Toshiba DW65X91 Service Manual

FILE NO. 020-200001

SERVICE MANUAL

COLOR TELEVISION

N8PS Chassis

DW65X91, D W56X91

(TAC9871)

(TAC9871)

PRINTED IN U.S.A. Jan., 2000 U

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS........................................................................................................................................3

CRT ASSEMBLY REPLACEMENT AND MOUNTING..............................................................................................4

PICTURE TUBE COMPONENTS ADJUSTMENT.................................................................................................... 6

REPLACEMENT OF THE CRT.................................................................................................................................9

SERVICE POSITION.............................................................................................................................................. 10

SERVICE MODE ....................................................................................................................................................11

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

DESIGN MODE ......................................................................................................................................................14

ELECTRICAL ADJUSTMENT ................................................................................................................................ 15

CONVERGENCE ADJUSTMENT .......................................................................................................................... 18

SCREEN AND MIRROR ALIGNMENTS ................................................................................................................24

CIRCUIT CHECKS .................................................................................................................................................25

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA..............................................................................................................................26

LOCATION OF CONTROLS...................................................................................................................................27

TABLE OF CONTENTS

PROGRAMMING CHANNEL MEMORY................................................................................................................. 29

CIRCUIT BLOCK DIAGRAM ..................................................................................................................................31

MECHANICAL DISASSEMBLY ..............................................................................................................................33

CHASSIS AND CABINET REPLACEMENT PARTS LIST......................................................................................35

PC BOARDS BOTTOM VIEW.................................................................................................................................75

TERMINAL VIEW OF TRANSISTORS ................................................................................................................... 94

SPECIFICA TIONS ..................................................................................................................................................95

APPENDIX:

CIRCUIT DIAGRAM

– 2 –

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” INSTRUCTIONS BELOW.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid such hazards, the high

voltage must not be abov e the specified limit. The nominal

value of the high voltage of this receiver is (A) kV at zero

beam current (minimum brightness) under a 120V AC

power source. The high voltage must not, under any circumstances, exceed (B) kV.

Refer to table-1 for high voltage (A), (B).

(See SETTING & ADJUSTING DATA on page 26)

Each time a receiver requires servicing, the high voltage

should be checked f ollowing the HIGH VOLTAGE CHECK

procedure in this manual. It is recommended that the reading of the high voltage be recorded as a part of the service

record. It is important to use an accurate and reliable high

voltage meter.

SAFETY PRECAUTION

WARNING : Service should not be attempted by any one unf amiliar with the necessary precautions on this receiver. The following are the necessary precautions to be observed before

servicing this chassis.

1. An isolation Transf ormer should be connected in the power

line between the receiver and the AC line bef ore any service is performed on the receiver.

2. Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube . The picture tube is highly evacuated and if broken, glass fragments will be violently expelled. Use shatter proof goggles and keep picture tube away from the unprotected body

while handling.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place,

such as; non-metallic control knobs, insulating covers,

shields, isolation resistor-capacitor network etc.

4. Before returning the set to the customer, always perform

an AC leakage current check on the exposed metallic parts

of the cabinet, such as antennas, terminals, screwheads,

metal overlays, control shafts etc. to be sure the set is

safe to operate without danger of electrical shock. Plug

the AC line cord directly into a 120V AC outlet (do not use

a line isolation transformer during this check). Use an AC

voltmeter having 5000 ohms per volt or more sensitivity in

the following manner:

PRODUCT SAFETY NOTICE

2. This receiver is equipped with a Fail Safe (FS) circuit which

prevents the receiver from producing an excessively high

voltage ev en if the B+ voltage increases abnormally. Each

time the receiver is serviced, the FS circuit must be checked

to determine that the circuit is properly functioning, following the FS CIRCUIT CHECK procedure in this manual.

3. The only source of X-RAY RADIATION in this TV receiver

is the picture tube. F or contin ued X-RAY RADIATION protection, the replacement tube must be exactly the same

type tube as specified in the parts list.

4. Some part in this receiver have special safety-related characteristics for X-RAY RADIATION protection. For continued safety, parts replacement should be undertaken only

after referring to the PRODUCT SAFETY NO TICE below.

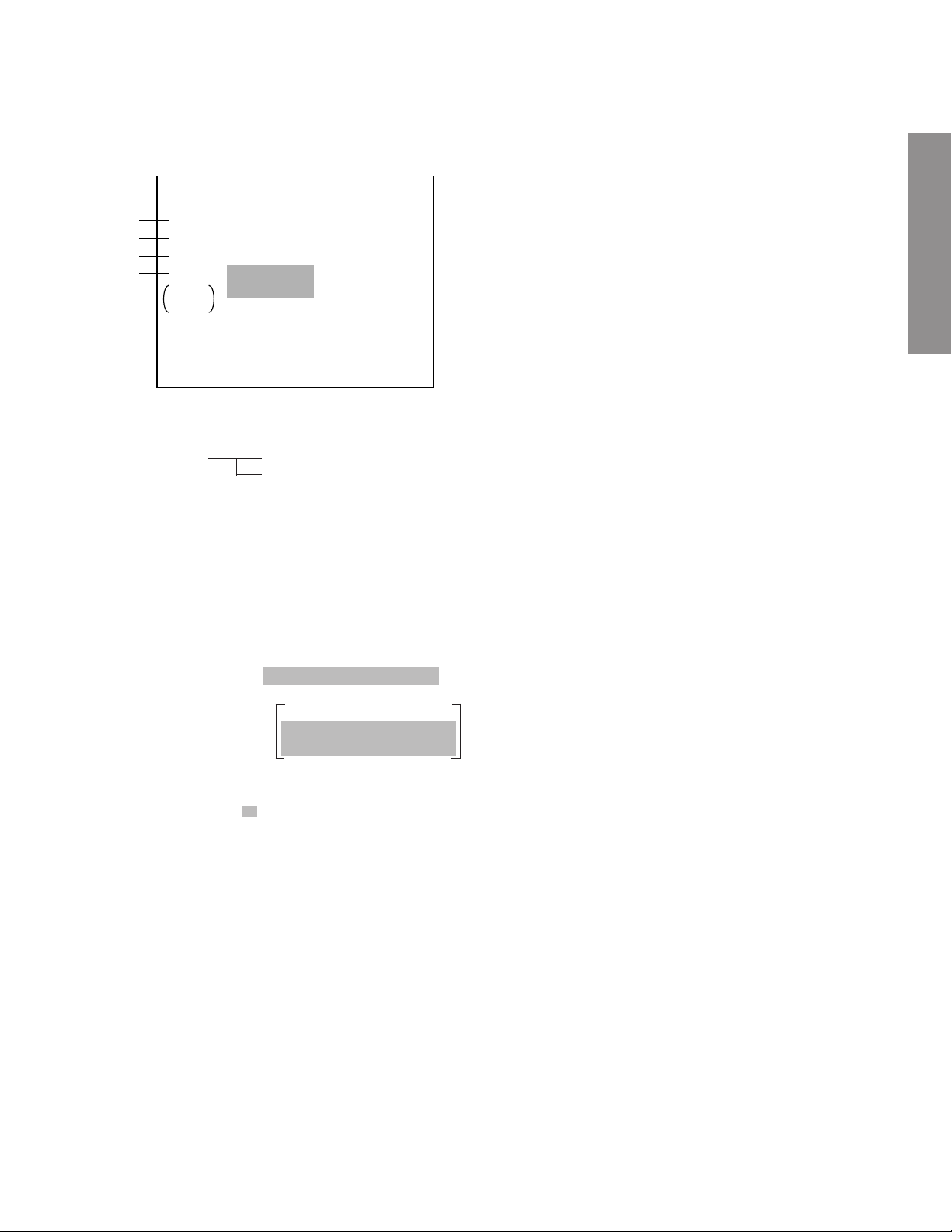

Connect a 1500 ohm 10 watt resistor , paralleled b y a 0.15

µF, AC type capacitor, between a known good earth ground

(water pipe, conduit, etc.) and the exposed metallic parts,

one at a time. Measure the AC voltage across the combination of 1500 ohm resistor and 0.15 µF capacitor. Reverse the AC plug at the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Voltage

measured must not exceed 0.3 volts rms. This corresponds

to 0.2 milliamp. AC. Any value exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

AC VOLTMETER

0.15µF

Place this probe on

Good earth ground

such as a water

pipe, conduit, etc.

1500 ohm

each exposed

metallic part.

10 watt

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics are

often passed unnoticed by a visual inspection and the protection afforded by them cannot necessarily be obtained b y using

replacement components rated for higher voltage, w attage, etc. Replacement parts which have these special saf ety characteristics are identified in this manual and its supplements; electrical components having such features are identified by the

international hazard symbols on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute replacement

parts which do not have the same safety characteristics as specified in the parts list may create shock, fire, X-ray radiation

or other hazards.

