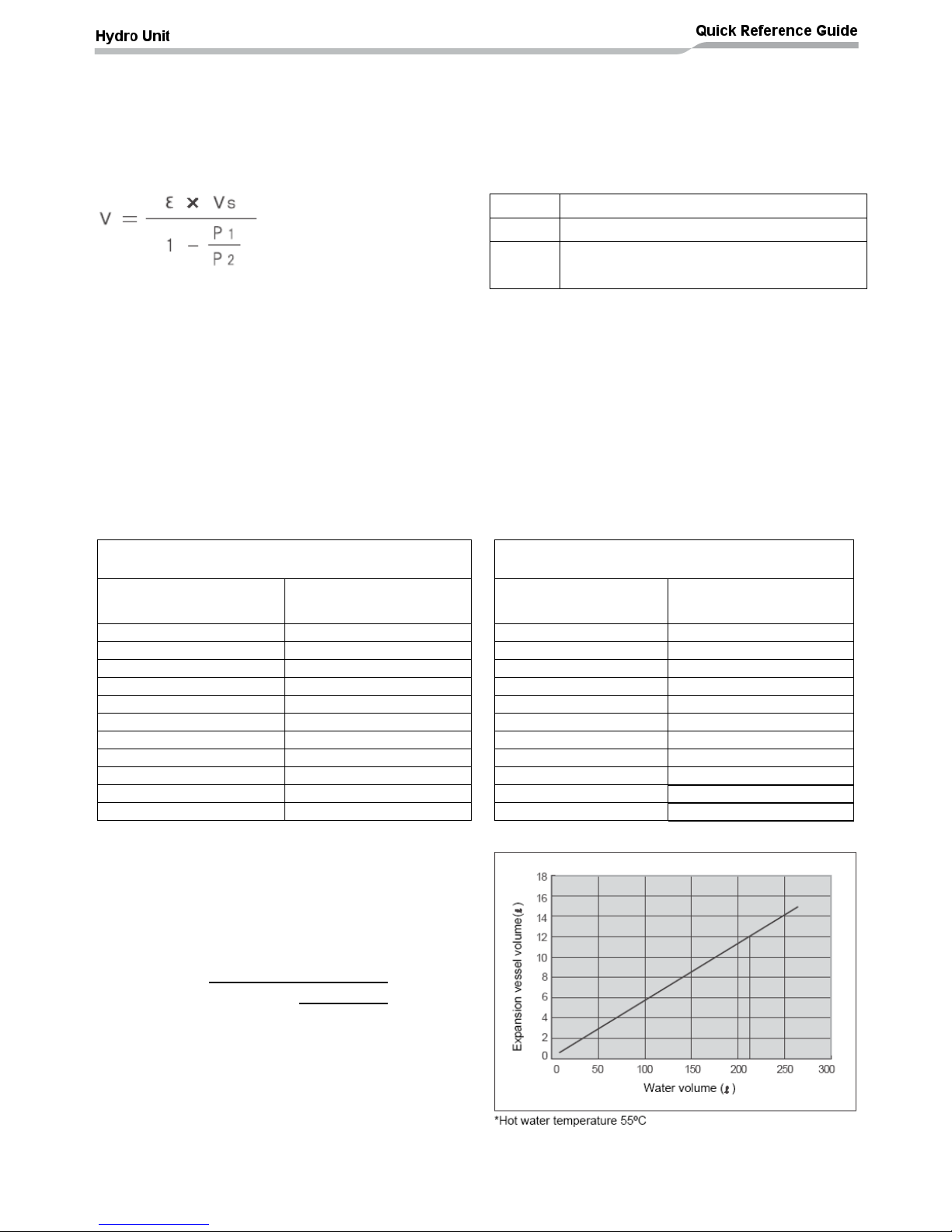

Checking water volume and initial pressure of expansion vessel

The expansion vessel of the Hydro Unit has a capacity of 12 litres.

The initial pressure of the expansion vessel is 0.1 MPa (1 bar).

The pressure of the safety valve is 0.3 MPa (3 bar).

Verify whether the capacity of the expansion vessel is sufficient using the following expression. If the

volume is insufficient, install an appropriate external expansion vessel.

V

Action

< 12 L

Internal Expansion Vessel Size OK

> 12 L

Internal Expansion Vessel Size too small.

Install appropriate external expansion vessel

V: Necessary total vessel capacity (L)

Ɛ: Water expansion coefficient at average hot water temperature

Vs: Total water volume in the closed system (Do not include Hot Water Cylinder)

P1: System pressure at tank setting position (Mpa_abs*).

(Pipe inner pressure during pump operation before heating device operates = water supply

pressure)

P2: Maximum pressure used during operation at tank setting position (MPa_abs*).

(= safety valve setting pressure)

* The absolute pressure value (abs.) is obtained by adding the atmospheric pressure (0.1 MPa (1 bar)) to

the gauge pressure.

Water temperature and expansion coefficient (Ɛ)

Water temperature and expansion coefficient (Ɛ)

Hot water temperature

(°C)

Expansion rate

(Ɛ)

Hot water temperature

(°C)

Expansion rate

(Ɛ)

0

0.0002

50

0.0121

4

0.0000

55

0.0145

5

0.0000

60

0.0171

10

0.0003

65

0.0198

15

0.0008

70

0.0229

20

0.0017

75

0.0258

25

0.0029

80

0.0292

30

0.0043

85

0.0324

35

0.0050

90

0.0961

40

0.0078

95

0.0967

45

0.0100

-

-

Example

Maximum Hot Water temperature: 55°C

Initial water charge: 0.2MPa

System volume: 200 L.

Calculate Vessel capacity (V):-

In this case V < 12 L therefore the internal expansion

vessel is sufficient, so there is no need to install an

external expansion vessel.

V =

0.0145

x

200

(0.2 + 0.1)

(0.3 + 0.1)

V =

11.6L

1

-

Page 12

11

Pump QH curves

HWS-804XWHM3-E, T6-E, T9-E

HWS-1404XWHM3-E, T6-E,T9-E

Page 13

12

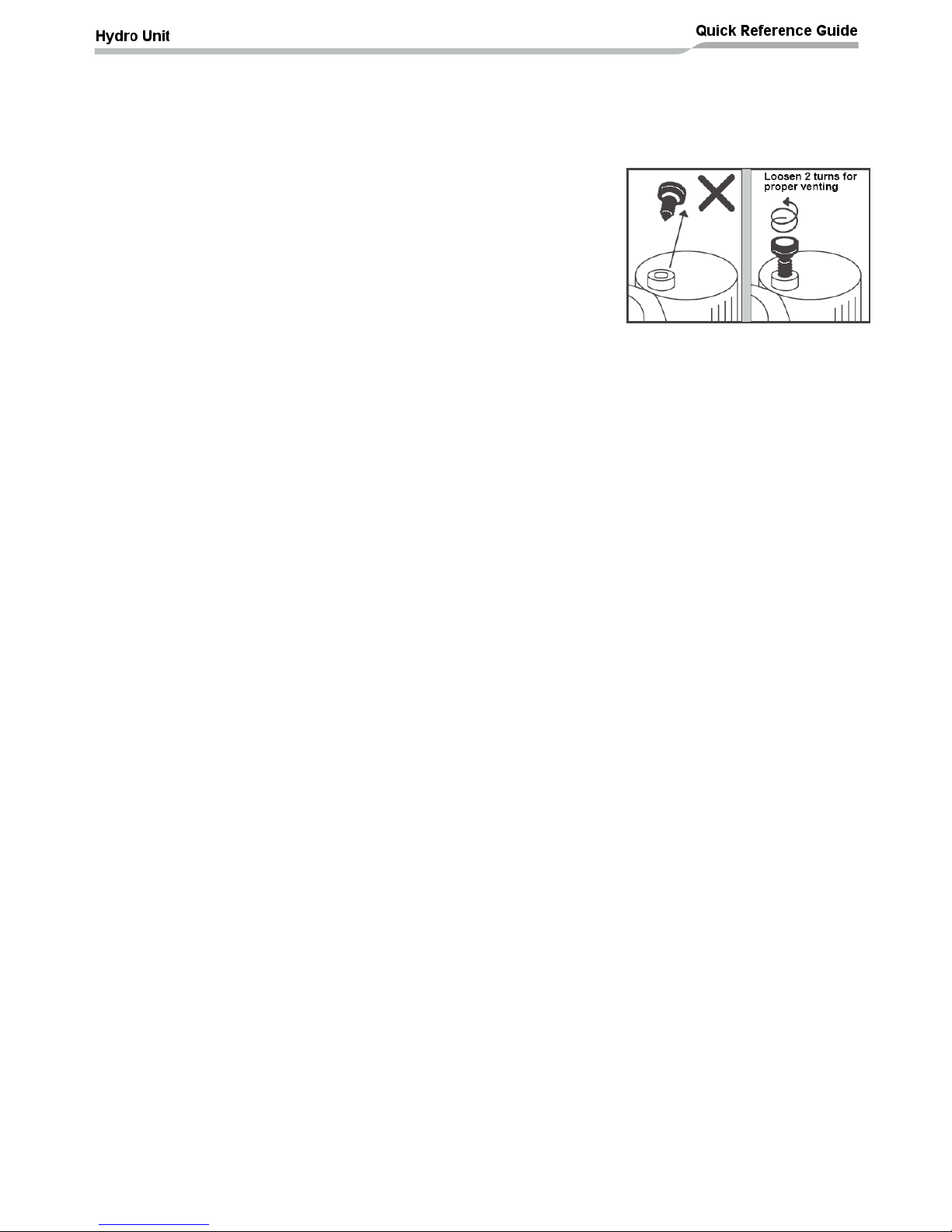

Water charging

Charge the water, in the heating circuit, until the pressure gauge shows 0.2 MPa (2 bar).

The hydraulic pressure may drop when the trial run begins. In this case, add water until the hydraulic

pressure returns to 0.2MPa (2 bar)

Air may enter the heating circuit if the hydraulic pressure is low.

Loosen the Air relief valve cap by two turns to release air (see diagram).

Ensure all air is removed from the system. If air remains in the system

then the system operation may STOP.

Note: Due to the design of the electrical back up heater it is not

recommended to add any corrosion inhibitors / additives to the

heating circuit.

Water quality

The water used must satisfy EN directive 98/83 EC.

Piping insulation

It is recommended that insulation is fitted to all pipes. To perform optional cooling operation, apply

insulation with a rating of 20t or more to all pipes.

