Page 1

6 F 2 S 0 8 5 7

INSTRUCTION MANUAL

TRANSFORMER PROTECTION RELAY

GRT100 - ∗∗∗D

© TOSHIBA Corporation 2007

All Rights Reserved.

( Ver. 4.0 )

Page 2

R

Safety Precautions

Before using this product, be sure to read this chapter carefully.

This chapter describes safety precautions when using the GRT100. Before installing and using the

equipment, read and understand this chapter thoroughly.

Explanation of symbols used

Signal words such as DANGER, WARNING, and two kinds of CAUTION, will be followed by

important safety information that must be carefully reviewed.

Indicates an imminently hazardous situation which will result in death or

DANGE

Indicates a potentially hazardous situation which could result in death or

WARNING

CAUTION Indicates a potentially hazardous situation which if not avoided, may result in

serious injury if you do not follow instructions.

serious injury if you do not follow instructions.

minor injury or moderate injury.

6 F 2 S 0 8 5 7

CAUTION Indicates a potentially hazardous situation which if not avoided, may result in

property damage.

⎯ 1 ⎯

Page 3

R

DANGE

• Current transformer circuit

Never allow the current transformer (CT) secondary circuit connected to this equipment to be

opened while the primary system is live. Opening the CT circuit will produce a dangerous high

voltage.

WARNING

• Exposed terminals

Do not touch the terminals of this equipment while the power is on, as the high voltage generated

is dangerous.

• Residual voltage

Hazardous voltage can be present in the DC circuit just after switching off the DC power supply. It

takes about 30 seconds for the voltage to discharge.

• Fiber optic

Do not view directly with optical instruments.

6 F 2 S 0 8 5 7

CAUTION

• Earth

Earth the earthing terminal of the equipment securely.

CAUTION

• Operation conditions

Use the equipment within the range of ambient temperature, humidity and dust as detailed in the

specification and in an environment free of abnormal vibration.

• Ratings

Before applying AC voltage and current or DC power supply to the equipment, check that they

conform to the equipment ratings.

• Printed circuit board

Do not attach and remove the printed circuit board while the DC power to the equipment is on, as

this may cause the equipment to malfunction.

• External circuit

When connecting the output contacts of the equipment to an external circuit, carefully check the

supply voltage used and prevent the connected circuit from overheating.

• Connection cable

Carefully handle the connection cable without applying excessive force.

• Modification

Do not modify this equipment, as this may cause the equipment to malfunction, and any such

modifications will invalidate the warranty.

• Short-link

Do not remove a short-link which is mounted at the terminal block on the rear of the relay before

⎯ 2 ⎯

Page 4

6 F 2 S 0 8 5 7

shipment, as this may cause the performance of this equipment such as withstand voltage, etc., to

reduce.

• Disposal

When disposing of this product, do so in a safe manner according to local regulations.

This product contains a lithium-ion battery, which should be removed at the end-of-life of the

product. The battery must be recycled or disposed of in accordance with local regulations. The

battery can be removed by withdrawing the Signal Processing module (SPM) from the relay case,

and cutting the connecting leads and plastic strap which hold the battery.

⎯ 3 ⎯

Page 5

Contents

Safety Precautions 1

1. Introduction 8

2. Application Notes 10

2.1 Protection Scheme 10

2.2 Current Differential Protection 12

2.3 Restricted Earth Fault Protection 34

2.4 Overcurrent Protection 38

2.5 Thermal Overload Protection 43

2.6 Frequency Protection 44

2.7 Overexcitation Protection 46

2.8 Trip by External Devices 48

2.9 Tripping Output 49

2.10 Characteristics of Measuring Elements 51

6 F 2 S 0 8 5 7

2.2.1 Differential Scheme 12

2.2.2 Stability for CT Saturation during Through-fault Conditions 16

2.2.3 Matching of CT Secondary Currents 18

2.2.4 Connection between CT Secondary Circuit and the GRT100 22

2.2.5 Setting 23

2.10.1 Percentage Current Differential Element DIF 51

2.10.2 High-set Overcurrent Element HOC 52

2.10.3 Restricted Earth Fault Element REF 52

2.10.4 Inverse Time Overcurrent Element OCI and EFI 54

2.10.5 Definite Time Overcurrent element OC and EF 55

2.10.6 Thermal Overload Element THR 55

2.10.7 Frequency Element FRQ 57

2.10.8 Overexcitation Element V/F 57

3. Technical Description 58

3.1 Hardware Description 58

3.1.1 Outline of Hardware Modules 58

3.1.2 Transformer Module 61

3.1.3 Signal Processing Module 62

3.1.4 Binary Input and Output Module 63

3.1.5 Human Machine Interface (HMI) Module 67

3.2 Input and Output Signals 69

3.2.1 Input Signals 69

3.2.2 Binary Output Signals 70

3.2.3 PLC (Programmable Logic Controller) Function 71

3.3 Automatic Supervision 72

3.3.1 Basic Concept of Supervision 72

3.3.2 Relay Monitoring and Testing 72

3.3.3 PLC Data and IEC61850 Mapping Data Monitoring 73

⎯ 4 ⎯

Page 6

6 F 2 S 0 8 5 7

3.3.4 IEC61850 Communication Monitoring 73

3.3.5 Failure Alarms 73

3.3.6 Trip Blocking 74

3.3.7 Setting 74

3.4 Recording Function 75

3.4.1 Fault Recording 75

3.4.2 Event Recording 76

3.4.3 Disturbance Recording 76

3.5 Metering Function 78

4. User Interface 79

4.1 Outline of User Interface 79

4.1.1 Front Panel 79

4.1.2 Communication Ports 81

4.2 Operation of the User Interface 82

4.2.1 LCD and LED Displays 82

4.2.2 Relay Menu 84

4.2.3 Displaying Records 87

4.2.4 Displaying the Status 90

4.2.5 Viewing the Settings 95

4.2.6 Changing the Settings 95

4.2.7 Testing 114

4.3 Personal Computer Interface 118

4.4 Communication Interface 118

4.4.1 RSM (Relay Setting and Monitoring System) 118

4.4.2 IEC 60870-5-103 Interface 119

4.4.3 IEC 61850 interface 120

4.5 Clock Function 120

5. Installation 121

5.1 Receipt of Relays 121

5.2 Relay Mounting 121

5.3 Electrostatic Discharge 121

5.4 Handling Precautions 121

5.5 External Connections 122

6. Commissioning and Maintenance 123

6.1 Outline of Commissioning Tests 123

6.2 Cautions 124

6.2.1 Safety Precautions 124

6.2.2 Cautions on Tests 124

6.3 Preparations 125

6.4 Hardware Tests 126

6.4.1 User Interfaces 126

6.4.2 Binary Input Circuit 127

6.4.3 Binary Output Circuit 128

6.4.4 AC Input Circuits 129

⎯ 5 ⎯

Page 7

6 F 2 S 0 8 5 7

6.5 Function Test 130

6.5.1 Measuring Element 130

6.5.2 Timer Test 146

6.5.3 Protection Scheme 148

6.5.4 Metering and Recording 148

6.6 Conjunctive Tests 149

6.6.1 On Load Test 149

6.6.2 Tripping Circuit Test 149

6.7 Maintenance 151

6.7.1 Regular Testing 151

6.7.2 Failure Tracing and Repair 151

6.7.3 Replacing Failed Modules 153

6.7.4 Resumption of Service 155

6.7.5 Storage 155

7. Putting Relay into Service 156

⎯ 6 ⎯

Page 8

6 F 2 S 0 8 5 7

Appendix A Block Diagram 157

Appendix B Signal List 159

Appendix C Variable Timer List 179

Appendix D Binary Output Default Setting List 181

Appendix E Details of Relay Menu and LCD & Button Operation 185

Appendix F Case Outline 193

Appendix G External Connections 199

Appendix H Relay Setting Sheet 207

Appendix I Commissioning Test Sheet (sample) 241

Appendix J Return Repair Form 247

Appendix K Technical Data 253

Appendix L Setting of REF Element 261

Appendix M Symbols Used in Scheme Logic 267

Appendix N Implementation of Thermal Model to IEC60255-8 271

Appendix O IEC60870-5-103: Interoperability and Troublehsooting 275

Appendix P IEC61850: MICS & PICS 287

Appendix Q Inverse Time Characteristics 321

Appendix R Failed Module Tracing and Replacement 325

Appendix S Ordering 331

The data given in this manual are subject to change without notice. (Ver.4.0)

⎯ 7 ⎯

Page 9

1. Introduction

GRT100 provides high-speed transformer and reactor protection, and realises high dependability

and security for diverse faults such as single-phase faults, multi-phase faults, overload and

over-excitation.

GRT100 is used as a main protection and backup protection of the following transformers and

reactors.

• Two-winding or three-winding power transformers

• Auto-transformers

• Generator-transformer units

• Shunt reactors

GRT100 is designed to provide stability under magnetizing inrush and overexcitation conditions.

GRT100 is available for mixed 1A/5A inputs

GRT100 provides the following metering and recording functions.

6 F 2 S 0 8 5 7

• Metering

• Fault records

• Event records

• Disturbance records

GRT100 provides the following human interfaces for relay setting or viewing of stored data.

• Relay front panel: LCD, LED display and operation keys

• Local PC

• Remote PC

Password protection is provided to change settings. Eight active setting groups are provided. This

allows the user to set one group for normal operating conditions while other groups may be set to

cover alternative operating conditions by binary input using the PLC.

GRT100 can provide the following serial interface ports:

- RS232C for a local PC and Relay Setting and Monitoring System (RSM100)

- RS485 for a remote PC, and Relay Setting and Monitoring System (RSM100) or Substation

control and Automation System (SAS) with IEC60870-5-103 protocol

- Fibre Optic (FO, option) for a remote PC, and Relay Setting and Monitoring System

(RSM100) or Substation control and Automation System (SAS) with IEC60870-5-103

protocol

- 100BASE-TX, or -FX (option) for Substation control and Automation System (SAS) with

IEC61850 protocol

Another interface IRIG-B port is provided for an external clock connection.

The RS232C port is located on the front panel of the relay. Other ports (RS485, FO, 100BASE-TX

and IRIG-B) are located on the rear of the relay.

Further, the GRT100 provides the following functions.

⎯ 8 ⎯

Page 10

6 F 2 S 0 8 5 7

- Configurable binary inputs and outputs

- Programmable logic for I/O configuration, alarms, indications, recording, etc.

- Automatic supervision

GRT100 has two model series which differ according to the number of three-phase current inputs

for differential protection as follows:

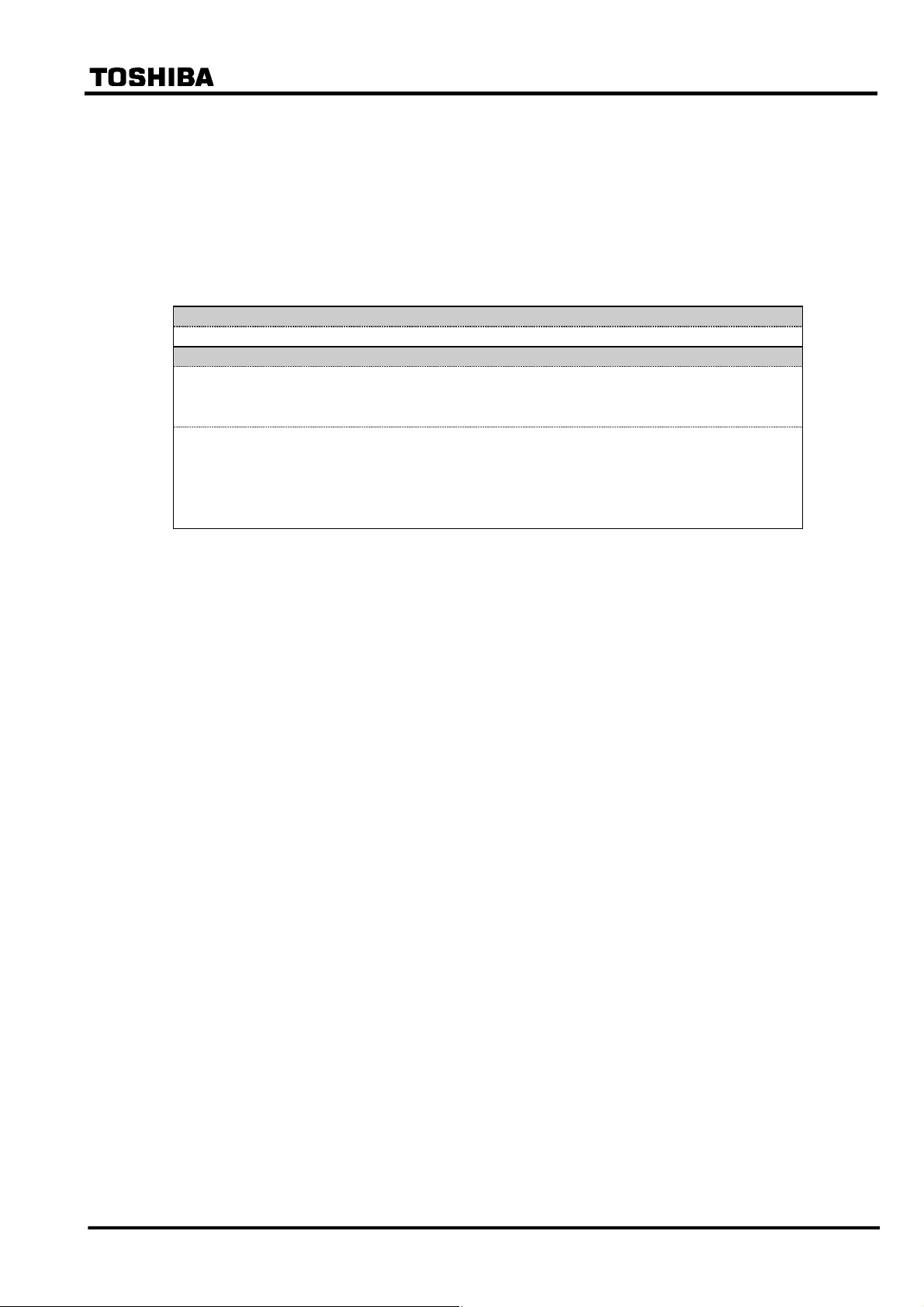

Relay Type and Model

Relay Type:

- Type GRT100; Numerical transformer protection relay

Relay Model:

- Model 100 series; 2 three-phase current inputs, applied to two-winding transformers

• Model 101; 16 binary inputs, 13 binary outputs, 5 binary outputs for tripping

• Model 102; 16 binary inputs, 23 binary outputs, 5 binary outputs for tripping

- Model 200 series; 3 three-phase current inputs, applied to two- and three-winding transformers

• Model 201; 16 binary inputs, 13 binary outputs, 5 binary outputs for tripping

• Model 202; 16 binary inputs, 23 binary outputs, 5 binary outputs for tripping

• Model 203; 15 binary inputs (12-independent), 13 binary outputs, 3 binary outputs for tripping

• Model 204; 15 binary inputs (12-independent), 23 binary outputs, 3 binary outputs for tripping

Model 100 series have 2 three-phase current inputs and can be applied to two-winding

transformers. Model 200 series have 3 three-phase current inputs and can be applied to two- and

three-winding transformers.

⎯ 9 ⎯

Page 11

2. Application Notes

GRT100 is applied to both main protection and backup protection for the following transformers

and reactors:

• Two-winding or three-winding power transformers

• Auto-transformers

• Generator-transformer units

• Shunt reactors

2.1 Protection Scheme

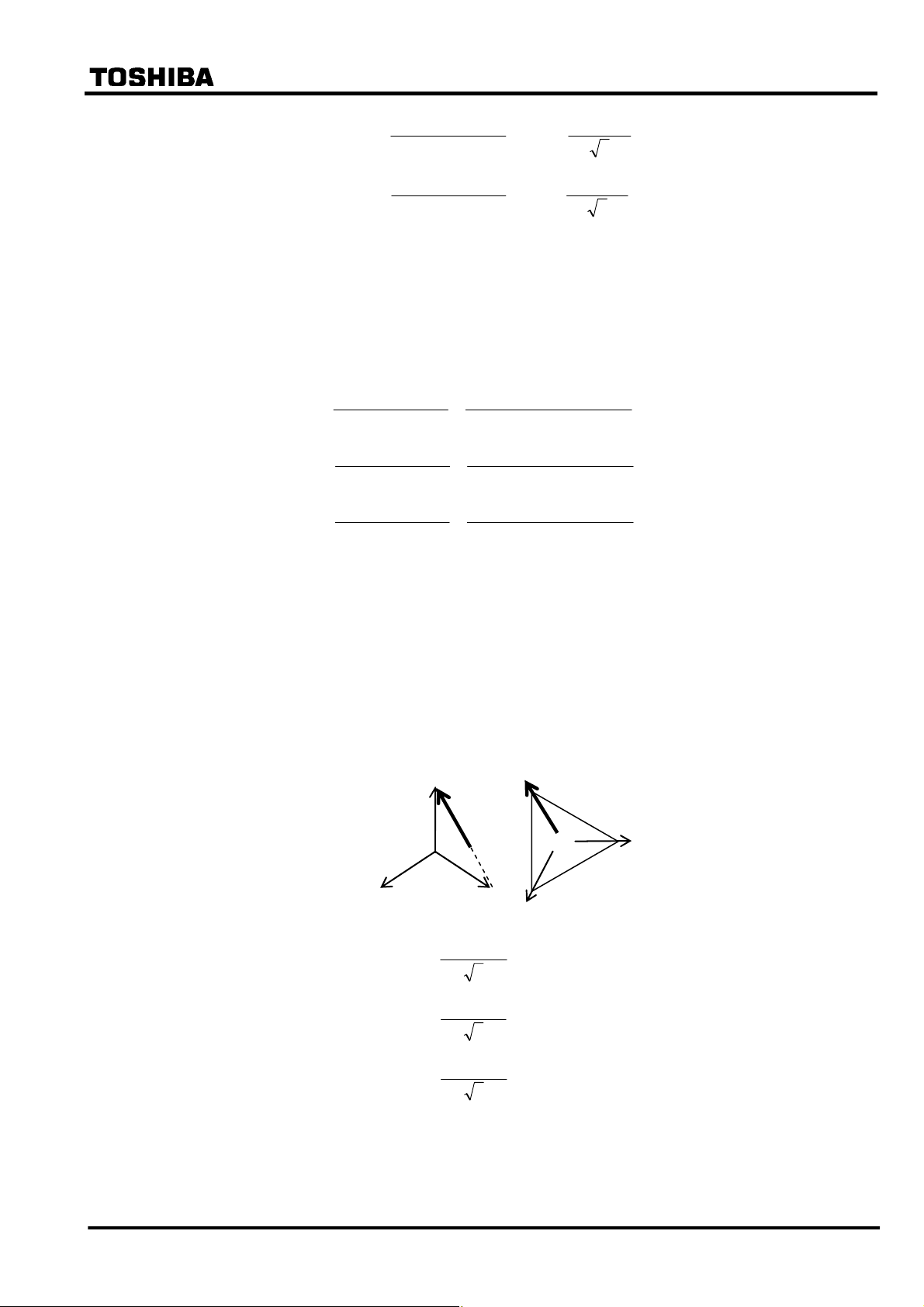

GRT100 provides the following protection schemes with measuring elements in parentheses.

