Page 1

Table of Contents

Page 2

TABLE OF CONTENTS

1. INTRODUCTION

1.1 APPLICABLE MODEL

1.2 ACCESSORIES

2. SPECIFICATION

2.1 PRINTER ..................................................

2.2 LABEL ....................................................

2.3 SERIAL INTERFACE (RS-232C)

2.4 OPTION ...................................................

3. OVERVIEW

3.1 FRONT/REAR VIEW

3.2 OPERATIONPANEL

3.3

3.4 KEYlAYOUT

4. PROCEDURE BEFORE OPERATION

5. LOADING LABELS

5.1 LOADING LABELS FOR BATCH ISSUE

5.2 LOADING LABELS FOR STRIP ISSUE

6. PROGRAMMING PROCEDURES

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

BATCH/STRIP SELECTION SWITCH

CHANGING UNIT PRICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SETTING PLU DATA .a........................................

SETTING ADDRESSES . . . . . . . . . . . . . . . e . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING PRINT POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SETTING DATE AND TIME

SETTING THE INITIAL STATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SETTING BAR CODE FORMATS

SETTING TITLE OF NUTRITION FACTS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SETTING INGREDIENT MESSAGE/COUPON/CARE INSTRUCTIONS/

DAYGLOWMESSAGE

SETTING NUTRITION INFORMATION

SENDING/RECEIVING PLU DATA

..................................................

.........................................

..............................................

..................................................

.....................................................

..........................................

..........................................

............... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...................................

................................................

......................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..a...

..................................

. : : : : : : : : : : : : : : : : : : : : : : : : : : : :

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . : : : : : : : : : : : : : : : : : : : : : : : : : : : : :

Page

l- 1

l- 5

l- 5

2- 1

2- 1

2- 1

22- 1

3- 1

3- 1

3- 1

3- 1

3- 2

4- 1

5- 1

5- 1

5- 2

6- 1

6- 3

6- 4

6- 5

6- 5

6- 6

6- 6

6-10

6-12

6-13

6-14

6-17

1

Page 3

7. OPERATING PROCEDURES .........................................

7.1

STANDARDTYPE ...........................................

7.1 .l Weighing Operation ........................................

7.1.2 By Count Operation

7.1.3

Fix Mode Operation (Issuing labels with net weight statement)

........................................

7.1.4 Batch Print Mode (with 30 PLUS assignment) ......................

7.2 FLORISTTYPE .............................................

7.2.1 Scanning Operation ........................................

7.2.2

Item Correction

...........................................

7.2.3 Estimate ................................................

7.2.4 Printing Labels for Ready-made Commodities ......................

..........

Page

77-

7- 2

7- 5

7- 7

7-10

7-12

7-14

7-17

7-19

7-20

1

1

8. READ OPERATION

................................................

9. RESETOPERATION ...............................................

10. REMOVING JAMMED LABEL ........................................

11. CLEANING PROCEDURES ..........................................

PRINT HEAD/PLATEN/STRIP FEED ROLLER MECHANISM

11 .l

COVERS/PANELS

11.2

............................................

12. CARE/HANDLING OF THE LABEL .....................................

13. ERROR MESSAGE TABLE ..........................................

14. TROUBLESHOOTING ..............................................

..............

8-

9- 1

lo- 1

ll- 1

ll- 1

ll- 1

12- 1

13- 1

14- 1

1

CAUTION:

1. This manual may not be copied in whole or in part without prior written permission.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorized Service representative with regard to any queries you

may have in this manual.

Copyright 0 1996

by TEC CORPORATION

All Rights Reserved

570 Ohito, Ohlto-cho. Taaata-sun. Shizuoka-ken. JAPAN

Page 4

1. INTRODUCTION

1. INTRODUCTION

1. INTRODUCTION

Thank you for purchasing the TEC H-240 series label printer.

prints at a maximum speed of 76.2 mm/set. (3 inchesisec.) with a high density print head (8

dots/mm). The H-240 series is provided in two types; Standard and florist.

The standard machine is equipped with an RS-232C interface, which allows for connection to a PC, a

TEC SL-2200 scale for weighing operations, or another H-240 series machine for data communication

(an interface cable must be purchased locally.)

The florist machine is used together with the BHS6060R hand scanner. Scanning bar codes printed

on the visual chart allows use of PLUS and sales transactions.

Installing the B-3604~QM external roll holder provided as an option allows for use of a label roll with a

maximum outer roll diameter of 180-mm.

This manual contains general set-up and maintenance information and should be read carefully to

help gain maximum performance and life from your printer. For questions regarding your printer,

please refer to this manual and keep it safe for future reference.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operations of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense. (for USA only)

Light and compact, the H-240 printer

This

Changes or modifications not expressly approved by manufacturer for compliance could void the user’s

authority to operate the equipment.

I

“This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.”

“Cet appareil numerique de la classe A respecte toutes les exigences du Reglement sur le materiel

brouilleur du Canada.”

ffor CANADA only)

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and

Cautions necessary for safe handling are included in this manual. All warnings and cautions contained

in this manual should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs to this equipment.

procedures described in this manual, turn off the power, unplug the machine, then contact your

authorized TEC representative for assistance.

If a fault occurs that cannot be rectified using the

I

l- 1

Page 5

1. INTRODUCTION

Safety Precautions

This User’s Manual and the products (machines) which you have purchased contain indications which

should be observed in order to use the machines safely and prevent harm to yourself and others and

damage to property. The meanings of these indications and symbols are given below.

Read these indications and become familiar with their contents before reading this User’s Manual.

The following safety precaution will help to ensure proper use of the printer.

. Unplug the printer whenever you are working inside the printer.

. Keep your work environment static free.

Meanings of Each Symbol

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside thensymbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the 8 symbol.

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the l symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

A

@

e

1

l

1. INTRODUCTION

Any other than the

specikd AC voltage IS

prohlblted.

n

Do not use voltages other than the

voltage (AC) specified on the rating

n

If the machines share the same

outlet with any other electrical

appliances which consume large

amounts of power, the voltage will

fluctuate widely each time these

appliances operate. Be sure to

provide an exclusive outlet for the

machine as this may cause the

machines to malfunction.

n

Do not insert or drop metal,

flammable or other foreign objects into

the machines through the ventilation

slits, as this may cause fire or electric

n

Do not plug in or unplug the power

cord plug with

n

Do not place metal objects or

water-filled containers such as flower

vases, flower pots or mugs, etc. on

top of the machines. If metal objects

or spilled liquid enter the machines,

this may cause fire or electric

n

Do not remove covers, repair or

modify the machine by yourself. You

may be injured by high voltage, very

hot parts or sharp

wet hands as this may

edges inside the

l-2

Page 6

1. INTRODUCTION

1. INTRODUCTION

the power cords. Also, do not place

heavy objects on, pull on, or excessively bend the cords, as this may

cause fire or electrical shock.

n

If foreign objects (metal fragments,

water, liquids) enter the machines, first

turn off the power switches and

disconnect the power cord plugs from

agent (or maintenance and service

agent). Continued use of the machine

in that condition may cause fire or

electric shock.

W Ensure that the equipment is

properly grounded. Extension cables

should also be grounded. Fire or

electric shock can occur on improperly grounded equipment.

an abnormal condition such as when

the machines are producing smoke o

strange smells may cause fire or

electric shock. In these cases,

n

If the machines are dropped or thei

cabinets damaged, first turn off the

power cord plugs from the outlet, and

condition may cause fire or electric

Prohlblted

they might be exposed to direct

sunlight, high humidity, or dust.

Otherwise fire or electric shock could

n

Do not place the machines on

unstable or slanted surfaces, as they

may drop or fall and cause injury.

may cause fire.

l-3

Page 7

1. INTRODUCTION

1. INTRODUCTION

these precautions may result in

n

Do not lean against the machine. It

may fall on you and could cause

sconnec! the

injury.

plug

[Precautions When Moving the

Machines]

1 When moving the machines, be

sure to first unplug the power cords.

Moving the machines with the power

cords plugged in may damage the

cords and cause fire or electric

Precaution

The following precautions will help to ensure that this machine will continue to function correctly.

@ Try to avoid locations that have the following adverse conditions:

l

* Temperatures below 5°C and above 40°C

l

Shared power socket * Excessive vibration

Direct sunlight

0 The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild

detergent solution. NEVER USE THINNER OR ANY OTHER VOLATILE SOLVENT on the

plastic covers.

@ USE ONLY TEC SPECIFIED labels, tags and ribbons.

@ DO NOT STORE the labels, tags or ribbons where they might be exposed to direct sunlight, high

temperatures, high humidity, dust, or gas.

6J Ensure the printer is operated on a level surface.

@ Any data stored in the memory of the printer could be lost during a printer fault.

l-4

Page 8

1. INTRODUCTION

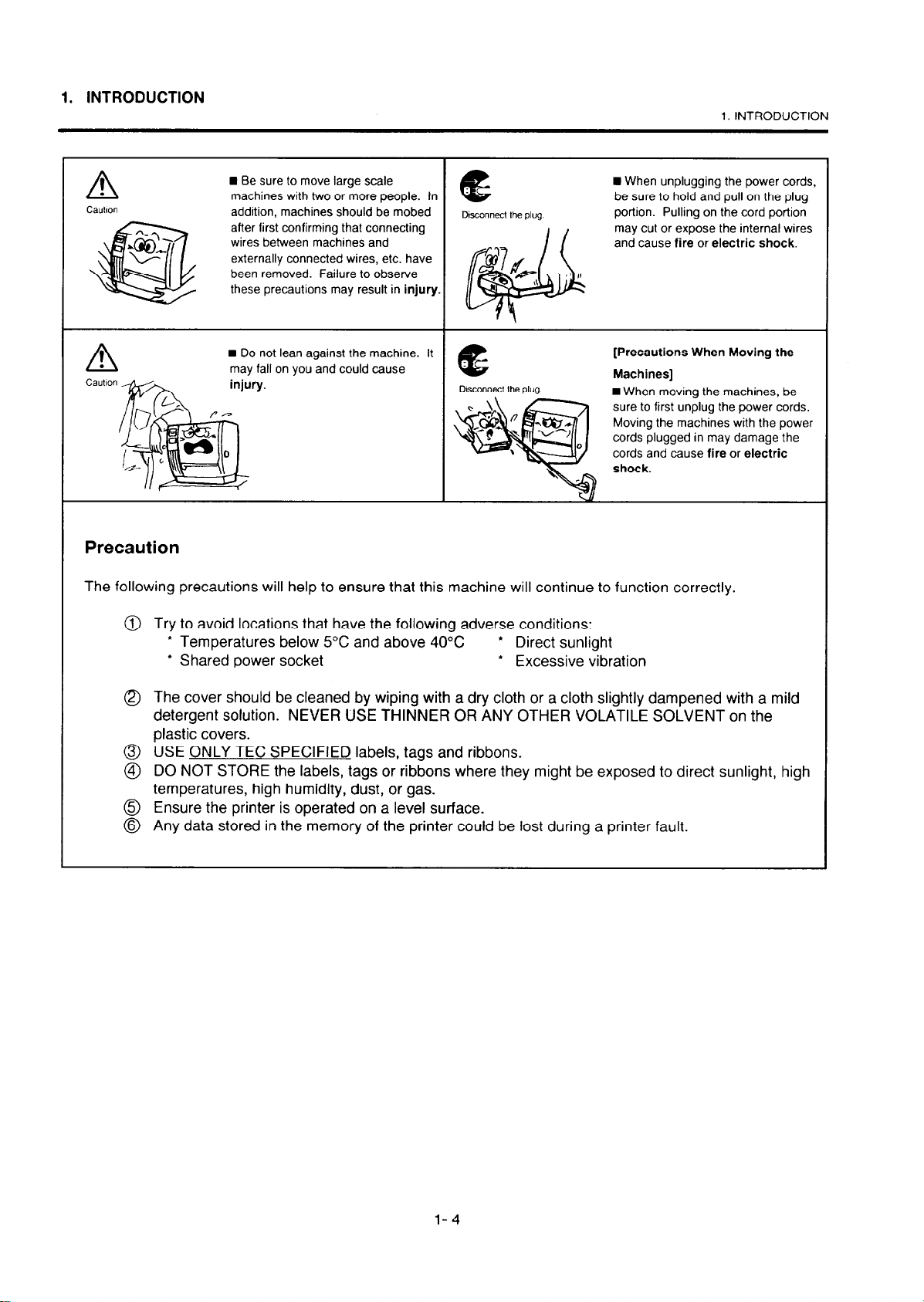

1 .I APPLICABLE MODEL

1.1

APPLICABLE MODEL

. H-240~QQ

Model name description

H-240-QQ

I

1.2 ACCESSORIES

Owner’s Manual

(EM1 -32005)

Paper Guide Ring

Destination Code

QQ: North America Bloc

Quality Control

Report

Print Head Cleaner

(24089500013)

l- 5

Page 9

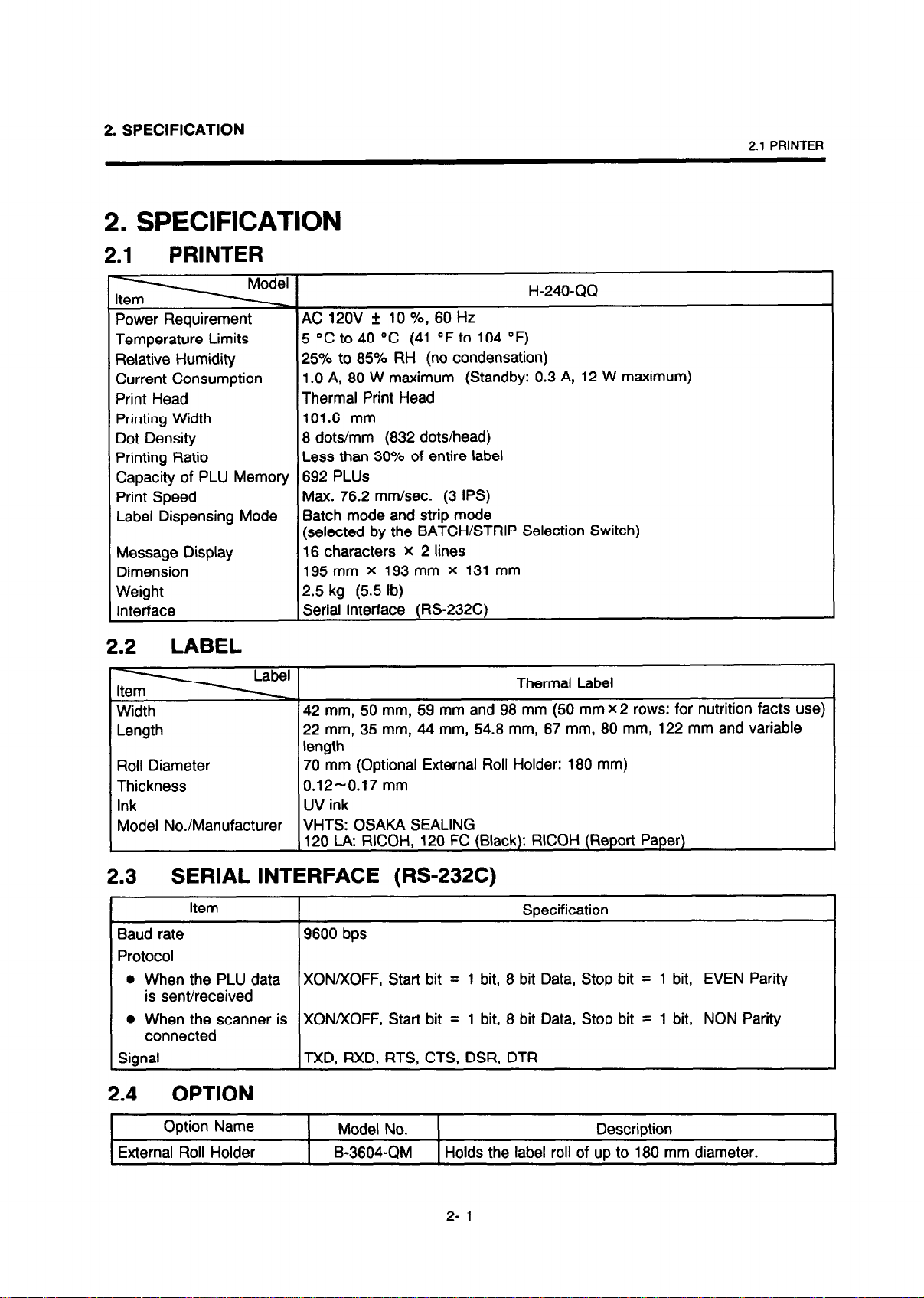

2. SPECIFICATION

2. SPECIFICATION

AC 120V + 10 %, 60 Hz

Temperature Limits

Relative Humidity

Current Consumption

Print Head

Printing Width

Dot Density

Printing Ratio

Capacity of PLU Memory

Print Speed

Label Dispensing Mode

Message Display

Dimension

Weight

Interface

5 “C to 40 “C (41 “F to 104 “F)

