Page 1

ADJUSTABLE SPEED DRIVES

GX7 Series

Page 2

Toshiba GX7

Toshiba’s GX7 Series PWM adjustable speed drive is a severe duty drive built to handle all

conventional applications in the industry, ranging from the simplest to the most complex.

The GX7 Series offers flux-vector technology with or without encoder feedback. This drive

maintains astoundingly tight control over both torque and speed with the industry’s most

user-friendly operator interface. The GX7 is designed to handle the most extreme conditions,

continuing the G-Series tradition of delivering a robust performance platform.

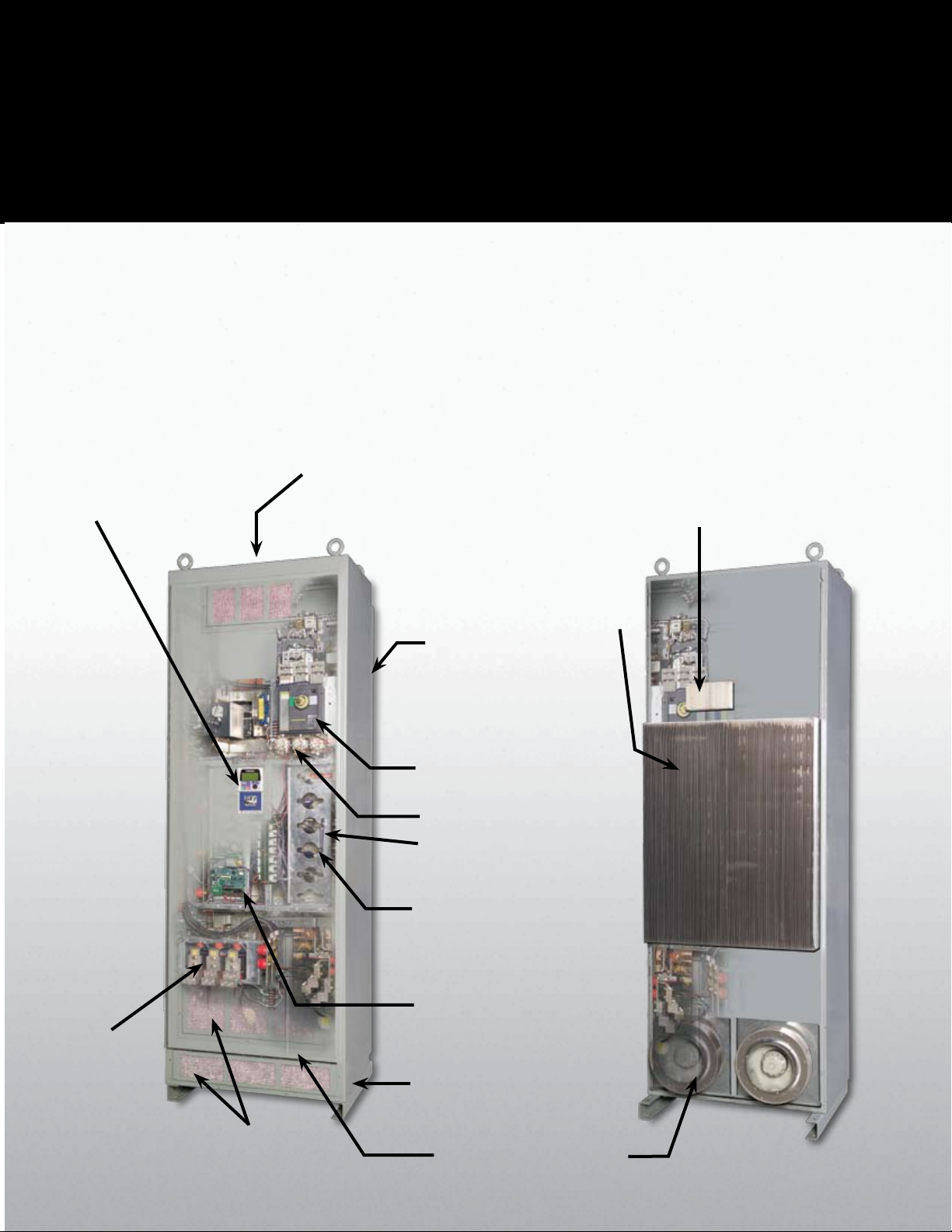

User-Friendly

Electronic Operator

Interface (EOI)

Top or Bottom

Cable Entry/Exit

All Models Include Dynamic

Braking IGBT Standard

Heatsink

Out-the-Back

Small

Footprint

Molded Case Circuit

Breaker with Throughthe-Door Operator

Input Fuses

Lockable Door Handle

with 3-Point Latch

Removable

Capacitor Assembly

for Easy Serviceability

Motor

Terminations

Optional Washable

Aluminum Mesh Filters

Removable

Terminal Strip

12-Gauge Steel

Enclosure

Long Life 1200 cfm FrontRemovable Heatsink Fan

Page 3

Industrial Solutions

32’’

95’’

Small Footprint

Today, the high cost of real estate and space constraints in

existing facilities make size an important factor in drive selection.

