Page 1

TEC Bar Code Printer

B-30 SERIES

Owirrer^s WinW

TOSHIBA TSC CORPORATIOIM

Page 2

EM1-33004

WARNING

This equipment generates, uses, and can radiate radio frequency energy and if not installed

and used in accordance with the instruction manual, may cause interference to radio

communications, it has been tested and found to comply with the limits for a Class A

computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference when operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause interference

in which case the user at his own expense will be required to take whatever measures may

be required to correct the interference.

(for U.S.A. only)

WARNING

“THIS DIGITAL APPARATUS DOES NOT EXCEED THE CLASS A LIMITS FOR RADIO

NOISE EMISSIONS FROM DIGITAL APPARATUS SET OUT IN THE RADIO INTERFER

ENCE REGULATIONS OF THE CANADIAN DEPARTMENT OF COMMUNICATIONS."

"LE PRÉSENT APPAREIL NUMÉRIQUE N’EMET PAS DE BRUITS RADIOÉLECTRIQUES

DÉPASSANT LES LIMITES APPLICABLES AUX APPAREILS NUMÉRIQUES DE LA

CLASSE A PRESCRITES DANS LE RÉGLEMENT SUR LE BROUILLAGE RADIOÉLEC

TRIQUE ÉDICTÉ PAR LE MINISTÈRE DES COMMUNICATIONS DU CANADA.”

(for CANADA only)

r

n

L

Copyright ©1999

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shtzuoka-ken, JAPAN

Page 3

INTRODUCTION

PRECAUTIONS

EM 1-33004

Thank you for choosing the TEC Bar Code Printer B-30-AS3. The B-30-AS3 has been

developed for issuing various kinds of bar codes, and can be connected to a personai

computer, etc., via a TEC interface. The B-30-AS3 adopts a state of the art thermai

printer so that it produces iess noise and more cleariy printed characters. You can

easily select either the thermal transfer or thermal direct printing method.

This manuai contains information about the general set-up and maintenance of the

B-30-AS3 printer, and should be read carefully to obtain maximum performance from

your printer. Since ample consideration has been given to safety, there is no danger

of damaging the printer by erroneous operation.

Should you have any questions concerning the printer, please refer to this manual.

Be sure to keep this manual for future reference.

1. Clean the cover by wiping with a dry cloth or a cloth soaked with detergent and

thoroughly wrung out. NEVER USE THINNER OR OTHER VOLATILE SOLVENT

for cleaning.

2. DO NOT POUR WATER directly on the printer.

3. When in use, avoid locations subject to vibration and direct sunlight.

4. Properly use the TEC-specified label, tag, and ribbon.

5. DO NOT STORE the labels, tags, and ribbons in locations exposed to direct

sunlight, high temperature, high humidity, dust, or gas.

6. Place the printer on a level surface.

CONTENTS

APPLICABLE MODEL

CHAPTER 1

CHAPTER 2

CHAPTER 3

CHAPTER 4

CHAPTER 5

B-30

-S1-EU, UK, US, EU P, UK P, US P

B-30

-H1-EU, UK, US, EU P, UK P, US P

B-30

-C1-EU, UK, US, EU P, UK P, US P

B-30

-S2-EU, UK, MA, EU P, UK P

B-30

-H2-EU, UK, MA, EU P, UK P

B-30

-C2-EU, UK, MA, EU P, UK P

B-30

•S3-US P, AU P, UK P.

B-30

H3-AU P

C3-AU P

B-30

B-30

AS2-US P

B-30

AS3-EU, UK. MA, EU P, US P

B-30-

AH3-EU

B-30

S5-US P

B-30

AS5-US P

B-30-

DS2-UK P

SPECIFICATIONS

BEFORE STARTING UP

INSTALLING THE PRINTER

OPERATION

MAINTENANCE

Page 4

CHAPTER 1

SPECIFICATIONS

EM1-33004

1. PRINTER............................................................................................................ 1- 1

2. SUPPLIES.......................................................................................................... 1- 9

3. RIBBON............................................................................................................. 1- 9

