Page 1

SERVICE MANUAL

CONTENTS

1. Safety Precautions……………………………………………………………………………….2

2. Exploded View And Final Assembly Details………………………………………………....3

3. Block Diagram…………………………………………………………………………................4

4. Drawing Site Of Main Parts................................................................................................5

5. List Of Replacement Parts……..........................................................................................6

6. Replacement of Memory IC……………………………………………………………...........11

7. Service Adjustment…………………………………………………………………………......11

8. IC’s Functional Description…………………………………………………………………....18

9. Test Point Waveform……………………………………………………………………………40

10. IC And Transistor’s Voltages.…….................................................................................41

11. Common Trouble Shooting Chart For Uoc Toshiba Chassis CRT TV

(TMPA889*-****)...............................................................................................................41

12. 290 Stereo PAL Secam Schematic Circuit Diagram.....................................................45

1

Page 2

SERVICE MANUAL

1. SAFETY RECAUTIONS

After re-assembling the product, always perform an isolation

shafts, etc.) to be sure the product is safe to operate without

The surface of the TV screen is coated with a thin film which

can easily be damaged. Be very careful with it when handle

(…Withstand a voltage of 1100V AC (r.m.s.) to an appliance.

method of test requires a test equipment not generally found

Leakage Current Tester”, measure the leakage current from

outlet and repeat each measurement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds to 0.5mA

1. The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the

original design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the

iginal circuits. Service should be performed by qualified

personnel only.

2. Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer’s warranty and will further relieve the

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics

are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using

replacement components rated for higher voltage, wattage,

etc. Replacement parts which have these special safety

characteristics are identified in the parts list of service manual.

Electrical components having such features are identified

by shading on the schematics and by (!) on the parts list

ervie manual. The use of a substitute replacent which

does no t have the same safety c haracteristic s as the

recommended replacement part shown in the parts list of

service manual may cause shock, fire, or other hazards.

4. Don’t short between the LIVE side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing. Some model’s power circuit is partly different in

the GND. The difference of the GND is shown by the LIVE:

( ) side GND, ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND. Don’t short between the LIVEide

GND and ISOLATED (NEUTRAL) side GND or EARTH side

GND and never measure with a measuring apparatus

(os cilloscope etc.) the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND at the same time.

If above note will not be kept, a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (See

ADJUSTMENT OF B1 POWER SUPPLY).

6. The high voltage applied to the picture tube must conform

with that specified in Service manual. Excessive high voltage

can cause an increase in X-Ray emission, arcing and

possible component damage, therefore operation under

excessi ve high voltage conditions shou ld be kept to a

minimum, or should be prevented. If severe arcing occurs,

remove the AC power immediatelyt and determine the cause

by visual inspection (incorrect installation, cracked or melted

high voltage harness, poor soldering, etc.). To maintain the

proper minimum level of soft X-Ray emission, components

in the high voltage circuitry including the picture tube must

be the exact replacements or alternatives approved by the

manufacturer of the complete product.

7. Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM. Discharge

the picture tube before attempting meter connect on, by

connecting a clip lead to the ground frame and connecting

the other end of the lead through a 10kΩ 2W resitor to the

anode button.

8. When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the manufacturer’s

replacement components.

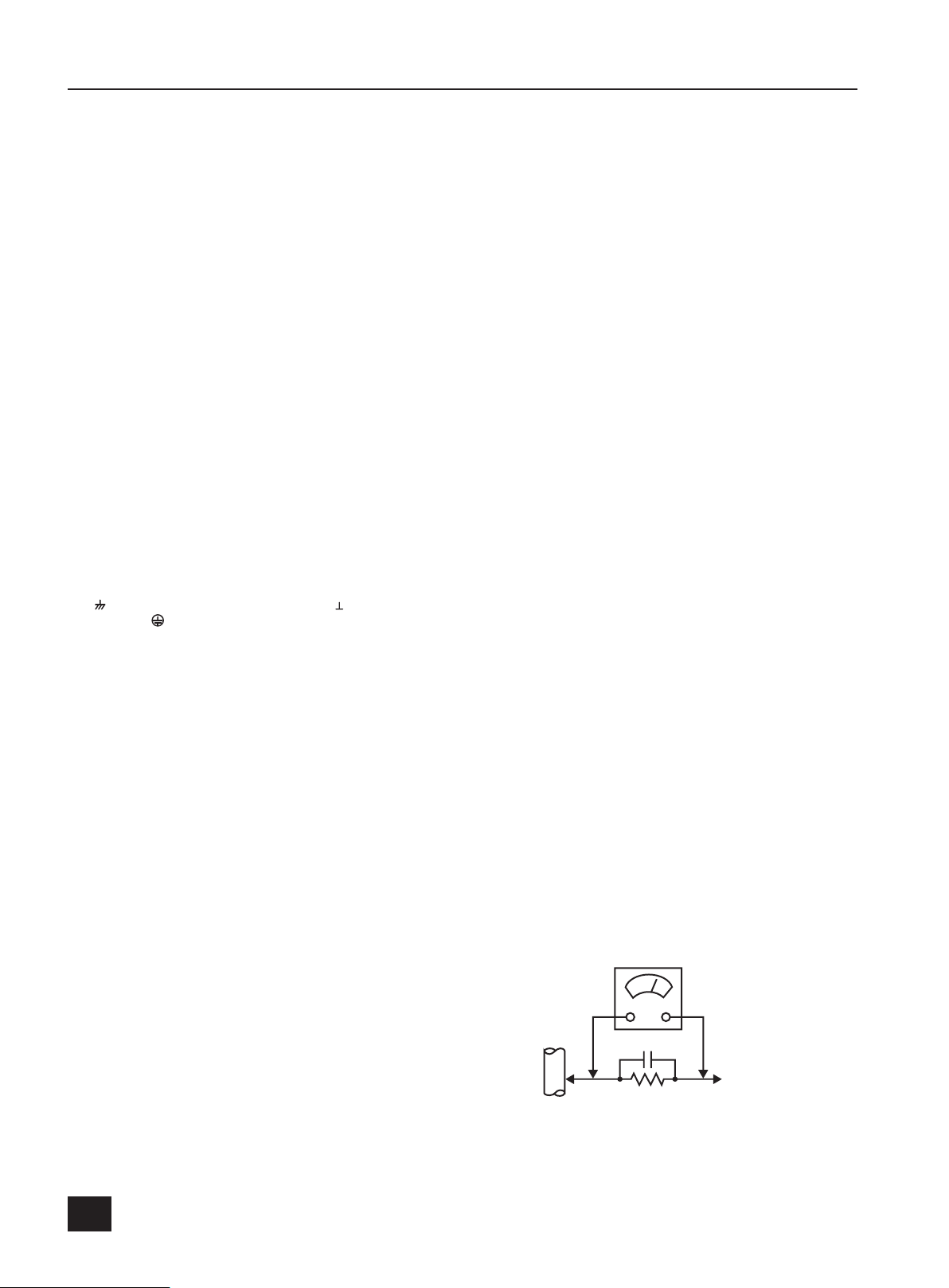

9. Isolation Check (Safety for Electrical Shock Hazard)

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Control

knobs, metal cabinet, screwheads, earphone jack, control

danger of electrical shock.

10.

the TV. Should the TV screen become soiled, wipe it with a

soft dry cloth. Never rub it forcefully. Never use any cleaner

or detergent on it.

(1) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

㩷

part having a return path to the chassis shuld withstand a

voltage of 3000V AC (r.m.s.) for a period of one second

rated up to 120V, and 3000V AC (r.m.s.) to an appliance

rated 200V or more, for a periode of one second.) This

in the service trade.

(2) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

“

each exposed metal part of the cabinet, particularly any

exposed metal part having a return path to the chassis, to

a known good earth ground (water pipe, etc.). Any leakage

current must not exceed 0.5mA AC (r.m.s.). However, in

tropical area, this must not exceed 0.2mA AC (r.m.s.).

● Alternate Check Method

Plug the AC line cord directly into the AC outlet ( do not use

a line isolation transformer during this check.). Use an AC

voltmeter having 1000 ohms per volt or more sensitivity in

the following manner. Connect a 1 500Ω 10W resist or

paralleled by a 0.1 5μ F AC -t ype capacitor between an

exposed metal part and a known good earth ground (water

pipe, etc.). Measure the AC voltage across the resistor with

the AC voltmeter. Move the resistor connection to each

exposed metal part, particularly any exposed metal part

having a return path to the chassis, and measure the AC

voltage across the resistor. Now, reverse the plug in the AC

AC (r.m.s.). However, in tropical area, this must not exceed

0.3V AC (r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

0.15μF AC-TYPE

1500Ω/V 10W

GOOD EARTH GROUND

AC VOLTMETER

(HAVING 1000Ω/V

OR MORE SENSITIVITY)

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

2

Page 3

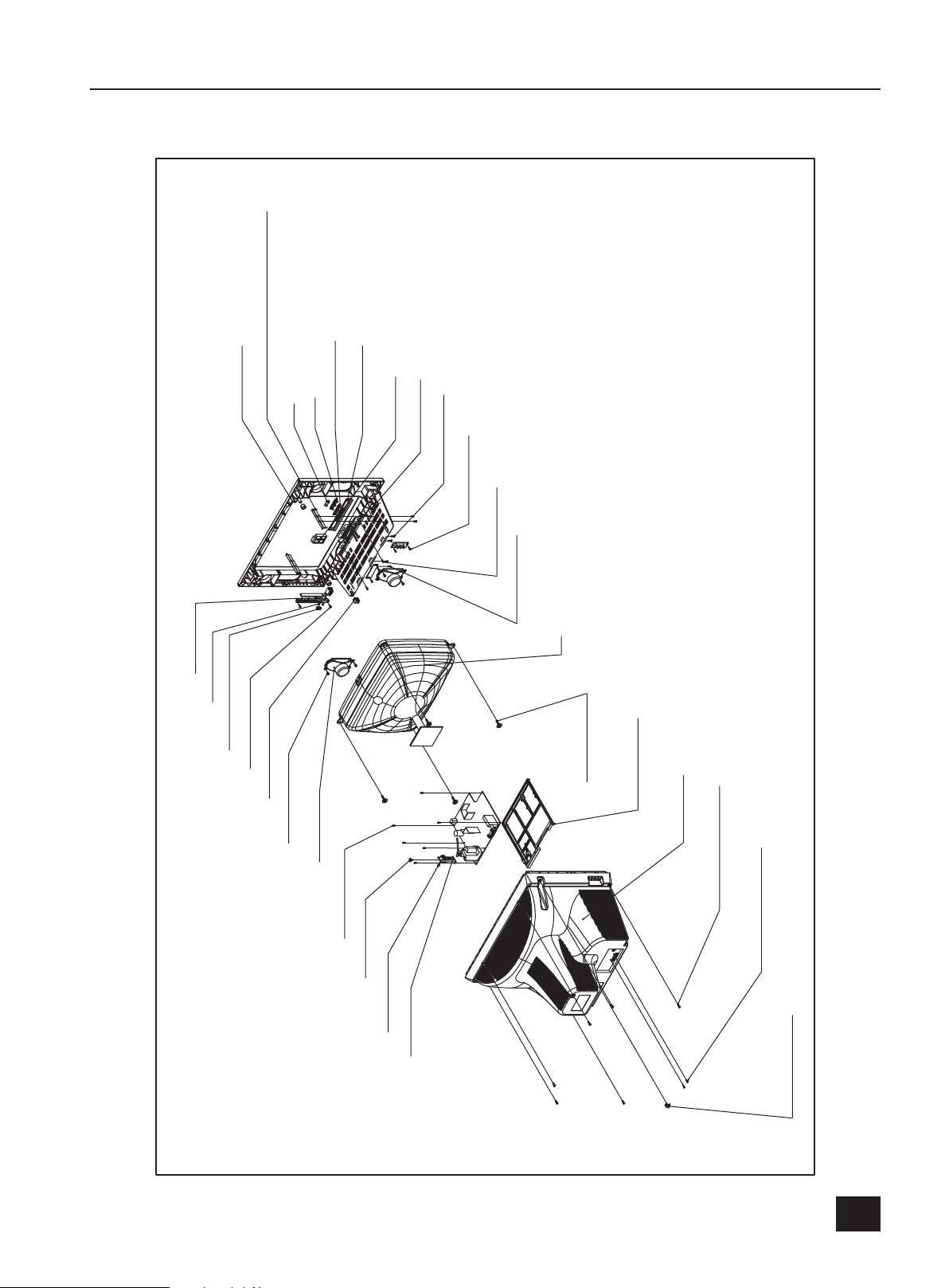

2. EXPLODED VIEW AND FINAL ASSEMBLY DETAILS

2-Plastic oriented bar for holding main

Front cabinet

Logo

Lens

Decorated part

Plastic decorated psrts with lens

CRT support

4-CRT washer

2-Screw ST4*16F

2-Screw ST3*12F

SERVICE MANUAL

Function button

2-Screw M3*8

Power switch button

2-Screw ST3*12F

Power cord clame

4-Screw ST4*12F

2-Speakers

6-Screw ST3*12F

4-Screw ST3*12F

4-Screw ST3*12F

CRT

4-Screw ST6*30F

Screw ST3*12F

Main board holder

Rear cabinet

6-Screw ST4*16F(Black)

2-Screw ST3*12F(Black)

NOTE: Inserted Parts Is Different According To The Cabinet, Just For Reference.