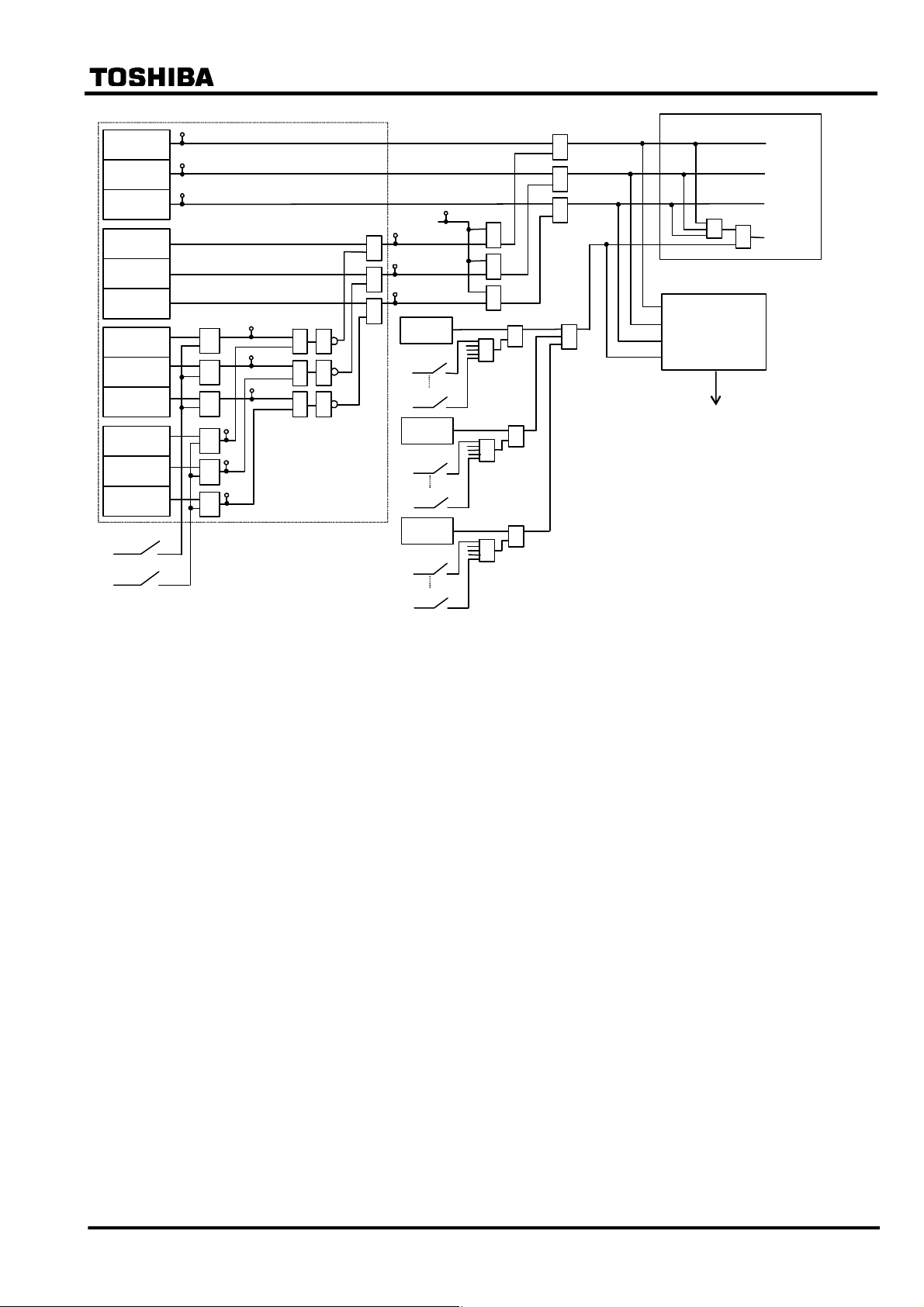

Appendix A shows the block diagrams of the GRT100 series.

• Current differential protection (DIFT)

• Restricted earth fault protection (1REF-3REF)

6 F 2 S 0 8 5 7

• Time-overcurrent protection (1OC-3OC, 1OCI-3OCI, 1EF-3EF and 1EFI-3EFI)

• Thermal overload protection (THR)

• Frequency protection (FRQ)

• Overexcitation protection (V/F)

• Trip and/or indication of external devices (Buchholtz relay, pressure or temperature sensing

devices etc.)

The DIFT, provided with DIF and HOC elements and the REF are applied for main protection. For

details, see Sections 2.2, 2.3 and 2.10.

They provide transformer protection coverage as follows:

REF: protection for winding to earth faults of star-winding side

DIF: protection for all internal transformer faults (The DIF can be blocked by 2F or 5F

element.)

HOC: protection for all internal transformer faults, specifically for heavy internal faults,

high-speed operation (The HOC is not blocked by 2F or 5F element. The sensitivity is

set above the estimated maximum inrush current.)

DIF

HOC

REF

For earth fault only

Small

The number of measuring elements for the restricted earth fault protection and time-overcurrent

protection is dependent on the relay models.

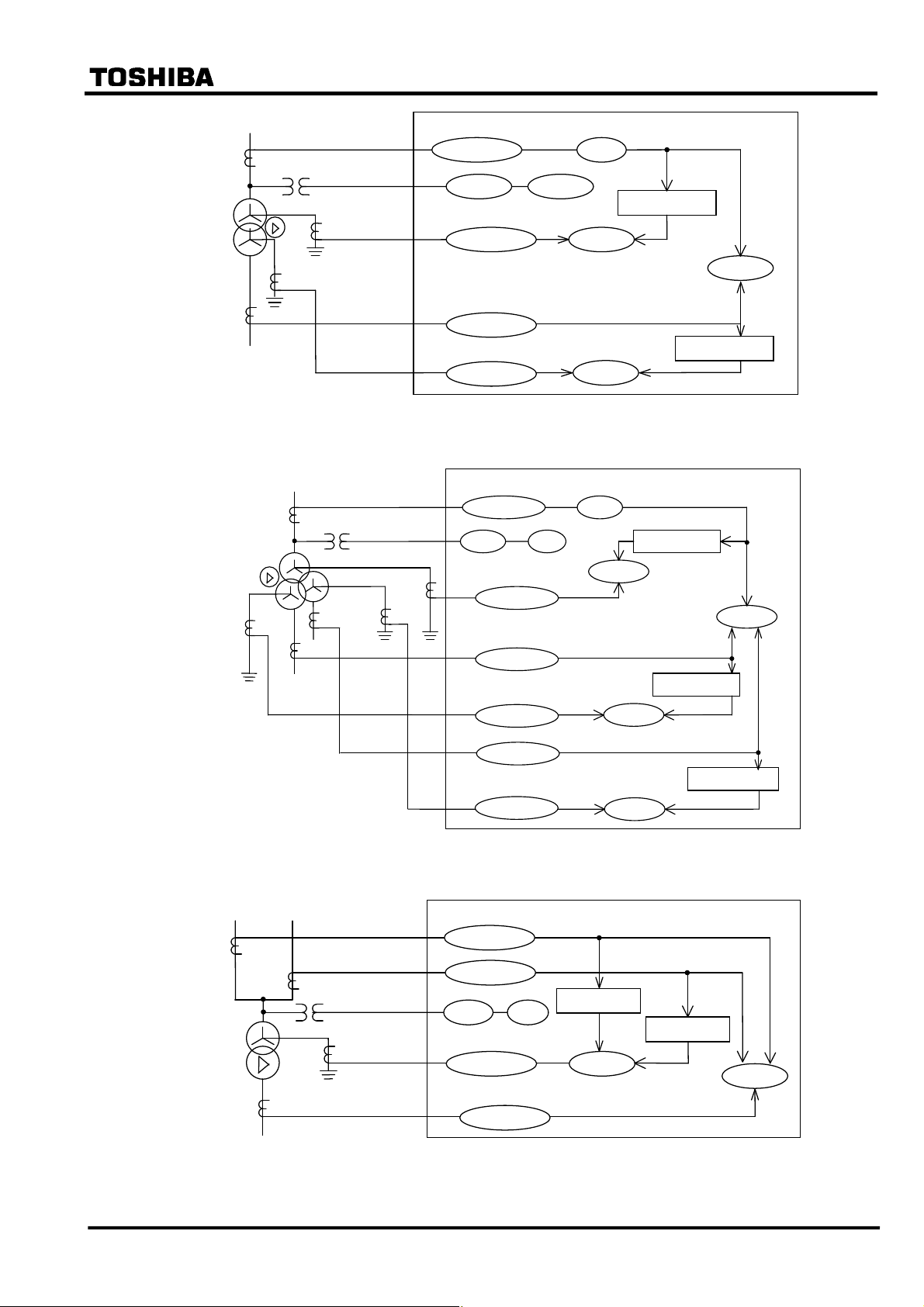

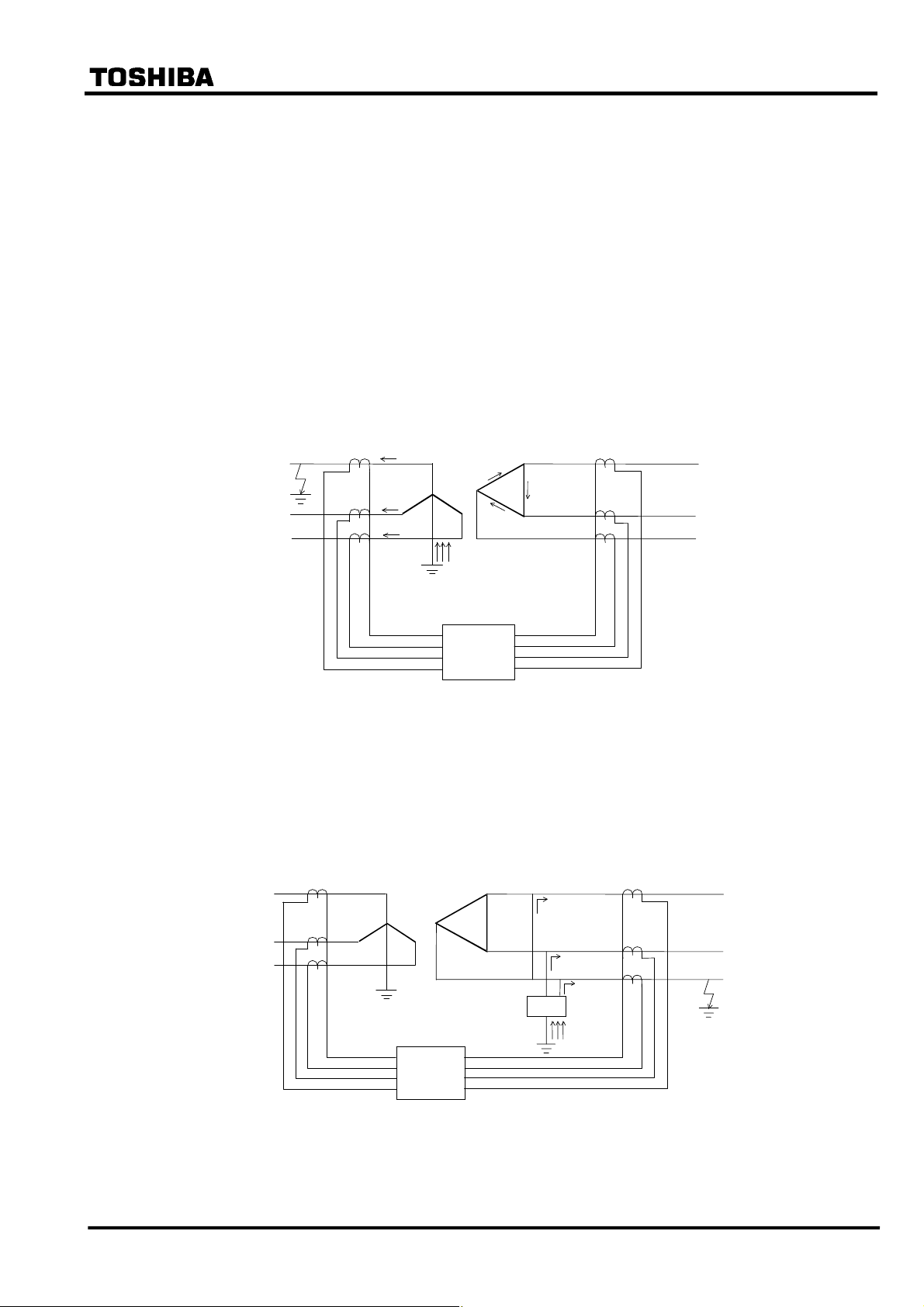

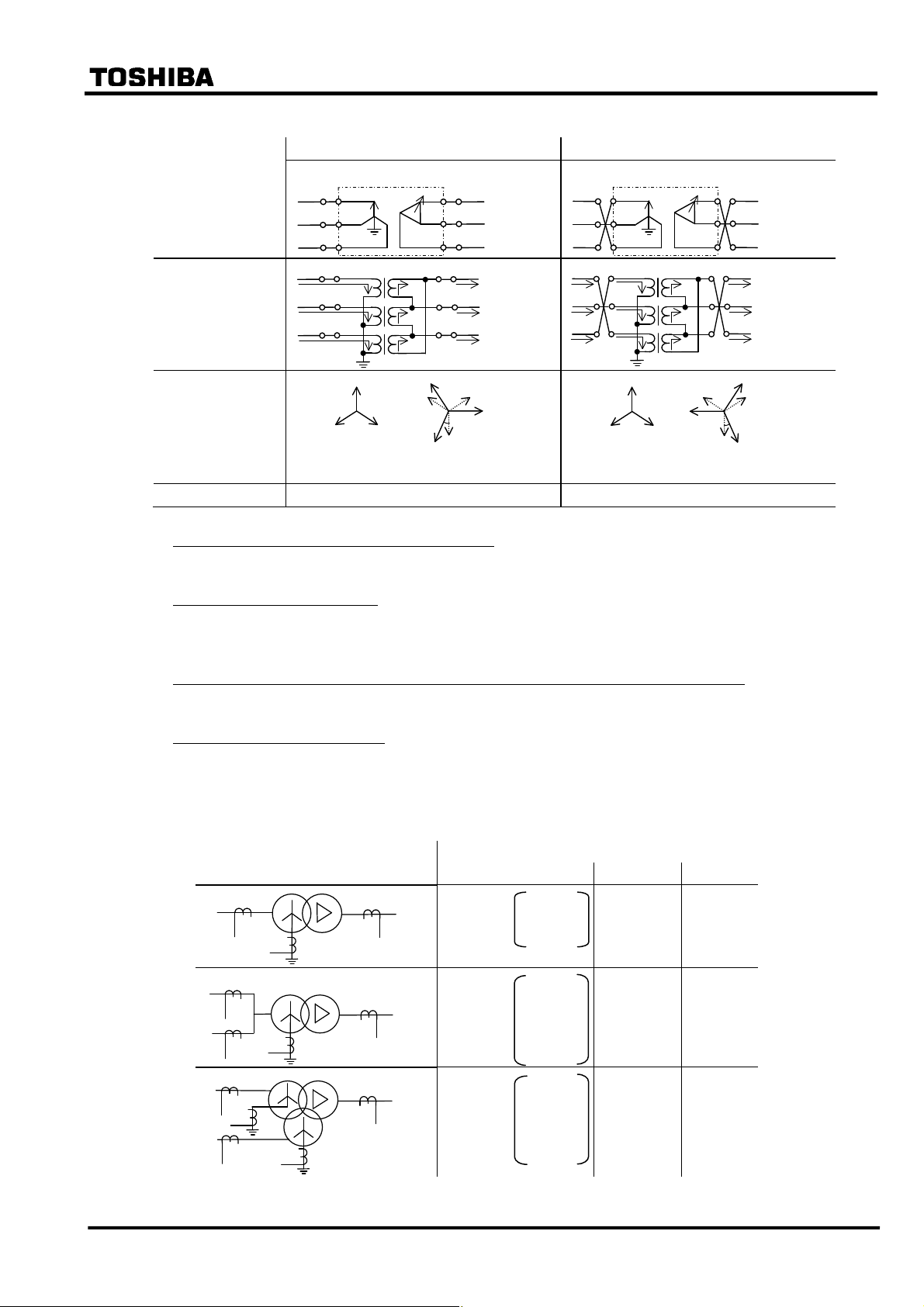

Figure 2.1.1, 2.1.2 and 2.1.3 show typical application and the relationship between AC inputs and

the measuring elements applied in each model.

