Page 1

TOSHIBA Thermal Printer

B-852-R SERIES

Maintenance Manual

Document No. EO18-33018

Original Mar., 2006

(Revised )

PRINTED IN JAPAN

Page 2

EO18-33018

A

TABLE OF CONTENTS

Page

1. UNPACKING --------------------------------------------------------------------------------------------1- 1

1.1 PROCEDURES---------------------------------------------------------------------------------------------1- 1

1.2 CHECKS -----------------------------------------------------------------------------------------------------1- 2

2. MAJOR UNIT REPLACEMENT --------------------------------------------------------------------2- 1

2.1 OPENING AND REMOVING THE COVERS -------------------------------------------------------2- 1

2.2 LUBRICATION----------------------------------------------------------------------------------------------2- 2

2.3 REPLACING THE CPU PC BOARD------------------------------------------------------------------2- 3

2.4 REPLACING THE PANEL PC BOARD---------------------------------------------------------------2- 6

2.5 REPLACING THE STEPPING MOTOR--------------------------------------------------------------2- 8

2.6 REPLACING THE HEAD UP SENSOR, SLIT SENSOR (REWIND/FEED)

AND RIBBON MOTOR (REWIND/FEED) --------------------------------------------------------- 2- 10

2.7 REPLACING THE PLATEN --------------------------------------------------------------------------- 2- 14

2.8 REPLACING THE MEDIA SENSOR---------------------------------------------------------------- 2- 16

2.8.1 Feed Gap Sensor (TR) and Black Mark Sensor (Upper Side)---------------------- 2- 16

2.8.2 Feed Gap Sensor (LED) and Black Mark Sensor (Lower Side) -------------------- 2- 17

2.9 REPLACING THE PRINT HEAD --------------------------------------------------------------------- 2- 19

2.10 REPLACING THE PS UNIT AND REACTOR ---------------------------------------------------- 2- 20

3. PERIODIC MAINTENANCE PROCEDURE.............................................................................3- 1

4. TROUBLESHOOTING -------------------------------------------------------------------------------------------4- 1

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA

TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorised Service representative with regard to any queries you

may have in this manual.