Screw ST4*10F

FBT holder

Power cord holder

3

Page 4

SERVICE MANUAL

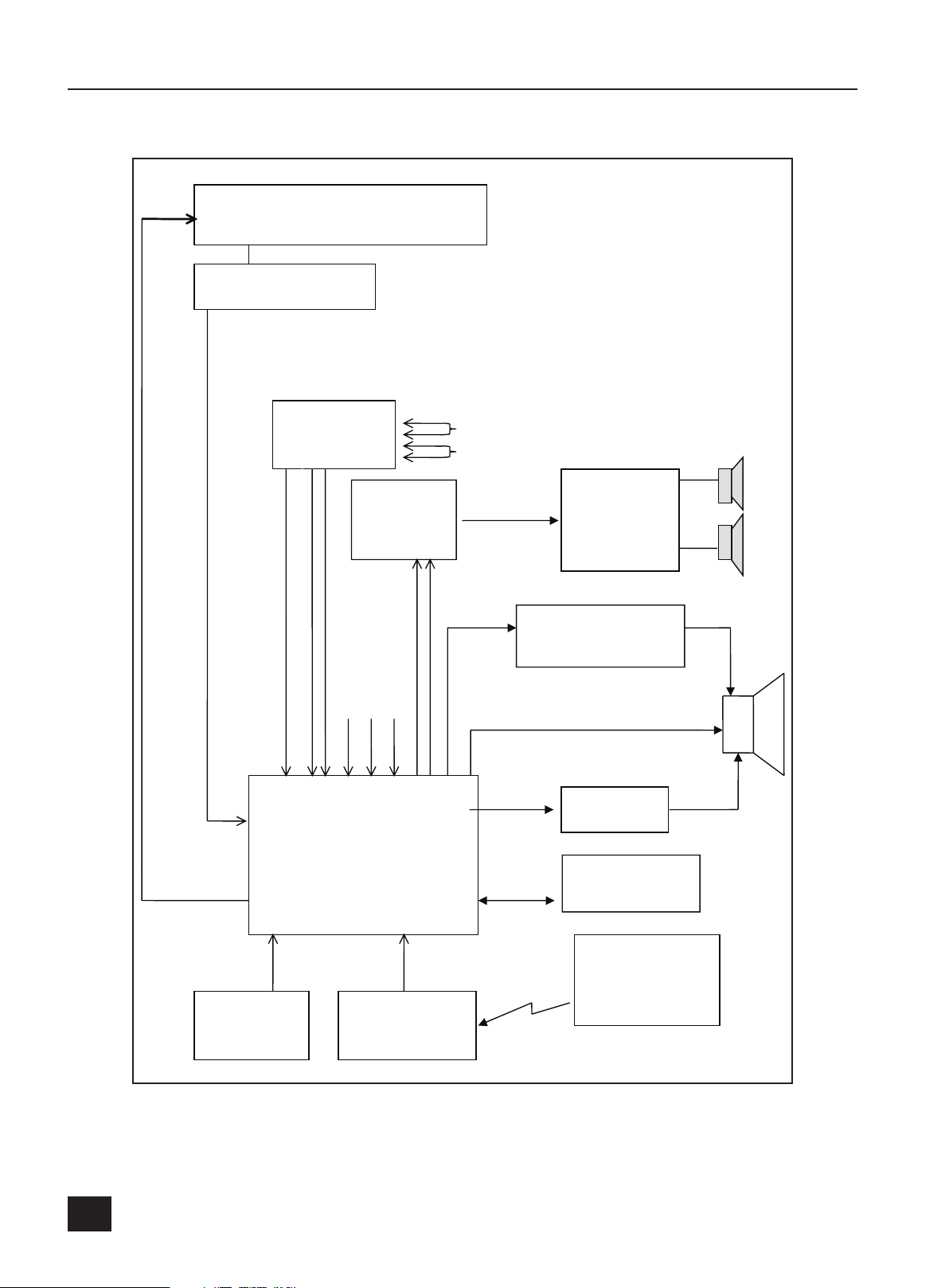

3 BLOCK DIAGRAM

TUNER A101

ET-5KIE-CV100K / ET-5TIE-EF109

SAW Z101 IF389AIM

TC4053BP

AV SW

TA/1304/1343

A1 A2

Video Audio

Y Cb Cr

2 in Chip

TMPA8897CSCNG****

N204

AV1

AV2

CD17821CS

VERIVE3

CD78040 / STV9302

HOUT

CRT

EEPROM

N901 24C08

SC6122

KEY

MATRIX

RECEIVEERMP

4

Page 5

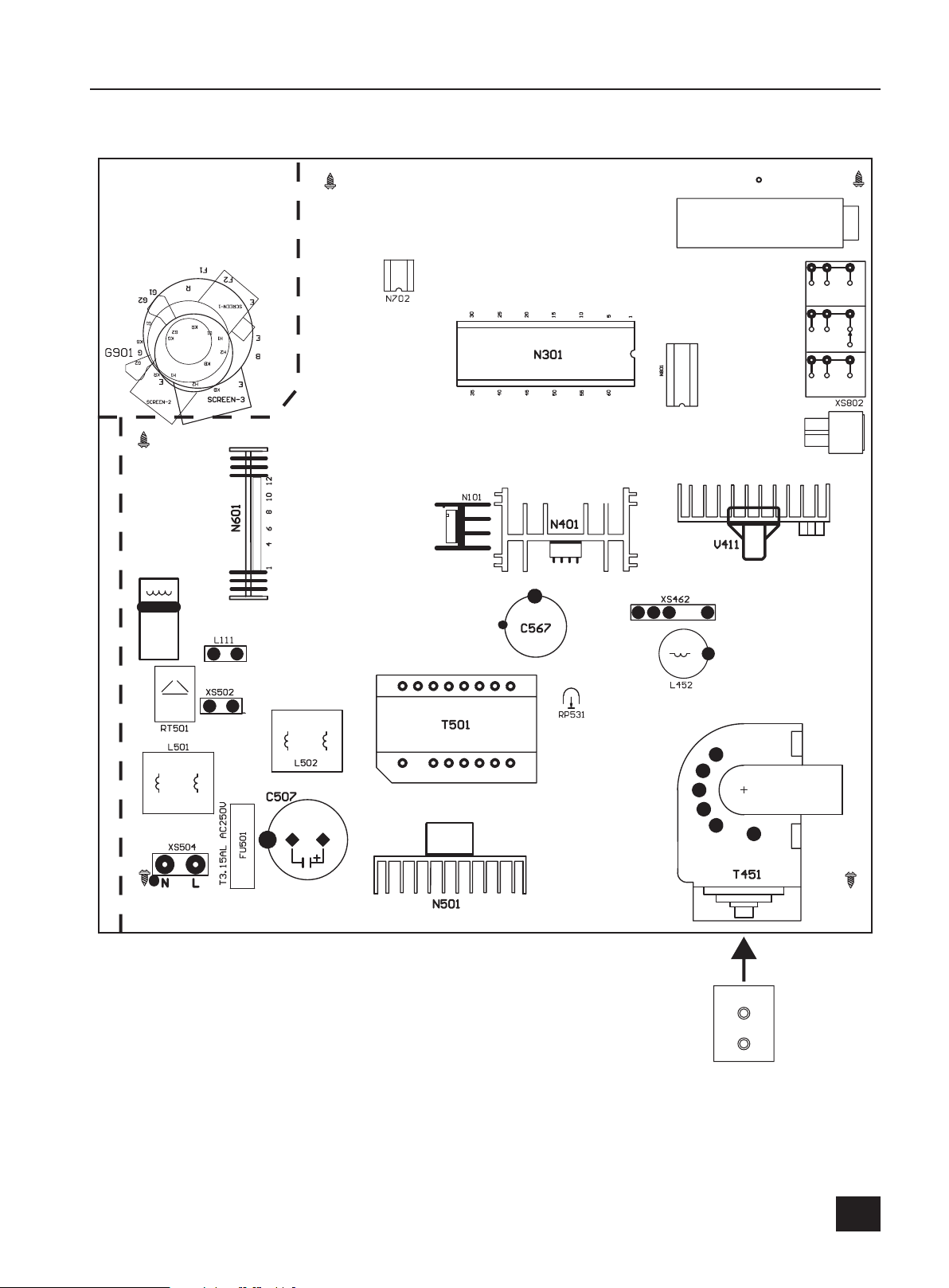

4. DRAWING SITE OF MAIN PARTS

SERVICE MANUAL

AGC TP

TUNER

+B Ad just

FOCUS

SCREEN

5

Page 6

SERVICE MANUAL

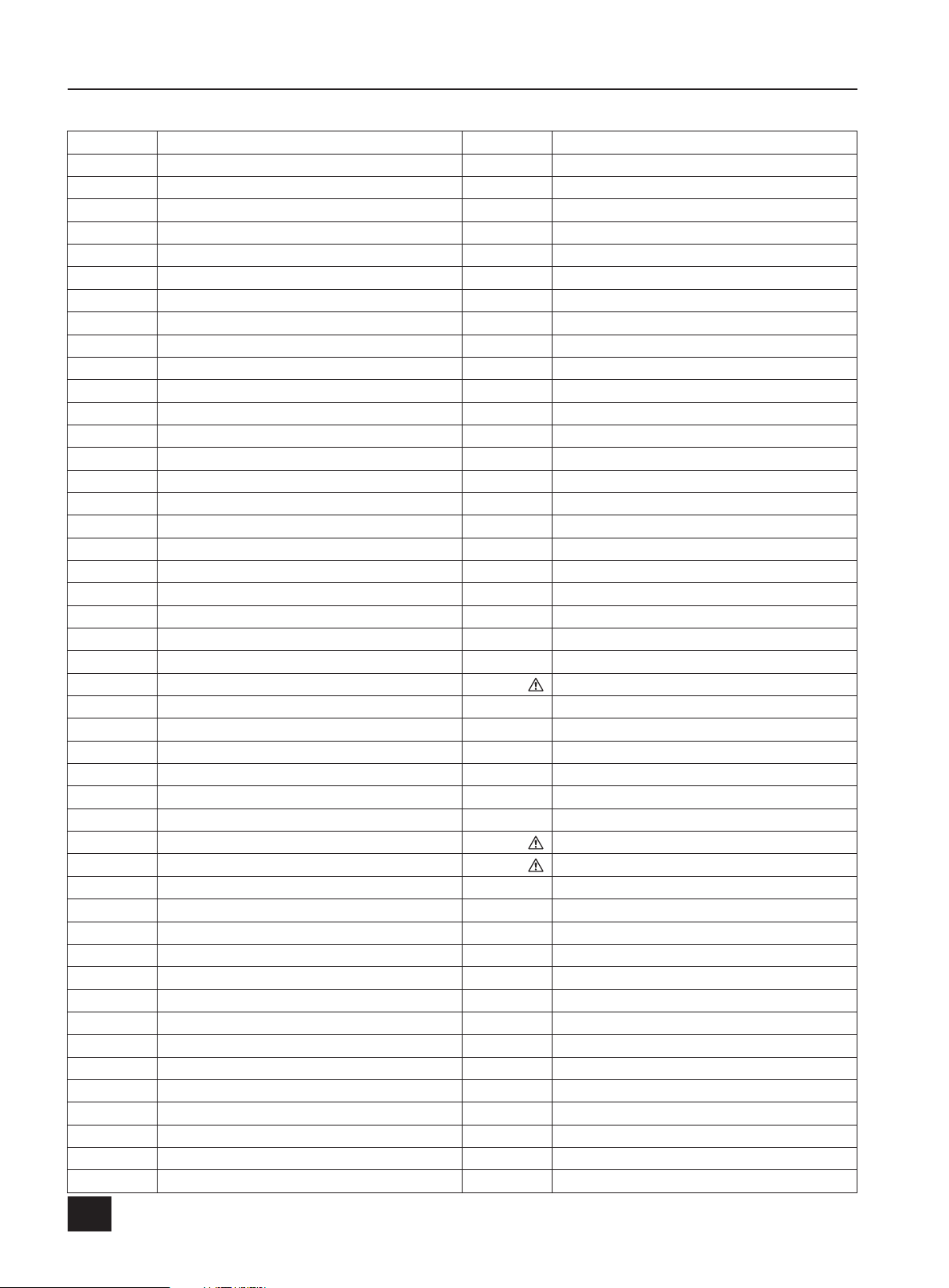

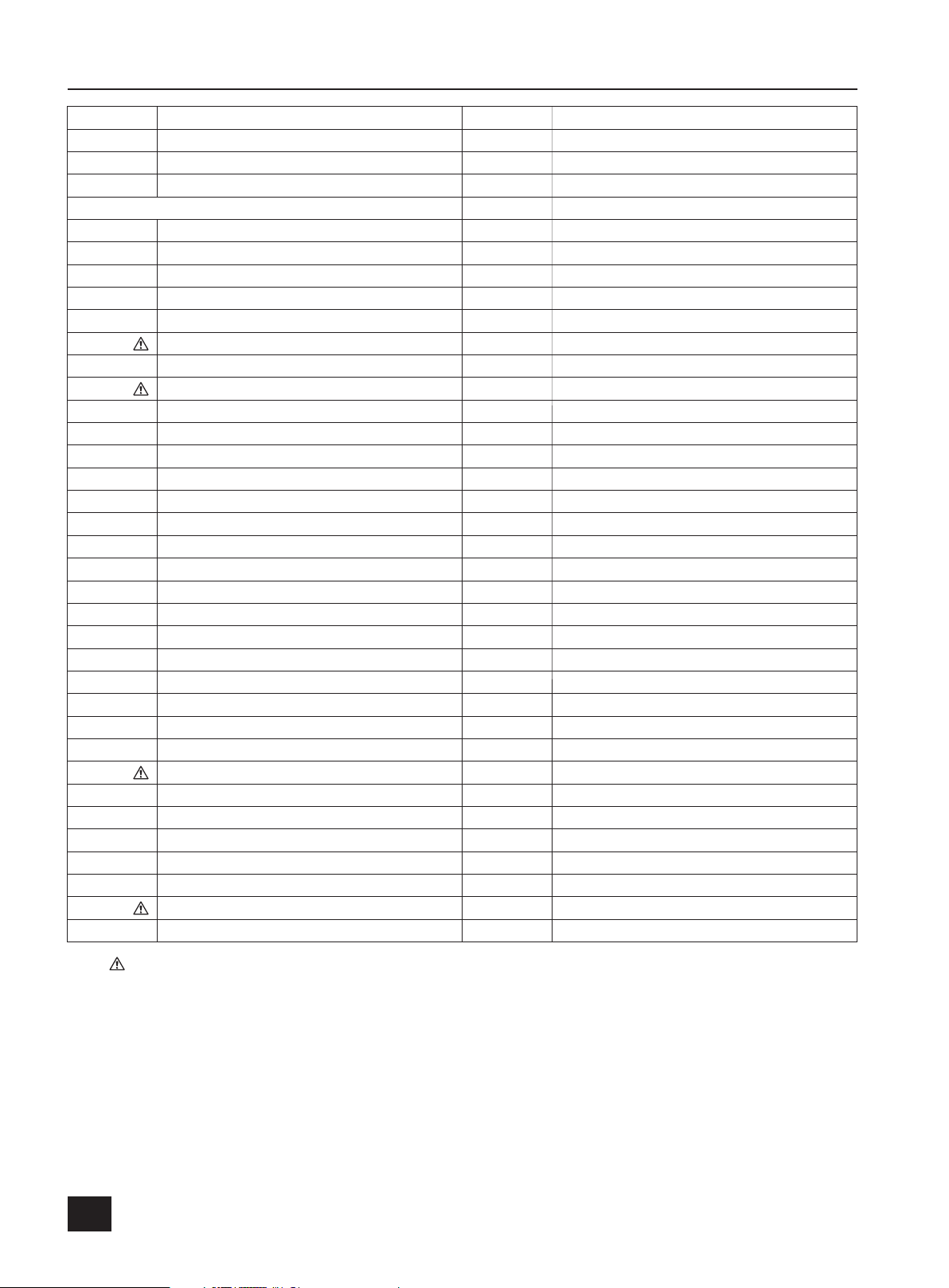

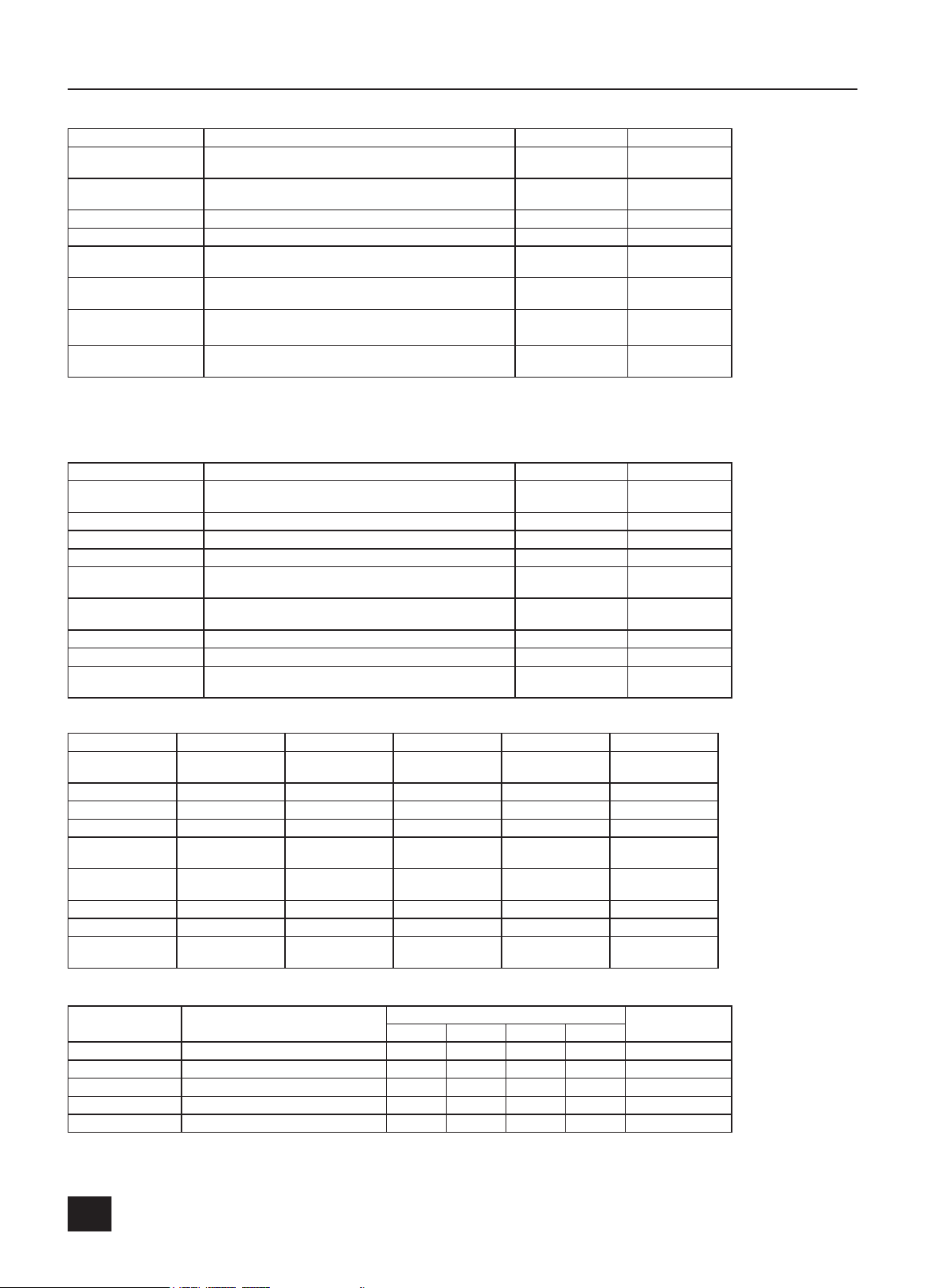

5. LIST OF REPLACEMENT PARTS

PCB NO.