Page 14

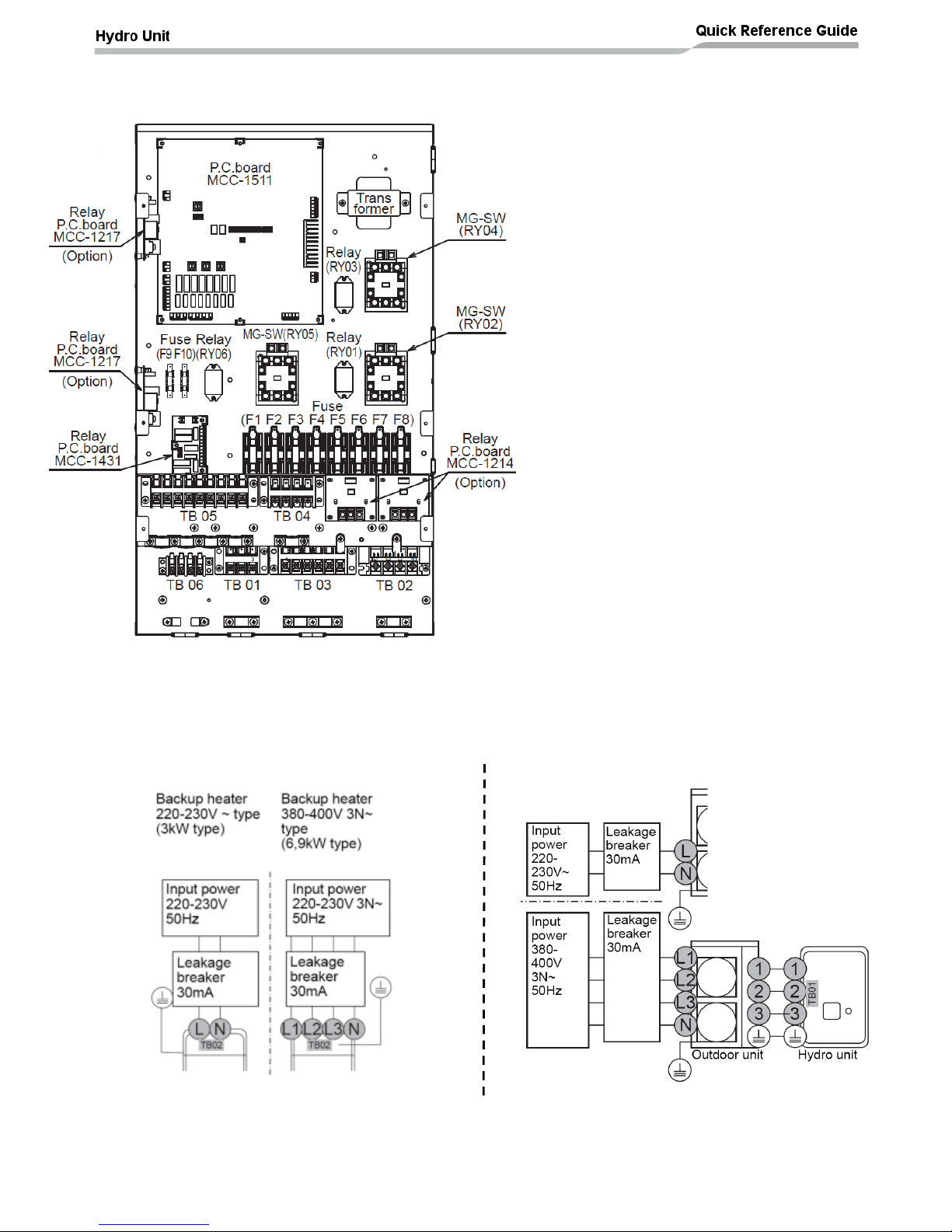

13

Electrical Connections

E Box layout

Power Lines Schematic

Fuses (AC250V T30A):

F1&F2: Hot water cylinder electric heater supply

F3&F4: Back up heater 1 (3kW)

F5&F6: Back up heater 2 (3kW)

F7&F8: Back up heater 3 (3kW)

Fuses (AC250V T3.15A)

F9&F10: A rated water pump

PCB’s:

MCC-1214: TCB-PCMO3E (optional input PCB)

MCC-1217: TCB-PCIN3E (optional output PCB)

MCC-1431: Relay PCB for control of second

water pump, 2 way valve and booster heater

outputs

MCC-1511: Main hydro unit control / interface

PCB

Contactors & Relays:

RY01: Interlock relay – flow switch / back up

heater circuit

RY02: Power contactor for back up heater supply

RY03: Control relay for back up heater s 2 & 3

operation

RY04: Power contactor for back up heater supply

RY05: Power contactor for hot water cylinder

electric heater supply

RY06: Control relay for mixing valve (2 zone)

operation

Page 15

14

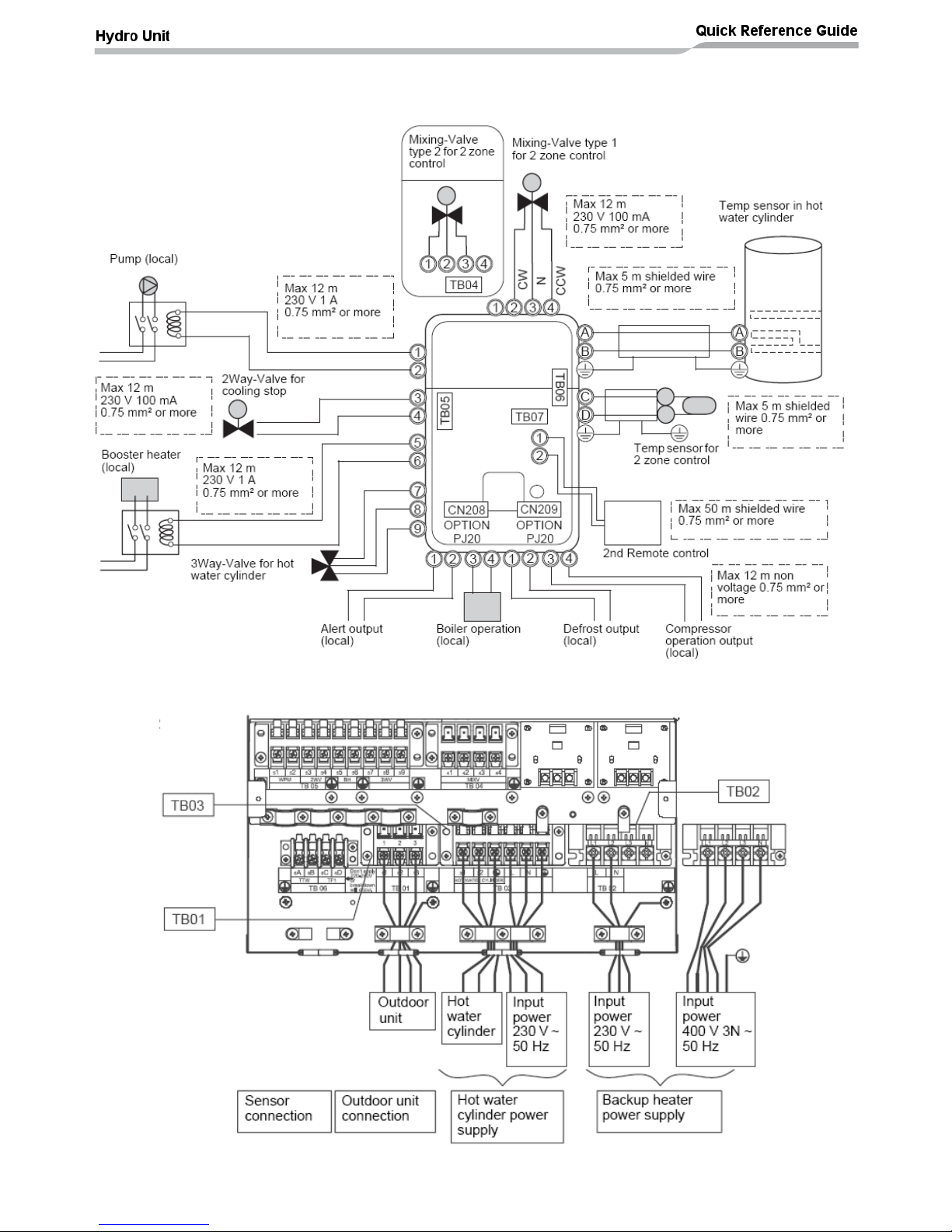

Control Lines Schematic

Terminal Block Connections

Page 16

15

Electrical supply / cable specifications

Wiring specifications (power line)

Description

Model Name

HWS

Power Supply

Current

(Max)

Install

Fuse

Rating

Power

Cable

Connection

Destination

Outdoor

Unit

Power

Power

Input

1404H-E

220V-230V ~

50Hz

22.8A

25A

≥2.5mm

2

L, N

-

1104H-E

220V-230V ~

50Hz

22.8A

25A

≥2.5mm

2

804H-E

220V-230V ~

50Hz

19.2A

20A

≥2.5mm

2

1604H8(R)-E

380-400V 3N~

50Hz

14.6A

16A

≥2.5mm

2

L1, L2, L3,

N

-

1404H8(R)-E

380-400V 3N~

50Hz

14.6A

16A

≥2.5mm

2

1104H8(R)-E

380-400V 3N~

50Hz

14.6A

16A

≥2.5mm

2

Hydro

unit

electric

heater

power

Power

input

for

back

up

heater

1404XWHM3-E

220V-230V ~

50Hz

13A

16A

≥1.5mm

2

L, N

TB02

1404XWHT6-E

380-400V 3N~

50Hz

13A (13Ax2P)

16A

≥1.5mm

2

L1, L2, L3,

N

1404XWHT9-E

380-400V 3N~

50Hz

13A (13Ax3P)

16A

≥1.5mm

2

804XWHM3-E

220V-230V ~

50Hz

13A

16A

≥1.5mm

2

L, N

804XWHT6-E

380-400V 3N~

50Hz

13A (13Ax2P)

16A

≥1.5mm

2

L1, L2, L3,

N

804XWHT9-E

380-400V 3N~

50Hz

13A (13Ax3P)

16A

≥1.5mm

2

Power input for DHW

cylinder heater

220V-230V ~

50Hz

12A

16A

≥1.5mm

2

L, N

TB03

Outdoor – hydro

unit connection

- - -

-

≥1.5mm

2

1, 2, 3

TB01

Hydro unit to DHW

cylinder

- - -

-

≥1.5mm

2

1, 2

TB03

Wiring specification (control line)

Description

Line Spec

Current (Max)

Length (Max)

