Toshiba HDXA-1-KN, HDD-1-KN, HDA-1-SN Service manual

SERVICE MANUAL

DOCUMENT CREATED IN JAPAN, MARCH, 2006

Revision 1

HD DVD PLAYER

HD-XA1KN

FILE NO. 810-200631GR

HD-A1SN

HD-D1KN

(HD-XA1KN)

The above models are classified as green products (*1), as indicated by the underlined serial numbers.

This Service Manual describes replacement parts for the green products. When repairing these green

product(s), use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), see the next page.

Mar., 2006 GREEN

(*1) GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for recycling

and reuse of Waste Electrical and Electronic Equipment and for the Restriction of the use of

certain Hazardous Substances. From July 1, 2006, the RoHS Directive will prohibit any marketing

of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba Corporation

recognizes environmental protection as a key management tasks, and is doing its utmost to

enhance and improve the quality and scope of its environmental activities. In line with this,

Toshiba proactively promotes Green Procurement, and seeks to purchase and use products,

parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts used in

manufacture must also be used as replacement parts.

(*2) LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the consumer

products industry at large to be environmentally responsible. Lead-free solder must be used in the

servicing and repair of this product.

WARNING

This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT !

The melting temperature of lead-free solder is higher than that of leaded solder by 86°F to 104°F

(30°C to 40°C). Use of a soldering iron designed for lead-based solders to repair product made

with lead-free solder may result in damage to the component and or PCB being soldered. Great

care should be made to ensure high-quality soldering when servicing this product especially when

soldering large components, through-hole pins, and on PCBs as the level of heat required to melt

lead-free solder is high.

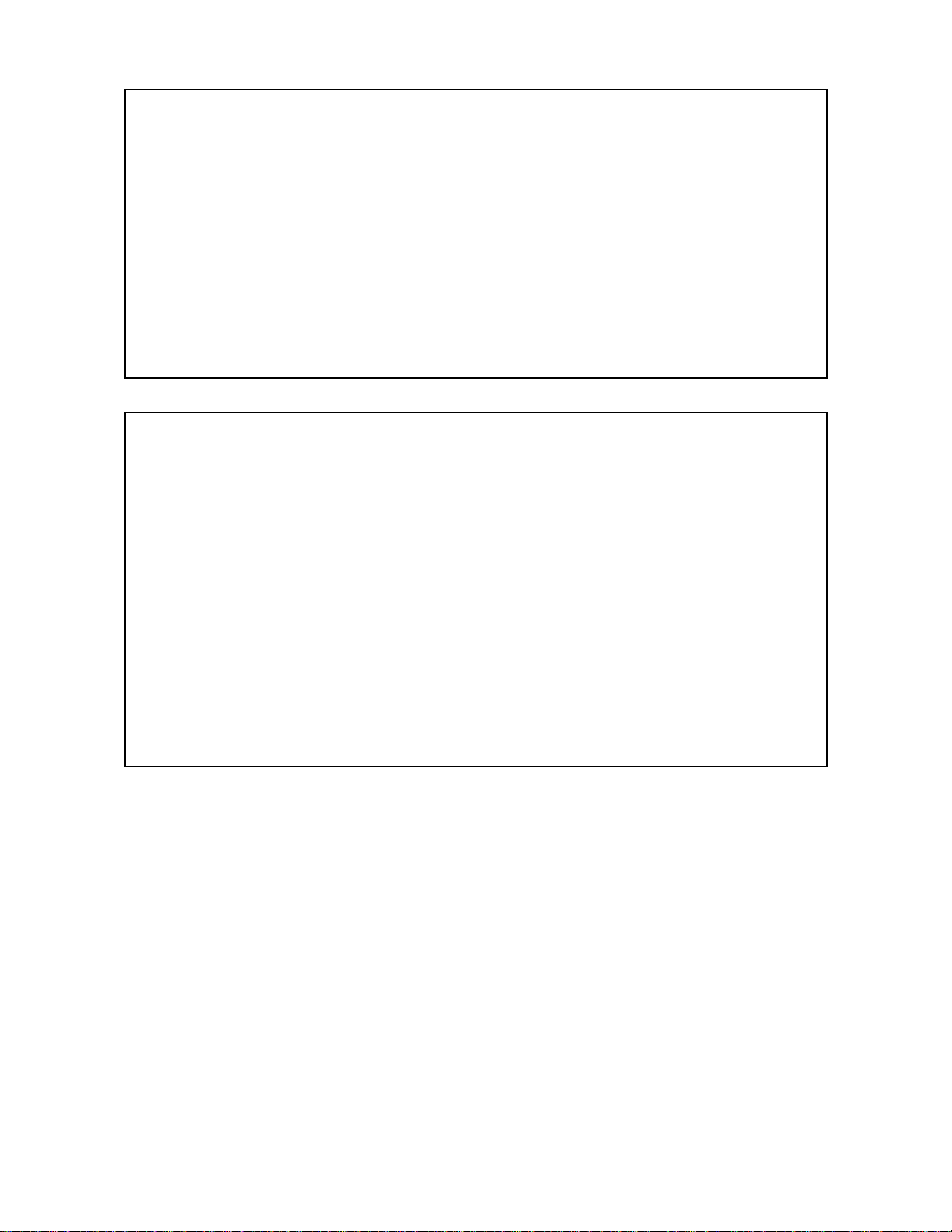

LASER BEAM CAUTION LABEL

When the power supply is being turned on, you may not remove this laser cautions label. If it removes, radiation of a laser

may be received.

PREPARATION OF SERVICING

Pickup Head consists of a laser diode that is very susceptible to external static electricity.

Although it operates properly after replacement, if it was subject to electrostatic discharge during replacement, its

life might be shortened. When replacing, use a conductive mat, soldering iron with ground wire, etc. to protect the

laser diode from damage by static electricity.

And also, the LSI and IC are same as above.

Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are trademarks of Dolby Laboratories.

·

Manufactured under license from Digital Theater Systems, Inc. U.S. Pat. No’s. 5,451,942; 5,956,674; 5,974,380; 5,978,762; 6,226,616;

·

6,487,535 and other U.S. and world-wide patents issued and pendling.

“DTS” and “DTS Digital Surround” are registered trademarks of Digital Theater Systems, Inc.

Copyright 1996, 2003 Digital Theater Systems, Inc. All Rights Reserved.

HDMI, the HDMI logo and High-Definition Multimedia Interface are trademarks or registered trademarks of HDMI Licensing LLC.

·

SHARC is a registered trademark and Melody is a trademark of Analog Devices, Inc.

·

All other brand and product names mentioned in this manual are trademarks and/or registered trademarks of their respective holders.

·

SAFETY NOTICE

SAFETY PRECAUTIONS

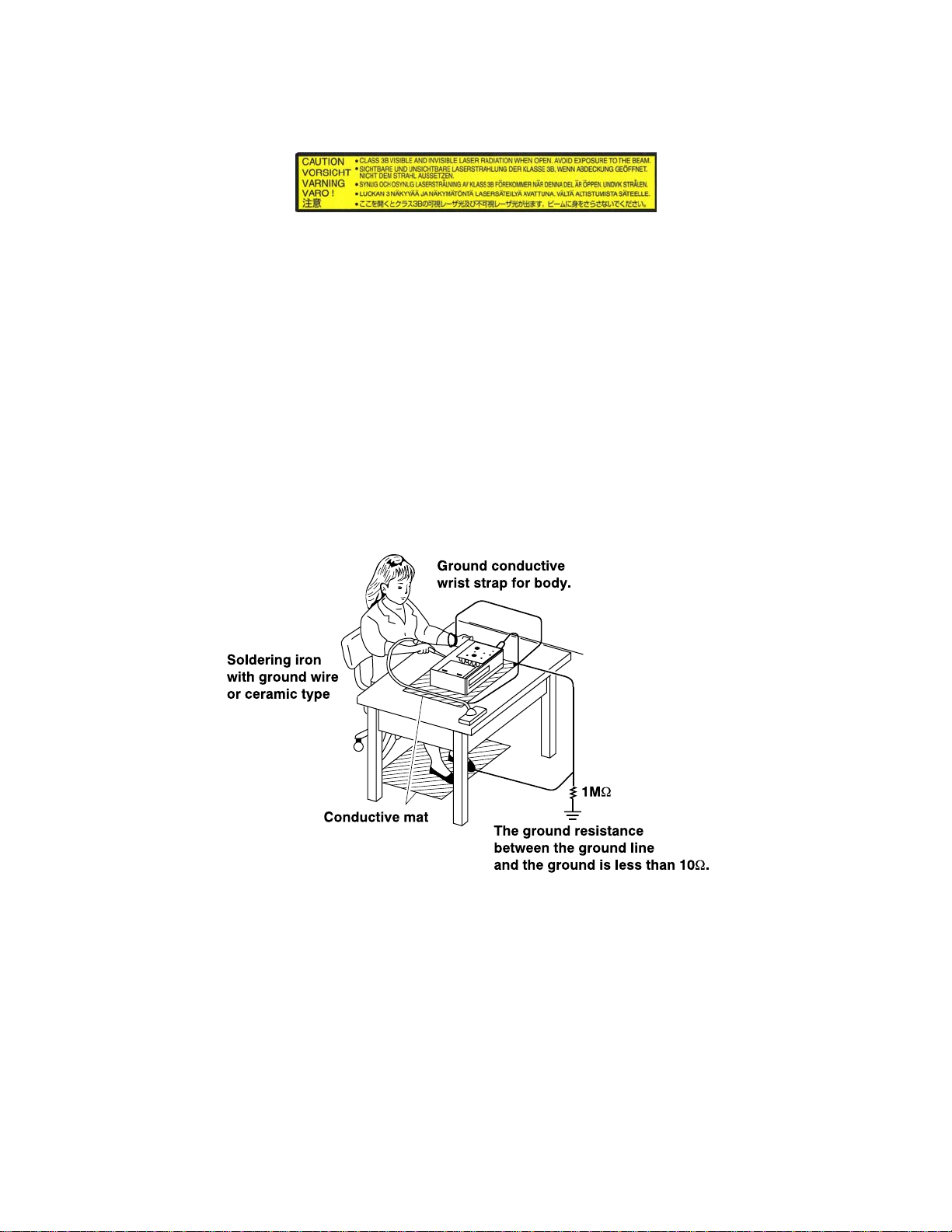

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120V AC outlet (do

not use an isolation transformer for this check). Use an

AC voltmeter, having 5000 Ω per volt or more sensitivity.