25% to 85% RH (no condensation)

1.0 A, 80 W maximum (Standby: 0.3 A, 12 W maximum)

Thermal Print Head

101.6 mm

8 dots/mm (832 dots/head)

Less than 30% of entire label

692 PLUS

Max. 76.2 mm/set. (3 IPS)

Batch mode and strip mode

(selected by the BATCH/STRIP Selection Switch)

16 characters X 2 lines

195mm X 193 mm x 131 mm

2.5 kg (5.5 lb)

Serial Interface (RS232C)

2.1 PRINTER

H-240~QQ

2.2

Width

Length

Roll Diameter

Thickness

Ink

Model No./Manufacturer

2.3

Baud rate

Protocol

1 ;gntti2FBnnBr is

LABEL

SERIAL INTERFACE (RS-232C)

Item

l

When the PLU data

is sent/received

Thermal Label

42 mm, 50 mm, 59 mm and 98 mm (50 mm X 2 rows: for nutrition facts use)

22 mm, 35 mm, 44 mm, 54.8 mm, 67 mm, 80 mm, 122 mm and variable

length

70 mm (Optional External Roll Holder: 180 mm)

0.12-0.17 mm

UV ink

VHTS: OSAKA SEALING

120 LA: RICOH, 120 FC (Black): RICOH (Report Paper)

Soecification

9600 bps

XON/XOFF, Start bit = 1 bit, 8 bit Data, Stop bit = 1 bit, EVEN Parity

XONIXOFF, Start bit = 1 bit, 8 bit Data, Stop bit = 1 bit, NON Parity

TXD, RXD, RTS, CTS, DSR, DTR

2.4 OPTION

Option Name

External Roll Holder B-3604-QM

Model No.

Description

Holds the label roll of up to 180 mm diameter.

2- 1

Page 10

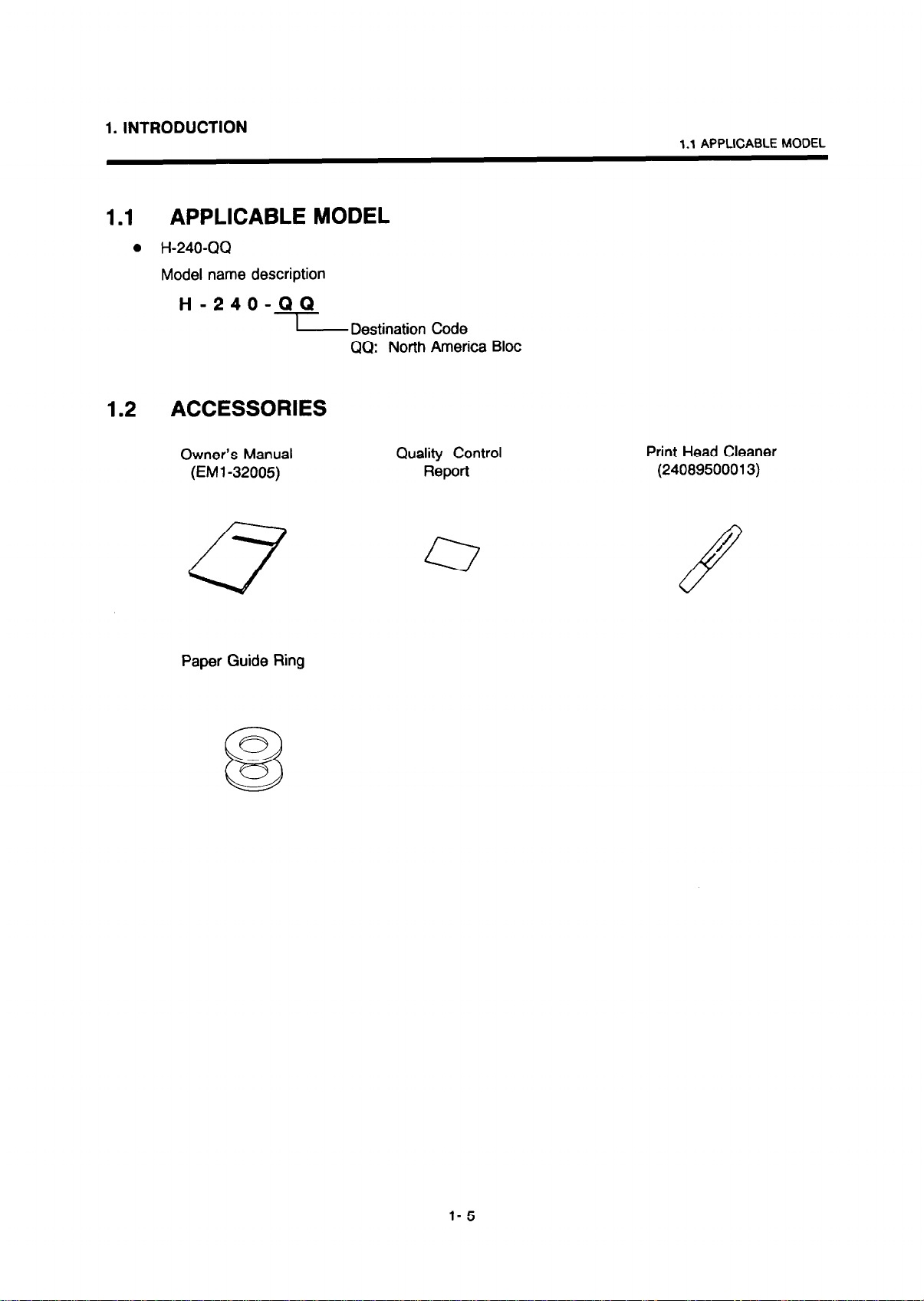

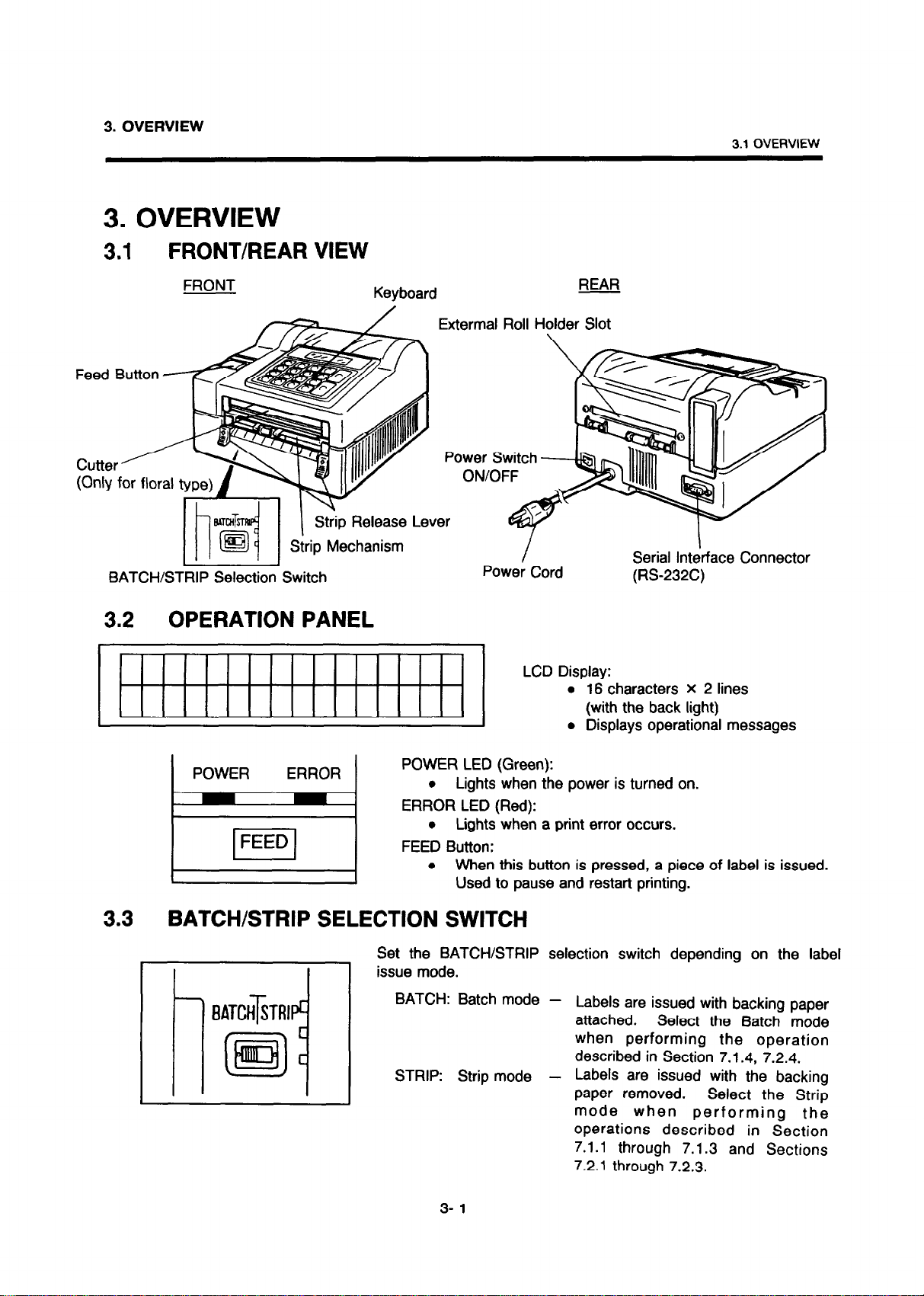

3. OVERVIEW

3. OVERVIEW

3.1 OVERVIEW

3.1

Feed Button 4

FRONT/REAR VIEW

FRONT

C”ttW A

(Only for flnral 1

BATCH/ST- Switch

3.2 OPERATION PANEL

T--J \

Strip Release Lever

Extermal Roll Holder Slot

,

/

47

Power Cord

LCD Display:

REAR

-.

Serial Interface Connector

(RS232C)

l

16 characters X 2 lines

(with the back light)

l

Displays operational messages

I

3.3

POWER ERROR

FEED

I

POWER LED (Green):

l

Lights when the power is turned on.

ERROR LED (Red):

l

Lights when a print error occurs.

FEED Button:

l

When this button is pressed, a piece of label is issued.

Used to pause and restart printing.

BATCH/STRIP SELECTION SWITCH

Set the BATCH/STRIP selection switch depending on the label

issue mode.

BATCH: Batch mode -

EATCHiTRl

P4

STRIP: Strip mode -

Labels are issued with backing paper

attached.

when performing the operation

described in Section 7.1.4, 7.2.4.

Labels are issued with the backing

paper removed.

mode when performing the

operations described in Section

7.1.1 through 7.1.3 and Sections

7.2.1 through 7.2.3.

Select the Batch mode

Select the Strip

3- 1

Page 11

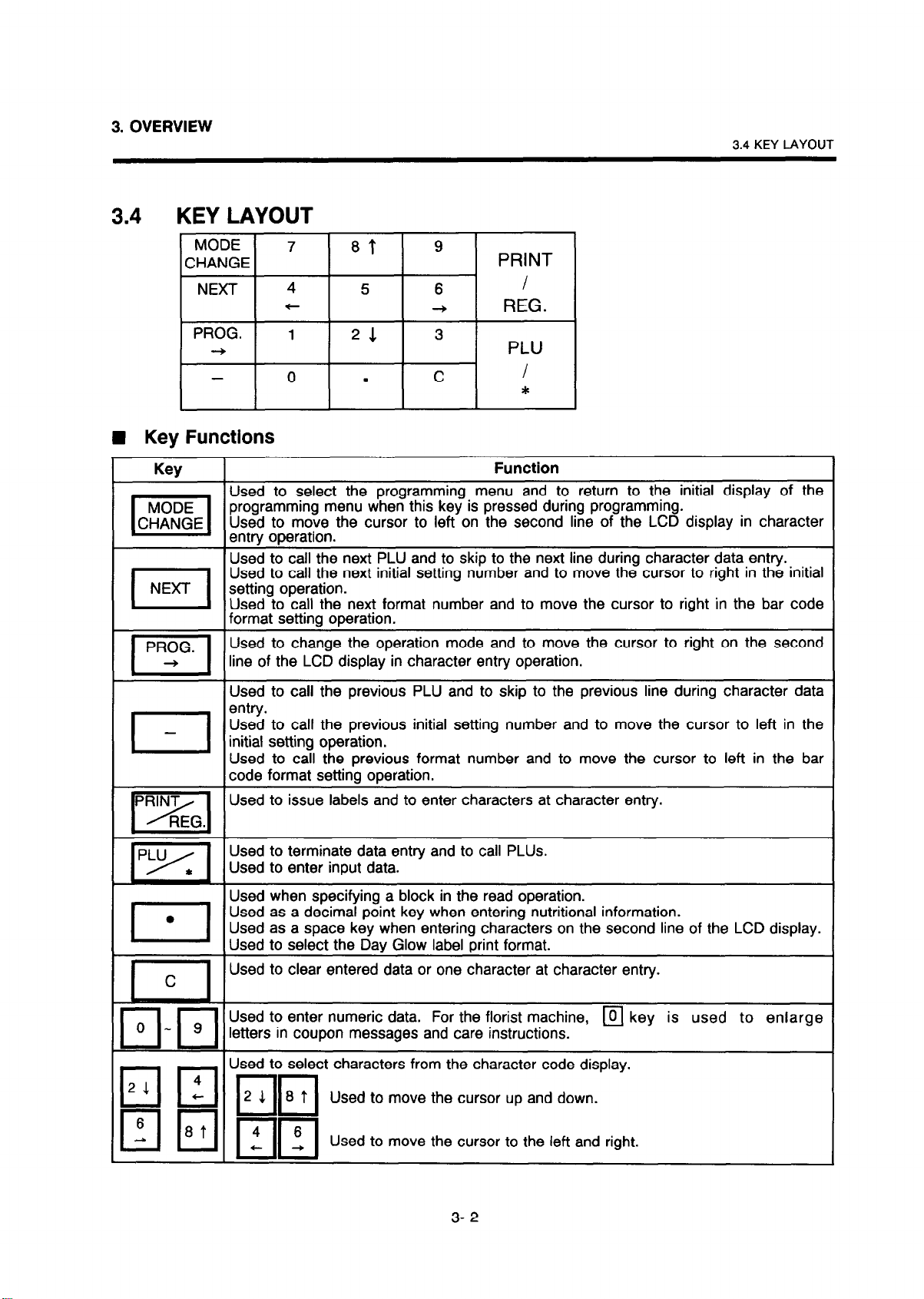

3. OVERVIEW

3.4 KEY LAYOUT

3.4 KEY LAYOUT

MODE 7 8t 9

CHANGE

NEXT 4 5 6 I

PROG. 1 21 3

+

- 0

n

Key Functions

Key

Used to select the programming menu and to return to the initial display of the

MODE

CHANGE

I

NEXT setting operation.