Cable Diameter

Connection

Destination

3 way diverting

valve

2 or 3 wire

100mA

12m

1.0mm

2

7, 8, 9 (TB05)

2 way valve

(cooling)

2 wire

100mA

12m

1.0mm

2

3, 4 (TB05)

3 way mixing

valve (2 zone)

3 wire

100mA

12m

1.0mm

2

1, 2, 3

or

2, 3, 4

(TB04)

2 zone thermo

sensor (TFI)

2 wire

100mA

5m

1.0mm

2

C, D (TB06)

HW cylinder

thermo sensor

(TTW)

2 wire +GND

(screened cable)

100mA

5m

1.0mm

2

A, B (TB06)

2nd remote

controller

2 wire

50mA

50m

≥ 0.5mm

2

1, 2 (TB07)

Page 17

16

Control parts specifications

Component

Power

Current (Max)

Specification

3 way diverting valve

AC 230V

100mA

Default: 2 wire spring return valve or 3 wire SPST

valve

Option: 3 wire SPDT valve (set DPSW13_1 to ON)

2 way valve (cooling )

AC 230V

100mA

2 wire spring return valve (normally OPEN)

3 way mixing valve (2 zone

control)

AC 230V

100mA

Default drive time = 60 seconds to 90°

3 wire SPST or SPDT with drive times to 90° between

30 and 240 seconds

Output line specifications

Description

Output

Current

(Max)

Voltage

(Max)

Cable

Length

(Max)

Comments

External water

pump (P2)

AC230V

1A - 12m

External booster

heater

AC230V

1A - 12m

Output enabled when outdoor air

temperature is ≤ -20°C

Alarm output

No volt contacts

0.5A

AC230V

12m

1A

DC24V

12m

Boiler output

No volt contacts

0.5A

AC230V

12m

Output enabled when outdoor air

temperature is ≤ -10°C (output trigger

temperature can be changed using FC23)

1A

DC24V

12m

Defrost output

No volt contacts

0.5A

AC230V

12m 1A

DC24V

12m

Compressor ON

output

No volt contacts

0.5A

AC230V

12m 1A

DC24V

12m

Input line specifications

Description

Input

Cable Length (Max)

External stop control

No voltage

12m

Cylinder thermostat

No voltage

12m

Room thermostat (cooling)

No voltage

12m

Room thermostat (heating)

No voltage

12m

Page 18

17

CAUTION

Earthing arrangements

The Hydro Unit and related equipment must be earthed in accordance with your local and national electrical

regulations.

It is essential that the equipment is earthed to prevent the electric shock and damage to the equipment.

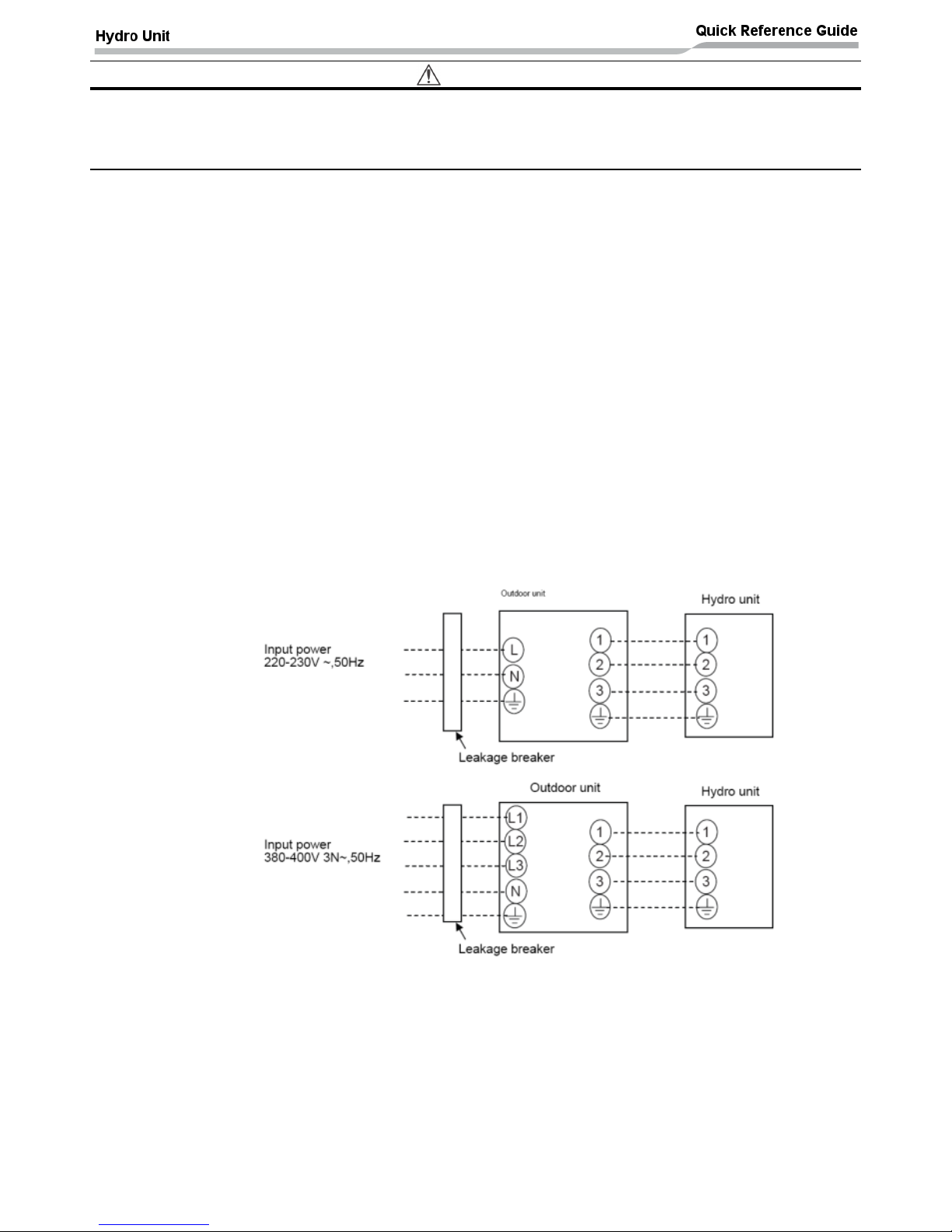

Electrical connection to hydro unit

• Remove the front cover and the electrical box cover from the Hydro Unit.

• The Hydro Unit power cable, for the electrical back up heaters, must be sized in accordance with the

Wiring Specifications table shown on page 15

• Connect the Hydro Unit power cable, for the electrical back up heaters, to Terminal 02 as shown below.

Single Phase Units: Live conductor – Terminal L1

Neutral conductor – Terminal L2

Earth conductor – Earth terminal

Three Phase Units: Phase 1 conductor – Terminal L1

Phase 2 conductor – Terminal L2

Phase 3 conductor – Terminal L3

Neutral conductor – Terminal N

Earth conductor – Earth

• Ensure the Hydro Unit power cable, for the electrical back up heaters, is secured using the cable clamp

fitted in the electrical box.

• Ensure the Hydro Unit power cable connection (for the electrical back up heaters) terminals are tight.

Outdoor unit to hydro unit electrical connection

• Ensure electrical circuits are isolated before commencing work.

• The Outdoor Unit to Hydro Unit interconnecting cable must be sized in accordance with the “Wiring

Specification” table shown on page 15

• Connect the Outdoor Unit to Hydro Unit interconnecting cable as shown in the diagram above.

• Ensure the Outdoor Unit to Hydro Unit interconnecting cable is secured using the cable clamp fitted in the

electrical box.

• Ensure the Outdoor Unit to Hydro Unit interconnecting cable connection terminals are tight.

HWS-804H-E

HWS-1104H-E

HWS-1404H-E

HWS-1104H8-E, H8R-E

HWS-1404H8-E, H8R-E

HWS-1604H8-E, H8R-E

Page 19

18

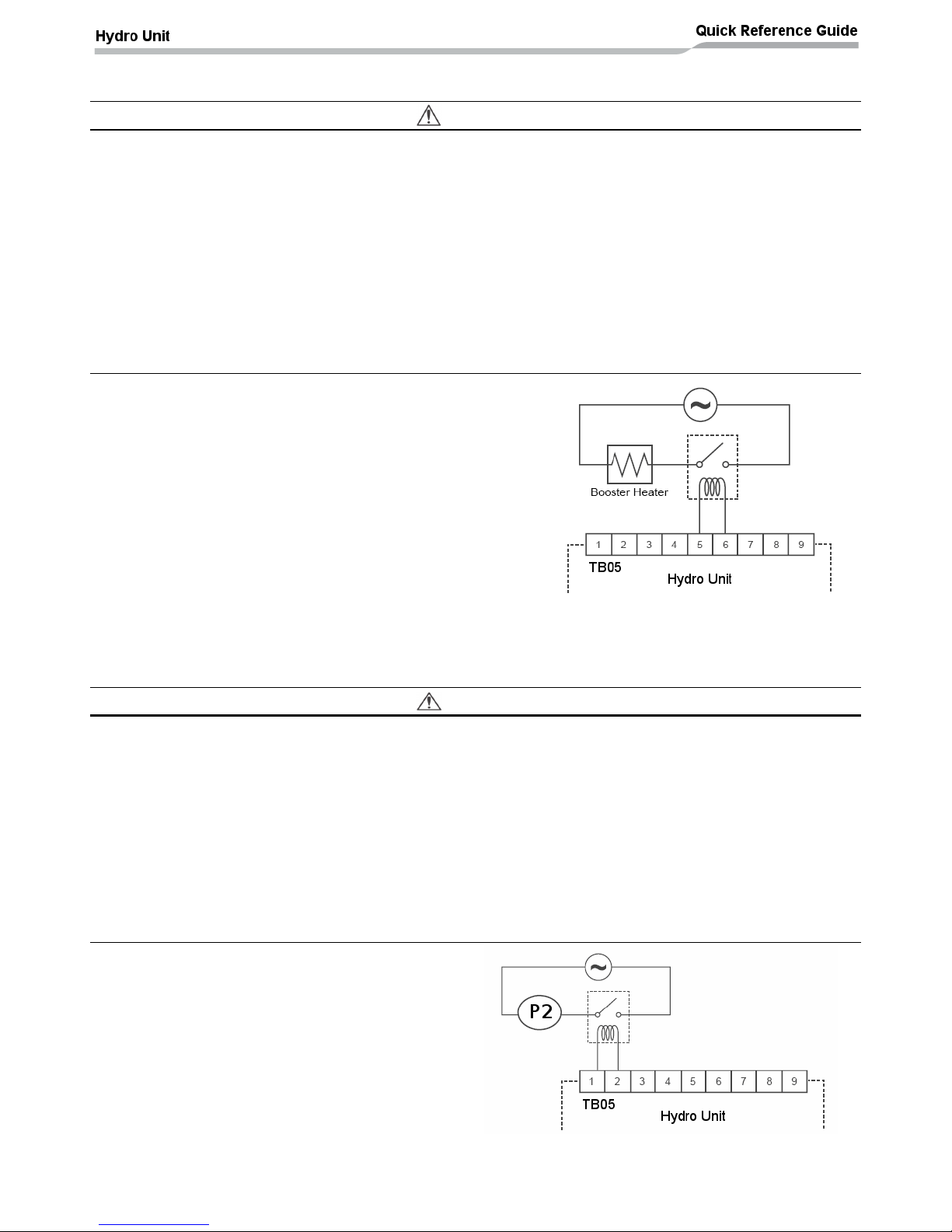

Electrical connection for external booster heater

CAUTION

• The maximum current available from the booster heater output is 1 A. Do not connect the booster

heater directly to Terminal Block 05 on the Hydro Unit. A separate contactor, supplied locally, must

be used to supply the booster heater.

