Page 1

E6581341

Expansion IO Card Option 2

ETB004Z Instruction manual

1. Make sure that this instruction manual is delivered to the end user of the expansion

IO card option.

2. Read this manual before installing or operating the expansion IO card option. Keep

it in a safe place for reference.

3. All information contained in this manual are subject to change without notice.

Please confirm the latest information on our web site “www.inverter.co.jp”.

NOTICE

Page 2

Safety precautions

On the inverter and in its instruction manual, important information is contained for

preventing injuries to users and damages to assets and for proper use of the device.

Read the instruction manual attached to VF-AS1/PS1 along with this instruction manual

for completely understanding the safety precautions and adhere to the contents of these

manuals.

Explanation of markings

Marking Meaning of marking

E6581341

Warning

Caution

(*1) Such things as injury, burns or shock that will not require hospitalization or long periods of

outpatient treatment.

(*2) Physical property damage refers to wide-ranging damage to assets and materials.

Meanings of symbols

Marking Meaning of marking

Indicates prohibition (Don't do it).

Indicates something mandatory (must be done).

Indicates danger or warning.

Indicates that errors in operation may lead to death or serious injury.

Indicates that errors in operation may lead to injury (*1) to people or that these errors

may cause damage to physical property. (*2)

What is prohibited will be described in or near the symbol in either text or picture

form.

What is mandatory will be described in or near the symbol in either text or picture

form.

What is dangerous, or what the warning should be applied to will be described in or

near the symbol in either text or picture form.

1

1/17

Page 3

E6581341

■ Limitation of use

Safety precaution

▼ Never use this unit with any device other than TOSVERT VF-AS1/PS1 series inverters. Doing so may

cause an accident.

■ General Operation

Warning

▼ Never disassemble, modify or repair.

Disassembly

prohibited

Prohibited

Doing so could result in electric shock, fire and injury. For repairs, call your sales

agency.

▼ Do not attach this option to any inverter other than the VF-AS1/PS1.

Doing so could result in electric shock or fire.

▼ Don't place or insert any kind of object into the ETB004Z (electrical wire cuttings, rods,

wires).

Doing so could result in electric shock or fire.

▼ Do not allow water or any other fluid to come in contact with the ETB004Z.

Doing so could result in electric shock or fire.

▼ If the inverter begins to emit smoke or an unusual odor, or unusual sounds, immediately

turn off the VF-AS1/PS1.

Mandatory

Mandatory

■ Transportation & installation

Prohibited

If the equipment is continued in operation in such a state, the result may be fire. Call

your local sales agency for repairs.

▼ Do not touch the sharp portions (such as leads of parts on the board, the corner of

board, or etc.) on this option. It may lead to injuries.

▼ This option is an electrostatic discharge sensitive device. Handle it, where the

environment is protected against electrostatic electricity.

Otherwise, permanent damage to device will result.

▼ Do not apply a dropping shock or other physical shocks.

Otherwise, damage or malfunction will result.

▼ Do not install or operate the inverter if it is damaged or any part of it is missing.

Operating a defective inverter may lead to electric shocks or fire.

For repairs, call your sales/repair agency.

▼ Do not put any flammable material near the product.

It may catch fire due to the product sparking in the case of a malfunction.

Caution

Warning

Mandatory

▼ Use this product under the environmental conditions prescribed in the instruction

manual.

Usage it under any other conditions may result in malfunction.

▼ An emergency stop device must be installed that fits with system specifications

(e.g. shut off input power then engage mechanical brake).

Operation cannot be stopped immediately by the inverter or this unit alone, thus risking

an accident or injuries.

2

Page 4

■ Wiring

Mandatory

■ Operations

Prohibited

E6581341

Caution

▼ Electrical construction work must be done by a qualified expert.

Installation or connection of input power by someone who does not have that expert

knowledge may result in fire or electric shock.

▼ Shut off power when installing and wiring this option.

Wait at least 15 minutes and check to make sure that the charge lamp (VF-AS1/PS1) is

no longer lit.

▼ Tighten the screws on the terminal block to the specified torque (Refer to Section 2.2).

If the screws are not tightened to the specified torque, it may lead to fire.