Toshiba responds with the GX7. The GX7 provides proper cooling

of internal electronic components to ensure optimum performance

and durability even in a small footprint enclosure.

500 to 800 HP; Only 32 Inches Wide

95 Inches High and 30.5 Inches Deep

Saves Real Estate on New Designs

Easy Replacement for Dated Drives in Existing Facilities

Industrially Hardened

The GX7 Series has the highest overload capability available

for a 600 V, 500 HP and above drive. Rated at 110% continuous

current, 130% up to 120 seconds, the GX7 can withstand load

conditions that would cause other drives to fail.

The GX7 is ready for continuous, trouble-free operation in the

most demanding manufacturing environments. In addition, it is

designed for an operating environment of -10 to 40°C at elevations

of -1000 to 1000 meters.

Variety of Communication Options

In the fast-paced manufacturing world, coordinated

systems require drive-to-drive or drive-to-control system

communication. Toshiba’s GX7 comes standard with

RS232/485 and TTL communication ports. In addition to

the standard communications features, Toshiba offers a

number of popular industrial communication protocol options

including: Modbus RTU, Modbus Plus, Ethernet IP, Profibus

DP, DeviceNet and Johnson Controls Metasys N2.

Page 4

Proven Technology

Advanced Electronic Operator Interface

The GX7’s Electronic Operator Interface (EOI) features a multi-line, graphics-capable,

plain English, back-lit LCD. The EOI is so intuitive that the manual is usually unneeded

to make setting adjustments. The GX7 has menu-driven programming as well as direct

access to the parameters. A high reliability rotary encoder makes programming easy.

Startup Wizard helps facilitate initial programming.

Configurables

• Easy to Remote-Mount the Display (up to 1000 Feet)

• Real-Time Clock Option (Stores up to 100 Past Faults with Date and Time Stamp)

• Graphics-Capable LCD to Aid in Diagnostics

• Flash-Upgradeable EOI Software

• Help from Toshiba Customizing Application-Specific Wizards

Standard Keypad Design for Low Voltage and Medium Voltage Drives

Monitor Software

The free monitor software allows the user to monitor and control critical operational

parameters using serial communication. The software contains real-time graphing, a very

useful tool for data analysis which allows files and tables to be created with the software

from the obtained data.

Process Control

The built-in Proportional/Integral/Derivative (PID) control loop provides regulation of

many processes without the need for external devices. Deviation limits, online switching,

and delay filtering functions are included to enhance the flexibility and reliability of PID

process control.

Page 5

Meets or Exceeds

Your Specications

GX7 Specications

Standard Specications

Item

Voltage Class 600 VAC

Maximum HP 500 HP 600 HP 700 HP 800 HP

Drive Rating (A) 481 A 601 A 698 A 770 A

Dimensions 95”H x 32”W x 30.5”D

Power Requirements

Output Frequency 0 to 299 Hz

Control Power DC Bus Control Power

Tolerance Voltage: ±10%; Frequency: ±2%

Control Specications

Control Method Sine Wave PWM System; Flux Field Current Vector Control

V/Hz Control Constant Torque, Variable Torque, Open-Loop Vector, Auto or Manual Torque Boost, 5-Point V/Hz Custom Curves

Overload Rating 130% for 120 Seconds; 110% Continuous

Frequency Setting Rotary Encoder Integrated into EOI, 0 to 10 V, ±10 V, 4 to 20 mA, Binary Input, Motorized Potentiometer Input

Frequency Precision Analog Input: ±0.2% of Maximum Output Frequency; Digital Input: ±0.01% of Maximum Output Frequency

Frequency Resolution Panel Operation: 0.01 Hz; Analog Input 10 to 12-Bit A to D Converter: 0.1 Hz

Acceleration / Deceleration 0.1 to 6000 Seconds

Speed Regulation Up to 0.1%; 60:1 Speed Range

Torque Setting ±250% of the Rated Torque

Set Point Control (PID)