Differential current

⎯ 10 ⎯

Large

Page 12

6 F 2 S 0 8 5 7

1CT

HV

LV

2CT

2nCT

HV

MV

GRT100

1OC/1OCI THR

VT

FRQ V/F

Calculate 3I0

1nCT

2nCT

1EF/1EFI

2OC/2OCI

2EF/2EFI

1REF

2REF

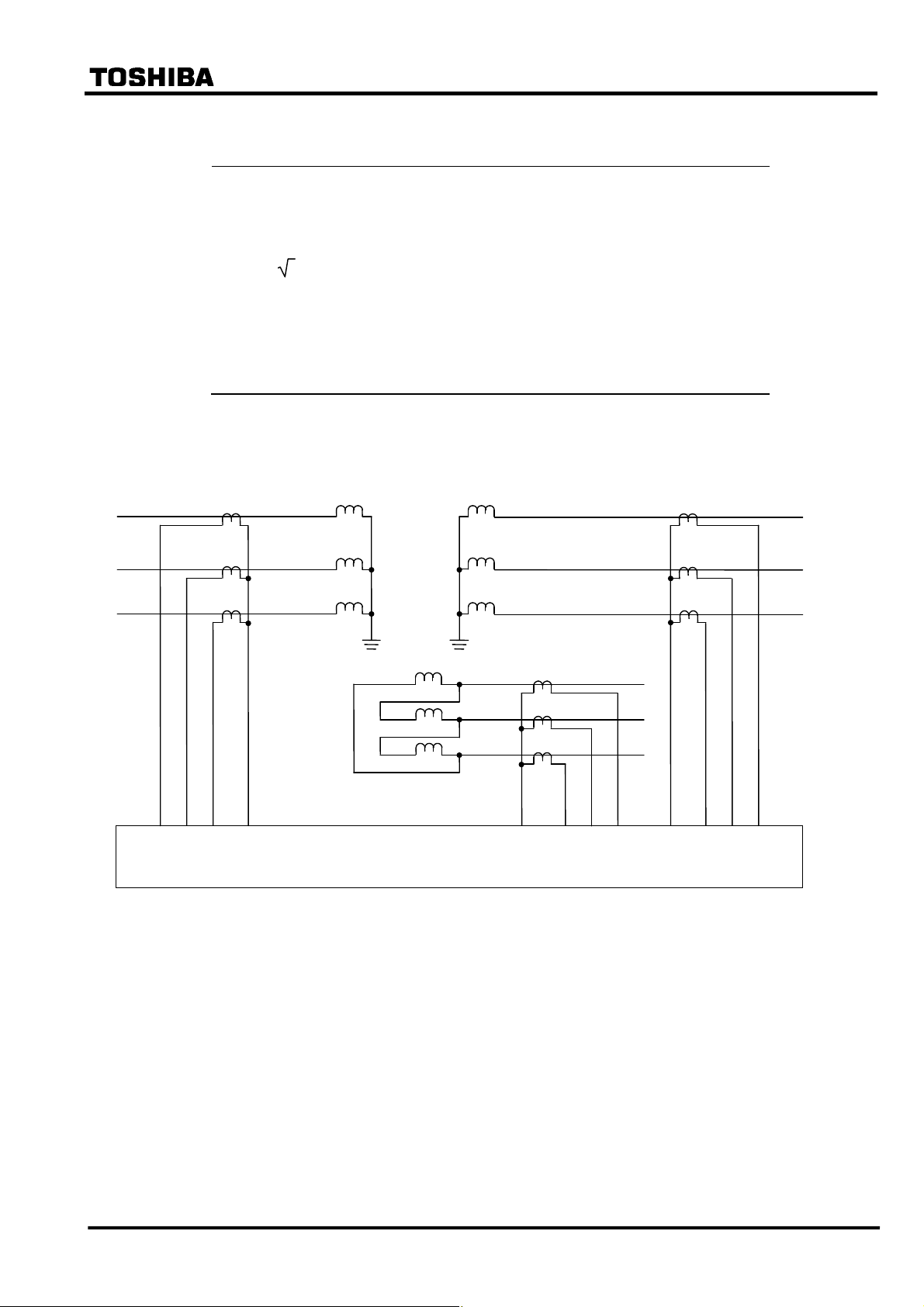

Figure 2.1.1 Measuring Elements of Model 100 series

GRT100

1CT

VT

LV

3CT

1nCT

3nCT

1OC/1OCI THR

FRQ V/F

1EF/1EFI

Calculate 3I0

1REF

DIFT

Calculate 3I0

DIFT

1CT

HV

LV

3CT

2CT

2OC/2OCI

2EF/2EFI

3OC/3OCI

3EF/3EFI

Figure 2.1.2 Measuring Elements of Model 200 series

GRT100

1OC/1OCI

2CT

VT

1nCT

2OC/2OCI

FRQ V/F

1EF/1EFI

3OC/3OCI

Calculate 3I

1REF

Calculate 3I0

2REF

Calculate 3I0

3REF

0

Calculate 3I0

DIFT

Figure 2.1.3 Measuring Elements of Model 200 series

⎯ 11 ⎯

Page 13

2.2 Current Differential Protection

2.2.1 Differential Scheme

Current differential protection DIFT provides an overall transformer protection deriving phase

current from each transformer winding, calculating the differential current on a per phase basis

and detecting phase-to-phase and phase-to-earth faults.

The current differential protection is based on Kirchhoff’s first law that the vector summation of

all currents flowing into a protected zone must be zero. Figure 2.2.1.1 shows the principle of

current differential protection. Differential current (id) is the vector summation of all terminal

current of the transformer. The differential current (id=i1+i2) is zero because the current (i1)

equals current (−i2) during a load condition or an external fault. During an internal fault, the

differential current (id) is not zero because the current (i1) does not equal to the current (−i2), and

the DIFT operates.

I1

Primary

6 F 2 S 0 8 5 7

Secondary

I2

Transformer

i1

id=i1+i2

Differential cu r r ent

detection

Figure 2.2.1.1 Current Differential Protection

DIFT

i2

Scheme logic

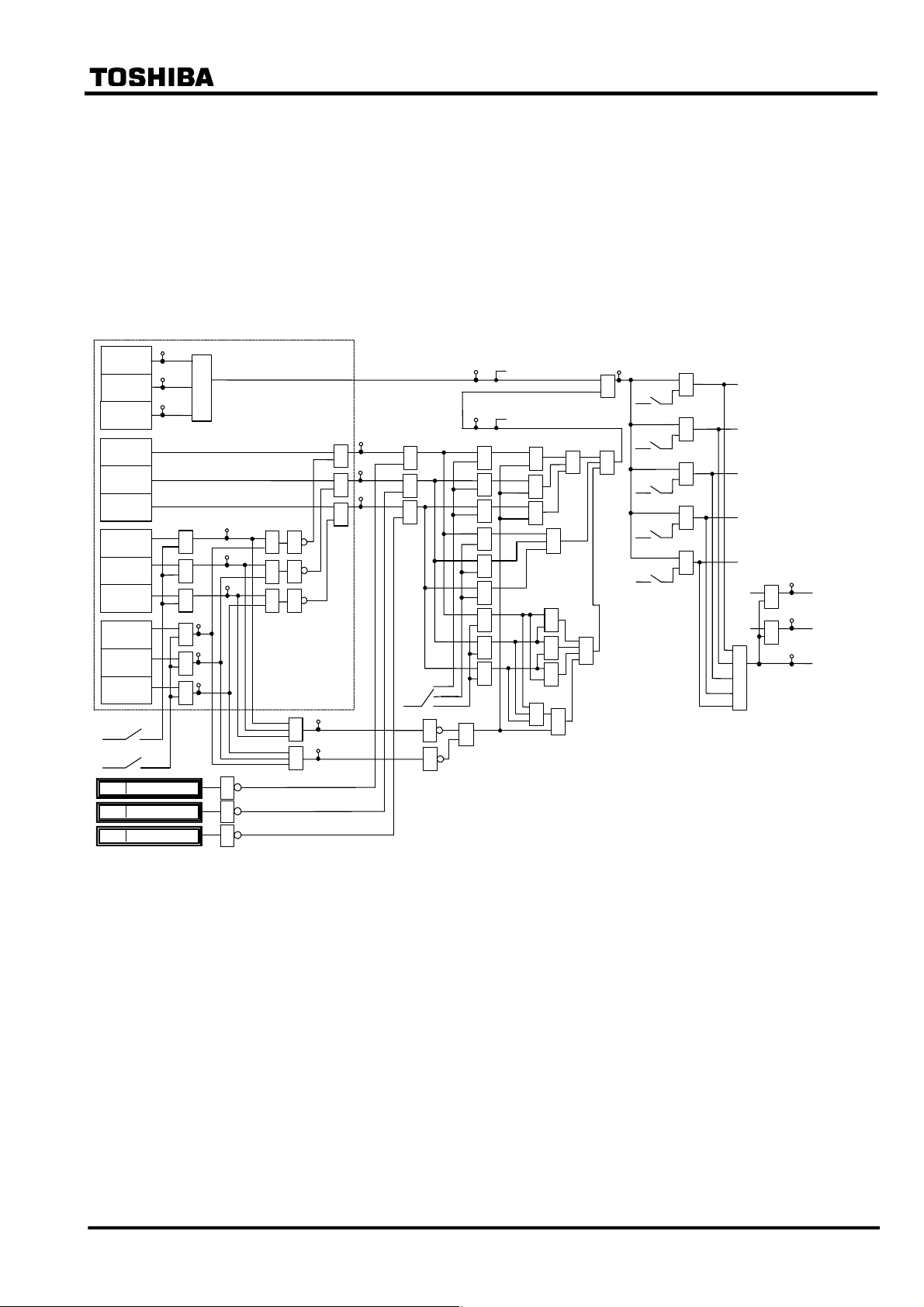

Figure 2.2.1.2 shows the scheme logic of the current differential protection. Current differential

element DIFT comprises sub-elements HOC, DIF, 2F and 5F which operate for differential

current on a per phase basis.

Note: For the symbols used in the scheme logic, see Appendix M.

HOC is a high-set overcurrent element operating for differential current. It provides high-speed

protection for heavy internal faults.

DIF is a percentage restraining element and has dual restraining characteristics, a weak restraint in

the small current region and a strong restraint in the large current region, to cope with erroneous

differential current which may be caused due to output imbalance of the CTs in case of an external

fault. (For the characteristics, see Section 2.10.)

The DIF output signal can be blocked when the 2F or 5F elements detect second harmonic inrush

current during transformer energization or fifth harmonic components during transformer

overexcitation. Blocking is enabled by setting scheme switch [2F-LOCK] or [5F-LOCK] to “ON”.

The following two or three blocking schemes are selectable by scheme switch [DIFTPMD].

“3POR”: When any one phase of the 2F or 5F element operates, tripping by the DIF

element is blocked in all 3 phases. “3POR” is recommended for transformers with

large capacity whose second harmonic component may be low. Its blocking

function is stronger than that of the “1P” or “2PAND” below.

“1P”: When any phase of the 2F or 5F elements operate, only the corresponding phase

output of the DIF element is blocked.

“2PAND”: Even if 2F or 5F element operates during manetising inrush, the trip by DIF

element is allowed when any two phases or more of DIF element operate.

⎯ 12 ⎯

Page 14

DIFT

+

+

1616

1617

1618

HOC-A

HOC-B

HOC-C

DIF-A

DIF-B

DIF-C

2F-A

2F-B

2F-C

5F-A

5F-B

5F-C

2F-Lock

5F-Lock

DIF-A_BLOCK

DIF-B_BLOCK

DIF-C_BLOCK

6 F 2 S 0 8 5 7

“2PAND” is recommended for a transformer with small or midium capacity

whose second harmonic component in inrush current is genarally higher than that

of transformer with large capacity. This mode is applicable if [Phase matching] is

set to “Beta”.

Protection by DIF and HOC can perform instantaneous three-phase tripping of up to five breakers.

Any of the five breaker tripping signals DIFT-1 to DIFT-5 are enabled or disabled by the scheme

switch [DIF1] to [DIF5] settings.

Note: Models 203 and 204 are not provided with DIFT-4 and DIFT-5, and perform tripping of up to

three breakers.

41

42

43

HOC

374

≥1

DIF

121

44

&

&

&

98

99

100

95

96

97

1

1

1

1

≥1

1

≥1

1

≥1

122

≥1

123

≥1 1

&

&

&

&

&

&

45

46

&

&

&

DIFTPMD

+

1

3POR

1P

2PAND (*2)

&

&

&

&

&

&

&

&

&

&

Note:

(*1) Models 203 and 204 are not provided with DIFT-4 and DIFT-5.

(*2) [Phase matching]="Beta" setting only

&

≥1

&

&

≥1

&

&

&

≥1

&

224

≥1

+

+

≥1

+

+

+

≥1

DIF1

DIF2

DIF3

DIF4

DIF5

&

&

&

&

&

TRIP

DIFT-1

DIFT-2

DIFT-3

DIFT-4 (*1)

DIFT-5 (*1)

DIF

HOC

≥1

330

&

331

&

352

DIFT-DIF TP

DIFT-HOC TP

DIFT TRIP

Figure 2.2.1.2 Scheme Logic of Current Differential Protection

⎯ 13 ⎯

Page 15

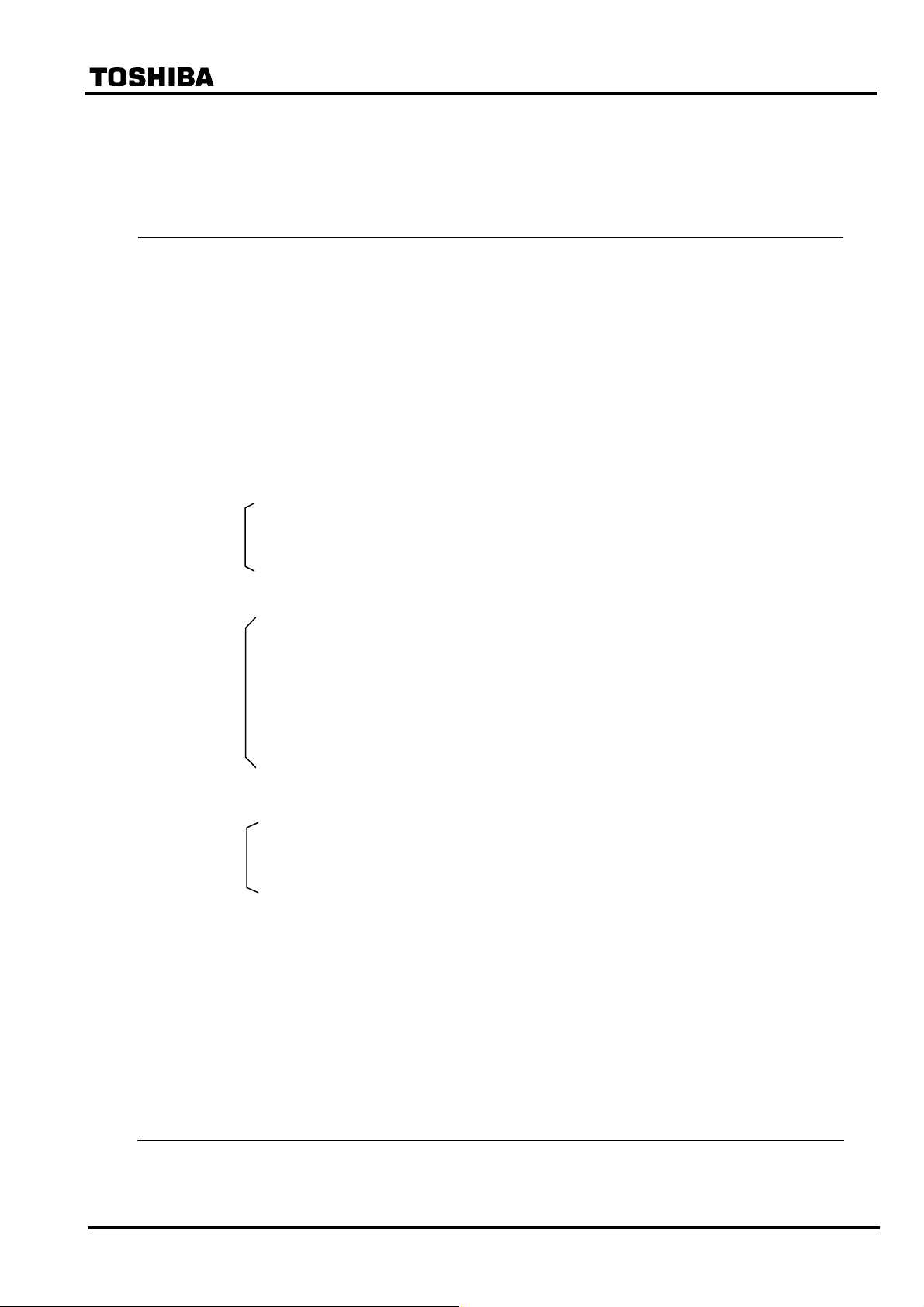

Display mode following differential tripping

Following a trip output, GRT100 can display either the operating phase or the faulted phase

according to the user’s requirements as shown in Table 2.2.1.1. The operating phase or faulted

phase display is selectable by a setting in the Record menu.