Connect a 1500 Ω 10 W resistor, paralleled by a 0.15 μF

150V AC capacitor between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of

cabinet (antennas, handle bracket, metal cabinet

screwheads, metal overlays, control shafts, etc.).

READING SHOULD NOT EXCEED 0.3V

Measure the AC voltage across the 1500 Ω resistor.

The test must be conducted with the AC switch on and

then repeated with the AC switch off. The AC voltage

indicated by the meter may not exceed 0.3 V. A reading

exceeding 0.3 V indicates that a dangerous potential

exists, the fault must be located and corrected.

Repeat the above test with the DVD PLAYER power plug

reversed.

NEVER RETURN A DVD PLAYER TO THE CUSTOMER

WITHOUT TAKING NECESSARY CORRECTIVE AC-

TION.

DVD PLAYER

AC OUTLET

AC VOLTMETER

(5000 Ω per volt

or more sensitivity)

Good earth ground

such as a water pipe,

1500 Ω

10 W

0.15 μF 150V AC

conduit, etc.

Test all exposed metal.

Voltmeter Hook-up for Leakage Current Check

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

1. OPERATING INSTRUCTIONS

2. LOCATION OF MAIN PARTS

2-1. Location of Main Parts

2-2. Location of PC Boards

CONTENTS

SECTION 1

GENERAL DESCRIPTIONS

3. TROUBLESHOOTING

3-1. Standby LED (red) does not lisht.

3-2. LED (green) does not light at power on.

3-3. CPU FAN does not work.

3-4. Indicator does not light. (“WELCOME” does not

light at startup.)

3-5. System does not run. (“WELCOME” displayed and

key operation disabled)

3-6. No picture appears.

3-7. No audio is played back.

3-8. Buzzer does not sound.

3-9. Extension port does not work.

3-10. Front panel key/remote control are disabled.

