Page 1

H9 ADJUSTABLE SPEED DRIVE

Installatio n and Operat ion

Manual

Page 2

Page 3

H9 ADJUSTABLE SPEED DRIVE

Document Number: 58682-000

Date: Febr ua r y, 2008

Installation and Operation Manual

Page 4

Introduction

Congratulations on the purchase of the new H9 True Torque Control2 Adjustable Speed Drive (ASD).

The H9 True Torque Control

T orque Contro l

and provide compensation for motor slip, which resul ts in smooth, quick starts a nd highly effi cie nt

operation. The H9 ASD uses digitally- controlled pulse width modulation. The prog ram mable functions

may be accessed via the easy-t o-use menu or via the Direct Access Numbers (see page 76). This feature,

combined with Toshiba’s high-performance software, delivers unparalle led motor control and rel iability.

The H9 ASD is a very powerful tool, yet surprisingly simple to operate. The user-fri endly Electronic

Operator Interface (EOI) of the H9 ASD h as an easy-to-read graphi cal LCD screen. There is al so a readonly LED display with enhanced visibility that can be read from a greater distance. The EOI provides

superior viewing feat ures for the user and easy acces s to the many monitoring and programming feat ures

of the H9 ASD.

The motor control software is menu-driven, which allows for easy access to the motor control parameter s

and quick changes when required.

To m aximize the abilities of your new H9 ASD, a working familiarity with this manual will be required.

This manual has been prepared for the H9 ASD installe r, user, and maintenance personnel. This manual

may also be used as a reference guide or for training. With this in mind, use this manual to develop a

system familiarity before attempting to install or operate the device.

2

. Toshiba’s V ec tor Control Algorithm enable s the motor to de velop hig h start ing to rque

2

Adjustable Speed Drive is a solid -s ta te AC dr i v e th at fe at u r es True

Important Notice

The instructions contained in this manual are not intended to cove r all details or variati ons in equipment

types, nor may they provide for every possible contingency concerning the insta llation, operation, or

maintenance of this equipment. Should additional inform ation be required contact your Toshiba

representative.

The contents of this ma nual shall not become a part of or modify any prior or existing agreement,

commitment, or relationship. The s ales contract contains the entire obligation of Toshiba International

Corporation. The warranty contained in the contract between the parties is the sole warranty of Toshiba

International Corpora tion and an y statement s containe d herein do not creat e new warranties or modify the

existing warranty.

Any electrical or mechanical modifications to this equipment without prior written consent of

Toshiba International Corporation will void all warranties and may void the UL/CSA listing or

other safety ce rtifications. Unauthorized modifications may also result in a safety hazard or

equipment damage.

Misuse of this equipment could result in injury and equipment damage. In no event will Toshiba

Corporation be responsible or liable for direct, indirect, special, or consequential damage or injury

that may result from the misuse of this equipment.

Page 5

About This Manual

This manual was written by the T oshiba Technical Publicatio ns Group. This group is tasked with

providing te chnical documenta tion for the H9 Adjustable Speed Drive. Every effort has been made to

provide accurate and concise informati on to you, our customer.

At Toshiba we are continuously search ing for better way s to meet the constan tly changing needs of our

customers. E-m ail your comments , questions, or conce r ns about this publication to

Techni cal-Publ ica tions-De pt@TIC. TOSHIBA.com.

Manual’s Purpose and Scope

This manual provides information on how to safely install, operate, maintain, and dispose of your

H9 Adjustable Speed Drive. The information provided in this manual is applicable to the

H9 Adjustable Speed Drive only.

This manual provides information on the various features and func tions of this powerful cost-saving

device, including

• Installation,

• System operation,

• Configuration and menu options, and

• Mechani cal and electrical specifications.

Included is a section on general safety instructions that describe the warning labels and symbols t hat are

used. Read the manual c omple tely be fore ins t allin g, op erati ng, perf orming mai nte nance, or dis posi ng of

this equipment.

This manual and the accompanying drawi ngs should be considered a permanent part of the equipmen t

and should be readil y available for reference and review. Dimensions shown in the m anual are in metric

and/or the English equiva lent.

Because of ou r commit ment to c ontinu ous im prov ement, Toshiba International Cor poratio n re serves the

right, without prior notice, to update information, make produ ct changes, or to discontinue any product

or service identified in this publica tion.

Toshiba International Corporation (TIC) shall not be liable for direct, indirect, special, or

consequential damages resulting from the use of the information contained within this manual.

This manual is copy righted. No part of this manual may be photocopied or reprod uced in any form

without the prior wr itten consent of Tos hiba International Corp or ation.

© Copyright 2008 Toshiba International Corporation.

TOSHIBA® is a register ed trademark of the Toshiba Corporation. All other product or trade references

appearing in thi s manual are registered trademarks of their respecti ve owners.

Reliability in motion

®

is a registered trademark of th e Toshiba Corporation.

All rights reserved.

Printed in the U.S .A.

Page 6

Cont acting T oshiba’ s Customer Support

TOSHIBA INTERNATIONAL CORPORATION

H9 Adjustable Speed Drive

Please complete t he Warranty Card s upplie d with t he H9 ASD and return it to Toshi ba by prepa id mail . This will

activate the 12 month warranty from the date of installation; but, shall not exceed 18 months from the shipping

date.

Complete the following information and retain for your records.

Model Number: ______________________________________________________________________

Serial Number: ______________________________________________________________________

Project Number (i f applicable): __________________________________________________________

Date of Installation: __________________________________________________________________

Inspected By: ______________________________________________________________________

Name of Application: ______________________________________________________________

Center

Toshiba’s Cus tom er Support Center can be contacted to obtain help in resolving any Adjustable Speed

Drive system problem tha t you may experience or to provide application information.

The center is open from 8 a.m. to 5 p.m. (CST), Monday through Friday. The Support Center’s toll free

number is US (800) 231-1412/Fax (713) 466-8773 — Canada (800) 527-1204.

You may also contact Toshiba by writing to:

Toshiba International Corporation

13131 West Little York Road

Houston, Texas 77041-9990

Attn: ASD Product Manager.

For further information on Toshiba’s products an d services, please visit our website at

www.toshiba.com/ind/.

Page 7

Table of Contents

Gener a l Sa fe t y Inf o r ma t i on........... ... .. .......... .. ... ................... ... .. ................... ... .. .......... ... .. 1

Safety A le r t Sy m b o l...... ... ......... ... .. .................... .. .. .................... .. ... ......... ... .. ...............1

Signa l Wo r ds ...................... .. ... ................... ... .. ... ......... ... .. .................... .. .. .................... 1

Specia l S y mb o ls ....... ... .. .......... .. ... ......... ... .. .................... .. ... ................... .. ... .......... .. ... .. 2

Equipment Warning Labels..........................................................................................2

Qualified Personnel .................................................. .. .......... ........................... .. .......... .2

Equipment Inspection................................................................................................... 3

Handling and Storage ................................................................................................... 3

Disposal........................................................................................................................3

Instal la t io n Precautio n s ............ ... .. .................... .. ... ................... .. ... ................... ... .. ..........4

Location and Ambient Requirements........................................................................... 4

Mounting Requirements...............................................................................................4

Conductor Routing and Grounding.......................................... ...... ....... ................... ....5

Power Connections.................. ..................................................................................... 6

Protection ..................................................................................................................... 6

System Integration Precautions ....................................................................................... 7

Personnel Protection....... ............. .................................... .......... .......... ................. ........7

System S et u p Req u i re m e n ts........... ... .. ................... ... .. .................... .. ... ................... ... .. 8

Operat i onal and Mai n ten a n c e Pr ecautions...... .. .................... .. .. ... .......... .. .. ....................9

Motor C h a ra ct e ri s tics ... .................... .. ... ................... .. ... ................... ... .. .................... .. ...10

Motor Autotuning....................................................................................................... 10

Pulse Width Modulation Operation............................................................................ 10

Low Speed O p er at i on.. .. .......... .. ... ............................. .. ... ................... ... .. .................... 10

Overload Protection Adjustment................................................................................ 10

Operation Above 60 Hz..............................................................................................10

Power F ac to r Co rr ection ...... ... .......... .. .. .................... .. ... ................... ... .. .................... 11

Light Load Condi tions .............................. .................................. ........................ .......11

Motor/Load Combinations.........................................................................................11

Load-p ro d uc e d Neg ative Torqu e ...... .. .. .......... ... .. ................... ... .. ..............................12