I

PROG.

I-I

-

I

pRYgG

m

pYc

programming menu when this key is pressed during programming.

Used to move the cursor to left on the second line of the LCD display in character

entry operation.

Used to call the next PLU and to skip to the next line during character data entry.

Used to call the next initial setting number and to move the cursor to right in the initial

Used to call the next format number and to move the cursor to right in the bar code

format setting operation.

Used to change the operation mode and to move the cursor to right on the second

line of the LCD display in character entry operation.

Used to call the previous PLU and to skip to the previous line during character data

entry.

Used to call the previous initial setting number and to move the cursor to left in the

initial setting operation.

Used to call the previous format number and to move the cursor to left in the bar

code format setting operation.

Used to issue labels and to enter characters at character entry.

Used to terminate data entry and to call PLUS.

Used to enter input data.

PRINT

t

-+

REG.

PLU

.

C

I

*

Function

Used when specifying a block in the read operation.

Used as a decimal point key when entering nutritional information.

Used as a space key when entering characters on the second line of the LCD display.

Used to select the Day Glow label print format.

Used to clear entered data or one character at character entry.

Used to enter numeric data. For the florist machine, m key is used to enlarge

letters in coupon messages and care instructions.

t characters from the character code display.

Used to move the cursor up and down.

Used to move the cursor to the left and right.

3- 2

Page 12

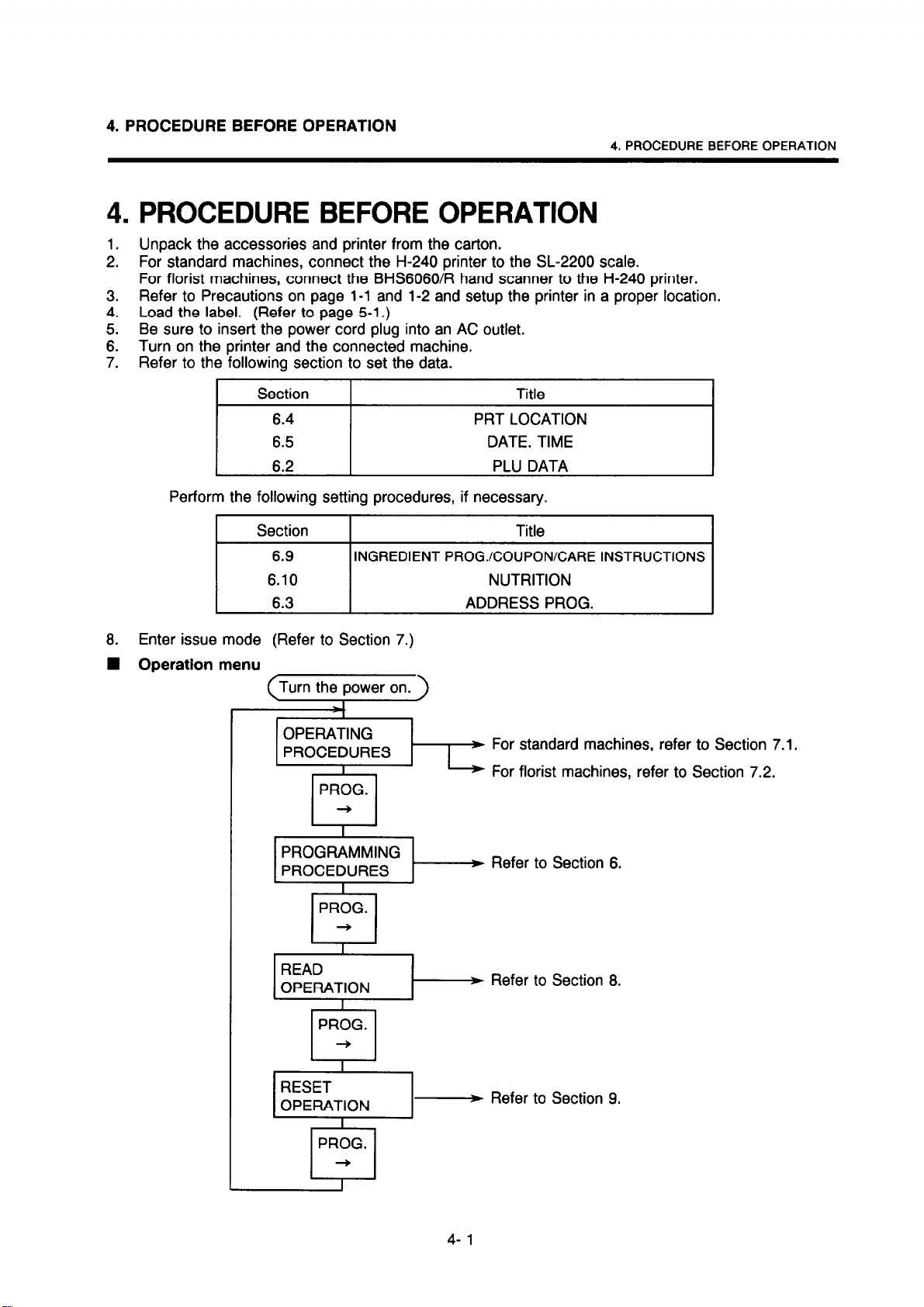

4. PROCEDURE BEFORE OPERATION

4. PROCEDURE BEFORE OPERATION

4. PROCEDURE BEFORE OPERATION

1. Unpack the accessories and printer from the carton.

2. For standard machines, connect the H-240 printer to the SL-2200 scale.

For florist machines, connect the BHS6060R hand scanner to the H-240 printer.

3. Refer to Precautions on page l-1 and l-2 and setup the printer in a proper location.

4.

Load the label. (Refer to page 5-l.)

Be sure to insert the power cord plug into an AC outlet.

::

Turn on the printer and the connected machine.

7. Refer to the following section to set the data.

Section Title

6.4 PRT LOCATION

6.5 DATE. TIME

6.2 PLU DATA

Perform the following setting procedures, if necessary.

INGREDIENT PROGXOUPONCARE INSTRUCTIONS

a.

Enter issue mode (Refer to Section 7.)

W Operation menu

urn the power on.

I 4

OPERATING

PROCEDURES

PROG.

+

PROGRAMMING

PROCEDURES

PROG.

+

READ

OPERATION

PROG.

I + I

* For standard machines, refer to Section 7.1.

I

I

I

For florist machines, refer to Section 7.2.

* Refer to Section 6.

* Refer to Section 8.

- Refer to Section 9.

Page 13

5. LOADING LABEL

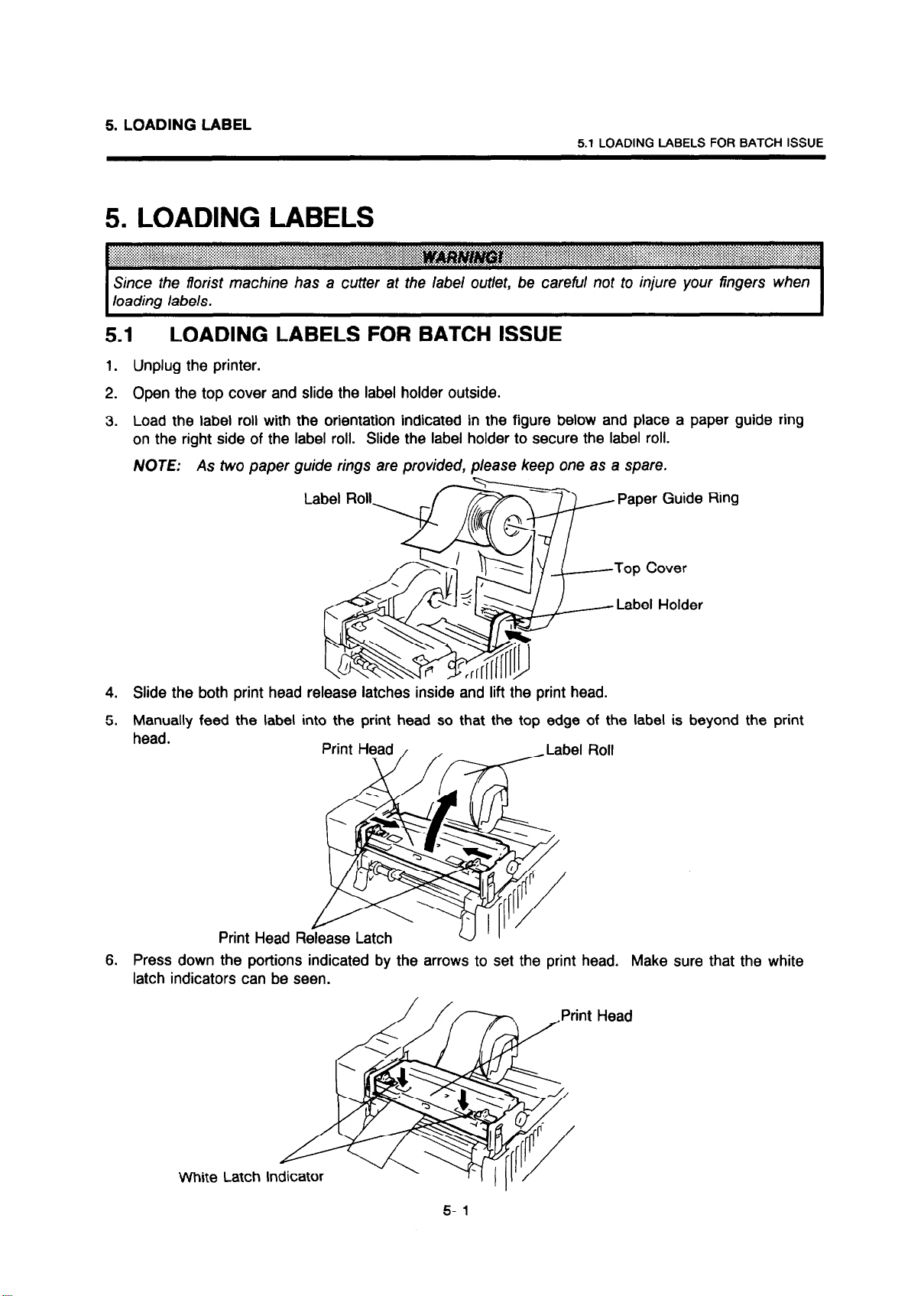

5.1 LOADING LABELS FOR BATCH ISSUE

5. LOADING LABELS

Since the florist machine has a cutter at the label outlet, be careful not to injure your fingers when

loading labels.

5.1

1. Unplug the printer.

2. Open the top cover and slide the label holder outside.

3. Load the label roll with the orientation indicated in the figure below and place a paper guide ring

4. Slide the both print head release latches inside and lift the print head.

5. Manually feed the label into the print head so that the top edge of the label is beyond the print

LOADING LABELS FOR BATCH ISSUE

on the right side of the label roll. Slide the label holder to secure the label roll.

NOTE: As two

Ring

head.

Print Head Release Latch

6. Press down the portions indicated by the arrows to set the print head. Make sure that the white

latch indicators can be seen.

Page 14

5. LOADING LABEL

5.2 LOADING LABELS FOR STRIP ISSUE

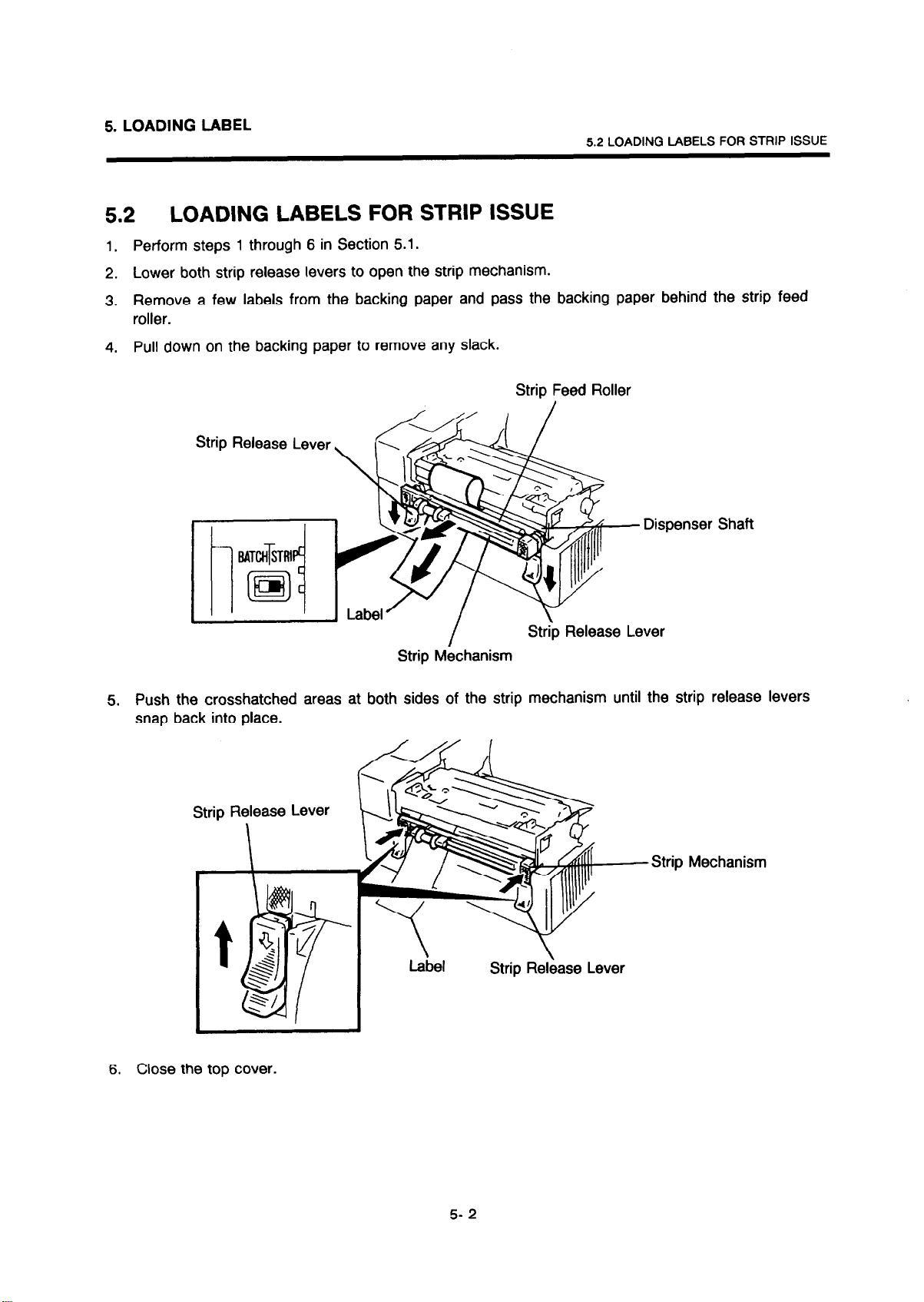

5.2

1.