Analog Inputs Four Programmable: (1) 4 to 20 mA, (1) 0 to 10 V, (1) -10 to +10 V, (1) 1 to 10kΩ Potentiometer Connection

Analog Outputs Two Programmable to 31 Functions

Discrete Inputs Eight Programmable to 67 Functions; Expandable to N-Value

Output Contacts Three Output Terminals, Programmable to 52 Functions; Form C Contacts Rated 250 V AC, Two Amps Inductive

Signal Isolation Available Three-Channel Signal Isolation for AM/FM Outputs and II Terminal Input, Rated at 750 V

Power Terminals

Control Board

Communication Ports

Data Transmission Probus, DeviceNet, Modbus RTU, Modbus+, Metasys, Ethernet (Some Devices are External)

Main Protective

Functions

Soft Stall Automatic Load Reduction Control During Overload

Retry Can Automatically Clear Fault Upon Trip; Programmable to 10 Tries with up to 10 Seconds Between Tries

Restart Restart into a Rotating Motor

LCD/EOI (Liquid Crystal

Display/Electronic

Operator Interface)

LED Indicators Run (Red)/Stop (Green), Remote/Local (Green), DC Bus Charge Indication (Red)

Keys Local/Remote, Monitor/Program, Run, Enter, ESC, Stop/Reset, Up, Down

Monitoring Main Display Shows Two Monitored Items Continuously, or Scrolls Up to 40 Items

Selectable Display Units

EOI Communication Ports RS232/485 and TTL Ports Standard

Remote-Mount Display Remote Mountable Up to 1000 Feet

Enclosure NEMA 1, IP20, Gasketed and Filtered

Panel Construction Free-Standing, Front-Maintenance Type, Top or Bottom Access for Motor and Power Cables

Cooling Forced-Air Cooled Top-Mounted Fans may be Removed During Shipment or Installation

Color ANSI-61 Gray

Ambient Temperature -10 to 40°C (-14 to 104°F)

Humidity Max. 95% (Non-Condensing)

Altitude 1000 Meters (3300 Feet) Above Sea Level or Less

Installation Indoor, No Direct Sunlight, Protect from Corrosive Gases and/or Explosive Gases

Electrical Compliance NEC, ANSI

Proportional Gain, Integral Gain, Feedback Settings Upper/Lower Deviation Limits, Feedback Source Delay Filter, Feedback Settings

Differential Gain

Input (L1, L2, L3) Output (T1, T2, T3) DCL (PO, PA), DBR (PA, PB), DCBUS (PA, PC)

RS232/485 and TTL Ports Standard

Current Limit, Overcurrent, Overvoltage, Undervoltage, Load-Side Short Circuit, Load-Side Ground Fault, Armature Short; Overtorque,

ASD Overload, Motor Overload, Heatsink Overheat, Open Output Phase, Loss of Feedback, CPU Error, Communications Error

Interface

Backlit LCD Display; Ability to Display Multiple Parameters on One Screen; Keypad may be Operated from External Power Source;

Software is Flash Upgradeable; Includes Multi-Function Rotary Encoder

User-Selectable and Congurable along with Scaling Factor Multiplier; Voltage Display Selectable: Volts or %;

Current Display Selectable: Amps or %.

Construction

Ambient Conditions

Standards

Page 6

North American Headquarters and Manufacturing Facility (Houston, TX)

TOSHIBA — Quality by Design

Toshiba's culture and history is strongly rooted in quality. Our designs are

technologically innovative, and our products are manufactured from start to

end using only the highest quality domestic and foreign parts.

Product Warranty

Toshiba offers a comprehensive warranty program on its full line of industrial

products. Consult your salesperson or the factory for specific information.

Medium Voltage Motor

G7 Drive

Need to Know More?

Be sure to visit our website located at www.toshiba.com/ind for the latest

information on Toshiba products and services.

Customer Support Services

Toshiba offers 24 hour service nationwide. For assistance of any type,

call: 1-800-231-1412.

ADJUSTABLE SPEED DRIVES MOTORS CONTROLS UPS INSTRUMENTATION PLC

Available Through:

INDUSTRIAL DIVISION

13131 West Little York Road, Houston, Texas 77041

Tel 713/466-0277 Fax 713/466-8773

US 800/231-1412 Canada 800/872-2192 Mexico 01/800/527-1204

www.toshiba.com/ind

Copyright 1/2008

*ASDgX7serIct080110*

Loading...

Loading...