Motor Braking............................................................................................................12

H9 ASD Characteristics.................................................................................................. 13

Over-current Protection.............................................................................................. 13

ASD Capacity............................................................................................................. 13

Using V ec to r Co n tro l ........................ .. .. .................... .. ... ................... ... .. .................... 13

Instal la t io n a n d Con nections .... ... ................... ... .. .................... .. .. .......... ... .. .................... 14

Install at i on N ot e s . ... ................... ... .. .................... .. .. .................... .. ... ................... ... .. ... 14

Mounting the H9 ASD ...............................................................................................15

Conne ct in g th e H 9 AS D..... .. .......... ... .. ................... ... .. .................... .. ... ................... ... 16

Power Connections .......... ................. ................. ................. ................................16

System G r o un d i ng....... .. ... .......... .. .. .................... .. ... ................... ... .. .................... 18

Lead Length Specifications.................................................................................20

I/O and Co n tr o l .. ................... ... .. .................... .. ... ................... .. ... ................... ... .. ........21

Termi na l Descripti ons. .. .................... .. ... ................... ... .. ................... ... .. ............. 22

I/O Circu i t Configur a ti o ns ............. ... .. .................... .. ... ................... .. ... .......... .. ... 25

Typical Connection Diagram.......... ...... ................. ................. ................. .......... .26

Startup and Test ..................................................................................................27

H9 ASD Installation and Operation Manual i

Page 8

Electronic Operator Interface........................................................................................28

EOI Oper at io n .................... .. ... ................... ... .. .................... .. .. .................... .. ... ..........28

EOI Remo t e M oun t in g ...................... .. .. .................... .. ... ................... ... .. .................... 28

EOI Featu r es.... .. .. .................... .. ... ................... ... .. ............................. ... .. .................... 29

LED Display .......................................................................................................30

LCD Display ....................................................................................................... 31

Keypad Re m o t e M o un t in g ...... .. .................... .. ... ................... .. ... .......... .. .. ..................33

Remot e K ey p ad Re q u ir e d H ar d ware .......... .. .. .......... ... .. ................... ... .. ............. 33

Keypad I ns ta ll at io n P recaution s............... ... .. ................... ... .. .................... .. ... .....33

Keypad Re m o t e M o un t in g w/o th e A S D- M T G- K I T ............... .. ... ......... ... .. ........34

Keypad Remote Mounting using the ASD-MTG-KIT ....................................... 35

Comma n d M o d e a nd Frequency Mo d e C o nt ro l .......... .. ... ............................. .. ... ..........36

Command Control (F003).............................................. ........................ ............... .....36

Frequency Control (F004).......................................................................................... 37

Command and Frequency Control Selections..................................................... 37

Override Operation..................................................................................................... 38

Comma nd an d Frequency -Control O ve r r ide Hierarch y ........ ... .. .................... .. ... 38

Comma nd Co n t r ol Sel e c ti o ns ..................... .. .. .................... .. ... ................... ... .. ... 39

Frequency Control Selections............................................................................. 39

System Configuration and Menu Options..................................................................... 41

Root Menus ................................................................................................................41

Frequency Command Mode................................................................................41

Monit or M o de .................... ... .. .................... .. .. .................... .. ... ......... ... .. ............. 43

Progra m M ode Menu Navi g ation ..... .. .......... .. ... ................... ... .. .................... .. ... 46

System Operation ............................................................................................................70

Initia l Set u p ........................ .. ... ................... ... .. .................... .. .. .................... .. ... .......... 70

Startup Wizard Parameters.........................................................................................70

Startup Wizard Parameter Requirements............................................................71

Opera ti on ( L o ca l) ........ .. .................... .. .. .................... .. ... ................... ... .. .................... 73

Default Setting Changes............................................................................................. 74

Save User Settings...................................................................................................... 75

Direct Ac ce s s Pa ra meter Info rmation...... .................... .. ... .. .......... .. ... ...........................76

Direct Access Parameters/Numbers...........................................................................76

Alarms, Trips, and Troubleshooting ........................................................................... 246

Alarms an d Tr ip s.................. ... .. .................... .. ... ......... ... .. .................... .. .. ................246

User No ti f ic at io n Co d es ... .. .. .................... .. ... ................... ... .. .......... .. ... ................... . 247

Alarms ...................................................................................................................... 247

Trips/Faults...............................................................................................................250

Viewi ng Tr i p I nfo r m a ti o n....... ... ......... ... .. .................... .. .. .................... .. ... ........ 255

Cleari ng a Tr ip ..... .. .................... .. .. .................... .. ... ................... ... .. .......... .. ... ...25 5

Enclosure Dimensions and Conduit Plate Information .............................................256

Enclosu r e D imension s. .. ... ................... .. ... .. .......... .. ... ................... ... .. .................... .. .256

Current/Voltage Specifications ....................................................................................263

Cable/Terminal/Torque Specifications........................................................................265

Short C ir cuit Protec tio n R ec o mmendati o ns.... .. ... ................... .. ... ............................. . 267

Dynamic Braking Resistor Wire/Cable Specifications ..............................................268

H9 ASD Optional Devices.............................................................................................270

ii H9 ASD Installation and Operation Manual

Page 9

General Safety Information

DANGER

WARNING

CAUTION

CAUTION

DO NOT attempt to install, operate, maintain or dispose of this equipment until you have read and

understood all of the product safe ty information and directions that are contained in this ma nual.

Safety Alert Symbo l

The Safety Alert Symbol indicates that a potential personal injury hazard exists. The symbol is

comprised of an equilateral triangle enclosing an exclamation mark.

Signal Words

Listed below are the signal words that ar e used throughout this manual followed by their descriptions

and associated symbols. When the words DANGER, WARNING, and CAUTION are used in t his

manual they will be followed by importa nt safety information that must be carefully followed.

The word DANGER prece d ed by th e sa fe ty al er t sy m bo l in di ca tes that an imminentl y h azardous

situatio n exis ts that, if not avoided, will result in death or serious injury to personnel.

The word WARNING preceded by the safety ale rt symbol indicat es that a potentially hazardous

situatio n exis ts that, if not avoided, could result in death or serious injury to personnel.

The word CAUTION preceded by the safety alert symbo l indicates that a potentially hazardous

situation exists which, if not a voided, may result in minor or moderate injury.

The word CAUTION without the safety alert symbo l indicates a potentially hazardous situation exist s

which, if not avoided, may result in equipment and property damage.

H9 ASD Installation and Oper ation Manual 1

Page 10

Special Symbols

To identify special hazards, other symbols may appear in conjunction with the DANGER, WARNING

and CAUTION signal words. Thes e symbols indicate areas that require special and/or strict adherence

to the proc edures to prevent serious injury to personnel or death.

Electrical Hazard Symbol

A symbol which indicates a hazard of injury from ele ctrical

shock or burn. It is comprised of an equilateral triangle

enclosing a lightning bolt.

Explosion Hazard Symbol

A symbol which indicates a hazard of injury from exploding

parts. It is comprised of an e quilateral triangle enclosing an

explosion image.

Equi pment Warning Labels

DO NOT attempt to insta ll, operate, perform maintenance, or dispose of this equipment until you have

read and understood all of the product la bels and user direc tions that are contained in this manual.

Warning labels that ar e attached to the equipment will include the exclamati on ma r k within a triangle.

DO NOT remove or cover any of these la bels. If the labels are damaged or if additional labels are

required, contact your Toshiba sales representative for additional labels.

Labels atta ched to the equipment are th ere to provide useful information or to ind ica te an imminently

hazardous s ituation that may result in serious injury, severe property and equipment damage, or death if

safe procedures or methods are not followed as outlined in this manual.

Qualified Personnel

Installatio n, ope ratio n, and maint enanc e shal l be perfor med by Qualified Personnel Only. A Qualified

Person is one that has the skills and knowledge relating to t h e c onstruction, ins tallation, operation, and

maintenance of the electrical equipment a nd has received safety training on the hazards involved (Re f er

to the latest edition of NFPA 70E for additional safety requirements ) .

Qualified Personnel shall:

• Have carefully read the entire manual.

• Be familiar with the constr uction and function of the H9 ASD, the equipment being driven, and the

hazards involved.

• Be able to recognize and properly address hazards associated with the appl ication of motor-d riven

equipment.

• Be traine d and au thorized to safely energize, de-ene rgize, ground, lockout/tagout circuits and

equipment, and clear faults in accord ance with established safety practices.

