Page 1

Ref.-No. SMMS01-AE-01-05

4-way ceiling cassette

MMU-AP0091H, AP0121H, AP0151H,

MMU-AP0181H, AP0241H, AP0271H,

MMU-AP0301H, AP0361H, AP0481H

MMU-AP0561H

Indoor unit

2-way ceiling cassette

MMU-AP0071WH, AP0091WH, AP0121WH,

MMU-AP0151WH, AP0181WH, AP0241WH,

MMU-AP0271WH, AP0301WH

1-way ceiling cassette

MMU-AP0071YH, AP0091YH, AP0121YH,

MMU-AP0151SH, AP0181SH, AP0241SH

Standard ducted unit

MMD-AP0071BH, AP0091BH, AP0121BH,

MMD-AP0151BH, AP0181BH, AP0241BH,

MMD-AP0271BH, AP0301BH, AP0361BH,

MMD-AP0481BH, AP0561BH

High-pressure ducted unit

MMD-AP0181H, AP0241H, AP0271H,

MMD-AP0361H, AP0481H, AP0721H,

MMD-AP0961H

Super Modular Multi

Design Manual

HFC R-410A

Slim duct unit

MMD-AP0071SPH, AP0091SPH,

MMD-AP0121SPH, AP0151SPH,

MMD-AP0181SPH

Ceiling-suspended unit

MMC-AP0151H, AP0181H, AP0241H,

MMC-AP0271H, AP0361H, AP0481H

High-wall unit

MMK-AP0071H, AP0091H, AP0121H,

MMK-AP0151H, AP0181H, AP0241H

MMK-AP0072H, AP0092H, AP0122H

Floor-mounted console unit

MML-AP0071H, AP0091H, AP0121H,

MML-AP0151H, AP0181H, AP0241H

Concealed chassis unit

MML-AP0071BH, AP0091BH, AP0121BH,

MML-AP0151BH, AP0181BH, AP0241BH

Floor-mounted cabinet unit

MMF-AP0151H, AP0181H, AP0241H

MMF-AP0271H, AP0361H, AP0481H

MMF-AP0561H

COOLING ONLY MODEL

Outdoor unit

Inverter unit

MMY-MAP0501T8, MAP0601T8

MMY-MAP0801T8, MAP1001T8

MMY-MAP1201T8

HEAT PUMP MODEL

Inverter unit

MMY-MAP0501HT8, MAP0601HT8

MMY-MAP0801HT8, MAP1001HT8

MMY-MAP1201HT8

Page 2

Page 3

Super Modular Multi System

Contents

1. Outline of Toshiba Super Modular Multi System (S-MMS) .................................................................................. 4

2. Summary of system equipment ........................................................................................................................... 7

3. Basic system configuration .................................................................................................................................. 13

4. Equipment selection procedure ........................................................................................................................... 19

5. Refrigerant piping design ..................................................................................................................................... 29

6. Wiring design ....................................................................................................................................................... 34

7. Controls ................................................................................................................................................................ 39

8. Accessories .......................................................................................................................................................... 45

9. Technical specifications ....................................................................................................................................... 46

10. Fan characteristics ............................................................................................................................................... 69

11. Dimensional drawings .......................................................................................................................................... 75

This manual is used for both cooling only and heat pump models.

3

Page 4

1. Outline of Toshiba Super Modular Multi System (S-MMS)

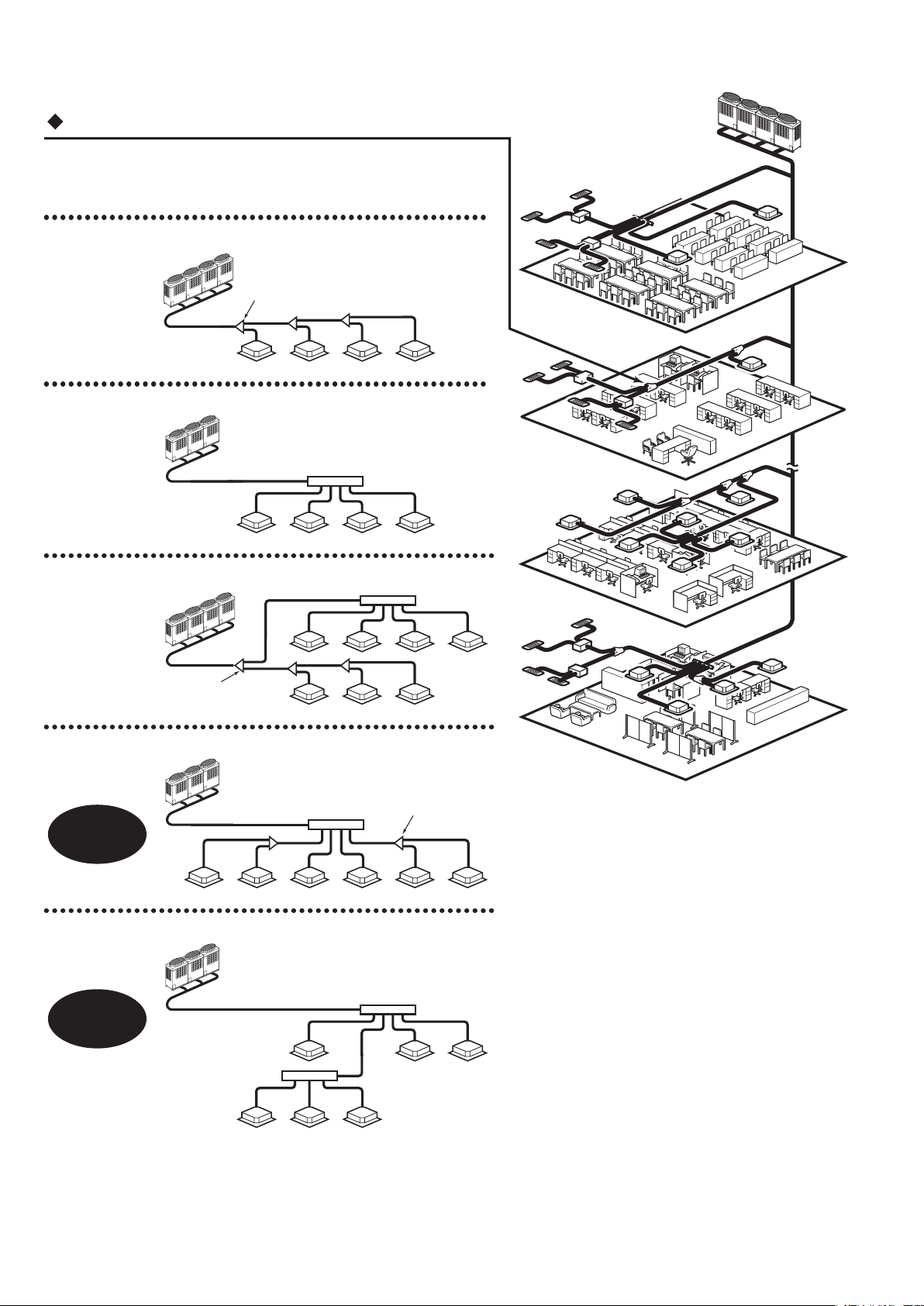

Branching

Combination of line and header branching is highly flexible. This

allows for the shortest design route possible, thereby saving on

installation time and cost. Line/header branching after header

branching is only available with Toshiba Super MMS.

Line branching

Outdoor unit

Branching joint

Indoor unit

Header branching

Outdoor unit

8F

Branching

header

Indoor unit

Line and header branching

Outdoor unit

Branching joint

Indoor

unit

Header

Line branching after header branching

Outdoor unit

Header

Super MMS

only

Indoor unit

7F

2F

1F

Branching joint

Header branching after header branching

Super MMS

Outdoor unit

Header

only

Header

Indoor unit

4

Page 5

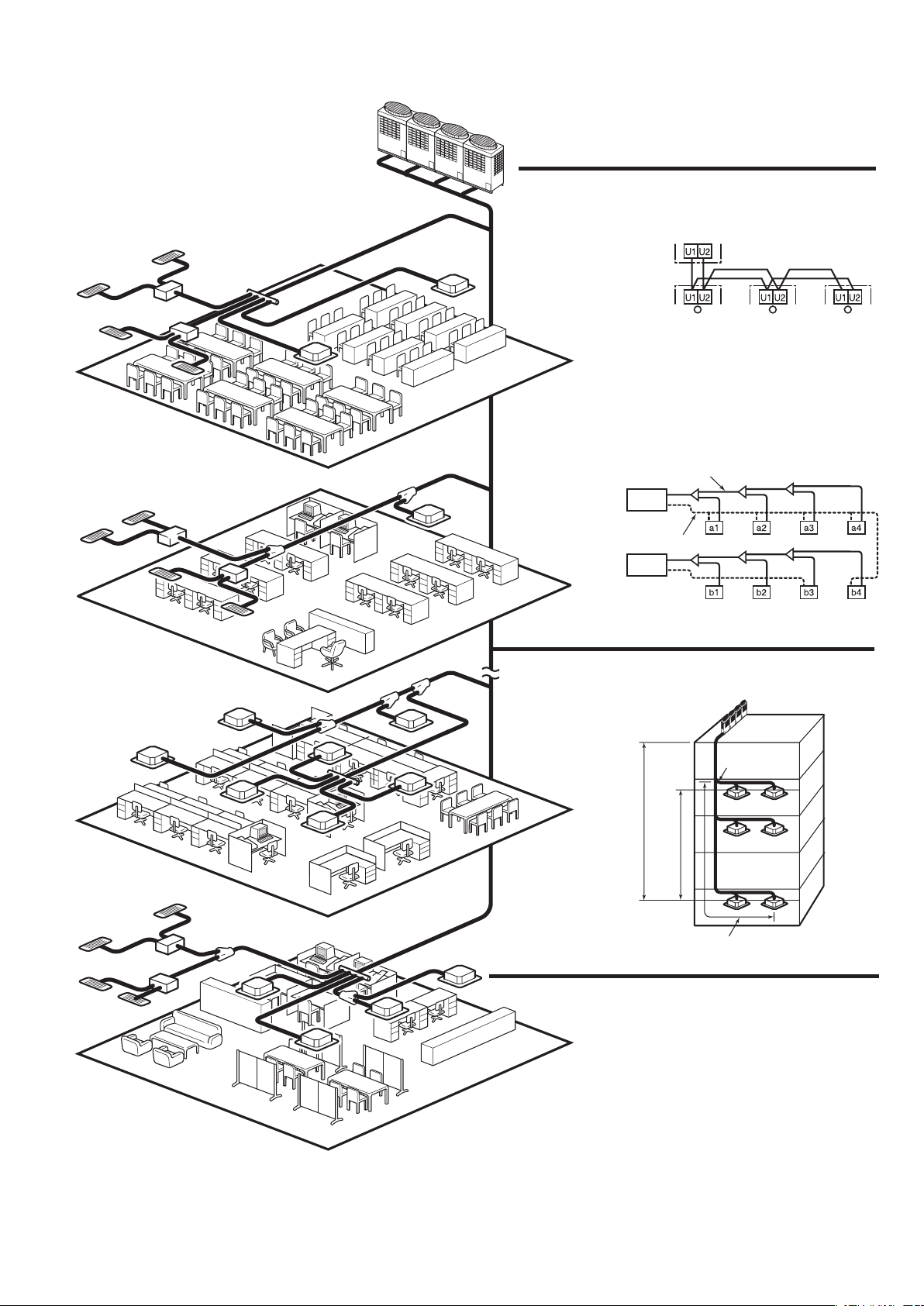

8F

• Non-polarized control wiring between

outdoor and indoor units

Outdoor unit

Indoor unit

• Wiring diagnosis system

Use the switches on the micro

processor PCB of the outdoor unit.

• Detects wiring to the indoor unit a4

which should not be in system A.

• b4 is missing in system B.

7F

2F

A

system

B

system

Outdoor unit

Wiring

Outdoor unit

Height difference between

Height difference between

indoor and outdoor unit: 50 m

Piping

Outdoor unit

indoor units: 30 m

Indoor unit

Allowable pipe length:

175 m equivalent length

1st branching

section

1F

From 1st branching to the

farthest indoor unit: 65 m

5

Page 6

Compact

The design of the modular Toshiba Super MMS outdoor unit allows for easy unit manoeuvring into

any standard lift. Its compactness also allows it to be easily installed in limited spaces.

Largest system capacity

Toshiba Super MMS can be combined up to 48 hp (135 kW) as one refrigerant system.

Energy saving design

The units have the best energy efficiency ratio of any VRF unit. Compared with a conventional chiller

fan coil system, a large energy saving can be realized.

Advanced bus communication system

Wiring between indoor and outdoor units is a simple 2-wire system.

The communication address is also automatically configured.

A default test mode operation is available.

Self-diagnostic system

Comprehensive troubleshooting code enables quick identification of problems arising.

High lift design

An equivalent pipe length of 175 m and vertical lift of 50 m are possible with the Toshiba Super

MMS.

The vertical lift between indoor units of 30 m is the highest in the industry.

This allows for greater flexibility in the location of the system.

Multiple indoor units

Indoor units with different capacities and configurations can be combined up to 135% of the

outdoor unit capacity.

A maximum of 48 indoor units can be combined with the 30-48 hp outdoor units.

Intelligent control

Toshiba Super MMS intelligent controls and modulating valves deliver the required capacity, in

accordance with the load variation from 50% to 100%.

The intelligent controls and modulating valves limit or increase the cooling capacity dynamically so

humidity and temperature are kept in the comfort zone.

Wide control applications

Artificial Intelligence Network system

• Central control and monitoring system available

• Weekly schedule operation through weekly timer

Integration with a Building Management System (BMS) is available.

6

Page 7

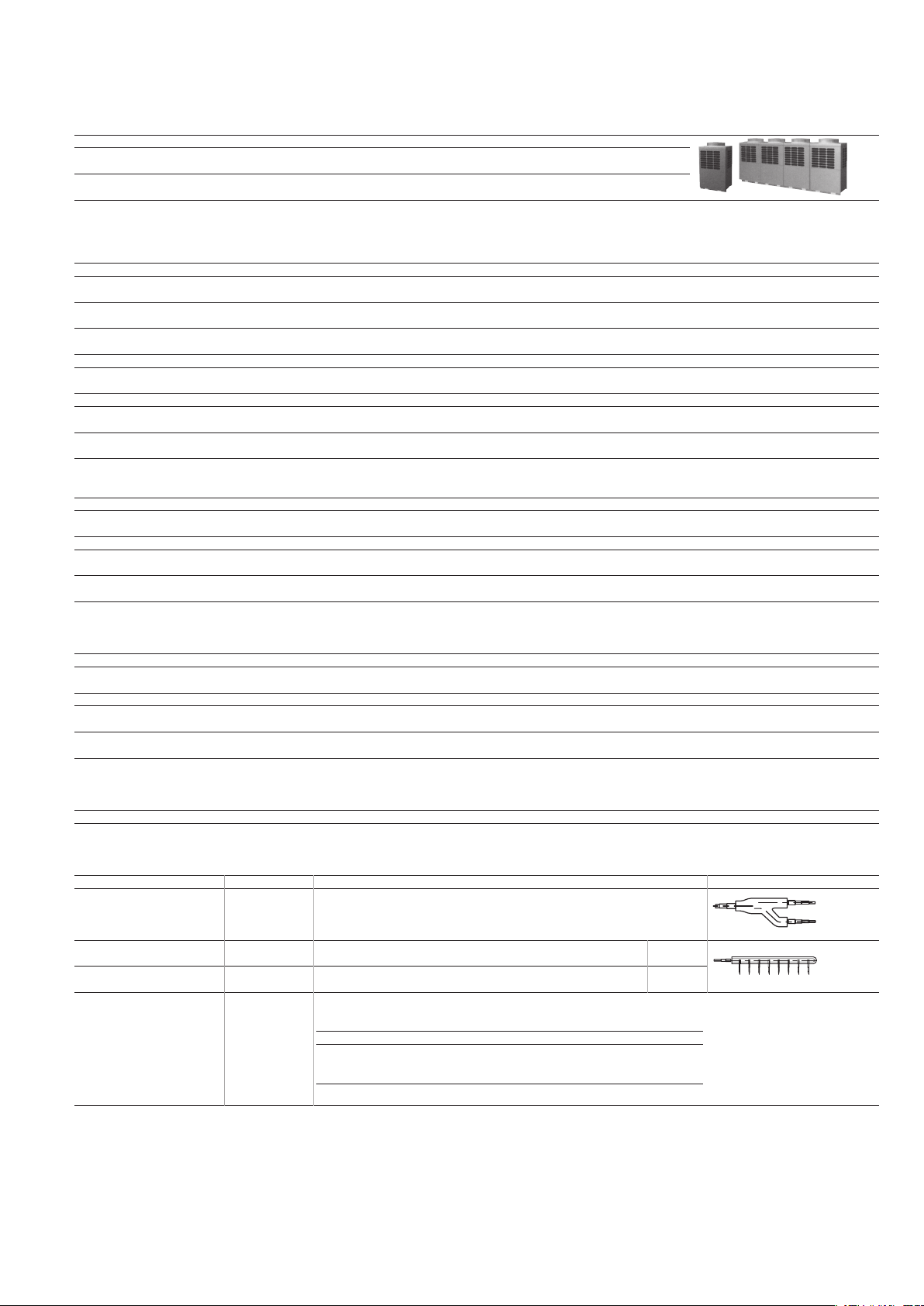

2. Summary of system equipment

Technical specifications - outdoor units

Rating hp 5 6 8 10 12

Cooling only model MMY-MAP 0501T8 0601T8 0801T8 1001T8 1201T8

Heat pump model MMY-MAP 0501HT8 0601HT8 0801HT8 1001HT8 1201HT8

Cooling capacity kW 14.0 16.0 22.4 28.0 33.5

Heating capacity kW 16.0 18.0 25.0 31.5 37.5

Technical specifications - combination of outdoor units

Rating hp 5 6 8 10 12 14 16

Cooling only model MMY-MAP 0501T8 0601T8 0801T8 1001T8 1201T8 1401T8 1601T8

Heat pump model MMY-MAP 0501HT8 0601HT8 0801HT8 1001HT8 1201HT8 1401HT8 1601HT8

Cooling capacity kW 14.0 16.0 22.4 28.0 33.5 38.4 45.0

Heating capacity kW 16.0 18.0 25.0 31.5 37.5 43.0 50.0

Combined outdoor units hp 5 6 8 10 12 8 8

- - - - - 6 8

No. of connectable indoor units 8 10 13 16 20 23 27

Rating hp 18 20 22 22 24 24 26

Cooling only model MMY-MAP 1801T8 2001T8 2201T8 2211T8 2401T8 2411T8 2601T8

Heat pump model MMY-MAP 1801HT8 2001HT8 2201HT8 2211HT8 2401HT8 2411HT8 2601HT8

Cooling capacity kW 50.4 56.0 61.5 61.5 68.0 68.0 73.0

Heating capacity kW 56.5 63.0 69.0 69.0 76.5 76.5 81.5

Combined outdoor units hp 10 10 8 12 8 12 10

8 10 8 10 8 12 8

- - 6 - 8 - 8

No. of connectable indoor units 30 33 37 37 40 40 43

Rating hp 28 30 32 32 34 34 36

Cooling only model MMY-MAP 2801T8 3001T8 3201T8 3211T8 3401T8 3411T8 3601T8

Heat pump model MMY-MAP 2801HT8 3001HT8 3201HT8 3211HT8 3401HT8 3411HT8 3601HT8

Cooling capacity kW 78.5 84.0 90.0 90.0 96.0 96.0 101.0

Heating capacity kW 88.0 95.0 100.0 100.0 108.0 108.0 113.0

Combined outdoor units hp 10 10 8 12 10 12 10

10 10 8 10 8 12 10

8 10 8 10 8 10 8

- - 8 - 8 - 8

No. of connectable indoor units 47 48 48 48 48 48 48

Rating hp 36 38 40 42 44 46 48

Cooling only model MMY-MAP 3611T8 3801T8 4001T8 4201T8 4401T8 4601T8 4801T8

Heat pump model MMY-MAP 3611HT8 3801HT8 4001HT8 4201HT8 4401HT8 4601HT8 4801HT8

Cooling capacity kW 101.0 106.5 112.0 118.0 123.5 130.0 135.0

Heating capacity kW 113.0 119.5 126.5 132.0 138.0 145.0 150.0

Combined outdoor units hp 12 10 10 12 12 12 12

12 10 10 10 12 12 12

12 10 10 10 10 12 12

- 8 10 10 10 10 12

No. of connectable indoor units 48 48 48 48 48 48 48

Branching joints and headers

Model Usage Appearance

Y-shape branching joint (*3) RBM-BY53E Indoor unit capacity code (*1) : Total below 6.4

RBM-BY103E Indoor unit capacity code (*1) : Total 6.4 or more and below 14.2 (*2)

RBM-BY203E Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2 (*2)

RBM-BY303E Indoor unit capacity code (*1) : Total 25.2 or more (*2)

4-branching header (*4) RBM-HY1043E Indoor unit capacity code (*1) : Total below 14.2 Max.4

RBM-HY2043E Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2 branches

8-branching header (*4) (*5) RBM-HY1083E Indoor unit capacity code (*1) : Total below 14.2 Max.8

RBM-HY2083E Indoor unit capacity code (*1) : Total 14.2 or more and below 25.2 branches

T-shape branching joint RBM-BT13E 1 set of 3 types of T-shape joint pipes as described below:

(For connection of The required quantity is arranged and they are combined at the site.

outdoor units)

Connection piping Corresponding dia. (mm) Q’ty

Balance pipe Ø3/8” 1

Liquid side piping Ø3/8” to Ø7/8” 1

Gas side piping Ø5/8” to Ø1-5/8” 1

*1 The capacity code can be obtained from page 10 (capacity code is not actual capacity).

*2 If total capacity code value of indoor unit exceeds that of outdoor unit, apply capacity code of outdoor unit.

*3 When using Y-shape branching joint for 1st branching, select according to capacity code of outdoor unit.

*4 Max. 6.0 capacity code in total can be connected.

*5 If capacity code of outdoor unit is 26 and more, it is not used for 1st branching.