• The booster heater can be installed only for room heating and cannot be used for hot water supply.

• Install the booster heater downstream of the 3-way valve on the heating circuit side of the installation

• The booster heater is an external heater, supplied locally, used to assist the Hydro Unit during low

ambient conditions.

• The AC230 V 1 A output from the Hydro Unit must only be used to energize an external contactor

(supplied locally).

• The output from the Hydro Unit is only enabled when either the outdoor air temperature to be lower than -

20°C.

• Ensure the external booster heater is installed and set up in accordance with all Local, National and

International regulations.

• Connect the external booster heater to the Hydro Unit

according to the diagram shown opposite:-

• The contactor will energize in the event of low ambient

conditions.

• A separate dedicated electrical supply must be used for the

external booster heater. This must be connected through the

contacts on the field supplied contactor.

Electrical connection for external additional pumps

CAUTION

• The maximum current available from the additional pump output is 1 A. Do not connect the

additional pump directly to Terminal Block 05 on the Hydro Unit. A separate contactor, supplied

locally, must be used to supply the additional pump.

• The Hydro Unit has the facility to connect an additional circulating pump, if required, into the heating or

cooling system.

• Install the pump so that its motive power does not affect the internal pump.

• The AC230 V 1 A output from the Hydro Unit must only be used to energize an external contactor

(supplied locally).

• The output for the pump is synchronized with the operation of the main circulating pump (P1) inside the

Hydro Unit.

• Ensure the pump is installed and set up in accordance with all Local, National and International

regulations.

• Connect the additional pump (P2) as shown in the

diagram opposite:-

• The contactor will energize synchronously with

operation of the main circulation pump (P1).

• A separate dedicated electrical supply must be

used for the pump. This must be connected through

the contacts on the field supplied contactor.

Page 20

19

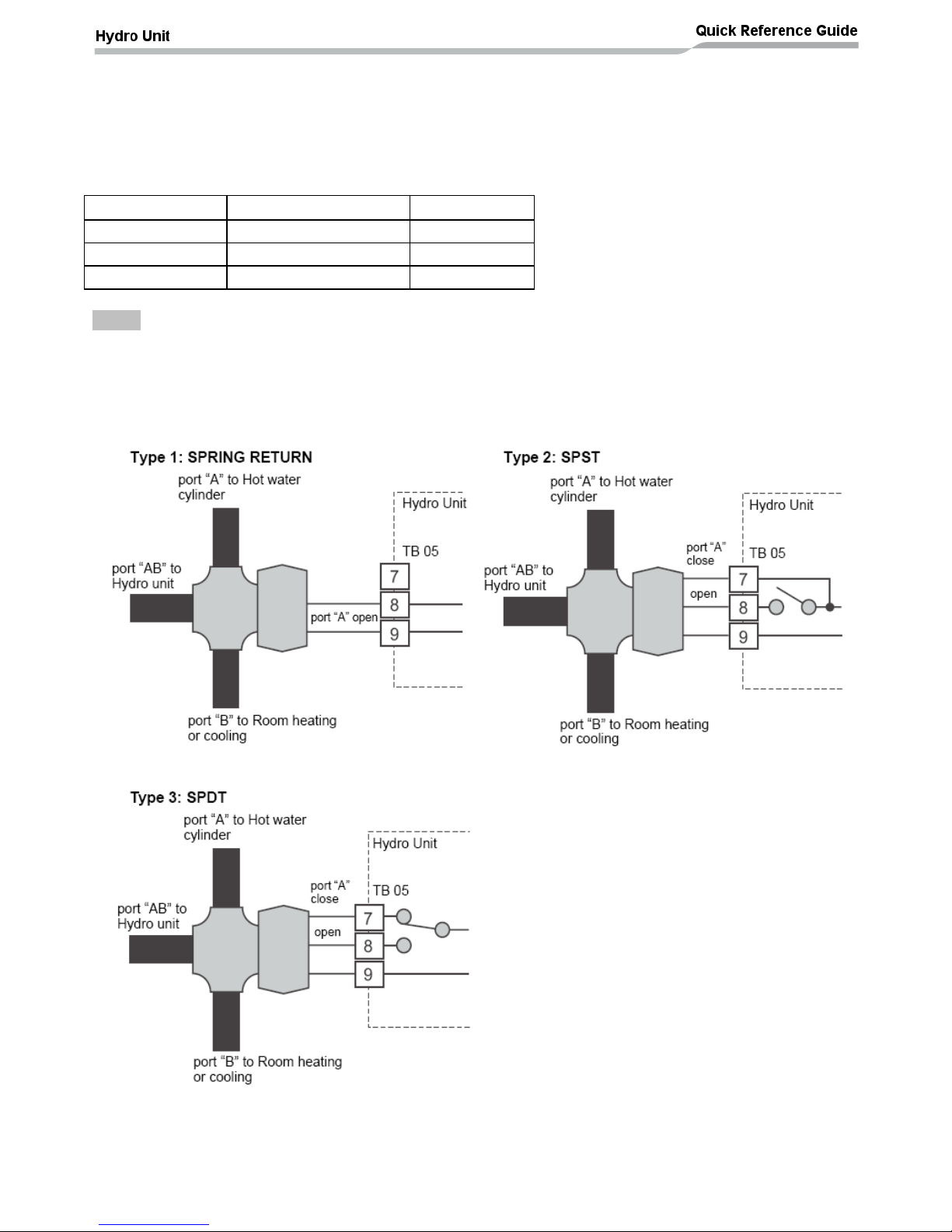

3-way valve (diverter) connection

Required Valve Specification:

Electrical Specification: 230 V; 50 Hz; <100 mA

Valve Diameters: Port A, Port B: Ø 1 1/4"

Return Mechanism: 3 types of 3-way valve (diverter) can be used.

Set the 3-way valve in use with the DIP switch SW13-1 on the Hydro Unit board.

Diverter Valve

Description

DPSW13-1

Type 1

2-wire spring return

OFF

Type 2

3-wire SPST

OFF

Type 3

3-wire SPDT

ON

NOTE

Continuous operation of the valve motor at the fully open position is not recommended.

• The 3-way diverter valve is used to select either domestic hot water or zone1 / zone2 space heating

• Connect the 3-way diverter valve in accordance with the diagram below:-

Page 21

20

3-way mixing valve connection

Required Actuator Specification

Electrical Specification:230 V; 50 Hz; <100 mA

The 3-way mixing valve is used to achieve the temperature differential needed in a 2-zone heating system.

• Connect the 3-way mixing valve in accordance with the diagrams below:-

Hot water cylinder connection (optional)

• Please refer to “Electrical supply/cable specifications” for fuse/cable size and for connection

details.

Electrical Connection (Hot Water Cylinder Electric Heater)

• The electric heater, incorporated in the hot water cylinder, requires a separate supply to the Hydro Unit.

• Connect the hot water cylinder heater electrical supply in accordance with shown below:

Live conductor: Terminal L on Terminal Block 03

Neutral conductor: Terminal N on Terminal Block 03

Earth Conductor: Earth terminal on Terminal Block 03

• Connect the hot water cylinder heater to the Hydro Unit as shown below:

Live conductor to hot water cylinder: Terminal 1 on Terminal Block 03

Neutral conductor to hot water cylinder: Terminal 2 on Terminal Block 03

Earth conductor to hot water cylinder: Earth terminal on Terminal Block 03

Please ensure that the interconnecting cable, between the Hydro Unit and the hot water cylinder, is

connected to earth at both ends of the cable using the shield wire or the earth conductor of the

interconnecting cable.

Electrical Connection (Hot Water Cylinder temperature Sensor)

• Connect the hot water cylinder temperature sensor as shown below to terminals A & B on Terminal Block

06 in the Hydro Unit.

Page 22

21

Second Remote Controller Installation (optional)

It is possible to connect a second remote controller to the ESTIA system.

The remote controller should be installed between 1m to 1.5m above floor level so that the remote

controller measures the average room temperature

The remote controller must not be installed in areas of:

Direct sunlight or areas exposed to outside air influences

Poor ventilation (near windows or other openings)

External heat sources (above radiators etc.)

Freezing or refrigerated areas

The remote controller must be installed in a vertical position

Second Remote Controller Connection

The remote controller can be set as either the header or second remote controller and to measure either

water temperature or room air temperature.

Remote Controller DIPS Switches - Setting

Set one of the remote controllers as the header remote controller (remote controller of hydro unit

is preset as the header remote controller (DPSW1 = OFF)

Set the DPSW’s on the other remote controller PC boards to “second” (optional remote controller

is preset as “second” – DPSW1 = ON)

For room air temperature control

set function code 40 (on the hydro unit) to “1”

Set DPSW2 to ON only on the remote controller used for room temperature measurement

Either the header or the second remote controller can be set for room temperature

measurement. Please do not set DPSW2 to ON on both the header and follower remote

controllers

2 core shielded cable – 0.5mm2

or more.

Maximum cable length – 50m

Second remote controller

connections. Terminals A

and B are non polar.

Terminal block TB07, for

remote controller

connection, to hydro unit.

Page 23

22

Input / Output Option PCB’s – Installation

Output Options:

It is possible to connect to outputs, using the TCB-PCIN3E option PCB’s, on the ESTIA hydro unit for the

following functions:

Alarm output

Boiler output

Defrost

Compressor ON

System alarm & boiler outputs:

Alarm output (L1): Output ON when the system is in alarm/fault conditions. The output is

available through a volt free contact on the TCB-PCIN3E option PCB.