• Be trained in the proper care and use of protecti ve eq uipment such as safety shoes, rubber gloves,

hard hats, safety glasses, face shields, flash clothing, etc., in ac cordance with esta blished safety

practices.

• Be trained in rend ering first aid.

For further information on workplace safety visit www.osha.gov .

2 H9 ASD Installati on and Operation Manual

Page 11

Equipment Inspection

• Upon receipt of the equipment inspect the packagi ng and equipment for shipping damage.

• Carefully unpack the equipment and check for parts that were damaged during shipping, mi ssing

parts, or conce aled damage. If any discrepancies are discovered, it should be noted with the carrier

prior to accepting the shipment, if possible. File a claim with the carrier if necessary and

immediately notify your Toshiba sales representative.

• DO NOT install or energize equipment that has been damaged. Damaged equipment may fail

during operation resulting in equipment damage or personal injury.

• Check to see that the rated capacity and the model number specified on the nameplate conform to

the order specifi cations.

• Modification of this equipment is dangerous and should only be performed by factory trained

representat ives. When modifica tions are required contact your Toshiba sales

representative.Inspections may be required before and after moving installed equipment.

• Inspections may be required before and after moving installed equipment.

• Keep the equ ipm ent in an upright position.

• Contact your Toshiba sales representative to report discrepancies or for assistance if required.

Handling and Storage

• Use proper li fting techniques when moving the H9 ASD; including properly sizing up the load,

getting assistance, and using a forklift if required.

• Sto re in a well-ventilated covered loc ation and preferably in the original carton if th e equipment

will not be used upon receipt.

• Store in a cool, clean, and dry location. Avoid storage locations with extreme temperatures, rapid

temperature ch anges, high humidity, moisture, dust, corrosive gases, or meta l particles.

• The storage temperature range of the H9 ASD is -13° to 158° F (-9 .4° to 70° C).

• Do not store the unit in pl aces tha t are e xposed to outside we ather c onditi ons (i. e., wi nd, rain , snow,

etc.).

• Store in an upright position.

Disposal

Never dispose of electrical components via incineration. Contact your state environm ental agency for

details on disposal of electrica l components and packaging in your area.

H9 ASD Installation and Oper ation Manual 3

Page 12

Inst a lla ti on Pre cautions

Location and Ambient Requ ire ments

• The Toshiba H9 ASD is intended for permanent installations only.

• Installation should conform to the 2005 National Ele ctr ical Code — Article 110 (NEC)

(Requirements For Electric al I n stallations), all regulations of the Occupational Safety and

Health Administration, and any other applicable na tional, regional, or industry codes and

standards.

• Select a mounting location that is easily accessible, has adequate personnel working space, and

adequate il lum ination for adjustment, inspection, and maintenance of the equipment (refer to 2005

NEC Article 110-13).

• A noncombustible insulating floor or mat should be provided in the area immediately surrounding

the electrical system.

• DO NOT mount the H9 ASD in a loca tion that would produce catastrophic results if it were t o fall

from its mounting location (equipment damage or injury).

• DO NOT mount the H9 ASD in a loc ation that would allow it to be exposed to flammable

chemicals or gases, water, solvents, or other fluids.

• Avoid installation in areas where vibration, heat, humidity, dust, fibers, steel pa rticles, explosive/

corrosive mists or gases, or sources of electric al noise are present.

• The installation location shall not be expo se d to direct sunlight.

• Allow proper cl earance spaces for installation. Do not obstruct the ventilation openings . Refer to

the section titled

requirements.

• The ambient operating temperature range of the H9 ASD is 14° to 104° F (-10° to 40° C).

• See th e sec ti on titl ed I nst alla tion an d Conne ctio ns on pg. 14 for a dditio nal informati on on i nsta lling

the drive.

Installation and Connections on pg. 14 for further information on ventilation

Mounting Re qui rem ents

• Only Qualified Personnel should install this equipment.

• Install the unit in a secure and upright position in a well-ventilated area.

• A noncombustible insulating floor or mat should be provided in the area immediately surrounding

the electrical syste m at the place where maintenance oper ations are to be perf o rmed.

• As a minimum, the ins tallation of the equipment should co nform to the 2005 National Ele ctrical

Code — Article 110 (NEC), OSHA, as well as any other applicable national, regional, or industry

codes and standards.

• Installation practi ces should conform to the late st revision of NFPA 70E Electrical Safety

Requirements for Employee Workplaces.

• It is the respo nsibility of the person ins tallin g the H9 ASD or the electrical maintenance personnel

to ensure that the unit is installed in an enclosure that will protect personnel against ele ctric shock.

4 H9 ASD Installati on and Operation Manual

Page 13

Conductor Routing and Groundi ng

WARNING

• Use sepa rate me tal c ondui ts fo r rout ing the i nput power, output power , a nd cont rol circui ts a nd eac h

shall have its own ground cable.

• A separate ground cable should be run inside the conduit with the input power, output power, and

and control circuit s.

• DO NOT connect CC to earth ground.

•Use IICC terminal as the return for the V/I input.

• Always ground the unit to prevent electrical shock and to help reduce electrical noise.

• It is the respo nsibility of the person ins tallin g the H9 ASD or the electrical maintenance personnel

to provide proper grounding and branch circuit protection in accordan ce with the 2005 NEC and

any applicable local codes .

The Metal Of Conduit Is Not An Acceptable Ground.

Grounding Capacitor Switch

The H9 ASD is equipped with leak reduction capacitors whic h are used to reduce the EMI leakage via

the 3-phase power -i nput cir cuit an d for complia nce with t he Elec trom agnet ic Compatib ilit y Dir ecti ve

(EMC).

The effective value of the capac itor may be increas ed, reduced, or removed entirely via the Selector

Switch, Switching Bar, or the Switching Screw — the type used is typeform-specific.

The Grounding Capacitor Switch allows the user to qui ckly cha nge the value of the le akage- redu ction

capacitance of the 3-phase input circuit without the use of tools.

See the section titled Power Connection Req uirements on pg. 17 for more on the Grounding Capac itor.

See figures 4, 5, 6, and 7 on pg. 19 an electrical depiction of the le akage-reduction functionality of the

Grounding Capacitor and the methods used to set the capacitance value.

The H9 ASD is equipped with a noise reduction capacitor which is used to re duce the noise of the 3phase input circuit. The capacitor may be removed from the circuit electrically us ing the Groundin g

Capacitor Switch (see

The switch has a push- pull activation mechanism. From the front of the unit, push the actuator to place

the noise reduct ion ca pacitor into the circuit. Pull the actuator to remove the noise reduction capacitor

from the circuit.

Figure 2 on pg. 16).

H9 ASD Installation and Oper ation Manual 5

Page 14

Power Connect ions

DANGER

Contact With Energized Wiring Will Cause Severe Injury Or Death.

• Turn off, loc kout, and tag out all power sources before connecting the power wiring to the

equipment.

• After ensuring that all power source s are turned off and isola ted in accordance with esta blished

lockout/tag out procedures, connect three-phase power source wiring of the correct voltage to the

correct input terminals and connect the output terminals to a motor of the correct voltage and type

for the application (refer to NEC Article 300 – Wiring Methods and Article 310 – Conductors For

General Wiring). Size the branch circuit conductors in acc ordance with NEC Table 310.16.

• If multipl e co nductors are used in parallel for the input or output power and it is nec essary to use

separate condu its, each paral lel set s hall ha ve its own conduit (i. e., place U1, V1, W1, an d a ground

wire in one conduit and U2, V2, W2 and a ground wire in another) (refer to NEC Article 300. 20

and Article 310.4). National and local electrical codes should be referenced if three or more power

conductors are run in the same conduit ( refer to 2005 NEC Article 310 adjustment factors).

• Ensure that the 3-phase input power is Not connected to the output of the H9 ASD. This will

damage the H9 ASD and may cause injury to personnel.

• DO NOT install the H9 ASD if it is damaged or if it is missing any compone nt(s).

• DO NOT connect resist ors across terminals PA – PC or PO – PC. This may cause a fire.

• Ensure the correct phase sequence and the desired direction of motor rotation in the Bypass mode

(if applicable).

• Turn the power on only after attaching and/or securing the front cover.

Protection

• Ensure that primary protect ion exis ts for the input wiring to the equipm ent. This protect ion must be

able to interru pt the availabl e fau lt current from the power line. The equipment may or may not be

equipped with an in put disconnect ( option).