– 3 –

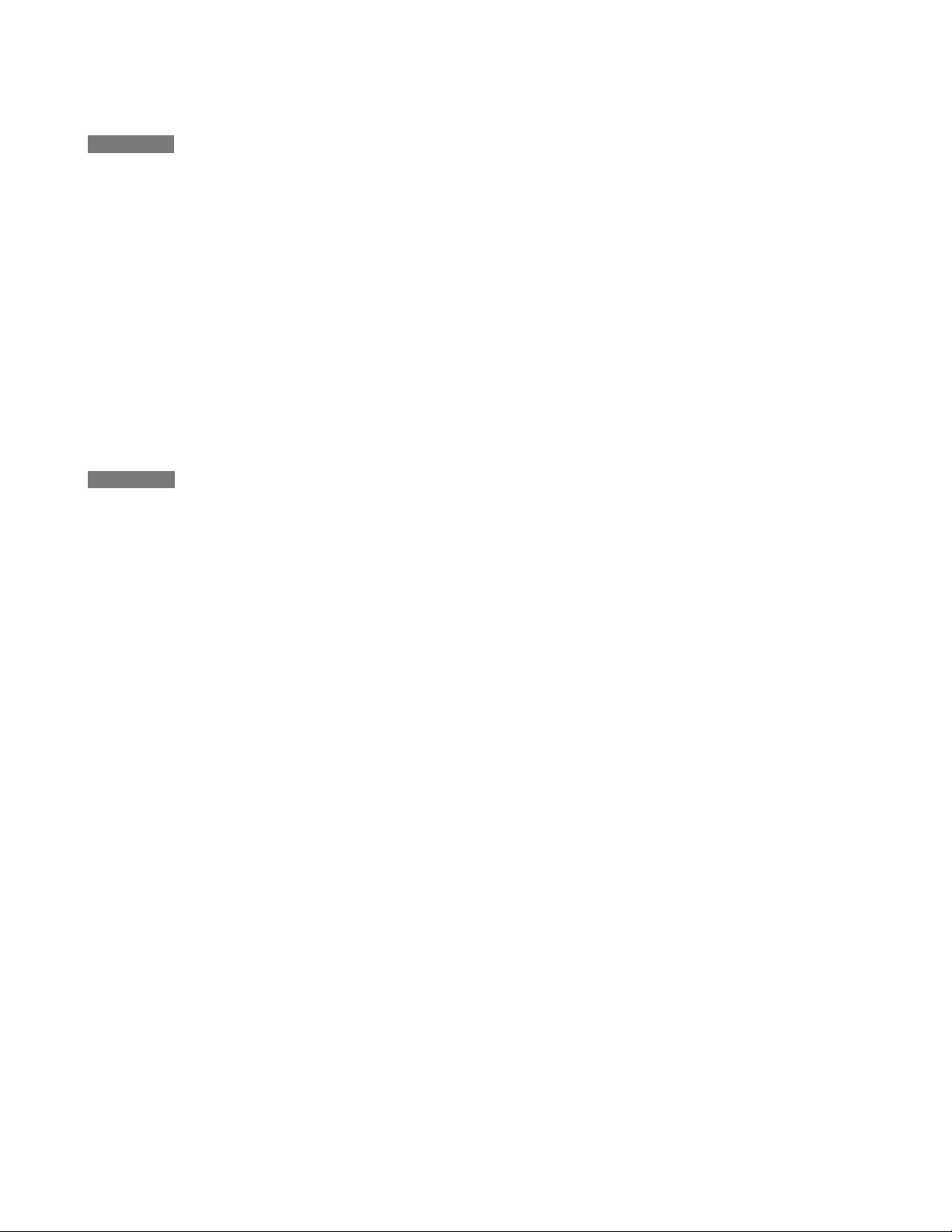

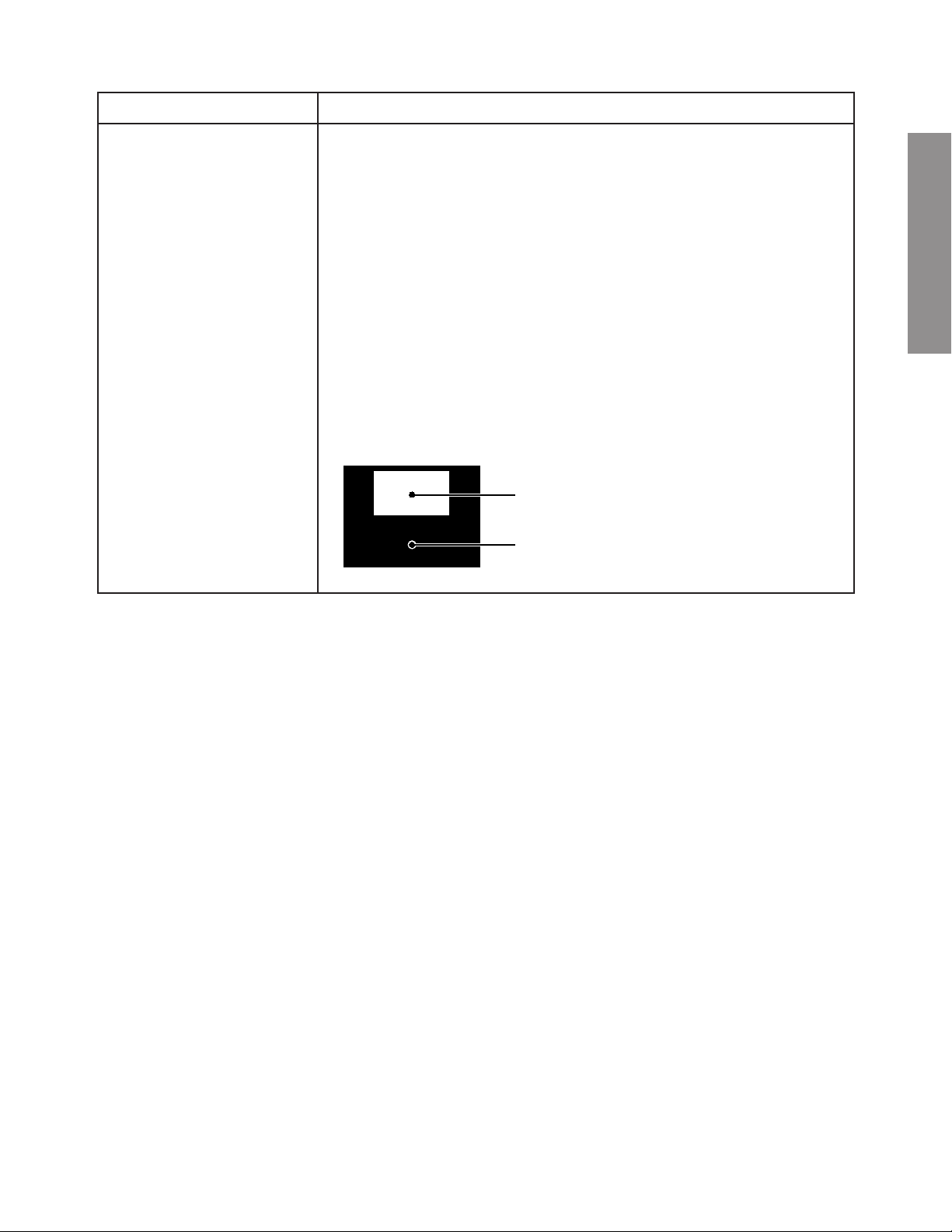

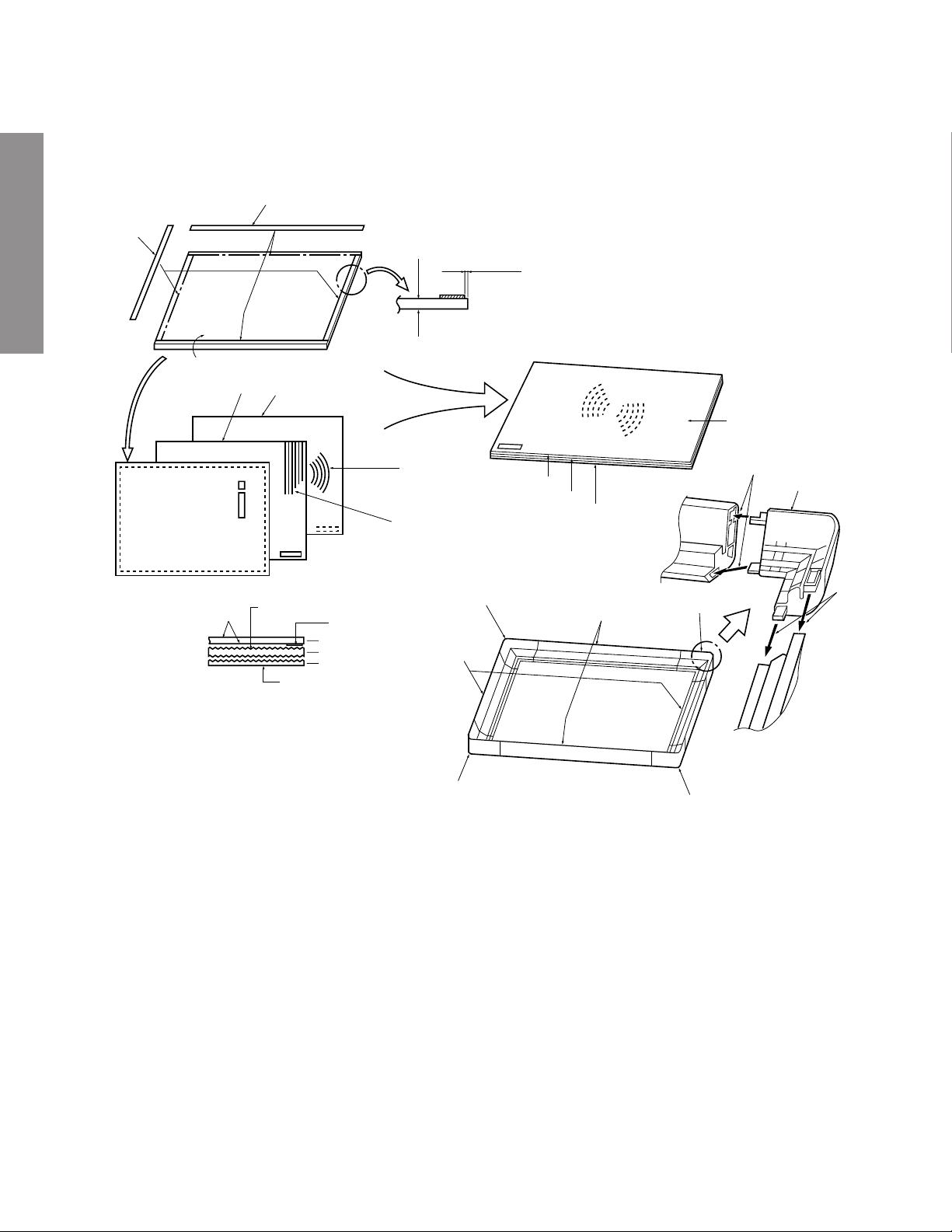

CRT ASSEMBLY REPLACEMENT AND MOUNTING

CAUTION : DO NOT LOOSEN THE HEX HEAD BOLTS WITH SPRINGS (12 PCS), BECAUSE THOSE ARE FOR

SEALING OF CRT COOLANT.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

8 o’clock

4 o’clock

Lens Assembly

R

GB

Attention Serviceman

The Hex Head

Bolts with

Springs. (see

sketch) used on

CRT assembly,

are “NOT”

Adjustment Screws

DO NOT LOOSEN-FLUID

LEAKAGE WILL OCCUR.