2. Lower both strip release levers to open the strip mechanism.

3. Remove a few labels from the backing paper and pass the backing paper behind the strip feed

4. Pull down on the backing paper to remove any slack.

LOADING LABELS FOR STRIP ISSUE

Perform steps 1 through 6 in Section 5.1.

roller.

Strip Feed Roller

Strip Release Lever

Strip Mbchanism

5. Push the crosshatched areas at both sides of the strip mechanism until the strip release levers

snap back into place.

Strip Release Lever

Strip Mechanism

Label

6. Close the top cover.

Strip Release Lever

5- 2

Page 15

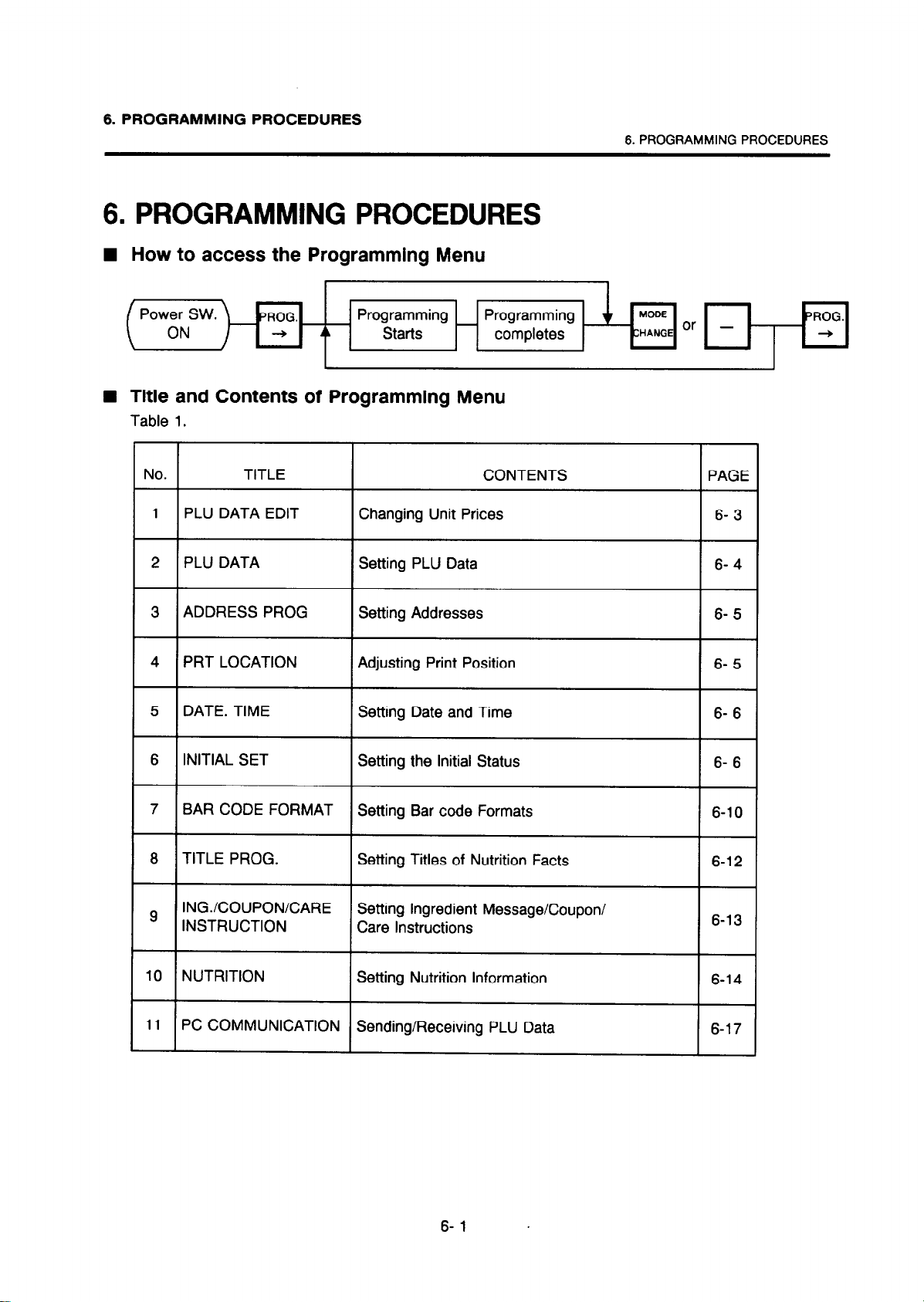

6. PROGRAMMING PROCEDURES

6. PROGRAMMING PROCEDURES

W How to access the Programming Menu

6. PROGRAMMING PROCEDURES

Power SW.

ON

W

Title and Contents of Programming Menu

Table 1.

r

JO.

1 PLU DATA EDIT

PLU DATA Setting PLU Data

2

3 ADDRESS PROG

PRT LOCATION Adjusting Print Position

4

5 DATE. TIME Setting Date and Time

6 INITIAL SET Setting the Initial Status

PROG.

+

TITLE CONTENTS

Programming

Starts

Changing Unit Prices

Setting Addresses

Programming

completes

PAGE

6- 3

6- 4

6- 5

6- 5

6- 6

6- 6

7 BAR CODE FORMAT

8 TITLE PROG.

INGXOUPONCARE Setting Ingredient Message/Coupon/

9

INSTRUCTION

IO NUTRITION Setting Nutrition Information

I1 PC COMMUNICATION Sending/Receiving PLU Data

Setting Bar code Formats

Setting Titles of Nutrition Facts

Care Instructions

6-l .

6-10

6-12

6-13

6-14

6-17

Page 16

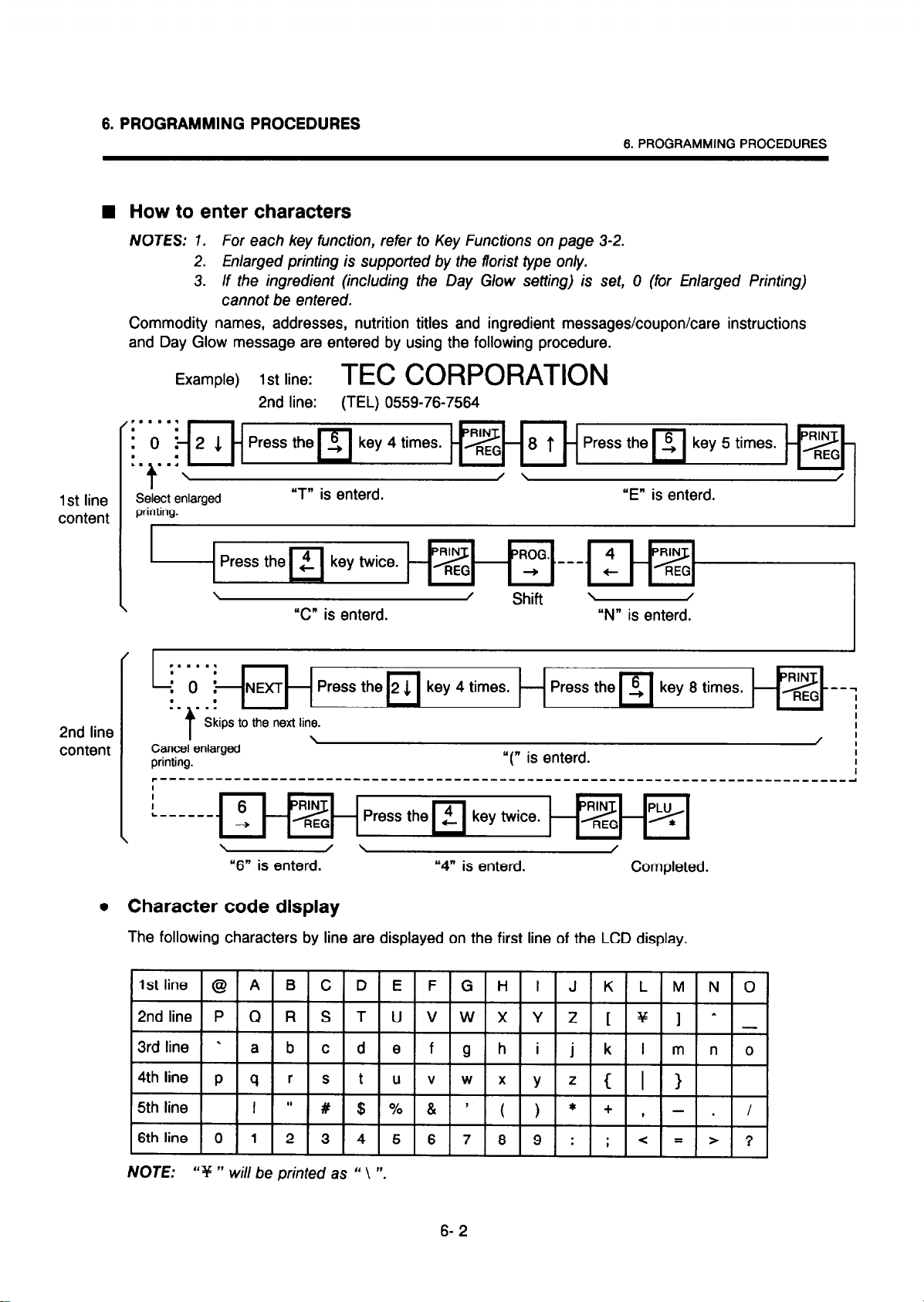

6. PROGRAMMING PROCEDURES

W How to enter characters

6. PROGRAMMING PROCEDURES

1st line

content

NOTES: 1.

Commodity names, addresses, nutrition titles and ingredient messages/coupon/care instructions

and Day Glow message are entered by using the following procedure.

For each key function, refer to Key Functions on page 3-2.

2.

Enlarged printing is supported by the florist type only.

3.

If the ingredient (including the Day Glow setting) is set, 0 (for Enlarged Printing)

cannot be entered.

Example) 1st line:

2nd line: (TEL) 0559-76-7564

TEC CORPORATION

P.....

i 0 !- 2 1

. .

. . . . . -

t ’

Select enlarged

printing.

\

/

. . . . . .

L

i 0 LNEXT-

- Press the !, key 4 times.

n-DzG- 8

-m

“T” is enterd. “E” is enterd.

Press the

\

“C” is enterd.

/

/ \

Shift -

-m-key-

7

“N” is enterd.

-

REG

/

I

2nd line

content

l

Skips to the next line.

I

Cancel enlarged

printing.

I

I

L - - - - - - _

\

6

+

\

“6” is enterd. “4” is enterd.

- Press then 2 key twice. - pzG - p*

/ \ /

“(, is enterd.

Completed.

Character code display

The following characters by line are displayed on the first line of the LCD display.

Y

NOTE: “Y ” will be printed as “ \ “.

z

i

j

z

y1--

k

I m n 0

C

I 1

I - .

< = :

ZF

/

6- 2

Page 17

6. PROGRAMMING PROCEDURES

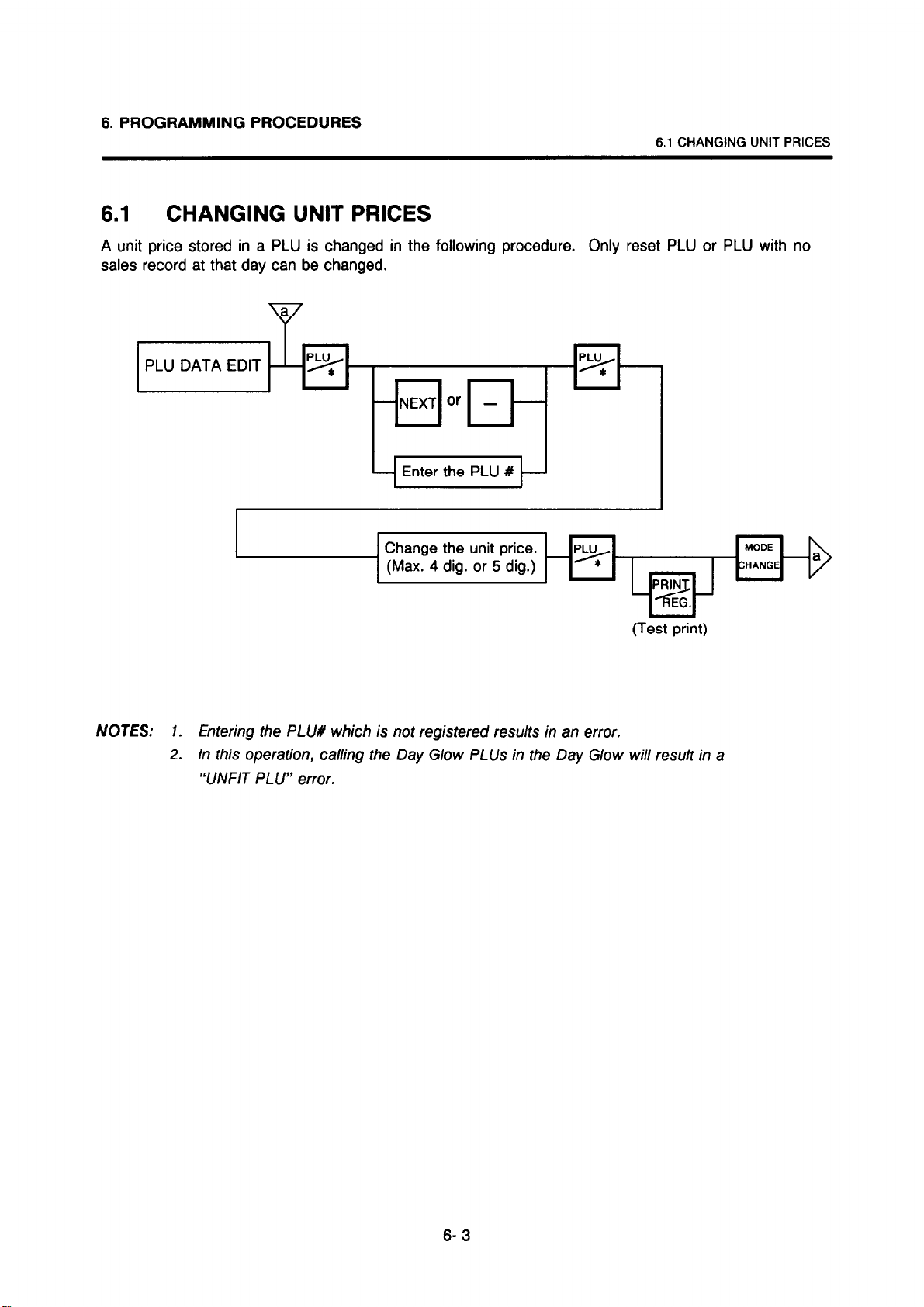

6.1 CHANGING UNIT PRICES

6.1 CHANGING UNIT PRICES

A unit price stored in a PLU is changed in the following procedure. Only reset PLU or PLU with no

sales record at that day can be changed.

a

Y

PLU DATA EDIT

I I - I b 1

NOTES: 1. Entering fhe PLU# which is not registered results in an error.