TUNER

A101

CAPACITOR

C104

C107

C112

C113

C114

C201

C202

C203

C204

C205

C206

C207

C208

C209

C210

C212

C216

C217

C218

C222

C227

C228

C229

C230

C231

C235

C236

C237

C238

C243

C289

C290

C293

C294

C296

C298

C301

C302

C303

C305

C306

C308

C309

TUNE ET-5T1E-EF109

CAP ELECTROLYTIC 50V 4.7UF 20%

CAP ELECTROLYTIC 16V 100UF 20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP ELECTROLYTIC 16V 10UF 20%

CAP CERAMIC 50V 20P 5%

CAP CERAMIC 50V 1000P 10%

CAP ELECTROLYTIC 50V 0.47UF 20%

CAP ELECTROLYTIC 50V 2.2UF 20%

CAP ELECTROLYTIC 50V 2.2UF 20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP ELECTROLYTIC 16V 470UF 20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP ELECTROLYTIC 16V 470UF 20%

CAP ELECTROLYTIC 16V 22UF 20%

CAP ELECTROLYTIC 16V 22UF 20%

CAP ELECTROLYTIC 50V 4.7UF 20%

CAP ELECTROLYTIC 16V 220UF 20%

CAP POLY 100V 2200P 10%

CAP ELECTROLYTIC 16V 100UF 20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP ELECTROLYTIC 50V 0.22UF 20%

CAP ELECTROLYTIC 16V 47UF 20%

CAP ELECTROLYTIC 16V 100UF 20%

CAP ELECTROLYTIC 50V 4.7UF 20%

CAP ELECTROLYTIC 50V 4.7UF 20%

CAP ELECTROLYTIC 50V 4.7UF 20%

CAP ELECTROLYTIC 50V 4.7UF 20%

CAP ELECTROLYTIC 16V 47UF 20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP ELECTROLYTIC 16V 47UF 20%

CAP POLY 100V 0.1UF 10%

CAP POLY 100V 8200P 10%

CAP ELECTROLYTIC 16V 10UF 20%

CAP ELECTROLYTIC 16V 100UF 20%

CAP ELECTROLYTIC 50V 4.7UF 20%

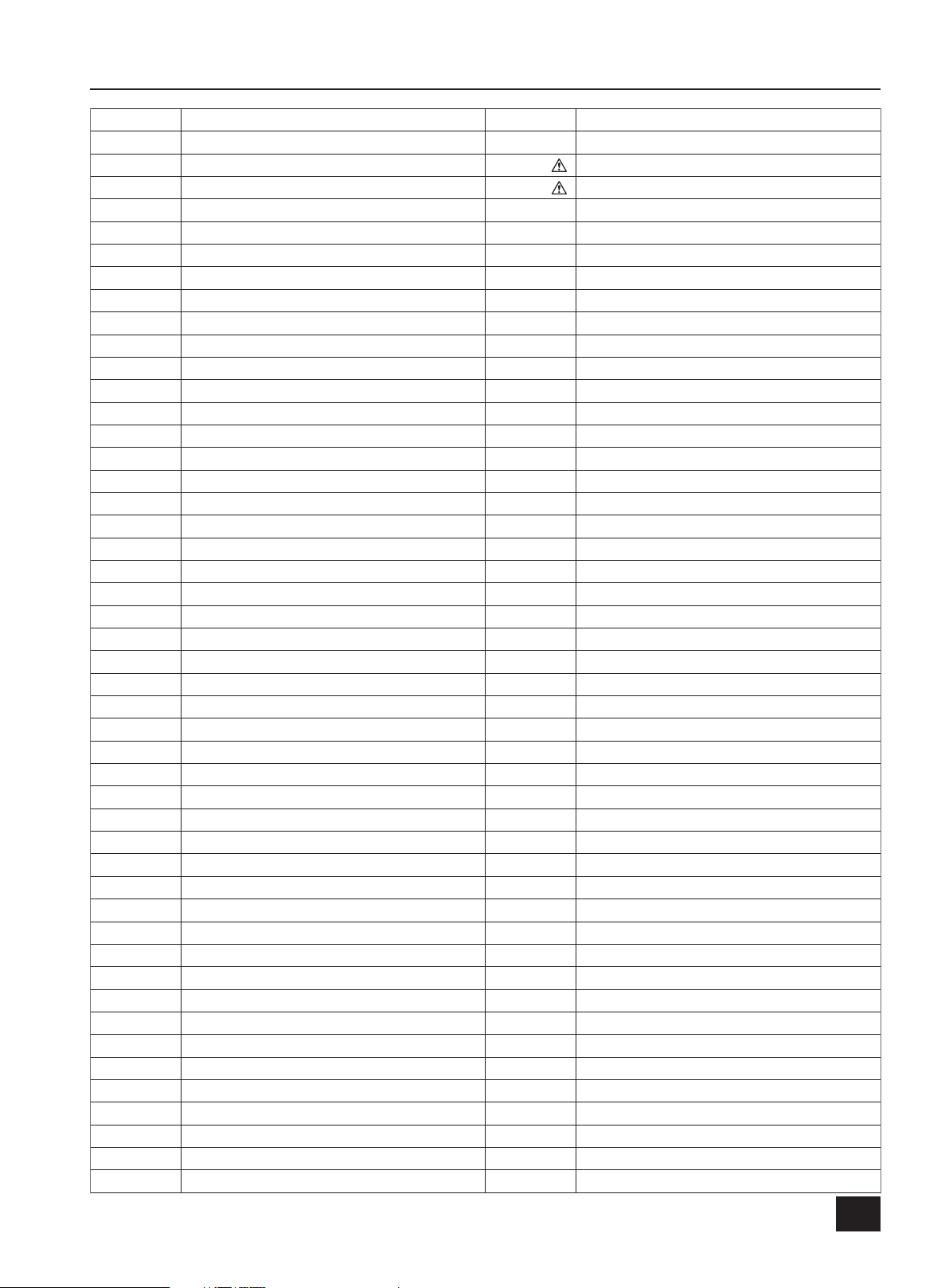

DESCRIPTION DESCRIPTIONPCB NO.

CAPACITOR

C310

C311

C312

C402

C403

C412

C413

C414

C418

C421

C430

C433

C443

C444

C446

C447

C449

C456

C463

C500

C501

C504

C506

C507

C513

C514

C515

C516

C517

C535

C536

C552

C556

C557

C559

C561

C563

C565

C571

C573

C574

C602

C612

C622

C630

CAP CERAMIC 50V 0.01UF +80%-20%

CAP ELECTROLYTIC 50V 0.47UF 20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP CERAMIC 500V 1000P 10%

CAP CERAMIC 500V 3900P 10%

CAP METAL FLIM 250V 0.27UF 5% D=20MM

CAP POLY 100V 0.1UF 10%

CAP ELECTROLYTIC 160V 1UF 20%

CAP ELECTROLYTIC 250V 22UF 20%

CAP POLY 100V 0.1UF 10%

CAP ELECTROLYTIC 35V 47UF 20%

CAP ELECTROLYTIC 25V 1000UF 20%

CAP ELECTROLYTIC 50V 2.2UF 20%

CAP POLY 100V 0.1UF 10%

CAP POLY 100V 2200P 10%

CAP POLY 100V 0.056UF 10%

CAP ELECTROLYTIC 50V 100UF 20%

CAP METAL FLIM 1.6KV 7.2N 5% D=22.5MM

CAP CERAMIC 500V 3900P 10%

CAP CERAMIC 2KV 680P 10%

CAP METAL FLIM AC280V 0.1UF 10%

CAP CERAMIC 1KV 1000P 10%

CAP CERAMIC 1KV 1000P 10%

CAP ELECTROLYTIC 400V 100UF 20%

CAP ELECTROLYTIC 35V 10UF 20%

CAP POLY 100V 0.033UF 10%

CAP POLY 63V 0.1UF 5%

CAP ELECTROLYTIC 35V 10UF 20%

CAP CERAMIC 50V 560P 10%

CAP CERAMIC AC400V 2200P 20%

CAP CERAMIC AC400V 1000P 10%

CAP CERAMIC 1KV 220P 10%

CAP CERAMIC 1KV 220P 10%

CAP ELECTROLYTIC 25V 470UF 20%

CAP ELECTROLYTIC 35V 100UF 20%

CAP ELECTROLYTIC 160V 10UF 20% D=5MM

CAP ELECTROLYTIC 160V 220UF 20%

CAP ELECTROLYTIC 35V 470UF 20%

CAP ELECTROLYTIC 16V 470UF 20%

CAP ELECTROLYTIC 35V 47UF 20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP CERAMIC 50V 390P 10%