*6 Model names for outdoor and indoor units described in this guide are shortened because of the space constraints.

7

Page 8

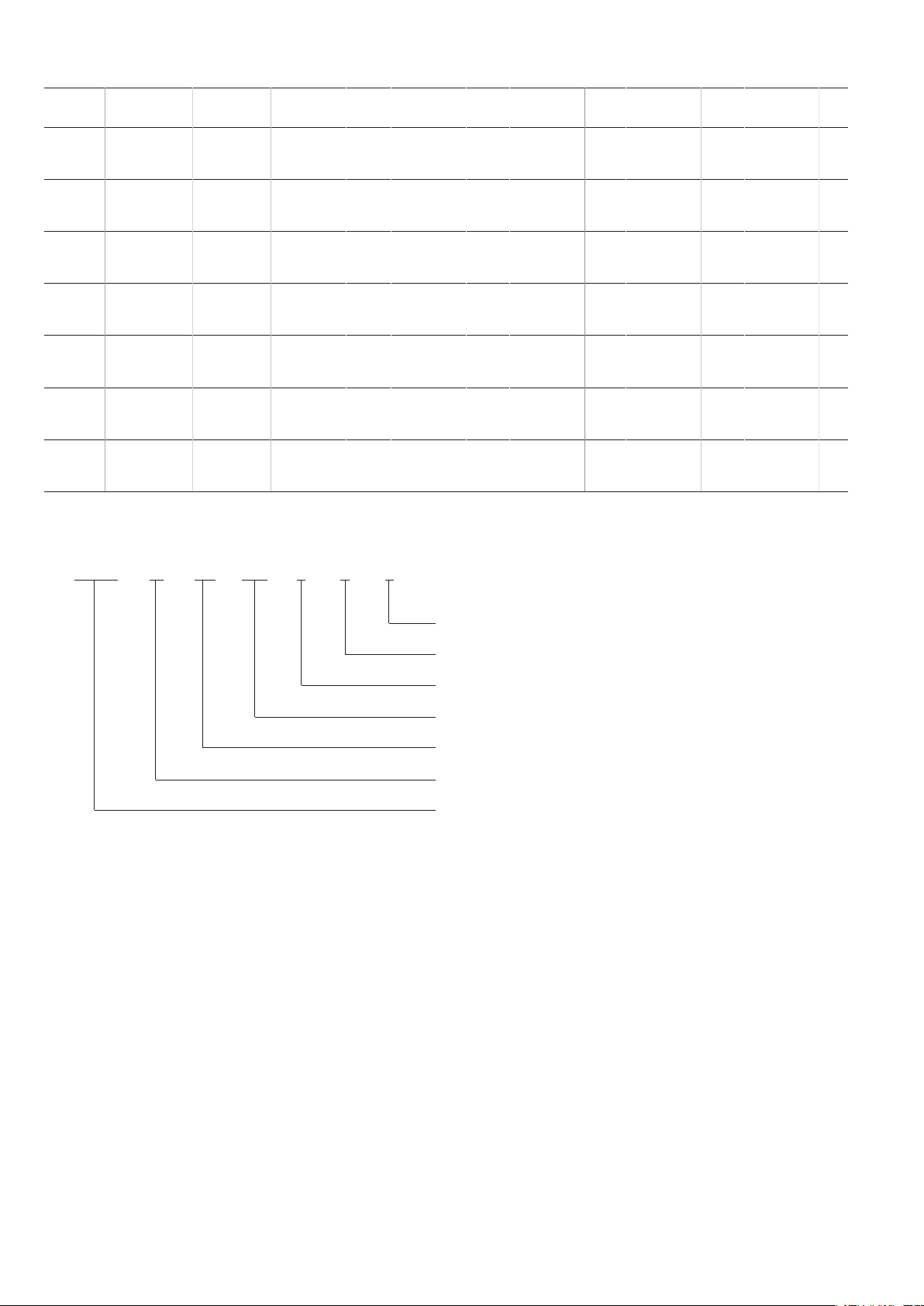

Outdoor unit model line-up - cooling only units

hp Model No. of Inverter Q’ty Inverter Q’ty Inverter Qty Inverter Q’ty Inverter Q’ty

(capacity MMY- combined 5 hp used 6 hp used 8 hp used 10 hp used 12 hp used

code) units MMY- MMY- MMY- MMY- MMY-

5 hp (5) MAP0501T8 1 MAP0501T8 1

6 hp (6) MAP0601T8 1 MAP0601T8 1

8 hp (8) MAP0801T8 1 MAP0801T8

10 hp (10) MAP1001T8 1 MAP1001T8 1

12 hp (12) MAP1201T8 1 MAP1201T8 1

14 hp (14) AP1401T8 2 MAP0601T8 1 MAP0801T8

16 hp (16) AP1601T8 2 MAP0801T8 2

18 hp (18) AP1801T8 2 MAP0801T8 1 MAP1001T8 1

20 hp (20) AP2001T8 2 MAP1001T8 2

22 hp (22) AP2201T8 3 MAP0601T8 1 MAP0801T8 2

22 hp (22) AP2211T8 2 MAP1001T8 1 MAP1201T8 1

24 hp (24) AP2401T8 3 MAP0801T8 3

24 hp (24) AP2411T8 2 MAP1201T8 2

26 hp (26) AP2601T8 3 MAP0801T8 2 MAP1001T8 1

28 hp (28) AP2801T8 3 MAP0801T8 1 MAP1001T8 2

30 hp (30) AP3001T8 3 MAP1001T8 3

32 hp (32) AP3201T8 4 MAP0801T8 4

32 hp (32) AP3211T8 3 MAP1001T8 2 MAP1201T8 1

34 hp (34) AP3401T8 4 MAP0801T8 3 MAP1001T8 1

34 hp (34) AP3411T8 3 MAP1001T8 1 MAP1201T8 2

36 hp (36) AP3601T8 4 MAP0801T8 2 MAP1001T8 2

36 hp (36) AP3611T8 3 MAP1201T8 3

38 hp (38) AP3801T8 4 MAP0801T8 1 MAP1001T8 3

40 hp (40) AP4001T8 4 MAP1001T8 4

42 hp (42) AP4201T8 4 MAP1001T8 3 MAP1201T8 1

44 hp (44) AP4401T8 4 MAP1001T8 2 MAP1201T8 2

46 hp (46) AP4601T8 4 MAP1001T8 1 MAP1201T8 3

48 hp (48) AP4801T8 4 MAP1201T8 4

1. Product designation

MMY- M AP 000 0 T 8

8: Power supply, 3 ph, 380-415 V, 50 Hz

T: Inverter unit

Development series number

Model size hp x 10

New refrigerant R-410A

M: Single module unit. No mark: Combined model name

Super Modular Multi

2. Combined capacity range

No. of combined units: 1 to 4 units

Capacity of combined units: 14 hp (140 type) to 48 hp (480 type)

3. Rated conditions

Cooling: Indoor air temperature 27°C db/19°C wb, outdoor air temperature 35°C db.

8

Page 9

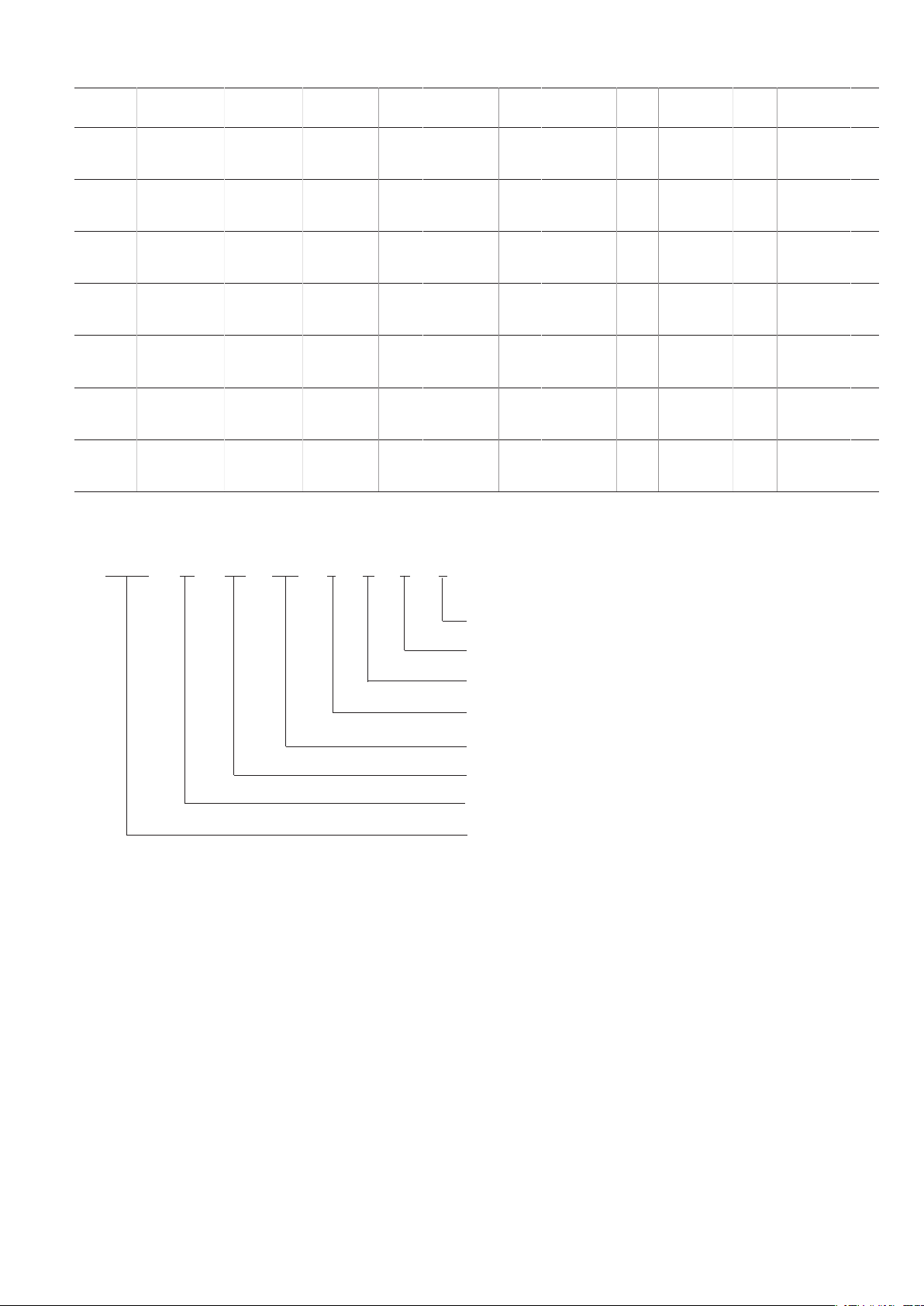

Outdoor unit model line-up - heat pump units

hp Model No. of Inverter Q’ty Inverter Q’ty Inverter Qty Inverter Q’ty Inverter Q’ty

(capacity MMY- combined 5 hp used 6 hp used 8 hp used 10 hp used 12 hp used

code) units MMY- MMY- MMY- MMY- MMY-

5 hp ( 5) MAP0501HT8 1 MAP0501HT8 1

6 hp ( 6) MAP0601HT8 1 MAP0601HT8 1

8 hp ( 8) MAP0801HT8 1 MAP0801HT8 1

10 hp (10) MAP1001HT8 1 MAP1001HT8 1

12 hp (12) MAP1201HT8 1 MAP1201HT8 1

14 hp (14) AP1401HT8 2 MAP0601HT8 1 MAP0801HT8 1

16 hp (16) AP1601HT8 2 MAP0801HT8 2

18 hp (18) AP1801HT8 2 MAP0801HT8 1 MAP1001HT8 1

20 hp (20) AP2001HT8 2 MAP1001HT8 2

22 hp (22) AP2201HT8 3 MAP0601HT8 1 MAP0801HT8 2

22 hp (22) AP2211HT8 2 MAP1001HT8 1 MAP1201HT8 1

24 hp (24) AP2401HT8 3 MAP0801HT8 3

24 hp (24) AP2411HT8 2 MAP1201HT8 2

26 hp (26) AP2601HT8 3 MAP0801HT8 2 MAP1001HT8 1

28 hp (28) AP2801HT8 3 MAP0801HT8 1 MAP1001HT8 2

30 hp (30) AP3001HT8 3 MAP1001HT8 3

32 hp (32) AP3201HT8 4 MAP0801HT8 4

32 hp (32) AP3211HT8 3 MAP1001HT8 2 MAP1201HT8 1

34 hp (34) AP3401HT8 4 MAP0801HT8 3 MAP1001HT8 1

34 hp (34) AP3411HT8 3 MAP1001HT8 1 MAP1201HT8 2

36 hp (36) AP3601HT8 4 MAP0801HT8 2 MAP1001HT8 2

36 hp (36) AP3611HT8 3 MAP1201HT8 3

38 hp (38) AP3801HT8 4 MAP0801HT8 1 MAP1001HT8 3

40 hp (40) AP4001HT8 4 MAP1001HT8 4

42 hp (42) AP4201HT8 4 MAP1001HT8 3 MAP1201HT8 1

44 hp (44) AP4401HT8 4 MAP1001HT8 2 MAP1201HT8 2

46 hp (46) AP4601HT8 4 MAP1001HT8 1 MAP1201HT8 3

48 hp (48) AP4801HT8 4 MAP1201HT8 4

1. Product designation

MMY- M AP 000 0 H T 8

8: Power supply, 3 ph, 380-415 V, 50 Hz

T: Inverter unit

H: Heat pump

Development series number

Model size hp x 10

New refrigerant R-410A

M: Single module unit. No mark: Combined model name

Super Modular Multi

2. Combined capacity range

No. of combined units: 1 to 4 units

Capacity of combined units: 14 hp (140 type) to 48 hp (480 type)

3. Rated conditions

Cooling: Indoor air temperature 27°C db/19°C wb, outdoor air temperature 35°C db.

