Page 1

Page 2

FOREWORD

This publication is intended to aid the electronic technician in servicing the CTC175/176/177

television chassis. It will explain the theory of operation, highlighting new and different

circuits associated with the digitally controlled chassis. This manual focuses on: PIP, TunerOn-Board and System Control circuitry. It is designed to help the technician become more

familiar with the chassis layout, increase confidence and improve overall efficiency in

servicing the product.

Note: This publication is intended to be used only as a training aid. It is not intended to replace

service data. Thomson Consumer Electronics Service Data for these instruments contains

specific information about parts, safety and alignment procedures and must be consulted

before performing any service. The information in this publication is as accurate as possible

at the time of publication. Circuit designs and drawings are subject to change without notice.

SAFETY INFORMATION CAUTION

Safety information is contained in the appropriate Thomson Consumer Electronics Service

Data. All product safety requirements must be compiled with prior to returning the instrument

to the consumer. Servicers who defeat safety features or fail to perform safety checks may be

liable for any resulting damages and may expose themselves and others to possible injury.

All integrated circuits, all surface mounted devices, and many other

semiconductors are electrostatically sensitive and therefore require special handling techniques.

Prepared by

Thomson Consumer Electronics, Inc.

Technical Training Department

600 North Sherman Drive Indianapolis, Indiana 46201

First Edition 9301 - First Printing

Copyright 1993 Thomson Consumer Electronics, Inc.

Trademark(s)® Registered Marca(s) Registrada(s)

Printed in U.S.A.

Page 3

Table of Contents

Overview ............................................................................................................... 5

Power Supply ....................................................................................................... 6

Troubleshooting................................................................................................. 7

CTC175 Power Supply .......................................................................................... 9

Troubleshooting............................................................................................... 10

Standby Supplies.................................................................................................10

Troubleshooting............................................................................................... 10

System Control .................................................................................................. 11

Reset Circuit ........................................................................................................ 12

Data Communications ......................................................................................... 14

Power-On Sequence ........................................................................................... 18

U3201 - EEPROM ............................................................................................... 1 9

Keyboard Interface .............................................................................................. 19

IR Input ................................................................................................................ 19

On Screen Display...............................................................................................19

Closed Caption .................................................................................................... 20

Service Menu....................................................................................................... 21

Alignment Parameters ......................................................................................... 23

System Control .................................................................................................... 25

Troubleshooting............................................................................................... 25

Horizontal Deflection ......................................................................................... 28

Horizontal AFC and APC ..................................................................................... 30

Shutdown Recovery............................................................................................. 31

Troubleshooting............................................................................................... 32

Pincushion Alignments ......................................................................................... 34

Troubleshooting............................................................................................... 34

Horizontal Standby Regulator .............................................................................. 35

Troubleshooting............................................................................................... 35

Vertical ................................................................................................................ 36

Troubleshooting............................................................................................... 38

Page 4

Tuning ................................................................................................................. 39

CTC175/76/77 Tuner ........................................................................................... 40

CTC175 Tuner Isolation Box ............................................................................... 42

Tuner Alignment Generator ................................................................................. 44

Troubleshooting............................................................................................... 46

Tuner Voltage Charts........................................................................................... 48

Video / Audio IF .................................................................................................. 55

IF Alignments ....................................................................................................... 56

Luminance Processing ..................................................................................... 59

Troubleshooting............................................................................................... 60

Chrominance Processing ................................................................................ 61

Troubleshooting............................................................................................... 62

Audio Processing .............................................................................................. 63

Troubleshooting............................................................................................... 64

PIP ....................................................................................................................... 65

User Controls....................................................................................................... 67

Alignments ........................................................................................................... 67

Troubleshooting............................................................................................... 67

Appendix...........................................................................................................72

Index..................................................................................................................76

Self-Test............................................................................................................77

Page 5

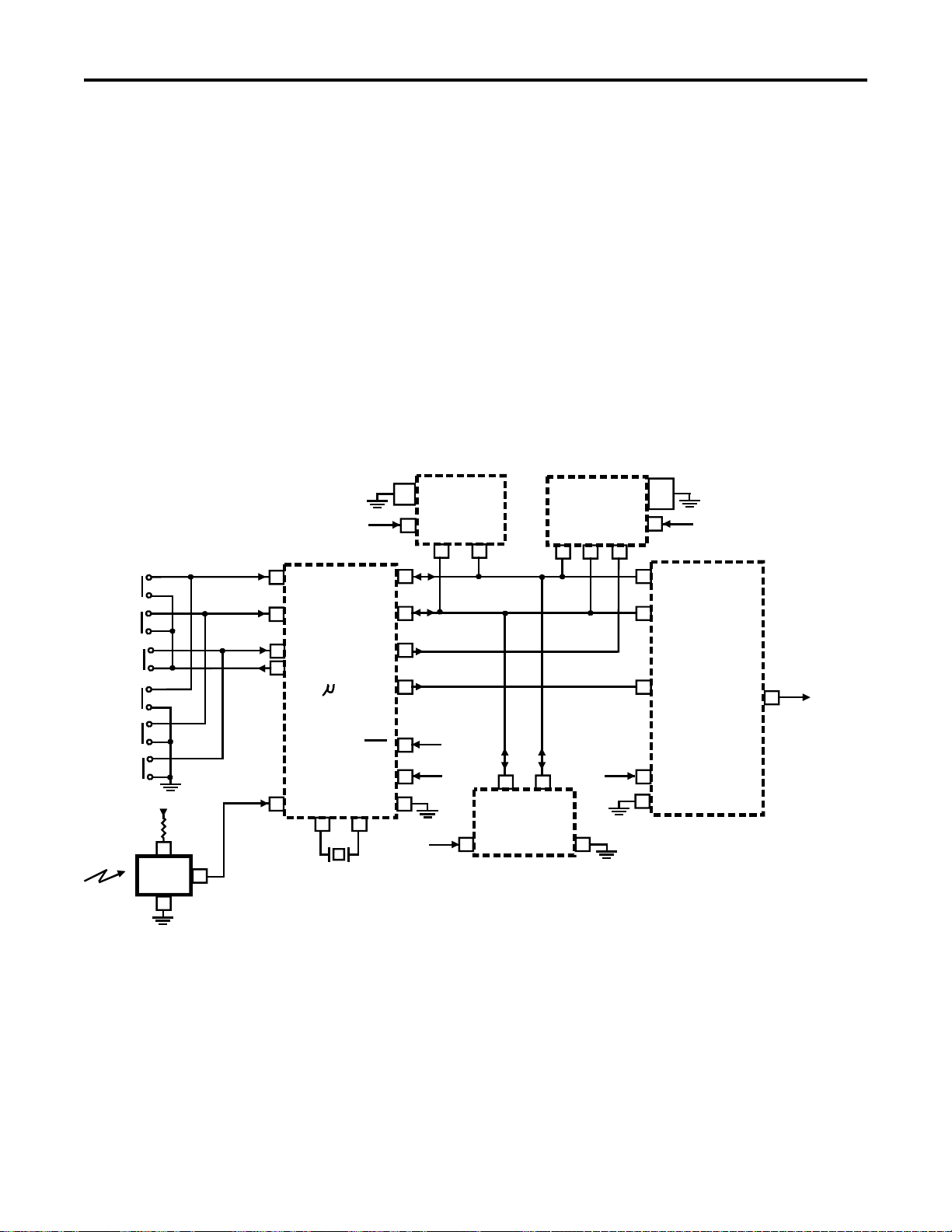

Figure 1, F25190

Page 6

PIP

Tuner

Overview 5

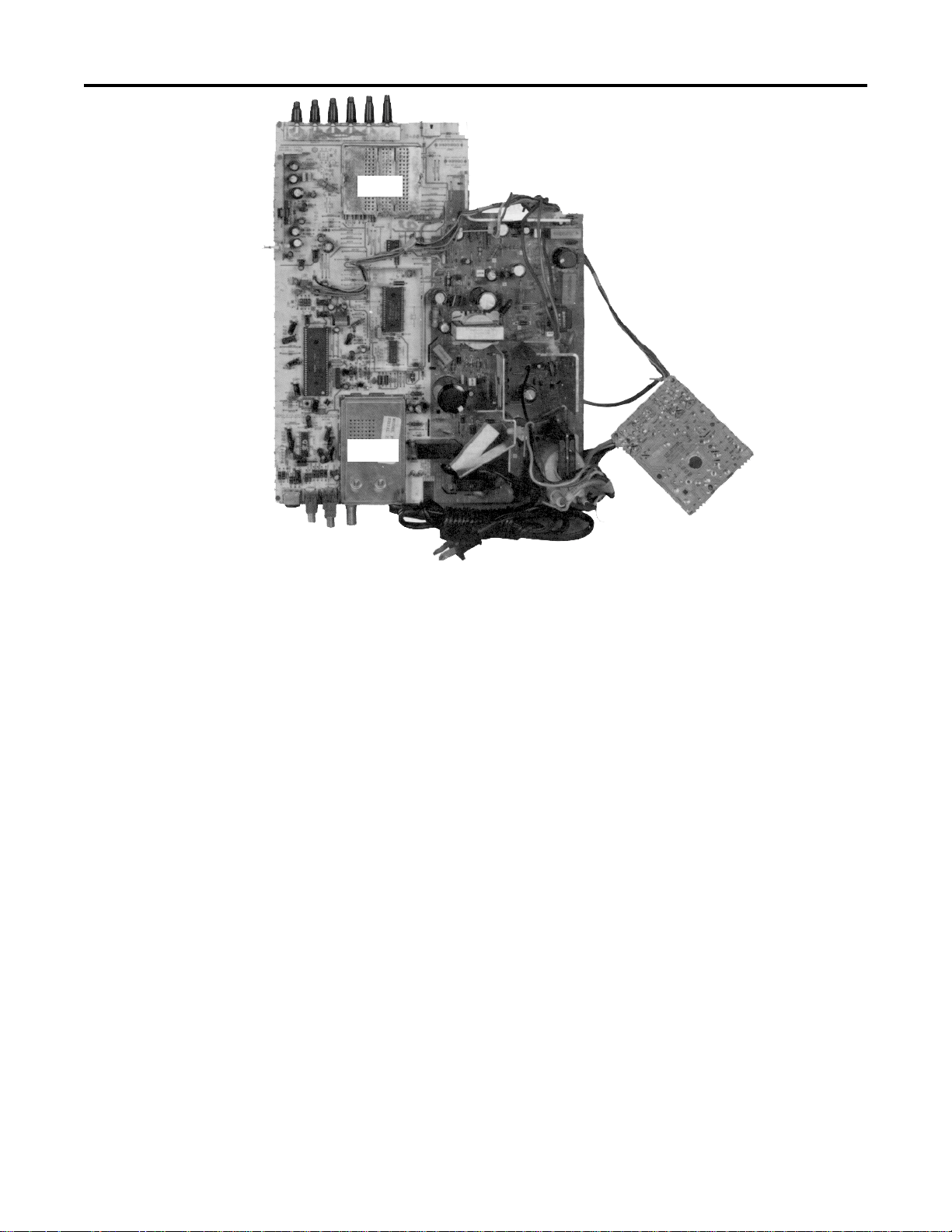

Figure 2, CTC177 Chassis

The CTC175/176/177 chassis is a new concept in television design. All three chassis

are very similar, with the primary differences being features and power supply. The

CTC175 chassis is a hot chassis with a linear regulator. Consequently, this version does

not have audio or video jacks on the back. The CTC176 and CTC177 have a switching

regulator that allows for a cold chassis.

Four innovations are incorporated in these chassis. First, all the alignments are

performed digitally using the remote control. There are no potentiometers on the

chassis. All alignments are stored in the EEPROM. Second, the tuner is located on

the main chassis circuit board. This requires the tuner to be serviced down to the

component level where it used to be a replaceable assembly. Third, the fully featured

models contain a new PIP (picture in picture) circuit. It too is located on the main board

and is much more integrated than similar circuits in the CTC169 chassis. There are only

two IC’s: the PIP processor, U2901 and the SRAM memory, U2902. The increased

integration makes troubleshooting much easier. Fourth, later versions of this chassis

will contain built-in closed caption decoders for the hearing impaired. This circuitry is

primarily contained within the system control microprocessor, U3101, and will require

practically no service from the technician.

OVERVIEW

Different models support 20", 25", 27" and 31" screen sizes. Various option packages

will accompany the different sets. Fully featured sets will have the new PIP circuit with

S-Video In jacks with the standard Video/Audio In/Out jacks. The composite video

jacks are used for the PIP source, as the S-Video is not routed through the PIP circuit.

Stereo audio with HI-FI out jacks are also included as options.

Page 7

6 Power Supply

Power Supply

The CTC176/177 power supply is a variable frequency/variable pulse width

hybrid IC power supply. U4101, the hybrid IC, contains most of the components

including the power switching FET (Field Effect Transistor). The switching

device turns on and off inducing a voltage into the secondary of the transformer.

The lower the frequency, the more energy is transferred to the secondary.