3-11. Other Symptoms

3-12. Power Circuit Troubleshooting

MEASURING POINTS

PART REPLACEMENT AND ADJUSTMENT PROCEDURES

1. REPLACEMENT OF MECHANICAL PARTS

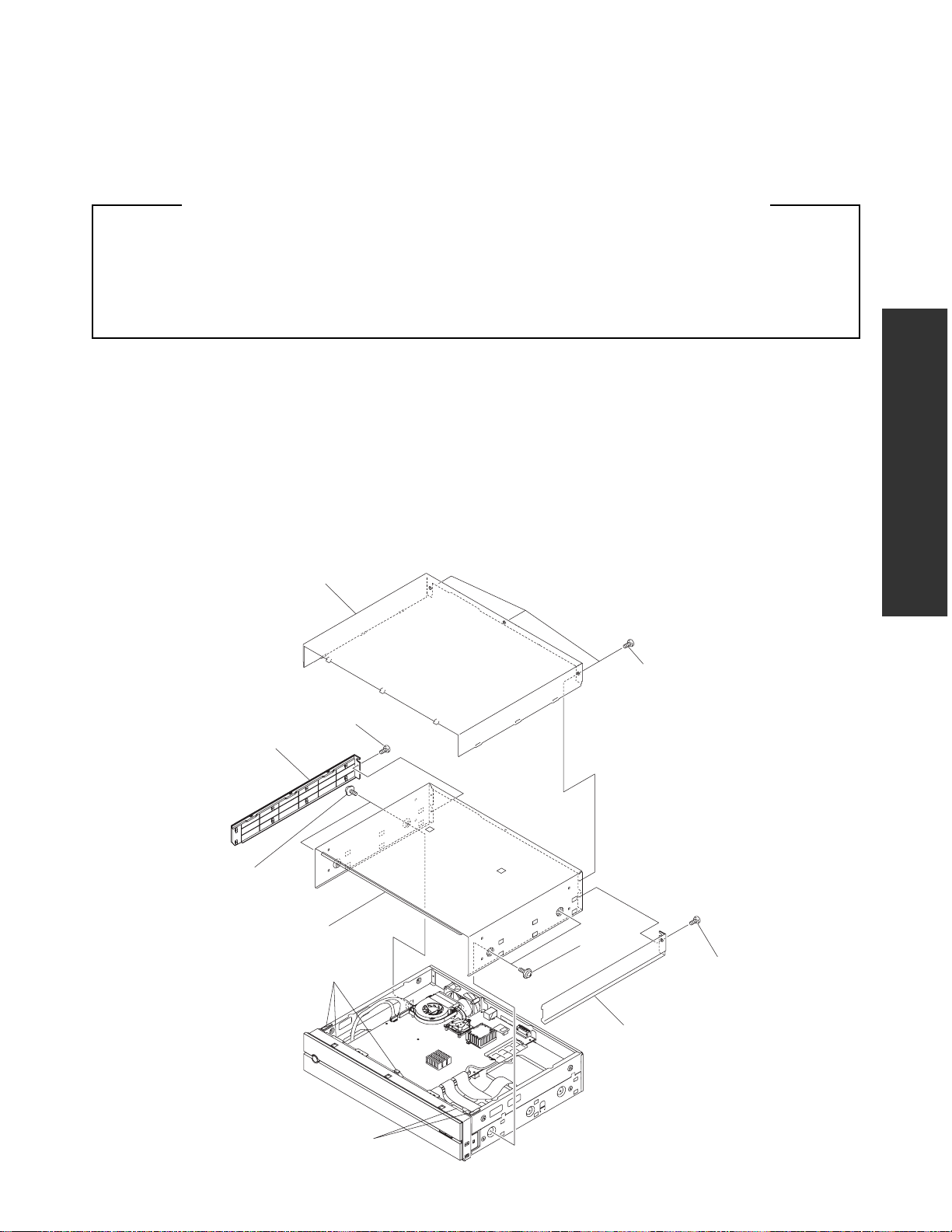

1-1. Cabinet Replacement

1-1-1. Top Panel and Top Cover

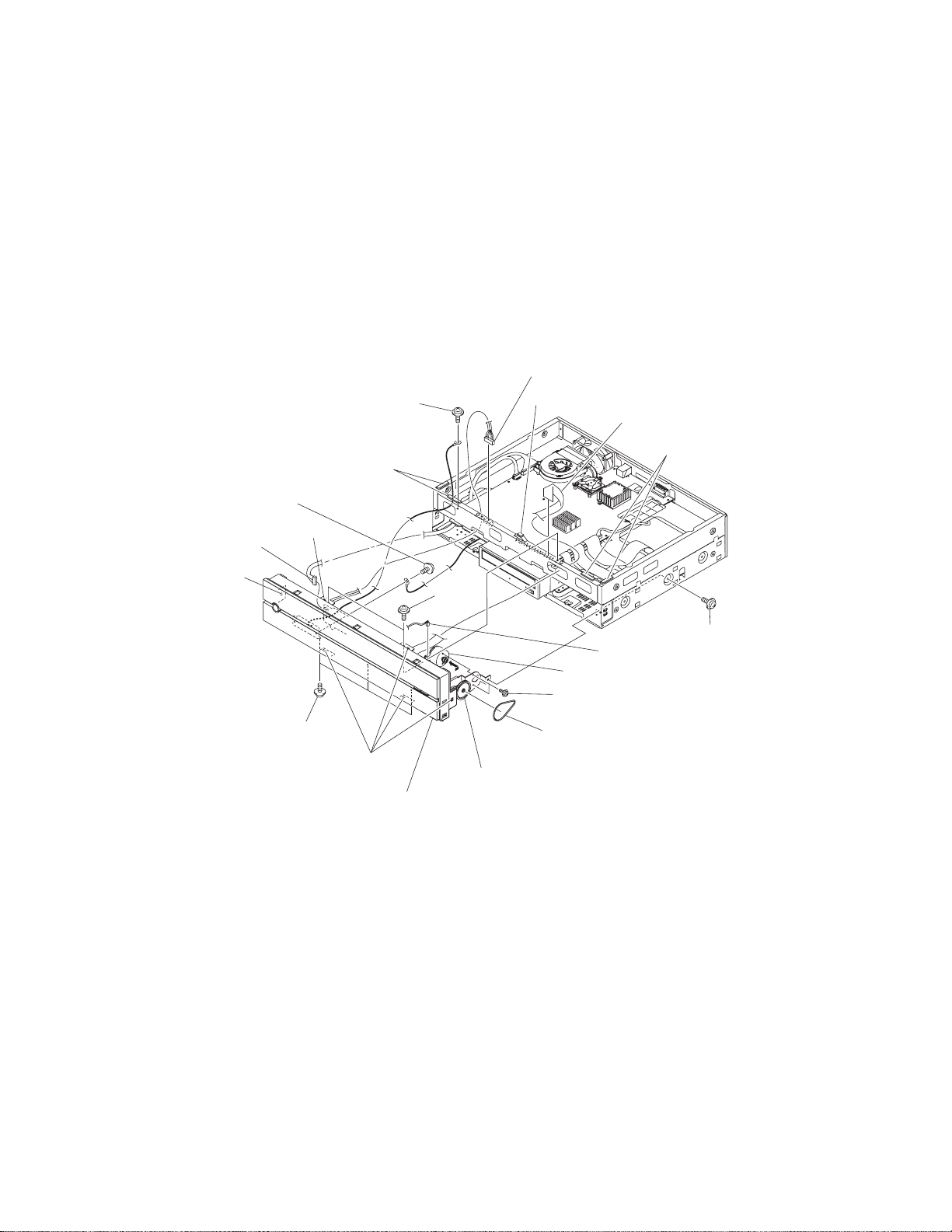

1-1-2. Front Panel and Motor

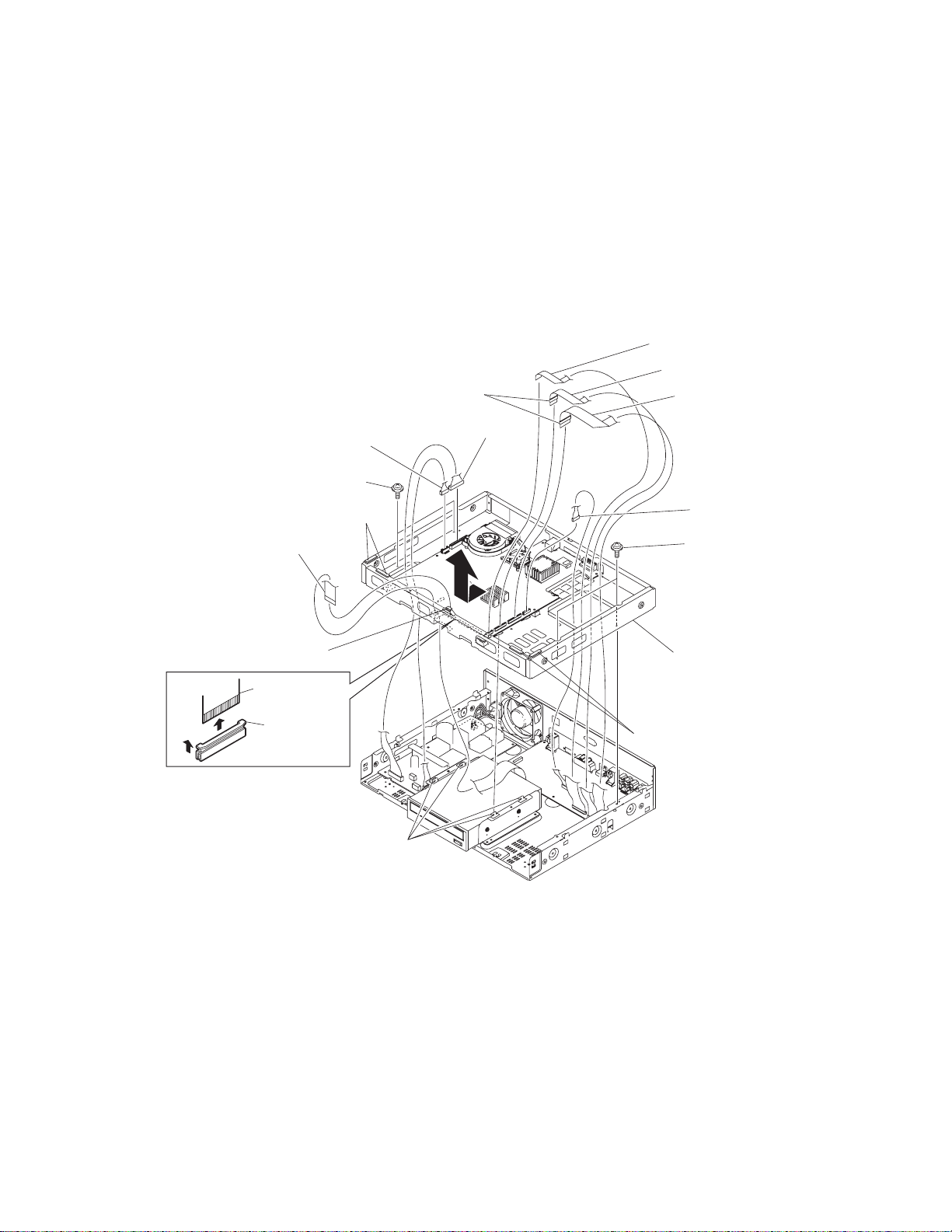

1-1-3. Sub-chassis

1-1-4. HD-DVD Drive

1-1-5. Rear Panel

1-1-6. Fan

1-2. PC Board Replacement

1-2-1. Digital PC Board

1-2-2. CPU

1-2-3. SO-DIMM

1-2-4. Power PC Board

1-2-5. AV PC Board

1-2-6. Front PC Boards

1. CIRCUIT SYMBOLS AND

SUPPLEMENTARY EXPLANATION

1-1. Precautions for Part Replacement

1-2. Solid Resistor Indication

1-3. Capacitance Indication

1-4. Inductor Indication

1-5. Waveform and Voltage Measurement

1-6. Others

2. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram

SECTION 2

2. WIRING CONNECTION DIAGRAM

2-1. Wiring Connection Diagram

2-2. Supplementary Instructions for Reassembling

SECTION 3

SERVICING DIAGRAMS

4. CIRCUIT DIAGRAMS

4-1. Power Supply Circuit Diagram

4-2. Front Circuit Diagram

4-2-1. PWR-SW Circuit Diagram

4-2-2. USB Circuit Diagram

4-2-3. Front-MAIN Circuit Diagram

4-2-4. Door-Detect Circuit Diagram (HD-XA1)

4-2-5. Motor Circuit Diagram (HD-XA1)

4-3. AV Circuit Diagram

4-3-1. Audio Circuit Diagram

4-3-2. Video Circuit Diagram

4-3-3. HDMI Circuit Diagram

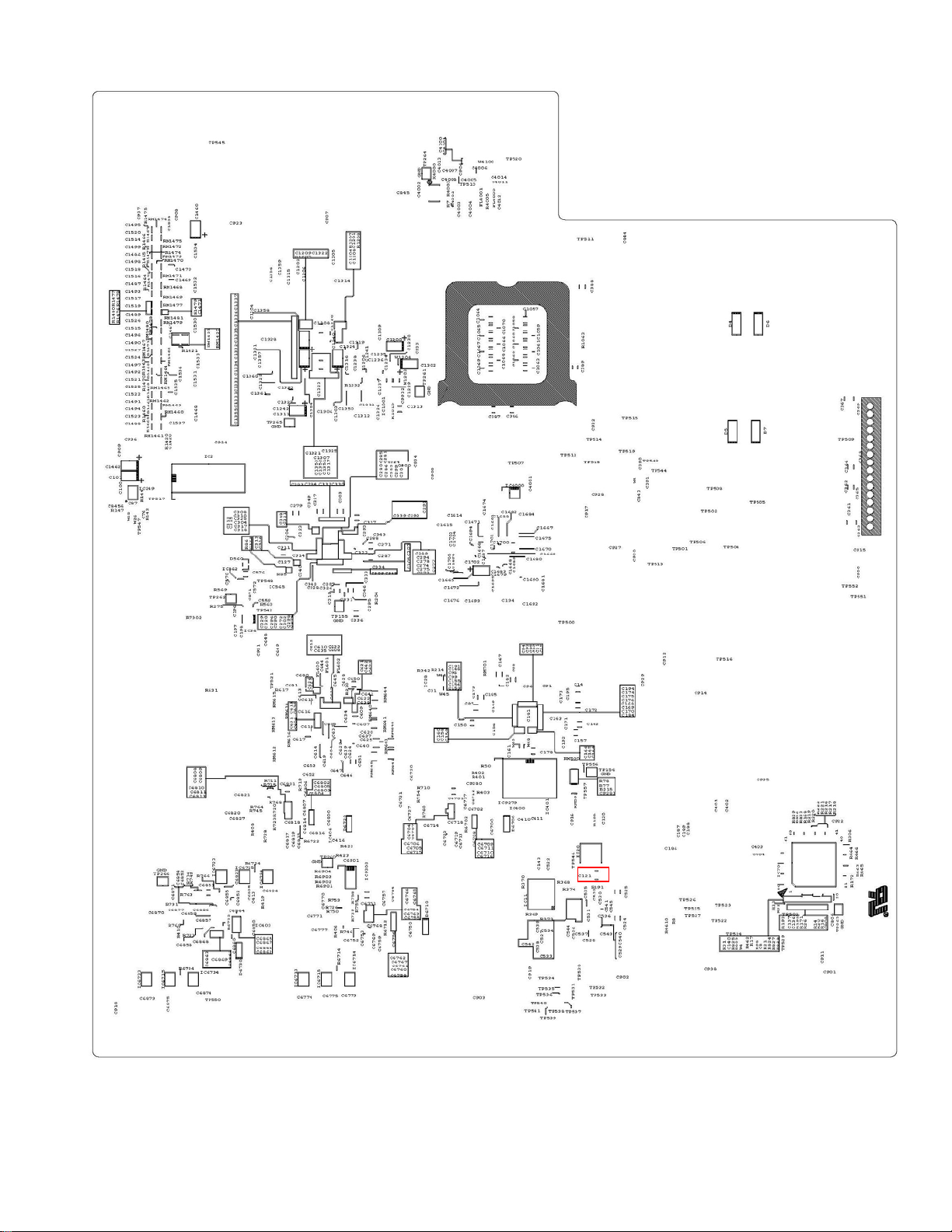

5. PC BOARDS

5-1. Front Main PC Board

5-2. PWR-SW PC Board

5-3. Door-Detect PC Board (HD-XA1)

5-4. USB PC Board

5-5. Motor PC Board (HD-XA1)

5-6. AV PC Board

SAFETY PRECAUTION

NOTICE

ABBREVIATIONS

SUPPLEMENT1. Firmware Version Update

SUPPLEMENT2. Error display

SECTION 4

PARTS LIST

1. EXPLODED VIEWS

1-1. Packing Assembly

1-2. Cabinet Assembly 1 (HD-XA1)

1-3. Cabinet Assembly 2 (HD-A1/HD-D1)

1-4. Chassis Assembly

2. PARTS LIST

SUPPLEMENT

GENERAL DESCRIPTIONS

SECTION 1

GENERAL DESCRIPTIONS

1. OPERATING INSTRUCTIONS

Please refer to the owner's manual about the contents.