Boiler control output (L2): Output ON when outdoor ambient temperature is less than or equal

to the temperature set in FC23. The output is available through a volt free contact on the TCBPCIN3E option PCB.

Defrost & compressor ON outputs:

Defrost output (L1): Output ON when the system / outdoor unit is under defrost control. The

output is available through a volt free contact on the TCB-PCIN3E option PCB.

Compressor ON output (L2): Output ON when the outdoor unit compressor is operating. The

output is available through a volt free contact on the TCB-PCIN3E option PCB.

Page 24

23

Volt free contact specification: The volt free contact specification, for the outputs detailed

above, is shown below:

AC230V: 0.5A (maximum)

DC24V: 1.0A (maximum)

Input Options:

It is possible to connect inputs, using the TCB-PCMO3E option PCB’s, on the ESTIA hydro unit for the

following functions:

External room thermostat

External hot water cylinder thermostat

External STOP

External room thermostat:

The diagram above shows the thermostat connections for heating and cooling mode. The

thermostat must be manually switched between heating and cooling (the operating mode, on the

ESTIA remote controller must also be changed manually). The system cannot change between

heating and cooling modes automatically.

For cooling operation connect the cooling contact, on the thermostat, between terminals 2 (COOL) &

3 (COM) on the option PCB (as shown above).

For heating operation connect the heating contact, on the thermostat, between terminals 1 (HEAT) &

3 (COM) on the option PCB (as shown above).

Control Logic:

Option PCB

Terminal Nos.

Cooling Operation

Heating Operation

ON

OFF

ON

OFF

2 ~ 3

OPEN

CLOSED

-

-

1 ~ 3

-

-

CLOSED

OPEN

Page 25

24

External hot water cylinder thermostat:

Connect the external hot water cylinder thermostat (S1 in the diagram below) to terminals 2 (COOL) and

3 (COM) on the option PCB.

When the hot water cylinder thermostat contact, S1, is CLOSED then there is a hot water demand and the

system will produce hot water (if all DPSW’s and function codes are set correctly)

External system STOP:

Connect the external STOP signal / contact (S2 in the diagram above) to terminals 1 (HEAT) and 3 (COM)

on the option PCB.

It is possible to set the operating logic of contact S2 (normally OPEN contact, normally CLOSED contact or

pulse input) using function code FC52 and the operating mode of the system, on restart, using FC61 (see

function code list on page 31 for options).

The external stop option can also be used for TEMPO control where an external signal, from the customers

electricity measuring meter, is applied to the option PCB (contact S2 connections). TEMPO control can be

used as part of the price contract provided by French electric power company EDF. The TEMPO control

options are set using FC61.

Page 26

25

Start up and Configuration

Setting DIP Switches on the Board in the Hydro Unit

• Detach the front cover and the electric parts box cover of the

Hydro Unit.

• Set the DIP switches on the main board.

Switch

No.

Bit

No.

Description

Factory

Position

02

1

Determines the position of the auxiliary boiler in the system installation:

OFF = Boiler positioned after the 3 way valve

ON = Boiler installed before the 3 way valve

OFF

2

Not Used

-

3

Used when an external cylinder thermostat is connected:

OFF = external cylinder thermostat not connected

ON = external room thermostat connected

OFF

4

Used when an external room thermostat is connected:

OFF = external room thermostat not connected

ON = External room thermostat connected

OFF

10

1

Synchronises pump P1 with HP during hot water production:

OFF = Pump P1 synchronised with HP during hot water mode when electric cylinder heater is

energised

ON = Pump P1 continuous operation

OFF

2

Pump P1 control using TO control (heating mode only):

OFF = Pump P1 continuous operation

ON = Pump P1 OFF when TO > 20°C (temperature can be changed using FC9E)

OFF

3

Synchronises pump P2 with pump P1:

OFF = Pump P2 continuous operation (P2 OFF when remote controller switched OFF)

ON = Pump P2 synchronised with pump P1

OFF

4

Pump P1 ON/OFF cycling (during long periods of system OFF):

OFF = Pump P1 normal operation

ON = Pump P1 ON for 10 minutes duration (if system has been stopped for 72 hours)

OFF

11

1

Used to enable the hydro unit back up heaters:

OFF = Back up heater control enabled

ON = Back up heater control disabled

OFF

2

Used to enable the hot water cylinder electric heater:

OFF = Hot water cylinder heater control enabled

ON = Hot water cylinder heater control disabled

OFF

3

Used to enable the external booster heater output control:

OFF = External booster heater control enabled (TO must be ≤ -20°C)

ON = External booster heater control disabled

OFF

4

Not Used

-

12

1

Used to determine hot water cylinder connection to the system:

OFF = Hot water cylinder connected to the system

ON = Hot water cylinder not connected to the system

OFF

2

Used to enable Zone 1 operation:

OFF = Zone 1 control enabled

ON = Zone 1 control disabled

OFF

3

Used to enable Zone 2 operation:

OFF = Zone 2 control disabled

ON = Zone 2 control enabled

OFF

4

Not Used

-

13

1

Used to determine type of 3 way diverting valve connected to system:

OFF = 2 wire spring return or 3 wire SPST valve connected

ON = 3 wire SPDT valve connected

OFF

2

Used to enable the external boiler output control (used with FC23):

OFF = External boiler output control disabled

ON = External boiler output control enabled

OFF

3

Used to enable system auto restart after system power failure:

OFF = Auto restart control enabled

ON = Auto restart control disabled

OFF

4

Not Used

-

Page 27

26

Hydro Unit Remote Control

Buttons

1. TEMP. button:

Changes the set temperature for

each operation mode (ZONE1 /

ZONE2 / HOT WATER) by 1°C

step.

10. NIGHT button:

Controls the night set back

operation.

2. SCHEDULE

button:

Sets the current time and

scheduled weekly operation.

11. AUTO TEMP.

button:

Switches setting temperature

automatically according to outside

temperature. (Pressing this button

long changes the mode to data

setting mode).

3. TIME button:

Changes time for current time

setting and scheduled weekly

operation setting with ▼ and ▲

buttons.

12. OPERATE

MODE button:

Selects ZONE1 / ZONE2 operation

mode (heating or cooling).

4. SET button:

Determines the entered current

time setting and scheduled weekly

operation setting.

13. ZONE1, 2

button:

Turns on/off the zone (floor

heating/radiator/FCU) operation.

5. CL button:

Clears settings for the current time

and scheduled weekly operation.

14. ANTI BACTERIA

button:

Regularly increases the hot water

temperature in the tank for

sterilization. (Pressing this button

long changes the mode to data

setting mode).

6. DAY button:

Sets days of the week for current

time setting and scheduled weekly

operation setting.

15. HOT WATER

BOOST button:

Boosts boiling when high tapping

temperature is required temporarily.

7. STEP button:

Specifies switching STEP number

in a day for weekly schedule.

16. HOT WATER

button:

Turns on/off hot water operation.

8. TEST button:

Used for test run or service.

17. SELECT button:

Selects an operation mode when

changing the set temperature of

each operation mode.

9. FROST

PROTECTION

button:

Controls minimum operation for

unused period (going out,

absence,etc.) for anti freezing.

NOTE

Some functions are not provided depending on the system specification in use.

Page 28

27

Display Explanation

18: ZONE1, ZONE2

20: HOT WATER

Display

Description

Display

Description

Lights when floor heater or radiator

is connected (when the system has

floor heater or radiator).

Lights when hot water supply system is

connected (when the system has hot

water supply).

ZONE1 selected for Temperature

to be changed.

Lights when system configured to

have 2 zones.

ZONE2 selected for Temperature

to be changed.

HOT WATER selected for Temperature

to be changed.

Lights during heating or cooling

operation using the heat pump.

Lights when hot water supply operation

is performed by heat pump.

Lights when the internal heater is

energized during heating

operation.

Lights when the internal heater is

energized during hot water supply

operation.

Lights when heating is selected.

Lights during hot water supply operation.

Lights when cooling is selected.

Lights while hot water boost is activated.

Lights when the FROST

PROTECTION button is pressed

and goes out when the button is

pressed again.

Lights when the ANTI BACTERIA button

is pressed and goes out when the button

is pressed again.

Lights when Auto operation is

selected.

Lights when unit enters the data set

mode.

Displays heating/cooling set

temperature. (Heating: 20 to 55°C,

factory setting: Auto, cooling: 7 to

25°C) Goes out when Auto

operation is selected.

Displays hot water set temperature.

(40 to 75°C, factory setting: 65°C)

°C

Lights when the set temperature or

sensor's water temperature is

displayed with the 7-segment

indicator.

°C

Lights when the set temperature or

sensor's water temperature is displayed

with the 7-segment indicator.

Page 29

28

Display Explanation (cont.)

19: TIMER

21: CONTROL

Display

Description

Display

Description

Clock: Displays the current time

(AM or PM).

Lights while internal pump (P1) or

external pump (P2) is driven.

Displays days of the week (Sunday

to Saturday).

Lights during backup operation only by

the heater.

Lights when the NIGHT button is

pressed and goes out when the

button is pressed again.

Lights when the unit enters the data set

mode and goes out when the unit exits

the data set mode.

Lights when night time quiet

operation is set.

Lights when the unit enters the service

mode and goes out when the unit exits

the service mode.

Indicates scheduled operation 1

status (including setting time).

Lights when an error occurs and goes

out when the error is cleared.

Displays the scheduled operation

step when the scheduled operation

STEP1-5 program is set.

Lights for two seconds when settings are

completed.

Lights during time setting and

scheduled operation setting.

Lights for two seconds when settings

failed.

Remote Controller – Schedule Timer

It is possible to set up timer control schedules on the ESTIA remote controller (when two remote controllers

are fitted to the ESTIA system the schedule timer is only available from the HEADER remote controller).

A maximum of eight control STEPS can be programmed / scheduled, into the ESTIA remote controller, for

each day of the week.

Using the schedule timer function (see page 42 for example):

Accessing the schedule timer function:

Press the SCHEDULE button for 4 second or more to enter the schedule timer setting

mode. The remote controller will show the following display:

Specifying the day for the schedule timer:

Press the Day button to move the ▼symbol, displayed above the days of the week on the remote

controller, to the day when the scheduled timer id to take place. Each press of the DAY button

moves the ▼symbol to the next displayed day. When the ▼symbol is above the required day, press

the SET button to confirm the day to be set

Specifying the control STEP number:

Press the STEP button to specify the control STEP to be set. The STEP selection increments by 1

STEP for each press of the STEP button from STEP 1 to STEP 8.