2. In this operation, calling the Day Glow PLUS in the Day Glow will result in a

“UNFIT PLU” error.

p* .e+---

-NEXT or - -

Enter the PLU #

Change the unit price.

(Max. 4 dig. or 5 dig.) -

p*-

RIN

LPdJ

EG.

(Test print)

MODE

CHANGE

6- 3

Page 18

6. PROGRAMMING PROCEDURES

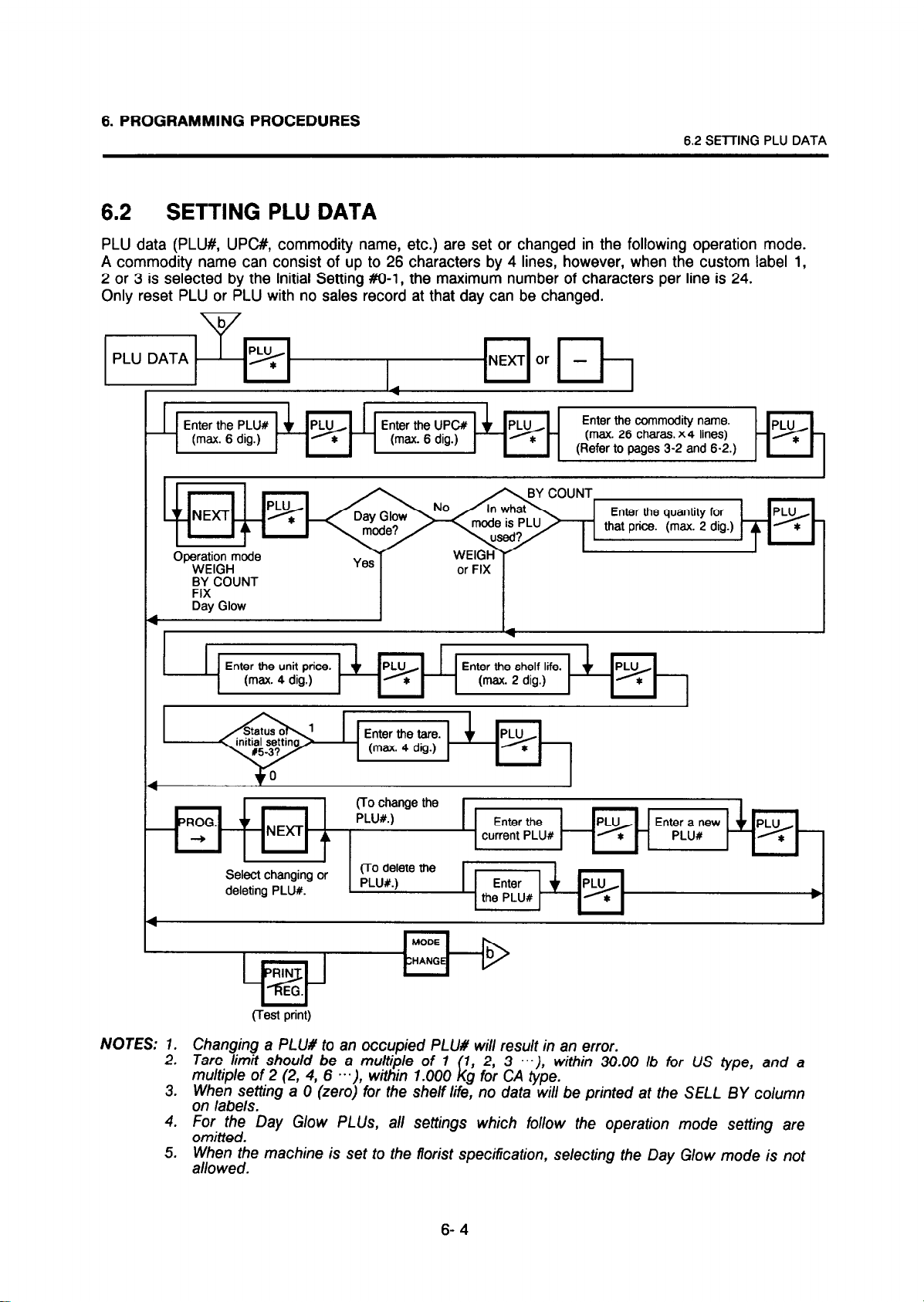

6.2 SETTING PLU DATA

6.2 SETTING PLU DATA

PLU data (PLU#, UPC#, commodity name, etc.) are set or changed in the following operation mode.

A commodity name can consist of up to 26 characters by 4 lines, however, when the custom label 1,

2 or 3 is selected by the Initial Setting #o-l, the maximum number of characters per line is 24.

Only reset PLU or PLU with no sales record at that day can be changed.

PLU DATA

Enter the PLUX Enter the UPCX

-

Op3;onHmode

BY COUNT

FIX

Day Glow

t

I

I

I 1 -

Enter the unit price.

(max. 4 dig.) (max. 2 dig.)

Enter the tare.

or FIX

v

Enter the shelf life.

Enter the commodity name.

(max. 26 charas. x4 lines)

(Refer to pages 3-2 and

Enter the quantity for

that price. (max. 2 dig.)

6-2.)

-

Se&t changing or

deleting PLUX.

(Test print)

NOTES: 1. Changing a PLU# to an occupied PLU# will result in an error.

2. Tare /imit should be a mu&p/e of 1

multiple of 2 (2, 4, 6 ...), wirhin 7.000 i

3.

When setting a 0 (zero) for fhe shelf life, no data wi// be printed at the SELL BY column

1, 2, 3 . ..). within 30.00 /b for US fype, and a

g for CA type.

on labels.

4. For the Day Glow PLUS, all settings which follow the operation mode setting are

omitted.

5. LVp/k’e$e machine is set to fhe florist specification, selecting the Day Glow mode is nor

6- 4

Page 19

6. PROGRAMMING PROCEDURES

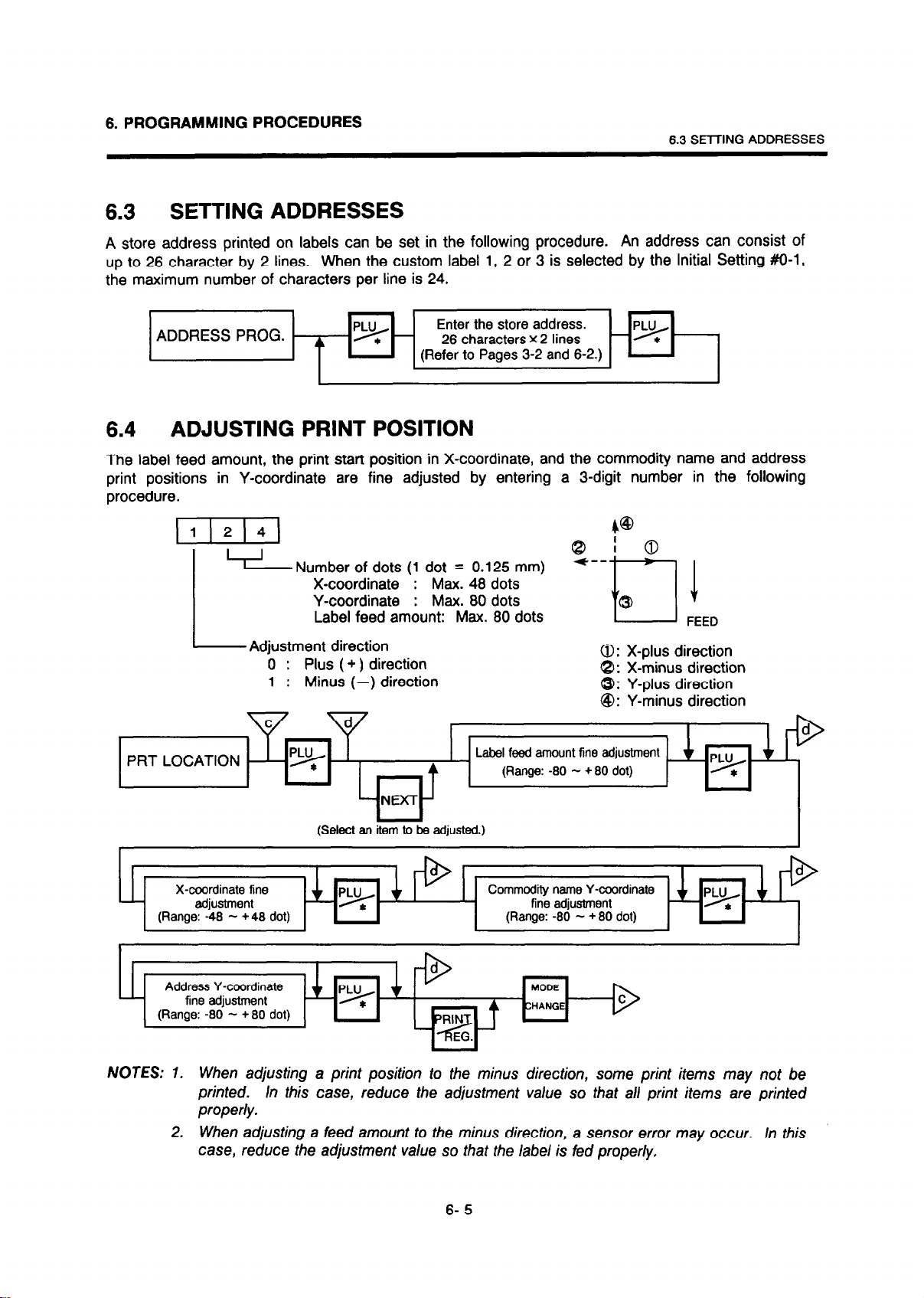

6.3 SElTNG ADDRESSES

6.3

SETTING ADDRESSES

A store address printed on labels can be set in the following procedure. An address can consist of

up to 26 character by 2 lines.

When the custom label

1,

2 or 3 is selected by the Initial Setting #O-l,

the maximum number of characters per line is 24.

6.4

I

ADDRESS PROG.

p*-

A

ADJUSTING PRINT POSITION

Enter the store address.

26

characters X

2 lines

(Refer to Pages 3-2

and

-*

6-2.)

The label feed amount, the print start position in X-coordinate, and the commodity name and address

print positions in Y-coordinate are fine adjusted by entering a 3-digit number in the following

procedure.

llj2)41

Number of dots

X-coordinate

(1

dot = 0.125 mm)

: Max. 48 dots

4@

Y-coordinate : Max. 80 dots

Label feed amount: Max. 80 dots

Adjustment direction

0 : Plus ( + ) direction

1 :

Minus (-) direction

0: X-plus direction

8: X-minus direction

0: Y-plus direction

@: Y-minus direction

PRT LOCATION

(Select an item to be adjusted.)

X-coordinate fine

Address Y-coordinate

(Range: -80 - +80 dot)

Label feed amount fine adjustment

(Range: -80 - + 80 dot)

Commodity name Y-coordinate

fine adjustment

(Range: -80 - +80 dot)

MODE

CHANGE

NOTES: 1. When adjusting a print position to the minus direction, some print items may not be

printed. In this case, reduce the adjustment value so that all print items are printed

properly.

When adjusting a feed amount to the minus direction, a sensor error may occur. In this

2.

case, reduce the adjustment value so that the label is fed properly.

6- 5

Page 20

6. PROGRAMMING PROCEDURES

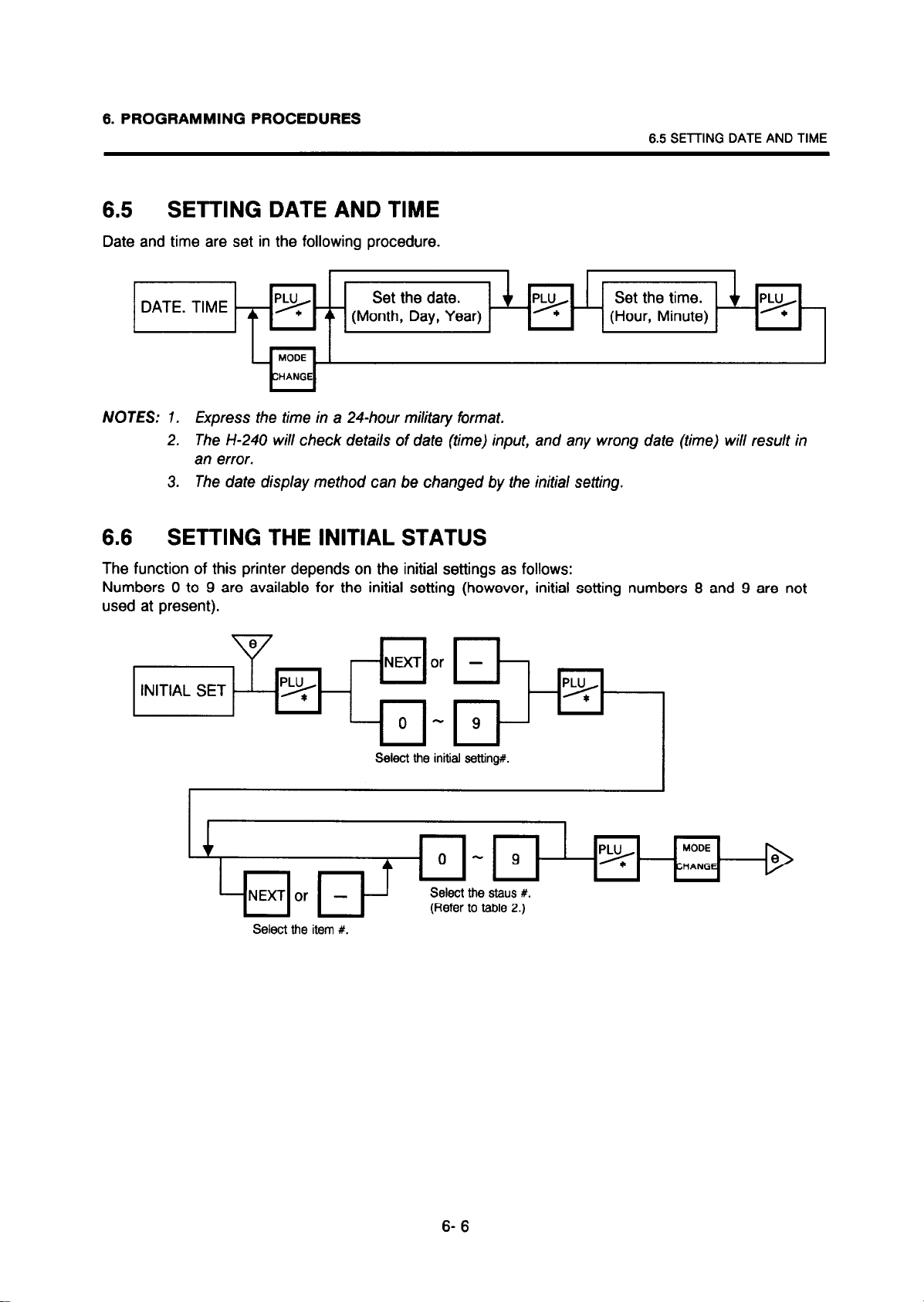

6.5 SETTING DATE AND TIME

Date and time are set in the following procedure.