Warning

▼ Do not pull on any cable itself.

Doing so could result in damage or malfunction.

▼ Do not touch switches when the hands are wet and do not try to clean the inverter with

a damp cloth.

Doing so could result in electric shock.

▼ Use this option under the environment specified in the instruction manual.

Mandatory

■ Disposal

Mandatory

■ Notes on use

▼ Use an additional safety device with your VF-AS1/PS1 or system to prevent a serious

▼ For safety's sake, do not dispose of the disused inverter yourself but ask an industrial

Usage under the environment other than them may cause damages or malfunctions or

an accident.

accident due to the unit malfunctions.

Usage without an additional safety device may cause an accident.

Caution

waste disposal agent (*).

If the collection, transport and disposal of industrial waste is done by someone who is

not licensed for that job, it is a punishable violation of the law. (Laws in regard to

cleaning and processing of waste materials)

(*) Persons who specialize in the processing of waste and known as “industrial waste

product collectors and transporters” or “industrial waste disposal persons.”

Notes

▼ Do not install the inverter where the temperature or the humidity will change rapidly.

▼ Keep a distance of 20cm or more between the inverter's power cable and the data

transmission cable.

Or the inverter might malfunction because of noise.

▼ Insert a magnetic contactor or similar device between the VF-AS1/PS1 and the power

supply to ensure that power is turned off if an emergency stop command is entered

through the network.

3

Page 5

Introduction

Thank you for purchasing a “Expansion IO card option 2” for industrial inverter

TOSVERT VF-AS1/PS1 inverter.

By the use of this option, the expansion of input/output terminal is possible. This

instruction manual describes connecting method and usage of the “Expansion IO card

option”. Read this manual carefully before using the unit.

Keep this manual near at hand of the operator who uses the “Expansion IO option” for

future reference in the maintenance and inspection.

