Page 1

TEC Thermal Printer

Table of Contents

B-450-QQ SERIES

Owner’s Manual

Page 2

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operations of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense. (for USA only)

Changes or modifications not expressly approved by manufacturer for compliance could void the user's

authority to operate the equipment.

"This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations."

"Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel

brouilleur de Canada."

(for CANADA only)

(for QQ, QQ-PAC only)

Copyright © 1999

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

Page 3

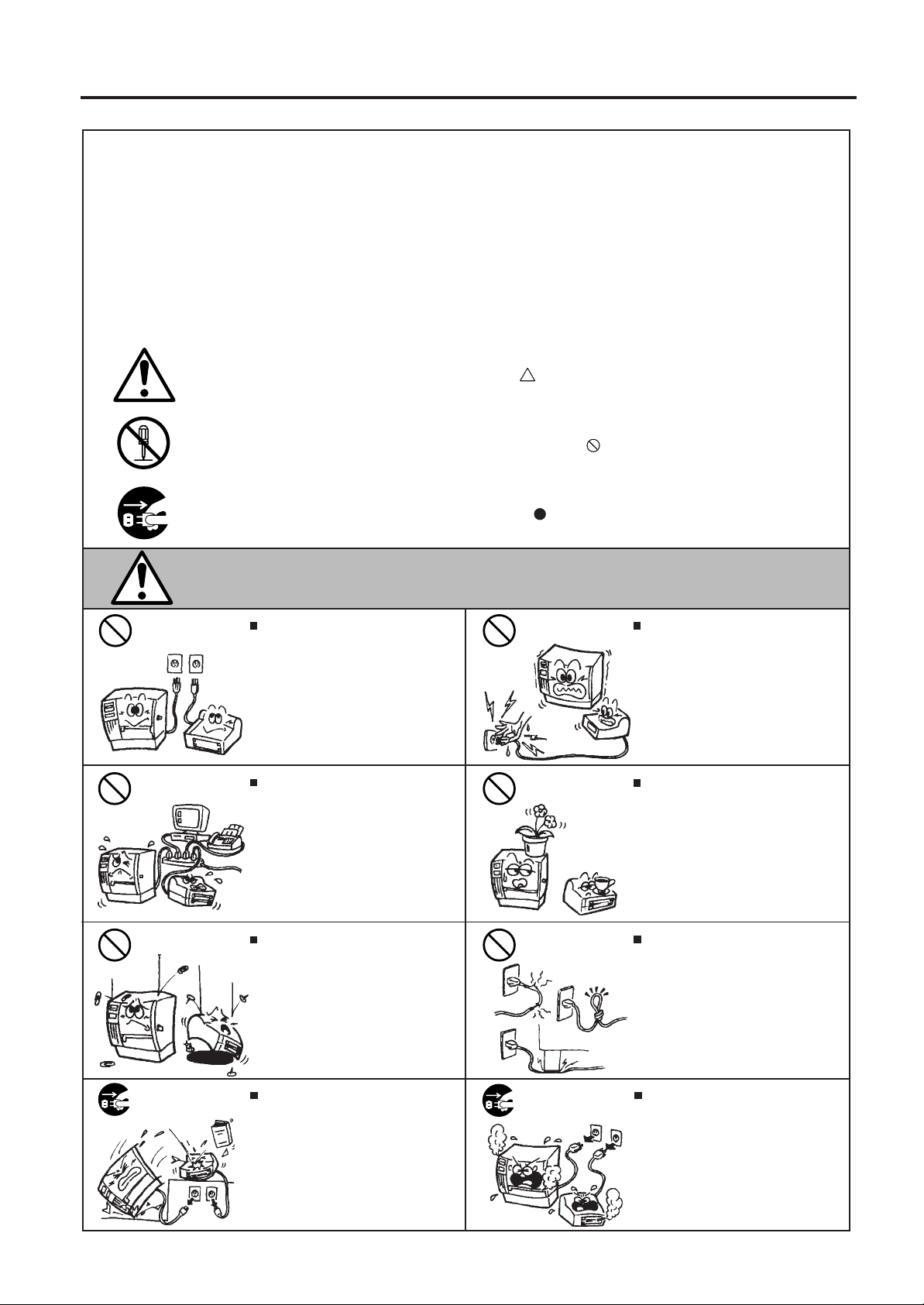

Safety Summary

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions

necessary for safe handling are included in this manual. All warnings and cautions contained in this

manual should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified

using the procedures described in this manual, turn off the power, unplug the machine, then contact your

authorized TOSHIBA TEC representative for assistance.

Meanings of Each Symbol

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the symbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the symbol.

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

EO1-33006

WARNING

Any other than the

specified AC voltage

is prohibited.

Prohibited

Prohibited

Do not use voltages other than the

voltage (AC) specified on the rating

plate, as this may cause fire or

electric shock.

If the machines share the same

outlet with any other electrical

appliances which consume large

amounts of power, the voltage will

fluctuate widely each time these

appliances operate. Be sure to

provide an exclusive outlet for the

machine as this may cause the

machines to malfunction.

Do not insert or drop metal,

flammable or other foreign objects into

the machines through the ventilation

slits, as this may cause fire or electric

shock.

This indicates that there is the risk of death or serious injury if the

machines are improperly handled contrary to this indication.

Prohibited

Prohibited

Prohibited

Do not plug in or unplug the power

cord plug with wet hands as this may

cause electric shock.

Do not place metal objects or

water-filled containers such as flower

vases, flower pots or mugs, etc. on

top of the machines. If metal objects

or spilled liquid enter the machines,

this may cause fire or electric

shock.

Do not scratch, damage or modify

the power cords. Also, do not place

heavy objects on, pull on, or excessively bend the cords, as this may

cause fire or electrical shock.

Disconnect

the plug.

If the machines are dropped or their

cabinets damaged, first turn off the

power switches and disconnect the

power cord plugs from the outlet, and

then contact your authorized

TOSHIBA TEC representative for

assistance. Continued use of the

machine in that condition may cause

fire or electric shock.

(i)

Disconnect

the plug.

Continued use of the machines in an

abnormal condition such as when the

machines are producing smoke or

strange smells may cause fire or elec-

tric shock. In these cases, immediately turn off the power switches and

disconnect the power cord plugs from

the outlet. Then, contact your authorized TOSHIBA TEC representative for

assistance.