Steps “C” and “L” are also available by continuing to press the STEP button when the remote

controller display shows STEP 8.

Page 30

29

If “C” is selected then the control details, already set for the specified day, are copied. These details

can be copied to other days of the scheduled timer

If “L” is selected then all of the control details, set for the specified day, are deleted

Specifying the Step ON/OFF time, operation mode & set temperature:

ON/OFF Time: Use the TIME ▲ ▼ buttons to set the required ON/OFF time for the specified control

step

Operating Mode: To select or deselect the hot water function press the HOT WATER button on the

remote controller

To select or deselect either space heating function press the Zone1, 2 button on the remote

controller

When the function is selected to turn ON (at the specified time) then a numerical temperature is

displayed in the relevant window on the remote controller. When the function is selected to Turn

OFF (at the specified time) then the remote controller will display - - - -

To select either heating or cooling press the OPERATE MODE button on the remote controller.

When heating is selected then will be displayed on the remote controller. If cooling mode is

selected then will be displayed.

Set Point Temperature: Press the SELECT button, on the remote controller to select either space

Zone 1, Zone 2 or HOT WATER. Press the TEMPERATURE ▲ ▼buttons to set the required

temperature

When the ON/OFF time, operating mode and set point temperature have been entered into the

schedule timer press the SET button to confirm the settings

Leaving the schedule timer function:

When the scheduled timer function has been set for the required days press the SCHEDULE button

to end the schedule setting function. The remote controller display will return to the main display

screen and the icon, on the remote controller display, will flash. Press the SET button within 5

seconds of the icon flashing – the icon changes to lit and is continuously displayed. The timer

schedule is now in operation

How to copy a program

When specifying the STEP number (see details above) select “C” and press the SET button. This

copies all of the previously set data for that day.

Press the DAY button to move the ▼ above the new schedule timer day. Press the SET button to

copy the required data into the new day.

Repeat this process for all days required

Page 31

30

Function Code Access

Set function codes for various operation modes, input using the remote controller.

There are 2 types of settings:-

1) Hydro Unit function code setting.

2) Remote controller function code setting.

Setting procedure for Hydro Unit function code

1. Press and hold + + buttons for four

seconds or more to enter the hydro unit function code setting mode.

2. Set the function code number with the TEMP. buttons

(CODE No.: 01 to B2).

3. Set data with the TIME buttons .

4. Press to confirm the settings.

5. Note that the Clear button is enabled only before the SET

button is pressed and the function code is changed.

6. Press to exit the settings menu.

Setting procedure for Remote Controller function code

1. Press and hold + + TEMP. buttons for four seconds

or more to enter the remote controller function code setting mode.

2. Set the function code number with the TEMP. buttons

(CODE No.: 01 to 13).

3. Set data with the TIME buttons .

4. Press to determine the settings.

5. Note that the Clear button is enabled only before the SET

button is pressed and the function code is changed.

6. Press to exit the settings menu.

Page 32

31

Function Code Setting

Function Code Setting

Function Code

Range

Default

Setting Address

Hydro

Unit

Remote

Controller

Setting Temperature

Range

Heating Upper Limit - Zone 1

1A

-

37~55°C

55

Heating Lower Limit - Zone 1

1B

-

20~37°C

20

Heating Upper Limit - Zone 2

1C

-

37~55°C

55

Heating Lower Limit - Zone 2

1D

-

20~37°C

20

Cooling - Upper Limit

18

-

18~30°C

25

Cooling - Lower Limit

19

-

7~20°C

7

Hot Water - Upper limit

1E

-

60~80°C

75

Hot Water - Lower limit

1F

-

40~60°C

40

Hot Water Operation

Heat Pump Start Temperature

20

-

20~45°C

38

Heat Pump Stop Temperature

21

-

40~50°C

45

Hot Water Temperature

Compensation

Temperature Compensation Outside Air

Temperature (°C)

24

-

-20~10°C

0

Compensation Temperature (K)

25 - 0~15K

3

Hot Water Boost

Operation Time (x10 min)

08 - 3~18

6

Setting Temperature (°C)

09

-

40~80°C

75

Anti Bacteria

Setting Temperature (°C)

0A

-

65~80°C

75

Start Cycle (Day)

-

0D

1~10

7

Start Time (Hour)

-

0C

0~23

22

Operation Time (min)

0B - 0~60

30

System Priority Setting

Hot water v heating – switching temperature (°C)

22

-

-20~20°C

0

External boiler – output ON temperature (°C)

23

-

-20~20°C

-10

Hot water v cooling priority selection:

0 = Cooling priority. Hot water produced by

electric cylinder heater

1 = Hot water priority. Hot water produced by HP

0F - 0~1

0

Heating Auto Curve

Settings

Outside Temperature T1 (°C)

29

-

-15~0°C

-10

Outside Temperature T2 (°C)

- - 0

0

Outside Temperature T3 (°C)

2B

-

0~15°C

10

Setting Temperature A @ OAT -20°C (°C)

2C

-

20~55°C

40

Setting Temperature B @ OAT T1 (°C)

2D

-

20~55°C

35

Setting Temperature C @ OAT T2 (°C)

2E

-

20~55°C

30

Setting Temperature D @ OAT T3 (°C)

2F

-

20~55°C

25

Setting Temperature E @ OAT 20°C (°C)

30

-

20~55°C

20

Ratio Of Zone 2 In Zone 1 Auto Mode (%)

31

-

0~100%

80

Auto Curve - Temperature Shift (K)

27 - -5~5K

0

Frost Protection

Function 0=Invalid; 1=Valid

3A - 0~1

1

Frost Protection Setting Temperature (°C)

3B

-

10~20°C

15

Frost Protection – Schedule End Day

-

12

0~20

0

Frost Protection – Schedule End Time

-

13

0~23

0

Back Up Heater

Control

Downtime Back Up Heater 0=5min;

1=10min;2=15min;3=20min

33 - 0~3

1

Uptime Back Up Heater 0=10min; 1=20min;

2=30min; 3=40min

34 - 0~3

0

Hot Water Cylinder

Heater Control

Determines the time between HP operation and

cylinder heater ON time

0 = 30 min, 1 = 60 min, 2 = 90 min, 3 = 120 min

73 - 0 ~3

0

Night Setback

Change Setback Temperature

26 - 3~20K

5

Zone selection 0=Zone 1 & 2; 1= Zone 1 Only

58 - 0~1

0

Start Time (Hour)

-

0E

0~23

22

End Time (Hour)

-

0F

0~23

06

CDU Night Time Low

Noise Operation

Low Noise Operation:

0 = Control disabled

1 = Control enabled

-

09

0~1

0

Start time (Hr)

-

0A

0~23

22

End time (Hr)

-

0B

0~23

6

Page 33

32

Function Code Setting

Function Code

Range

Default

Setting Address

Hydro

Unit

Remote

Controller

Pump Control

Hydro unit pump (P1) synchronisation:

0 = P1 stops when in DHW mode and the

electric cylinder heater is energised (no

heating demand)

1 = P1 runs continuously

5A 0~1

0

Pump P1 operation ON/OFF controlled by

room temperature:

0 = Pump P1 operates continuously

1 = Pump P1 synchronised with room

temperature control. When using the room

temperature controller or external room

thermostat, pump P1 will STOP when the room

air temperature reaches thermo OFF condition

65 - 0~1

0

Pump P2 operation in cooling mode:

0 = Pump P2 operates continuously

1 = Pump P2 OFF in when cooling mode

selected

64 - 0~1

0

Pump P1 control using TO sensor (heating

mode only):

P1 OFF when TO>set value in FC9E

(DPSW10_2 must be ON)

9E - 10~30

20

A-rated pump (P1) speed control. Changes the

percentage duty of the PWM control:

00 = 0% PWM duty (Max. RPM)

01 = 10%

02 = 20%

03 = 30%

04 = 40%

05 = 50%

A0 - 0~5

0

E-Stop Switch Logic /

System Restart &

TEMPO Control

Forced stop input – switch logic:

0 = Contacts low > high (terminals 1-3 CLOSE)

system stop. System restart with remote

controller

1 = Contacts high > low (terminals 1-3

OPEN)system stop. System restart with

remote controller

2 = Contacts high > low (terminals 1-3

OPEN)system stop. Contacts low > high

(terminals 1-3 CLOSE) system restart

3 = Contacts low > high (terminals 1-3 CLOSE)

system stop. Contacts low > high (terminals 13 CLOSE -second time) system restart

(PULSE INPUT)

52 - 0~3

0

System Restart Logic / TEMPO Control:

0 = System restarts in heating and hot water

mode

1 = System restarts in the last mode prior to

stopping

2 = System restarts in hot water mode

3 = System restarts in heating mode

4 = TEMPO Control 1: All electric heaters

disabled

5 = TEMPO Control 2: HP and all electric

heaters disabled

61 - 0~5

0

A02 Error Detection with

Boiler Output Enabled

Allows A02 error detection to be enabled /

disabled when boiler output is ON:

0 = A02 active: When TWI,TWO or THO≥70°C

then the boiler output is switched OFF

1 = A02 deactivated: When TWI,TWO or

THO≥70°C then the boiler output stays ON

62 - 0~1

0

Page 34

33

Function Code Setting

Function Code

Range

Default

Setting Address

Hydro

Unit

Remote

Controller

Auxillary Boiler / Heat

Pump Operation

Boiler / heat pump synchronisation to set the

controlling device to be set:

0 = Boiler & heat pump synchronised. The heat

pump is the controlling device. When TWI

reaches the target water temperature of the

hydro unit the boiler output switches OFF

1 = Boiler & heat pump not synchronised. The

heat pump and auxillary boiler work as

independent devices. When TWI reaches the

target water temperature of the hydro unit the

boiler output remains ON

3E - 0~1

0

System operating mode when TO ≤ FC23:

0 = HP & boiler operation

1 = Boiler only operation (pump P1 remains

ON)

2 = Electric heater operation

3 = Boiler only operation (pump P1 OFF)

5B - 0~2

3

Room Temperature

Control

Room temperature control (2nd RC) selection:

0 = control disabled

1 = control enabled

40 - 0~1

0

Setting room temperature range (2nd RC):

Cooling room temperature upper limit

92 - 15~30

29

Setting room temperature range (2nd RC):

Cooling room temperature lower limit

93 - 15~30

18

Setting room temperature range (2nd RC):

Heating room temperature upper limit

94 - 15~30

29

Setting room temperature range (2nd RC):

Heating room temperature lower limit

95 - 15~30

18

Room temperature offset - HEATING (offset

between actual room temperature and

measured room temperature)