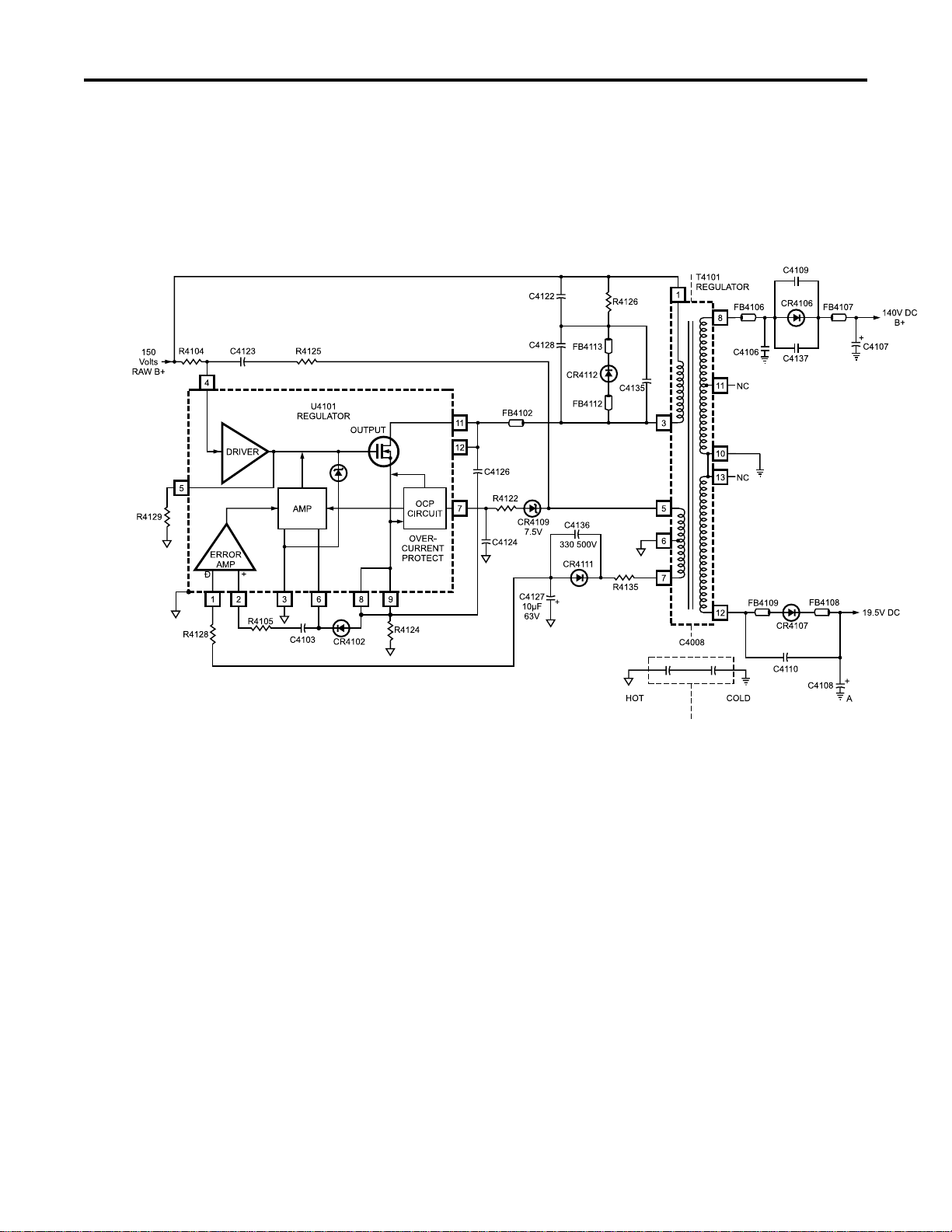

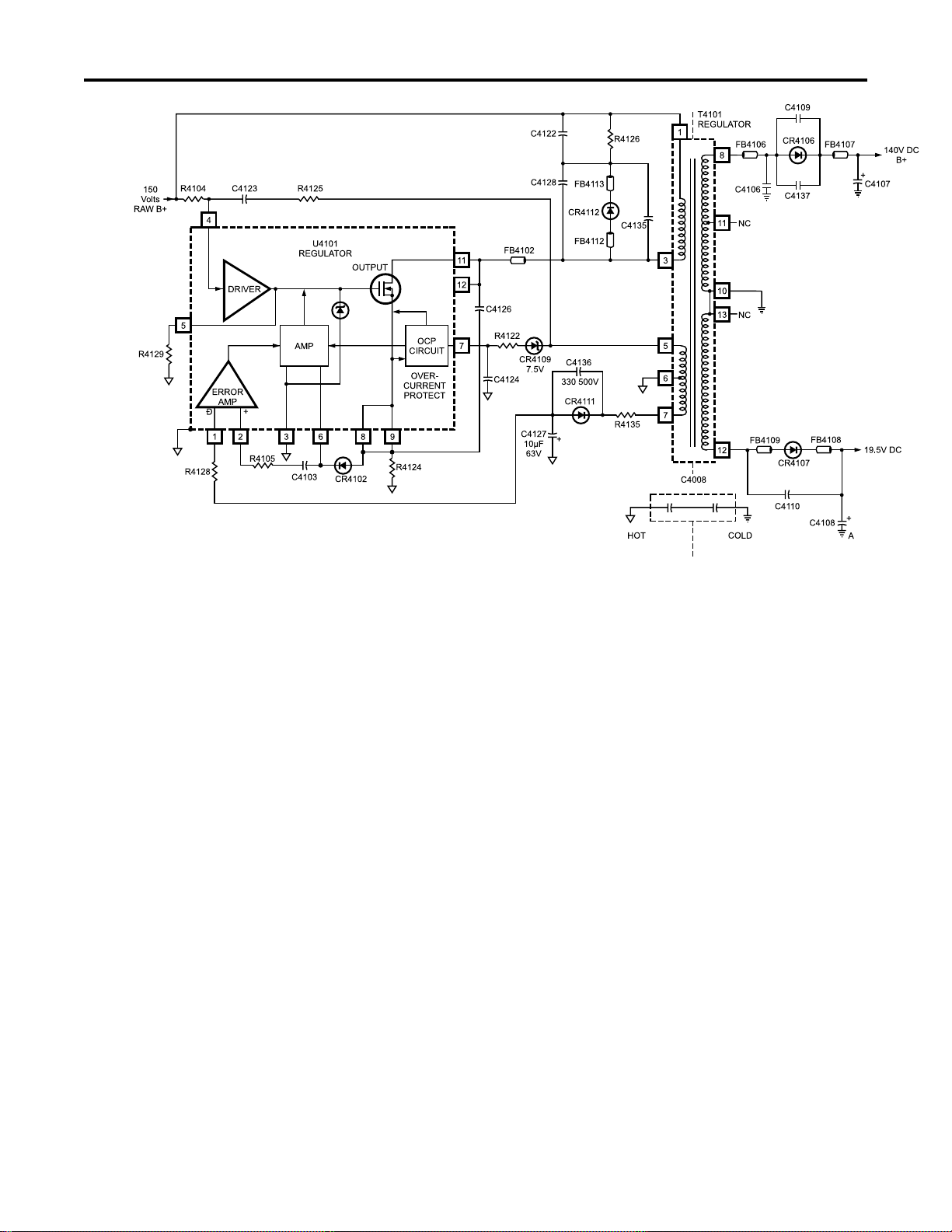

Figure 3, CTC176/177 Power Supply

When power is first applied to the set, approximately 150 VDC raw B+ is

developed by the bridge rectifier (CR4001 - CR4004) and filter capacitor (C4007).

This is applied through the primary winding of T4101 pins 1 and 3 to U4101 pins

11 and 12. Pins 11 and 12 are connected to the drain of the power FET inside

U4101. The source of the power FET is connected to pins 8 and 9. These pins are

connected to ground through R4124. The start-up resistor (R4104) provides

enough bias to gate the FET on through pin 4 of the IC. When the FET is turned

on, the drain current flows through the primary winding of T4101, through the FET

to ground. Current flowing in the primary induces a voltage between pins 5 and

6 of the transformer. This voltage is coupled from pin 5 through R4125 and C4123

to pin 4 of the regulator IC. The polarity of the voltage at pin 4 is such that it turns

the FET on harder. As more current flows through the FET, the greater the voltage

drop across R4124, the FET source resistor. The voltage will eventually become

Page 8

large enough to turn on the over-current protection circuit (OCP) inside U4101.

This will cause the FET to turn off. When the FET turns off, energy transfers to

the secondary windings of T4101 charging C4107 and C4108. This repeats for

several cycles and stable oscillation starts. The frequency of oscillation will vary

with load from approximately 100Khz in standby to 38Khz with a full load (120

watts AC input power).

The feedback winding between pins 5 and 7 on T4101 is tightly coupled to the

secondary windings. The voltage on the feedback winding will follow the voltage

changes on the secondary windings. The voltage developed on pin 7 of T4101 is

rectified by CR4111 and filtered by C4127. This negative voltage is applied to pin

1 of U4101. There is a precision voltage reference inside U4101 trimmed to -40.5

volts +/- .5 volts. The error amplifier tries to make the voltage on pin 1 of U4101

equal to the reference voltage. If the load on the secondaries increases and the

voltage drops, the voltage developed at pin 7 of T4101 would decrease (less

negative). This would allow the FET to stay on longer increasing the output

voltage. In this way, the IC is able to hold the output of the supply constant with

varying line voltages and loads.

If an excessive load is placed on the power supply outputs, the on time of the FET

will increase. This will result in more current through the FET and the source

resistor R4124. The voltage drop will be proportional to the current. This voltage

will charge C4124 and at some point turn on the OCP circuitry in U4101 causing

the FET to turn off. The value of C4124 is critical the OCP trip point.

Power Supply 7

The network composed of C4122, C4128, R4126 and CR4112 is a snubber

network used to reduce the high voltage spike developed when the FET turns off.

C4103 and R4105 are part of a compensation network that stabilize the supply

from parasitic oscillations. R4129 is an ESD (Electrostatic Discharge) protection

resistor for the gate of the FET inside U4101. R4122 and CR4109 help stabilize

the OCP circuit against line voltage variations. Ferrite beads in the circuit are for

RFI (Radio Frequency Interference) emission reduction. C4107, L4102 and

C4105 form a filter network to reduce the ripple in the regulated B+ and reduce

high frequency switching noise.

Troubleshooting

1. Measure the voltage on pin 1 of U4101. It should be -40.5 volts +/- 0.50 volts.

If it is correct, the IC is probably working. If it is not correct, there is most likely

an abnormal load on the power supply. As the output loads increase above the

design ratings, the output voltages and the oscillation frequency will drop. If

the loads are high enough, the frequency of the power supply will be in the

audible range. If there is a short on the secondary of T4101, the supply will shut

down until the short is removed. Under normal conditions, a short on the

secondary will not damage the supply. Under no load conditions, the regulated

B+ will rise and the supply will go into a burst mode where there is a series of

burst pulses.

DIGITAL

Page 9

8 Power Supply

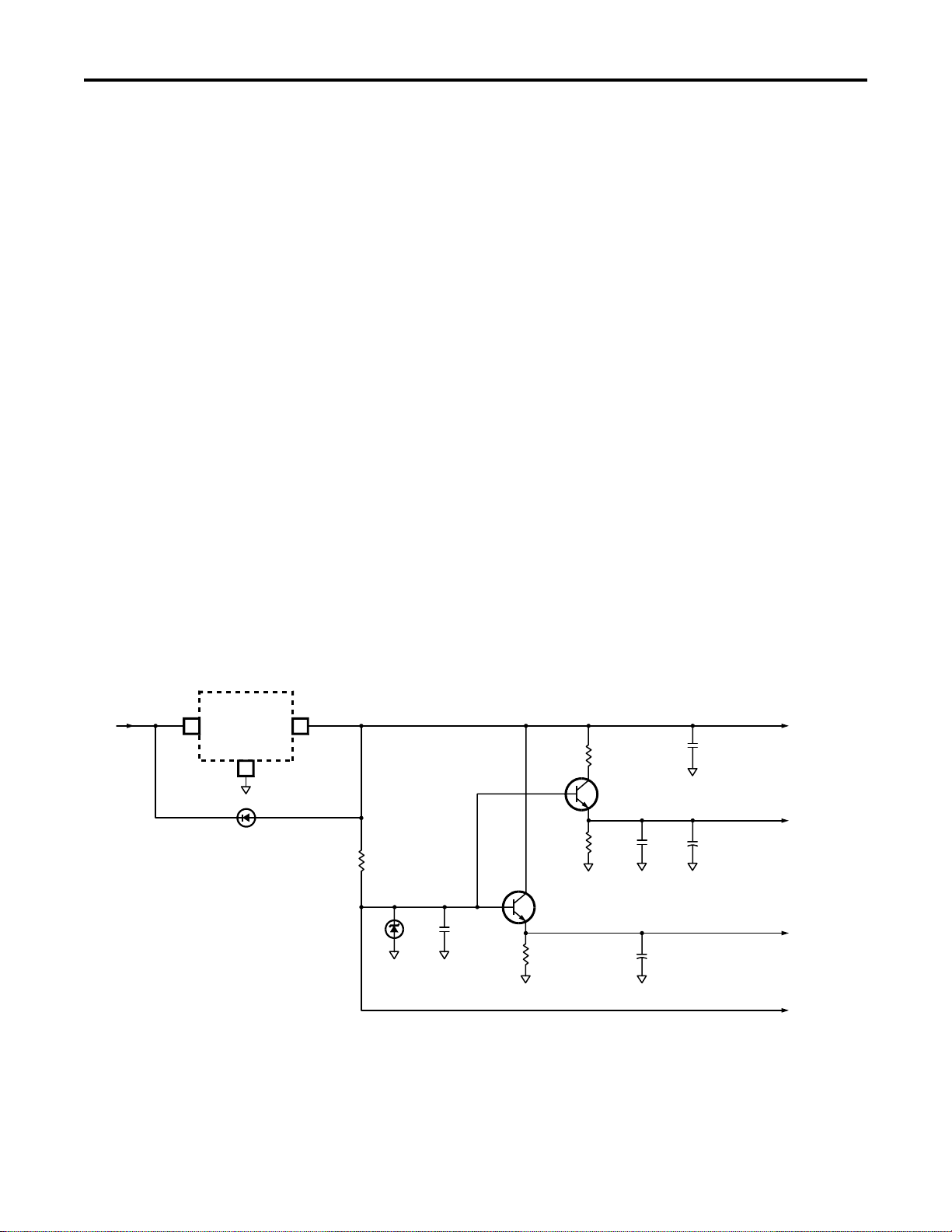

Figure 4, CTC176/177 Power Supply

Note: It is not recommended running the supply with no load. The output

filter capacitors may be stressed by over-voltage.

2. If pin 1 of U4101 is shorted, the regulated 140 volt B+ will be low, approximately

30 volts. If pin 1 is open, the regulated 140 volt B+ will rise to over 200 volts.

3. If F4001 blows, U4101 is most likely shorted.

4. If regulated B+ is too low, suspect an excessive output load, defective T4101

or a shorted C4127.

5. If regulated B+ is too high, suspect a no-load condition on the secondary of

T4101 or an open in the feedback path to pin 1 on U4101.

Note: It is normal for the 140 volt supply to rise 4 or 5 volts in the standby mode.

6. If the supply will not oscillate, suspect a defective U4101, T4101, R4104,

R4125 or C4123.

7. For poor regulation, suspect a defective T4101, U4101, C4103 or R4105.

Page 10

Power Supply

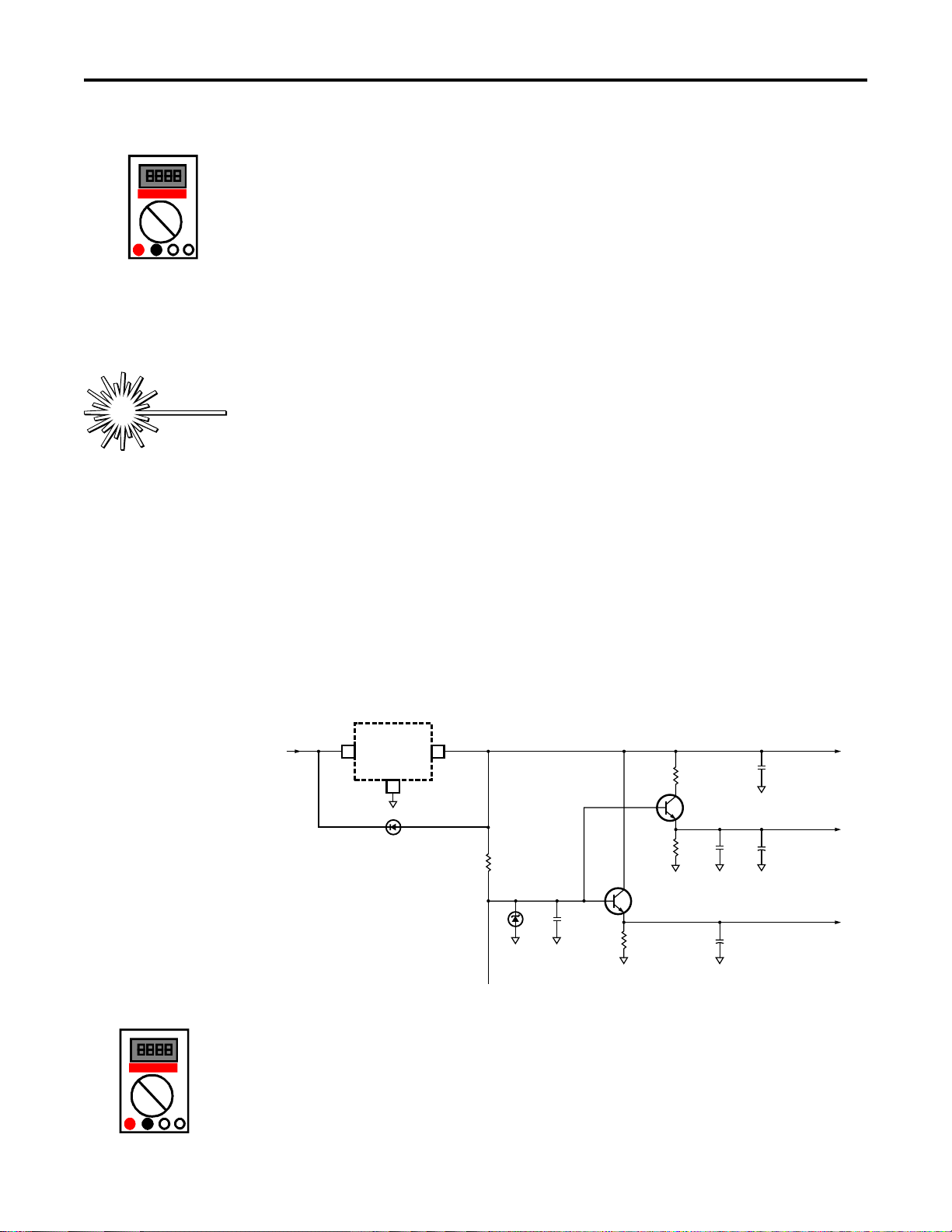

The power supply in the CTC175 is a simple series pass regulator with

microprocessor controllability. 150 volts raw B+ is applied to the collector of

Q4150, an integrated darlington regulator. R4155 passes a portion of the total

current around Q4150 to minimize current dissipation in the transistor. The output

of the regulator is filtered by C4153.

The feedback loop for the supply begins with a voltage divider made up of R4157

and R4158. The divider feeds the input of a comparator at pin 30 of U1001. A

PWM (pulse width modulated) output from pin 28 of U1001 feeds Q4153

inverting the control voltage to the base of Q4151. Q4151 controls the base bias

of Q4150. As a load increases on the 140B+ supply, the voltage to pin 30 drops,

causing the PWM output from pin 28 of U1001 to increase, forward biasing Q4153

harder. This in turn reduces the base bias to Q4151 increasing the forward bias on

Q4150, increasing the B+ output of the power supply.