CAP CERAMIC 50V 390P 10%

CAP CERAMIC 50V 390P 10%

CAP CERAMIC 2KV 2200P 10%

6

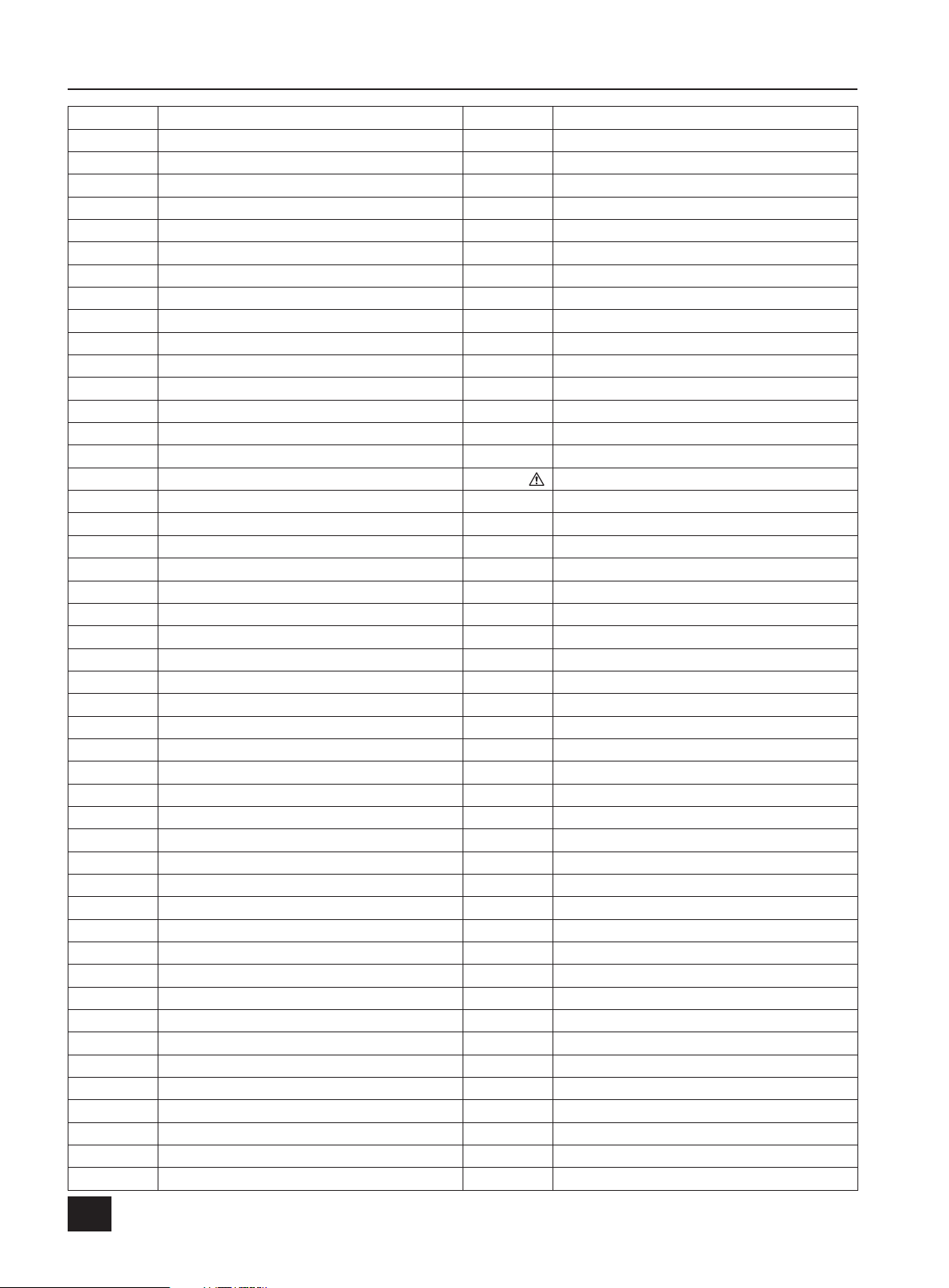

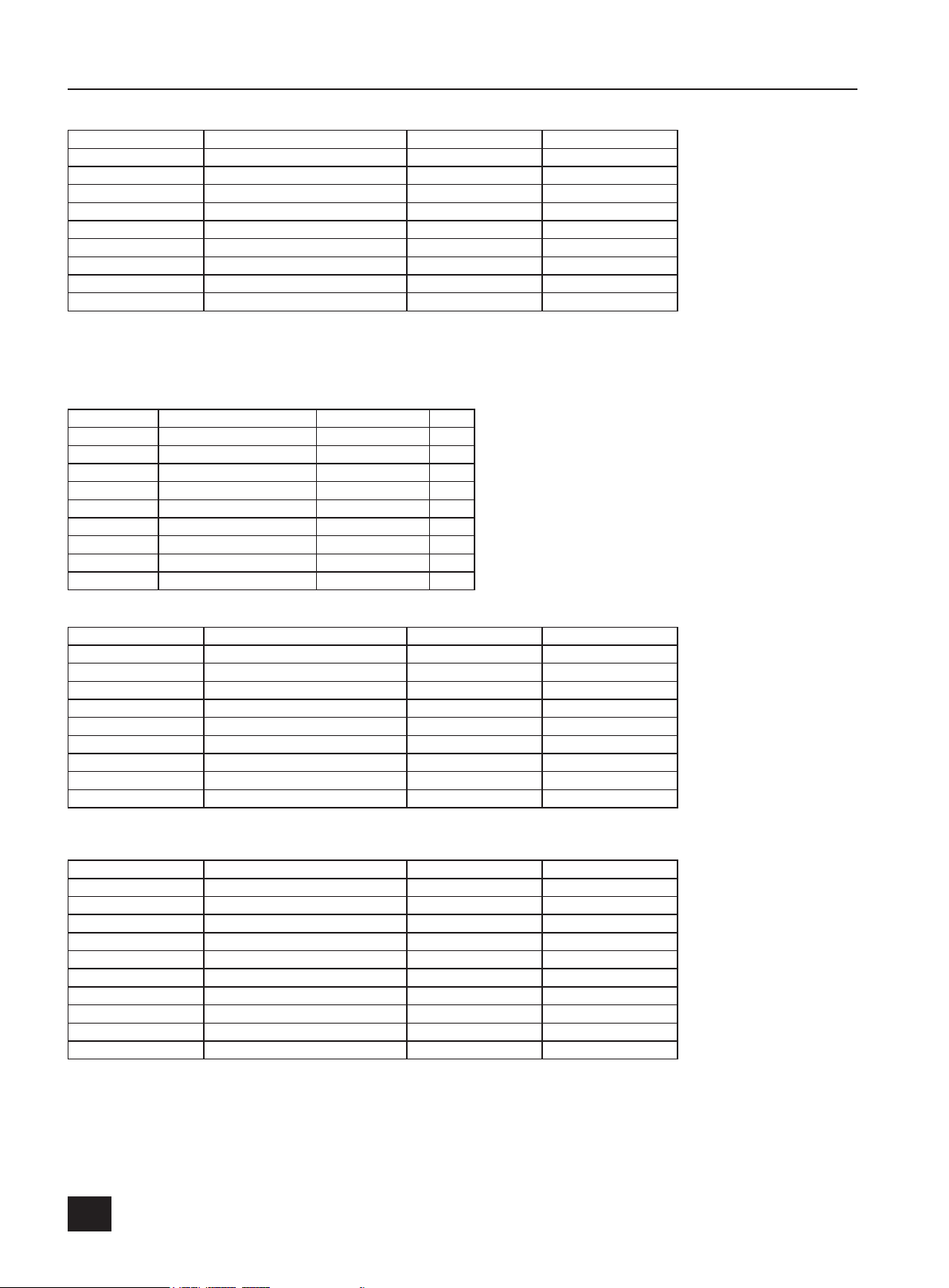

Page 7

SERVICE MANUAL

CAPACITOR

C632

C635

C701

C702

C705

C710

C711

C713

C720

C721

C722

C723

C730

C901

C902

C903

C910

C911

C913

C914

C916

C917

C924

C926

C927

C928

C929

C930

C934

C981

INDUCTANCE

L101

L103

L201

L202

L305

L414

L451

L501

L502

L901

IC

N203

N204

N402

N402

DESCRIPTION DESCRIPTIONPCB NO.

CAP ELECTROLYTIC 16V 47UF 20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP ELECTROLYTIC 25V 1000UF 20%

CAP POLY 100V 0.1UF 10%

CAP ELECTROLYTIC 50V 4.7UF 20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP POLY 100V 6800P 10%

CAP ELECTROLYTIC 50V 1UF 20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP POLY 100V 6800P 10%

CAP ELECTROLYTIC 50V 1UF 20%

CAP ELECTROLYTIC 50V 1UF 20%

CAP ELECTROLYTIC 16V 10UF 20%

CAP CERAMIC 50V 33P 5%

CAP CERAMIC 50V 20P 5%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP CERAMIC 50V 33P 5%

CAP CERAMIC 50V 33P 5%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP ELECTROLYTIC 16V 47UF 20%

CAP ELECTROLYTIC 16V 47UF 20%

CAP ELECTROLYTIC 50V 0.47UF 20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP ELECTROLYTIC 50V 2.2UF 20%

CAP ELECTROLYTIC 16V 100UF 20%

CAP ELECTROLYTIC 16V 100UF 20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP CERAMIC 50V 0.01UF +80%-20%

CAP CERAMIC 50V 1000P 10%

CAP ELECTROLYTIC 50V 4.7UF 20%

FILTER COIL 15UH-K

FILTER COIL 1UH-K

FILTER COIL 15UH-K

FILTER COIL 15UH-K

FILTER COIL 15UH-K

LINEARITY COIL LX-036 D=10MM

RESISTOR CEMENT 3W 3.9OHM 10% D=10MM

FILTER COIL 15-LB6×1.0×6

LINE FILTER LG-031-NLG

FILTER COIL 15UH-K

IC HEF4053

IC 8891-****

IC CD78040

HEAT SINK V HXXX0063-40

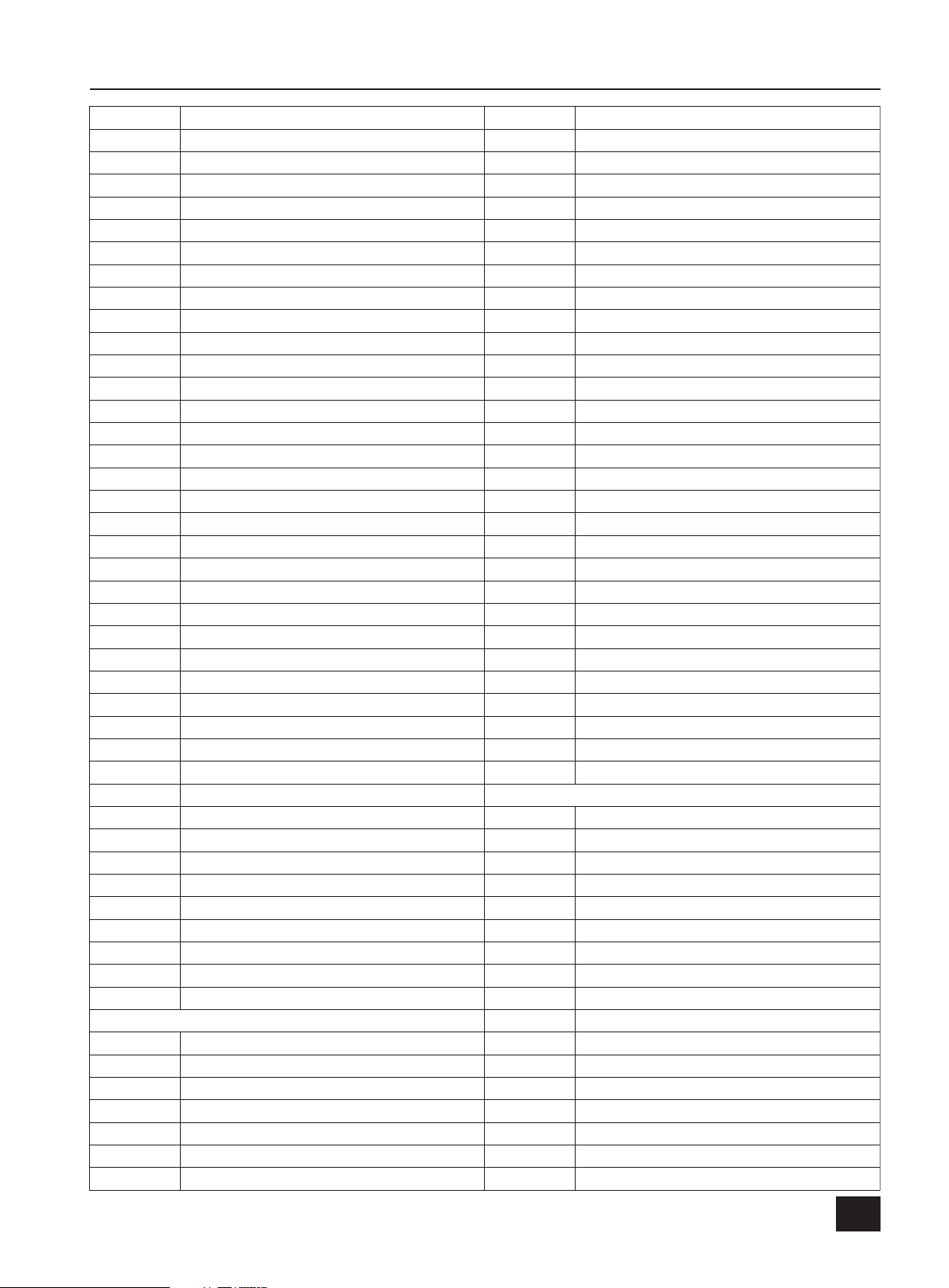

PCB NO.

IC

V501

VD515

N550

N701

N701

N901

N902

N902

N904

RESISTOR

R101

R106

R107

R108

R108

R111

R112

R113

R115

R121

R201

R203

R205

R206

R207

R208

R211

R213

R215

R217

R219

R220

R221

R222

R225

R228

R229

R230

R232

R233

R236

R237

R238

R239

R243

R244

IC FSCQ0765RT

IC LTV817C

IC 78L05

IC CD17821CS

HEAT SINK SOUND HXXX0151-30

IC FM24C08A

IC CW7808

HEAT SINK 8V HXX0050-30

IC KA33V/CW574CS

RESISTOR CARBON 1/6W 100KOHM 5%

RESISTOR CARBON 1/6W 220OHM 5%

RESISTOR CARBON 1/6W 220OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 3.3KOHM 5%

RESISTOR CARBON 1/6W 150OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 33OHM 5%

RESISTOR CARBON 1/6W 1.5KOHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 560OHM 5%

RESISTOR CARBON 1/6W 3.3KOHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 1MOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 68OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 1KOHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 33KOHM 5%

RESISTOR CARBON 1/6W 220KOHM 5%

RESISTOR CARBON 1/6W 270OHM 5%

RESISTOR CARBON 1/6W 270OHM 5%

RESISTOR CARBON 1/6W 270OHM 5%

RESISTOR CARBON 1/2W 220OHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

RESISTOR CARBON 1/6W 5.6KOHM 5%

7

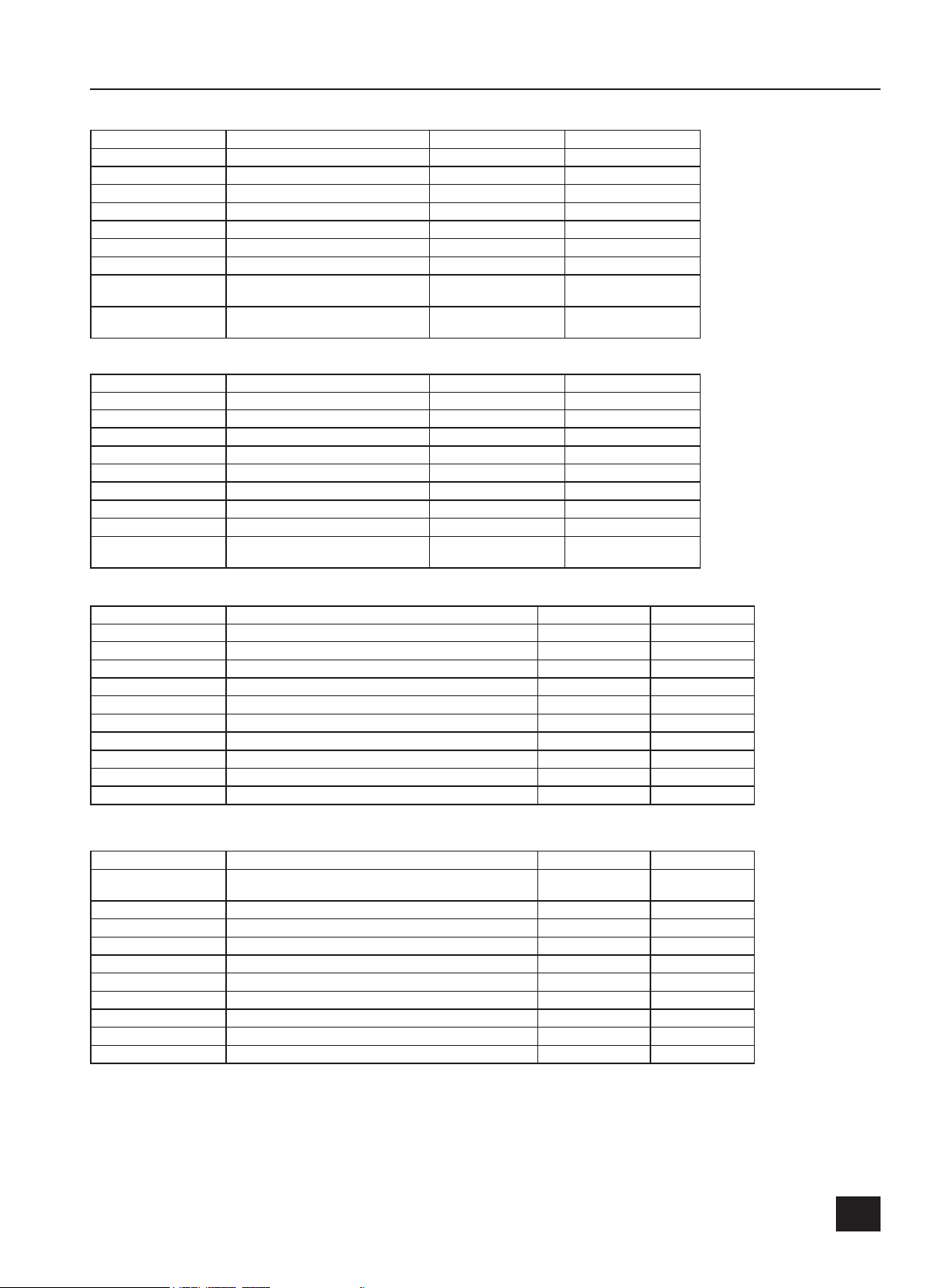

Page 8

SERVICE MANUAL

RESISTOR

R245

R250

R253

R254

R256

R279

R280

R283

R290

R291

R292

R294

R295

R301

R306

R310

R312

R320

R321

R322

R326

R328

R330

R331

R404

R407

R410

R413

R418

R420

R423

R424

R435

R437

R442

R443

R444

R446

R448

R449

R450

R463

R464

R467

R473

R480

DESCRIPTION DESCRIPTIONPCB NO.

RESISTOR CARBON 1/6W 100KOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 22KOHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 1KOHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 270OHM 5%

RESISTOR CARBON 1/6W 4.7OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 560OHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

RESISTOR CARBON 1/6W 8.2KOHM 5%

RESISTOR CARBON 1/6W 270OHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 220OHM 5%

RESISTOR CARBON 1/6W 3.9KOHM 5%

RESISTOR CARBON 1/6W 150OHM 5%

RESISTOR CARBON 1/2W 1.0KOHM 5%

RESISTOR METAL 2W 2.0OHM 5% D=12.5MM

RESISTOR METAL 1WS 4.7KOHM 5% D=12.5MM

RESISTOR FUSE 1/2W 3.3OHM 5% D=15MM

RESISTOR CARBON 1/2W 220KOHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 330KOHM 5%

RESISTOR METAL 2W 270OHM 5% D=15MM

RESISTOR CARBON 1/2W 330OHM 6%

RESISTOR CARBON 1/6W 5.6KOHM 5%

RESISTOR CARBON 1/6W 4.7OHM 5%

RESISTOR CARBON 1/6W 3.9KOHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 47KOHM 5%

RESISTOR CARBON 1/2W 12KOHM 5%

RESISTOR CARBON 1/2W 1.5OHM 5%

RESISTOR FUSE 1W 0.47OHM 5% D=15MM

RESISTOR CARBON 1/6W 100KOHM 5%

RESISTOR CARBON 1/6W 18KOHM 5%

PCB NO.

