Toshiba Compliant Manager BMS-CM1280TLE, Compliant Manager BMS-CM1280FTLE Installation Manual

Page 1

COMPLIANT MANAGER

Model name:

BMS-CM1280TLE

BMS-CM1280FTLE

Installation Manual

• Save These Instructions!

ENGLISH

Page 2

–2–

Compliant Manager

Installation Manual

Contents

1 PRECAUTIONS FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 PACKAGED ITEMS OF COMPLIANT MANAGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 INSTALLATION OF THE COMPLIANT MANAGER . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 CONNECTION OF POWER CABLES/SIGNAL WIRES/EARTH WIRES . . . . . . . . . . . 6

5 MODE SETTING FOR THE CONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 SWITCHES FOR SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 CENTRAL CONTROL ADDRESS (GROUP NUMBER) SETTING . . . . . . . . . . . . . . . 14

8 ZONE SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9 CHANGING RETURN-BACK TIME/TEMPERATURE SETTINGS . . . . . . . . . . . . . . . 18

10 TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-EN

Page 3

–3–

Compliant Manager

Installation Manual

1 PRECAUTIONS FOR SAFETY

After the installation work, perform a trial operation to check for any problem. Explain how to use and maintain the

unit to the customer. Ask the customer to keep this Installation Manual.

WARNING

• Ask an authorized dealer or qualified installation professional to install or reinstall the Compliant

Manager.

Improper installation may result in electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Perform installation work properly according to this Installation Manual.

Improper installation may result in electric shock or fire.

• Do not modify the unit.

Any modification may cause a malfunction, resulting in overheating or fire.

CAUTION

• Do not install the unit at a place subject to leakage of flammable gas.

If flammable gas leaks and remains around the unit, it may catch fire.

• Perform wiring correctly in accordance with the specified current capacity.

Failure to do so may result in short-circuiting, overheating, or fire.

• Connect the specified cables for the terminals securely to prevent external forces from affecting

them.

Failure to do so may result in disconnection, overheating, or fire.

• Make sure that the ground connection has been properly made.

Improper grounding may result in electric shock. Ask your dealer or an installation professional about how to check

the ground connection.

• Do not install the unit at a humid place or a place subject to vibration.

High humidity or vibration may cause a failure of the unit.

• Do not expose the unit to direct sunlight or a heat source.

This may cause a failure of the unit.

• Do not install the unit at a place where noise is generated.

This may cause a malfunction of the unit.

REQUIREMENT

• Disconnect the appliance from the main power supply.

This appliance must be connected to the main power supply by a circuit breaker or switch with a contact

separation of at least 3mm.