Heating: Indoor air temperature 20°C db, outdoor air temperature 7°C db/6°C wb

9

Page 10

4. Technical specifications - indoor units

Model type Model Capacity Cooling Heating Height Width Depth Weight

name code capacity capacity mm mm mm kg

kW kW

4-way ceiling cassette MMU-AP0091H 1 2.8 3.2 256 840 840 20

MMU-AP0121H 1.25 3.6 4.0

MMU-AP0151H 1.7 4.5 5.0 256 840 840 22

MMU-AP0181H 2 5.6 6.3

MMU-AP0241H 2.5 7.1 8.0 256 840 840 23

MMU-AP0271H 3 8.0 9.0

MMU-AP0301H 3.2 9.0 10.0

MMU-AP0361H 4 11.2 12.5 319 840 840 28

MMU-AP0481H 5 14.0 16.0

MMU-AP0561H 6 16.0 18.0

2-way ceiling cassette MMU-AP0071WH 0.8 2.2 2.5 398 830 550 33

MMU-AP0091WH 1 2.8 3.2

MMU-AP0121WH 1.25 3.6 4.0

MMU-AP0151WH 1.7 4.5 5.0 398 1350 550 44

MMU-AP0181WH 2 5.6 6.3

MMU-AP0241WH 2.5 7.1 8.0 398 1350 550 48

MMU-AP0271WH 3 8.0 9.0

MMU-AP0301WH 3.2 9.0 10.0

MMU-AP0481WH 5 14.0 16.0 406 1650 620 52

1-way ceiling cassette MMU-AP0071YH 0.8 2.2 2.5 235 850 400 22

MMU-AP0091YH 1 2.8 3.2

MMU-AP0121YH 1.25 3.6 4.0

MMU-AP0151SH 1.7 4.5 5.0 198 1100 655 27

MMU-AP0181SH 2 5.6 6.3

MMU-AP0241SH 2.5 7.1 8.0 198 1200 655 31

Standard ducted unit MMD-AP0071BH 0.8 2.2 2.5 320 550 800 27

MMD-AP0091BH 1 2.8 3.2

MMD-AP0121BH 1.25 3.6 4.0

MMD-AP0151BH 1.7 4.5 5.0 320 700 800 30

MMD-AP0181BH 2 5.6 6.3

MMD-AP0241BH 2.5 7.1 8.0 320 1000 800 39

MMD-AP0271BH 3 8.0 9.0

MMD-AP0301BH 3.2 9.0 10.0

MMD-AP0361BH 4 11.2 12.5 320 1350 800 51

MMD-AP0481BH 5 14.0 16.0

MMD-AP0561BH 6 16.0 18.0

High-pressure ducted unit MMD-AP0181H 2 5.6 6.3 380 850 660 50

MMD-AP0241H 2.5 7.1 8.0 380 850 660 52

MMD-AP0271H 3 8.0 9.0

MMD-AP0361H 4 11.2 12.5 380 850 660 56

MMD-AP0481H 5 14.0 16.0 380 1200 660 67

MMD-AP0721H 8 22.4 25.0 470 1380 1250 155

MMD-AP0961H 10 28.0 31.5

Slim duct unit MMD-AP0071SPH 0.8 2.2 2.5 210 845 645 22

MMD-AP0091SPH 1 2.8 3.2 22

MMD-AP0121SPH 1.25 3.6 4.0 22

MMD-AP0151SPH 1.7 4.5 5.0 23

MMD-AP0181SPH 2 5.6 6.3 23

Ceiling-suspended unit MMC-AP0151H 1.7 4.5 5.0 210 910 680 21

MMC-AP0181H 2 5.6 6.3

MMC-AP0241H 2.5 7.1 8.0 210 1180 680 25

MMC-AP0271H 3 8.0 9.0

MMC-AP0361H 4 11.2 12.5 210 1595 680 33

MMC-AP0481H 5 14.0 16.0

High-wall unit MMK-AP0071H 0.8 2.2 2.5 368 895 210 18

MMK-AP0091H 1 2.8 3.2

MMK-AP0121H 1.25 3.6 4.0

MMK-AP0151H 1.7 4.5 5.0 368 1055 210 19

MMK-AP0181H 2 5.6 6.3

MMK-AP0241H 2.5 7.1 8.0 368 1430 210 25

MMK-AP0072H 0.8 2.2 2.5 275 790 208 11

MMK-AP0092H 1.0 2.8 3.2

MMK-AP0122H 1.25 3.6 4.0

Floor-mounted console unit MML-AP0071H 0.8 2.2 2.5 630 950 230 37

MML-AP0091H 1 2.8 3.2

MML-AP0121H 1.25 3.6 4.0

MML-AP0151H 1.7 4.5 5.0

MML-AP0181H 2 5.6 6.3

MML-AP0241H 2.5 7.1 8.0 630 950 230 40

Concealed chassis unit MML-AP0071BH 0.8 2.2 2.5 600 745 220 21

MML-AP0091BH 1 2.8 3.2

MML-AP0121BH 1.25 3.6 4.0

MML-AP0151BH 1.7 4.5 5.0 600 1045 220 29

MML-AP0181BH 2 5.6 6.3

MML-AP0241BH 2.5 7.1 8.0

Floor-mounted cabinet unit MMF-AP0151H 1.7 4.5 5.0 1750 600 210 48

MMF-AP0181H 2 5.6 6.3

MMF-AP0241H 2.5 7.1 8.0 1750 600 210 49

MMF-AP0271H 3 8.0 9.0

MMF-AP0361H 4 11.2 12.5 1750 600 390 65

MMF-AP0481H 5 14.0 16.0

MMF-AP0561H 6 16.0 18.0

10

Page 11

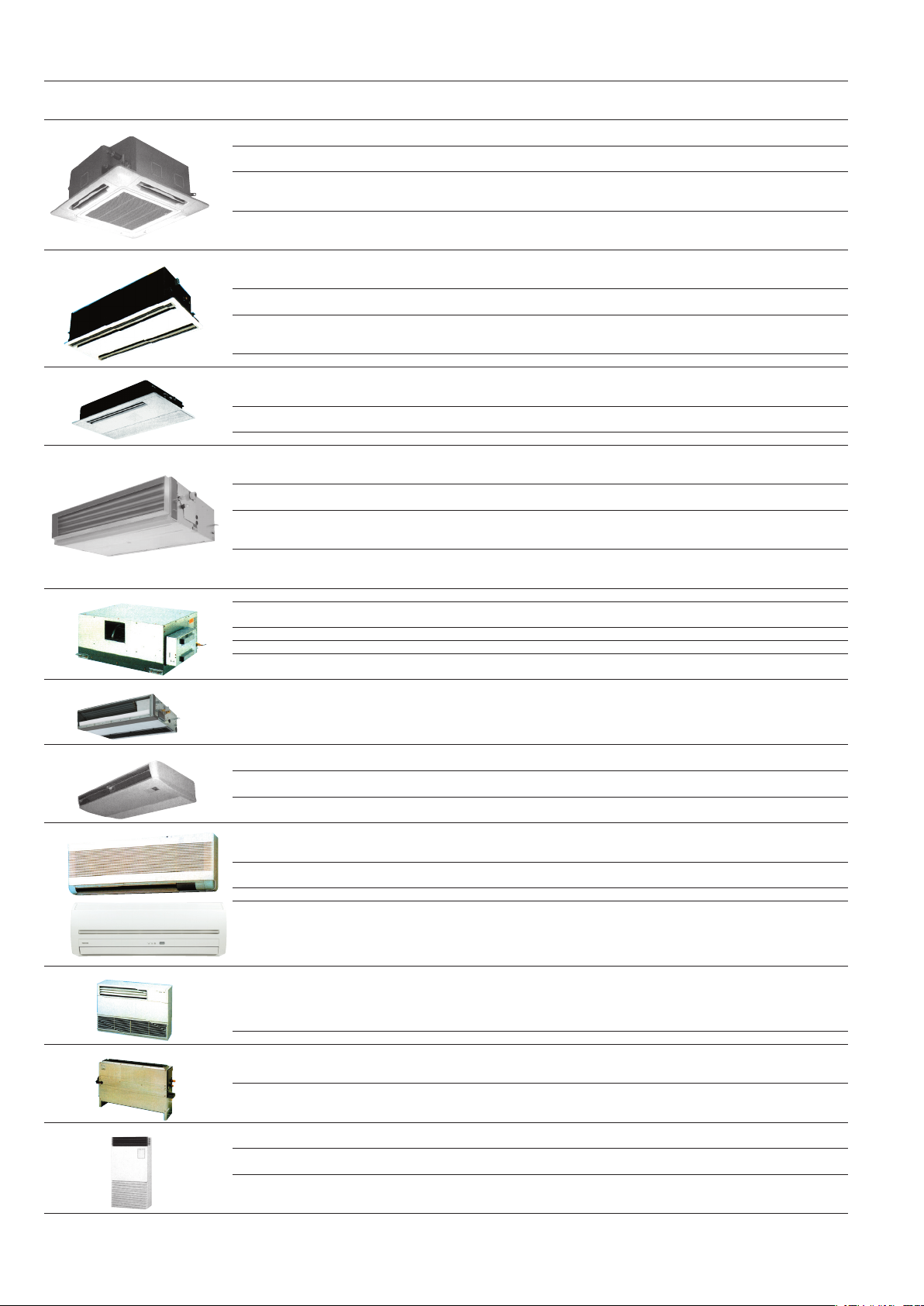

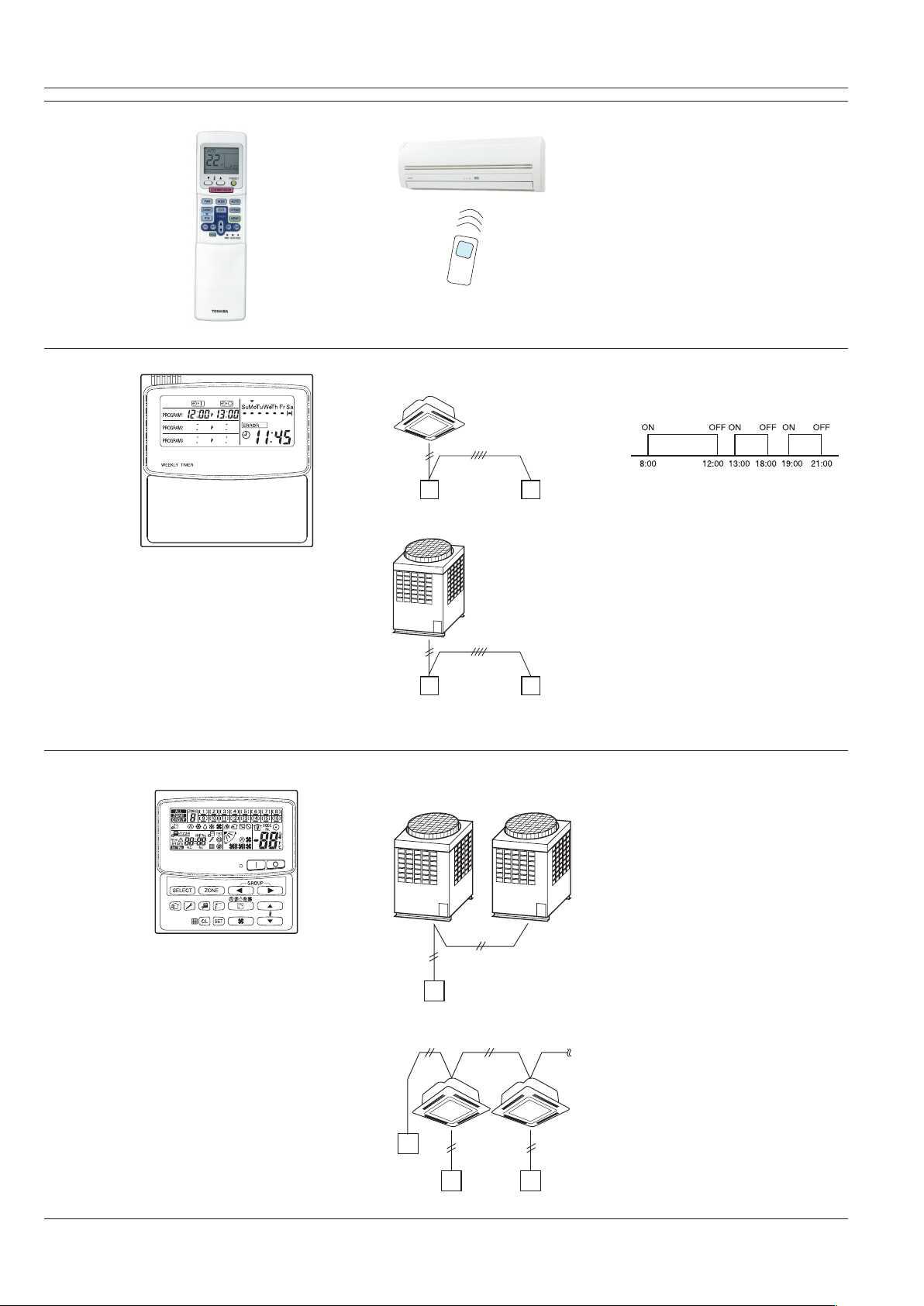

5. Remote controller

Appearance Application Function

Wired remote controller

• Mode change

RBC-AMT31E • Temperature adjustment

• Air flow adjustment

• Timer function

Three options are available:

To use, choose one of these options and

• Filter maintenance time

Automatically displays the maintenance

Filter LED flashes.

• Self-diagnosis function

Pressing the ‘CHECK’ button displays the

• Two controlling positions are available.

Two remote controllers can be connected

Simplified remote controller Connected to indoor unit • Start/stop

• Temperature adjustment

RBC-AS21E • Air flow adjustment

• Check code display

Connected to indoor unit • Start/stop

On after selected time (one cycle)

Off after selected time (one cycle)

Off after selected time (re-occurring)

the time delay before it occurs (minimum

period is 0.5 hours).

Combined with the weekly timer a

weekly operating schedule can be set.

Wired remote

controller

Wired remote controller

(for control with two

controlling positions)

time of the indoor filter.

problem cause using a check code.

to one indoor unit. The indoor unit can then

be operated from two separate locations.

Simplified remote controller

Wireless remote controller kit Connected to indoor unit • Start/stop

• Mode change

TCB-AX21U (W)-E • Temperature adjustment

RCB-AX22CE • Air flow adjustment

TCB-AX21E • Timer function

Three options are available:

On after selected time (one cycle)

Off after selected time (one cycle)

To use, choose one of these options and

• Two controlling positions are available.

Two wireless remote controllers can be

• Check code display.

(For 4-way ceiling cassette)

(For ceiling-suspended unit)

(For all units except high-pressure ducted units)

Off after selected time (re-occurring)

the time delay before it occurs (minimum

period is 0.5 hours).

connected to one indoor unit. The indoor

unit can then be operated from two

separate locations.

TCB-AX21U (W)-E

RBC-AX22CE

TCB-AX21E

11

Page 12

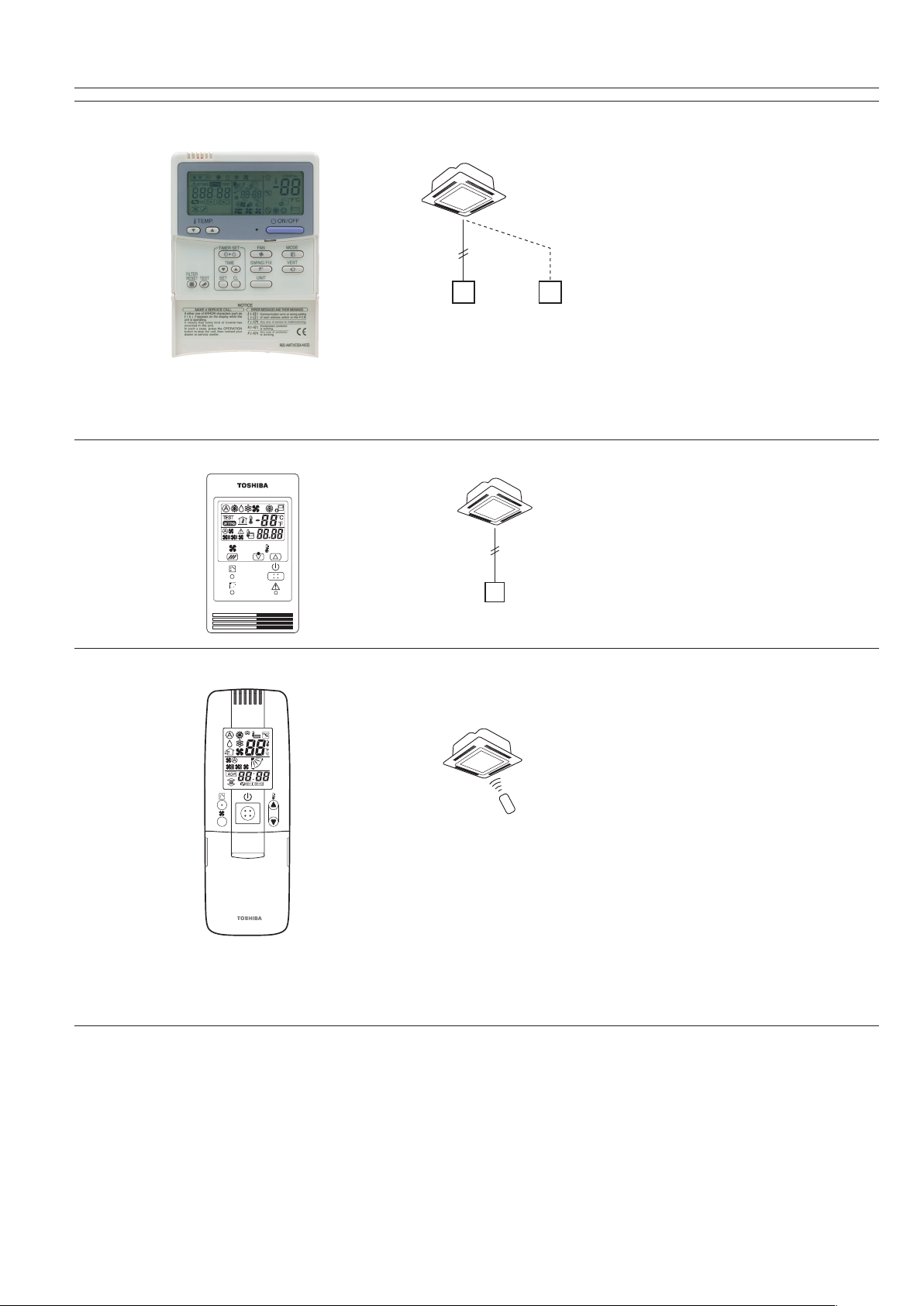

Appearance Application Function

Infrared remote controller

• Mode change

WH-H2UE • Temperature adjustment

• Air flow adjustment (5 steps)

• Clock

• Timer function

- ON/OFF timer (10 min. steps)

- Daily timer

• High power mode

• ECO mode (sleep timer with ECO-logic)

• One-touch pre-set memory

Weekly timer Connected to central remote • Weekly schedule operation

controller, wired remote controller

RBC-EXW21E of the week

Connected to indoor unit • Start/stop

Setting start/stop times for each day

ON/OFF can be set 3 times a day.

Press ‘CANCEL’ ‘DAY’ button for easy

Central remote controller Connected to outdoor unit, • Individual control of up to 64 indoor units

TCB-SC642TLE divided into 1 to 4 zones.

Up to 16 indoor units for each

zone.

• Up to 16 outdoor master units are

• 4 central control setting types to inhibit

• Setting for one of 1 to 4 zones is available.

• Usable with other central control devices

• Two control mode choices

Centrol controller mode

Remote controller mode

• Settings of simultaneous ON/OFF 3 times

Wired remote

controller

Outdoor unit

Central remote

controller

indoor unit • Individual control of max. 64 indoor units

Master

Outdoor unit

Central remote

controller

Weekly

timer

Weekly

timer

Slave

Press ‘CHECK’ ‘PROGRAM’ ‘DAY’

button for easy program copying.

Two schedules a week can be

specified (summer/winter schedule).

holiday override setting.

If power supply fails, the settings are

stored in the memory for 100 hours.

(

connectable.

individual operation by remote controller

can be selected.

(up to 10 central control devices in one

control circuit).

(

for each day of the week combined with

weekly timer.

)

)

12

Central

remote

controller

Indoor remote controller

Page 13

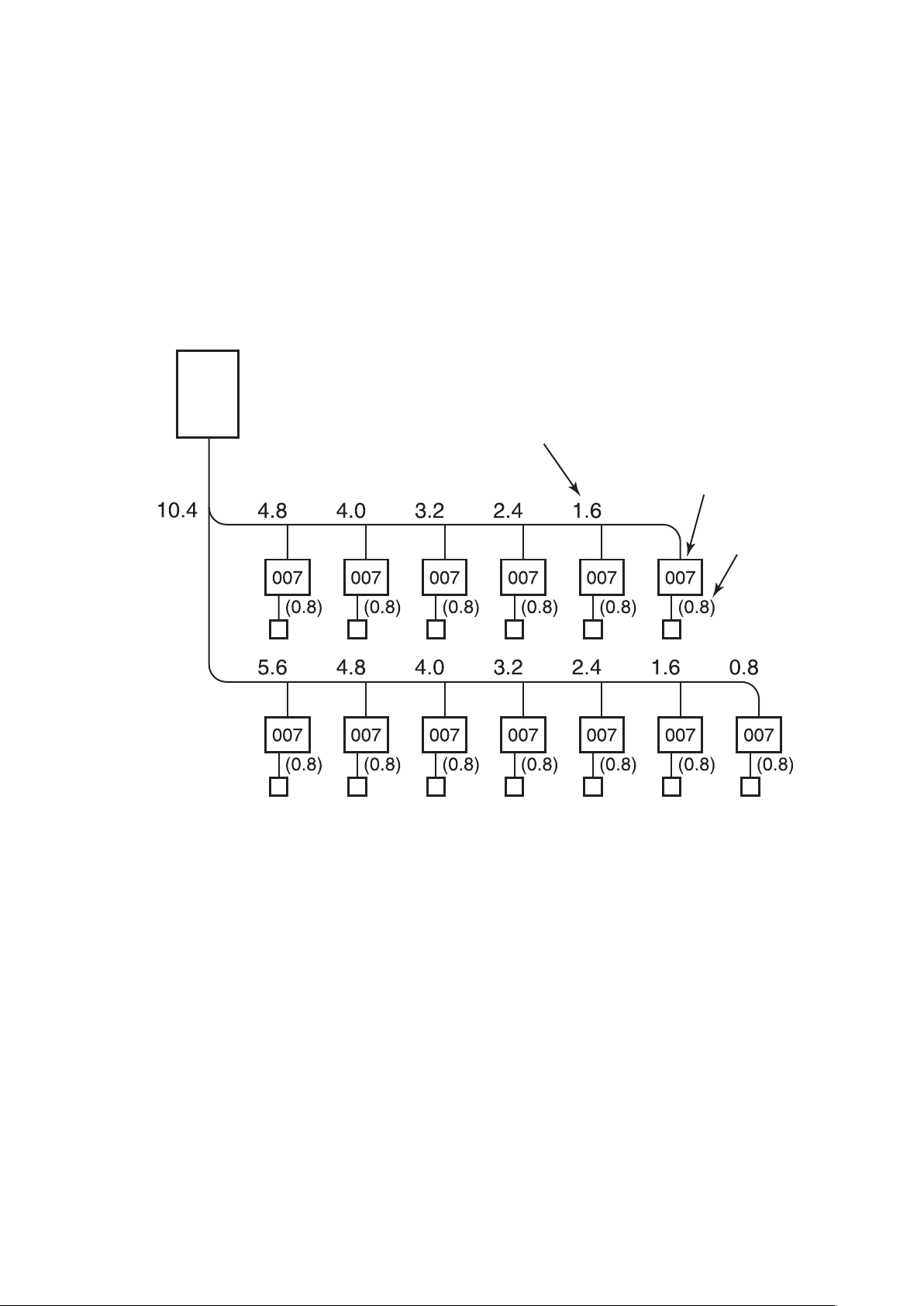

3. Basic system configuration

System legend (example)

8 hp system

• Max. number of indoor units: 13 units

• Indoor unit capacity code: Min. 4

Max. 10.8

Capacity code - total 10.4

Total number of units - 13

Outdoor unit

8HP

Indoor unit

Remote

controller

Capacity code

over the branch

(0.8 + 0.8 = 1.6)