4 Screws

4 Screws

CRT Assembly

CRT Anode Cap Assembly

S.V.M. Coil

CRT DRIVE Board

CRT Mounting

Deflection Yoke and Conver Yoke

Lens and Neck Components View

– 4 –

TO REMOVE CRT (Same procedure for R, G, B)

1. Remove CRT DRIVE Board, S . V. M. COIL and DEF.

YOKE from CRT.

2. Remove Lens Assembly.

3. Detach CRT Anode Cap from CRT.

4. Remove CRT Assembly from CRT Mounting.

CRT REPLACEMENT (Same procedure for R, G, B)

Reverse the removal procedures except the followings.

1. Anode Cable should be replaced with new one.

See “SERVICING PRECAUTIONS” shown below.

2. Install silicon (T461B) to the CRT, replace the Anode

cable and put enough silicon again on around the Anode Cap as illustrated.

CAUTION: Align the Anode cable as illustrated on page

4.

ADJUSTING PROCEDURE IN REPLACING CRT

1. R.G.B. CUTOFF (SCREEN VR) ADJUSTMENT

(See owner's manual)

2. R.G.B. FOCUS ADJUSTMENT (page 7.)

3. PICTURE TILT ADJUSTMENT (page 7.)

4. USER CONVERGENCE CENTER CHECK

(See owner's manual)

5. CENTERING ADJUSTMENT (page 7.)

6. CONVERGENCE ADJUSTMENT (page 18.)

7. WHITE BALANCE ADJUSTMENT (page 17.)

Adjustments are complete.

Anode Cap

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Silicon

(On shaded area)

TSE3843W #23960136

2 ~ 5 mm

SERVICING PRECAUTIONS

■ Do not use a magnetized screw driver f or screws of

Deflection Yoke and V elocity Modulation Coil to av oid

magnetization of electron gun.

Magnetization of electron gun will degrade basic

function and result in unbalance of right and left shift

of user static convergence, and result in no v ariable

quantity .

Screw

for D.Y

15 ~ 25 mm

■ When replacing the anode cap assembly (CRT) or

anode lead assembly (F.B.T.), remo ve the anode lead

holder from old one and attach the holder again to

new anode lead.

■ Check the point of anode lead in a straight

line, if it is winding, please revise it.

Anode lead holder

Screw for SVM coil

– 5 –

WARNING : BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECA UTION”, “SAFETY PRECAUTION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

PICTURE TUBE COMPONENTS ADJUSTMENT

DESCRIPTION OF NECK COMPONENTS

2

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

1 Deflection yoke and convergence yoke

The position on the neck is required most front (CRT

funnel side) and the screw is fastened after rotating

yoke adjusting picture tilt.

2 Centering magnet

After adjusting picture tilt, picture position is finally

fixed by this magnet.

In order to get maximum margin of user convergence

control for center of screen, this magnet hav e to be

used for center convergence adjustment.

PREPARATION

Operate the receiver for at least 5 minutes.

R, G, B CUTOFF (SCREEN VR) ADJUSTMENT

1. Adjust before replacing the SCREEN assembly.

2. Press RESET button on TV or remote hand set.

3. Call up the adjustment mode display, then adjust the

data of items RCUT, GCUT and BCUT to “40”.

4. Press TV (ANT)/VIDEO button on TV.

5. Gradually rotate R, G and B SCREEN volume of FOCUS PAC (page 8) clockwise or counterclockwise until the raster appears slightly on the CRT through the

each lens, and leave them.

(Look into the lens in order to check the raster.)

6. Press TV (ANT)/VIDEO button on TV again.

RGB ALIGNMENT & ASTIGMATISM ADJUSTMENT

1. Set the knobs of the pole 2, 4, 6 magnets of the SVM

coil so that their magnetic fields override each other.

Pole 6

1

Pole 4

Pole 2 magnet

Pole 4, 6 magnet

2. Enter the adjustment mode (see page 11).

3. Adjust the centering magnets for the RED, GREEN,

and BLUE colors. (See CENTERING ADJUSTMENT.)

4. Press the TV/VIDEO button on the remote controller

to display the internally-generated white cross dots.

(White cross dots on black backg round. Ref er to TEST

SIGNAL SELECTION on page 12.)

5. Adjust the alignment and astigmatism of the projection tube for RED. (See steps (1) to (6) below. Cover

the projection tubes for the other two colors with lens

caps, etc.)

(1) Slightly turn the focus VR of RED to the left.

(2) Adjust the pole 2 magnet so that the bright section of

the dot falls on the center of the dark section (flare).

Dark section (flare)

Bright section

(3) Readjust the centering magnets for the RED colors.

(4) Slightly turn the focus VR of RED to the right for the

sharp focus.

(5) Adjust the pole 4 magnet to the desired degree so that

the blurred dot becomes rectangular. (The shape

should become basically same when turning the focus VR to both the left and right.)

Pole 2

– 6 –

(6) Reconfirm that the alignment, astigmatism, and

centering are correct. If necessary, repeat the steps

(1) to (5) above to adjust appropriately.

SIGNAL SELECTION on page 12.)

12. Use the focus VR of “G” of the focus pack in order to

adjust the electric focus in the middle section of the

screen to its sharpest level.

6. Adjust the electric focus of RED as well as possible.

(See RGB FOCUS ADJUSTMENT.)

7. Adjust the alignment and astigmatism of GREEN and

BLUE using the above procedure for adjusting RED.

R, G, B FOCUS ADJUSTMENT

1. Call-up the adjustment mode (see page 11)

2. Press TV/VIDEO button on the remote controller in

order to display the internally-generated white crossdot. (White cross-dot on a b lack background. See TEST

SIGNAL SELECTION on page 12.)

3. Expose only RED by covering the GREEN and BLUE

lenses with caps.

4. Loosen the RED lens fixing screws (refer to Fig. a),

and adjust the RED lens focus to obtain the sharpest

point while observing the middle section of the screen.

Fig. a

5. Use the focus VR of “R” of the focus pack in order to

adjust the electric focus in the middle section of the

screen to its sharpest level.

6. Check the RED focus of the whole screen and if necessary repeat steps 4 and 5.

7. Fix the RED lens by tightening its fixing screws.

8. Expose only GREEN by cov ering the RED and BLUE

lenses with caps.

9. Display the internally-generated white cross-dot signal.

10. Adjust the GREEN lens focus to obtain the sharpest

point while observing the middle section of the screen.

11. Press TV/VIDEO button on the remote controller in

order to display the internally-generated white crossbar. (White crossbar on a blac k background. See TEST

Note:Normally the most clearly visible point of the scan-

ning line is the sharpest point of the Green focus.

13. Check the GREEN focus of the whole screen and if

necessary repeat steps from 10 to 12.

14. Fix the GREEN lens by tightening up its fixing screws.

15. Expose only BLUE by covering the RED and GREEN

lenses with caps.

16. Press TV/VIDEO button on the remote controller in

order to display the internally-generated white crossdot. (White cross-dot on a b lack background. See TEST

SIGNAL SELECTION on page 12.)

17. Loosen the BLUE lens fixing screws (refer to Fig. a),

and adjust the BLUE lens focus while observing the

middle screen section of the screen.

18. Press TV/VIDEO button on the remote controller in

order to display the internally-generated black crossdot. (Blac k cross-dot on a white background. See TEST

SIGNAL SELECTION on page 12.)

19. Use the focus VR of “B” of the focus pack in order to

adjust the focus in the middle section of the screen to

its sharpest level.

(The point of the Blue focus becomes sharpest when

the brightness level of BLUE is lowest, while the crossdot is clearly visible.)

Note: Keep in mind that only the BLUE electric focus is

adjusted with the black cross-dot.

20. Check the BLUE focus of the whole screen and if necessary repeat steps from 17 to 19.

21. Fix the BLUE lens by tightening its fixing screws.

TILT ADJUSTMENT

Rotate R, G, B deflection yoke so that picture becomes

horizon, then fasten screw.

CENTERING ADJUSTMENT

1. Stretch a thread between two center slots of screen

edge (top and bottom, left and right).

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 7 –

2. Select the adjustment mode, and adjust the data of

item “HPOS” to 45H.