• All cable entry ope nings must be sealed to reduce the risk of entry by vermin and to allow for

maximum cooling efficiency.

• Follow all warnings a nd precautions and do not exceed equipment ratings.

• External dynamic braking resistors must be therm ally protected.

• It is the respo nsibility of the person ins tallin g the H9 ASD or the electrical maintenance personnel

to setup the Em e r gency Off braking system of the H9 ASD. The function of the Emergency Off

braking function is to remove output power from the drive in the event of an emergency. A

supplemental braking system may also be enga ged in the event of an emerg ency . For further

information on braking systems, see parameters

F250 and F304.

Note: A supplemental eme rgency stopping syst em s hould be used with the H9 ASD.

Emergency stopping should not be a task of the H9 ASD alone.

• Follow all warnings a nd precautions and do not exceed equipment ratings.

6 H9 ASD Installati on and Operation Manual

Page 15

System Integration Precautions

WARNING

The following preca utions are provide d as gene ral guidelines for the setup of the H9 ASD within the

system.

• The Toshiba H9 ASD is a general-purpose product. It is a system component only and th e system

design should take this into consideration. Please contact your Toshiba sales repres entative for

application-specific information or for training support.

• The Toshiba H9 ASD is part of a larger system and the safe operation of the H9 ASD will depend

on observing certain precautions and perform ing proper system integration.

• A detailed system analysis and job safety analysis shoul d be performed by the systems desig ner

and/or systems integrator before the installation of the H9 ASD component. Contact your Toshiba

sales representative for options availability a nd for application-specific system integration

information if required.

Pers onnel Protect ion

• Instal lation, operation, and maintenance sha ll be performed by Qualified Personnel Only.

• A thorough understanding of the H9 ASD will be required be fore the installation, operatio n, or

maintenance of the H9 ASD.

• Rotating machinery and live conductors can be hazardous and shall not come into contact with

humans. Personnel should be protected from all rotating machinery and electrical hazards at all

times.

• Insulat ors , machine guards, and electrical safeguards ma y fail or be defeated by the purposeful or

inadvertent actions of workers. Insulators, machine guards, and electrical safeguards are to be

inspected (and tested where possible) at installation and periodically after inst allation for potential

hazardous conditions.

• DO NOT allow personnel ne ar rota ti ng machin ery. W arning s igns to this ef fec t shall be p osted at or

near the machinery.

• DO NOT allow personnel near e lectr ical conduct ors. Hu man conta ct wit h elec trica l condu ctors can

be fatal. Warning signs to this effect shall be posted at or near the ha zard.

• Personal protection equipment shall be provided and used to protect employees from any hazards

inherent to system operation.

• Follow all warnings a nd precautions and do not exceed equipment ratings.

H9 ASD Installation and Oper ation Manual 7

Page 16

System Setup Requirements

CAUTION

• When using the H9 ASD as an int egra l part of a larger system, it is the respons ibility of the

H9 ASD installer or maintena nce personnel to ensure that there is a fail-safe in place, i.e., an

arrangement designed to switch the system to a saf e con dition if there is a fault or failure.

• System safety features should be empl oyed and designed into the integr ate d system in a manner

such that s ys te m op e r at io n , ev en in th e ev e nt of sy s te m fa i lu r e, wi ll no t cau s e h arm o r res ul t in

personnel injury or system damage (i.e., E-Off, Auto-Rest art settings, System Interlocks, e tc.).

• The programming s etup and system configuration of the H9 ASD may allow it to start the motor

unexpectedly. A familiarity with the Auto-restart set tings are a requirement to use this product.

• Improperl y desig ned or impr operly inst al led syst em interl ocks may ren der the m otor unabl e to sta rt

or stop on command.

• The failure of external or ancillary components may ca use intermittent s ystem operation, i. e., the

system may sta rt the motor without warning.

• There may be thermal or physical properties, or ancillary devices integrated in to the overall system

that may allow for the H9 ASD to start th e motor without warning. Signs at the equipment

installa tion must be posted to this effect.

• Power factor improvement capacitors or surge absorbers must not be installed on the output of the

H9 ASD.

• Use of the built-in system protective fea tures is highly recommended (i.e., E-Off, Overload

Protection, etc.).

• The operating controls and system status indic ators should be clearly read able and positi oned

where the operator can se e the m wit hout obstruction.

• Additi onal warnings and not ifications shall be posted at the equipment installation locatio n as

deemed required by Qualified Personnel.

• Follow all warnings a nd precautions and do not exceed equipment ratings.

• If a secondary magn etic contactor (MC) or an ASD output disconnect is used between the H9 ASD

and the loa d, it should be interlocked to halt t he H9 ASD before the secondary contact opens. If the

output contactor is used for bypass operation, it must be interlocked such that commer cia l power is

never applied to the H9 ASD output terminals (U, V, W).

• When using an ASD output dis connect the ASD and the motor must be stopped be fore the

disconnect is eithe r ope ned or clo sed. Closin g the outpu t disc onne ct while the 3-pha se out put of the

ASD is active may result in equipment damage or injury to personnel.

8 H9 ASD Installati on and Operation Manual

Page 17

Operational and Maintenance

WARNING

Precautions

• Turn off, lockout, and tag out the main power, the control power, and instrumentation connections

before inspecti ng or servicing the drive, or ope ning the door of the enclosure.

• Turn off, lockout, and tag out the main power, the control power, and instrumentation connections

before proceeding to disconnect or connect the power wiri ng to the equipment.

• The capacitors of th e H9 ASD maintain a resi dual char ge for a period of ti me after turn ing th e ASD

off. The required time for each ASD typeform is indicated with a cabine t label and a Charge LED.

Wait for at least the minimum time indicated on the enclosure-mounted label and ensure that the

Charge LED has gone out before opening the door of the ASD once the ASD power has been

turned of f.

• Turn the power on only after attaching (or closing) the front cover and Do Not remove the front

cover of the H9 ASD when the power is on.

• Do Not attempt to disassemble, modify, or repair the H9 ASD. Call your Toshiba sales

representative for repair information.

• Do not place any objects inside of the H9 ASD.

• If the H9 ASD should emit smoke or an unusua l odor or sound, turn the power off immediatel y.

• The heat si nk and other components may become ext remel y hot to the t ouch. All ow the unit to cool

before coming in contact with these items.

• Remove power from the H9 ASD during extended periods of non-use .

• The system should be inspected pe riodically for damaged or improperly functioning parts,

cleanliness, and to ensure that the connectors are tightened securely.

H9 ASD Installation and Oper ation Manual 9

Page 18

Motor Characteristics

Listed below are some variable speed AC motor control concepts with which the user of the

H9 Adjustable Speed Drive should become familiar.

Motor Autotuning

Motor production methods may cause minor differences in the motor operation. The negative effects of

these diffe r ences may be minimized by using the Autotune feature of the H9 ASD. Autotuning is a

function of the H9 ASD that measures several parameters of the connected motor and places these

readings in a stored table. The software uses the information in the table to help optimize the response of

the ASD to applica tion-specific load an d op er ational requirements. The Autotuning function may be

enabled for automatic tuning, conf ig ured manually at

The measured parameters include the rotor resistance, the stator resistance, the required excitation

inductance, rotational inertia values, and leakage inductance values.

Pulse Width Modula tio n Op e ration

The H9 ASD uses a sinusoidal Pulse Width Modulation (PWM) control system. The output current

waveform generated by the ASD approac hes that of a perfect sine wave; however, the output waveform is

slightly distorted. For this re as on, the motor may produce more heat, noise, and vibration when oper ated

by an ASD, rather than directly from commercial power.

F400, or disabled.

Low Sp eed Operation

Operating a general-purpose motor at lower speeds may cause a decrease in the cooling ability of the

motor. Reducing the torque requirement of the motor at lower spee ds will decrease the generated heat at

lower speeds.

When the motor is to be operated at low spee d (less than 50% of full speed) and at the rate d torque

continuously, a Toshiba VF motor (designe d for use in conjunction with a n ASD) is recommended.

Overload Protecti on Adjustment

The H9 ASD software monitors the output curre nt of the system and determin es when an overload

condition occurs. The overload current level is a percentage of the rating of the motor. This function

protects the motor from overload.