The PWM circuit inside U1001 is also affected by beam current via the size

compensation input pin 16 which is also used in the vertical circuit to minimize

raster blooming (see vertical circuit). This helps stabilize the linear regulator

during heavy beam current transitions. As beam current increases, regulator

output decreases.

Power Supply 9

TANDBY

B+

U4102

2

CR4103

31

+5V STBY

REGULATORS

R4111

CR4104

5.6V

C4114

Figure 5, CTC175 Power Supply

Q4105

R4112

R4103

Q4103

R4108 C4111 C4118

+

C4112

C4104

+

+12V STBY

+5V STBY2

+5V STBY1

+5V REF

Page 11

10 Power Supply

Troubleshooting

DIGITAL

Failures of the linear regulator can be difficult to detect if the AC line voltage is

constant. Using a variac to check proper regulation is the best approach. If the

regulator circuit is suspected of being defective, perform the following steps:

1. Apply 105 to 130 VAC to the TV and check the 140 B+ output. If the B+ is

not 140 volts, enter the service alignments and attempt to raise and lower the

B+ with the digital B+ Trim adjustment (parameter #18). If the adjustment

has no effect, go to the next step. If the 140 B+ can be set, the circuit is most

likely functioning correctly.

2. Monitor the collector voltages on Q4153 and Q4151. The voltages should

increase and decrease inversely as the B+ trim adjustment is performed. If this

is not the case, suspect Q4153 or Q4151. If the voltage varies with the

alignment, but the B+ does not change, suspect a defective Q4150.

TECH

TIP

Standby

Supplies

Note: A shorted horizontal output, Q4401, will most likely cause Q4150 to

short. Always check Q4150 after replacing a defective Q4401.

The standby supplies provide a Standby 12 volt supply, two Standby 5 volt

supplies and one 5.6 volt reference supply. Approximately 20 volts, from the

switching supply on the CTC176/177 or the standby bridge rectifier on the

CTC175, is applied to pin 1 of U4102, a three-legged 12 volt regulator. The output

on pin 3 serves as the 12 volt standby supply. The 12 volt supply is also applied

to the cathode of CR4104, a 5.6 volt zener diode, that sets up the base bias for

Q4103 and Q4105. A portion of the 12 volts is sent to the collectors of the same

transistors for the voltage source. The voltage drop across of the base emitter

junction of the transistors produces the 5 volt supplies on their emitters.

STANDBY

B+

U4102

2

CR4103

31

R4103

Q4103

R4108 C4111 C4118

R4 111

+5V STBY

REGULATORS

+12V STBY

C4104

+5V STBY2

+

DIGITAL

CR4104

5.6V

C4114

Q4105

R4112

+5V STBY1

+

C4112

+5V REF

Figure 6, Standby Supplies

Troubleshooting

1. Check the 12 volt supply on pin three of U4102.

2. Check the 5.6 volt reference on the cathode of CR4104.

3. Check the 5 volt standby 1 and 2 supplies on the emitter of Q4105 and Q4103

respectively.

Page 12

System Control 11

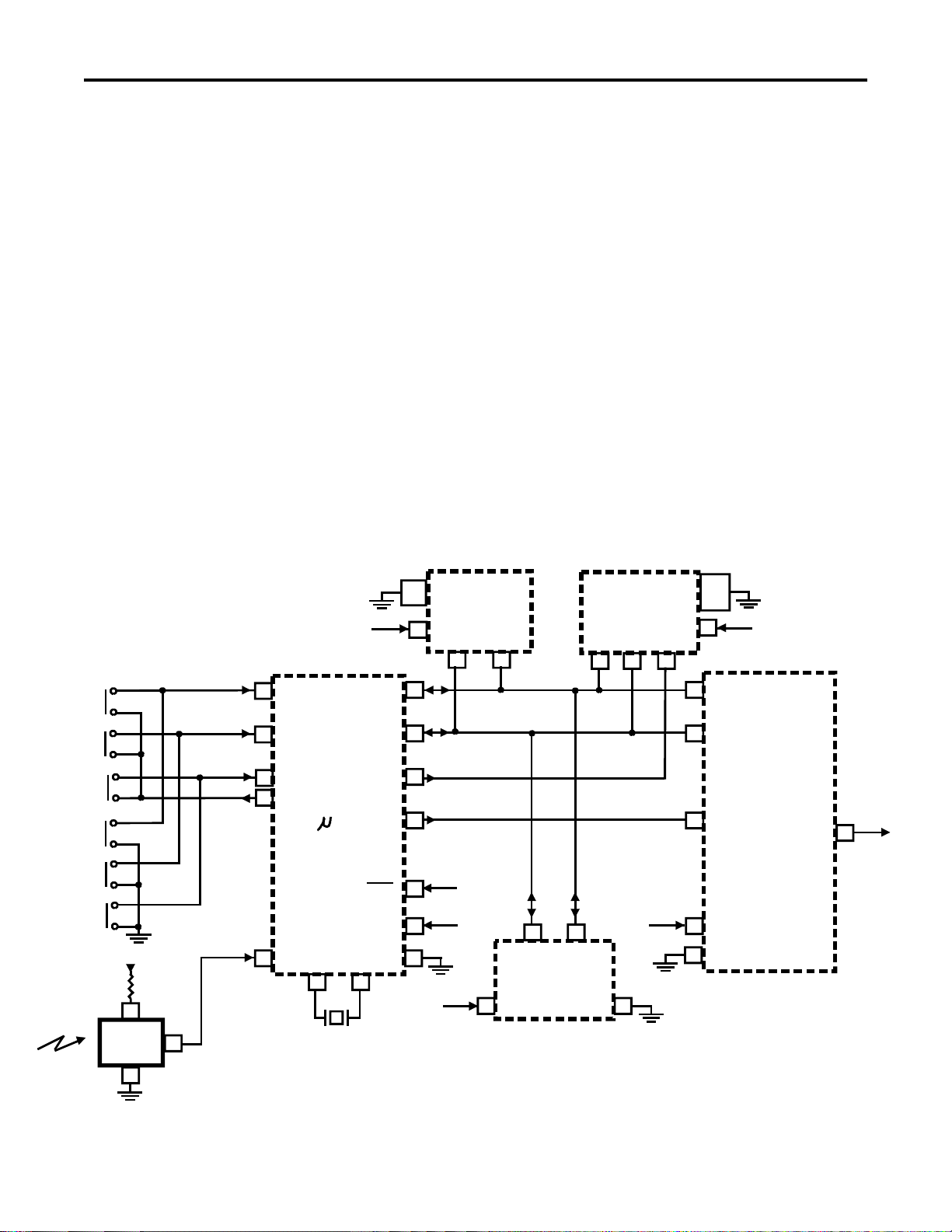

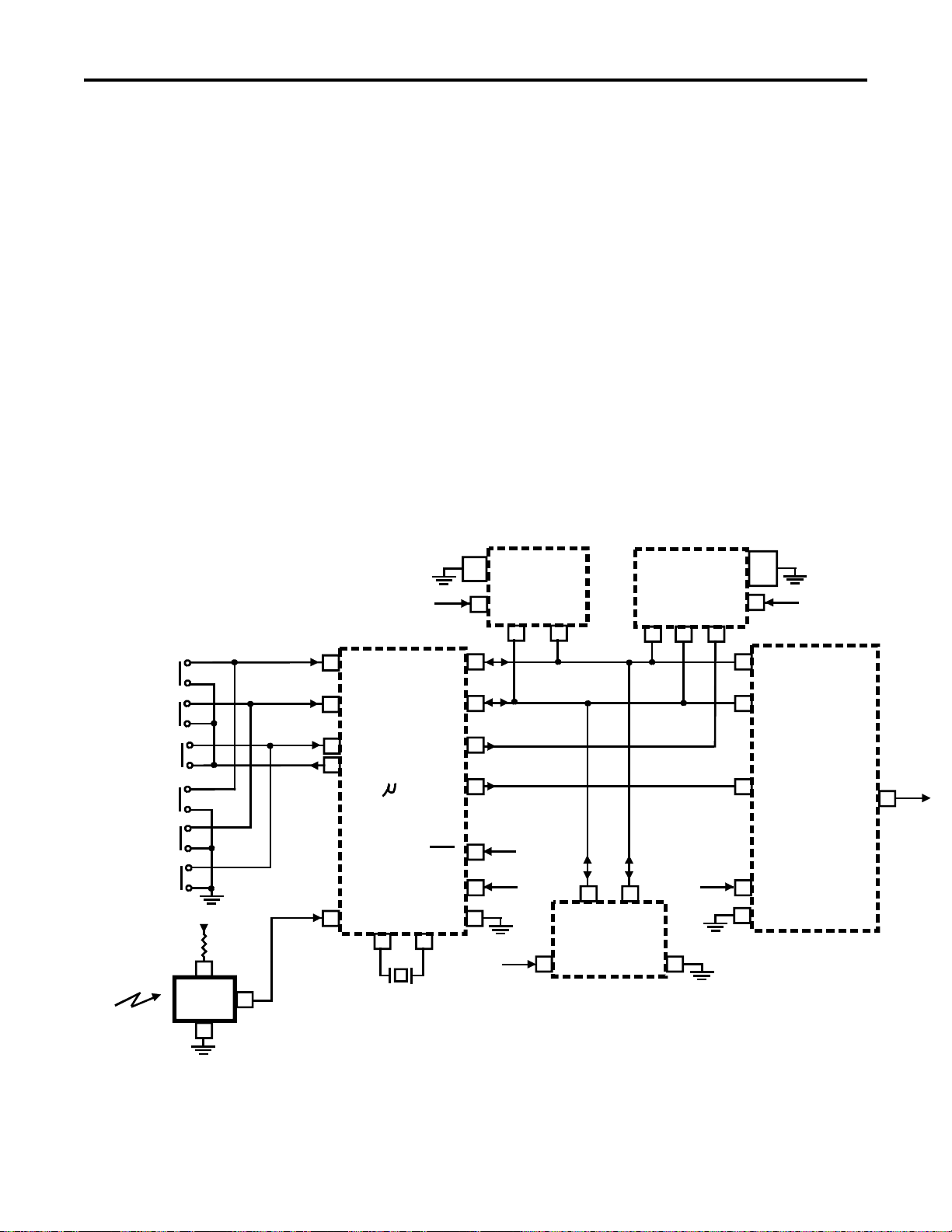

The CTC177 chassis family is a digitally controlled television receiver. The system

control circuit governs the entire television. The control circuits are not only

responsible for turning the set on and off, but also for aligning the different circuits

such as deflection and signal. Adjustments once made by adjusting a potentiometer

or coil are now performed by reading and writing data to the EEPROM (Electrically

Erasable Programmable Read Only Memory) using an on-screen menu and the

television’s remote control.

A newly developed television processing IC, called the T-Chip (Thomson Chip),

exchanges information with the system control microprocessor over the serial data

bus. This communication is carried out over a three wire bus utilizing the new T-Bus

(Thomson Bus) protocol. The T-Chip implements a new level of integration by

housing more circuitry than ever before, and reducing the number of external

peripheral components.

The system control microprocessor can decode Line 21 closed caption information

and display the text on the screen. When implemented, the customer will be able to

selectively view the text on closed captioned encoded programs.

System

Control

POWER

VOL. UP

VOL. DN.

CH. UP

CH. DN.

MENU

5V

2

IR3401

1,2,3

4,7

GND

U3201

EEPROM

5V

KS1

6

KS2

7

KS3

8

KD1

5

3

1

T-CHIP DATA

TUNER CLOCK

T-CHIP CLOCK

TUNER DATA

U3101

P

OSC

OUT

41 42

Y3101

ENABLE

T-CHIP

ENABLE

RESET

OSC

IN

PIP

VDD

GND

8

15

16

12

14

1

20

21

5V

VDD

DATA CLOCK

56

5V

5V

10

4

DATA CLOCK

U7401

TUNER PLL

VCC

U2901

D-PIP

DATA CLOCK ENABLE

20 21

7.6 V

STBY

5

GND

13

22

GND

VDD

54

53

52

22

56

3,5

15,16

40,41

39

DATA

CLOCK

ENABLE

BUS

GND

5V

U1001

T-CHIP

HORZ.

OUT

24

3

Figure 7, System Control Block Diagram

Page 13

12 System Control

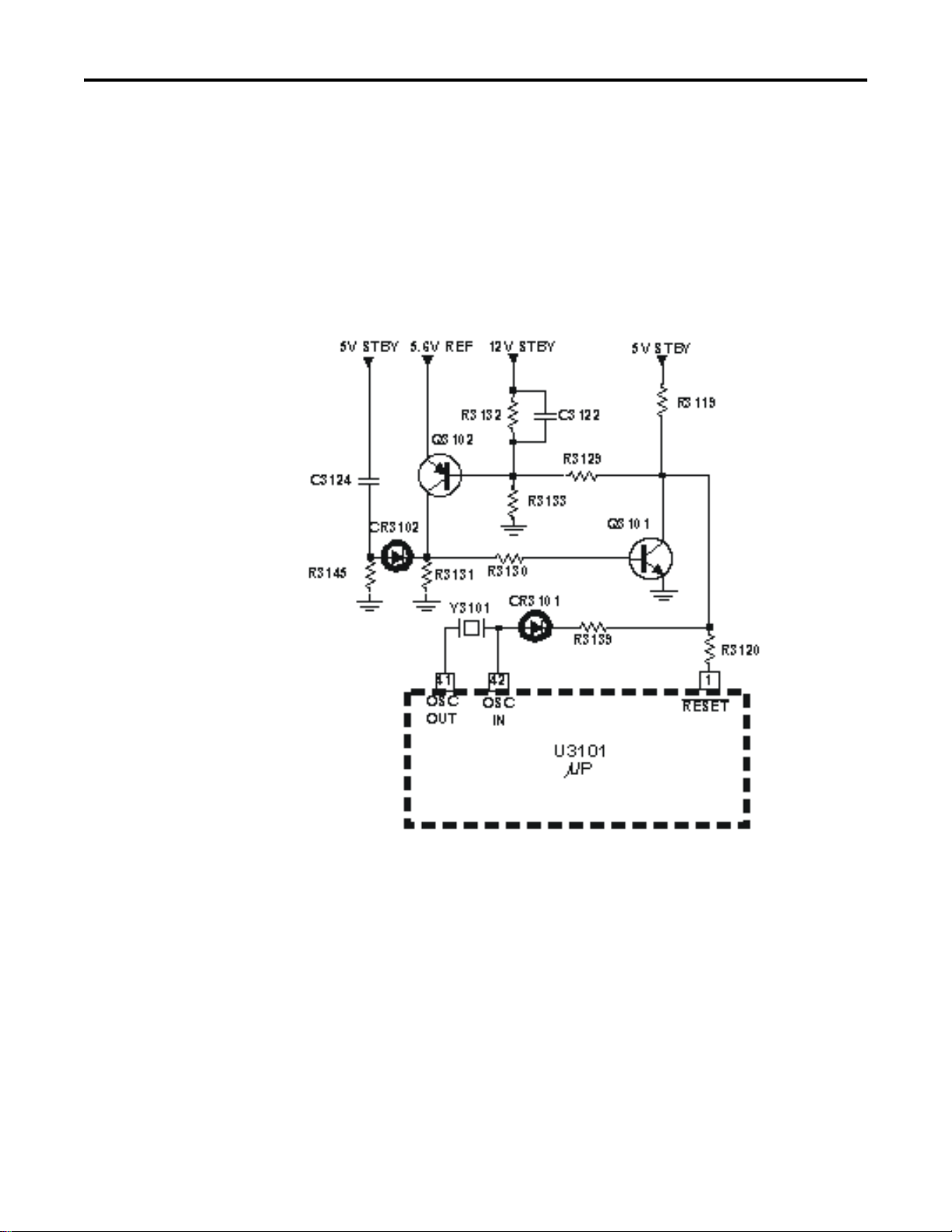

Reset Circuit

The reset circuit starts the microprocessor at a known place in its program. U3101 reset

is an active low to pin 1. When AC power is first applied, the reset circuit goes high

after approximately 55msec. This allows the crystal oscillator time to come up and

stabilize before allowing the microprocessor to run. The reset circuit also monitors the

condition of the 12 volt standby supply. If the 12 volt standby supply drops below 10

volts, the reset circuit activates and puts the microprocessor in a low power mode.