3. Press TV/VIDEO button on the Remote Control to display the white cross-bar.

4. Adjust G centering magnet so that the cross-bar pattern center comes to screen center.

5. Perform HEIGHT adjustment . (See page 16.)

6. Perform VERT. LINEARITY adjustment.

7. Perform WIDTH adjustment. (See page 16.)

8. Check whole quality of green line.

9. Adjust R, B centering magnet so that the cross-bar

pattern center comes to screen center.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

LOCATION OF SCREEN AND FOCUS VR’S

6 Screws

SCREEN VR

FOCUS VR

RGB

Speaker grille

– 8 –

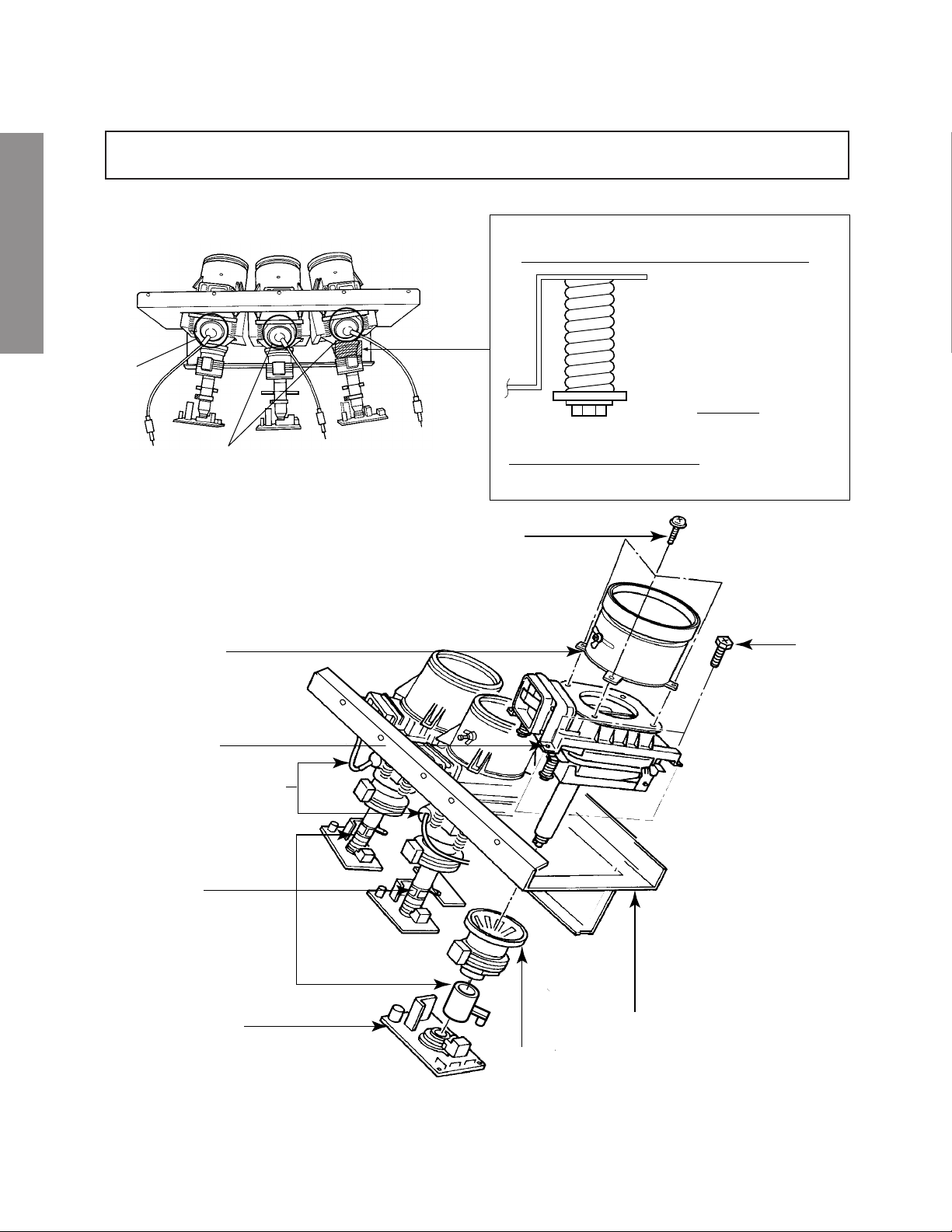

REPLACEMENT OF THE CRT

Service parts are provided for each R, G and B.

The contents of the parts are as follows.

40" 23003518 23003519 23003520

56" 23003817 23003781 23003818

65" 23003780 23003781 23003782

RGB

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

REPLACEMENT OF HIGH VOLTAGE CABLE

ANODE LEAD

RUBBER BOOT

LEAD HOLDER

Fig. a

Z450 TP A5007

1. When replacing Anode Lead or Anode Cap with new

one, remove Lead Holder from old lead as shown in

figure below, and put it on ne w lead. Do not throw awa y

Lead Holder.

NOTE : THE LEAD HOLDER IS ATTACHED TO

TP A5007 (Z450), BUT IS NO T A TTACHED T O

ANODE LEAD AND ANODE CAP. RUBBER

BOOT IS ATT A CHED T O ANODE LEAD AND

ANODE CAP.

2. Detaching Lead Holder

OLD

ANODE LEAD

or

ANODE CAP

LOCK

RUBBER BOOT

LEAD HOLDER

Fig. b

Cut here rubber boot

and lead together to

detach Lead Holder.

– 9 –

WARNING: BEFORE SERVICING THIS CHASSIS , READ THE "X-RAY RADIATION PRECAUTION", "SAFETY PRECAU-

TION" AND "PRODUCT SAFETY NOTICE" ON PAGE 3 OF THIS MANUAL.

In order to assure the performance, processed wires shall be replaced after the repair work.

Work procedures are as follows:

1. Remove the back board.

2. Remove lead wires.

3. Draw out the chassis.

4. Rest the chassis against the back cabinet, chassis as shown bellow.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

After repair work finished, replace it in the opposite procedure.

SERVICE POSITION

– 10 –

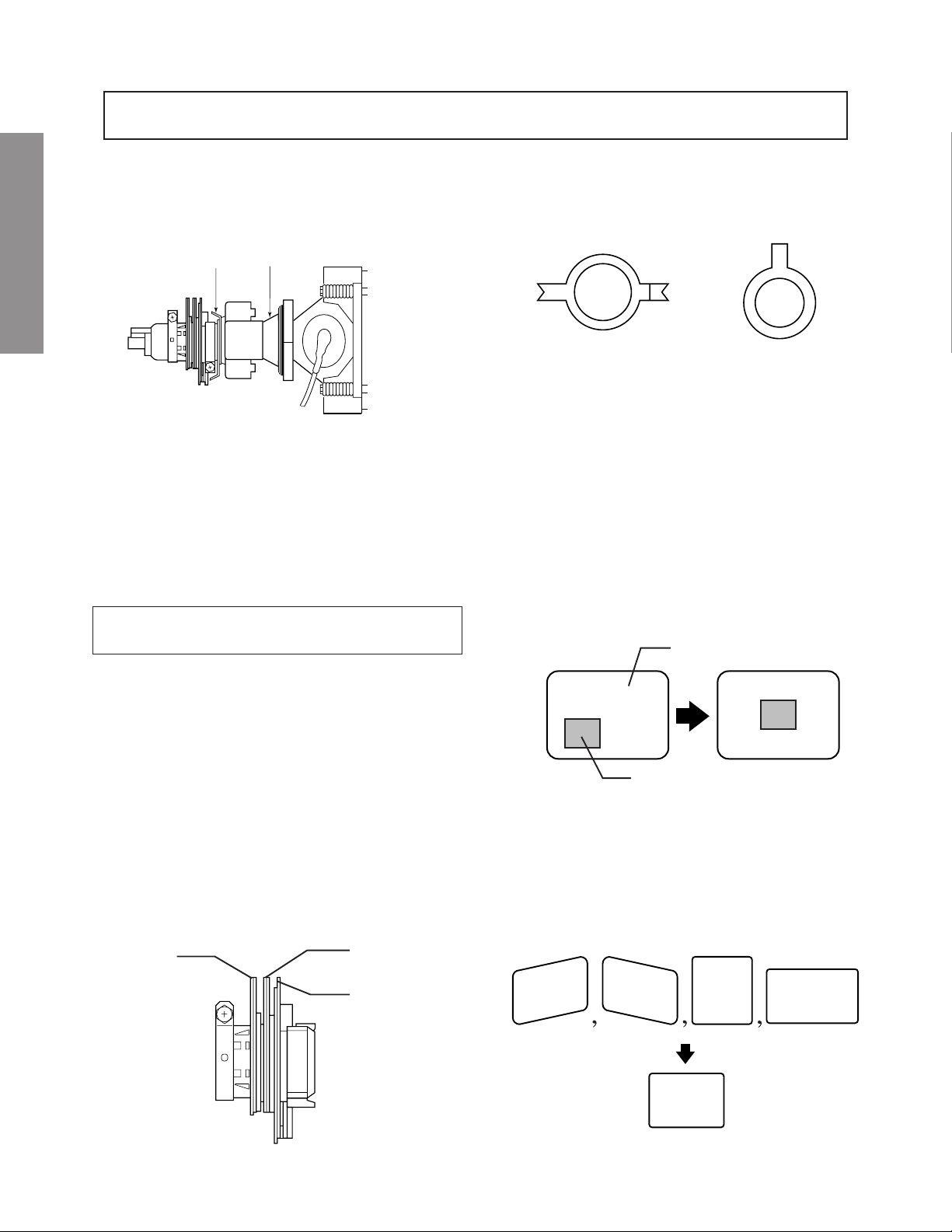

SERVICE MODE

1. ENTERING TO SERVICE MODE

1) Press CHANNEL t Button (on TV) and TV/SAT button (on TV) at the same time.

S

M

2. DISPLAYING THE ADJUSTMENT MENU

1) Press MENU button on Remote (or INFO button on TV).

Service mode

S

M

Press

Press

Adjustment mode

3. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

Screen adjustment mode ON/OFF: TV (ANT)/VIDEO button (on Remote)

Test signal selection : TV (ANT)/VIDEO button (on Remote)

Selection of the adjustment items : Channel s/t (on Remote)

Change of the data value : Volume s/t (on Remote)

Adjustment menu mode ON/OFF : MENU button (on Remote)

Initialization of the memory (QA02) : SUB TITLE + DVD ENTER (by DVD mode)

Initialization of the self diagnostic data: SET UP + DVD ENTER (by DVD mode)

“RCUT” selection : 1 button

“GCUT” selection : 2 button

“BCUT” selection : 3 button

“CNTX” or "SCNT" selection : 4 button

“COLC” or "SCOL" selection : 5 button

“TNTC” selection : 6 button

Convergence adj : 7 button

Test audio signal ON/OFF (1kHz) : 8 button

Self diagnostic display ON/OFF : 9 button

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Item

Data

– 11 –

4. SELECTING THE ADJUSTING ITEMS

1) Every pressing of CHANNEL s button in the service mode changes the adjustment items in the order of table-2.

(t button for reverse order)

Refer to table-2 for preset data of adjustment mode.

(See SETTING & ADJUSTING DATA on page 26)

5. ADJUSTING THE DATA

1) Pressing of VOLUME s or t button will change the value of data in the range from 00H to FFH. The variable range

depends on the adjusting item.

6. EXIT FROM SERVICE MODE

1) Pressing INFO button on Remote.