4. DIMENSIONS.................................................................................................... 1-10

5. ACCESSORIES................................................................................................. 1-10

Page 5

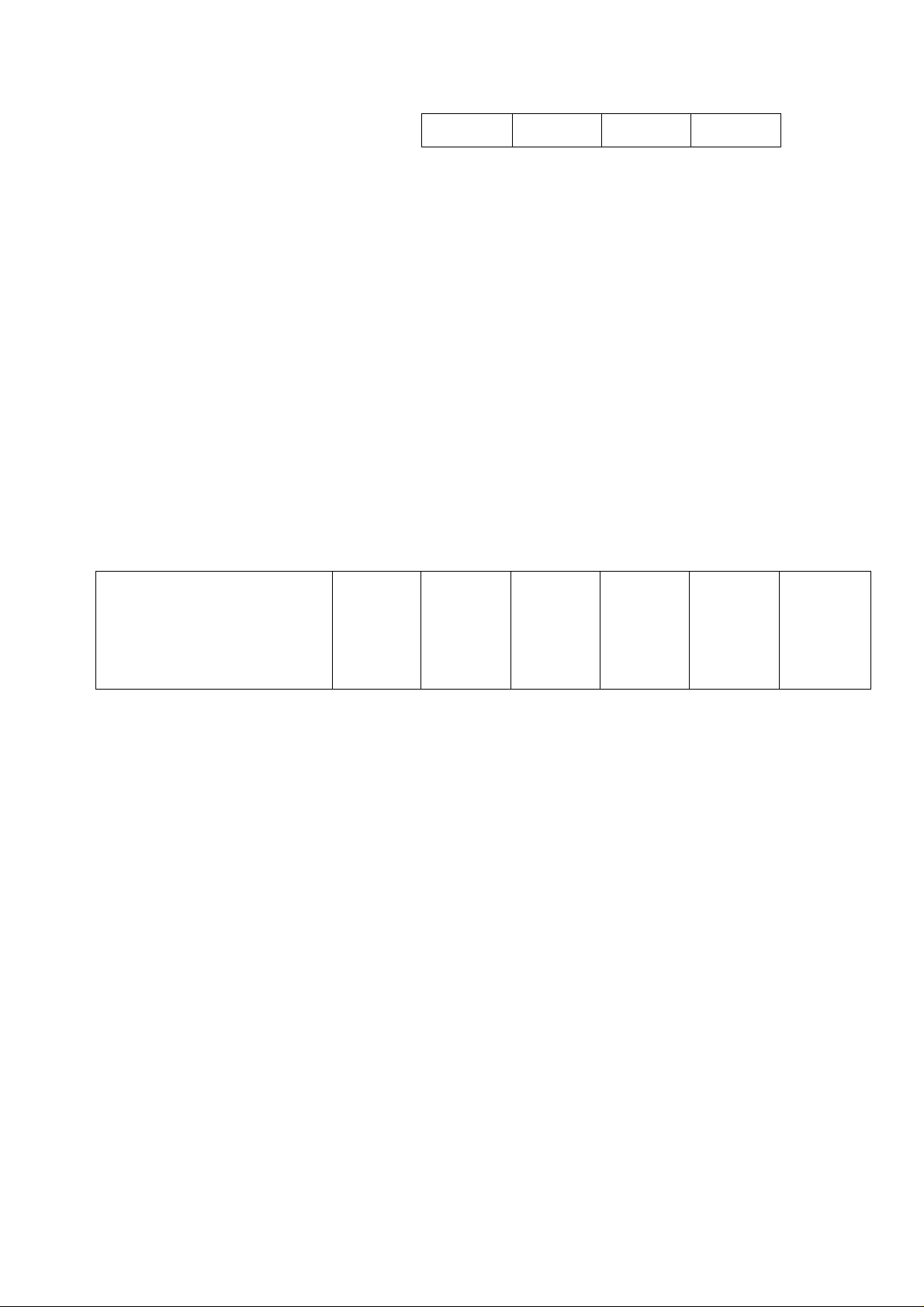

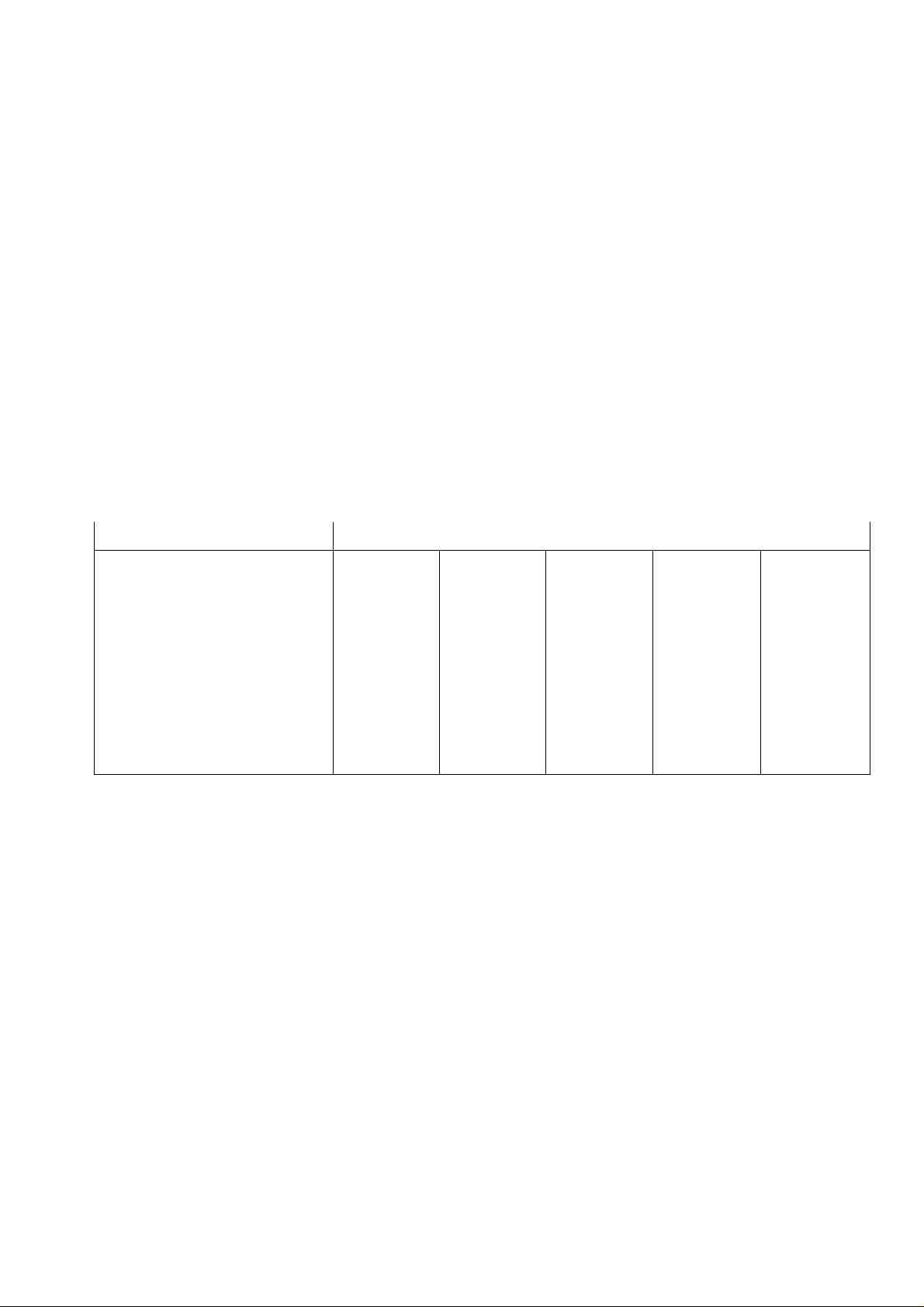

1. PRINTER

• B-30-S1/H1/C1

Item

Power Requirement

Current Consumption

Temperature Limits

Relative Humidity

Print Head

Printing Method

Print Speed

Available Printing Width

Bar Code Format

Type Fonts

Rotation

Type

EM 1-33004

B-30-S1 B-30-S1 P B-30-H1

B-30-H1 P B-30-C1

B-30-C1 P

AC 120V ± 10%, 60Hz ... for US version

AC 220V ± 10%, 50Hz ... for EU version

AC 240V ± 10%, 50Hz ... for UK version

220W Max. (Standby: 35W)

5“C to 40'’C(4rF to 104“F)

25% to 85% RH (no condensation)

Thermal Print Head at 76.2 mm (3 inches) wide. 7.6 dots per mm (193

dots per inch)

Thermal Transfer or Thermal Direct

50 mm (2 inches) per sec., 75 mm (3 inches) per sec., 100 mm (4 inches)

per sec.

75.8 mm (2.98 inches) Max.

EAN, UPC, ITF. Code 39, Code 93, Code 128, NW-7

Standard font. Bold Face font. Reduced font, OCR-MA, OCR-B

0“, 90“, 180“, 270“

Issue Method Batch

Weight 17 kg (37.5 lbs)

Memory Card Interface

Serial Interface (RS-232C)

Centronics Interface

1 slot (for 32 KB SRAM card)

O O O O

A O A O

Rewinder B-1103 A

Rewinder B-1103R A

Stacker B-1403

—

Batch or On-demand

A A A

A A A

—

— —

Auto cut

19 kg (41.9 lbs)

O O

A O

—

—

—

—

A A

O: Standard A: Option

1-1

Page 6

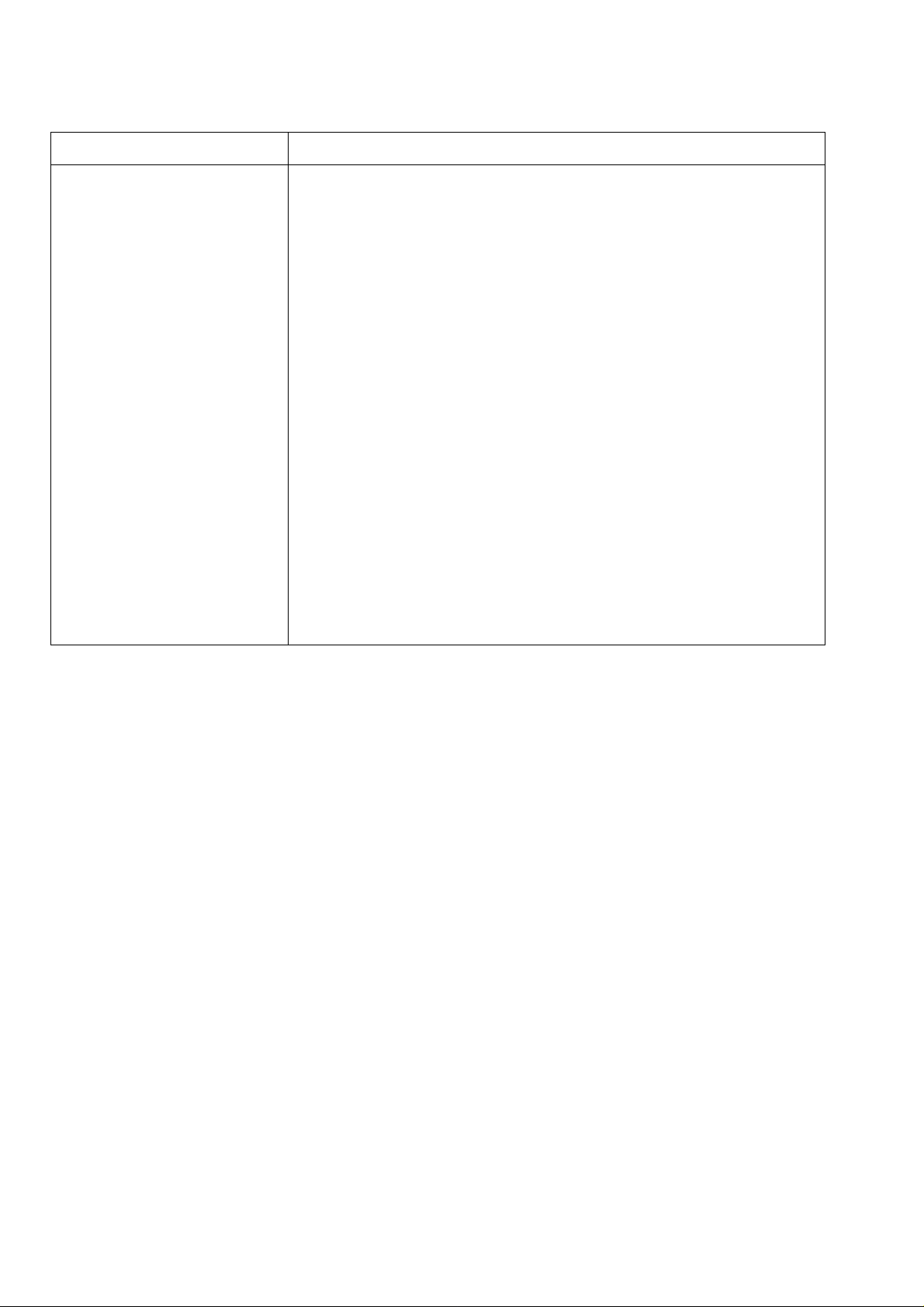

Ù B-30-S2/H2/C2 (EU, UK version only)

EM 1-33004

Item

Power Requirement

Current Consumption

Temperature Limits

Relative Humidity

Print Head

Printing Method

Print Speed

Available Printing Width

Bar Code Format

Type Fonts

Rotation

Issue Method

Weight

Memory Card Interface

Type

B-30-S2

B-30-S2 P

B-30-H2

B-30-H2 P

B-30-C2 B-30-C2 P

AC 220V ± 10%. 50Hz ... for EU version

AC 240V ± 10%, 50Hz ... for UK version

220W Max. (Standby: 35W)

5“C to 40‘’C (41“F to 104"F)

25% to 85% RH (no condensation)

Thermal Print Head at 76.2 mm (3 inches) wide, 7.6 dots per mm (193

dots per inch)

Thermal Transfer or Thermal Direct

50 mm (2 inches) per sec., 75 mm (3 inches) per sec., 100 mm (4 inches)

per sec.

75.8 mm (2.98 inches) Max.