Copyright © 2006

by TOSHIBA TEC CORPORATION

ll Rights Reserved

570 Ohito, Izunokuni-shi, Shizuoka-ken, JAPAN

Page 3

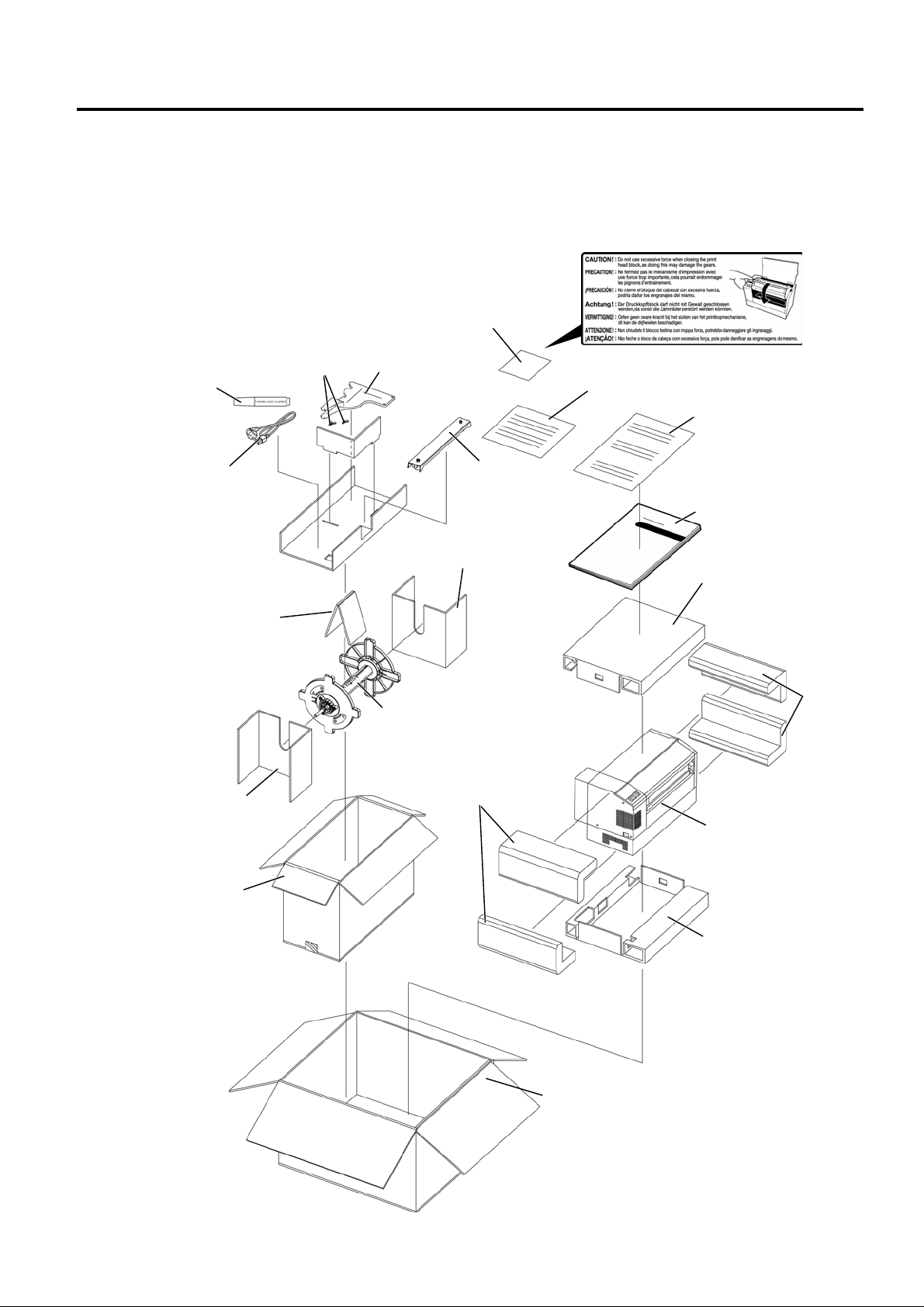

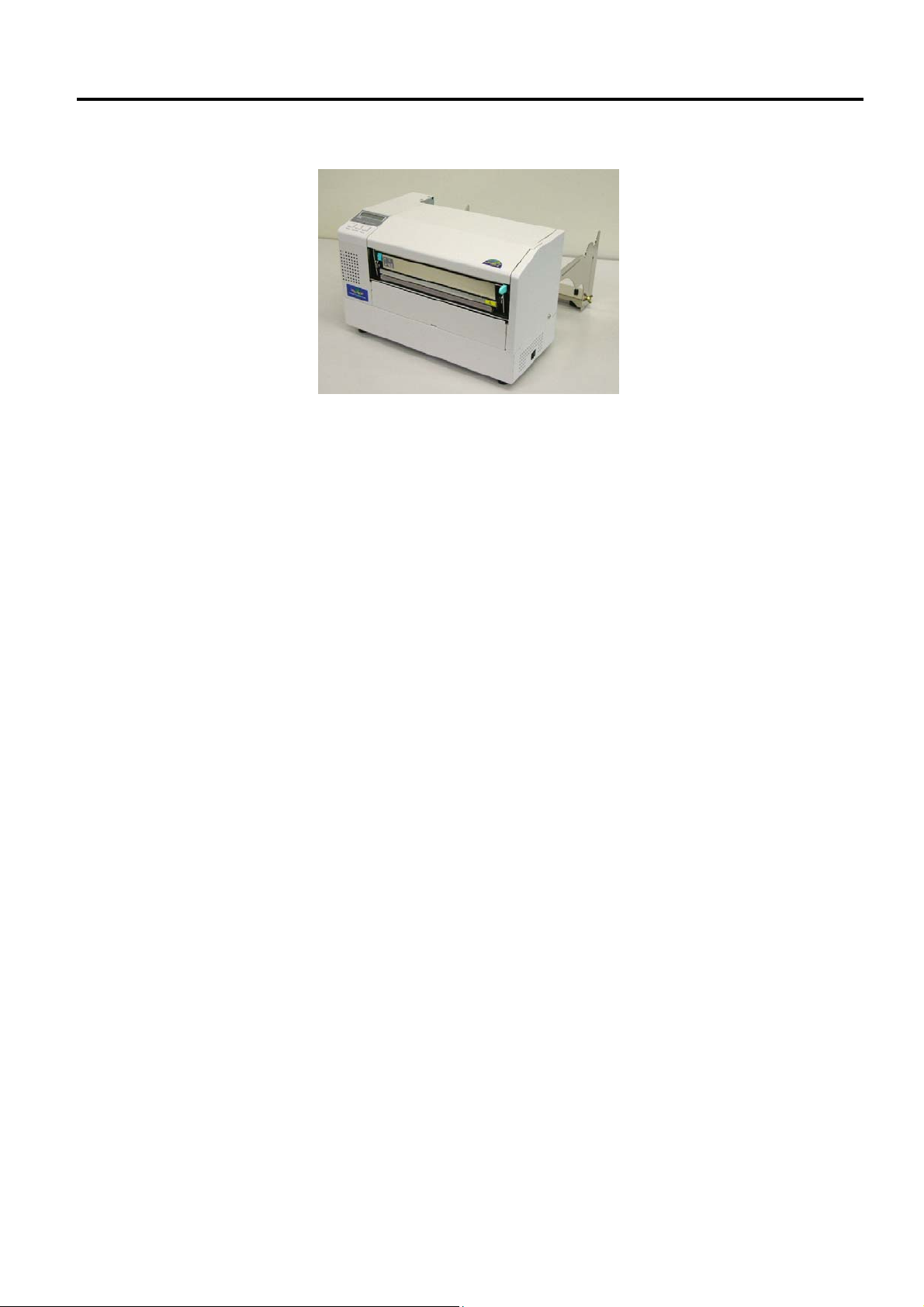

1. UNPACKING

A

A

1. UNPACKING

1.1 Procedure

1) Open the carton.

2) Unpack the accessories from the carton.

3) Unpack the pads and the printer from the carton.

Print Head Cleaner

Power Cord

Supply Holder Pad B

Supply Holder Pad A

ccessory Carton

Wing Bolt

Caution Label

(QQ/QP model)

Supply Holder

Frame (L) and (R)

Supply Holder

Base

Supply Holder

Pad

Supply Holder

Unit

Cushion

(Revision Date: Sep. 28, 2007

Caution Label Instruction

(QQ/QP model)

Unpacking Instruction

Owner’s Manual

Top Pad

B-852-R Printer

Bottom Pad

EO18-33018

1.1 Procedure

Cushion

Carton

1- 1

Page 4

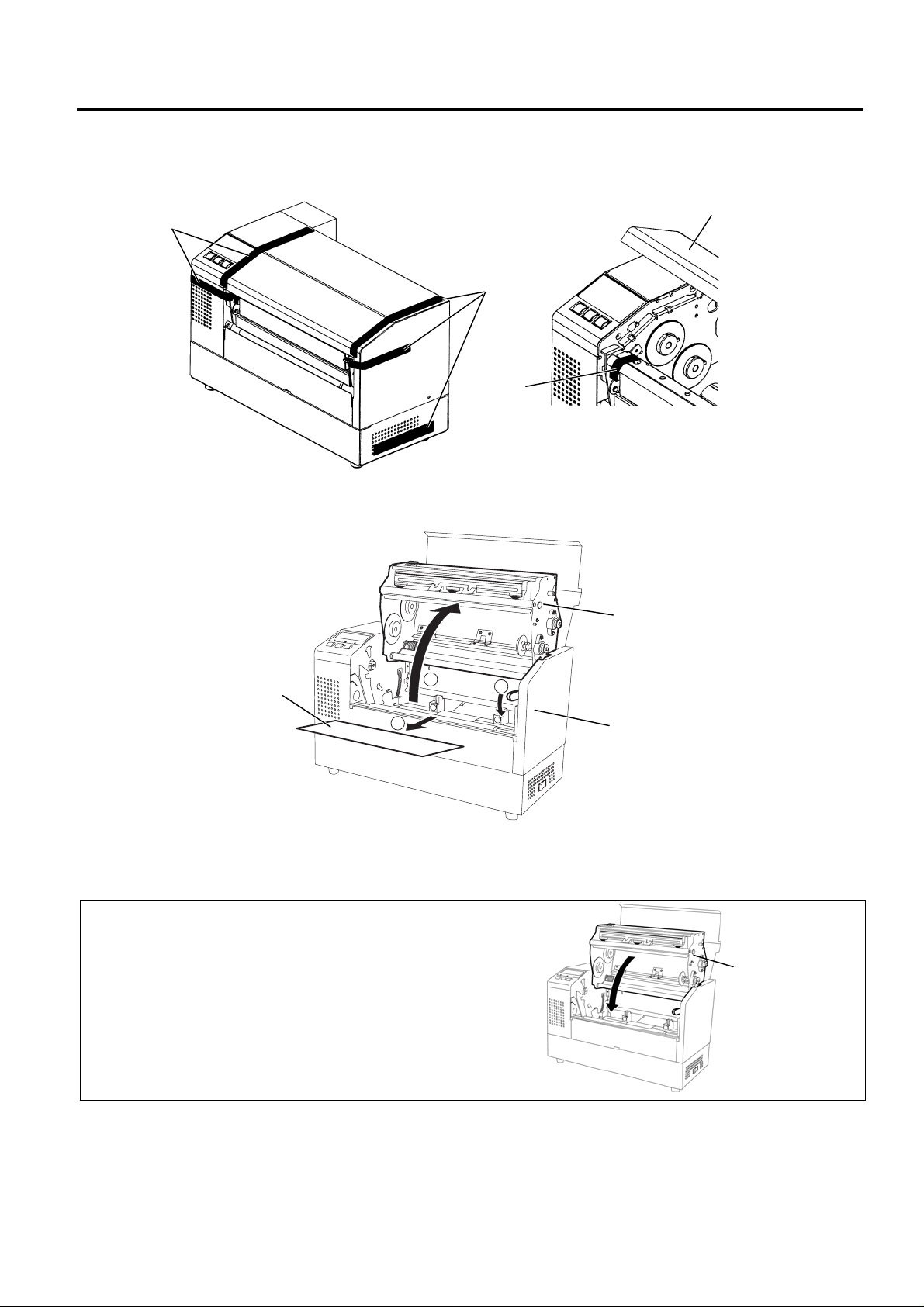

1. UNPACKING

(Revision Date: Sep. 28, 2007)

4) Remove the five pieces of tape from the printer.

5) Open the top cover.

6) Remove the one piece of tape.

Tape

Top Cover

Tape

Tape

7) Press down the head block release lever (1) and raise the print head block (2).

8) Remove the print head pad (3).

Print Head Block

Print Head Pad

2

1

3

Head Block Release Lever

9) Place the printer on a level surface.

10) Please attach the supplied Caution Label to an easily visible position on the printer. (QQ/QP

model)

CAUTION!

Do not use excessive force when closing the print head block,

as doing this may damage the gears.

Print Head Block

EO18-33018

1.2 Checks

1.2 Checks

1) Check for damage or scratches on the machine.

2) Confirm that none of the accessories are missing.

NOTE: Keep the carton and pads for later transport.