6.5 SElTlNG DATE AND TIME

p*

(Hour, Minute)

DATE. TIME

p*

MODE

ZHANGE

(Month, Day, Year)

NOTES: 1. Express the time in a 24-hour military format.

2. The H-240 will check details of date (time) input, and any wrong date (time) will result in

an error.

3. The date display method can be changed by the initial setting.

6.6 SETTING THE INITIAL STATUS

The function of this printer depends on the initial settings as follows:

Numbers 0 to 9 are available for the initial setting (however, initial setting numbers 8 and 9 are not

used at present).

or

Select the item #.

Select the initial setting#.

6- 6

Page 21

Table 2: Initial Setting Function Table

1) Initial Setting #0

Item

No.

Function

Label format

1

Bar code type UPC-A EAN-13 0

2

Status No.

0 123456789

NON POS

label

POS label

ING. 0

POS LW301

ING. 12

POS label

ING. 32

POS label

ING. 32

(for nutrition

facts)

CUSTOM

Label 1

(22mm)

CUSTOM

Label 2

(54.7 mm)

CUSTOM

Label 3

(54.7 mm)

FLORIST

label 1, 2

The status

selected by

the initial

Setting #8-1

6. PROGRAMMING PROCEDURES

Standard

Status No.

Standard: 1

Florist: 8

3

4

2) Initial Setting #1

Item

No.

6-7

1

2

3

4

3) Initial Setting #2

Item

No.

Print format for custom

label 1

Issue method Automatic Manual 0

Status No.

Function

Time mode on Label 12 hrs. 24 hr.. 1

Baud Rate when

communicating with a

scale

Number of digits of

TMCC Machine #

TMCC Baud Rate 4800 9600 0

Status No.

Function

Bar code

0 123456789

4800 BPS. 9600 BPS. 1

3 digit 1 digit 0

0 123456789

Bar code +

Price in

Small letters

Bar code +

Price in

capital

Standard

Status No.

Standard

Status No.

0

6.5 SETTING DATE AND TIME

Date setting order YY-MM-DD DD-MM-W MM-DD-YY 2

1

Type of data print Numeral

2

Change to unit prim in

REG

3

mode (BY COUNT: T.

Price)

Reset operation Not available Available 0

4

Not available Available 0

Print month

ex.) JA, FE

Print month

ex.) JAN,

FEB

US: 2

CA: 1

Page 22

4) Initial Setting #3

Item

No.

Function

Status No.

0 123456789

Standard

Status No.

6. PROGRAMMING PROCEDURES

1

2

3

4

5) Initial Setting #4

Item

No.

6-8

1

2

3

4

Open price selection

Change of weight and

price when issuing NET

WT. Statement label

No function 0

No function 0

Status No.

Function

Each country spec. US CA

Specification change Standard Florist

TMCC N/A Available 0

No function 0

Total amount

entry

Available

0 123456789

Unit price

entry

Not

Available

Standard

Status No.

US: 2

CA: 1

Standard: 0

Florist: 1

0

0

6) Initial Setting #5

Item

No.

Function

Unit price and total

1

amount capacity

Unit price shift in the

2

REG. Mode

PLU Preset Tare

3

No function 0

4

Status No.

0 123456789

Unit price 4

digits Total

amount 5 digits

Cyclic

Shift

Not

Available

Unit price 5

digits Total

amount 6 digits

End-off

Shift

Available 1

Standard

Status No.

0

1

6.5 SETTING DATE AND TIME

Page 23

7) Initial Setting #6

Item

No.

Function

Status No.

0 123456789

Standard

Status No.

6. PROGRAMMING PROCEDURES

1

2

3

4

8) Initial Setting #7

Item

No.

6-9

1

2

3

4

Decimal point position

Decimal point

Display/print

Print position of “PIECES”

in By count mode

No function 0

Status No.

Function

Printing PACKED ON

DATE

Printing SELL BY DATE Not print Print 1

Printing COMMODITY

NAME

Printing WEIGHT Not print Print 1

U. Price 0

T. Price 0

Comma

( , )

Unit price

Position

0 123456789

Not print Print

Not print Print 1

0.0

0.0

Period

( . )

Weight

position

0.00

0.00

0.000

0.000

0

0.0

Standard

Status No.

US: 0

CA: 1

2

1

1

9) Initial Setting #8

Item

No.

1

Function

Label format 2

Status No.

0 123456789

Net Wt.

Statement

Label

6.5 SETTING DATE AND TIME

Standard

Status No.

0

Page 24

6. PROGRAMMING PROCEDURES

6.7 SETTING BAR CODE FORMATS

6.7 SETTING BAR CODE FORMATS

With the H-240 label printer, three kinds of bar code formats are available. These formats can be

changed freely.

Example)

Current format 2 9 Cl

I

I I

Flag UPC #

C2 C3 C4 C5 C6 P2 P3 P4

I I I I

n

Price Total check digit

P5 C/D

v

Changed format 0 2

I

C2 C3 C4 C5 C6 PC/D

I I

UPC #

I I I I I I

P.rice check Price or weight

dlglt

Pl P2 P3

When changing the above example format into the weigh format described in NOTE 1,

following procedure.

Select the format #.

Format # 1: WEIGH

BAR CODE FORMAT

‘% - Format # 2: BY COUNT - ‘%

Format # 3: FIX PRICE

P4 C/D

Total check digit

use the

I

I

(Right)

(Move the cursor to

the column to be set.)

- WOG.

Switch over

UPC # -*PC/D check digit

NOTES:

- 1 -PROG.-

+

Set the price Switch over

1. When UPC-A is selected as a bar code type (initial set # O-2), the first line is not

printed. Therefore, the dag must be set to ‘02’.

In this printer the previous/y set bar code format is initialized to the following default by

2.

RAM clear or ALL clear.

Default

Bar

0 Weigh or Fix Price Format

0 2

@ By Count Format

l

Standard type

Set the flag.

ex\ C...*r uy\r)n

, LfllW “C

Switch over the setting

item. (Refer to NOTE 8 on

the following page.)

exl Press the kev twice to

select UPC # asa

setting item.

+

PC/D + Price

1 2 3 4 -p*-‘HANGE

Enter a price

Code Format:

C2 C3 C4 C5 C6 PC/D

WOG.

+

2 3 4 5 6-

Enter an UPC #.

MODE

Pl P2 P3

P4 C/D

0 0 0

l

Florist type

c2 c3 c4 c5 0 0 0 0 C6

0 0 0 0 0 0

PC/D PI P2 P3 P4 P5

6-10

C/D

C/D

Page 25

6. PROGRAMMING PROCEDURES

3. When the ppLu/*I key is pressed, the bar code format is checked. An error occurs in

the following cases.

@ Check digit (CID) is in other than digit-13.

@ Price check digit (PC/D) cannot be calculated. (Price and weight are other than 4

or 5 digits or no price/weight is programmed.)

@ Price is not set serially beginning from PI (PI to P4, or PI to P5).

@I Weight is not set serially beginning from W7 (WI to W4, or W7 to W5).

6.7 SETTING BAR CODE FORMATS

FLAG

PLU #

UPC #

PC/D

PRICE

WEIGHT

C/D

4. Digits and display of PLU #

PLU # 123456

HHHHHH

Display 123456

Digits and display of price

6.

Price # $12 .34

PP PP

Display 12 34

m-El

El -El

El-El

q

;lo

1

ilo

1

0

- 6

- 6

5. Digits and display of UPC #

UPC #

123456

cccccc

Display 123456

$123 .45

PPP PP

123 45

7. Display of weight Digits

Weight 1 2 . 3 4

ww ww

Display 1 2 3 4

8. Setting Items

1

- PLU #-UPC # - PC/D

C/D -Weight -Price

7

2

6 5

6-11

3

4

+J

Page 26

6. PROGRAMMING PROCEDURES

6.8 SETTING TITLE OF NUTRITION FACTS

6.6 SETTING TITLE OF NUTRITION FACTS

Titles of nutrition facts are set in the following procedure.

characters.

v

-NExTor - -

TITLE PROG.

p*-

Enter the title No.

Enter the title.

- (Refer to Pages 3-2 and 6-2.)

Table 3: Default title of nutrition facts

+ The title of additional information area 1.

(See NOTE 1.)

Each title can consist of up to 22

I

+-The title of additional information area 2.

+-The title of additional information area 3.

+ The title of additional information area 4.

t-The title of additional information area 5.

+ The title of additional information area 6.

The title of additional information area 7 and 8.

The title of additional information area 9 and 10.

The title of additional information area 11 and 12.

6-12

(See NOTE 1

and 2.)

!

Page 27

6. PROGRAMMING PROCEDURES

6.8 SElTlNG TITLE OF NUTRITION FACTS

NOTES: 1. The fit/es of the addil

Additional Information Area

Additional Information Area 1

1 Additional Information Area 5

1 Additional Information Area 6

onal information areas are displayed in the following positions.

Displayed position

No. 7 Additional Information Area 7 No. 24, column 1 to 18

No. 17 cclumn 1 to 18 Additional Information Area 8 No. 24, column 12 to 21

No. 18 column 1 to 18 Additional Information Area 9 No. 25, column 1 to 10

19 column 1 to 18 Additional Information Area 10 No. 25, column 12 to 21

No.

No. 20 column 1 to 18 Additional Information Area 11 No. 26, column 1 to 10

21 column 1 to 18 Additional Information Area 12 No. 26, column 12 to 21

No.

Additional Information Area Displayed position

2. Set a colon ‘I’ at the column 20 and a ‘g’ or ‘mg’ at the column 21 and 22 when

entering titles into No. 9 through No. 21.

6.9

SETTING INGREDIENT MESSAGE/COUPON/

CARE INSTRUCTIONS /DAY GLOW MESSAGE

Up to 45 characters by 32 lines of ingredient message, and 29 characters by 22 lines of coupon and

care instructions are set in the following procedure.

y$pqt.

Enter the PLUM.

(ING. + COUPON-+ Instruction)

+ I

Enter the message.

- (Refer to pages 3-2 and 6-2)

p*

LD%d

RIN

EG.

MODE

CHANGE

(Test print)

NOTES: 1. When customer label 2 or 3 is selected under initial Setting #O-l, the max. number of

characters per line is 41.

2. For the florist machine, coupon messages or care instructions can be enlarged to a

two-line size within 16 characters by 71 lines. The display shows as follows when

setting enlarged messages.

jl

N: Line No. is every other number

3. Though you can set characters outside of the above range, those characters are not

printed.

4. A maximum of 7 or 14 characters for Day Glow message can be set in the same way

as the ingredient message. A maximum of 45 characters can be set, however, only 7

or 14 characters can be printed.

(X4, 1 line: 7 characters, X2, 2 or 3 fines: 14 characters)

6-13

Page 28

6. PROGRAMMING PROCEDURES

6.10 SElTING NUTRITION INFORMATION

6.10 SETTING NUTRITION INFORMATION

Nutrition information and caloric intake are set in the following procedure.

Serving Size consists of a maximaum of 13 characters.

including title characters must not exceed 25.

However, total number of characters

NUTRITION

Enter the

Serving Size.

(Within 13 chars.)

Enter the Calories.

(O-9999)

Additional Information.

Area 1 (O-9999)

Enter the Total Fat.

(0.0-9999)

PROG.

+

4

Enter the PLU#

(max. 6 dig.) A

NEXT Or - -

Enter the Servings

- * - Per Container.

p*

(Within 3 chars.)

NEXT

,p*

I

I

- ‘*

A

0

Enter the cholesterol.

(0.0-9999)

Enter the Total

Carbohydrates.

(0.0-9999)

Enter the Sodium.

(0.0-9999)

6-14

Page 29

6. PROGRAMMING PROCEDURES

6.10 SETTING NUTRITION INFORMATION

I

NOTES: 1.

l

Set the Daily Value Table

Be careful that selecting a PLU# which is not stored in the PLU file results in an error.

2.

Nutrition file is saved each time the IpLu/*I key is pressed.

procedure along the way, data entered without pressing m/ key is not stored.

2: r-1 key.

3.

The additional information can be used only when its title has been registered in Section

6.8.

Basic Calories.

(Content No.

Enter the Basic

Saturated Fat.

(Content No. 3)

MODE

3iANGE

(lest print)

Thus, if you quit the

To exit

ress the [PLU/Sl key until “Enter the PLU” is displayed, and then press

1)

Basic Total Fat.

(Content No. 2)

-

p*

Basic Cholesterol.

(Content No. 4)

Enter the Enter the Basic

Basic Sodium.

(Content No. 5)

Enter the Basic

- Dietary Fiber.

(Content No. 7)

I ,

!3+

Total Carbohydrate. p*-

(Content No. 6)

.

L

NOTE: Caloric intake data is entered as 8 digits, however, only the first 4 digits are used and the

last 4 digits are ignored.

6-15

Page 30

6. PROGRAMMING PROCEDURES

l

Deleting

Nutrition

Data

6.10 SElTING NUTRITION INFORMATION

Nutrition

Facts

Enter the PLU# -

(max. 6 dig.)

!+-

Additional information area 1

9dditional information area 2

tdditional information area 3

tdditional information area 4

tdditional information area 5

9dditional information area 6

Nutrition

Serving Size 1234567690123

Servings Per Container 223

Amount Per Serving

Facts

Calories 3

Calories from Fat 4

X Daily Value*

Tatal Fat 5a 8%

Saturated Fat 60 30% I

Cholesterol

Sodium 8mg

Total Carbohydrate 9g 3%

Dietarv Fiber 10a

Sugars llg

Protein

Vitamin A 13X.Vitamin C 14%

Calcium

* Percent Daily Values are based on a 2,000

calorie dlat.