2-EN

Page 4

–4–

Compliant Manager

Installation Manual

2

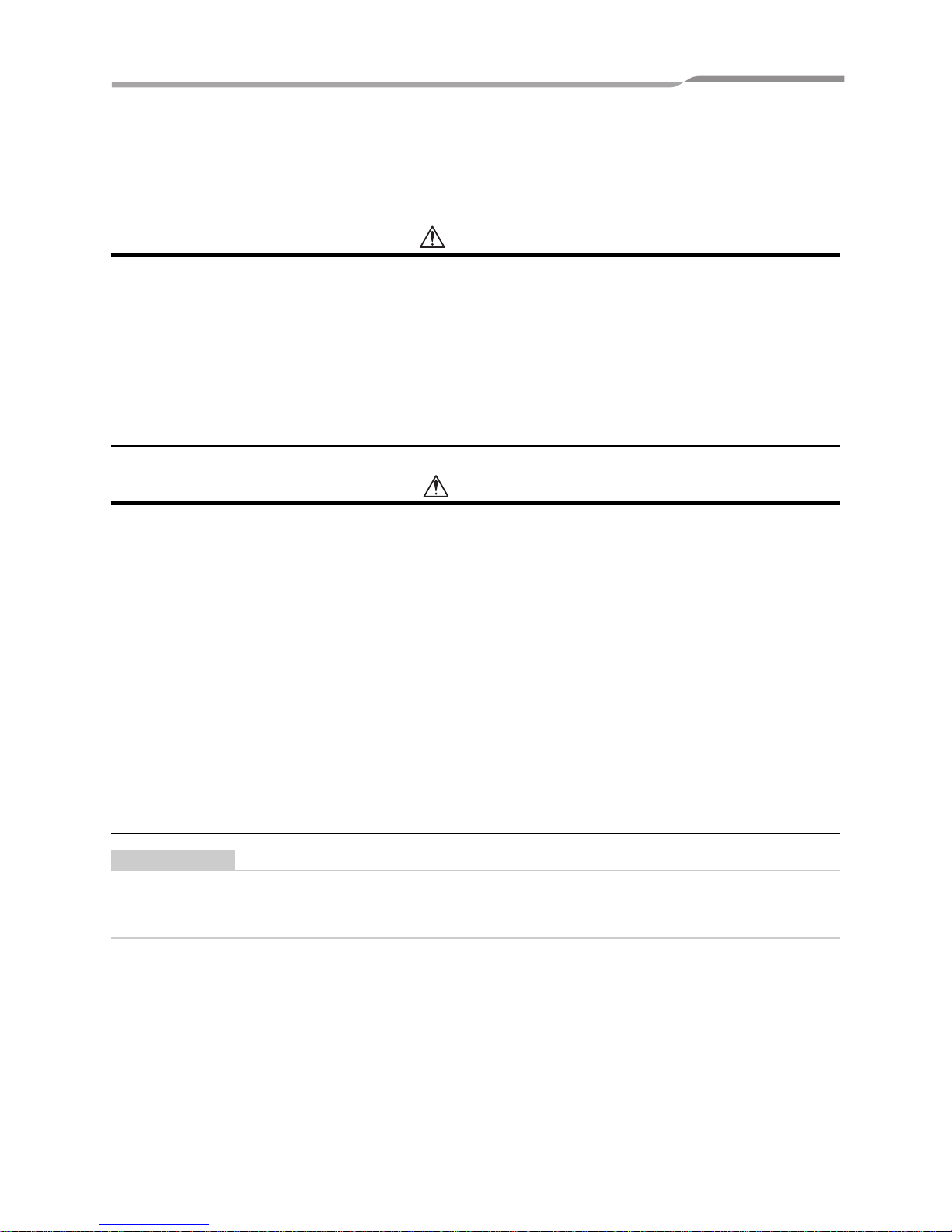

PACKAGED ITEMS OF COMPLIANT MANAGER

External Dimensions

Part name Image Quantity Remarks

Compliant Manager 1

Manual

1 Owner’s Manual

1 Installation Manual

1

Network Setting Manual

* Packaged for BMS-CM1280FTLE only

CD-R 1 * Packaged for BMS-CM1280FTLE only

Clamp filter

2 BMS-CM1280TLE

4 BMS-CM1280FTLE

Tie-wraps

2 BMS-CM1280TLE

4 BMS-CM1280FTLE

180

8.5

5Ø

8.5 155

142

172

19 69

90

158

42

46 66

120

8

17.9

76

12.7

106.6

70

140

108

90

*

* Reserve space of 10mm or more

when installin

g

the unit.

Dimensions of unit fixing holes in the wall, etc.

3-EN

Page 5

–5–

Compliant Manager

Installation Manual

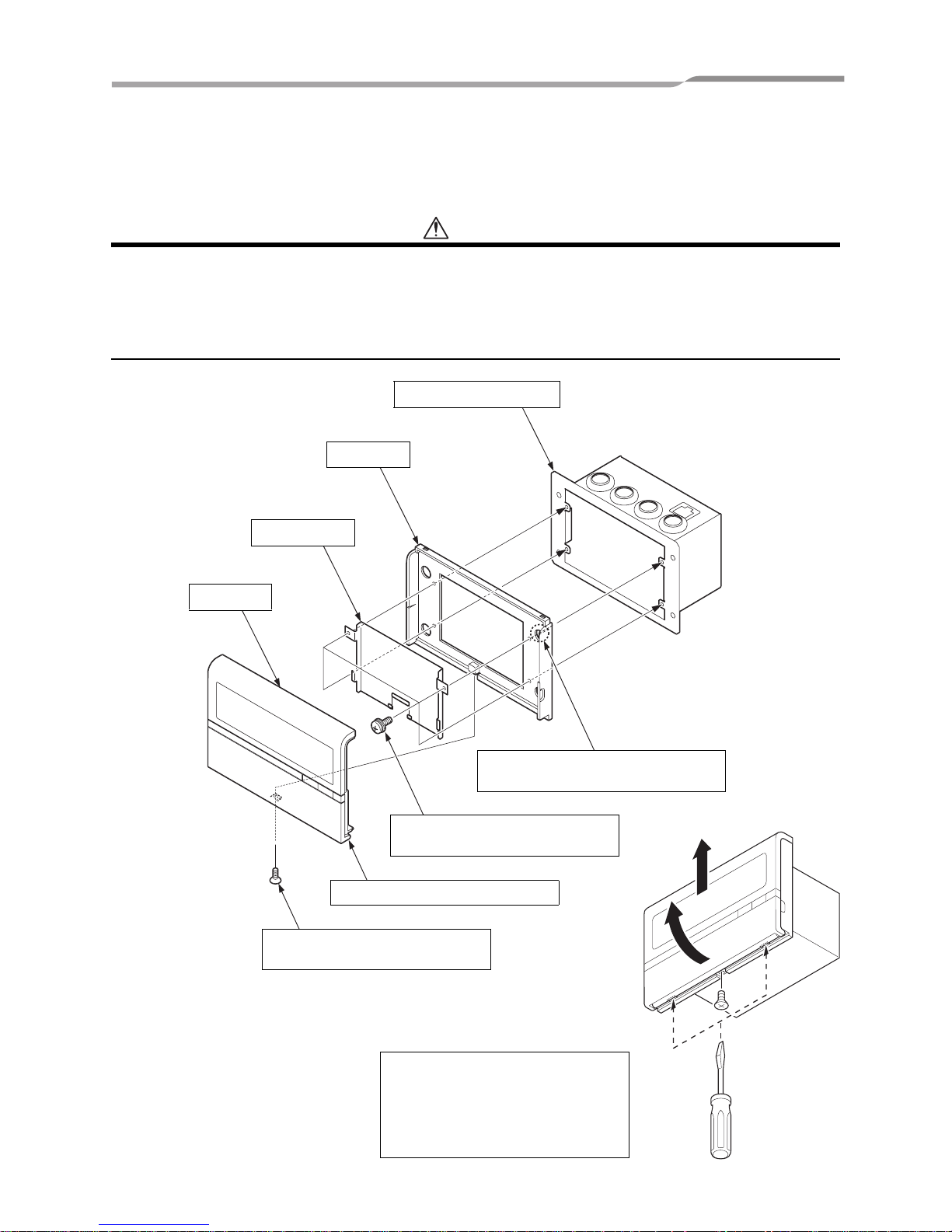

3 INSTALLATION OF THE COMPLIANT

MANAGER

CAUTION

• Do not twist communication wires (used between indoor unit and outdoor unit and used for central control) and input/

output wires with power wires or bundle them together with power wires in a metal tube. Doing so may cause

malfunction.

• Install the Compliant Manager away from a noise source.

• When noise is induced into the power supply of the Compliant Manager, take proper measures such as attaching of

a noise filter.

Panel

Shield plate

Base

Power supply box

The panel is secured with the claw.

This screw secures the power

supply box, base, and shield plate.

The panel is secured with the screw

at the bottom.

This hole is provided for penetration of

the power supply box fixing screw.

Remove the screw at the bottom of the

panel, insert a flat-blade screwdriver or

the like into the right and left grooves at

the bottom of the panel, and then

carefully detach the panel with the

screwdriver.