-

02

-10~10

-1

Room temperature offset - COOLING (offset

between actual room temperature and

measured room temperature)

-

03

-10~10

-1

Sets water temperature when HP to restart

when the control is in A zone (based on TWI

control: FCB1 = 2)

B2 - 20~55

25

Initial target water temperature – COOLING

(2nd RC or external room thermostat)

96 - 10~25

20

Initial target water temperature – HEATING

(2nd RC or external room thermostat)

9D

-

20~55

40

Hydro Unit 2 Way Valve

Operation Control

Sets the operating logic for the 2 way valve in

COOLING mode:

0 = Valve energised during COOLING

1 = Valve de-energised during COOLING

3C - 0~1

0

Hydro Unit 3 Way Valve

Operation Control

Sets the operating logic for the 3 way diverting

valve:

0 = Valve energised during hot water operation

1 = Valve de-energised during hot water

operation

54 - 0~1

0

Zone 2 Mixing Valve

Control

Sets the specified drive time for the mixing

valve (x 10 sec)

0C - 3~24

6

Sets the sample time (drive OFF) period, for

the mixing valve control (mins)

59 - 1~30

4

Cooling Operation

Enables or disables COOLING mode:

0 = HEATING mode only enabled

1 = HEATING & COOLING mode enabled

02 - 0~1

1

Page 35

34

Function Code Setting

Function Code

Range

Default

Setting Address

Hydro

Unit

Remote

Controller

Remote Controller Time

Display Format

Sets the format for the time display on the

remote controller:

0 = 24hr clock display

1 = 12hr clock display

-

05

0~1

0

Remote Controller Alarm

Tone

Enables or disables the alarm tone, from the

remote controller, when the system generates

a fault code alarm:

0 = alarm tone OFF

1 = alarm tone ON

-

11

0~1

1

Remote Controller Pump

P2 Icon Display

Enables or disables the display icon for pump

P2:

0 = P2 icon not displayed

1 = P2 icon displayed

42 - 0~1

0

Function Change for

Option PCB (connected

to CN209)

Sets the output function of the option PCB

connected to CN209 on the hydro unit PCB:

0 = EMG terminals – output ON during defrost,

OPERATION terminals – output ON when

compressor is running

1 = EMG terminals – output ON when

error/alarm detected, OPERATION terminals –

output ON during operation (remote controller

ON)

67 - 0~1

0

Hydro Unit Capacity

Setting

Sets the hydro unit capacity (804XWH**E &

1404XWH**E). This code is factory set but

setting required for PCB replacement or if FC

reset completed

0012 = 804XWH**E

0017 = 1404XWH**E

01

-

0012

Or

0017

Depending

on hydro

unit model

code

CAUTION

The following procedures require access to the hydro unit electrical box while the system electrical

supply is switched ON

Please ensure all National and Local regulations are followed with regards to working on LIVE

equipment

Function Code Reset Procedure:

The following procedure explains how to reset the hydro unit function codes back to the factory default

settings:

1. Turn the ESTIA system OFF using the ESTIA remote controller

2. Turn OFF the power supply to the ESTIA system

3. Remove the hydro unit front cover and the cover to the hydro unit electrical box

4. Set DPSW06_1 and DPSW06_2, on the hydro unit PCB, to ON

5. Turn ON the power supply to the ESTIA system – the yellow LED, near the MCU, will start to flash

(SLOW)

6. Press and hold the tactile switch, SW07, for 15 seconds. During this time the yellow LED will go

through a sequence of flashing / LED OFF / LED ON

7. Turn OFF the power supply to the ESTIA system

8. Set DPSW06_01 and DPSW06_2, on the hydro unit PCB, to OFF

9. Replace the cover to the hydro unit electrical box and the front cover for the hydro unit

10. Turn ON the power supply to the ESTIA system

11. Reset function code FC01 to the correct capacity code. L09 fault code will be displayed if FC01 is

not set to show the correct capacity setting for the system

Component Operation Check Mode using Hydro Unit PCB:

This mode allows the commissioning engineer to check the operation of various components (pump, 2 way

valve, 3 way valve etc.) installed in the heating circuit.

1. Turn the ESTIA system OFF using the ESTIA remote controller

2. Turn OFF the power supply to the ESTIA system

3. Remove the hydro unit front cover and the cover to the hydro unit electrical box

4. Set DPSW06_2 to ON

5. Turn ON the electrical supply to the ESTIA system

Page 36

35

6. Turn rotary switch SW01 to position 1 and press and hold the tactile switch, SW07, for 8 seconds

7. The operation of the heating circuit components can be checked by rotating SW01 to the relevant

position detailed in the table below

8. Set DPSW06_2 to OFF

9. Replace the cover to the hydro unit electrical box and the front cover for the hydro unit

SW01

Pos

Heating Circuit

Component

Component Operation Using Check Mode

Comments

1

None

-

2 2 way valve

Cycle: valve ON for 2 sec ~ valve OFF for 3 sec

3 3 way diverting valve

4

Mixing valve

Cycle: Drive valve OPEN 30 sec ~ Drive valve

CLOSED 30 sec

5

Hydro unit pump (P1)

Pump ON 20 sec

6 External water pump (P2)

Pump ON 20 sec

7 None (reserved)

-

-

8

Hydro unit back up heaters

Cycle: stage 1 ON, stage 2 ON, all OFF every

20 sec

Hydro unit pump will

operate

9

DHW cylinder electrical

heater

Cycle: Heater ON 10 sec ~ heater OFF 10 sec

10

Booster heater output

Cycle: heater output ON 10 sec ~ heater output

OFF 10 sec

Hydro unit pump will

operate

11

Alarm output*

Cycle: output ON 10 sec ~ output OFF 10 sec

12

Boiler output*

Cycle: output ON 10 sec ~ output OFF 10 sec

13

Defrost output*

Cycle: output ON 10 sec ~ output OFF 10 sec

14

Compressor ON output*

Cycle: output ON 10 sec ~ output OFF 10 sec

15

None

-

16

Hydro unit pump (P1)

continuous operation

Continuous operation of hydro unit pump (P1)

Do not operate the hydro

unit pump continuously if

there is no water in the

heating circuit

SW01, SW07 & DPSW06 Location

SW01

Yellow LED

DPSW06

Tactile

switch SW07

Page 37

36

System Installation – Set Up Examples

1 Zone Heating

Equipment Required:

DPSW Settings:

DPSW11_2 = ON: Hot water cylinder electric heater disables

DPSW12_1 = ON: Hot water cylinder not connected to system

All other DPSW’s set in the OFF position.

Function Code Settings:

Please check the following pages for the set-up of:

External room thermostat pg.40

Room temperature controller (HWS-AMS11-E) pg.41

Auto curve set up pg.43

Note: Care should be taken when setting FC1A if the heating emitter used for Zone 1 is under floor

heating. If FC1A is set to high there is a risk that the floor surface could be damaged.

FC No

FC Description

FC Range

Default Setting

1A

Heating – upper temperature set point limit - Zone 1( °C)

37 ~ 55

55

1B

Heating – lower temperature set point limit - Zone 1( °C)

20 ~ 37

20

Page 38

37

1 Zone Heating with Domestic Hot Water

Equipment Required:

DPSW Settings:

All DPSW’s set in the OFF position.

DPSW 13_1 to be set depending on the type of 3 way diverting valve fitted(2 wire / spring return, 3 wire

SPST or 3 wire SPDT)

Function Code Settings:

Please check the following pages for the set-up of:

External room thermostat pg.40

Room temperature controller (HWS-AMS11-E) pg.41

Auto curve set up pg.43

Hot water anti bacteria function pg.47

Hot water boost function pg.48

Note: Care should be taken when setting FC1A if the heating emitter used for Zone 1 is under floor

heating. If FC1A is set to high there is a risk that the floor surface could be damaged.

FC No

FC Description

FC Range

Default Setting

1A

Heating – upper temperature set point limit - Zone 1( °C)

37 ~ 55

55

1B

Heating – lower temperature set point limit - Zone 1( °C)

20 ~ 37

20

1E

Hot water – upper temperature set point limit (°C)

50 ~ 80

75

1F

Hot water – lower temperature set point limit (°C)

40 ~ 60

40

20

Heat pump start temperature – hot water operation (TTW:°C)

20 ~ 45

38

21

Heat pump stop temperature – hot water operation (TTW:°C)

40 ~ 50

45

22

Hot water / heating priority switching temperature (°C)

-20 ~20

0

24

Hot water temperature compensation – OAT start temperature (°C)

-20 ~ 10

0

25

Hot water set point temperature – compensation temperature (°C)

0 ~ 15

3

Page 39

38

Zone 1 Heating With Existing Auxiliary Boiler

Equipment Selection:

DPSW Settings:

DPSW11_2 = ON: Hot water cylinder electric heater disables

DPSW12_1 = ON: Hot water cylinder not connected to system

DPSW13_2 = ON: Boiler output control enabled (use in conjunction with FC23)

All other DPSW’s set in the OFF position.

Function Code Settings:

Please check the following pages for the set-up of:

External room thermostat pg.40

Room temperature controller (HWS-AMS11-E) pg.41

Auto curve set up pg.43

Auxiliary boiler output pg.44

FC No

FC Description

FC Range

Default Setting

1A

Heating – upper temperature set point limit - Zone 1( °C)

37 ~ 55

55

1B

Heating – lower temperature set point limit - Zone 1( °C)

20 ~ 37

20

23

Trigger temperature to turn boiler output (on TCB-PCIN3E) ON (°C)

-20 ~ 20

-10

3E

Boiler / heat pump synchronisation: 0 = synchronised; 1 = not

synchronised

0 ~ 1

0

Page 40

39

1 Zone Heating & Cooling With Domestic Hot Water

Equipment Selection:

DPSW Settings:

All DPSW’s set in the OFF position.