7mo

12g

15X.Iron

2%

0%

40%

16%

\dditional information area 7,8

4dditional information area 9,lO

l

Percent Dally Values are basad on a 2,000

calorla diet.

1 St Address _ _ _ _ _ _ _ _ _ _ _ _ _ _

2

nd Address _ _ _ _ _ _ _ _ _ _ _ _ _ _

idditional information area 11,12

1-0000000000000000000000-1

2-0000000000000000000000-2

(Sample label)

h\\b Area for titles:

v//k Area for entry data:

~~ Area for data:

NOTE: Nutrition facts can be printed only when the Initial Setting #O-l is set to 4.

When the Initial Setting #O-l is set to 4, the basic data and the nutrition facts

simultaneously on the 98-mm wide label (two pieces of labels are attached side by side on

one backing paper) to save printing time.

facts are printed on the right.

Set to No.1 to No.26 in Section 6.8

Set in this menu (Nutrition Setting procedure.)

Calculated on the basis of the entered data in Section 6.10

The basic data is printed on the left, the nutrition

are

printed

6-16

Page 31

6. PROGRAMMING PROCEDURES

6.11 SENDING/RECEIVING PLU DATA

6.11 SENDING/RECEIVING PLU DATA

The H-240 printers can communicate with each other, and with a PC if an exclusive application is

installed in it. Regarding the exclusive application, refer to the service representative. When

purchasing the interface cable, contact the service representative.

When communicating between the H-240 printers, get the receiving side ready before sending data.

PC COMMUNICATION

I

Receive

I I

t-l

(Starts receiving data.)

I

1:

Sending P

(Starts sending data.)

-

PROG.

+

ROG.

-9

Receiving

Sending !q

(Terminates sending data.)

C

(Abort)

C

+

b

(Terminates receiving data.)

+

NOTE: When an error occurs during data receiving, data sent after occurrence of the error is not

received. If an error occurs, contact the service representative.

\

01 (1) Character parity check method is incorrect.

(2) Baud rate setting is incorrect.

(3) Character length setting is incorrect.

02 The header text is incorrect. Check the format and contents of the header

03 The data text is incorrect. Check the format and contents of the data text.

04 The number of PLU set in the header text differs Check the number of PLU set in the header text

from that actually received.

05 The result of BCC calculation differs between

sent data and received data.

06 The sender controls XON/XOFF improperly.

Cause

(1) Change the parity check method to even.

(2) Set the baud rate to 9600 bps.

(3) Set the character length to 8 bit, stop bit to

1 bit.

text.

and that to be sent.

Check both BCC calculation methods.

Check the sender’s XONlXOFF control method.

6-17

Page 32

7. OPERATING PROCEDURES

7. OPERATING PROCEDURES

7.1 STANDARD TYPE

~

“““..“:::::,::,:,:;.;.

:::::::::.:.::::::‘:‘:~:::‘.‘.‘.’.:.:.:~~.~~.~.~.~.~:~:~:~:~:~:~:~:~:~:~:~:‘:‘:‘:‘:‘:‘:::~~:~~:::~:~:~:~:~:~~:::::::::::.:::::.:.:::::::.:::.:::::::::::::::.:.:::.::::::~:.:.:::.:~:::::::::: .,.. .,,,.,.: ,,.,,:,,,,,,.~.,‘, ..,,... .,.,.,,,.,.,.,.,: ,.,,,./,/,,,,. ,,,,,,, ,,.,,,, .., . ,,.;,. ,(,/,,,,, ,,,,., ,., ,.( ,..

:.:::.::.:::::::::.:........,

:.:.: ‘:.:‘:‘;

. . . . .A., ,. ., (, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~~.!~........................................,:,:

Since the florist machine has a cutter at the label outlet, be careful not to injure your fingers when

removing printed labels.

7.1 STANDARD TYPE

n NOTES BEFORE STARTING OPERATION

(1) Connect the TEC SL-2200 scale or PC to the H-240 printer.

(2) Set the BATCH/STRIP selection switch depending on your usage.

(3) Insert the power cord plug into the AC outlet.

(4) Check the date and time.

(5) Press the m button to feed a label.

(6) Remove the fed label.

(7) Press the IPRINT/REG.I key.

BATCH mode:

Label Print Head

STRIP mode:

Printing the label is ready.

The label is fed reversely

to the print start position.

Printing the label is completed.

Remove the printed label.

NOTES: 1. When the loaded label does not match the label format setting, print start and end

positions may become misaligned.

2. Labels will not be issued when the print head is raised, the label ended, or printed

label is detected by the strip sensor.

7- 1

Page 33

7. OPERATING PROCEDURES

7.1 .l Weighing Operation

7.1 .l Weighing Operation

The weighing operation is available only when the SL-2200 scale is connected to the printer

and the selection switch is set to STRIP side. This operation is performed on the SL-2200

scale.

The weigh mode is used to issue the label of a commodity for an unknown weight, printing the

Weight, Unit Price (price per unit weight), and the Total Price (calculated as a result of the

weighting operation). This mode may be applied to cases such as a store that weighs each

commodity and issues the label on demand of customers on the sales floor or that a store

issues that labels for repacked commodities of different kinds and weights.

NOTE: When printing the Day Glow label in weigh mode, set the selection switch to BATCH.

(For details, refer to “7.1.2 By Count Operation” and subsequent sections.)

l

Weighing a commodity and issuing a label

Example) T-BONE STEAK (PLU#lOl) sold at $3.00Ab is to be weighed and labeled.

Enter the PLU #.

Press:

Place a commodity on the

SL-2200 scale platter.

(Example: 5.00 lb)

1 Single label is issued. 1

AUTO

MANUAL

I

1 Single label is issued. 1

T-BONE STEAK

7- 2

*,r- ,//- m

TEC CORPORATION

(TEL)0559-76-7564

DC,‘: y gj

(Sample label)

Page 34

7. OPERATING PROCEDURES

l

Weighing a fixed price commodity and issuing a label

7.1 .l Weighing Operation

Example)

Press:

Enter the PLU #.

Press:

Place a commodity on the

SL-2200 scale platter.

(Example: 2.00 lb)

T-BONE STEAK (PLU#lOl) sold at $3.00/lb is purchased for 2 lb.

pz

1 0 1

6

PLU

9

I

I

Single

label

is issued. Single label is issued.

T -BONE STEAK

::- -- -’

APR 14

;F

_L.. F.

~~~lllllll~~llll~~llllll

2 00005 80030

2.00

Ia - ‘i;- an

TEC CORPORATION

(TEL)0559-76-7564

w.T 17 0

(Sample label)

APR 19

2

$3.00

7- 3

Page 35

7. OPERATING PROCEDURES

~~~lllllll~~~lll~

l

Counting a fixed price commodity and issuing a label

Example) T-BONE STEAK (PLU#lOl) sold at $3.00/lb is purchased for 10 pieces.

Enter the PLU #.

I

7.1 .l Weighing Operation

Press:

Press:

Enter the purchased

Quantity.

(maw: 99)

Press:

PLU

I

\

‘9

x

1 0

pz

I

I

Single label is issued.

T -BONE STEAK

:: .I- -,

APR 14

ii p,

2 00005

10 Fws

IlI /

80300 6

Ilk-‘:,- IEI lCL I:0 m ,,.. :

TEC CORPORATION

(TEL)0559-76-7564

APR 19

$30.00

(Sample label)

7- 4

Page 36

7. OPERATING PROCEDURES

IDONUTSp3

IOONUTSp3

7.1.2

By Count

Operation

7.1.2

In the by count mode, PLU cannot be called from the SL-2200 scale, but by the H-240 label

printer.

The by count mode is used to issue the label for packed commodities (or may be unpacked.)

The whole package quantity (or a certain quantity) and the whole package price (or the price

per quantity) are usually preset.

scale in such cases.

Example) When selling 3 DONUTS which are sold at $0.93 per 6 DONUTS. (When data of

Enter the PLU #.

Press:

Select the Day Glow message

print format.

Cancels the Day Glow message

print format.

By Count Operation

Thus, it is not necessary to weigh the commodities by the

$0.9316 DONUTS is set to the PLU #813.)

Press:

Enter the sold quantity.

(max. 99)

Press:

Press:

Open price:

Initial Setting #3-l : 0

Total amount

initial Setting #3-l : 1

Unit price

Press:

ex)

4 0

Initial Setting

x3-1: 0

w

7- 5

Page 37

7. OPERATING PROCEDURES

7.1.2 By Count Operation

TODAY’S

SPEC I AL

NOTES:

AUTO

A

Single label is issued in Single label is issued.

succession after peeling it.

Press to suspend label

issued temporarily.

I

C

0

Press to cancel label

issue

The display returns to

the initial screen.

The Day G/ow PLUS are printed on the Day G/ow (22-mm length) labels on/y.

1.

2. Issuing the Day Glow labels does not affect the memory.

MANUAL

Press to

resume label

issue

(Sample Day Glow label)

I

DONUTS

APR 22

;z

,_.. :i

‘~ ‘~.

APR

n

3

PIMS

,i;- ‘?,- m -RICE It 0 w ,..* T

21

$0.48

7- 6

Page 38

7. OPERATING PROCEDURES

7.1.3 Fix Mode Operation (Issuing labels wlth net weight statement)

In the Fix mode, PLU cannot be called from the SL-2200 scale, but by the H-240 label printer.

Data can be printed only on the label which accommodates 32 ingredient lines. (Set the initial

Setting #O-l to 3 or 4) Unit price and tare preset in each PLU are regarded and printed as

price and net weight, respectively.

Example) The preset Price is $2.10 and the preset Net Weight is 12 oz. The store knows that

the actual Net Weight of this commodity is 19 oz. and decides to sell it at $2.00.

Enter the PLU #.

7.1.3 Fix Mode Operation (Issuing labels with net weight statement)

Press:

Select the Day Glow message

print format.

Cancels the Day Glow message

print format.

Initial set #3-2:0

Enter the sold quantity.

(max. 99)

Press:

Enter the new weight.

(Unit of weight: oz)

(The numeric data is

displayed in the

incremental display

method, i.e., the data is

shifted to the left as each

digit value is entered.)

L

r

.

0

Y

4-c-

71 Initial set #3-2:l

I

IPRICE

I

/UT.

Press:

Enter the quantity.

(Max. 99)

-

0

3

9

A

0

I

I

7- 7

Page 39

7. OPERATING PROCEDURES

Press:

1 The label is issued. 1

7.1.3 Fix Mode Operation (Issuing labels with net weight statement)

The display returns to

the initial screen.

NOTES: 1. Weight data exceeding 480 oz results in an error.

2. Unit price calculation formula

(Step 1) Weight data is

(Round off the data to two decimal places.)

ex.) 21 oz + 1.3125 /b+ round + 1.31 lb

(Step 2) Price is divided by the value obtained above.

(Round off the data to two decimal p/aces.)

ex.) 1.5 $11.31 lb

3. When the unit price is less than $0.01//b or either the weight or price is 0, the unit price

will not be printed.

calculated

= 1.145 + round + $1.15//b

from royal lb into decimal lb.

This data is printed.

ENTER THE PLUX

I

P

I

7- 8

Page 40

7. OPERATING PROCEDURES

4. AMtiplication registration of NET WT. statement

The maximum quantify of a commodity is 99.

In the following cases, an error occurs when pressing the IPRT/REGI key to issue the

label.

(1) Quantity = 0

(2) Price X quantity ) max. price

LEMON MERINGUE PIE

7.13 Fix Mode Operation (Issuing labels with net weight statement)

I*~RfDIEYTF Urnbl fLmJR’30%, nERIffiVbl5%,

/

LElGU%

6iJllER=lO%. EGG-W!.

MEsE:s/.. swM%. stlt1:2%.

lWER’ll%.

PWED on

APR 22

SELL BY

8111111 lwlllllll

00003 30060

3 Pm

APR 25

6 %l!!!lCE

NET WT, 57t.U 16164

TEC CORPORATION

(TEL)0559-76-7564

Data set in Section 6.9 is printed here.

(Sample label)

5.

The Day Glow PLUS are printed on the Day Glow (22-mm length) labels only.

6.

Issuing the Day Glow labels does not affect the memory.

7- 9

Page 41

7. OPERATING PROCEDURES

7.1.4 Batch Print Mode (with 30 PLUS assignment)

A maximum of 30 PLUS can be printed in a range of 0 to 99 label pieces in batch mode.

(When entering 0 for the number of labels to be issued, printing will be canceled). As this

function accepts only PLUS set in the by count or fix mode, calling the PLU set in the weigh

mode will result in an error. When calling the PLU set in the fix mode, be sure to use the label

which accommodates 32 ingredient lines, otherwise an error occurs.

Before starting the procedure, set the BATCH/STRIP selection switch to the BATCH side.

7.1.4 Batch Print Mode (with 30 PLUS assignment)

Enter the PLU #.

Press:

Select the Day Glow message

print format.

Cancels the Day Glow message

print format.

FIX mode:Enter the new price.

By count mode: Enter the new

Purchased Quantity.

Press:

FIX mode: Enter the new weight.

Fix

ENTER THE PLUX

P 819

By Count I Day Glow mode

mode

Press:

FIX mode: Enter the new pieces.

Press:

Enter the number of labels to

be issued (max. 99)

7-10

Page 42

7. OPERATING PROCEDURES

7.1.4 Batch Print Mode (with 30 PLUS assianment)

Press:

The label is issued. 1

r

l

Stopping or cancelling the label issue

Clears an error or stops issuing

labels.

Cancels the PLU being printed.

Press:

Cancels all unprinted PLUS.

-

FEED

I I

C

Automatic issue

Manual issue

Automatic issue 1

Manual issue

1 ISSUING LABELS 1

f75pimy

1 ISSUING

I I

1 [PRINT] TO

I

LABELS

PRINT 1

I

I

EJOTES: 1. Selected PLUS are canceled in the following cases:

@ The power is turned off after selecting PLUS.

The -1 key is pressed to exit the registration mode.

@

@ The n

@ All the selected PLUS have been printed.

2. As more than 30 PLUS cannot be selected, selection of the 31st item will result

in an error when the

3. The following display will appear when the selected PLU is printed, aborted or a

print error is cleared.

#II(PPPPPP)NN MM

cccccccccccccccc

I

II: The serial number of the selected PLU which is aborted.

PP: PLU No.

NN:

The number of labels to be issued.

MM: The number of unprinted labels when aborting printing.

CC:

Commodity name of the PLU

4. The Day Glow PLUS are printed on the Day Glow (22-mm length) labels on/y.

5. Issuing the Day Glow labels does not affect the memory.

6. If the initial setting #O-l is set to other than 5 (custom label I: 22 mm), calling the

Day Glow PLUS in this mode is not allowed. Doing so will result in a ‘UNFIT

PLU’ error.

key is pressed to cancel all unprinted PLUS.

PRINTIREG

I

key is pressed.