4-EN

Page 6

–6–

Compliant Manager

Installation Manual

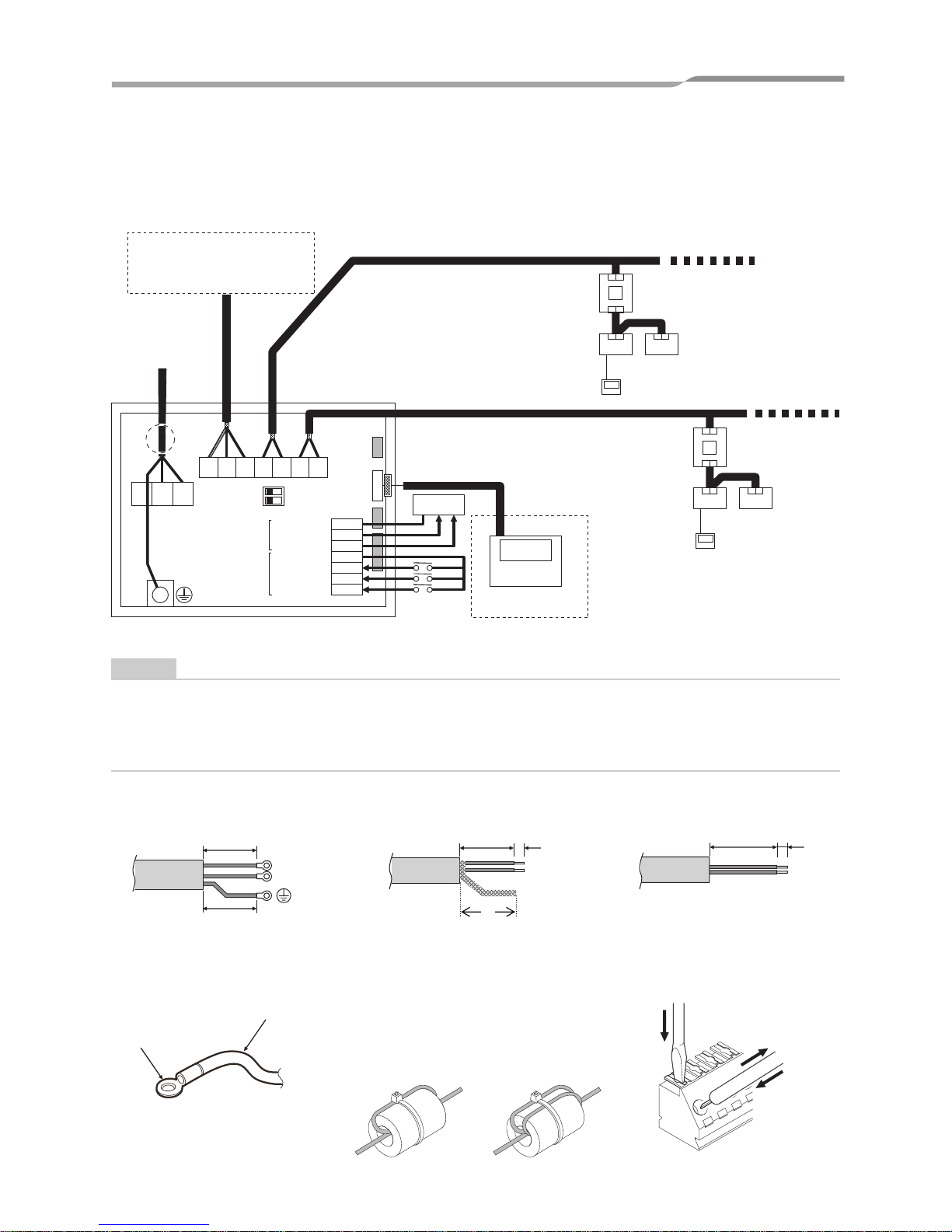

4 CONNECTION OF POWER CABLES/SIGNAL

WIRES/EARTH WIRES

Connect power cables, signal wires, and earth wires to the specified terminals on the terminal block.

NOTE

• TCC-LINK does not have polarity.

• RS-485 has a polarity. Connect A(+) to A(+) and connect B(-) to B(-).

• For TCC-LINK, connect the shield wire to the ground on the air conditioner side (single-point grounding).

• For RS-485, connect the shield wire to the ground on the Compliant Manager side (single-point grounding).

Common (Out)

Alarm

Common (In)

Fire alarm

All Start

All Stop

RunStatus Output

ON

Control Input

12

FG B (-)A (+)

U2/U4 U1/U3 U2/U4 U1/U3

FG N

COM-DO

DO2

DO1

COM-DI

DI3

DI2

DI1

TIMER

L

Power Supply

220-240VAC

Optional for BMSCM1280FTLE only

Energy Monitoring Interface

Digital I/O Interface

TCC-LINK main Bus (LINE2)

Outdoor Unit

Indoor Unit

Remoto controller

TCC-LINK main Bus (LINE1)

Outdoor Unit

Indoor Unit

Remoto

controller

Schedule Timer

RS-485

*1 Secure the power cable with the clamp in the case.

*1

Optional

N

L

20

80

15 10

35

20 10

Length of stripped power cable

Length of stripped TCC-LINK

and RS-485 communication wire

Length of stripped digital Input/

Output communication wire

Be sure to attach the supplied clamp filter to

the communication wire.

* When attaching the clamp filter, be sure to

pass the communication wire twice through

the clamp filter as shown below. Then

fasten the communication wire with the

supplied cable tie-wrap.

TCC-LINK wire

RS-485 wire

LAN cable

Remove and insert the wire

while pressing the upper button

with a screwdriver.

Power wire

Round pressure

terminal

Attach a round pressure

terminal to the end of each wire

of the power cable.