1- 2

Page 5

2. MAJOR UNIT REPLACEMENT

r

A

EO18-33018

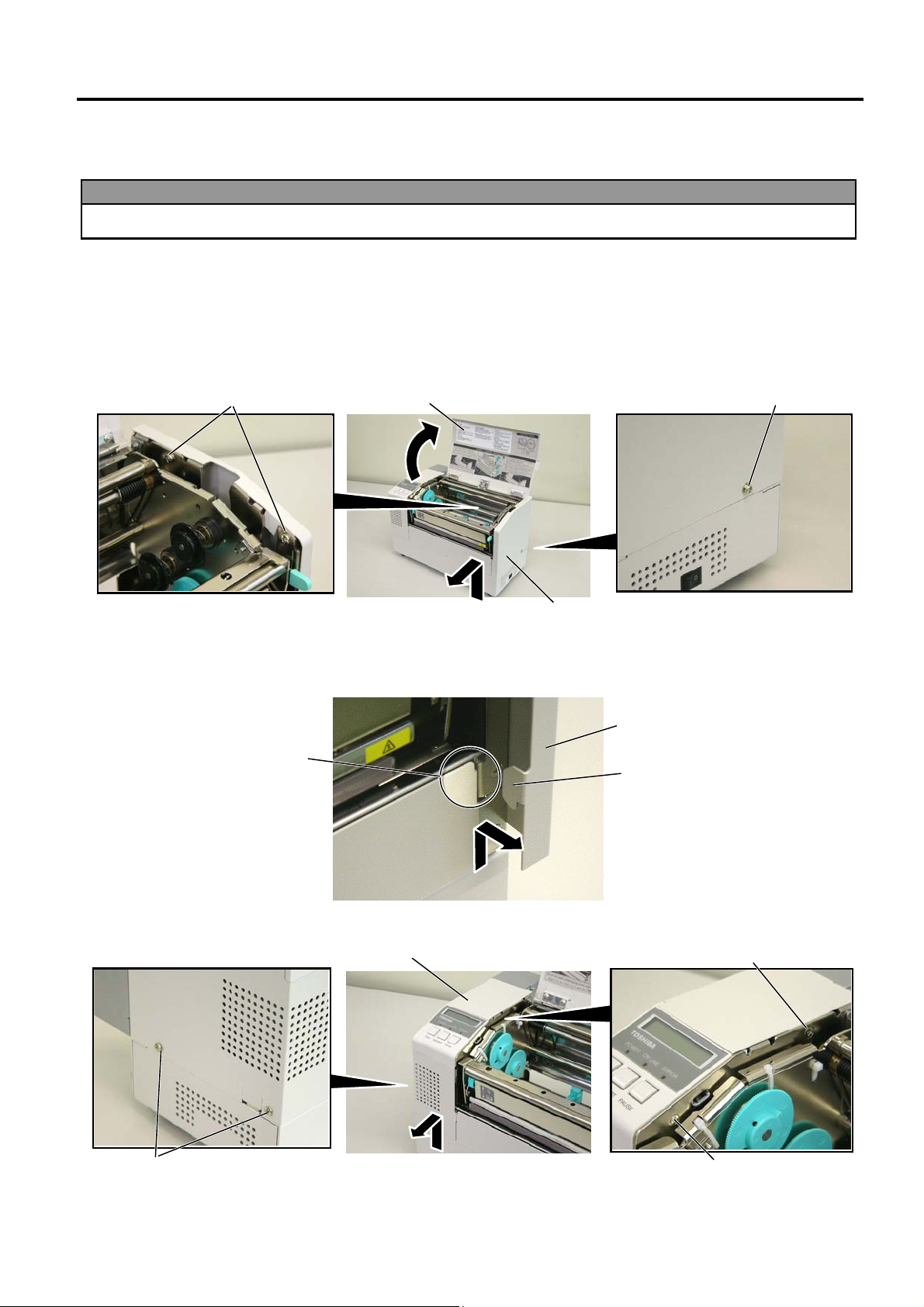

2.1 OPENING AND REMOVING THE COVERS

2. MAJOR UNIT REPLACEMENT

Disconnect the power cord before replacing the parts.

WARNING!

2.1 OPENING AND REMOVING THE COVERS

1) Turn the power off.

2) Open the top cover.

3) Remove the three B-4x6 screws to detach the side cover R.

B-4x6 Screw

Top Cove

B-4x6 Screw

Side Cover R

NOTE: After removing the screws, unhook the side cover R from portion A by lifting and moving it toward

the front of the printer.

Side Cover R

Portion

Hook

4) Remove the two B-4x6 screws, PT-3x8 screw and D-4x6 screw to detach the side cover L.

Side Cover L

D-4x6 Screw

B-4x6 Screw

2-1

TT-3x8 Screw

Page 6

2. MAJOR UNIT REPLACEMENT

2.1 OPENING AND REMOVING THE COVERS

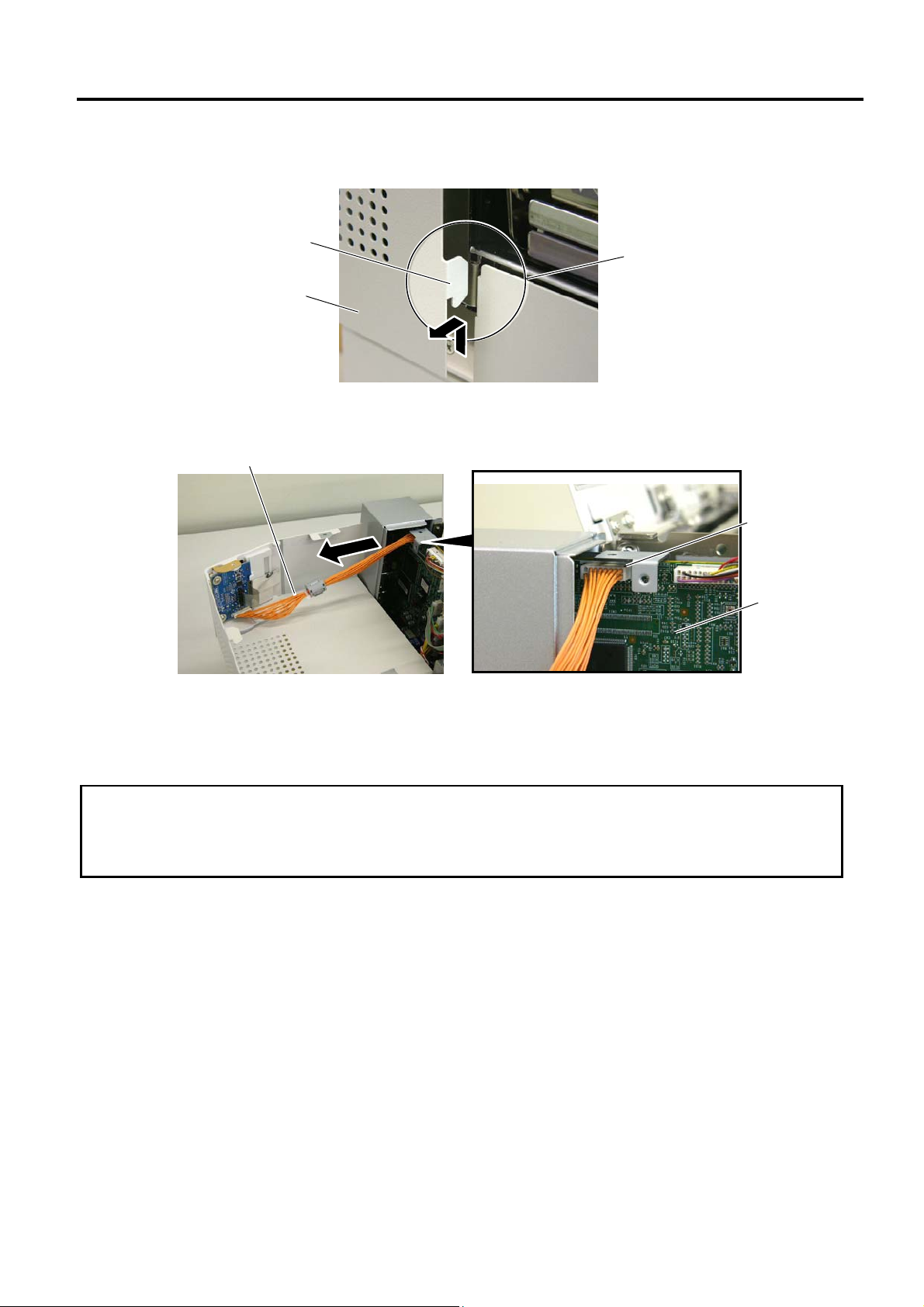

NOTE: After removing the screws, unhook the side cover L from portion B by lifting and moving it toward

the front of the printer.

EO18-33018

Hook

Side Cover L

Portion B

5) Disconnect the operation panel harness from CN13 on the MAIN PC Board.

Operation Panel Harness

CN13

MAIN PC

Board

NOTE: Instructions to open the top cover and to detach the side covers L and R are omitted from each

removal/installation procedure provided below.

2.2 LUBRICATION

CAUTION!

1. Lubrication: During parts replacement

2. Kinds of oil: FLOIL G-488: 1 Kg can. (Parts No. 19454906001)

3. Do not spray the inside of the printer with lubricants. Unsuitable oil can damage the mechanism.

All machines are generally delivered in their best condition. Efforts should be made to keep them that

way. Lack of oil, or the presence of debris or dust, may cause an unexpected failure. To maintain in

optional operating condition, periodically clean the machine and apply the proper kind of oil to each part

in which lubrication is needed.

Although the frequency of lubrication varies according to how often the machine is used, as a minimum

it is necessary to lubricate before any part becomes dry. It is also necessary to wipe off excessive oil

or it will collect dirt.

