Page 1

TEC Barcode Printer

B-492L/R-TH10 SERIES

Owner’s Manual

Page 2

(

y)

(

For QP

CE Compliance (for EU only)

This product complies with the requirements of EMC and Low Voltage Directives including their

amendments.

VORSICHT:

•

Schallemission: unter 70dB (A) nach DIN 45635 (oder ISO 7779)

Die für das Gerät Vorgesehene Steckdose muß in der Nähe des Gerät es und leicht zugänglich sein.

•

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Ce produit est de classe A. Dans un environnement domestique, il peut causer des interférences radio.

Auquel cas, l’utilisateur sera amené à prendre les mesures adéquates.

Dies ist ein Klasse A Produkt. In einer örtlichen Umgebung kann dieses G erät Funkst örungen

verursachen.

WARNING!

ATTENTION!

WARNUNG!

¡ATENCIÓN!

Este es un producto de la clase A. En ambientes domésticos éste producto puede causar radio

interferencias en cuyo caso el usuario deberá tomar las medidas oportunas.

VERWITTIGING!

Dit is een klasse A produkt. Het gebruik hiervan kan radio interferenties veroorz aken die de gebruiker

ertoe kunnen dwingen sommige maatregelen te moeten treffen.

ATTENZIONE!

Questo è un prodotto in Classe A . In un contesto domestico, questo prodotto può causare interferenze

radio ,per le quali l’utente dovrebbe prendere le adeguate precauzioni.

For QQ

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio f requency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operations of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the int er ference at his own expense.

for USA onl

Changes or modifications not expressly approved by manufacturer for compliance could void the

user’s authority to operate the equipm ent .

“This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.”

“Cet appareil numériq ue de la classe A respecte t outes les exigences du Règlement sur le matér iel

brouilleur du Canada.”

for CANADA only)

Copyright © 2001

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

Page 3

Safety Summary

6DIHW\6XPPDU\

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions

necessary for safe handling are included in this manual. All warnings and cautions contained in this manual

should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified

using the procedures described in this manual, turn off the power, unplug the machine, then contact your

authorised TOSHIBA TEC representative for assistance.

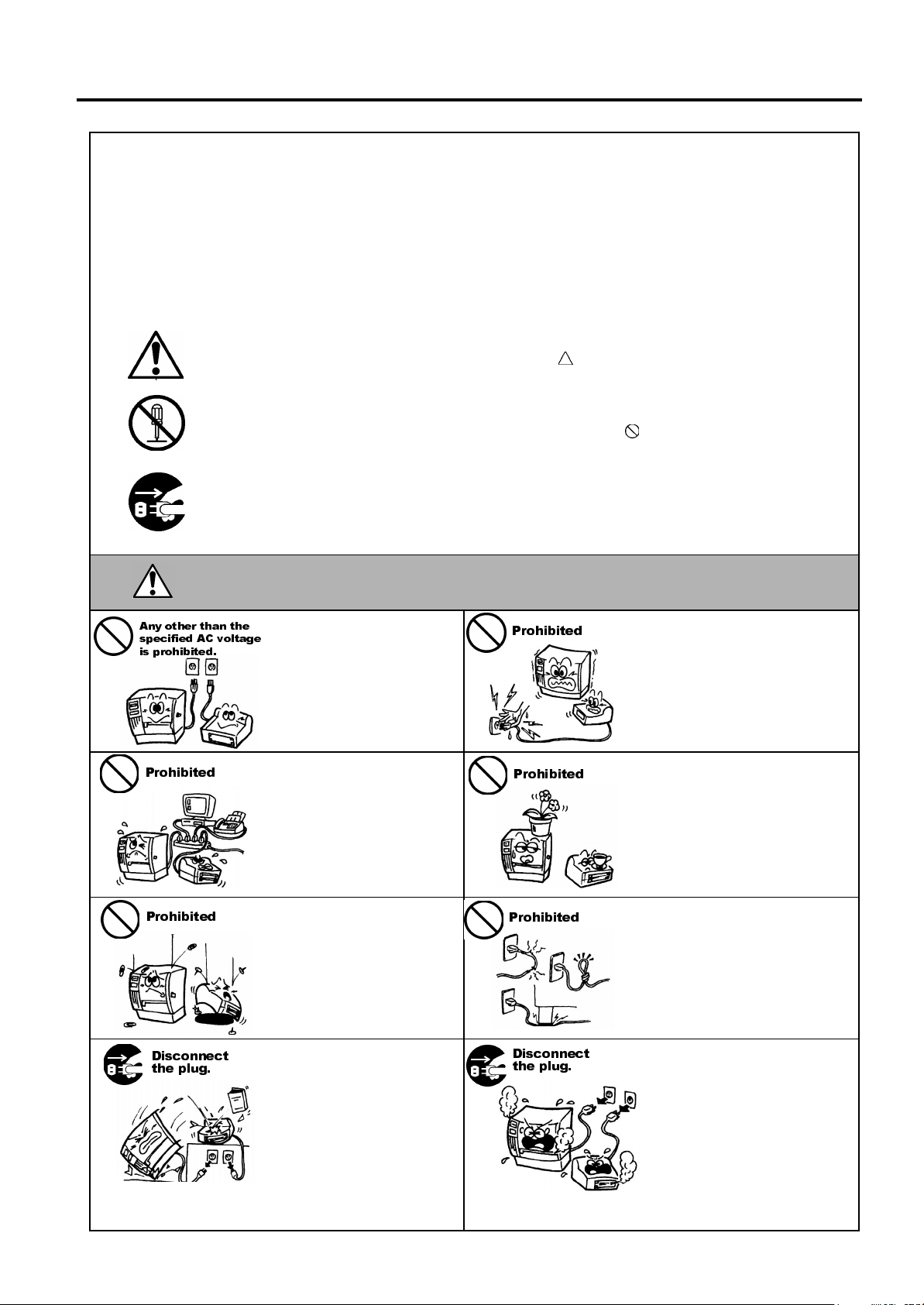

0HDQLQJVRI(DFK6\PERO

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the symbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the ● symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

symbol.

EO1-33032

$Q\ RWKHU WKDQ WKH

VSHFLILHG $& YROWDJH

LV SURKLELWHG

3URKLELWHG

3URKLELWHG

:$51,1*

Do not use voltages other than

the voltage (AC) specified on th e

rating plate, as thi s may cause

or

fire

electric shock

If the machines share the same

outlet with any other electrical

appliances which consume large

amounts of power, the voltage

will fluctuate widely each time

these appliances operate. Be sure

to provide an exclusive outlet for

the machine as this may cause

or

fire

electric shock

Do not insert or drop metal,

flammable or other foreign

objects into th e machines through

the ventilation slits, as this may

cause

fire

or

electric shock

This indicates that there is the risk of death or serious injury if the

machines are improperly handled contrary to this indication.

3URKLELWHG

.

3URKLELWHG

.

3URKLELWHG

.

Do not plug in or unplug the power

cord plug with wet hands as this

may cause

Do not place metal objects or

water-filled containers such as

flower vases, flower pots or mugs,

etc. on top of the machines. If

metal objects or spilled liquid enter

the machines, this may cause

or

Do not scratch, damage or modify

the power cords. Also, do not

place heavy objects on, pull on, or

excessively bend the cords, as this

may cause

electric shock

electric shock

or

fire

.

.

electrical shock.

fire

'LVFRQQHFW

WKH SOXJ

If the machines are dropped or

their cabinets damaged, first turn

off the power switches and

disconnect the power cord plugs

from the outlet, and then contact

your authorised TOSHIBA TEC

representative for assistance.

Continued use of the machine in

that condition may cause

electric shock

.

fire

or

'LVFRQQHFW

WKH SOXJ

Continued use of the machines in

an abnormal condition such as

when the machines are producing

smoke or strange smells may cause

or

fire

electric shock

cases, immediately turn off the

power switches and disconnect the

power cord plugs from the outlet.

Then, contact your au thorised

TOSHIBA TEC representative for

assistance.

. In these

( ) i

Page 4

Safety Summary

EO1-33032

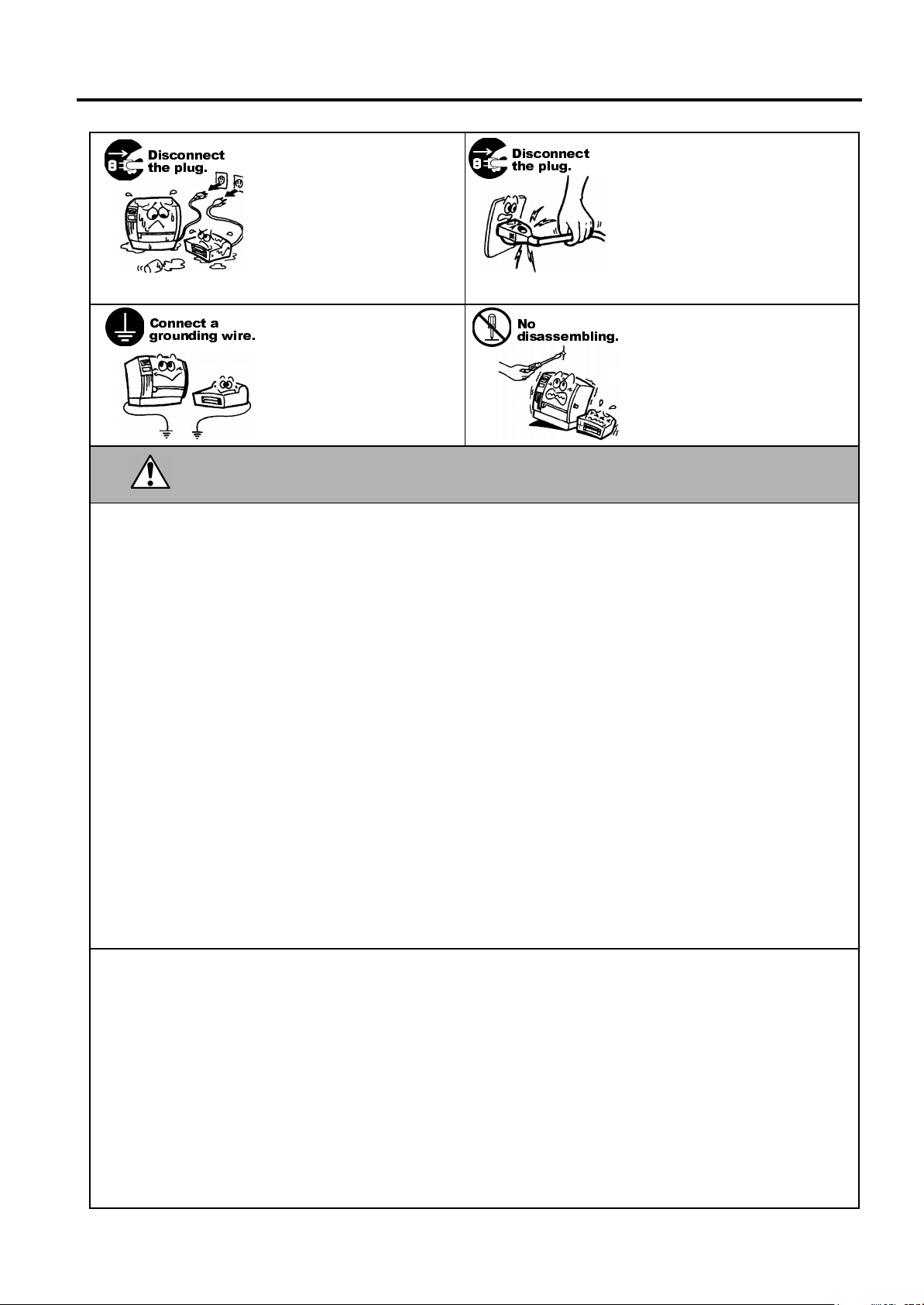

'LVFRQQHFW

WKH SOXJ

&RQQHFW D

JURXQGLQJ ZLUH

If foreign objects (metal

fragments, water, liquids) enter

the machines, first turn off the

power switches and disconnect

the power cord plugs from the

outlet, and then contact your

authorised TOSHIBA TEC

representative for assistance.

Continued use of the machine in

that condition may cause

electric shock

Ensure that the equipment is

properly grounded. Extension

cables should also be grounded.

Fire

or

occur on improperly grounded

equipment.

.

electric shock

fire

could

or

'LVFRQQHFW

WKH SOXJ

1R

GLVDVVHPEOLQJ

When unplugging the power cords,

be sure to hold and pull on the plug

portion. Pulling on the cord portion

may cut or expose the internal wires

fire

and cause

Do not remove covers, repair or

modify the machine by yourself.

You may be

voltage, very hot parts or sharp

edges inside the machin e.

electric shock

or

injured

by high

&$87,21

This indicates that there is the risk of personal

Injury

objects if the machines are improperly handled contrary to this indication.

damage

or

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

●

Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power source * Excessive vibration * Dust/Gas

●

The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild

detergent solution. NEVER USE THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic

covers.

●

USE ONLY TOSHIBA TEC SPECIFIED paper and ribbons.

●

DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high

temperatures, high humidity, dust, or gas.

●

Ensure the printer is operated on a level surface.

●

Any data stored in the memory of the printer could be lost during a printer fault.

●

Try to avoid using this equipment on the same power supply as high voltage equipment or equipment

likely to cause mains interference.

●

Unplug the machine whenever you are working inside it or cleaning it.

●

Keep your work environment static free.

●

Do not place heavy objects on top of the machines, as these items may become unbalanced and fall

causing injury.

●

Do not block the ventilation slits of the machines, as this will cause heat to build up inside the

machines and may cause fire.

●

Do not lean against the machine. It may fall on you and could cause injury.

●

Care must be taken not to injure yourself with the printer paper cutter.

●

Unplug the machine when it is not used for a long period of time.

to

.

Request Regarding Maintenance

●

Utilize our maintenance services.

After purchasing the machine, contact your authorised TOSHIBA TEC representative for assistance

once a year to have the inside of the machine cleaned. Otherwise, dust will build up inside the

machines and may cause a fire or a malfunction. Cleaning is particularly effective before humid rainy

seasons.

●

Our preventive maintenance service performs the periodic checks and other work required to maintain

the quality and performance of the machines, preventing accidents beforehand.

For details, please consult your authorised TOSHIBA TEC representative for assistance.

●

Using insecticides and other chemicals

Do not expose the machines to insecticides or other volatile solvents. This will cause the cabinet or

other parts to deteriorate or cause the paint to peel.

( ) ii

Page 5

EO1-33032

TABLE OF CONTENTS

Page

1. PRODUCT OVERVIEW...........................................................................................................1-1

1.1 Introduction.....................................................................................................................1-1

1.2 Features.........................................................................................................................1-1

1.3 Unpacking ...................................................................................................................... 1-1

1.4 Accessories ...................................................................................................................1-1

1.5 Appearance of the Printer...............................................................................................1-2

1.5.1 Dimensions..................................................................................................................... 1-2

1.5.2 Front View...................................................................................................................... 1-3

1.5.3 Side View ....................................................................................................................... 1-3

1.5.4 Interior ............................................................................................................................ 1-4

1.5.5 Operation Panel............................................................................................................. 1-4

1.6 Appearance of the Power Supply Unit ............................................................................1-5

1.6.1 Dimensions..................................................................................................................... 1-5

1.6.2 Front View...................................................................................................................... 1-5

2. PRINTER SETUP....................................................................................................................2-1

2.1 Precautions ....................................................................................................................2-1

2.2 Procedure before Operation ...........................................................................................2-2

2.3 Fitting the Fan Filter........................................................................................................2-2

2.4 Connecting the Cables to Your Printer............................................................................2-3

2.5 Connecting the Power Cord............................................................................................2-4

2.6 Turning the Printer ON/OFF............................................................................................2-5

2.6.1 Turning ON the Printer................................................................................................... 2-5

2.6.2 Turning OFF the Printer................................................................................................. 2-5

2.7 Loading the Media..........................................................................................................2-6

2.8 Loading the Ribbon ......................................................................................................2-11

2.9 Inserting the Optional PCMCIA Cards ..........................................................................2-12

2.10 Test Print......................................................................................................................2-13

3. ON LINE MODE ......................................................................................................................3-1

3.1 Operation Panel..............................................................................................................3-1

3.2 Operation........................................................................................................................3-2

4. MAINTENANCE......................................................................................................................4-1

4.1 Cleaning.........................................................................................................................4-1

4.1.1 Print Head/Platen........................................................................................................... 4-1

4.1.2 Media Guide Plate/Pinch Roller/Sensors....................................................................... 4-2

4.1.3 Paper Holder.................................................................................................................. 4-4

4.1.4 Covers and Panels......................................................................................................... 4-4

4.2 Care/Handling of the Media and Ribbon.........................................................................4-5

5. TROUBLESHOOTING ............................................................................................................5-1

5.1 Error Messages..............................................................................................................5-1

5.2 Possible Problems..........................................................................................................5-2

5.3 Removing Jammed Media..............................................................................................5-3

5.4 Threshold Setting ...........................................................................................................5-3

6. PRINTER OPERATION...........................................................................................................6-1

6.1 Overview ........................................................................................................................6-1

6.2 Installing the Printer Drivers............................................................................................6-1

6.2.1 System Requirements.................................................................................................... 6-2

6.2.2 Driver Installation............................................................................................................ 6-2

6.2.3 Uninstalling the TEC B-492 Printer Driver..................................................................... 6-6

Page 6

EO1-33032

APPENDIX 1 SPECIFICATIONS ................................................................................................ A1-1

A1.1 Printer.......................................................................................................................... A1-1

A1.2 Options........................................................................................................................ A1-2

A1.3 Media .......................................................................................................................... A1-2

A1.3.1 Media Type.................................................................................................................A1-2

A1.3.2 Detection Area of the Transmissive Sensor...............................................................A1-3

A1.3.3 Detection Area of the Reflective Sensor ....................................................................A1-4

A1.3.4 Effective Print Area.....................................................................................................A1-4

A1.4 Ribbon......................................................................................................................... A1-5

APPENDIX 2 MESSAGES AND LED ......................................................................................... A2-1

APPENDIX 3 INTERFACE.......................................................................................................... A3-1

APPENDIX 4 SYSTEM MODE.................................................................................................... A4-1

A4.1 Operation Panel........................................................................................................... A4-1

A4.2 Overview ..................................................................................................................... A4-2

A4.3 Reset Mode................................................................................................................. A4-3

A4.4 Self-Diagnostic Test .................................................................................................... A4-3

A4.5 Printer Parameter Fine Adjustment.............................................................................. A4-6

A4.6 Test Print................................................................................................................... A4-14

A4.7 Dump Mode............................................................................................................... A4-20

A4.8 Additional Information................................................................................................ A4-21

A4.8.1 Self-Diagnostic Test Result Sample and Descriptions.............................................A4-21

A4.8.2 Maintenance Counter/Parameter Check Print Sample and Descriptions................A4-24

A4.8.3 Magnified Views of Slant Line Pattern......................................................................A4-27

APPENDIX 5 PRINT SAMPLES ................................................................................................. A5-1

GLOSSARIES

INDEX

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorized Service representative with regard to any queries you may have in

this manual.

Page 7

1. PRODUCT OVERVIEW

(

EO1-33032

1. PRODUCT OVERVIEW

1.1 Introduction

1.2 Features

1.3 Unpacking

1. Check for damage or

scratches on the printer.

However, please note that

TOSHIBA TEC shall have no

liability for any damage of

any kind sustained during

transportation of the

product.

2. Keep the cartons and pads

for future transportation of

the printer.

NOTES:

1.4 Accessories

Thank you for choosing the TEC B-492L/R series barcode printer. This

Owner’s Manual contains valuable information from general set-up to

confirming the printer's operation using test prints. You should read it

carefully to help you gain maximum performance and life from your

printer. This manual should be kept close at hand for everyday reference.

Please contact your TOSHIBA TEC representative for further

information concerning this manual.

The B-492L/R printer has the following features:

•

Superior hardware, including a specially developed 12 dots/mm (300

dots/inch) thermal print head which gives very clear print quality at

print speeds of 127 mm/sec. (5 inches/sec.), 203.2 mm/sec. (8

inches/sec.), and 254 mm/sec. (10 inches/sec.).

•

Separation of the power supply unit realized a compact body of the

printer.

•

When the optional interface board is installed, Web functions such as

remote maintenance and other advanced network functions are

available.

•

The PCMCIA Interface Board and the KB-80-QM Keyboard Unit are

provided as optional equipment.

Unpack the printer as per the Unpacking Instructions supplied with the

printer.

When unpacking the printer, please check that the following accessories

are supplied with the printer.

Owner’s Manual (1 copy)

(Doc./No. EO1-33032)

US Power Cord (1 pc.)

(P/No. FBCB0030202)

TEC Label/Tag Printer

B-492-QQ

Owner?s Manual

TOSHIBA TEC CORPORATION

1.1 Introduction

CD-ROM

Fan Filter

(P/No. FMBB0036801)

EU Power Cord (1 pc.)

P/No.: EKA-0055001)

(P/No. FMQB0083801)

1- 1

Page 8

1. PRODUCT OVERVIEW

5x 5.5

117.5 (4.6)

117.5 (4.6)

223 (8.8) 18 (0.7)

5 (0.2)

256 (10.1)

265 (10.4)

5 (0.2)

300 (11.8)

100 (3.9)

149.3 (5.9)

264 (10.4)

300 (11.8)

282 (11.1)

232.5 (9.2)

209.3 (8.2)

10 (0.4)

125 (4.9)

EO1-33032

1.5 Appearance of the Printer

1.5.1 Dimensions

125 (4.9)

264 (10.4)

300 (11.8)

10 (0.4)

232.5 (9.2)

209.3 (8.2)

[L Type]

[R Type]

18 (0.7)

100 (3.9)

282 (11.1)

149.3 (5.9)

5 (0.2)

5 (0.2)

265 (10.4)

300 (11.8)

117.5 (4.6)

1.5 Appearance of the Printer

Dimension: mm+(inch)

223 (8.8)

117.5 (4.6)

5x 5.5

256 (10.1)

1- 2

Page 9

1. PRODUCT OVERVIEW

EO1-33032

1.5 Appearance of the Printer

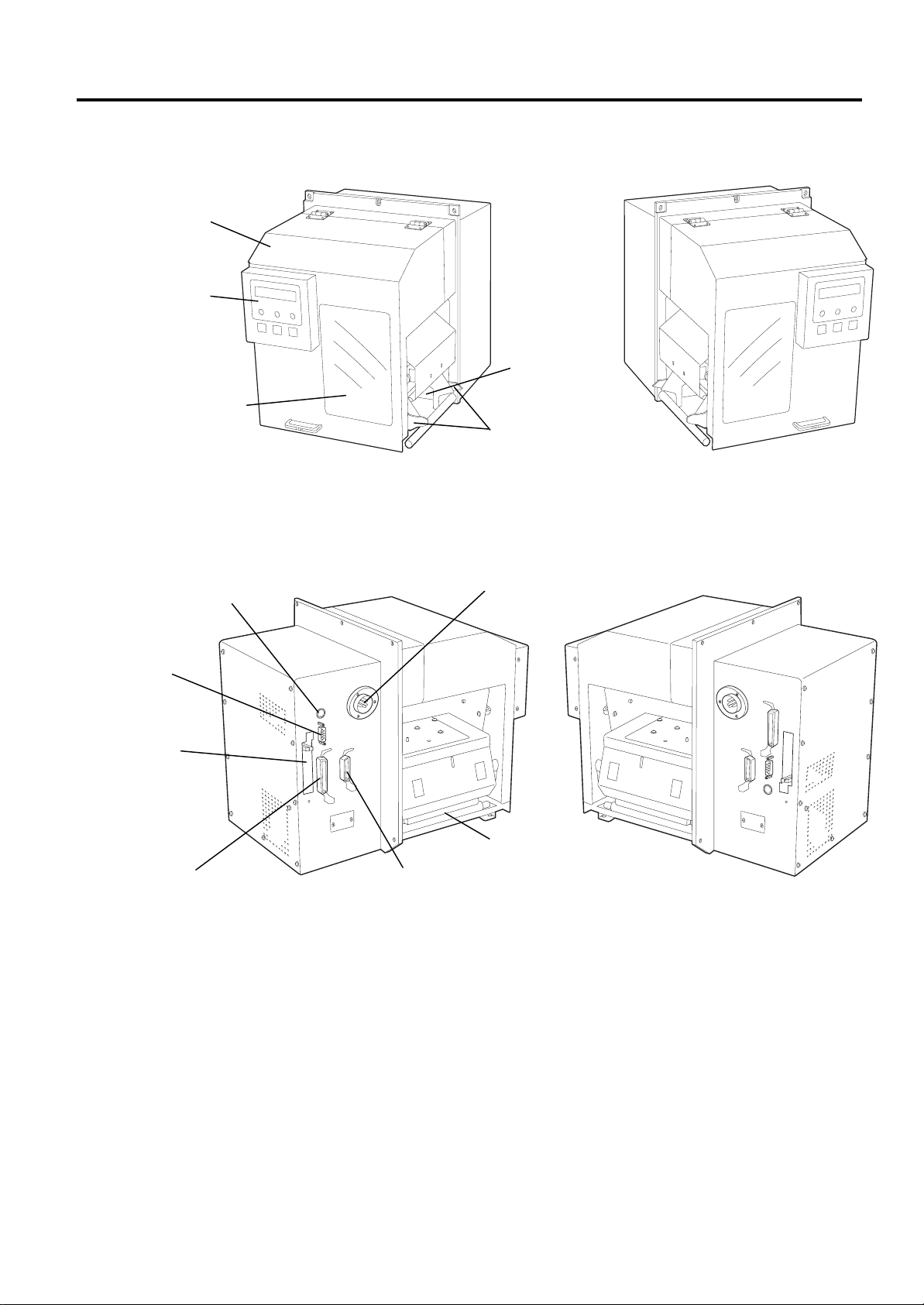

1.5.2 Front View

Top Cover

Operation Panel

Supply Window

Media Inlet

Media Guide

[L Type] [R Type]

1.5.3 Side View

Keyboard Interface

Connector

DC Power Connector

Serial Interface

Connector

(RS-232C)

PCMCIA Card

Slot (2 slots)

Parallel Interface

Connector

(Centronics)

Expansion I/O

Interface Connector

Print Head

[L Type] [R Type]

1- 3

Page 10

1. PRODUCT OVERVIEW

FEED RESTART PAUSE

POWER ON LINE ERROR

[

]

N

EO1-33032

1.5 Appearance of the Printer

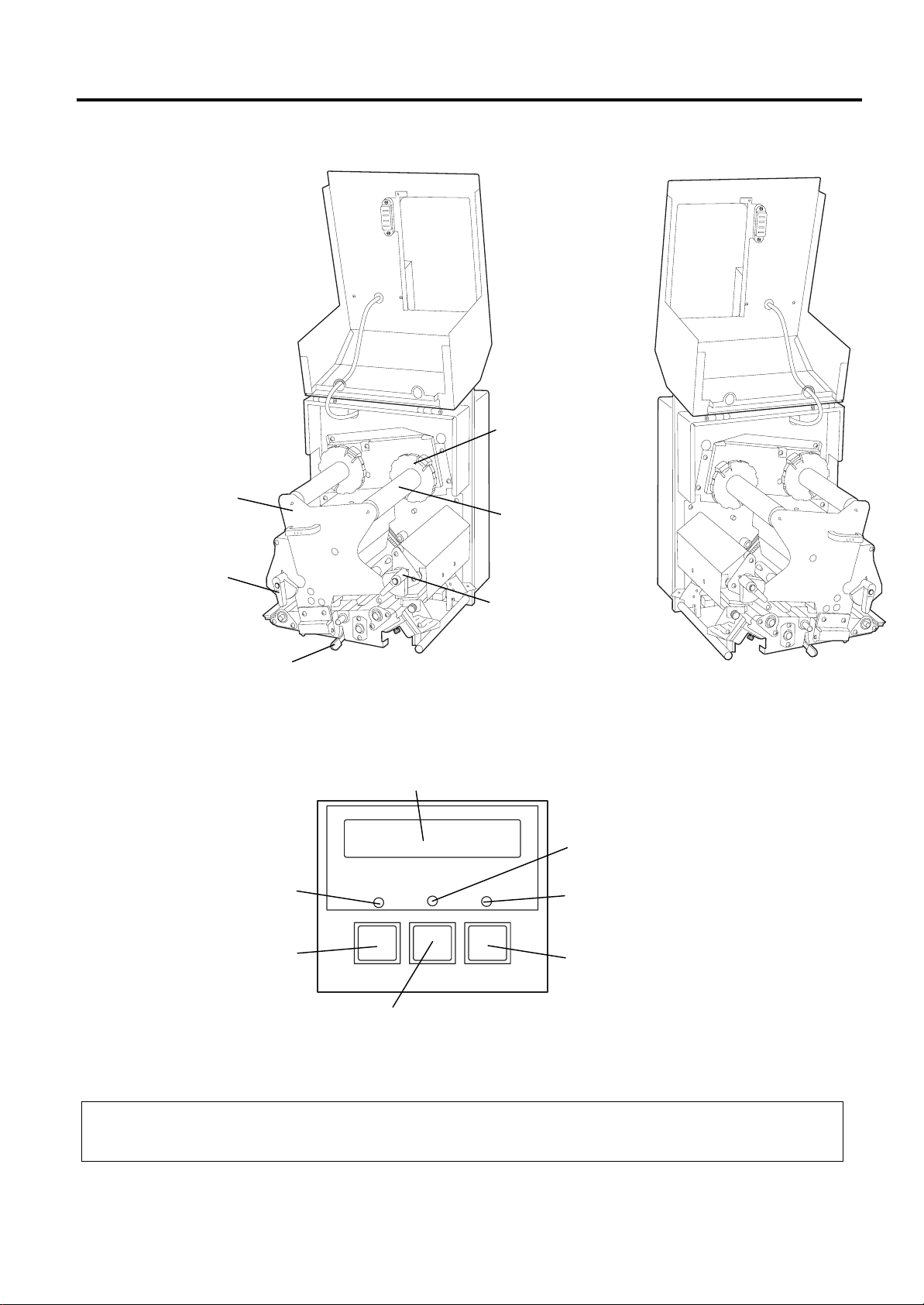

1.5.4 Interior

Ribbon Stopper

Ribbon Shaft

Holder Plate

Ribbon Shaft

Head Lever

Strip Roller Release Lever

Pinch Roller Lever

[L Type] [R Type]

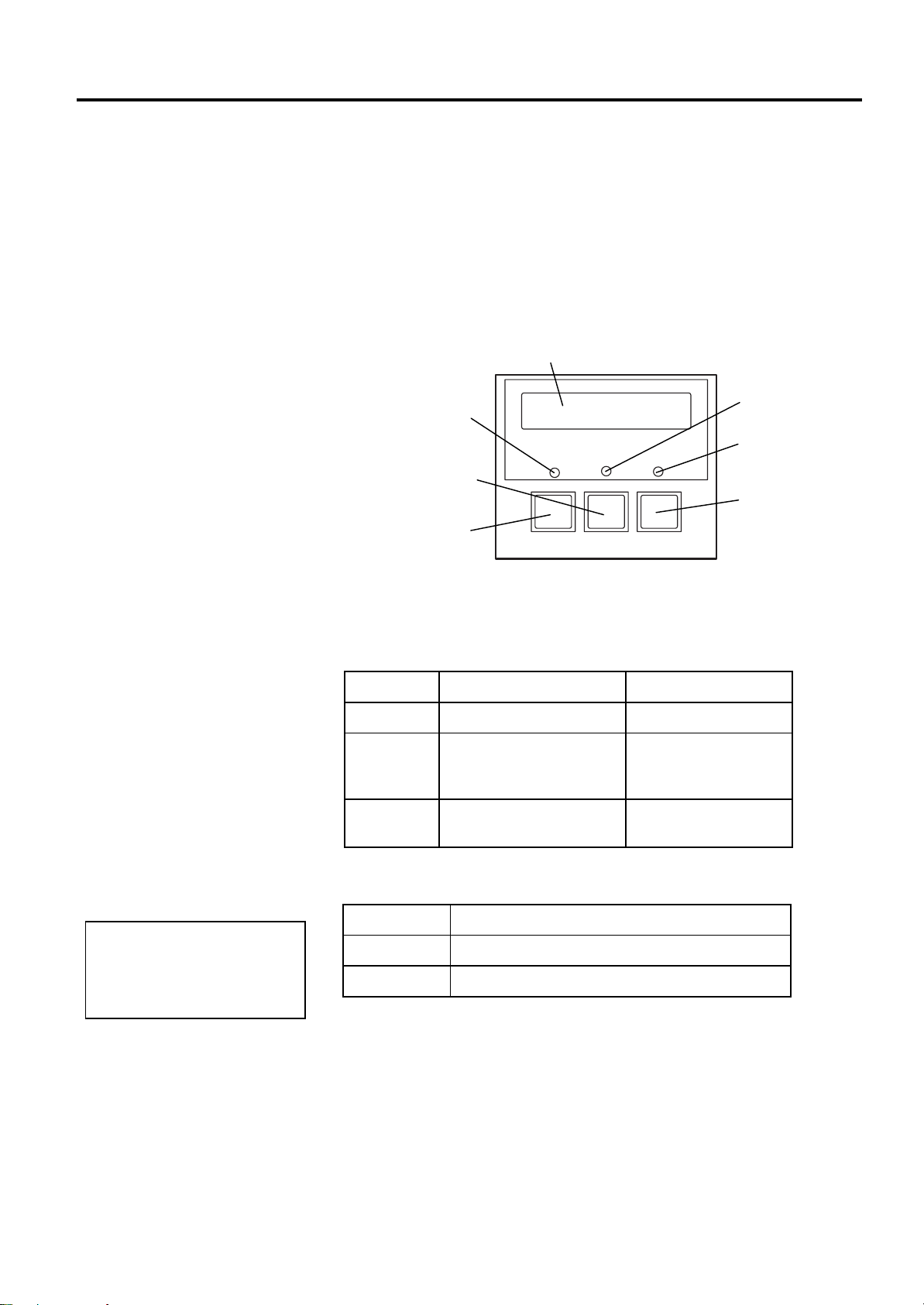

1.5.5 Operation Panel

LCD Message Display

POWER LED (Green)

FEED

Key

[RESTART]

key

Please see Section 3.1 for further information about the Operation Panel.

OTE:

The illustrations used hereafter are of the L type, as the operating procedure is common to both L and R types.

ON LINE LED (Green)

ERROR LED (Red)

[PAUSE]

key

1- 4

Page 11

1. PRODUCT OVERVIEW

2000 (78.7)

265 (10.4)

10 (0.4)

76 (3.0)

170 (6.7)

EO1-33032

1.6 Appearance of the Power Supply Unit

1.6.1 Dimensions

1.6.2 Front View

1.6 Appearance of the Power Supply Unit

Dimensions: mm+(inch)

Power Switch

DC Power Connector

Inlet

1- 5

Page 12

2. PRINTER SETU P

EO1-33032

2. PRINTER SETUP

2.1 Precautions

2.1 Precautions

This section outlines the steps necessary to setup your B-492L/R printer

prior to its operation. The section includes precautions, connecting

cables, assembling accessories, loading media and ribbon, inserting an

optional memory card, and performing a test print.

• To insure the best operating environment, and to assure the safety of

the operator and the equipment, please observe the following

precautions.

• Operate the printer on a stable, level, operating surface in a location

free from excessive humidity, high temperature, dust, vibration or

direct sunlight.

• Keep your work environment static free. Static discharges can cause

damage to delicate internal components.

• Make sure that the printer is connected to a clean source of AC Power

and that no other high voltage devices that may cause line noise

interference are connected to the same mains.

• Ensure that the printer is connected only to AC mains that has a

proper ground (earth) connection.

• Only use the power cable provided with this unit to power it..

• Do not operate the printer with the cover open. Be careful not to

allow fingers or articles of clothing to get caught into any of the

moving parts of the printer.

• Make sure to turn off the printer power and to remove the power cord

from the printer whenever working on the inside of the printer or

when cleaning the printer.

• For best results, and longer printer life, use only TOSHIBA TEC

recommended media and ribbons.

• Store the media and ribbons in accordance with their specifications.

• This printer mechanism contains high voltage components; therefore

you should never remove any of the covers of the machine as you may

receive an electrical shock. Additionally, the printer contains many

delicate components that may be damaged if accessed by unauthoriz ed

personnel.

• Clean the outside of the printer with a clean dry cloth or a clean cloth

slightly dampened with a mild detergent solution.

• Use caution when cleaning the thermal print head as it may become

very hot while printing. Wait until it has had time to cool before

cleaning. Use only the TOSHIBA TEC recommended print head

cleaner to clean the print head.

• Do not turn off the printer power or remove the power plug while the

printer is printing or while the ON LINE lamp is blinking.

2- 1

Page 13

2. PRINTER SETU P

p

I

M

EO1-33032

2.2 Procedure before Operation

To communicate directly

with a host computer, either

an RS-232C cable or

Centronics cable is required.

(1) RS-232C cable: 9 pins

(do not use a null modem

cable)

(2) Centronics cable: 36 pins

(3) Expansion I/O cable: 24

pins (Option)

Use of a Windows Driver will

allow issuing media on the B492L/R printer from a

Windows application.

The printer can also be

controlled with its own

rogramming commands.

Please contact your TOSHIBA

TEC reseller for the

nterface/Communication

anual.

NOTE:

NOTE:

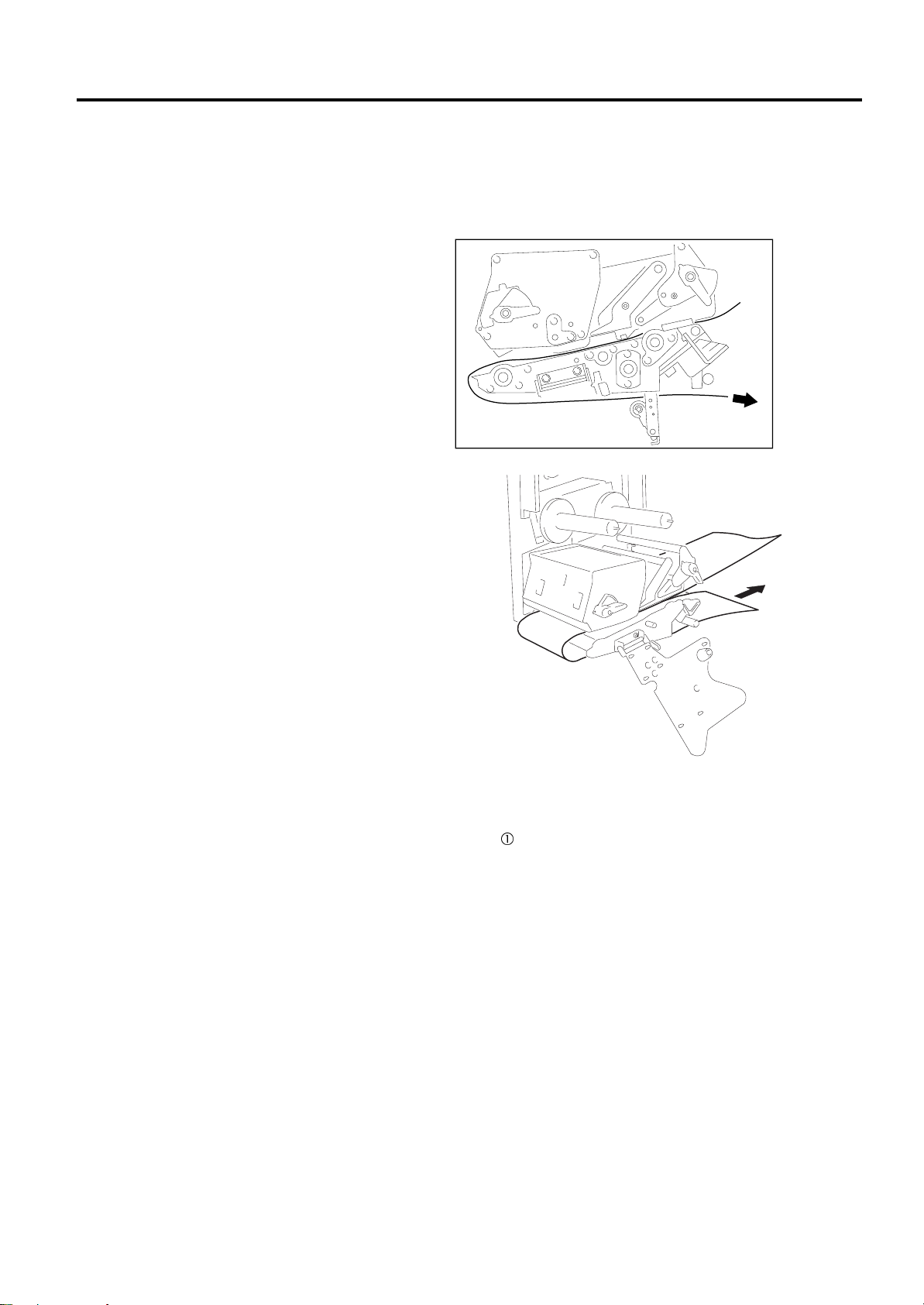

2.3 Fitting the Fan Filter

2.2 Procedure before Operation

This section describes the outline of the printer setup.

1.

Unpack the accessories and printer from the box.

2.

Refer to Safety Precautions in this manual and set up the printer at a

proper location.

3.

Attach the fan filter to the rear of the printer. (Refer to Section 2.3.)

4.

The host computer must have an available serial port, Centronics

parallel port or a Ethernet (option) connection. (Refer to Section

2.4.)

5.

Connect the DC power cord plug to the printer. Connect the AC

power cord to the Power Supply Unit. (Refer to Section 2.5.)

6.

Load the media in the printer. (Refer to Section 2.7.)

7.

Adjust the position of the Feed Gap Sensor or Black Mark Sensor to

match the media being used. (Refer to Section 2.7.)

8.

Load the ribbon onto the Ribbon Shafts. (Refer to Section 2.8.)

9.

Turn the Power ON. (Refer to Section 2.6.)

10.

Set the threshold. (Refer to Section 5.4.)

11.

Perform a test print. (Refer to Section 2.10 and Appendix 4.6.)

12.

Install the Printer Drivers. (Refer to Section 6.)

When installing the printer, it is important to ensure that the fan filter is

attached before using the printer.

The fan filter consists of 2 parts:

(1) Filter Pad

(2) Filter Retainer

To fit the fan filter, put the filter pad inside the filter retainer and simply

press into place as shown in the diagram below, ensuring connecting pins

are aligned with the connecting holes.

Snap on

(2)

Snap on

(1)

2- 2

Page 14

2. PRINTER SETU P

EO1-33032

2.4 Connecting the

Cables to Your

Printer

2.4 Connecting the Cables to Y our P ri nter

The following paragraphs outlines how to connect the cables from the B492L/R printer to your host computer, and will also show how to make

cable connections to other devices such as the KB-80-QM keyboard, etc.

Depending on the application software you use to print labels, there are

two possibilities for connecting the printer to your host computer. These

are:

• A serial cable connection between the printer’s RS-232 serial

connector and one of your host computer’s COM ports

(Refer to APPENDIX 3.)

• A parallel cable connection between the printer’s standard parallel

connector and your host computer’s parallel port (LPT).

• An Ethernet connection using the optional PCMCIA interface

board and LAN card (Refer to section 2.9)

The diagram below shows all the possible cable connections to the

current version of the B-492L/R printer.

c

d

e

f

e

d

f

c

[L Type] [R Type]

Parallel Interface Connector (Centronics)

Serial Interface Connector (RS-232C)

KB-80-QM Keyboard Interface Connector (Option)

Expansion I/O Interface Connector

f

c

d

e

2- 3

Page 15

2. PRINTER SETU P

EO1-33032

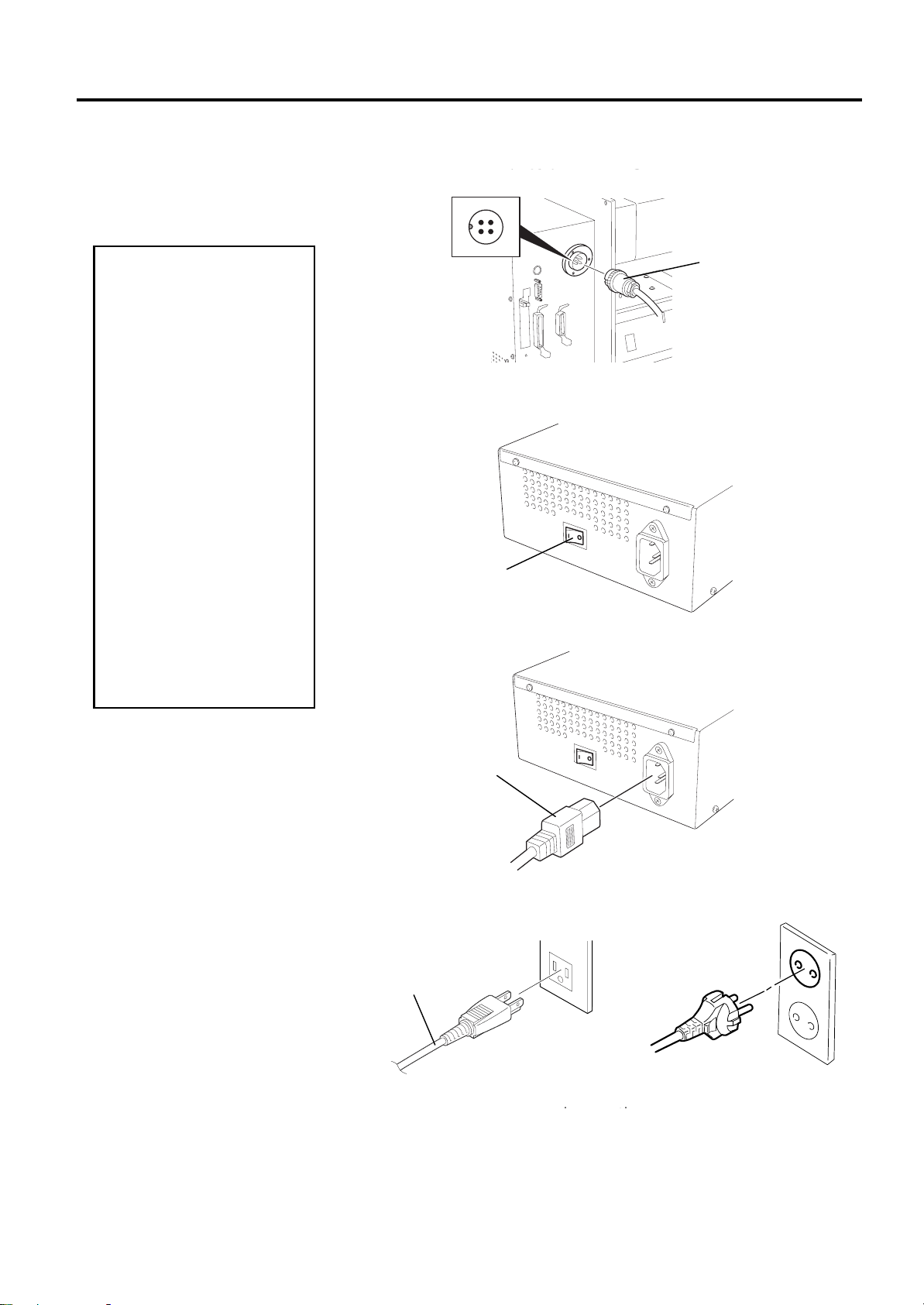

2.5 Connecting the

Power Cord

1. Make sure that the

2. Use only the power

3. Connect the power

CAUTION!

printer power switch is

turned to the off

position before

connecting the power

cord to prevent

possible electric shock

or damage to the

printer.

cord supplied with the

printer. Use of any

other cord may cause

electric shock or fire.

cord to a supply outlet

with a properly

grounded (earthed)

connection.

2.5 Connecting the Power Cord

1

. Connect the DC power cable from the DC Power Supply Unit to the

printer.

DC Power Cable

2.

Make sure that the printer power switch is in the OFF (O) position.

Power Switch

3.

Connect the power cord to the Power Supply Unit as shown in the

figure below.

Power Cord

4.

Plug the other end of the power cord into a grounded outlet as shown

in the figure below.

Power Cord

[QQ Type] [QP Type]

2- 4

Page 16

2. PRINTER SETU P

I

L

r

EO1-33032

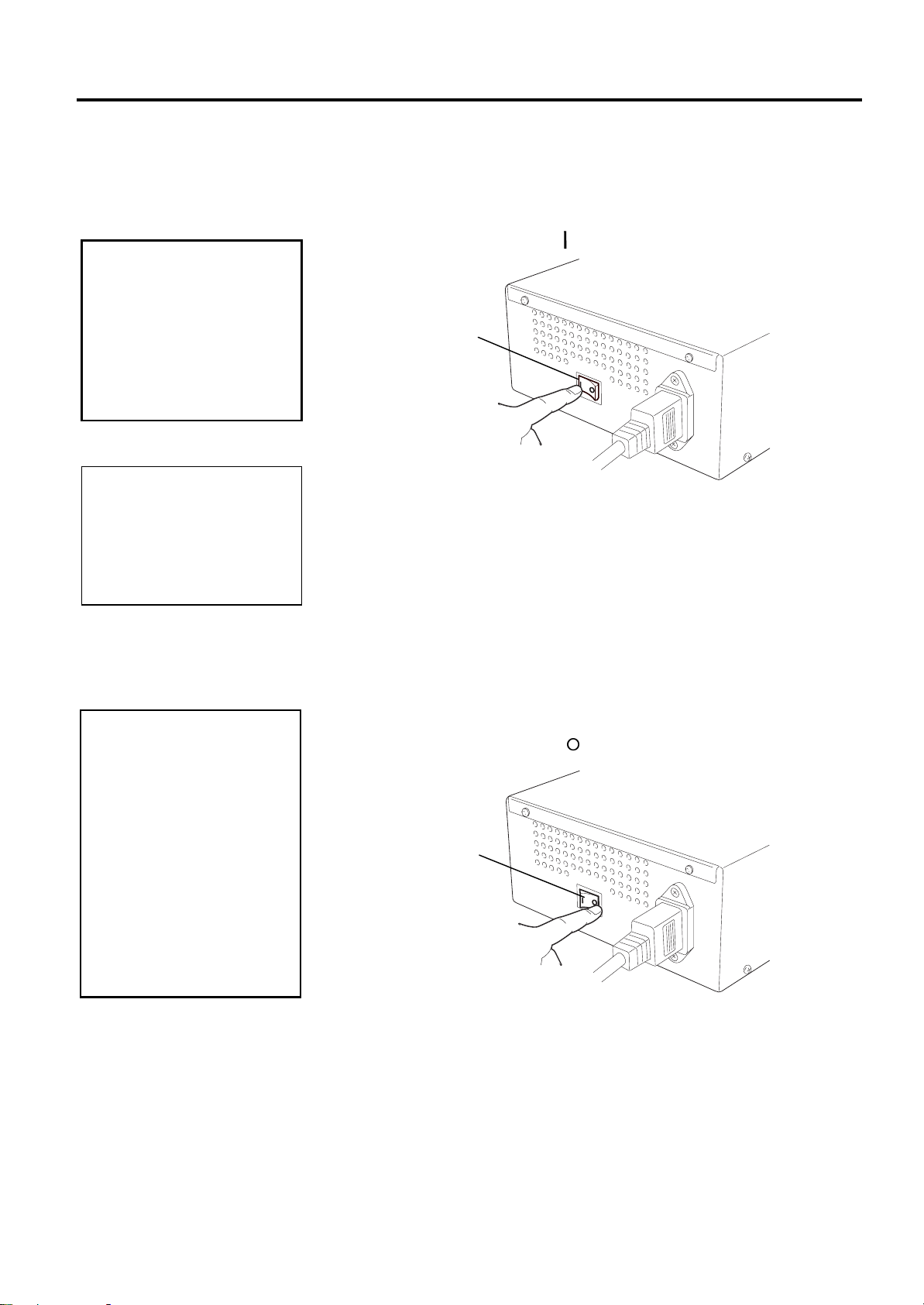

2.6 Turning the Printer

ON/OFF

2.6.1 Turning ON the Printer

Use the power switch to

turn the printer On/Off.

Plugging or unplugging the

power cord to turn the

printer On/Off may cause

fire, an electric shock, or

damage to the printer.

the ERROR LED lamp is

illuminated, go to Chapter 5.1,

Error Messages.

2.6.2 Turning OFF the

1. Do not turn off the

2. Do not turn off the

CAUTION!

NOTE:

f a message other than ON

INE appears on the display o

Printer

CAUTION!

printer power while the

media is being printed

as this may cause a

paper jam or damage

to the printer.

printer power while the

ON LINE light is

blinking as this may

cause damage to your

host computer.

2.6 Turning the Printer ON/OFF

When the printer is connected to a host computer it is good practice to

turn the printer ON before turning on the host computer and to turn OFF

the host computer before turning off the printer.

1.

To turn ON the printer power, press the power switch as shown in the

diagram below. Note that ( ) is the power ON side of the switch.

Power Switch

2.

Check that the message ON LINE appears on the LCD Display and

that the ON LINE and POWER LED lights are illuminated

1.

Before turning off the printer power switch verify that the ON LINE

message is on the LCD Message Display and that the ON LINE LED

light is on and not flashing.

2.

To turn OFF the printer power press the power switch as shown in the

diagram below. Note that ( { ) is the power OFF side of the switch.

Power Switch

2- 5

Page 17

2. PRINTER SETU P

k

HEAD

2

1

EO1-33032

2.7 Loading the Media

1. Do not touch any moving

2. To avoid injury, be

3. Be sure to open the top

1. When the head lever is

2. When the pinch roller lever

3. To enable printing the head

WARNING!

parts. To reduce the ris

of fingers, jewellery,

clothing, etc. being

drawn into the moving

parts, be sure to load the

media once the printer

has stopped moving

completely.

careful not to trap your

fingers while opening or

closing the cover.

cover fully, otherwise the

top cover may close,

causing injury.

NOTES:

turned to position d, the

print head is raised.

is turned to position d, the

pinch roller is raised.

lever and the pinch roller

lever must be set to position

c

. This ensures that the

print head and the pinch

roller are closed.

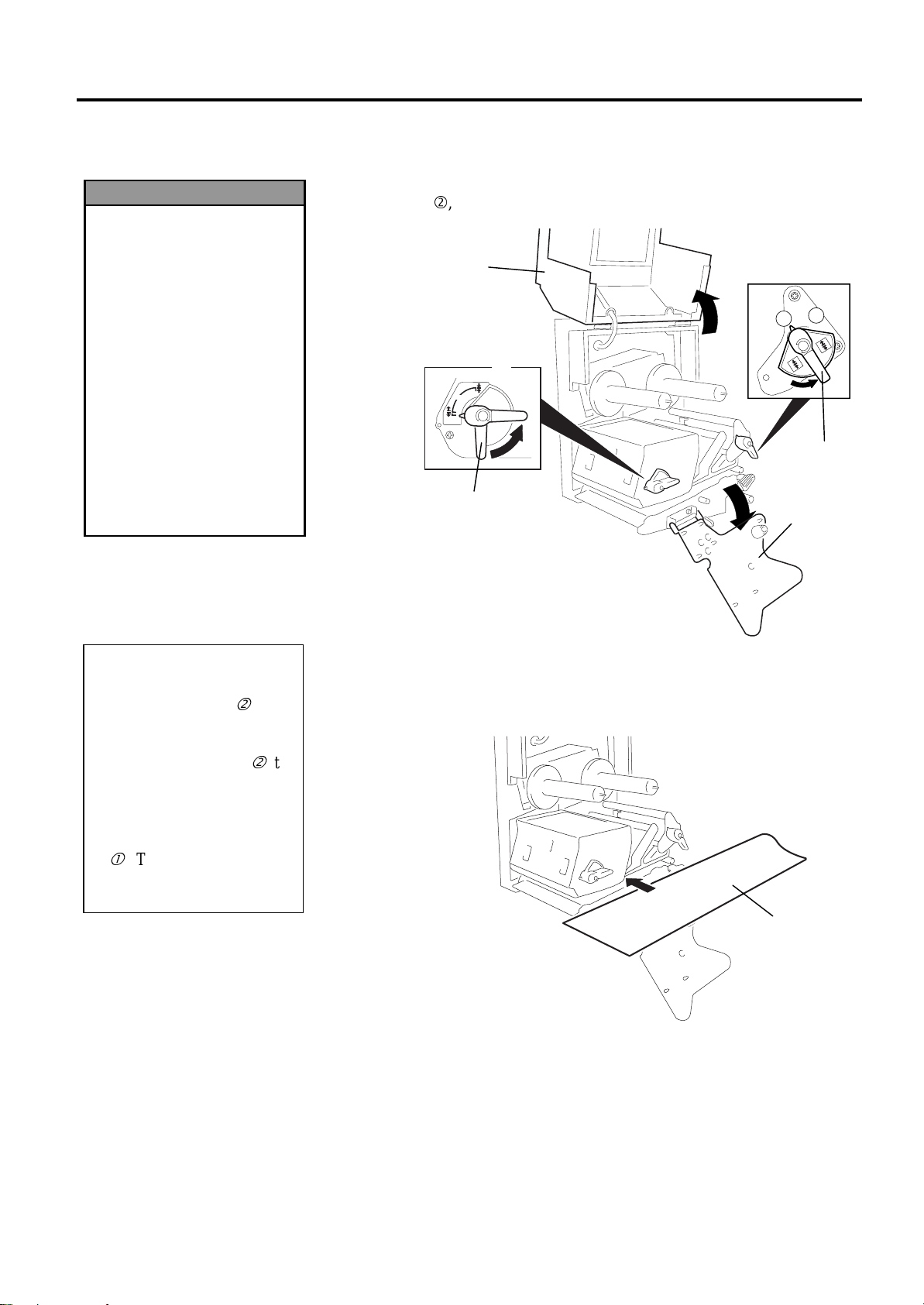

2.7 Loading the Media

This section describes in detail how to load the media.

1.

Open the top cover and turn the head lever and pinch roller lever to

position d, then open the ribbon shaft holder plate.

Top Cover

d

c

Pinch Roller

Lever

Head Lever

Ribbon Shaft

Holder Plate

2.

Insert the media into the printer from the side as shown in the figure

below. Ensure that the media is positioned in the black mark/feed gap

sensor.

Media

2- 6

Page 18

2. PRINTER SETU P

p

A

B

EO1-33032

2.7 Loading the Media

(Cont.)

The media guide should be

ositioned so that the media

can feed smoothly.

NOTE:

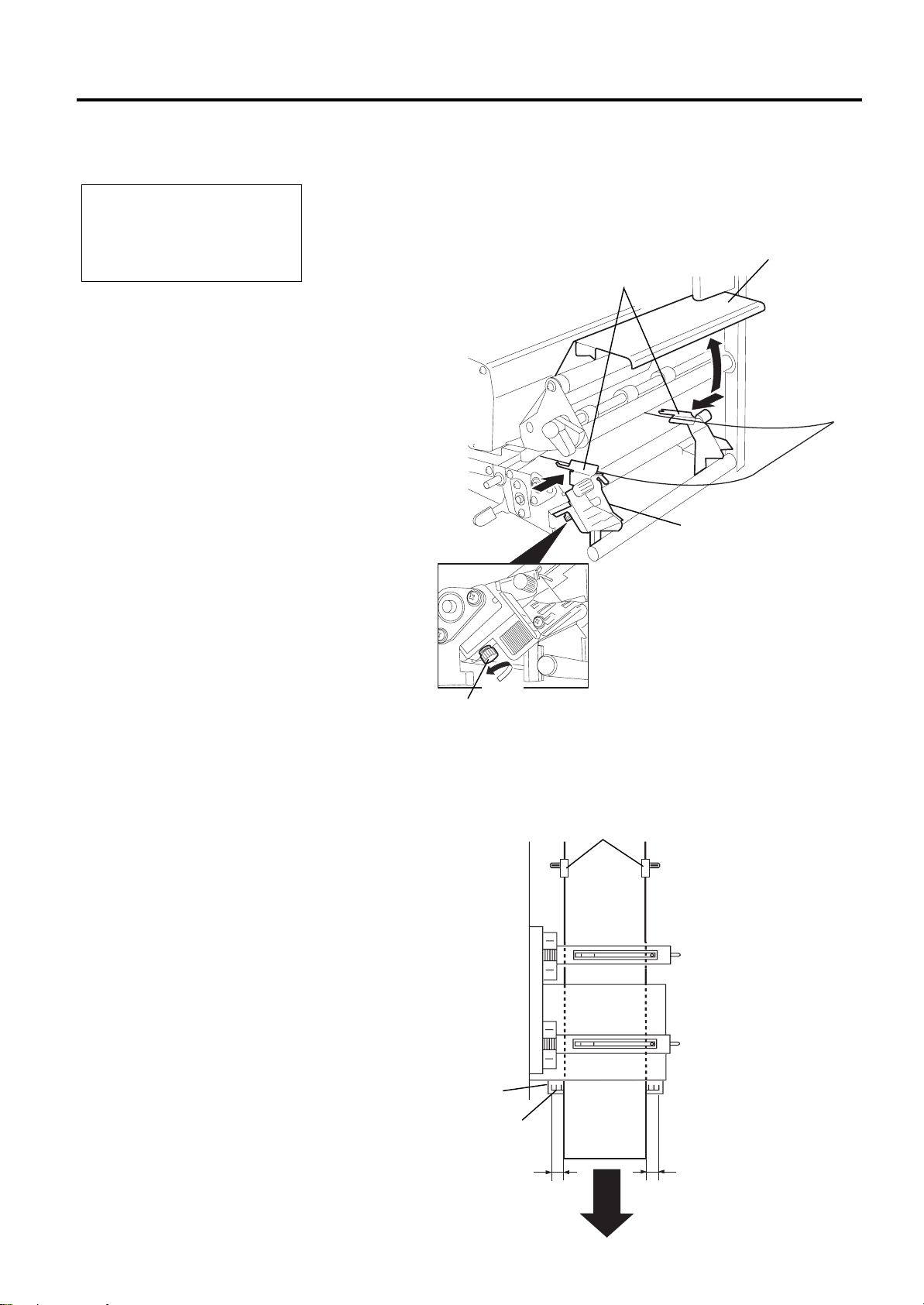

2.7 Loading the Media

3.

Open the paper entry guide.

4.

Loosen the locking screw of the right side of the media guide and

open the media guides.

5.

Insert each edge of the media into the paper holders of the media

guides by adjusting the media guides positions to the media width.

Then tighten the locking screw.

Paper Holder

Paper Entry Guide

Media Guide

6.

Locking Screw

Pass the media straight from the paper holders to paper outlet. The

media should be centred on the strip plate, otherwise skew feeding or

a paper jam may occur. Check that the media is positioned so that the

distances from the media edge to the end of the scale marked on the

strip plate (Distances A and B in the figure below.) are almost equal.

Loose

Paper Holder

Strip Plate

Scale

Media

Distances A and B should

be almost equal.

2- 7

Page 19

2. PRINTER SETU P

EO1-33032

2.7 Loading the Media

(Cont.)

1. Turning the adjusting knob

to the right will move the

sensor towards the center

of the media while turning

it to the left will move it

away from the center of the

media.

2. Be sure to set the black

mark sensor to detect the

center of the black mark,

otherwise a paper jam or

no paper error may occur.

NOTES:

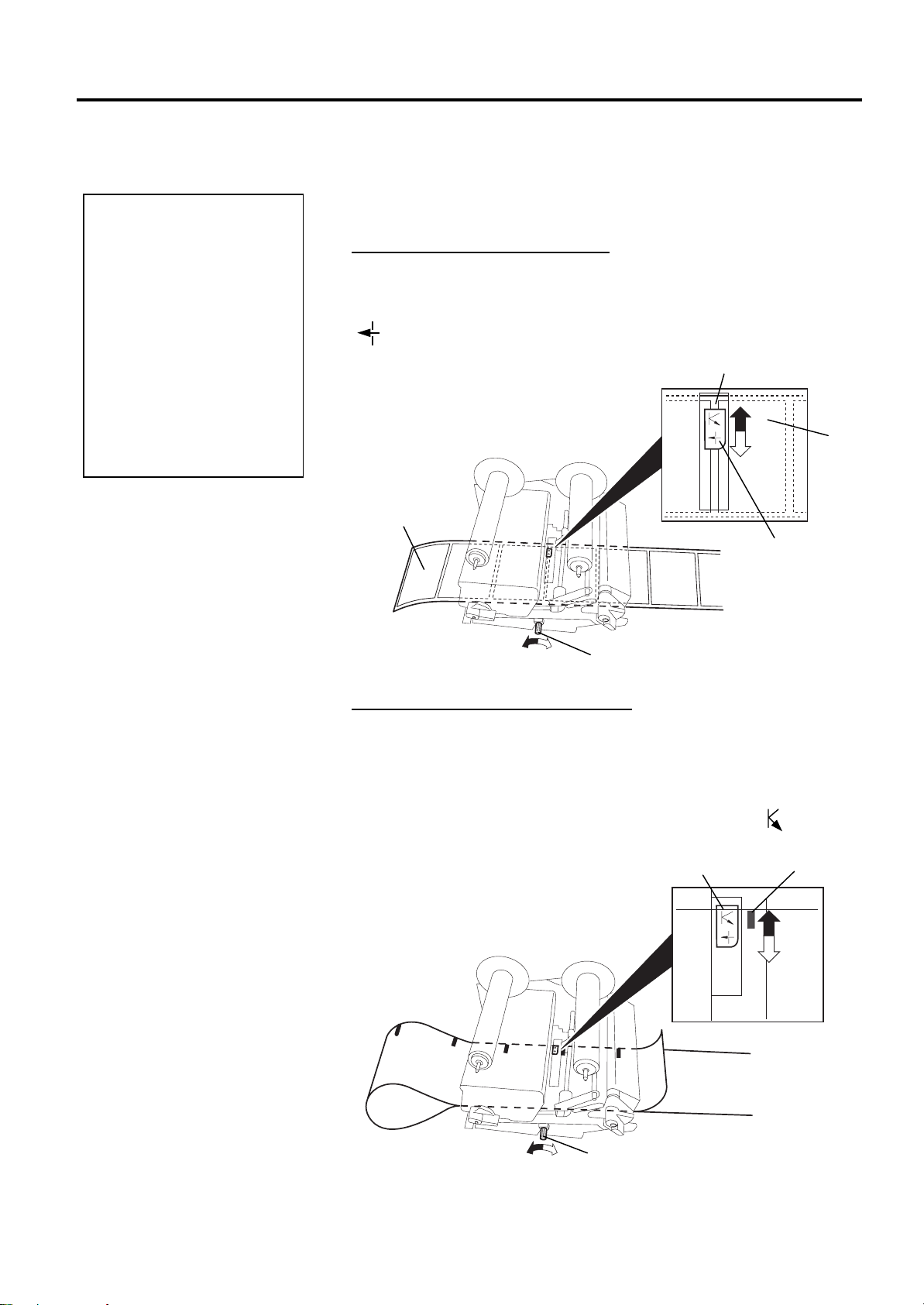

2.7 Loading the Media

7.

After loading the media, it may be necessary to set the media sensors

used to detect the print start position of the labels. Set the black

mark/feed gap sensor to the correct position by turning the adjusting

knob.

Setting the feed gap sensor position

Turn the adjusting knob to move the feed gap sensor to the centre of the

labels to detect the gap between labels. If the labels are round, set the

sensor to detect the area of the shortest distance between the labels.

( indicates the position of the feed gap sensor).

Gap between Labels

Label

Label

Feed Gap Sensor

Adjusting Knob

Setting the black mark sensor position

(1) Pull about 500 mm of media out of the front of the printer, turn the

media back on itself and feed it under the print head past the sensor

so that the black mark can be seen from above.

(2) Turn the adjusting knob to move the black mark sensor so that it is

in line with the center of the black mark on the media. ( indicates

the position of the black mark sensor.)

Black Mark Sensor

Black Mark

Adjusting Knob

2- 8

Page 20

2. PRINTER SETU P

EO1-33032

2.7 Loading the Media

(Cont.)

To separate the printed

media from the media roll

in batch mode, be sure to

tear off the media at the

strip shaft or cut the media

past the strip shaft.

However, if you tear off

the media at the print

head by mistake, be sure

to feed one label (10 mm

or more) with the [FEED]

key prior to next issue.

Failure to do this may

cause a paper jam.

CAUTION!

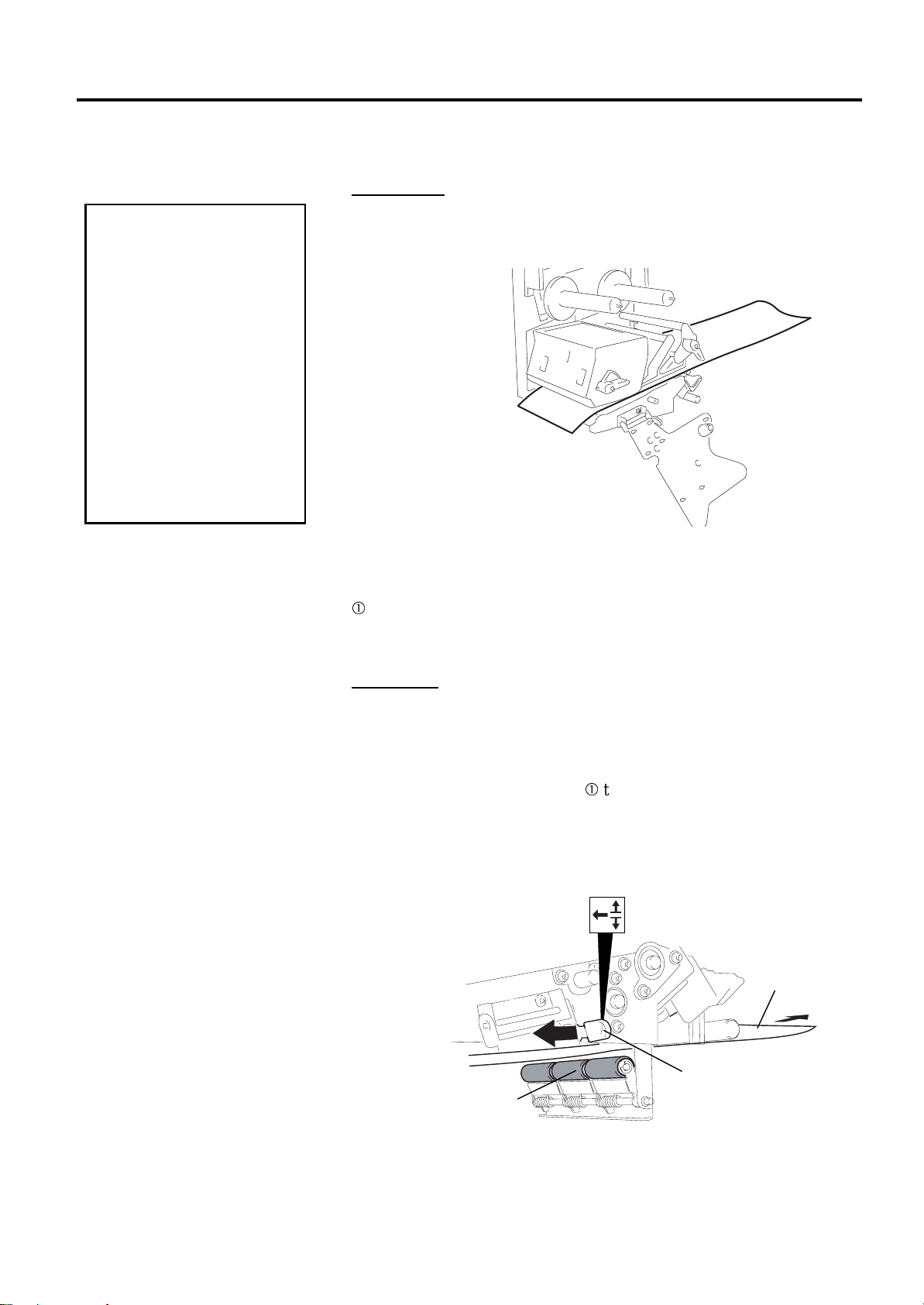

2.7 Loading the Media

8.

There are two issue modes available on this printer.

Batch mode:

In the batch mode, the media is continuously printed and fed until the

number of issues specified in the label issue command has been printed.

Media

If the loaded media is direct thermal media (a chemically treated surface),

the media loading procedure is now complete. Close the ribbon shaft

holder plate, and turn the head lever and the pinch roller lever to position

c

to close. Then, close the top cover.

If the media is a standard media, it is also necessary to load a ribbon.

Refer to the section, 2.8 Loading the Ribbon.

Strip mode:

In strip mode, as each label is printed the backing paper is automatically

removed from the label at the strip plate.

(1) Set the ribbon shaft holder plate, and turn the head lever and the

pinch roller lever to position c to close.

(2) Remove enough labels from the leading edge of the media to leave

500 mm of backing paper free.

(3) Push the pinch roller release lever toward the front of the printer to

release the strip pinch roller unit.

Backing Paper

Strip Pinch Roller Unit

Pinch Roller

Release Lever

2- 9

Page 21

2. PRINTER SETU P

EO1-33032

2.7 Loading the Media

(Cont.)

2.7 Loading the Media

(4) Pass the backing paper under the strip plate and abov e the strip pinch

roller.

(5) While pulling the backing paper push up the strip pinch roller until it

locks into position.

(6) If the loaded media is direct thermal media (a chemically treated

surface), the media loading procedure is now complete. Close the

ribbon shaft holder plate, and turn the head lever and the pinch roller

lever to position c to close. Then, close the top cover.

If the media is a standard media, it is also necessary to load a ribbon.

Refer to the following section, 2.8 Loading the Ribbon.

2-10

Page 22

2. PRINTER SETU P

k

R

L

EO1-33032

2.8 Loading the Ribbon

1. Do not touch any moving

2. To avoid injury, be

3. Be sure to open the top

WARNING!

parts. To reduce the ris

of fingers, jewellery,

clothing, etc. being

drawn into the moving

parts, be sure to load the

ribbon once the printer

has stopped moving

completely.

careful not to trap your

fingers while opening or

closing the cover.

cover fully, otherwise the

top cover may close,

causing injury.

2.8 Loading the Ribbon

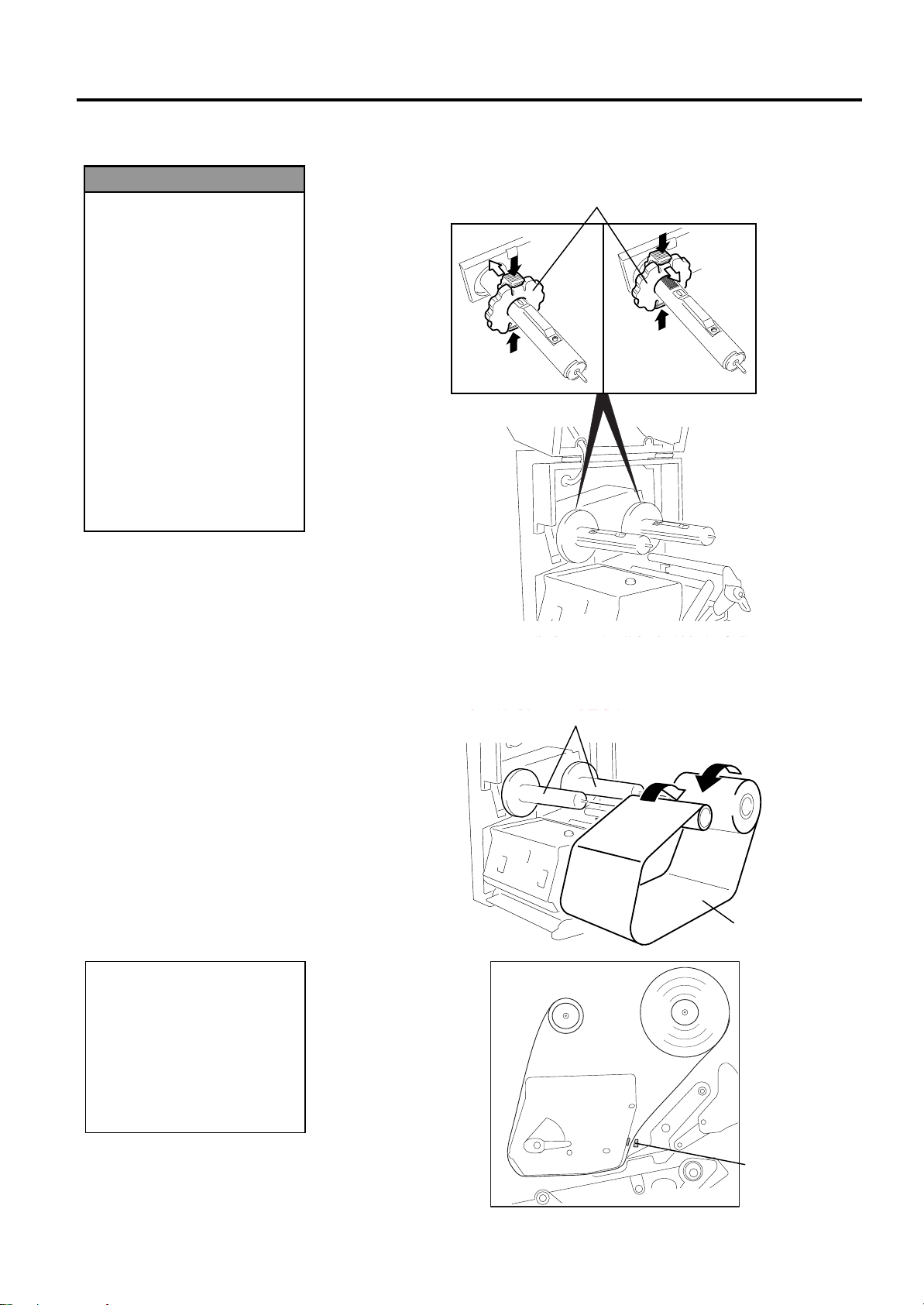

1.

Grasp the tabs on the top and bottom of the ribbon stoppers and move

the ribbon stoppers back to the end of the shaft.

2.

Leaving plenty of slack between the ribbon spools, place the ribbon

onto the ribbon shafts as shown below. When the ribbon is fitted, it

must be positioned in the ribbon sensor.

Ribbon Stopper

Ribbon Shafts

Ribbon

NOTE:

The ribbon sensor is mounted on

the rear of the printer block to

detect a ribbon end. When a

ribbon end is detected, “NO

IBBON” message will appear

on the display and the ERROR

ED will illuminate.

Ribbon Sensor

2-11

Page 23

2. PRINTER SETU P

)

EO1-33032

2.8 Loading the Ribbon

(Cont.)

2.9 Inserting the Optional

PCMCIA Cards

1. To protect PC cards,

2. Before inserting or

3. Be sure to protect

4. Do not subject the card

5. The card may be

CAUTION!

discharge static

electricity from your body

by touching the metal

cabinet of the printer

before touching the card.

removing a PCMCIA

card make sure that the

printer’s power is turned

off.

PCMCIA Cards when not

in use by putting them

into their protective

covers.

to any shocks or

excessive force nor

expose the card to

extremes in temperature

or humidity

inserted into the slot

halfway even in the

wrong orientation.

However, the slot is

safety designed so that

the card will not seat

against the connector

pins.

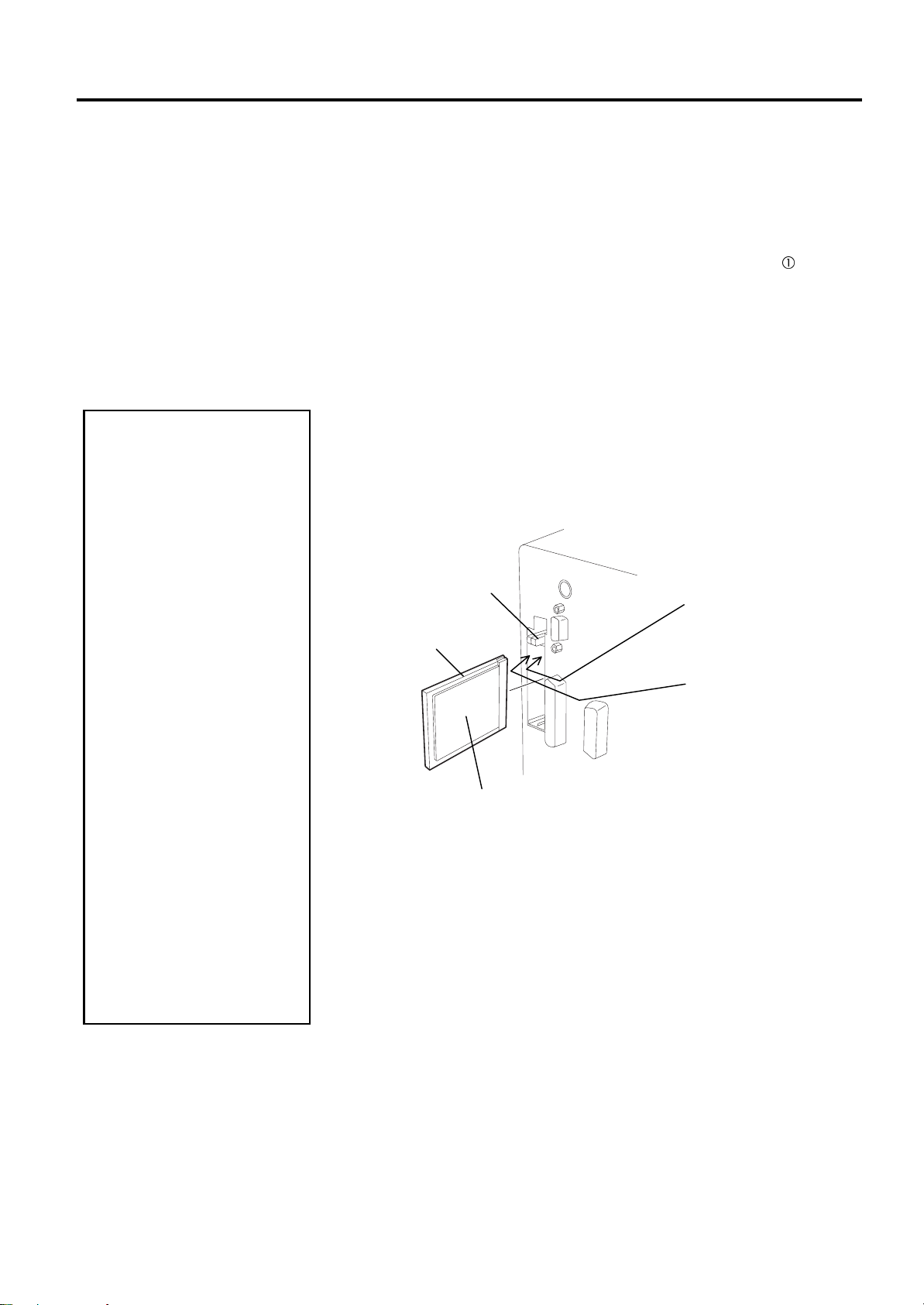

2.9 Inserting the Optional P CMCIA Cards

3.

Slide the ribbon stoppers along the ribbon shafts to a position where

the ribbon is centered when fitted.

4.

Take up any slack in the ribbon. Take the leading tape onto the ribbon

take-up roll until the ink ribbon can be seen from the front.

5.

Set the ribbon shaft holder plate aligning its holes with the ribbon

shafts.

6.

Turn the head lever and the pinch roller lever to position c to close

the print head and the pinch roller.

7.

Close the top cover.

When the optional PCMCIA interface board is installed in the B-492L/R

printer, there will be two PCMCIA slots available as shown in the figure

below. This allows the use of Flash Memory Type Cards or I/O Cards

such as LAN Cards.

1.

Make sure that the printer’s power switch is in the OFF position.

2.

Hold the PCMCIA Card so that the side printed with the model name

faces right. Insert the card into the proper slot until the Eject Button

pops out.

Eject Button

Flash Memory

Type Card

Model Name Printed Side

Slot 1:

(I/O type cards such as

LAN cards

Slot 0:

(Memory type cards only)

2-12

Page 24

2. PRINTER SETU P

EO1-33032

2.9 Inserting the

Optional PCMCIA

Cards (Cont.)

2.10 Test Print

2.10 Test Print

3.

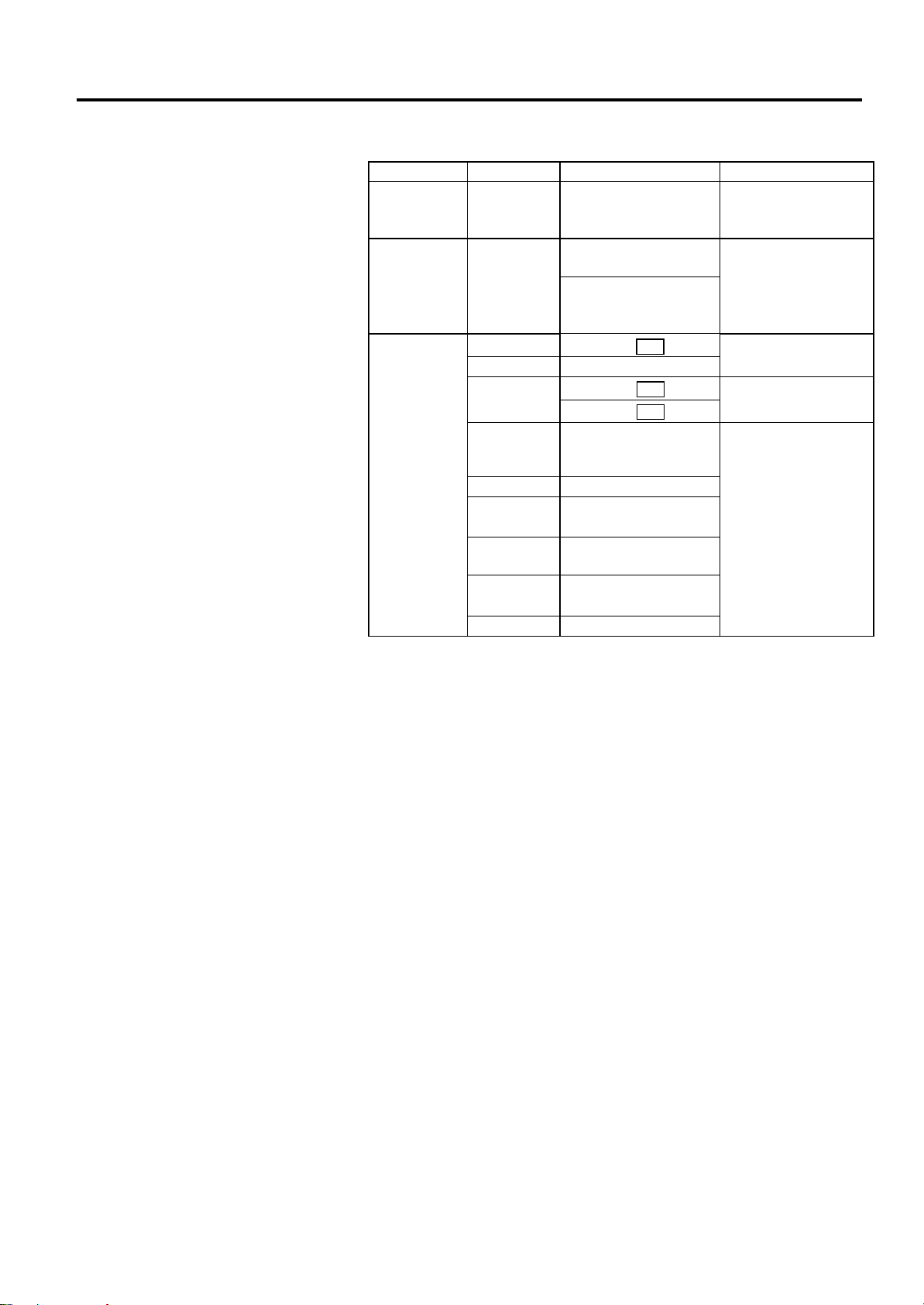

The following PCMCIA cards can be used.

Type Maker Description Remarks

ATA Card

LAN Card 3 COM

Flash Memory

Card

A print test should be performed to check that the printer is operating

correctly. During this test, the printer will first issue a blank page of

media to allow the sensors to detect the Black Mark or Label G ap. Then it

will print five pages of slanted lines followed by five pages of sample bar

codes then finally by printing five pag es that contain characters of v arious

sizes.

For the test print procedure, please refer to Appendix 4.6 Test Print.

San Disk

Hitachi

Maxell

Mitsubishi MF-81M1-GBDAT01

Maxell

Centennial

Technologies

INC.

INTEL IMC004FLSA

Simple

TECHNOLOGY

Mitsubishi MF84M1-G7DAT01

PC Card KING

MAX

PC Card FJP-004M6R

A card conforming to

the PC card ATA

standard

Ether Link III 3C589D

PC card

Megahertz®

10M bps LAN PC Card

3CCE589ET Series

EF-1M-TB AA

EF-4M-TB CC

EF-4M-TB DC

FL04M-15-11119-03

STI-FL/4A

FJN-004M6R

----------

Install into the slot (1)

only. (This card

installed into the slot

(0) will not work.)

Capacity: 1MB

Read only

Capacity: 4MB

Readable/writable

Capacity: 4MB

Read only

2-13

Page 25

3. ON LINE MODE

(

y

y

EO1-33032

3. ON LINE MODE

3.1 Operation Panel

Use the

resume printing after a pause,

or after clearing an error.

NOTE:

[RESTART]

key to

3.1 Operation Panel

This chapter describes usage of the keys on the Operation Panel in On

Line Mode.

When the printer is in On Line Mode and connected to a host computer,

the normal operation of printing images on labels can be achieved.

The figure below shows the Operation Panel and key functions..

POWER LED

[RESTART] ke

The LCD Message Display shows messages to indicate the printer’s

current status. Up to 16 characters can be displayed on this line.

There are three LED lights on the Operation Panel.

POWER

ON LINE

ERROR

There are three keys on the Operation Panel.

PAUSE

RESTART

FEED

Green)

[FEED] ke

LED Illuminates when… Flashes when…

LCD Message Display

POWER ON LINE ERROR

FEED RESTART PAUSE

The printer is turned on. ----The printer is ready to

print.

Any error occurs on the

printer.

Used to stop printing temporarily.

Used to restart printing.

Used to feed the media.

The printer is

communicating with

your computer.

-----

ON LINE LED (Green)

ERROR LED (Red)

[PAUSE] key

3- 1

Page 26

3. ON LINE MODE

EO1-33032

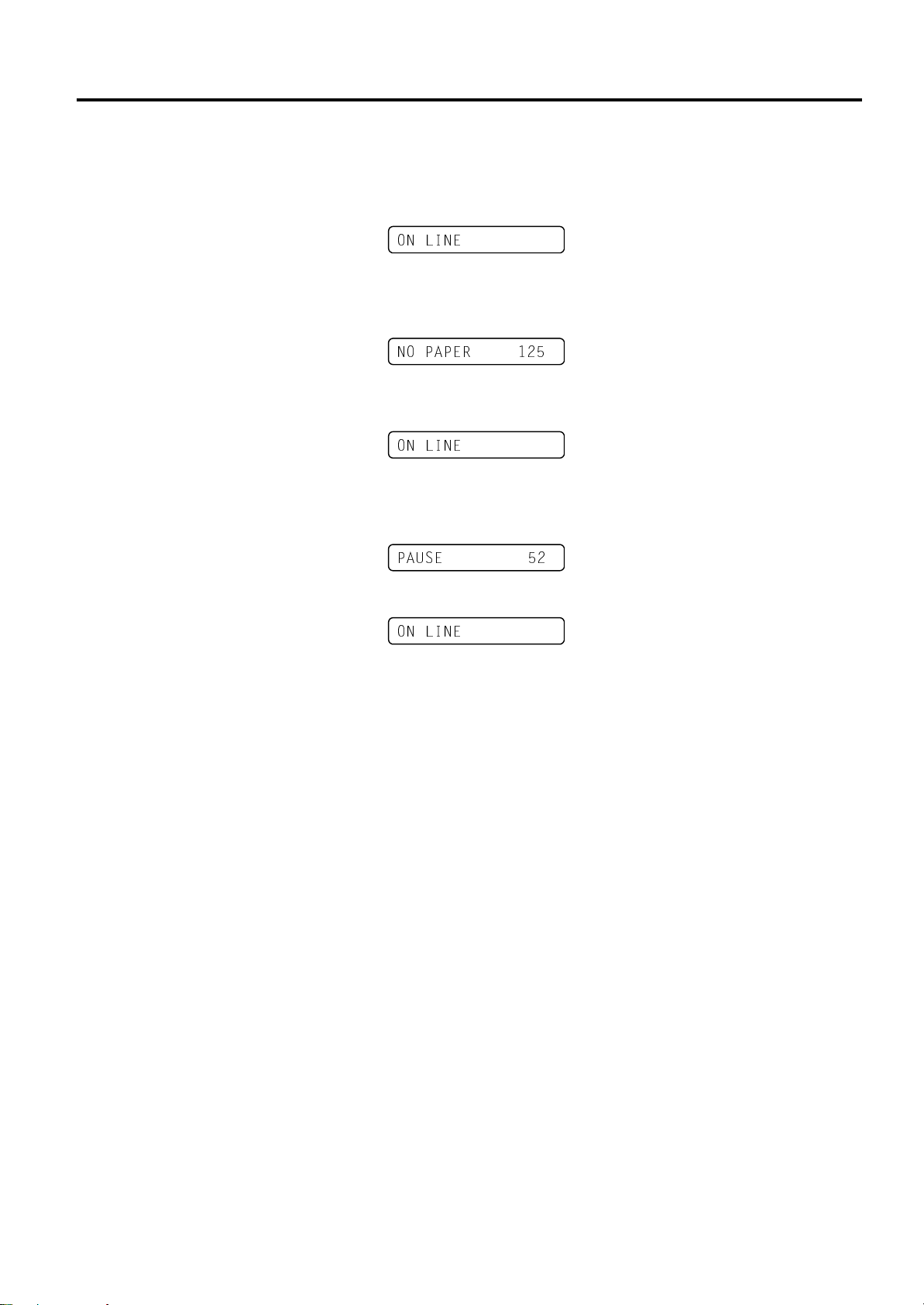

3.2 Operation

3.2 Operation

When the printer is turned on, the “ON LINE” message appears on the

LCD message display. It is displayed during standby or normal printing.

1.

The printer is turned on, standing by, or printing.

21 /,1(

2.

If any error occurs during printing, an error message appears. The

printer stops printing automatically. (The number on the right hand

side shows the remaining number of labels to be printed.)

12 3$3(5

3.

To clear the error, press the

printing.

21 /,1(

4

. If the

printing temporarily. (The number on the right hand side shows the

remaining number of labels to be printed.)

5.

When the

[PAUSE]

3$86(

[RESTART]

21 /,1(

key is pressed during printing, the printer stops

[RESTART]

key is pressed, the printer resumes printing.

key. The printer resumes

3- 2

Page 27

4. MAINTENANCE

EO1-33032

4. MAINTENANCE

1. Be sure to turn OFF the

power of the power supply

unit before performing

maintenance. Failure to do

this may cause an electric

shock.

2. To avoid injury, be careful

not to pinch your fingers

while opening or closing the

cover and print head block.

3. Be careful when handling

the print head as it

becomes very hot

immediately after printing.

Allow it to cool before

performing any

maintenance.

4. Do not pour water dir ectly

onto the printer.

4.1 Cleaning

4.1.1 Print Head/Platen

1. Do not allow any hard

objects to touch the print

head or platen, as this may

cause damage to them.

2. Do not use any volatile

solvents including thinner

and benzene, as this may

cause discoloration of the

cover, print failure, or

breakdown of the printer.

3. Do not touch the print head

element with bare hands,

as static may damage the

print head.

WARNING!

CAUTION!

4.1 Cleaning

This chapter describes how to perform routine maintenance.

To ensure the continuous high quality operation of your B-492L/R, you

should perform a regular maintenance routine. For high throughput it

should be done on a daily basis. For low throughput it should be done on

a weekly basis.

To maintain the printer performance and print quality, please clean the

printer regularly, or whenever the media or ribbon is replaced.

1.

Turn the power off.

2.

Open the top cover.

3.

Turn the head lever and pinch roller lever to position d, then open the

ribbon shaft holder plate.

4. Remove the ribbon and media.

5. Clean the element of the print head with the print head cleaner or a

soft cloth slightly moistened with ethyl alcohol or isopropyl alcohol.

Element (positioned at

the print head edge)

Platen

Print Head Cleaner

(Part No.: 24089500013)

or Lapping Sheet

4- 1

Print Head

Page 28

4. MAINTENANCE

EO1-33032

4.1.1 Print Head/Platen

(Cont.)

1. A print head cleaner or

lapping sheet is not enclosed

with the printer. Please use a

TEC approved print head

cleaner or lapping sheet which

can be purchased from an

authorised TOSHIBA TEC

service representative.

2. Do not rub the print head

element with a lapping sheet

excessively, or the print head

life will be shortened.

3. When purchasing a lapping

sheet locally, it should meet the

following specifications.

Product name: Imperial lapping

film sheet

Model: #4000 (Grain size: 3

Abrasive coating: Aluminum

oxide, Backing material: 3MIL)

Maker: Sumitomo 3M

NOTES:

WARNING!

µ

4.1.2 Media Guide Plate/

Pinch Roller/Sensors

m,

4.1 Cleaning

6.

When you are using some semi-resin ribbons the print head element

can still be stained with burned ribbon particles even after performing

the above-mentioned cleaning. In this case wipe the print head

element from end to end in both directions 4 – 5 times with a 30 mm

by 30 mm piece of lapping sheet.

7.

Wipe the platen with a soft cloth moistened with alcohol.

1.

Carefully pull out the media guide plate from the two guide shafts.

2.

Wipe the bottom of the media guide with a cloth moistened with

alcohol.

Guide Shaft

Media Guide Plate

Turn over the media

guide plate and clean

the bottom surface.

Clean these surfaces.

4- 2

Page 29

4. MAINTENANCE

EO1-33032

4.1.2 Media Guide Plate/

Pinch Roller/Sensors

(Cont.)

4.1 Cleaning

3.

Remove the locking screw to detach the paper guide B from the

printer.

Pinch Roller

Feed Roller

Paper Guide B

4.

Push the pinch roller release lever toward the front of the printer to

release the strip pinch roller unit.

5.

Wipe the feed roller and pinch rollers with a soft cloth moistened with

alcohol.

6.

Remove dust or paper particles from the black mark and feed gap

sensors using an air blower.

Strip Feed Roller

Strip Pinch Roller

Locking Screw

4- 3

Page 30

4. MAINTENANCE

EO1-33032

4.1.3 Paper Holder

4.1.4 Covers and Panels

Do not use any volatile

solvents including thinner and

benzene, as this may cause

discoloration or distortion of

the cover.

CAUTION!

4.1 Cleaning

1.

Open the paper entry guide.

2.

Loosen the locking screw and move the media guides toward the

center.

3.

Remove the set screws to detach both paper holders’ upper plates.

4.

Wipe the paper holders’ upper and lower plates with a soft cloth

moistened with alcohol.

Paper Holders’ Lower Plate

Paper Entry Guide

Set Screw

Set Screw

Paper Holders’

Upper Plate

Locking Screw

Loose

Wipe the Cover and Operation Panel with a dry soft cloth. Wipe off dirt

with a soft cloth slightly moistened with water.

4- 4

Page 31

4. MAINTENANCE

d

q

EO1-33032

4.2 Care/Handling of the

Media and Ribbon

Be sure to carefully review an

understand the Supply

Manual. Use only media and

ribbons which meet specified

requirements. Use of nonspecified media and ribbons

may shorten the head life and

result in problems with bar

code readability or print

uality. All media and ribbons

should be handled with care to

avoid any damage to the

media, ribbons or printer.

Read the guideline in this

section carefully.

CAUTION!

4.2 Care/Handling of the Media and Ribbon

• Do not store media or ribbon for longer than the manufacturer’s

recommended shelf life

• Store media rolls on the flat end. Do not store them on the curved

sides as this might flatten that side causing erratic media advance and

poor print quality.

• Store the media in plastic bags and always reseal after opening.

Unprotected media can get dirty and the extra abrasion from the dust

and dirt particles will shorten the print head life.

• Store the media and ribbon in a cool, dry place. Avoid areas where

they would be exposed to direct sunlight, high temperature, high

humidity, dust or gas.

• The thermal paper used for direct thermal printing must not have

specifications which exceed Ca

2+

, K+, Na+ 800 ppm, and Cl- 600 ppm.

• Some ink used on pre-printed media may contain ingredients which

shorten the print head’s product life. Do not use labels pre-printed

with ink which contain hard substances such as carbonic calcium

(CaCO

) and kaolin (Al2O3, 2SiO2, 2H2O).

3

For further information, please contact your local distributor or your

media and ribbon manufacturers.

4- 5

Page 32

5. TROUBLESHOOTING

N

e

EO1-33032

5.1 Error Messages

5. TROUBLESHOOTING

This chapter lists the error messages, possible problems, and their solutions.

If a problem cannot be solved by taking actions described in this chapt er, do not attempt to repair th

printer. Turn off and unplug the printer. Then contact an authorized TOSHIBA TEC service

representative for assistance.

5.1 Error Messages

OTES:

•

If an error is not cleared by pressing the

•

After the printer is turned off, all print data in the printer is cleared.

“****”

•

HEAD OPEN

HEAD OPEN

COMMS ERROR

PAPER JAM ****

NO PAPER ****

RIBBON ERROR ****

indicates the remaining number of labels to be printed. Up to 9999 (pieces)

Error Messages Problems/Causes Solutions

The print head block is opened in Online

Mode.

****

Feeding or printing has been attempted

with the Print Head Block open.

A communication error has occurred. Make sure the interface cable is correctly

1. The media is jammed in the media

path. The media is not fed smoothly.

A wrong media sensor is selected for

2.

the media being used.

The Black Mark Sensor is not

3.

correctly aligned to the Black Mark

on the media.

Size of the loaded media is different

4.

from the programmed size.

The Feed Gap Sensor cannot

5.

distinguish the print area from a

label gap.

1. The media has run out.

The media is not loaded properly.

2.

The media is slack.

3.

The ribbon is not fed properly.

WARNING!

[RESTART]

5- 1

key, turn the printer off and then on.

Close the print head block. Then press

[RESTART]

the

Close the print head block. Then press

[RESTART]

the

connected to the printer and the host, and

the host is turned on. Then press the

[RESTART]

Remove the jammed media, and clean

1.

the platen. Then reload the media

correctly. Finally press the

RESTART]

[

2.

Turn the printer off and then on. Then

select the media sensor for the media

being used. Finally resend the print

job.

Adjust the sensor position. Then press

3.

[RESTART]

the

Replace the loaded media with one

4.

that matches the programmed size

then press the

turn the printer off and then on, select

a programmed size that matches the

loaded media. Finally resend the print

job.

Refer to Section 6.4 to set the

5.

threshold. If this does not solve the

problem, turn off the printer, and call

an authorized service representative.

Load new media. Then press the

1.

[RESTART]

Reload the media correctly. Then

2.

press the [

3.

Take up any slack in the media.

Remove the ribbon, and check the status

of the ribbon. Replace the ribbon, if

necessary. If the problem is not solved,

turn off the printer, and call an authorized

service representative.

key.

key.

key.

key.

[RESTART]

key.

RESTART]

key.

key, or

key.

Page 33

5. TROUBLESHOOTING

EO1-33032

5.2 Possible Problems

5.1 Error Messages (Cont.)

Error Messages Problems/Cause Solutions

NO RIBBON ****

EXCESS HEAD TEMP

The ribbon has run out. Load a new ribbon. Then press the

[RESTART]

key.

The print head has overheated. Turn off the printer, and allow it to cool

down (for about 3 minutes). If this does

not solve the problem, call a TOSHIBA

TEC authorized service representative.

HEAD ERROR

COVER OPEN ****

PINCH OPEN ****

PEEL OPEN ****

There is a problem with the Print Head. Replace the Print Head. Then press the

Media feed or print operation is

attempted with the top cover opened.

Media feed or print operation is

attempted with the pinch roller raised.

Media feed or print operation is

attempted with the strip pinch roller unit

[RESTART]

Close the top cover, then press the

[RESTART]

Set the pinch roller, then press the

[RESTART]

Close the strip pinch roller unit, then press

[RESTART]

the

key.

key.

key.

key.

opened.

GUIDE OPEN ****

Media feed or print operation is

attempted with the media guide plate

Set the media guide plate, then press the

[RESTART]

key.

removed.

Other error messages A hardware or software problem may

have occurred.

Turn the printer off and then on. If this

does not solve the problem, turn off the

printer again, and call a TOSHIBA TEC

authorized service representative.

5.2 Possible Problems

This section describes problems that may occur when using the printer, and their causes and solutions.

Possible Problems Causes Solutions

The printer will not

turn on.

The media is not fed. 1. The media is not loaded properly.

Nothing is printed on

the media.

The printed image is

blurred.

1. The AC Power Cord or DC Power

Cord is disconnected.

2. The AC outlet is not functioning

correctly.

3. The fuse has blown, or the circuit

breaker has tripped.

2. The printer is in an error condition.

1. The media is not loaded properly.

2. The ribbon is not loaded properly.

3. A print head is not installed properly.

4. The ribbon and media are not

matched.

1. The ribbon and media are not

matched.

2. The Print Head is not clean.

1. Plug in the AC Power Cord or DC

Power Cord.

2. Make sure that the power is supplied

using another electric appliance.

3. Check the fuse or breaker.

1. Load the media properly.

2. Solve the error in the Message

Display. (See Section 5.1 for more

detail.)

1. Load the media properly.

2. Load the ribbon properly.

3. Install the Print Head properly. Close

the Print Head Block.

4. Select an appropriate ribbon for the

media type being used.

1. Select an appropriate ribbon for the

media type being used.

2. Clean the print head using a Print

Head Cleaner.

5- 2

Page 34

5. TROUBLESHOOTING

EO1-33032

5.3 Removing Jammed Media

5.3 Removing Jammed

Media

Do not use any tool that

may damage the print

head.

CAUTION!

5.4 Threshold Setting

1. If the

released within 3 seconds

while in the pause state, the

paper will not feed.

2. Failure to feed more than

1.5 labels may result in an

incorrect threshold setting.

3. While the Print Head Block

is raised, the

does not work.

4. A paper end error cannot

be detected during paper

feed.

5. Selecting the Transmissive

Sensor (for pre-printed

labels) within software

commands allows the

printer to detect the proper

print start position even

when using pre-printed

labels.

6. If using the transmissive

sensor and the printer

continues to print out of

position even after setting

the threshold, adjust the

Feed Gap Sensor in the

system mode. Reset the

threshold again. Make sure

that the Transmissive

Sensor (for pre-printed

labels) is selected in the

feed and issue commands.

NOTES:

[PAUSE]

[PAUSE]

key is

key

This section describes in detail how to remove jammed media from the

printer.

1.

Open the top cover.

2.

Turn the head lever and the pinch roller lever to position d, then open

the ribbon shaft holder plate.

3. Pull out the media guide plate from the printer side.

4. Remove the ribbon and media.

5. Remove the jammed media from the printer. DO NOT USE any sharp

implements or tools as these could damage the printer.

To maintain a constant print position the printer uses the Transmissive

Sensor to detect the gap between labels by measuring the amount of light

passing through the media. When the media is pre-printed, darker (or

more dense) inks can interfere with this process causing paper jam errors.

To get around this problem a minimum threshold can be set for the sensor

in the following way.

Threshold setting procedure

1. Turn the power ON. The printer is in stand by mode.

2. Load the media.

3. Press the [PAUSE] key.

4. The printer enters the pause mode.

5. Press and hold the [PAUSE] key for at least 3 seconds in the pause

6. The sensor type is displayed.

7. Select the sensor to be adjusted by pressing the [FEED] key.

21 /,1(

3$86(

state.

75$160,66,9(

5()/(&7,9(

75$160,66,9(

Black Mark Sensor

[FEED] key

Feed Gap Sensor

5- 3

Page 35

5. TROUBLESHOOTING

5.4 Threshold Setting

(Cont.)

EO1-33032

5.4 Threshold Setting

8.

Press and hold the

[PAUSE]

key until more than 1.5 labels have

been issued.

The media will continue to be fed until the

[PAUSE]

key is

released.

(Threshold setting for the selected sensor is completed by this

operation.)

3$86(

9.

Press the

[RESTART]

key.

21 /,1(

10.

The printer is in stand-by.

11.

Send an issue command from the PC to the printer.

21 /,1(

5- 4

Page 36

6. PRINTER OPERATION

EO1-33032

6. PRINTER OPERATION

6.1 Overview

6.2 Installing the Printer

Drivers

“X” will be replaced with your

CD drive’s letter. (e.g. D, E, etc.)

1. When downloading the

printer driver from TEC Web

Site, confirm the version and

use the latest printer driver.

The supplied CD-ROM

contains

‘Bdrv_V6_5_Build77.exe”.

2. Driver file name, capacity,

and date of the driver may be

changed without prior

notification. For the latest

information about the driver,

please contact your

authorised TOSHIBA TEC

representative.

NOTE:

NOTE:

This section provides a functional overview of how the printer receives

print data from your host computer and how it will operate in the various

operating conditions. This section also shows you how to install the TEC

Printer Drivers into your computer.

Labels will be created on the host computer connected to your printer,

using either a commercially available label creation program or using the

TEC Command Program Language. The label information sent from

your host computer will consist of a series of commands that inform the

printer of the labels size, layout, orientation, and number of copies to

print and will also contain the print data including scaleable text,

graphics, and bar codes. The printer electronics will decode the

commands and manipulate the data to create a bit graphic image of the

label that will be stored in the printer’s memory. The printer electronics

will then transfer the image as a series of dots, one line at a time, to the

thermal print head.

The thermal print head consists of a line of 1280 thermal elements with

each element shaped like a tiny dot. The dot line is 4 inches (101.6 mm)

in length resulting in a dot density of 305 DPI. As the paper is advanced

through the printer by the paper feed mechanism, the thermal head

continuously prints the image as a series of dot lines at a resolution of

305 dots per inch, horizontally and vertically.

Precision feeding and back feeding of the label stock is accomplished

through the use of specialized stepping motors and photo-sensors. The

label gap sensor or the black mark sensor tells the printer electronics

when the label stock is properly positioned under the head for accurate

printing.

Before you can use the printer, it is necessary to install the printer driver

to your PC. Installation is accomplished by first installing the set of

printer driver files from the supplied CD-ROM.

Run the following SETUP.EXE.

“X”:\DRIVE\SETUP.EXE

The latest printer driver can be obtained from the TOSHIBA TEC

Barcode Web Site. Access the TOSHIBA TEC Barcode World Wide

Web Site at the following URL:

http://barcode.toshibatec.co.jp/Eng/download.html

Double click on the downloaded file (“Bdrv_Vx_x_Buildxx.exe”), and

then run the following SETUP.EXE. (“C:\TEC\MONO\CD”is the

default install directory.)

“C:\TEC\MONO\CD”\SETUP.EXE

6.1 Overview

6- 1

Page 37

6. PRINTER OPERATION

M

EO1-33032

6.2.1 System Requirements

Windows 3.1® is not supported.

Windows 3.1®, Windows 95®,

Windows 98®, Windows NT®

and Windows 2000 ®

registered trademarks of

icrosoft Corporation.

Pentium® is a registered trademark of Intel Corporation

NOTE:

are

,

6.2.2 Driver Installation

1. How to install the printer

driver from the supplied CDROM is described below.

2. When the printer driver is

downloaded from TOSHIBA

TEC Web Site, type in

“C:\TEC\MONO\CD\SETUP

.EXE”. C:\TEC\MONO\CD

is the default install directory

generated when the printer

driver file

(Bdrv_Vx_x_Buildxx.exe) is

run.

NOTE:

6.2 Installing the Pri nt er Dri vers

1.

System

a. IBM Compatible PC running Windows 95® or Windows 98® or

Windows NT® Version 4.0 Workstation, Windows NT® Version

4.0 Server, Windows 2000® Professional, or Windows 2000®

Server.

b. Pentium® processor, 133MHz or greater recommended.

c. Installed memory of 16MB minimum (32MB recommended).

d. Available Hard Disk space of 10MB or more.

2.

Interface

a. The RS-232C interface

b. Centronics interface

1.

Insert the supplied CD-ROM into the CD drive of your PC.

2.

Click on the

3.

Type in ‘D:\DRIVER\SETUP.EXE” and click on the OK button.

START

button, then select and click on the

Run…

.

(“D” may be replaced with your CD drive’s letter.)

4.

The screen will change as shown below.

5.

After the Install Shield temporary files have been loaded, the display

will change to the Welcome screen as shown below.

6- 2

Page 38

6. PRINTER OPERATION

I

EO1-33032

6.2.2 Driver Installation

(Cont.)

f you click on the No button

in the License Agreement

screen, the program will not

be installed.

NOTE:

6.2 Installing the Pri nt er Dri vers

6.

Click on the

Next

button to continue the installation. The screen will

change to the Software License Agreement screen.

7.

Carefully read the Software License Agreement. To accept the

conditions of the agreement, click on the

Yes

button. If you do not

accept the conditions click on the No button.

8.

Upon clicking on the Yes button, the screen will change to list the

available TEC driver sets. For this printer, select “TEC B-492” and

click on the

Next

button.

9.

The screen will change to the following.

When the printer is directly connected to this PC, select “Local

Printer”, otherwise, select “Network Printer”. Then click on the

Next

button.

6- 3

Page 39

6. PRINTER OPERATION

B

I

p

EO1-33032

6.2.2 Driver Installation

(Cont.)

e sure to select the same printer

that you are going to install.

NOTE:

NOTE:

f you specify the same name as

already installed printer, that

rinter will be overwritten.

When you desire to install the

same printer for many times,

change the printer name each

time.

6.2 Installing the Pri nt er Dri vers

If you selected the Local Printer in the previous step, go to Step 10.

If you selected the Network Printer in the previous step, go to Step 11.

10.

When you selected the Local Printer in Step 9, select the PC port to

which this printer is connected.

11.

When you selected the Network Printer in Step 9, enter a network

path, and click on the

click on the

chose in Step 8.

12.

The screen will show the selected printer name. Change the printer

name, if necessary.

Browse…

Next

button. If the network path is unknown,

button and select the same printer that you

6- 4

Page 40

6. PRINTER OPERATION

EO1-33032

6.2.2. Driver Installation

(Cont.)

6.2 Installing the Pri nt er Dri vers

13.

Upon clicking on the

Next

button on the previous screen, the printer

driver files copy will start.

14.

After all of the files have been transferred the display will change to

the Setup Complete screen. Select “Yes, I want to restart my

computer now.”, then click on the

Finish

button.

15.

After the TEC Printer Driver has been successfully loaded, the

Printers screen should appear as shown below, showing the TEC B492 as being successfully installed.

6- 5

Page 41

6. PRINTER OPERATION

I

p

EO1-33032

6.2 Installing the Pri nt er Dri vers

6.2.3 Uninstalling the TEC

B-492 Printer Driver

f the registration information is

deleted, the registered labels will

not be able to be used when the

rinter driver is re-installed.

NOTES:

If it becomes necessary to remove the TEC-B-492 printer driver from

your host computer, then it can be removed as follows.

1.

Access the Windows Control Panel and click on the

Programs

icon.

Add/Remove

2.

Select “TEC B-492 Printer” and click on the

Add/Remove

button.

3.

When the following screen appears, click on the

Yes

button.

4.

When the Registration information deletion screen appears, click on

Yes

the

button if you desire to delete the paper information. If you do

not desire to delete the information, click on No button.

If this message does not appear, go to the next step.

6- 6

Page 42

6. PRINTER OPERATION

D

EO1-33032

6.2 Installing the Pri nt er Dri vers

6.2.3 Uninstalling the TEC

B-492 Printer Driver

(Cont.)

NOTE:

eleting the shared files does

not affect other programs.

NOTE:

Please note that it may take time

to delete the printer driver.

5.

When the following screen appears, click on the

Yes To All

button.

If this screen does not appear, the screen of Step 7 will appear instead.

6.

Upon clicking on the

to confirm the deletion of shared file. Click on the

Yes To All

button, the following screen appears

Yes

button.

7.

Printer driver deletion starts. When the deletion is completed, click on

the OK button.

6- 7

Page 43

APPENDIX 1 SPECIFICATIONS

N

EO1-33032

A1.1 Printer

APPENDIX 1 SPECIFICATIONS

Appendix 1 describes the printer specifications and supplies for use on the B-492L/R printer.

A1.1 Printer

The following are the printer specifications.

Model

Item

Supply voltage

Power consumption

During a print job

During standby

Operating temperature range

Relative humidity

Resolution

Printing method

Printing speed

Thermal transfer printing

Thermal direct printing

Available media width (including

backing paper)

Effective print width (max.)

Product type

LCD Message display

Dimension (W × D × H)

Weight

Available bar code types

Available two-dimensional code

Available bar font

Rotations

Standard interface

AC120V, 60 Hz

1.3 A, 123 W maximum

0.17 A, 22 W maximum

5°C to 40°C (40°F to 104°F)

25% to 85% RH (no condensation)

12 dots/mm (305 dpi)

Thermal transfer or Thermal direct