Page 4

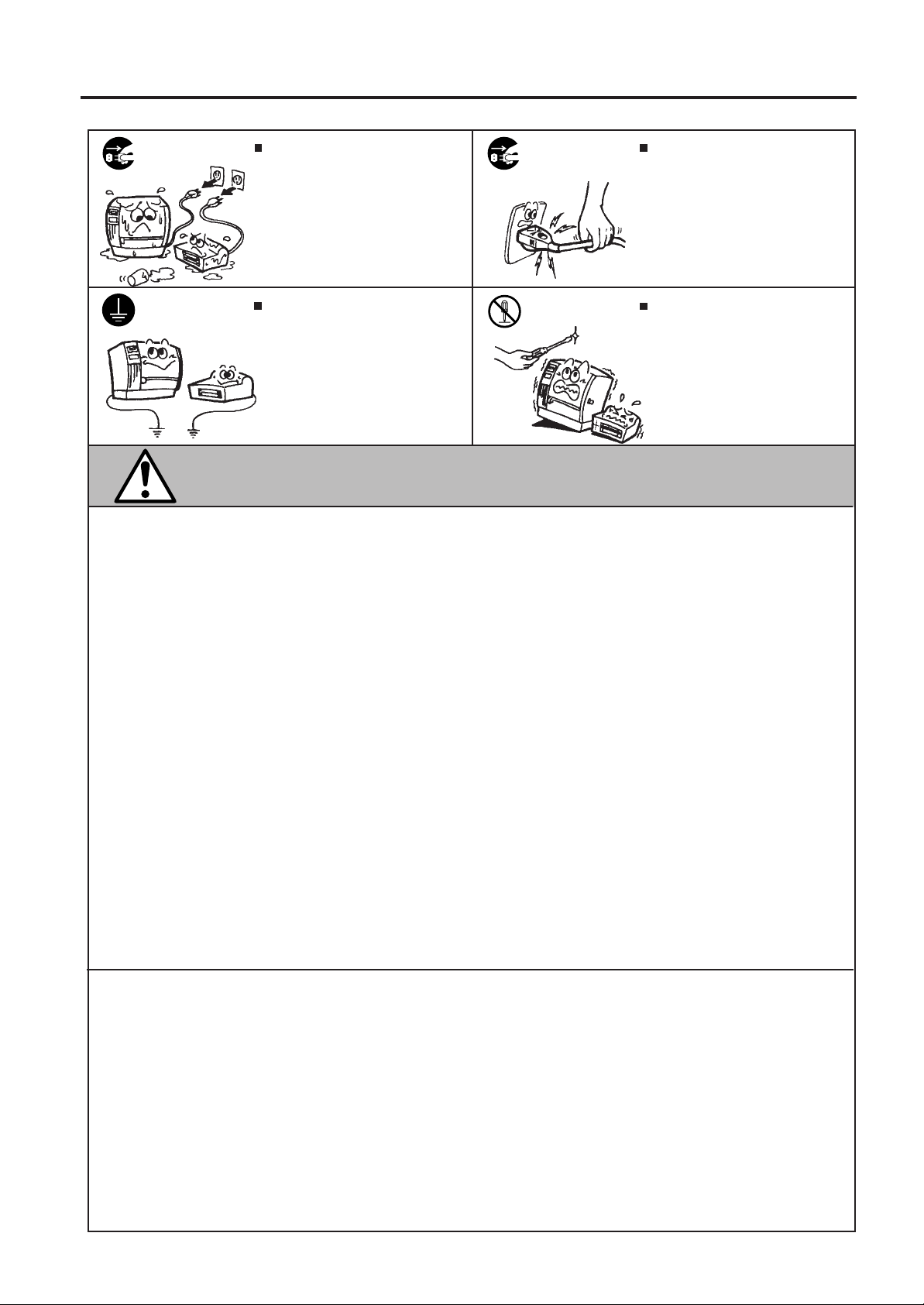

Safety Summary

EO1-33006

Disconnect

the plug.

Connect a

grounding

wire.

If foreign objects (metal fragments,

water, liquids) enter the machines,

first turn off the power switches and

disconnect the power cord plugs from

the outlet, and then contact your

authorized TOSHIBA TEC representative for assistance. Continued

use of the machine in that condition

may cause fire or electric shock.

Ensure that the equipment is

properly grounded. Extension cables

should also be grounded. Fire or

electric shock could occur on

improperly grounded equipment.

Disconnect

the plug.

No disassembling.

When unplugging the power cords,

be sure to hold and pull on the plug

portion. Pulling on the cord portion

may cut or expose the internal wires

and cause fire or electric shock.

Do not remove covers, repair or

modify the machine by yourself. You

may be injured by high voltage, very

hot parts or sharp edges inside the

machine.

This indicates that there is the risk of personal Injury or damage to

CAUTION

objects if the machines are improperly handled contrary to this indication.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

• Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power source * Excessive vibration * Dust/Gas

• The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild

detergent solution. NEVER USE THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic

covers.

• USE ONLY TOSHIBA TEC SPECIFIED paper and ribbons.

• DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high temperatures, high humidity, dust, or gas.

• Ensure the printer is operated on a level surface.

• Any data stored in the memory of the printer could be lost during a printer fault.

• Try to avoid using this equipment on the same power supply as high voltage equipment or equipment likely to cause mains interference.

• Unplug the machine whenever you are working inside it or cleaning it.

• Keep your work environment static free.

• Do not place heavy objects on top of the machines, as these items may become unbalanced and fall

causing injury.

• Do not block the ventilation slits of the machines, as this will cause heat to build up inside the

machines and may cause fire.

• Do not lean against the machine. It may fall on you and could cause injury.

• Care must be taken not to injure yourself with the printer paper cutter.

• Unplug the machine when it is not used for a long period of time.

Request Regarding Maintenance

• Utilize our maintenance services.

After purchasing the machine, contact your authorized TOSHIBA TEC representative for assistance

once a year to have the inside of the machine cleaned. Otherwise, dust will build up inside the

machines and may cause a fire or a malfunction. Cleaning is particularly effective before humid

rainy seasons.

• Our preventive maintenance service performs the periodic checks and other work required to

maintain the quality and performance of the machines, preventing accidents beforehand.

For details, please consult your authorized TOSHIBA TEC representative for assistance.

• Using insecticides and other chemicals

Do not expose the machines to insecticides or other volatile solvents. This will cause the cabinet or

other parts to deteriorate or cause the paint to peel.

(ii)

Page 5

TABLE OF CONTENTS

Page

1. INTRODUCTION ................................................................................................ 1- 1

1.1 APPLICABLE MODEL ................................................................................ 1- 1

1.2 ACCESSORIES .......................................................................................... 1- 1

2. SPECIFICATIONS.............................................................................................. 2- 1

2.1 GENERAL SPECIFICATIONS .................................................................... 2- 1

2.2 PRINTING SPECIFICATIONS .................................................................... 2- 1

2.3 PAPER (LABEL/TAG) SPECIFICATIONS .................................................. 2- 2

2.4 RIBBON SPECIFICATIONS ....................................................................... 2- 2

2.5 OPTION ...................................................................................................... 2- 2

3. APPEARANCE................................................................................................... 3- 1

3.1 FRONT/REAR VIEW................................................................................... 3- 1

3.2 OPERATION PANEL .................................................................................. 3- 1

4. DIP SWITCH FUNCTIONS................................................................................. 4- 1

5. SETUP PROCEDURE ........................................................................................ 5- 1

5.1 REQUIREMENTS FOR OPERATION ........................................................ 5- 1

5.2 SETTING UP THE PRINTER...................................................................... 5- 1

6. INSTALLATION PROCEDURE ......................................................................... 6- 1

6.1 INSTALLING THE SUPPLY HOLDER UNIT .............................................. 6- 1

6.2 CONNECTING THE POWER CORD AND CABLES.................................. 6- 1

7. LOADING THE RIBBON .................................................................................... 7- 1

8. LOADING THE PAPER...................................................................................... 8- 1

9. THRESHOLD SETTING..................................................................................... 9- 1

10.CARE/HANDLING OF THE PAPER AND RIBBON ........................................ 10- 1

11.GENERAL MAINTENANCE............................................................................. 11- 1

11.1CLEANING ................................................................................................ 11- 1

11.2COVERS ................................................................................................... 11- 2

11.3REMOVING JAMMED PAPER ................................................................. 11- 3

12.TROUBLESHOOTING ..................................................................................... 12- 1

APPENDIX............................................................................................................. 13- 1

INDEX

EO1-33006

CAUTION:

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA

TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorized Service representative with regard to any queries you may

have in this manual.

Page 6

1. INTRODUCTION

1.1 APPLICABLE MODEL

EO1-33006

1. INTRODUCTION

Thank you for choosing the TEC B-450 Series thermal/transfer printer. This new generation high

performance high quality printer is equipped with the latest hardware including the newly developed high

density (11.8 dot/mm, 300 dot/inch) print head. This allows very clear print at a maximum speed of 101.6

mm/sec. (4 inch/sec.). Other standard features include an external paper supply.

