Page 1

TEC Bar Code Printer

B-411 SERIES

Owner’s Manual

TEC

TcncYO fEUBCTfUia ca.,LTO

Page 2

Page 3

TABLE OF CONTENTS

Page

INTRODUCTION ............................................................................................................................. 1

PRECAUTIONS.............................................................................................................................. 1

APPLICABLE MODEL .................................................................................................................... 1

1. SPECIFICATIONS ........................................................................................................................... 2

1.1 PRINTER ............................................................................................................................... 2

1.2 PAPERS ................................................................................................................................ 2

1.3 INTERFACE ........................................................................................................................ 2

1.4 BATTERY CHARGER.......................................................................................................... 3

EM 1-33017

1.5 DIMENSIONS ........................................................................................................................ 3

2. OVERVIEW .................................................................................................................................... 4

2.1 FRONT VIEW ....................................................................................................................... 4

2.2 REARVIE\^ ............................................................................................................................ 4

2.3 OPERATION PANEL ............................................................................................................. 5

3. INSTALLING THE PRINTER ............................................................................................................ 5

3.1 HOW TO INSTALLING AND ADJUST THE SHOULDER STRAP ........................................ 5

3.2 REPLACING AND INSTALLING THE BATTERY ..................................................................... 6

3.3 CHARGING THE BATTERY ............................................................................................... 6

4. LOADING PAPERS ........................................................................................................................ 7

5. REMOVING THE JAMMED PAPERS .............................................................................................. 9

6. CLEANING ................................................................................................................................. 10

6.1 THERMAL HEAD/PLATEN/PINCH ROLLER ......................................................................... 10

6.2 COVERS/PANELS ............................................................................................................... 10

7. SELECTING A DATA TRANSMISSION SPEED ............................................................................. 11

8. TROUBLESHOOTING .................................................................................................................. 12

Page 4

Page 5

EMl-33017

INTRODUCTION

Thank you for choosing the TEC Bar Code Printer B-411 Series. The B-411 has been developed for

issuing various kinds of bar codes. The B-411 adopts a state of the art thermal printer so that it

produces less noise and more clearly printed characters.

This manual contains information about the general set-up and maintenance of the B-411 printer, and

should be read carefully to obtain maximum performance from your printer. Since ample

consideration has been given to safety, there is no danger of damaging the printer by erroneous

operation.

Should you have any questions concerning the printer, please refer to this manual. Be sure to keep

this manual for future reference.

PRECAUTIONS

1. Clean the cover by wiping with a dry cloth or a cloth soaked with detergent and thoroughly wrung

out. NEVER USE THINNER OR OTHER VOLATILE SOLVENT for cleaning.

2. DO NOT POUR WATER directly on the printer.

3. When in use, avoid locations subject to vibration and direct sunlight.

4. Properly use the TEC-specified labels.

5. DO NOT STORE the labels, in locations exposed to direct sunlight, high temperature, high

humidity, dust, or gas.