Figure 8, Reset Circuit

A stable 5.6 volt reference is applied to the emitter of Q3102. The 12 volt standby

supply is divided by R3132 and R3133 so approximately 6 volts is applied to the base

of Q3102. The collector of Q3102 is tied to the base of Q3101. The collector of Q3101

is connected to the 5 volt standby supply and to the reset pin 1 of U3101. Under normal

operating conditions, the voltage on the base of Q3102 is at 6 volts which is high

enough to keep Q3102 off. If the 12 volt standby supply drops far enough to allow the

voltage on the base of Q3102 to drop to 5 volts, Q3102 will turn on. When Q3102 turns

Page 14

on, Q3101 will also turn on and disable the 5 volt reset line to ground initiating a reset

to U3101. Q3101 also disables the crystal oscillator by grounding it through R3139

and CR3101. This places the microprocessor in a low power mode to maintain the nonvolatile memory.

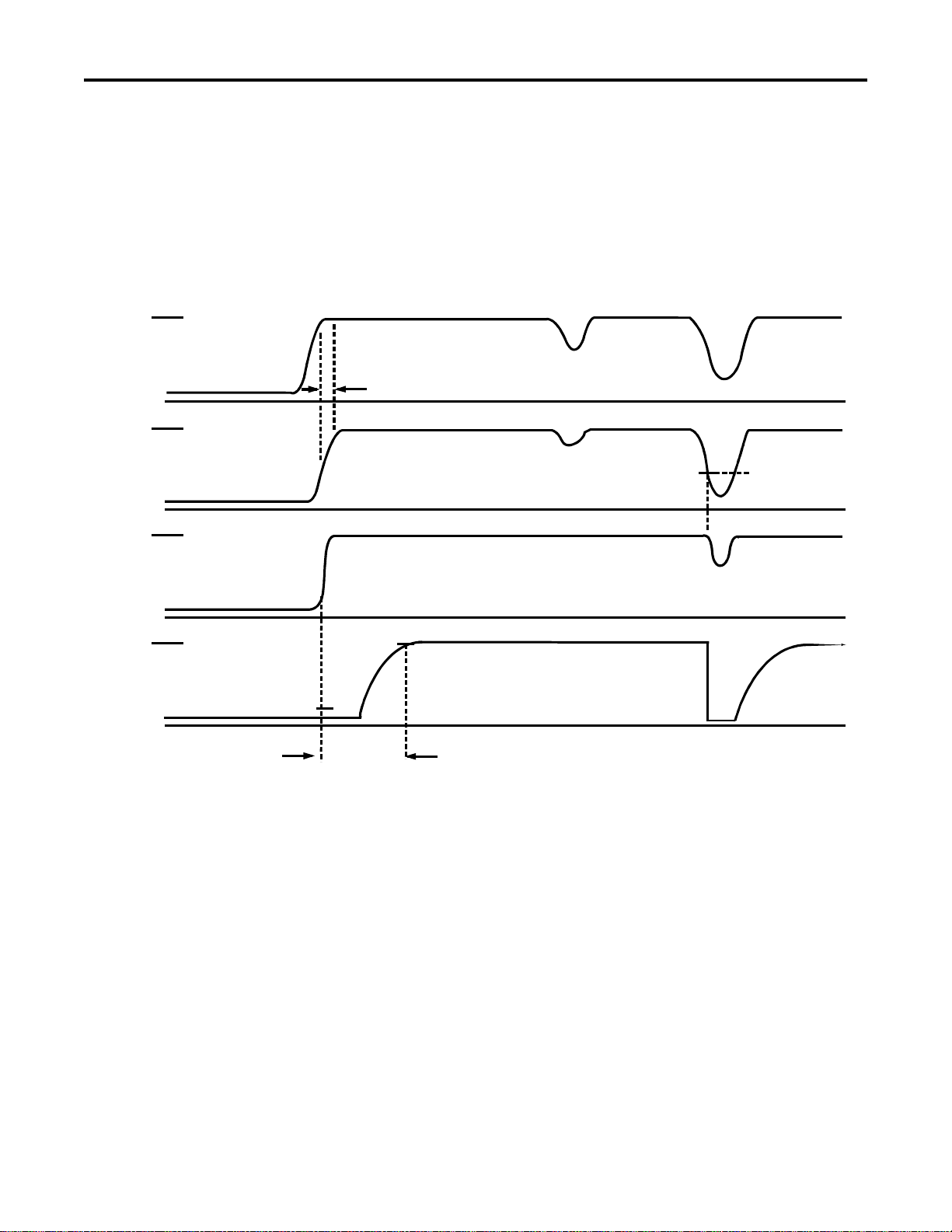

120V

System Control 13

120VAC

12V

2V STBY

5V

5V STBY #1

5V

RESET

(ACTIVE = 0)

10 mSEC APPROX.

5V

55 mSEC APPROX.

Figure 9, Reset Circuit Timing

Page 15

14 System Control

Data

Communications

POWER

VOL. UP

VOL. DN.

CH. UP

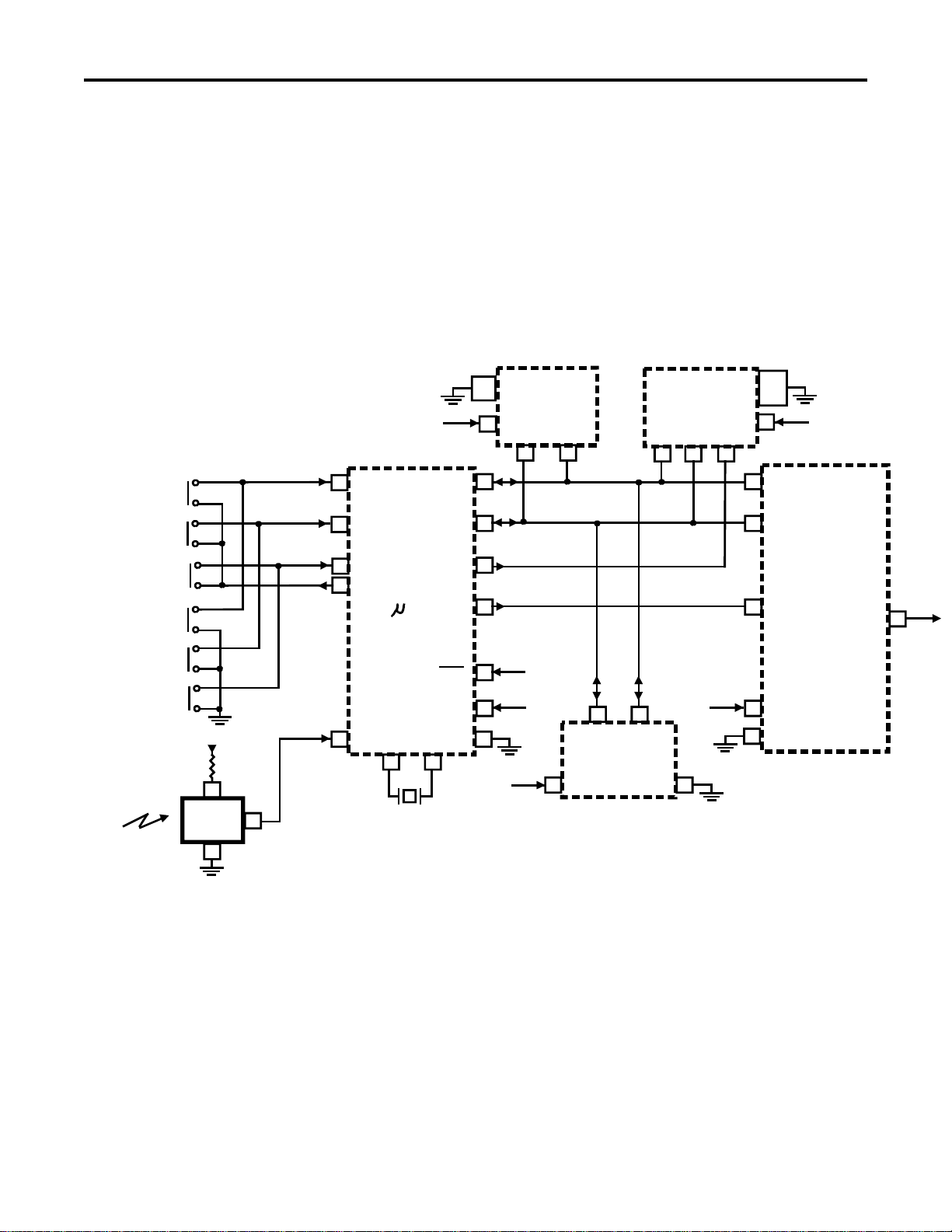

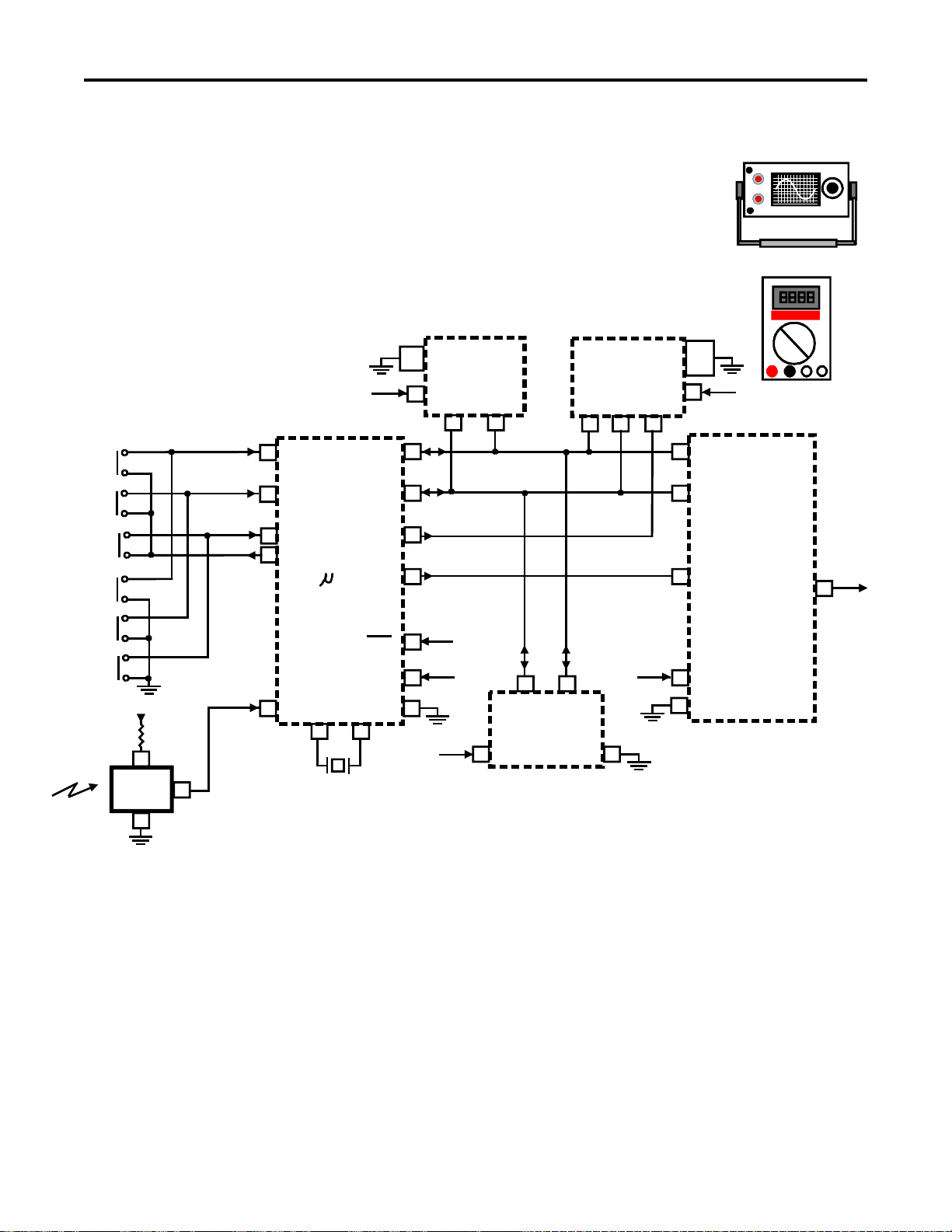

Five IC’s make up the system control circuit: U3101, main microprocessor; U1001,

T-Chip; U2901, D-PIP microprocessor; U3201, EEPROM; and U7401, tuner PLL(Phase

Lock Loop). These IC’s communicate with U3101 via serial data lines. The format

used to communicate is called “bus protocol.” Three bus protocols are used in this

system: IM Bus, I

2

C Bus and the T-Bus. While it is not necessary for the technician

to completely understand the individual protocols for troubleshooting the system

control circuits, knowing what type of information is exchanged and what IC pins are

involved will make troubleshooting more efficient and effective. All circuits in the

CTC177 chassis family interface with the system control circuit in one form or another.

It is important to decide whether the circuit itself is at fault or if the system control

circuit is the problem.

1,2,3

4,7

GND

U3201

EEPROM

5V

KS1

6

KS2

7

KS3

8

KD1

5

T-CHIP DATA

TUNER CLOCK

T-CHIP CL OCK

TUNER DATA

U3101

P

PIP

ENABLE

T-CHIP

ENABLE

15

16

12

14

VDD

8

DATA CLOCK

56

U2901

D-PIP

DATA CLOCK ENABLE

20 21

22

GND

VDD

54

53

52

3,5

15,16

40,41

39

DATA

CLOCK

ENABLE

5V

U1001

T-CHIP

HORZ.

OUT

24

CH. DN.

MENU

5V

2

IR3401

3

RESET

VDD

20

OSC

OSC

3

OUT

41 42

1

Y3101

GND

IN

21

5V

1

5V

4

DATA CLOCK

U7401

7.6 V

STBY

5

22

56

BUS

GND

TUNER PLL

5V

10

VCC

GND

13

Figure 10, System Control Circuit (repeated)

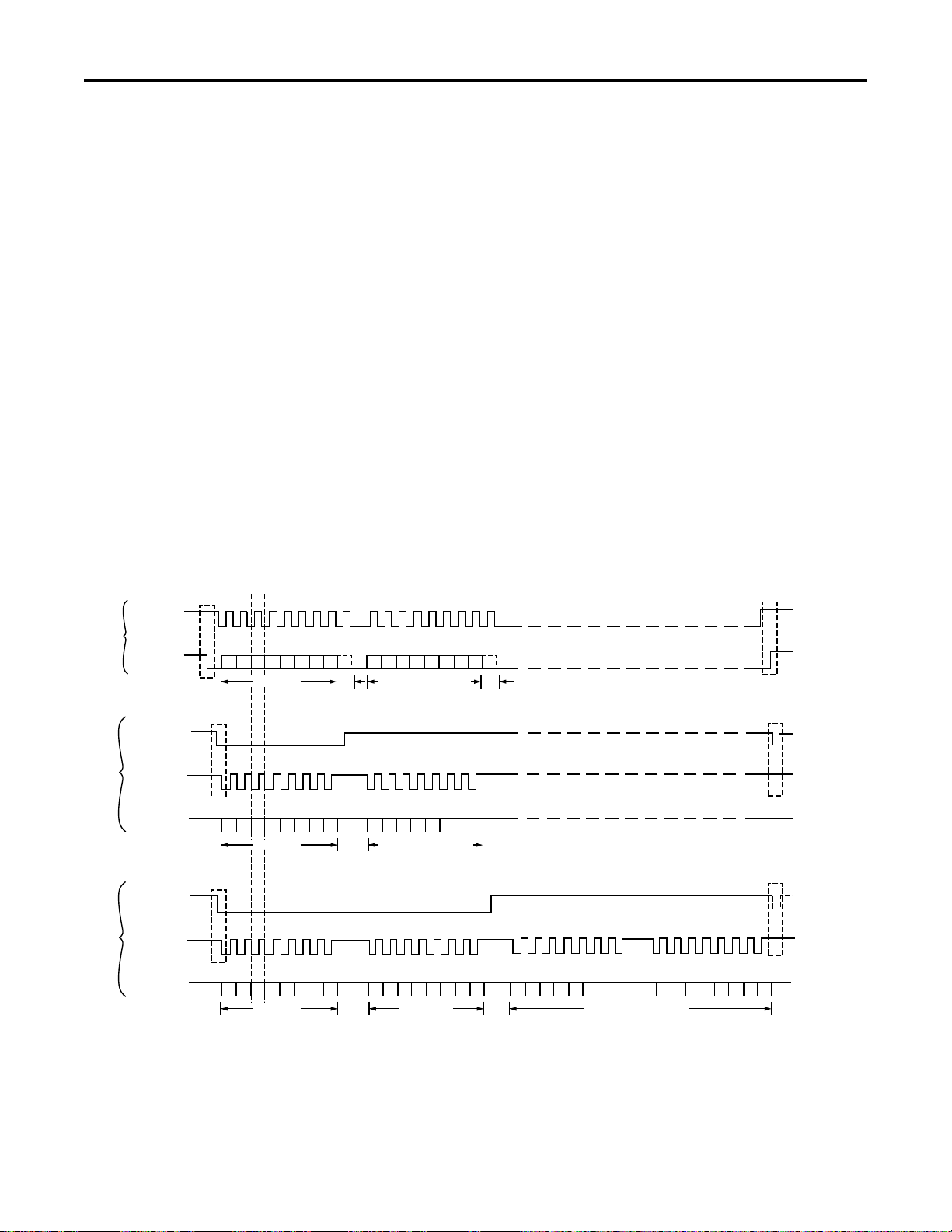

IM Bus

The IM Bus is a three wire bus U3101 uses to communicate with the D-PIP

microprocessor. Pins 15, 16 and 12 on U3101 are the IM Bus Data, Clock and PIP

Enable lines. These are connected to pins 20, 21 and 22 respectively on U2901, the

D-PIP microprocessor. When the PIP Enable line goes low, eight bits of address data

synchronized to clock transitions are sent. Next, the Enable line goes high followed

by eight bits of “Write” or “Read” information. The Enable line then momentarily goes

low to signal the end of the transaction. Because the PIP Enable line and data protocol

are unique to the PIP microprocessor, other devices that share the data and clock lines

are unaffected by communications between U3101 and U2901.