5-EN

Page 7

–7–

Compliant Manager

Installation Manual

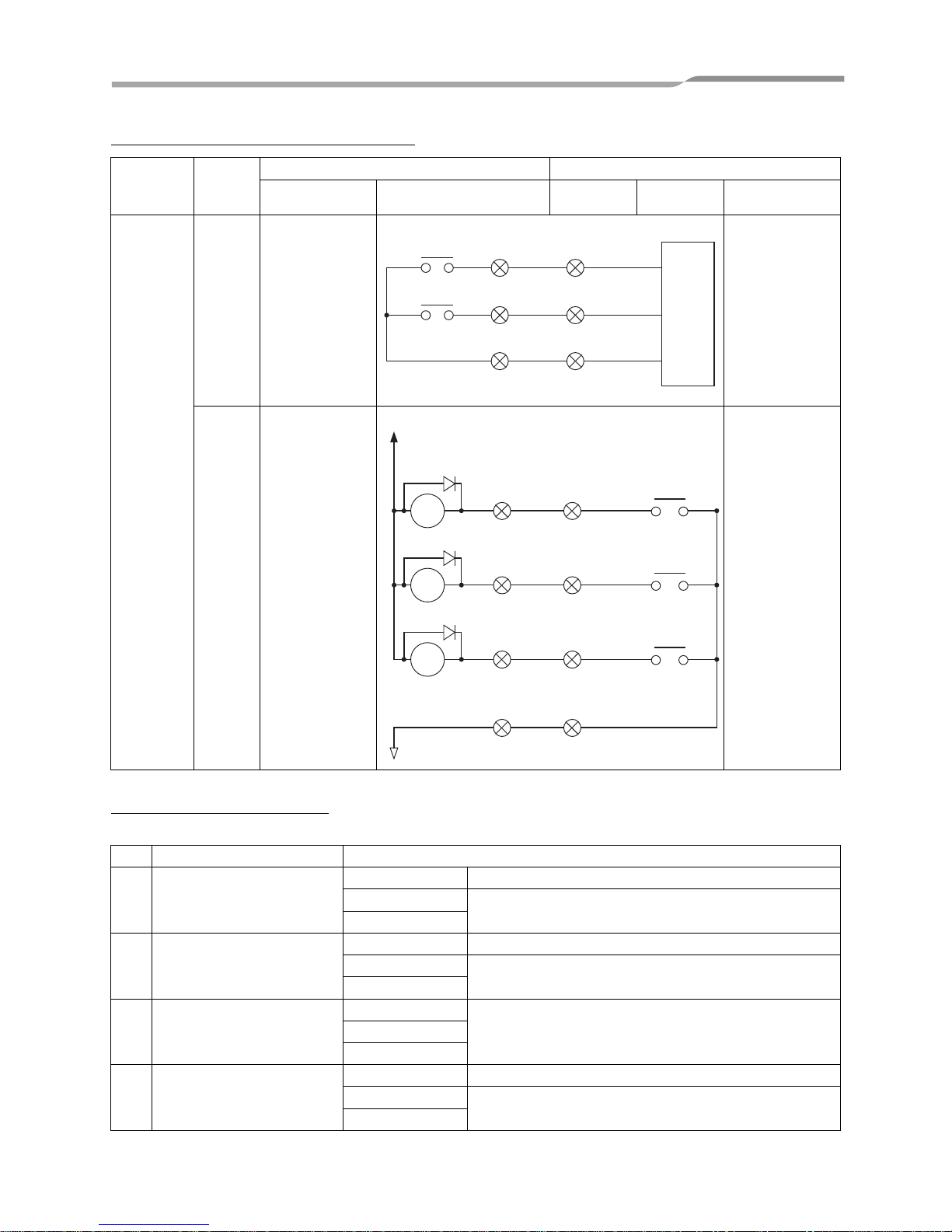

<Connections to External Equipment>

<Specifications for Wiring>

Use the following materials to connect signal lines and power lines (procured on site)

Designation

Input/

Output

item

Compliant Manager side External equipment side

Input/output

conditions

Terminal name

Demarcation

terminal

Example of

circuit

Input/output

conditions

Digital

input/output

terminals

Status

output

Alarm output

Run output

Non-voltage “A”

contacts

Static

(Relay output)

Allowable contact

voltage/current 30

VDC, 0.3 A

Wiring length:

100 m or less

Control

input

All stop input

All start input

Fire alarm input

Voltage-applied

“A” contacts

All stop:

Pulse or static

All start:

Pulse or static

Fire alarm: Static

(Photocoupler

input)

* Select non-

voltage contacts

that allow minute

current (12V,

1mA)

Pulse width:

300 ms or more

Wiring length:

100 m or less

No Line Description

1 For TCC-LINK

Type 2-wire sheld cord

Wire size

1.25mm², 1000m max. (total length including

2.00mm², 2000m max. air conditioner area)

Length

2 For RS-485

Type 2-wire sheld cord

Wire size

1.25mm², 500m max. (total length)

Length

3For Power

Type

H07 RN-F or 245IEC66

0.75mm², 50m max.

Wire size

Length

4

For Digital Input/Output

connection

Type 2-wire cord

Wire size

0.3mm², 100m max.

Length

0.4 to 1.2 Ø

Alarm

Run

Output common

Digital

input

+12V

COM

0.4 to 1.2 Ø

All stop (+)

Fire alarm (+)

All start (+)

Input

common (–)

(Pulse or static)

(Pulse or static)

(Static)