The default setting for the overload detection circuit is set to the maximum rated current of the ASD at the

factory. This setting will have to be adjusted to match the rating of the motor wit h which the ASD is to be

used. To change the overload reference level, see

Motor Overload Protection Level 1 on pg. 182.

Operation Above 60 Hz

A motor produces more noise and vibration when it is operate d at frequencies above 60 Hz. Also, when

operating a motor a bove 60 Hz, th e rated lim it of the motor or its bear ings m ay be ex ceeded; t his may void

the motor warranty.

Contact the motor manufacturer for additi onal information before operating the motor above 60 Hz.

10 H9 ASD Installation and Operation Manual

Page 19

Power Factor Correction

DO NOT connect a power factor correction capacitor or surge absorber to the output of the H9 ASD.

If the ASD is used with a motor that is equipped with a capacitor for power factor co rrec tion, remove the

capacitor from the motor.

Connecting eit her of these devices to the output of the ASD may cause the ASD to malfunction and trip ,

or the output device may cause an over-current condition resulting in damage to the device or the ASD.

Light Load Conditions

When a motor is operated under a co ntinuous light load (i.e., at a load of less tha n 50% of its rated

capacity) or it drives a load which produces a very small amount of inertia, it may become unstable and

produce abnormal vibration or trips because of an over-current condition. In such a case, the carrier

frequency may be lowered to compensate for this undesirable condition (see Program ⇒ Special ⇒

Carrier Frequency ⇒

Note: When op eratin g in the Vector Control mode the carri er frequency should be set to

2.2

kHz or above.

PWM Carrier Frequency).

Motor/Load Comb inations

When the H9 ASD is used in co mbination with one of th e f o llowing motors or loads, it may result in

unstable oper ation.

• A motor with a rated capacity that exceeds the motor capacity recommended for the ASD.

• An explosion-proof motor.

When using the ASD with an explosion-proof motor or other spec ial motor types, lowe r the carrier

frequency to s tabilize the operation. DO NOT set the carrier frequency below 2.2 kHz if operating the

system in the vector control mode.

Note: When op eratin g in the Vector Control mode the carri er frequency should be set to

2.2

kHz or above.

• If the motor that is coupled to a load that has a large ba cklash or a reciprocating loa d, use one of the

following procedures to stabilize its operation.

• Adjust the S-pattern acceleration/deceleration setting,

• If in the Vector control mode, adjust the response time, or

• Switch to the Constant Torque control mode.

H9 ASD Installation and Oper ation Manual 11

Page 20

Load-pro du ce d Nega tiv e Torq ue

CAUTION

When the H9 ASD is used with a load that produces negative torque (an overhauling load), the overvoltage or over-current protect ive functions of the ASD may cause nuisance tripping.

To m inimize the undesira ble effects of negative torque the dynamic braking system may be used. The

dynamic braking syste m converts the regenerate d energy into heat that is dissipated us ing a braking

resistor. The braking resistor must be suitabl y matched to the load. Dynamic braki ng is also effective in

reducing the DC bus voltage during a momentary over-voltage condition.

If under extreme conditions the dynamic braking system or a component of this system were to fail, the

dynamic braking resistor may experience an extended over-current condition. The DBR circuit was

designed to dissipate excessive amounts of heat a nd if the extended over-current condition were allowed

to exceed the circuit parameters, t his condition could result in a fire hazard.

To c ombat this c onditi on, the 3-pha se in put may be connect ed usi ng conta ctors that a re confi gure d to open

in the event of an extende d DBR over-current condition or an internal ci rcuit failure. Using a thermal

sensor and/or overload protec tion as the 3-phase input contactor drive signal, the cont actors will ope n and

remove the 3-phase input power in the event of an extended DBR over-current or system over-voltage

condition.

Motor Braking

The motor may continue to rotat e and c oast t o a sto p after being shu t off due to t he inert ia of the load. If an

immediate stop is required, a braking system should be used. The two most common types of motor

braking systems used with the H9 ASD are DC I n j ec t ion Brak ing and Dynamic Braking.

For further information on braking systems, see DC Injection Braking on pg. 124 and Dynamic Braking

on pg. 136.

12 H9 ASD Installation and Operation Manual

Page 21

H9 ASD Characteristics

Over- current Protection

Each H9 ASD model was designed for a specified operating power range. The H9 ASD will incur a trip if

the desi gn sp ecificati o n s are ex ce ed ed .

However, the H9 ASD may be operated at 100% of the specified output-current range continuously or at

120% for a limited amount of time as indicated in the section titled

263. Also, the Stall Prevention Level may be adjusted to hel p with nuisance over-current trips (see F601).

When using the H9 ASD for an application that controls a motor which is rated significantly less than the

maximum current rating of the ASD, the over-current limit (Thermal Overload Protection) setting will

have to be changed to match th e FLA of the motor. For furt her information on this parameter, see

Overload Protection Level 1 on pg. 182.

ASD Capacity

The H9 ASD must not be used with a motor that has a significantly larger capacity, even if the motor is

operated under a small load. An ASD being used in this way will be susceptible to a high-output peak

current which may result in nuisance tripping.

Do not apply a level of input voltage to an ASD that is beyond that which the ASD is rated. The input

voltage may be stepped down when requ ired with the use of a step-down transformer or some other type

of voltage-reduction system.

Current/Voltage Specifications on pg.

Motor

Using Vector Cont rol

Using Vector Control enables the system to produce very high torque over the entire operating range

even at ex t r emely low sp ee ds . Vector Control may be used with or without feedback. However, us ing

feedback increases the speed accuracy for applications requiring precise speed control .

See F015 on pg. 81 for further informati on on us ing Vector Control.

H9 ASD Installation and Oper ation Manual 13

Page 22

Installation and Connections

CAUTION

The H9 True Torque Contr ol2 Adjustable Speed Drive may be set up initially by performing a few

simple config uration sett ings. To operate properly, the ASD must be securely mounte d and conn ecte d to

a power source (3-phase AC input at the R/L1, S/L2, and T/L3 terminals). The co ntr ol terminals of the

H9 ASD may be used by connecting the terminals of the Terminal Board to the proper sensors or

signal input sources (see the section titled

System performan ce may be further enha nced by assigning a function to the output terminals of the

Terminal Board and connecting the terminals to the proper indicators or actuators ( r elays, contactors,

LEDs, etc.).

Note: The option al H9 ASD interface boards may be used to expand the I/O functionality of

the H9 ASD.

Installation Notes

When a brake-eq uipped motor is connected to the H9 ASD, it is po ssible that the brake may not relea se

at startup because of insuffi cient voltage. To avoid this, DO NOT conne ct th e brake or the br ak e

contactor to th e output of the H9 ASD.

If an output cont actor i s used for byp ass opera tion, it mus t be int erlock ed such tha t commer cial po wer is

never applied to the output termina ls of the H9 ASD (U/T1, V/T2, and W/T3).

I/O and Control on pg. 21

and

Figure 9 on pg. 24).

DO NOT apply commercial power to the H9 ASD output terminals U/T1, V/T2, and W/T3.

If a secondary magnetic contactor (MC) is used between the output of the H9 ASD and the motor, it

should be interlocked such that the ST – CC connection is disconnected be fore the output contactor is

opened.

DO NOT open and then close a secondary magnetic cont actor between the H9 ASD and the motor

unless the ASD is off and the motor is not rotating.

Note: Re-applicat ion of power via a secondary contact whi le the H9 ASD is on or while the

motor is s t il l turnin g m a y ca u s e AS D da m age.

The H9 ASD input voltage should remain within 10% of the specified input voltage range. Input

voltages approaching the upper or lower limit settings may require that the overvolt age and

undervoltage stall pr otection level parameters be adjusted. Voltages outside of the permi ssible tolerance

should be avoided.

The frequency of the inp ut power should be ±2 Hz of the sp ec ified input frequency.

DO NOT use an ASD with a motor that has a current rating that is higher than the rated current of the

ASD.

The H9 ASD is designed to operat e NEMA B motors. Consult with your sales representative before

using the ASD for specia l applications such as with an explosion-proof motor or applications with a

piston load.

Disconnect the H9 ASD from the motor before megging or applying a bypass voltage to the motor.

Interface problems may occur when an ASD is used in conjunction with some types of process

controllers. Signal isolation may be required to prevent controller and/or ASD malfun ction (contact

your Toshiba sales representative or the process controller manufacturer for a dditional information

about compatibility and signal isolation).