7-11

Page 43

7. OPERATING PROCEDURES

7.2 FLORIST TYPE

7.2 FLORIST TYPE

NOTES BEFORE STARTING OPERATION

n

Connect the BHS6060/R hand scanner to the H-240 printer.

(1)

NOTES: 1. Be sure to turn off the printer before connecting the hand scanner to the H-240

printer. If the hand scanner is disconnected from the printer while the power is

on, turn off the printer, connect the hand scanner fo the printer again, and then

turn on the printer.

2. The florist machine cannot be connected to a scale. When connecting the printer

to a PC, be sure to use the cab/e exclusively for the H-240~QQ V2.0. Failure to

do this may result in ma/functions with the machine. (The cable is no1 enclosed

with the printer.)

Set the BATCH/STRIP selection switch depending on your usage.

(2)

Insert the power cord plug into the AC outlet.

(3)

Check the date and time.

(4)

Press the [FEED] button to feed a label.

(5)

Remove the fed label.

(6)

Press the 1-1

(7)

key.

BATCH mode: STRIP mode:

I -

Print Head

1,

Printing the label is ready.

Backing Paper

The label is fed reversely

to the print start position.

Printing the label is completed.

Remove the printed label.

L&w!?;;

Strip Plate

i

-

i

Label

+?F=

,

H-0

NOTES: 1. When the loaded label does not match the label format setting, print start and end

positions may become misaligned.

2. Labels will not be issued when the print head is raised, the label ended, or printed

label is detected by the strip sensor.

7-12

Page 44

7. OPERATING PROCEDURES

l

Sales Mode Outline

Sales Mode

7.2.1 Scanning Operation

I

I

I

+ I

1 7.2.2 Item Correction 1 1

7.2 FLORIST TYPE

1

When the slide switch is

set to STRIP.

When the slide switch is

set to BATCH.

I

I

t

7.2.4 Printing labels for 7.2.4 Printing labels for

ready-made commodities ready-made commodities

(The number of copies are (The number of copies are

specified.) specified.)

J

0

L

J.

@

7-13

Page 45

7. OPERATING PROCEDURES

7.2.1 Scanning Operatlon

Sales transactions are performed by scanning the bar codes, which represent the flower name,

quantity, and several functions, printed on the visual chart with the hand scanner in the

following procedure.

NOTES: 1. In sales mode, only the PI and the I] keys are available.

2. The CLEAR code is effective in the following cases:

(7) Right after a quantity entry.

(2) Right after scanning the SUBTRACT code.

(3) Right afier scanning the PREVIEW code.

3. When a commodity’s quantity is I, the quantity code need not be scanned.

7.2.1 Scanning Operation

4. PLUS to be sold by quantity only are entered.

in a “DATA ENTRY ERROR”.

5. Max. 20 items including VOID, CLEAR, CHARGE, etc. can be entered in one

sales transaction.

6. Be sure to match the slide switch status with the label type.

Florist label I:

Florist label 2:

7. a label will not be issued.

8. are printed in batch mode stops printing

. . . . . . . . . . . . . . . . . . . . . . . . . STRIP

. . . . . . . . . . . . . . . . . . . . . BATCH

Using the other PLUS will result

and the number of unprinted copies.

NN MM

NN: Total number of labels to be printed

MM: Unprinted labels

7-14

Page 46

7. OPERATING PROCEDURES

(1) Sample operation for a commodity entry

NOTE: Items enclosed by single rectangles indicate bar codes.

7.2.1 Scanning Operation

Sales Mode

a

2

b

ROSE

C

TOTAL

d

Label A is issued.

a

(Display)

ap2ifELL

bl

I

Ccl

A commodity is entered.

7-15

Page 47

7. OPERATING PROCEDURES

(2) Sample operation for plural commodities entry

Sales Mode

II

151

e

II

I

1 RO,SE ]

1 SUMMER BOUQUET 1

(Display)

f ROSE

I 5

7.2.1 Scanning Operation

$5.00

i

CARNATION

j

2

k

XxXx CHARGE

I

TOTAL

I

m

Label B is issued.

a

Plural commodities

are entered.

XXXX CHARGE

2

$5.00

$36.00

Please scan

the Visual chart

7-16

Page 48

7. OPERATING PROCEDURES

7.2.2 Item Correction

72.2 Item Correction

(Display)

al

12

bl

DAISY

cl

IRIS

dl

ALL VOID

I

el

SUMMER BOUQUET

a2

12

b2

I

I

All commodities are

canceled.

al

pimymyJ

bl

cl

dl

el

a2

b2

DAISY

12

ALL VOID

$6.00

DAISY

c2

c2

DAISY

12 $6.00

I

5

d2

d2

1

7-17

Page 49

7. OPERATING PROCEDURES

7.2.2 Item Correction

(Display)

f2,1

92

VOID

h2

Aiter displaying h2, e2 will be displayed.

I

SUBTRACT

i2

6

P

DAISY

k2

After displaying k2, e2 will be displayed.

4

12

PANSY

I

I

I

: _ The preceding

commodity and quantity

are canceled.

The entered commodity

l--

and quantity are

canceled by subtracting

them.

I

:

I

I

I

3

I

!Pjl

h2r1

I241

m2

TOTAL

n2

Display n2 is shown while a label is issued.

I

Label C is issued.

a

7-18

m214.[10)

t-Q 1 TOTAL

I

$17.00 1

1

Page 50

7. OPERATING PROCEDURES

7.2.3 Estimate

1 GIFT SPECIAL 1

7.23 Estimate

(Display)

a3-1

b3vl

h3

a

Total amount is displayed.

is shown. is shown.

Page 51

7. OPERATING PROCEDURES

7.2.4 Printing Labels for Ready-made Commodities

Issuing single label

(1)

7.2.4 Printing Labels for Ready-made Commodities

(Display)

I

Label E is issued.

+,

Issuing plural labels

(2)

v

I

DAISY

a4

b4

a

a4 ROSE

1 $1.00

b471

I

a5 DAISY

I

(Display)

2 $1.00

I

TOTAL

I

c5

3 pieces of label F are issued.

pziiT&q

a

I

b5

3

7-20

Page 52

7. OPERATING PROCEDURES

l

Label Samples

7.2.4 Printing Labels for Ready-made Commodities

Glorious Creations

Atlanta, Ga.

COUNT CT./PRICE PR I CE [$I

ROSE

2 l/l .oo

2.00

Total i!pcs, #!,OO

Sample label A

G I or i ous Creat ions

Atlanta, Ga.

COUNT CT./PRICE

ROSE

Ii l/l .oo

SUMMER BOUQUET

2 l/6.00

CARNAT I ON

8 l/2.00

XXXX CHARGE

2 l/2.50

PR I CE [$I

5.00

10.00

16.00

5.00

Total VPCS, $36,00

~llllllll~~lilill~l~l#

0 05555 00005

5

7-2-l

Sample label B

Page 53

7. OPERATING PROCEDURES

7.2.4

Printing Labels for Ready-made Commodities

Glorious Creations

Atlanta, Ga.

COUNT CT. /PR I CE PR I CE [$I

SUMMER BOUPUET

1 l/5.00 5.00

DAISY

12 2/l. 00 6.00

ROSE

5 l/l .oo 5.00

fA*RHT,fm- - - - - --^--- - - - -- ---- --- -

-se--- ----,. &..()(y __------- +6-m

DAISY

-6 2/l .oo -3.00

PANSY

4 l/l .oo 4.00

G I or i ous

Creat i ons

Atlanta, Ga.

COUNT CT./PRICE PR I CE [$I

SUMMER BOUQUET

1 l/5.00 5.00

GIFT SPECIAL

4

VIOLET

1 112.00 2.00

ROSE

I l/l.00 1.00

CARNAT I ON

8 l/2.00 16.00

113.00 12.00

Total 15~~ $36,00

Total I~PCS, $17.00

0

Sample label C

3

lilllllalllll111

0

03333 00003

Sample label D

1

7-22

Page 54

7. OPERATING PROCEDURES

7.2.4 Printing Labels for Ready-made Commodities

Glorious Creations

Atlanta. Ga.

ROSE

1 PNfS

Glorious Creations

Atlanta, Ga.

DAISY

2PIKR

$2.00

Sample label E

$1 . 00

How to care

for your

Water only

When soil is

completely dry.

Feed week I

when blooming.

How to care

for your plant:

~ Water only

When soil is

completely dry.

Feed week I

when blooming.

plant:

Y

Y

~llllllllllll~llll~lll~

0

02222 00002

8

Sample labels F

7-23

Page 55

8. READ OPERATION

8. READ OPERATION

In this mode, sales information and PLU data are checked by printing a report. A report is printed on

either label or receipt, however, when using the receipt, set the slide switch to the BATCH side.

The total data in the memory is not cleared after issuing a report.

dia selection)

(ME

I

8. READ OPERATION

-

m

NEXT

(Label CI Receipt)

jc

NOTES: 1. When checking “NUTRITION”, use the label which accommodates 32 lines of

ingredient message.

2. VOID TOTAL is summed for the florist machine only.

8-

1

Page 56

8. READ OPERATION

8. READ OPERATION

All total

I I

individual total

-12 0 0

H Sample Label

I,E' 'Vi- m

TEC CORPORATION

(TEL)0559-76-7564

Block total

Zone total

PROG.

+

. GRAND TOTAL

GRAND TOTAL

APR 25

O’:

0.00 7

r:?,-[ rO

12 . .

11 8 0

1

-12 5 0

-Read mark

13.05

I

(Print)

l

NUTRITION

Returns to each mode.

MODE

HANGE

. PLU PROGRAMED

DONUTS

CA.,:- ^,

., _/

APR 25

SE.. 2’

6 PIMS 5 B

000002 0.93 000002

'Z-h- II3 F3ICC It 0

TEC CORPORATION

(TEL)0559-76-7564

NOTE: Regardless of ingredient data amount, the label length

is fixed to the value set by the initial Setting #O-l.

8- 2

TEC CORPORATION

(TEL)0559-76-7564

Page 57

9. RESET OPERATION

9. RESET OPERATION

9. RESET OPERATION

In this mode, the sales information of all PLUS are printed on either a label or a receipt. When using

a receipt, set the slide switch to the BATCH side. After performing this operation, the memory will be

cleared.

This operation is available only when the Initial Setting #2-4 is set to

1.

(Media selection)

PROG.

-+

PROG.

-7

(Label c, Receipt)

-!q-

GRAND TOTAL

II !

0.00 7 13.05

Flf-‘i.- m ‘“IZi bf3

TEC CORPORATION

(TEL)0559-76-7564

(Sample Label)

I

APR 25

-Reset mark

NOTE: Regardless of ingredient data amount, the label length is fixed to the value set by the Initial

Setting #O- 1.

9- 1

Page 58

10. REMOVING JAMMED LABEL

10. REMOVING JAMMED LABEL

10. REMOVING JAMMED LABEL

Since the florist machine has a cutter

removing jammed

When the label jams, take the following action.

1) Turn the printer power off and open the top cover.

2) Open the print head by sliding the print head release latches to the open positions.

3) When the label jams in strip mode, open the strip mechanism by pushing down on the strip

release levers.

labels.

Print Head Rtfease Latch

Strip

Release

Le

at the label outlet, be caretid nor to injure your fingers when

Print Head,Release

Latch

Stric Release Lever

4) Carefully remove jammed label. Do not

5) Remove any glue residue from the print head, platen and paper guide (Refer to section 11).

6) Reload the label (Refer to section 5).

use

sharp objects.

lo- 1

Page 59

11. CLEANING PROCEDURES

11 .l PRINT HEAD/PLATEN/STRIP FEED ROLLER MECHANISM

Il. CLEANING PROCEDURES

Since the florist machine has a curter at the label outlet, be careful nor to injure your fingers when

cleaning adjacent parts.

I

11 .I PRINT HEAD/PLATEN/STRIP FEED ROLLER MECHANISM

The print head, platen, and strip feed roller should be cleaned

0

After any part of the mechanism becomes stained with glue.

0

If printing becomes blurred.

To clean the print head, platen, and strip feed roller, do the following:

Turn the printer power off.

1)

Open the top cover.

2)

Open the print head by sliding the print head release latches to the open positions.

3)

Open the strip mechanism by pushing down on the strip release levers.

4)

Clean the print head with the print head cleaner.

5)

Wipe the platen, strip feed roller, and paper guide with a cloth moistened with alcohol.

6)

I

I

Paper-Guide

I) Be sure to disconnect the power cord prior to performing any maintenance.

2) Do nor use any tool that may damage the Print Head.

3) DO NOT POUR WATER directly on the printer.

I

11.2 COVERS/PANELS

Clean the covers by wiping them with a dry cloth or with a cloth slightly damped with the cleaner.

NOTE:

I) DO NOT pour water directly on the printer.

2) DO NOT apply cleaner or detergent direct/y to the cover.

3) NEVER use thinner or other volatile solvent

4) DO NOT clean the printer cover with alcohol. The printer cover may become discolored, loose

Clean the printer cover with an electrostatic free cleaner for automated office equipment.

for

cleaning.

ifs shape, or develop structural damage if alcohol is used.

I

ll- 1

Page 60

12. CARE/HANDLING OF THE LABEL

12. CARE/HANDLING OF THE LABEL

12. CARE/HANDLING OF THE LABEL

CAUTION:

Be sure to read carefully and understand the Supply Manual. Use on/y labels which meet specified

requirements. Use of non-specified labels may shorten the print head life and result in problems

wirh bar code readability or print quality.

damage to the label or printer. Read the following guidelines

l

Do not store the label for longer than the manufacture’s recommended shelf life.

l

Store label rolls on the flat end, do not store them on the curved sides as this might flatten the

roll causing erratic label advance and poor print quality.

l

Store the label in plastic bags and always reseal after opening. Unprotected labels can get dirty

and the extra abrasion from the dust and dirt particles will shorten the print head life.

l

Store the label in a cool, dry place. Avoid areas where they would be exposed to direct sunlight,

high temperature, high humidity,

dust

For further information please contact your local distributor or your label manufacturer.

All labels should be handled with care to avoid any

carefully.

or gas.

12- 1

Page 61

13. ERROR MESSAGE TABLE

13. ERROR MESSAGE TABLE

13. ERROR MESSAGE TABLE

When an error message appears on the LCD display, follow the instructions below.

If you cannot solve the problem with the following solution instructions, do not attempt further trouble

shooting by yourself. Turn the power off, unplug the printer, then contact your Authorized Service

representative for assistance.

Do not attempt to repair or adjust on your own, because electrical equipment is dangerous.

Message Cause Solution

PAPER END Label runs out during printing Load a new label and press the IFEED

or feeding the label. button.

HEAD UP ERROR

SENSOR ERROR

The print head is not in

position when label is being

printed or going to be printed.

1. The loaded label does not

match the specified label

format.

2. Sensor failure

head in position and press

1. Load the correct label on the printer or

2. Call your authorized service

representative.

13- 1

Page 62

14. TROUBLESHOOTING

14. TROUBLESHOOTING

14. TROUBLESHOOTING

Problems

No print

Missing dot

Unclear (or blurred) 1. Dirty print head. --+ Clean the print head.

printing 2. Poor media quality. + Change media type.