Page 1

Mounting

instructions,

sn:

English

03/96

Edition

0323

7223

Page 2

PAGE

p

e

Technical

Data

ピロ

ビ

νι

δω

ビビ

ビビ

ビビ

σσ

O

ποσο

ビビ

2.

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.10a

2.11

2.12

2.13

2.14

2.15

2.16

2.17

General

General

Measures

Component

Equipment

Mains

Measuring

Wiring

Power

Physical

and

Safety

Specifications

and

Designations

Checklist

Connection

Instruments

and

Supply

Location

Electric

Installation

Uncrating

Removal

Mounting

Mounting

Mounting

Mounting

Mounting

Mounting

Drive

Mounting

of

of

of

of

of

of

of

Belt

of

Modifikation

Mounting

of

Installation

Installation

Installation

Reinstallation

Installation

Mounting

of

Procedures

Weights

Current

Field

Covers

Bracket

Tomo

Fulcrum

Tomo

Tomo

Drive

tighten

Tube

on

Tomo

of

of

of

of

of

Covers

for

Data

Required

Diagrams

of

Electrical

Installation

Coupler

Tower

Control

Drive

Belt

on

to

Coupler

DST

100A

Interface

Electrical

Relais

Tomo

Board

Marks

Covers

Tomo

Marks

Shipment

Box

Ceiling

Ceiling

Support

Unit

to

Components

Diagrams

Column

Rail

Arm

Ceiling

WW

AUF

EN

PoONNI

14-19

20

20

20

22

22

22

23

23

23

23

24

25

25

25

26

26

27

27

3.

3.1

3.2

3.3

3.4

4.

4.1

4.2

4.3

4.4

0323

Adjustments

Adjustment

Setting

Timing

Switch

Technical

Mechanical

Functional

Spare

Parts

Inspection

7223

of

of

Layer

of

Exposure

Flap

Adjustment

Maintenance

and

Tests

Certification

Fulcrum

Height

Cycles

Electrical

-

to

2-

Film

Tests

Plane

27

28

29

30

31-32

33

34-36

27

03/96

Page 3

1.

TECHNICAL

DATA

1.1

In

lation

the

lay-out

During

ground

properly

The

components

in

General

the

of

provisions

installation

wire

protective

the

Regulations

and

No

than

If

accident

work

42

it

is

movements

tion

procedure,

pletion

Federal

rooms

plan.

made

and

wiring

may

be

V

(Peak

necessary

of

of

these

Safety

Notes

Republik

used

of

VDE

connections

before

ground

the

diagram.

of

professional

prevention

performed

Voltage).

the

equipment

it

must

movements.

for

it

the

wires

power

to

turn

be

of

Germany,

medical

Standard

is

important

provided

equipment

supply

associations

must

on

parts

in

shut

0107.

betweem

be

carrying

on

the

the

down

the

electrical

purposes

Consult

|

that

by

the

is

the

are

connected

observed.

power

course

immediately

must

conform

installation

all

manufacturer

started

individual

protective

concerning

a

voltage

for

execution

of

the

after

instal-

are

up.

system

as

shown

safety

higher

installa-

com-

to

of

1.2

Note:

The

posures

If

stalled.

General

motor

supplied

Film-Focus

tomographic

Fulcrum

Plane

Angles,

Speeds,

Height

Specifications

driven

with

the DST

with

Distance

exposures:

Range:

Indication:

Tomography:

Tomo

Tomo

Zono

40°

40°

8°:

ET

the

and

and

2000-Tomo

100A.

ET

(FFD)

20°

fast:

20°

slow:

2000,

for

device

several

100

O - 24

Digital

40°

c.

c.

c.

allows

cm

and

24

12

9

parts

cm,

Display

20°

cm.p.s.

cm.p.s.

cm.p.s.

tomographic

are

motor

Zonography:

driven

ex-

prein-

8°

03/96

-3-

0323

7223

Page 4

Approximate

Exposure

Times:

Plane

Height

24

cm

18

cm

12

cm

6

cm

1.3

1.3.1

40°

c.2,1

c.2,1

c.2,5

c.2,6

Measures

1

Crate

Gross

Net

weight

During

Temperature:

Humidity:

Air

pressure:

<<

sec

sec

sec

sec

and

weight

regular

40°

c.4,1

c.4,6

c.5,0

c.5,2

Weights

1350

c.53

c.

c.

work

<

sec

sec

sec

sec

125

58

for

mm

in.

kg

kg

20°

c.1,05

c.1,1

c.1,25

c.1,3

Shipment

x

x

c.30,7

274

127

-25

5%

700

<<

sec

sec

780

lbs.

lbs.

to

to

hPa

sec

sec

70?

95%

mm

to

20°

c.2,1

c.2,3

c.2,5

c.2,6

x

in.x

1100

600

<

sec

sec

sec

sec

mm

c.23,6

hPa

ピロ

QQQOQ

ビビ

in.

“ou

ο

ο

νι

ω

sec

sec

sec

sec

During

transport

Temperature:

Humidity:

Air

pressure:

10°

20%

700

to

to

hPa

40°

80%

to

1100hPa

0323

7223

03/96

Page 5

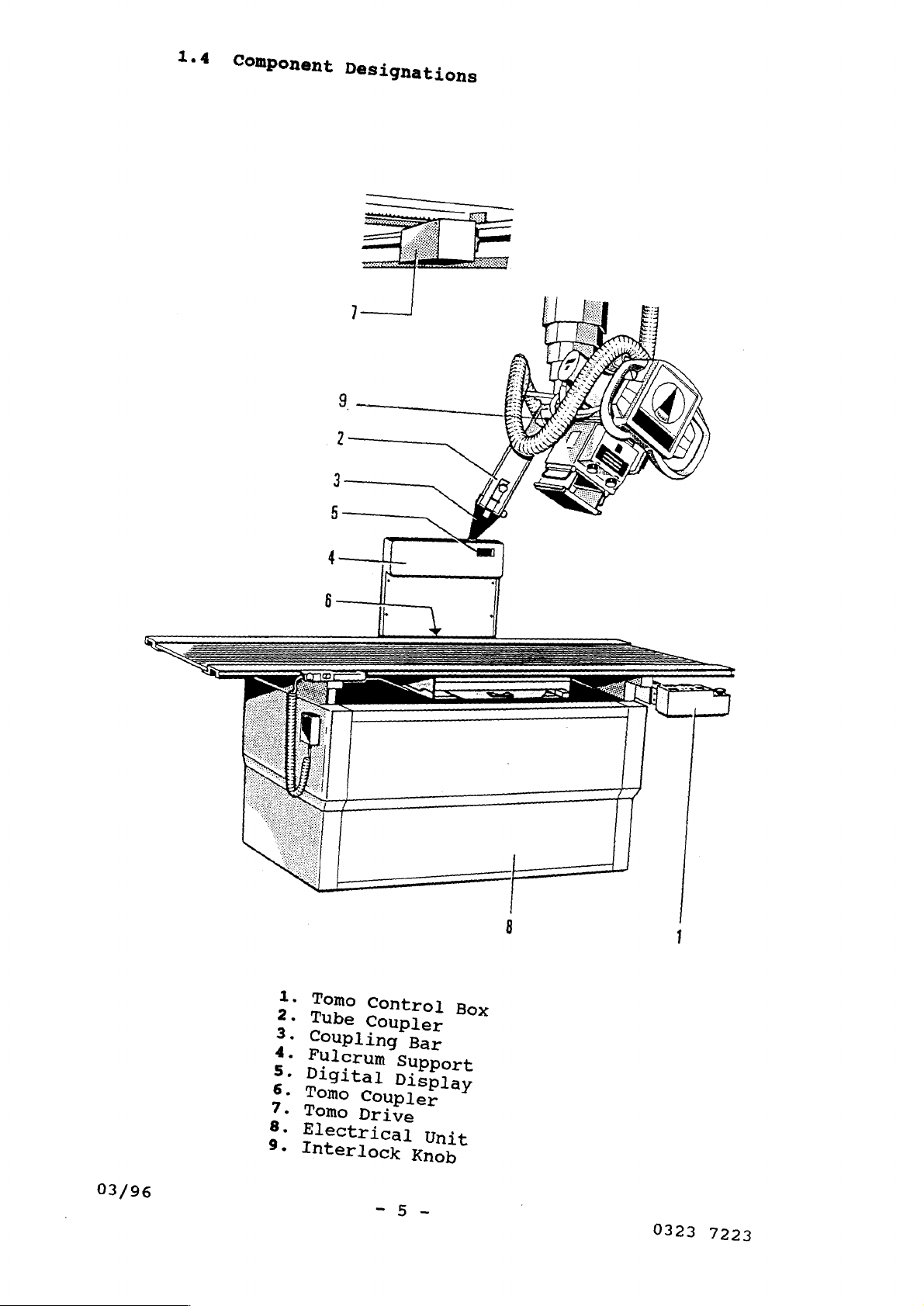

1.4

Component

Designations

ο

Tomo

pa

Tube

Coupling

BUN

Fulcrum

Digital

OU

Tomo

Tomo

au

Electrical

©

Interlock

Control

Coupler

Support

Display

Coupler

Drive

Box

Bar

Unit

Knob

03/96

0323

7223

Page 6

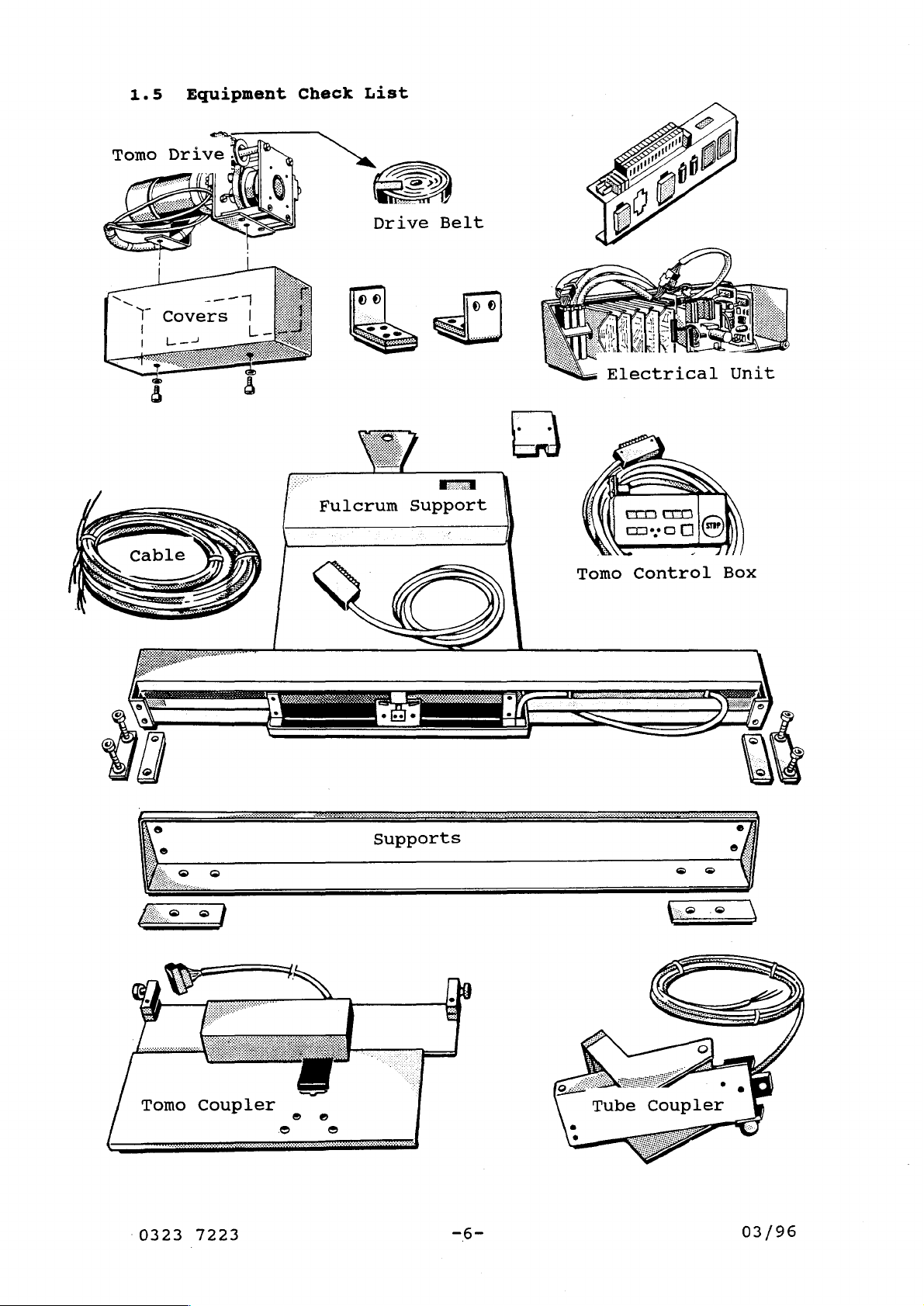

1.5

Equipment

Check

List

Supports

0323

7223

—6-

03/96

Page 7

1.6

The

of

Mains

mains

the

ET

2000.

Connection

connection

Data

is

carried

out

via

plug-in

connectors

Mains

Frequency:

Nominal

Connection:

Nominal

1.7

Air

Phontom

Measuring

Level

Current:

Capacity:

Instruments

230

50/60

A

1

0,2

Required

V

(2)

KVA

or

Hz

115

V

03/96

-7-

0323

7223

Page 8

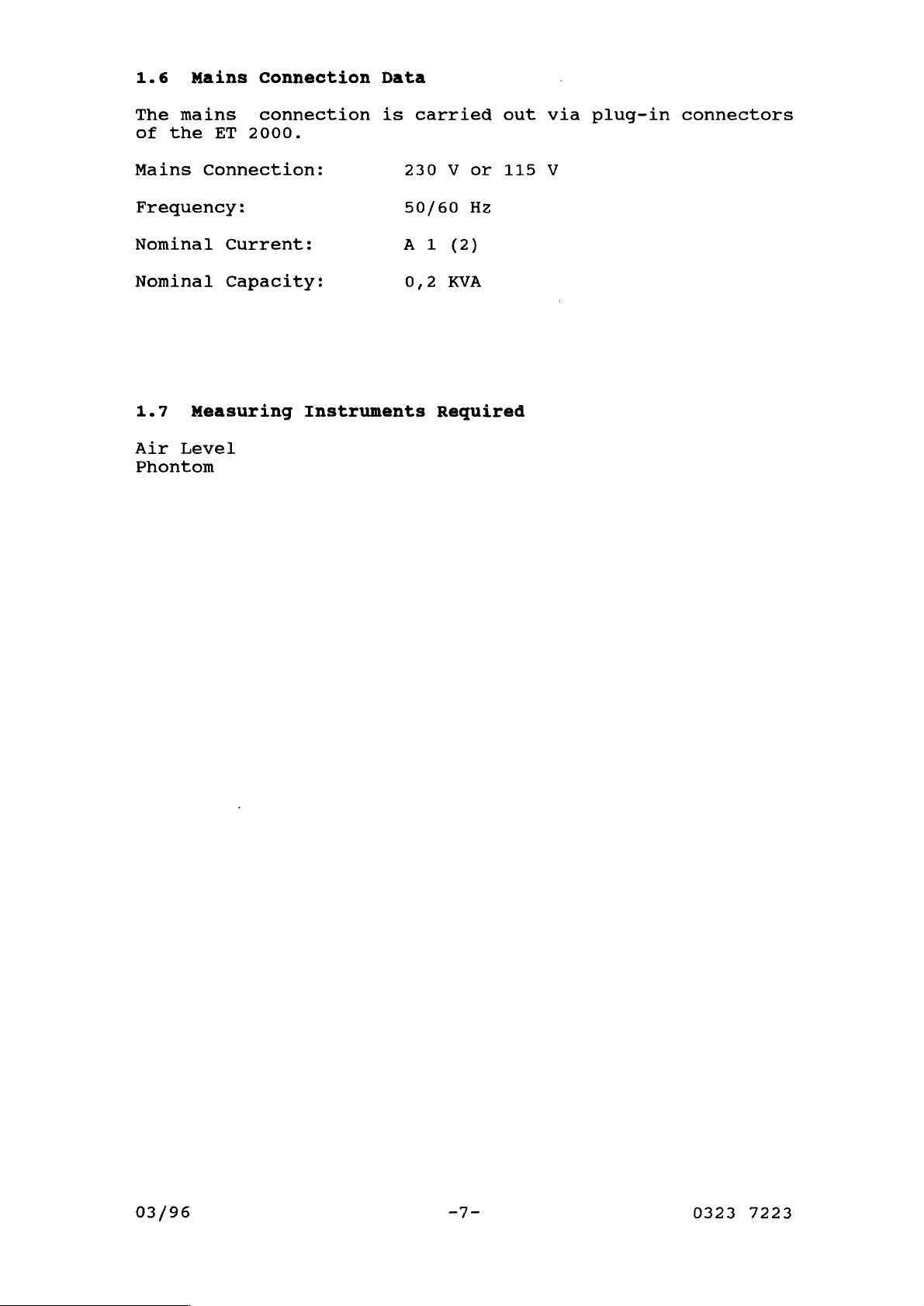

1.8

W

1r1

ing

Diagram

"ET

poe

Le

so

ε

(GS-SEA3)

で

0003

i

SAe6E

LE

#/86E

È

6€

:

!

|

7

Tot

(666)

666

i

+

8/6£

V/BE

5

Е

D

>

>

076€

2/66

1

<)

1768

9

,

376€

=

ro

o

一

一

L/e6E

60966

二

一

+

이

6

T

H76E

T/6E

o

EL/e6€

El

L

ER

$

2

176€

メ

/6E

4/26

È

Y

yi

(V)

;

【0-

う

Ys

iz

。

:

1

se

zzo-

nol

mm

O

7750;

“DOE

ul.