EAN, UPC, ITF, Code 39, Code 93, Code 128, NW-7

Standard font. Bold Face font. Reduced font. Outline font, OCR-MA,

OCR-B

0“, 90“, 180“, 270“

Batch

17 kg (37.5 lbs)

Batch or On-demand

Auto cut

19 kg (41.9 lbs)

1 slot (for 32 KB or 64 KB SRAM card)

Serial interface (RS-232C)

Centronics Interface

Memory Card MC32-EX

Memory Card MC64-EX

Rewinder B-1103

Rewinder B-1103R

Stacker B-1403

O

A

A

A

A

A

O

O

A

A

A

A

O

A

A

A

A

A

O

O

A

A

A

A

P

A

A

A

O

O

A

A

O: Standard A: Option

1-2

Page 7

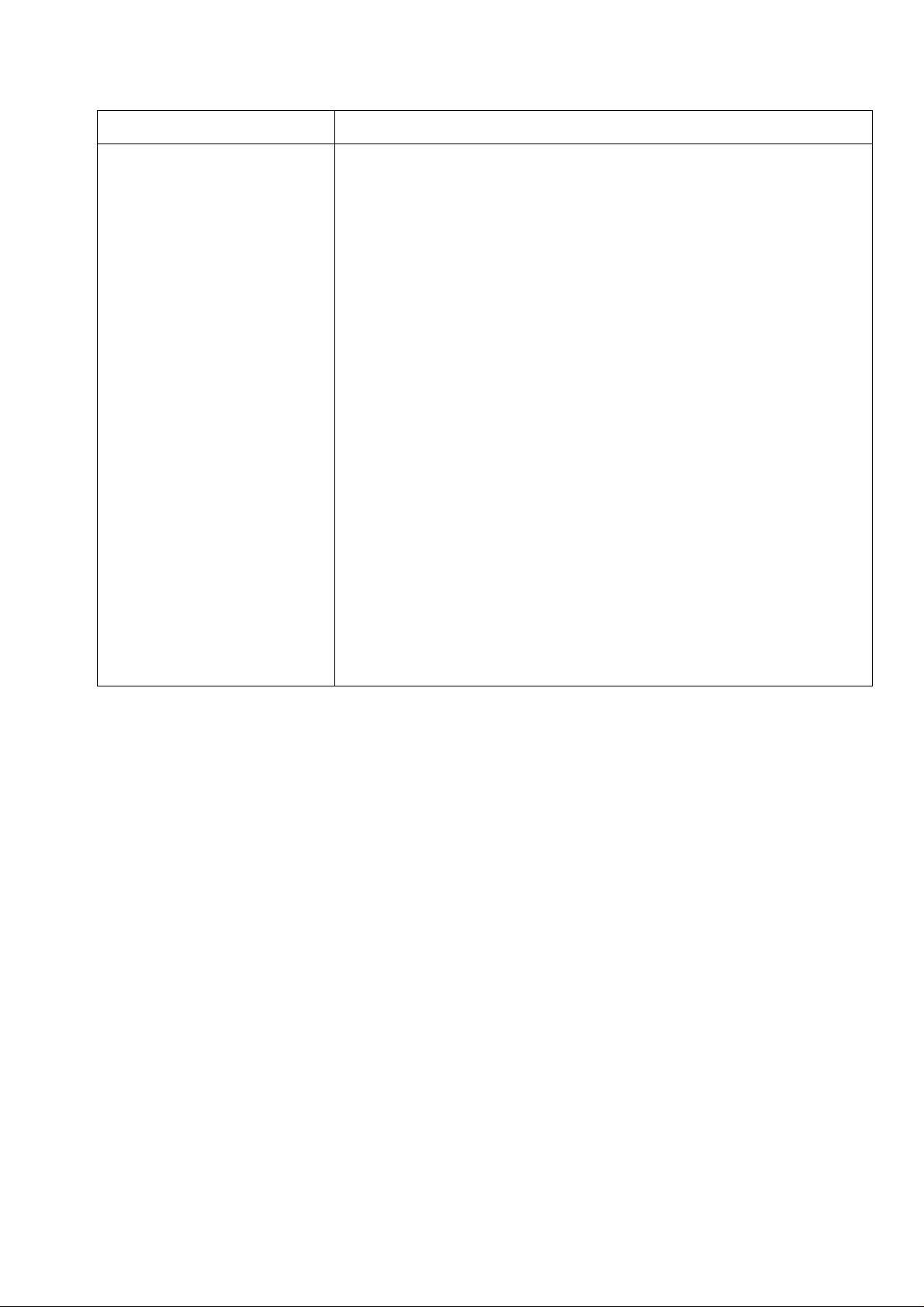

• B-30-S3/H3/C3 (US, AU version only)

EM 1-33004

, ^Version

Item ~~—-—

Power Requirement

S3-US P

AC 120 V

± 10%, 60Hz

Current Consumption

Temperature Limits

Relative Humidity

Print Head

220W Max. (Standby: 35W)

5“C to 40"C(4rF to 104T)

25% to 85% RH (no condensation)

Thermal Print Head at 76.2 mm (3 inches) wide, 7.6 dots per mm

(193 dots per inch)

Printing Method

Print Speed

Thermal Transfer or Thermal Direct

50 mm (2 inches) per sec., 75 mm (3 inches) per sec., 100 mm

(4 inches) per sec,

Available Printing Width

Bar Code Format

Type Fonts

75.8 mm (2.98 inches) Max.

EAN, UPC, ITF, Code 39. Code 93, Code 128, NW-7

Standard font. Bold Face font, Reduced font, Outline font, OCR-MA,

OCR-B

Rotation

0“. 90“, 180“, 270“

Issue Method

Weight 17 kg (37.5 lbs.)

S3-AU P H3-AU P

AC240V ± 10%, 50Hz

Batch

Batch or

on-demand

C3-AU P

Auto cut

19kg (41.9lbs.)

Memory Card interface 1 slot (for 32 KB or 64 KB SRAM card)