SECTION 1

2. LOCATION OF MAIN PARTS

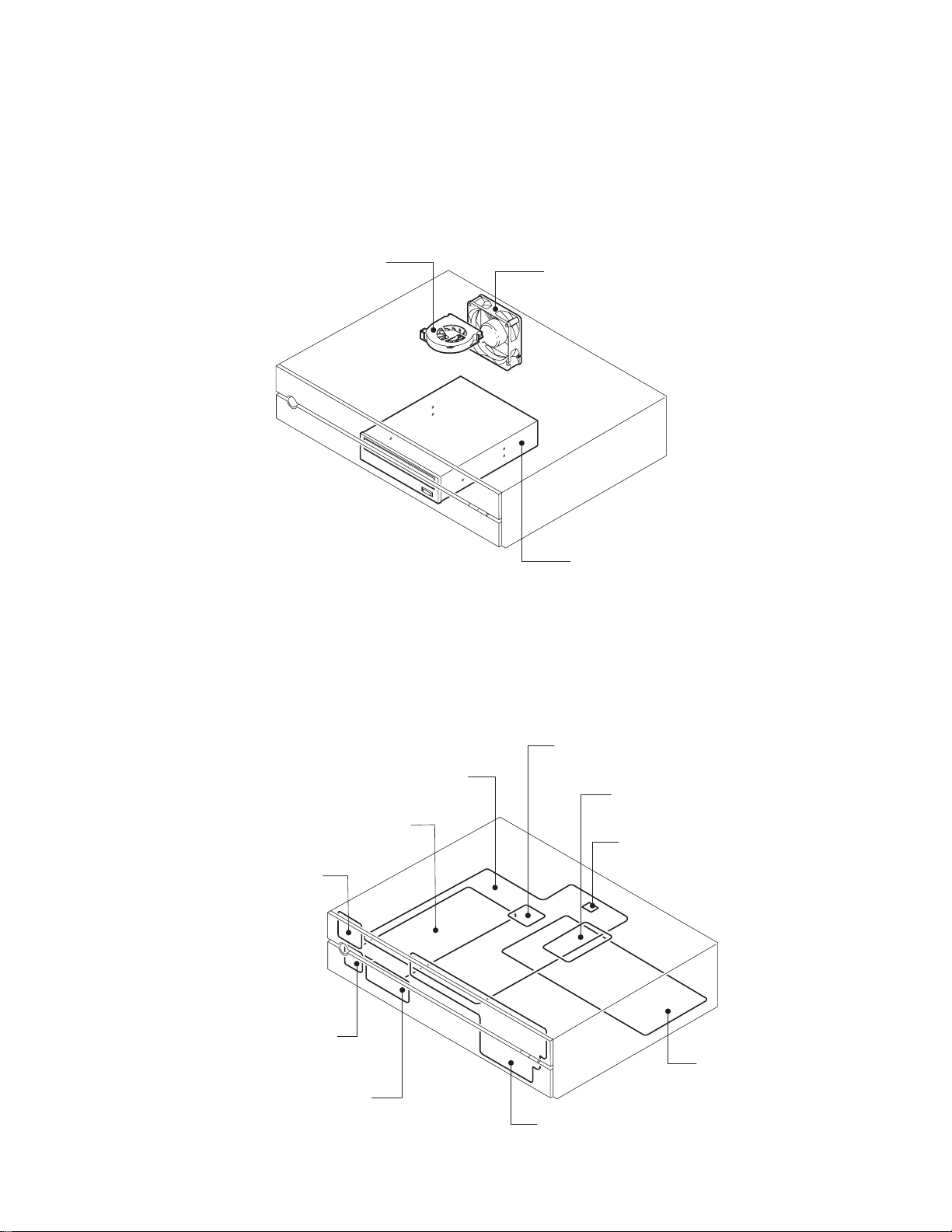

This section describes the location of main parts and PC boards of HD-XA1 as a representative.