Table 2.2.1.1 Operating Phase / Faulted Phase Display

Operating phase display Faulted phase display

6 F 2 S 0 8 5 7

Setting

(Setting/Record/Fault

record/Phase mode)

Displayed phase Operating phase

Application All two- and three-winding transformers

1 = Operating 2 = Fault

Generally, the operating phase of the DIF element

does not correspond with the faulted phase, but

depends on the transformer configuration and the

electrical quantities that are input to the GRT100

current differential calculation.

Faulted phase (for single-phase to earth, phase to

phase, two-phase to earth and three-phase to

earth faults)

• Faults at primary side or secondary side of Yy0

and Yy6 transformers

• Faults at primary side of Yd1, Yd3, Yd5, Yd7,

Yd9, Yd11, Yy2, Yy4, Yy8 and Yy10

transformers

• Faults at secondary side of Dy1, Dy3, Dy5, Dy7,

Dy9 and Dy11 transformers

• Faults on Dd2, Dd4, Dd6, Dd8 and Dd10

transformers, faults at Zig-zag connected side

of transformers and faults at tertiary side of

three-winding transformers are not supported.

Logic Refer to Figure 2.2.1.4.

∗ Phase (A/B/C) display is based on the operating

signal of DIF or HOC element, and “N” display is

based on the operating signal of REF and DIFT

elements. If the REF is not used, “N” is not

displayed.

Refer to Figure 2.2.1.4.

∗ Phase (A/B/C) display is based on the operating

signal of DIF or HOC element and a differential

current value, and “N” display is based on the

operating signal of REF and DIFT elements. If the

REF is not used, “N” is not displayed.

⎯ 14 ⎯

Page 16

6 F 2 S 0 8 5 7

DIFT

HOC-A

HOC-B

HOC-C

DIF-A

DIF-B

DIF-C

2F-A

2F-B

2F-C

5F-A

5F-B

5F-C

2F-Lock

+

5F-Lock

+

41

42

43

[Op erating phase]

≥1

≥1

121

DIF

44

&

45

&

46

&

98

99

100

95

96

97

≥1

≥1

≥1

1

1

1

&

&

&

&

&

&

1REF

1REF1

+

1REF5

+

2REF

2REF1

+

2REF5

+

3REF

3REF1

+

3REF5

+

&

&

&

≥1

≥1

≥1

≥1

≥1

Fau lt ed phase

& ≥1

&

&

Not e: Mod els 203 and 20 4 are not provided with 1RE F-4,

1REF-5, 2R EF-4, 2REF-5, 3REF-4 and 3REF -5.

selection logic

[Fau lted ph ase]

Phas e A

Phas e B

Phas e C

&

Phas e N

Figure 2.2.1.4 Operating Phase and Faulted Phase Selection Logic

⎯ 15 ⎯

Page 17

6 F 2 S 0 8 5 7

2.2.2 Stability for CT Saturation during Through-fault Conditions

For current differential protection of transformers, GRT100 has a strong restraint characteristic in

the large current region for erroneous differential current due to CT saturation. Further, GRT100

provides a CT saturation countermeasure function. If any CTs saturate due to a large through-fault

current, an apparent differential current is generated in the differential circuit and may cause false

operation of the differential protection.

Operation Principle

Even when a CT saturates under very large primary currents, the waveform of the saturated CT

secondary current has two identifiable periods in each cycle: a non-saturated period and a

saturated period. The GRT100 utilizes this phenomenon and provides very secure operation for

external faults with a large through-fault current.

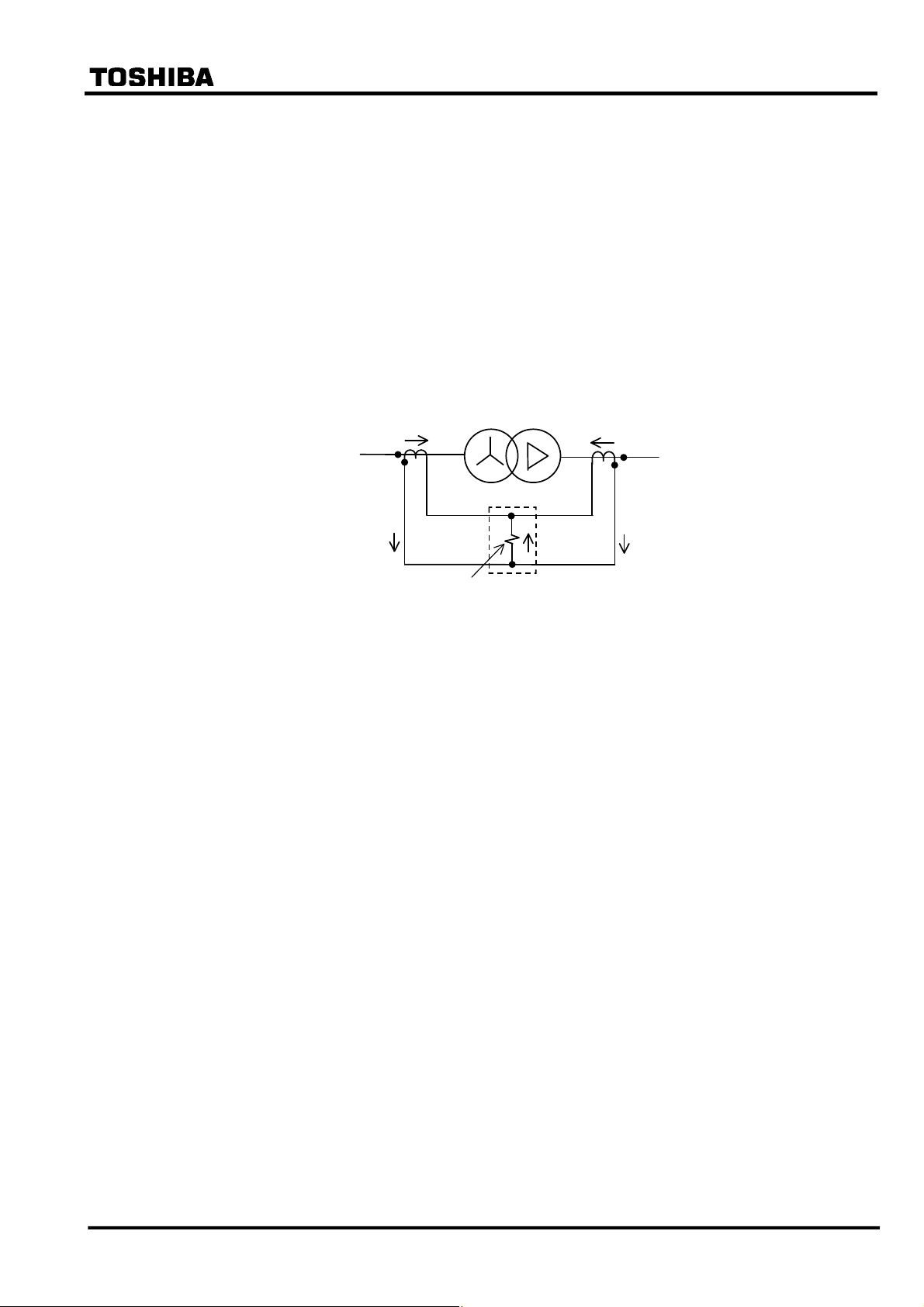

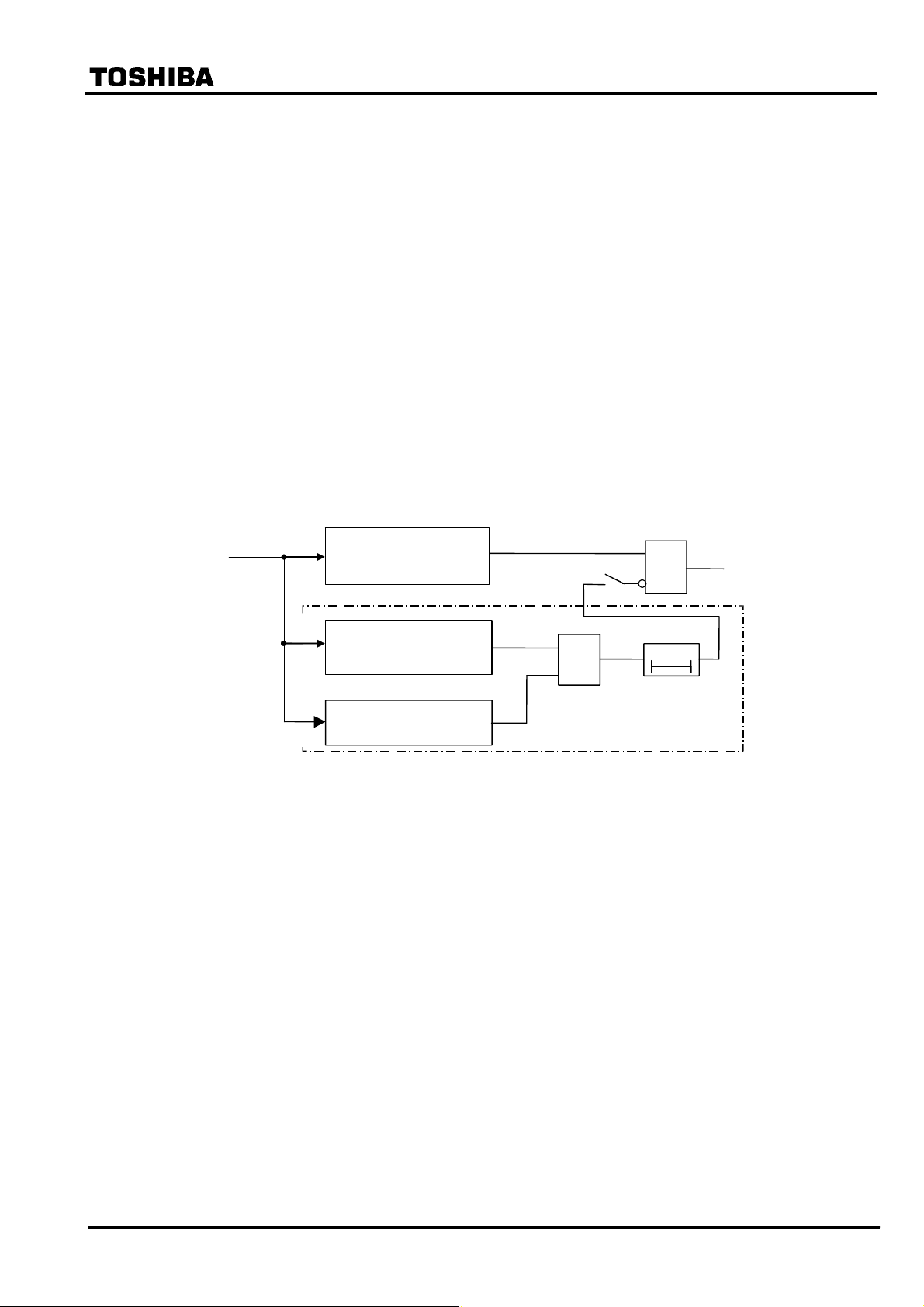

Figure 2.2.2.1 shows a block diagram of the CT saturation countermeasure (CTS). The CTS has a

waveform discriminating element (WDE) and starting element (SE). WDE operates if the change

in the instantaneous value of the differential current is less than a specified percentage of the

change in the instantaneous value of the restraining current. In the CTs non-saturated period, the

differential current is theoretically zero for through-fault currents. The element operates in this

period.

Current

Input

Figure 2.2.2.1 Differential Element with CT Saturation Countermeasure

Differential Element

(DIFT_DIF)

Waveform Discriminating

Element

Starting Element

[CTSEN]

&

ON

&

0

CTS

t

The algorithm of this element is given by the following equation:

ΔId < 0.15×(ΔIp + ΔIn)

where,

ΔId : Change in the differential current Id

(ΔIp + ΔIn) : Change in the restraining current in the positive and negative cycles

Tripping

Output

Id : Differential current

Ip : Sum of positive input currents

In : Sum of negative input currents

SE operates when the sum of the absolute values of the difference between the instantaneous

values of current data at each current input from one cycle is greater than 0.5 × (CT secondary

rated current).

SE discriminates between healthy and faulty power system conditions and blocks the output of

WDE which may otherwise operate during healthy conditions.

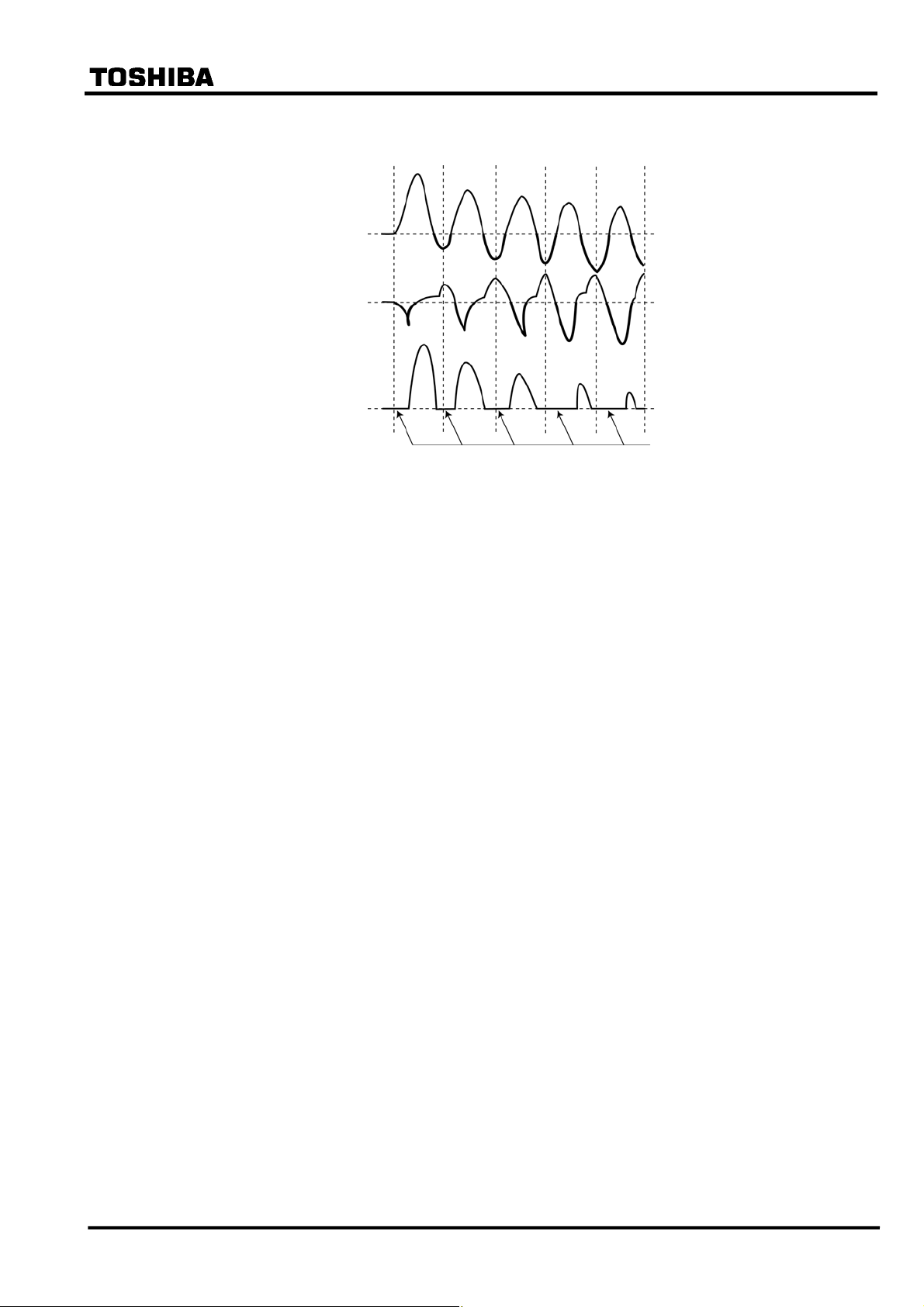

Figure 2.2.2.2 shows CT secondary current waveforms of the incoming and outgoing terminals,

⎯ 16 ⎯

Page 18

6 F 2 S 0 8 5 7

and also the differential current at the time of an external fault with outgoing terminal CT

saturation.

Incoming terminal

current

Outgoing terminal

current

Differential

current

No change period

Figure 2.2.2.2 CT Secondary Current Waveforms and Differential Current for an External

Fault with CT Saturation

From the inception of the fault until the CT secondary current at the outgoing terminal saturates,

the differential current Id is zero and the change in the differential current ΔId obtained from

equation (2) is also zero. However, the change in the restraining current given by equation (3) is a

sufficiently large positive value, so equation (1) is met and WDE operates.

SE detects changes in the terminal currents and rapidly operates, producing an AND output with

WDE. After this, since there is a period during which equation (1) is not satisfied, a certain time

delay is inserted to reliably block the operation of the DIFT_DIF differential element.