Indoor unit

designation

Capacity

code

13

Page 14

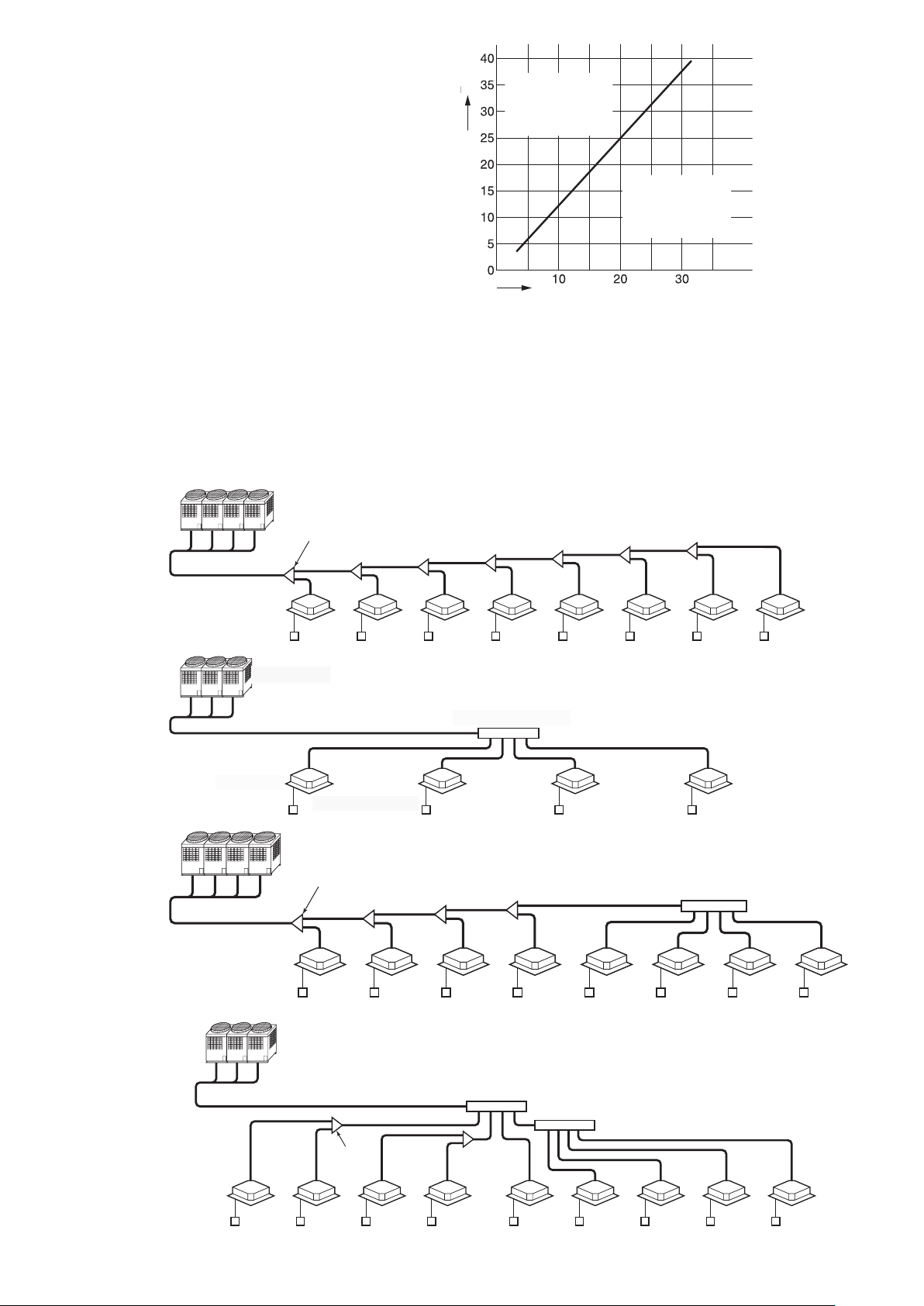

10 hp system

• Max. number of indoor units: 16 units

• Indoor unit capacity code: Min. 5

Max. 13.5

Capacity code - total 12.8

Total number of units - 16

Outdoor unit

10HP

Indoor unit

Remote

controller

14

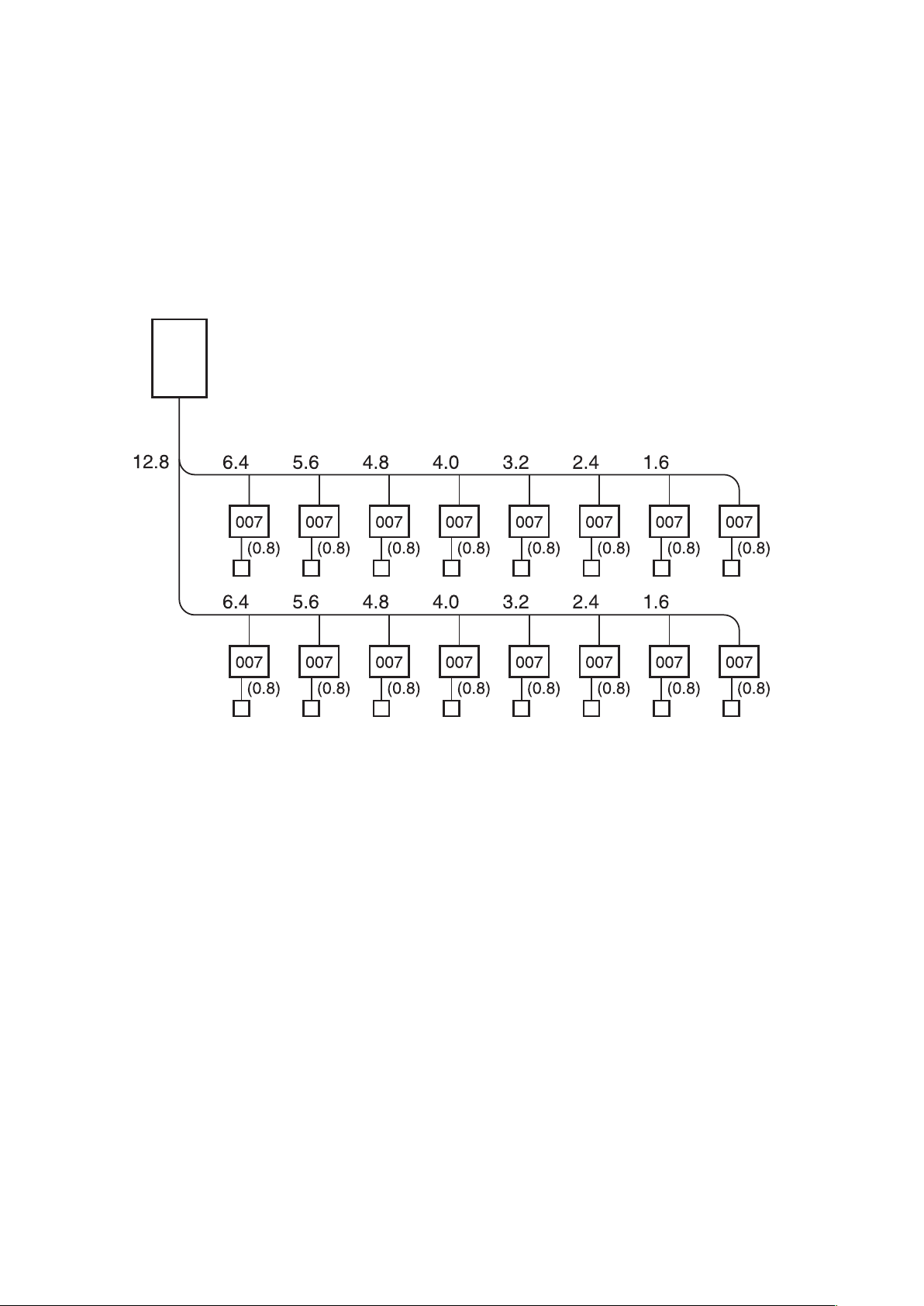

Page 15

20 hp system

• Max. number of indoor units: 33 units

• Indoor unit capacity code: Min. 10

Max. 27

Capacity code - total 26.75

Total number of units - 19

Outdoor unit

10HP 10HP

Indoor unit

Remote

controller

15

Page 16

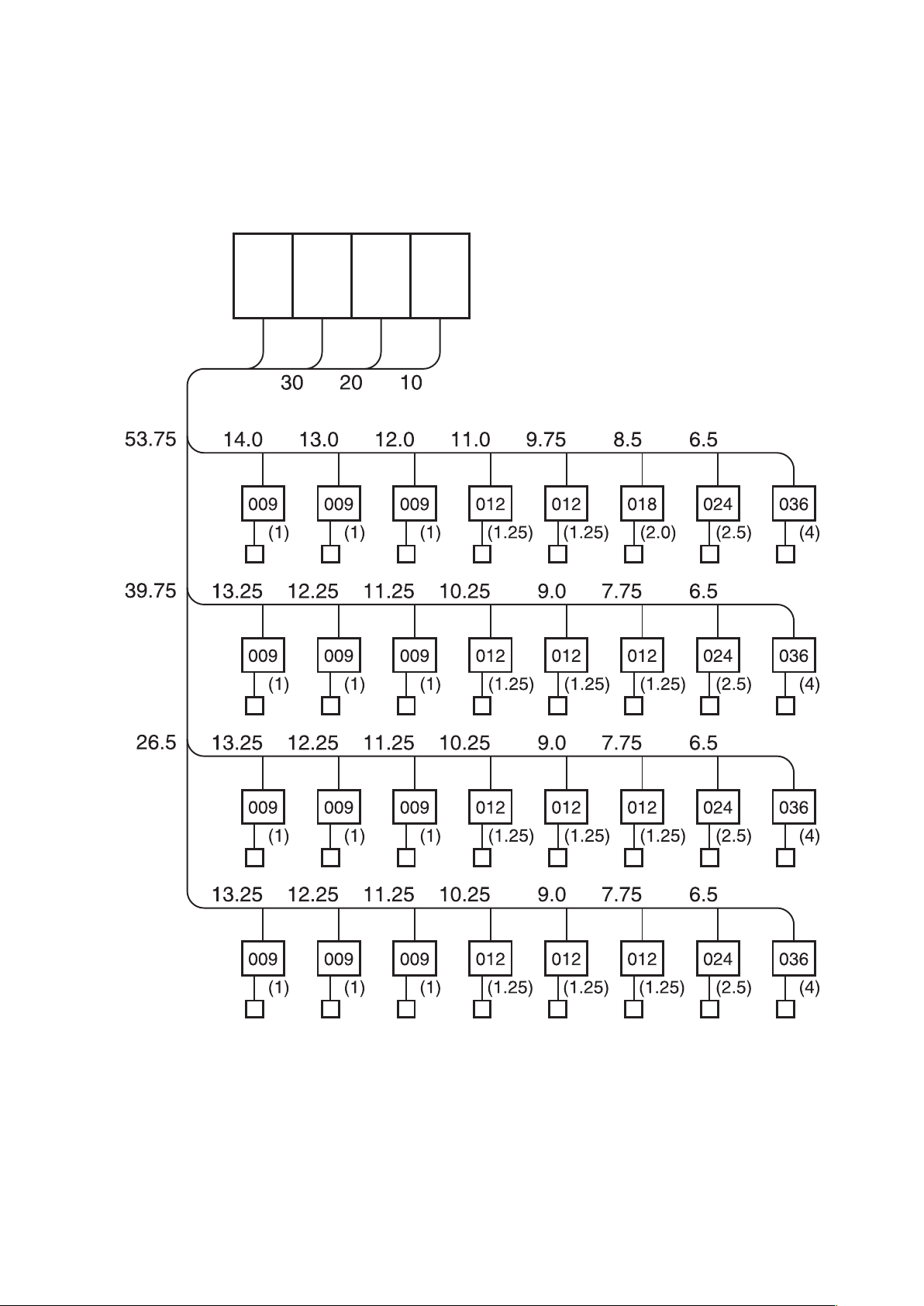

30 hp system

• Max. number of indoor units: 48 units

• Indoor unit capacity code: Min. 15

Max. 40.5

Capacity code - total 40

Total number of units - 28

Outdoor unit

10HP

10HP 10HP

16

Indoor unit

Remote

controller

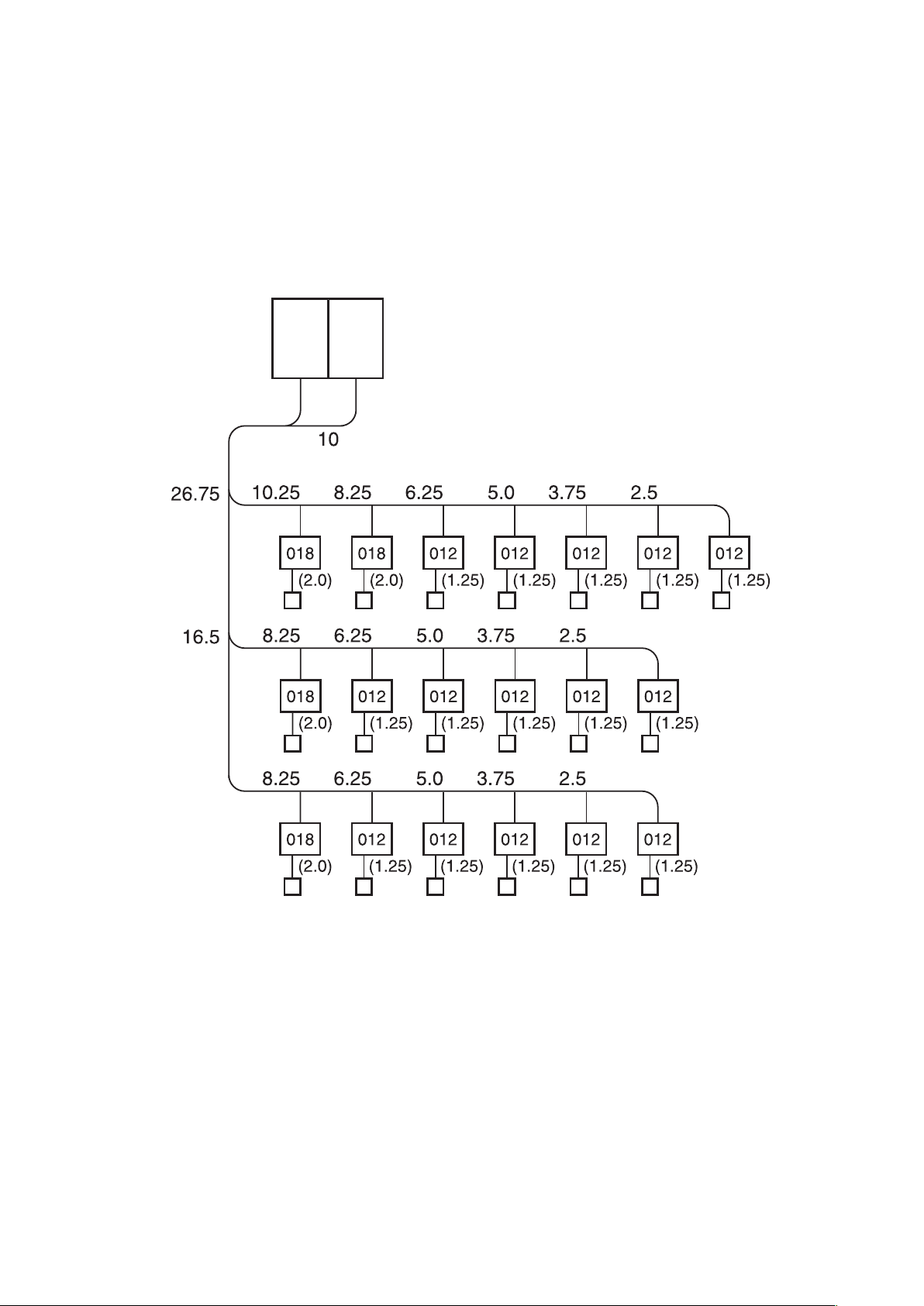

Page 17

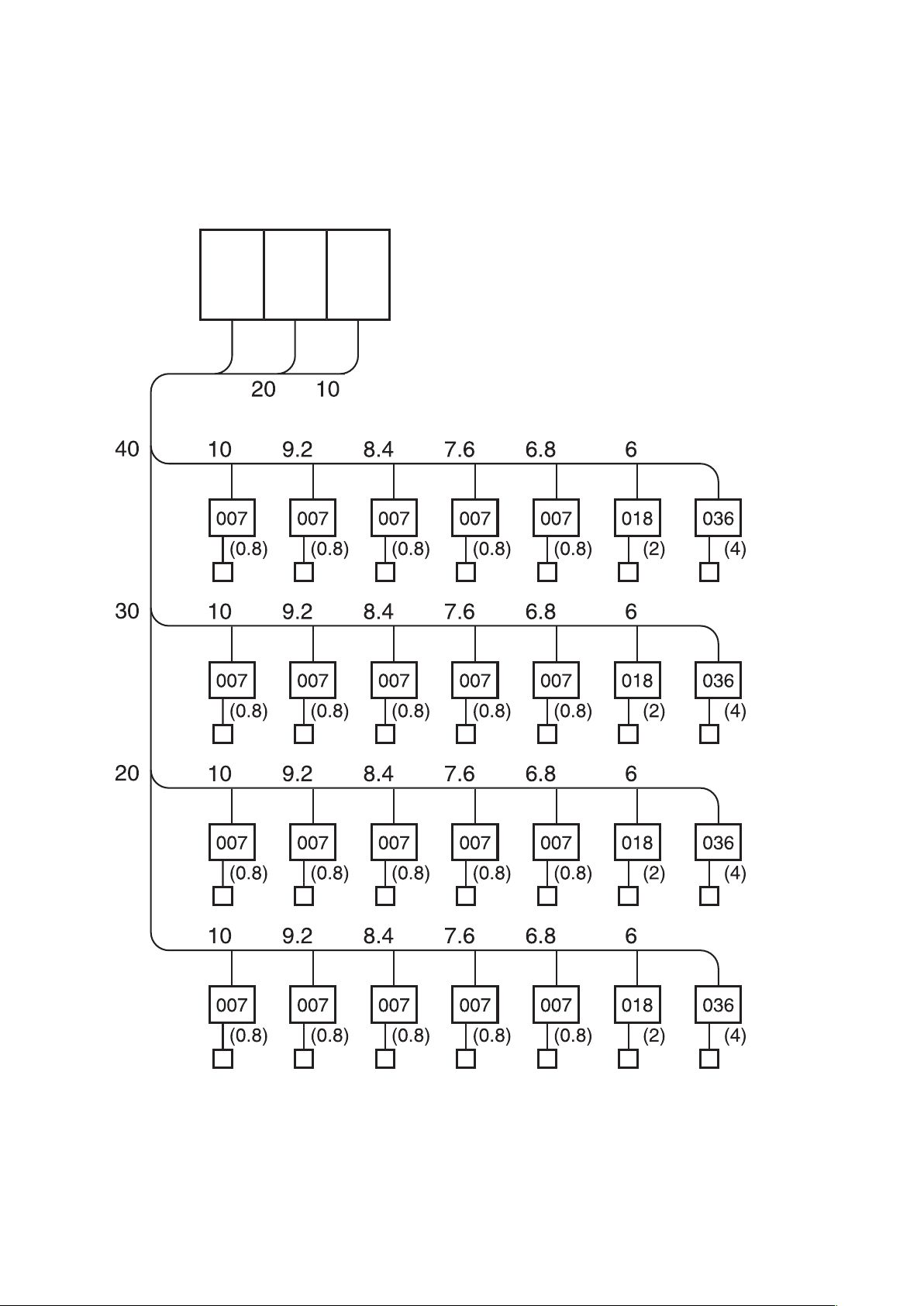

40 hp system

• Max. number of indoor units: 48 units

• Indoor unit capacity code: Min. 20

Max. 54

Capacity code - total 53.75

Total number of units - 32

Outdoor unit

10HP

10HP

10HP 10HP

Indoor unit

Remote

controller

17

Page 18

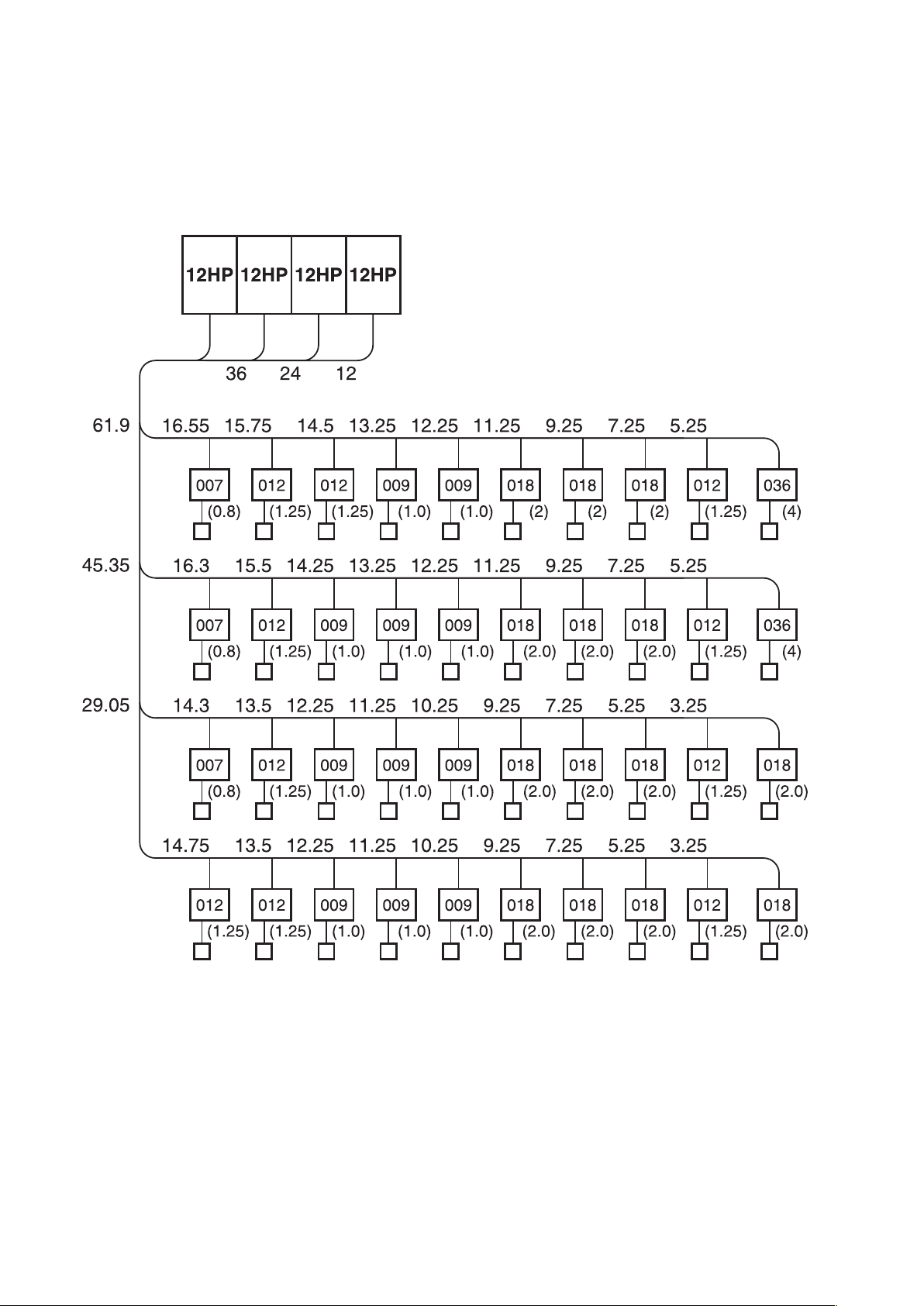

48 hp system

• Max. number of indoor units: 48 units

• Indoor unit capacity code: Min. 24

Max. 64.8

Capacity code - total 61.9

Total number of units - 40

Outdoor unit

18

Indoor unit

Remote

controller

Page 19

4. Equipment selection procedure

1. Selection flow chart

1. Determination of indoor air conditioning load

2. Preliminary selection of indoor units

3. Preliminary selection of outdoor unit with indoor units

4. Capacity correction for piping length/height between indoor and outdoor units

5. Capacity correction based on indoor and outdoor temperature

6. Validate preliminary selection of indoor units

No

7. Confirmation of selection for indoor unit and outdoor units

End

2. Indoor unit and outdoor unit combination

For indoor unit, the capacity code is decided for each model size.

Model size 007 009 012 015 018 024 027 030 036 048 056 072 096

Cooling capacity, kW 2.2 2.8 3.6 4.5 5.6 7.1 8.0 9.0 11.2 14.0 16.0 22.4 28.0

Capacity code 0.8 1 1.25 1.7 2 2.5 3 3.2 4 5 6 8 10

Note: Model size: corresponding to Btu/h. Capacity code: corresponding to horsepower.

For outdoor unit, maximum number of connectable indoor units and total capacity code of indoor units are decided.