2-2

Page 7

2. MAJOR UNIT REPLACEMENT

w

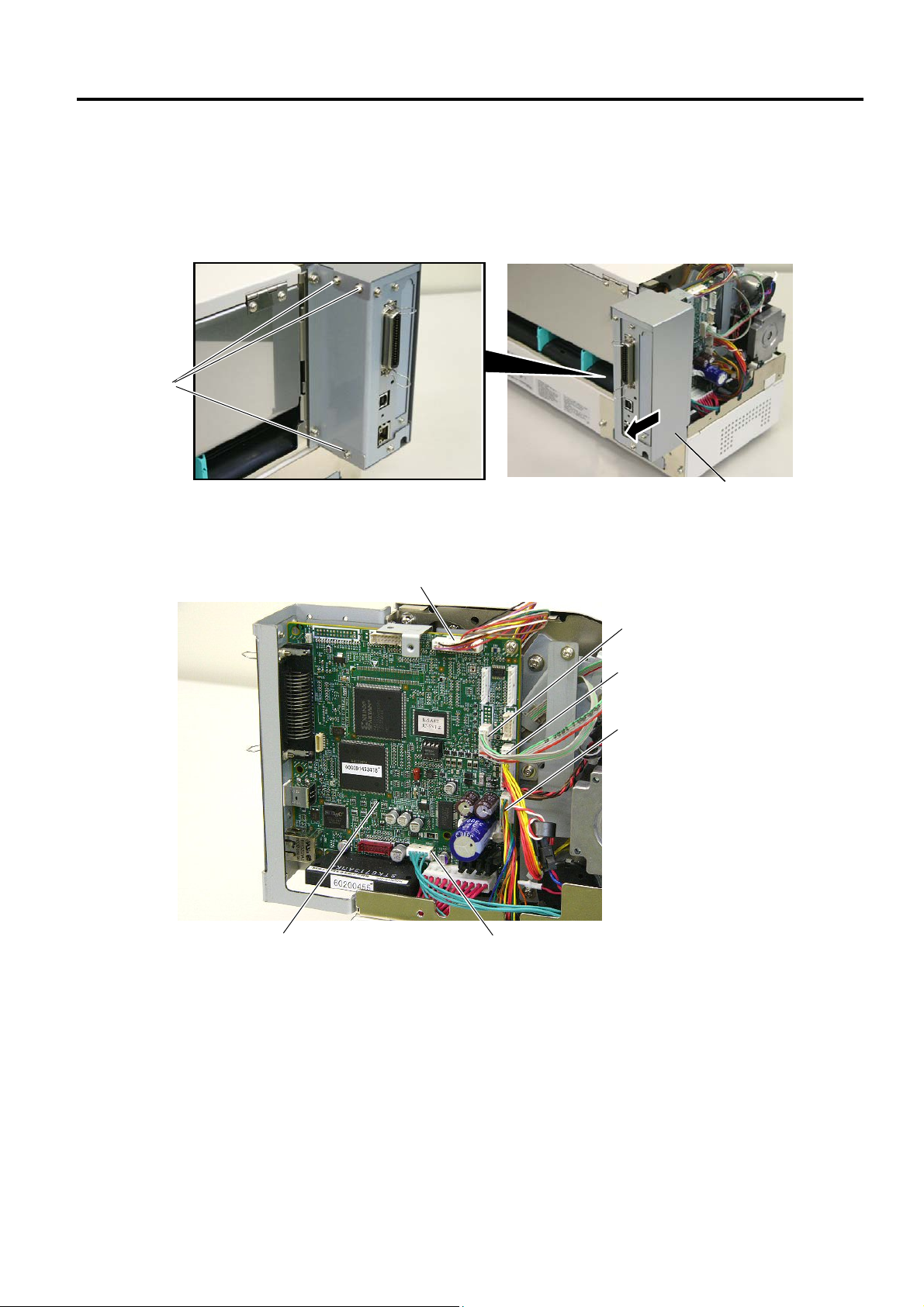

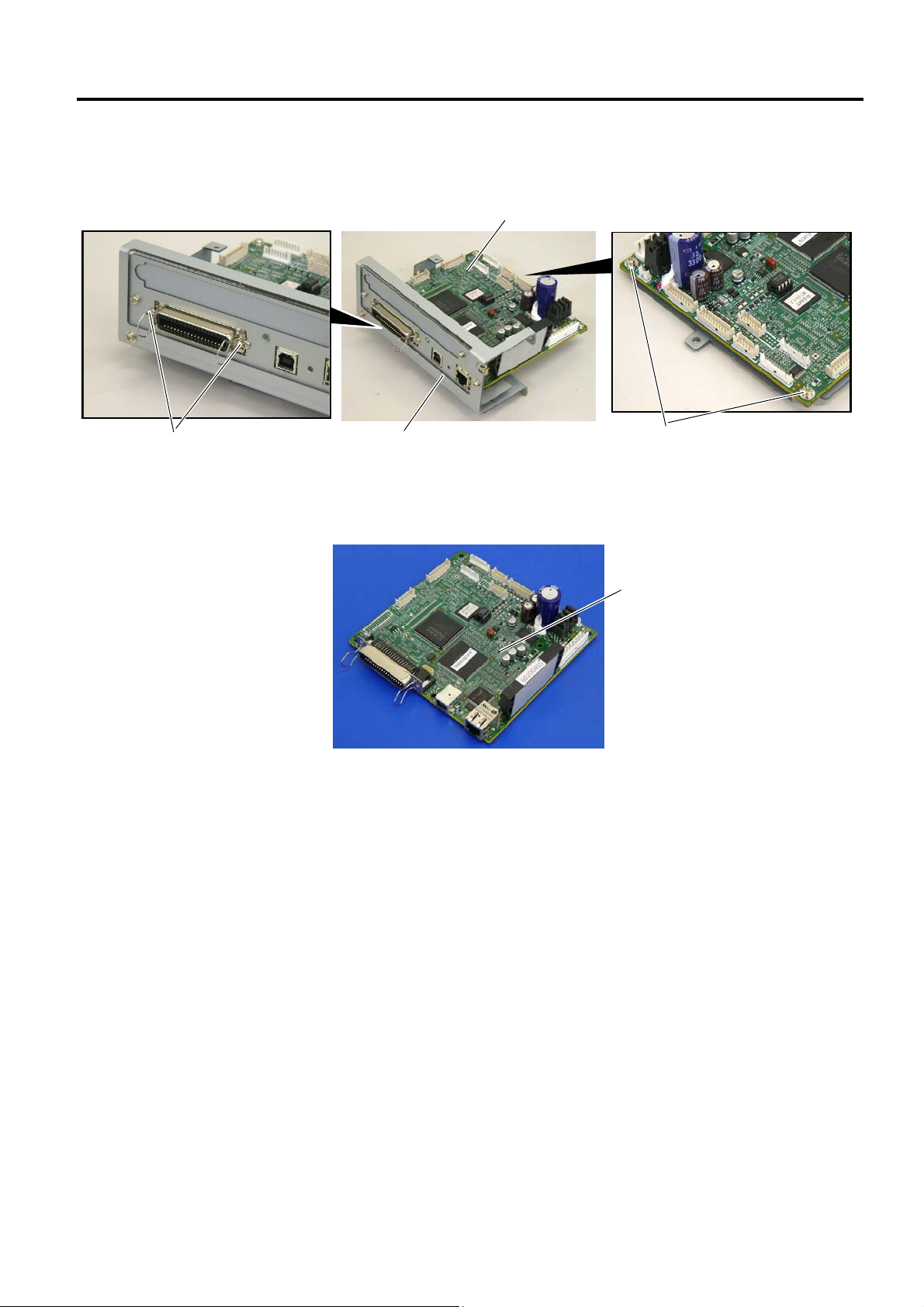

2.3 Replacing the MAIN PC Board

2.3 Replacing the MAIN PC Board

1) Prior to replacing the MAIN PC board, print out the parameter settings for future reference.

2) Remove the side cover L from the printer. (Refer to Section 2.1.)

3) Remove the three SMW-3x6 screws to detach the rear frame cover.

SMW-3x6

Scre

EO18-33018

Rear Frame Cover

4) Disconnect the harnesses from CN1, CN2, CN5, CN8, CN9 and CN500 on the MAIN PC board.