2-1. Location of Main Parts

CPU FAN

2-2. Location of PC Boards

FAN

HD-DVD DRIVE

Fig. 1-2-1

Power PC board

PWR-SW PC board

DOOR-DETECT PC board

USB PC board

CPU

Dgital PC board

SO-DIMM

FLASH ROM MODULE

AV PC board

Front Main PC board

Fig. 1-2-2

3. TROUBLESHOOTING

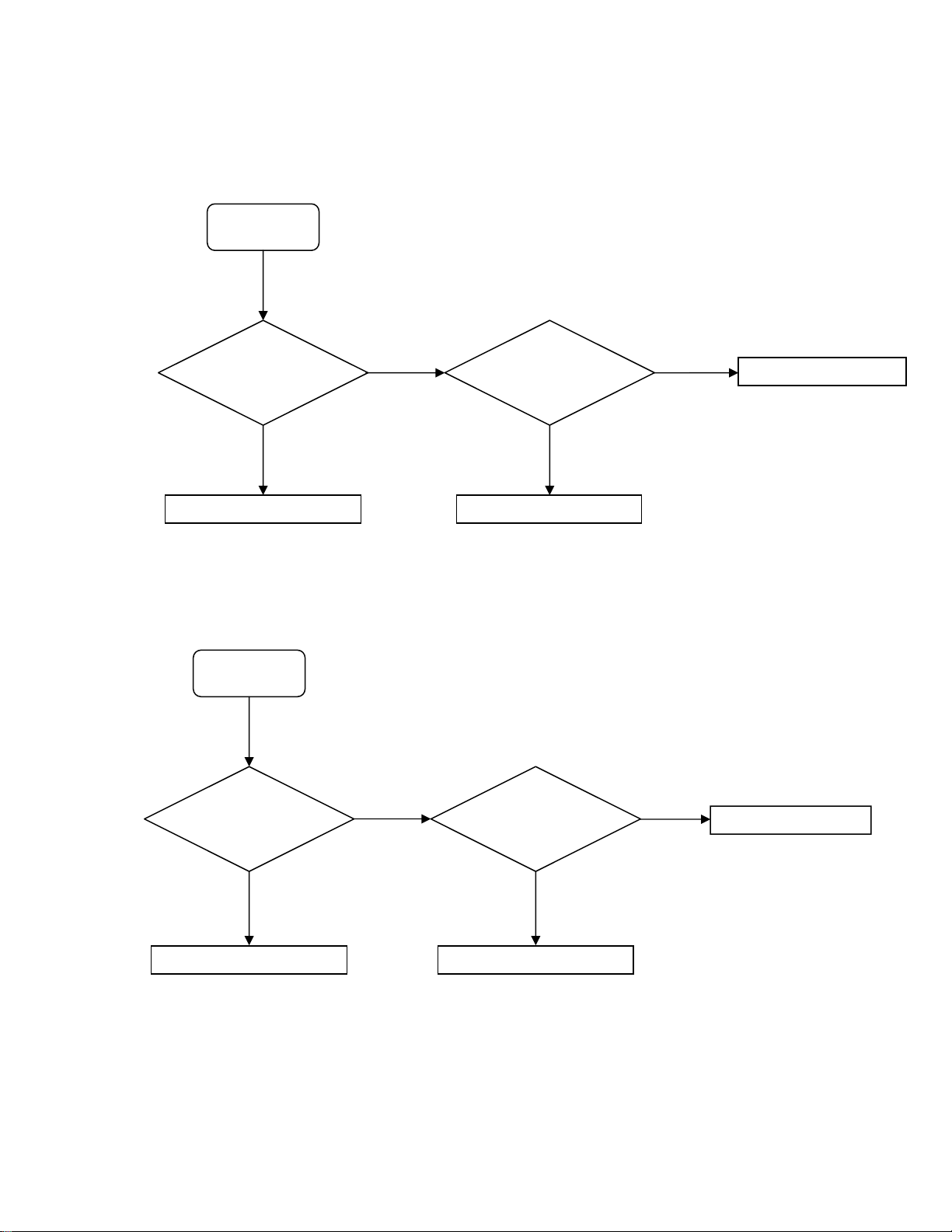

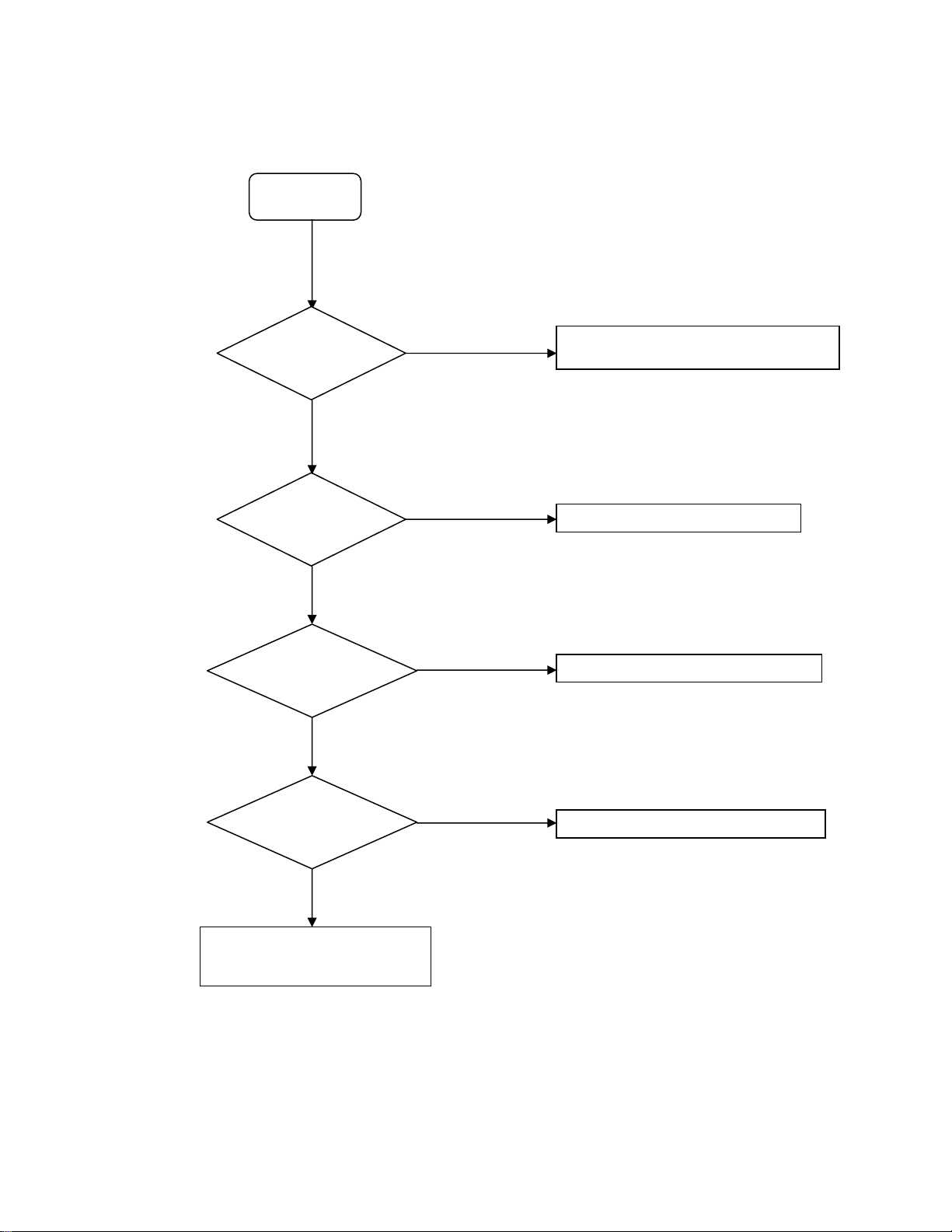

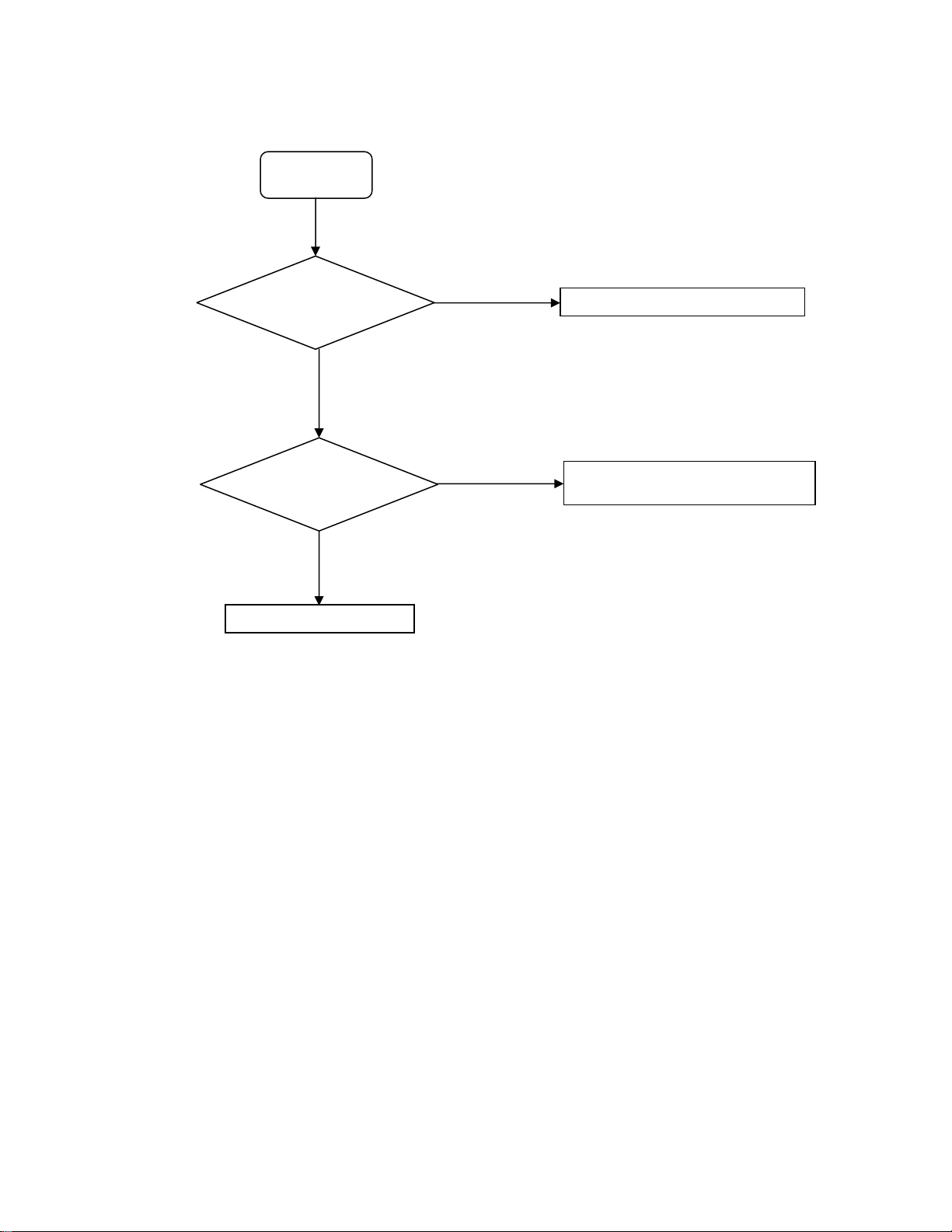

3-1. Standby LED (red) does not light.

START (1)

VCC+6V supplied to pin

16 of PJ11 from power

unit?

Replace power unit.

㩷

No

㩷

Yes

㩷

㩷

Yes

LEDOUT1 on pin 6 of

PJ7 is “L”?

No

Failure of digital unit

㩷

㩷

Replace front unit.

㩷

3-2. LED (green) does not light at power on.

LEDOUT1 on pin 6 of PJ7

START (2)

is “H”?

Failure of digital unit

No

㩷

㩷

Yes

PJ7 FFC cable inserted

Replace FFC cable.

correctly?

No

Yes

㩷

Replace front unit.

㩷

㩷

3-3. CPU FAN does not work.

START (3)

Pin 1 of PJ8770

develope 5V±5%?

Power circuit

troubleshooting

No

㩷

Yes

㩷

㩷

Replace CPU FAN unit.

㩷

3-4. Indicator does not light. (“WELCOME” does not light at startup.)

START (4)

㩷

Pin 4 of PJ7 reset and

VFD driver IF bus

working at startup?

1: CS#

2: CLK

3: RESET#

4: DOUT

No

㩷

Failure of digital unit

㩷

Yes

㩷

PJ7 FFC cable inserted

correctly?

No

Replace FFC cable.

㩷

Yes

㩷

Replace front unit or

power unit.