If, during an internal fault, there is a period during which the change in the instantaneous value of

the differential current is small due to CT saturation, WDE will not operate because the change in

the restraining current is also small during that period. Thus, during an internal fault, operation of

the differential element is not blocked falsely.

The CTS function can be disabled by the scheme switch [CTSEN].

⎯ 17 ⎯

Page 19

×

6 F 2 S 0 8 5 7

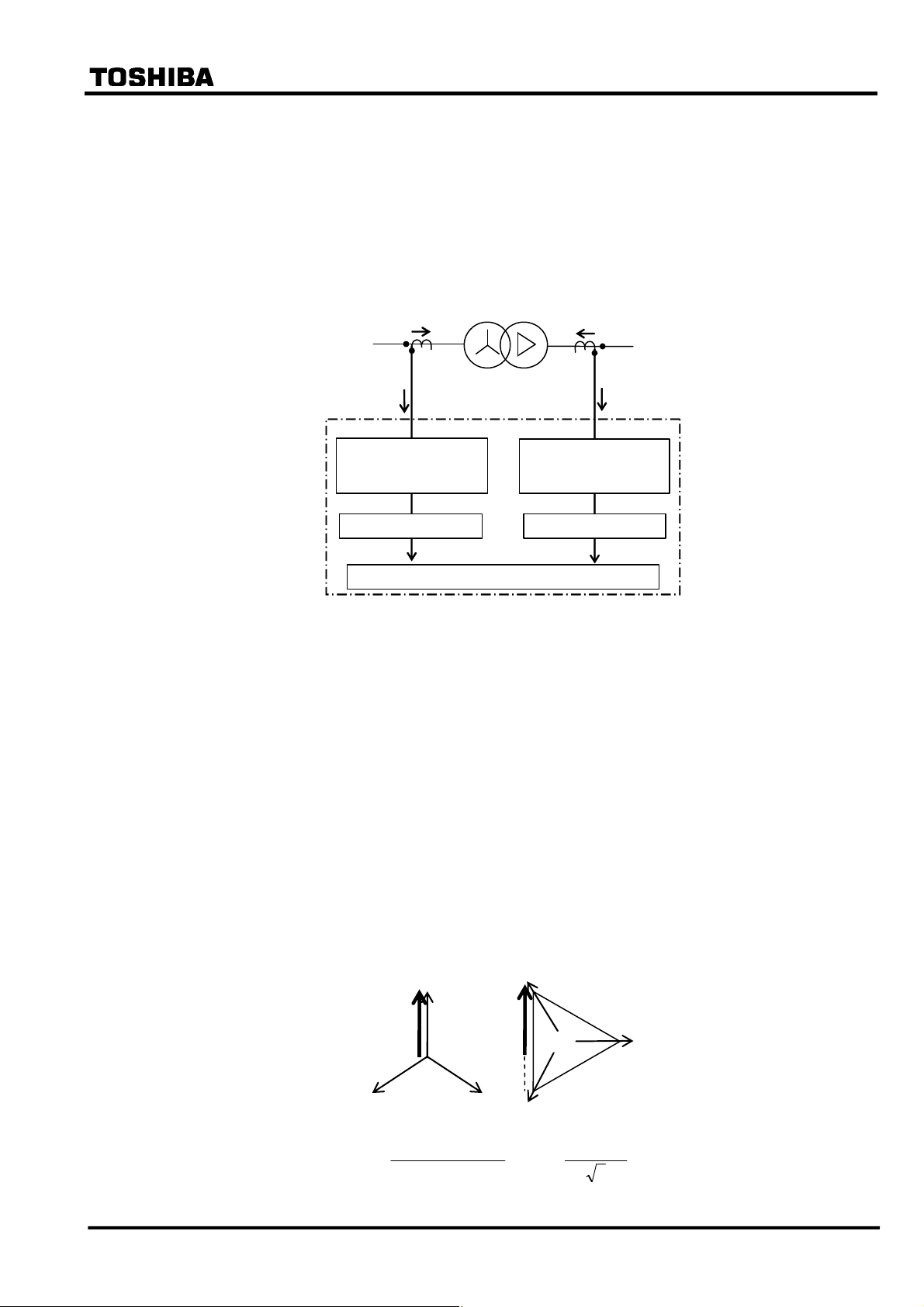

2.2.3 Matching of CT Secondary Currents

The currents supplied to the differential elements must be matched in phase displacement and

amplitude under through-load and through-fault conditions.

Generally, it is difficult to completely match the incoming current with the outgoing current for

the relay input because the CT ratios at the primary, secondary and tertiary sides of a transformer

are not matched in terms of the CT ratio, phase angle and cancelling of zero-sequence current.

GRT100 provides the following matching method:

CT ratio: N1

Ip/N1=i1

GRT100

Matching of phase

angle / Zero-sequence

current elimination

Matching of CT ratio Matching of CT ratio

Primary

Ip

Transformer

i1 Kct2×i2

Kct1

Differential relay calculation

Secondary

Is

CT ratio: N2

Is/N2=i2

Matching of phase

angle / Zero-sequence

current elimination

Figure 2.2.2.1 Matching Method

GRT100 supports selectable two matching methods, α-method (Alpha) and β-method (Beta). The

method is selected by the scheme switch [Phase matching].

Phase matching is performed by setting according to the hands of a clock and the transformer

connections described in IEC60076-1. For details of the setting, refer to 2.2.5.

2.2.3.1 α-method phase matching

This method corrects the phase angle by using each winding current calculated as follows:

- Current substructed zero-sequence current from each phase current in Star- winding side of

transformer

- Phase-to-phase Current in Delta-winding side of transformer

The followings show calculation formula and current vectors in an example of a transformer

Yd11.

Is

1

Isa

Isb

Isc

Ipa

Ip1

Ipb Ipc

2

&

1

pI

=

&&&

pcIpbIpaI

−−

,

&

1

sI

=

3

&&

scIsaI

−

(1)

3

⎯ 18 ⎯

Page 20

6 F 2 S 0 8 5 7

&&&

2

&

=

2

pI

−−

paIpcIpbI

&

,

2

sI

=

3

2

&

3

pI

=

&&&

pbIpaIpcI

−−

,

&

3

sI

=

3

where,

Further, zero-sequence current is eliminated from the relay input current (Ip∗) for the calculation

of the differential current as follows:

&&&

pcIpbIpaI

,, : Primary side terminal current of transformer

&&&

scIsbIsaI

,, : Secondary side terminal current of transformer

&&&

2

&

pI −=

=

1

2

&

pI −=

=

2

2

&

pI −=

=

3

−−

3

=

&&&

−−

=

3

&&&

−−

=

3

3

3

3

&&

saIsbI

−

(2)

3

&&

sbIscI

−

(3)

3

IpcIpbIpaIpapcIpbIpaI

++−

)(3

IpcIpbIpaIpbpaIpcIpbI

++−

)(3

IpcIpbIpaIpapbIpaIpcI

++−

)(3

IpoIpa

IpoIpb

IpoIpc

2.2.3.2 β-method (Traditional method) phase matching

This is a traditional method that delta current (phase-to-phase current) on the Star-winding side of

a Star/Delta transformer and phase current on the Delta-winding side of that is introduced into a

relay input for the calculation of the differential current. Traditionally, the phase matching is

realized by Delta connecting the CTs on the Star-winding side and by Star connecting the CTs on

the Delta-winding side. In GRT100, however, it is realized by software.

The followings show calculation formula and current vectors in an example of a transformer

Yd11.

Ipa

Ip1

I

&

1

pI

Ipb

&&

−

=

pbIpaI

Is1

,

I

Isc

saIsI&&=1

I

(4)

3

&&

pcIpbI

&

2

pI

−

=

,

sbIsI&&=2

(5)

3

&

=

3

pI

⎯ 19 ⎯

&&

−

paIpcI

,

scIsI&&=3

(6)

3

Page 21

6 F 2 S 0 8 5 7

2.2.3.3 Zero-sequence current elimination

In addition to compensating for the phase angle between the primary and secondary currents of the

transforemer, also phase angle matching prevents unnecessary operation due to zero-sequence

current during an external earth fault, such as in the following cases.

Case 1:

When an external fault occurs at the star-connected side of the transformer shown in Figure

2.2.3.2, a zero-sequence current flows in star-connected side, but the zero-sequence current at the

delta-side circulates in the delta winding. The zero-sequence current is only fed into the star

winding side of the DIFT which is star-connected at the CT secondary, thus causing the DIFT to

operate incorrectly. In α-method phase matching, the zero-sequence current is eliminated from a

relay input current as described above. In β-method phase matching, the zero-sequence current is

eliminated from the relay input current by Delta connection on the Star-winding side.

Since the DIFT provides a function to eliminate the zero-sequence current by software, the DIFT

is insensitive the fault described.

I

0

Transforme

I

0

I

0

I

0

I

0

3

0

I

I

0

I

I

DIFT

Figure 2.2.3.2 External Earth Fault at the Star-connected side of a Transformer

Case 2:

When the delta winding of a power transformer is earthed through an earthing transformer as

shown in Figure 2.2.3.3 and the earthing transformer is located within the differential protection

zone, in case of an external earth fault the zero-sequence current flows only on the delta side of the

power transformer and appears as a differential current.

I

0

I

0

Earthing

Transforme

3I

0

Ia

Ib

Ic

DIF

I

0

Figure 2.2.3.3 External Earth Fault at the Delta-winding side of a Transformer with

in-zone Earthing Transformer

⎯ 20 ⎯

Page 22

6 F 2 S 0 8 5 7

In α-method phase matching, since the DIFT provides a function to eliminate the zero-sequence

current by software, the DIFT is insensitive to the fault described.

In β-method phase matching, however, since the zero-sequence current is not eliminated because

of Star connection on the Delta-winding side, the DIFT may operate unnecessary.

In case the GRT100 is applied to a transformer with in-zone earthing transformer, the [Phase

matching] = “Alpha” setting is recommended.

2.2.3.4 Matching of CT Ratio

If I

to I3 correspond to 1CT to 3CT secondary currents, differential current Id is calculated

1

according to the following equation,

= kct1⋅I1 + kct2⋅I2 + kct3⋅I3

I

d

where kct1 to kct3 are settings corresponding to 1CT to 3CT.

Setting kct1 is obtained by using the following equation.

kct1 = I

= I

n/Ibase1

/( 3 × I

n

) if 1CT is delta-connected.

base1

where

I

= rated secondary current of 1CT (1A or 5A)

n

I

= transformer capacity(kVA)/(

If the 1CT secondary circuit is delta-connected,

= secondary current of 1CT based on the kVA rating of the power transformer.

base1

3 × rated voltage(kV)) × CT ratio of 1CT

3 × I

is used instead of I

base1

above.

Settings kct2 and kct3 are obtained in the same way.

The differential current I

kct1 × I

to kct3 × I3 are equal to the rated secondary current of each CT when the rated line

1

is zero under through-load and through-fault conditions.

d

currents based on the kVA rating of the power transformer flow.

in the equation

base1

⎯ 21 ⎯

Page 23

9

12

22 11

21

6 F 2 S 0 8 5 7

2.2.4 Connection between CT Secondary Circuit and the GRT100

GRT100 is provided with 2 or 3 three-phase current input terminals depending on the relay model.

To validate the phase angle matching described previously and apply in-phase current from each

winding to the relay, connect the CT secondary circuits to the current input terminals of the relay

as follows;

As shown below, the phases used in the phase angle setting (indicated by an arrowhead) must be

connected to the AC input terminals with the lowest number in the terminal group such as 1, 9, 17,

then the other two phases should be connected to the terminals with a larger number clockwise

from the setting phase, such as 3 and 5, 11 and 13, or 19 and 21.

Primary

Tertiary

Secondary

3

1 5

2 4 6

17 19

GRT100

18 10

13

14 20

Figure 2.2.4.1 Connection of CT Secondary Circuit and the GRT100

Terminal numbers and corresponding input currents are shown in the following table.

Model Terminal block Terminal number Input current

100 series / 200 series TB1 1-2

3-4 Current of primary winding

5-6

9-10

11-12 Current of secondary winding

13-14

17-18

19-20 Current of tertiary winding

21-22

⎯ 22 ⎯

Page 24

6 F 2 S 0 8 5 7

2.2.5 Setting

The following shows the setting elements necessary for the current differential protection and their

setting ranges. Setting can be performed on the LCD screen or PC screen.

Element Range Step Default Remarks

DIFT

DIF

ik

0.10 − 1.00

(∗)

0.01 0.30 Minimum operating current

p1

p2

kp

k2f

k5f

HOC kh

CT matching

kct1

CT ratio kct2

kct3

Phase angle matching

yd_p 1(star) / 2(delta) 1 Primary winding

(α-method)

yd_t 1(star) / 2(delta) 1 Tertiary winding

vec_s 0 – 11 1 0 Phase angle difference between primary

vec_t 0 – 11 1 0 Phase angle difference between primary

If [Phase matching]=Alpha setting

yd_s 1(star) / 2(delta) 1 Secondary winding

10 − 100%

10 − 200%

1.00 − 20.00(*)

10 − 50%

10 − 100%

2.00 − 20.00(*)

0.05 − 50.00

0.05 − 50.00

0.05 − 50.00

1% 100% % slope of small current region

1% 200% % slope of large current region

0.01 1.00 Break point of dual characteristics

1% 15% Second harmonic detection

1% 30% Fifth harmonic detection

0.01 2.00 High-set overcurrent protection

0.01 1.00 Primary winding

0.01 1.00 Secondary winding

0.01 1.00 Tertiary winding

and secondary

and tertiary

If [Phase matching]=Beta setting

d1

(β-method)

d3

Scheme switch

[Phase matching] Alpha / Beta Beta Matching methods of CT secondary

[DIFTPMD] 3POR / 1P 3POR Trip mode (if [Phase matching] = Alpha)

[DIFTPMD] 3POR / 2PAND / 1P

[2F – LOCK] Off / On On Block by second harmonic

[5F - LOCK] Off / On On Block by fifth harmonic

[DIF1] to [DIF5] Off / On (**) Output tripping signal

[CTSEN] Off / On Off CT saturation function

(∗): Multiplier of CT secondary rated current including CT ratio correction.

(**): Default settings are dependent on the models. See Appendix H.

d2

0 − 11

0 − 11

0 − 11

1 0 Primary winding

1 0 Secondary winding

1 0 Tertiary winding

currents

3POR Trip mode (if [Phase matching] = Beta)

⎯ 23 ⎯

Page 25

6 F 2 S 0 8 5 7

Setting of ik

ik determines the minimum operation sensitivity of the DIF element. ik is set as a ratio to the CT

secondary rated current.

The minimum sensitivity setting ik is determined from the maximum erroneous differential

current under normal operating conditions.

Setting of p1, p2 and kp

Percentage restraining factor (% slope)

= (Differential current) / (Through current)

= (Differential current) / [{(Incoming current) + (Outgoing current)} /2]

p1 is the percentage restraining factor which defines the DIF restraining characteristic in the small

current region. The setting is determined by the sum of:

• CT accuracy error (generally considered as 5%)

• Tap error: Error between maximum/minimum tap and the middle tap when taking the middle

tap of the tap changer as a reference.

• Matching error: The error due to CT mismatch may be small enough to be neglected in the

setting.

• Relay calculation error, and others (5%)

The recommended setting is “Sum of above” × 1.5 (margin).

p2 is the percentage restraining factor which defines the restraining characteristic in the large

current region. The setting is determined from the maximum erroneous differential current which

is generated when a large through fault current flows.

kp is the break point of the dual percentage restraining characteristics. It is set above the maximum

operating current level of the transformer between the maximum forced-cooled rated current and

the maximum emergency overload current level, as a ratio to the CT secondary rated current.

Setting of k2f

k2f is set to detect the second harmonic content in the inrush current during transformer

energization and blocks GRT100 to prevent incorrect operation due to the inrush current. A

setting of 15% is suggested if there is no data on the minimum second harmonic content.

Setting of k5f

k5f is set to detect the fifth harmonic content during transformer over-excitation and blocks

GRT100 to prevent incorrect operation due to transient over-excitation conditions.

A setting of 30% is suggested if there is no data on the minimum fifth harmonic content.

Setting of k

h

Kh is the HOC setting and should be set above the estimated maximum inrush current.

The recommended setting is more than “Maximum peak value of Inrush current” × kct.

Setting for CT ratio matching

Taking the transformer shown in Figure 2.2.5.1 as an example, the CT ratio matching settings kct1

to kct3

can be calculated as follows. For transformer capacity, take the maximum of the rated

capacites of the three windings.

⎯ 24 ⎯

Page 26

A

6 F 2 S 0 8 5 7

Calculation steps Primary Secondary Tertiary

3

(1) Transformer capacity (kVA)

40 × 10

(2) Voltage(kV) 154 66 11

(3) Rated line current(A) 150 350 2100

=(1)/(

3 × (2))

(4) CT ratio 60 120 240

(5) Secondary rated line current(A) =(3)/(4)

2.50 2.92 8.75

(6) CT secondary rating(A) 5 5 5

(7) Setting =(6)/(5) Kct1=2.00 Kct2=1.71 Kct3=0.57

Note: kct1 to kct3 should be set to 2.00 or less. If more, the CT ratio matching of relay input current

may be not stable.