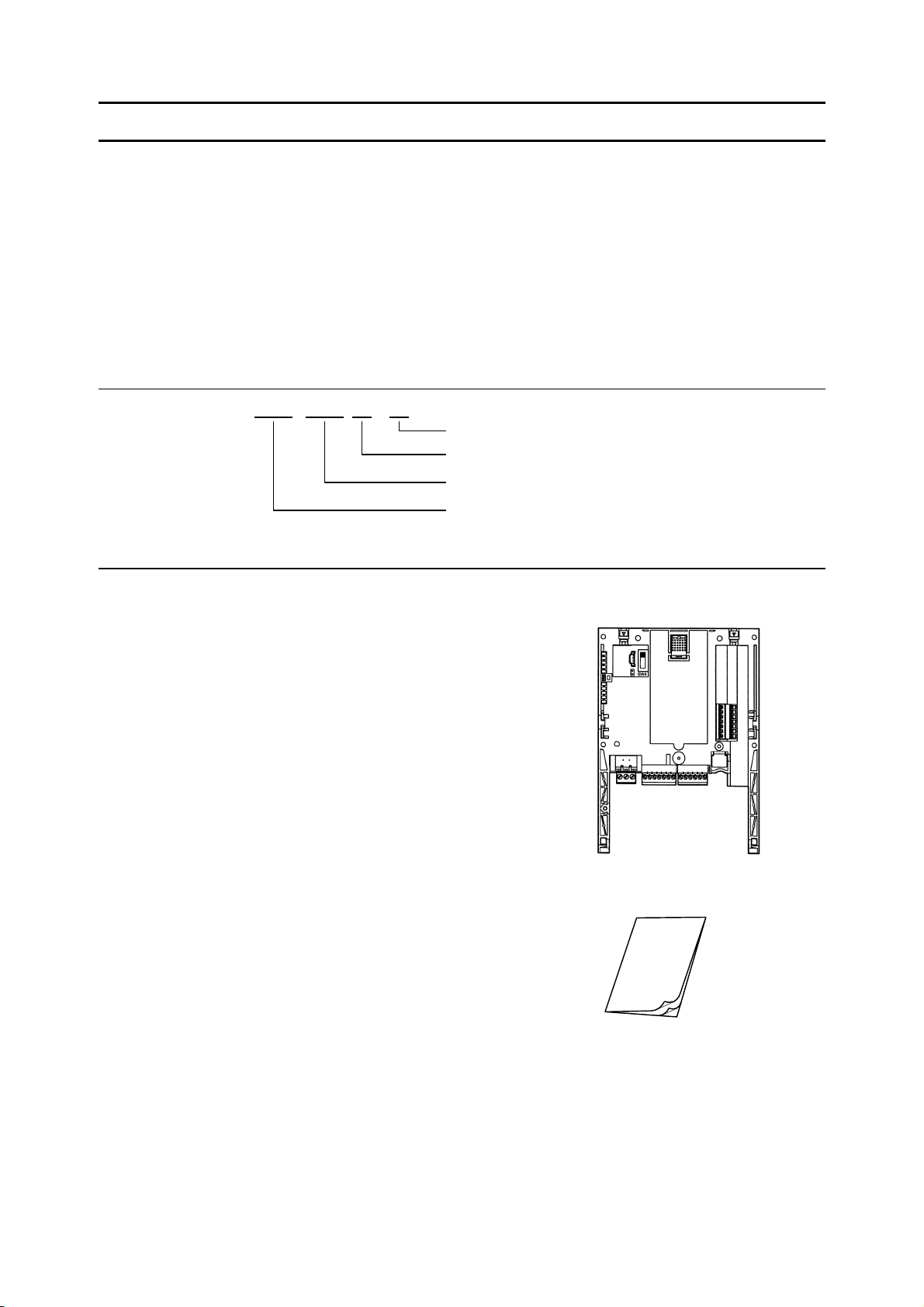

Type of expansion IO option card

E T B 0 0 4 Z − 0

E6581341

Revision number

Without cable

Model number of expansion IO card option

Expansion IO card option

Confirmation on accessories

Following accessory parts are included in the expansion IO card option.

Upon unpacking, confirm on the following parts.

Expansion IO card option unit

(1) Instruction manual of expansion IO card option (this manual)

E6581341(English)

Manual

4

Page 6

E6581341

Contents

1. Name and function of each section ............................................................................ 6

1.1. Appearance ......................................................................................................................................6

1.2. Name of each section (terminal) ......................................................................................................6

2. Installing the IO card option in the VF-AS1/PS1......................................................... 7

2.1. Connection to the inverter ................................................................................................................7

2.2. Wiring ...............................................................................................................................................8

3. Functional description .............................................................................................. 10

3.1. Multi-function output terminal .........................................................................................................10

3.2. Multi-function input terminal ...........................................................................................................11

3.3. -10V power supply..........................................................................................................................11

3.4. Multi-function analog output ...........................................................................................................12

3.5. Differential current input (AI1+, AI1-) .............................................................................................12

3.6. Analog input (AI2)...........................................................................................................................13

3.7. External thermal trip input (TH2+, TH2-)........................................................................................13

3.8. Pulse train input (RP) .....................................................................................................................14

4. External diagram ...................................................................................................... 15

5. Specification............................................................................................................. 16

6. Warranty................................................................................................................... 17

5

Page 7

1. Name and function of each section

Following figure shows appearance and name of each section of the expansion IO card

option.

1.1. Appearance

E6581341

SINK/SOURCE

Select SW

SOURCE

SINK(PLC)

SINK(INT)

1.2. Name of each section (terminal)

R2A Programmable relay output 2

T

B

R2B Programmable relay output 2

1

R2C Programmable relay output 2

N10 Analog input setting power output -10V

AI1+ Differential analog current input (+)

AI1- Differential analog current input (-)

T

B

AI2 Current or voltage analog input

2

CCA Analog input/output signal equipotential (0V)

MON1 Multifunction programmable analog output 1

MON2 Multifunction programmable analog output 2

Inverter cover hook for the fixation

TB4

TB3

TB2

TB1

TH2+ PTC input terminal (+)

TH2- PTC input terminal (-)

RP Pulse train input terminal

T

OUT5

B

4

OUT6

NO2 Output 5 and 6 common terminal

CC Digital signal equipotential (0V)

Multifunction programmable open collector output 5

Multifunction programmable open collector output 6

P24/PLC Common terminal of extension terminal input

LI5 Extension terminal input LI5

T

LI6 Extension terminal input LI6

B

LI7 Extension terminal input LI7

3

LI8 Extension terminal input LI8

CC Digital signal equipotential (0V)

6

Page 8

E6581341

2. Installing the IO card option in the VF-AS1/PS1

2.1. Connection to the inverter

(1) Turn off input power before installing.