Serial Interface (RS-232C)' O O

Centronics Interface O O

Memory Card: MC32-EX A

Memory Card: MC64-EX

Keyboard KB-30-NP

A A

A O

O O

Rewinder B-1103 A A

Rewinder B‘-1103R

Rewinder unit B-1103M

Cutter unit B-1203M A

Stacker B-1403

A A

A A

A

A A

O

O

A

O

A

A

A

-

-

O: Standard A: Option

O

O

O

A

O

—

—

O

A

1-3

Page 8

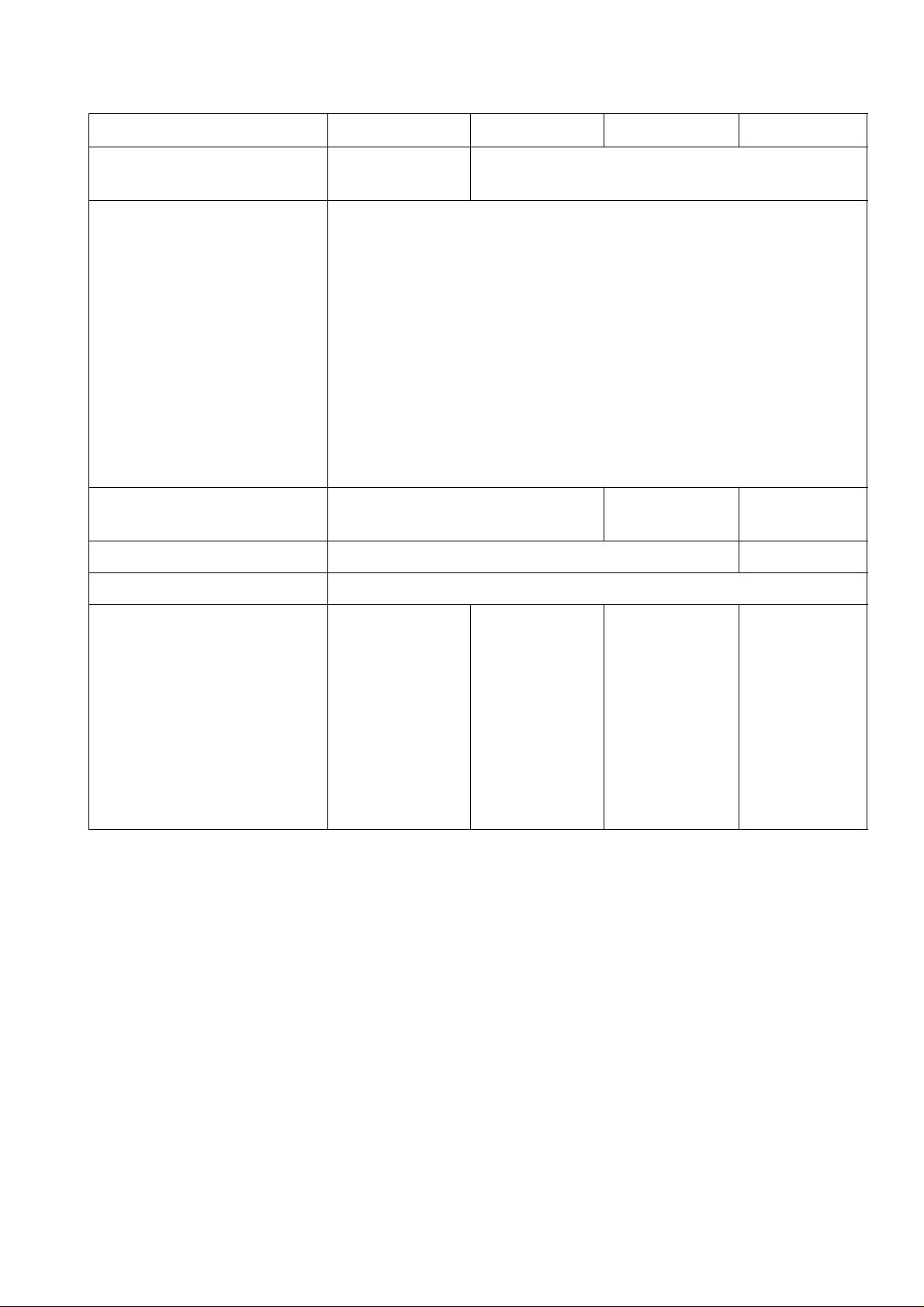

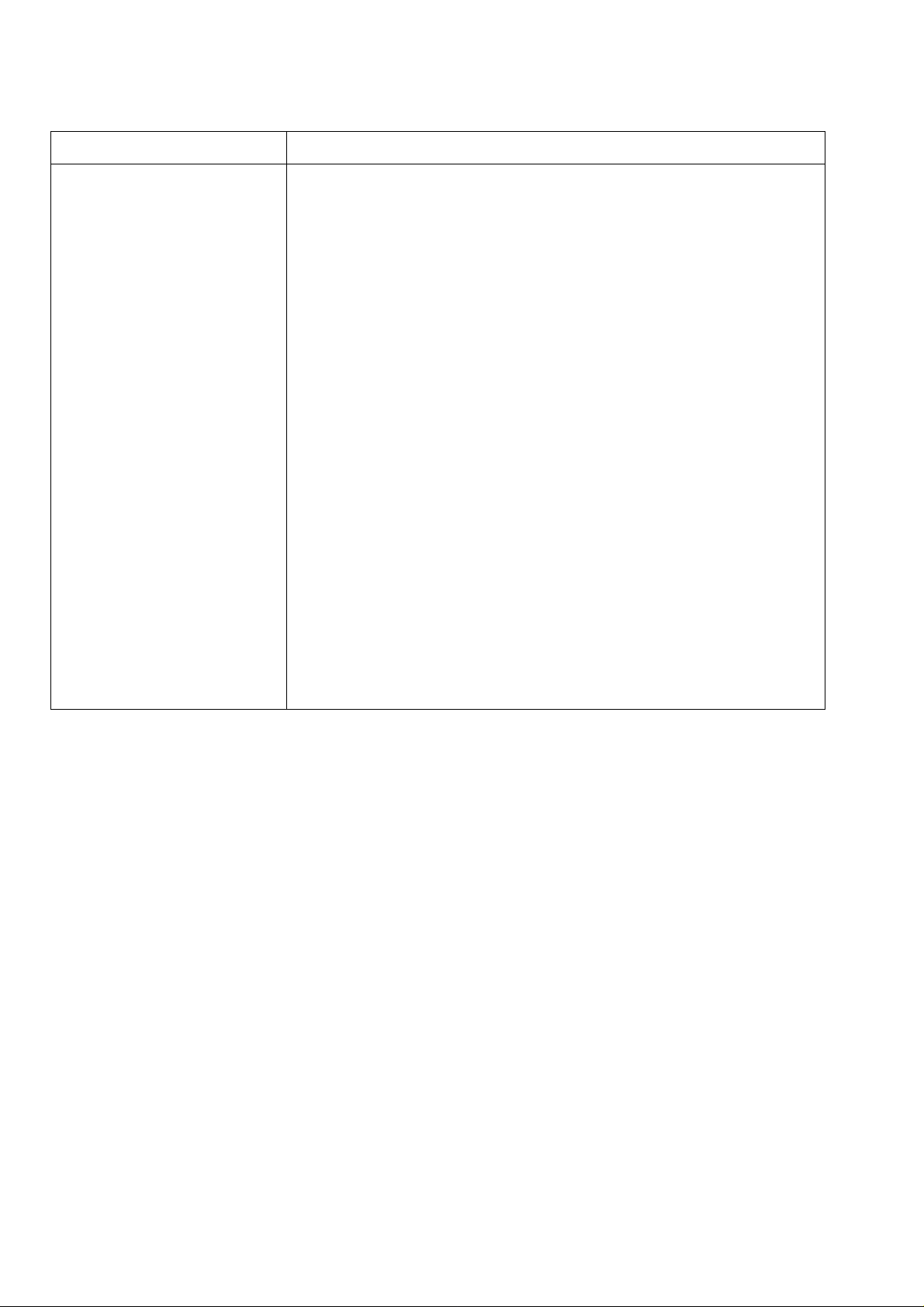

0 B-30-AS2 (US version only)

EM1-330C

, -——Model

Item ■——

Power Requirement

Current Consumption

Temperature Limits

Relative Humidity

Print Head

Printing Method

Print Speed

Available Printing Width

Bar Code Format

Type Fonts

Rotation

Issue Method

Weight •

Interface

Option

B-30-AS2-US P

AC 120V ± 10%, 60Hz

220W Max. (Standby: 35W)

5“C to 40“C (41“FtOl04“F)

25% to 85% RH (no condensation)

Thermal Print Head at 76.2 mm (3 inches) wide, 10.5 dots per mm (266

dots per inch)

Thermal Transfer or Thermal Direct

50 mm (2 inches) per sec., 75 mm (3 inches) per sec., 100 mm (4 inches)

per sec.

72.9 mm (2.87 inches) Max.

BAN, UPC, ITF, Code 39, Code 93, Code 128, NW-7

Standard font, Bold Face font, Reduced font. Outline font, OCR-MA,

OCR-B

0“, 90”, 180”, 270”

Batch

17 kg (37.5 lbs.)

Memory Card Interface

Serial Interface (RS-232C)

Centronics Interface

Memory Card: MC32-EX, MC64-EX

Keyboard: KB-30-EX

Rewinder: B-1103, B-1103R

.............

1 slot (for 32 KB or 64 KB SRAM card)

• B-30-DS2 (UK version only)

■——-

_____

Item ——

Power Requirement

Current Consumption 220W Max. (Standby: 35W)

Temperature Limits 5”C to 40“C (4rF to 104”F)

■Relative Humidity 25% to 85% RH (no condensation)

Print Head

Printing Method Thermal Transfer or Thermal Direct

Print Speed 50 mm (2 inches) per sec., 75 mm (3 inches) per sec., 100 mm (4 inches)

Available Printing Width

Bar Code Format

Type Fonts

Rotation

Issue Method

Weight 17 kg (37.5 lbs.)

interface Memory Card Interface

Memory Card

Keyboard

Option

Model

AC 240V ± 10%, 50Hz

Thermal Print Head at 76.2 mm (3 inches) wide, 6 dots per mm (152 dots

per inch)

per sec.

74.8 mm (2.94 inches) Max.

EAN, UPC, ITF, Code 39, Code 93, Code 128, NW-7

Standard font. Bold Face font. Reduced font. Outline font, OCR-MA,

OCR-B

0”, 90”, 180”, 270”

Batch

Serial Interface (RS-232C)

Centronics Interface

MC32-EX

KB-30-EX

Rewinder: B-1103, B-1103R

B-30-DS2-UK P

.............

1 slot (for 32 KB SRAM card)

1-4

Page 9

B-30-AS3

EM 1-33004

Item

Power Requirement

Version

US P

AC 120V ±

EU

EU P

AC 220V ± 10%, 50Hz | AC 240V ± 10%, 50Hz

10%, 60Hz

Current Consumption

Temperature Limits

Relative Humidity

Print Head

220W Max. (Standby: 35W)

5°C to 40“C (4rFto 104“F)

25% to 85% RH (no condensation)

Thermal Print Head at 76.2 mm (3 inches) wide, 10.5 dots per mm (266

dots per inch)

Printing Method

Print Speed

Thermal Transfer or Thermal Direct

50 mm (2 inches) per sec., 75 mm (3 inches) per sec., 100 mm (4 inches)

per sec.

Available Printing Width

Bar Code Format

Type Fonts

72.9 mm (2.87 inches) Max.

EAN, UPC, ITF, Code 39, Code 93, Code 128, NW-7

Standard font. Bold Face font, Reduced font. Outline font, OCR-MA,

OCR-B

Rotation

Issue Method

Weight (approx.)

0“, 90", 180", 270“

Batch, On-demand (option), or Auto cut (option)

17 .kg (37.5 lbs.)