Outdoor unit Outdoor unit Capacity code Max. No. of Total indoor unit

(cooling only) (heat pump) of outdoor unit indoor units capacity code

MMY-MAP0501T8 MMY-MAP0501HT8 5 8 2.5 to 6.75

MMY-MAP0601T8 MMY-MAP0601HT8 6 10 3 to 8.1

MMY-MAP0801T8 MMY-MAP0801HT8 8 13 4 to 10.8

MMY-MAP1001T8 MMY-MAP1001HT8 10 16 5 to 13.5

MMY-MAP1201T8 MMY-MAP1201HT8 12 20 6 to 16.2

MMY-AP1401T8 MMY-AP1401HT8 14 23 7 to 18.9

MMY-AP1601T8 MMY-AP1601HT8 16 27 8 to 21.6

MMY-AP1801T8 MMY-AP1801HT8 18 30 9 to 24.3

MMY-AP2001T8 MMY-AP2001HT8 20 33 10 to 27.0

MMY-AP2201T8 MMY-AP2201HT8 22 37 11 to 29.7

MMY-AP2211T8 MMY-AP2211HT8 22 37 11 to 29.7

MMY-AP2401T8 MMY-AP2401HT8 24 40 12 to 32.4

MMY-AP2411T8 MMY-AP2411HT8 24 40 12 to 32.4

MMY-AP2601T8 MMY-AP2601HT8 26 43 13 to 35.1

MMY-AP2801T8 MMY-AP2801HT8 28 47 14 to 37.8

MMY-AP3001T8 MMY-AP3001HT8 30 48 15 to 40.5

MMY-AP3201T8 MMY-AP3201HT8 32 48 16 to 43.2

MMY-AP3211T8 MMY-AP3211HT8 32 48 16 to 43.2

MMY-AP3401T8 MMY-AP3401HT8 34 48 17 to 45.9

MMY-AP3411T8 MMY-AP3411HT8 34 48 17 to 45.9

MMY-AP3601T8 MMY-AP3601HT8 36 48 18 to 48.6

MMY-AP3611T8 MMY-AP3611HT8 36 48 18 to 48.6

MMY-AP3801T8 MMY-AP3801HT8 38 48 19 to 51.3

MMY-AP4001T8 MMY-AP4001HT8 40 48 20 to 54.0

MMY-AP4201T8 MMY-AP4201HT8 42 48 21 to 56.7

MMY-AP4401T8 MMY-AP4401HT8 44 48 22 to 59.4

MMY-AP4601T8 MMY-AP4601HT8 46 48 23 to 62.1

MMY-AP4801T8 MMY-AP4801HT8 48 48 24 to 64.8

50 to 135% of outdoor unit capacity

19

Page 20

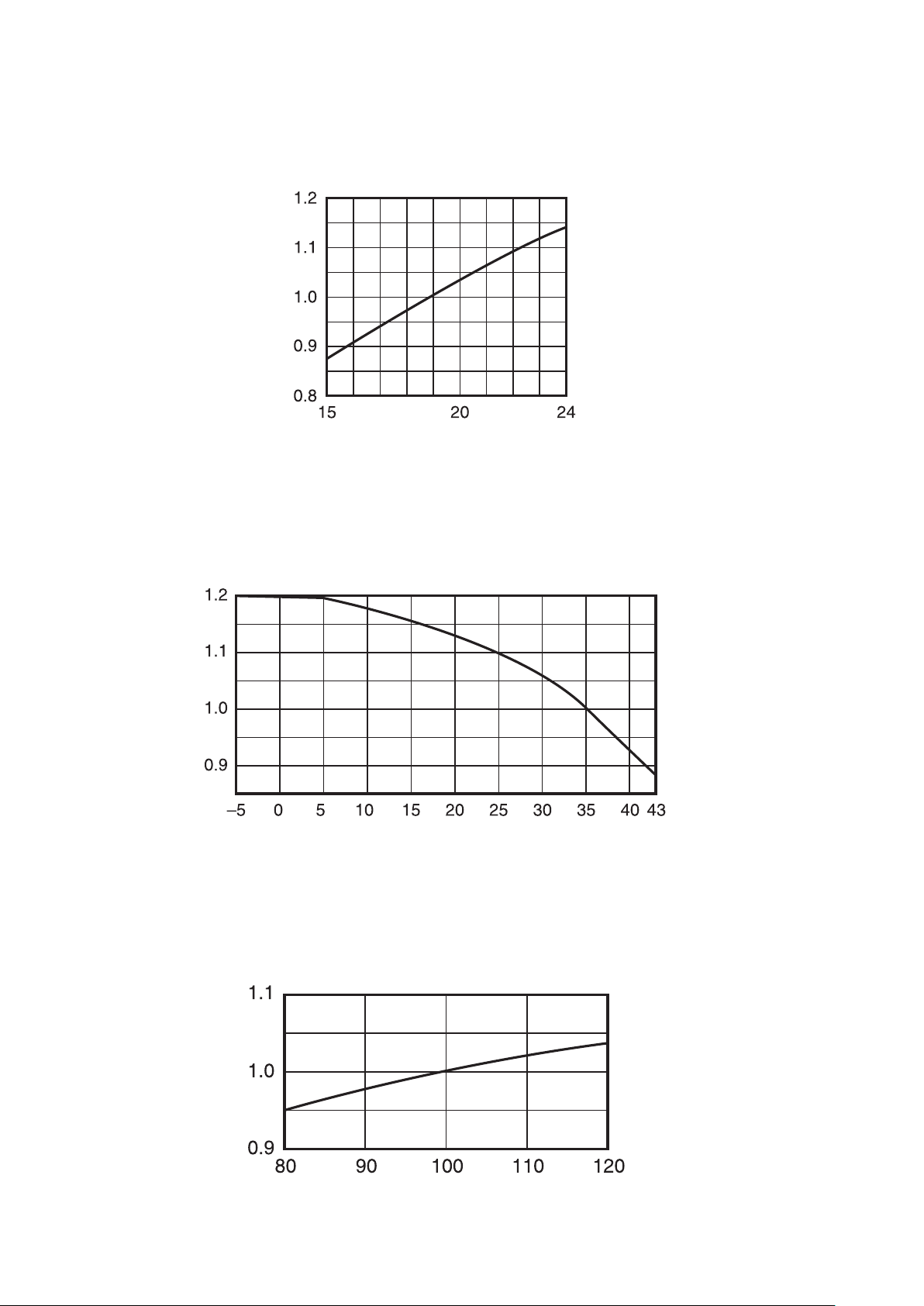

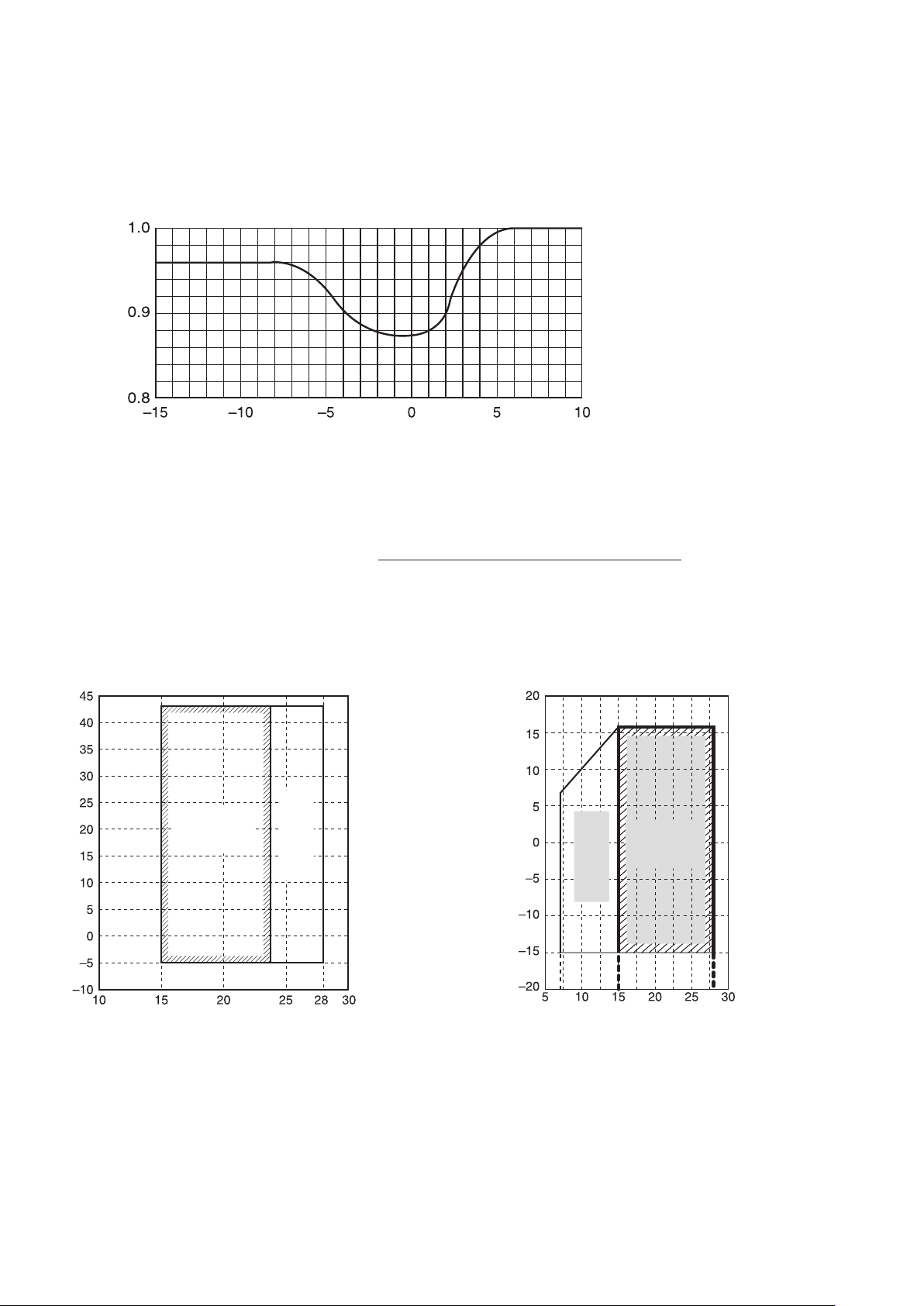

3. Cooling/heating capacity characteristics

Cooling capacity calculation method:

Required cooling capacity = cooling capacity x factor (, , , ,

Indoor air wet bulb temperature vs. capacity correction value

Capacity correction value

Indoor air wet bulb temperature (°C)

*1

) kW

Outdoor air dry bulb temperature vs. capacity correction value

Capacity correction value

Outdoor air dry bulb temperature (°C)

Air flow variation ratio of indoor unit vs. capacity correction (for ducted units only)

Capacity correction value

Air flow variation ratio (%)

*1 Outdoor unit capacity correction factor when total capacity of the indoor units is not equal to the outdoor unit capacity.

20

Page 21

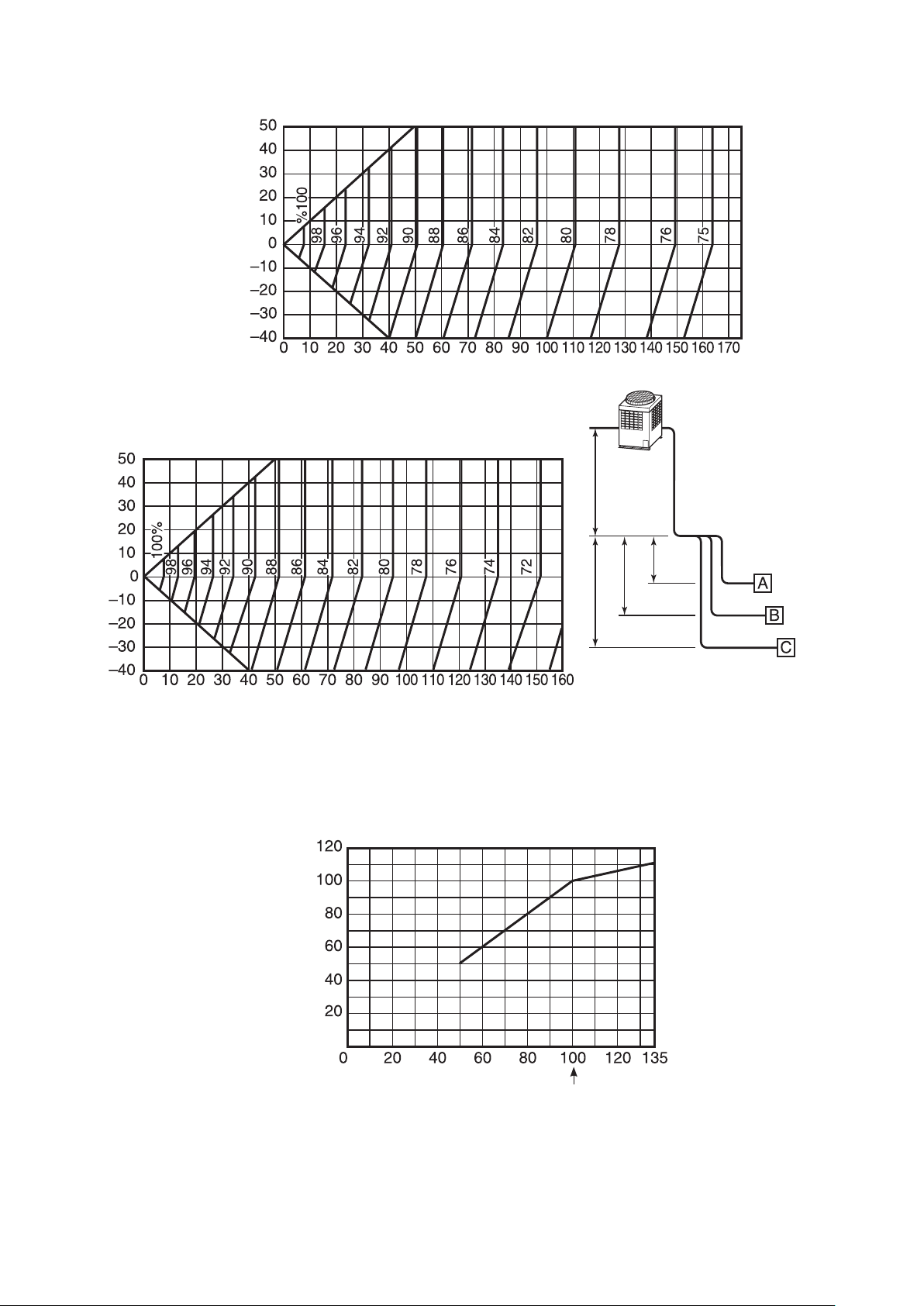

Connecting pipe length and lift difference between indoor and outdoor units vs. capacity correction value

Outdoor unit (5 to 44 hp)

Outdoor unit height H (m)

Pipe length (equivalent length) L (m)

Outdoor unit

Outdoor unit (46 to 48 hp)

Outdoor unit height H (m)

Pipe length (equivalent length) L (m)

Correction of outdoor unit diversity

ho l’o

hb

hc

L’ is the longest dimension of

(l’o + l’a, l’o + l’b, l’o + l’c)

H = ho + (longest dimension of

ha, hb and hc)

ha

l’a

l’b

l’c

Indoor unit

Correction (%)

Standard capacity ratio

Indoor unit total capacity ratio (%)

21

Page 22

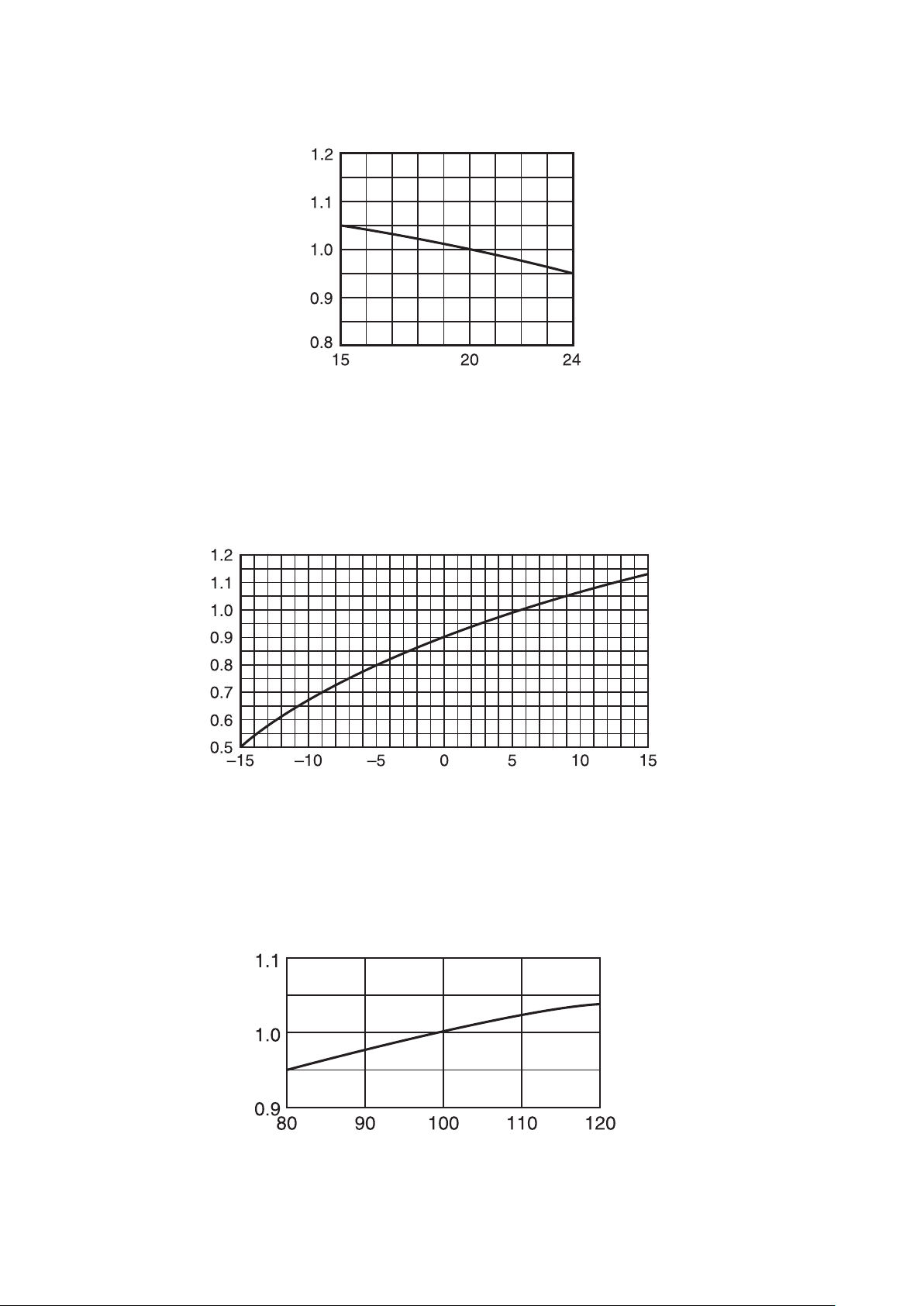

Heating capacity calculation method:

Required heating capacity = heating capacity x factor (, , , , *1, *2) kW

Indoor air dry bulb temperature vs. capacity correction value

Capacity correction value

Indoor air dry bulb temperature (°C)

Outdoor air wet bulb temperature vs. capacity correction value

Capacity correction value

Outdoor air wet bulb temperature (°C)

Air flow variation ratio of indoor unit vs. capacity correction (for ducted units only)

Capacity correction value

Air flow variation ratio (%)

*1 Outdoor unit capacity correction factor when total capacity of the indoor units is not equal to the outdoor unit capacity.

*2 Refer to the capacity correction for frosting on the outdoor heat exchanger section on page 24.

22

Page 23

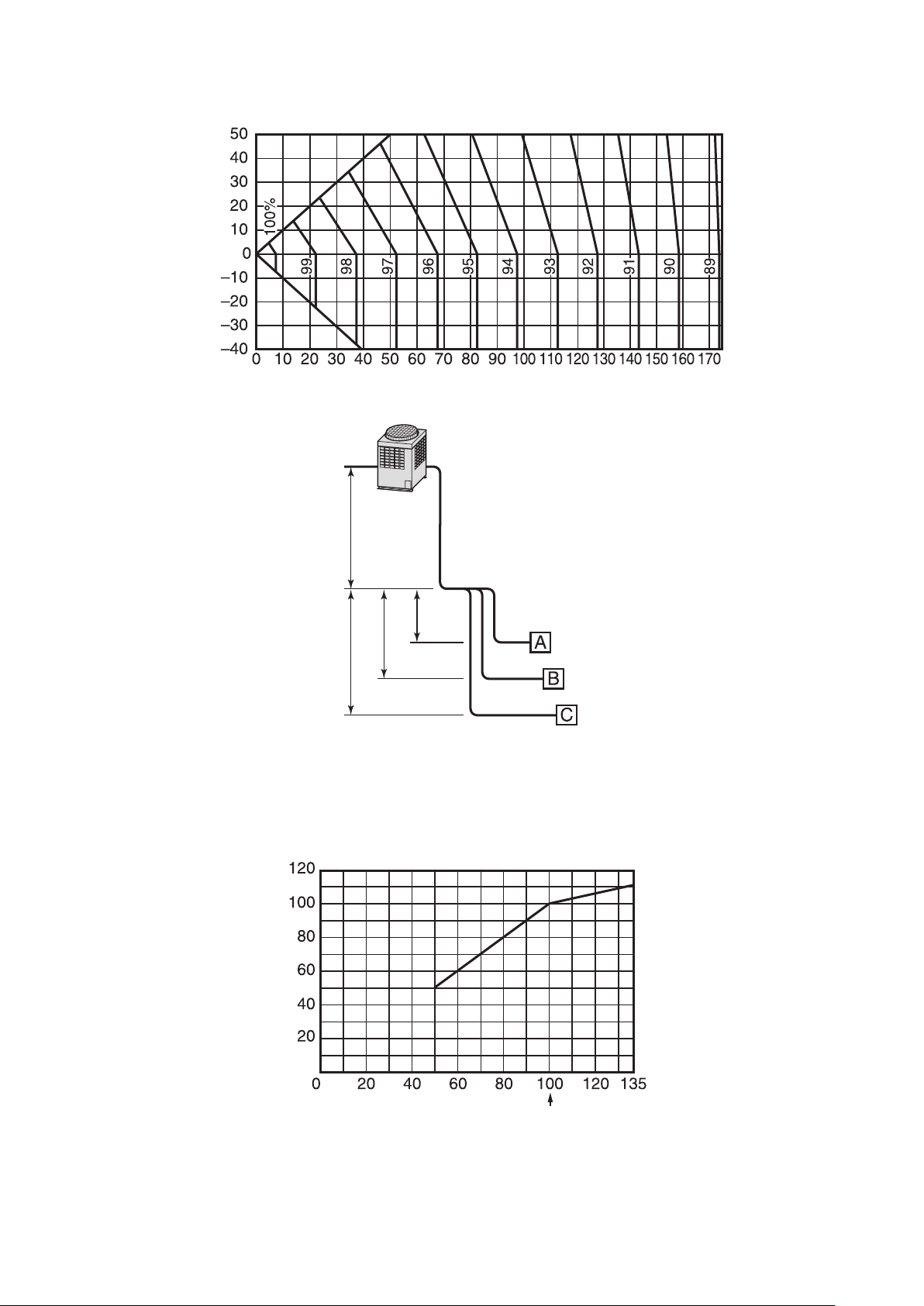

Connecting pipe length and lift difference between indoor and outdoor units vs. capacity correction value

Outdoor unit (5 to 48 hp)

Outdoor unit height H (m)

Pipe length (equivalent length) L (m)

Outdoor unit

L’ is the longest dimension of

(l’o + l’a, l’o + l’b, l’o + l’c)

Correction of outdoor unit diversity

ho

hc

hb

l’o

H = ho + (longest dimension of

ha, hb and hc)

ha

l’a

l’b

l’c

Indoor unit

Correction (%)

Standard capacity ratio

Indoor unit total capacity ratio (%)

23

Page 24

Capacity correction for frosting on the outdoor heat exchanger (heating mode)

Correct the heating capacity when frost was found on the outdoor heat exchanger.

Heating capacity = Capacity after correction of outdoor unit × correction value of capacity resulting from frost

(Capacity after correction of outdoor unit: Heating capacity calculated in the previous

section.)

Capacity correction for frosting on the outdoor heat exchanger

Capacity correction value

Outdoor air wet bulb temperature (°C)

Capacity calculation for each indoor unit

Capacity for each indoor unit =

Capacity after correction of outdoor unit ×

Required standard capacity of indoor unit

Total value of standard indoor unit capacity

Operating temperature range

In cooling mode In heating mode

Continuous

Outdoor air dry bulb temperature (°C)

operating

range

Usable range

(in pull-down mode)

Usable range

Outdoor air wet bulb temperature (°C)

Continuous

operating

range

(in warming-up mode)

Indoor air wet bulb temperature (°C)

Rated conditions

Cooling: Indoor air temperature 27°C db/19°C wb.