Mandatory

Turn off the input power of VF-AS1/PS1 and wait for at least 15 minutes and then check

that the CHARGE lamp on VF-PS1 is no longer lit.

(2) Securing the option to the inverter

a) Insert a flat-blade screwdriver in each of the two holes at the upper part of the front

panel, release the panel mounting tab by pushing the screwdriver down, and

remove the front panel cover.

b) Install the

the slots at the lower part of the inverter front panel.

c) Make sure the option is securely attached to the inverter. Then, check whether the

plastic bosses on the inverter case have fitted in the holes at the upper and lower

parts of the

d) Insert the tabs at the lower part of the front cover into the slots at the lower part of

the inverter to attach the front cover to the inverter.

option in the inverter by fitting the tabs on the lower side of the option into

option*.

a)

* When installing this option to below capacities,

remove the Add-on type option case.

VFAS1: 200V 55, 75kW

VFPS1: 200V 55 - 90kW

400V 90 - 500kW

400V 90 - 630kW

b)

c)

d)

7

Page 9

2.2. Wiring

When conducting wiring, follow the instructions below.

• Use shield wire for control signal line and ground the unit with shield wire

(Use twisted pair shield cable for wiring of the analog monitor output.

• Never bind the signal line and main circuit connection wire together

• Fix the communication cables after connected.

Terminal Block Applicable wire size

The wire length of

peel off the end

Using screwdriver

(The blade tip)

E6581341

)

.

Tightening

torque

TB1 0.2 to 2.5 mm2 About 7mm

TB2 to TB4 0.2 to 1.5mm2 About 5mm

< Input/output terminal interface >

Terminal

symbol

R2A

R2B

R2C

Function Electrical specification Internal circuit

Configuration of 1C contact point

Relay contact

point output

250Vac - 2A (cosφ=1)

250Vac - 1A (cosφ=0.4)

30Vdc - 1A

No voltage contact input

24Vdc - 5mA

Sink input(common voltage 24V)

ON :less than 10Vdc

OFF :16Vdc or more

Source input

ON :11Vdc or more

OFF :less than 5Vdc

LI5

LI6

LI7

LI8

Contact point

input Changeover

of sink or source

Note:

Even when an external power supply

is used (in sink logic mode i.e. when

SINK(PLC) is selected), connect the

reference potential-side (0V side)

cable from the power supply to the CC

terminal.

Lan current signal.

Chose low current contacts to

avoid poor attaching.

24Vdc power output (when SW is

in any position other than PLC)

24V internal output terminal

24Vdc - 60mA max

If SW is turned to the PLC position,

this terminal can be used as a

common terminal when an external

power supply is used.

PLC/

P24

24V power supply

Common terminal

for external

power supply

0.6mm thickness

and 3.5mm width.

0.4mm thickness

and 2.5mm width.

R2A

R2B

R2C

SINK Logic(SW=SINK(INT))

P24/

PLC

SW

SINK

(INT)

LI5

LI6

LI7

LI8

2.2k ohm

CC

SINK Logic (SW=SINK(PLC))

P24/

PLC

SW

SINK

(INT)

LI5

LI6

LI7

LI8

2.2k ohm

CC

SOURCE Logic (SW=SOURCE)

LI5

LI6

LI7

LI8

SW

SINK

P24/

(INT)

PLC

CC

0.5 to 0.6 Nm

0.22 to 0.25 Nm

Ry

SINK(PLC)

2.2k ohm

2.2k ohm

2.2k ohm

2.2k ohm

SINK(PLC)

SOURCE

P24

SINK(PLC)

SOURCE

P24

P24

SOURCE

8

Page 10

f

Terminal

symbol

TH2+

TH2-

N10

OUT5

OUT6

NO2

E6581341

Function Electrical specification Internal circuit

The resistance between TH2+ and

TH2-

Thermal trip input

Tripping value: about under 50 ohm

Reset value: about 1.8k ohm

-10V power supply DC-10V - 10mA

Open collector output

Drive current

Multifunction

programmable

open collector

output.