Memory Card Interface 1 slot (for 32 KB or 64 KB SRAM card)

Serial Interface (RS-232C) O

Centronics Interface

Keyboard KB-30-EX

O

A

Memory Card MC32-EX A

Memory Card MC64-EX

Rewinder B-1103

Rewinder B-1103R

Rewinder unit B-1103M

Cutter unit B-1203M

Stacker B-1403

A

A

A

A

A

A

O

A

O

A

A

A

A

A

A

A

UK

O

O

O

A

A

A

A

A

A

A

O

A

O

A

A

A

A

A

A

A A

UK P

O

O

o

A

A

A

A

A

A

O: Standard A: Option

1-5

Page 10

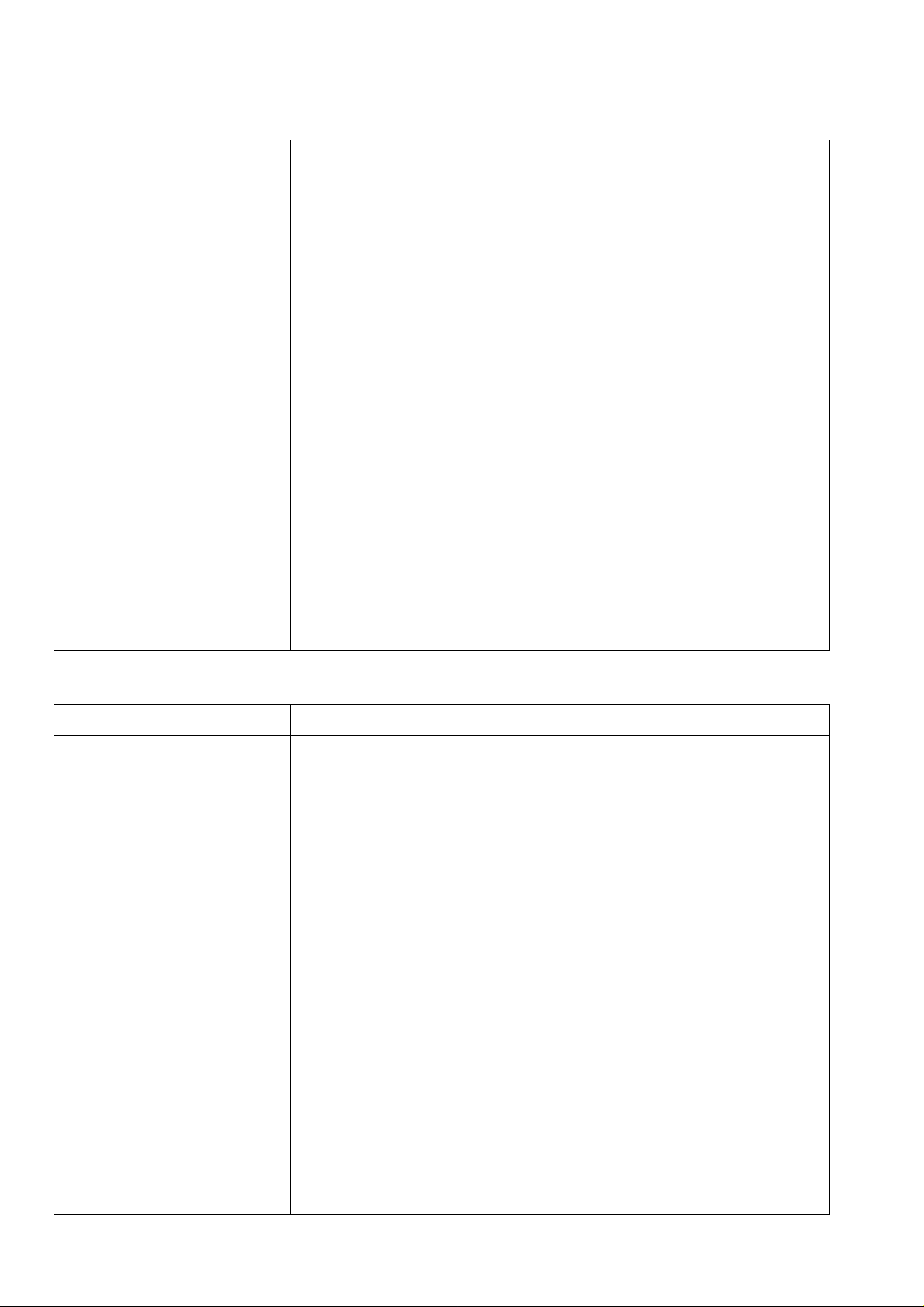

© B-30-AH3

“

Item “—

----------------

Model

B-30-AH3-EU

Power Requirement AC 220V ± 10%, 50Hz

Current Consumption 220W Max. (Standby: 35W)

Temperature Limits

Relative Humidity

Print Head

5“C to 40“C (41“F to 104T)

25% to 85% RH (no condensation)

Thermal Print Head at 76.2 mm (3 inches) wide, 10.5 dots per mm (266

dots per inch)

Printing Method Thermal Transfer or Thermal Direct

Print Speed

50 mm (2 inches) per sec., 75 mm (3 inches) per sec., 100 mm (4 inches)

per sec.

Available Printing Width 72.9 mm (2.87 inches) Max.

Bar Code Format

Type Fonts

BAN, UPC, ITF, Code 39, Code 93, Code 128, NW-7

Standard font. Bold Face font, Reduced font, Outline font, OCR-MA,

OCR-B

Rotation O', 90', 180“, 270“

Issue Method

On-demand or Batch

Weight 17 kg (37,5 ibs.)

Interface

Memory Card Interface ............. 1 slot (for 32 KB or 64 KB SRAM card)

Serial Interface (RS-232C)

Option Centronics Interface

Memory Card: MC32-EX, MC64-EX

Keyboard: KB-30-EX

Rewinder: B-1103, B-1103R

EM 1-33004

1-6

Page 11

• B-30-S5 (US version only)

'—

Item

---------

Mode)

Power Requirement

Current Consumption

Temperature Limits

Relative Humidity

Print Head

Printing Method

Print Speed

Available Printing Width

Bar Code Format

Type Fonts

Rotation

Issue Method

Weight

Interface

Option

EM 1-33004

B-30-S5-US P

AC 120V ± 10%, 60Hz

220W Max. (Standby: 35W)

5“C to 40“C (41T to 104“F)

25% to 85% RH (no condensation)

Thermal Print Head at 76.2 mm (3 inches) wide, 7.6 dots per mm (193

dots per inch)

Thermal Transfer or Thermal Direct

50 mm (2 inches) per sec., 75 mm (3 inches) per sec., 100 mm (4 inches)

per sec.

75.8 mm (2.98 inches) Max.

EAN, UPC, ITF, Code 39, Code 93, Code 128, NW-7, MSI

Standard font. Bold Face font, Reduced font. Outline font, OCR-MA,

OCR-B

0“, 90“. 180“, 270“

Batch, On-demand (option), or Auto cut (option)

17 kg (37.5 lbs.)

Memory Card Interface

.............

1 slot (for 32 KB or 64 KB SRAM card)

Serial interface (RS-232C)

Centronics Interface

Memory Card: MC32-EX, MC64-EX

Keyboard: KB-30-EX

Rewinder: B-1103, B-1103R

Rewlnder unit: B-1103M

Cutter unit: B-1203M

Stacker: B-1403

1-7

Page 12

® B-30-AS5 (US version only)

EM 1-33004

~ Model

Item —-—

Power Requirement

Current Consumption

Temperature Limits

Relative Humidity

Print Head

AC 120V ± 10%, 60Hz

220W Max. (Standby: 35W)

5“C to 40"C (41T to 104“F)

25% to 85% RH (no condensation)

Thermal Print Head at 76.2 mm (3 inches) wide, 10.5 dots per mm (266

B-30-AS5-US P

dots per inch)

Printing Method Thermal Transfer or Thermal Direct

Print Speed

50 mm (2 inches) per sec., 75 mm (3 inches) per sec., 100 mm (4 inches)

per sec.

Available Printing Width

Bar Code Format

Type Fonts

72.9 mm (2.87 inches) Max.

BAN, UPC, ITF, Code 39, Code 93, Code 128, NW-7, MSI

Standard font, Bold Face font, Reduced font, Outline font, OCR-MA,

OCR-B

Rotation 0“, 90“, 180“, 270“

Issue Method

Weight

Interface

Batch, On-demand (option), or Auto cut (option)

17 kg (37.5 lbs.)

Memory Card Interface

.............

1 slot (for 32 KB or 64 KB SRAM card)

Serial Interface (RS-232C)

Centronics Interface

Option

Memory Card: MC32-EX, MC64-EX

Keyboard: KB-30-EX

Rewinder: B-1103, B-1103R

Rewinder unit: B-1103M

Cutter unit: B-1203M

Stacker: B-1403

1-8

Page 13

2. SUPPLIES

• B-30-S1/H1/C1/S2/H2/C2/S3/H3/C3/S5

EM 1-33004

^HEPiyjy^

Width

Length

Thickness

Roll Diameter

B-30-AS2/AS3/AH3/AS5

Width

Length

Thickness .13 to .17 mm

Roll Diameter 230 mm (9 inches) Max.

30 to 81 mm (1.18 to 3.18 inches)

15 to 152.4 mm (.59 to 6 inches)

.13 to .17 mm

(.005 to .006 inches)

230 mm (9 inches) Max.

30 to 81 mm (1.18 to 3.18 inches)

15 to 160 mm (.59 to 6.29 inches)

(.005 to .006 inches)

Label

Label

3. RIBBON

Tag

.15 to .26 mm

(.006 to .010 inches)

Tag

.15 to .26 mm

(.006 to .010 inches)

Ribbon Type One-time carbon: Black

Width

Length

Roll Diameter Max. 71 mm (2.79 inches)

48 mm (1.89 inches), 58 mm (2.28 inches), 83 mm (3.26 inches)

400 m (1312 feet)

4. USING B-1403

-

----------------------

Paper

Width

Lenght

supply

Label

Paper with a minimum label-to-label

gap of 4 mm.

30 ~ 81 mm (1.18 to 3.19 inches)

30 ~ 80 mm (1.18 to 3.15 inches)

Tag

Perforated paper cannot be used.

30 — 81 mm (1.18 to 3.19 inches)

30 — 105 mm (1.13 to 4.1 inches)

1-9

Page 14

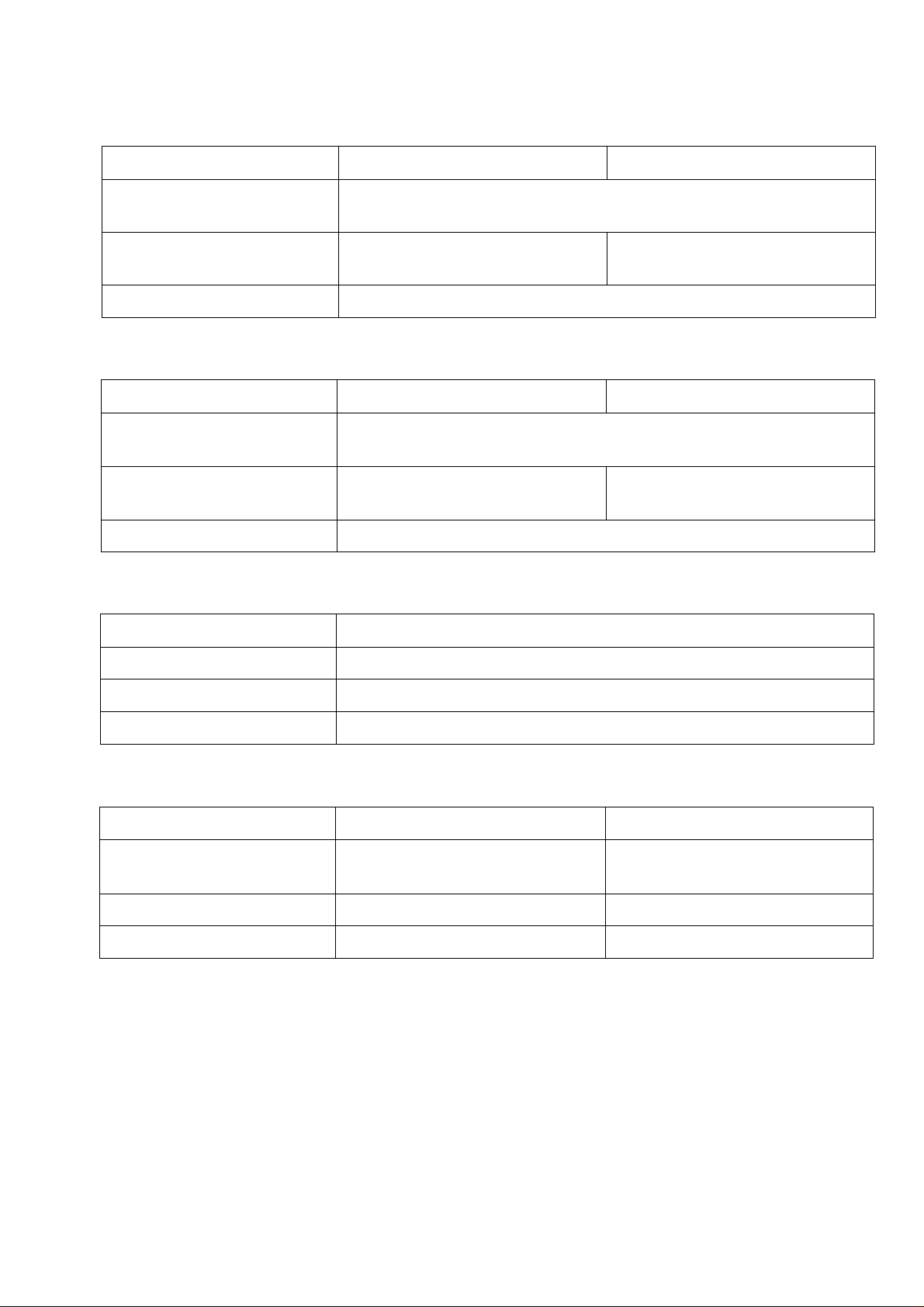

4. DIMENSIONS (approximate)

EM1-33004

M Printer

mm (inches)

Keyboard

5. ACCESSORIES

Make sure you have all the items shown the accessory list on the carton.

NOTE : The specifications are subject to change without notice.

1-10

Weight: 430g (.95 lbs.)

Page 15

CHAPTER 2

BEFORE STARTING UP

EM 1-33004

1. OVERVIEW......................................................:................................................... 2-1

1.1. Front View................................................................................................... 2-1

1.2. Side View..................................................................................................... 2-5

1.3. Keyboard Unit.............................................................................................. 2-5

2. KEY FUNCTIONS................................................................................................ 2-6

Page 16

1. OVERVIEW

1.1. Front View

• B-30-SVDS2

EM 1-33004

• B-30-S2/S3/AS2/AS3/AS5

Supply Roll Holder Unit

POWER Indicator

Lights when the power

is turned on.

r— STOP/RESTART Button

This button is used to stop or

restart printing.

FEED Button

This button is used to feed

the supply.

ON-LINE Indicator

1) Blinks when communicating

with a personal computer.

2) Lights when the printer

prints out.

ERROR Indicator

Lights when the printer does

not operate correctly.

Figure 2-2

Front Door

2-1

Page 17

® B-30-H1

EM 1-33004

■Front Door

B-30-H2/H3/AH3

Figure 2-3.

2-2

Page 18

• B-30-S3/AS3/S5/AS5 (with Rewinder unit B-1103M...option)

EMI-33004

• B-30-C1

2-3

Page 19

« B-30-C2/C3

EM1-33004

O B-30-S3/AS3/S5/AS5 (with Cutter unit B-1203M....Option)

2-4

Page 20

1.2. Side View

Power Switch

AC Power Inlet

1.3. Keyboard Unit

• KB-30-EX

EM 1-33004

Fuse

Figure 2-9.

KB-30-NP

-

TEC

select IlnESTAArj

0 Q

ItIH

mi-

Function keys Numeric keys

foaimtH j

FI

E E

F2

BEE

otMrim'

BEE

1 0 11 . 11=<-

Display (Liquid Crystal Display)

f

■ Intensity Adjustment wheel

\

• Turning up darkens the display.

• Turning down lightens the display.

PRINT

Function keys

ENTER

Figure 2-11.

2-5

Page 21

2. KEY FUNCTIONS 9 KB-30-EX

Key

ENTER

FEED

FI F2

EM1-33004

Function

This key is used for enter-clear of a numeric key.

It is also used to release the printer from an error mode.

This key is used to enter the data recall mode.

This key is used to feed and cut supplies.

NOTICE: The available functions are different depending on the

program used.

Special assigned function.

{These keys are used by service personnel.)

PAUSE

PRESET

COUNT

PRINT/

PROG.

*

This key is used to temporarily stop printing.

It is also used to restart printing supplies after pausing.

This key is used to preset the number of tags/labels you want

to print.

This key is used to start printing.

It is also used to register the next data while the supplies are

being printed.

This key is used to input the data to the printer.

This key is used to separate plural input data.

0

Other

keys

These keys are used to enter numeric data.

These keys are not used during normal operations.

(These keys are also used by service personnel.)

2-6

Page 22

KB-30-NP

EMI-33004

Key

CLEAR

ENTER

FEED

PAUSE

PRINT

3UANT)T\

Function

This key is used for enter-dear of a numeric key.

It is also used to release the printer from an error mode.

This key is used to enter the data to the printer.

This key is used to feed and cut supplies.

NOTICE: The available functions are different depending on the

program used.

This key Is used to temporarily stop printing.

This key is used to start printing.

This key is used to preset the number of tags/labels you want

to print.

RESTART

SELECT

FORMAT

FI

0 ... 9

□

□

F2

□

□

This key is used to select a print format.

This key is used to select a print format.

This key is used to separate plural Input data.

F2 is a purchase order separator.

(These keys are also used by service personnel.)

These keys are used to enter numeric data.

These keys are used to during normal operations to move the

cusor within a data field and to display formats.

2-7

Page 23

CHAPTER 3

INSTALLING THE PRINTER

EM 1-33004

1. CONNECTING THE POWER CORD AND CABLES..........................................

2. INSTALLING THE SUPPLY ROLL HOLDER

3. INSTALLING THE SUPPLY STOPPER B

4. INSTALLING THE PAPER GUIDE

5. INSTALLING THE BACKING PAPER GUIDE..................................................... 3-3

6. MOUNTING THE LOCK AND ADJUSTMENT KNOBS....................................... 3-4

B Adjusting the cutting position............................................................................ 3-4

7. INSTALLING THE STACKER.............................................................................. 3-4

8- INSTALLING THE REWINDER B-1103

......................................................................

.......................................................

............................................................

...............................................................

3-1

3-1

3-2

3-3

3-5

Page 24

1. CONNECTING THE POWER CORD AND CABLES

EM 1-33004

WARNING; The power switch must be off before connecting the power cord.

2. INSTALLING THE SUPPLY ROLL HOLDER

• Installing the supply roll holder on the top of the printer.

a. Remove the cover of the supply roll holder unit, and attach the supply stand to

the top of the printer using the two wing screws.

b. Insert the cover over the top of the supply stand.

3-1

Page 25

EM 1-33004

• Installing the supply roll holder on the right side of the printer (except for B-30-S3/

AS3 with Rewinder unit).

a. Remove the cover of the supply roll holder unit, then remove the supply spool

from the supply stand.

b. Attach the supply stand to the right side of the printer using the two wing screws.

c. Mount the supply spool by inserting it into the horizontal mounting holes of the

supply stand.

d. Attach the cover by inserting it horizontally from the side of the supply stand.