Outdoor air temperature 35°C db.

Heating: Indoor air temperature 20°C db.

Outdoor air temperature 7°C db/6°C wb.

24

Indoor air dry bulb temperature (°C)

The unit can be operated even if outdoor

temperature falls to -20°C. However, the warranty

only covers operation down to -15°C, as lower

temperatures are outside the operating range.

When the outdoor air temperature falls to below

-15°C, unit operation may reduce the product life.

Page 25

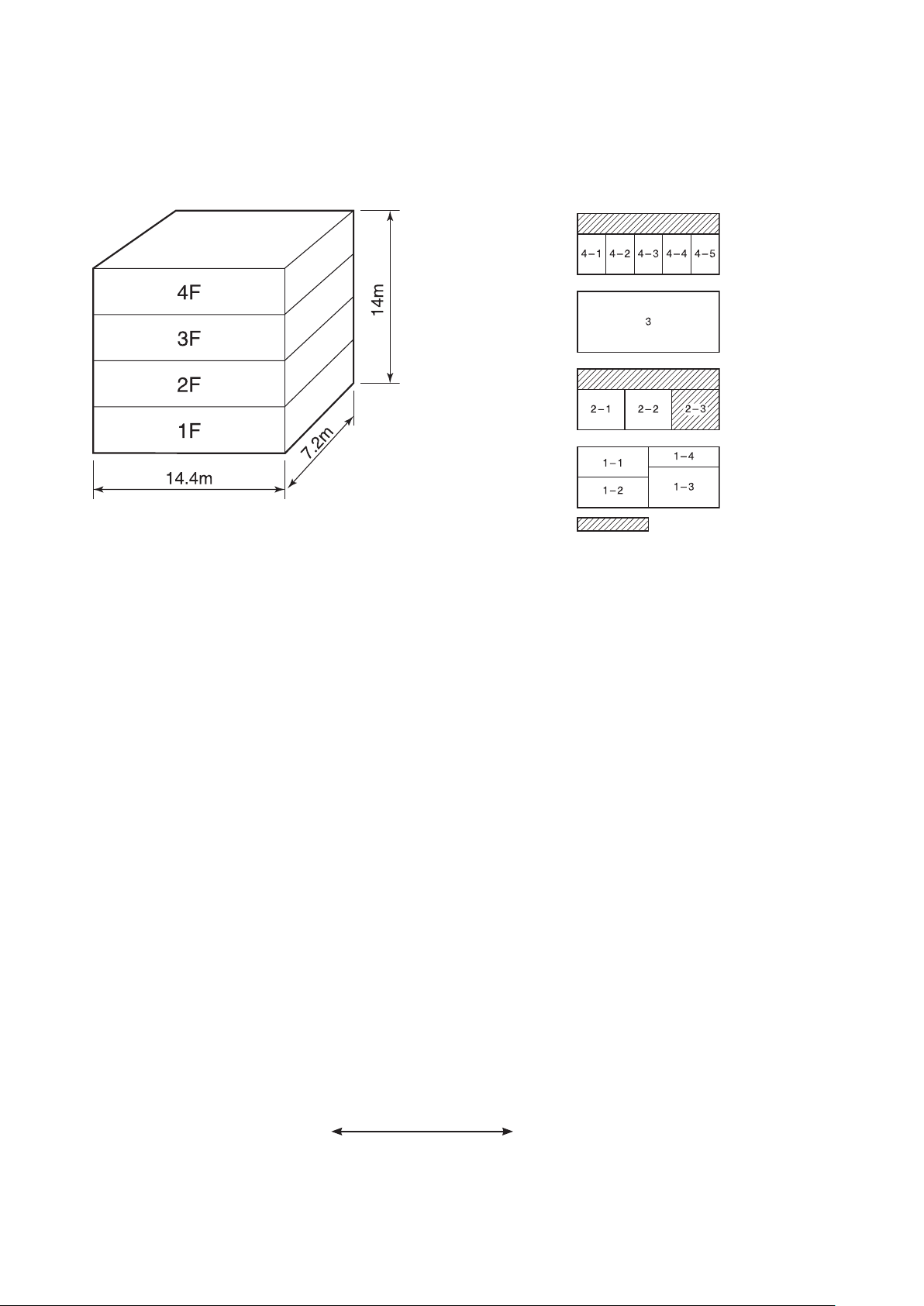

Example of equipment selection

The following shows an example of equipment selection based upon a building model.

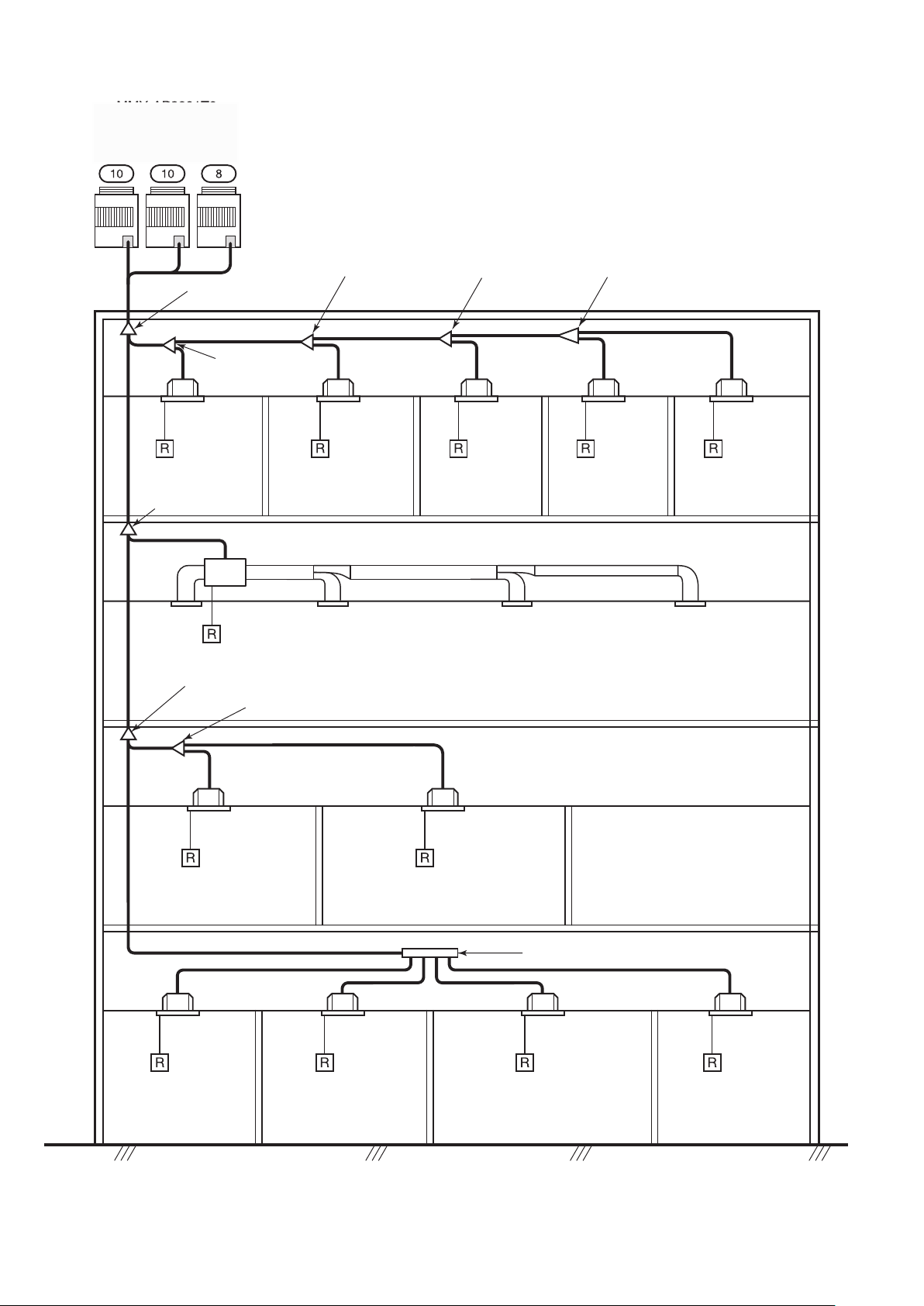

Fig. 1 - Overview of building model

Outside view Floor configuration

Small meeting room

Executive rooms

Office rooms

(Entire floor)

Office rooms

Stores

Non-air conditioning zone

• Steel frame, reinforced concrete building, four floors

above ground. Total floor area : 415 m²

Outdoor unit is installed on the roof.

• Indoor design conditions:

Cooling: 27.0/19.0°C db/wb. Heating: 20°C db

• Outdoor design conditions:

Cooling: 35°C db (standard condition). Heating: 3°C wb (standard condition: 6°C wb)

Selection criteria for each floor

1F: Outdoor unit capacity exactly matches the total indoor unit capacity.

Total indoor unit hp = Outdoor unit hp Indoor: 2.5 hp x 2 units + 3.2 hp + 2 hp = 10.2 hp

Outdoor: 10 hp Same capacity

2F: Outdoor unit capacity matches the potential total indoor unit capacity with the possibility of future

extension.

Office rooms 2 and 3 are to be used as warehouses at first, so air conditioning is not necessary at present.

However, there is a plan to convert them into offices, so an outdoor module with extra capacity is required.

Piping/wiring are carried out. Indoor unit is not yet installed.

When the rooms are used as an office later, the indoor unit is installed.

3F: One indoor unit is connected to one outdoor unit.

The outdoor module should have sufficient capacity to cover the peak demand of the indoor unit connected.

4F: Consider the diversity factor and have the outdoor module match 135% of indoor unit capacity.

This is a typical matching of indoor/outdoor units for a Super MMS system.

• Total indoor unit hp > Outdoor unit hp

• Select each indoor unit based on individual peak room load.

Indoor: 2.5 hp + 2.5 hp + 2 hp + 2 hp (capacity difference in each room) + 1.3 hp =

10.3 hp (different capacity) Outdoor: 8 hp (different capacity)

• The cooling load profile needs to be taken into consideration.

25

Page 26

Procedure and result of equipment selection

1. Procedure of equipment selection

a. Calculate cooling for every room.

b. Select an indoor unit to match the cooling load for every room from the table on page 10.

c. Select the outdoor module to match the indoor units selected in point b. Select the outdoor modules

based on the critical factors and the combination rule. Choose a tentative outdoor module that will match

the indoor units, and check whether the selection agrees with the combination rule. Perform the capacity

correction based on the pipe length, system lift, indoor set temperature, outdoor temperature.

Then, make sure the corrected system cooling capacity satisfies the cooling load.

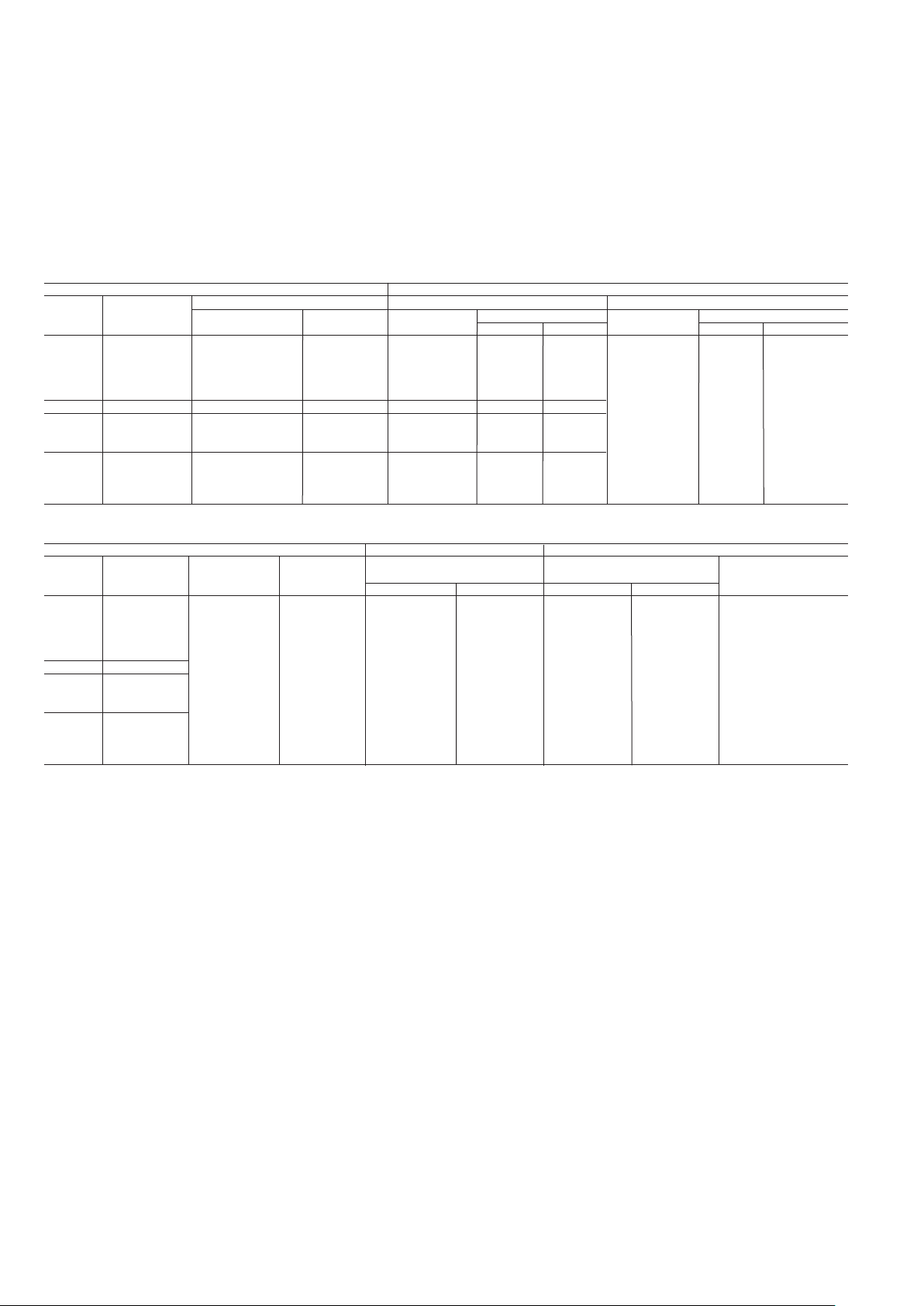

2. Equipment selection and capacity check

Air conditioning load Equipment selection

Floor Room No. Indoor air conditioning

Model Capacity (kW) Model Capacity (kW)

Cooling Heating MMU- Cooling Heating

4F 4-1 6.0 (16 o’clock) 5.4 AP0241H 7.1 8.0 AP2801HT8 78.5 88.0

4-2 5.2 (14 o’clock) 4.2 AP0181H 5.6 6.3

4-3 5.0 (14 o’clock) 4.2 AP0181H 5.6 6.3

4-4 3.2 (12 o’clock) 2.7 AP0121H 3.6 4.0

4-5 6.4 (10 o’clock) 5.4 AP0241H 7.1 8.0

3F 3-1 12.7 12.0 AP0481H 14.0 16.0

2F 2-1 4.8 4.5 AP0181H 5.6 6.3

2-2 4.6 4.8 AP0181H 5.6 6.3

2-3 — — — — —

1F 1-1 6.5 6.0 AP0241H 7.1 8.0

1-2 6.5 6.3 AP0241H 7.1 8.0

1-3 7.2 7.0 AP0301H 9.0 10.0

1-4 5.1 4.5 AP0181H 5.6 6.3

Note: ( ): Peak occurrence time

load (kW) Indoor unit Outdoor unit

MMY Cooling Heating

Piping distance Capacity correction Capacity check after correction

Floor Room No. Equivalent

length (m) difference (m) temp. correction

Cooling Heating Cooling Heating

4F 4-1 43 12 0.920 0.957 6.5 6.9 Good

4-2 x x 5.2 5.4

4-3 1.0 1.0 5.2 5.4

4-4 x x 3.3 3.5

4-5 1.0 0.95 6.5 6.9

3F 3-1 = x 12.9 13.8

2F 2-1 0.920 0.95 5.2 5.4

2-2 = 5.2 5.4

2-3 0.864 — —

1F 1-1 6.5 6.9

1-2 6.5 6.9

1-3 8.3 8.6

1-4 5.2 5.4

Height Pipe correction x Capacity (kW) Result

26

Page 27

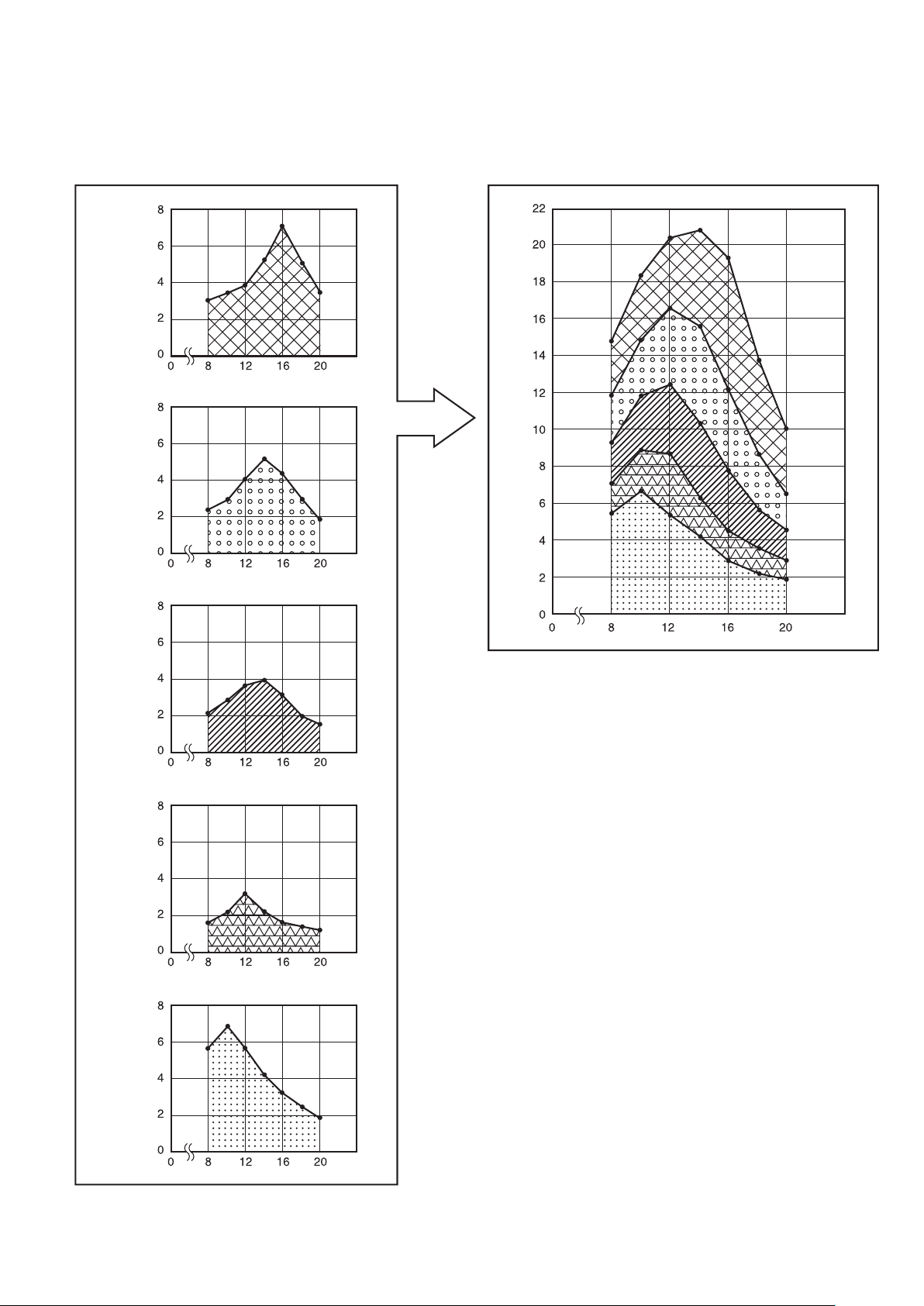

Example: Equipment selection based on system load profile

Since the five rooms on the 4th floor face different directions, their hourly cooling load profile will also be different.

We select each indoor unit based on the individual room peak load. However, we need to use the total load profile

on the 4th floor as a base to choose the outdoor module.

Load in each room Total load in all rooms of 4th floor

4-1

Load (kW)

Time

4-2

Total load (kW)

Load (kW)Load (kW)Load (kW)Load (kW)

4-3

4-4

4-5

Time

Time

Time

Time

1. The total load on the 4th floor is calculated by

adding up the hourly cooling loads of the five

rooms.

2. The maximum value of the total load is used to

select the outdoor module.

Time

27

Page 28

Schematic diagram

MMY-AP2801T8

MMY-AP2801HT8

Outdoor unit

1st branching

joint

Indoor unit

MMU-AP0241H

2nd branching

joint

3rd branching

joint

3rd branching

joint

2nd branching

joint

Indoor unit

MMU-AP0181H

4-1 4-2

Indoor unit

MMD-AP0481H

4th branching

joint

4th branching

joint

Indoor unit

MMU-AP0181H

5th branching

joint

Indoor unit

MMU-AP0121H

4-3 4-4

Indoor unit

MMU-AP0241H

4-5

3-5

28

Indoor unit

MMU-AP0181H

Indoor unit

MMU-AP0241H

2-1

Indoor unit

MMU-AP0241H

Indoor unit

MMU-AP0181H

No air conditioner

Branching header

Indoor unit

MMU-AP0301H

2-32-2

Indoor unit

MMU-AP0181H

1-41-31-21-1

Page 29

5. Refrigerant piping design

1. Warnings on refrigerant leakage

Check of concentration limit

The room in which the air conditioner is to be installed requires a design that ensures that the concentration of

refrigerant gas will not exceed a set limit if there is a leak.