Optional features include a strip mechanism and cutter mechanism.

This manual contains general set-up and maintenance information and should be read carefully to help

gain maximum performance and life from your printer. For most queries please refer to this manual and

keep it safe for future reference.

1.1 APPLICABLE MODEL

• B-452-TS10-QQ • B-452-TS10-QQ-US

• B-452-TS11-QQ-PAC • B-452-TS11-US-PAC

Model name description

B - 4 5 2 - T S 1 0 - Q Q - P A C

Resolution

T: 11.8 dots/mm (300 dpi)

Thermal direct/Thermal transfer

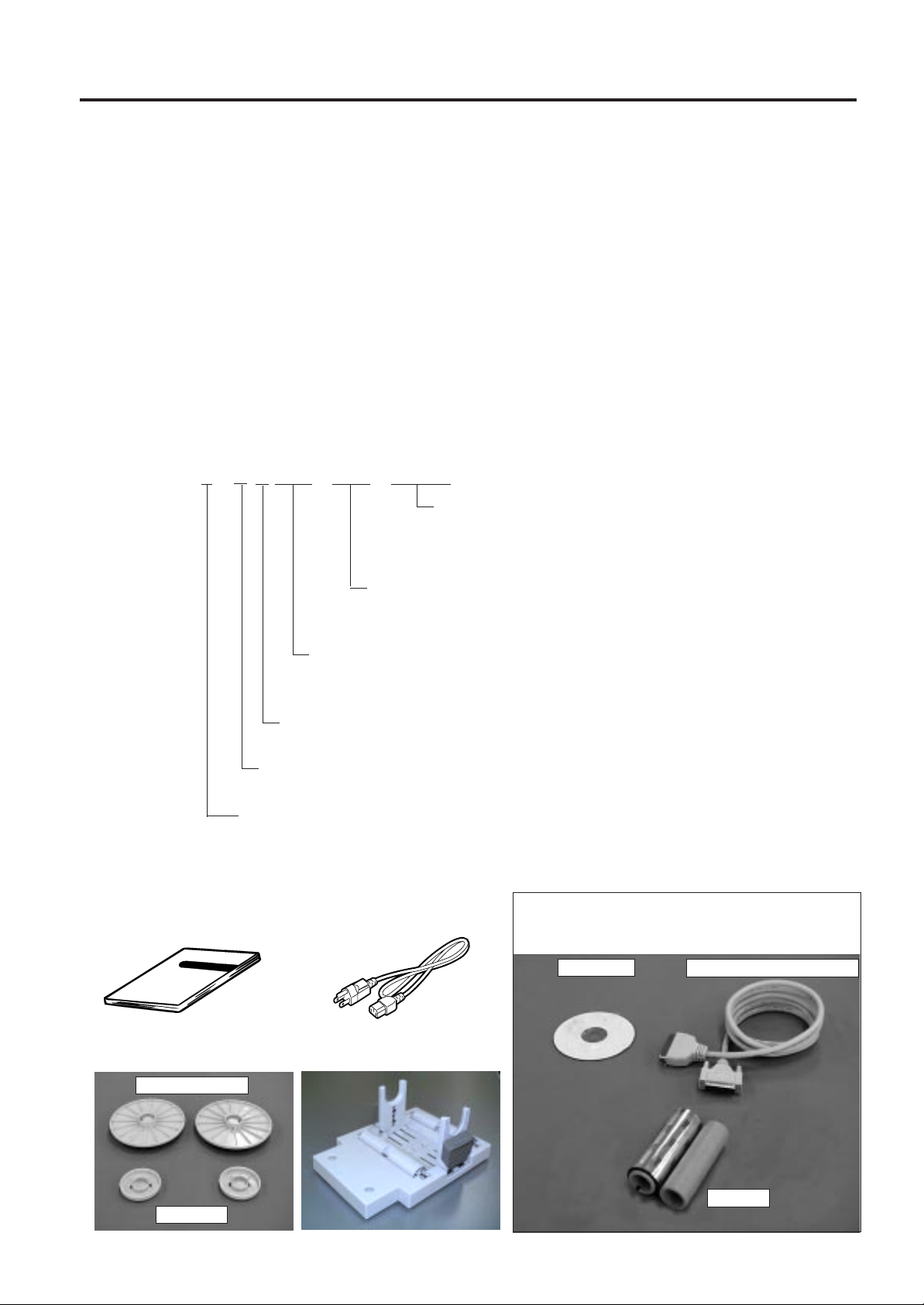

1.2 ACCESSORIES

Owner's Manual

(EO1-33006)

Special Code

US: North America Block

PAC: with a start up kit

No description: without a start up kit

Destination Code

QQ: Canada, Mexico, etc.

US: North America Block

Specification

10: without Centronics interface and expansion memory

11,12: with Centronics interface and expansion memory

Issue mode

S: Batch

Start Up Kit

Power Cord

The PAC model also includes the following

accessories.