3. INSTALLING THE SUPPLY STOPPER B

Install supply stopper B on the supply roll holder unit when using the narrow supply.

Supply Stopper B

3-2

Page 26

4. INSTALLING THE PAPER GUIDE Place the paper guide in the position shown below.

5. INSTALLING THE BACKING PAPER GUIDE (for B-30-H1/H2/H3) When issuing a label in the “On-demand” mode, mount the backing paper guide in the position shown below and eject the backing paper from the lower exit on the left side of the printer.

EMI-33004

Figure 3-6.

3-3

Page 27

EM 1-33004

6. MOUNTING THE LOCK AND ADJUSTMENT KNOBS (for Cutter type only)

insert each knob. (Align the groove of the knob with the pin on the shaft.)

NOTICE: When inserting the adjustment knob, make sure that the triangular indicator (Á) points to “55” on

the scale.

B Adjusting the cutting position

1. Turn the lock knob to the unlock position.

2. Set the adjustment knob to the designated position.

3. Turn the lock knob to the lock position.

2nd scale: 30 mm ~ 54 mm

3rd scale: 15 mm, 20 mm ~ 25 mm

7. INSTALLING THE STACKER (for Cutter type only)

Assemble the stacker and hang the tabs of the stacker on the tag exit.

3-4

Page 28

8. INSTALLING THE REWINDER B-1103 (Option) To rewind labels issued in batch printing mode, or backing paper in the on-demand

printing mode, attach the Rewinder B-1103 (option) at the position shown below.

• Label (except for Cutter type)

• Backing Paper (for B-30-H1/H2/H3 only)

EM 1-33004

\

Backing Paper Threading

NOTICE: When installing other optional equipments, refer to the owner’s manual provided with those

equipment.

3-5

Page 29

CHAPTER 4

OPERATION

EM 1-33004

1. LOADING THE RIBBON.................................................................................... 4- 1

2. LOADING SUPPLIES........................................................................................ 4- 4

2.1. For B-30-S1/H1/C1/DS2............................................................................ 4- 4

2.2. For B-30-S2/H2/C2/S3/H3/C3/AS2/AS3/AH3............................................ 4- 6

2.3. For B-30-S5/AS5....................................................................................... 4- 8

B Threading the backing paper....................................................................... 4-10

3. INSERTING THE MEMORY CARD.................................................................. 4-11

4. ADJUSTING THE SENSORS

4.1. Black Mark or Feed Gap Sensor

4.2. Label Issue Sensor.................................................................................... 4-12

...........................................................................

...............................................................

4-12

4-12

Page 30

1. LOADING THE RIBBON

EM 1-33004

There are two types of supplies, standard paper and thermal paper.

DO NOT LOAD a ribbon when using thermal paper.

1. Turn the power off.

2. Open the front door.

3. Move the head lock lever to the right to release the print head.

*4. Remove the supply if it has been loaded.

4-1

Page 31

Ribbon Shaft

EM1-33004

5. Load the ribbon.

a. Guide the edge of the ribbon around the ribbon shaft.

b. Place the ribbon rolls onto the two shafts.

c. Insert the ribbon between the ribbon end sensor.

Ribbon Shaft

Figure 4-3.

Figure 4-4.

6. Lock the ribbon rolls.

a. Match the notch on the supply and rewind reels with the protrusion on the

shafts as shown.

Protrusion

4-2

Figure 4-5.

Page 32

b. Pull the head of the shaft while holding the ribbon roll.

NOTICE: Depress the stoppers when removing the ribbon roll.

EM 1-33004

Stopper

Ribbon Shaft

7. Turn the rewind shaft as shown, to pull the ribbon tight.

8. Reload the supply (standard paper).

9. Move the head lock lever to the left to move the print head against the ribbon

and platen.

10. Close the front door.

Head Lock Lever

Rewind Shaft

Figure 4-8.

4-3

Page 33

2. LOADING SUPPLIES

2.1. For B-30-S1/H1/C1/DS2

The printer prints both tags and labels.

1. Turn the power off.

2. Place the supply roll onto the supply roll holder.

3. Open the front door.

4. Move the head lock lever to the right to release

the print head.

5. Thread the supply as shown.

a. Pull enough supply out from the

b. Pull down and hold the guide

c. insert the supply between the

d. Feed the supply to the label exit

EMI-33004

roll to reach the label exit (for

HI and SI types) or platen (for

C1 type).

roller lever, and slide the supply

under the paper guide. Then

release the lever.

label sensors.

Figure 4-11.

or platen as shown below, and

push the inside edge of the

supply against the back wall.

B-30-S1/DS2

B-30-H1

B-30-C1

Figure 4-12.

4-4

Page 34

EM 1-33004

6, Move the head lock lever to position 1 or 2 according to the thickness of the

supply.

7. Close the front door.

4-5

Page 35

2.2. For B-30-S2/H2/C2/S3/H3/C3/AS2/AS3/AH3

The printer prints both tags and labels.

1. Turn the power off.

2. Place the supply roll onto the supply roll holder.

3. Open the front door.

4. Move the head lock lever to the right to release

the print head.

5. Press down the roller open lever to release the skew roller.

EM 1-33004

Figure 4-15.

6. Thread the supply as shown.

a. Pull enough supply out from the roll to reach the paper setting zone.

b. Slide the supply under the paper guide, and push the inside edge of the supply

against the back wall.

Figure 4-16.

4-6

Page 36

7- Push the roller close lever.

EMI-33004

Figure 4-17.

8.. Move the head lock lever to position 1 or 2 according to the thickness of the

supply. ,

9. Close the front door.

4-7

Page 37

2.3. For B-30-S5/AS5

EM 1-33004

The printer prints both tags and labels.

1. Turn the power off.

2. Place the supply roll onto the supply roll holder.

3. Open the front door.

4. Move the head lock lever to the right to release

the print head.

5. Thread the supply as shown.

a. Pull enough supply out from the roll to reach the paper setting zone.

b. Slide the supply under the paper guide, and push the inside edge of the supply

against the back wall.

4-8

Page 38

supply-

EM 1-33004

1 or 2 according to the thickness of the

7. Use the

Figure 4-28, Position 1: Thin paper

Position 2: Thick paper

supply guide to the supply.

supply guide lever to fit «te

Close the front door.

8.

4-9

Page 39

Threading the backing paper (B-30-AH3 and B-30-H3/S3/AS3/S5/AS5 with Rewinder unit)

To rewind backing paper in the on-demand printing mode, thread the backing paper

shown below.

1. Pass the backing paper under the guide rollers.

2. Secure the backing paper to the rewind shaft with clamp.

EM 1-33004

4-10 '

Page 40

3. INSERTING THE MEMORY CARD

1. Turn the power off.

2. Insert the memory card with preregis

tered print data into the memory card

slot.

3. To prevent the memory card from being

removed accidentally, be sure to attach

the memory card cover.

EM 1-33004

WARNING; Replace battery with Hitachi Maxell Ltd., type CR2016

only. Use of another battery may present a risk of fire

or explosion.

WARNING: A battery may explode if handled improperly. DO NOT

recharge, disassemble or dispose of in fire.

NOTICE: The data is protected by a backup battery which is

installed inside the memory card. The service life of the

battery is eighteen (18) months. To replace the battery,

consult your TEC dealer or service representative.

If the memory card is used with an expired battery,

correct operations are not guaranteed by TEC.

Memory

Card

Memory Card

Cover

Figure 4-21,

4-11

Page 41

4. ADJUSTING THE SENSORS

The sensors detect black marks or feed gaps. The adjustment shafts move the

sensors in and out.

4.1. Black Mark or Feed Gap Sensor

Adjust the position of the sensor according to the length, from the left end of the

supply to the black mark or from the center of the feed gap.

EM 1-33004

NOTICE: Which sensor is used depends on the conditions of supply,

4.2. Label Issue Sensor (for On-demand type)

Adjust the position of the label issue sensor to the blank portion of the issued label

(the portion where no characters are printed).

Figure 4-25.

4-12

Page 42

CHAPTER 5

MAINTENANCE

EM1-33004

1. REMOVING JAMMED SUPPLIES

1.1. For Standard Type,

1.2. For On-demand Type................................................................................... 5-1

1.3. For Cutter Type............................................................................................ 5-2

■ When the supply is exhausted........................................................................ 5-2

2. CLEANING THE PRINT HEAD............................................................................ 5-3

3. CLEANING THE CUTTER................................................................................. 5-4

4. TROUBLESHOOTING......................................................................................... 5-5

.....................................................................................

.........................

.............................................

5-1

5-1

Page 43

1. REMOVING THE JAMMED SUPPLIES

1.1 For Standard Type

1. Open the front door.

2. Move the head lock lever to the right to release the print head.

3. Remove the supplies jammed inside.

EM 1-33004

Head Lock Lever

1.2. For On-demand Type (for B-30-H1/H2 only)

1. Open the front door.

2. Move the head lock lever to the right to release the print head.

3. Turn and hold the backing roller lever, and pull the backing paper.

5-1

Figure 5-2.

Page 44

1.3. For Cutter Type

EM 1-33004

1. Pull out the lock knob and adjustment knob.

2. Pull at the upper side of the cutter cover to remove it.

3. Remove screw ® to take out the supply guide cover, then remove the supplies

jammed (blocking) inside.