■ INITIALIZATION OF MEMORY DATA OF QA02

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

After replacing QA02, the following initialization is required.

1. Enter the service mode, then move the slide switch to DVD mode on Remote.

2. Press SUB TITLE button on the Remote, then press the DVD ENTER button on the Remote. And power off and on temporary after disappear the indication "S" on the screen. The initialization of QA02 has been complated.

3. Check the picture carefully. If necessary, adjust any adjustment item above.

Perform “Programming Channel Memory” on owner's manual.

CAUTION: Never attempt to initialize the data unless QA02 has been replaced.

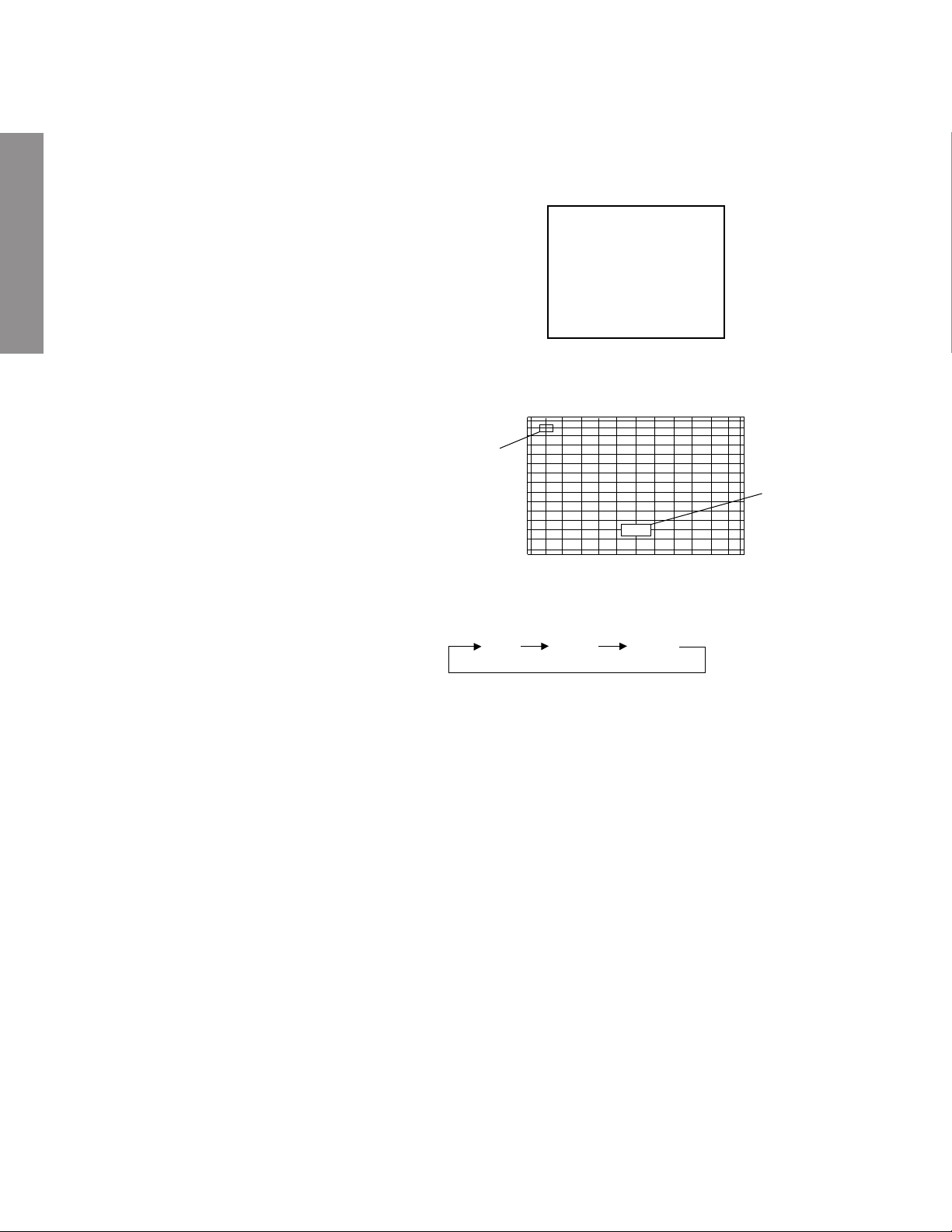

7. TEST SIGNAL SELECTION

1) Every pressing of TV/VIDEO button on the Remote Control in the Service mode, changes the built-in test patterns

on screen in the following order.

Normal picture

Red raster

Green raster

Blue raster

All black

All white

White and black

Black cross-bar

White cross-bar

Note: If the video cable is connected to the VIDEO1 INPUT jack, the

built-in pattern signals are not displayed.

White cross-dot

Black cross-dot

White cross-hatch

Black cross-hatch

Signals Picture

• Red raster

• Green raster

• Blue raster

• All Black

• All White

• Black & White

• Black cross-bar

• White cross-bar

• Black cross-bar

on green raster

• Black cross-hatch

• White cross-hatch

• Black cross-dot

• White cross-dot

The signals marked with are not usable to display in the Test signal for some model.

*

– 12 –

8. SELF DIAGNOSTIC FUNCTION

1) Press “9” button on Remote Control during display of adjustment menu in the service mode.

The diagnosis will begin to check if interface among IC’s are executed properly.

2) During diagnosis, the following displays are shown.

SELF CHECK

1

2

3

4

5

1 Part number of microprocessor (QA01)

2 Operation number of protection circuit (current limiter) . . . . “000” is normal.

3 BUS line check “OK” ................... Normal

4 BUS line ACK (acknowledge) check

5 Sync. signal check Green display..... Normal

NO. 23XXXXXX

POWER : 000

BUS LINE : OK

BUS CONT : OK

BLOCK : UV V1 V2

or QV01 QV01S

SYNC

“SCL-GND” or “NG” ........... SCL-GND short circuit

“SDA-GND” or “NG” ........... SDA-GND short circuit

“SCL-SDA” or “NG” ............ SCL-SDA short circuit

“OK” ..................... Normal

Display of Location Number . . . . NG

(Display example)

“QA02 NG”, “H001 NG”, “Q501 NG” etc.

Note: The indication of failure place is only one place though failure places are plural. When repair

of a failure place finishes, the ne xt failure place is indicated. (The order of priority of indication

is left side.)

Cyan display ......No check

Red display ........ NG

UV........... TV mode

V1............ VIDEO 1 mode

V2............ VIDEO 2 mode

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

The item marked with are not usable to display in the SELF DIAGNOSTIC FUNCTION for some model.

*

– 13 –

1. ENTERING TO DESIGN MODE

1) Select the Service mode.

DESIGN MODE

2) Press DVD TITLE and ENTER button on

Remote by DVD mode.

3) Press MENU button on Remote.

When QA02 is initialized, items “OPT0” and “OPT1” of DESIGN MODE are set to the data of the representative model of this

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

chassis family.

Therefore, because ON-SCREEN specification remains in the state of the representative of model. This model is required to

reset the data of items “OPT0” and “OPT1”.

2. SELECTING THE ADJUSTING ITEMS

Every pressing of CHANNEL t button in the design mode changes the adjustment items in the order table-3.

(s button for reverse order)

Refer to table-3 for data of design mode.

(See SETTING & ADJUSTING DATA on page 26)

3. ADJUSTING THE DATA

Pressing of VOLUME s or t button will change the value of data.

S D

(Design mode) (Adjustment mode)

Press

Press

ITEM

DATA

– 14 –

STANDARS

ADJUSTMENT

31.0±0.2kV

ELECTRICAL ADJUSTMENT

33.75±

0.15kHz

A=0.76±0.1[µs]

ADJUSTING METHODS

voltage meter between T461-Z450

and adjust high pressure with R466.

1) Perform connection of the high

High voltage

meter

Between

T461-Z450

1) Short-circuit test pin (H) and (+9V).

2) Adjust fH with R4055.

Frequency counter

Between

R431-GND

the lowest line on the synchroscope.

1) Adjust DC=0 of both wave forms to

Synchroscope

D441-K

(2V/div range)

points and make adjustments with the

2) Take measurement of 3 div.

3) Observe the wave forms at the two

R4011-BB50 side

(1V/div range)

D441 cathode wave form

BB connector side wave

form of R4011

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

HPOS.

A

3div

0

INPUT MEASURING MEASURING

SIGNALS POINTS INSTRUMENTS

Retoma signal

CONTRAST :MAX

BRIGHTNESS :CNT

ITEMS NAMES SETTING

adjustment

High voltage

COLOUR :CNT

TINT :CNT

(Unit)

• Retoma signal

CNTRAST :MAX

BRIGHTNESS :CNT

COLOUR :CNT

Horizontal

oscillation

frequency

fH. ADJ.

(Chassis)

Retoma signal

TINT :CNT

CONTRAST :MAX

BRIGHTNESS :CNT

Horizontal

phase

HPOS

(Chassis)

COLOUR :CNT

TINT :CNT

– 15 –

ITEM ADJUSTMENT PROCEDURE

SUB-BRIGHTNESS

(BRTC)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

SUB-COLOR

(SCOL)

SUB-TINT

(TNTC)

PICTURE POSITION

HEIGHT

WIDTH

VERT. LINEARITY

(Service mode data)

1. Constrict the picture height until the verti-

cal retrace line appears adjusting the

HEIGHT control on the MAIN board.

2. Adjust the CONTRAST to the minimum.

3. Enter the service mode, then select

“BRTC” register.

4. Adjust the data value so the belt of verti-

cal retrace line just disappear.

5. Adjust the CONTRAST for the desired

contrast.

6. Adjust the HEIGHT control.

Vertical retrace line

1. Receive color-bar signal from color-bar generator.

2. Adjust the BRIGHTNESS and CONTRAST to the center (RESET status).

3. Connect oscilloscope to TP50 on the MAIN board.

4. Enter the service mode, then select “SCOL”.

5. Temporarily adjust the data value to achieve about 1V

6. Select “TNTC” register.

7. Adjust the data value to obtain the blue

bar to magenta bar ratio of 3:2 as shown.