External power supply used : 50mA

Internal power supply used : 20mA

Drive voltage

12V min - 30V max

Isolated other circuit.

or over 3k ohm

TH2+

10k ohm

TH2-

N10

100 ohm

OUT5

OUT6

NO2

3k

20 ohm

20 ohm

P5

Voltage

detection

circuit

OP

MON1

MON2

CC

AI1+

AI1-

AI2+

CCA

RP

Common to

input/output

Differential current

input

Analog input

Monitor output

Pulse train input

Digital signal equipotential (0V)

terminal for the control circuit

Current input :

Equal or under 20mA

Voltage :

Differential input voltage under 5V

Input voltage from –10V to 10V

Current input :

Equal or under 20mA

Voltage input :

0 to 10V

Multifunction programmable analog

output.

-10V - 10V output

0V - 10V output

0mA - 20mA output

Input pulse

Voltage : 5Vmax

Current : 15mA max

Frequency : 30kHz max

Duty : 50±10%

The resistor is needed when input

voltage is over 5V to 30V if the

current is under maximum current.

AI1-

AI1+

AI2

CCA

MON1

MON2

RP

R

CC

Von > 3.5V

Vof

< 1.2V

242Ω

16.2k ohm

242

0 - 20mA

235

4700pF

OP

15k ohm

121 ohm

-10V - 10V

121 ohm

0 - 10V

68 ohm

Vf = 1.3 - 1.85V

(at 10m A)

OP

OP

OP

9

Page 11

E6581341

3. Functional description

In this section, functions added by the installation of this expansion IO card option, on

top of the standard inverter functions, are described.

Note: When power on or reset the inverter, the initialization of the ETB004Z terminal

inputs and outputs are delayed about 300ms from the inverter own terminals.

3.1. Multi-function output terminal

Two output terminals and one relay output can be added. Function is similar to that of

the output terminals of the inverter, so refer to the inverter instruction manual.

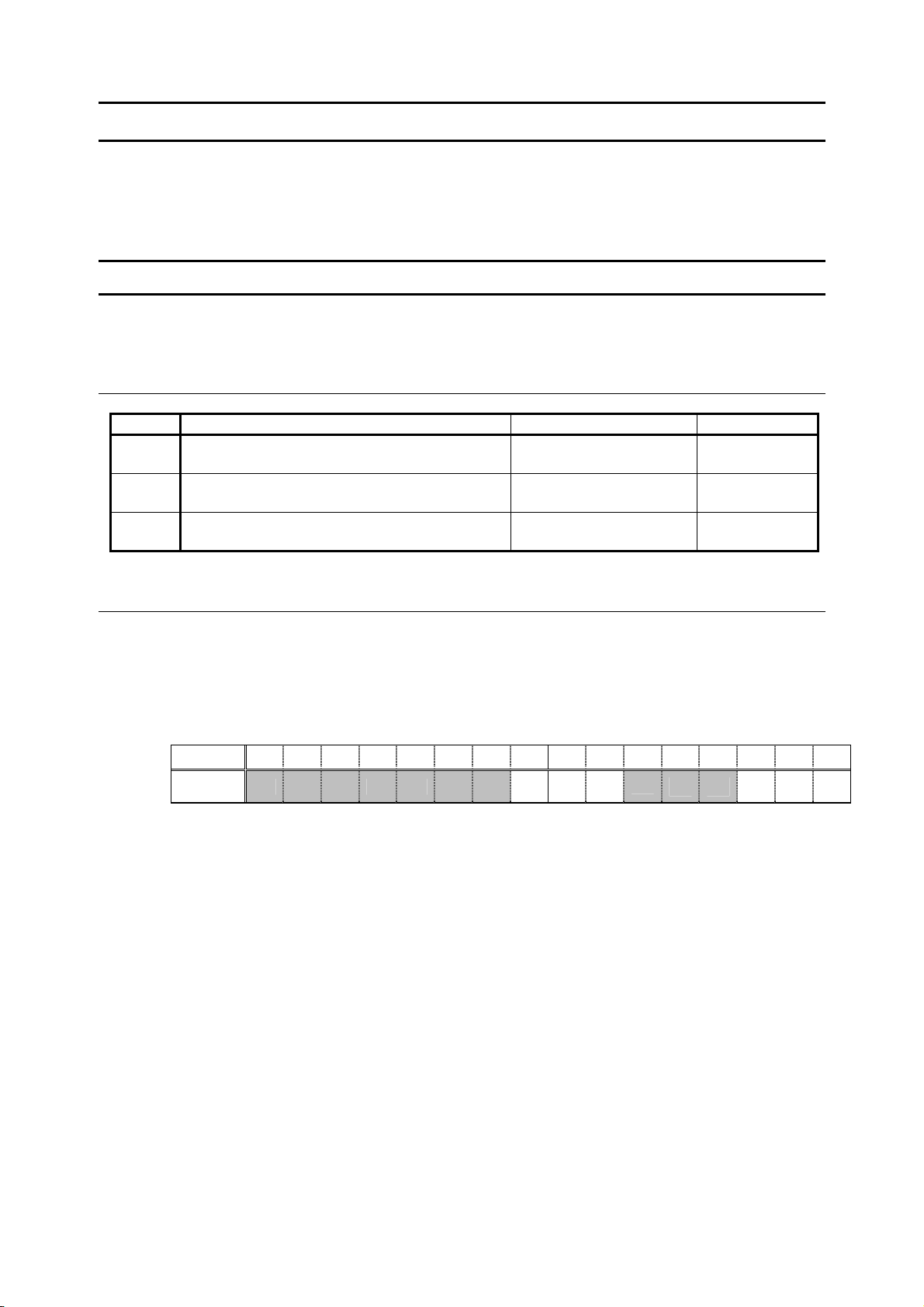

Parameter

Title Function Adjustment range Default setting

f136Output terminal function selection 7 (OUT5) 0 - 255

f137Output terminal function selection 8 (OUT6) 0 - 255

f138Output terminal function selection 9 (R2) 0 - 255

(Always OFF)

(Always OFF)

(Always OFF)

254

254

254

Monitor

fe07

Note: The OUT3, OUT4 and R1 are the terminal function of the expansion IO card option 1.

Refer to the description on status monitor mode of inverter’s instruction manual.

The output terminal status can be monitored by the output terminal status parameter

(fe07), and the parameter can be monitor by the serial communication.

bit No. 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

OUT

Symbol

--- --- --- --- --- --- ---

R2

OUT6 OUT

5

R1

4

OUT

3

FL

OUT2 OUT

1

10

Page 12

E6581341

3.2. Multi-function input terminal

Four output terminals can be added. Function is similar to that of the input terminals of

the inverter, so refer to the inverter instruction manual.

Parameter

Title Function Adjustment range Default setting

f123Input terminal selection 13 (LI5) 0 - 135 0

f124Input terminal selection 14 (LI6) 0 - 135 0

f125Input terminal selection 15 (LI5) 0 - 135 0

f126Input terminal selection 16 (LI5) 0 - 135 0

f145 *Input terminal 13 - 20 response time selection 5 - 200ms 8

* VF-PS1 does not have this parameter.

Monitor

Refer to the description on status monitor mode of inverter’s instruction manual.

The input terminal status can be monitored by the input terminal status parameter

(fe06), and the parameter can be monitor by the serial communication.

fe06

bit No. 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Symbol

LI8 LI7 LI6 LI5 LI4 LI3 LI2 LI1 S4 S3 S2 S1

Note: The LI1 ~ LI4 are the terminal function of the expansion IO card option 1.

3.3. -10V power supply

The frequency command can be input from RX terminal with pulse and negative voltage

using N10(-10V) and PP(+10V) power.

Inverter Terminal

PP(+10)

RX

2kΩ

Option Terminal

N10(-10V)

RES

ST R F

Potentiometer

Center position: 0V command

Pulse side position: +10V command

Negative side position: -10V command

The recommended wiring cable length is

less than 1.5m with shielded cable.

11

Page 13

3.4. Multi-function analog output

V

MON1, MON2 terminal output +/-10V, 0 - 10V, 0 - 20mA (4 - 20mA) analog signal.

Example : MON1 output (0 - 10V)

Gain adjustment:

f673

Example : MON1output (-10V - 10V)

10

E6581341

Gain adjustment:

f673

Bias adjustment:

f690

0V

0%

Gradient

characteristics

f689

100%

-100%

0%

-10V

Bias adjustment:

f690

Gradient characteristics

f689

(

) is invalid when the

output setting is -10V - 10V.

Parameter

Title Function Adjustment range Default setting

f672MON1 terminal meter selection

0 - 64

(4: Output voltage)

4

f673MON1 terminal meter adjustment --- ---

f674MON2 terminal meter selection

(5: Compensated frequency)

0 - 64

5

f675MON2 terminal meter adjustment --- ---

0: Voltage -10 - 10V output

f688

MON1 voltage/current output switching

1: Voltage 0 - 10V output

1

2: Current 0 - 20mA output

f689

MON1 output gradient characteristic

0: Negative inclination

(downward slope)

1: Positive inclination

Note1

1

(upward slope)

f690

MON1 bias adjustment -10.0 - 100.0% 0.0

0: Voltage -10 - 10V output

f691

MON1 voltage/current output switching

1: Voltage 0 - 10V output

1

2: Current 0 - 20mA output

f692

MON2 output gradient characteristic

0: Negative inclination

(downward slope)

1: Positive inclination

Note1

1

(upward slope)

f693MON2 bias adjustment -10.0 - 100.0% 0.0

Note1: When MON1 (MON2) setting is the voltage -10 - 10V output, f689 (f689) setting is invalid

and the MON1 (MON2) gradient characteristics becomes the positive inclination.

100%

3.5. Differential current input (AI1+, AI1-)

The frequency command can be input from the differential current input AI1 and AI2

terminal current. Keep the each terminal voltage from CC terminal from -10V to 10V, and

keep voltage under 5V between each terminal.

12

Page 14

E6581341

Parameter

Title Function Adjustment range Default setting

f222AI1 input point 1 setting -100 - 100% 0

f223AI1 input point 1 frequency 0.0 - fh Hz 0.0

f224AI1 input point 2 setting -100 - 100% 100

f225AI1 input point 2 frequency 0.0 - fh Hz 60.0

f226 * AI1 input point 1 rate

f227 * AI1 input point 2 rate

f476

f477

* VF-PS1 does not have these parameters.

Optional AI1 input bias 0 - 255 --Optional AI1 input gain 0 - 255 ---

-250 - 250%

(for torque control etc.)

-250 - 250%

(for torque control etc.)

3.6. Analog input (AI2)

The frequency command can be input from the voltage or current analog input.

0

100

Parameter

Title Function Adjustment range Default setting

f109

f228AI2 input point 1 setting 0 - 100% 0

f229AI2 input point 1 frequency 0.0 - fh Hz 0.0

f230AI2 input point 1 setting 0 - 100% 100

f231

f478

f479

Analog AI2 (optional circuit board)

voltage/current switching

AI2 input point 1 frequency 0.0 - fh Hz 60 (or 50)

Optional AI2 input bias 0 - 255 --Optional AI2 input gain 0 - 255 ---

0: Voltage

1: Current

3.7. External thermal trip input (TH2+, TH2-)

By connecting the thermistor to TH2+ and TH2- terminal, when the thermistor value is

unusual, the inverter can be trip.

The resistor value

between TH2+ and TH2-

about under 50 ohm Thermistor short broken detection oh2 trip

about 50 0- about 1.5k ohm Normal value ―――

about 1.8k ohm Thermistor fault reset ―――

about 3k ohm Thermistor fault detection oh2 trip

Detect condition Movement

0

Parameter

Title Function Adjustment range Default setting

f638PTC thermal selection

13

0: Deselect

1: Select

0

Page 15

Expansion IO card option

3k

PTC

thermistor

TH2+

TH2-

3.8. Pulse train input (RP)

The frequency command can be input from the pulse train input.