Page 16

2

I

C Bus

The I2C Bus is a two wire bus U3101 uses to communicate with the tuner PLL, U7401

and EEPROM, U3201. Pins 15 and 16 of U3101 are the clock and data lines for the

I2C Bus. Notice this is reversed compared to the IM Bus. These pins are connected

to pins 6 and 5 of U3201 and pins 5 and 4 of U7401 respectively. Data transfers are

signaled when the data line goes LOW while the clock is HI. Eight bits of address data

followed by an acknowledge bit are sent. Next, eight bits of Read/Write data followed

by an acknowledge bit are sent. Because the data protocols are unique and the enable

lines are not used, only I2C Bus devices respond to I2C Bus commands.

T-Bus

The T-Bus protocol is a three wire bus enabling U3101 to communicate with U1001.

This bi-directional bus allows the microprocessor to control the operations within

U1001 and allows U1001 to report operation status back.

System Control 15

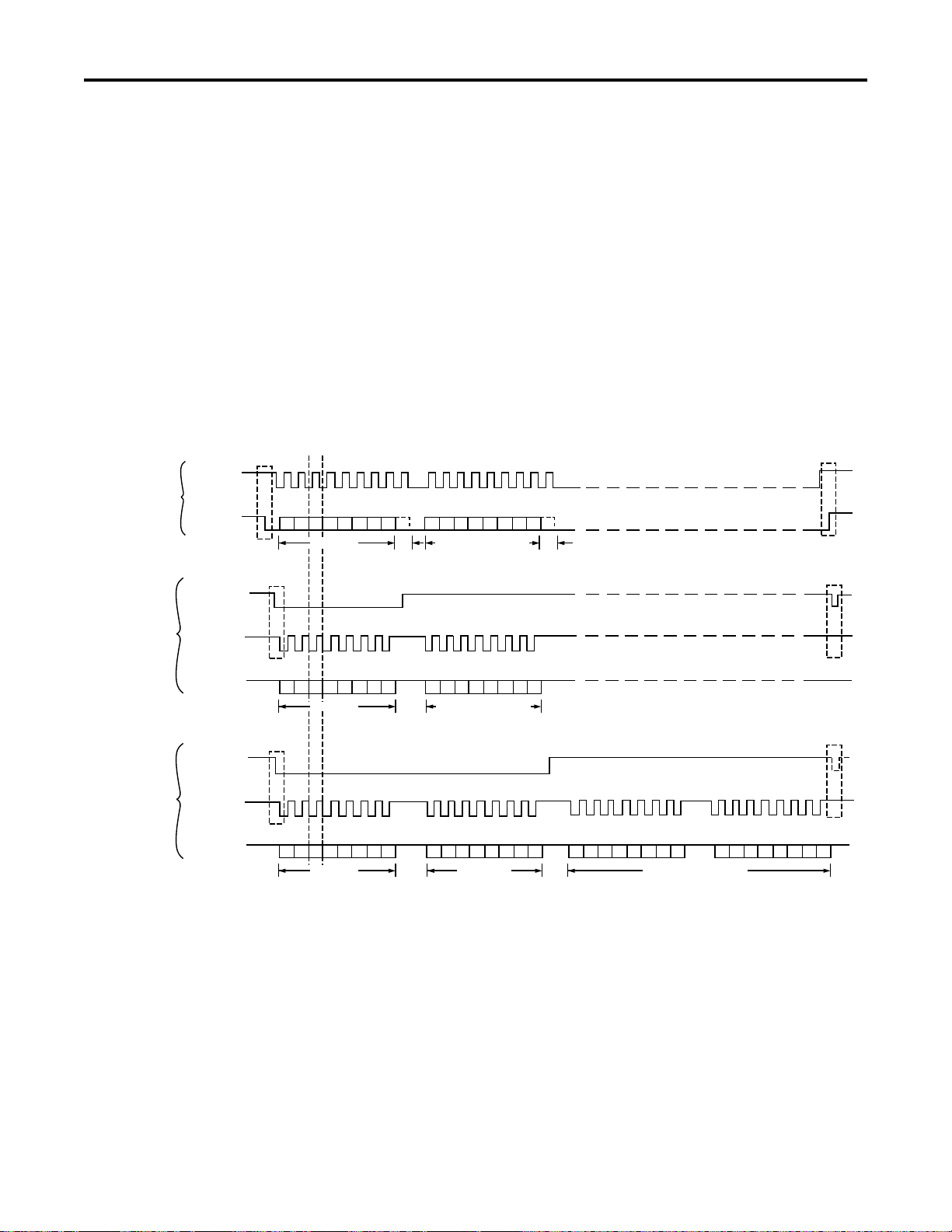

I2 C

BUS

IM

BUS

THOMSON

BUS

CLOCK

(SCL)

DATA

(SDA)

ENABLE

CLOCK

DATA

ENABLE

CLOCK

DATA

START

123456789

ADDRESS

START

12345678

ADDRESS

START

12345678

ADDRESS

123456789

ACK “WRITE” OR “READ” DATA

12345678

“WRITE” OR “READ” DATA

12345678

“WRITE” DATA

(OPTIONAL DATA BYTES)

ACK

(OPTIONAL DATA BYTES)

12345678 12345678

“READ” DATA (2 BYTES)

STOP

STOP

OPTIONAL

STOP

Figure 11, Bus Protocols

Page 17

16 System Control

Two distinct sections of a T-Bus transaction are called Read and Write. During the

Write portion, the microprocessor drives the DATA line to send new register

information to U1001. During the Read portion, U1001 drives the DATA line to

transfer status information to the microprocessor, U3101.

The Write portion of the transaction is 16 bits long consisting of an IC Address (4 bits),

Subaddress (5 bits) and Data field (7 bits). The Address identifies U1001. The

Subaddress indicates the register inside U1001 and the Data is the value of the

information being sent to U1001 by U3101. The Write portion of the transaction

begins when U3101 pulls the ENABLE line low. Once the ENABLE line is low, the

microprocessor must drive the DATA line one bit at a time while toggling the clock

line. U1001 accepts data on the rising edge of the clock pulse.

I2 C

BUS

IM

BUS

THOMSON

BUS

CLOCK

(SCL)

DATA

(SDA)

ENABLE

CLOCK

DATA

ENABLE

CLOCK

DATA

START

123456789

ADDRESS

START

12345678

ADDRESS

START

12345678

ADDRESS

123456789

ACK “WRITE” OR “READ” DATA

12345678

“WRITE” OR “READ” DATA

12345678

“WRITE” DATA

(OPTIONAL DATA BYTES)

ACK

(OPTIONAL DATA BYTES)

12345678 12345678

“READ” DATA (2 BYTES)

STOP

STOP

OPTIONAL

STOP

Figure 12, Bus Protocols (repeated)

After the Write portion of the transaction is completed, the Read portion begins. The

Read portion is the answer back to U3101 from U1001. It too is 16 bits long consisting

of Acknowledge (4 bits), Status (4 bits) and Data (8 bits). The Acknowledge bits let

U3101 know it did in fact access U1001. The Status bits S0 through S3 inform U3101

of operating conditions in U1001:

Page 18

S0 - Power-ON-Reset (POR)

S1 - X-ray Protection Fault (XRP)

S2 - Horizontal Lock Detector

S3 - Delayed Transfer Complete (BID)

The last 8 bits of the Read portion contain the Digital AFT information from the IF.

This information is only looked at during channel change.

POR (Power-ON-Reset)

U1001 has a standby power monitor called POR. This circuit detects when the Standby

Vcc has dropped below approximately 6 volts and shuts the IC off by stopping both

the PWM and horizontal outputs. The output of the POR circuit is available to U3101

as one bit every T-Bus transaction.

The POR circuit output is latched and reset on the OFF to ON transition of the ON/

OFF bit. This means when the TV is ON and a standby transient occurs that triggers

the POR circuit, it is necessary to send an OFF command followed by an ON command

to get the set started again. If the Standby Vcc is still too low when an ON command

is received, the IC will stay in the OFF mode requiring the process to be repeated.

System Control 17

XRP

The XRP bit in the status portion of the T-Bus transaction informs U3101 if an XRP

condition has occurred. When the XRP input is above the reference value, the

comparator’s output will turn the TV off by stopping both the PWM and Horizontal

outputs.

The XRP bit is latched internally and gets reset at the ON to OFF transition of the ON/

OFF bit. This means to restart the TV after an XRP trip, the microprocessor must first

send an OFF command followed by an ON command.

When the ON/OFF bit is in the OFF state, the XRP latch is disabled internally. This

means for U3101 to read the valid state of the XRP detector, it is necessary for the ON/

OFF bit to be in the ON state.

Horizontal Lock Detector

This detector compares the position of the flyback pulse with the sync of the selected

video source. This output is available to the microprocessor as a bit on the Read portion

of every T-Bus transaction. While this detector can be used to detect the presence of

an active channel, it is not used for tuning. A separate sync pulse input is applied to

pin 39 of U3101 for that purpose.

The horizontal lock detector is used for detecting whether or not an active video source

is connected to the composite or s-video input jacks. When s-video or composite video

is selected, U3101 selects the video source and looks at the horizontal lock bit. If lock

is detected, the source appears on the screen. If no lock is detected, U3101 displays

“UNUSABLE SIGNAL” on the screen.

Page 19

18 System Control

The horizontal lock bit also informs U3101 whether or not to select s-video or

composite video. When “00” is entered to select a video source, U3101 first selects

s-video and checks for a lock. If no lock occurs, composite video is selected.

Delayed Transfer Mode (BID)

This bit is used in transferring of data to the T-Chip registers. It is currently not used.

Power-On

Sequence

POWER

VOL. UP

VOL. DN.

CH. UP

U3101 does not have a single on/off control pin to turn the television on or off as in

previous chassis. The T-Chip is controlled entirely via the serial bus. Power on/off

commands are accomplished by U3101 telling U1001 to turn on horizontal drive by

means of a data command. U1001 contains its own standby 7.6 volt regulator to keep

data communications alive and the horizontal drive stage operative while the set is off

(Standby Mode). When the On command is received and horizontal drive is

established, run supplies come up and bias the rest of U1001’s circuits bringing the set

into the full on mode. An Off command from U3101 will cause horizontal drive to

cease resulting in the scan derived supplies turning off. This removes power to the

other circuits associated with U1001, placing the set in the standby mode.

1,2,3

4,7

GND

U3201

EEPROM

5V

KS1

6

KS2

7

KS3

8

KD1

5

T-CHIP DATA

TUNER CLOCK

T-CHIP CLOCK

TUNER DATA

U3101

P

PIP

ENABLE

T-CHIP

ENABLE

14

15

16

12

VDD

8

DATA CLOCK

56

U2901

D-PIP

DATA CLOCK ENABLE

20 21

22

GND

VDD

54

53

52

3,5

15,16

40,41

39

DATA

CLOCK

ENABLE

5V

U1001

T-CHIP

HORZ.

OUT

24

CH. DN.

MENU

5V

2

IR3401

3

RESET

VDD

20

OSC

OSC

3

OUT

41 42

1

Y3101

GND

IN

21

5V

1

5V

4

DATA CLOCK

U7401

7.6 V

STBY

5

56

22

BUS

GND

TUNER PLL

5V

10

VCC

GND

13

Figure 13, System Control Circuit (repeated)

Page 20

System Control 19

U3201 is the Electrically Erasable Programmable Read-Only Memory and uses the

I2C Bus DATA and CLOCK lines to communicate with U3101. It provides non-volatile

memory for storing the following:

• Channel Scan List

• Customer Features

• Chassis Alignments

• CRT Alignments

• DPIP Alignments

• Tuner Alignments

• Channel Labels

If for any reason the EEPROM is replaced, the television will have to be

completely realigned to store the correct alignment data in the new chip. For

this reason, it is important not to change U3201 unless it is absolutely

necessary.

The keyboard interface is very similar to those used in the past. An important

difference is only one key drive line, KD1, is used. POWER, VOL. UP and VOL. DN.

are driven by KD1. When one of these buttons is pressed, KD1 pulses the corresponding

sense line low. U3101 detects which button has been pressed by monitoring the sense

lines for the KD1 pulse. The other three switches pull KS1, KS2 and KS3 to ground.

When U3101 sees a constant LO instead of a HI to LO pulse, it knows one of the other

three buttons has been pressed and will initiate the appropriate function based on which

sense line is pulled low.

U3201 EEPROM

TECH

TIP

Keyboard

Interface

Infrared remote signals are amplified by IR3401 and appear at U3101 pin 3 as 5 Vpp

data pulses. When no IR is received, the DC level at U3101 pin 3 is 5 volts. IR3401

is powered by the 5 volt standby supply.

C2707

.SYNC

V. SYNC

24

25

GRN OSD

U3101

Micro

OUT

18

Q2701

C2709

+

+

41

42

GRN OSD

IN

BLU OSD

IN

U1001

T-CHIP

Figure 14, Non-Closed Caption, Early Production OSD Circuit

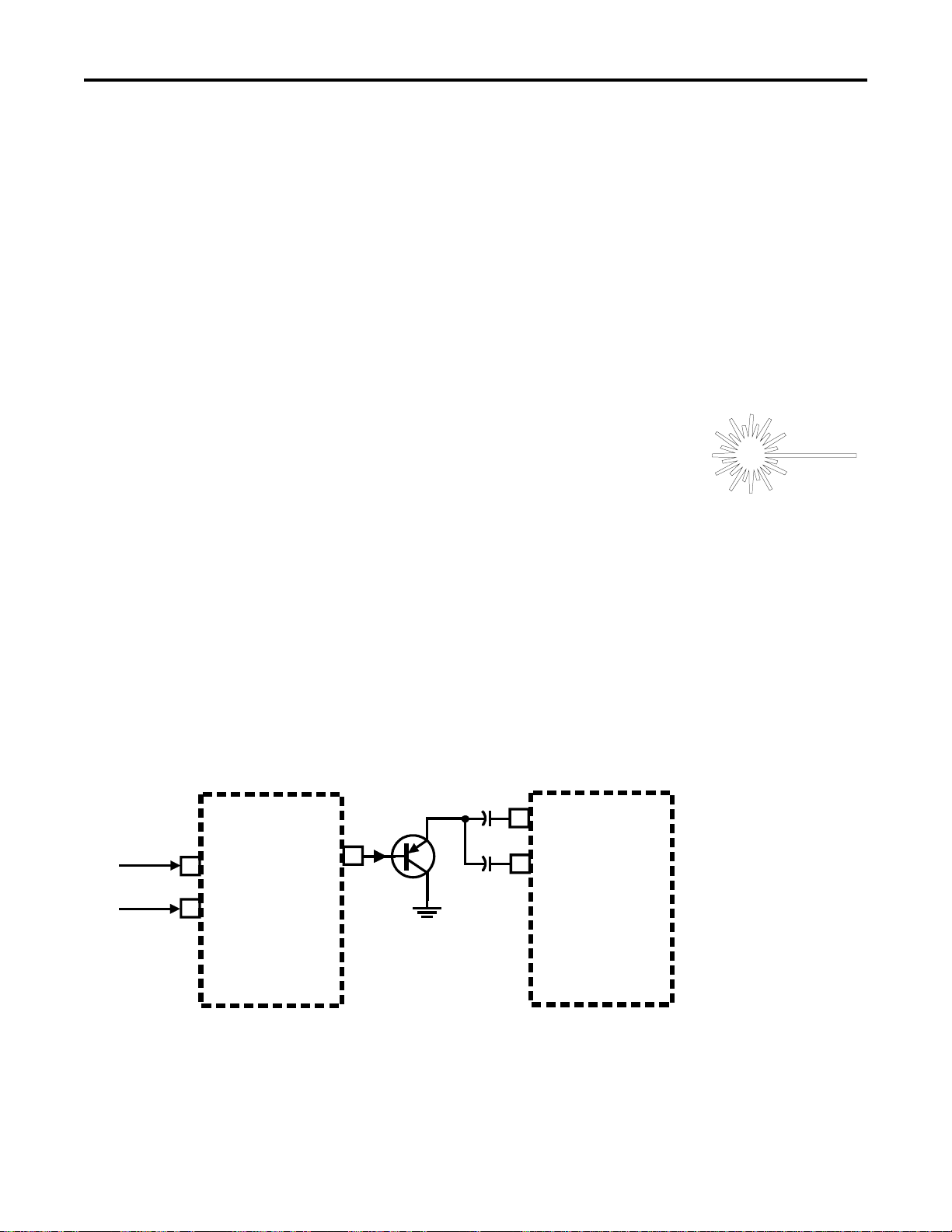

Two OSD circuits are used in the CTC177 chassis family. Early production televisions

that do not support a closed caption decoder have a cyan OSD. Later production sets

that include a closed caption decoder have a full color OSD.