8. Select “SCOL” register .

9. Adjust the data value to achieve 1.8V

of blue bar on scope.

10. Check the picture with off-air signal.

Magenta

0-p

0

0-p of blue bar.

Blue

Adjust the Service mode data: Refer to table-2 on page 26.

2

3 (1.8V

0-P

)

– 16 –

ITEM ADJUSTMENT PROCEDURE

WHITE BALANCE

(RCUT)

(BCUT)

(RDRV)

(BDRV)

1. Press RESET button on TV or remote hand set.

2. Don’t put any signal in Video 1 jack.

3. Call up the adjustment mode display, then adjust the data of items RCUT, GCUT

and BCUT to “40”.

4. Press TV (ANT)/VIDEO button on TV.

5. Gradually rotate R, G and B SCREEN volume of FOCUS PAC (page 8) cloc kwise

or counterclockwise until the raster appears slightly on the CRT through the each

lens, and leave them.

(Look into the lens in order to check the raster.)

6. Press TV (ANT)/VIDEO button on TV again.

7. Exit from service mode, and adjust the contrast to the minimum and brightness to

the maximum.

8. Call up the adjustment mode and press the TV (ANT)/VIDEO button on Remote

until the Black & White pattern appears on the screen.

9. Adjust the data of items RCUT and BCUT for low light area.

10. Adjust the data of items RDRV and BDRV Controls for proper white-balanced

picture in high light area.

11. Check the white balance in both low and high light areas. If necessary, perform

again steps from 9 to 10.

High light area

Adjust "RDRV" or "BDRV" to be white.

Low light area

Fine adjust "RCUT" or "BCUT" to be black.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 17 –

CONVERGENCE ADJUSTMENT

Adjust convergence from center to circumference in order.

1. Select the adjustment mode following the steps on page 11.

KEY FUNCTION IN THE

CONVERGENCE ADJUSTMENT:

RCUT

40H

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Up : 2 button

Selet Green color: 3 button

Left : 4 button

Blinking of cursor ON/OFF: 5 button

Right: 6 button

Adjust mode ON/OFF: 7 button

Down: 8 button

Erase Green line: 0 button

Erase Red line: 100 button

Erase Blue line: ENT button

Note:

Adjusting procedure in replacing convergence board.

1. User convergence center check. Make

sure the best convergence setting is

about the center of adjustable range.

2. CENTERING ADJUSTMENT

3. PICTURE POSITION ADJUSTMENT

4. HIT, WID ADJUSTMENT

5. CONVERGENCE ADJUSTMENT

2. Press “7” button to display the built-in cross-hatch pattern.

Cursor

X: I

Y: I

FULL

C: R

FULL

3. Press PIC-SIZE button to select the FULL mode.

FULL

WIDE1 WIDE2

The pattern includes three colors (R, G, B).

The cursor should be blinking in Red.

This means that the Red color is adjustable.

Adjustment around cursor can be done.

4. Press “3” button to select Green color to be adjusted.

5. Press “5” button to stop the blinking of cursor.

6. Press “2 (up)”, “8 (down)”, “4 (left)” or “6 (right)” to obtain the correct

cross-hatch pattern as above.

If necessary, the specified color line can be erased from the screen.

100 button .................. to erase Red line

0 button .................. to erase Green line

ENT button .................. to erase Blue line

7. Press “5” button to make the cursor blinking.

8. Press “2”, “8”, “4”, “6” buttons to move the cursor to other point to be

adjusted.

9. Repeat steps 5 to 8.

10. Repeat steps 4 to 9 to adjust Red and Blue colors.

Converge the selected color line into the Green line.

11. Press “7” button to enter the adjusted states.

At this time, picture changes for about 1 second.

12. Repeat steps 3 to 12 for WIDE mode.

13. Press “7” button again to return to the normal picture.

– 18 –

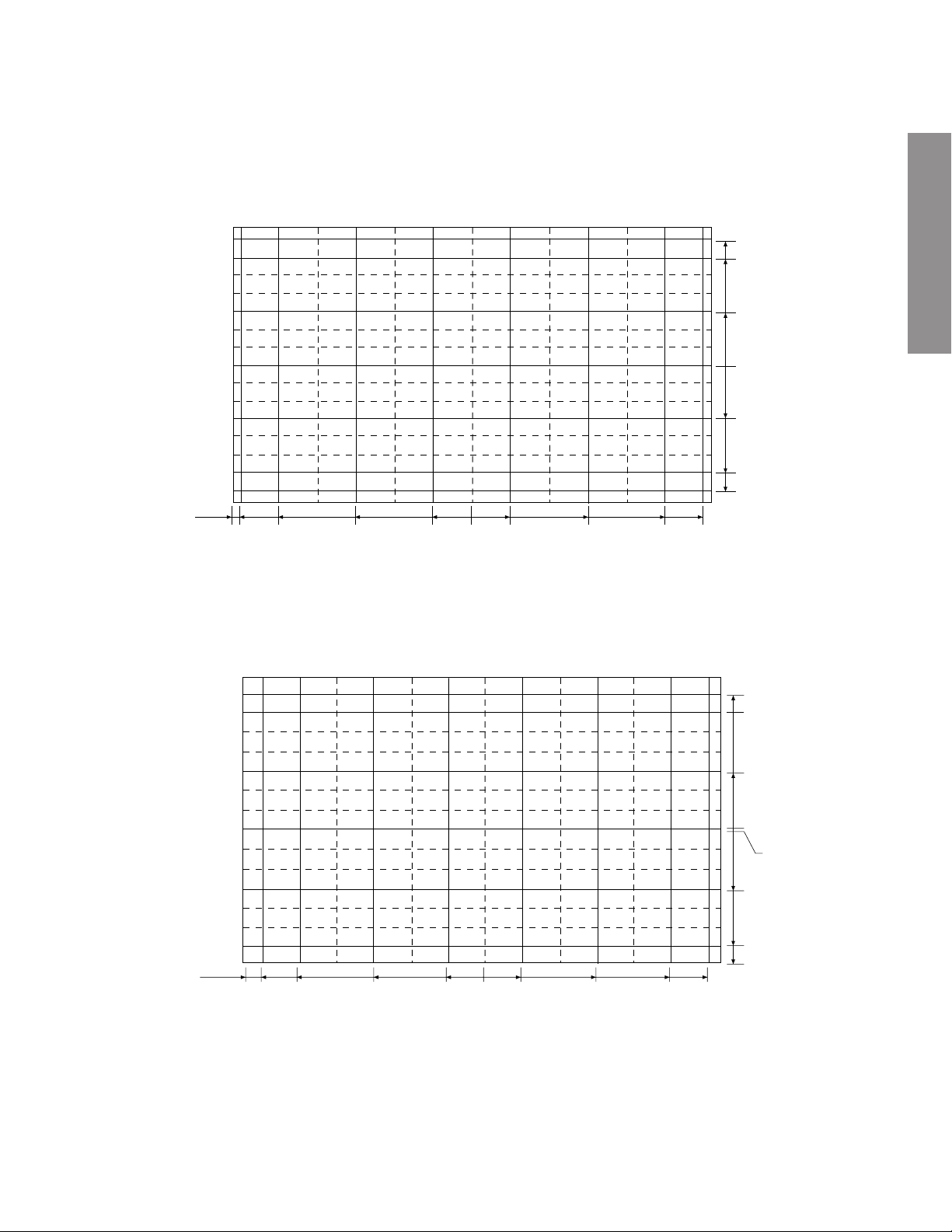

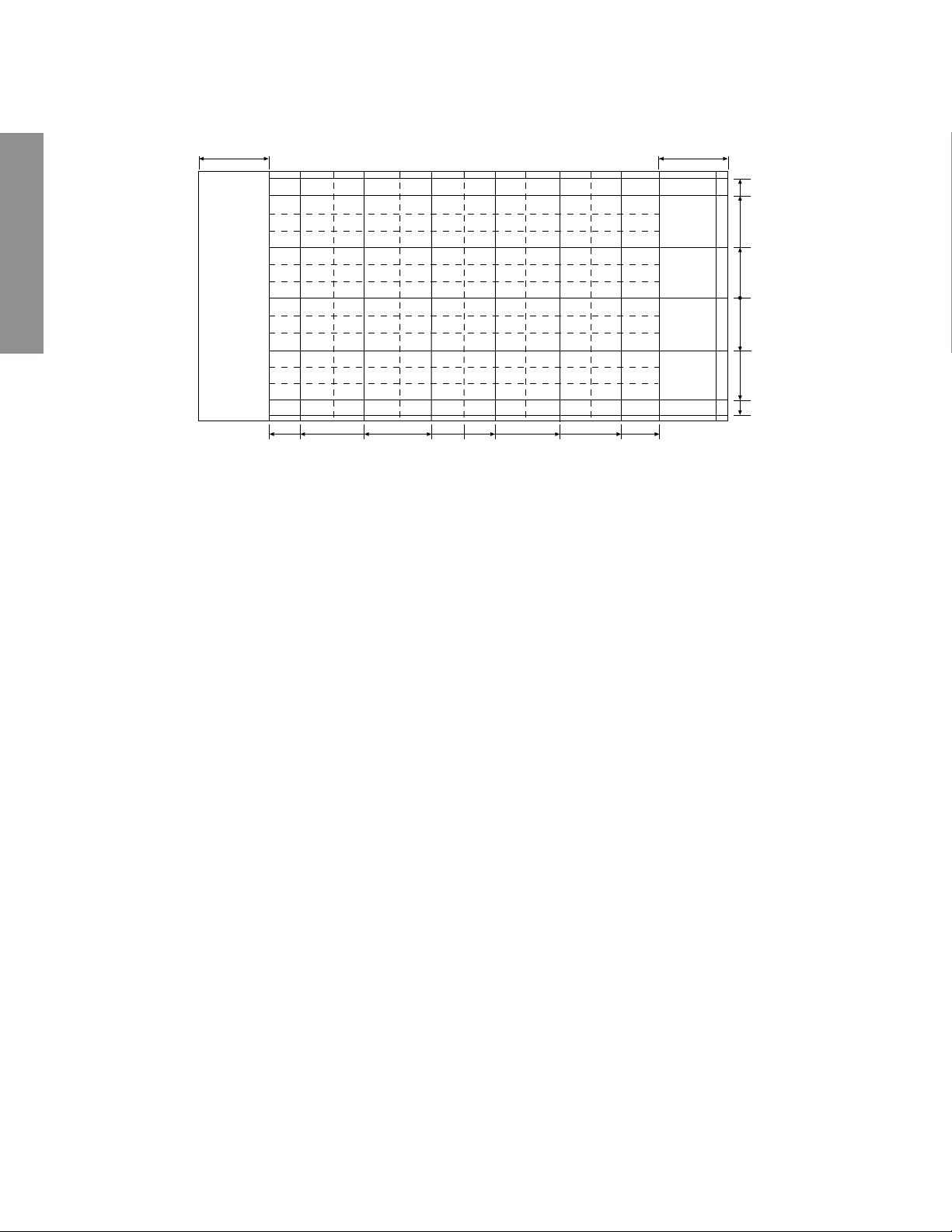

Adjusting Dimension of Each Picture Screen (65")

65 inches 16:9 screen size:

• Horizontal 1442 mm

• Vertical 810 mm

(1) FULL/WIDE2

7

714

595

357

119

339.5

291.0

145.5

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

0

145.5

291.0

339.5

V. SPAN 48.5 mm

119

0

357

595

H. SPAN 119 mm

714

(2) WIDE1

7.0

714.0

584.0

337.5

110.0

341.0

293.0

143.0

0

-7.0

Pattern center

152.0

295.0

342.0

110.0

0

337.5

584.0

714.0

– 19 –

(3) 525P (STANDARD)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

184

537

447.5

268.5

89.5

184

339.5

291.0

145.5

0

145.5

291.0

339.5

0

89.5

268.5

447.5

537

V. SPAN 48.5 mm

H. SPAN 89.5 mm

– 20 –

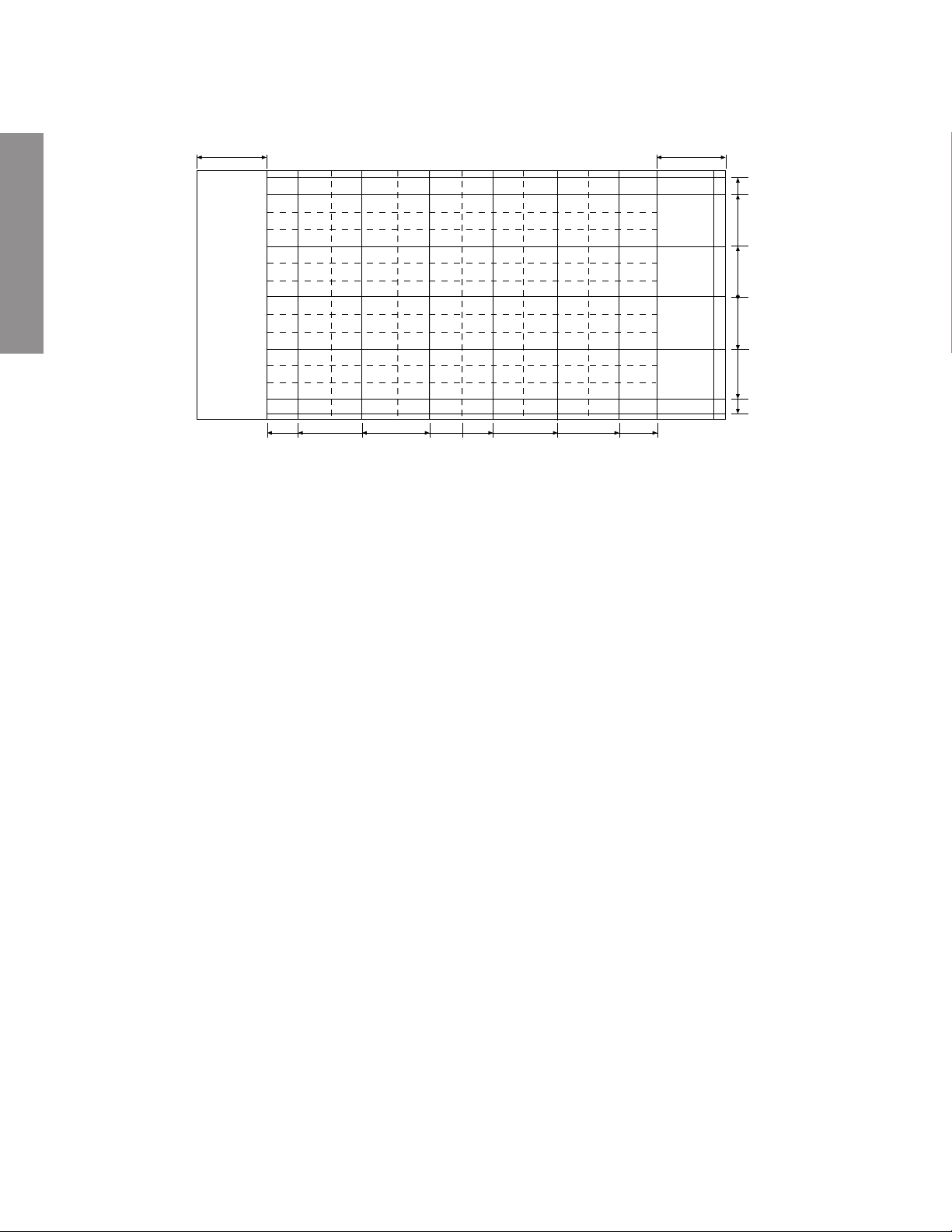

ADJUSTING DIMENSION OF EACH PICTURE SCREEN (56")

16:9 screen size:

• Horizontal 1240 mm

• V ertical 700 mm

1. FULL/WIDE2

2. WIDE1

293.5

251.5

125.5

0

125.5

251.5

293.5

6

614614

511.5

307

102.3

0

102.3

307

511.5

V. SPAN 41.9 mm

H. SPAN 102.3 mm

614

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

6.0

614.0

502.0

290.0

94.5

294.5

253.0

123.5

0

-6

Pattern center

131.5

255.0

295.5

V. SPAN

0

94.5

290.0

502.0

614.0

H. SPAN

**

**

mm

mm

– 21 –

3. 525P (STANDARD)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

158

462

385

231

158

293.5

251.5

125.5

0

125.5

251.5

293.5

0

77

77

231

385

462

V. SPAN 41.9 mm

H. SPAN 77 mm

– 22 –

NOTES

In many cases, color misconvergence may be corrected by returning HIT and WID data to initial adjusting values.

Following cases will surely require readjustment of convergence.

REPLACING CONVERGENCE UNIT

When replacing convergence unit, all picture screens require readjustment basically, but the follo wing method allows process be

reduced considerably.

1. Replace the memory (QH174, QH173) on defective unit with memory on new unit. Mounting the unit on the SET after the

above working realizes picture screen before replacement immediately.

2. Mount unit which has combination of old and new memories, on SET and turn it on. Screen shows whole picture looks like

straightly shifted towards vertical or horizontal direction.

3. Adjust again centers of green, red and blue with centering magnets.

4. Check each picture screen for slight disparity of color and picture size. If necessary, add some adjustments of main deflection and color matching of convergence.

CRT REPLACEMENT

When CRT is replaced, main deflection readjustment and color matching are required.

Perform following procedures.

1. Replace two CRT’s of blue and red.

2. Perform horizontal adjustment for blue and red yokes on base of green CR T data. Mount yoke and velocity mod. coil alignment, pushing towards CRT without gap.

3. Adjust alignment of blue and red. (Refer Alignment adjustment for details.)

4. Rotating centering magnet, adjust CRT centers of red and blue to CRT center of green.

(Center adjustment)

5. Adjust HIT and WID data of main deflection, and decide data at the most precise screen comparing to green data.

6. Adjust convergence of each screen picture for color matching. Do not move green one at this time.

7. After convergence adjustment of each screen picture finishes, replace green CRT.

For green CRT as well, repeat steps 3 to 6 above on bases of red and blue color matching to adjust convergence.

8. If it is need the adjustment of green, keep the specified dimensions.

When adjust the whole picture screen size, adjust the HEIGHT (HIT) and WIDTH (WID) in the ELECTRICAL ADJUSTMENT.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 23 –

SPACER x2

SCREEN AND MIRROR ALIGNMENTS

SPACER x2

INSIDE

0 to 1 mm

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

K503 FRONT PANEL

LENTICULAR

<OUTSIDE>

SMOOTH

K501

BLACK STRIPES

K502

FRESNAL

<INSIDE>

SMOOTH

OUT SIDE

BLACK STRIPES

SPACER

FRONT PANEL

LENTICULAR

FRESNEL

LENS

A260

PIECE

BEZEL x2

FRESNEL

LENTICULAR

FRONT PANEL

BEZEL x2

SMOOTH

INSERT

A260

INSERT

A260 PIECE

A260

PIECE

CAUTION : Do not hold the optical system parts (lens and

mirror) with bare hand to avoid finger-prints on

the surface of those parts.

HOW TO CLEAN LENS AND MIRROR

1. Be sure to remove sand dust with an air brush, etc.

2. When it is stained slightly , breathe upon it and wipe awa y

with the specified cleaning cloth.

For other stains than the above, wipe the stains away

with the specified cloth into which a cleaning liquid has

been soaked.

Cleaning liquid.................... LENS LUSTER (Manufac-

tured by Edmund Scientific

Co.), etc.

A260

PIECE

HOW TO CLEAN SCREEN

When cleaning the screen, use a soft cloth so as not to

damage the screen.

1. Wipe the stain away with a diluted neutral detergent

soaked cloth.

2. Wipe the detergent away with a water soaked cloth.

3. Wipe the screen with a dry cloth to remove moisture on

the screen.

Note : Absolutely do not use alcohol, benzine, thinner, etc.

for cleaning in order not to wipe away the black

print on the surface.

– 24 –

CIRCUIT CHECKS

HIGH VOLTAGE CHECK

CAUTION: Checking should be done following the steps be-

low.

1. Connect an accurate high voltage meter. (See ANODE

VOLTAGE MEASURING METHOD)

2. Turn on the receiver. Set the BRIGHTNESS and CONTRAST to minimum (zero beam current).

3. High voltage must be measured below (B) kV.

Refer to table-1 for high voltage (B).

(See SETTING & ADJUSTING DATA on page 26)

4. Vary the BRIGHTNESS to both extremes to be sure the

high voltage does not exceed the limit under any conditions.

CAUTION:

When the following parts fail, check the High Voltage after replacing.

Location

No.

T461

Z450

C404

C407

C408

R465

R466

R467

Q437

ANODE VOLTAGE MEASURING METHOD

CAUTION: Take extra precaution when measuring this high

1. Disconnect the FBT anode cable as outlined below . Measure high voltage at the point where the cable enters the

FBT.

2. Holding the rubber cover firmly, turn it counterclockwise

and check that the lock has been disengaged. (See Fig. b

on page 9.)

3. Determine the extent of the rubber cover before disconnecting the cable.

4. Pull straight up the anode cable to disconnect.

5. When reconnecting the cable, proceed in the reverse order.

After reconnecting, tug on the cable to check that it is secure.

Name

Flyback Trans.

CR Block

Capacitor

Capacitor

Capacitor

Resistor

VR

Resistor

IC

voltage. High voltages are also present in surrounding circuit boards (CRT DRIVE assembly, DEFLECTION assembly , and PO WER SUPPLY assembly).

Remark

TFB3083AD

TPA5007

1200pF, ±3%

1200pF, ±3%

1200pF, ±3%

2.2kΩ ±1%

2kΩB

5.6kΩ ±1%

TA75902p

FS CIRCUIT CHECK

The Fail Safe (FS) circuit check is indispensable for the final

check in servicing. Checking should be done following the

steps below.

1. Turn the receiver on.

2. Temporarily short TP-R-1 and TP-X-1 on the DEF Board

with a jumper wire.

Raster and sound will disappear.

3. The receiver must remain in this state ev en after removing

the jumper wire. This is the evidence that the FS circuit is

functioning properly.

4. To obtain a picture again, temporarily turn the receiver off

and allow the FS circuit more than 5 seconds to reset. Then

turn the receiver on to produce a normal picture.

Troubleshooting Guide for Fail Safe Circuit

(When Fail Safe Circuit Operate)

Check that the set returns to normal operation when

the terminal "TP-X1" is grounded with jumper wire.

YES NO

Check the voltage across

Capacitor C471 is

approximately (C) volts.

Refer to table –4 for

FBT detection voltage

(C) .

YES

Fail Safe circuit is faulted.

(See SETTING & ADJUSTING

DATA on page 26)

NO

Power circuit or

horizontal circuit

or vertical circuit

is faulted.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 25 –

CHAPTER 2 SPECIFIC INFORMATIONS

X-RAY RADIATION PRECAUTION

SERVICE MODE

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

ADJUSTING ITEMS AND DATAS IN THE SERVICE MODE:

SETTING & ADJUSTING DATA

Data

HIGH VOLTAGE AT ZERO BEAM: (A) 31.0 kV

MAX HIGH VOLTAGE:

Table-1

(B) 31.3 kV

Item Name of adjustment

RCUT

GCUT

BCUT

RDRV

BDRV

CNTX

BRTC

COLC

TNTC

SCOL

SCNT

HPSD

DESIGN MODE

ADJUSTING ITEMS AND DATAS IN THE DESIGN MODE:

R CUTOFF

G CUTOFF

B CUTOFF

R DRIVE

B DRIVE

SUB-CONTRAST MAX

SUB-BRIGHT CENTER

SUB-COLOR CENTER NTSC

SUB-TINT CENTER

SUB-COLOR

SUB-CONTRAST

H-POS (FULL)

Item Name of adjustment

OPT0 OPTION 0 00H 02H 02H

OPT1 OPTION 1 01H 01H 01H

Data

40H

40H

40H

40H

40H

7FH

80H

50H

46H

06H

0CH

85H

Item Name of adjustment

HIT

VLIN

VSC

VCP

WID

TRAP

HCP

VFC

PARA

VCEN

VPOS

Table-2

Preset Data 65" 56"

V-HEIGHT (FULL)

V-LINEARITY (FULL)

V-S CORRECTION (FULL)

V-COMPENSATION (FULL)

PICTURE WIDTH (FULL)

TRAPEZIUM (FULL)

H-COMPENSATION (FULL)

V-F CORRECTION (FULL)

PARA (FULL)

V-CENTER (FULL)

V-POSITION (FULL)

Data

Data

41H

0FH

08H

07H

17H

09H

00H

00H

10H

83H

00H

Remarks

CIRCUIT CHECKS

Table-3

FBT DETECTION VOLTAGE (C) 39.0 V

Table-4

– 26 –

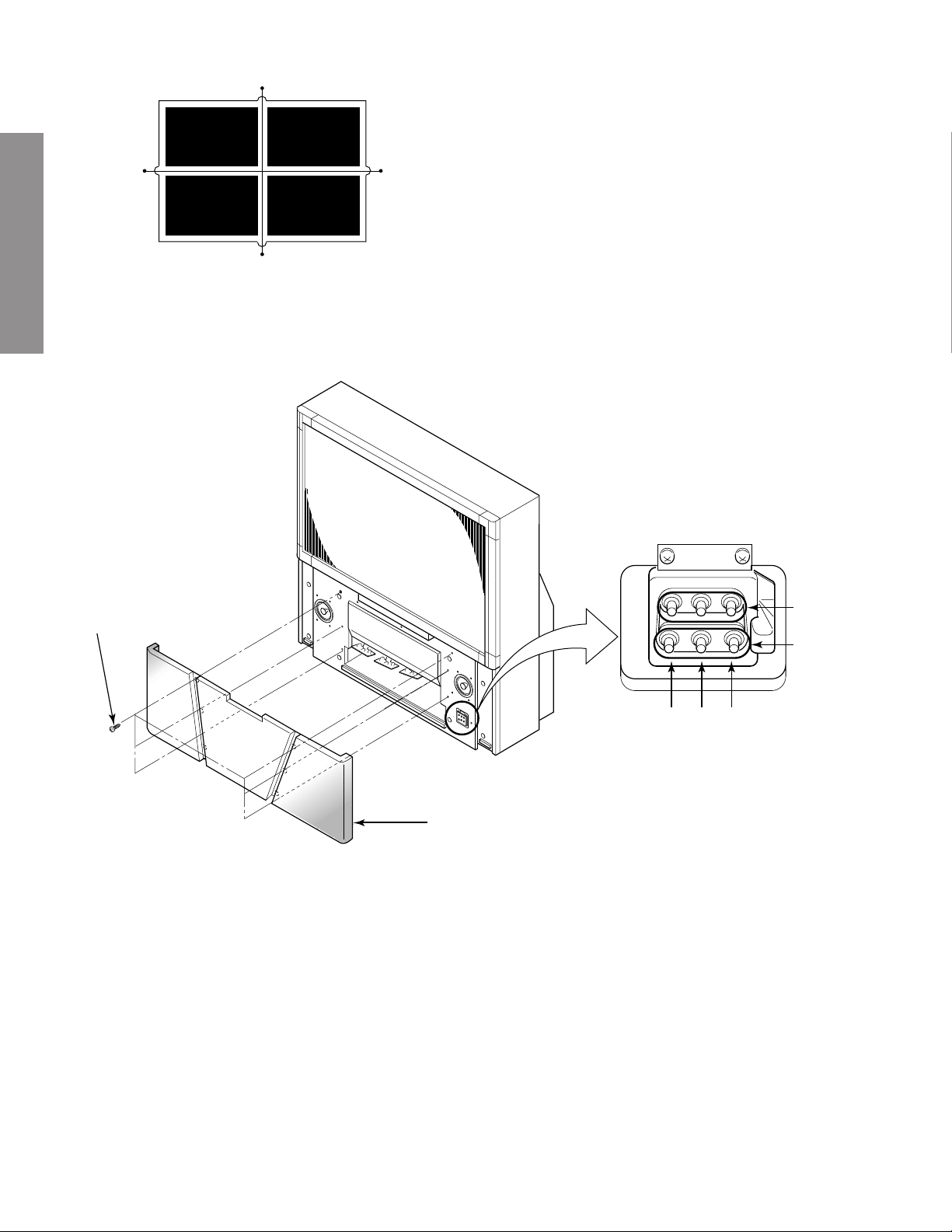

LOCATION OF CONTROLS

TV set (Replacementive: DW65X91)

Front view

Behind the door

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

RESET

Rear view

IN—VIDEO 3

S-VIDEO

VIDEO

VIDEO 3 INPUTS

RESET button

AUDIO

L/MONO R

ANTENNA-IN

A B

INFO button

MENU button

TV/SAT button

ENTER button

ENTER

MENU

/

INFO

OK

TV/SAT

VOLUME

/ buttons

PHONE

JACK

OPTICAL

DIGITAL

AUDIO OUT

VOLUME CHANNEL

CHANNEL

/ buttons

buttons

TOP OF CARD

FACE DOWN

ACCESS CARD

AUDIO CENTER

CHANNEL IN

ON OFF

S-VIDEO

VIDEO

L/

MONO

AUDIO

IN

POWER

buttons

Remote sensor

POWER indicator

POWER button

SATELLITE-IN

OUT

VAR

R L

AUDIO

Y

B

P

PR

COLOR

STREAM

VIDEO-2

VIDEO-1

HD 1

IN IN OUT IN

VIDEO

L/

L

MONO

AUDIOAUDIO

R

COLOR

STREAM

HD 2

Y

L

B

P

AUDIO

PR

RR

– 27 –

Loading...

Loading...