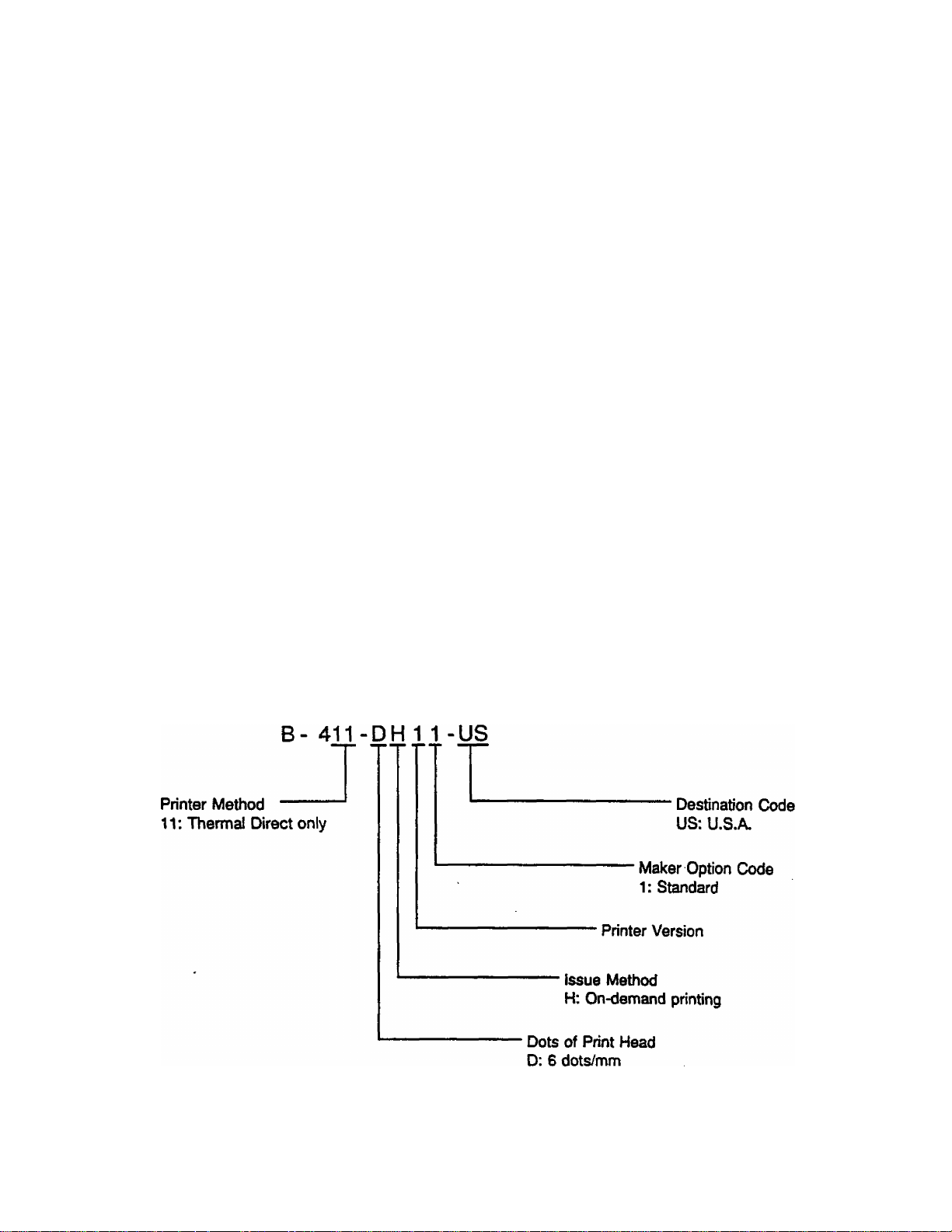

APPLICABLE MODEL

Page 6

1. SPECIFICATIONS

1.1 PRINTER

EMI-33017

——Model

Item ^

Power Requirement

Temperature Limits

Relative Humidity

Print Head

Printing Method

Print Speed

Available Printing Width

Bar Code Format Codabar, ITF, CODE39 Parallel only

Type Fonts

Interface /

Ni-Cd battery (DC 13.2V)

Capacity: 19.7mm (500") or 1.4AH

Charging time: 7—8AH (Rechargeable a minimum of 300 times)

5*0 to 4&C (41*F to 104-F)

25% to 85% RH (no condensation)

Thermal Print Head (6 dots/mm)

Thermal Direct

25.4mm (1”)/sec.

46,8mm (1.84"), 72.2mm (2.84"), 97.6mm (3.84")

(Barcode height is less than 139 dots)

Standard 1 (8 x 18) dots

Standard 2 (16X24) dots

Bold 1 (8X18) dots

Bold 2 16x24) dots

3/4" character (38 x 75) dots

Graphic Font (8X12) dots

Serial Interface (RS-232C)

B-411

1.2 PAPERS

Item

Width

Length (Pitch)

Thickness

Roll Diameter

—-^^Paper Type

1.3 INTERFACE

■■ —

Item —

------------

Baud rate

Protocol

Signal

Interface

Thermal Paper (Label)

53.8mm (2.12"), 79.2mm (3.12"), 104.6mm (4.12”)

Max. 998mm (Max. 39.3")

0.14mm-'0.15mm (0.0055"-0.0059")

52mm (2.04") max.

Electronics specification

RS-232C

9600bps or 19200bps

XON/XOFF, 8 bit Data, Non Parity, Stop bit = 2 bit

TXD, RXD, RTS, CTS

Page 7

1.4 BATTERY CHARGER

Use a battery charger having the following specifications.

EMV33017

1.5 DIMENSIONS (APPROXIMATE)

hem

Input Voltage

Output Voltage

Safety Standard Complying with UL and CSA

Charging Time

AC120V±10%

DC16.0V

8 hours ± 10%

(13.2V 1.4AH Battery)

Specification

Weight: 1.7kg (3.74 lbs.)

Page 8

2. OVERVIEW

2.1 FRONT VIEW

EM 1-33017

2.2 REARVIEW

Auxiliary Handle

Page 9

2.3 OPERATION PANEL

ERROR O

BATTERY O

PRINT □

FEED

o

ON POWER OFF

EMI-33017

ERROR Indicator (Green)

Lights when the printer does not operate correctly.

BATTERY Indicator (Orange)

Lights when the battery voltage drops. (Replace

the battery)

PRINT Indicator (Green)

Lights for one second when the power ts turned

ON.

Lights while printing or issuing labels.

FEED Button

<3

This button is used to feed the labels.

POWER Slide switch

Power supply switch for the printer.

3. INSTALLING THE PRINTER

3.1 HOW TO INSTALLING AND ADJUST THE SHOULDER STRAP

Pass the end of the Shoulder Strap through the tab of the printer from the inside, then pass it through

parts A, B and C as shown in the figure. After adjusting the length of the strap, insert the loose end

of the strap into the shoulder pad.

Page 10

EMI-33017

3.2 REPLACING AND INSTALLING THE BATTERY

To replace the battery;

If the Battery Indicator on the operation panel lights, turn the power OFF, pull up the lock button, slide

the battery to the right to remove it. Replace the battery.