14 H9 ASD Installation and Operation Manual

Page 23

Use caution when setting the output frequency. Over speeding a motor decrease s its ability to deliver

Figure 1. Typical circuit breaker configuration.

CAUTION

torque and may result in da ma ge to the motor and/o r the driven equipment.

Not all H9 ASDs are equipped with internal primary power input fuses (HP depe ndent). When

connecting two or more drives that have no internal fuse to the sa me power line as shown in

select a circuit-breaking configuration that will ensure that if a short circuit occurs in ASD 1, only

MCCB2 trips, not MCCB1. If it is not feasible to use this configuration, insert a fus e between MCCB2

and ASD 1.

Mounting the H9 ASD

Figure 1,

— The following thermal specifications apply to the 230- and the 460-volt ASDs ONLY —

Install the unit securely in a well ventilated area that is out of direct sunli ght.

The process of converting AC to DC, and then back to AC produces heat. During normal ASD

operation, up to 5% of the input energy to the ASD may be dissipated as he at. If installing the ASD in a

cabinet, ensure that there is adequate ventilation.

DO NOT operate the H9 ASD with the enclosure door open.

The ambient operating temperature rating of the 3.0 to 20 HP H9 ASD is 14° to 104° F (-10° to 40° C).

The ambient operating temperature rating of the 25 HP and above H9 ASDs is 14° to 122° F (-10° to

50° C). If the ASD is being operat ed ab ove its specifie d range derate the ASD and in accordance with

the Carrier Frequency/Derating specifications listed in Fi gure 31 on pg. 190 — and provide a minimum

clearance space of 20 cm above and below the ASD from any obstruction.

The aforementioned thermal specifications apply to the 230- and the 460-volt ASDs.

When installing adjacent ASDs horizontally Toshiba recommends that there be at least 5 cm of space

between adjace nt units. However, horizontally mounted ASDs may be installed side-by-side with no

space in between the adjacent units — Side-b y-side installations require that the top cove r be removed

from ea ch ASD.

For 150 HP ASDs and above, a minimum of 50 cm of space is required above and below adjacent units

and any obstruction.This space is the recommended minimum space req uirement for the H9 ASD and

ensures that adequate ventilation is provided f or each unit. More space will provide a better

environment for cooling (see the section titled Enclosure Dim ensions and Conduit Plate Information on

pg. 256 for additiona l information on mounting space requirements) .

Note: Ensure that the ventilation openings are not obstr u cted.

H9 ASD Installation and Oper ation Manual 15

Page 24

Connecting the H9 ASD

DANGER

DANGER

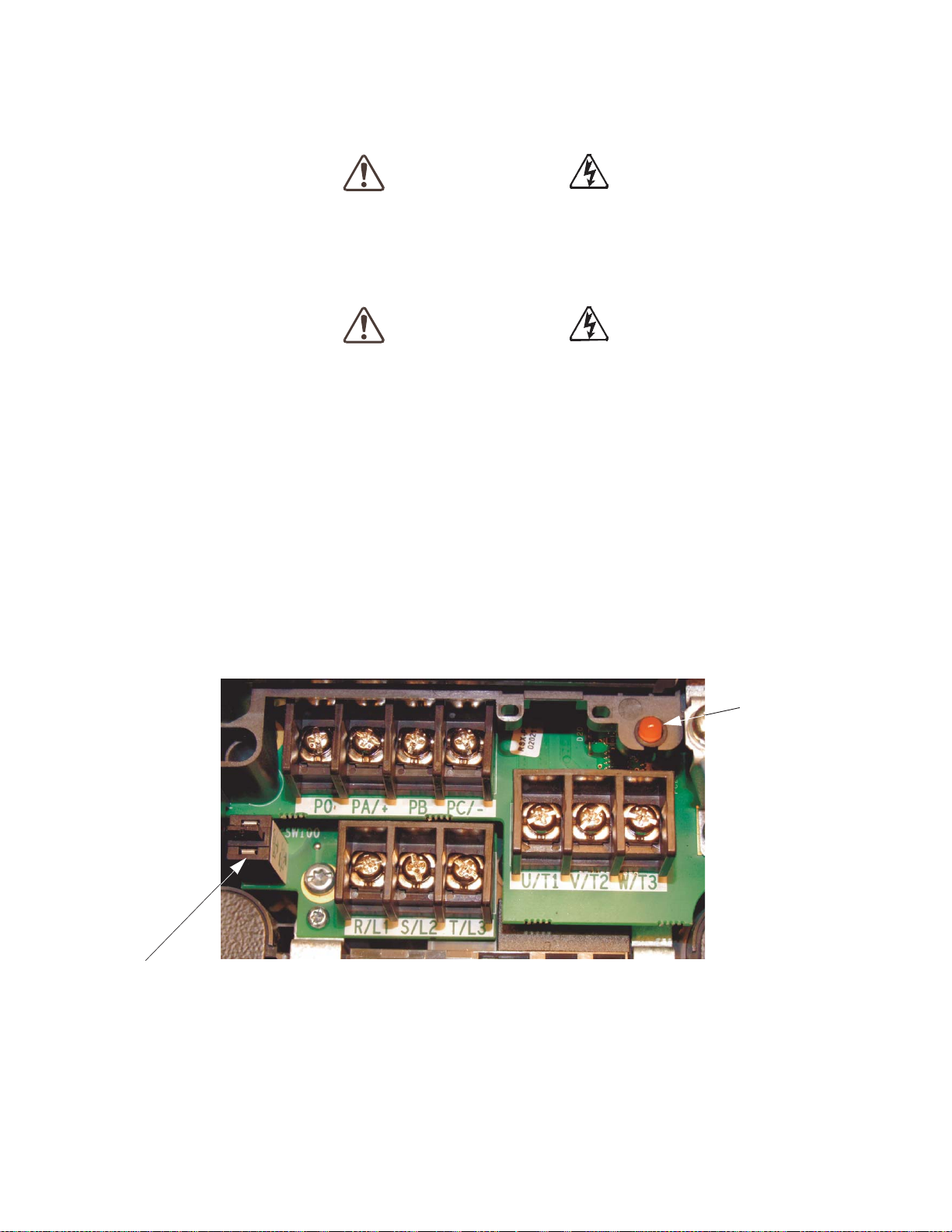

Charge LED

Grounding Capacitor Switch — Pull for Small capacitance/Push for Large capaci tance.

Refer to the section titled Installation Precautions on pg. 4 and the sect io n titled Lead Length

Specifications on pg. 20 before attempting to connect the H9 ASD and the motor to el ectrical power.

Power Connections

Contact with the 3-phase input or output terminals may cause an electrical shock

resulting in injury or loss of life.

See Figure 20 on pg. 26 for a system I/O connectivity sche ma tic.

An inductor (DCL) may be connected a cross the PO and PA/+ termin als to provide additional filtering.

When not used, a jumper must be connected across these terminals (see Figure 20 on pg. 26).

PA/+ and PB are us ed for the DBR connection if using a braking resistor.

PC/- is the negative terminal of the DC bus.

R/L1, S/L2, and T/L3 are the 3-phase input supply terminals for the H9 ASD.

U/T1, V/T2, and W/T3 are the output terminals of the H9 ASD that connect to the motor.

The location of the Charge LED for the smalle r typeform ASD is provided in Figure 2. The Charge

LED is located on the front door of the enclosure of the larger ASDs.

Figure 2. Typical H9 ASD input/output terminals and the Grounding Capacitor Switch.

16 H9 ASD Installation and Operation Manual

Page 25

Power Connection Requirements

Connect the 3-phase input power to the input terminals of the H9 ASD at R/L1, S/L2, and T/L3 (see

Figure 3 for the typical el ec tri cal con nec ti on scheme ). Con nect the outpu t of the ASD to the motor f rom

the ASD terminals U/T1, V/T2, and W/T3. The input and output conductors and terminal lugs used

shall b e in accordan ce wi th the requirements li sted in the section tit led Current/Voltage Specifica tions

on pg. 263.

If multiple conductors are used in parallel for the input or output power and it is nec essary to use

separate conduits, each parall el set shall have its own conduit and not sha re its conduit with other

parallel sets — i.e., plac e U1, V1, and W1 in one conduit and U2, V2, and W2 in another (refer to NEC

Article 300.20 and Article 310.4). National and local electrical codes should be refe renced if three or

more power conducto rs are run in the same conduit (re fer to 2005 NEC Article 310 adj us tm ent factors).