CT1

300/5

Primary

40MVA

154kV

B

Tertiary

12MVA

11kV

Secondary

40MVA

66kV

CT3

1200/5

CT2

600/5

C

kct1 kct3

GRT100

kct2

Figure 2.2.5.1 CT Ratio Matching

As explained in Section 2.2.3 for Mathcing of CT Secondary Currents, examples of setting for

both α-method and β-method are described as follows:

⎯ 25 ⎯

Page 27

2 3 4

10

6 F 2 S 0 8 5 7

Setting for phase angle matching

The phase angle difference between line currents on either side of the power transformer are

corrected by setting according to the hands of a clock and the transformer connections described in

IEC60076-1 as follows:

(When α-method is selected for [Phase matching])

If a winding is star-connected, set 1 (=star) for winding setting yd_p, yd_s, and yd_t. If

delta-connected, set 2 (=delta). Next, set the phase angle difference vec_s and vec_t from the

primary winding as a lagging angle winding expressed in hours. One hour corresponds to lagging

by thirty degrees.

Note: In the case of a zigzag connected winding, set 2 (=delta).

Example: Setting for star/star/delta transformer.

Primary

Secondary

Tertiary

IEC60076-1

yd_p yd_s vec_s yd_t vec_t

Y y 0 d 11 1 1 0 2 11

Setting

yd_p: Because the primary winding is star-connected, set 1.

yd_s: Because the secondary winding is star-connected, set 1.

vec_s: Because the secondary winding is in phase with the primary winding, set 0.

yd_t: Because the tertiary winding is delta-connected, set 2.

vec_t: Because the tertiary winding lags the primary winding by 330°, set 11.

The settings for the transformer connections described in IEC60076-1 are listed in Table 2.2.5.2.

Note: The following calculation is performed in the relay for phase angle correction.

Table 2.2.5.1 Phase Angle Matching Calculation

O’clock Calculation Remarks

0

1

2

3

4

5

6

7

8

9

10

11

Ia’ = (2Ia − Ib − Ic)/ 3 Ib’ = (2Ib − Ic − Ia)/ 3

Ia’ = (Ia – Ib)/

Ia’ = (Ia − 2Ib + Ic)/ 3 Ib’ = (Ia + Ib − 2Ic)/ 3

Ia’ = (Ic − Ib)/

Ia’ = (2Ic − Ia − Ib)/ 3 Ib’ = (2Ia − Ib − Ic)/ 3

Ia’ = (Ic – Ia)/

Ia’ = (Ib + Ic −2Ia)/ 3 Ib’ = (Ia − 2Ib + Ic)/ 3

Ia’ = (Ib − Ia)/

Ia’ = (2Ib − Ia − Ic)/ 3 Ib’ = (2Ic − Ia − Ib)/ 3

Ia’ = (Ib – Ic)/

Ia’ = (Ia + Ib − 2Ic)/ 3 Ib’ = (Ib + Ic −2Ia)/ 3

Ia’ = (Ia – Ic)/

3 Ib’ = (Ib − Ic)/ 3 Ic’ = (Ic – Ia)/ 3

3 Ib’ = (Ia – Ic)/ 3 Ic’ = (Ib − Ia)/ 3

3 Ib’ = (Ia – Ib)/ 3 Ic’ = (Ib – Ic)/ 3

3 Ib’ = (Ic − Ib)/ 3 Ic’ = (Ia – Ic)/ 3

3 Ib’ = (Ic – Ia)/ 3 Ic’ = (Ia – Ib)/ 3

3 Ib’ = (Ib − Ia)/ 3 Ic’ = (Ic − Ib)/ 3

Ic’ = (2Ic − Ia − Ib)/ 3

Ic’ = (Ib + Ic −2Ia)/ 3

11

Ic’ = (2Ib − Ia − Ic)/ 3

9

Ic’ = (Ia + Ib − 2Ic)/ 3

8

Ic’ = (2Ia − Ib − Ic)/ 3

Ic’ = (Ia − 2Ib + Ic)/ 3

Setting value

0

7

6

1

5

⎯ 26 ⎯

Page 28

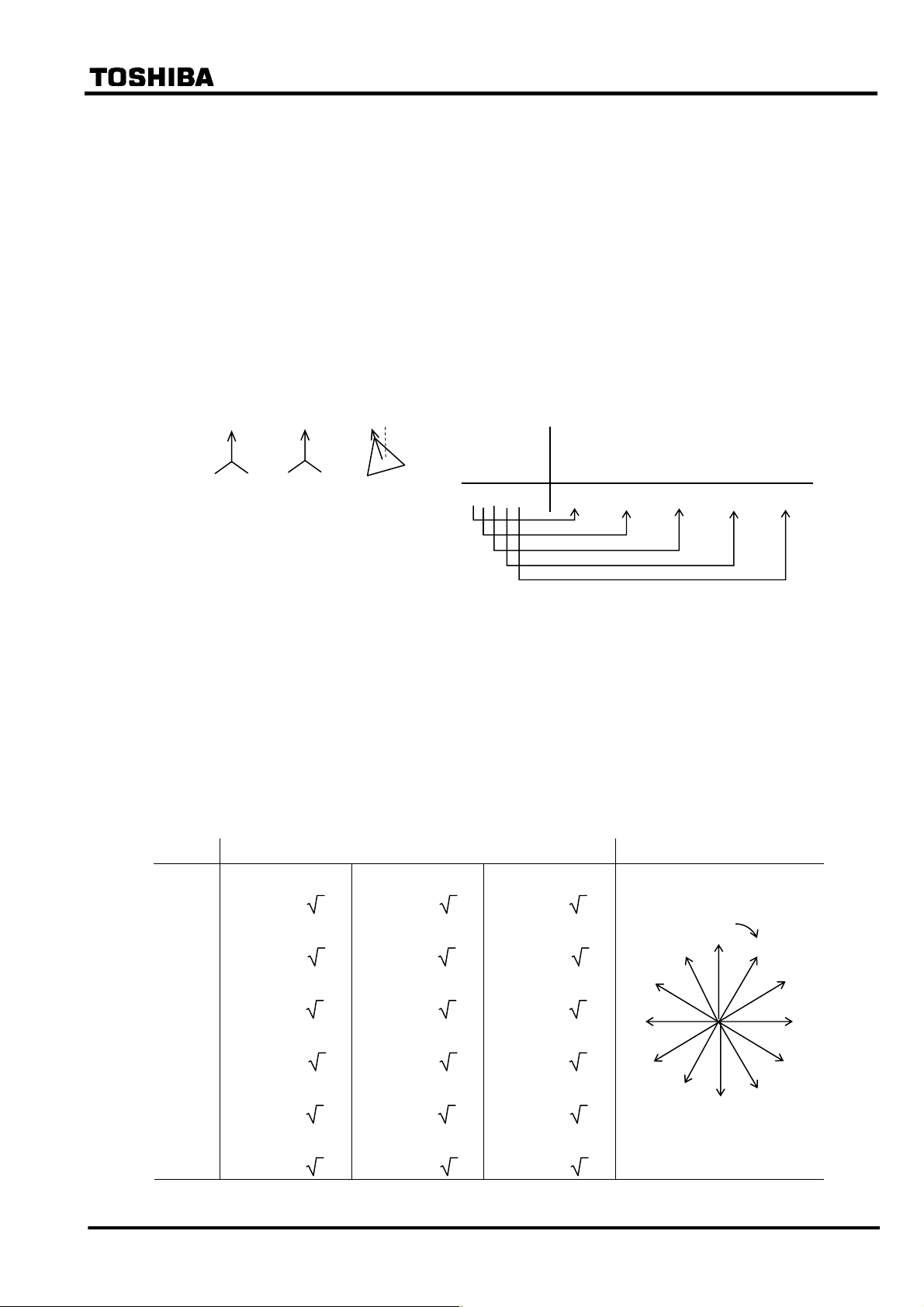

Table 2.2.5.2 Setting for Phase Angle Matching (for α-method)

(a) Settings for typical connections of 2-windings transformer

Transformer connections

described in IEC60076-1

Primary, Secondary

(P) (S)

Yy0

Dd0

Yd1

Dy1

Dd2

Dd4

Yd5

Dy5

Yy6

Dd6

Yd7

Dy7

Dd8

Dd10

Yd11

Dy11

Dz10

Note: A 2-windings transformer covers a 3-windings transformer with a stabilizing-winding circuit

for which 2-windings transformer protection relay can be applied.

Settings for phase angle correction Remarks

Primary, Secondary, Phase angle Diff.

(yd_p) (yd_s) (vec_s)

1 1 0

2 2 0

1 2 1

2 1 1

2 2 2 P: 1 O’clock

2 2 4 P: 1 O’clock

1 2 5 P: 0 O’clock

2 1 5 P: 7 O’clock

1 1 6 P: 0 O’clock

2 2 6 P: 1 O’clock

1 2 7 P: 0 O’clock

2 1 7 P: 5 O’clock

2 2 8 P: 1 O’clock

2 2 10 P: 1 O’clock

1 2 11 P: 0 O’clock

2 1 11

2 2 10 P: 1 O’clock

Phase angle matching

calculation (Table 2.2.5.1)

P: 0 O’clock

S: 0 O’clock

P: 1 O’clock

S: 1 O’clock

P: 0 O’clock

S: 1 O’clock

P: 11 O’clock

S: 0 O’clock

S: 3 O’clock

S: 5 O’clock

S: 5 O’clock

S: 0 O’clock

S: 6 O’clock

S: 7 O’clock

S: 7 O’clock

S: 0 O’clock

S: 9 O’clock

S: 11 O’clock

S: 11 O’clock

P: 1 O’clock

S: 0 O’clock

S: 11 O’clock

6 F 2 S 0 8 5 7

⎯ 27 ⎯

Page 29

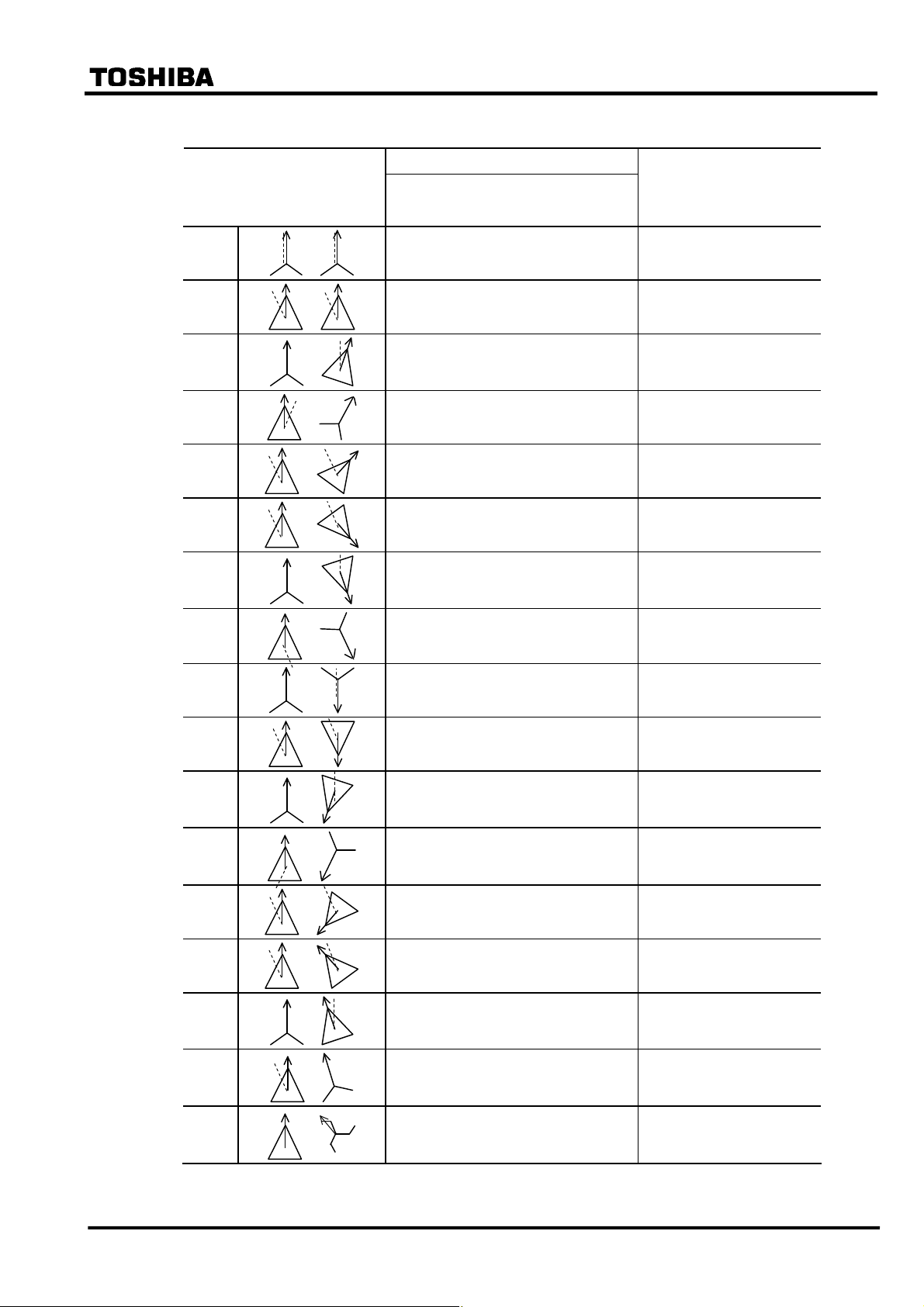

(b) Settings for typical connections of 3-windings transformer

6 F 2 S 0 8 5 7

Transformer connections described in

IEC60076-1

Primary , Secondary,

Tertiary

(P) (S) (T)

Yy0d1

Yy0d11

Yd1d1

Yd11d11

Dy11d0

Dy1d0

Dd0d0

Yy0y0

Settings for phase angle correction

Primary, Secondary, PA Diff., Tertiary, PA Diff.

(yd_p) (yd_s) (vec_s) (yd_t) (vec_t)

1 1 0 2 1

1 1 0 2 11

1 2 1 2 1

1 2 11 2 11

2 1 11 2 0

2 1 1 2 0

2 2 0 2 0

1 1 0 1 0

Remarks

Phase angle matching

calculation (Table

2.2.5.1)

P: 0 O’clock

S: 0 O’clock

T: 1 O’clock

P: 0 O’clock

S: 0 O’clock

T: 11 O’clock

P: 0 O’clock

S: 1 O’clock

T: 1 O’clock

P: 0 O’clock

S: 11 O’clock

T: 11 O’clock

P: 1 O’clock

S: 0 O’clock

T: 1 O’clock

P: 11 O’clock

S: 0 O’clock

T: 11 O’clock

P: 1 O’clock

S: 1 O’clock

T: 1 O’clock

P: 0 O’clock

S: 0 O’clock

T: 0 O’clock

Note: Dotted line: Reference phase

<How to set phase angle matching for GRT100>

Reference phase for phase angle matching

The phase of a star-connected winding side is used as the reference phase for phase angle

matching.

Yd: primary

Dy: secondary

Yy: primary

Dd: the reference vector leads the A phase of the primary side by 30°.

Phase rotation

The relationship between each terminal current vector of a transformer, which depends on the

transformer connection and the connection between the transformer and the power system, must

be checked. The phase displacement of a delta-connected side may not be determined only by the

transformer connection described in IEC60076. Table 2.2.5.3 shows an example illustrating the

connection of a transformer and power system and their current vectors when a Yd1 type

transformer is connected to the power system with both clockwise and anticlockwise phase

rotation. In this case, the setting for phase angle correction is not corresponding to that of Table

2.2.5.1.

⎯ 28 ⎯

Page 30

−

−

−

−

−

−

−

−

−

−

−

6 F 2 S 0 8 5 7

Table 2.2.5.3 Transformer Connection and Current Vector

Connection between

Yd1 Transformer

and Power system

Each winding

connection and

Incoming/Outgoing

current

Incoming current

vector and Outgoing

current vector

Delta-side connected with 30° lagging Delta-side connected with 30° leading

Primary

a

I1a

b

I

1b

c

I

1c

a

b

c

Transformer

U

V

W

Transformer

U

V

W

Yd1

I

2a

I

2b

I

2c

Secondary

u

a

v

b

w

c

u

a

I

2a’=I2a

v

b

I

2b’=I2b

w

c

I

2c’=I2c

Primary

a

I

I

2c

I

2a

I

2b

1a

b

I

1b

c

I

1c

a

b

c

Transformer

U

V

W

Transformer

U

I

1c

V

I

1b

W

I

1a

Yd1

I2c

I

I

2b

2a

Secondary

u

a

v

b

w

c

u

a

I

2a’=I2a

v

b

I

2b’=I2b

w

c

I

2c’=I2c

I

2b

I

2c

I

2a

I

I

1a

I

1c

Incoming

Current

I

1b

I

2a’=I2a

2b’=I2b

I

2b

I

2c

Outgoing

Current

I

2a

I

2c

30

°

I

I

2c’=I2c

2b

I

2a

I

I

1c

Incoming

Current

1a

I

2b’=I2b

I1b

I2b

I

−

2c

I

2a

Outgoing

Current

I

2c’=I2c

I

2c

30°

I

2a’=I2a

I

2a

I

2b

Setting Yd_p=1, yd_s=2, vec_s=1 (Same as Yd1) Yd_p=1, yd_s=2, vec_s=11 (same as Yd11)

Auto-transformer (with internal delta-winding)

Set Yy0.

Zigzag connected transformer

Set yd_p, yd_s and vec_s to 2 (=delta) for zigzag connected side. Zero-sequence current is

canceled.

When three-winding model (model 200 series) applied to two-winding transformer:

Keep the settings of “yd_t” and “vec_t” to the default setting values.