Supply Holder

Spacer

Supply Holder Unit

1-1

CD-ROM

Parallel Interface Cable

Ribbon

Page 7

2. SPECIFICATIONS

2. SPECIFICATIONS

2.1 GENERAL SPECIFICATIONS

EO1-33006

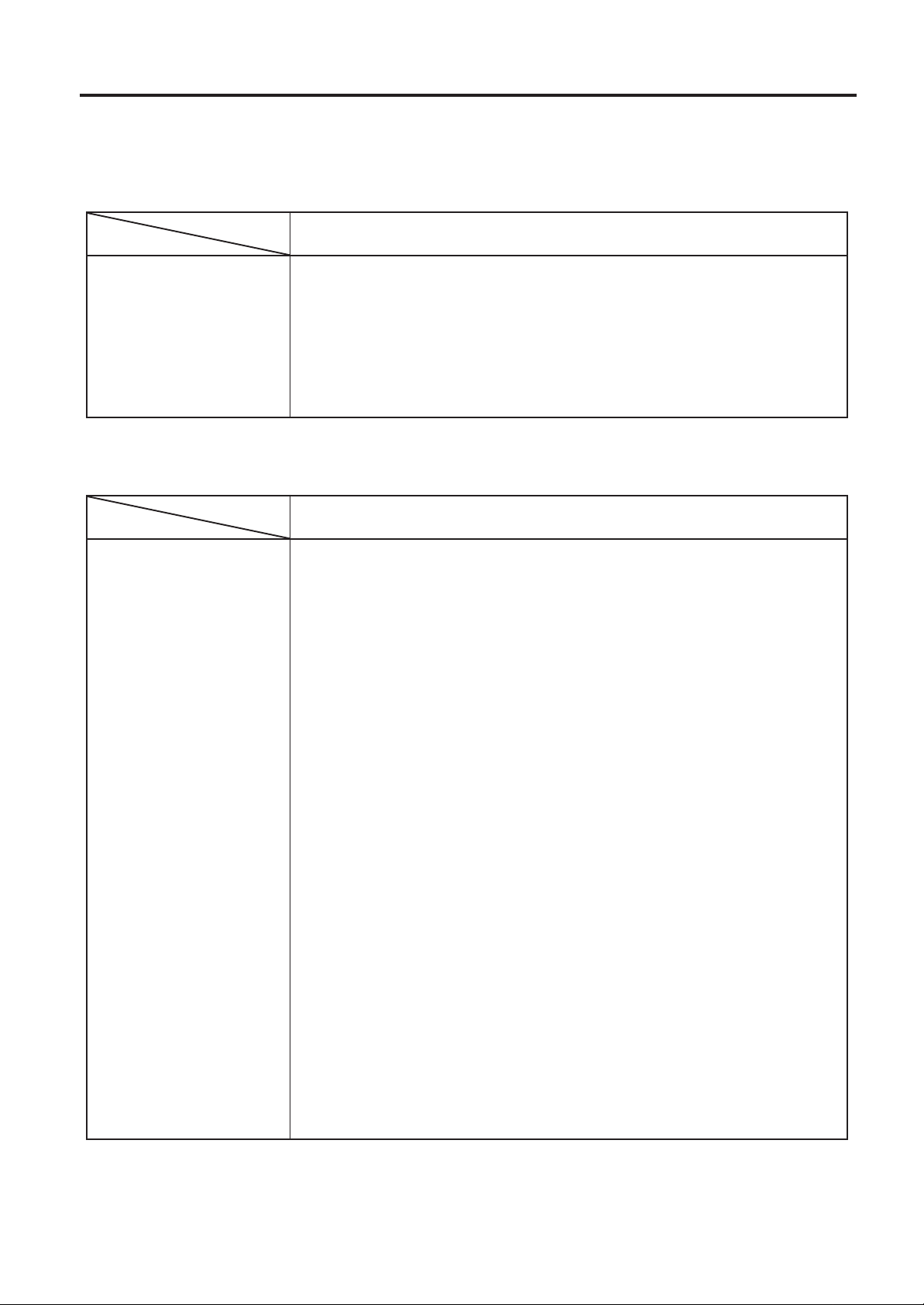

2.1 GENERAL SPECIFICATIONS

Model

Item

B-452-TS10-QQ

Supply voltage 100 ~ 120V, 60Hz

Power consumption 0.94 A, 47 W maximum (standby: 0.3 A, 18 W maximum)

Operating temperature 5˚C ~ 40˚C

Relative humidity 25% ~ 85%RH (no condensation)

Dimensions 270 mm (width) x 245 mm (height) x 200 mm (depth), with Supply holder

unit 410 mm (depth)

Weight 4.7 kg (without paper and ribbon)

2.2 PRINTING SPECIFICATIONS

Model

Item

Print head Thermal print head 11.8 dots per mm (300 dots per inch)

Printing methods Direct thermal or Thermal transfer

Print speeds 50.8 mm/sec. (2 inch/sec.) for serial barcodes and two-dimensional codes,

101.6 mm/sec. (4 inch/sec.)

Maximum print width 105.7 mm (4.16 inches)

Dispensing modes Batch (Continuous), Strip (Option) and Cut modes (Option)

(Both cut and strip modes are available only when their respective modules

are fitted.)

Available bar-code types JAN8, JAN13, EAN8, EAN8 + 2 digits, EAN8 + 5 digits

EAN13, EAN13 + 2digits, EAN13 + 5 digits

UPC-E, UPC-E + 2 digits, UPC-E + 5 digits

UPC-A, UPC-A + 2 digits, UPC-A + 5 digits

MSI, ITF, NW-7, CODE39, CODE93, CODE128

Industrial 2 to 5, UCC/EAN128, Customer bar code, POSTNET

RM4SCC, KIX code

Two-dimensional code Data Matrix, PDF417, QR code, Maxi code

Graphics All types of graphic files are available when using the windows driver.

However, only BMP and PCX files are available when using the program-

ming commands.

Fonts Times Roman (6 sizes), Helvetica (6 sizes), Presentation (1 size),

Letter Gothic (1 size), Prestige Elite (2 sizes), Courier (2 sizes),

OCR (2 types), Writable characters, Outline font (7 type)

Optional Ture Type Fonts (20 type)

Rotations 0˚, 90˚, 180˚, 270˚

Standard interfaces Serial interface (RS-232C)

Optional parallel interface (Centronics)

Optional keyboard interface

B-452-TS10-QQ

∗

Data MatrixTM is a trademark of International Data Matrix, Inc.

PDF417 is a trademark of Symbol Technologies, Inc.

QR code is a trademark of DENSO CORPORATION.

Maxi code is a trademark of United Parcel Service of America, Inc.

2-1

Page 8

2. SPECIFICATIONS

EO1-33006

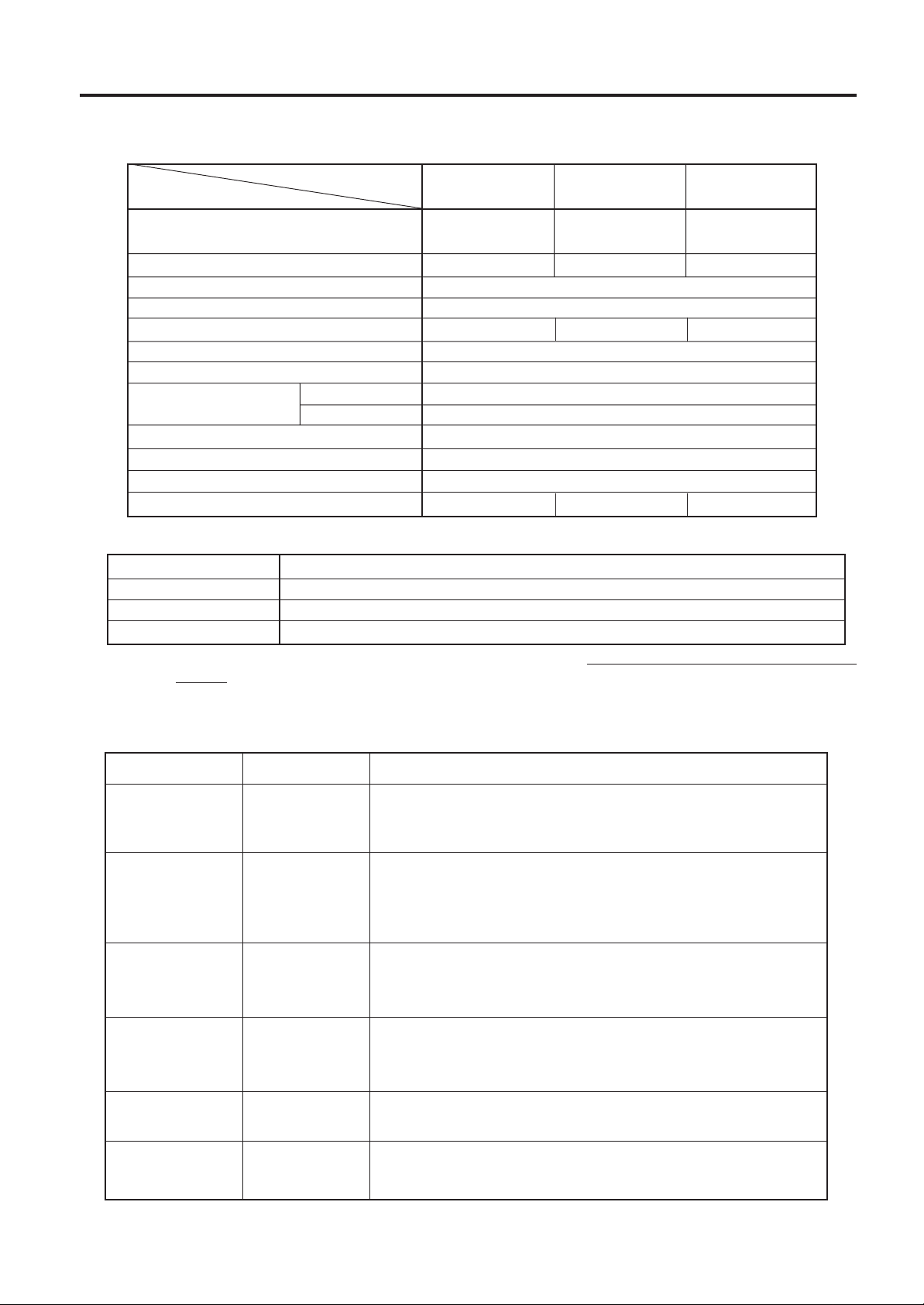

2.3 PAPER (LABEL/TAG) SPECIFICATIONS

2.3 PAPER (LABEL/TAG) SPECIFICATIONS

Label dispensing mode

Item

Span of one label/tag

Label length

Width including backing paper

Label width

Gap length

Black mark length (Tag paper)

Effective print width

Effective print length

Label

Tag

Print speed up/slow down area

Black mark length (Label)

Outer roll diameter

Thickness

2.4

RIBBON SPECIFICATIONS

Type Spool type

Width 60 mm ~ 110 mm

Length (300 m)

Outer diameter Ø65 mm (max.)