RESISTOR

R480

R480

R515

R517

R520

R521

R522

R523

R531

R552

R553

R555

R556

R557

R558

R560

R564

R565

R566

R572

R573

R580

R605

R606

R607

R608

R615

R616

R617

R618

R626

R627

R628

R629

R635

R640

R641

R702

R704

R710

R710

R711

R713

R715

R718

R720

RESISTOR CARBON 1/6W 33KOHM 5%

RESISTOR CARBON 1/6W 33KOHM 5%

RESISTOR CARBON 1/6W 2.7KOHM 5%

RESISTOR CARBON 1/6W 2.4KOHM 5%

RESISTOR CARBON 1/2W 120KOHM 5%

RESISTOR CARBON 1/2W 120KOHM 5%

RESISTOR CARBON 1/4W 8.2OHM 5%

RESISTOR CARBON 1/6W 560OHM 5%

RESISTOR GLASS GLAZE 1/2W 24MOHM +80%-20%

RESISTOR CARBON 1/4W 5.6KOHM 5%

RESISTOR METAL 2W 12KOHM 5% D=15MM

RESISTOR CARBON 1/4W 150KOHM 5%

RESISTOR CARBON 1/4W 47KOHM 5%

RESISTOR CARBON 1/6W 22KOHM 5%

RESISTOR FUSE 1/2W 0.47OHM 5% D=15MM

RESISTOR CARBON 1/2W 3.3KOHM 5%

RESISTOR CARBON 1/2W 47KOHM 5%

RESISTOR METAL 2W 22KOHM 5% D=10MM

RESISTOR CARBON 1/2W 3.3KOHM 5%

RESISTOR CARBON 1/4W 47KOHM 5%

RESISTOR FUSE 1W 0.47OHM 5% D=15MM

RESISTOR METAL 2W 68OHM 5% D=15MM

RESISTOR CARBON 1/2W 3.3KOHM 5%

RESISTOR METAL 2W 12KOHM 5% D=15MM

RESISTOR CARBON 1/6W 470OHM 5%

RESISTOR CARBON 1/6W 3.9KOHM 5%

RESISTOR CARBON 1/2W 3.3KOHM 5%

RESISTOR METAL 2W 12KOHM 5% D=15MM

RESISTOR CARBON 1/6W 470OHM 5%

RESISTOR CARBON 1/6W 3.9KOHM 5%

RESISTOR METAL 2W 12KOHM 5% D=15MM

RESISTOR CARBON 1/6W 470OHM 5%

RESISTOR CARBON 1/6W 3.9KOHM 5%

RESISTOR CARBON 1/2W 3.3KOHM 5%

RESISTOR CARBON 1/6W 47KOHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

RESISTOR CARBON 1/4W 2.2OHM 5%

RESISTOR CARBON 1/6W 4.7KOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 1KOHM 5%

RESISTOR CARBON 1/6W 8.2KOHM 5%

RESISTOR CARBON 1/6W 4.7KOHM 5%

RESISTOR CARBON 1/6W 1KOHM 5%

RESISTOR CARBON 1/6W 2.2KOHM 5%

RESISTOR CARBON 1/6W 4.7KOHM 5%

RESISTOR CARBON 1/6W 8.2KOHM 5%

8

Page 9

SERVICE MANUAL

RESISTOR

R721

R722

R723

R725

R726

R727

R728

R730

R900

R901

R904

R905

R909

R910

R916

R918

R919

R920

R922

R925

R927

R928

R929

R930

R935

R939

R941

R943

R945

R946

R947

R960

R961

R980

R981

R988

R989

RP551

TRANSFORMER

T401

T402

T501

TRANSISTOR

V203

V230

V290

DESCRIPTION DESCRIPTIONPCB NO.

RESISTOR CARBON 1/6W 4.7KOHM 5%

RESISTOR CARBON 1/6W 8.2KOHM 5%

RESISTOR CARBON 1/6W 8.2KOHM 5%

RESISTOR CARBON 1/6W 33KOHM 5%

RESISTOR CARBON 1/6W 47KOHM 5%

RESISTOR CARBON 1/6W 15KOHM 5%

RESISTOR CARBON 1/6W 4.7KOHM 5%

RESISTOR CARBON 1/6W 1KOHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 100OHM 5%

RESISTOR CARBON 1/6W 1KOHM 5%

RESISTOR CARBON 1/6W 5.6KOHM 5%

RESISTOR CARBON 1/6W 47OHM 5%

RESISTOR CARBON 1/6W 47OHM 5%

RESISTOR CARBON 1/6W 3.9KOHM 5%

RESISTOR CARBON 1/6W 4.7KOHM 5%

RESISTOR CARBON 1/6W 4.7KOHM 5%

RESISTOR CARBON 1/6W 5.6KOHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

RESISTOR CARBON 1/6W 1KOHM 5%

RESISTOR CARBON 1/6W 22KOHM 5%

RESISTOR CARBON 1/6W 4.7KOHM 5%

RESISTOR CARBON 1/6W 22KOHM 5%

RESISTOR CARBON 1/6W 1.2KOHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

RESISTOR CARBON 1/6W 22KOHM 5%

RESISTOR CARBON 1/6W 4.7KOHM 5%

RESISTOR CARBON 1/6W 12KOHM 5%

RESISTOR CARBON 1/6W 560OHM 5%

RESISTOR CARBON 1/6W 1.5KOHM 5%

RESISTOR CARBON 1/6W 8.2KOHM 5%

RESISTOR CARBON 1/4W 470HM 5%

RESISTOR CARBON 1/2W 47OHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

RESISTOR CARBON 1/6W 4.7OHM 5%

RESISTOR CARBON 1/6W 10KOHM 5%

VARISTOR 1/2W 2KOHM 20%

H.DRIVER TRANS TD-0004-OL

TRANS FLY BACK T9XX0124E-X

TRANS POWER TM-0105-ON

TRANSISTOR 2SA1015Y

TRANSISTOR 2SA1015Y

TRANSISTOR 2SC1815Y

PCB NO.

TRANSISTOR

V301

V411

V444

V551

V601

V611

V621

V630

V721

V722

V900

V902

V904

V905

V980

DIODE

VD230

VD232

VD233

VD234

VD292

VD401

VD403

VD414

VD434

VD435

VD436

VD503

VD504

VD505

VD506

VD514

VD516

VD517

VD518

VD519

VD551

VD552

VD553

VD554

VD556

VD574

VD601

VD611

VD621

VD901

TRANSISTOR 2SC1815Y

TRANSISTOR 3DD5023

TRANSISTOR 2SC2383-O

TRANSISTOR 2SC1815Y

TRANSISTOR 2SC2482Y

TRANSISTOR 2SC2482Y

TRANSISTOR 2SC2482Y

TRANSISTOR 2SC1815Y

TRANSISTOR 2SC1815Y

TRANSISTOR 2SC1815Y

TRANSISTOR 2SC1815Y

TRANSISTOR 2SA1015Y

TRANSISTOR HSB892/KTB772

TRANSISTOR 2SD400D

TRANSISTOR 2SC1815Y

DIODE IN4148

DIODE IN4148

DIODE IN4148

DIODE IN4148

DIODE HZ4A2

DIODE IN4148

DIODE RF107

DIODE RF107

DIODE 1N4004

DIODE RF107

DIODE HZ11C1

DIODE TVR4N

DIODE TVR4N

DIODE TVR4N

DIODE TVR4N

DIODE RF107

DIODE IN4148

DIODE RF107

DIODE HZ4A2

DIODE HZ18C2

DIODE HZ7A3

DIODE RGP15D

DIODE RF105

DIODE RF105

DIODE RGP15J D=15MM

DIODE HZ4A2

DIODE IN4148

DIODE IN4148

DIODE IN4148

DIODE IN4148

9

Page 10

SERVICE MANUAL

TRANSISTOR

VD902

VD921

DIODE HZ4A2

DIODE HZ6B1

DESCRIPTIONPCB NO.

XZ601

Z101

Z304

Z901

OTHERS

R502A

PS501

F501

F501A

F501B

XZ201

XZ207

XZ411

XZ501

XZ504

XZ602

XZ603

XZ711

XZ901

XZ903

XZ905

Z902

ZN402

ZN701

ZN902

ZV411

ZV501

TP602

V411

V501

V600

CRT SOCKET GZS8-6-FD

SAW FILTER IF389A1M

FILTER F10.7MHZ

CRYSTAL 8MHZ(18.5PF)

PTC MF72 4.7OHM D=11MM

PTC MZ72B 9OHM AC270V

FUSE 3.15A 250V

FUSE SOCKET

FUSE SOCKET

AV SOCKET AV9-01K-D

4S SOCKET TJC3-4A(S)

DY SOCKET TJC2-5A(M)

2S SOCKET TJC1-2A-10MM(L)

2S SOCKET TJC2-2A-7.5MM(M)

4P LINE 400MM

6P LINE 400MM

4S SOCKET TJC3-4A(S)

3S SOCKET TJC3-3A(S)

3S SOCKET TJC3-3A(S)

2S SOCKET TJC3-2A(S)

MAIN PCB BSC7.820.290-C(247×247MM)

SCREW GB845F SF3×10MM

SCREW GB845F SF3×8MM

SCREW GB845F SF3×8MM

SCREW GB845F SF3×10MM

SCREW GB845F SF3×10MM

1S SOCKET TJC1-1A(L)

HEAT SINK H HXXX0156-40

HEAT SINK POWER HXXX0146-40

CRT

REMOTE CONTROL YKQ8891-***

Note: Security Parts.

10

Page 11

SERVICE MANUAL

6. REPLACEMENT OF MEMORY IC

6.1 MEMORY IC.

This TV uses memory IC. In the memory IC are memorized data for correctly operating the video and deection circuits.

When replacing memory IC, be sure to use IC written with the initial value of data.

6.2 PROCEDURE FOR REPLACING MEMORY IC

(1) Power off

Switch the power off and unplug the power cord from AC outlet.

(2) Replace IC

Be sure to use memory IC written with the initial data values.

(3) Power On

Plug the power cord into the AC outlet and switch the power On.

7. SERVICE ADJUSTMENT

Descriptions for the operation of factory mode

AGING MODE

1. With factory remote controller to press “D-mode” directly enter AGING mode, screen will display “factory”. Press “DISP” key to

exit “factory” to enter “WHITE BALANCE”.

2. With user remote controller to press “MENU” key to turn to “TUNING” menu, press “CH-” key to Select “TARGET POS” bar,

Input“2483”, “6483”, “6568”, then enter AGING mode.

3. At “factory” mode or “AGING” mode, press “SYS”, “SOUND”, “SLEEP” key to adjust data, screen will display relevant

menu+factory. Press “MENU” to display main Menu to adjust all data. Press “DISP” to exit, screen only display “factory”.

WHITE BALANCE MODE

1. At AGING mode, press “D-mode” exit “factory” to enter WHITE BALANCE mode.

2. Press “D-mode” key two time (factory key) to enter WHITE BALANCE mode.

3. At “factory” mode, press gure key “0” enter WHITE BALANCE mode.

4. At WHITE BALANCE mode, press “MUTE”, one horizontal bright line appear on screen, use “1,4” key to adjust RCUT,

“2,5” key to adjust GCUT, “3,6” key to adjust BCUT.

ENTER FACTORY MODE

A. USER REMOTE CONTROLLER

1. At rst enter AGING mode, at AGING mode, press “DISP” to exit “factory”, enter WHITE BALANCE mode.

2. At WHITE BALANCE mode, press gure 1,2,3,4,5,6, DISP to enter “factory” mode.

B. Press “D-mode” key three time (factory key) to enter factory’s adjustment menu.

ENTER FACTORY MODE F8~F15

Press “2483”,”6483”,”6568” enter F8, and also open F8-F15. Press “Mute” Key to turn Page Up and “RETURN” key to turn

Page Down for factory mode menu. Press gure Key 1, 2, 3, 4, 5, 6, 7, 8, 9 to enter “factory” mode F1~F9.

EXIT FACTORY MODE

1. Press “DISP” to exit from “factory” menu.

2. Press power switch, exit “factory’s mode.

EXPLANATION FOR ADJUSTMENT SPEED KEY

After entering factory mode, some remote controller key function will change to suit for the production adjustment.

1. Press “MUTE” key to turn page up, press “RETURN” key to turn page down.

2. Press “CH+” and “CH-“ key to select item, and press “VOL+” and “VOL-” key to change data value.

3. Press “SLEEP” key to display CHIP inner 6 kinds test signal.

11

Page 12

SERVICE MANUAL

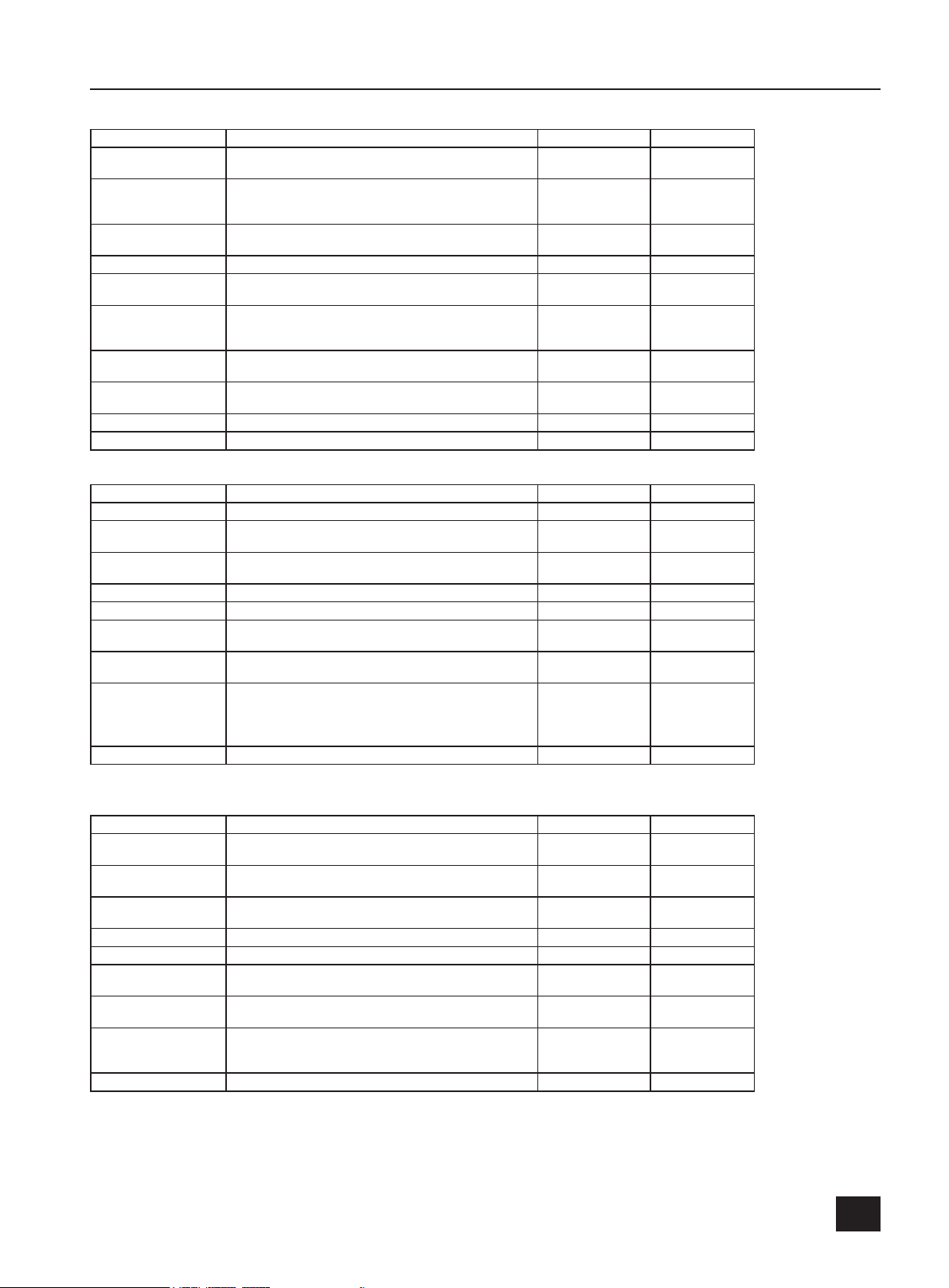

White Balance adjustment

OSD Descriptions Recommend Data Max

RC R-CUT 110 255

GC G-CUT 110 255

BC B-CUT 110 255

GD G-Diver 60 127

BD B-Driver 72 127

U.BLK U signal black level adjust 8 15

V.BLK V signal black level adjust 8 15

S.RY SECAM, R signal black level adjust 8 15

S.BY SECAM, B signal black level adjust 8 15

Notes:

press “MUTE”, one horizontal bright line appear on screen, use “1,4” key to adjust RCUT, “2,5” key to adjust GCUT,

“3,6” key to adjust BCUT.

Geometry parameter adjustment for PAL (Not available for NTSC)

OSD Descriptions Recommend Data Max

H.PHASE Horizontal Phase for 50Hz 18 31

V.SIZE Vertical Amplitude for 50Hz 20 63

V.POS Vertical Phase for 50Hz 02 15

V.LIN Vertical Linearity for 50Hz 15 31

V.SC V-S correction for 50Hz 15 31

HBOW H Bow correction for 50Hz 4 7

HPARA H Para correction for 50Hz 4 7

H.BLK.RIGHT H.Right Blanking 0 07

H.BLK.LEFT H.Left Blanking 0 07

Geometry parameter adjustment for NTSC (offset for PAL system, NTSC only)

OSD Descriptions Recommend Data Max

NT.H.PHASE Horizontal Phase for 60Hz 10 20

NT.V.SISE Vertical Amplitude for 60Hz 10 20

NT.V.POS Vertical Phase for 60Hz 11 20

NT.V.LIN Vertical Linearity for 60Hz 10 20

NT.V.SC V-S correction for 60Hz 10 31

NT.HBOW H Bow correction for 60Hz 4 7

NT.HPARA H Para correction for 60Hz 4 7

V.BLK.TOP V.Top Blanking 0 3

V.BLK.BTM V.Bottom Blanking 0 3

Brightness, Contrast, Color adjustment

OSD Descriptions Recommend Data Max

SUB.CONT Sub Contrast 15 15

SUB.BRIGHT Brightness 0 -63~63

SUB.COLOR Sub Color 10 -128~—+127

S.SUB.COLOR Sub Color for SECAM 64 127

RF.AGC IF Gain 30 63

BACKGROUND Background 0:OFF 1:ON 1 1

BACK.COLOR BACK COLOR, 0:blue 1:black 0 1

POW.CONT

LOCK Child lock 0 1

LOGO MOVE LOGO MOVE 0:OFF 1:ON 0 1

Brightness boost speed for “POWER ON”

5 15

12

Page 13

OSD1 adjustment

OSD Descriptions Remark Recommend Data

MENU BACK

MENU ICON MNEU icon display selection 0:OFF 1:ON 1

OPEN CURT. Curtain style when switch on 0:OFF 1:ON 1

CLOSE CURT. Curtain style when switch off 0:OFF 1: ON 1

CALENDER Calendar switch 0:OFF 1: ON 1

P.ON.LOGO LOGO display when power on 0:OFF 1:SET 0

NO.SG.LOGO LOGO display without signal 0:OFF 1:SET 0

OSD.CONT OSD contrast

ANALOG ADJ

MENU translucent background selection

Adjust main MENU simulation value,

Whether make main MENU disappear

0:OFF 1:ON 1

0:95IRE 1:60IRE

2:70IRE 3: 80IRE

0:No disappear

1:disappear

Function control adjustment

OSD Descriptions Recommend Data Recommend Data

TV TV SWITCH 0:OFF 1:ON 1 1

AV2 AV2 SWITCH 0: OFF 1: ON 1 1

DVD DVD SWITCH 0: OFF 1: ON 1 1

FM FM SWITCH 0: OFF 1: ON 0 1

BG BG 0: OFF 1: ON 1 1

I I SWITCH 0: OFF 1: ON 1 1

DK DK SWITCH 0: OFF 1: ON 1 1

M M SWITCH 0: OFF 1: ON 1 1

FM-BAND

SOUND IF MODULATE WIDTH,

0: BG\DK\I division 1: no division

0 1

SERVICE MANUAL

1

0

Screen Protection OSD position and H.V. compensation

OSD Descriptions Recommend Data Max

LEFT Left position limit for Screen protection OSD moving 16 255

RIGHT Right position limit for Screen protection OSD moving 125 255

TOP Top position limit for Screen protection OSD moving 24 255

BOTTOM Bottom position limit for Screen protection OSD moving 180 255

CURT.WAIT.TIME Wait time for pulling curtain 10 188

CURT.CENT Center position for pulling curtain 160 255

CURT.STEP Speed for pulling curtain 3 16

OSD.H.POSI. Horizontal position for Screen protection OSD 40 127

OSD.V.POSI Vertical position for Screen protection OSD 18 47

ZOOM ZOOM 0 15

OSD2 adjustment

OSD Descriptions Recommend Data Max

POS.TIMER

CH DARK Black screen for exchange channels 0:OFF 1:ON 0 1

FRANCE France 0:OFF 1:ON 1 1

RUSSIAN Russian 0:OFF 1:ON 1 1

T.VIET Vietnam 0:OFF 1:ON 0 1

TURKEY Turkey 0:OFF 1:ON 0 1

ARABIA Arabia 0:OFF 1:ON 0 1

PERSIA Persia 0:OFF 1:ON 0 1

GERMAN German 0:OFF 1:ON 0 1

ITALIAN Italian 0:OFF 1:ON 0 1

Black screen time adjustment for exchange channels,

8MS time for data “1”

32 255

13

Page 14

SERVICE MANUAL

OSD3 Main MENU Color adjustment

OSD Descriptions Recommend Data Max

UP BOX

BACKGROUND

UP BOX MOVE

UP ICON ACKGROUND UP ICON color selection in main MENU 1 07

UP ICON MOVE Color selection to pitch on UP ICON in main MENU 4 07

DOWN BOX KGROUND

DOWN BOX MOVE

DOWN TEXT GROUND

DOWN TEXT MOVE

Notes:

Press “MENU” key on this page, blue screen MENU appear, and also display “FACTORY”,

directly use P+,P-,V+,V- key to adjust all items color in MENU, after adjustment then press “DISP” to exit.

VOLUME Parameters adjustment 1

OSD Descriptions Recommend Data Max

S. AUDIO

AUDIO IN Sound input combination, 0: Stereo 1: 32PIN 2: 22PIN 0 2

TV.MUTE MUTE control without TV signal, 0:TV no MUTE 1:MUTE 1 1

AV.MUTE MUTE control without AV signal, 0:AV no MUTE 1:MUTE 1

ALC GAIN

Sound IC

S.WOOFER Woofer switch 0: OFF 1: ON 0 1

BALC Sound Balance center value 64 114

REMOTE

Background color selection for up window

of main menu

Color selection to pitch on picture in up window

of main MENU

Background color selection for down window of

main menu

Color selection to pitch on menu item bar in down

window of main MENU

Character color selection for down

window in main MENU

Color selection to pitch on character in down

window of main MENU

When video input, sound input from AV1 or AV2,

0:AV1 1:AV2

Volume automatic control grade,

0:off ,1:1.1Vp-p, 2:1.6Vp-p, 3:2.3Vp-p

Sound IC selection,

0: OFF 1: Balance 2:TA1343 3:TA1304

Remote control code selection: 0:9028-0E0E

1:6122-BF40 2:7461-611C 3:7461-1AA1 4: AUTO

15 15

2 15

15 15

15 15

2 07

4 07

0 1

1 3

0 3

4 4

High, Middle, Low simulation curve adjustment

OSD Descriptions Minimum Middle Recommend Data Max

CONTRAST Contrast 00 95 127 127

BRIGHT Brightness 64 69 53 127

COLOR Color 15 64 69 127

TINT Tint 40 58 66 127

SHARP Sharpness 32 32 X 63

VOLUME Volume 64 96 127 127

BASS Bass 24 72 X 127

TREBLE Treble 40 X X 127

WOOFER Woofer 114 X X 127

Register control to Color

OSD Descriptions

Y.DELAY Brightness delay 5 3 3 3 7

DEMO.PHASE Color modulate amplitude & phase 0 1 1 3 2

P/N ID Color sensitivity 0 0 1 1 1

KILLER.OFF Brightness Killer switch 0 0 0 0 1

SYS.SHARP Different status SHARP value 37 37 37 37 63

TV/PAL TV/NTSC AV DVD

Recommend Data

Notes:

Y DELAY TIME

0:0ns 1:40ns 2:80ns 3:120ns 4:160ns 5:200ns 6:240ns 7:280ns

Max

14

Page 15

Chip pins status control

OSD Descriptions Recommend Data Max

PANEL KEY DETECT

REMOTE KEY LOVE

23PIN

59PIN 50/60HZ-UHF 0:50/60HZ 1:High level When UHF 0 1

31PIN

56PIN 3 STATUS

56PIN V.CHG

64PIN

VIF mage IF 0:38M 1:38.9M 2:45.75M 2

VIDEO DSP USB AV2 DISPLAY USB 1

Whether “POWER ON” to test voltage level for

control key PCB, 0: 1:default TOSHIBA

Whether remote control key has “FAVOURITE”

function: 0:as Up,Down,Left,Right key

1:as Favorite, Scan, Music key

TMPA889X Chip Tint signal input or CVBS input

0:Tint signal 1:CVBS

TMPA8891 Chip 31pins function

0:SIF OUT 1: AU OUT 2. 3:NO USE

56pins function, 3 status ?

0:High & Low two level

1:High, Middle, Low three level

56pins function,TV/AV1/AV2 three status voltage selection

0:0V 2.5V 5V 1:0V 5V 2.5V

64pins function, “POWER ON” level selection:

0:Low level “ON”, 1:High level “ON”

0 1

1 1

0 1

0 2

0 1

0 1

0 1

Function control

OSD Descriptions Recommend Data Max

V.AGC.DC V. AGC power source selection, 0: external 1: inner 1 1

PIF.LEVER

CVBS.PASS

POS.NO. Channels quantity selection, 0:248 1:256 0 1

TUNING.MODE Tuning mode, 0:VS 1:FS 0 1

TUNER.TYPE

POWER.TIME

STANBY.MODE

U.BAND Tuner U band level selection, 0:00 1:11 1 1

CVBS output amplitude control,

00:1.1V 3:2.4V

Whether CVBS output pass band lter,

0: PASS 1: NO PASS

Frequency Synthesize Tuner selection

0:38M 1:38A 2:38.9M 3:38.9A

Cold “POWER ON” power pin wait time:

0:0 second, 1:1 second, 2:2 seconds, 3:3 seconds

“POWER ON” power pin memory status, 0:Remember status

1:Stand-by status, remote control to “POWER ON”

2:Do not remember last time “POWER ON” status

automatic “POWER ON”

3 3

0 1

0 3

0 3

0 2

SERVICE MANUAL

Register control to ABCL, Brightness

OSD Descriptions Recommend Data Max

ABL.POINT

ACL.ST

ABL.GAIN

YPL Brightness peak value, 0:OFF 1:105IRE 0 1

BS.SW Black level delay switch, 0:OFF 1:105IRE 1 1

BS.START

Y.GAMMA

P.OFF.RGB

SHARP.BLANCE Balance adjustment for Vertical line roll 4 7

Start point for automatic brightness control

0:0V,1:-0.2V,2:-0.3V,3:-0.4V

Start point for automatic contrast control,

0:0V,1:-0.2V,2:-0.3V,3:-1V(OFF)

Start point for automatic brightness control gain

0:-0.2V,1:-0.35V,2:-0.5V,3:-0.65V;

Start point for black level delay

0:30IRE, 1:40IRE, 2:50IRE, 3:75IRE

Brightness Gamma correction

0:OFF, 1:78IRE, 2:68IRE, 3:58IRE

“POWER OFF” brightness vanish, 0:OFF

1: Brightness vanish : RGB/Cut as 0

2: Brightness vanish, RGB/Cut as FF

2 3

1 3

3 3

3 3

0 3

0 2

15

Page 16

SERVICE MANUAL

Register control to Sound trap

OSD Descriptions

S.TRAP F0 Sound trap center frequency width 08 08 08 03 15

S.TRAP Q Sound trap Q value 0 0 0 0 3

S.TRAP GD Sound trap GD value 2 2 2 2 3

S.TRAP HP/LP Sound trap HP/LP value 0 0 0 3 3

STANDARD Standard status contrast, brightness, color, sharpness 50 50 50 50 100

MILD Lild status contrast, brightness, color, sharpness 30 30 40 30 100

VIVID Vivid status contrast, brightness, color, sharpness 70 70 60 60 100

DYNAMIC Dynamic status contrast, brightness, color, sharpness 80 80 50 40 100

BG DK I M

H. Synchronization parameters adjustment

OSD Descriptions Recommend Data Max

SYNC.DET

SYNC.SEARCH Inner sync. searching, Sync. signal test mode 14 15

SYNC.BB Inner sync. blue screen, Sync. signal test mode 14 15

BB.COUNT Inner sync. Blue screen, Sync. Signal counting quantity 04 255

PYNX External sync. Status H.Sync. pulse counting maximum 46 63

PYNN External sync. Status H.Sync. pulse counting minimum 24 63

PYXS

PYNS

H.Sync. test mode, 0: inner sync.,

1: external sync.

External sync. Searching status H.Sync.

pulse counting maximum

External sync. Searching status H.Sync.

pulse counting minimum

Recommend Data

0 1

34 63

30 63

Max

Seldom used adjustment items 1

OSD Descriptions Recommend Data Max

HAFC AFC gain 0 255

VCEN V. center value, valid for “+,-” power source 0 3F

NOISE.SW Noise test switch 0:OFF 1:ON 0 1

NOISE.COUNT Test and conrm the noise counting value 31 255

SEARCH1 Automatic searching calculation 1, 0:quick 1:slow 0 1

SEARCH2 Automatic searching calculation 2, 0:quick 1:slow 0 1

NOISE Test the noise comparison value F 15

UCOM Select input mode for test pattern from U-COM 0 7

CH SHADE Fade in when change 0:OFF 1:ON 0 1

DSP POSITION TV Station display position 0:right 1:left 0 1

Seldom used adjustment items 2

OSD Descriptions Recommend Data Max

HVBSW H/V Blanking on/OFF switch, 0:OFF 1:ON 0 1

C.TRP.Q C-Trap Q, 0:low 1:high 0 1

AFTCH

SEAUD

BYRGB

UV.SW UV SW 0:Cb/Cr 1:U/V 0 1

C.TRAP

YUV.DIS YUV display status 0:YUV 1:DVB 0 1

TINTP TINT polarity 0: Plus 1:Minus 1 1

AFT check, 0:check AFT for TV or AV,

1: only check AFT for TV

Automatic tuning, whether search signal downwards

0:search downwards 1:no

Black screen switch Y/RGB option

0:off Y 1:off RGB

C trap mode selection, 00:01 interlocking “video sw”

10 :off 11:on

1 1

0 1

0 1

0 3

16

Page 17

Seldom used adjustment items 3

OSD Descriptions Recommend Data Max

VFREQ V.frequency setting without signal, 0:automatic, 1:313 1 1

OVMO Over modulation switch 0:normal set 1:ON 0 1

AFT SENS. AFT sensatory 0:wide(250hz ) 1:normal(83hz) 0 1

NYBUSW Nyquist Buzz reducer Switch, 0:ON, 1: OFF 1 1

SHARPF0

VCOADJ

HSTOP power on H STOP 0:H STOP=0, 1:H STOP=1 0 1

SYNC.SEP. H. Sync. division degree, 0:40% 1:50% 1 1

SYNC.SLI. Weak signal sync. Level, 0:standard 1:low 0 1

SYNC.SKEW Test H.Sync. incline mode, 0:30% 1:50% 0 1

Select sharpness center frequency,

0:2.75MHz, 1:4MHz

Whether adjust VC0 when change channel,

0:adjust VCO, 1:no

0 1

0 1

SECAM adjustment items

OSD Descriptions Recommend Data Max

SECAM.GP 00:normal 01:+200ns 10:center 11:-200ns 0 1

SECAM.INT secam inhibit swich 0:detecting 1:inhibit 0 1

SECAM.ID SECAM sensatory 0:normal 1:low 1 1

SECAM.BEL.SW sel secam bell lter bandwith 0: bell lter 1:boost mode 0 1

SECAM.ID.MOD select secam ident mode 0:H ID 1:H+V ID 0 1

SECAM.BLACK.SW

SECAM.BELL select secam bell lter Q 0:low 1:high 1 1

select YS-SW mode 0:normal operation

1:secam black level alignment mode

0 1

SERVICE MANUAL

LOGO seting:

At AV mode, press remote gure key “2 4 8 3”, “6483”, “6568” to enter LOGO setting MENU, according to MENU to

select item, press P+, P-, V+, V- key to set LOGO Parameters, after setting, press DISP key to exit.