To Install the battery;

Align the left edge of the battery with the line of part A. and slide the battery to the left to lock it in

place. (At this time, push the battery until a click is heard from the lock button.)

3.3 CHARGING THE BATTERY

Turn OFF the printer power. Open the jack cover and connect the battery charger plug to the printer.

It requires 8 hours to charge the battery.

Page 11

4. LOADING PAPERS

The printer prints labels of the thermal paper.

1) Turn the power off and open the label panel and roll cover.

Label Panel

2) Load the roll paper and pass the leading part of the paper into the printer.

EMI-33017

3) Lift the print head and pull out the paper.

CAUTION: Use only designated paper, or trouble may result.

Thermal Head

Page 12

4) Push down the pinch roller lever, pass the paper through the printer, and pull out the paper from

under the label panel.

Pinch Roller Lever

Label Panel

5) Align both sides of the paper with the left and right label guides (red marks) of the print head.

Make sure that there is no sag between the thermal head and the pinch roller.

EMl-33017

6) Close the label panel and roll cover.

Label Panel

Label Guide

Thermal head

Pinch Roller

Paper

7) Turn the power ON and press the FEED button to ensure that the printer operates normally.

CAUTION: After replacing the paper or removing the jammed paper from the printer, the depressing

of the FEED button allows the reinserted paper to be automaticatly fed to the printing

position.

Page 13

5. REMOVING THE JAMMED PAPERS

If a paper jam has occurred while the printer is in use. take the following action.

1) Turn the power OFF and open the label panel and roll cover.

2) Press down the head release plate and pull it out toward you.

Head Release Plate

EMI-33017

3) Lift the thermal head and remove the jammed paper.

4) Be sure to clean the print head platen to remove glue from it if any. {Refer to Section 6)

5) After removing the jammed paper, install the head release plate in place.

Page 14

6. CLEANING

6.1 THERMAL HEAD/PLATEN/PINCH ROLLER

Clean the Thermal Head when the followings happen.

* 50 rolls of paper issued.

* Paper jam.

■ The paper stained.

Procedure

1) Turn the power OFF.

2) Open the label pane! and remove the head release plate.

3) Then clean the print head, platen, and pinch roller with a soft doth moistened with alcohol.

Thermal Head

EM 1-33017

Platen

Pinch Roller

NOTES: 1) For cleaning, use industrial alcohol which does not contain impurities.

2) Do not clean the covers by atcohol.

3) Do not use any tools which may damage the thermal head.

6.2 COVERS/PANELS

When cleaning the printer surface, use a electrostatic-free cleaner for office automation equipment.

CAUTION: Do not use alcohol for cleaning, or deformation, discoloration or a drop in strength of

the covers may result.

Page 15

7. SELECTING A DATA TRANSMISSION SPEED

In case the data transmission speed of the PC to be connected to this printer is not 9600 BPS,

change the speed by following the procedure.

1) Turn the power OFF and remove the battery. (Refer to Section 3)

2) Remove the DIP switch cover and change the DIP switches as shown below.

EMI-330 U

Dip Switch

OFF

2 3 4 5 6 7 8

1

#8 SELECT SENSOR

ON: TRANSMISSIVE SENSOR

OFF: NO SENSOR

#5 RS-232C

ON: 9600BPS

OFF: 19200BPS

WARNiNG:Do not change any other DIP switches, or a malfunction may result

Page 16

EMI-33017

8. TROUBLESHOOTING

It is our primary concern to give you full satisfaction and better service. If, however, any problem

arises in connection with the operation of this printer, please check the following points before you call

for service.

ERROR LED

ERROR LED blinks

Other Problems

No print

Dots missing in print

Unclear (of blurred)

printing

Power is not turned

ON.

Printer trouble

Error has occurred in

communicating with a

personal computer

Hardware and/or

Software trouble.

Problem

1. The paper is not placed

correctly.

2. The feeding paper is jammed

and does not feed smoothly.

3. Installed paper size is different

form the programmed paper

size.

4. The paper ran out

1. Check whether the paper is loaded correctly or not

2. Check whether the print head is set correctly or not.

3. Check whether the interface cable is connected correctly or not.

1. Dirty thermal head. Clean it by industrial alcohol.

(Refer to page 10)

2. Defective thermal head. Call your representative.

Dirty thermal head. -»■ Clean the thermal head.

1, Insert the Battery firmly.

2. Call your representative, if necessary.

Turn off the power and call your representative.

Check the programmed data.

Turn off the power and call your representative.

1. Place the paper correctly.

2. Remove the jammed paper and

place the undamaged paper

correctly.

3. Turn off the power and then

turn it on again.

Set the correct paper size.

-> Feed the paper.

4. Load a new paper.

Solution

Solution

This printer has been manufactured under strict quality control. If you have any trouble, however, DO

NOT ATTEMPT TO FIX IT BY YOURSELF. Turn the power off, and contact your representative.

Page 17

Page 18

Page 19

Page 20

TEC

TOKVO

CO., LTD.

PRINTED IN JAPAN

ЕМ1-ЗЭ017А 9202300

a

Loading...

Loading...