で

5-9Y

|

c

|

う

EXD

FDO

《A-9Y

COTTI

7

OTHER

Sf

う

fh

di

İma

»

>

ari

©

DA

Sw

Hood

ix

LAV

>

БУТ

3

>

E

LISO

TRE

0

3S

A

to

3252

+

x

dt

ne

be

pe

è

に

に

seh

ex

+

Ex

È

se

PR

Ba

Ab

>

iP

>

—*

>

d

+

=

5

ESE

SE

izlel“

EE

ES

+

ss

Y

x

zčšéx

&

2°

č

56

”

606)

ISA

7

OS

|

=

Mo

ye

sX7502

el

|

た

Vi

ara

+

し

주

[은은

loloty

|

は

し

8

し

中

|!

echa

E

KİSİK

UE

ICI

olè

>

10

BIT

rd

DIS

TERESA

ETE

nad

i

q

s

E

ο-

s6razuy

kerdsip

860

SUe6E

D

5

A

PF

i

|

+

[in

“ли

„esp

<

|

a

VA,

гих

——

M/6E

2/6

AZE

SZC

555665

二

T

Risigse

55

BR

sis

RR

155

Bee

Is

sis

ほ

5

>

5

jojslel>

sls

sis

に

E

©

©

©

©

©

©

©

om

O

WM/tee

9/e6E

si

u

5

8

때

ーー

HE

9%

SI6€

He

sus

sr

ии

-

“au

*

s.

u

9

ve

ta

Tae

amı

at

E

©

nevi

—

A

HEADS

“

vacci

ED

MK

DE

PEREA

KE

]

00705

σε

e

τί

と

τα

[A

are

AAA

HME

zo

er

к

C

5

λε

ee

한

rad

E

<

Ny

O/LEVÝ

Е

a

Е

ÆRE

|

ες

49

70%

ví

©

ει

2/0€

タイ

リコ

Ио

De

/%E

v?

TEE

ulk:

5С

ae

129€

ここ

3770

うーーー

82/86

26

5/6E

XVe

С

92/SE

“て

U,

M

ye

A/9T

X

|

|

2066

7

TA

ㅜㅜ

LIVRE

~

C

9/e6E

ar

<

3/6]

[RAE

S/EE

RI

47

》

一

IRENE

sx

一

て

ZA

fie

É

-

[UR

Li

ВЕ

НЕВЕ

ES

02/5E

FO

1/8%

LINE

Sia

3

HA

JA

TTC

ZETEC

W/LE

em

Hıza

ace

ATA

EYE

V/6€

©

Tar

527%

L1/8E

İS

TO

MA

OL/R6E

9/86E

=

[279

7

NO

7?

TUSX-DW>

TAX

rex

v

с

Passe

®

0L/9€

uC

УЕ

82/9€

σος

RAE

τς

K

—

a

70%

x

тс

or

a

A

ас

~~

71/06

A

Jet

æt

m

πε

ROE}

[6179

[LZ/IE

ИЕ

區

/

$

a?

NT

в

>

EYE

SUSX

Gis

€l/sx-Dw=

ay

Dye

OY

u/se

+

rg

<

Mir

K

ro

50

SIE

s

<

|

[are

て

VV

a

E

rest

Tar

z

m

ni

-re

pase

ii

8/6

<

975

use

I;

c

7)

Е

(x

Na

>

УЗВ

|

|

!

|

!

TS

ー

TEP

hs

my

02796

yo

Гия

て

ie

YE

LT

ar

vee

En

75

l'as

ep

Re

€

下

EC

RE

IZLE

D

wor

nor

ze

9/98

AC

3°

MT

ACT

ZseE

6i786€

gi/86E

-

a

9/46

RC

M

pach

<

8706

/

Τσε

у

fee

Z9E

E

AT

^

2

AAA

4/5X-9Y=

ws

N/A

WSK“

-0\=

v

|

oy:

と

TAR

HA

|

AA

|

HE

sz

se

Tare

ЕЛЕ

|

πι

7

via

FA

WC

TA

DE

wC

Ня

s

ELE

77E

ooo

с

9

で

270

σος

|

S

NEI

ose

、

一

一

Wale

一

一

>

QD

va

"<

Γκαρ

ze

ας

za

anal

一

RT

一

ec

EAS

CC

EL/LE

Se

ue]

92/0€

pe

yor

©

E

了

-一

一

-一

一

一

一

-|

e

ia

+

τση

τς

흐름

y

Le

НЕЕ

EE

aC

E

ED

e

ua

FER

be

AT

τς

be

ec

ge

8/6£

3

KI

TE

W/6E

3766

11

mr

DE/O£

62/0€

LEZDEİ

[57606

E/R0E

τς

τὸ

v7

€

>

2

9/9(-0

5/99

SAS

버

7

-

7

i

=

i

”

|

E

L

上

に

go

7707

cage

вы!

n

VSx-9b=

><

Sí

Dj

1

SU

3T*

FEET

75005

aca]

ZE

ci

うーーーーーーー

9/5Xx-9b=

———

v

0323

7223

DI

Ty

ως

E

Z,

PBD)

ursos

ops

car

=

"3

01

<

0/5X-96=

|

SD

р

о

=

8

GE)

9

ロニ

S

“av

69/10

-Ζ1/0ἱ

X-9v

=

TOBY

ELE

IO

nie

し

9

о

OX

ABN"

И"

E70ZX-BV*

AV"

トー

—

HE

HAS

人

O

e

ane

SEAN

XY

]

BB

-

o

371

SAS

m

?

na

6"

qn

875ZX-BVY=

670ZX-dV*

0U0LX-9V]

ae

3

|

WAT

MAY

22022]

7

o

7

7

|

Tİ

[ans

a

==

É

DT

dei

[249

a

Mg

la

LE)

2/EY-Ib=

=

Alo

lun

00

HO

Es

-owo]

43045

B/IE

E

1790

D

E

ㄷ

22

e

o

上

一

ST

KB

STE

(0

кю

ADV

37?

©

|?

3

č

]

i

03/96

Page 9

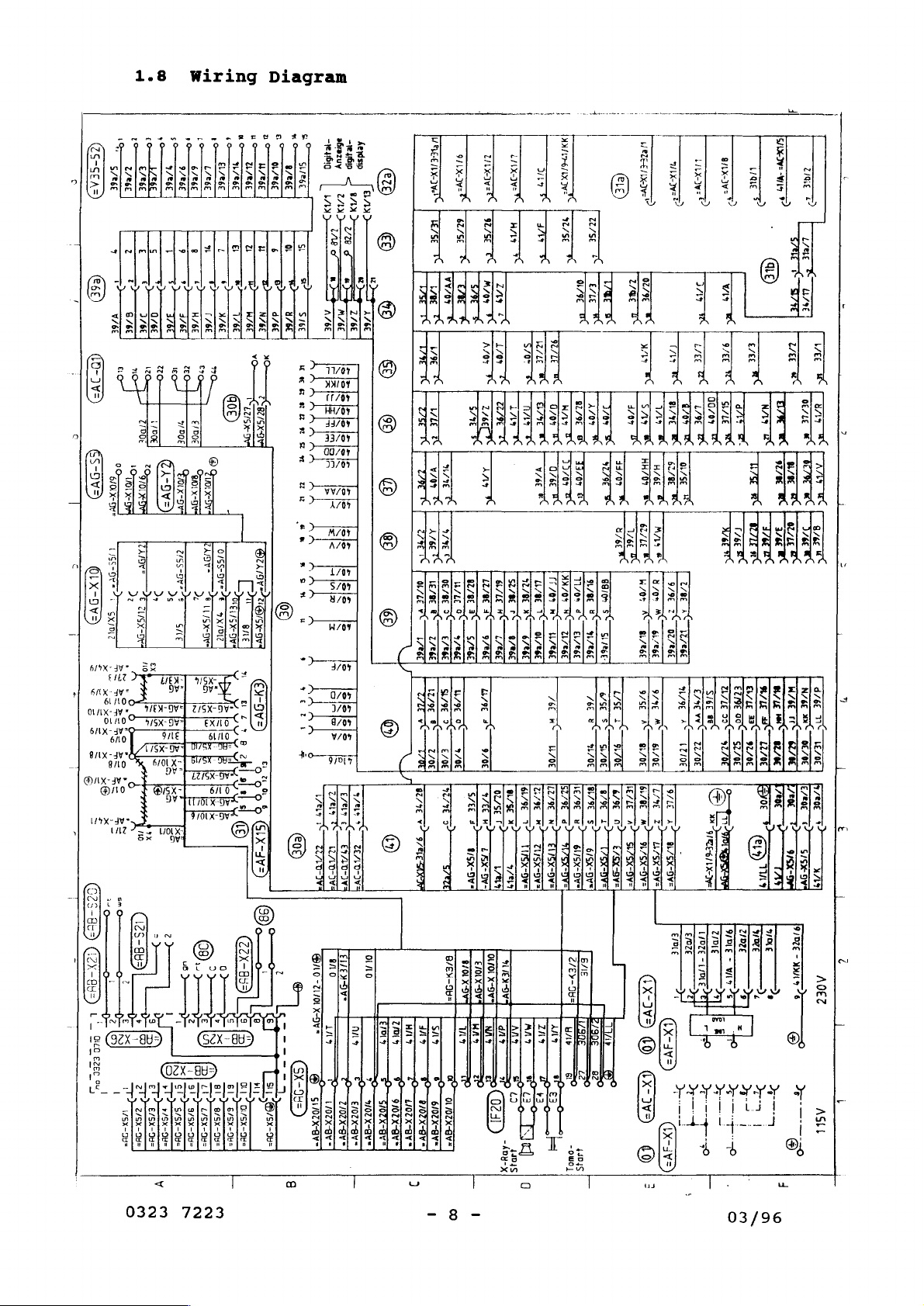

1.8.1

Current

Diagram

<

|

ZLI

vuo

ae

mek

4

33/09

|

Ц

95

—

た

SZ/0E

Å

이

42

“ny

ZH0O9/A0S

A0€EZ/GSIL

DAIYSO]

AI4DJSUSYI9(

AOEZ

IN}

ASK

OWOL

у

SL/TE

A

AAA

Y

OY

|

i

L

OY

>

1

|

|

|

1

“ay

-

„te

À

Ξ

2

|

|

va

+4

ζ

||

|

|

|

=

00705

4

9384

se

halısı

08A

set,

1

voe]

il

108€]

TE

|

|

dy

ae

;

|

-一

avs

SO

一

|8

一

一

;

Peer

LE

a

ή

KEM

LUNE

上

|

LOE

me

au

02706

a5pno

FE

were

|

|

|

|

|

|

=

25

05

>

e

Ard

dns

|

E/DiE

©

D

Е

>

|

|

¡

/

sf

.

|

|

|

REA

sie

AA

LEA

any

moj

|

:

|

。

LISE

A

332%

ELZE

à

62/8E

AARÓN

SATA

АЧХ

МИА

ТЕ

vi

1/DLE

で

S/DZE

>

LE

!

|

ER

=

|

|

|

3

we

>

vel

|

|

MEG

SEN

L/0

e

v

ny

|

|

>

>

κα

ケー

|

$

Ema

ml

Ť

|

i

|

|

|

ZEY

wind

5

=

TT

Y

39

Dig

x

0./5€

θε

OE

LED

ote

|

|

(AO

UK

|

lino

LAK

la

59€

Y

-

9

|

|

RLS

4

—_

pen

|

ELA

и

|

69A

더

zooms!

LA

[zoom

OLA

[τοπ]

LL

=

coord

"L

[zoom

SL

©

o

L

|

i

i

|

|

|

|

--

BE

©

Bud

o

3

AE

9

미

09

9

YE

99

19

VEL

τς

89

as

uso]

αξ

[η

—

|

71

|

|

85755

95

-

GE

の

sc

za

VOZEM

>

8

|

テナー

8

|

イイ

|

|

3

sa

Si

МЕ

I

TTT]

i/$E

I

LUNEY

|

!

|

|

|

|

Li

“ol

DOS

WLE

2AE

|

|

une

|

i

|

LINED

E

0231

>

ζ

49518

ον

“|

AA

+

|

ps

L--

o

1

“buo?

JD

rave

O,

10

„©

@ax-avely

710

A

一

一

一

二

一

一

一

一

一

一

一

一

7

o-

РЕ

3

-

É

ZL/0LX

-Dy=

2

ь

03/96

0323

7223

Page 10

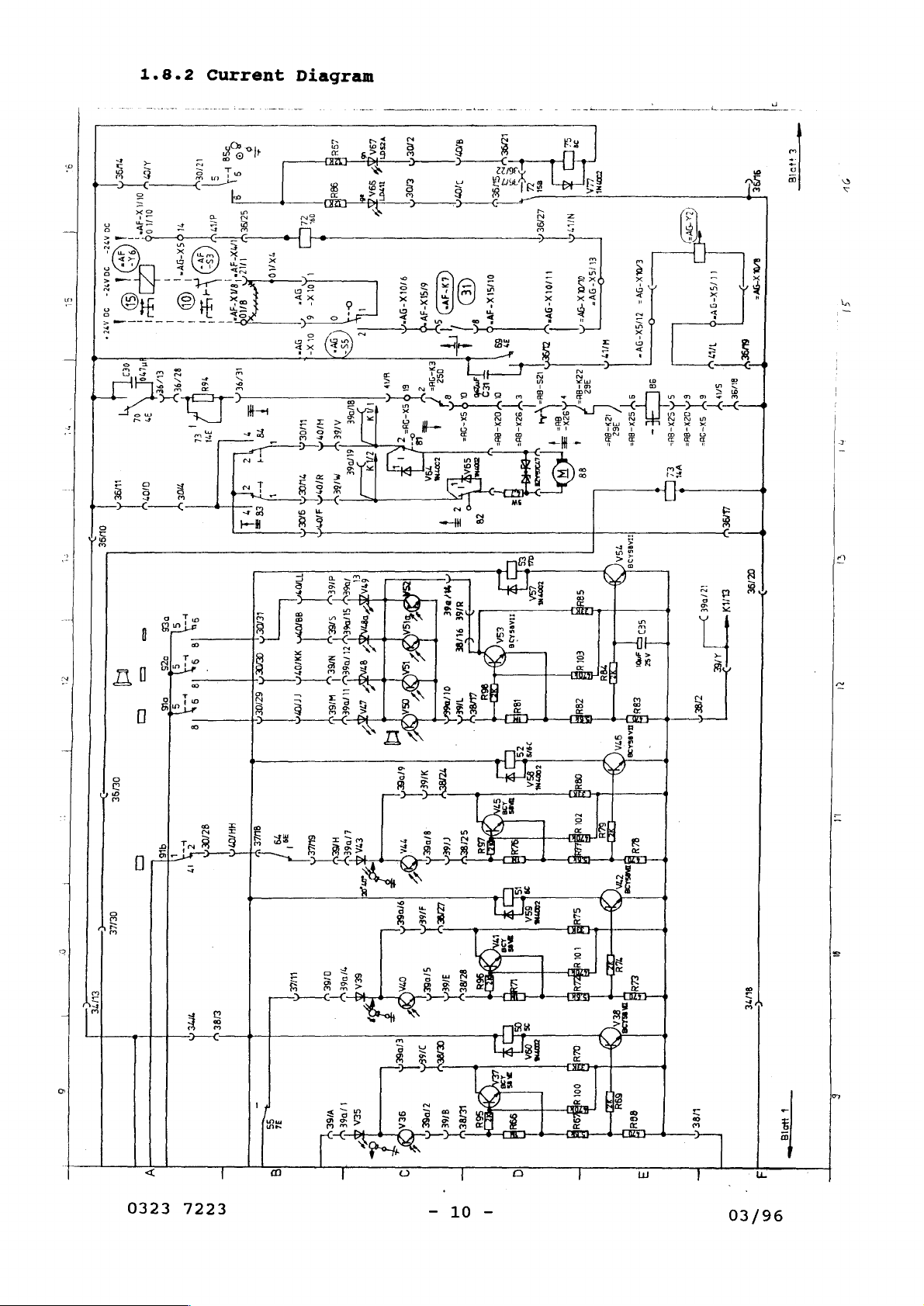

1.8.2

Current

Diagram

?U9E

3

Г

st

|

PH

т

Zerrin

=

στ

АК

[or

|

OL

36

0

1

^72-

65)

COE

29492-

|

©

DG

i

|

A7

|

não

063

37

0

PSE

0/07

|

01798

=

=

더

σα

I

DES

075

PIS

12706

5

817

53а

F-

8°

9

aj

SET

20Е

van

ESA

Z98

09

ZL

seu

A

ns

11507

A

EME

On

2079)

oo

|

(CA

DE)

SUSE

A

Е

НОВ

rampa

2v

(rav)

GE)

al

/

č

|

4/066

HSE

9L/8E

OL

mec

1/6E

OL/SLX-

Jv"

8

z|

DY

OCX-Bb=

ze

ESA

3%

“oes

=

E

ES

oy

4

ITARSAIG

.

an

tam

9/01

saca

X-9¥"

1

I

|

|

i

A

5

8

FA

S

・

8

3

S

|

8

ーー

LEDEM

EIDE

|

6204

|

Tw

]

da

al

OTA

|

[1/07

|

Pose

d76E

T

ЗОВ

SIE

Y

21

NEN,

DGE

Y

LL

HISEW

D6E:

GAR

A

M

ww

ong?

EL/5X-9V=

14/01X-9

OMOLX

LIOLX-Dys

-9V=

zzyーBB=

zs-

362

GZX-

시

y

σσ

28

sas

ML9

124788

|

EALX-OW=

TUSX-DV=

sy

sara

36z

massas

A

ョ

ビー

oAsax-aue

고

5

へ

ロ

ZX-

昌

=

vm

a

210€

|

((/5X-gV

>

SUSE

v

Βἰ/9ε

DET

sy

m-

gey

品

10

АЛЕ

RANA:

|

+

+

+

OZ/SE

P

at

m

pro

<

u

DEISE

НН?

9Z/OE

CU

916

L

σα

ーー

|

ELITE

T

06746

re

y

SULE

р

d

|

一

eee

=

ет

a

|)

|

39

oe

」

HÆE

İ

L10667

em

2

r=

À

<

~

LI

suUTE

ー

で

e

+

|

|

a

一

3

=

eia

J

,

5

un

LE

Q/6€

T

VIGE

Y

106€

SEA

11

sea

96E

B”

E

3

=

0323

7223

10

03/96

Page 11

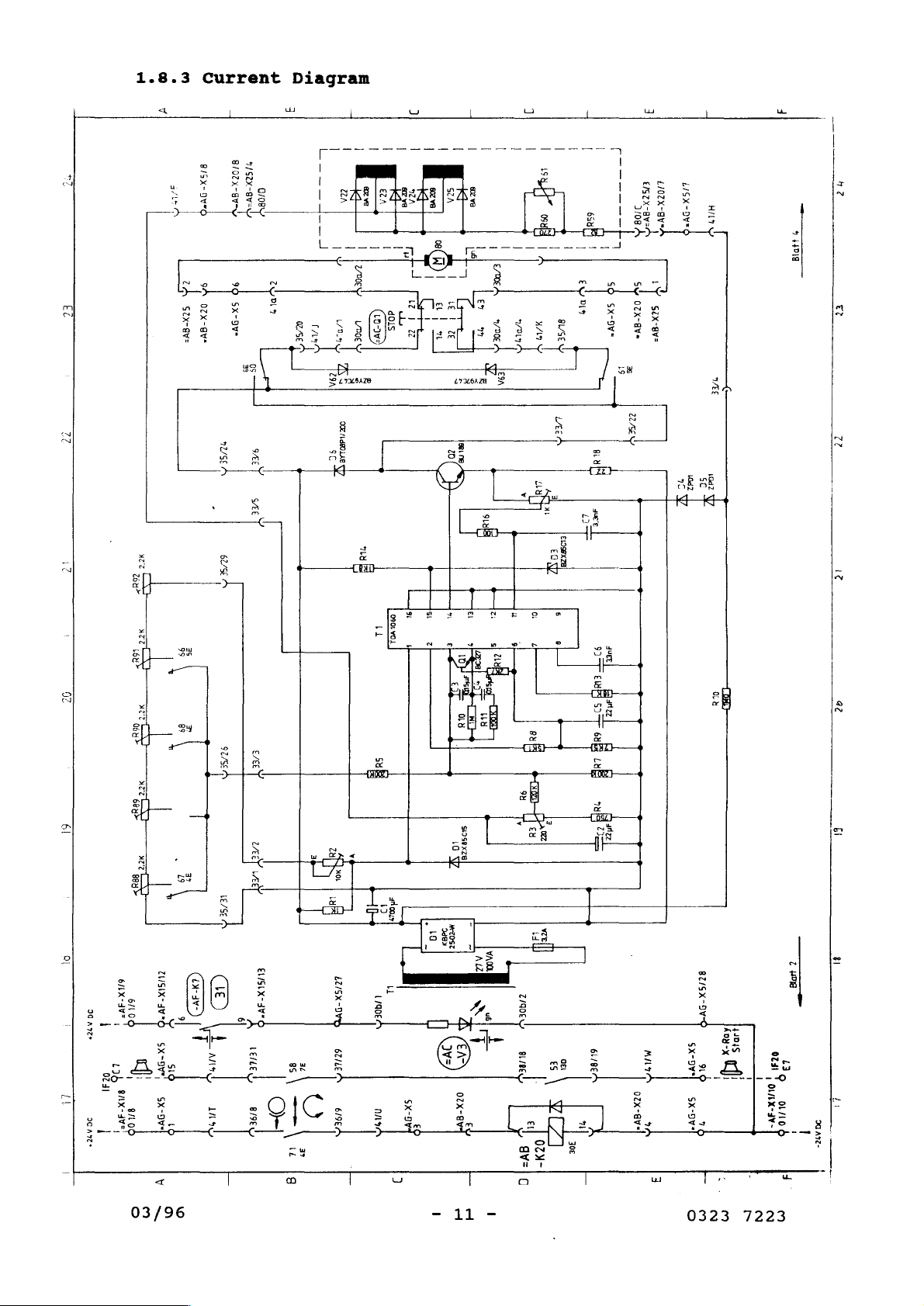

1.8.3

“2

зи

Current

B/02K-

8/5X-

avy

DW

ZÁ

EC

S7x-8v=

22

iz

9

6ἱ

!

9

ZU/SIX-4V*Ď

64x-307

610

LI

39

^лэё+

IAM

i

0231

|

|

Ч

Db

SUAVE,

ano

|

SX-DV5

|

σχ-ον"

9

$

【

90

94

|

Sx-Dv-

0ZX-8v

ッ

の

SE

-

(>)

CE)

7

Lan

ins

Diagram

|

|

also

0/08

aval,

PANA

IN)

Os

Εμ

we

on

|

ZA

|

|

|

レ

Ὕ

İzi

AS

SA

E

OC

/νάΡΟ1Λ8

9,

AE

SAL

E/EE

Y

LÆRT

A

可

LÆG

し

ESLX-

AVE

A

tele

BEL

O

9

85

36

LE

EM

3

O

ro

|

ig

ETISX-9

GTILE

6/96

9C

7

ny

i

09001

bd

Su

—

„ony

İM

u

1790

-

A

NAN

|

|

|

!

ンジ

Ls

st

ζ

ㅣ

Ly

。

348%

19

_

SX-DYA

εφ

|

|

|

Ve

5

À

ва,

eN

пе

CIR

「

z

“

와

29028

0

로

ーー

weosz

a

>

x

T

i

02x-evY

|

|

|

ESA

-

za

v

οι

4

£

eu

«

sx

나

EN

吃

we

id

27906

ФЕ

.

ει

02%-

gv-

=

|

|

VER

al

coy

ss

3

ες

-

£1058X

78

σει

|

30€

|

seyfi

aee

LT

|

927

emp)

or

вай

Lu

vali

12

6L/8€

ui

19

|

3υεε

azz

ala

E/SZX-8v=

470ZX-BV

-gy=

1

À

Γι

ay:

x

usem

|

+

|

MIS

о2х-ву*

9

21SX-9Y=

НИЯ

|

EE

で

1042

56

y

yy

TDK

이선

6775X-9V

J

Аоз-х

SX-DY*|

9%

1

UU)

σχ-ον”

9

44045

pl;

i

1

—

9

44018

一

—

7

—

ung

e

O24!

13

|

ounx-av-

01/10

DO

AT-

I

t

EL

72

tz

a?

fi

gl

L

|

03/96

11

0323 7223

Page 12

ZE

と

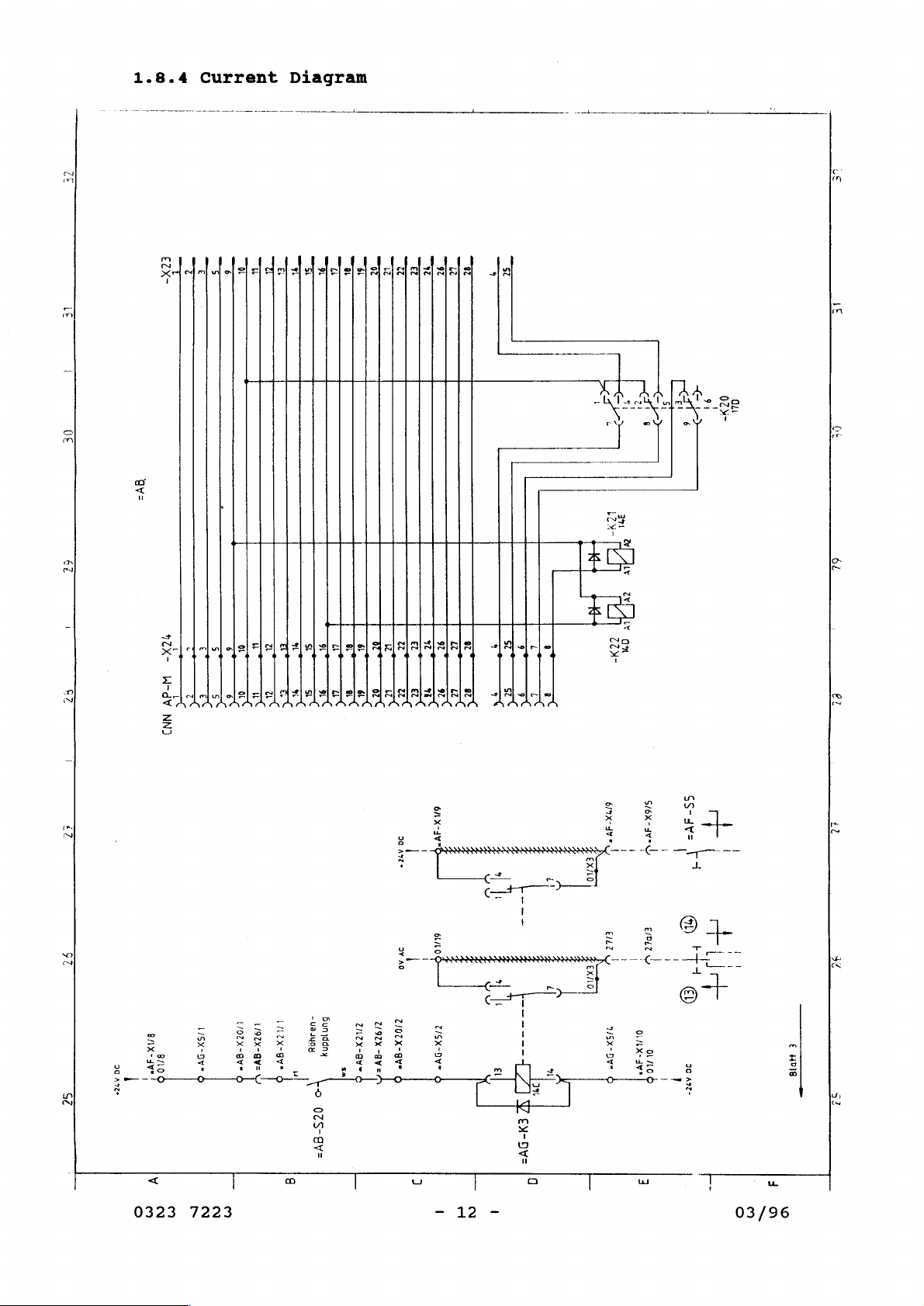

1.8.4

i

Current Diagram

|

|

|

|

|

|

|

|

DE

6L

i

57

iz

-

、

1ZX-

W-dV

r

て

NN)

て

TS

>

se

ES

Er

πι

o>

ü

ws

a

μη

Et

E

。

ni

EC

>

το

6

ωδή

9”

u

“с

は

ας

>

위

>

区

ws

a

ui

EZ

EM

52

“>

οί

%

LT

>

awe

8

^

>

+

+“

M

SS

L

9

。

>

bs

9

ED:

LEN

ni

LA

Ora

i

N

Cx

|

|

s76X-』y*

レ

|

|

SS-dv=

-

|

1

(i

o

rv

6&

,

er

pe

c

52

LISX-9v*

sno

56

IC

AE

gnx-avr

|

0323

7223

07X-BY*

1/92x-8w=

Lay

M

“ua

5un1ddn

sos

©

02S-8v

Lavz

Z7LZX-V~

sm

ov

Ao

tIOTX-gv*

79ZX

-8Y=

6140

|

I

ZISX-D¥"

+)

ww

|

ει

-=

A

L

|------

a

2%

EX-DV=

ento

|

EXALO

975X-Y・

EDL

wy

!

|

|

017LX-JV*

oL/10

!

i

Gb

+i

上

十

T

€)

ao

Anz-

pot

po

03/96

Е

#018

Μου

oN

U

me

Page 13

1.8.5.Current

Diagram

of

D

igi

ital

Display

SA

JA

EA

60.

4095511

tt

Z€

Lg

60

411855

1Z

11

€

£

8

601

HU9sSI1

26,

8

NOIIVIIONI

IHOIFTH

YIAVI

TVLISIC

75080

JH

вом

De

Z/6E

StA

gro

eu

и

e

O

AISE

č

σι

a

ㅣ

зави

tA

8

9

oz

64

VOLA

UA

SAYRE

圖

ZİYA

Dm

AGE

ELA

03/96

13

0323

7223

Page 14

1.9

R1-3.3kQ

R3-6,82

R4-1,65kQ

R5-6.04kQ

R6-6,80

R7-6,80

R8-3,65kQ

R9-1kQ

R10-1.1kQ

R11-6,8k9

812-5009

R13-0,689

R14-0,680

R15-Brůcke

R16-3kQ

.Current

Diagram

of

Power

Supply

C1-470uF/35V

C3-220nF/1kV

C4-10pF/50V

C5-1000uF/63V

C6-1000uF/63V

C7-1000uF/63V

C8-1000uF/63V

C11-2204F

CR1-1N4002

CR4-1N4003

CR5-1N5401

CR6-1N5401

CR7-1N5401

CR8-1N5401

CR10-1N4002

CR12-1N4002

01-2N3055

02-P31823

U1-LM723CN

/63V

ζω

©

u

=

u

o

a

um

>

|CRS5

|CR7

F2i||32A(T1

16A(T)

nov

ADI.

(T)

Ri2-|Umit

220V0,8A

Condor,

0323

7223

D.C.Power

ー

14

Supply

-

HC.24-2,4A

03/96

Page 15

1.10

Physical

Location

of

Electrical

Components

(32)

(4)

(38)

03/96

7775

I5

-

ㆍ

0323

(37) (36)

(38)

(38)

(40)

7223

Page 16

1.10.1

Electric

Field

Installation

Diagram

ον

*

(Gi

BN

ne

bars

F1

3.2A

D1

0006

0248

a

0323

7223

hp

0322

-

16

0869

-

03/96

Page 17

1.10.2

ーー

IT

トト

HI

トト

トト

トト

Electric

E9A

-A

HI

Field

>

5

Installation

AF

OLA

LH

89A

—L

69A

LH

ILA

Diagram

©

©

E

9

x

る

2

5 = a

||

£

トト

トル

m

-=

A

111111111

Dal

раба

аа

|

LOI

hp

H+

ZLA

0322

0866

©

R94

=

аа

_

ŞE

[TITI

а

ва

Да

[а

[аа

03/96

69

hp

0322

70

0867

-

17

71

V74

-

72

75

H+

V77

0323

73

7223

Page 18

1.10.3

Electric

Field

Installation

Diagram

m

=

y

sE

に

Do

=

mm

し

ー

ΕΕ

|

|

[È

Я

T

62

55

Ap

63

56

0322

va

64

57

V78

0868

on

63a

54

V76

CT

V80

61a

58

NNW.

603

圖

—

na

E

—

上

m

53 52

Asl

©

9

hp

ASI

W

-BBC

0322 0865

一

一

AGI

⑯)

HE

51 50

一

6

RZ

一

ka

(e)

一

一

0323

7223

-

18

-

03/96

Page 19

1.10.4

ーー

一

ーー

=

=

Electric

Field

Installation

=

(eh

,

R10

|»

adL

val

Pr

Diagram

|

1131

|

IM,

pb

Ec

1441

EE

1451

|

86

+]

R7

O

ペグ

SS

0

=

*

‘E

=

hp

0322

Sa

0952

ο

и

|

M

AE

©

03/96

-

19-

0323

7223

Page 20

2.

INSTALLATION

2.1

Remove

Uncrating

shipping

2.2

Removal

Drive

Switch

Remove

screws

and

pull

the

strut

little

Remove

12,

and

packing

damage.

the

ET

plastic

with

bit,

screws

14).

ET

2000

up.

(Item

tilt

of

2000

power

4

mm

Remove

(Fig.

material.

Covers

of

maximum

off.

caps

(Fig.

wrench.

3).

it

to

Check

Swing cover

the

two

Lift

1,

the

up

front

Item

for

height.

1,

Item

screws

the

7 + 8)

completeness

1).

trim

and

pull

|

Loosen

(Item

(Item

cover

and

2)

4)

down.

(Fig.

two

to

and

(Item

2,

and

the

take

Item

upon

socket

front

out

5)

10,

a

2.3

Hold

insert

Attention:

The

border.

0323

Mounting

bracket

bracket

7223 -20-

the

of

Bracket

(Fig.

reinforcing

has

to be

2,

Fig.1

Item

strips

conclusive

8)

and

from

tighten

the

with

back

with

the

to

the

screws.

table

table,

frame

03/96

Page 21

03/96

Fig.

5

一 2 1-

0323

7223

Page 22

2.4

Tomo

Coupler

Installation

Install

screws

20).

Place

2.5

Place

8).

table

stiffening

(Item

thread

2.6

Fasten

26)

put

cables

is

and

fastener

plug

Mounting

Put

17).

rail

Mounting

with

cables

enough

fasten

the

(Item

with

fulcrum

through

frame

control

screws.

for

in

cable

space

cables

and

Bucky-Tomo-Coupler

21

+

22)

cables

of

Fulcrum

tower

cables

rail

plates

Fasten

(Item

of

then,

and

(Item

fulcrum

14).

Control

box

Remove

control

guide

for

on

lay

(Fig.

the

the

to

the

up

to

Tower

(Fig.

with plug

Bucky

13)

tower

Box

6,

cover

box

them

(Item

box

cables.

bottom

down.

the

3,

carriage

on

Item

(Item

(Fig.

carriage

plate

Item

of

of

both

with

29)

12)

(Item

25)

side

through

31).

Mount

the

5,

of

for

on

guide

sides

screws

to

table

wall

Check

cable

tube

Item

the

parts.

bracket

16)

between

rail.

under

(Item

(Item

bore-hole.

whether

box

side

18)

Bucky

frame

to

with

with

(Item

(Item

rear

Put

two

balance

15)

and

(Item

31)

and

Put

there

table

cable

Fig.

6

Fig.

7

0323

7223 -22-

03/96

Page 23

2.7

Mounting

of

Motor

Drive

Move

rail

temporarily.

in

(Item

sliding

36)

block

and

(Fig.

fasten

7,

column

Item

drive

35)

motor

in

cross

(Item

guide

34)

2.8

Mount

side

angle

to

ceiling

2.9

Insert

fixing

screw

fasten

2.10

Remove

Fasten

consideration

49)

over

Mounting

belt

to

ceiling

(Fig.

Tightening

drive

angle

(Fig.

finally.

Mounting

cover

tupe

of

the

the

flexible

of

fixing

9,

guide

belt

(Item

9,

of

from

coupler

ceiling

Fig.

Item

of

of

Drive

angle

guide

rail

Drive

(Fig.

49

Item

Tube

ceiling

the

tube

8

Motor

(Fig.

rail

43)

under

(Item

Belt

8

and

46).

Coupler

with

8

mm

column

to

8,

(Item

consideration

41).

und

Fig.

Item

Align

column

screws

space

(Item

ceiling

.

Item

41).

9,

Item

37)

and

column

(Fig.

(Fig.

to

axis

51).

column

Fig.

45)

Mount

tighten

drive

10,

of

Put

guide.

9

on

the

of

37)

11,

Item

rotation

connection

left-hand

belt

the

to

both

to

motor

Item

48)

fixing

tension

belt

fixing

and

53).

under

(Item

cable

03/96

-23-

|

0323

7223

Page 24

Main

2.10a

Remove

See

Mount

Philips

Remove

and two

plate,

unit

Mount

Remove

the

shafc

Modification

(Fig.

See

joint

the

support

lla).

bracket

plan head

the

and use

bracket

M4

(Fig.

the

and

two

resin

Fig.

x

10

C

after

screws.

M3

12

Philips

the

12)

D

after

connecting

of

arm

x

screws

cap

the

cover,

removing

8

Philips

removing

from

plate.

DST-100A

and

See

screws

(Fig.

to

standard

Support

brackets

bracket

11b)

screws

from

secure

bracket

See

(Fig.

Interlock

Spring

Fig.

B

from

the

solenoid

the

A.

support

12)

switch

T

11

Arm

A

and

B.

(with

the

interlock

See

arm

M4 x 12

Phillips

pao

head

screw

unit

a

DE

a

:

>

two

solenoid,

mounting

switch

(Fig.

and

.

12)

mount

Solenoid

、

M4

X

Rocacion

Magnec

lock

brake

pin

Brackec 8 Brackec

A

Cover

Fig.

0323 7223

lla

-24-

1

\

Ring,

E-cype

Brackec

Joint

x 8

Solenoid

Phillips

D

03/96

A

C

Fig.

Brackec

M3

11b

pan

mouncing

head

place

screw

Page 25

2.11

Mounting

of

Tomo-Interface

Mount

component

tomo-interface

plate

(Item

Fig.

12

angle

56).

(Fig.

Lo

12,

—

Item

ие

55)

to

electro

2.12

Mount

guide

electrical

Installation

drawer

rail

angle

unit

guide

(Fig.

of

Electrical

(Fig.

(Item

14,

57)

Item

13,

to

Unit

Item

back

61)

to

58)

wall

drawer

with

(Item

guide.

both

57).

cable

Insert

2.13

Disconnect

03/96

Insert

Fig.

Relais

plug-in

14

Board

connection

to

Ceiling

-25-

CNN

Fig.

Column

AP-M.

15

Fasten

0323

relais

7223

Page 26

board

0323

0710

to

ceiling

column

mechanically.

2.14

Cabeling

Attention:

Pay

attention

Part

Press cable

Plate

terminal

uncouple

line

plug

Ceiling

Put

relais

relais

of

to

grooved

drive

board

to

desription.

box

coupler

=AF-X1/8

01/X4.

plug

the

relais

(Fig.

and

the

(Item

Column

board

board)

ET

flexible

motor

in

(Fig.

beam

=AF-X1.

and

CNN

2000

board.

couple

Put

62)

=AG-X10.

to

tighten

(comes

(Fig.

AP-M

0323

to

6)

from

drive

cable

wiring

12)

to

Line

from

to

0710.

pin

to

ceiling

Place

tube

with

considering

in

tomo

diagram

relais

off

unsolvable

=AF-X1)

15)

plug-in

Put

plug

the

fulcrum

cable

to

relais

motor

plug

CNN

=AB-X25.

electric

!!!

=AF-X15

=AF-X1

connexion

new

AP-M.

column

from

board

drive

the

tower

and

(comes

with plug

and

tighten

plug

(coming

Place

and

connect

the

tube

and

starting

Then

colour

(Fig.

(Item

clamp

from

01/X3.

unsolvable

=AB-X23

connection

plug

coupler

couble

connect

as

well

14)

cable

61)

cable

to

=AF-X9)

Uncouple

of

from

over

for

to

each

control

screw

the

the

cable

=AB-X5

the

motor

relais

line

as

the

tomo

to

2.15

Mount

Dismount

cable

support.

Attention:

stand

Range

from

of

New

Cable

cable

The

grooved

the

opposite.

movement:

support

-70°

TOMO

TOMO

Support

(Fig.

flexible

-

+125°

11,

Item

tube

has

respectively

71)

to

and

mount

mounted

-125°

-

to

+70°

new

wall

0323 7223

Fig.

16

—26-

03/96

Page 27

2.16

Installation

of

Tomo

Marks

Bring

with

and

column

3.

3.1

Remove

74).

radiation

pencil.

install

(Item

Adjustment

Adjustment

front

Move

Tomo

81).

of

panel

unit

radiation

mark

Fulcrum

(Fig.

up

to

(Fig.

to

25,

100

unit

16,

Film

Item

cm

some

Item

Plane

73)

SID.

and

Mark

cm to

80)

rear

on

the

to

cover

telescope

foot side

telescope

(Item

Place

ble

top.

Measure

plane

ling

ruler

(Fig.

bar

the

to

Fig.25

(Fig.

distance

27,

the

26,

Item

distance measured

Item

between

78).

76)

across

lower

Adjust

(Fig.

the

Fig.

profile

edge

fulcrum

28).

26

of

rails

ruler

of

and

the

of

film

coup-

ta-

03/96

'

-27-

0323

7223

Page 28

3.2.

Remove

(Fig.

Push

The

equal

potentiometer

height

table

Note:

Proper

procedure

29,

Setting

front

26,

button

distance

the

to

top.

adjustment

Item

of

Layer

cover

Item

until

between

distance

(Fig.

24

cm

Set

pot

must

84 + 85)

Fig.27

(Fig.

76)

layer

between

distance

(Item

requires

be

repeated

are

Height

across

upper

29,

interactive.

25,

profile

height

table

ruler

Item

between

85)

to

a

Item

and

84)

"24

10

minute

several

Fig.

73

rails

is

level

edge

fulcrum

to

fulcrum

cm",

times,

28

+

and

"O

and

warm-up

75).

of

with

(Item

cm".

the

Place

table

table

ruler

Drive

upper

period.

pots

must

77).

edge

ruler

top.

top.

be

Set

layer

of

The

(Fig.

0323

7223

-28-

03/96

Page 29

Fig.29

3.3

Open

gnetic

cycles

24

12

9

Timing

clamp

'

clutch.

for

cm.p.s

cm.p.s.30

cm.p.s.22,5.r.p.m.at

60

of

(Fig.

60

r.p.m.

r.p.m.

Exposure

15,

Mark

seconds.

the

at

at

Cycles

Item

12

12

12

58)

clutch.

cm

layer

cm

layer

cm

layer

to

Push

interrupt

TEST

height,

height,

height,

function

button

40°

20°

Zono

and

<<,

2,2

< , 2,2

1,2

sec.

of

count

sec.

sec.

ma-

09/95

Fig.30

-29-

0323

7223

Page 30

In

case

of

deviations,

adjust

with

pots:

Fig.

3.4

Remove

Item

The

carriage.

(Item

30,

Switch

cover

91)

switch

93)

Item

Item

Item

by

Adjust,

and

87

88

89

flap

of

hand

flap

turn

(R

88)

(R

90)

(R

91)

TOMO

and

should

if

lever

fast

slow

Zono

coupling.

move

necessary.

not

(Item

speed

speed

speed

the

touch

Actuate

bucky

Therefore

94).

the

in

edge

solenoid

coupling

of

loosen

(Fig.

position.

the

sliding

31,

screws

Fig.31

0323

7223

-30-

09/95

Page 31

4.

TECHNICAL

MAINTENANCE

4.1

Note:

The

out

power,

Defective

acc.

Use

Do

Preperation

Switch

Mechanical

maintenance

at

switch

to

only

not

grease

off

12month

parts

spare

non-acid

equipment.

and

schedule

intervals.

off

must

parts

or

oil

Electrical

power

be

list.

grease

ball

Tests

described

If

functional

immediately

replaced

for

maintenance.

bearings

below

afterwards.

by

genuine

with

sealing

must

tests

be

carried

require

spare

washers.

parts

Remove

Fig.32

covers

(Fig.

32,

Item

B-F

and

73 - 75).

09/95

-31-

0323

7223

Page 32

Tube

Check

Check

Adjust

Check

sition.

Check

Coupling

Check

Coupler:

screws

on

smooth

with

compression

magnet

mechanism

and

and

set

to

replace,

tighten,

operation

screw,

spring

hold

coupler

must

if

if

necessary.

and

if

necessary.

to

in

have

no

necessary.

play.

pull

park

play.

coupler

position.

in

park

po-

Fulcrum

Check

Limit

Check

Check

Adjust

Check

Clean

slide

Check

Check

ce,

Digital

Layer

cessary,

Tomo

Check

Operate

Flap

Check

Check

Support:

and

switches

and

spindle

or

belt

coupling

rail

fulcrum

electrical

if

necessary.

Display:

height

Coupler:

and

magnet

must

and

microswitch

tighten

adjust,

drive

replace,

drive

and

on

must

readjust

tighten

not

be

readjust,

screws,

must

contact

if

on

if

on

tension.

bar

carriage

fulcrum.

film

connections

coincide

acc.

screws,

by

hand

too

if

actuation.

if

in

necessary.

play

and

necessary.

plane

and

with

3.2.

if

and

couple

high

and

necessary.

necessary.

end

positions.

grease

Adjust

(film

and

if

plane).

adjust,

cables

height

necessary.

flap

should

lightly.

necessary.

if

on

indicated.

with

couple

Lightly

necessary.

damage.

bar

carriage.

without

grease

Repla-

If

ne-

play.

Electrical

Check

ce,

if

Check

sary.

Check

Control

Check

necessary.

Check

Check

0323

7223

Unit:

electrical

necessary.

and

tighten

all

parts

Box:

and

tighten

friction

functioning

connections

mechanical

on

firmness.

mechanical

of

swing

of

all

and

controls

-32-

and

cables

fastening

Tighten,

fastening

readjust,

and

on

damage.

devices,

if

necessary.

to

table

if

buttons.

Repla-

if

neces-

frame,

necessary.

09/95

if

Page 33

4.2.

Functional

Tests

Tube

-

-

Coupler:

Folding

Remaining

up

spring, magnet)

-

Locking

Fulcrum

-

Layer

-

Coupling

Digital

-

Display

-

No

Tomo

-

Coupling

~

Not

indication

Coupler:

the

Support:

height

Display:

correct?

bumping

and

in

coupling

drive

bar

remaining

without

against

down

park

jumps?

play?

smoothly?

position

bar

running

in

sledge

Without

without

without

center

edges?

play?

accurately?

play?

noise?

position

(Recuperating

accurately?

Electrical

-

All

electrical

-

All

connections

Control

-

Swing

-

All

buttons

Unit:

Box:

having

cables

correct

friction

switching

without

and

tight?

in

any

position?

accurately?

damage?

09/95

-33-

0323

7223

Page 34

4.3

SPARE

Ansicht

B

PARTS

4

に

RETA

14

-

24

25

Sl

|

$

NE

21

mo

=

à

T

Ansicht

A

0323

7223

Page 35

4.3.1

Part

SPARE

Names

PARTS

/

Ordering

LIST

Numbers

Failed

as

listed

serial

change

selves

See

also

REF.No.

1

2

3

4

48

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

27a

28

29

30

31

32

33

34

35

36

37

38

39

40

spare

parts

below.

number

of

parts

or

by

qualified

chapter:

Name

Frame

Harness

Transformer

Control

P.C.

Frame

Board,

Supporting

Circuit

Circuit

Circuit

Circuit

Amplifying

Drawer

Angle

Nut

Belt

Tomo-interface

Bracket

Belt

Return

Bracket

Mounting

Coupling

Gear

Drive

Motor

Tomo

Tube

Magnet

Compression

Bolt

guide

for

clamp

pulley

wheel

system

mark

coupler

board

board

board

board

T-notch

Compression

Strap

Coupling

bar

When

of

unit

or

"Safety

variable

part

board

plate

bracket

complete

spring

spring

may

be

ordering

and

elements

personnel

replaced

complete

may

Notes".

」

only

spare

only

being

with

parts

number

be

carried

authorized

original

always

of

part.

parts

indicate

The

out

by

to do

Part

0322

0322

0622

0006

0006

0006

0006

0322

0322

No.

0910

1070

0651

0248a

0248b

0213

0214a

0869

0866

0322 0867

0322

0322

0005

0323

0323 0654

0323 0663

0323

0323 0682

0660

0323

0323

0323

0006

0322

0323

0006

0322

0323

0005

0005

0322 0733

0005

0322

0868

0865

0158f

0335

0706

0877

0648

0651

0644

0478

0754a

0642

0195a

0786

0590

0094

0040a

0042p

0736

0322 0627

ex-

our-

so.

09/95

-

35

-

0323

7223

Page 36

REF.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

No.

Name

Gearmotor

Toothed

Toothed

Switching

Switch

'

Circuit

Switch

Reflector

Reflector

Acme

thread

Bridge

Lifting

10-speed

Gear

Gear

Pinion

Switch

Driver

Carriage

Catch

Spring

Bridge

Clamp

Spacer

Cable

Rear

Top

Front

Dry

cover

cover

cover

rot

Switch

Control

Switch

Cable

Bulb

Bucky

tomo

Switch

Solenoid

Cable

Extension

Magnet

Coupling

belt

belt

wheel

bar

board

(on

-

(on)

nut

spindle

potentiometer

complete

key

element

part

complete

board

coupler

cover

plate

off)

Part

0322

0322

0005

0322

0006

0322

0322

0322

0322

0322

0322

0322

0006

0322

0322

0322

0322

0322

0322

0322

0322

0322

0322

0322

0323

0323

0323

0323

0006

0322

0323

0322

0323

3360

0323

0006

0006

0323

0322

0322

0322

No.

0528

0530

0116

0586

0079a

0952

0875

0588a

0588b

0526

0534

0522

02518

0971

0968

0960

0569

0572

0558

0566

0567

0608

0616

0615

0435

0318

0320

0317

0260

0816

0444

0909

0453

0001

0580

0079a

0245

0582

0674

0672

0642

0323

7223

-

36

-

09/95

Page 37

4.4

Inspection/Maintenance

Certification

Inspection/Maintenance

the

maintenance

quired,

parts

Replacements:

9 ο 9 ㄴ … 5 ο ο

Date

defective

as

listed

οσο

(Give

©

0 0

è 0

Service

has

instructions

parts

have

below:

Item-No.

0 0 0 o

2..

0 0 0 o © 0 0 0 0 0 ο ο 0

Company

been

of

the

been

only)

(Stamp)

carried

manufacturer.

replaced

0»

ο

9 9 9 5

Signature

out

by

according

Where

genuine

EE

LE

to

re-

spare

ο ο .

Subject

Hans

09/95

Pausch

to

technical

alterations.

Rôntgengerätebau

D-91056

Erlangen

Graf-Zeppelin-StraBe

ー37ー 0323

TV/Ru

Germany

1

7223

Loading...

Loading...