Page 1

6F9G0154

INSTRUCTION MANUAL

HIGH-VOLTAGE

VACUUM CONTACTORS

CAPACITOR APPLICATION

TYPE:CV-10HB 12(13.8)kV-400A-5kA

TYPE:CV-10HBL 12(13.8)kV-400A-5kA

TOSHIBA CORPORATION

© TOSHIBA Corporation 2001-2009

All Rights Reserved.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 2

- 2 -

6F9G0154

CONTENTS

1.GENERAL DESCRIPTION・・・・・・・・・・・・・・・・・・・・ 2

2.PRECAUTIONS IN SPECIAL APPLICATION・・・・・ 3

3.RECEIVING AND UNPACKING・・・・・・・・・・・・・・・・ 4

4.STORAGE AND HANDLING・・・・・・・・・・・・・・・・・・・ 4

5.INSTALLATION・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5

6.RATING・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

7.OUTLINE DRAWING・・・・・・・・・・・・・・・・・・・・・・・・ 7

8.STRUCTURE・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 8

9.OPERATION・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 9

10.TRIAL OPERATION・・・・・・・・・・・・・・・・・・・・・・・・13

11.INSPECTION AND MAINTENANCE・・・・・・・・・・・・・14

12.CRITERIA FOR DURABILITY・・・・・・・・・・・・・・・・18

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 3

- 3 -

6F9G0154

Read this manual carefully to fully understand the operation.

And keep for maintenance.

WARNING : Never remodel or disassemble the equipment nor mount

nonstandard components.

This equipment shall only be used inside a metal enclosure (grounded)

in other establishments than domestic , or those that are connected to

the public power source system.

1. GENERAL DESCRIPTION

(1) Ambient condition

The type CV vacuum contactor is manufactured in accordance with IEC 60470(2000).

The vacuum contactor should be used in the following conditions.

Table 1

Normal service condition

-Altitude : Less than 1000m

-Ambient temperature : -5℃ min. to +40℃ max.

Its average over a period of 24h

does not exceed +35℃

-Relative humidity : 45% min. to 85% max.

-Vibbration : 20Hz -9.8m/s

2

or less

CAUTION : Do not use in condition other than those specified

above , please consult .

(2) Locative condition

The location where the contactor is to be installed should be free from dust.

Corrosive gas and moisture.

When it is be used in a chemical plant or in outdoor panels,

take necessary precautions against corrosion,

water seepage and condensation.

See page 2.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 4

- 4 -

6F9G0154

2. PRECAUTIONS IN SPECIAL APPLICATION (outdoor cubicle etc.)

In application, check the follow items, please carry out the maintenance

frequently. or perform the countermeasure.

(Visual inspection: once a month, regular inspection: once a year)

Table 2 Precaution in special application

Special condition Instance Caution items

Contamination

Sea breeze

Dust, iron-dust etc.

is very more place.

Place where suffer the

sea breeze.

Reduction of ventilation

Setting of ventilation for

sea breeze.

Frequent inspection.

High humidity

Place where very more

snow and ice.

More humidity.

Place where near the

cooling tower.

Place where cause changing

the temperature suddenly.

Setting the space heater.

Setting the ventilation.

Prevention of flooding

into the cable pit.

Corrosion gas

Corrosion gas which come

into the airport, chemical

Industry and water cleaning.

(EX.)

SO

2

, Cl2 ,NO2

Protection from corrosion

gas .

Anti-gas treatment.

Examination of changing

of the insulation material.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 5

- 5 -

6F9G0154

3. RECEIVING AND UNPACKING

WARNING : If any parts are damaged or missing.

Do not install that has been damaged.

Make the following checks after unpacking :

(1) Check if there is any damage , foreign matter trapped , or water seepage

into the contactor.

(2) Check the nameplate to see if the specifications on the plate are correct.

(3) Check the contact wear gauge and control cable.

(4) Check the tripping rod (Latched type).

4.STORAGE AND HANDLING

When the contactor is to be stored over a long period , the storage area

should be dry and dust free area.

If the contactor is left outdoors or in adverse conditions , corrosion

from gas , rust or insulation deterioration may result.

CAUTION : In handling , do not throw or drop contactor.

The contactor may break.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 6

- 6 -

6F9G0154

5.INSTALLATION

When installing , protect from dust. Particularly when the contactor

is installed while the building is under construction , shield it from

cement dust and other foreign matter.

The following precautions should be taken.

(1) The mounting surface must be horizontal (level : less than ±1mm).

When the mounting surface is not horizontal , adjust with spacers.

(2) There are four mounting holes.

Use M10 bolts to securely mount the contactor.

(3) In wiring the main circuit terminals , ground terminals and control

circuit , wires should be given sufficient length to be flexible.

The ground wires should be more than 5.5mm

2

in cross section.

(4) Do not mount the contactor with its front inclined downward.

This may result in malfunction.

(5) Do not touch the vacuum interrupter surface with soiled hands.

(6) When it is applied to a capacitor load , be sure to used a space heater

to keep humidity low.

CAUTION : Do not install on energize contactor that has been bad condition.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 7

- 7 -

6F9G0154

6.RATING

DANGER : Do not exceed the ratings specified on the contactor.

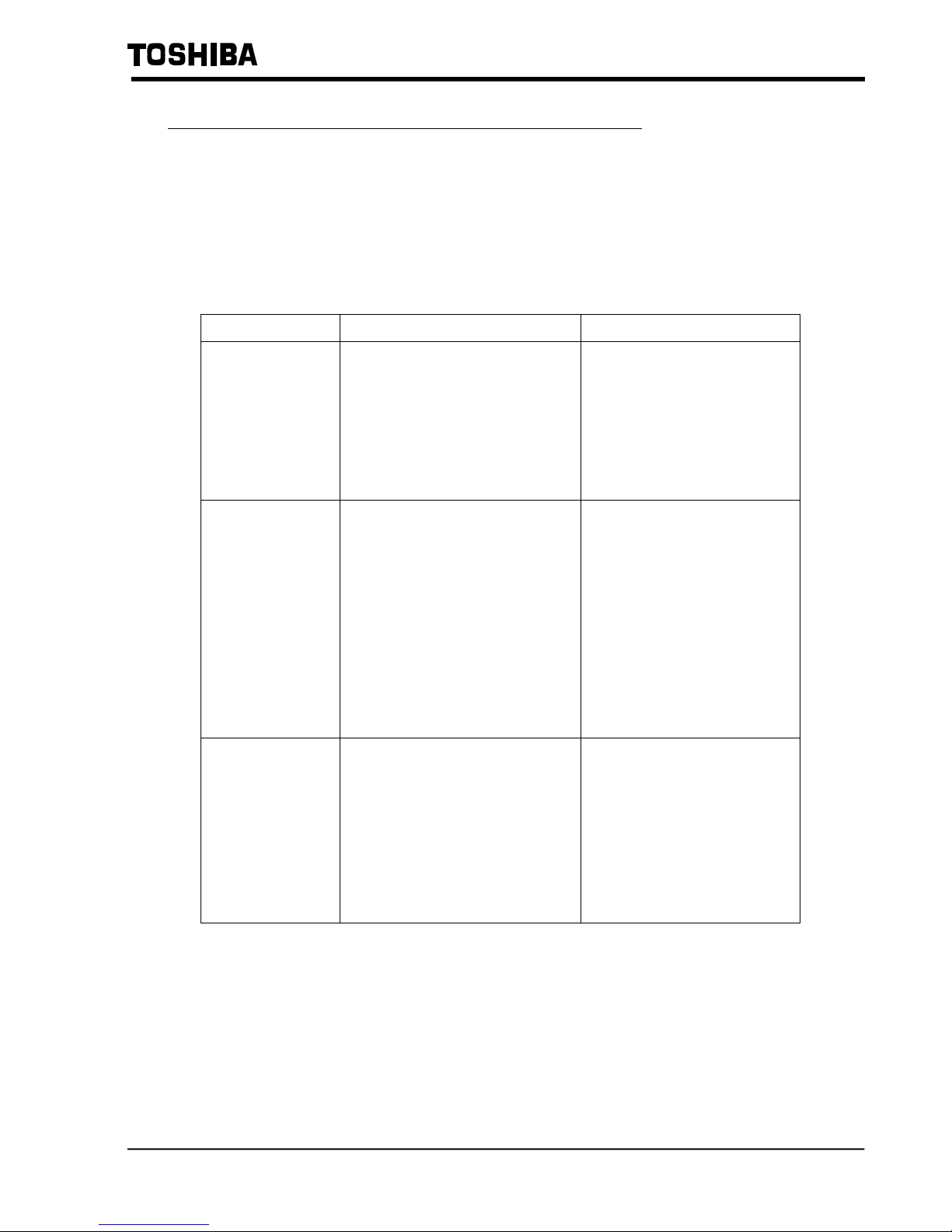

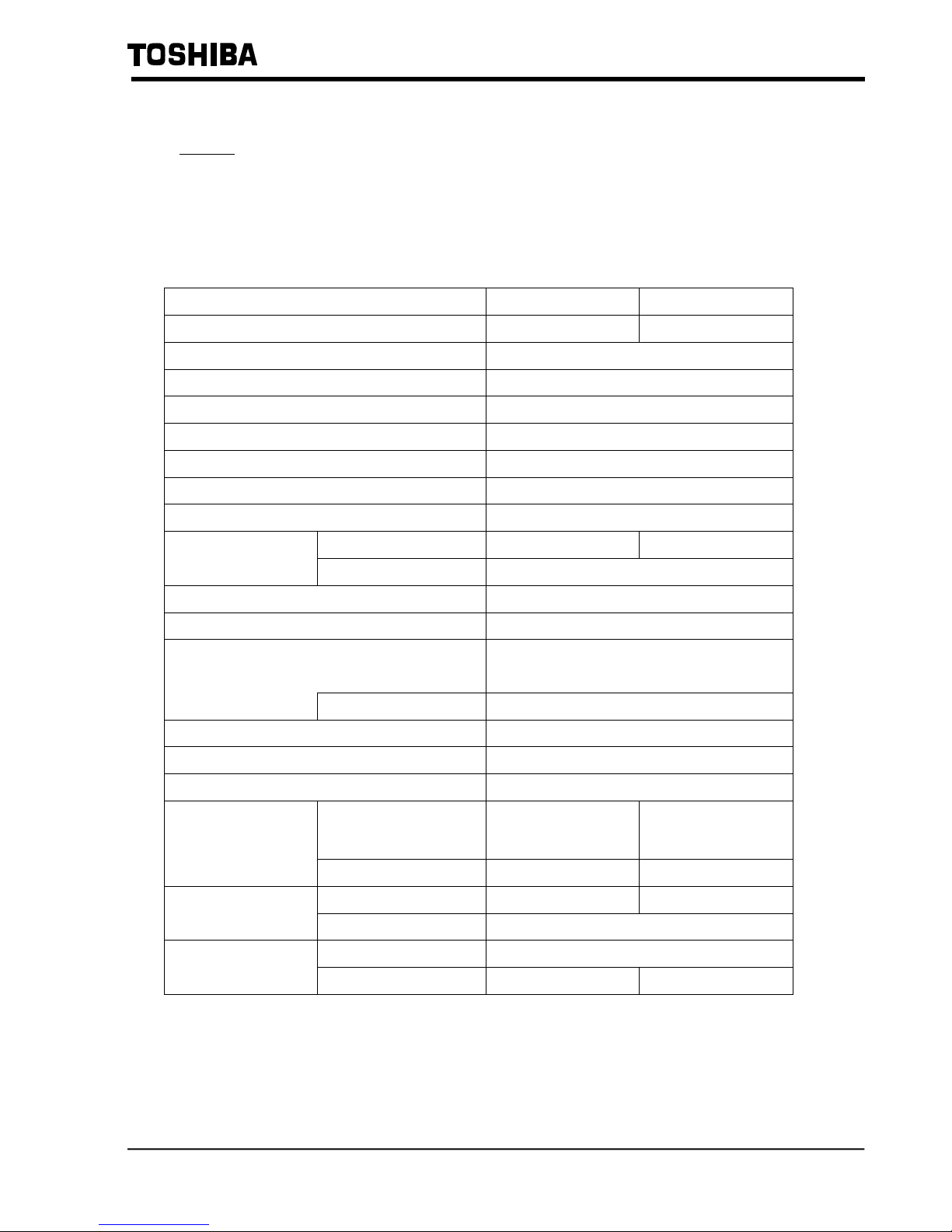

Table 3 Ratings

Type- form CV-10HB CV-10HBL

Operating mechanism Non-latched Latched

Rated operation voltage (kV)

12 (13.8)*

Rated insulation level (kV) AC.28 , Imp.75

Rated operational current (A) 400

Thermal current (A) 450

Rated frequency (Hz) 50/60

Rated short-time withstand current (A-s)

5000-1

Rated peak withstand current (A) 12500

Operations/hour 300 120 Rated duties

On load factor 40%

Rated making capacity (kA)

3.2(C-10s×100times)

Rated breaking capacity (kA)

2.56(CO-30s×25times)

Short-circuit making and breaking current

(kA)

5

Duties

O-3min-CO-3min-CO

Withstand overload current (kA-s)

8.0-1sec , 1.92-30sec

Mechanical operation (million) 0.25

Electrical operation (million) 0.1

Closing voltage

100-240VAC

100-220VDC

100-240VAC

100-250VDC

Rated supply voltage

(Standard)

Tripping voltage

- 100-110VDC

Contact arrangement

4NO-2NC 2NO-1NC

Auxiliary switches

Life (million) 0.1

Closing

6~7

Operating current (A)

(at 100V)

Holding/Tripping

0.6~0.7 3~4

* :13.8kV (maximum) for capacitor switching.

The rated making/breaking capacity has been confirmed at 12kV.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 8

- 8 -

6F9G0154

7.OUTLINE DRAWING

COUNTER

INDICATOR

OPENING

CONTROL

METAL

MAIN

TERMINALS

INSULATION

TYPE

CV-10HB(L)

INTERRUPTERS

526

500

475

165 165

235

193

146

30

165 165

30

MOUNTING HOLES

15

15

24

137 376565

RECOMMEND

CONNECTOR

DIA.13-6HOLES

VACUUM

BARRIER

(OPTION)

DIA.4-14

DIA.20-2

LIFTING

HOLES

PARTITION

DISTANCE

COVER

FOR

MANUAL

TRIP

(LATCHED TYPE)

(HORIZONTAL MAIN TERMINALS)

Fig.1 OUTLINE DRAWING(mm)

200

474

565

110

320

6

206

6

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 9

- 9 -

6F9G0154

8.STRUCTURE

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 10

- 10 -

6F9G0154

9.OPERATION

The drive unit for the electromagnet is installed in the bottom frame.

Molded and wired on the printed circuit.

The closing circuit can be operated using either in AC or DC by the drive unit.

The optional latch trip circuit uses DC as standard.

When a latched contactor is operated using AC power, it is recommended that a

Capacitor trip device be used.

The standard operating voltage is as follows:

Non-latched type(normally energized) : 100-240 V AC /100-220V DC

Latched type :100-240V AC /100-250V DC closing voltage

:100-110V DC tripping voltage

1

2

SWITCHING

OSCILLATION

POWER

TIMER

VOLTAGE

DETECT

52CC

Diode

(Latched type)

Fig.3 Internal Configuration of Drive Unit

CAUTION : Do not touch the drive unit without trouble.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 11

- 11 -

6F9G0154

(1) CONNECTION OF CONTROL POWER SUPPLY

Fig.4 and Fig.5 show the internal connections of the normally energized type

latched type respectively.

According to there figures, connection should be made of the control power

supply and open / close command contact (power relay contact).

Du

5

1

6

2

T1 T5 T6 T7 T10

T11 T15 T16 T17 T19T18

1~6

CONTACTOR TERMINAL NUMBERS

記 号

名 称

52CC

Du

AUS

CLOSING COIL OF CONTACTOR

DRIVE UNIT

AUXILIARY SWITCH

123456789

10

20191817161514131211

T7T5

T6

T17T15

T16

AC/DC

AC/DC

T1

T11

10

11

12 8

97

654

31

AUS

2

52CC

T8

T8T9T10

T18

T19

T20

CONTROL CONNECTOR

T9

T20

Fig.4 Internal connection of the normally energized type.

Du

5

1

6

2

T1 T5 T6 T7 T3

T11 T15 T16 T17 T13T18

1~6

CONTACTOR TERMINAL NUMBERS

記 号

名 称

52CC

Du

AUS

CLOSING COIL OF CONTACTOR

DRIVE UNIT

AUXILIARY SWITCH

123456789

10

20191817161514131211

T7T5T3

T6

T17T15T13

T16

DC/AC

DC/AC

T1

T11

10

11

12 8

97

654

31

AUS

2

52CC

T8

52TC

4

52TC

D

TRIPPING COIL OF CONTACTOR

DIODE

D

T8

T18

CONTROL CONNECTOR

Fig.5 Internal connection of latched type

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 12

- 12 -

6F9G0154

(2) STANDARD OPERATION CIRCUIT

Shown below are the vacuum contactor and its auxiliary circuits (control and

monitoring).

Fig.6 represents the standard operation circuit of the normally energized type

and Fig.7 the latched type.

Wiring should be done according to these circuit diagrams.

Du

5

1

6

2

T1

T5 T6 T7 T10

T11 T15 T16 T17 T19T18

10

11

12 8

97

654

31

AUS

2

52CC

T8 T9

T20

OFF

REMOTE

SWITCH

ON

START

INTERLOCK

STOP

INTERLOCK

2E-RY

4

E

E

EE

4

4

VMC

AC100-240V

DC100-220V

COS

*1

Fig.6 Standard operation circuit of normally energized type.

NOTE:● Be sure to use quickly AC auxiliary relay contact NO for self-holding.

If the self-holding circuit is formed by using the auxiliary contact No

of the vacuum contactor , welding of the main contact may result when

the start button is pushed incompletely(refer to *1 in Fig.6).

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 13

- 13 -

6F9G0154

Du

5

1

6

2

T1

T5

T6 T7 T3

T11

T15

T16 T17 T13T18

10

11

12

8

97

654

31

AUS

2

52CC

T8

52TC

4

D

EE

START

INTERLOCK

4

E

OFF

4

E 2E-RY

ON

REMOTE SWITCH

VMC

DC100-220V

COS

(a) Shunt trip

Du

5

1

6

2

T1

T5

T6 T7 T3

T11

T15

T16 T17 T13T18

10

11

12

8

97

654

31

AUS

2

52CC

T8

52TC

4

D

EE

START

INTERLOCK

4

E

OFF

4

E 2E-RY

ON

REMOTE SWITCH

VMC

AC100-240V

PU

NV

CTD

COS

(b) Capacitor trip

Fig.7 Standard operation circuit of latched type.

NOTE:● Electrical trip-free circuit must be prepared outside the contactor.

● A stable DC power source such as battery is recommended for the

control circuit.

If DC power source is not available, employ a AC closing and a

Capacitor trip.

● Be sure to use the control connector between No.3 and No.13

(auxiliary contact) for trip circuit.

Connect the control connector between No.5 and No.15

(auxiliary contact) for control relay circuit.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 14

- 14 -

6F9G0154

10.Trial operation

Warning : Make sure main power is OFF.

After mounting and wiring of the vacuum contactor, make the following inspections.

1) Check for any loose connections.

2) Check for any wiring errors. Perform this test with only the control circuit energized.

confirm that the operation is correct. For the latched type contactor, check that the

latch correctly engages and trips when the close/trip signals are applied. Also,

manually trip the contactor using trip lever to verify proper operation.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 15

- 15 -

6F9G0154

11.INSPECTION AND MAINTENANCE

To maintain the function and performance of the vacuum contactor for a long period

of time, the following inspections and maintenance procedures are recommended.

The intervals between inspections may vary depending on the conditions of use and

the environment under which the contactor is used. The initial inspection should be

carried out within one year of the start of equipment operation, and the succeeding

check intervals should be determined according to the result of the initial inspection.

See Section 2 for use under special environment as in outdoor cubicles.

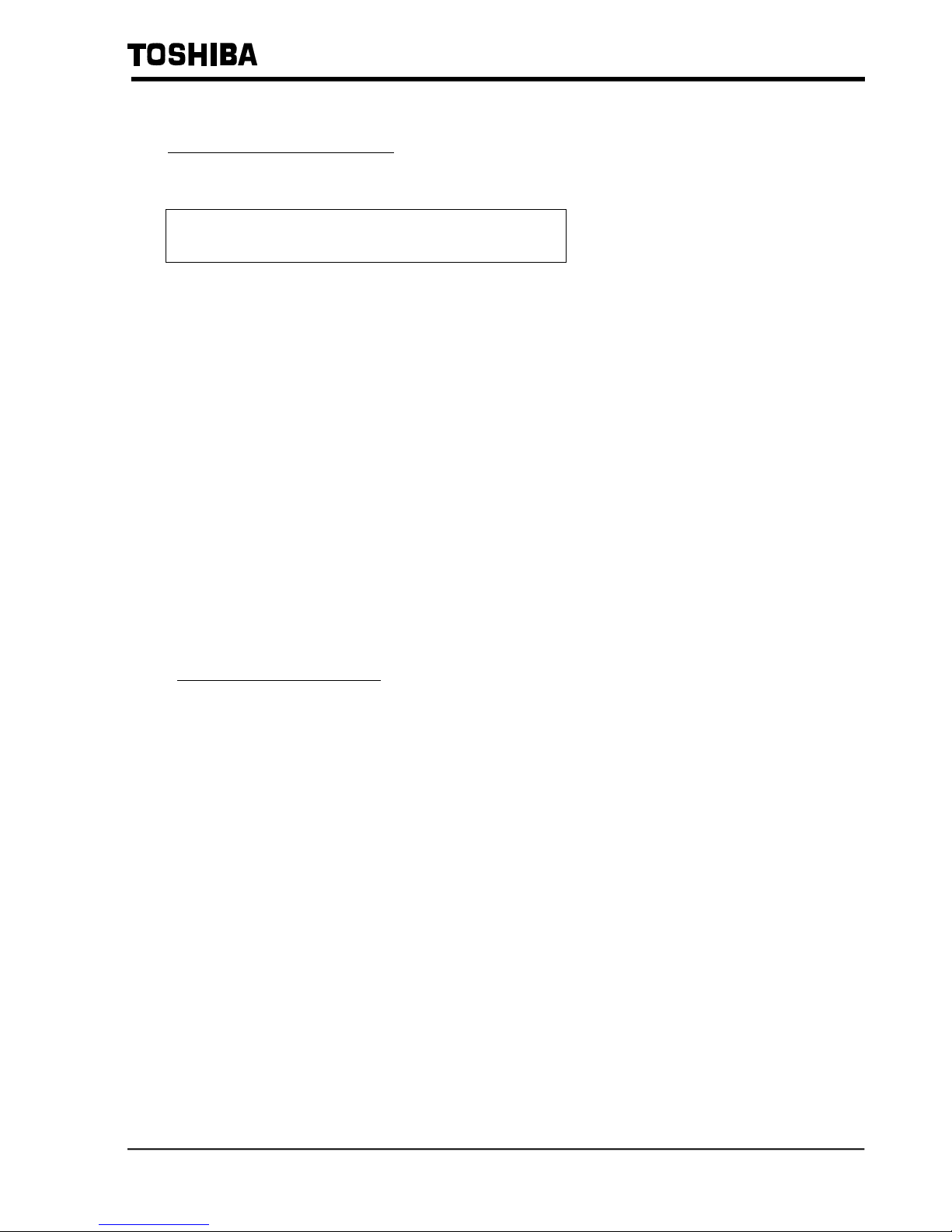

(1) Patrol Inspection(every 1-6 months)

With the cubicle energized, visually check from out side the cubicle according to

the check list of Table 4,5.

WARNING : When opening the door of the cubicle, do not come close

to danger area.

Table 4 Patrol inspection items

Check item What to check

Abnormal noise Check if corona discharges or operation

magnets are not producing noise.

Abnormal smell Check if corona discharges or overheat are

not producing abnormal smell.

Table 5 Patrol inspection items(cont.)

Check item What to check

Abnormal discoloration Is there not any discoloration due to

overheat?

Damage Is there not any crack, break or dislocation

of insulating material or operation tools?

Open/close indication Is the OPEN/CLOSE indication (lamp)

normal?

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 16

- 16 -

6F9G0154

(2) Periodical Inspection/Detailed Inspection(every 1-2 years or every

20,000 operations)

The facility should be removed out of service and perform inspection

According to the instruction given in Table 6.

WARNING : Contact with energized components can cause severe injury

or death.

Turn-off and lock out primary and control circuit before servicing.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 17

- 17 -

6F9G0154

Table 6 Periodical inspection and detailed inspection

Location What to inspect Decision criteria What to do

Appearance

Abnormal appearance

damage

Check by sight. Replace broken

Parts.

Contactor as

a whole

Insulating

Material

Check if moisture or

dust adheres to the

insulator.

Under dusty environments,

frequent inspection

should be done.

Check by sight.

Clean.

Sliding parts

Check for wear, loose or

seized parts.

Spring

Rust, deformation,

discoloration, or damage.

Electromagnets Discoloration, rust,

wear, or loose mounting.

Latch

mechanism

Check for scores and

wear

Closing coil,

trip coil

Check for discoloration

and burned parts.

Operating

devices

Fastenings

Check for loose bolts or

nuts.

Check bye sight.

If necessary,

check correct

operation.

Also check loose

fastenings.

Clean parts and

remove foreign

matters.

Pour oil in

Adequate amount.

Primary

circuit

Terminal,

movable

conductor

Discoloration of terminal

and coupling conductor,

loose fastenings.

Check by sight.

check the

tightness.

Retighten.

If necessary,

investigate the

cause and replace

parts.

Vacuum

Contact wear

Check contact wear and

wipe.

See Table 7.

Replace vacuum

Interrupter.

Vacuum

container

Check moisture and dust

adhering to the surface.

Check by sight. Clean.

Interrupter

Vacuum level Check vacuum level by

withstand voltage test.

Apply AC17kV

for 1minutes.

If found abnormal,

inform the maker.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 18

- 18 -

6F9G0154

Location What to inspect Decision criteria What to do

wiring

Check for discoloration

and tightness.

-

Retighten.

Auxiliary switch Amount of dust attached. Check by sight. Replace if damage

is excessive.

Control

equipment

Drive unit Overheat, discoloration. Check by sight. Replace if abnormal

Main circuit

Measure insulation

resistance between

phases, between

electrodes and between

circuits and ground.

(Measurement is taken

by 1000V megger.)

More than 50MΩ

Insulation

resistance

Operation

circuit

Measure insulation

resistance between

circuits and ground.

(Measurement is taken

by 500V megger.)

More than 1MΩ

When the insulation

resistance is

below the standard

level, investigate the

cause and, if

necessary, replace

parts.

Dielectric

strength

Main circuit Measure dielectric

strength between phases,

between electrodes and

between circuits and

ground.

AC 1.5E for

10 minutes.

If found abnormal

inform the maker.

Open/close operation Perform open/close

operation by electric

operation test to confirm

the correct operation.

If found abnormal,

check and repair.

If necessary,

replace faulty parts.

Remarks: For extraordinary (unscheduled) inspections , pick up check items from the above

table.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 19

- 19 -

6F9G0154

Table 7 Gap/wipe standard value

(mm)

Parts name Gap Wipe Allowable wear

Normally

energized

type

7.0~7.5

More than 3.0 2.0

Vacuum

interrupter

Latch type

7.0~7.5

More than 2.8 1.8

12.CRITERIA FOR DURABILITY

(1) Electrical service life

The electrical service life of the vacuum interrupter is defined by the electrode wear the

number of open/close operations (mechanical life).

To determine the electrode wear, measure the gap between the lever and washer

(dimension A) in a closed start , as shown in Figure8. With the vacuum interrupter

closed, if a contact wear gauge or a 1.0mm thickness gauge cannot be inserted ,

this means the end of life is reached.

For the components listed below, replacement or detailed inspection and cleaning

are recommended after the indicated number of operations.

Table 8 Electrical service life

Parts . name Electrical service life

Vacuum interrupter 100,000 operations or 15 years

Auxiliary switch 100,000 operations or 10 years

Drive unit 100,000 operations or 10 years

Movable conductor 100,000 operations or 15 years

Hence, parts should be replaced around electrical service life operations.

CONTACT SPRING

LEVER

WASHER(M8)

Fig.8 Parts to be inspected

A

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 20

- 20 -

6F9G0154

(2) Mechanical service life

The normally energized type has the mechanical service life of 0.25 million operations ,

and the latch type 0.25 million operations. (The mechanical service life of the vacuum

interrupter is 100,000 operations.)

For the components listed below , replacement or detailed inspection and cleaning are

recommended after the indicated number of operations.

Table 9 Recommended replacement parts

Parts name No. of operation for replacement

Vacuum interrupter 100,000 operations or 15 years

Auxiliary switch 100,000 operations or 10 years

Movable conductor 100,000 operations or 15 years

Latch mechanism 250,000 operations or 10 years

Closing/trip coil 250,000 operations

Movable core Detailed inspection and cleaning

every 100,000 operations.

Stationary core Detailed inspection and cleaning

every 100,000 operations.

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Page 21

- 21 -

6F9G0154

(3) Service life of capacitor

Opening and closing of the capacitor produces sever conditions for contactors,

such as high frequency inrush current and interpole recovery voltage more than

twice the normal voltage.

The criteria of the maximum number of the capacitor current switching operations

is shown in the graph below. The vacuum interrupter should be replaced when the

number of switching operations in the graph is reached.

20 50 100 200 300 400

1

2

3

4

5

10

switching current(A)

switching life

(ten thousand)

Fig.9 Capacitor switching life

(with 6% reactor)

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Loading...

Loading...