Batch mode

15.0 ~ 999.0

13.0 ~ 997.0

2.0 ~ 20.0

MAX. ø152.4 (Paper Core ø38, 40, 42 or 76.2)

0.1 ~ 0.17

[Unit: mm]

Strip mode Cut mode

25.4 ~ 999.0

23.4 ~ 997.0

Label: 37.0 ~ 999.0

Tag: 25.4 ~ 999.0

31.0 ~ 993.0

25.4 ~ 114.0

22.4 ~ 111.0

2.0 ~ 20.0

6.0 ~ 20.0

2.0 ~ 20.0

10.0 ~ 105.7

15.0 ~ 500.0

15.0 ~ 500.0

1.0

MIN. 2.0

0.13 ~ 0.17

0.1 ~ 0.17

NOTES: 1. To ensure good print quality and maximum print head life use only TOSHIBA TEC specified paper and

ribbons.

2. For further information about paper and ribbon, refer to Section 10. CARE/HANDLING OF THE PAPER

AND RIBBON.

2.5 OPTION

Option Name

Cutter module

Strip module

Programmable

Keyboard

module

Expansion I/O

interface board

Centronics

interface board

Type

B-7204-QM

B-7904-H-QM

KB-80-QM

B-7704-IO-QM

B-7704-C-QM

This cutter module uses a rotary cutter. It cuts backing

paper of labels and tag paper automatically in "stop and

cut" mode.

This strip module strips the label from the backing paper

with the take-up block and strip block. When the

rewinder guide plate is attached, the tag paper and label

with backing paper are wound.

This module is an external intelligent keyboard unit.

Installing this board in the printer allows a connection with

an external device with the exclusive interface, such as

the Keyboard module.

Installing this board in the printer allows a connection with

a PC by the Centronics parallel interface.

Use

LAN I/F Board

(TS model only)

B-7704-LANQM

This board enables the printer to be used in a LAN

network by using the command language.

NOTE: To purchase the OPTIONAL KIT, please contact your authorized TOSHIBA TEC represen-

tative or TOSHIBA TEC Head Quarter.

2-2

Page 9

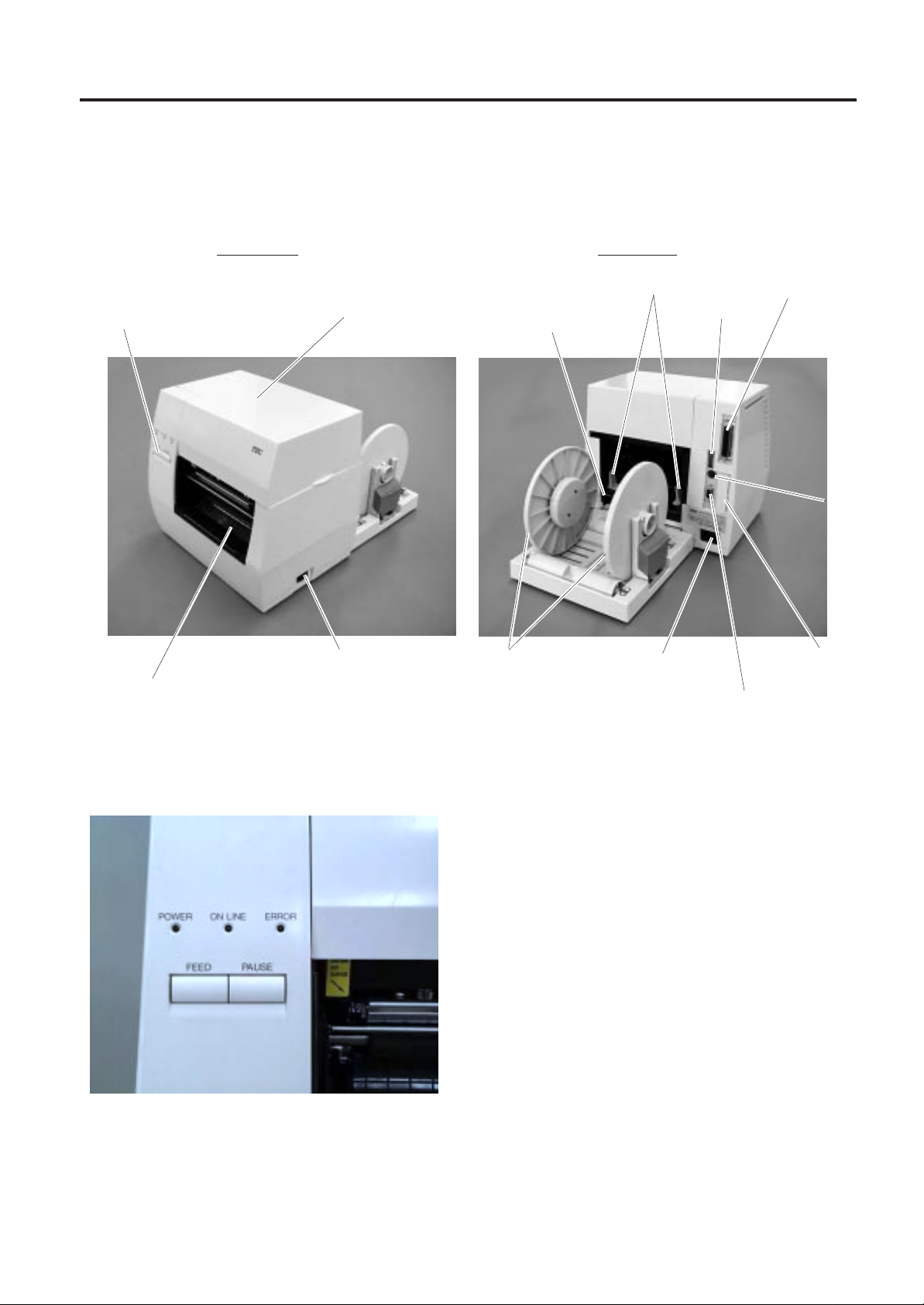

3. APPEARANCE

3. APPEARANCE

3.1 FRONT/REAR VIEW

EO1-33006

3.1 FRONT/REAR VIEW

Operation Panel

Paper Outlet

Front View Rear View

Paper Guide

Top Cover

Paper Guide Lock Lever

Power Switch

O : OFF

I:ON

Supply Holder

AC Power Inlet

Fig. 3-1

Optional parallel

Interface Connector

(Centronics)

DIP Switch

Optional

Keyboard

Connector

Optional LAN

Interface Connector

Serial Interface Connector (RS-232C)

3.2 OPERATION PANEL

Fig. 3-2

POWER LED (Green)

Lights when the power is turned on.