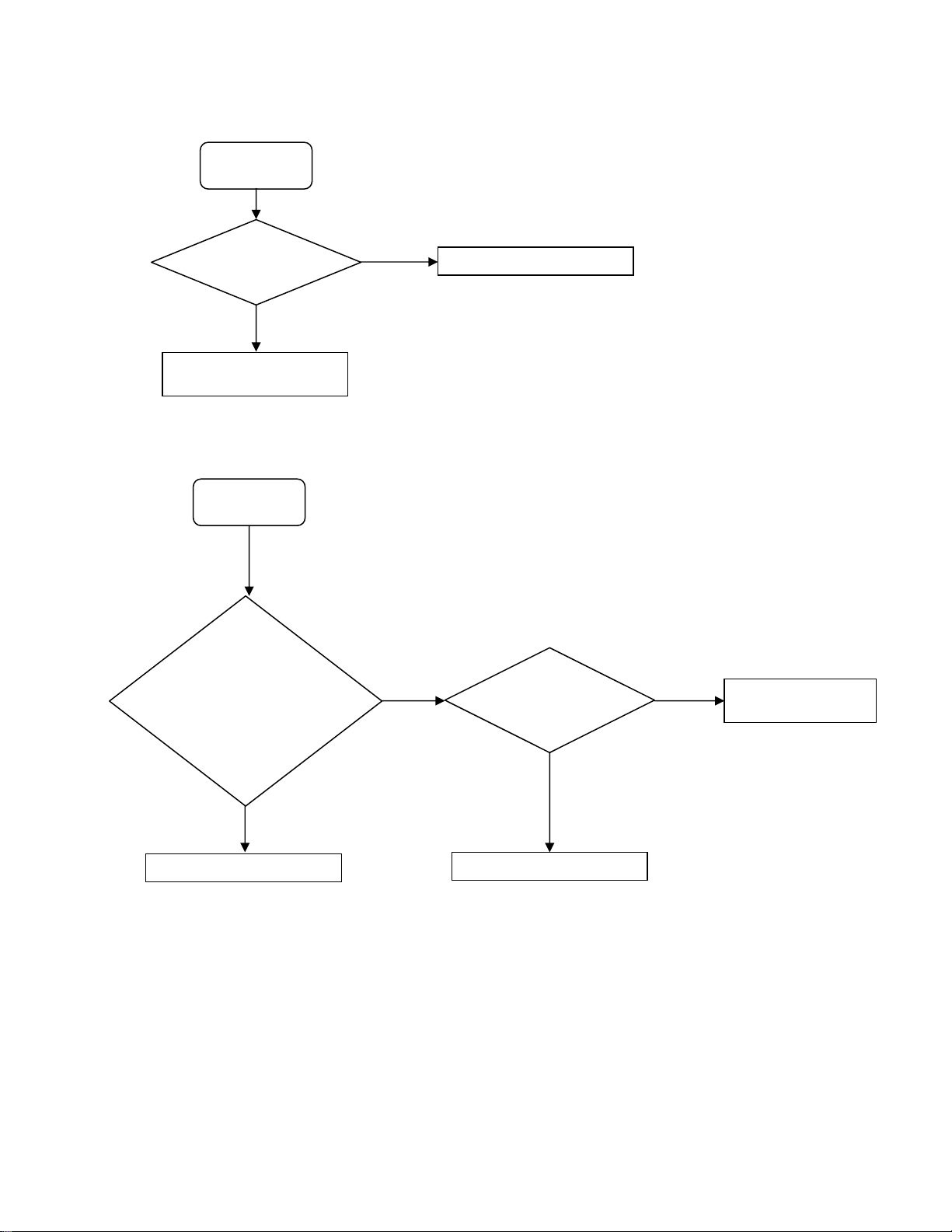

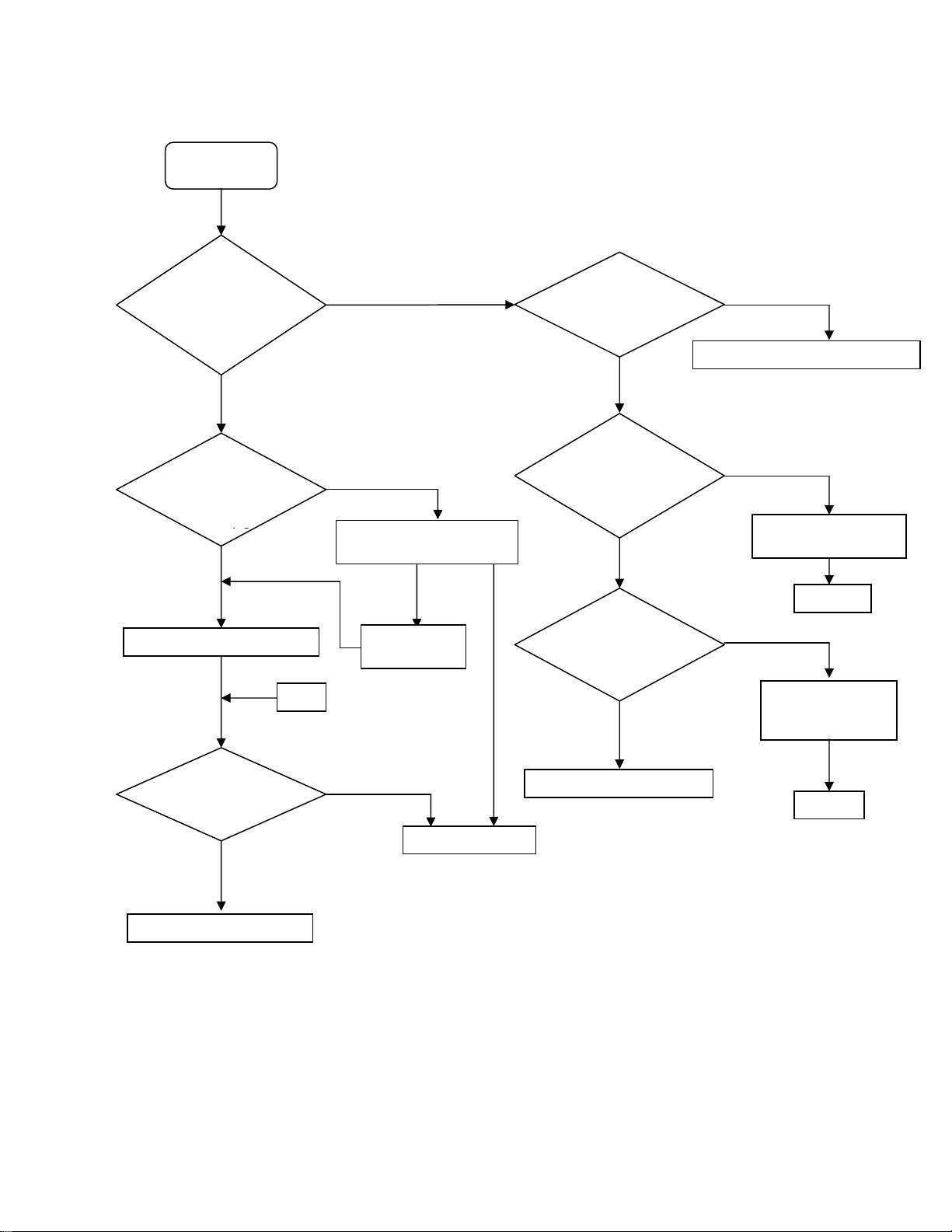

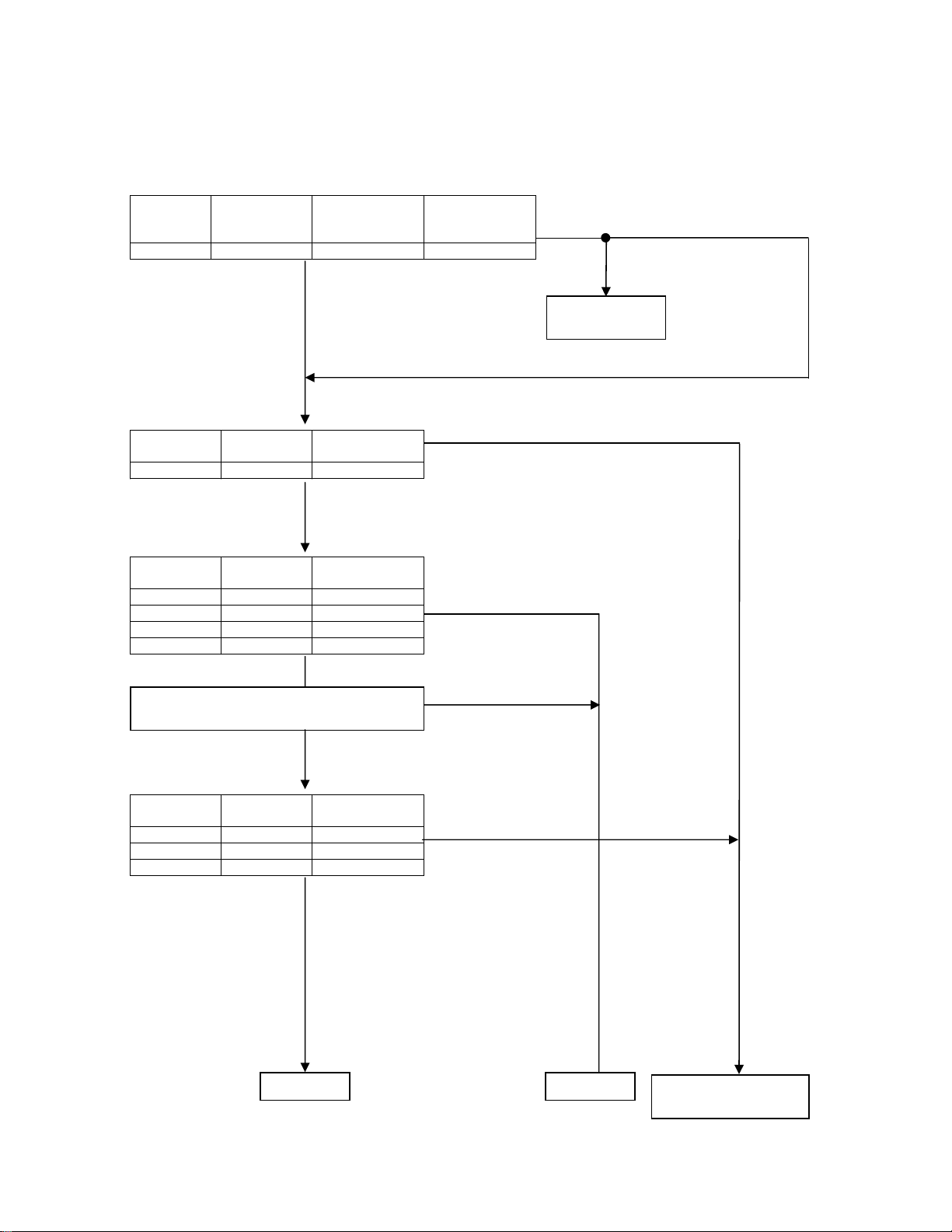

3-5. System does not run. (“WELCOME” displayed and key operation disabled)

START (5)

㩷

LED on FLASH ROM

module (PJ15) flashing

about 10 seconds after

power on?

Yes

㩷

Connector (PJ9) of

DVD drive and

power connector

connected

Yes

㩷

Upgrade firmware again.

㩷

(A)

No

No

㩷

Check PJ9 connection

and replace FFC cable.

Not

restored

Replace

DVD drive.

㩷

TP105(P5V) voltage

output correctly?

Yes

LED of FLASH ROM

module (PJ15) lights up after

replacement?

No

Restored

SO-DIMM module

(PJ1420) inserted

correctly?

Yes

No

Power circuit troubleshooting

Yes

Upgrade firmware

again.

㩷

To (A)

No

Insert again or

replace SO-

DIMM?

㩷

㩷

System is restored

after firmware

upgrade?

No

㩷

Failure of digital unit

Yes

㩷

END

㩷

Failure of digital unit

To (5)

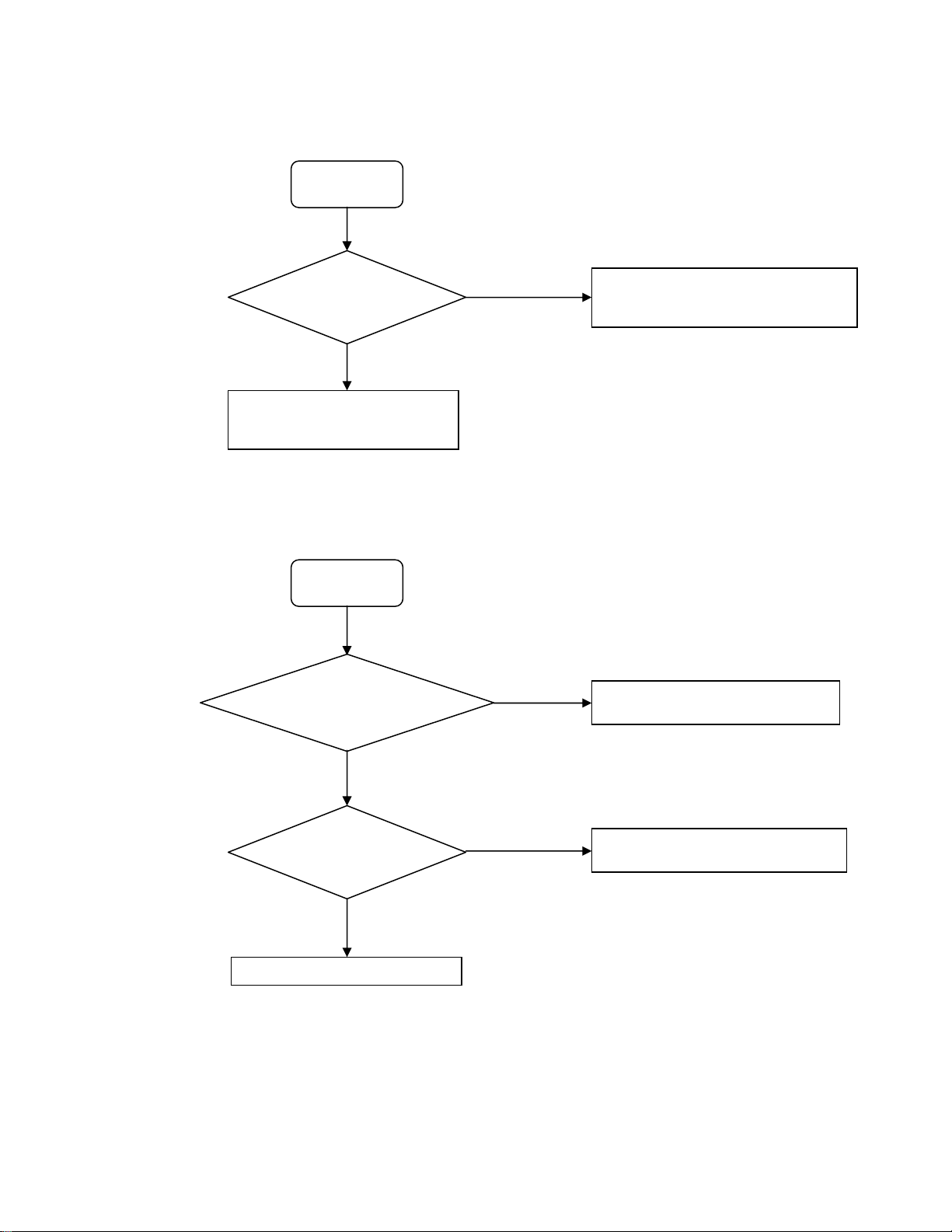

3-6. No picture appears.

g

START (6)

Before repair, confirm the connection with a TV

x

and the settings of XA1/A1/D1.