IR Input

On Screen

Display

Page 21

20 System Control

Early production sets with a cyan display use only one OSD line out of U3101 to drive

the green and blue OSD input on U1001. The OSD is produced in U3101 and is output

from pin 18. Q2701 buffers the signal and capacitively couples it to the green and blue

input on U1001 pins 41 and 42. Green and blue are driven equally resulting in the cyan

display.

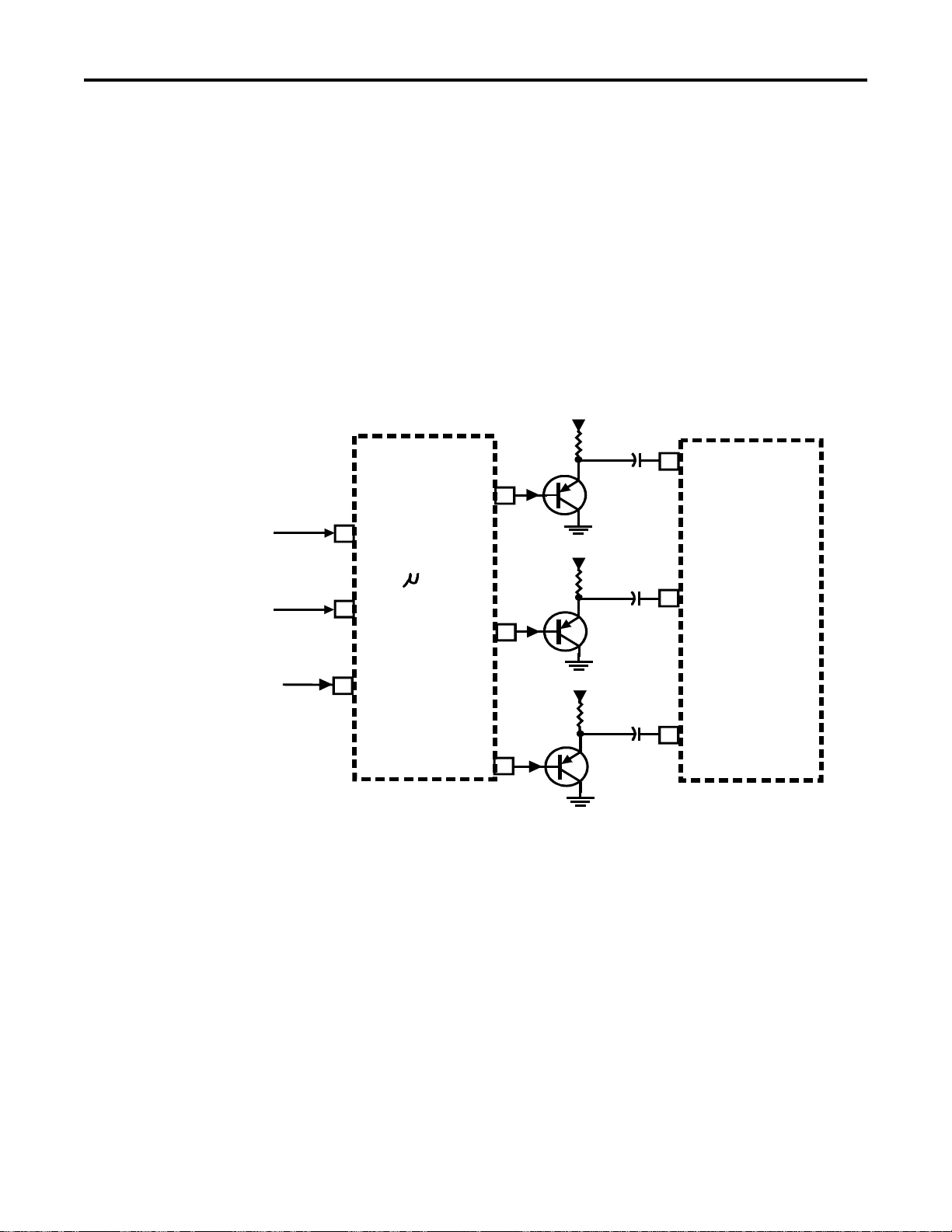

Later production sets that support closed caption decoders use red, green and blue

outputs from U3101 (pins 19, 18 and 17) to drive the red, green and blue OSD inputs

on U1001 (pins 40, 41 and 42) producing a full color OSD. Q2702, Q2701 and Q2703

buffer the red, green and blue signals and capacitively couple them to pins 40, 41 and

42 of U1001 respectfully.

Horizontal and vertical sync are input to pins 24 and 25 of U3101 and are used to

control the position of the OSD on the screen.

+7.6

C2707

+

GRN OSD

41

IN

U1001

T-CHIP

42

BLU OSD

IN

+

H. SYNC

V. SYNC

24

25

GRN OSD

U3101

P

BLU OSD

OUT

OUT

Q2701

18

+7.6

C2709

Q2703

17

Closed

Caption

CC. VIDEO

13

RED OSD

OUT

19

Q2702

+7.6

C2708

+

40

RED OSD

IN

Figure 15, Closed Caption OSD Circuit

U3101 contains a closed caption decoder that interprets the closed caption data sent

on line 21 of the first field in each frame of video. Sets that support the closed caption

feature, video is input to pin 13 of U3101. The closed caption signal begins with a

seven cycle burst of pulses to synchronize the decoder’s data clock. This is followed

by a start bit followed by two eight-bit words consisting of seven bits of data followed

by a parity bit for error correction. Since two characters are sent on line 21 of the first

field of each frame, there are a total of 60 characters per second. This format sends two

data channels called C1 and C2 (caption channel 1 and caption channel 2). Channel

1 is used for the main captioning text while channel 2 is used for alternate text, such

as a second language or abbreviated captioning for children or slow readers. C1 and

C2 are selectable from the menu; however, the TV will default to C1 each time the TV

is unplugged for prolonged periods of time.

Page 22

System Control 21

All closed caption processing is performed inside U3101. Horizontal and vertical sync

at pins 24 and 25 of U3101 are also used by the closed caption decoder.

H SYNC

COLOR BURST

50

25

0

-40

CLOCK RUN-IN START BITS CHARACTER ONE CHARACTER TWO

S1 S2 S3 B0 B1 B2 B3 B4 B5 B6 P1 B0 B1 B2 B3 B4 B5 B6 P2

IRE

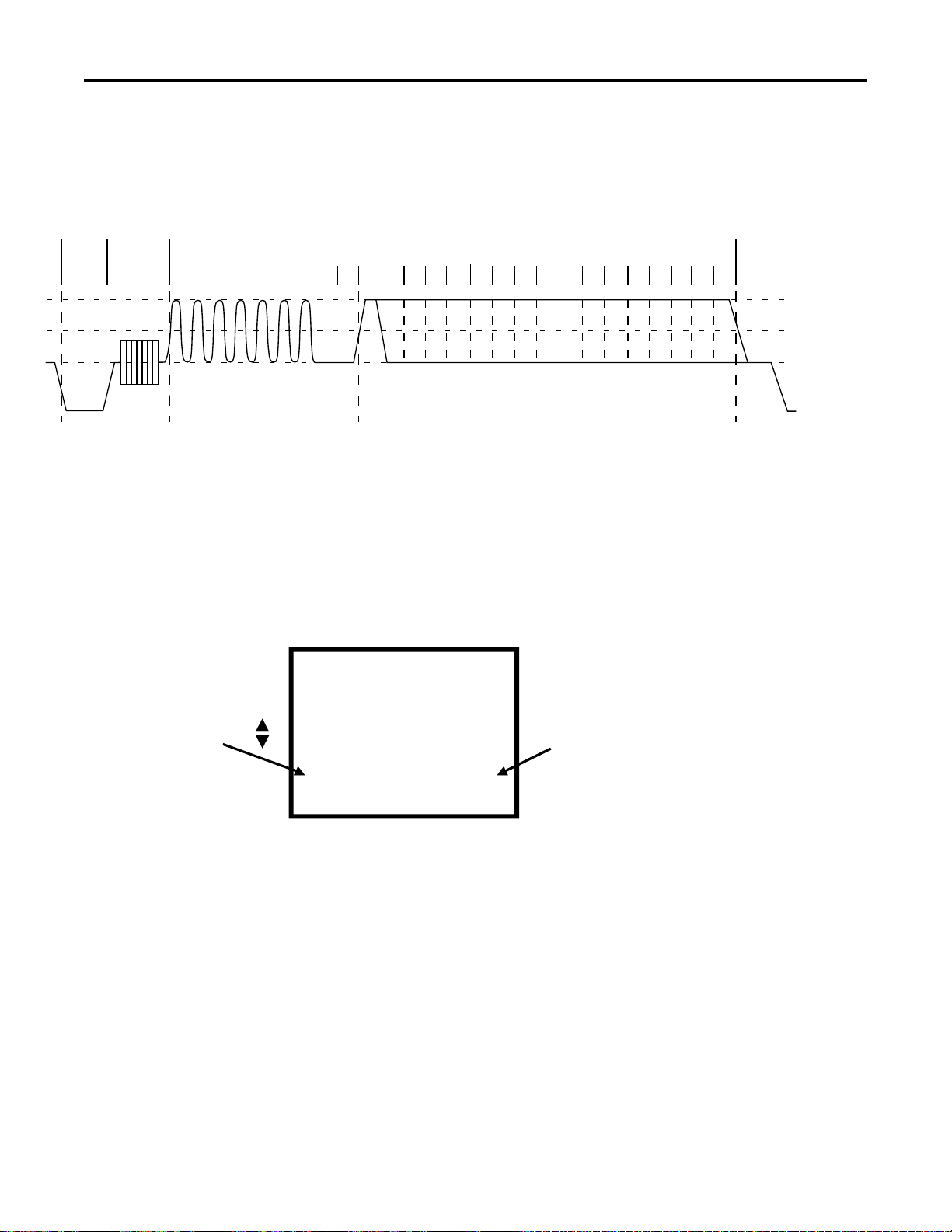

Figure 16, Line 21 Closed Caption Signal

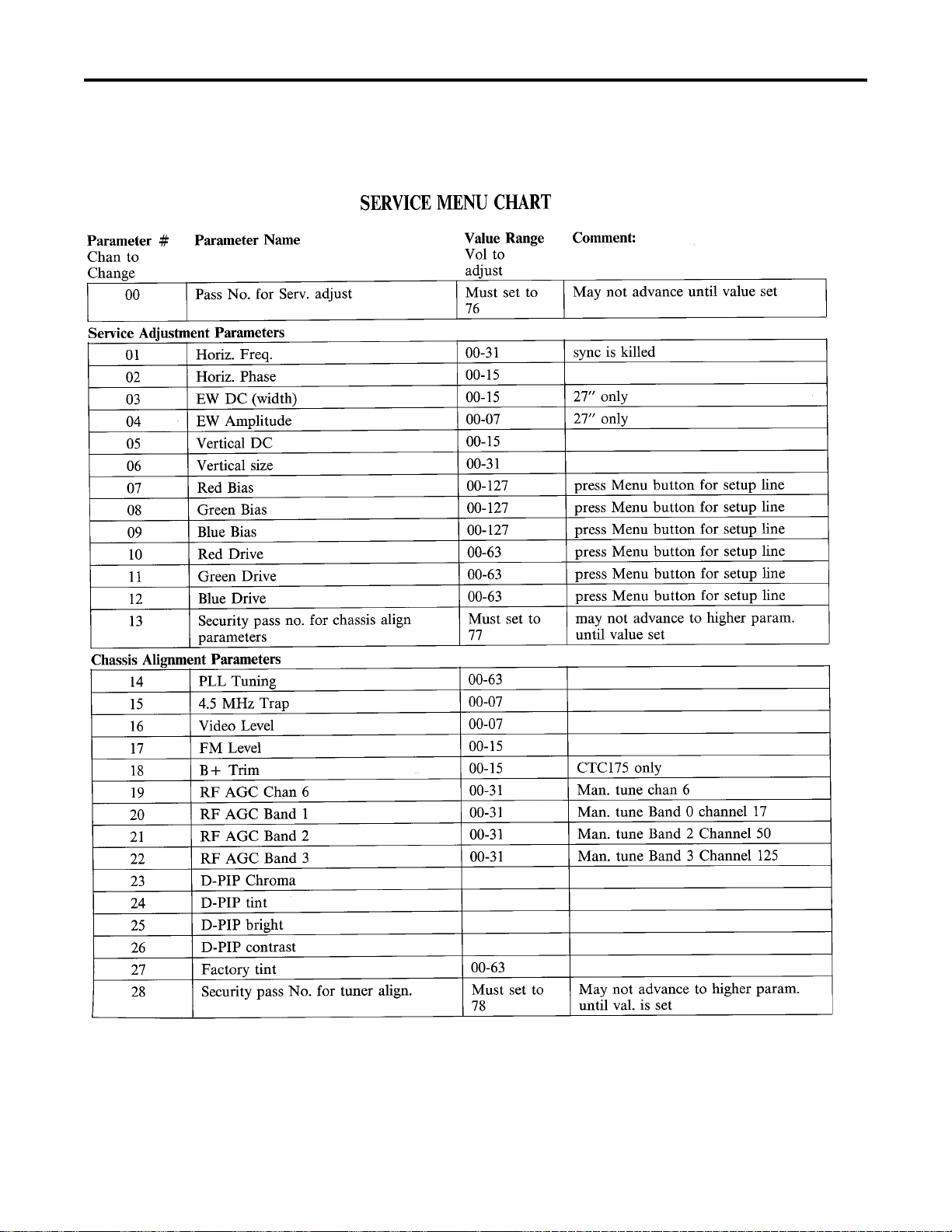

The service menu provides a method for instrument alignment and setup. This mode

is accessed by pressing two combinations of buttons on the front panel keyboard. With

the instrument on, press and hold the menu button and then simultaneously press the

power button. While continuing to hold the menu button, release the power button and

then press the volume + button. The instrument should immediately display a one line

menu on the screen:

PARAMETER

CONTROLLED

BY CHANNEL

P00 V00

VALUE

CONTROLLED

BY VOLUME +/-

Figure 16, Service Menu

Service

Menu

The decimal value on the left is the parameter number and the decimal value on the

right is the current value of that parameter. Channel up and down increment and

decrement the parameter number. Volume + / - adjust the current value of that

parameter. Three parameters are used for security purposes to protect the factory

alignments from being modified by the customer. The first security parameter, 00,

requires a specific value to be selected with the volume +/- buttons before other

parameters may be selected. If channel up/down is pressed without the correct security

pass-number set, the service mode is exited. There are three main groups of

parameters: instrument parameters, chassis parameters, and tuner parameters. The

chassis and tuner parameters are each preceded by a security pass-number parameter

to make changes very deliberate.