ON-LINE LED (Green)

1) Flashes when communicating with a host computer.

2) On while printing.

ERROR LED (Red)

Lights when a communication error occurs, when the

paper/ribbon ends or the printer is not operating correctly.

FEED Key

Feeds paper.

PAUSE Key

Pauses printing.

Resets the printer when paused or when an error

occurs.

3-1

Page 10

4. DIP SWITCH FUNCTIONS

4. DIP SWITCH FUNCTIONS

The DIP switches are located at the rear of the printer.

WARNING!

Turn the POWER OFF before

changing the DIP switches.

DIP SW

EO1-33006

4. DIP SWITCH FUNCTIONS

Fig. 4-1

DIP SW

No.

1

2

3

4

5

6

7

8

ON/OFF

1

OFF

ON

OFF

ON

6

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

2

OFF

OFF

ON

ON

7

OFF

OFF

ON

ON

Function

2400 bps

4800 bps

9600 bps

19200 bps

None

EVEN

Not available

Available

Available

Not available

RAM clear mode (Maintenance counter)

Threshold manual setting mode

Sensor adjustment mode

RAM clear mode (Parameter)

Normal operation mode

Program down load operation

Remarks

Transmission speed

(Baud rate)

Parity

Stacker

Auto media feed

Selectable only when

DIP SW #8 is ON.

Operating mode

NOTES: 1. DIP Switch settings are read at power on time.

2. To enter the program download mode first set DIP SW #8 to ON. The printer will then enter

the relevant modes, as selected by DIP SWS #6 and #7. To initialize these modes hold

down the [FEED] or [FEED] and [PAUSE]

keys whilst turning the power on. If the printer

is turned on without pressing a key, it will enter the program download mode.

Do not set the switches to the maintenance mode as this may cause a failure.

3. When DIP SW#8 is set to OFF, the backing paper thickness setting can be changed by

the following combination of DIPSWs #6 and #7.

No.6

OFF

ON

No.7

OFF

OFF

Thickness of Backing Paper

70µm Thin Backing Paper

80µm Thick Backing Paper

4-1

Page 11

5. SET UP PROCEDURE

5.1 REQUIREMENTS FOR OPERATION

EO1-33006

5. SET UP PROCEDURE

5.1 REQUIREMENTS FOR OPERATION

This machine has the following requirements:

• The host computer must have a serial port or centronics parallel port.

• To communicate with host, either an RS-232C cable or Centronics cable is required.

(1) RS-232C cable..........9 pins

(2) Centronics cable .......36 pins

• To print a label format, create the complete program using the interface/communication manual.

■ Interface Cables

To prevent radiation and reception of electrical noise, the interface cables must meet the following

requirements:

• Fully shielded and fitted with metal or metalized connector housings.

• Kept as short as possible.

• Should not be bundled tightly with power cords.

• Should not be tied to power line conduits.

■ RS-232C Cable description

The serial data cable used to connect the printer to the host computer should be one of the following two

types:

NOTE:Use an RS-232C cable with imperial (inch) connector securing screws.

DB-9S

Connector to PC

PIN No.

1

2

3

4

5

6

7

8

9

Housing

Signal

N.C.

RXD

TXD

DTR

GND

DSR

RTS

CTS

N.C.

Shield

DB-25S

Connector to PC

PIN No.

1

2

3

4

5

6

7

20

Signal

Shield

TXD

RXD

RTS

CTS

DSR

GND

DTR

Connector to Printer

DB-9P

PIN No.

1

2

3

4

5

6

7

8

9

Housing

Signal

N.C.

TXD

RXD

DSR

GND

DTR

CTS

RTS

N.C.

Shield

DB-9P

Connector to Printer

PIN No.

1

2

3

4

5

6

7

8

9

Signal

N.C.

TXD

RXD

DSR

GND

DTR

CTS

RTS

N.C.

Fig. 5-1

5.2 SETTING UP THE PRINTER

• Place the printer on a flat, stable surface.

• Use a grounded electrical outlet do not use adapter plug.

• Be sure there is adequate room around the printer for easy operation and maintenance.

• Keep your work environment static free.

5-1

Page 12

6. INSTALLATION PROCEDURE

6.1 INSTALLING THE SUPPLY HOLDER UNIT

6. INSTALLATION PROCEDURE

6.1 INSTALLING THE SUPPLY HOLDER UNIT

WARNING!

Turn the power OFF before installing the supply holder unit.

Fit the two studs on the bottom of the printer into the holes in the supply holder unit.

EO1-33006

Supply Holder Unit

6.2 CONNECTING THE POWER CORD AND CABLES

WARNING!

Turn the POWER SWITCH to OFF before connecting the power cord or cables.

Fig. 6-1

Parallel Interface Cable

(Centronics)

Power Cord

6-1

Serial Interface Cable

(RS-232C)

Fig. 6-2

Page 13

7. LOADING THE RIBBON

7. LOADING THE RIBBON

7. LOADING THE RIBBON

The printer is capable of printing in both direct thermal and thermal transfer modes.

DO NOT LOAD a ribbon when using a direct thermal paper.

1. Turn the power off and open the top cover.

2. Move the head release lever toward the front of the printer and raise the print head block.

EO1-33006

Top Cover

Print Head Block

Head Release Lever

3. Fit the protrusion of the guide wheel into the notch of the ribbon core (take-up side).

Fig. 7-1

4. Pull the knob and set the ribbon core to the spring guide wheel.

Knob

Spring Guide Wheel

Ribbon Core

(Take-up side)

Guide Wheel

Protrusion

Notch

Fig. 7-2

7-1

Page 14

7. LOADING THE RIBBON

5. Set the ribbon core (supply side) by fitting the protrusion into the notch.

EO1-33006

7. LOADING THE RIBBON

Fig. 7-3

6. Turn the guide wheel in the arrow-indicating direction to remove any slack of the ribbon.

NOTE: Make sure that the ribbon has no wrinkles and the protrusions are fitted into the notches of the

ribbon cores.

Guide Wheel

7-2

Fig. 7-4

Page 15

8. LOADING THE PAPER

8. LOADING THE PAPER

EO1-33006

8. LOADING THE PAPER

This supply holder accepts four sizes of label core: 38 mm, 40 mm, 42 mm and 76.2 mm.

When using a paper roll of 38 mm, 40 mm or 42 mm, remove the spacers from the supply holders

using the following procedure.

1. Push both hooks of the spacer to remove it from the supply holder. Keep the removed spacers safe.

Supply Holder

Hook

Spacer

2. Set the supply holders to both sides of the paper roll.

Fig. 8-1

Fig. 8-2

Supply Holder

Paper Roll

Fig. 8-3

8-1

Page 16

8. LOADING THE PAPER

8. LOADING THE PAPER

EO1-33006

3. Put the paper roll and supply holders on the supply holder unit.

NOTE: Paper may be wound outside or inside. Regardless of the paper roll, the paper must be loaded

so that the print side faces upward.

Paper wound inside.

Paper wound outside.

Fig. 8-4

4. Push both sides of the supply holder guides against the paper roll, then lock them with the lock lever.

NOTE: Make sure that the supply holders rotate slightly.

5. Pass the paper through the printer until it is past the paper outlet.

6. Adjust the position of the paper guides to the paper width, then lock them with the lock lever.

Paper Guide

Paper Roll

Supply Holder

Paper Guide Lock Lever

Supply Holder Guide

Fig. 8-5

Lock Lever

7. Close the print head block by pressing both sides of the print head block’s top until it clicks.

Head Block

8-2

Fig. 8-6

Page 17

8. LOADING THE PAPER

8. LOADING THE PAPER

EO1-33006

NOTE: Pass the paper straight from the supply holder to paper outlet. Failure to do this may cause

skew feeding or paper jam.