㩷

Both components and

HDMI do not output

picture?

Yes

㩷

PJ730 and cable

normal?

Yes

㩷

PJ731 and FFC cable

normal?

Yes

㩷

No

No

No

Check and replace PJ731 FFC cable.

Replace AV unit.

Check and replace PJ730 cable.

Check and replace PJ731 FFC cable.

㩷

PJ732 and FFC cable

normal?

Yes

㩷

Replace AV unit

or

failure of di

ital unit.

㩷

No

Check and replace PJ732 FFC cable.

3-7. No audio is played back.

START (7)

Before repair, confirm the connection with a TV

x

and the settings of XA1/A1/D1.

㩷

All analog, digital, and

HDMI audio are not

played back?

Replace AV unit

or

failure of digital unit.

3-8. Buzzer does not sound.

START (8)

[Remote Controller Sound] in

Setup menu selected?

Yes

No

㩷

㩷

㩷

Not selected

Check and replace PJ732㪝FC cable.

Check and replace PJ733 㪝FC cable.

Replace AV unit.

Select [Remote Controller Sound] in

application’s Setup menu.

㩷

Selected

PJ7 and FFC cable normal?

Yes

Failure of digital unit

㩷

No

㩷

㩷

Check and replace PJ7㩷㪝FC cable.

Replace front unit.

㩷

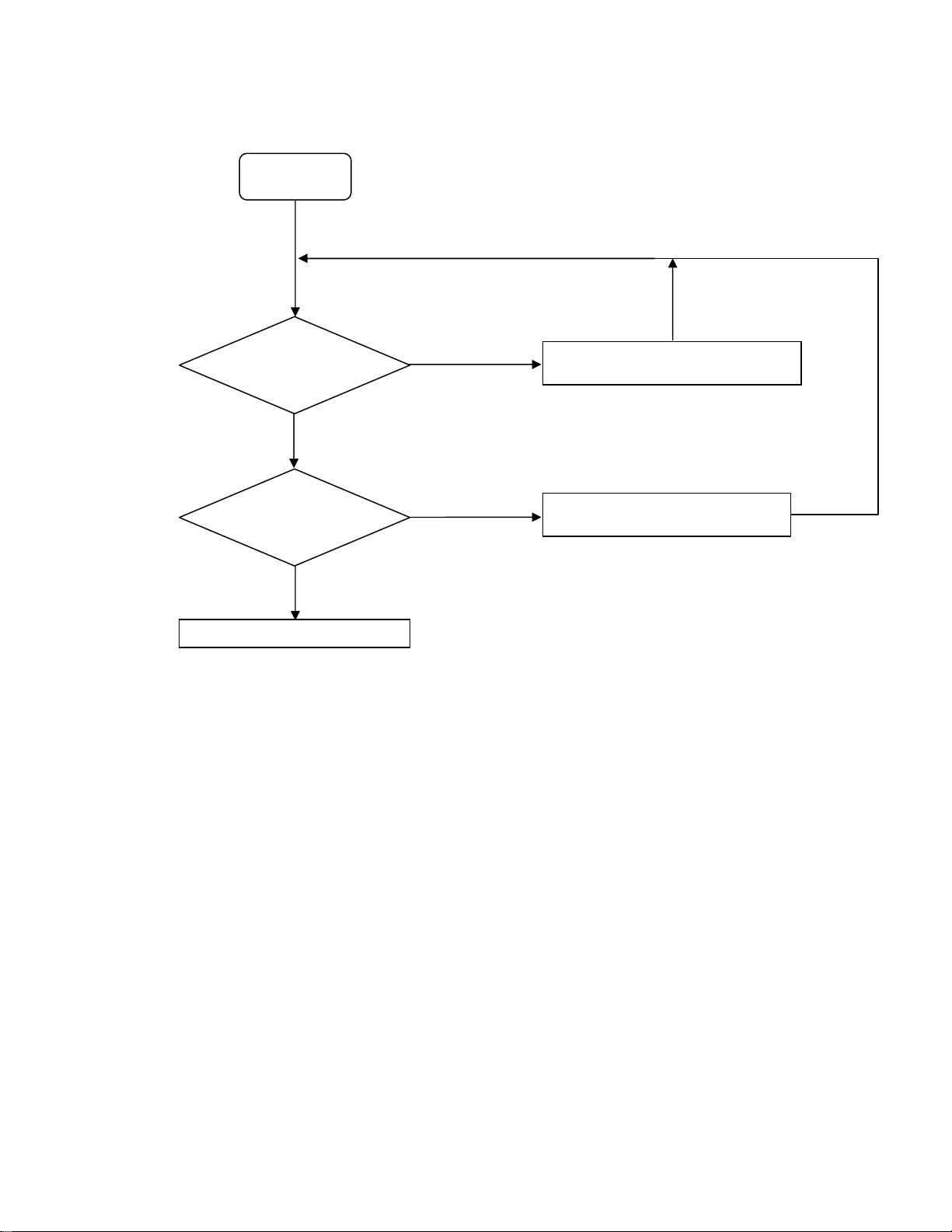

3-9. Extension port does not work.

r

START (9)

Neither right port nor

left port works?

Device to be connected is

supported?

Yes

Yes

㩷

㩷

㩷

No

Eitherone port

does not work.

No

Check and replace PJ14 cable o

replace front USB unit.

Check with the device supported by

HD-XA1/A1/D1.

㩷

㩷

Failure of digital unit

㩷

3-10. Front panel keys/remote control are disabled.

START (10)

Front LED lighting?

PJ7 connected correctly?

Failure of digit unit

Yes

Yes

㩷

㩷

㩷

㩷

No

No

Change power unit.

Check and replace PJ7㩷㪝FC cable.

Replace front unit.

㩷

㩷

3-11. Other Symptoms

Improper LAN connection

x

LAN depends on the quality of the environment and lines to which LAN is connected. Check the main unit as well as

network settings, cables, and connected devices.

Improper CONTROL pin connection

x

Use a serial cross cable to connect the unit to a PC.

Check the above. However, if the problem still remains, the digital unit may be faulty.

3-12. Power Circuit Troubleshooting

r

r

RTC backup voltage

Power

R3V TP113 2.0-3.0V

Measuring

point

EVER system voltage

Power unit output

Power

PS5VSB TP159 5.5-6.5V

EVER system voltage

M/B REG output, etc.

Power

M5V TP115 4.75-5.25V

M3V TP114 3.13-3.47V

MM5V TP135 4.5-5.0V

MS5V C842-2PIN 4.75-5.25V

Power unit ON/OFF control signal check

PS_ON(Pin 1 of PJ12)

Measuring

point

Measuring

point

Output voltage

range

(AC OFF)

Yes

Output voltage

range

Output voltage

range

Yes

㩷

Yes

㩷

㩷

㩷

Output voltage

range

(AC ON)

3.4-3.0V

NoNo

No

“H”

No

Incorrect voltage at

AC OFF

Battery(BT1)

erro

㩷

Incorrect voltage

at AC ON

Power system voltage

Power unit output

Power

PS12VDC TP160 11.4-12.6V

PS5VDC TP165 4.75-5.25V

PS3VDC TP164 3.13-3.47V

Measuring

points

To (B)

“L”

㩷

Output voltage

range

Yes

㩷

㩷

No

To (C)

㩷

Failure of harness

power unit

and/o

㩷

Power system voltage

Power unit output

Power

2R6-P2V TP109 2.5–2.7V

1R2-P1V TP112 1.19–1.26V

2R5-P2V TP108 2.40–2.60V

P5V TP105 4.75–5.25V

1R25-P1V TP162 1.19–1.30V

1R5-P1V TP110 1.45–1.57V

P3V TP107 3.13–3.47V

VID1R2-P1V TP166 1.19–1.26V

1R8-P1V C121-2PIN 1.71–1.89V

VPL3R3-P1V IC560-2/3PIN 3.13–3.47V

APL3R3-P3V C577-2PIN 3.13–3.47V

PCOREV TP111 1.2–1.3V

To (B)

Measuring

points

㩷

Output

voltage range

Yes

㩷

To (C)