WARNING: Turn the power off befoer removing jammed supplies.

When the supply is exhausted

1. Depress the FEED key.

2. Pull out the piece of paper remaining in the cutter unit using tweezers.

Figure 5-4.

Tweezers

Page 45

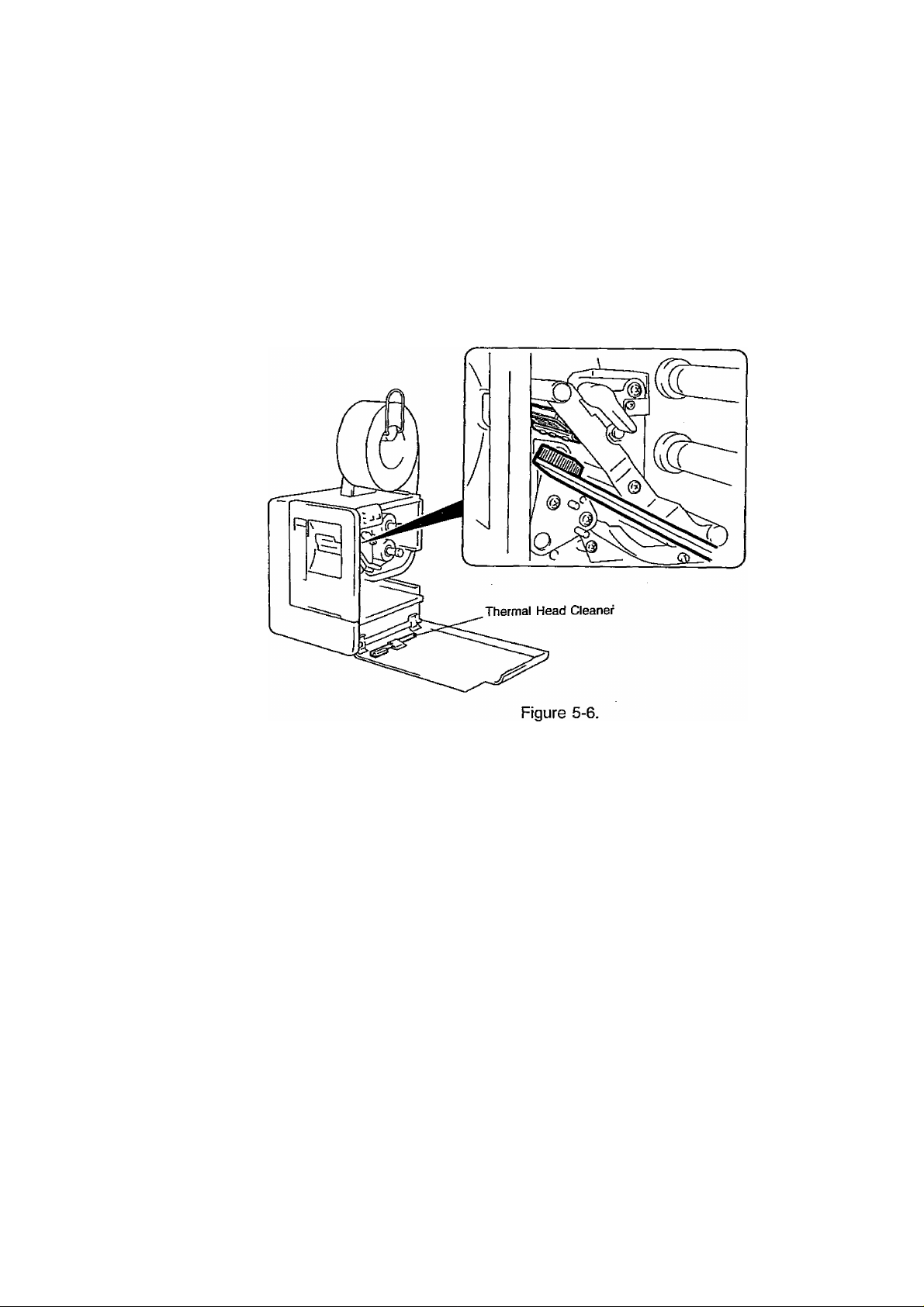

2. CLEANING THE PRINT HEAD

If the print head is dirty, clear printing is not performed.

It is recommended to clean the head with thermal head cleaner before loading a

new ribbon,

1. Turn the power off.

2. Open the front door.

3. Move the head lock lever to the right to release the print head.

4. Remove the ribbon if it has been loaded.

5. Move the supply back past the top of the paper guide.

EM 1-33004

6. Rub back and forth across the print head using thermal head cleaner.

7. Reload the supply and/or ribbon.

WARNING: Turn the power off before cleaning the print head.

WARNING: Be careful NOT TO DAMAGE the print head when cleaning.

5-3

Page 46

EM 1-33004

3. CLEANING THE CUTTER

WARNING: Turn the power off before cleaning the cutter. stationary blade

WARNING: Be extremely careful NOT TO CUT your fingers.

1. Pull out the lock knob and adjustment knob.

2. Pull the upper section of the cutter cover toward

you to remove the cover.

3. Remove screws ® to remove the supply guide

cover.

4. Clean “dust” on the cutter with a soft cloth

moistened with alcohol. Figure 5-7.

WARNING: At this time, DO NOT WIPE OFF the cylinder guides (hatched parts) at both ends of the cutter.

5. If the rotating noise of the blade becomes particularly great, apply grease using

a soft cloth. (Excessively applied grease may stain the supplies.)

Grease should b.e applied to the rotary blade, stationary blade, and cylinder

guides. For the cylinder guides (hatched parts), apply grease to their exposed

parts so that grease spreads all around when the blade turns.

------------------■

i

Cylinder

guide

Rotary blade

‘/M

m

• Cutter Life

Observe raised nap on the cut end of the supply to determine whether the cutter

has worn out. The life of a cutter largely varies according to the material, thickness,

and kind of supply,

ex.)

Good No good

—

Supply

If the cut end of the supply is no longer straight as shown above, contacty your

TEC representative.

5-4

Supply

___

Page 47

4. TROUBLESHOOTING

EM 1-33004

It is our primary concern to give you full satisfaction and better service.

If, however, any problem arises in connection with the operation of this printer, please

check the following points before you call for service.

Error Message

SENSOR OR

LENGTH ERROR

NO PAPER

NO RIBBON

^HEAD OPEN

Problem

1. The paper is not

placed correctly.

2. The feeding paper

is jammed and does

not feed smoothly.

1. Place the paper correctly.

2. Remove the jammed paper

and place the undamaged

paper correctly,

Solution

Press PAUSE key.

-> Press I PAUSE key.

3. The black mark or

feed gap sensor po

3. Adjust the sensor position.

Press j PAUSE key.

sition is incorrect.

4. The combination of

the issuing condi

tion and paper or

sensor does not

4. Select the paper or sensor

matching the issuing con

dition.

Press PAUSE I key.

match.

The supply ran out.

Load a new supply.

Press I PAUSE j kev.

The ribbon ran out. Load a new ribbon.

^ Press PAUSE key.

When the print head is

not set correctly, the

Set the print head correctly.

^ Press PAUSE key.

supply tries to feed or

issue.

CUTTER JAMMED

(for Cutter type only)

1. The paper is not cut

correctly.

1. Set the cutter at the home

position.

^ Press PAUSE key.

2. The supply is jam

med in the cutter

unit.

2. Open the cutter cover and

remove the jammed (block

ing) supply.

“> Press ¡PAUSEI key.

CUTTER COVER

OPEN

(for Cutter type only)

1. The cutter cover is

not closed firmly.

2. The cutter is not at

the home position.

1. Close the cutter cover

securely.

^ Press ! PAUSE key.

2. Set the cutter at the home

position.

-> Press I PAUSE key.

MISSING FEED KEY

ERROR

COMMUNICATION

ERROR

(except for

After replacing with a

new supply, the supply

tries to issue one time

without feeding.

Error has occurred in

communicating with a

personal computer.

Change the issuing condition

for a new supply.

^ Turn off the power and then

turn it on again.

Turn off the power and then

turn it on again.

B-30-S1/H1/C1)

NOTE: When an error is not cleared by pressing the PAUSE! key. turn off the

power and then turn it on again.

When the power is turned on again, print data to be issued is cleared.

5-5

Page 48

EMI-33004

No print.

Problem

1. Check whether the supply or ribbon is loaded correct

Solution

ly or not.

2. Check whether the print head is set correctly or not.

3. Check whether the memory card is inserted correctly

or not.

4. Check whether the interface cable is connected

correctly or not

Printed characters are

unclear (or blurred).

1. Dirty print head. Clean the print head.

2. Bad ribbon. Change to new ribbon.

3. Wrong supply for printing. Change to new supply.

Power is not turned

ON.

1. insert the power plug into the AC outlet firmly.

2. Check the circuit breaker.

3. Check whether the printer fuse is blown or not.

This printer has been manufactured under strict quality control. If you have any

trouble, however, DO NOT ATTEMPT TO FIX IT BY YOURSELF. Turn the power

off, pull the power plug out of the AC outlet, and contact your TEC representative.

5-6

Page 49

(B-30-AU,EU,UK.US)

TOSHIBA TEC CORPORATION

^5:

PRINTED IN JAPAN

m

EM1-33004D ,9404400

Loading...

Loading...