CN9 (Print Head Harness, Signal)

CN5 (Media Sensor Harness)

CN2 (Ribbon Motor Harness)

CN1 (Print Head Harness, Power)

MAIN PC Board

CN500 (Stepping Motor Harness)

2-3

Page 8

2. MAJOR UNIT REPLACEMENT

y

y

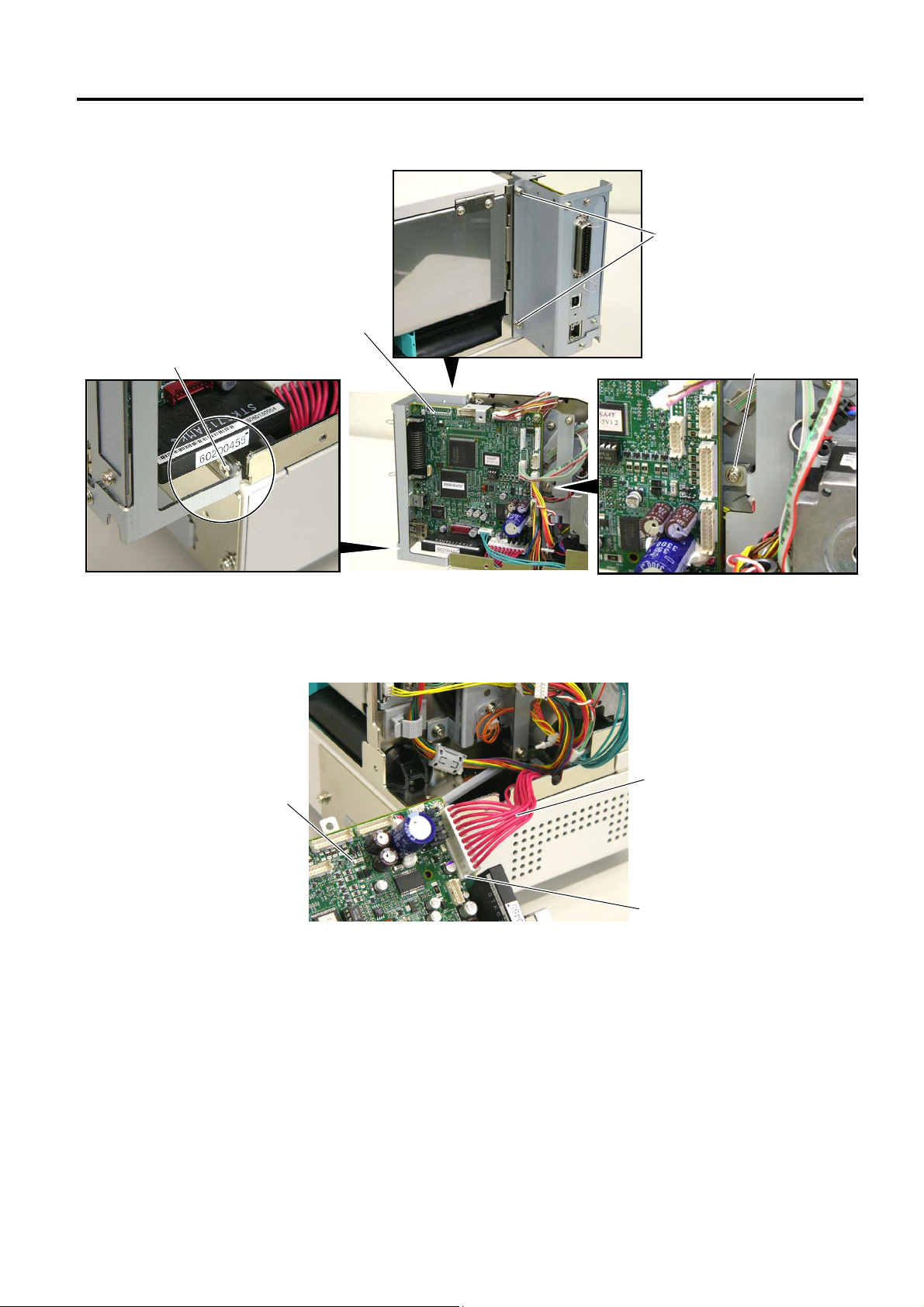

4) Remove the two SMW-4x8 screws, SMW-3x6 screw and B-3x6 screw.

EO18-33018

2.3 Replacing the MAIN PC Board

SMW-4x8 Screw

B-3x6 Screw

MAIN PC Board Ass’

SMW-3x6 Screw

5) Disconnect the power harness from CN8 on the MAIN PC board ass’y, then remove the MAIN PC

board ass’y from the printer.

MAIN PC Board Ass’

Power Harness

CN8

2-4

Page 9

2. MAJOR UNIT REPLACEMENT

2.3 Replacing the MAIN PC Board

EO18-33018

6) Remove the two B-3x6 screws and the two SMW-3x6 screws, then remove the MAIN PC board

from the MAIN PCB support frame.

MAIN PC Board

B-3x6 Screw

MAIN PCB Support Frame

SMW-3x6

7) Replace the MAIN PC board with a new one, and reassemble in the reverse order of removal.

MAIN PC Board

8) After replacing the MAIN PC board, perform the following operations.

(1) Perform a RAM clear.

(2) Restore the printer system setting according to the printout of the parameter settings.

(3) Perform a media sensor adjustment.

(4) Perform a test print to print to confirm that the printer works properly.

2-5

Page 10

2. MAJOR UNIT REPLACEMENT

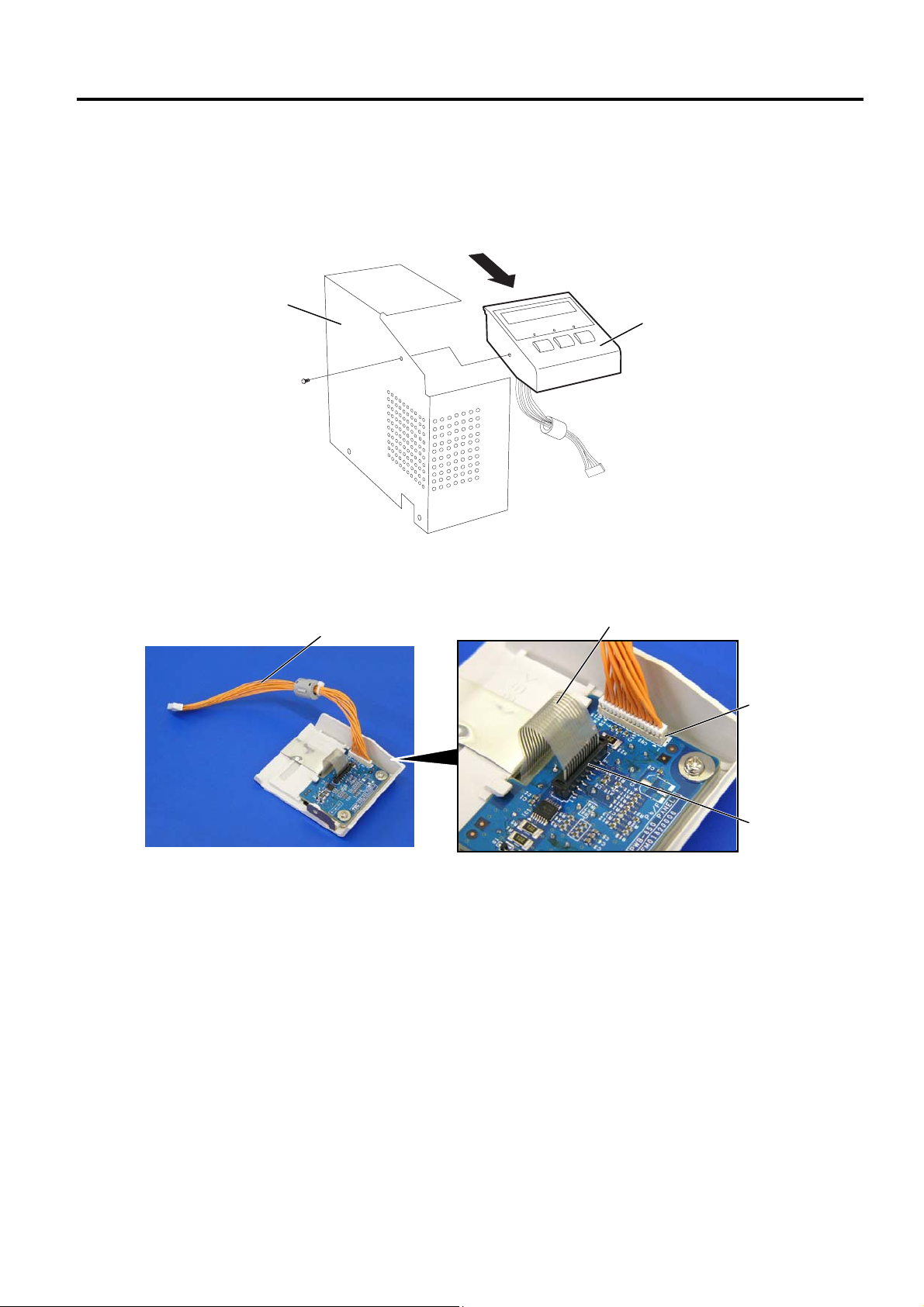

2.4 Replacing the Panel PC Board

EO18-33018

2.4 Replacing the Panel PC Board

1) Remove the side cover L from the printer. (Refer to Section 2.1.)

2) Remove the PT-3x8 screw to detach the operation panel ass’y from the side cover L in the direction

indicated by the arrow.

3) Disconnect the operation panel harness from CN2 on the panel PC board.

4) Disconnect the flat cable from CN3 on the panel PC board.

Side Cover L

PT-3x8 Screw

Operation Panel Harness

Operation Panel Ass’y

Flat Cable

CN2

CN3

2-6

Page 11

2. MAJOR UNIT REPLACEMENT

2.4 Replacing the Panel PC Board

5) Remove the two PT-3x6 screws and W-4 washers to detach the panel PC board from the operation

EO18-33018

panel cover.

Operation Panel Cover

Flat Cable

E Plate

Key Switch

Panel PC Board

W-4

W-4

PT-3x6 Screw

6) Replace the panel PC board with a new one, then reassemble in the order removal.

7) Turn the power on, then confirm that the LCD message is displayed properly.

2-7

Page 12

2. MAJOR UNIT REPLACEMENT

r

w

r

2.5 Replacing the Stepping Motor

2.5 Replacing the Stepping Motor

1) Remove the side cover L and MAIN PC board ass’y from the printer.

(Refer to Sections 2.1 and 2.3.)

2) Remove the two SMW-3x6 screws to detach the PCB support plate from the printer.

SMW-3x6 Screw

PCB Support Plate

3) Remove the two SM-4x8 screws to detach the stepping motor from the printer.

EO18-33018

SM-4x8 Screw

Stepping Moto

SM-4x8 Scre

4) Disconnect the harness from the stepping motor.

Stepping Moto

Stepping Motor Harness

5) Replace the stepping motor with a new one, then reassemble in the reverse order of removal.

6) Perform a test print to print to confirm that the printer works properly.

2-8

Page 13

2. MAJOR UNIT REPLACEMENT

r

r

2.5 Replacing the Stepping Motor

EO18-33018

NOTE:

Apply FLOIL to the stepping motor’s pulley and the motor gear when reassembling the stepping motor.

Motor Gea

Pulley

Stepping Moto

2-9

Page 14

2. MAJOR UNIT REPLACEMENT

r

r

A

r

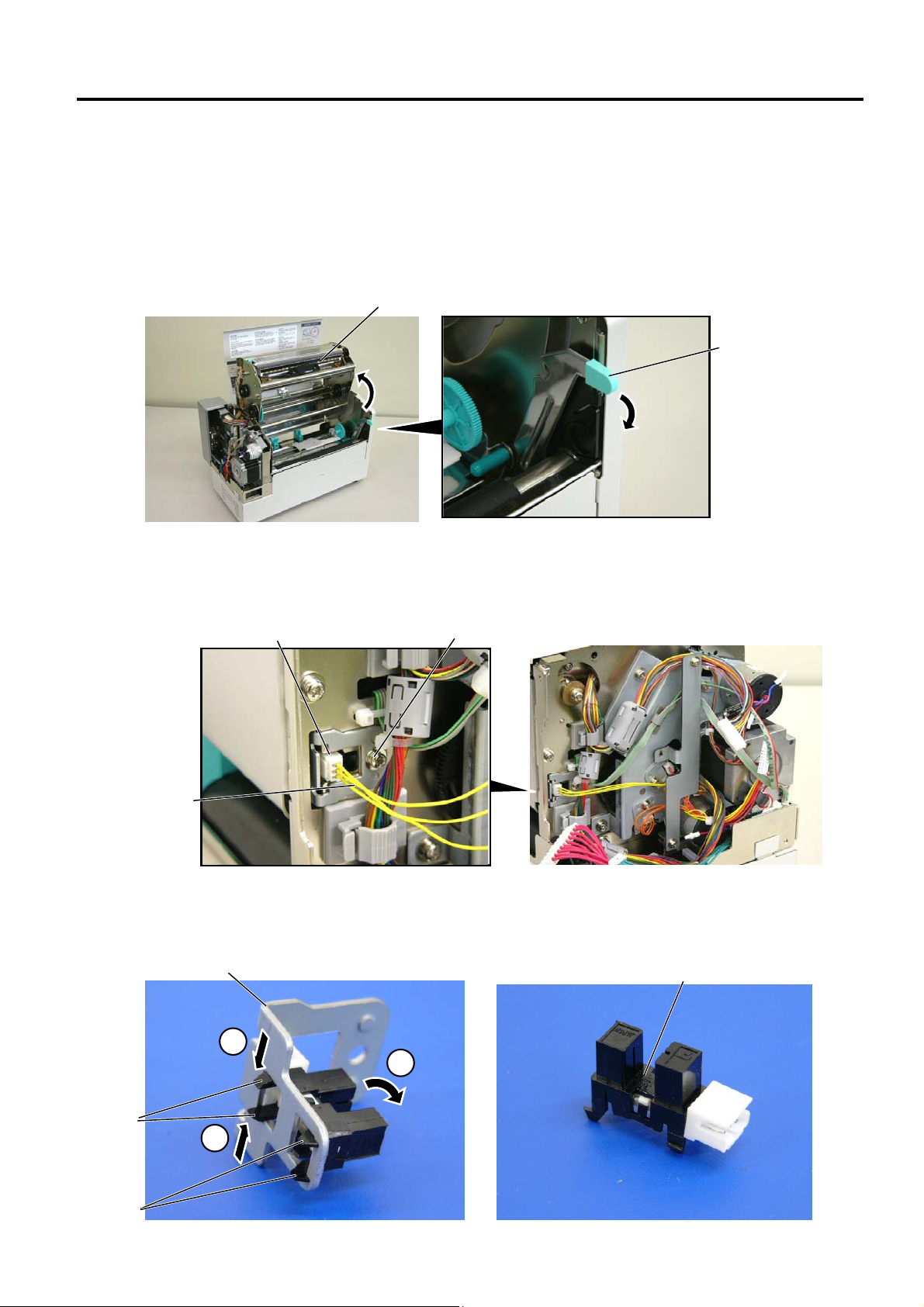

2.6 Replacing the Head Up Sensor, Slit Sensor (Rewind/Feed) and Ribbon Motor (Rewind/Feed)

EO18-33018

2.6 Replacing the Head Up Sensor, Slit Sensor (Rewind/Feed) and Ribbon

Motor (Rewind/Feed)

Prior to replacing the sensors or ribbon motor, perform the following operations.

1) Open the top cover. (Refer to Section 2.1.)

2) Remove the side cover L from the printer. (Refer to Section 2.1.)

3) Press down the head block release lever and raise the print head block.

Print Head Block

Head Block

Release Lever

4) Remove the MAIN PC board ass’y. (Refer to Section 2.3.)

2.6.1 Replacing the Head Up Sensor

1) Remove the sensor harness and the SMW-3x6 screw, then remove the head up sensor from the

printer.

Head Up Senso

Senso

Harness

SMW-3x6 Screw

2) Push and release the hook A, then release the hook B to remove the head up sensor from the

sensor holder.

Sensor Holde

Head Up Sensor

Hook

Hook B

1

2

1

2-10

Page 15

2. MAJOR UNIT REPLACEMENT

2.6 Replacing the Head Up Sensor, Slit Sensor (Rewind/Feed) and Ribbon Motor (Rewind/Feed)

EO18-33018

3) Replace the head up sensor with a new one, then reassemble in the reverse order of removal.

4) Perform a test print to print to confirm that the printer works properly.

NOTE: Be careful not to damage the slit sensor (Rewind/Feed) when replacing it, as this may cause a

malfunction.

2.6.2 Replacing the Slit Sensor (Rewind/Feed)

1) Remove the two SMW-3x6 screws, then remove the PCB support plate from the printer.

PCB Support Plate

SMW-3x6 Screw

2) Remove the media sensor harness from the clamp.

3) Remove the two SMW-4x6 and the two D-3x6 screws, then remove the motor block from the

printer.

SMW-4x6 Screw

Sensor Harness

Motor Block

SMW-4x6 Screw

Cable Clamp

D-3x6 Screw

4) Remove the three SMW-3x6 screws and sensor harnesses, then remove the slit sensor

(rewind/feed) from the motor block.

Slit Sensor (Feed)

Sensor Harness (Red)

Sensor Harness (Brown)

Slit Sensor (Rewind)

Motor Block

Sensor Harness (Orange)

Slit Sensor (Feed)

SMW-3x6 Screw

2-11

Page 16

2. MAJOR UNIT REPLACEMENT

A

r

2.6 Replacing the Head Up Sensor, Slit Sensor (Rewind/Feed) and Ribbon Motor (Rewind/Feed)

EO18-33018

5) Push and release the hook A, then release the hook B to remove the slit sensor from the sensor

holder.

Sensor Holde

Hook

Hook B

1

2

1

Slit Sensor

6) Replace the slit sensor with a new one, then reassemble in the reverse order of removal.

7) Perform a test print to print to confirm that the printer works properly.

NOTES:

1. The colors of the sensor harnesses are different according to the sensor to be connected.

2. Be careful not to damage the slit sensor (Rewind/Feed) when replacing it, as this may cause a

malfunction.

2.6.3 Replacing the Ribbon Motor (Rewind/Feed)

1) Prior to replacing the ribbon motor, print out the maintenance counter for future reference.

2) Remove the SMW-2.6x6 screws to remove the ribbon motor (rewind/feed).

SMW-2.6x6 Screw

Ribbon Motor (Rewind)

Ribbon Motor (Feed)

SMW-2.6x6 Screw

3) Replace the ribbon motor with a new one, then reassemble in the reverse order of removal.

2-12

Page 17

2. MAJOR UNIT REPLACEMENT

r

r

2.6 Replacing the Head Up Sensor, Slit Sensor (Rewind/Feed) and Ribbon Motor (Rewind/Feed)

EO18-33018

NOTES:

1. After replacing the ribbon motor, refer to Section System Mode Manual to perform a Maintenance

Counter clear.

2. Secure the ribbon motors while inserting a 0.1 mm-thick paper (or folded backing paper) between

the ribbon motor pulley and the idler gear to adjust the backlash. After the ribbon motors is

secured, remove the paper.

Ribbon Motor Pulley (Rewind)

Idler Gea

Ribbon Moto

Pulley (Feed)

Idler Gear

4) Perform a test print to print to confirm that the printer works properly.

2-13

Page 18

2. MAJOR UNIT REPLACEMENT

2.7 Replacing the Platen

EO18-33018

2.7 Replacing the Platen

1) Prior to replacing the platen, print out the maintenance counter for future reference.

2) Open the top cover, and raise the print head block by pressing down the head block release lever.

Top Cover

Print Head

Head Block

2

1

Release Lever

3) While pulling the top part of the platen holders L and R to the ce nter of the printer, move them to the front

of the printer to remove.

4) Push the platen and strip plate to the left side and then, move them to the front side to remove.

Platen Holder L

Platen

Platen Holder R

Shaft Holder

Strip Plate

5) Remove the shaft holder from the platen.

NOTE: Be careful not to damage the shaft holder when removing it.

Platen

Shaft Holder

2-14

Page 19

2. MAJOR UNIT REPLACEMENT

2.7 Replacing the Platen

EO18-33018

6) Replace the platen with a new one, then reassemble in the reverse order of removal.

NOTE: When reassembling, confirm the orientation of the shaft holder. (See the picture below.)

Platen

Shaft Holder

7) Perform a test print to confirm that the printer works properly.

2-15

Page 20

2. MAJOR UNIT REPLACEMENT

p

)

A

2.8 REPLACING THE MEDIA SENSOR

EO18-33018

2.8 REPLACING THE MEDIA SENSOR

2.8.1 Feed Gap Sensor (TR) and Black Mark Sensor (Upper Side)

1) Open the top cover and raise the print head block.

2) Pull up the two tabs of the sensor case cap to remove it from the sensor block.

3) Remove the feed gap sensor (TR) and black mark sensor (upper side) from the sensor case.

Disconnect the media sensor harness.

Tab

Sensor Case Cap

Media Sensor Harness

Black Mark Sensor

(Upper Side)

Sensor Case

Feed Ga

Sensor (TR

Hook

Front side of

the printer

4) Replace the sensors with new ones, then reassemble in the reverse order of removal.

NOTES: 1. When reassembling the sensor case cap, fit the hooks of the sensor case into portion A of

the sensor case cap.

2. When reassemblin g the sensors, align the pins on the sensor case with the holes of the

sensors.

3. Connect the harness including the green wire to the black mark sensor (Upper side).

4. Pass the media sensor harness between the harness guides.

Black Mark Sensor (Upper side)

(Number of pins: 3)

Green

Sensor Case

Pin

Feed Gap Sensor (TR)

Sensor Guide

Media Sensor Harness

Front side of the printer

5. Since connectors of the sensors are small, be careful not to break their pins.

2-16

Page 21

2. MAJOR UNIT REPLACEMENT

A

2.8.2 Feed Gap Sensor (LED) and Black Mark Sensor (Low er Side)

2.8 REPLACING THE MEDIA SENSOR

EO18-33018

1) Remove the platen holder R, platen holder L, platen, and strip plate from the printer

2) Remove the SMW-4x8 screw to detach the front cover from the printer.

3) Unhook the two springs.

4) Remove the two SMW-3x6 screws to detach the sensor block from the pritner.

A

SMW-3x6 Screw

Sensor Block

Spring

SMW-4x8 Screw

To CN15 on the

CPU PC board

ass’y

A

Spring

Front Cover

5) Turn over the sensor block.

6) Pull up the two tabs of the sensor case cap to remove it from the sensor case.

7) Remove the feed gap sensor (LED) and black mark sensor (lower side) from the sensor case,

and disconnect the media sensor harness from each sensor.

Tab

Sensor Case Cap

Black Mark Sensor

(Lower Side)

Front side of

the printer

Media Sensor Harness

Sensor Case

Feed Gap Sensor (LED)

Hook

8) Replace the sensor with a new one, then reassemble in the reverse order of removal.

2-17

Page 22

2. MAJOR UNIT REPLACEMENT

2.8 REPLACING THE MEDIA SENSOR

EO18-33018

NOTES: 1. When reassembling the sensor case cap, fit the hooks of the sensor case into

portion A of the sensor case cap.

2. When reassembling the sensors, align the pins on the sensor case with the holes of

the sensors.

3. Connect the harness including the green wire to the black mark sensor (lower side).

4. Pass the media sensor harness between the harness guides.

Front side of

the printer

Black Mark Sensor

(Lower side)

Green

Sensor Case

Pin

Feed Gap Sensor (LED)

(Number of pins: 2)

Sensor Guide

Media Sensor Harness

5. Since connectors of the sensors are small, be careful not to break their pins.

2-18

Page 23

2. MAJOR UNIT REPLACEMENT

2.9 REPLACING THE PRINT HEAD

EO18-33018

2.9 REPLACING THE PRINT HEAD

CAUTION:

1. Never touch the print head element when handling the print head.

2. Never touch the connector pins to avoid a breakdown of the print head by static electricity.

3. Never remove the screws which secure the print head to the bracket. Doing so may cause

improper print quality.

4. Never disassemble the head block frame. Doing so may cause a print failure, such as ribbon

wrinkle, blurred print, etc.

NEVER remove these screws.

Print Head

Head Block Frame

Bracket

1) Open the top cover and raise the print head block.

2) Push the print head ass’y to the right side, lift it in the direction of the arrow, and release it from the

print head fixing pin.

3) Disconnect the print head harnesses from the three connectors of the print head.

Hole

Print Head Ass’y

Print Head Harness

Spring

Print Head Fixing Pin

Print Head Harness

5) Replace the print head with a new one, then reassemble in the reverse order of removal.

NOTES: 1. Install the print head in position by fitting its holes into the spring and print head fixing

pin.

2. After replacing the print head, refer to Section 6.8 to perform a Maintenance Counter

Clear.

2-19

Page 24

2. MAJOR UNIT REPLACEMENT

w

2.10 Replacing the PS Unit and Reactor

EO18-33018

(Revision Date: May 21, 2007)

2.10 Replacing the PS Unit and Reactor

1. Hazardous electrical parts. Before disassembling the unit, unplug the power cord from the mains.

2. As the printer block and PS unit are heavy, be careful not to pinch your fingers or drop it on your

feet.

3. The PS unit should be replaced as a unit. Never disassemble the PS unit. Doing so may cause a

fire or machine failure.

WARNING!

NOTE: The reactor is installed in the B-852-TS22-QP-R and B-852-TS22-CN models.

1) Remove the side covers L, side cover R and MAIN PC Board from the printer.

2) Raise the print head block.

3) Remove the platen.

4) Remove the four SMW-4x8 screws to remove the power supply block from the printer block.

SMW-4x8 Screw

SMW-4x8 Scre

SMW-4x8 Screw

SMW-4x8 Screw

Printer Block

Power Supply Block

2-20

Page 25

2. MAJOR UNIT REPLACEMENT

t

5) Disconnect the PSU harness from CN4 on the PS unit.

EO18-33018

(Revision Date: May 21, 2007)

2.10 Replacing the PS Unit and Reactor

PS Uni

PSU Harness

CN4

6) Disconnect the harnesses from CN1 on the PS unit. For the QP and CN models, disconnect the

harness from CN2, too.

7) Remove the two SMW-4x8 screws to detach the PS unit from the PSU base.

8) Remove the SMW-4x8 screws to detach the reactor from the PSU base. (QP and CN models)

SMW-4x8 Screw

CN2

B

Inlet Harness

A

CN1

SMW-4x8 Screw

Reactor (QP and CN models)

PS Unit

Reactor Harness

B

PSU Base

A

2-21

Page 26

2. MAJOR UNIT REPLACEMENT

t

2.10 Replacing the PS Unit and Reactor

EO18-33018

9) Replace the PS unit or reactor with a new one, then reassemble in the reverse order of removal.

Pass the reactor harness and inlet harness through the cut in the PS unit frame. Care must be taken

not to pinch the harnesses in the frame. Failure to do this may break the harnesses causing a fire or

electric shock.

WARNING!

Inlet

PSU Base

Reactor Harness

Inlet Harness

Cu

PS Unit

2-22

Page 27

3. PERIODIC MAINTENANCE PROCEDURE

3. PERIODIC MAINTENANCE PROCEDURE

3. PERIODIC MAINTENANCE PROCEDURE

EO18-33018

1. Be sure to turn the power off before cleaning the cutter unit.

2. As the cutter blade is sharp, care should be taken not to injure yourself when cleaning.

WARNING!

All machines are generally delivered in their best condition. To maintain optimal operating condition

and help gain maximum performance and life of machines, we would recommend you to conduct

periodic maintenance. Doing this is also effective in preventing unexpected troubles and avoiding

wasteful system down time, by which more benefit is produced to your customers and greater reliance

is placed on the product quality.

Please refer to the following general maintenance procedure and perform periodic servicing.

NOTE: Before starting the periodic maintenance, be sure to read carefully and understand the Service

Manuals, especially warnings, cautions and adjustment.

1. Ask an operator or a manager about any machine trouble.

2. Check the run distance on the maintenance counter.

3. Unplug the power cord, and then open the top cover and the head block.

Head

Block

Top

Cover

Power Cord

4. Clean the inside of the printer.

1) The entire inside of the printer should be cleaned.

2) Wipe the platen with a cloth moistened with alcohol.

Platen

3-1

Page 28

3. PERIODIC MAINTENANCE PROCEDURE EO18-33018

Element

Media Sensor

3. PERIODIC MAINTENANCE PROCEDURE

3) Clean the print head elements with the TOSHIBA TEC-approved print head cleaner.

(Please instruct your customers to clean them daily.)

Print Head Cleaner

Print Head

Print Head

4) Remove any paper dust and glue of the label. Wipe off moving range of the media sensor.

Media Path

Moving range of the

3-2

Page 29

3. PERIODIC MAINTENANCE PROCEDURE EO18-33018

3. PERIODIC MAINTENANCE PROCEDURE

5. Apply FLOIL G-488 to the cutter unit using a soft cloth.

6. Clean the Cutter Blade with a cotton swab moistened with absolute ethyl alcohol.

Cutter Blade

Cutter Unit

7. Confirm that the problem occurs as reported, and then take correct ive action.

8. Replace the following parts periodically, if necessar y. The following table shows approximate

product life for each part.

No.

Part Name Part No.

Standard interval of

replacement

1 Cutt er unit (Option) G0-00415000 1,000,000 cuts

2 Platen FMCC0054701 50 km

NOTES: 1. The above values of the cutter life are obtained on condition that the periodically

maintained cutter is used with TOSHIBA TEC-approved supplies by the proper

method described in the manuals.

2. The above values differ depending on t he t hickness and subst ances of the media to

be used. When using t he cut ter to cut the labels, be sure to cut the backing paper.

Failure to do this may cause the glue to stick to the cutter and shorten the cutter life.

8. Confirm each part adjustment . Make any necessary adjustments.

9. Conduct the following tests and make sure that there is no problem.

1) Print test with TOSHIBA TEC-approved media and ribbon. (Print tone, print head position,

etc.)

2) Paper skew

3) Print star t position adjustment (Horizontal: media position, vertical: sensor

adjustment/adjustment by issuing com m ands. )

4) Communication test

5) Abnormal noise

6) Confirm that there are not any other error s .

10. Close the top cover.

3-3

Page 30

3. PERIODIC MAINTENANCE PROCEDURE

3. PERIODIC MAINTENANCE PROCEDURE

11. Clean the outside of the printer.

12. Fill out a report form. Hand it to the manager and obtain a signature.

EO18-33018

3-4

Page 31

4. TROUBLESHOOTING

EO18-33018

4. TROUBLESHOOTING

Problems Cause Solution

Power does not

turn ON.

LED or LCD does

not light.

Poor printing 1. Poor media quality.

Printer does not

print.

Dot missing 1. Broken print head element

Blurred print 1. Poor media quality.

Ribbon wrinkle 1. Poor ribbon quality.

1. Input voltage to the printer is not

within the rated voltage.

2. Output voltage from the printer is not

within the rated voltage.

3.

No voltage to the MAIN PC board.

4.

Failure of MAIN PC board.

1. Failure of the panel PC board or

operation panel

2.

Failure of the operation panel

harness

3.

Failure of the MAIN PC board

2. Dirty print head

3.

The print head block is not set

completely.

1. Print head failure

2. Connection of the print head

connector is incomplete, a bad

contact, or broken elements.

3. Failure in rewinding/feeding of the

ribbon.

4. Failure of the MAIN PC board.

5. Failure of the software

6.

Failure of the printer cable.

2. Broken print head cable wires

3.

Failure of the MAIN PC board

2.

Dust is on the media.

2.

Ribbon is not rewound or fed

smoothly.

4. TROUBLESHOOTING

Replace the power cable or power

inlet.

Replace the PS unit.

Check if the power harness is

connected to CN8 on the MAIN PC

board correctly.

Replace the power harness or Power

Supply Unit.

Replace the MAIN PC board.

Replace the panel PC board or

operation panel.

Replace the operation panel harness.

Replace the MAIN PC board.

Use the media approved by

TOSHIBA TEC.

Clean the print head.

Close the print head block

completely.

Replace the print head.

Connect the harness completely, or

replace the harness.

Replace the ribbon rewind motor,

ribbon feed motor or MAIN PC board.

Replace the MAIN PC board.

Check the program.

Replace the printer cable.

Replace the print head.

Replace the print head harness.

Replace the MAIN PC board.

Use only TOSHIBA TEC-approved

media.

Clean the print head and remove any

dust from the media.

Use only TOSHIBA TEC-approved

ribbon.

Replace the ribbon rewind motor or

ribbon feed motor.

4- 1

Page 32

4. TROUBLESHOOTING

EO18-33018

Problems Cause Solution

Media feed failure 1. Media is not set properly.

2.

Poor media quality

3.

Improper adjustment of the feed gap

sensor or black mark sensor.

4.

Threshold is improper.

5.

Failure of the feed gap sensor or

black mark sensor

6.

The cutter mechanism is not

installed properly.

7.

Failure of the stepping motor.

Communication

error

1. Failure of the communication cable

2.

Failure of the RS-232C connector

3.

Failure of the communication

connector

4.

Failure of the PC or application

software

5.

Failure of the SIO PC board.

(Option)

4. TROUBLESHOOTING

Set the media properly.

Use the media approved by

TOSHIBA TEC.

Re-adjust the sensor.

Set the threshold correctly.

Replace the feed gap sensor or black

mark sensor.

Install the cutter module properly.

Replace the stepping motor or MAIN

PC board.

Replace the cable.

Replace the connector

Replace the connector.

Modify the program.

Replace the SIO PC Board.

4- 2

Loading...

Loading...