Page 23

22 System Control

Most of the instrument and chassis parameters correspond to individual (unpacked)

register fields in the T-chip. When these parameters are modified, the T-chip and the

corresponding EEPROM location is updated.

The Menu button may be used to enable the vertical collapse setup line - it functions

as a toggle. This setup line has the following characteristics:

S-video source is automatically selected (make sure no signal is

connected to the S-video input)

Contrast is set to minimum

Brightness is set to 7.5 IRE

Vertical kill enabled

When the setup line is toggled off, the characteristics modified above return to their

prior settings except contrast which is set to the factory default. Changing to another

parameter (with channel up/down) also toggles off the setup line.

The tuner parameters correspond to the three alignments for each of 19 channels for

a total of 57 parameters. When these parameters are modified, the tuner D/A and the

EEPROM are updated. Note that you must manually select the proper channel for each

tuner alignment. These adjustments may be made from the front panel as well as the

remote. The digit entry buttons (on the remote) allow tuning to any channel in this

mode. Pressing the power on, off, or power toggle buttons exits this service mode.

Page 24

System Control 23

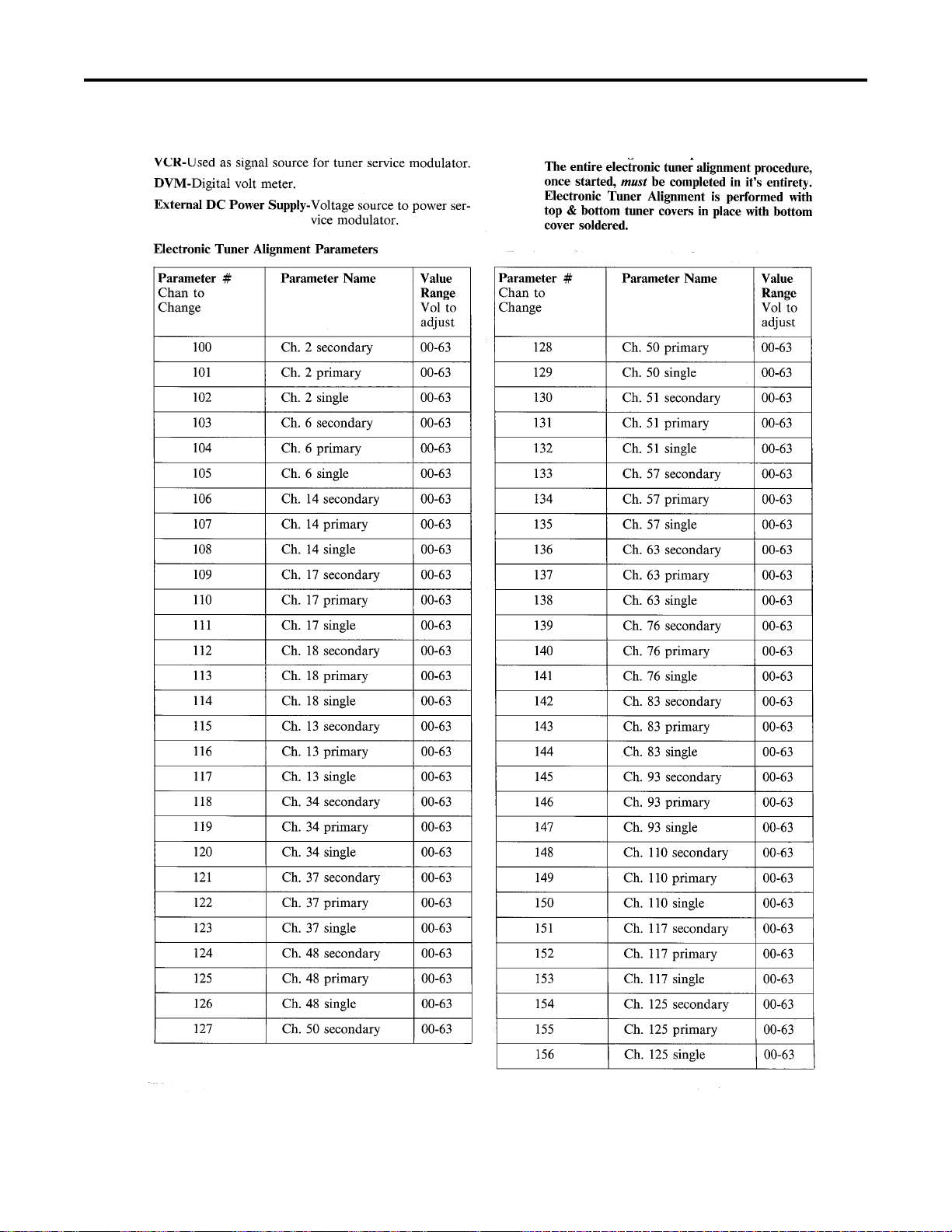

Alignment

Parameters

Page 25

24 System Control

Page 26

System Control 25

The system control circuit controls every function of the TV. A failure in this circuit

will cause the entire TV to malfunction. Because U3101 and U1001 are so interrelated,

there is a lot of overlapping in troubleshooting procedures. A failure of U3101, U1001,

U3201, U2901 or U7401 can make the television completely inoperative. It is

important to follow a systematic isolation approach to localize the problem. Because

U3101 turns the TV ON via a serial data bus command to U1001, a failure in the system

control circuit can result in a DEAD SET condition.

POWER

VOL. UP

VOL. DN.

CH. UP

1,2,3

4,7

GND

U3201

EEPROM

5V

KS1

6

KS2

7

KS3

8

KD1

5

T-CHIP DATA

TUNER CLOCK

T-CHIP CLOCK

TUNER DATA

U3101

P

PIP

ENABLE

T-CHIP

ENABLE

14

15

16

12

VDD

8

DATA CLOCK

56

U2901

D-PIP

DATA CLOCK ENABLE

20 21

22

GND

VDD

System Control

Troubleshooting

DIGITAL

3,5

15,16

40,41

DATA

CLOCK

ENABLE

5V

U1001

T-CHIP

HORZ.

OUT

39

54

53

52

24

CH. DN.

MENU

5V

2

IR3401

3

OSC

3

OUT

41 42

1

Y3101

OSC

IN

RESET

VDD

GND

20

21

5V

1

5V

4

DATA CLOCK

7.6 V

STBY

5

U7401

TUNER PLL

5V

10

VCC

GND

13

Figure 17, System Control Circuit (repeated)

Dead Set

1. Make sure the standby power supplies are working. (12, 7.6 & 5)

2. Check for horizontal drive pulses out of pin 24 of U1001 when the power button

is pressed. If the pulses are there even momentarily, system control is working and

the problem is in the deflection circuits. If the pulses do not appear, check the 7.6

volt standby voltage on pin 22 of U1001. If the supply is not present on pin 22,

unsolder the pin and see if the supply comes up on the pad. If it does, U1001 is

defective. If it does not, trace the supply back to its source. If 7.6 volts is present

on U1001 pin 22 in circuit, go to the next step.

56

22

BUS

GND

Page 27

26 System Control

3. Check for standby 5 volts on pin 20 of U3101. If it is missing, check the power

supply. If present, go to the next step.

4. Check the reset pin 1 of U3101 for 5 volts. If it is low or missing, check the reset

circuit. If it is, go to the next step.

5. Check pins 41 and 42 of U3101 for a 5 Vpp oscillator. If the signal is not 5 Vpp,

check Y3101 and its peripheral components. If the signal is completely absent,

suspect U3101 or Y3101. If the 4 MHz signal is present, go to the next step.

6. Monitor pins 14, 15 and 16 of U3101. There should be no data activity in the

standby mode. When the power button is pressed, 5 Vpp data pulses should appear.

If no pulses appear when the power button is pressed, unsolder pins 20, 21 and 22

of U2901 and pins 4 and 5 of U7401. Now re-check U3101 pins 14, 15 and 16. If

data activity returns, suspect a defect in U2901’s or U7401’s circuit areas. If data

activity does not return, go to the next step.

7. Unsolder pins 14, 15 and 16 on U3101 and check for constant 5 Vpp data pulses

in the standby mode on those pins.

TECH

TIP

TECH

TIP

Note: When U3101 is initialized, it checks to see if U3201 is present. Under

normal conditions, it immediately finds U3201 and ceases data activity . With

the enable, data and clock lines disconnected, U3101 continues to send out

data activity looking for U3201. This is normal and indicates U3101 is

working.

If no data activity is seen on U3101 pins 14, 15 and 16 with the pins out of circuit,

U3101 is probably defective. If data activity is present, reconnect the pins and go

to the next step.

8. Having confirmed data activity on pins 14, 15 and 16 of U3101 out of circuit,

disconnect pins 5 and 6 of U3201. Check for data activity in the standby mode on

the circuit board foil side of U3201 pins 5 and 6. If data activity is present on the

foil pads for those pins with the IC out of circuit, U3201 is defective.

Do not throw away the original U3201 until the problem is absolutely

confirmed. If U3201 turns out not to be the problem, putting the old IC back

in will prevent a complete chassis alignment from having to be performed.

If no data activity is seen on the circuit board with U3201 out of circuit, connect

the IC and go to the next step.

9. Unsolder pins 52, 53 and 54 on U1001. Check to see if the data pulses are present

on the foil that leads to the pins. If data pulses are present on the circuit board foil,

U1001 is most likely defective. If no data pulses appear on circuit board foil side

of U1001 pins 52, 53 and 54, suspect an open connection or resistor, or possibly

a leaky capacitor on the data bus.

Page 28

10. Once the problem is isolated and repaired, do not forget to re-connect U2901,

U7401 and any other parts that may have been unsoldered during troubleshooting.

System Control 27

POWER

VOL. UP

VOL. DN.

CH. UP

CH. DN.

MENU

5V

2

IR3401

3

1,2,3

GND

U3201

4,7

5V

EEPROM

VDD

8

DATA CLOCK

56

KS1

6

KS2

7

KS3

8

KD1

5

3

1

T-CHIP DATA

TUNER CLOCK

T-CHIP CLOCK

TUNER DATA

U3101

P

OSC

OUT

41 42

Y3101

ENABLE

T-CHIP

ENABLE

RESET

OSC

IN

PIP

VDD

GND

15

16

12

14

5V

1

5V

20

21

4

DATA CLOCK

U7401

TUNER PLL

5V

VCC

10

U2901

D-PIP

DATA CLOCK ENABLE

20 21

7.6 V

STBY

5

GND

13

3,5

15,16

GND

40,41

VDD

5V

39

22

DATA

54

CLOCK

53

U1001

T-CHIP

ENABLE

52

22

BUS

56

GND

HORZ.

OUT

24

Figure 18, System Control Circuit (Repeated)

Page 29

28 Horizontal Deflection

Horizontal

Deflection

HORIZ

OUT

U1001

HORIZ

GND

The horizontal deflection circuitry is responsible for generating a current ramp

through the horizontal windings of the yoke to deflect the electron beam from left

to right. In addition, the horizontal output circuitry generates the high voltage

necessary to bias the CRT.

U1001 (T-Chip) performs low level horizontal processing. The functions performed

in U1001 are very similar to previous chassis such as the CTC149. The difference

is the functions are controlled via the serial data bus. The horizontal processing

circuits contained in U1001 are:

• Horizontal Automatic Frequency Control (AFC)

• Horizontal Automatic Phase Control (APC)

• Horizontal Drive

• East West (EW) Pincushion Correction

• X-ray Protection

• Horizontal Vcc Standby Regulator

T4301

NC

HORIZONTAL

2

R4305

DRIVE

51

Q4301

HORIZONTAL

C4310

15

CR4303

DRIVER

C4304

C4305

R4306

C4306

Q4302

HORIZONTAL

R4311

24

R308

C4311

21

R4301

R4310

BUFFER

+12V

STBY

R4309

R4304 C4302

C4309

C4303

63

BAND/

GAP

STBY

+140V

22

7.6V

CR4115

9.1V

R4134

R4102

+12V

STBY

Figure 19, Horizontal Drive Circuit

The horizontal drive and output circuits are conventional in design. The horizontal

drive section of U1001 is similar to the CTC149. The output at pin 24 is an open

collector that is low (on) when horizontal drive is on. The pulse width is adjustable

from 32µsec to 36µsec via serial bus commands to T-Chip register H. Duty

(Horizontal Duty). This is set at the factory and is not adjustable in the field.

Q4302 is the horizontal drive buffer that capacitively couples the drive signal to

the horizontal driver Q4301. Q4301 drives the primary of T4301, the horizontal

drive transformer, to provide the current step-up needed to produce about 1 amp

of base drive to the horizontal output transistor, Q4401.

Page 30

Horizontal Deflection 29

T4401

IHVT

HV

NC

T4301

HORIZONTAL

DRIVE

3

2

HORIZONTAL

DEFLECTION YOKE

L4402

L4401

6

4

NC

C4401

51

Q4401

R4402

FB4401

C4406C4402

JW310 JW316

+

E4402

C4404

C4403R4401CR4401

C4405

R4403

E4401

1

2

3

+140V

Figure 20, 20" and 25" Horizontal Output Circuit

In 25" and smaller sets, Q4401 is an integrated transistor/damper diode package.

27" and larger sets have a separate output transistor and damper diode which are

utilized to allow the use of a diode modulator for pincushion correction. The

transistors are NOT interchangeable. The collector of Q4401 is connected to pin

2 of T4401, the IHVT. The 140 volt B+ is input on pin 3 and the horizontal yoke

is connected to pin 1 of T4401. The switching action of Q4401 will cause the yoke

and retrace capacitor, C4402, to resonate creating a 1000 Vpp retrace pulse. The

retrace pulse induces a voltage in the secondary of the IHVT to create the high

voltage and scan derived power supplies. The electron beam is scanned across the

screen by the resulting current sawtooth through the yoke.

T4401

IHVT

FS

SC

4

7

8

5

9

6

10

HV

NC

HORIZONTAL

DRIVE

3

2

T4301

HORIZONTAL

DEFLECTION YOKE

L4402

L4401

6

C4401

4

NC

51

Q4401

R4402

CR4402

FB4402

CR4403

FB4401

C4406C4402

C4407

+

C4404

TO PIN

BOARD

E4402

C4403R4401CR4401

C4405

R4403

E804

E4401

1

2

3

+140V

NC

53

4

12

NC

Figure 21, 27" and 31" Horizontal Output Circuit

FS

SC

4

7

8

5

9

6

10

NC

Page 31

30 Horizontal Deflection

Horizontal AFC

and APC

The purpose of the AFC and APC is to maintain proper synchronization between

horizontal scan and the incoming sync signal. The T-Chip employs a “two-loop”

approach to accomplish this task. The first loop is the AFC and second loop is the

APC. The AFC phase locks the horizontal oscillator to the incoming sync signal.

The APC locks the phase of the horizontal output to the phase of the horizontal

oscillator. This type of frequency control system is similar to the one used in the

CTC149 and is superior to the single loop system seen in the CTC159 and CTC169

family of chassis. This system is superior because it is adjustable for good noise

immunity in the presence of noisy signals and can track rapid phase changes in

signals from VCR’s. There is a one bit register in the T-Chip that is adjusted to

obtain optimum performance. The register is called AFC Gain. This register is

adjusted at the factory and cannot be aligned in the field. The external circuit at

pin 23 of U1001 is the loop filter for the phase lock loop (PLL) and is used to

optimize the frequency response of the AFC loop.

The APC loop is used to track out the phase errors due to variable delays in the

horizontal driver and output circuit. The APC has a two bit register (APC Gain)

that controls the gain of the APC loop. APC Gain like AFC Gain is pre-set at the

factory and cannot be adjusted by the service technician. The reference signal for

this loop is a flyback pulse applied to an RC network and input to U1001 pin 25.

C4312

100

R4302

APC

FLYBACK IN

R4313

AFC

FILTER

U1001

C4307

+

R4307

C4904

R4312

PROTECT

+

+7.6V

RUN

X_RAY

R4904

10K

R4906

22K

CR4302

BAND/

STBY

Vcc

Q4901

X RAY

R4903

CR4902

10V

22

7.6V

R4902

C4905

1000

CR4115

9.1V

XRP 1 XRP 2

12

GAP

262325

+

C4903

PROTECT

R4905

R4907

20K

R4134

R4102

J4901

TP4902

C4902

C4313

Figure 22, Horizontal APC/AFC and XRP Circuit

+12V

STBY

CR4901

R4303

C4133

C4901

TP4405

R4901

TO FBP

E802

Page 32

Horizontal Deflection 31

Although AFC and APC Gain are fixed adjustments at the factory, two horizontal

alignments are accessible to the service technician:

• Horizontal Frequency

• Horizontal Phase

U1001 has a five bit register to adjust the free-running frequency of the horizontal

oscillator. This is not unlike the coil adjustments performed on previous chassis.