Note: National and local codes should be referenced when running more than three

conductors in the same conduit .

Install a molded case circ uit breaker (MCCB) or fuse be tween the 3-phase power source and the H9

ASD in accordance with the faul t curre nt setting of the H9 ASD and 2005 NEC Article 430.

The H9 ASD is designed and tes ted to comply with UL Standard 508C. Modifications to the ASD

system or failure to comply with the short circuit protection requirements outlined in this manual may

disqualify the UL rating. See Table 22 on pg. 267 for typeform-specific shor t circuit protec tion

recommendations.

As a minimum, the installation of the H9 ASD shall conform to 2005 NEC Article 110, the

Occupational Safety and Health Administration requirements, and to any other local and regional

industry code s a nd st andards.

Note: In the event that the motor rotate s in the wrong direction when powered up, reverse

any two of the three H9 ASD output power leads (U, V, or W) connected to the motor.

Figure 3. H9 ASD/Motor typical connection scheme.

H9 ASD Installation and Oper ation Manual 17

Page 26

System Grounding

Proper grounding helps to prevent electrical shock and to reduce electrical noise. The H9 ASD is

designed to be grounded in accordanc e with Article 250 of the 2005 NEC or Section 10/Par t One of

the Canadian Electrical Code (CEC).

The grounding condu ctor shall be sized in accordan ce with Arti cle 250-122 of the NEC or Part One-

Table

6 of the CEC.

The Metal Of Conduit Is Not An Acceptable Ground.

The input, output, and control lines of the system shall be run in separate metal conduits and each shall

have its own ground conductor.

ASDs produce high-fre quency noise — take steps to avoid the negative effects of noi se. L is ted below

are some ex amples of measures that wi l l he l p to co mb at noise prob l ems.

• DO NOT install the input power and output power wires in the same duc t or in parallel with each

other, and do not bind them together .

• DO NOT install the input/output power wires and the wires of the control circuit in the same duct

or in parallel with each other, and do not bind them together.

• Use shielded wires or twis te d wires for the control circuits.

• Ensure that the grounding terminals (G/E) of the H9 ASD are securely connected to groun d.

• Connect a surge suppress or to every electromagnetic contactor and every relay installed near the

ASD.

• Install noise filters as required.

The Grounding Capacitor Switch and the 3-phase input and output terminals are shown on pg. 16 (see

pg. 5 for more information on the Grounding Capacitor Switch).

Grounding Capacitor

The Grounding Capacitor plays a role in minimizing the effects of leakage current through the ASD

system and through ground paths to other sys tems. Leakage current may cause the improper operation

of earth-leakage curre nt breakers, leakage -current relays, ground relays, fire alarms, and othe r sensors

— and it may cause superimposed noise on CRT screens.

The Grounding Capacitor Switch allows the user to qui ckly cha nge the value of the le akage- redu ction

capacitance of the 3-phase input circuit. See figur es 4, 5, 6, and 7 on pg. 19 fo r an electrical depiction of

the leakage-reduction functiona lity and the methods used to change the capac itance value. The method

used is typeform-specific.

If using a 460-volt 5 HP ASD or a 460-volt ASD that is i n the range of 7.5 HP to 25 HP, and the U/T1,

V/T2, and W/T3 connections to the motor are 100 meters or more in length, the ASD Carrier

Frequency must be set to 4 kHz or less when activating or deactiv ating the Grounding Capacitor

Switch. ASD ov erheat ing may o c c ur if the Carrie r Freq uency is set above 4 kHz when activating or

deactivating the Grounding Capacitor Switch.

See pg. 5 for more information on the Grounding Capacitor Switch and pg. 16 for the location.

18 H9 ASD Installation and Operation Manual

Page 27

Figure 4. The Grounding Capacitor Switch is

used on typeforms 230-volt 0.5 HP to 10 HP

and the 25 and 30 HP/460-volt 1.0 HP to

250 HP.

The value may be set to Maximum (default

setting) or to zero by pushing or pulling the

switch actuator, respectively.

Figure 5. The Grounding Capacitor

Switch is used on typeforms 230-volt

15 HP to 20 HP and the 40 HP to 60

HP/460-volt 30 HP to 100 HP.

The value may be set to Large

(default setting) or Small by pushing

or pulling the switch actuator,

respectively.

Figure 6. The Grounding Capacitor Bar is

used on typeforms 230-volt 75 HP and the

100 HP/460-volt 125 HP and the 150 HP.

The value may set to Large or Small (default

setting) by connecting or disconnecting the

switching bar, respectively.

Figure 7. The Ground ing Cap aci tor Screw is

used on typeforms 460-volt 175 HP and

above.

The value may set to Large or Small (default

setting) by placing the screw in the A position

or by placing the screw in the B position,

respectively.

H9 ASD Installation and Oper ation Manual 19

Page 28

Lead Length Specifications

Adhere to the NEC and any local codes during the installation of ASD/Motor systems. Excessive lead

lengths may adversely effect the performance of the motor. Special cables are not re quired. Lead lengths

from the ASD to the motor in excess of those listed in

of the ASD. Table 1 lists the suggested maximum lead lengths for the listed motor voltages.

Table 1.

Table 1 may require filters to be added to the output

Model

230 Volt All 1000 feet

460 Volt

Note: Contact Toshiba for application assistance when using lead lengths in excess of those

listed.

PWM Carrier

Frequency

< 5 kHz 600 feet

≥ 5 kHz 300 feet

NEMA MG-1-1998 Section IV Part 31

Compliant Motors

2

Exceeding the peak voltage rating or the allowable ther mal rise time of the motor

insulation will reduce the life expectancy of the motor.

When operating in the Vector Control mode the carrier frequency should be set to

2.2

kHz or above.

20 H9 ASD Installation and Operation Manual

Page 29

I/O and Control

The H9 ASD can be controlled by several input types and combinati ons thereof, as well as operate within

a wide range of output freque ncy a nd voltage level s. This section discusses the H9 ASD control methods

and supported I/O functions.

The Terminal Board supports d iscrete and analog I/O functions and is shown in F igure 9 on pg. 24. Table

2 lists the names, functions, and the settings (default settings of programmable terminals) of the input and

output terminals of the Terminal Board.

Note: To use the input lines of the Terminal Board to provi d e Run commands the Command

Mode setting must be set to Terminal Block.

Figure 20 on pg. 26 shows the typica l connection diagram for the H9 ASD system.

Table 2. Terminal Board terminal names and functions.

Te rm. Na me Input/Output

ST

RES Reset — Multifunctional programmable discrete input. Resets ASD.

F

R

S1

S2

S3

S4

O1A/B (OUT1)

O2A/B (OUT2)

FLC

FLB

FLA

RR

RX

V/I

(Select V or I

via SW301)

AM

FM

SU+

P24

PP

FP Pulsed Output

IICC

CCA — Return for the RR, RX, P24, and the PP terminals.

CC

Discret e Input

Connect to CC

to activate

(Sink mode) .

Switched

Output

Analog Input

Analog

Output

DC Input Externally-supplied 24 VDC backup control power (1.1 A max.). Referenc e CC.

DC Output

— Return for the V/I input terminal.

— Return for discrete input terminals and the SU+ input terminal.

Standby — Multifu nct io nal pr ogr ammabl e di scre te inpu t. Act iv ation req uired

for normal ASD operation.

Forward — Multifunctional programmable discrete input.

Reverse — Multifunctional programmable discrete input.

Prese t Speed 1 — Multifunctional programmable discrete input.

Prese t Speed 2 — Multifunctional programmable discrete input.

Prese t Speed 3 — Multifunctional programmable discrete input.

Prese t Speed 4 — Multifunctional programmable discrete input.

Low Speed — Multifunctional programmable discret e output.

Reach Frequency — Multifunctional programmabl e discrete output.

Fault relay (common).

Fault relay (N.C.).

Fault relay (N.O.).

Multifunction programmable anal og input (0.0 to 10 volt input — 0 Hz to

Maximum Frequency). Reference CCA.

Multifunctional programmable analog input (-10 to +10 VDC input —

0 to ±Maxim um Frequency). Reference CCA.

V — Multifunctional programmable isol ated analog voltage input

(0 to 10 VDC input — 0 to Maximum Frequency output). Reference IICC.

I — Multifun ctional programmable isolate d analog current input (0 [4] to

20 mADC inpu t — 0 to Max im um Frequency output). Reference IICC.