6-EN

Page 8

–8–

Compliant Manager

Installation Manual

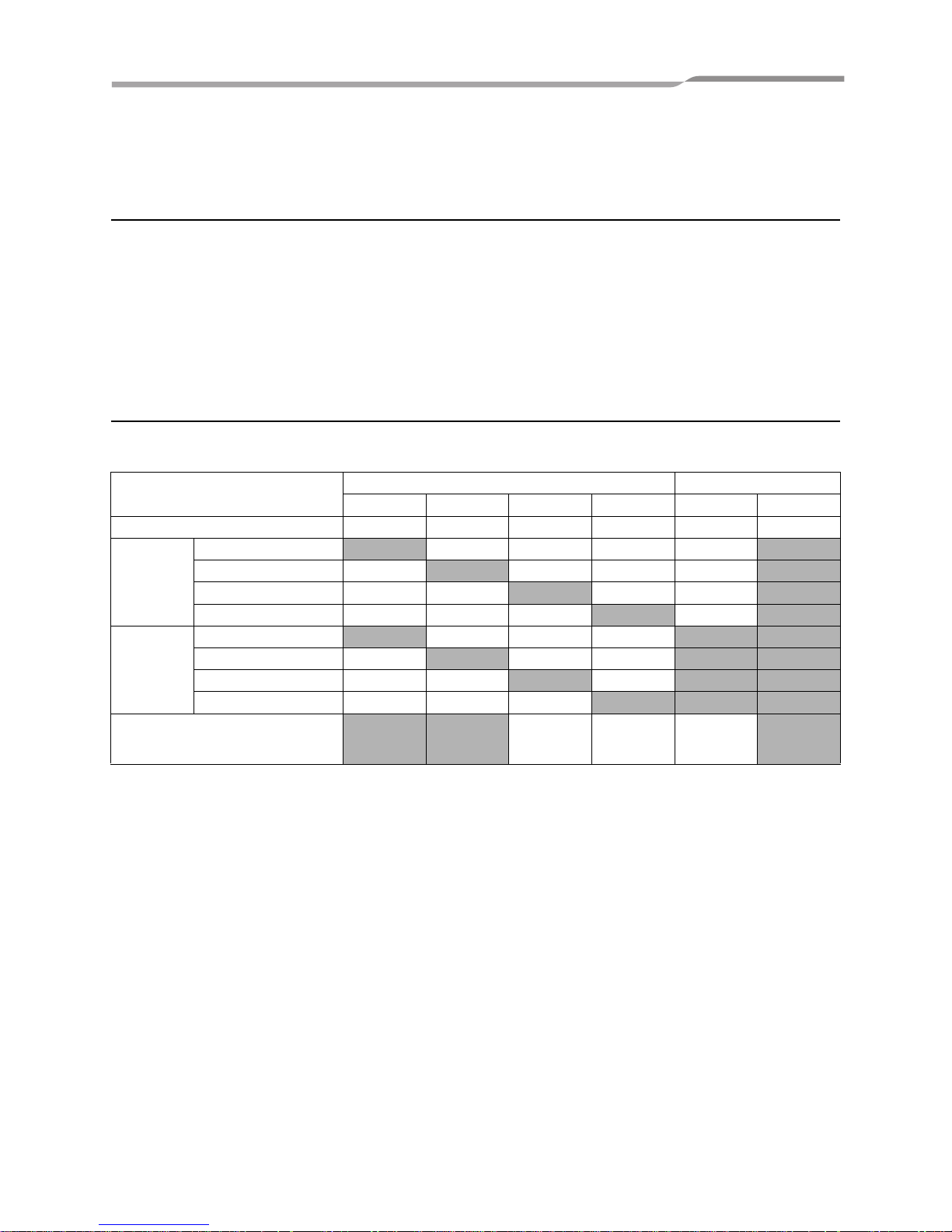

5 MODE SETTING FOR THE CONTROLLER

Operation mode

Use SW1-<6> for the operation mode setting.

Control group selection

Either simultaneous mode or an arbitrary range of a line and 16 groups (1 to 16, 17 to 32, 33 to 48, and 49 to 64)

can be selectively set.

* When the control group selection is used, only the set group range is displayed.

* The control group selection is available only for one line.

OFF side: Central control mode

This Compliant Manager is used as a central control unit.

Settings with the remote controller are inhibited by the setting of the Compliant Manager.

ON side: Remote control mode

This Compliant Manager is used as a remote controller.

Settings with the Compliant Manager are inhibited by the setting of another central control unit.

DIP-SW1 DIP-SW2

<2><3><4><5><5><6>

All groups OFF OFF OFF OFF OFF OFF

LINE 1

Group 1 to 16 ON OFF OFF OFF OFF ON

Group 17 to 32 OFF

ON OFF OFF OFF ON

Group 33 to 48 OFF OFF

ON OFF OFF ON

Group 49 to 64 OFF OFF OFF

ON OFF ON

LINE 2

Group 1 to 16

ON OFF OFF OFF ON ON

Group 17 to 32 OFF

ON OFF OFF ON ON

Group 33 to 48 OFF OFF

ON OFF ON ON

Group 49 to 64 OFF OFF OFF

ON ON ON

Example:

When setting LINE 1 (group 1 to 32) in

the control group selection

ON ON OFF OFF OFF ON

7-EN

Page 9

–9–

Compliant Manager

Installation Manual

<System Configuration of the Compliant Manger>

• Each line consists of up to 64 zones and 64 groups (up to 128 zones and 128 groups in total).

• Each group number is a central control address. (Effective values 1 to 64 and 99 are unset values.)

• Default setting when shipped: One group is assigned to one zone (zone number = group number)

• Groups that can be registered in each zone must meet the following conditions.

1. Groups are connected to the same line.

2. Groups are in the same group number range when the control group selection is used.

* When the control group selection is not used ("ALL group"), all groups and zones on LINE 1 and LINE 2 can be

controlled.

* When the control group selection is used, only groups and zones in the set group range can be controlled.

• When the control group selection is used, groups and zones outside this range are not displayed and cannot

be operated.

• means the entire set group range.

• Zones can be registered and operated only within the set group range. (No groups outside the range can be

registered or operated.)

• The group control mode is available only for one line.

* Multiple group ranges can be specified by the control group setting.

(Example) When groups 33 to 48 and groups 49 to 64 are specified at the same time, a group range (groups

33 to 64) is set by the control group setting.