Platen

A

.

A = B

.

B

8. Close the top cover. Paper loading is now completed.

Batch type:

Paper GuidePaper

Supply Holder

Fig. 8-7

Top Cover

Fig. 8-8

Cutter type: Where a cutter is fitted load the paper as standard and feed it through the cutter module.

NOTES: 1. When using the cutter, be sure to cut the backing paper between the labels. Cutting

on the label will cause the glue to stick to the cutter, which may affect the cutter quality

and shorten it's life.

2. Use of tag paper that exceeds the specified thickness may affect the cutter life.

Cutter Module

Paper Outlet

Paper

Fig. 8-9

8-3

Page 18

8. LOADING THE PAPER

8. LOADING THE PAPER

EO1-33006

Strip type:

1 Strip the labels from the backing paper for about 200-mm long from the top edge of the label roll.

2 First push the strip lever toward the printer to release the hook, and then pull the strip lever.

3 Pass the backing paper between the strip roller and the strip guide roller. After taking up any slack of

the paper, set the strip lever in position.

Strip Lever

Strip Guide Roller

Backing Paper

Fig. 8-10

8-4

Page 19

9. THRESHOLD SETTING

9. THRESHOLD SETTING

EO1-33006

9. THRESHOLD SETTING

For the printer to maintain a constant print position it uses the transmissive sensor to measure the amount

of light passing through the gap between labels. When the paper is pre-printed, the darker (or more

dense) inks can interfere with this process causing paper jam errors. To eliminate this problem a

minimum threshold can be set for the sensor in the following way.

Power OFF

DIPSW

6

ON

7

OFF

8

ON

[FEED]

Power ON

Power Online Error

[FEED]

Power Online Error

[PAUSE]

Power Online Error

(1) The power is off.

(2) Set the DIP switches to enter the manual threshold

setting mode.

(3) Turn the power ON while pressing and holding the

[FEED] key.

The transmissive sensor is selected.

(4) Press the [FEED] key.

The reflective sensor is selected.

The sensor type is switched by pressing the [FEED]

key. Load the pre-printed label roll in the usual way.

(5) Press and hold the [PAUSE] key.

The paper will feed through the printer until the

[PAUSE] key is released. Release the [PAUSE]

key after more than 1.5 labels have been fed.

(Threshold setting is completed by this operation.)

(6) Turn the power OFF.

: ON

: OFF

: BLINK

NOTES: 1. To set the threshold properly, be sure to feed more than 1.5 labels. Insufficient paper feeding

may result in an incorrect threshold setting. In this case, repeat the procedure.

2. While the print head is raised, the [PAUSE] key does not work.

3. If the paper runs out or a cutter error occurs, it will not be detected during the paper feed.

4. If the printer does not print in the correct position even after the threshold setting, the

transmissive sensor adjustment may be wrong. In this case, re-adjust the transmissive

sensor, and then set the threshold again. (When the backing paper is thick, the transmissive

sensor adjustment is required.)

9-1

Page 20

10. CARE/HANDLING OF THE PAPER AND RIBBON

10. CARE/HANDLING OF THE PAPER AND RIBBON

EO1-33006

10. CARE/HANDLING OF THE PAPER AND RIBBON

CAUTION:

Be sure to read carefully and understand the Supply Manual. Ask your nearest authorized TOSHIBA

TEC representative for the Supply Manual. Use only paper and ribbon which meet specified

requirements. Use of non-specified paper and ribbon may shorten the head life and result in problems

with bar code readability or print quality. All paper and ribbon should be handled with care to avoid any

damage to the paper, ribbon or printer. Read the following guideline carefully.

• Do not store the paper and ribbon for longer than the manufactures recommended shelf life.

• Store paper rolls on the flat end, do not store them on the curved sides as this might flatten that side

causing erratic media advance and poor print quality.

• Store the paper in plastic bags and always reseal after opening. Unprotected paper can get dirty and

the extra abrasion from the dust and dirt particles will shorten the print head life.

• Store the paper and ribbon in a cool, dry place. Avoid areas where they would be exposed to direct

sunlight, high temperature, high humidity, dust or gas.

• The thermal paper used for direct thermal printing must not have the specifications which exceed Na

800 ppm, K+ 250 ppm and CL- 500 ppm.

+

• Some ink used on pre-printed labels may contain ingredients which shorten the print head’s product

life. Do not use labels pre-printed with ink which contain hard substances such as carbonic calcium

(CaCO

) and kaolin (Al2O3, 2SiO2, 2H2O).

3

For further information please contact your local distributor or your paper and ribbon manufacturer.

10-1

Page 21

11. GENERAL MAINTENANCE

EO1-33006

11.1 CLEANING

11. GENERAL MAINTENANCE

WARNING!

Be careful when handling the print head as it becomes very hot.

11.1 CLEANING

WARNING!

1. Be sure to disconnect the power cord prior to performing any maintenance.

2. DO NOT POUR WATER directly onto the printer.

CAUTION:

1. Do not use any sharp objects to clean the print head and platen. Doing so may damage them,

causing poor print quality or missing dots.

2. Never use a organic solvents like thinners or venzene for cleaning. Using such solvents may

discolor the covers, cause poor print quality, or printer failure.

3. Do not touch the print head element as static build-up may damage the print head.

To help retain the high quality and performance of your printer it should be regularly cleaned. The greater

the usage of the printer, the more frequent the cleaning. (i.e. low usage=weekly : high usage=daily).

1. Turn the power off.

2. Open the top cover.

3. Turn the head lever to raise the print head.

4. Remove the ribbon and paper.

5. Clean the print head element with print head cleaner

NOTE: Please purchase the print head cleaner from the authorized TOSHIBA TEC service

representative.

Print Head Cleaner

(24089500013)

Print Head (Thermal Element)

11-1

Fig. 11-1

Page 22

11. GENERAL MAINTENANCE

EO1-33006

11.2 COVERS

6. Clean the platen with a cloth moistened with alcohol.

7. Remove any dust or glue from the detection area of the sensors and paper path with a soft cloth.

Platen

Black mark/Feed gap sensor

Fig. 11-2

8. Remove the supply holder rollers from the supply holder unit. Remove any dust from the recessed

portions of the base and wipe glues from the rollers with a slightly moistened soft cloth.

Recessed portion of the base

Supply Holder Roller

Supply Holder Base

Fig. 11-3

11.2 COVERS

The covers should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild detergent

solution.

NOTE: Clean printer cover with an electrostatic free cleaner for automated office equipment.

WARNING!

1. DO NOT POUR WATER directly onto the printer.

2. DO NOT APPLY cleaner or detergent directly onto any cover.

3. NEVER USE THINNER OR OTHER VOLATILE SOLVENT on the plastic covers.

4. DO NOT clean the covers with alcohol as it may cause them to discolor, loose their shape or develop

structural weakness.

11-2

Page 23

11. GENERAL MAINTENANCE

11.3 REMOVING JAMMED PAPER

EO1-33006

11.3 REMOVING JAMMED PAPER

1. Turn the power off.

2. Open the top cover.

3. Move the head release lever toward the front of the printer to raise the print head block.

4. Remove the ribbon and paper.

5. Remove the jammed paper. DO NOT USE any sharp implement or tool as these could damage the

printer.

6. Clean the print head and platen, then remove any further dust or foreign substances.

Top Cover

Print Head Block

Head Release Lever

Fig. 11-4

7. Paper jams in the cutter unit can be caused by wear or residual glue from label stock on the cutter. Do

not use unspecified paper in the cutter. If frequent jams occur in the cutter contact your Authorized

Service representative.

■ Cleaning the Cutter Unit

WARNING!

1. Be sure to disconnect the power cord before cleaning the cutter unit.

2. The cutters are sharp and care should be taken not to injure yourself when cleaning.

1. Press the cutter cover release lever to detach the cutter cover.

Cutter Cover

Release Lever

Cutter Cover

11-3

Fig. 11-5

Page 24

11. GENERAL MAINTENANCE

11.3 REMOVING JAMMED PAPER

2. Fit the enclosed Allen Key into the right side of the cutter unit to rotate the cutter manually. Remove

the jammed paper and any paper particles from the cutter.

3. Clean the cutter with dry cloth.

Allen Key

Cutter

EO1-33006

Fig. 11-6

4. Assembling is reverse order of removal.

■ Cleaning the Strip Unit

WARNING!

1. Be sure to disconnect the power cord before cleaning the strip unit.

2. Do not touch the moving parts. To reduce the risk that fingers, jewelry, clothing, etc., be drawn into

the moving parts, push the switch in the "OFF" position to stop movement.

1. First push the strip lever toward the printer to release the hook, and then pull the strip lever.

2. Remove the jammed paper, if any.

3. Clean the strip guide rollers A and B with a cloth moistened with alcohol.

Strip Guide Roller B

Strip Lever

Strip Guide Roller A

Fig. 11-7

11-4

Page 25

12. TROUBLESHOOTING

12. TROUBLESHOOTING

EO1-33006

12. TROUBLESHOOTING

WARNING!

If you cannot solve a problem with the following solutions, do not attempt to repair it yourself. Turn the

power off, unplug the printer, then contact your TOSHIBA TEC representative for assistance.

If the error lamp lights during printing, refer to the following troubleshooting to solve the problem.

Error type

PAPER JAM

Problem

1. The paper is not fitted correctly.

2. The paper path is jammed and does not

feed smoothly.

3. The installed paper type does not match

the selected sensor.

4. The installed paper size is different from

the programmed size.

5. The feed gap sensor cannot see the

difference between the print area and

the gap.

Solution

1. Reload the paper correctly.

→ Press the [PAUSE] key.

2. Remove the cause of the jam and

replace the paper correctly.

→ Press the [PAUSE] key.

3. Turn the power off then on again.

Select the correct sensor.

→ Feed the paper.

4. Turn the power off then on again.

Set the correct paper size.

→ Feed the paper.

5. Set the threshold (see page 9-1).

Else

Turn the power off and call your

Authorized Service representative.

HEAD OPEN

NO PAPER

EXCESS HEAD

TEMP.

RIBBON ERROR

Feeding or printing has been attempted

while the print head is raised.

The paper has run out.

The print head is too hot.

1. The ribbon has run out.

2. There is a fault with the ribbon sensor.

Lower the print head block.

→ Press the [PAUSE] key.

Load new paper.

→ Press the [PAUSE] key.

Turn the power off and decrease the

print head temperature.

1. Load a new ribbon.

→ Press the [PAUSE] key.

2. Turn the power off and contact

your Authorized Service representative.

12-1

Page 26

12. TROUBLESHOOTING

EO1-33006

12. TROUBLESHOOTING

Error type

CUTTER ERROR

Problem

Paper is jammed in the cutter.

Remove the jammed paper and feed

Solution

the undamaged media through the

cutter (See page 11-3).

→ Press the [PAUSE] key.

Else

Turn the power off and contact your

Authorized Service representative.

Other Error

Hardware or software trouble.

Turn the power off then on again. If

the problem still exists turn the power

off and contact your Authorized Service representative.

NOTE: If an error cannot be cleared by pressing the [PAUSE] key, the power must be switched off

then on again.

Once the power has been switched off and on, all the print data in the printer is cleared.

Problem

No print.

Dots missing in the

print.

Unclear (or blurred)

printing.

Power does not come

on.

Printer does not cut.

Solution

1. Check that the paper and ribbon are loaded correctly.

2. Check that print head is set correctly.

3. Check the cabling between the printer and the host.

Dirty print head. → Clean the print head.

Call your Authorized Service representative if necessary.

1. Dirty print head. → Clean the print head.

2. Bad or faulty ribbon. → Replace ribbon.

3. Poor paper quality. → Change paper type.

1. Plug power cord into an AC socket.

2. Check the circuit breakers or fuses.

3. Plug another appliance into the AC socket to check if there is power

supplied.

Call your Authorized Service representative if necessary.

Check for a paper jam in the cutter.

Call your Authorized Service representative if necessary.

You see a raised nap

where the paper has

been cut.

1. Clean the cutter blades.

2. The blades are worn.

→ Call your Authorized Service representative.

12-2

Page 27

APPENDIX

APPENDIX

■ ASCII Code Chart

EO1-33006

APPENDIX

■ Font Sample

■ Barcode Sample

13-1

Page 28

INDEX

A

AC Power inlet........................................ 3-1

Auto media feed ..................................... 4-1

B

Bar code types ....................................... 2-1

C

Cleaning ............................................... 11-1

D

DIP switch ....................................... 3-1, 4-1

F

Fonts ...................................................... 2-1

I

Interface .......................................... 1-1, 2-1

Centronics cable ............................... 5-1

Parallel interface ............................... 2-1

RS-232C cable description ............... 5-1

Serial interface.................................. 2-1

Serial interface cable ........................ 6-1

Serial interface connector ................. 3-1

Issue mode............................................. 1-1

J

Jammed paper ..................................... 11-3

L

Label length............................................ 2-2

Label width ............................................. 2-2

O

Operation panel...................................... 3-1

ERROR LED..................................... 3-1

FEED key.......................................... 3-1

ON-LINE LED ................................... 3-1

PAUSE key ....................................... 3-1

POWER LED .................................... 3-1

Option..................................................... 2-2

Cutter .............................................. 11-4

Cutter module ............................ 2-2, 8-3

Expansion I/O interface board .......... 2-2

Keyboard module.............................. 2-2

Strip mechanism ............................... 1-1

Strip module...................................... 2-2

EO1-33006

INDEX

INDEX

P

Paper............................................. 2-2, 10-1

Paper jam ............................................. 12-1

Power consumption................................ 2-1

Power cord ...................................... 1-1, 6-1

Power switch .......................................... 3-1

Print head ...............................1-1, 2-1, 11-1

Print head cleaner ................................ 11-1

Print length ............................................. 2-2

Print speed ............................................. 2-1

Print width............................................... 2-2

Printing method ...................................... 2-1

Program down load operation ................ 4-1

R

Relative humidity .................................... 2-1

Resolution .............................................. 1-1

Ribbon ....................................2-2, 7-1, 10-1

S

Sensor

Black mark sensor .......................... 11-2

Feed gap sensor............................. 11-2

Sensor adjustment mode.................. 4-1

Specifications ......................................... 2-1

Stacker ................................................... 4-1

Supply holder ...........................1-1, 3-1, 8-1

Supply holder unit.....................1-1, 2-1, 6-1

Supply voltage........................................ 2-1

T

Thermal print head ................................. 2-1

Thermal transfer .............................. 1-1, 2-1

Threshold manual setting mode ............. 4-1

Threshold setting.................................... 9-1

Transmission speed ............................... 4-1

Troubleshooting.................................... 12-1

Two-dimensional code ........................... 2-1

W

Weight .................................................... 2-1

14-1

Page 29

Page 30

PRINTED IN JAPAN

E

EO1-33006

Loading...

Loading...