Refrigerant R-410A which is used in the air conditioner is safe, without the toxicity or combustibility of ammonia,

and is not restricted by laws that protect the ozone layer. However, since it contains more than air, it poses the

risk of suffocation if its concentration should rise excessively. Suffocation from leakage of R-410A is almost nonexistent. With the recent increase in the number of high concentration buildings, however, the installation of multi

air conditioner systems is on the increase because of the need for effective use of floor space, individual control,

energy conservation by curtailing heat and carrying power, etc.

Most importantly, the multi air conditioner system is able to contain a large amount of refrigerant compared with

conventional individual air conditioners. If a single unit of the multi air conditioner system is to be installed in a small room,

select a suitable model and installation procedure so that if the refrigerant accidentally leaks out, its concentration

does not reach the limit (and in the event of an emergency, measures can be made before injury can occur).

In a room where the concentration may exceed the limit, create an opening to adjacent rooms, or install mechanical

ventilation combined with a gas leak detection device. The concentration is as given below.

Total amount of refrigerant (kg)

Min. volume of the indoor unit installed room (m³)

≤ Concentration limit (kg/m³)

The concentration limit of R-410A which is used in multi air conditioners is 0.3 kg/m³.

Note 1: If there are 2 or more refrigeration systems in

a single refrigeration device, the amounts of refrigerant

should be as charged in each independent device.

e.g. charged

amount (10 kg)

For the amount of charge in this example:

• The possible amount of leaked refrigerant gas in

rooms A, B and C is 10 kg.

• The possible amount of leaked refrigerant gas in

Room A

Room B

Room C Room D Room E Room F

rooms D, E and F is 15 kg.

Note 2: The standards for minimum room volume are as

follows:

(1) No partition (shaded portion)

(2) When there is an effective opening with the adjacent

room for ventilation of leaking refrigerant gas (opening

without a door, or an opening 0.15% or larger than the

respective floor spaces at the top or bottom of the door).

Outdoor unit

e.g. charged amount (15 kg)

Indoor unit

Outdoor unit

Refrigerant piping

Indoor unit

(3) If an indoor unit is installed in each partitioned room and

the refrigerant piping is interconnected, the smallest

room is the critical room. But when a mechanical

ventilation device is installed in combination with a gas

leak detector in the smallest room where the density

limit is exceeded, the volume of the next smallest

room is used.

Very

small

room

Small

Medium room

room

Mechanical ventilation device - gas leak detector

Large room

Refrigerant piping

Outdoor unit

Indoor unit

29

Page 30

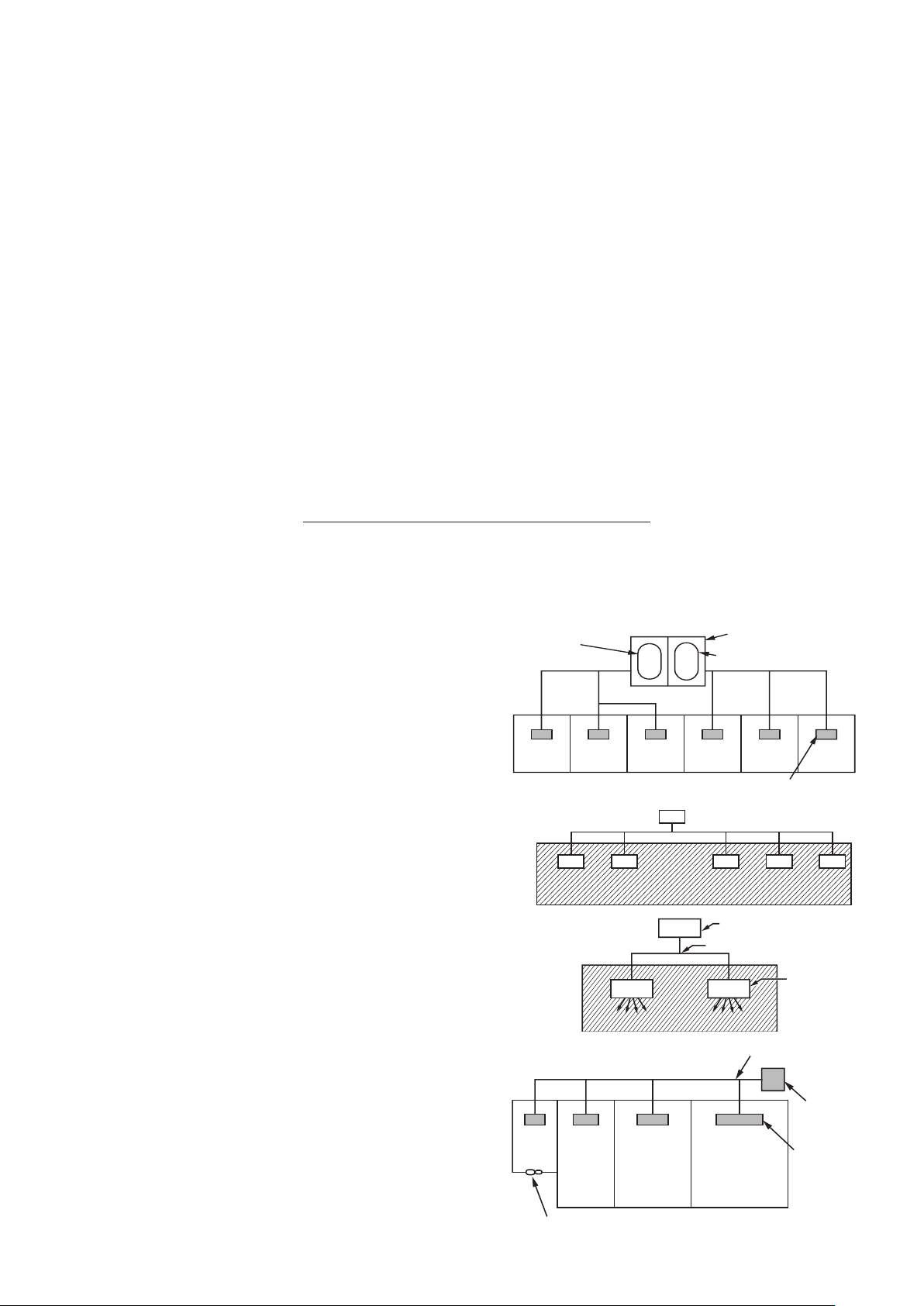

Note 3: The minimum indoor floor area compared with

the amount of refrigerant is roughly as follows (when the

ceiling is 2.7 m high):

m

Min. indoor floor area

density limit of

0.3 kg/m3

(countermeasures

not needed)

Range above the

density limit of

0.3 kg/m3

(countermeasures

needed

Range below the

2

Total refrigerant amount

kg

2. Free branching system

Line branching system

Header branching system

Header branching after line branching

Line branching after header branching

Header branching after header branching

The above five branching systems are available to increase significantly the flexibility of refrigerant piping design.

Outdoor unit

Line

branching

system

Indoor unit

Header

branching

system

Branching joint

Remote

controller

Outdoor unit

Branching header

Header

branching

after line

branching

Line

branching

after header

branching

Header

branching

after header

branching

Indoor unit

Remote controller

Outdoor unit

Branching joint

Branching header

Indoor unit

Remote

controller

Outdoor unit

Branching header

Branching

joint

Indoor unit

Remote

controller

30

Page 31

3. Allowable length/height difference of refrigerant piping

Height difference

between outdoor

units H3 ≤ 5 m

Height difference

betweeen outdoor

units H1 ≤ 50 m

A master

unit

Outdoor unit

T-shape branching

joint

Main

piping

L1

1st branching

section

D slave

unit 3

B slave

La

LA LB

Main connecting piping between outdoor units

Length corresponding to farthest piping

between outdoor units LO ≤ 25 m

L3

C slave

unit 1

Y-joint

unit 2

Connecting

piping of

outdoor unit

Lb Lc

Branching piping L2

Connecting piping of indoor unit

Equivalent length corresponding to farthest piping L ≤ 175 m

Equivalent length corresponding to farthest piping after 1st branching Li ≤ 65 m

L4

Ld

Branching

Indoor unit

L5

Example 1

Master

unit

Note: In case of connecting method in Example 2, a large amount of

refrigerant and refrigerant oil may return to the master unit. Therefore,

set the T-shape joint so that oil does not enter directly.

header

Slave

unit 1

L6

Slave

unit 2

Master

unit

Example 2

Slave

unit 1

Slave

unit 2

Height difference

between indoor

units H2 ≤ 30 m

Indoor unit

System restrictions

Max. No. of combined outdoor units 4 units

Max. capacity of combined outdoor units 48 hp

Max. No. of connected indoor units 48 units

Max. capacity of combined H2 ≤ 15 135%

indoor units H2 > 15 105%

Note 1: Combination of outdoor units: Master unit (1 unit) + slave units (0 to 3 units).

Master unit is the outdoor unit nearest to the connected indoor units.

Note 2: Install the outdoor units in order of capacity.

(Master unit ≥ slave unit 1 ≥ slave unit 2 ≥ slave unit 3)

Note 3: Refer to outdoor unit combination table on page 7.

Note 4: Piping to indoor units shall be perpendicular to piping to the master outdoor unit as in

Example 1. Do not connect piping to indoor uints in the same direction as the master

outdoor unit in Example 2.

Allowable length and height difference of refrigerant piping

Allowable value Piping section

Piping length Total extension of pipe (liquid pipe, actual length) 300 m LA + LB + La + Lb + Lc + Ld + L1 + L2 + L3 + L4+

L5 + L6 + L7 + a + b + c + d + e + f + g + h + i + j

Farthest piping length L (*) Actual length 150 m LA + LB + Ld + L1 + L3 + L4 + L5 + L6 + j

Equivalent length 175 m

Equivalent length of farthest piping from 1st branching Li (*) 65 m L3 + L4 + L5 + L6 + j

Equivalent length of farthest piping between outdoor units LO (*) 25 m LA + LB + Ld, (LA + Lb, LA + LB + Lc)

Max. equivalent length of main piping (***) 85 m L1

Max. equivalent length of outdoor unit connection piping 10 m Ld, (La, Lb, Lc)

Max. actual length of indoor unit connection piping 30 m a, b, c, d, e, f, g, h, i, j

Height difference Height between indoor Upper outdoor unit 50 m ——

and outdoor units H1 Lower outdoor unit 40 m (**) ——

Height between indoor units H2 30 m ——

Height between outdoor units H3 5 m ——

* (D) is outdoor unit farthest from 1st branching, and ( j ) is indoor unit farthest from 1st branching.

** If the height difference (H2) between indoor units exceeds 3 m, set below 30 m.

*** If the maximum combination capacity of the outdoor units is 46 hp or more, the maximum equivalent length is restricted up to 70 m.

31

Page 32

4. Selection of refrigerant piping

Slave

unit 3

Outdoor unit

connection

piping

Pipe size of outdoor unit (Table 1)

Model name MMY- Gas side Liquid side

MAP0501T8 MAP0501HT8 Ø5/8” Ø3/8”

MAP0601T8 MAP0601HT8 Ø3/4” Ø3/8”

MAP0801T8 MAP0801HT8 Ø7/8” Ø1/2”

MAP1001T8 MAP1001HT8 Ø7/8” Ø1/2”

MAP1201T8 MAP1201HT8 Ø1-1/8” Ø1/2”

Connecting pipe size between outdoor units (Table 2)

Total capacity code of Gas side Liquid side Balance pipe

outdoor units downstream

14 to below 22 Ø1-1/8” Ø5/8” Ø3/8”

22 to below 26 Ø1-3/8” Ø5/8” Ø3/8”

26 to below 36 Ø1-3/8” Ø3/4” Ø3/8”

36 or more Ø1-5/8” Ø7/8” Ø3/8”

Size of main pipe (Table 3)

Total capacity code of Gas side Liquid side

all outdoor units (*1)

Below 6 Ø5/8” Ø3/8”

6 to below 8 Ø3/4” Ø3/8”

8 to below 12 Ø7/8” Ø1/2”

12 to below 14 Ø1-1/8” Ø1/2”

14 to below 22 Ø1-1/8” Ø5/8”

22 to below 26 Ø1-3/8” Ø5/8”

26 to below 36 Ø1-3/8” Ø3/4”

36 to below 46 Ø1-5/8” Ø7/8”

46 or more Ø1-5/8” (*5) Ø7/8”

Determine thickness of the main pipe according to capacity of the outdoor units.

Pipe size between branching sections (Table 4)

Total capacity code of Gas side Liquid side

indoor units downstream (*1)

2.8 or less Ø1/2” Ø3/8”

2.8 to below 6.4 Ø5/8” Ø3/8”

6.4 to below 12.2 Ø7/8” Ø1/2”

12.2 to below 20.2 Ø1-1/8” Ø5/8”

20.2 to below 25.2 Ø1-3/8” Ø5/8”

25.2 to below 35.2 Ø1-3/8” Ø3/4”

35.2 or more Ø1-5/8” Ø7/8”

If the total capacity code value of indoor units exceeds that of the outdoor units,

apply the capacity code of the outdoor units.

Slave

unit 2

Slave

unit 1

Main connection

piping between

outdoor units

Master

unit

Outdoor unit

Balance pipe

T-shape

branching joint

Main piping

1st branching

section

Indoor unit

connection piping

Branching pipe

Indoor unit connection piping

Y-shape

branching

joint

Piping of indoor unit (Table 5)

Indoor unit size Gas side Liquid side

007 to 012 Actual length 15 m or less Ø3/8” Ø1/4”

Actual length exceeds 15 m Ø1/2” Ø1/4”

015 to 018 Ø1/2” Ø1/4”

024 to 056 Ø5/8” Ø3/8”

072 to 096 Ø7/8” Ø1/2”

Selection of branching section (Table 6)

Total capacity code of indoor unit (*1) Model

Y-shape Below 6.4 RBM-BY53E

branching joint 6.4 to below 14.2 RBM-BY103E

(*2) 14.2 to below 25.2 RBM-BY203E

25.2 or more RBM-BY303E

Branching For 4 Below 14.2 RBM-HY1043E

header branching 14.2 to below 25.2 RBM-HY2043E

(*3) For 8 Below 14.2 RBM-HY1083E

branching 14.2 to below 25.2 RBM-HY2083E

T-shape 1 set of 3 types of T-shape joint pipes as RBM-BT13E

branching joint described below:

(For connecting The required quantity is arranged and

outdoor unit) combined at the site.

• Balance pipe (Corresponding difference

Ø3/8”) × 1

• Piping at liquid side (Corresponding

difference Ø3/8” to Ø7/8”) × 1

• Piping at gas side (Corresponding

difference Ø5/8” to Ø1-5/8”) × 1

Minimum wall thickness for R-410A application (Table 7)

Soft Half hard or hard OD (Inch) Minimum wall thickness (mm)

OK OK 1/4” 0.80

OK OK 3/8” 0.80

OK OK 1/2” 0.80

OK OK 5/8” 1.00

NG OK (*4) 3/4” 1.00

NG OK (*4) 7/8” 1.00

NG OK (*4) 1-1/8” 1.00

NG OK (*4) 1-3/8” 1.10

NG OK (*4) 1-5/8” 1.25

Header branching pipe

Indoor unit

Indoor unit

*1 Code is determined according to the unit size. For details, refer to pages 7-9.

*2 When using Y-shape branching joint for 1st branching, select according to capacity code of outdoor unit.

*3 For one line after header branching, indoor units with a maximum of 6.0 capacity code in total can be connected.

*4 If the pipe size is Ø3/4” or more, use a hard type or half hard type for material of the pipe.

*5 The maximum equivalent length of the main pipe should be 70 m or shorter.

32

Page 33

5. Charging requirement with additional refrigerant

After the system has been evacuated, replace the vacuum pump with a refrigerant cylinder and charge the system

with additional refrigerant.

Calculating the amount of additional refrigerant required

Refrigerant in the system when shipped from the factory

5 hp 6 hp 8 hp 10 hp 12 hp

Factory refrigerant Heat pump 8.5 kg 8.5 kg 12.5 kg 12.5 kg 12.5 kg

charge Cooling only 8.0 kg 8.0 kg 11.0 kg 11.0 kg 11.0 kg

When the system is charged with refrigerant at the factory, the amount of refrigerant needed for the pipes at the site

is not included. Calculate the additional amount needed, and add that amount to the system.

Calculation

Additional refrigerant charge amount is calculated from the size of the liquid pipe at the site and its actual length.

Additional refrigerant charge amount at the site =

Actual length of liquid pipe × Additional refrigerant charge amount + Compensation by system hp (Table 2)

per 1 m liquid pipe (Table 1)

Example: Additional charge amount R (kg) = (L1 x 0.025 kg/m) + (L2 x 0.055 kg/m) + (L3 x 0.105 kg/m) + (3.0 kg)

L1: Actual total length of liquid pipe Ø1/4” (m)

L2: Actual total length of liquid pipe Ø3/8” (m)

L3: Actual total length of liquid pipe Ø1/2” (m)

Table 7-1

Liquid side pipe diameter Ø1/4” Ø3/8” Ø1/2” Ø5/8” Ø3/4” Ø7/8”

Additional refrigerant amount/1 m 0.025 kg 0.055 kg 0.105 kg 0.160 kg 0.250 kg 0.350 kg

Table 7-2

Combined Outdoor unit combination Compensation

horse power (hp) by system hp

(hp) (kg)

5 5 0.0

6 6 0.0

8 8 1.5

10 10 2.5

12 12 3.5

14 8 6 0.0

16 8 8 0.0

18 10 8 0.0

20 10 10 3.0

22 12 10 5.0

8 8 6 0.0

24 12 12 7.0

8 8 8 -4.0

26 10 8 8 -4.0

Combined Outdoor unit combination Compensation

horse power (hp) by system hp

(hp) (kg)

28 10 10 8 -2.0

30 10 10 10 0.0

32 12 10 10 1.0

8 8 8 8 -6.0

34 12 12 10 3.0

10 8 8 8 -6.0

36 12 12 12 4.0

10 10 8 8 -6.0

38 10 10 10 8 -6.0

40 10 10 10 10

42 12 10 10 10 -4.0

44 12 12 10 10 -2.0

46 12 12 12 10 0.0

48 12 12 12 12 2.0

-5.0

33

Page 34

6. Wiring design

1. General

(1) Perform wiring of the power supply in conformance with the regulations of the local electric company.

(2) For the control wires connecting indoor units, outdoor units, and between indoor and outdoor units, use of

double-core shielded wires is recommended to prevent noise disturbance.

(3) Be sure to set the earth leakage breaker and the switches to the power supply section of the indoor unit.

(4) Supply power to each outdoor unit and provide an earth leakage breaker or hand switch for each outdoor unit.

(5) Never connect the 220–240 V power to the terminal block (U1, U2, U3, U4, U5, U6) for control cables, as this

will cause problems.

(6) The control wiring system and refrigerant piping system should be in the same line.

(7) Arrange the cables so that the power cables do not come into contact with the high-temperature part of the

pipe; otherwise the coating may melt and cause an accident.

(8) Do not turn on the power to the indoor unit until the refrigerant pipes have been completely evacuated.

2. Outdoor unit power supply

• Select the power supply cabling and fuse of each outdoor unit from the following specifications:

5-core cable, in accordance with 60245 IEC 66.

• Connect the outdoor units via the incorporated terminal block (L1, L2, L3, N).

3. Electrical wiring design

3-phase

50 Hz, 380-415 V

Earth leakage breaker

manual switch

Outdoor unit

power source

Indoor unit

power source

Single-phase

50 Hz, 220-240 V

Earth leakage breaker

power switch

Model Outdoor unit power supply

MMY-AP***T8, HT8 3-phase, 380-415 V, 50 Hz

Outdoor unit power supply

3-phase, 380-415 V, 50 Hz

Earth

Junction box

Unit capacities and power supply wire sizes (reference)

Model

MMY- Wire size Field-supplied fuse

MAP0501T8 MAP0501HT8 3.5 mm² (AWG #12) Max. 26 m 20 A

MAP0601T8 MAP0601HT8 3.5 mm² (AWG #12) Max. 26 m 20 A

MAP0801T8 MAP0801HT8 3.5 mm² (AWG #10) Max. 20 m 30 A

MAP1001T8 MAP1001HT8 5.5 mm² (AWG #10) Max. 28 m 30 A

MAP1201T8 MAP1201HT8 5.5 mm² (AWG #10) Max. 27 m 30 A

• Determine the wire size for the indoor unit according to the number of connected indoor units downstream.

• Observe local regulations regarding wire size selection and installation.

Power supply wiring

34

Page 35

4. Indoor unit power supply (must be independent from outdoor unit power)

Model Power supply wiring

Wire size Field-supplied fuse

All models of indoor units 2.0 mm² (AWG #14) Max. 20 m 3.5 mm² (AWG #12) Max. 50 m 15 A

Note: The connecting length indicated in the table represents the length from the junction box to the outdoor unit when the indoor units are connected in parallel for

power, as shown in the illustration on the previous page. A voltage drop of no more than 2% is assumed. If the connecting length exceeds the length indicated

in the table, select the wire thickness in accordance with local wiring standards.

CAUTIONS

(1) Keep the refrigerant piping system and the indoor-indoor/indoor-outdoor control wiring systems

together.

(2) When running power wires and control wires parallel to each other, either run them through separate

conduits, or maintain a suitable distance between them.

(Current capacity of power wires: 10 A or less for 300 m, 50 A or less for 500 m)

5. Control wiring design

Power supply

Single-phase

220-240 V, 50 Hz

[Central remote controller] (option)

TCB-SC642TLE (for line 64)

Earth

(Open)

Interconnecting wire for control

between outdoor units

Interconnecting wire for control

between outdoor unit and indoor

unit

Shielded wire must be connected

to each outdoor unit

Shielded wire must be connected

to each indoor unit

Standard

remote controller

Wire specification, quantity, size of interconnecting wiring and remote controller wiring

Name Quantity Size Specification

Up to 500 m Up to 1000 m 1000 to 2000 m

Interconnecting wiring 2 cores 1.25 mm² 2.0 mm² Shielded wire

(indoor-indoor/indoor-outdoor/outdoor-outdoor

control wiring, central control wiring)

Remote controller wiring 2 cores 0.5 to 2.0 mm² - - -

(1) The interconnecting wiring and central control wiring use 2-core non-polarity interconnecting wires. Use 2-core shielded wires to prevent noise disturbance. In

this case, close (connect) the end of shielded wires, and perform the functional grounding for the end of the shielded wires which are connected to both indoor

and outdoor units. For the shielded wires which are connected between the central remote controller and the outdoor unit, perform the functional grounding at

only one end of the central control wiring.