Gr1 Gr5 Gr8 Gr16

Gr32Gr32

Gr32Gr48

Gr2 Gr10

ZONE 39

ZONE 1

Gr17

Gr33 Gr35

Gr22 Gr25

Gr39 Gr43

Gr30

Gr45

Gr32Gr64Gr49 Gr50 Gr55 Gr58 Gr60

Gr19

ZONE 17

ZONE 33

ZONE 19 ZONE 22

ZONE 32

ZONE 64

ZONE 30

ZONE 2 ZONE 10 ZONE 16

ALL

LINE 1

LINE 2

Compliant Manager

Group

1 ~ 16

Group

17 ~ 32

Group

33 ~ 48

Group

49 ~ 64

ALL: The Compliant Manger operates as follows in combination with LINE selection.

LINE 1 ALL (All groups on LINE 1 are selected.)

LINE 2 ALL (All groups on LINE 2 are selected.)

Gr = Group

8-EN

Page 10

–10–

Compliant Manager

Installation Manual

6 SWITCHES FOR SETTING

The settings switch is installed on the rear of the Compliant Manager.

1 2 3 OFF ON ON OFF

NOT CHANGE

CENTRAL 2

ALL OFF

ALL OFF AND CENTRAL 2

ALL OFF AND CENTRAL 1

CENTRAL 1

ALL ON ALL OFF

PERMITTED ALL

INDOOR UNIT

OPERATION BY

USING RCU

2

1

Must be set

to OFF

ON

OFF

Fire alram input

switching

Synchronization of

Setting Zone data

Fire alram

Normal

Fire alram

Normal

4

SW3

ON

OFF

3

Must be set

to OFF

SW2

ON

OFF

4

Must be set

to OFF

5

LINE 2

LINE 1

7

OFF

ON

Buzzer

Control group

Selection Line

8

OFF

ON

Indicate

SW1

2 3 4 5

SW2

6

ALL groups

group 1 ~ 16

group 17 ~ 32

group 33 ~ 48

group 49 ~ 64

Control groups Selection

SW1

ON

OFF

1

SUB

MAIN

6

RCU

CENTRAL

7

SUB

MAIN

8

INHIBIT

PERMIT

Central/Individual

Sys.con

Central/RCU change

Central Control

To avoid an electric shock hazard. DO NOT touch any

terminal on the Printed Circuit Board with a metal rod a

screwdriver edge nor a bare hand when power is supplied.

State for Weekly timer

DIP-SW2

DIP-SW1

DIP-SW3

9-EN

Page 11

–11–

Compliant Manager

Installation Manual

1

ON

OFF

2 3 4 5 6 7 8

DIP-SW1

<1> Compliant Manager main/sub selection

OFF: Main

ON: Sub

Normally, this bit is set to OFF.

When two Compliant Manager units are used as a main unit and a sub

unit with the same mode setting, set this bit to OFF (Main) for one unit

and to ON (Sub) for the other unit.

<2> to <5> Control group selection

These bits specify a group range used in the control group selection.

The Compliant Manager for which control group selection is set controls

only groups within the set group range.

* To use the control group selection, set SW1-<2> to <5> and SW2-<5>

to <6>.

Control group selection SW2-<6> SW1

All groups OFF -

Group 1 ~ 16 ON <2> ON

Group 17 ~ 32 ON <3> ON

Group 33 ~ 48 ON <4> ON

Group 49 ~ 64 ON <5> ON

<6> Central control/remote controller mode selection

OFF: Central control mode

ON: Remote controller mode

Central control mode: Individual setting by remote controller can be

inhibited by Compliant Manager.

Remote controller mode: Setting by Compliant Manager is inhibited by

other centra control equipments.

<7> Central control Main/Sub selection

OFF: Main

ON: Sub

This setting is required when multiple Compliant Manager units are

used or another central control unit is used.

(1) Set this bit to OFF when one Compliant Manager unit is used.

(2) When multiple central control units are used as a main unit and sub

units, set to OFF (Main) for one unit and set to ON (Sub) for other

units.

* It is recommended that the “All groups” (control group selection

setting) be set for the central control main unit.

Factory setting: All OFF

<8> Central button enable/

disable

OFF: button operation is

permitted

ON: button operation is

inhibited

* The button is disabled in

the remote controller mode

regardless of this setting.

<DIP-SW1>

10-EN

Page 12

–12–

Compliant Manager

Installation Manual

1

ON

OFF

2 3 4 5 6 7 8

DIP-SW2

<4> Always OFF

Always set this bit to OFF.

<5> Control group Selection line

OFF: LINE 1

ON: LINE 2

* Set a line number for which the control group selection is used.

Factory setting: All OFF

Switch No.

#1 #2 #3Central controller operation

Timer OFF → ON Timer ON → OFF

(1) All ON All OFF OFF OFF OFF

(2) No change All OFF ON OFF OFF

(3)

Individual control of all indoor

units to be permitted

All indoor units CENTRAL 1 OFF ON OFF

(4) Ditto

All OFF and all indoor units to

be CENTRAL 1

ON ON OFF

(5) Ditto All indoor units CENTRAL 2 OFF OFF ON

(6) Ditto

All OFF and all indoor units to

be CENTRAL 2

ON OFF ON

<6> Control group selection enable

OFF: Normal mode

ON: Control group selection

Set this bit to ON when the control group selection is used.

* To use the control group selection, set SW1-<2> to <5> and SW2-<5> to

<6>. For details, see the table on the previous page.

<7> Buzzer

OFF: With buzzer sound

ON: Without buzzer sound

<8> indication

OFF: Displayed

ON: Not displayed

<1> to <3> Timer input switching

These bits switch operation when the schedule timer has changed.

• Use (1) and (2) only in the remote control mode.

• When the control group selection is used, “All ON,” “All OFF” and

“all indoor units” mean those within the set group range.

<DIP-SW2>

11-EN

Page 13

–13–

Compliant Manager

Installation Manual

1

ON

OFF

2 3 4

DIP-SW3

<1> Always OFF

• Always set this bit to OFF.