17

Page 18

SERVICE MANUAL

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

8. IC’S FUNCTIONAL DESCRIPTION

TMPA8891-XXXX

33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

8.1 TMPA889* FUNCTION: MAIN IC

PIN

1

2

3

4

5

6/7

8

9

10

54

55

56

57

58

59

60

61

62

63

64

11

12

13

14

15

16

17

18

19

20

21

DESCRIPTION

U/V

L/H

KEY

GND

REST

X-TAC

TEST

5V

Vss

GND

5V

AV SW

SDA

SOL

50/60HZ

VT

MUTE

TVSYNC

RMT IN

Power

TV GND

FBP-IN

H-out

H-AFC

V-SAW

V-out

H-Vcc

TV GND

Cb

Y-IN

Cr

PIN

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41/42

43

44

45

46

47

48

49

50

51

52

53

DESCRIPTION

EXT-AU1

C-in

Sin

ACL

TV-in

ABC-in

Audio-out1

Audio-out2

TV-out

SIF OUT

EXT-AU2

SIF in

DC NF

PIF•PLL

IF-5V

S-Reg

AU OUT1

IF AGC

IF GND

IF in

RF AGC

Black Det

Monitor out

APC fil

YC VCC5V1

SYNC OUT

DVCC—3.3V

R out

G out

B out

GND

18

Page 19

8.2 FSCQ-SERIES

FSCQ0765RT GREEN MODE FAIRCHILD POWER SWITCH (FPS™)

Features

● Optimized for Quasi-Resonant Converter (QRC)

● Advanced Burst-Mode Operation for under 1W

Standby Power Consumption

● Pulse-by-Pulse Current Limit

● Over Load Protection (OLP) – Auto estart

● Over Voltage Protection (OVP) – Auto Restart

● Abnormal Over Current Protection (AOCP) – Latch

● Internal Thermal Shutdown (TSD) – Latch

● Under Voltage Lock Out (UVLO) with Hysteresis

● Low Startup Current (typical: 25µA)

● Internal High Voltage SenseFET

● Built-in Soft Start (20ms)

● Extended Quasi-Resonant Switching

Description

A Quasi-Resonant Converter (QRC) typically showslower

EMI and higher power conversion efciency com-pared to

conventional hard-switched converter with axed switching

frequency. Therefore, a QRC is wellsuited for noise-sensitive

applications, such as color TVand audio. Each product in the

FSCQ-Series contains anintegrated Pulse Width Modulation

(PWM) controller anda SenseFET, and is specically designed

for quasi-resonant off-line Switch Mode Power Suppl ie s

(SMPS)with minimal external components.

The PWM controllerincludes an integrated xed frequency

oscillat or, under vol tage lockout , leading edge blankin g

(LEB), optimized gatedriver, internal soft start, temperaturec o mp en s at ed pr e ci s e c ur r e nt s ou rc e s f or a lo o p

compensation, and selfprotection circuitry. Compared with a

discrete MOSFET and PWM controller solution, the FSCQSeries canreducetota l cost, component count, size, and

weight, whilesimultaneously increasing efciency, productivity,

an d s ys-t em rel iab ilit y. These d evi ces pro vid e a b asi c

platform thatis well suited for cost-effective designs of quasi-

resonantswitching yback converters.

Maximum Output Power

3

2

Product

FSCQ0765RT

Output Power Table

230 VAC±15%

Open Frame

100W

1

Notes:

1. Maximum practical continuous power in an open frame design at 50°C ambient.

2. 230 VAC or 100/115 VAC with doubler.

3. The junction temperature can limit the maximum output power.

SERVICE MANUAL

85–265 VAC

Open Frame

1

85W

TYpical Circuit

AC

IN

Sync

FSCQ-Series

PWM

V

FB

V

CC

Typical Flyback Application

Drain

GND

V

O

19

Page 20

SERVICE MANUAL

5. Sync

Pin Configuration

Pin Definitions

TO-220F-5L

4. Vfb

3. Vcc

2. GND

1. Drain

Pin Configuration (Top View)

Pin Name

1

2

3

4

5

Drain

GND

CC

V

Vfb

Sync

High voltage power SenseFET drain connection.

This pin is the control ground and the SenseFET source.

This pin is the positive supply input. This pin provides internal operating current for both

start-up and steady-state operation.

This pin is internally connected to the inverting input of the PWM comparator.

The collector of an optocoupler is typically tied to this pin. For stable operation, a capacitor

should be placed between this pin and GND. If the voltage of this pin reaches 7.5V, the over

load protection triggers, which results in the FPS shutting down.

This pin is internally connected to the sync detect comparator for quasi-resonant switching.

In normal quasi-resonant operation, the threshold of the sync comparator is 4.6V/2.6V.

Whereas, the sync threshold is changed to 3.0V/1.8V in an extended quasi-resonant operation.

Pin Fuction DescriptionPin Number

Notes:

1. Maximum practical continuous power in an open frame design at 50°C ambient.

2. 230 VAC or 100/115 VAC with doubler.

3. The junction temperature can limit the maximum output power.

Absolute Maximum Ratings

A

(T

= 25°C, unless otherwise specied)

Parameter

Drain Pin Voltage

Supply Voltage

Analog Input Voltage Range

Drain Current Pulsed

Continuous Drain Current (TC = 25°C)

C: Case Back Surface Temperature)

(T

Continuous Drain Current* (TDL= 25°C)

(TDL: Drain Lead Temperature)

Continuous Drain Current (TC= 100°C)

Single-Pulsed Avalanche Energy

Total Power Dissipation

(Tc = 25°C with Innite Heat Sink)

TerutarepmeT noitcnuJ gnitarep

TerutarepmeT tneibmA gnitarep

TegnaR erutarepmeT egarot

ESD Capability, HBM Model (All pins except Vfb)

ESD Capability, Machine Model (All pins except Vfb)

4

5

IDM

ID

ID*

ID

EAS

PD

Symbol

DS

V

VCC

Vsync

VFB

TJ

TA

TSTG

-

-

Value

650

20

-0.3 to 13V

CC

-0.3 to V

15.2

3.8

7

2.4

570

45

+150

-25 to +185

-55 to +150

(GND -Vfb =1.7KV)

(GND -Vfb =170V)

Unit

V

V

V

V

A

A

(rms)

A(rms)

A(rms)

m

J

W

°C

°C

°C

KV

V

Notes:

4. Repetitive rating: pulse width limited by maximum junction temperature.

5. L = 15mH, starting Tj = 25°C, These parameters, although guaranteed at the design, are not tested in mass production.

20

Page 21

Thermal Impedance

(TA= 25°C, unless otherwise specied)

SERVICE MANUAL

Parameter

Junction to Case Thermal Impedance

Electrical Characteristics (SenseFET Part)

A

(T

= 25°C, unless otherwise specied)

Parameter

Drain-Source Breakdown Voltage

Zero Gate Voltage Drain Current

Drain-Source ON-State Resistance

Input Capacitance

Output Capacitance

BVDSS

IDSS

RDS(ON)

CISS

COSS

Electrical Characteristics (Continued)

(TA= 25°C unless otherwise specied)

Parameter

Control Section

Switching Frequency

Switching Frequency Variation

Feedback Source Current

Maximum Duty Cycle

Minimum Duty Cycle

UVLO Threshold Voltage

Soft Start Time

6

Burst Mode Section

Burst Mode Enable Feedback Voltage

VBurst Mode Feedback Source Current

Burst Mode Switching Time

Burst Mode Hold Time

Protection Section

Shutdown Feedback Voltage

Shutdown Delay CurrentI

Over Voltage Protection

Over Current Latch Voltage

Thermal Shutdown Temp

7

6

7

θJC FSCQ0765RT

2.60

Symbol Condition Min.

GS= 0V, ID= 250μA

FSCQ0765RT

FSCQ0765RT

FSCQ0765RT

Symbol

F

OSC

∆FOSC

IFB

DMAX

DMIN

VSTART

VSTOP

TSS

VBEN

IBFB

TBS

TBH

VSD

IDELAY

VOVP

VOCL

TSD

V

DS= 650V,VGS= 0V

V

GS= 10V, ID=1A

V

GS= 0V, VDS= 25V,

V

GS= 0V, VDS= 25V,

V

Condition Min.

FB= 5V, VCC= 18V

V

-25°C≤ T

V

V

V

V

V

V

V

V

V

V

V

A≤ 85°C

FB= 0.8V, VCC= 18V

FB= 5V, VCC= 18V

FB= 0V, VCC= 18V

FB =1V

FB =0V

FB= 0.9V, Duty=50%

FB =0.9V → 0V

CC= 18V

FB= 5V, VCC= 18V

FB= 3V

CC= 18V

650

-

-

-

-

18

0

0.5

92

-

14

8

18

0.25

60

1.2

1.2

70

4

11

0.9

140

eulaVlobmyS

Unit

°C/W

Typ.

-

-

1.4

1415

100

Typ.

Max.

250

1.6

Max.

Unit

-

V

μA

Ω

-

-

pF

pF

Unit

20

±5

0.65

95

0

15

9

20

0.40

100

1.4

1.4

7.5

5

12

1.0

-

22

±10

0.8

98

-

16

10

22

0.55

140

1.6

1.6

8.0

6

1.3

1.1

-

KHz

%

mA

%

%

V

ms

V

μA

ms

ms

V

μA

V

V

°C

Notes:

6. These parameters, although guaranteed, are tested only in EDS (wafer test) process.

7. These parameters, although guaranteed at the design, are not tested in mass production.

21

Page 22

SERVICE MANUAL

Electrical Characteristics (Continued)

(TA= 25°C, unless otherwise specied)

Parameter

Sync Section

Sync Threshold in Normal QR (H)

Sync Threshold in Normal QR (L

Sync Threshold in Extended QR (H)

Sync Threshold in Extended QR (L)

Extended QR Enable Frequency

Extended QR Disable Frequency

Total Device Section

Operating Supply Current

- In Normal Operation

- In Burst Mode (Non-switching)

Startup Current

Sustain Latch Current

Current Sense Section

Maximum Current Limit

Burst Peak Current

11

10

)

9

SH1

V

VSL1

VSH2

VSL2

FSYH

F

SYL

IOP

IOB

ISTART

ISN

ILIM

IBUR(pk)

Symbol Condition Min.

CC= 18V, VFB= 5V

V

V

FSCQ0765RT

FSCQ0765RT

FSCQ0765RT

FB = 5V

FB =GND

V

CC=VSTART - 0.1V

V

CC=VSTOP -

V

V

CC= 18V, VFB= 5V

CC= 18V, VFB= Pulse

V

0.1V

8.3 CD7522CS DUAL 5W BTL AUDIO POWER AMPLIFIER (ONLY FOR AV STEREO)

Overview

CD7522CS is an audio power amplier IC for the stereo system. In the BTL (balanced

transformerless) method, fewer external parts and easier design for applications are required.

Features

● 5W output (8Ω) with supply voltage of 12 V

● On-chip standby function

● On-chip volume function

● Package: FSIP12

Block Diagram and Pin Descriptions

Block Diagram

4.2

2.3

2.7

1.6

-

-

-

-

-

-

4.4

0.65

Typ.

4.6

2.6

3.0

1.8

90

45

4

0.25

25

50

5

0.9

Max.

5.0

2.9

3.3

2.0

-

-

6

0.50

50

100

5.6

1.15

Unit

V

V

V

V

KHz

KHz

mA

mA

μA

μA

A

A

22

1A

1 2 43 5 6 7 8 109 11 12

2A

2B-1B+ 1B- 2B+

Page 23

Pin Descriptions

SERVICE MANUAL

Pin Name

1

2

3

Drain

GND

CC

V

High voltage power SenseFET drain connection.

This pin is the control ground and the SenseFET source.

This pin is the positive supply input. This pin provides internal operating current for both

Pin Fuction DescriptionPin Number

start-up and steady-state operation.

4

Vfb

This pin is internally connected to the inverting input of the PWM comparator.

The collector of an optocoupler is typically tied to this pin. For stable operation, a capacitor

should be placed between this pin and GND. If the voltage of this pin reaches 7.5V, the over

load protection triggers, which results in the FPS shutting down.

5

Sync

This pin is internally connected to the sync detect comparator for quasi-resonant switching.

In normal quasi-resonant operation, the threshold of the sync comparator is 4.6V/2.6V.

Whereas, the sync threshold is changed to 3.0V/1.8V in an extended quasi-resonant operation.

Electrical Characteristics

Absolute Maximum Ratings: Except for the operating ambient temperature and storage temperature,

all ratings are for Tamb = 25°C.

Parameter Symbol

Supply voltage

Supply Current

Power Dissipation

Operating Ambient Temperature

Storage Temperature

cc

V

Icc

PD

Tamb

Tstg

Condition

in = 0

V

T

a = 70°C

Ratings

-25 ~ 70

-55 ~ 150

14

2

1.92

Unit

V

A

W

°C

°C

Recommended Operating Range

Parameter

Supply voltage

Symbol

Vcc

Range

3.5 ~ 13.5

Unit

V

Electrical Characteristics at Vcc= 8.0 V, RL = 8Ω, f = 1 KHz, Tamb = 25°C ± 2°C

Parameter Symbol Condition

Quiescent Current

Standby Current

Output Noise Voltage

Voltage Gain

Total Harmonic Distortion

Maximum Output Power

Ripple Rejection Ratio

Output Offset Voltage

Volume Attenuation Ratio

Channel Balance 1

Channel Balance 2

Middle Voltage Gain

Channel Crosstalk

Standby Pin Current

Volume Pin Current

ICCQ

ISTB

VNO

AV

THD

P

RR

VOF

Att

CB1

CB2

G

CT

STB2

I

IVOL

VM

in = 0mV, VVOL = 0V

V

in = 0mV, VVOL = 0V

V

g = 10KΩ, VVOL = 0V

R

O = 0.5W, VVOL = 1.25V

P

O = 0.5W, VVOL = 1.25V

P

THD = 10%, V

O

THD = 10%, V

THD = 10%, V

g = 10KΩ, VVOL = 0V

R

R = 0.5Vrms, fR = 120Hz

V

g = 10KΩ, VVOL = 0V

R

O = 0.5W, VVOL = 0V

P

O = 0.5W, VVOL = 1.25V

P

O = 0.5W, VVOL = 0.6V

P

O = 0.5W, VVOL = 0.6V

P

O = 0.5W, VVOL = 1.25V

P

in = 0mV, VSTB = 3V

V

in = 0mV, VVOL = 3V

V

VOL = 1.25V

VOL = 9.5V

VOL = 12V

Min

31

2.4

3.2

4.9

30

-250

70

-1

-3

20.5

40

-12

Ratings

Typ.