Parameter

10k

E6581341

P5

Voltage

detection

circuit

Title Function Adjustment range Default setting

fmodFrequency setting mode selection 1

1 - 12

11: RP pulse input

f234RP/high speed pulse input point 1 setting -100 - 100% 0

f235RP/high speed pulse input point 1 frequency 0.0 - fh Hz 0.0

f236RP/high speed pulse input point 2 setting 0 - 100% 100

f237

f378

f660Override additional input selection

RP/high speed pulse input point 2 frequency 0.0 - fh Hz 60.0

Number of RP terminal input 12 - 9999 500

0 - 12

11: RP pulse input

2

0

14

Page 16

4. External diagram

Do not forget to reserve the space for the options at time of installation.

External diagram of option (unit: mm)

Dimension of optional unit

E6581341

The control panel depth increases about 21.6mm when the option is installed. Secure

the front space from the inverter control panel fully. The space which is necessary for the

option installation varies in the inverter capacity rate. Please refer to the inverter

instruction manual.

15

Page 17

5. Specification

<Environment Specification>

Item Specification

Indoor, less than 3,000 m from the sea level.

Use Environment

Ambient Temperature 10 to 60℃

Storage Temperature 25 to 65℃

Relative Humidity 20 to 93 % (No condensation)

Vibration 5.9m/s² (0.6G) or less (from 10Hz to 55Hz)

< Control specification >

Function Specification

Relay contact output

Multi-function programmable output

Contact point input

(Changeover of sink / source)

Multi-function programmable input

24V power supply DC24V - 60mA

External thermal trip input 1 circuit. The detection level is below.

-10V power supply DC-10V - 10mA

Open collector output

Multi-function programmable output

Differential current input Accuracy : ±0.2% (25±10℃), Resolution : 11bit

Analog input Accuracy : ±0.2% (25±10℃), Resolution : 11bit

Monitor output 2 circuit

Pulse train input Input pulse

No direct sunlight, corrosive or explosive gas, steam, cutting dusts or

dusts, grinding solution, and grinding oil.

1 circuits for output of 1C contact point

250Vac - 2A (cosφ=1)

250Vac - 1A (cosφ=0.4)

30Vdc - 1A

4 contact inputs

Sink input (24V common voltage)

ON : less than 10Vdc

OFF : 16Vdc or more

Source input

ON : 11Vdc or more

OFF : less than 5Vdc

Tripping value : about 50 ohm or less,

or about 3k ohm or more

Reset value : about 1.8k ohm

2 circuit

Current : 50mA max with external power supply

20mA max with internal power supply

Voltage : min. 12V, max 30V

Input resistance : 31.2k ohm (voltage input),

242 ohm (current input)

Current input : 20mA or less

Voltage input : differential voltage input less than 5V

-10V or more, and 10V or less

Input resistance : 31.2k ohm (voltage input),

242Ω(current input)

Voltage input : 0 - 10V

Current input : 20mA or less

Voltage output :

0V - 10V±1%

Current output :

Voltage : 5V max

Current : 15mA max

Frequency : 30kHz max

Duty : 50±10%

E6581341

16

Page 18

6. Warranty

TOSHIBA provides warranty with the product under the following conditions.

1. If and when a trouble occurs on the option unit properly installed and handled within

one year of delivery, and if the trouble is clearly attributable to defects inherent in our

design and manufacture, the product will be repaired free of charge.

2. The warranty covers only the delivered option unit.

3. Even in the term of the warranty, repair/adjustment service will be charged for the

following cases.

1) Fault or damage resulting from misuse, unauthorized modification or repair.

2) Fault or damage resulting from falling down of the product or traffic accident during

3) Fault or damage originating from fire, salt water/salty breezes, some kind of gas,

4) Fault or damage caused by improper use of this option unit as it is used for a

4. If there is another special warranty contracted for this option unit , the special

warranty has priority over this warranty.

E6581341

transportation.

earthquake, storm or flood, lightning, abnormal supply voltage, other natural

disasters.

purpose out of its original function.

17

17E

Loading...

Loading...