One-and-a-half breaker system

When applied to one-and-a-half breaker system, note the DIFT and REF setting as shown in Table

2.2.5.4.

Table 2.2.5.4 Example of DIFT and REF Setting

Setting

DIFT 1REF 2REF

Yd11

One-and-a-half breaker system

Yd11

Yy0d11

Yd11 yd_p=1

yd_s=2

vec_s=11

Yy0d11

yd_p=1

yd_s=1

vec_s=0

yd_t=2

vec_s=11

Yy0d11

yd_p=1

yd_s=1

vec_s=0

yd_t=2

vec_s=11

1I0 --

2Io --

1I0 1I0

⎯ 29 ⎯

Page 31

6 F 2 S 0 8 5 7

(When β-method is selected for [Phase matching])

The phase angle differences between line currents on each side of the power transformer are

corrected by setting according to the hands of a clock as follows:

Rule 1:

If all the windings are star-connected, then take one of the windings as a reference winding and set

1 (= one o’clock) for it. For other winding(s), set the phase angle difference from the reference

winding by the expression of the leading angle. One hour corresponds to leading by thirty degrees.

Example 1 If the setting winding leads the reference winding by 60°, set 3 (= three o’clock).

Example 2 If the setting winding is in phase with the reference winding, set 1 (= one

o’clock).

Example 3 If the setting winding lags the reference winding by 60° (that is leading by 300°),

set 11 (= eleven o’clock).

Rule 2:

If any of the windings are delta-connected, take one of the delta-connected winding(s) as a

reference winding and set 0 (= noon) for it. For other star- or delta-connected winding(s), set

according to the Rule 1 mentioned above.

Example 1 If the setting winding leads the reference winding by 60°, set 2 (= two o’clock).

Example 2 If the setting winding is in phase with the reference winding, set 0 (= noon).

Example 3 If the setting winding lags the reference winding by 60° (that is leading by 300°),

set 10 (ten o’clock).

The settings for the two-winding transformer connections described in IEC60076-1 are listed in

Table 2.2.5.5.

Three-winding transformers are also set according to the above mentioned rules.

Example 4 Setting for star/star/delta transformer.

Setting (d1 / d2 / d3)

Primary (d1) 11

Primary

Secondary

Tertiary

Secondary (d2) 11

Tertiary (d3) 0

⎯ 30 ⎯

Page 32

1

6 7 8 9 10 11 Ia

Note: The following calculation is performed in the relay for phase angle correction.

Setting Calculation Remarks

0 Ia = Ia

1

2

3

4 Ia = Ib

5

6

7

8 Ia = Ic

9

10

11

Ia = (Ia – Ic)/

Ia = −Ic

Ia = (−Ic + Ib)/

Ia = (Ib – Ia)/

Ia = −Ia

Ia = (−Ia + Ic)/

Ia = (Ic – Ib)/

Ia = −Ib

Ia = (Ia – Ib)/

3

3

3

3

3

3

Setting value

0

2

3

4

5

6 F 2 S 0 8 5 7

⎯ 31 ⎯

Page 33

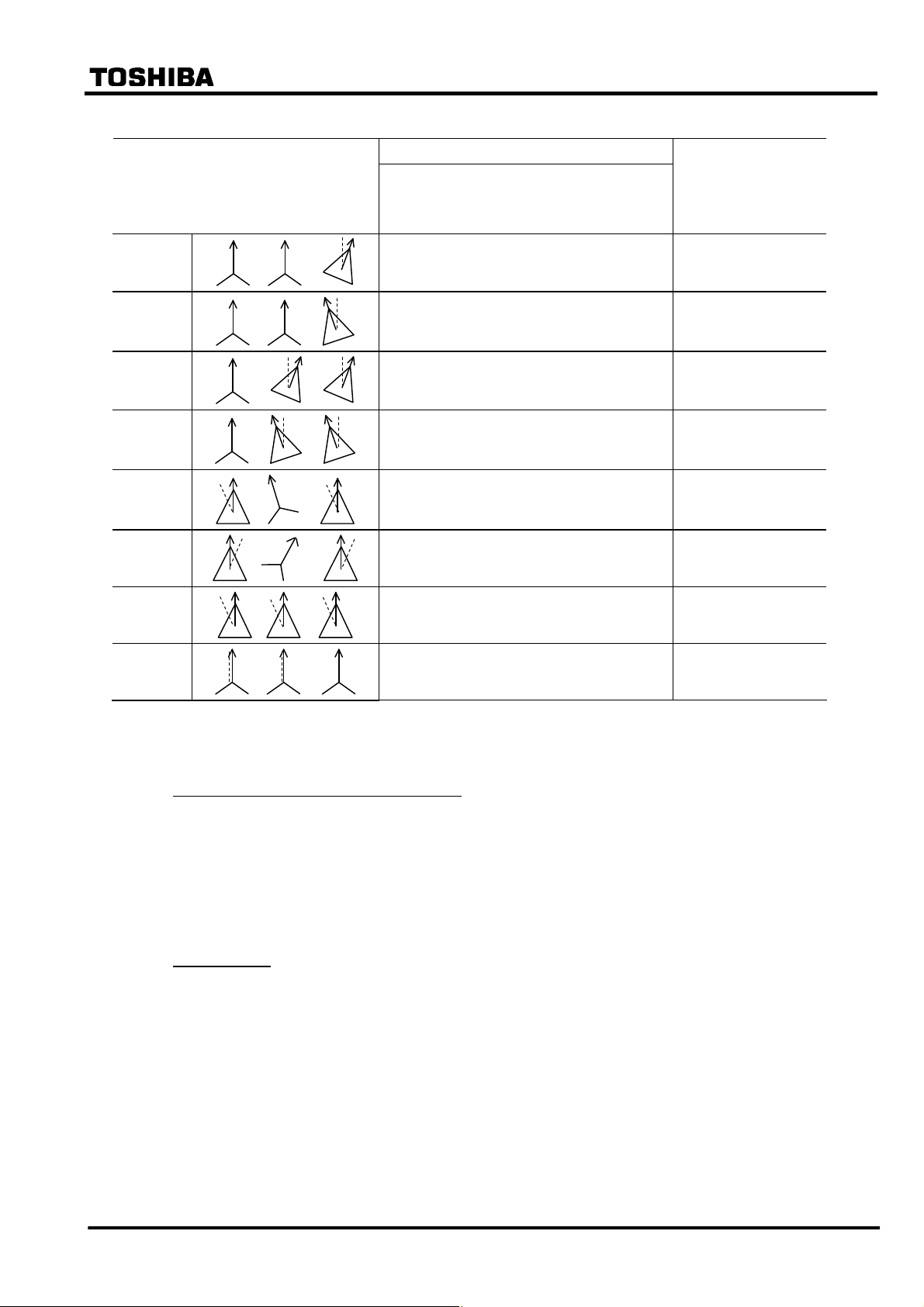

Table 2.2.5.5 Setting for Phase Angle Matching (for β-method)

(a) Settings for typical connections of 2-windings transformer

Transformer connections

described in IEC60076-1

Settings for phase angle correction Remarks

Primary , Secondary

6 F 2 S 0 8 5 7

(d1) (d2)

Yy0

1 , 1

Dd0

Yd1

Dy1

Dd2

Dd4

Yd5

Dy5

Yy6

0 , 0

1 , 0

0 , 11

0 , 10

or 2 , 0

0 , 8

or 4 , 0

5 , 0

0 , 7

1 , 7

Based on primary winding.

Based on secondary winding.

Based on primary winding.

Based on secondary winding.

Based on primary winding.

Dd6

Yd7

Dy7

Dd8

Dd10

Yd11

Dy11

Note: A 2-windings transformer covers a 3-windings transformer with a stabilizing-winding circuit

or 7 , 1

0 , 6

or 6 , 0

7 , 0

0 , 5

0 , 4

or 8 , 0

0 , 2

or 10 , 0

11 , 0

0 , 1

Based on secondary winding.

Based on primary winding.

Based on secondary winding.

Based on primary winding.

Based on secondary winding.

for which 2-windings transformer protection relay can be applied.

⎯ 32 ⎯

Page 34

(b) Settings for typical connections of 3-windings transformer

6 F 2 S 0 8 5 7

Transformer connections described in

IEC60076-1

Yy0d1

Yy0d11

Yd1d1

Yd11d11

Dy11d0

Dy1d0

Dd0d0

Yy0y0

Settings for phase angle correction

Primary, Secondary, Tertiary

(d1) (d2) (d3)

1 , 1 , 0

11 , 11 , 0

1 , 0 , 0

11 , 0 , 0

0 , 1 , 0

0 , 11 , 0

0 , 0 , 0

1 , 1 , 1

Remarks

Note :

1. If all the windings are star-connected, then take one of the windings as a reference winding

and set 1 (= one hour) for it.

2. If any of the windings are delta-connected, take one of the delta-connected winding(s) as a

reference winding and set 0 for it.

⎯ 33 ⎯

Page 35

2.3 Restricted Earth Fault Protection

Restricted earth fault protection (REF) is a zero-phase current differential scheme applied to a

star-connected winding whose neutral is earthed directly or through a low impedance. It gives

highly sensitive protection for internal earth faults.

REF employs a low impedance current differential scheme which detects the differential current

between the zero-sequence current I

current I

in the neutral conductor as shown in Figure 2.3.1.

N

Figure 2.3.1 Restricted Earth Fault Protection

6 F 2 S 0 8 5 7

derived from the three-phase line currents and the neutral

0

Ia+Ib+Ic

REF

I

N

REF and the overall differential protection DIFT use the three-phase line currents in common.

GRT100 has two or three REF elements depending on the model, providing separate protection

for all star-connected and neutral-earthed windings.

The elements have the same percentage restraining characteristics and are stable for all faults

outside the protected zone.

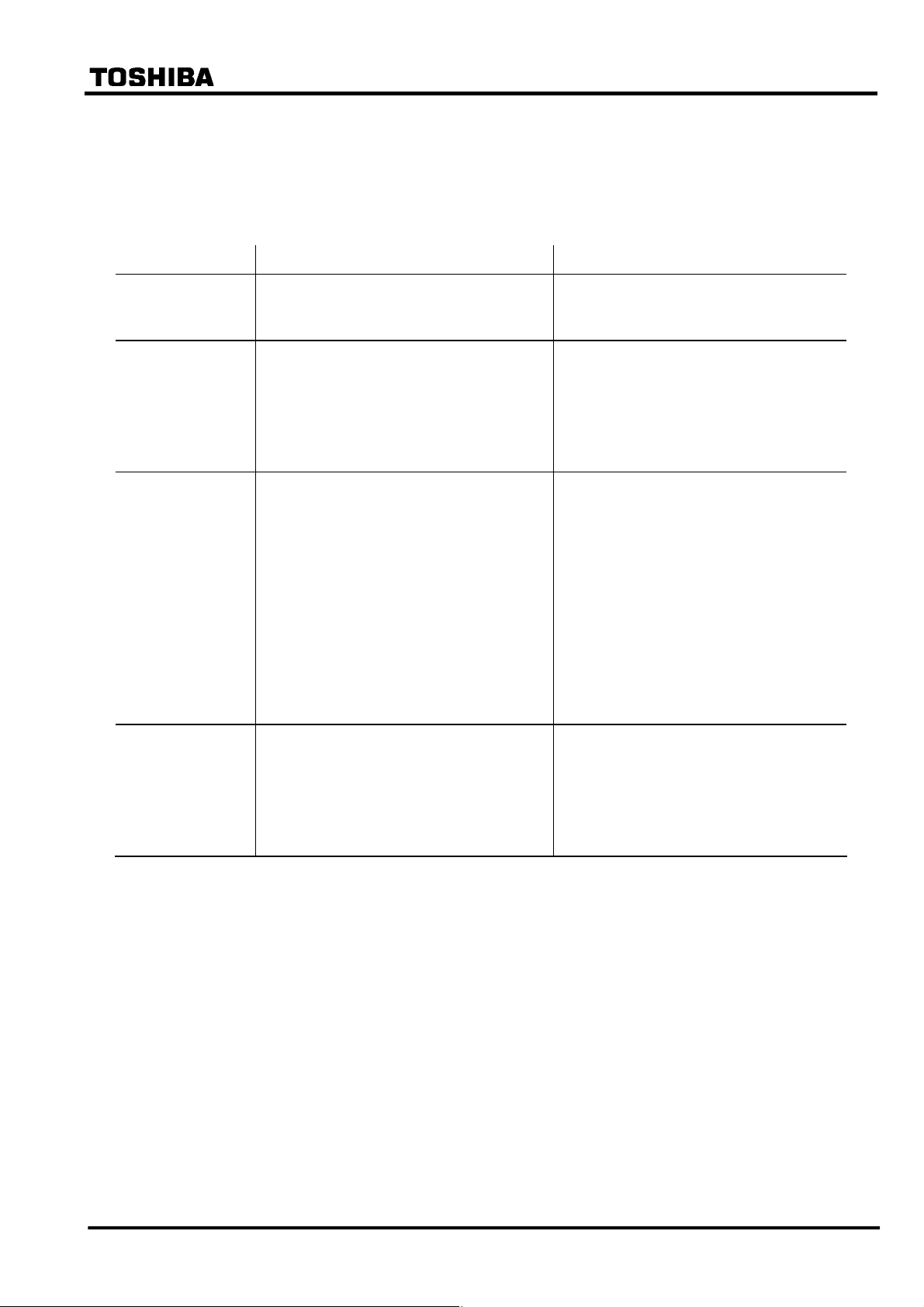

Figure 2.3.2 shows the block diagram of the REF element which is composed of REF_DIF and

REF_DEF. The REF_DIF has a percentage restraining characteristic while the REF_DEF

provides a directional check feature to discriminate between internal and external faults. When the

REF_DEF is “ON”, the REF_DEF element is used. The REF_DEF element provides additional

security against incorrect operation of the REF element in the event of saturation of the neutral

CT. The REF_DEF is blocked when the maximum phase current exceeds 2 × kct × (Rated current

of neutral CT), since the REF element is used for earth fault protection of transformer winding.

For details, see Section 2.10.3. In case of terminal current larger than that, the DIFT element

provides tripping. The REF_DEF can be disabled by setting the scheme switch [REF_DEF] to

“OFF”.

REF_DIF

REF_DEF

internal fau lt d e tec t ion

Ires≦ 2.0× Max_kct

&

≥1

&

REF

[REF_DEF]

+

ON

OFF

Figure 2.3.2 Block Diagram of REF

Figure 2.3.3 shows the scheme logic of the restricted earth fault protection when three REF

elements are applied. Each REF element can perform instantaneous or time-delayed tripping of up

to five breakers. Any of the five breaker tripping signals 1REF-1 to 3REF-5 are enabled or

disabled by the scheme switch [1REF1] to [3REF5] settings.

Note: Models 203 and 204 are not provided with 1REF-4, 1REF5, 2REF-4, 2REF-5, 3REF-4 and

⎯ 34 ⎯

Page 36

[

]

[

]

[

]

[

]

[

]

6 F 2 S 0 8 5 7

3REF-5.

1REF

2REF

T1REF

71

74

t 0

0.00 - 10.00s

Same as above

+

+

+

+

+

1REF1

“ON”

1REF2

“ON”

1REF3

“ON”

1REF4

“ON”

1REF5

“ON”

&

&

&

&

&

1REF-1

1REF-2

1REF-3

1REF-4

1REF-5

≥1

2REF-1

2REF-2

2REF-3

2REF-4

2REF-5

≥1

332

1REF TRIP

333

2REF TRIP

≥1

3REF-1

3REF-2

3REF-3

3REF-4

3REF-5

334

3REF TRIP

3REF

77

Same as above

Note: Models 203 and 204 are not provided with 1REF-4, 1REF-5, 2REF-4, 2REF-5, 3REF-4 and

3REF-5.

Figure 2.3.3 Scheme Logic of Restricted Earth Fault Protection

Appendix L shows applications of the three REF elements to various types of transformers. When

protecting a two- or three-winding transformer, 1REF, 2REF and 3REF elements should be

applied to the primary (or high-voltage) winding, secondary (or medium-voltage) winding and

tertiary (or low-voltage) winding respectively. This is also valid for auto-transformer protection

but the application must comply with Appendix L.

In the application to auto-transformers, one REF element may introduce two or three line currents

and one neutral current as shown in Appendix L. 1REF to 3REF elements recognize the number of

the line currents according to the scheme switch setting of [1REF] to [3REF].

⎯ 35 ⎯

Page 37

6 F 2 S 0 8 5 7

Setting

The following shows the setting elements for the restricted earth fault protection and their setting

ranges.

Element Range Step Default Remarks

1REF 1ik

1kct1

1kct2

1kct3

1p2

1kp

2REF 2ik

2kct1

2kct2

2kct3

2p2

2kp

3REF 3ik

3kct1

3kct2

0.05 − 0.50(*)

1.00 − 50.00

1.00 − 50.00

1.00 − 50.00

50 − 100%

0.50 − 2.00(*)

0.05 − 0.50(*)

1.00 − 50.00

1.00 − 50.00

1.00 − 50.00

50 − 100%

0.50 − 2.00(*)

0.05 − 0.50(*)

1.00 − 50.00

1.00 − 50.00

0.01 0.50 Minimum operating current

0.01 1.00

0.01 1.00 CT ratio matching

0.01 1.00

1% 100% % slope of DF2

0.01 1.00 DF2 restraining current section of

large current characteristic

0.01 0.50 Minimum operating current

0.01 1.00

0.01 1.00 CT ratio matching

0.01 1.00

1% 100% % slope of DF2

0.01 1.00 DF2 restraining current section of

large current characteristic

0.01 0.50 Minimum operating current

0.01 1.00

0.01 1.00 CT ratio matching

3kct3

3p2

3kp

T1REF

T2REF

T3REF

Scheme switch

[1REF1] to [1REF5]

[2REF1] to [2REF5]

[3REF1] to [3REF5]

[1REF] to [3REF]

[REF_DEF]

(*): Multiplier of secondary rated current

(**): Default settings are dependent on the models. See Appendix H.