<4> Fire alarm input switching

• OFF: CLOSE: Fire alarm (OPEN: Normal)

• ON: OPEN: Fire alarm (CLOSE: Normal)

COM-DI

DI3

COM-DI

DI3

(Fire alarm)(Normal)

COM-DI

DI3

COM-DI

DI3

(Fire alarm)(Normal)

Factory setting: All OFF

<2> Synchronization of Setting Zone data

OFF: With transfer

ON: Without transfer

This bit specifies whether to perform synchronous communication of Setting Zone

data between Compliant Managers.

* When this bit is set to ON (without transfer), synchronous communication is not

performed, and when zone setting is made, the data is not reflected in other

Compliant Managers.

<3> Always OFF

• Always set this bit to OFF.

<DIP-SW3>

12-EN

Page 14

–14–

Compliant Manager

Installation Manual

7 CENTRAL CONTROL ADDRESS (GROUP

NUMBER) SETTING

• Central control addresses must be assigned to all air conditioners to be controlled.

• Under the control of the Compliant Manager, central control address equals group number.

<Preparations for central control address (group number) setting>

• Turn on the power of all air conditioners.

• This Compliant Manager or a standard wired remote controller is necessary for setting central control addresses.

• Terminate the operation of air conditioners, and then set central control addresses.

* To set central control addresses with the Compliant Manager, initial communication with all connected indoor

and outdoor units must have been completed. Therefore, wait at least 10 minutes after power-on, and then start

central control address setting.

NOTE

If the address setting is made before the initial communication is completed, an address is not assigned

to some units.

• Connect terminals U1 and U2 in the outdoor unit (Header unit) to the relay connector of terminals U3 and U4.

• Set SW30-2 on the interface P.C. board of the outdoor unit (Header unit) to ON only for one system, and to OFF

for others.

* The location of SW30 is shown in the wiring diagram supplied with the outdoor unit.

<Setting central control addresses (group numbers)>

Use “manual setting from wired remote controller,” “manual setting,” or “automatic setting” to set central control

addresses.

A Manual setting from wired remote controller

Set central control addresses (group numbers) from a standard wired remote controller.

* The following setting procedure is described based on button operations of the wired remote controller RBC-

AMT32E or RBC-AMT31E.

(1) Press the button and button simultaneously for at least 4 seconds.

(Note: Do not press the button during setting.)

(2) Press the button to change the CODE No. 03.

(3) Set central control addresses (group numbers) with the buttons.

• Group numbers used for the Compliant Manager are central control addresses (DN item 03).

• The effective address range is 1 to 64. However, there must be no duplicate address on the same line.

• An address value of 99 is used as an unset address.

(4) Press the button to fix the setting.

(5) Press the button to exit the address setting mode.

* This setting procedure may vary depending on the wired remote controller model.

* Perform these steps while air conditioners are not working.

B Manual setting

Set central control addresses (group numbers) manually from the Compliant Manager.

(1) Press the button and ZONE button simultaneously for at least 4 seconds.

(CODE No. C1 flashes.)

(2) Check CODE No. C1, and then press the button.

(3) Select the line on which the unit exists and the zone and group in which addresses are to be registered with the

LINE button, ZONE and buttons, and GROUP and buttons.

For address setting when connecting a TCC-LINK adapter to the central control system, refer to this

manual and the TCC-LINK adapter installation manual.

13-EN

Page 15

–15–

Compliant Manager

Installation Manual

• When a zone is selected, group numbers registered in the zone are displayed.

• Groups whose numbers are displayed are already registered.

• Even when addresses have been registered, the registration can be cancelled with the button.

(4) Select the unit to be registered in the group selected in step (3).

• Switch refrigeration system No.1 to 31 with the button, and then switch indoor unit No.1 to 64 with the

button.

• When no system exists, indoor unit number is displayed as “- -”.

• System number 31 is for a local adapter and heat exchange ventilators. An indoor unit number is always

displayed regardless of whether the unit exists or not.

(5) Press the button to register the setting or press the button to cancel the setting.

(6) To continue registration, repeat steps (3) to (5).

(7) Press the button to terminate the address setting.

C Automatic setting

Set central control addresses automatically from the Compliant Manager.

(Central control addresses are set automatically in ascending order of unit number.)

(1) Press the button and ZONE button simultaneously for at least 4 seconds.

(CODE No. C1 flashes.)

(2) Press the SET TEMP. or button to change the CODE No. to C2.

(3) Press the button. (Central control addresses are automatically registered. This registration requires several

minutes. lights during this address setting.)

(4) goes out and the indication of C2 flashes, which shows completion of the automatic address

registration.

(5) Press the button to exit the address setting mode.

<Checking duplicate central control address>

NOTE

This function is not available for custom air conditioners.

For details, refer to the manual of the TCC-LINK adapter.

(1) Press the button and ZONE button simultaneously for at least 4 seconds.

(CODE No. C1 flashes.)

(2) Press the SET TEMP. or button to change the CODE No. C3.

(3) Press the button to start checking a duplicate central control address error. ( lights during this

check.)

(4) When goes out, the check has been completed.

* When nothing appears in the group number display area at the end of checking, no duplicate address error

has been detected.

* When a group number in the group number display area flashes at the end of checking, a duplicate address

error has been detected.

(Correct the duplicate address.)

14-EN

Page 16

–16–

Compliant Manager

Installation Manual

<Correcting duplicate address>

Correct the duplicate address detected through the check using the following procedure.

(1) When the duplicate address check has been completed, select CODE No. C1 with the SET TEMP. or

button.

(2) Press the button.

(3) The number of group in which the error has been detected flashes.

Select the flashing group number to be corrected with the GROUP or button.

(4) Press the button to clear the set incorrect central control address.

After that, set a correct central control address.

(5) Press the button to terminate the duplicate address correction.

15-EN

Page 17

–17–

Compliant Manager

Installation Manual

8 ZONE SETTING

Register groups in a zone or cancel them.

(1) Change the mode to the zone setting mode.

• Press the button, button, and ZONE button simultaneously for at least 4 seconds.