The oscillator is completely contained within the T-Chip with no external coils to

adjust. The adjustment is made over the serial data bus via the service menu. See

the section on system control in this publication or consult the service data on

using the service menu.

Horizontal Frequency Adjustment

1. Set service menu to alignment #01.

2. Adjust value range for stable or slowly moving horizontal lines.

Note: Be careful not to adjust the horizontal frequency too low or the set can

go into XRP shutdown. If this happens, the set will not turn back on to

facilitate changing the value high to prevent shutdown.

Horizontal

Alignments

TECH

TIP

The technician can re-start the TV after an alignment induced shutdown in two

ways. One step is to replace the U3201, the EEPROM, with a new IC that has the

nominal values loaded. This means of course the entire chassis, including the

tuner, will have to be re-aligned. The other step is to temporarily add additional

capacitance across the retrace capacitor, C4402, to de-tune the circuit. This will

lower the high voltage allowing the set to stay on while the horizontal oscillator

frequency alignment is changed.

Some precautions in adding capacitance must be followed in order to prevent

damage to the horizontal circuit. The 20" versions will require an extra 1000 to

1500 pf, while the 25" versions will require a bit more, approximately 3000 pf.

Both of these versions have pin free yokes so double the capacitance will not be

dangerous (parallel an identical C4402 across the one in the circuit - stock number

214751). The versions with diode modulator pin correction ( 27" and the 31") are

a little trickier. These sets have a balance between the resonant frequency of the

horizontal scan circuits and the EW pin output circuit. If this balance is disturbed

too much, damage to one of the damper diodes can occur. This damage is always

proceeded by a significant reduction in horizontal scan and usually takes a long

time to occur so care can be taken to avoid problems. It is best to keep additional

capacitance under 2000 pf. if possible. It may be necessary to add additional

capacitance across the pin retrace capacitor, C4407, to maintain the balance. A

rule of thumb is, “add four times as much capacity to C4407 as you add to the

retrace cap.” Capacitors used must have a working voltage of at least 1.6 kV.

Any additional capacitors must be removed once the horizontal frequency

has been adjusted.

Shutdown

Recovery

TECH

TIP

Page 33

32 Horizontal Deflection

U1001 also has a four bit register to control sync to flyback phase. This is

accessible to the servicer through the service menu and is used to center the video

on the CRT.

Horizontal Phase

1. Set service menu to alignment #02.

2. Adjust value range to center picture left to right.

T roubleshooting

TECH

TIP

DIGITAL

Dead Set

A failure in the horizontal circuitry will most likely cause a dead set symptom.

1. Check the collector of Q4401 for +140 volts. If missing, check for a shorted

Q4401 and troubleshoot the power supply. If present, go to the next step.

Note: On the CTC175 chassis with a series pass regulator power supply,

if the horizontal output transistor is shorted, check for a 7shorted Q4150

in the power supply. It is likely a shorted horizontal output transistor will

take out the regulator.

2. Check for 7.6 volts on pin 22 of U1001. If it is not there, check the 12 volt

standby supply. If it is there go to the next step.

3. Check pin 24 of U1001 for horizontal drive pulses when the power button is

pressed. If no pulses are seen, see dead set troubleshooting in the “System

Control section of this publication. If they are present, go to the next step.

4. Check for horizontal drive pulses on the emitter of Q4302 and the collector of

Q4301. If they are missing, check the corresponding stages. If they are there,

go to the next step.

5. Check the drive to signal to the base of the horizontal output transistor, Q4401.

If it is present, suspect a defective Q4401. If it is not, suspect a defective T4301

No Horizontal Sync

1. Check to see if the horizontal frequency alignment in the service menu will

correct the problem. Make note of the original alignment parameter so it can

be returned if aligning does not correct the problem.

2. Make sure the problem is a horizontal sync problem by comparing the

horizontal drive signal to incoming video sync (one complete horizontal drive

cycle begins and ends with the horizontal sync in the video).

3. Check for the APC feedback signal to pin 25 of U1001. If missing, trace it back

to T4401, the IHVT. If the signal is present at pin 25, go to the next step.

4. Check the APC filter voltage on pin 23 of U1001 with service data. If it is

incorrect, suspect the components off pin 23.

Page 34

Horizontal Deflection 33

E

P

The electron beam scanning the face of the CRT must travel further to the corners

than it does to the edges. If not corrected, the picture would have an hourglass

shape called pincushion distortion. The pincushion correction circuit modulates

the horizontal yoke current at a vertical rate to correct the distortion. The

pincushion correction circuit is used in 27" and larger instruments. Sets with

CRT’s smaller than 27" use the horizontal linearity coil and a pin corrected yoke.

U1001 produces a vertical rate parabola at pin 19 that drives the pincushion

correction circuitry. This output has bus controlled DC and AC components which

are aligned over the serial bus. The DC register is controlled by a four bit register,

E-W DC. This is used to align raster width. The AC component is controlled by

a three bit register, E-W Amplitude. This controls the amount of pin or barrel

distortion in the raster.

15V RUN

6V RUN

FILAMENT

ULSE FROM

FLYBACK

PIN 8

1.

4805

E4808

E4802

R4854

R4856

C4861

C4857

R4865

R4859

CR4851

R4853

8

3

-

U4851

2

+

6

5

4

1

7

C4860

R4860

Q4851

R4852

C4855

R4864

C4853C4852

CR4853

R4862

R4863

+

L4853

1

3

45

2

NC

R4851

C4854

C4858

R4858

R4861

+

R4855

82K

C4859

C4851

C4856

+

R4857

E4804

E4804

TO HORZ

YOKE

3

Pincushion

Correction

EW OUT

FROM

U1001-19

Figure 23, Pincushion Correction Circuit

The vertical parabola from pin 19 of U1001 is combined with a filament pulse at

pin 2 of U4851. The DC reference for the inverting input on pin 3 of U4851 is set

to approximately 3.5 volts by the divider composed of R4854 and R4865. U4851

turns on Q4851 at the horizontal rate while the amplitude of the signal is

modulated at the vertical rate. C4851 is connected to the low side of the horizontal

yoke . When Q4851 is on, current is pulled from the horizontal yoke, through

L4853 to ground through the collector-emitter junction of Q4851. This lowers the

voltage on C4851 increasing the current flow through the horizontal yoke.

Increased current flow through the yoke will cause the raster to be wider. In this

way, the current through the yoke is modulated to correct for pincushion distortion.

When Q4851 turns off, the energy stored in L4853 is released. This voltage is

dumped to the 26 volt supply when it is high enough to forward bias CR4851

(approximately 26.6 volts). This prevents excessive voltage from damaging

Q4851.

Page 35

34 Horizontal Deflection

TECH

TIP

Pincushion

Alignments

T roubleshooting

Note: Malfunctions in the pincushion circuit can make the 26 volt supply rise

causing repeat failure of the vertical output IC, U4501.

(27" and 31" only)

Pincushion E-W DC

1. Set the service menu to alignment #03.

2. Adjust the value range for approximately 1/2 inch overscan on the left and right

sides.

Pincushion E-W Amplitude

1. Set the service menu alignment #04.

2. Display a crosshatch pattern on the screen.

3. Adjust the value range for straight vertical lines on the left and right sides.

If the pincushion circuit fails completely, the picture will either go to maximum width

or will pull in on the sides depending on the mode of failure. If the geometry of the

picture is off due to pincushion problems, see if the alignment procedure will help

correct the problem. Make sure to note the parameter setting of the adjustment so they

can be returned to their original settings if it is found not to be an alignment related

problem.

DIGITAL

X-ray Protection

T roubleshooting

Width/Hourglass

1. Check for a defective Q4851.

2. Check the DC voltages on U4851.

3. Check for the E/W drive signal on E4804 and the filament pulse on E4802.

The XRP (X-ray Protection) circuit shuts the TV down before high voltage climbs high

enough to pose an x-ray hazard. The circuit rectifies a flyback pulse at CR4901 and

applies the voltage to the base of Q4901 through a voltage divider and to the cathode

of a zener diode, CR4902. Q4901 is a PNP transistor that is off under normal operating

conditions. When high voltage rises high enough to overcome the 10 volt zener diode,

CR4902 conducts and applies a positive voltage to the emitter of Q4901, turning it on.

This applies a positive voltage to U1001 pin 26, causing horizontal drive to shutdown.

The shutdown is a latching shutdown and will reset when the voltage on pin 26 is

removed; however, the system control circuit will toggle the set to the “off” state if the

set fails to start after three tries. The power on/off button will have to be pressed to

attempt to re-start the set again.

A failure in the XRP circuit can shut the TV down and/or keep the set from turning on

completely.

XRP Shutdown

1. If the set tries to start three times and then stays off (noticeable by the degaussing

relay clicking), the set is in XRP shutdown. Also, monitor pin 26 of U1001 with

an oscilloscope while pressing the power button. If DC voltage appears momentarily

as the set shuts down, the set is going into XRP shutdown. If no voltage appears

at pin 26 and the set fails to turn on, XRP shutdown is not the problem.

Page 36

Horizontal Deflection 35

C4312

100

R4302

APC

FLYBACK IN

R4313

AFC

FILTER

U1001

C4307

+

R4307

C4904

R4312

PROTECT

+

+7.6V

RUN

X_RAY

R4904

10K

R4906

22K

CR4302

BAND/

STBY

Q4901

X RAY

R4903

CR4902

Vcc

10V

22

7.6V

R4902

C4905

1000

CR4115

9.1V

XRP 1 XRP 2

12

R4907

20K

C4902

GAP

262325

+

C4903

PROTECT

R4905

Figure 24, XRP and 7.6 Volt Regulator Circuit

R4134

J4901

TP4902

C4313

R4102

+12V

STBY

CR4901

R4303

C4133

C4901

TP4405

R4901

TO FBP

E802

2. Check Q4901 and CR4902. Note: all the components in the XRP circuit are

safety critical components and must be replaced with the exact originals.

Follow the guidelines set forth in the service data.

The 7.6 volt standby supply is regulated by an internal regulator at pin 22 of U1001.

The 9.1 volt zener diode, CR4115, is for protection against excessive input

voltage. This supply is used by the horizontal drive circuits to start the set from the

standby mode.

The television will not operate without the 7.6 volt standby voltage on pin 22 of

U1001.

No 7.6 volt Standby

1. Check the 12 volt standby supply.

2. Check for a shorted CR4115.

3. Check for an internal short or a leaky pin 22 to ground (if 7.6V < 7.3V). If it

is leaky or shorted, U1001 will have to be replaced and completely realigned.

Horizontal

Standby

Regulator

T roubleshooting

DIGITAL

Page 37

36 Vertical Deflection

Vertical

R2701

7.6 V

RUN

U1001

VERT OUT

VERT

RAMP ALC

33

The vertical circuit in the CTC175/176/177 is very similar to the previous linear

vertical circuits using a vertical output IC. One important difference to point out is this

vertical circuit is DC coupled instead of capacitively AC coupled. The DC coupled

circuit has advantages of fewer parts, lower cost and less dependence of linearity on

electrolytic capacitor tolerance and aging. The “S” correction is accomplished inside

the LA7610 T-chip, U1001.

Because of DC coupling, the DC level of the vertical reference ramp from U1001 pin

17 affects vertical centering. This provides a new adjustment, Vertical DC (vertical

centering), to be included in the digital alignments. It compensates for tolerances in

the reference ramp DC voltage.

The vertical circuit acts as a voltage to current converter. It converts the vertical rate

DC ramp out of the T-Chip to a current ramp through the yoke to deflect the electron

beam from top to bottom on the CRT. U4501 is an inverting amplifier that sinks

current at pin 5 when pin 1 is high and sources current from pin 5 when pin 1 is low.

U4501 is supplied by the 26 volt run source from the IHVT.

26V RUN

R4511

C4506

4

5

+

1

7

1.4 V

2.0 V

26

-

PWR AMP

+

U4501

4

CR4501

+

3

FB

GEN

C4504

R4519

C4505

5

R4507

+

C4507

C4502

R4501

R4502

55V

VERT. RETRACE

0V

E4502

E4501

TO OSD

R4517

R4518

SUPPLY

SIZE

COMP

BEAM

LIMITER

VID/VERT

VCC

BEAM

LIMIT

16

31

17

32

18

R4523

R2731

C4501

C4503

C2706

+

7.6 V

RUN

R4520

R2702

CR2702

2

1

7

8

7.6 V

RUN

36

18K

51K X 4

18K

RN4501

VERTICAL

YOKE

12V RUN

HALF

FROM

CR4407

Figure 25, Vertical Deflection Circuit

The low side of the yoke connects to a “half supply” (approximately half of the 26 volt

supply) developed from the 12 volt run supply. R4517 limits the current in the yoke

to keep the beam from deflecting off the screen if U4501 shorts to ground or to the 26

volt source. R4518 adjusts the circuit for different screen sizes and is currently only

used in the 20" sets. C4502 is used as a filter for the 12 volt run supply and with R4518

helps reduce the vertical rate ripple current on the 12 volt run supply. R4519 and

Page 38

R4502 form a current sense resistor that develops a voltage drop across it proportional

to the yoke current. A fraction of this voltage from the “half supply” is input to pin 5

of RN4501 and an equal fraction of voltage is input to pin 4 of RN4501. Both signals

feed back equally to the inverting and non-inverting inputs of U4501 resulting in no

error output. This cancels any parabola signal resulting from vertical rate current on

C4502. The quality of the canceling effect is determined by the match of the resistors

in RN4501 which in this case are matched to .5 percent.

Pin 17 of U1001 provides the vertical sawtooth to pins 1 and 2 of RN4501. The

average DC level of the ramp is approximately half the Vertical VCC supplied to pin

32 of U1001 (approximately 3.8 VDC). The ramp can be adjusted +/- 150mV via the

Vertical DC adjustment over the data bus. The vertical ramp and the error signal riding

on the 12 volt “half” supply from the current sense resistors, R4519 and R4502, are

added together and input to the inverting input, pin 1, of U4501. The 7.6 volt supply

is input to pin 7 of RN4501 where it is divided down to half VCC. It is then added to

the error signal riding on the 12 volt half supply from the current sense resistors, output

at pin 6 of RN4501 and applied to the non-inverting input, pin 7, of U4501. The

average DC voltage on pin 7 is approximately 9 volts during normal operation.

Vertical Deflection 37

When the vertical ramp is at the bottom of the slope, pin 5 of U4501 sources current

from the 26 volt supply through the yoke to the 12 volt “half supply” deflecting the

electron beam to the top of the screen. As the ramp climbs in voltage on pin 1, the

current source from pin 5 proportionally decreases lowering the voltage across the

yoke, deflecting the beam towards the center of the screen. When the voltage on pin

1 of U4501 reaches the same voltage as pin 7, pin 5 is at approximately half the 26

volt supply. Because the low side of the yoke is tied to the 12 volt “half supply,” there

is no current through the yoke resulting in the electron beam being at the center of the

screen. As the voltage on pin 1 of U4501 rises higher than pin 7, pin 5 begins to sink

current. This causes the current to flow from the 12 volt “half supply,” through the

yoke to pin 5. Because the current flow reverses, the beam is deflected towards the

bottom of the screen. During retrace, the ramp resets causing pin 5 of U4501 to go

high, deflecting the beam back up to the top of the screen. The extra current required

to deflect the beam from the bottom to the top of the screen is produced by C4505.

During scan time, the negative lead of C4505 is grounded through pin 3 of U4501. The

positive lead is charged to 26 volts. At retrace, the flyback generator inside U4501

connects pin 3 to pin 2 applying 26 volts to the negative side of C4505. The charge

stored on C4505 plus the 26 volts on the negative terminal produce 52 volts on pin 6.

The increased B+ quickly retraces the beam to the top of the screen.

Note: A failure in the pincushion circuit can cause repeat failure of U4501. See

pincushion circuit for troubleshooting hints.

Vertical size compensation with varying beam current is achieved via pin 16 of U1001.

The vertical reference ramp at U1001 pin 17 will change about 1 percent per volt

change at pin 16. Pin 16 is nominally 3.8 volts (half VCC) during normal operation.

TECH

TIP

Page 39

38 Vertical Deflection

As beam current increases toward the beam limiter threshold, a point is reached when

the beam sense line will begin pulling down the voltage at pin 16 through R4523. This

causes about a 1.7 percent drop in the vertical reference ramp at U1001 pin 16 reducing