DPSW 13_1 to be set depending on the type of 3 way diverting valve fitted

Function Code Settings:

Please check the following pages for the set-up of:

External room thermostat pg.40

Room temperature controller (HWS-AMS11-E) pg.41

Auto curve set up pg.43

Hot water anti bacteria function pg.47

Hot water boost function pg.48

FC No

FC Description

FC Range

Default Setting

1A

Heating – upper temperature set point limit - Zone 1( °C)

37 ~ 55

55

1B

Heating – lower temperature set point limit - Zone 1( °C)

20 ~ 37

20

1E

Hot water – upper temperature set point limit (°C)

50 ~ 80

75

1F

Hot water – lower temperature set point limit (°C)

40 ~ 60

40

20

Heat pump start temperature – hot water operation (TTW:°C)

20 ~ 45

38

21

Heat pump stop temperature – hot water operation (TTW:°C)

40 ~ 50

45

22

Hot water / heating priority switching temperature (°C)

-20 ~20

0

24

Hot water temperature compensation – OAT start temperature (°C)

-20 ~ 10

0

25

Hot water set point temperature – compensation temperature (°C)

0 ~ 15

3

02

Cooling operation: 0 = heating & cooling available; 1 = heating only

available

0 ~ 1

1

0F

Cooling / hot water priority setting: 0 = cooling priority – hot water

produced by electric cylinder heater; 1 = hot water priority – hot water

produced by heat pump

0 ~ 1

0

Page 41

40

2 Zone Heating With Domestic Hot Water

Equipment Selection:

DPSW Settings:

DPSW 10_3: Set switch to ON if end user requests pump P2 (Zone 2 pump) is synchronised with pump

P1 (hydro unit)

DPSW12_3 = ON: Zone 2 control enabled

DPSW 13_1 to be set depending on type of 3 way diverter valve fitted (2 wire / spring return, 3 wire

SPST or 3 wire SPDT)

All other DPSW’s set in the OFF position

Function Code Settings:

Please check the following pages for the set-up of:

External room thermostat pg.40

Room temperature controller (HWS-AMS11-E) pg.41

Auto curve set up pg.43

Mixing valve set up pg.46

Hot water anti bacteria function pg.47

Hot water boost function pg.48

Note: Care should be taken when setting FC1C if the heating emitter used for Zone 2 is under floor

heating. If FC1C is set to high there is a risk that the floor surface could be damaged.

FC No

FC Description

FC Range

Default Setting

1A

Heating – upper temperature set point limit - Zone 1( °C)

37 ~ 55

55

1B

Heating – lower temperature set point limit - Zone 1( °C)

20 ~ 37

20

1C

Heating – upper temperature set point limit – Zone 2 (°C)

37 ~ 55

55

1D

Heating – lower temperature set point limit – Zone 2 (°C)

20 ~ 37

20

1E

Hot water – upper temperature set point limit (°C)

50 ~ 80

75

1F

Hot water – lower temperature set point limit (°C)

40 ~ 60

40

20

Heat pump start temperature – hot water operation (TTW:°C)

20 ~ 45

38

21

Heat pump stop temperature – hot water operation (TTW:°C)

40 ~ 50

45

22

Hot water / heating priority switching temperature (°C)

-20 ~20

0

24

Hot water temperature compensation – OAT start temperature (°C)

-20 ~ 10

0

25

Hot water set point temperature – compensation temperature (°C)

0 ~ 15

3

0C

Specified drive time for mixing valve – 0° ~ 90° (10sec)

3 ~ 24

6

59

Sets the sample time (drive OFF) period, for the mixing valve control (mins)

1 ~ 30

4

Page 42

41

2 Zone Heating with Auxiliary Boiler

Equipment Selection:

DPSW Settings

DPSW12_3 = ON: Zone 2 control enabled

DPSW 13_1 to be set depending on type of 3 way diverter valve fitted (2 wire / spring return, 3 wire

SPST or 3 wire SPDT)

DPSW13_2 = ON: Boiler output control enabled (use in conjunction with FC23)

All other DPSW’s set in the OFF position

Function Code Settings:

Please check the following pages for the set-up of:

External room thermostat pg.40

Room temperature controller (HWS-AMS11-E) pg.41

Auto curve set up pg.43

Auxiliary boiler output pg.44

Mixing valve set up pg.46

FC No

FC Description

FC Range

Default Setting

1A

Heating – upper temperature set point limit - Zone 1( °C)

37 ~ 55

55

1B

Heating – lower temperature set point limit - Zone 1( °C)

20 ~ 37

20

1C

Heating – upper temperature set point limit – Zone 2 (°C)

37 ~ 55

55

1D

Heating – lower temperature set point limit – Zone 2 (°C)

20 ~ 37

20

1E

Hot water – upper temperature set point limit (°C)

50 ~ 80

75

1F

Hot water – lower temperature set point limit (°C)

40 ~ 60

40

20

Heat pump start temperature – hot water operation (TTW:°C)

20 ~ 45

38

21

Heat pump stop temperature – hot water operation (TTW:°C)

40 ~ 50

45

22

Hot water / heating priority switching temperature (°C)

-20 ~20

0

23

Trigger temperature to turn boiler output (on TCB-PCIN3E) ON (°C)

-20 ~ 20

-10

24

Hot water temperature compensation – OAT start temperature (°C)

-20 ~ 10

0

25

Hot water set point temperature – compensation temperature (°C)

0 ~ 15

3

3E

Boiler / heat pump synchronisation: 0 = synchronised; 1 = not

synchronised

0 ~ 1

0

0C

Specified drive time for mixing valve – 0° ~ 90° (10sec)

3 ~ 24

6

59

Sets the sample time (drive OFF) period, for the mixing valve control (mins)

1 ~ 30

4

Page 43

42

Remote Controller Schedule Timer

On an ESTIA site the customer requires the hot water function to be ON between the hours of 01:00

and 06:00. The customer requires the set point for the domestic hot water to be set to 65°C

For space heating the customer requires the ESTIA to run in heating mode for the following periods:

Period 1: 07:00 ~ 10:00

Period 2: 15:00 ~ 22:00

The customer is using radiators as the heating emitters and requires the water set point temperature

to be set to 50°C. The schedule timer must be set the same for all days of the week.

For each day the timer function will be set as shown below:

STEP No.

Time

Function

STEP 1

01:00

DHW ON, DHW set point = 65°C

STEP 2

06:00

DHW OFF

STEP 3

07:00

Zone 1 ON, heating mode, water set point = 50°C

STEP 4

10:00

Zone 1 OFF

STEP 5

15:00

Zone 1 ON, heating mode, water set point = 50°C

STEP 6

22:00

Zone 1 OFF

Schedule Timer Set Up

1. Access remote controller (RC) timer function – press the SCHEDULE button for a minimum of 4

seconds. Check the RC display changes to show the schedule timer display

2. Select the required day for the schedule timer – press the DAY button until the ▼symbol is

displayed above the required day. Press the SET button to accept the command

3. Set up the required timer steps for the selected day – press the STEP button until STEP 1 is

displayed on the RC:

Press the STEP button > check STEP 1 is displayed on the RC

Press the SET button

Press the TIME ▼▲buttons to set 01:00 on the time display of the RC

Press the HOT WATER button to set the hot water function ON > check that a

numerical temperature is displayed on the RC for the hot water function

Press the TEMPERATURE ▼▲ buttons to set the 65°C hot water set point

Press the SET button

Press the STEP button > check STEP 2 is displayed on the RC

Press the SET button

Press the TIME ▼▲buttons to set 06:00 on the time display of the RC

Press the HOT WATER button to set the hot water function to OFF > check that the

RC display changes to - - - - for the hot water function

Press the SET button

Press the STEP button > check STEP 3 is displayed on the RC

Press the TIME ▼▲buttons to set 07:00 on the time display of the RC

Press the ZONE1, 2 button to set the space heating function ON > check that a

numerical temperature is displayed on the RC for the zone 1 function

Press the OPERATING MODE button > check that the heating mode symbol is

displayed on the RC

Press the TEMPERATURE ▼▲ buttons to set the 50°C zone 1 set point

Press the SET button

Press the STEP button > check STEP 4 is displayed on the RC

Press the SET button

Press the TIME ▼▲buttons to set 10:00 on the time display of the RC

Press the ZONE1, 2 button to set the space heating function OFF > check that the

RC display changes to - - - - for zone 1

Press the SET button

Press the STEP button > check STEP 5 is displayed on the RC

Press the SET button

Page 44

43

Press the TIME ▼▲buttons to set 07:00 on the time display of the RC

Press the ZONE1, 2 button to set the space heating function ON > check that a

numerical temperature is displayed on the RC for the zone 1 function

Press the OPERATING MODE button > check that the heating mode symbol is

displayed on the RC

Press the TEMPERATURE ▼▲ buttons to set the 50°C zone 1 set point

Press the SET button

Press the STEP button > check STEP 4 is displayed on the RC

Press the SET button

Press the TIME ▼▲buttons to set 10:00 on the time display of the RC

Press the ZONE1, 2 button to set the space heating function OFF > check that the

RC display changes to - - - - for zone 1

Press the SET button

4. Copy the data, shown above, for use on other days of the week:

Press the STEP button until STEP C is displayed on the RC

Press the SET button

5. Paste the copied timer schedule into the other days of the week

Press the DAY button until the ▼symbol is displayed above all day’s of the week

(timer schedule to run on all days of the week)

Press the SET button

Repeat the above steps for all the days of the week

6. Exit schedule timer function

Press the SCHEDULE button > check that the RC display changes back to the main

screen and that CLOCK icon, on the RC display is flashing

Press the SET button > check that the CLOCK icon changes from flashing to

continuously lit.

The timer schedule is now set

Page 45

44

ESTIA - System Set Up

Please refer to the ESTIA Service Manual for a detailed description for

each of the controls / functions listed below

1. External room thermostat

Isolate the electrical supply to the ESTIA system and remove the cover to the electrical box

in the hydro unit

Install the room thermostat into the room to be monitored / controlled. Care must be taken to

ensure that the thermostat is installed in the correct position and away from the influences of

other external heat sources (sunlight, radiators etc.). Follow the thermostat manufacturers

installation instructions for correct positioning

Connect the room thermostat as to the TCB-PCBMO3E option PCB as shown in the diagram

above

In the hydro unit set DPSW 02_4 to ON

For HEATING mode:

Set FC1A to the required setting. This will set the maximum target water temperature of the

system when running in heating mode. This setting is particularly important – if the heating

emitter used is under floor heating then damage may be caused to the floor surface if FC1A

is set too high

Set FC1B to the required setting. This will set the minimum target water temperature of the

system when running in heating mode

Set FC9D to the required setting. This will set the initial target water temperature of the

system, when the electrical supply is restored to the ESTIA system, when running in heating

mode

For COOLING mode:

Set FC18 to the required setting (only required if cooling mode is available). This will set the

maximum target water temperature, of the system when running in cooling mode

Set FC19 to the required setting (only required if cooling mode is available). This will set the

minimum target water temperature, of the system when running in cooling mode

Set FC96 to the required setting. This will set the initial target water temperature of the

system, when the electrical supply is restored to the ESTIA system, when running in cooling

mode

Replace the cover on the electrical box in the hydro unit and restore the electrical supply to

the ESTIA system

NOTE: