Page 1

TEC Thermal Printer

B-480-QP SERIES

Owner’s Manual

Mode d’emploi

Bedienungsanleitung

Manual de instrucciones

Gebruikershandleiding

Manuale Utente

Page 2

LIST OF STANDARDS OF CONFORMITY

Manufacturer : TOSHIBA TEC Corporation

Address : 570 Ohito, Ohito-Cho, Tagata-Gun, Shizuoka-Ken, 410-2323

Japan

declares that following product

Product Name : Bar Code Printer

Model : B-48X-YY

Options : All

conforms to the following product specifications

Safety : EN 60 950

EMC : EN 55 022

EN 50082-1

Harmonics : EN 60 555-2

Voltage Fluctuations : EN 60 555-3

Supplementary Information

The product herewith complies with the requirements of the Low Voltage Directive 73/23/

EEC, and the EMC directive 89/336/EEC.

1) The product was tested in a typical set up TOSHIBA TEC personnel advocated.

2) The following technical documentation has been filed for review.

• Factory Inspection Certificate by TÜV

• Owner's Manual

• Schematic

• Certificates and Test Reports

Copyright © 1999

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

Page 3

TEC Thermal Printer

B-480-QP SERIES

Owner’s Manual

Page 4

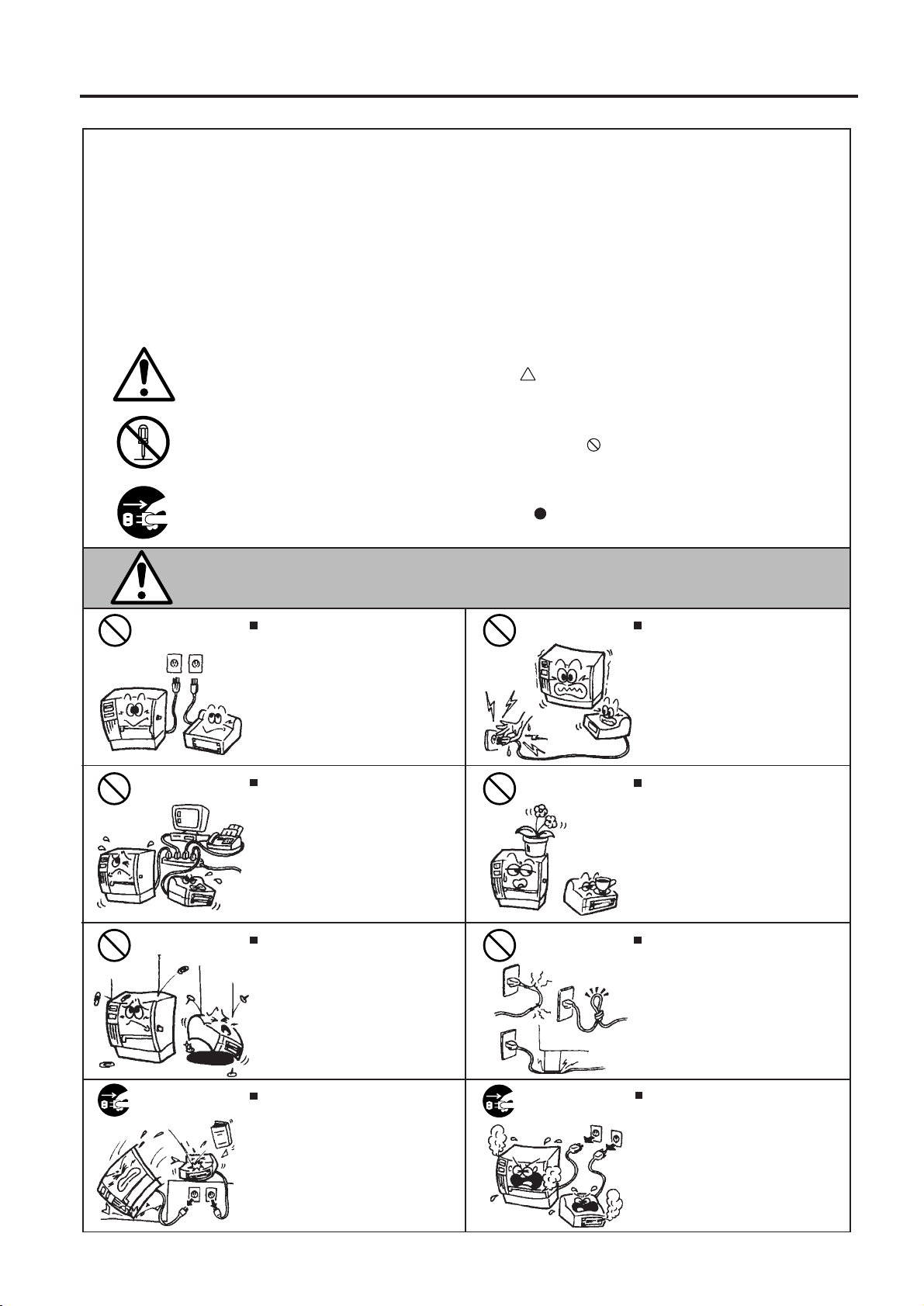

Safety Summary

ENGLISH VERSION EO1-33007

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions

necessary for safe handling are included in this manual. All warnings and cautions contained in this

manual should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified

using the procedures described in this manual, turn off the power, unplug the machine, then contact your

authorized TOSHIBA TEC representative for assistance.

Meanings of Each Symbol

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the symbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the symbol.

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

WARNING

Any other than the

specified AC voltage

is prohibited.

Prohibited

Prohibited

Do not use voltages other than the

voltage (AC) specified on the rating

plate, as this may cause fire or

electric shock.

If the machines share the same

outlet with any other electrical

appliances which consume large

amounts of power, the voltage will

fluctuate widely each time these

appliances operate. Be sure to

provide an exclusive outlet for the

machine as this may cause the

machines to malfunction.

Do not insert or drop metal,

flammable or other foreign objects into

the machines through the ventilation

slits, as this may cause fire or electric

shock.

This indicates that there is the risk of death or serious injury if the

machines are improperly handled contrary to this indication.

Prohibited

Prohibited

Prohibited

Do not plug in or unplug the power

cord plug with wet hands as this may

cause electric shock.

Do not place metal objects or

water-filled containers such as flower

vases, flower pots or mugs, etc. on

top of the machines. If metal objects

or spilled liquid enter the machines,

this may cause fire or electric

shock.

Do not scratch, damage or modify

the power cords. Also, do not place

heavy objects on, pull on, or excessively bend the cords, as this may

cause fire or electrical shock.

Disconnect

the plug.

If the machines are dropped or their

cabinets damaged, first turn off the

power switches and disconnect the

power cord plugs from the outlet, and

then contact your authorized

TOSHIBA TEC representative for

assistance. Continued use of the

machine in that condition may cause

fire or electric shock.

(i)

Disconnect

the plug.

Continued use of the machines in an

abnormal condition such as when the

machines are producing smoke or

strange smells may cause fire or elec-

tric shock. In these cases, immediately turn off the power switches and

disconnect the power cord plugs from

the outlet. Then, contact your authorized TOSHIBA TEC representative for

assistance.

Page 5

Safety Summary

ENGLISH VERSION EO1-33007

Disconnect

the plug.

Connect a

grounding

wire.

If foreign objects (metal fragments,

water, liquids) enter the machines,

first turn off the power switches and

disconnect the power cord plugs from

the outlet, and then contact your

authorized TOSHIBA TEC representative for assistance. Continued

use of the machine in that condition

may cause fire or electric shock.

Ensure that the equipment is

properly grounded. Extension cables

should also be grounded. Fire or

electric shock could occur on

improperly grounded equipment.

Disconnect

the plug.

No disassembling.

When unplugging the power cords,

be sure to hold and pull on the plug

portion. Pulling on the cord portion

may cut or expose the internal wires

and cause fire or electric shock.

Do not remove covers, repair or

modify the machine by yourself. You

may be injured by high voltage, very

hot parts or sharp edges inside the

machine.

This indicates that there is the risk of personal Injury or damage to

CAUTION

objects if the machines are improperly handled contrary to this indication.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

• Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power source * Excessive vibration * Dust/Gas

• The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild

detergent solution. NEVER USE THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic

covers.

• USE ONLY TOSHIBA TEC SPECIFIED paper and ribbons.

• DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high temperatures, high humidity, dust, or gas.

• Ensure the printer is operated on a level surface.

• Any data stored in the memory of the printer could be lost during a printer fault.

• Try to avoid using this equipment on the same power supply as high voltage equipment or equipment likely to cause mains interference.

• Unplug the machine whenever you are working inside it or cleaning it.

• Keep your work environment static free.

• Do not place heavy objects on top of the machines, as these items may become unbalanced and fall

causing injury.

• Do not block the ventilation slits of the machines, as this will cause heat to build up inside the

machines and may cause fire.

• Do not lean against the machine. It may fall on you and could cause injury.

• Care must be taken not to injure yourself with the printer paper cutter.

• Unplug the machine when it is not used for a long period of time.

Request Regarding Maintenance

• Utilize our maintenance services.

After purchasing the machine, contact your authorized TOSHIBA TEC representative for assistance

once a year to have the inside of the machine cleaned. Otherwise, dust will build up inside the

machines and may cause a fire or a malfunction. Cleaning is particularly effective before humid

rainy seasons.

• Our preventive maintenance service performs the periodic checks and other work required to

maintain the quality and performance of the machines, preventing accidents beforehand.

For details, please consult your authorized TOSHIBA TEC representative for assistance.

• Using insecticides and other chemicals

Do not expose the machines to insecticides or other volatile solvents. This will cause the cabinet or

other parts to deteriorate or cause the paint to peel.

(ii)

Page 6

ENGLISH VERSION EO1-33007

TABLE OF CONTENTS

Page

1. INTRODUCTION............................................................................E1-1

1.1 Applicable Model ...................................................................................E1- 2

1.2 Accessories ...........................................................................................E1- 2

2. SPECIFICATIONS .........................................................................E2-1

2.1 Printer....................................................................................................E2- 1

2.2 Options ..................................................................................................E2- 2

2.3 Ribbon ...................................................................................................E2- 2

2.4 Media.....................................................................................................E2- 3

3. OVERVIEW....................................................................................E3-1

3.1 Front/Rear View.....................................................................................E3- 1

3.2 Operation Panel ....................................................................................E3- 1

4. INSTALLING THE PRINTER .........................................................E4-1

4.1 Connecting the Power Cord and Cables ...............................................E4- 1

4.2 Procedure for Fitting Fan Filter..............................................................E4- 1

5. LOADING THE MEDIA..................................................................E5-1

6. LOADING THE RIBBON ...............................................................E6-1

7. INSERTING THE OPTIONAL PCMCIA CARD..............................E7-1

8. CARE/HANDLING OF THE MEDIA AND RIBBON.......................E8-1

9. GENERAL MAINTENANCE ..........................................................E9-1

9.1 Cleaning ................................................................................................E9- 1

9.2 Covers and Panels ................................................................................E9- 2

9.3 Removing Jammed Paper.....................................................................E9- 2

9.4 Threshold Setting ..................................................................................E9- 4

10. TROUBLESHOOTING.................................................................E10-1

CAUTION:

1. This manual may not be copied in whole or in part without prior written permission of

TOSHIBA TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorized Service representative with regard to any queries

you may have in this manual.

Page 7

1. INTRODUCTION

ENGLISH VERSION EO1-33007

1. INTRODUCTION

1. INTRODUCTION

Thank you for choosing the TEC B-480 series thermal/transfer printer. This high performance printer is

equipped with superior hardware including the specially developed (12 dots/mm, 304.8 dots/inch) near

edge print head which will allow very clear print at a maximum speed of 203.2 mm/sec. (8 inches/sec.).

The media supply is internal. Optional features include an automatic ribbon saver, a built-in rewinder/strip

mechanism and external media supply.

This manual contains general set-up and maintenance information and should be read carefully to help

gain maximum performance and life from your printer. For most queries please refer to this manual and

keep it safe for future reference.

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

CAUTION

To avoid injury, be careful not to catch or jam your fingers while opening or closing the cover.

CAUTION

Do not touch moving parts. To reduce the risk that fingers, jewelry, clothing, etc., be drawn into the

moving parts, push the switch in the "OFF" position to stop movement.

E1-1

Page 8

1. INTRODUCTION

1.1 Applicable Model

• B-482-TS10-QP

Model name description

B - 4 8 2 - T S 1 0 - Q P

Resolution

T: 12 dots/mm

2: Thermal direct/Thermal transfer

ENGLISH VERSION EO1-33007

1.1 Applicable Model

QP: European version

Issue mode

S: Batch

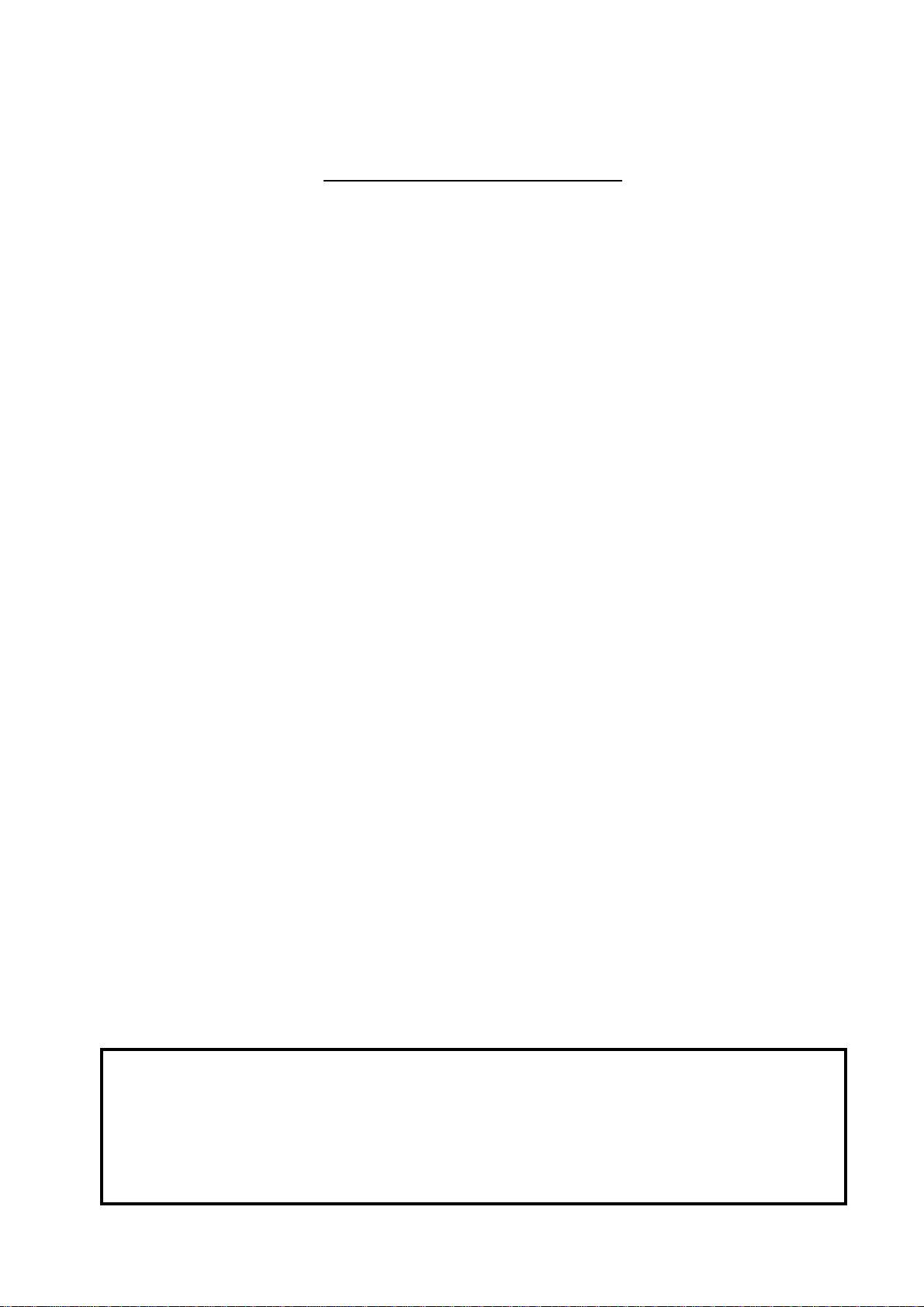

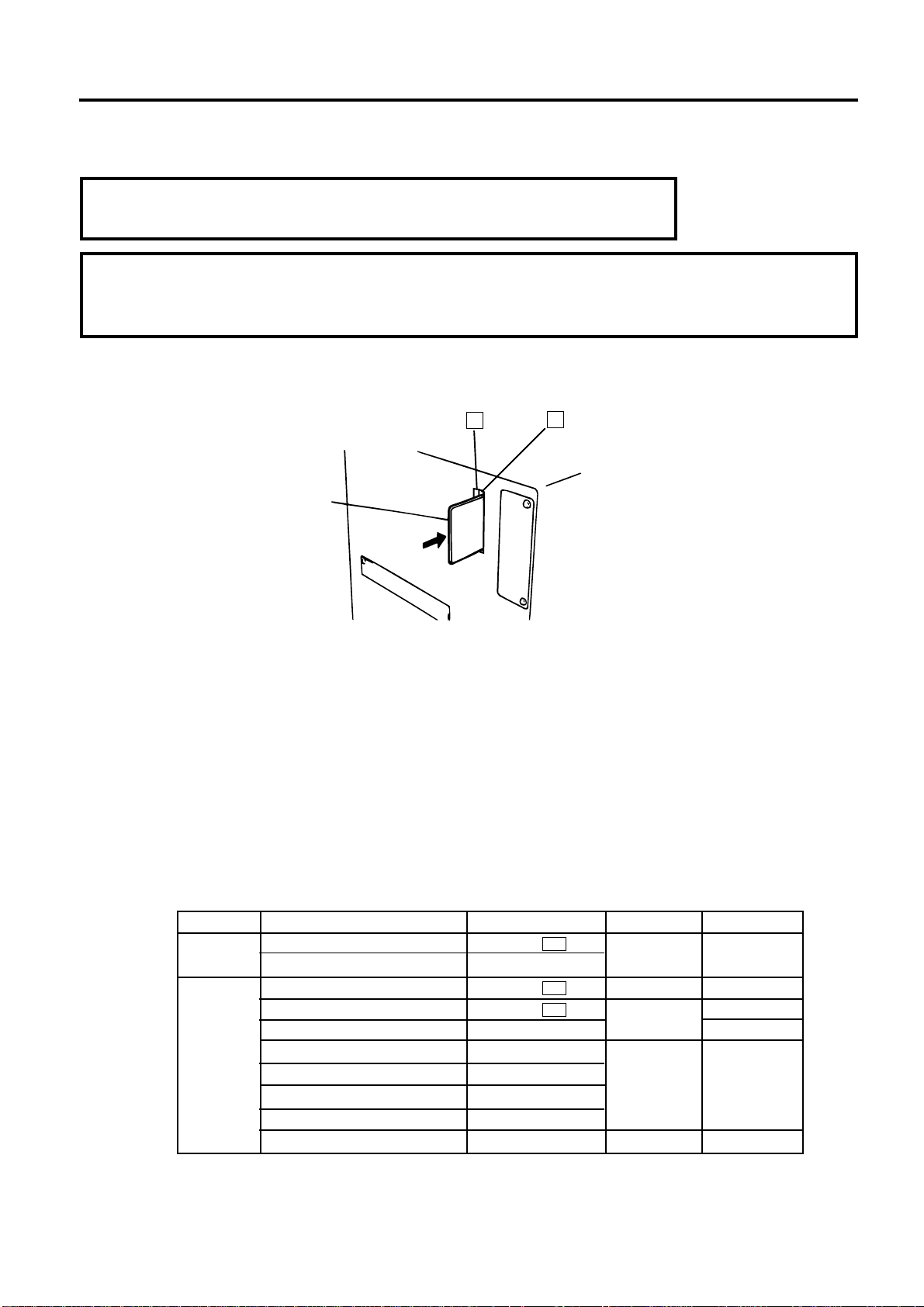

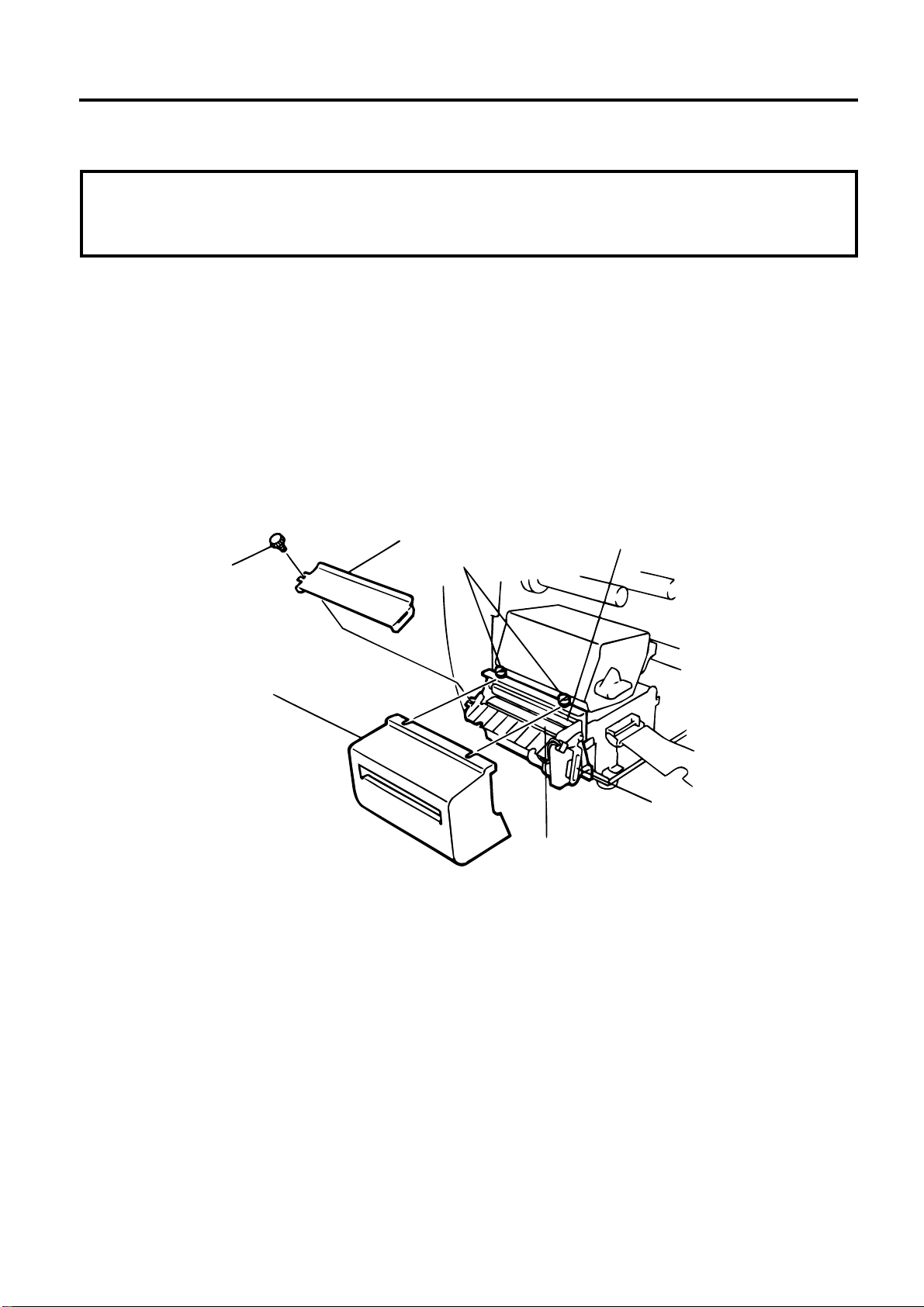

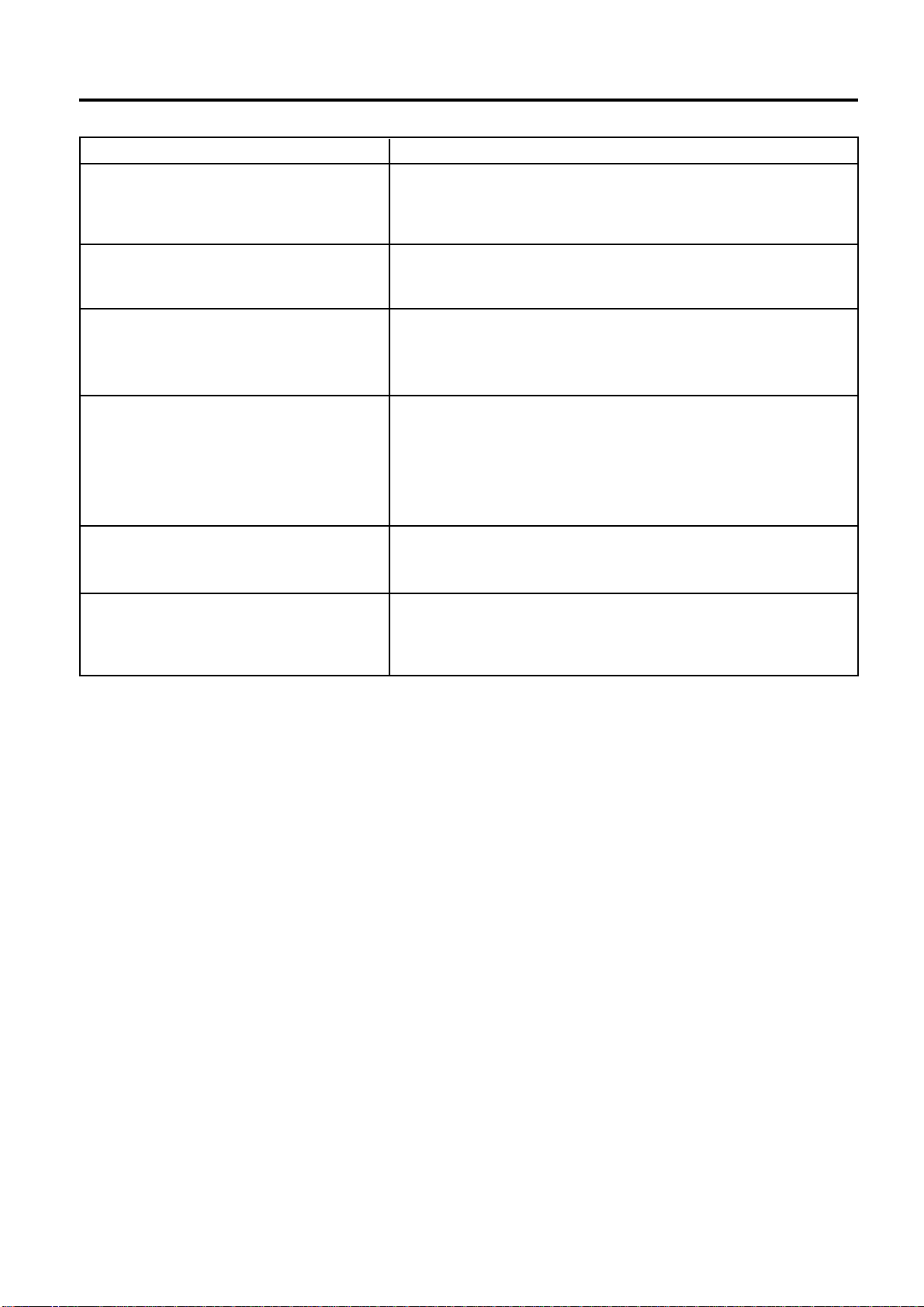

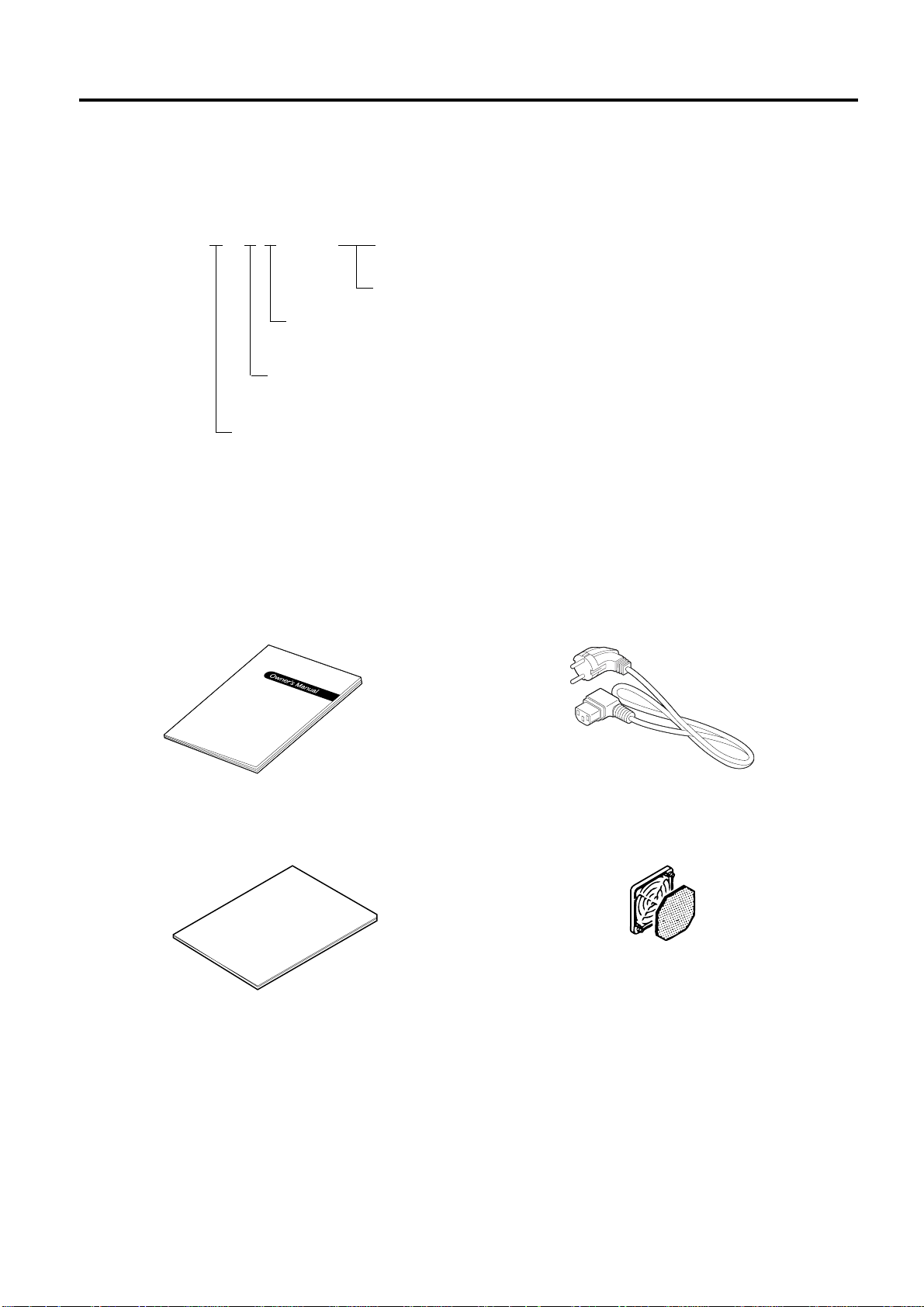

1.2 Accessories

Owner's Manual Power Cord

(EO1-33007)

Unpacking Procedure Fan Filter

(FMBB0036801)

E1-2

Page 9

2. SPECIFICATIONS

2. SPECIFICATIONS

2.1 Printer

ENGLISH VERSION EO1-33007

2.1 Printer

Item

Supply voltage

Power consumption

Operating temperature range

Relative humidity

Print head

Printing methods

Print speeds

Maximum print width

Dispensing modes

Message display

Dimensions

Weight

Available bar code types

Fonts

Rotations

Standard interface

Optional interfaces

Model

B-480-TS10-QP

AC 220V ~ 240V +10%, -15%, 50Hz

1.13A, 128W maximum (standby: 250mA, 23W)

5 C ~ 40 C (41 F ~ 104 F)

25% ~ 85%RH (no condensation)

Thermal print head 12 dots per mm (304.8 dots per inch)

Thermal direct or Thermal transfer

76.2 mm/sec. (3 inch/sec.), 127 mm/sec. (5 inch/sec.),

203.2 mm/sec. (8 inch/sec.),

101.6 mm/sec. (4inch/sec.) ... Thermal direct only

106.6 mm (4.09 inches)

Batch (Continuous), Strip (On-demand) and Cut modes

(Both cut and strip modes are available only when their respective

modules are fitted.)

16 characters x 1 line

291 mm (width) x 460 mm (depth) x 308 mm (height)

17 kg (without media and ribbon)

JAN8, EAN8, JAN13, EAN13, UPC-A, UPC-B

EAN8, EAN13, UPC-A, UPC-E + 2digit

EAN8, EAN13, UPC-A, UPC-E + 5digit

NW-7

CODE39 (STANDARD)

CODE39 (FULL ASCII)

ITF

MSI

CODE93

CODE128

EAN128

Data Matrix

PDF417

QR Code

industrial 2 of 5

Customer Bar Code

POSTNET

RM4SCC (ROYAL MAIL 4STATE CUSTOMERCODE)

KIX CODE

Maxi Code

Micro PDF417

Times Roman (6 sizes), Helvetica (6 sizes), Presentation (1 size),

Letter Gothic (1 size), Prestige Elite (2 sizes), Courier (2 sizes),

OCR (2 types), Writable characters (2-byte character is available),

Outline font (4 type), Price font (3 types)

0 , 90 , 180 , 270

Serial interface (RS-232C)

Parallel interface (Centronics)

Expansion I/O interface

PCMCIA card interface

E2-1

Page 10

2. SPECIFICATIONS

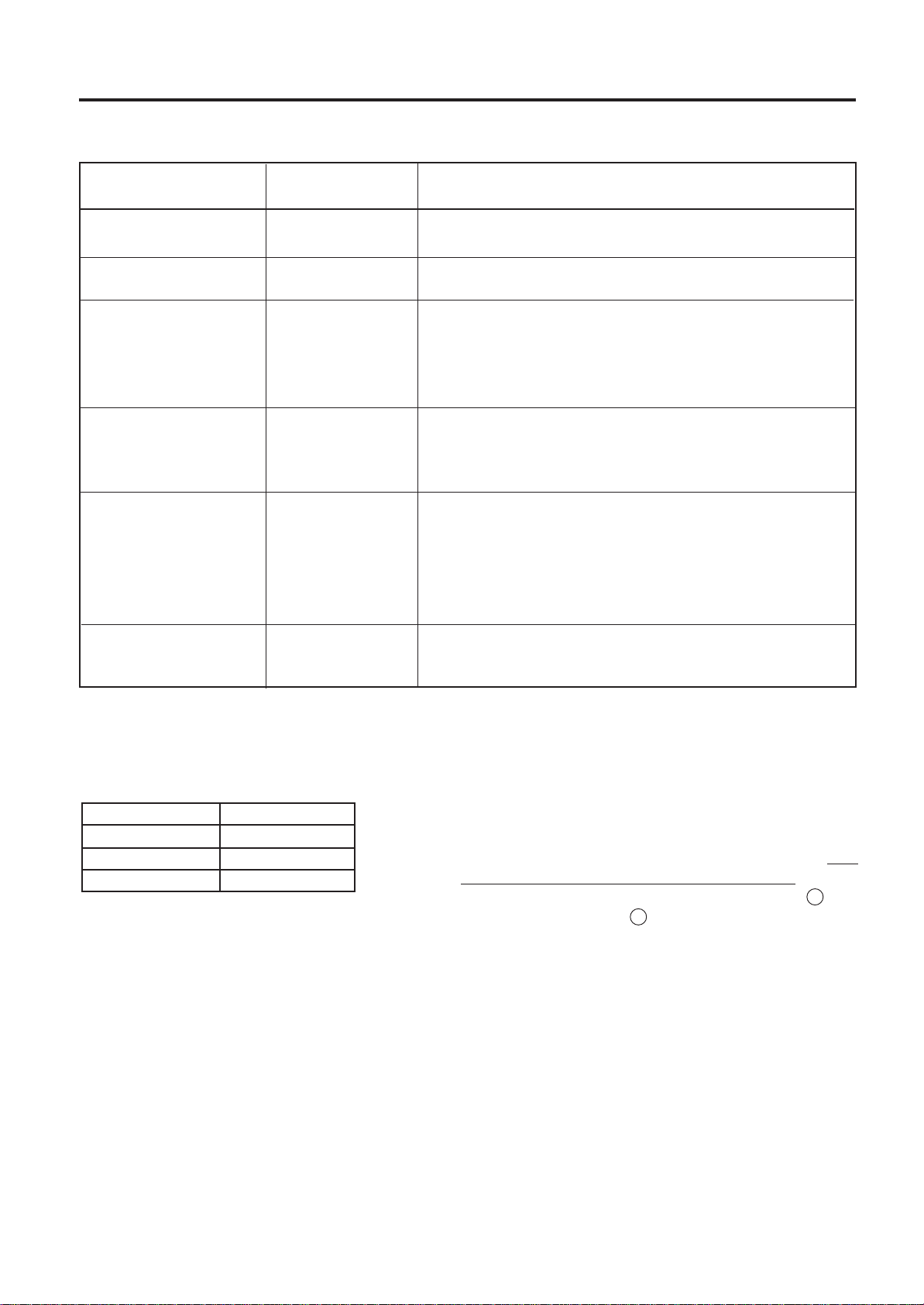

2.2 Option

ENGLISH VERSION EO1-33007

2.2 Option

Option Name

Swing cutter module

Rotary cutter module

Peel off module

Fanfold paper guide

module

PCMCIA interface

board

Type

B-4205-QM

B-8204-QM

B-4905-H-QM

B-4905-FF-QM

B-8700-PC-QM

Usage

A stop and cut swing cutter

Rotary cutter

This allows use of on-demand (peel-off) operation or to

rewind labels and backing paper together when using the

rewind guide plate. To purchase the strip module, please

inquire at your local distributor.

This is a paper guide exclusively used for fanfold paper.

Attaching it in place of the standard paper guide allows the

printer to print on fanfold paper.

This board enables the following PCMCIA cards to be used.

®

* LAN card: 3 COM EtherLink

III (recommended)

3 COM 3CCE589ET (recommended)

* ATA card: Conforming to PC card ATA standard

* Flash memory card:1MB and 4MB cards (See Page 7-1.)

Expansion I/O interface

board

2.3 Ribbon

Type

Width

Length

Outer diameter

Spool type

68 mm ~ 112 mm

600 m

ø90 mm (max.)

B-8700-IO-QM

NOTES: 1. "On the fly issue" means that the printer can draw and

Installing this board allows connection to external device.

print without stopping between labels.

2. To ensure print quality and print head life use only

TOSHIBA TEC specified media and ribbons.

3. When using the cutter ensure that label length B plus

inter label gap length E exceeds 35 mm. (i.e. label

pitch should be greater that 35 mm.) (See Page 2-3.)

4. When rewinding the media onto the take-up spool in

batch mode, the max. outer roll diameter should be 180

mm.

5. Use of rough media for the ribbon saving issue may

cause ribbon smudges.

E2-2

Page 11

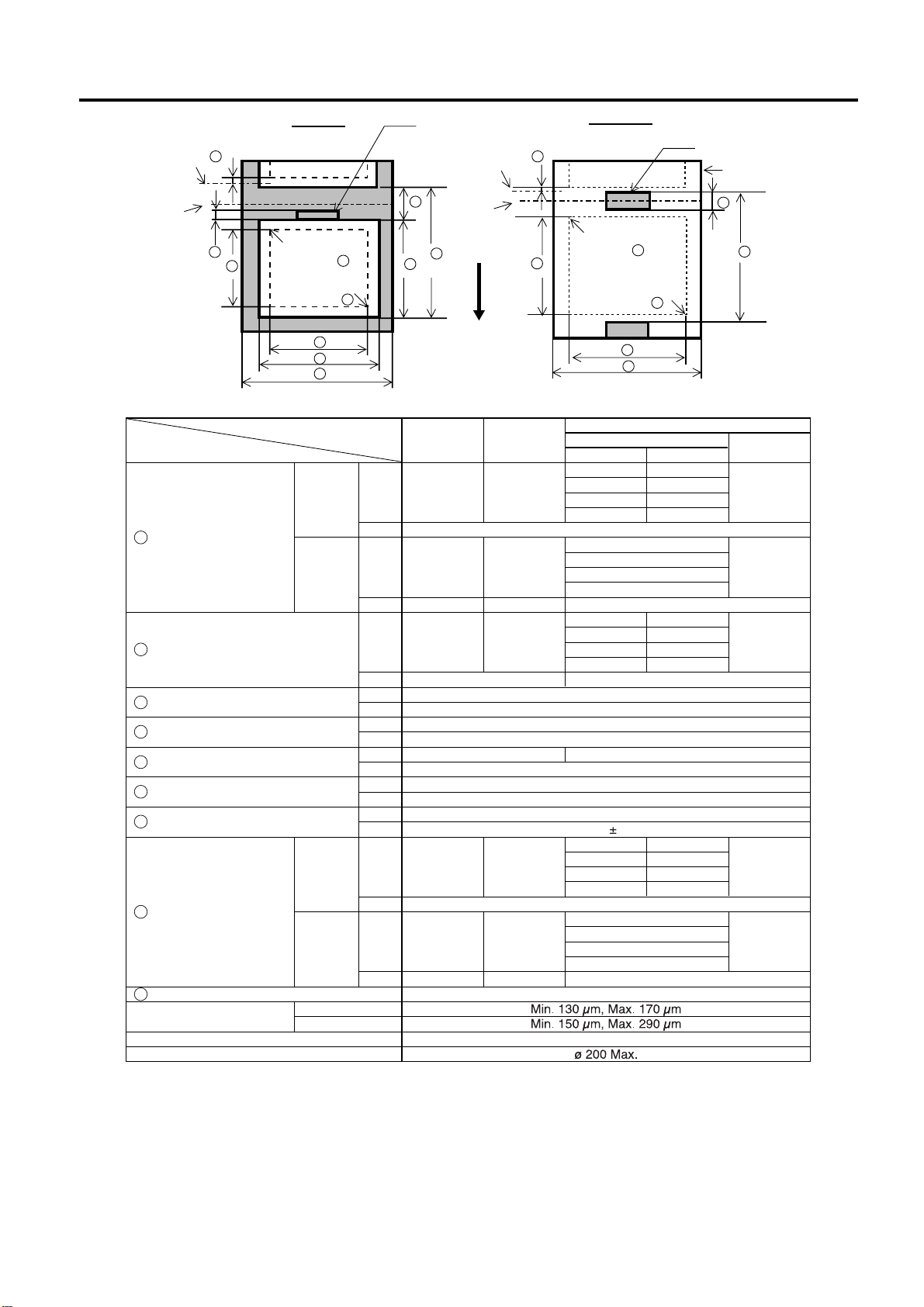

2. SPECIFICATIONS

ENGLISH VERSION EO1-33007

2.4 Media

2.4 Media

Stop

position

Cut

position

Label

I I

F

H

Reference

coordinate

Reference

coordinate

G

D

C

1

2

Refer to the following

NOTE 2. Black Mark

(on reverse side)

Stop

position

E

B

Cut

position

A

Feed direction

Fig. 2-1

Label dispensing mode

Item

Label

A : Span of one label/tag

Tag

B : Label/tag length

C : Width including backing paper

D : Label width

E : Gap length

F : Black mark length (Tag paper)

G : Effective print width

Label

H : Effective print length

Tag

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

10.0Min.

2730.0

2728.0

2.0

2726.0

I : Print speed up/slow down area

Thickness

Label

Tag

Maximum effective length for on the fly issue

Outer roll diameter

NOTES: 1. The media specification other than above are unchanged.

2. The label length specifications for use with both cutters are:

(*1) When issuing a label using the rotary cutter, printing at a speed of 3"/sec., label length should be:

91.0mm - (Gap length/2) or more

(*2) When issuing a label using the rotary cutter, printing at a speed of 4"/sec., label length should be:

95.0mm - (Gap length/2) or more

(*3) When issuing a label using the rotary cutter, printing at a speed of 5"/sec., label length should be:

99.0mm - (Gap length/2) or more

(*4) When issuing a label using the rotary cutter, printing at a speed of 8"/sec., label length should be:

110.0mm - (Gap length/2) or more

(*5) When issuing a label using the swing cutter, label length should be:

35.0mm - (Gap length/2)

E2-3

Tag paper

Black Mark

(on reverse side)

Tag paper

F

H

Reference

coordinate

Reference

coordinate

G

C

1

2

A

[Unit: mm]

Cut mode

Strip modeBatch mode

25.4

Rotary cutter

Head-up is OFF Head-up is ON

3"/sec.:94.0 3"/sec.:38.0

4"/sec.:98.0 4"/sec.:38.0

5"/sec.:102.0 5"/sec.:38.0

8"/sec.:113.0 8"/sec.:38.0

Swing cutter

38.0

2730.0

3"/sec.:30.0

-10.0

4"/sec.:30.0

5"/sec.:30.0

25.4

8"/sec.:38.0

-

3"/sec.:81.0(*1) 3"/sec.:25.0

23.48.0

4"/sec.:85.0(*2) 4"/sec.:25.0

5"/sec.:89.0(*3) 5"/sec.:25.0

8"/sec.:100.0(*4) 8"/sec.:25.0

2730.0

25.0 (*5)

2724.0

50.8

112.0

47.8

109.0

6.0

20.0

2.0

10.0

10.0

106.7 0.2

3"/sec.:79.0 3"/sec.:23.0

4"/sec.:83.0 4"/sec.:23.0

5"/sec.:87.0 5"/sec.:23.0

8"/sec.:98.0 8"/sec.:23.0

23.021.46.0

2726.0

3"/sec.:28.0

4"/sec.:28.0

5"/sec.:28.0

23.0-8.0

8"/sec.:36.0

-

2726.0

1.0

1361.0

Page 12

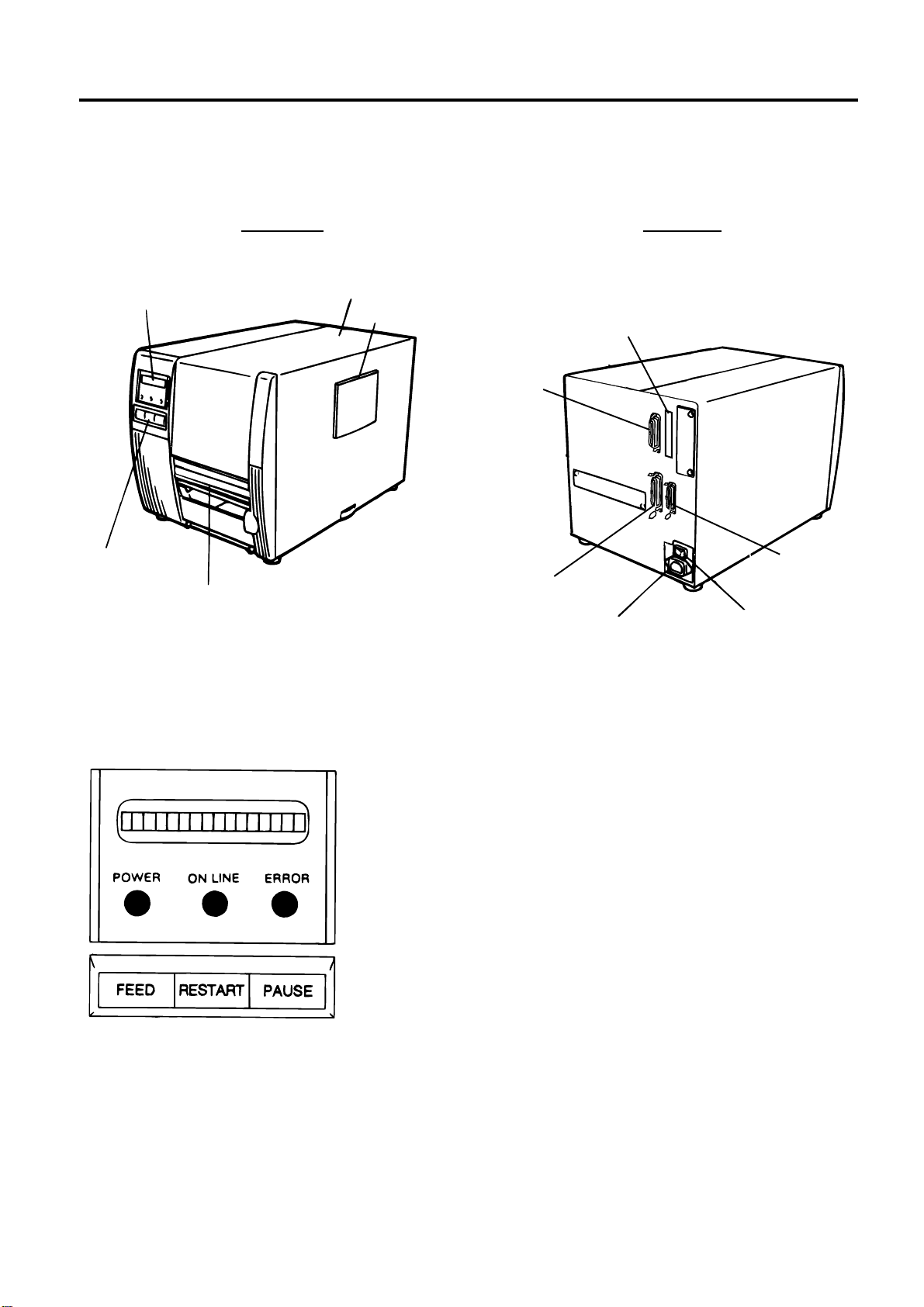

3. OVERVIEW

3. OVERVIEW

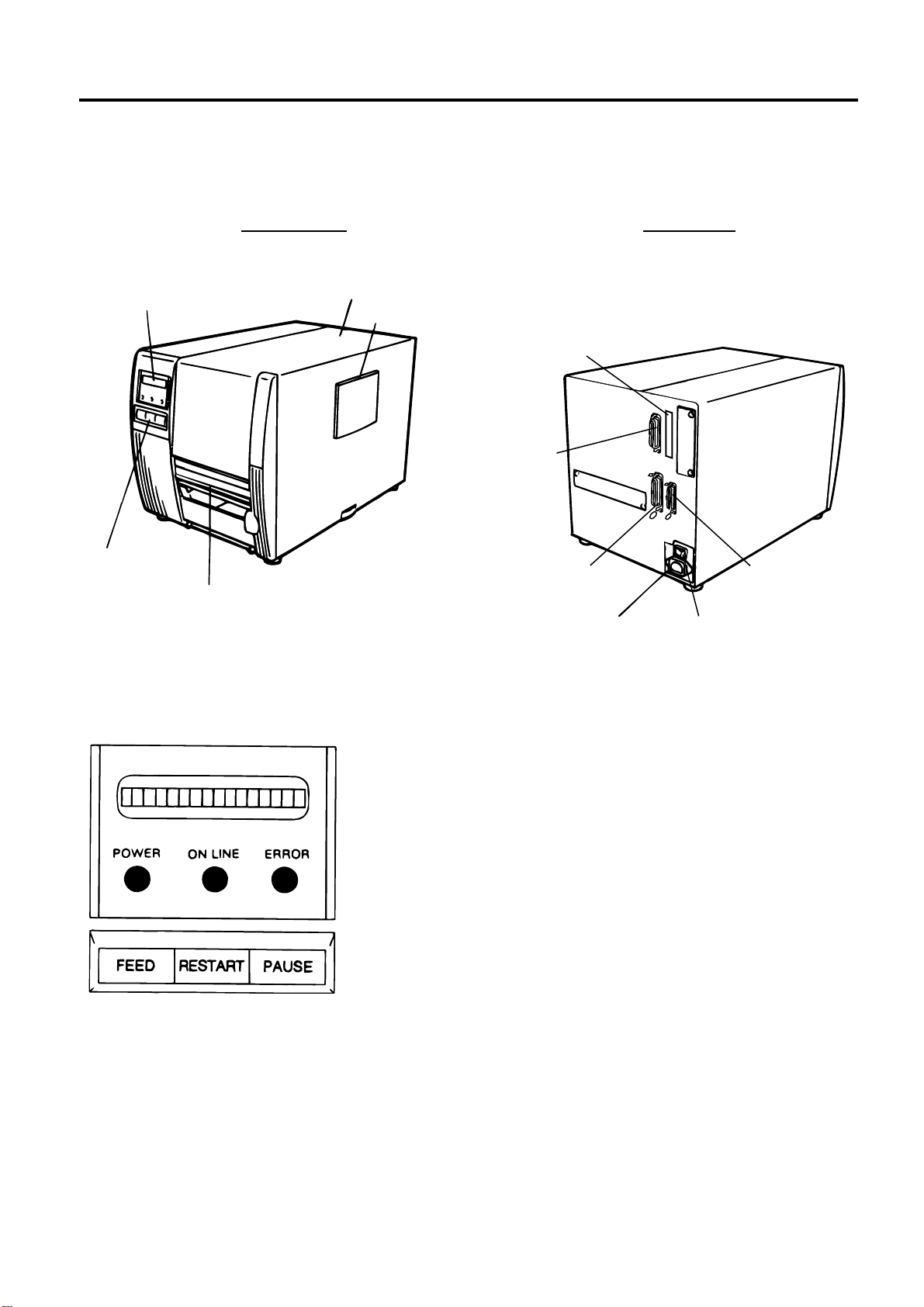

3.1 Front/Rear View

Front View Rear View

Message Display (LCD)

ENGLISH VERSION EO1-33007

3.1 Front/Rear View

Top Cover

Supply Window

PCMCIA Card Slot (2 slots)

Serial Interface

Connector

(RS-232C)

Operation Panel

Media Outlet

3.2 Operation Panel

Fig. 3-2

Parallel I/F Connector

(Centronics)

AC Power Inlet

Power Switch

0: OFF

1: ON

Expansion I/O

Interface Connector

(Option)

Fig. 3-1

MESSAGE DISPLAY (LCD)

When power is turned on and it is ready to print, "ON LINE" is

displayed.

POWER LED (Green)

Lights when the power is turned on.

ON-LINE LED (Green)

1) Flashes when communicating with a host computer.

2) On while printing.

ERROR LED (Red)

Lights when a communication error occurs, when the media/

ribbon ends or the printer does not operate correctly.

FEED key

Feeds paper.

RESTART key

Resets the printer when paused or when an error occurs.

Used to set the threshold. (Refer to page 9-4)

PAUSE key

Pauses printing.

Message display shows "PAUSE" and an unprinted count.

Used to set the threshold. (Refer to page 9-4)

E3-1

Page 13

4. INSTALLING THE PRINTER

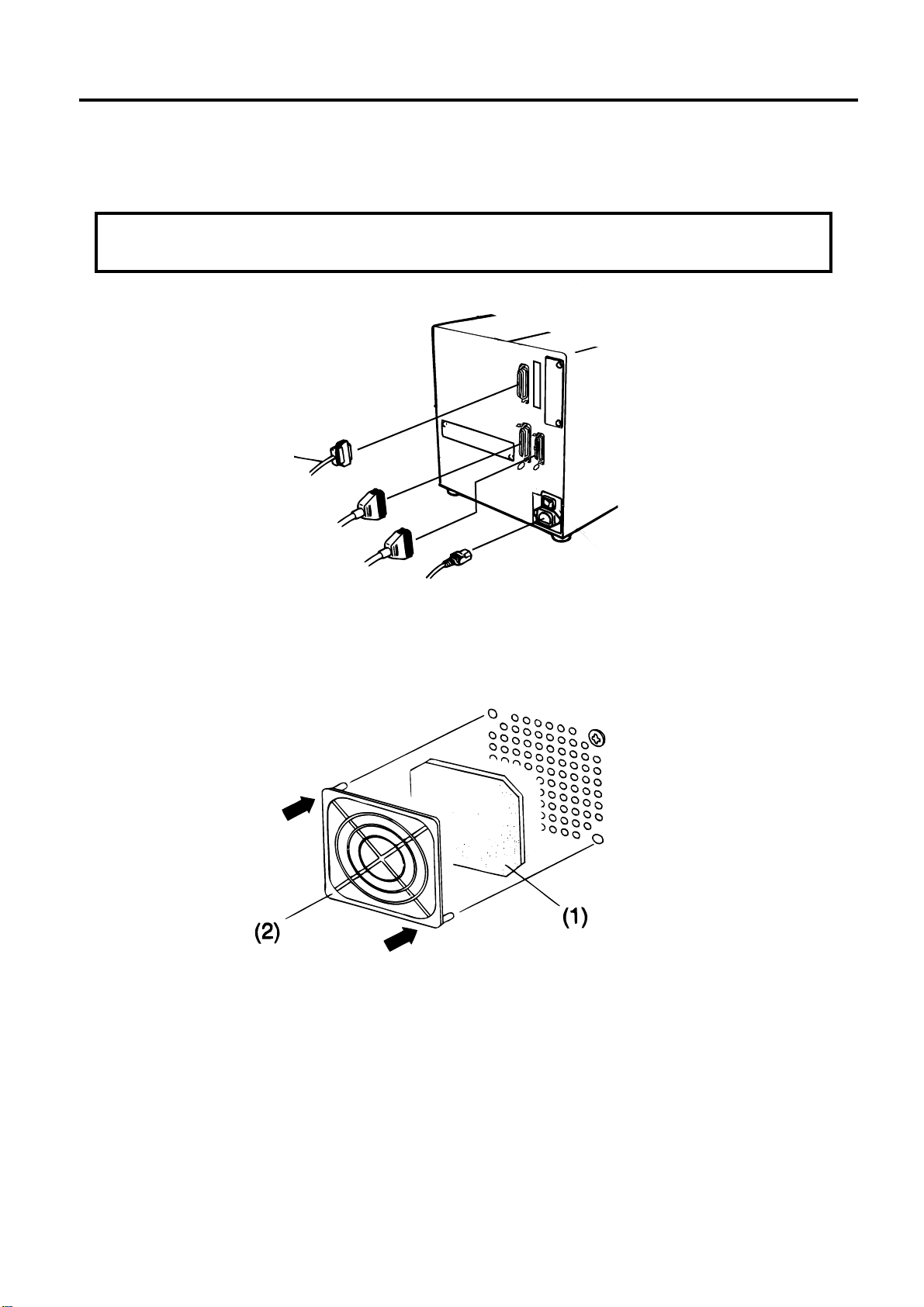

4.1 Connecting the Power Cord and Cables

4. INSTALLING THE PRINTER

4.1 Connecting the Power Cord and Cables

WARNING:

Turn the POWER SWITCH to OFF before connecting the power cord or cables.

Serial I/F Cable (RS-232C)

ENGLISH VERSION EO1-33007

Parallel I/F Cable (Centronics)

Expansion I/O Cable (Option)

Power Cord

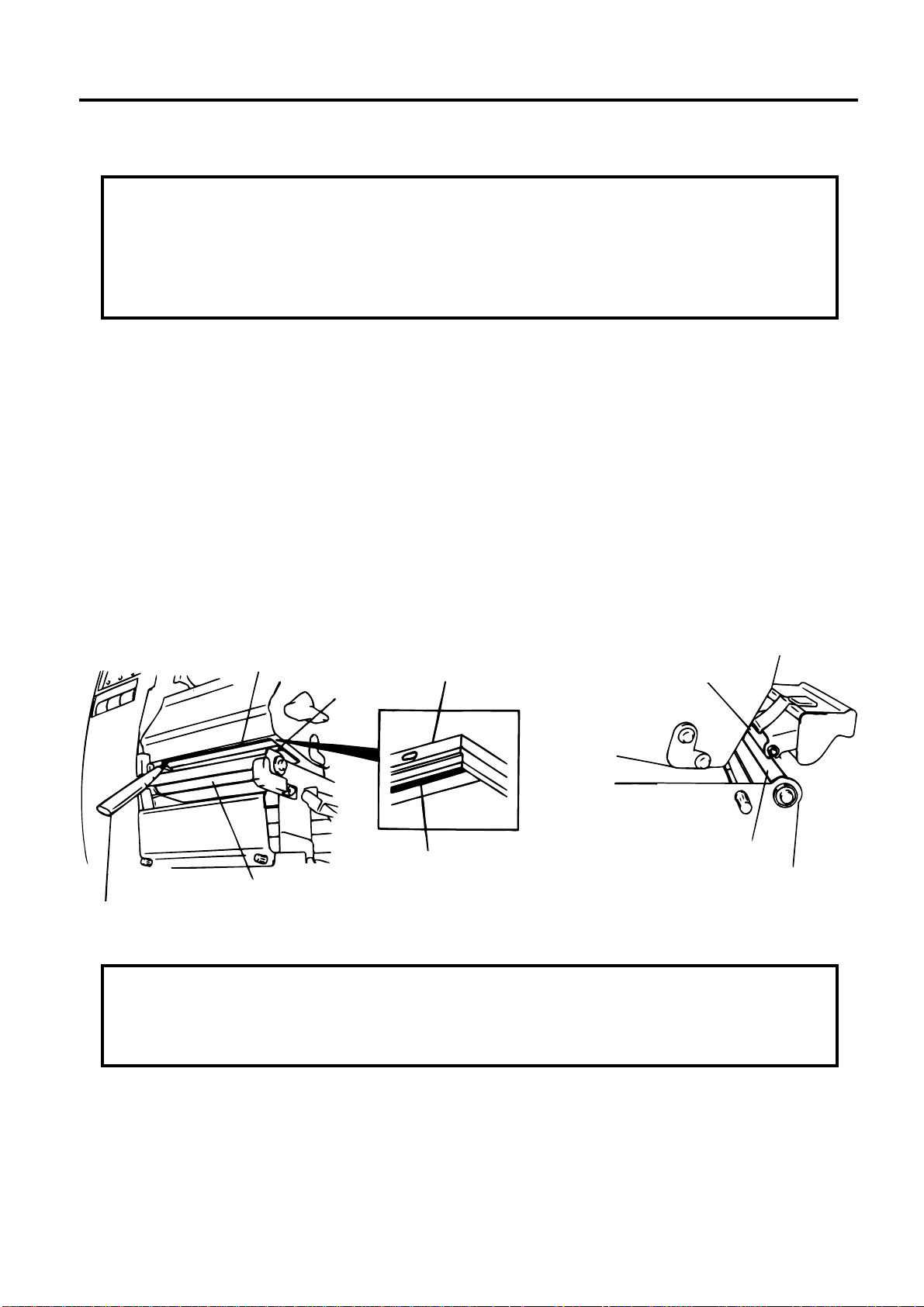

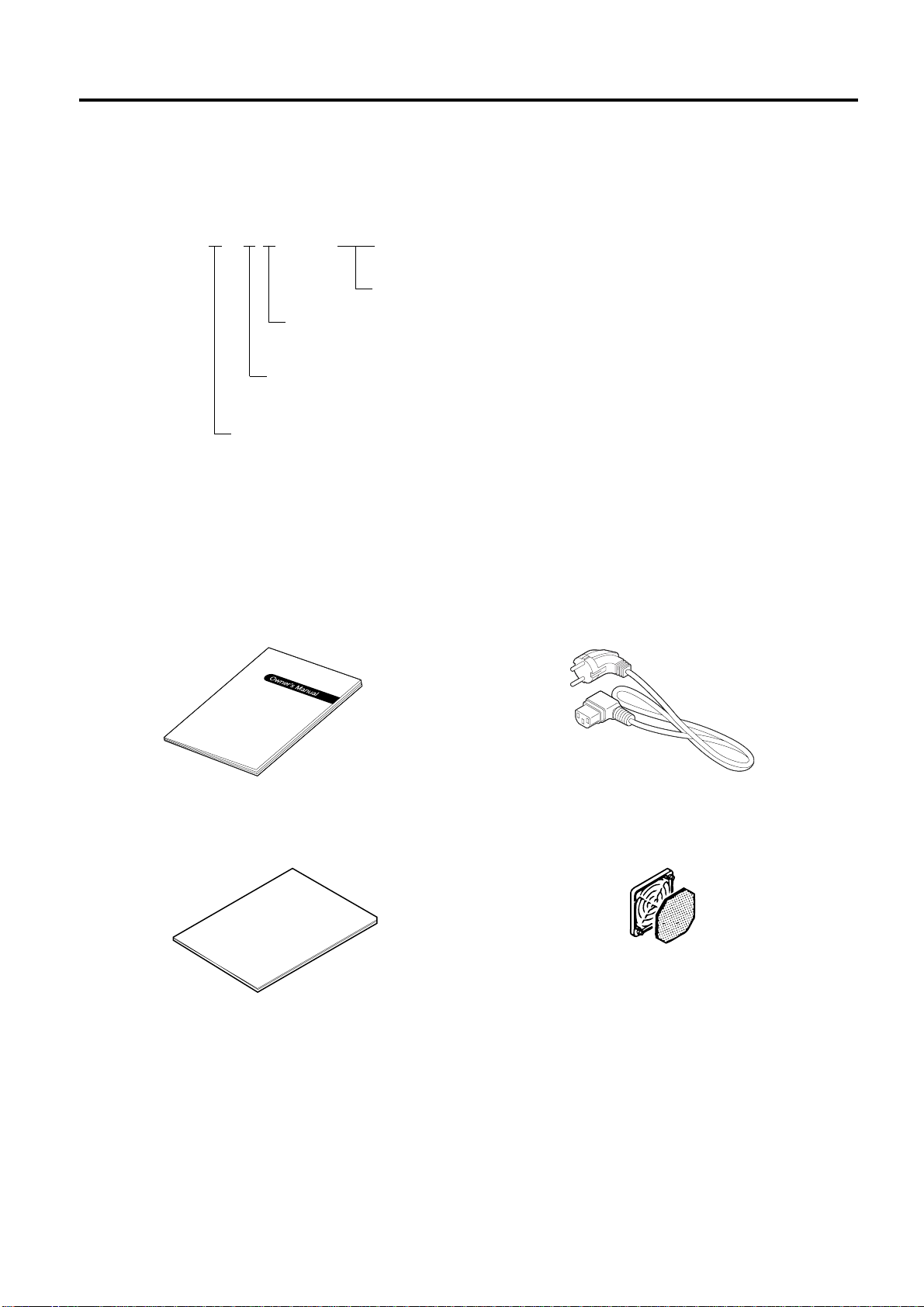

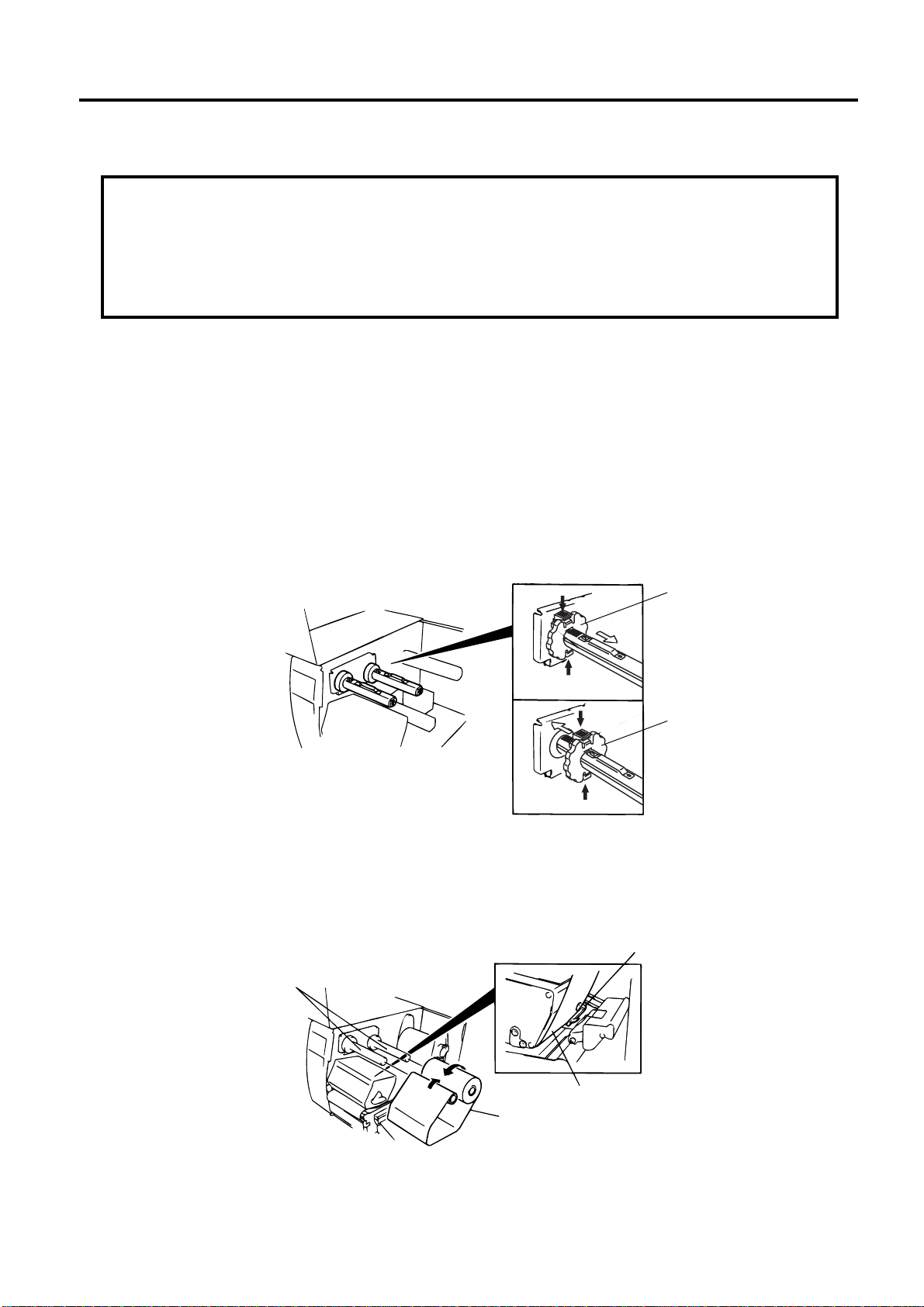

4.2 Procedure for Fitting Fan Filter

Snap on

Snap on

Fig. 4-1

Fig. 4-2

When installing the printer, it is important to ensure that the fan filter is attached before using the printer.

The filter comes in 2 parts:

(1) FILTER PAD

(2) FILTER RETAINER

To fit put the filter pad inside the filter retainer and simply press into place according to the diagram above,

ensuring connecting pins are aligned with connecting holes.

E4-1

Page 14

5. LOADING THE MEDIA

ENGLISH VERSION EO1-33007

5. LOADING THE MEDIA

5. LOADING THE MEDIA

WARNING:

1. Do not touch moving parts. To reduce the risk that fingers, jewelry, clothing, etc., be drawn

into the moving parts, push the switch in the “OFF” position to stop movement.

2. To avoid injury, be careful not to catch or jam your fingers while opening or closing the cover.

The printer prints both labels and tags.

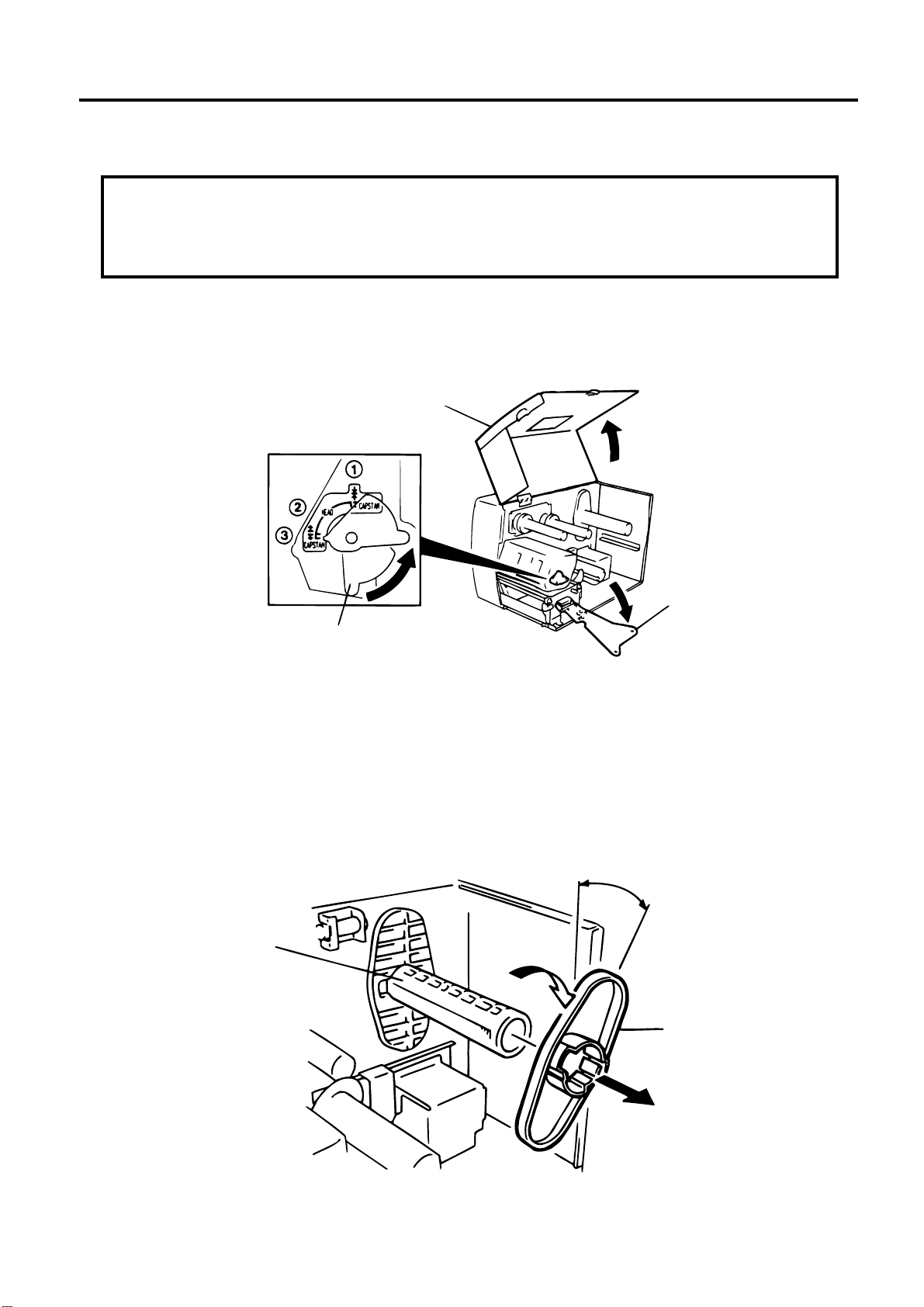

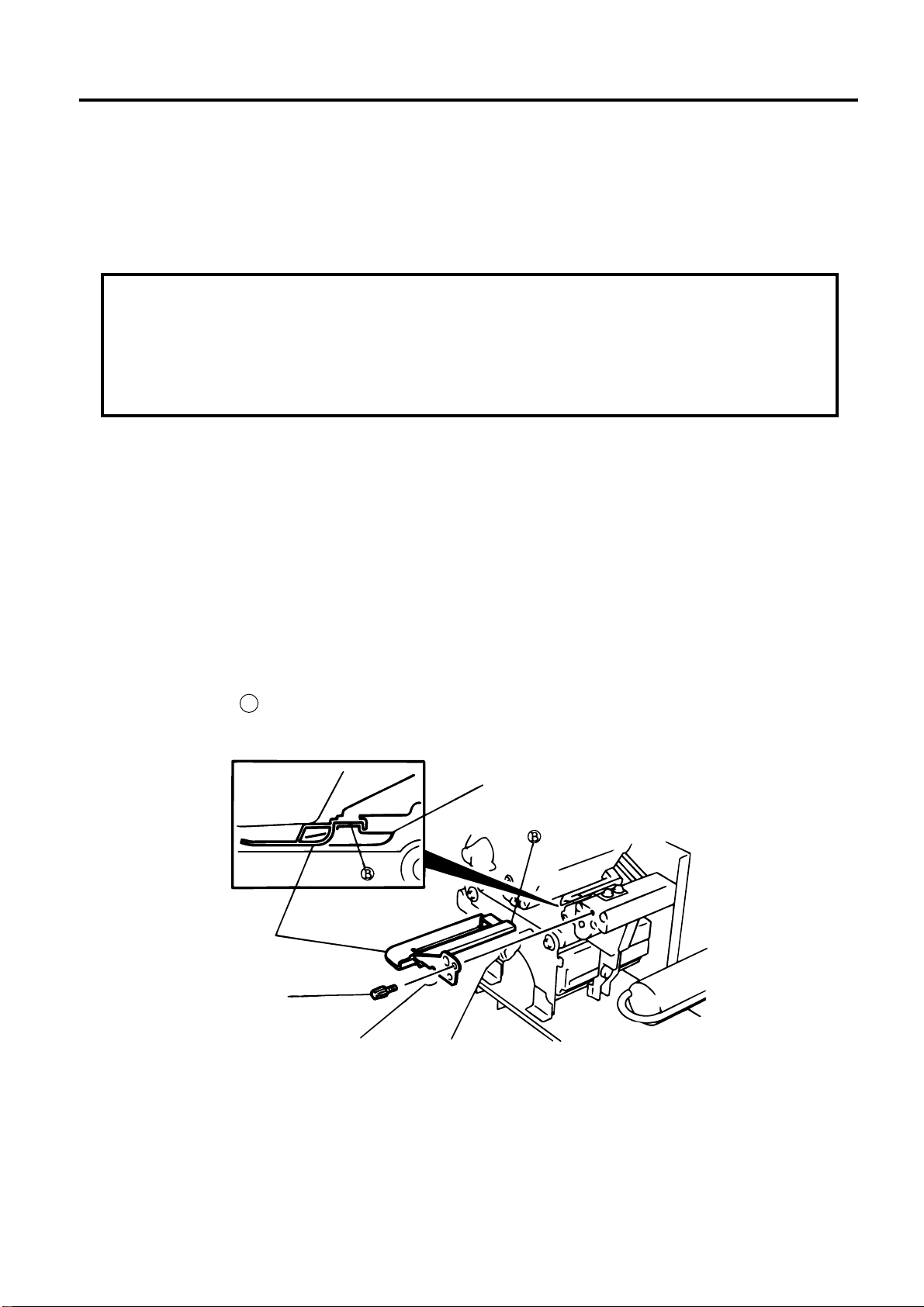

1. Turn off the power and open the top cover.

2. Turn the head lever to position 3, then release the ribbon shaft holder plate.

Top Cover

Ribbon Shaft Holder Plate

Head Lever

NOTES: 1.When the head lever is turned to position 2, the print head is raised.

3

2.When the head lever is turned to position

3.To allow printing the head lever must be set to position

, the print head and the pinch roller are raised.

1

. (This ensures that the print head

and the pinch roller are closed.)

3. Untape the supply holder.

4. Turn the outside supply holder 30 degrees and remove from the supply shaft.

30

Supply Shaft

Supply Holder

(FMHD0005502)

Fig. 5-1

NOTE: Set the inside supply holder to the scale on the shaft according to media to be used.

E5-1

Fig. 5-2

Page 15

5. LOADING THE MEDIA

ENGLISH VERSION EO1-33007

5. LOADING THE MEDIA

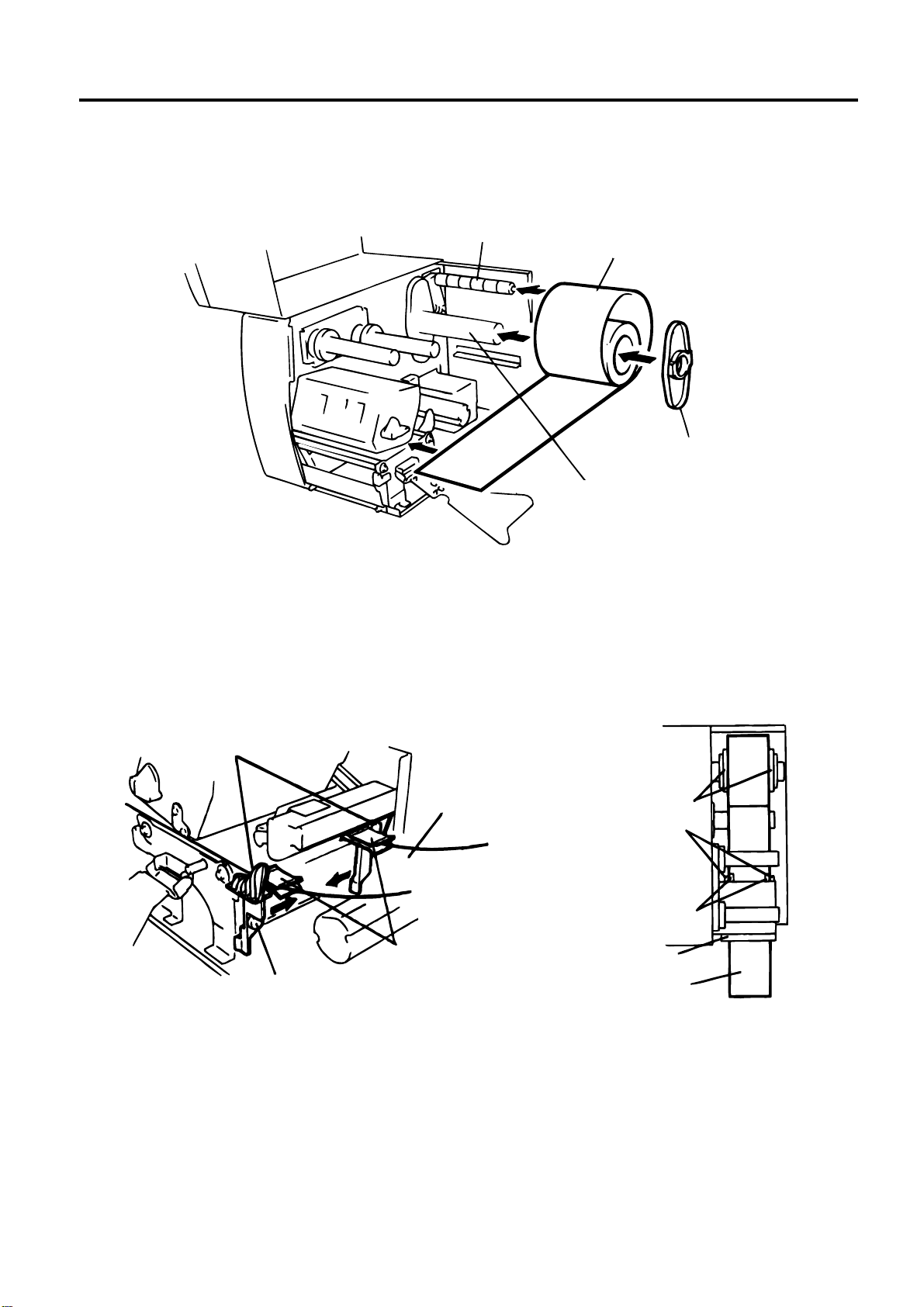

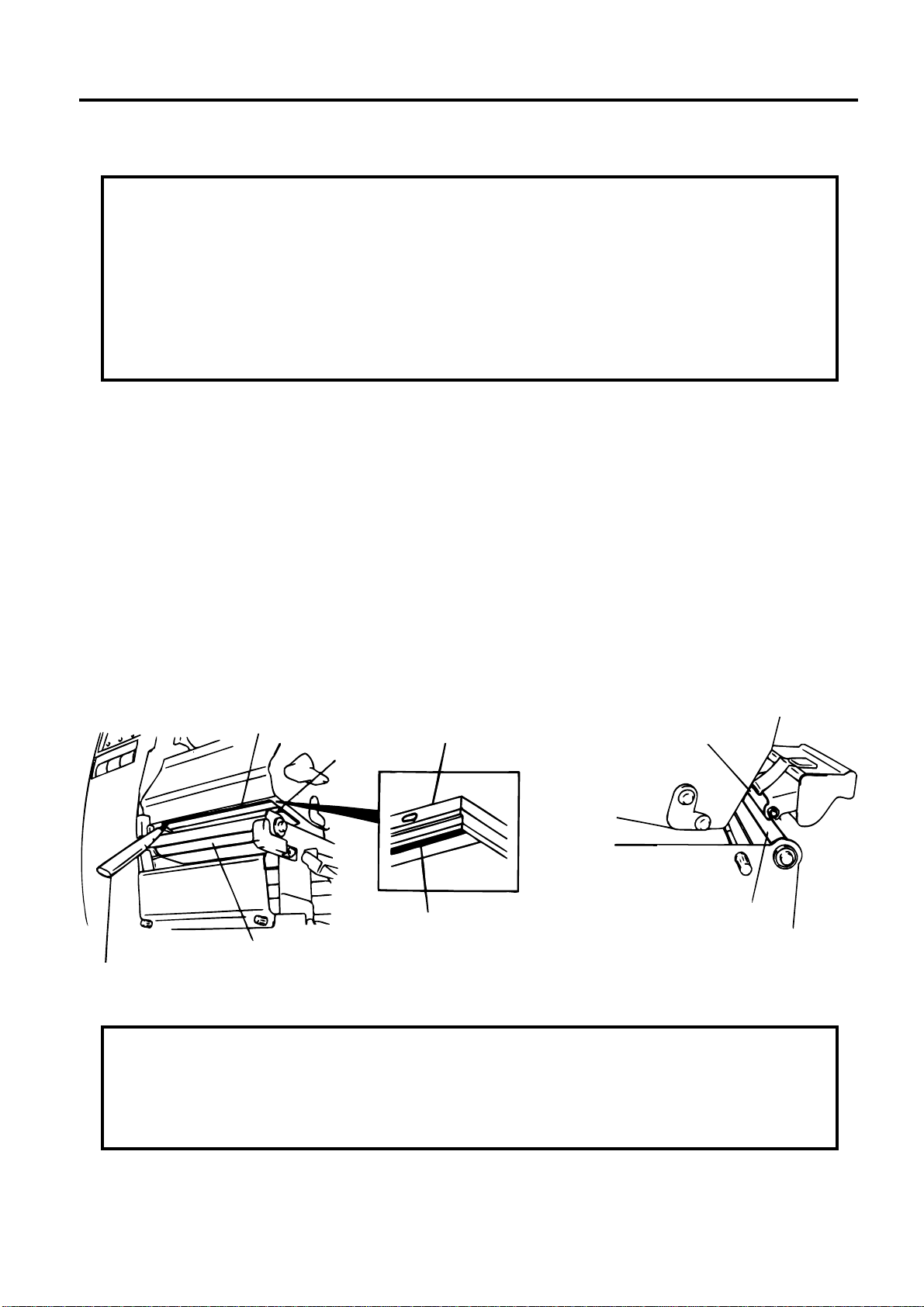

5. Put the media on the supply shaft.

6. Pass the media around the damper, then pull the media towards the front of the printer. Fix the remaining

supply holder to the supply shaft with the pinchers facing away from the printer.

Damper

Media

Supply Holder

(FMHD0005502)

Supply Shaft

Fig. 5-3

7. Insert the media into the paper holders of the media guide, adjust the media guides to the media width,

and tighten the locking screw.

8. Check that the media path through the printer is straight. The media should be centered under the print

head.

Media Guide

Media

Paper Holder

Locking Screw

Supply Holder

Media Guide

Paper Holder

Print Head

Media

Fig. 5-4

NOTE: When using the label rolled with labels facing outside, please remove the upper plates of both

paper holders using the following procedure. Failure to do this may cause a paper jam error.

If you have any questions, please contact your nearest TOSHIBA TEC service representative.

E5-2

Page 16

5. LOADING THE MEDIA

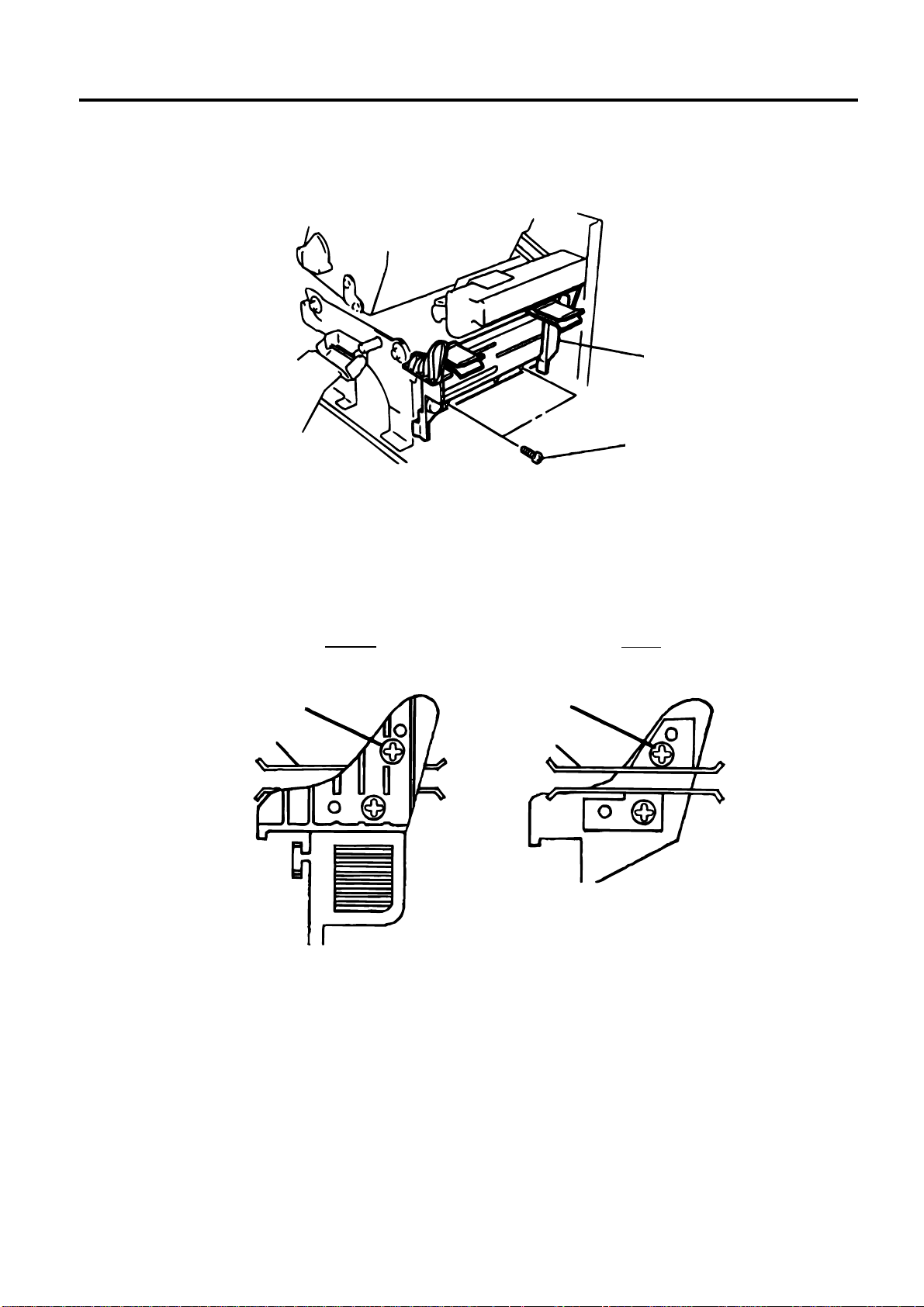

■ Removing the paper holders' upper plates from the media guide

1 Remove the two T-4x8 screws to detach the media guide from the printer.

Media Guide

Screw (T-4x8)

ENGLISH VERSION EO1-33007

5. LOADING THE MEDIA

Fig. 5-5

2 Remove the SM-3x6 screw or the SM-3x8 screw to detach the paper holders' upper plates from

the media guide.

Screw (SM-3x6)

Paper Holder

(Right)

Screw (SM-3x8)

Paper Holder

(Left)

Fig. 5-6

3 Attach the media guide back in position.

NOTE: Do not lose the removed upper plates because they are required when using the label rolled

with labels facing inside.

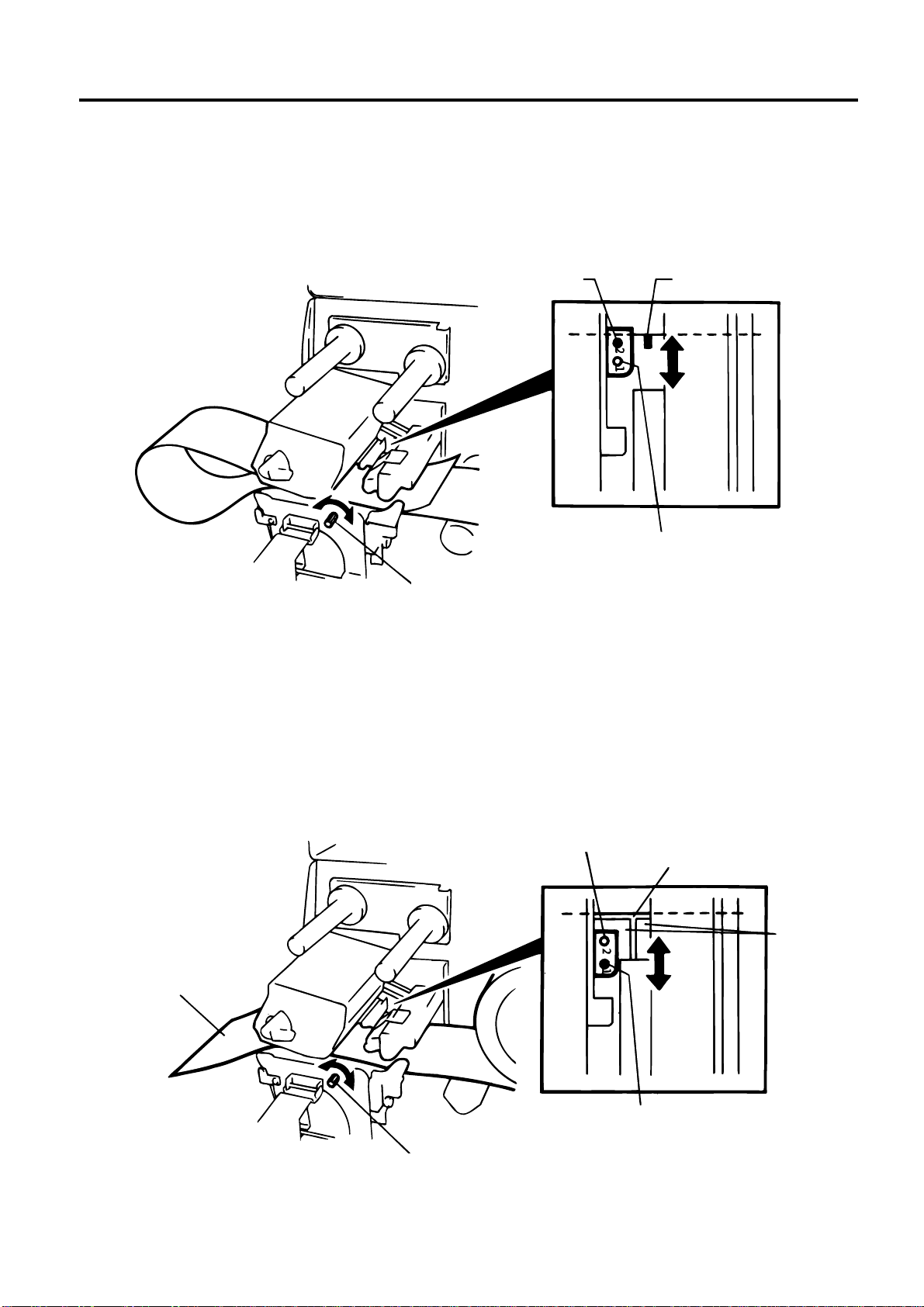

9. Set the black mark/feed gap sensor to the correct position by turning the adjusting knob. Turning the

knob right will move the sensor towards the center of the media while turning left will move it away from

the center of the media.

E5-3

Page 17

5. LOADING THE MEDIA

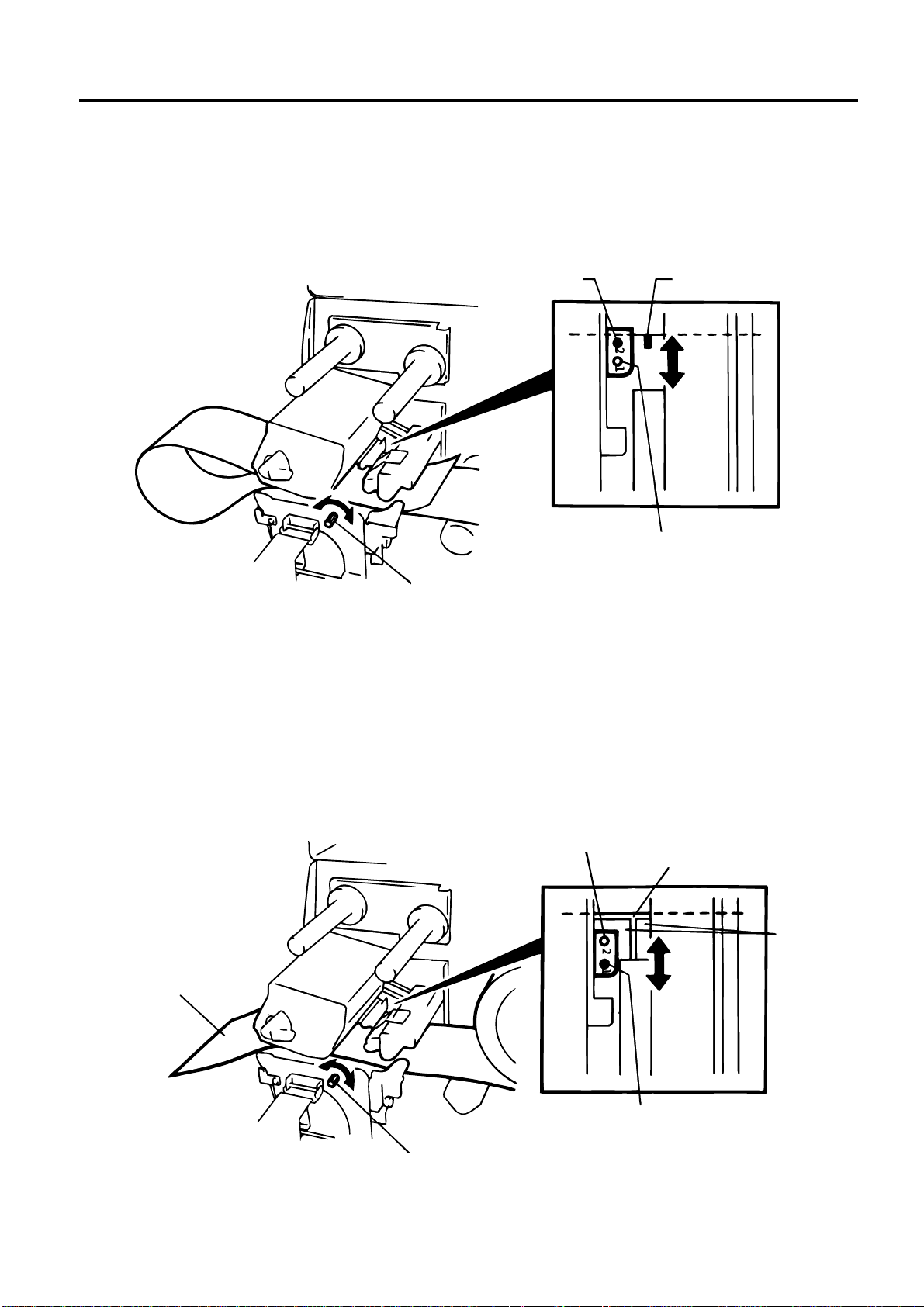

■ An easy way to set the black mark sensor position

1 Pull the media about 500 mm out of the front of the printer, turn the media back on it's self and

feed it under the print head past the sensor so that the black mark can be seen from above.

2 Adjust the sensor position to that of the black mark (the upper hole indicates the position of the

black mark sensor).

ENGLISH VERSION EO1-33007

5. LOADING THE MEDIA

Black Mark Sensor

Media

(Feed Gap Sensor)

Adjusting Knob

Black Mark

Fig. 5-7

NOTE: Make sure to set the sensor to detect the center of the black mark, otherwise a paper jam

error could occur.

■ Setting the feed gap sensor position

1 Adjust the sensor to detect on the gap (the lower hole indicates the position of the feed gap

sensor.)

Media

Adjusting Knob

(Black Mark Sensor)

Backing Paper

Media

Feed Gap Sensor

Fig. 5-8

E5-4

Page 18

5. LOADING THE MEDIA

10. The media is now loaded and the sensor position is set.

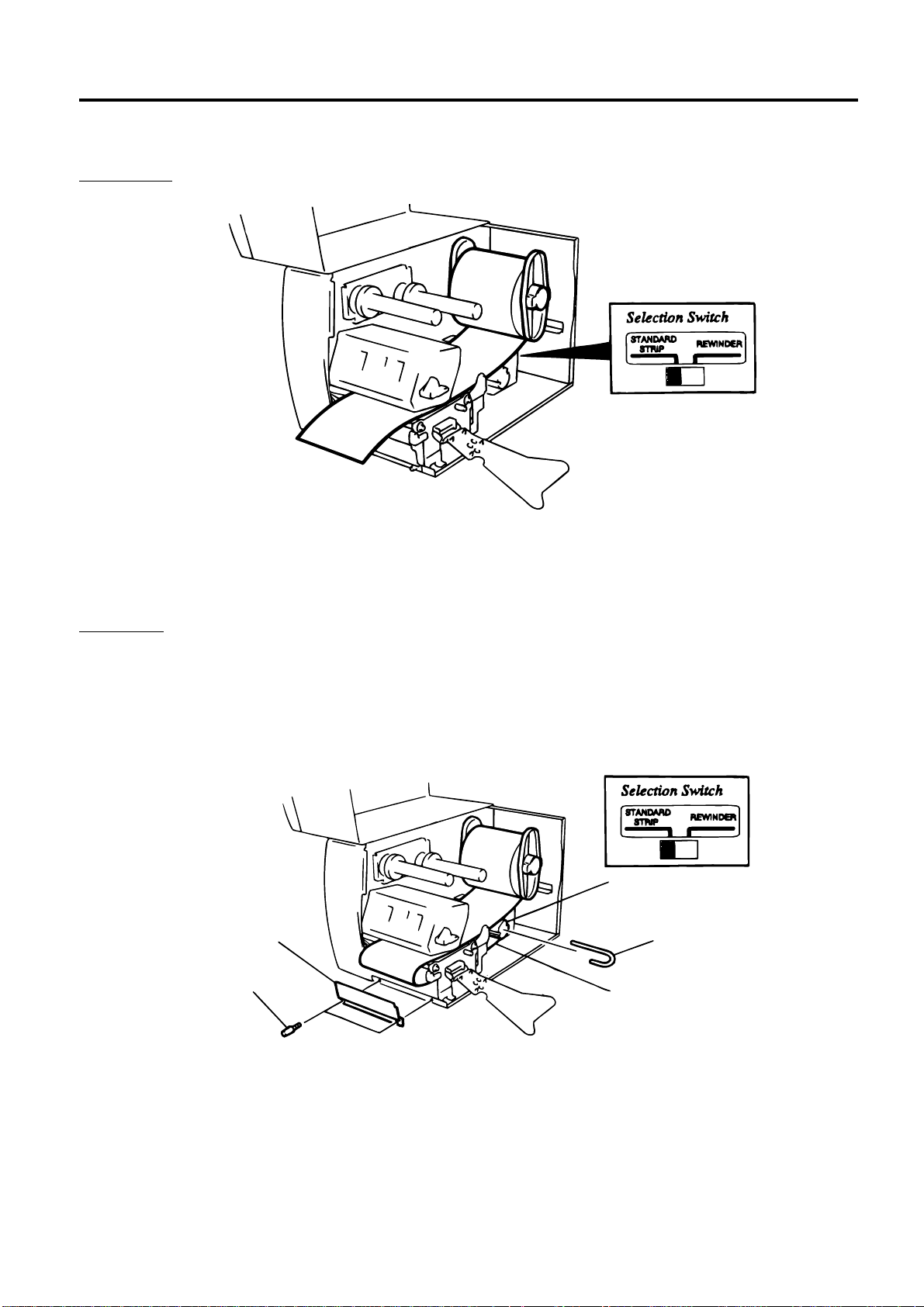

Batch type:

Media

ENGLISH VERSION EO1-33007

5. LOADING THE MEDIA

Fig. 5-9

NOTE: Set the selection switch to the STANDARD/STRIP position. Improper setting can affect the print

quality.

Strip type:

1 Remove enough labels from the leading edge media to leave 500 mm of backing paper

exposed.

2 Wind the backing paper onto the take-up spool and fix in position with the take-up clip.

(Wind the paper counter clockwise around the spool as this is the direction it rotates.)

3 Rotate the take-up spool anti-clockwise a few times to take up any slack in the backing paper.

Media

Take-up Spool

Front Plate

Take-up Clip

Black Screw

(HAA-0004001)

Backing Paper

Fig. 5-10

NOTES: 1. The backing paper is easier to feed back to the take-up spool if the front plate is removed.

2. When fitting the tace-up clip the longer side of the clip should be fitted into the shallow groove

on the take-up spool.

3. Set the selection switch to the STANDARD/STRIP position.

E5-5

Page 19

5. LOADING THE MEDIA

ENGLISH VERSION EO1-33007

5. LOADING THE MEDIA

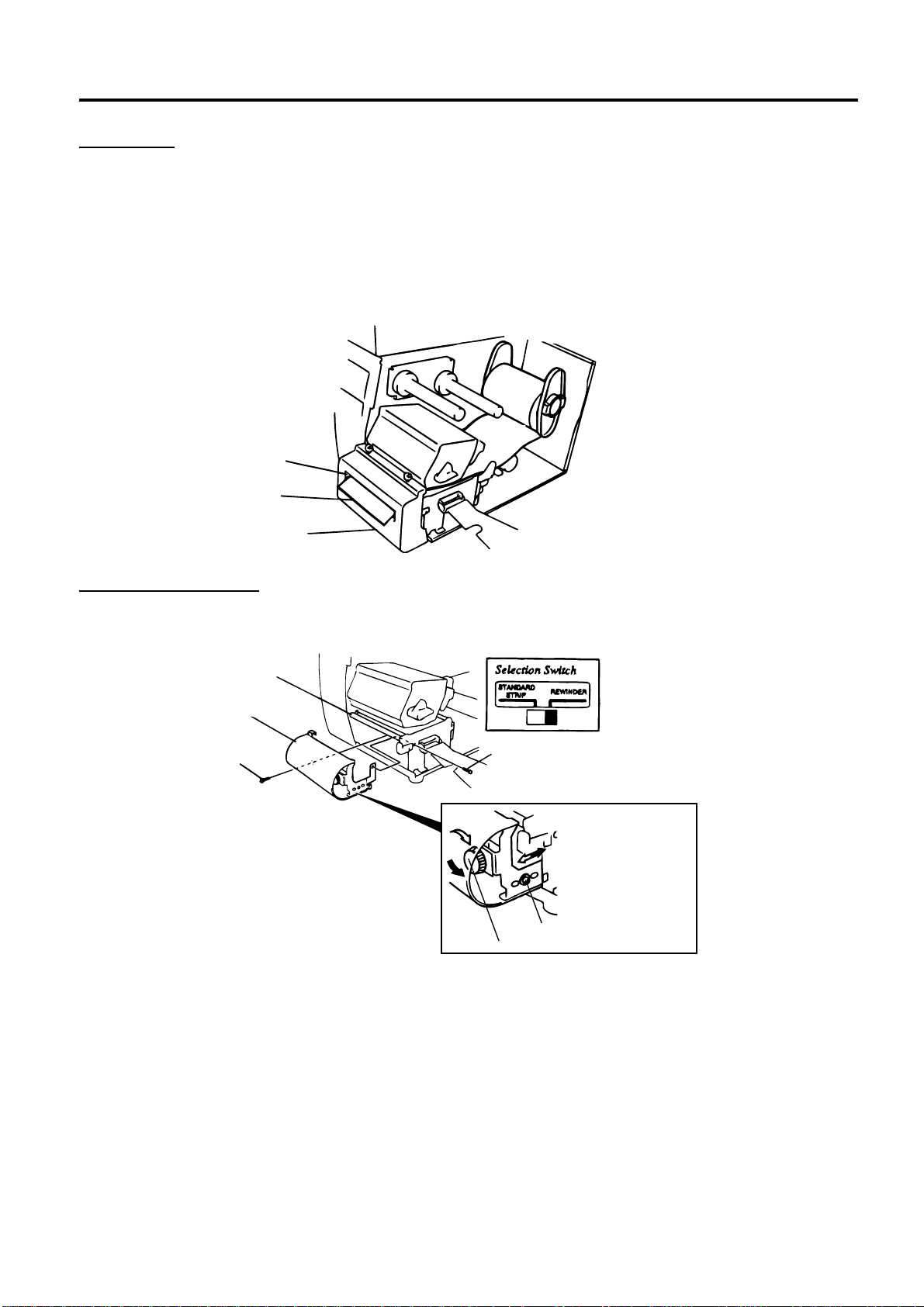

Cutter type: Where a cutter is fitted load the media as standard and feed it through the cutter module.

Swing cutter and rotary cutter are available as an option. They are used in the same way

regardless of different shapes. Now, how to load the media using the swing cutter will be

introduced.

NOTES: 1. Be sure to cut the backing paper of label. Cutting labels will cause the glue to stick to the cutter,

which may affect the cutter quality and shorten the life.

2. If a label winds onto the platen during cut issue, please contact your nearest TOSHIBA TEC

service representative.

3. For the cutter type, the selection switch can be set to either position.

Media Outlet

Media

Cutter Module

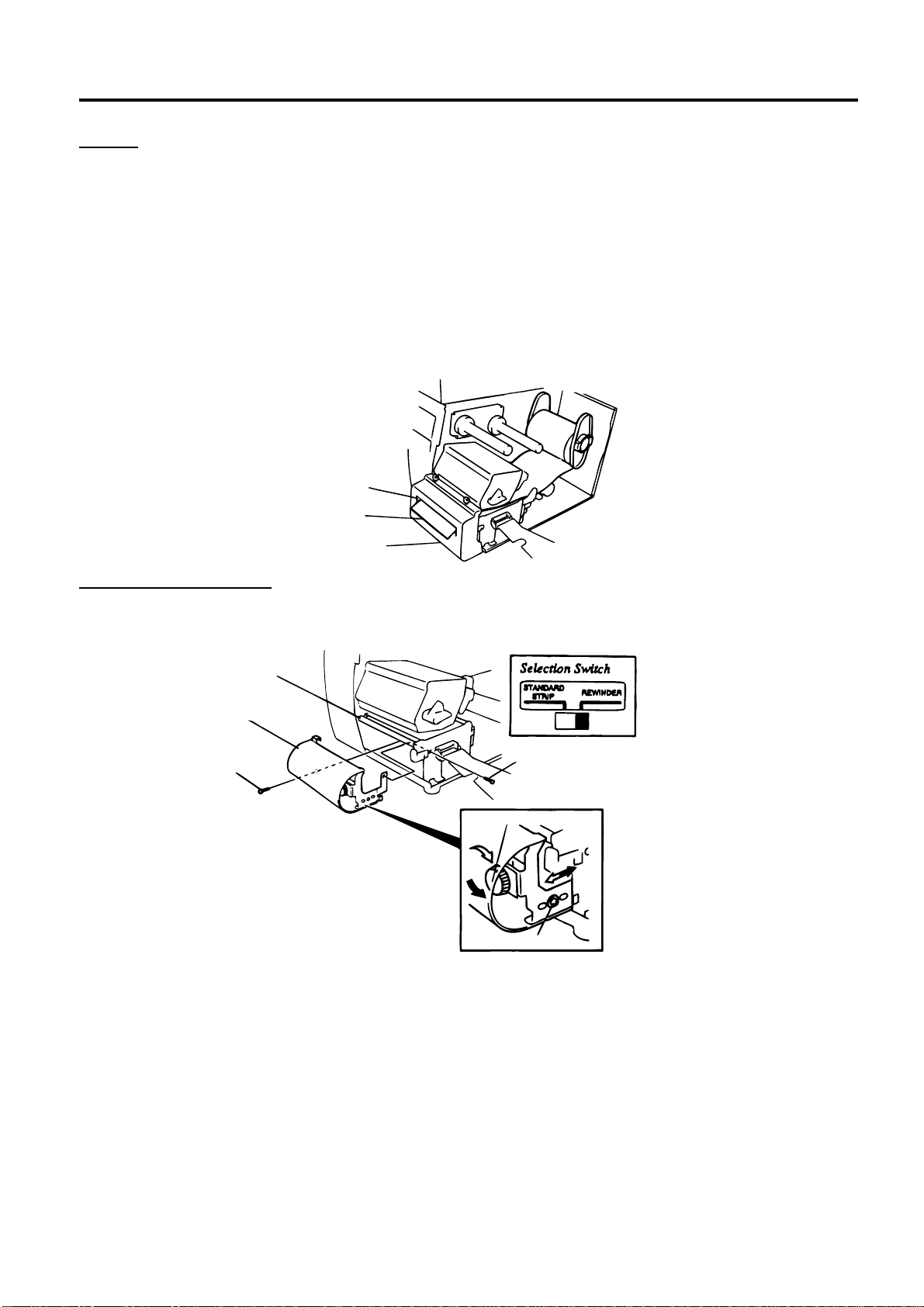

Built-in rewinder type:

1 Remove two black screws and front plate.

2 Fit the rewinder guide plate to the strip shaft, then attach it with the sems screws.

Tear-off Bar

Rewinder Guide Plate

(FMBD0034501)

SM-4x6B Sems Screw

SM-4x6B Sems Screw

Adjustment Knob

NOTES: Set the selection switch to the REWINDER position.

3 Follow the procedure for strip type.

4 Adjustment

If the label skews when using built-in rewinder unit, turn the adjustment knob of the rewinder

guide plate to correct the label feed. Clockwise turn moves the rewinder guide plate forward

and counterclockwise moves it backward.

* When labels skew to the right:

Loosen the SM-4x8 sems screw with a philips-head screw driver. Turn the adjustment knob

clockwise, and tighten the SM-4x8 screw when the rewinder guide plate is positioned

correctly.

* When labels skew to the left:

Loosen the SM-4x8 screw with a phillips-head screw driver. Turn the adjustment knob

counterclockwise, and tighten the SM-4x8 screw when the rewinder guide plate is positioned correctly.

E5-6

Fig. 5-11

SM-4x8 Sems Screw

Fig. 5-12

Page 20

6. LOADING THE RIBBON

ENGLISH VERSION EO1-33007

6. LOADING THE RIBBON

6. LOADING THE RIBBON

WARNING:

1. Do not touch moving parts. To reduce the risk that fingers, jewelry, clothing, etc., be drawn

into the moving parts, push the switch in the “OFF” position to stop movement.

2. To avoid injury, be careful not to catch or jam your fingers while opening or closing the cover.

There are two types of media available for printing on, these are standard media and direct thermal media

(a chemically treated surface). DO NOT LOAD a ribbon when using a direct thermal media.

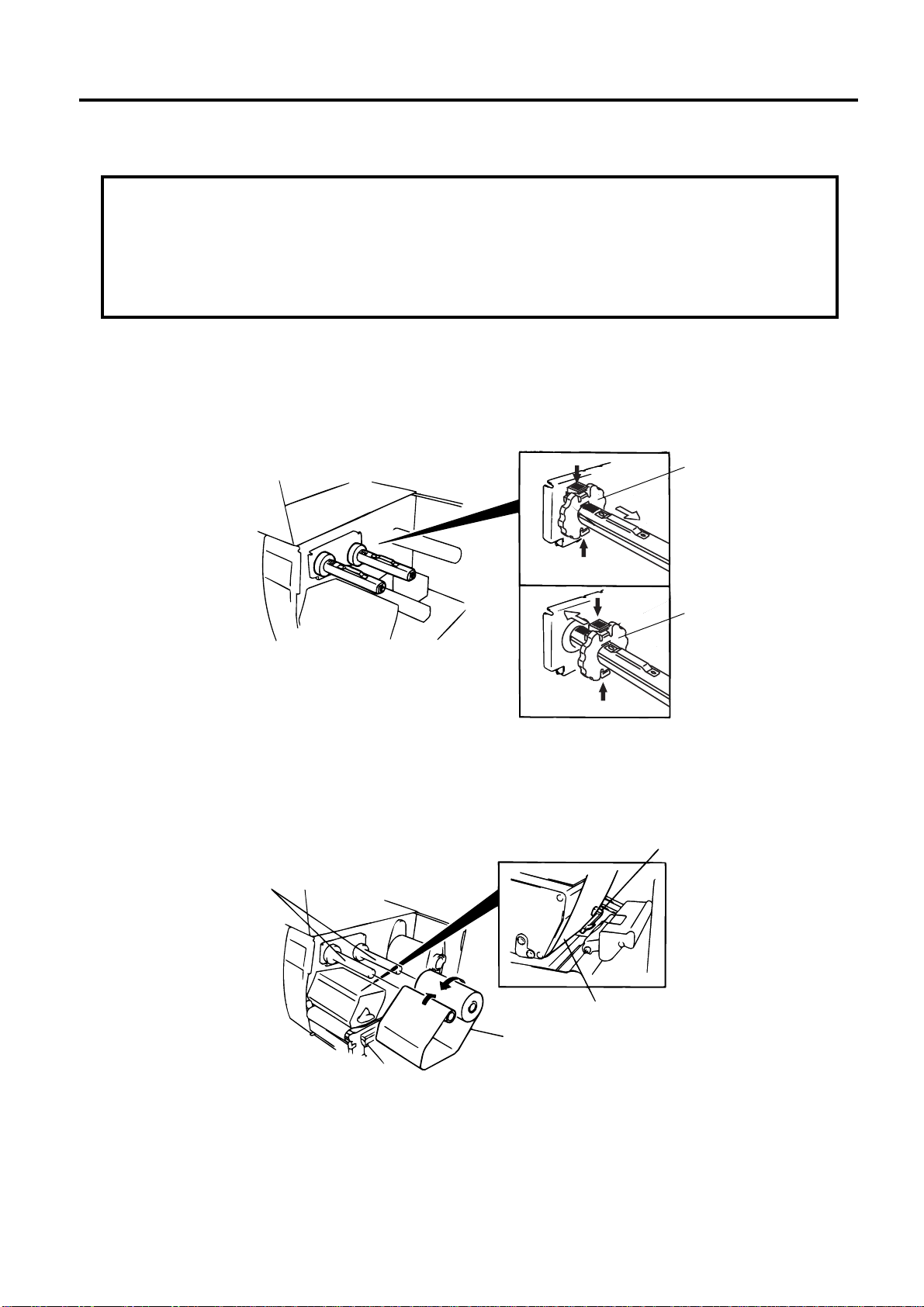

1. When using a narrow width ribbon, slide the ribbon stoppers along the shafts to a position where the

ribbon will be centered when it is fitted. When changing from a narrow width to a wider one rotate the

ribbon stoppers by 90 , push them back to the correct position and then rotate back to lock.

NOTE: When attaching the ribbon stoppers, fit them to the shafts with the pinchers facing into the printer.

Ribbon Stopper

Ribbon Stopper

Fig. 6-1

2. Leaving plenty of slack between the spools, fit the ribbon as shown below. When the ribbon is fitted it

must be positioned over the ribbon sensor.

3. Wind both shafts towards each other to tighten the ribbon.

Ribbon Sensor

Ribbon Shafts

Ribbon

Ribbon

4. Reset the ribbon shaft holder plate by aligning it with the ribbon shaft.

5. Turn the head lever clockwise to lower the print head.

6. Close the top cover.

E6-1

Fig. 6-2

Page 21

7. INSERTING THE OPTIONAL PCMCIA CARD

7. INSERTING THE OPTIONAL PCMCIA CARD

ENGLISH VERSION EO1-33007

7. INSERTING THE OPTIONAL PCMCIA CARD

WARNING:

Turn the power OFF when inserting or removing the PCMCIA card.

CAUTION:

To protect PCMCIA cards, discharge static electricity from your body by touching the printer rear

cover prior touching the PCMCIA cards.

1. Turn the power off.

2. Insert the PCMCIA card into the card slot at the rear of the printer.

3. Turn the power on.

1

0

PCMCIA Card

Fig. 7-1

NOTES: 1. Be sure to protect a PCMCIA card when not in use in the printer by putting it in its protective

cover.

2. Do not subject the card to any shocks or excessive forces.

3. Do not expose the card to extremes of heat by either storing in direct sunlight or close to a

heater.

4. Do not expose the card to excessive humidity by wiping it with a wet cloth or storing it in a damp

place.

5. Before inserting or removing the card, make sure that the power switch is turned off.

6. The following flash cards can be used. (The 1MB-card is read only and the 4MB card can read/

write.)

Capacity

1M Byte

4M Byte

Maker

Maxell

Mitsubishi

Maxell

Maxell

Centennial Technologies INC.

INTEL

Simple TECHNOLOGY

Mitsubishi

PC Card KING MAX

PC Card

Type

EF-1M-TB AA

MF81M1-GBDAT01

EF-4M-TB CC

EF-4M-TB DC

FL04M-15-11119-03

IMC004FLSA

STI-FL/4A

MF84M1-G7DAT01

FJN-004M6C

FJP-004M6R

Device code

D0H

88H

ADH

A2H

A0H

Maker code

1CH

B0H

04H

01H

89H

89H

7. Install the LAN card into the slot (1).

E7-1

Page 22

8. CARE/HANDLING OF THE MEDIA AND RIBBON

8. CARE/HANDLING OF THE MEDIA AND RIBBON

ENGLISH VERSION EO1-33007

8. CARE/HANDLING OF THE MEDIA AND RIBBON

CAUTION:

Be sure to read carefully and understand the Supply Manual. Use only media and ribbon

which meet specified requirements. Use of non-specified media and ribbon may shorten the

head life and result in problems with bar code readability or print quality. All media and ribbon

should be handled with care to avoid any damage to the media, ribbon or printer. Read the

following guideline carefully.

• Do not store the media and ribbon for longer than the manufactures recommended shelf life.

• Store media rolls on the flat end, do not store them on the curved sides as this might flatten that side

causing erratic media advance and poor print quality.

• Store the media in plastic bags and always reseal after opening. Unprotected media can get dirty and

the extra abrasion from the dust and dirt particles will shorten the print head life.

• Store the media and ribbon in a cool, dry place. Avoid areas where they would be exposed to direct

sunlight, high temperature, high humidity, dust or gas.

• The thermal paper used for direct thermal printing must not have the specifications which exceed Na

800 ppm, K+ 250 ppm and CL- 500 ppm.

+

• Some ink used on pre-printed labels may contain ingredients which shorten the print head's product life.

Do not use labels pre-printed with ink which contain hard substances such as carbonic calcium (CaCO

and kaolin (Al2O3, 2SiO2, 2H2O).

For further information please contact your local distributor or your media and ribbon manufacturer.

)

3

E8-1

Page 23

9. GENERAL MAINTENANCE

ENGLISH VERSION EO1-33007

9.1 Cleaning

9. GENERAL MAINTENANCE

WARNING:

1. Be careful when handling the print head as it becomes very hot.

2. Care must be taken not to injure yourself with the printer paper cutter.

3. Do not touch moving parts. To reduce the risk that fingers, jewelry, clothing, etc., be drawn

into the moving parts, push the switch in the “OFF” position to stop movement.

4. To avoid injury, be careful not to catch or jam your fingers while opening or closing the cover.

9.1 Cleaning

To help retain the high quality and performance of your printer it should be regularly cleaned. The

greater the usage of the printer, the more frequent the cleaning. (i.e. low usage=weekly : high usage=daily).

A print head cleaner is not enclosed with the printer, so please inquire at your local distributor.

1. Turn the power off.

2. Open the top cover.

3. Turn the head lever to raise the print head.

4. Remove the ribbon and media.

5. Clean the element of print head with print head cleaner.

6. Wipe the platen, feed roller and pinch roller with a cleaner moistened with alcohol.

Remove dust or foreign substances from the internal part of the printer, if any.

Element

Print Head

Platen

Print Head Cleaner

(24089500013)

Print Head

Element

WARNING:

1. Be sure to disconnect the power cord prior ot performing any maintenance.

2. Do not use any tool that may damage the print head.

3. DO NOT POUR WATER directly onto the printer.

Pinch Roller

Feed Roller

Fig. 9-1

E9-1

Page 24

9. GENERAL MAINTENANCE

ENGLISH VERSION EO1-33007

9.2 Covers and Panels

9.2 Covers and Panels

The covers should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild detergent

solution.

NOTE: Clean the printer cover with an electrostatic free cleaner for automated office equipment.

WARNING:

1. DO NOT POUR WATER directly onto the printer.

2. DO NOT APPLY cleaner or detergent directly onto any cover or panel.

3. NEVER USE THINNER OR OTHER VOLATILE SOLBENT on the plastic covers.

4. DO NOT clean the panel covers or the supply window with alcohol as it may cause them to

discolor, loose their shape or develop structural weakness.

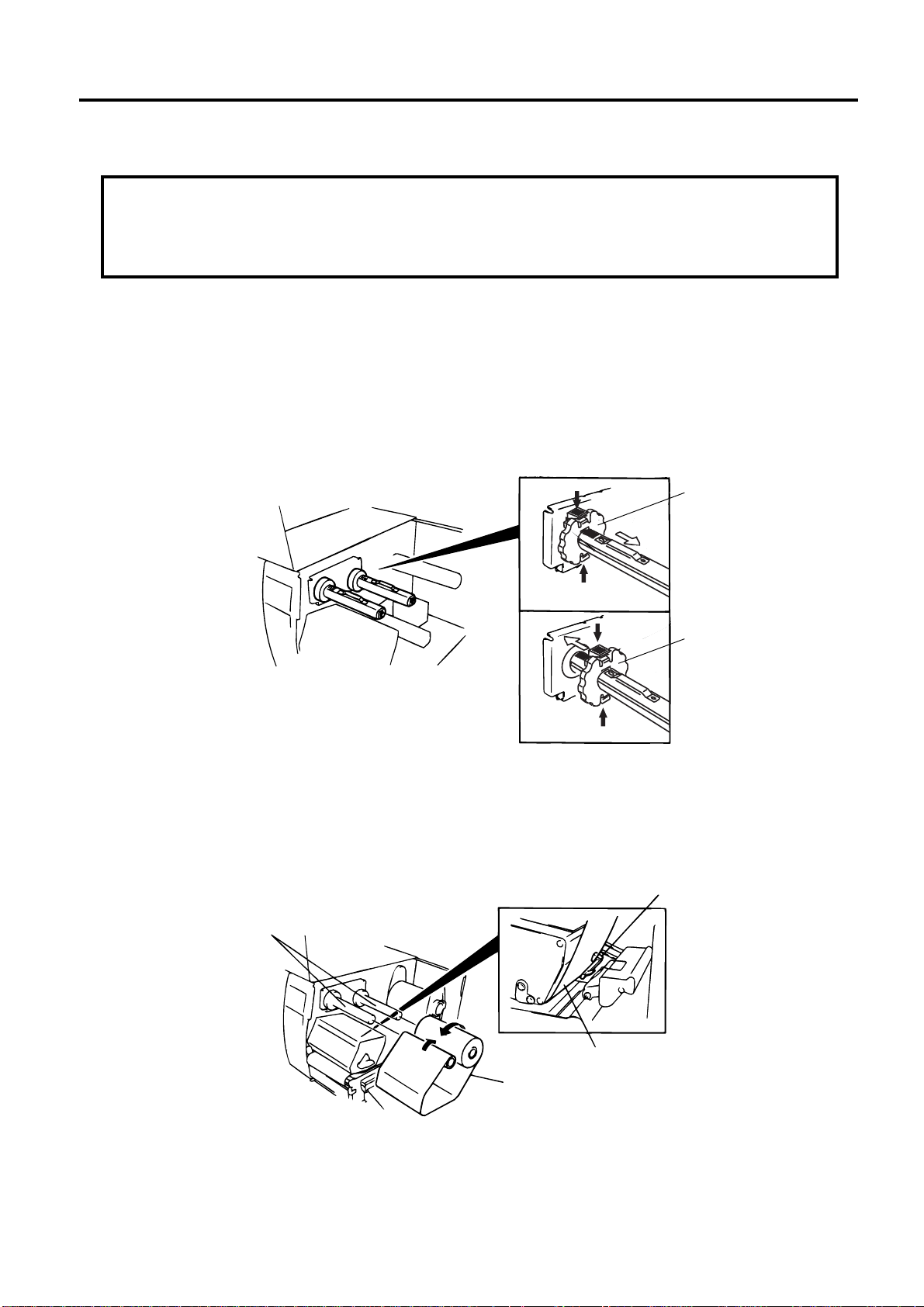

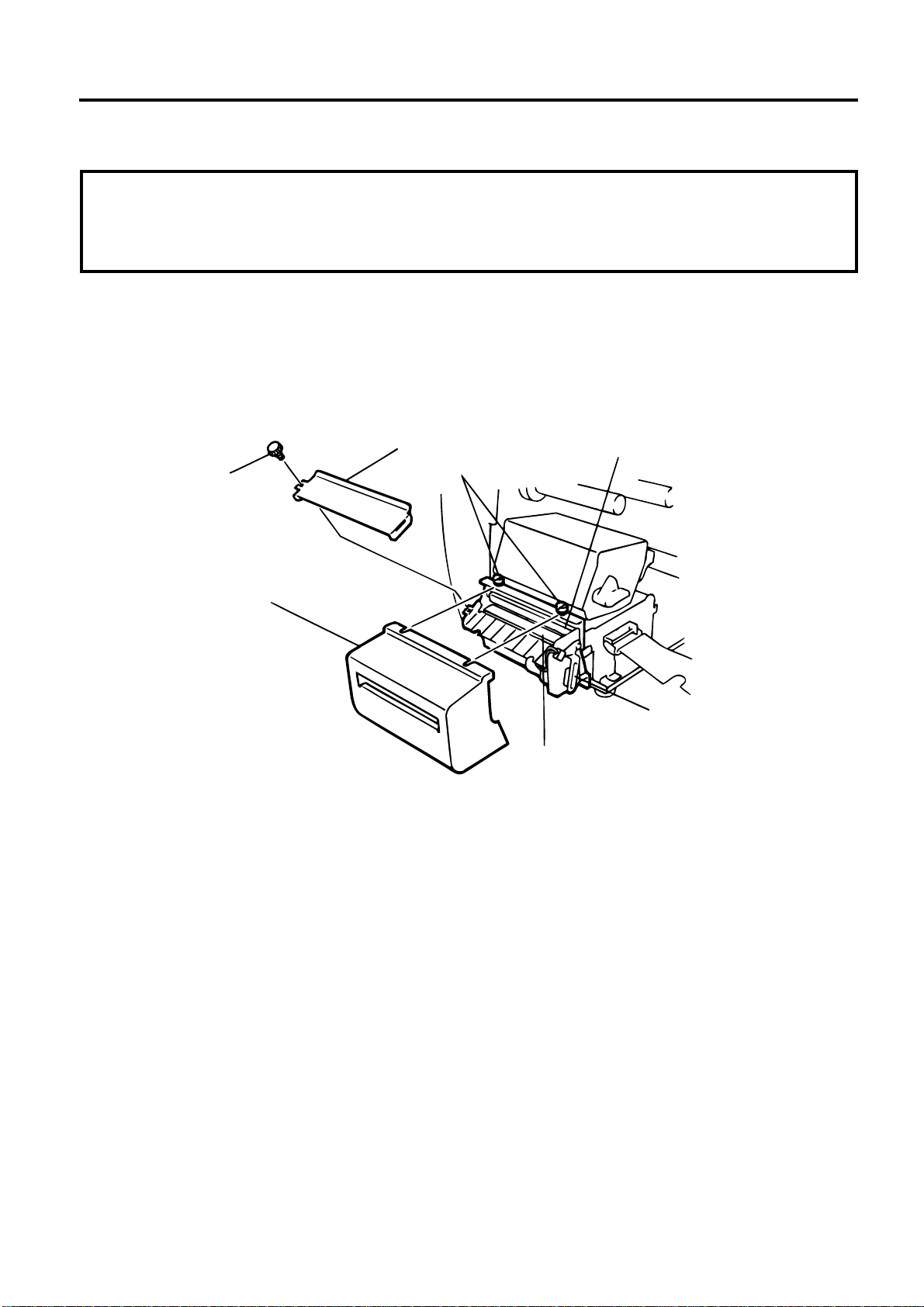

9.3 Removing Jammed Paper

1. Turn the power off.

2. Open the top cover.

3. Turn the head lever to position 3, then release the ribbon shaft holder plate.

4. Remove the flanged screw to detach the media guide plate. (See Fig. 9-2.)

5. Remove the ribbon and media.

6. Remove the jammed paper. DO NOT USE any sharp implement or tool as these could damage the

printer.

7. Clean the print head and platen, then remove any further dust or foreign substances.

8. Place the portion B of the media guide plate on the media sensor. Secure the media guide plate with

the flanged screw.

Media Sensor

Media Guide Plate

Flanged Screw

FL-4x 12

Fig. 9-2

9. Paper jams in the cutter unit can be caused by wear or residual glue from label stock on the cutter. Do

not use none specified media in the cutter. If you get frequent jams in the cutter contact your Authorized

Service representative.

E9-2

Page 25

9. GENERAL MAINTENANCE

ENGLISH VERSION EO1-33007

9.3 Removing Jammed Paper

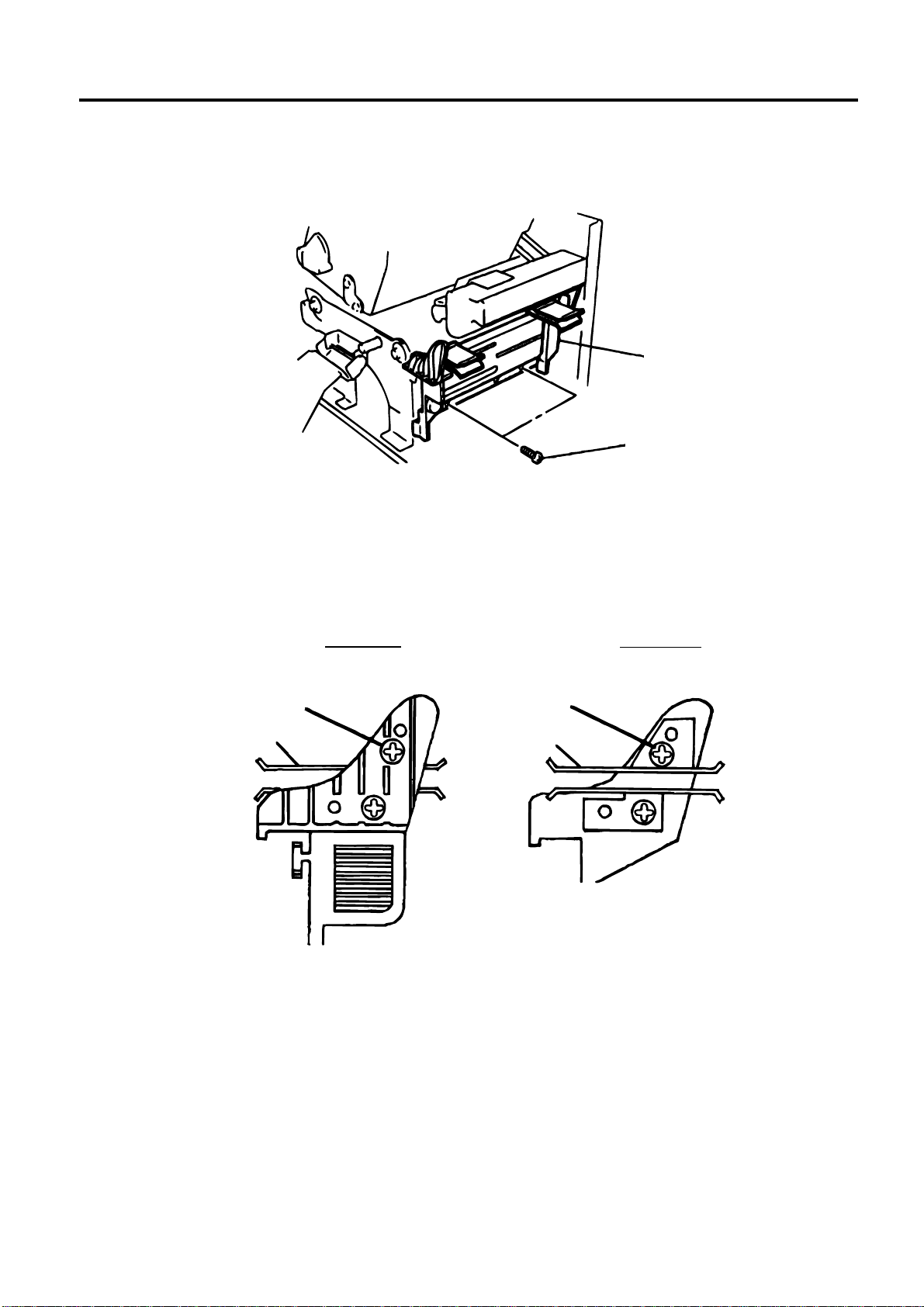

■ Cleaning the Cutter Unit

WARNING:

1. Be sure to turn the power off before cleaning the cutter unit.

2. The cutters are sharp and care should be taken not to injure yourself when cleaning.

The swing cutter and rotary cutter are available as an option. They are both cleaned in the same way

regardless of different shapes. Now, how to clean the cutter unit installing the swing cutter will be

introduced.

1. Loosen two screws and remove the cutter cover.

2. Remove the white screw and media guide.

3. Remove the jammed paper and trash.

4. Clean the cutter with dry cloth.

5. Assembling is reverse order of removal.

White Screw

(24741710304)

Cutter Cover

Media Guide

Screw

Fixed Cutter

Cutter Unit

Swing Cutter

Fig. 9-3

E9-3

Page 26

9. GENERAL MAINTENANCE

ENGLISH VERSION EO1-33007

9.4 Threshold Setting

9.4 Threshold Setting

For the printer to maintain a constant print position it uses the feed gap sensor to detect the gap between

labels by measuring the amount of light passing through the media. When the media is pre-printed, the

darker (or more dense) inks can interfere with this process causing paper jammed errors. To get around

this problem a minimum threshold can be set for the sensor in the following way.

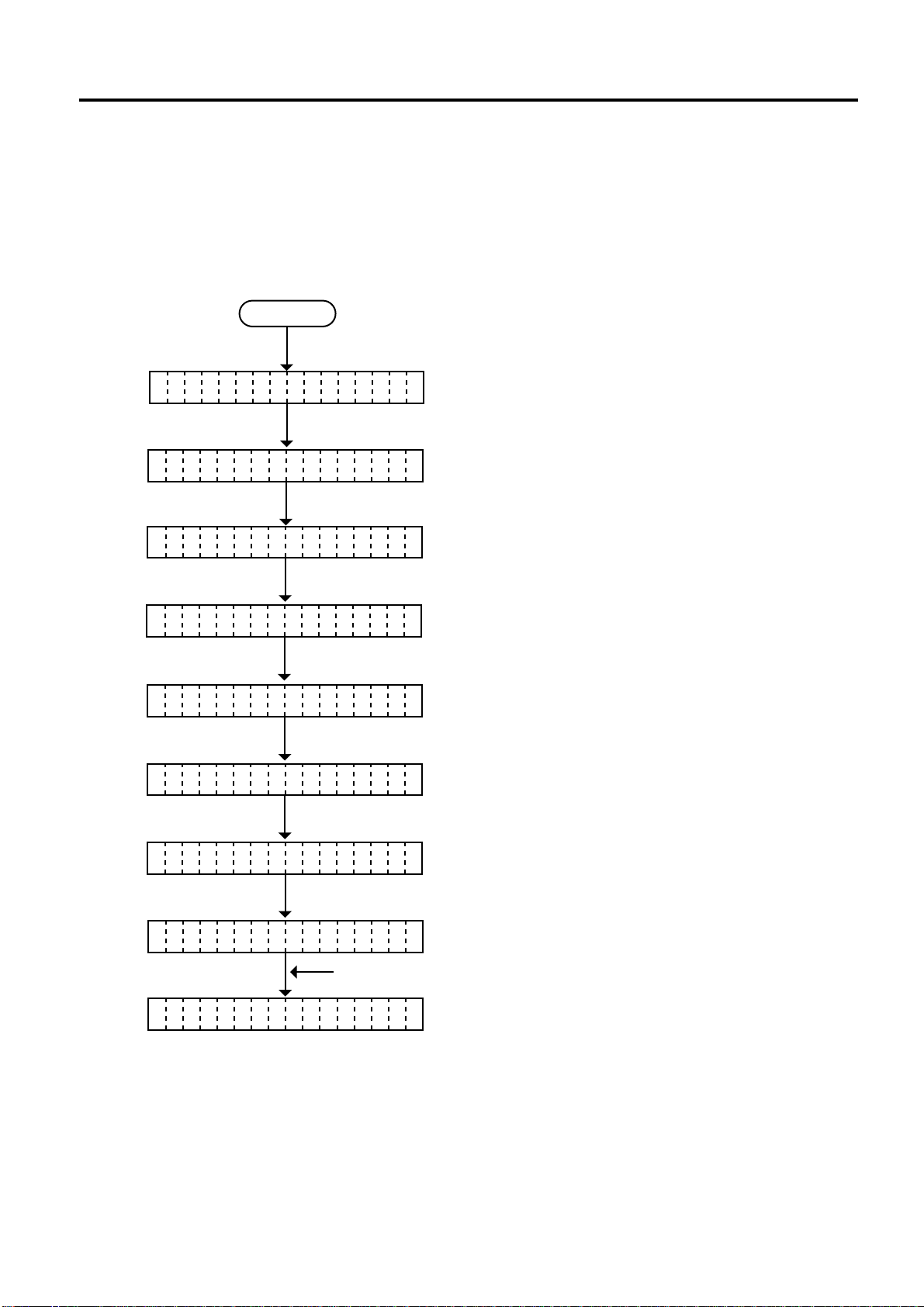

■ Threshold setting procedure

Power on

ON LINE

PA SE U

TR NSMIS

RE LECTI

TR NSMIS

TR NSMIS

PA SE U

[PAUSE] key.

[PAUSE] key.

SIV

E

A

[FEED] key.

VE

F

[FEED] key.

SIV

E

A

[PAUSE] key.

SIV

E

A

(1) Online

(2) Load the preprinted label. (No particular positioning is required.)

(3) Press the [PAUSE] key.

(4) The printer is in the pause state.

(5) Press the [PAUSE] key for 3 seconds or more while the printer

is paused.

(6) The sensor selection to set the threshold manually is displayed.

The transmissive sensor designation is displayed.

(7) Press the [FEED] key.

(8) The reflective sensor designation is displayed.

(9) Press the [FEED] key.

(10) The transmissive sensor designation is displayed.

(11) Press and hold the [PAUSE] key.

(12) The printer feeds labels until the [PAUSE] key is released.

(13) The [PAUSE] key should be held until more than 1.5 sheets

of the label are fed. When the [PAUSE] key is released, the

printer stops feeding the label. (Threshold setting for the

selected sensor is completed.)

(14) Press the [RESTART] key.

[RESTART] key.

ON LINE

(15) Online

Command

ON LINE

(16) The label is printed according to the command issued from the

PC.

< Supplementary Explanation >

(1) When the [PAUSE] key is released within 3 seconds while printer pauses, the [PAUSE] key is invalid.

(2) When the threshold is programmed, 1.5 sheets of the label should be fed. (If less than 1.5 labels are

fed, the threshold may not be properly programmed. In this case, reprogramming is required.)

(3) When the [PAUSE] key is pressed for 3 seconds or more in a head-up state, the [PAUSE] key is invalid.

(4) During a label feed, an error including the paper end, ribbon end or cutter error is not detected.

E9-4

Page 27

9. GENERAL MAINTENANCE

ENGLISH VERSION EO1-33007

9.4 Threshold Setting

■ Auto Ribbon Saving Mode

Auto ribbon saving function is activated when a no print area extends more than 17 mm.

For further information on this function, please ask your nearest TOSHIBA TEC service representative.

NOTE: According to the relation between the outer diameter of rewound ribbon and print speed, ribbon

loss per saving varies as follows:

Print speed

3"/sec.

5"/sec.

8"/sec.

Ribbon loss

Approx. 5 mm

Approx. 8 mm

Approx. 17 mm

E9-5

Page 28

10. TROUBLESHOOTING

ENGLISH VERSION EO1-33007

10. TROUBLESHOOTING

10.TROUBLESHOOTING

WARNING:

If you cannot solve a problem with the following solutions, do not attempt to repair it yourself. Turn

the power off, unplug the printer, then contact your Authorized Service representative for assistance.

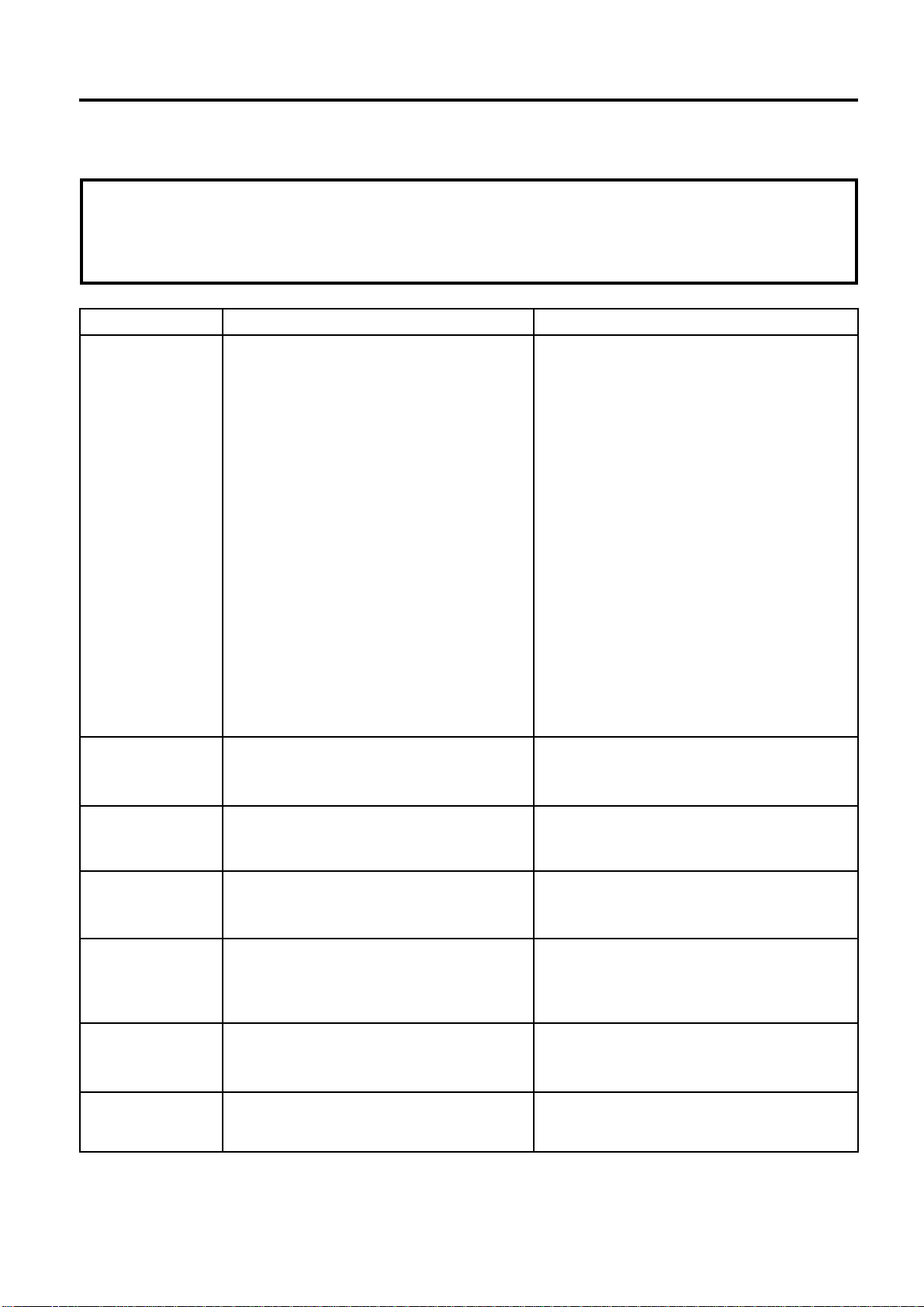

Error Message

PAPER JAM

****

HEAD OPEN

****

Problem Solution

1. The media is not fitted correctly.

2. The media path is jammed and

does not feed smoothly.

3. The installed media type does not

match the selected sensor.

4. The black mark position on the

media does not match the sensor

position.

5. The installed media size is different

from the programmed size.

6. The feed gap sensor cannot see

the difference between the print

area and the gap.

Feed or printing has been attempted

while the print head is raised.

1. Re-fit the media correctly.

➔ Press the [RESTART] key.

2. Remove the cause of the jam and

replace the media correctly.

➔ Press the [RESTART] key.

3. Turn the power off then on again.

Select the correct sensor.

➔ Feed the media.

4. Adjust the sensor position.

➔ Press the [RESTART] key.

5. Turn the power off then on again.

Set the correct media size.

➔ Feed the media.

6. Set the threshold (see page 9-4).

Else

Turn the power off and call your

Authorized Service representative.

Lower the print head.

➔ Press the [RESTART] key.

NO PAPER

****

NO RIBBON

****

REWIND FULL

****

EXCESS HEAD

TEMP

RIBBON ERROR

****

The media has run out.

The ribbon has run out.

Too much backing paper or media is

wound on the internal take-up spool.

The print head is too hot.

There is a fault with the ribbon sensor.

E10-1

Load new media.

➔ Press the [RESTART] key.

Load a new ribbon.

➔ Press the [RESTART] key.

Remove the backing paper or media

from the internal take-up spool.

Then press the [RESTART] key.

Turn the power off and decrease the

print head temperature.

Turn the power off. Contact your Authorized Service representative.

Page 29

10. TROUBLESHOOTING

ENGLISH VERSION EO1-33007

10. TROUBLESHOOTING

Error Message

CUTTER ERROR

****

FLASH WRITE

ERR.

FORMAT ERROR

Problem Solution

Media is jammed in the cutter.

An error has occurred when loading

data onto a flash memory card or ATA

card.

An error has occurred while formatting

a flash memory card or ATA card.

Remove the jammed media and feed

the undamaged media through the

cutter.

➔ Press the [RESTART] key.

Else

Turn the power off and contact your

Authorized Service representative.

1. Turn the power off, re-seat the flash

memory card or ATA card and try again.

2. Replace the flash memory card or

ATA card and retry.

3. Turn the power off and contact your

Authorized Service representative.

1. Turn the power off, re-seat the flash

memory card or ATA card and try again.

2. Replace the flash memory card or

ATA card and retry.

3. Turn the power off and contact your

Authorized Service representative.

FLASH CARD

FULL

COMMS ERROR

example)

PC001; 0A00,

Command error

0300, 2, 2

Other Error

Message

No more data can be saved in the

flash memory card or ATA card.

A communication error has occurred

with the host.

When an error is detected in a command 16 bytes of the command are

displayed.

(ESC, LF, NUL are not displayed.)

Hardware or software trouble.

Replace the card with a new one and

re-send data.

(In case of flash memory card, only

1MB and 4MB cards can be used.)

Turn the power off then on again or

press the [RESTART] key.

Check the program data.

➔ Call your Authorized Service repre-

sentative if necessary.

Correct the command and re-send it

again.

Turn the power off then on again. If the

problem still exists turn the power off

and contact your Authorized Service

representative.

NOTE: If an error is not cleared by pressing the [RESTART] key, the power must be switched off then

on again.

After the power has been switched off and on, all print data in the printer is cleared.

**** denotes a remaining count of unprinted labels.

E10-2

Page 30

10. TROUBLESHOOTING

Problem Solution

ENGLISH VERSION EO1-33007

10. TROUBLESHOOTING

No print.

Dots missing in the print.

Unclear (or blurred) printing.

Power does not come on.

Printer does not cut.

You see a raised nap where the media

has been cut.

1. Check that media and the ribbon is loaded correctly.

2. Check whether the print head is set correctly or not.

3. Check the cabling between the printer and the host.

Dirty print head. ➔ Clean the print head.

Call your Authorized Service representative if necessary.

1. Dirty print head. ➔ Clean the print head.

2. Bad or faulty ribbon. ➔ Replace ribbon.

3. Poor media quality. ➔ Change media type.

1. Plug power cord into an AC socket.

2. Check the circuit breakers or fuses.

3. Plug another appliance into the AC socket to check if

there is power supplied.

Call your Authorized Service representative if necessary.

Check for a paper jam in the cutter.

Call your Authorized Service representative if necessary.

1. Clean the cutter blades.

2. The blades are worn.

➔ Call your Authorized Service representative.

E10-3

Page 31

I'imprimante Transfert Thermique TEC

B-480-QP SERIES

Mode d’emploi

Page 32

Résumé des précautions

FRENCH VERSION FO1-33007

Résumé des précautions

La sécurité personnelle lors de la manipulation ou de líentretien du matériel est extrémement importante.

Les avertissements et précautions nécessaires à la manipulation en toute sécurité du matériel sont inclus

dans ce manuel. Les avertissements et précautions contenus dans ce manuel doivent être lus et assimilés

avant toute manipulation ou entretien.

Ne tentez pas díeffectuer des réparations ou des modifications sur ce matériel. Si une erreur se produit

qui ne peut être résolue en suivant les instructions de ce manuel, coupez le courant, déconnectez le câble

secteur et contactez votre revendeur agréé TOSHIBA TEC pour une assistance technique.

Explication des symboles

Ce symbole signale une mise en garde (ou des précautions).

Le dessin à l’intérieur du symbole précise quelle est l’action à exécuter.

(Le symbole ci-contre indique une précaution d’ordre général.)

Ce symbole signale une action interdite (interdictions).

Le dessin à l’intérieur ou près du symbole précise quelle est l’action interdite.

(Le symbole ci-contre indique “Ne pas démonter”.)

Ce symbole indique une action à effectuer.

Le dessin à l’intérieur du symbole précise quelle est l’action à exécuter.

(Le symbole ci-contre indique “Retirer la fiche secteur de la prise”.)

ATTENTION

Interdiction d'utiliser

une tension autre que

celle spécifiée

Interdit

Interdit

Ne faites pas fonctionner la

machine avec une tension électrique

différente de celle indiquée sur la

plaquette des caractéristiques. Ceci

pourrait provoquer un incendie ou

une électrocution.

Si la machine partage une même

prise avec d’autres appareils

consommant beaucoup d’électricité, il

y aura des fluctuations de tension

importantes lorsque ces appareils

fonctionnent. Pour éviter une

anomalie causée par de telles

fluctuations, ne branchez pas d’autres

appareils à la même prise que la

machine.

N’introduisez pas et ne faites pas

tomber de pièces métalliques, de

matières inflammables ou d’autres

objets dans les ouvertures d’aération

de la machine. Ils pourraient

provoquer un incendie ou une

électrocution.

Indique un danger de mort ou de blessures graves si l’équipement

est utilisé en négligeant ces instructions.

Interdit

Interdit

Interdit

Ne branchez pas et ne débranchez

pas la fiche secteur avec les mains

mouillées. Vous risqueriez une

électrocution.

Ne placez pas d’objets métalliques

ou de récipients contenant un liquide

(vases, pots de fleurs, tasses, etc.)

sur la machine. Un objet métallique

ou un liquide peut provoquer un

incendie ou une électrocution s’il

pénètre accidentellement dans la

machine.

N’essayez pas de réparer ou de

modifier vous-même la machine. Ceci

pourrait provoquer un incendie ou

une électrocution. Pour toute

question sur les réparations,

adressez-vous à votre revendeur (ou

au service après-vente).

Débranchez

la fiche.

Si les machines tombent, ou que leur

capot est endommagé, commencez par

positionner le bouton marche/arrêt sur

arrêt et par déconnecter le câble

secteur de la prise murale. Ensuite,

contactez votre revendeur agréé

TOSHIBA TEC pour une assistance

technique. Une utilisation prolongée de

l'imprimante dans ces conditions peut

être source d'incendie ou de choc

électrique.

(i)

Débranchez la

fiche.

Une utilisation prolongée de

l'imprimante dans une condition anormale,

comme par exemple lorsque l'imprimante

produit de la fumée ou des odeurs

étranges peut être source d'incendie ou

de choc électrique. Dans ce cas, éteignez

immédiatement l'interrupteur marche/

arrêt et déconnectez le câble secteur de

la prise murale. Ensuite, contactez votre

revendeur agréé TOSHIBA TEC pour

une assistance technique.

Page 33

Résumé des précautions

FRENCH VERSION FO1-33007

Débranchez la

fiche.

Connectez

un fil de

terre.

Si des corps étrangers (fragments de

métal, eau, liquides) pénètrent à l'intérieur

de la machine, commencez par

positionner le bouton marche/arrêt sur

arrêt et par déconnecter le câble secteur

de la prise murale. Ensuite, contactez

votre revendeur agréé TOSHIBA TEC

pour une assistance technique.

Une utilisation prolongée de l'imprimante

dans ces conditions peut être source

d'incendie ou de choc électrique.

Assurez vous que votre installation

est correctement relié à la terre. Une

mauvaise installation peut provoquer

un début d'incendie ou un choc

électrique.

Débranchez

la fiche.

Démontage

interdit

Pour débrancher le câble

d’alimentation, tirez-le par la prise. Ne

tirez pas directement sur le câble.

Ceci pourrait sectionner et exposer les

fils internes du câble et causer un

incendie ou une électrocution.

Ne pas retirer les capots, réparer ou

modifier l'imprimante par vous mème.

Vous pouvez recevoir un choc

électrique ou vous blessé par des

bords tranchants dans l'imprimante.

Indique un risque de blessures ou de dommages si l’équipement

PRECAUTION

est utilisé en négligeant ces instructions.

Précautions

Ies précautions suivantes vous permettront d'avoir un fonctionnement correct de l'imprimante.

• Evitez les endroits qui présentent les conditions défavorables suivantes :

* Température hors des spécifications * Exposition directe au soleil. * Humidité éIevée

* Alimentation secteur partagée avec * Vibrations excessives * Poussiére/Gaz

d'autres dispositifs.

• Nettoyez le couvercle en l'essuyant au moyen d'un chiffon sec ou d'un chiffon imbibé de détergent.

NE JAMAIS UTILISER DE DILUANT NI D'AUTRES SOLVANTS VOLATILES sur les capots en

platique.

• Utilisez des étiquettes et des rubans recommandés par TOSHIBA TEC.

• N'entreposez pas les films et media à un endroit où ils seraient exposés à la lumière directe du

soleil, à des températures élevées, à une humidité importante, à de la poussière ou à des gaz.

• Assurez-vous d'utiliser l'imprimante sur une surface plane.

• Toute information mémorisée dans la mémoire de l'imprimante peut être perdue lors d'une erreur

d'impression.

• Evitez d'utiliser cet équipement sur la même ligne secteur que des appareils de forte puissance ou

susceptibles d'émettre des interférences.

• Eteindre l’imprimante lors des interventions à l’intérieur ou lors des nettoyages.

• s’assurer de garder l’environnement de travail à l’abri de l’électricité statique.

• Ne placez pas d’objets lourds sur la machine. Ils pourraient tomber et blesser quelqu’un.

• Ne bouchez pas les ouvertures d’aération de la machine. La chaleur s’accumulerait à l’intérieur et

pourrait provoquer un incendie.

• Ne pas s'appuyer contre l'imprimante Celle-ci peut tomber et vous pouvez ètre blessé.

• Faire attention au couteau de l'imprimante.

• Débranchez I'imprimante lorsqu'ellen n'est pas utilisée pendant une longue période.

Au sujet de la maintenance

• Faites appel à nos services de maintenance.

Aprés avoir reçu le matériel, prenez contact avec votre revendeur agréé TOSHIBA TEC pour une

visite de maintenance annuelle, de manière à effectuer un nettoyage complet de líintérieur de la

machine.

Autrement, la poussiére qui síaccumule à líintérieur de la machine peut être source díincendie ou de

mauvais fonctionnement. Le nettoyage est particulièrement nécessaire avant les saisons humides

ou pluvieuses.

• Nos services de maintenance effectuent les vérifications périodiques et les autres opèrations

nécessaires à maintenir la qualité et la performance des imprimantes. Prévenant de ce fait les

problèmes.

Pour tous détails, consultez votre revendeur agréé TOSHIBA TEC.

• Utilisations díinsecticides et díautres produits.

Níexposez pas les machines aux insecticides ou à díautres solvants volatiles, dans la mesure où

cela peut endommager les capots ou entraîner un écaillage de la peinture.

(ii)

Page 34

FRENCH VERSION FO1-33007

TABLE DES MATIERES

Page

1. INTRODUCTION............................................................................F1-1

1.1 Modèle Applicable .................................................................................F1- 2

1.2 Accessoires ...........................................................................................F1- 2

2. SPECIFICATIONS .........................................................................F2-1

2.1 Imprimante.............................................................................................F2- 1

2.2 Options ..................................................................................................F2- 2

2.3 Film........................................................................................................F2- 2

2.4 Papier ....................................................................................................F2- 3

3. VUE GENERALE...........................................................................F3-1

3.1 Face Avant et Arrière .............................................................................F3- 1

3.2 Panneau de Contrôle ............................................................................F3- 1

4. MISE EN ROUTE DE L'IMPREIMANTE........................................F4-1

4.1 Connexion du cordon d'alimentation et des câbles...............................F4- 1

4.2 Installation du filtre sur le ventilateur .....................................................F4- 1

5. CHARGEMENT DU PAPIER .........................................................F5-1

6. CHARGEMENT DU FILM..............................................................F6-1

7. INSTALLATION DE LA CARTE PCMCIA OPTIONNELLE........... F7-1

8. PRECAUTION DE STOCKAGE DES CONSOMMABLES ........... F8-1

9. MAINTENANCE.............................................................................F9-1

9.1 Nettoyage ..............................................................................................F9- 1

9.2 Capot, Face Avant.................................................................................F9- 2

9.3 Elimination des Fournitures Coincées...................................................F9- 2

9.4 Régler la détection des Étiquettes pré-imprimées................................. F9- 4

10. DEPISTAGE DES PANNES......................................................... F10-1

ATTENTION:

1. Ce manuel ne peut être copié, en entier ni en partie sams autorisation préalable de

TOSHIBA TEC.

2. Le contenu de ce manuel peut être changé sans information préalable.

3. Veuillez contacter votre distributeur TOSHIBA TEC pour toutes questions.

Page 35

1. INTRODUCTION

FRENCH VERSION FO1-33007

1. INTRODUCTION

1. INTRODUCTION

Nous vous remercions d'avoir porté votre choix sur l'imprimante transfert thermique de la série B-480.

Cette nouvelle génération d'imprimante intègre le meilleur compromis performance qualité. La tête

thermique est à impression rapprochée dispose de 12 points par millimètre 304.8 DPI et permet une

impression à la vitesse maximum de 203.2 mm/sec.

Les accessoires disponibles en option incluent un économiseur de film, un dispositif interne de prédécollage d'étiquettes et de ré-enrouleur, ainsi qu'un support média externe.

Ce manuel contient des informations sur l'installation générale et l'entretien de l'imprimante B-480. Nous

vous conseillons de le lire attentivement pour obtenir de votre imprimante des performances maximales.

Les dispositifs de sécurité ayant été étudiés avec soin, il n'y a aucun danger d'endommager l'imprimante

par une opération incorrecte. Pour toute question au sujet de l'imprimante, veuillez vous référer au présent

manuel. Prière de le conserver à toutes fins utiles.

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

ATTENTION

Afin d'éviter tout dommage, viter d'accrocher ou de coincer vos doigts lorsque vous ouvrez ou le capot.

ATTENTION

Ne pas toucher des parties mobiles. Pour réduire le risque que deses doigts, la joaillerie, les vêtements,

etc., seraient tirer dans les parties mobiles, pousser l'interrupteur à la "coupé" pour arrêter le

mouvement.

F1-1

Page 36

1. INTRODUCTION

1.1 Modèle Applicable

• B-482-TS10-QP

Description du modèle

B - 4 8 2 - T S 1 0 - Q P

Mode d'impression

S: Par Série

Résolution

T: 12 points : mm

2: Thermique direct et transfert thermique

FRENCH VERSION FO1-33007

1.1 Modèle Applicable

QP: Version pour l'Europe

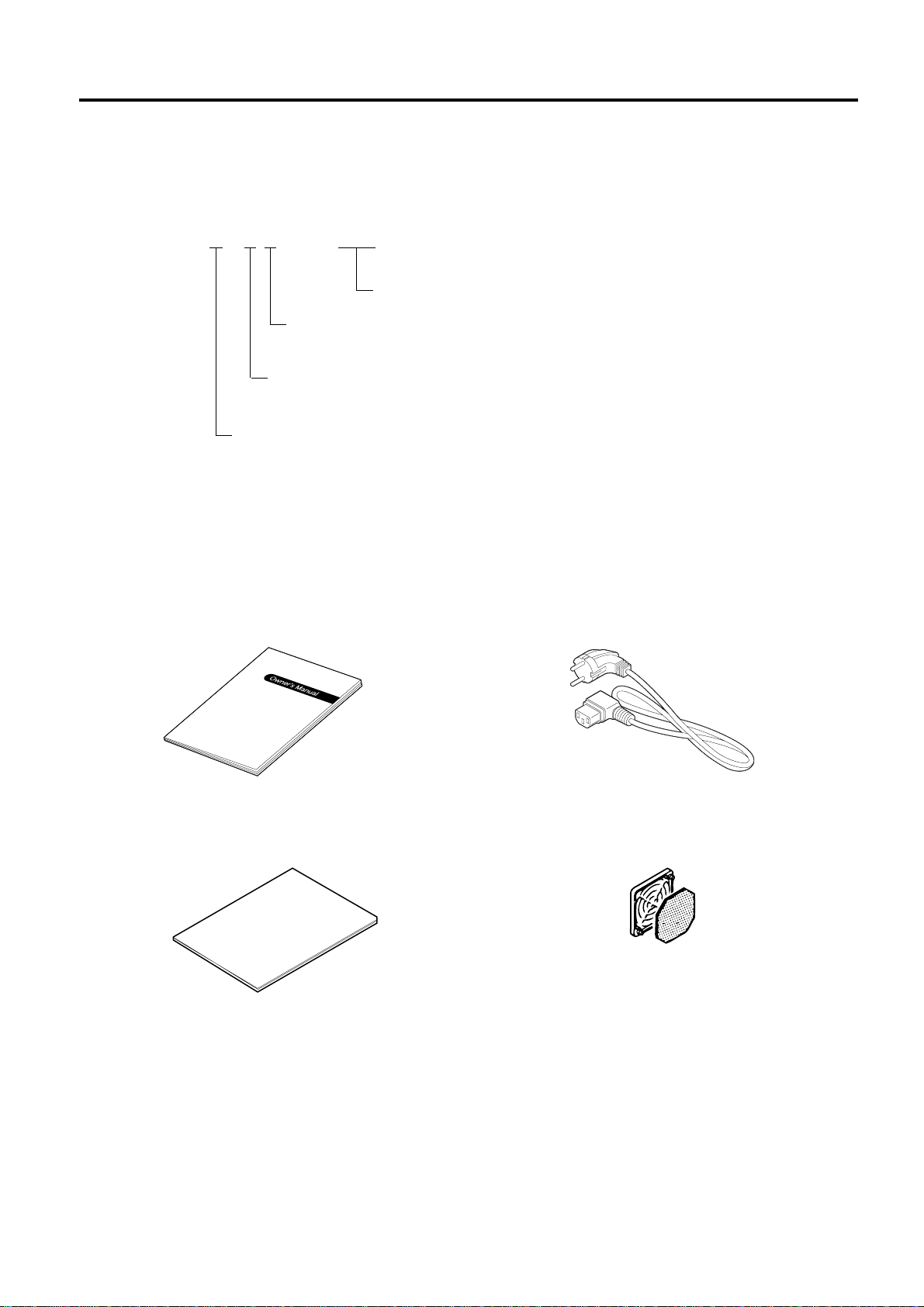

1.2 Accessoires

Manuel utilisateur Cordon d'alimentation

(EO1-33007)

Procédure de déballage Filtre de ventilateur

(FMBB0036801)

F1-2

Page 37

2. SPECIFICATIONS

2. SPECIFICATIONS

2.1 Imprimante

FRENCH VERSION FO1-33007

2.1 Imprimante

Article

Alimentation

Consommation

Limites de température

Humidité relative

Tête d'impression

Méthode d'impression

Vitesse d'impression

Largeur d'impression

Méthode de sortie

Affichage de message

Dimension

Poids

Type de codes à barre

Polices

Rotation des zones

Interface standard

Interface en option

Type

B-480-TS10-QP

CA 220 ~ 240 V + 10 %, -15 %, 50 Hz

1.13A, 128W max. (attente: 250 mA, 23 W)

5 C ~ 40 C

25 % ~ 85 % HR (sans condensation)

Tête d'impression thermique 12 points au mm

Transfert thermique ou thermique direct

76.2 mm/sec., 127 mm/sec., 203.2 mm/sec.,

101.6 mm/sec. ... Thermique direct seulement.

106.6 mm

En lot, en pré-decollage ou en coupe

(Les modes coupe et pré-décollage sont des options.)

16 caractères sur une ligne (LCD)

291 mm (L) x 460 mm (I) x 308 mm (H)

17 Kg

JAN8, EAN8, JAN13, EAN13, UPC-A, UPC-B

EAN8, EAN13, UPC-A, UPC-E + 2digit

EAN8, EAN13, UPC-A, UPC-E + 5digit

NW-7

CODE39 (STANDARD)

CODE39 (FULL ASCII)

ITF

MSI

CODE93

CODE128

EAN128

Data Matrix

PDF417

QR Code

industrial 2 of 5

Customer Bar Code

POSTNET

RM4SCC (ROYAL MAIL 4STATE CUSTOMERCODE)

KIX CODE

Maxi Code

Micro PDF417

Times Roman (6), Helvetica (6), Presentation (1),

Letter Gothic (1), Prestige Elite (2), Courier (2),

OCR (2 types), Polices télé-chargeables (mode 2 octets disponible),

Police vectorielle (4), Polices prix (3 types).

0 , 90 , 180 , 270

Série (RS-232C)

Parallèle (CENTRONICS)

Carte Entrée-Sortie

Interface carte PCMCIA

F2-1

Page 38

2. SPECIFICATIONS

2.2 Options

FRENCH VERSION FO1-33007

2.2 Options

Nom

Massicot à baïonnette

Massicot rotatif

Module pré-décollage

Guide Papier Paravent

Interface carte PCMCIA

Type

B-4205-QM

B-8204-QM

B-4905-H-QM

B-4905-FF-QM

B-8700-PC-QM

Utilisation

Massicot pour coupe à l'arrêt.

Massicot rotatif, coupe en continu.

Ce module pré-décolle l'étiquette à la sortie de

l'imprimante.

Ce guide papier est spécifique au paravent.

Cette Interface permet l'utilisation des cartes PCMCIA

suivantes:

®

• LAN CARD: 3 COM EtherLink

III (recommandé).

3 COM 3CCE589ET (recommandé).

• Carte ATA conforme au standard PC des cartes ATA.

• Carte mémoire Flash 1 Mo et 4 Mo (Voire page 7-1)

Carte Interface I/O

2.3 Film

Type

Largeur

Longueur

Diamètre externe

B-8700-IO-QM

Bobine

68 mm à 112 mm

600 m

ø90 mm (max.)

L'installation de cette carte permet l'interfaçage avec des

dispositifs externes par le biais de ports spécifiques.

NOTES: 1. L'impression au vol' signifie que l'imprimante procède à

l'impression et au dessin de l'étiquette en même temps, il

n'y a pas d'arrêt entre deux étiquettes.

2. Il est recommandé d'utiliser des rubans et des papiers

recommandés par TOSHIBA TEC.

3. La coupe des étiquettes adhésives peut se faire à partir

d'une hauteur de 35 mm. (Voir page 2-3.)

4. Si vous utilisez le ré-embobineur interne, le diamètre

externe de la bobine papier doit être de 180 mm maximum.

5. En mode d'économie de film, n'utilisez pas de papier dont

la surface est rugueuse, afin d'éviter des traces noires à

l'impression.

F2-2

Page 39

2. SPECIFICATIONS

2.4 Papier

Position

d but

d’impression

I I

Etiquette

Reportez-vous la

NOTE 2 ci-dessous.

Marque noir

(au dos)

Position d but

d’impression

Etiquette carton

FRENCH VERSION FO1-33007

2.4 Papier

Marque noir

(au dos)

Etiquette carton

Position

de coupe

F

H

Coordonn es

de R f rence

Coordonn es

de R f rence

Article

A : Hauteur hors tout

C : Largeur hors tout

E : Echenillage

F : Marque noir (Etiquette carton)

G : Largeur d’impression

H : Hauteur d’impression

I : Distance de non impression

Epaisseur

Longueur max.

1

2

G

D

C

Mode d’impression

Etiquette

Max.

Carte

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Etiquette

Min.

Max.

Carte

Min.

Max.

Etiquette

Carte

E

A

B

Sens d’impression

Par lot

10.0Min.

2730.0

2726.0

Position

de coupe

A la demande

2728.0

H

25.4

-10.0

-

23.48.0

-

Coordonn es

de R f rence

Coordonn es

de R f rence

1

2

G

C

A la coupe

Massicot rotatif

3"/sec.:94.0 3"/sec.:38.0

4"/sec.:98.0 4"/sec.:38.0

5"/sec.:102.0 5"/sec.:38.0

8"/sec.:113.0 8"/sec.:38.0

2730.0

3"/sec.:30.0

4"/sec.:30.0

5"/sec.:30.0

8"/sec.:38.0

2730.0

3"/sec.:81.0(*1) 3"/sec.:25.0

4"/sec.:85.0(*2) 4"/sec.:25.0

5"/sec.:89.0(*3) 5"/sec.:25.0

8"/sec.:100.0(*4) 8"/sec.:25.0

2724.0

50.8

112.0

47.8

109.0

20.0

2.0

10.0

10.0

106.7 0.2

3"/sec.:79.0 3"/sec.:23.0

4"/sec.:83.0 4"/sec.:23.0

5"/sec.:87.0 5"/sec.:23.0

8"/sec.:98.0 8"/sec.:23.0

2726.0

3"/sec.:28.0

4"/sec.:28.0

5"/sec.:28.0

8"/sec.:36.0

2726.0

1.0

1361.0

F

A

Fig. 2-1

38.0

25.4

25.0 (*5)

6.02.0

23.021.46.0

23.0-8.0

NOTES: 1. Les media spécifications qui n'ont pas été écrites là-dessus n'ont pas été changées.

2. La longueur de l'étiquette doit répondre aux critères suivants :

1) Lors de l’impression avec massicot rotatif à 3"/sec.:

91.0 mm - (échenillage / 2) ou supérieure.

2) Lors de l’impression avec massicot rotatif à 4"/sec.:

95.0 mm - (échenillage / 2) ou supérieure.

3) Lors de l’impression avec massicot rotatif à 5"/sec.:

99.0 mm - (échenillage / 2) ou supérieure.

4) Lors de l’impression avec massicot rotatif à 8"/sec.:

110.0 mm - (échenillage / 2) ou supérieure.

5) Lors de l’impression avec massicot à baïonnette :

35.0 mm - (échenillage / 2)

F2-3

Page 40

3. VUE GENERALE

3. VUE GENERALE

3.1 Face Avant et Arrière

Vue de face Vue de la face arrière

Afficheur (LCD)

FRENCH VERSION FO1-33007

3.1 Face Avant et Arrière

Capot

Vue des consommables

Emplacements pour

carte PCMCIA (2 ports)

Connecteur

série (RS-232C)

Panneau de contrôle

Sortie du papier

3.2 Panneau de contrôle

Fig. 3-2

Connecteur parallèle

(CENTRONICS)

Alimentation

Interrupteur

0: ARRET

1: MARCHE

Connecteur

interface Entrée/

Sortie (Option)

Fig. 3-1

AFFICHAGE DES MESSAGES (LCD)

Lors de la mise sous tension, "PRETE" est affiché.

VOYANT POWER (Vert)

Allumé lorsque l'imprimante est sous tension.

VOYANT ON-LINE (Vert)

1) Clignote pendant une communication avac l'ordinateur.

2) Allumé pendant l'impression.

VOYANT ERREUR (Rouge)

Allumé lors d'une erreur de transmission, d'une fin de papier ou

de ruban.

Touche FEED

Avance d'une étiquette.

Touche RESTART

Relance l'impression lors d'une pause ou à la suite d'une erreur.

Utilisé pour la détection des papiers pré-imprimés. (Voir page

9-4)

Touche PAUSE

Arrête l'impression en cours.

L'afficheur indique "PAUSE" suivi du nombre d'étiquettes restant

à imprimer. Utilisé pour la détection des papiers pré-imprimés.

(Voir page 9-4)

F3-1

Page 41

4. MISE EN ROUTE DE L'IMPRIMANTE

4.1 Connexion du cordon d'alimentation et des câbles

FRENCH VERSION FO1-33007

4. MISE EN ROUTE DE L'IMPRIMANTE

4.1 Connexion du cordon d'alimentation et des câbles

AVERTISSEMENT:

Prendre soin de couper l'alimentation avant de connecter le cordon d'alimentation et les autres

câbles.

Câble d'interface série

(RS-232C)

Câble d'interface parallèle

(CENTRONICS)

Câble d'interface

Entrée/Sortie (Option)

Cordon d'alimentation

4.2 Installation du filtre sur le ventilateur

Pousser

Pousser

Fig. 4-1

Fig. 4-2

Pendant l'installation de l'imprimante, il est important de vérifier le bon positionnement du filtre.

Le système de filtrage est composé de deux parties:

(1) La mousse filtrante

(2) Le support

Pour installer le filtre, placer la partie de mousse dans le support, puis le positionner en face des trous et

le pousser.

F4-1

Page 42

5. CHARGEMENT DU PAPIER

FRENCH VERSION FO1-33007

5. CHARGEMENT DU PAPIER

5. CHARGEMENT DU PAPIER

AVERTISSEMENT:

1. Ne pas toucher des parties mobiles. Pour réduire le risque que deses doigts, la joaillerie, les

vétements, etc., seraient tirer dans les parties mobiles, pousser l’interrupteur à la “coupé” pour

arréter le mouvement.

2. Afin d’éviter tout dommage, viter d’accrocher ou de coincer vos doigts lorsque vous ouvrez

ou le capot.

L'imprimante peut imprimer sur des étiquettes autocollantes ou cartonnées.

1. Mettre l'imprimante hors tension et ouvrir le capot.

2. Tourner le levier de tête en position 3 afin de déverrouiller la plaque des supports ruban.

Capot

Plaque des supports ruban

Levier de tête

NOTES: 1.Lorsque le levier de tête est ouvert, la tête d'impression est relevée.

2.Lorsque le levier de tête est ouvert, le galet d'entraînement arrière du papier est libéré.

1

3.Pendant l'impression, le levier de tête doit être en position

, la tête et l'entraînement du papier

sont fermés.

3. Retirer le guide du rouleau papier.

4. Tourner le guide papier extérieur de 30 et le retirer du support.

30

Support de rouleau papier

Guide de rouleau papier

(FMHD0005502)

Fig. 5-1

F5-1

Fig. 5-2

Page 43

5. CHARGEMENT DU PAPIER

FRENCH VERSION FO1-33007

5. CHARGEMENT DU PAPIER

5. Mettre la bobine sur l'axe support papier.

6. Passer le papier autour du regulateur de tension, puis le tirer vers la face avant de l'imprimante. Fixer

le guide de rouleau papier restant sur le support papier.

Support-papier

Rouleau de papier

Guide de rouleau papier

(FMHD0005502)

Support de rouleau papier

Fig. 5-3

7. Insérez le papier entre les plaques porte-papier du guide, ajustez les guides en largeur et serrez les vis

de blocage.

8. Vérifier que le défilement du papier entre le support et la sortie est bien aligné.

Guide papier

Papier

Plaques porte-papier

Vis de blocage

Guide de rouleau papier

Guide papier

Plaques porte-papier

Tête d'impression

Papier

Fig. 5-4

NOTE: Lors de l'utilisation de rouleaux d'étiquettes avec enroulement extérieur, veuillez enlever les deux

plaques porte-papier en suivant la procédure suivante. Laisser les plaques pent provoquer des

bourrages papier.

N'hésitez pas à contacter votre agence TOSHIBA TEC la plus proche pour tous renseignements.

F5-2

Page 44

5. CHARGEMENT DU PAPIER

■ Démontage des plaques porte papier du guide papier

1 Retirez les deux vis T-4x8 pour séparer le guide papier de l'imprimante.

FRENCH VERSION FO1-33007

5. CHARGEMENT DU PAPIER

Guide papier

Vis (T-4x8)

Fig. 5-5

2 Retirez les vis SM-3x6 ou SM-3x8 pour séparer les plaques porte papier supérieures du guide

papier.

Vis (SM-3x6)

Plaques portepapier

(Droite)

Vis (SM-3x8)

Plaques portepapier

(Gauche)

Fig. 5-6

3 Remettez le guide papier en place.

NOTE: Ne perdez pas les plaques supérieures car vous pourrez en avoir besoin si vous utilisez des

rouleaux d'étiquettes avec enroulement intérieur.

9. Ajuster la position des cellules de détection papier. Lorsque vous tournez la vis vers la droite, les cellules

se rapprochent du milieu, vers la gauche, elles s'éloignent.

F5-3

Page 45

5. CHARGEMENT DU PAPIER

■ Positionnement de la cellule de marque noire

1 Sortir le papier de 500 mm et le faire entrer de nouveau sous la tête jusqu'aux cellules.

2 Ajuster la position de la cellule marque noire pour avoir votre marque au milieu de celle-ci.

FRENCH VERSION FO1-33007

5. CHARGEMENT DU PAPIER

Cellule marque noire

Papier

(Cellule échenillage)

Vis de reglage

Marque noire

Fig. 5-7

ATTENTION: Veiller à positionner la cellule au milieu de la marque, dans le cas contraire, vous

aurez des problèmes de détection papier.

■ Positionnement de la cellule d'échenillage

1 Positionner la cellule pour la détection de l'échenillage.

Etiquette

Vis de reglage

(Cellule marque noire)

Support d'étiquettes

Etiquette

Cellule échenillage

Fig. 5-8

F5-4

Page 46

5. CHARGEMENT DU PAPIER

FRENCH VERSION FO1-33007

5. CHARGEMENT DU PAPIER

10. Les opérations de chargement du papier et du réglage des cellules sont terminées.

Impression par lot:

Papier

Fig. 5-9

NOTE: Placer le DIP SWITCH en position de STANDARD/STRIP. Une mauvaise position peut affecter

la qualité de l'impression.

Pré-décollage:

1 Retirer les étiquettes sur 50 cm du support silicone.