1.00 − 50.00

50 − 100%

0.50 − 2.00(*)

0.00 − 10.00s

0.00 − 10.00s

0.00 − 10.00s

Off/On

Off/On

Off/On

1Io/2Io/3Io

Off/On

0.01 1.00

1% 100% % slope of DF2

0.01 1.00 DF2 restraining current section of

large current characteristic

0.01s 0.00s

0.01s 0.00s Delayed tripping

0.01s 0.00s

(**)

(**)

(**)

1Io

Off

Enable or disable to output

tripping signal

Number of line currents input to

1REF, 2REF and 3REF elements

Setting of ik (1ik, 2ik and 3ik)

1ik, 2ik and 3ik are minimum operating current settings and are set as a ratio to the line CT

secondary rated current. ik is determined from the maximum erroneous zero sequence differential

current under normal operating conditions. A typical setting would be between 10% and 50%.

⎯ 36 ⎯

Page 38

6 F 2 S 0 8 5 7

Setting of kct (1kct1-1kct3, 2kct1-2kct3 and 3kct1-3kct3)

CT ratio matching is performed between the line CT(s) and the neutral CT by setting 1kct1-1kct3

for 1REF element, 2kct1-2kct3 for 2REF element and 3kct1-3kct3 for 3REF element. The settings

are obtained as a ratio of the line CTs ratio to the neutral CT ratio and the line CTs have the

notations shown in Appendix L according to 1REF to 3REF applications.

For example, the settings of 1kct1, 1kct2, 2kct1 and 2kct2 are calculated;

1kct1 = (CT ratio of line CT 1ct-1)/(CT ratio of neutral CT 1nCT)

1kct2 = (CT ratio of line CT 1ct-2)/(CT ratio of neutral CT 1nCT)

2kct1 = (CT ratio of line CT 2ct-1)/(CT ratio of neutral CT 2nCT)

2kct2 = (CT ratio of line CT 2ct-2)/(CT ratio of neutral CT 2nCT)

where,

CT ratio = (primary rated current)/(secondary rated current).

Setting of scheme switch [1REF] to [3REF]

[1REF] to [3REF] are set to "1I0", "2I0" or "3I0" when they introduce one, two or three line

currents respectively.

Setting of scheme switch [REF_DEF]

The function of REF_DEF is set to “On/Off” by setting.

⎯ 37 ⎯

Page 39

2.4 Overcurrent Protection

GRT100 provides definite time and inverse time overcurrent elements for both phase faults and

earth faults, separately for each transformer winding. Three phase currents from each set of line

CTs are used for the phase fault protection elements, while the earth fault protection is based on

the neutral CT input.These elements can be used selectively depending on the requirements of the

particular application, but the following points should be noted:

• In the case of large power transformers, overcurrent protection is usually employed only as

back-up protection for terminal faults, and for uncleared LV system faults. In such cases, the

overcurrent elements can be applied either on one or both sides of the transformer as

required.

• Coverage of internal transformer faults is generally limited.

• It is common practice to apply IDMTL phase and earth fault overcurrent protection as

back-up for the LV system. Current and time settings must be arranged to grade with

downstream relays and fuses. The phase fault current setting must also be set to exceed the

maximum overload current.

• High-set instantaneous overcurrent protection can be applied on the primary side to provide

back-up protection for terminal faults. The current setting must be higher than the maximum

through-fault current to ensure that the element does not operate for faults on the LV side.

6 F 2 S 0 8 5 7

One of the following IEC-standard-compliant inverse time characteristics or one long time inverse

characteristic is available for the inverse current protection.

• standard inverse IEC 60255-3

• very inverse IEC 60255-3

• extremely inverse IEC 60255-3

Up to three definite time elements (1OC to 3OC) and inverse time elements (1OCI to 3OCI) input

three phase currents from line CTs in the transformer windings.

Up to three definite time elements (1EF to 3EF) and inverse time elements (1EFI to 3EFI) input

neutral currents from CTs in the neutral circuit.

Figure 2.4.1 and Figure 2.4.2 show the scheme logic of overcurrent protection. Each element can

perform time-delayed tripping of up to five breakers. The breaker tripping signals are blocked by

the scheme switch settings.

The number of overcurrent elements applied depends on the relay models.

⎯ 38 ⎯

Page 40

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

6 F 2 S 0 8 5 7

1OC

1OCI

A

B

C

A

B

C

47

48

49

50

51

52

≥1

≥1

370

0.00 - 10.00s

225

T1OC

t 0

1OC1

1OC2

1OC3

1OC4

1OC5

1OCI1

&

&

&

&

&

&

1OC-1

1OC-2

1OC-3

1OC-4

1OC-5

≥1

1OCI-1

335

1OC TRIP

&

1OCI2

&

1OCI3

&

1OCI4

&

1OCI5

Note: 2OC and 3OC provide the same logic as 1OC. 2OCI and 3OCI provide the same logic as 1OCI.

Models 203 and 204 are not provided with 1OC-4, 1OC-5, 2OC-4, 2OC-5, 3OC-4, 3OC-5,

1OCI-4, 1OCI-5, 2OCI-4, 2OCI-5, 3OCI-4 and 3OCI-5.

1OCI-2

1OCI-3

1OCI-4

1OCI-5

≥1

339

1OIC TRIP

Figure 2.4.1 Scheme Logic of the Overcurrent Protection

⎯ 39 ⎯

Page 41

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

[

]

+

6 F 2 S 0 8 5 7

1EF

1EFI

72

73

T1EF

t 0

0.00 - 10.00s

1EF1

1EF2

1EF3

1EF4

1EF5

1EFI1

&

&

&

&

&

&

≥1

1EF-1

1EF-2

1EF-3

1EF-4

1EF-5

343

1EFI-1

1EF TRIP

&

1EFI2

&

1EFI3

&

1EFI4

&

1EFI5

Note: 2EF and 3EF provide the same logic as 1EF. 2EFI and 3EFI provide the same logic as 1EFI.

Models 203 and 204 are not provided with 1EF-4, 1EF-5, 2EF-4, 2EF-5, 3EF-4, 3EF-5, 1EFI-4,

1EFI-5, 2EFI-4, 2EFI-5, 3EFI-4 and 3EFI-5.

1EFI-3

1EFI-4

1EFI-5

≥1

1EFI-2

346

1EFI TRIP

Figure 2.4.2 Scheme Logic of the Overcurrent Protection for Earth Faults

⎯ 40 ⎯

Page 42

6 F 2 S 0 8 5 7

Setting

The following shows the setting elements for the overcurrent protection and their setting ranges.

Element Range Step Default Remarks

1OC

2OC

3OC

T1OC

T2OC

T3OC

1OCI

2OCI

3OCI

T1OCI

T2OCI

T3OCI

1EF

2EF

3EF

T1EF

0.10 − 20.0(*)

0.10 − 20.0(*)

0.10 − 20.0(*)

0.00 − 10.00s

0.00 − 10.00s

0.00 − 10.00s

0.10 − 5.00(*)

0.10 − 5.00(*)

0.10 − 5.00(*)

0.05 − 1.00

0.05 − 1.00

0.05 − 1.00

0.10 − 20.00(*)

0.10 − 20.00(*)

0.10 − 20.00(*)

0.00 − 10.00s

0.01 2.00 Definite time overcurrent (line)

0.01 2.00 Definite time overcurrent (line)

0.01 2.00 Definite time overcurrent (line)

0.01s 1.00s Delayed tripping for 1OC

0.01s 1.00s Delayed tripping for 2OC

0.01s 1.00s Delayed tripping for 3OC

0.01 1.00 Inverse time overcurrent (line)

0.01 1.00 Inverse time overcurrent (line)

0.01 1.00 Inverse time overcurrent (line)

0.01 1.00 Time multiplier setting for 1OCI

0.01 1.00 Time multiplier setting for 2OCI

0.01 1.00 Time multiplier setting for 3OCI

0.01 2.00 Definite time overcurrent (neutral)

0.01 2.00 Definite time overcurrent (neutral)

0.01 2.00 Definite time overcurrent (neutral)

0.01s 1.00s Delayed tripping for 1EF

T2EF

T3EF

1EFI

2EFI

3EFI

T1EFI

T2EFI

T3EFI

Scheme switch

M1OCI to M3OCI

M1EFI to M3EFI

Scheme switch

[1OC1] to [3OC5]

[1OCI1] to [3OCI5]

[1EF1] to [3EF5]

[1EFI1] to [3EFI5]

0.00 − 10.00s

0.00 − 10.00s

0.10 − 5.00(*)

0.10 − 5.00(*)

0.10 − 5.00(*)

0.05 − 1.00

0.05 − 1.00

0.05 − 1.00

Long-Std-Very-Ext

Long-Std-Very-Ext

Off/On (**) Enable or disable tripping by

0.01s 1.00s Delayed tripping for 2EF

0.01s 1.00s Delayed tripping for 3EF

0.01 1.00 Inverse time overcurrent (neutral)

0.01 1.00 Inverse time overcurrent (neutral)

0.01 1.00 Inverse time overcurrent (neutral)

0.01 1.00 Time multiplier setting for 1EFI

0.01 1.00 Time multiplier setting for 2EFI

0.01 1.00 Time multiplier setting for 3EFI

Std

Std

Inverse time characteristic selection of

OCI elements

EFI elements

OC elements

OCI elements

EF elements

EFI elements

(*) : Multiplier of CT secondary rated current.

(**) : Default settings are dependent on the models. See Appendix H.

The overcurrent elements use the same three-phase line currents and neutral current as the

⎯ 41 ⎯

Page 43

6 F 2 S 0 8 5 7

differential protection and the restricted earth fault protection. When choosing settings, the

following relationships between the overcurrent elements and the connected windings must be

taken into account.

1OC, 1OCI : Primary (high-voltage) winding

2OC, 2OCI : Secondary (medium-voltage) winding

3OC, 3OCI : Tertiary (low-voltage) winding

1EF, 1EFI : 1REF applied neutral circuit

2EF, 2EFI : 2REF applied neutral circuit

3EF, 3EFI : 3REF applied neutral circuit

⎯ 42 ⎯

Page 44

+

[

]

+

[THR2]

+

+

[THR4]

+

+

[

]

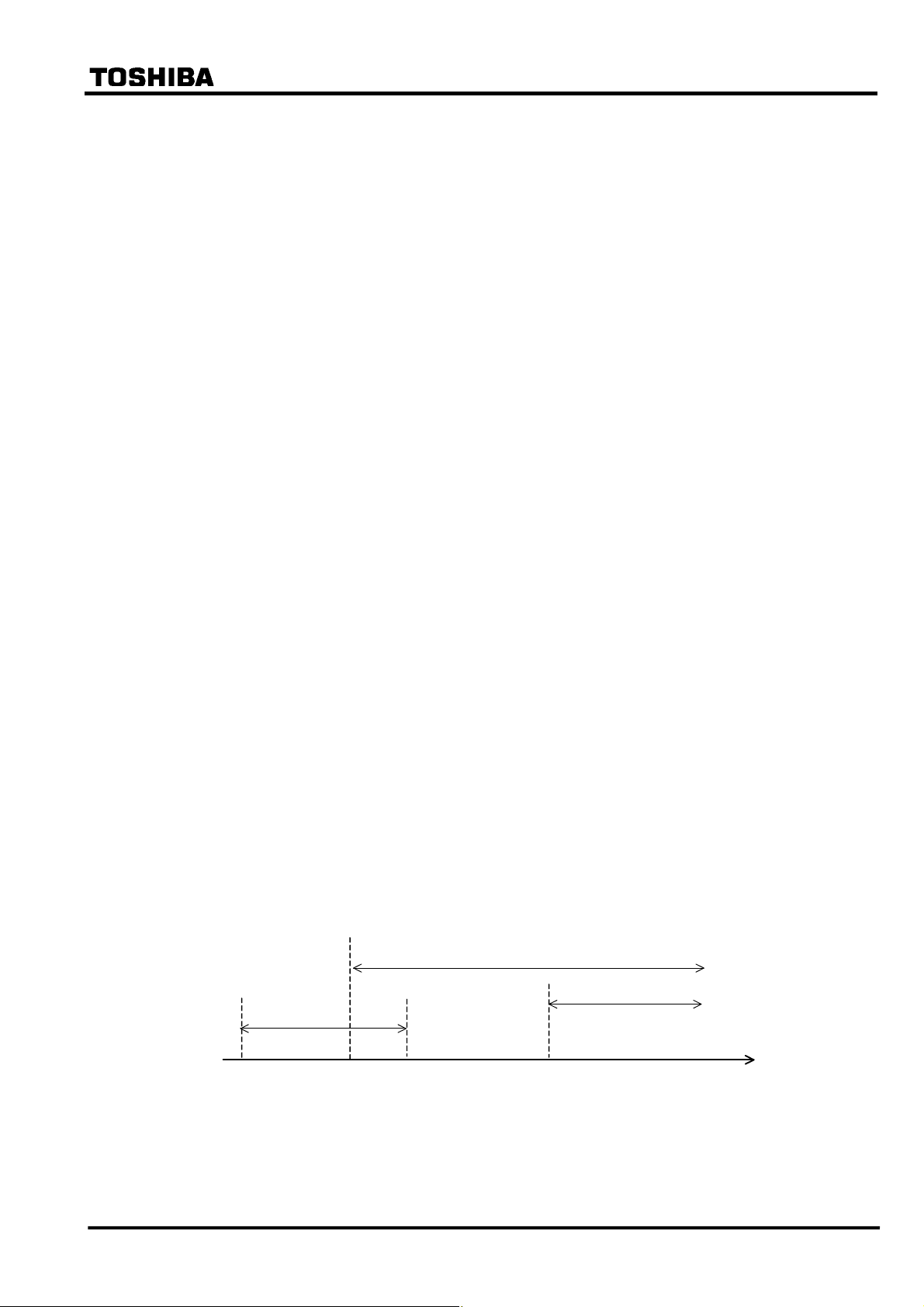

2.5 Thermal Overload Protection

The thermal overload protection is applied to protect transformers from electrical thermal damage.

A-phase current is used to detect the thermal overload of a transformer. The characteristics are

exponential functions according to the IEC 60255-8 standard and take into account the I

due to the particular operational current and the simultaneous cooling due to the coolant. In this

way the tripping time during an overload condition takes the pre-load into consideration. An alarm

stage can be set to operate before reaching the tripping condition.

Figure 2.5.1 shows the scheme logic of the thermal overcurrent protection. THR tripping output

can be given to up to five breakers. Any of the five breaker tripping signals THR-1 to THR-5 can

be blocked by the scheme switch [THR1] to [THR5] settings. Alarming signal THR-A can be

blocked by the scheme switch [THRA] setting.

THR

83

S

87

A

THR1

“ON”

6 F 2 S 0 8 5 7

2

R losses

&

&

THR-1

THR-2

“ON”

[THR3]

“ON”

“ON”

[THR5]

“ON”

THRA

“ON”

Note: Models 203 and 204 are not provided with THR- 4 and THR-5.

&

&

&

248

THR-3

THR-4

THR-5 &

THR-A

≥1

351

THR TRIP

Figure 2.5.1 Scheme Logic of Thermal Overload Protection

Setting

The following shows the setting elements for the thermal overload protection and their setting

ranges.

Element Range Step Default Remarks

τ 0.5 − 500.0min

k

IB

0.10 − 4.00

0.50 − 2.50(*1)

0.1min 60.0min Thermal time constant

0.01 1.30 Constant

0.01 1.00 Basic current

Ip

TA

Scheme switch

THR1 to THR5

THRA

0.00 − 1.00(*1)

0 − 10min

Off/On

Off/On

0.01 0.00 Pre-specified load current

1min 10min Time for alarm (before trip) (*3)

(*2)

On

Enable or disable

Trip

Alarm

(∗1): Multiplier of CT secondary rated current

(*2): Default settings are dependent on the models. See Appendix H.

(*3): Alarming time = THR trip time (operating time) – TA (setting time)

Note: Ip sets a minimum level of previous load current to be used by the thermal element, and is

typically used when testing the element. For the majority of applications, Ip should be set to

zero, in which case the previous load current, Ip, is calculated internally by the thermal

model, providing memory of conditions occurring before an overload.

⎯ 43 ⎯

Page 45

[

[

]

[

[

]

[

]

[

]

[

]

[

]

[

2.6 Frequency Protection

GRT100 provides underfrequency or overfrequency protection and/or alarms for load shedding or

for detecting such an overfrequency condition caused by disconnecting load from a particular

generation location.

The frequency element FRQ comprises two frequency elements 81-1 and 81-2, the former is used

for tripping and the latter for alarms.

Figure 2.6.1 shows the scheme logic of the frequency protection. The tripping element 81-1

outputs underfrequency and overfrequency trip signals L1 and H1. Either underfrequency or

overfrequency protection is selected by setting the scheme switch [FRQ-UF1] to “ON” or “OFF”.

The alarm element 81-2 outputs underfrequency and overfrequency alarm signals L2 and H2.