45

1

0.10

33

0.10

3.0

4.0

6.1

50

0

85

0

0

23.5

55

Max.

100

10

0.4

35

0.5

250

1

3

26.5

25

Unit

mA

μA

mVrms

dB

%

W

dB

mV

dB

dB

dB

dB

dB

μA

μA

23

Page 24

SERVICE MANUAL

8.4 CD7523CS 3W BTL AUDIO POWER AMPLIFIER (ONLY FOR AV MONO)

Overview

CD7523CS is an audio power amplier IC. In the BTL (balanced transformerless) method, fewer external parts and easier

design for applications are required.

Features

● 3W output (8Ω) with supply voltage of 8V

● On-chip standby function

● On-chip volume function

● Package: FSIP9

Block Diagram and Pin Descriptions

Block Diagram

B+ B-

A

1 2 43 5 6 7 8 9

Pin Descriptions

Pin No.

1

2

3

4

5

Symbol

Vcc

OUT 1+

GND 1

OUT 1-

ST-BY

Supply voltage

Ch.1 + output

Ground (output ch.1)

Ch.1 - output

standby (standby state if this pin is open)

Electrical Characteristics

Absolute Maximum Ratings: Except for the operating ambient temperature and storage temperature, all ratings are for

Tamb = 25°C.

Parameter Symbol

Supply voltage

Supply Current

Power Dissipation

Operating Ambient Temperature

Storage Temperature

Descriptions Pin No.

6

7

8

9

cc

V

Icc

PD

Tamb

Tstg

Symbol

IN1

GND

NC

VOL

Condition

in = 0

V

T

a = 70°C

Descriptions

Ch.1 - input

Ground (input)

NC.

Volume (max. volume if this pin is open)

Ratings

14

1

1.22

-25 ~ 70

-55 ~ 150

Unit

V

A

W

°C

°C

Recommended Operating Range

Parameter

Supply voltage

Symbol

Vcc

24

Range

3.5 ~ 13.5

Unit

V

Page 25

Electrical Characteristics at Vcc= 8.0 V, RL = 8Ω, f = 1 KHz, Tamb = 25°C ± 2°C

SERVICE MANUAL

31

30

70

Ratings

Typ.

25

1

0.10

33

0.10

3.0

4.0

6.1

50

0

85

23.5

Max.

60

10

0.4

35

0.5

250

26.5

25

Unit

mA

μA

mVrms

dB

%

W

dB

mV

dB

dB

μA

μA

Parameter Symbol Condition

Quiescent Current

Standby Current

Output Noise Voltage

Voltage Gain

Total Harmonic Distortion

ICCQ

ISTB

VNO

AV

THD

P

P

THD = 10%, V

Maximum Output Power

O

THD = 10%, V

P

THD = 10%, V

Ripple Rejection Ratio

Output Offset Voltage

Volume Attenuation Ratio

Middle Voltage Gain

Standby Pin Current

Volume Pin Current

RR

VOF

Att

VM

G

ISTB2

IVOL

V

P

in = 0mV, VVOL = 0V

V

in = 0mV, VVOL = 0V

V

g = 10KΩ, VVOL = 0V

R

O = 0.5W, VVOL = 1.25V

O = 0.5W, VVOL = 1.25V

VOL = 1.25V

VOL = 9.5V

VOL = 12V

g = 10KΩ, VVOL = 0V

R

R = 0.5Vrms, fR = 120Hz

g = 10KΩ, VVOL = 0V

R

O = 0.5W, VVOL = 0V

P

O = 0.5W, VVOL = 0.6V

in = 0mV, VSTB = 3V

V

in = 0mV, VVOL = 3V

V

Min

2.4

3.2

4.9

-250

20.5

-12

8.5 LA78040 - TV and CRT Display Vertical Output IC with Bus Control Support (only for 14”-21” PF)

Overview

The LA78040 is a vertical deection output IC for high image quality TV and CRT displays that supports the use of a bus control

system signal-processing IC. The sawtooth waveform from the bus control system signal-processing IC can directly drive the

deection yoke (including the DC component).

Functions

● Built-in pump-up circuit for low power dissipation.

● Vertical output circuit.

● Thermal protection circuit.

Specifications

Maximum Ratings at Ta = 25°C

Parameter Symbol

Pump-up block supply voltage

Output block supply voltage

Allowable power dissipation

Deflection output current

Thermal resistance

Operating temperature

Stroage temperature

+B2 max

+B6 max

Pd max

I5 max

θj-c

Topr

Tstg

Operating Conditions at Ta = 25°C

Parameter Symbol

Recommended supply voltage

Operating supply voltage range

Deflection output current

+B2

+B2op

I5p-p

Conditions Ratings

Mounted on an arbitrarily large heat sink.

Conditions Ratings

Mounted on an arbitrarily large heat sink.

34

70

9

-1.5 to +1.5

3

-20 to +85

-40 to +150

24

-16 to 33

To 1.8

Unit

V

V

W

Ap-o

°C/W

°C

°C

Unit

V

V

Ap-p

25

Page 26

SERVICE MANUAL

+Vsat5-4

+Vsat6-5

+Vsat3-4

+Vsat2-3

ldI

Vmid

I5 = 0.9A

I5 = -0.9A

I3 = 20mA

I3 = 0.9A

Deflection output saturation

voltage (lower)

Deflection output saturation

voltage (upper)

Pump-up charge saturation

voltage

Pump-up discharge saturation

voltage

ldI current

Midpoint voltage

Parameter Symbol Condition

Ratings

V

V

V

V

mA

V

Min

20

11.0

Typ.

12.0

Max.

1.3

3.2

1.8

3.0

50

13.0

Unit

Operating Characteristicsat Ta = 25°C, +B2 = 24V

Notes:

Current owing into the IC is positive (+) and current owing out is negative (-).

Package Dimensions

unit : mm

Block Diagram

10.4 max

Φ3.6

10.0

2.7

0.7

1.27 0.6 0.45 3.15

-

AMP

+

4.5

15.0

8.8

8.23

THERMAL

PROTECTION

1.3

14.5

17.0

21.5

22.3

26

PUMP UP

1 2 3 4 5 6 7

INVERTING INPUT

VCC

PUMP UP OUT

GND

CC

Ver. OUTPUT

OUTPUT STAGE V

NON INV. INPUT

Page 27

SERVICE MANUAL

8.6 STV 8172A VERTICAL DEFLECTION BOOSTERFOR 3-APPTV/MONITOR APPLICATIONS (ONLY FOR 21” SLIM)

WITH 70-V FLYBACK GENERATOR

Main Features

● Power Amplier

● Flyback Generator

● Stand-by Control

● Output Current up to 3App

● Thermal Protection

Description

The STV8172A is a vertical deection booster

designed for TV and monitor applications.

This device, supplied with up to 35V, provides up to

3App output current to drive the vertical deection yoke.

The internal yback generator delivers yback

voltages up to 75V.

In double-supply applications, a stand-by state will

be reached by stopping the (+) supply alone.

HEPTAWATT

(Plastic Package)

ORDER CODE: STV8172A

Non-Inverting

Input

Inverting

Input

7

6

5

4

3

2

1

Tab connected

to pin 4

Output Stage

Supply

6

7

1

+

Power

Amplifier

-

Flyback

Generator

3

Thermal

Protection

Supply

Voltage

2

Flyback

Generator

Input (Non Inverting)

Output Stage Supply

Output

Ground Or Negative Supply

Flyback Generator

Supply Voltage

Input (Inverting)

5

Output

4

Ground or Negative Supply

27

Page 28

SERVICE MANUAL

Absolute Maximum Ratings

Symbol

Voltage

V

S

V5, V6

V3

V1, V7

Current

I0(1)

0(2)

I

3 Sink

I

3 Source

I

3

I

ESD Susceptibility

ESD1

ESD2

Temperature

TS

TJ

Supply Voltage (pin 2) - Note 1 and Note 2

Flyback Peak Voltage - Note2

Voltage at Pin 3 - Note2, Note3 and Note6

Amplifier Input Voltage - Note2, Note6 and Note7

Output Peak Current at f = 50 to 200 Hz, t ≤ 10µs - Note4

Output Peak Current non-repetitive - Note5

Sink Current, t<1ms - Note3

Source Current, t <1ms

Flyback pulse current at f=50 to 200Hz, t≤10µs - Note4

Human body model (100pF discharged through 1.5k)

ESD2EIAJ Standard (200pF discharged through 0)

Storage Temperature

Junction Temperature

Parameter Value

40

75

-0.4 to (V

-0.4 to (V

S + 2) + 40

±5

±2

2

2

±5

2

300

-40 to 150

+150

S + 3)

Note:

1. Usually the yback voltage is slightly more than 2 x VS. This must be taken into consideration when settingVS.

2. Versus pin 4.

3. V3 is higher than VS during the rst half of the yback pulse.

4. Such repetitive output peak currents are usually observed just before and after the yback pulse.

5. This non-repetitive output peak current can be observed, for example, during the Switch-On/Switch-Off phases. This

peak current is acceptable providing the SOA is respected (Figure8 and Figure9).

6. All pins have a reverse diode towards pin 4, these diodes should never be forward-biased.

7. Input voltages must not exceed the lower value of either VS + 2 or 40 volts.

Unit

V

V

V

V

A

A

A

A

A

KV

V

°C

°C

Thermal Data

Symbol

Parameter Value

thjc

R

TT

TJ

Junction-to-Case Thermal Resistance

Temperature for Thermal Shotdown

Recommended Max. Junction Temperature

3

150

120

Unit

°C/W

°C

°C

28

Page 29

Electrical Characteristics

(VS = 34 V, TAMB = 25°C, unless otherwise specied)

SERVICE MANUAL

ParameterSymbol

Text Conditions Min.

Typ.

Supply

S

V

I2

I

6

Operating Supply Voltage Range (V2-V4)

Pin 2 Quiescent Current

Pin 6 Quiescent Current

Note 8

3 = 0, I5 = 0

I

3 = 0, I5 = 0, V6 = 35v

I

10

5

8

19

Input

1

I

I7

VIR

VI0

VI0/dt

Input Bias Current

Input Bias Current

Operating Input Voltage Range

Offset Voltage

Offset Drift Versus Temperature

V

1 = 1V, V7 = 22V

1 = 2.2V, V7 = 1V

V

0

-0.6

-0.6

2

10

Output

0

I

V

V5H

Operating Peak Output Current

5L

Output Saturation Voltage to pin 4

Output Saturation Voltage to pin 6

0°<Tcase <125°C

5 = 1.5A

I

5 = 1.5A

I

1

1.8

Stand-by

V

5STBY

V

Output Voltage in Stand-by

V

1 = V7 = VS = 0

S - 2

See Note 9

Miscellaneous

G

D5-6

V

VD3-2

V3SL

V3SH

Voltage Gain

Diode Forward Voltage Between pins 5-6

Diode Forward Voltage Between pins 3-2

Saturation Voltage on pin 3

Ssturation Voltage to pin 2 (2nd part of flyback)

5 = 1.5A

I

3 = 1.5A

I

3 = 20mA

I

3 = -1.5A

I

80

1.8

1.6

0.4

2.1

Note:

8. In normal applications, the peak yback voltage is slightly greater than 2 x (VS - V4). Therefore,

(VS- V4) = 35V is not allowed without special circuitry.

9. Refer to Figure 4, Stand-by condition.

Max.

35

20

50

1.5

-1.5

S-2

V

±1.5

1.7

2.3

2.3

2.2

1

2.8

Unit

V

mA

mA

µA

µA

V

mA

µV/°C

A

V

V

V

dB

V

V

V

V

Fig.

1

1

1

3

2

3

8.7 2SD2499 HORIZONTAL DEFLECTION OUTPUT FOR COLOR TV (ONLY FOR 14”-21” PF)

High Voltage : VCBO = 1500 V

Low Saturation Voltage : VCE (sat) = 5 V (Max.)

High Speed : tf = 0.3 µs (Typ.)

Bult-in Damper Type

Collector Metal (Fin) is Fully Covered with Mold Resin.

Package Dimensions

unit:mm

Φ3.4

21.0

4.0

1 2 3

16.0

2.8

1.0

2.0

5.6

3.1

5.0

8.0

5.45

22.0

2.0

2.0

20.4

0.6

1 : Base

2 : Collector

3 : Emitter

3.5

5.45

29

Page 30

SERVICE MANUAL

Package Dimensions

Equivalent Circuit

Collector

Base

Maximum Ratings (Tc = 25°C)

Characterstic Rating

Collector-Base Voltage

Collector-Emitter Voltage

Emitter-Base Voltage

Collector Current

Base Current

Collector Power Dissipation

Junction Temperature

Storage Temerature Range

Electrical Characteristics (Tc = 25°C)

Parameter

Drain-Source Breakdown Voltage

Zero Gate Voltage Drain Current

Drain-Source ON-State Resistance

Input Capacitance

Output Capacitance

DC

Pulse

BVDSS

IDSS

RDS(ON)

CISS

COSS

40Ω(Typ.)

Symbol Condition Min.

FSCQ0765RT

FSCQ0765RT

FSCQ0765RT

Emitter

Symbol

CBO

V

VCEO

VEBO

Ic

CP

I

IB

PC

Tj

Tstg

GS= 0V, ID= 250μA

V

DS= 650V,VGS= 0V

V

GS= 10V, ID=1A

V

GS= 0V, VDS= 25V,

V

GS= 0V, VDS= 25V,

V

650

-

-

-

-

1500

600

5

6

12

3

50

150

-55 ~ 150

Typ.

-

-

1.4

1415

100

Max.

-

250

1.6

-

-

Unit

V

V

V

A

A

W

°C

°C

Unit

V

μA

Ω

pF

pF

8.8 2SC5299 ULTRAHIGH-DEFINITION CRT DISPLAY HORIZONTAL DEFLECTION OUTPUT APPLICATIONS

(ONLY FOR 21” SLIM, 29” SF/PF/ SLIM)

Features

● High speed : tf=100ns typ.

● High breakdown voltage : VCBO=1500V.

● High reliability (Adoption of HVP process).

● Adoption of MBIT process.

Equivalent Circuit

30

Base

Collector

Emitter

unit:mm

Φ3.4

21.0

4.0

1 2 3

16.0

2.8

1.0

2.0

5.6

3.1

5.0

8.0

22.0

2.0

20.4

0.6

5.45

2.0

1 : Base

2 : Collector

3 : Emitter

3.5

5.45

Page 31

Specifications

Package Dimensions

Equivalent Circuit

Absolute Maximum Ratings at Ta = 25˚C

Parameter Symbol

Collector-to-Base Voltage

Collector-to-Emitter Voltage

Emitter-to-Base Voltage

Collector Current

Collector current (Pulse)

Collector Dissipation

Junction Temperature

Storage Temperature

CBO

V

VCEO

VEBO

IC

ICP

PC

Tj

Tstg

Electrical Characteristics at Ta = 25˚C

Tc=25˚C

SERVICE MANUAL

Conditions Ratings

1500

800

6

10

25

3.0

70

150

-55 to +150

Unit

V

V

V

A

A

W

W

˚C

˚C

Collector Cutoff Current

Collector-to-Emitter Sastain Voltage

Emitter Cutoff Current

Collector-to-Emitter Saturation Voltage

Base-to-Emitter Saturation Voltage

DC Current Gain

Storage Time

Fall Times

8.9 FQPF10N20C (ONLY FOR 21” SLIM, 29” SF/PF/ SLIM)

200V N-CHANNEL MOSFET

Parameter Symbol Condition

I

CBO

ICES

VCEO(sus)

IEBO

VCE(sat)

VBE(sat)

hFE1

hFE2

tstg

tf

V

= 800V, IE = 0

CB

CE = 1500V, RBE = 0

V

C = 100mA, IB = 0

I

EB = 4V, IC = 0

V