(The displayed zone number flashes and the Compliant Manager enters the zone setting mode. Indicates

CODE No. “E1”.)

(2) Select the zone to be set.

• Select the zone number to be set with the ZONE or button, and then press the button to fix the

selection.

(When the selection has been fixed, the selected zone number flashes.)

• When selection of zone has been fixed, the marks of the group numbers registered in the zone light up.

(3) Change registration of groups in a zone.

Register groups in a zone.

1. Select the group number to be set with the GROUP or button. Pressing the SET TEMP. or

button skips the group number by +16 or by -16.

2. Press the button.

The marks of the registered group numbers light up. (

→ )

3. Pressing the button restores the state before the button is pressed.

4. To continue registration of groups, repeat this procedure from the beginning.

NOTE

No zone data has been stored at this time. If the ZONE or button is pressed before the registration

change is fixed, the set content for registration change is discarded.

(4) Fix the registration change.

Press the button. The set content for registration change is stored in the memory.

* After the memory write operation has been completed, the Compliant Manager exits the zone setting mode.

16-EN

Page 18

–18–

Compliant Manager

Installation Manual

9 CHANGING RETURN-BACK TIME/

TEMPERATURE SETTINGS

Return-back time and return-back temperature (CODE No. settings) can be changed using the following

procedure.

NOTE

Do not change the data of CODE No. 0A and the following item codes to prevent the remote controller from

malfunctioning.

Changing settings

The following shows an example of changing the time (factory setting) in the case of return-back 1 heating from 30

minutes to 45 minutes.

(1) Change the mode to the CODE No. setting change mode.

Press the , , and ZONE buttons simultaneously for at least 4 seconds.

( and CODE No. flash.)

(2) Set the data of the CODE No..

1. Change the CODE No. to “02” with the SET TEMP. or button.

2. Change the set data to “045” with the GROUP or button.

( and CODE No. are still flashing.)

3. Press the button to determine the data. and CODE No. change to lighting.

4. To continuously change other settings, repeat steps 1 to 3 above.

NOTE

At this time, the entered data of the selected CODE No. has not been saved yet.

(3) Determine the change.

Press the button to write the updated data in the memory of the remote controller.

* When the data has completely been written in the memory, the CODE No. setting change mode is exited.

CODE

No.

Item

Data

Factory setting Setting range

01 Return-back Enable/Disable 001 (Enabled) 000 (Disabled), 001 (Enabled)

02 Return-back 1 Time, Heating 030 (30 minutes) 1 to 60 minutes (in units of 1 minute)

03 Return-back 1 Time, Cooling 030 (30 minutes) 1 to 60 minutes (in units of 1 minute)

04 Return-back 1 Temp., Heating 018 (18°C) 18 to 29°C (in units of 1°C)

05 Return-back 1 Temp., Cooling 028 (28°C) 18 to 29°C (in units of 1°C)

06 Return-back 2 Time, Heating 030 (30 minutes) 1 to 60 minutes (in units of 1 minute)

07 Return-back 2 Time, Cooling 030 (30 minutes) 1 to 60 minutes (in units of 1 minute)

08 Return-back 2 Temp., Heating 018 (18°C) 18 to 29°C (in units of 1°C)

09 Return-back 2 Temp., Cooling 028 (28°C) 18 to 29°C (in units of 1°C)

17-EN

Page 19

–19–

Compliant Manager

Installation Manual

LINE 1

ZONE GROUP

Indoor unit

No.

Installation place ZONE GROUP

Indoor unit

No.

Installation place

133

234

335

436

537

638

739

840

941

10 42

11 43

12 44

13 45

14 46

15 47

16 48

17 49

18 50

19 51

20 52

21 53

22 54

23 55

24 56

25 57

26 58

27 59

28 60

29 61

30 62

31 63

32 64

18-EN

Page 20

–20–

Compliant Manager

Installation Manual

LINE 2

ZONE GROUP

Indoor unit

No.

Installation place ZONE GROUP

Indoor unit

No.

Installation place

133

234

335

436

537

638

739

840

941

10 42

11 43

12 44

13 45

14 46

15 47

16 48

17 49

18 50

19 51

20 52

21 53

22 54

23 55

24 56

25 57

26 58

27 59

28 60

29 61

30 62

31 63

32 64

19-EN

Page 21

–21–

Compliant Manager

Installation Manual

10TEST RUN

<Conducting a Test Run for the Compliant Manager>

• A test run is necessary to confirm that the Compliant Manager has recognized air conditioner units after the

central control address setting.

(1) Turn on the power of all connected air conditioners.

(2) Turn on the power of the Compliant Manager.

(3) Make sure that the number of air conditioners connected to each line (only main units when group control is

performed) equals the group number count displayed on the Compliant Manager.

(4) When these numbers are identical, there is no problem.

If they differ, set central control addresses again according to “Central Control Address (Group Number)

Setting.” Also make sure that there is no incorrect wiring.

<Conducting a Test Run for Air Conditioners>

(1) Press the button for at least 4 seconds. (The “TEST” indication lights in the test run mode.)

(2) Press the button and button. (Temperature cannot be set during a test run.)

(3) When the test run is completed, press the button to exit the test run mode.

11SPECIFICATIONS

Model BMS-CM1280TLE BMS-CM1280FTLE

Power supply 220-240 VAC 50/60Hz

Power consumption 3W 5W

Number of connectable indoor units (TCC-LINK) 128 Units (LINE1 64 Units, LINE2 64 Units)

Energy Monitoring Relay Interface (RS-485) 4 Units (max.)

Digital Input/Output Relay Interface 4 Units (max.)

Operating temperature 0 to 40°C to 90%RH

Dimensions -20 to +60°C (no condensation)

Mass 120 (H) × 180 (W) × 88 (D)

Weight 1.1Kg 1.2Kg

20-EN

Page 22

–22–

MEMO

21-EN

Page 23

–23– 22-EN

Page 24

DH84309201

Loading...

Loading...