Current output that is proportion al to the magni tude of the function assigned

to this term i na l (s ee

Current or voltag e output that is proportion al to the magni tude of the function

assigned to this terminal (see

at F681. Reference CC.

24 VDC (200 mA max.) output. Reference CCA. Figure 14 on pg. 25.

10.0 VDC/10 mA voltage source for the externa l potentiometer . CCA Ref. Figure 15 on pg. 25.

Frequency Pulse — Multifunctional programmable out put pulse t rain of a

frequency based on the output frequency of the ASD (see

Function (Default setting if progr am m able)

(see Terminal Description s on pg. 22)

Table 6 on pg. 239). Reference CC.

Table 6 on pg. 239). The output selection is set

Table 6 on pg. 239).

Circuit Config.

Figure 10 on pg. 25.

Figure 16 on pg. 25.

Figure 19 on pg. 25.

Figure 11 on pg. 25.

Figure 12 on pg. 25.

Figure 13 on pg. 25.

Figure 18 on pg. 25

Figure 17 on pg. 25.

Do Not connect to

Earth Gnd or to

each other.

H9 ASD Installation and Oper ation Manual 21

Page 30

Terminal Descriptions

Note: The programmable term inal assignments may be accessed and changed from their

default settings as mapped on

Direct Access ⇒ applicable paramete r number. See th e sec tio n tit le d Program Mode

Menu Navigation on pg. 46 for the applicable Direct Access parameter numbers.

For further information on terminal assignments and default setting changes, see the

sections titled

Note: See the section titled Cable/Terminal/Torque Specifications on pg. 265 for the H9

ASD conductor and terminal electrical spec ifications.

Note: Programmable te rminals will not retain their settings indefinit ely in the event o f a

power loss. Connect an external +24V DC supply to the SU+ terminal to retain the

programmable settings in the event of Control Power loss (see

ST — The default se tting for this terminal is the Standby mode controller. As the default setting, this

terminal must be activate d for normal system oper ation. The ST t ermin al is act ivate d by connec ting CC

to this ter minal (Sink mode). When deactivated the Not Ready to Run icon is displayed on the LCD

screen as sh own in

functi o ns that are listed in Table 5 on pg. 236 (see F113).

RES — The default setting for this terminal is Reset. The RES termin al is activated by connecting CC

to this termina l (S ink mode). A momentary connection to CC resets the ASD and any fault indications

from the display. Reset is effective when faulted only. This input termin al may be program me d to any

one of the functions that are listed in

Default Setting Changes on pg. 74 and Ter minal on pg. 47.

Figure 22. on pg. 31.This input terminal may be programmed to any one of the

pg. 46 or via the Direct Access method: Program ⇒

Figure 20 on pg. 26).

Table 5 on pg. 236 (see F114).

F — The default setting for this terminal is the Forward Run Command. The F term in a l is ac ti v a t ed

by connecting CC to this terminal (Sink mode). This input terminal may be programmed to any one of

the functions that are listed in

R — The default setting for this terminal is the Re verse Run Command. The R termina l is activat ed

by connecting CC to this terminal (Sink mode). This input terminal may be programmed to any one of

the functions that are listed in

S1 — The default setting for this terminal is the Preset Speed #1 Command. The S1 terminal is

activated by connecting CC to this terminal (Sink mode) . This input termina l ma y be progr ammed to

any one of the functions that are listed in

S2 — The default setting for this terminal is the Preset Speed #2 Command. The S2 terminal is

activated by connecting CC to this terminal (Sink mode) . This input termina l ma y be progr ammed to

any one of the functions that are listed in

S3 — The default setting for this terminal is the Preset Speed #3 Command. The S3 terminal is

activated by connecting CC to this terminal (Sink mode) . This input termina l ma y be progr ammed to

any one of the functions that are listed in

S4 — The default setting for this terminal is the Preset Speed #4 Command. The S4 terminal is

activated by connecting CC to this terminal (Sink mode) . This input termina l ma y be progr ammed to

any one of the functions that are listed in

RR — The default function assigned to this terminal is the Frequency Mode 1 setting. The RR

terminal accepts a 0 – 10 VDC input signal that is used to carry out the function assigned to this

terminal. This input terminal may be programmed to control the speed or torque of the motor via an

amplitude se tting or regulate by setting a limit. The gain an d bias of this terminal may be a djusted for

application-specific suit ability (see

the RR terminal. This terminal reference s CC A.

Table 5 on pg. 236 (see F111).

Table 5 on pg. 236 (see F112).

Table 5 on pg. 236 (see F115).

Table 5 on pg. 236 (see F116).

Table 5 on pg. 236 (see F117).

Table 5 on pg. 236 (see F118).

F210 – F215). See Figure 20 on pg. 26 for an electrical depiction of

22 H9 ASD Installation and Operation Manual

Page 31

RX — The default fu nction assigne d t o this termi nal is the Torque Comma nd se tti ng. The RX te rmina l

accepts a ±10 VDC input signal that is used to carry out the function assigned to this terminal. This

input terminal may be programmed to raise or lower the speed or torque of the motor via an amplitu de

setting or thi s te rminal may be used to regulat e the speed or torque of a motor by sett ing a limit. The

gain and bias of t his te rm inal m ay be adj us ted f or a pplic at ion- spec ifi c sui tab ili ty (s ee

F216 – F221). See

Figure 20 on pg. 26 for an electrical depiction of the RX te rminal. This terminal references CCA.

V/I (I) — The function of the I input is to receive a 0 – 20 mA input signal that controls a 0 – 80 Hz

output. T his is an isolated input te r minal. This terminal is identified as V/I on the terminal board and

may be programmed to control the speed or torque of the motor. This terminal cannot be used when

using the V input function. SW301 must be set to I to receive a current input signal at this terminal and

is the def ault setting from the factory (see

Figure 9 on pg. 24). This terminal refere nces IICC. Scaling

of the V/I terminal is accomplished via F201 – F206. The gain and bias of t his te rmina l may b e adjus ted

for appli cation- sp ec if i c su it ab i li ty ( s ee F470 and F471).

V/I (V) — The function of the V input termin al is to receive a 0 – 10 VDC input signal that controls a

0 – 80 Hz output. This is an isolated input terminal. This term inal is identified as V/I on the terminal

board and may be programm ed to cont rol the s peed or tor que of the motor. This terminal cannot be used

when using the I input. SW301 must be set to V to receive a voltage input signal at this te rminal (see

Figure 9 on pg. 24). This terminal references IICC. Scaling of the V/I terminal is accomplis h ed vi a

F201 – F206. The gain and bias o f t h is terminal may be adju sted for application-specific suitability

(F470 and F471).

SU+ — Externally suppli ed +24 VDC ± 10% @ 1.1 A (minimum) backup contro l power. This terminal

references CC.

P24 — +24 VDC @ 200 mA power supply for cu stomer use. This term inal references CCA.

PP — The function of out put PP is to provide a 10 VDC/10 m ADC output that may be divided using a

potentiome ter. The tapped voltag e is applied to the RR input to provide manual control of the RR

programmed function. This terminal refe rences CCA.

O1A/B (OUT1A/B) — The default function assigned to this term inal is Output Low Speed. This

output may be programmed to provide an indication (open or closed) that any 1 of the functions that are

listed in

Table 8 on pg. 241 has taken plac e. This function may be used to signal external e quipm ent or

to activ a t e th e b r ak e ( see F130). The OUT1 terminal is rated at 2 A/120 VAC and 2 A/30 VDC.

O2A/B (OUT2A/B) — The default function assigned to this terminal is ACC/DEC Complete. This

output may be programmed to provide an indication (open or closed) that any 1 of the functions that are

listed in

Table 8 on pg. 241 has taken plac e. This function may be used to signal external e quipm ent or

to activ a t e th e b r ak e ( see F131). The OUT2 terminal is rated at 2A/120 VAC and 2A/30 VDC.

FP — The default function of this output terminal is to output a series of pulses at a rate that is a

function of the output frequency of the ASD. As the output frequency of the ASD goes up so does the

FP output pulse rate. This terminal may be programmed to provide an output pulse rate that is

proportional t o an y one of th e it ems li sted i n

T abl e 6 on pg. 239. For further informatio n on this terminal

see F676 on pg. 196.

AM — This output terminal produces an output curre nt that is proportional to the magnitude of the

function assigned to this terminal. The available assignme nts for this output t erm inal are lis ted in

Table