(2) Use 2-core non-polarity wire for remote controller (A, B terminals).

Use 2-core non-polarity wire for wiring of group control (A, B terminals).

35

Page 36

6. Control wiring diagram

1. All control wiring is 2-core non-polarity wire.

2. Be sure to use shielded wire for the following wiring to prevent noise disturbance.

• Outdoor-outdoor/indoor-indoor/outdoor-indoor control wiring, central control wiring.

Central control

device

Outdoor unit

Indoor unit

Master

unit

Master

unit

Table 3

Super Modular Multi System

Slave

unit

Slave

unit

Table 1

Slave

unit

Master

unit

Table 1 Table 2

Slave

unit

Remote

controller

Table 1 Control wiring between indoor and outdoor units (L1, L2, L3)

Central control wiring (L4)

Wiring 2-core, non-polarity

Type Shielded wire

Size 1.25 mm²: Up to 1000 m

Length 2.0 mm²: Up to 2000 m (*1)

(*1): Total of control wiring length for all refrigerant circuits ( L1 + L2 + L3 + L4 )

Table 2 Control wiring between outdoor units (L5)

Wiring 2-core, non-polarity

Type Shielded wire

Size 1.25 mm² to 2.0 mm²

Length Up to 100 m (L5)

Table 3 Remote controller wiring (L6, L7)

Wire 2-core

Size 0.5 mm² to 2.0 mm²

Length • Up to 500 m ( L6 + L7 ).

• Up 400 m in case of wireless remote controller in group control.

• Up to 200 m total length of control wiring between indoor units ( L6 ).

Remote controller

Remote controller

36

Page 37

7. Design

Type Model Nominal voltage Voltage range Fan motor Power supply

(V-ph-Hz) Min. Max. kW FLA MCA MOCP

4-way ceiling cassette MMU-AP0091H 230-1-50 198 264 0.060 0.20 0.25 15

MMU-AP0121H 230-1-50 198 264 0.060 0.20 0.25 15

MMU-AP0151H 230-1-50 198 264 0.060 0.22 0.28 15

MMU-AP0181H 230-1-50 198 264 0.060 0.24 0.30 15

MMU-AP0241H 230-1-50 198 264 0.060 0.28 0.35 15

MMU-AP0271H 230-1-50 198 264 0.060 0.28 0.35 15

MMU-AP0301H 230-1-50 198 264 0.060 0.40 0.50 15

MMU-AP0361H 230-1-50 198 264 0.090 0.68 0.85 15

MMU-AP0481H 230-1-50 198 264 0.090 0.93 1.16 15

MMU-AP0561H 230-1-50 198 264 0.090 0.95 1.19 15

2-way ceiling cassette MMU-AP0071WH 230-1-50 198 264 0.053 0.36 0.45 15

MMU-AP0091WH 230-1-50 198 264 0.053 0.36 0.45 15

MMU-AP0121WH 230-1-50 198 264 0.053 0.36 0.45 15

MMU-AP0151WH 230-1-50 198 264 0.039 0.37 0.46 15

MMU-AP0181WH 230-1-50 198 264 0.039 0.37 0.46 15

MMU-AP0241WH 230-1-50 198 264 0.053 0.53 0.66 15

MMU-AP0271WH 230-1-50 198 264 0.053 0.53 0.66 15

MMU-AP0301WH 230-1-50 198 264 0.053 0.54 0.68 15

MMU-AP0481WH 230-1-50 198 264 0.092 1.33 1.67 15

1-way ceiling cassette MMU-AP0071YH 230-1-50 198 264 0.022 0.28 0.35 15

MMU-AP0091YH 230-1-50 198 264 0.022 0.28 0.35 15

MMU-AP0121YH 230-1-50 198 264 0.022 0.28 0.35 15

MMU-AP0151SH 230-1-50 198 264 0.034 0.55 0.69 15

MMU-AP0181SH 230-1-50 198 264 0.034 0.55 0.69 15

MMU-AP0241SH 230-1-50 198 264 0.034 0.63 0.79 15

Standard ducted unit MMD-AP0071BH 230-1-50 198 264 0.120 0.33 0.41 15

MMD-AP0091BH 230-1-50 198 264 0.120 0.33 0.41 15

MMD-AP0121BH 230-1-50 198 264 0.120 0.39 0.49 15

MMD-AP0151BH 230-1-50 198 264 0.120 0.39 0.49 15

MMD-AP0181BH 230-1-50 198 264 0.120 0.50 0.62 15

MMD-AP0241BH 230-1-50 198 264 0.120 0.60 0.75 15

MMD-AP0271BH 230-1-50 198 264 0.120 0.60 0.75 15

MMD-AP0301BH 230-1-50 198 264 0.120 0.70 0.88 15

MMD-AP0361BH 230-1-50 198 264 0.120 0.96 1.20 15

MMD-AP0481BH 230-1-50 198 264 0.120 1.13 1.41 15

MMD-AP0561BH 230-1-50 198 264 0.120 1.13 1.41 15

High-pressure ducted unit MMD-AP0181H 230-1-50 198 264 0.160 0.93 1.16 15

MMD-AP0241H 230-1-50 198 264 0.160 1.55 1.94 15

MMD-AP0271H 230-1-50 198 264 0.160 1.55 1.94 15

MMD-AP0361H 230-1-50 198 264 0.260 1.87 2.34 15

MMD-AP0481H 230-1-50 198 264 0.260 2.12 2.65 15

MMD-AP0721H 230-1-50 198 264 0.370 × 3 6.04 7.55 15

MMD-AP0961H 230-1-50 198 264 0.370 × 3 6.35 7.94 15

Slim duct unit MMD-AP0071SPH 230-1-50 198 264 0.060 0.35 0.44 15

MMD-AP0091SPH 230-1-50 198 264 0.060 0.35 0.44 15

MMD-AP0121SPH 230-1-50 198 264 0.060 0.37 0.47 15

MMD-AP0151SPH 230-1-50 198 264 0.060 0.38 0.48 15

MMD-AP0181SPH 230-1-50 198 264 0.060 0.47 0.59 15

Ceiling-suspended unit MMC-AP0151H 230-1-50 198 264 0.030 0.33 0.41 15

MMC-AP0181H 230-1-50 198 264 0.030 0.37 0.46 15

MMC-AP0241H 230-1-50 198 264 0.040 0.48 0.60 15

MMC-AP0271H 230-1-50 198 264 0.040 0.48 0.60 15

MMC-AP0361H 230-1-50 198 264 0.080 0.90 1.13 15

MMC-AP0481H 230-1-50 198 264 0.080 0.96 1.20 15

High-wall unit MMK-AP0071H 230-1-50 198 264 0.030 0.35 0.44 15

MMK-AP0091H 230-1-50 198 264 0.030 0.35 0.44 15

MMK-AP0121H 230-1-50 198 264 0.030 0.35 0.44 15

MMK-AP0151H 230-1-50 198 264 0.030 0.37 0.46 15

MMK-AP0181H 230-1-50 198 264 0.030 0.37 0.46 15

MMK-AP0241H 230-1-50 198 264 0.030 0.40 0.50 15

MMK-AP0072H 230-1-50 198 264 0,030 0,20 0,24 15

MMK-AP0092H 230-1-50 198 264 0,030 0,21 0,26 15

MMK-AP0122H 230-1-50 198 264 0,030 0,22 0,27 15

Floor-mounted console unit MML-AP0071H 230-1-50 198 264 0.045 0.30 0.37 15

MML-AP0091H 230-1-50 198 264 0.045 0.30 0.37 15

MML-AP0121H 230-1-50 198 264 0.045 0.49 0.62 15

MML-AP0151H 230-1-50 198 264 0.045 0.49 0.62 15

MML-AP0181H 230-1-50 198 264 0.070 0.54 0.68 15

MML-AP0241H 230-1-50 198 264 0.070 0.54 0.68 15

Concealed chassis unit MML-AP0071BH 230-1-50 198 264 0.019 0.29 0.36 15

MML-AP0091BH 230-1-50 198 264 0.019 0.29 0.36 15

MML-AP0121BH 230-1-50 198 264 0.019 0.29 0.36 15

MML-AP0151BH 230-1-50 198 264 0.070 0.52 0.65 15

MML-AP0181BH 230-1-50 198 264 0.070 0.52 0.65 15

MML-AP0241BH 230-1-50 198 264 0.070 0.53 0.66 15

Floor-mounted cabinet unit MMF-AP0151H 230-1-50 198 264 0.037 0.77 0.96 15

MMF-AP0181H 230-1-50 198 264 0.037 0.77 0.96 15

MMF-AP0241H 230-1-50 198 264 0.063 1.01 1.27 15

MMF-AP0271H 230-1-50 198 264 0.063 1.01 1.27 15

MMF-AP0361H 230-1-50 198 264 0.110 1.48 1.85 15

MMF-AP0481H 230-1-50 198 264 0.160 1.84 2.30 15

MMF-AP0561H 230-1-50 198 264 0.160 1.84 2.30 15

Legend

MCA Minimum circuit current, A

FLA Full load current, A

MOCP Maximum overcurrent protection current, A

37

Page 38

Single outdoor unit

Heat pump Cooling only Nominal Voltage Compressor Fan motor Power supply

MMY- MMY- voltage range

(V-ph-Hz) Min. Max. RLA kW FLA MCA MOCP

MAP0501HT8 MAP0501T8 400-3-50 342 457 4.0 + 4.0 0.60 0.8 16.5 20

MAP0601HT8 MAP0601T8 400-3-50 342 457 4.6 + 4.6 0.60 0.8 16.5 20

MAP0801HT8 MAP0801T8 400-3-50 342 457 5.2 + 5.2 0.60 1.0 20.0 30

MAP1001HT8 MAP1001T8 400-3-50 342 457 6.5 + 6.5 0.60 1.1 22.5 30

MAP1201HT8 MAP1201T8 400-3-50 342 457 9.5 + 9.5 0.60 1.1 24.5 30

Combination of outdoor units

Heat pump Cooling only Nominal Voltage Compressor Fan motor Power supply

MMY- MMY- voltage range Unit No. 1 Unit No. 2 Unit No. 3 Unit No. 4

(V-ph-Hz Min. Max. RLA RLA RLA RLA kW FLA MCA MOCP

AP1401HT8 AP1401T8 400-3-50 342 457 5.2 + 5.2 4.6 + 4.6 — — 0.6 × 2 1.0 + 0.8 36.5 40

AP1601HT8 AP1601T8 400-3-50 342 457 5.2 + 5.2 5.2 + 5.2 — — 0.6 × 2 1.0 + 1.0 40.0 50

AP1801HT8 AP1801T8 400-3-50 342 457 6.5 + 6.5 5.2 + 5.2 — — 0.6 × 2 1.0 + 1.1 42.5 50

AP2001HT8 AP2001T8 400-3-50 342 457 6.5 + 6.5 6.5 + 6.5 — — 0.6 × 2 1.1 + 1.1 45.0 60

AP2201HT8 AP2201T8 400-3-50 342 457 5.2 + 5.2 5.2 + 5.2 4.6 + 4.6 — 0.6 × 3 1.0 + 1.0 + 0.8 56.5 70

AP2211HT8 AP2211T8 400-3-50 342 457 9.5 + 9.5 6.5 + 6.5 — — 0.6 × 2 1.1 + 1.1 47.0 60

AP2401HT8 AP2401T8 400-3-50 342 457 5.2 + 5.2 5.2 + 5.2 5.2 + 5.2 — 0.6 × 3 1.0 + 1.0 + 1.0 60.0 70

AP2411HT8 AP2411T8 400-3-50 342 457 9.5 + 9.5 9.5 + 9.5 — — 0.6 × 2 1.1 + 1.1 49.0 60

AP2601HT8 AP2601T8 400-3-50 342 457 6.5 + 6.5 5.2 + 5.2 5.2 + 5.2 — 0.6 × 3 1.1 + 1.1 + 1.0 62.5 70

AP2801HT8 AP2801T8 400-3-50 342 457 6.5 + 6.5 6.5 + 6.5 5.2 + 5.2 — 0.6 × 3 1.1 + 1.1 + 1.0 65.0 80

AP3001HT8 AP3001T8 400-3-50 342 457 6.5 + 6.5 6.5 + 6.5 6.5 + 6.5 — 0.6 × 3 1.1 + 1.1 + 1.1 67.5 80

AP3201HT8 AP3201T8 400-3-50 342 457 5.2 + 5.2 5.2 + 5.2 5.2 + 5.2 5.2 + 5.2 0.6 × 4 1.0 + 1.0 + 1.0 + 1.0 80.0 90

AP3211HT8 AP3211T8 400-3-50 342 457 9.5 + 9.5 6.5 + 6.5 6.5 + 6.5 — 0.6 × 3 1.1 + 1.1 + 1.1 69.5 80

AP3401HT8 AP3401T8 400-3-50 342 457 6.5 + 6.5 5.2 + 5.2 5.2 + 5.2 5.2 + 5.2 0.6 × 4 1.1 + 1.0 + 1.0 + 1.0 82.5 100

AP3411HT8 AP3411T8 400-3-50 342 457 9.5 + 9.5 9.5 + 9.5 6.5 + 6.5 — 0.6 × 3 1.1 + 1.1 + 1.1 71.5 80

AP3601HT8 AP3601T8 400-3-50 342 457 6.5 + 6.5 6.5 + 6.5 5.2 + 5.2 5.2 + 5.2 0.6 × 4 1.1 + 1.1 + 1.0 + 1.0 85.0 100

AP3611HT8 AP3611T8 400-3-50 342 457 9.5 + 9.5 9.5 + 9.5 9.5 + 9.5 — 0.6 × 3 1.1 + 1.1 + 1.1 73.5 90

AP3801HT8 AP3801T8 400-3-50 342 457 6.5 + 6.5 6.5 + 9.5 6.5 + 6.5 5.2 + 5.2 0.6 × 4 1.1 + 1.1 + 1.1 + 1.0 87.5 100

AP4001HT8 AP4001T8 400-3-50 342 457 6.5 + 6.5 6.5 + 6.5 6.5 + 6.5 6.5 + 6.5 0.6 × 4 1.1 + 1.1 + 1.1 + 1.1 90.0 100

AP4201HT8 AP4201T8 400-3-50 342 457 9.5 + 9.5 6.5 + 6.5 6.5 + 6.5 6.5 + 6.5 0.6 × 4 1.1 + 1.1 + 1.1 + 1.1 92.0 110

AP4401HT8 AP4401T8 400-3-50 342 457 9.5 + 9.5 9.5 + 9.5 6.5 + 6.5 6.5 + 6.5 0.6 × 4 1.1 + 1.1 + 1.1 + 1.1 94.0 110

AP4601HT8 AP4601T8 400-3-50 342 457 9.5 + 9.5 9.5 + 9.5 9.5 + 9.5 6.5 + 6.5 0.6 × 4 1.1 + 1.1 + 1.1 + 1.1 96.0 110

AP4801HT8 AP4801T8 400-3-50 342 457 9.5 + 9.5 9.5 + 9.5 9.5 + 9.5 9.5 + 9.5 0.6 × 4 1.1 + 1.1 + 1.1 + 1.1 98.0 110

Legend

MCA Minimum circuit current, A

FLA Full load current, A

MOCP Maximum overcurrent protection current, A

kW Rated fan motor output, kW

RLA Rated load current, A

Note: RLA is based on the following conditions:

Indoor temperature: 27°C db/19°C wb

Outdoor temperature: 35°C db

38

Page 39

7. Controls

A range of controls to meet various system needs

As the size of the building increases so does the number of air conditioning units required. The multiple air

conditioning system Super MMS ensures energy savings and comfort by allowing control of multiple units requiring

different loads.

The Super MMS provides a range of functions to enable integrated, centralized control of multiple units. Design an

optimal system that best suits the application and scale of your project.

1. Control via indoor remote controller

1-1. Remote contoller

Individual air conditioning units can be controlled remotely.

1-2. Group control

One remote controller can control a maximum of 8 indoor units in a group.

1-3. Two controlling positions

The units can be controlled from two locations using two remote controllers.

1-4. Weekly timer

The units can be run on a weekly schedule using a “remote controller with weekly timer”.

2. Control via the central remote controller

2-1. Central control + individual control

Up to 64 units can be controlled using the central remote controller and/or indoor remote controllers.

2-2. Weekly timer controller

The central remote controller can be connected to a weekly timer to set a weekly running schedule.

2-3. Control without indoor remote controller

The units can be operated from the central remote controller only, without the use of indoor remote controllers.

2-4. Central control with 1 to 1 models

Additionally, 1 to 1 models like the Digital Inverter or Super Digital Inverter can be joined into the Super MMS

central control scheme.

3. Network control

The Super MMS control system can offer flexible centralized network control according to various customer

requirements, for both open network building control in combination with other building apparatus such as

elevator, fire alarm, lighting, etc., and also for stand-alone central air conditioning control.

These central control systems are mainly established by advanced local server platforms.

3-1. Open network control

Super MMS open network control is applicable for major global building management standards.

3-1-1. LONWORKS

The LONWORKS interface manages the Super MMS air conditioning system as a LON device to

command a building computer message and to monitor the operating status.

3-1-2. BACnet

The local server serves air conditioning sub-system in a building control BACnet system.

3-2. Stand-alone central control

Simple exclusive air conditioning central control with less system integration work.

3-2-1. Touch-screen controller

A combination of touch-screen and local server enables easy operation and user-friendly display.

3-2-2. Windows-based plug-in central controller

The local server provides the central control function only by plug-in into a customer’s computer.

39

Page 40

1. Applications for indoor remote controller

Basic function System diagram Model

1-1 Individual control • Wired remote controller

Air conditioner is individually RBC-AMT31E

operated at a distance. • Simplified remote controller

RBC-AS21E

• Wireless remote controller kit

TCB-AX21U(W)-E

RBC-AX22CE

TCB-AX21E

Main remote controller

Indoor

unit

Possible up to max.

total length 500 m

Remote

controller

Wireless remote controller

Indoor

unit

Receiver unit

Wireless

remote

controller

1-2 GROUP control • Wired remote controller

One remote controller can RBC-AMT31E

control a group of max. 8 • Simplified remote controller

indoor units. Operating on RBC-AS21E

the same setting.

1-3 Two remote controllers • Wired remote controller

Air conditioner is controlled by

two remote controller in two • Simplified remote controller

places. RBC-AS21E

• Wireless remote controller kit

RBC-AX22CE

TCB-AX21E

Indoor

unit

Remote

controller

Wired system Wireless system

Indoor

unit

Remote

controller

Master

Possible up to max.

total length 500 m

Max. 8 indoor units

Indoor

unit

Possible up to max. total length 500 m

Remote

controller

Sub-controller

Indoor

unit

Indoor

unit

Wireless

remote

controller 1

Master

Indoor

unit

RBC-AMT31E

TCB-AX21U(W)-E

Wireless

remote

controller 2

Sub-controller

Indoor

unit

Wired and wireless

combination control

(either controller

should be set as

sub-controller)

1-4 Control by weekly timer • Wired remote controller

Weekly schedule operation.

+

• Weekly timer

RBC-EXW21E

Indoor

unit

Remote

controller

Remote

controller

Weekly timer function

Settings of ON/OFF

3 times per day

Timer time is displayed

Designation of holiday

Weekly

timer

Wireless

remote

controller

RBC-AMT31E

40

Page 41

2. Application controls for central remote controller

Basic function System diagram Model

2-1 Central management • Central remote controller

controller for 64 units TCB-SC642TLE

Indoor remote controller

• Wired remote controller

• Simplified remote controller

RBC-AS21E

Zone 4

U3, U4

Master

unit

U1, U2

Outdoor unit

Line 3

U5, U6

Indoor unit

RBC-AMT31E

Master

U3, U4

Zone 3

Zone 2

U3, U4

Zone 1

Power

supply

Function of central remote controller

• Individual control of up to 64 indoor units.

• Individual control for max. 64 indoor units divided into 1 to 4 zones (up to

16 indoor units for each zone).

• Up to 16 outdoor master units are connectable.

• 4 central control settings to inhibit individual operation by remote controller

can be selected.

• Setting for one of 1 to 4 zones is available.

• Usable with other central control devices (up to 10 central control devices

in one control circuit).

• Choice of two control modes: central controller mode/remote controller

mode.

• Setting of simultaneous ON/OFF 3 times for each day of the week

combined with weekly timer.

unit

U1, U2

Master

unit

U1, U2

Central

remote controller

Single-phase

220/240 V

Indoor remote controller

Outdoor unit

U5, U6

Outdoor unit

Line 1

Line 2

Indoor remote controller

Indoor remote controller

Indoor unit

Indoor unit

2-2 Central remote controller • Central remote controller

+ TCB-SC642TLE

weekly timer +

• Weekly timer

RBC-EXW21E

Weekly operation schedule can

be set by connecting a weekly Indoor remote controller

timer to the contral remoter • Wired remote controller

controller. RBC-AMT31E

or

• Simplified remote controller

RBC-AS21E

U3, U4

Single-phase

220/240 V

Power

supply

remote controller

Central

Outdoor unit

Indoor unit

Indoor remote controller

Weekly timer

U1, U2

41

Page 42

Basic function System diagram Model

2-3 Remote central control • Central remote controller

without indoor remote

controller

Indoor remote controller

• Wired remote controller

RBC-AMT31E

Power

supply

Single-phase,

U3, U4

Outdoor unit

Central remote controller

U1, U2

Indoor unit

TCB-SC642TLE

220-240 V

Even when grouping operation is performed

by connecting multiple indoor units to 1 line,

the indoor remote controller is required.

Example of grouping operation

U3, U4

Outdoor unit

U1, U2

Power

supply

(Group)

Indoor remote controller is required

Single-phase,

220-240 V

Central remote controller

U3, U4

Outdoor unit

Available

U1, U2

Power

supply

(Group)