㩷

No

Failure of digital unit END

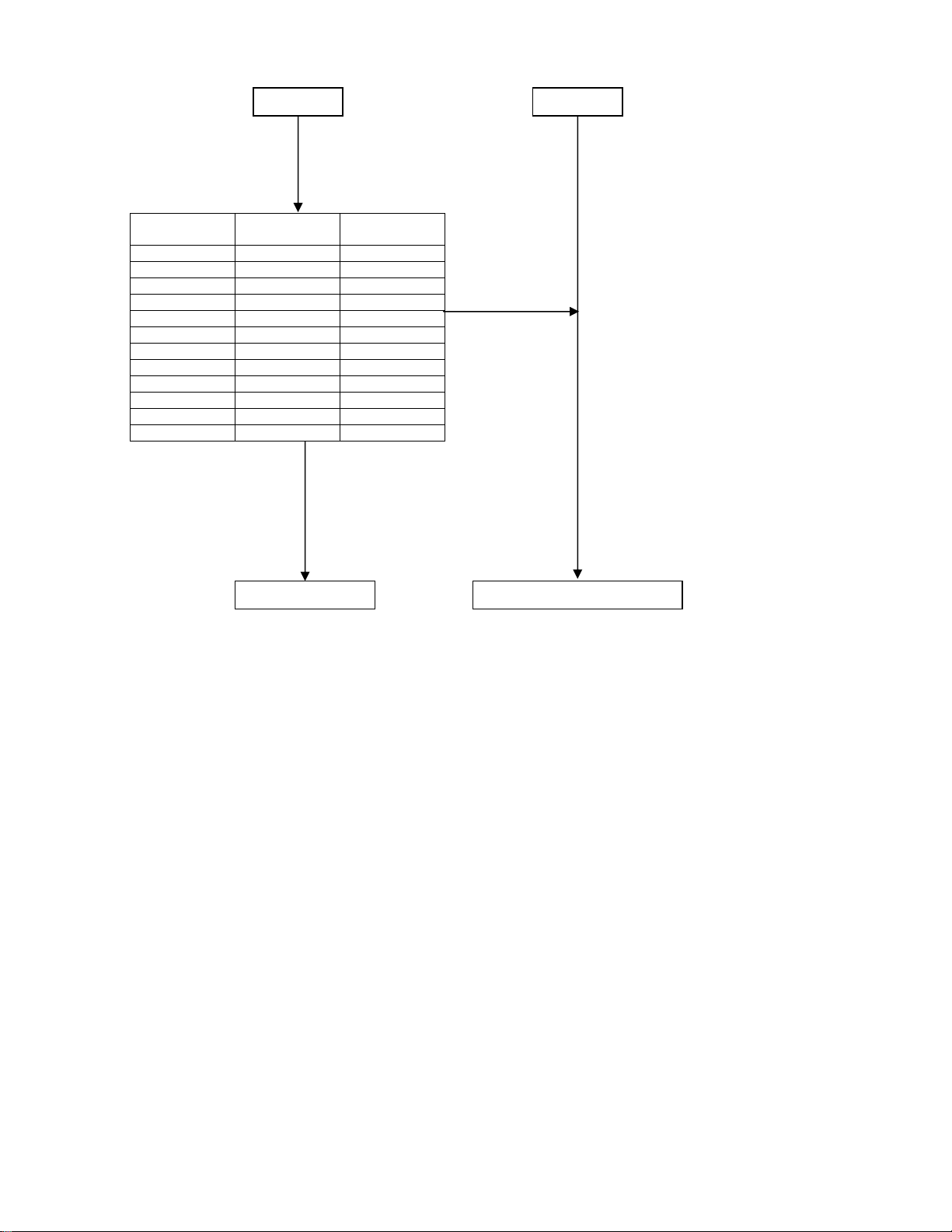

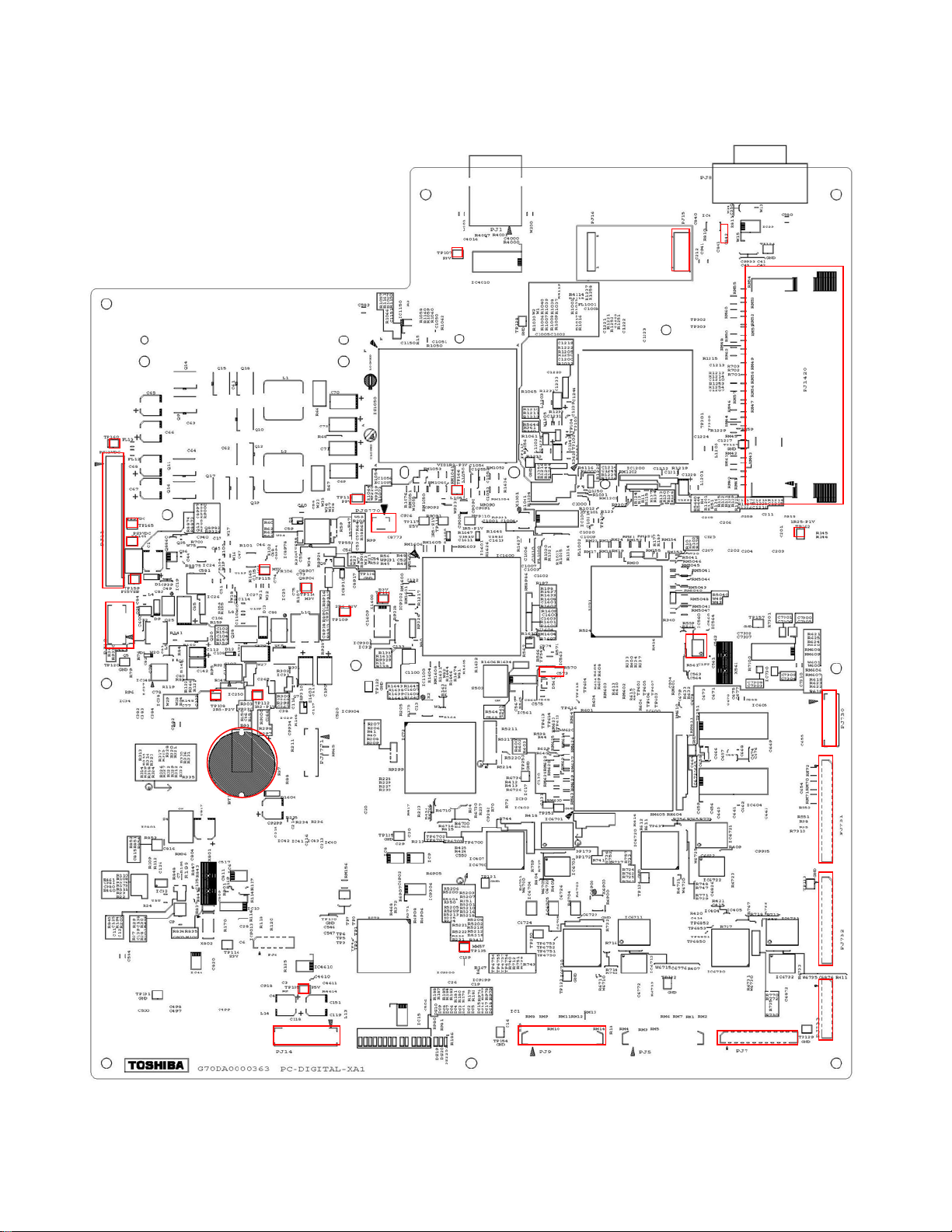

MEASURING POINTS

Fig. 1-4-1 Digital Unit (Top Side)

TP16

PJ1

PJ1

TP16

TP16

TP15

TP11

TP11

TP10 TP11

TP11

TP10

PJ877

TP11

TP10

TP16

C577

PJ15

C842

PJ1420

TP16

IC560

PJ730

BT1

TP13

TP10

PJ14 PJ9 PJ7

PJ731

PJ732

PJ733

Fig. 1-4-2 Digital Unit (Bottom Side)

C121

SECTION 2

PART REPLACEMENT AND

ADJUSTMENT PROCEDURES

CAUTIONS BEFORE STARTING PART REPLACEMENT

Electronic parts are susceptible to static electricity and may be easily damaged, so do not forget to ground as required.

Many screws are used inside the unit. To prevent the screws from missing or dropping, etc. always use magnetized

screwdriver in servicing. Several kinds of screws are used and some of them need special cautions. That is, take care of

the tapping screws securing molded parts and fine pitch screws used to secure metal parts. If they are used improperly,

the screw holes will be easily damaged and the parts can not be fixed.

This section describes how to replace the parts of HD-XA1 as a representative.

ADJUSTMENT PROCEDURES

PART REPLACEMENT AND

1. REPLACEMENT OF MECHANICAL PARTS

1-1. Cabinet Replacement

1-1-1. Top Panel and Top Cover

1. Remove two screws (1), then remove the side panel L (2) and side panel R (3).

2. Remove three screws (4), then remove the top panel (5).

3. Remove four screws (6), then remove the top cover (7).

Top panel (5)

Screws (1)

Side panel L (2)

SECTION 2

Screws (4)

Screws (6)

Top cover (7)

Gasket

Gasket

Screws (6)

Screws (1)

Side panel R (3)

Fig. 2-1-1

1-1-2. Front Panel and Motor

1. Remove the top panel and top cover. (Refer to item 1-1-1.)

2. Remove the screw (1), two screws (2), three screws (3), and the screw (4).

3. Remove six claws, then draw the front panel (5).

4. Remove the screw (6), then remove the front panel (5).

5. Disconnect the connectors (7) and (8) and the flexible cable (9).

6. Disconnect the connector (10).

7. Remove the belt (11).

8. Remove two screws (12), then remove the motor (13) in the arrow direction.

Connector (8)

Screw (6)

Connector (7)

Claws

Screws (3)

Claws

Screw (4)

Gasket

Claws

Front panel (5)

Gasket

Flexible cable (9)

Gasket

Screws

(2)

Screw (1)

Connector (10)

Motor (13)

Screws (12)

Belt (11)

Gear assy

Fig. 2-1-2

1-1-3. Sub-chassis

1. Remove the top panel and top cover. (Refer to item 1-1-1.)

2. Remove the front panel. (Refer to item 1-1-2.)

3. Disconnect the connectors (1), (2), and (3).

4. Disconnect the flexible cables (4), (5), and (6).

5. Disconnect the flexible cable (7) while raising the claws (8) in the arrow A direction.

6. Remove four screws (9).

7. Move the sub-chassis (10) in the arrow direction, release it from the four claws, and then remove it.

Flexible cable (4)

Flexible cable (5)

Ferrite core

Flexible cable (6)

Connector (1)

Screws (9)

Gasket

Flexible cable (7)

Gasket

Flexible cable

(7)

Claws (8)

A

Claws

Connector (2)

Connector (3)

Screws (9)

Sub-chassis (10)

Gasket

Fig. 2-1-3

Loading...

Loading...